Inverse emulsion polymer thickener for fracturing fluid and preparation method thereof

An inverse emulsion and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inconvenient use, poor temperature resistance, slow dispersion speed, etc., and achieve fast dispersion speed and high speed. Sand-carrying, easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

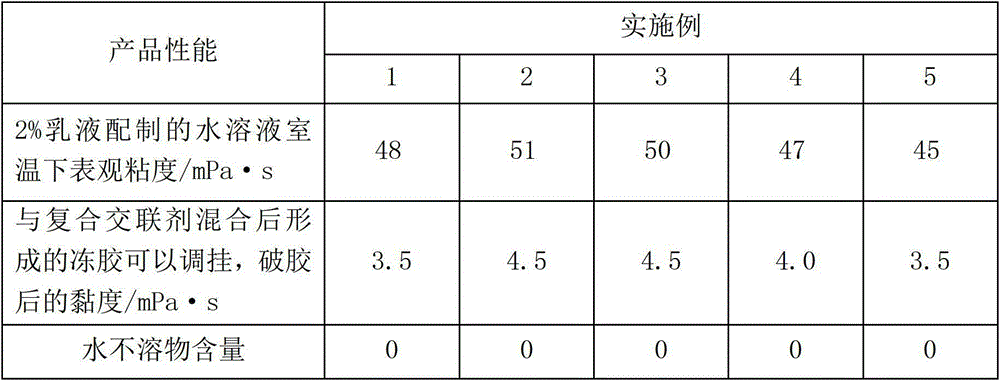

Examples

Embodiment 1

[0024] Add 130kg of water to the reaction kettle, start stirring and add mass fraction 120kg50% 2-acrylamido-2-methylpropanesulfonate sodium solution, 5kg N,N-dimethylacrylamide, 40kg acrylamide, 5kg methacrylic acid Acyloxyethyltrimethylammonium chloride, 0.0075kg N, N-methylenebisacrylamide, 2kg Tween-80 emulsifier, 0.015kg ethylenediaminetetraacetic acid disodium salt, stirred until completely dissolved, and then used 30% sodium hydroxide adjusted the pH of the system to be 7.5 to obtain the water phase; add 155kg of white oil, 3kg of isooctyl acrylate and 10kg of Span-80 emulsifier in the reactor, and stir until fully dissolved to obtain the oil phase; Slowly add the water phase to the oil phase, stir for 30 minutes, and emulsify at high speed for 20 minutes to obtain a monomer compound emulsion; put the above emulsion into the reaction kettle, turn on the mixer, raise the temperature to 50°C, and pass nitrogen for 15 to 30 minutes. Add 0.05kg sodium bisulfite, 0.1kg potas...

Embodiment 2

[0026] Add 145kg of water to the reaction kettle, start stirring and add 30kg of 50% 2-acrylamido-2-methylpropanesulfonate sodium solution, 10kg of N,N-dimethylacrylamide, 75kg of acrylamide, and 15kg of methacrylamide Acyloxyethyltrimethylammonium chloride, 0.001kg N, N-methylenebisacrylamide, 6kg Tween-80 emulsifier, 0.005kg ethylenediaminetetraacetic acid disodium salt, stirred until completely dissolved, and then used 30% sodium hydroxide regulates the pH of the system to be 9 to obtain the water phase; add 115kg of white oil and 0.5kg of stearyl acrylate and 15kg of Span-80 emulsifier in the reactor, stir until fully dissolved to obtain the oil phase; Slowly add the water phase into the oil phase under certain conditions, stir for 30 minutes, and emulsify at high speed for 20 minutes to obtain a monomer compound emulsion. Put the above emulsion into the reaction kettle, turn on the mixer, raise the temperature to 35°C, pass nitrogen for 15-30 minutes, then add 0.15kg sodi...

Embodiment 3

[0028] Add 145kg of water to the reaction kettle, start stirring and add mass fraction 60kg50% 2-acrylamido-2-methylpropanesulfonate sodium solution, 15kg N,N-dimethylacrylamide, 75kg acrylamide, 10kg methacrylamide Acyloxyethyltrimethylammonium chloride, 0.005kg N, N-methylenebisacrylamide, 3.5kg Tween-80 emulsifier, 0.01kg ethylenediaminetetraacetic acid disodium salt, stirred until completely dissolved, then Regulate the system pH with 30% sodium hydroxide to be 9 to obtain the water phase; add 125kg white oil, 0.75kg cetyl acrylate and 14kg Span-80 emulsifier in the reactor, stir until fully dissolved to obtain the oil phase; Slowly add the water phase to the oil phase under stirring conditions, stir for 30 minutes, and emulsify at high speed for 20 minutes to obtain a monomer compound emulsion; put the above emulsion into the reaction kettle, turn on the mixer, heat up to 40°C, and pass nitrogen for 15-30 Minutes, add 0.1kg sodium thiosulfate, 0.12kg ammonium persulfate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com