Preparation method of inorganic-organic compound-type adsorbent based on clinoptilolite and application for removing Cr(VI) in industrial waste water

A technology for industrial wastewater and adsorbents, applied in the fields of adsorbed water/sewage treatment, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of inability to remove anionic pollutants, and achieve the effects of abundant reserves, increased adsorption capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

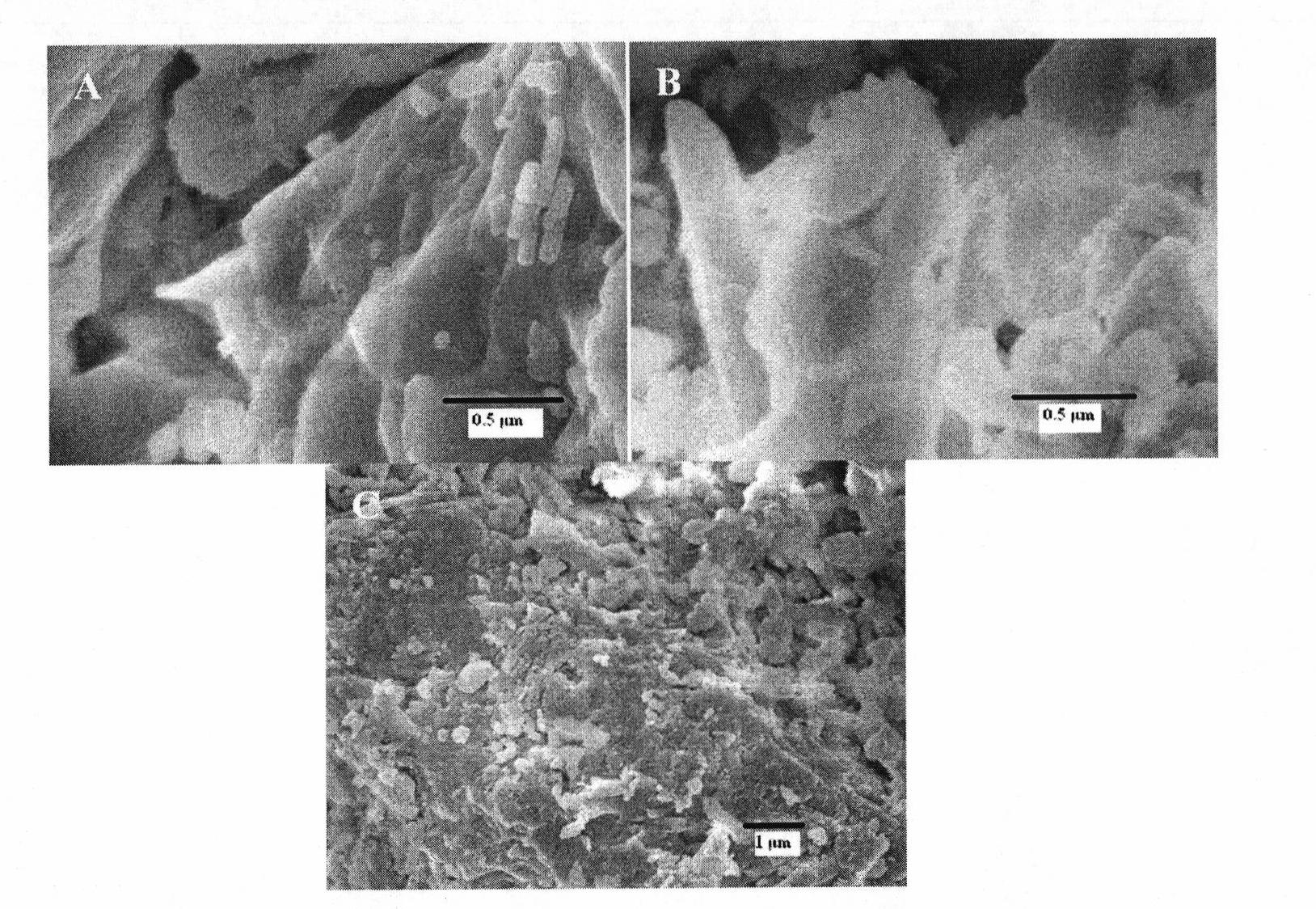

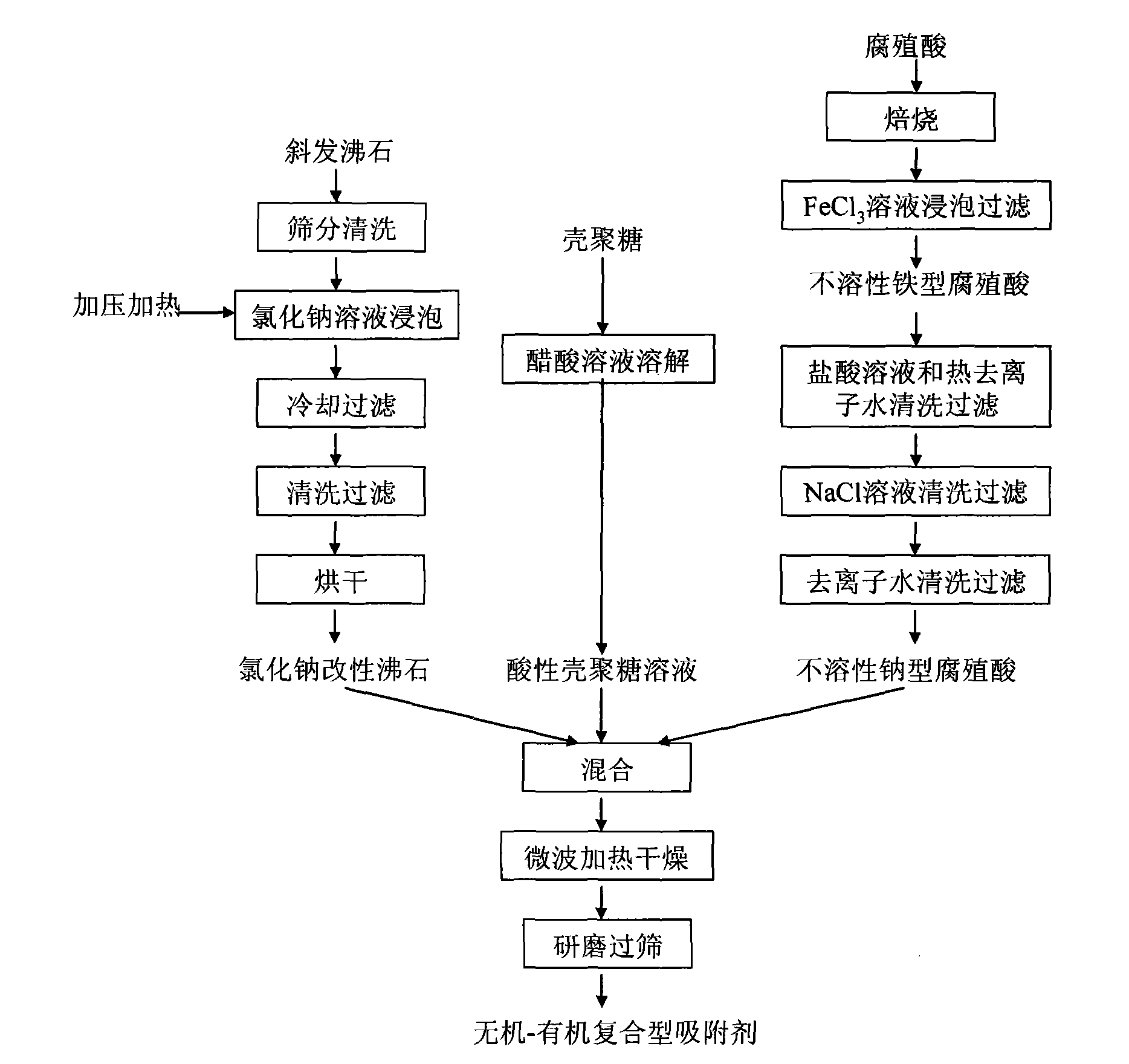

[0020] Preparation of inorganic-organic composite adsorbent (see figure 2 ): Place 100g of cleaned 80-100 mesh natural clinoptilolite in 500ml of sodium chloride solution with a concentration of 2mol / L, heat for 2.0h at 2 atmospheric pressure and 110-120°C, and wait for complete cooling Filter, wash 3 times with deionized