Patents

Literature

1628results about How to "Reduce COD" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

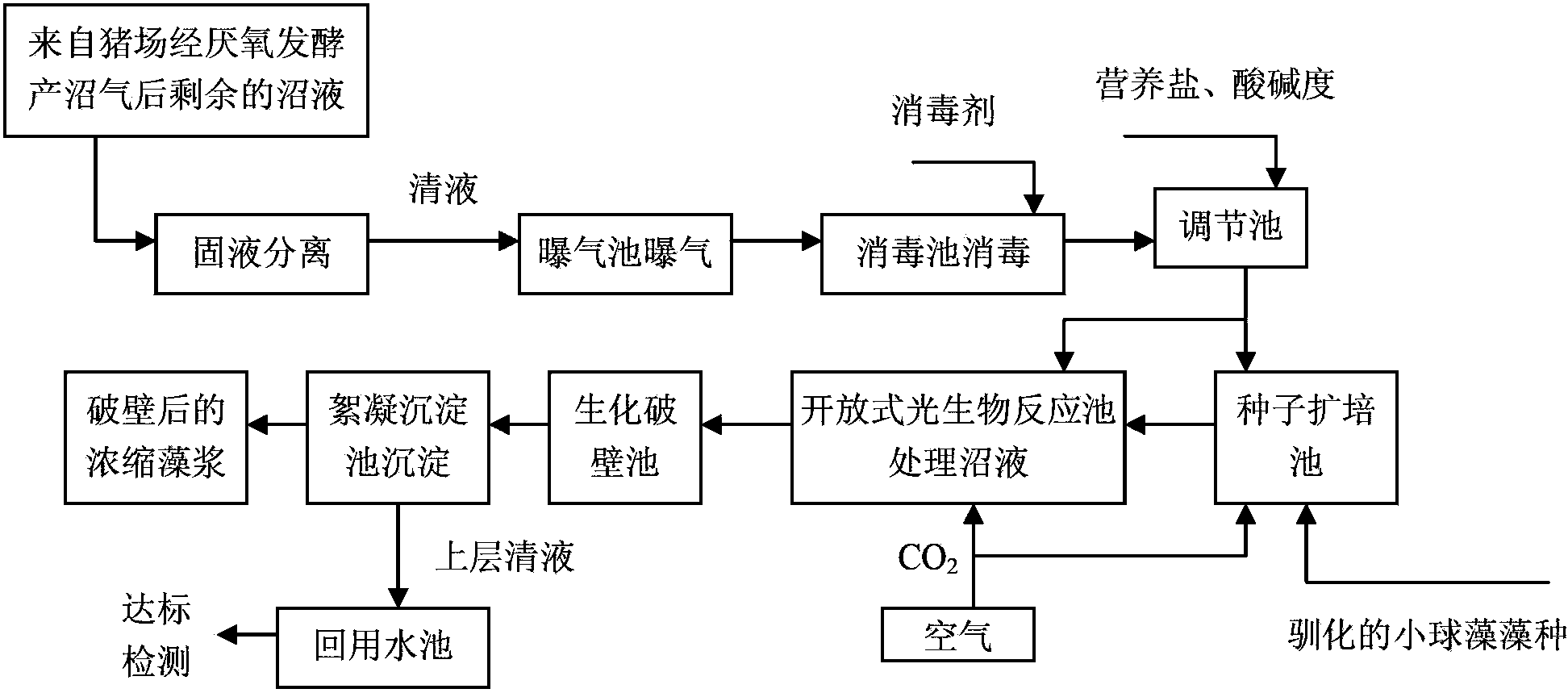

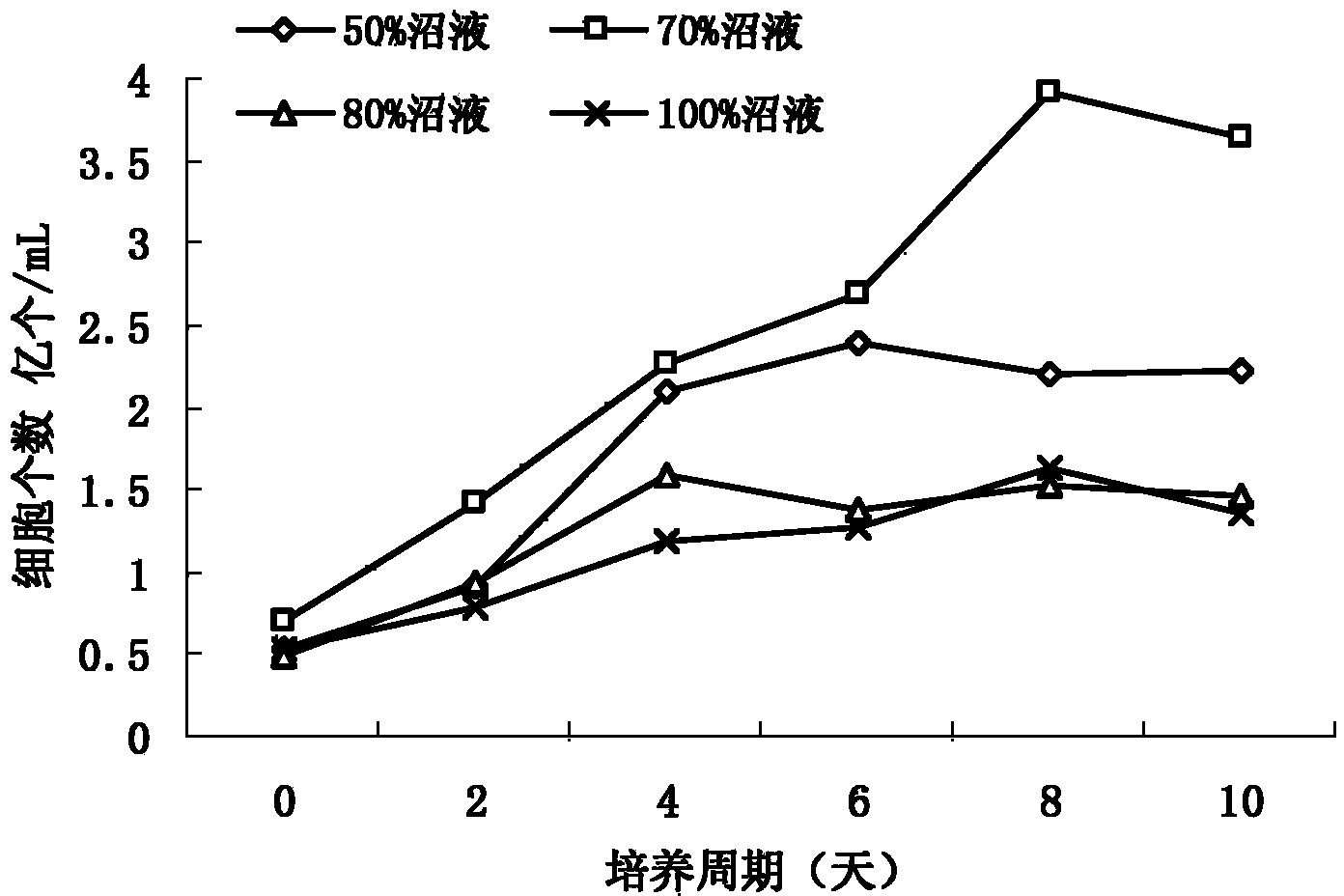

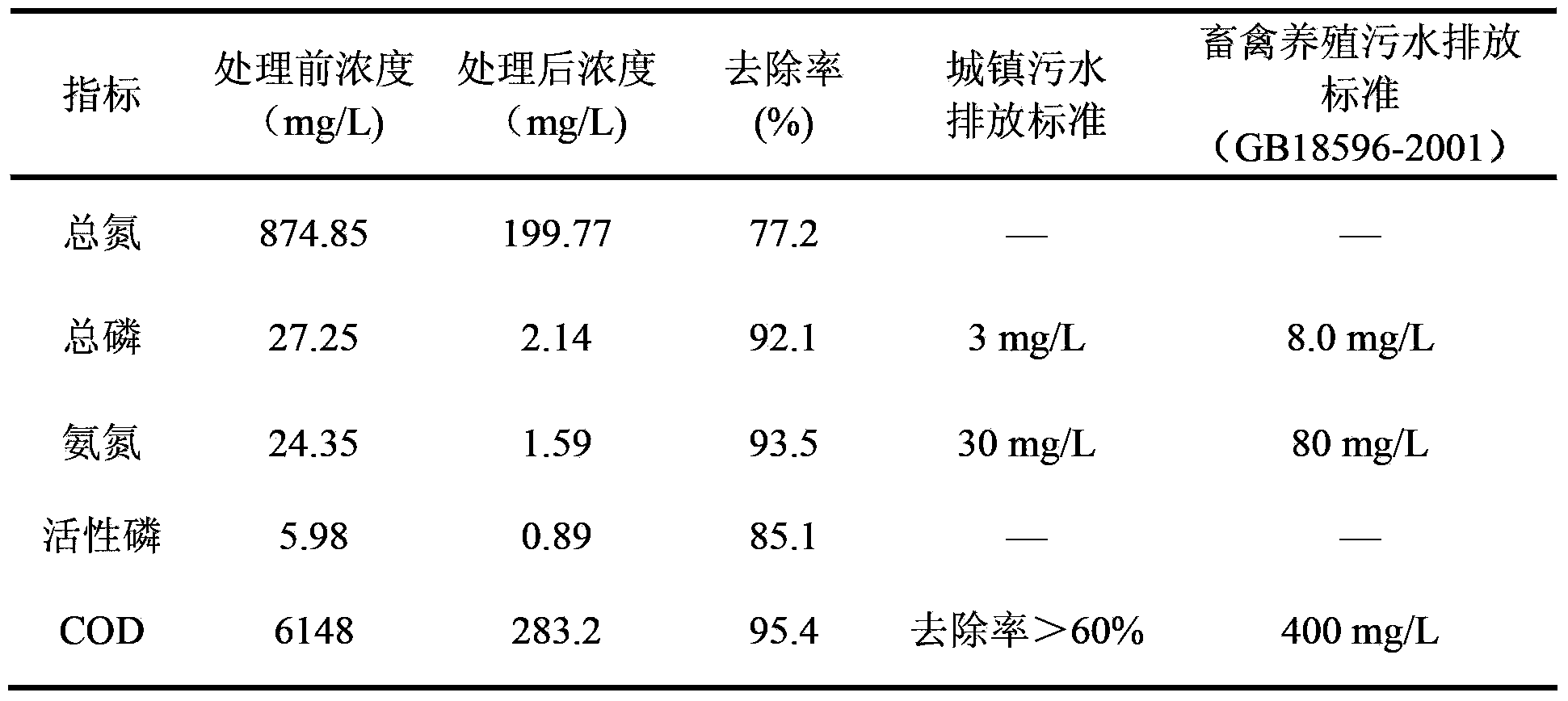

Biogas slurry ecological purification method based on microalgae cultivation

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

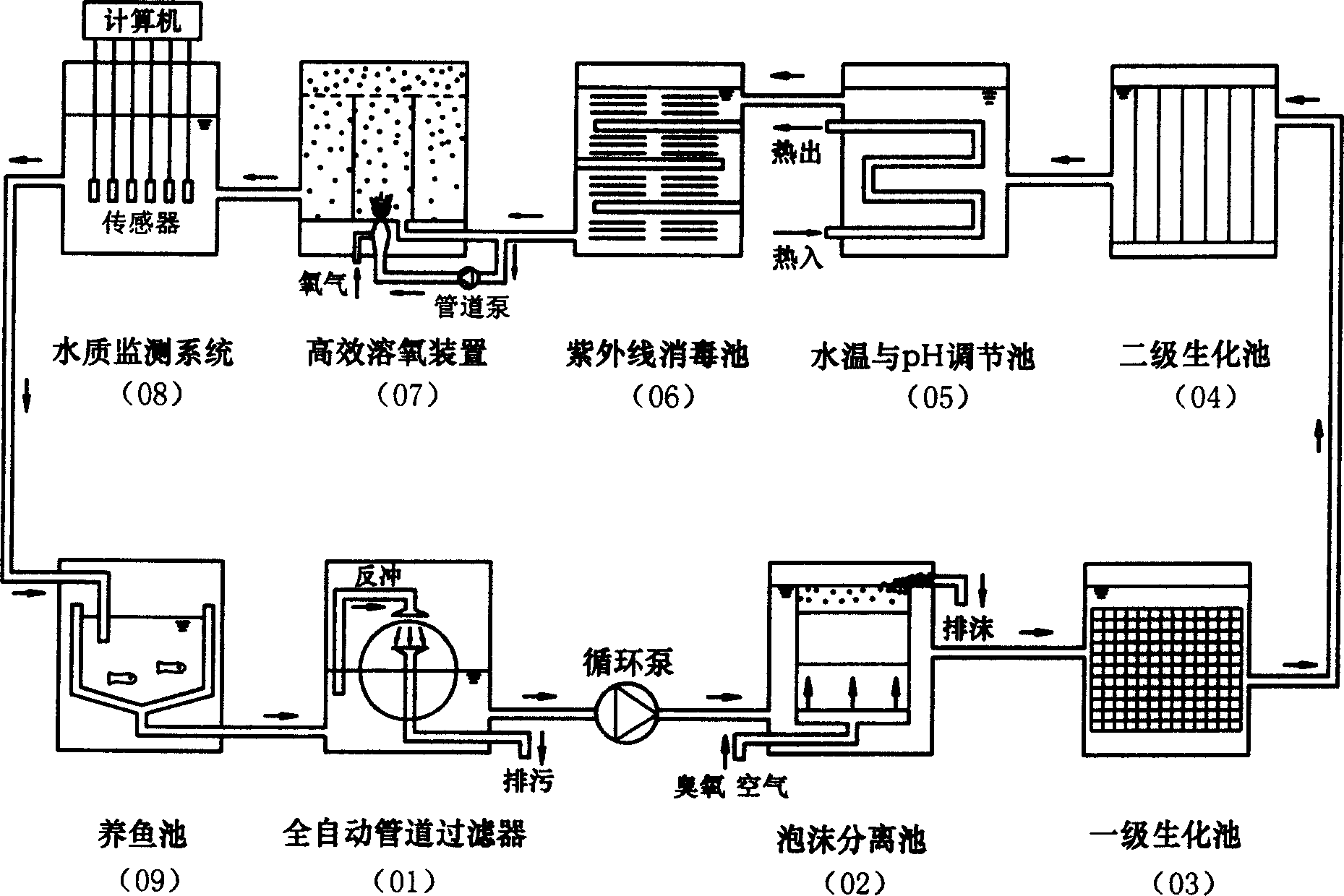

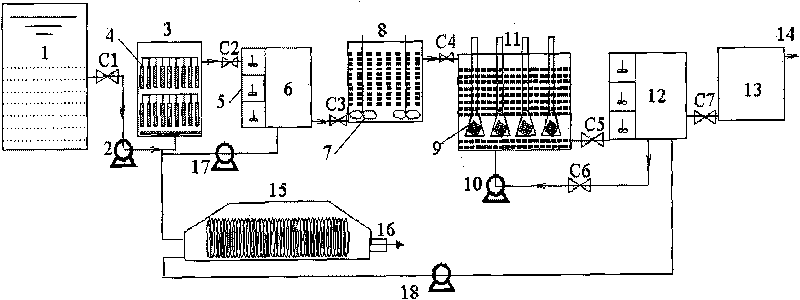

Water treatment method of circulating water fish culture in factory style

InactiveCN1545865AReduce BODReduce CODClimate change adaptationPisciculture and aquariaHuman wasteWater quality

The invention discloses a seawater factory-style circulating water fish farming treatment method which comprises, removing the residual bait and excrement from the seawater flowing out of the fish pond through full-automatic conduit pipe filter apparatus, entering foam separate tank from the circulating pump to remove part of the suspended matter and protein, then removing ammonia nitrogen through biological cleaning tank, adjusting water temperature and pH, disinfecting through ultraviolet rays, oxygenation, charging the detected water into the fish pond again, thus completing a circulation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

