Patents

Literature

2176 results about "Sodium thiosulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium thiosulfate (sodium thiosulphate) is an inorganic compound with the formula Na₂S₂O₃·xH₂O. Typically it is available as the white or colorless pentahydrate, Na₂S₂O₃·5H₂O. The solid is an efflorescent (loses water readily) crystalline substance that dissolves well in water. It is also often called sodium hyposulfite or hypo.

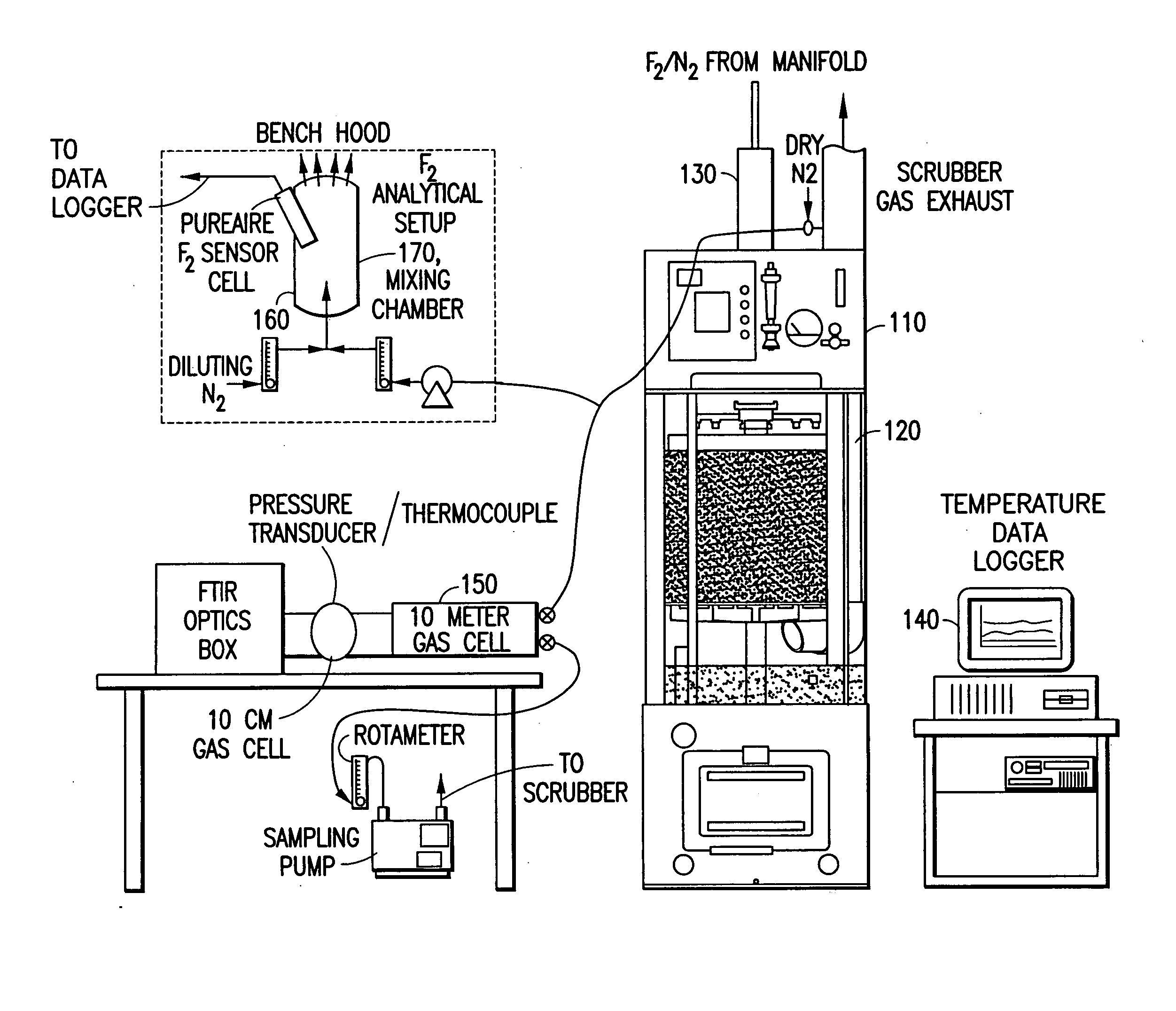

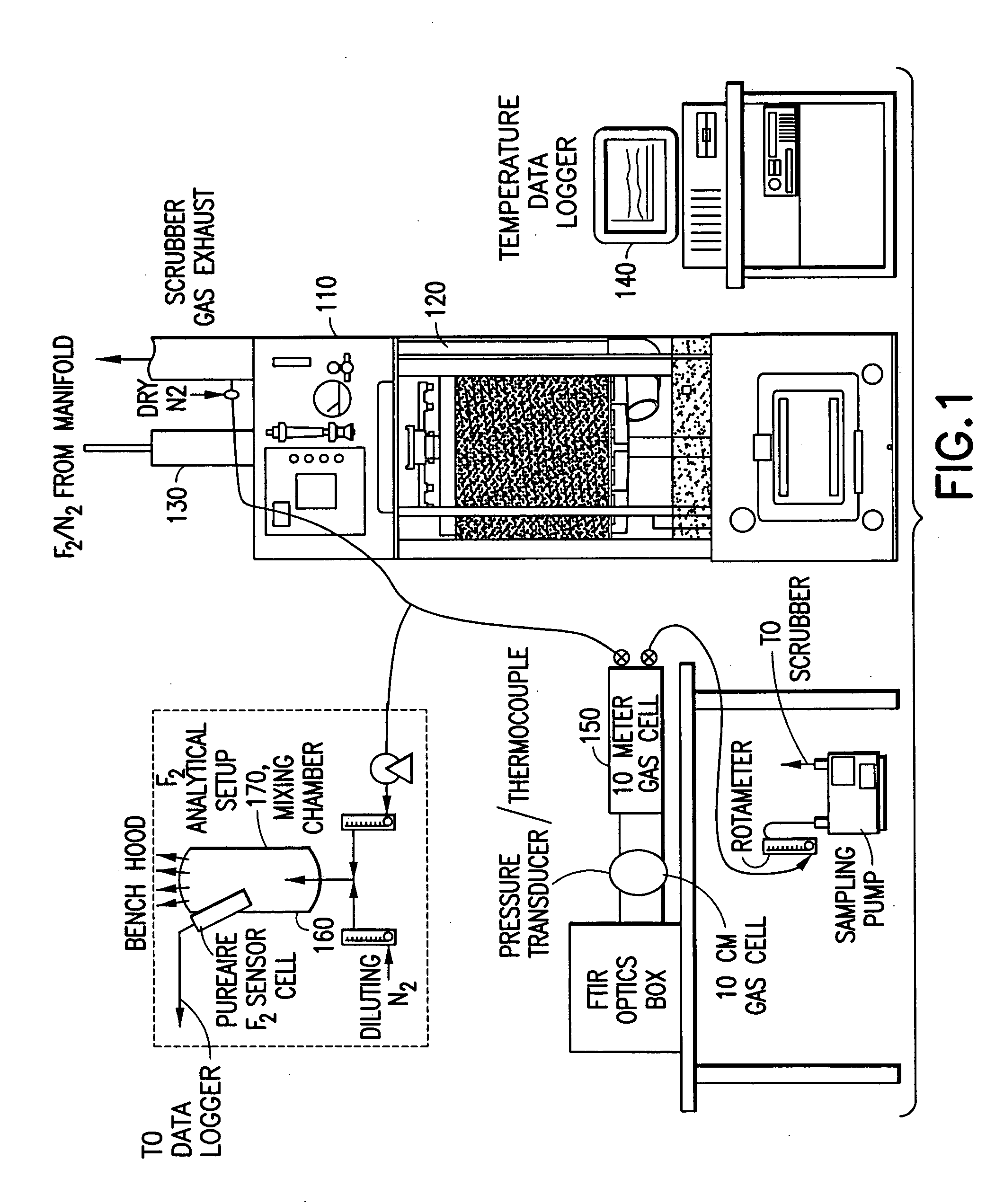

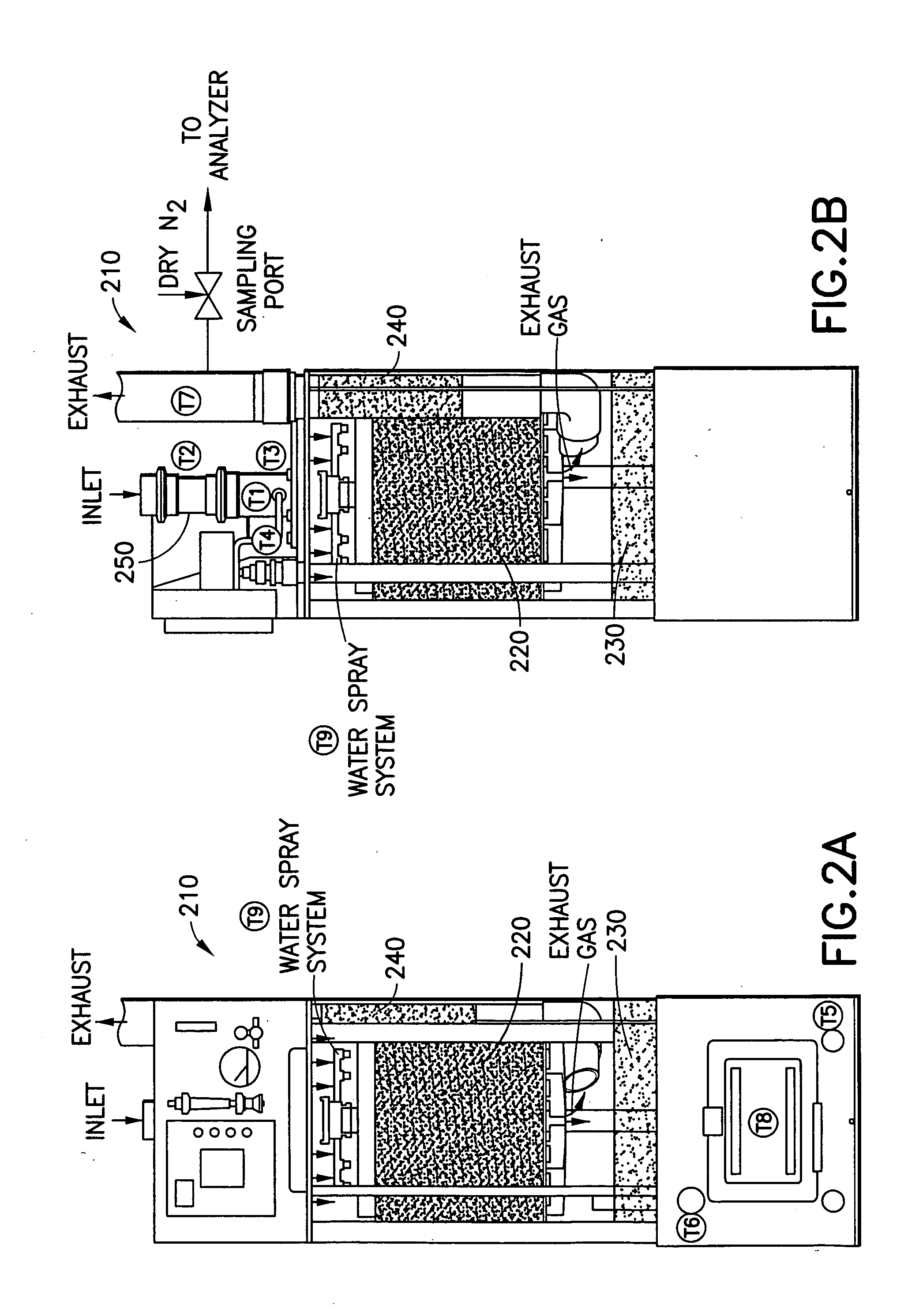

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

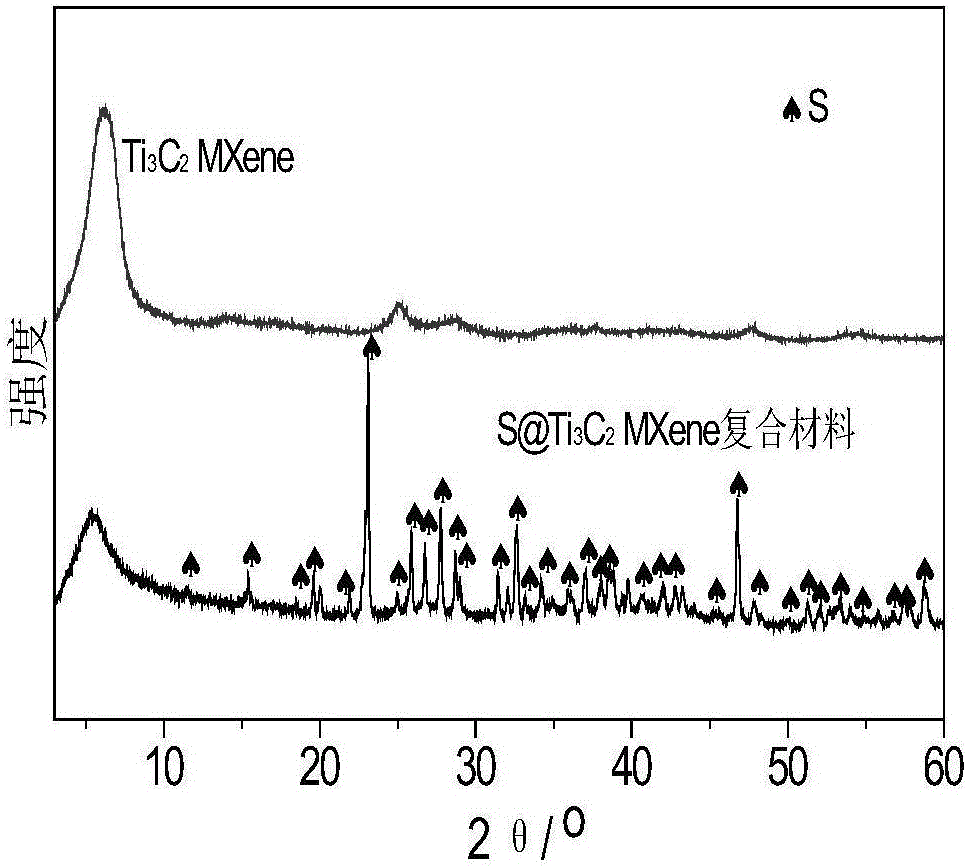

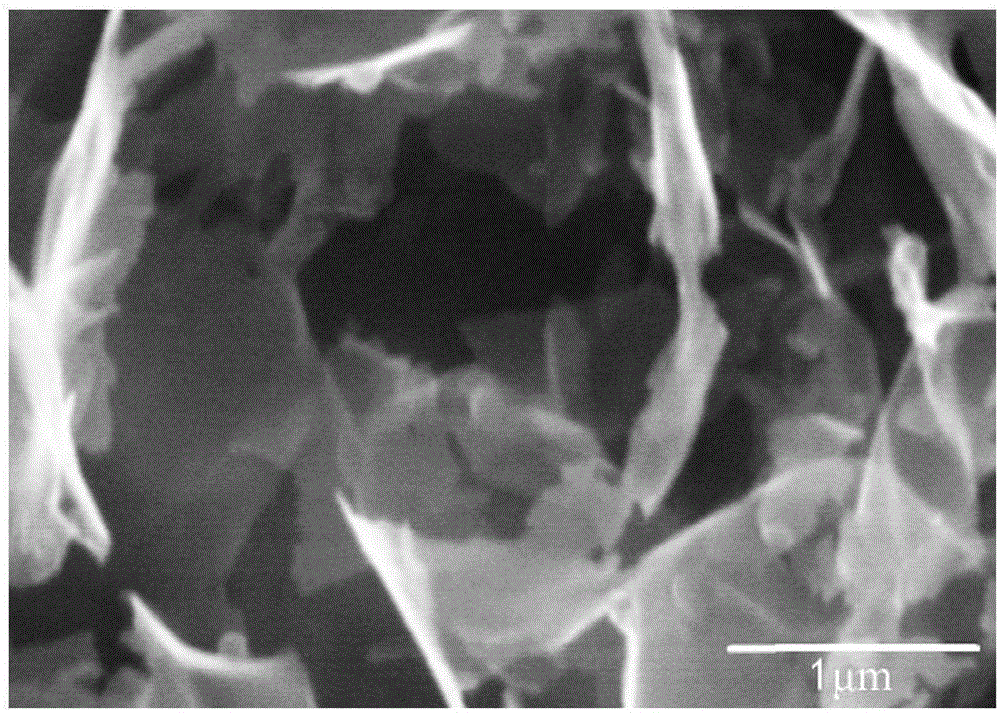

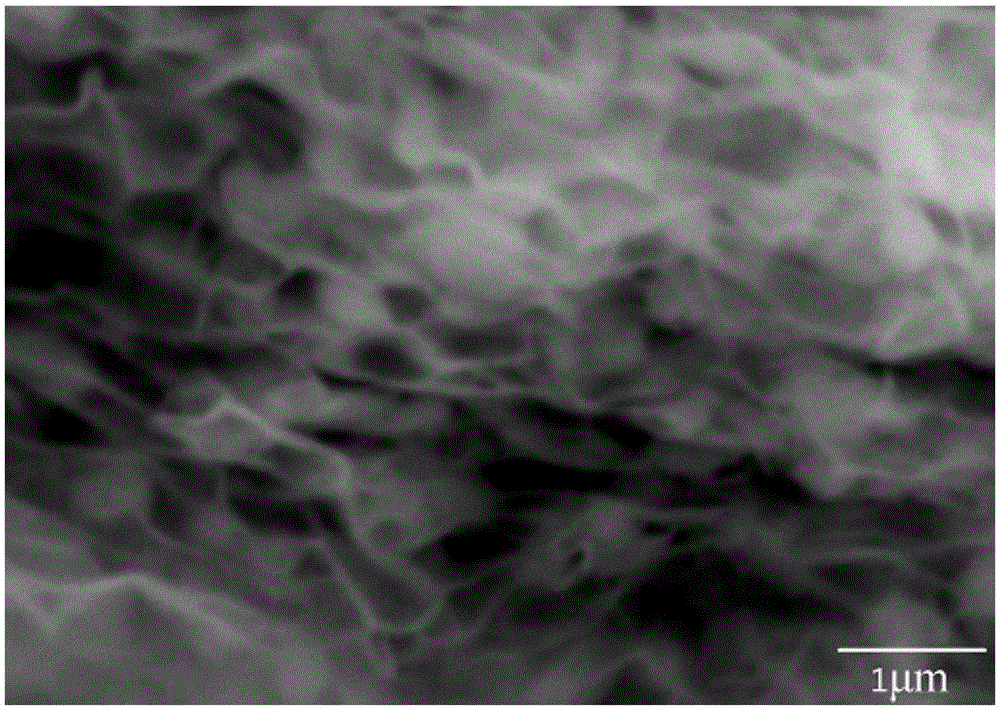

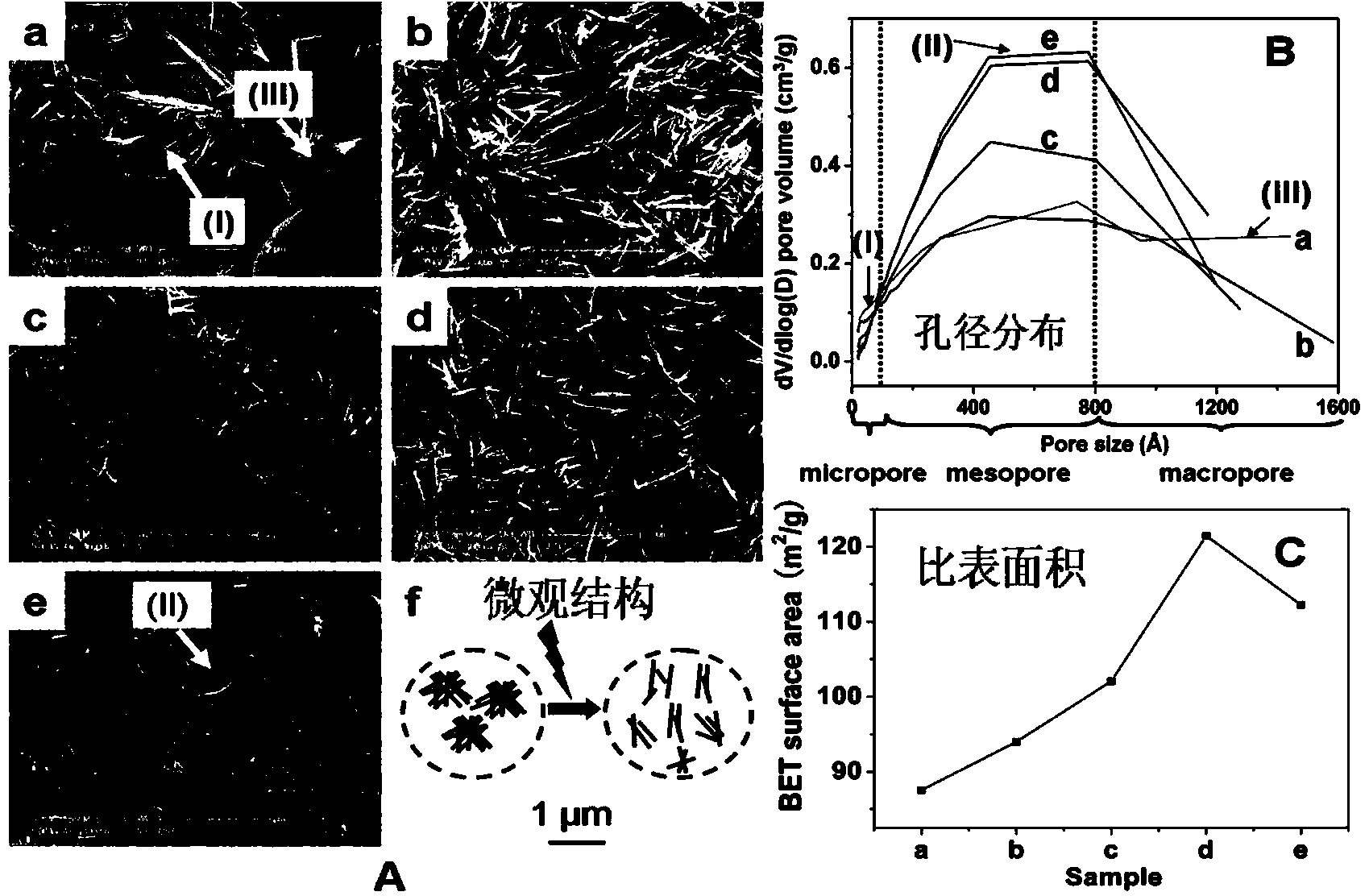

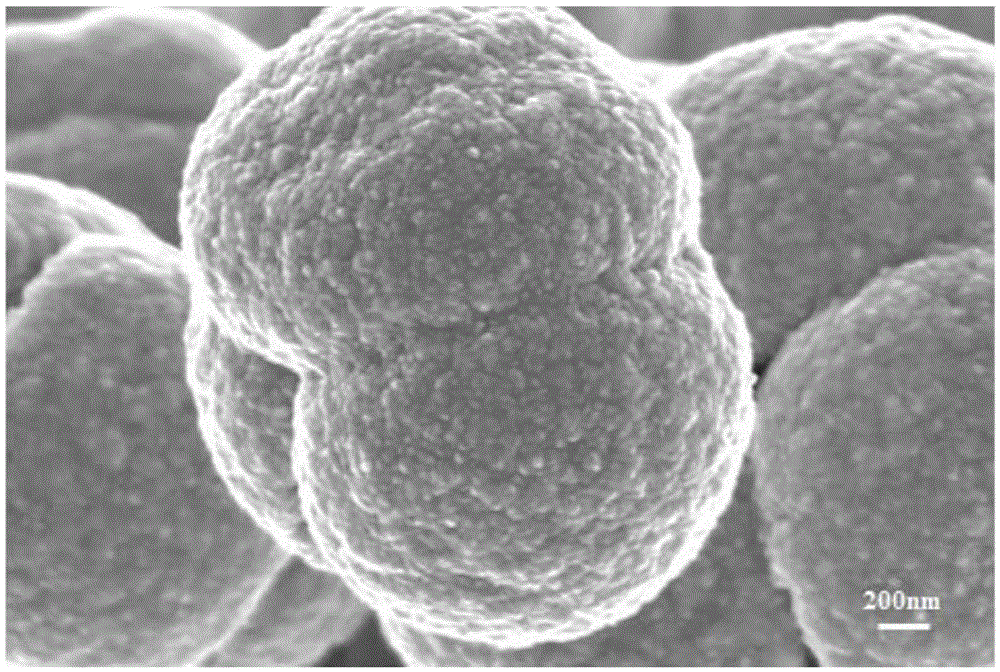

Two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof

ActiveCN106450205AGive full play to the sulfur fixation effectEvenly dispersedMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSodium polysulfideReducing agent

The invention relates to a two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof. The composite is formed by two-dimensional transition metal carbide (nitride) MXene nanosheets and nano sulfur particles, wherein the nano sulfur particles grow on the surface of the two-dimensional transition metal carbide (nitride) MXene nanosheets in an in-situ manner, marked as S@MXene. The stable suspension of a single layer or a few layers of two-dimensional transition metal carbide (nitride) MXene nanosheets is mixed with a sodium thiosulfate or sodium polysulfide solution; with formic acid as a reducing agent, the nano sulfur generated by the reaction uniformly grows on the surface of the two-dimensional MXene nanosheet; and the two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite is obtained through neutralization, washing and centrifugation and serves as the anode of a lithium-sulfur battery. According to the invention, a high-conductivity two-dimensional transition metal carbide (nitride) MXene nanosheet carrier is uniformly compounded with nano sulfur particles, introduction of a binder and a conductive agent is not needed, and the composite has excellent electrochemical performance as the anode of a lithium-sulfur battery; and moreover, the technology is simple and can meet the requirements of large-scale production.

Owner:NANJING TECH UNIV

Functional fertilizer and repair agents for repairing soil heavy metal

ActiveCN103788960AReduce the content of high-priced heavy metal ionsLow ion contentAgriculture tools and machinesOrganic fertilisersSolubilitySoil heavy metals

