Patents

Literature

2013 results about "Methylene bisacrylamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N,N-methylene bisacrylamide is a molecule that is used as a crosslinking agent in chemical reactions during the formation of polymers.

Gel pad and UV-curving production method thereof

The invention relates to a gel pad and a uv-curing production method thereof. This invention, including the gel bag, is characterized in that the gel bag is filled with gel which is prepared from gel monomers, a cross-linking agent and a photoinitiatorandwater prepared from the UV curving. The gel consists of monomers, cross-linking agents, cross-linking agents, photo initiators and water. The said monomer are two or more than two of an acrylic acid alkali metal salt, ester generated by methacrylic acid ,acrylamide ,methacrylamide and AMPS(2-acrylamide-2-methyl-propanesulfonic acid ). The said cross-linking agent is a non-conjugated double bond compound which is polyol(glycerol )N,N'-methylene bisacrylamide. The said photoinitiator is a cracking type initiator or a photosensitive initiator or a cationic initiator. The advantages of the method are that the production process is simple, the gel solidification is fast and the gel pad produced is flattened.

Owner:朱雪兵

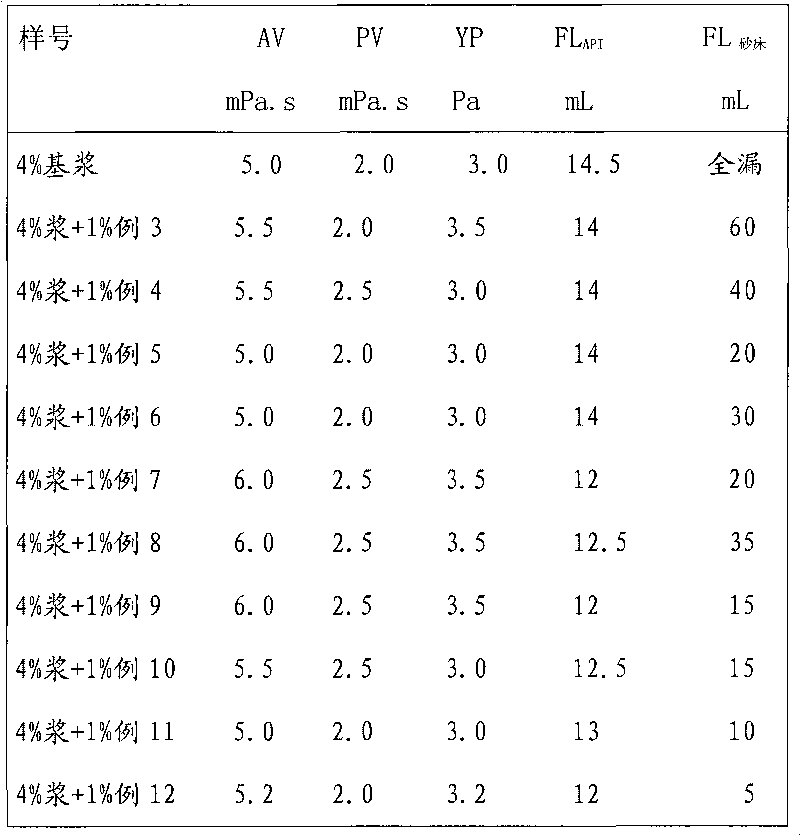

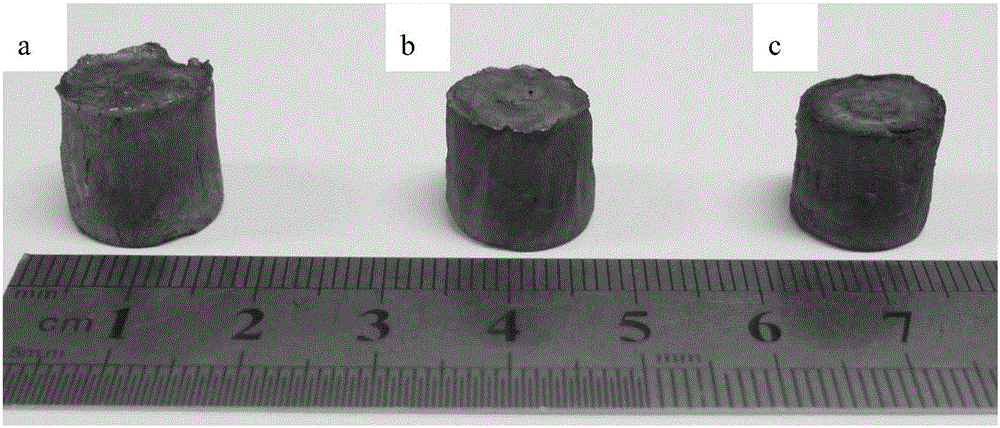

Drilling fluid plugging agent while drilling

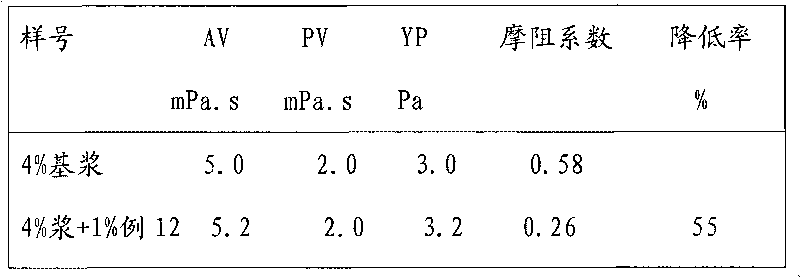

The invention relates to a drilling fluid plugging agent while drilling, comprising 60-100 parts of plant fibers, 5-20 parts of asphalt, 5-15 parts of graphite and 5-20 parts of weak water absorbent gel by weight. The weak water absorbent gel is a polymer which has mean grain size of 200-20 meshes and water absorbent multiple of 10-100g.g-1 and is prepared by reacting 20-60 parts of monomer, 0.05-1.0 part of potassium peroxydisulfate, 0.05-1.0 part of sodium bisulfite, 0.005-0.5 part of methylene-bis-acrylamide and 2-10 parts of inorganic fillers by weight under constant temperature of 20-60 DEG C for 8-12h by way of aqueous solution polymerization, drying and pelleting, wherein the polymeric monomer is one or more of acrylamide, acrylic acid, dimethyl diallyl ammonium chloride and 2-acrylamide-2-methyl propanesulfonic acid. The plugging agent has little effect on the rheological property of the drilling fluid, can reduce the API filtration and the coefficient of friction resistance of the drilling fluid in an auxiliary manner and is suitable for controlling leakage of and plugging the windows with high density and narrow pressure.

Owner:PETROCHINA CO LTD

Polyacrylamide hydrogel for arthritis

InactiveUS20030065389A1Mechanical stressLow viscosityOrganic active ingredientsPharmaceutical non-active ingredientsArthritisMethylene bisacrylamide

A hydrogel for use as a prosthetic device for supplementing, augmenting or replacing cartilage in the intra-articular cavity of a joint and for treatment or prevention of arthritis. The hydrogel may be a polyacrylamide hydrogel obtained by combining acrylamide and methylene bis-acrylamide. A prosthetic device comprising the polyacrylamide hydrogel is also disclosed.

Owner:AXONICS WOMENS HEALTH LTD

Postoperation anti-adhesion hydrogel and preparing method thereof

ActiveCN105194740AMeet postoperative anti-adhesion requirementsMeet nursing treatment needsSurgerySolventBiological materials

The invention discloses postoperation anti-adhesion hydrogel and a preparing method thereof. The hydrogel is prepared from sodium alginate powder, chitosan powder, acrylamide monomers, N,N'-methylene bisacrylamide, calcium sulfate, ammonium persulfate and N,N,N',N'-tetramethylethylenediamine. The preparing method of the high-strength high-tenacity chitosan and sodium alginate compound hydrogel is easy to operate, parameters are controllable, the materials are easy to obtain, and the solvent is nontoxic or low in toxicity and safe to treat and use; the method integrates advantages of the two natural biological materials, and the requirement for postoperation adhesion prevention of patients and the requirement for nursing care and treatment of medical workers can be met well. The hydrogel is soft, can be attached to the skin easily, has good flexibility and can effectively prevent wound surface adhesion and be degraded and absorbed, secondary trauma is avoided, and the hydrogel is expected to become a novel postoperation anti-adhesion material.

Owner:HARBIN INST OF TECH

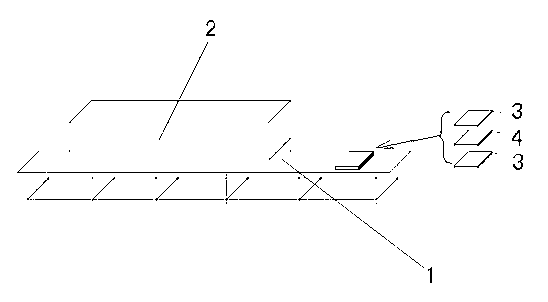

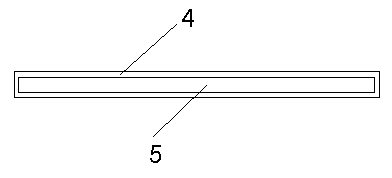

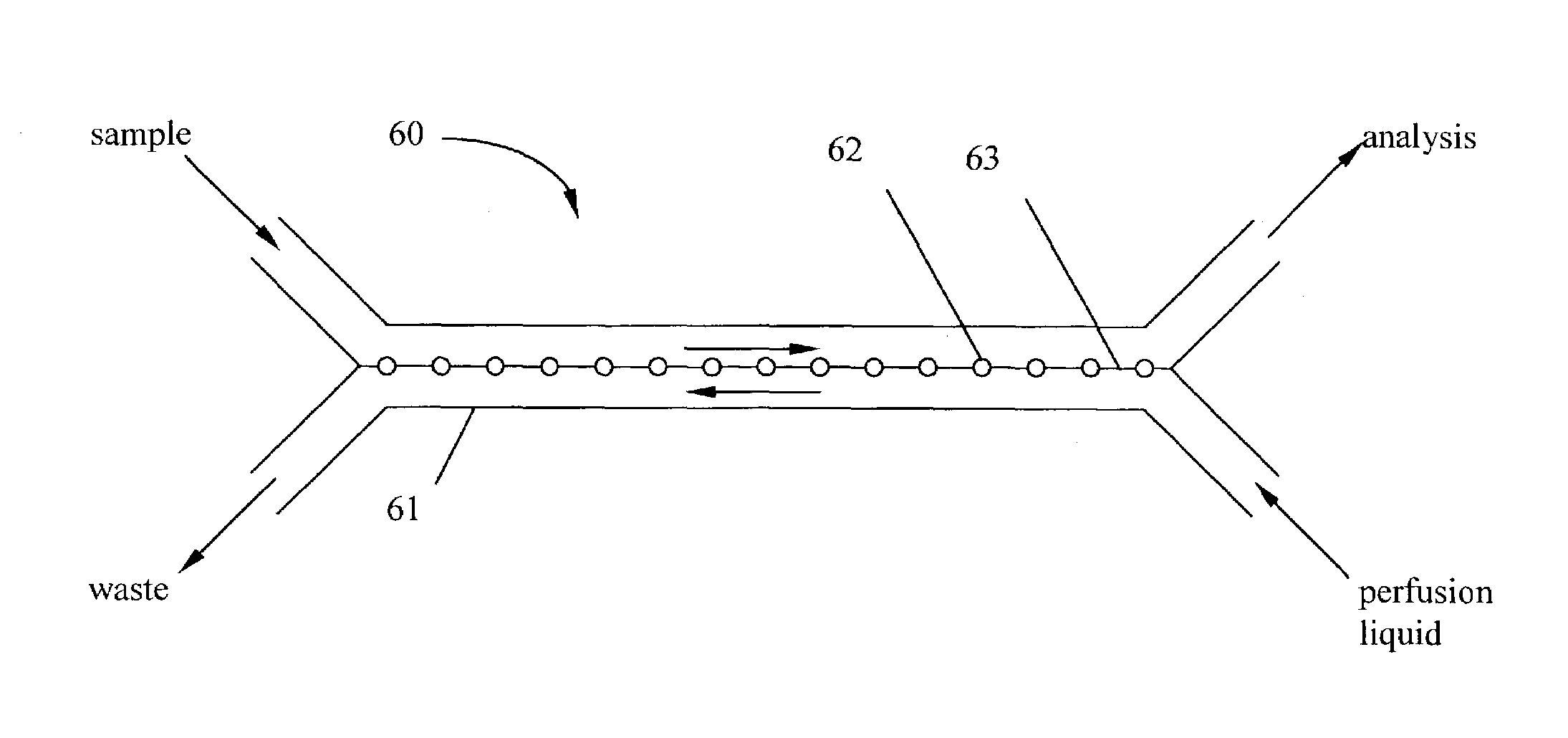

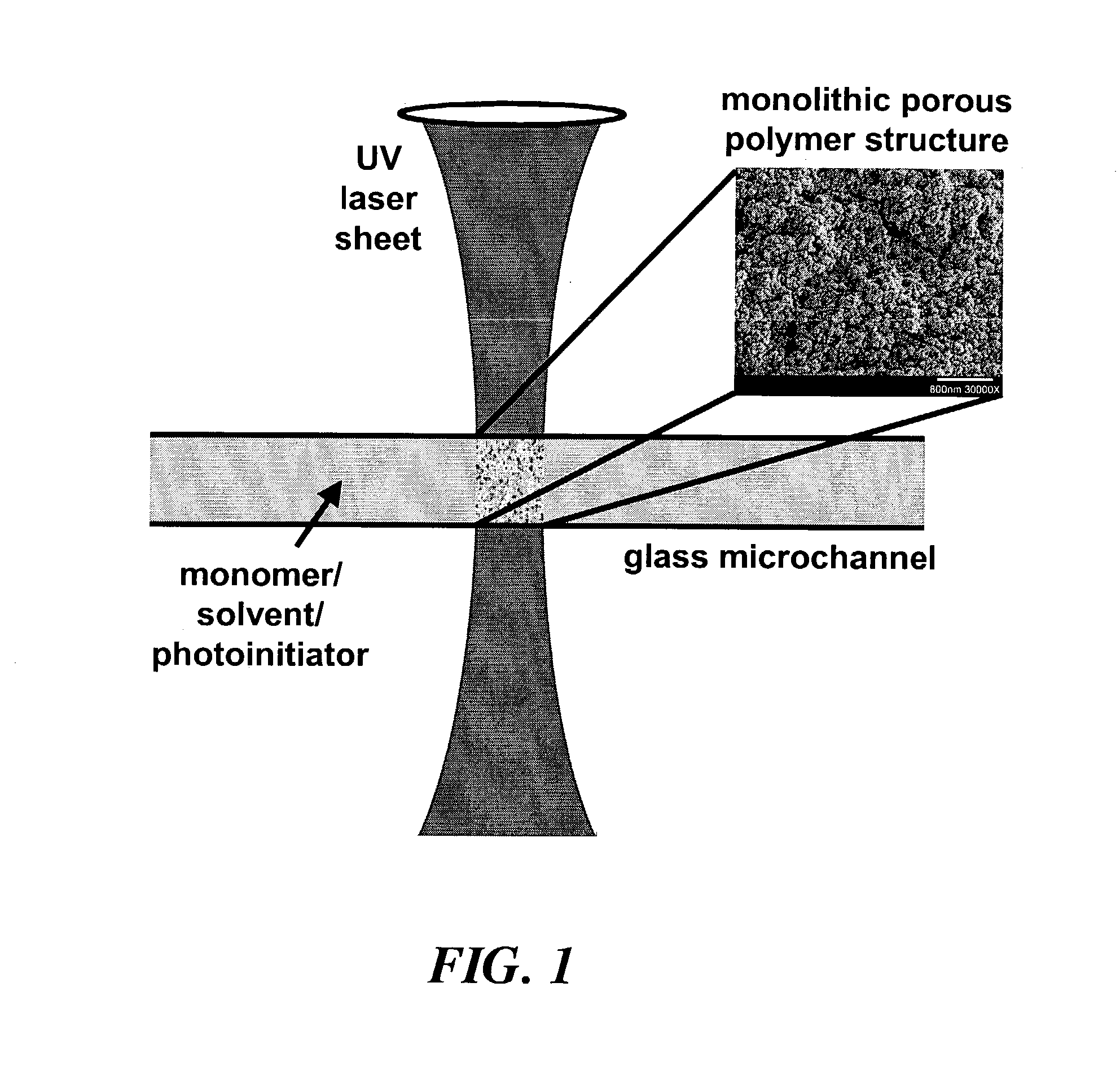

Dialysis on microchips using thin porous polymer membranes

ActiveUS7264723B2Minimize handlingComplicated operationSolvent extractionTransportation and packagingDialysis membranesMeth-

