Heating maintenance method for winter construction of base layer in cold region

A cold area, grass-roots technology, applied to roads, pavement details, roads, etc., to achieve excellent results, constant temperature, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

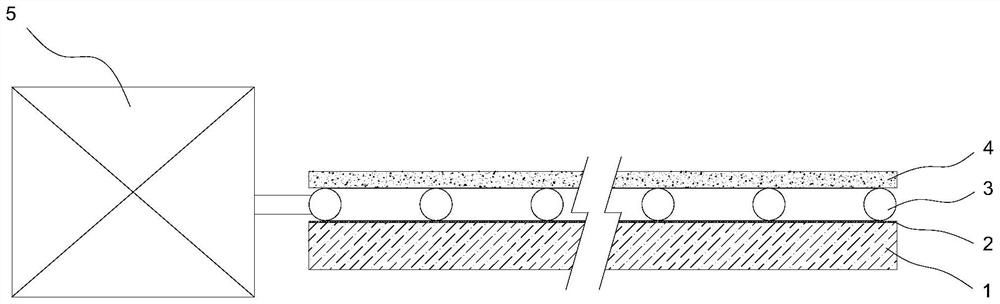

[0051] The winter construction heating and maintenance method for grassroots in cold regions includes the following steps:

[0052] S1. Calculation of heat loss value

[0053] Take the minimum daily average temperature T of the area where the base layer 1 to be heated and cured is located during the construction period to be heated and cured 1 As a standard, take the curing temperature T 0 and the minimum daily average temperature T 1 The difference is used as the set ambient temperature difference T 2 , it is calculated that when the surface of the base layer 1 to be heated and cured is covered with a layer of insulation layer 4, the base layer 1 to be heated and cured is set at the temperature difference T 2 The heat loss value Q per unit time and unit area below; when calculating the heat loss value, the setting of the insulation layer 4 should be consistent with the actual construction plan, usually the insulation layer 4 is usually laid with cotton quilts or straw mats; ...

Embodiment 2

[0077] Present embodiment has exemplified adopting the method of the present invention to carry out the winter period construction heating maintenance of cement stabilized crushed stone base in Xinjian Road (South Inner Ring-Xuanshi Street) and South Inner Ring (Yujing Bridge-Jianshe Road) road engineering in Gaoping City, Shanxi Province effect, as shown in the table below.

[0078] maintenance date Ambient temperature range of the day (°C) Cavity center temperature (°C) Circulating water temperature (℃) Base strength December 22 -3~10 7.2 15 / December 23 -3~5 6.5 15 / December 24 -1~3 6.1 15 / December 25 -3~4 6.1 15 / December 26 -6~3 5.5 15 / December 27 -4~7 6.1 15 / December 28 -4~10 7.3 15 / December 29 -2~11 7.5 15 3.2MPa

[0079] Note: The curing temperature is set at 5°C during the construction of the project; in the above table, the cavity center temperature is: when the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com