Patents

Literature

1388results about How to "Stable manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

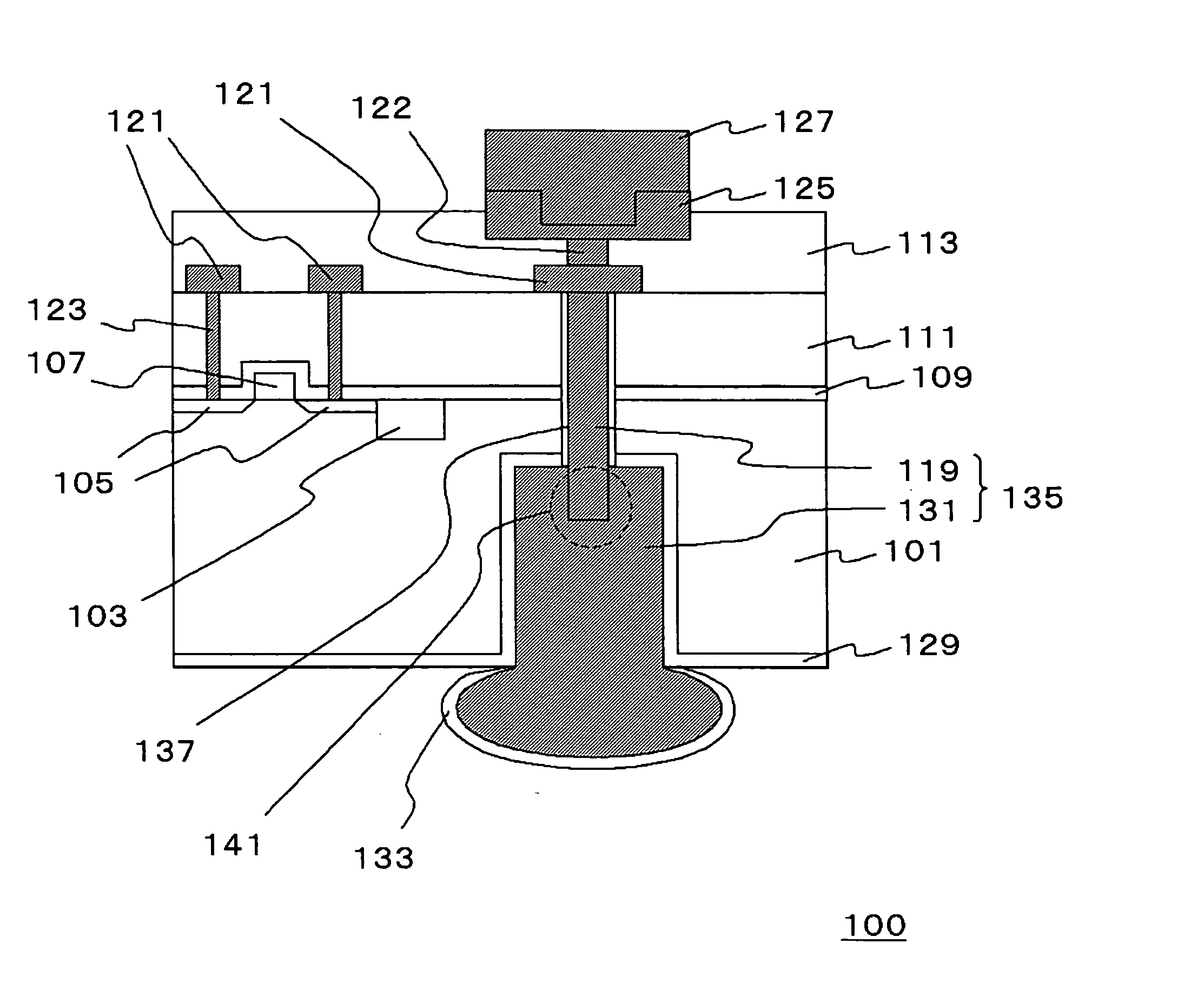

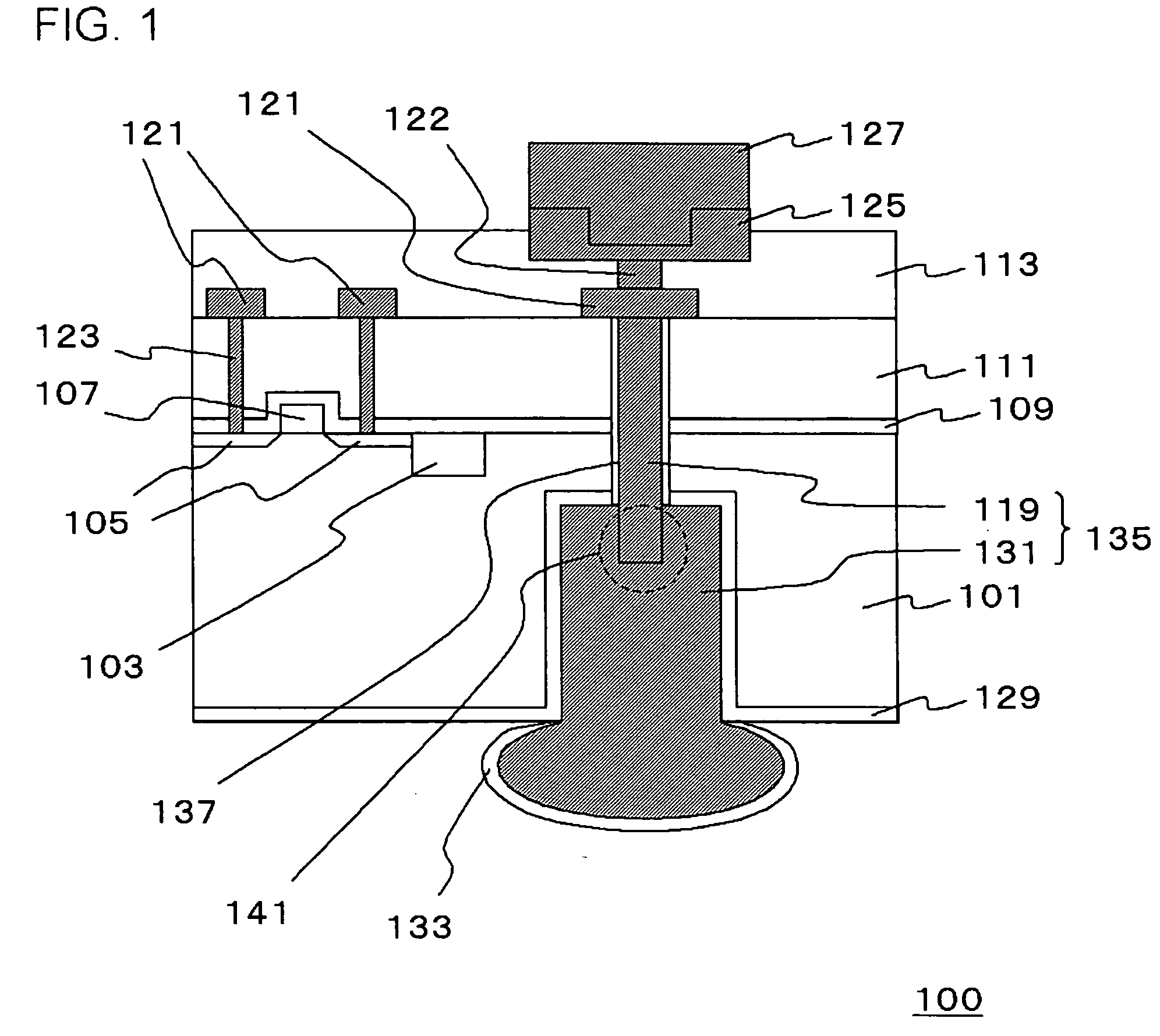

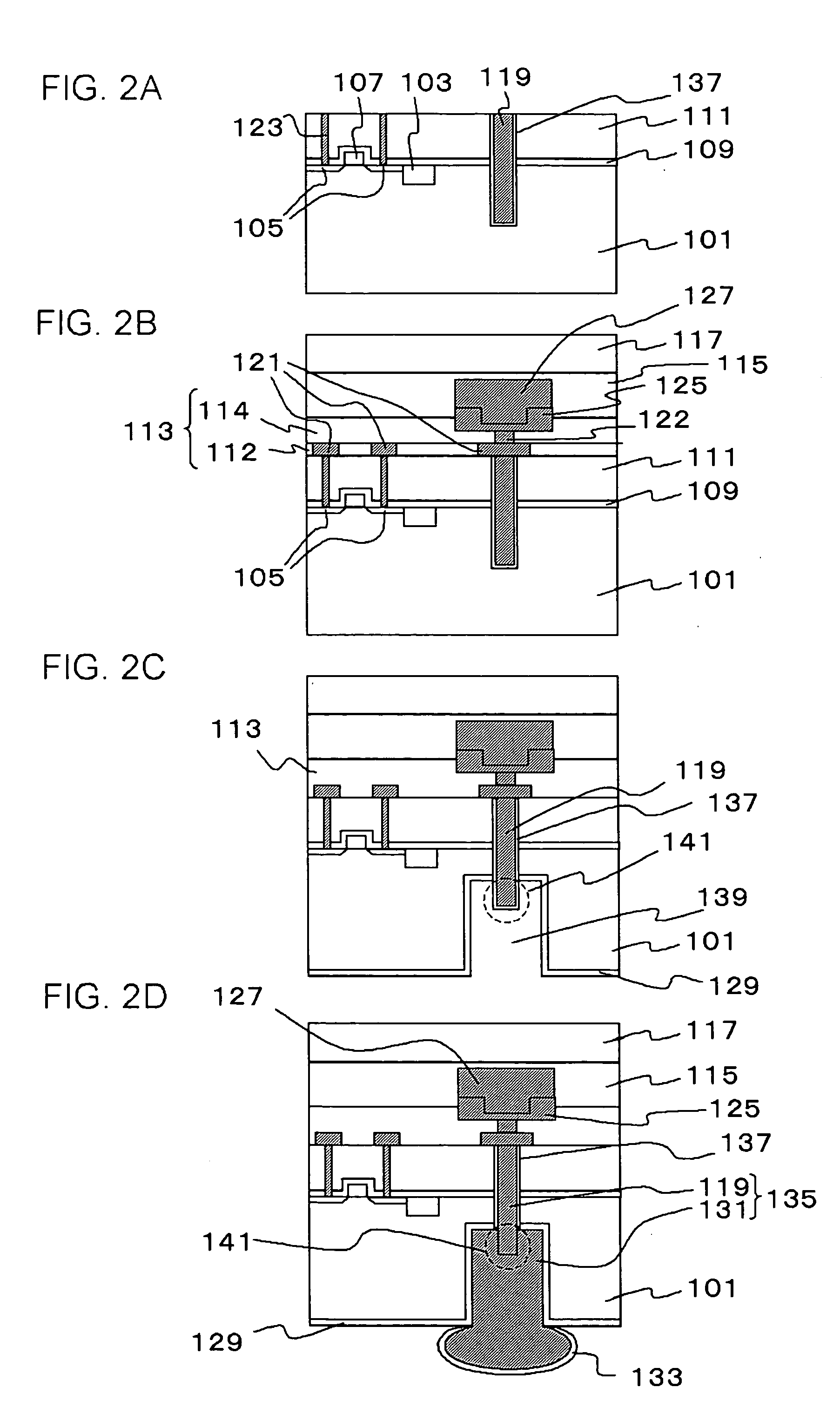

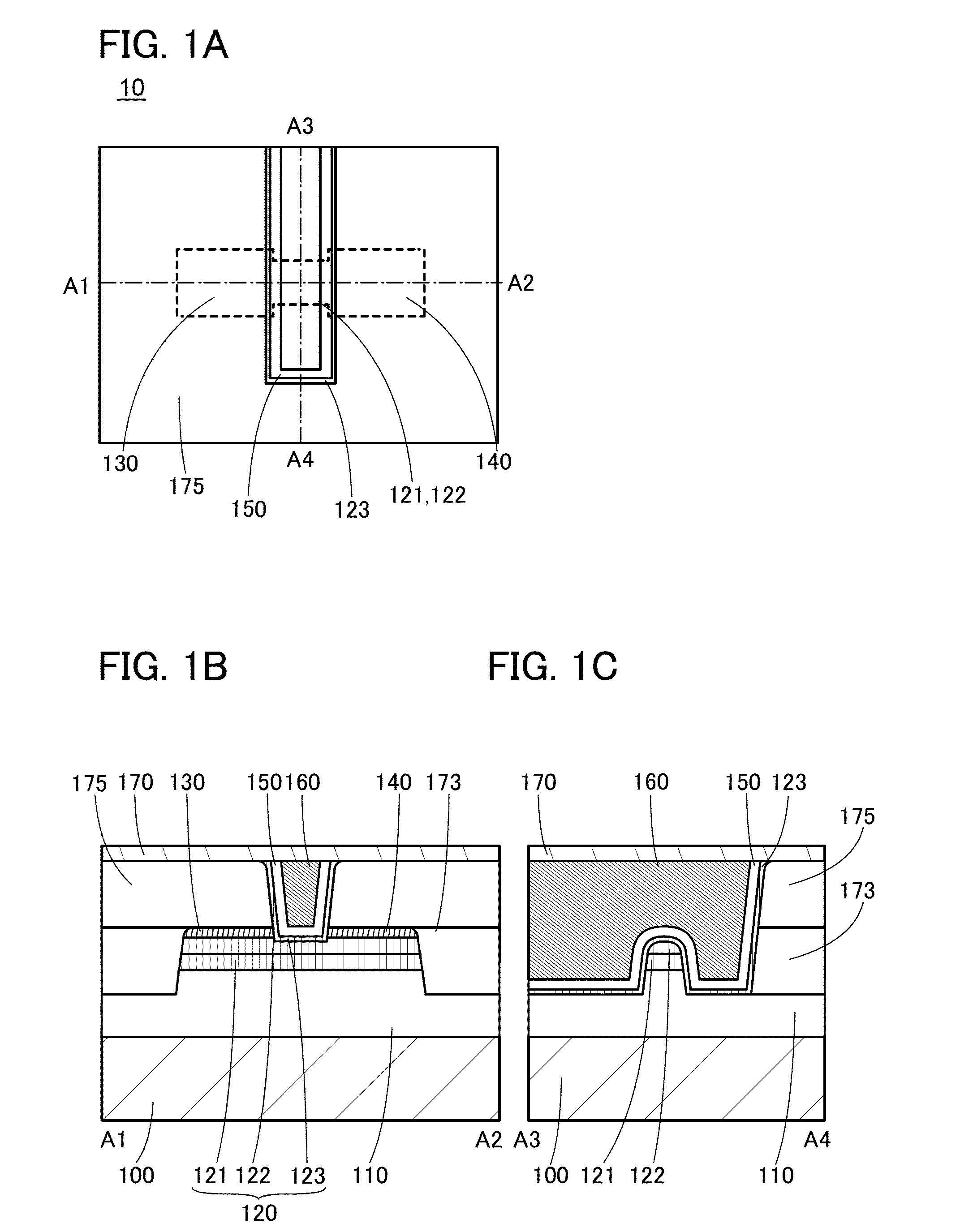

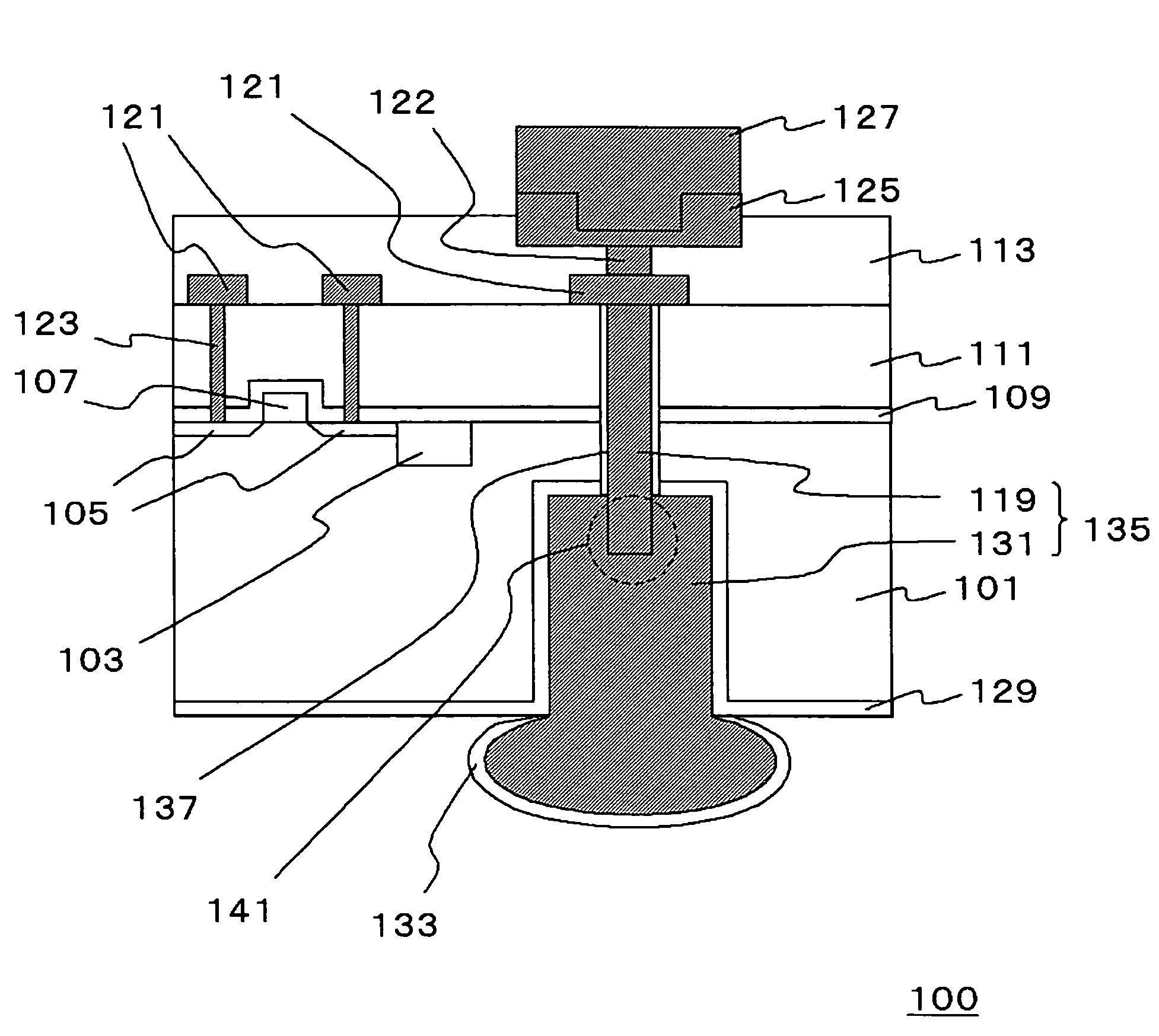

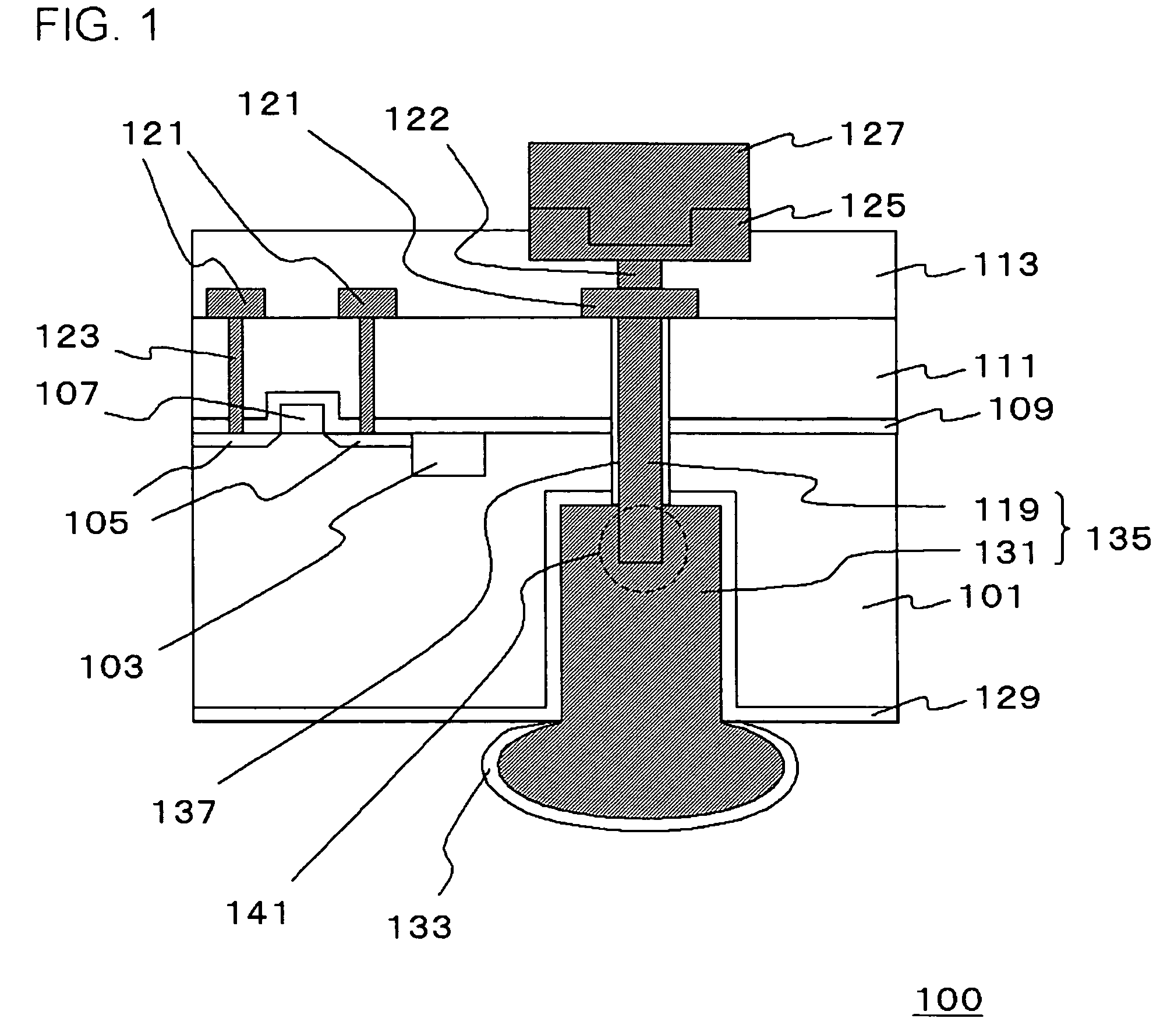

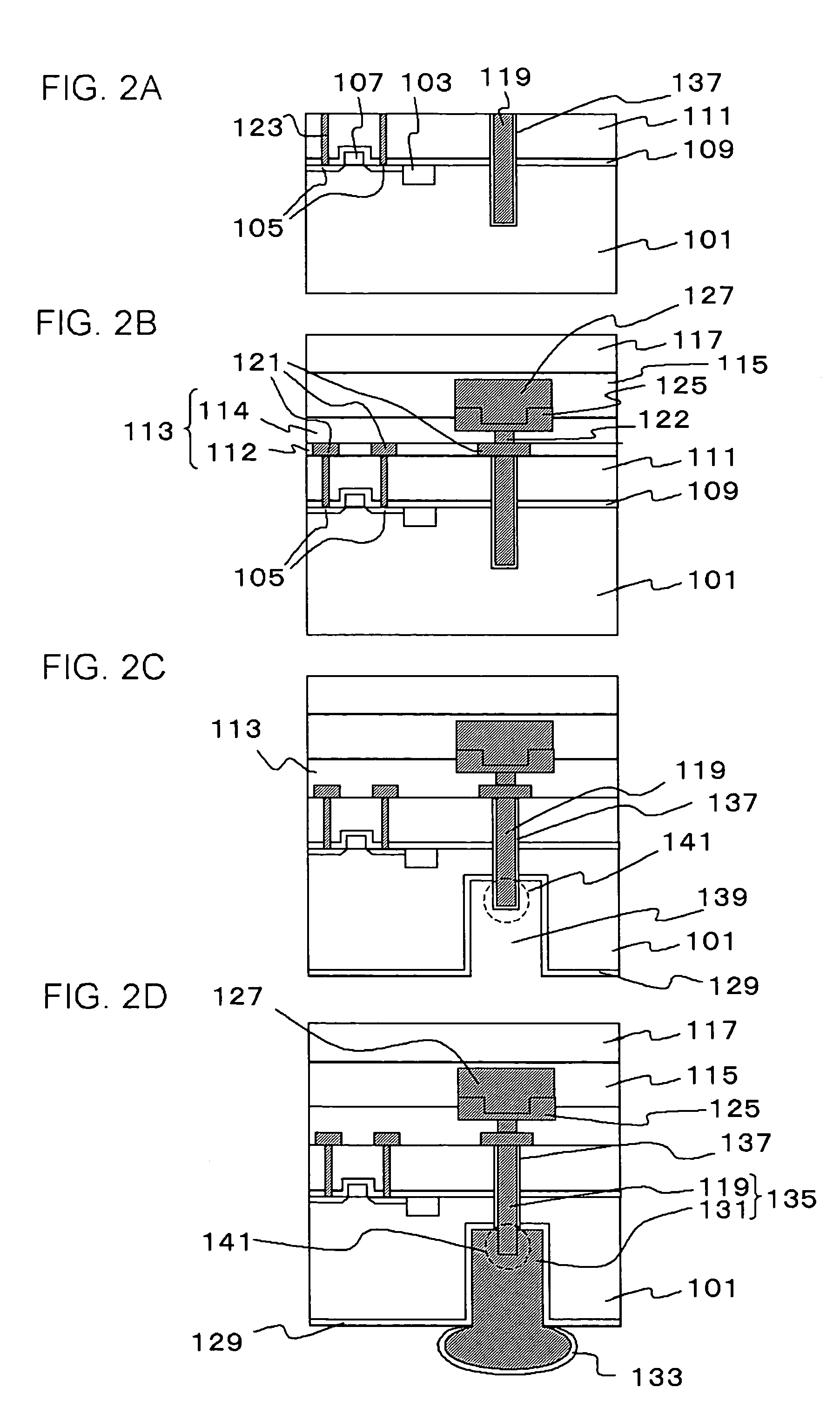

Method for manufacturing semiconductor device

InactiveUS20050233581A1Highly integratedExcellent manufacturing stabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

