Patents

Literature

15499 results about "Heat conservation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber reinforced cement composite concrete precast construction member and production method thereof

InactiveCN102561584ARealize industrialized prefabrication productionImprove product qualityMouldsClimate change adaptationCement compositesArchitectural engineering

The invention relates to a fiber reinforced cement composite concrete precast construction member (PC-FRC) and a production method thereof, which are suitable for engineering of building exterior wall decoration, building structure containment, and energy conservation and heat preservation, are particularly suitable for prefabricated housing industrialization projects and are suitable for the fields of people's livelihood such as natural disaster prevention and post-disaster reconstruction. The fiber reinforced cement composite concrete precast construction member comprises a decorative finish layer, a fiber reinforced cement layer, a concrete structure layer, a heat preservation layer and a steel reinforcement framework, wherein the fiber reinforced cement layer is composited on the decorative finish layer and is connected with the concrete structure layer; the heat preservation layer is laid in the concrete structure layer and is completely coated by the concrete structure layer; the steel reinforcement framework is laid in the concrete structure layer; and the fiber reinforced cement layer, the heat preservation layer and the concrete structure layer are composited and molded in molds with models. According to the fiber reinforced cement composite concrete precast construction member, the connecting part of the surface of the precast construction member is provided with exposed steel reinforced bars, and the exposed steel reinforced bars are used for connecting precast pieces with building structures during building assembly; and suspension embedded pieces are laid in the concrete structure layer.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

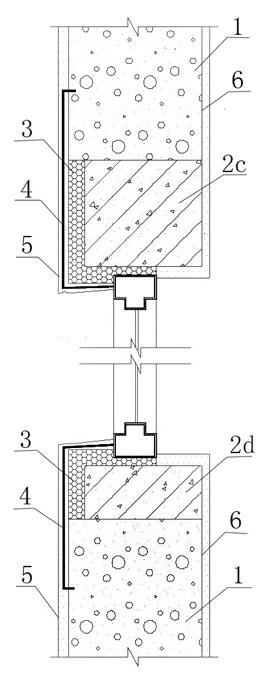

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

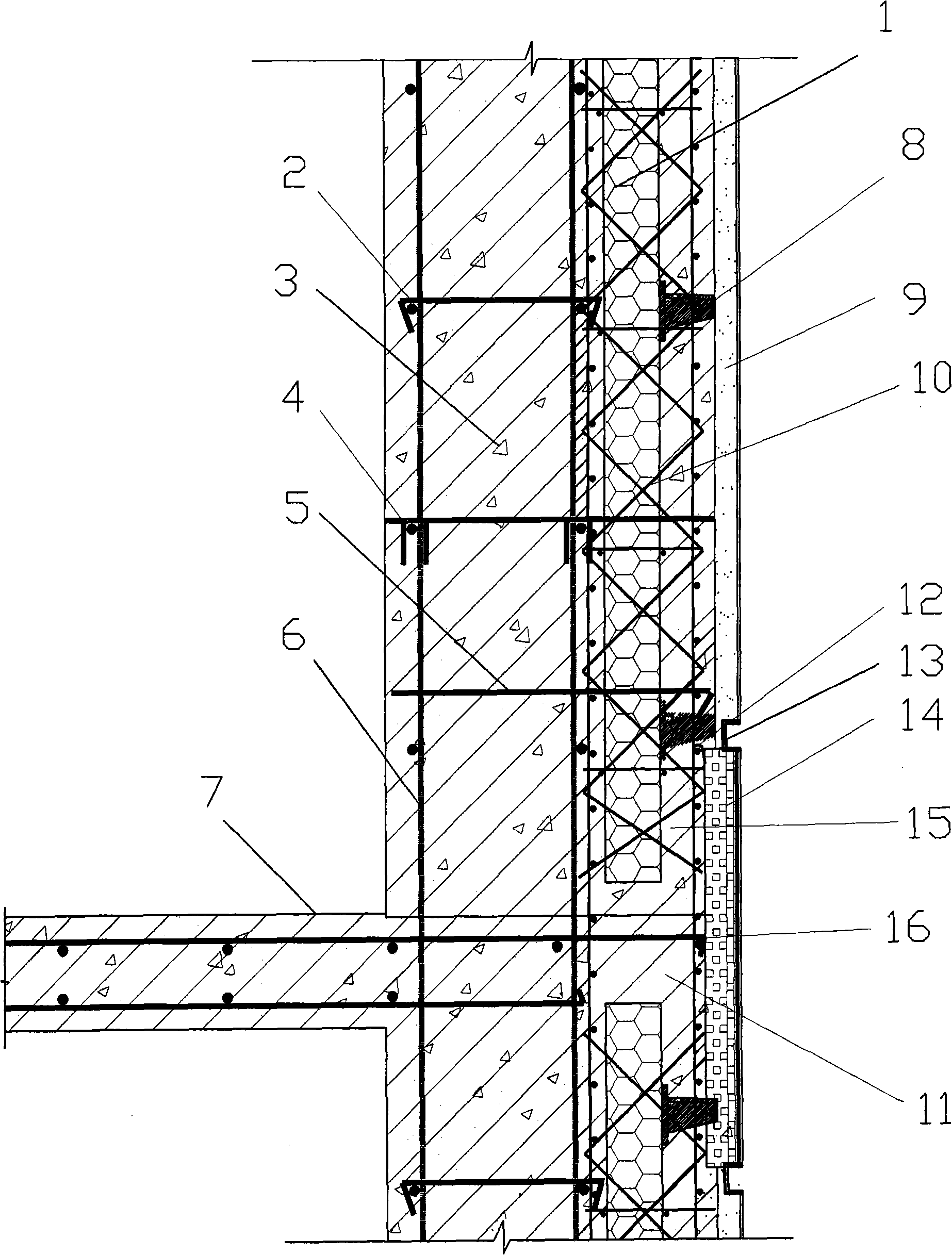

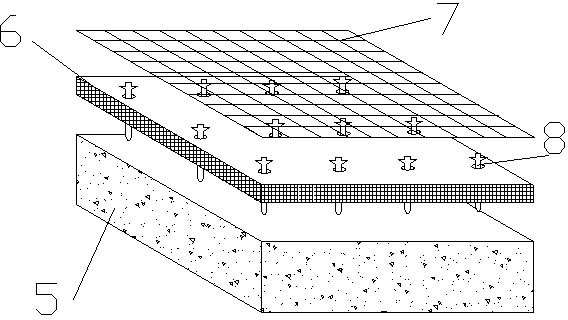

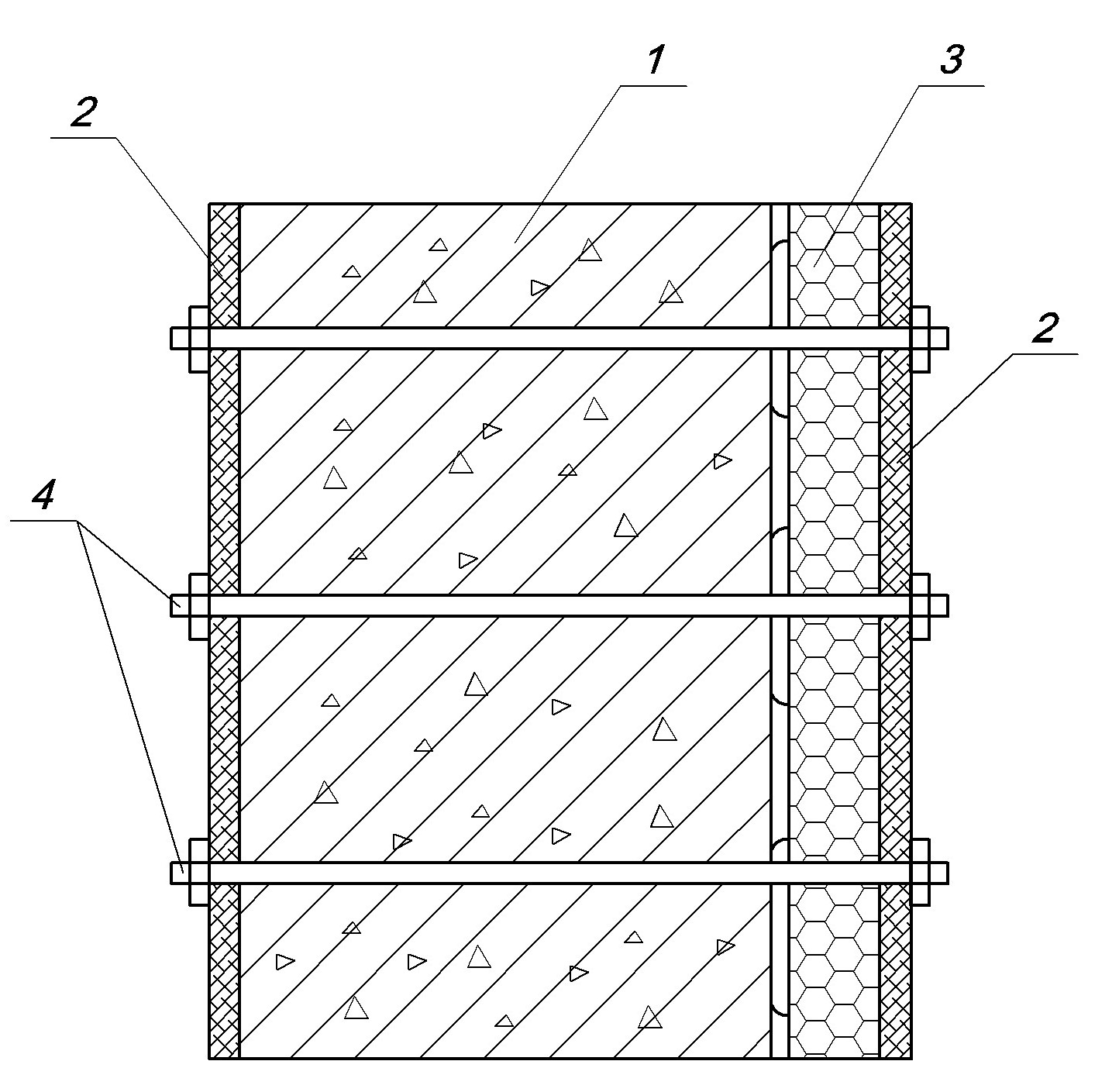

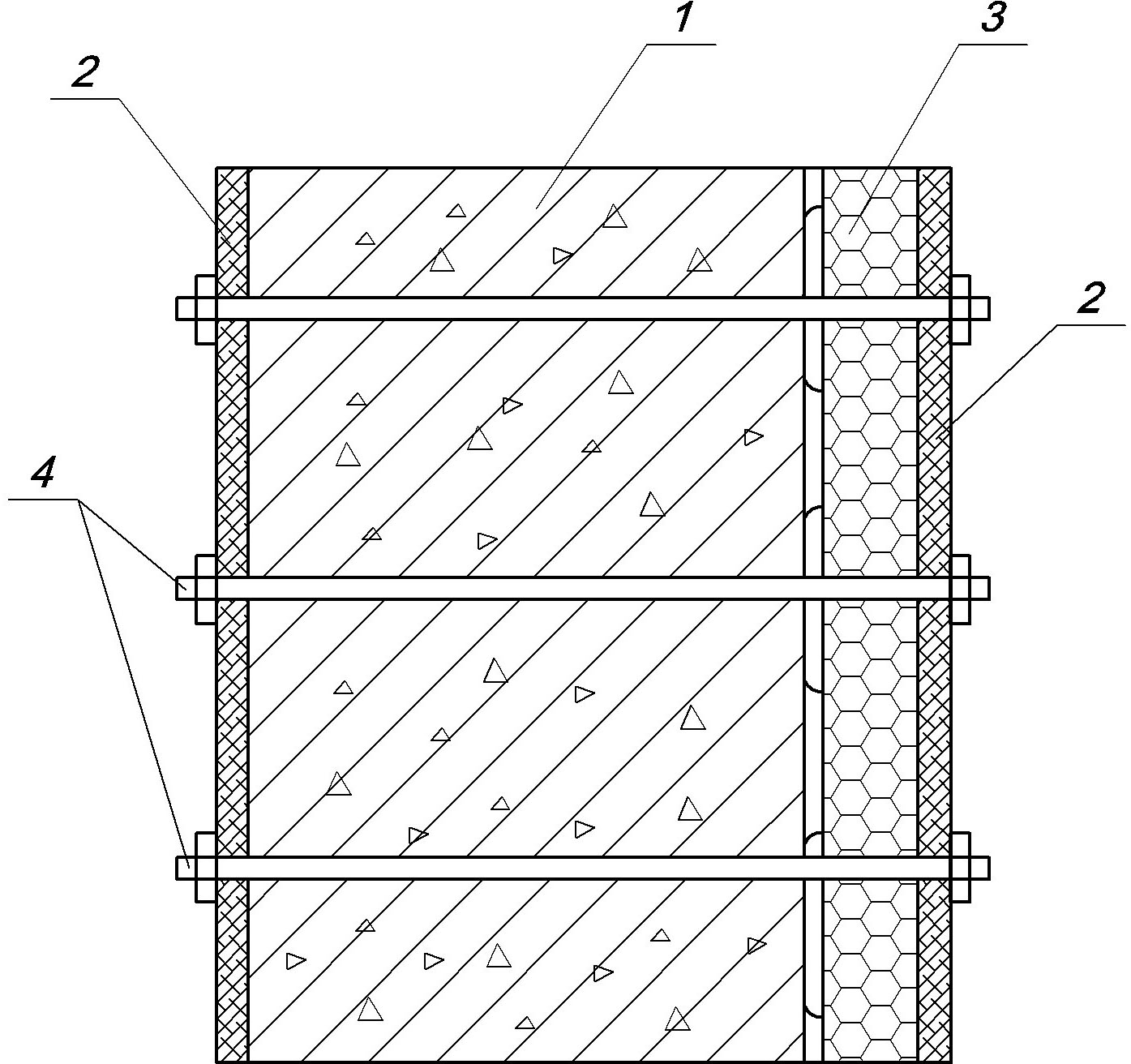

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

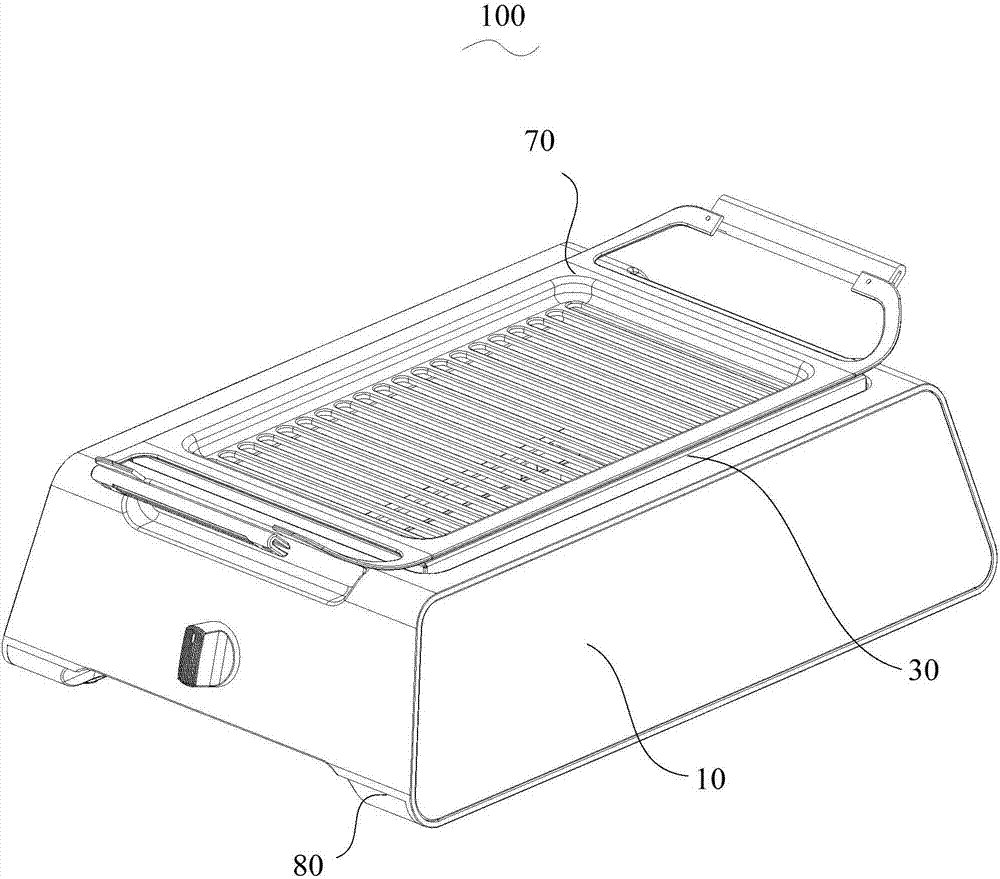

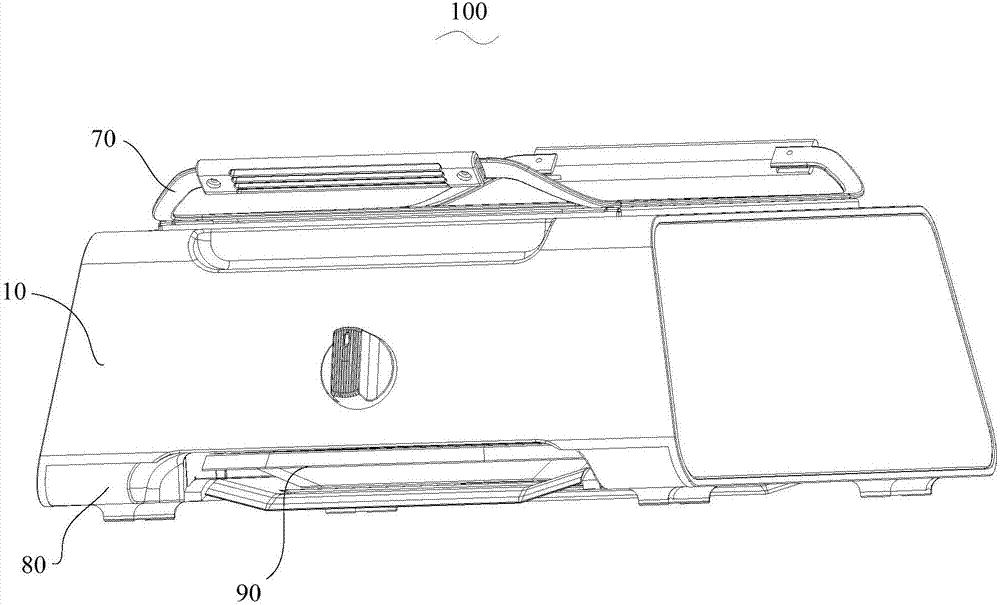

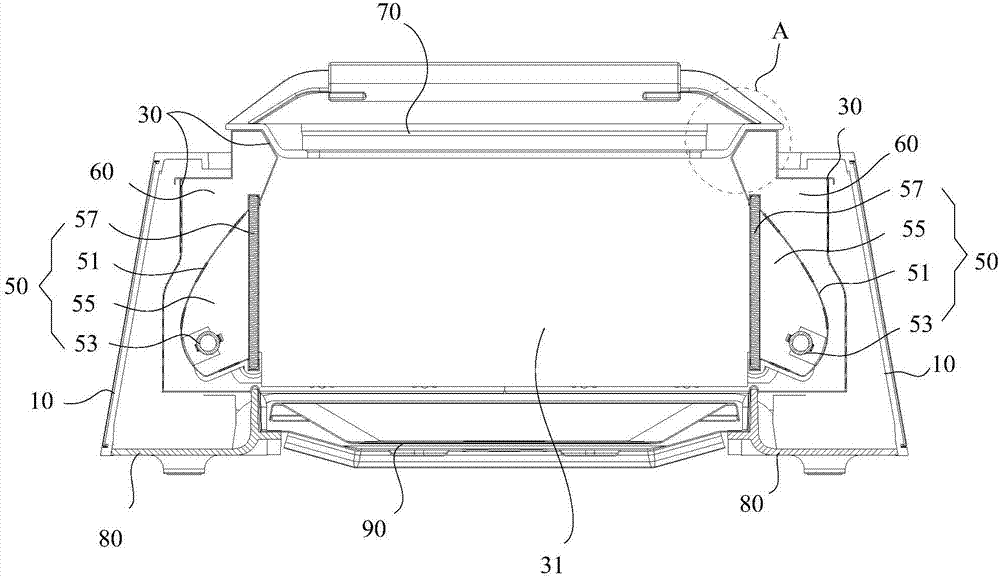

Electric grill

ActiveCN107951407AImprove food heating efficiencyImprove the safety of useRoasters/grillsEngineeringHeat conservation

