Solvent dewaxing method by use of dewaxing assistant

A technology of dewaxing aids and dewaxing solvents, which is applied in the field of solvent dewaxing of vacuum heavy distillate oil and lubricating oil solvent dewaxing using additives, which can solve problems such as difficult process and adverse effects of wax stability, etc. Achieve the effects of increasing filtration speed, good oil and wax separation effect, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

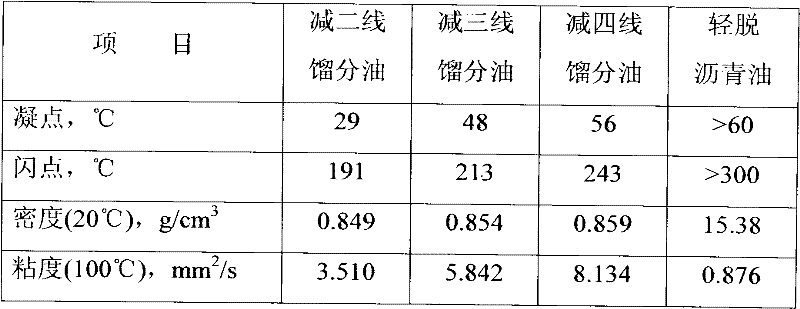

[0013] The properties of the dewaxing raw materials used in the examples of the present invention and the comparative examples are shown in Table 1.

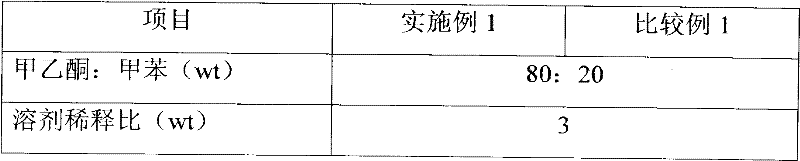

[0014] The dewaxing solvent used in the examples and comparative examples of the present invention is a mixed solvent of methyl ethyl ketone-toluene, and the solvent composition is shown in each example and comparative example.

[0015] The solvent dilution in the solvent dewaxing process of the embodiment of the present invention and the comparative example adopts four-point dilution, and the dilution points are 75°C, 35°C, -10°C and -20°C.

[0016] The auxiliary agent that the embodiment of the present invention adopts is:

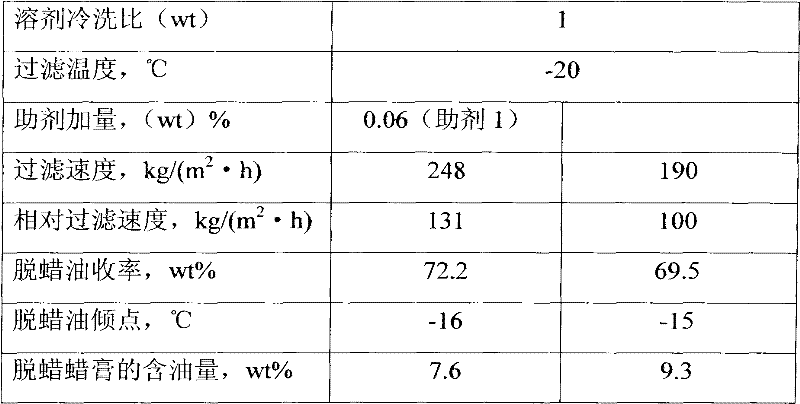

[0017] Additive 1: 590-700°C fraction of Fischer-Tropsch synthetic wax, with an average molecular weight of 735 and a dropping point of 98°C.

[0018] Additive 2: Fischer-Tropsch synthetic wax >700°C fraction, average molecular weight 990, dropping point 108°C.

[0019] See Tables 2-5 for the operating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com