Patents

Literature

807results about How to "Self-cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluororesin radiating paint and preparation method thereof

ActiveCN103131274AReduce thermal contact resistanceHigh thermal conductivityCoatingsCarbon nanotubeElectron transfer

The invention discloses fluororesin radiating paint and a preparation method thereof. The paint mainly comprises an electron transfer type organic compound, graphene, a carbon nanotube, titanium white, other additives and fluororesin, wherein the fluororesin is a paint brand having the highest comprehensive property at present; the electron transfer type organic compound can greatly enhance the thermal radiation rate of the paint; the graphene and the carbon nanotube can further accelerate thermal conduction; and the electron transfer type organic compound, the carbon nanotube and the graphene finally form a full three-dimensional network distribution of granules (electron transfer type organic compound), wires (carbon nanotube) and planes (graphene) in a fluid. The fluororesin radiating paint disclosed by the invention has high thermal radiation rate, high thermal conductivity and low thermal resistance, can realize radiation cooling, and simultaneously has the effects of self cleaning, acid / alkali resistance and super high insulativity, thereby having high practical value.

Owner:明朔(北京)电子科技有限公司

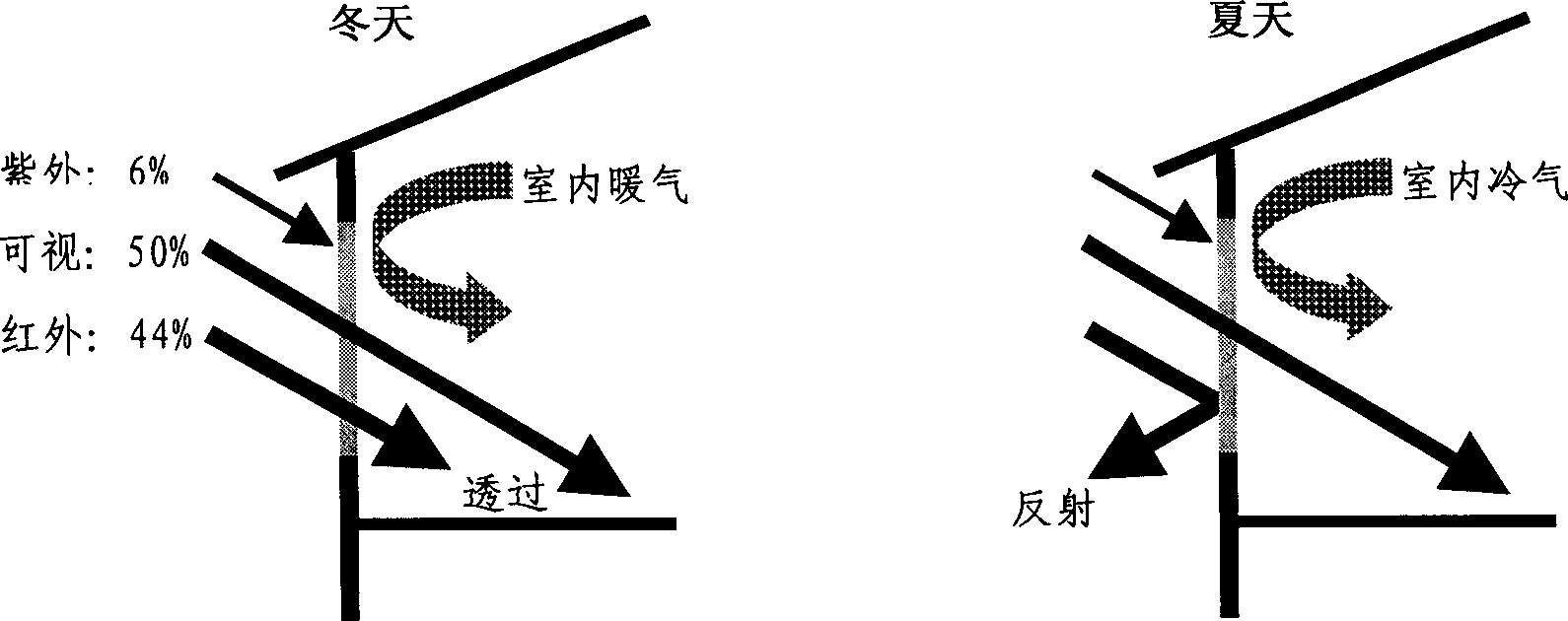

Highly energy-saving coating glass automatically adjusting light according to environment temperature and multi-layed assembled glass body

The invention provides a high-efficient energy-saving coating glass of automatic adjusting light with the environmental temperature and a multilayer assembly glass body, and the coating glass comprises: a glass substrate, and an energy-saving multilayer coating on the substrate with a thermalchromic layer of vanadium dioxide thin film and an optical transparent anti-reflection layer with an organic or inorganic thin film. The multilayer assembly glass body is formed by parallelly assembling the multilayer coating glass with gaps. The invention realizes the high adjustment efficiency to solar energy and hot ray reflection mechanism for sunshade in summer and thermal insulation for warm in winter, provides a solid base for VO2 intelligent energy-saving window application, has advantages comprising automatic aperture-control, simple structure, low cost and wear well, at the same time, selecting material appropriately for anti-reflection film can realizes the multi-functionalization for ultraviolet ray, such as absorbing, self-cleaning, sterilizing, anti-atomizating, and the application prospect is great in building energy efficiency.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

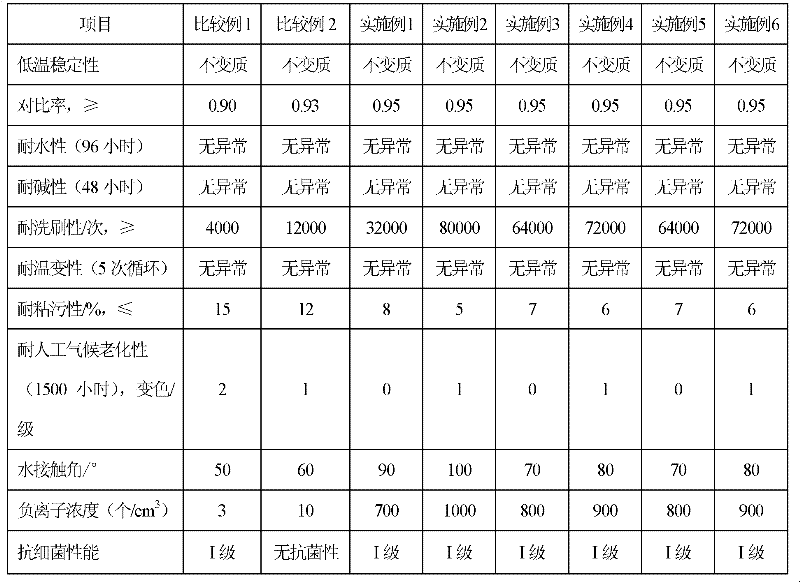

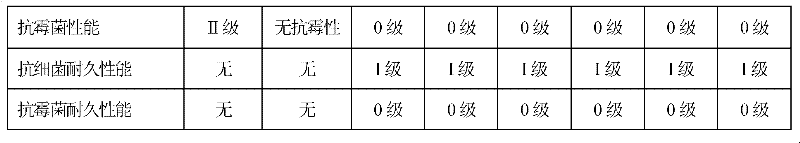

High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

ActiveCN102417748AEasy to disperseStorage stableAntifouling/underwater paintsPaints with biocidesVolatile organic compoundEmulsion

The invention relates to a paint technology, an environment-friendly technology and an antibacterial mould-proof technology, in particular to high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and a preparation method thereof. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint comprises the following components in percentage by weight: 0.5 to 5 percent of wetting dispersant, 0.01 to 20 percent of inorganic composite nano antibacterial agent concentrated pulp, 0.5 to 10 percent of hydrophobing agent, 0.5 to 10 percent of anionic powder, 0.5 to 8 percent of film-forming aid, 0.1 to 2 percent of anti-settling agent, 0.8 to 10 percent of antifreezing agent, 0.1 to 3 percent of defoaming agent, 4 to 30 percent of pigment, 0 to 30 percent of filler, 15 to 45 percent of emulsion, 0.1 to 4 percent of thickening agent, 0.1 to 3 percent of flatting agent, 0 to 3 percent of pH regulator and 0.5 to 45 percent of water. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint is mainly prepared by adding the inorganic composite nano antibacterial agent into the basic materials, so that the paint has the coating characteristic of high performance, is low is cost, and has a function of purifying air, can eliminate harmful gas volatile organic compounds (VOC), formaldehyde and the like and also has a durable and high-efficiency antibacterial mould-proof function, so that the sterilizing rate within 6 hours reaches 100 percent and the mould-proof grade reaches the first grade. By the high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and the preparation method thereof, self-cleaning performance, hydrophobicity, scrubbing resistance, dirt resistance and weather resistance of the coating are improved; and the high-efficiency and durable antibacterial and mould-proof effect is achieved.

Owner:广东腐蚀科学与技术创新研究院

Environment protectional photocatalyzed paint for inner wall

The invention relates to an environment-friendly photocatalysis inner wall paint and process for preparation, wherein the weight percent of raw material constituents are, one or two of acrylic-styrene emulsion and polyacrylic ester emulsion or their mixed liquor 10-35%, silicasol 5-15%, or mixed phase titanium oxide particles of octahedrite phase and rutile phase, or surface treated titanium oxide composite particles, the paint comprises photocatalyst 2-15%, pigment, filling material and other additive 10-20%, and water for the rest. The invention can effectively degrade the contaminant in the surrounding air.

Owner:SHANGHAI UNIV

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

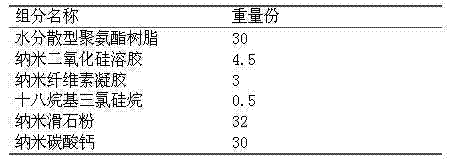

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

High weather resistant water-thinned wall paint and its preparing method

InactiveCN1392210ASelf-cleaningMildew proofPolyurea/polyurethane coatingsEmulsion paintsWeather resistanceEngineering

The present invention relates to high weather resistant water-thinned wall paint, and especially relates to environment friendly high weather resistant water emulsion paint and its preparation process. The paint consists of water emulsion, netted skeleton material, nano functional material, hydrophilic and hydrophobic raedical containing material, solid stuffing and assistant. The preparation principle includes basing on emulsion with excellent performance, constructing netted structure, introduction nano material with UV resisting, photocatalytic and high shielding performance, introducing assistant with both hydrophilic and hydrophobic characteristic to form compact and high-adhesion coating with integrated high weater resistance.

Owner:SUN YAT SEN UNIV

Aqueous functional coatings possessing effects of self-cleaning, anti mold, sterilization and purifying air

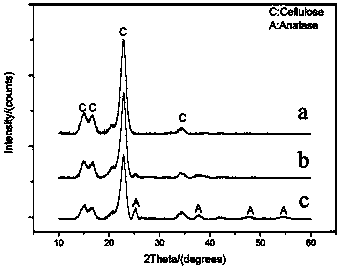

A functional water paint with self-cleaning, antimildew, bactericiding and air-cleaning functions for building contains (5-100)-nm anatase-type titanium oxide as photocatalyst (10-46%) and water-soluble resin or polymer emulsion or silicon sol or their composition as water adhesive (26-35%). It features that the various organic substances in the air or water in contact with its surface can be decomposed into CO2 and water. Its advantages are high effect and safety and durable acting.

