Preparation of magnetic chitosan composite adsorption material and application in dye wastewater treatment

A composite adsorption material, chitosan technology, applied in the preparation of magnetic chitosan composite materials, the preparation of magnetic chitosan composite adsorption materials, can solve the problems of difficult separation and degradation, low adsorption capacity, poor adsorption effect, etc. Achieve the effect of good adsorption effect, large adsorption capacity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

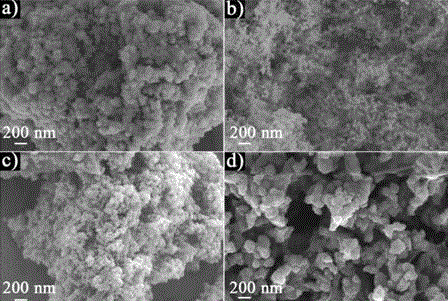

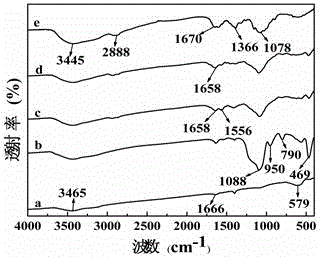

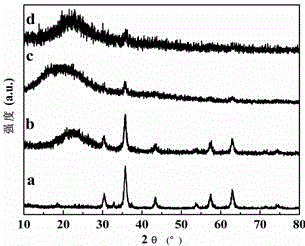

[0044] (1) Preparation of ferroferromagnetic nanoparticles: FeCl 2 4H 2 O and FeCl 3 ·6H 2 O by nFe 2+ / nFe 3+ Dissolve in distilled water at a ratio of 1:1, stir at 50°C, and add 15mL of ammonia water (25%) quickly dropwise to the above solution after nitrogen gas flow, react for 30min, wash, and dry to obtain ferroferric oxide magnetic nanoparticles;

[0045] (2) Preparation of silicon dioxide-ferric oxide composite: disperse 0.5 g of ferric oxide nanoparticles into a mixture of 50 mL of absolute ethanol and 50 mL of distilled water by ultrasonication for 30 min, add 1 mL of tetraethyl orthosilicate solution, 1mL ammonia solution (15%), react for 10h, wash and dry to obtain the silica-ferric oxide complex;

[0046] (3) Preparation of magnetic chitosan composite adsorption material: Dissolve 1g chitosan in 100mL acetic acid solution (0.5 wt.%), add 1g silica-ferric oxide complex, stir well; then slowly add 1mL glutaraldehyde produces a black gel-like substance—magnetic ...

Embodiment 2

[0048] (1) Preparation of ferroferromagnetic nanoparticles: same as in Example 1;

[0049] (2) Preparation of silica-ferric oxide composite: disperse 0.5 g ferric oxide particle ultrasonically for 30 min in a mixture of 75 mL absolute ethanol and 25 mL distilled water, add 1.5 mL ethyl orthosilicate solution , 2.3mL ammonia solution (20%), reacted for 24h, washed and dried to obtain the silica-ferric oxide complex;

[0050] (3) Preparation of magnetic chitosan composite adsorption material: Dissolve 1.5g chitosan in 150mL acetic acid solution (1 wt.%), add 1 g silica-ferric oxide complex, stir well; slowly Add 3mL of glutaraldehyde to produce a black gel-like substance—magnetic chitosan; then disperse 1g of magnetic chitosan in 50mL of distilled water, add 0.5g of 2,3-epoxypropyltrimethylammonium chloride , and reacted at 80°C for 12h; after the reaction was completed, it was washed with distilled water and absolute ethanol in turn to obtain the product magnetic chitosan comp...

Embodiment 3

[0052] (1) Preparation of ferroferromagnetic nanoparticles: same as in Example 1;

[0053] (2) Preparation of silicon dioxide-ferric oxide composite: disperse 0.5 g of ferric oxide nanoparticles into a mixture of 80 mL of absolute ethanol and 20 mL of distilled water by ultrasonication for 30 min, add 2 mL of tetraethyl orthosilicate solution, 4mL of ammonia solution (25%), reacted for 12h, washed and dried to obtain the silica-ferric oxide complex;

[0054] (3) Preparation of magnetic chitosan composite adsorption material: Dissolve 2g chitosan in 200mL acetic acid solution (1 wt.%), add 1g silica-ferric oxide complex, stir well and slowly add 6mL Glutaraldehyde produces a black gel-like substance—magnetic chitosan; then 1g of magnetic chitosan is dispersed in 50mL of distilled water, and 1g of 2,3-epoxypropyltrimethylammonium chloride is added, at 60 It was reacted at ℃ for 24 h; after the reaction, it was washed with distilled water and absolute ethanol to obtain the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com