Patents

Literature

1249results about How to "With sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

Foaming agent for civil construction as well as preparation method and use thereof

The weight percentage of a constructional foaming agent is that the anion surface active agent is 40-70%, the cationic surface active agent is 5-30%, the foam stabilizing agent by 5-15%, and the filling agent by 5-15%. The solid raw material is cracked into particle with the diameter smaller than 100 meshes, and mixed evenly, then liquid raw material spray is agglomerated on the solid raw material which is mixed evenly, stirred evenly and dried, even powder is conformed. The invention has advantages of simple process, and being easy to be shaped, hard to be degenerated and convenient for transportation, which has good water solubility and high stability, with less reduction of concrete strength, low cost etc.

Owner:CHINA RES INST OF DAILY CHEM IND

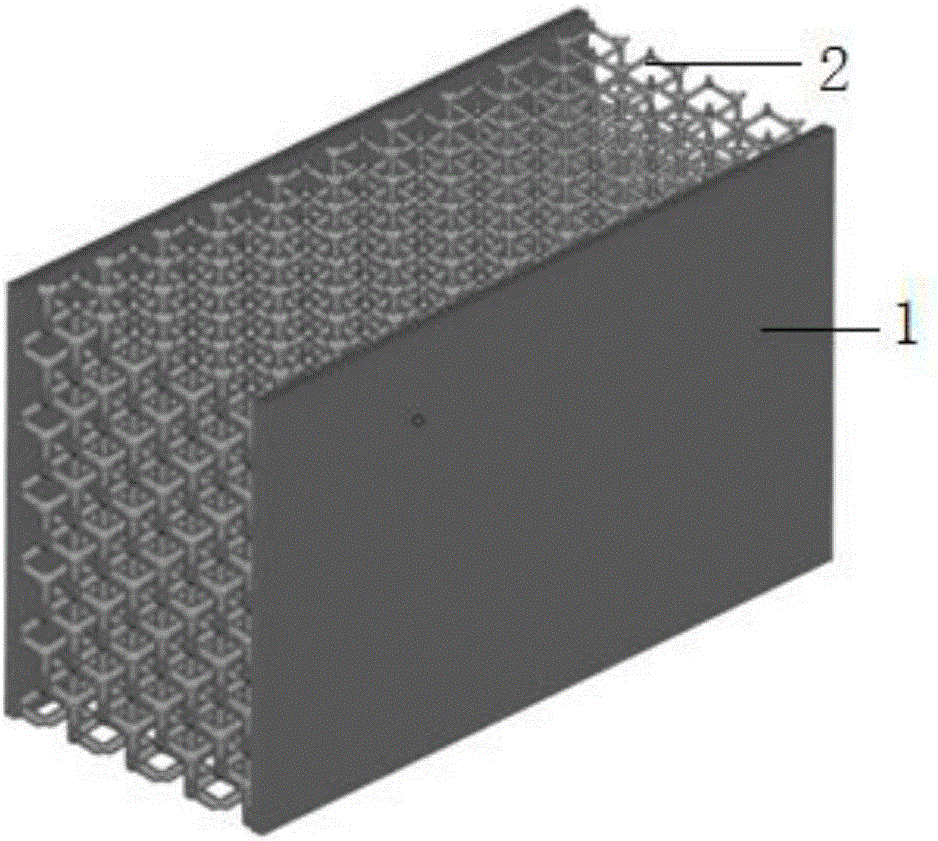

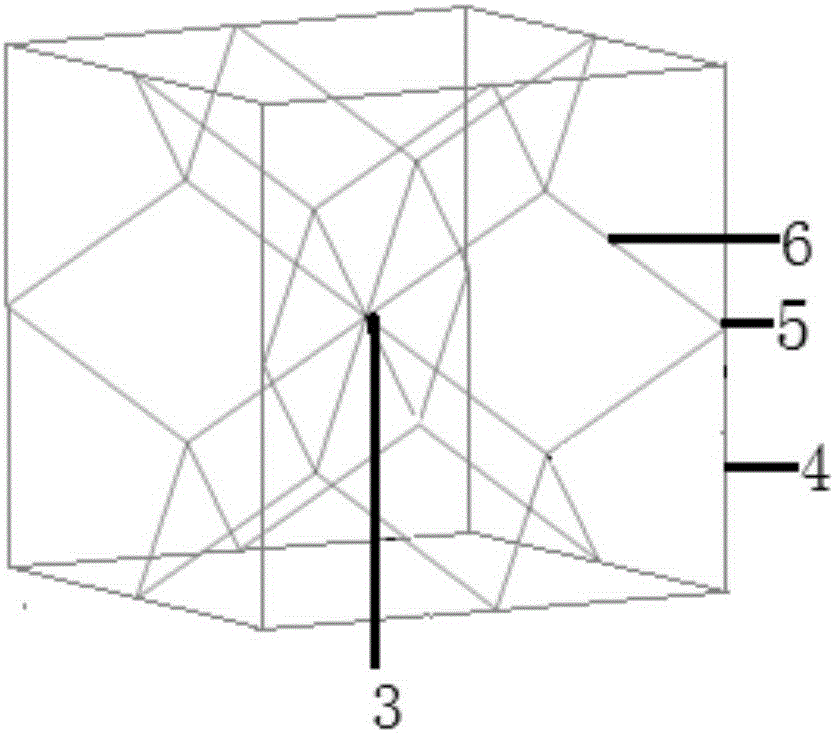

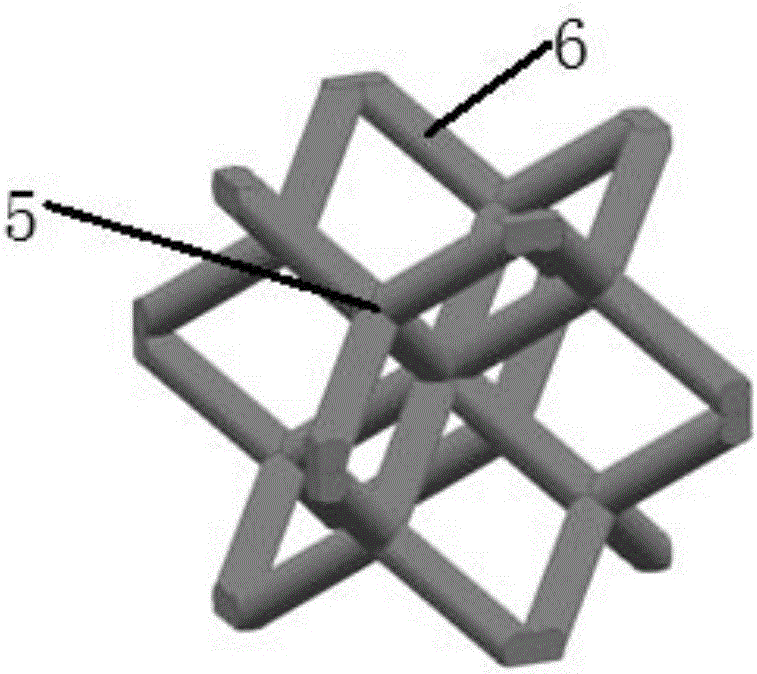

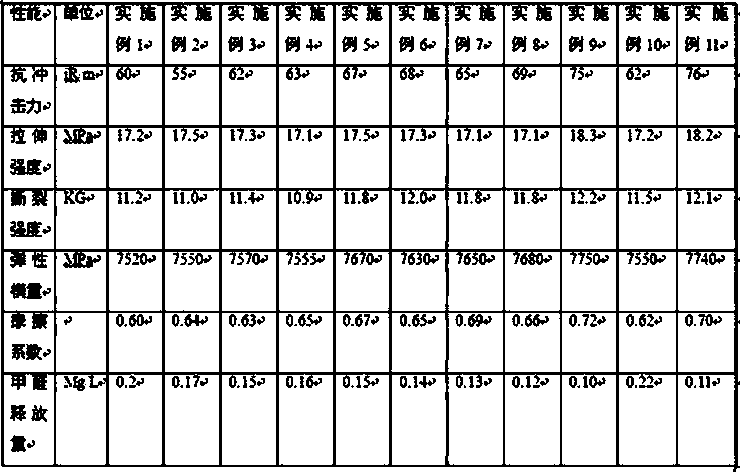

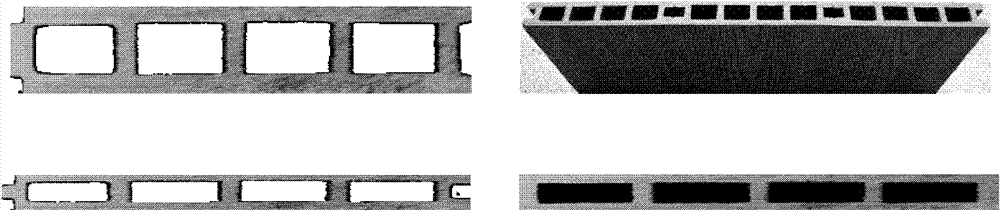

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Foaming powder coating

InactiveCN101205425AImprove the decorative effectHigh mechanical strengthPolyurea/polyurethane coatingsPowdery paintsNon toxicityElectrostatic coating

Then invention discloses a foaming powder coating, belonging to the electrostatic coating powder coatings technical field. The coating is prepared by melting extrusion hybrid method from the following materials in weight portions: resin of 40 to 60 portions, curing agent of 0 to 24 portions, pigment and filler of 40 to 60 portions, foaming agent of 1 to 15 portions, flame retardant of 1 to 5 portions, and flow agent of 1 to 5 portions. The invention has the advantages of non-toxicity and harmlessness, no solvent contained, green and environmental protection; the coating can be directly coated on metal plates and easily operated; the foaming expansion layer has good decorative effect and high mechanic strength; the foaming powder coating of the invention can be used to produce building material products with heat insulation, heat preservation, fire proof, and sound proof effects; the building material products are economic, environmental protective, poisonless, harmless and flame retardant.