Owner:UNIV OF SCI & TECH OF CHINA

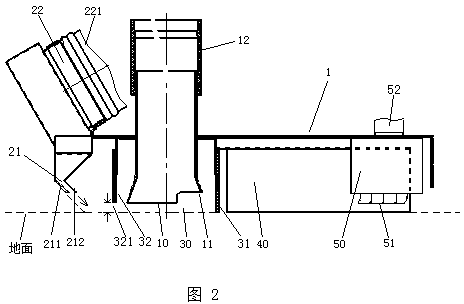

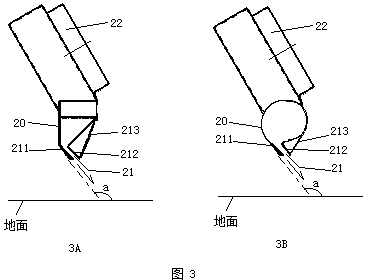

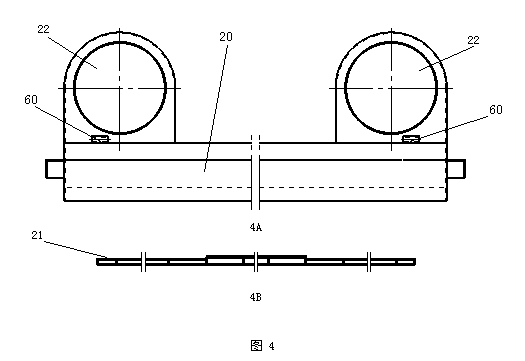

Cooking heating furnace

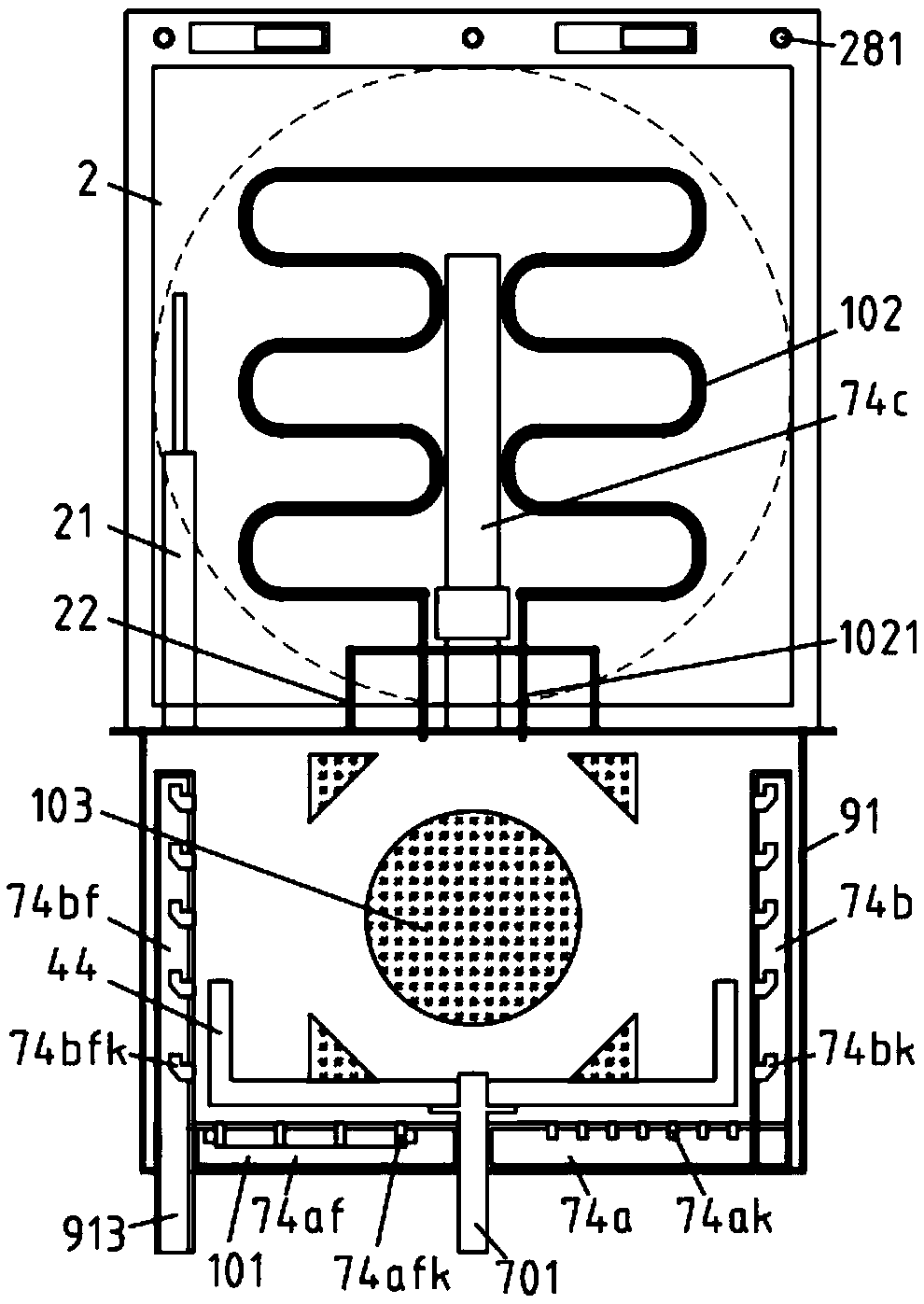

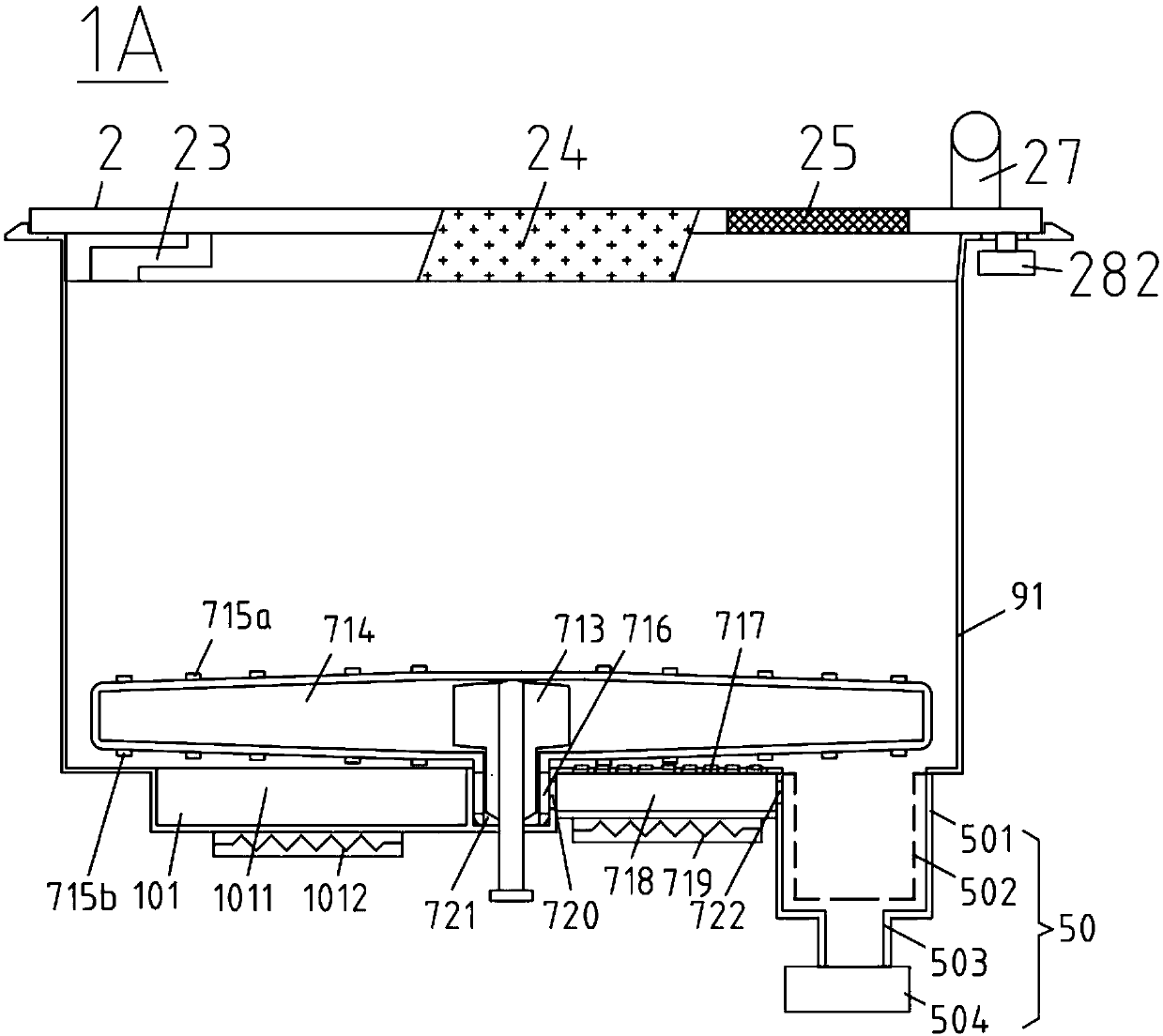

PendingCN110720871ASave spaceLow costTableware washing/rinsing machine detailsThermodynamicsProcess engineering

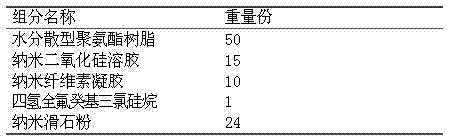

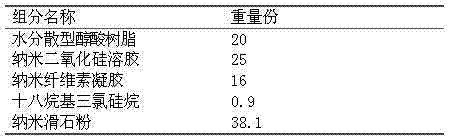

The invention relates to the technical field of smart home equipment, and discloses a cooking heating furnace. The heating furnace is combined with a water tank and / or a dishwasher. The dishwasher iscombined with the heating furnace to form a dishwashing heating furnace, and the effects of saving space and reducing the total cost are achieved by combined use of functional units of the dishwasherand the heating furnace. Further, the water tank of a kitchen is combined with the heating furnace and the dishwasher, and the water tank is used as a cavity of the heating furnace and the dishwasher,so that the space of the kitchen is saved or the kitchen is simpler and cleaner; the heating furnace is provided with a cover plate opened and closed from the top, so that food is put into or taken out from an oven more conveniently; and furthermore, self-cleaning of the heating furnace can be achieved, so that a user can use the heating furnace without cleaning concerns, multiple purposes are achieved, the life quality of the user is greatly improved, and a new high-performance and highly integrated kitchen appliance product is provided for households.

