Patents

Literature

669results about How to "Improve crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

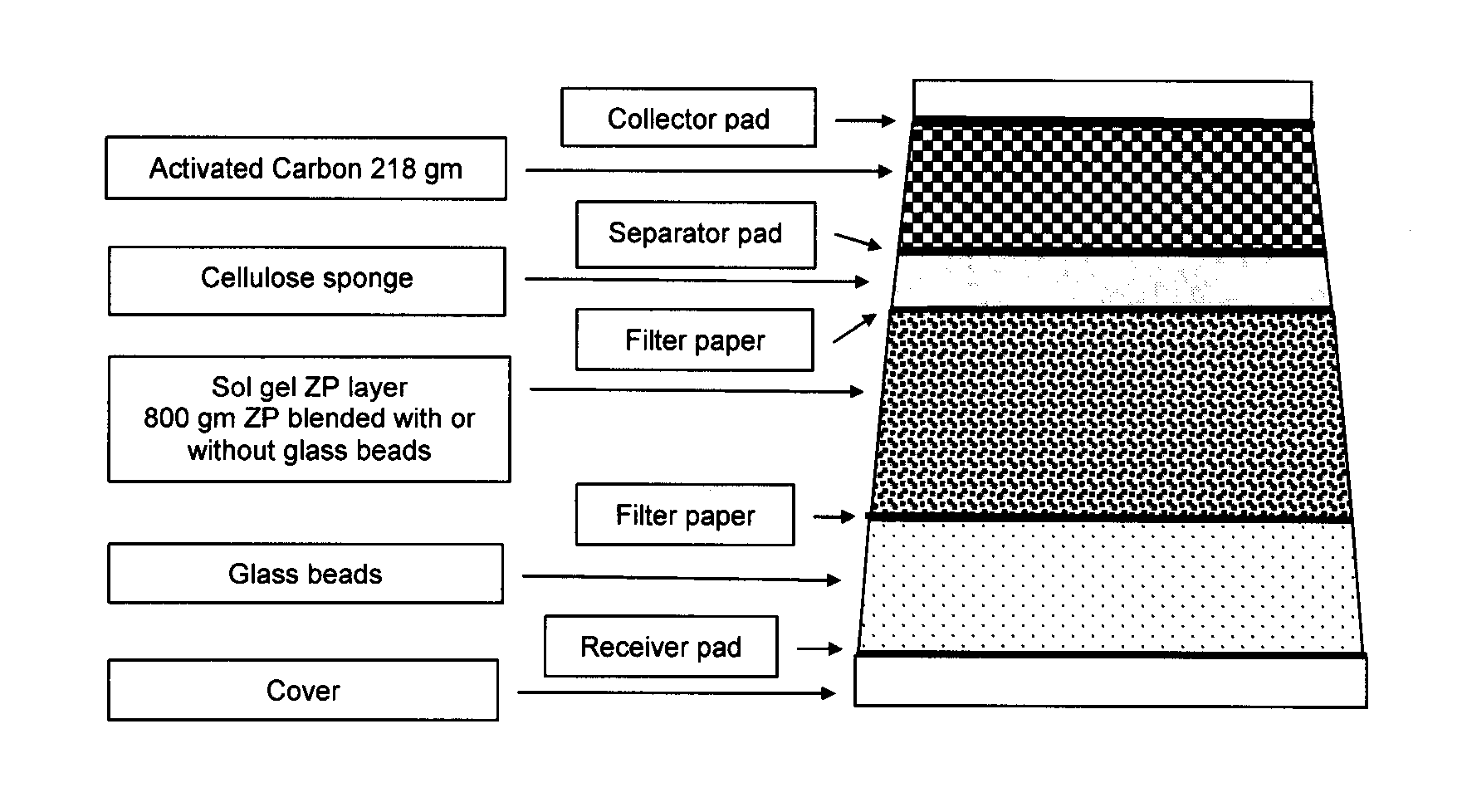

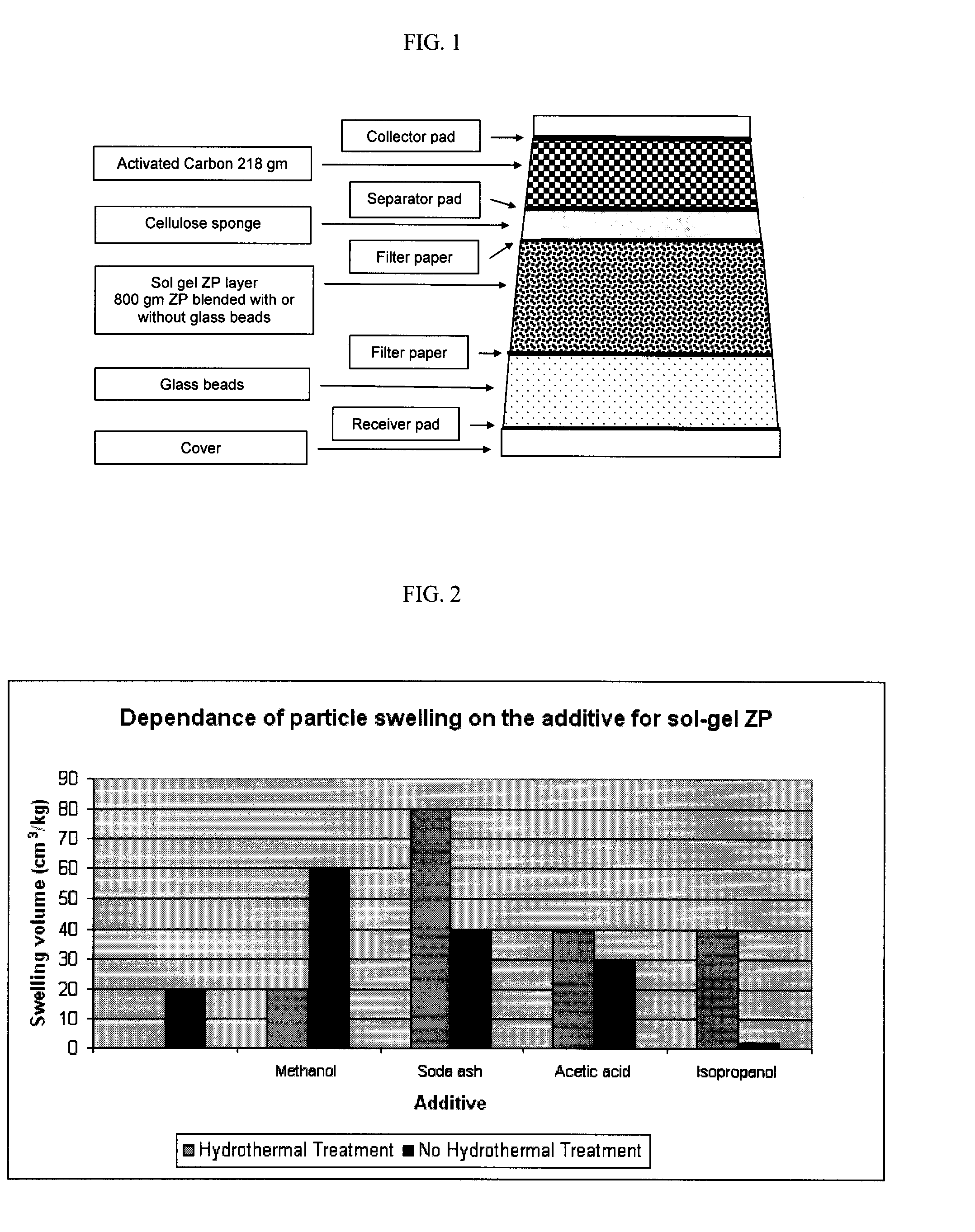

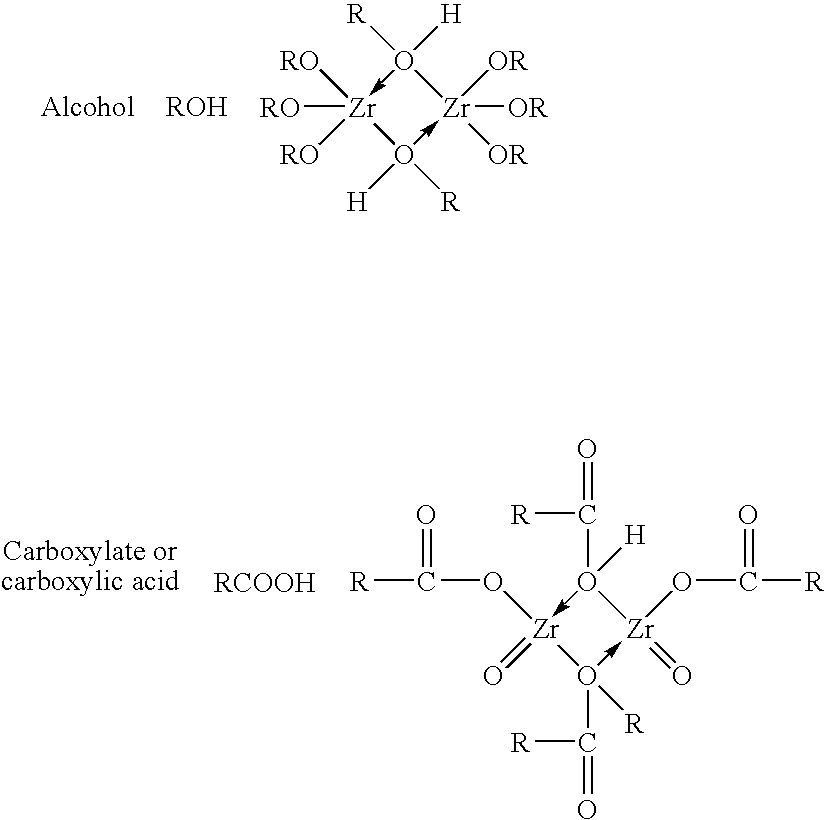

Zirconium Phosphate Particles Having Improved Adsorption Capacity and Method Of Synthesizing The Same

InactiveUS20100084330A1Avoid disadvantagesHigh porosityPhosphatesDialysis systemsPhosphoric acidOxygen

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one low molecular weight, oxygen containing, monofunctional, organic additive to the solution, and combining this solution with heated phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

