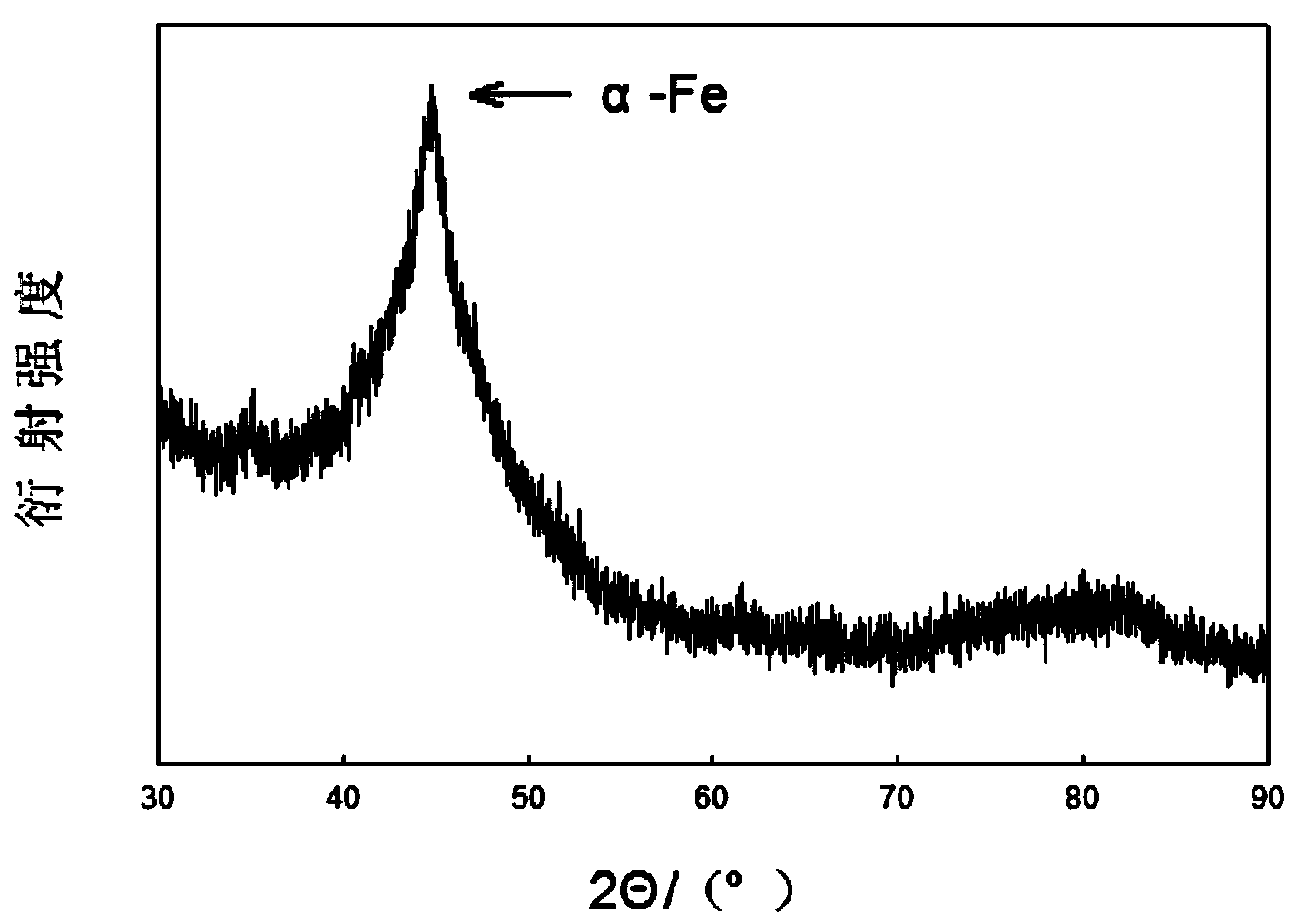

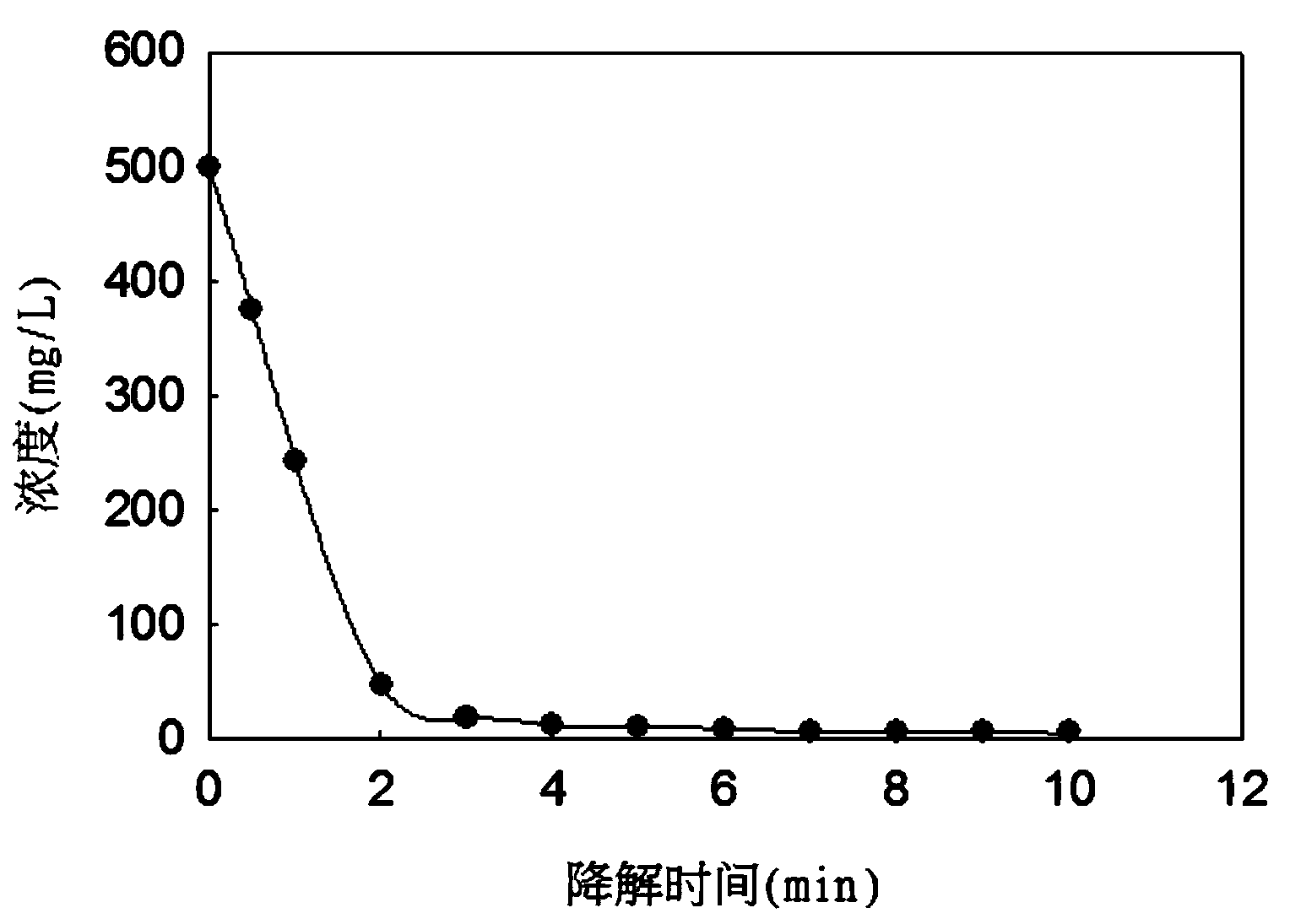

Green synthesis method for nanometer zero-valent iron by utilizing grape seeds and application thereof

A nano-zero-valent iron, green synthesis technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, to achieve the effect of good effect, reduce environmental pollution, and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) After washing the grape seeds, dry them at 105°C for 24 hours.

[0045] (2) Grinding the dried grape seeds and sieving to 300-600 μm to obtain grape seed powder.

[0046] (3) The grape seed solution was prepared according to the standard of adding 3 g of grape seed powder per 100 mL of distilled water.

[0047] (4) The grape seed solution was subjected to ultrasonication for 60 min at 20° C. under the condition of ultrasonic power of 250 W, then vacuum filtered, and then filtered through a 0.45 μm filter membrane to obtain a grape seed extract.

[0048] (5) At room temperature, mix the grape seed extract with 0.01mol / L ferrous chloride solution and stir evenly to obtain a mixed solution of ferrous chloride-grape seed extract, wherein the ferrous chloride-grape seed extract The mass fraction of grape seeds in the mixed solution is 0.1wt%.

[0049] (6) According to Fe 2+ :BH 4 The molar ratio is 1:2, the sodium borohydride solution is slowly added to the mixed sol...

Embodiment 2

[0054] (1) After washing the grape seeds, dry them at 105°C for 24 hours.

[0055] (2) Grinding the dried grape seeds and sieving to 300-600 μm to obtain grape seed powder.

[0056] (3) The grape seed solution was prepared according to the standard of adding 3 g of grape seed powder per 100 mL of distilled water.

