Patents

Literature

156results about "Mineral wax recovery/refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

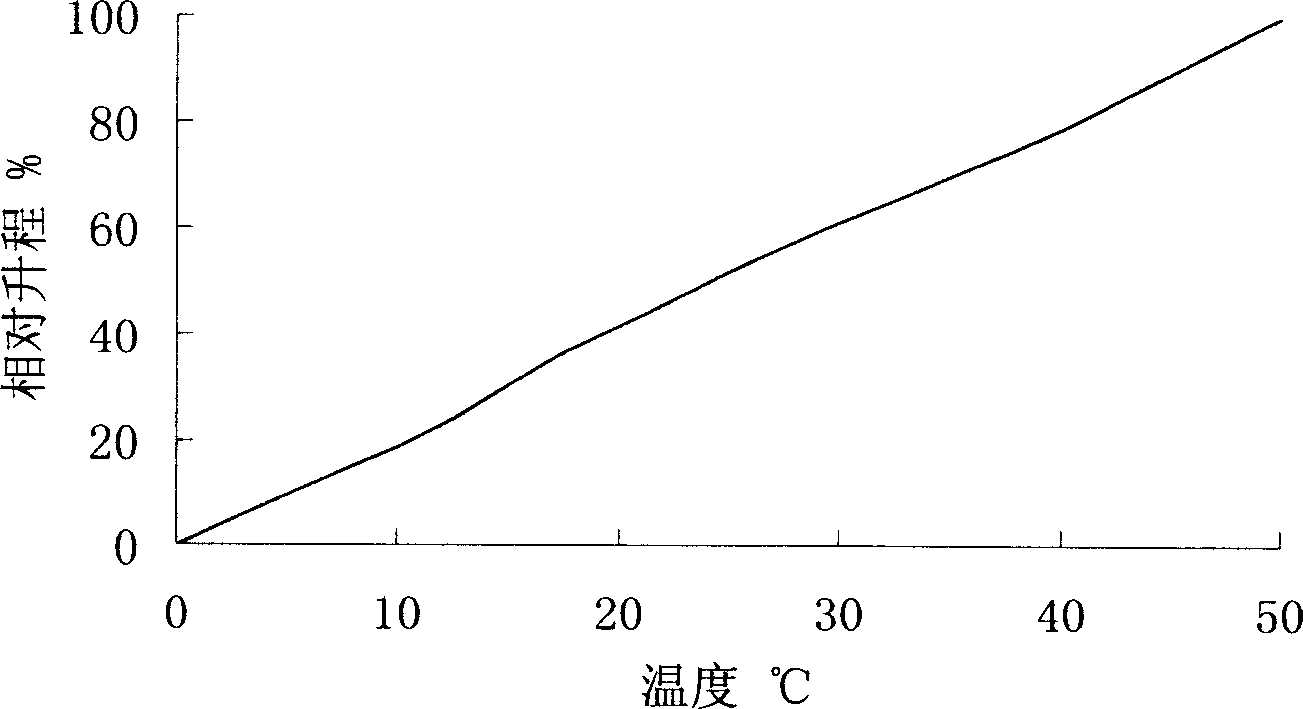

Wax dielectric for heating temperature control valve and its preparing method

InactiveCN1458241ALow pricePhysical stabilityHeating/cooling contact switchesMineral wax recovery/refiningTemperature controlDielectric

The present invention relates to wax dielectric for heating temperature control valve and its preparation process. The destination product is prepared with fluid wax, wax paste, soap wax, etc containing C9-C20 components and through decompression distillation in 5-20 deg.c fraction width, sweating of the fractions in the smelting point temperature as the ultimate temperature, equal weight ratio mixing, refining and other technological steps. The product may be used in heating temperature controlling valve for temperature control in 5-30 deg.c and has basically the same stroke each degree of temperature. The product may be also used in other automatic temperature controlling devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of low sulfur, moderately aromatic distillate fuels by hydrocracking of combined Fischer-Tropsch and petroleum streams

The present invention relates to distillate fuels or distillate fuel blend stocks comprising a blend of a Fischer-Tropsch derived product and a petroleum derived product that is hydrocracked under conditions to preserve aromatics. The resulting distillate fuel product is a low sulfur, moderately aromatic distillate fuel. The resulting distillate fuel or distillate fuel blend stock exhibits excellent properties, including good seal swell, density, and thermal stability. The present invention also relates to processes for making these distillate fuels or distillate fuel blend stocks.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

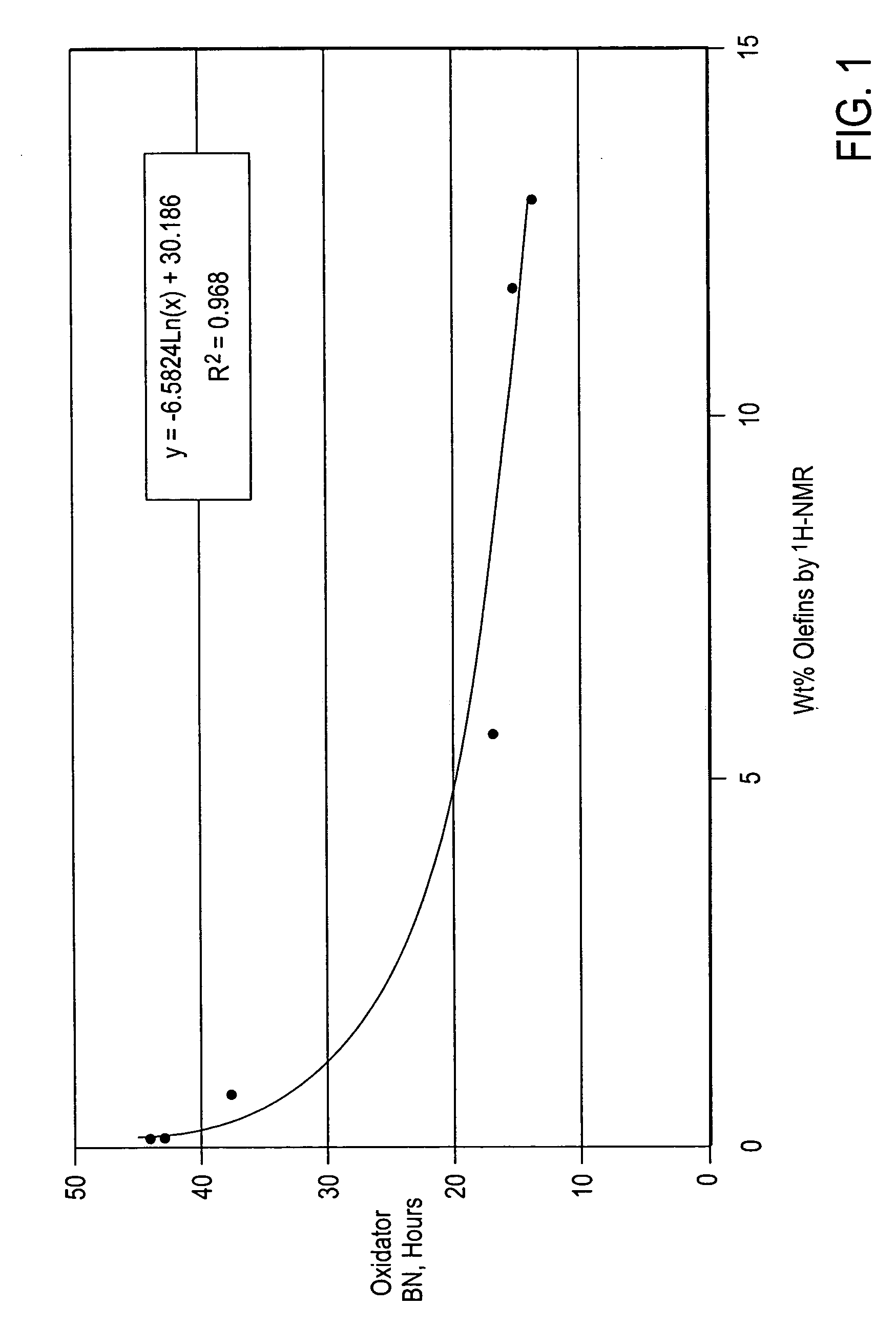

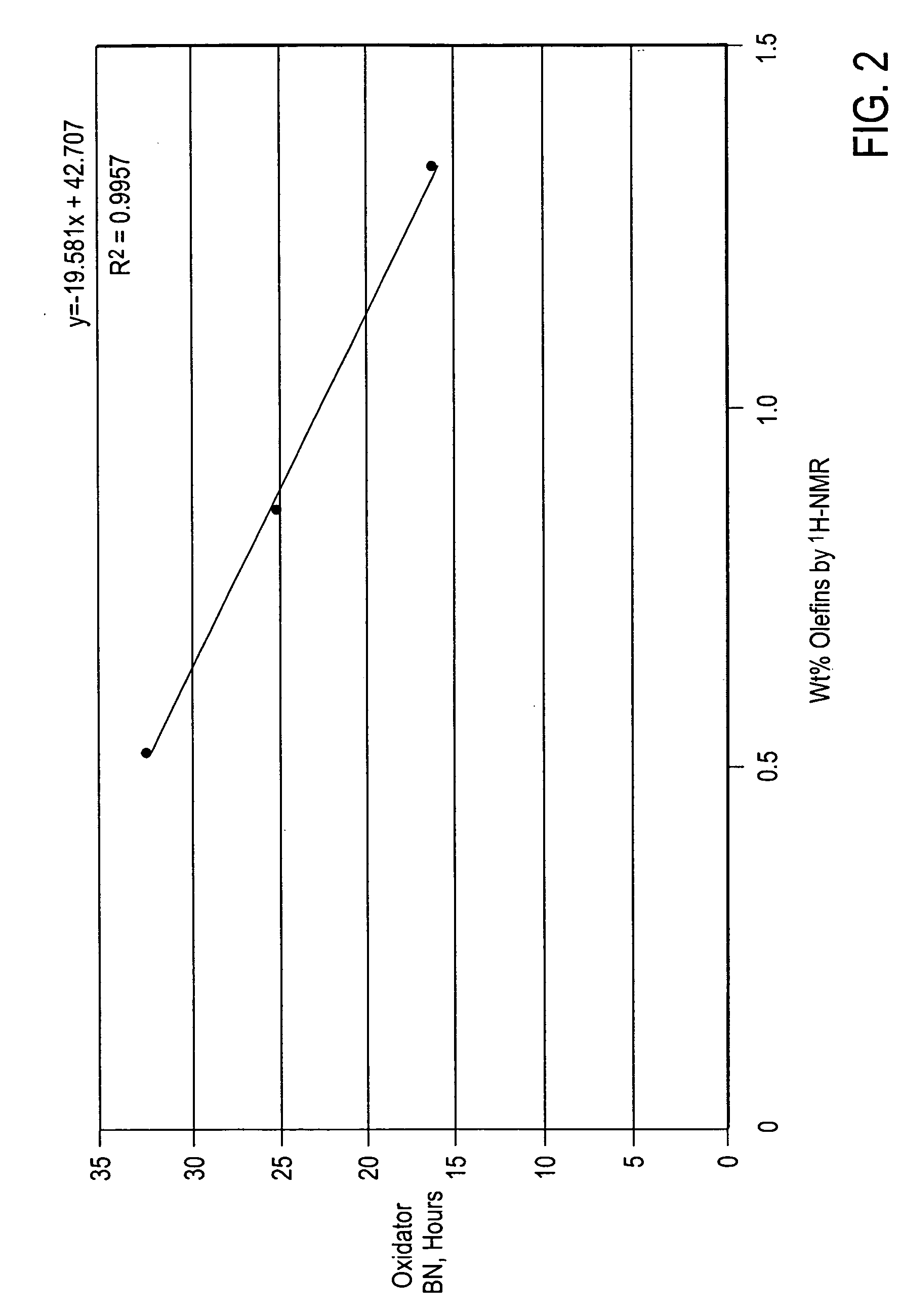

Process to enhance oxidation stability of base oils by analysis of olefins using ¹H NMR

InactiveUS20060237344A1Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationOxidation stabilityBase oil

A process for producing a lubricating base oil having high oxidation stability, wherein the feed used to prepare the lubricating base oil contains at least 5 wt. % olefms, said process comprising (a) determining the weight percent of olefins present in the feed by means of 1H NMR; (b) hydroprocessing the feed under hydroprocessing conditions selected to reduce the amount of olefins present to a target value which has been pre-determined by means of 1H NMR to produce a lubricating base oil having the desired oxidation stability; and (c) collecting a lubricating base oil having the selected oxidation stability from the hydroprocessing zone.

Owner:CHEVROU USA INC

Chemical composition of matter for the liquefaction and dissolution of asphaltene and paraffin sludges into petroleum crude oils and refined products at ambient temperatures and method of use

ActiveUS20060035793A1Resists separationHigh viscosityTransportation and packagingWorking-up tarParaffin waxSludge

Owner:MALCERA

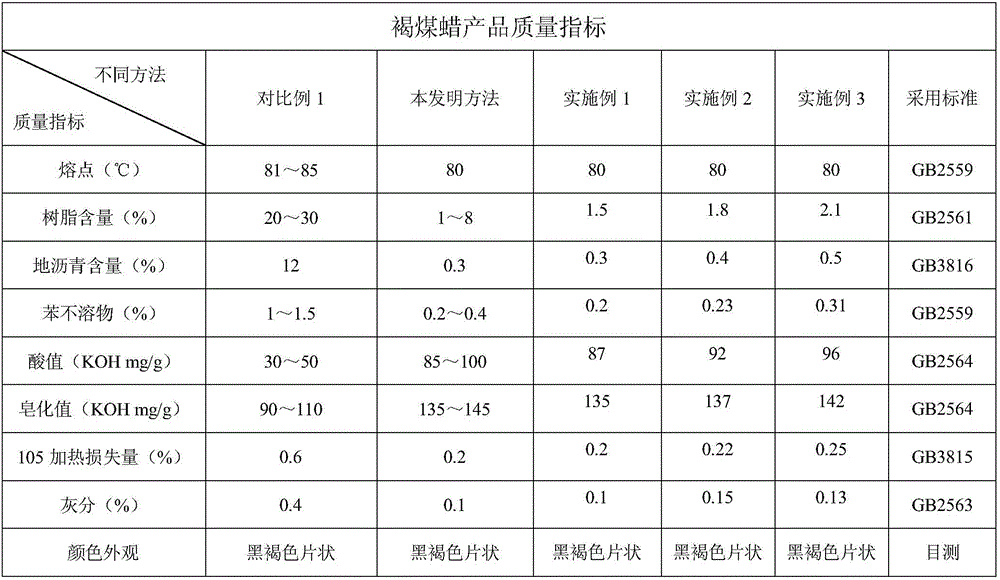

Method for extracting montan wax from lignite

ActiveCN101434868ANo pollution in the processSimple processMineral wax recovery/refiningSocial benefitsComing out