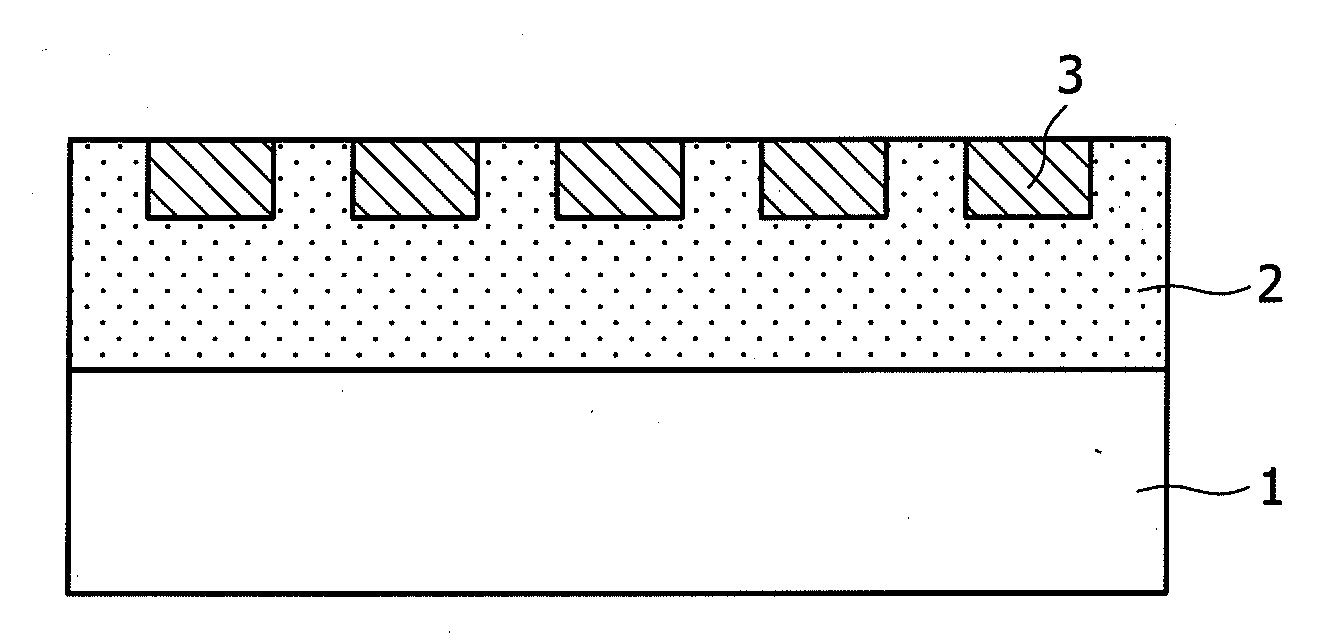

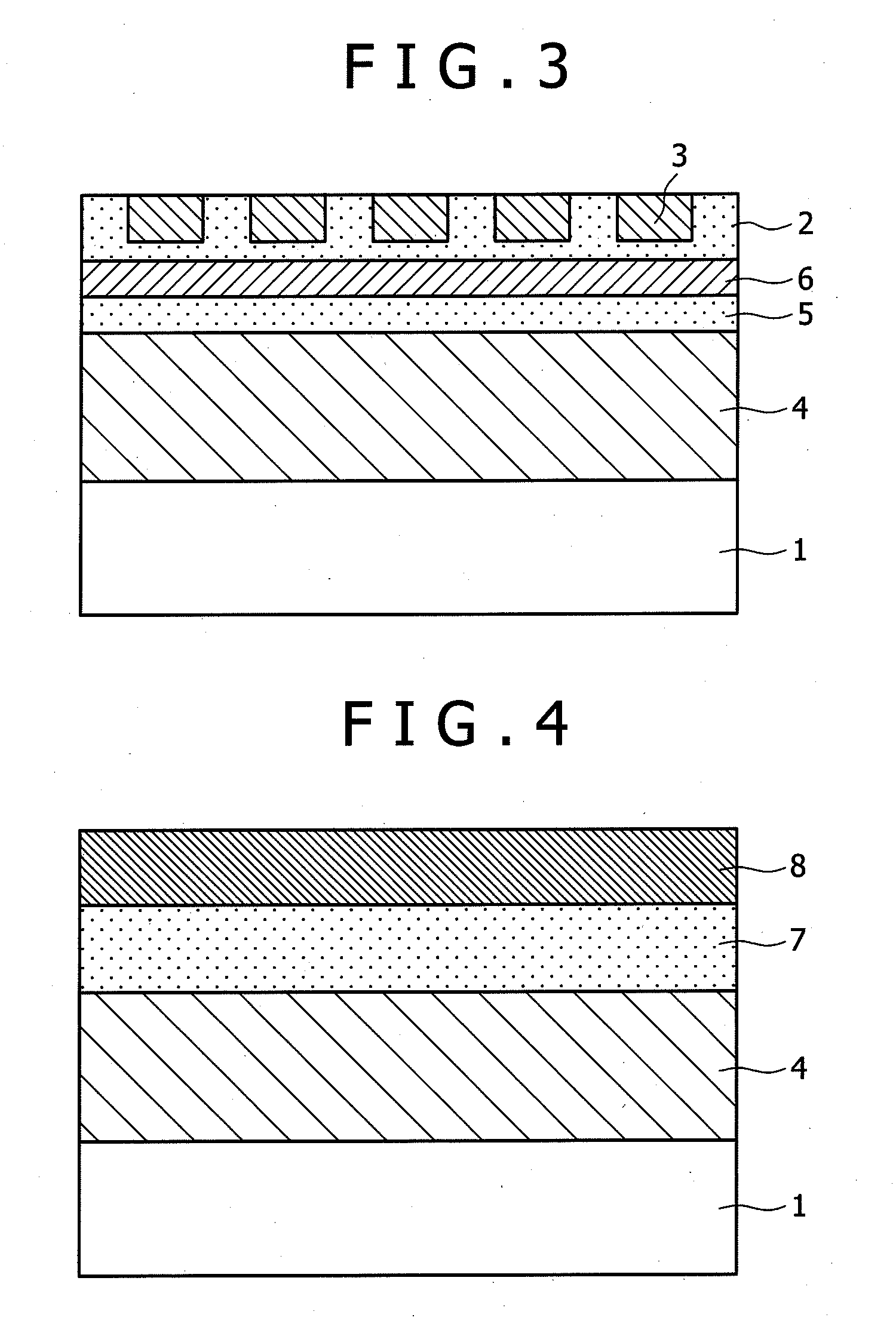

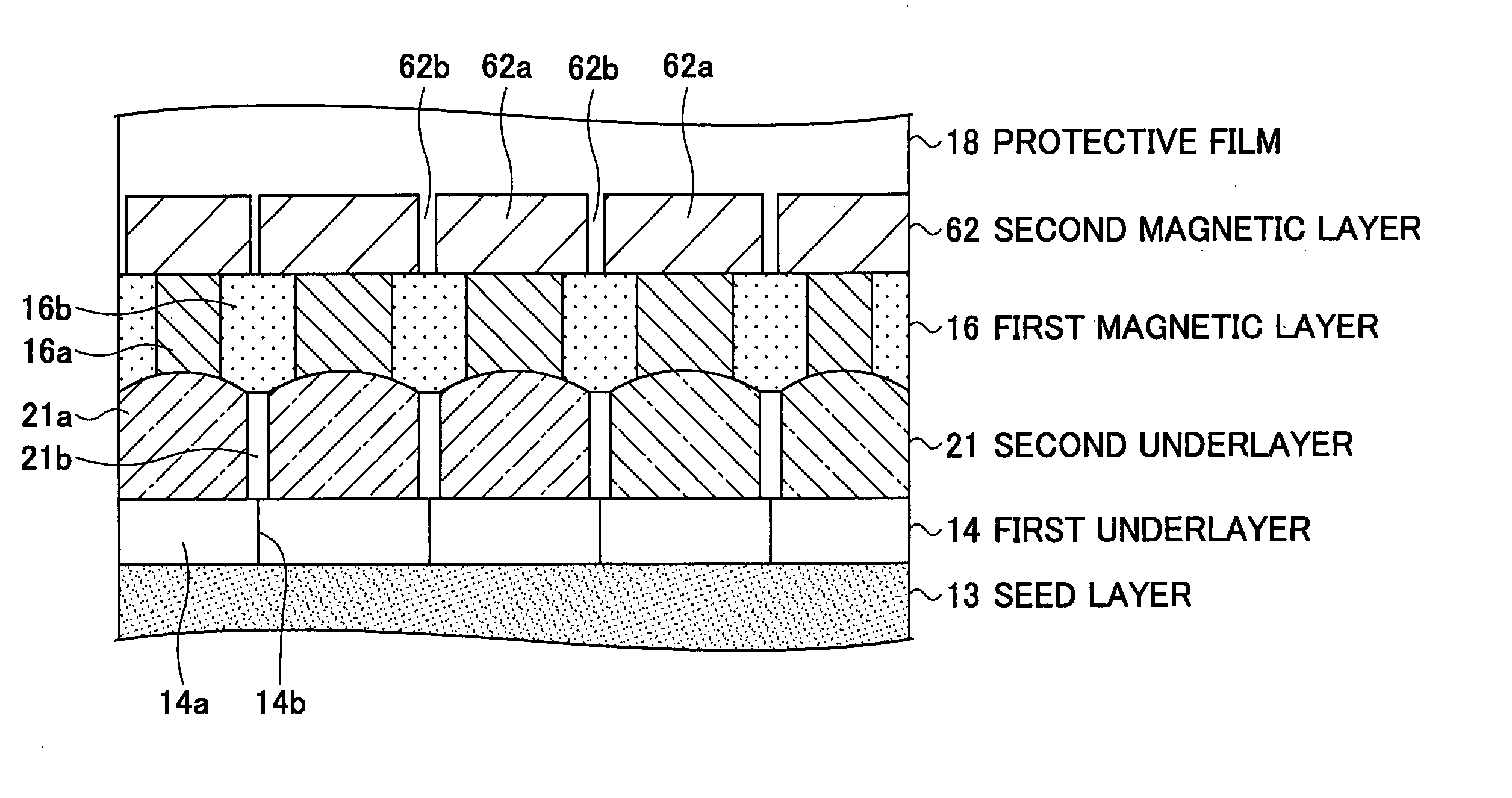

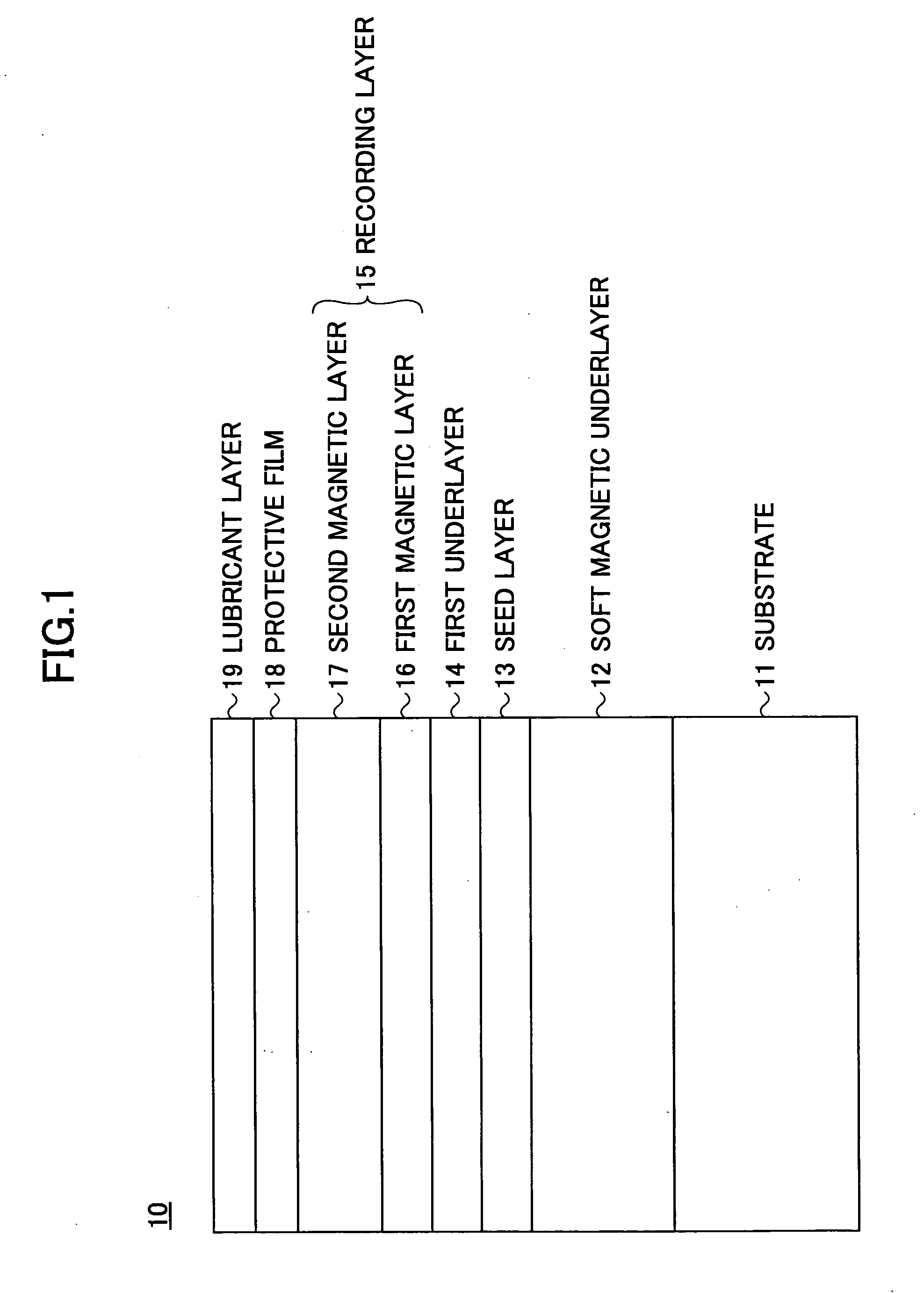

Dot-patterned structure magnetic recording medium and method for production thereof

InactiveUS20090098413A1Function increaseHigh crystallinityRecord information storageDisk carriersCrystallinityRecording layer

Disclosed herein are a dot-patterned structure for magnetic recording bits and a magnetic recording medium provided therewith. The former exhibits high functionality and high performance owing to good crystallinity. The dot-patterned structure is composed of a first layer, which is continuous, and a second layer, which is discrete. The magnetic recording medium having a dot-patterned recording layer is formed by the steps of treating an underlying layer by lithography, thereby forming grooves, filling the grooves by epitaxial growth with the same material as the underlying layer, removing the photoresist used for lithography in a solvent, thereby forming pits, and filling the pits by epitaxial growth with a magnetic film as the recording layer.

