Patents

Literature

3730 results about "Dyeing wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

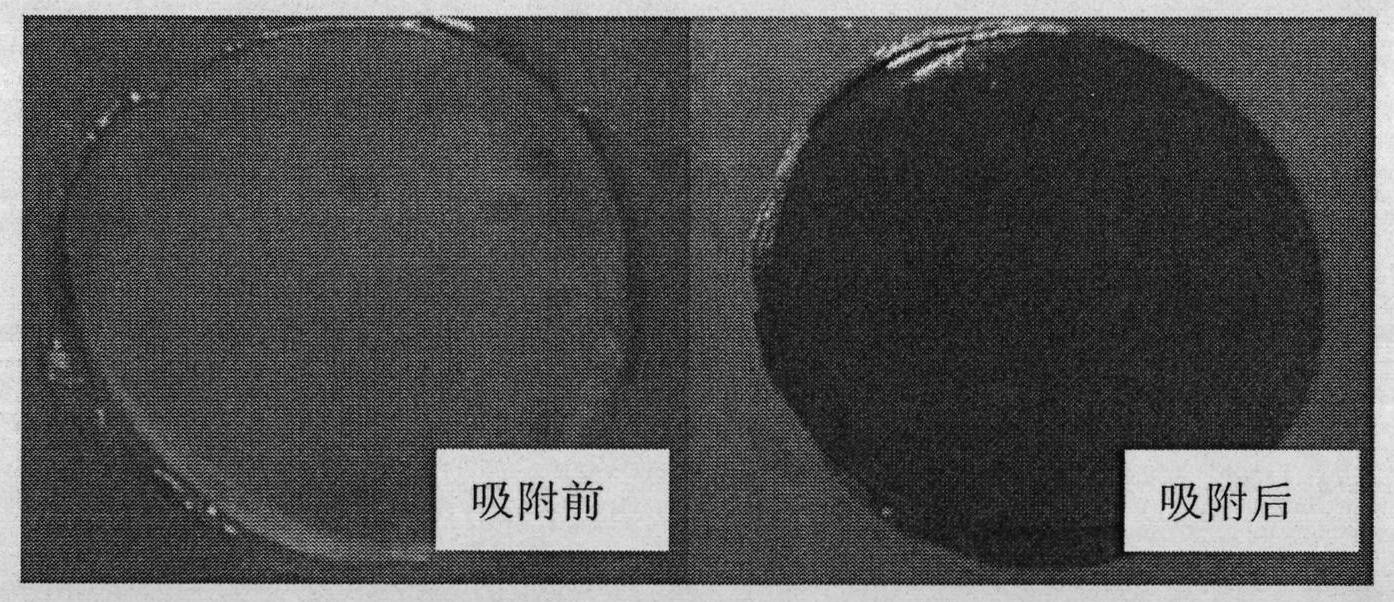

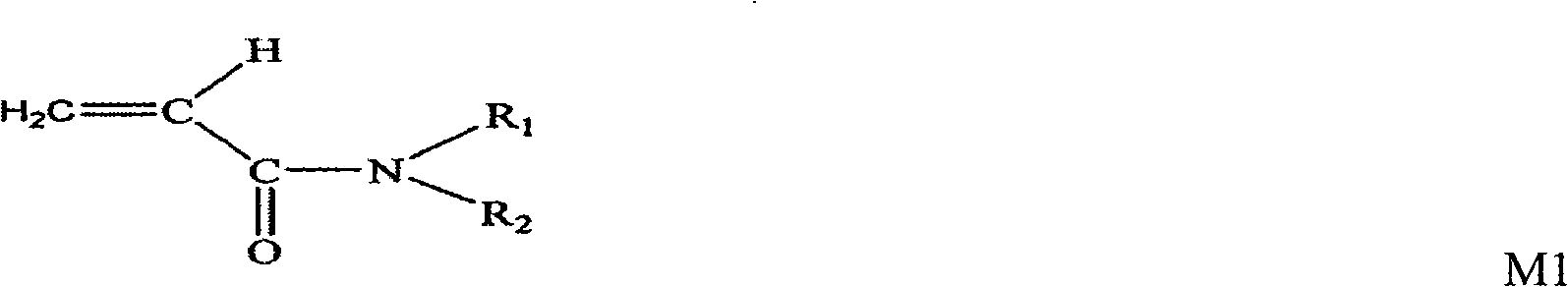

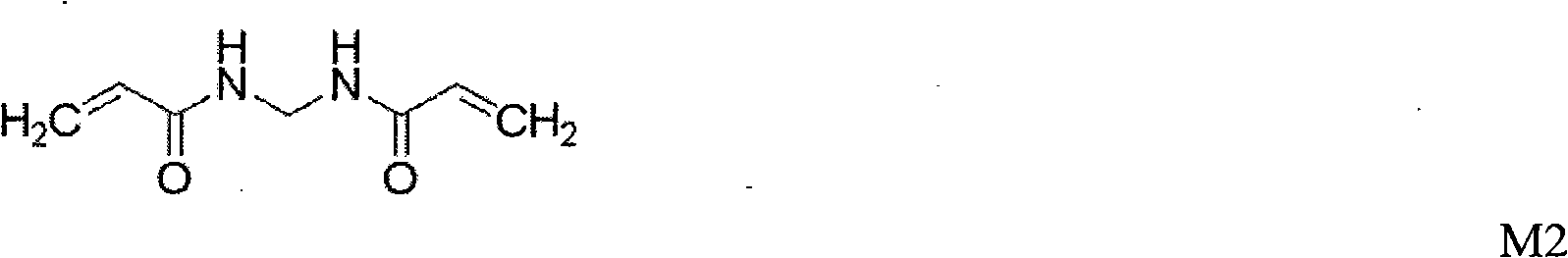

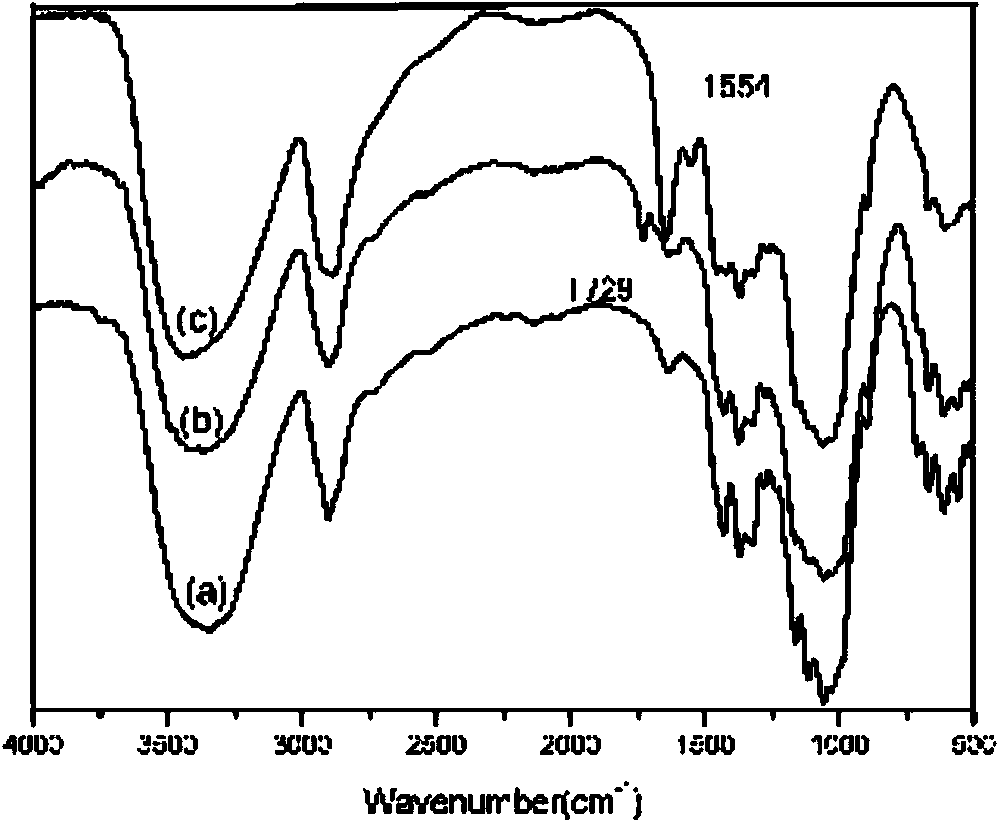

Nanometer clay-containing high absorptive hydrogel as well as preparation method and application thereof

InactiveCN101942167AImprove adsorption capacityImprove mechanical propertiesOther chemical processesWaste water treatment from textile industryBiopolymerWater soluble

The invention relates to a nanometer clay-containing high absorptive hydrogel as well as a preparation method and application thereof. The hydrogel contains an acrylamide monomer M1, a chemical crosslinking agent M2, inorganic nanometer clay M3 and a water soluble biopolymer M4 with use level of 98-50:0-10:2-25:015 in mass percent. The preparation method comprises the following step of: taking M3 as a filler or a reinforcing agent or a physical crosslinking agent and taking M4 as a second component in a water solution to prepare the environmentally-friendly hydrogel with high water soluble dye adsorption property and excellent mechanical property. The method has the advantages of simple and reliable preparation process, no environmental pollution, very strong dye adsorption removal effects and practicability; and the dye adsorption quantity can be adjusted by temperature, pH value, crosslinking degree, dye concentration, nanometer clay or biopolymer variety and use level and a reactant charge ratio. The hydrogel can be used for the fields of weaving and dyeing wastewater treatment, dye adsorption, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of supported metal catalyst

InactiveCN105562116ALow costHigh operational controllabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityDyeing wastewater

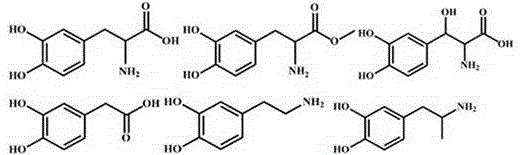

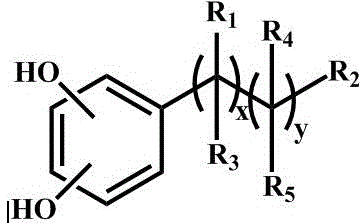

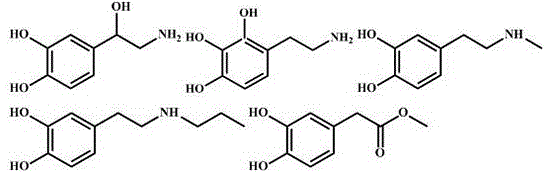

The invention discloses a preparation method and application of a supported metal catalyst. The supported metal catalyst comprises carrier framework materials and nano particles, loaded on the surfaces of the carrier framework materials, of metal or metal oxide, or metal ions chelated on the surfaces of the carrier framework materials, wherein the metal ions and nano particles of the metal or metal oxide are loaded on the surfaces of the carrier framework materials through the polymerization layers, adhered to the surfaces of the carrier framework materials, of catechol derivatives. The preparation method of the supported metal catalyst has the advantages that the method is simple, various carrier framework materials are used, one or more metal ions or nano particles can be loaded, and universality is achieved; the supported metal catalyst is good in active metal dispersity, large in carrier specific surface area, low in use amount, low in cost, and the like; the catalyst loaded with noble metal is catalyst material which is widely used and environmental friendly and is efficiently applicable to environmental chemical engineering fields such as dye wastewater decoloring, wastewater organic pollutant removing, car tail gas treatment, air purification, hydrogenation and reforming catalytic reaction, gas sensors and fuel cells.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Anaerobic zero-valent iron sewage treatment method

