High-viscosity and high-elasticity modified asphalt as well as preparation and application thereof

A modified asphalt, viscoelastic technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of expensive modified asphalt, complicated manufacturing process, poor aging resistance, etc., achieve high cost performance, improve relative Capacitive, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

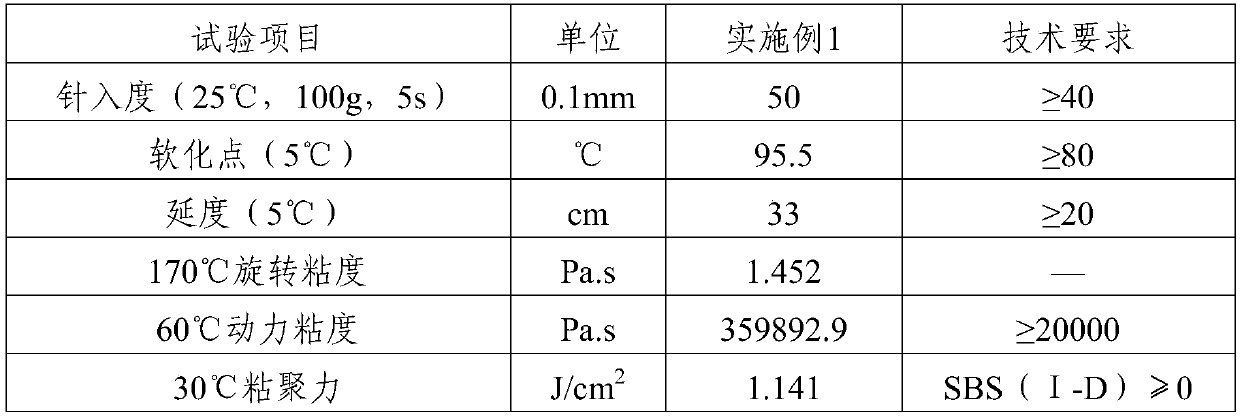

Embodiment 1

[0035] The high-viscosity and high-elasticity modified asphalt in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 9.5 parts of SBS graft copolymer, 0.5 part of tackifying resin modified rosin ester, 0.2 part of antioxidant 1010, and 1.0 parts of sulfur part, 0.2 part of compatibilizer rubber oil; the SBS is a star-shaped styrene-butadiene-styrene block copolymer, purchased from Yanshan Petrochemical.

[0036] The method for preparing high-viscosity and high-elasticity modified asphalt in this embodiment comprises the following steps:

[0037] Step 1: The solvent is toluene. Put SBS and solvent in the reactor at a volume ratio of 1:1. After dissolving completely at 60°C, add the toluene solution of benzoyl peroxide (BPO), blow nitrogen, stir and heat up To 80 DEG C, dropwise add the methyl methacrylate (MMA) that is dissolved with BPO, wherein, BPO total amount is 0.9% of SBS quality, MMA quality is 25% of SBS quality, insul...

