Method of preparing isotropic super-hydrophobic and superoleophobic regular porous silicone rubber with anisotropic structure

A super-hydrophobic, super-oleophobic, isotropic technology, applied in the direction of processing and manufacturing, liquid material additive processing, additive processing, etc., can solve the problems of limiting the application range of reinforced materials, unfavorable material properties, etc., and achieve excellent resistance to mechanical damage effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Preparation of Coupling Agent Pretreated Inorganic Nanoparticles

[0076] The inorganic nanoparticles are pre-soaked with a coupling agent with a mass concentration of 0.1-5.0% for 5-60 minutes, and then dried at a temperature of 20-90°C for 5-60 minutes to prepare the inorganic nanoparticles treated with the coupling agent. Concrete preparation raw material and parameter are as follows:

[0077]

Embodiment 2

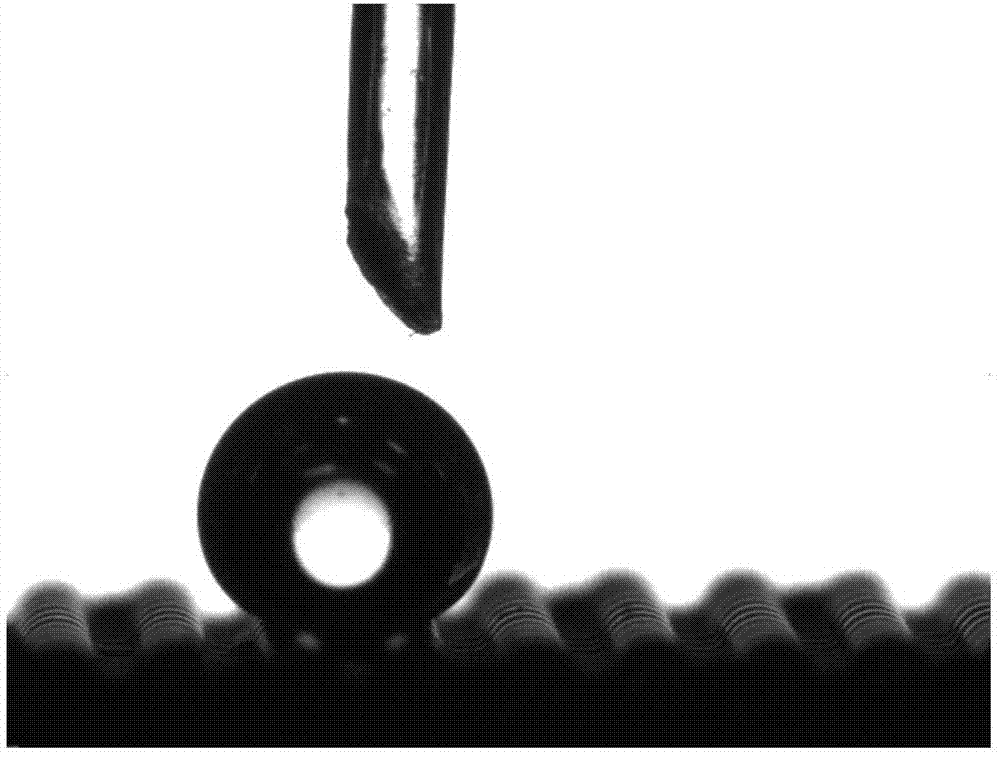

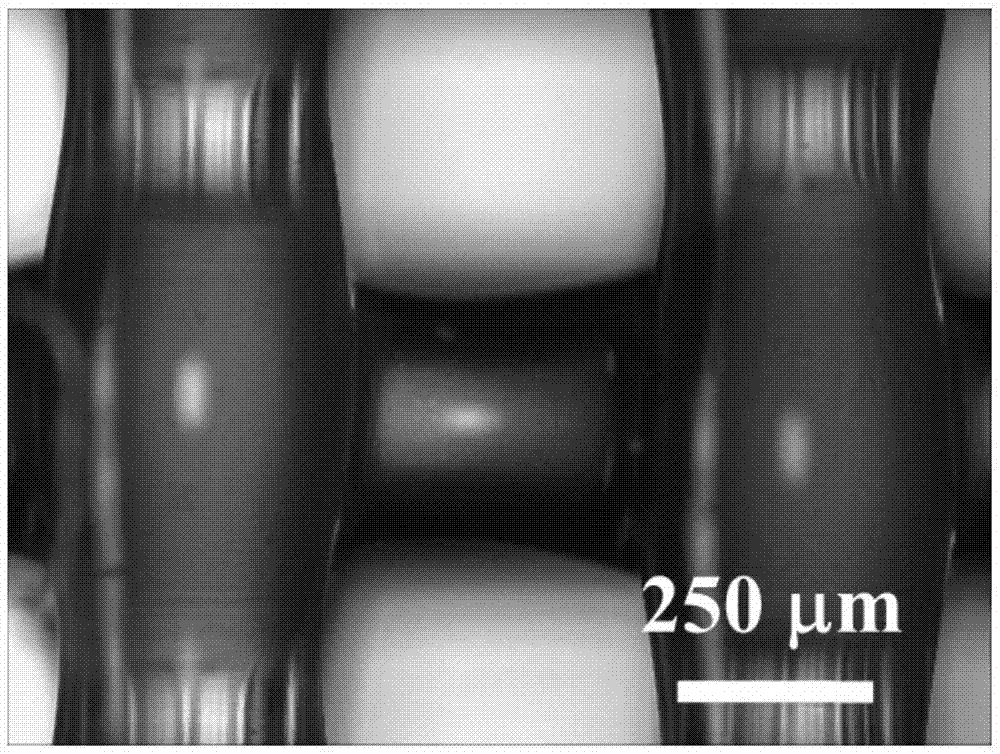

[0079] Preparation of isotropic superhydrophobic and superoleophobic silicone rubber materials through anisotropic structure

[0080] (1) be that 40.0% vinyl silicone oil, 14.0% mass fraction are prepared by the embodiment 1 of 101 mass fraction, 0.5% Dow Corning RD27 platinum catalyst and 0.5% 1- The ethynyl-1-cyclohexanol inhibitor was uniformly mixed to obtain the first mixture. In the mixing process, the parameters of ball mill mixing are revolution 50r / min, rotation 100r / min, and time 40min.