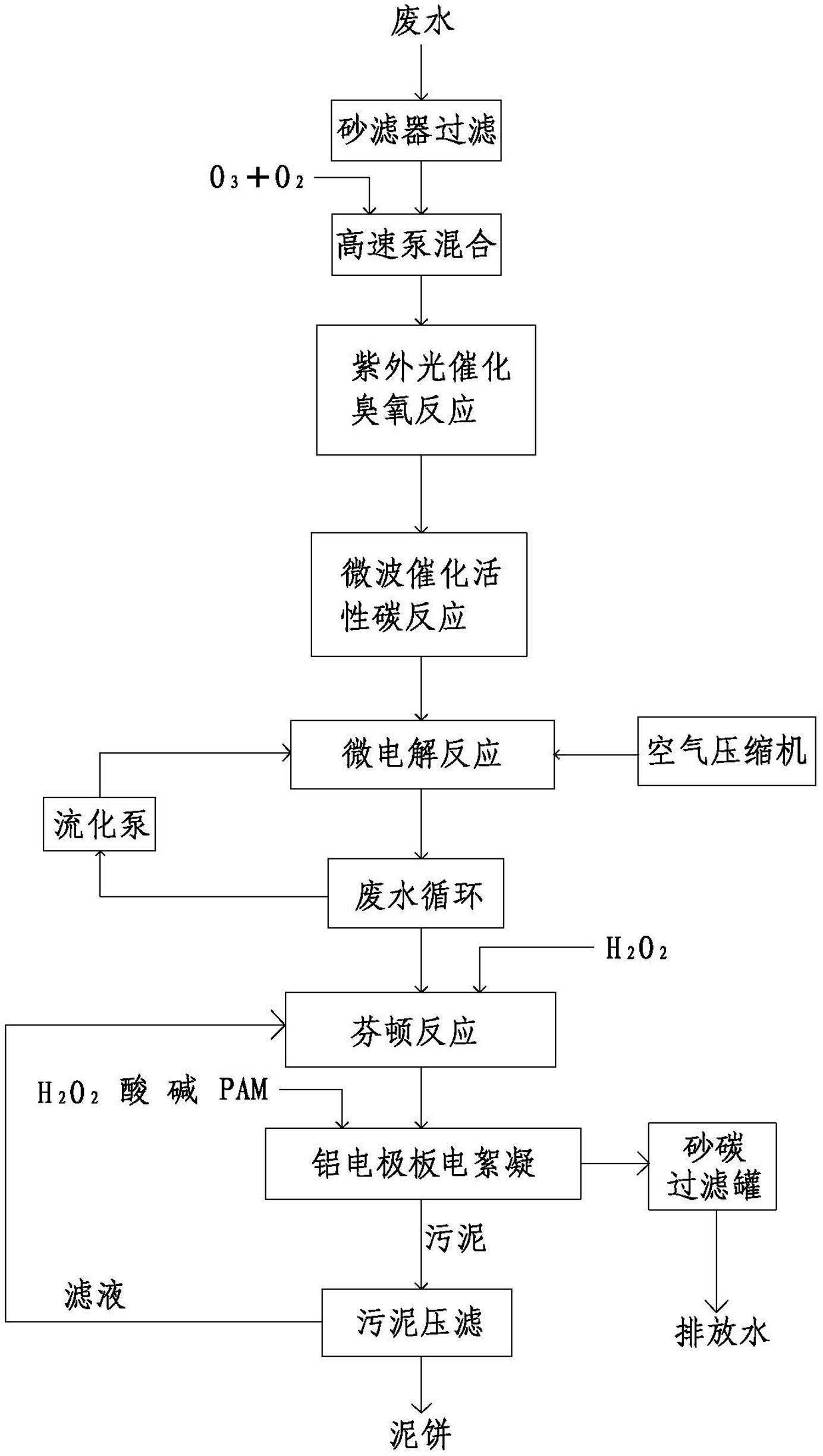

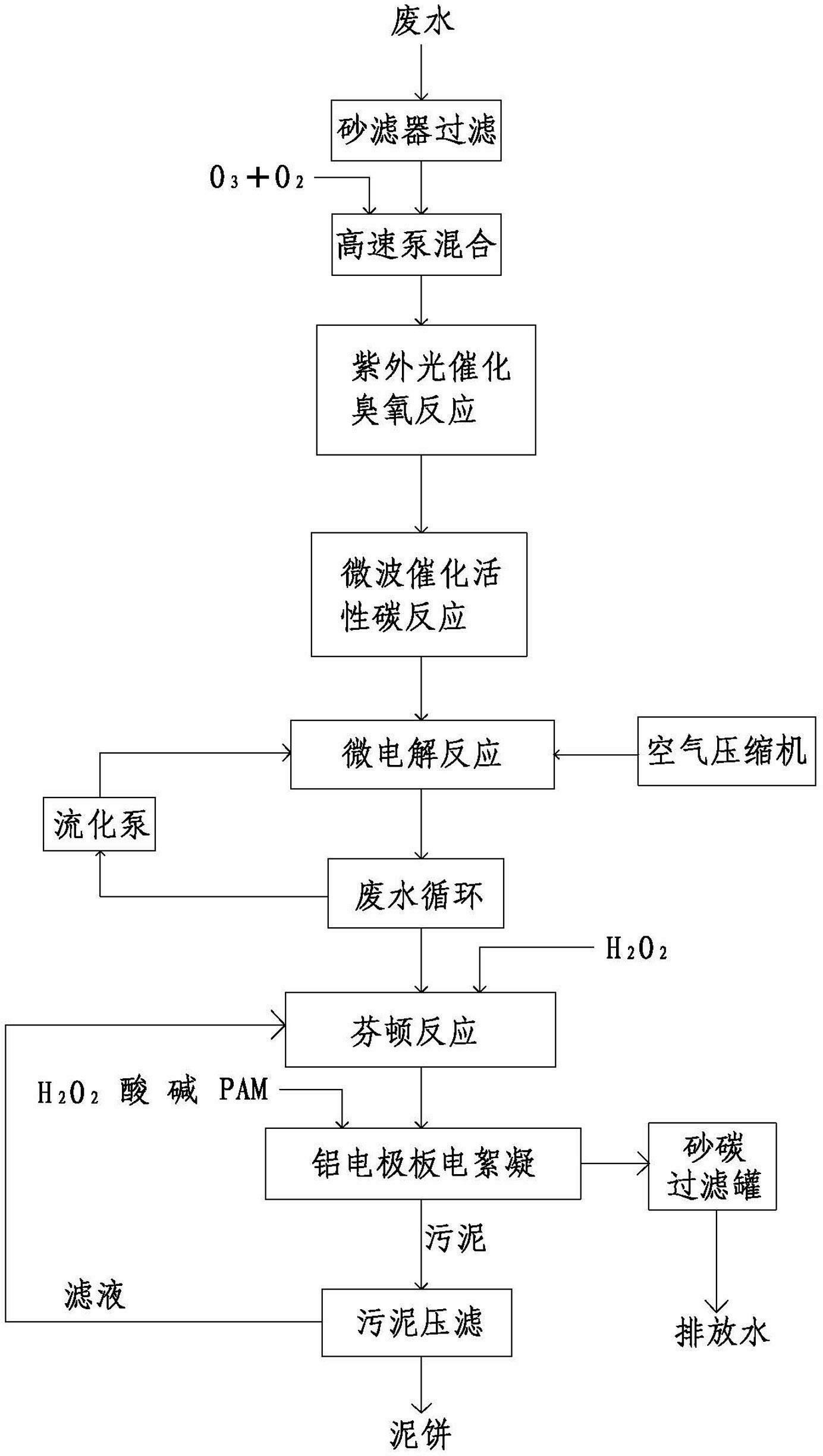

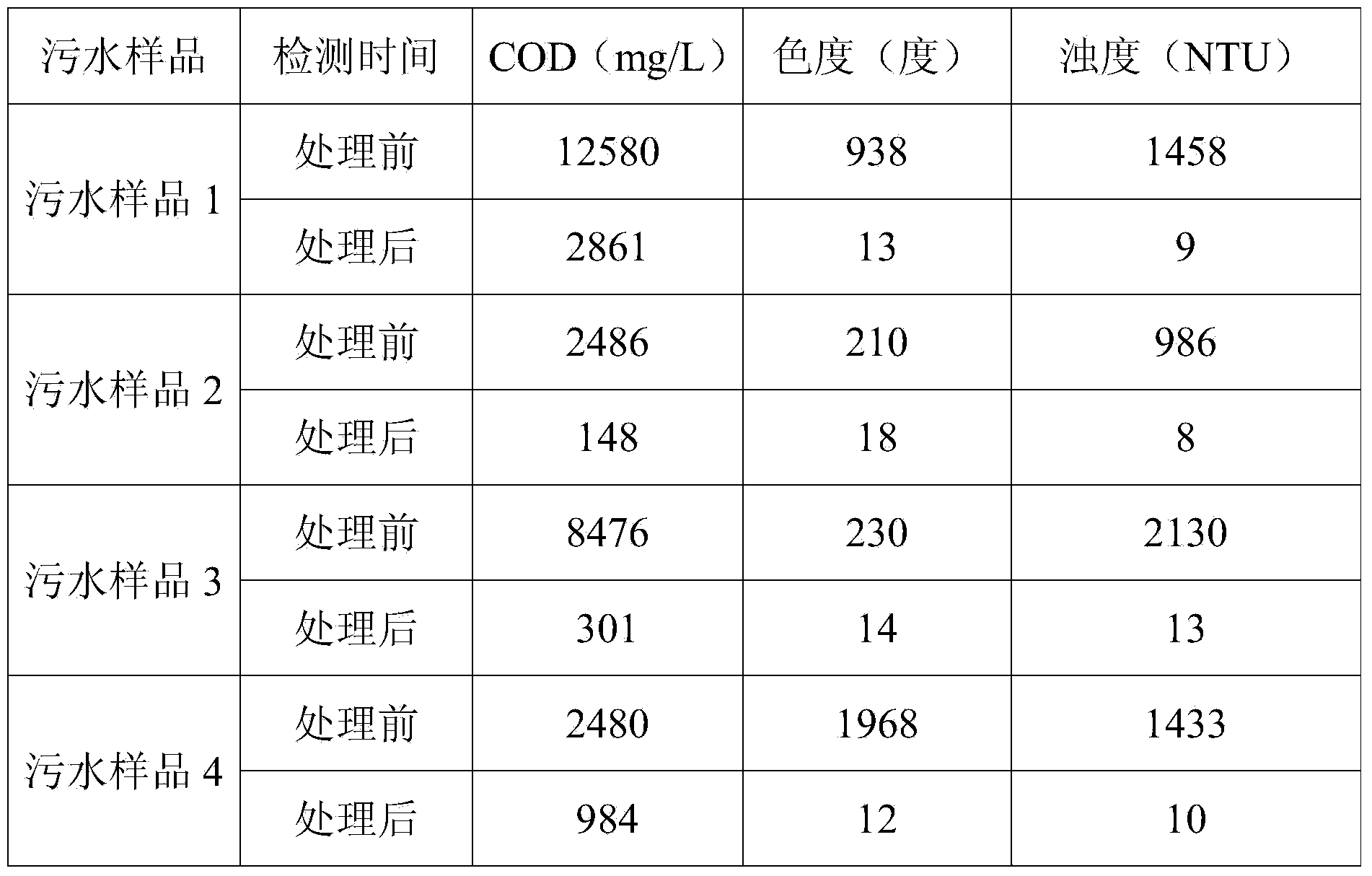

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

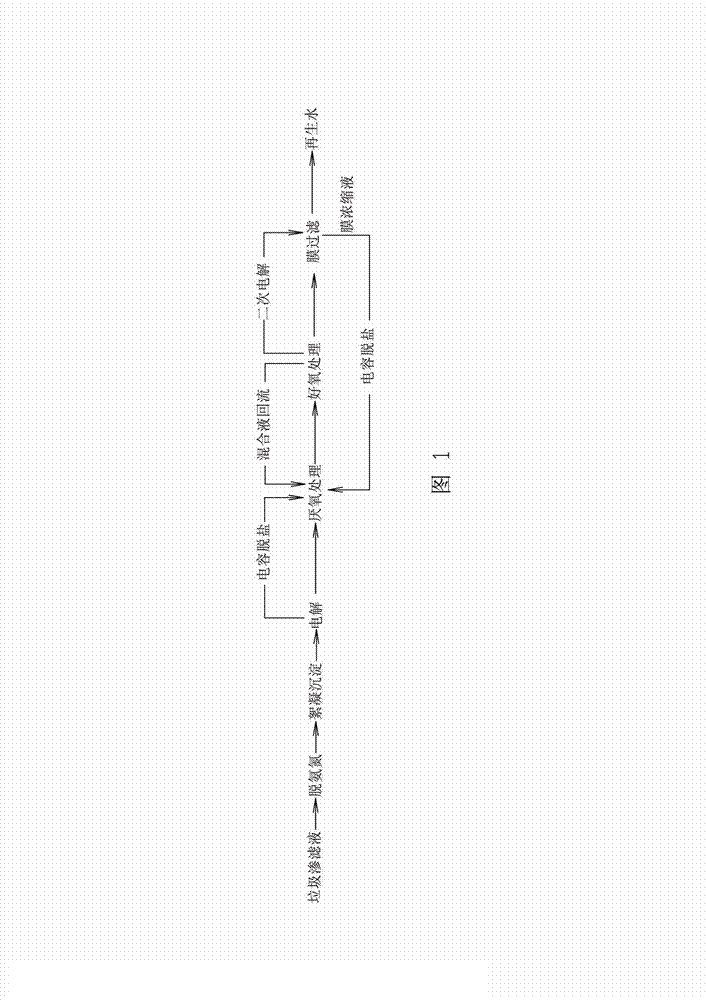

Method for processing garbage leachate

InactiveCN102786183AImprove biodegradabilityReduce CODGeneral water supply conservationTreatment with aerobic and anaerobic processesChemistryCapacitance

The invention discloses a method for processing a landfill leachate, which comprises the following steps of ammonia nitrogen removal, flocculent precipitate, electrolysis, capacitance desalination, anaerobic treatment, aerobic treatment, membrane filtration and membrane concentrate treatment. The method for processing the landfill leachate has the advantages that an electrolysis technology, a membrane technology and a bio-chemical technology are combined to form a method for processing the landfill leachate, the method has the characteristics of stable operation, strong adaptive capacity on water quality change, low cost, high treatment efficiency, effective reduction of index of ammonia nitrogen, COD, SS, chromaticity in the landfill leachate and standard discharge of effluent.