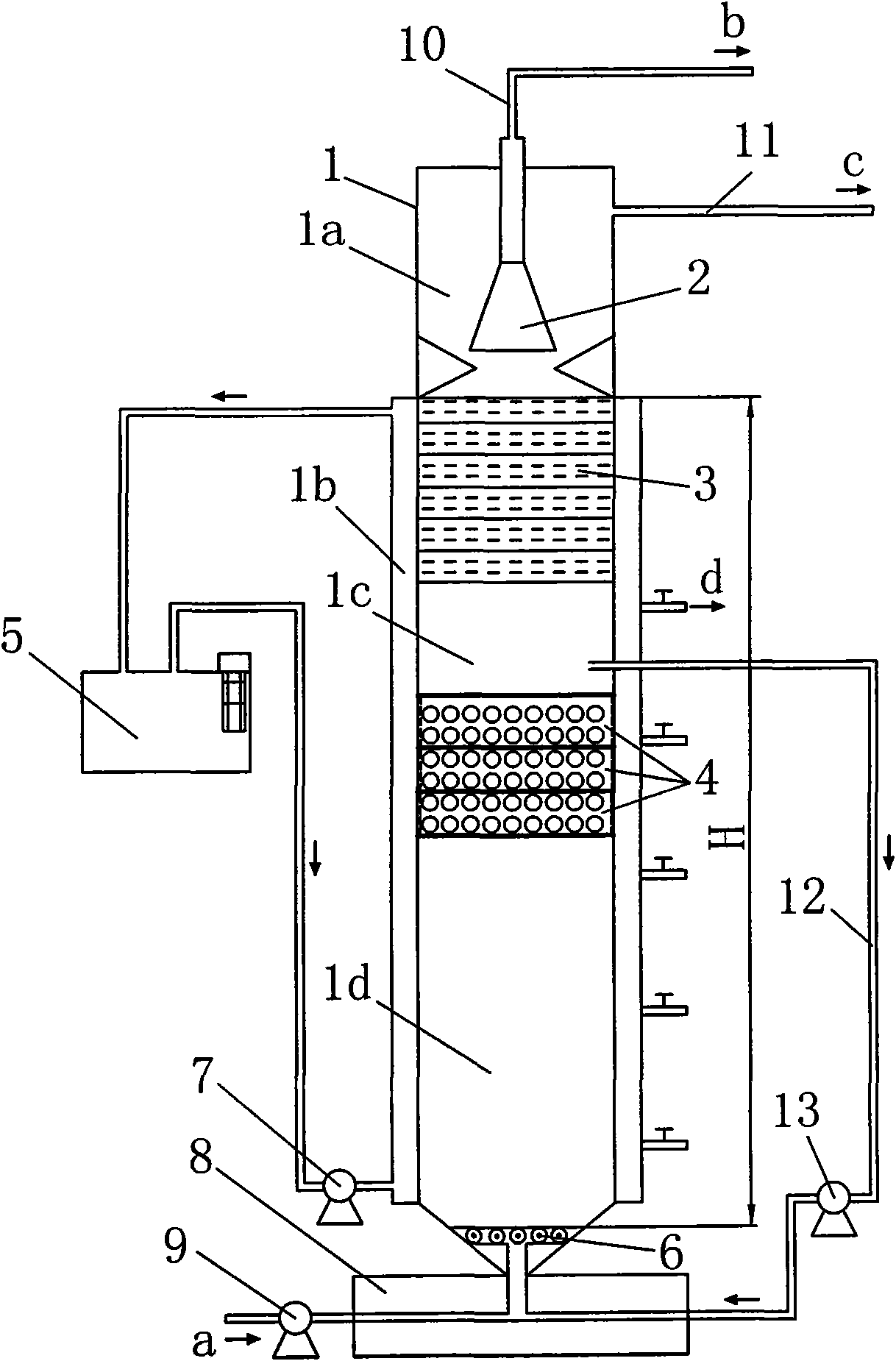

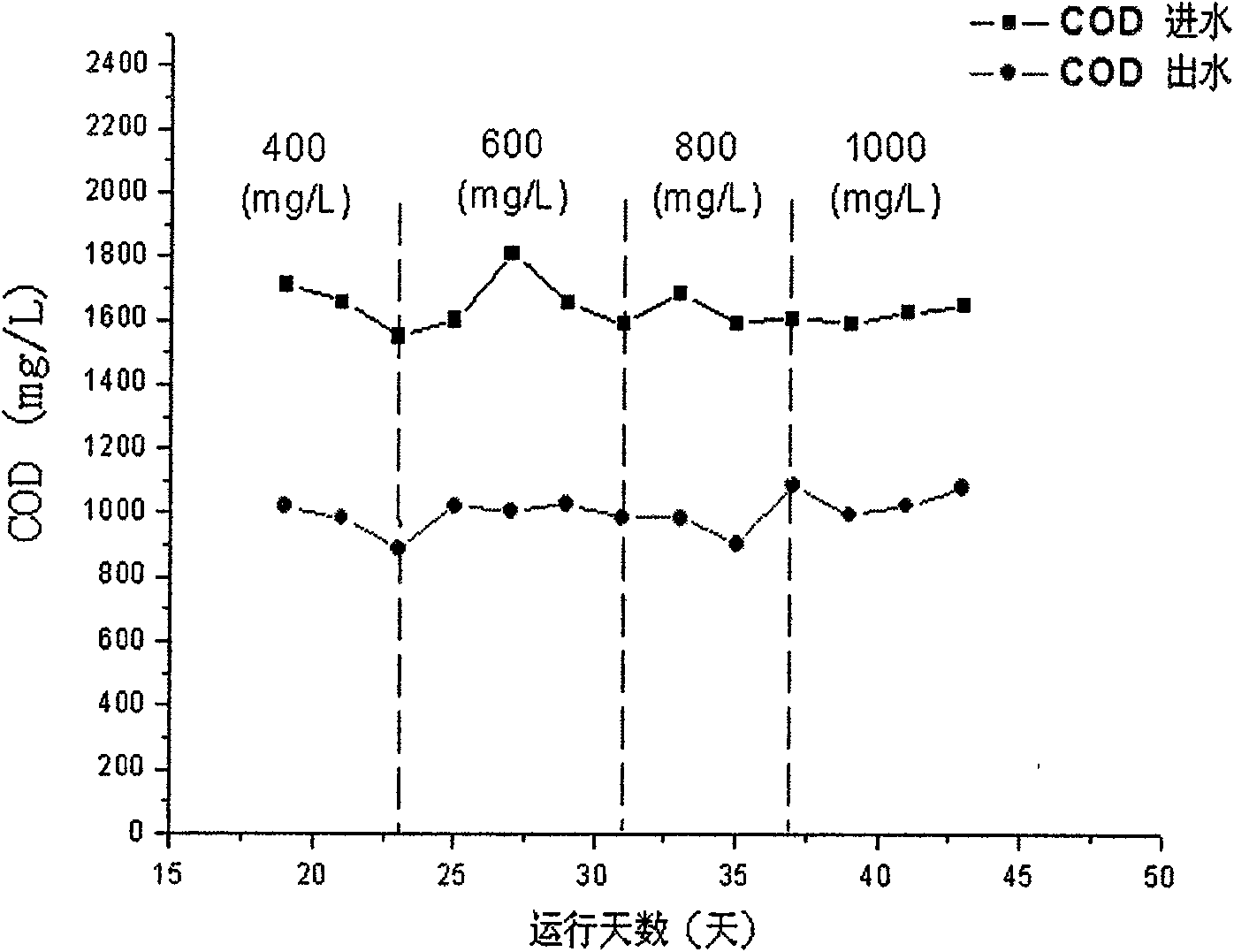

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

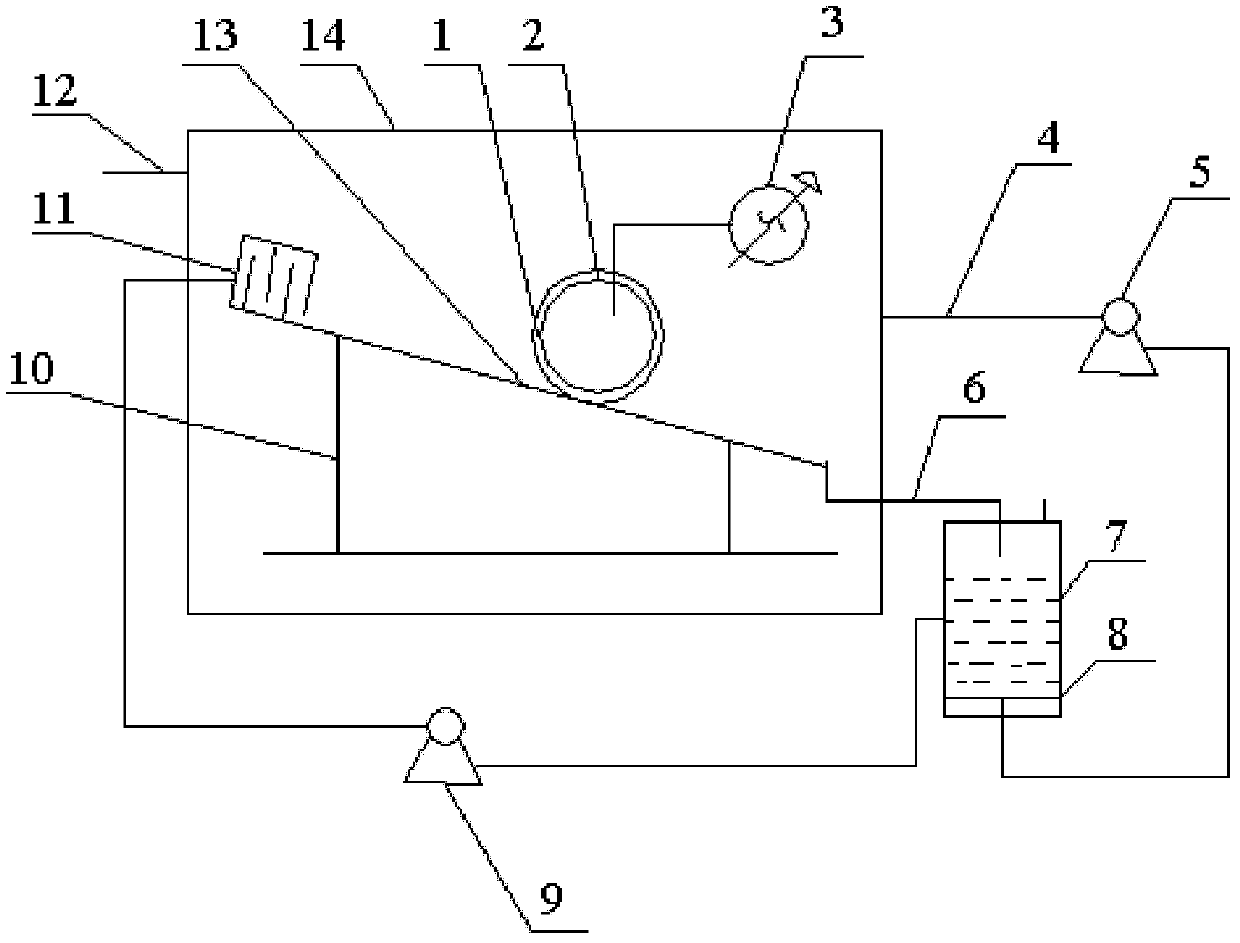

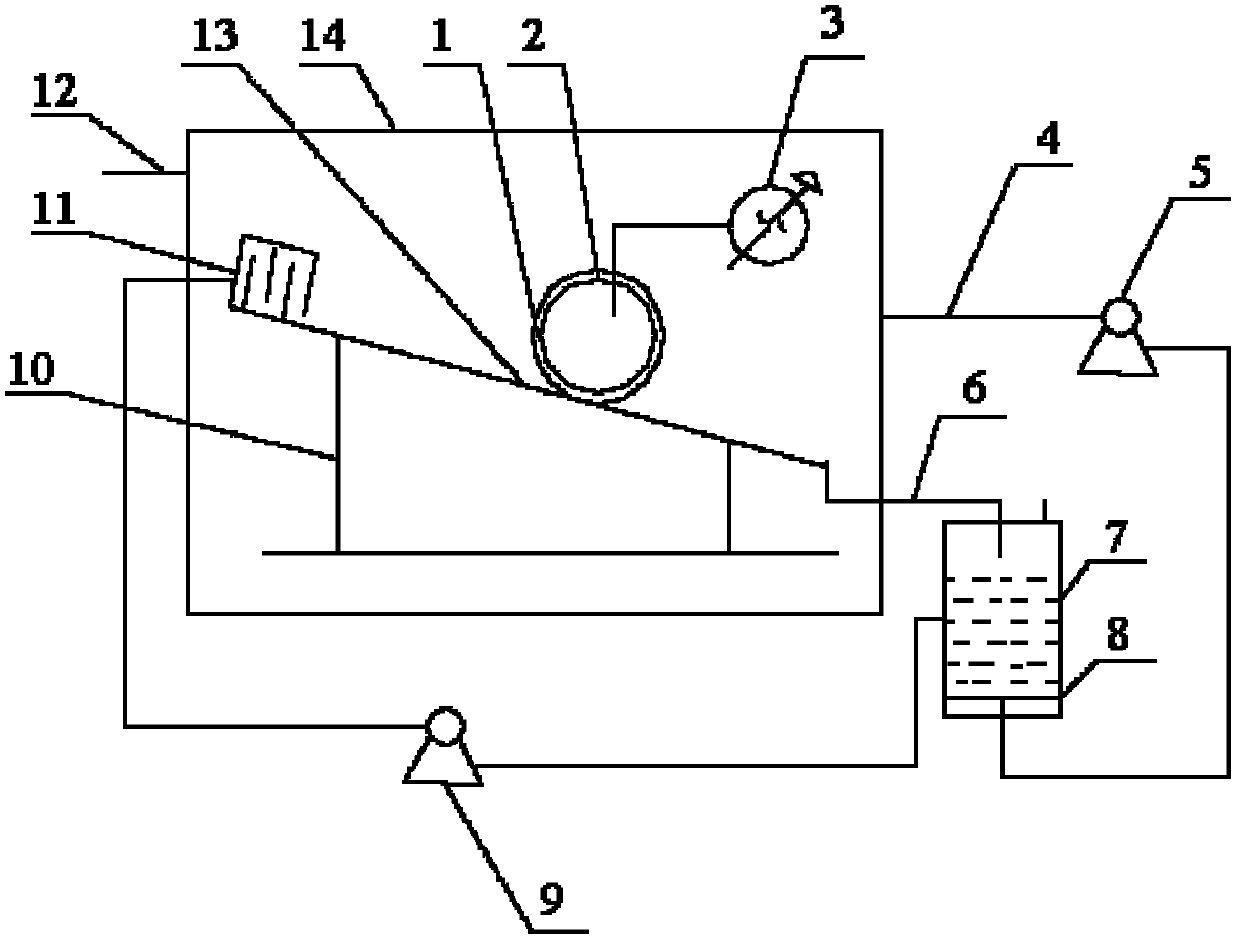

Detection box used for detecting light transmittance of printing and dyeing wastewater

ActiveCN104034702ALonger sedimentation distanceLengthen the timePreparing sample for investigationTransmissivity measurementsControl signalTransmittance

The invention relates to detection equipment used in a printing and dyeing wastewater physicochemical treatment system, in particular to a detection box used for detecting the light transmittance of printing and dyeing wastewater. The detection box comprises a box body, a sedimentation device and a light detecting device used for detecting the light transmittance of clear liquid on the printing and dyeing wastewater. The box body is provided with an input end used for being connected with a printing and dyeing wastewater sampling water inlet tube, a first output end used for being connected with a printing and dyeing wastewater sampling water outlet tube and a second output end used for discharging sediments. The sedimentation device and the light detecting device are all placed in the box body. The detection box can be used for conducting light transmittance capacity detection on the printing and dyeing water entering the inside of the detection box, measured light intensity signals are measured to be used as usable control signals, so that the clarity of the separated clear liquid is expressed, and human eyes are replaced to observe whether the printing and dyeing wastewater is fully flocculated or not.

Owner:林丽兵

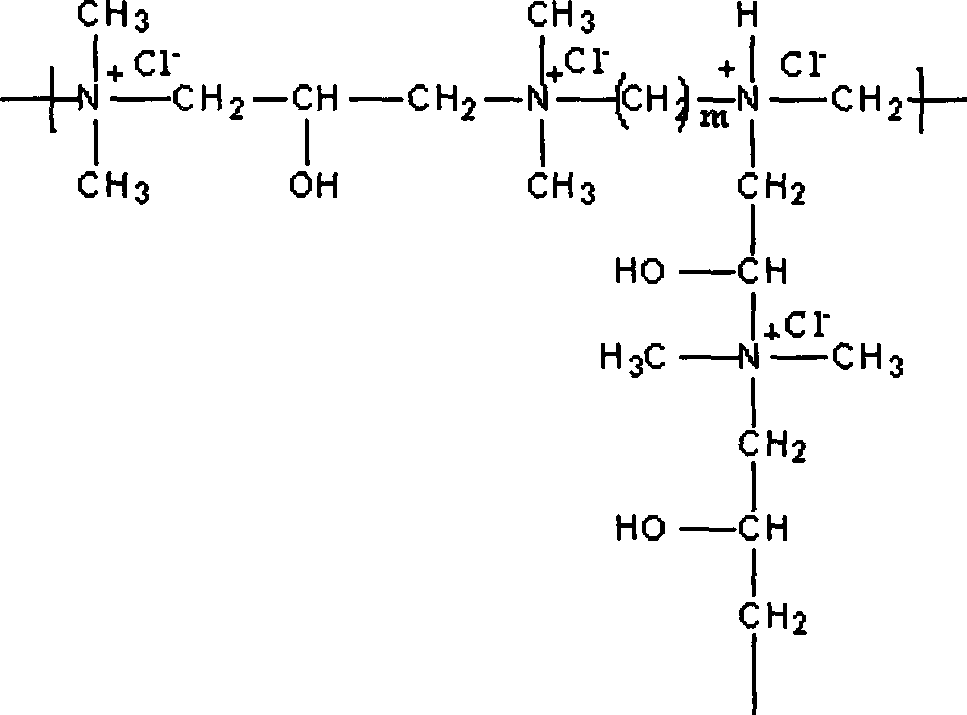

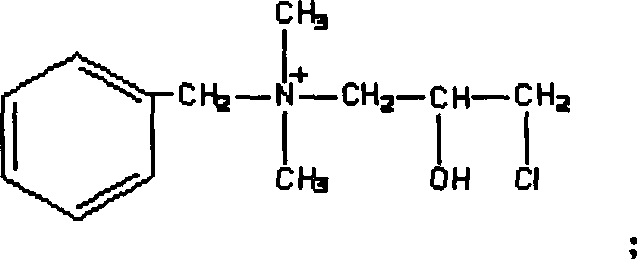

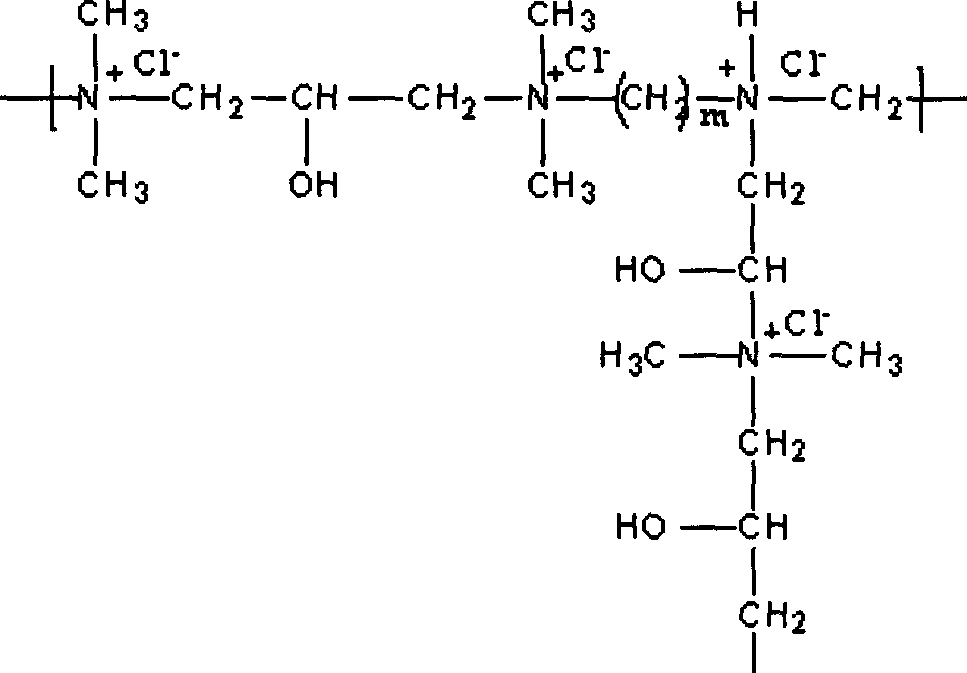

Ecological low-salt dyeing and finishing agent for reactive dyes and preparation method and applications thereof

The invention discloses an ecological low-salt dyeing and finishing agent for reactive dyes, which comprises a crosslinking cationic modifier A and a branched cationic modifier B, wherein the weight ratio of the crosslinking cationic modifier A to the branched cationic modifier B is (30-50): 50. The ecological low-salt dyeing and finishing agent for reactive dyes disclosed by the invention has the advantages that in the process of treating cotton fibers by using the crosslinking cationic modifier and the branched cationic modifier, the inner portions and surfaces of the fibers can be modified through cationization, therefore, the utilization rate of reactive dyes can be improved, and the dye-uptake rate and fixation rate of cotton fabrics are significantly higher than those in conventional dyeing; salt-free low-alkali dyeing even salt-free alkali-free dyeing can be achieved, and dyeing wastewater can be recycled for secondary utilization; and the color fastness to washing and the color fastness to rubbing are consistent with those of conventional cotton fabrics.

Owner:南通曙光染织有限公司

Composite reagent for treating recycled water of printing and dyeing wastewater and application method of composite reagent

InactiveCN104108775AAchieve efficiencyAchieve economyWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolubilityFlocculation

The invention discloses a composite reagent for treating recycled water of printing and dyeing wastewater and an application method of the composite reagent. The composite reagent comprises the following components by weight percent: 20% to 70% of aluminum salt coagulant, 5% to 30% of iron salt coagulant, 5% to 40% of mineral material and 5% to 45% of activated carbon. The method comprises the following steps: preparing the composite reagent for treating the recycled water of the printing and dyeing wastewater into powder or an aqueous liquid in which the content of effective components accounts for 5% to 30%; regulating a pH value of effluent in a printing and dyeing wastewater biochemical system to be within 3 to 9; adding the powder or the aqueous liquid of the composite reagent into the effluent in the printing and dyeing wastewater biochemical system under the condition that the adding quantity of the effective components is between 20mg / L and 1000mg / L after the pH value of the effluent is regulated; and stirring for 0.2 to 2 hours and then standing so as to obtain the recycled water conforming to the water quality standard in textile industry. According to the method, macromolecular colloidal pollutants in the biochemical effluent of the printing and dyeing wastewater, which are difficult to degrade, can be removed by utilizing the coagulation / flocculation performance of aluminum salts and iron salts in the composite reagent; and meanwhile, soluble inert pollutants in the wastewater are removed by utilizing the adsorbability of the activated carbon and the mineral material in the composite reagent.