Embodiment 2

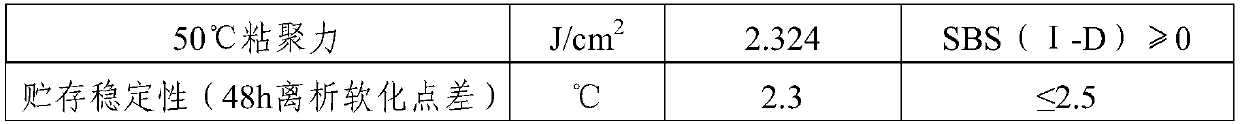

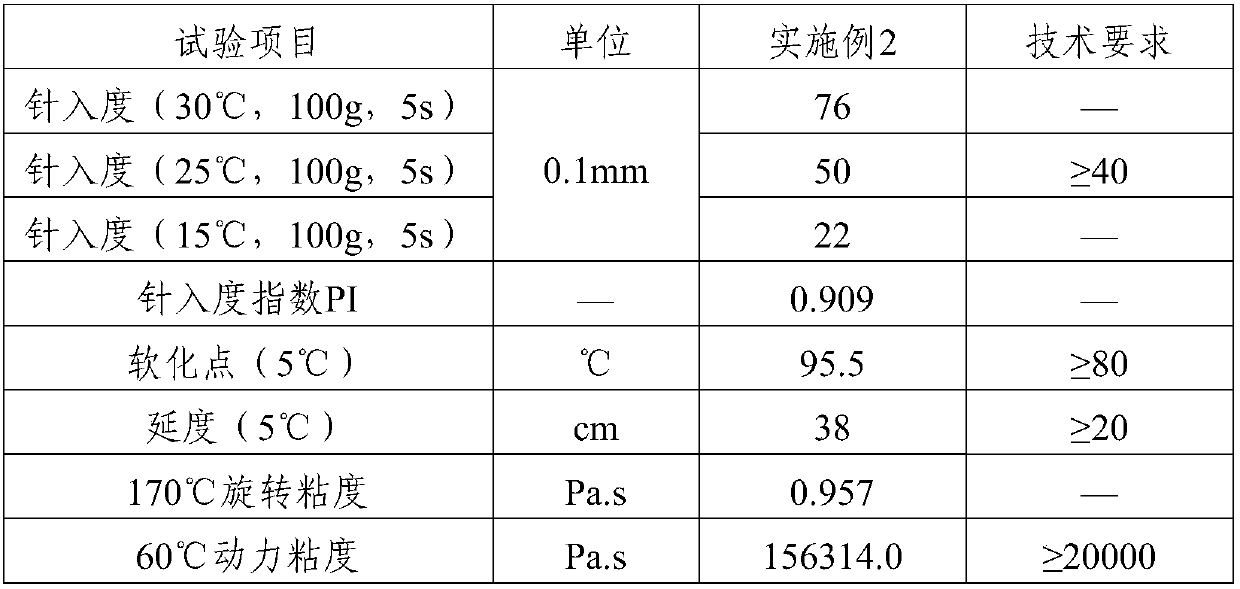

[0047] The high-viscosity and high-elasticity modified asphalt in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 6.5 parts of SBS graft copolymer, 2 parts of tackifying resin paraffin petroleum resin, 0.35 part of antioxidant BHT, and 0.8 parts of sulfur part, 0.5 part of compatibilizer rubber oil; the SBS is a star-shaped styrene-butadiene-styrene block copolymer.

[0048] The method for preparing high-viscosity and high-elasticity modified asphalt in this embodiment comprises the following steps:

[0049] Step 1: The solvent is cyclohexane. Put SBS and solvent at a ratio of 1:1 (the solvent must completely dissolve SBS) and place it in the reactor. After the solution is completely dissolved at 55°C, add BPO cyclohexane solution and blow nitrogen. Stir and heat up to 75°C, add BPO-dissolved butyl acrylate (BA) dropwise, wherein the total amount of BPO is 1.0% of the mass of SBS, and the mass of BA is 30% of the mass of SB...

Embodiment 3

[0058] The high-viscosity and high-elasticity modified asphalt in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 8 parts of SBS graft copolymer, 1.5 parts of tackifying resin polyterpene resin, 0.3 part of antioxidant BHT, sulfur 1.0 parts of the donor, 0.8 parts of rubber oil as a compatibilizer; the SBS is a star-shaped styrene-butadiene-styrene block copolymer.

[0059] The method for preparing high-viscosity and high-elasticity modified asphalt in this embodiment comprises the following steps:

[0060] Step 1: The solvent is 120# solvent oil, put SBS and solvent in the reactor at a ratio of 1:1, and after it is completely dissolved at 50°C, add azobisisobutyronitrile (AIBN) 120# solvent oil solution, and blow nitrogen , stirred and heated up to 70°C, and added dropwise methyl methacrylate (MAA) having AIBN dissolved therein, wherein the total amount of AIBN was 1.5% of the mass of SBS, and the mass of MAA was 25% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com