Owner:BOYING XIAMEN SCI & TECH

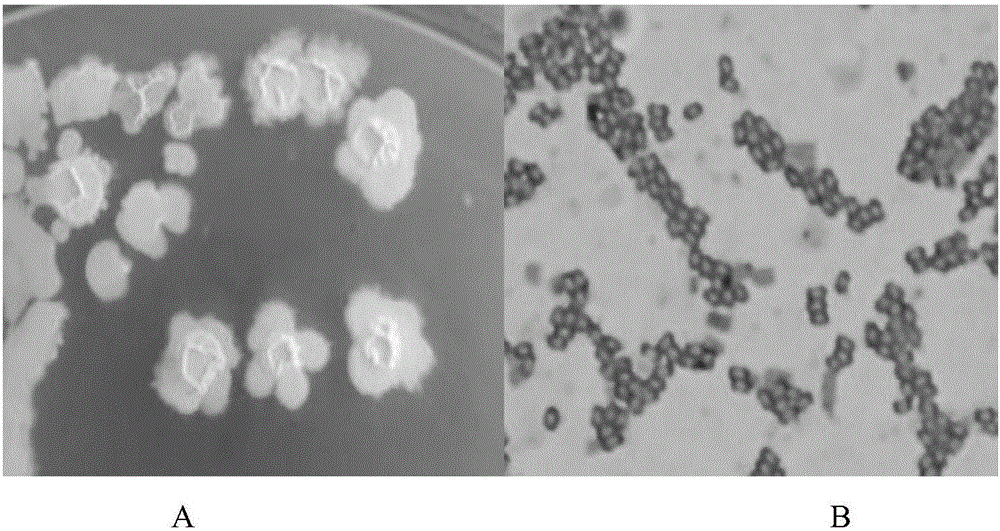

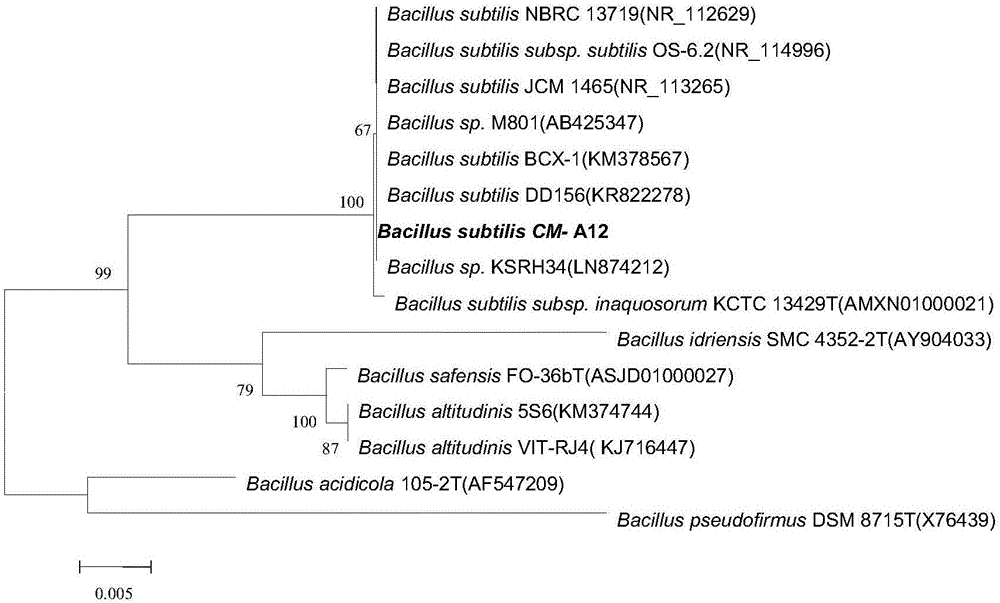

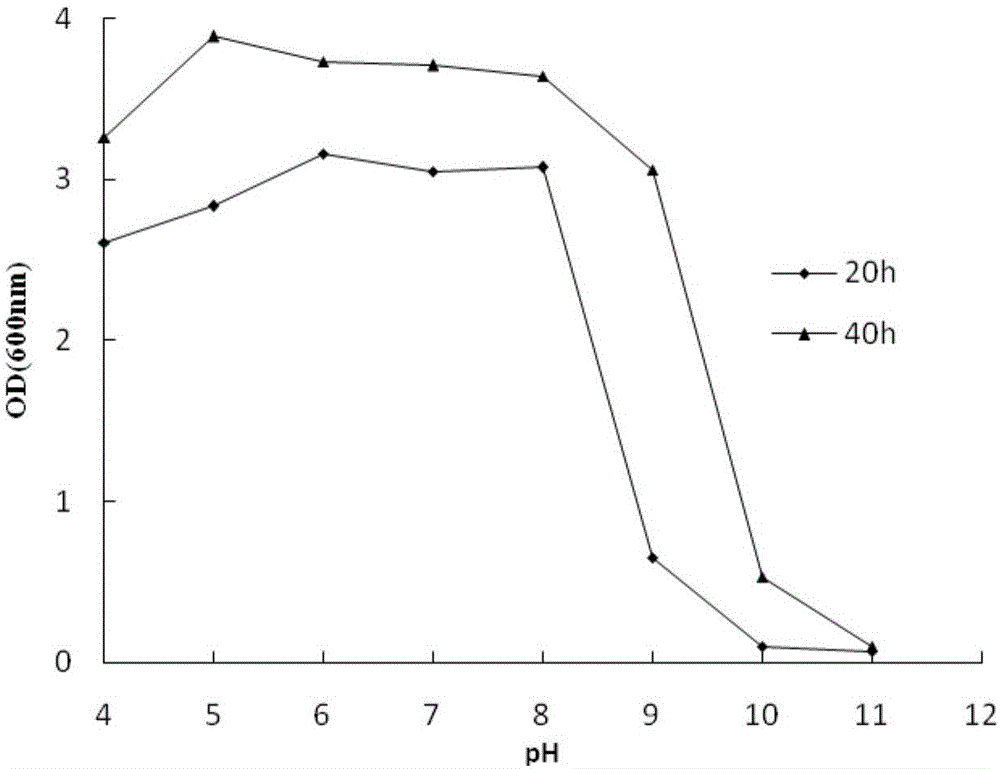

Bacillus subtilis strain and application thereof

ActiveCN106011034ASimple cultivation conditionsReduce CODImmobilised enzymesBacteriaMicroorganismWater quality

Belonging to the field of environmental microorganism application, the invention discloses a Bacillus subtilis strain and application thereof. The strain is named as Bacillus subtilis CM-A12, is currently preserved in China Center For Type Culture Collection (called CCTCC for short) with a preservation number of CCTCC NO:M 2015688, and the preservation date is November 23, 2015. The Bacillus subtilis strain provided by the invention has the advantages of simple cultivation condition, high temperature resistance, acid and alkali resistance, and high salinity resistance, can secrete protease, amylase and cellulase, and can effectively improve water quality and reduce COD and ammonia nitrogen in water.

