Multifunctional bacterium-resisting and smell-removing thermal insulation coating

A technology for thermal insulation coatings and deodorization, which is applied in the fields of environmental protection, antibacterial, thermal insulation latex coatings, and deodorization. It can solve the problems of high thermal conductivity and achieve the effects of high surface finish, high covering power of the paint film, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

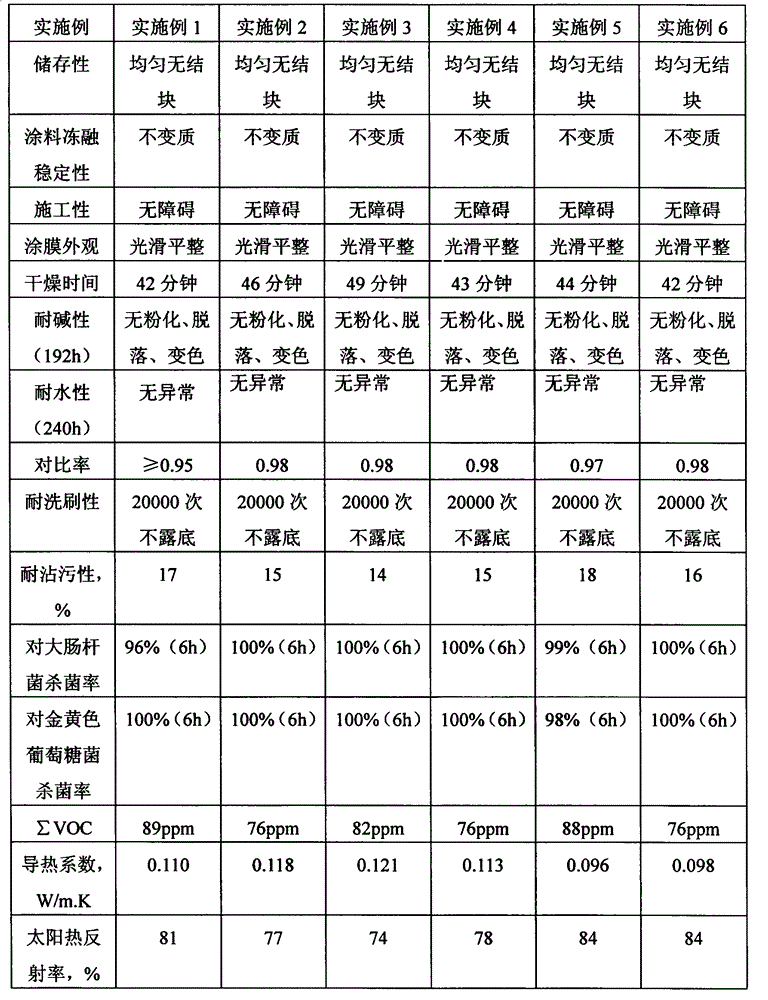

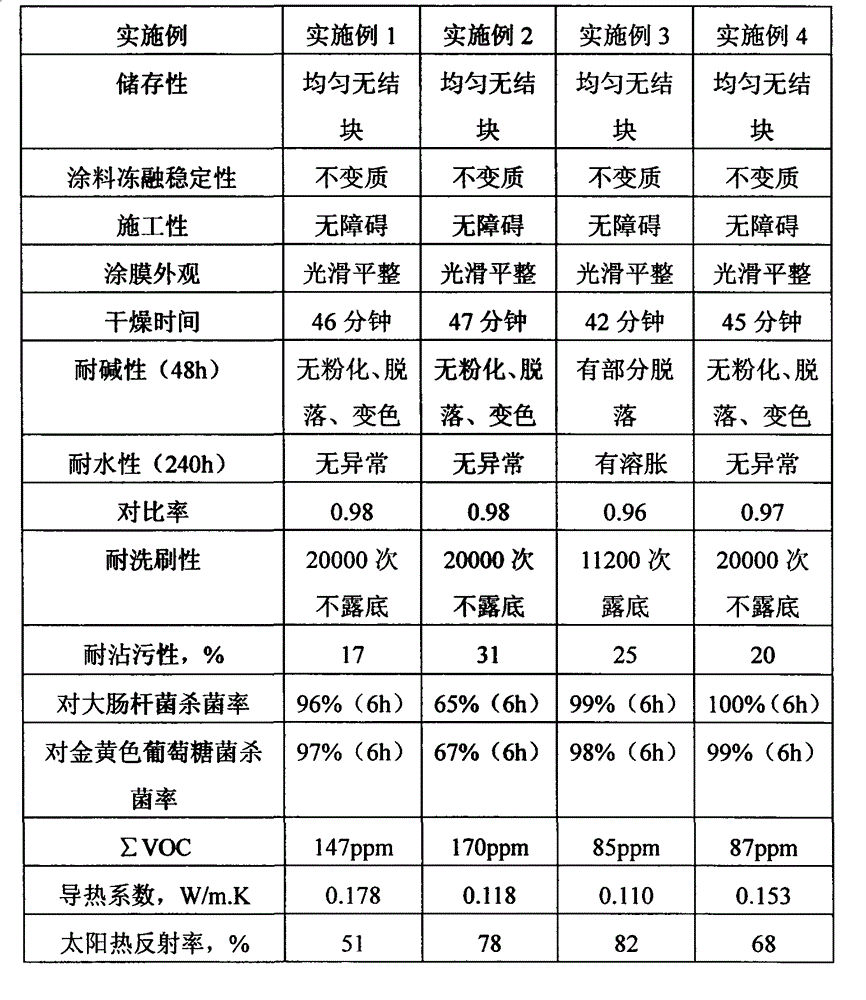

Examples

Embodiment 1

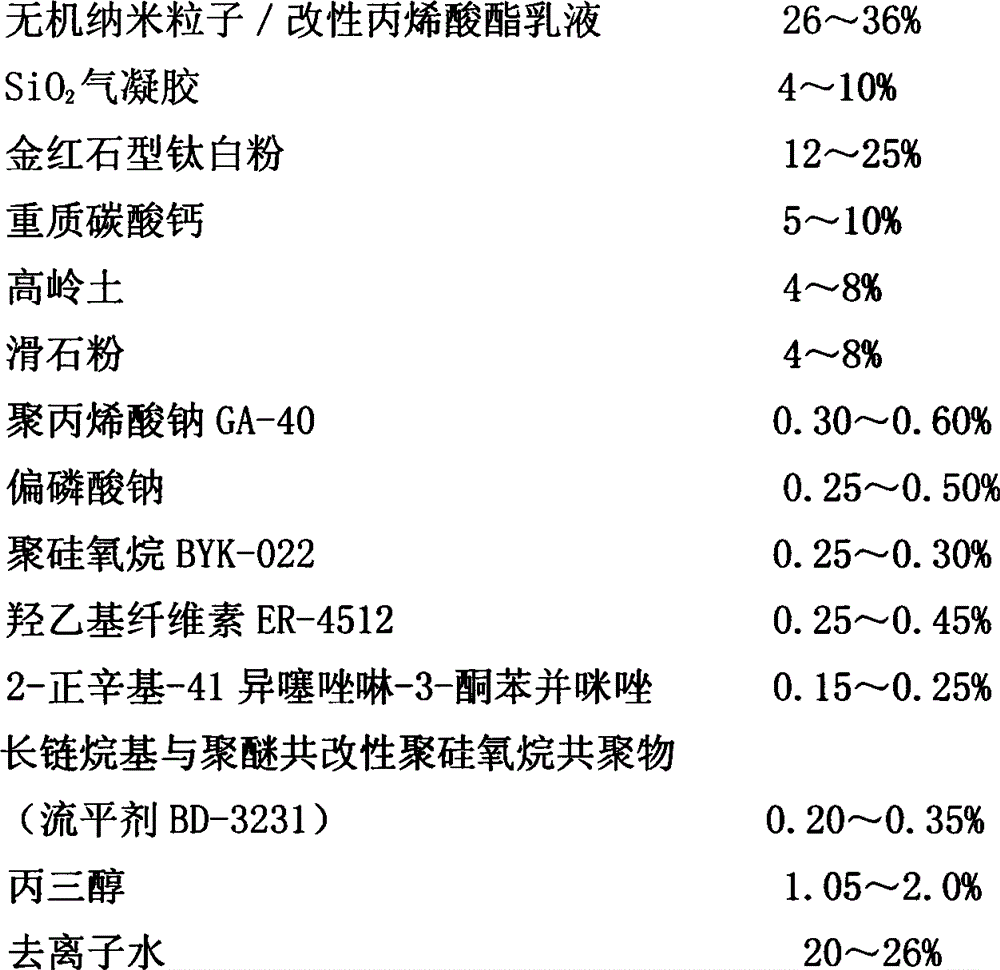

[0025] The preparation of a kind of antibacterial odorless heat preservation coating comprises the following steps:

[0026] (1) Get 0.60 kg of sodium polyacrylate (GA-40) and 0.50 kg of sodium metaphosphate and disperse them in 25 kg of deionized water, stir at high speed and add SiO 2 Aerogel 7.5 kg, mixed for 0.5 hours.

[0027] (2) Under medium speed stirring, slowly add 25 kg of rutile type titanium dioxide, 6 kg of heavy calcium carbonate, 5 kg of kaolin, 4 kg of talc, 2-n-octyl-41 isothiazole to the material (1) 0.25 kg of lin-3-one benzimidazole, 1.25 kg of glycerol, 0.1 kg of polysiloxane (BYK-022), 0.15 kg of hydroxyethyl cellulose (ER-4512), stirring at high speed for 0.5 hour.