The invention discloses an electric grill, which comprises an outer shell as well as an inner shell and a heating device which are arranged in the outer shell, wherein the inner shell is located between the outer shell and the heating device; and a heat-insulating cavity is defined between the inner shell and the heating device. The electric grill provided by the invention is good in heat-preserving and insulating effects, low in loss of heat energy and high in heat utilization rate.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

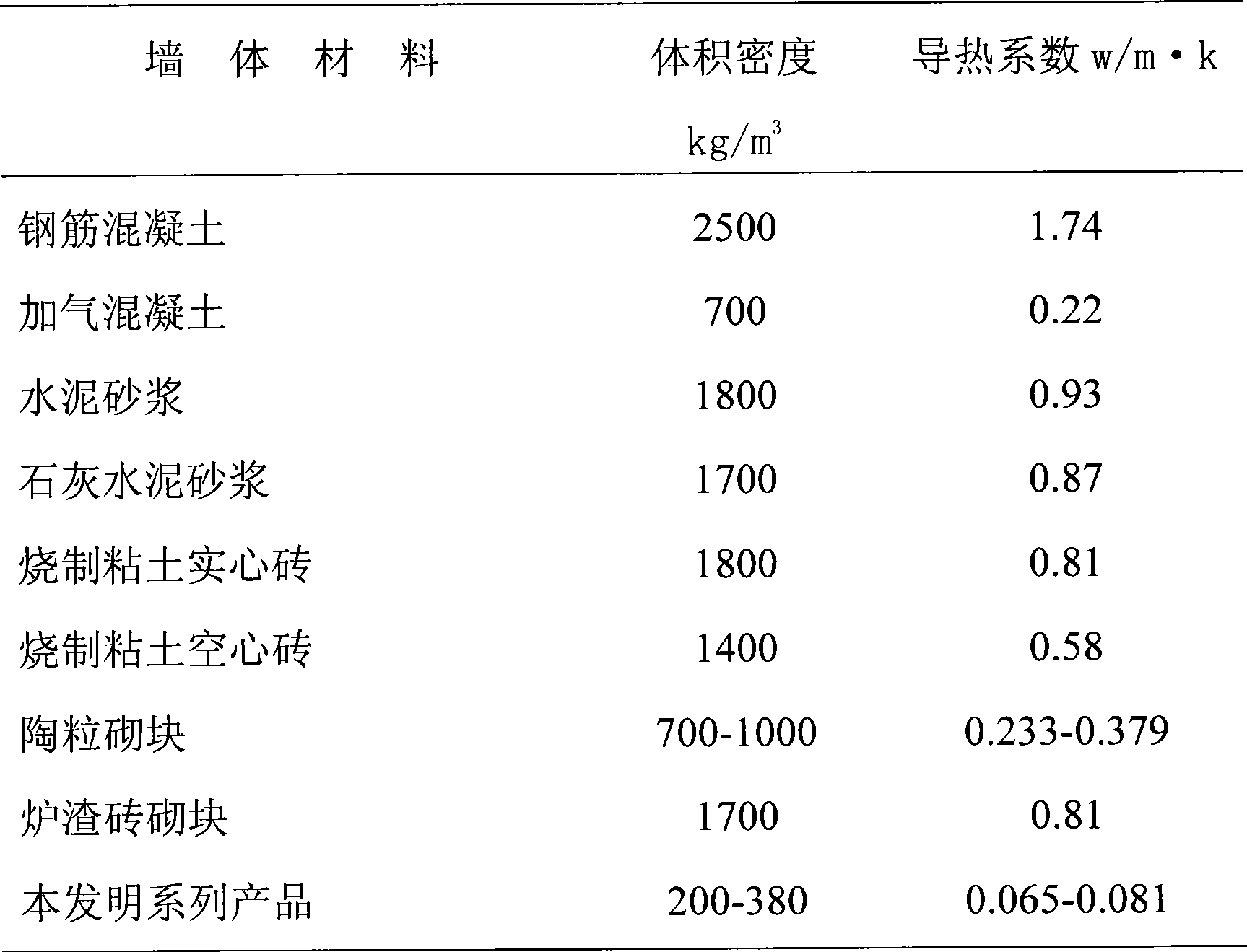

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

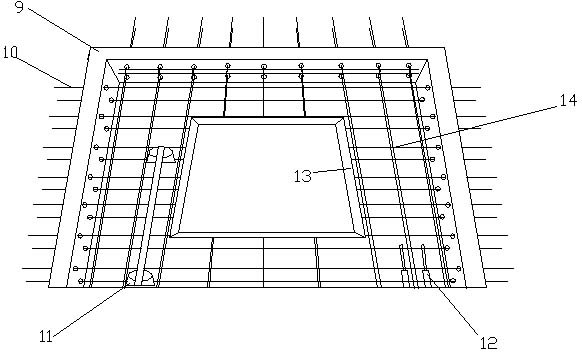

Prefabricated sandwich heat-preservation heat insulation concrete external wall panel and fabrication method

InactiveCN102650152AImprove manufacturing precisionReduce mistakesCeramic shaping apparatusBuilding componentsFire protectionEnergy conservation

The invention discloses a prefabricated sandwich heat-preservation heat insulation concrete external wall panel and a fabrication method. An integral composite wall panel which is structured in a way of wall body- heat insulation-architectural decoration from interior to exterior is adopted, the wall body is a load-bearing concrete structural layer, the middle of the wall panel adopts a heat insulation board, and the outermost side of the wall panel is an architectural decoration cladding panel, the three layers of the wall panel are connected into a whole by heat insulation connectors, so that the composite external wall panel is applicable to assembling an integral shear wall structure or an integral frame-shear wall structure, and also meets the requirements of buildings on energy conservation and fire protection. The prefabricated sandwich heat-preservation heat insulation concrete external wall panel is prefabricated in a factory and is mounted on site, so that the production and construction efficiencies are high, and the quality is also ensured; besides, the external wall panel realizes energy conservation, environmental protection, fire protection and heat insulation, and also has remarkable comprehensive benefits.

Owner:CHINA MCC17 GRP

Production method for multifunctional rigid foam polyurethane composite heat-conservation board

InactiveCN101487297AImprove flame retardant performanceGood weather resistanceWallsHeat proofingTO-18Polymer science

The invention discloses a preparation method used for preparing a multifunctional polyurethane hard foam insulation composite board. The method includes the following steps: a waterproof and fireproof polymer cement sheet is prefabricated; a polyurethane foaming machine manufacturing line is adopted to froth a foam material into the polyurethane hard foam board and the waterproof and fireproof polymer cement sheet is simultaneously compounded on two surfaces of the polyurethane hard foam board to prepare the multifunctional polyurethane hard foam insulation composite board. The method is characterized in that the foam material is prepared by the following materials according to the weight portions: 54 to 64 percent of PAPI, 10 to 15 percent of flame-retardant polyether polyol, 13 to 18 percent of polyether polyol, 4 to 7 percent of vesicant, 0.8 to 1 percent of catalyzer, 5 to 8.5 percent of flame retardant and 0.7 to 1 percent of foam-leveling agent. The polyurethane hard foam insulation composite board prepared by the method not only has the waterproof and insulation properties, but also has the high intensity and fireproof property; and the board can be used for the outer-wall large-area waterproof, fireproof and insulation engineering of buildings.

Owner:夏良强

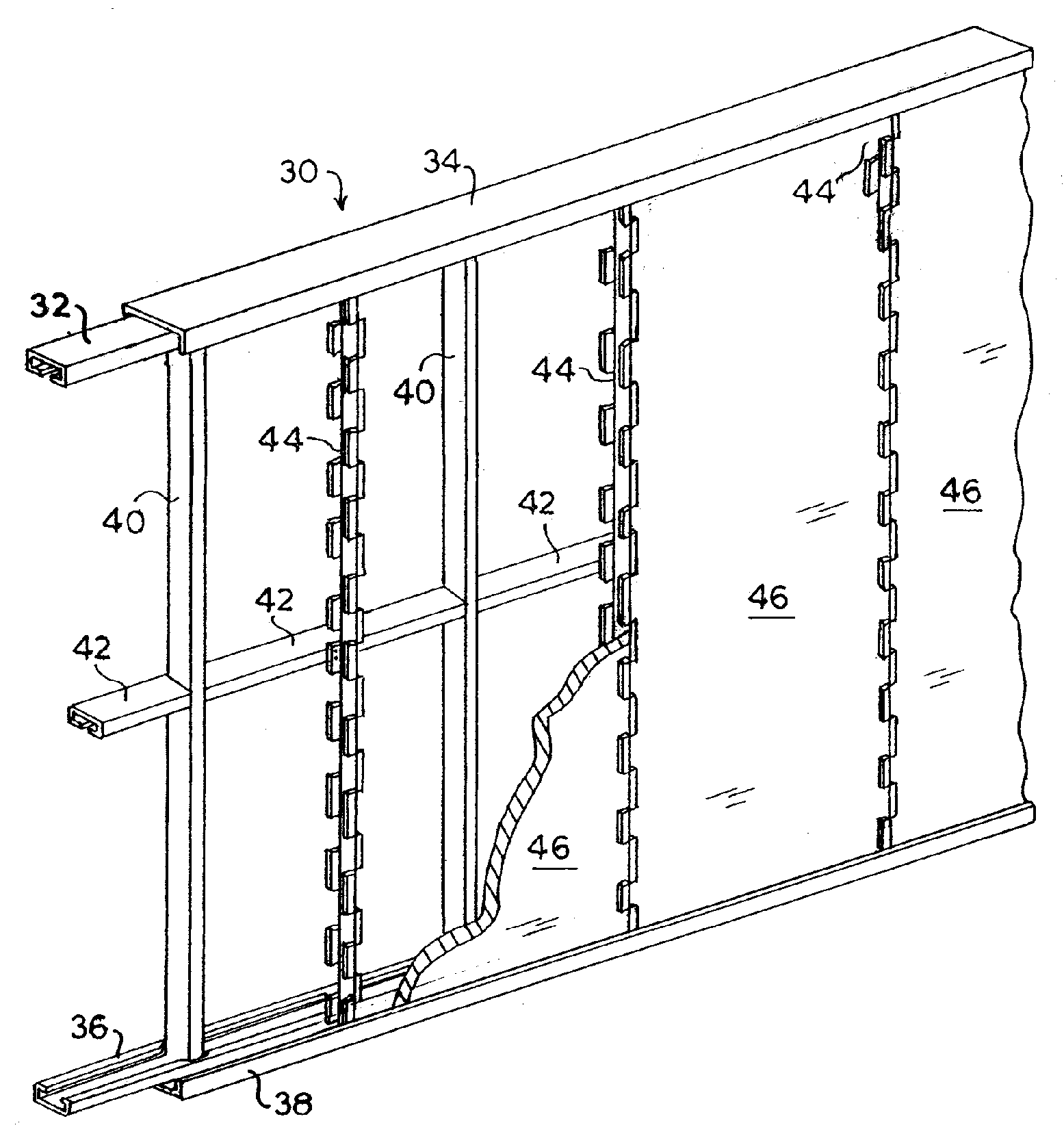

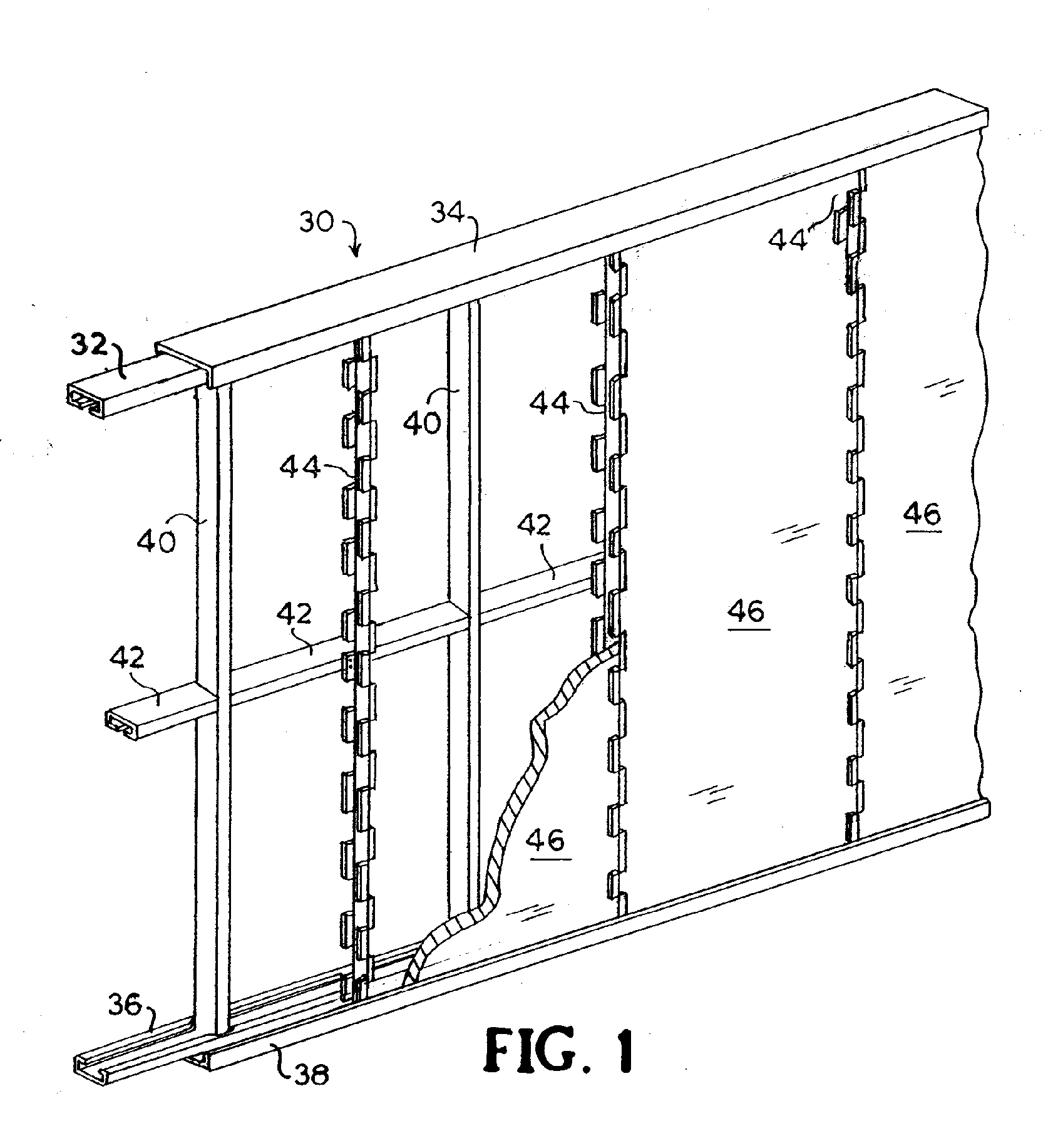

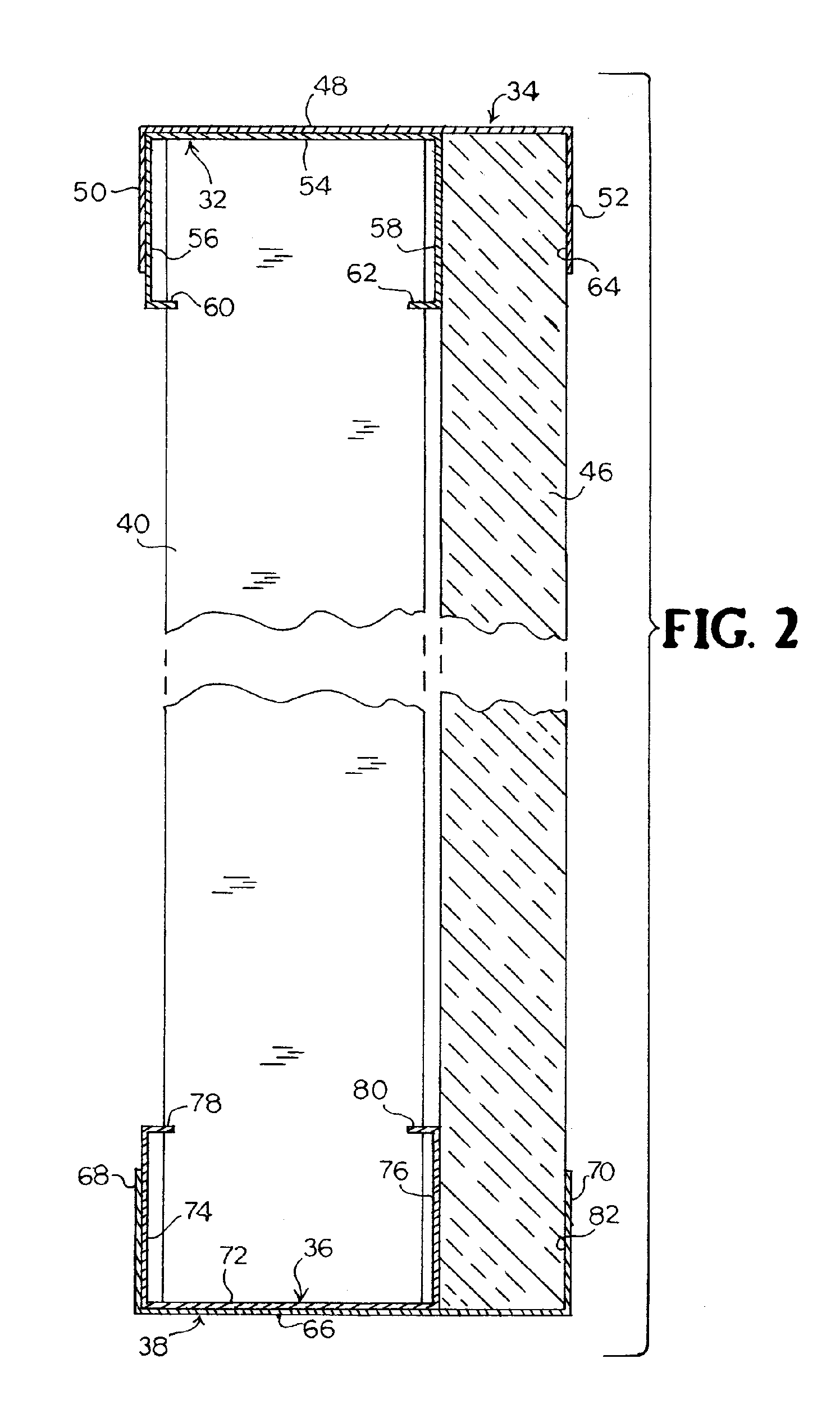

Thermal wall system

A thermal wall system for slowing heat transfer through walls. The system includes horizontal top and bottom tracks, horizontal top and bottom plates, and vertical studs mounted to and extending between the top and bottom plates. The top tracks and plates have flanges that extend downward. The bottom tracks and plates have flanges that extend upward. The width of the plates fits within the width of the tracks. Top and bottom tracks and plates are respectively nested along their webs and one flange to form a longitudinal opening between their respective opposing flanges. Rigid insulation may be disposed in the longitudinal opening. Thermal framing components may also be provided, extending between the top and bottom plates, to support vertical edges of insulation sheets. Thermal end caps may be used to treat the terminal edges of insulation.

Owner:NUCONSTEEL

Atmosphere control method for sintering process of high-frequency wide-temperature low-loss MnZn ferrite

ActiveCN107555984AHigh densityIncreased power lossInorganic material magnetismInductances/transformers/magnets manufactureHeat conservationFerrite (magnet)

The invention provides a sintering atmosphere control method in preparation of high-frequency wide-temperature low-loss MnZn ferrite. The method comprises the following steps: carrying out primary heating and heat preservation, carrying out secondary heating and heat preservation, cooling, carrying out heat preservation, and finally cooling. According to the method, corresponding oxygen partial pressure is adjusted at different temperatures and in different temperature changing processes, zinc loss in a sintering process can be reduced, and element valence change and impure phase precipitationat high temperature are inhibited, so that the soft magnetic property of the material is improved; and by adding reasonable heat preservation time, sintering internal stress can be effectively reduced, and the material is prevented from cracking in the sintering process. The method provided by the invention is applicable to preparation of multiple MnZn ferrites, and the wide-temperature low-lossMnZn power ferrite used at the frequency of 0.1-5MHz can be obtained; reasonable technological parameters can improve yield in preparation process, and a product with uniform and stable performance can be beneficially obtained; and the method is simple and practicable and has practical value.