Owner:李亚锐

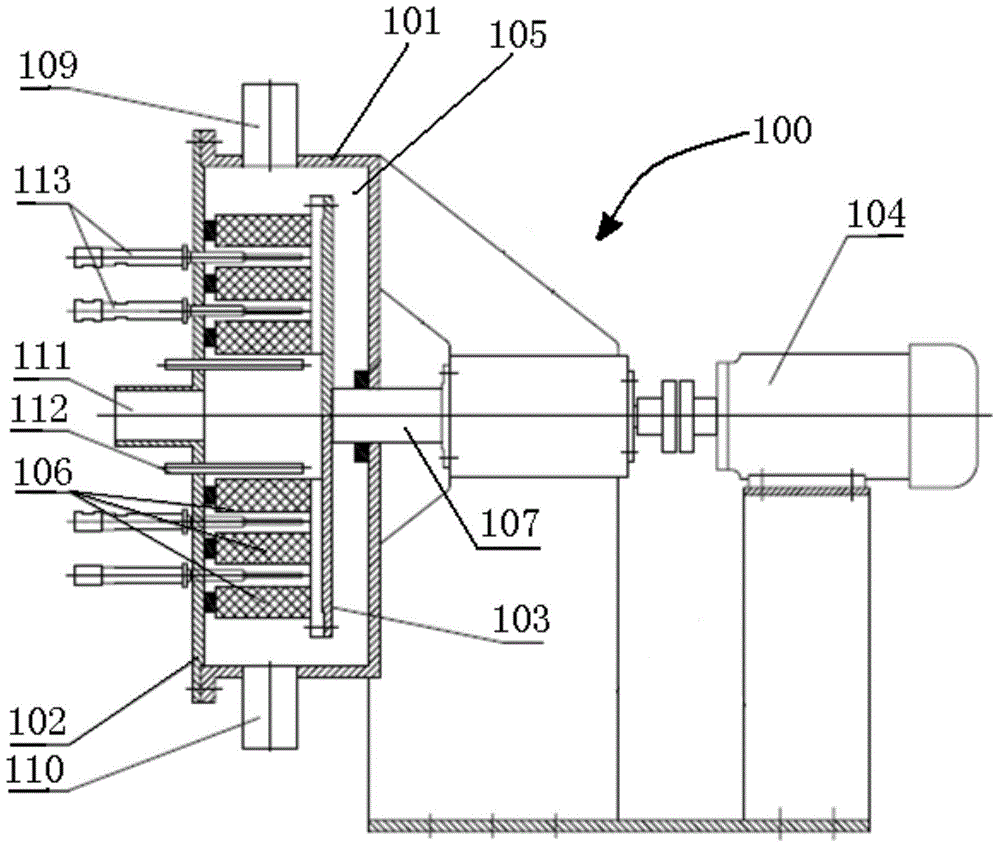

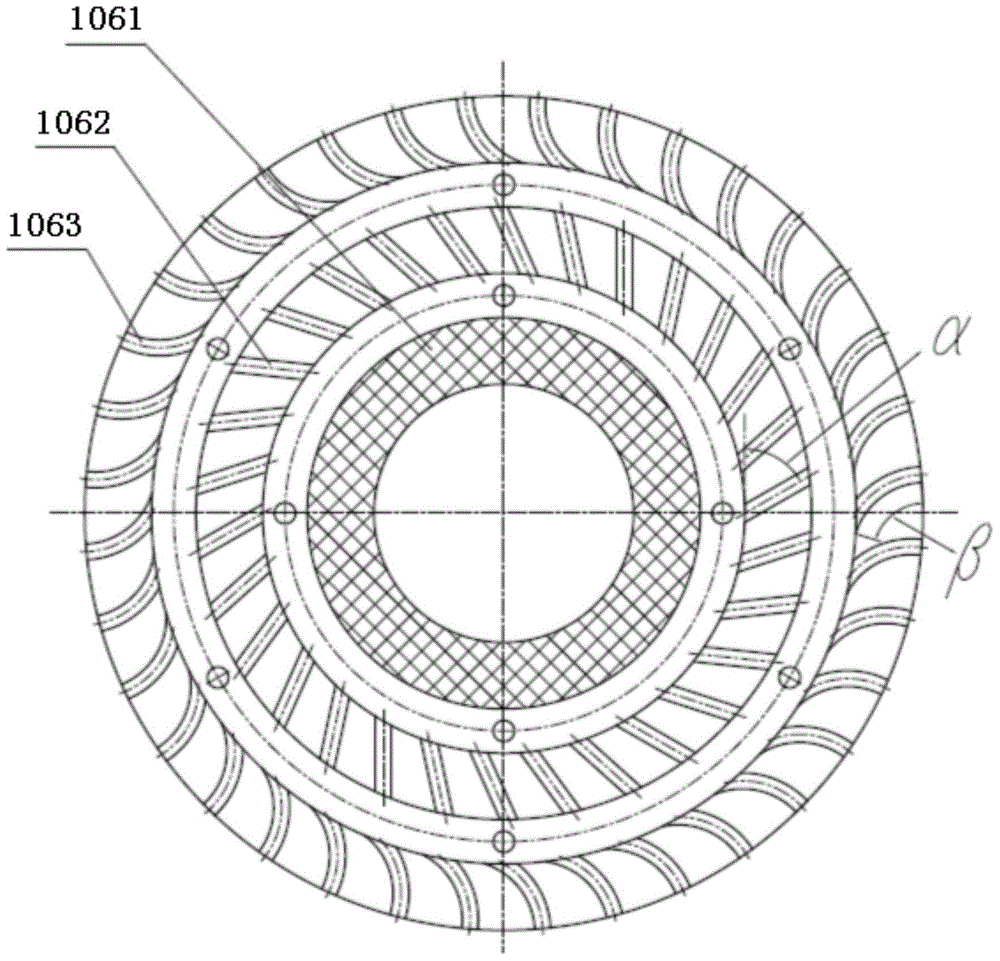

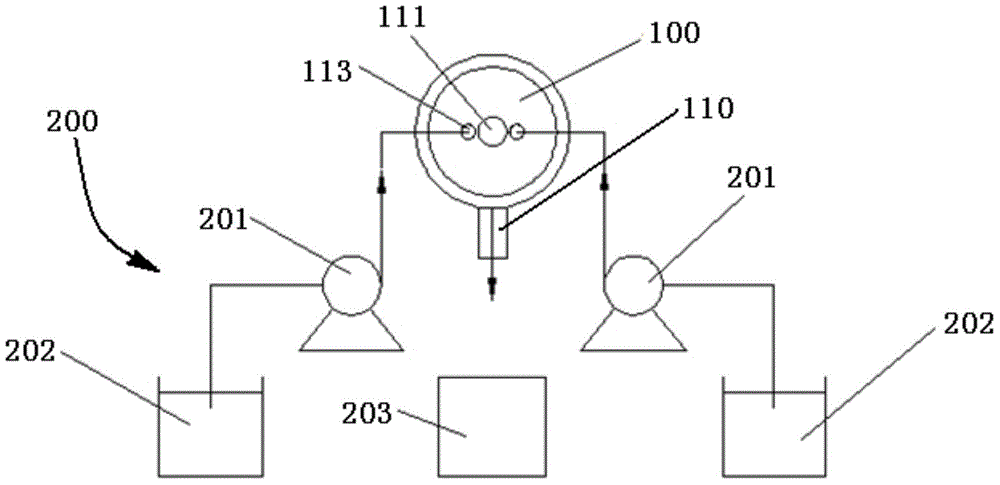

Ultrasonic coupling supergravity rotary packed bed and application thereof

ActiveCN105080436ASelf-cleaningWith substantial expansionMixersEnergy based chemical/physical/physico-chemical processesCouplingEngineering

The invention discloses an ultrasonic coupling supergravity rotary packed bed which comprises a housing, an end cover, a rotator and a transmission device, wherein the housing and the end cover form a sealed cavity; the sealed cavity is internally provided with the rotator which is provided with a filler ring; the rotator is connected with the transmission device out of the sealed cavity through a rotary shaft; a gas inlet and a liquid outlet are formed on the housing; a gas outlet and a liquid input distributor are arranged on the end cover, the gas input distributor penetrates and extends to a central cavity of the rotator from the end cover and is close to the inner edge of the filler ring of the innermost inner ring; the filler ring is composed of multiple reaction filler rings which are concentrically arranged with different diameters or multiple blade rings are concentrically arranged with different diameters or multiple reaction filler rings and blade ring which are concentrically arranged in a combined manner with different diameters; a functional bade which penetrates and extends from the end cover is arranged in annular space between two adjacent filler rings. According to the device and process disclosed by the invention, the efficiency is 1.1-3 times that of the efficiency without ultrasonic waves at different ultrasonic frequencies, and the device and process can be applied to processes such as reaction, emulsification and the like. The ultrasonic coupling supergravity rotary packed bed disclosed by the invention has the advantages of being less in equipment investment, low in energy consumption, small in occupied space of equipment and the like.

Owner:BEIJING UNIV OF CHEM TECH

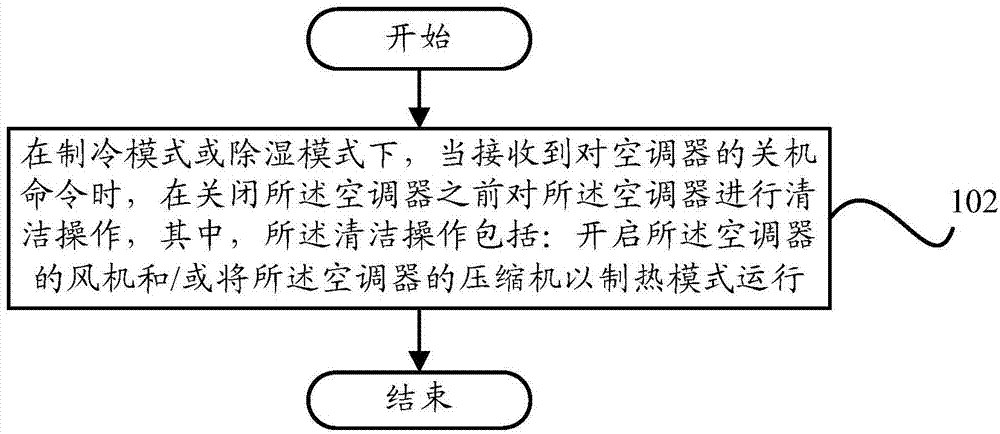

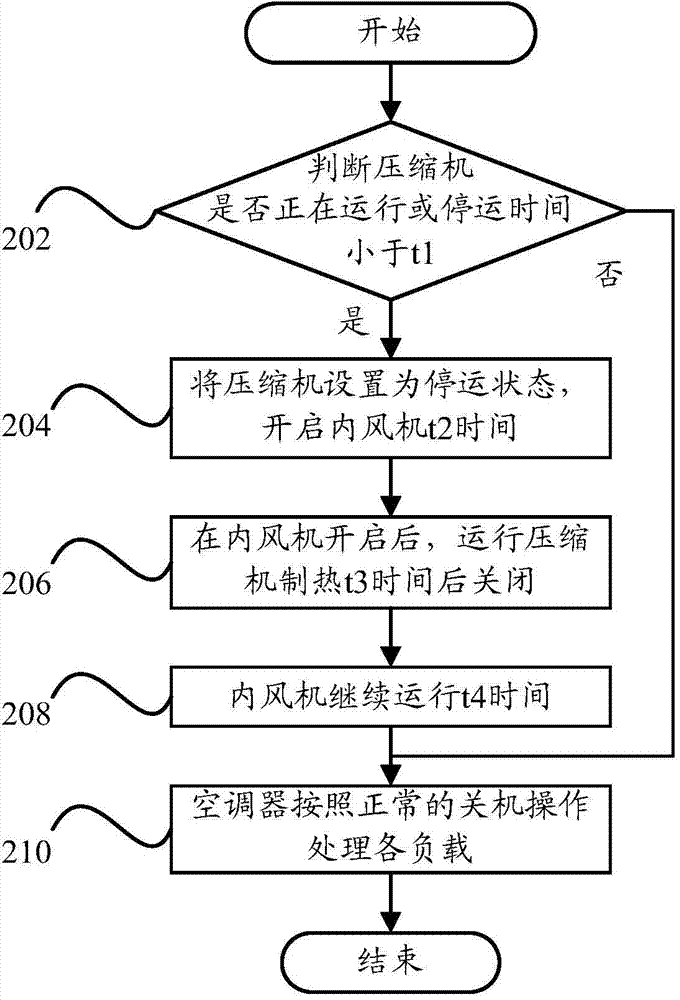

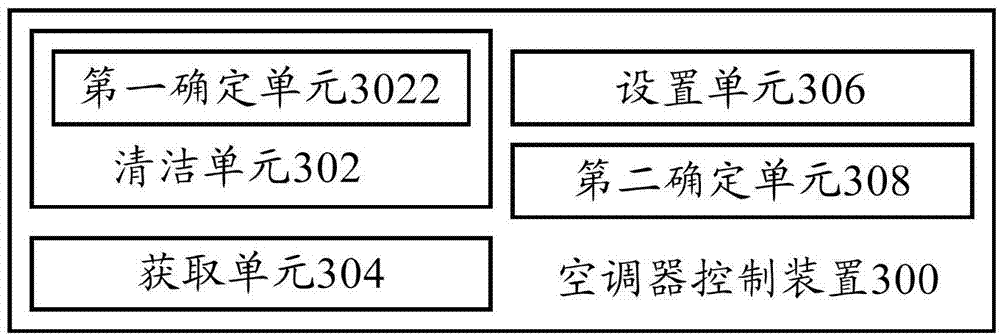

Air conditioner control method, air conditioner control device and air conditioner

ActiveCN104764149ASelf-cleaningImprove air qualityMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl theory

The invention discloses an air conditioner control method, an air conditioner control device and an air conditioner. The air conditioner control method includes that under a refrigerating mode or a dehumidifying mode, cleaning the air conditioner before turning off the air conditioner when an air conditioner shutdown command is received, wherein the cleaning operation includes starting a fan of the air conditioner and / or running a compressor of the air conditioner in a heating mode. By means of the technical scheme, when turning off the air conditioner after refrigerating or dehumidifying, condensed water generated by refrigerating or dehumidifying in the evaporator and an indoor unit is dried through starting the fan and / or using the compressor to heat so as to automatically clean the air conditioner, the germ generation even mildewing of the indoor evaporator and air outlet frame due to condensed water stagnation is effectively avoided, the air outlet quality of the air conditioner is improved, and the user experience is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Super-hydrophobic self-cleaning paint

InactiveCN101205439ASuperhydrophobicSelf-cleaningPolyurea/polyurethane coatingsPolyether coatingsEngineeringSolvent

The invention relates to super-hydrophobic self-cleaning paint suitable to be used in various surfaces. The paint comprises the following components: 100 portions of filler, 30 to 50 portions of polyurethane, 300 to 500 portions of mixed solvent and 1 to 5 portions of Gamma-aminopropyltrimethoxysilane. The invented paint has the advantages of super-hydrophoby, self cleaning, antifouling, antisticking, denoise and drag reduction, etc.; meanwhile, the paint has low price cost, convenient construction and less environmental pollution.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multifuntional green environmental protection nanometer titania coating and preparing method thereof

InactiveCN1583907ASolve technical problems that are easy to reuniteGood weather resistanceCoatingsSilicic acidTalc

This invention is that a kind of multi-functional green nanometer two of environmental protection is oxidized Titanium coating and method of preparing, this coating can not merely be solved now. There is coating that is able to bear staining difference, is able to bear waiting difference, not the skills, such as environmental protection, etc. Skill question, it is clean to give the coating at the same time, disinfect and disinfect, Purify new functions, such as air, etc., it is the green environmental protection of more than one kind of kinetic energy Coating. Coating this by titanium white powder, exceed detailed silicic acid aluminium, nanometer Oxidize the titanium and disperse the liquid two times, the calcium carbonate of light quality, the calcium carbonate of heavy quality, Silicon lime powder, lithopone, talc powder, dispersant is moist. It is the dispersant, thickener, disappear and steep and pharmaceutical, become membrane auxiliary, flow flat pharmaceuticla, water, the cream base material, etc. make up, it is simple to prepare the craft. The cost performance is high, have very good economic benefits and social result Benefit.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