Owner:HITACHI LTD

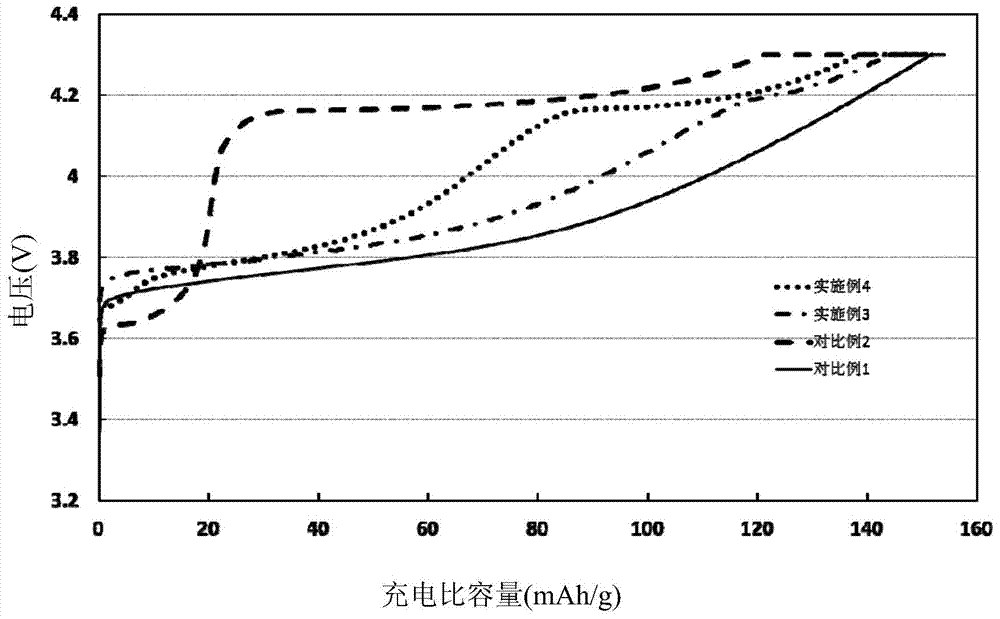

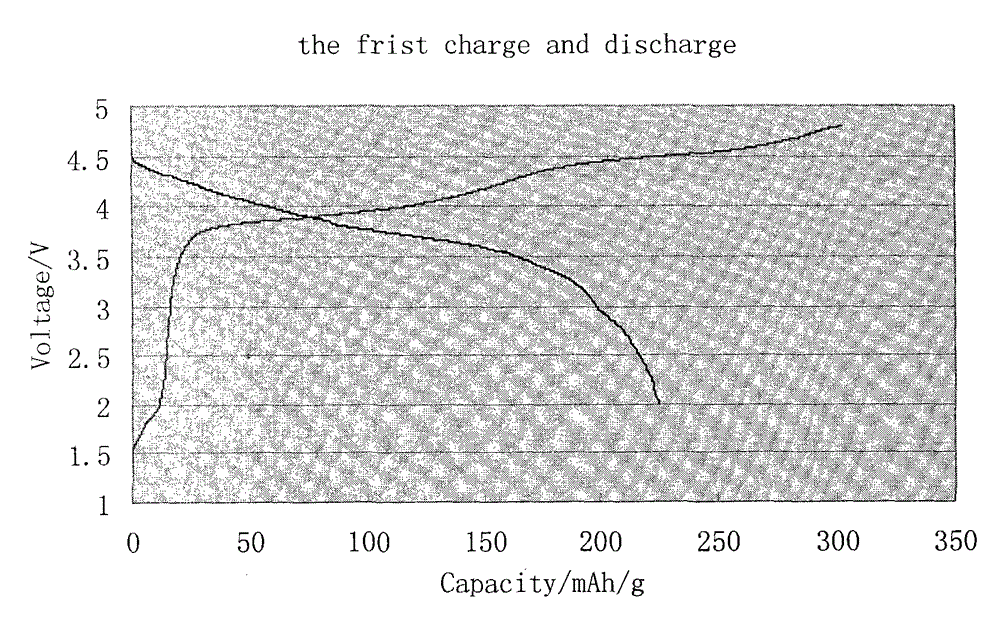

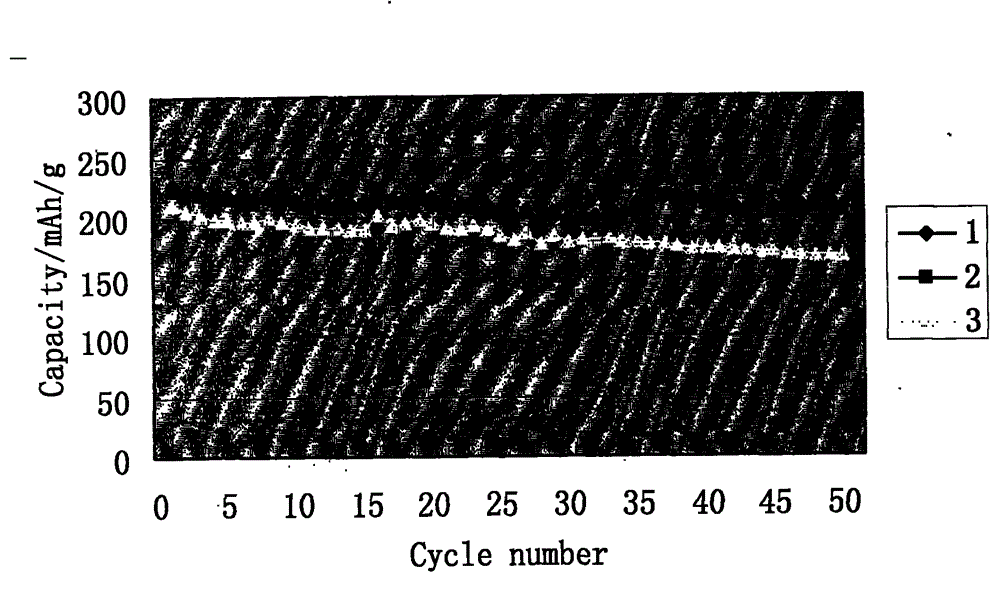

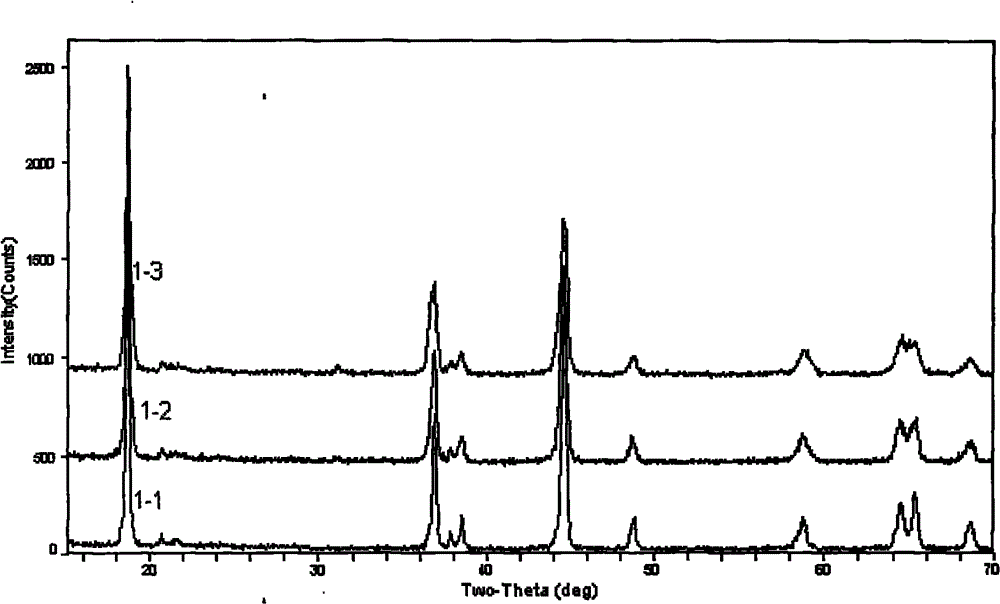

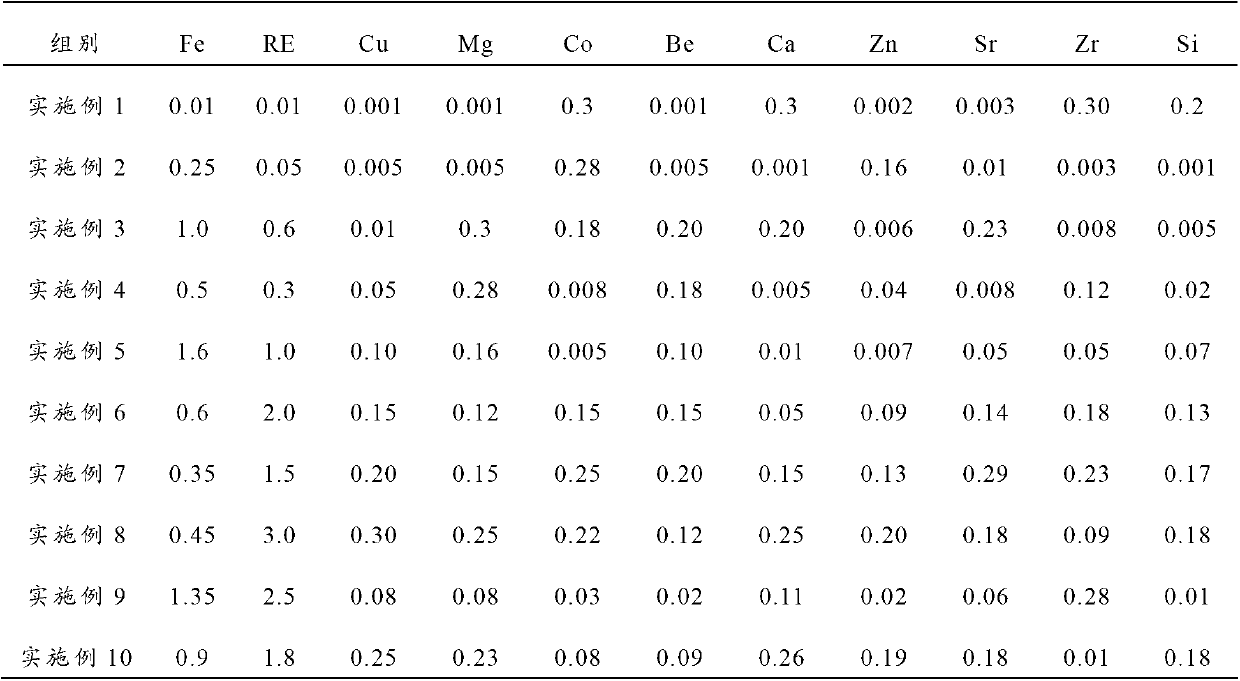

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

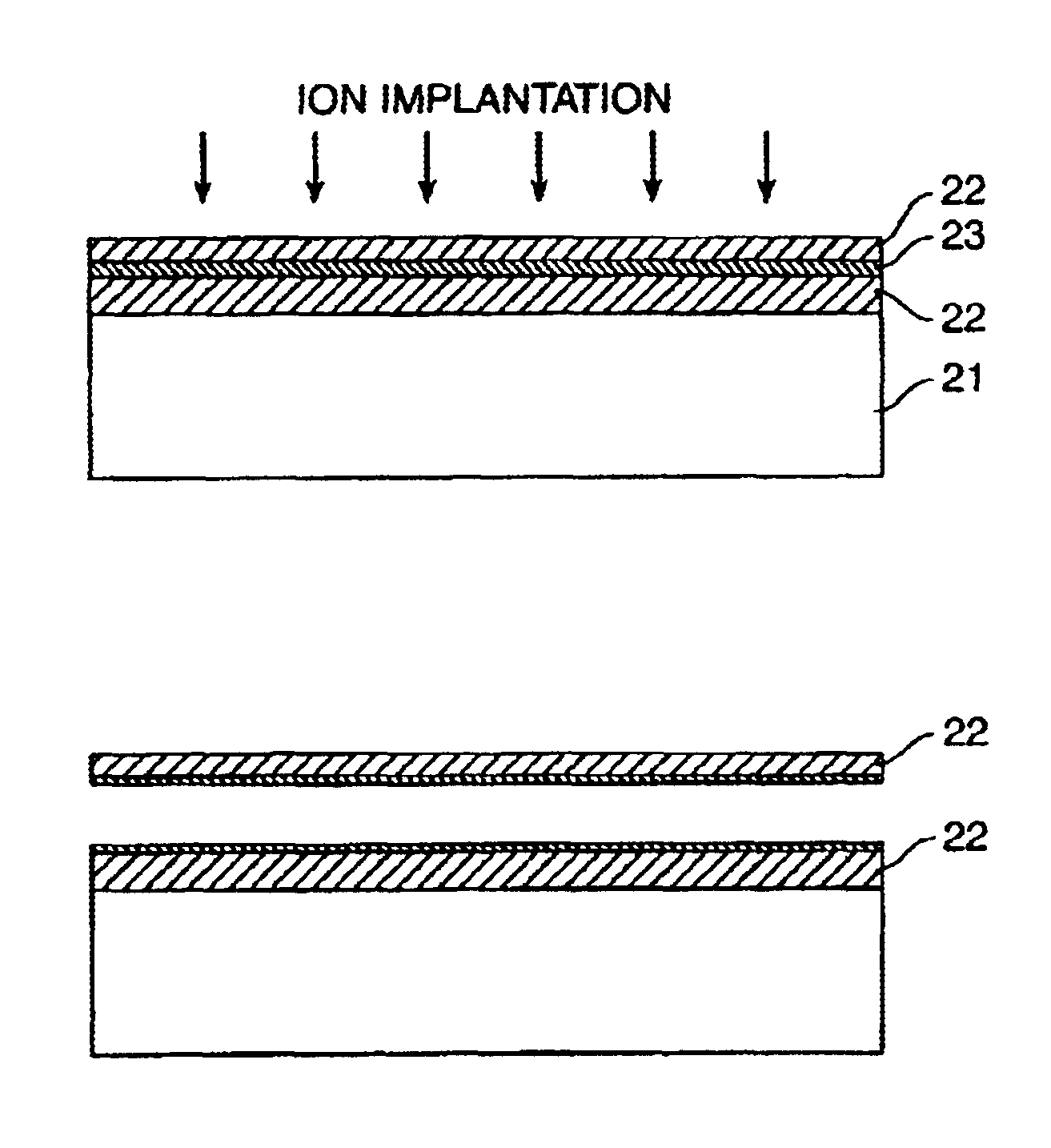

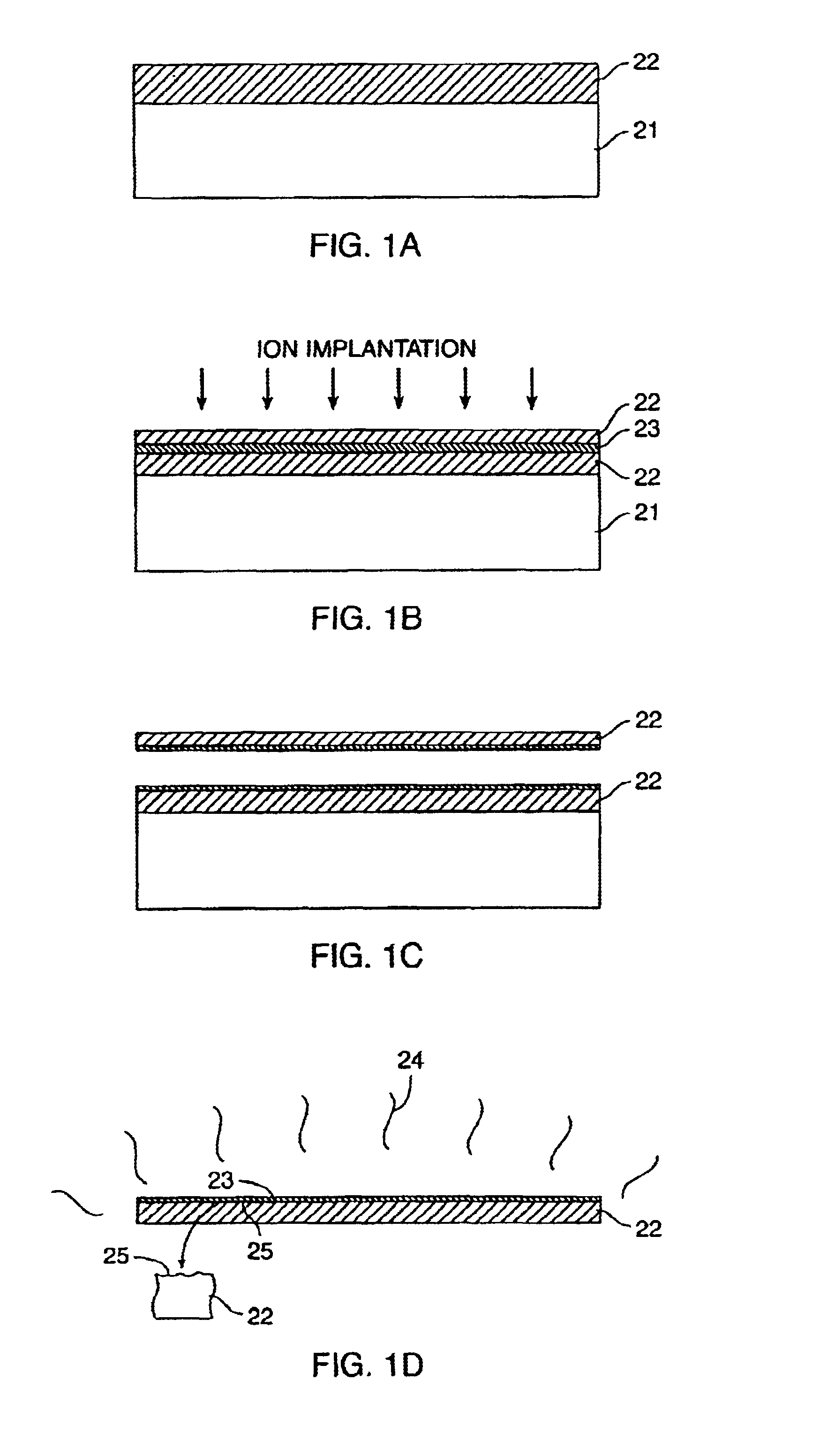

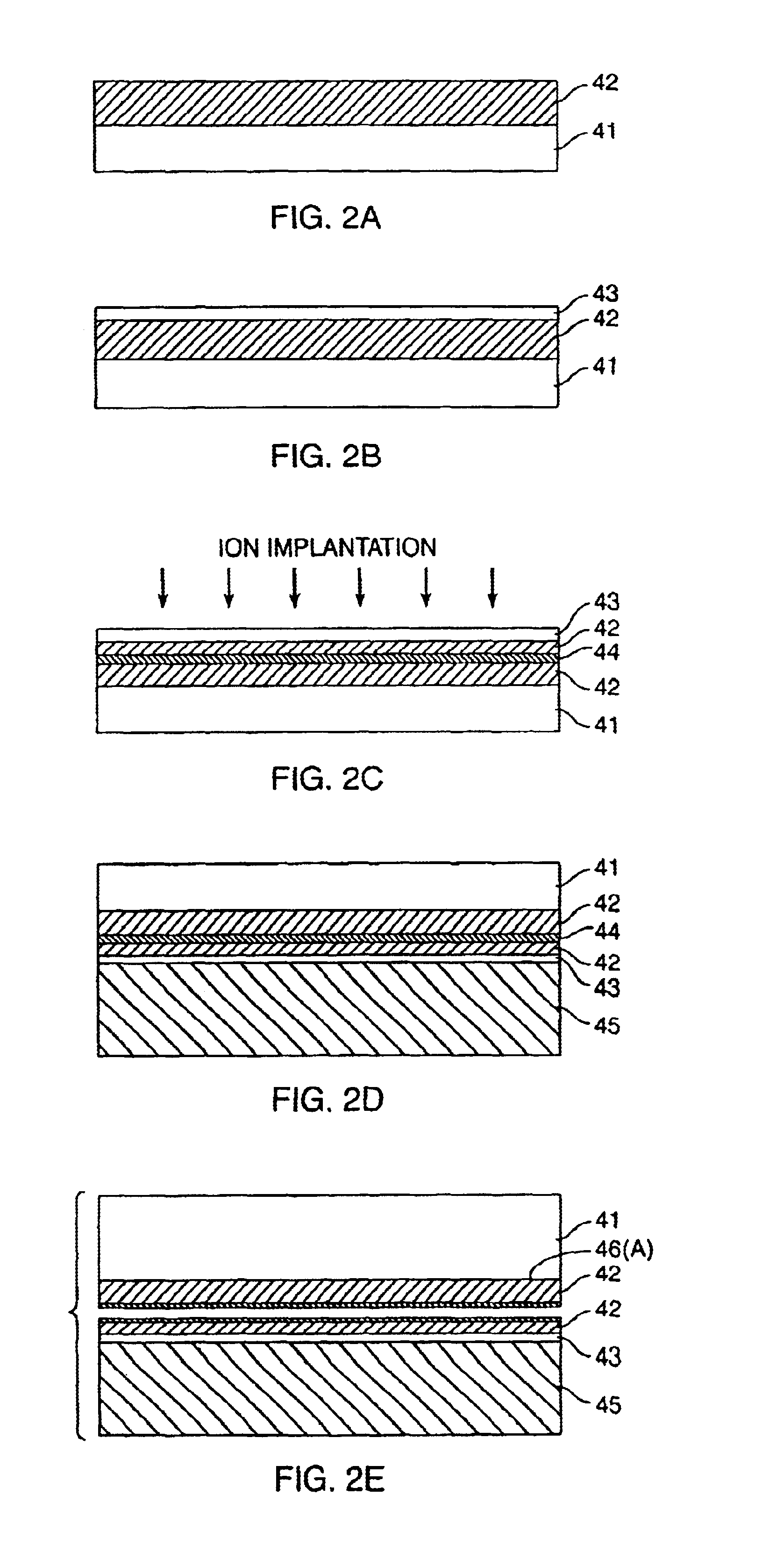

Smoothing method for cleaved films made using a release layer

InactiveUS6881644B2Improve crystal structureReduce defectsPaper/cardboard articlesDecorative surface effectsPorous siliconMaterials science

A method for treating a film of material, which can be defined on a substrate, e.g., silicon. The method includes providing a substrate comprising a cleaved surface, which had a porous silicon layer thereon. The substrate may have a distribution of hydrogen bearing particles defined from the cleaved surface to a region underlying said cleaved surface. The method also includes increasing a temperature of the cleaved surface to greater than about 1,000 Degrees Celsius while maintaining the cleaved surface in a etchant bearing environment to reduce a surface roughness value by about fifty percent and greater. Preferably, the value can be reduced by about eighty or ninety percent and greater, depending upon the embodiment.

Owner:SILICON GENERAL CORPORATION

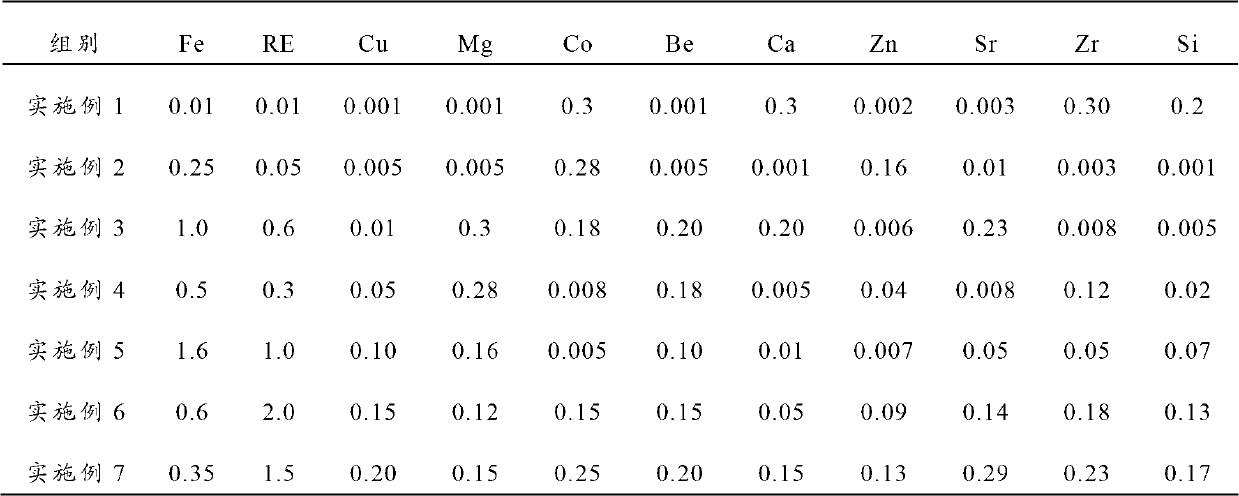

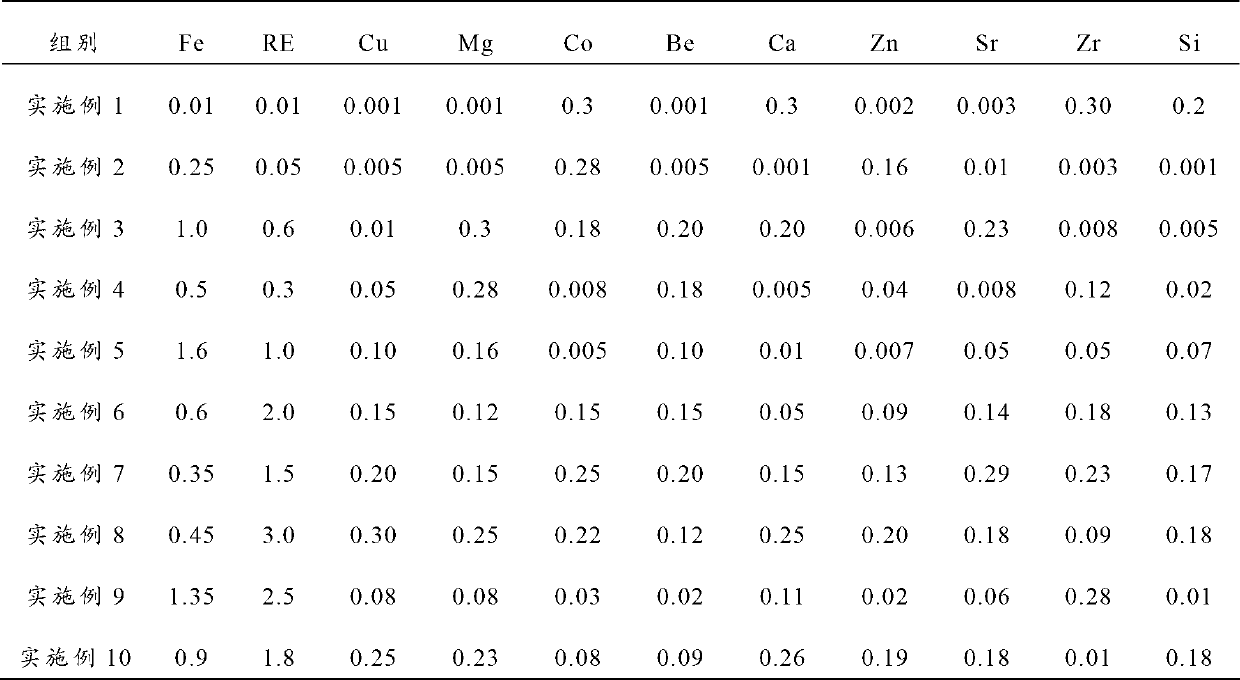

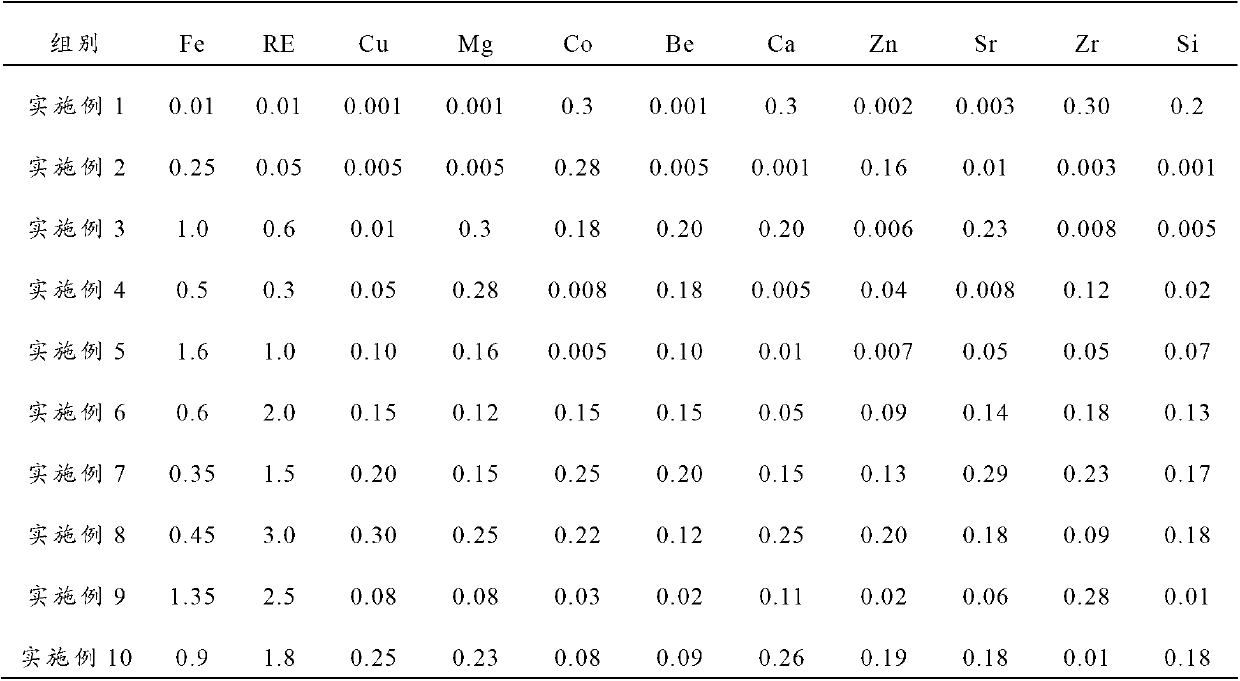

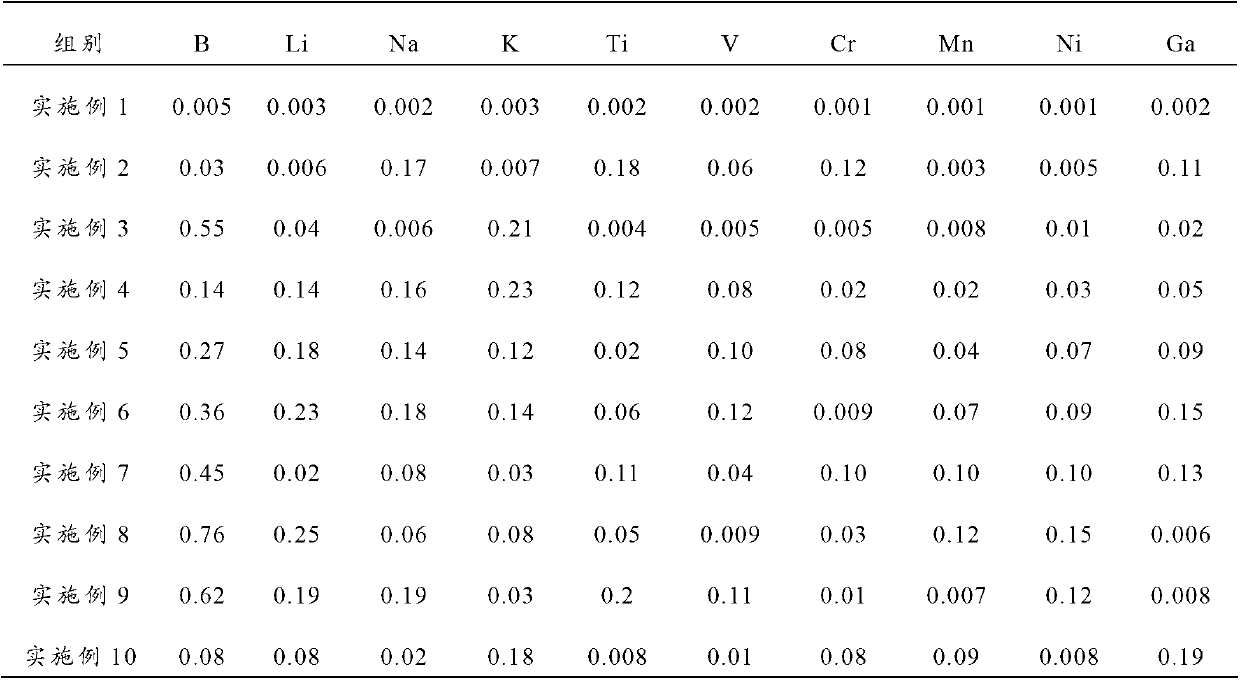

Al-Fe-C-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103387AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-C-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