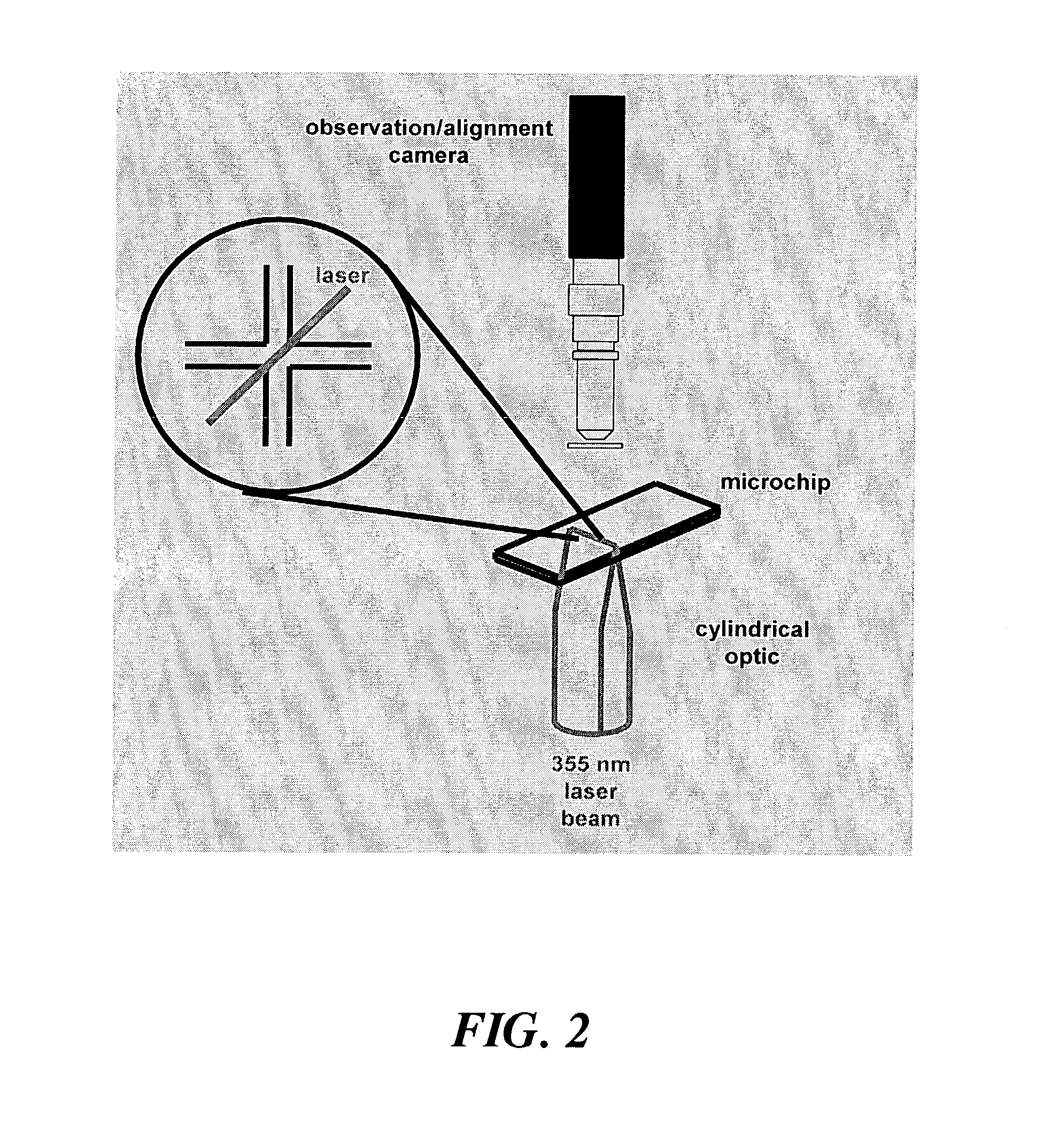

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and form a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:SANDIA NAT LAB

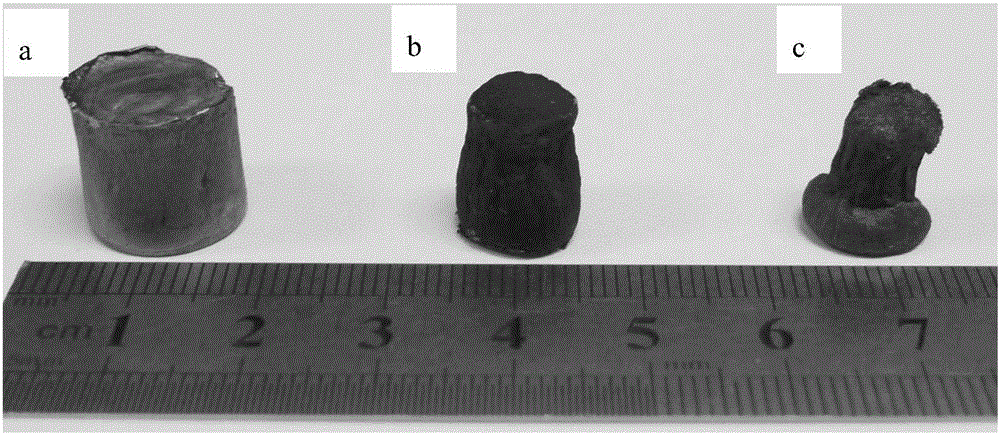

High-strength temporary blocking agent and preparation method thereof

ActiveCN101906292AGood sealingMeet the needs of on-site constructionDrilling compositionHigh intensityMethylene bisacrylamide

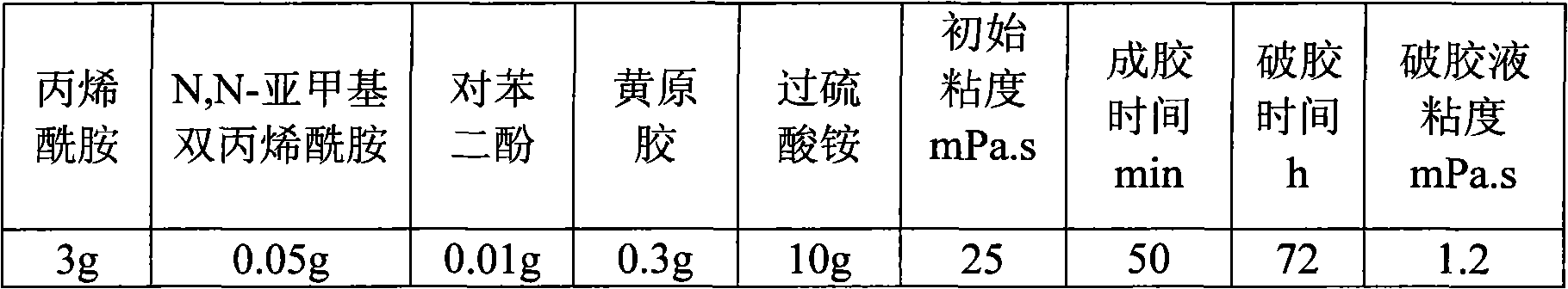

The invention relates to a high-strength temporary blocking agent and a preparation method thereof. The temporary blocking agent consists of the following components in percentage by mass: 2 to 20 percent of acrylamide, 0.02 to 0.1 percent of N,N-methylene-bisacrylamide, 0.001 to 0.1 percent of polymerization inhibitor, 0 to 1.0 percent of thickening agent, 2 to 50 percent of initiation gel breaker and the balance of water. The high-strength temporary blocking agent can form high-strength gel under intermediate / low-temperature reservoir conditions, can realize gel-formation and complete gel breaking in a given time, has no damage to the reservoir after the gel breaking and can be adapted to the temporary blocking operation of intermediate / low temperature oil-gas reservoirs.

Owner:PETROCHINA CO LTD

Polyacrylamide hydrogel for arthritis

A hydrogel for use as a prosthetic device for supplementing, augmenting or replacing cartilage in the intra-articular cavity of a joint and for treatment or prevention of arthritis. The hydrogel may be a polyacrylamide hydrogel obtained by combining acrylamide and methylene bis-acrylamide. A prosthetic device comprising the polyacrylamide hydrogel is also disclosed.

Owner:AXONICS WOMENS HEALTH LTD

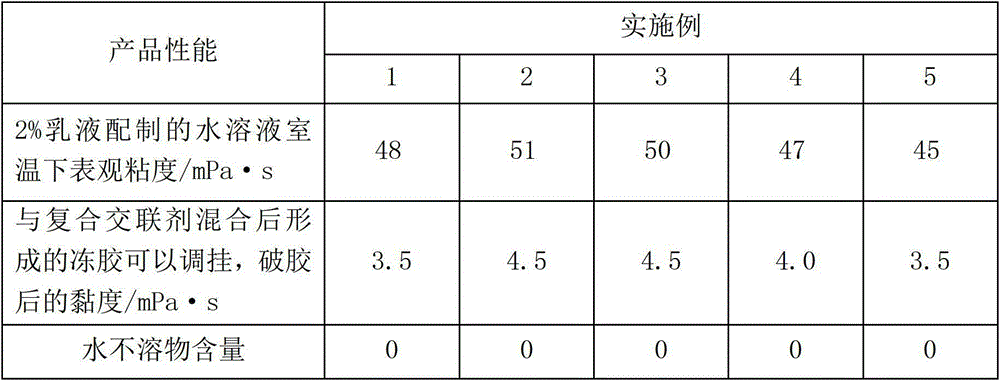

Inverse emulsion polymer thickener for fracturing fluid and preparation method thereof

ActiveCN103146372AAvoid harmMeet the fracturing constructionDrilling compositionPolymer sciencePersulfate

The invention relates to an inverse emulsion polymer thickener for a fracturing fluid and a preparation method thereof. The thickener is polymerized by water, 2-acrylamidyl-2-methyl sodium proparesulfonic acid liquid with mass fraction of 50%, alkyl acrylamide, acrylamide, a cationic monomer, N, N-methylene bisacrylamide, a tween-80 emulsifier, ethylene diamine tetraacetic acid disodium salt, 30% sodium hydroxide, white oil, acrylic ester, a span-80 emulsifier, sulfite, a peroxysulphate initiator, a water-soluble azo initiator and OP-15. According to the invention, raw materials are industrial products, and purification is not needed before reaction; polymerization is initiated by initiators by adding a complexing agent, and the preparation process is simple; the thickener provided by the invention is fast in dispersing, easy to prepare, free from pollution and harm, small in use level and good in stability, in particular resists high temperature of 220 DEG C, and is suitable for fracturing a high-temperature stratum; and the thickener is higher in shear resistance, can meet the fracturing construction of high flow, has high sand carrying performance, and is free from residue and is not harmful to the reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temporary plugging agent for medium/high-temperature oil-gas reservoir

ActiveCN102191023AMeet different requirements of temporary blocking performanceGood sealingDrilling compositionAcetic acidMethylene bisacrylamide

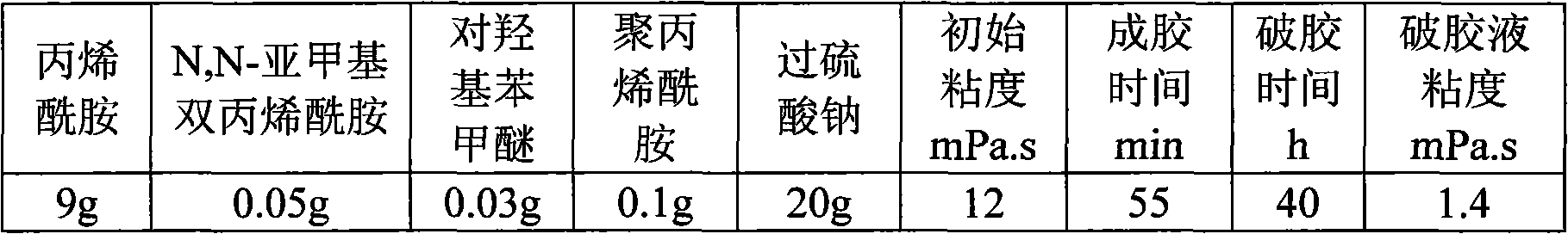

The invention relates to a temporary plugging agent for a medium / high-temperature (80-100 DEG C) oil-gas reservoir. The temporary plugging agent is prepared from the following components in percentage by mass: 2-20% of acrylamide, 0.02-0.5% of N,N-methylene-bisacrylamide, 0.005-0.03% of polymerization inhibitor, 0.05-0.3% of thickener, 0.005-1.0% of initiator, 0.1-10% of viscosity breaker and thebalance of water. The initiator is azobis(isobutylamidine hydrochloride), azodiisopropyl imidazoline or azodiisopropyl imidazoline hydrochloride; and the viscosity breaker is hydrogen peroxide, peracetic acid or peracetate. The temporary plugging agent can form high-strength gel under medium / high-temperature stratum conditions, can gelatinize within the specified time and thoroughly break the viscosity, does not damage the stratum after viscosity breaking, and can adapt to sectionalized reconstruction, repeated reconstruction and turning reconstruction of a long well interval of a medium / high-temperature oil-gas reservoir as well as temporary plugging operation of the well interval and stratum in need of temporary plugging.

Owner:PETROCHINA CO LTD

Hydrolysiable high elastic well remending liquid temperary blocking agent

ActiveCN1869147APrevent leakageRestore permeabilityDrilling compositionSulfateMethylene bisacrylamide

The invention relates to hydrolysable high elasticity well workover liquid temporary blocking agent used in oil field workover treatment. It is made up of 40-80% de-ionized water, 10-30% acrylic acid, 8-30% starch, 0.1-1.5% sodium per-sulfate, and 0.1-1.0% N,N-methylene-bisacrylamide. The water-bearing of the product is 40%-80%. It can be degraded easily in water, and can lose full strength in 24 hours below 60 centigrade degree. The degraded residue is little and has low system viscosity.

Owner:PETROCHINA CO LTD

Core-shell polymer microsphere profile control and oil displacement agent and preparation method thereof

InactiveCN102504793AImprove elastic deformation abilityImprove temperature resistanceDrilling compositionHydrophilic monomerPolymer science

The invention relates to a core-shell polymer microsphere profile control and oil displacement agent for oil reservoir profile control and displacement and increase of water drive recovery factor and a preparation method of the core-shell polymer microsphere profile control and oil displacement agent, which can solve the technical problems of difficulty in injection and poor temperature resistance and salt resistance. The invention adopts a technical scheme as follows: the profile control and oil displacement agent is made from the following raw materials in parts: 15 to 20 of a hydrophobic monomer (such as styrene or a styrene derivative or an acrylate ester), 2 to 10 of a hydrophilic monomer (such as acrylic acid or an acrylate salt or acrylamide), 60 to 85 of deionized water, divinylbenzene as core-phase cross-linking agent, N,N'-methylene-bis-acrylamide as shell-phase cross-linking agent, and a sulfate salt as initiator. The method comprises the following steps of: adding the shell-phase cross-linking agent and acrylic acid into a three-necked flask with water, adding the core-phase cross-linking agent and styrene after dissolving completely, introducing nitrogen gas (30 DEG Cto 75 DEG C), adding the initiator, and allowing reactions to take place for 6 to 8 hours under stirring, to obtain the polymer microsphere profile control and oil displacement agent. The polymer microsphere profile control and oil displacement agent is suitable for middle / low-permeability oil reservoirs, can be applied to high-permeability oil reservoirs in combination with other profile controlagents, and can greatly increase the crude oil recovery ratio.

