High strength hot rolled steel sheet and method for producing same

A technology of hot-rolled steel plate and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, heat treatment furnace, etc., can solve the problems such as the decrease of toughness, achieve the effects of improving hole expansion processability, reducing the weight of the car body, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0058] [Embodiment 1: Regarding resilience]

[0059] Hereinafter, Embodiment 1 will be described in detail.

[0060] First, the reasons for limiting the composition of the hot-rolled steel sheet according to the present invention will be explained. In addition,% which shows the following component composition means mass% unless otherwise stated.

[0061] C: 0.05%~0.18%

[0062] C increases the strength of steel and promotes the formation of bainite. Therefore, in the present invention, the C content needs to be 0.05% or more. On the other hand, if the C content exceeds 0.18%, the formation control of bainite becomes difficult, the formation of hard martensite increases, and the toughness of the hot-rolled steel sheet decreases. Therefore, the C content is set to 0.05% to 0.18%. It is preferably 0.08% to 0.17%, more preferably more than 0.10% and 0.16% or less. In addition, when the amount of Mn is 2.5% to 3.5%, the amount of C is preferably 0.06% to 0.15%.

[0063] Si: 1.0% or les...

Embodiment 1

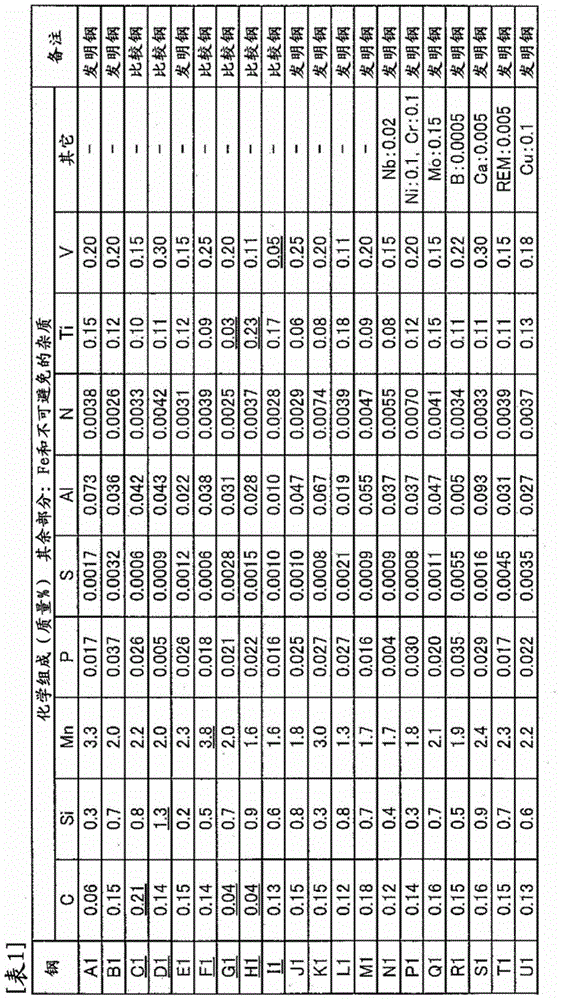

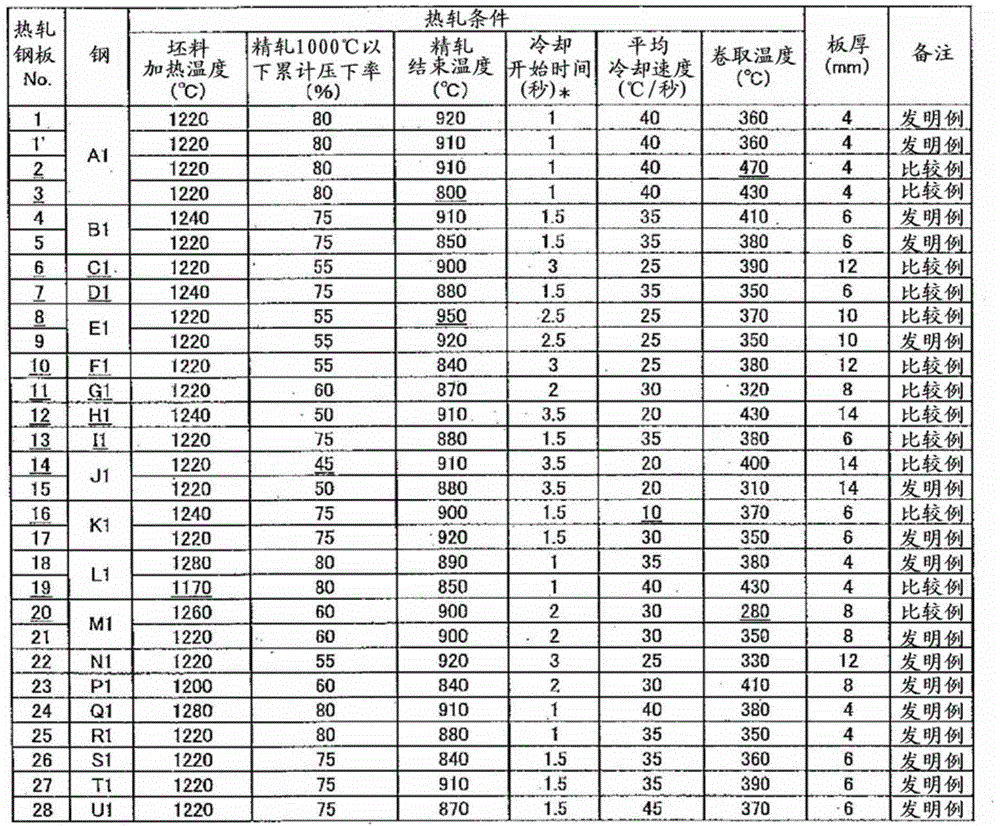

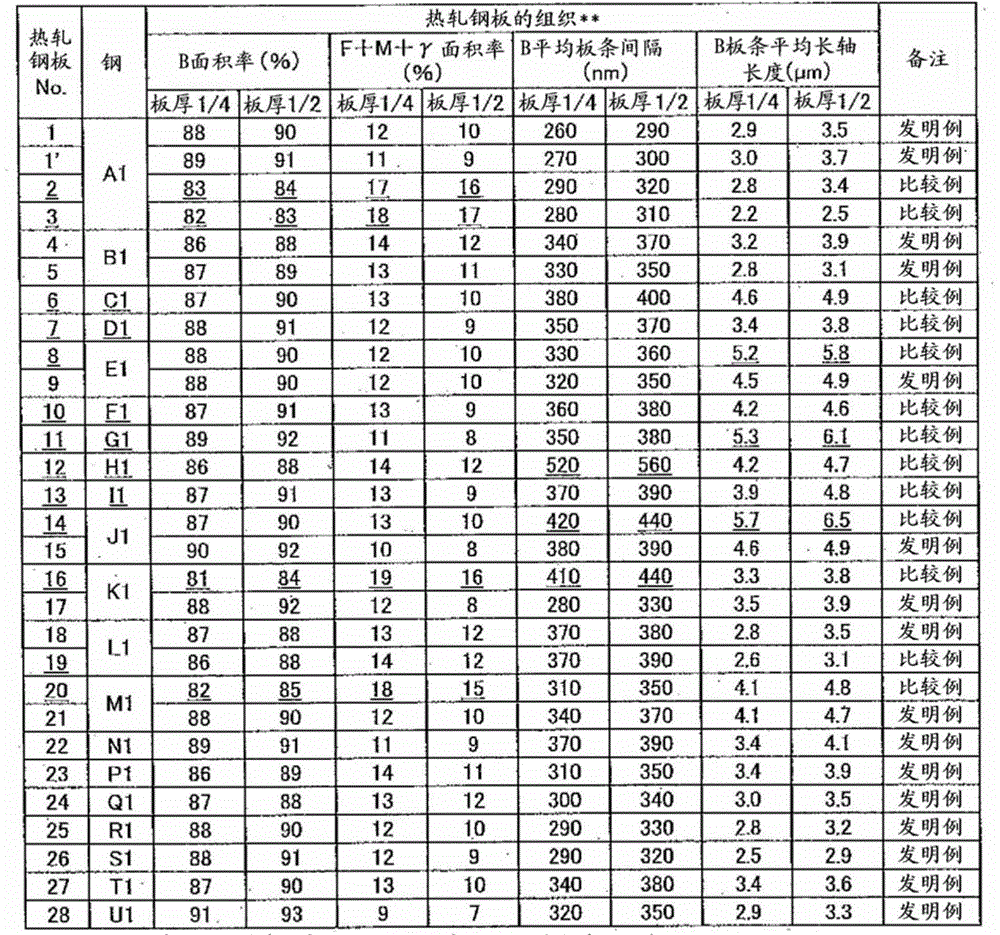