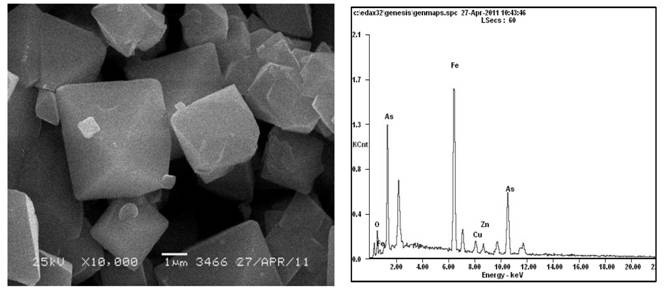

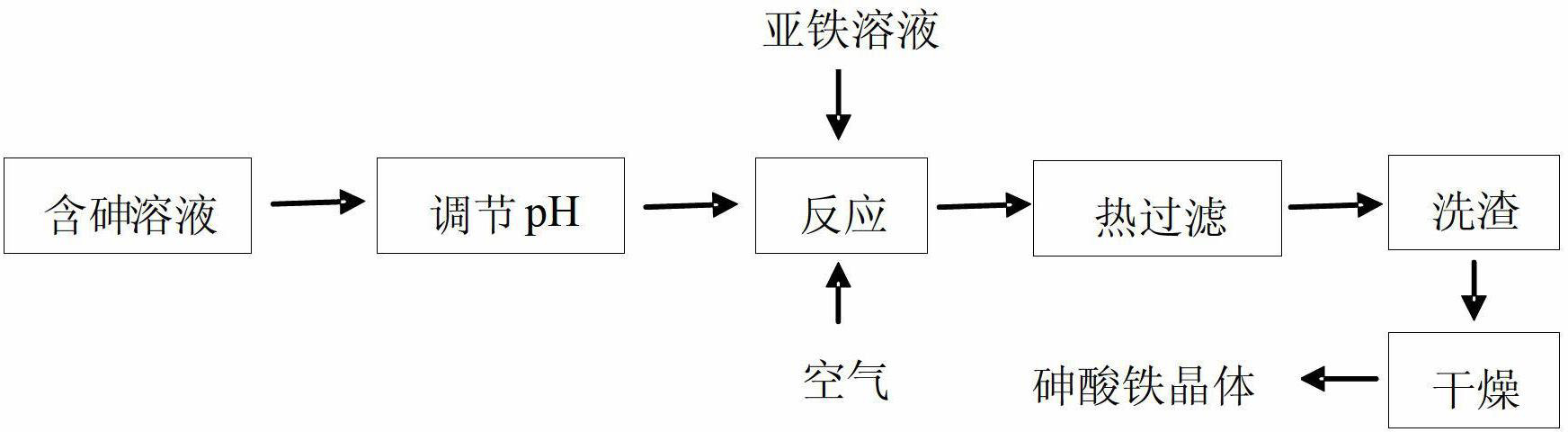

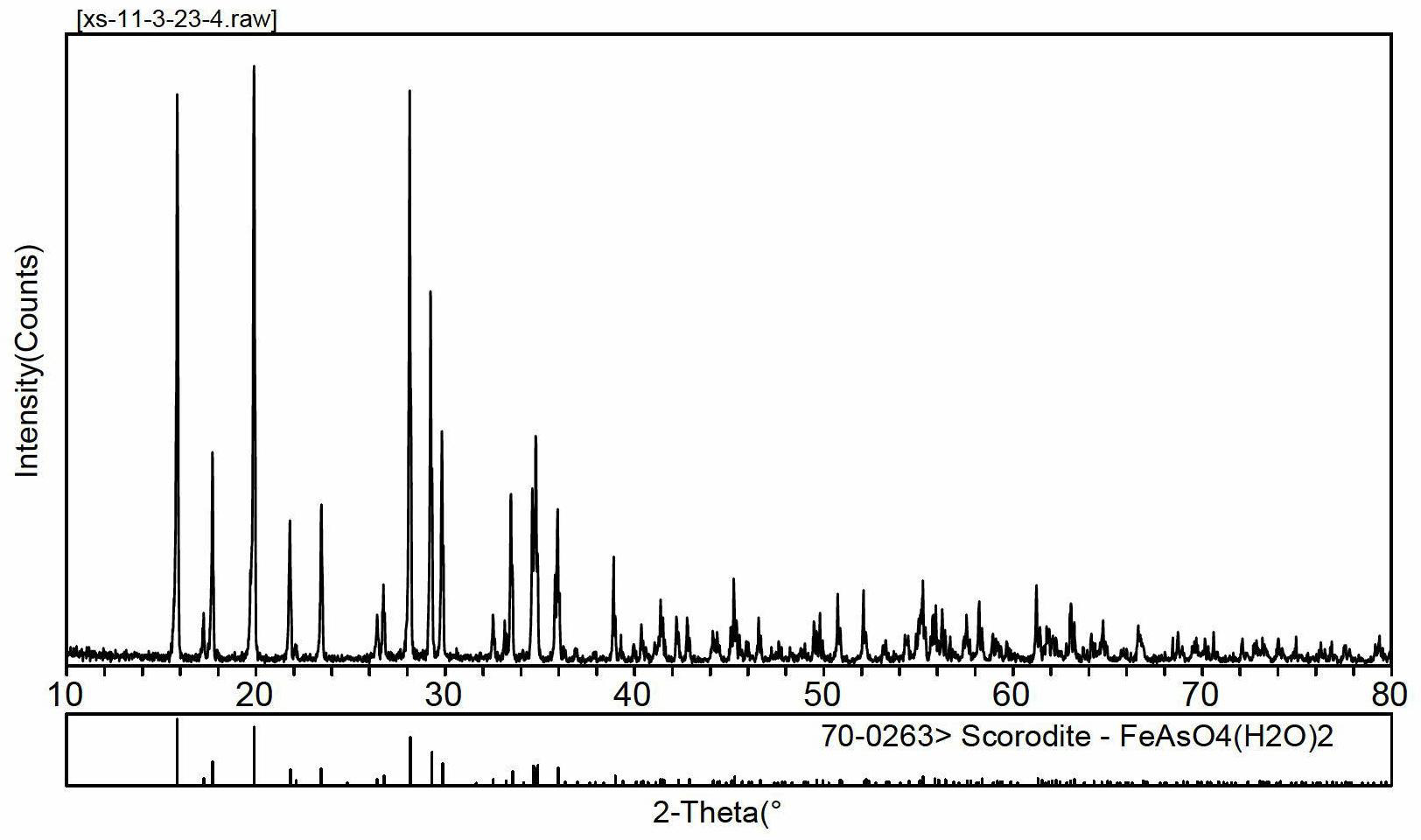

Method for precipitating and stabilizing As from As-containing solution

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

Al-Fe-Sb-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978449AEvenly heatedEliminate damagePower cables with screens/conductive layersMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-Sb-RE aluminum alloy, and a preparation method of the Al-Fe-Sb-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

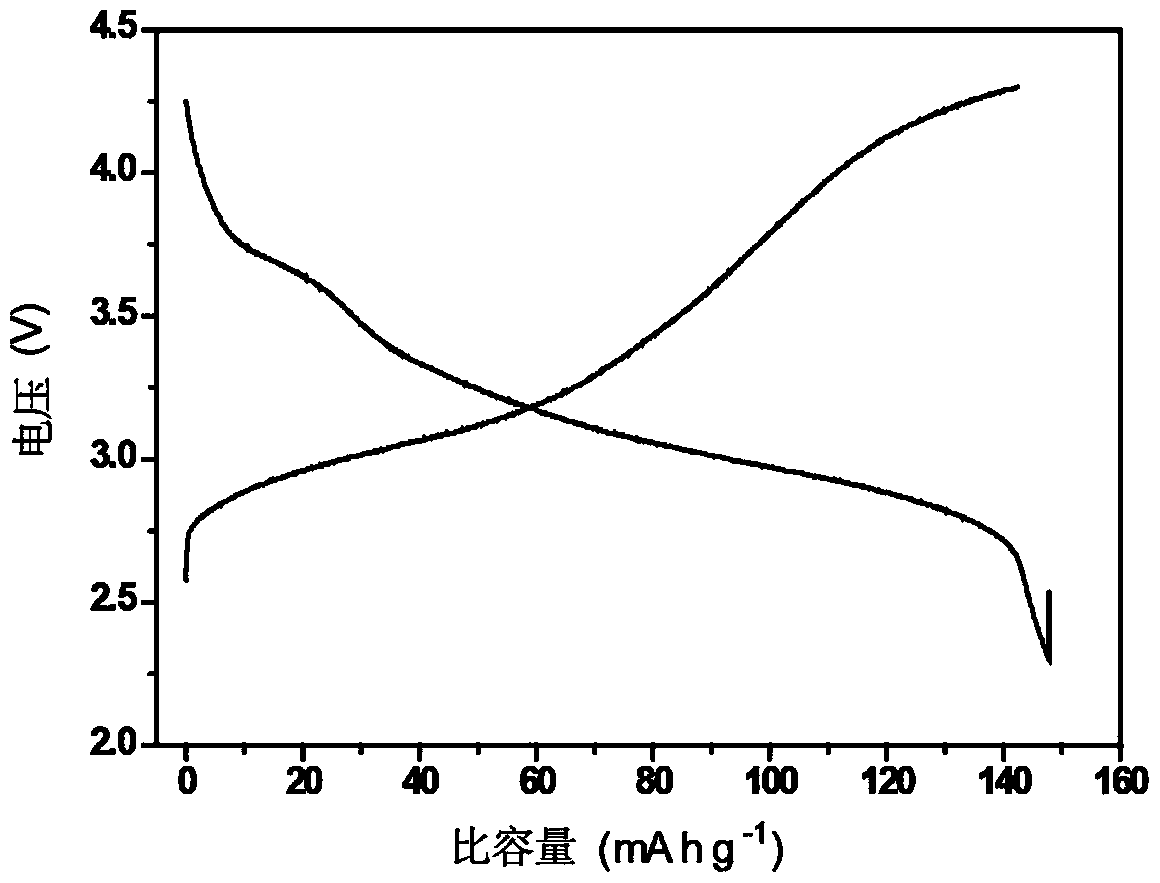

Mixed positive electrode material, positive plate using the same, and lithium ion battery

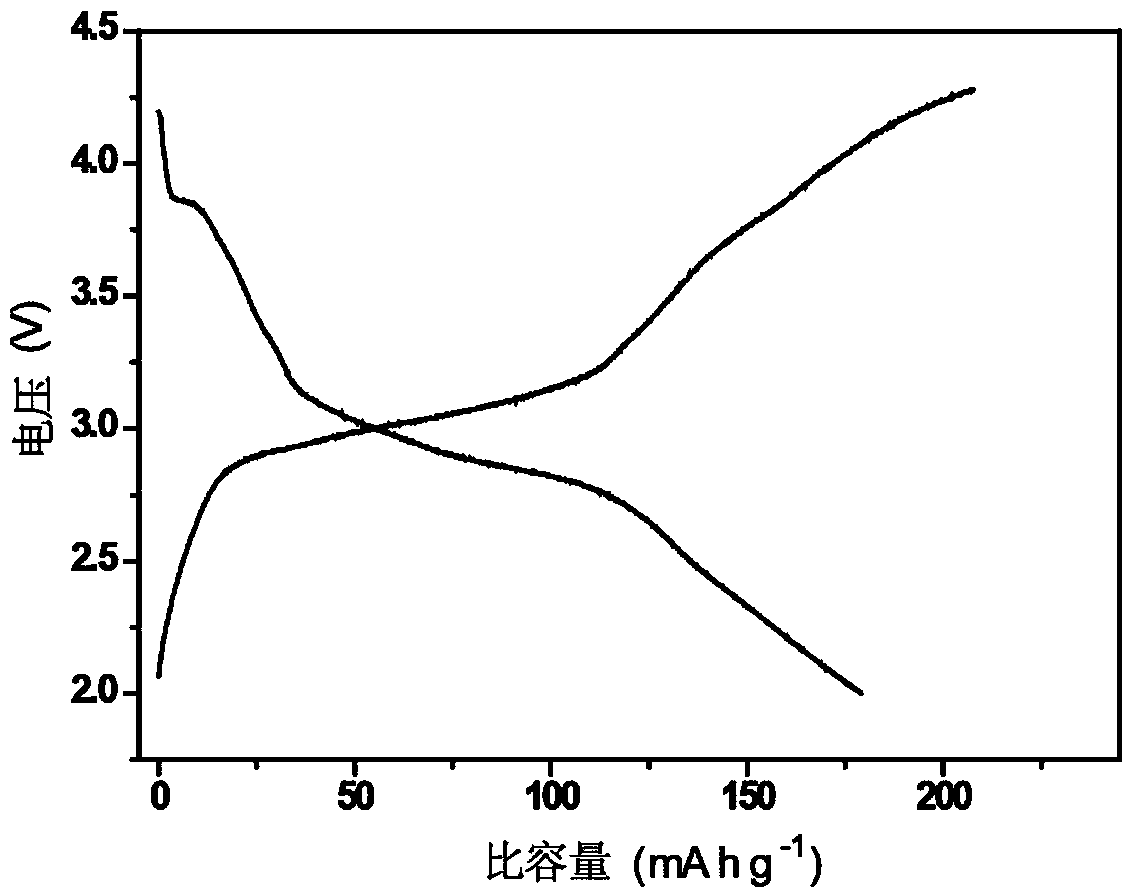

ActiveCN104300123AIncrease energy densityStable thermal decompositionCell electrodesSecondary cellsHigh energyManganese

The invention discloses a mixed positive electrode material, a positive plate using the same, and a lithium ion battery. The mixed positive electrode material comprises the following component by weight: 50-90 parts of a nickel-cobalt-manganese ternary material and 10-50 parts of lithium-manganese-iron phosphate. The mixed positive electrode material provided by the invention combines the nickel-cobalt-manganese ternary material with high energy density and lithium-manganese-iron phosphate with high safety performance, and plays complementary advantages of nickel-cobalt-manganese and lithium-manganese-iron phosphate, so that comprehensive performances of the positive electrode active material are improved. The positive plate prepared by using the mixed positive electrode material increases the safety performance and cycle performance of the lithium ion battery, increases average voltage of the lithium ion battery, and keeps relatively high energy density; and the lithium ion battery using the positive plate has excellent electrochemical performances, high energy density and high safety performances and long cycle life, and is suitable for popularization and application.