Owner:SOUTHWEST PETROLEUM UNIV

Method for water plugging and profile controlling of underground polymerization of oil exploitation sludge

The invention relates to a method for water plugging and profile controlling of underground polymerization of oil exploitation sludge, comprising the following steps of: adding 2-7% of crylic acid, 0-3% of acrylamide, 0.2-0.6% of cross linking agent and 0.01-0.05% of initiator into 15-25% of oil exploitation sludge, injecting the mixture together with the oil field water or tap water in the ground; and subsequently generating plugging substances of solid mesh structure wrapping sludge owning to the polymerization reaction under the action of oil pool temperature, thus playing an effect of sealing the underground seams, wherein the oil exploitation sludge is a tank bottom sludge generated during the oil exploitation process of the oil field or the sludge in the sludge pool; the sludge is athin oil sludge; the cross linking agent is a polyol, a glycerin, an N, N-methylene bisacrylamide or N, N-dimethybisacrylamide; and the initiator is the alkali metal salt or the ammonium salt of a persulphuric acid. The method changes the aboveground polymerization process of the oil exploitation sludge grain profile control agent into the underground polymerization process, saves corresponding procedures and the equipment and devices, and generates the water-plugging profile control agent with high intensity and long-term effect by adjusting the concentration of the monomer.

Owner:PETROCHINA CO LTD

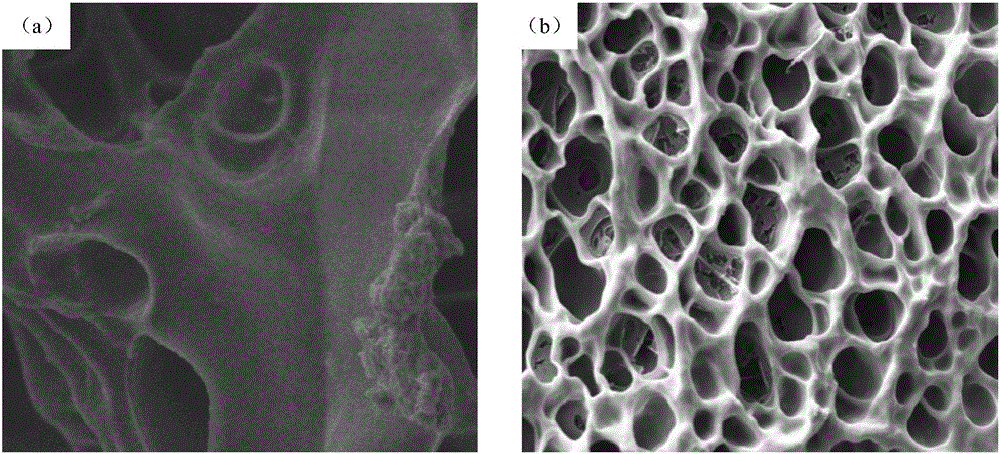

Graphene aerogel and hybrid composite material thereof as well as preparation method and application of graphene aerogel

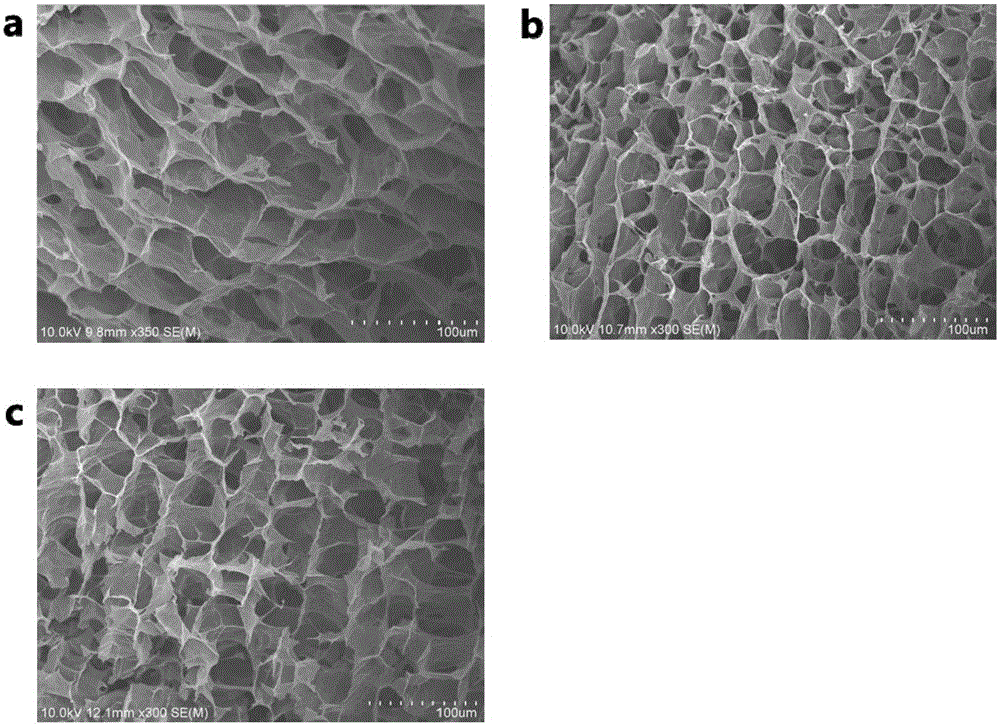

ActiveCN106422995AUniform cell structureIncrease elasticityColloidal chemistry detailsPotassium persulfateNanoparticle

The invention discloses graphene aerogel and a hybrid composite material thereof as well as a preparation method and application of the of graphene aerogel. The preparation method comprises the following steps: 1) mixing graphene oxide, a reducing agent, acrylamide, N,N-methylene-bisacrylamide and potassium persulfate and reacting to obtain partially-reduced graphene / polyacrylamide hydrogel; 2) carrying out pre-freezing and reduction on the partially-reduced graphene / polyacrylamide hydrogel in sequence to obtain graphene / polyacrylamide hydrogel; 3) dialyzing and drying the graphene / polyacrylamide hydrogel in sequence to obtain the graphene aerogel. The graphene aerogel has the characteristics of uniform cellular structure and light weight, excellent resilience, relatively high mechanical strength and good solvent resistance; a preparation process is simple, rapid and low in cost; the graphene aerogel can also be used for preparing polymer / graphene composite aerogel, nanoparticle / graphene composite aerogel and polymer / graphene composite materials and the like, so that application of the graphene aerogel is expanded.

Owner:INST OF CHEM CHINESE ACAD OF SCI

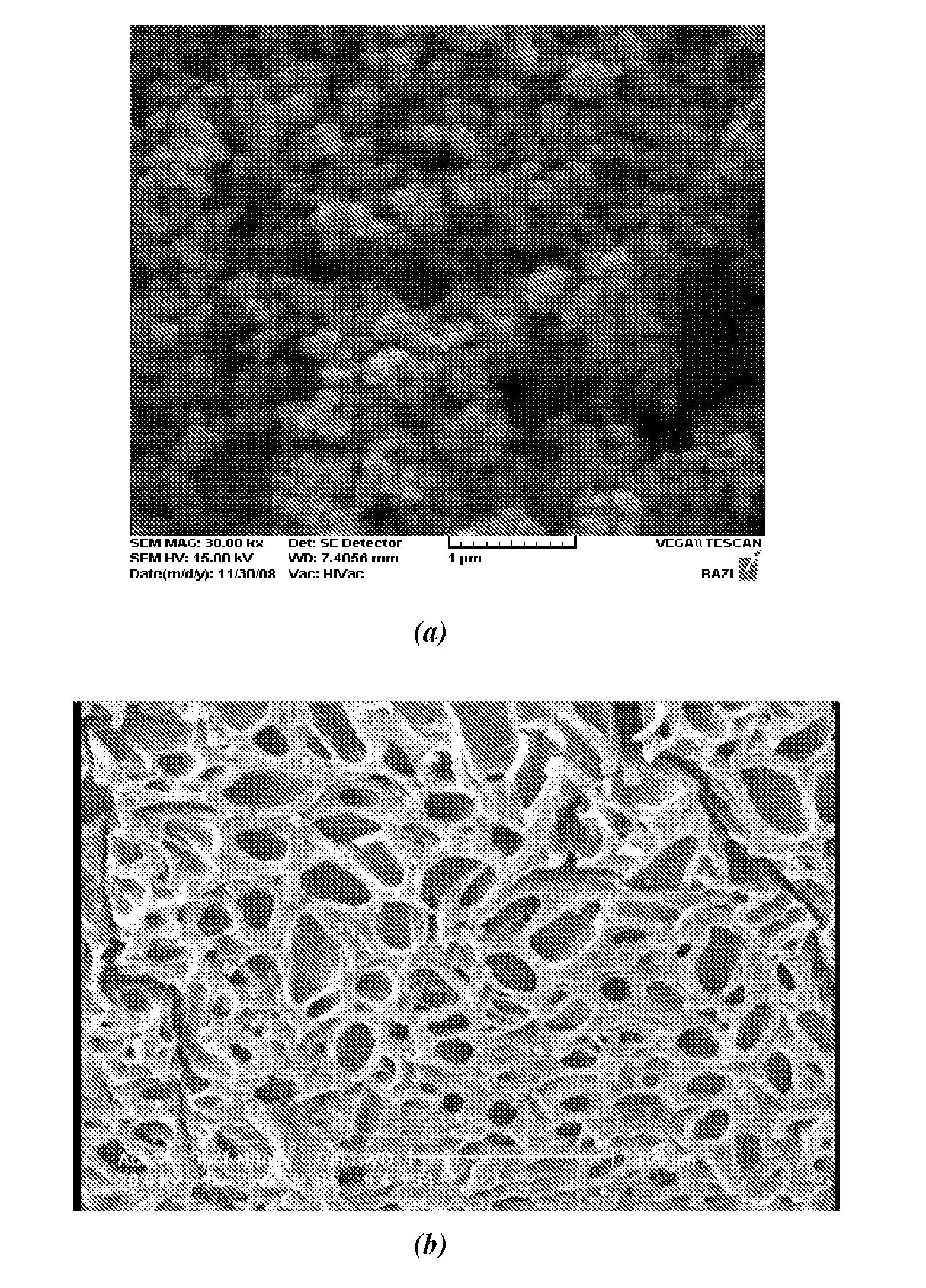

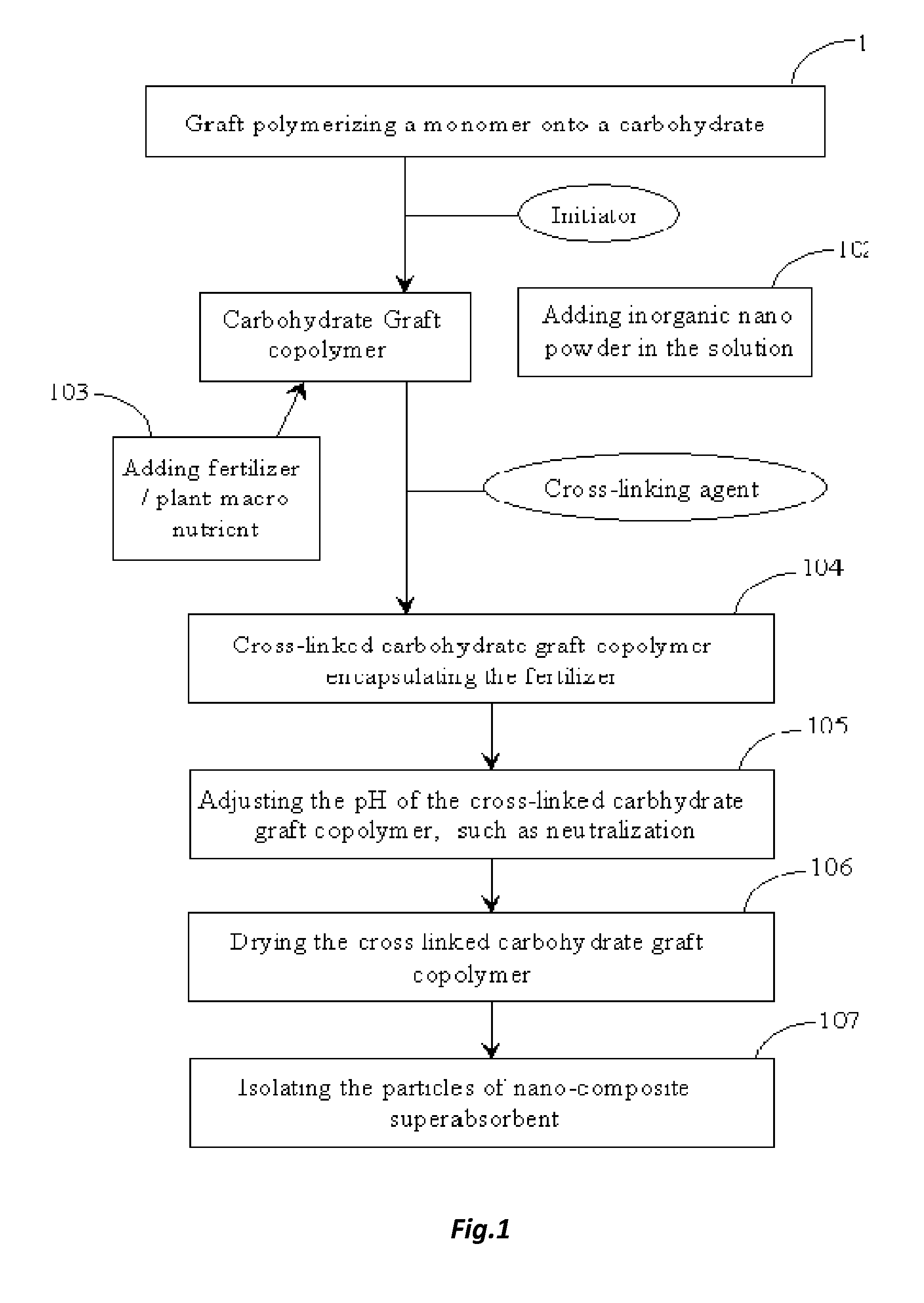

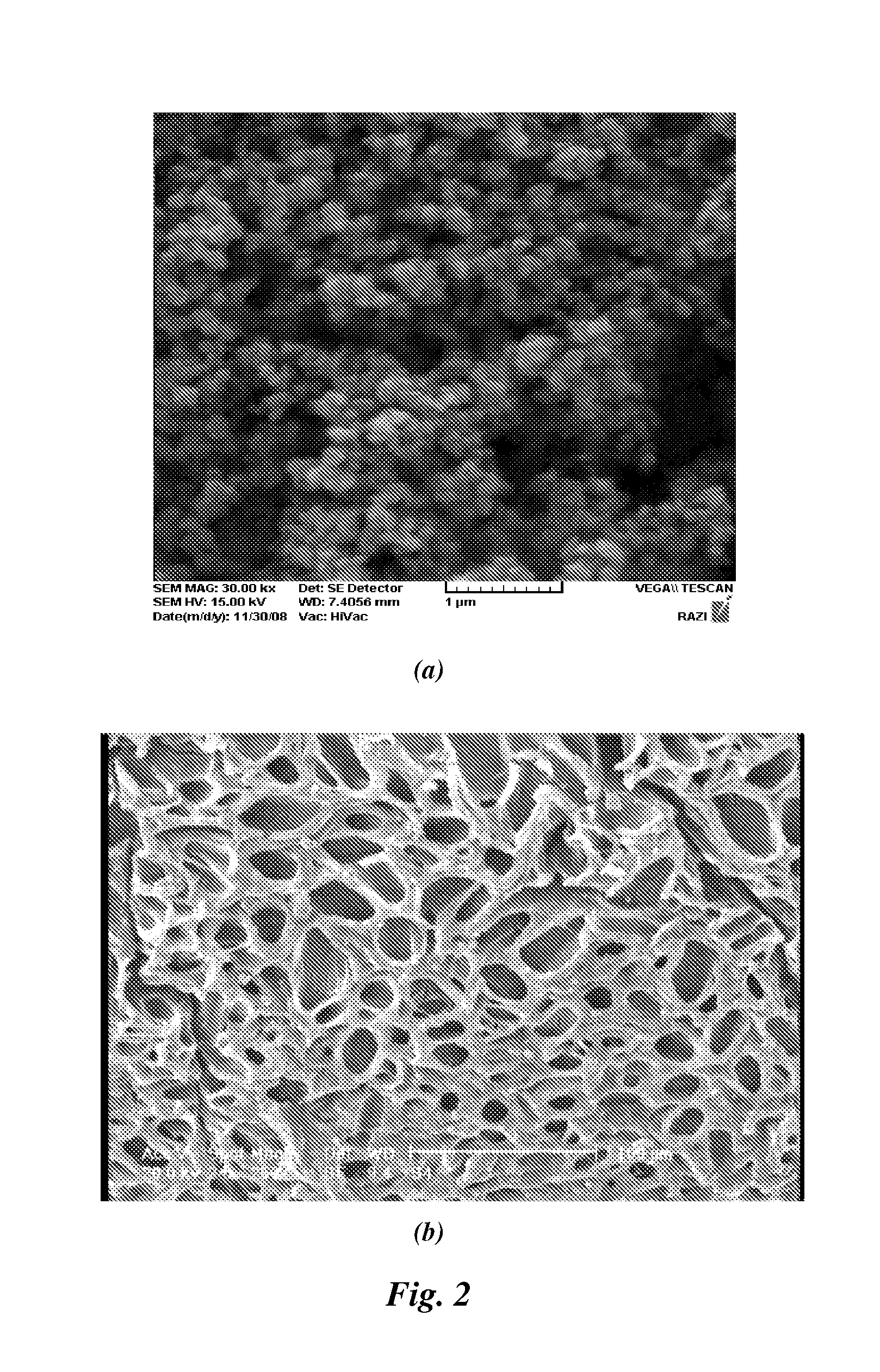

Nano-composite superabsorbent containing fertilizer nutrients used in agriculture

InactiveUS20100139347A1Slow release/controlled release of a plant nutrientBio-organic fraction processingWaste based fuelCross-linkAcrylonitrile

The embodiments herein disclose a nano-composite superabsorbent polymer (NC-SAP) composition encapsulating fertilizer / plant nutrient products and a method of producing NC-SAP based products. According to one embodiment, the method involves graft polymerizing a monomer, other than acrylonitrile, onto a carbohydrate in the presence of an initiator to form a graft carbohydrate copolymer, dispersing an inorganic nano powder, adding fertilizer nutrient to the reaction mixture, cross-linking the carbohydrate graft copolymer by adding a cross-linking agent, such as methylene bis-acrylamide, adjusting the pH of the cross-linked nano-composite carbohydrate graft copolymer and isolating the nano-composite carbohydrate graft copolymer. The method also includes drying the nano-composite carbohydrate graft copolymer, to yield particles that are NC-SAP containing fertilizer. The isolation of particles of NC-SAP polymer product may occur by the methods, including, but not limited to, granularization, extrusion and pelletization.