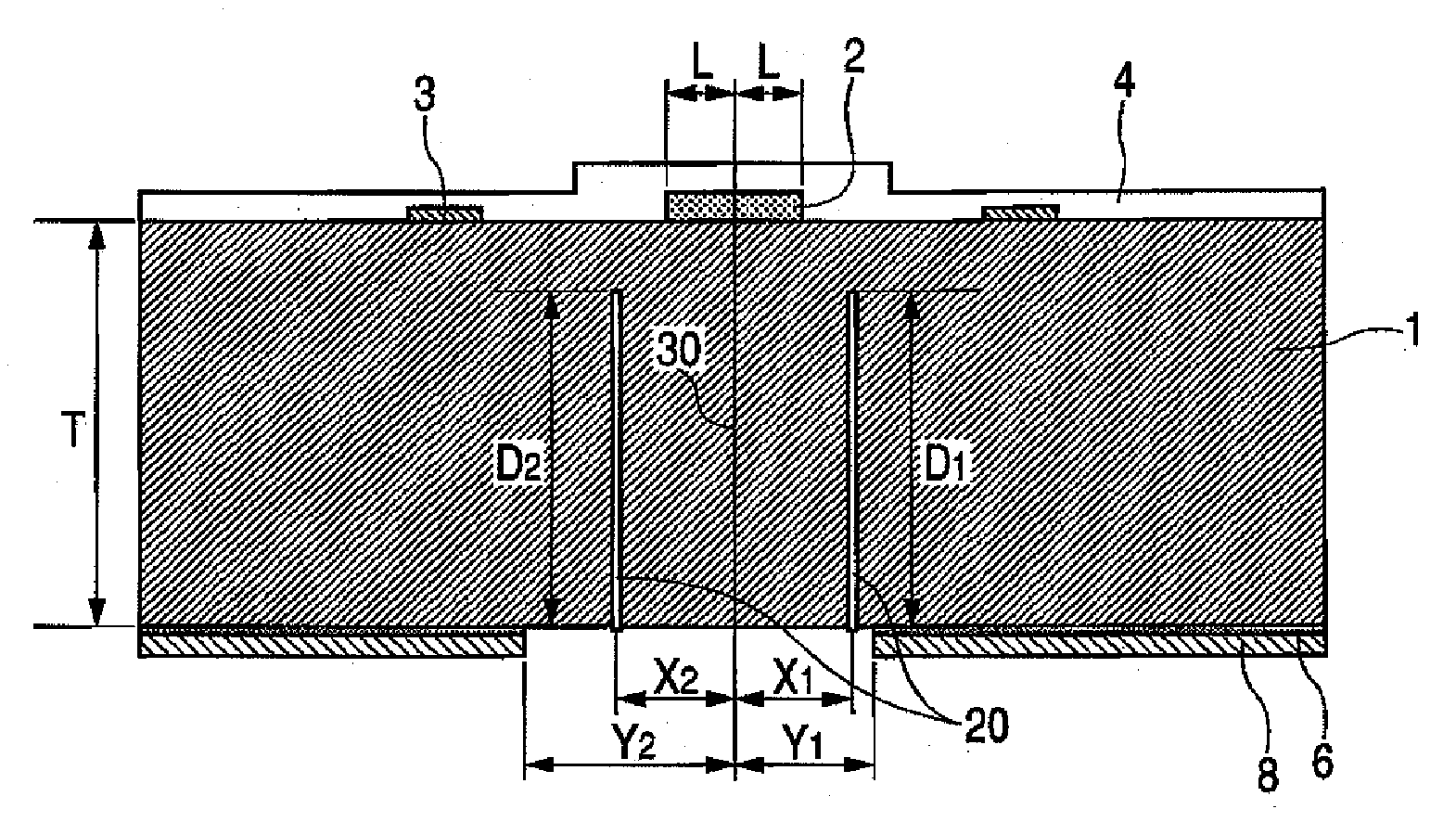

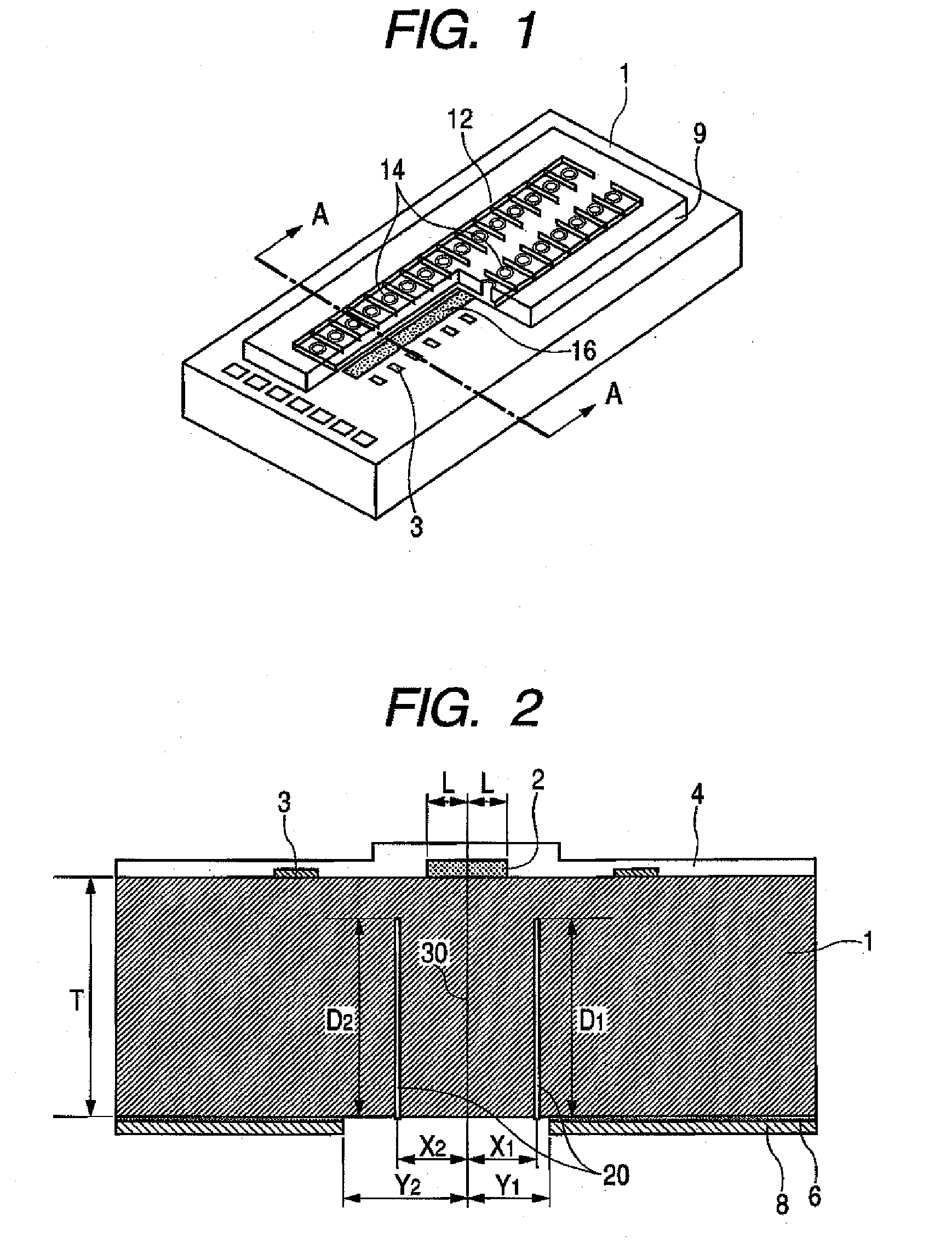

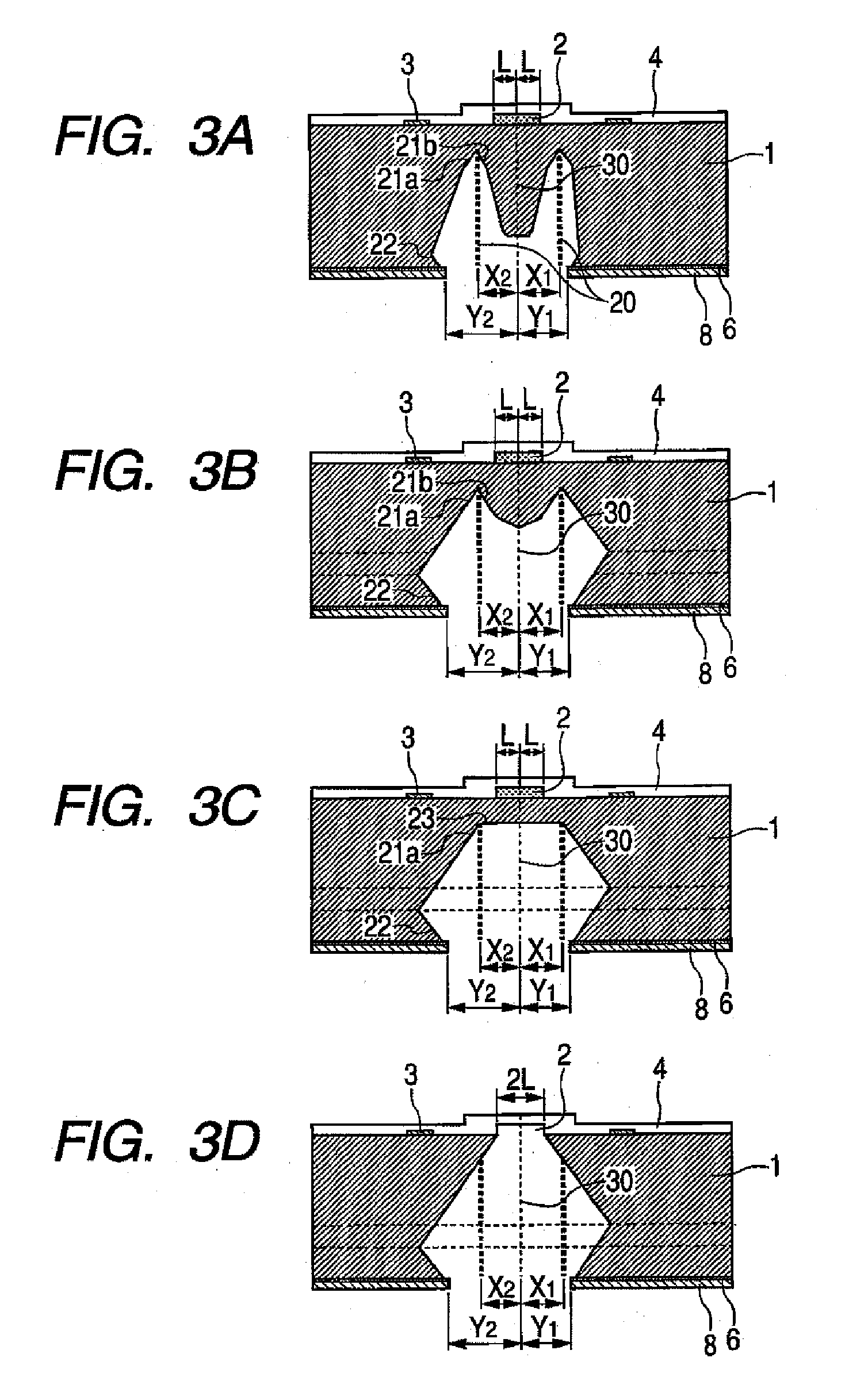

A semiconductor device has through electrodes with property as an electrode and excellent in manufacturing stability. The through electrode composed of a conductive small diameter plug and a conductive large diameter plug is provided on the semiconductor device. A cross sectional area of the small diameter plug is made larger than a cross sectional area of a connection plug and its diameter each, and the cross sectional area of the small diameter plug is made smaller than a cross sectional area of the large diameter plug and its diameter each. Further, a projecting portion where the small diameter plug is projected from a silicon substrate is put into an upper face of the large diameter plug. Further, an upper face of the small diameter plug is connected to a first interconnect.

Owner:RENESAS ELECTRONICS CORP

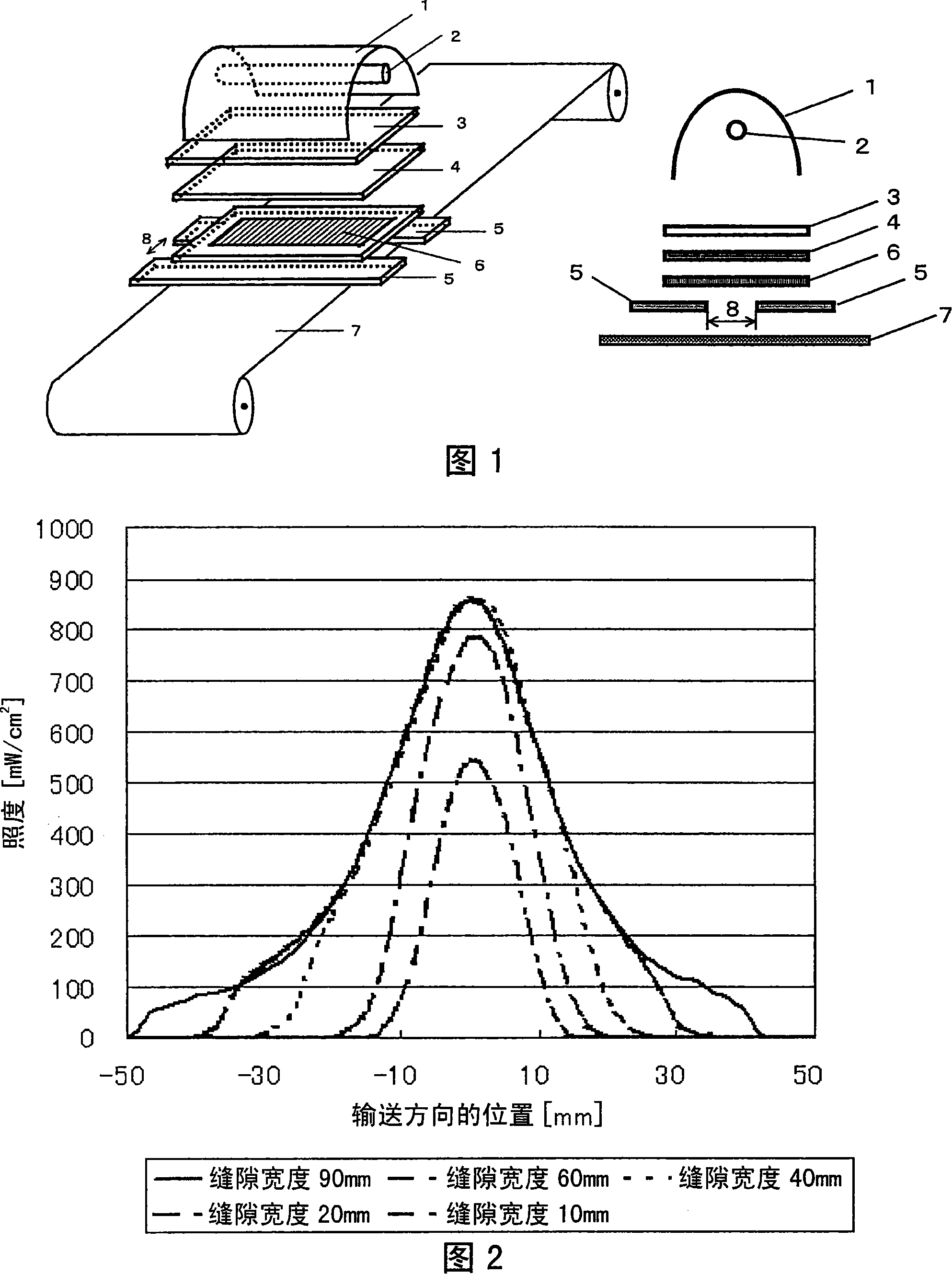

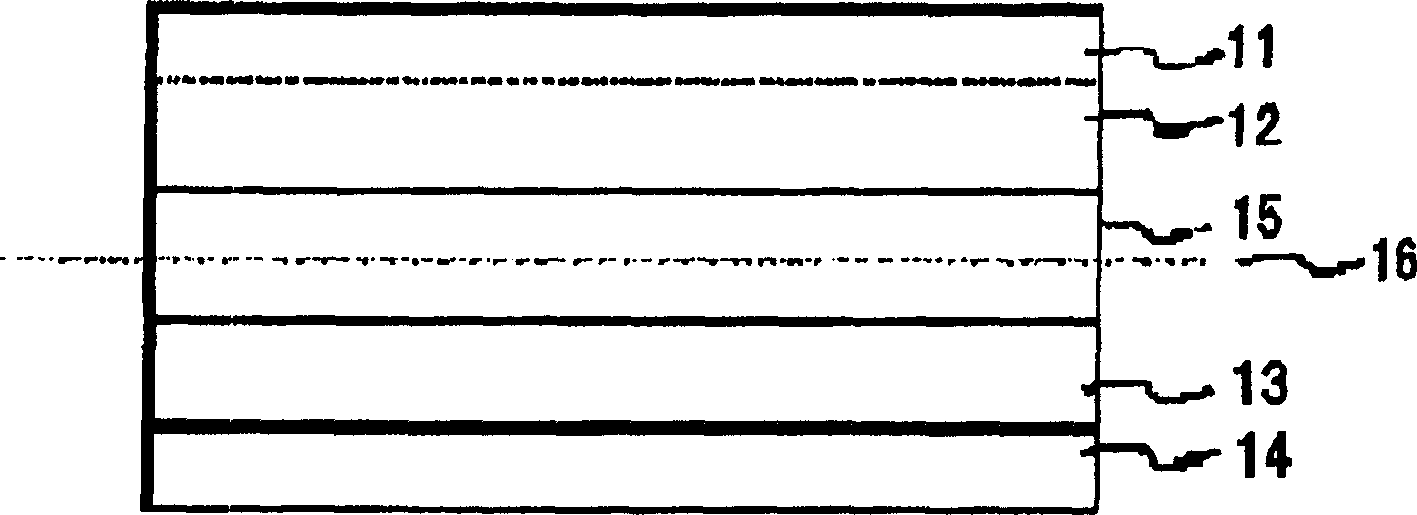

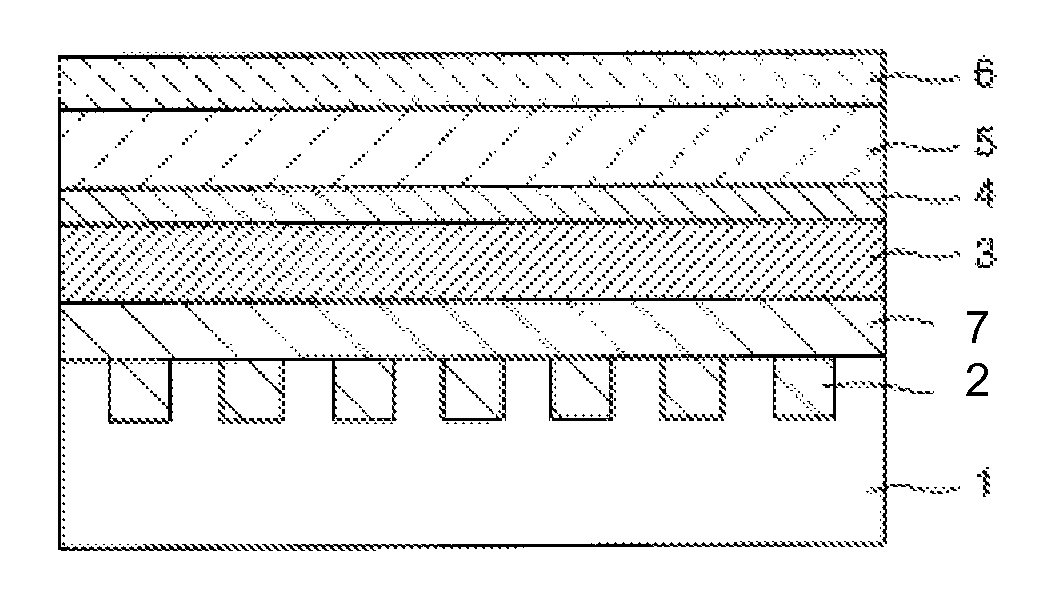

Method of producing optical film, optical film, polarizer plate, transfer material, liquid crystal display device, and polarized ultraviolet exposure apparatus

InactiveCN101131436AExcellent optical propertiesHigh film strengthPolarising elementsNon-linear opticsUltraviolet lightsPolarizer

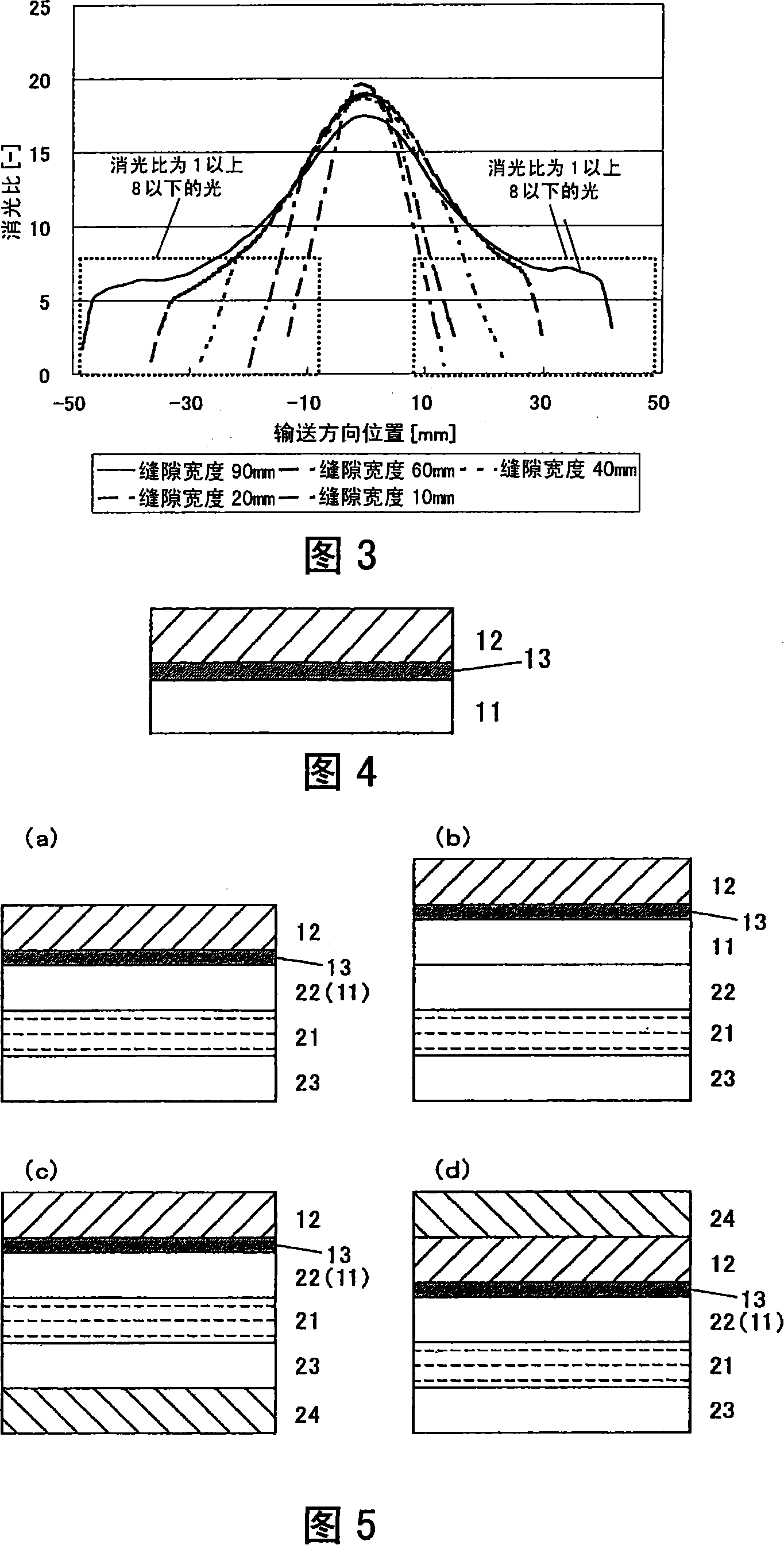

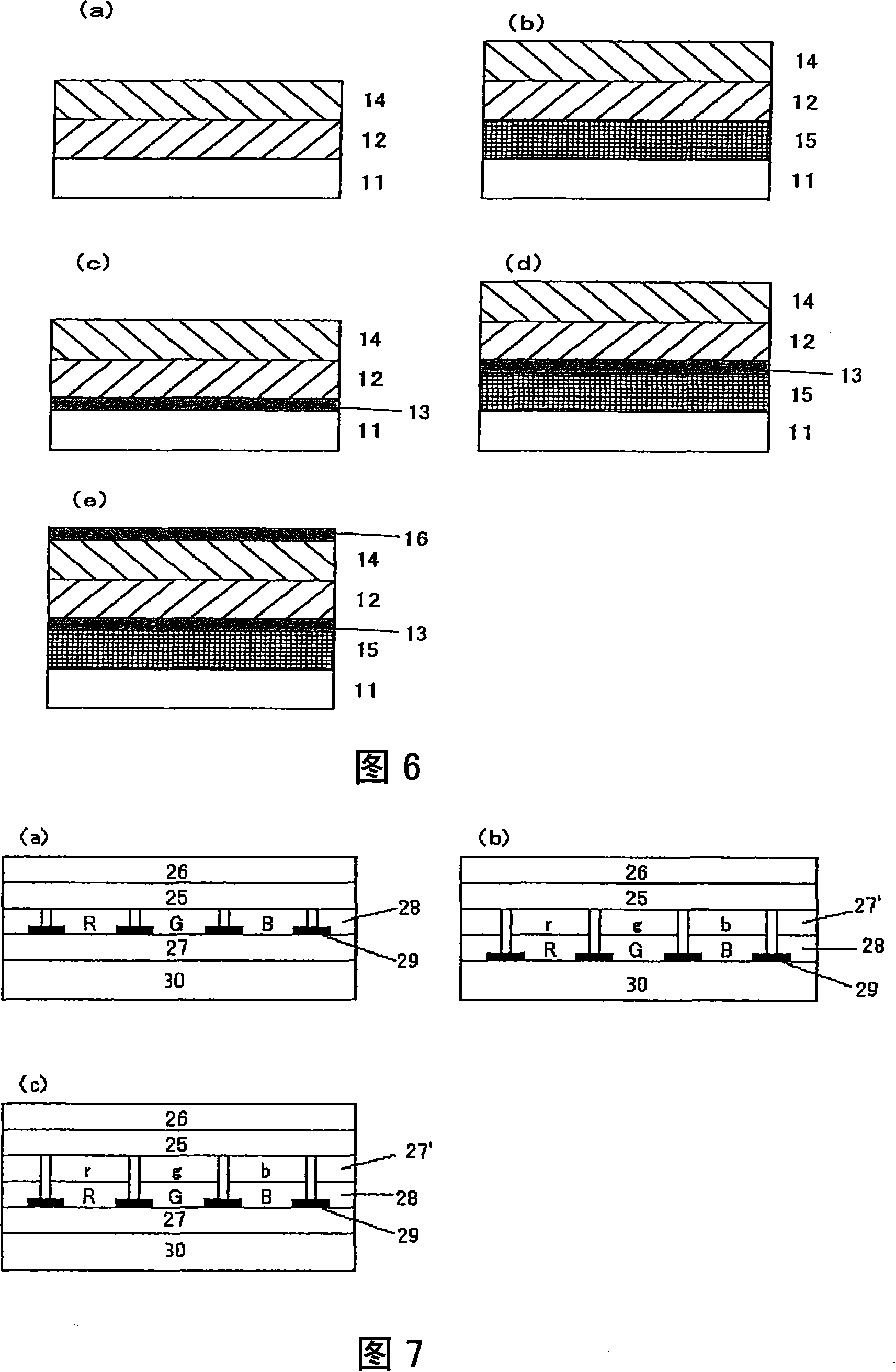

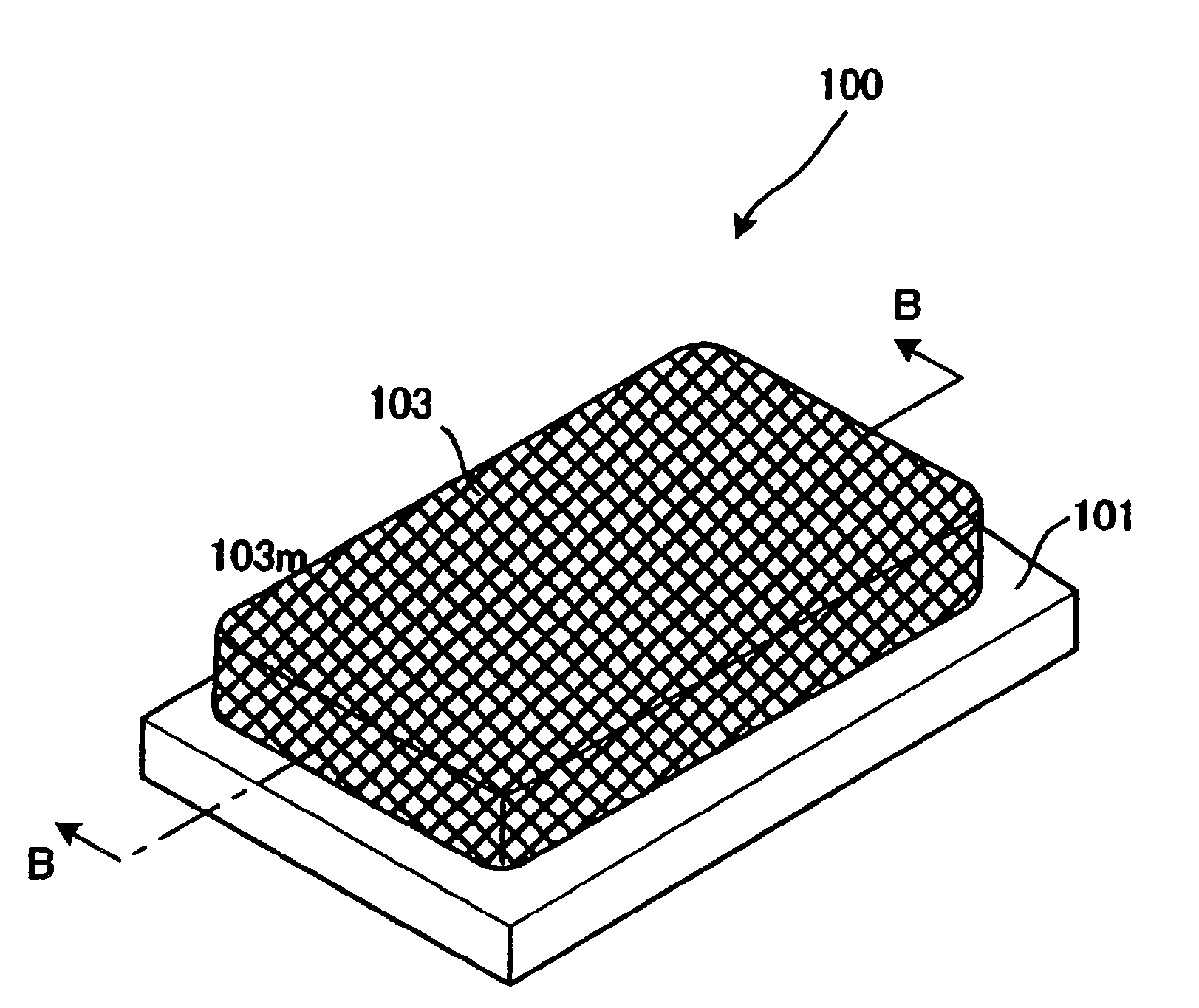

The present invention provides a method for producing an optical film exhibiting excellent optical characteristics and film strength with high productivity in a production method of an optical film including a step of irradiating polarized ultraviolet rays. The method for producing an optical film is characterized in that it is a method for producing an optical film comprising the following steps (1) to (3) in the order of (1) to (3): (1) A layer composed of a polymerizable composition containing a polymerizable liquid crystal compound and a dichroic polymerization initiator is formed on the surface; (2) the molecules of the polymerizable liquid crystal compound in the layer are formed into a first alignment state; (3) The layer is irradiated with polarized ultraviolet rays to polymerize the polymerizable liquid crystal compound, and fix the molecules of the polymerizable liquid crystal compound in the second alignment state to form an optically anisotropic layer. Exposure to area (J / cm 2 ), the proportion of polarized ultraviolet rays with an extinction ratio of 1 to 8 is 15% or less.