Owner:XUZHOU ZENITH COATING

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

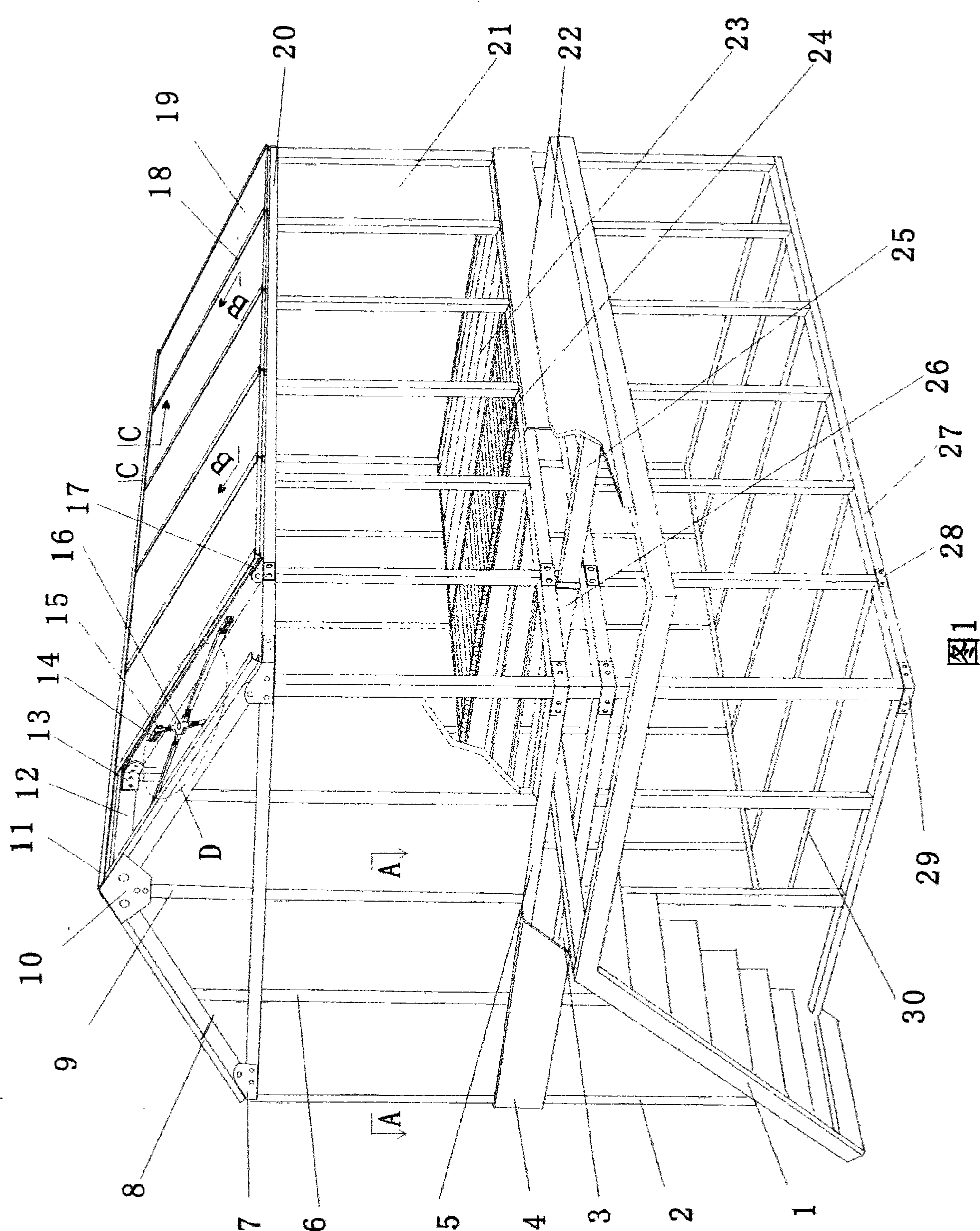

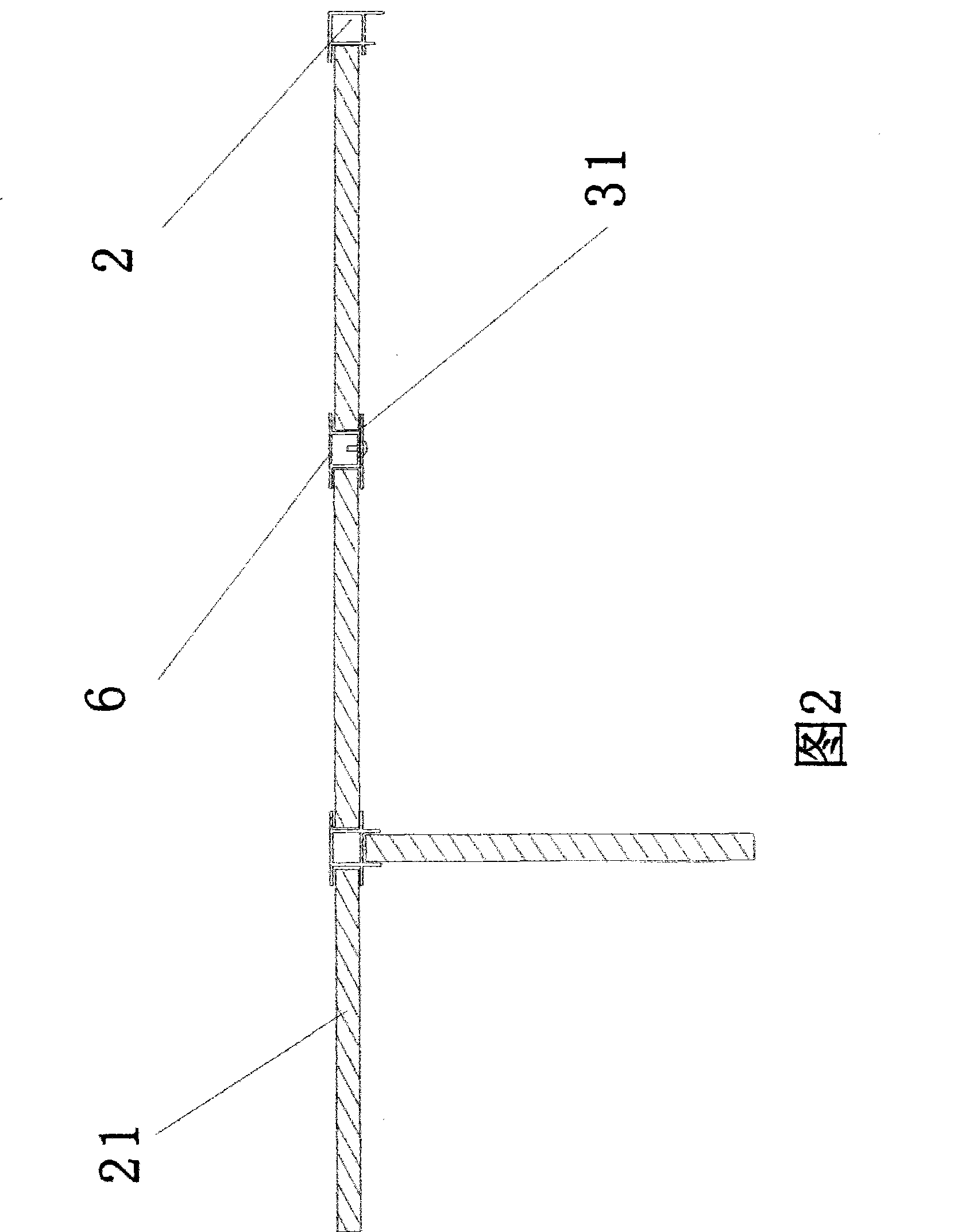

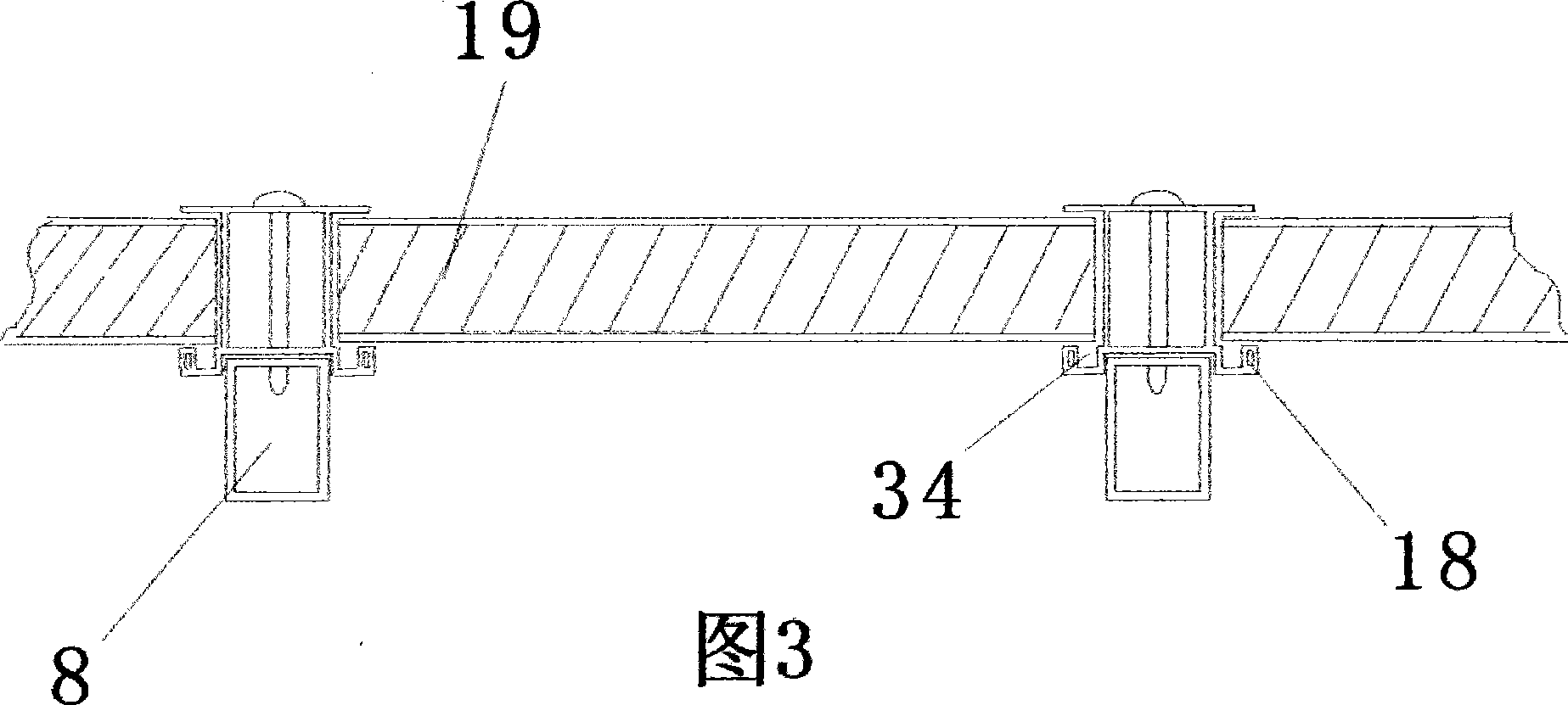

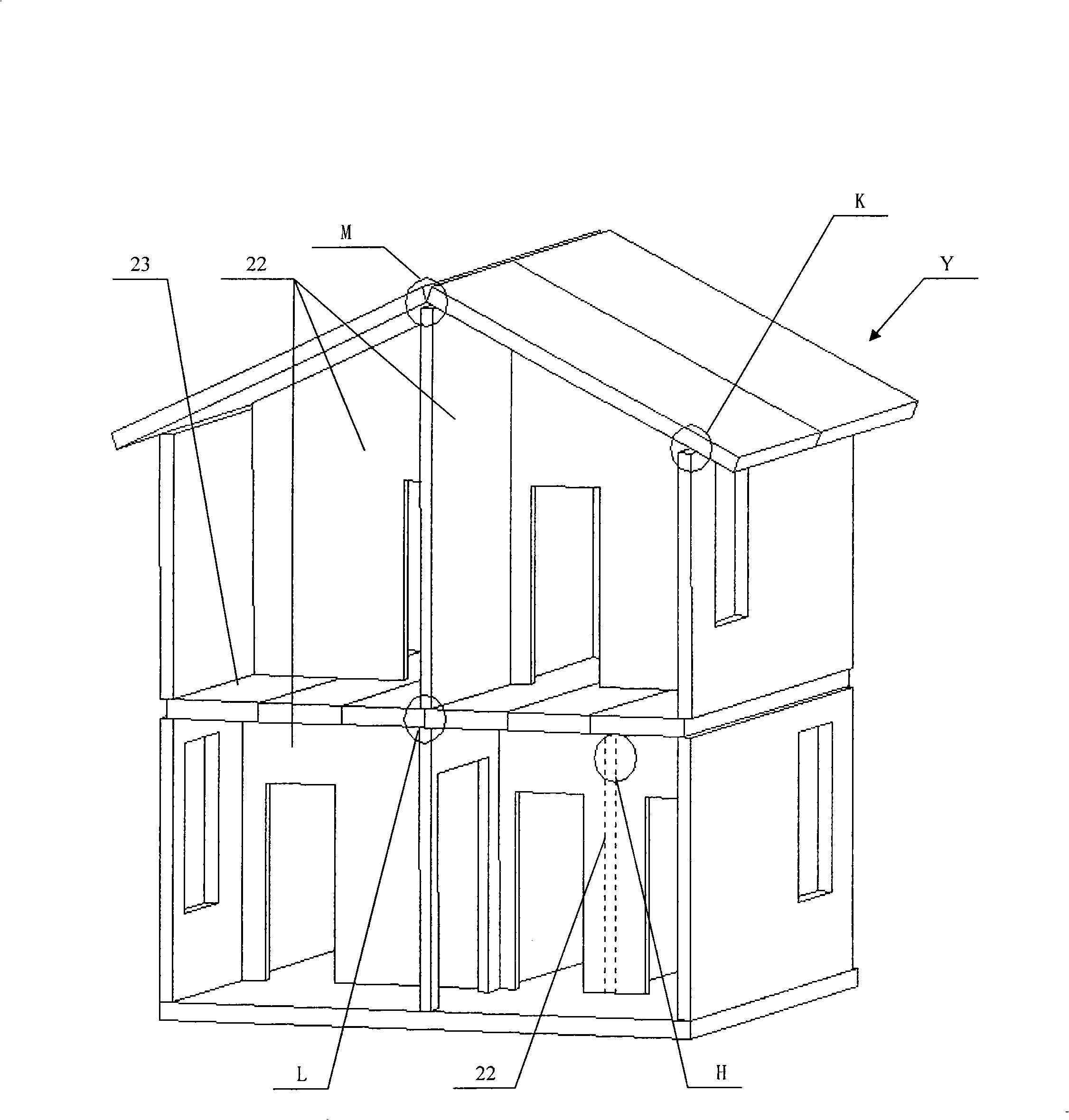

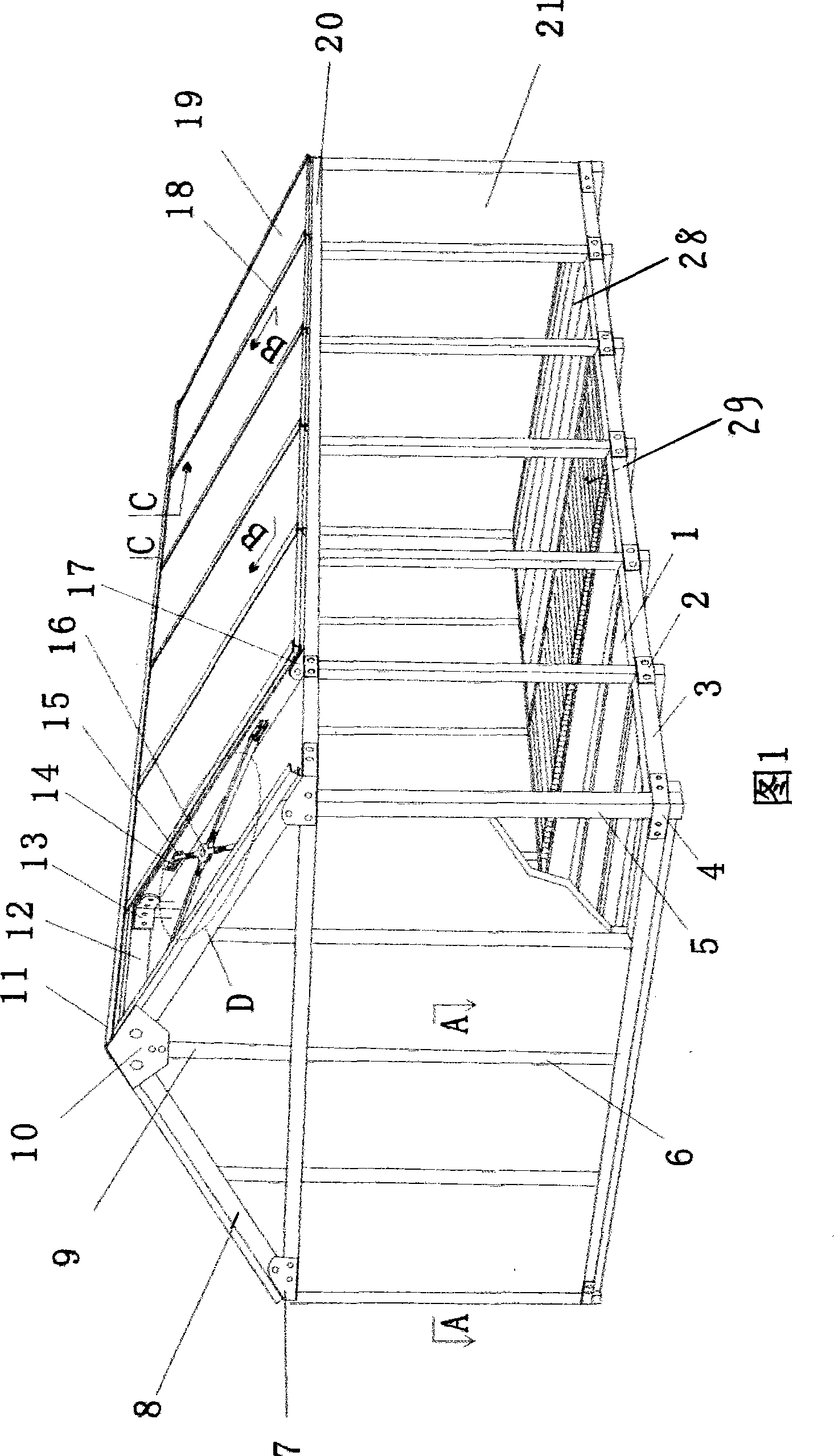

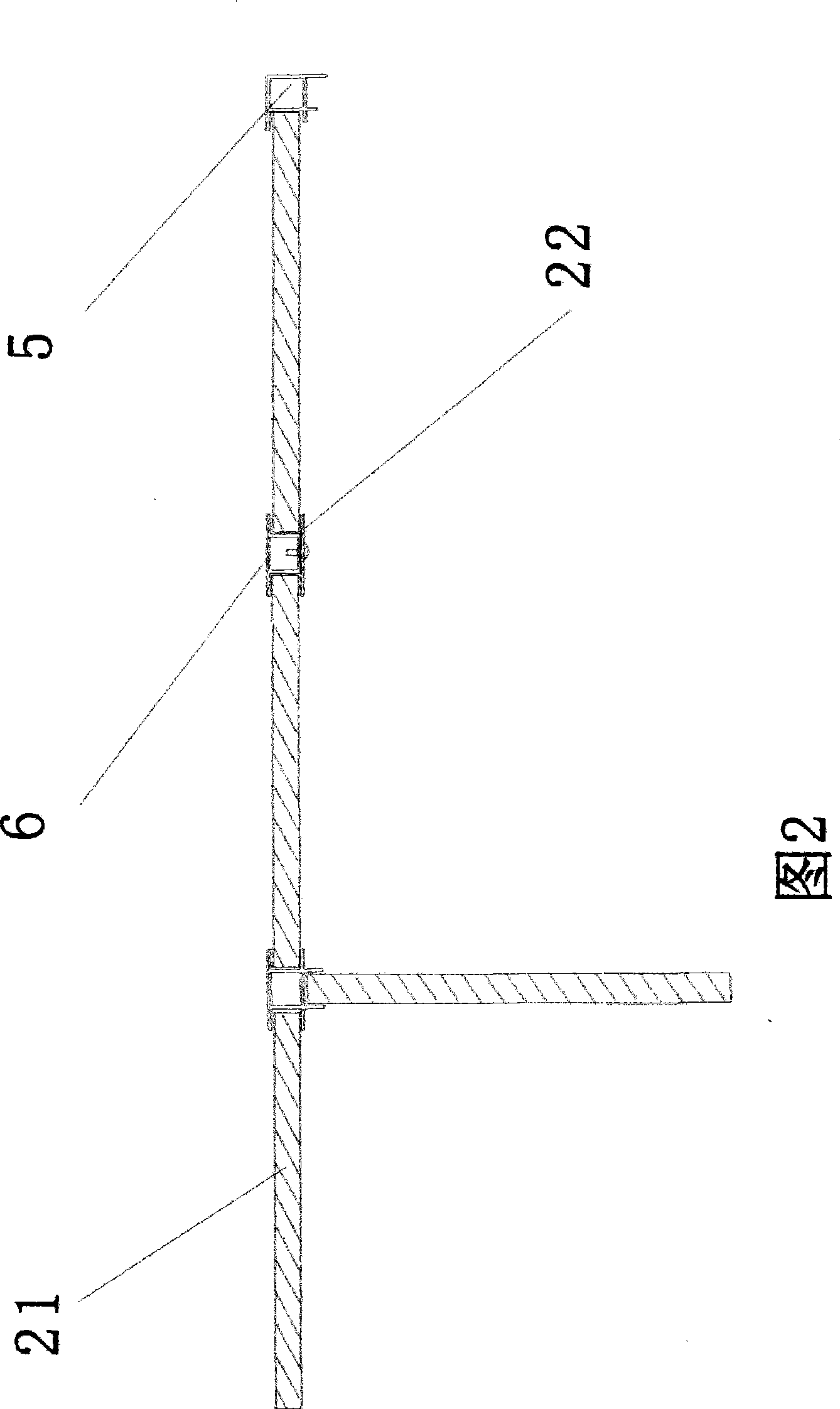

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

High-performance cast-in-place foam concrete and preparation method thereof

The invention belongs to the technical field of an energy-saving building material, and relates to high-performance cast-in-place foam concrete and a preparation method thereof. The high-performance cast-in-place foam concrete is prepared from the following raw materials in parts by weight: 100-520 parts of cement, 25-180 parts of admixture, 80-320 parts of lightweight aggregate, 0.8-6.4 parts of foaming agent, 75-300 parts of water, 1.6-12 parts of additive and 2-28 parts of modifier in a mixing manner. The foam concrete prepared by the preparation method is light in weight, high in strength, excellent in waterproofness, good in heat preservation effect, free of poison, durable and the same as a building in service life, and is suitable for casting internal and external wall bodies in place, roof and ground heat preservation and foundation pit backfill of a pier pavement and the like.

Owner:沈阳红姗石新型建材有限公司

Composite interior material for motor car and preparation method thereof

InactiveCN102619022AGood compatibilityImprove functionalityNon-woven fabricsAdhesivesWork in processHot pressing

The invention relates to a composite interior material for a motor car and a preparation method thereof. The composite interior material comprises 60-80% of high performance fibers, 10-20% of flame retardant fibers and 10-20% of hot-melt fibers; and the preparation method comprises the following specific steps of: 1) opening the high performance fibers, the flame retardant fibers and the hot-melt fibers by a bale opener; reopening the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a rough opener; and then mixing the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a cotton blending machine; finely opening the mixture by using a fine opener; and combing the mixture by using a carding machine; 2) by using a nonwoven needle-punched machining technology, lapping the combed fibers in a cross way by a lapping machine; and then carrying out needle punching on the fibers by using a needle machine; and processing the fibers by using a singeing machine and a glazing calendar; and 3) carrying out composite hot pressing on a fiber felt which is a needle-punched, singed and calendared semi-finished product; and finally, forming the composite interior material together with a thermoplastic resin.