Owner:ZHEJIANG UNIV +1

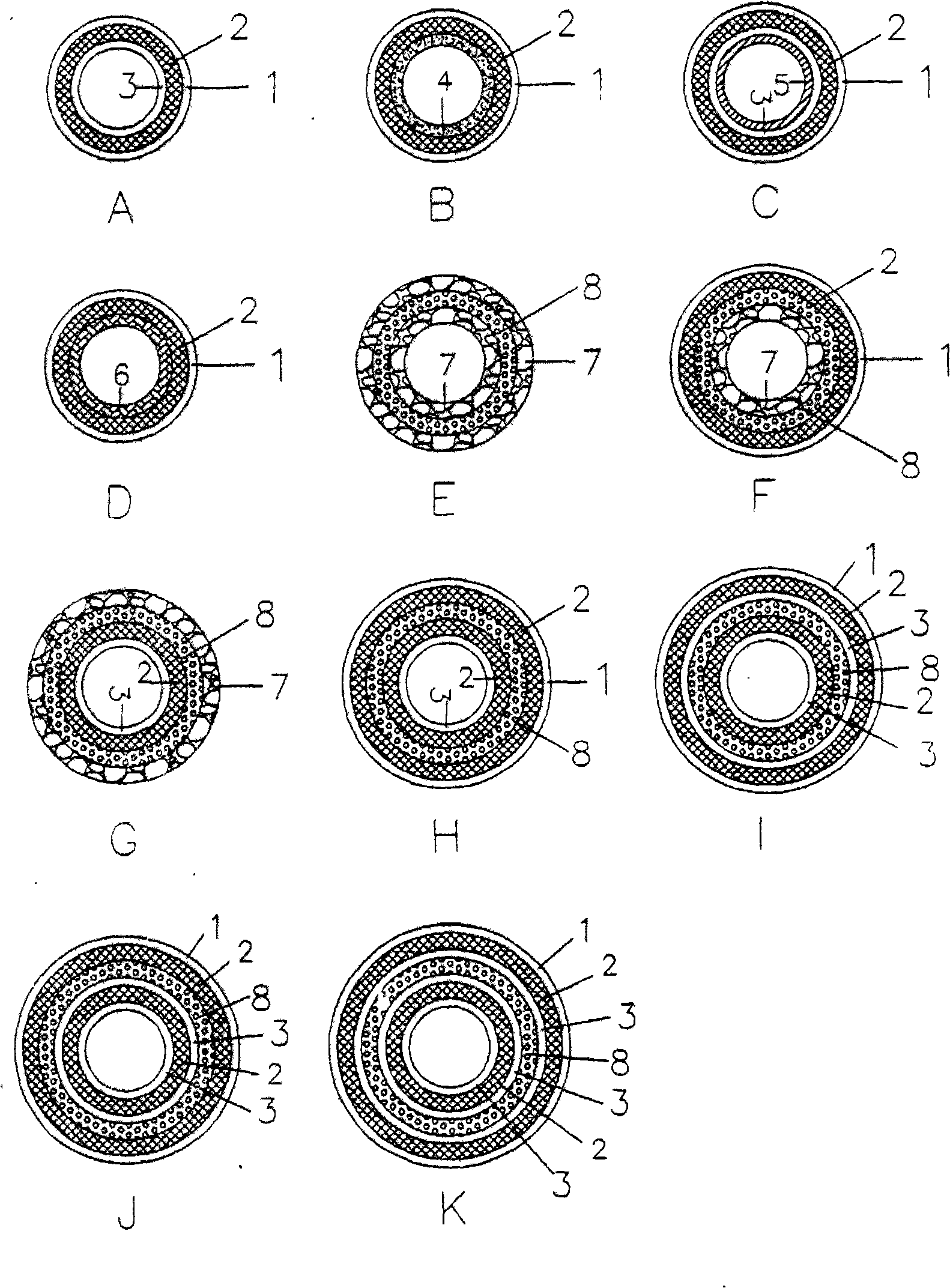

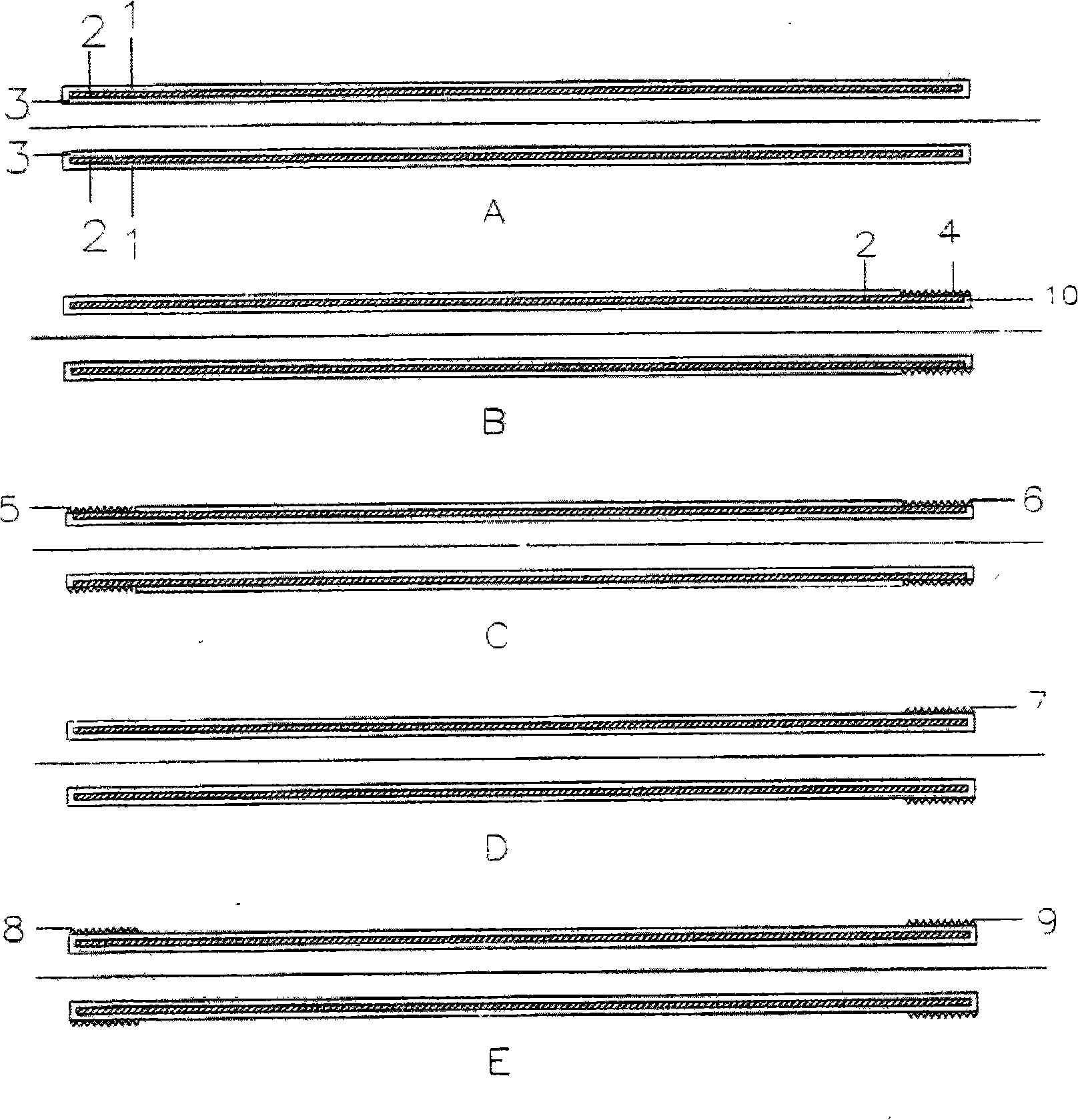

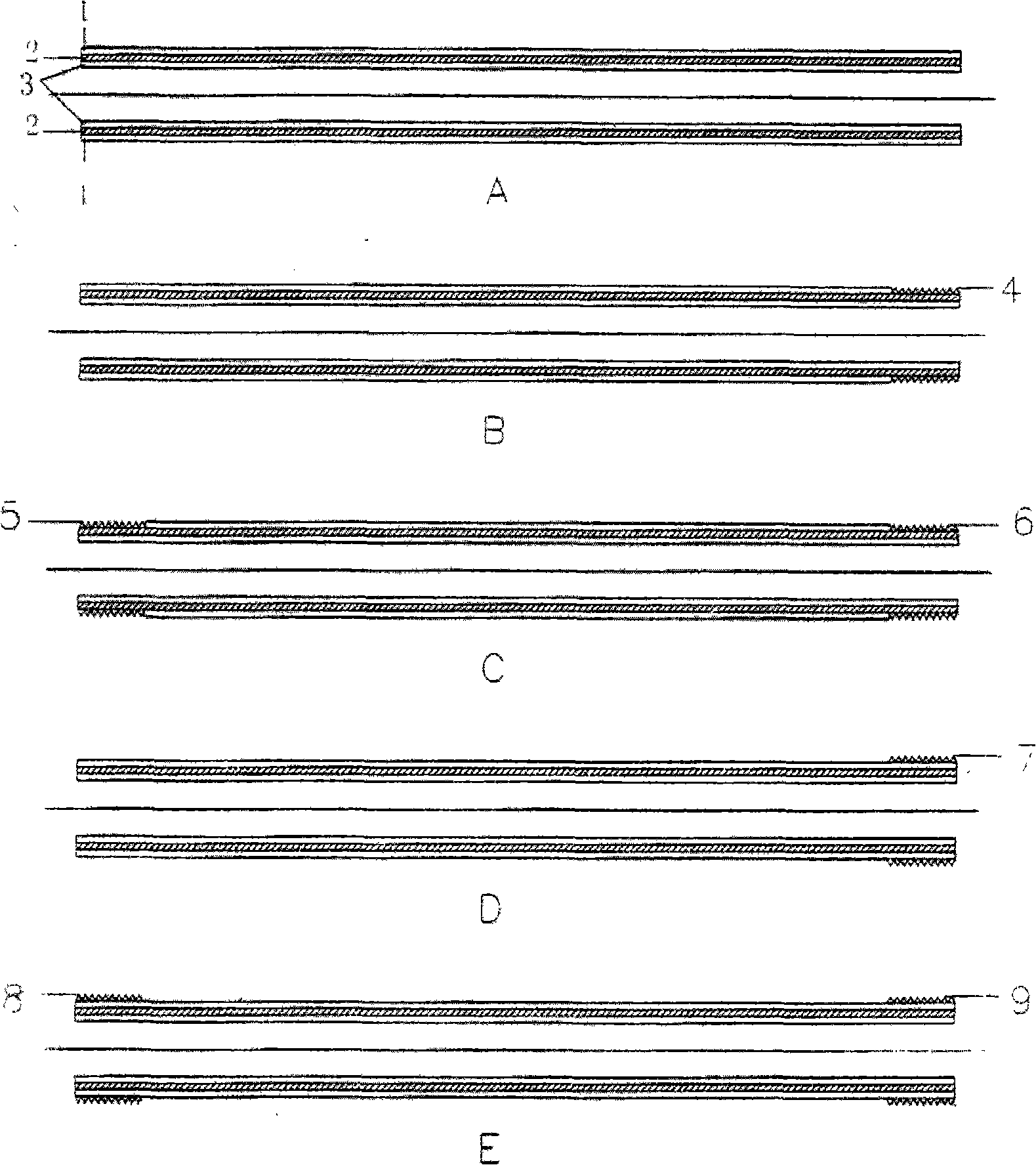

Multilayered structure and multifunction pipeline and connecting device

The invention relates to a multilayered structure and multifunction pipeline and a connecting device, solving the disadvantages of poor corrosion resistance, poor crushing resistance, poor heat-insulating property, no shapely appearance, high production cost, single structure, and the like of the existing pipelines. The pipeline comprises a corrosion resistance layer, a crushing resistance layer, a heat-insulating layer and a bacteria resistance layer, and can be of the types of single corrosion resistance and crushing resistance, bacteria resistance, corrosion resistance and crushing resistance and heat-insulating, corrosion resistance and crushing resistance. The invention has the advantages of favorable corrosion resistance, high crushing resistance, favorable heat-insulating property, bacteria resistance, simple installation and connection, reduced production and installation cost, diversified structural type of pipeline and connecting device, and the like. The pipeline can be used for drinking water supply projects, drainage engineering, oil transportation, corrosive liquid transportation, high temperature liquid and gas transportation, etc.

Owner:韦鸿雁

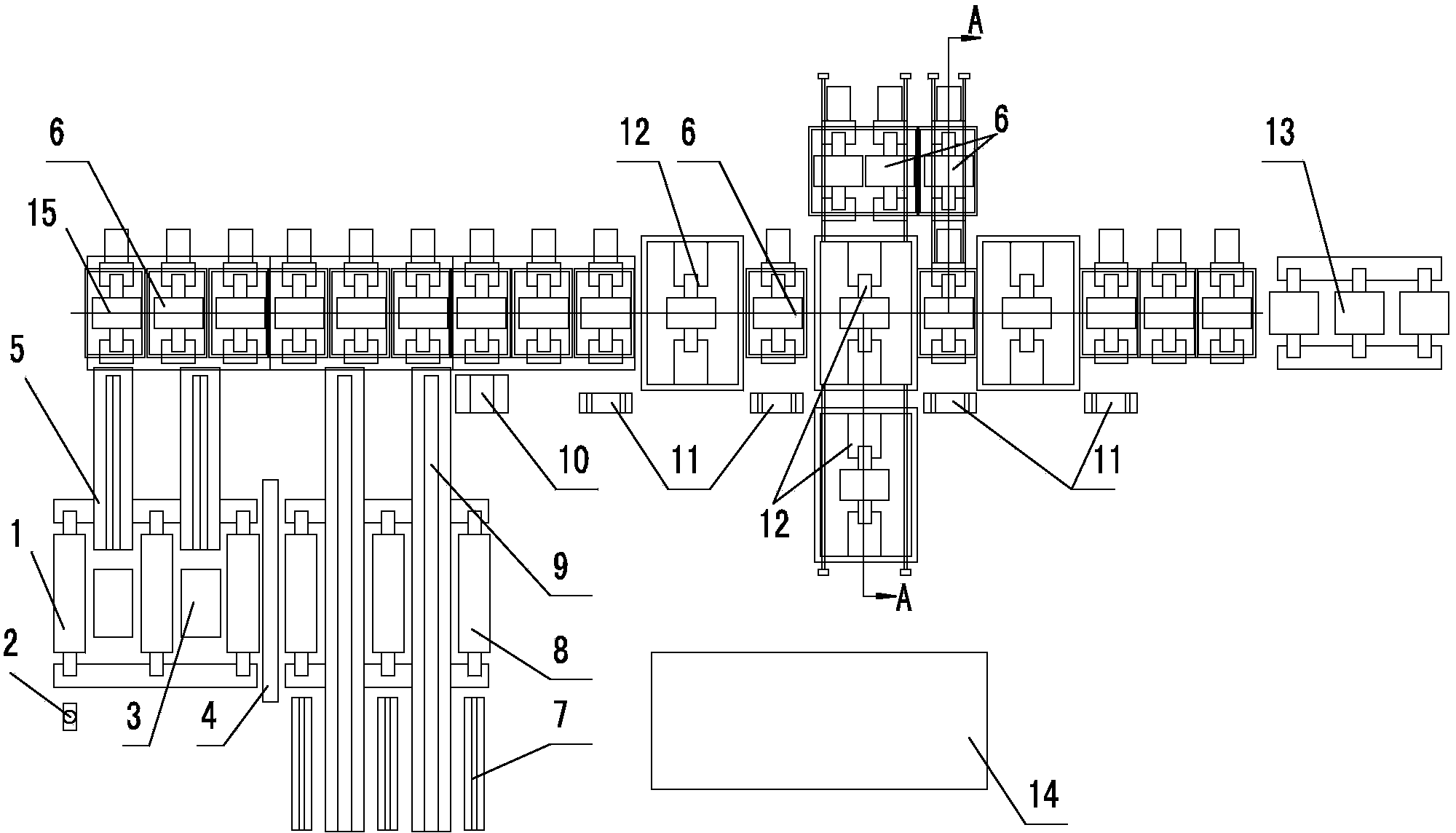

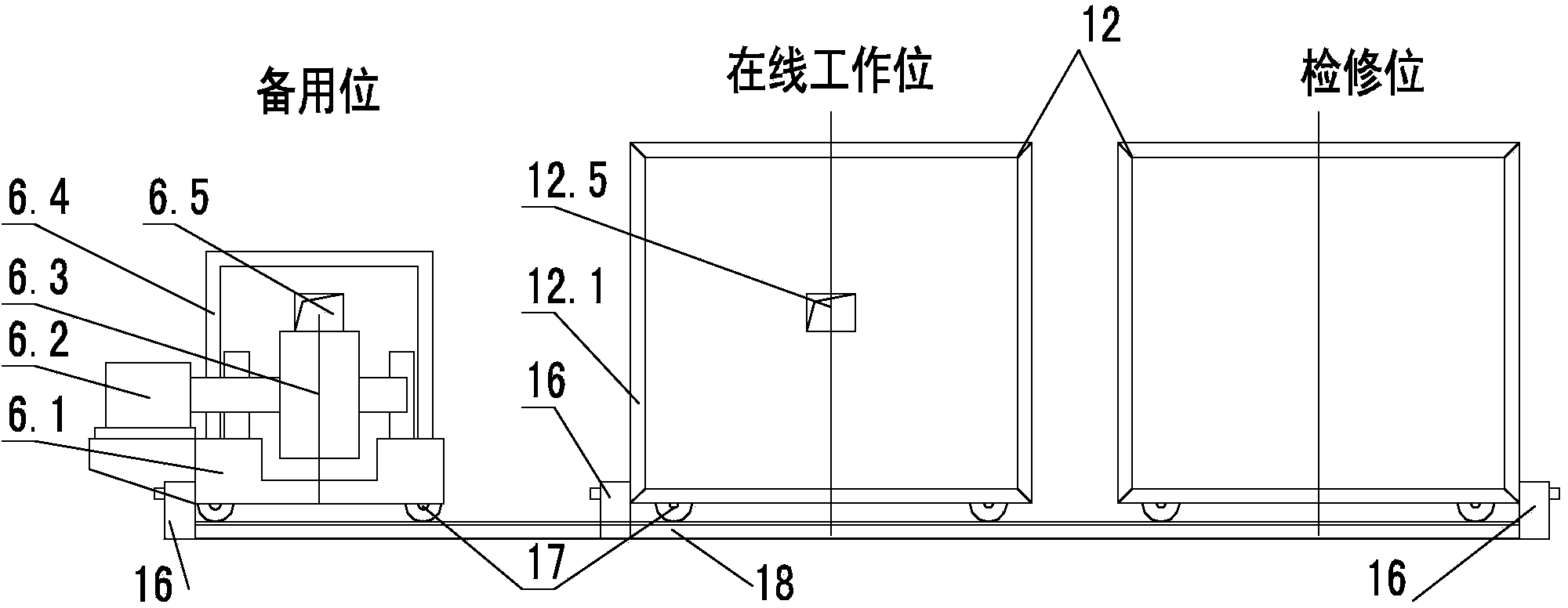

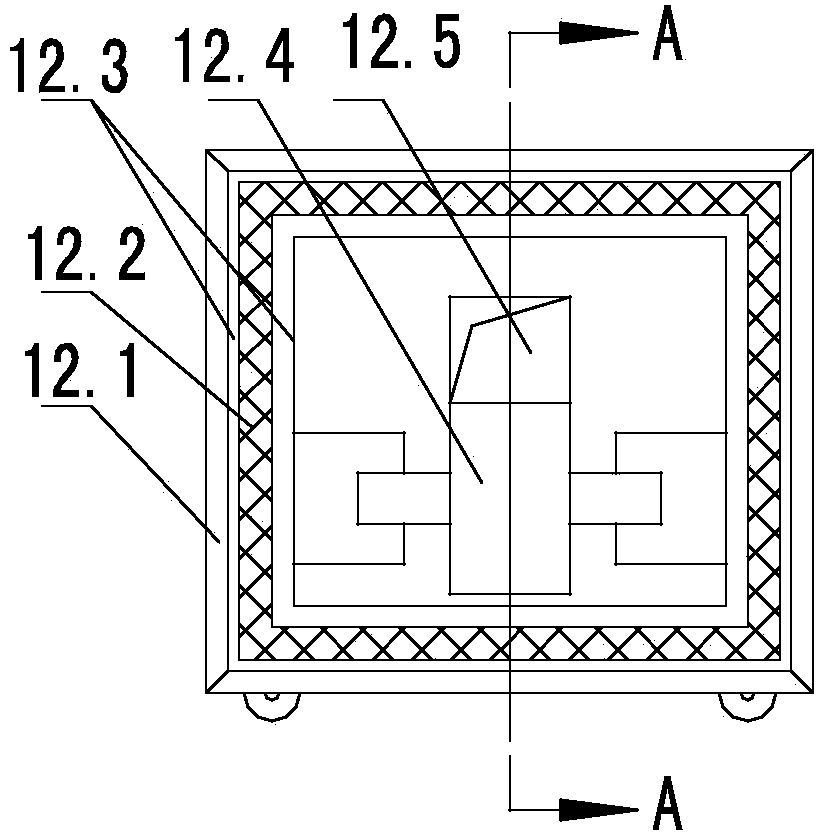

Continuous-casting and continuous-rolling integrating device and process

ActiveCN103464463AReduce heat lossIncrease profitTemperature control deviceMetal rolling arrangementsHeating timeEngineering

The invention relates to a continuous-casting and continuous-rolling integrating device and a continuous-casting and continuous-rolling integrating process. An ejection roller way in an ejection roller way ejection area and a transition roller way are linearly and continuously jointed and a moveable baffle plate which can automatically lift is arranged at the joint; the ejection roller way and a heat conveying roller way are jointed through a casting blank separating device with a heat-preserving device; a set of blank-separating collecting device which can move bi-directionally is jointly used between a cooling bed and the transition roller way as well as between the transition roller way and the heat conveying roller way and can drive casting blanks to bi-directionally move between the cooling bed and the transition roller way; a heater is arranged on the heat conveying roller way; the tail end of the heat conveying roller way is jointed with a rolling machine. According to heat conveying and rolling requirements, the casting blanks are selected, separated and collected, according to casting blank temperature data which is detected in real time, the heating temperature and the heating time are automatically adjusted, the casting blanks are heated to the temperature meeting the rolling requirement and are fed into the rolling machine to be rolled, the metal yield can be increased, the continuous-casting blank quality can be improved, the energy consumption can be reduced, the utilization efficiency, the maintenance rate and the production efficiency of equipment are improved, and the investment cost and the operation cost are reduced.