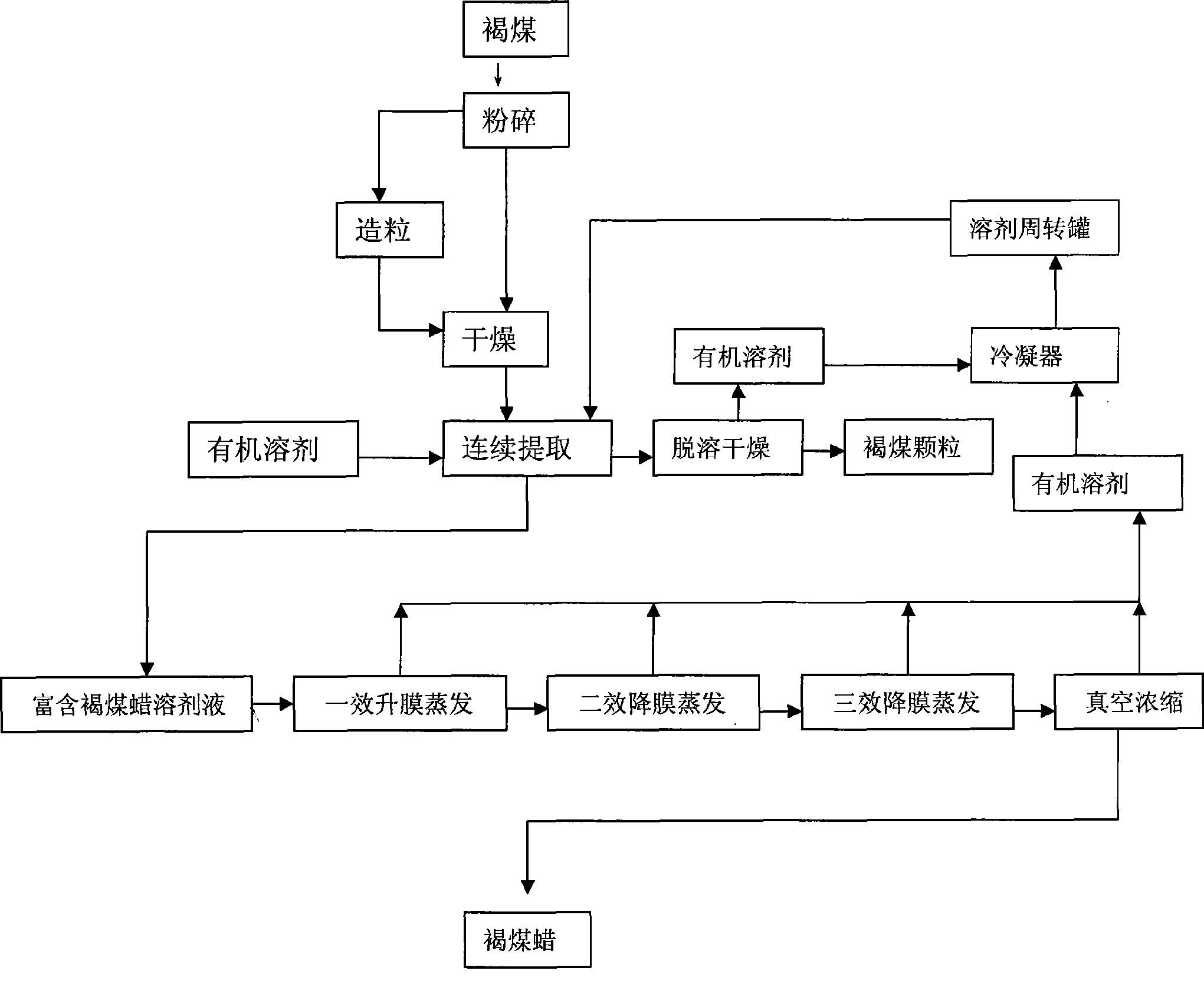

The invention relates to a production method used for extracting lignite wax from lignite, which can effectively solve the problems that the lignite wax is difficult to be prepared, has small yield and can not meet the practical requirements. The technical proposal used for solving the problems is as follows: the lignite is crushed and prepared into grains, dried and sent to an extractor for carrying out extraction; the lignite grains with the lignite wax extracted are sent to a continuous dry desolventizer so as to remove an organic solvent; the lignite grains coming out of the dry desolventizer are used for extracting a humic acid; three-effectiveness separation of the organic solvent rich in lignite wax is carried out so as to remove 95 percent of the organic solvent; subsequently, vacuum condensation is carried out so as to obtain the lignite wax; and subsequently, the solvent is recovered and circularly used. The method has simple process, can carry out production of large scale in batches, has high production efficiency, low cost and no environmental pollution, saves material, is a great creation on the preparation of lignite wax, and the application of the method has huge economical and social benefits.

Owner:河南华泰粮油机械股份有限公司

Treatment of crude oil fractions, fossil fuels, and products thereof

ActiveUS20040074812A1Reduce the burden onImprove effectivenessOrganic compounds purification/separation/stabilisationRefining to change hydrocarbon structural skeletonCentrifugationHydrodesulfurization

In crude oil fractions, fossil fuels, and organic liquids in general in which it is desirable to reduce the levels of sulfur-containing and nitrogen-containing components, the process reduces the level of these compounds via the application of heat, an oxidizing agent and, preferably, sonic energy. The invention is performed either as a continuous process or a batch process, and may further include optional steps of centrifugation or hydrodesulfurization.

Owner:PETROSONICS

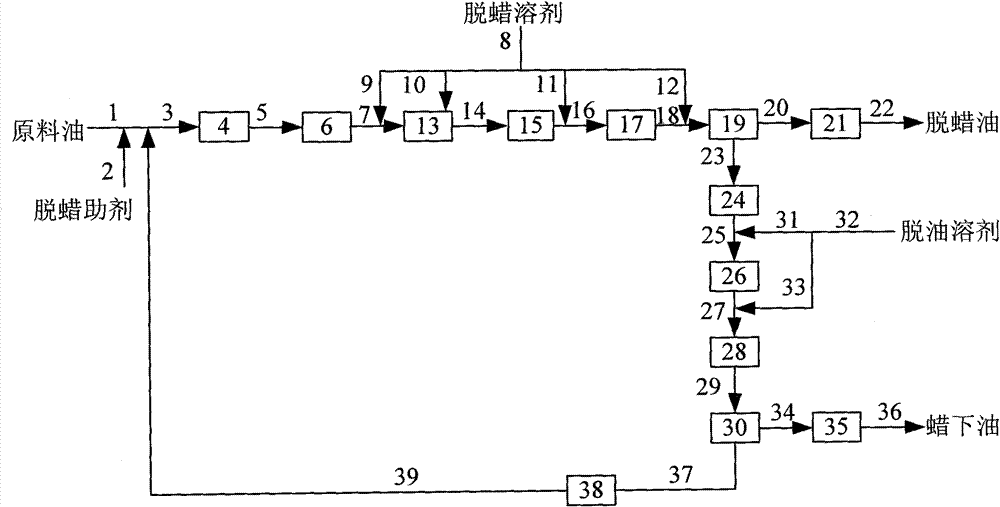

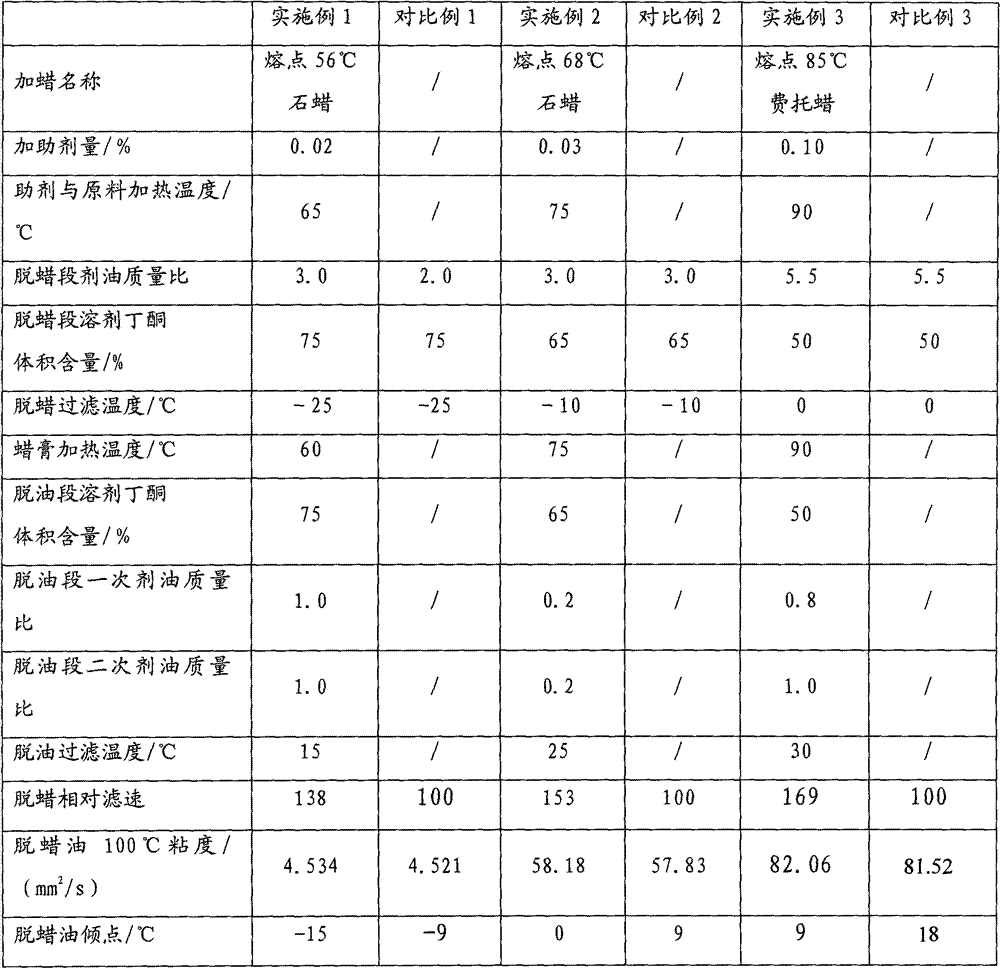

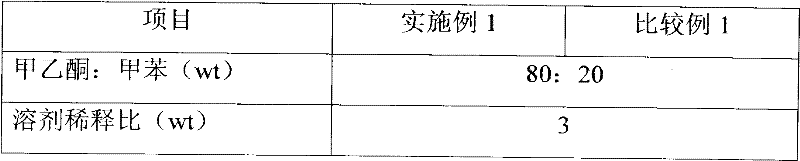

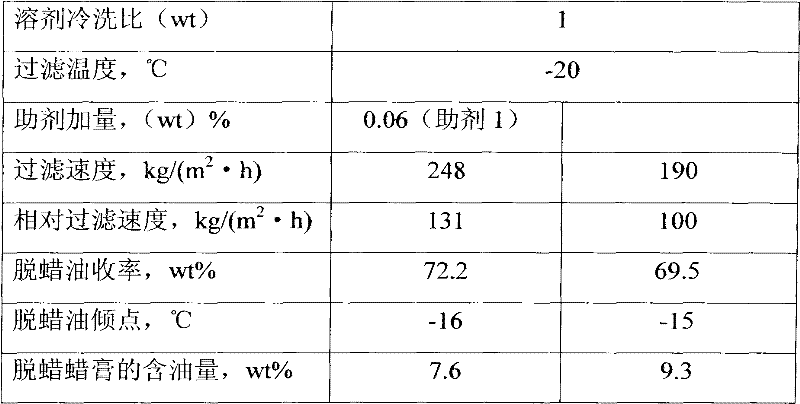

Solvent dewaxing method

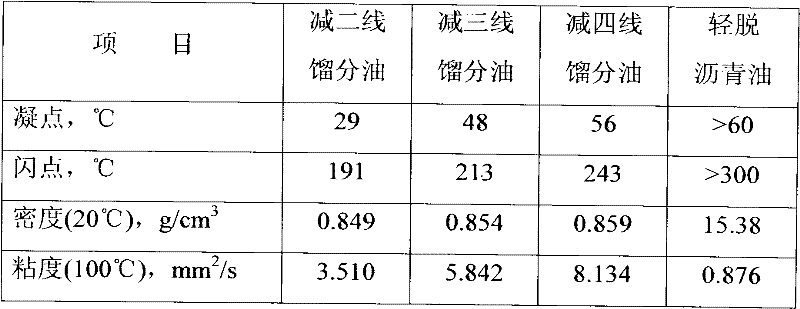

ActiveCN1648216AImprove crystal structureEasy to separateMineral wax recovery/refiningParaffin waxMicrocrystalline wax

During solvent dewaxing, the mixture of wax containing material oil, dewaxing solvent and dewaxing assistant is made to pass through two stages of dewaxing material oil and deoiling cerate; the filtrate from the deoiling stage is returned to the dewaxing stage completely; and dewaxed oil and deoiled wax are obtained after recovering the solvent. The dewaxing assistant is ashless polymer mixture of high branched chain degree polymer and low branched chain degree polymer. The method improves the crystal structure of wax, raises oil-wax separating effect, raises dewaxed oil yield and filtering speed obviously, lowers the solvent ratio and lowers the oil content in cerate. The cerate may be used in producing paraffin or microcrystal wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for transporting Fischer-Tropsch products

InactiveUS20020128332A1Hydrocarbon purification/separationLiquid hydrocarbon mixture productionGasolineProcess engineering

Facilities to convert natural gas into syncrude often are located at remote sites. At these sites and in their surrounding communities there exists demand for salable products: gasoline, distillate fuels, solvents, lubricants, etc. While it would be possible to produce these products from syncrude, the construction of such production facilities would be very expensive, and their operation would be difficult at the remote site. Fischer-Tropsch syncrude will be waxy and will also contain volatile components, complicating the shipping of both Fischer-Tropsch products from remote production sites to developed sites and salable products from developed sites to remote sites. This invention describes a safe process to both transport Fischer-Tropsch syncrude from the remote site to the developed site and supply salable products from the developed site to the remote site.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