Owner:浙江至美环境科技有限公司

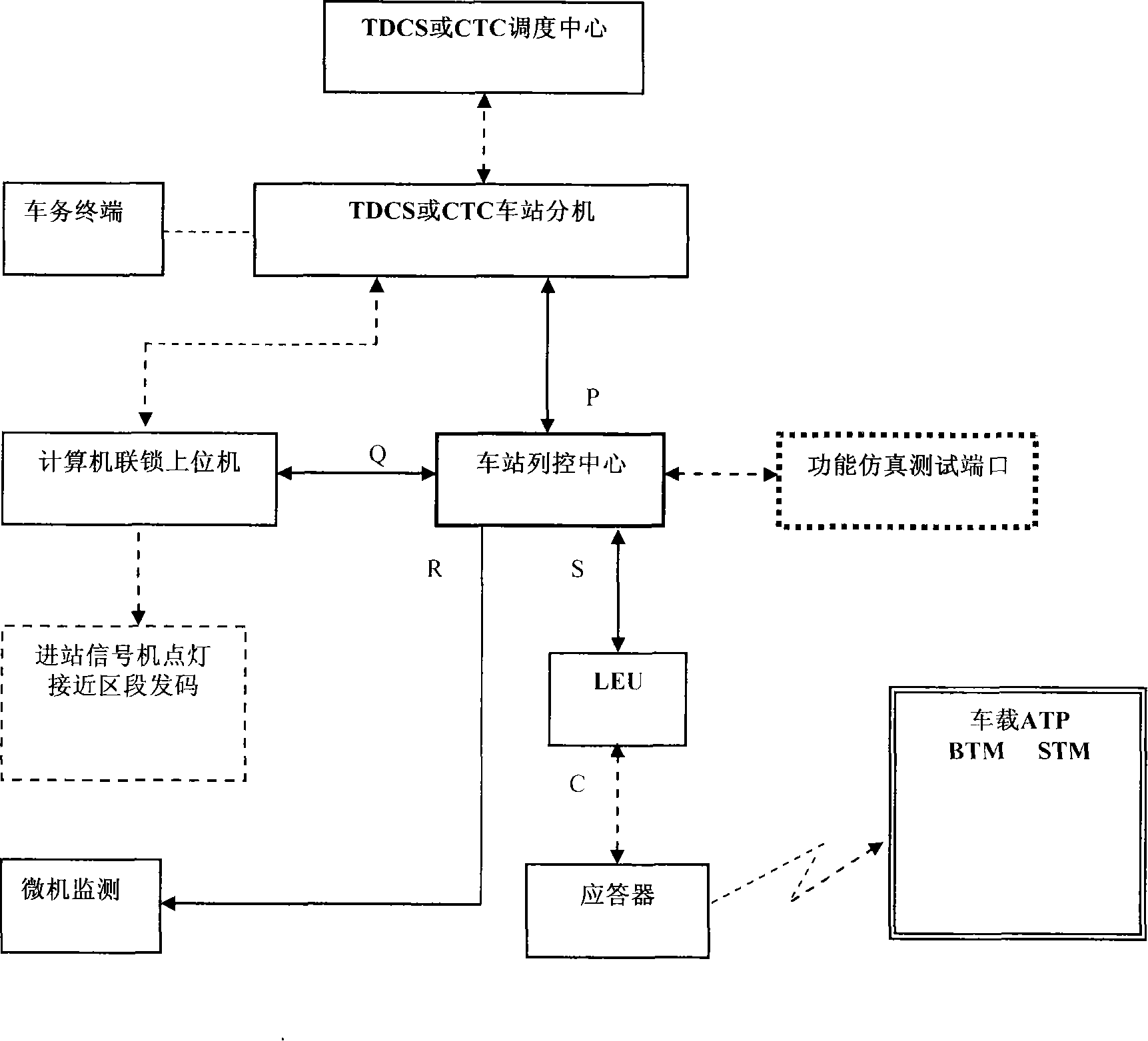

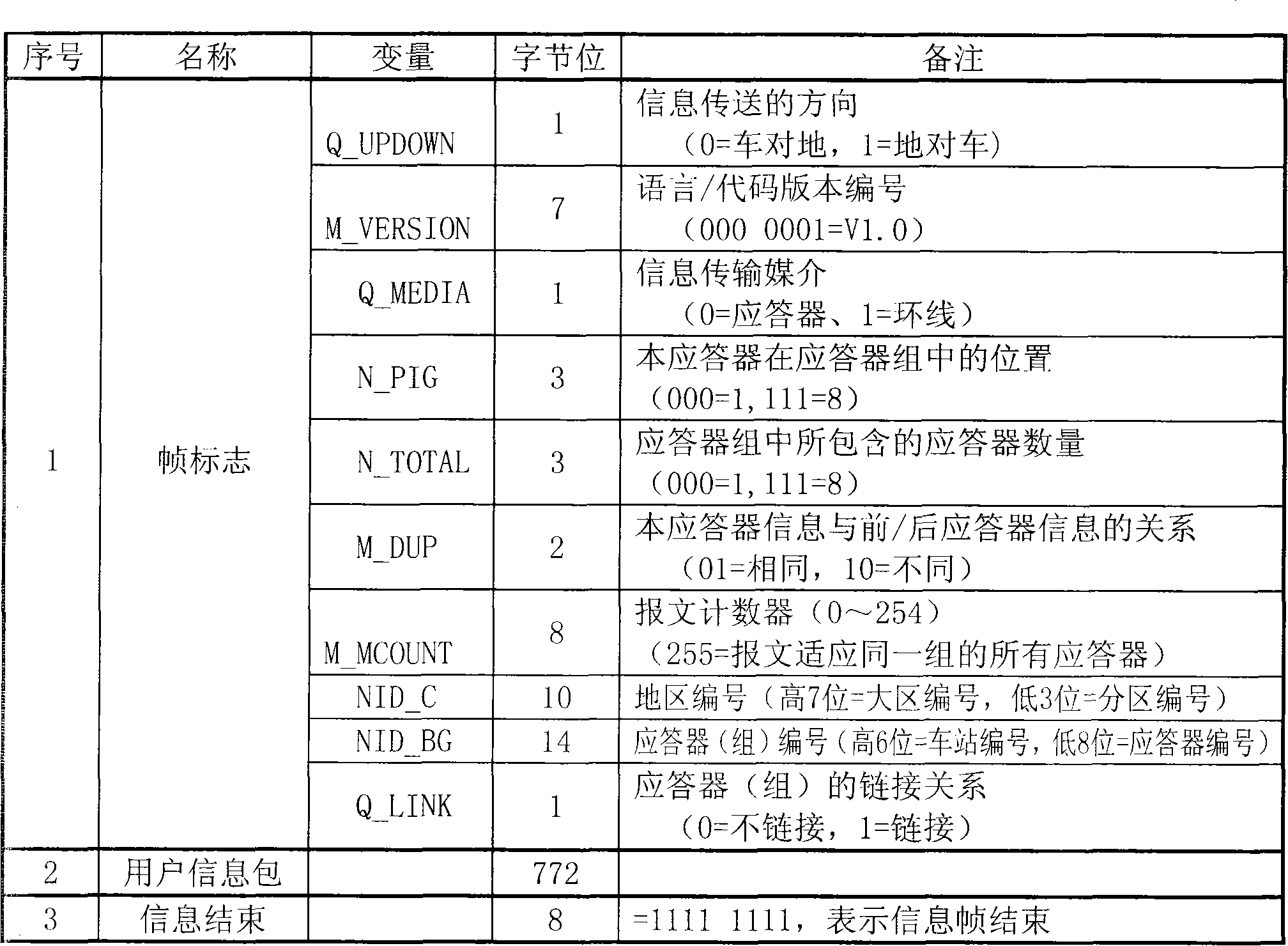

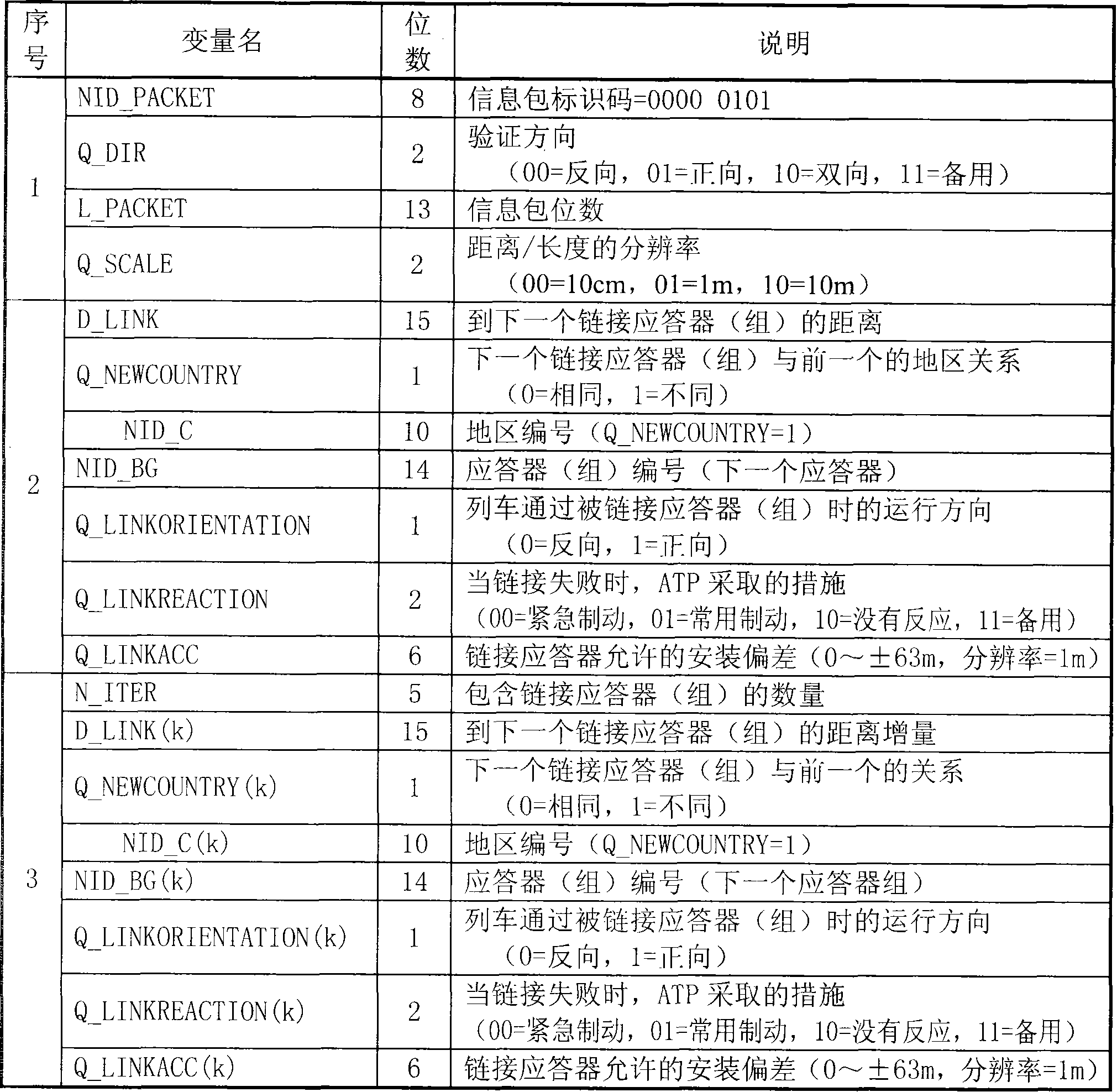

Dynamic message encoding method of train control system

InactiveCN101174921AWork around length limitationsReduce CODError preventionStore-and-forward switching systemsDatasheetControl system

A train control dynamic message coding method can reduce the message coding links in the design stage and save message storage space and omit part of the links of message management to promote the running efficiency of train. The technical proposal is that the method comprises the following steps of dynamic coding design and responder message processing; the dynamic coding design comprises the following steps in specific that the system is collocated with a datasheet; a station static datasheet, a route measurement table, a track sectional table, a responder location table and a long-short linked list are processed; based on the station route condition and responder location, the correspondence between the responder and the route is established and every responder is separately corresponding to difference route and forms circuit parameter packets according to the design principle; the parameter packets comprise a responder link packet, a circuit velocity packet, a circuit slope packet, a track sectional packet, a reverse operational packet, a large-sized switch packet and a shunting danger packet.