Owner:NANTONG UNIVERSITY +1

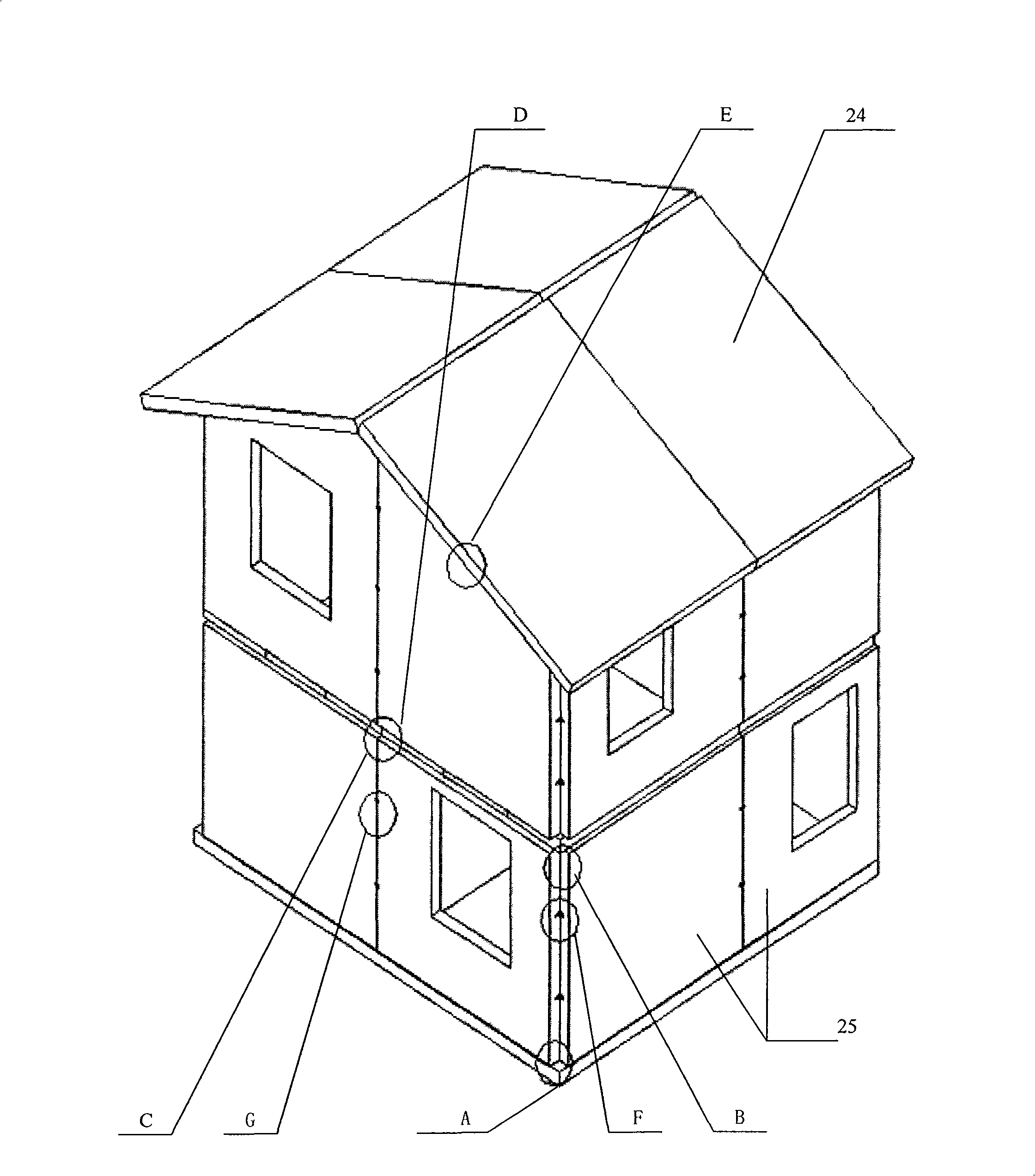

Architecture structure system assembled by composite building board and building method

ActiveCN101265723ARealize production integrationRealize industrializationRoof covering using slabs/sheetsWallsFloor slabFire resistance

The invention belongs to the architecture field, and particularly relates to an architecture structural system assembled by composite architecture boards and a construction method. The system comprises a load bearing partition plate performing functions as the beam and the column of a building and an external wall plate. Transverse frames performing the function of the beam, inner plate structure connectors and external structure connectors are arranged in a floor plate and a roof plate. The external structure connector comprises a wall bottom connector; an angle connector; a positioning connector; a connector connecting the floor plate, the external wall plate and the partition plate; a connector connecting the roof, the external wall and the gable wall; a ridge connector and so on. The invention is a plate-type total prefabricated housing construction technology, which has the comprehensive service performance of load bearing, shock absorption, hear and sound insulation, high efficiency, energy saving, durability and fire resistance, and conforms to the requirements of the green architecture. The method is capable of rapidly assembling and installing on the field and reducing the total cost of a house, as well as achieving the integration and the industrialization of the housing construction.