Owner:BARATI ABOLFAZL

Method for preparing high-strength polyvinyl alcohol-based dual-network hydrogel

The invention discloses a method for preparing high-strength polyvinyl alcohol-based dual-network hydrogel. The method comprises the following steps: taking polyvinyl alcohol as an initial raw material, and heating for dissolving, so as to obtain polyvinyl alcohol aqueous solution; adding metric acrylamide, acrylic acid, a cross-linking agent N'-N-methylene bisacrylamide and an initiator Irgacure2959 into the polyvinyl alcohol solution, and heating for dissolving, so as to obtain a uniform solution; freezing the solution in a low-temperature environment so as to obtain a physical cross-linked network structure of polyvinyl alcohol; performing photo-initiation under ultraviolet light so as to obtain chemically cross-linked polyacrylamide-acrylic acid chemical cross-linking structure, and constructing the high-strength polyvinyl alcohol-based dual-network hydrogel. The physical cross-linked and chemical cross-linked dual-network structures can be sequentially constructed by a one-step process. The preparation method provided by the invention is simple and feasible, the high-strength hydrogel of any shape can be constructed, and the prepared dual-network hydrogel is excellent in mechanical property.

Owner:FUZHOU UNIV

Controllable cross linked gel water blockage plugging material

InactiveCN101353569AImprove sealingSimple production processDrilling compositionCross-linkPolymer science

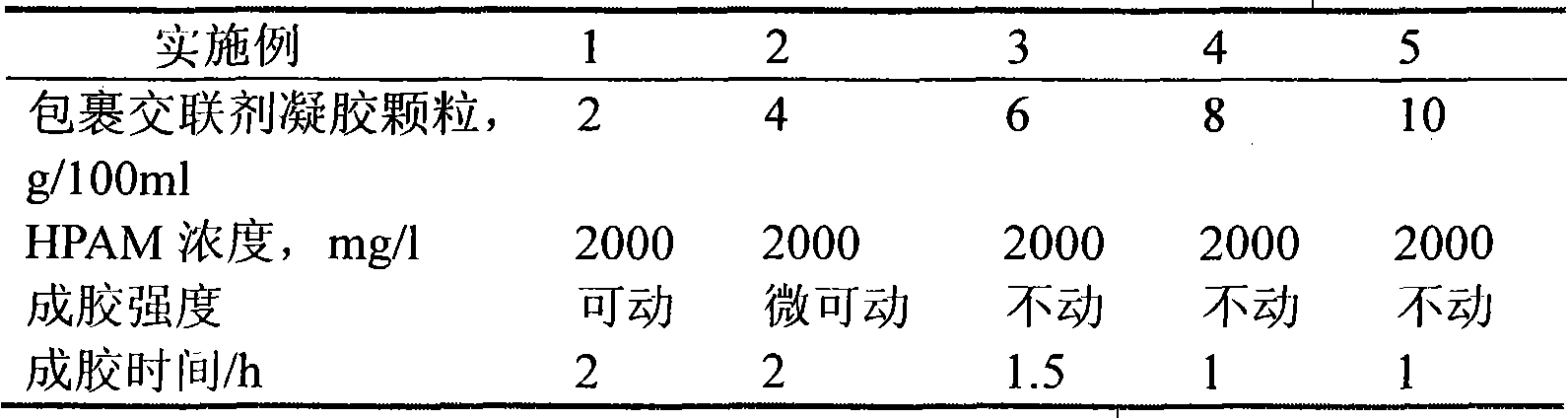

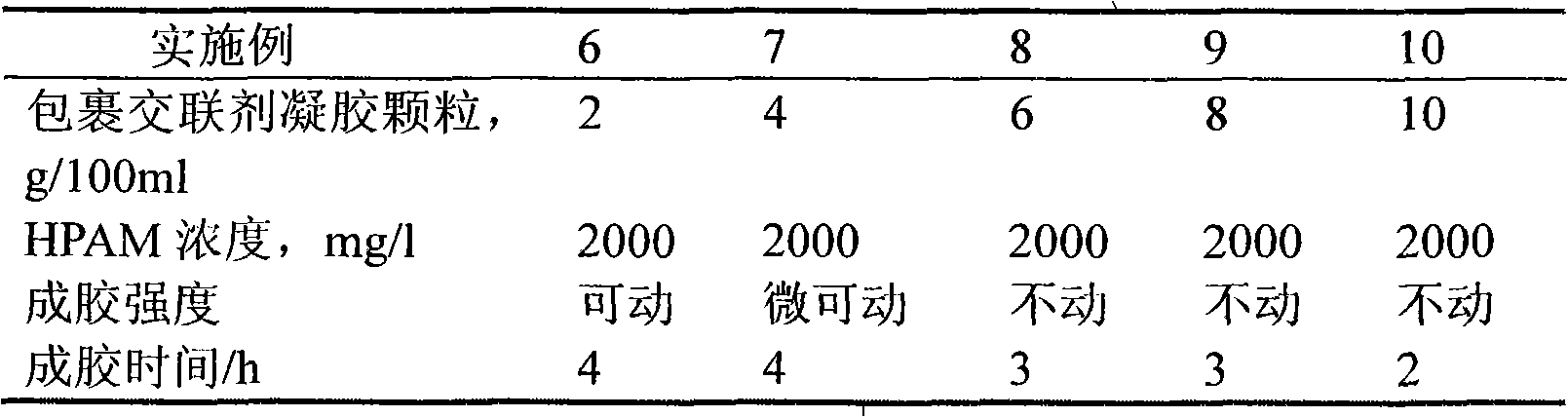

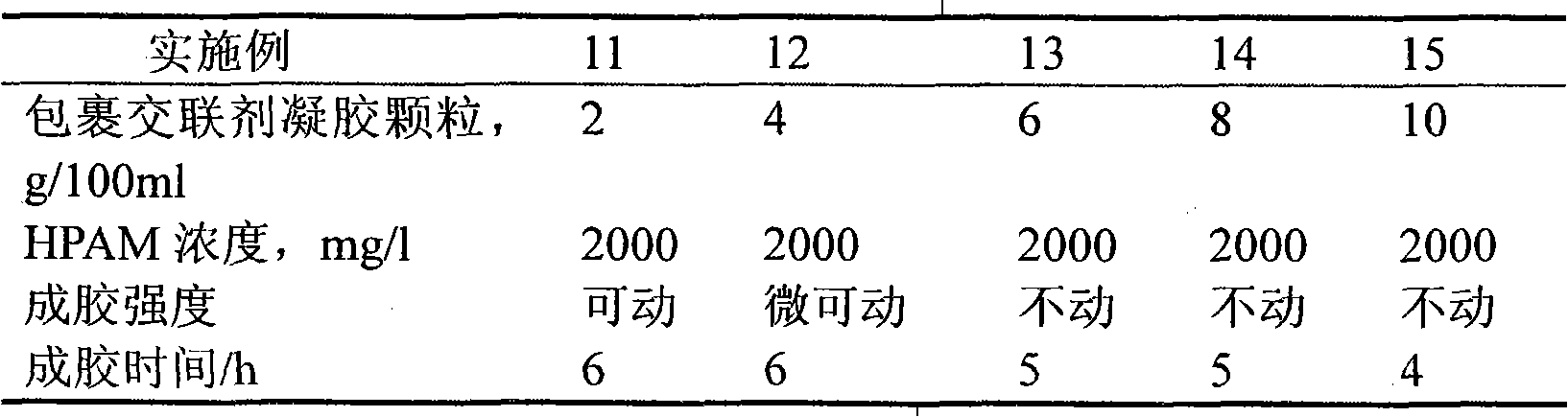

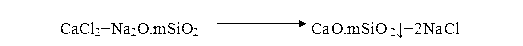

The invention relates to a controllable cross linking gel water shutoff and lost circulation material used for oil-gas fields, which can block off a fractured, vuggy or malignant leaking formation and increase the strength and stability of gel. The technical proposal is as follows: acrylamide of certain amount is added into a breaker containing deionized water, after the acrylamide dissolved, N, N-methylene-bisacrylamide and initiating agent are added, the mixture stands still for 1h at room temperature after 0.5h of gelation, therefore, lump gel product is obtained and finally becomes gel particles after granulation, parching and sieving; the gel particles are then soaked in the solution of chromium trichloride, cross linker is fully absorbed in the gel particles, and the obtained material is dried for spare; the product is then added into the solution of polyvinyl alcohol and the packaged gel particles are obtained after packaging 1-3 times and drying; finally the packaged gel particles containing the cross linker are added into the solution of the water soluble polymer HPAM for slow cross linking reaction, thus obtaining quiescent strong gel. The material is characterized by simple manufacturing process, low cost, little filtration loss and good leak tightness and stability.

Owner:SOUTHWEST PETROLEUM UNIV

Modified petroleum coke granule composite profile control water blocking agent and multi-round bidirectional blocking control technology

InactiveCN103013480AExpand the affected volumeEnhanced ultimate recoveryFluid removalDrilling compositionMeth-Thiourea

The invention discloses a modified petroleum coke granule composite profile control water blocking agent and a multi-round bidirectional blocking control technology. The water blocking agent comprises agents A, B and C, the agent A comprises the ingredients: polyacrylamide solution with the concentration of 0.1-0.3% (by weight), sodium silicate, aluminum potassium sulfate, hydrochloric acid with the concentration of 30% ( by weight), and calcium chloride, the agent B comprises polyacrylamide solution with the concentration of 0.1-0.3% (by weight), modified petroleum coke granules of 20-800mum and surfactant, and the agent C comprises the ingredients: polyacrylamide solution with the concentration of 0.3-0.7% (by weight), N-N' methylene bisacrylamide, organic chromium crosslinking agent, and thiocarbamide; and the multi-round bidirectional blocking control technology is of a multi-round bidirectional blocking control measure developed according to geologic features, state and oil producing conditions of different regions of oil fields; and the water blocking agent is matched with the blocking control technology, so that the problems that the conventional profile control water blocking agent is low in strength, and bad in anti-erosion property and shearing resistance property can be solved, further digging of remaining petroleum is conducted, the water content ratio of an oil well can be reduced, the effect of displacement in flooding can be improved, and the production demand of the oil field can be met.

Owner:DAQING ZHONGYOU TAIKE PETROLEUM TECH SERVICE

Polyacrylamide hydrogel for the treatment of incontinence and vesicouretal reflux

InactiveUS20030077244A1Excellent templateExcellent matrixPharmaceutical delivery mechanismPharmaceutical non-active ingredientsMedicineMethylene bisacrylamide

The present invention relates to a bio-stable hydrogel for use in the treatment and prevention of incontinence and vesicouretal reflux. The hydrogel is obtainable by combining acrylamide and methylene bis-acrylamide in amounts to provide about 0.5 to 25% by weight polyacrylamide, based on the total weight of the hydrogel.

Owner:AXONICS WOMENS HEALTH LTD

Polyacrylamide microgel as well as preparation method and application thereof

ActiveCN102127189AImprove stabilityPrevent implosionDrilling compositionN,N-MethylenebisacrylamideMethylene bisacrylamide

The invention discloses a polyacrylamide microgel as well as a preparation method and application thereof. The particle size of the polyacrylamide microgel is 30-150 micrometers, acrylamide, sodium acrylate, N,N'-bisacrylamide, 2-acrylamide-2-methylpropanesulfonic acid sodium, styrenesulfonate and the like serve as polymerized monomers, white oil and the like serve as disperse phases, and the polymerized monomers and the disperse phases are subjected to thermal initiation suspension polymerization to obtain the polyacrylamide microgel. The polyacrylamide microgel synthetized by the method can be directly injected into an oil layer without being processed and has a good plugging effect.