[0081] (2) To the first mixture prepared in step 1, add a mass fraction of 40.0% hydrogen-containing silicone oil with a mass fraction of 2.0% Si-H groups and a mass fraction of 5.0% polyvinylidene fluoride silicone rubber Auxiliaries, continue to mix evenly, using ball milling parameters for revolution 50r / min, rotation 100r / min, time 60min, to obtain the second mixture. The second mixture was degassed in vacuum for 60 minutes to obtain "ink" for printing. Note: The mass fract...

Embodiment 3

[0085] Preparation of isotropic superhydrophobic and superoleophobic silicone rubber materials through anisotropic structure

[0086] (1) the numbering that the mass fraction is 35.0% divinyl silicone oil, mass fraction is 14.0% is the filler that the embodiment 1 prepares, the mass fraction is the DX-3080 platinum of Guangzhou Daxi Chemical Raw Materials Co., Ltd. of 0.5% The catalyst and the 2-methyl-3-butyn-2-ol inhibitor with a mass fraction of 0.5% were uniformly mixed to obtain a first mixture. In the mixing process, the parameter of grinding and mixing is 100r / min, and the time is 60min.

[0087] (2) To the first mixture prepared in step 1, add a mass fraction of 40.0% hydrogen-containing silicone oil with a mass fraction of 1.5% Si-H group-containing silicone oil and a mass fraction of 10.0% 1H, 1H, 2H, 2H -Perfluorooctyltrimethoxysilane silicone rubber additive, continue to mix evenly, adopt the parameters of grinding and mixing at 100r / min, and the time is 60min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com