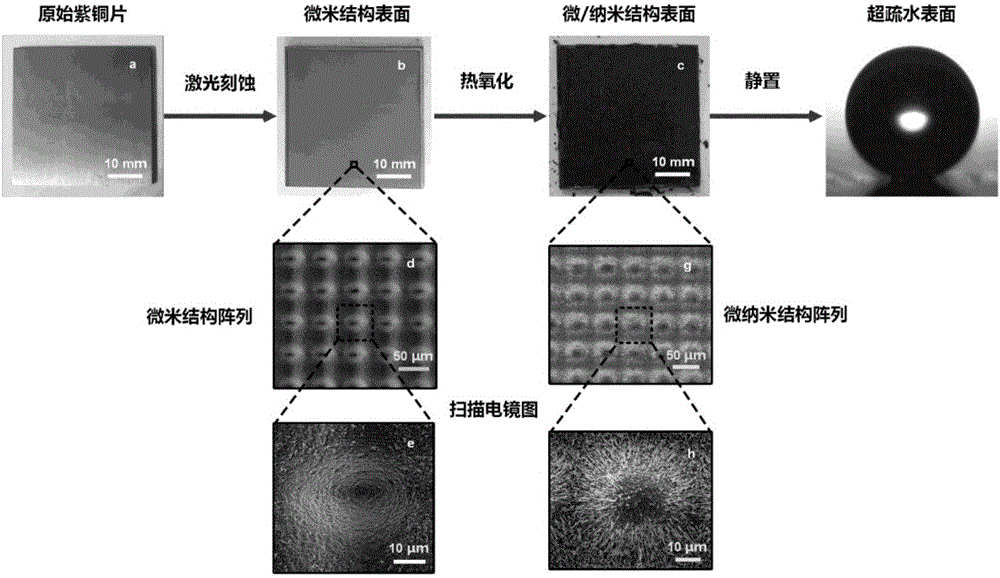

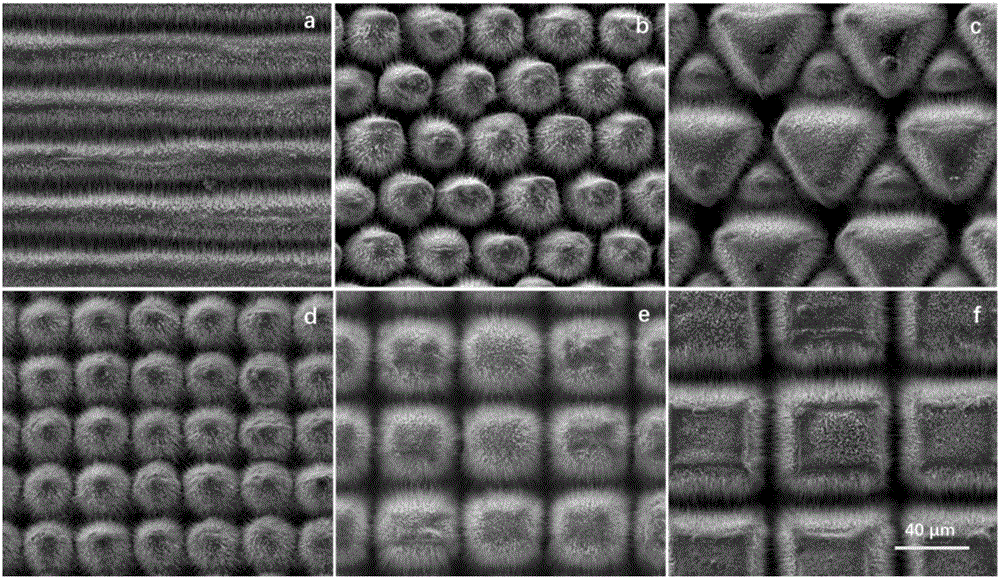

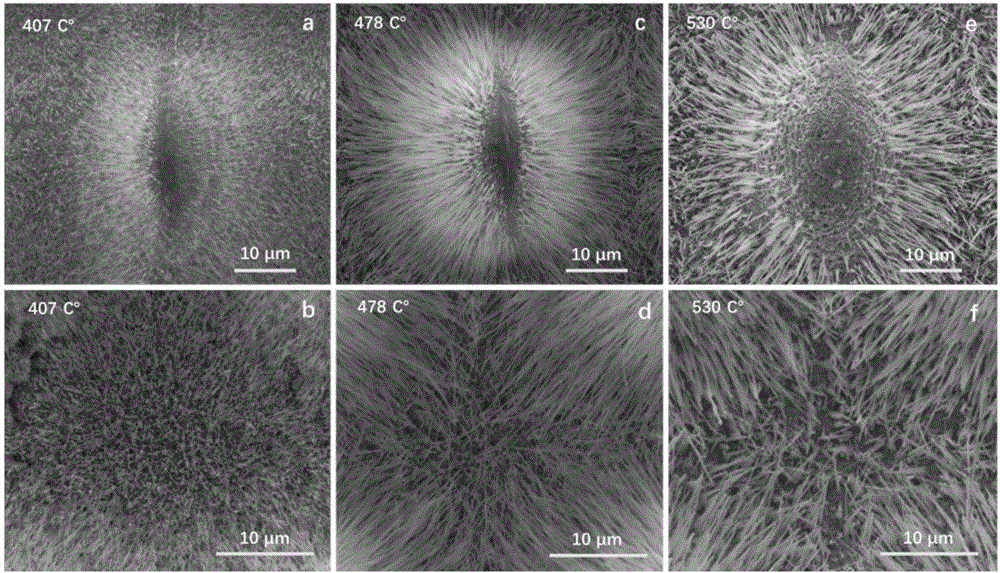

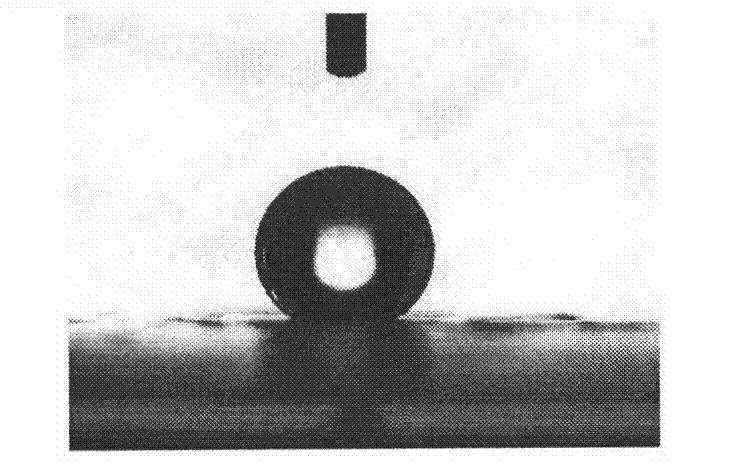

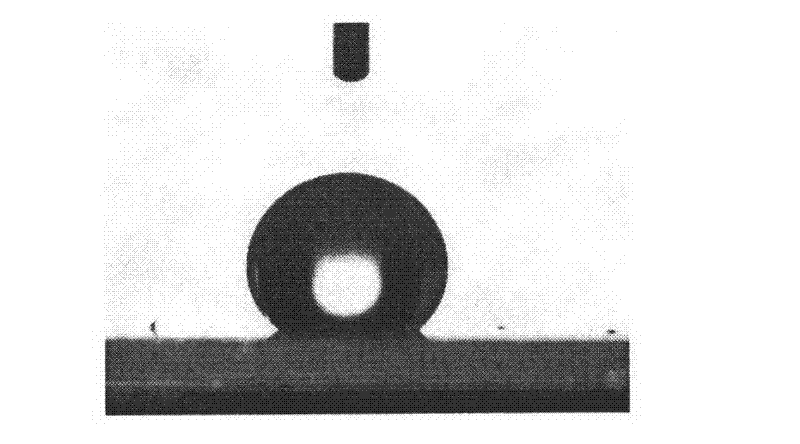

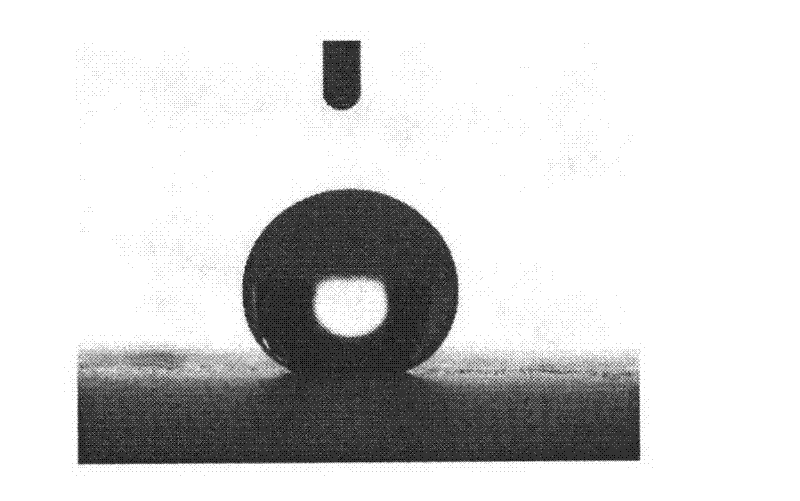

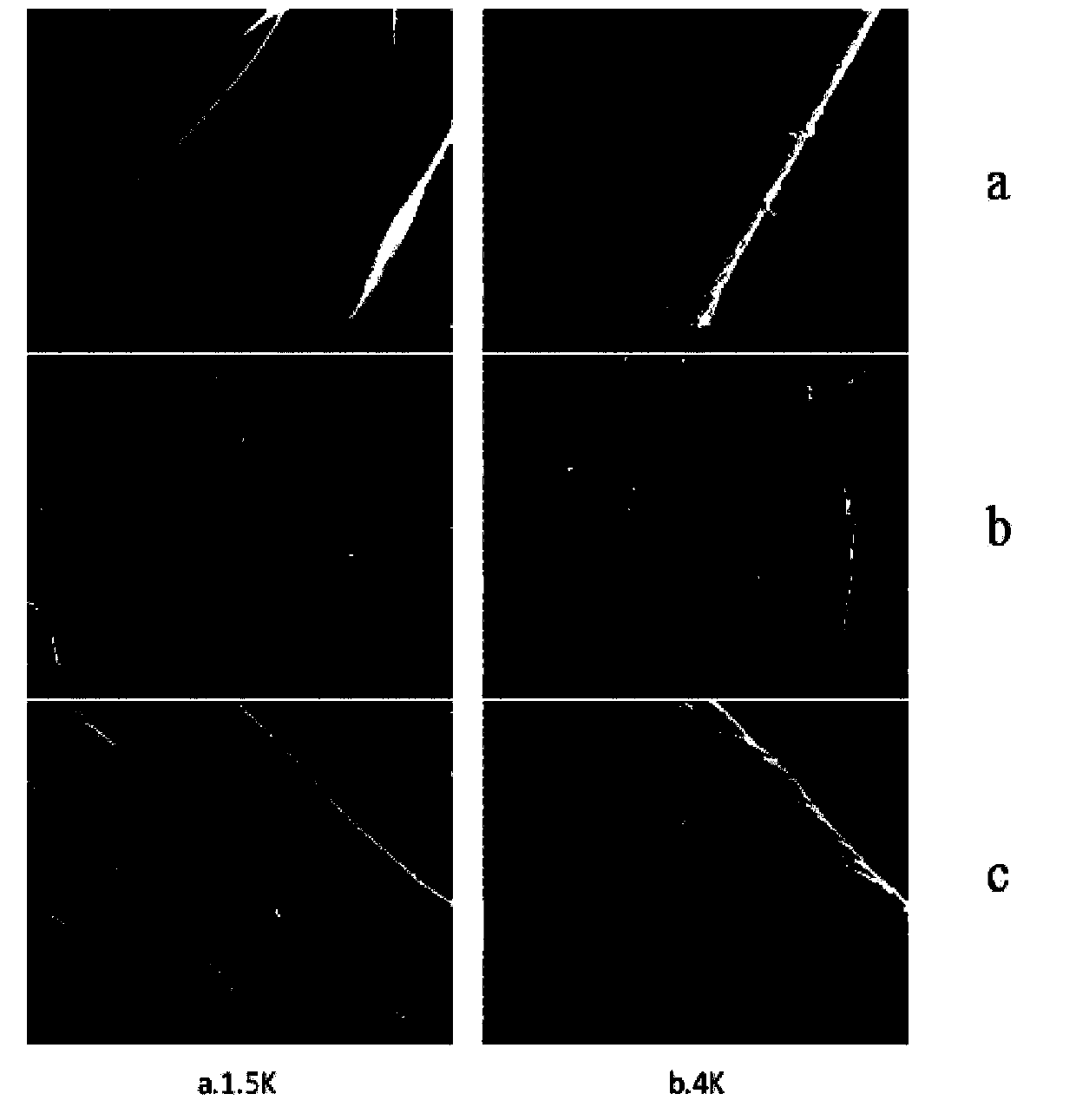

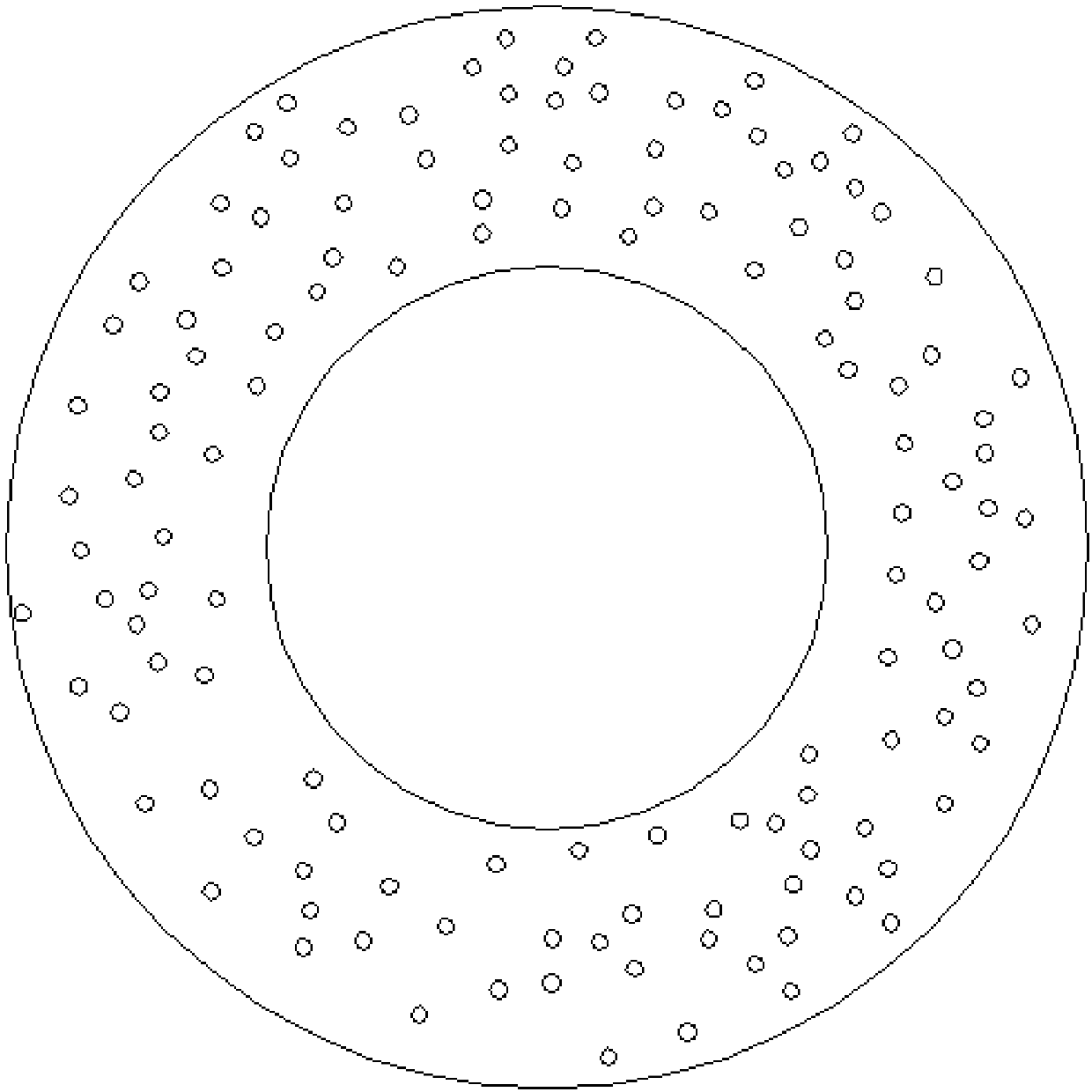

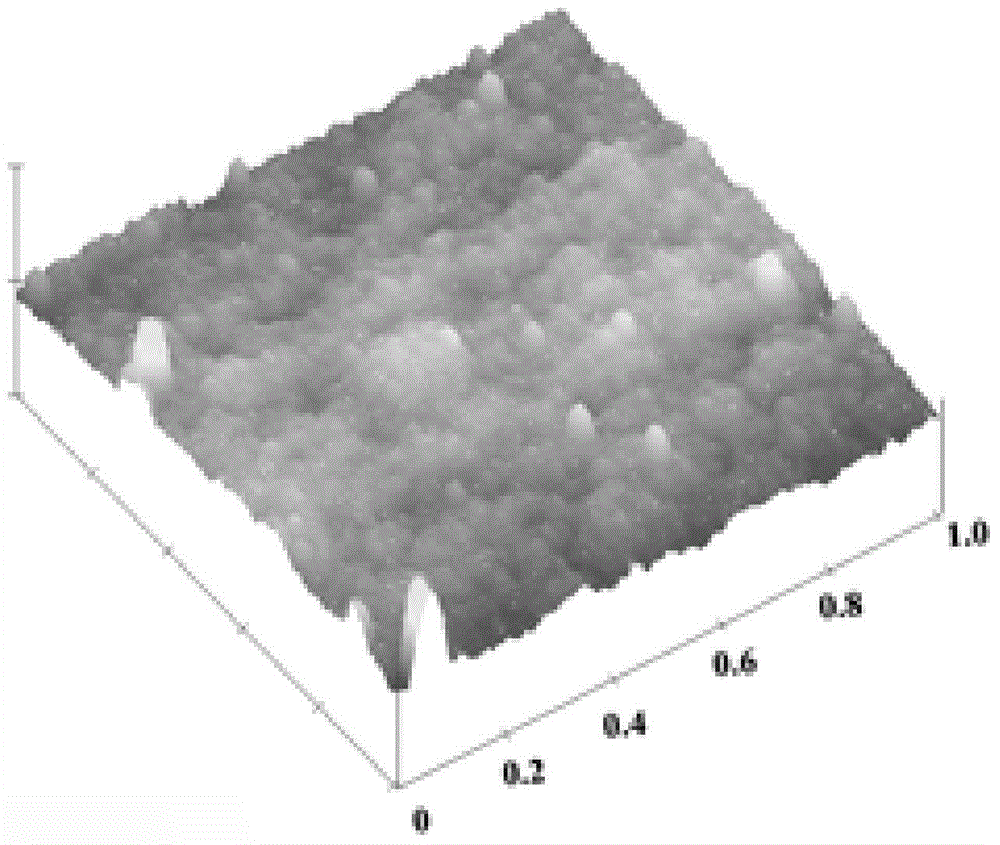

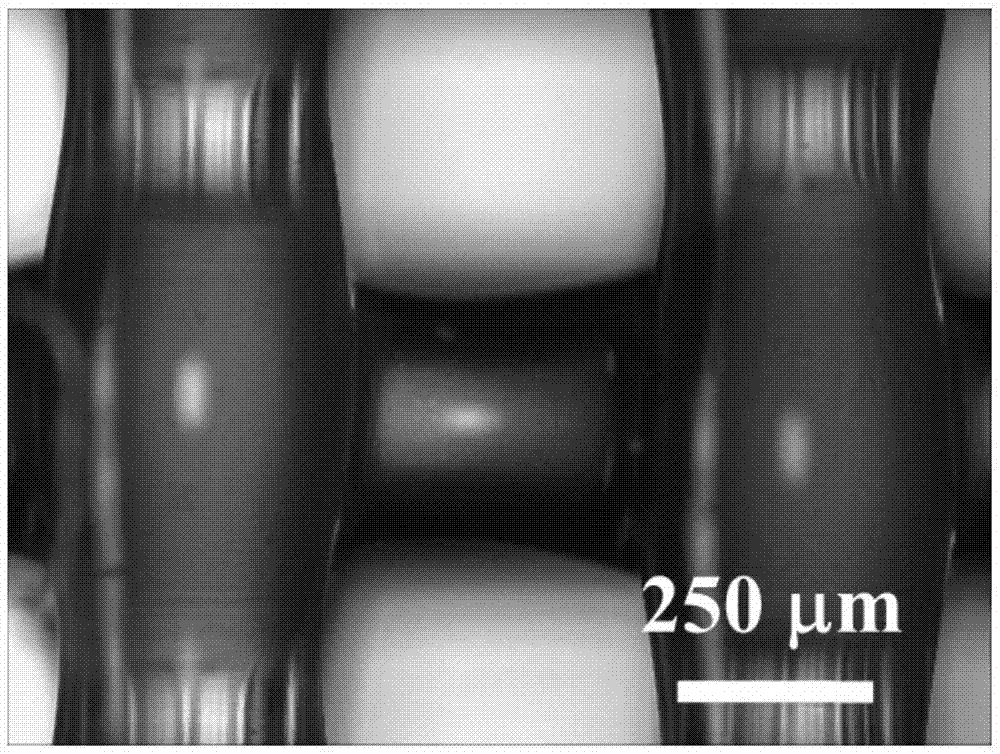

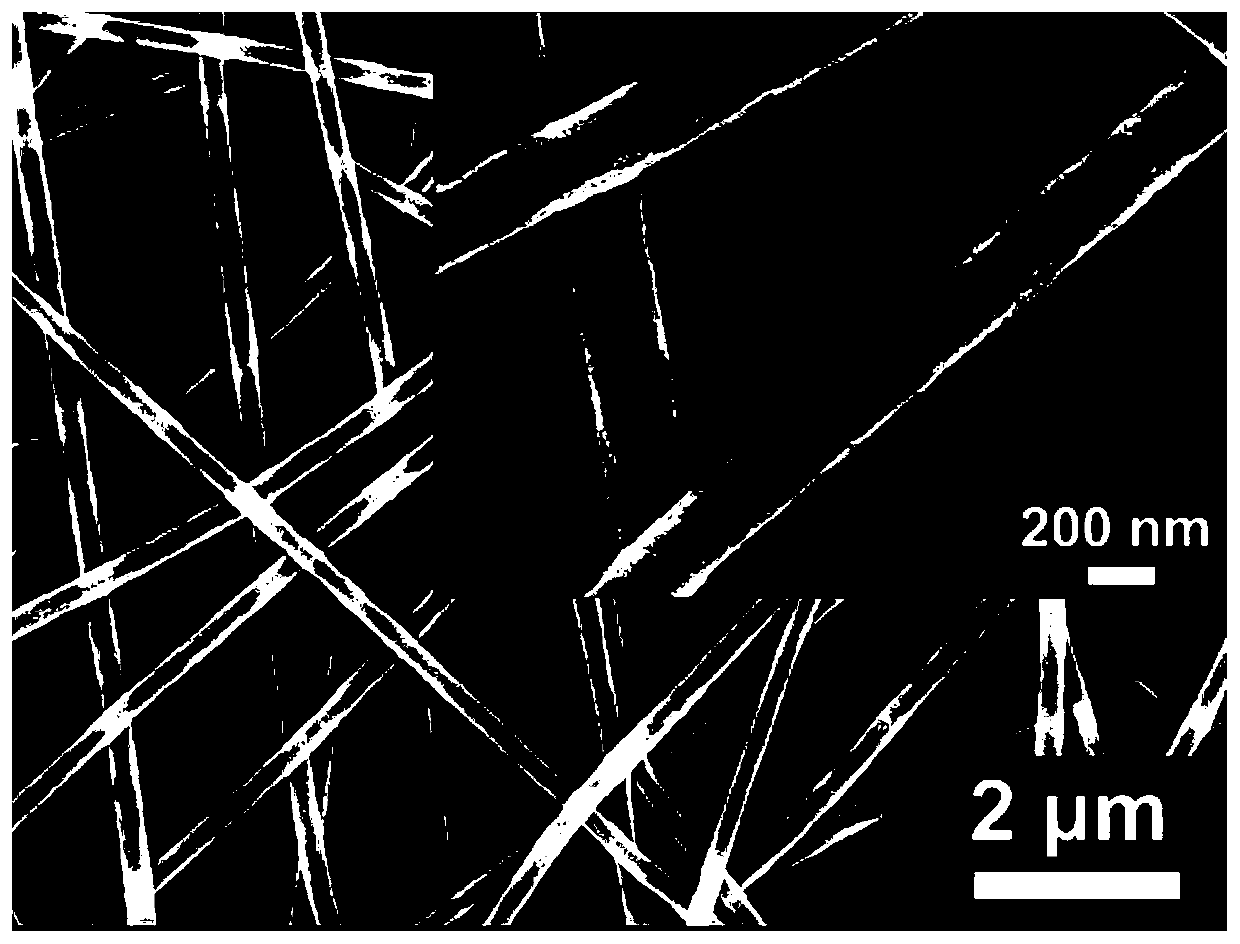

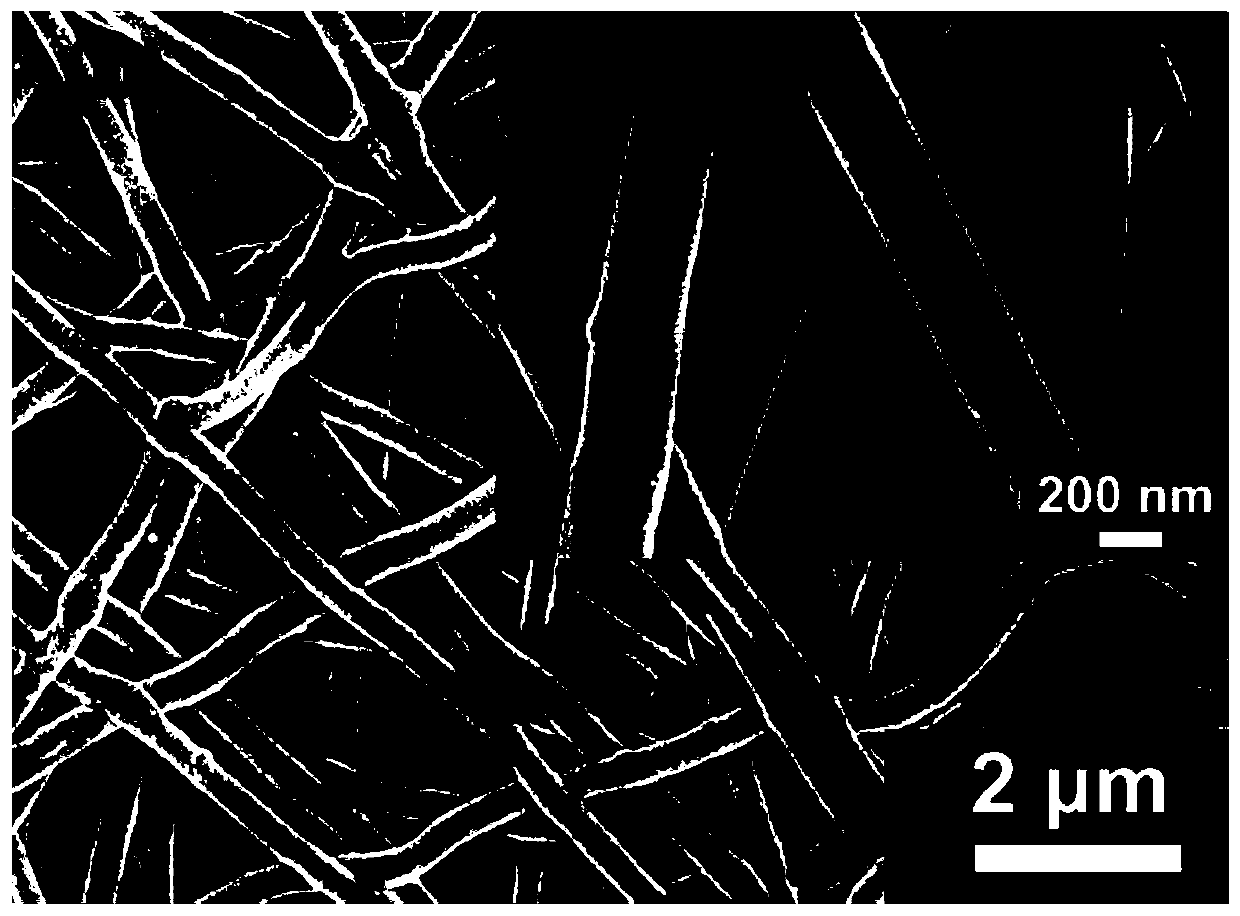

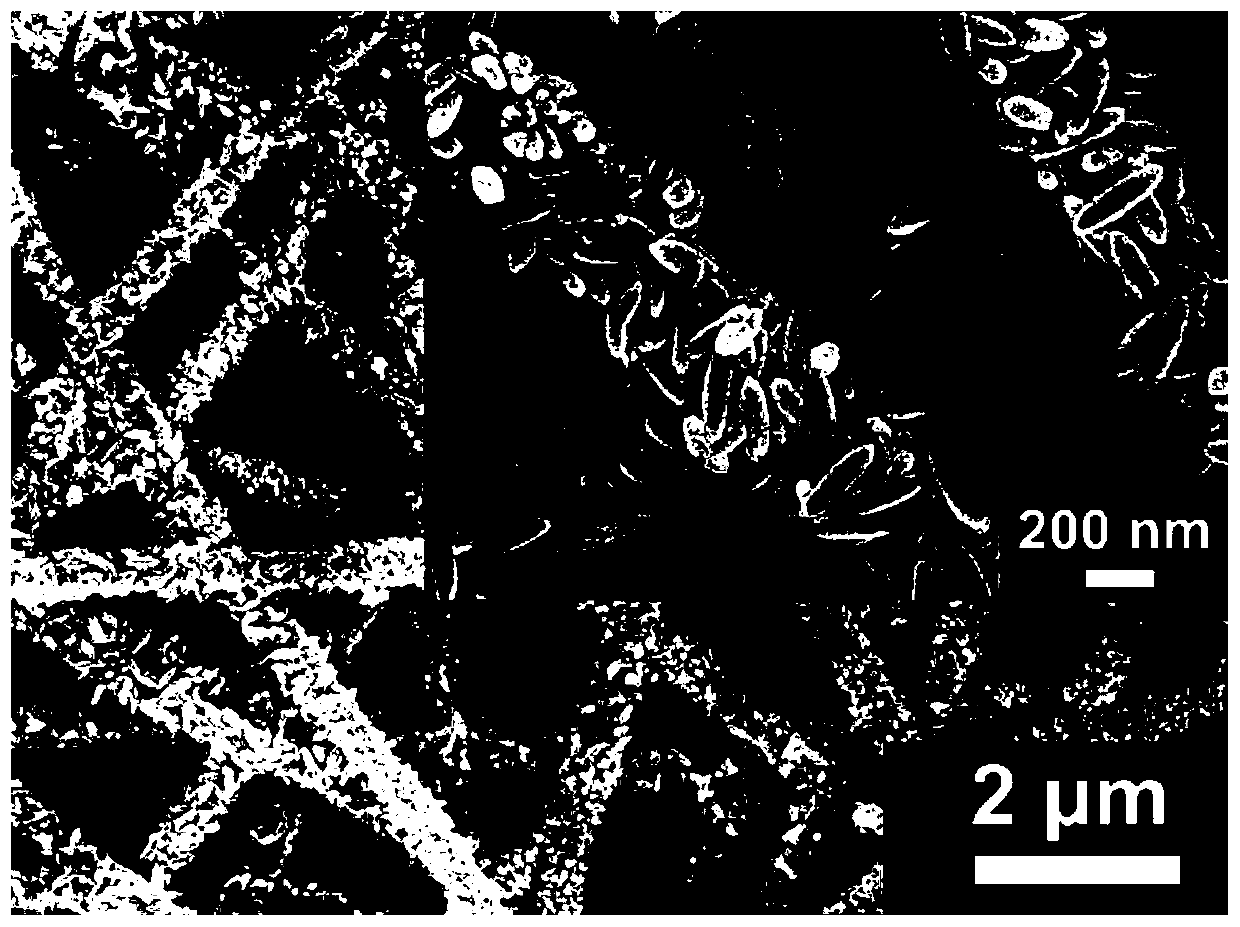

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

Superhydrophobic acrylic resin paint

InactiveCN102417773AStable superhydrophobic propertiesChanges in superhydrophobic propertiesCoatingsAcrylic resinNanoparticle

The invention provides a superhydrophobic acrylic resin paint. The paint comprises a nanoparticle, an acrylic resin, a mixed solvent, and heptadecafluoro trimethoxy ethoxy silane, wherein the ratio of the nanoparticle to the acrylic resin to the mixed solvent to heptadecafluoro trimethoxy ethoxy silane is 100:20-60:20-600:3-10. When the paint is sprayed on the surface of a solid, the contact angle of water drops on the surface is 150-160DEG, and the roll angle of the water drops on the surface is less than 10DEG. The superhydrophobic acrylic resin paint of the invention, which has the advantages of low cost, simple construction technology and small pollution to environment, has a good industrialized application prospect.

Owner:袁志庆 +2

Self-cleaning nona composite environment-friendly type emulsion paint and preparation method thereof

The invention discloses a self-cleaning nanometer composite environmental protection latex paint and preparing method, which comprises the following parts: 0.5-5% wetting disperser, 0.5-50% nanometer concentrated slurry, 0.5-10% hydrophobic agent, 0.5-10% anion powder, 0.5-8% filming adjuvant, 0.1-2% anti-settling agent, 0.8-10% antifreeze agent, 0.1-3% defoamer, 4-30% dye, 0-30% filler, 15-45% emulsion, 0.1-4% thickener, 0.1-3% levelling agent, 0-3% pH adjuster, 0-4% microbe eliminating agent and 0.5-45% water. The preparing method comprises the following steps: 1) placing water in the container with high-speed disperser; adding microbe eliminating agent, nanometer condensing slurry, hydrophobic agent, anion powder; blending evenly; adding dye and filler; dispersing until finesse reaches 20-60um; 2) adding emulsion, pH value adjuster, thickener and leveling agent continuously.

Owner:中科纳米涂料技术(苏州)有限公司

Nano-titanium dioxide sol finishing agent prepared at low temperature and application thereof

ActiveCN103397513AImprove responseFacilitate rearrangementTitanium dioxideVegetal fibresFiberEvaporation