Owner:HANGZHOU DIANZI UNIV

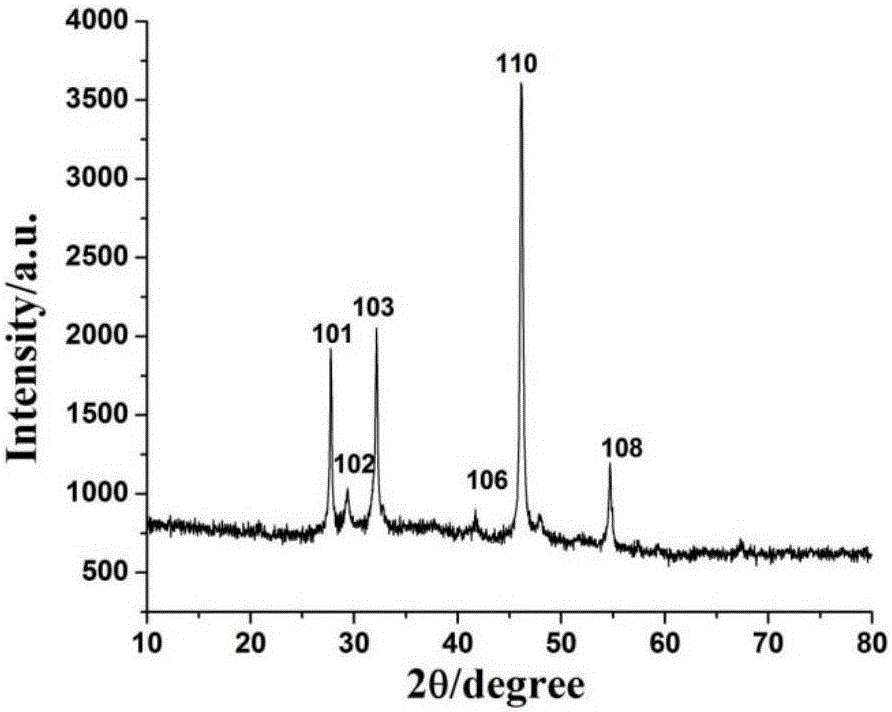

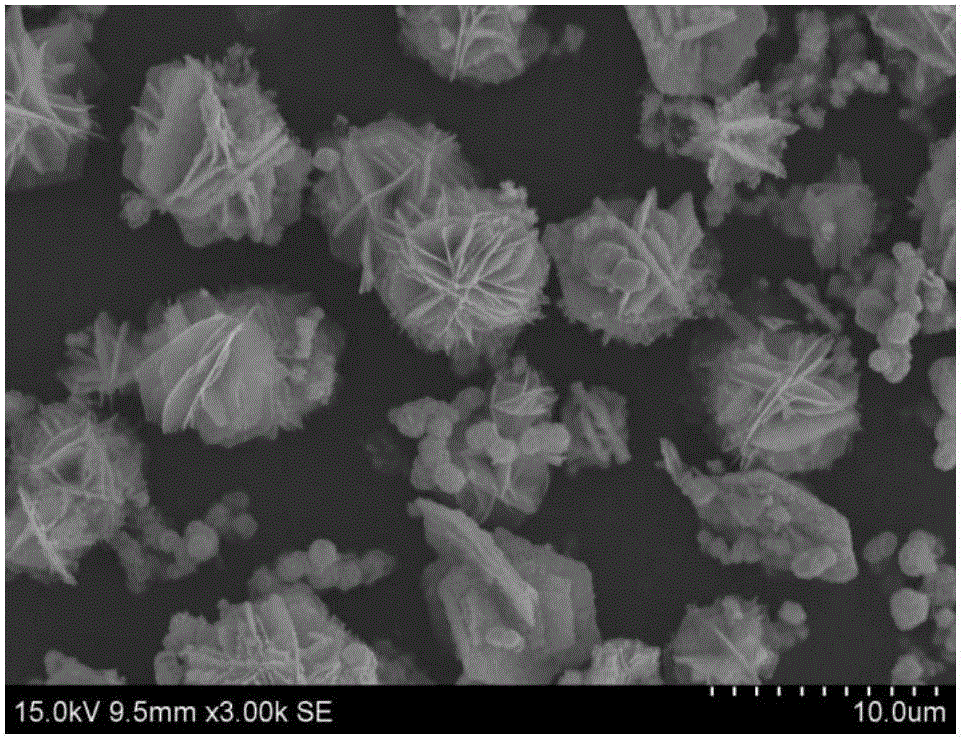

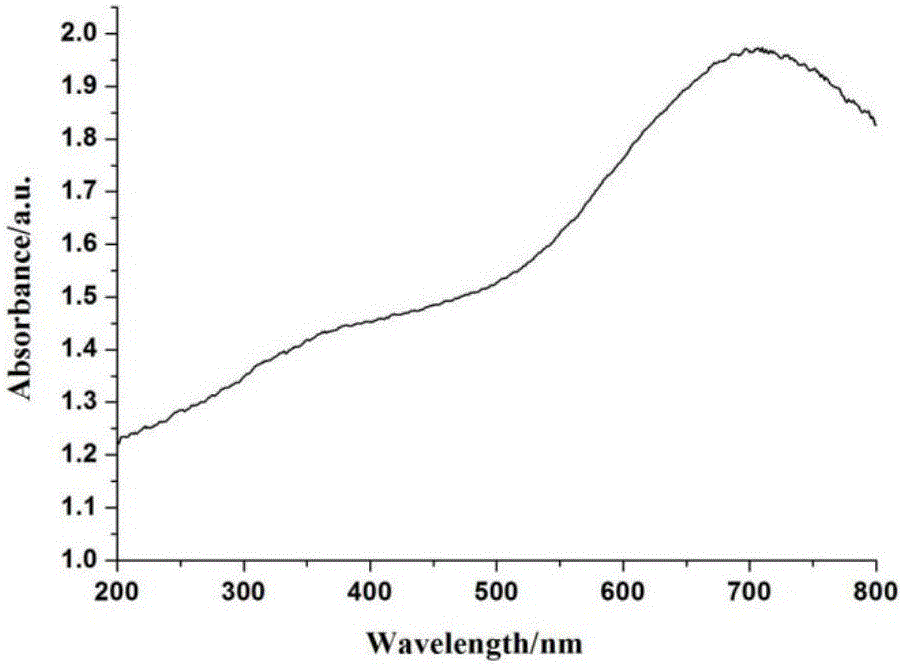

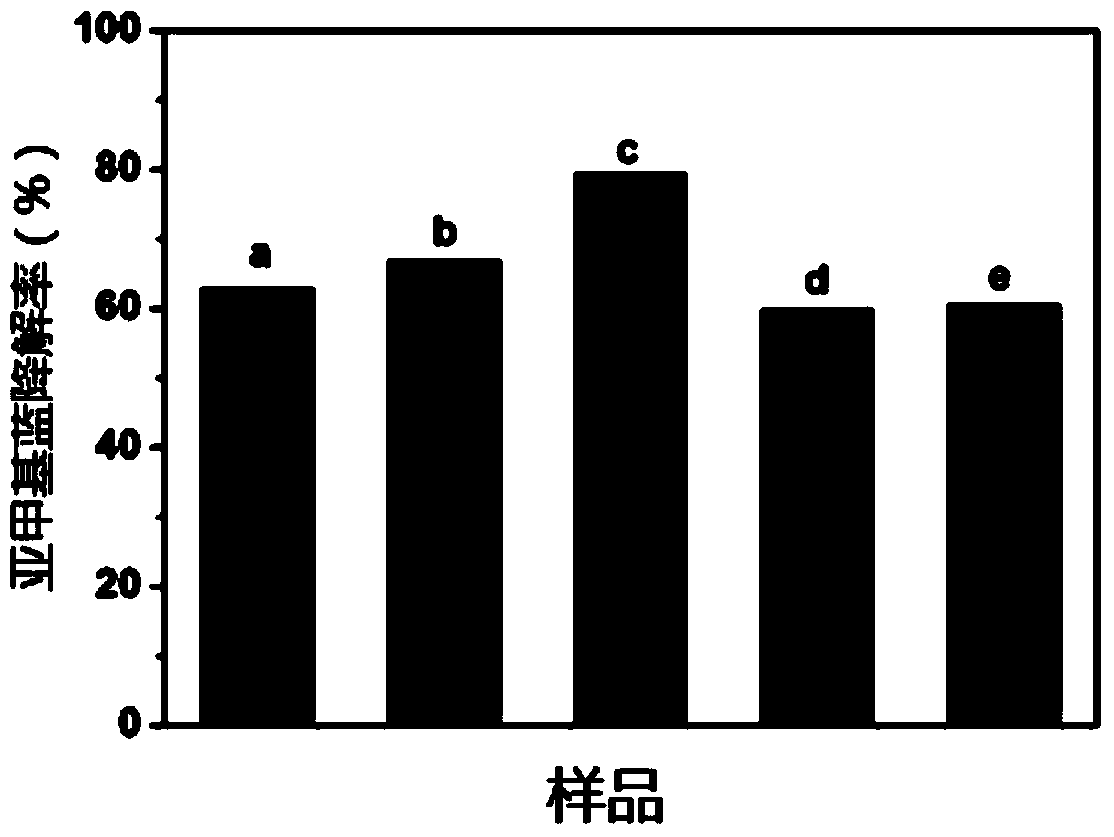

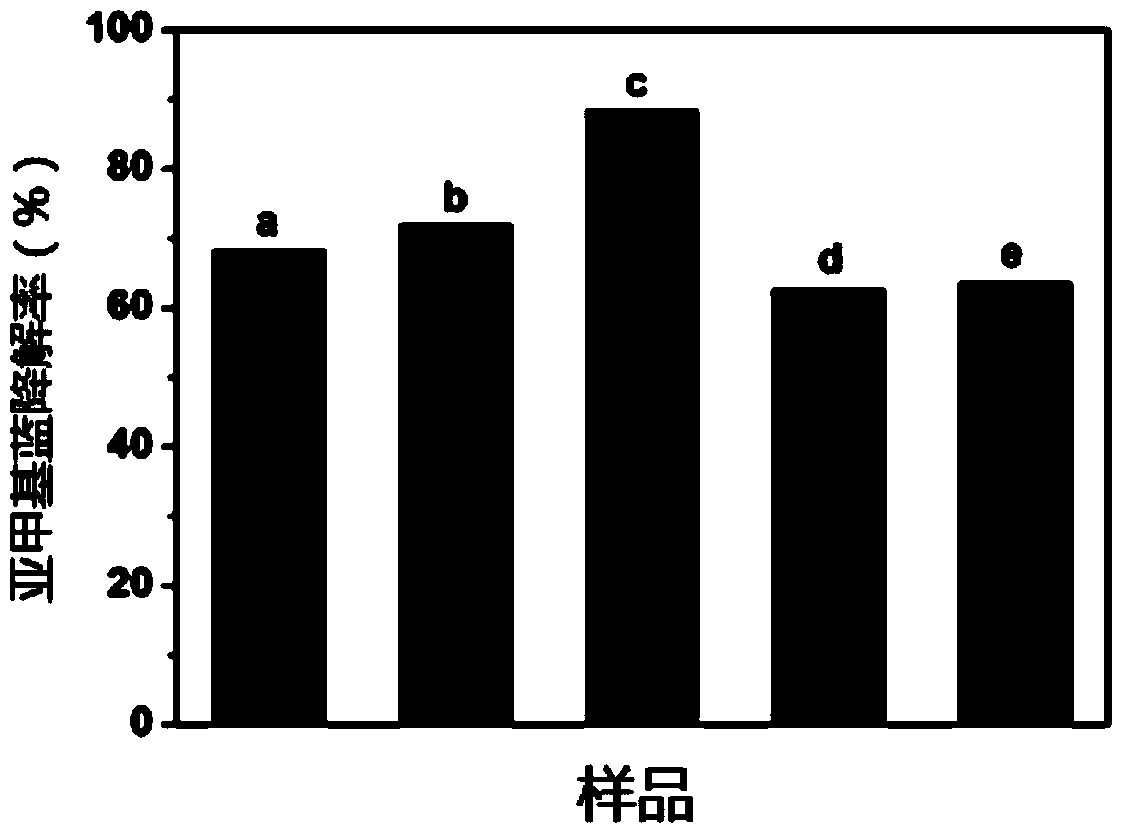

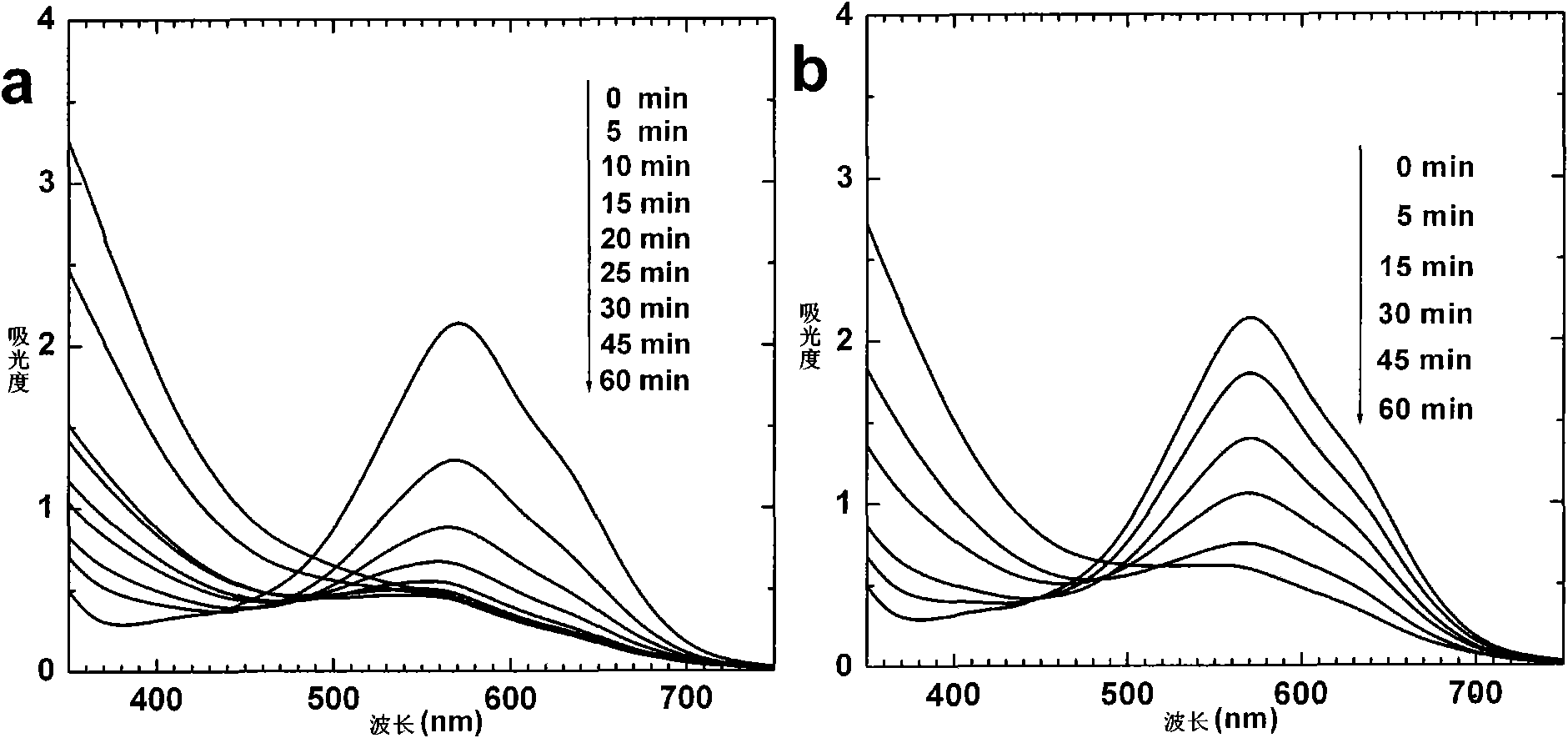

Flower-like structured CuS material as well as preparation method and application thereof

InactiveCN106082303AThe synthesis process is simpleModerate speed of self-assemblyPhysical/chemical process catalystsWater/sewage treatment by irradiationDyeing wastewaterPhotocatalytic degradation

The invention relates to a flower-like structured CuS material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a cupric compound and a solvent, and sufficiently stirring the components at certain temperature so as to obtain a homogeneous solution; under acute stirring, slowly adding a sulfur-containing compound into the homogeneous solution, and performing temperature-keeping treatment; transferring the solution into a hydrothermal reaction kettle, and performing a sealed heating reaction at certain temperature, performing cooling till the room temperature, performing filtration and collection, washing the product, performing filtration again, performing vacuum drying, and grinding the product, thereby obtaining a black product, that is, the flower-like structured CuS material. The flower-like structured CuS material can be applied to photocatalytic degradation dye wastewater. Compared with the prior art, the flower-like structured CuS material is wide in visible light response range of CuS, and high in visible light utilization rate.

Owner:SHANGHAI UNIV OF ENG SCI

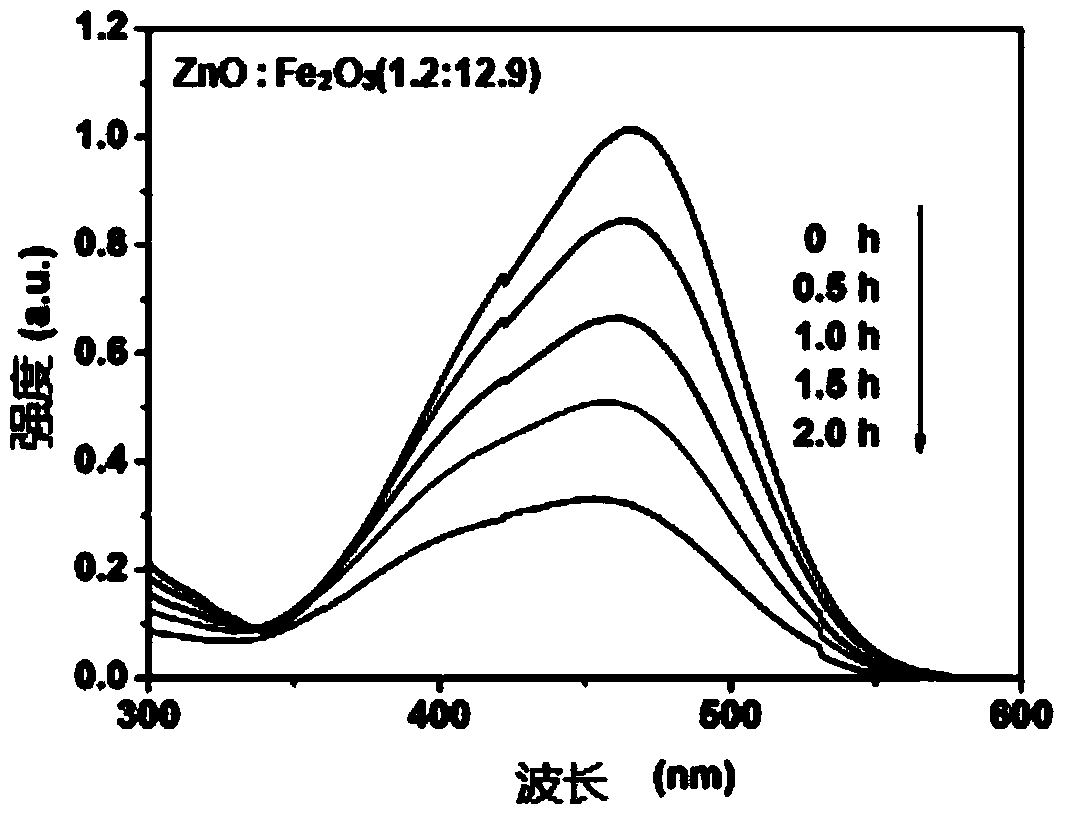

Novel C3N4/ZnO/Fe2O3 composite photocatalyst and preparation method as well as application thereof

ActiveCN103736514AWide absorption wavelength rangeIncrease profitPhysical/chemical process catalystsWater/sewage treatment by irradiationHazardous substanceCarbon nitride

The invention discloses a novel C3N4 / ZnO / Fe2O3 composite photocatalyst and a preparation method thereof. The method comprises the following steps: preparing a carbon nitride (C3N4) catalyst and a ZnO / Fe2O3 catalyst, then mixing according to the proportion, grinding and preparing the C3N4 / ZnO / Fe2O3 composite photocatalyst. The novel C3N4 / ZnO / Fe2O3 composite photocatalyst has the advantages that the photocatalytic efficiency is high, photocatalysis can be carried out in the range of ultraviolet band and visible light wavelength, the application range is wider, high-efficiency degradation can be carried out on wastewater, especially pollutants in the dye wastewater, the degradation is thorough and the used time is short; the method is simple in operation, mild in reaction condition, does not use toxic and harmful substances as materials, and is green and environment-friendly, thus avoiding secondary pollution.