Owner:北京石大万嘉新材料科技有限公司

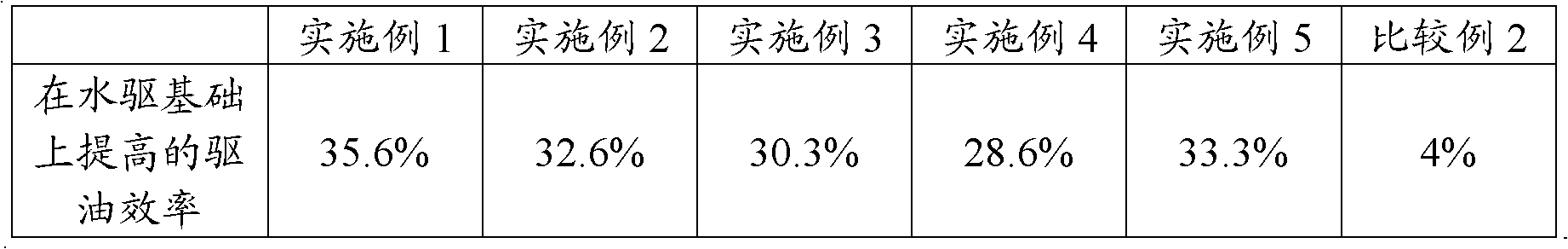

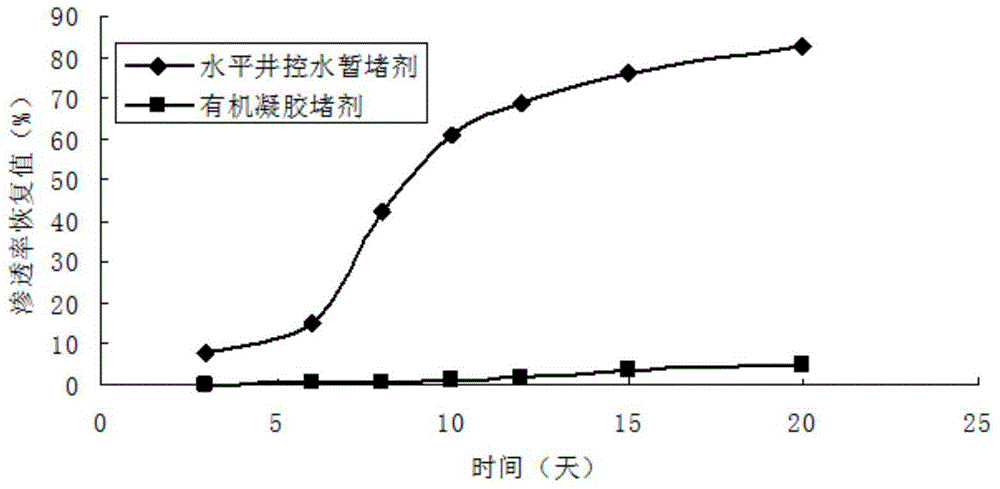

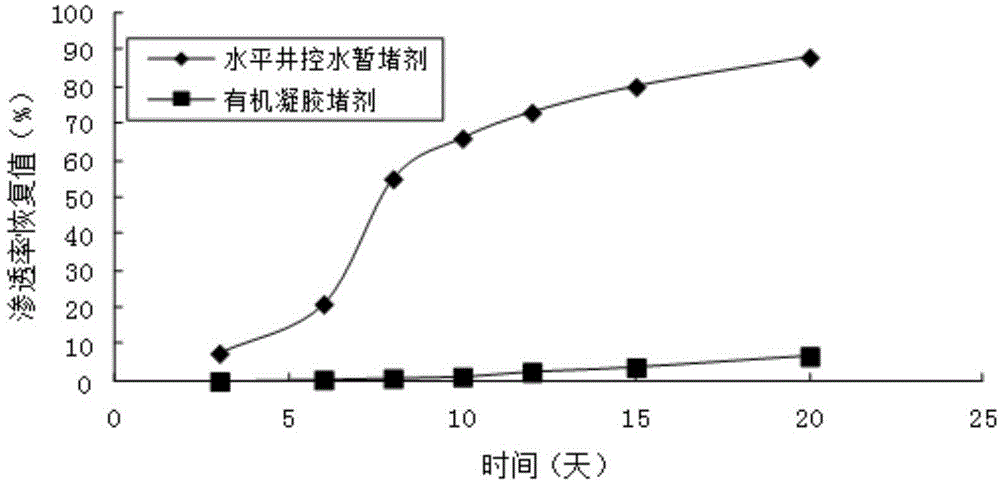

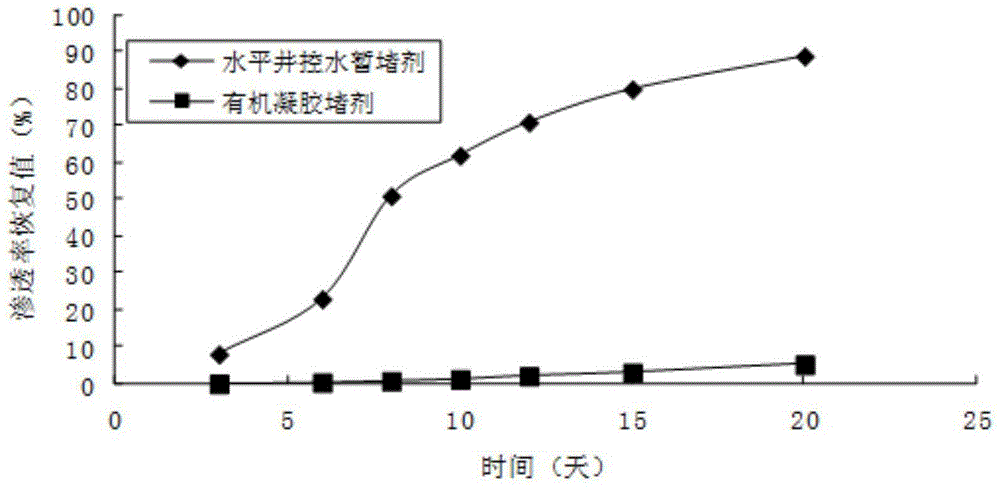

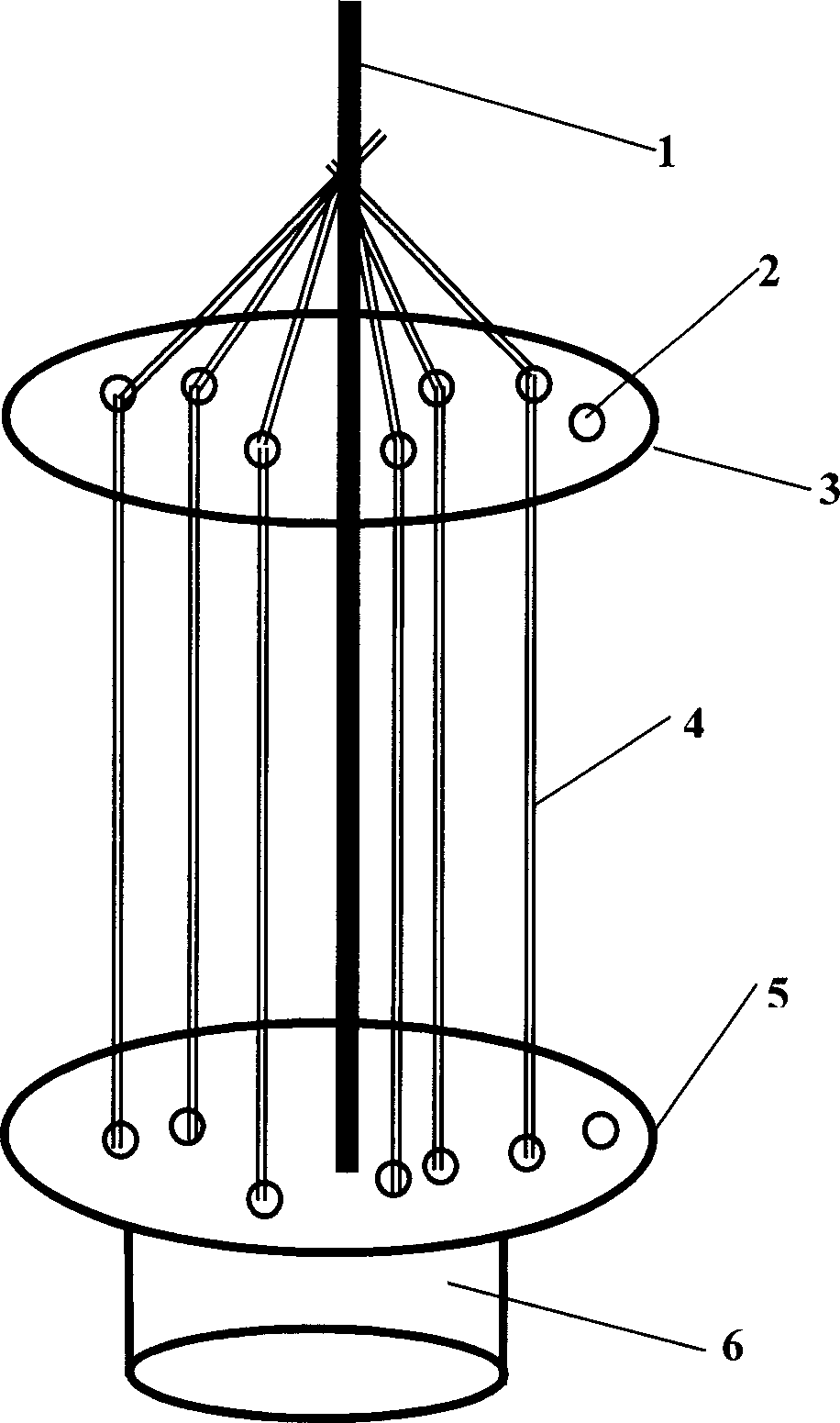

Temporary plugging agent for horizontal well water control, and preparation method and application thereof

ActiveCN104531115AReduce harmStrong blocking abilityDrilling compositionMass ratioMethylene bisacrylamide

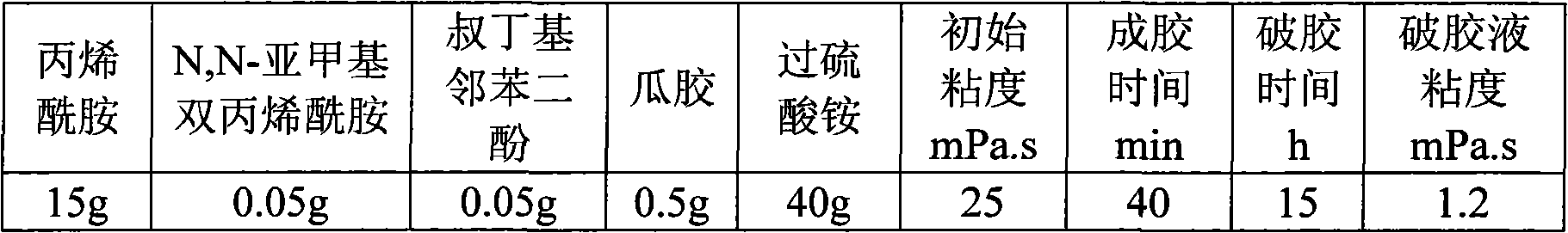

The invention provides a temporary plugging agent for horizontal well water control, and a preparation method and application thereof. The temporary plugging agent for horizontal well water control comprises the following raw materials in parts by weight: 4-15 parts of acrylamide, 0.5-3 parts of polypropylene fiber, 1.5-4 parts of reinforcer, 0.5-1.0 part of composite crosslinking agent, 0.1-0.2 part of initiator and the balance of water, totaling 100 parts. The composite crosslinking agent is a mixture composed of polyethyleneglycol diacrylate and N,N-methylene-bis acrylamide in a mass ratio of 10:(1-4). The preparation method of the temporary plugging agent comprises the following steps: sequentially adding the acrylamide, polypropylene fiber, reinforcer and composite crosslinking agent into water, stirring uniformly, adding the initiator, and standing to react for 1-3 hours, thereby obtaining the temporary plugging agent. The invention also provides application of the temporary plugging agent in horizontal well water control. The temporary plugging agent provided by the invention has the characteristics of high gelling viscosity, controllable degradation time, thorough degradation and the like, can plug the high-permeability zone and implement adjustable degradation time, and can lower the damage to the reservoir.

Owner:PETROCHINA CO LTD

Chemical modification technique for microfiltering separation film of polyvinylidene fluoride

InactiveCN1772359AChemical modification applicableImprove hydrophilicitySemi-permeable membranesPotassium persulfateFiber

The present invention is chemical modification technique for grafting radical with hydrophilic and ion exchange performance onto the surface of hollow fiber microfiltering film and plate microfiltering film of polyvinylidene fluoride. By using acrylic acid, PVA, acrylamide, methylene bis-acrylamide, potassium persulfate and other reagents as material and through chemical cross-linking polymerization reaction, carboxyl radical and hydroxyl radical are grafted onto the surface of the microfiltering film. The technique has the advantages of simple operation and high grafting efficiency, and can improve the hydrophilic performance of the microfiltering film and raise the treating capacity of the microfiltering film. The modified microfiltering film can eliminate the suspended matter, colloid matter and water soluble heavy metal ion in water simultaneously, and has raised drinking water purifying effect and expanded application field of microfiltering film of polyvinylidene fluoride.

Owner:YANSHAN UNIV

Method for prepaing granular profile control agent in copolymerization crosslinking type

This invention describes a process for preparing a new copolymerized and cross-linked granular profile control agent. The process uses two organic monomers, acrylamide and acrylic acid, as the major raw materials, bentonite or montmorillonite as the reinforcing agent, ammonium persulfate or potassium persulfate as the initiator, potassium metabisulfite as the reductant, and N,Ní»-methylene diacrylamide as the cross-linker to synthesize the granular profile control agent. Since the process uses bentonite or montmorillonite as the reinforcing agent, and ammonium persulfate or potassium persulfate / potassium metabisulfite as the oxidation-reduction system, ití»s easy to operate and the PH value is adjustable.

Owner:李松棠

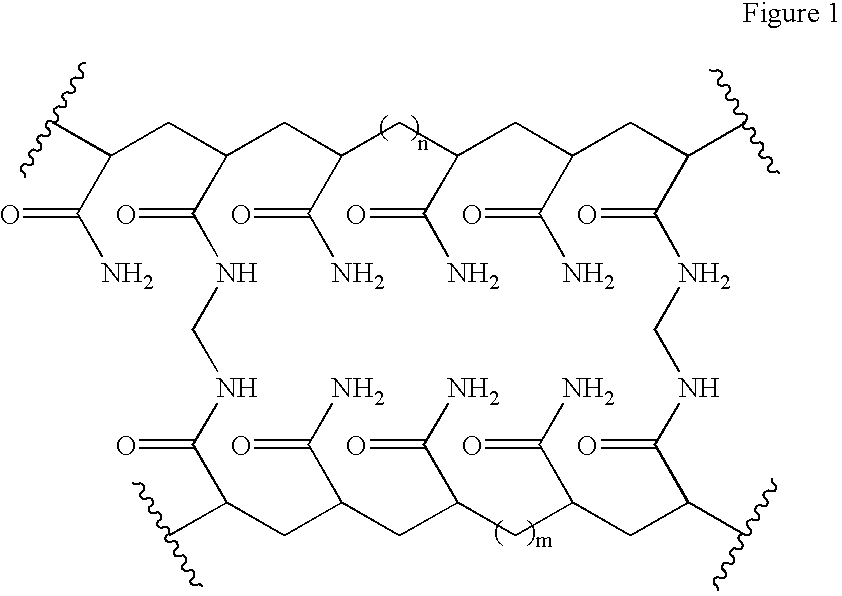

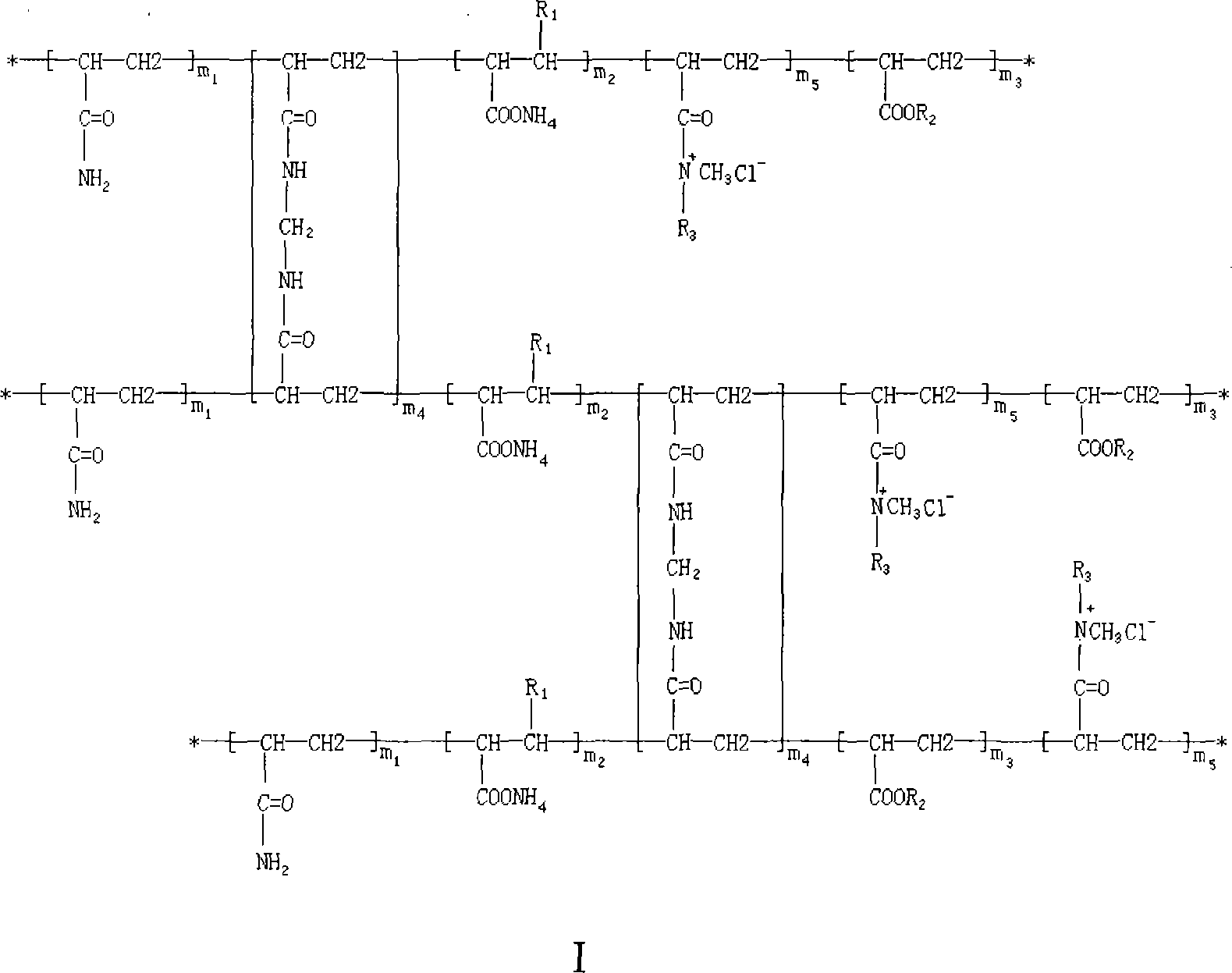

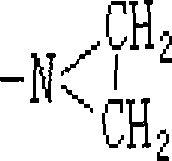

Method for preparing amphiprotic polyacrylamide oil field compression fracture thickening agent