Owner:HUBEI CENT STEEL UNION METALLURGICAL ENG

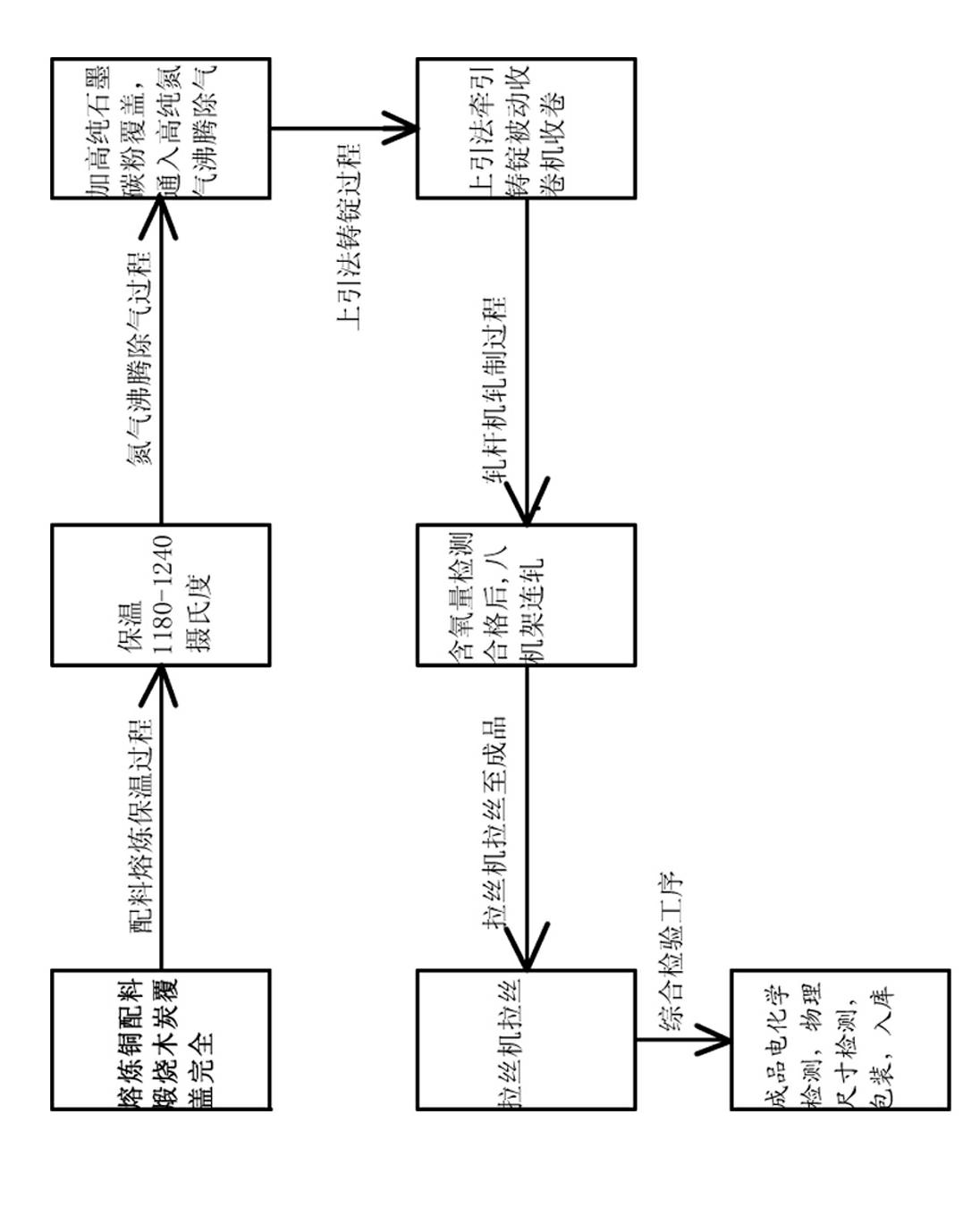

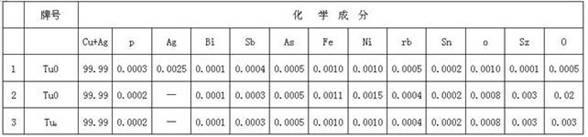

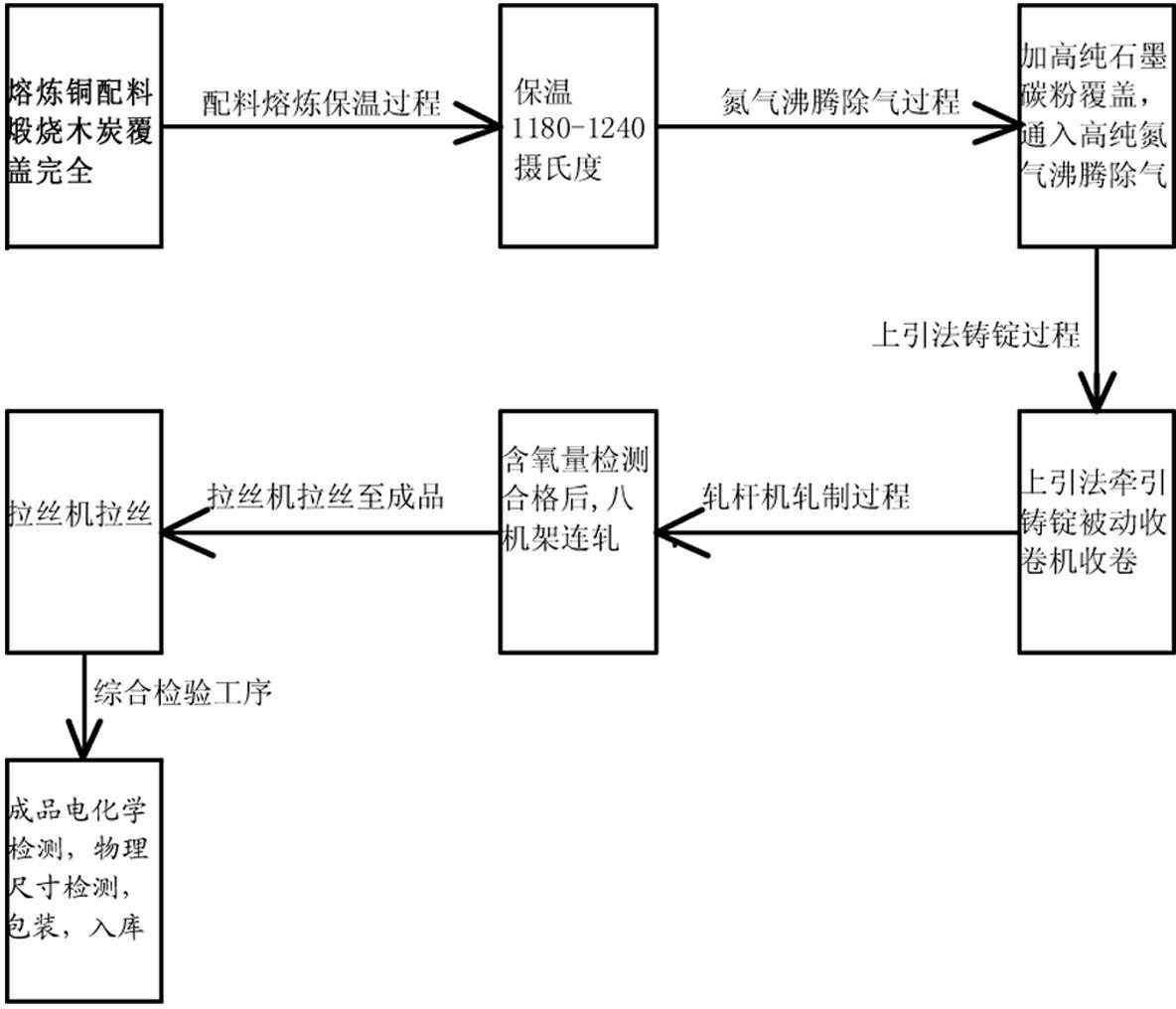

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

Thermal treatment method for wear-resistant low alloy steel

InactiveCN102758067AImprove wear resistanceImprove mechanical propertiesHeat treatment process controlTemperingMetallic materials

The invention discloses a thermal treatment method for wear-resistant low alloy steel, and relates to the field of the machining of metal materials. The thermal treatment method provided by the invention comprises the following steps of: heating a low alloy steel workpiece in thermal equipment, discharging out of a furnace after heat preservation at constant temperature, immediately putting the part which needs wear resistance in the workpiece discharged out of the furnace into a quenching pond which is filled with water and quenching oil at the same time to be quenched, naturally cooling after quenching, transforming the workpiece into a tempering furnace, preserving the heat in a heating way, and carrying out furnace cooling or air cooling in a discharging way after the heat is preserved. The thermal treatment method disclosed by the invention has the characteristics that the local water quenching, the local oil quenching and the local air cooling of the workpiece can be combined with one another, the hardness, the strength and the abrasive resistance of the part which is easy to wear in the workpiece can be improved as required, the workpiece is guaranteed to be hard to wear, the impact toughness of the part which needs high tenancy can be guaranteed, the whole comprehensive mechanical property of the workpiece can be improved, and the use requirement of wear-resistant pieces such as the wear-resistant plate hammer, the lining plate, the hammer head, the impact plate, the bucket teeth and the like can be met. The thermal treatment method disclosed by the invention has the advantages of being simple and easy, and low in production cost.

Owner:JINAN UNIVERSITY

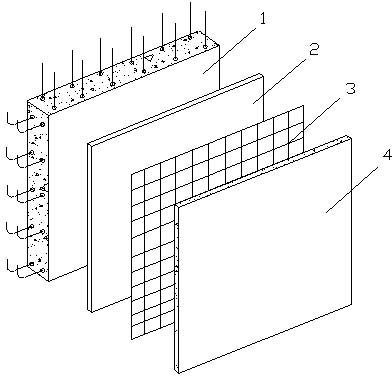

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

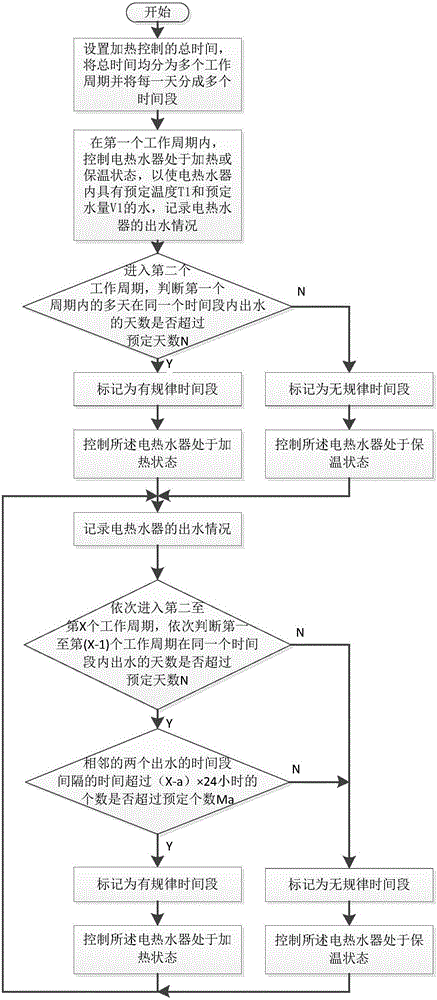

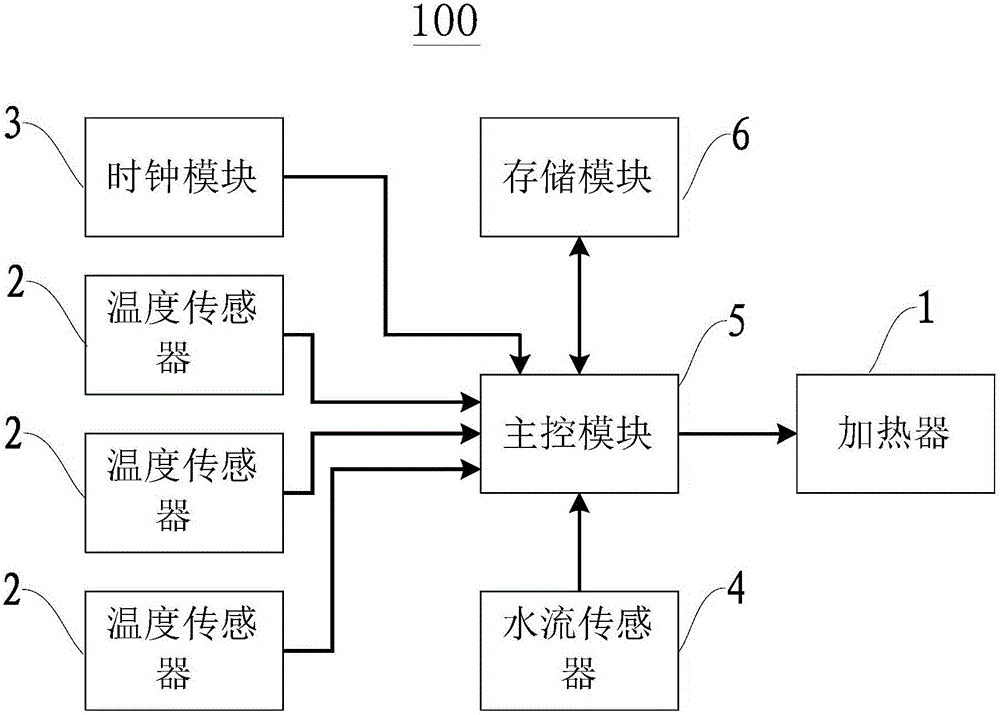

Electric water heater and heating control method thereof

ActiveCN105698397AHeating real-time adjustmentAvoid repeated heatingFluid heatersWater useWork period

The invention discloses an electric water heater and a heating control method thereof. The heating control method comprises steps as follows: the total time for heating control is arranged and equally divided into a plurality of work period, and each day in each work period is divided into a plurality of time slots; in the first work period, the electric water heat is controlled to carry out heating or heat preservation, so that reserved hot water is kept in the electric water heater; the second work period is entered, whether the number of days, in which water is discharged at the same time slot, in a plurality of days in the first work period is larger than the predetermined number of days (N), is judged; if the number of days is larger than A, the time slot is a regular time slot; if not, the time slot is an irregular time slot; in the second work period, the electric water heat is controlled to carry out heating or heat preservation, so that reserved heat water volume is kept in the regular time slot; work periods after the second work period are entered sequentially, in each work period, whether time slots are regular or irregular time slots is judged, and the electric water heater is controlled to carry out heating or heat preservation according to the result. According to the heating control method, water use habits of users can be followed up, and heating is adjusted in real time.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

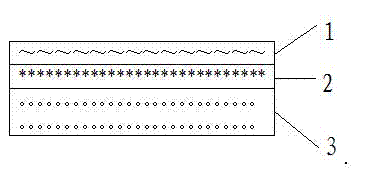

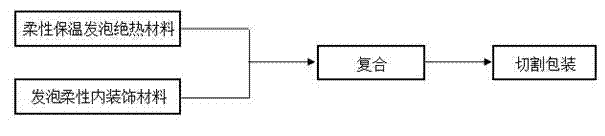

Flexible thermal-insulating decorative material for internal wall and method for producing flexible thermal-insulating decorative material

ActiveCN102505820ALow densityImprove the decorative effectCovering/liningsSynthetic resin layered productsAdhesive cementThermal insulation

The invention discloses a flexible thermal-insulating decorative material for an internal wall and a producing method for the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material is composed of a flexible inner decorative layer, an adhesive layer and a flexible foamed heat-insulating layer. The invention also provides a method for producing the flexible thermal-insulating decorative material. The flexible thermal-insulating decorative material for the internal wall has the advantages of low energy consumption, good benefit, simple construction and large market, and integrates thermal insulation, damp prevention, mold prevention, sound insulation and decoration; the combination of a flexible foamed heat-insulating material and a flexible decorative material for the internal wall to form the unique decorative material for the internal wall is a great breakthrough for emission reduction and energy conservation of a wall body; and the flexible thermal-insulating decorative material for the internal wall is particularly applicable to energy-saving reconstruction of old buildings.