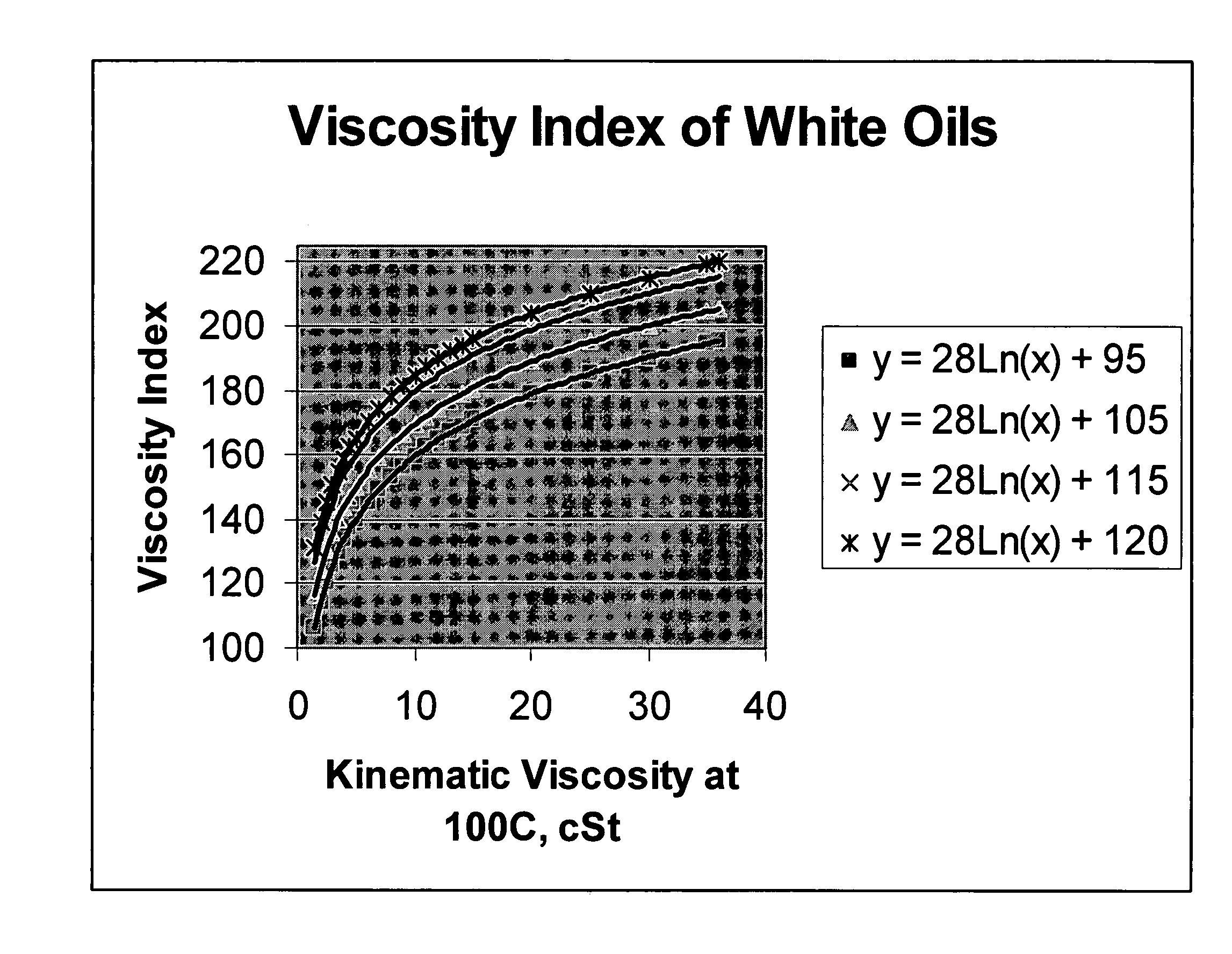

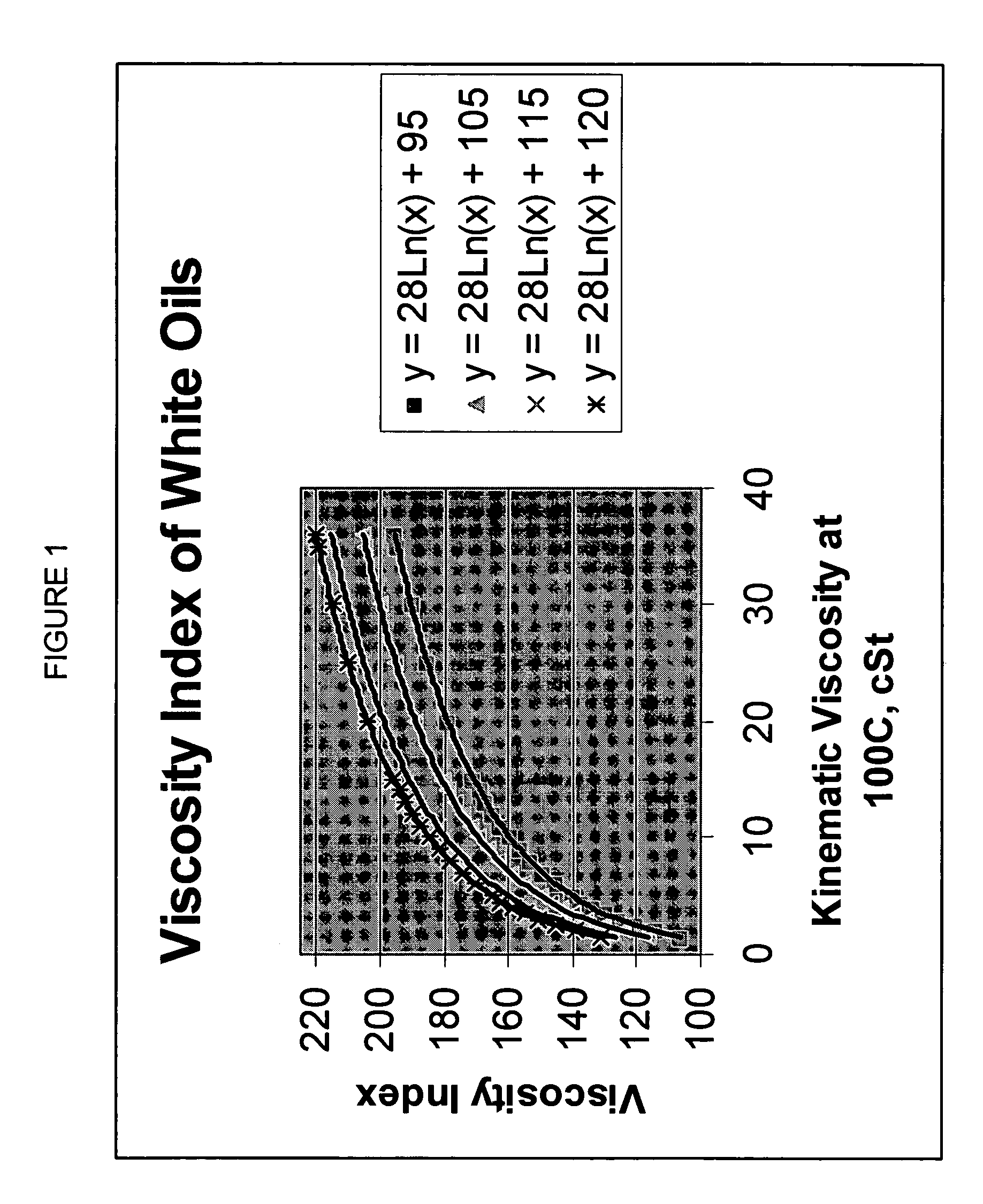

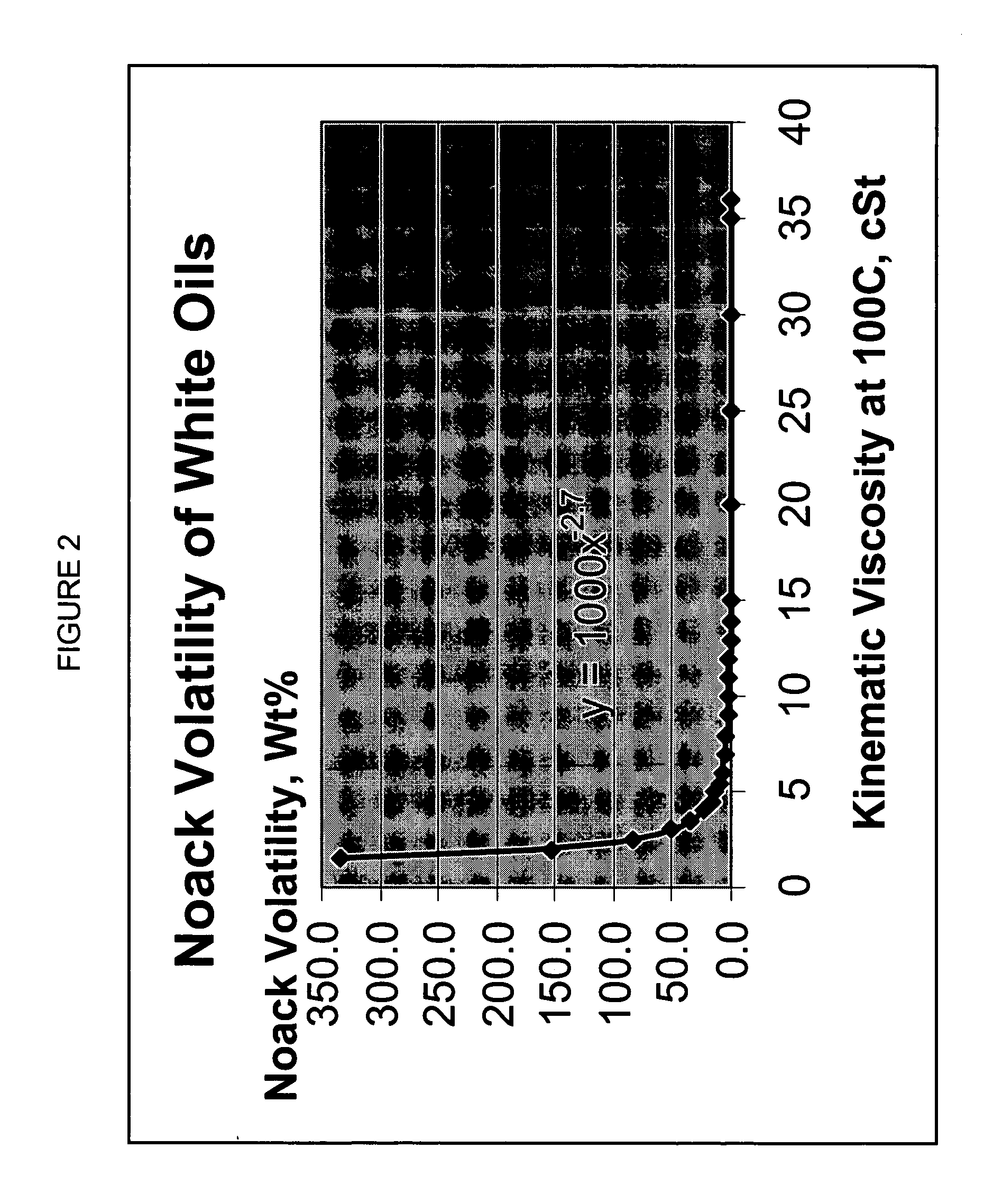

White oil from waxy feed using highly selective and active wax hydroisomerization catalyst

A composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+105, less than 18 weight percent of molecules with cycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater. Also, a composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+95, between 5 and less than 18 weight percent of molecules with cycloparaffin functionality, less than 1.2 weight percent molecules with multicycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater.