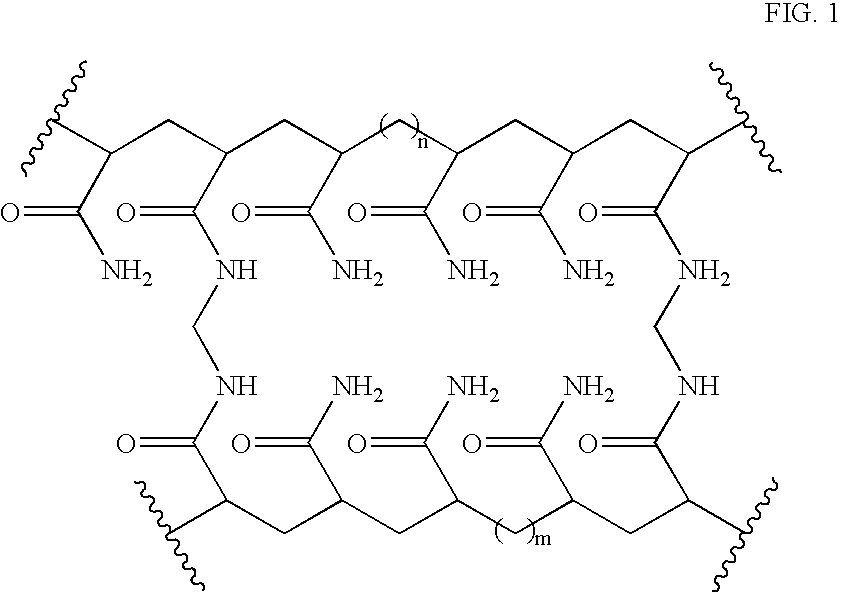

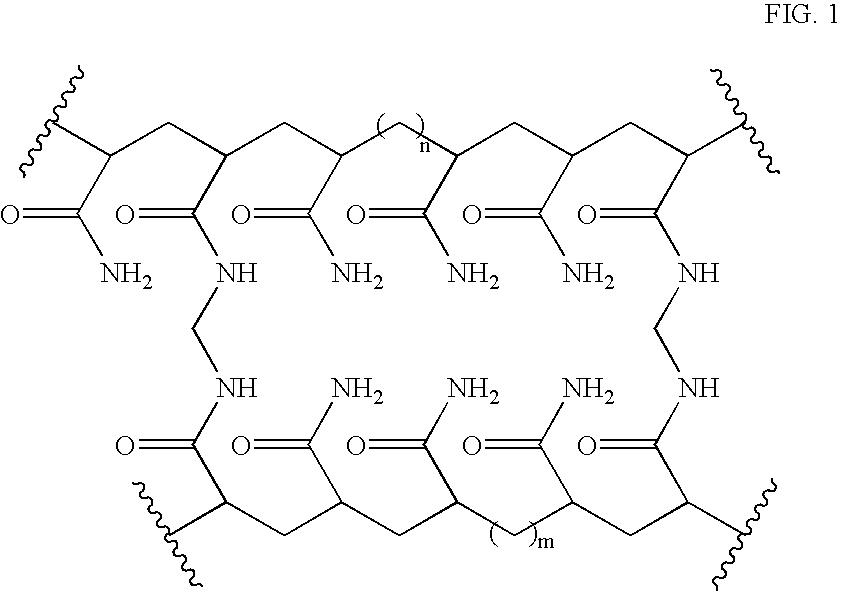

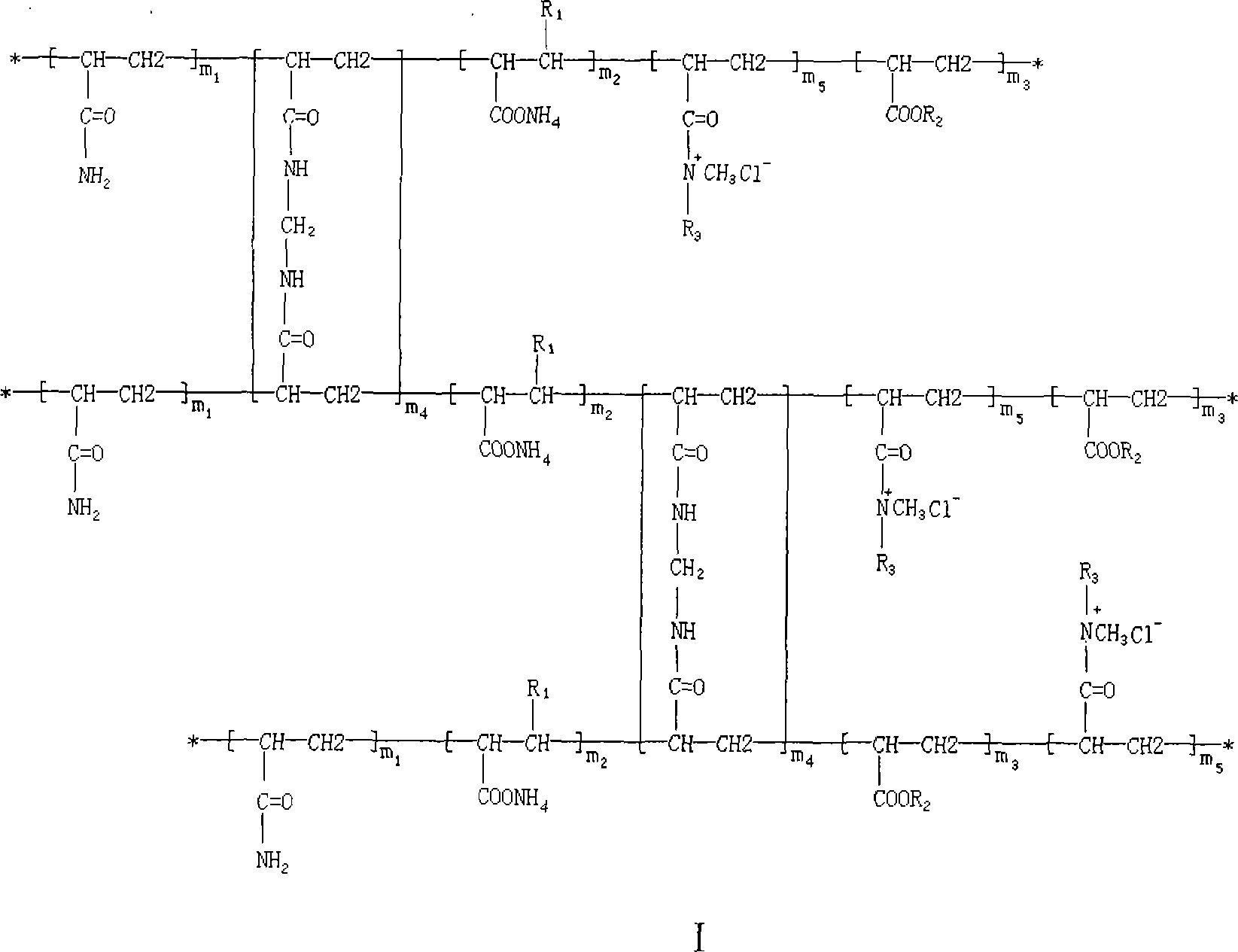

InactiveCN101235283AExcellent thickening and viscosifying efficiencyAggregation is controllableDrilling compositionCross-linkStructural formula

An amphiprotic polyacrylamide oil field fracturing gelatinizer and a preparation process are disclosed. The gelatinizer has the structural formula which is showed by I, wherein R1 is H or CH3, R2 is C1-C4 alkyl, R3 is C2-C14 alkyl, m1, m2 and m5 are integers from 2 to 10, m3 is an integer from 0 to 100, and m4 is the integer from 0 to 1. The preparation process comprises using the compound of dehydration sorbic alcohol fatty acid ester, nonyl phenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether non-ionic emulsifier as emulsifier, using acrylamide, acroleic acid or methacrylic acid, methyl alkyl pi-allyl ammonium chloride, N, N -methylene bisacrylamide as monomer, obtaining even and stable invert emulsion through conducting invert emulsion system polymerization reaction for water, oil, alcohol, amine sulphurate and ethanedioic acid hexamethylene diamine, and conducting cross-linking through utilizing Cr3+, Zr4+ and Ti4+, -CHO, or the structural formula II as cross linking agent to obtain gelatinizer gel.

Owner:HUBEI UNIV

Oilwell cement filtrate loss reduction additive

The invention provides a filtration-reducing agent for oil well cement, which is used in well drilling and well cementing processes of petroleum and natural gas to reduce filtration of cementing paste. The filtration-reducing agent is a penta-copolymer, and a copolymerized monometer is 2-acrylamide-2-methyl propane sulfonic acid (AMPS), N, N'-dimethyl acrylamide (DMAA), unsaturated monocarboxylic acid, unsaturated dicarboxylic acid, and N, N'-methane biacrylamide (MBA). The filtration-reducing agent has favorable filtration reducing performance and rheological performance, and wide applicable temperature range, and is suitable for fresh-water and salt-water cementing paste.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