Owner:BEIJING JIAXUN FEIHONG ELECTRIC CO LTD

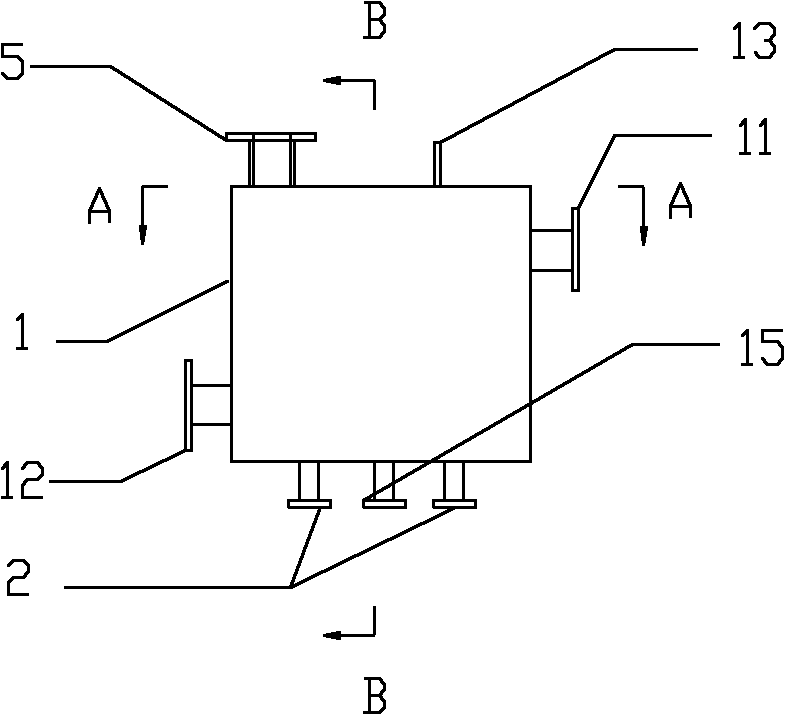

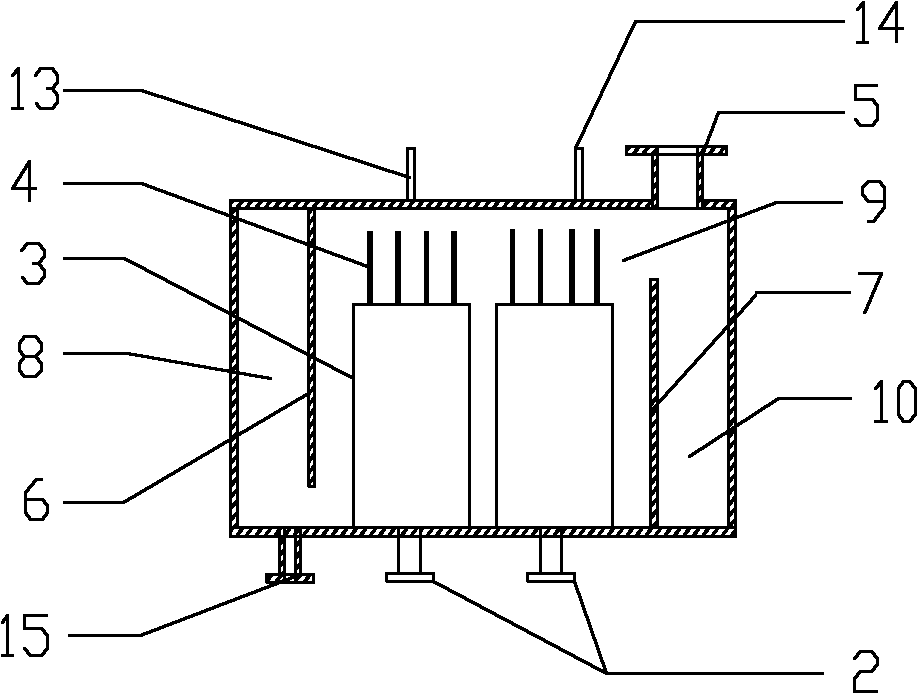

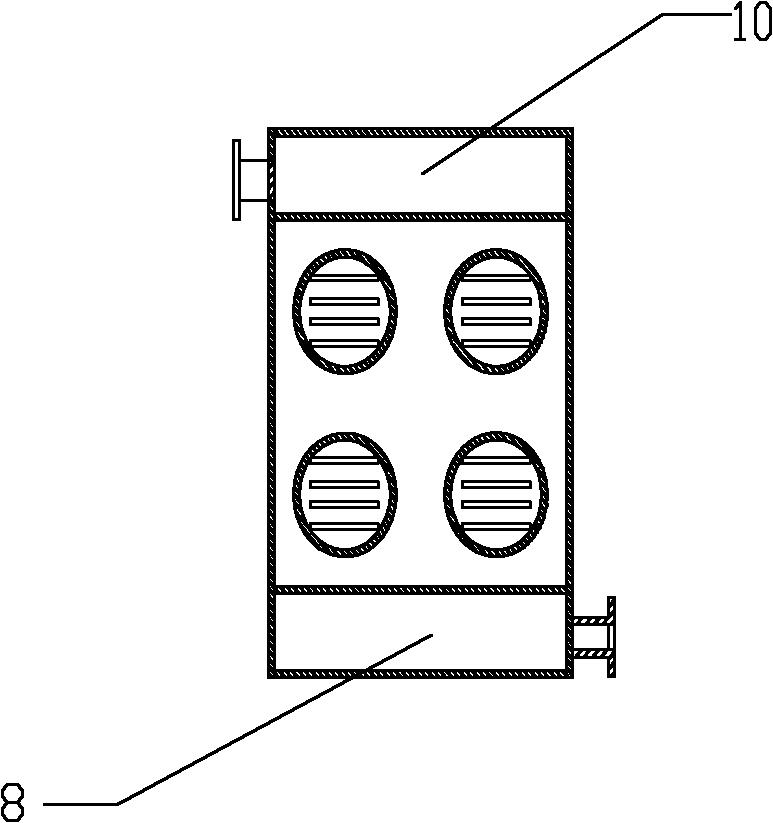

Nano catalytic electrolysis flocculation device

InactiveCN102010038APromote aggregation and sedimentationReduce dosageWater treatment compoundsSpecific water treatment objectivesFlocculationWater discharge

The invention discloses a nano catalytic electrolysis flocculation device, relating to an electrolysis flocculation device. The nano catalytic electrolysis flocculation device has the advantages of extremely low working voltage between two adjacent electrodes, large current density, small energy consumption, high electrical efficiency and no electrode consumption and electrolysis, and integrates solid-liquid separation function and gas-liquid separation function. The bottom of a shell is provided with a water inlet; the shell is internally provided with a scum baffle and a watertight shutter; the scum baffle and one inner side of the shell form a water discharging chamber; a gap is reserved between the bottom of the scum baffle and the bottom of the shell; the scum baffle and the other inner side of the shell form a slag discharging chamber; a gap is reserved between the top of the watertight shutter and the top of the shell; a hydrogen exhaust port is arranged on the top of the shell; an electrolyzer is arranged between the scum baffle and the watertight shutter; the top of the electrolyzer is open and the gap is reserved between the top of the electrolyzer and the top of the shell; electrodes are installed in the electrolyzer; a gas-liquid separation chamber is formed in the shell on the upper part of the electrolyzer; and a drain outlet is arranged at the bottom of the shell and us positioned between the watertight shutter and the adjacent electrolyzer.