Owner:CHEVROU USA INC

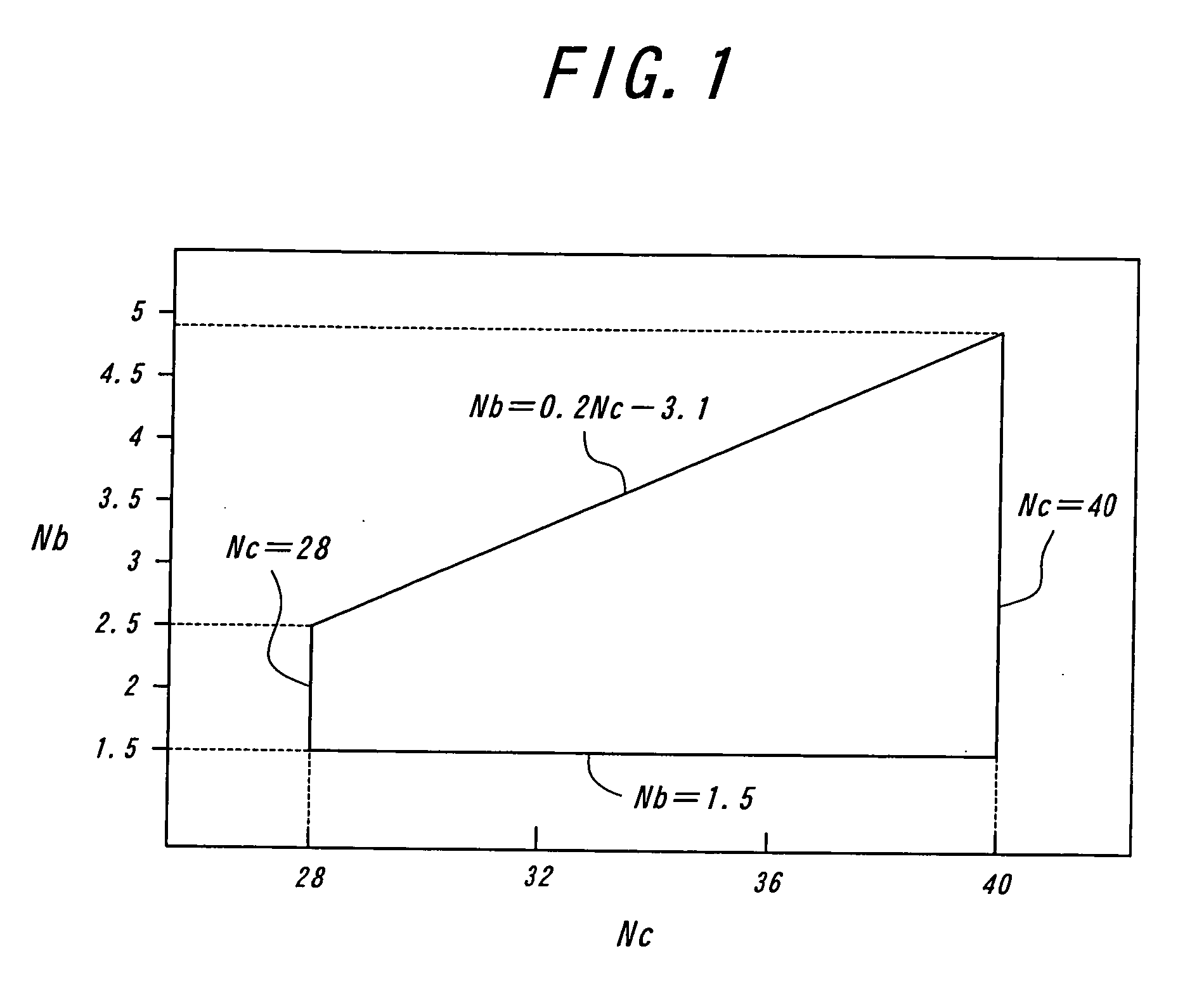

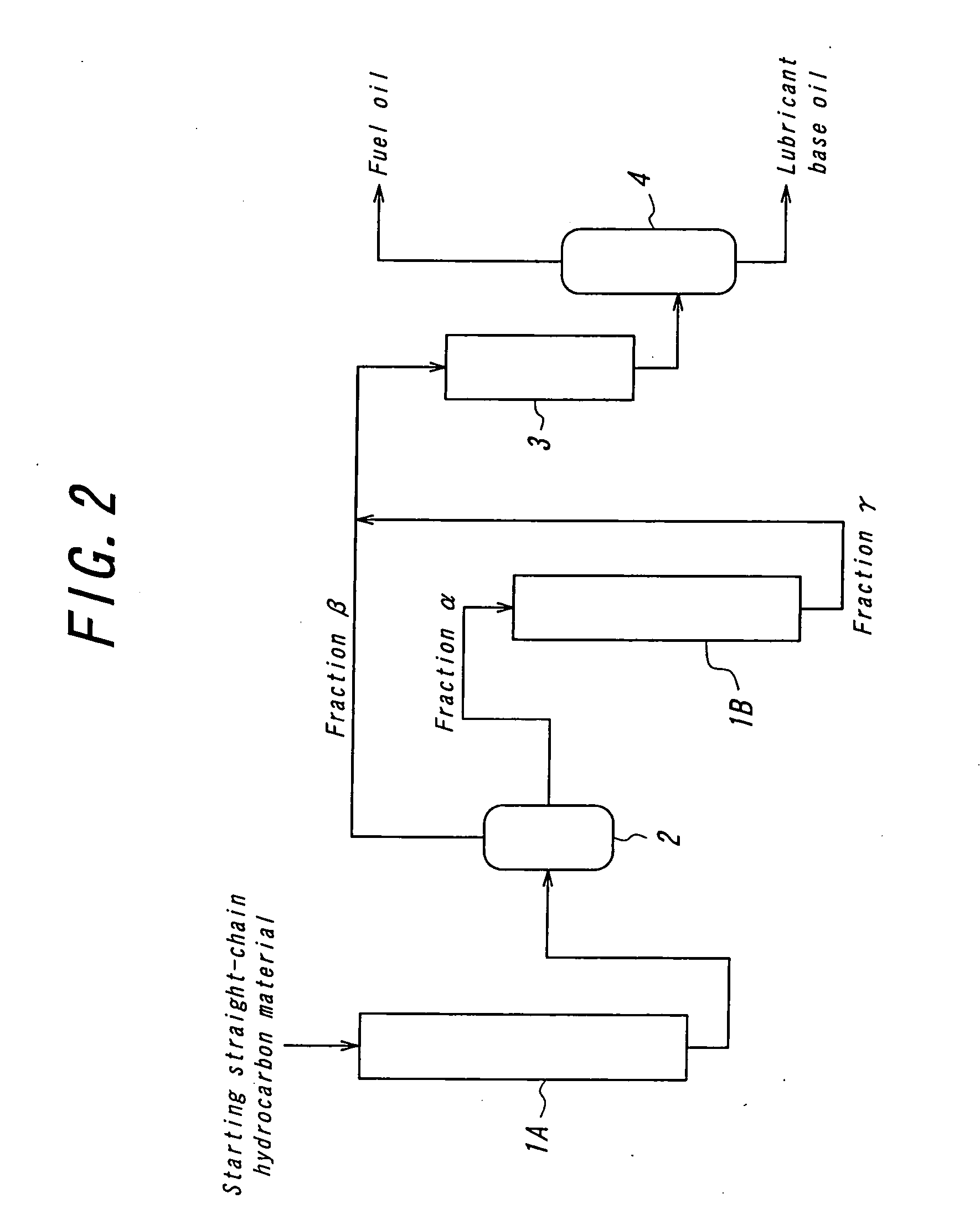

Lubricant base oil and method of producing the same

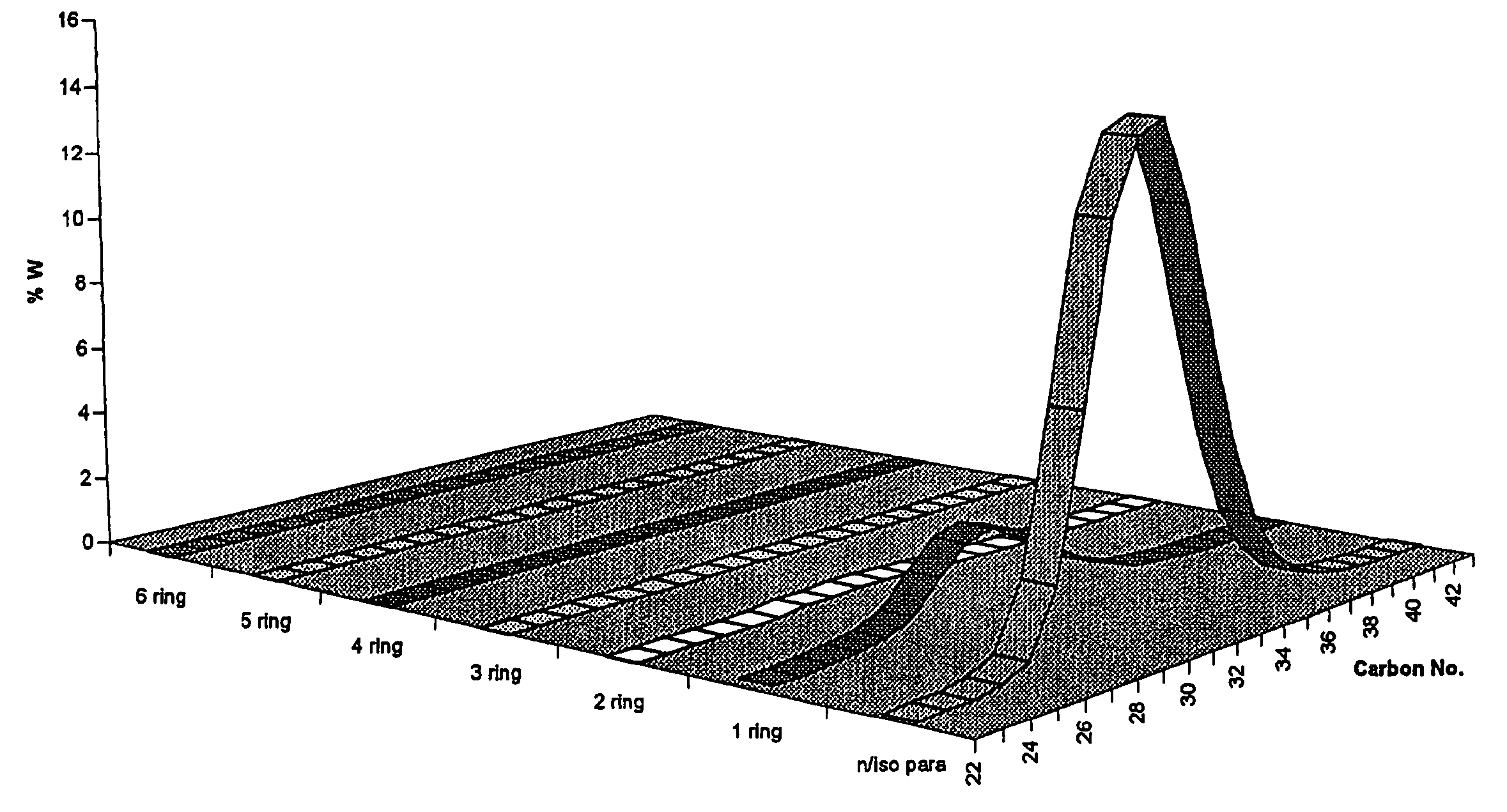

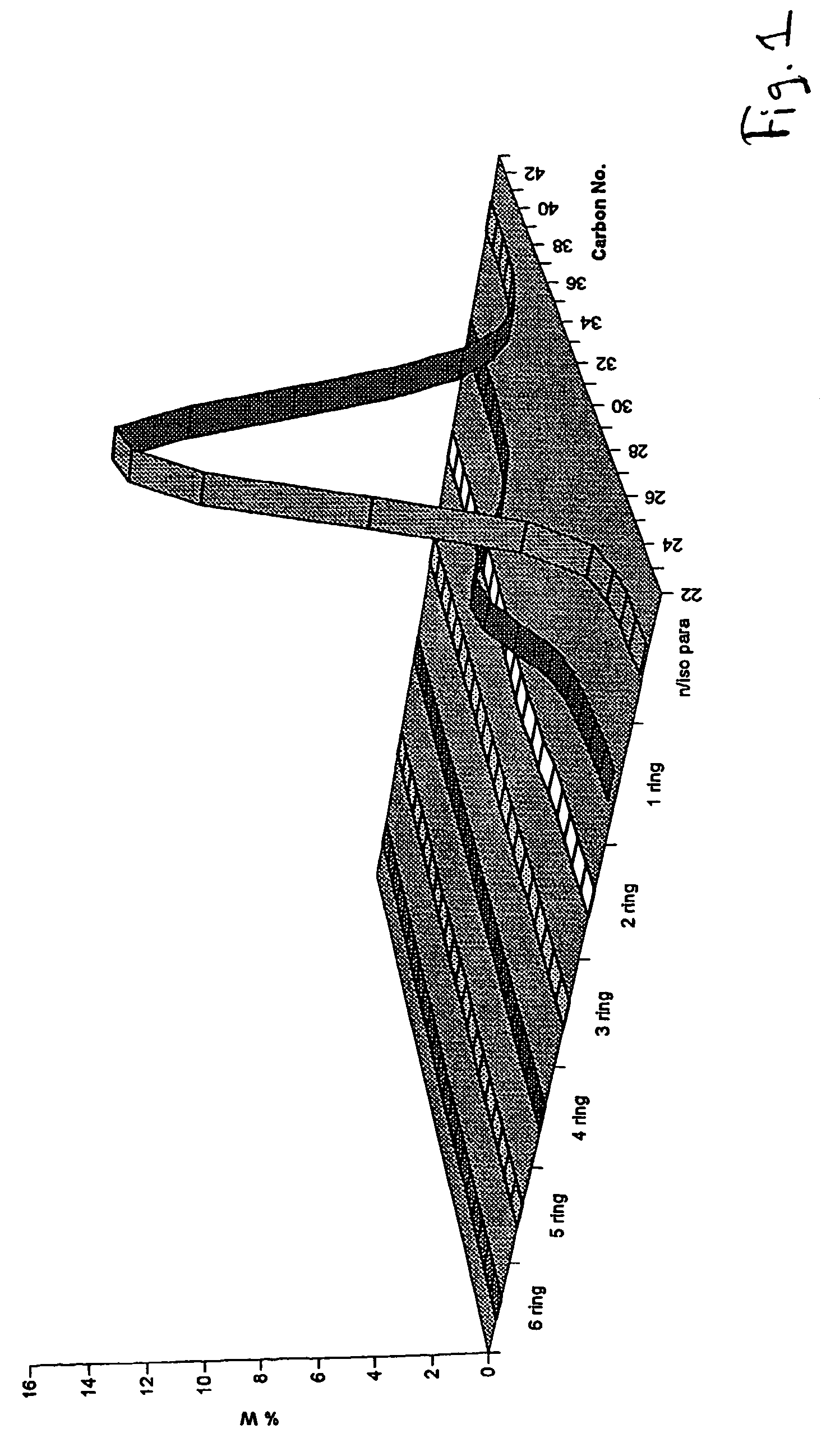

InactiveUS20070138052A1High viscosity indexHigh yieldLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesAlkaneCarbon number

This invention relates to lubricant base oil having high viscosity indexes and low pour points, and particularly to lubricant base oil consisting essentially of a normal paraffin and an isoparaffin, wherein (a) an average carbon number Nc in one molecule is not less than 28 but not more than 40, and (b) an average branch number Nb in one molecule calculated from a ratio of CH3 carbon to total carbon determined by 13C-NMR analysis and the average carbon number Nc in one molecule is not more than (0.2Nc−3.1) but not less than 1.5.

Owner:JAPAN ENERGY CORP

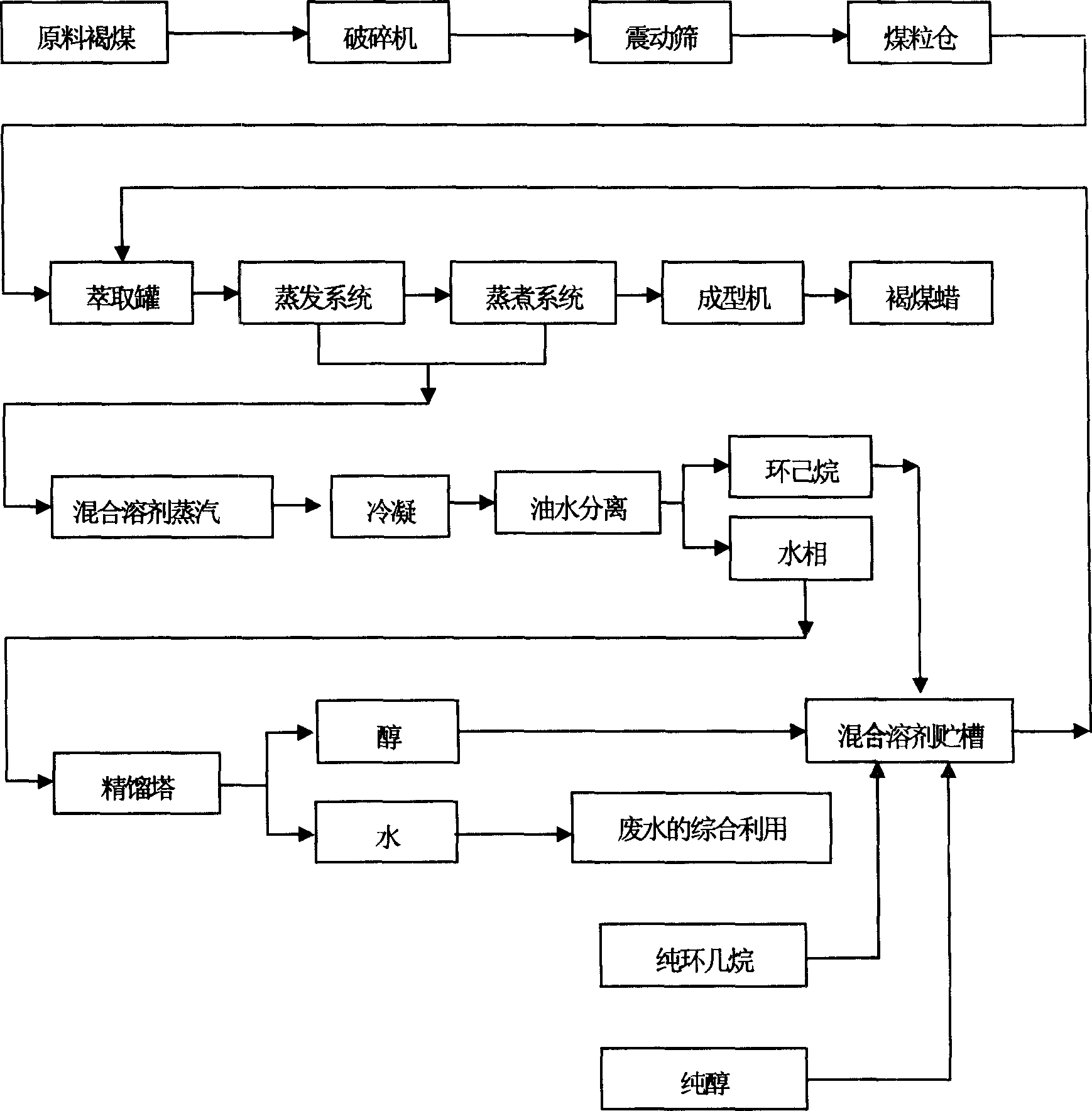

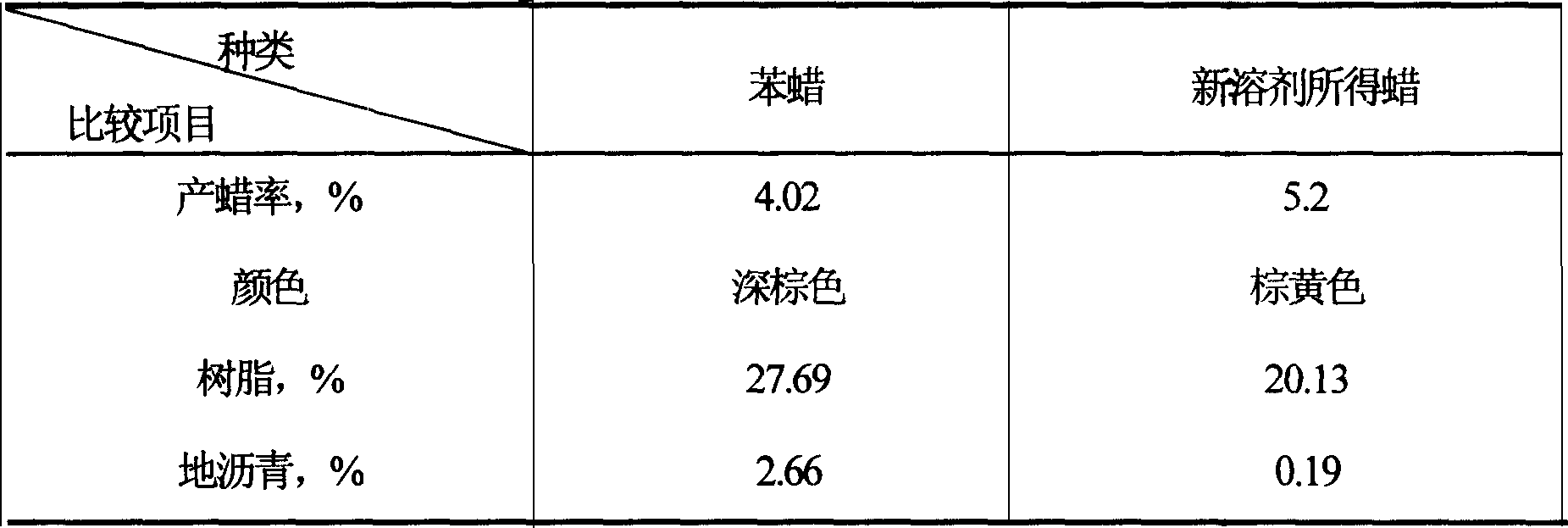

Brown-coal green extractive solvent and its production

InactiveCN101029255ALow asphalt contentImprove product qualityMineral wax recovery/refiningBrown coalWax

A lignite wax green extractive solvent and its production are disclosed. The process is carried out by taking mixed solvent of cyclohexane and alcohol, crushing for lignite, screening, putting lignite coal grain into extractor, mixing with solvent in proportion of 1:1-1:4 while extracting, flash evaporating, recovering solvent, evaporating for residual mixed solvent by stewing system to obtain crude lignite wax, condensing for mixed solvent steam by heat exchanger, oil-water separating, delivering cyclohexane to solvent trough, separating tert-butyl from water while rectifying, inducing tert-butyl into solvent trough, inspecting cyclohexane or tert-butyl content, supplement cyclohexane and alcohol, mixing proportionally and using. It's cheap, simple reliable, and economical, it has more wax yield and no environmental pollution.