The invention discloses functional fertilizer and repair agents for repairing soil heavy metal. Modified attapulgite, chitosan, biochar and sodium thiosulfate are compounded, and on one hand, the absorption performance of the attapulgite and the biochar and the chelation of the chitosan are used for fixing heavy metal ions in soil and preventing the heavy metal ions in the soil from migrating through leaching and runoff. On the other hand, the sodium thiosulfate is used for restoring the high-valence-state heavy metal ions (like hexavalent chromium ions) to low-valence-state ions (like trivalent chromic ions), and therefore virulence and solubleness of the ions are reduced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Materials and methods for treatment of gastrointestinal disorders

InactiveUS7312243B1Reduced activityIncrease incidenceBiocideHeavy metal active ingredientsColonic epitheliumUlcerative colitis

The subject invention pertains to materials and methods for the prevention and treatment of gastrointestinal diseases, including inflammatory bowel diseases such as Crohn's disease and ulcerative colitis. Therapeutic compositions of the invention include compositions that can neutralize hydrogen peroxide, such as reducing agents and oxidizing agents. In one embodiment, a therapeutic composition of the invention comprises a reducing agent such as sodium thiosulfate. Therapeutic compositions of the invention can optionally include compounds with antibacterial activity, compositions that inhibit bacterial adherence to cells and tissue, compositions that inhibits epithelial lipid peroxidation, compositions that add viscosity to a solution, compositions that inhibit most cells, and / or compositions that help to seal or repair tight junctions between cells of the colonic epithelium of the gastrointestinal tract. Methods of the invention include administration of compounds or compositions of the invention. In one embodiment, compounds or compositions of the invention are rectally instilled in a patient.

Owner:THERAPEUTIC RES

Vaccine stabilizer method

InactiveUS20050186221A1Adjust qualityBacterial antigen ingredientsViral antigen ingredientsSodium thiosulfateDomestic animal

A method of treating livestock with a vaccine includes mixing a reducing agent, such as sodium thiosulfate, with water, which may include oxidizing water sanitizers, mixing the vaccine with the water after the reducing agent has neutralized the water sanitizers, and treating the livestock with the vaccine and water mixture. The method may include adding a buffer to the water along with the reducing agent to adjust the pH, and adding a coloring agent to the water to aid in identifying livestock that has been treated with the vaccine. The vaccine may be administered to the livestock in different ways, such as by including it in drinking water or by spraying the livestock with the vaccine and water mixture.