Owner:中创新航科技(江苏)有限公司

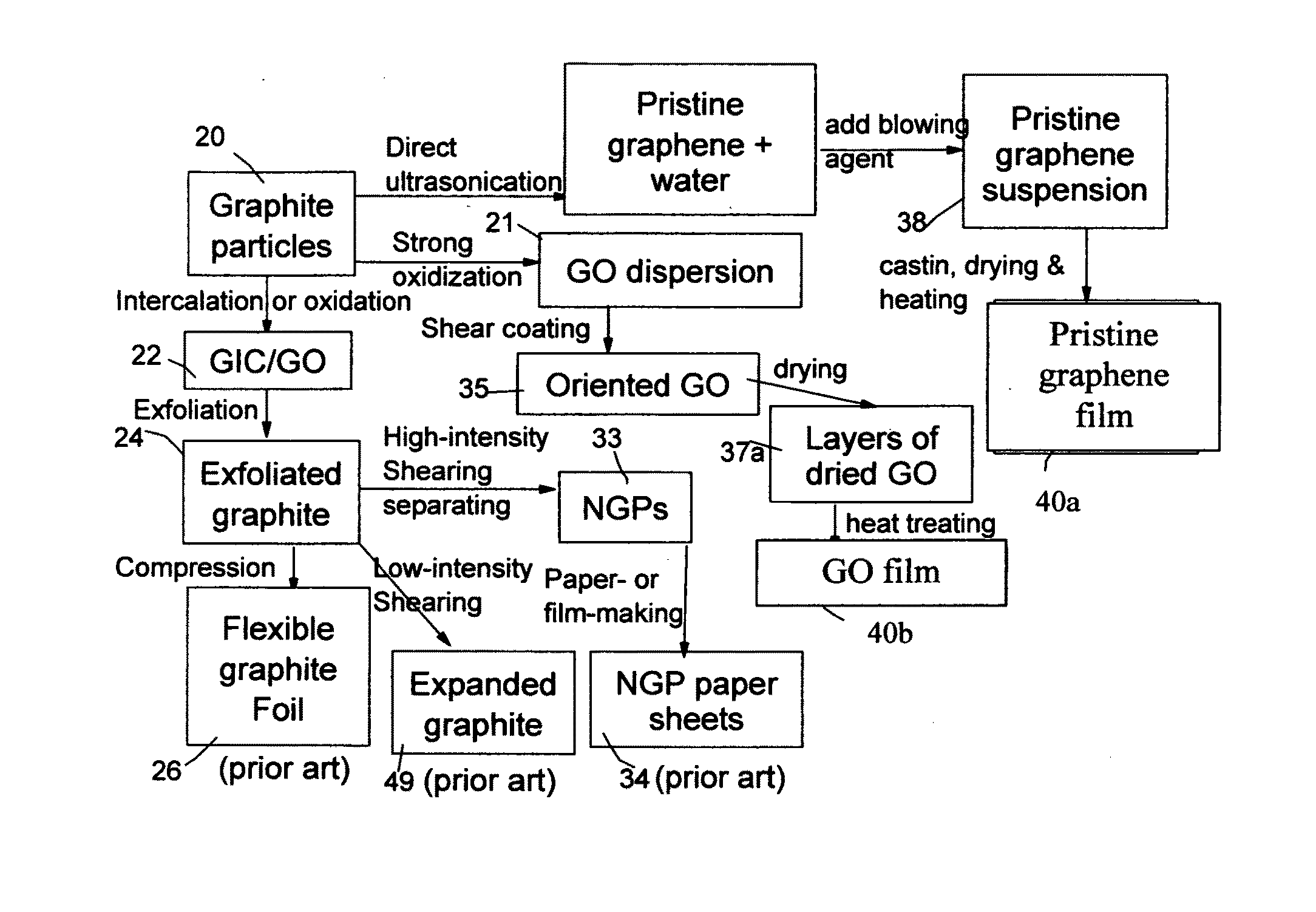

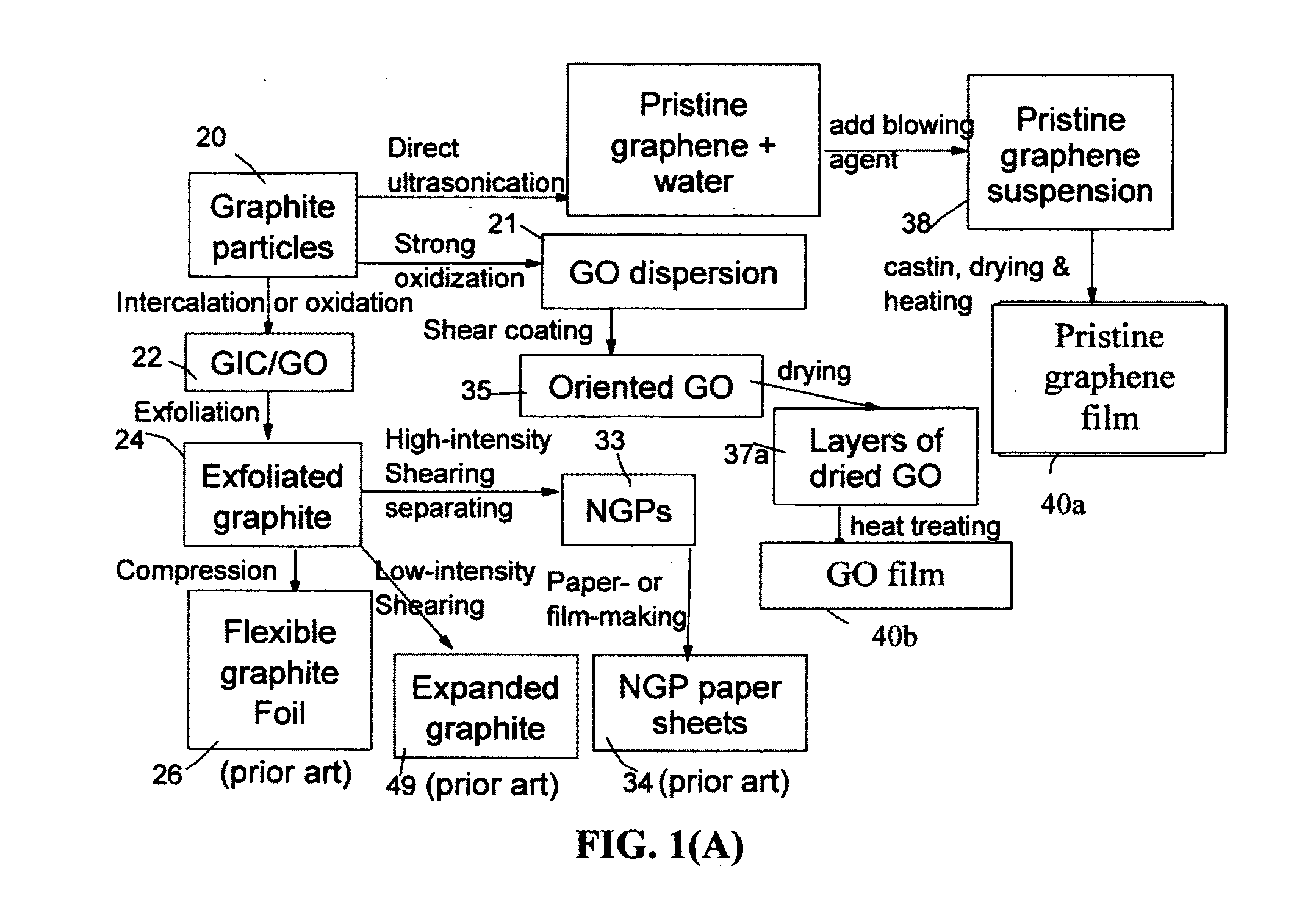

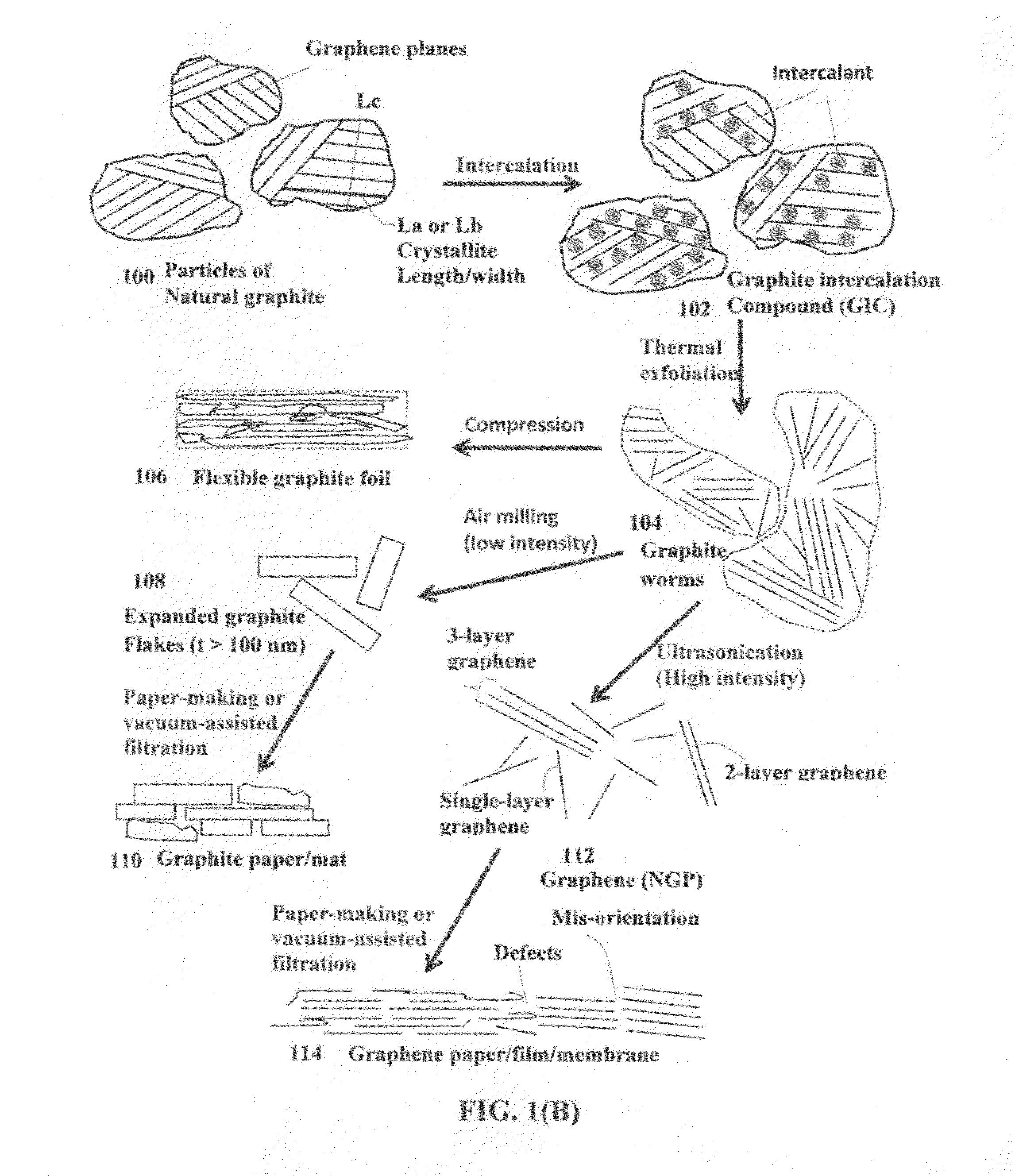

Graphene Electrode Based Ceramic Capacitor

ActiveUS20160079001A1Improve crystal structureGood physical propertiesFixed capacitor electrodesFixed capacitor dielectricDoped grapheneIodide

A ceramic capacitor comprising at least a dielectric ceramic layer and at least a graphene electrode layer deposited on the ceramic layer, wherein the graphene electrode layer has a thickness no less than 2 nm and consists of a graphene material or a graphene composite material containing at least 0.1% by weight of a graphene material dispersed in a matrix material or bonded by a binder material, wherein the graphene material is selected from (a) a plurality of single-layer or multi-layer pristine graphene sheets having less than 0.01% by weight of non-carbon elements, or (b) one or a plurality of a non-pristine graphene material having at least 0.01% by weight of non-carbon elements, wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

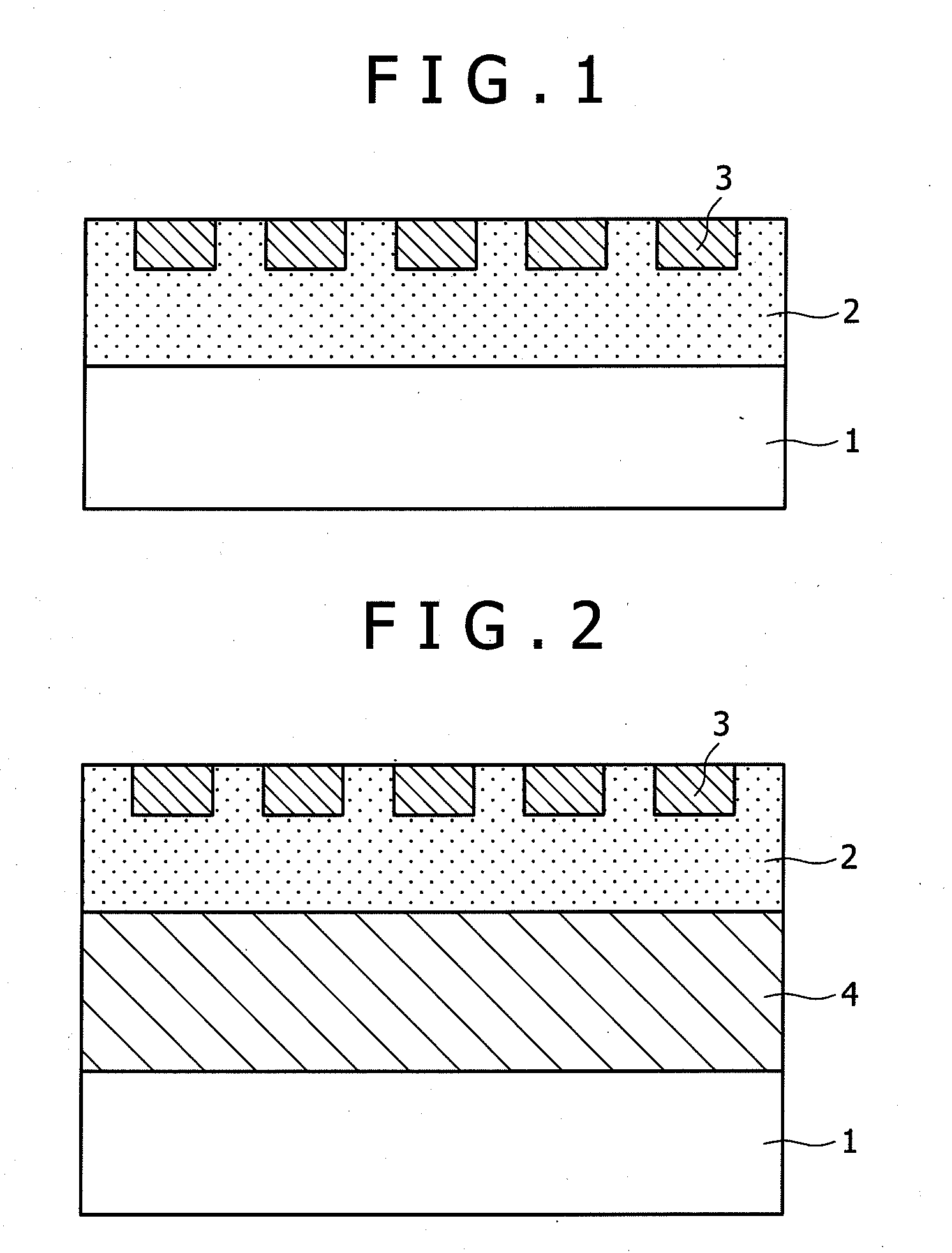

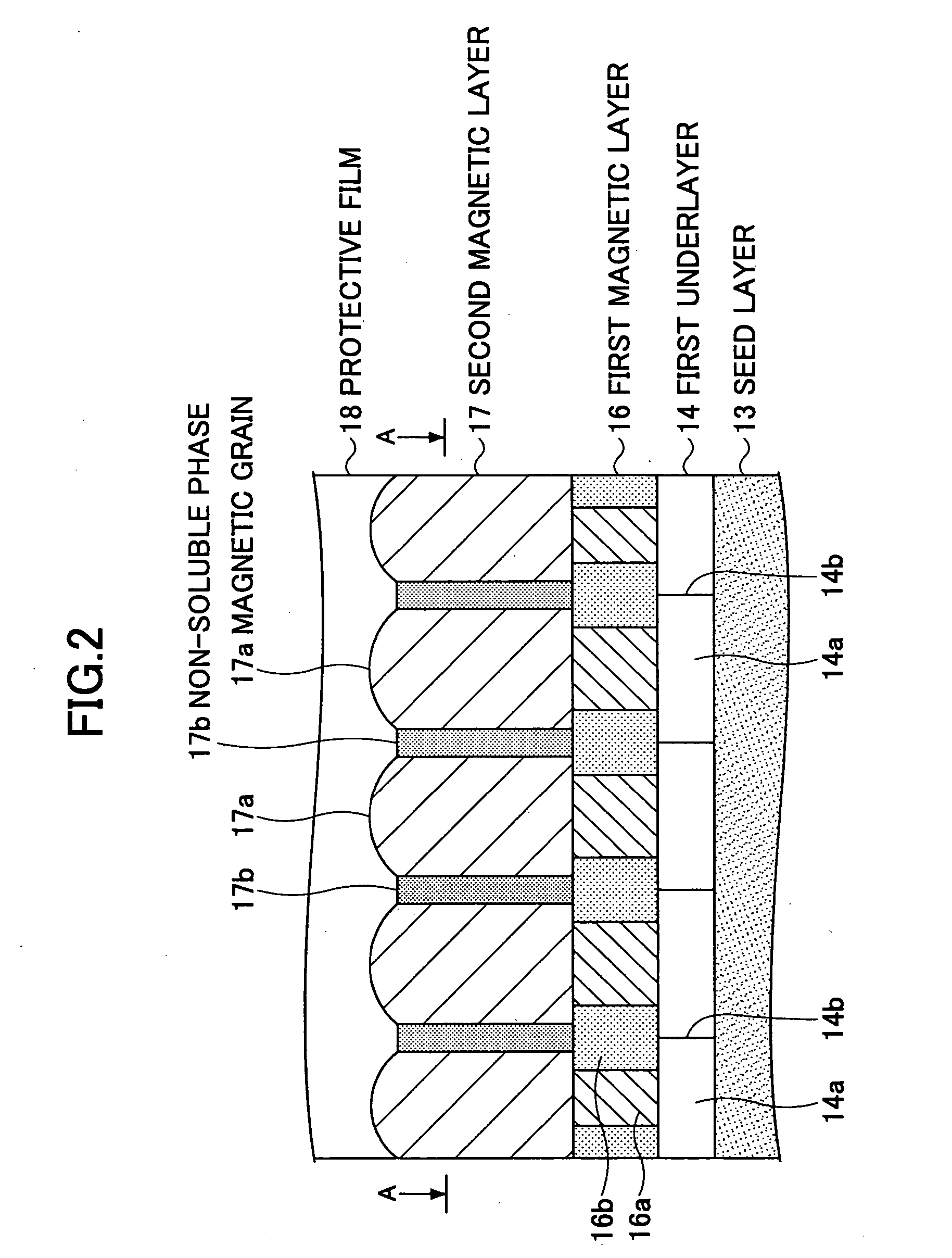

Perpendicular magnetic recording medium, manufacturing method thereof, and magnetic storage device

InactiveUS20060222902A1Medium noise is reducedImprove signal-to-noise ratioVacuum evaporation coatingSputtering coatingHigh densityMagnetic storage

A perpendicular magnetic recording medium for enabling high density recording is disclosed. The perpendicular magnetic recording medium includes a substrate on which a soft magnetic underlayer, a seed layer made of a non-crystalline material, an underlayer made of Ru or an Ru alloy including Ru as a main component, and a recording layer including a first magnetic layer and a second magnetic layer. The first and second magnetic layers include a plurality of magnetic grains having easy magnetization axes in a substantially perpendicular direction with respect to the substrate surface, and first and second nonmagnetic non-soluble phases segregating the magnetic grains of the first and second magnetic layers, respectively. The first magnetic layer includes the first non-soluble phase at a first atomic concentration that is higher than a second atomic concentration of the second non-soluble phase in the second magnetic layer.