Owner:FUJIFILM CORP

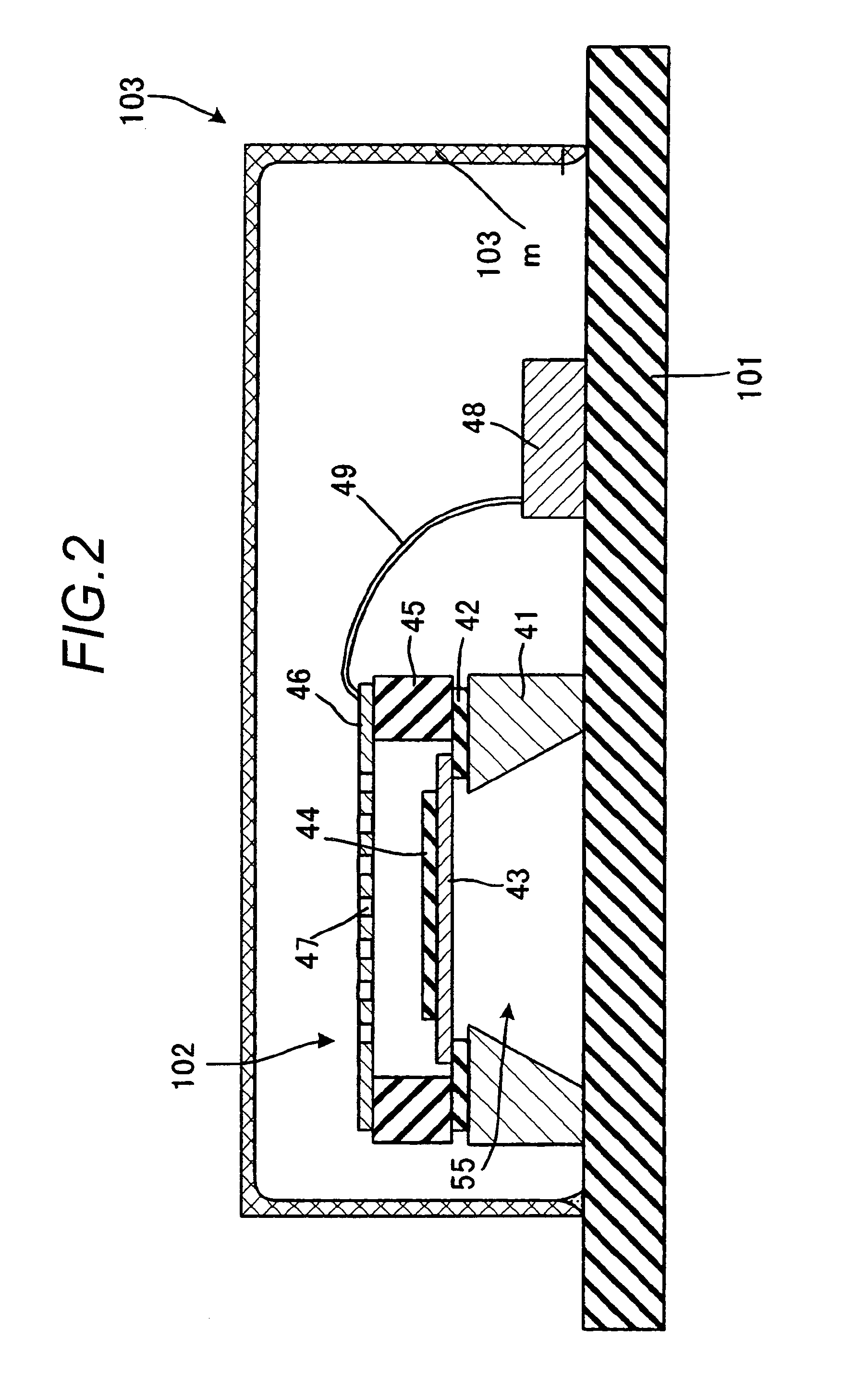

Microphone device and manufacturing method thereof

InactiveUS20100119097A1Flat frequency characteristicImprove accuracyPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersEngineeringFrequency characteristic

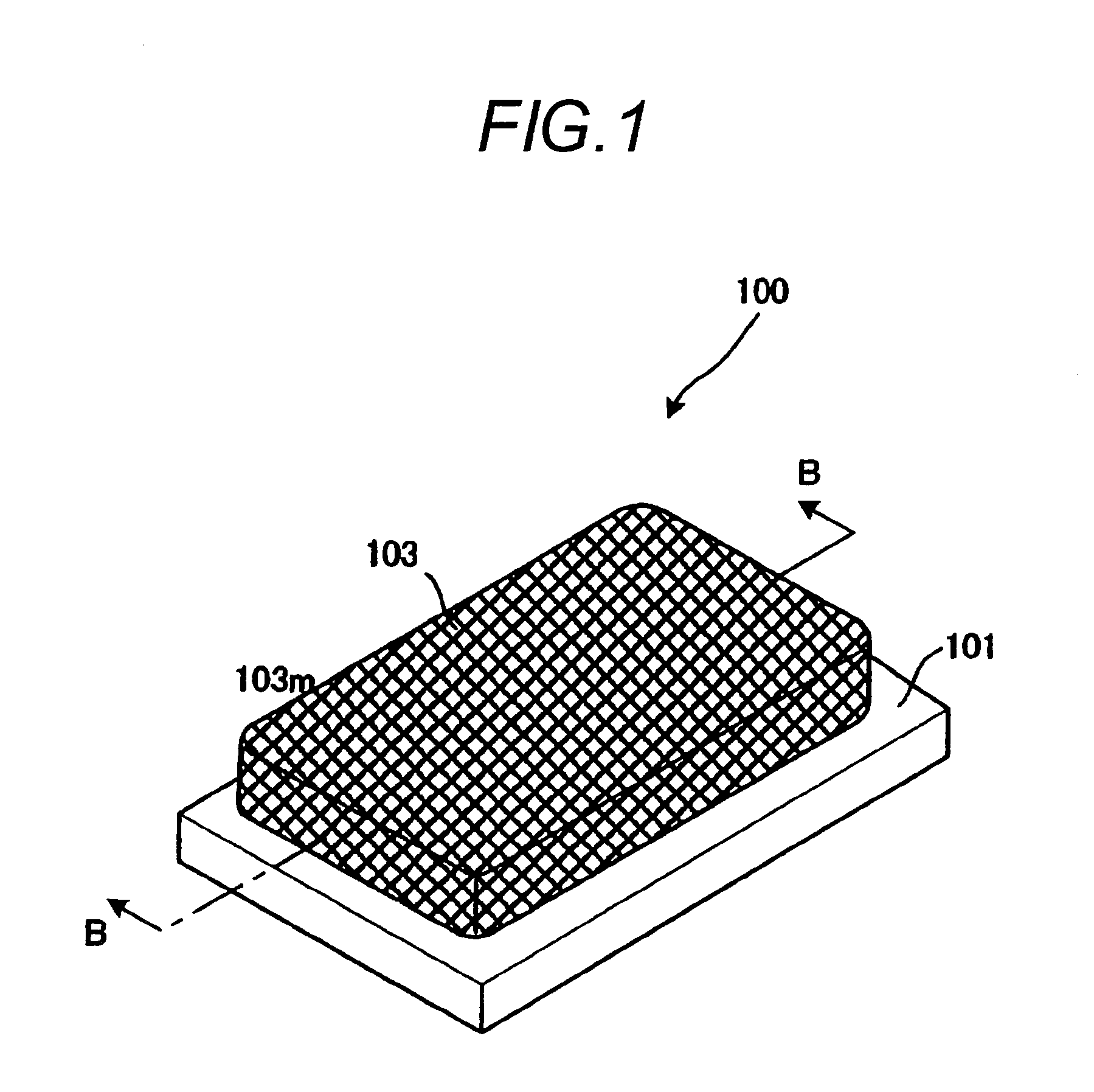

The present invention provides a microphone device with good frequency characteristics. The microphone device can pick up sound faithfully. In detail there is provided a microphone device comprising a microphone element, a signal processor, and a cover disposed over the microphone element and the signal processor, the cover including a mesh structure occupying 25% or more of at least one surface of the cover.

Owner:PANASONIC CORP

Electroluminescent display device

ActiveUS20050077820A1Well luminescent propertyHigh luminous efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceMolecular physics

Owner:SAMSUNG DISPLAY CO LTD

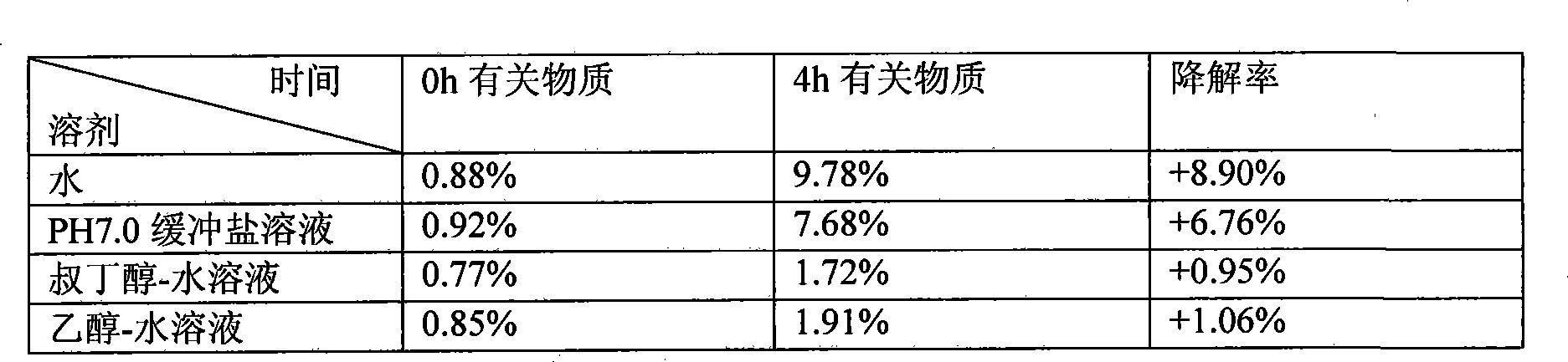

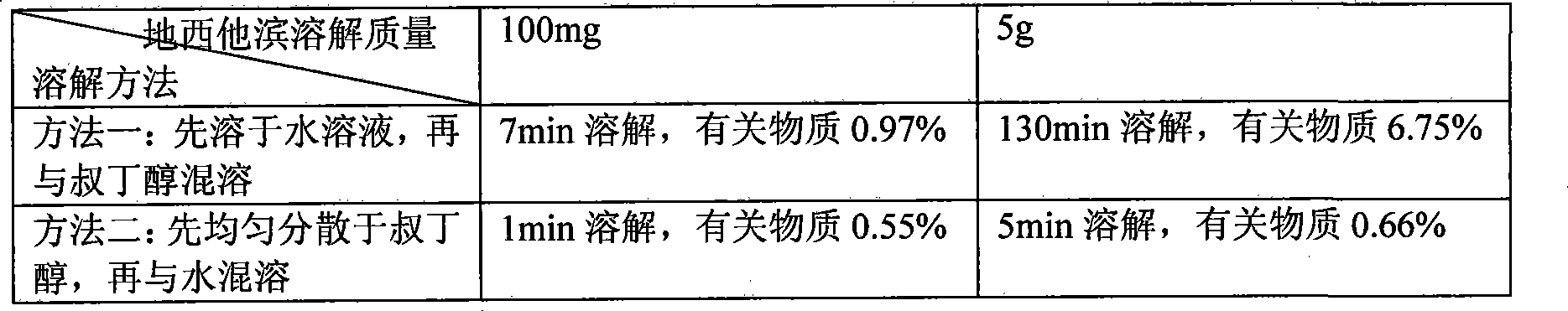

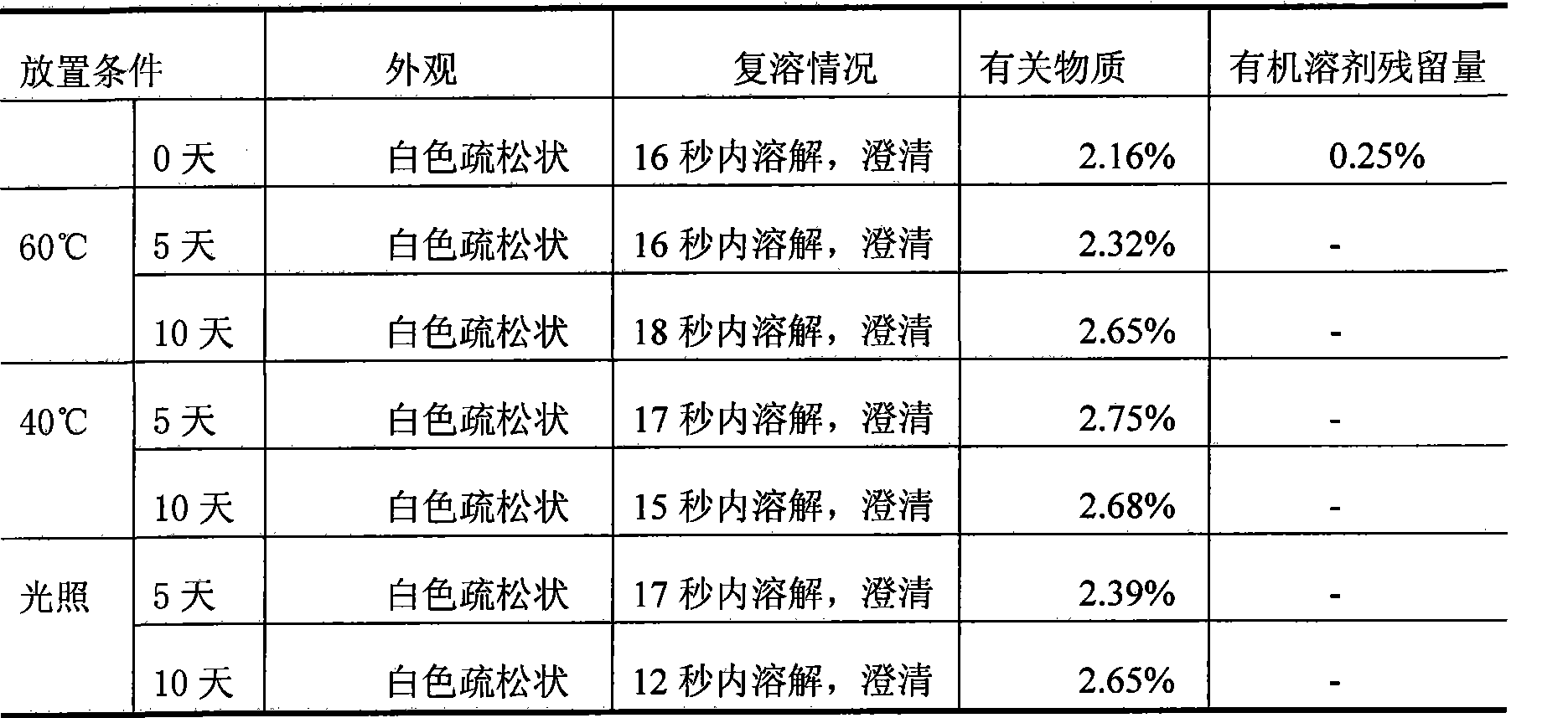

Stable preparation method of decitabine freeze-dry preparation

InactiveCN101361718AAvoid degradationReduce the rate of degradationOrganic active ingredientsPowder deliveryOrganic solventFiltration

The invention discloses a method for preparing a stable Decitabine freeze-dried preparation, which comprises the following steps: Decitabine is uniformly dispersed in at least one of organic solvents including tertiary butyl alcohol, ethanol and methanol or dissolved in the organic solvent dimethyl sulfoxide; and then the mixed solution is mixed with water for injection or the water for injection with freeze-dried propping agents and / or pH regulators dissolved, thus obtaining a new mixed solution and the organic solvent accounting for 5-80 percent of the mixed solution in volume; and organic solution is removed after filtration and freeze drying. The method can prepare a stable Decitabine freeze-dried preparation, in which the residual quantity of organic solvent is not more than 1 percent.

Owner:深圳万乐药业有限公司

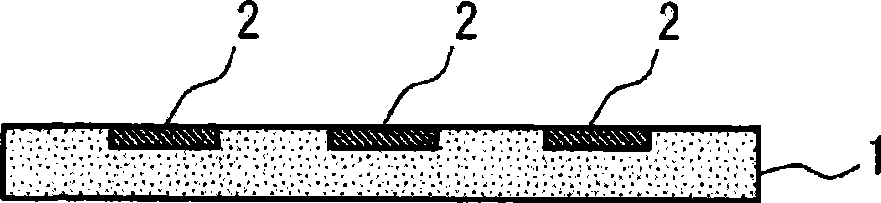

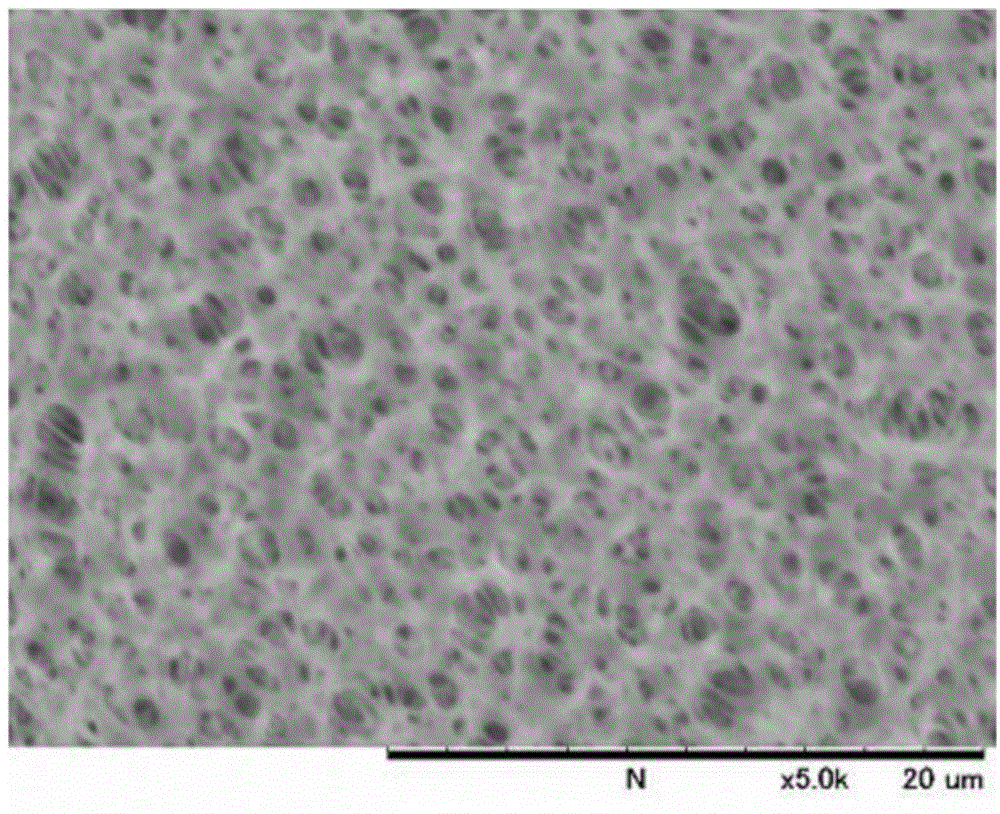

Porous film and multilayer assembly using the same

InactiveCN101384425ASmall widthImprove adhesionLayered productsPrinted circuit manufactureAdhesive beltPorous layer

To provide a porous-film layered product which has excellent porousness, has flexibility, and is excellent in handleability and formability; and a process for producing the layered product. [MEANS FOR SOLVING PROBLEMS] The porous-film layered product comprises a base and, superposed on at least one side thereof, a porous layer having many fine interconnecting pores having an average pore diameter of 0.01-10 [mu]m, and is characterized by suffering no interfacial separation between the base and the porous layer when examined in a tape peeling test by the following method. Tape peeling test A 24 mm-wide masking tape [Film Masking Tape No. 603(#25)] manufactured by Teraoka Seisakusho Co., Ltd. is applied to the surface of the porous layer of the porous-film layered product and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf. Thereafter, this sample is subjected to a T-peel test with a tensile tester at a peeling rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

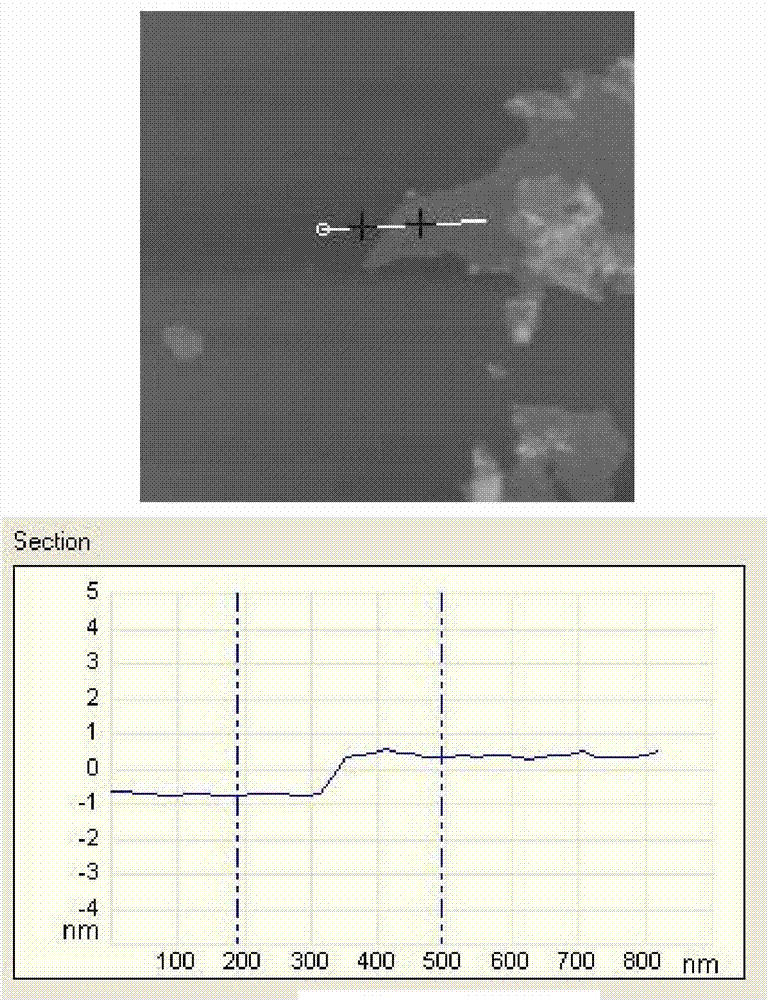

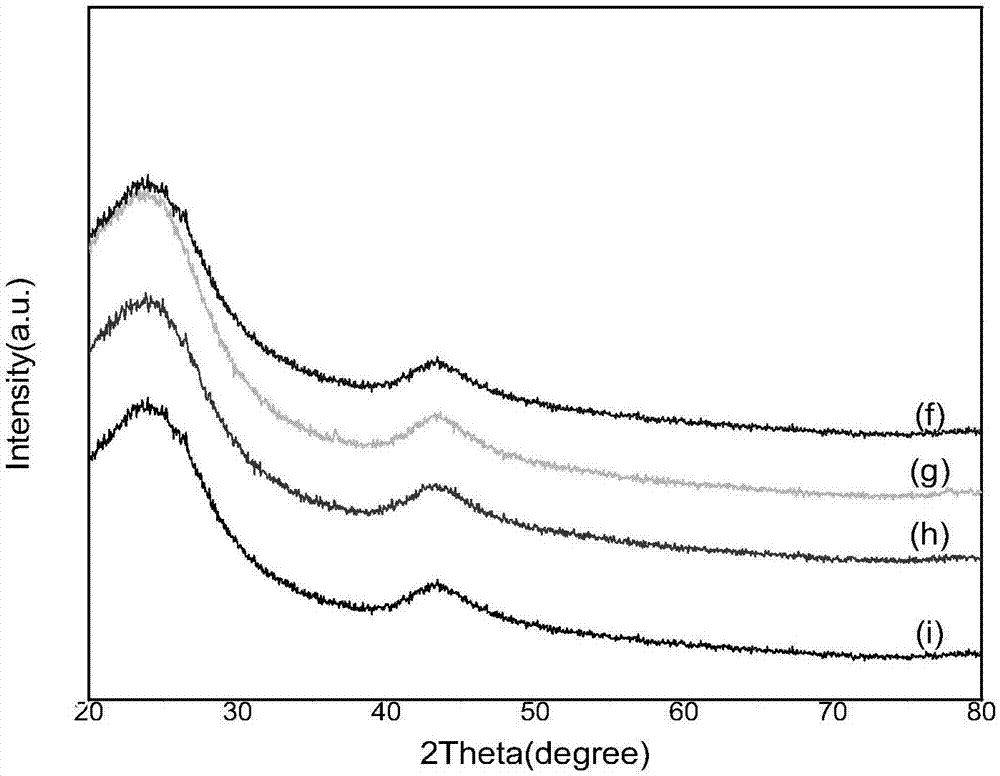

Graphene oxide/polystyrene nano composite and preparation method thereof

The invention discloses a graphene oxide / polystyrene nano composite and a preparation method thereof. The preparation method includes preparing a graphene oxide nanosheet; using graphene oxide as a solid surfactant to obtain stable Pickering emulsion under actions of coordination and stabilization of salt; and polymerizing the in-situ emulsion to obtain the graphene oxide / polystyrene nano composite. The specific steps of the preparation method include oxidizing natural flake graphite by oxidants to obtain graphite oxide, carrying out ultrasonic exfoliation and centrifugal separation to obtain graphene oxide, adding the graphene oxide into salt solution and stirring the mixed solution to form a uniform dispersed system containing the graphene oxide and salt; and adding styrene into the dispersed system, carrying out ultrasonic treatment to obtain the stable Pickering emulsion, adding initiators into the Pickering emulsion, stirring and polymerizing to obtain the graphene oxide / polystyrene nano composite. The preparation method is good in repeatability, has the advantages of mild reaction conditions, low energy consumption and easiness in operation and brings convenience for industrialized implementation.