Owner:REYNOLDS BAILEY +1

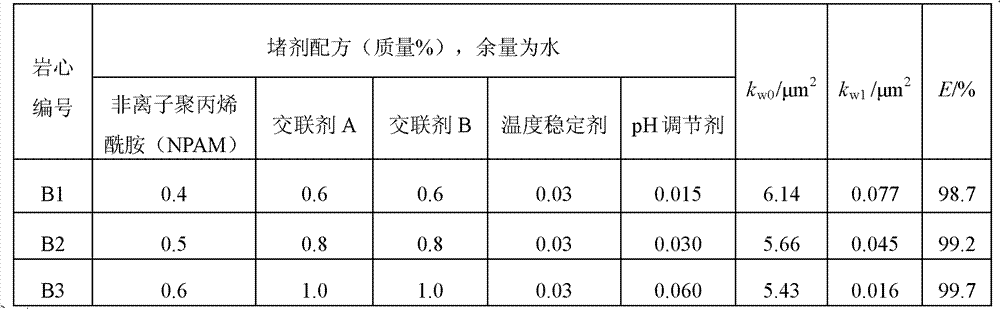

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

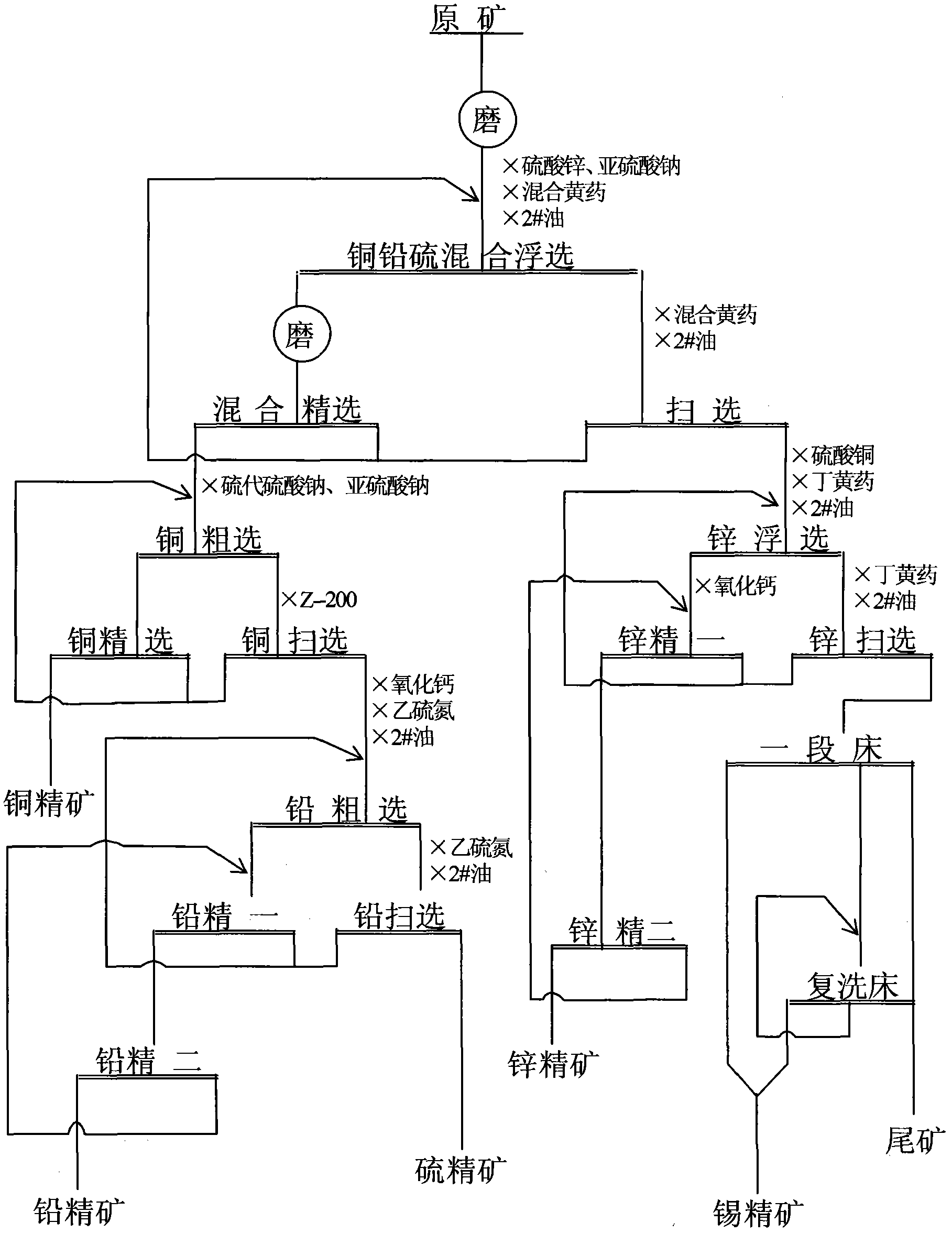

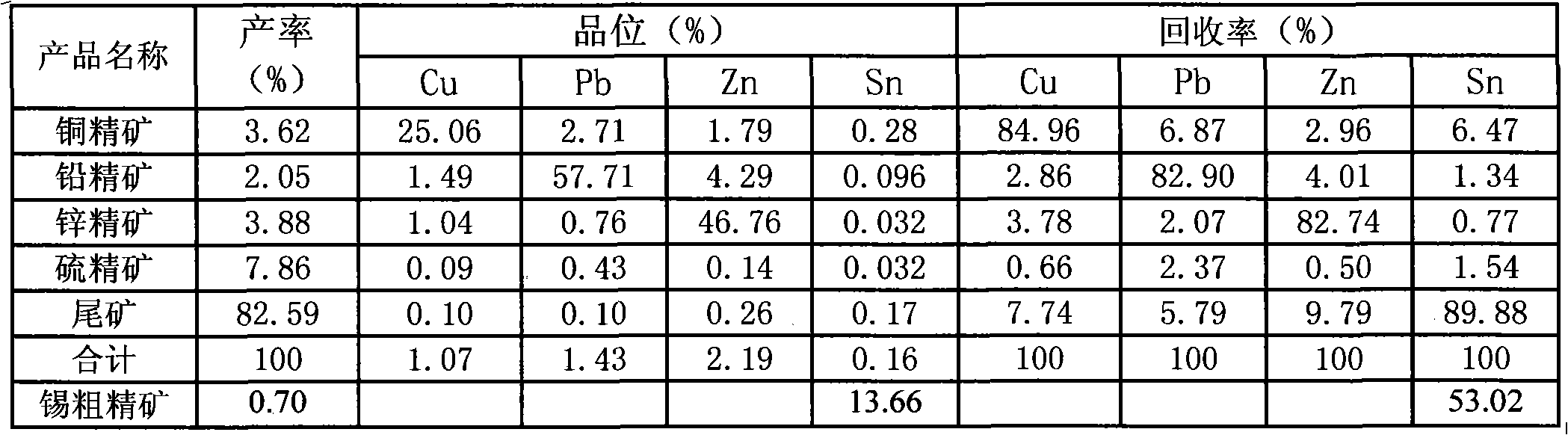

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

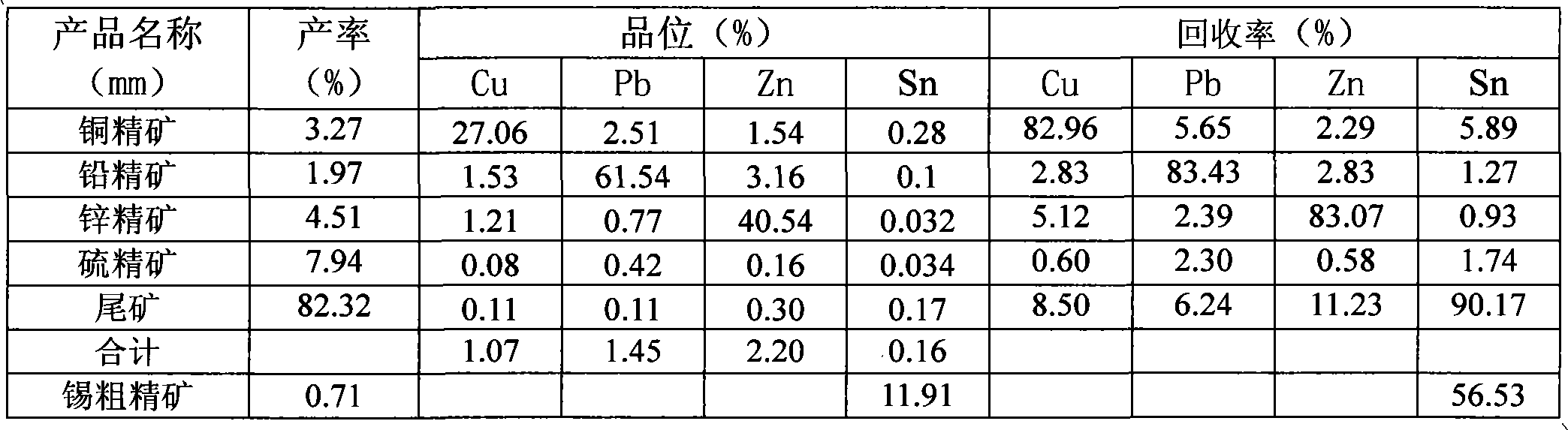

Method for efficiently recovering active materials of positive poles in waste lithium batteries

InactiveCN101599563AWaste accumulators reclaimingProcess efficiency improvementCycloneElectrical battery

The invention discloses a method for efficiently recovering active materials of positive poles in waste lithium batteries, which is mainly characterized by adding crushed electrical core fragments into hot water, stirring the mixture, and performing first vibration screening after the filtration and drying to separate most of an active material; dissolving aluminum foil through alkaline leaching after an oversize part is magnetically separated, adjusting the pH value of an alkaline leaching filtrate by dilute acid and ammonium bicarbonate solution, and recovering aluminum; performing second vibration screening after the filtration and drying to separate a residual powder material; and placing the oversize part into water for water cyclone separation, dumping to remove an upper-layer plastic diaphragm, then using dilute sulfuric acid and sodium thiosulfate solution to wash a copper sheet to ensure that carbon powder and active powder which are adhered to the copper sheet are loosened and fall off, making the powder float on an upper layer through cyclone separation after the washing, mixing the powder and the active powders obtained by two screenings, using NaOH solution to soak the mixture after the magnetic separation, calcining the alkali-leached active powder material after the filtration and drying, and taking the active powder material as active powder for subsequent treatment. The use of the method can ensure that the recovery rates of copper and aluminum in waste lithium ion batteries reach 98.5 percent and 97 percent respectively, and the recovery rate of the active materials is about 99 percent.

Owner:CENT SOUTH UNIV

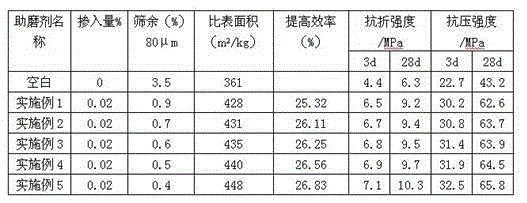

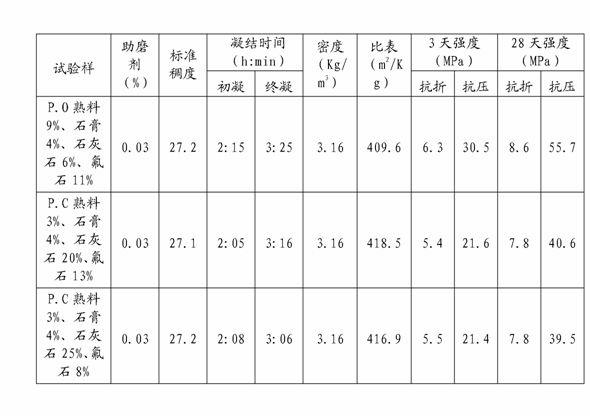

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

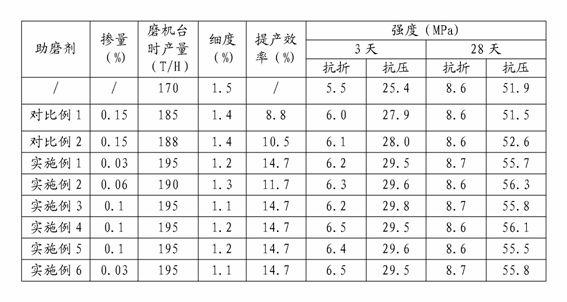

Liquid cement grinding aid

The invention discloses a liquid cement grinding aid. The liquid cement grinding aid comprises the following components by weight percent: 10-24% of triethanolamine, 10-16% of polymeric polyol, 10-13% of molasses, 1-3% of calcium formate, 3-5% of sodium acetate, 5-10% of sodium thiosulfate and the balance water. Compared with the prior art, the liquid cement grinding aid has the advantages that the grain composition of a cement material is changed, the strength of cement is improved, enhancing effect of the cement mixed with a large quantity of limestone is improved obviously; the cost is lower as the using amount of triethanolamine is reduced; the cement output in the unit time is increased effectively, and the power consumption of per unit output is reduced as the mixing amount in the cement finishing process is low; the liquid cement grinding aid is green and environmental-friendly and cannot hurt people, or cannot damage buildings and the like as chloridion content is not contained.

Owner:柳州宝能建材科技有限公司

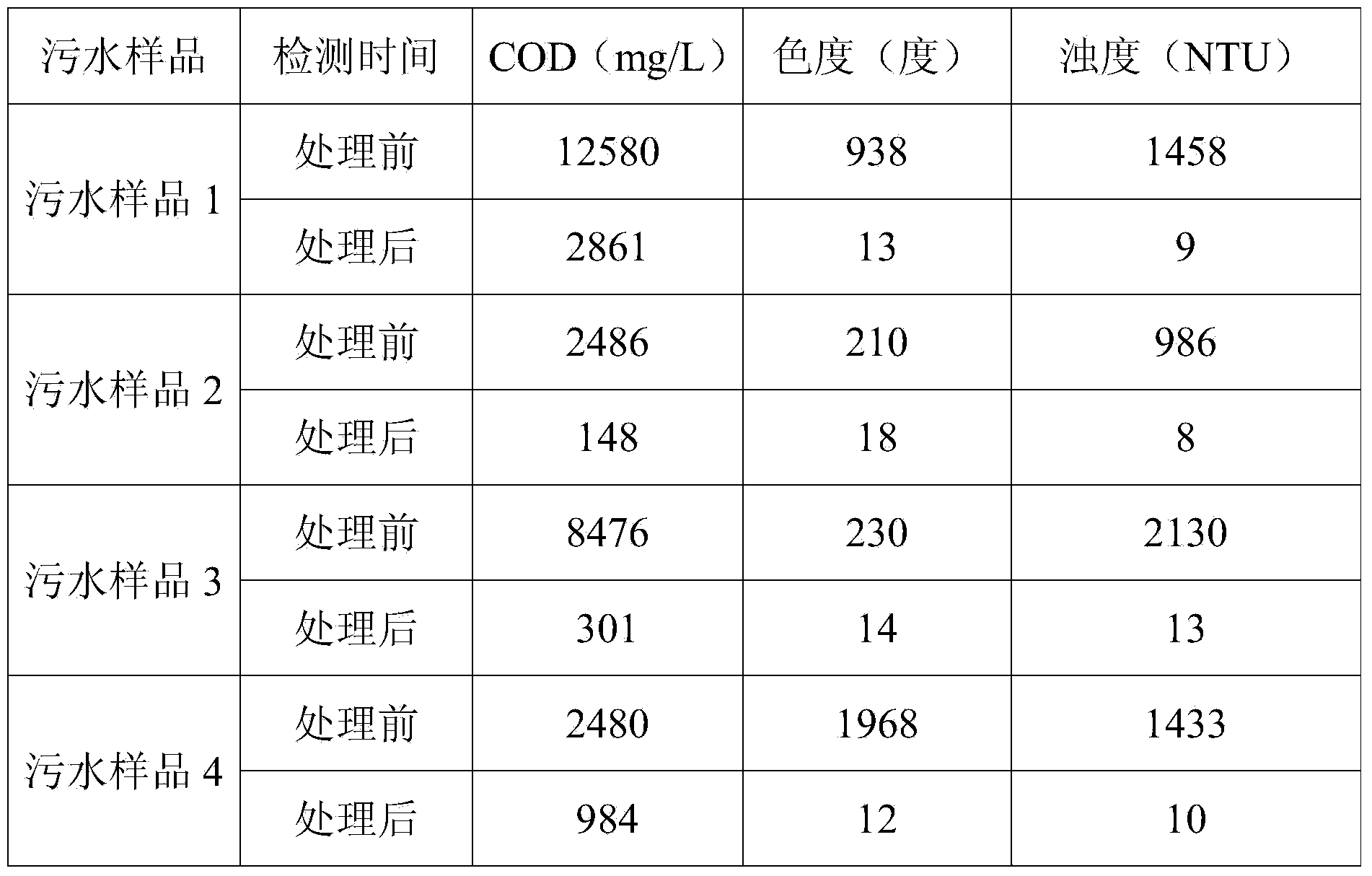

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

Sodium thiosulfate-containing pharmaceutical compositions

Provided herein are pharmaceutically acceptable sodium thiosulfate and pharmaceutical compositions thereof. Also provided herein are methods for determining the total non-purgable organic carbon in a sodium thiosulfate-containing sample. Further provided herein are methods for producing pharmaceutically acceptable sodium thiosulfate. Still further provided herein are methods of treatment comprising the administration of pharmaceutically acceptable sodium thiosulfate.