Owner:安徽丰华医药包装有限公司

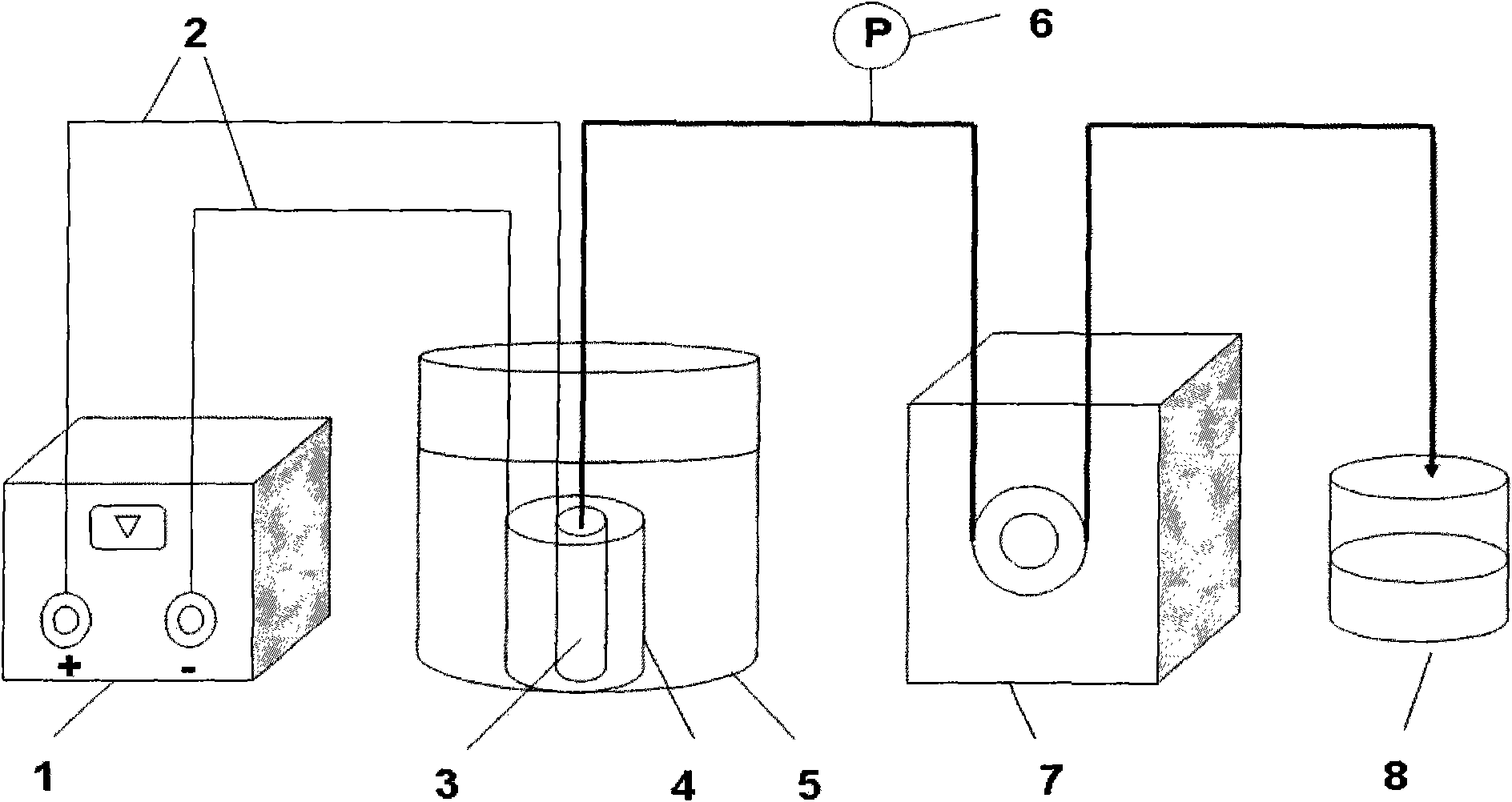

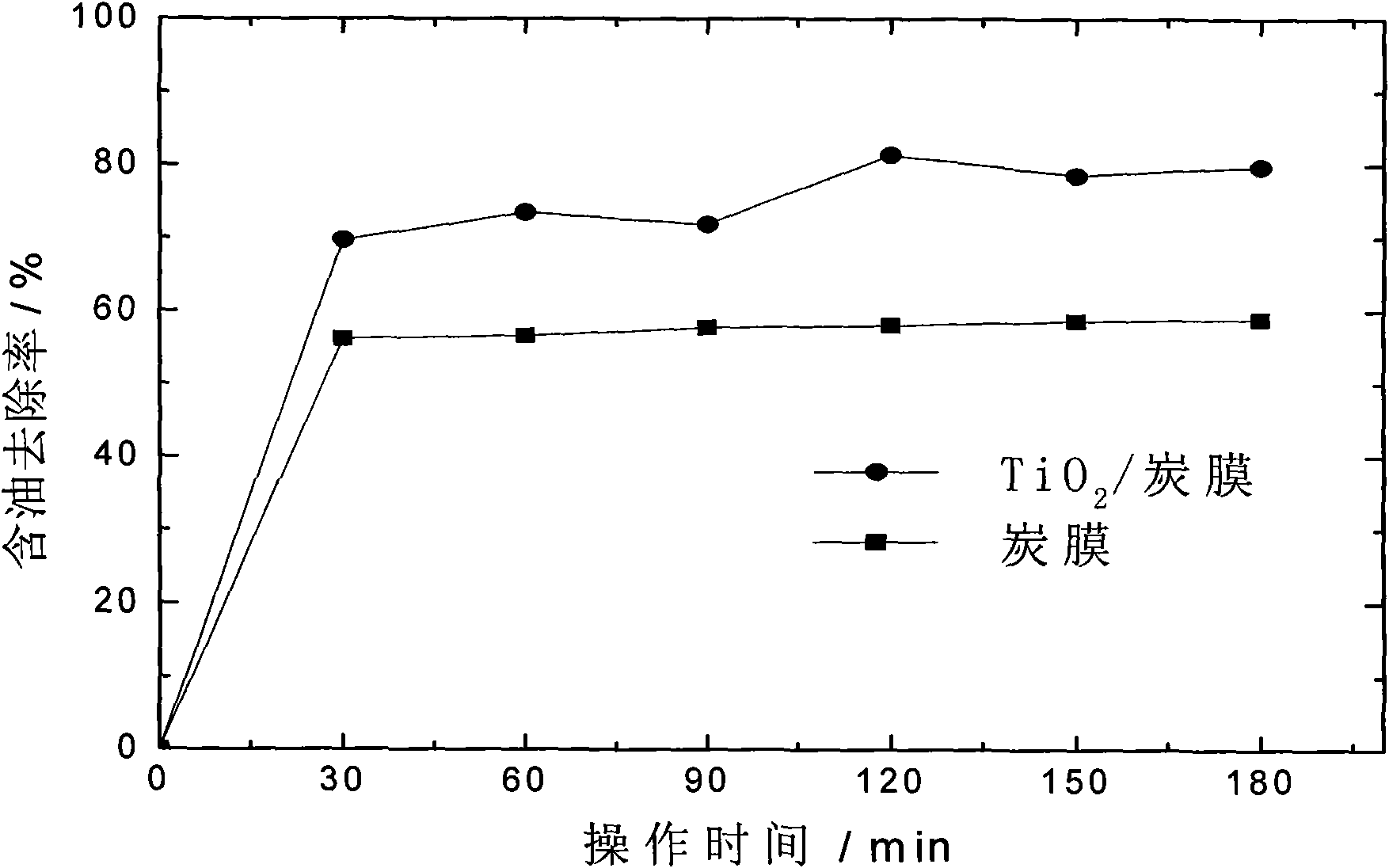

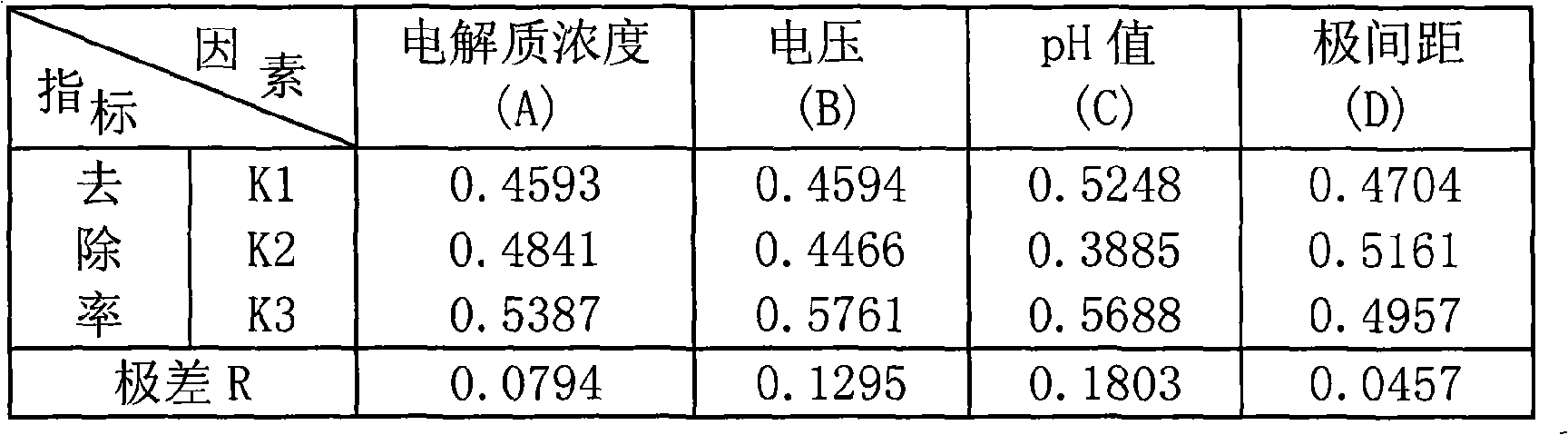

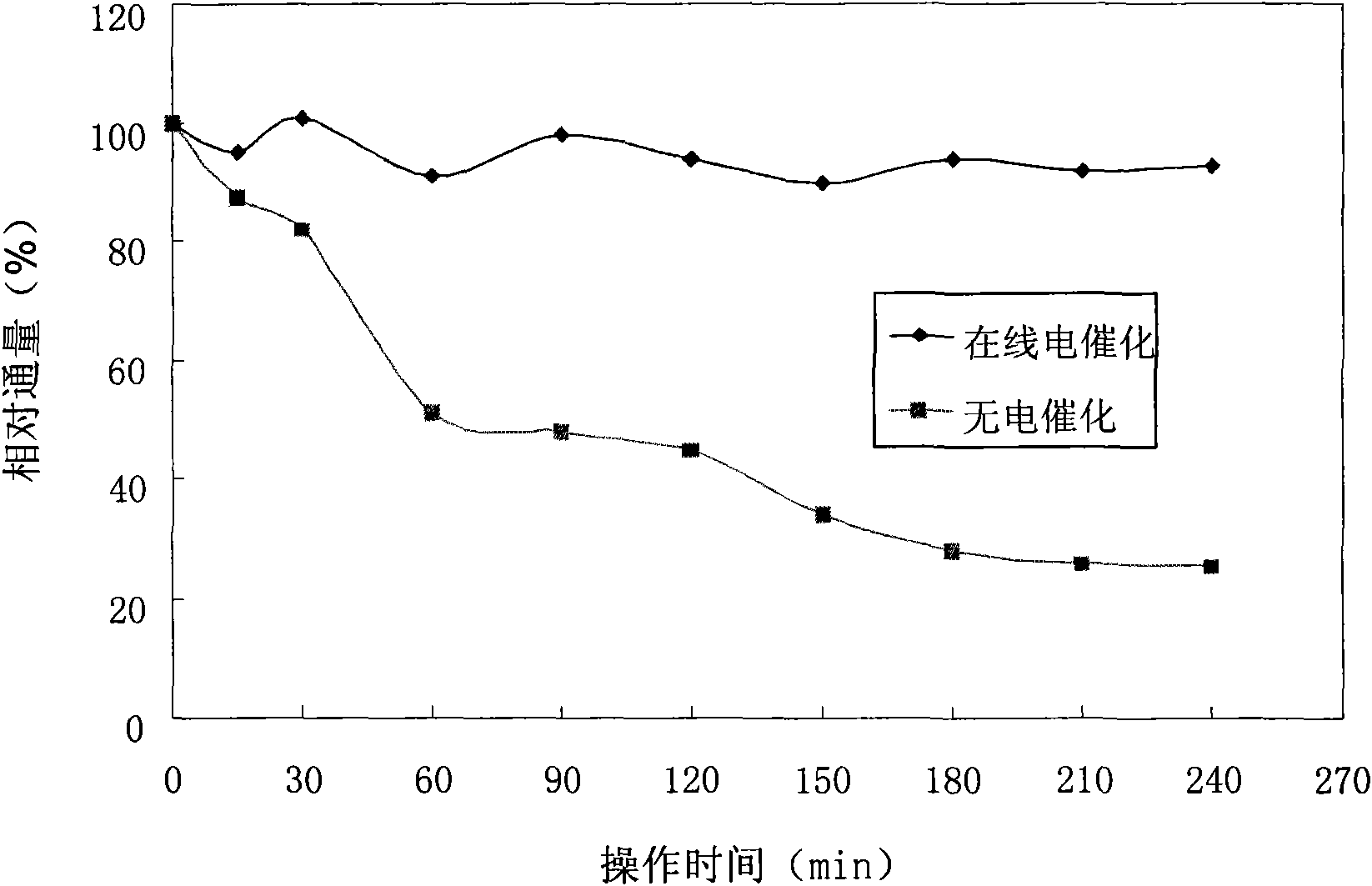

Electro-catalytic membrane reactor device

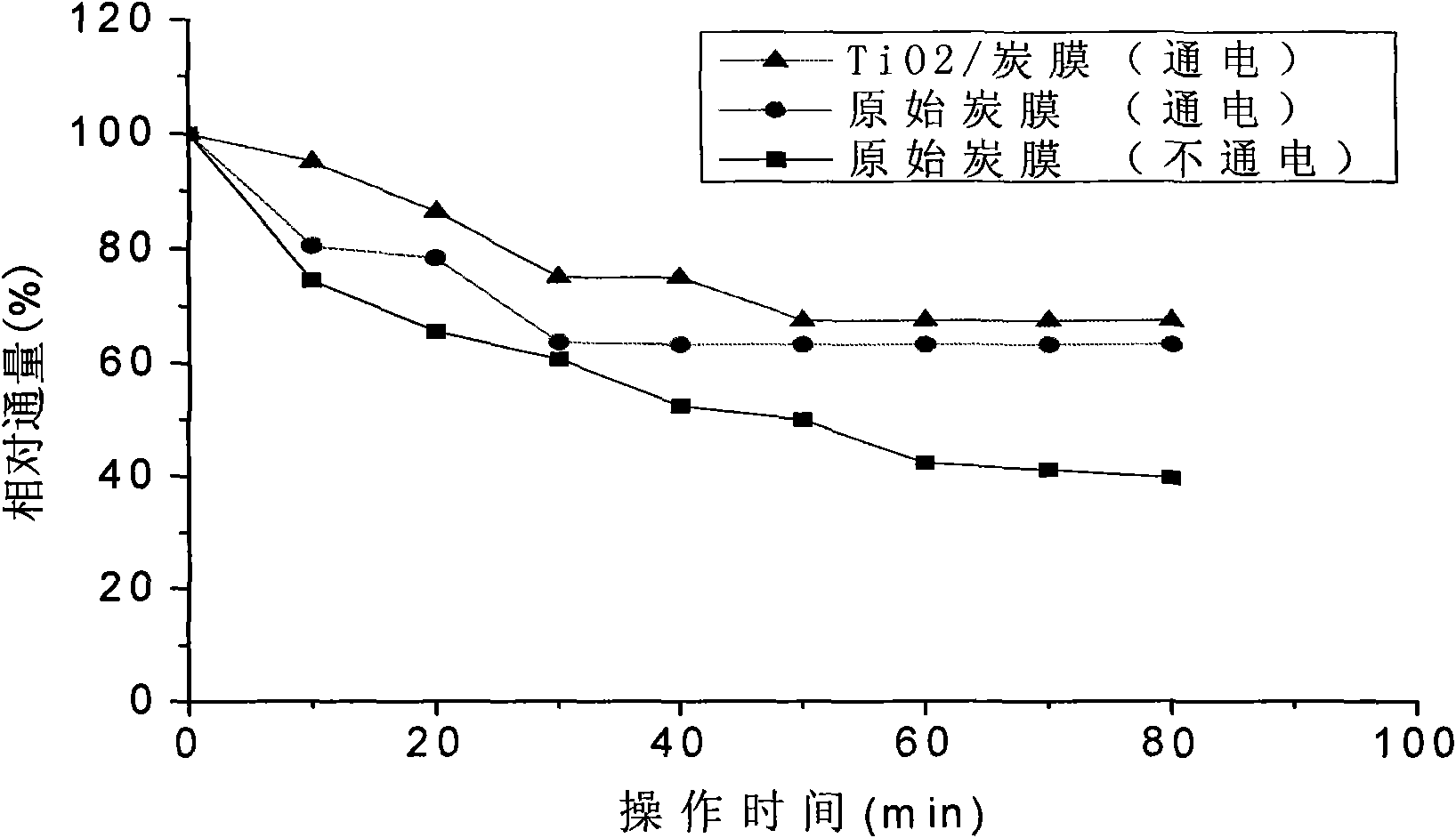

InactiveCN101597096AImprove electrocatalytic activitySimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPeristaltic pumpElectrolysis

The invention describes an electro-catalytic membrane reactor device, which is characterized in that the device can couple the membrane separation technology and electro-catalysis technology for wastewater treatment, thereby solving the problem of membrane pollution and realizing self-cleaning function of the membrane. The reactor device comprises a feed liquid tank, an electro-catalytic composite membrane, an auxiliary electrode, a regulated power supply, a vacuum gauge, a peristaltic pump and the like; wherein, the electro-catalytic composite membrane is a novel membrane material prepared by taking a microporous carbon membrane as a matrix and a metal or metallic oxide as a catalytic coating layer; one end of the electro-catalytic membrane is closed and the other end thereof is connected with the peristaltic pump through a pipeline; the pump continuously supplies negative pressure so that the feed liquid permeates a separation membrane and seeps from outside to inside along the pipeline; meanwhile, the electro-catalytic composite membrane is taken as the anode and the auxiliary electrode is taken as the cathode; the electro-catalytic composite membrane and the auxiliary electrode are respectively connected with the regulated power supply by leads to form an electrolysis device. By applying voltage to the composite membrane in the process of membrane separation, the organic pollutants deposited on and adhered to the surface and holes of the membrane are electrolytically oxidized to realize antipollution of the membrane. The reactor device has the advantages of simple device, convenient operation, high efficiency, small energy consumption and the like, and can be widely used for treatment and reuse of such industrial wastewater as oily wastewater, dye wastewater, papermaking wastewater and the like.

Owner:大连华鑫源科技发展有限公司

Device for treating dye wastewater by dielectric barrier discharge technology and method thereof

InactiveCN102603029AEfficient degradationEasy to operateWater/sewage treatment by irradiationWaste water treatment from textile industryHigh energyUltraviolet lights

The invention relates to a device for treating dye wastewater by a dielectric barrier discharge technology and a method thereof. Uniform grooves are processed on a surface of a metal negative plate to make dye wastewater formed into a uniform liquid film on the surface of the negative plate; a metal column closely clings to a dielectric barrier inner wall to form a sleeve structure, the distance between the sleeve and the negative plate is adjusted to form dielectric barrier discharge between the negative plate and a high-voltage electrode, and pollutants are degraded by O3, .OH, H2O2, high-energy electrons, ultraviolet light and the like generated in the discharge process; unused ozone and other active substances generated in reaction are injected into a container through a micropore aeration device so as to further degrade organic matter in the dye wastewater; and in addition, Mn2+, Cu2+, Zn2+, Co2+ and other metal ions or MnO2, FeOOH, TiO2, active carbon and other heterogeneous catalysts are added into the reaction container to strengthen a treatment effect.

Owner:DONGHUA UNIV

Preparation method for adsorbent for treating dye wastewater

InactiveCN103551124ALow costWide variety of sourcesOther chemical processesWaste water treatment from textile industryFiberCongo red

The invention discloses a preparation method for an adsorbent for treating dye wastewater, and particularly discloses a preparation method for a biomass adsorbent for treating anionic dye wastewater. The adsorbent is prepared by pretreating sugarcane bagasse, performing alkali activation and oxidization treatment, and then grafting a hyperbranched polyamidoamine polymer. The preparation method comprises the following steps: (1) performing pretreatment, alkali activation and oxidization treatment on sugarcane bagasse fiber; (2) grafting the oxidized sugarcane bagasse fiber with the hyperbranched polyamidoamine to obtain the polyamino-modified sugarcane bagasse-based adsorbent. The prepared adsorbent has the characteristics of being good in stability, good in adsorption effect, wide in application range and the like, and can be used for treating the anionic dye wastewater. Taking Congo red dye wastewater for example, the Congo red adsorption capacity and adsorption efficiency of the adsorbent respectively achieve 240mg / g and 97%. The prepared adsorbent is wide in raw material source, low in price and easily available, low in cost, convenient to operate when being applied to wastewater treatment, and simple in technology.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