Owner:HEFEI UNIV OF TECH

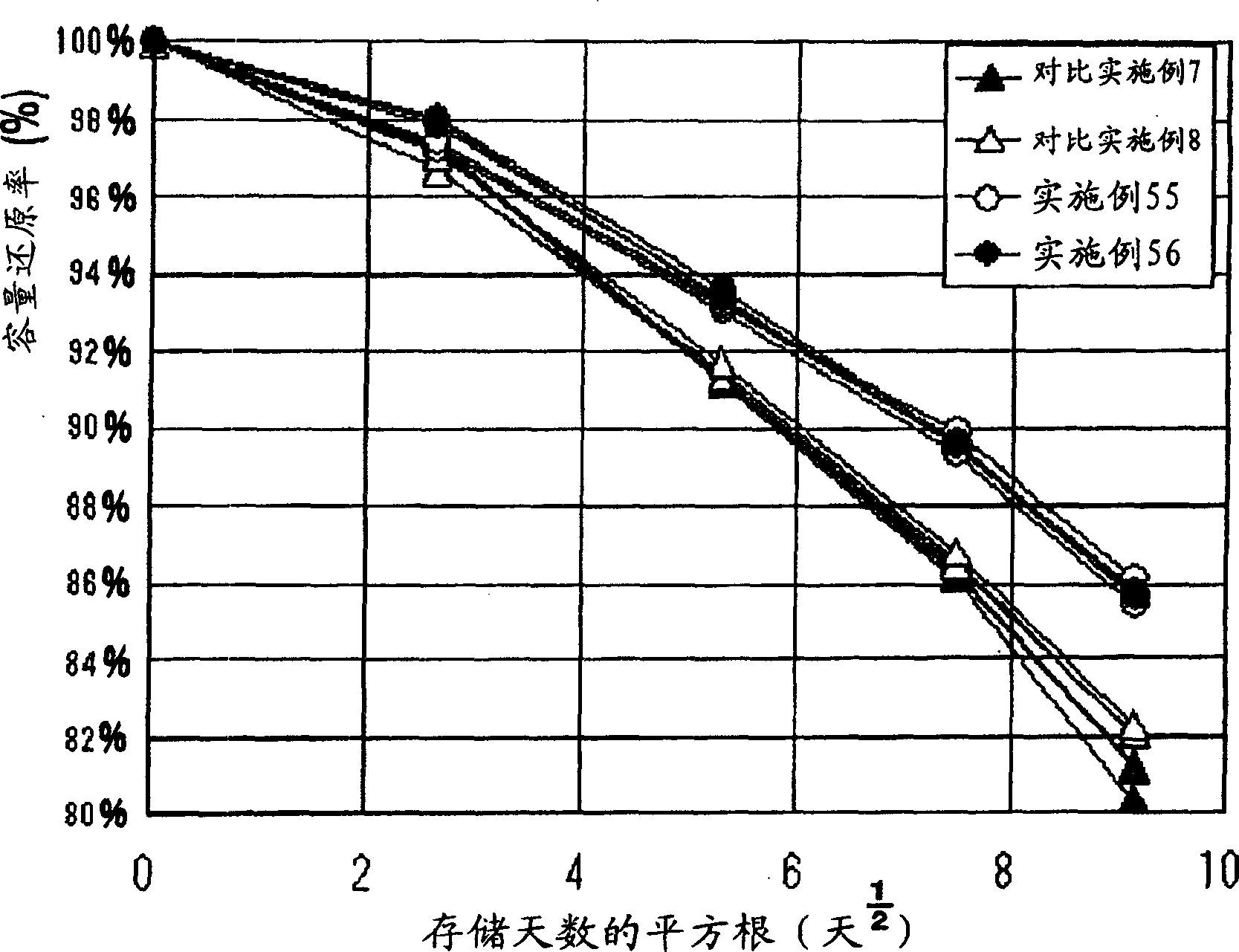

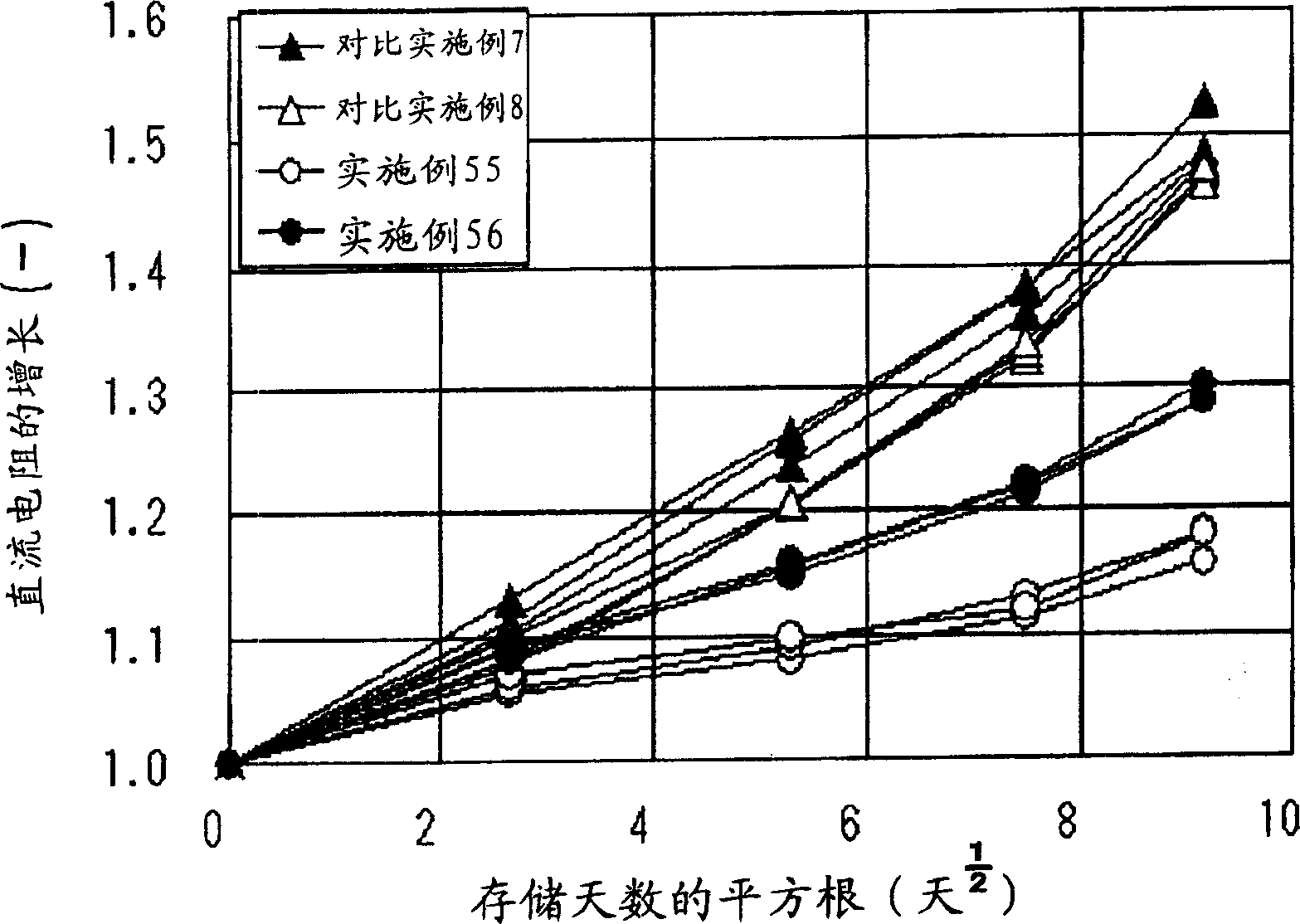

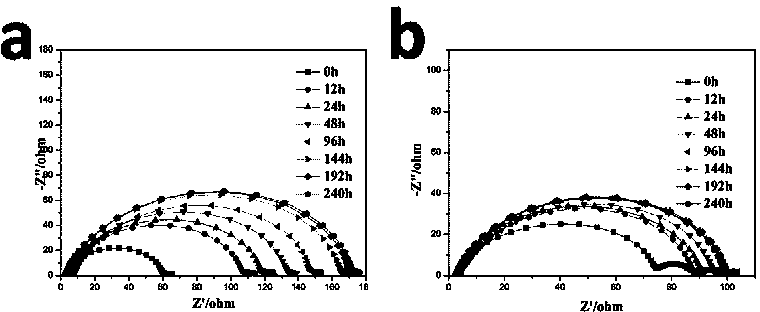

Electrolyte for xecondary battery and secondary battery using said electrolyte

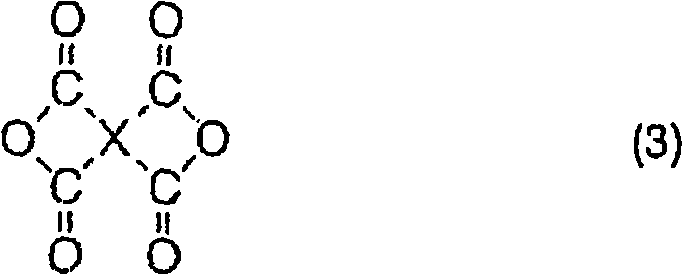

InactiveCN1495959AStable manufacturingThe manufacturing method is simple and stableOrganic electrolyte cellsActive material electrodesElectrolytic agentElectrical battery

The present invention provides a technology of inhibiting the decomposition of the solvent of the electrolyte solution for a secondary battery. Further, the present invention provides a technology of prohibiting the resistance increase of a secondary battery and improving the storage properties such as improving the capacity retention ratio. An electrolyte solution 15 comprising non-proton solvent and cyclic sulfonic ester including at least two sulfonyl groups may be used.

Owner:NEC CORP

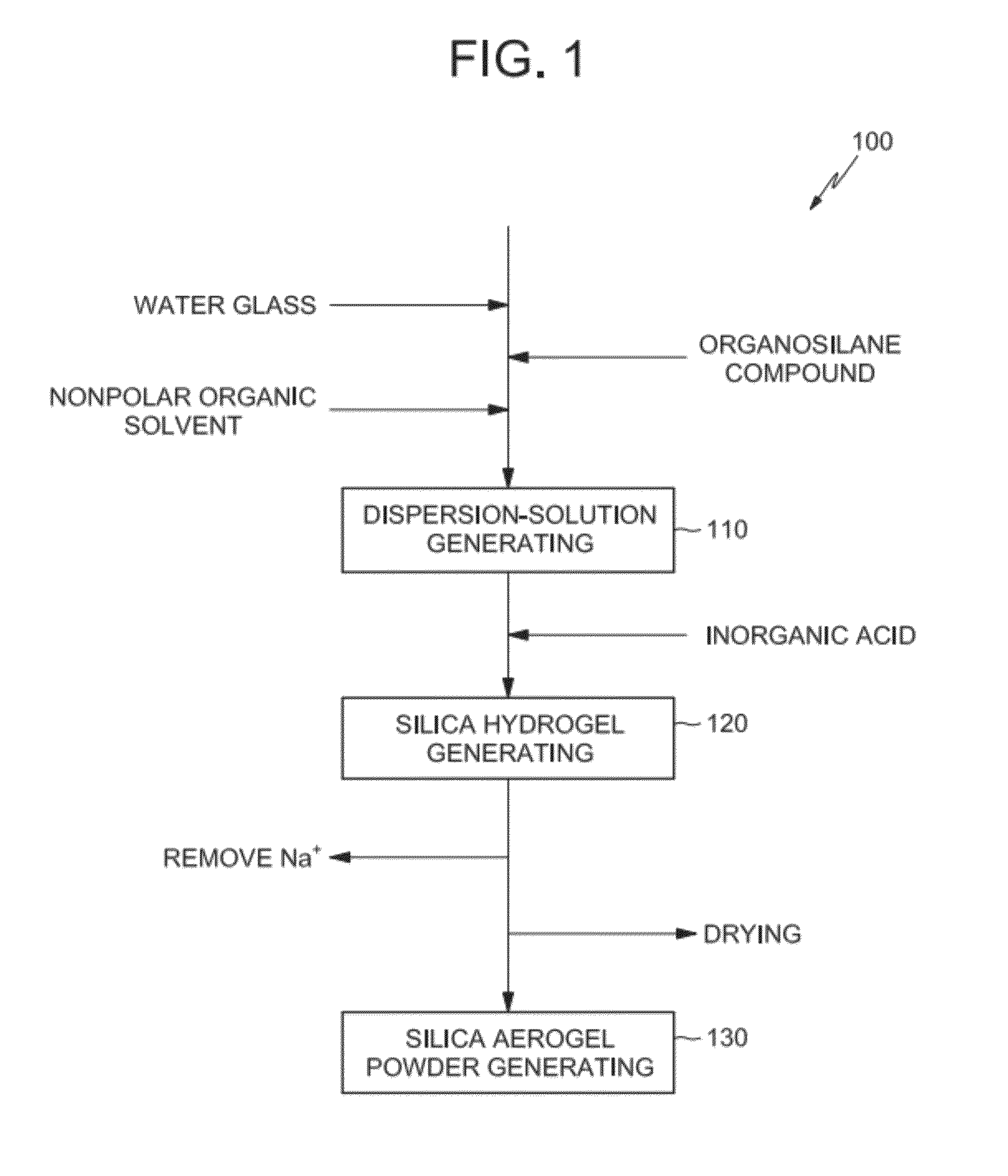

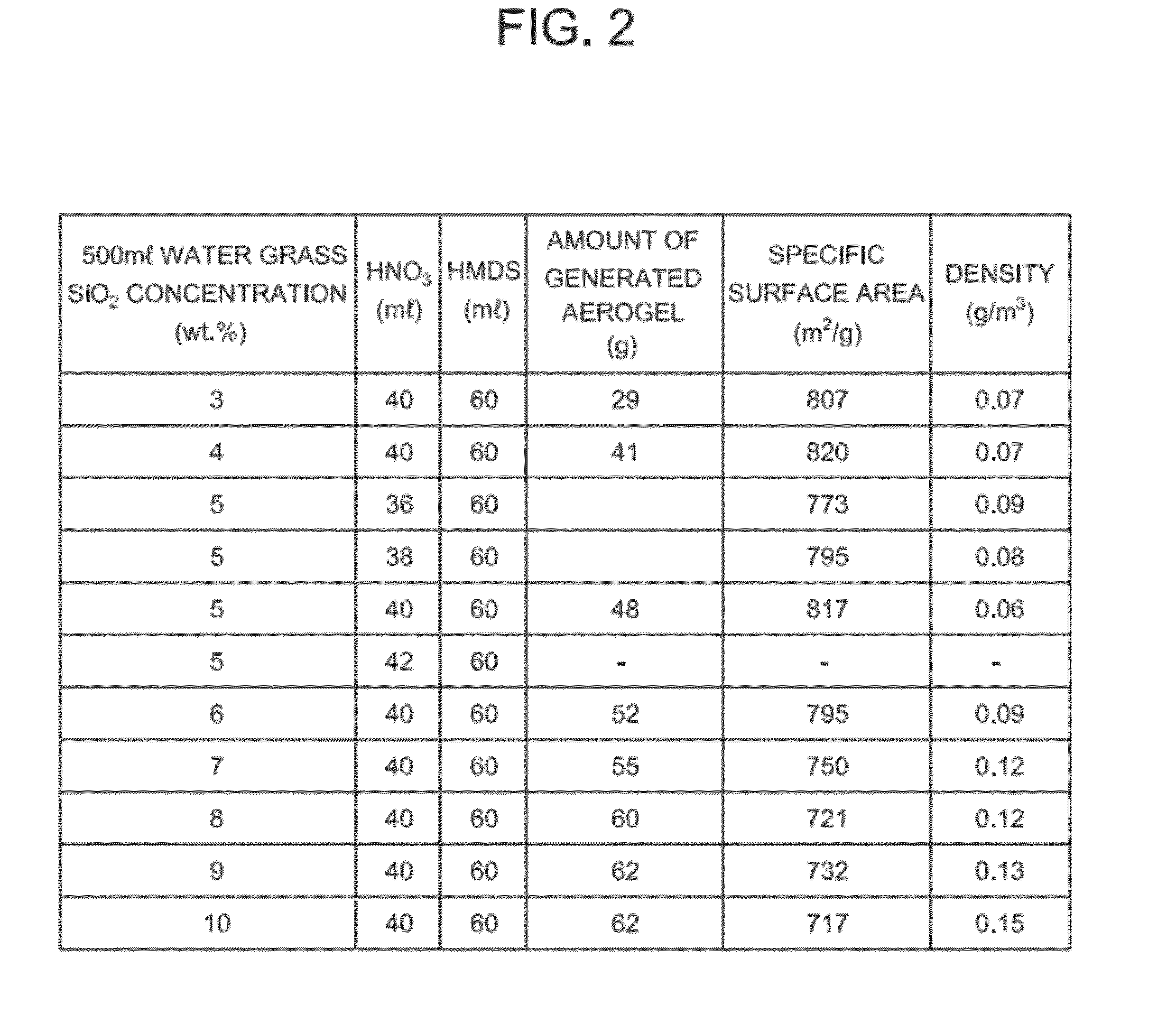

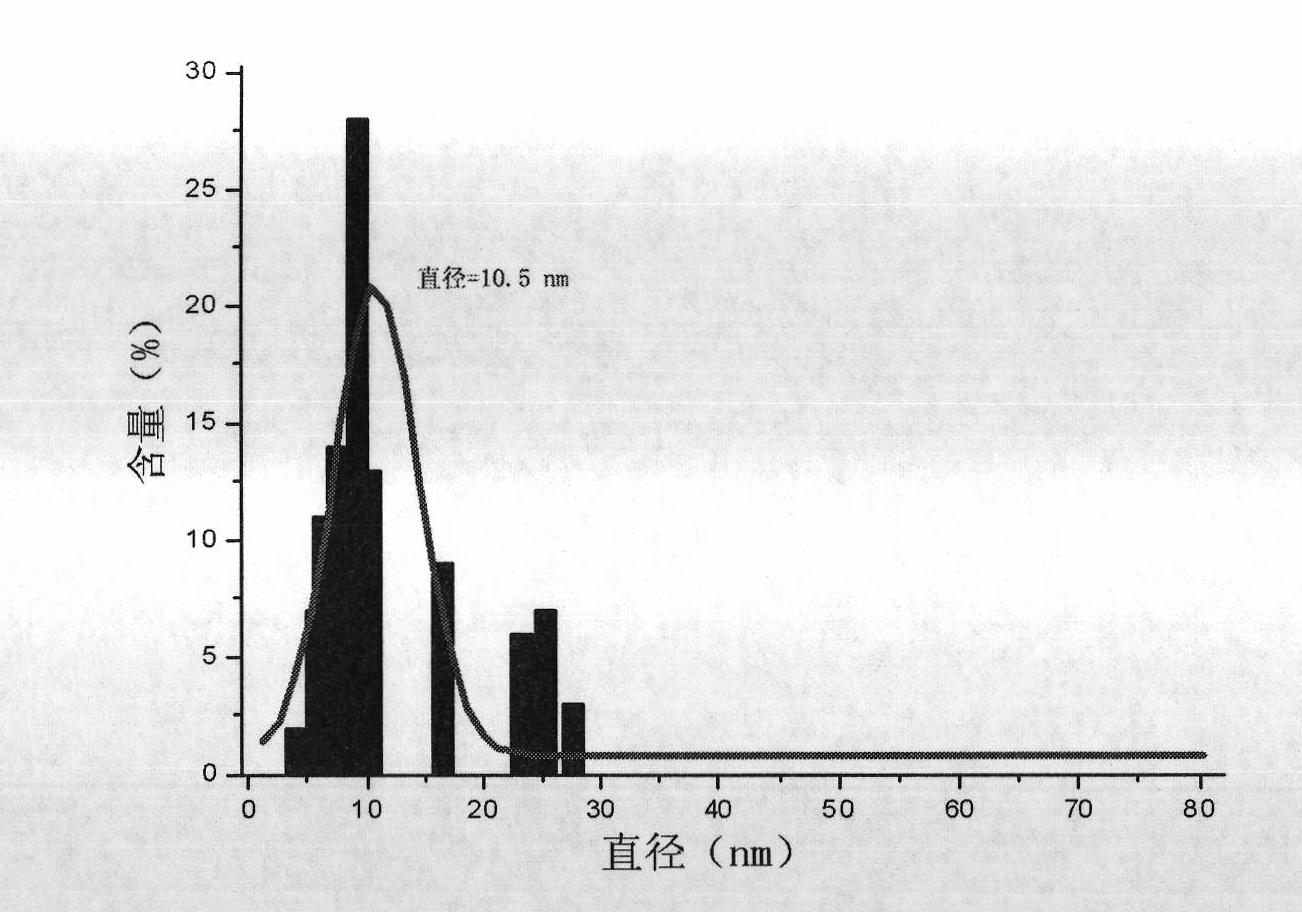

Method of preparing silica aerogel powder

A method of preparing silica aero-gel powders having a short preparation time and stable preparation processes. In the method, the silica aerogel powders are generated by using a water glass solution, an inorganic acid, an organosilane compound and an organic solvent. The method includes dispersion-solution generating, gelating and solvent exchanging and drying. In the dispersion-solution generating, a dispersion solution is generated by dispersing the water glass solution and the organosilane compound in the organic solvent. In the gelating and solvent exchanging, silica hydrogel is generated by adding the inorganic acid to the dispersion solution and simultaneously performing gelating and solvent-exchanging. In the drying, the silica aerogel powders are generated by drying the silica hydro-gel.

Owner:AEROGEL R&D PTE LTD

Preparation method and use of poly(lactic-co-glycolic acid) (PLGA) microspheres as nucleic acid vaccine vectors

InactiveCN102485274AGood monodispersityImprove stabilityAntibacterial agentsGenetic material ingredientsMicrosphereGluconic acid

The invention discloses a preparation method and a use of poly(lactic-co-glycolic acid) (PLGA) microspheres as nucleic acid vaccine vectors. A result of an animal immunization experiment shows that the PLGA microspheres can be utilized as gene vaccine vectors. Principles of the PLGA microspheres comprise that 1, the PLGA microspheres have core-shell structures; surface polymers comprise polymine, PLGA, glucose, chitosan, polylysine, FeCl3 and FeCl2; and through static electricity, dewatering interaction and hydrogen bond-nucleic acid vaccine interaction, a nucleic acid vaccine is concentrated to form a compact nucleic acid vaccine so that nucleic acid vaccine degradation is reduced in vivo; 2, the PLGA microspheres have magnetism and thus after immunization injection, in a strong magnetic field, the distribution of the PLGA microspheres in muscular tissue is improved and the defect of limited contact between the PLGA microspheres and target cells is overcome; and 3, through long-term strong magnetic field induction, a magnetic PLGA microsphere / nucleic acid vaccine complex can enter into the skin; and because of rich antigen presenting cells in the skin, a strong and fast immune response can be induced.

Owner:JILIN UNIV

Manufacturing method of substrate for ink jet head and manufacturing method of ink jet recording head

InactiveUS20070212891A1Improve accuracyShort timeRecording apparatusDecorative surface effectsEngineeringAnisotropic etching

The present invention provides a manufacturing method of a substrate for an ink jet head including forming an ink supply opening to a silicon substrate, including (a) forming, at the back surface of the silicon substrate, an etching mask layer, which has an opening that is asymmetric with a center line, extending in the longitudinal direction, of an area on the surface of the silicon substrate where the ink supply opening is to be formed; (b) forming a non-through hole on the silicon substrate via the opening on the etching mask layer; and (c) forming the ink supply opening by performing a crystal anisotropic etching to the silicon substrate from the opening.