Owner:CHINA UNIV OF MINING & TECH

Process for making high viscosity index lubricating base oils

A process for making a lubricating base oil having a viscosity index of at least 110, comprising the steps of: combining a waxy light neutral base oil and a wax derived from pyrolyzing a plastics feed comprising polyethylene to form a blend; hydroisomerization dewaxing the blend; and recovering the lubricating base oil from an effluent from the hydroisomerization dewaxing step.

Owner:CHEVROU USA INC

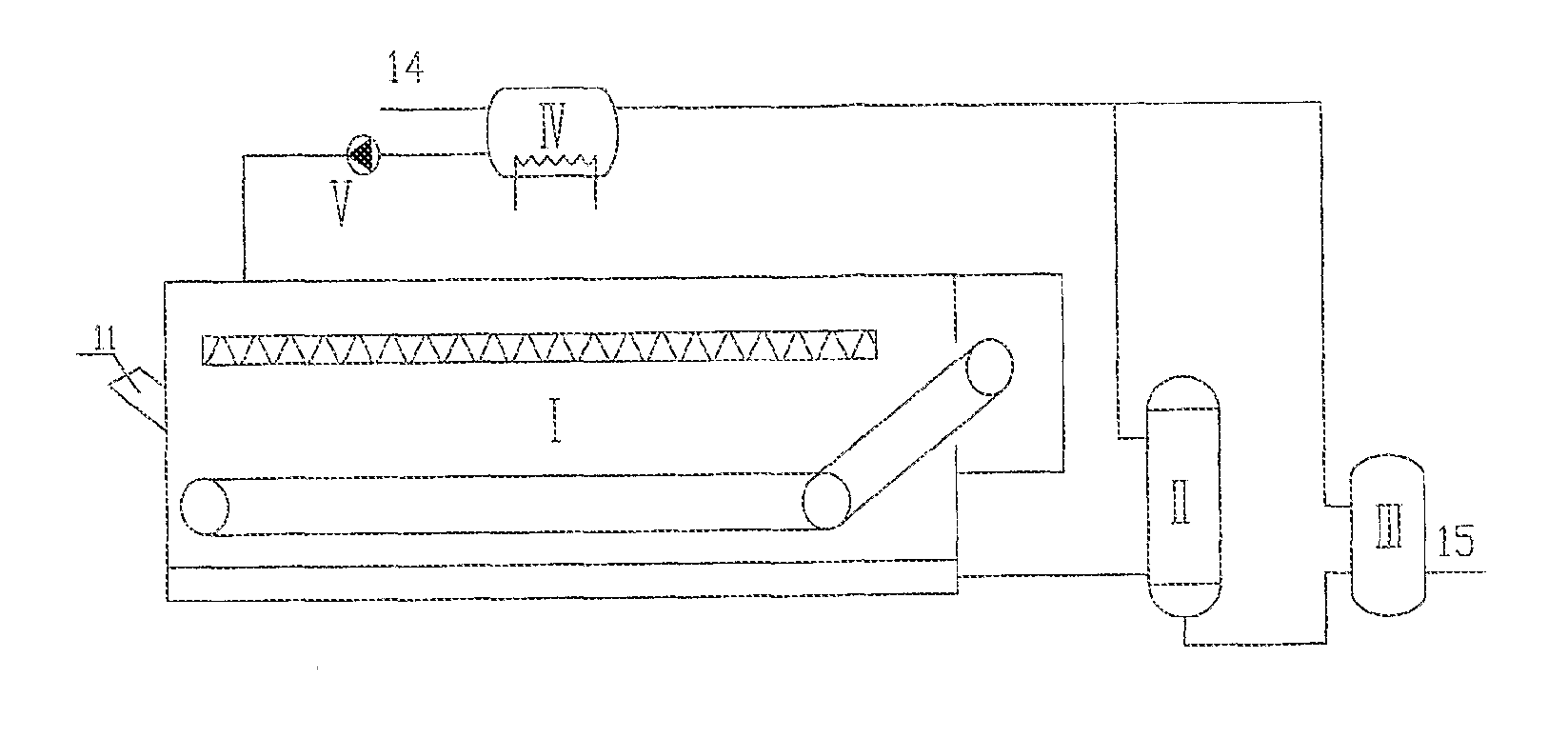

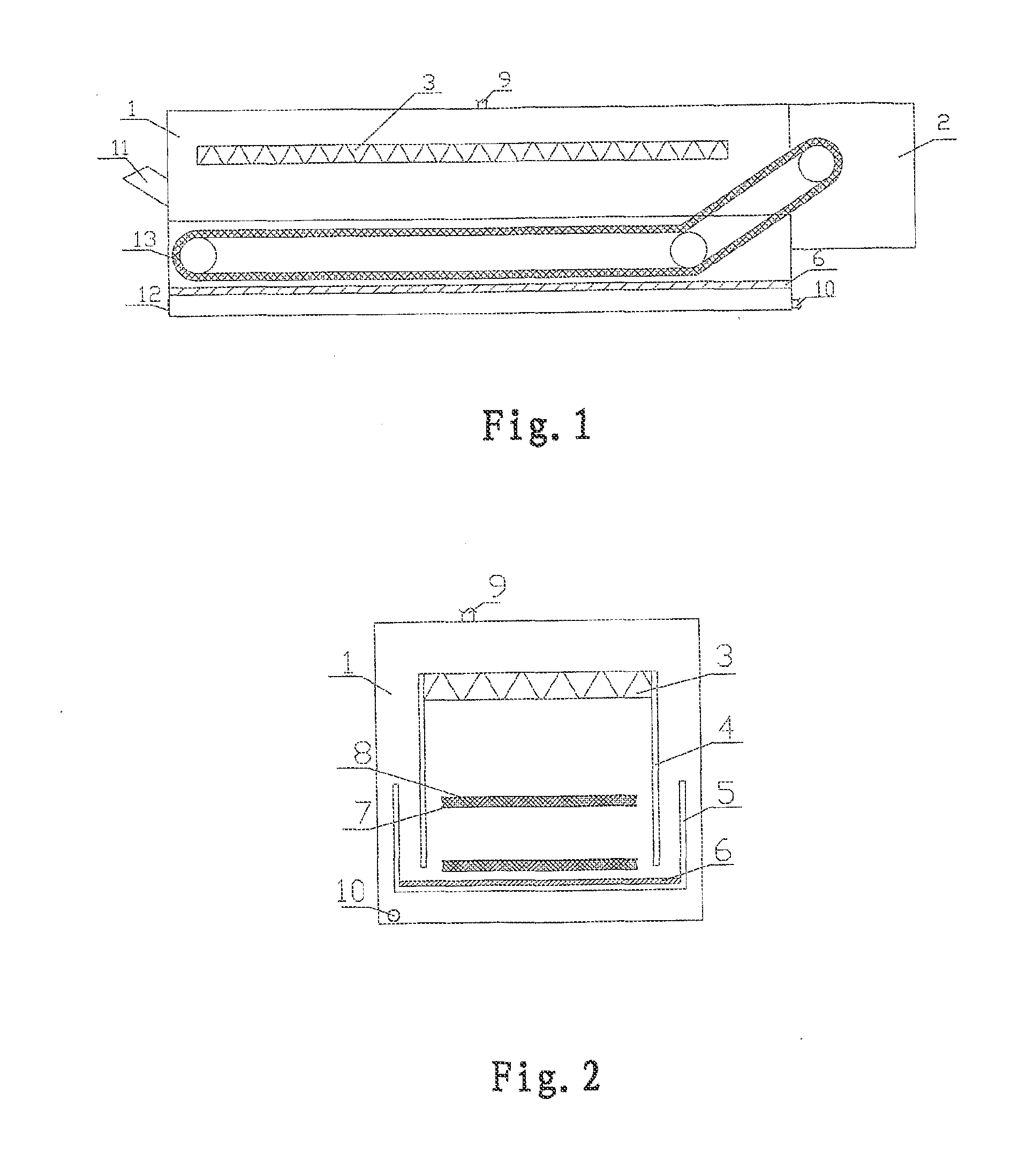

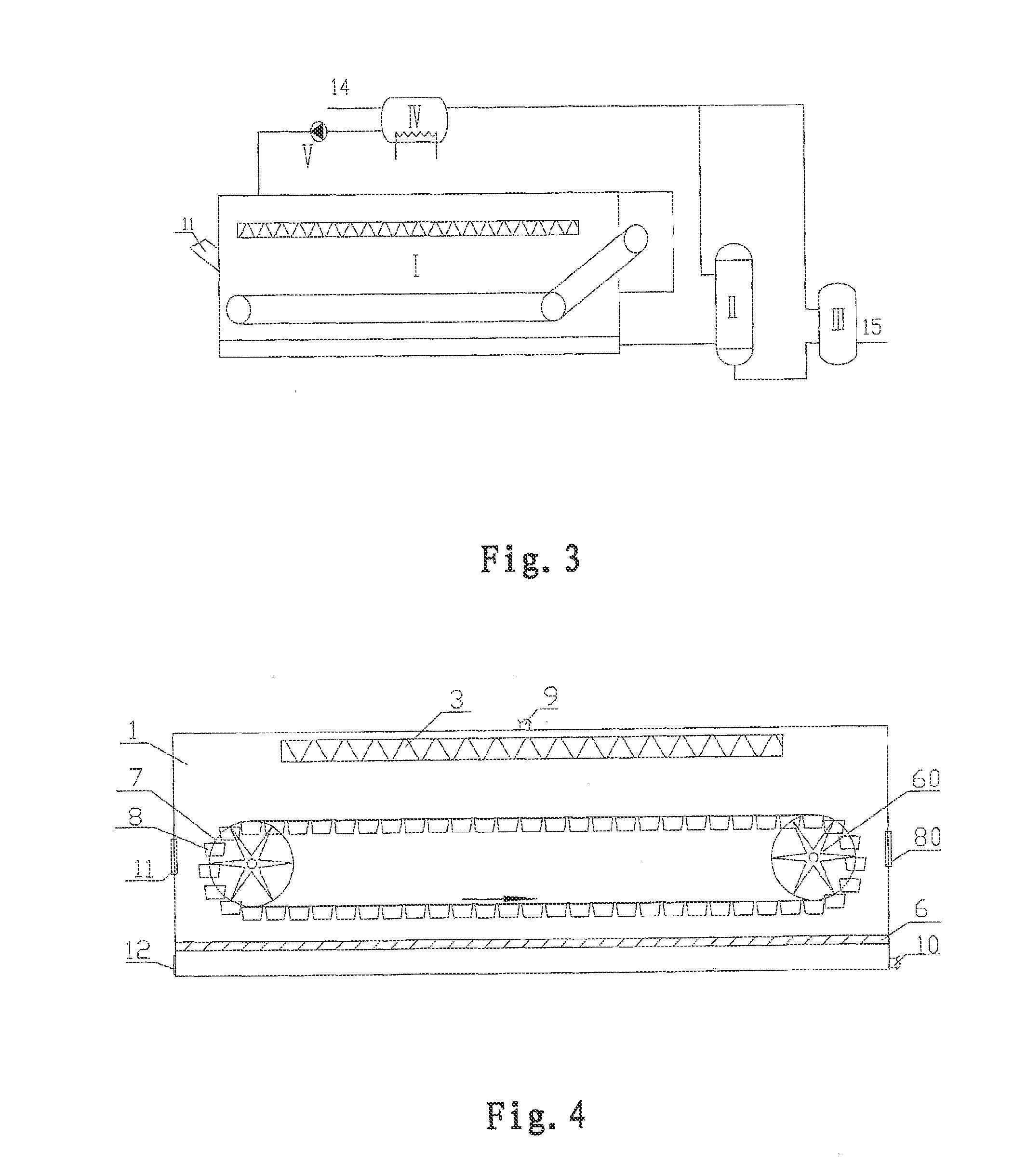

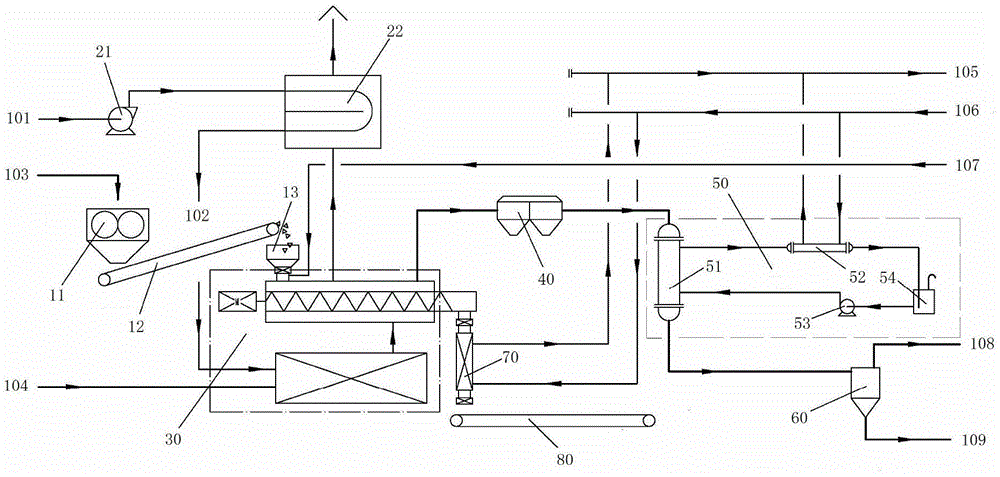

System and Method for Continuous Extraction of Material

ActiveUS20120251642A1Reinforce and accelerate reactionFatty oils/acids recovery from wasteBiocideSolventUltrasonic generator

The present invention discloses a continuous material extraction system for continuously extracting valuable components in the material by means of a solvent, the system comprising: an extraction tank which is a sealed container being substantially parallelepiped, wherein in the longitudinal direction of the extraction tank, the extraction tank has a first end at which a material inlet is provided, and a second end, and a material outlet is provided at the first end or the second end; the upper portion of said extraction tank is provided with a solvent inlet, and the lower portion of said extraction tank is provided with a solution outlet; in the longitudinal direction of said extraction tank, the lower portion of said extraction tank is provided with an extraction bath which is applied for accommodating the solvent and the material, wherein in the longitudinal direction of said extraction tank said extraction bath is provided with a material conveying mechanism and an ultrasonic generator. The present invention further discloses a method of extracting valuable components in the material by the continuous material extraction system mentioned above.