Owner:四川金路高新材料有限公司

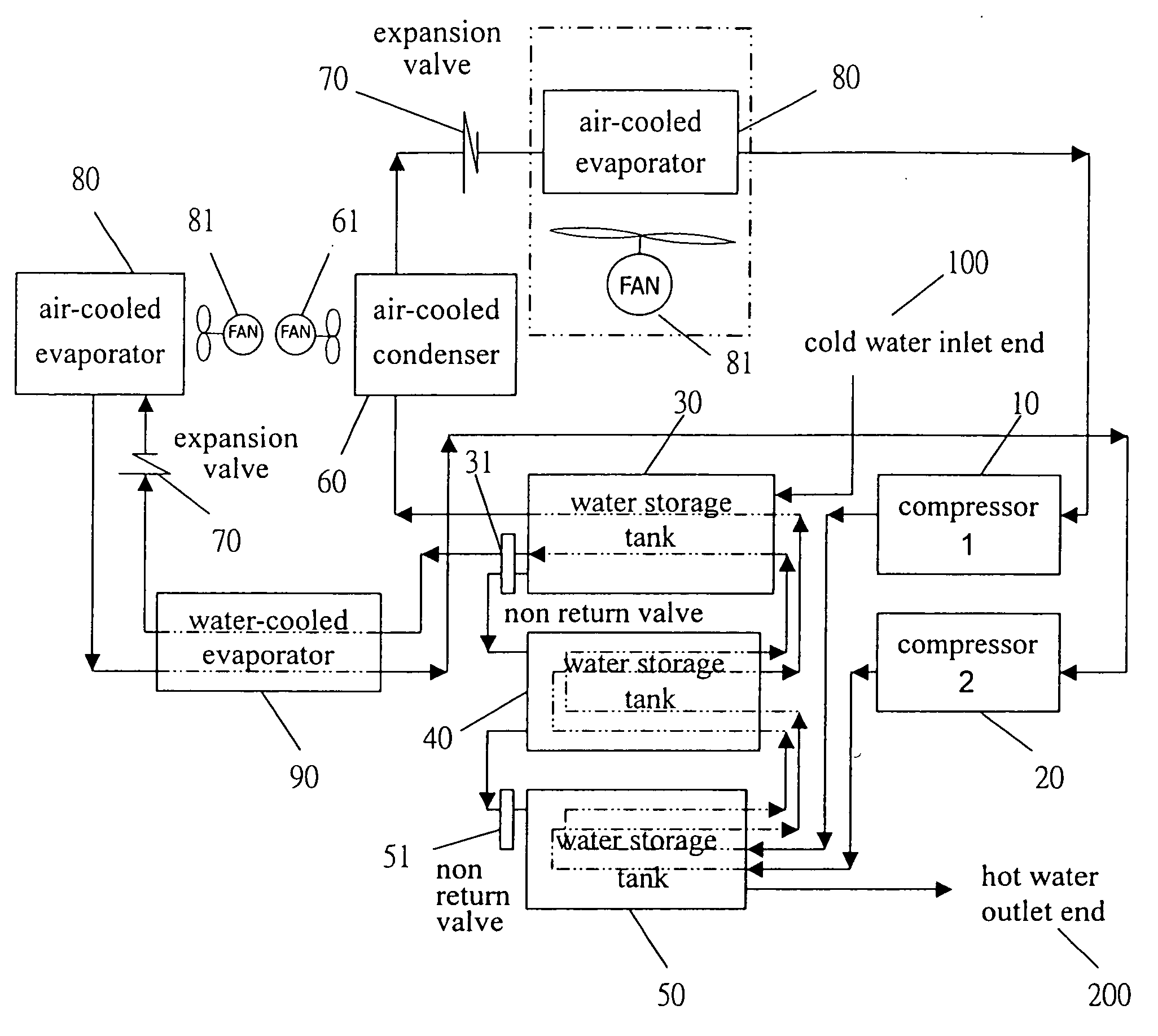

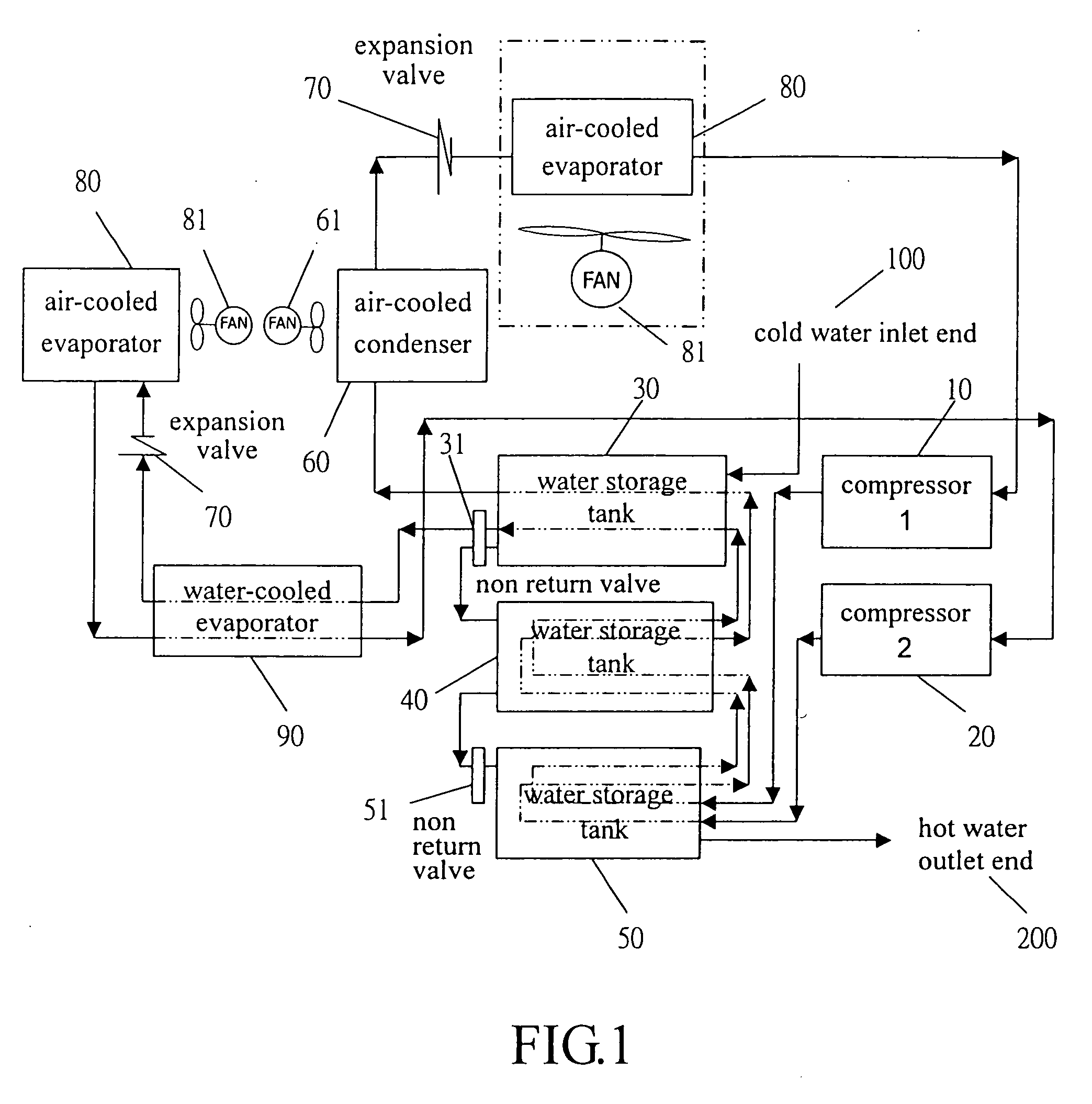

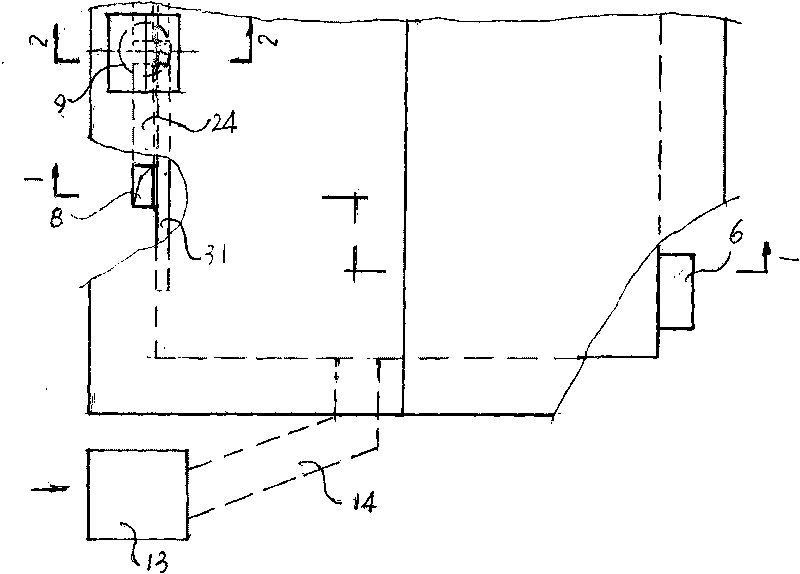

Heating and heat recovery unit for an air conditioning system

InactiveUS20100000709A1Facilitates heat recoveryImprove efficiencyCentral heating with accumulated heatHeat storage plantsWater storage tankEngineering

A heating and heat recovery unit for an air conditioning system, which is assembled from compressors, several insulated water storage tanks, an air-cooled condenser, expansion valves, air-cooled evaporators and a water-cooled evaporator. The compressors are suitable for various types of air conditioning systems and refrigerant heat pump water heater systems. The installed water storage tanks are arranged according to size, from the largest at the top down to the smallest at the bottom. A high-temperature and high-pressure refrigerant from the compressors is first input into the smallest tank, and after passing through to the largest tank, it is then passed on to the expansion valve and the evaporator. A configuration of cold water pipes is provided for input into the largest tank through to the smallest tank 50, and output therefrom. Hence, the heat exchange flow process consists of heating of cold water after entering from a cold water inlet end, and heating the water before output at a hot water outlet end, moreover, each of the tanks can be independently heated to raise the temperature thereof.

Owner:CHANG TSUNG CHE

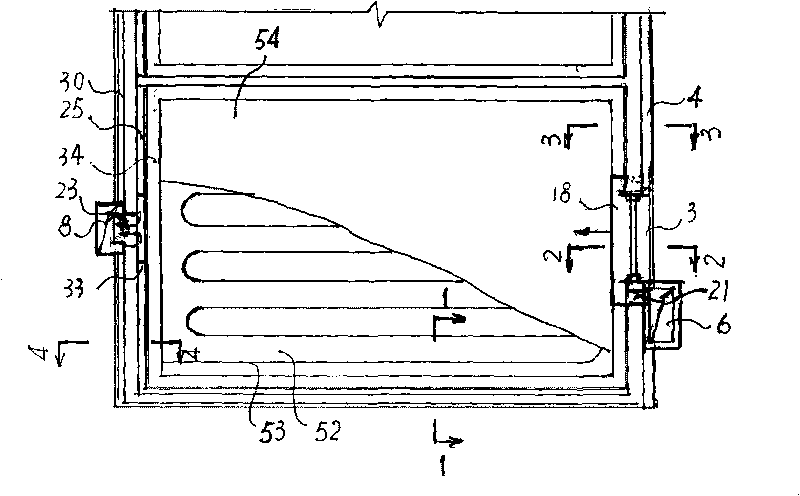

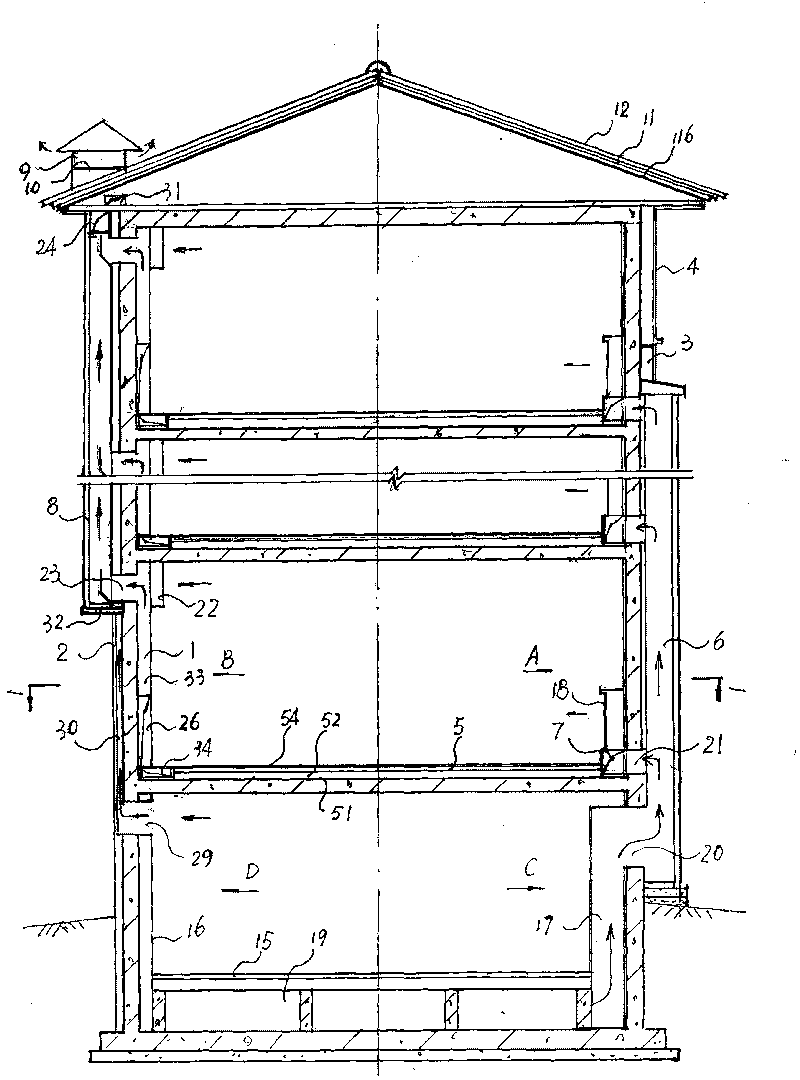

Novel ventilation air-conditioning ecologic building and construction method thereof

InactiveCN101736818ACondition the indoor airAdjustable temperatureRoof covering using tiles/slatesLighting and heating apparatusCold airBasement

The invention relates to a novel ventilation air-conditioning ecologic building which is suitable for various industrial and civil buildings. The novel ventilation air-conditioning ecologic building is characterized by comprising an ecologic ventilation air-conditioning circulation system, a ventilation air-conditioning heat and sound insulating wall, a solar energy heated air-conditioning wall, a ventilation air-conditioning floor, and the like. By utilizing solar energy and wind energy power generation to provide natural and clean power for ventilation, when the outdoor fresh air and an underground gas in a basement, i.e., ground-source heat which is warm in winter and cool in summer, are collected by the ecologic ventilating circulation system, the hot air or cold air generated by the solar energy heated air-conditioning wall and the ventilation air-conditioning floor is also delivered into a room. In addition, the residual heat in the indoor air is discharged outside after being effectively utilized by the ventilation heat and sound insulating wall which can effectively utilize the residual heat in the indoor air and an ecologic exhaust system, thereby achieving the effect of adjusting the indoor air and temperature. The invention has the advantages of commercial assembly type construction, simple and convenient construction, high working efficiency, short construction period, low cost, energy saving, environmental protection, and the like.