Owner:HOPE MEDICAL ENTERPRISES HOPE PHARMA

Liquid cement grinding aid

InactiveCN101318792AEasy to measureChange the production processSodium phosphatesTriterpenoid saponin

The invention relates to a liquid cement grinding aid which can obviously reduce the dosage of trolamine and does not contain urea. The grinding aid comprises the following compositions in weight percentage: 1 to 10 percent of trolamine, 5 to 10 percent of diglycol, 1 to 10 percent of trimeric sodium phosphate, 10 to 30 percent of molasses, 0 to 20 percent of sodium thiosulfate, 0 to 10 percent of air entraining component and the balance being water, wherein the air entraining compositions are triterpenoid saponin air entraining agent, sodium lignin sulfonate or a mixture of the triterpenoid saponin air entraining agent and the sodium lignin sulfonate at any proportion. The invention obviously reduces the dosage of the trolamine, does not contain the urea, lowers product cost and simultaneously facilitates the environmental protection. The sodium thiosulfate has the function of exciting mixed materials of cement and can improve the initial strength and the later strength of the cement, thereby effectively improving the service performance of the cement grinding aid. The triterpenoid saponin air entraining agent and the sodium lignin sulfonate have the action of the auxiliary aided grinding and simultaneously properly entrain air to reduce the water consumption of the cement standard consistence.

Owner:NANJING YONGNENG MATERIALS

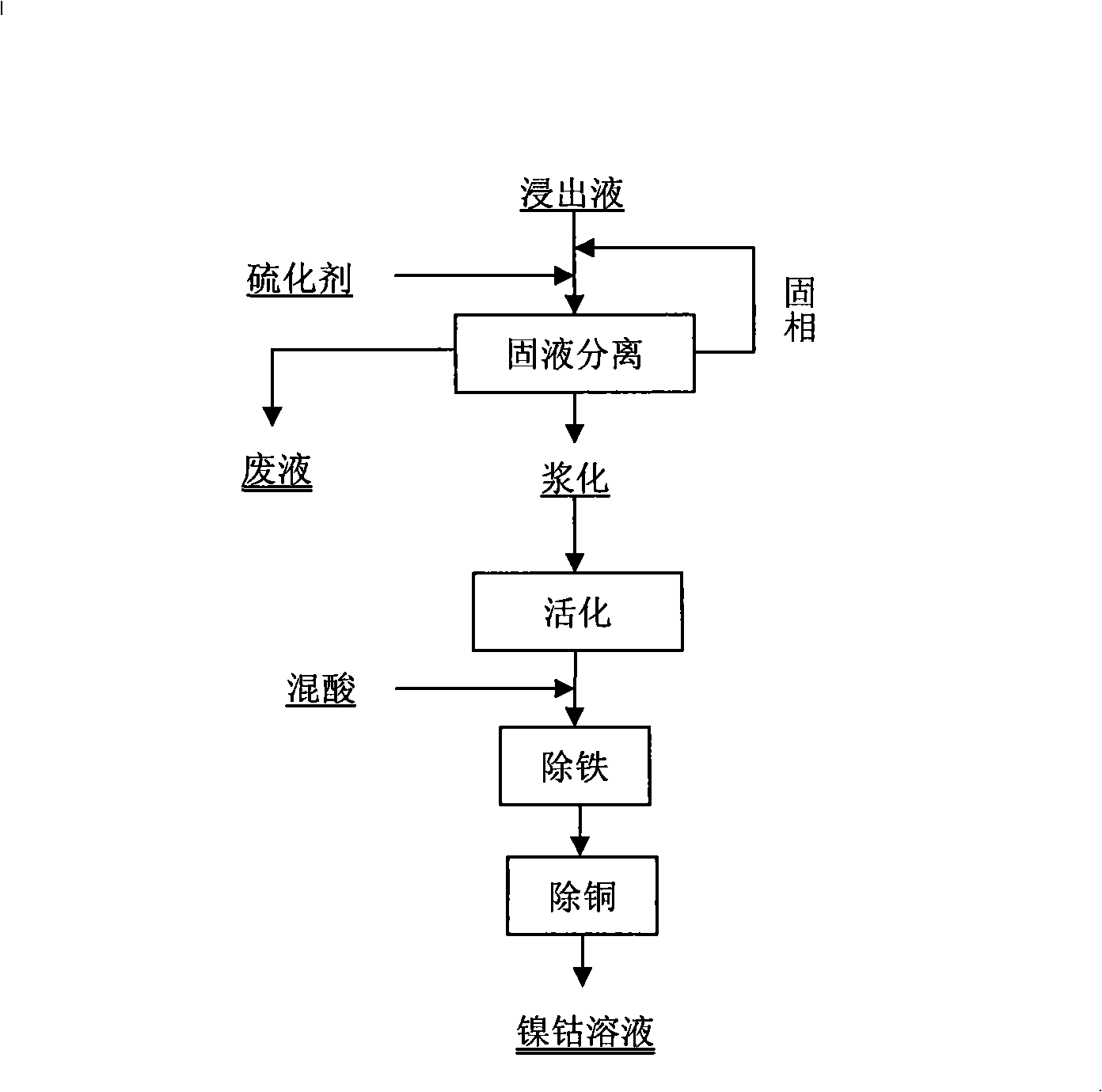

Method for collecting nickel and cobalt from laterite-nickel ore lixivium

ActiveCN101298638AHigh extraction rateReduce energy consumptionProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a method for separating enriched nickel and cobalt from a laterite nickel ore lixivium, which comprises the following steps: after solid and liquid separation between the laterite nickel ore lixivium and ore slag is implemented, a vulcanizing agent is added into the lixivium, the solid and the liquid are separated after reaction precipitation, and precipitated solid is washed by a new lixivium, thus obtaining sulfide precipitate; after the sulfide precipitate is pulpified, sulphuric acid and solution of nitric acid and mixed acid are added so as to implement oxidizing leaching; the goethite method is adopted for removing iron from a superior pickle liquor; a sodium thiosulfate solution is added so as to implement copper removing; a filtering liquor that is the enriched nickel and cobalt solution is obtained. Compared with the prior art, the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium is implemented at normal temperature and normal pressure, does not need a high-pressure caldron, has less device investment, low running cost, simple technical path, short process and controllable production scale; the vulcanizing agent and acids that are used in the technique can be recycled to the utmost extent and do not have emissions and environment pollution; the extraction yield of nickel and cobalt can achieve over 95 percent, and the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium has low production cost and easy industrialization.

Owner:福建常青新能源科技有限公司

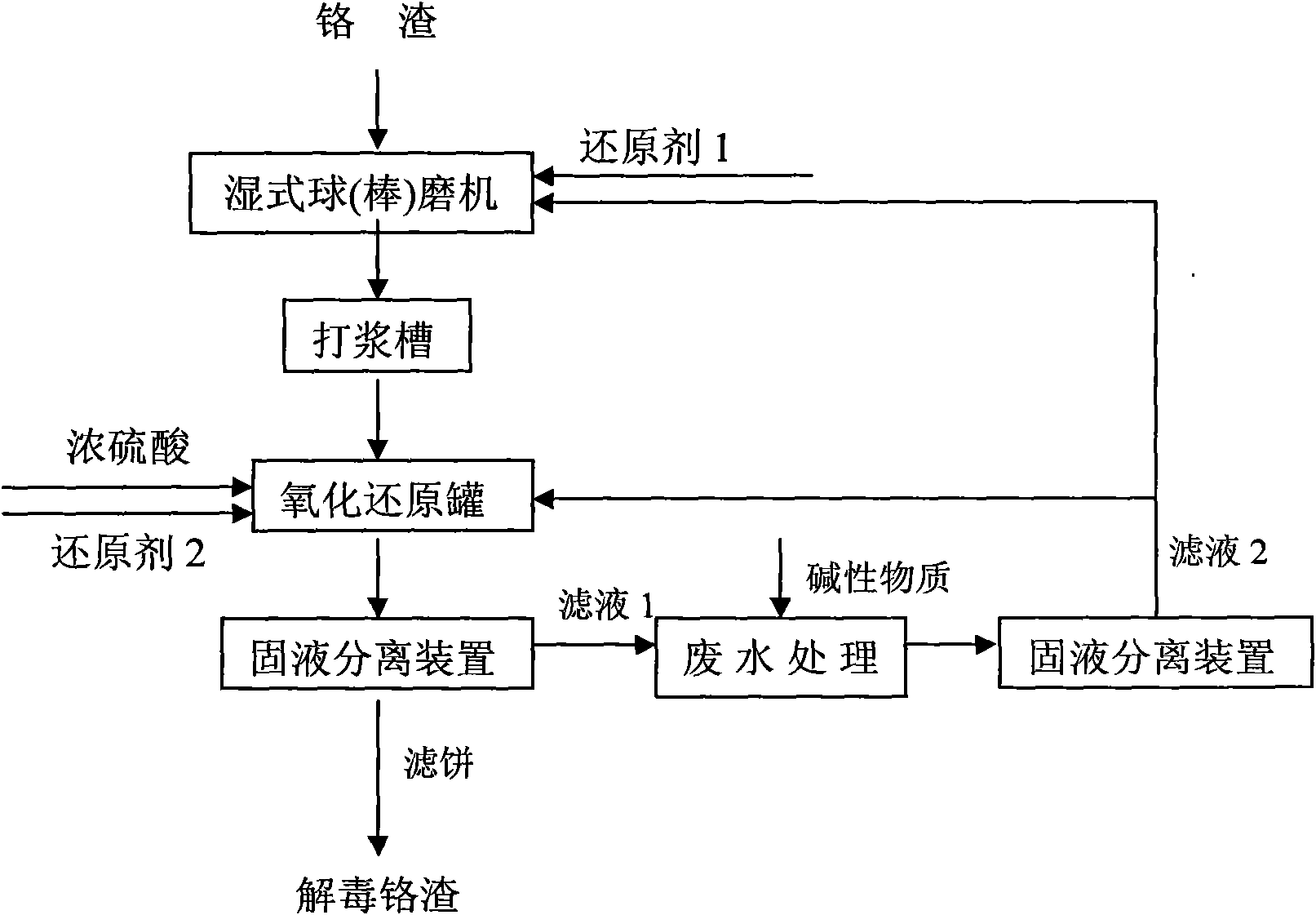

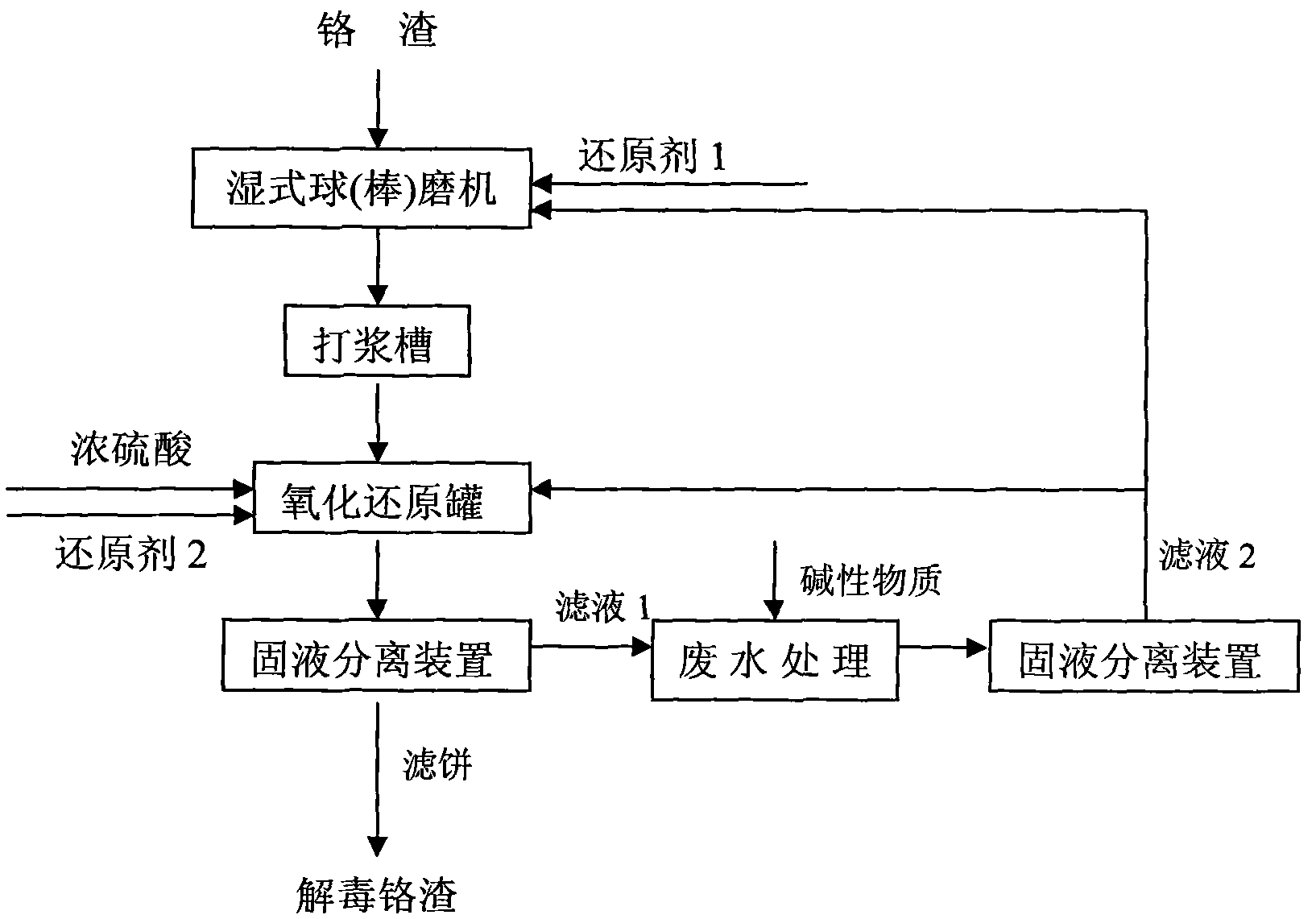

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

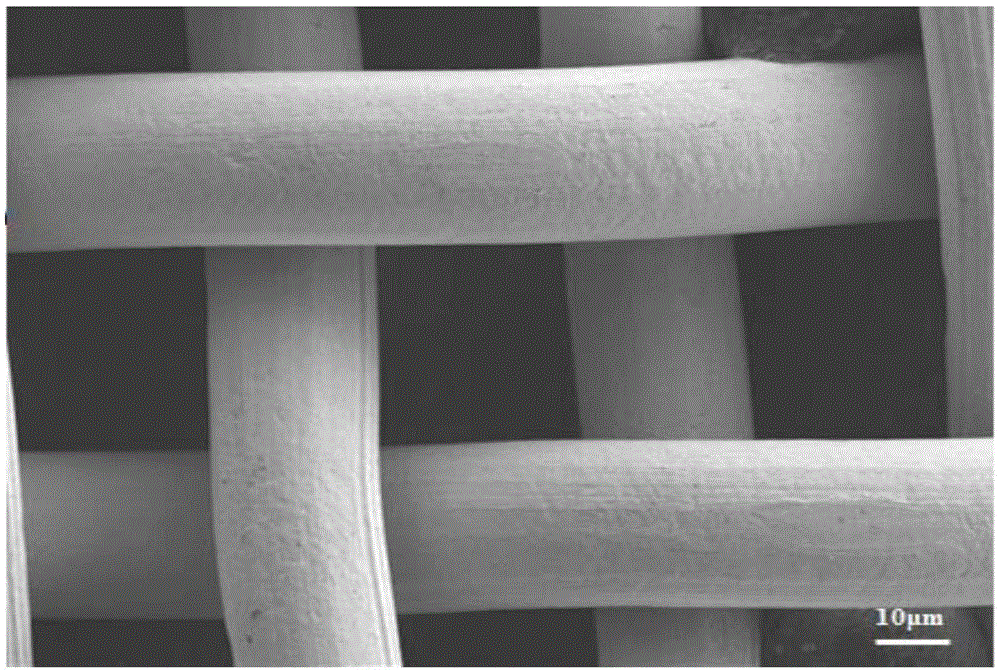

Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

ActiveCN105536296AImprove separation efficiencyEfficient separationNon-miscible liquid separationKeroseneCopper sulfate

