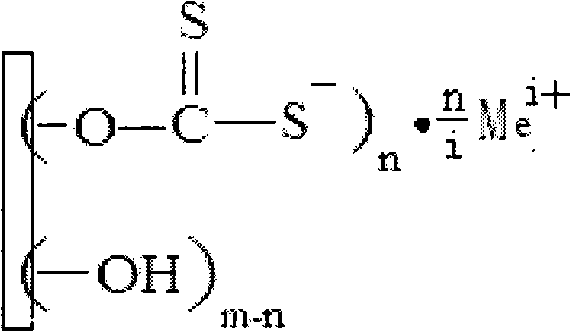

Clay-based xanthogenate, and preparation method and application thereof

A clay-based yellow and xanthate technology, applied in the field of chemical materials, can solve the problems of unfavorable large-scale development and utilization of non-metallic mineral materials, disposal and treatment, preparation methods and applications that have not been reported, and complex technical solutions, etc., to achieve Ease of large-scale production and popularization and application, easy solid-liquid separation, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

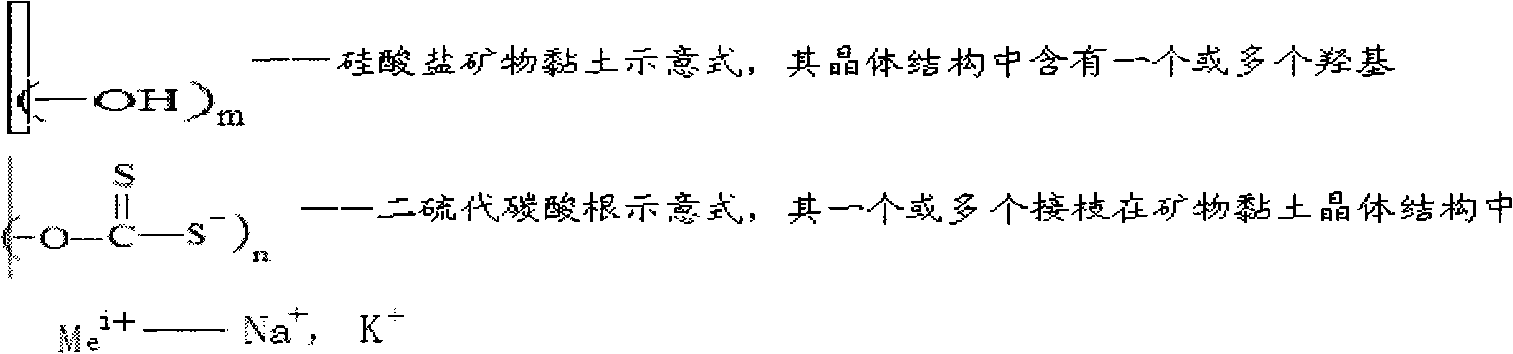

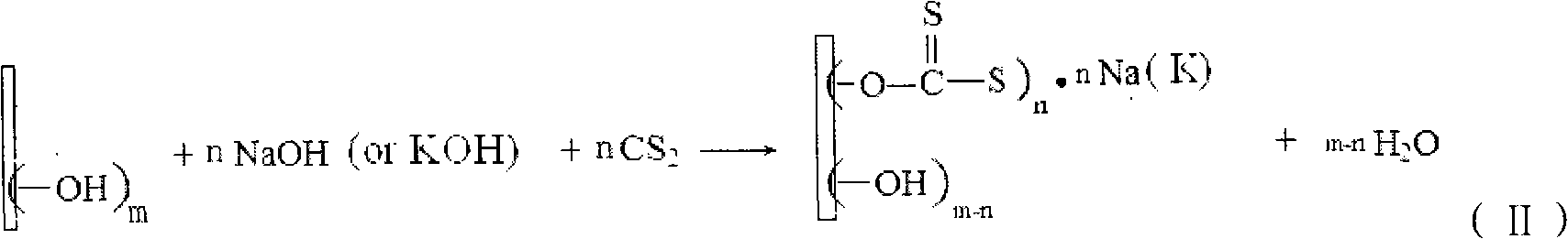

Method used

Image

Examples

Embodiment 1

[0058] Example 1: A wet preparation method of attapulgite clay-based xanthate sodium salt

[0059] The wet preparation method of described attapulgite clay-based xanthate sodium salt comprises the following steps:

[0060] (a) The raw materials used and their weight proportions are: attapulgite clay 100kg, sodium hydroxide solid (chemically pure) 12kg, carbon disulfide 20kg, tap water 150kg. The attapulgite clay was taken from a mine in Jingyuan, and after crushing, sieving, grinding, purification, dehydration and drying, a powder product of 70-200 meshes was obtained;

[0061] (b) In the stirred reactor, first add water and sodium hydroxide according to the proportion of step (a), stir and dissolve, then add carbon disulfide liquid according to the proportion of step (a), the temperature is controlled at 5-30 ° C, and then Add attapulgite clay while stirring according to the proportion of step (a), continue stirring for 20 minutes to make it evenly mixed, and control the rea...

Embodiment 2

[0064] Example 2: A dry method for preparing attapulgite clay-based xanthate sodium salt

[0065] The dry preparation method of the attapulgite clay-based xanthate sodium salt comprises the following steps:

[0066] (a) The raw materials used and their weight proportions are: attapulgite clay 100kg, sodium hydroxide solid (60 mesh) 60kg, carbon disulfide 100kg, water 100kg. The attapulgite clay is taken from a mine sample of Jiangsu Jiuchuan Company. After crushing, screening, grinding, purification, dehydration and drying, a powder product of 70-6000 meshes is obtained;

[0067] (b) In the high-speed heat dissipation kneader, now sodium hydroxide and water in the step (a) are added to the kneader, stirring and dissolving becomes a concentrated alkali solution (also can be replaced with an equivalent amount of 37.5% industrial liquid alkali), and the temperature is lowered to After the temperature is below 30°C, add all the remaining raw materials in step (a), stir thoroughly...

Embodiment 3~12

[0069] Examples 3-12: A preparation method of attapulgite clay-based xanthate

[0070] For the preparation method of the attapulgite clay-based xanthate, the attapulgite clay used is 100kg, the other raw materials used and their weight ratios are shown in Table 1, and the preparation method is the same as in Example 1 or Example 2 is the same.

[0071] Table 1: Raw materials and their amounts in the preparation method of attapulgite clay-based xanthate

[0072]

[0073] Example 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com