Owner:CANON KK

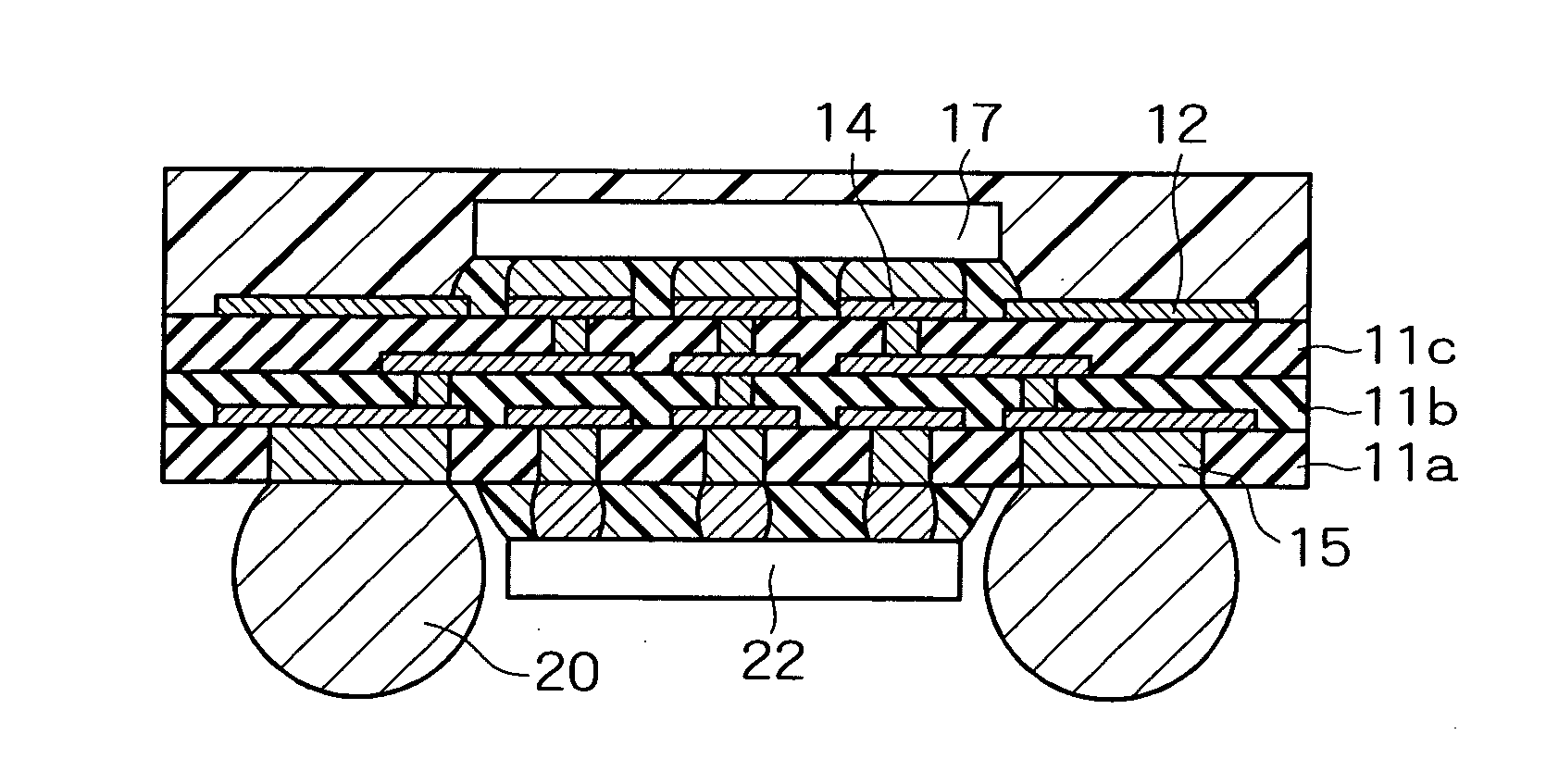

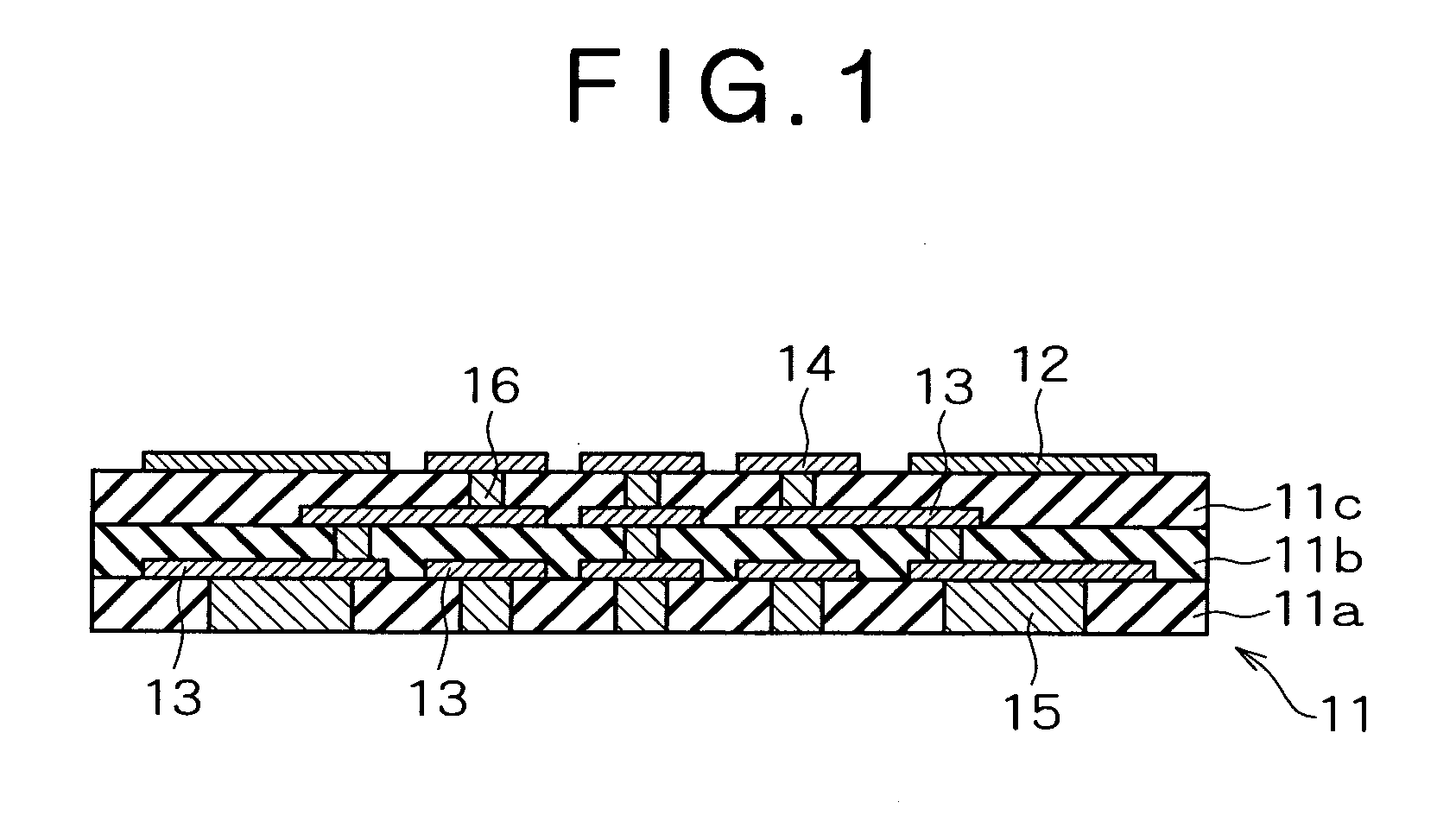

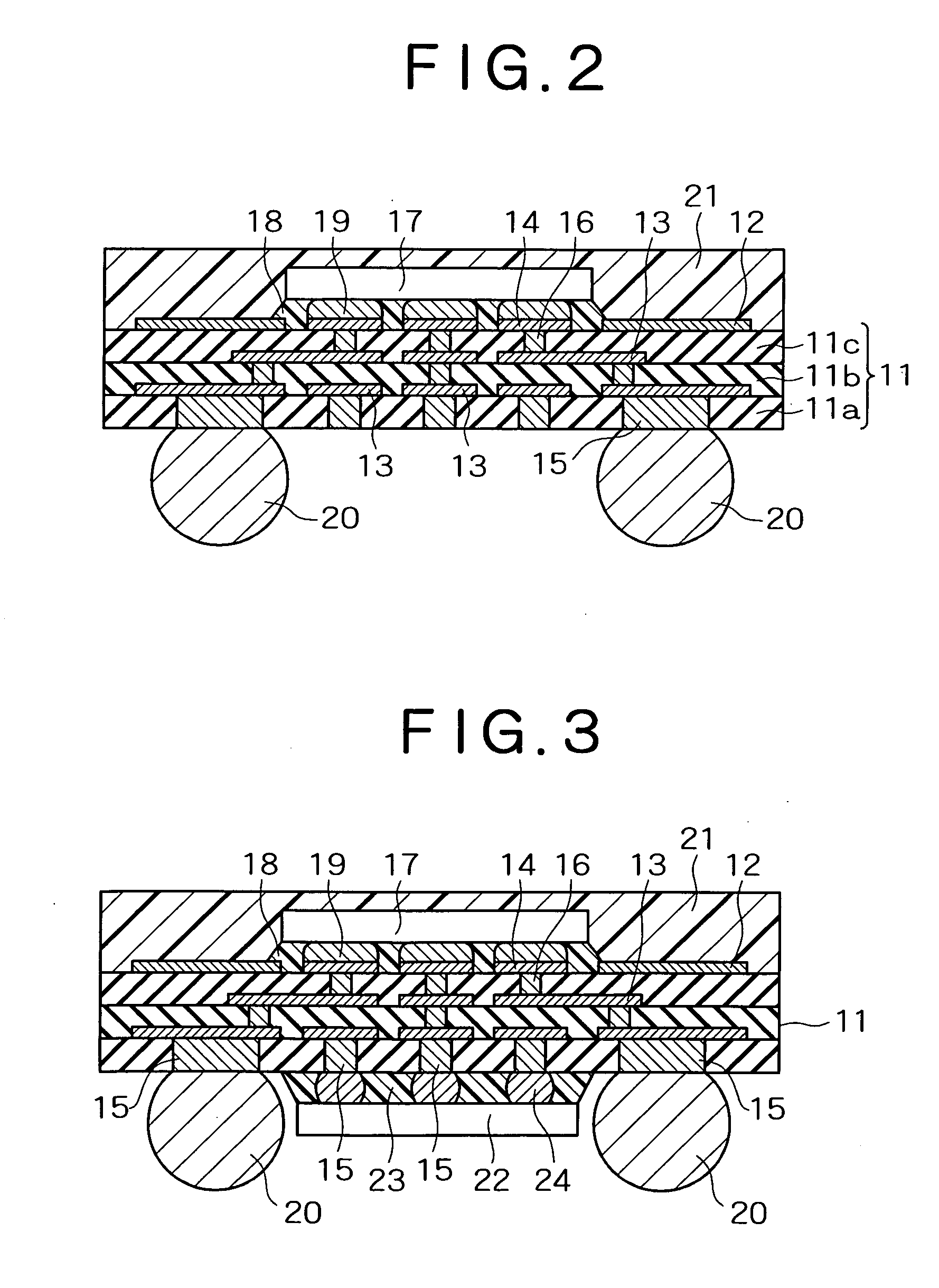

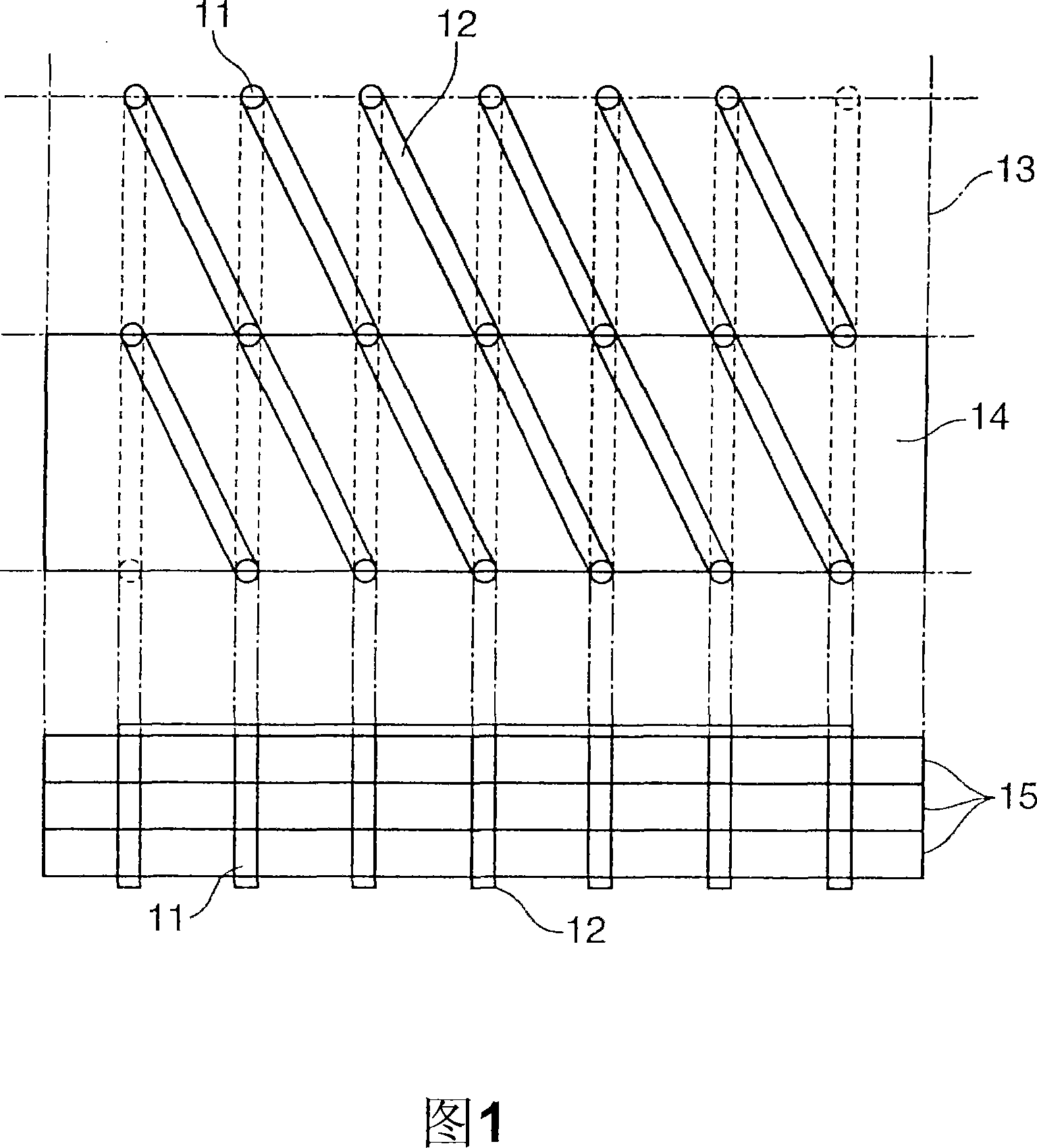

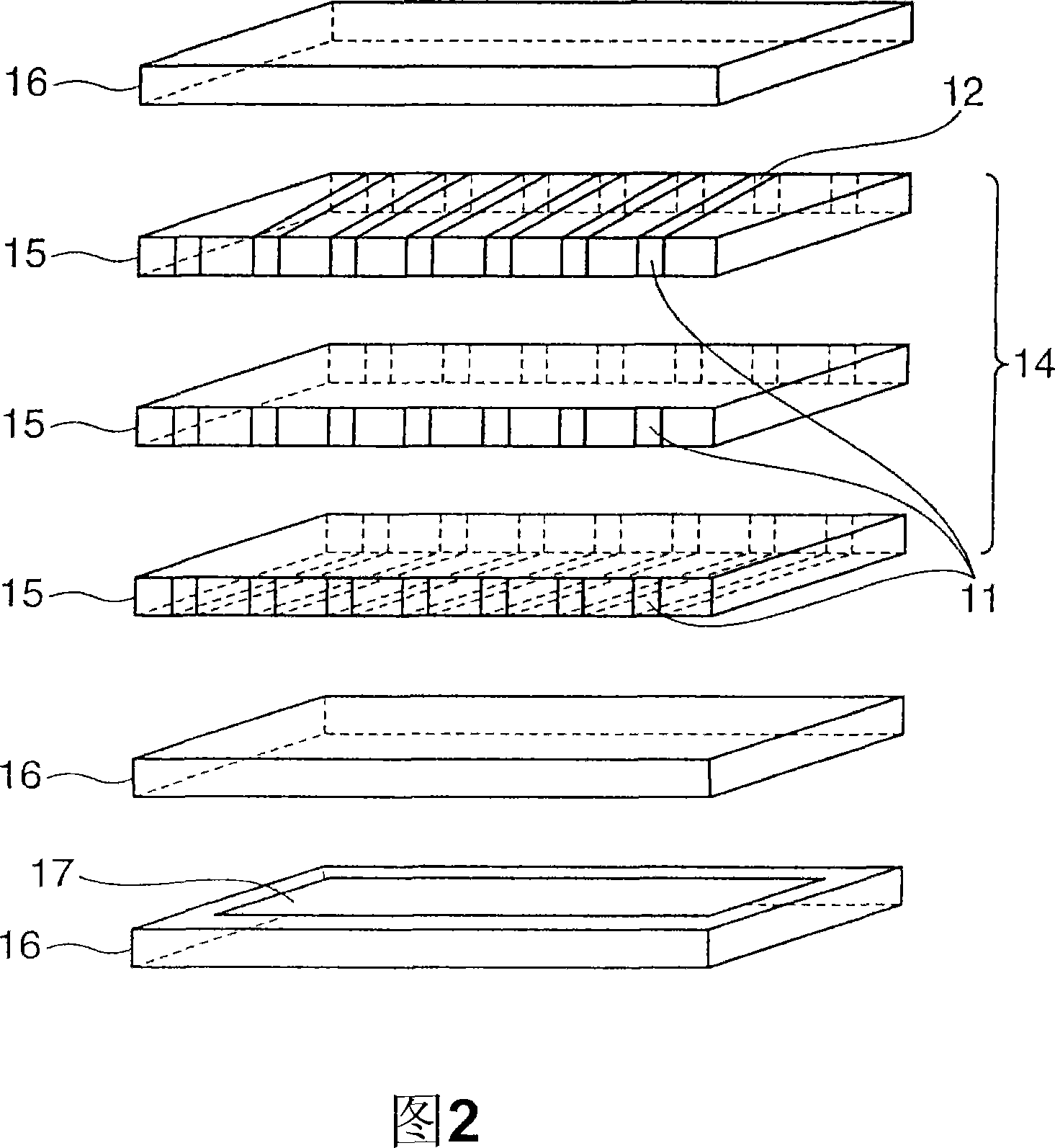

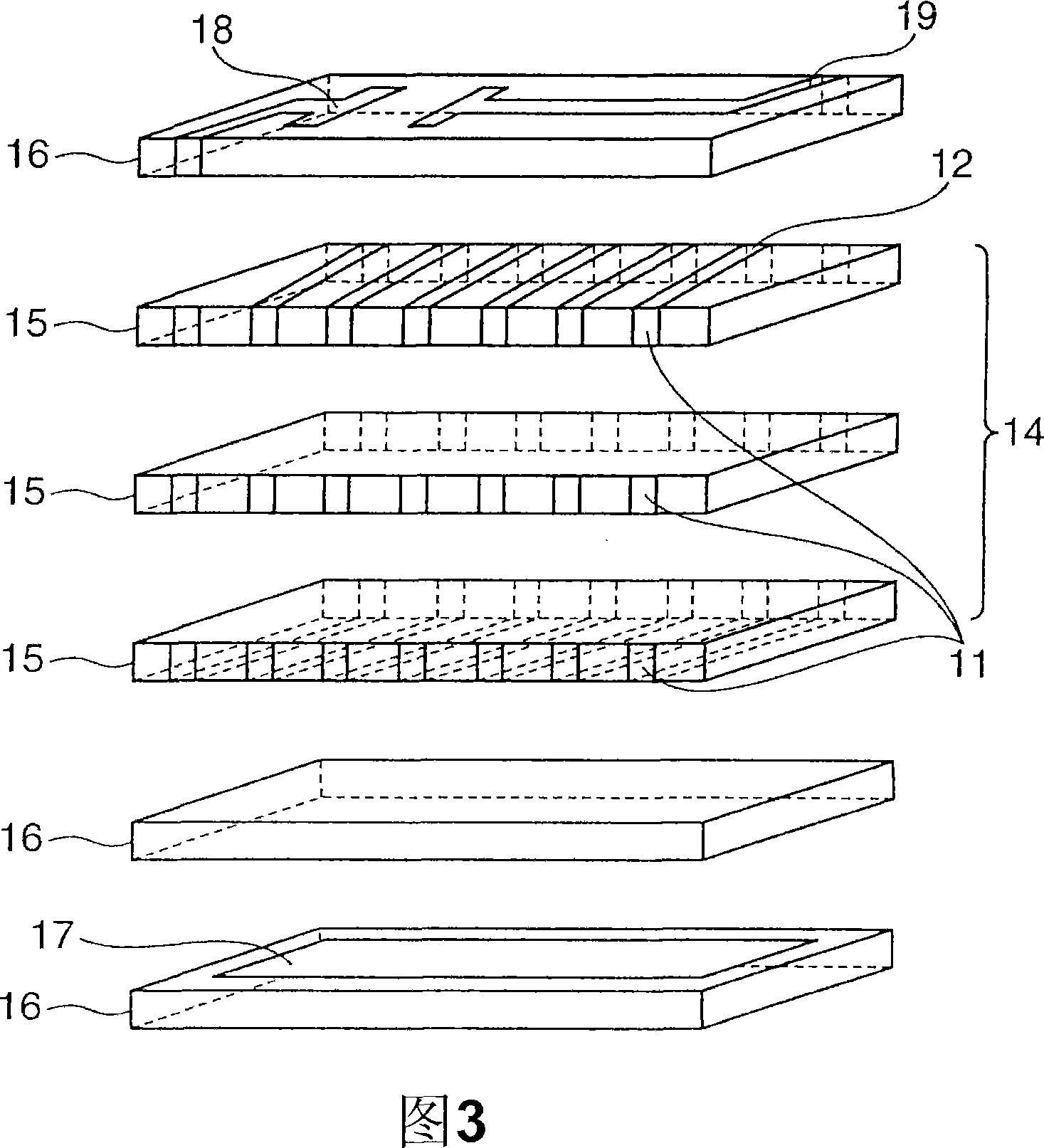

Multilayered wiring board, semiconductor device in which multilayered wiring board is used, and method for manufacturing the same

ActiveUS20070079986A1Avoid heatMinimize signalingPrinted circuit assemblingSemiconductor/solid-state device detailsInsulation layerDevice material

A multilayered wiring board has electrodes disposed on a first surface and a second surface, alternately layered insulation layers and wiring layers, and vias that are disposed in the insulation layer and electrically connect the wiring layers. The second electrode disposed on the second surface is embedded in the insulation layer exposed on said second surface, and the second wiring layer covered by the insulation layer exposed on said second surface does not have a layer for improving adhesion to the insulation layer.

Owner:RENESAS ELECTRONICS CORP

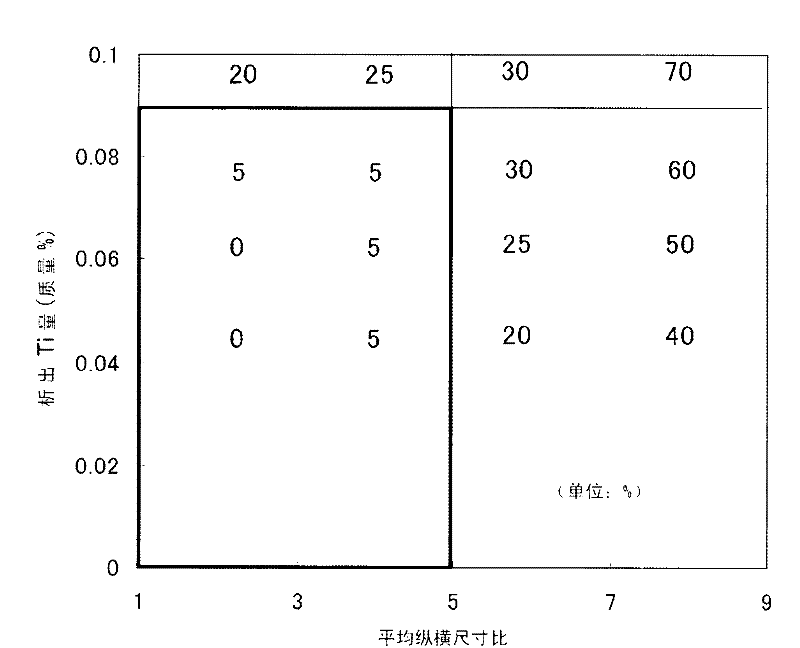

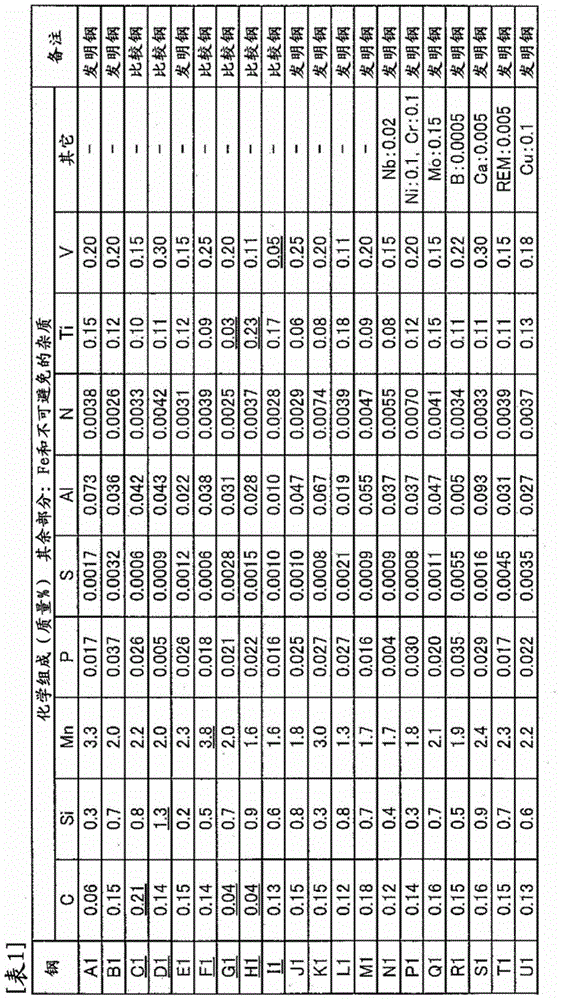

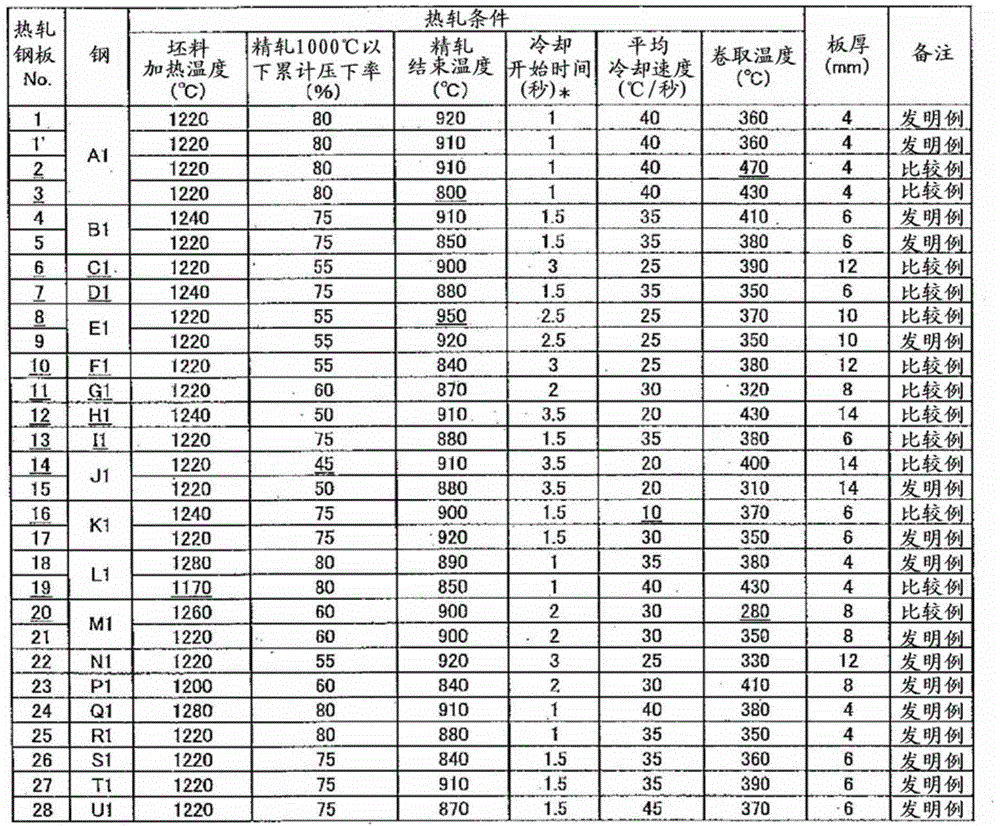

Hot rolled steel sheet having excellent punching workability and fatigue properties, hot dip galvanized steel sheet, and method for producing the same

ActiveCN102333899ALess end face damageExcellent fatigue propertiesFurnace typesMetal rolling arrangementsCarbideBrittle fracture

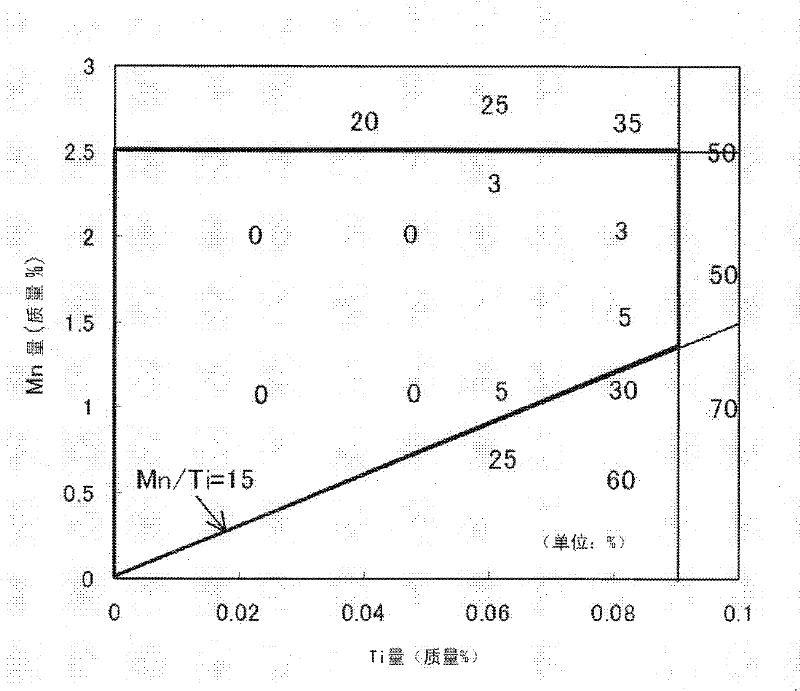

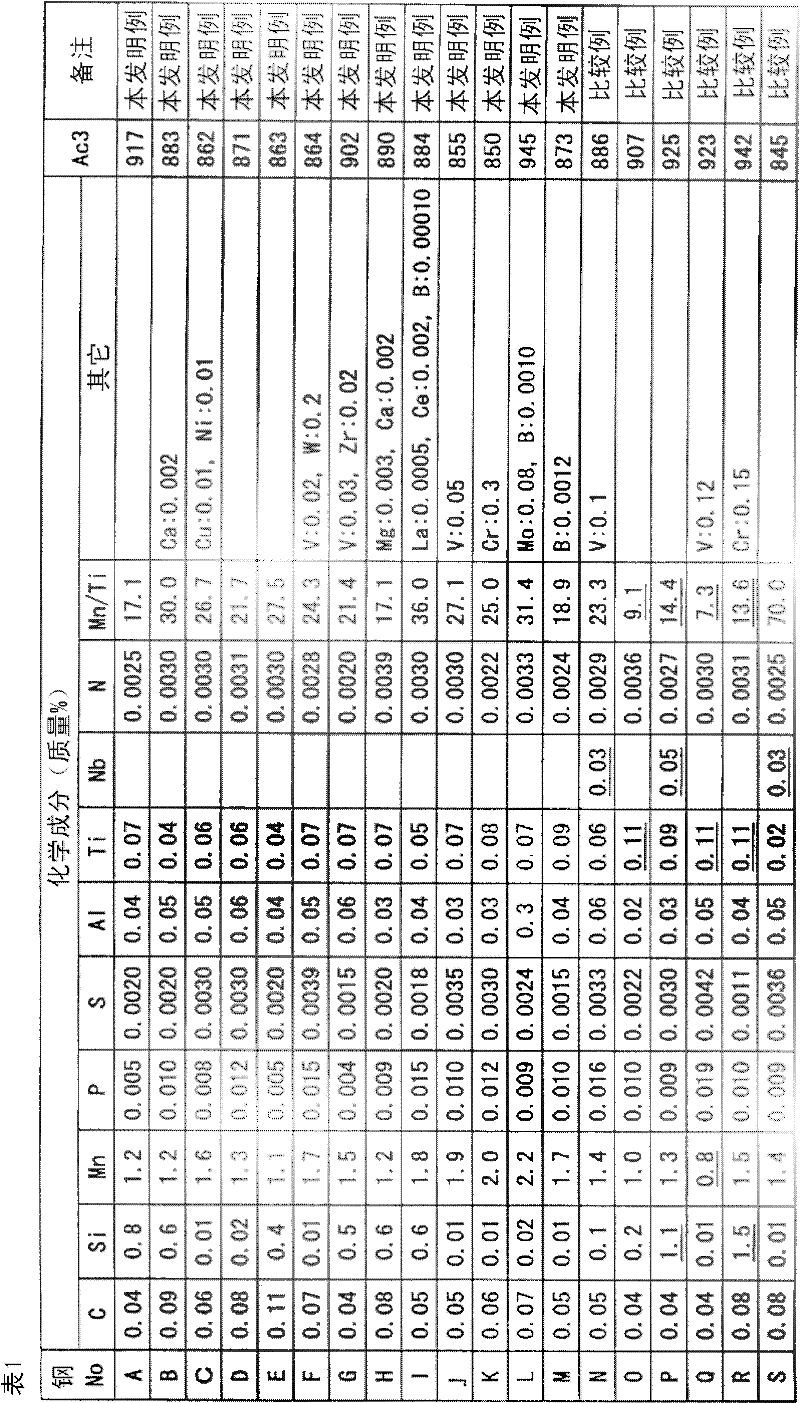

Provided is a hot rolled steel sheet comprising, by mass%, 0.025 to 0.15% of C, 0.01 to 1.0% or less of Si, 1.0 to 2.5% of Mn, 0.02% or less of P, 0.005% or less of S, 0.5% or less of Al, 0.04 to 0.10% of Ti, and 0.007% or less of N, as well as Fe and inevitable impurities as the balance, wherein the Mn / Ti ratio is 15 or greater; Nb is not added; the ferrite volume percentage is 30% or greater and the balance comprises one of or both pearlite and bainite; the average aspect ratio of the crystal grain corresponding ellipsoid is 5 or less; the average distribution density on the ferrite grain boundary surface of Ti carbide having a grain size of 20 nm or greater is 10 grains / [mu]m or less; the brittle fracture rate of surface fractured by punching is less than 20%; and the maximum tensile strength is 590 MPa or greater.