The invention relates to a nano-titanium dioxide sol finishing agent prepared at low temperature and an application thereof. The nano-titanium dioxide sol finishing agent is prepared from the following components in parts by weight: 10-40 parts of nano-titanium dioxide sol, 2-10 parts of hand feeling regulating agent and 900-950 parts of deionized water, and the prepared nano-titanium dioxide sol finishing agent can be used for finishing fabric. Compared with the prior art, the temperature of the nano-titanium dioxide sol finishing agent is low when used for treating the fabric, and the sol can be uniformly dispersed onto the fabric and forms the firm combination with the fabric without adding a dispersing agent; and when the fabric is treated by water boiling evaporation, the titanium dioxide sol can be hydrolyzed and condensed on a fiber surface, the TiO2 sol can be converted to gel to be fixed on cotton, and the combination with the cotton is firmer.

Owner:SHANGHAI UNIV OF ENG SCI

Anti-corrosion super-hydrophobic heat reflecting paint and preparation method thereof

ActiveCN105925073AImprove lotus leaf effectImprove hydrophobicityAnti-corrosive paintsReflecting/signal paintsNano sio2Water contact

The invention discloses an anti-corrosion super-hydrophobic heat reflecting paint and a preparation method thereof. The anti-corrosion super-hydrophobic heat reflecting paint is prepared from the following raw materials: modified nano TiO2, modified nano SiO2, micron TiO2 and / or SiO2, fluorocarbon resin, a solvent, a curing agent, a defoaming agent, a wetting dispersant and a flatting agent. After experiments, the heat reflecting rate of the obtained product reaches 90 percent or more, the water contact angle reaches 145 degrees or more, and the product can meet the requirements on a coating under outdoor severe environments.

Owner:SHANDONG UNIV OF SCI & TECH

Fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and preparation and usage method thereof

InactiveCN104987032AThe composition of the formula is reasonableReasonable ratioCeramic coatingSpray coating

The invention relates to a fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and a preparation and usage method thereof. The ceramic paint comprises, by mass, the components of 20-30% of filler, 23-29% of binders, 0.8-1.2% of addition agents and the balance water. According to the ceramic paint, the formula component and ratio are reasonable, the filler granularity is small, granularity matching among different filler components is reasonable, and the matching compatibility of the filler and a binder system is good. A ceramic coating prepared by spray coating can resist high temperature 1320 DEG C, is thinner, has the functions of resisting fouling and slagging and resisting high temperature and corrosion, and cannot be pulverized and fall off in a long-term high-temperature operating environment; the high