The invention discloses a super-hydrophobic / super-oleophilicity copper wire mesh for oil and water separation and a preparation method and application thereof. The preparation method comprises the steps that firstly, the copper wire mesh is ultrasonically cleaned through diluted hydrochloric acid, absolute ethyl alcohol and deionized water respectively and dried through nitrogen; chemical deposition liquid of copper sulfate and a sodium thiosulfate solution is prepared; the cleaned copper wire mesh is placed into the chemical deposition liquid for a deposition reaction; the copper wire mesh is taken out and cleaned through the deionized water and dried in the air; the dried copper wire mesh is placed in a solution of a curing agent and polydimethylsiloxane with hydroxyl sealed end, and the copper wire mesh is taken out and heated. No expensive fluorine-containing substance is needed, the copper wire mesh has the advantages that the preparation technology is simple, reaction conditions are mild, no strong acidity or strong basicity or corrosivity reagents are needed, and no harm is caused to the environment, separation of oily wastewater can be achieved rapidly and efficiently, the good separation effect on chloroform, normal hexane, petroleum ether, plant oil, diesel oil, aviation kerosene and the like is achieved, and separation of strong acidity, strong basicity and high salinity oily wastewater can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

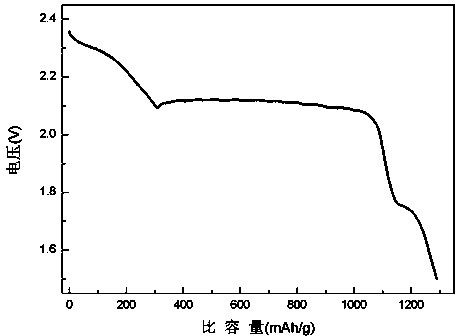

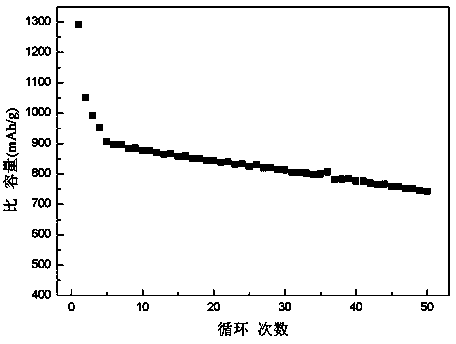

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

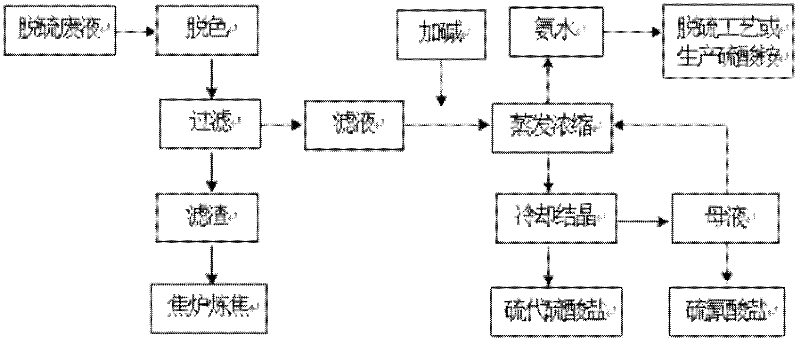

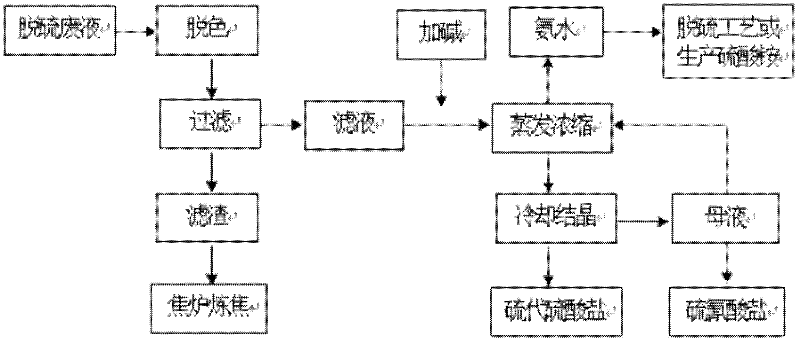

Method for treating desulfurization waste liquid of wet oxidation method

ActiveCN102295379AReduce manufacturing costNot easily decomposed by heatThiosulfates/dithionites/polythionitesThiocyanic acidSodium thiocyanateEvaporation

A method for treating desulfurization waste liquid of a wet oxidation method. The method comprises the following steps: firstly adding a decolorant into desulfurization waste liquid for decolorizing treatment, filtering after decolorization, adding alkali into the filtrate, controlling the PH to be 8-9, performing evaporation concentration under a condition with a negative pressure, condensing the evaporated ammonia gas and water vapor to obtain concentrated ammonia liquor which can be returned to the system for recycle or be used to produce ammonium sulfate, performing fractional crystallization of the concentrated desulfurization liquid to respectively obtain high-purity sodium thiocyanate and sodium hyposulfite. The invention has a simple process, and stable operations, and effectively solves the problem of difficult HPF desulfurization waste liquid treatment in coking enterprises; the method not only reduces the discharge of the waste liquid, but also recovers a lot of chemical products with economic value, and the method has quite significant economic benefits and environmental benefits.

Owner:SHOUGANG CORPORATION

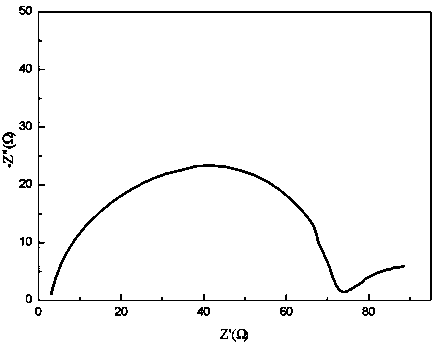

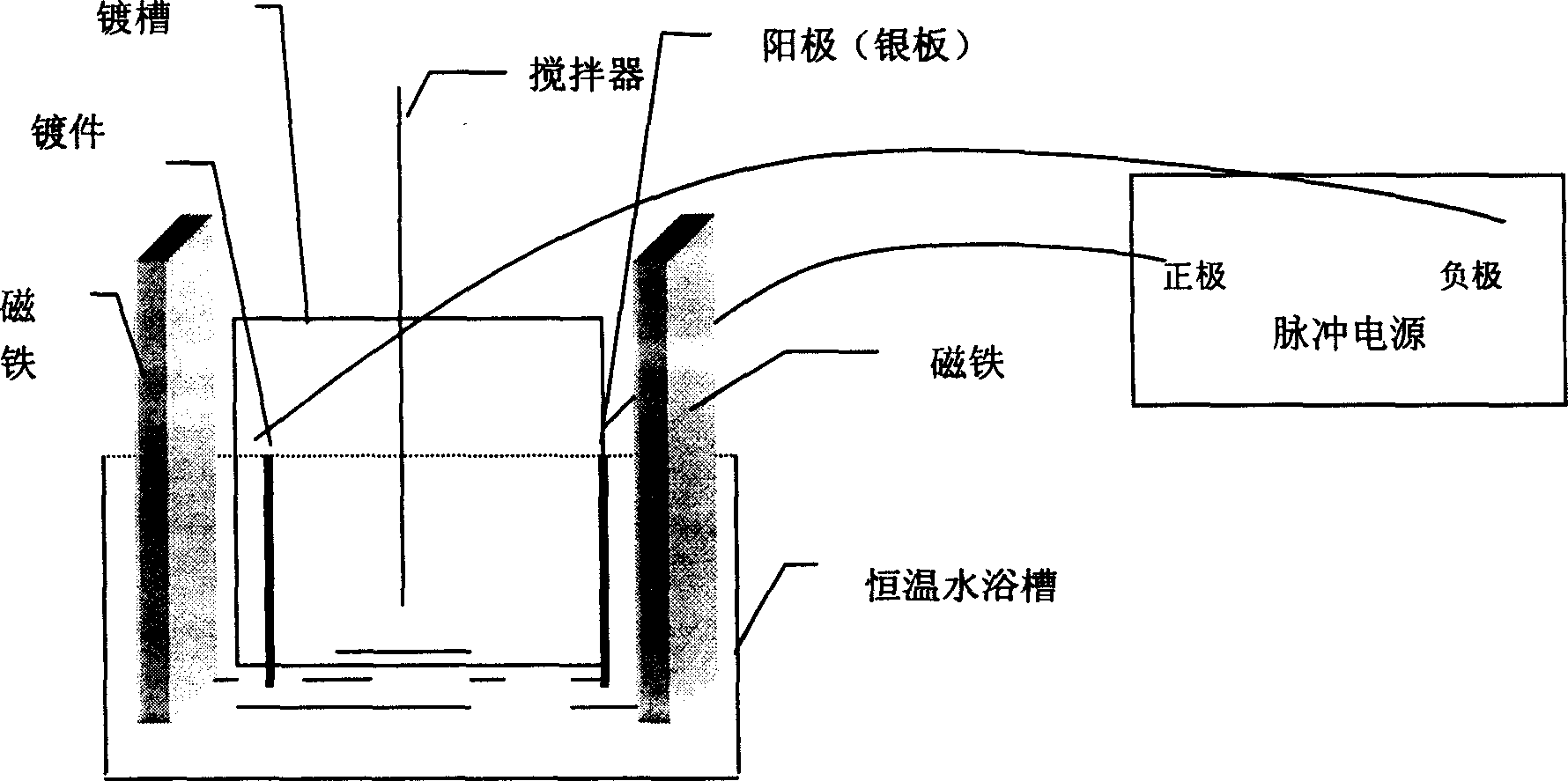

Technology of non-cyanide silver coating

A process of silver coating with no cyanogens at the action of magnetic field and impulse current. The main process is impulsive silver coating. Ingredients of the solution are as follow. AgNO3,50-60g / L; sodium thiosulfate, 250-350g / L; potassium, 90-110g / L; K2SO4,20-30g / L; boracic acid, 25-35g / L; brightener,5m / L. Stir at 20-40deg.C for 10min. pH of silvering solution is 4.2-4.8. Mean impulse current density is 0.5-1ms. Duty ratio is 5-15%. Orientation of magnetic field is parallel with that of impulse current. Square ratio of positive and negative pole is bigger than 2.

Owner:SHANGHAI UNIV

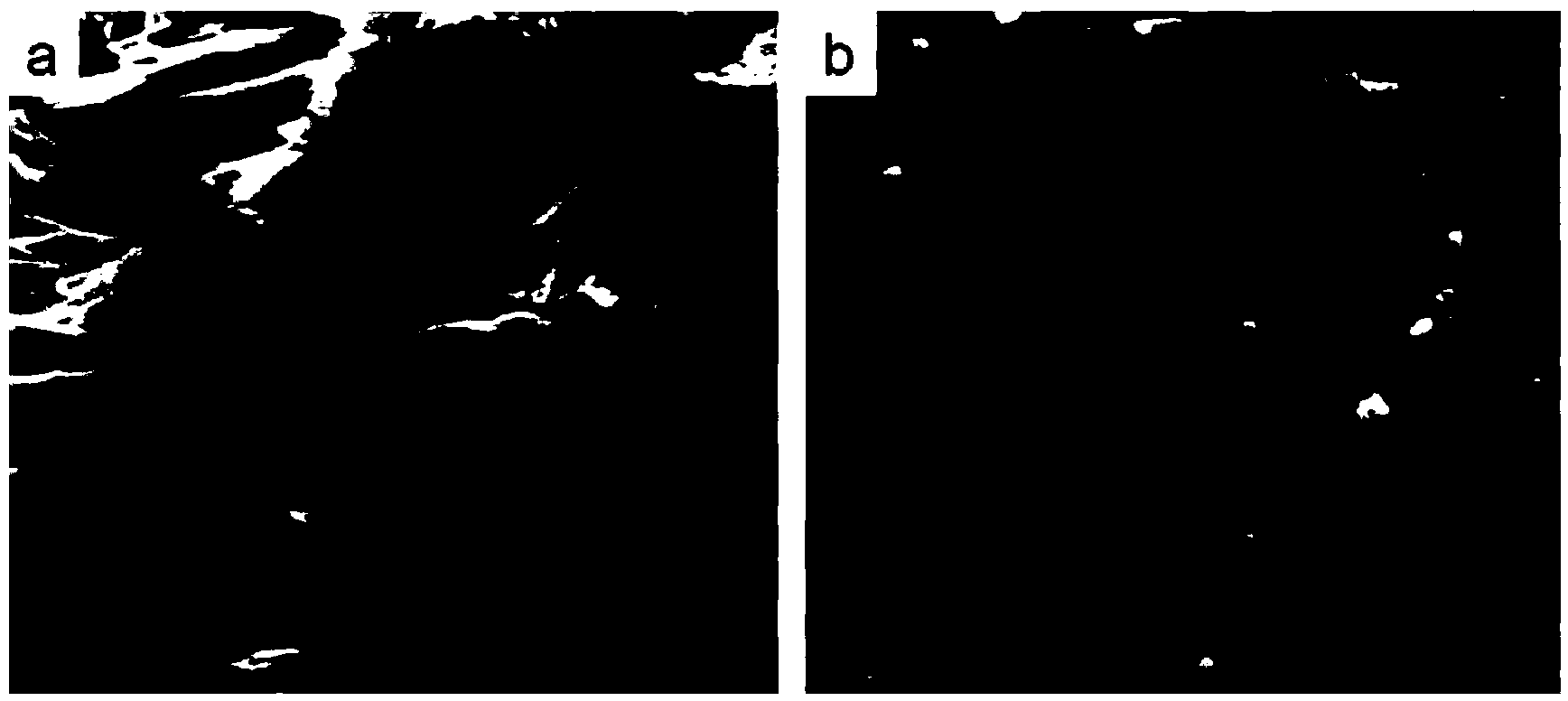

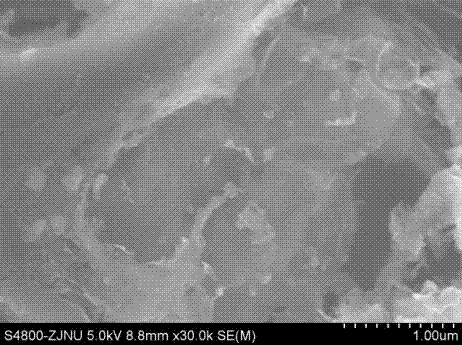

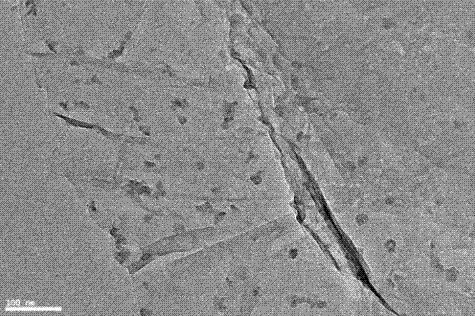

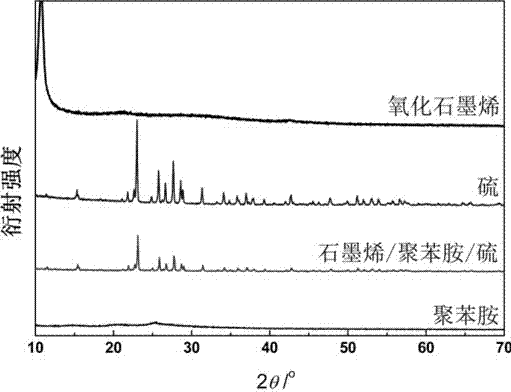

Graphene/polyaniline/sulfur composite material and preparation method thereof

InactiveCN103682274AEasy to operateConditions are easy to controlCell electrodesSecondary cellsGraphite oxideSodium thiosulfate