Owner:ENN SCI & TECH DEV

Improved solvent-dewaxing method

The invention discloses an improved solvent dewaxing method, which is characterized by the following: adding ash-free macromolecular mixture with A) poly-alpha- olefin, B) polyethylene or ethane, propylene copolymer, C) alcohol polymer and derivant in the regular solvent dewaxing or solvent dewaxing de-oiling course; reducing oil content of dewaxing obviously to improve the quality of wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high purity montan wax

InactiveCN101906320ALow impurity contentImprove product qualityMineral wax recovery/refiningSolventImpurity

The invention provides a method for producing high purity montan wax, including solvent extraction; wherein no solvent for submerging montan is added in the extraction process, the solvent is composed of the following components by mass ratio: 20-100% of isopropanol and 0-80% of alcohol or hydrocarbon or water, the alcohol is one or more than one of methyl alcohol, ethyl alcohol and tertiary butanol, and the hydrocarbon is one or more than one of petroleum ether, solvent No. 6, normal hexane and cyclohexane. The invention thoroughly solves the problems that the existing extraction solvent benzene has high toxicity, pollutes the environment and is harmful to human body health. Besides, non-toxic isopropanol or isopropanol mixed solvent with extremely low toxicity is used for extracting montan wax in montan, impurity content in montan wax is effectively reduced, resin content is lower than 16%, asphaltos is lower than 6%, high purity product is obtained, product quality of montan wax isgreatly improved, and the difficult problem of the current montan wax extraction technology is solved, thus providing a beneficial approach for producing high quality montan wax in scale.

Owner:李定忠 +2

System for treating petroleum and petrochemical slop oil and sludge wastes

InactiveUS20020066391A1Reduced activityIncrease ratingsTransportation and packagingMixingParaffin waxHydrotrope

An initial chemical composition comprising selected surfactants, dispersants, and degreasers that liquefy, disperse, demulsify, degrease, inhibit corrosion and scale formation, and lower the pour point of a petroleum, coal, Fischer-Tropsch synthesized, or naturally occurring paraffin-based wax and asphaltene. Such a product is capable of converting crystalline wax (paraffin) in, for example, slop oil into an amorphous form of wax at room temperature, allowing the wax to be dissolved in, for example, crude oil without the need for heating, and maintaining it in solution at room temperature, substantially reducing, indeed in some applications, preventing, for example, wax build-up in pipelines, processing and transportation equipment, etc., and the recovery of the hydrocarbons in the slop oil. In a second aspect of the invention, the pre-blend addition of a hydrotrope-demulsifier, a chelating agent and a wax plasticizer can result in a BS&W of zero for the recovered hydrocarbon blend.

Owner:MALCERA

Method for extracting wax in lignite

The invention provides a method for extracting wax in wood coal, which is characterized by comprising the following steps: adopting methylbenzene as extraction solvent, and extracting the wood coal for 30min-5h under the temperature condition of 10-100 DEG C according to the mass / volume ratio 1:2-4 of the wood coal to the methylbenzene. The wax has no harm to the environment and the human body, and the extracted wood coal wax has the quality, the mass, and the like similar to those of the wood coal wax extracted by benzene; in addition, the extraction method has simple process, convenient operation, non-toxicity, safety, high yield, and low cost, and is suitable for the mass production.

Owner:李定忠

System for treating petroleum and petrochemical slop oil and sludge wastes

An initial chemical composition comprising selected surfactants, dispersants, and degreasers that liquefy, disperse, demulsify, degrease, inhibit corrosion and scale formation, and lower the pour point of a petroleum, coal, Fischer-Tropsch synthesized, or naturally occurring paraffin-based wax and asphaltene. Such a product is capable of converting crystalline wax (paraffin) in, for example, slop oil into an amorphous form of wax at room temperature, allowing the wax to be dissolved in, for example, crude oil without the need for heating, and maintaining it in solution at room temperature, substantially reducing, indeed in some applications, preventing, for example, wax build-up in pipelines, processing and transportation equipment, etc., and the recovery of the hydrocarbons in the slop oil. In a second aspect of the invention, the pre-blend addition of a hydrotrope-demulsifier, a chelating agent and a wax plasticizer can result in a BS&W of zero for the recovered hydrocarbon blend.

Owner:PARAFLOW ENERGY SOLUTIONS LLC

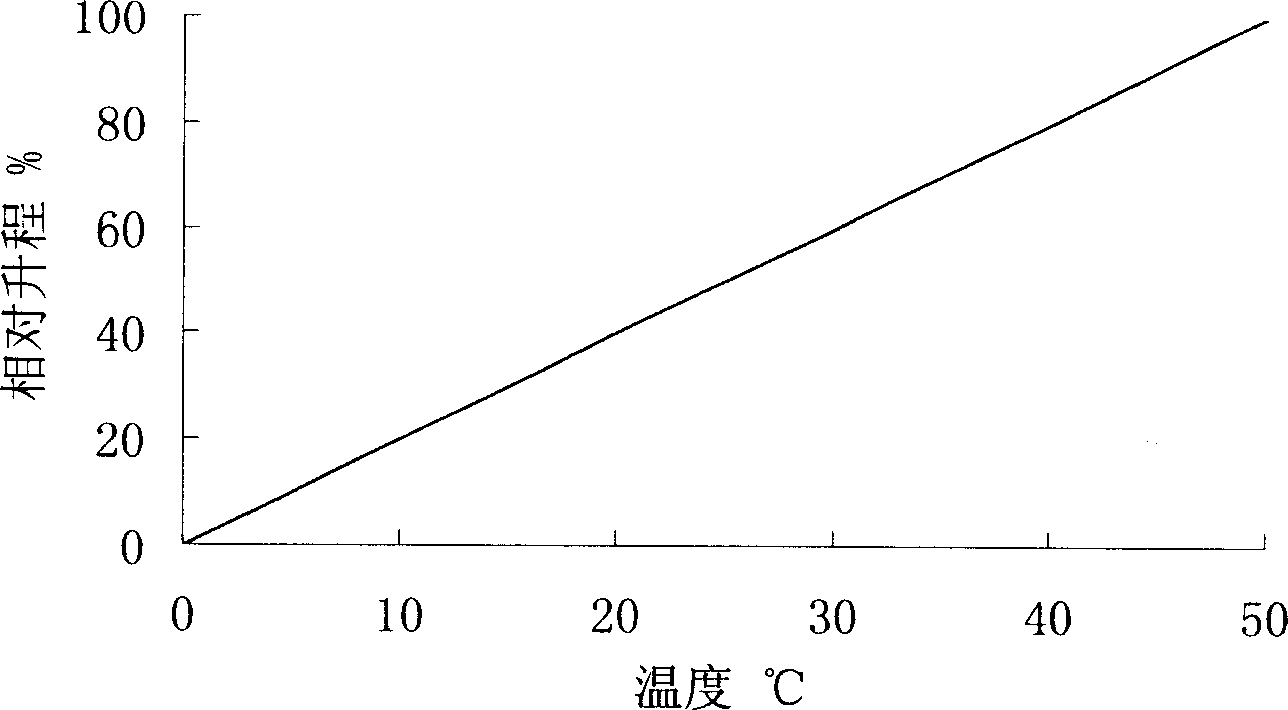

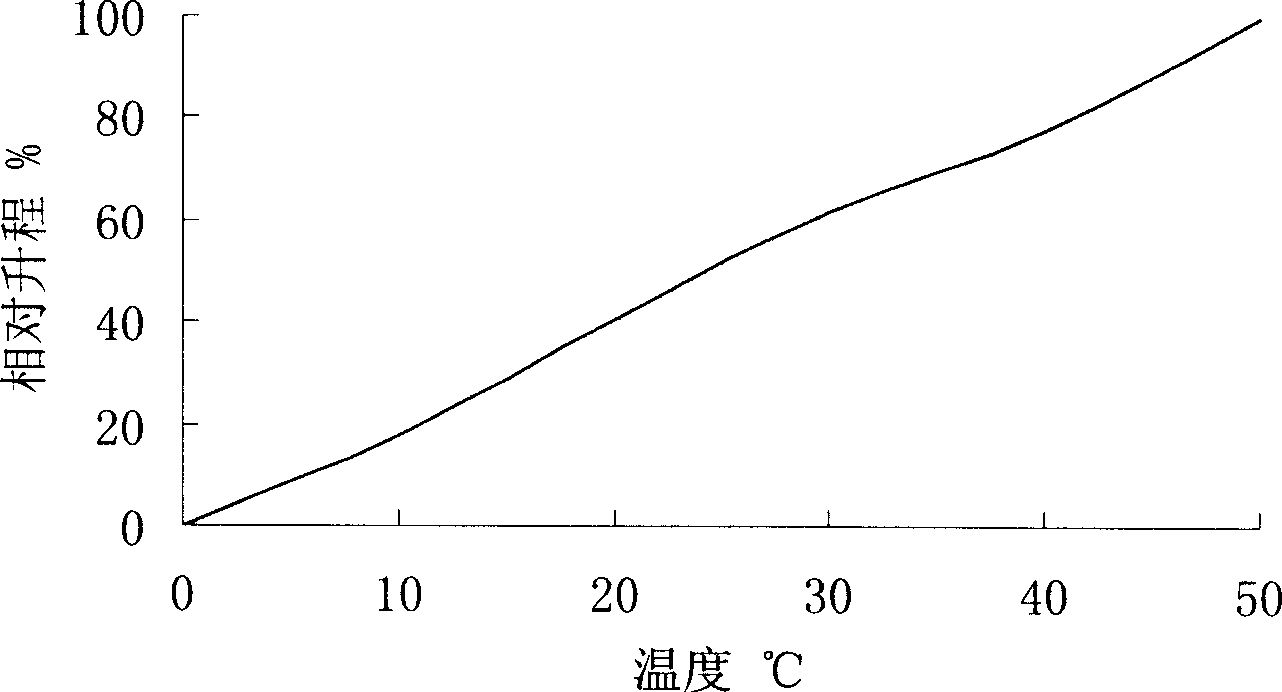

Automatically adding concentrated wax medium for valve of motorcycle and preparation process thereof

ActiveCN1861761ALow priceImprove performanceOperating means/releasing devices for valvesMineral wax recovery/refiningWaxAutomatic control

This invention relates to a wax mediator which is applied to the automatic enrichment valve of the motorbike and its preparation method. It takes use of the liquid wax which contains the component of C9-C30 and soap wax as the material, and it can be prepared by the processes of vacuum distillation, mixing, refining and so on. The wax controlled valve which is prepared by this product can control the temperature during 0-50 deg.C, and the driving value of each degree is basic same. This invention can be applied to the automatic controlled part which can control the temperature during 0-50 deg.C and the driving value of which can change homogeneously as the temperature. It is especially suitable to as the temperature sensitive mediator of the automatic enrichment valve in motorbike.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting lignite wax from lignite

The invention discloses a method for extracting lignite wax from lignite. According to the method, single solvent alcohol is adopted as an extracting agent. The method includes the following steps that 1, lignite particles are prepared; 2, a solution containing the lignite wax is prepared; 3, the lignite wax is prepared. The method is simple in process and good in repeatability, the selected extracting agent is low in toxicity, environmental hazards are small, the extracting grade is high, and the extracted lignite wax can be applied to the fields of automobiles, chemical engineering, light industries, daily chemicals and the like.

Owner:KINGENTA ECOLOGICAL ENG GRP

Method for directly producing paraffin or micro crystal wax

ActiveCN1648217AImprove crystal structureEasy to separateMineral wax recovery/refiningParaffin waxPolyolefin

During direct production of paraffin or microcrystal wax, wax-containing material oil, dewaxing solvent and dewaxing assistant are mixed, and the mixture is cooled to -5 deg.c to -30 deg.c and separated to obtain wax product and dewaxed oil. The dewaxing assistant is ashless polymer mixture of high branched chain degree polymer and low branched chain degree polymer, the high branched chain degree polymer is polymethacrylate or polyolefin, and the low branched chain degree polymer is polyethylene or ethylene-propylene copolymer. The method improves the crystal structure of wax and raises oil-wax separating effect, and the oil-containing cerate obtained through the dewaxing process reaches the requirement of paraffin or microcrystal wax in oil content, and may be used in producing paraffin or microcrystal wax through refining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Base oil composition

InactiveUS7531081B2Improved solvency propertyImprove solubilityOrganic chemistryRefining to change hydrocarbon structural skeletonParaffin oilsViscosity index

A lubricating base oil composition having at least 95 wt % saturates, of which saturates fraction between 10 and 30 wt % are cyclo-paraffins and the remainder being n- and iso-paraffins, having a viscosity index of above 120 and a pour point of below −15° C.

Owner:SHELL OIL CO

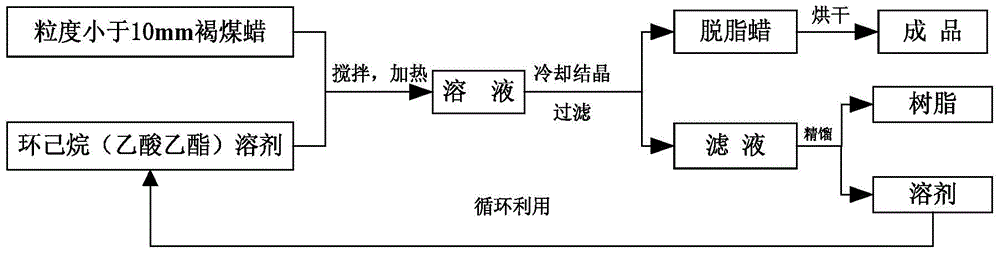

Solvent and method for removing resin from lignite wax by virtue of crystallization process

The invention discloses a solvent and method for removing resin from lignite wax by virtue of a crystallization process, belonging to methods for removing resin from lignite wax. The method comprises the following steps: (1) heating and dissolving, namely putting lignite wax particles into a crystallization kettle, injecting a cyclohexane solvent or an acetic ester solvent according to a material-liquid mass ratio of 1:(5-50), stirring, heating the crystallization kettle by using steam, and controlling the pressure of the container to be 1.0-5.0 MPa until the lignite wax particles are dissolved; (2) cooling and crystallizing, namely after the lignite wax particles are dissolved, stopping heating, performing water cooling on the crystallization kettle until the temperature is between -10 and 20 DEG C, and keeping the low temperature for crystallization for 10-50 minutes; (3) filtering and drying, namely after crystallization, filtering to separate filter residues and filtrate, performing reduced pressure drying on the filter residues at 40 DEG C in a vacuum drying machine, and then performing press forming; and (4) recovering the filtrate, namely recovering by virtue of rectification, and separating the solvent and resin for recycling. The solvent adopted in the method disclosed by the invention is cyclohexane or acetic ester, and the two solvents are nontoxic, cause small harm to human bodies, are not corrosive, can be recycled, are harmless to the ecological environment and are environment-friendly.