emissivity above 0.95 can be still kept at high temperature and is close to the thermal expansion coefficients of metal, and heat transfer can be enhanced; the coating integrates chemical inertness and passivation protection into a body, and therefore a high-temperature corrosion environment is prevented from corroding the metal through the compact ceramic coating; meanwhile, due to the fact that the coating has the self-cleaning effect, the coating can be applied easily and conveniently.

Owner:HANGZHOU CHITIAN ENERGY TECH CO LTD

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

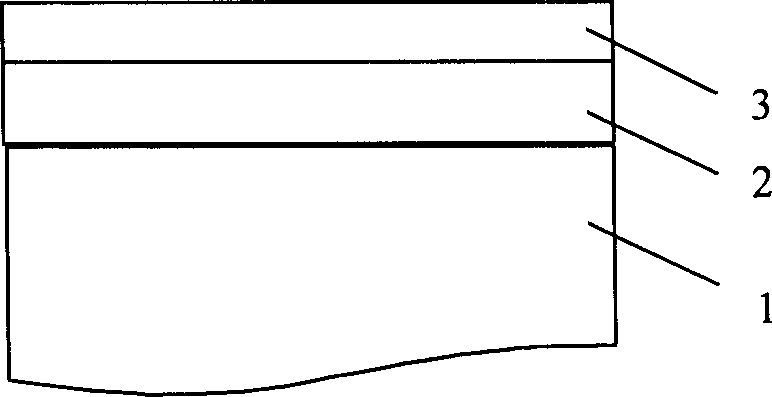

Low-radiation self-cleaning composite function glass and producing method

This invention relates to a low radiation self-cleaning complex function glass. This glass has trilamellar membrane structure, membranous layer from glass outward in turns is : SiO2 transition layer, ion adulterated SnO2 layer, ion adulterated SiO2 - TiO2 layer. The on-line preparation method is sol-gel method, combine with atomizing sedimentation, utilize thermal decomposition and coagulation process of collosol at 450 to 550 deg to proceed heat sedimentation, in turns form membranous layer on the on-line glass plate surface. This invention through controlling the coating material concentration, dopant ion variety, thermal decomposition temperature and membranous layer thickness bring low radiation to the glass coated this membrane, execute stable uniwafer low emissivity glass, reduce cost, and realize reprocessing treatment of low radiation steeling and hot bending. This invention applies to common building and shield glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Conductive super-hydrophobic paint and production method thereof

ActiveCN102492351AImprove conductivityLarge aspect ratioEpoxy resin coatingsElectrically-conductive paintsEpoxyGas phase

The invention relates to conductive super-hydrophobic paint and a production method thereof, belonging to the field of special coating. The conductive super-hydrophobic paint comprises a component A and a component B which are separately packaged, wherein the component A comprises epoxy resin, carbon nano tube, hydrophobic gas-phase silicon dioxide and diluent, and the component B is polyamide curing agent. The hydrophobic gas-phase silicon dioxide is spherical nano particle and has a micro structure different from the carbon nano tube, and a more uniform super-hydrophobic surface is obtainedafter the synergy of the hydrophobic gas-phase silicon dioxide and the carbon nano tube. The conductive super-hydrophobic paint provided by the invention has a static water contact angle more than 150 degrees and a slide angle of less than 10 degrees, thus a coated surface has self-cleaning property, anti-pollution property and conductivity.