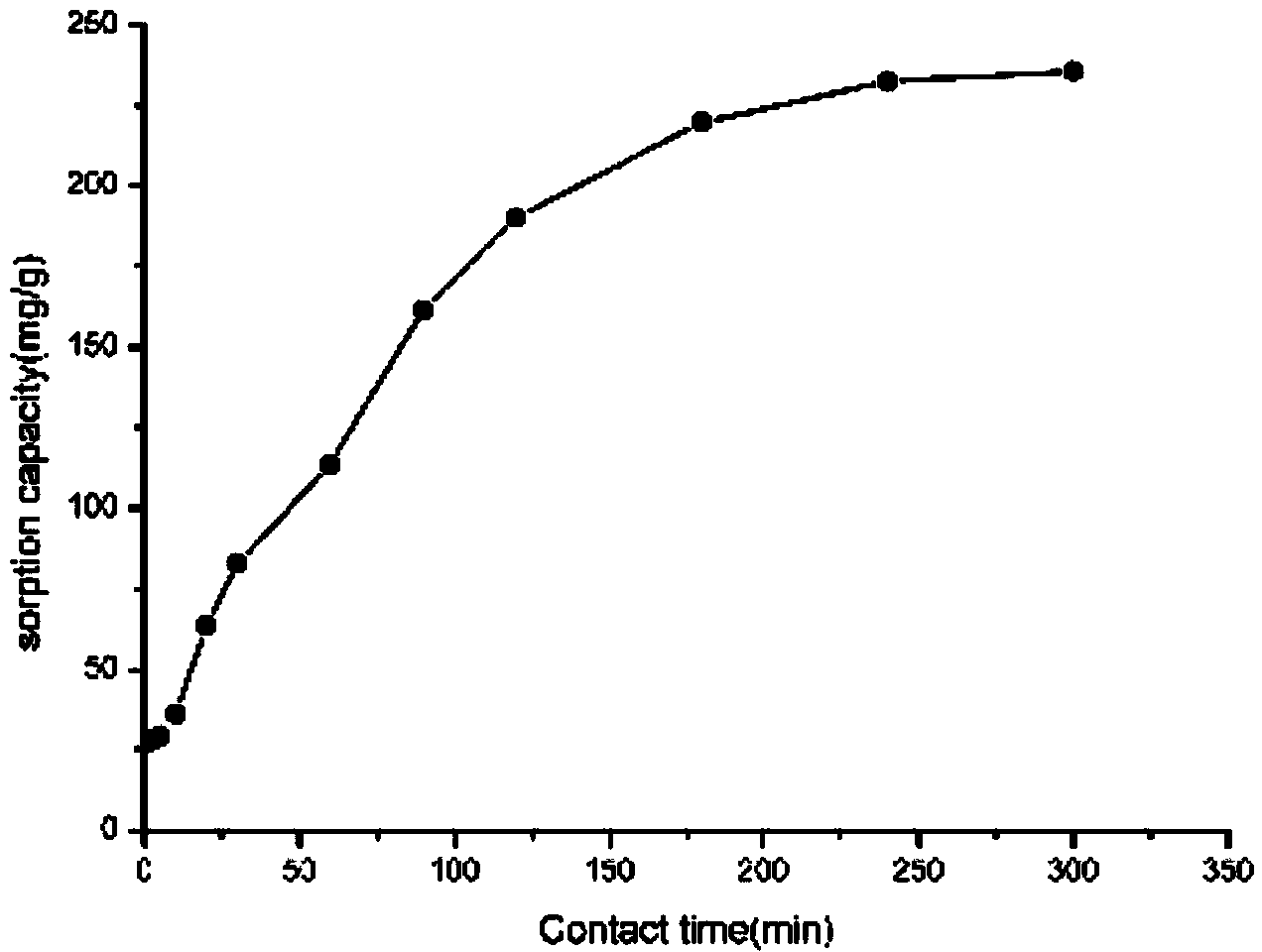

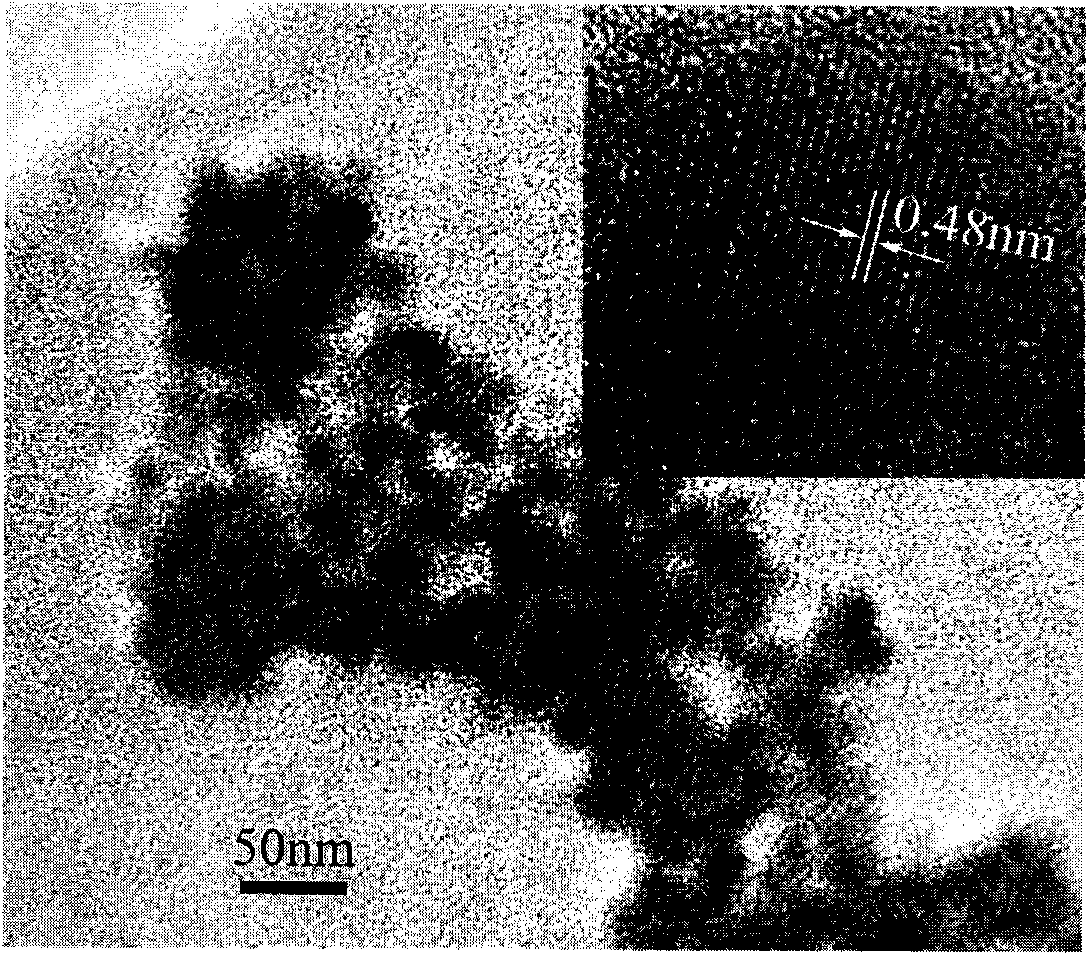

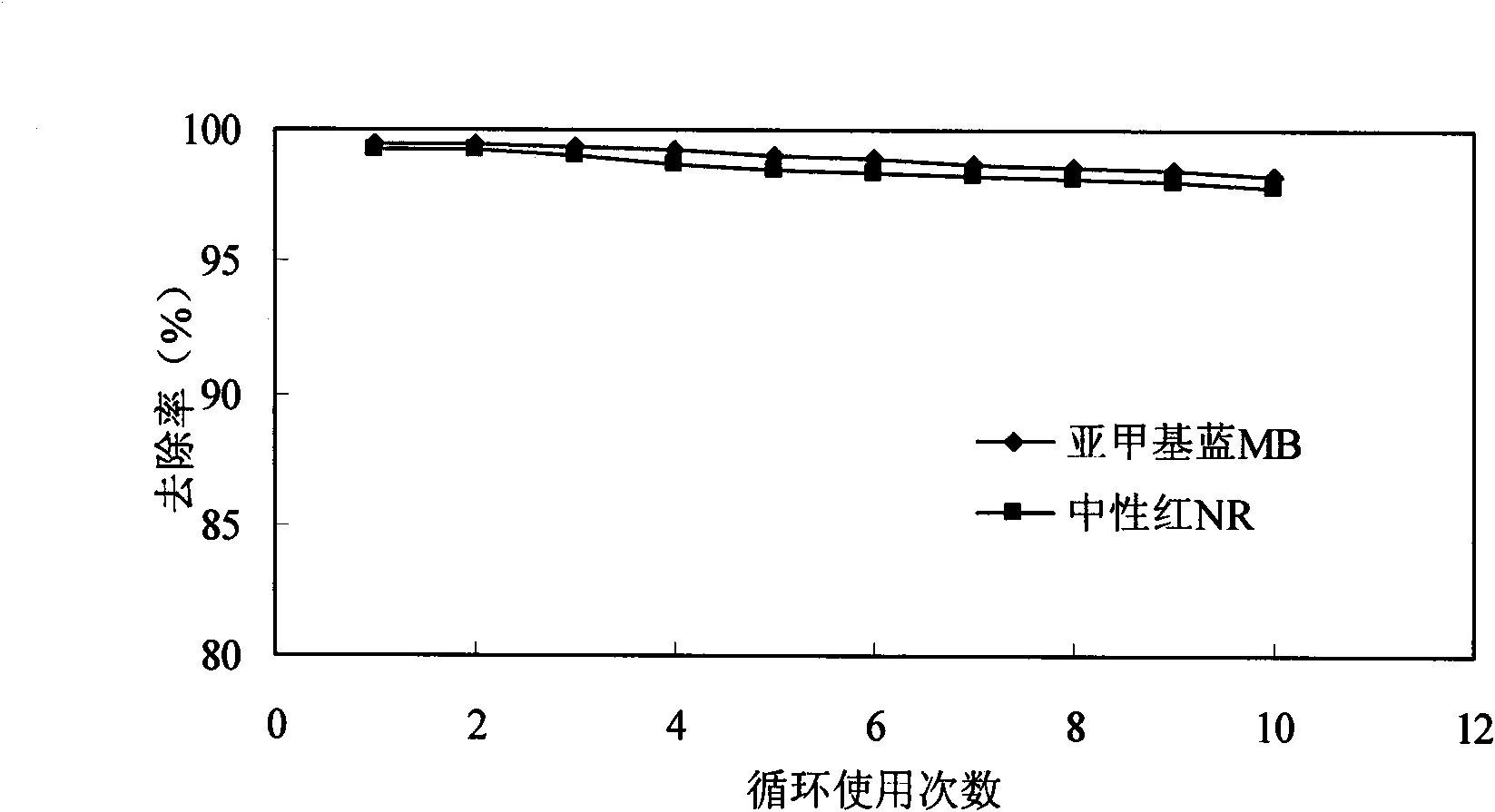

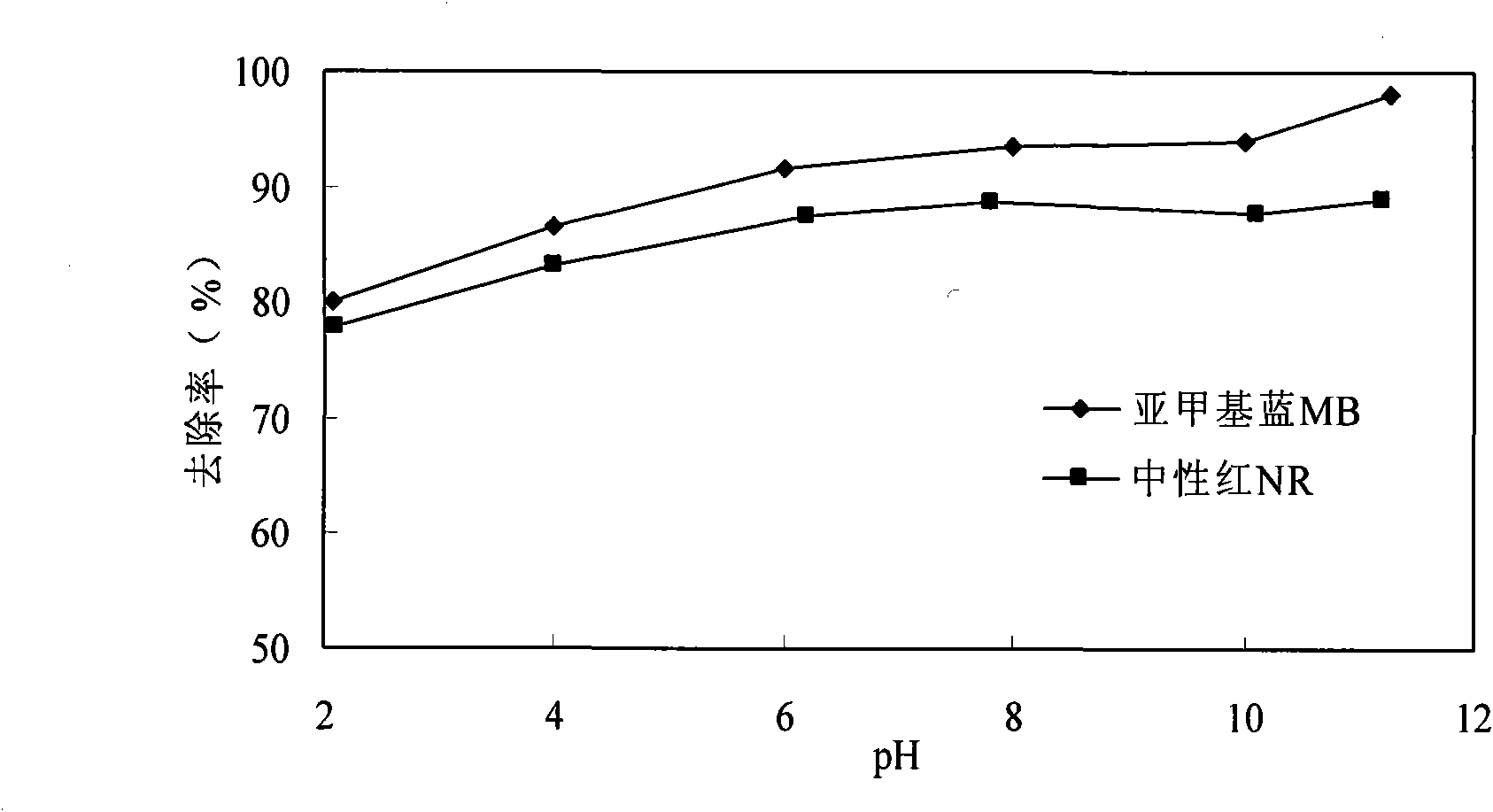

Method for removing organic cationic dyes from waste water by magnetic nano adsorption material

InactiveCN101670266AReduce internal diffusion resistanceImprove adsorption capacityOther chemical processesWater/sewage treatment by magnetic/electric fieldsDesorptionSorbent

The invention relates to preparation of a magnetic nano adsorbent and a method for removing organic cationic dyes from waste water by the same, and belongs to the technical field of wastewater treatment. The magnetic nano adsorbent uses Fe3O4 particles as a carrier, and coated humic acid as an active adsorbing component. The method comprises the following steps: adding mixed solution of ferric chloride and ferrous sulfate to alkaline humic acid solution, reacting under anaerobic, heating and stirring conditions, and obtaining the magnetic nano adsorbent after magnetic separation, washing, drying and grinding. The removal rate of methylene blue and neutral red reaches more than 95% by treating organic cationic dye wastewater with the magnetic nano adsorbent. The magnetic nano adsorbent after magnetic solid-liquid separation is regenerated by methanol-acetic acid solution, a desorption solvent recovers methanol and acetic acid by distillation for recycling use. The magnetic nano adsorbent has the advantages of nanoscale size, high active surface radicals, extremely high adsorption removal rate for cationic dyes, simple process, high efficiency and easy control.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation and application of hierarchical pore metal-organic framework loaded heteropolyacid catalyst

InactiveCN107694611AGuarantee structureImprove stabilityWater/sewage treatment by irradiationWater treatment compoundsMetal-organic frameworkCatalytic oxidation

The invention discloses a preparation method and application of a hierarchical pore metal-organic framework loaded heteropolyacid catalyst. The catalyst adopts hydrothermal-extraction method for preparation. The method includes: dissolving an organic ligand, a template agent, a metal salt and Keggin type heteropolyacid in a solvent, conducting hydrothermal synthesis of a crystal product, and thenperforming Soxhlet extraction to obtain a catalyst. The obtained catalyst has a meso-micro hierarchical porous structure, realizes high dispersion of the active component heteropolyacid and ultra-highloading capacity, and at the same time solves the problems of large mass transfer resistance, long diffusion path and small reaction place in microporous materials. The catalyst provided by the invention shows excellent catalytic performance in both photocatalytic degradation of dye wastewater and catalysis of oxidation-extraction desulfurization reaction, the catalysis reaction uses visible light and hydrogen peroxide respectively, the process is clean, environment-friendly and green, and after repeated use, the catalyst still maintains high activity, and has high industrial application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

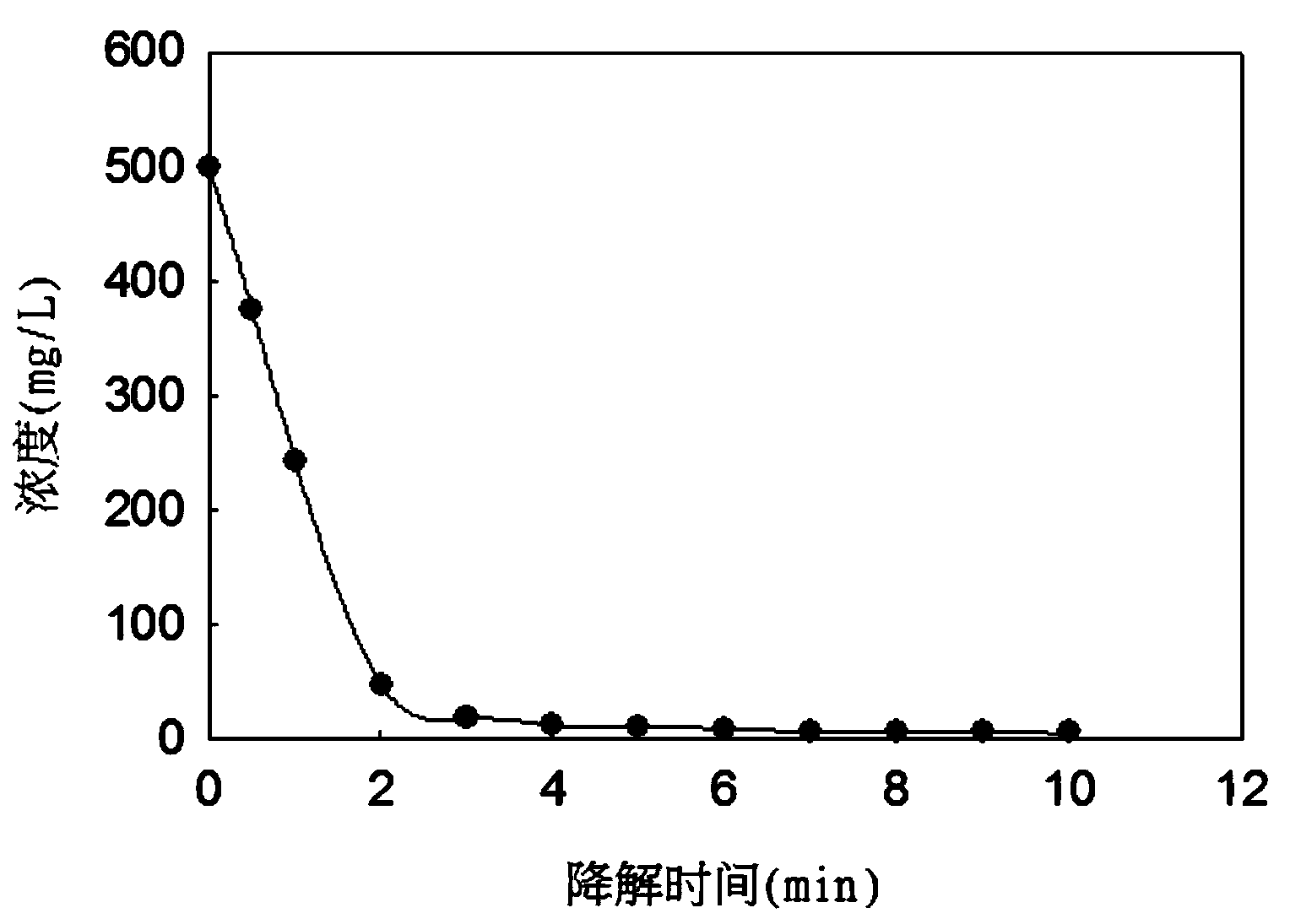

Green synthesis method for nanometer zero-valent iron by utilizing grape seeds and application thereof

ActiveCN104174870AThe method works wellGood effectMaterial nanotechnologyWater/sewage treatment by oxidationBrilliant RedGrape seed

The invention relates to a green synthesis method for nanometer zero-valent iron by utilizing grape seeds and an application, and belongs to the field of nanometer material and wastewater treatment. The preparation method is characterized in that nanometer zero-valent iron particles are prepared by taking waste grape seed extracting solution as dispersing agent and antioxidant under the condition of room temperature, and the nanometer zero-valent iron particles prepared through the method has good dispersibility and stability. The nanometer zero-valent iron particles prepared by the method are used for catalytically degrading reactive dye in wastewater, under the condition that the pH of the dye wastewater is equal to 2 to 10, more than 98% of azo-dye reactive brilliant red K-2G is degraded in 9min, more than 95% of anthraquinone dye reactive brilliant blue KN-R is degraded in 30min, and the environmental adaptability is high, and the degrading efficiency is high. The method is simple in technology, economic and efficient, resource utilization of grape seeds is realized, the synthetic nanometer zero-valent iron has extremely high activity, and the method has wide application prospect.

