Spiral extruding filter

A screw extrusion and filter technology, which is applied in filtration and separation, fixed filter element filters, presses, etc., can solve the problems of low filtration speed of materials, affect production capacity, and small filtration driving force, so as to improve the filtration speed, Improve production efficiency and promote the effect of material dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

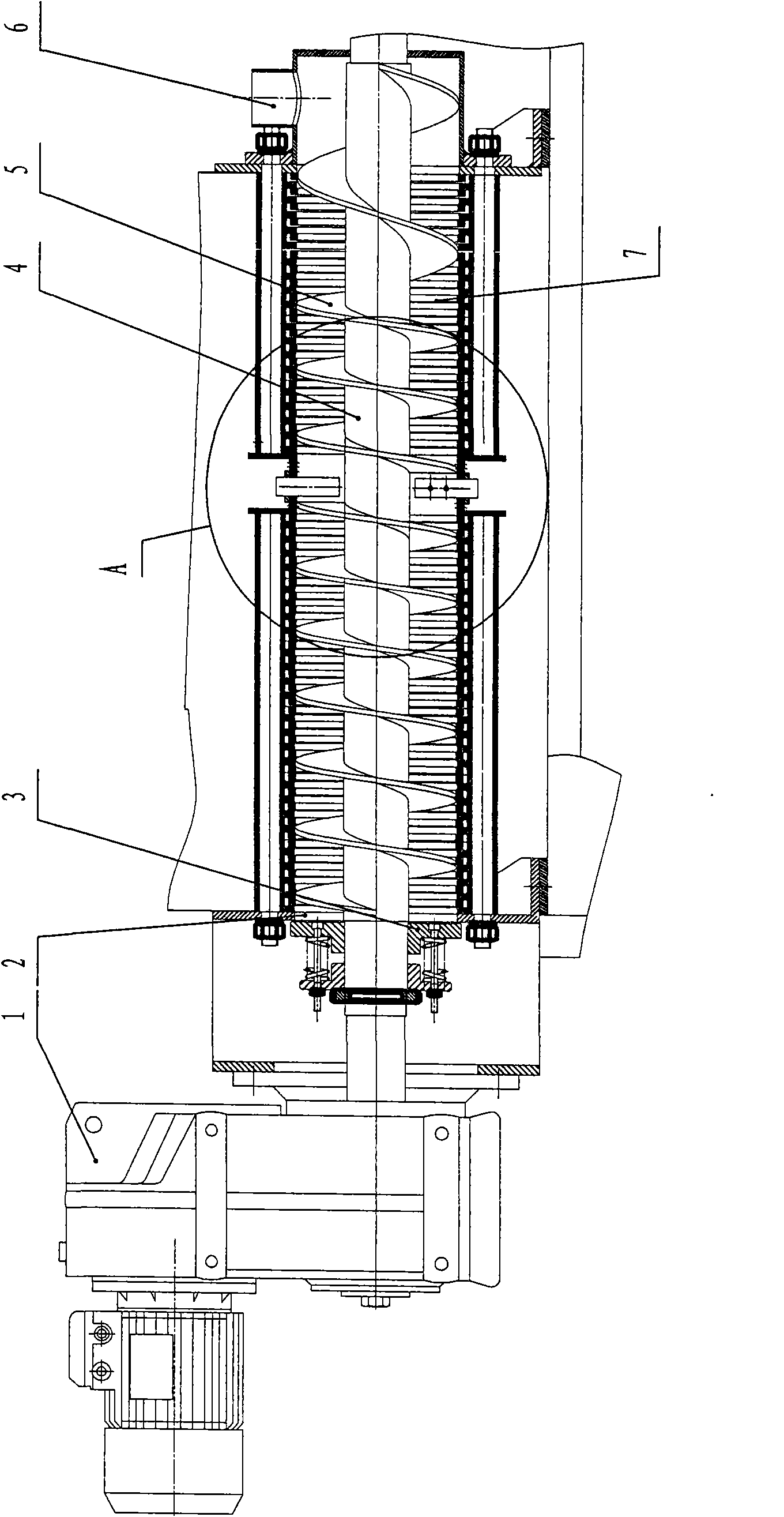

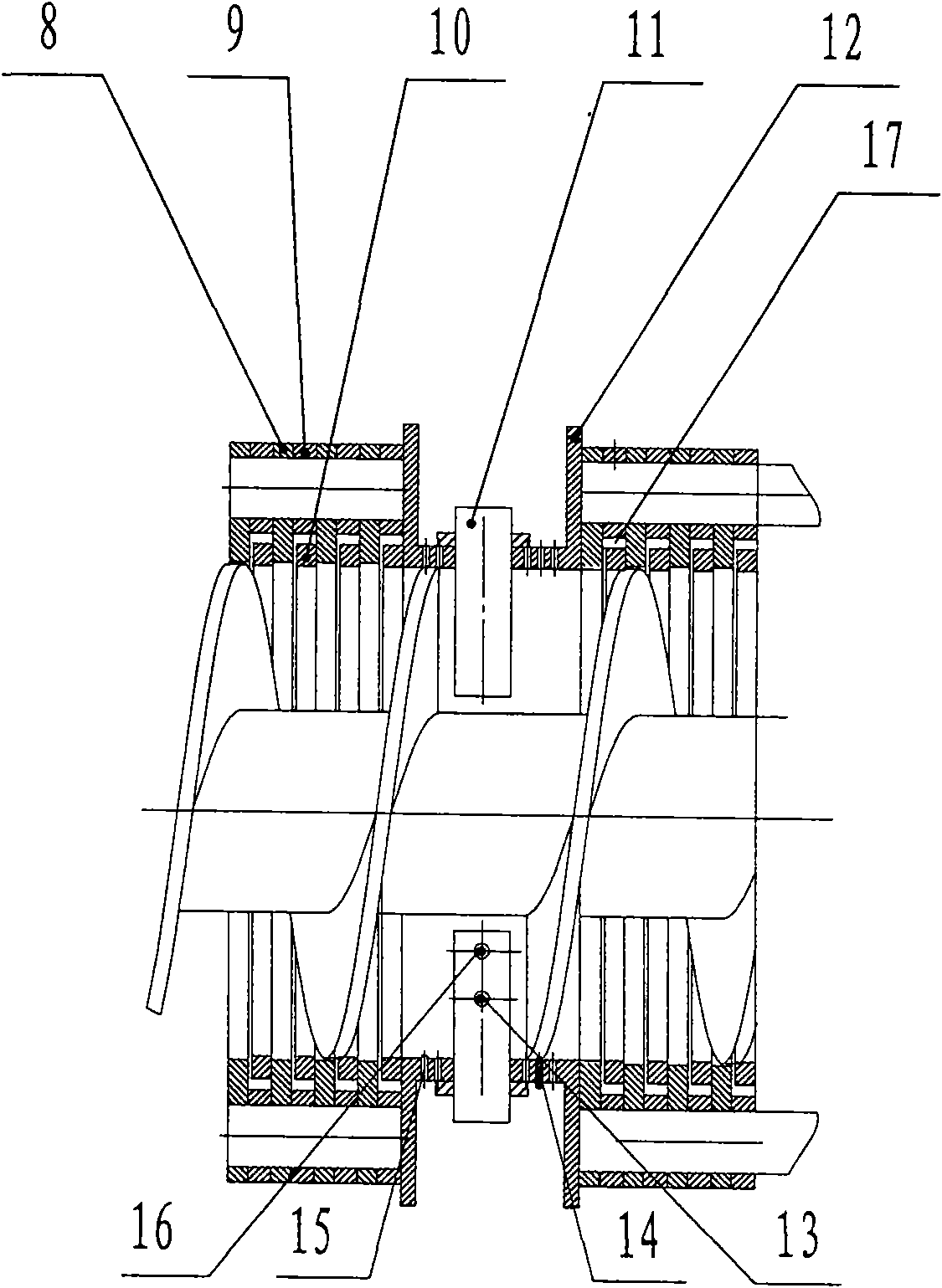

[0015] Such as figure 1 with figure 2 As shown, this screw extruding filter mainly includes a motor 1 and a filter cartridge 7 , a screw shaft 4 runs through the filter cartridge 7 , and the screw shaft 4 is connected to the output shaft of the motor 1 . The screw shaft 4 is provided with at least one discontinuous screw shaft blade 5 . The filter cartridge 7 is composed of several annular fixed plates 8, adjusting plates 9 and movable plates 10, the fixed plates 8 and the adjusting plates 9 are arranged alternately, and the diameter of the inner hole of the adjusting plates 9 is larger than that of the fixed plate 8 , an annular groove 17 is formed between the two fixed plates 8; the movable plate 10 is installed in the annular groove 17, an adjustment gap is formed between the outer surface of the movable plate 10 and the inner wall of the adjusting piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com