Owner:CUBIC DIGITAL TECH CO LTD

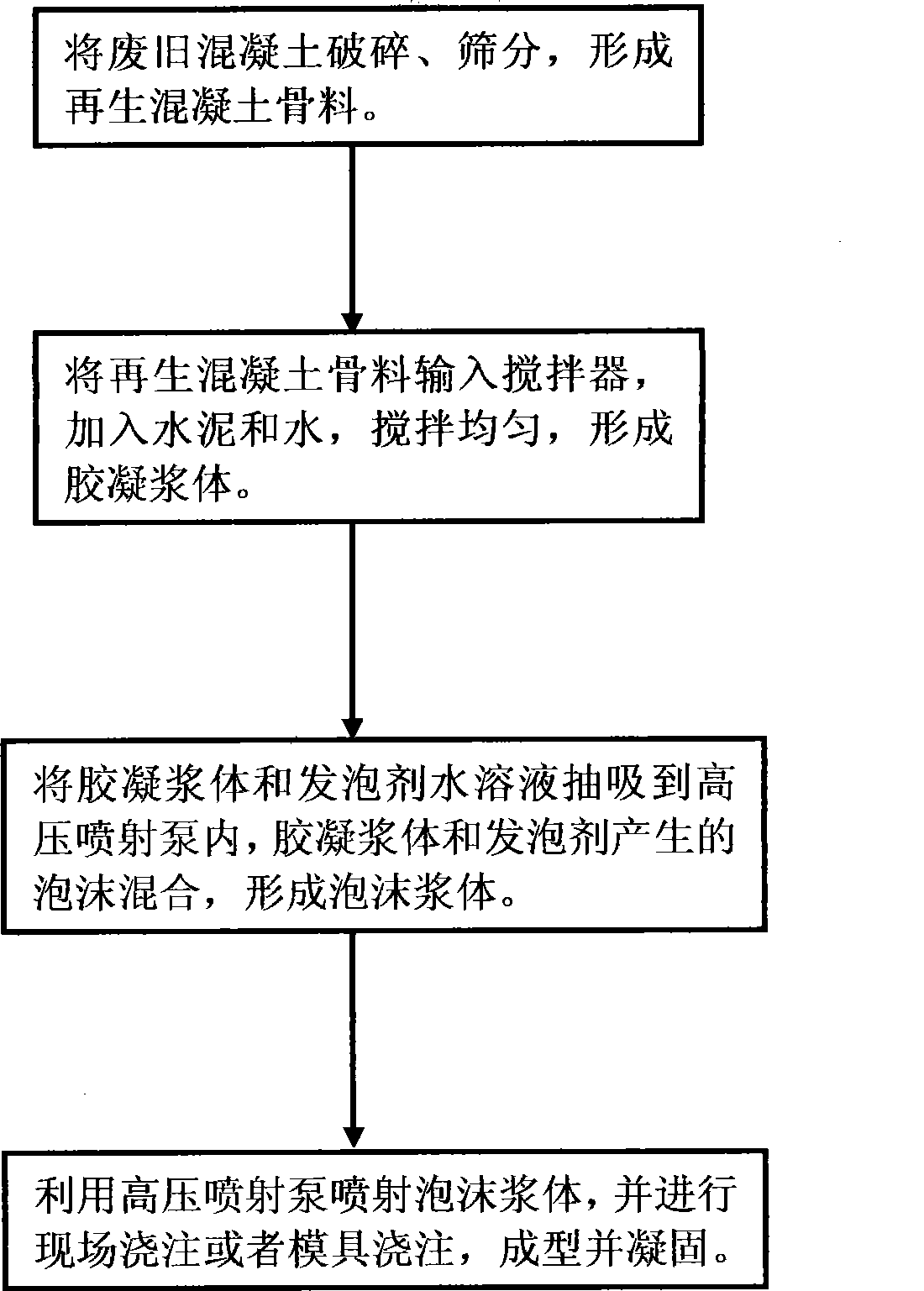

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

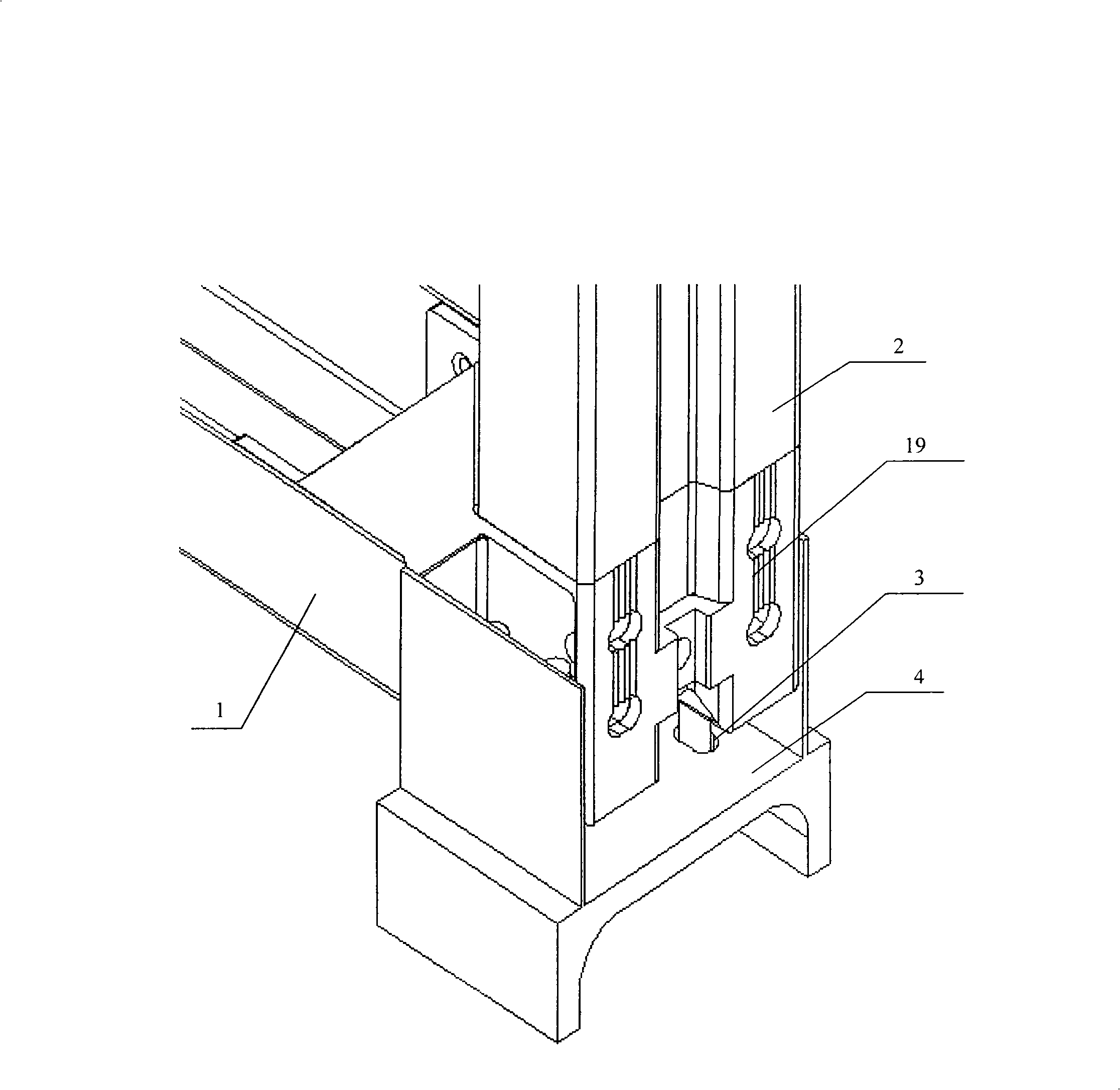

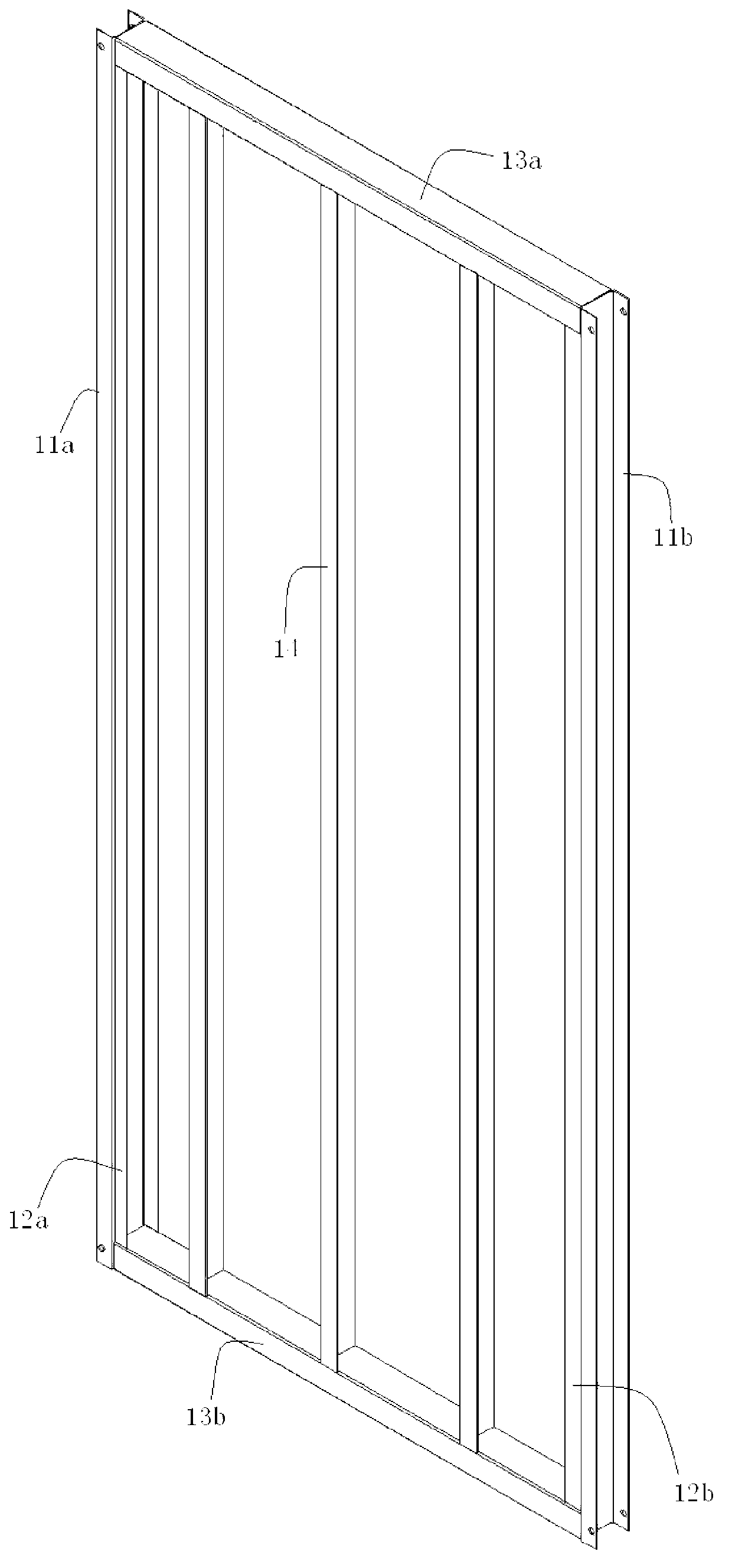

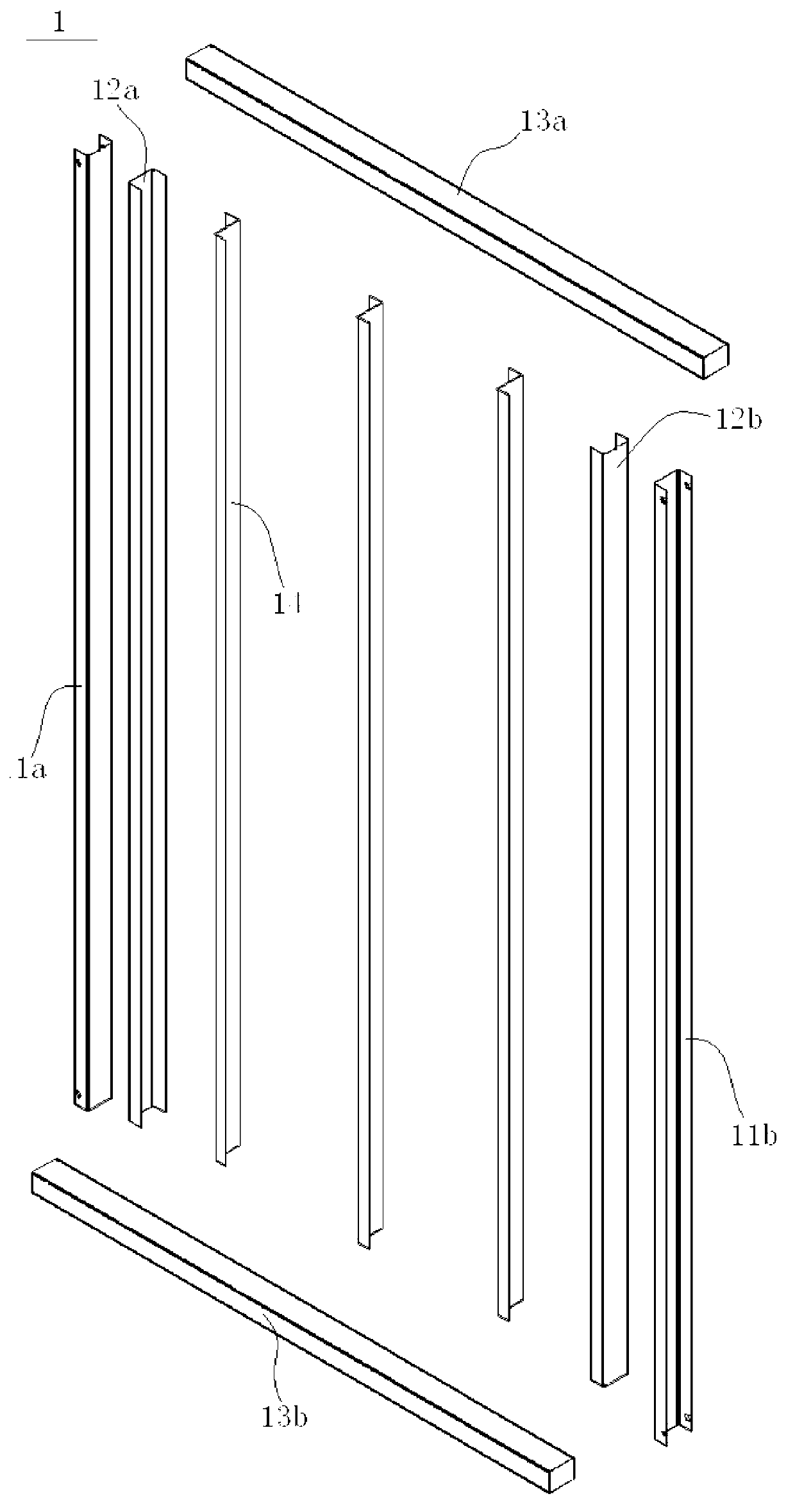

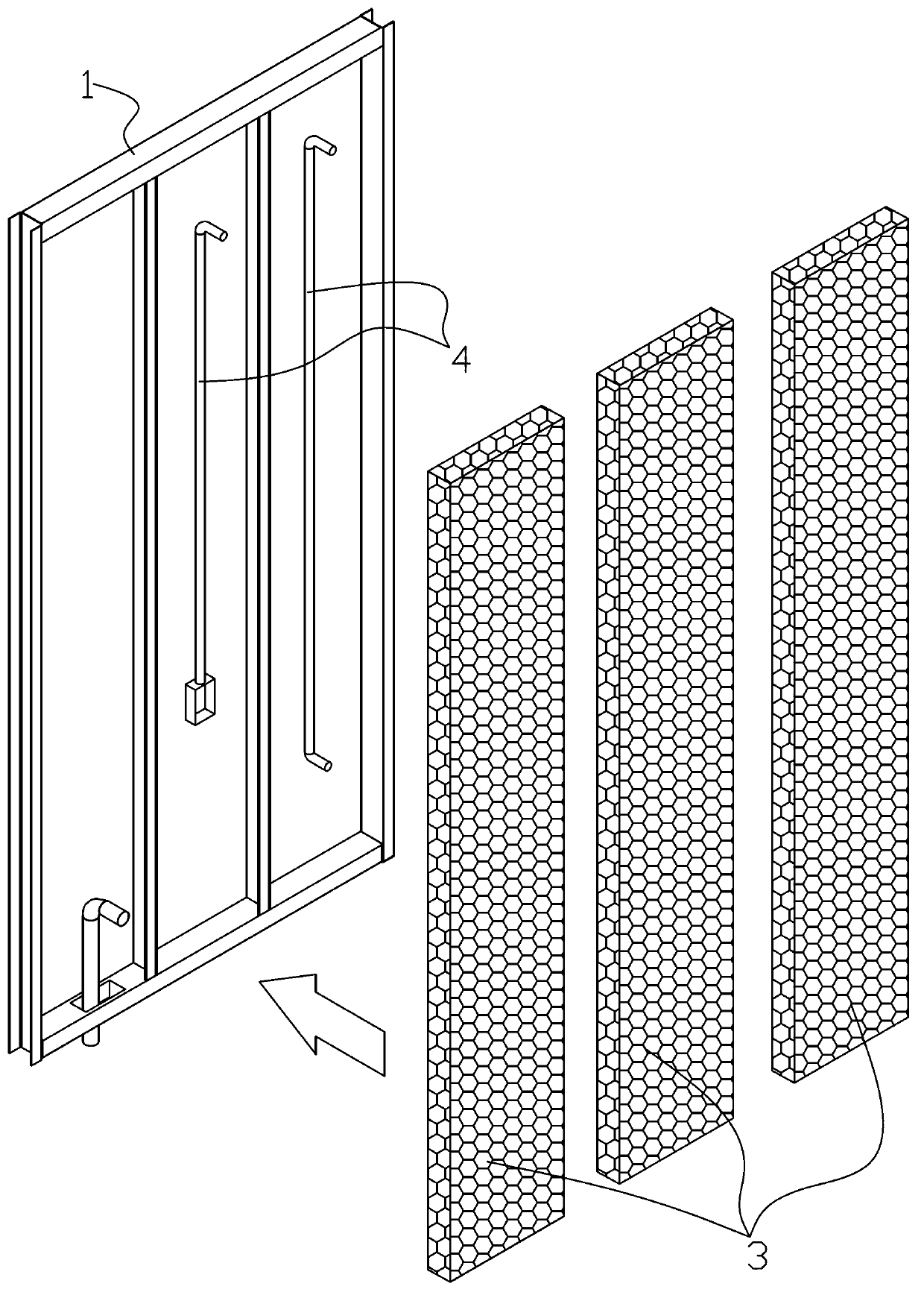

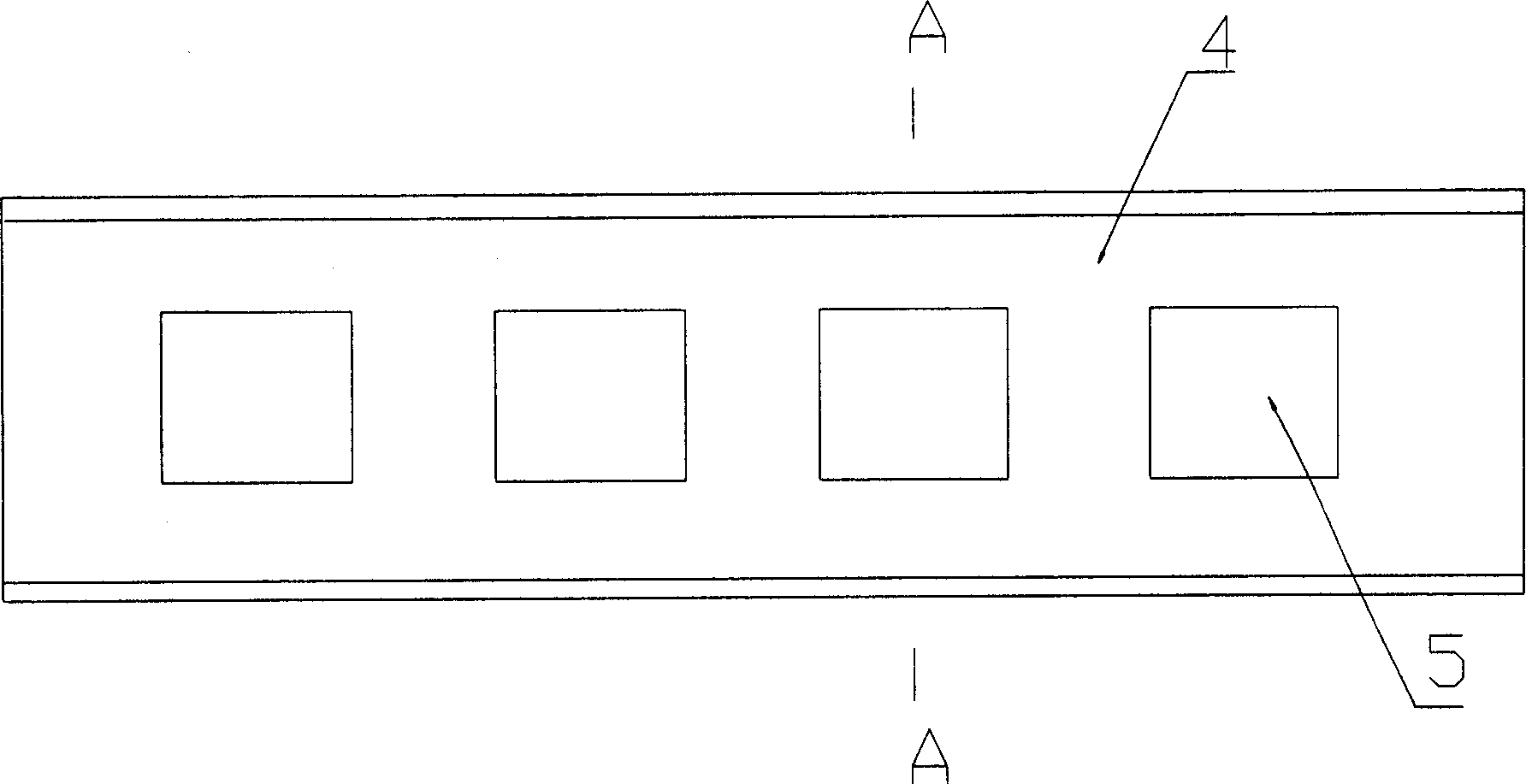

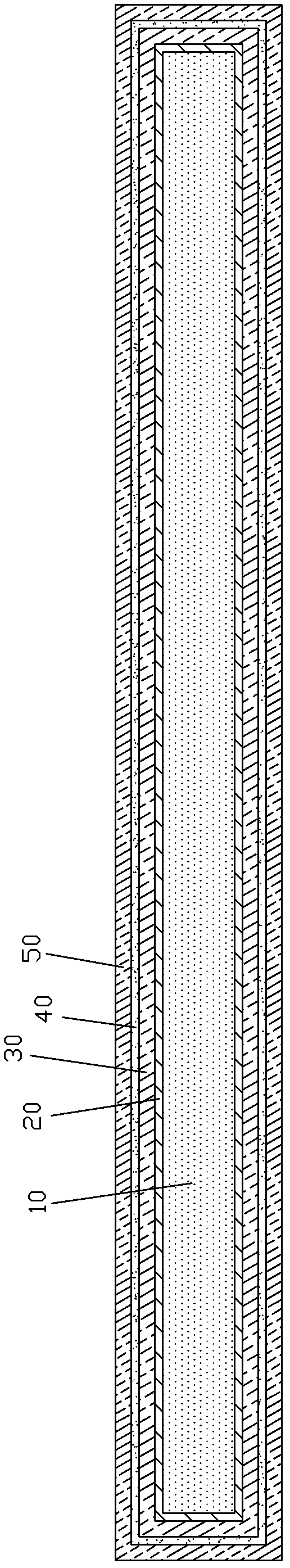

Prefabricated slab and fixed mounting structure thereof

The invention discloses a prefabricated slab and a fixed mounting structure thereof. The prefabricated slab comprises a light steel frame, a front board and a rear board, wherein the light steel frame comprises a left border, a right border, an upper border, and a lower border, which are enclosed together to form a square frame; U-shaped notches of the left border and the right border are respectively arranged towards the left and the right, so that the prefabricated slab can be inserted together with a structure member through the U-shaped notches; mounting holes through which bolts penetrate to fix the prefabricated slab on the structure member are arranged on front and rear connecting arms of the left and right borders; the front board and the rear board are respectively paved on the light steel frame as front and rear panels of the light steel frame; and the top surfaces and the bottom surfaces of the upper and lower borders are exposed outside. The light steel frame is internally built into the prefabricated slab; the light board is paved outside a skeleton by a 'stressed-skin effect' technology; the performance stronger than that of a single material is developed; and the light steel skeleton internally arranged inside the prefabricated slab is exposed at the periphery of the prefabricated slab, so that the prefabricated slab can be conveniently and effectively connected with a steel structure by the existing steel structure connecting technology.

Owner:广州市澳居科技有限公司

Lightweight ceramic material and process for manufacturing same

The present invention is one kind of light ceramic material and its production process, and belongs to building material technology. The ceramic material is produced with waste slag from polishing ceramic product, ceramic clay, high temperature sand and low temperature sand and through material compounding, crushing, forming, drying, sintering in kiln and packing. The produced ceramic material has the features of light weight, high strength, heat insulation, sound insulation, fireproofing, waterproofing and long service life. The present invention raises the utilization of ceramic raw material, reduces environmental pollution, and the produced ceramic material may be used in decorating outer and inner walls of building, as tunnel sound insulating material, house ceiling decoration, etc.