Owner:中昊北方涂料工业研究设计院有限公司

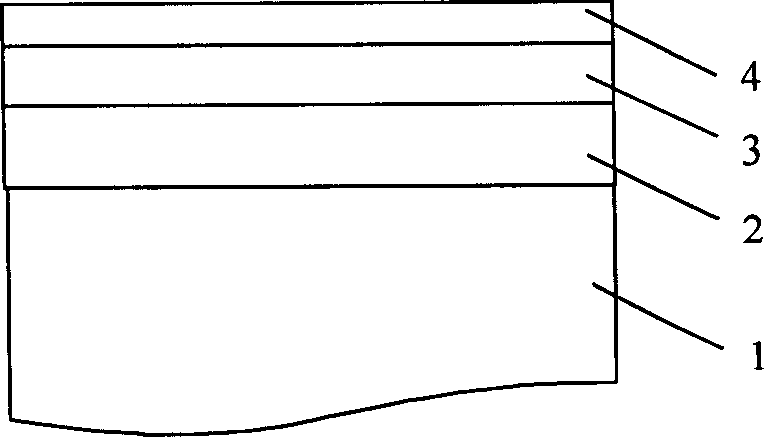

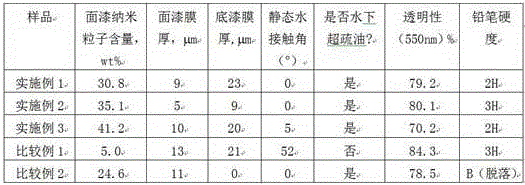

Superhydrophilic/underwater superoleophobic coating material and preparation method thereof

ActiveCN106634275AImprove mechanical propertiesHigh transparencyAntifouling/underwater paintsPretreated surfacesNano structuringAcrylic resin

The invention relates to a superhydrophilic / underwater superoleophobic coating material and a preparation method thereof. The coating material is composed of a primer layer and a finish coat layer, wherein the primer layer is mainly composed of a hydroxy acrylic resin and a curing agent thereof; the finish coat layer is composed of polyvinyl alcohol and nanoparticles; and the curing agent in the primer can produce chemical crosslinking reaction with the polyvinyl alcohol. The preparation method comprises the following steps: applying the primer layer on the substrate surface; applying the finish coat layer, and precrosslinking by drying at room temperature or low temperature to initiate the chemical bonding between the primer layer finish coat layer; soaking the coating in a crosslinking agent water solution for some time; and taking the coating out of the crosslinking agent water solution, and sufficiently curing the primer layer by drying at room temperature or high-heat treatment. The coating material obtained by the method has a gradient micro / nano structure surface, and has the advantages of outstanding superhydrophilicity and underwater superoleophobicity, high binding force with the substrate and favorable transparency. The coating material can be used as an antifogging coating, and can also be used as a self-cleaning antifouling coating on the surface of an underwater facility.

Owner:FUDAN UNIV

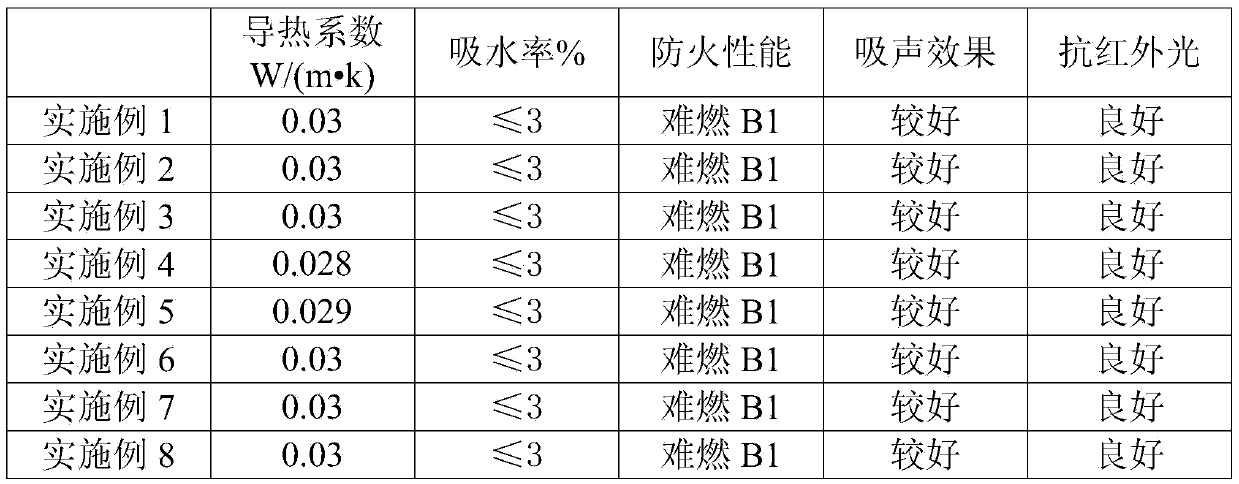

Heat-preserving material for outer wall

The present invention discloses a heat-preserving material for an outer wall which comprises the following raw materials in parts by weight: 45-55 parts of coal ash silicate cement, 15-20 parts of white floating beads, 1.5-2 parts of nano TiO2, 0.5-1.2 parts of ceramic cotton fiber, 5-10 parts of aluminium silicate fiber cotton, 0.2-0.6 part of a water repellent, 3-7 parts of an elastic emulsion, 6-9 parts of swelled vitrified microbead heat-preserving slurry, 3.5-4.5 parts of polypropylene fiber, 2-5 parts of an inorganic nano coating, 0.05-0.1 part of foam filaments, 0.05-0.1 part of bamboo fiber and 10-15 parts of a flame retardant. The heat-preserving material for the outer wall has the characteristics of good heat preservation, thermal insulation, sound insulation, self-cleaning, ray resistance, water resistance, energy conservation and environment protection and high strength.

Owner:NANYANG INST OF TECH

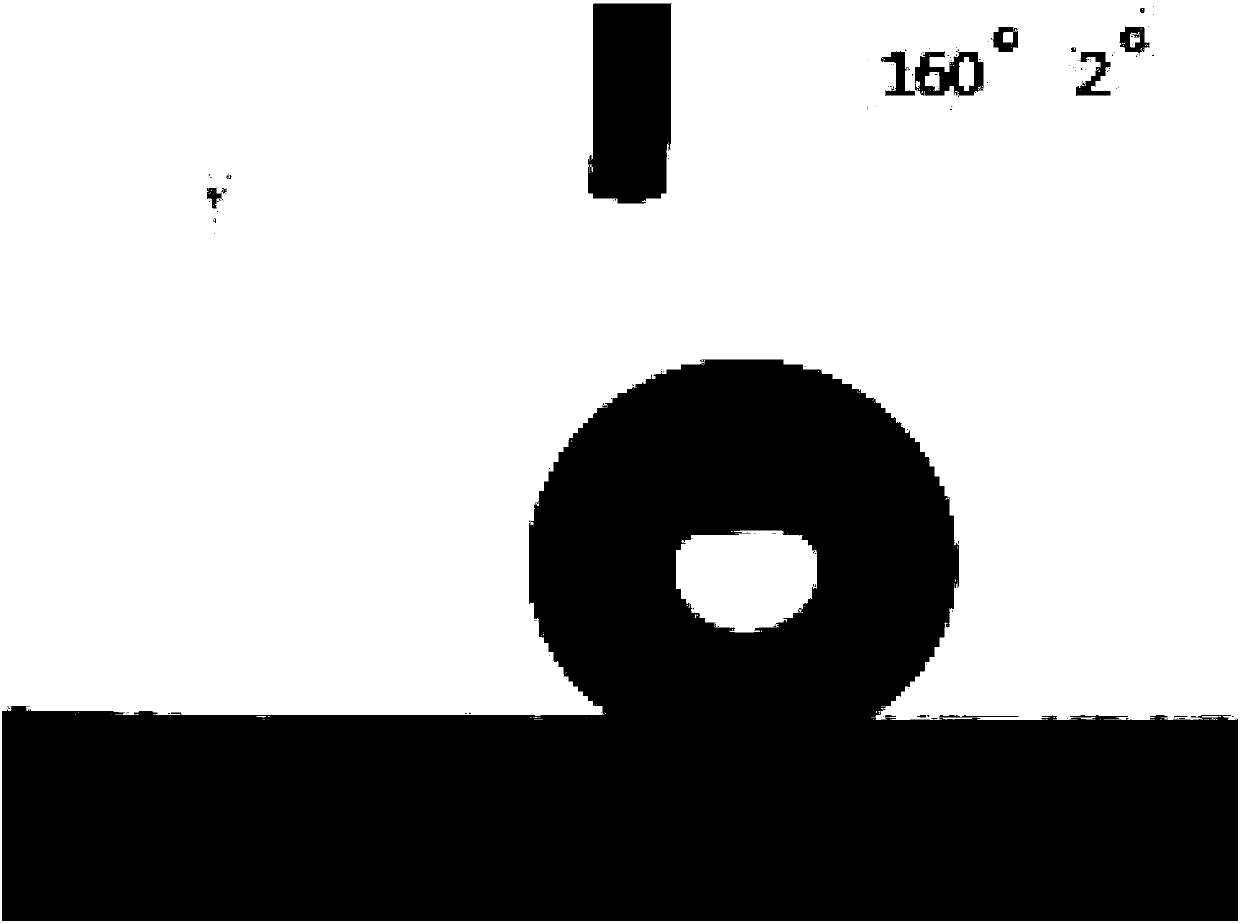

Film with self-cleaning property and preparation method thereof

InactiveCN107626211ASimple processSimple ingredientsSemi-permeable membranesGeneral water supply conservationSurface energySolvent

The invention discloses a film with a self-cleaning property and a preparation method thereof. The method comprises the following steps: selecting a high-molecular polymer as a substrate; using a solvent compatible with high-molecular polymer for dissolving the high-molecular polymer; taking a nanometer filler as a hydrophobic group introducing source; forming a dispersing solution with the solvent by adopting an ultrasonic auxiliary physical blending method; adding cosolvent and additive; and lastly, adopting a low surface energy reagent for modifying and forming a super-hydrophobic surface.According to the invention, the preparation method is simple in process and low in cost; the operation process is controllable; the preparation method is simple and convenient; the maximal contact angle between the film with the self-cleaning property and water reaches up to 160 degrees and the minimal rolling angle is at 2 degrees; the film has a self-cleaning function, is high in water flux, hasexcellent mechanical properties and durability and can be applied to the dehumidification or seawater desalination.

Owner:SOUTH CHINA UNIV OF TECH +1

Super-hydrophilic and underwater super-lipophobic coating and preparation method thereof

InactiveCN104629616ASimple processRaw materials are easy to getAntifouling/underwater paintsPaints with biocidesBiological adhesionZwitterion

The invention discloses a super-hydrophilic and underwater super-lipophobic coating which consists of a substrate and an organic / inorganic hybrid coating, wherein the organic / inorganic hybrid coating containing an ampholytic ionic group is coated on the surface of the substrate. 1, the method disclosed by the invention is simple in process, easy in preparation of raw materials, simple in equipment and low in cost, and the functional coating can be prepared on the surfaces of different substrates in a large area, so as to achieve super hydrophilicity and underwater super lipophobicity; and 2, by introducing a betaine-type ampholytic ionic compound of a cell outer membrane simulating molecular structure to the prepared super-hydrophilic and underwater super-lipophobic coating, the prepared functional coating not only has functions of self-cleaning, anti-fogging, underwater oil resistance and the like, but also has excellent performances of resisting biological adhesion and the like.

Owner:佛山市高明区生产力促进中心

Dust collection disc of cleaning trolley

InactiveCN103741630ASimple structural designReduce maintenance costsRoad cleaningHigh energyEnergy consumption

The invention discloses a dust collection disc of a cleaning trolley. The dust collection disc comprises a suction inlet and a strip air duct which are formed on the disc body; the suction inlet is connected with a suction pipe; the air duct is connected with an air outlet pipe of a fan; a slit type air duct air outlet is formed in the lower side of the stripe air duct along the air duct; the orientation of the air duct air outlet corresponds to that of the suction inlet; high-speed air draft blown out from the air duct air outlet blows garbage on the ground to the suction inlet. The dust collection disc has a simple structure, is skillful in design, properly solves the problems of high energy consumption, unsatisfactory cleaning effect, high maintenance cost and the like in the conventional dust collection disc, has a simple structure, is low in maintenance cost, saves energy consumption, and is high in cleaning efficiency, and compared with the prior art, the dust collection disc has very positive technical effect.