The invention discloses a graphene / polyaniline / sulfur composite material characterized in that graphene oxide is reduced to graphene by aniline, meanwhile, the aniline is oxidized and polymerized to polyaniline, and sulfur particles produced by sodium thiosulfate and hydrochloric acid are evenly distributed on a graphene polyaniline conducting layer in a reaction process. The invention further discloses a preparation method of the graphene / polyaniline / sulfur composite material. The method comprises the steps as follows: firstly, dispersing the graphene oxide in water to form a uniform graphene oxide solution, then dissolving an aniline solution into the hydrochloric acid to form an aniline salt solution, and adding the aniline salt solution into the graphene oxide solution; dissolving a sodium thiosulfate solid into the water to form a sodium thiosulfate solution, dropwise adding the odium thiosulfate solution into a graphene oxide and aniline mixed solution, stirring the mixture at a certain temperature for a moment, and separating, washing and drying produced deep green precipitation to obtain the graphene / polyaniline / sulfur composite material. The method is low in energy consumption, simple to operate, good in controllability, high in yield and suitable for mass production.

Owner:ZHEJIANG NORMAL UNIVERSITY

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

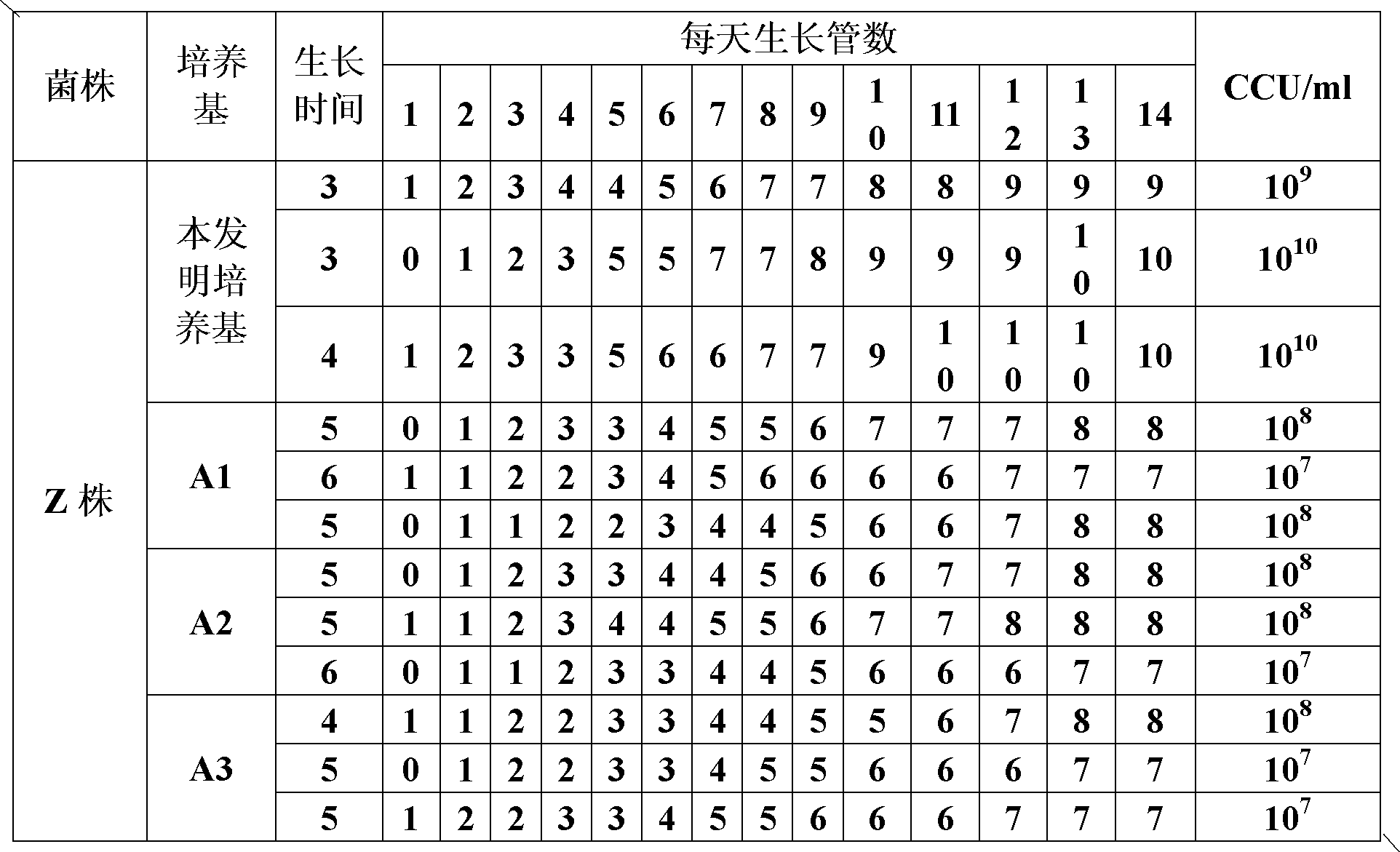

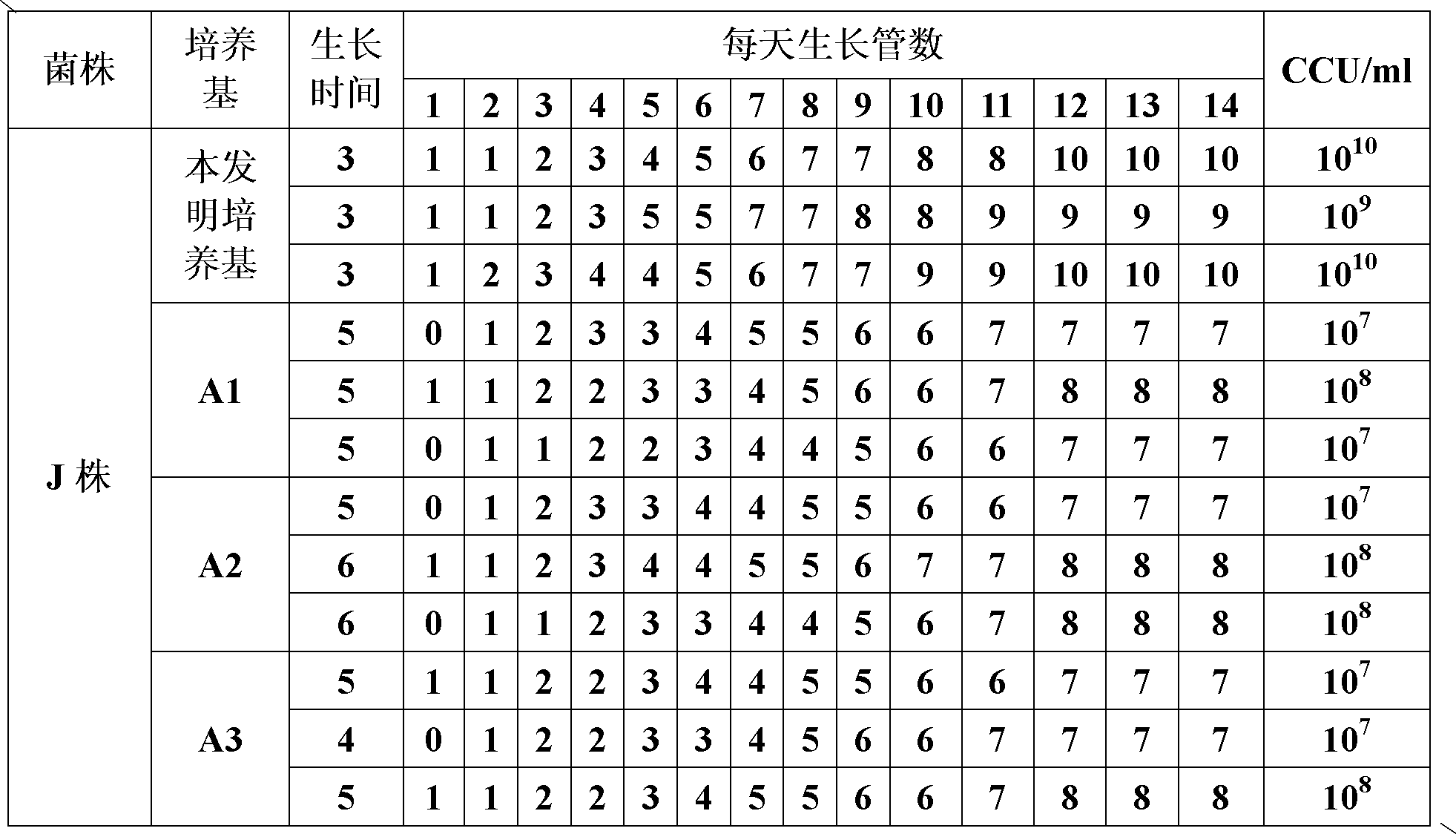

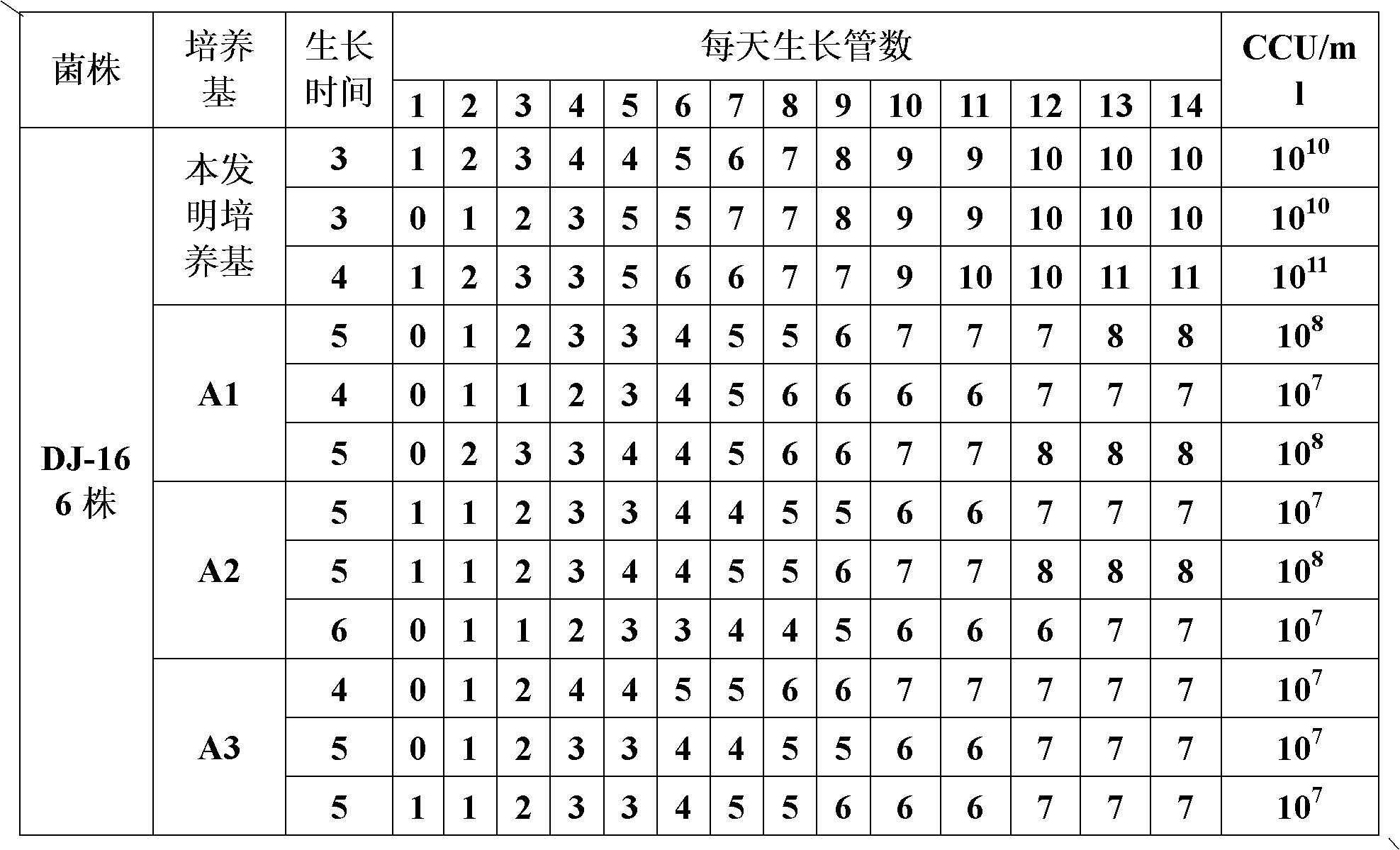

Mycoplasma hyopneumoniae culture medium and preparation method thereof

ActiveCN102154167ARich in nutrientsIncrease the titer of live bacteriaBacteriaMicroorganism based processesPenicillinMycoplasma culture

The invention provides a mycoplasma hyopneumoniae culture medium and a preparation method thereof, belonging to the technical field of veterinary biology. The mycoplasma hyopneumoniae liquid culture medium comprises the components as follows: brain heart infusion, lactalbumin hydrolysate, PPLO (pleuropneumonia-like organism) broth, yeast extract powder, proteose peptone, sodium thiosulfate, Hank's liquid, sodium pyruvate, 0.1% phenol red solution, penicillin and deionized water. The preparation method comprises the following steps of: adding health horse serum before using, and adding agar into the liquid culture medium to obtain a solid culture medium of mycoplasma hyopneumoniae. The viable bacteria titer of the mycoplasma hyopneumoniae culture medium can reach 1*109CCU / ml-1*1010CCU / ml; the viable bacteria titer and the separation sensibility are far higher than those of the existing culture medium, and the mycoplasma hyopneumoniae is fast in growth speed and high in the separation sensibility; and the preparation method of the culture medium is simple in technology, strong in operability, and suitable for industrial large-scale production.