Owner:冯刚克

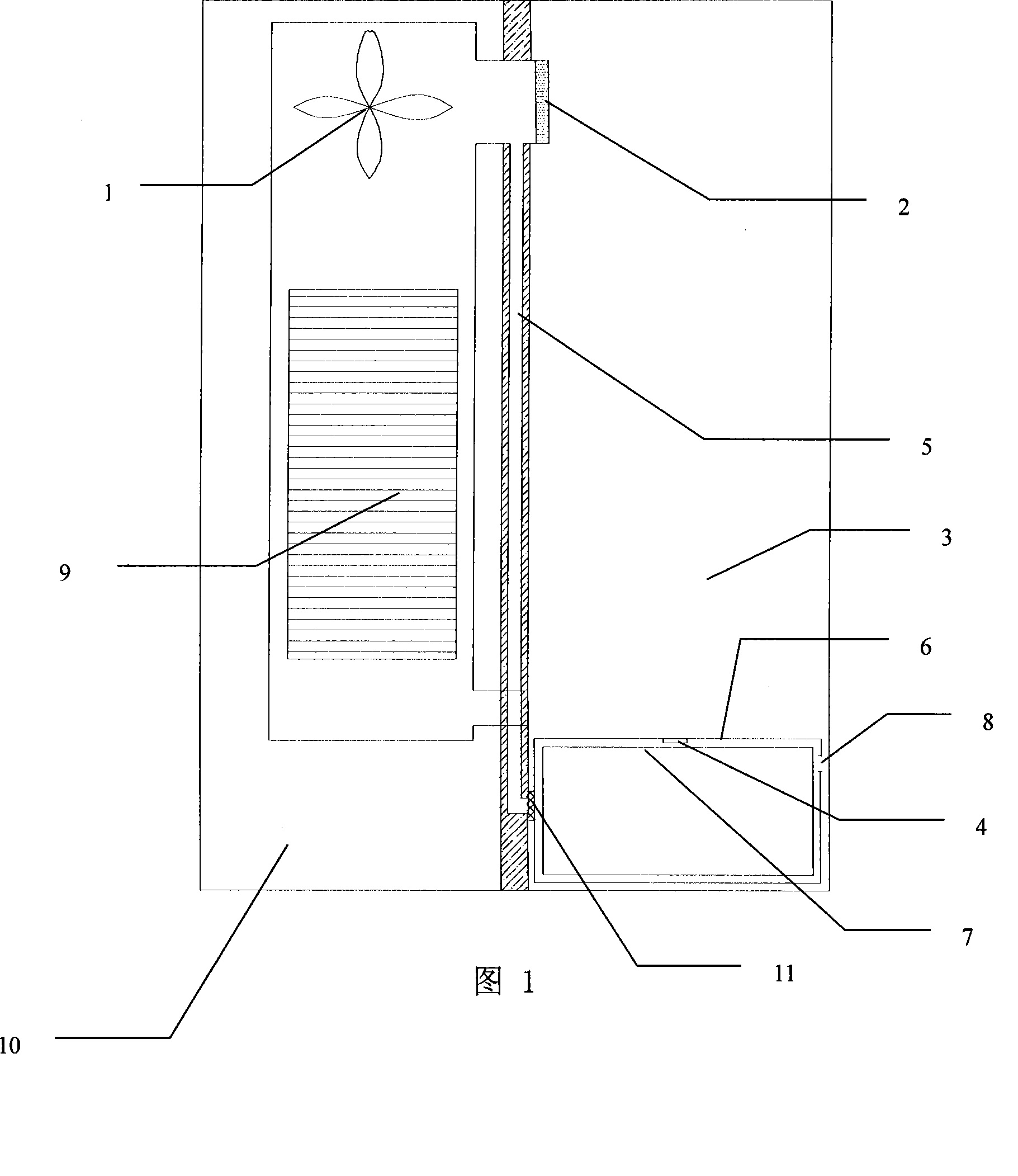

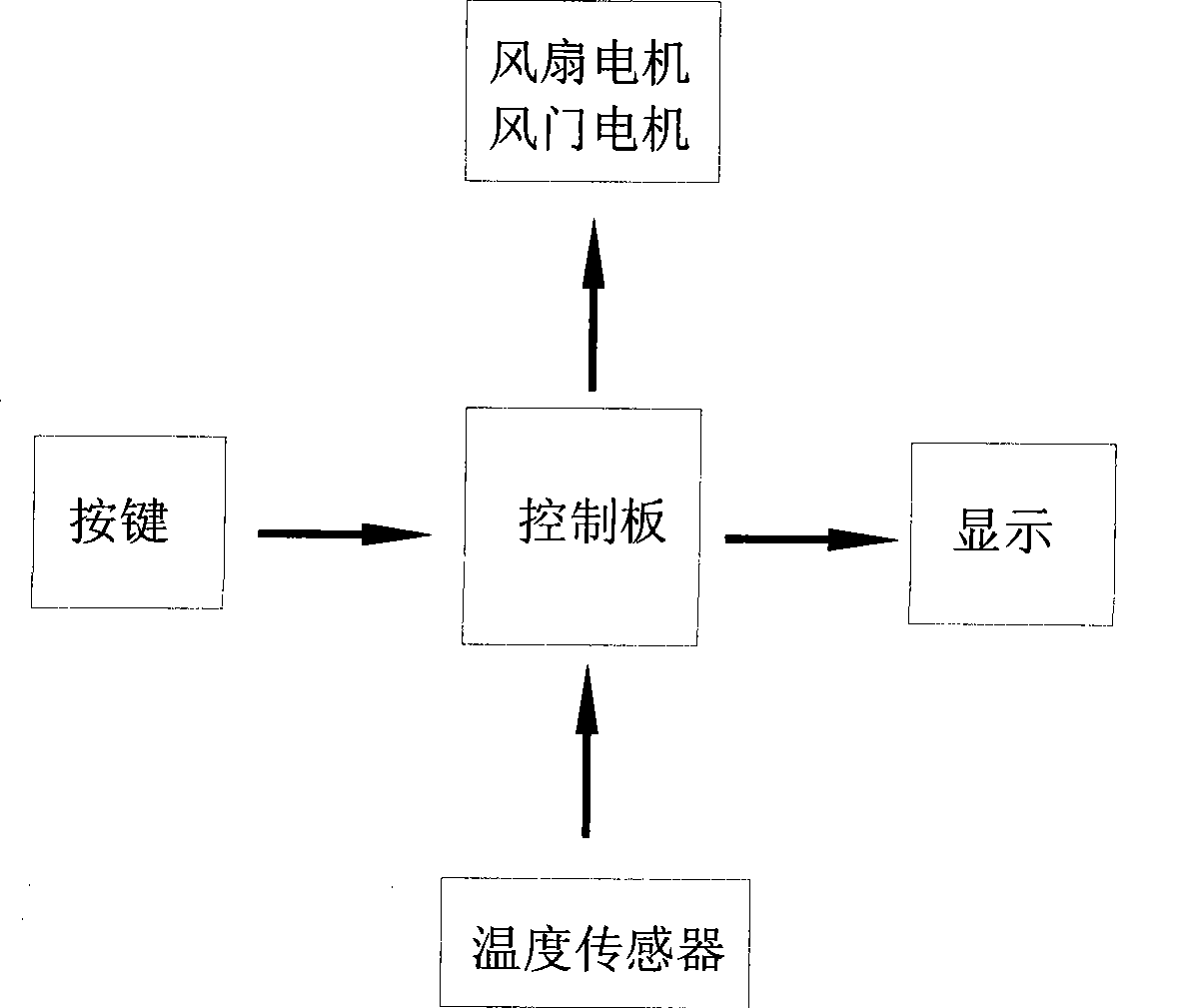

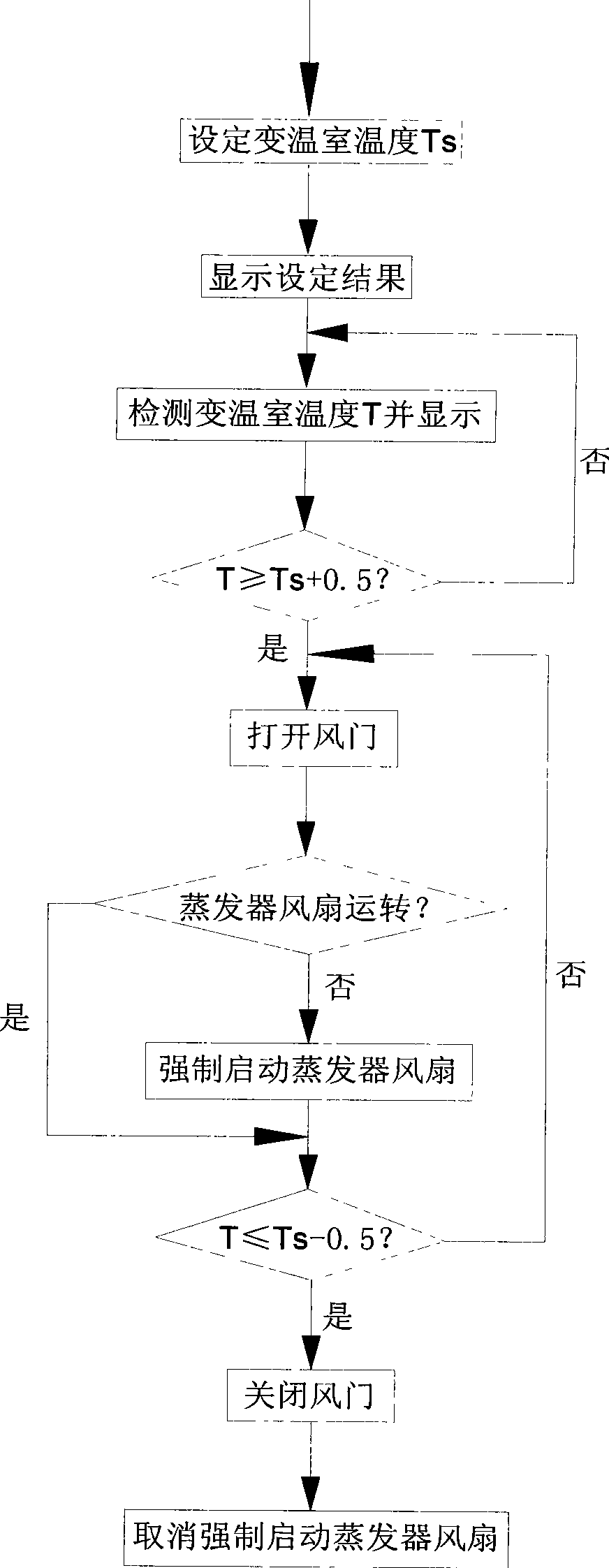

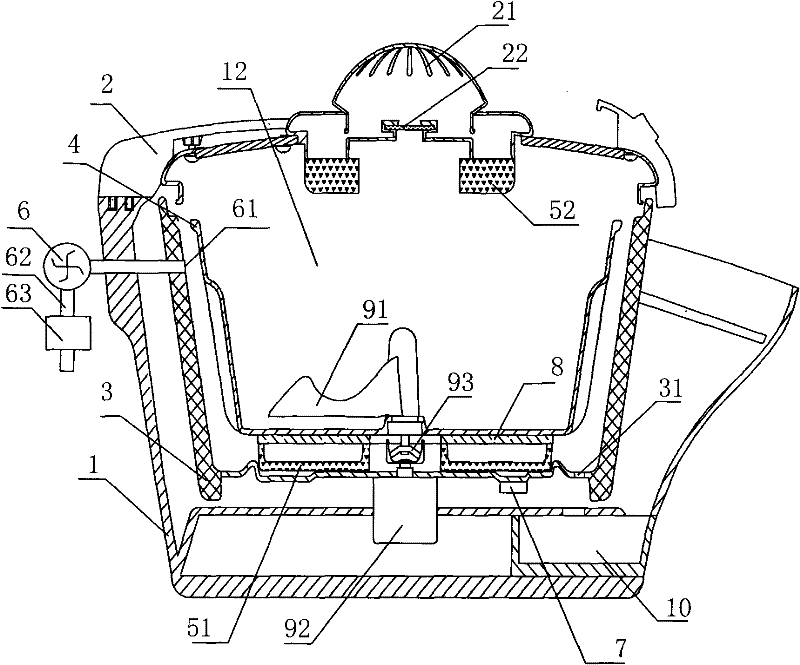

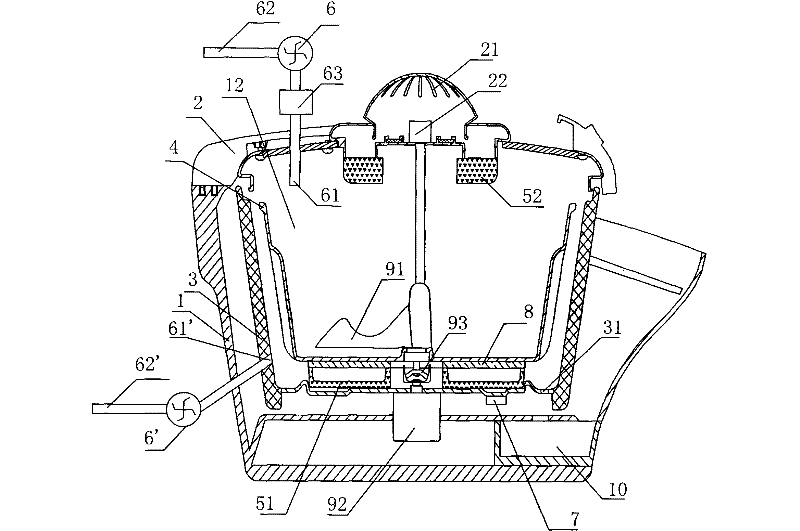

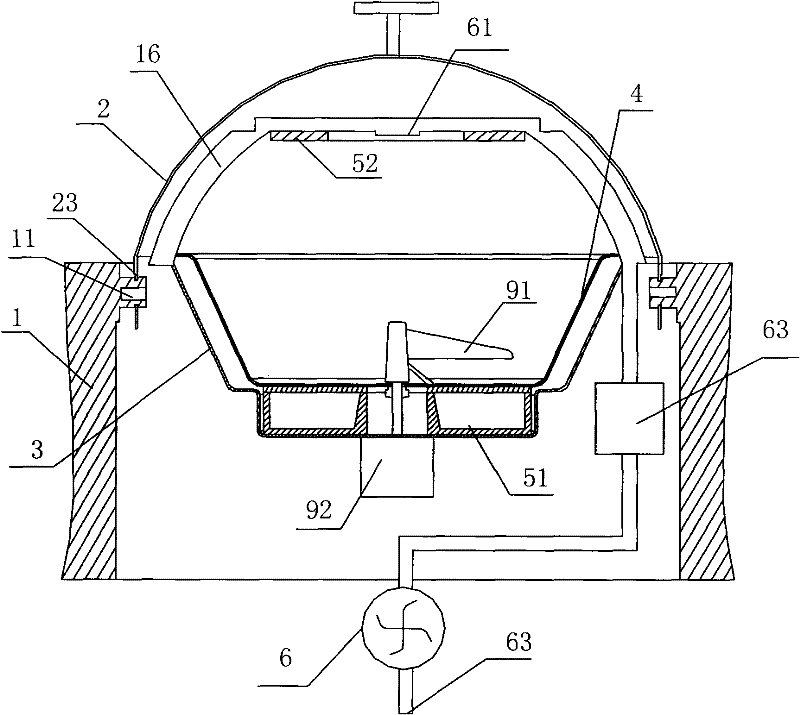

Improved refrigerator with temperature-variable room

InactiveCN101413747ASatisfy preservation requirementsWill not formLighting and heating apparatusDomestic refrigeratorsFrostAir volume

An improved refrigerator with a cool select zone comprises a refrigerating room, a cold room, the cool select zone and a control part. The cool select zone is arranged in the cold room and provided with an air inlet and an air outlet. The refrigerator also comprises an induced duct, one end of which is connected with the refrigerating room and the other end of which is connected with the air inlet of the cool select zone; as well as an air quantity control structure connected with the induced duct. The control method for the refrigerator comprises: when T is more than Ts-0.5, a controller opens an electric air door to lead cooling air and the on-state of an evaporator fan is retained, if the fan stops, the fan is forcedly started to speed up the flow of cooling air and lower the temperature; when T is less than Ts-0.5, the controller closes the electric air door, the fan recovers to the normal operating state for heat preservation. The refrigerator can conveniently set the temperature to satisfy the fresh-keeping requirements of most daily food; moreover, the refrigerator has the advantages of simple structure, high speed of temperature change, wide regulation range, no remaining frost formation, etc..

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

Cooking device

The embodiment of the invention provides a cooking device comprising a shell, an upper cover hinged with the upper end part of the shell, a heat insulating inner cylinder fixedly arranged in the shell, a cooking pot arranged in the heat insulating inner cylinder and a control device used for controlling the running of the cooking device, as well as a lower heating device positioned at the lower part of the cooking pot and fixedly arranged on an inner bottom surface of the heat insulating inner cylinder; an air inlet of an exhaust device is communicated with a cavity which is formed by the shell and the upper cover, and an air outlet thereof is communicated with the atmosphere and used for discharging waste gas in the cavity; a temperature control device is arranged at the bottom surface of the heat insulating inner cylinder and used for detecting the temperature of the cooking pot and sending temperature information to the control device so as to control a switch of the lower heating device; and the lower heating device, the exhaust device and the temperature control device are respectively electrically connected with the control device. In the cooking device, the lower heating device is used for heating food in the cooking pot, and the exhaust device is used for exhausting oil fume and water stream in the cavity of the cooking device, thus improving the quality of cooking food.

Owner:钱海鹏

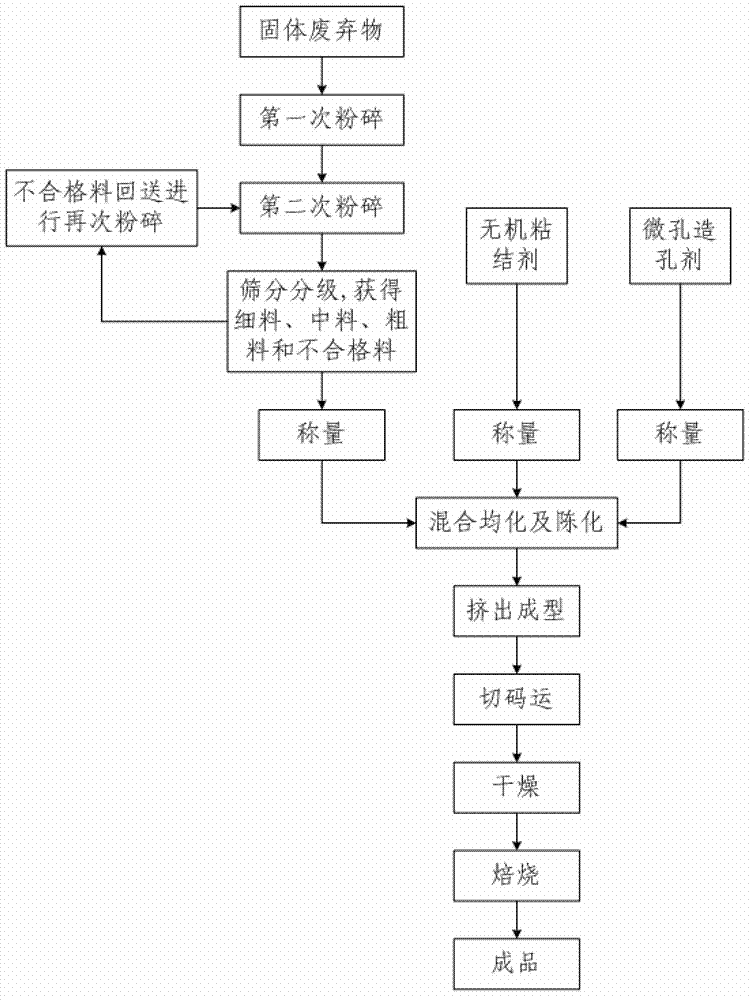

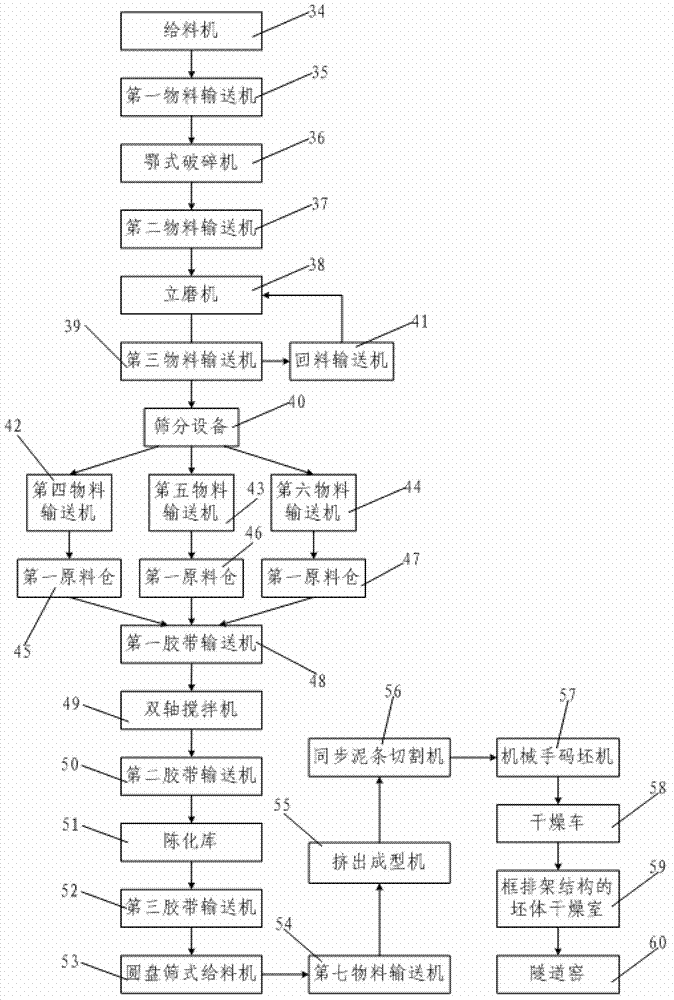

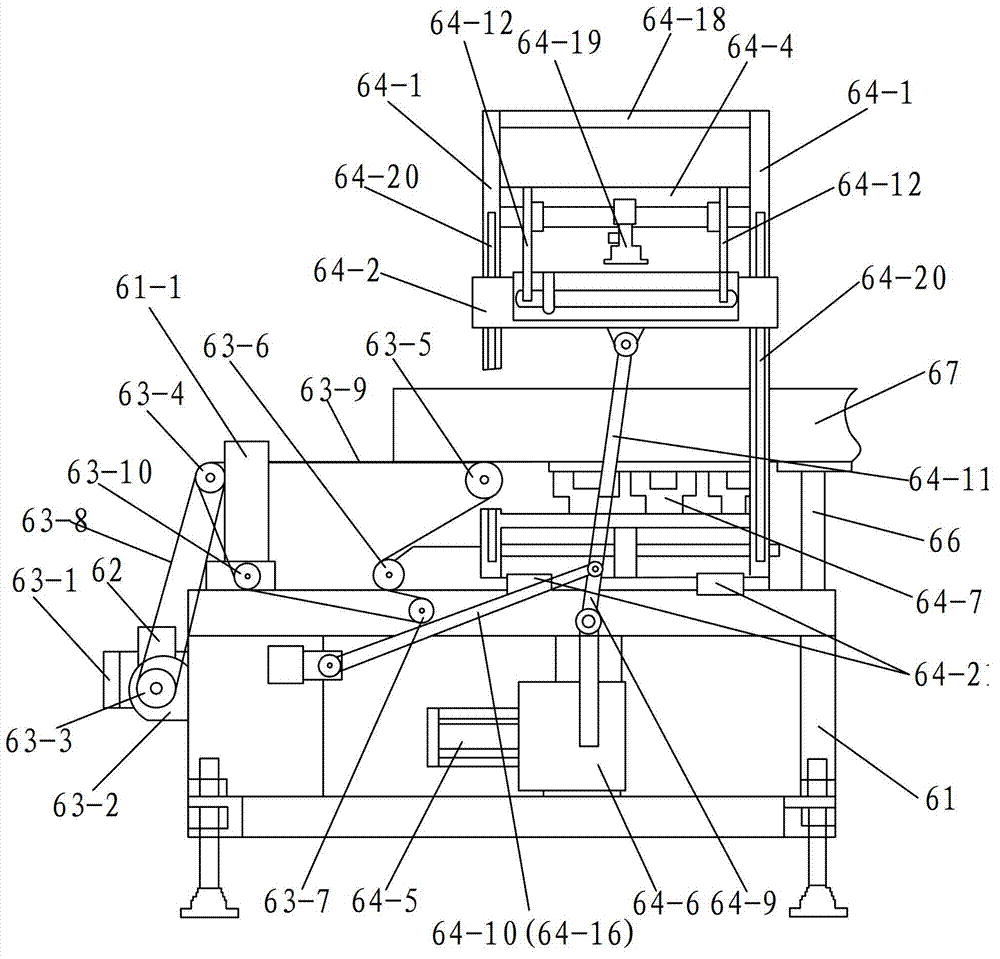

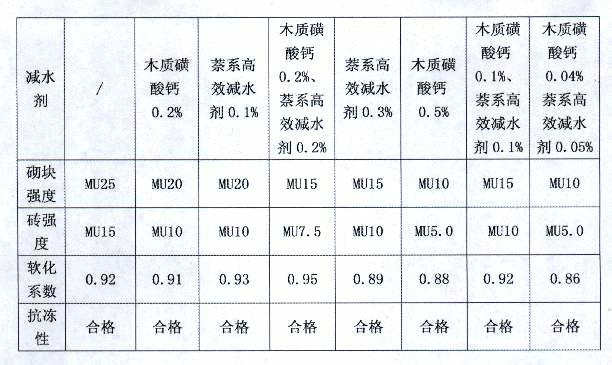

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Baking-free and steaming-free brick and building block and preparation method thereof

InactiveCN102010175ACuring reaction at room temperatureWith sound insulationSolid waste managementBrickLand resources

The invention discloses a baking-free and steaming-free brick, a baking-free and steaming-free building block and a preparation method thereof. The brick and the building block comprise the following components in percentage by weight: 5 to 40 percent of calcined magnesia, 1 to 25 percent of industrial waste slag, 4 to 35 percent of conditioner solution, 0 to 30 percent of reinforcing and thickening agent, 5 to 85 percent of aggregate, 0.01 to 8 percent of waterproof admixture and 0 to 0.5 percent of water reducing agent. The brick and the building block have the advantages of normal-temperature curing reaction, quick condensation and hardening, high strength, heat insulation, sound insulation, flame resistance and freezing resistance; the water resistance is improved, the service life of the product is prolonged, and meanwhile, the defects of moisture absorption, halogenation and scumming of the product are overcome; recycle and comprehensive utilization of solid wastes are promoted, and environmental pollution can be reduced; and the volume weight of the product can be lightened, the transportation energy consumption can be reduced, the thermal resistance can be improved, and the heat insulation performance can be improved. The brick and the building block have no toxicity, no smell, no radioactivity, no harm to human body and no environmental pollution, and have the characteristics of cleanliness and environmental friendliness; and clay is not adopted so that the tilled land resources can be effectively protected.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