water, and dry at 80°C. Put the humic acid in a muffle furnace, roast it at 350°C for 1.0h, and then soak it in 2.0mol / L ferric chloride solution for 1.5h to obtain insoluble iron-type humic acid. After grinding, use 1mol / L hydrochloric acid solution and hot deionized water for repeated washing, and then repeated washing with 1.0-2.0mol / L sodium chloride solution and deionized water to convert humic acid into insoluble sodium humic acid. Sodium chloride modified clinoptilolite and insoluble humic acid are formulated into a mixture with a mass ratio of 10:1, and chitosan with a deacetylation degree of 90% is slowly dissolved with a concentration of 2% aceti...

Embodiment 2

[0023] Preparation of inorganic-organic composite adsorbent: the difference between this embodiment and Example 1 is the mass ratio used when sodium chloride-modified clinoptilolite and insoluble humic acid are formulated into a mixture in the preparation of inorganic-organic composite adsorbent 5:1. Other steps and parameters are the same as in Example 1.

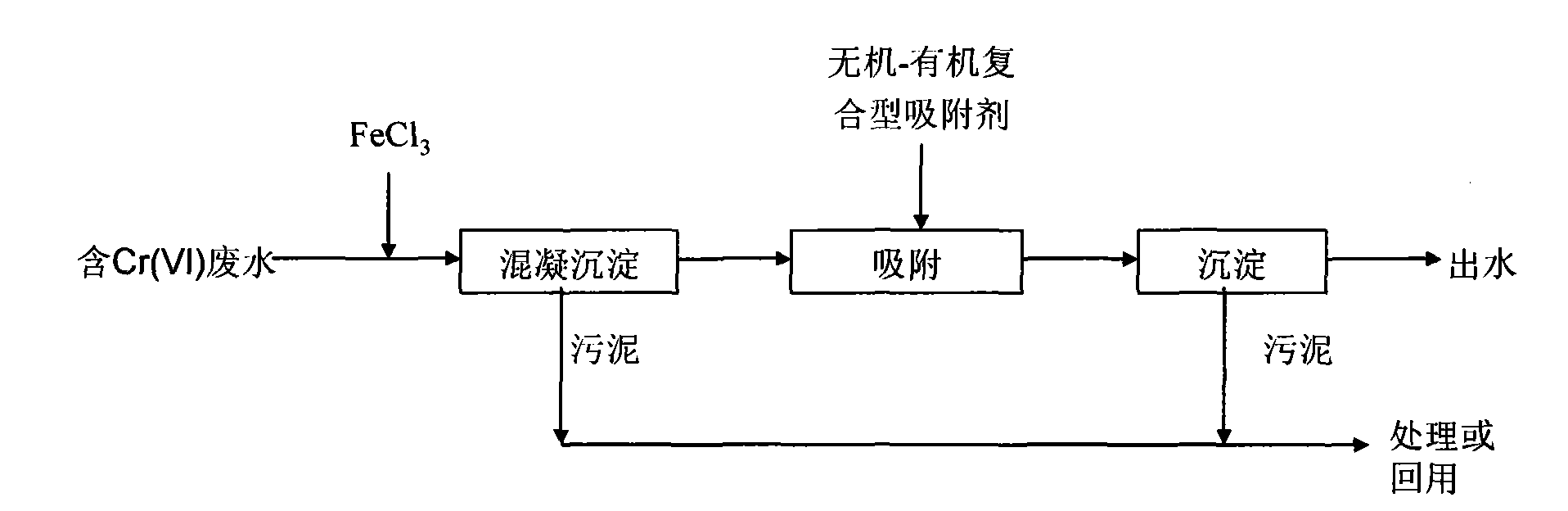

[0024]The inorganic-organic composite adsorbent prepared by the above method contains Cr(VI) wastewater: the treated wastewater in Example 2 is the high-concentration wastewater of 100mg / L Cr(VI) concentration prepared in the laboratory, and the wastewater is adjusted The pH value is 3, then add inorganic-organic composite adsorbent to the wastewater at 5mg / L, stir with compressed air, after 30min of adsorption, settle for 1h, the supernatant is introduced into the second stage of adsorption, and the second stage of adsorption into the wastewater The dosage of adding inorganic-organic composite adsorption is 1mg / L, and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com