Owner:SHOWA DENKO KK

Al-Fe-Ba-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Ba-RE aluminum alloy, and a preparation method of the Al-Fe-Ba-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Tl-RE aluminum alloy, and preparation method and power cable thereof

InactiveCN102978463AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-Tl-RE aluminum alloy, and a preparation method of the Al-Fe-Tl-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Bi-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Bi-RE aluminum alloy, and a preparation method of the Al-Fe-Bi-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Ni-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Ni-RE aluminum alloy, and a preparation method of the Al-Fe-Ni-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

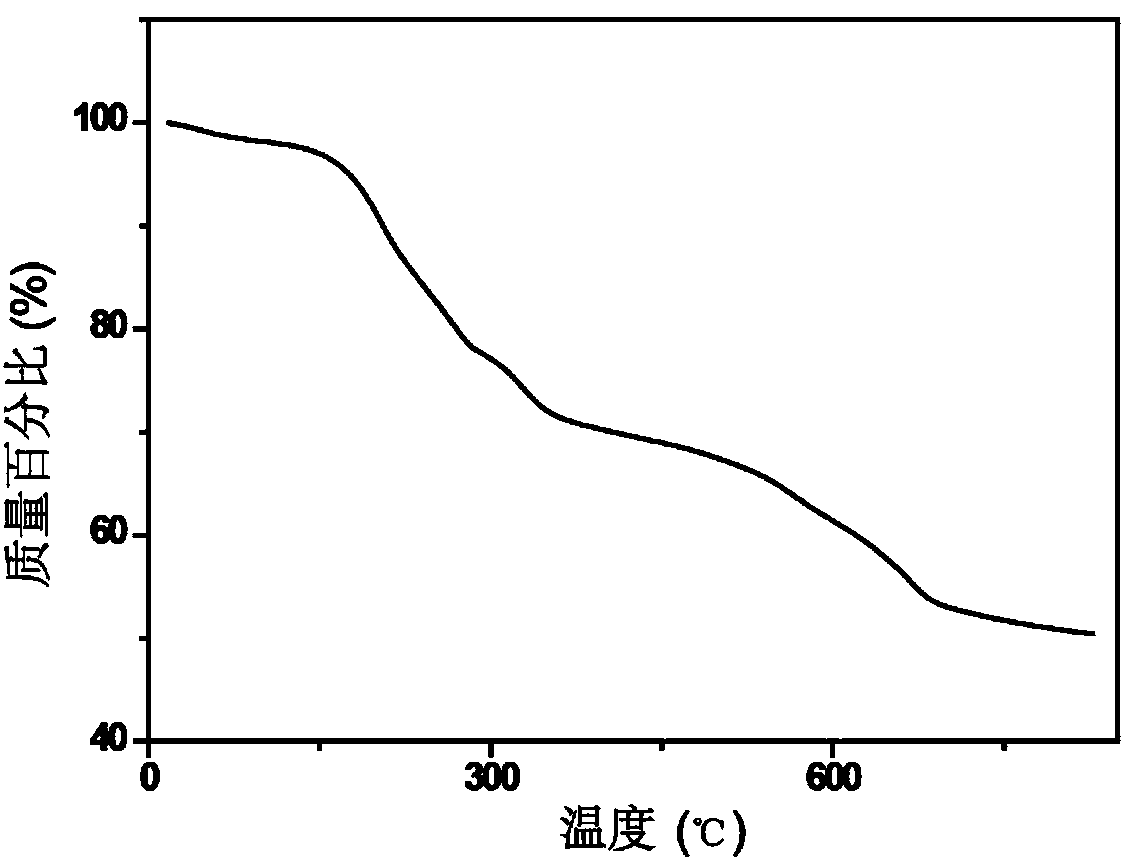

Preparation method and application of prussian blue complex/carbon composite material

ActiveCN103441241AHigh degree of practicalityPromote growthCell electrodesCarbon compositesSodium-ion battery

The invention discloses a preparation method of a prussian blue complex / carbon composite material and an application of the composite material as a positive electrode material for lithium ion and sodium ion batteries. The preparation method of the prussian blue complex / carbon composite material comprises at least the steps of uniformly dispersing a transition metal cyano complex, an inorganic acid and a carbon material in water to obtain a reaction solution; and heating the solution for a certain time to obtain the prussian blue complex / carbon composite material. The method is simple in preparation, can be controlled easily and has high practical degree. Crystal water content and coordinated water content in the obtained prussian blue complex / carbon composite material are little, so that the prussian blue complex / carbon composite material presents high capacity and excellent cycle performance when being used as the positive electrode material for the lithium ion and sodium ion batteries.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Al-Fe-Ta-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978451AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-Ta-RE aluminum alloy, and a preparation method of the Al-Fe-Ta-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

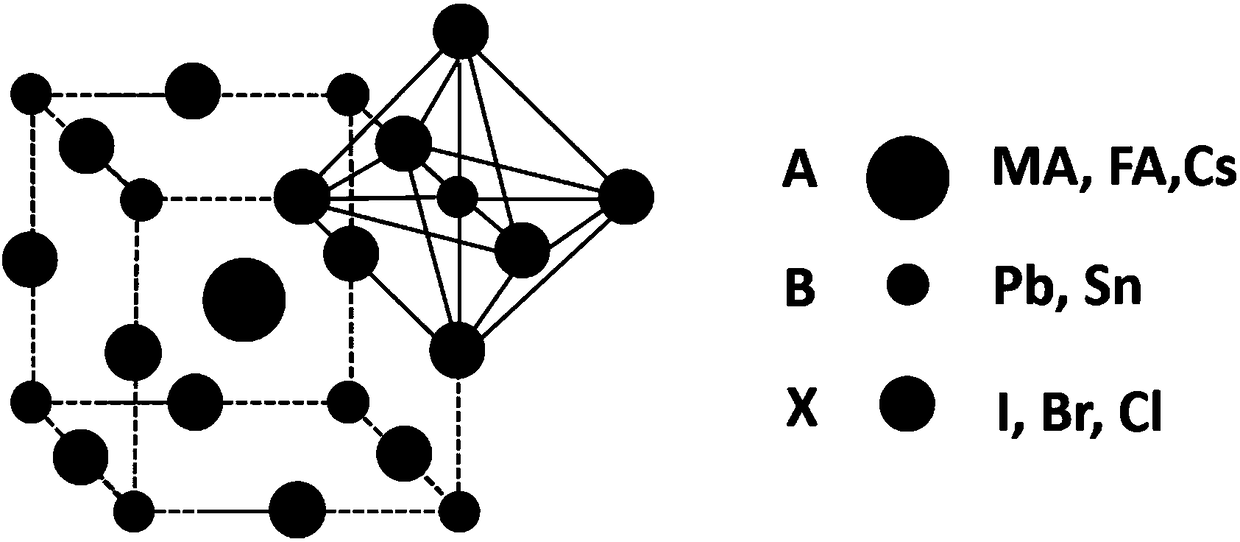

Perovskite solar cell with interface modification layers and preparation method of perovskite solar cell

ActiveCN108258128AImprove crystal structureImprove photoelectric conversion efficiencyFinal product manufactureSolid-state devicesPerovskite solar cellCrystal structure

The invention relates to a perovskite solar cell with interface modification layers. The cross-sectional structure of the perovskite solar cell includes a transparent conductive substrate, a first transmission layer, a perovskite active layer, a second transmission layer and a back electrode; at least one first interface modification layer is disposed between the perovskite active layer and the first transmission layer; and no or at least one second interface modification layer is disposed between the perovskite active layer and the second transmission layer. The invention also discloses a preparation method of the perovskite solar cell. According to the method, the interface modification layers are additionally arranged between the perovskite active layer and transmission layers of a perovskite solar cell, so that the perovskite solar cell with the interface modification layers can be prepared; the surfaces of the transmission layers are passivated; the crystal structure of the perovskite is optimized; ion migration in the perovskite active layer is suppressed to a certain extent; and therefore, the photoelectric conversion efficiency and long-term stability of the perovskite cellare improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

Al-Fe-W-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978468AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-W-RE aluminum alloy, and a preparation method of the Al-Fe-W-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Technology for processing high strength large hexagon-headed bolt used for steel structure

InactiveCN101934466AImprove heating uniformityFast heatingBoltsFurnace typesHigh intensityElectrical current

The invention provides a technology for processing high strength large hexagon-headed bolt used for steel structure. The invention relates to a technology for processing high strength connecting piece. High frequency induction current hot forging and cold extruding are adopted, so as to produce a bolt. The invention is on the basis of patent application with patent application number of 200810020090.5, high frequency induction heating is adopted in hot forging, frequency thereof is controlled to be 20000-50000Hz, and the advantages of high frequency induction heating that speed is fast and heating is uniform are utilized, so that work piece surface can obtain uniform tissue and properties from center part to the surface, heating uniformity of work piece is improved, better crystal phase structure can be obtained, and high strength bolt with better property can be obtained.

Owner:扬州狮鹤高强度螺栓有限公司

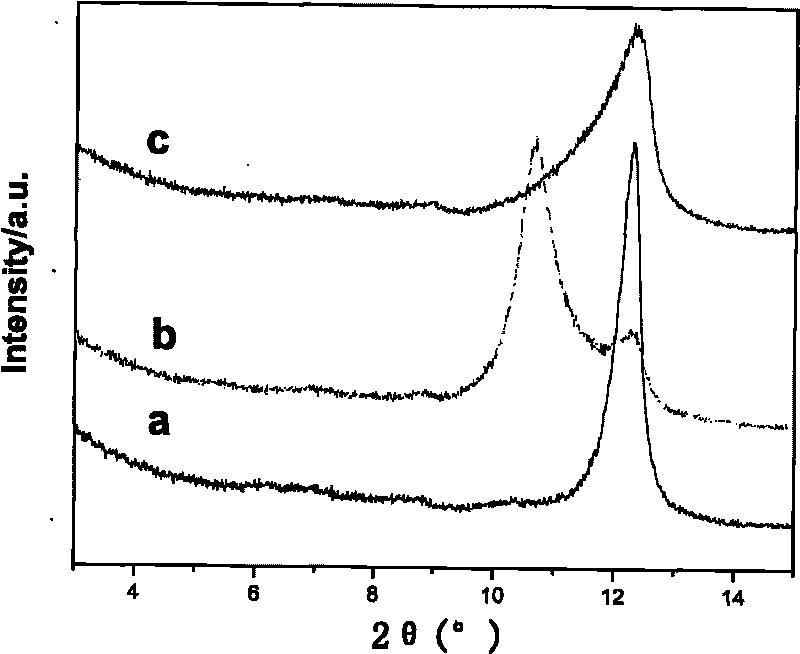

Method for stripping laminated inorganic material

The invention relates to a method for stripping a laminated inorganic material, which comprises the following steps of: firstly preparing a laminated inorganic material organic intercalation compound, then decomposing the organic substance at the interlayer of the solid of the laminated inorganic material organic intercalation compound or the laminated inorganic material organic intercalation compound added into a proper solution within short time under the condition of ultrasonic waves or microwaves, escaping from the interlayer of the laminated inorganic material so as to rapidly strip the laminated inorganic material, and finally separating, washing, drying and grinding to obtain a product. By using the method, not only the laminated inorganic material can be stripped within short time, but also the good crystal structure of the laminated inorganic material can be kept, so that the traditional application of the laminated inorganic material is qualitatively improved, and the value is doubled and redoubled.