Owner:NIPPON STEEL CORP

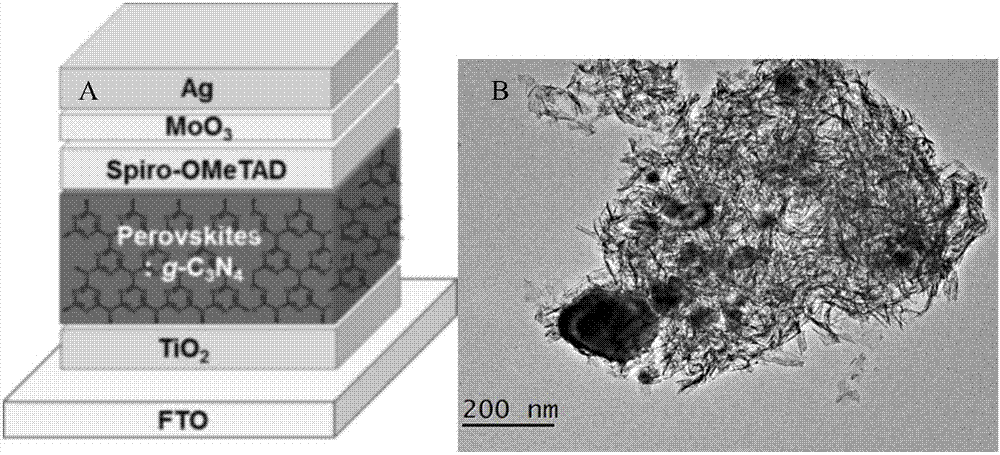

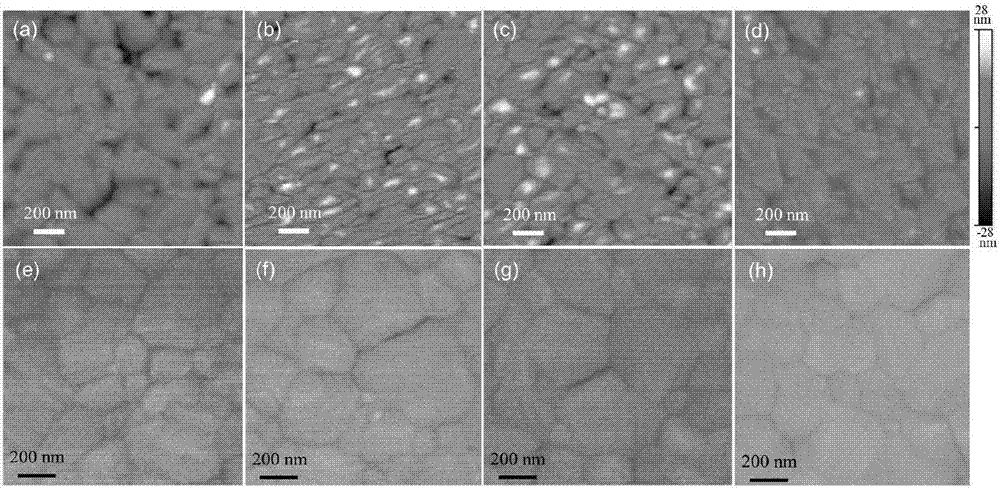

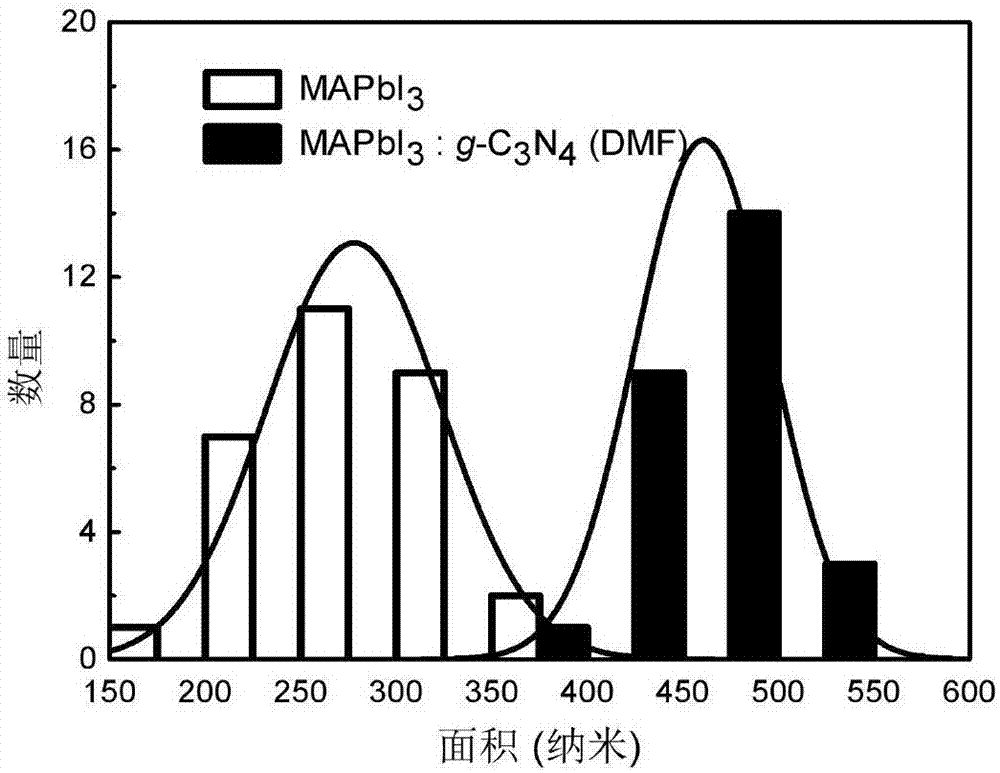

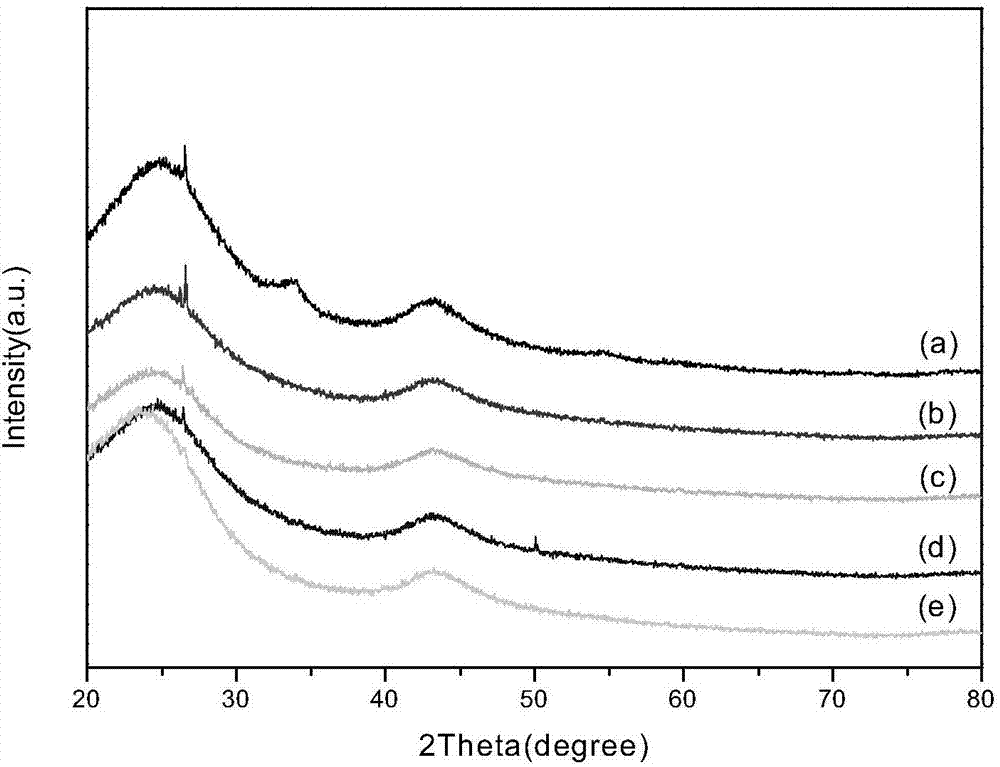

Method for preparing perovskite solar cell on basis of two-dimensional material graphene-phase carbon nitride

ActiveCN107887511AImprove crystallizationStable manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

The invention provides a method for preparing a perovskite solar cell on the basis of a two-dimensional material graphene-phase carbon nitride. The graphene-phase carbon nitride is doped into a perovskite precursor solution to prepare the perovskite solar cell. The method has the following advantages that (1) the raw material required for synthesis of the material is low in cost, and the product is small in toxicity; (2) solvent volatilization during the annealing process is effectively slowed down, so that a perovskite thin film crystal is more uniform and compact; (3) the grain crystal sizeof a perovskite layer is increased, a crystal boundary easy to combine with charge is effectively reduced, and the filling factor of a device is improved; (4) a surface of the perovskite thin film ispassivated, and the hysteresis phenomenon of the device is effectively improved; and (5) the conductivity of the surface of the perovskite thin film is improved, the contact resistance of the interface is reduced, and the short-circuit current of the device is increased. The preparation process is simple and convenient and is low in preparation difficulty; by doping of the graphene-phase carbon nitride, the smoothness and the uniformity of the perovskite thin film can be effectively improved; and by a series of gradient doping, the device performance is remarkably changed.

Owner:SUZHOU UNIV

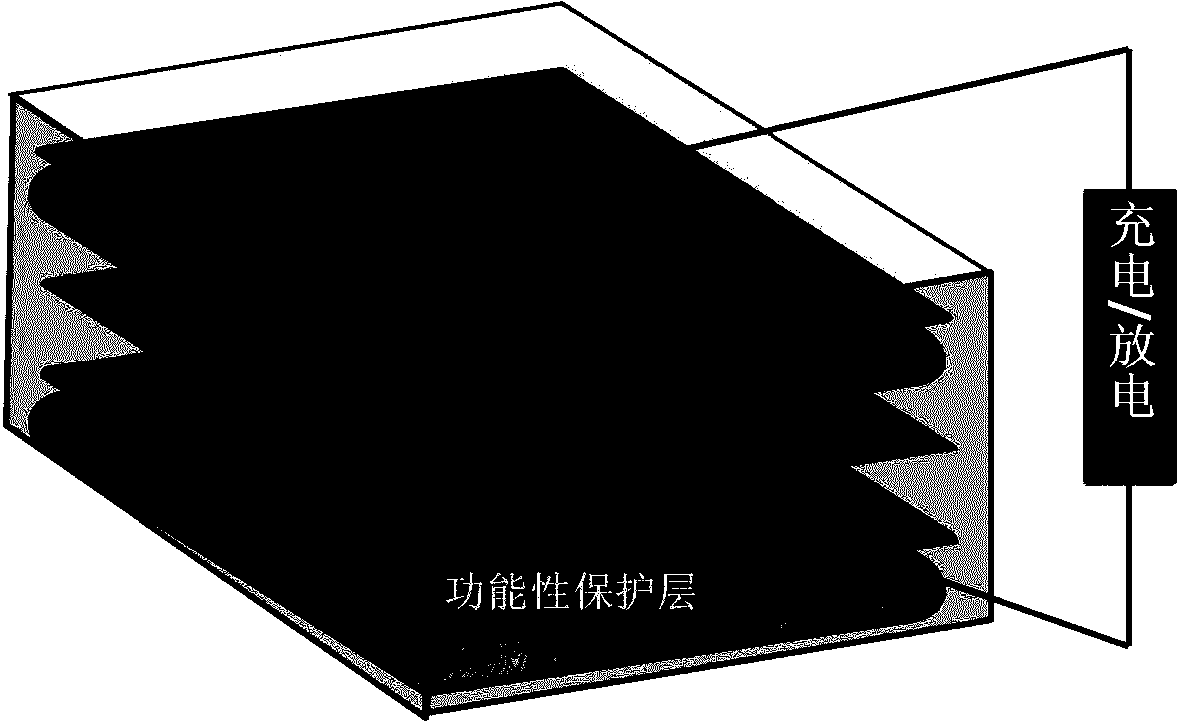

Lithium negative electrode with functional protective layer and lithium sulfur battery

InactiveCN103985840ASafe preparationStable manufacturingNon-aqueous electrolyte accumulator electrodesLi-accumulatorsConductive polymerLithium–sulfur battery

The invention relates to a lithium negative electrode with a functional protective layer and a lithium sulfur battery. The lithium negative electrode is provided with a functional protective layer which is coated on the surface and includes a conductive polymer. In the lithium sulfur battery, the functional protective layer of the lithium negative electrode is contacted with an electrolyte, so that a stable interface is formed between the electrolyte and a base body of the lithium negative electrode.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

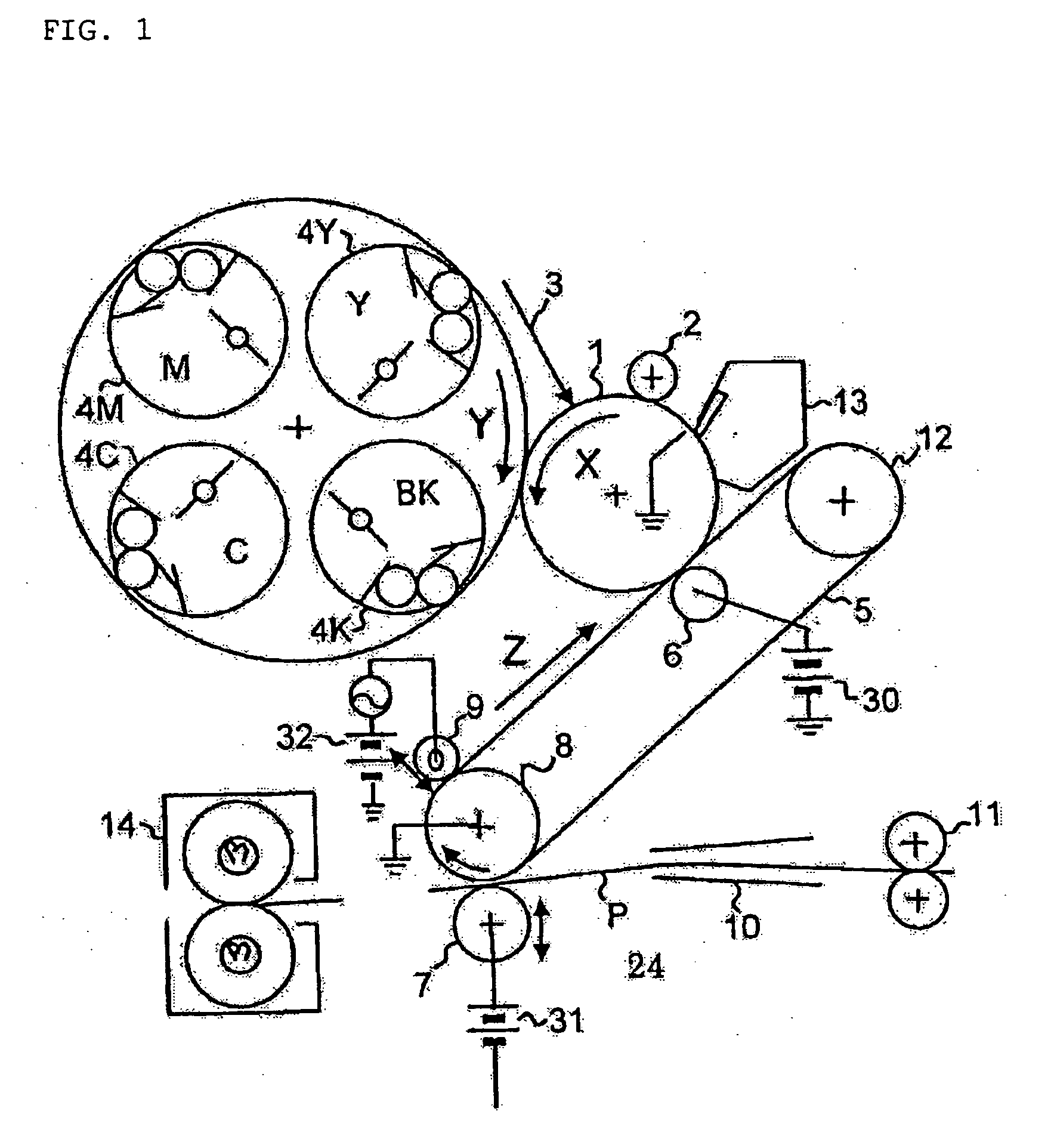

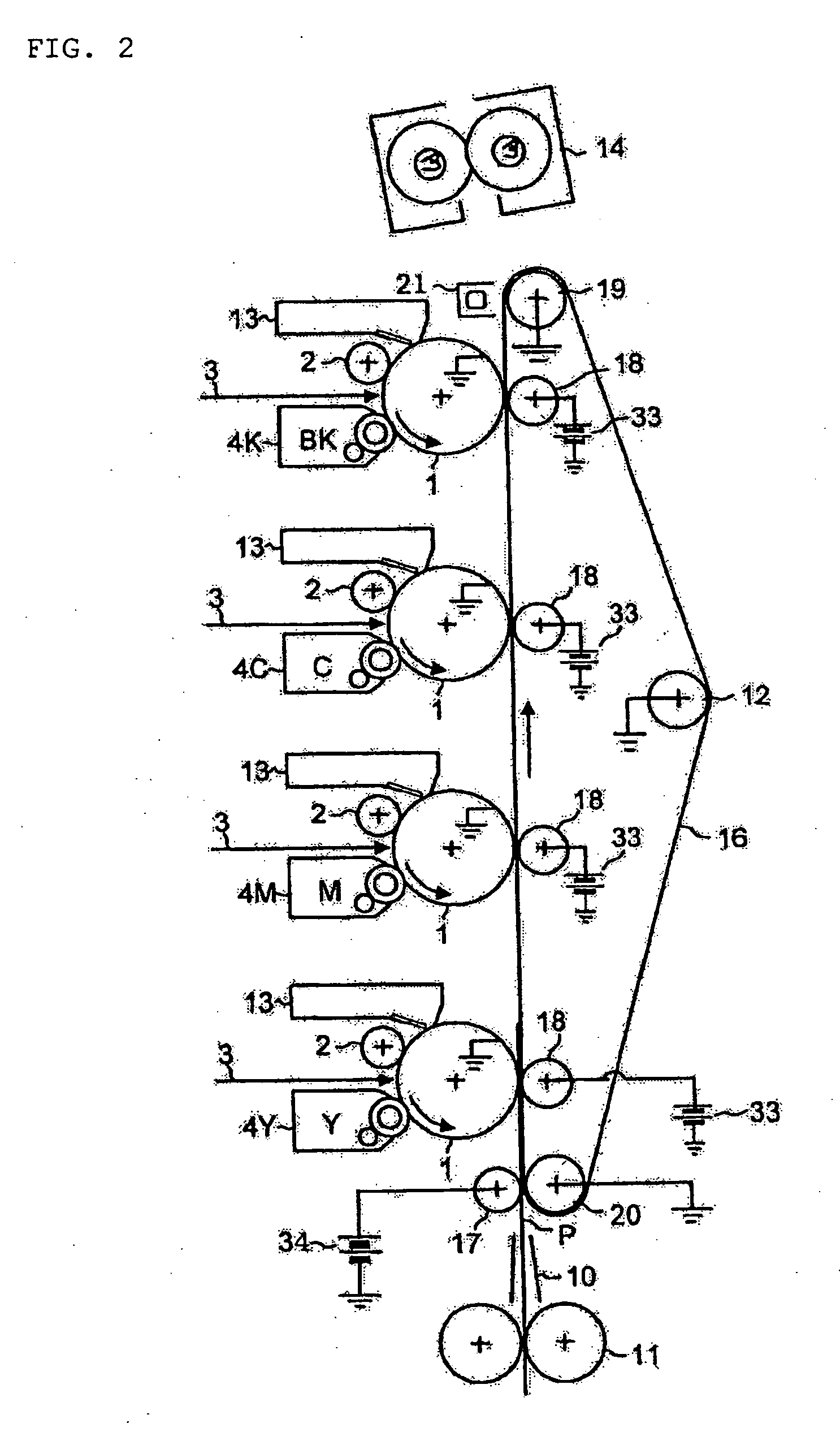

Method of manufacturing electrophotographic seamless belt and electrophotographic apparatus

InactiveUS20060151907A1Low costIncreased durabilityElectrographic process apparatusBeltsEngineeringBlow molding

A method of manufacturing an electrophotographic seamless belt, includes setting a substantially cylindrical preform made of a thermoplastic resin mixture containing a thermoplastic resin and having an outer diameter “a”, in a seamless belt molding die including a cylindrical cavity having an inner diameter “b”, and stretch blow molding at a predetermined stretch temperature T1 to obtain a stretch-blow-molded part; and cutting the stretch-blow-molded part to obtain a seamless belt. The thermoplastic resin mixture has a temperature T2 at which a parameter S / P calculated from a tensile-stress to strain curve obtained by performing a JIS K7161 test on a sheet test piece made of the thermoplastic resin mixture is 2.0 to 15.0 T2 is set as the predetermined stretch temperature T1. P indicates stress when a stretch magnification is 0.6×(b / a) and S indicates stress when the stretch magnification is 1.6×(b / a) and (b / a)≧1.7.

Owner:CANON KK

Nitrogen-doped activated carbon supported noble metal catalyst and application thereof

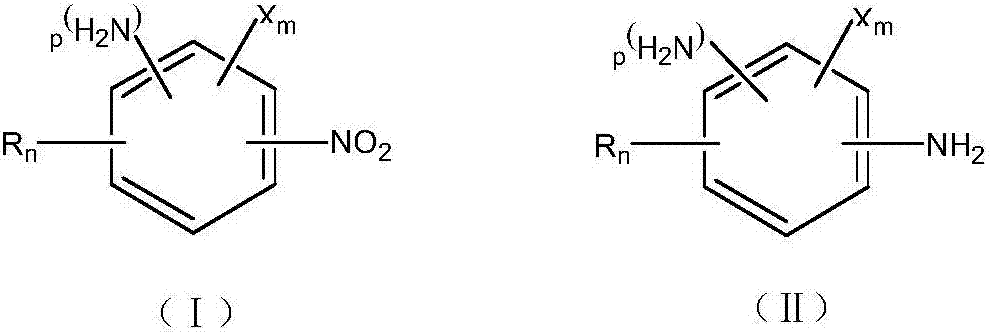

ActiveCN107413331AEnhanced electron transfer capabilityRedistribution of electronsOrganic compound preparationAmino compound preparationActivated carbonIridium

The invention discloses a nitrogen-doped activated carbon supported noble metal catalyst and an application thereof. The catalyst is composed of a carrier and an active component; the carrier is nitrogen-doped activated carbon; the active component is one of palladium, platinum, rhodium, ruthenium and iridium; and the load of the active component is not higher than 15wt% based on the mass of the carrier. The invention provides the application of the nitrogen-doped activated carbon supported noble metal catalyst to reaction for preparing an alkyl-containing halogenated aromatic aminocompound shown as a formula (II) by carrying out catalytic hydrogenation reduction on an alkyl-containing halogenated aromatic nitrocompound shown as a formula (I) to show that the nitrogen-doped activated carbon supported noble metal catalyst has the characteristics of high hydrogenation reaction rate, high catalytic activity, high selectivity and high stability.

Owner:ZHEJIANG UNIV OF TECH

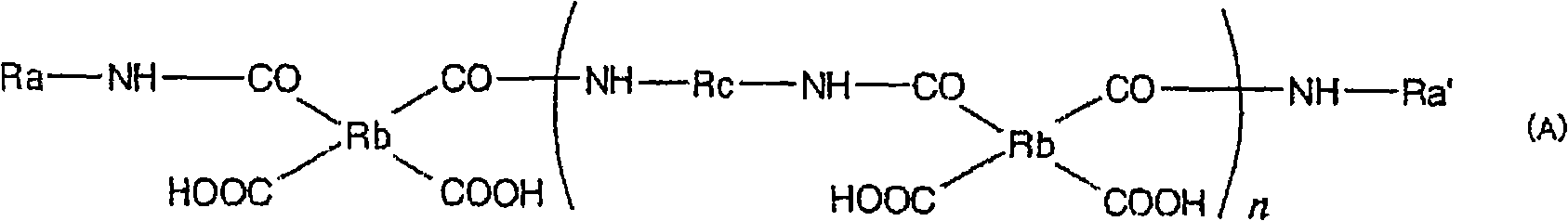

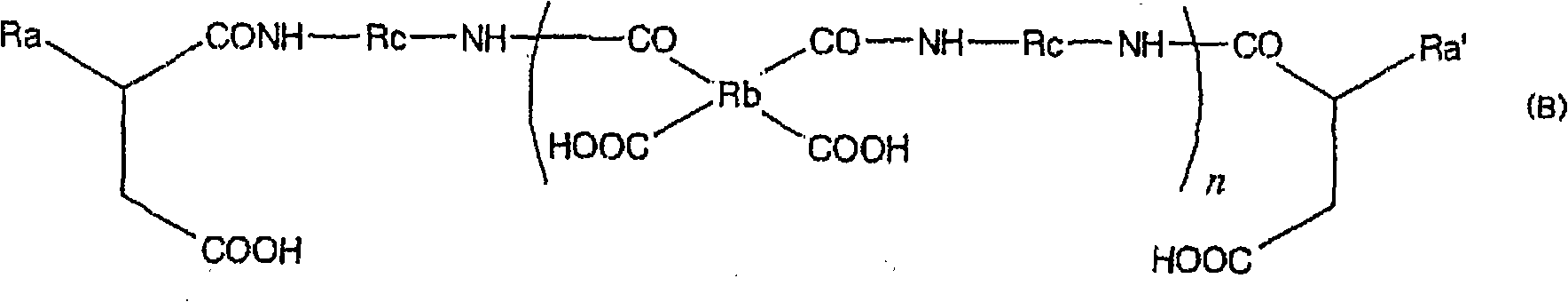

Process for producing polyimide film and polyimide film

InactiveCN101289544AExcellent adhesion improvement effectNo difference in adhesionFilm/foil adhesivesAdhesive processes with surface pretreatmentOligomerPolyamic acid

A solution containing a polyamic acid oligomer having at least one terminal alkoxysilyl group is applied to one side or both sides of a self-supporting film of a polyimide precursor solution, and then the self-supporting film is heated to effect imidization, thereby providing a polyimide film with reliably improved adhesiveness.

Owner:UBE IND LTD

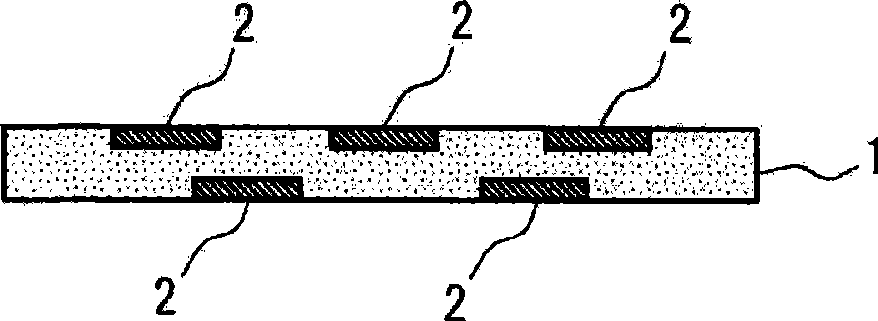

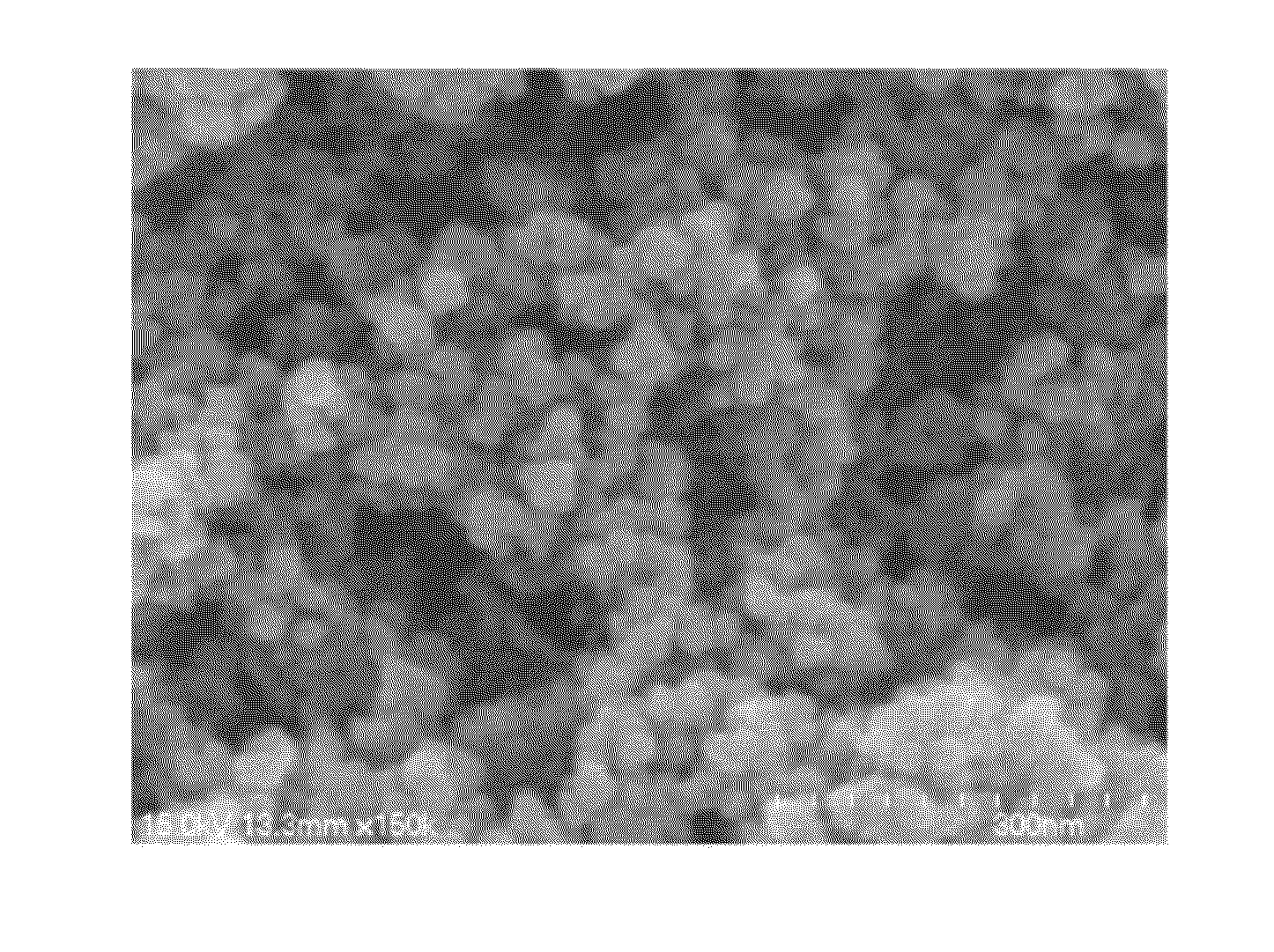

Method for preparing magnetic composite nanoparticles with core-shell structure

InactiveCN101817960AUniform particle sizeLarge particle sizeMagnetic materialsMicroballoon preparationMicrosphereNanoscopic scale

The invention discloses a method for preparing magnetic composite nanoparticles with a core-shell structure. In the method, electrostatic self-assembly and seeded emulsion polymerization are combined, wherein the electrostatic self-assembly is used to synthesize particles with the core-shell structure first and then emulsion polymerization is performed by using the particles with the core-shell structure seeds and using an initiator to prepare the magnetic composite nanoparticles with the sandwich core-shell structure which has three or more layers. The magnetic composite particles prepared by the method have a multi-layer sandwich core-shell structure, wherein in the structure, the core is a polymer microsphere, a Fe3O4 magnetic particle layer is in the middle, and different polymer layers are covered outside. The prepared particles have stable structures, strong and uniformly-distributed magnetism, smooth surfaces, controllable sizes, high stability and low cost, the thicknesses of the covering layers of the prepared particles can be controlled by nanoscale, and the adaptability of the prepared particles is high. Particles with specific surface groups can be prepared according to requirements and can be used in fields of biochemical separation, targeting preparation, immobilized enzyme, immunoassay, catalysis study and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