Owner:BOYING XIAMEN SCI & TECH

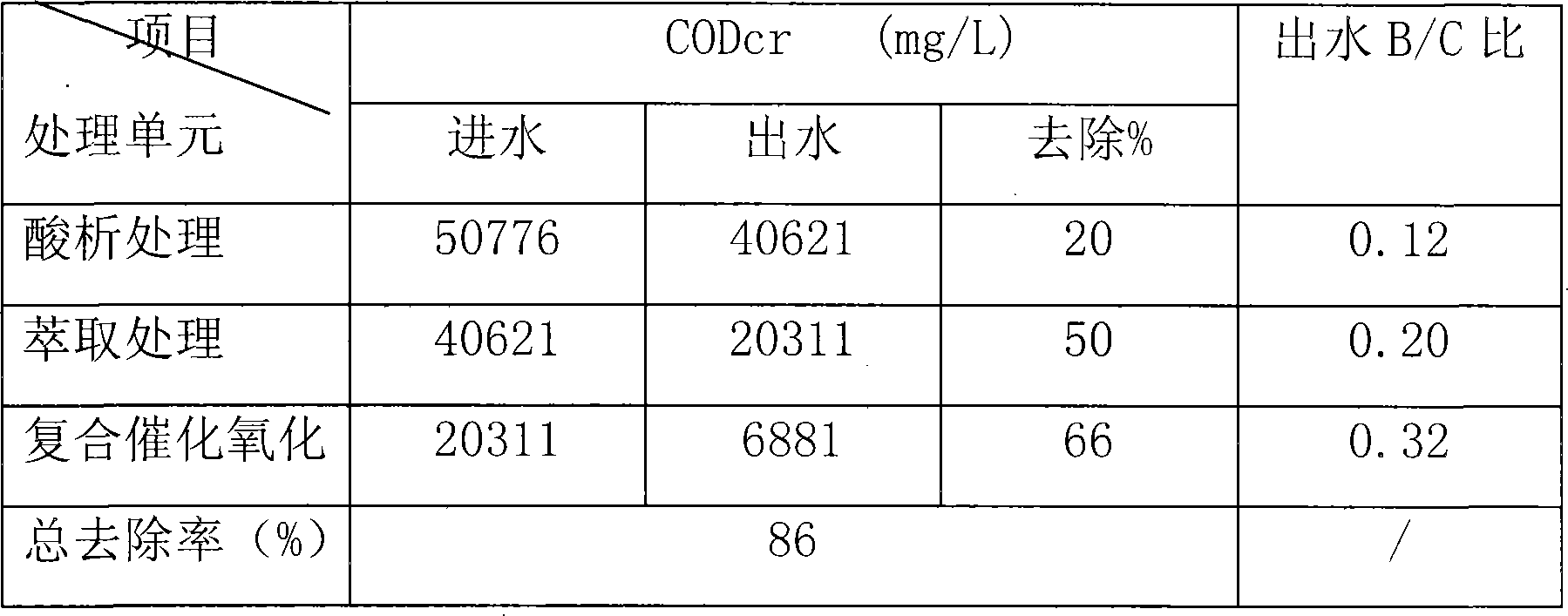

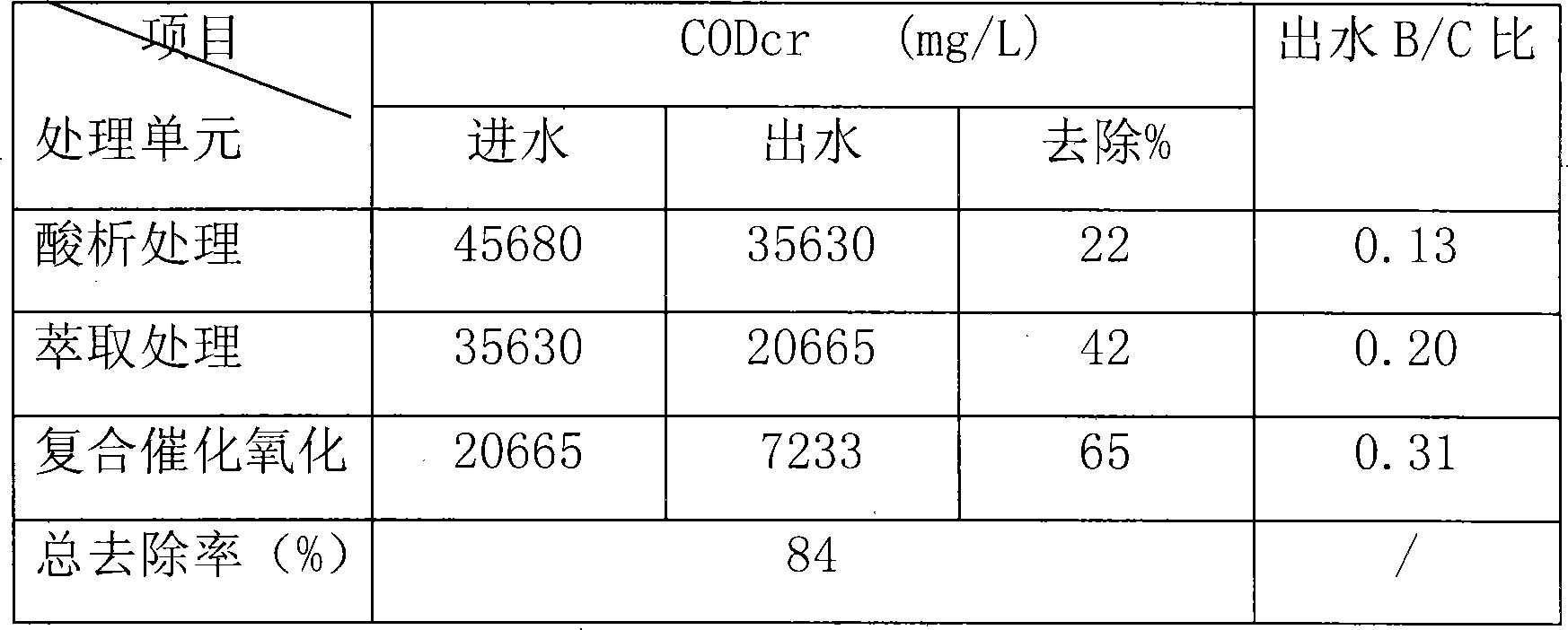

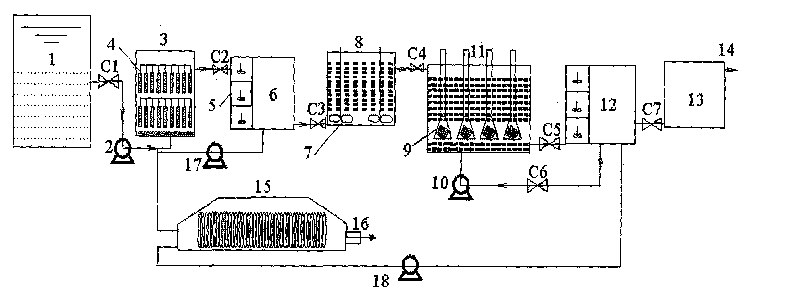

Chlopyrifos pesticides waste water treatment process

InactiveCN101172728APromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCatalytic oxidationPendimethalin

The invention discloses a treatment process of waste water polluted by the pesticide of Dursban, and the process includes the procedures of acid eduction, complexation and extraction, Fenton oxidation and catalytic oxidation. The invention is characterized in that Dursban waste water and herbicide Pendimethalin waste water are comprehensively treated, thereby achieving the proposal of waste controlled by the waste, decreasing the load of organic pollutant being hard to be graded in the waste water, improving the biological degradability of the waste water, removing the pollutant from the waste water, and increasing the biochemical performance of the waste water. Besides, the invention has the advantages of safe and advanced technique, clean operation and low waste water treatment cost.

Owner:山东华阳农药化工集团有限公司

Method for processing high-concentration wastewater containing alkaline mud

ActiveCN101693579ALow toxicityReduce loadTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAerobic treatment systemHigh concentration

The invention discloses a method for processing wastewater containing alkaline mud with high COD concentration, high toxicity, low biodegradability and high chroma. In the invention, a micro-electrolysis pretreatment, and flocculating and decoloring process are adopted to reduce the COD concentration and chroma and improve the biodegradability, thus providing precondition for the subsequent acidified hydrolysis and aerobic treatment system to further eliminate alkaline mud contamination load; and the yielding water is deposited by a deposition pool and discharged after disinfection. In the invention, the COD concentration (80,000-300,000mg / L) and the chroma (12,500-50,000 times) of inflowing water are improved to maximum degree, stability for the running of system is considered sufficiently, a large amount of diluted water required in the running process is saved, the yielding water can be directly exhausted to urban sewage pipelines, received by waterbody or combined in other treatment systems for treatment, and can comply with the recycling standard. In the whole treatment process, the secondary pollution is not generated, the total emission amount of COD is reduced, the whole system runs conveniently and quickly, and the investment and running expense is far lower than that of the traditional film treatment system.

Owner:TONGJI UNIV +1

Washing process for denim garment

ActiveCN104532592ANo effect on air qualityReduce storage pressureBiochemical fibre treatmentDry-cleaning apparatus for textilesChemical oxygen demandRoom temperature

The invention relates to a washing process for a denim garment. The washing process comprises the following steps: performing bio-enzyme de-sizing treatment in an amylase solution after performing denim garment fabric pre-treatment; performing enzyme washing by neutral enzyme powder; dehydrating and drying after cleaning with clean water; performing monkey wash on the fabric surface; performing neutralization treatment on the fabric which is subjected to monkey wash; adding a softening agent to perform softening treatment on the fabric; cooling the denim garment fabric to room temperature after dehydrating and drying, thereby completing washing on the denim garment. Compared with the prior art, the washing process has the advantages of quickly removing residual manganese ions, shortening the processing time, removing the color of a bleaching liquid, reducing the cleaning frequency, being low in sewage COD (chemical oxygen demand), and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