Owner:BEIJING UNIV OF CHEM TECH

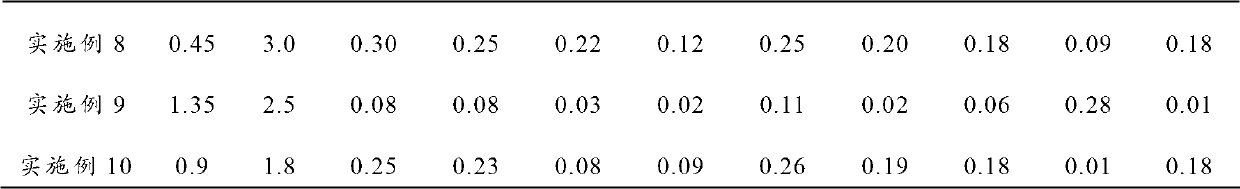

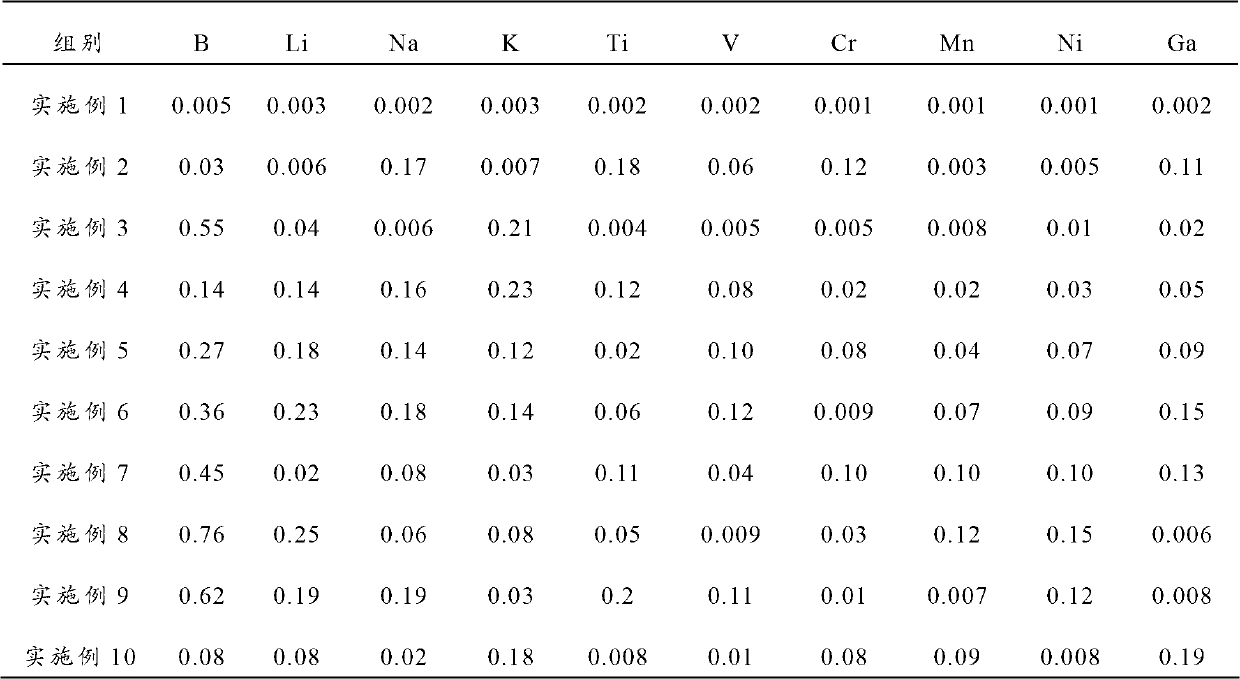

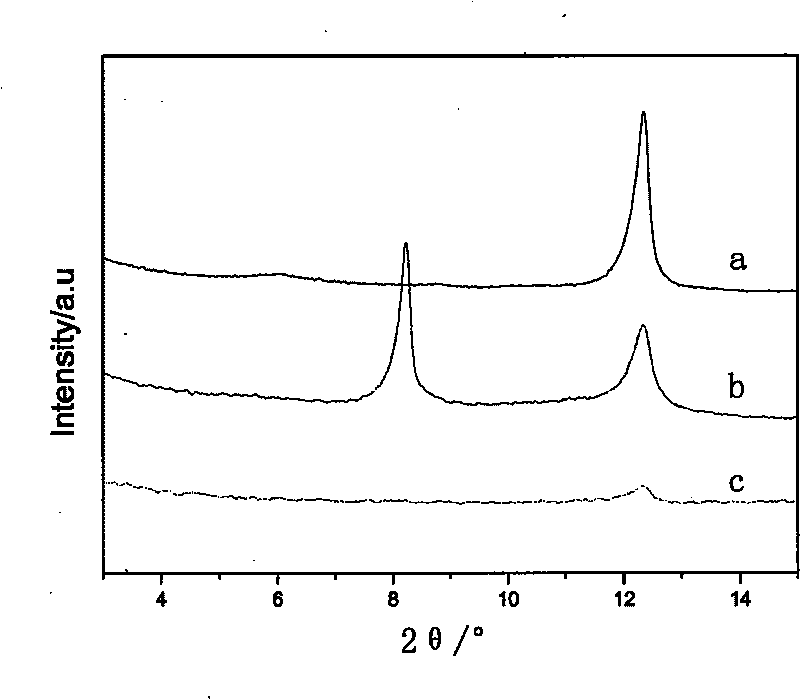

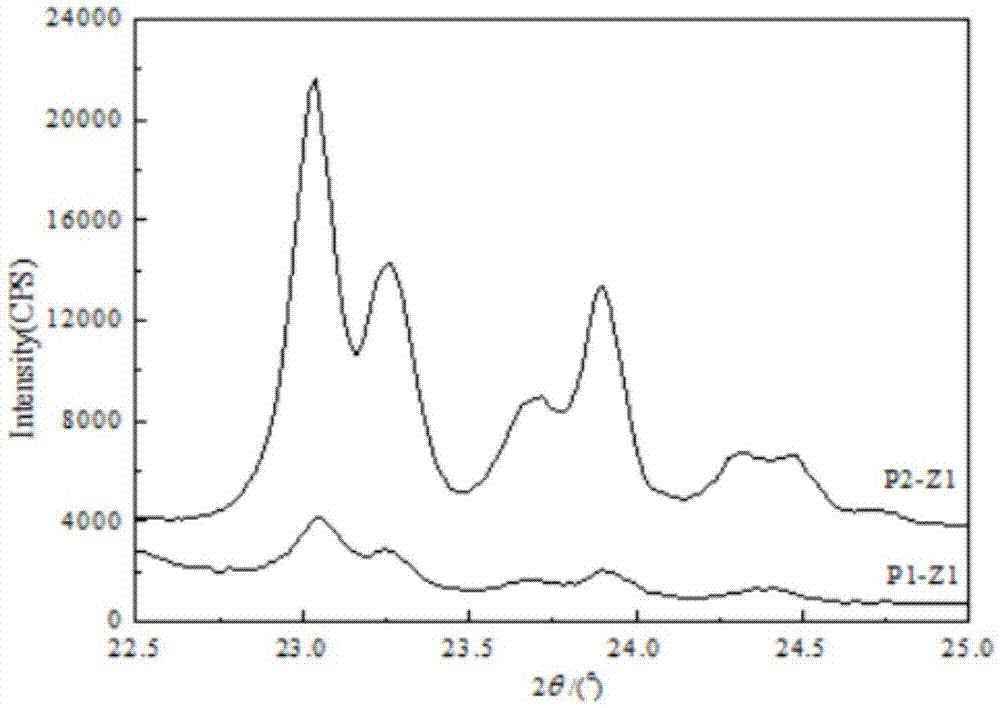

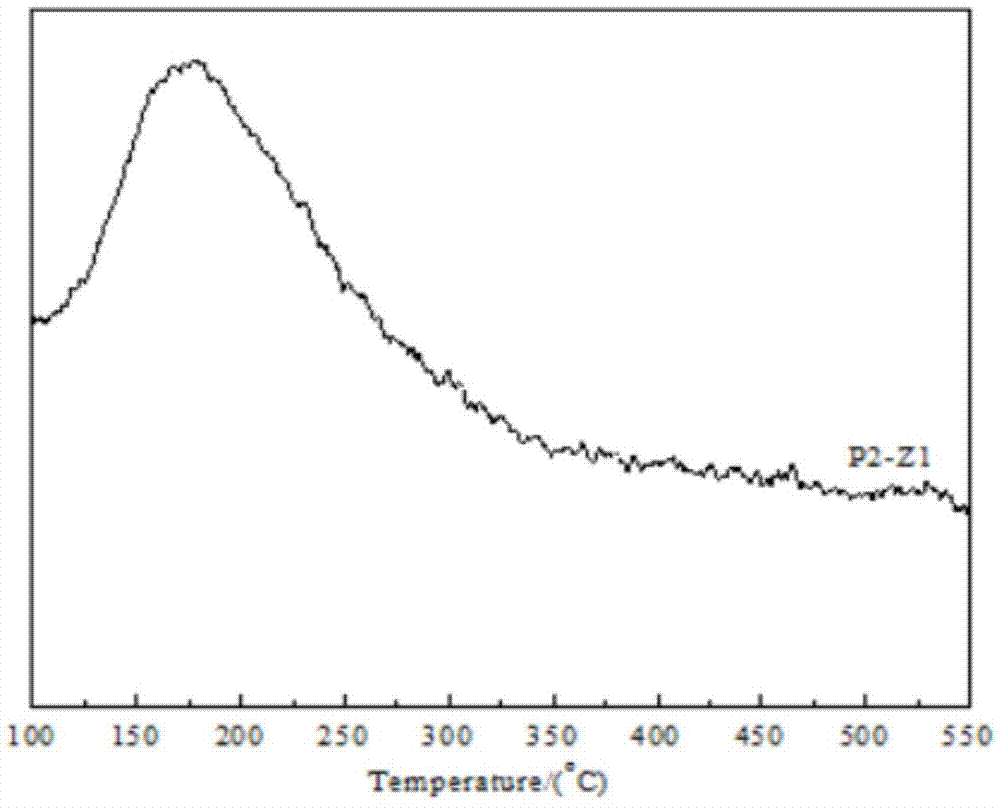

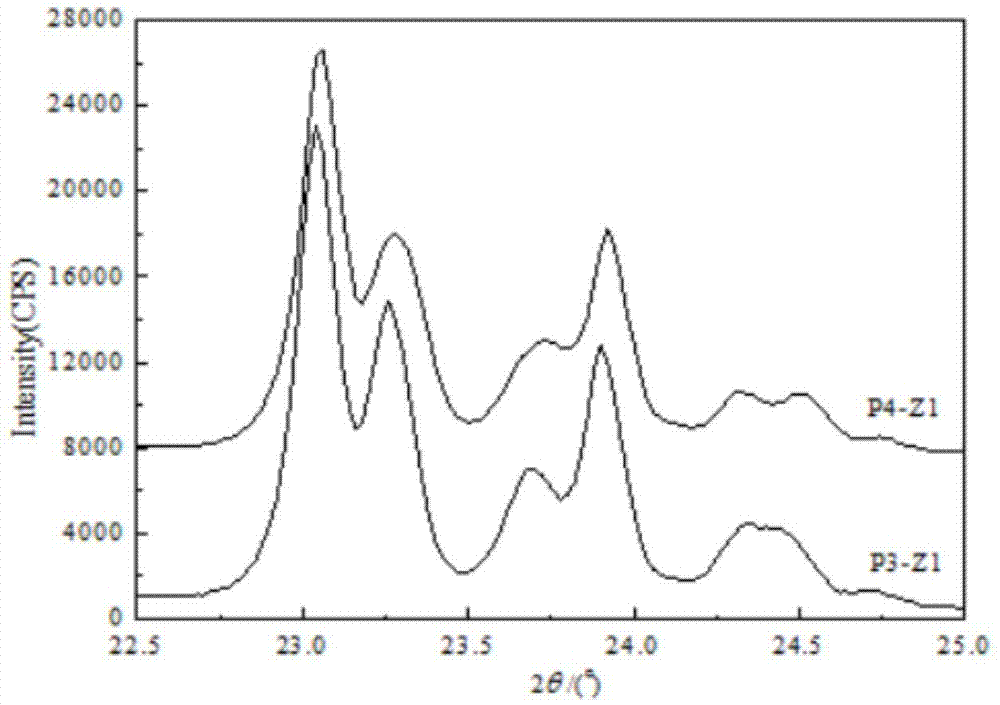

Phosphorus modification method of ZSM-5 molecular sieve

ActiveCN106994364ASuperior Catalytic PerformanceHigh selectivityCatalytic crackingMolecular sieve catalystsIonPhosphoric acid

The invention provides a phosphorus modification method of a high-alkali-metal-ion-content ZSM-5 molecular sieve. The method is characterized by comprising mixing a phosphorus-containing compound selected from one or more of phosphoric acid, diammonium phosphate, ammonium biphosphate and ammonium phosphate with a high-alkali-metal-ion-content ZSM-5 molecular sieve to obtain a mixture with at least 0.1 wt% of phosphorus-loading content, wherein phosphorus is counted in terms of P2O5, drying and calcinating the mixture, carrying out an ammonium exchange process and a washing process to make the alkali metal ion content no more than 0.10 wt%, performing drying, and carrying out hydrothermal aging at the temperature of 400-1000 DEG C in a 100% of vapor condition. The obtained phosphorus-containing ZSM-5 molecular sieve is high in total acid amount, is excellent in cracking conversion rate and propylene selectivity, and is good in hydro-thermal and active stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microwave method for peeling laminar inorganic material quickly

The invention relates to a method for peeling a laminar inorganic material quickly. The method comprises the following steps of: firstly, preparing laminar inorganic intercalating composite of the laminar inorganic material; secondly, decomposing or evaporating the inter-laminar organic material of the organic intercalating composite solid of the laminar inorganic material in a short time in the presence of microwaves and allowing the inter-laminar organic material to escape from the space between the layers of the laminar inorganic material so as to quickly peal the laminar inorganic material; and finally, performing separation, washing, drying and grinding to obtain the products. The method not only can peal the laminar inorganic material in a short time but also keep a good crystal structure of the laminar inorganic material, so the application of the laminar inorganic material is substantially widened and the use value thereof is multiplied.

Owner:BEIJING UNIV OF CHEM TECH

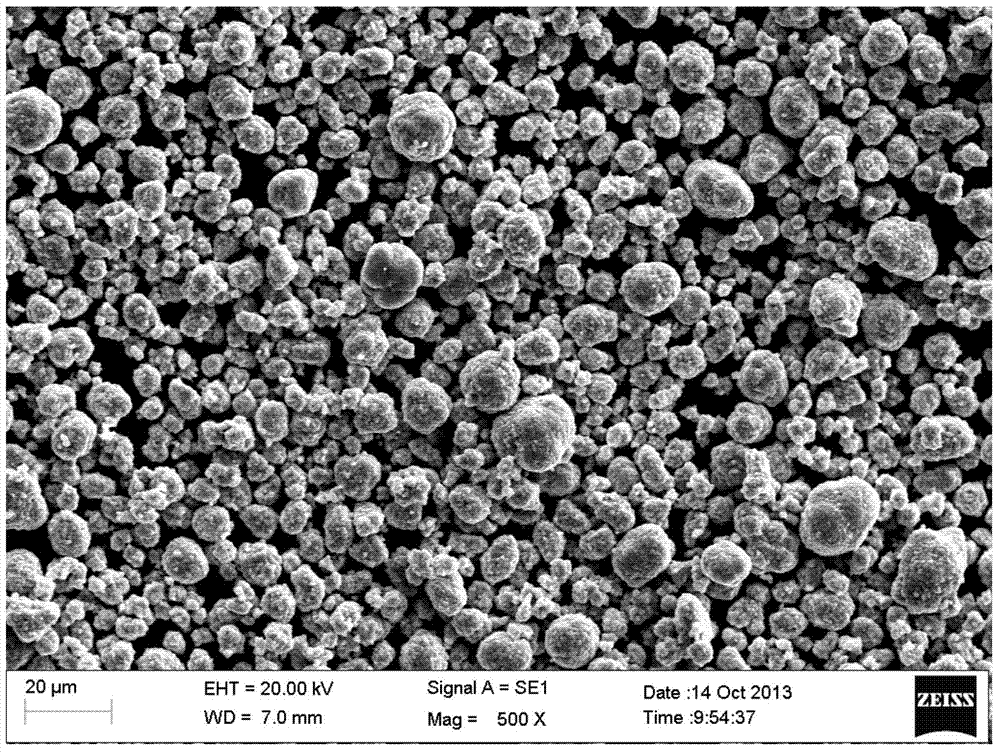

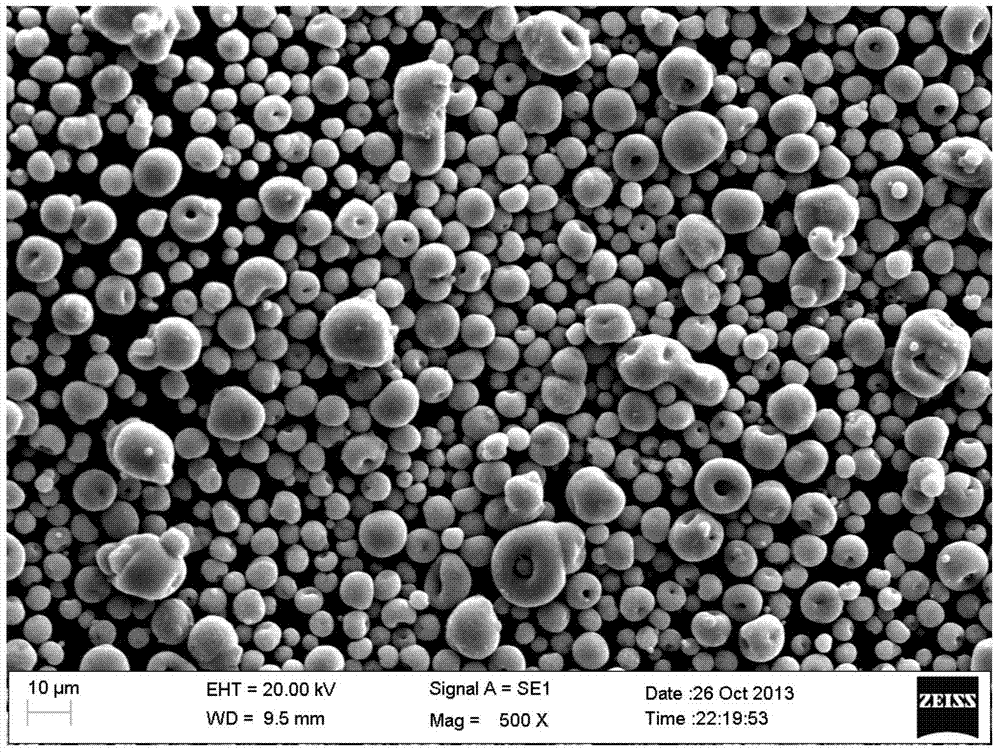

Coated lithium-rich manganese base material and preparation method thereof

ActiveCN102751480AImprove cycle performanceHigh specific capacityCell electrodesManganeseSodium-ion battery

A coated lithium-rich manganese base material and a preparation method thereof relate to the field of lithium ion battery. A coated lithium-rich manganese base material for lithium ion battery anode material comprise chemical molecules of a coated layer Li (NiaMn2-a) O2 and a main phase Li[LixNiyCo1-x-y-z Mnz]O2. The preparation method comprises steps of: (a) preparing soluble nickel, cobalt and manganese salt into a mixed solution, and preparing soluble nickel and manganese salt into a mixed solution; (2) preparing an alkali solution; (3) adding the alkali solution and the mixed solution containing nickel, cobalt and manganese into a reaction kettle, stirring fiercely to obtain a coprecipitation, then pumping the mixed solution containing nickel and manganese salt and the alkali solution, and carrying out a co-precipitation reaction, aging, treatment by a centrifugal machine and drying to obtain a coated precursor M (OH)2 (M=Ni, Co, Mn); and (4) uniformly mixing the precursor with a lithium source, carrying out segment sintering, and then sieving to obtain the lithium-rich manganese base material. The invention provides a lithium ion battery anode material with good cycle performance, and the process has the advantages of simpleness, low production cost, short production cycle and stable product performance.

Owner:HENAN KELONG NEW ENERGY CO LTD

Tantalum sputtering target and method for preparation thereof

InactiveUS7156963B2Enhancing evenness (uniformity)Quality improvementCellsMetal-working apparatusCrystal structureIngot

Provided is a tantalum sputtering target having a crystal structure in which the (222) orientation is preferential from a position of 10% of the target thickness toward the center face of the target, and a manufacturing method of a tantalum sputtering target, including the steps of forging and recrystallization annealing, and thereafter rolling, a tantalum ingot or billet having been subject to melting and casting, and forming a crystal structure in which the (222) orientation is preferential from a position of 10% of the target thickness toward the center face of the target. As a result, evenness (uniformity) of the film is enhanced, and quality of the sputter deposition is improved.

Owner:JX NIPPON MINING & METALS CORP

Al-Fe-Sn-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Sn-RE aluminum alloy, and a preparation method of the Al-Fe-Sn-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Solvent dewaxing method

ActiveCN1648216AImprove crystal structureEasy to separateMineral wax recovery/refiningParaffin waxMicrocrystalline wax

During solvent dewaxing, the mixture of wax containing material oil, dewaxing solvent and dewaxing assistant is made to pass through two stages of dewaxing material oil and deoiling cerate; the filtrate from the deoiling stage is returned to the dewaxing stage completely; and dewaxed oil and deoiled wax are obtained after recovering the solvent. The dewaxing assistant is ashless polymer mixture of high branched chain degree polymer and low branched chain degree polymer. The method improves the crystal structure of wax, raises oil-wax separating effect, raises dewaxed oil yield and filtering speed obviously, lowers the solvent ratio and lowers the oil content in cerate. The cerate may be used in producing paraffin or microcrystal wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Al-Fe-Re-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Re-RE aluminum alloy, and a preparation method of the Al-Fe-Re-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:于贵良 +1

Al-Fe-Ir-RE aluminum alloy, preparation method thereof and power cable

ActiveCN103045913AEvenly heatedEliminate damagePower cables with screens/conductive layersMetal/alloy conductorsPower cableIngot

The invention provides Al-Fe-Ir-RE aluminum alloy, and also provides a preparation method of the Al-Fe-Ir-RE aluminum alloy. The preparation method comprises the following steps of: a) casting an aluminum alloy ingot; b) homogenizing the aluminum alloy ingot, and rolling the homogenized aluminum alloy ingot to obtain an aluminum alloy rod; c) intermittently annealing the aluminum alloy rod obtained in the step b); and d) performing aging treatment on the aluminum alloy rod obtained in step c) to obtain the aluminum alloy. The invention further provides a power cable. According to the invention, the aluminum alloy has a good comprehensive performance by choosing and controlling added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