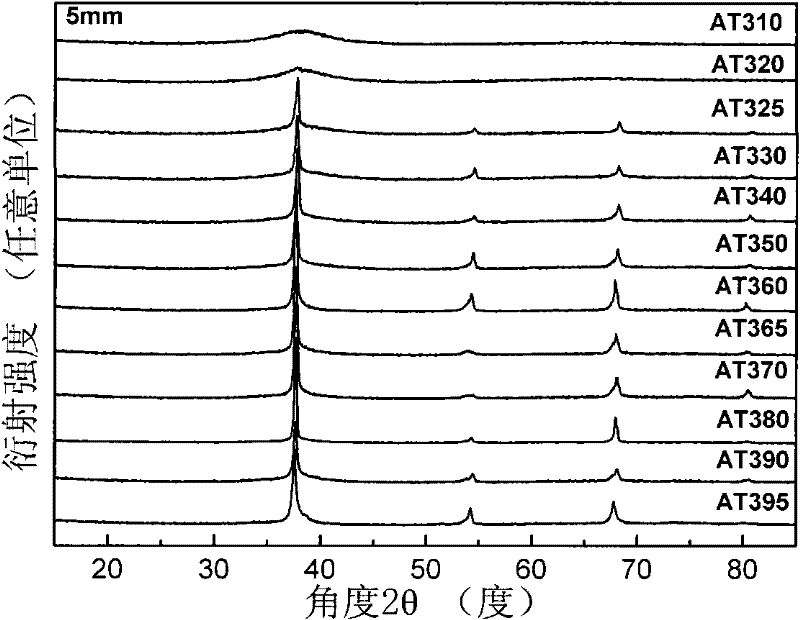

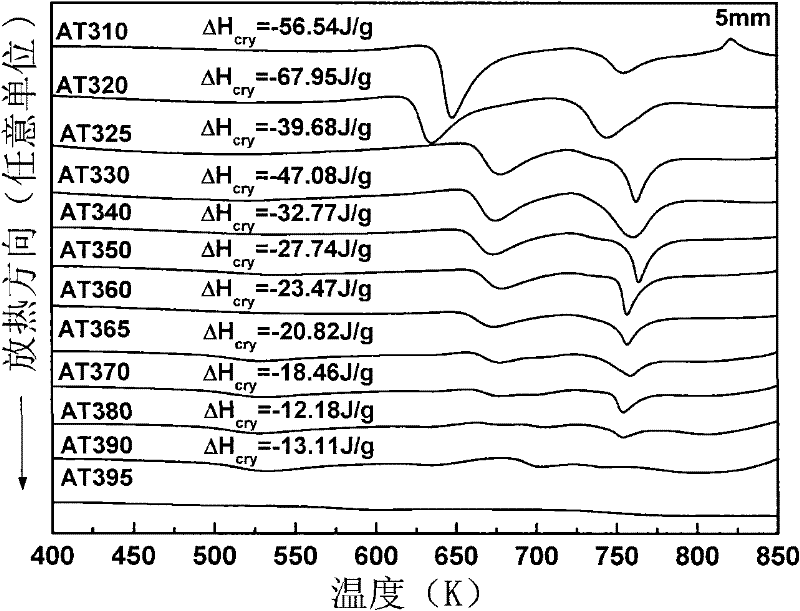

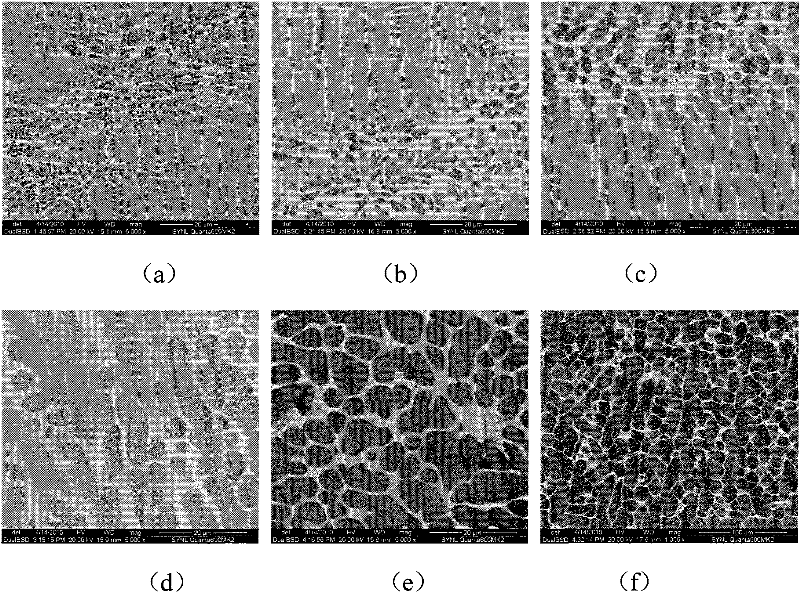

Endogenous ductile phase reinforced ti-based amorphous composite material and preparation method thereof

ActiveCN102296253AStable manufacturingNo post-treatment process requiredTensile strainSolid solution strengthening

The invention relates to the field of Ti-based amorphous composite materials, in particular to the design and preparation method of endogenous toughness β-Ti solid solution reinforced Ti-based amorphous composite materials. The composition of the composite material is (atomic percentage) TiaAbBcBed, wherein: A is one or several elements of Zr, Nb, Ta, Mo, V, and W, and B is one or several elements of Cu, Ni, Fe, and Co. species, a=30-65; b=26-38; c=1-25; d=0-25. The toughness β-Ti solid solution reinforced Ti-based amorphous composite material with different volume fractions is obtained by adjusting the alloy composition, the size of the β-Ti solid solution is 1-200 μm, and the volume fraction is 0-100. The composite material exhibits excellent comprehensive mechanical properties, and has a certain degree of plastic deformation behavior while having high strength. The compressive yield strength is 1000-1900MPa, the compressive breaking strength is 1200-2300MPa, and the compressive strain is 2-20%; the tensile yield strength of the composite material is 1000-1900MPa, the tensile breaking strength is 1200-2000MPa, and the tensile strain is 2 -20%. It plays an important role in the application of Ti-based amorphous composite materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

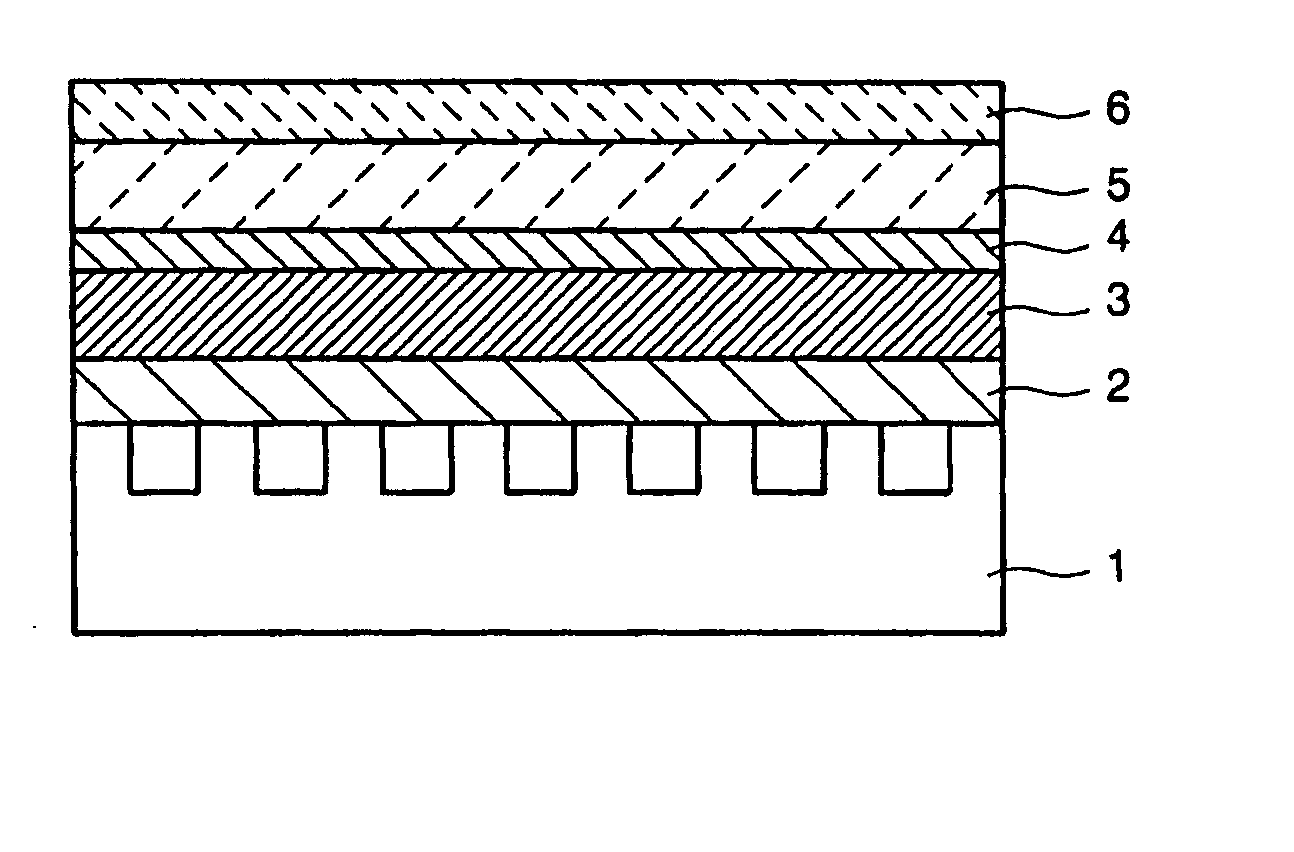

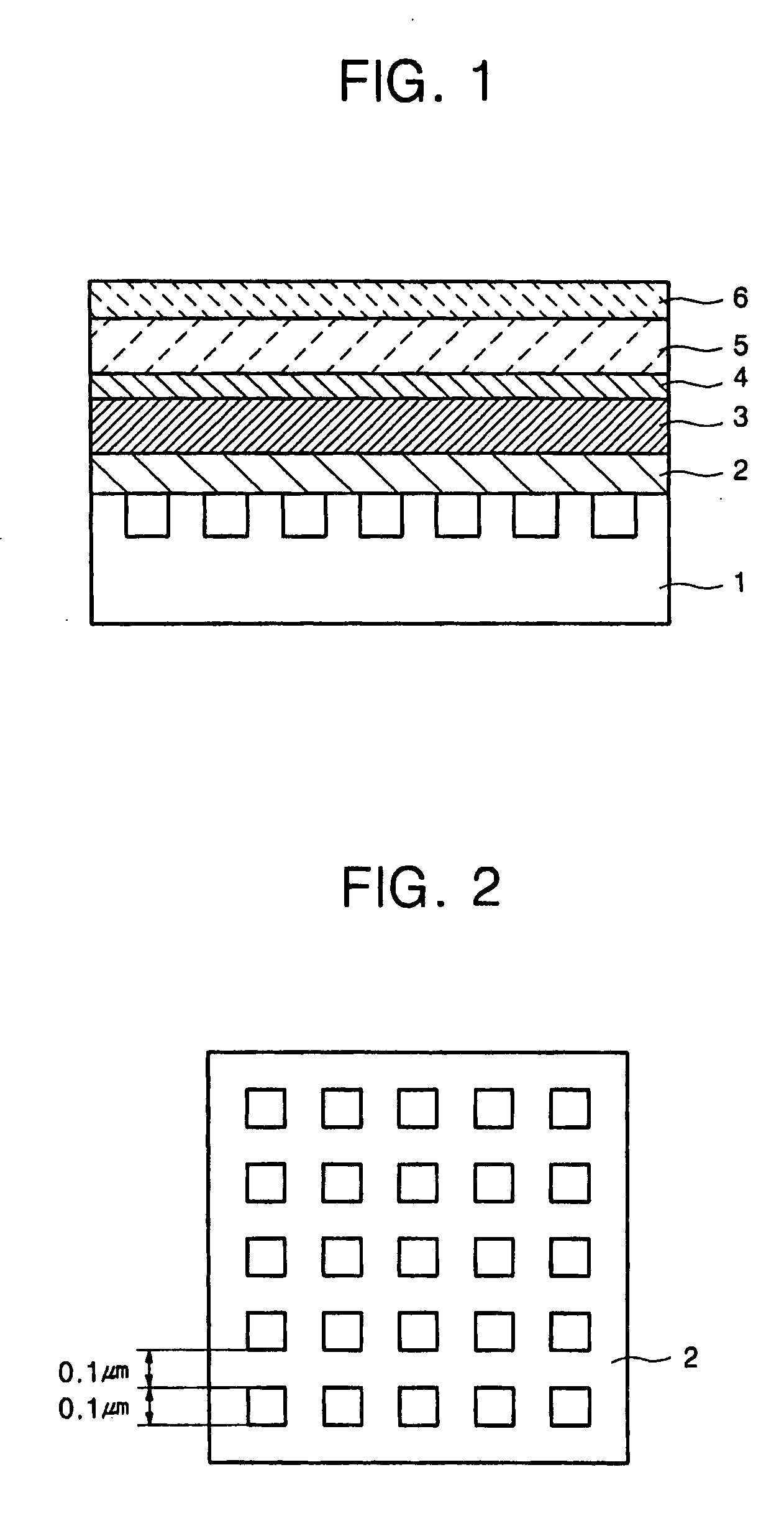

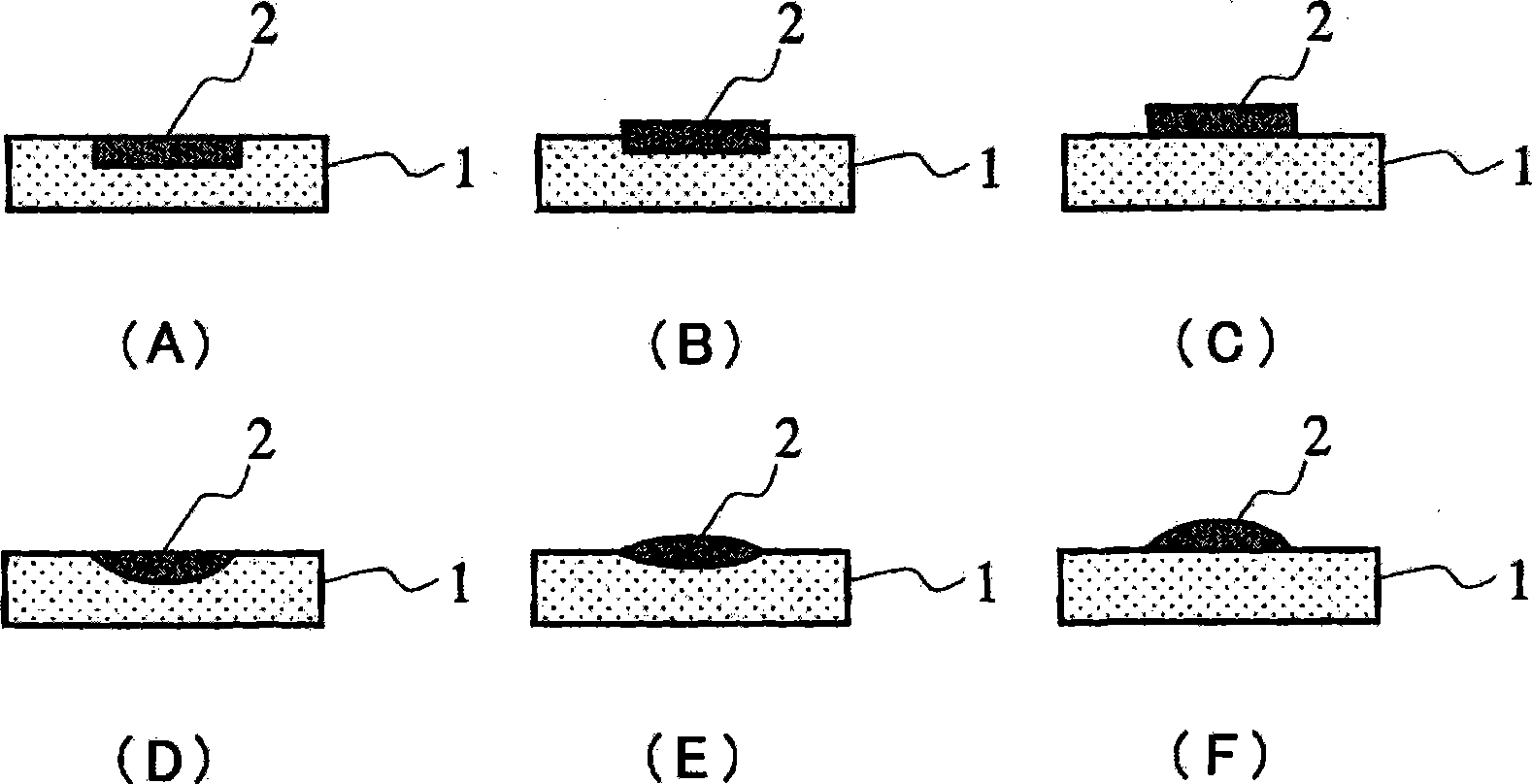

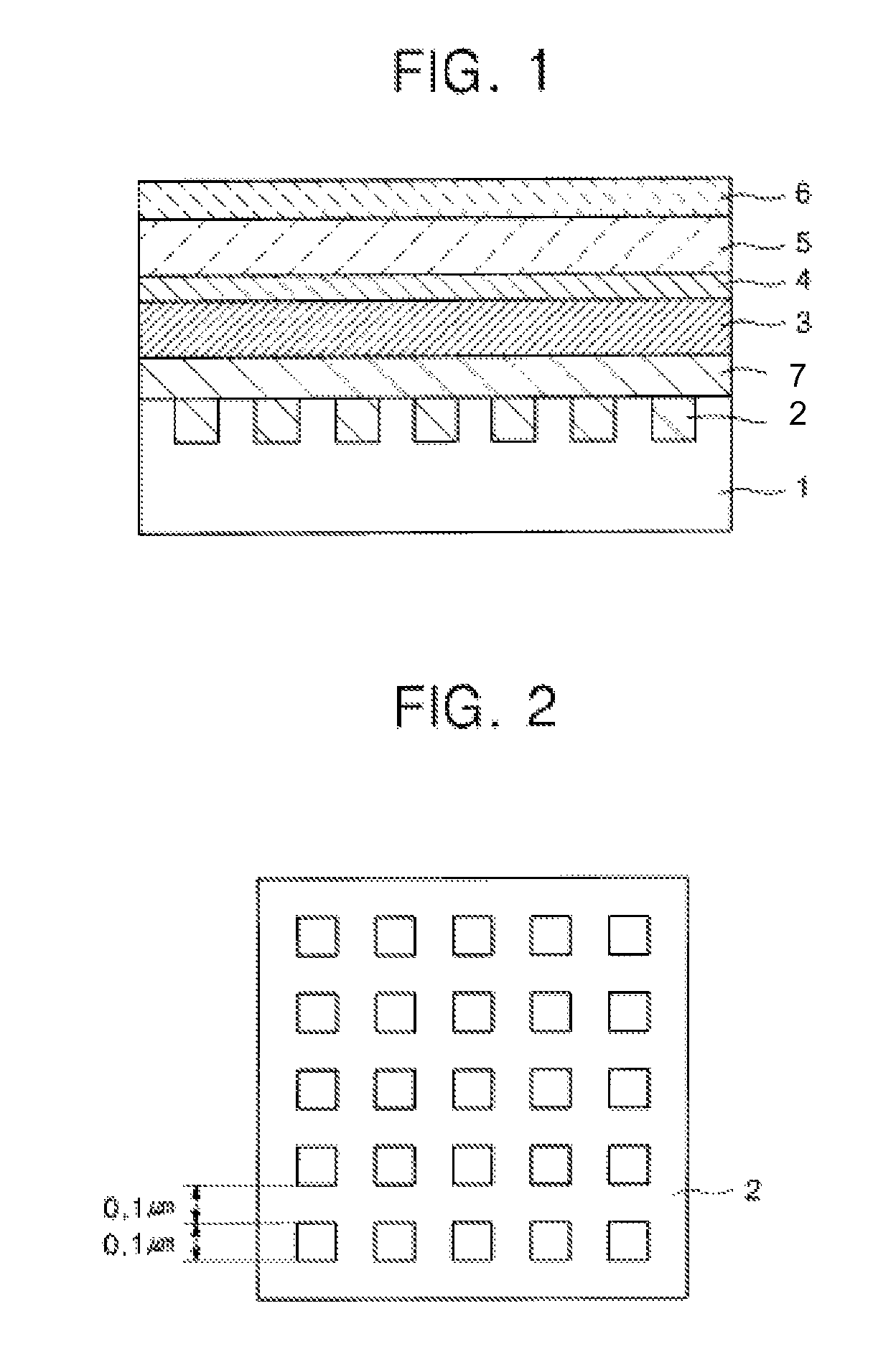

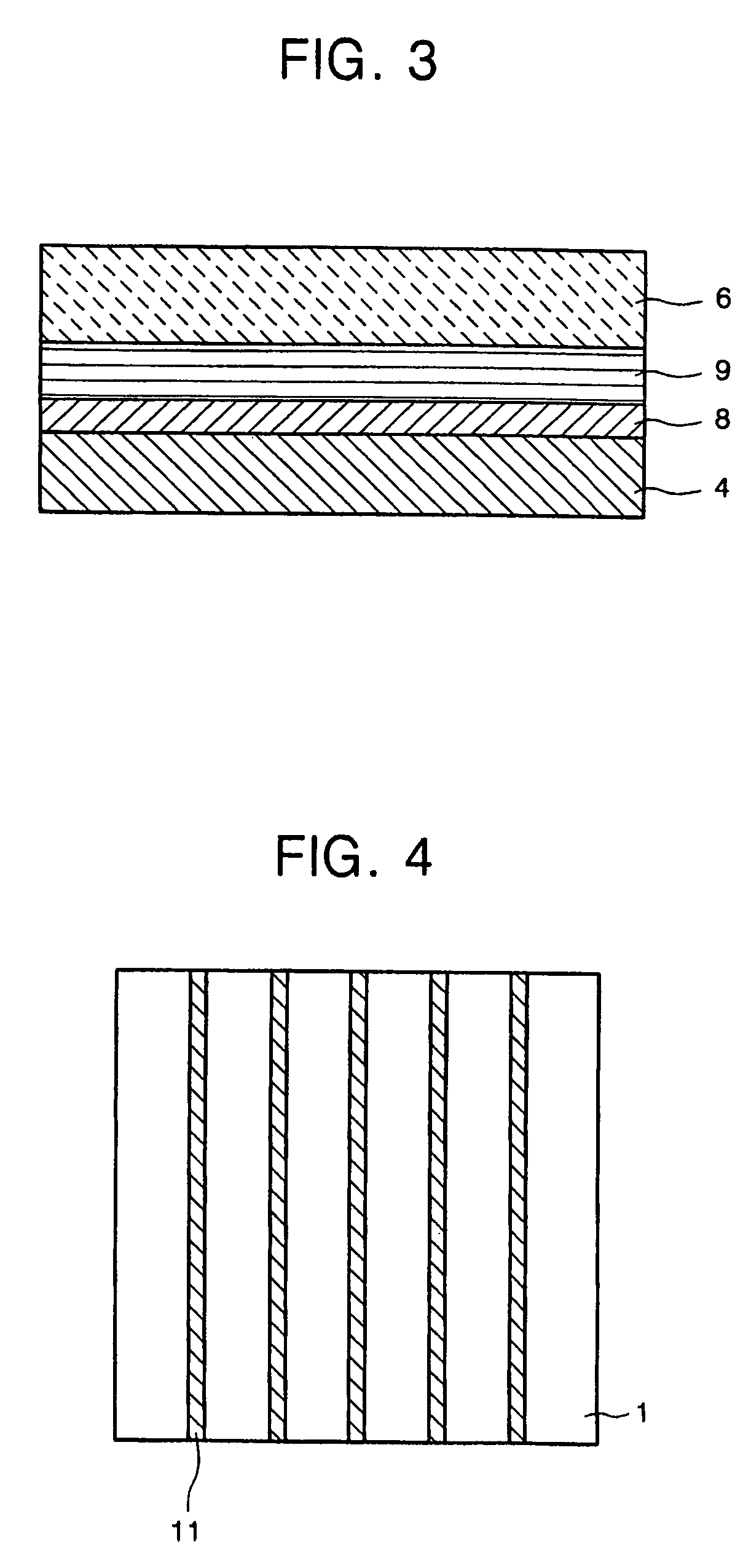

Electroluminescent display device

ActiveUS7619357B2Improve luminous performanceHigh luminous efficiencyIncadescent screens/filtersDischarge tube luminescnet screensOrganic electroluminescenceLuminescence

The present invention relates to an organic electroluminescent device. There is provided an organic electroluminescent device with a good luminescence property and high luminous efficiency in which the organic electroluminescent device has a diffraction grating 2 on the surface of the substrate 1 and an organic EL layer 5 including an emission layer between an anode 4 an a cathode 6 via an intermediate layer 3.

Owner:SAMSUNG DISPLAY CO LTD

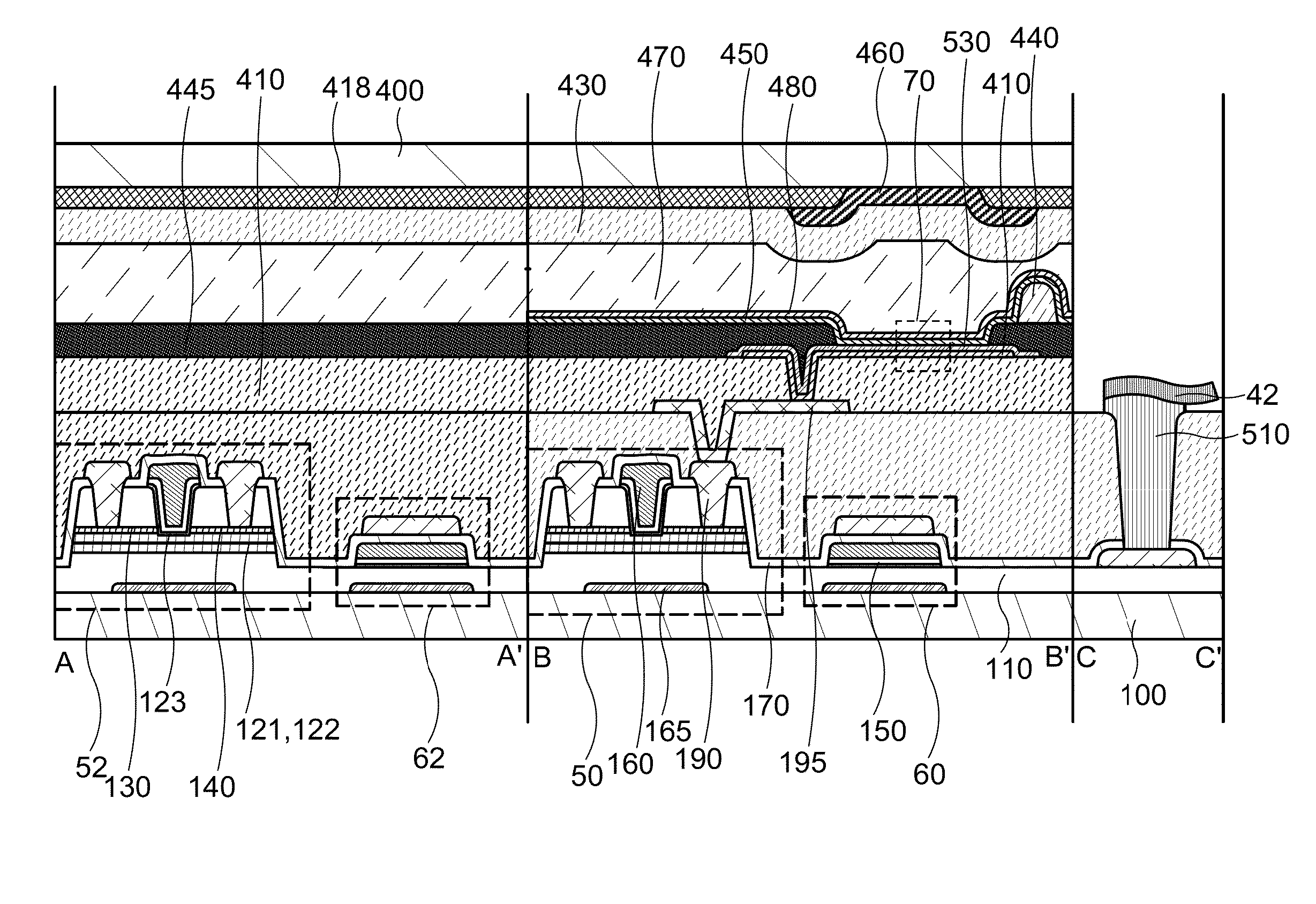

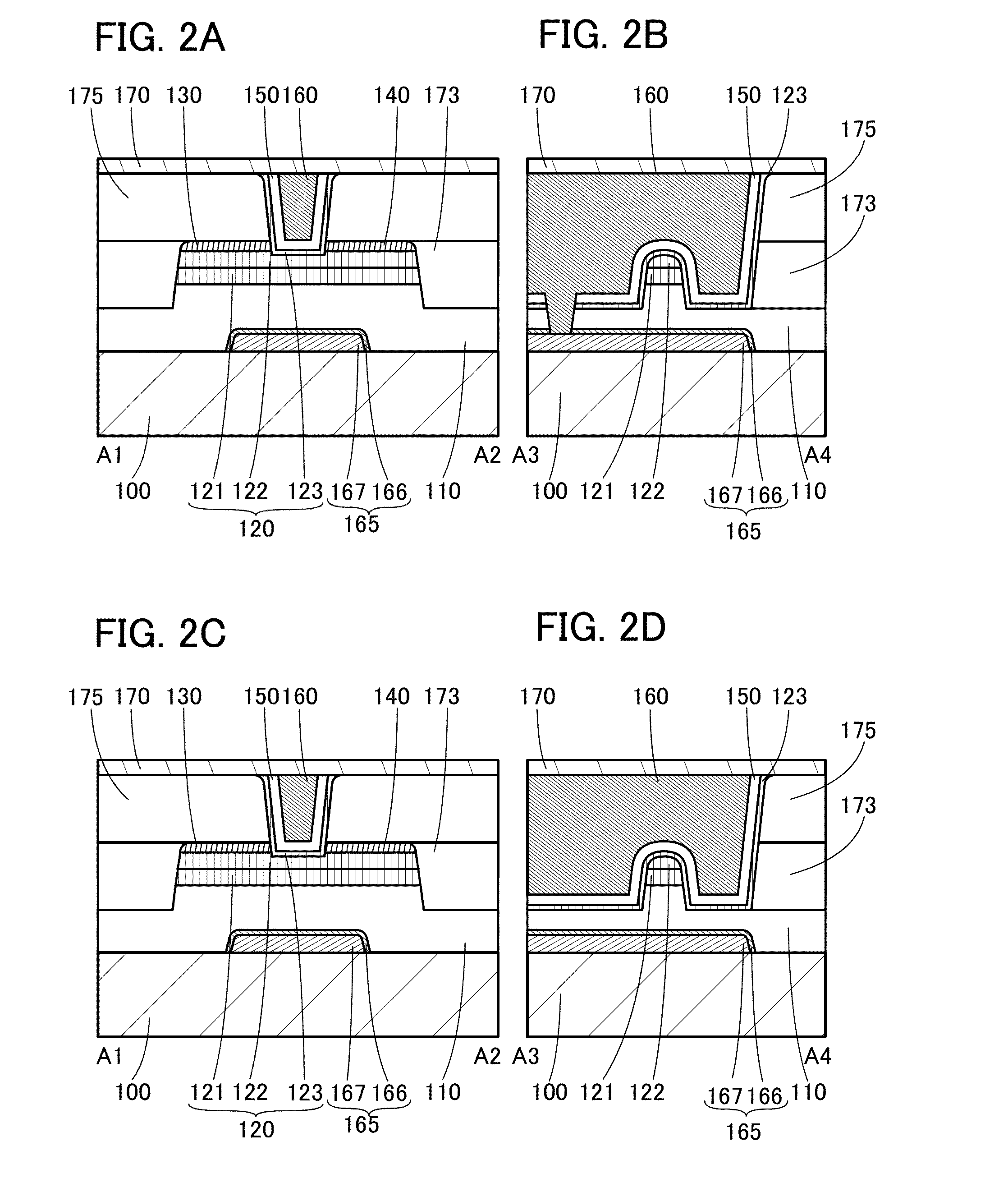

Semiconductor device and method for manufacturing the same

ActiveUS20160247832A1Excellent electrical propertiesImprove reliabilityTransistorSolid-state devicesParasitic capacitanceSemiconductor

A semiconductor device with reduced parasitic capacitance is provided. The semiconductor device includes a first insulating layer; a first oxide layer over the first insulating layer; a semiconductor layer over the first oxide layer; a source electrode layer and a drain electrode layer over the semiconductor layer; a second insulating layer over the first insulating layer; a third insulating layer over the second insulating layer, the source electrode layer, and the drain electrode layer; a second oxide layer over the semiconductor layer; a gate insulating layer over the second oxide layer; a gate electrode layer over the gate insulating layer; and a fourth insulating layer over the third insulating layer, the second oxide layer, the gate insulating layer, and the gate electrode layer.