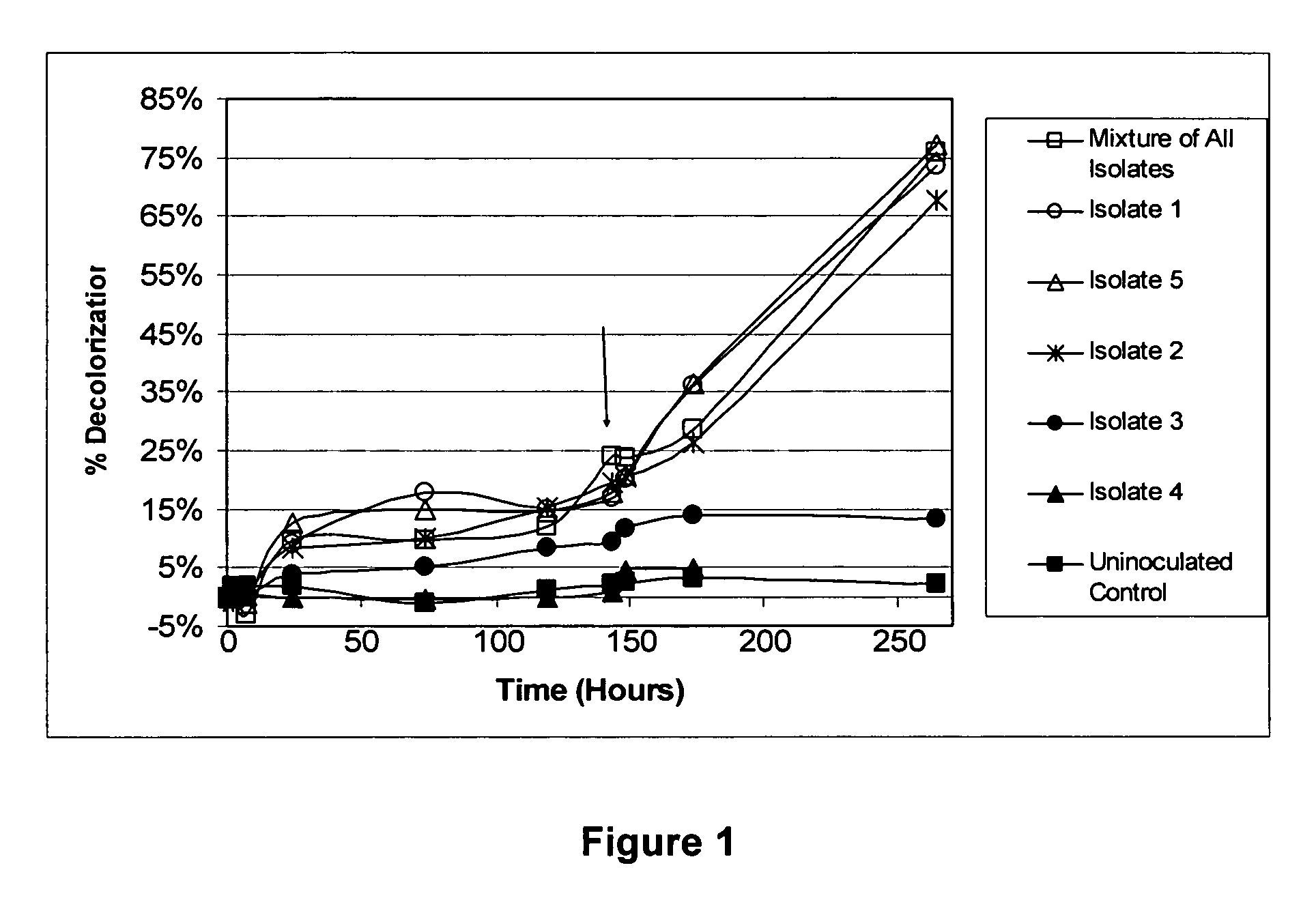

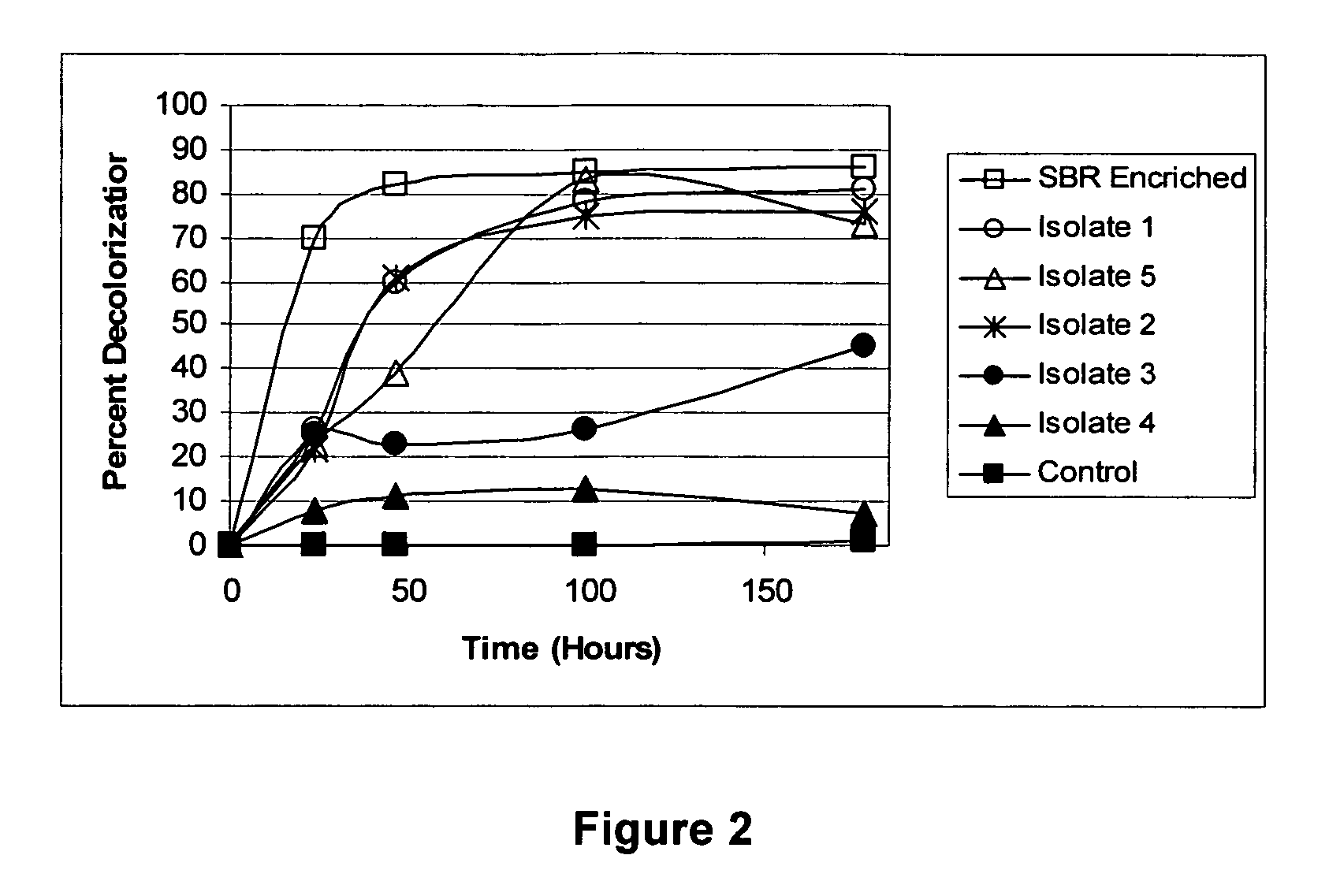

Wastewater treatment compositions

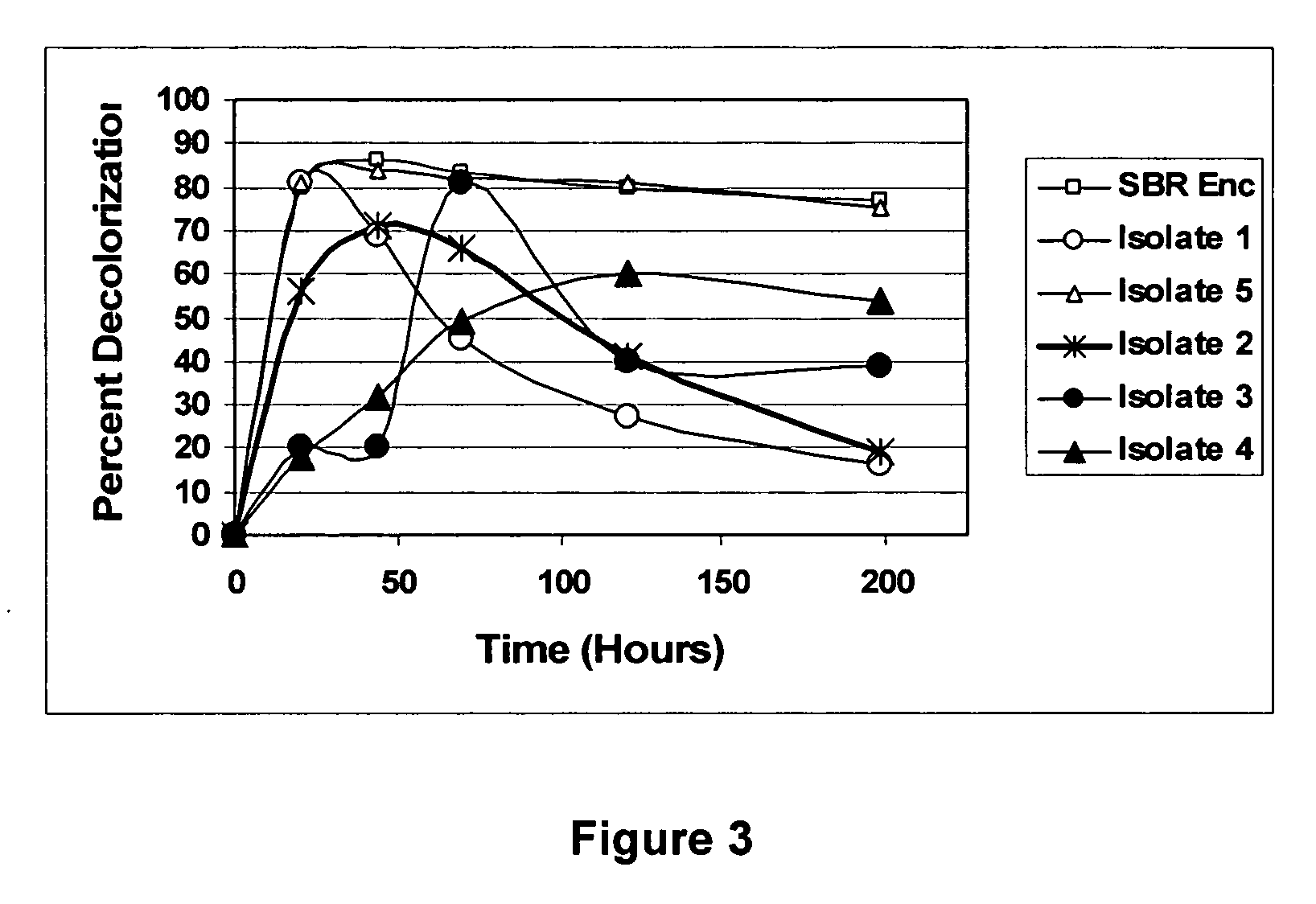

InactiveUS20060194303A1Remove and reduce colorReduce CODWater treatment compoundsWater contaminantsMicroorganismPaper mill

The present invention relates to a wastewater treatment composition and a process of decolorizing pulp and paper mill wastewater and, more specifically, to a process for treating wastewater effluent from a pulp or paper mill with a microorganism whereby color bodies in the pulp and paper wastewater are thereby removed and the wastewater is decolorized.

Owner:NOVOZYMES BIOLOGICALS +1

Compound microorganism agent for treating black and odorous water body

ActiveCN108441444AImprove the problem of smelly and blackHigh transparencyFungiBacteriaBacillus licheniformisCandida tropicalis

The invention provides a compound microorganism agent for treating a black and odorous water body. The compound microorganism agent comprises compound bacteria and a compound enzyme preparation, wherein the compound enzyme preparation comprises candida tropicalis, candida utilis, bacillus natto, bacillus subtilis, bacillus licheniformis, nitrobacter, achromobacter denitrificans, nitrosomonus, acinetobacter, lactobacillus, aspergillus niger, aspergillus oryzae and photosynthetic bacteria; the compound enzyme preparation comprises protease, amylase, lipase, sucrase, and cellulase.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

Microbial deodorant and preparation method thereof

InactiveCN102258796AStrong fermentation and decomposition abilityGrowth inhibitionFungiBacteriaCfu - colony-forming unitSaccharomyces cerevisiae

The invention applies to provide a microbial deodorant which is a microbial colony composed of lactobacillus plantarum, bacillus subtilis, saccharomyces cerevisiae and rhodopseudomonas palustris, wherein counted by 108CFU (colony-forming unit) / ml as a unit, the total viable count is not less than 10, the lactobacillus plantarum count is not less than 3, the saccharomyces cerevisiae count is not less than 3, the rhodopseudomonas palustris count is not less than 2 and the bacillus subtilis count is not less than 2. The microbial deodorant applied by the invention has stronger zymolysis ability under both aerobic and anaerobic conditions, and the beneficial bacteria mutually play a role in inhibiting the growth of putrefactive bacteria and interrupting the putrefactive process, secrete organic acid while reproducing quickly, and generate antioxidation substances, thus converting odorous substances such as NH3, H2S, indoles and the like into non-odorous substances.

Owner:黄小娃

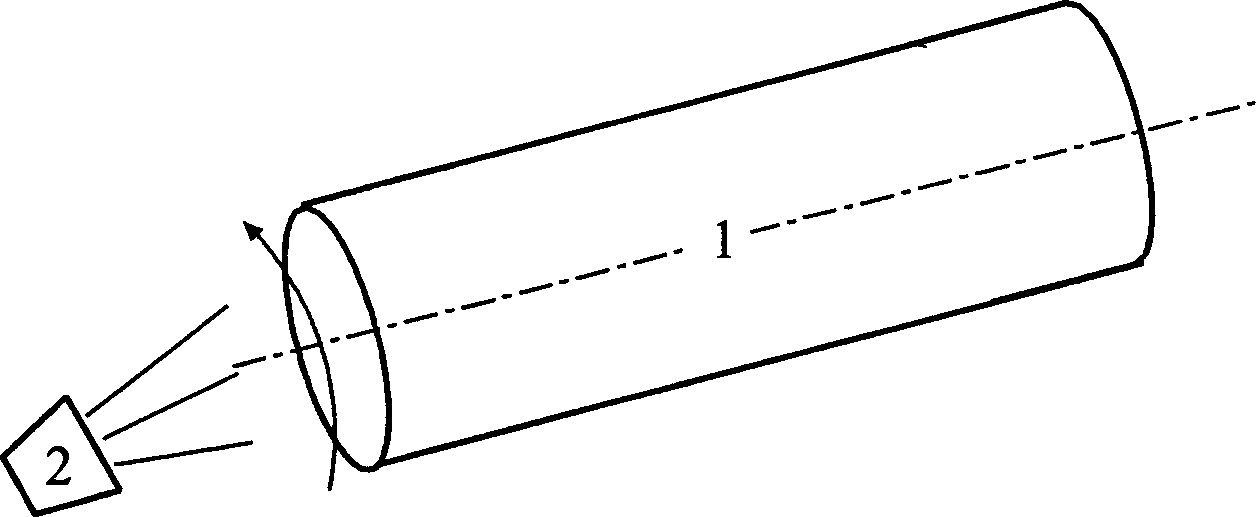

Rotary tubular photo-catalytic reactor and its water treating method

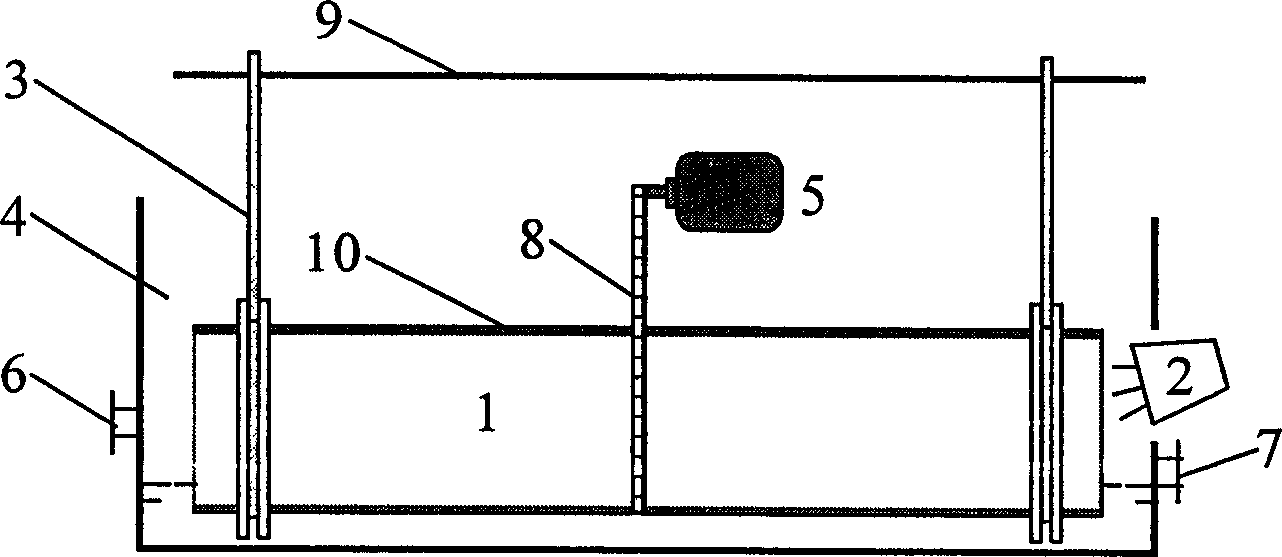

InactiveCN1587085AIncrease contact surfaceFast updateWater/sewage treatment by irradiationPhoto catalyticPhotocatalytic reaction

The rotary tubular photocatalytic reactor includes water trough with water inlet and water outlet, ultraviolet lamp set onto side of the water trough, rotary drum, which has bearing plates and supports in two ends and is set inside the water trough, speed regulating motor meshed to gear on the outer wall of the rotary drum for driving, and thin titania photocatalyst layer painted to the inner wall of the water trough. The present invention has rotary drum as the main body of the reactor and titania photocatalyst layer loaded onto the rotary drum, regulates the rotation speed of the rotary drum to alter the distribution of treated waste water and photocatalyst and to increase the contact area between the catalyst, reactant and light source, and has low power consumption, low treating cost, mild treating condition and other advantages.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