Owner:兆丰华生物科技(南京)有限公司 +1

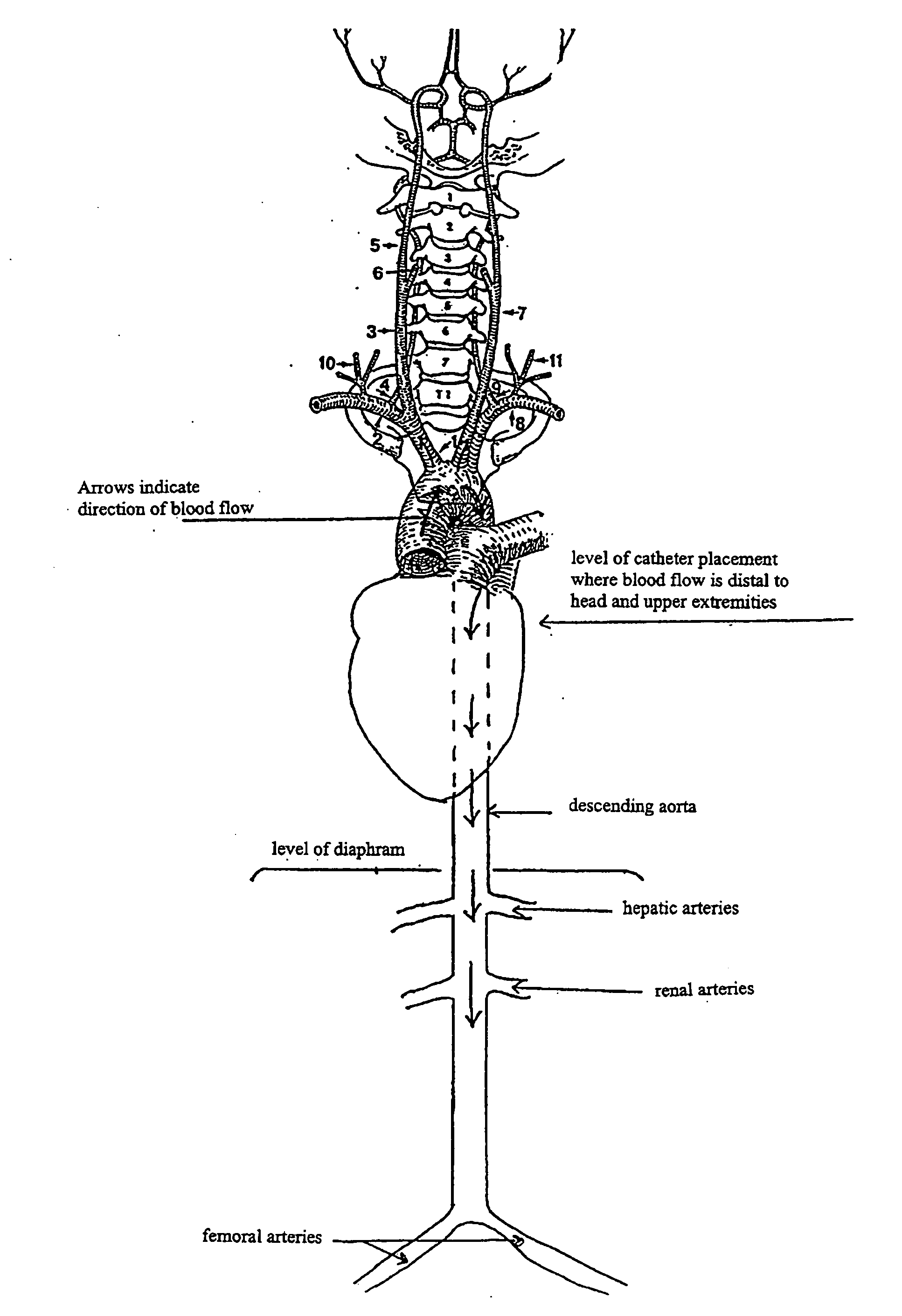

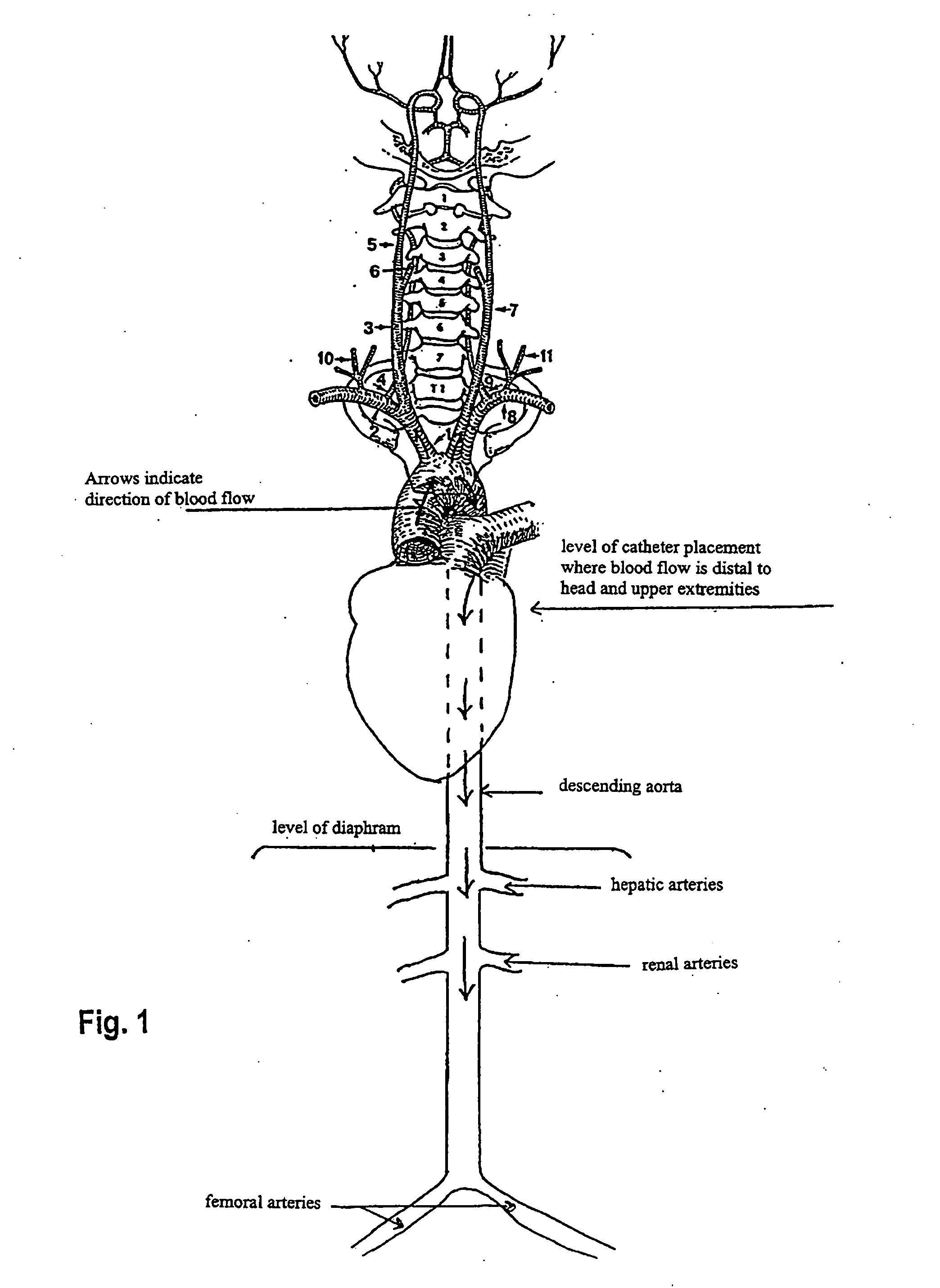

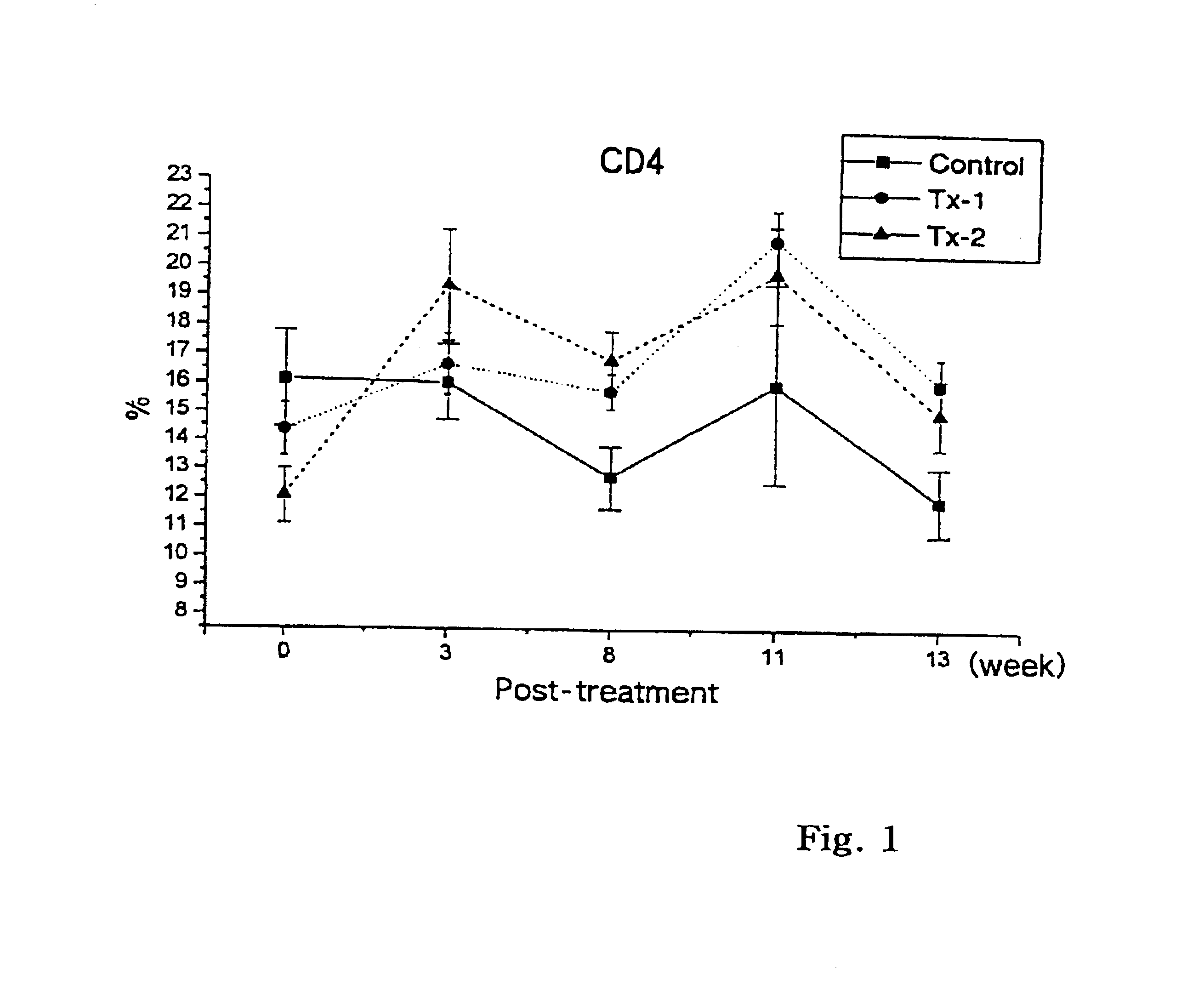

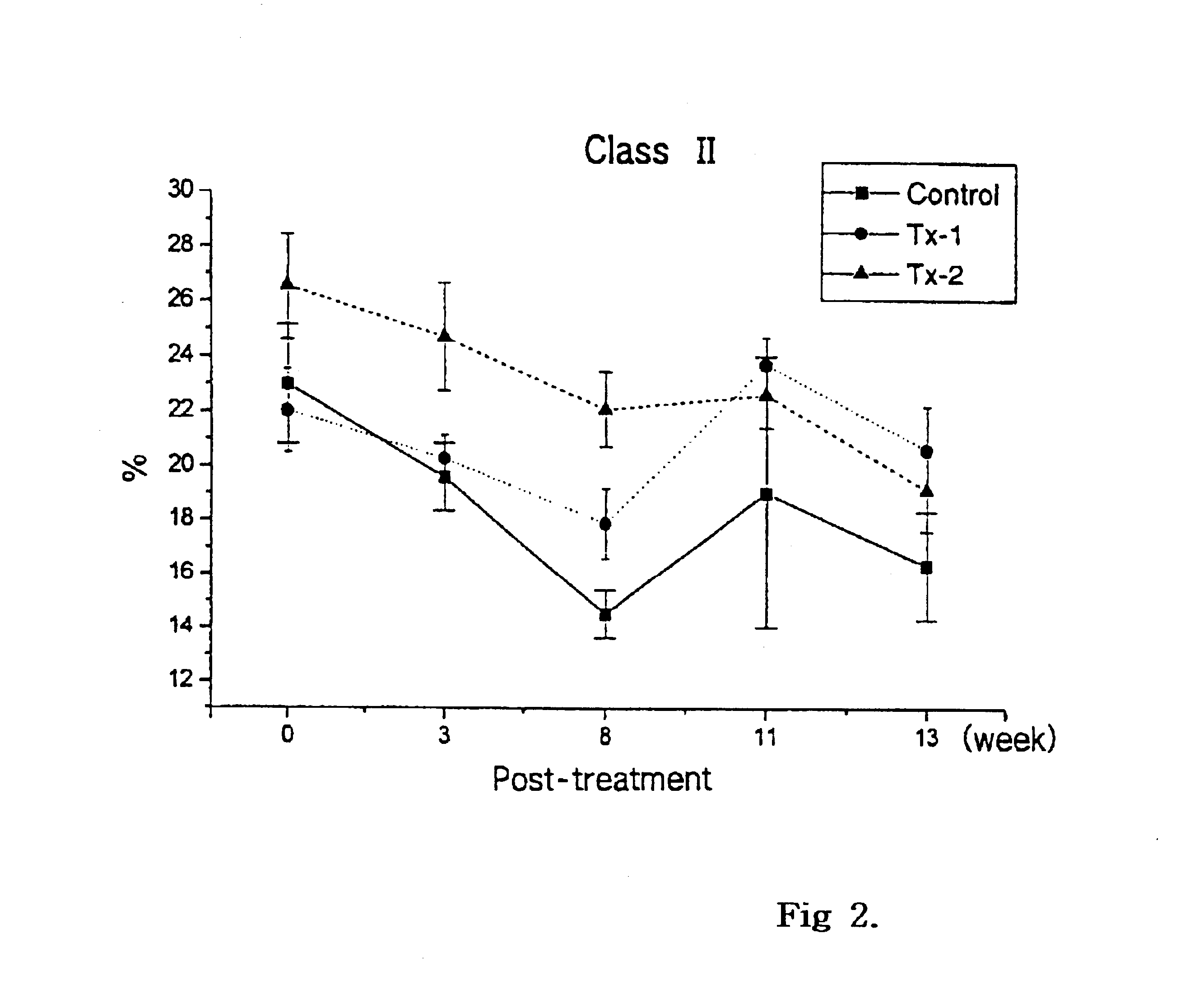

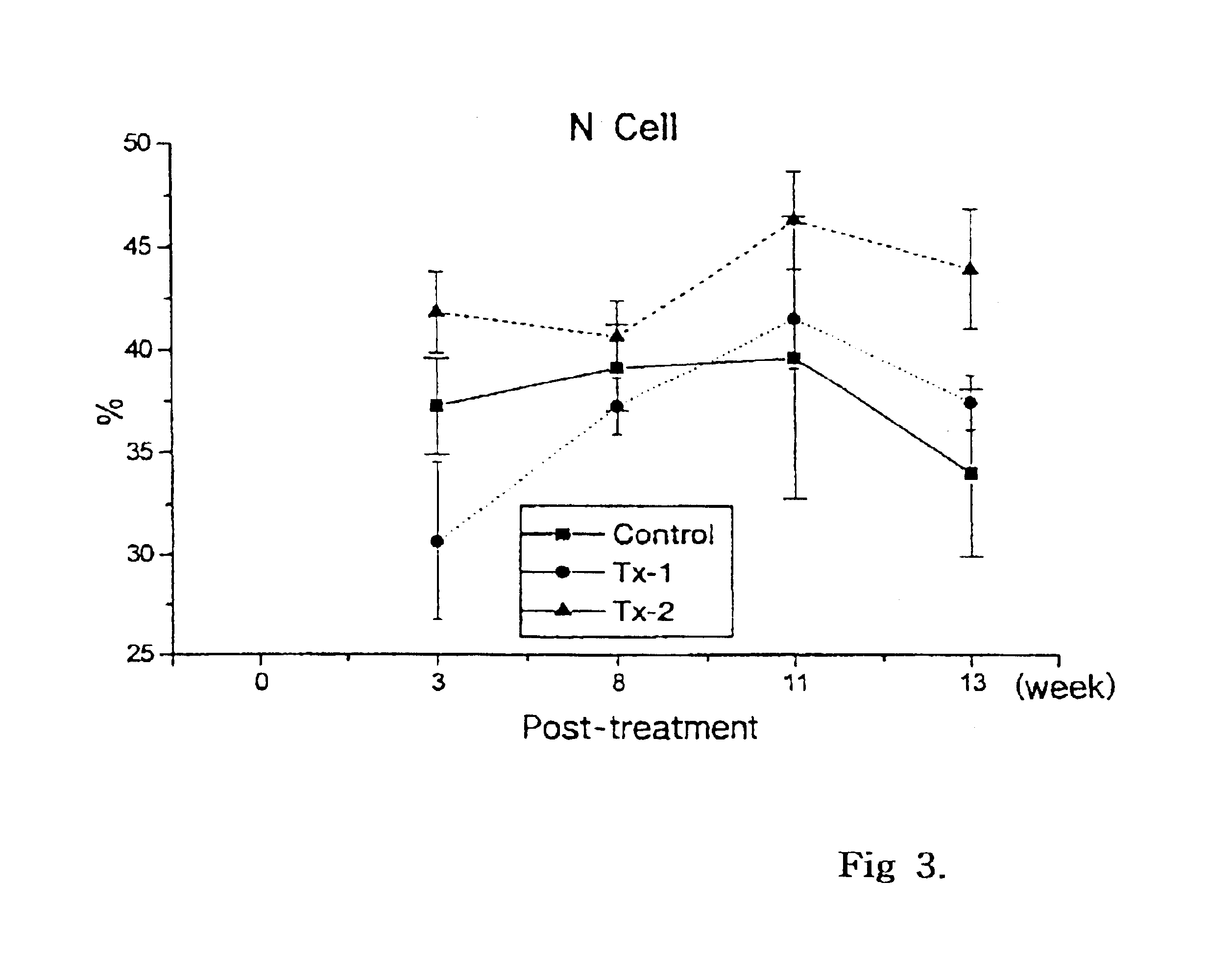

Administration of a thiol-based chemoprotectant compound

InactiveUS20060177523A1Treat and mitigate side effectProtect from harmBiocideDipeptide ingredientsAbnormal tissue growthSide effect

A method of administration of a thiol-based chemoprotectant agent including NAC (N-acetylcysteine) and STS (sodium thiosulfate) that markedly affects biodistribution and protects against injury from diagnostic or therapeutic intra-arterial procedures. A method for treating or mitigating the side effects of cytotoxic cancer therapy for tumors located in the head or neck and brain tumors. The thiol-based chemoprotectant agent is administered intra-arterially with rapid and first pass uptake in organs and tissues other than the liver.

Owner:OREGON HEALTH & SCI UNIV +1

Agent special for bioleaching municipal sludge and production process thereof

ActiveCN101913743AMeet growth needsPromote growthSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeDipotassium phosphate

The invention provides an agent special for bioleaching municipal sludge, which belongs to the technical field of engineering technology. The agent for bioleaching the municipal sludge contains a carbon source and nutrient substances, which are needed by the growth of thiobacillus and acid-resistant heterotrophic bacteria, including ammonium sulfate, potassium chloride, dipotassium phosphate, calcium nitrate, magnesium sulfate, vitamins, trace elements, carbon source substances, sodium thiosulfate, sulphur powder, finished pyrite or ferrous sulfate heptahydrate, surfactant, dressing and the like. The production process comprises the following steps of: adsorbing a liquid material on diatomite serving as the dressing; and fully mixing the liquid material, other solid materials and the diatomite serving as the dressing to obtain the agent. The agent can meet the growth demands of various microorganisms in a bioleaching composite microorganism at the same time and greatly improve sludge bioleaching efficiency.

Owner:NANJING AGRICULTURAL UNIVERSITY

Composition of multipurpose high functional alkaline solution composition, preparation thereof, and for the use of nonspecific immunostimulator

Disclosed are a multipurpose, high-functional, alkaline solution composition, preparation therefor and use thereof as a nonspecific immunostimulator. The composition comprises 1-25 parts by weight of borax (Na2B4O7.10H2O), 10−5-10−4 parts by weight of sodium thiosulfate (Na2S2O3.5H2O), 30-150 parts by weight of potassium carbonate, 30-200 parts by weight of refined sugar (C12H22O11), and 100-200 parts by weight of water, based on 100 parts by weight of sodium metasilicate (Na2SiO3.5H2O). In addition to bringing about an improvement in disease resistance, weight gain rate, crop yield, crop quality, harvest time, the composition shows nonspecific immunostimulating activities, including antibody production and immune enhancement, by activating immune cells, thereby maximizing vaccination effects on malignant viral diseases.

Owner:BARODON S F CORP

Iron pyrite inhibitor for use under low-alkalinity condition

The invention discloses an iron pyrite inhibitor for use under a low-alkalinity condition. The iron pyrite inhibitor consists of the following components in parts by weight: 40-50 parts of sodium thiosulfate, 40-50 parts of citric acid and 5-15 parts of polyacrylamide, wherein the polyacrylamide is hydroxyl-containing low molecular polyacrylamide of which the molecular content is 400-600. The inhibitor is prepared by using a method comprising the following steps of weighing sodium thiosulfate, citric acid and polyacrylamide; uniformly mixing to obtain 1-5 percent by weight of aqueous solution; and stirring. The iron pyrite inhibitor is used for selectively inhibiting iron sulfide minerals under a low-alkalinity condition, has good inhibition effects on minerals such as pyrite, magnetic pyrite and the like, has the advantages of stable performance, small using amount, low cost and environment friendliness, can be widely applied to sulfide ore dressing of copper, copper lead, copper zinc, lead zinc, copper lead zinc, gold and the like, and contributes to effectively increasing the scoring indexes of copper, lead, zinc, metal minerals and pyrite, effectively enhancing the flotation separation effect of multi-metal sulfide minerals and increasing the recovery rate of associated gold and silver.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Blackening liquid for chromium-free titanium-zinc panel surface and using method of blackening liquid

InactiveCN103849868ASimple compositionStrong corrosion resistanceMetallic material coating processesAluminium chlorideChromium free