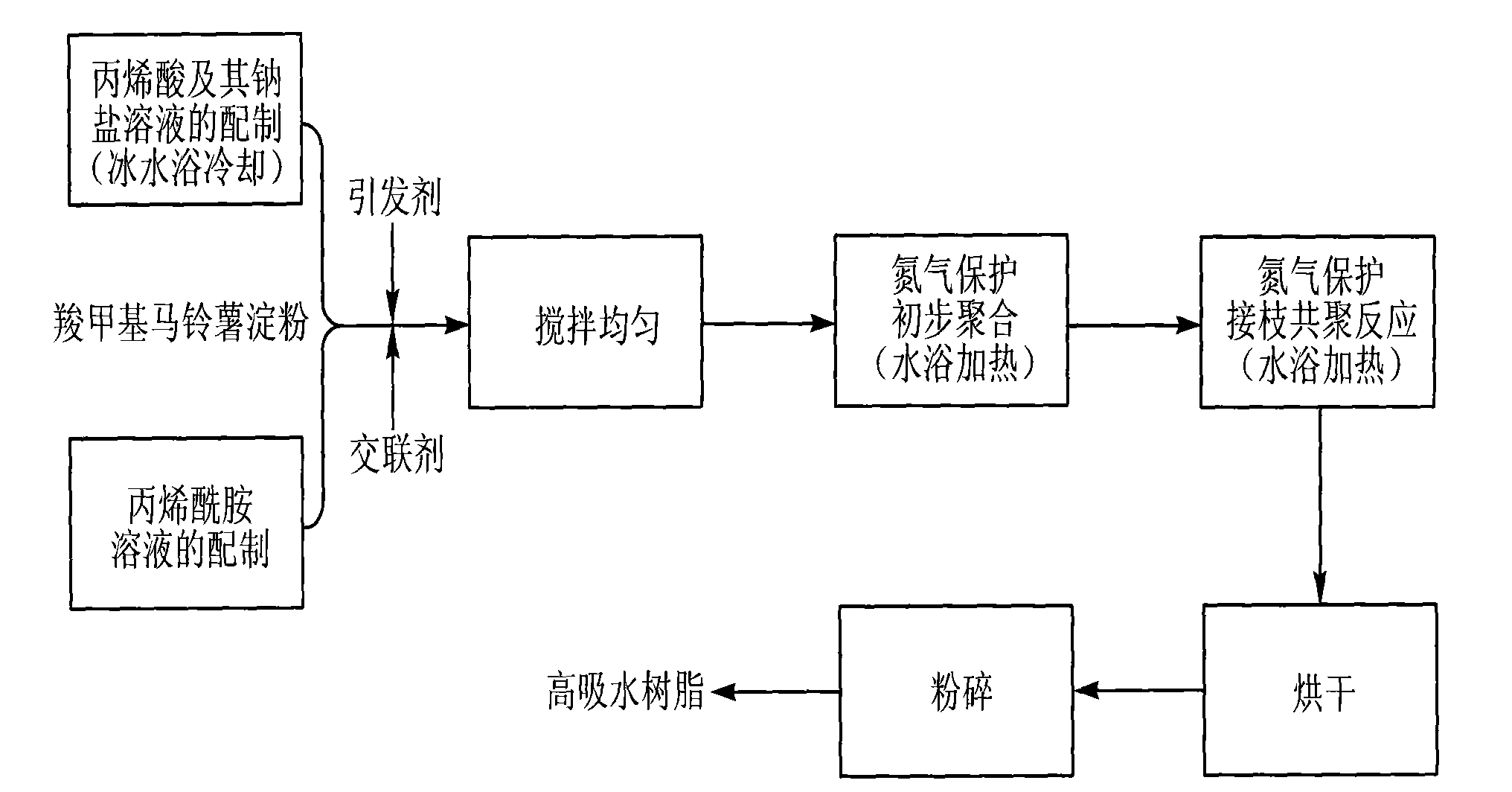

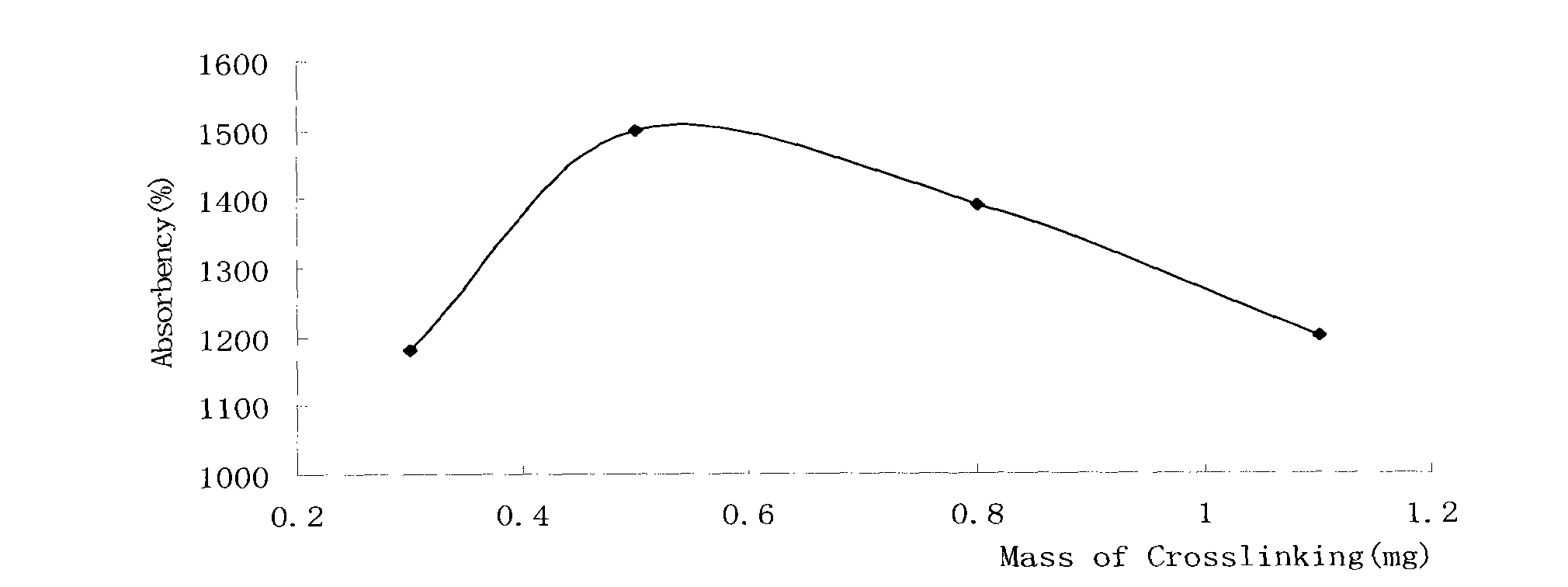

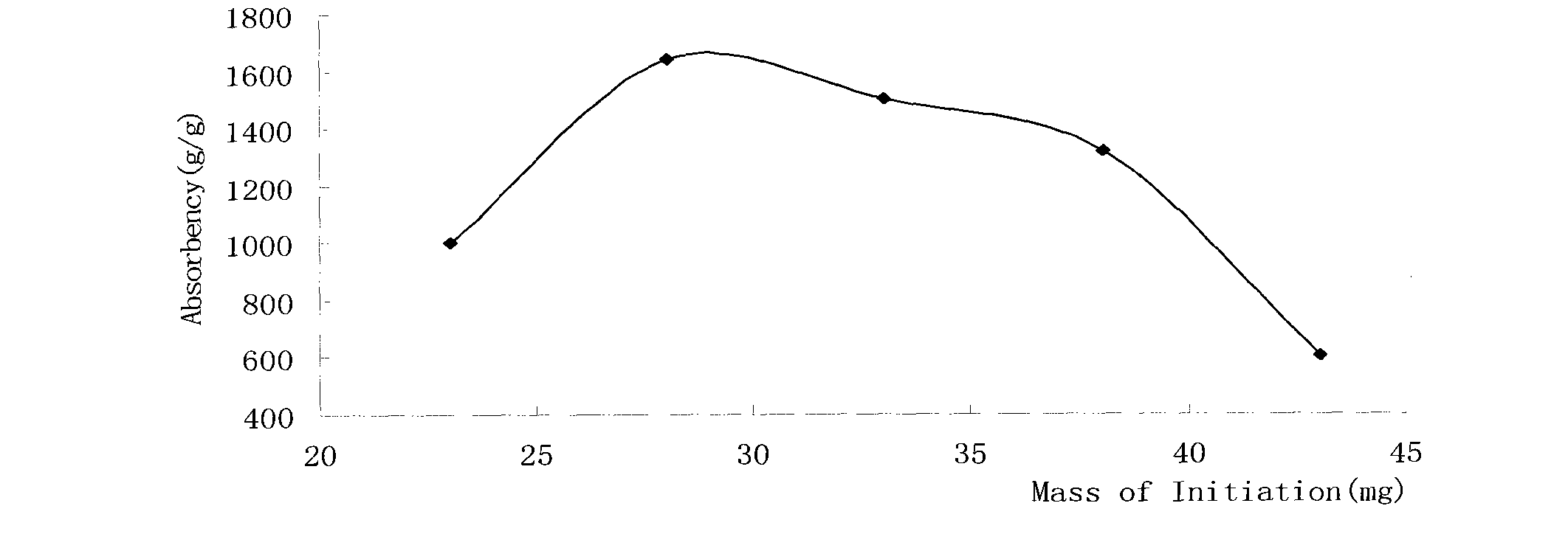

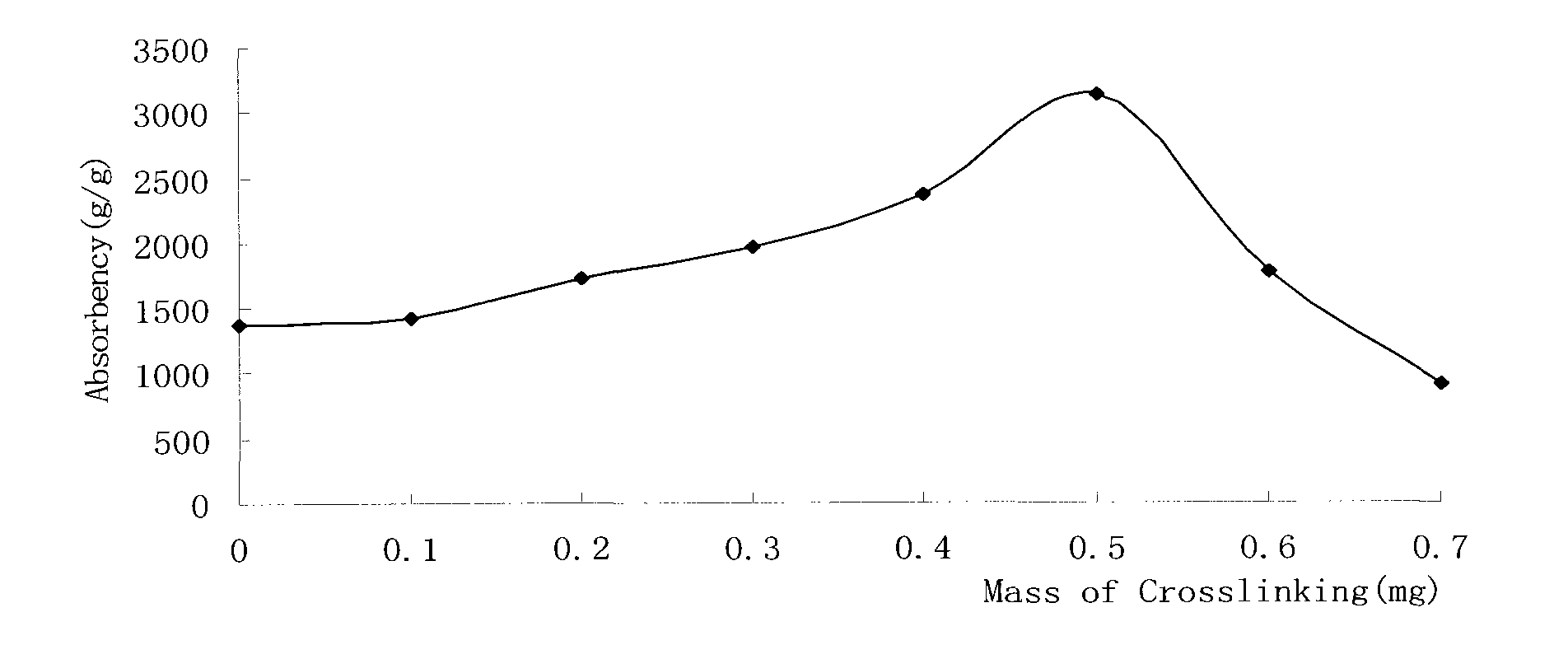

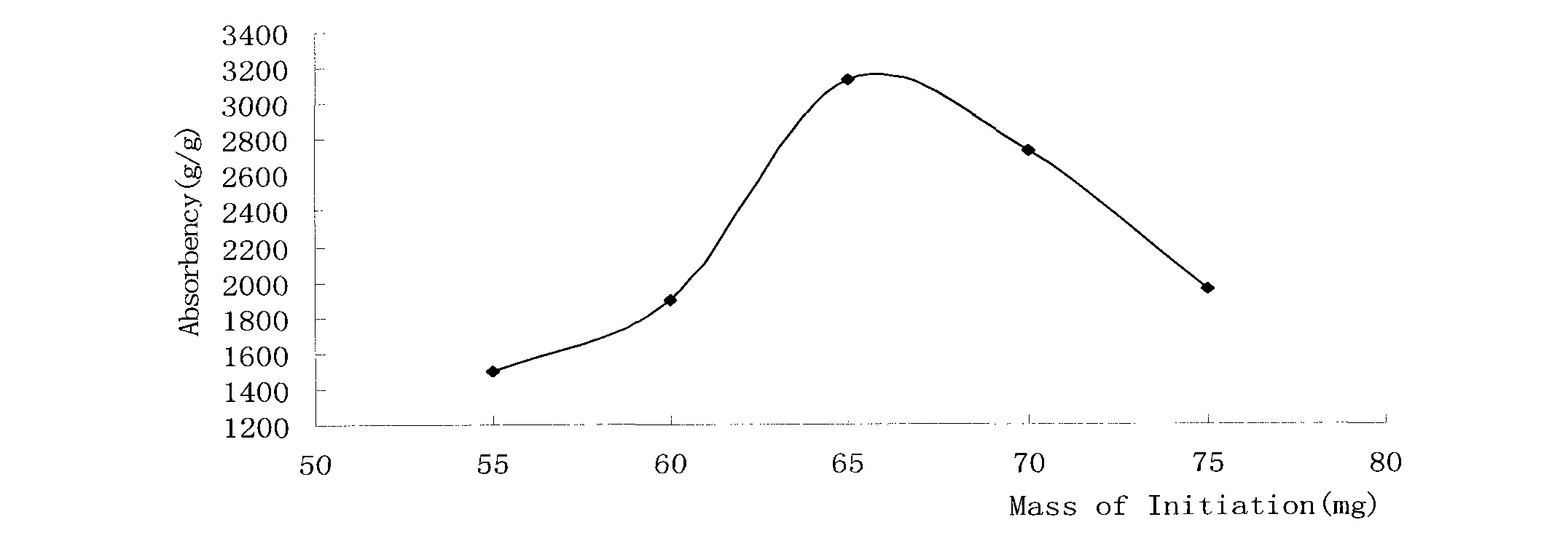

Method for preparing super absorbent resin by graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof

The invention discloses a method for preparing super absorbent resin by the graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof, which comprises the following main processes: carrying out neutralization reaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing acrylamide with de-ionized water to obtain an acrylamide solution; mixing the carboxymethyl potato starch with the prepared acrylic acid and the sodium salt solution and the acrylamide solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature so as to ensure that the carboxymethyl potato starch, the acrylic acid and the sodium salt thereof and the acrylamide generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin with high potassium content by using carboxymethyl potato starch as the raw material. Compared with the similar products, the water absorption of the super absorbent resin is greatly enhanced; the super absorbent resin contains nitrogen nutrition element, does not need pasting in comparison with theprocess of directly using starch and greatly improves the preparation process. The super absorbent resin has great effect on the water conservation, the desert control, the plant growth promotion andthe like of soil in dry regions.

Owner:内蒙古永业生物技术有限责任公司

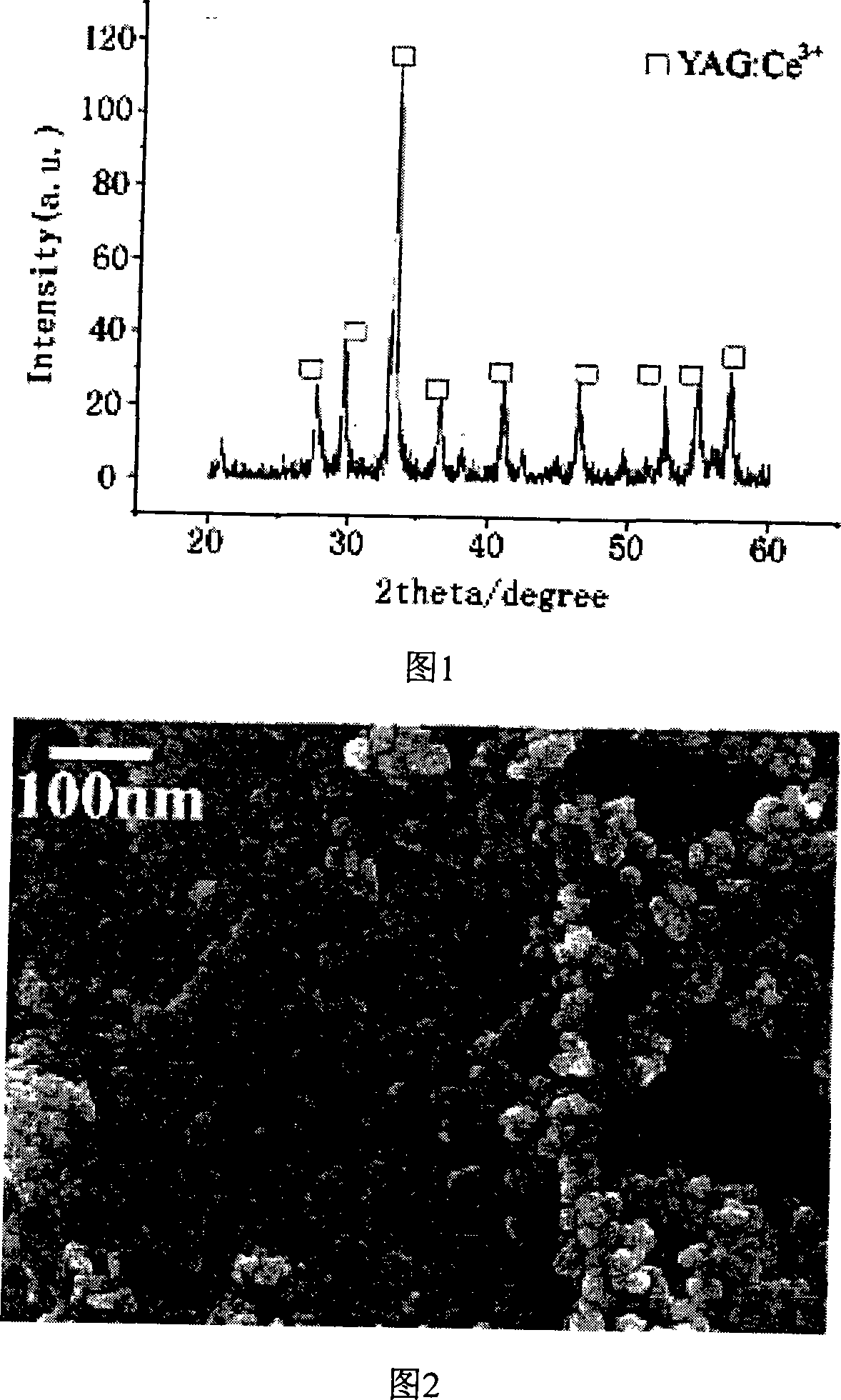

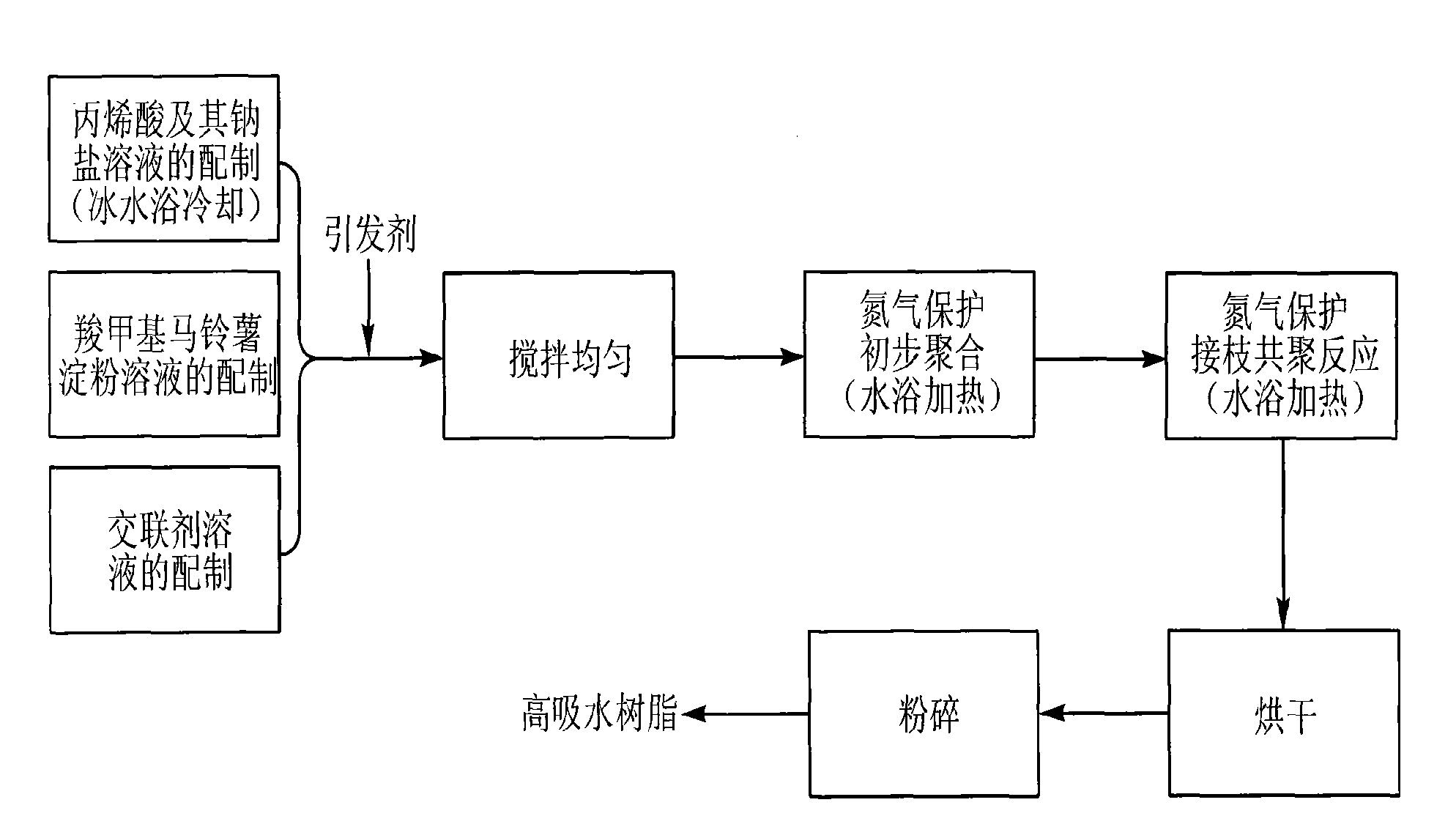

Method for preparing YAG nano powder

InactiveCN101249978ASimple requirementsWell mixedRare earth metal compoundsPolymer sciencePolymer network

Disclosed is a process for preparing YAG nano-powder, which belongs to the inorganic materials and the preparation field. The invention utilizes acrylamide as monomer, employs N, N'-methylene diacrylamide as polymer network agent, utilizes Al(NO3)3Y(NO3)3, Ce(NO3)3*6H2O as raw materials, employs citric acid as regulator, and uses a polymer network gel method and an active carbon adsorption process to prepare the nano-powder of Y3Al5O12(YAG):Ce3+. The method is characterized in that requirements to raw materials are simple and inorganic saline solution can be utilized as the raw materials, the component of the obtained micro powder is mixed evenly, most importantly, the polymer network formed in the gel process and the active carbon decomposed under nitriding atmosphere reduce the contact opportunity of precursor grains, thereby agglomeration is reduced, the nano-powder which is small in grain size and uniform in dispersion can be obtained, thereby largely reducing preparation temperature of materials, and calcination temperature is only 800 DEG C.