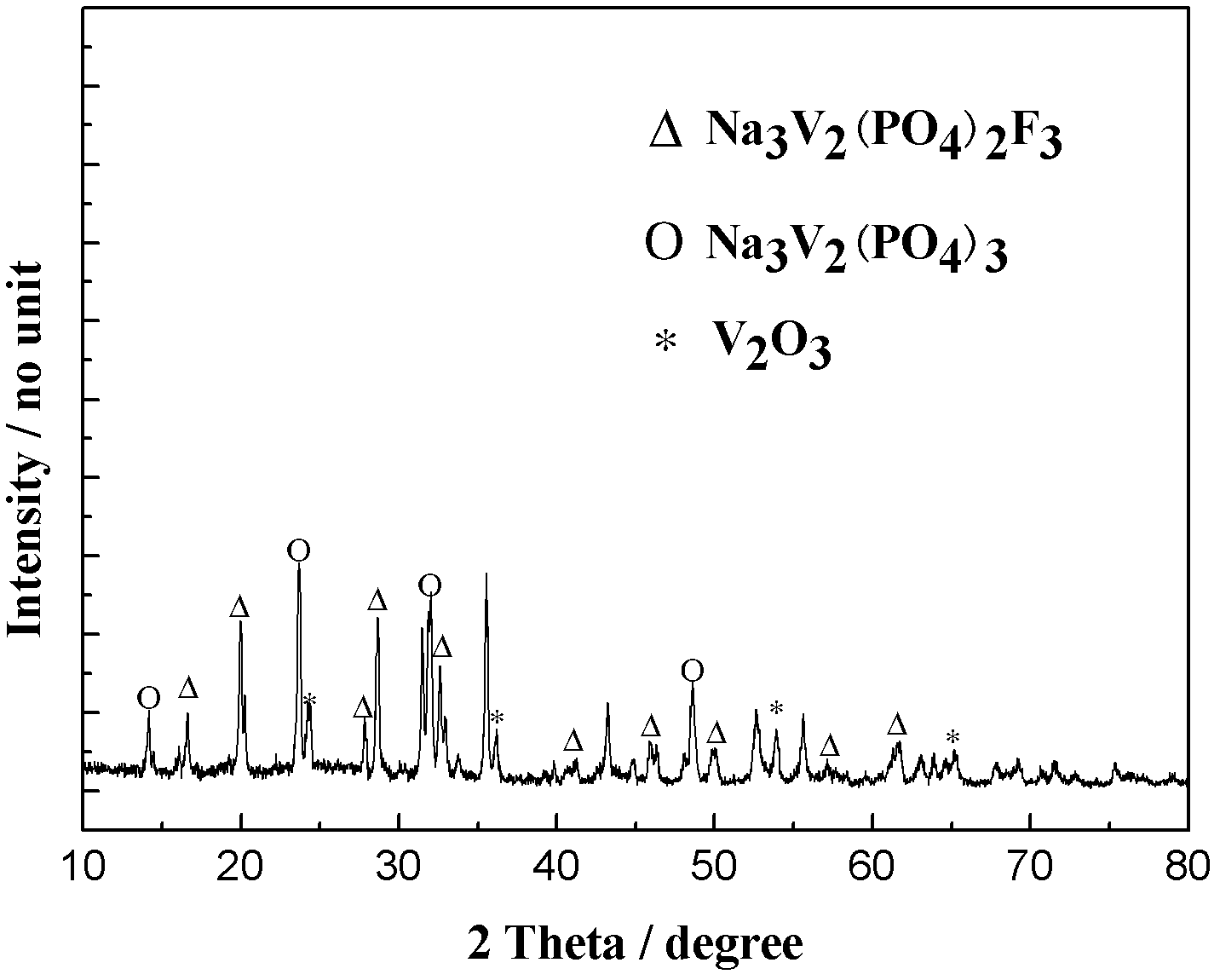

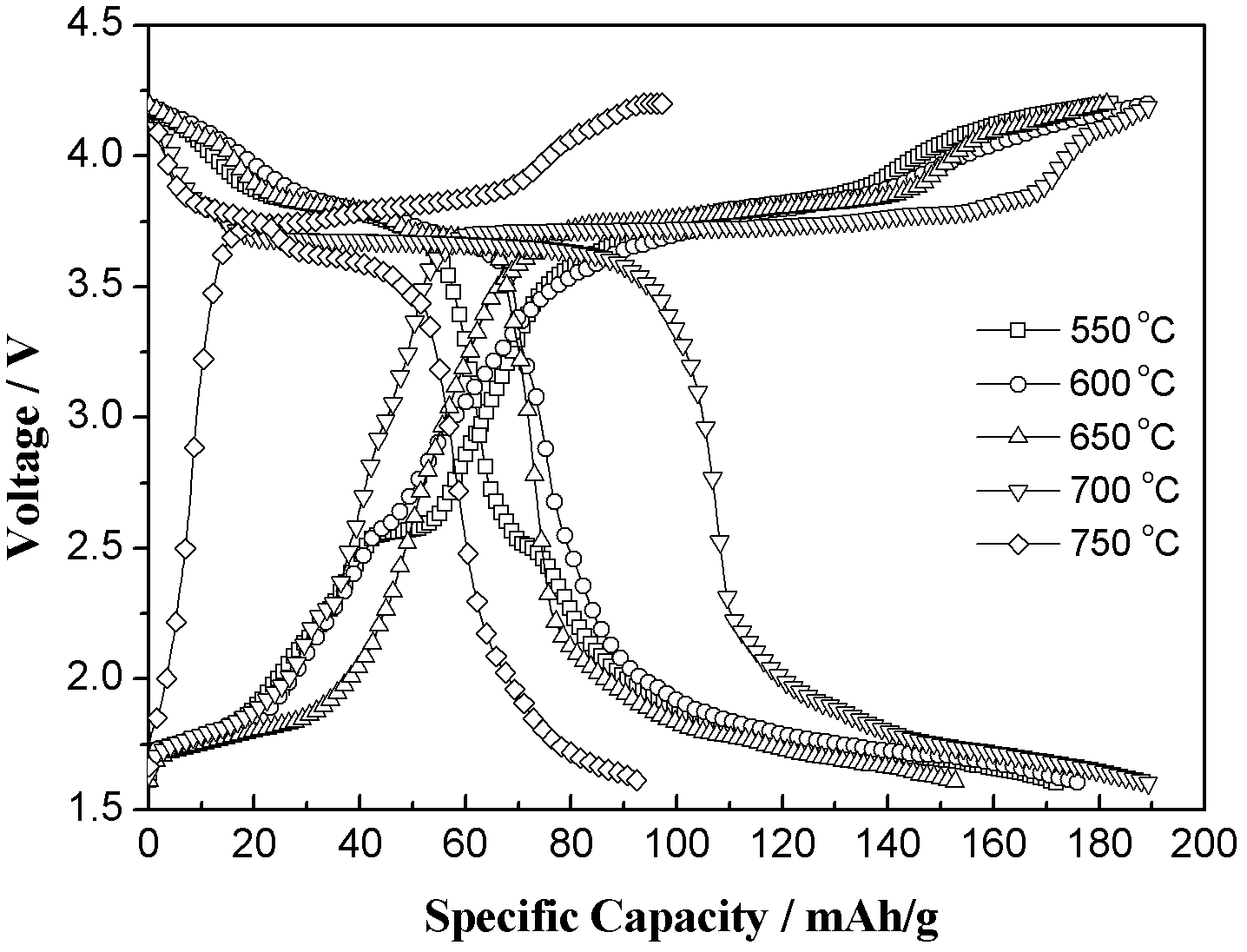

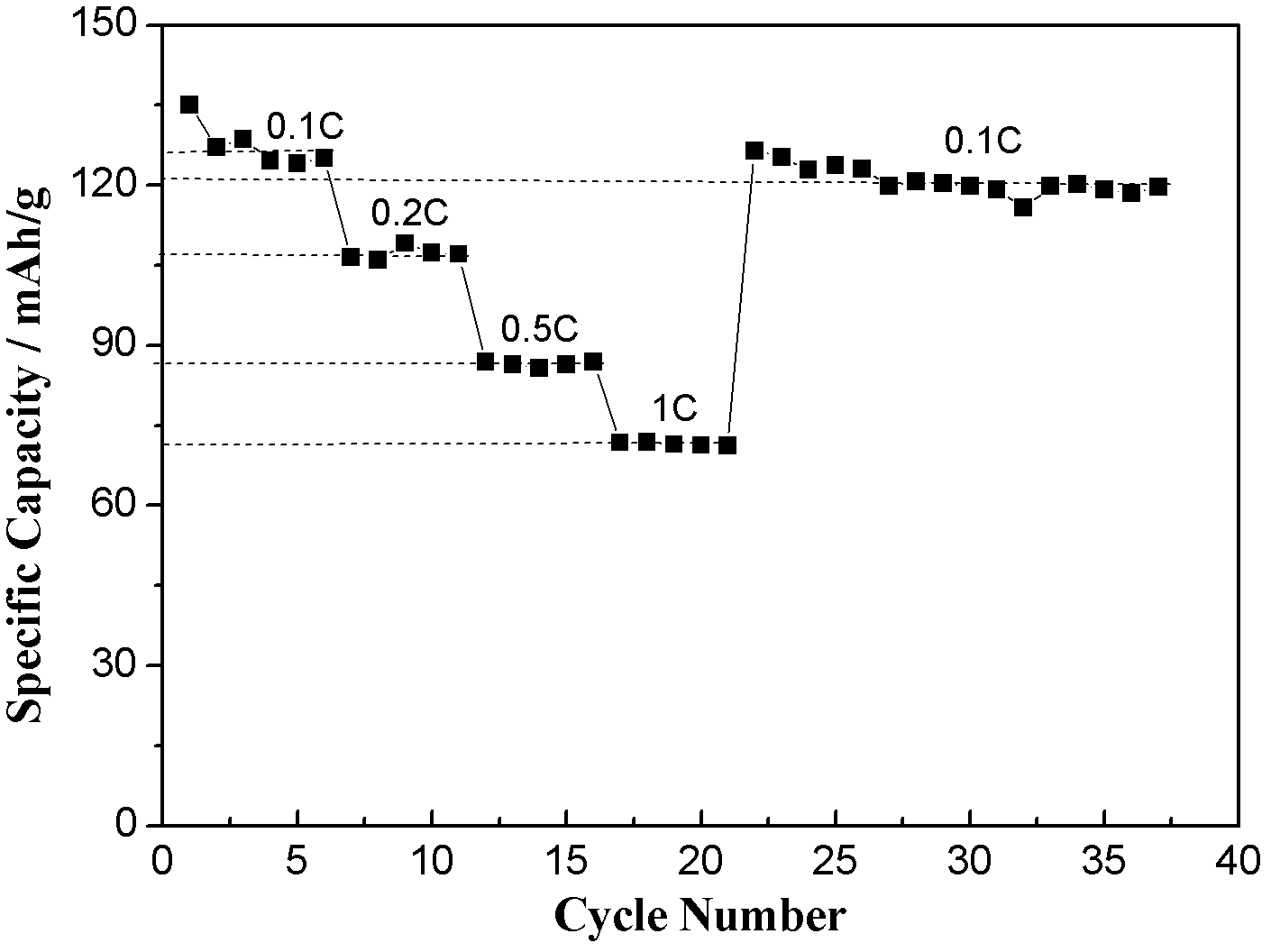

Preparation method of vanadium sodium fluophosphate cathode material of hybrid ion battery

InactiveCN102306771AShape is easy to controlGood carbon coatingCell electrodesRoom temperatureFree cooling

The invention provides a preparation method of a vanadium sodium fluophosphate cathode material of a hybrid ion battery. The method comprises the following steps: 1) grinding of a mixed material: taking trivalent or pentavalent vanadium oxide (V), ammonium dihydrogen phosphate (P), sodium fluoride (F) and a reducing agent carbon source (C) as raw materials, wherein the molar ratio of V to P to F is 2:(1.9-2.3):3, the molar ratio of V to C in the reducing agent carbon source is 1:(1-2), then weighing carbon source accounting for 3-5% of the total weight of the raw materials to serve as a conductive agent, and carrying out mixed grinding to obtain a precursor mixture; 2) precalcination: precalcinating the precursor mixture for 6-10 hours at the temperature of 300-400 DEG C at the warming speed of 3-5 DEG C per minute under the protection of inert gas, cooling the mixture to room temperature and taking out the mixture for secondary grinding; and 3) secondary calcination: carrying out the secondary calcination on the mixture ground in the step 2) for 6-10 hours at the temperature of 550-750 DEG C at the warming speed of 3-5 DEG C per minute under the protection of the inert gas, and naturally cooling to room temperature to obtain the vanadium sodium fluophosphate cathode material. The vanadium sodium fluophosphate cathode material has good electrochemical performance which is obviously improved.

Owner:CENT SOUTH UNIV

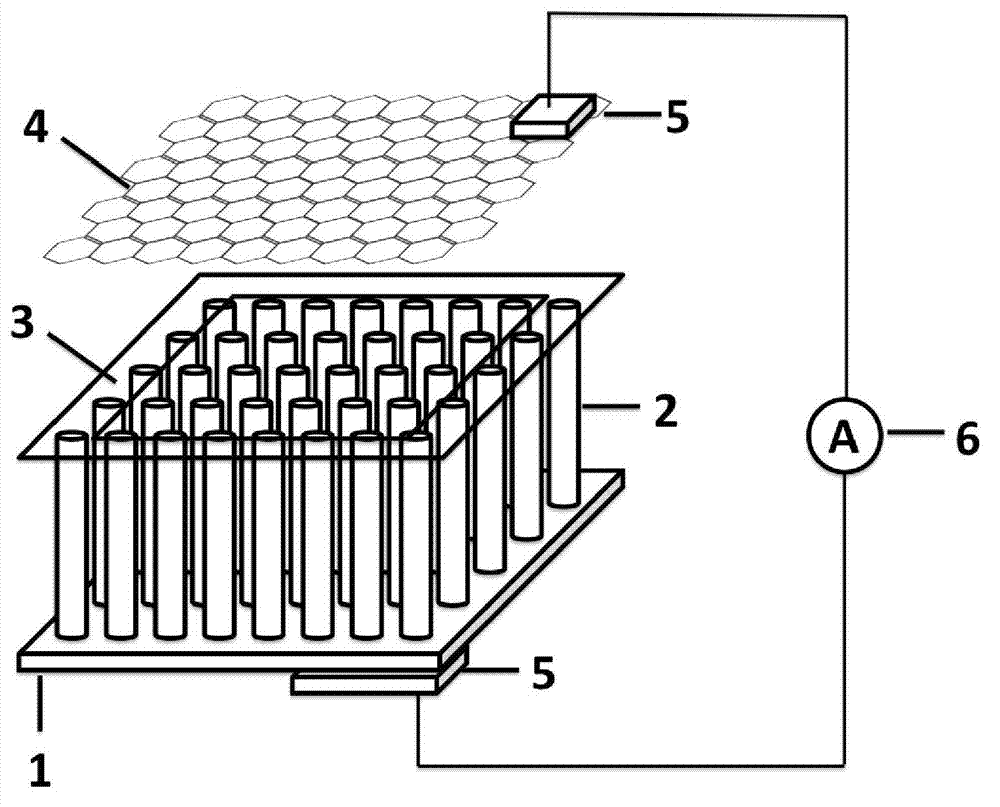

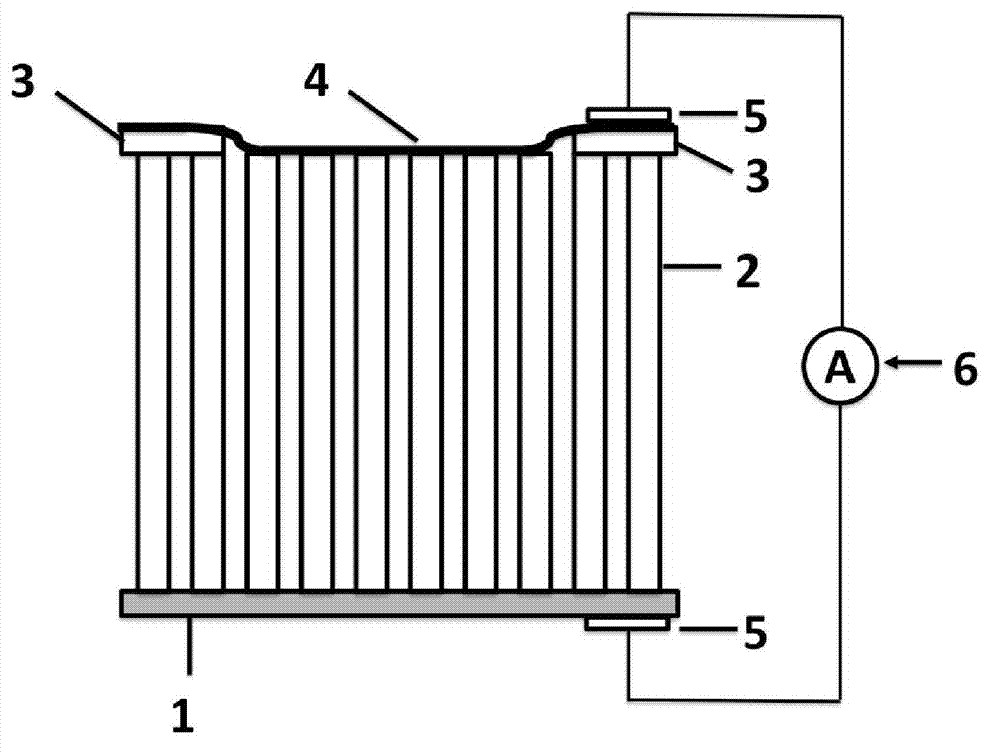

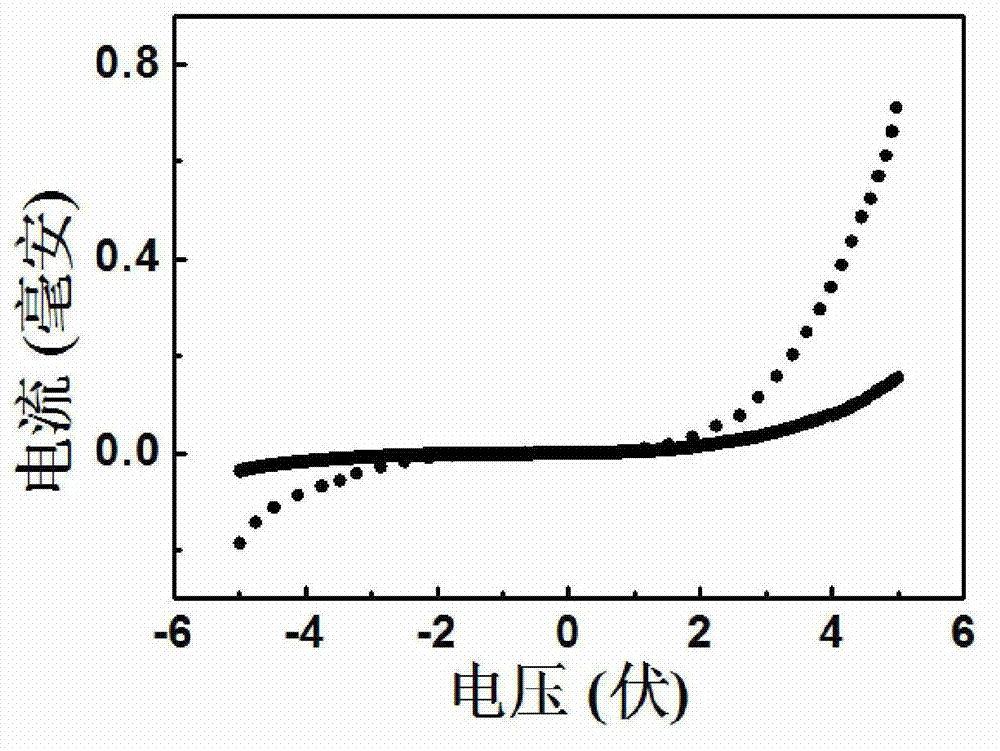

Ultraviolet light detector with titanium dioxide nanotube array serving as matrix and preparation method thereof

InactiveCN102856423AImprove responsivenessReduce dark currentFinal product manufactureSemiconductor devicesCvd grapheneOxygen vacancy

The invention discloses an ultraviolet light detector with a titanium dioxide nanotube array serving as a matrix and a preparation method thereof. The ultraviolet light detector comprises a titanium sheet substrate (1), the titanium dioxide nanotube array (2), an insulating layer (3) and a graphene film (4) sequentially from bottom to top, extraction electrodes (5) are arranged on the lower surface of the titanium sheet substrate (1) and the upper surface of the graphene film (4) respectively and are connected with a current measurer (6). The titanium dioxide nanotube array is prepared on the titanium sheet substrate by an anodizing method, oxygen vacancy of the array prepared by the method is less, and mismatch of stoichiometric ratio is avoided. Therefore, titanium dioxide is good in crystalline structure after annealing to lead to high response, low dark current and high ultraviolet-to-visible rejection ratio.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com