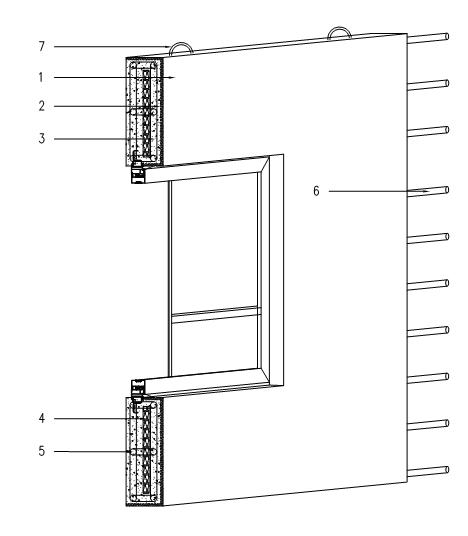

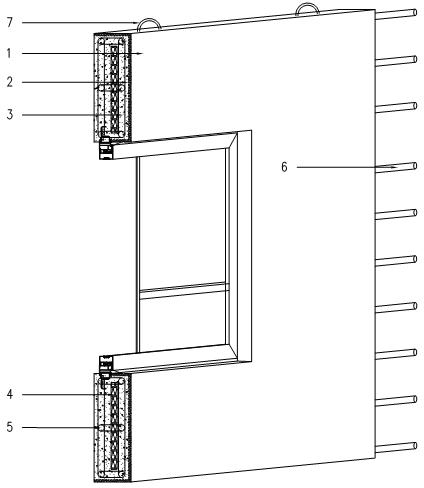

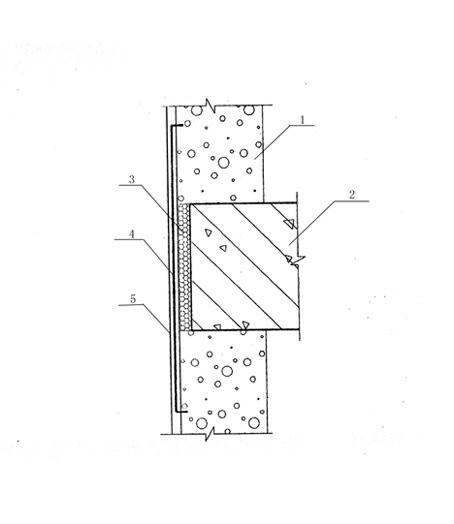

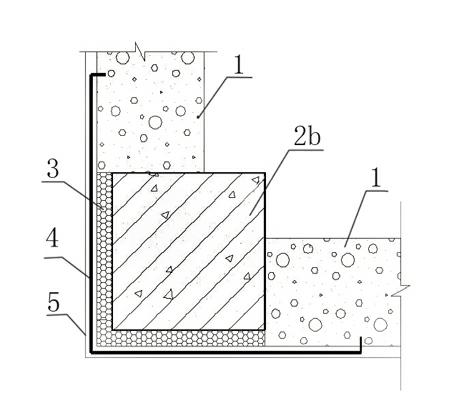

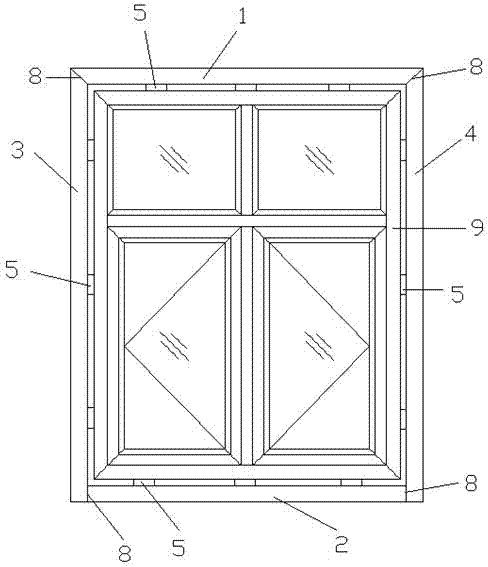

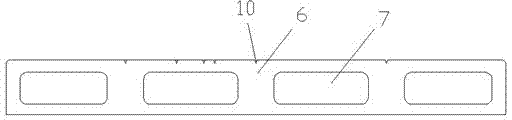

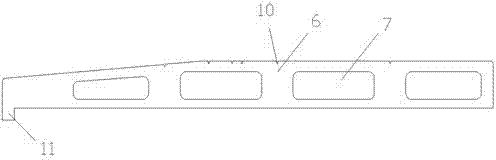

Energy-saving door and window attached frame and door and window installation method

ActiveCN102777103AAvoid installationSolve the connection waterproof problemFrame fasteningWindow/door framesBuilding energyConstruction engineering