Owner:BEIJIG TIANLUTONG TECH

Raw material prescription of the heat preserving waterproof paint and method of preparing the same

InactiveCN101585987AHigh solar reflectanceIncrease elasticityReflecting/signal paintsEmulsionSun protection

The invention belongs to a heat preserving waterproof paint for structures such as exterior wall of building, thin roofing, and metal tank housing and so on and fabricating method thereof. Raw material prescription of the heat preserving waterproof paint of the invention based on weight is: 10 parts to 90 parts of water, 10 parts to 90 parts of elastic polyacrylic emulsion, 10 parts to 50 parts of filler, 1 part to 10 parts of propylene glycol, 1 part to 10 parts of thickener, 1 part to 10 parts of rutile type titanium dioxide, 1 part to 3 parts of water- and stain-proofing agent of exterior wall. The paint of the invention is great in heat preservation, waterproofing property, self-cleaning property, filling property, radioresistance and sun protection and has long service life.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

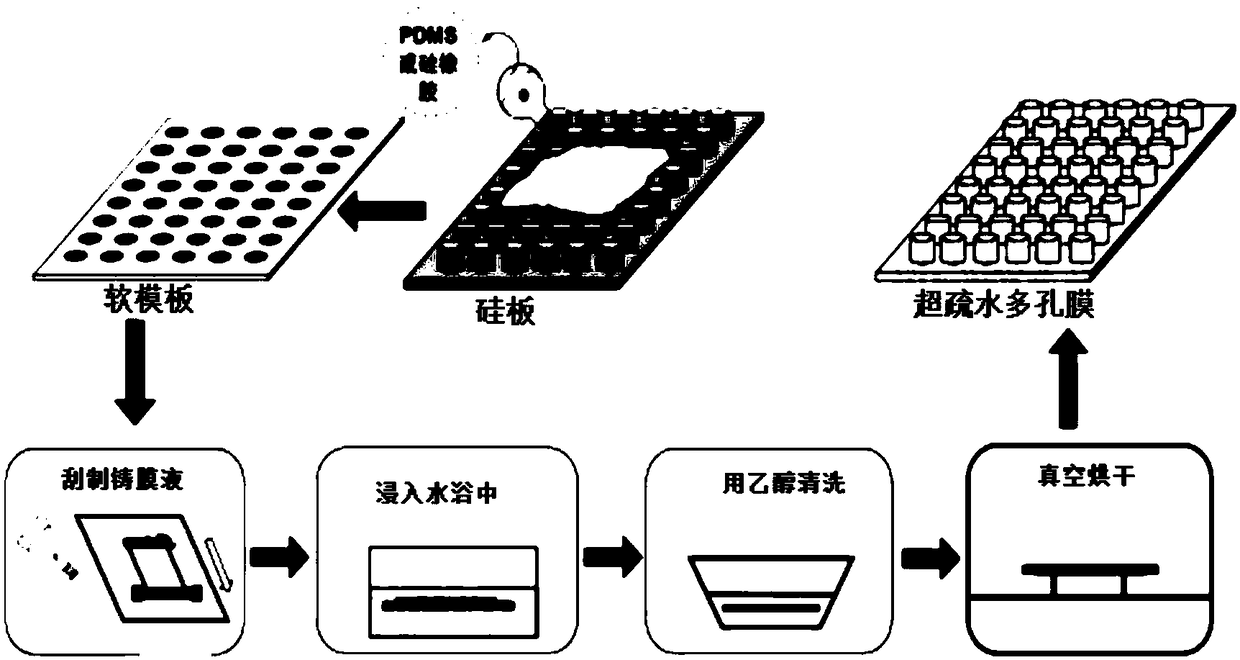

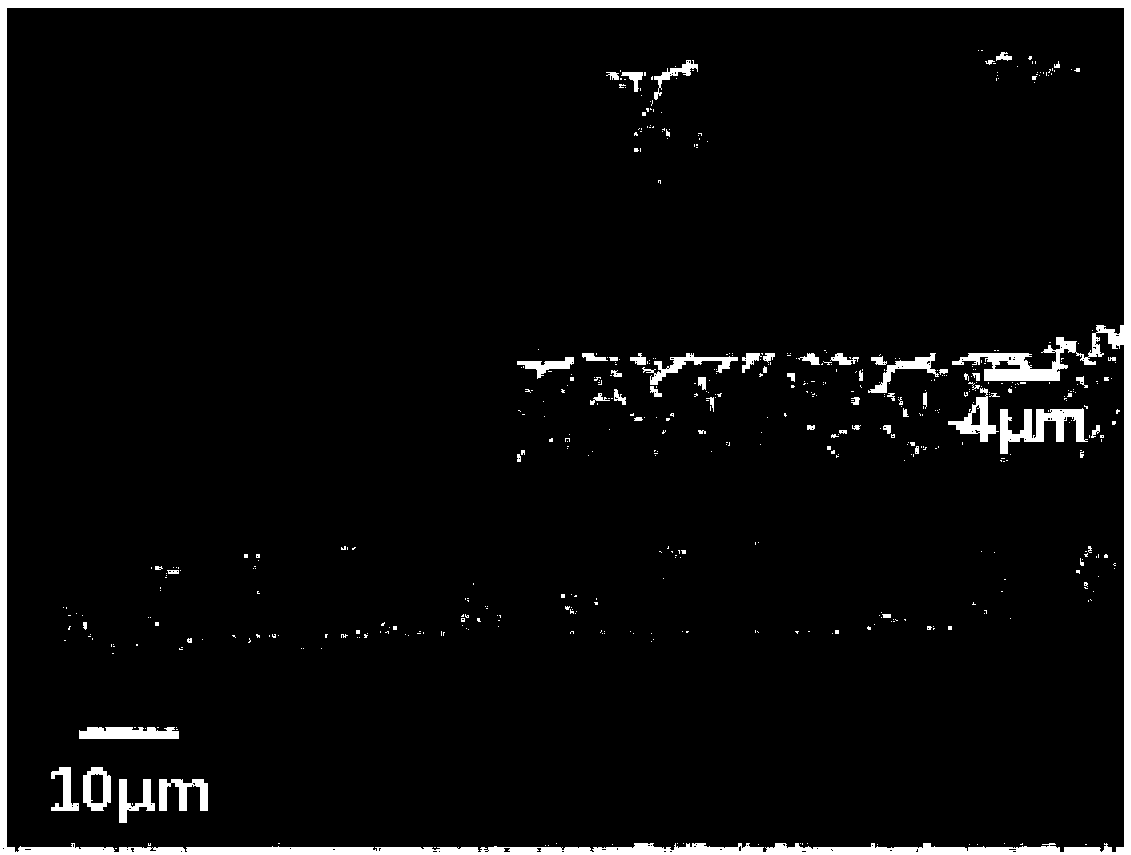

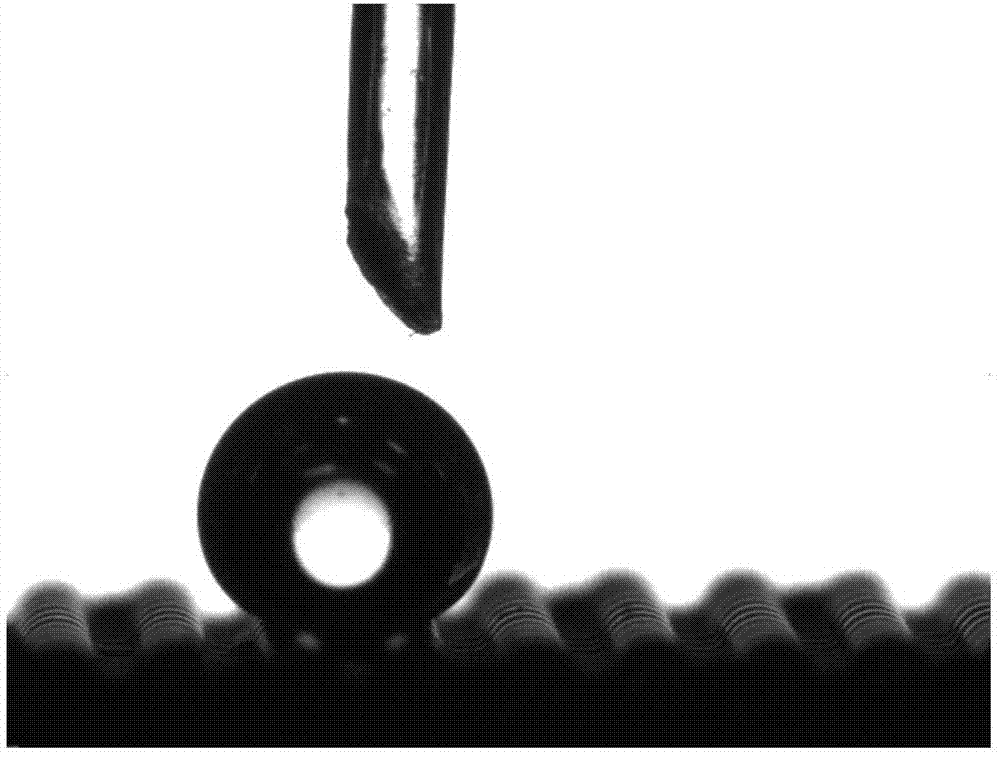

Super-hydrophobic porous membrane as well as preparation method and application thereof

InactiveCN108421418AImprove hydrophobicitySimple preparation processDistillationSalt resistanceWater baths

The invention discloses a super-hydrophobic porous membrane as well as a preparation method thereof. A micro molding technology and a phase separation technology are combined, a membrane scraping bottom plate on which a membrane casting solution is scraped is placed in a water bath at the preset temperature for phase separation membrane formation, a formed membrane material is stripped, and the super-hydrophobic porous membrane is obtained. The membrane scraping bottom plate is a grooved soft template produced with a reverse mold process, the super-hydrophobic porous membrane produced throughthe grooved soft template comprises micron-size surface bulges which are consistent in size and arranged regularly, and the distance between adjacent surface bulges is micron-sized. The surface morphology of the membrane material is reconstructed, the super-hydrophobic porous membrane with multiple scales is prepared while additional modifiers are not added, and the super-hydrophobic porous membrane can be applied to a membrane distillation technology, has the advantages of high hydrophobicity, pollution resistance, wetting resistance and the like and thus has high salt resistance, and a novelmembrane production technology is provided for industrialization of membrane distillation and is low in cost and prone to mass production.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Method of preparing isotropic super-hydrophobic and superoleophobic regular porous silicone rubber with anisotropic structure

ActiveCN107974089ARegular porous structureFlexibleAdditive manufacturing apparatusAdditive manufacturing with liquidsPolymer sciencePtru catalyst

The invention discloses a method of preparing an isotropic super-hydrophobic and superoleophobic regular porous silicone rubber with an anisotropic structure. The method comprises the following stepsof (1) uniformly mixing silicone oil containing C=C double bond, inorganic nanometer filler, a catalyst and an inhibitor to obtain a first mixture; (2) adding hydrogen-containing silicone oil and a silicone rubber additive in the first mixture prepared in the step 1, performing uniform mixing to obtain a second mixture, and performing defoaming to obtain ink for printing; (3) charging the ink in a3D printer, and performing printing according to the anisotropic porous structural characteristics to prepare silicone rubber with a porous structure; and (4) performing pre-solidification treatment,then performing dip coating and drying on the treated silicone rubber in a treating agent solution, performing superthermal hydrogen treatment, taking out the treated silicone rubber for cleaning, and then performing drying again to obtain the isotropic super-hydrophobic and superoleophobic silicone rubber material. According to the method provided by the invention, by combining the silicone rubber with the inorganic nanometer filler, organic combination of a physical structure and the material characteristics is realized by utilizing 3D printing, and the isotropic super-hydrophobic and superoleophobic silicone rubber is prepared.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Beta-FeOOH/polyacrylonitrile composite nanofiber membrane, preparation method thereof and application of membrane

ActiveCN110205748ALarge specific surface areaImprove adsorption capacityNon-woven fabricsComposite nanofibersNanofiber

The invention provides a beta-FeOOH / polyacrylonitrile composite nanofiber membrane, a preparation method thereof and an application of the membrane, and belongs to the technical field of materials. The preparation method of the beta-FeOOH / polyacrylonitrile composite nanofiber membrane includes the steps: polyacrylonitrile nanofiber membrane preparation: preparing a polyacrylonitrile nanofiber membrane by electrostatic spinning; stabilizing treatment: performing gradient heating treatment on the polyacrylonitrile nanofiber membrane; biological mineralization treatment: preparing ferric chloridesolution and hydrochloric acid according to the volume ratio of 2:1, placing the stabilized polyacrylonitrile nanofiber membrane into mixed solution and stirring the mixed solution for 1-3 minutes, performing reaction under the condition of 55-65 DEG C for 10-14 hours, and then cleaning and drying the polyacrylonitrile nanofiber membrane to prepare the beta-FeOOH / polyacrylonitrile composite nanofiber membrane. The beta-FeOOH / polyacrylonitrile composite nanofiber membrane has good stability, mechanical performance, super-hydrophilic-underwater super-oleophobic properties and high adsorption efficiency and can be recycled.

Owner:成都石大力盾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com