[0057] (4) The grape seed solution was ultrasonicated for 50 min under the condition of 30° C. and ultrasonic power of 200 W, then filtered by vacuum suction, and then filtered through a 0.45 μm filter membrane to obtain a grape seed extract.

[0058] (5) Under room temperature conditions, the grape seed extract is mixed with 0.03mol / L ferric sulfate solution, and stirred evenly to obtain a mixed solution of ferric sulfate-grape seed extract, wherein the amount of grape seed in the ferric sulfate-grape seed extract mixed solution is The mass fraction is 0.2wt%.

[0059] (6) According to Fe 3+ :BH 4 - Under the condition that the molar ratio is 1:2.5, the sodium...

Embodiment 3

[0064] (1) After washing the grape seeds, dry them at 105°C for 24 hours.

[0065] (2) Grinding the dried grape seeds and sieving to 300-600 μm to obtain grape seed powder.

[0066] (3) The grape seed solution was prepared according to the standard of adding 3 g of grape seed powder per 100 mL of distilled water.

[0067] (4) The grape seed solution was subjected to ultrasonication for 40 min at 40° C. under the condition of ultrasonic power of 150 W, then vacuum filtered, and then filtered through a 0.45 μm filter membrane to obtain a grape seed extract.

[0068] (5) At room temperature, the grape seed extract and Fe 2+ Concentration is the ferrous chloride of 0.05mol / L and the mixed solution of ferrous sulfate is mixed, stir, obtain ferrous chloride, ferrous sulfate-grape seed extract mixed solution, wherein ferrous chloride, ferrous sulfate- The mass fraction of grape seeds in the mixed solution of grape seed extract is 0.3wt%.

[0069] (6) According to Fe 2+ :BH 4 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com