Owner:JIANGSU HONGSHA DOOR & WINDOW +1

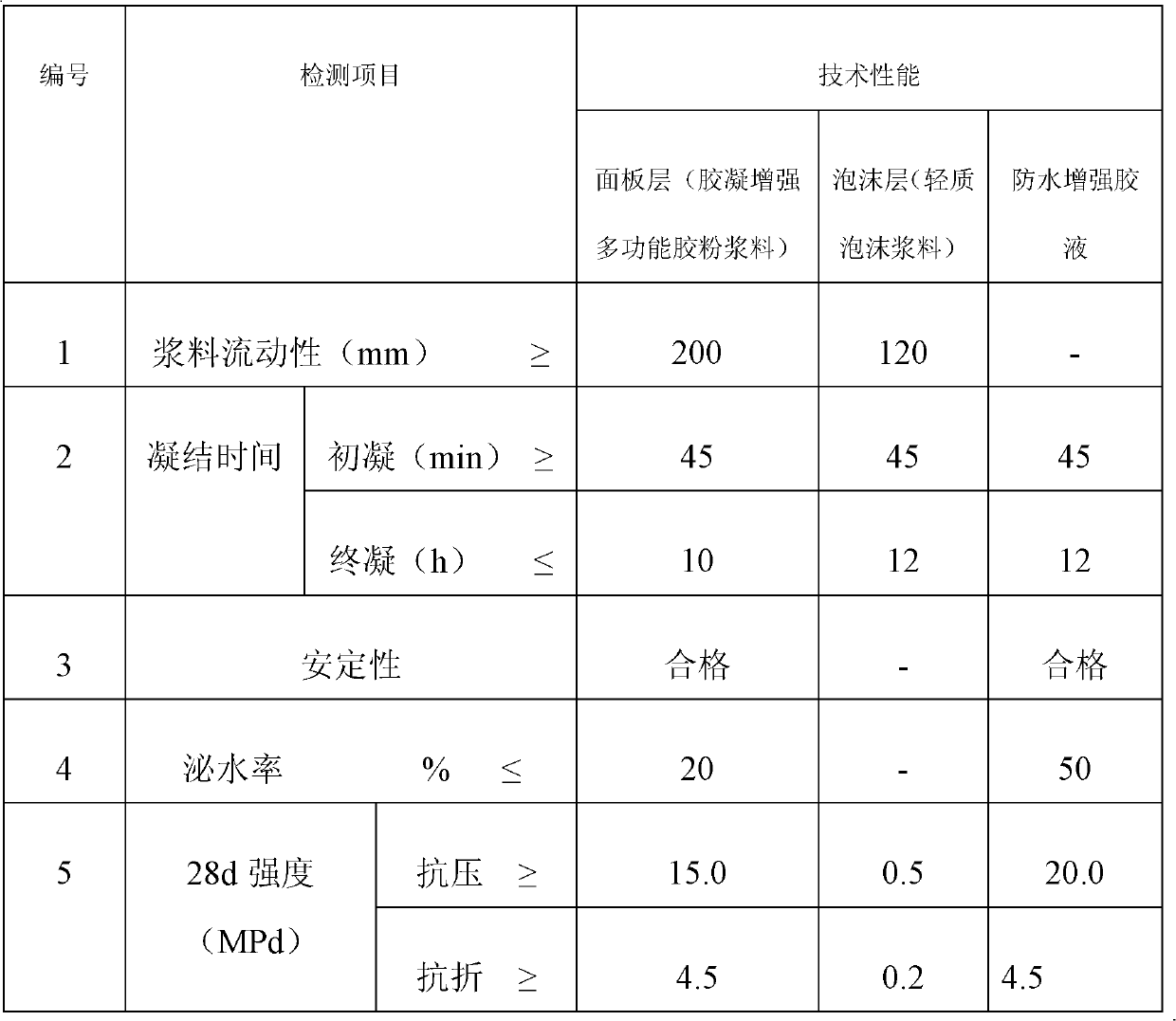

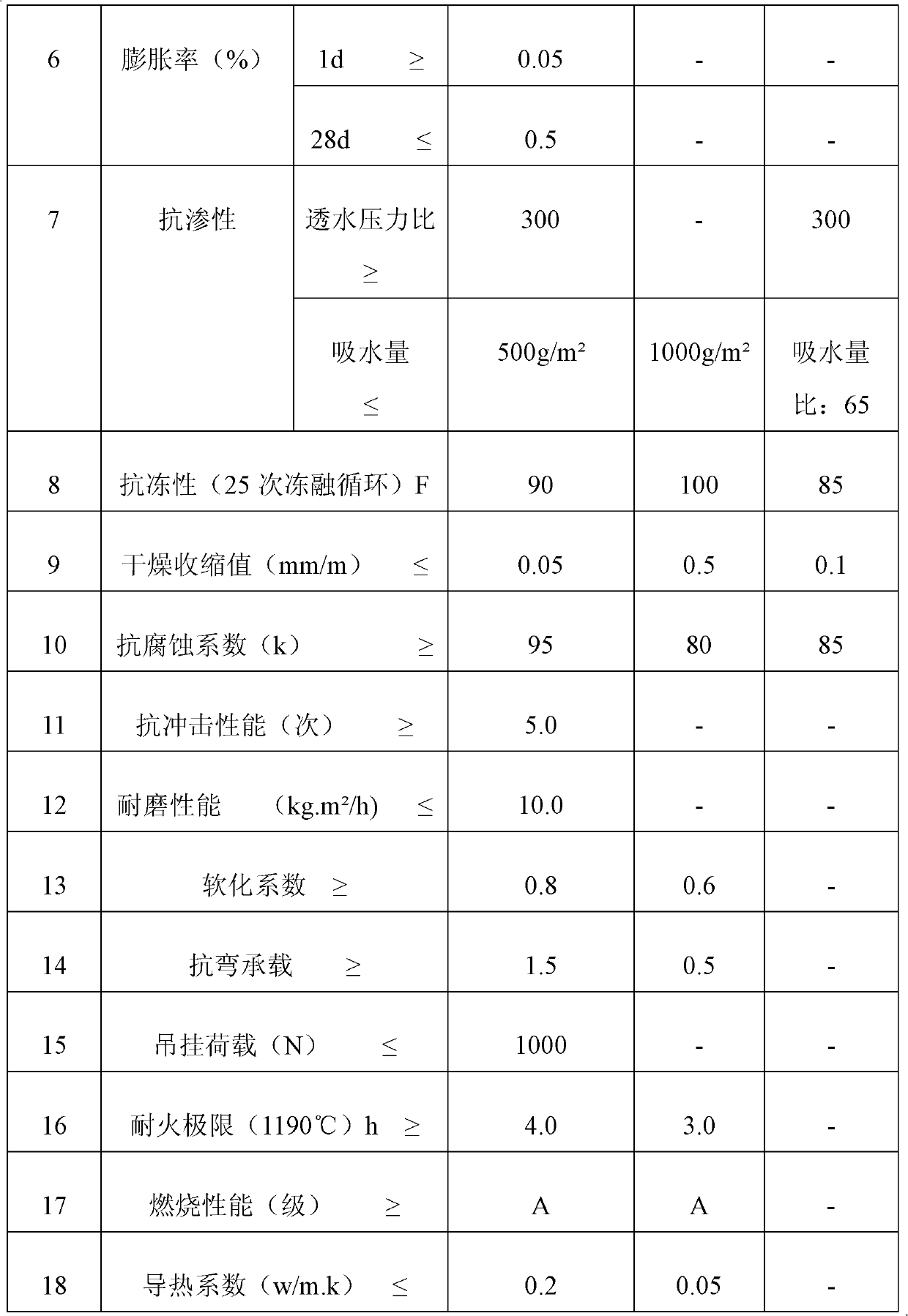

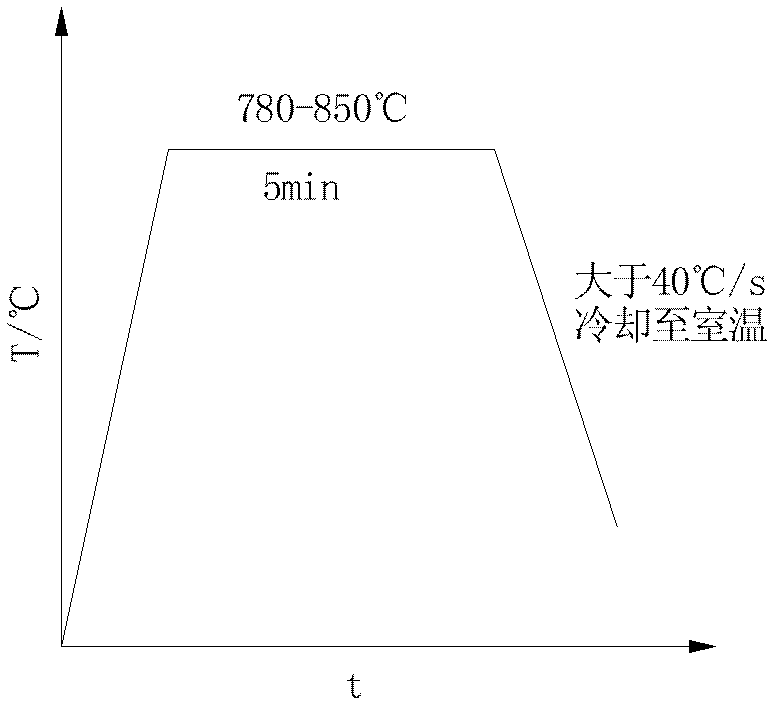

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

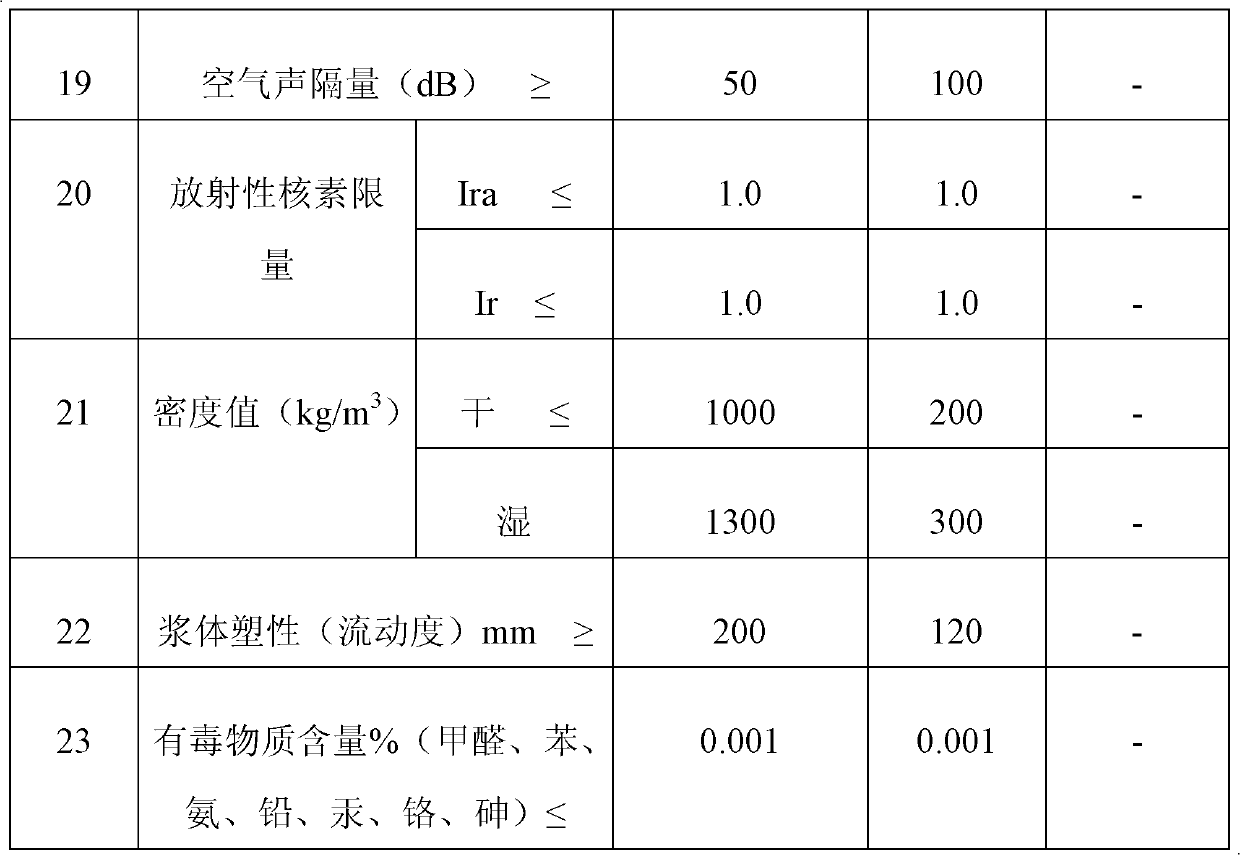

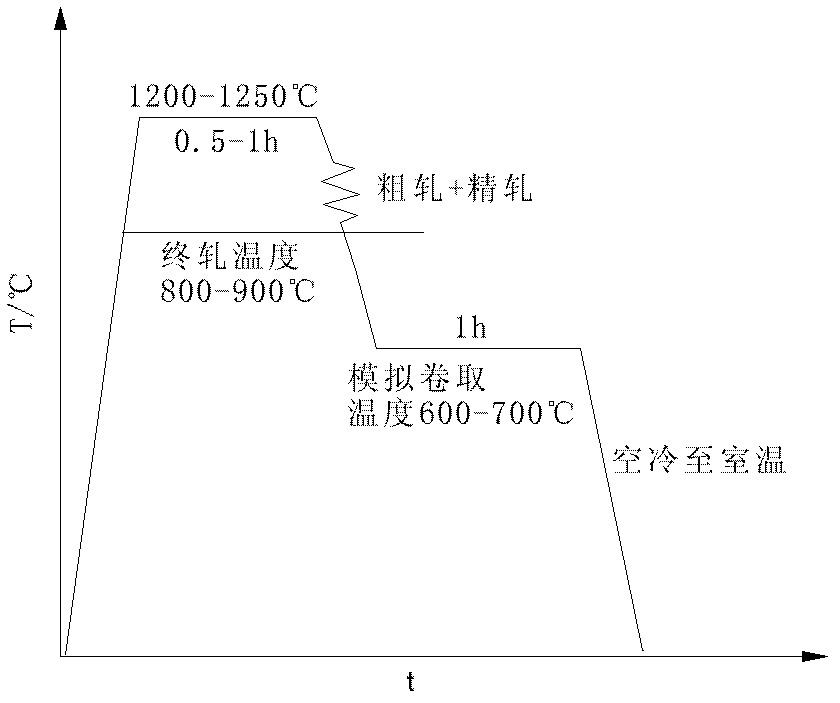

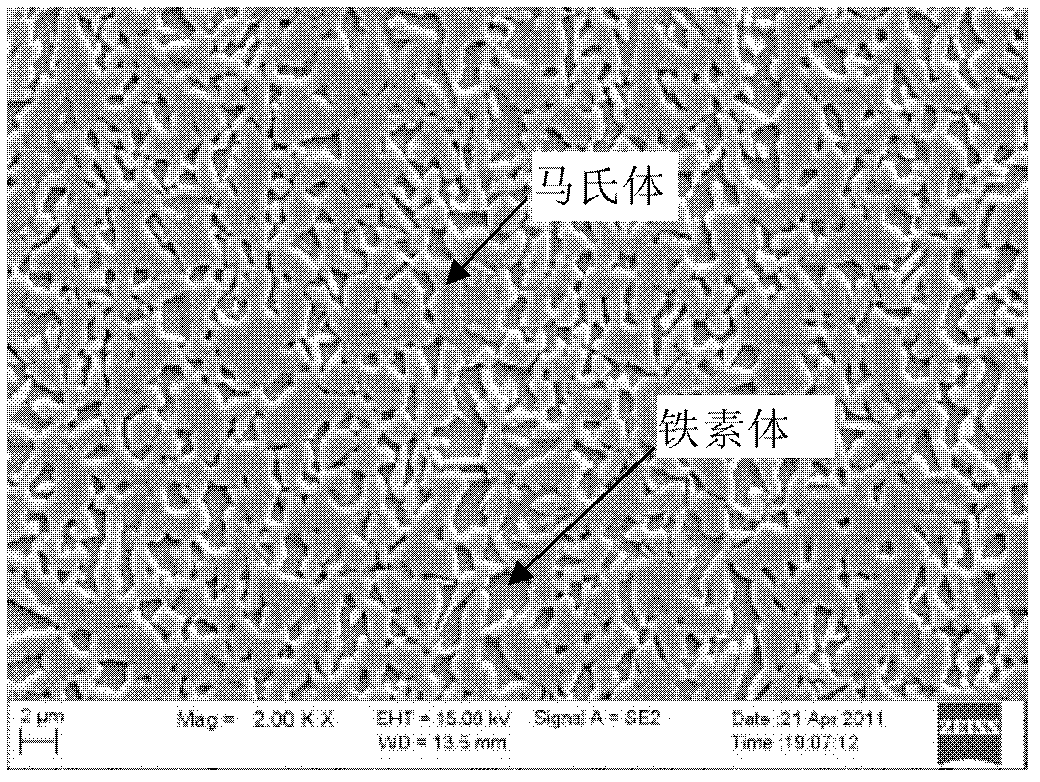

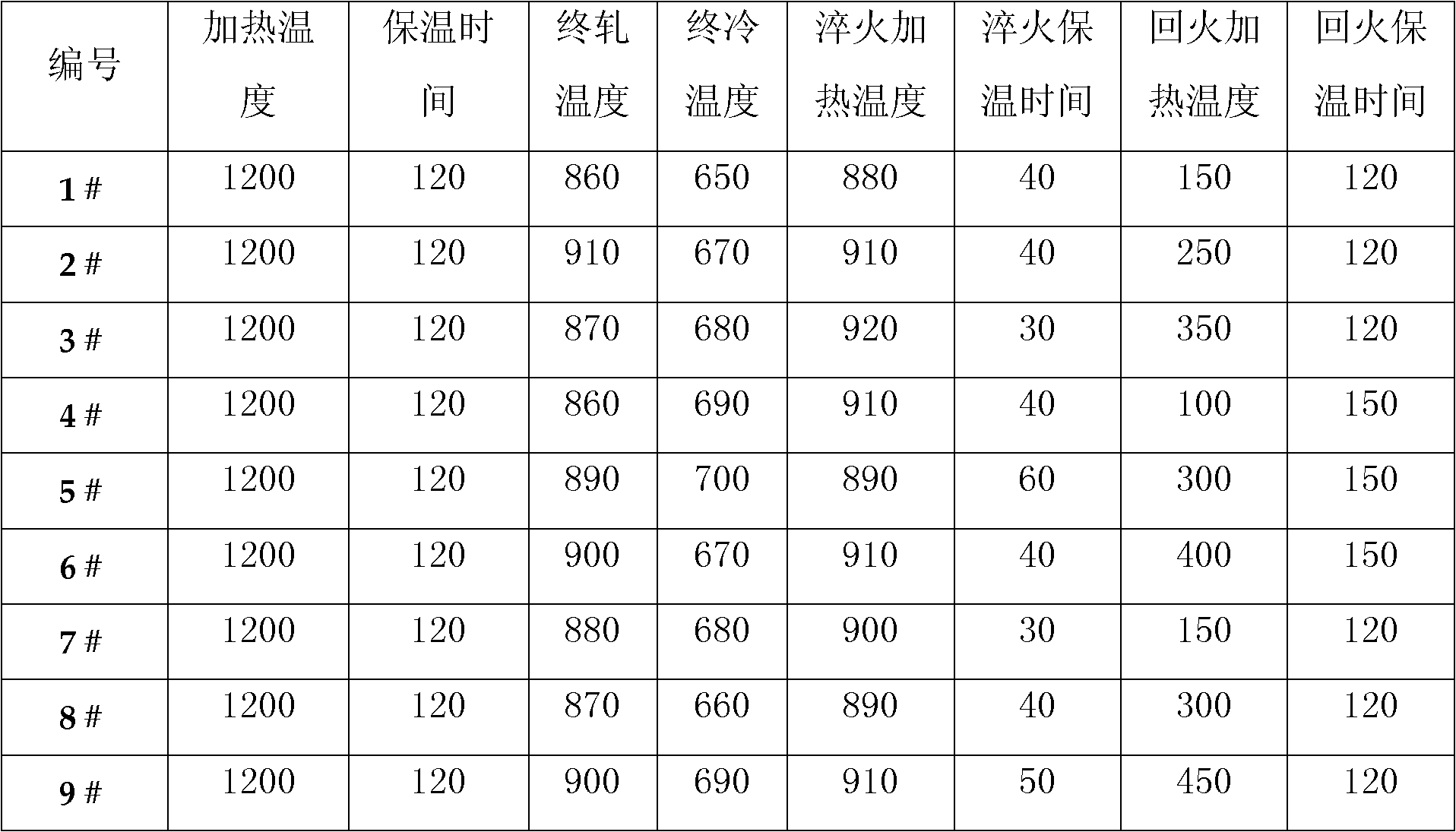

A kind of preparation method of dual-phase hot forming steel

The invention provides a preparation method for double-phase forming steel, which belongs to the technical field of high-intensity steel for automobiles. The steel comprises the following ingredients by mass percent: 0.1 to 0.5 percent of C, 0.3 to 2.5 percent of Si, 1.0 to 3.0 percent of Mn, 1.0 to 3.0 percent of Al, at most 0.02 percent of P, at most 0.01 percent of S, at most 0.01 percent of Nand the balance iron and unavoidable impurities. A production process comprises the following steps of: smelting, hot rolling and hot forming process simulation after the hot rolling. The controlled process parameters are as follows: hot rolling plate blanks are heated to 1200 to 1250 DEG C, the heat insulation is carried out for 0.5 to 1 hour, the final rolling temperature is 800 to 900 DEG C, and the coiling temperature is 600 to 700 DEG C. The hot forming process comprises the following steps of: carrying out heat insulation for 5min at the heating temperature being 750 to 850 DEG C and cooling the materials to the room temperature at the speed greater than 40 DEG C / s. The preparation method adopts the Al micro alloying treatment. Compared with the traditional thermal forming manganeseboron steel, the double-phase forming steel has the advantages that: 1, the hot forming heating temperature is low, and the surface oxidation is reduced; and 2, tissues after the hot forming are ferrite and martensite double-phase tissues.

Owner:UNIV OF SCI & TECH BEIJING

Water-based interior wall thermal insulation nano coating

InactiveCN101948652ALow toxicitySimple preparation processRadiation-absorbing paintsWater basedThermal insulation

The invention provides a water-based interior wall thermal insulation nano coating, belonging to the technical field of environment-friendly water-based building energy conservation coating. The coating comprises the following components by weight percentage: 20-40% of emulsion, 20-35% of pigment filler, 5-15% of thermal insulation function material, 0.1-1% of thickening agent, 0.5-2.5% of wetting and dispersing agent, 0.1-0.6% of defoaming agent, 0.4-2.5% of anti-creaming agent, and the balance water. Due to containing no organic matters with large volatility, the coating in the invention has little toxicity and is favor to environment protection. The adopted pigment filler in the invention is nano-level or superfine magnesium carbonate or magnesium silicate, thus greatly improving the surface area of the pigment, and increasing gaps among coating particles by a large margin, thereby enhancing the thermal separation property of the coating. The water-based interior wall thermal insulation nano coating provided in the invention has obvious radiative thermal insulation and separation type thermal insulation effects, and has simple preparation process and wide application.

Owner:CHINA MCC17 GRP

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

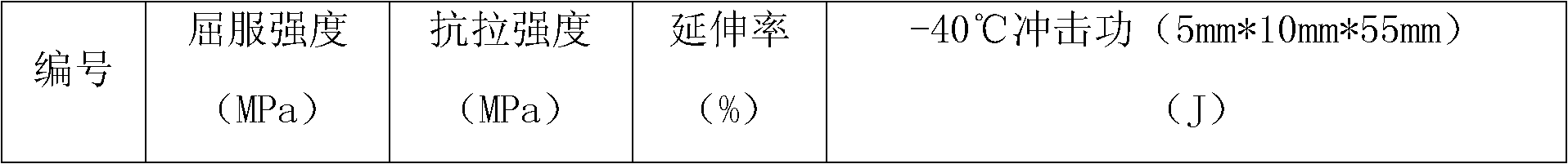

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

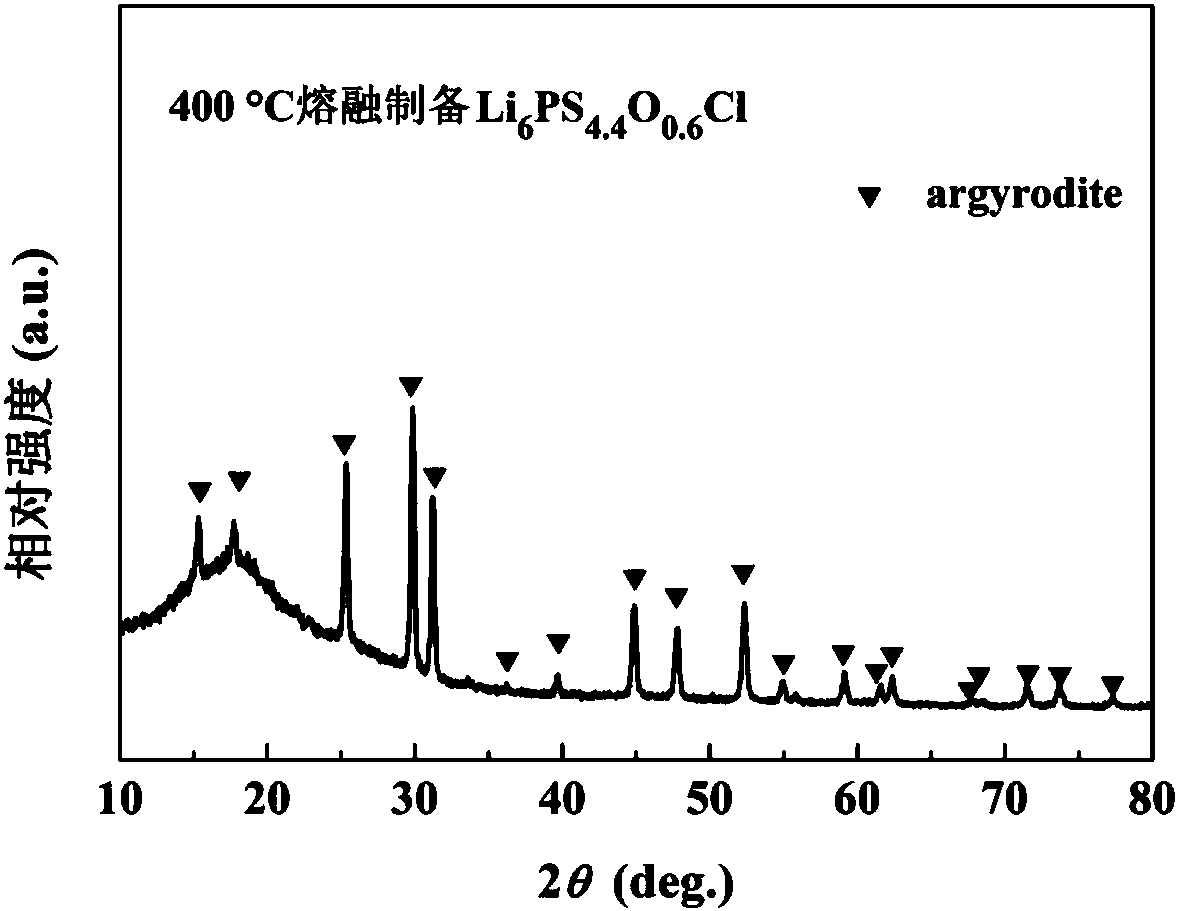

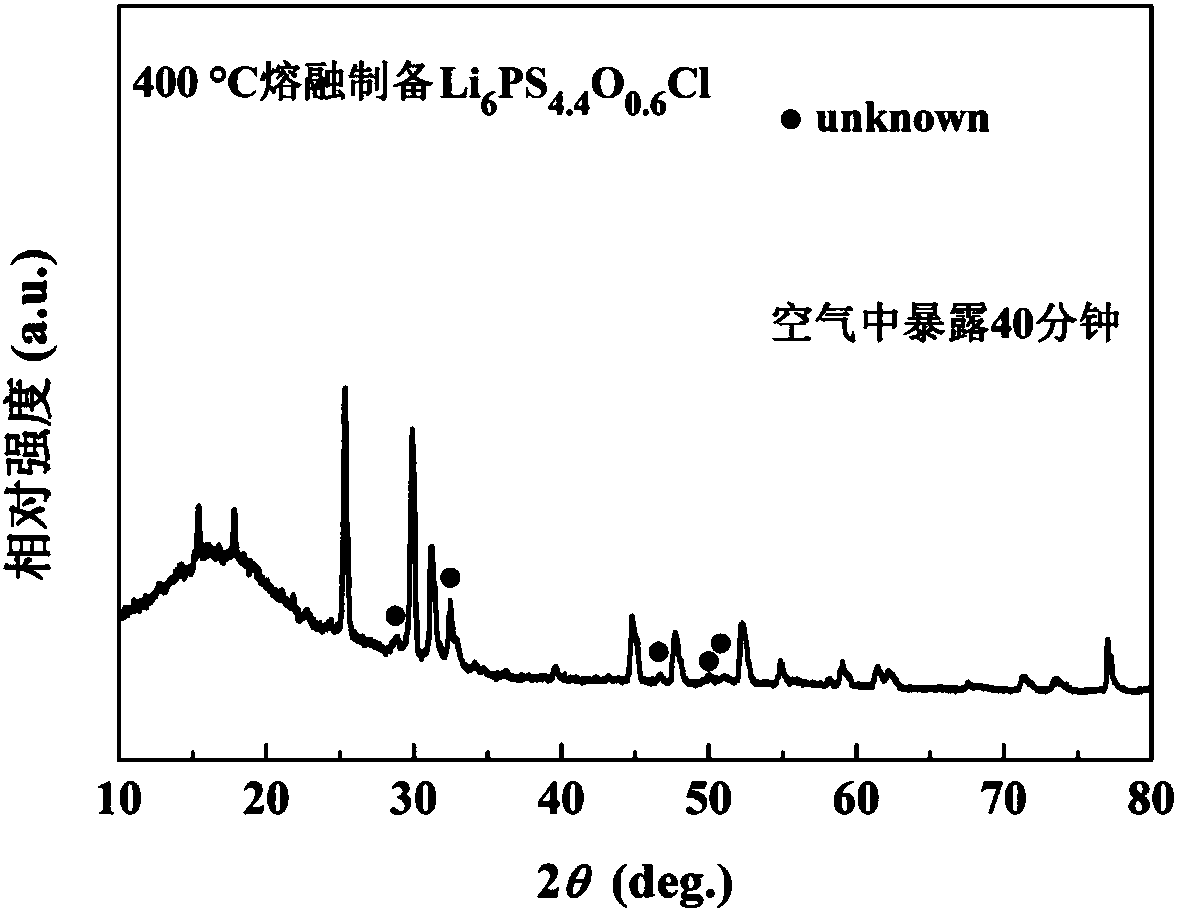

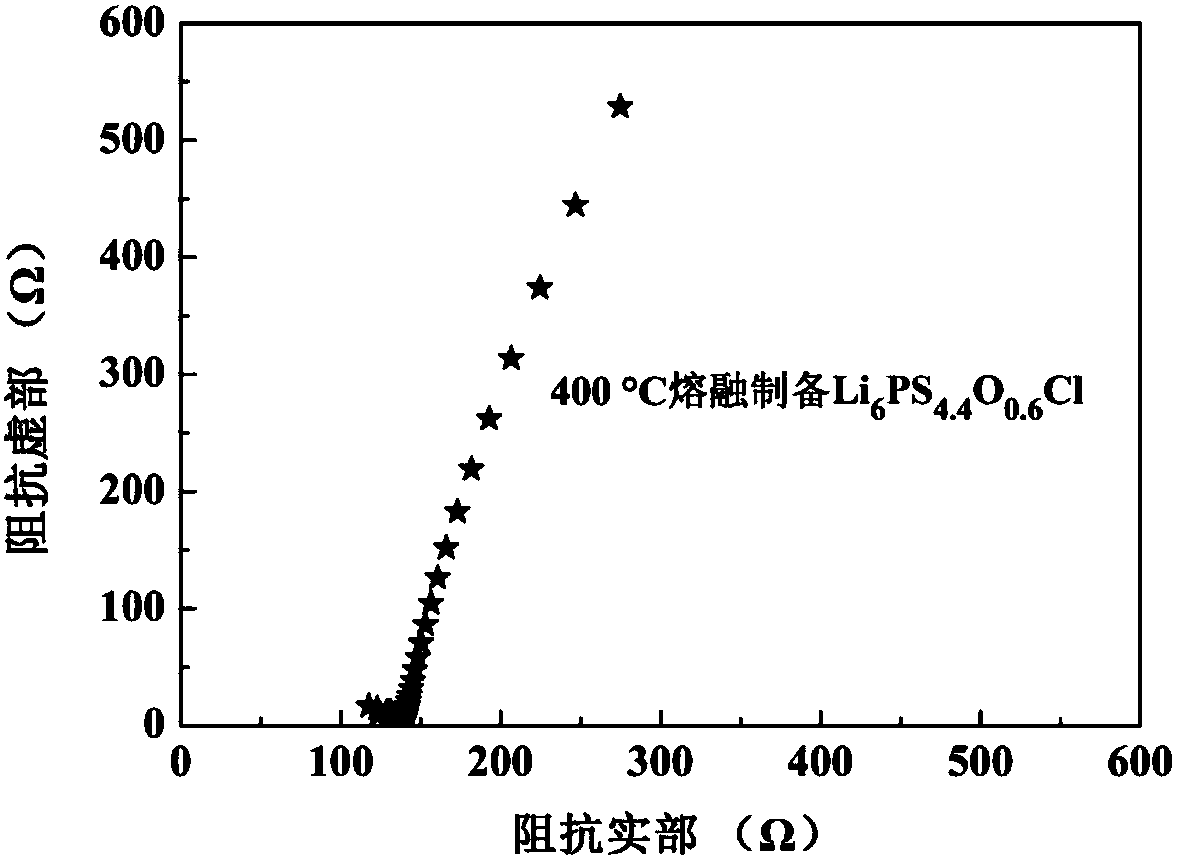

Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

ActiveCN108493479AImprove stabilityImprove ionic conductivitySolid electrolytesLi-accumulatorsLithium chloridePhosphorus pentasulfide

The invention provides a sulfide solid electrolyte based on oxygen doping. The sulfide solid electrolyte is prepared from the chemical ingredients, in percentage by mass: 36-60% of lithium sulfide orlithium selenide, 18-48% of phosphorus pentasulfide or phosphorus selenide, 1-23% of metal oxide or specific nonmetallic oxide and 8-37% of lithium chloride, lithium bromide or lithium iodide. The preparation method of the sulfide solid electrolyte mainly comprises the steps that the raw materials are sufficiently blended and subjected to tabletting, then placed in a quartz tube to be burned and sealed, the product is placed in a muffle furnace and heated to be 400-600 DEG C at a slow heating rate, the optimal heating rate is 0.3 DEG C / minute, heat preservation is conducted for 12-48 hours, and then the product is cooled to reach the room temperature; and the product is ground to be powder, and the sulfide solid electrolyte based on oxygen doping is prepared. The sulfide solid electrolyteis easy to prepare and high in repeatability, the prepared solid electrolyte has the high ionic conductivity and good stability to the air and positive and negative electrodes.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com