Owner:聂曼云

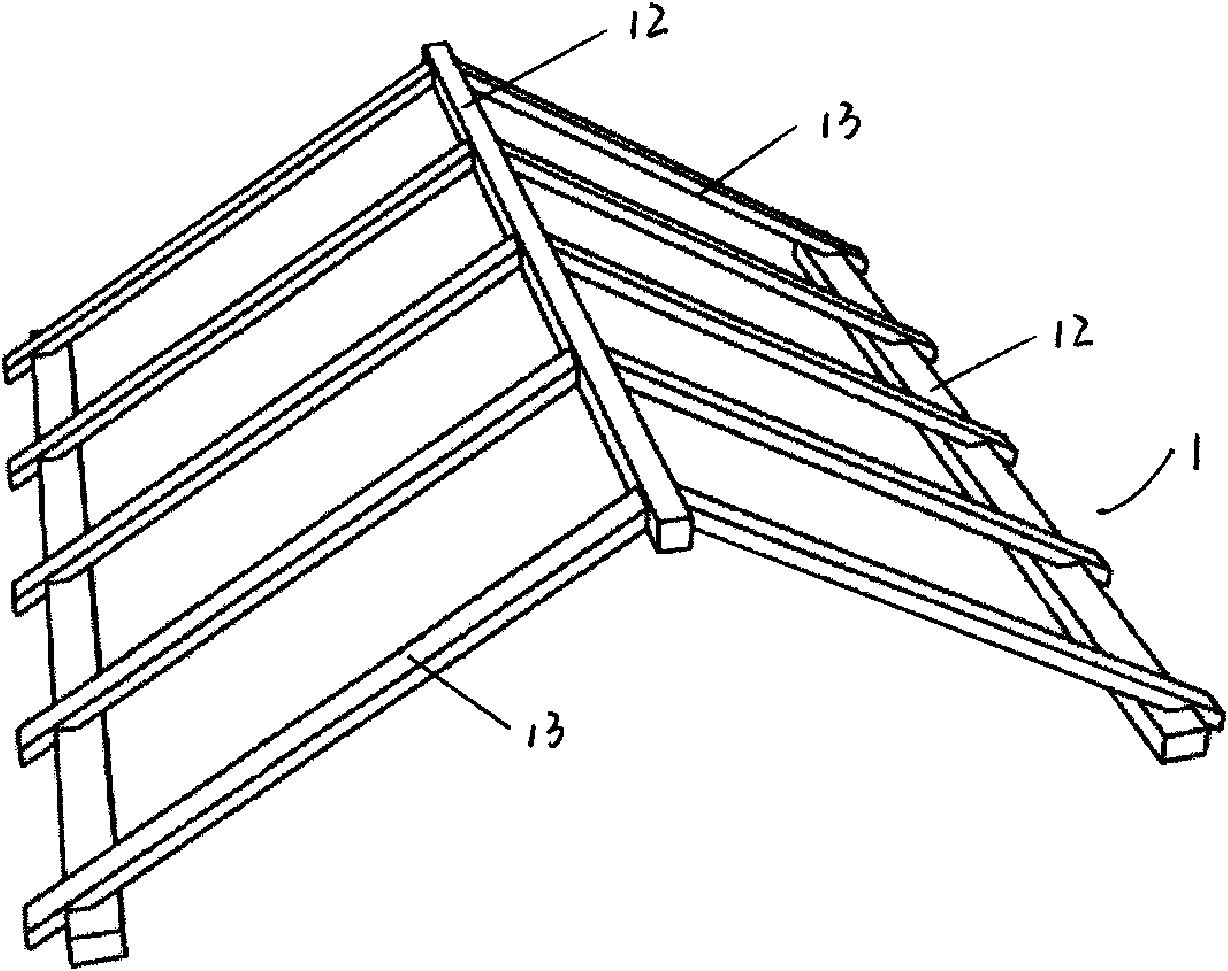

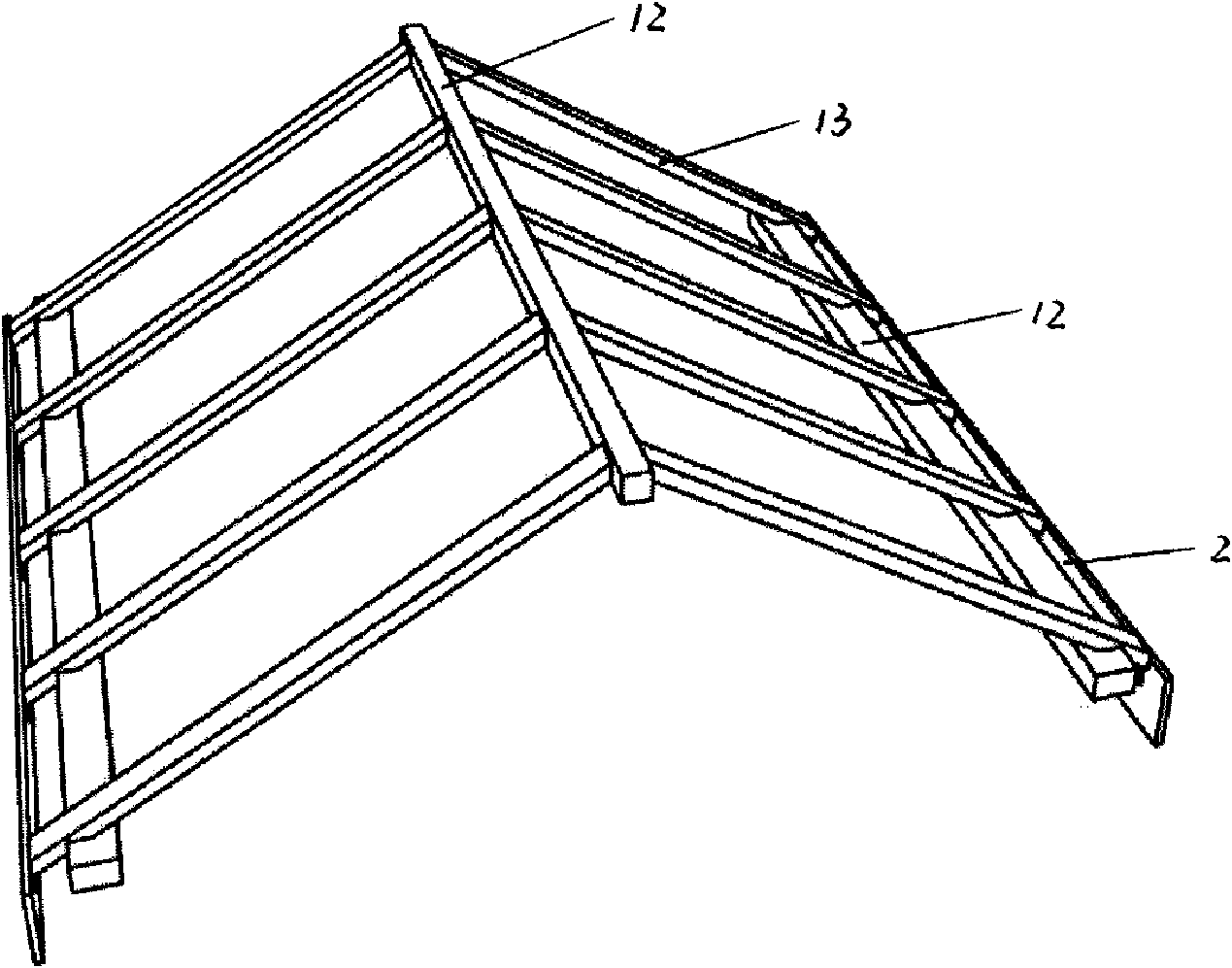

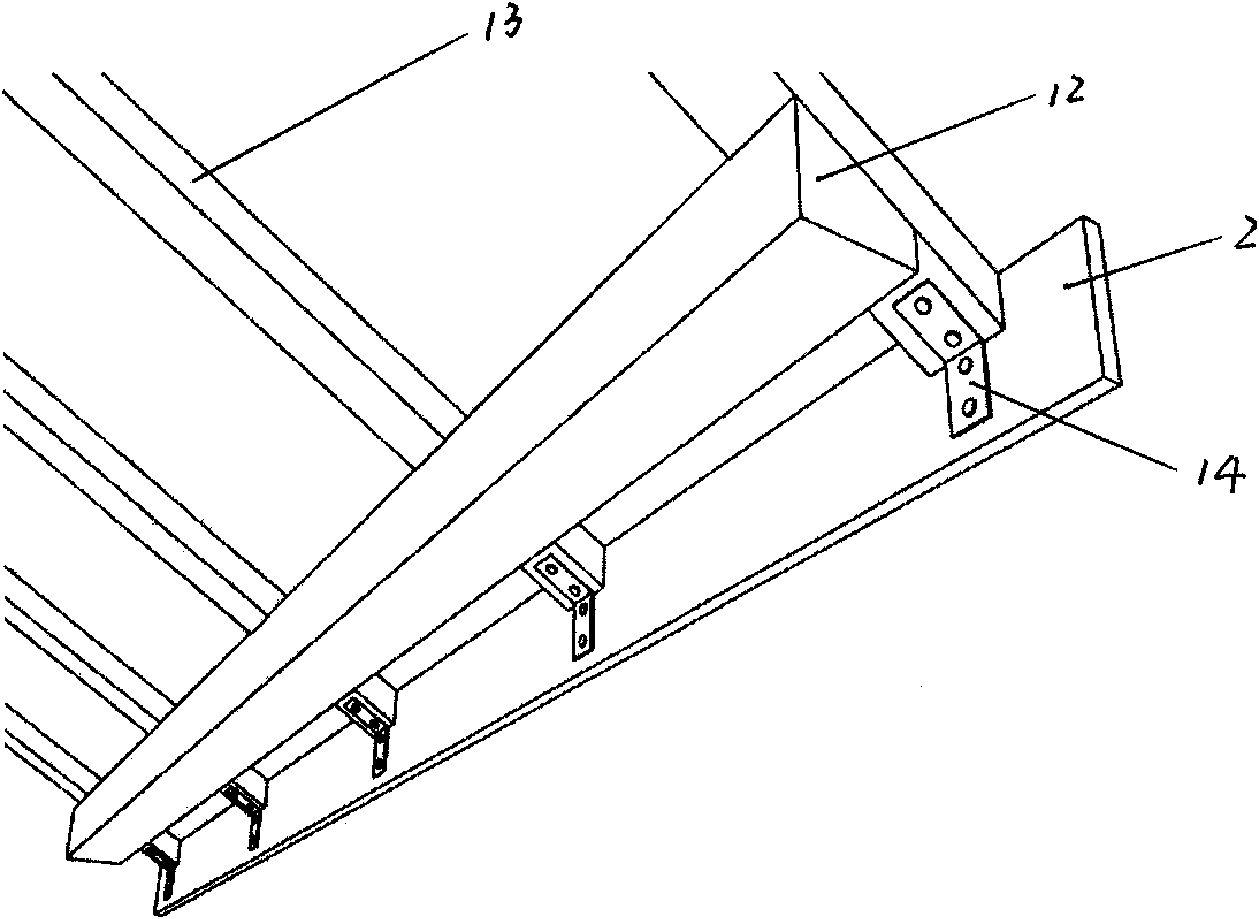

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

Ultra-large light-transmission-type decorative board

InactiveCN102061790AHigh light transmittanceHigh mechanical strengthCovering/liningsWallsTransmittanceHoneycomb

The invention belongs to building enclosure materials, in particular to a light-transmission-type composite sandwich decorative board with an ultra-large face. In the decorative board, a wholly-reinforced composite sandwich structure of a light-transmission-type FRP (Fiber Reinforced Plastic) panel, a honeycomb core material and latticed FRP reinforcing ribs is adopted, mounting holes are arranged on the periphery and in other specified positions, the product is formed by adopting a die, and the surface is coated with a high-weather-resistant facing layer. The decorative board provided by the invention is suitable for the mass production of boards with ultralarge faces. Compared with hollow glass of a curtain wall, the decorative board provided by the invention has equivalent light transmittance as well as the advantages of great veneer area, light weight, high strength, good impact resistance, sound and heat isolation, good decoration effect, capability of night illumination, easiness for maintenance, long service life, and the like and can meet the demands of curtain walls, enclosures and decoration engineering of buildings and large-scale landscape structures for light-transmission-type decorative boards with ultra-large areas.

Owner:秦皇岛耀华装备集团股份有限公司

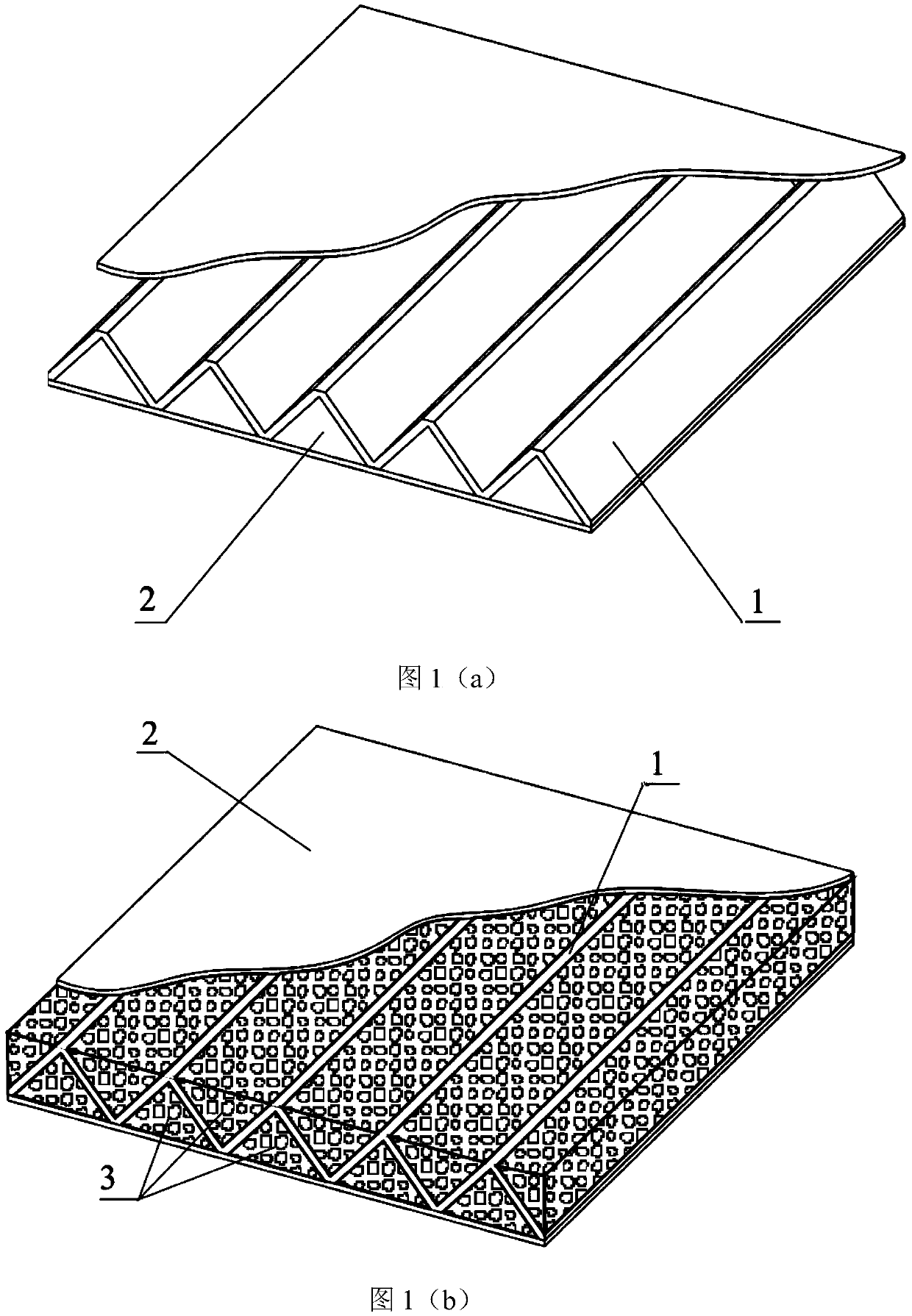

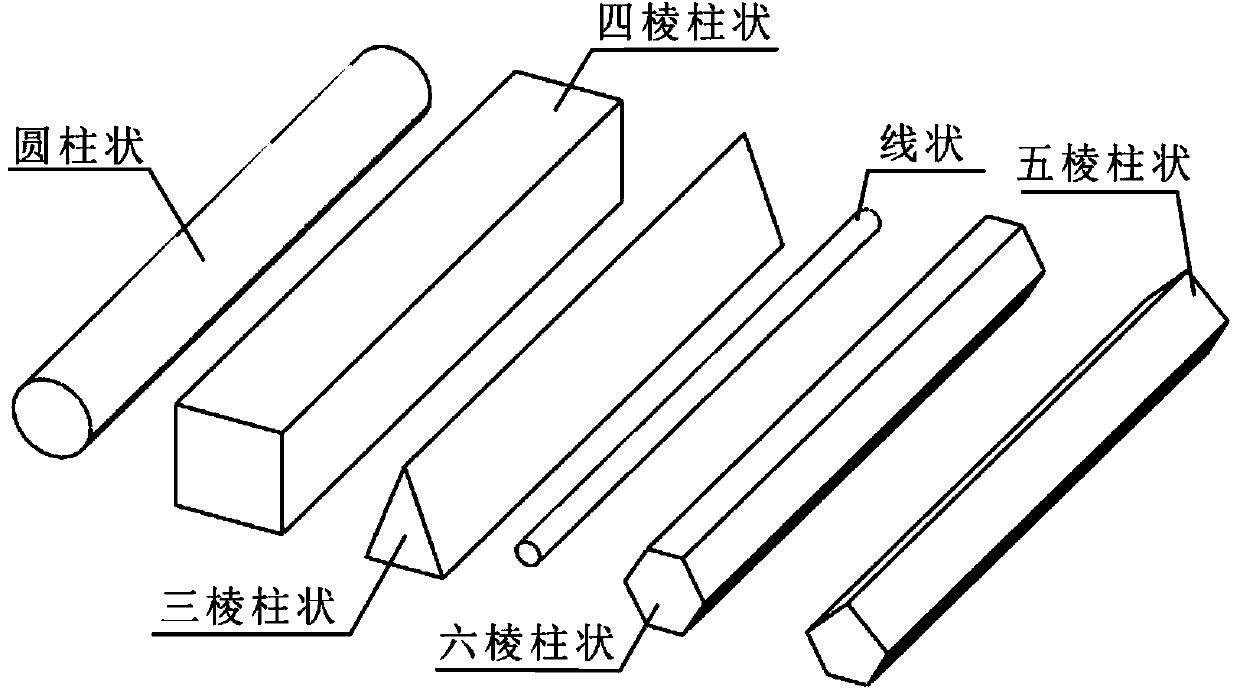

Foamed aluminum-corrugated plate composite sandwich plate and preparation method thereof

InactiveCN104175623AHigh shear mechanical propertiesWith heat insulationLamination ancillary operationsLaminationFoaming agentEnergy absorption

The invention relates to a foamed aluminum-corrugated plate composite sandwich plate and a preparation method thereof. The method comprises the following steps: firstly, manufacturing a corrugated core body; welding the corrugated core body to a panel to form a corrugated plate; putting basal powder and a foaming agent in a mixing machine for uniform mixing, and then extruding the mixed powder into a primary blank; putting the blank in a mould for pressing, filling the inside of the corrugated plate with a pressed foaming prefabricated body, and putting the corrugated plate in an atmosphere furnace for foaming; and heating and keeping warm until the prefabricated body is expanded to form foamed aluminum with which pores of the corrugated plate are completely filled, and then cooling. By using a powder metallurgy method, the inside of lattice metal is foamed in situ to form the metallurgical-bonding foamed aluminum-corrugated plate composite sandwich plate. The excellent mechanical property of the lattice metal and the advantages of energy absorption, sound insulation, shock absorption and thermal insulation of the foamed aluminum are utilized, so that the multifunctional coupling is realized, and the structure and function integration material with the relatively excellent comprehensive performance is obtained. The bonding strength is effectively improved by virtue of metallurgical bonding, and the performance of the composite material is further improved.

Owner:XI AN JIAOTONG UNIV +1

Rubber reinforced cement functional composite material and preparation method thereof

InactiveCN101857399AWith noise reductionWith sound insulationSolid waste managementNoise barrierAdhesive

The invention discloses a rubber reinforced cement functional composite material and a preparation method thereof. The rubber reinforced cement functional composite material is prepared from waste rubber and cement or cement mortars by the following steps of: applying coupling adhesives to surfaces of waste rubber grains and / or powder by using coupling agents; mixing the waste rubber grains and / or powder with the cement or the cement mortars; adding water into the rubber-cement mixed materials for uniform stirring, and performing pavement, pressing, demoulding and maintaining to obtain the functional composite material product having a high mechanical strength and endurance. The composite material has the characteristics of noise reduction, sound isolation, high impact resistance, damping vibration attenuation, wear resistance, static resistance, water resistance and the like, has the advantages of insulation, environmental protection and the like and can be used in the field of functional materials, such as buildings, roads, railways, tunnels, noise barriers and the like. The functional composite material and the method thereof also provide a new way for solving the global problem of 'black pollution' of increasing waste tyres and have a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