[0028] (3) Slowly add nano-titanium dioxide / organosilicon-acrylate composite emulsion (solid content 49.5%, titanium dioxide content 6%, silicone content 2%, minimum film forming temperature -20 ℃, volatilization to (2) material 82ppm.) 26kg, BD-3231 leveling agent 0.35kg and the remainin...

Embodiment 2

[0031] The preparation of a kind of antibacterial odorless heat preservation coating comprises the following steps:

[0032] (1) Get 0.40 kg of sodium polyacrylate (GA-40) and 0.50 kg of sodium metaphosphate and disperse them in 22 kg of deionized water, stir at high speed and add SiO 2 Aerogel 6.7 kg, mixed for 0.5 hours.

[0033](2) Under medium speed stirring, slowly add 12 kg of rutile type titanium dioxide, 10 kg of heavy calcium carbonate, 6 kg of kaolin, 6 kg of talc, 2-n-octyl-41 isothiazole to the material (1) 0.15 kg of lin-3-one benzimidazole, 1.5 kg of glycerol, 0.1 kg of siloxane (BYK-022), 0.1 kg of hydroxyethyl cellulose (ER-4512), stirring at high speed for 0.5 hour.

[0034] (3) Slowly add nano-silica / organosilicon-acrylate composite emulsion (solid content 49.2%, silica content 2%, organosilicon content 2.5%) to the material (2), and the minimum film-forming temperature is - 16℃, volatile content 90ppm.) 34kg, BD-3231 leveling agent 0.2kg and remaining poly...

Embodiment 3

[0037] The preparation of a kind of antibacterial odorless heat preservation coating comprises the following steps:

[0038] (1) Get 0.30 kg of sodium polyacrylate (GA-40) and 0.4 kg of sodium metaphosphate and disperse them in 25 kg of deionized water, stir at high speed and add SiO 2 4 kg of aerogel, mixed for 0.5 hours.

[0039] (2) Under medium-speed stirring, slowly add 15 kg of rutile type titanium dioxide, 9 kg of heavy calcium carbonate, 4 kg of kaolin, 4 kg of talc, 2-n-octyl-41 isothiazole to the material (1) 0.15 kg of lin-3-one benzimidazole, 1.05 kg of glycerol, 0.1 kg of polysiloxane (BYK-022), 0.2 kg of hydroxyethyl cellulose (ER-4512), stirring at high speed for 0.5 hour.

[0040] (3) Slowly add nano-zirconia / organosilicon-acrylate composite emulsion (solid content 49.9%, zirconia content 4%, organosilicon content 3%, minimum film-forming temperature -23 ℃) to (2) material , volatile content 76ppm.) 36 kg, BD-3231 leveling agent 0.35 kg and the remaining poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com