Owner:SEMICON ENERGY LAB CO LTD

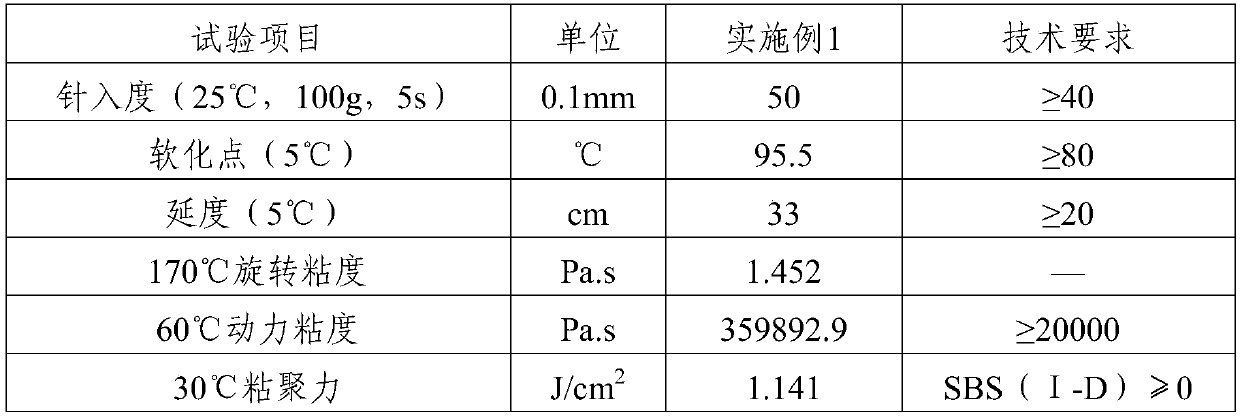

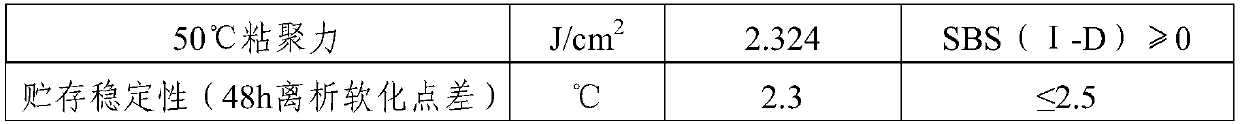

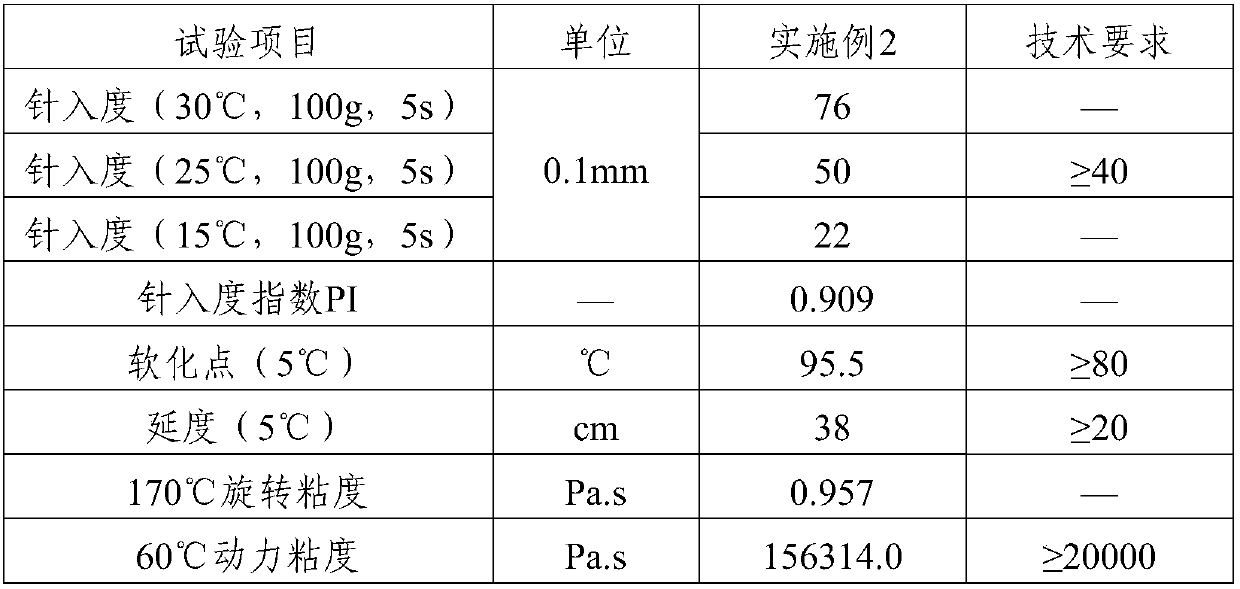

High-viscosity and high-elasticity modified asphalt as well as preparation and application thereof

ActiveCN107722648AImprove high temperature stabilityImprove aging resistanceBuilding insulationsCrack resistanceAntioxidant

The invention provides a high-viscosity and high-elasticity modified asphalt, which is prepared from the following raw materials in parts by weight: 100 parts of matrix asphalt, 6.5 to 9.5 parts of SBS graft copolymer, 0.5 to 2 parts of tackifying resin, 0.1 to 0.35 part of antioxidant, 0.2 to 1.5 parts of vulcanizing agent and 0.1 to 1.0 part of compatibilizer rubber oil. The invention also provides a preparation method and application of the high-viscosity and high-elasticity modified asphalt. The high-viscosity and high-elasticity modified asphalt provided by the invention has the advantages of having good high temperature stability, low temperature crack resistance and anti-aging performance, replacing the expensive imported high-viscosity modified asphalt without affecting the use performance of pavement, and reducing the engineering cost, and can be widely applied to paving of domestic high-performance pavements.

Owner:中路交建(北京)工程材料技术有限公司

Method for manufacturing semiconductor device

InactiveUS7528068B2Simple processImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesSiliconSemiconductor

Owner:RENESAS ELECTRONICS CORP

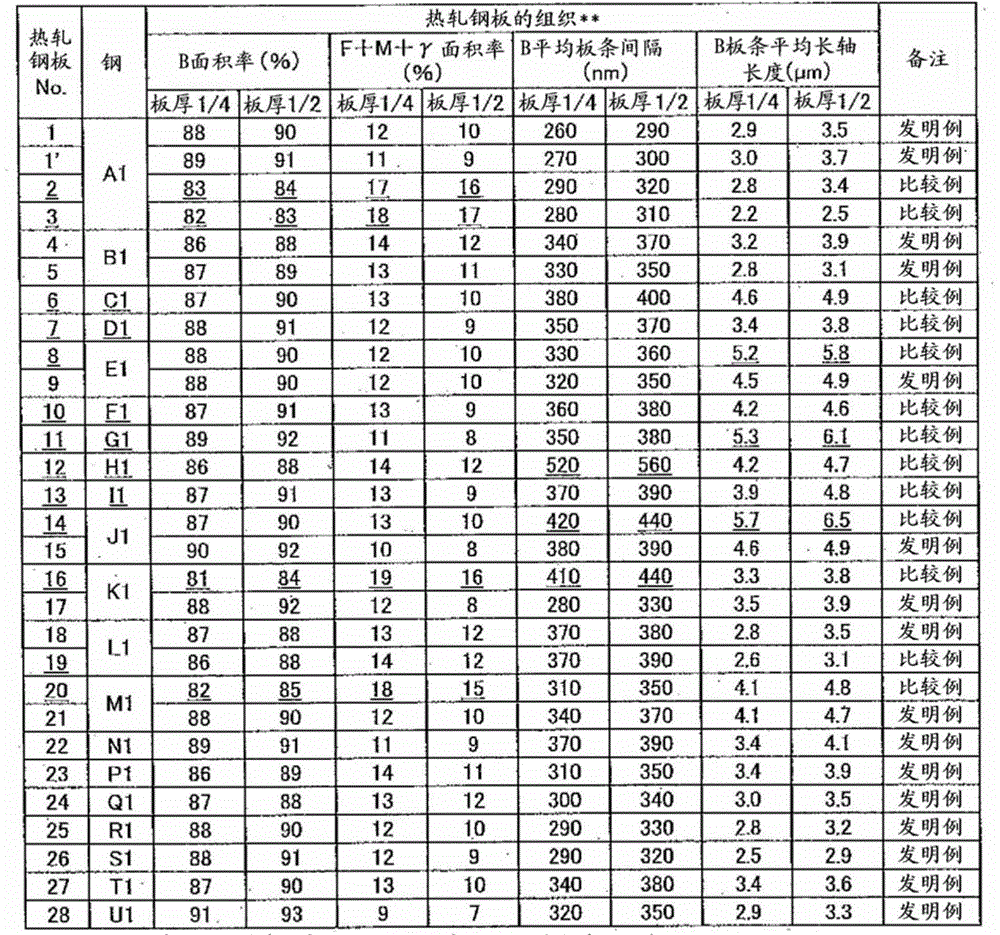

High strength hot rolled steel sheet and method for producing same

InactiveCN105102662AHigh tensile strengthImprove toughnessFurnace typesMetal rolling arrangementsSheet steelHigh intensity

This high strength hot rolled steel sheet has a composition that contains, in mass%, from 0.05% to 0.18% (inclusive) of C, 1.0% or less of Si, from 1.0% to 3.5% (inclusive) of Mn, 0.04% or less of P, 0.006% or less of S, 0.10% or less of Al, 0.008% or less of N, from 0.05% to 0.20% (inclusive) of Ti and more than 0.1% but 0.3% or less of V with the balance made up of Fe and unavoidable impurities. This high strength hot rolled steel sheet has a structure that contains a bainite phase as the main phase in an area ratio of more than 85%, while containing one or more phases selected from among a ferrite phase, a martensite phase and a residual austenite phase as the second phase in an area ratio of 0% or more but less than 15%. The average lath interval of the laths of the bainite phase is 400 nm or less, and the average length of long axes of the laths is 5.0 μm or less. This high strength hot rolled steel sheet has a tensile strength (TS) of 980 MPa or more.

Owner:JFE STEEL CORP

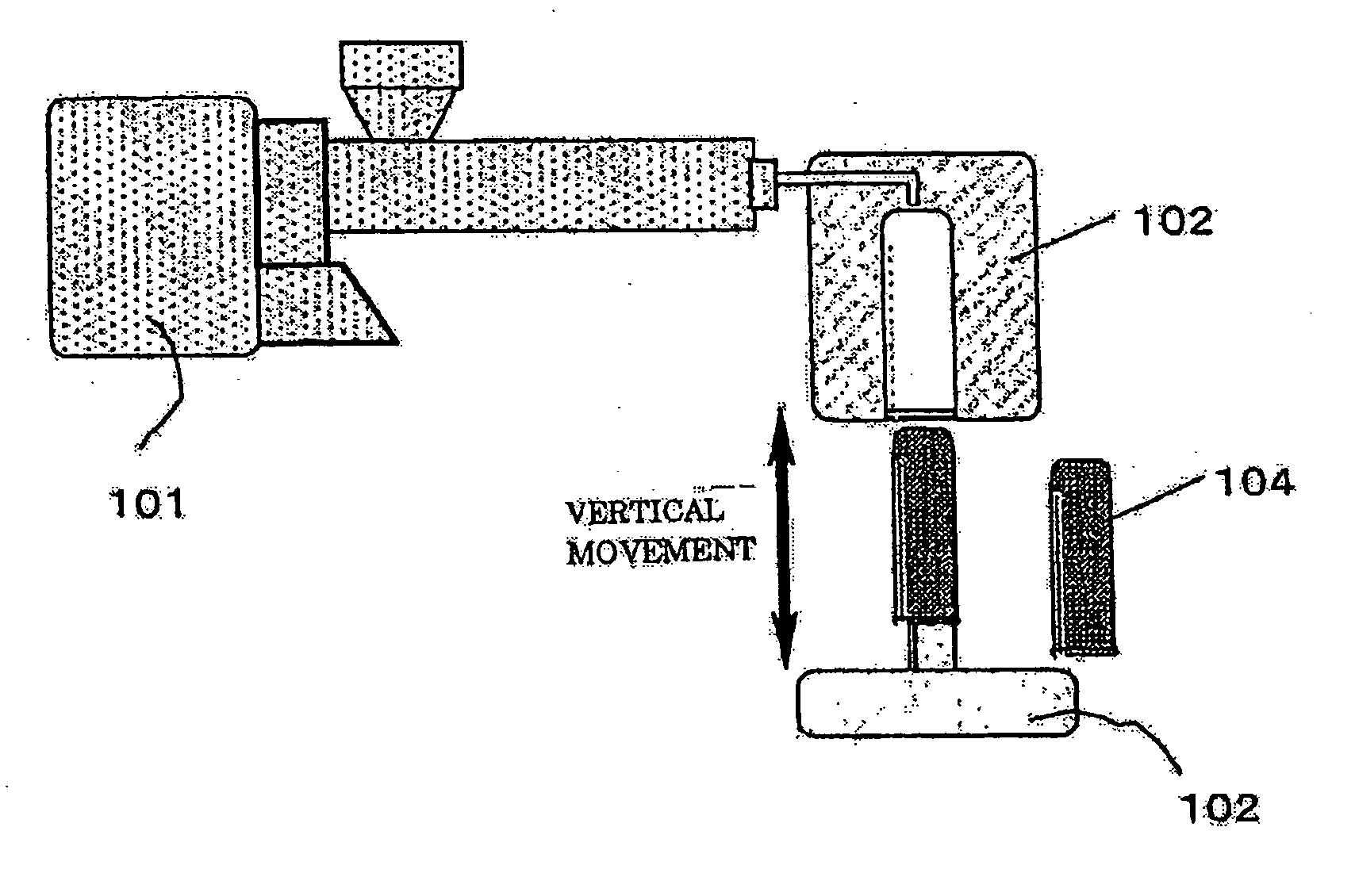

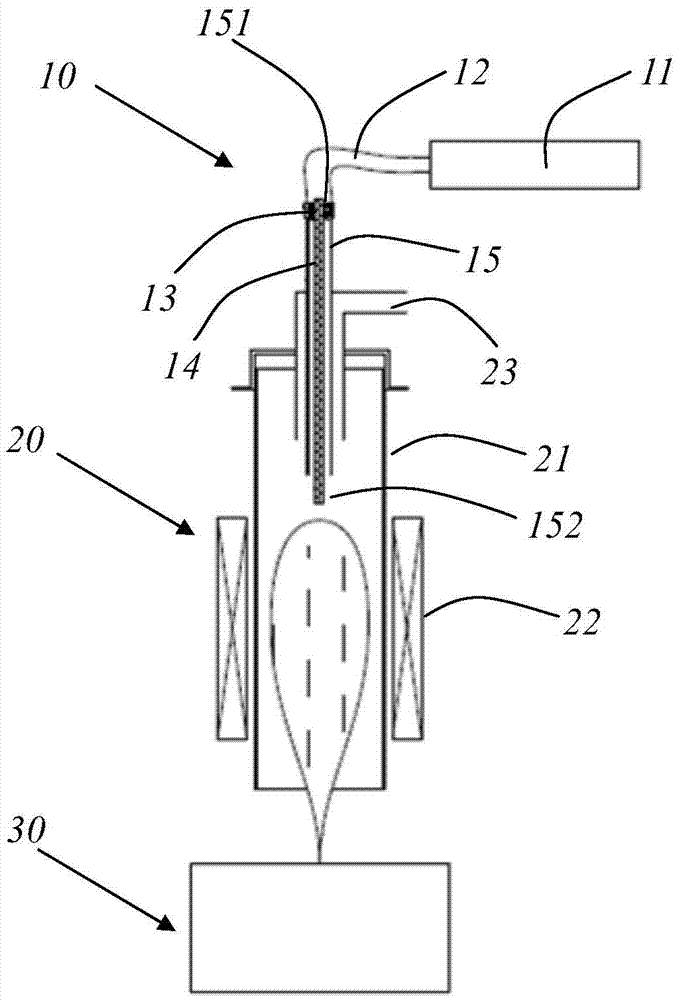

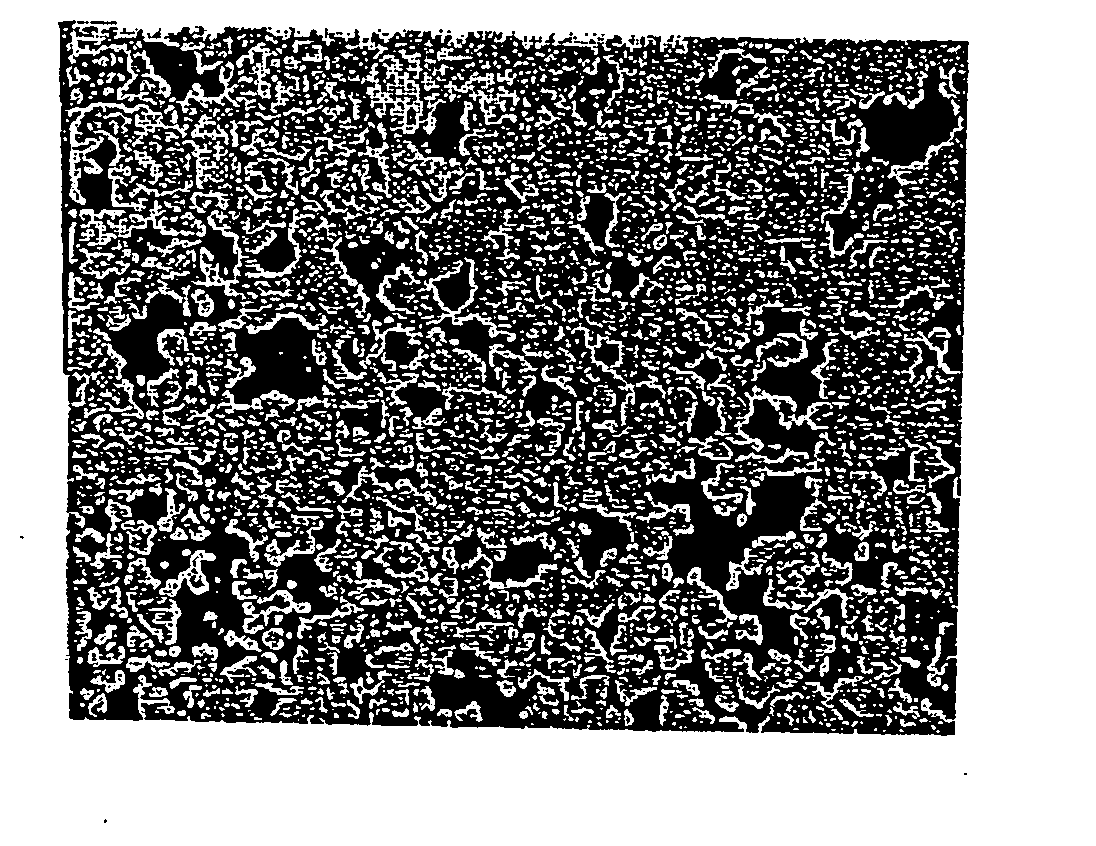

Vertical continuous preparing device for carbon nano tube fibers and preparing method

The invention provides a vertical continuous preparing device for carbon nano tube fibers. The vertical continuous preparing device comprises a carbon source injector, a tube furnace and a collecting box communicated with the tube furnace. The carbon source injector comprises a carbon source injection pump, a carbon source injection tube, a carbon source conveying tube and a flow limiting part, wherein one end of the carbon source injection tube is located in the tube furnace, the carbon source injection pump and the carbon source injection tube are communicated through the carbon source conveying tube, and the flow limiting part is arranged between the carbon source conveying tube and the carbon source injection tube. The carbon source injection pump injects a liquid-phase carbon source into the tube furnace through the carbon source conveying tube and the carbon source injection tube, a carbon source injection tube core is further arranged in the carbon source injection tube, one end of the carbon source injection tube core is arranged in the flow limiting part, and the other end of the carbon source injection tube core protrudes and stretches out of the carbon source injection tube. Compared with the prior art, the carbon source injector which is simple in structure and low in cost is adopted so that the liquid-phase carbon source can be uniformly injected and gasified, and finally the purpose of stably and continuously preparing the carbon nano tube fibers is achieved.

Owner:SUZHOU CREATIVE CARBON NANOTECH

Ta sputtering target and method for preparation thereof

ActiveUS20050268999A1Fine and uniformStable manufacturingMetal-working apparatusVacuum evaporation coatingIngotHeat treated

A manufacturing method of a Ta sputtering target in which a Ta ingot or billet formed by melting and casting is subject to forging, annealing, rolling processing and the like to prepare a sputtering target, wherein the ingot or billet is forged and thereafter subject to recrystallization annealing at a temperature of 1373K to 1673K. As a result of improving and devising the forging process and heat treatment process, the crystal grain diameter can be made fine and uniform, and a method of stably manufacturing a Ta sputtering target superior in characteristics can be obtained thereby.

Owner:JX NIPPON MINING& METALS CORP

Magnetic antenna

ActiveCN101208830AImprove bindingStable manufacturingLoop antennas with ferromagnetic coreRadiating elements structural formsElectrical polarityMetallic Object

There is provided a magnetic antenna, suitable for use in an RFID tag and an RFID tag reader / writer, which operates stable even if brought close to a metallic object and suitable for mass-production, and a board mounted with the magnetic antenna. The magnetic antenna has a coil comprising a magnetic layer and a conductive layer provided on the magnetic layer via an insulating layer. Alternatively, the magnetic antenna has a plurality of coils each comprising a magnetic layer having a square or rectangular shape and arranged radially. One ends of the coils are connected in series or parallel to one another by the magnetic layers thereof such that the coils have the same polarity. An insulating layer is provided on one or both outer surface of the coils, and a conductive layer is provided on an outer surface of at least one of the insulating layers. The magnetic antenna is produced using an LTCC technology.

Owner:TODA IND

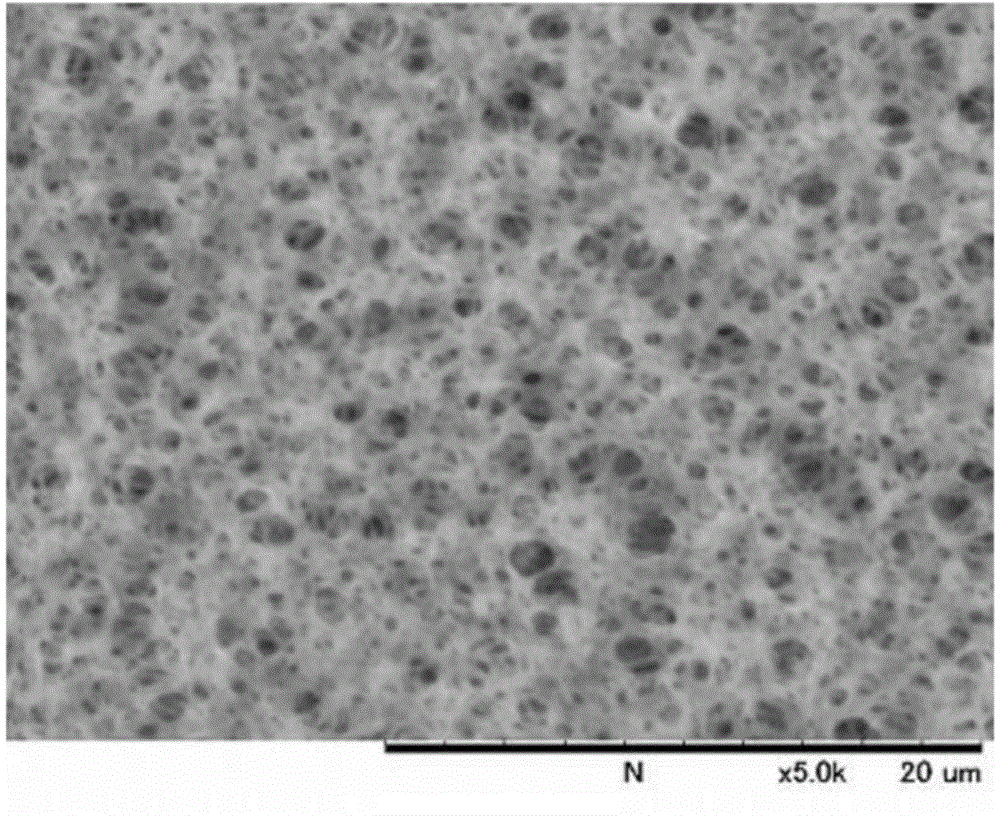

Microporous laminated membrane and method for producing the same

InactiveCN104999745AStable manufacturingGood flexibilitySievingHybrid capacitor separatorsSurface roughnessPore diameter

Disclosed is a microporous laminated membrane including a nonwoven-fabric substrate and a microporous membrane. The microporous membrane is disposed on at least one side of the nonwoven-fabric substrate. The microporous membrane includes a multiplicity of interconnecting micropores. The micropores have an average pore diameter of from 0.01 to 10 μm. The microporous membrane has an arithmetic mean surface roughness Sa of 0.5 μm or less. The microporous laminated membrane has an air permeability of from 0.5 to 30 seconds. The microporous laminated membrane has a tensile strength of 4.0 N / 15 mm or more. The microporous laminated membrane does not undergo interfacial peeling between the substrate and the microporous membrane as a result of a tape peel test.

Owner:DAICEL CHEM IND LTD

Method for manufacturing of insulated soft magnetic metal powder formed body

InactiveCN101213041AStable manufacturingReduce iron lossTransportation and packagingMetal-working apparatusMetal powderHeat treated

A method of manufacturing an insulating soft magnetic metal powder compact, by forming an inorganic insulating film on the surface of soft magnetic metal powder particles, compacting and molding the powder, and then performing heat treatment to provide an insulating soft magnetic metal powder compact, The method includes: compacting and forming the powder; then, at a high temperature higher than the Curie temperature of the soft magnetic metal powder and lower than the critical temperature for destroying the insulating film, in a non-oxidizing atmosphere such as vacuum, inert gas, etc., making the powder The powder is magnetically annealed; then further heat-treated in an oxidizing atmosphere such as air at a temperature of 400°C to 700°C.

Owner:MITSUBISHI STEEL MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com