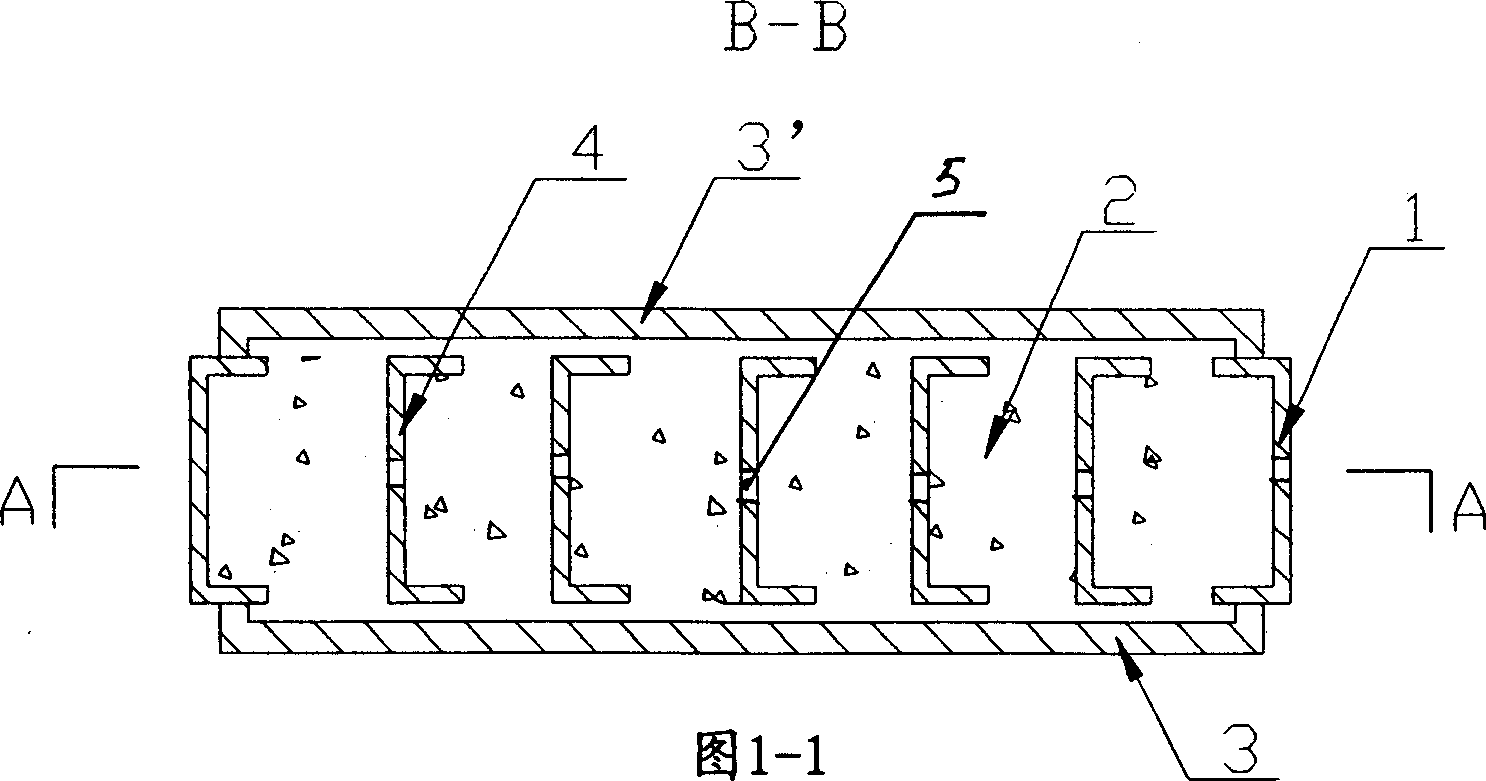

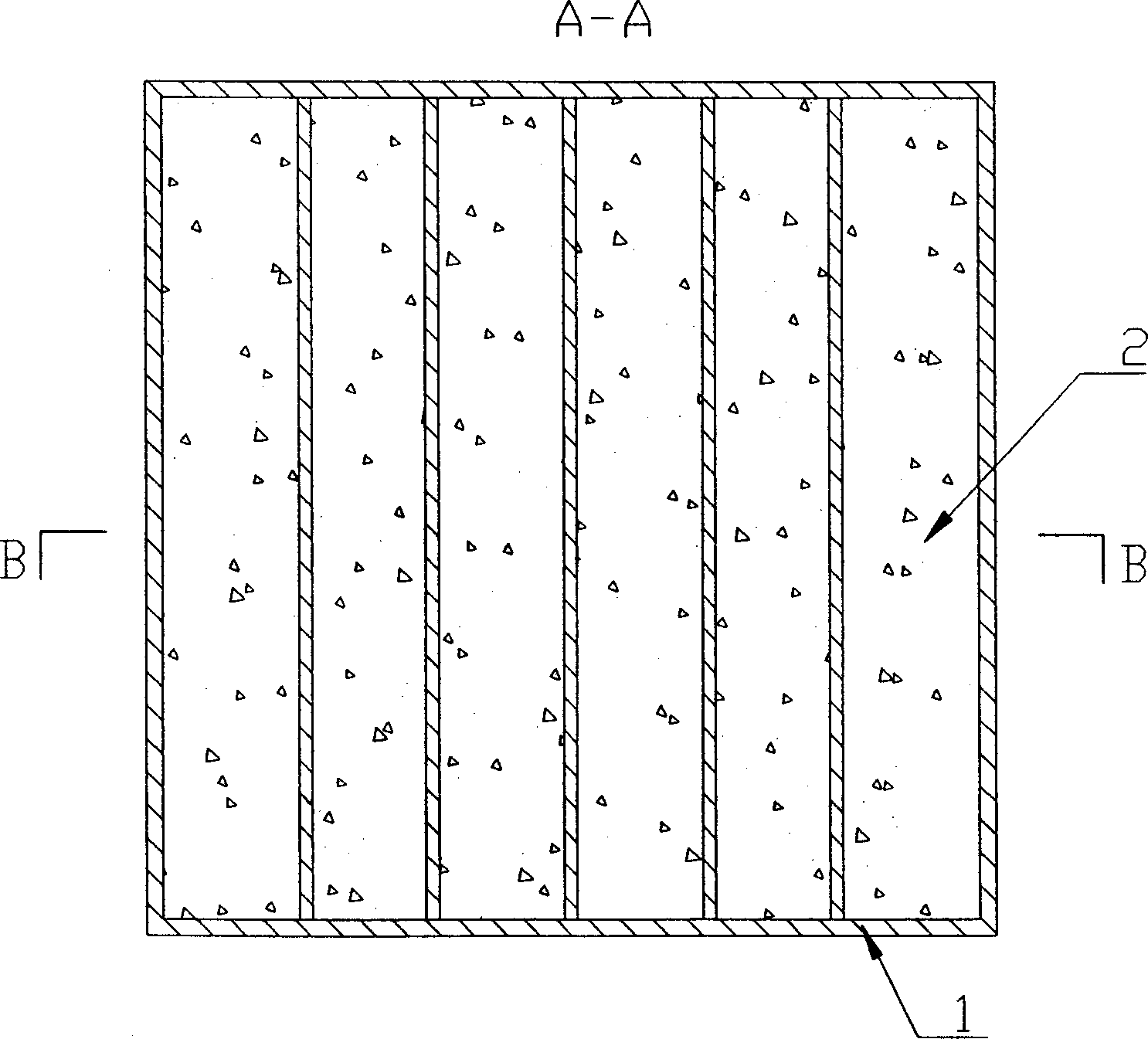

Composite building board material capable of load bearing and its productioin method

InactiveCN1478971AFireproofWith sound insulationMouldsBuilding componentsSteel columnsLoad-bearing wall

A composite building plate able to bear load is composed of the external frame, foamed cement layer filled into the frame, and surfacial layers, and features that several steel columns or beams are unidirectionally arranged in the frame, which have through holes for allowing the foamed cement to penetrate through them. Its advantages are light weight, high weatherability, insulation to heat and sound, and resistance to water, acid and alkali, and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

Composite material of imitated glass reinforced plastic, its manufacture method and its application

The invention discloses a composite material of an imitated glass reinforced plastic, which comprises a basic layer, the basic layer comprises the following ingredients by weight: 120-160 parts of active light calcium carbonate powder, 60-130 parts of recovered plastic, 30-60 parts of glass fiber and / or basalt fiber, 10-30 parts of coupling agent, 1-30 parts of foaming agent, 30-60 parts of processing auxiliary agent and 1-5 parts of stabilizing agent. The composite material also comprises a superficial layer and a filling layer. The composite material can replace a plurality of glass reinforced plastic products, steel products, stone products, ceramic products, wood products and plastic products. The composite material possesses the characteristics of wood, such as nailing, sawing, pasting and shaving, and enables secondary processing; and has the characteristics of B-1 grade fire protection, insect protection, no fumigation, water resistance, corrosion resistance, rust resistance, sound insulation, heat insulation, light weight, high intensity, impact resistance, strong plasticity, good physical properties, long service life, no formaldehyde containing, no radiation, acid and alkali resistance, hot and cold resistance, ultraviolet resistance, no paint requirement, easy construction, recoverable property, regeneration and utilization and the like.

Owner:黄云清

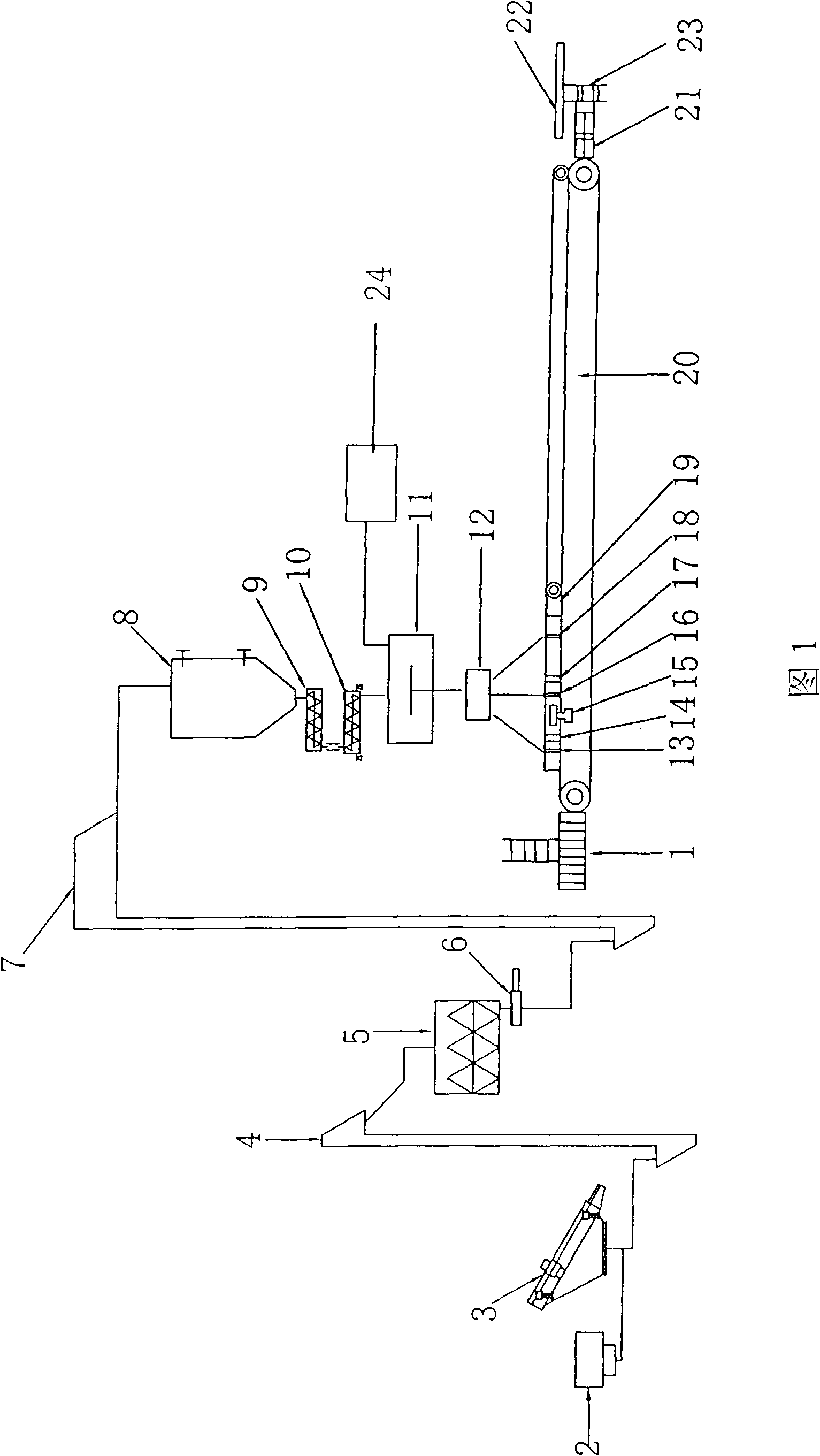

Method and apparatus for producing exterior wall self-heat preservation composite ecological light wall board

InactiveCN101328758AInsulation hasShorten the production cycleCovering/liningsCeramic shaping apparatusFiberSlurry