Owner:SHANGHAI INST OF TECH

Method for preparing super absorbent resin by using carboxymethyl potato starch as raw material

The invention discloses a method for preparing super absorbent resin by using carboxymethyl potato starch as the raw material, which comprises the following main processes: carrying out neutralizationreaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing carboxymethyl potato starch with de-ionized water; mixing the prepared acrylic acid and the sodium salt solution thereof with the carboxymethyl potato starch solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature gradually so as to ensure that the carboxymethyl potato starch and the acrylic acid and the sodium salt thereof generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin by using carboxymethyl potato starch as the raw material. Compared with similar products, the water absorption of the super absorbent resin is greatly enhanced, the process of pasting is omitted incomparison with the process of using starch as the raw material and the preparation process is greatly improved. The super absorbent resin has great effect on the water conservation, the production of the physical hygiene sundries, the environmental improvement, the desert control, the plant growth promotion and the like of soil in dry regions.

Owner:广西珅信科技有限公司

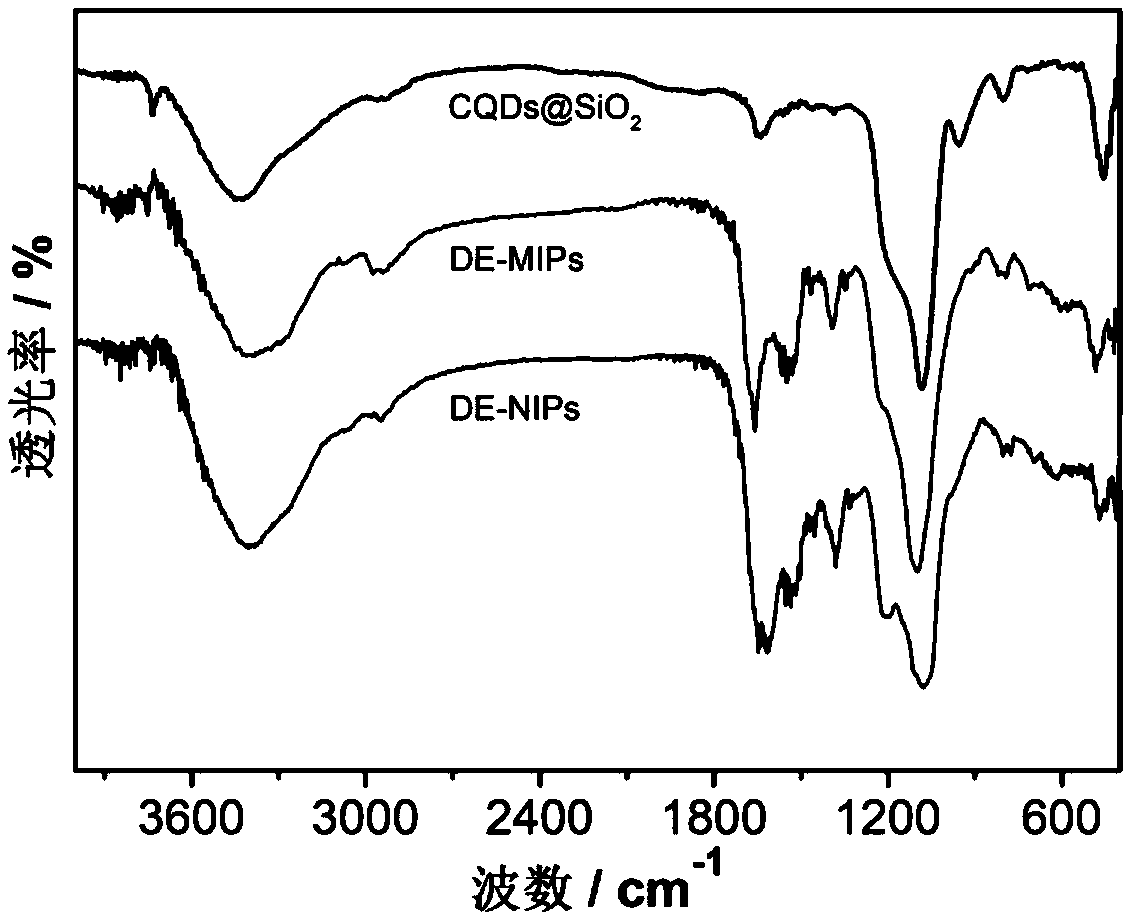

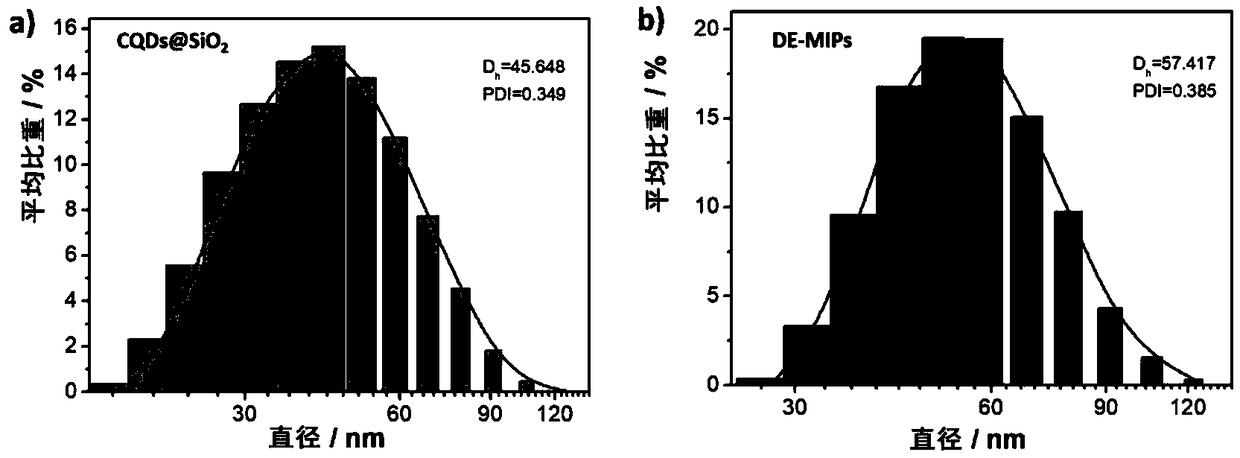

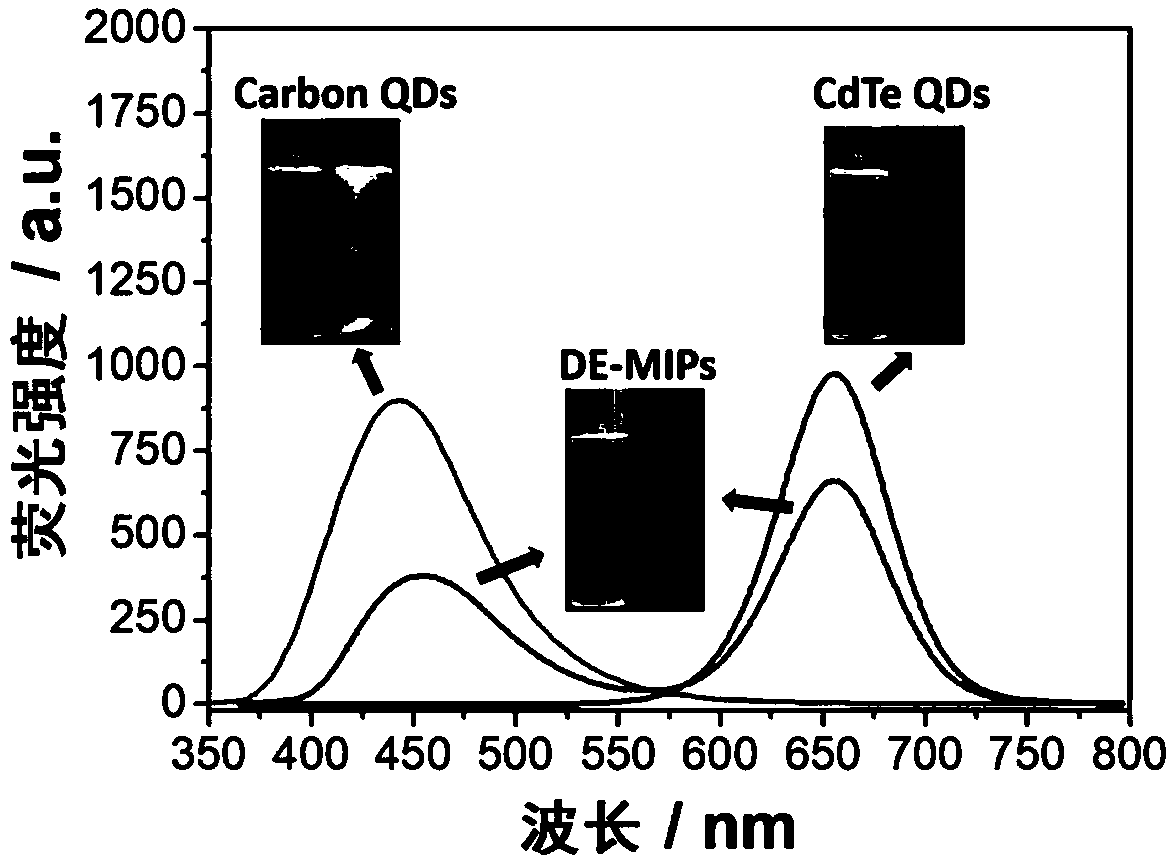

Dual-emission fluorescent molecularly imprinted polymer nanoparticles and preparation method and application thereof

ActiveCN109370565AHigh selectivityAvoid interferenceMaterial nanotechnologyFluorescence/phosphorescenceCadmium CationSilicon dioxide

The invention relates to the technical field of preparation of bio-functional materials, in particular to dual-emission fluorescent molecularly imprinted polymer nanoparticles and a preparation methodand application thereof. carbon quantum dots are coated with silica nanospheres to form a core of a ratio fluorescence probe; red cadmium telluride quantum dots are used as response signals, acrylamide and 4-vinylbenzeneboronic acid are used as bifunctional monomers, N,N-methylene bisacrylamide is used as a crosslinker, dopamine is used as templating molecules, dual-emission fluorescent molecularly imprinted polymer nanoparticles having specific recognition sites for dopamine are synthesized in an alcohol phase under initiating of azodiisobutyronitrile, and fluorescent detection test paper with visualizing effect is prepared then by means of impregnating so as to provide visual detection for DA (dopamine); the fluorescent detection test paper is applied to the detection of DA in a human serum sample, and the results prove that the fluorescent detection test paper prepared herein is suitable for half-quantitative detection of DA in actual complex samples.

Owner:JIANGSU UNIV

Soil water-holding agent and preparation method thereof

InactiveCN101550326AIncrease production capacitySimple production processOther chemical processesNitrogen atmosphereNitrogen

The invention relates to a farmland soil water-holding agent, in particular to a soil water-holding agent and a preparation method thereof. The soil water-holding agent is prepared by the following solutions according to the parts by weight: 100-150 of modified corn straw solution, 100-300 of sodium polyacrylate solution, 5-20 of ammonium persulfate solution and 1-12 of N, N '-methylenebisacrylamide solution. The preparation method comprises the following steps: the modified corn straw solution, the sodium polyacrylate solution and the N, N '-methylenebisacrylamide solution are mixed according to a certain proportion, evenly blended and added with the 5-20 parts of the ammonium persulfate solution after a period of time and then react for a period of time under the protection of nitrogen atmosphere at the temperature of 50-90 DEG C to obtain transparent colloid; and the colloid is dried, crushed and sieved to obtain yellow brown soil water-holding agent solid particles. The soil water-holding agent has good hydroscopicity and mechanical property, low price and better application prospect.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

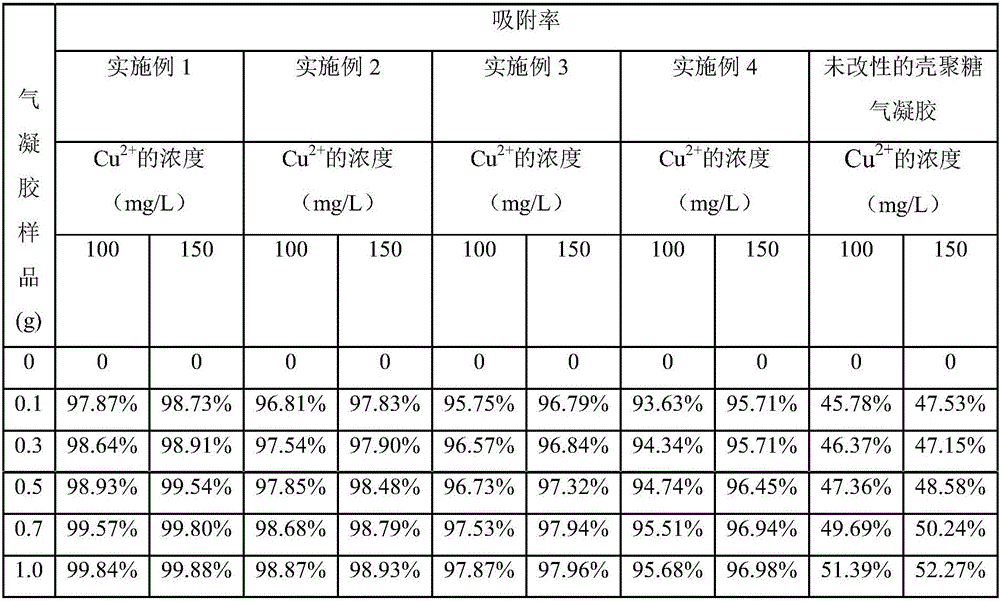

Modified chitosan/nanocellulose composite aerogel and preparation method and application thereof

InactiveCN106243282AImprove adsorption capacityPromote sustainable developmentOther chemical processesWater contaminantsFreeze-dryingPotassium peroxodisulfate

The invention belongs to the technical field of high polymer materials and specifically discloses modified chitosan / nanocellulose composite aerogel and a preparation method and application thereof. The preparation method comprises the following steps: letting pretreated chitosan react with a hydrochloric acid solution, adding dithiobispropionate, and reacting to prepare modified chitosan; dissolving modified chitosan with an acetic acid solution, adding nanocellulose and fully reacting; adding potassium peroxodisulfate and uniformly mixing; adding acrylic acid and NaOH solution and fully dissolving; adding a N,N'-methylene bisacrylamide solution to prepare modified chitosan / nanocellulose composite aerogel, and freeze-drying to obtain the aerogel product. The prepared modified chitosan / nanocellulose composite aerogel has efficiency and enhanced adsorptive property, and has a remarkable effect of adsorbing heavy metal Cu<2+> with low concentration. Meanwhile, the preparation technology is simple and has strong operability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com