[0129] The molten steel having the composition shown in Table 1 was smelted in a converter, and a billet (steel raw material) was produced by a continuous casting method. During continuous casting, steel sheets other than the hot-rolled steel sheet No. 1'of steel A1 in Tables 1 to 3 described later were subjected to electromagnetic stirring (EMS) for the treatment of reducing segregation of components. Next, these steel materials were heated under the conditions shown in Table 2, and subjected to hot rolling consisting of rough rolling and finish rolling under the conditions shown in Table 2. After finishing rolling, they were cooled under the conditions shown in Table 2. It was coiled at the coiling temperature shown in Table 2 to produce a hot-rolled steel sheet having a thickness shown in Table 2.

[0130] A test piece was collected from the obtained hot-rolled steel sheet, and the structure observation, tensile test, and Charpy impact test were performed. The tissue observat...

Embodiment approach 2

[0157] [Embodiment 2: Regarding hole reaming workability]

[0158] First, the reason for the composition limitation of the hot rolled steel sheet of the present invention will be explained. In addition, "%" indicating the content of each component element means "% by mass" unless otherwise specified.

[0159] C: more than 0.1% and less than 0.2%

[0160] C is an element that promotes the formation of bainite, increases the strength of steel, and promotes the formation of bainite, and is one of the important elements in the present invention. In order to obtain this effect, the C content needs to be greater than 0.1%. On the other hand, C combines with Fe to form cementite, so containing excessive C increases the number of cementites and shortens the distance between cementites that are the starting point of the voids, thereby reducing local ductility and expanding the hole. Sexual decline. In addition, containing more than 0.2% of excessive C reduces the weldability. Therefore, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com