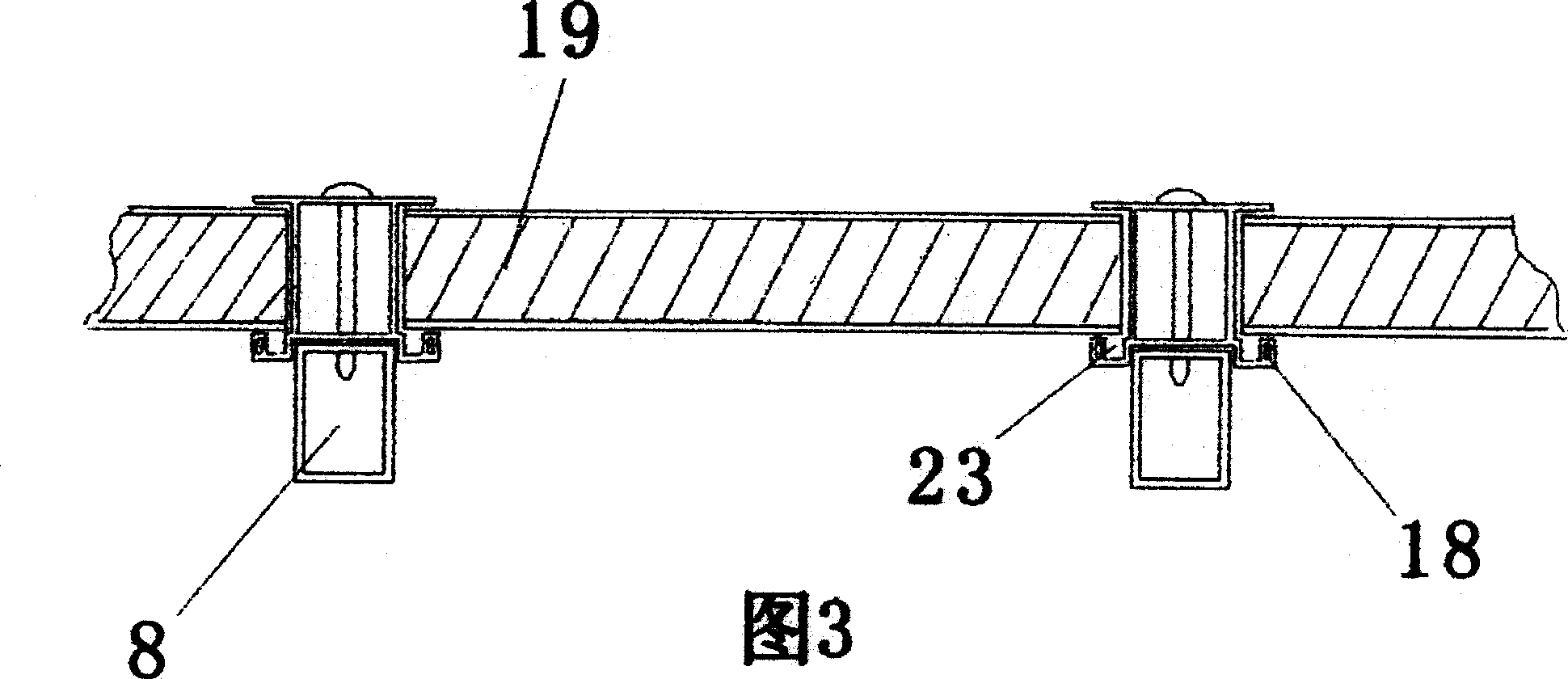

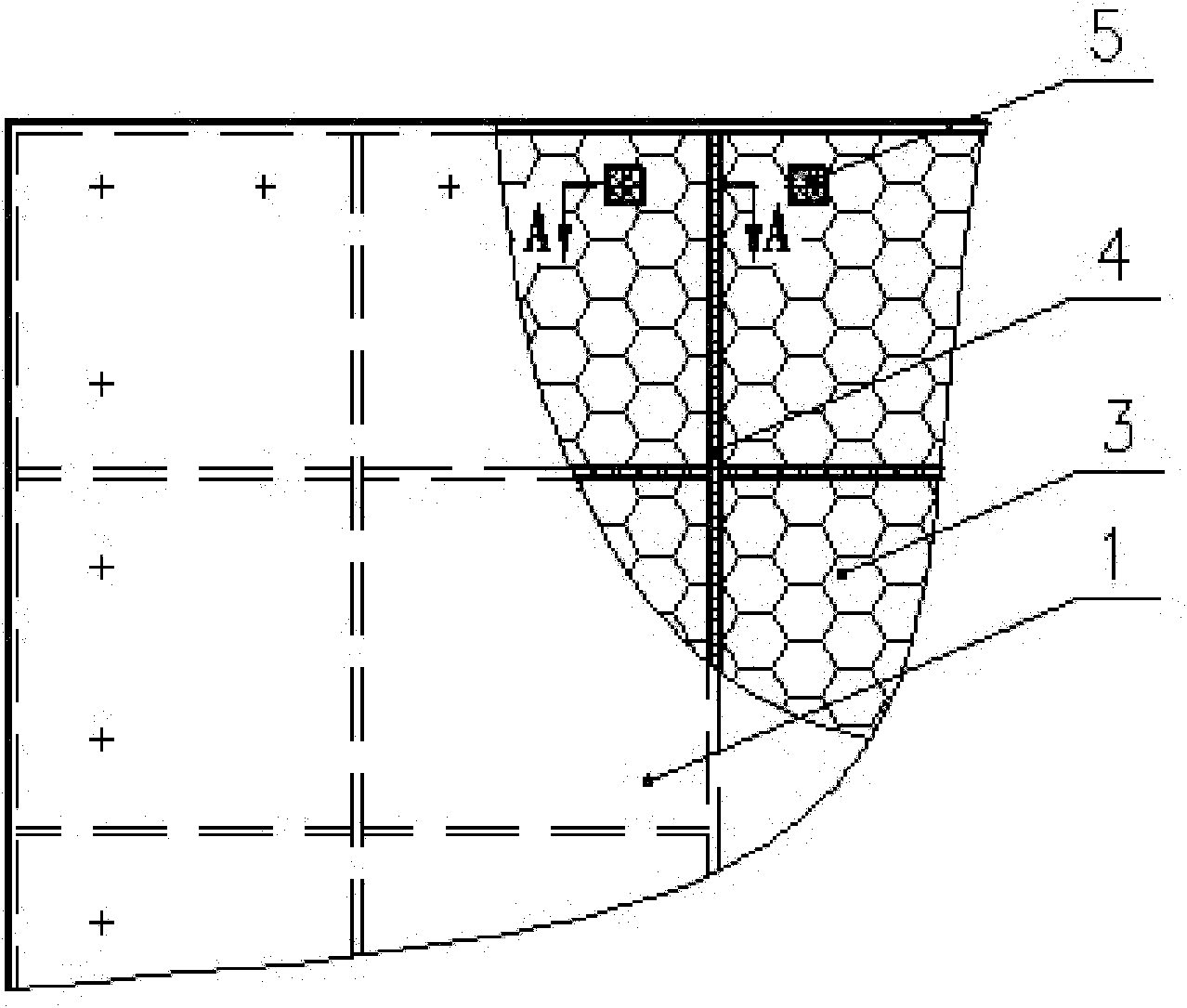

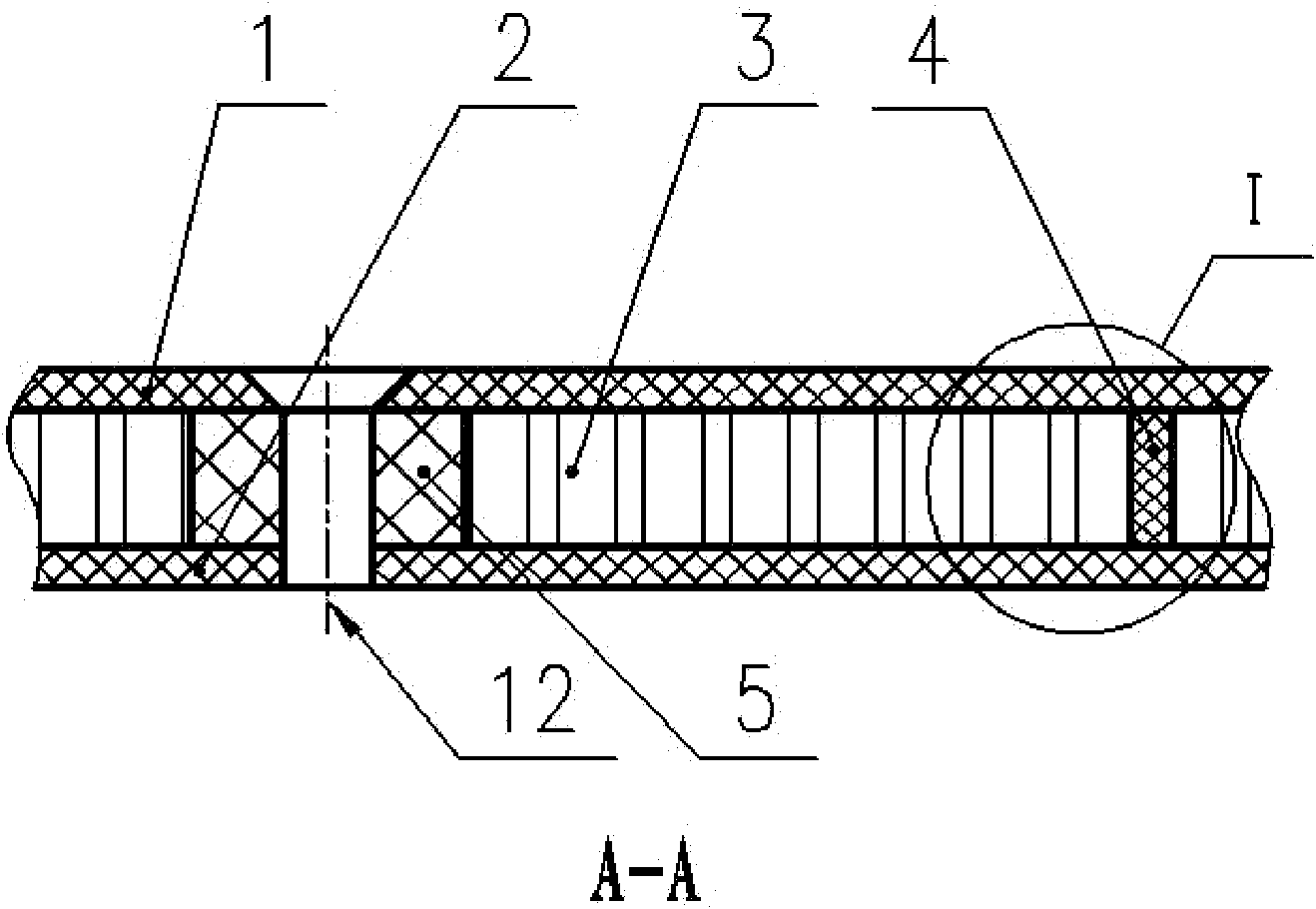

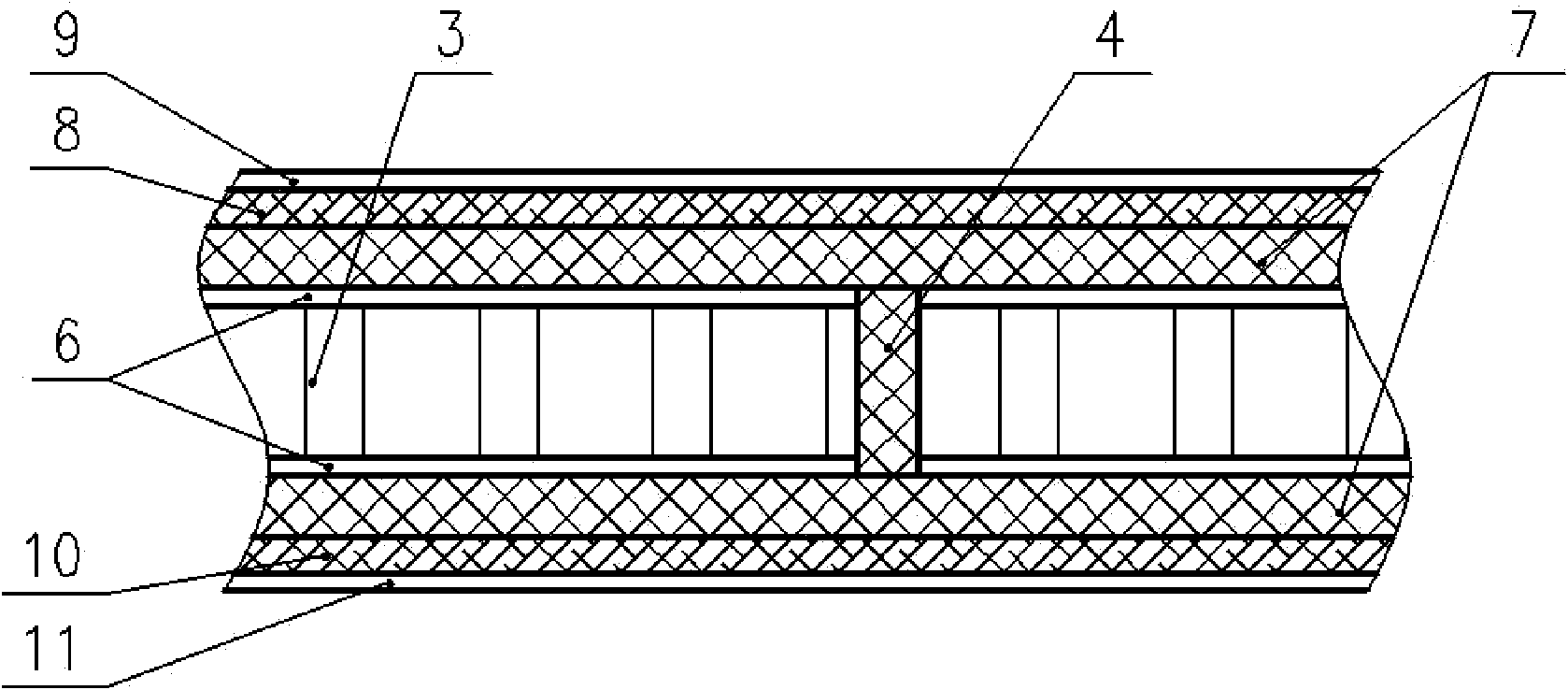

The invention provides a method and equipment for producing an external wall selfinsulation composite ecological light wall plate. The method comprises the following steps of: (1) sending a multicellular plate material to a production line; (2) mixing materials and sieving; (3) adding plant fibers into the materials, putting the mixed materials in a tank after the mixed materials are stirred; (4) stirring the mixed materials into slurry; (5) pouring the slurry to produce a first layer of plasterboard; (6) spreading a grid cloth and a foam plate on the first layer of the plasterboard for secondary pouring to produce a foam plaster layer; and (7) spreading the grid cloth on the foam plaster layer for third pouring, and spreading and pressing an adhesive tape on the poured foam plaster layer to produce a finished product which is cut into pieces and is loaded and transported into a warehouse. The equipment comprises a backplane feeding support (1), conveyors (2, 9), a grading screen (3), hoisting machines (4, 7), mixers (5, 11), a storage tank (8), a pressure distributor (12), a leveling device (19), a forming machine frame (20), a cutting machine (21) and a plate grasping and feeding machine (23). The method and the equipment have the advantages of reasonable structure, perfect process, continuous operation, great increased yield, heat insulated product, energy conservation, sound isolation and ecological environmental protection.

Owner:罗国军

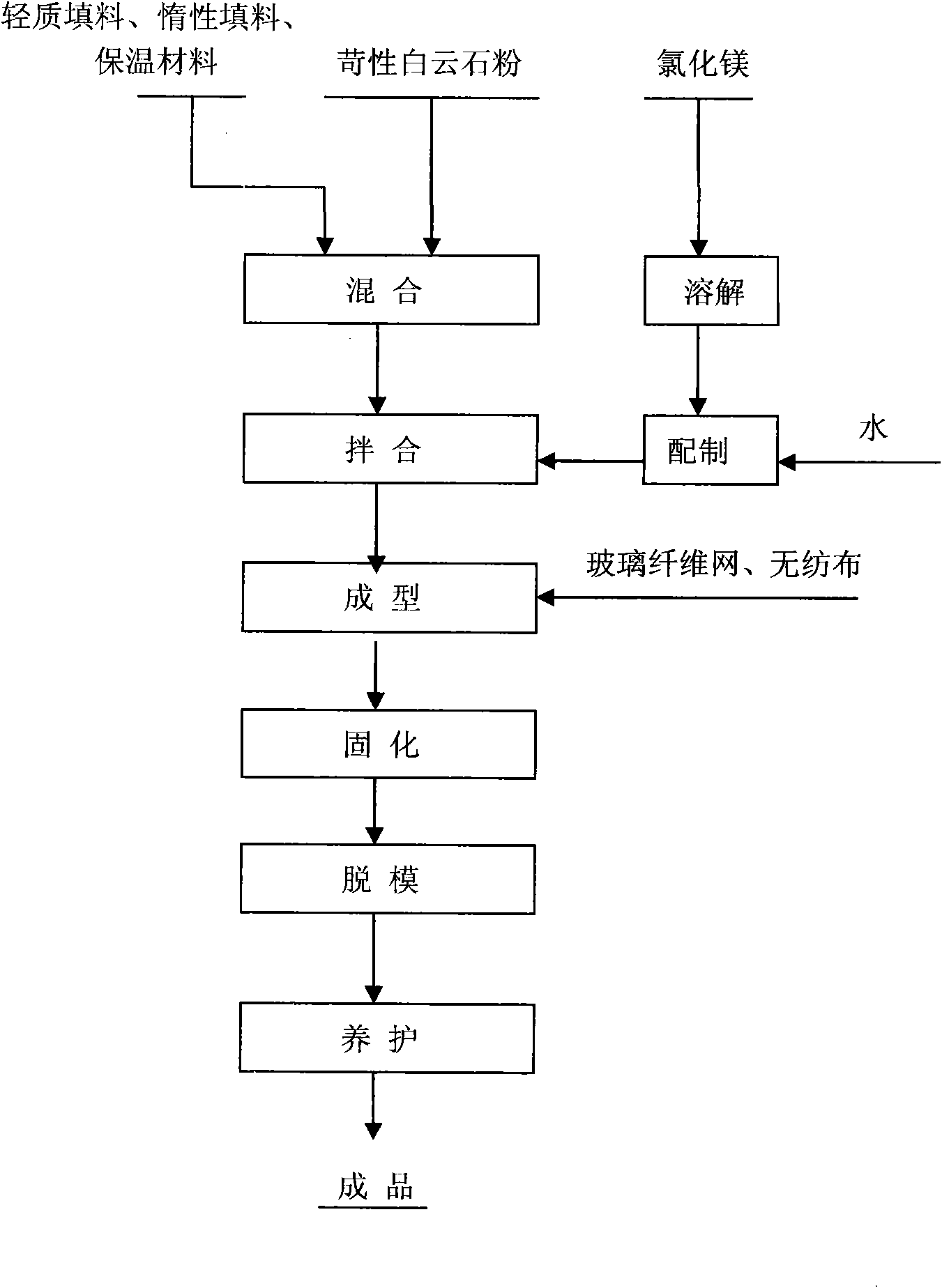

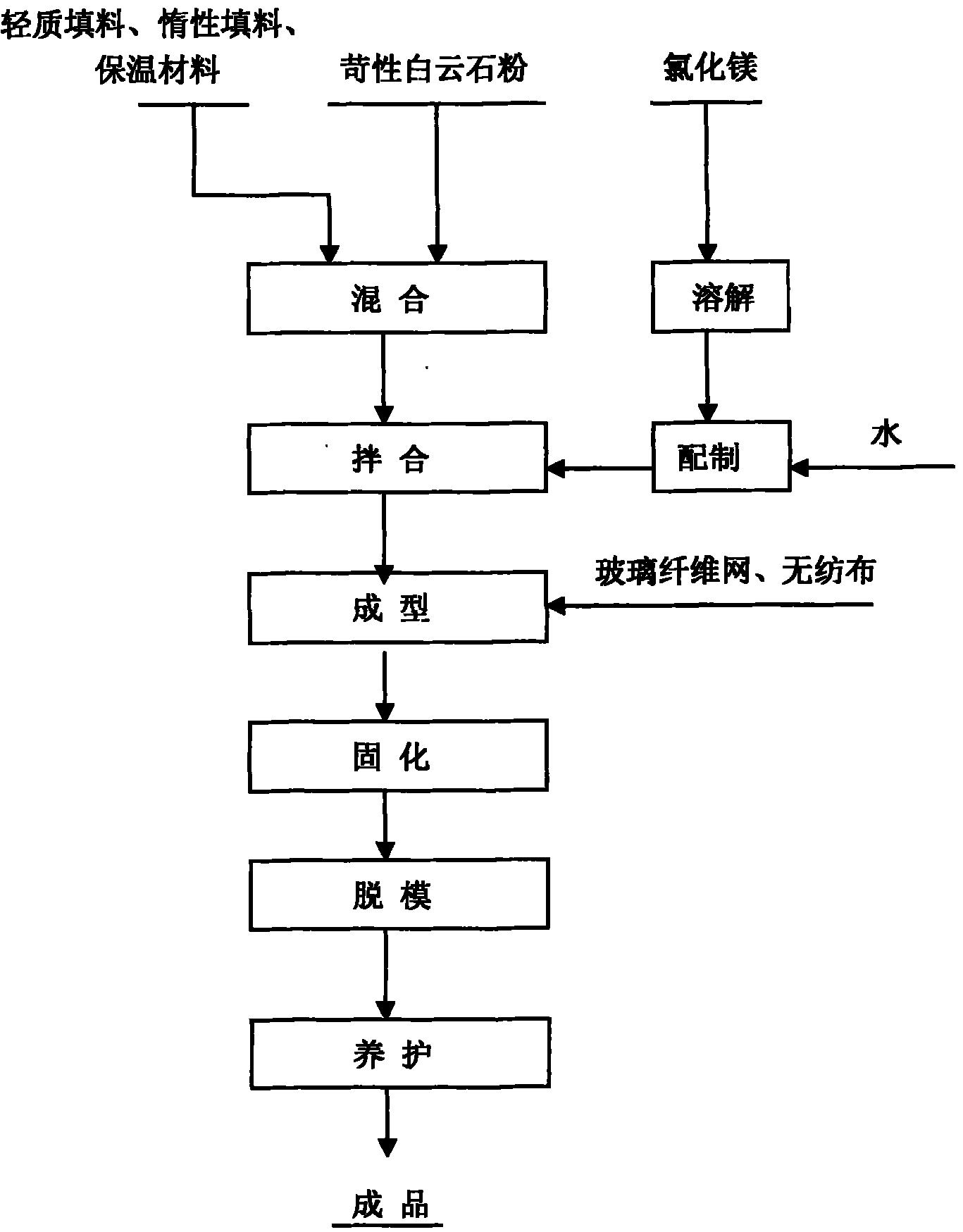

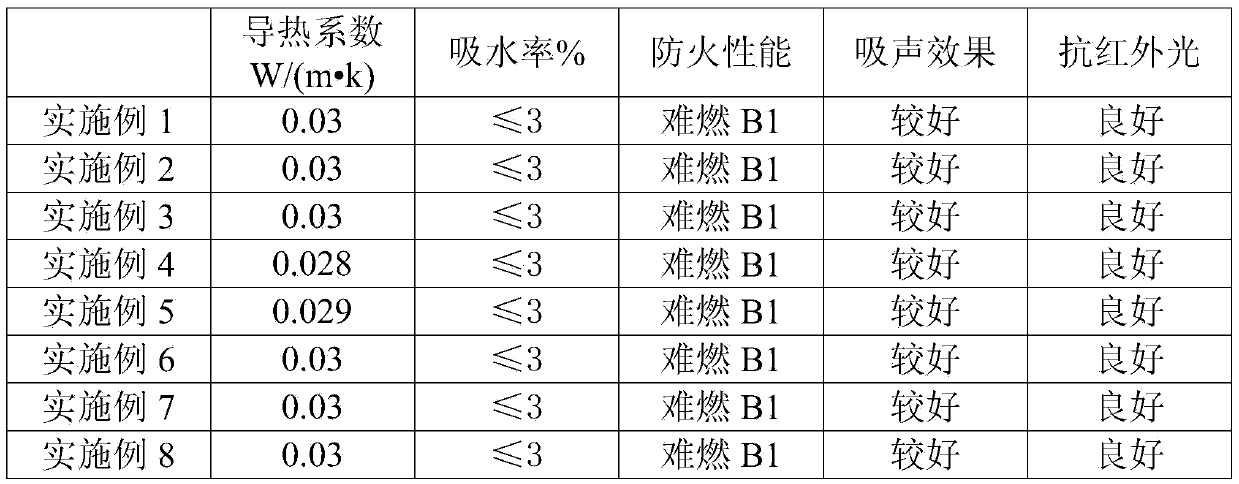

Light dolomite magnesium cement partition plate and manufacturing method thereof

The invention relates to a light dolomite magnesium cement partition plate and a manufacturing method thereof, and belongs to the field of chemical building materials. The light dolomite magnesium cement partition plate consists of caustic dolomite powder, magnesium chloride, light filler, inert filler, water and a heat insulating material in a mass ratio of 1.00:(0.12-0.40):(0.10-0.60):(0.05-0.30):(0.44-1.20):(0.05-0.30); and an appropriate amount of reinforcing material is added into the materials; and the manufacturing method of the light dolomite magnesium cement partition plate comprises the following steps of: stirring and mixing slurry, molding and solidifying, and curing. The light dolomite magnesium cement partition plate for building, which is produced by the manufacturing method, has the advantages of fire protection, heat preservation, high strength and water tolerance, anticorrosion, vibration resistance, sound insulation, easiness in construction, environmental-friendliness, energy conservation, simple production process and low consumption, and the like, is a generation-substituting product which can replace various plates, such as color steel light partition plates, portland cement partition plates and the like, belongs to environmental-friendly building materials and can be widely applied to a building industry.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Insulation board made of fiber reinforced composites and preparation method of insulation board

InactiveCN102797299ADimensionally stableImprove impact resistanceHeat proofingWater-setting substance layered productFiberglass meshGlass fiber

The invention discloses an insulation board made of fiber reinforced composites. The insulation board is characterized in that enhancement layers are paved on an upper layer and a lower layer of an insulation layer, and are of glass fiber gridding cloth. The invention also discloses a preparation method of the insulation board made of fiber reinforced composites. The preparation method comprises the steps of mixing all raw materials of the insulation layer with water uniformly; pouring the slurry mixed uniformly into a mold, wherein the glass fiber gridding cloth is paved at the bottom of the mold; paving a layer of glass fiber gridding cloth on the upper layer of the slurry; after the paving, pressing and molding the slurry. Due to the mode, the double layers of glass fiber gridding cloth are adopted for enhancing, so that the size stability, the shock resistance and the crack resistance of the insulation plate are improved obviously; the requirement on the insulation and fire resistance of an outer wall are met by adopting the technology that inorganic bond materials wrap the insulation fillers; and the service life of the insulation board is long and basically keeps the pace with that of a building.