Owner:CHINA UNIV OF MINING & TECH

Solvent dewaxing method of low-wax content hydrocarbon oil

ActiveCN102952573AReduce particle concentrationReduce filtration performanceTreatment with plural serial refining stagesMineral wax recovery/refiningWaxFiltration

The invention relates to a solvent dewaxing method of low-wax content hydrocarbon oil. The solvent dewaxing method comprises the following steps of mixing one or more raw material oil, one or more dewaxing assistants and dewaxing solvents, cooling to a filtration temperature, filtering to obtain a dewaxed solution and dewaxed cerate, removing the solvents in a dewaxed filtrate to obtain dewaxed oil, heating the dewaxed cerate until dissolution, cooling for crystallization, before dewaxed cerate heating dissolution and / or after dewaxed cerate heating dissolution, adding a deoiling solvent into the crystallized dewaxed cerate, cooling to a deoiling filtration temperature, and filtering to obtain a deoiled filtrate and deoiled cerate, wherein C17-C100 n-alkane mass content of the one or more dewaxing assistants is greater than or equal to 40% and a mass ratio of the one or more dewaxing assistants to the one or more raw material oil is in a range of (0.01: 1) to (0.3: 1). Compared with the conventional solvent dewaxing technology, the solvent dewaxing method provided by the invention can effectively remove wax in low-wax content hydrocarbon oil, reduce a dewaxing temperature difference and improve a filtration speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

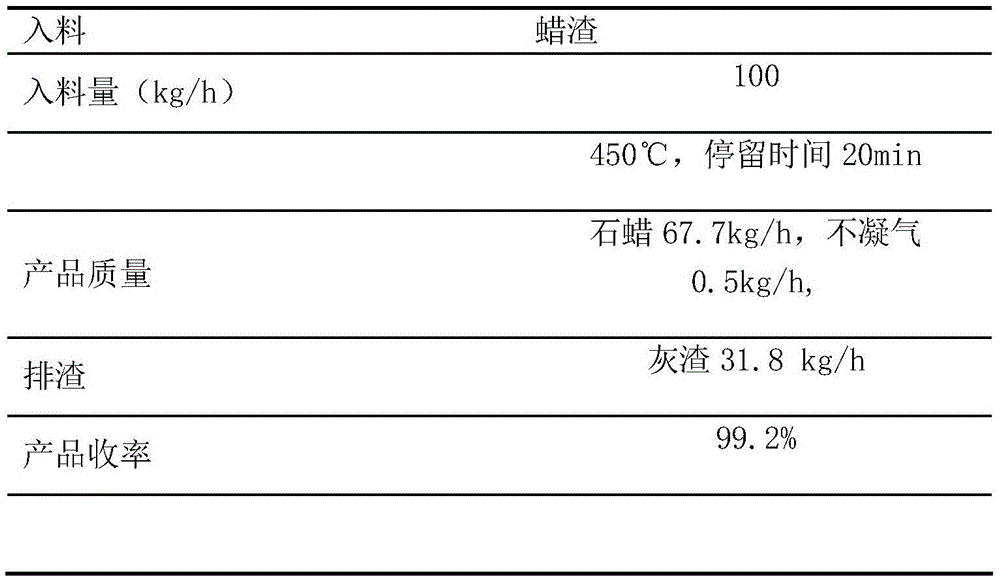

Device and method for recovering paraffin from Fischer-Tropsch paraffin residues

InactiveCN105542854AEmission reductionTo achieve the purpose of recycling paraffinMineral wax recovery/refiningHydrocarbon oils treatmentParaffin waxCombustion

The invention belongs to the technical field of recovery from Fischer-Tropsch paraffin residues and particularly relates to a device and a method for recovering paraffin from the Fischer-Tropsch paraffin residues. The device comprises a pyrolysis furnace, a precipitator, a condensing device and a gas-liquid separator, wherein the pyrolysis furnace is connected with the precipitator which is connected with the condensing device, and the condensing device is connected with the gas-liquid separator which is connected with the pyrolysis furnace; an inner barrel and an outer barrel are arranged in the pyrolysis furnace, a boost screw is arranged in the inner barrel, and a flue is formed between the inner barrel and the outer barrel; the pyrolysis furnace is further provided with a nitrogen inlet and a residue discharge port. The device and the method have the advantages that the purpose of paraffin recovery is achieved through separation of the paraffin from catalyst residues, the effective constituent yield of the paraffin residues is higher than 82%, produced non-condensable gas returns to the hearth of the pyrolysis furnace for combustion, flue gas emission is reduced, and the method is a clean process for recovering the paraffin from the Fischer-Tropsch paraffin residues.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

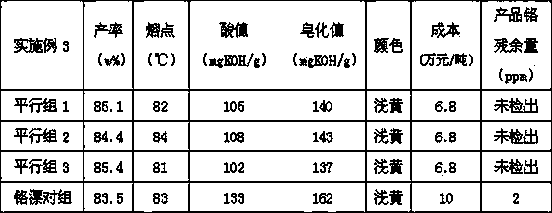

Lignite wax oxidizing and refining method

ActiveCN103525462AReduce usageShort reaction timeMineral wax recovery/refiningProcess engineeringIndustrial engineering

The invention discloses a lignite wax oxidizing and refining method which comprises the following steps: on the basis of taking degreased lignite wax as a raw material, refining the lignite wax by using a sectional method, firstly, performing primary rinsing by using peracetic acid and assistant, subsequently performing secondary rinsing by using hydrogen peroxide and hydrogen peroxide assistant, and finally drying and preparing a refined lignite wax product in a hot melting mode. The method disclosed by the invention is simple, feasible in technique, environment-friendly and energy-saving, the prepared wax is excellent in quality, and the method is an effective method for oxidizing and refining lignite wax of a non-chromium system.

Owner:KUNMING UNIV OF SCI & TECH

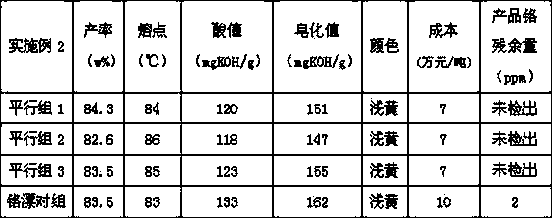

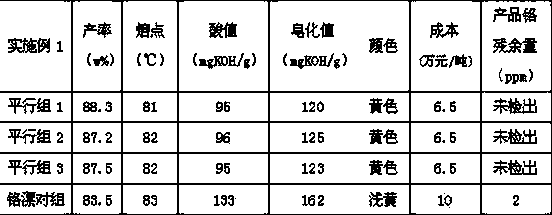

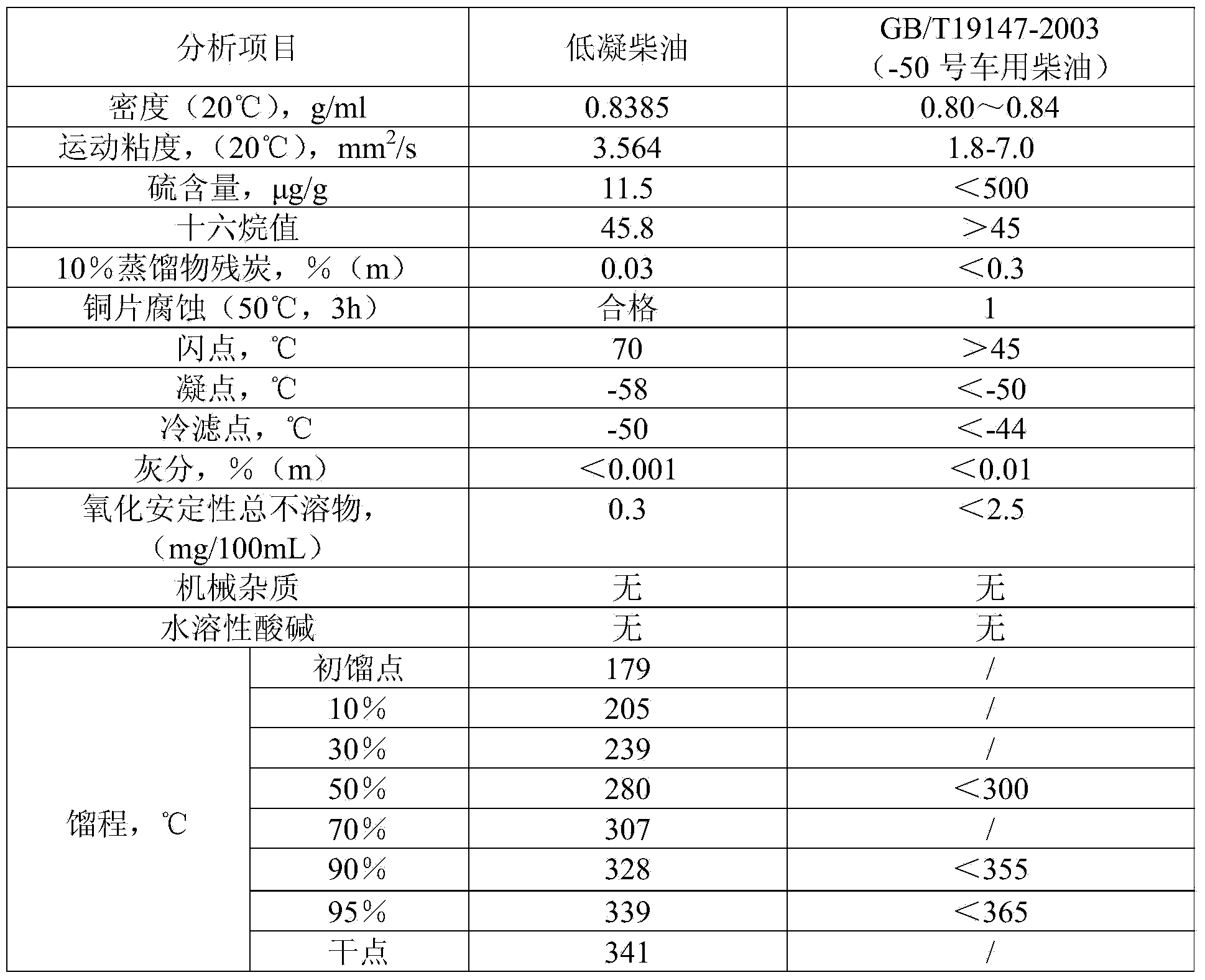

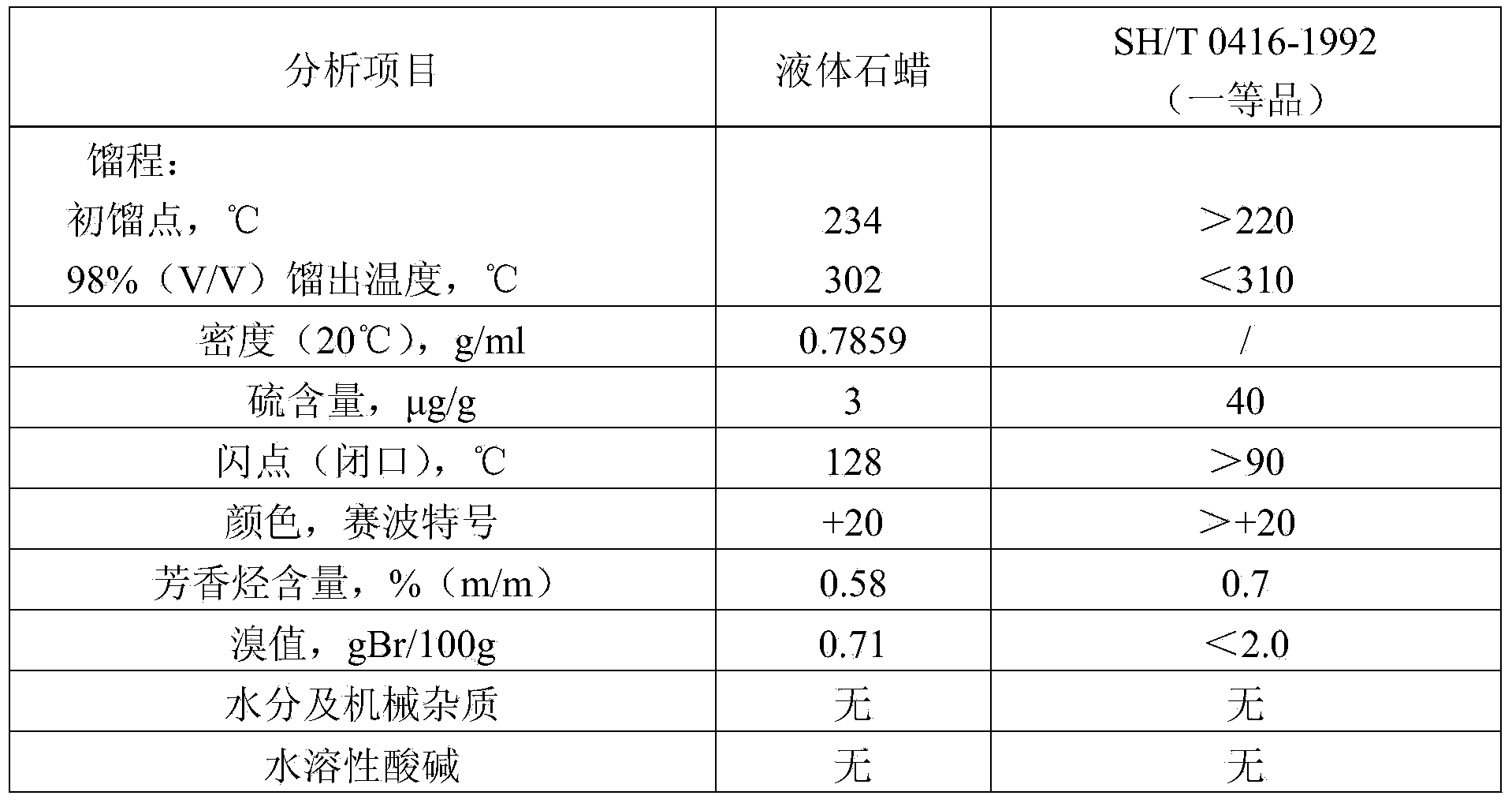

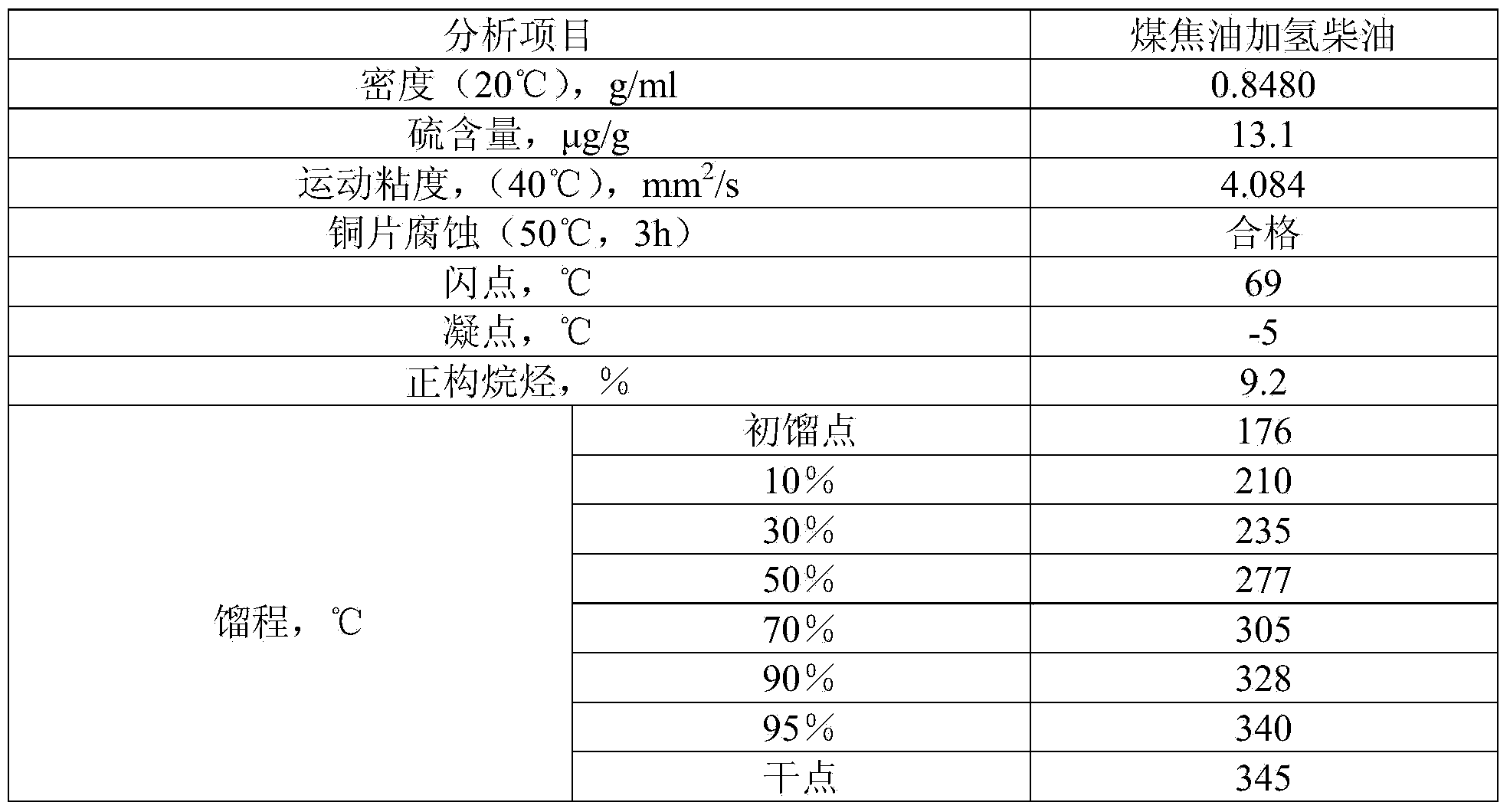

Method for producing low-condensation-point diesel oil and liquid paraffin by using coal tar