Owner:BEIJING UNIV OF TECH

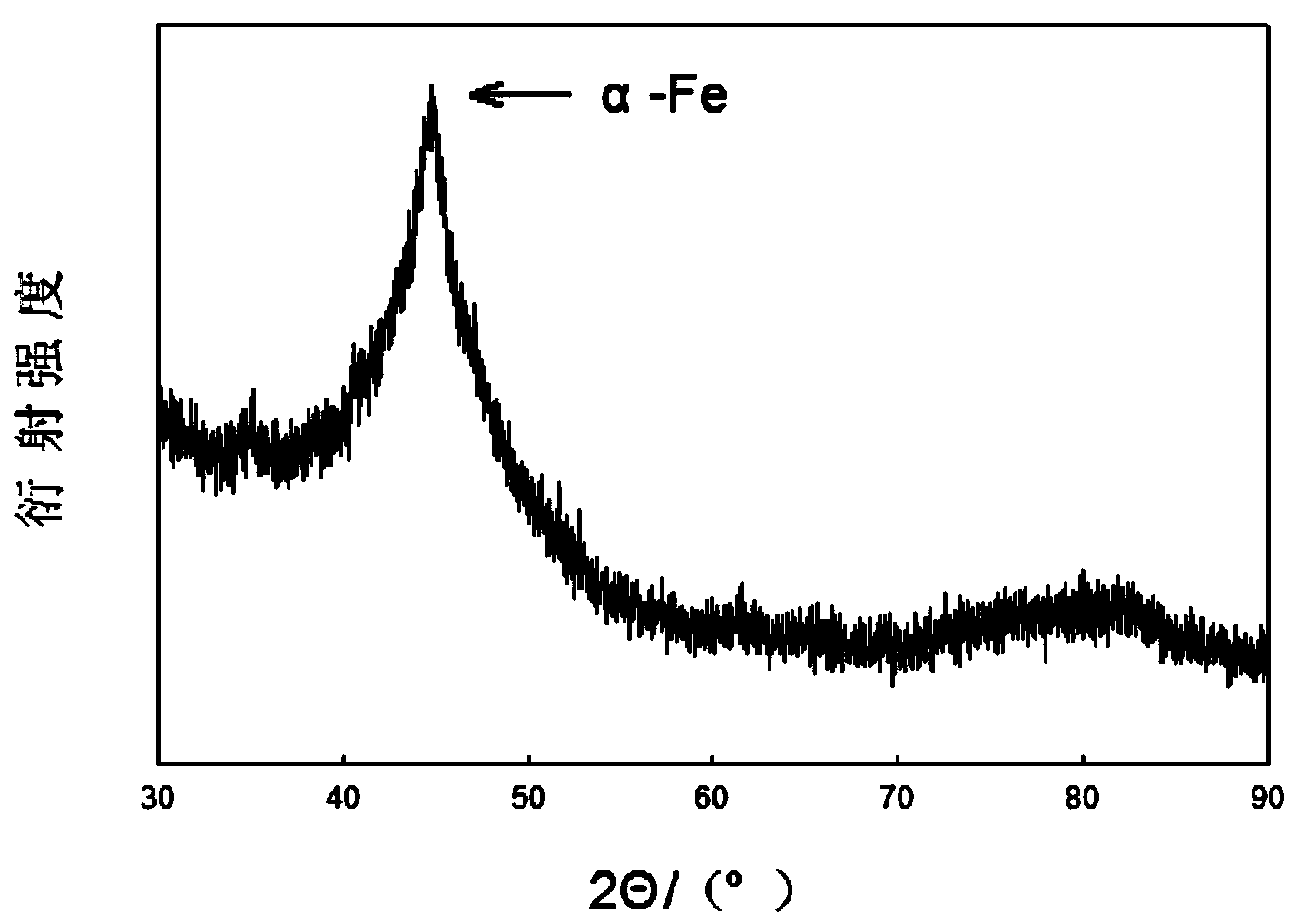

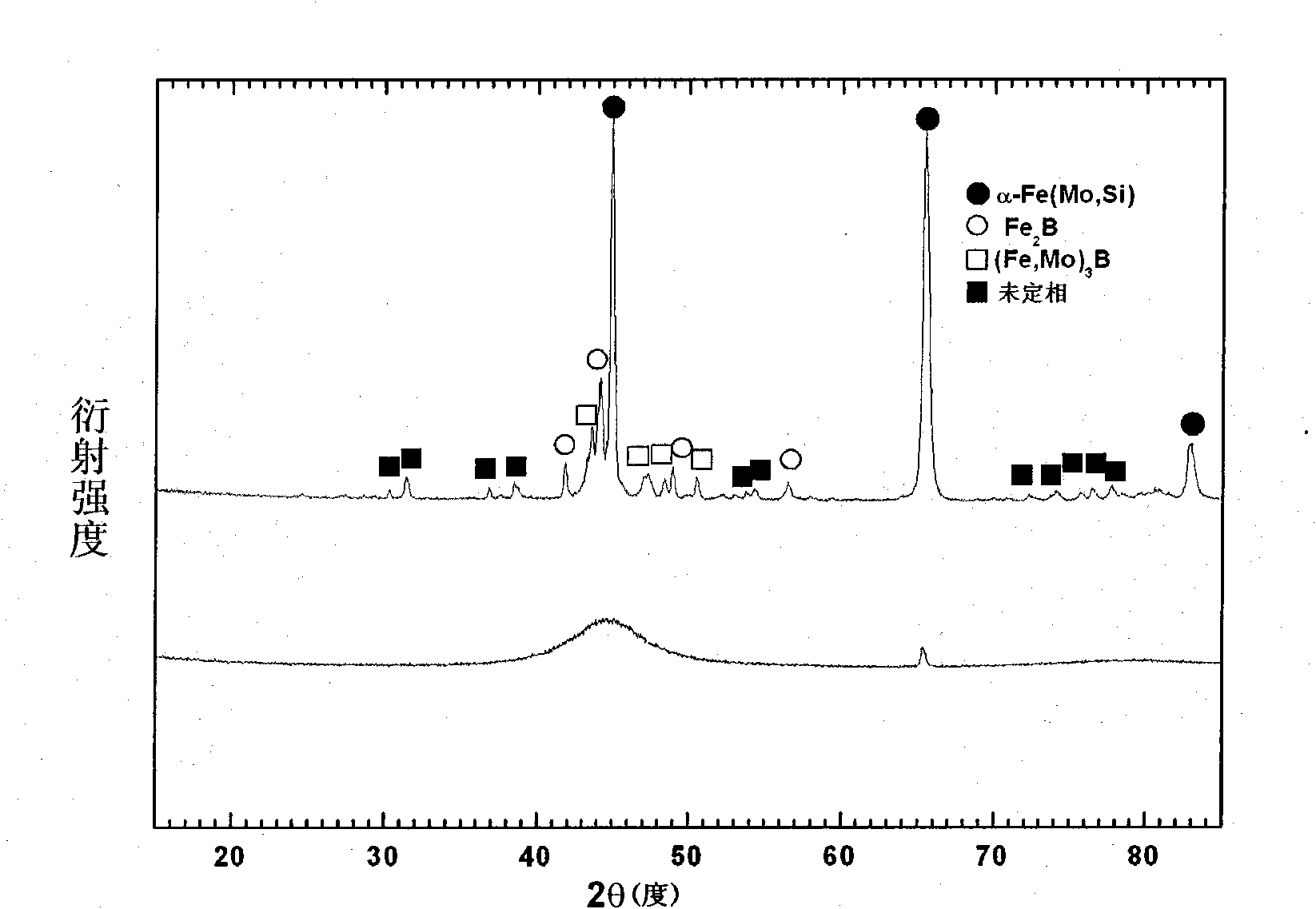

Ferrum-based amorphous alloy strip for treating printing and dyeing wastewater and preparation method thereof

ActiveCN102070236AAchieve amorphizationRetain color removal abilityWaste water treatment from textile industryWater/sewage treatment by reductionIron powderDyeing wastewater

The invention relates to a ferrum (Fe)-based amorphous alloy material, in particular to a Fe-based amorphous alloy strip for treating printing and dyeing wastewater and a preparation method thereof. According to the conventional literatures and technical data, an alloy component with Fe-based amorphous alloy strip forming capacity is selected; and general requirements show that the selected alloy component comprises more than 50 percent of Fe atoms, preferably 60 to 85 percent, so the reduction decoloring capacity of the Fe atoms is exerted. The amorphous alloy strip is obtained by adding a small amount of other elements and performing rapid solidification by using melt spinning equipment. The decrystallization of zero-valent Fe is realized by preprocessing technology; the decoloring capacity of the Fe atoms is kept; the rusting consumption of the Fe in the wastewater treatment process is effectively reduced; the strip is repeatedly and persistently utilized on the premise of guaranteeing the decoloring rate; the technical defects and the application defects in the conventional method for treating the printing and dyeing wastewater by using reducing Fe powder or waste cast Fe scraps are overcome; and the Fe-based amorphous alloy strip relates to the field of potential application of decrystallization technology in the industrial field, and has an extremely high application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

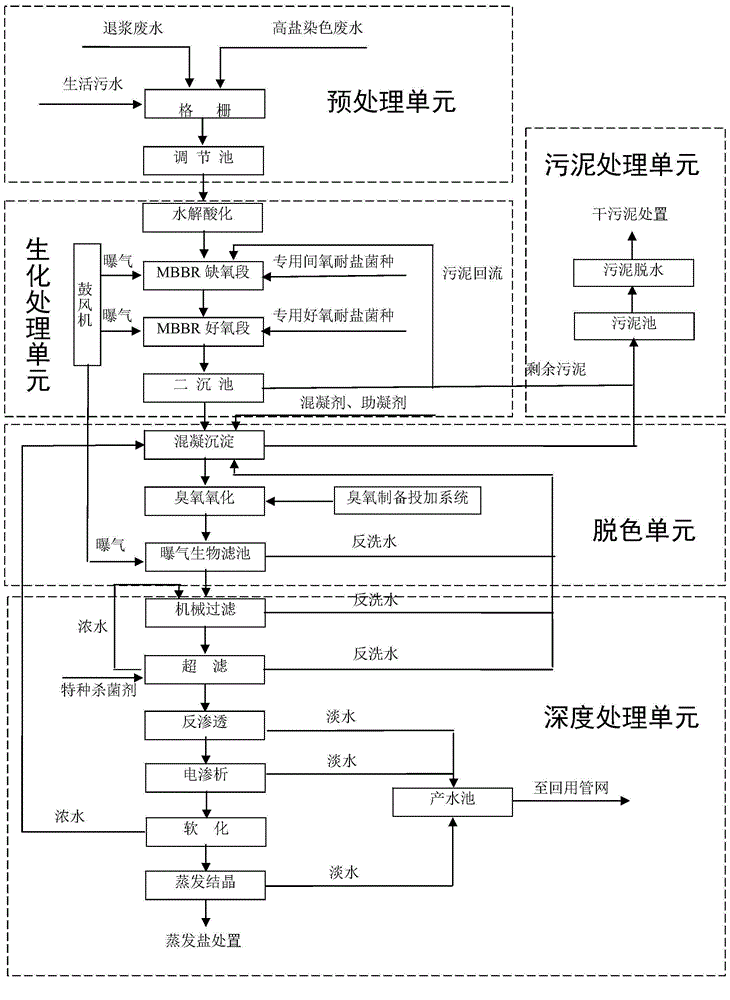

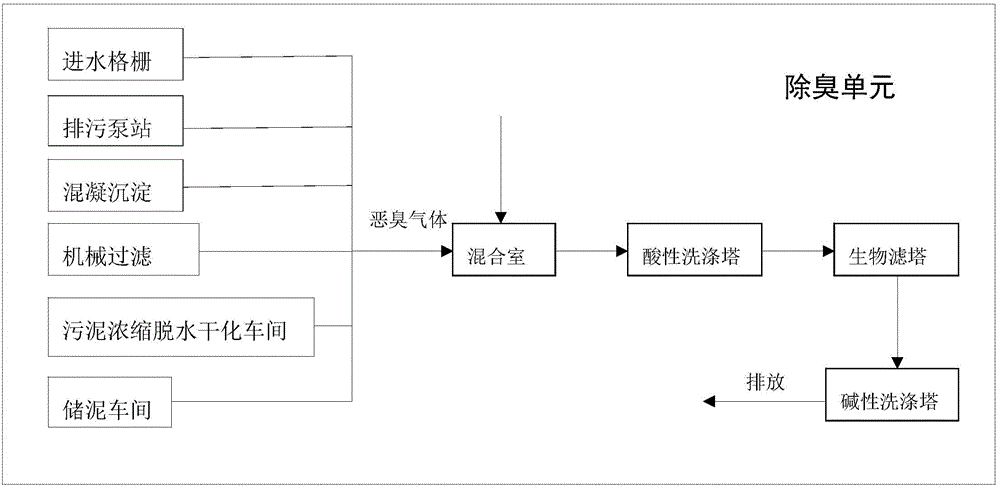

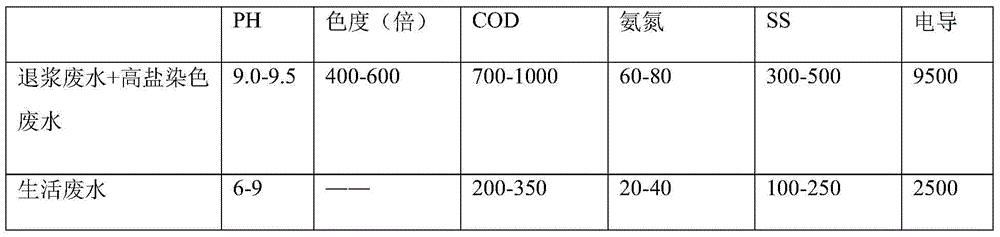

High-salt-content dyeing wastewater treatment recovery zero discharge integration method

ActiveCN104478174APromote growthAvoid emissionsSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesTextile printerSalt content

The invention belongs to the technical field of sewage treatment, and particularly discloses a high-salt-content dyeing wastewater treatment recovery zero discharge integration method. The method can perform deep treatment recovery on the high-salt-content dyeing wastewater to obtain production water for textile printing industry, thereby achieving the goal of zero discharge. The integration method is composed of a pretreatment unit, a biochemical treatment unit, a decolorization unit, an advanced treatment unit, a sludge treatment unit and a deodorizing deodorization unit. The integration method is mainly used for treating high-salt-content dyeing wastewater.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

Application and preparation method of nanometer Fe(0)-porous sludge carbon material

InactiveCN106076256AGood dechlorination and detoxification effectSolve pollutionOther chemical processesWaste water treatment from textile industryToxicity reductionIron salts

The invention discloses a preparation method of a nanometer Fe(0)-porous sludge carbon material. The method includes: taking iron salt as an iron source of nanometer Fe(0), taking sludge as a precursor for thermal reduction of porous carbon and iron salt, taking an organic matter capable of generating a great quantity of gas by thermal decomposition at 300-500 DEG C as a pore forming agent, taking waste organics as a carbon regulating agent (in order to solve the problem of difference of organic carbon composition of sludge different in source), taking water as a harmonizing agent, and performing pyrolysis carbonization and thermal reduction at 500-900 DEG C to obtain the nanometer Fe(0)-porous sludge carbon material being 0.01-100micron in pore diameter, wherein Fe(0) average particle size is 30-80mm. The nanometer Fe(0)-porous sludge carbon material is effective in dechlorination and toxicity reduction and has a promising application prospect in various environmental pollution control fields including dehalogenation reduction, soil remediation, heavy metal wastewater treatment, printing and dyeing wastewater treatment and / or anaerobic wastewater treatment and the like, and sludge recycling and 'using waste to treat waste' are realized.

Owner:SUN YAT SEN UNIV

Regeneration treatment and cyclic utilization method of printing and dyeing wastewater