Owner:JIANGSU NIGAO SCI & TECH +1

Heat-preserving material for outer wall

The present invention discloses a heat-preserving material for an outer wall which comprises the following raw materials in parts by weight: 45-55 parts of coal ash silicate cement, 15-20 parts of white floating beads, 1.5-2 parts of nano TiO2, 0.5-1.2 parts of ceramic cotton fiber, 5-10 parts of aluminium silicate fiber cotton, 0.2-0.6 part of a water repellent, 3-7 parts of an elastic emulsion, 6-9 parts of swelled vitrified microbead heat-preserving slurry, 3.5-4.5 parts of polypropylene fiber, 2-5 parts of an inorganic nano coating, 0.05-0.1 part of foam filaments, 0.05-0.1 part of bamboo fiber and 10-15 parts of a flame retardant. The heat-preserving material for the outer wall has the characteristics of good heat preservation, thermal insulation, sound insulation, self-cleaning, ray resistance, water resistance, energy conservation and environment protection and high strength.

Owner:NANYANG INST OF TECH

Complex heat-preservation roof and construction method thereof

ActiveCN101781917AAchieve ventilationAchieve heat preservationRoof covering using slabs/sheetsBuilding roofsPurlinThermal insulation

The invention relates to a building member, in particular to a complex heat-preservation roof and a construction method thereof. The roof comprises a roof truss, EPS boards and waterproof boards, the multiple EPS boards are arranged between purlins of the roof truss, and the waterproof boards are arranged on the EPS boards and the purlins; and the two end surfaces of the roof truss are also provided with the waterproof boards. The construction method is as follows: the EPS boards are arranged on the roof truss, the upper surface of each EPS board and the upper surfaces of the purlins are coplanar; reflecting films are stuck on the upper surfaces of the purlins and the EPS boards; the waterproof boards are assembled on the two sides of the lowest end of the roof truss, and then are paved on the previous layer until the surface of the roof truss is completely paved; a baffle is arranged on the roof truss and is provided with a first bracket, the first bracket is provided with an external pinchplate, and a drain tank is arranged on the first bracket by the external pinchplate; a second bracket is arranged below the first bracket, and a perforated plate is arranged on the second bracket; and the waterproof boards are used to seal the two end surfaces o the roof truss. The invention has the advantages of environment protection, heat preservation, thermal insulation, sound insulation, convenient installation and the like.

Owner:谭齐阳

Wall body vacuum insulation plate and preparation method thereof

ActiveCN103104044AImprove wear resistanceImprove fire performanceClimate change adaptationInsulation improvementBuilding energyEngineering

The invention relates to the field of building energy-saving insulation, in particular to a wall body vacuum insulation plate and a preparation method thereof. The wall body vacuum insulation plate comprises a vacuum heat isolation plate formed by a high isolation package bag and an insulation core material arranged in the high isolation package bag through vacuum sealing, and a fiber reinforced composite isolation bag is arranged outside the vacuum heat isolation plate in a seal and vacuum mode. Compared with the prior art, due to the fact that the fiber reinforced composite isolation bag is arranged outside the vacuum heat isolation plate in the seal and vacuum mode, abrasion resistance, fire-proof performance and bonding performance with other materials of the wall body vacuum insulation plate are reinforced. The wall body vacuum insulation plate is particularly suitable for being used in the field of building energy-saving insulation, not only can be applied to external wall insulation, internal wall insulation and sandwich insulation, but also can be applied to thin-plastered and various decorating dry-hanging systems, and is particularly suitable for energy-saving buildings which have high requirements for heat insulation in cold areas.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Fiber-reinforced fireproof insulation board and preparation process thereof

InactiveCN103979918AOvercome defectsAvoid defectsSolid waste managementClimate change adaptationCalcium formateFire retardant

The invention discloses a fiber-reinforced fireproof insulation board. The fiber-reinforced fireproof insulation board is prepared from the raw materials in parts by weight: 80-100 parts of fly ash, 30-50 parts of expanded perlite, 10-20 parts of ceramsite, 10-20 parts of plant fiber, 5-10 parts of floating bead, 5-8 parts of meerschaum, 3-5 parts of sodium fluosilicate, 3-5 parts of calcium formate, 3-5 parts of flame retardant, 0.1-0.5 part of oleic triisopropanolamine and 0.1-0.3 part of glycol dimethyl ether. According to the fiber-reinforced fireproof insulation board, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; through the organic combination and generated synergism of the fly ash, lightweight aggregate and additives, the defects in the existing building insulation boards can be effectively overcome.

Owner:秦菊霞

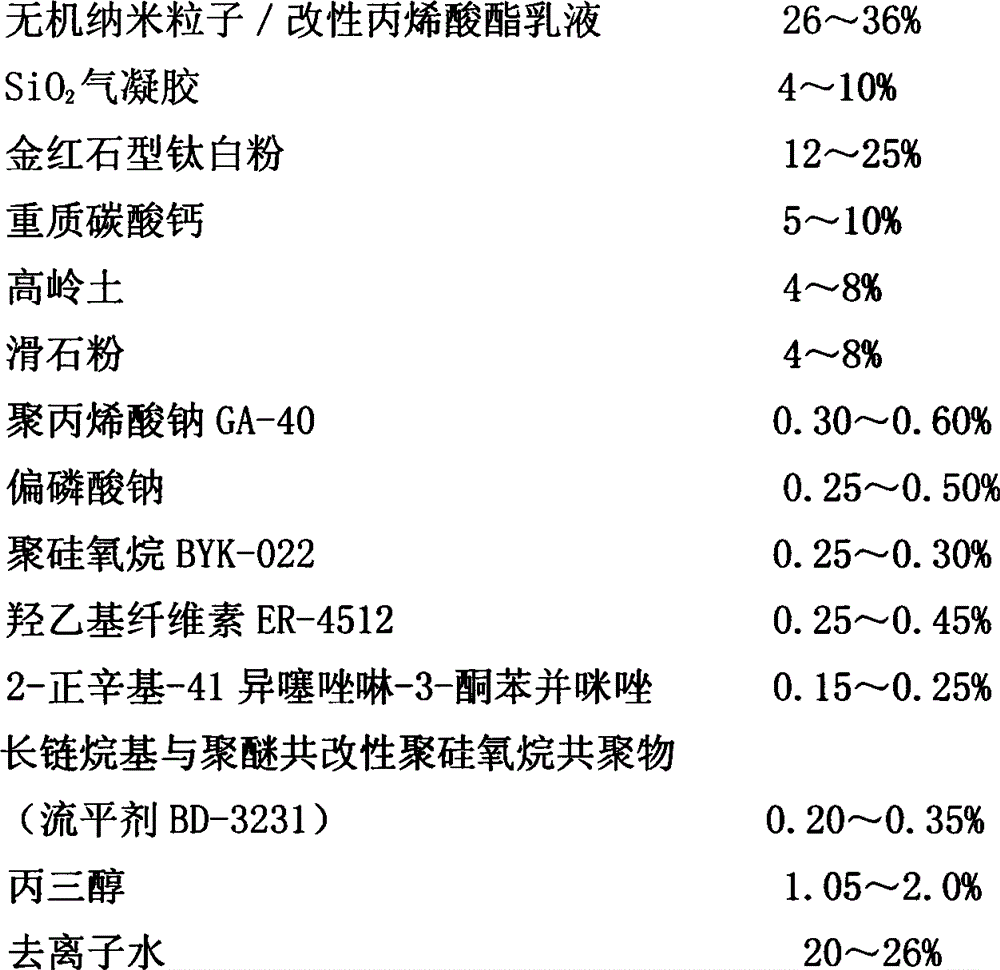

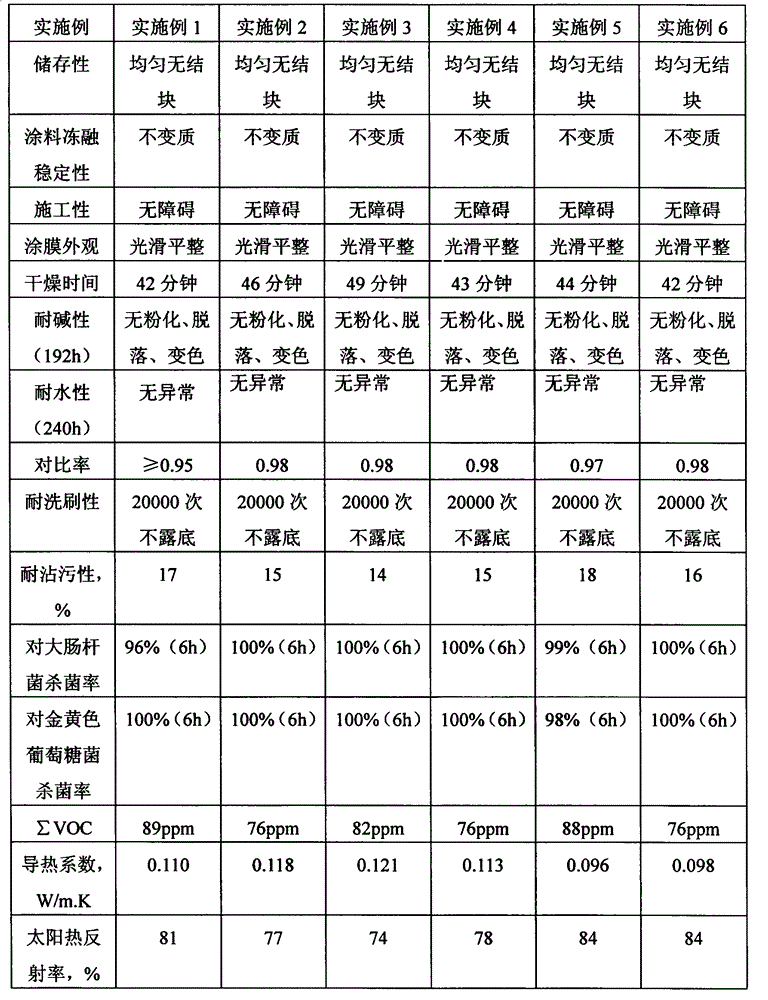

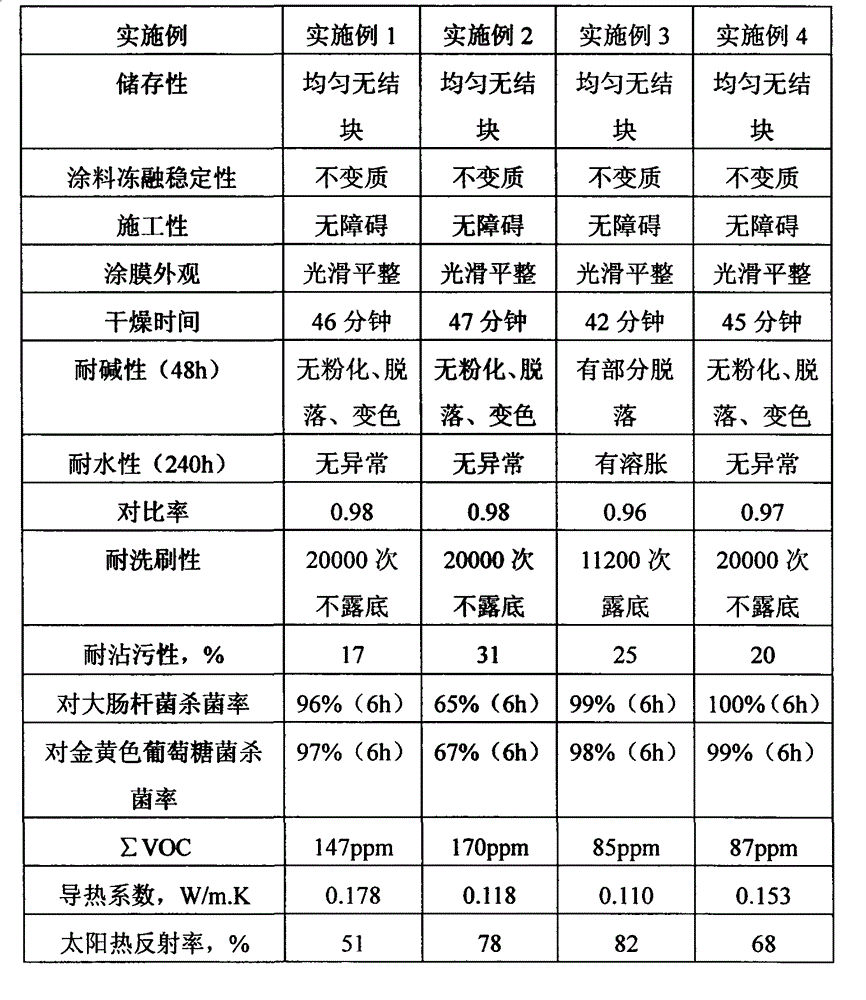

Multifunctional bacterium-resisting and smell-removing thermal insulation coating

InactiveCN102977721AImprove adhesionGood scrub resistanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to an environment friendly bacterium-resisting and smell-removing thermal insulation latex coating which is suitable for coating an inner wall and an outer wall. The environment friendly bacterium-resisting and smell-removing thermal insulation latex coating comprises inorganic nano particle / modified acrylic ester emulsion, SiO2 aerogel, a pigment filler, a thickening agent, a dispersing agent, a flatting agent and a film-forming additive. By using two functions of the inorganic nano particle / modified acrylic ester emulsion and the SiO2 aerogel, the coating is endowed with multiple functions of resisting and killing bacteria, removing smell, blocking and insulating sound, insulating heat and preserving heat.

Owner:上海滋普环保科技有限公司

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

Two-layer co-extruding plastic drainage pipe and preparation method thereof

The invention relates to the plastic pipe field, in particular to a two-layer co-extruding plastic drainage pipe used outdoors. The drainage pipe contains an inner layer and an anti-aging outer layer, wherein the inner layer comprises the following components in parts by weight: 90-110 parts of polyvinyl chloride resin, 3.5-4.8 parts of composite stabilizer, 3-8 parts of impact modifier, 0.2-0.5 part of stearic acid, 0.2-0.6 part of calcium stearate, 0.3-0.6 part of AC foaming agent, 4-8 parts of foaming regulator ZB530, 5-40 parts of calcium carbonate, 0.4-1.0 part of polyethylene (PE) wax and 0.3-0.8 part of lead stearate. The outer layer of the drainage pipe is the anti-aging layer, thus the aging resistant problem can be solved. The inner layer adopts the foaming technology, thus the overall weight of the drainage pipe can be reduced, the impact resistance of the pipe can be increased, the pipe has the effect of sound insulation and the cost of the drainage pipe can be reduced. In addition, the invention also discloses a preparation method of the two-layer co-extruding plastic drainage pipe.

Owner:GUANGDONG LIANSU TECH INDAL

Aerated concrete block with composition of mica powder and fly ash and preparation method

InactiveCN103332916AImprove hydrophobicityHigh strengthCeramicwareTemperature resistanceSodium sulfate

Provided is an aerated concrete block with composition of mica powder and fly ash and a preparation method. The aerated concrete block is characterized by being prepared from, by weight, 12-15 parts of cement, 15-20 parts of quicklime, 12-16 parts of gypsum, 30-35 parts of fly ash, 0.2-0.4 parts of aluminium powder, 30-35 parts of mica powder, 12-16 parts of talcum powder, 2-3 parts of ferric nitrate, 2-3 parts of lard, 2-3 parts of sodium dodecyl benzene sulfonate, 1-2 parts of iron mine tailings, 2-3 parts of sodium persulfate, 3-4 parts of oil foot, 3-4 parts of polyisobutylene and 8-10 parts of alum. The aerated concrete block employs composition of mica powder and fly ash, and is advantaged by high temperature resistance acid and alkali resistance, corrosion resistance and high block strength.

Owner:梁莉

Water-based heat insulation paint and preparation method thereof

The invention relates to a water-based heat insulation paint and a preparation method of the paint; the water-based heat insulation paint is prepared by mixing water, film forming matter, a dispersing agent, an anti-freezing agent, a defoaming agent, a film forming auxiliary agent, a thickening agent, functional filler, composite phase change material and titanium dioxide. The water-based heat insulation paint is coated on the surface of a wall body, and has the effects of heat insulation and building indoor temperature regulation after being cured at the room temperature and completely dried.

Owner:大连高宝龙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com