ActiveCN103450937ASolve the problem of high freezing point of hydrogenated diesel componentsExtend the hydrogenation industry chainTreatment with hydrotreatment processesMineral wax recovery/refiningParaffin waxDecomposition

The invention relates to a method for producing low-condensation-point diesel oil and liquid paraffin by using coal tar. The method comprises the steps of mild hydrofining of the coal tar, fractionation of a hydrogenated product, urea complexation dewaxing of diesel oil fraction and decomposition of a urea complex, so that the low-concentration-point diesel oil and the liquid paraffin are prepared. According to the method, the cola tar is processed by adopting a mild hydrofining-dewaxing coupling technique, so that the obtained low-condensation-point diesel oil and liquid paraffin have good quality; the low-concentration-point diesel oil meets the standard on 50# diesel oil of GB / T19147-2003 Automotive Diesel Fuel, and can be used in alpine regions; the liquid paraffin meets the standard of SH / T0416-1992 Heavy Liquid Paraffin, and utilizes the coal tar source more reasonably. The method for producing the low-condensation-point diesel oil and the liquid paraffin by using the coal tar efficiently solves the problem that the concentration point of the coal tar hydrogenated diesel oil component is relatively high, prolongs a hydrogenation industry chain of the coal tar, improves use value of the coal tar, is suitable for industrial application, and increases economic benefits greatly.

Owner:SHENMUFUYOU ENERGY TECH

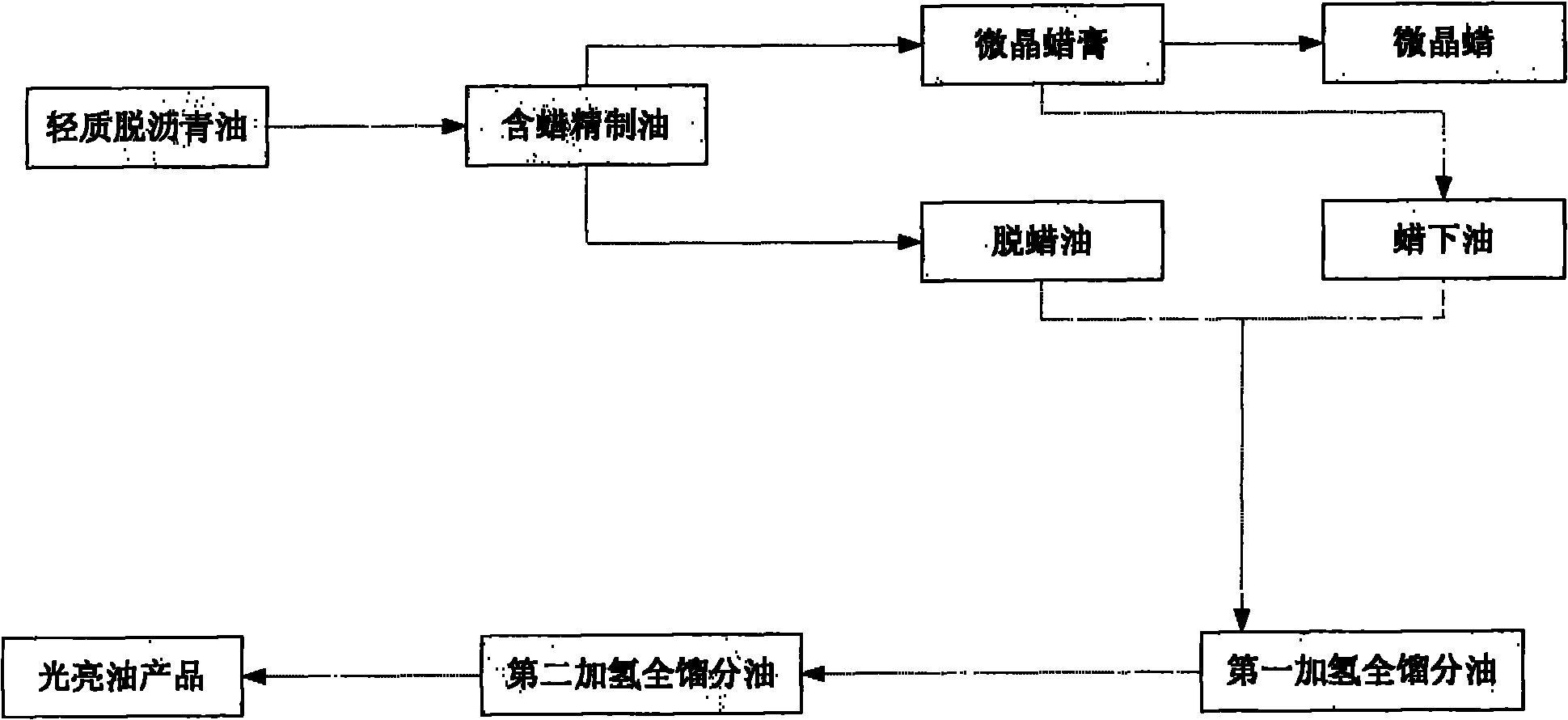

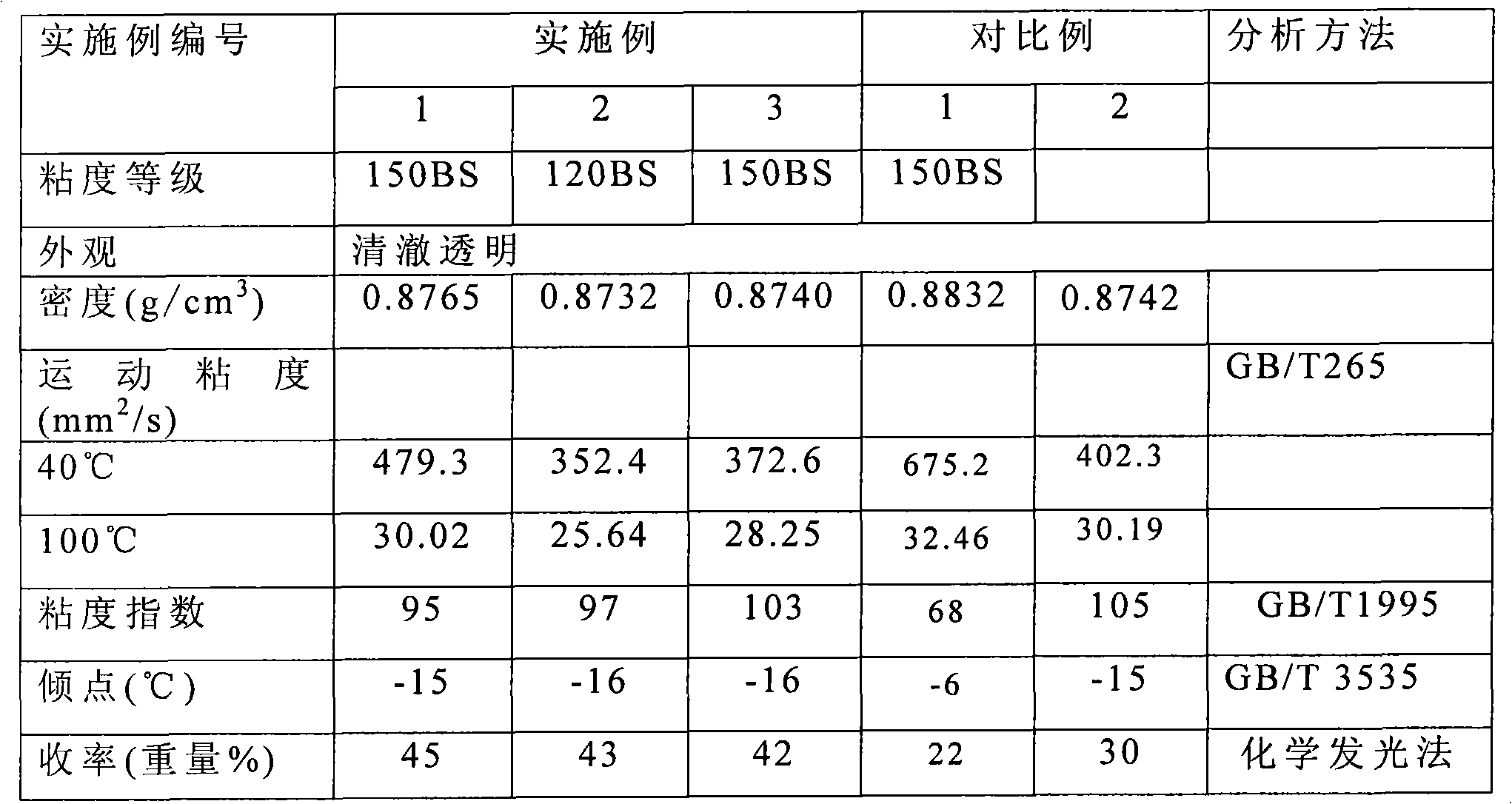

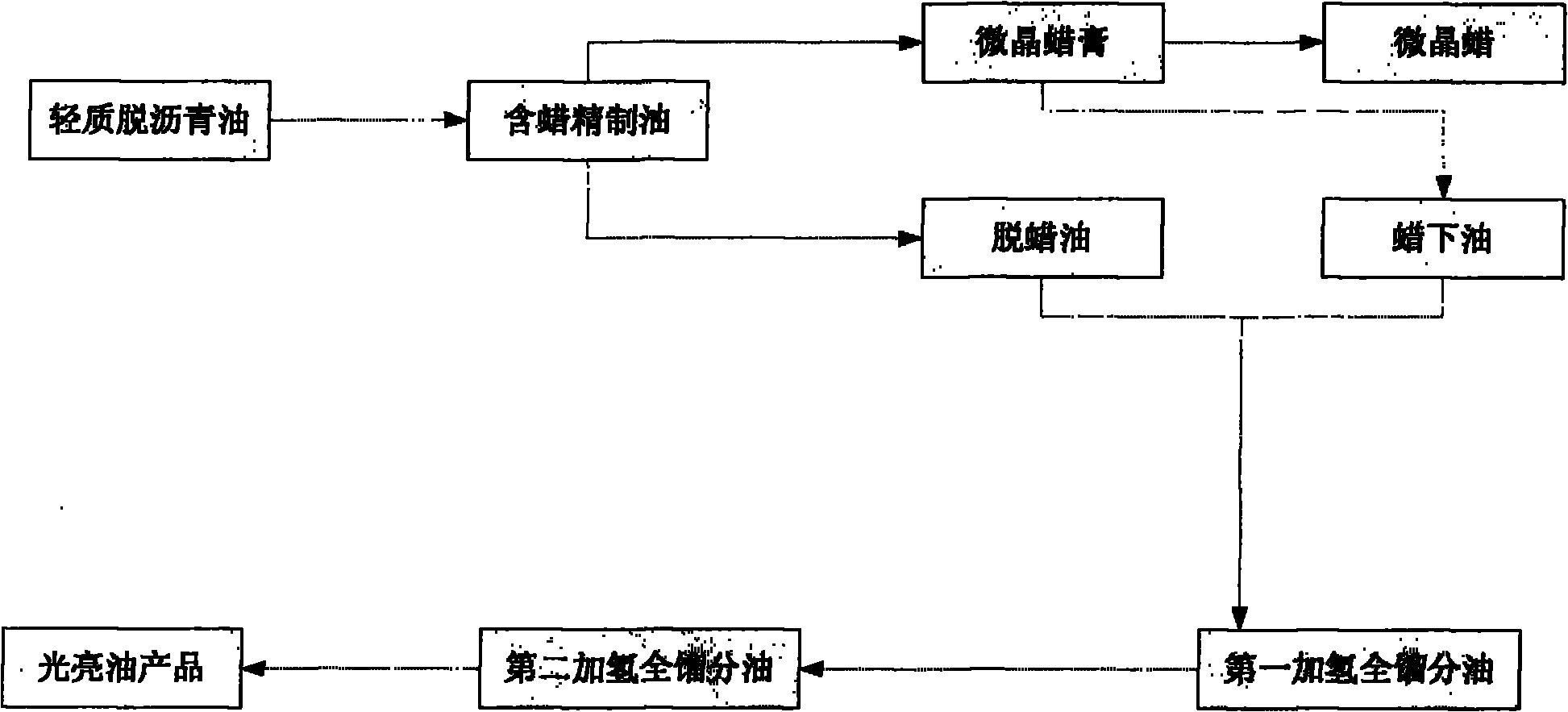

Preparation method of bright oil

ActiveCN102079994ALow viscosityQuality improvementTreatment with hydrotreatment processesMineral wax recovery/refiningPolycyclic aromatic hydrocarbonWax

The invention relates to a preparation method of a bright oil, which comprises the following steps: enabling light-weight deasphalted oil to be in contact with a solvent in which macro-molecule polycyclic aromatic hydrocarbon can be selectively dissolved, thus obtaining a wax-containing refined oil; enabling the wax-containing refined oil to be in contact with a dewaxing solvent, thus obtaining a dewaxed oil and a micro-crystalline wax paste; enabling a mixture of the dewaxed oil and hydrogen gas to be in contact with a hydrotreating catalyst, thus obtaining a first hydrogenated full distillate oil; respectively enabling a mixture of the first hydrogenated full distillate oil and hydrogen gas to be in contact with a hydroisomerizing catalyst and a hydrorefining catalyst, thus obtaining a second hydrogenated full distillate oil; and separating out the distillate of which the boiling point is higher than 500 DEG C from the second hydrogenated full distillate oil, wherein the distillate is the bright oil product. By using the traditional method, only a low-viscosity index bright oil product can be produced; or by using the conventional isomerization dewaxing method, a high-viscosity intermediate-base or mixed-base material of the bright oil can not be obtained. By using the preparation method provided by the invention, a bright oil product which has satisfactory kinematic viscosity, high viscosity index and low pour point and does not contain floccules at normal temperature can be produced, and the micro-crystalline wax can be produced as a byproduct.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solvent dewaxing method by use of dewaxing assistant

The invention discloses a solvent dewaxing method by the use of a dewaxing assistant, comprising the following steps of: mixing molten dewaxing materials and a dewaxing assistant, adding a dewaxing solvent, and cooling to a dewaxing temperature. The addition mode of the solvent is a multipoint dilution method or a one-time full dilution method. Dewaxing oil and dewaxing cerate can be obtained by filtration and separation at the dewaxing temperature. The dewaxing assistant is Fischer-Tropsch synthetic wax with high-melting point. According to the invention, the filtration speed and the dewaxing oil yield are raised, and simultaneously the applied assistant needs not to be separated from wax and generates no unfavorable impact on wax properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com