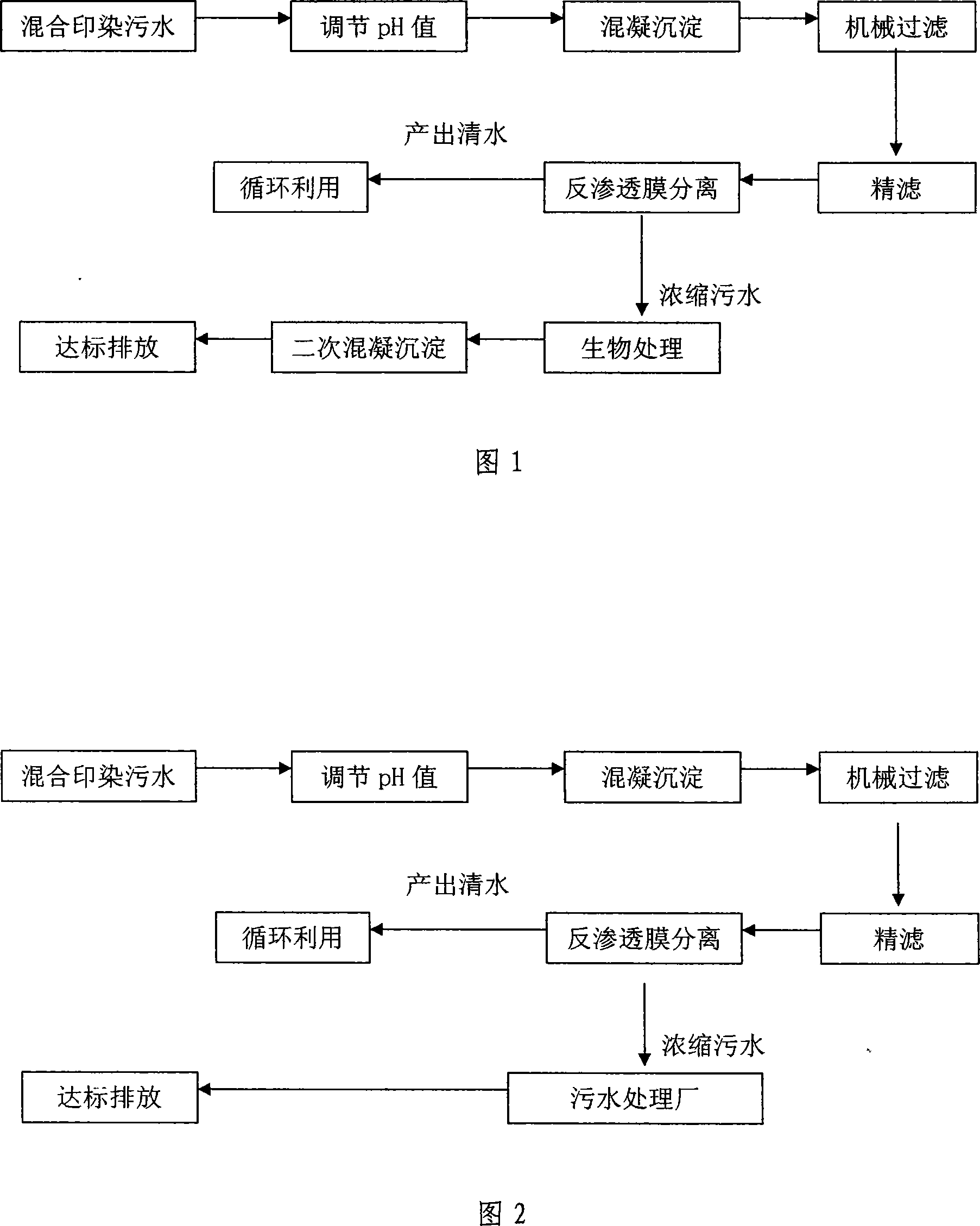

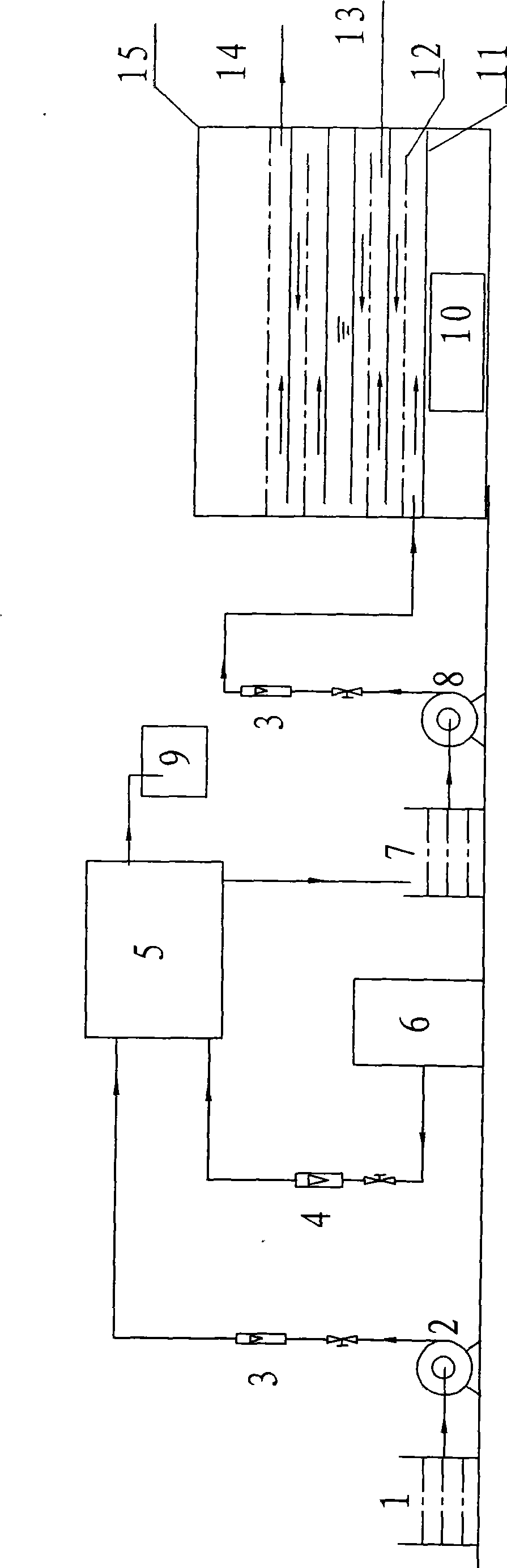

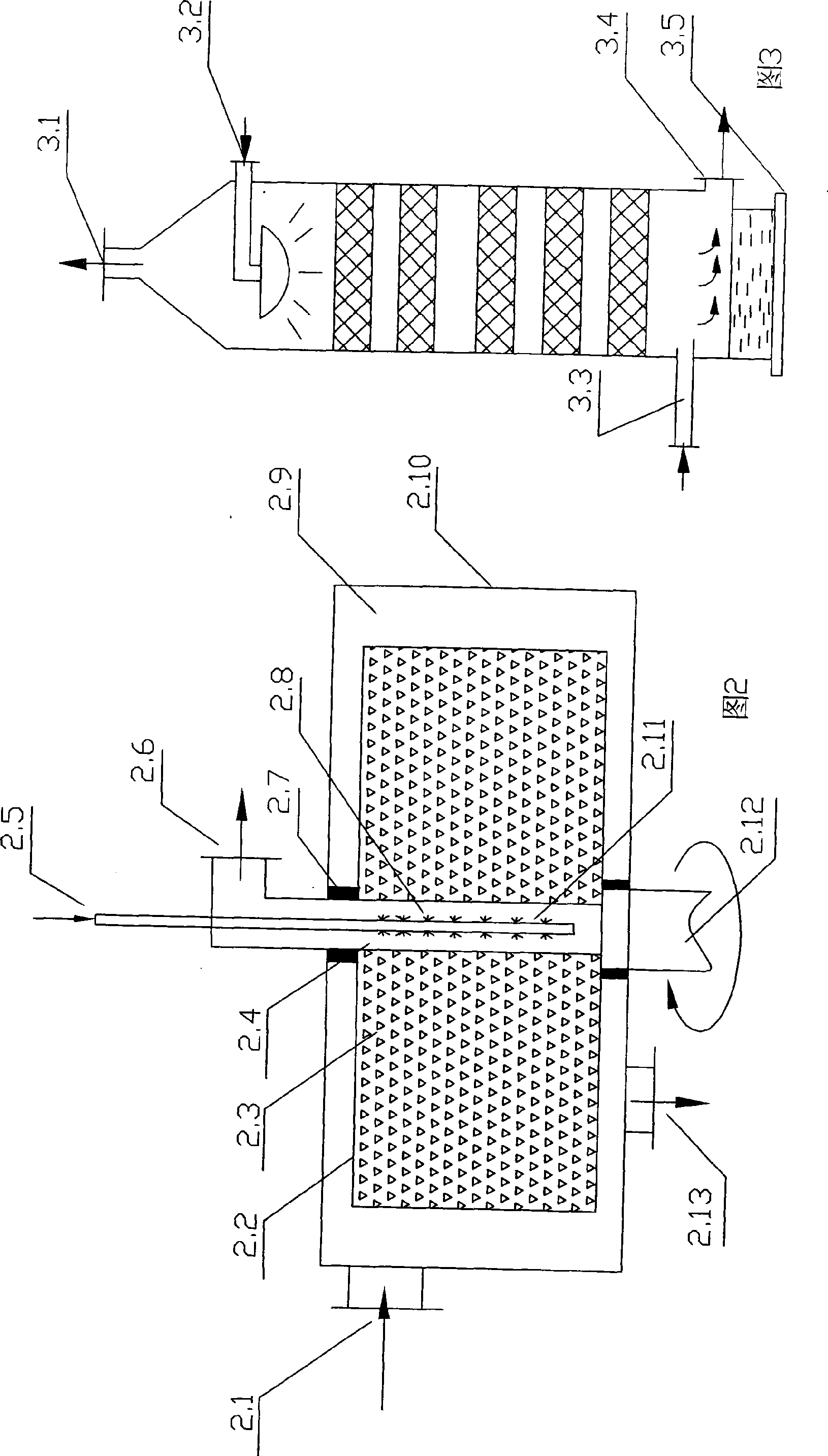

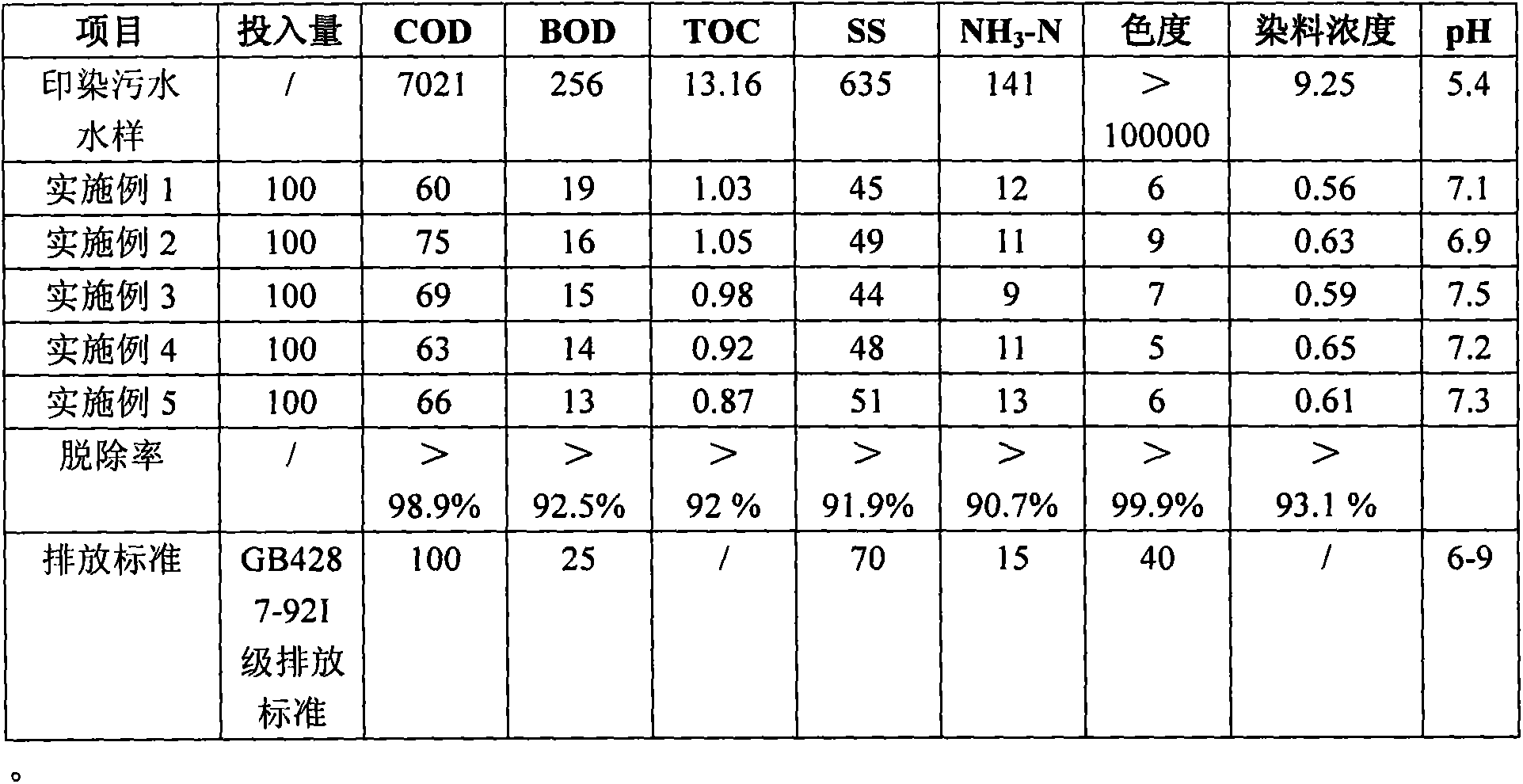

InactiveCN101205105AReduces problems with separation operating pressure increasesGood effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to a method for reproducing, treating, cycle using dyeing sewage, which is characterized in that the method comprises that: (1) adjustment of pH value: the pH value of the mixed dyeing sewage is on-line real-time detected and adjusted by automatically adding acid or alkali to a best pH value corresponding to adopted coagulant; (2) coagulation sedimentation: the coagulant is added to stirring reaction and gravity sedimentation; (3) mechanical filtration: supernatant is filtered by the mechanism to remove a little plurality of suspended particles in the water; (4) fine filtration: by adopting security filter, residual micro particles are caught; (5) reserve osmosis membrane separation: by using the reserve osmosis membrane to carry out membrane separation, output clear water is cycled for use; (6) biological treatment: by adopting the biological treatment to membrane separate concentrated sewage, organic pollutants in the sewage are removed; (7) secondary coagulation sedimentation: bio-chemical effluent adding with the coagulant is reacted and precipitated again, and discharged after reaching the national first class discharge standard.The biological treatment and the secondary coagulation sedimentation can be replaced by sewage treatment plant for centralized treatment.The method is characterized by small occupied area, little investment and low operating cost.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Technological process and apparatus for advanced oxidation degradation of nitrobenzene wastewater

ActiveCN101462788AReduce processing costsBiochemical effectWater contaminantsWater/sewage treatment with mechanical oscillationsDetonatorElectrolysis

The invention belongs to the technical field of nitrobenzene class wastewater treatment and in particular relates to a process method for advanced oxidation and degradation of nitrobenzene class wastewater. The invention solves the problem that the prior method for degrading nitrobenzene class wastewater has long time consumption and high cost. The method comprises that: wastewater and ozone undergo full haptoreaction in gas-liquid mass transfer equipment; after the haptoreaction, the wastewater enters a coupling reactor consisting of an ultrasonic wave field and an electrolysis field; and nitrobenzene class substances in the wastewater are degraded under the synergistic action of ultrasonic wave and micro-electrolysis. The device comprises the gas-liquid mass transfer equipment; a gas inlet of the gas-liquid mass transfer equipment is connected with an ozone generator; a liquid inlet of the gas-liquid mass transfer equipment is connected with a nitrobenzene class wastewater pool; a liquid outlet of the gas-liquid mass transfer equipment is connected with the wastewater coupling reactor; and the bottom of the wastewater coupling reactor is provided with an ultrasonic wave generator. The process method has the following advantages: the process method has simple process flow and convenient operation, farthest reduces treatment cost and can be applied to various organic industrial wastewater such as phenol-containing wastewater, detonator wastewater, dye wastewater, wastewater in a petrochemical enterprise, detergent wastewater and the like.

Owner:ZHONGBEI UNIV

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

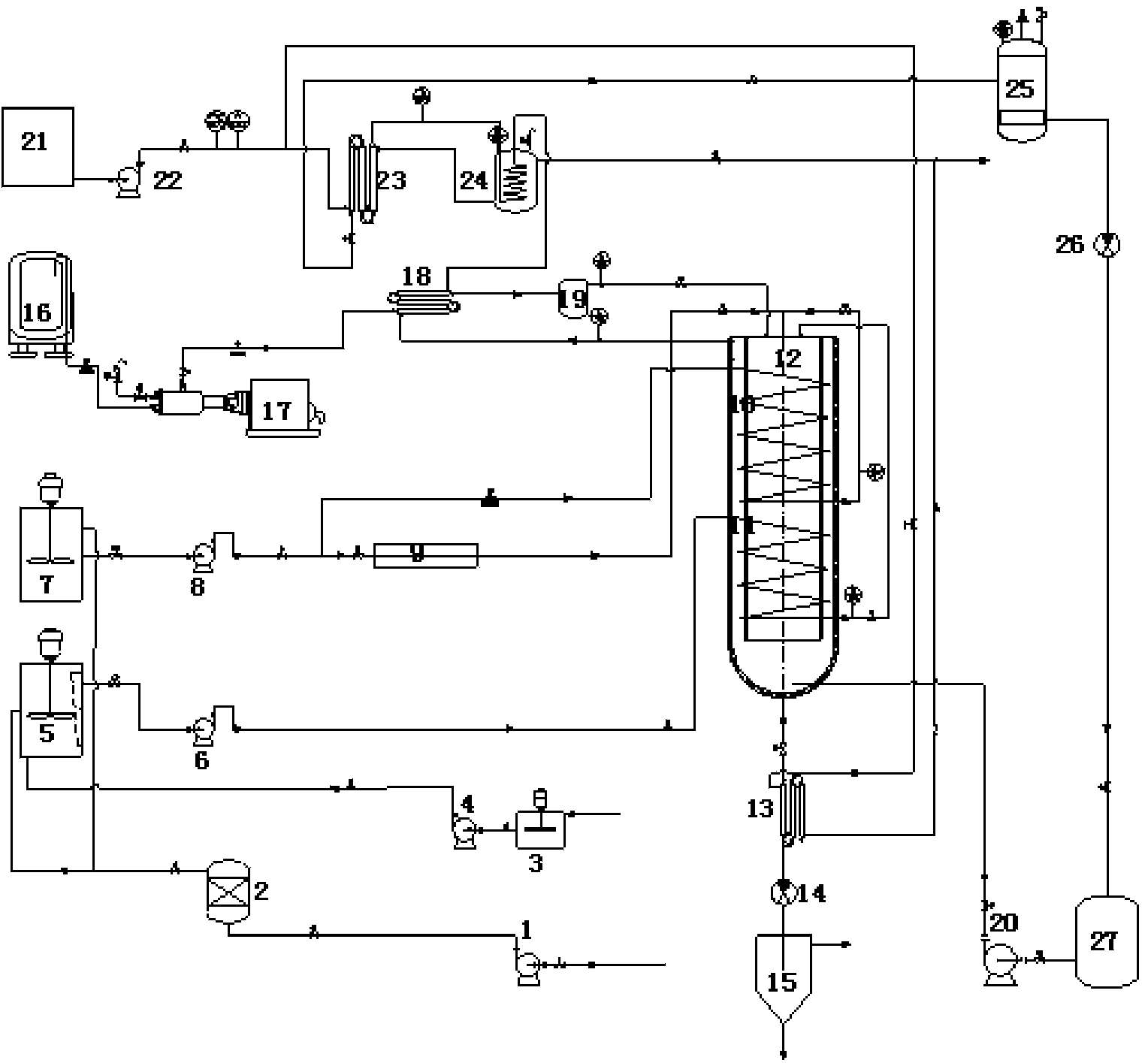

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

InactiveCN104030427AReduce volumeReduce secondary pollutionSludge treatment by oxidationWaste water treatment from textile industryLiquid wasteHigh concentration

The invention discloses a supercritical water oxidation treatment system for printing and dyeing wastewater and sludge. The system comprises a concentration pretreatment device, a supercritical water oxidation device, an oxidizing agent supply device and a wastewater recycling system, wherein the concentration pretreatment device comprises a waste liquid storage tank, a nanofiltration membrane concentration module and a printing and dyeing sludge storage pool, the oxidizing agent supply device comprises a liquid oxygen storage tank, a liquid oxygen gasifier and a buffer tank, and the supercritical water oxidization device comprises an auxiliary heating supercritical water oxidization reactor, a methyl alcohol starting preheater, a methyl alcohol preheater and a waste liquid preheater. The system can be used for realizing efficient, clean and harmless treatment of high-concentration printing and dyeing wastewater and sludge at low cost.

Owner:山川丽(苏州)环保科技有限公司

Biological modified straw adsorbent, and reparation method and application thereof

InactiveCN102847516ARaw materials are cheap and easy to getWide variety of sourcesOther chemical processesWaste water treatment from animal processingSorbentDyeing wastewater

The invention discloses a biological modified straw adsorbent, and a preparation method and application thereof. The method comprises the steps of: crushing the straw to prepare a straw powder; mixing the straw powder with a synergistic agent and water, and inoculating microbial strain for modification to conduct fermentation; and after the fermentation, taking out the modified straw powder and drying to prepare the adsorbent. The microbial strain is Trichoderma viride CGMCC3.5455, Trichoderma koningii CGMCC3.2774, Aspergillus niger CGMCC3.4309, Rhizopus stolonifer CICC40317, and Trichoderma koningii CICC 40108. The invention uses straw powder as a carbon source to conduct solid fermentation, so as to produce the adsorbent. The production process does not produce wastewater, waste gas or waste residue, and is energy-saving and environment-friendly. The prepared adsorbent has strong capacity, and can be used for treatment of tanning wastewater and dyeing wastewater.

Owner:JIAXING UNIV

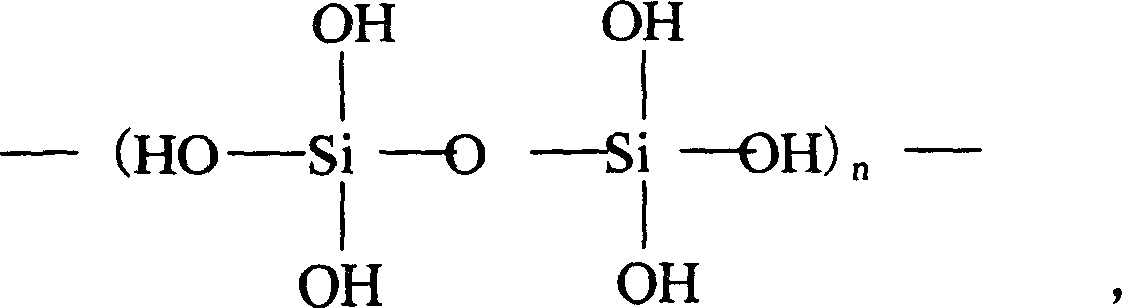

Organic-inorganic in-situ composite flocculant and preparation method thereof

InactiveCN101717141ALow costSimple methodWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationFully developedIn situ polymerization

The invention discloses an organic-inorganic in-situ composite flocculant and a preparation method thereof. The organic-inorganic in-situ composite flocculant is prepared by the steps of taking inorganic powder as a disperse phase, adding acrylamide, initiating agent and solvent to form a mixed solution system and carrying out in-situ polymerization reaction for 10 to 24 hours at 40 to 70 DEG C, wherein the mass percentage of the inorganic powder in the solution system is 1 to 60 percent, the mass percentage of the acrylamide in the solution system is 1 to 50 percent, and the mass ratio between the initiating agent and the acrylamide is 0.5 to 2: 100. The invention integrates the advantages of organic flocculant and inorganic flocculant and fully develops the flocculating effects of the acrylamide and the inorganic powder; and the organic-inorganic flocculant prepared by utilizing an in-situ composite technology can ensure that the decoloration ratio of dyeing wastewater can reach more than 90 percent. The flocculant has wide application range, low cost, simple and convenient method, mild synthesis conditions, strong practicability and easy industrial production.