The invention discloses blackening liquid for a chromium-free titanium-zinc panel surface and a using method of the blackening liquid. Raw materials of the blackening liquid comprise a main salt, auxiliary components, a complexing agent, a pH conditioning agent and water, wherein the main salt is one or several of molybdate with the massic volume concentration of 5-40g / L or sodium tungstate with the massic volume concentration of 0.5-10g / L or copper sulfate with the massic volume concentration of 0.5-20g / L or silver nitrate with the massic volume concentration of 5-40g / L; the auxiliary components comprise nickel sulfate with the concentration of 1.0-4g / L, sodium sulfite with the concentration of 0.5-4g / L, sodium thiosulfate with the concentration of 1.0-5g / L, aluminium chloride with the concentration of 2.0-5g / L, zinc chloride with the concentration of 2.0-5g / L and fluoric acid with the concentration of 0-40g / L. A black protective layer of a titanium-zinc panel is obtained by a series of treatment of the titanium-zinc panel workpiece. The black protective layer of the titanium-zinc panel is compact, uniform, pitch-black and glossy and has the characteristics of being low in cost, chromium-free, environmental-friendly and the like, the performances of the titanium-zinc panel can reach the level of foreign products, and therefore, the titanium-zinc panel has relatively strong application prospect and market competitiveness.

Owner:ZHEJIANG UNIV OF TECH +1

Concrete reinforcing agent as well as preparation method and application thereof

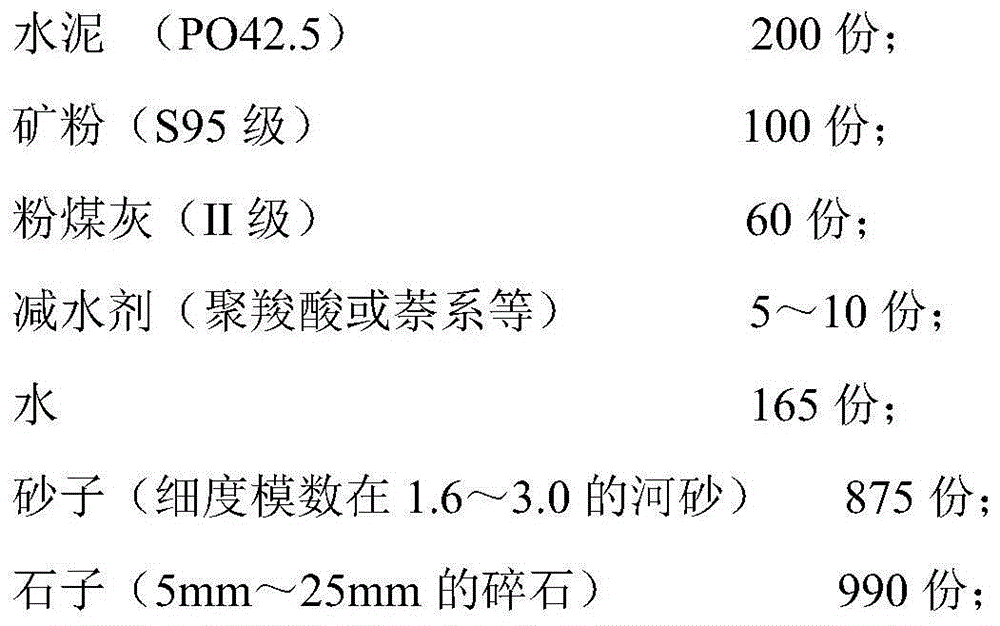

ActiveCN103951304AImprove mechanical propertiesHigh strengthSolid waste managementSodium thiosulfateUltimate tensile strength

The invention discloses a concrete reinforcing agent which is mainly prepared from the following components by mass parts: 30-40 parts of an isopropanolamine compound, 10-12 parts of triethanolamine, 1-5 parts of polyalcohol and 3-5 parts of sodium thiosulfate. The preparation method comprises the following steps: preparing the isopropanolamine compound, mixing the isopropanolamine compound, triethanolamine, polyalcohol and sodium thiosulfate with water, adding water for diluting, and uniformly stirring to obtain the concrete reinforcing agent. When being applied, the concrete reinforcing agent is directly mixed with cement, mineral powder, coal ash, a water reducing agent, water, sand and stone. The concrete reinforcing agent is well adaptive to an additive, and the later concrete strength is remarkably improved.

Owner:湖南润攸科技发展有限公司

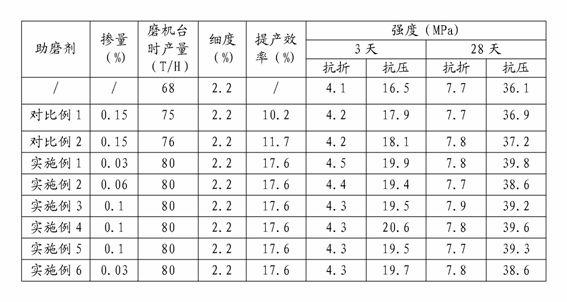

Reinforced cement grinding aid

The invention discloses a reinforced cement grinding aid which comprises the following ingredients in parts by weight: 10-15 parts of diethanolisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 6-10 parts of sodium thiosulfate, 10-12 parts of sodium chloride, 4-6 parts of sodium carboxymethylcellulose and 15-18 parts of papermaking black liquid. The reinforced cement grinding aid is low in mixing amount, good in reinforcement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing taurine by adopting sulfonation of ammonium sulfite

InactiveCN102633689ASimple operation processMild reaction conditionsOrganic compound preparationSulfonic acid preparationTaurineSulfuric Acid Esters

The invention discloses a method for preparing taurine by adopting sulfonation of ammonium sulfite. The method comprises the steps of: firstly carrying out esterification reaction to synthetize an intermediate 2-aminoethanol sulfate by taking concentrated sulfuric acid and ethanolamine as raw materials; carrying out sulfonation reaction to prepare taurine by taking ammonium sulfite and 2-aminoethyl sulfate as the raw materials, wherein ammonia is introduced to protect before the reaction, the temperature of the reaction solution is reduced after the sulfonation reaction is finished, and the conversion ratio of 2-aminoethyl sulfate is analyzed by adopting a sodium thiosulfate inverse titration method; cooling the reaction solution to room temperature, adding calcium hydroxide, heating, agitating and filtering to remove calcium sulfate, removing ammonia in mother liquor and repeatedly utilizing the mother liquor; then purifying the taurine by a cooling and crystallizing method to obtain crystal, carrying out suction filtration and baking the obtained crystal, and analyzing the taurine crystal by a thermal analysis method. The method disclosed by the invention is an integrated preparation method of combining the synthesis and separation of the taurine. The method is the preparation method of the taurine with simple operating process and mild reaction condition, wherein the primary conversion rate of 2-aminoethyl sulfate can be up to 79% and the desalination efficiency is 99.12%.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com