Owner:JINAN UNIVERSITY

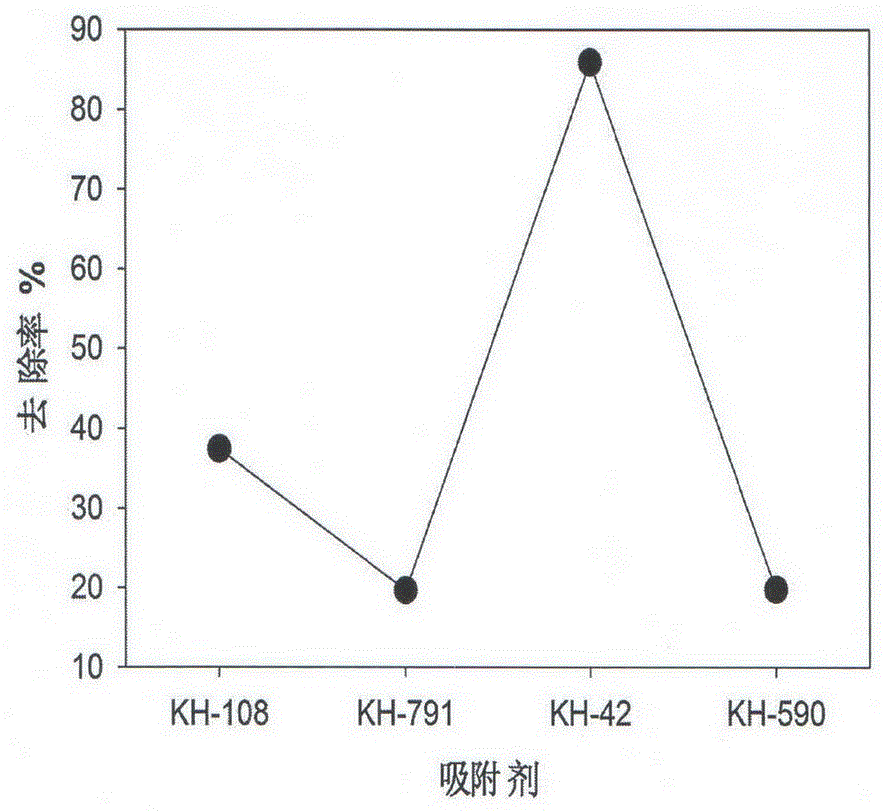

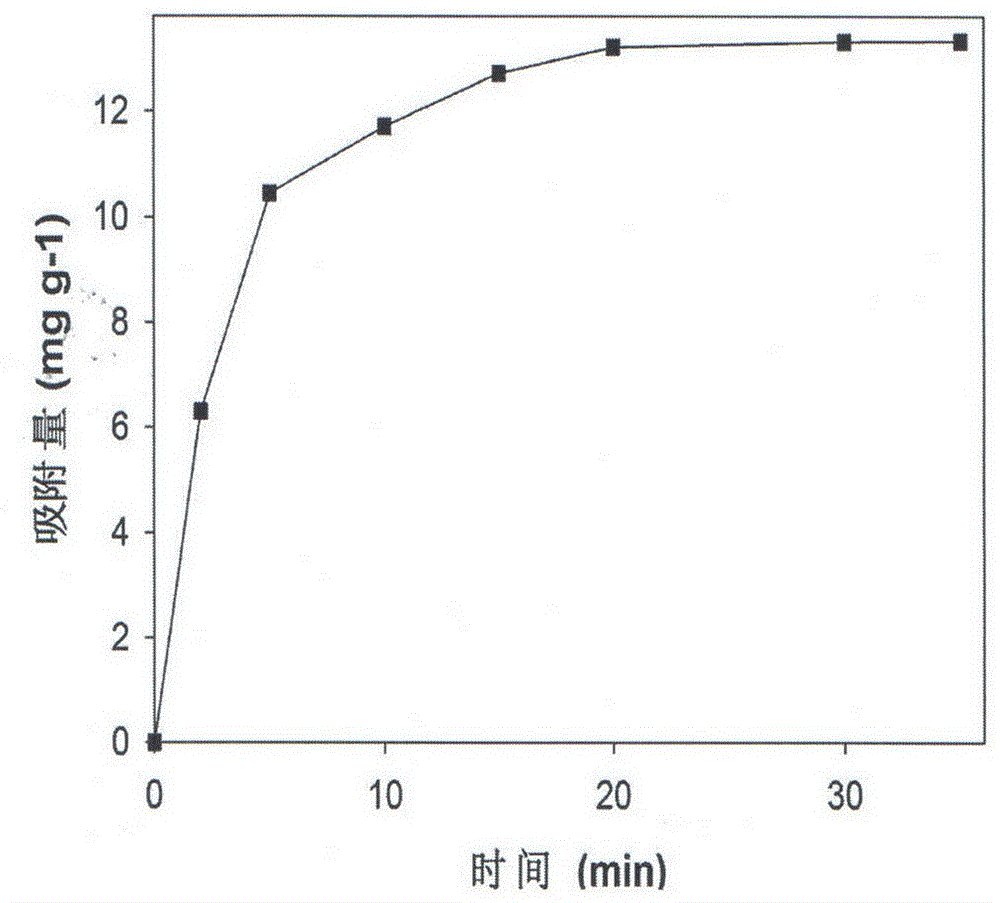

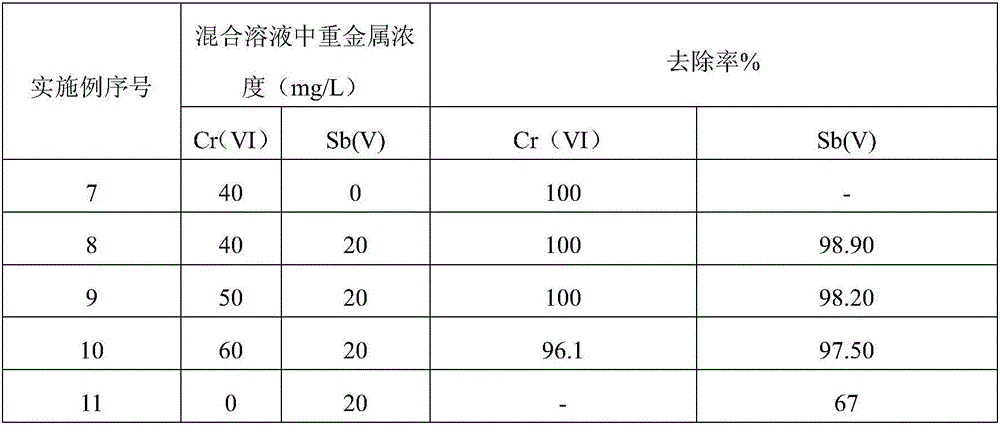

Preparation method and application of silane coupling agent modified magnetic halloysite material

InactiveCN106111067AImprove separation efficiencyEasy to separateOther chemical processesWater contaminantsHalloysiteSorbent

The invention belongs to the field of water treatment material preparation and in particular relates to a preparation method and application of a silane coupling agent modified magnetic halloysite material. The method is characterized by taking halloysite as a template and adhering Fe3O4 particles to the surface of a halloysite nanotube by an in-situ synthesis method; mixing a silane coupling agent with halloysite / Fe3O4 and grafting the silane coupling agent onto the surface of halloysite through reaction. The method has the beneficial effects that the raw materials are cheap and accessible; a functional group on the surface of the silane coupling agent modified magnetic halloysite material obtained by the method is bonded with a matrix via chemical bonds, so the material has strong bonding force; the material has high thermal stability, is convenient and fast to separate and recover, can be recycled multiple times, can serve as an adsorbent for eliminating heavy metal pollution of printing and dyeing wastewater and enables that the treated printing and dyeing wastewater can reach the national wastewater discharge standards.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

High efficiency composite flocculant, its preparation method and application

InactiveCN1785836AEasy to prepareLow costWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationCalcium hydroxideInorganic compound

The present invention relates to a high-effective compound flocculating agent, its preparation method and application. Said flocculating agent is composed of flocculating agent and coagulant aids, in which the flocculating agent mainly is polymeric aluminium iron or polymeric aluminium, and the coagulant aids mainly have two classes, one is inorganic compound, for example sodium silicate, calcium hydroxide, calcium carbonate, magnesium hydroxide and high-molecular coagulant aids, and another is organic substance, for example polyacrylamine, dodecyl dimethyl tertiary amine, dicyandiamide and modified chitosan. It can be used for treating dyeing waste water.

Owner:SHANGHAI UNIV OF ENG SCI

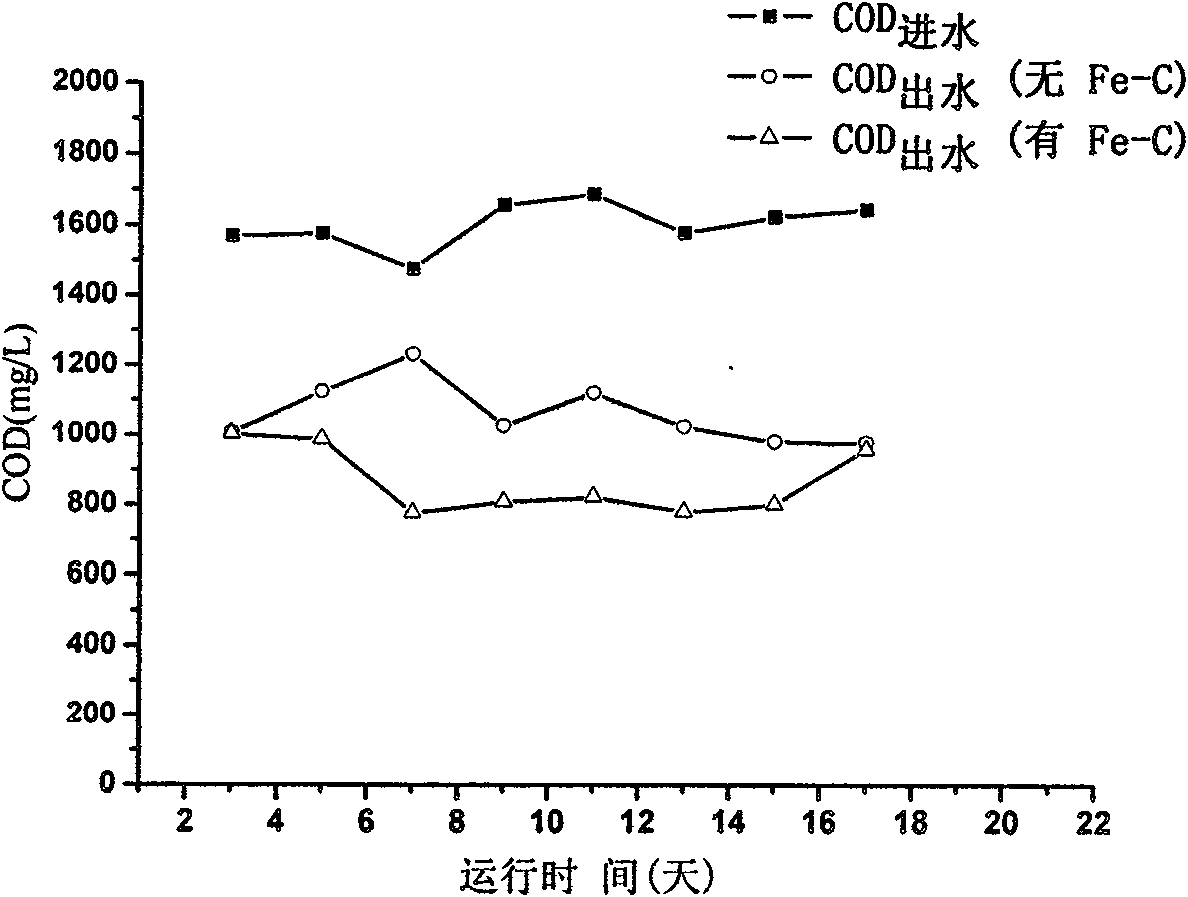

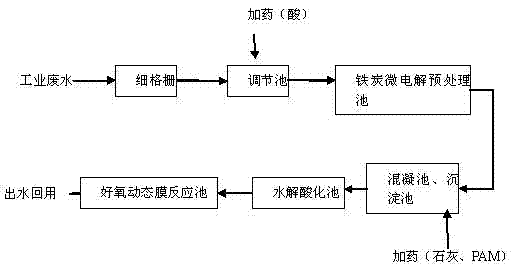

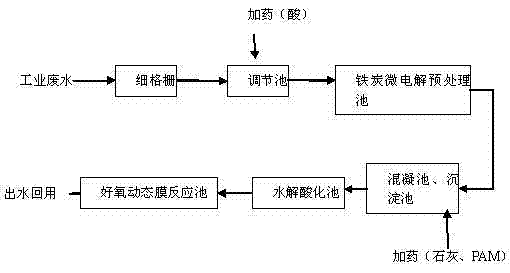

Iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process

ActiveCN102372401AStable water outputEasy to handleMultistage water/sewage treatmentSuspended particlesWater use

The invention relates to an iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process. The process comprises the following steps: pretreating pollutants in industrial wastewater by iron-carbon micro-electrolysis so as to remove partial pollutants and improve the biochemical performance of the wastewater; then, carrying out microorganism degradation by mainly using mixed liquids in a hydrolysis acidification pool and an aerobic dynamic membrane reaction pool so as to remove the pollutants; and finally, completing the solid-liquid separation and water discharge process of the mixed liquid with a dynamic membrane assembly. The invention aims at providing the iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process which is simple in process flow and efficient; the process can be effectively used for removing the difficultly-degradable organic substances in the industrial wastewater and improving the biochemical performance of the wastewater, and has obvious decoloring effect and good solid-liquid separation effect; the effluent is clear and does not contain suspended particles; and the process is suitable for standard-reaching discharge and deep treatment of various industrial wastewaters (such as dyeing and printing wastewater, pharmaceutical wastewater, heavy metal wastewater, coking wastewater, paper-making wastewater and the like), and the index of the quality of the treated effluent can meet the water quality standard of reused water.

Owner:TONGJI UNIV

Novel electro-catalytic composite membrane material and preparation method thereof

InactiveCN101559332ATo achieve reinforcementRealize self-cleaningSemi-permeable membranesWater/sewage treatment by electrochemical methodsLow voltageSeparation technology

The invention relates to a novel electro-catalytic composite membrane material and a preparation method thereof. The novel electro-catalytic composite membrane material is characterized in that the material can couple electro-catalytic technology and membrane separation technology. The preparation method comprises the following steps: taking a microporous separation membrane with electric conductivity, namely a carbon membrane, as a substrate, adopting a sol-gel method, mixing a metallic compound, water, a solvent, a catalyst, other additives and the like to be configured into a precursor solution, and obtaining an electro-catalytic composite membrane by sol ageing, film coating, drying and heat treatment; and preparing the composite membrane with superior performances by pretreating a substrate and controlling the mixture ratio of raw materials, the soakage time, the pulling speed, the sintering temperature and the like. The novel electro-catalytic composite membrane material takes the electro-catalytic composite membrane as an anode and a metallic material as a cathode to treat wastewater and realizes the reinforcement of the membrane separation process and the self-cleaning function under the action of a low-voltage electric field. The electro-catalytic membrane material has the advantages of low energy consumption, high separation efficiency, strong antifouling property and the like, and can be widely used for treating and recycling heavily polluted wastewater such as oily wastewater, dye wastewater, paper-making wastewater and the like. The preparation method has the advantages of simple preparation process, cheap equipment, easily-obtained raw materials, convenient operation and suitability for industrialized implementation.

Owner:DALIAN HUAXINYUAN TECHNOLOGY DEVELOPMENT LIMITED COMPANY

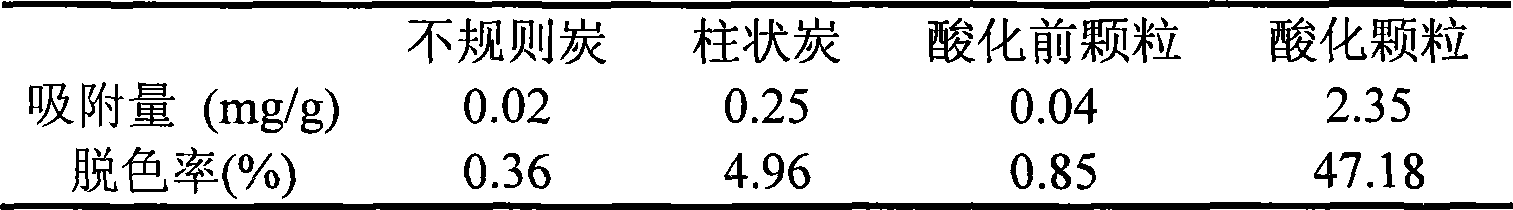

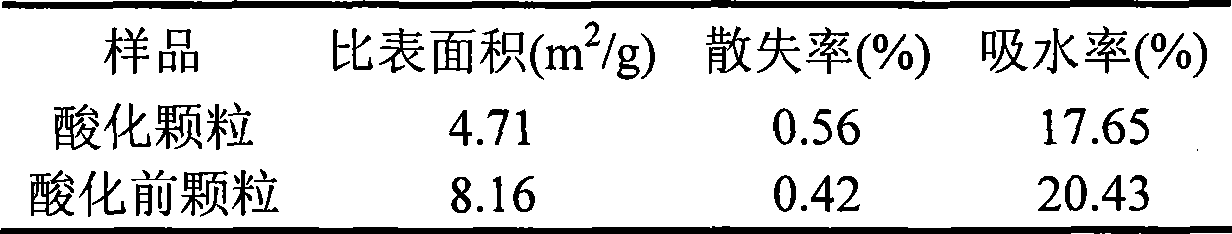

Preparation method of acidification sludge bentonite granules

InactiveCN101362073AReasonable designSimple processOther chemical processesGranulation by material expressionSodium BentoniteSludge

The invention relates to a preparation method of acidified sludge bentonite particles, pertaining to the technical field of environmental protection. Sludge and nano-bentonite powder are mixed together according to a certain ration, porous sludge bentonite particles are prepared by roasting under high temperature and the activity of the porous sludge bentonite particles is further modified by sulphuric acid to prepare the acidified sludge bentonite particles. The acidified sludge bentonite particles is yellow solid particles, with organic substance content reaching 165.788mg / g, specified surface area being 4.71m<2> / g, lost ratio being 0.56 percent and water absorptivity being 17.65 percent. The preparation method has the advantages of simple technology, economic efficiency, low cost, and the like, and the prepared acidified sludge bentonite particles have stable quality, uniform appearance and good absorptivity, thereby not only realizing the utilization of sludge as resource and the reduction of the pollution caused by the sludge, but also having wide application value in the aspect of decoloring processing of waste water produced in printing and dyeing, and realizing the purpose of treating waste by utilizing waste.

Owner:SHANDONG UNIV

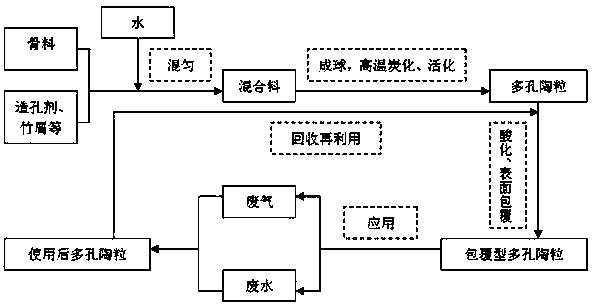

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

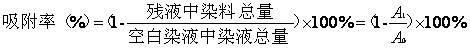

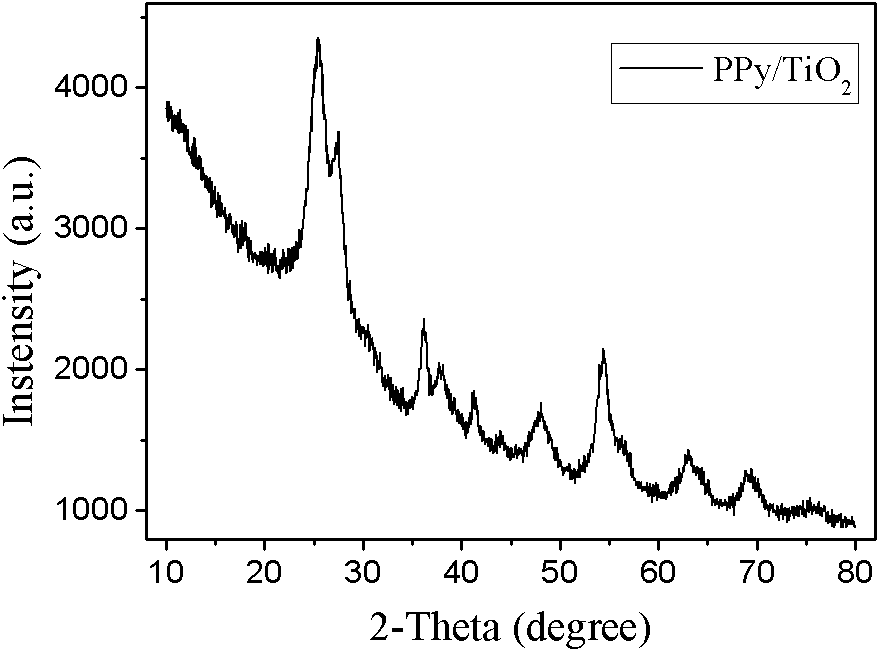

Polypyrrole/titanium dioxide composite adsorbent, its preparation, application and regeneration methods

ActiveCN102350317ARaw materials are easy to getSimple processOther chemical processesCombustible gas purificationPolypyrrolePhysical chemistry

The invention relates to an adsorbent for adsorbing dye in water, and its preparation, application and regeneration methods. The adsorbent provided by the invention is prepared by in situ composition of polypyrrole and titanium dioxide. The mass ratio of titanium dioxide to polypyrrole in the composite adsorbent is 1: 0.05-50. The preparation method comprises the following steps of: using an organic or inorganic titanium source as a raw material, and adopting a sol-gel method at the temperature of 0-100 DEG C to prepare a titanium dioxide sol; Mixing the obtained titanium dioxide sol with a pyrrole monomer at the temperature of minus 20-80 DEG C, realizing in situ composite by the chemical oxidation process, filtering and drying to obtain the polypyrrole nanometer titanium dioxide composite adsorbent. By the adoption of the adsorbent, dye in high-density dye wastewater can be effectively adsorbed. The preparation method is simple, and has short process and mild reaction condition; theaddition quantity of the prepared adsorbent during the dye wastewater treatment process is little; the adsorption balance time is short; the adsorbent can be repeatedly regenerated and used for a long time; and the regenerated adsorbent still has high adsorption performance.

Owner:浙江宏铭环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com