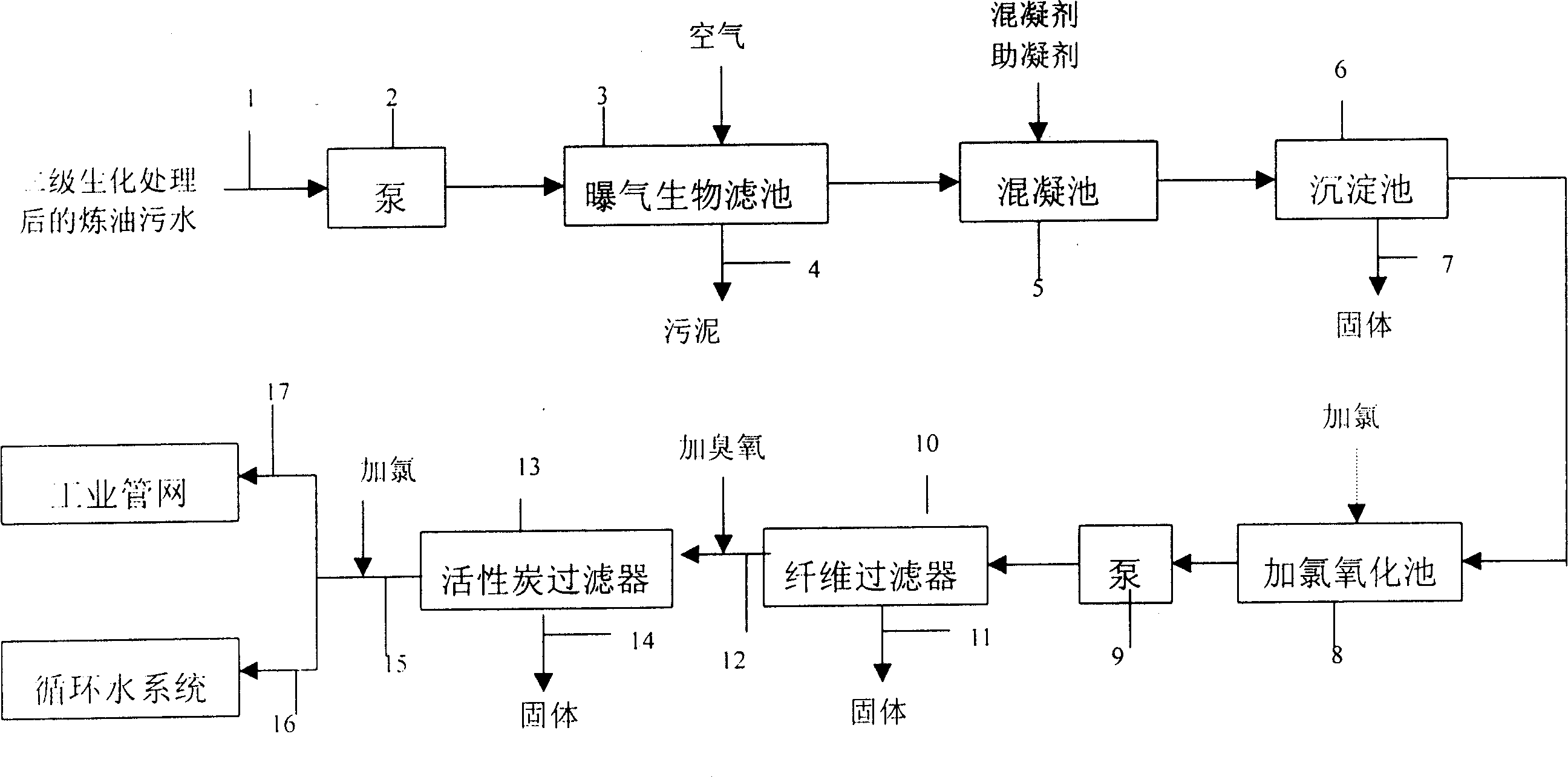

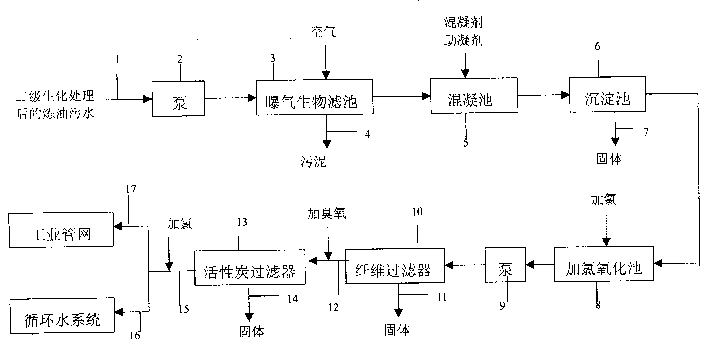

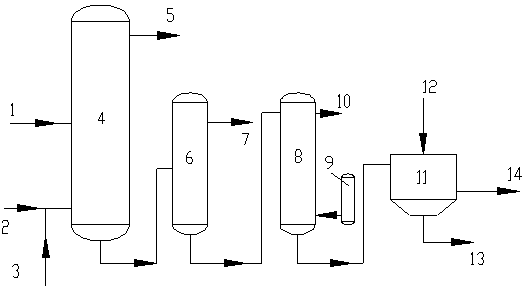

Method for reclamation and utilization of oil refining sewage

The invention relates to a process for reclamation and utilization of oil refining sewage, wherein the the oil refining sewage water is processed in the following steps after second level biological chemical treatment, sending the sewage into aeration biological filter for treatment and then transferring it into coagulation basin, filling coagulating agent and coagulant aid to accelerate the agglomeration of the colloid particles, seding into sedimentation basin for deposition and segregation, adding chlorine to the deposited and segregated water for removing ammonia nitrogen, then performing fiber filter filtration, ozonization, activated charcoal filter filtration, and sterilization by chlorine before being sent into industrial pipe network or as the supply water for circulated water to be sent into circulating water system.

Owner:BEIJING YANSHAN PETROCHEM IND CHINA PETROCHEM GROUP

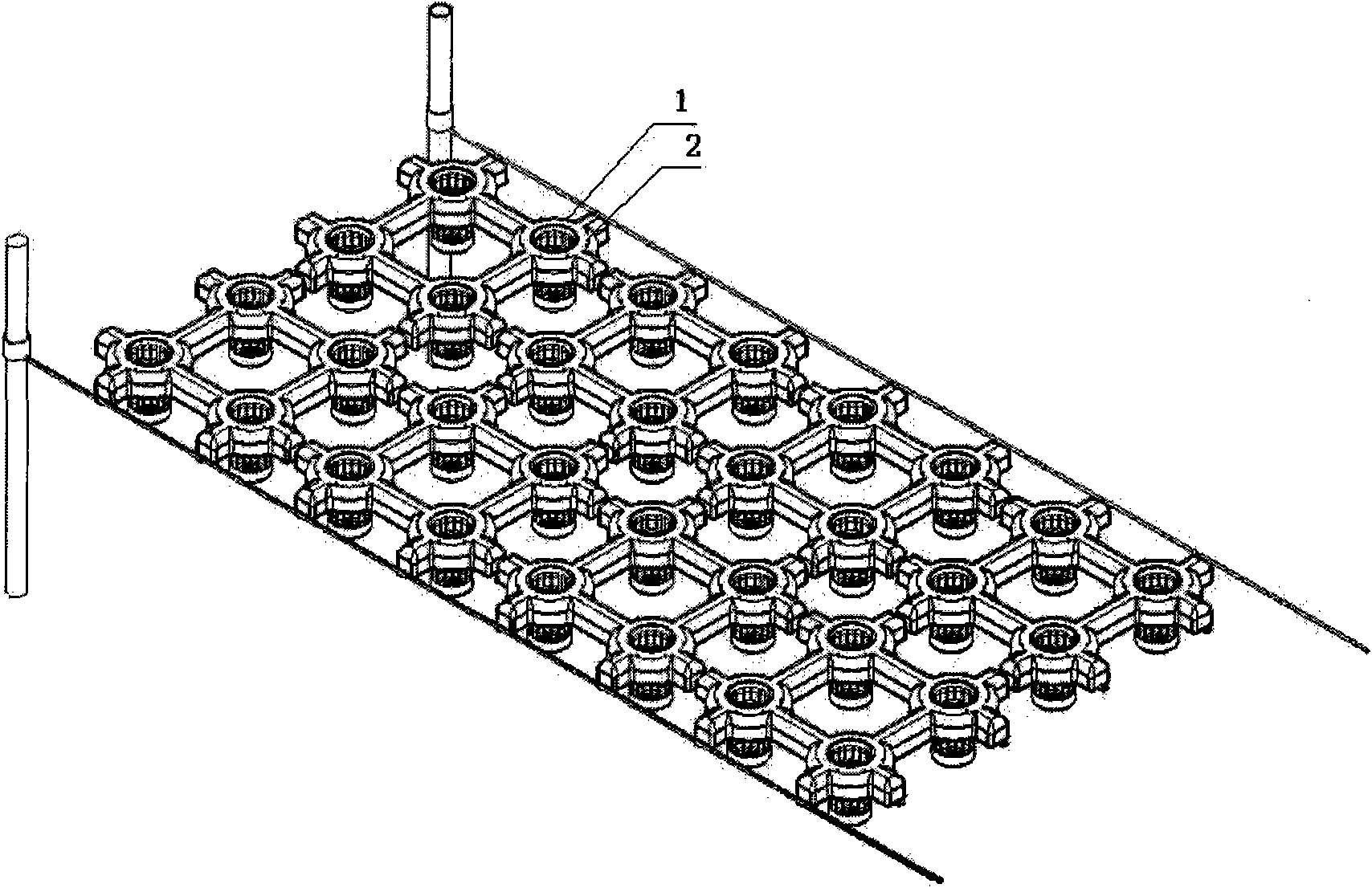

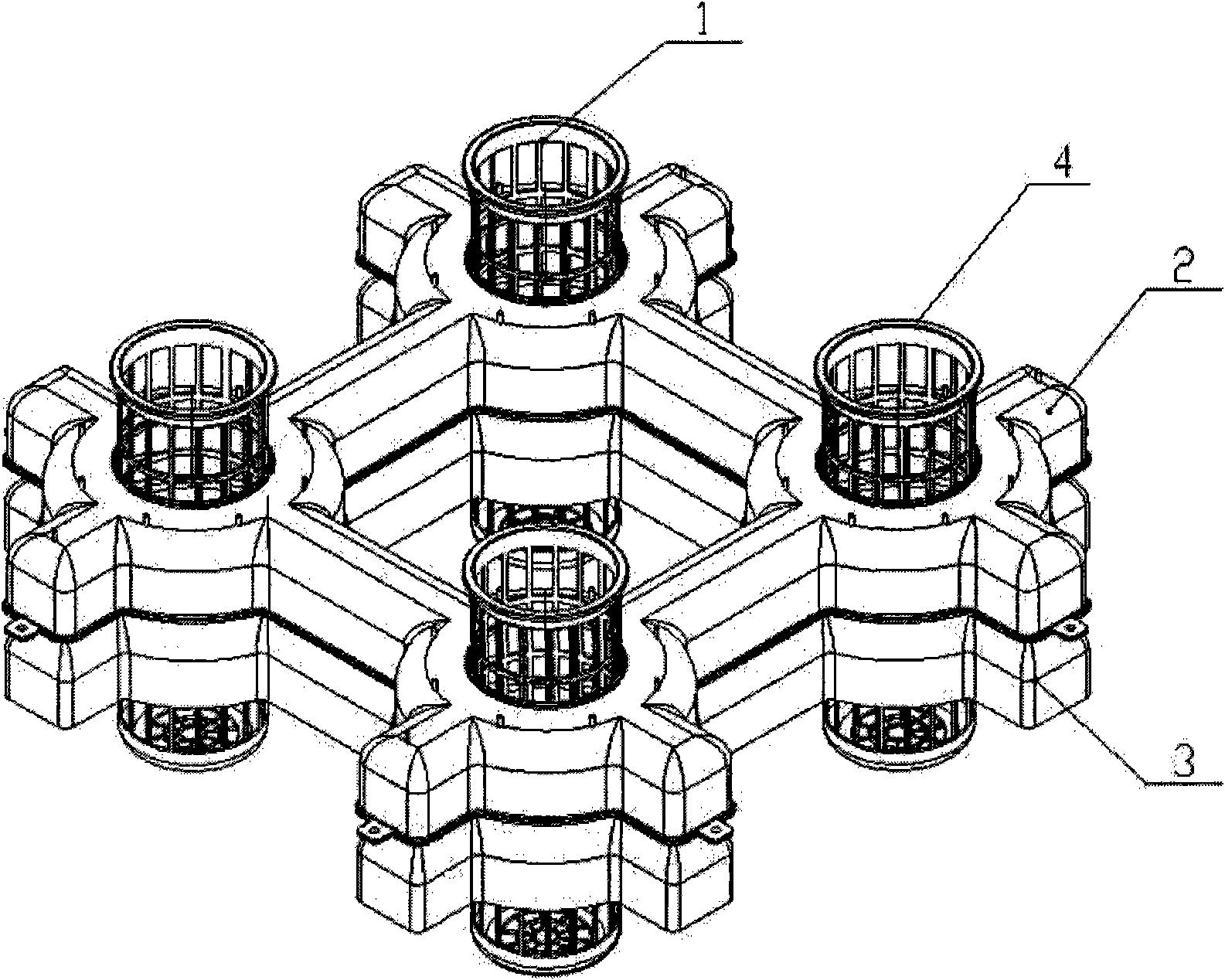

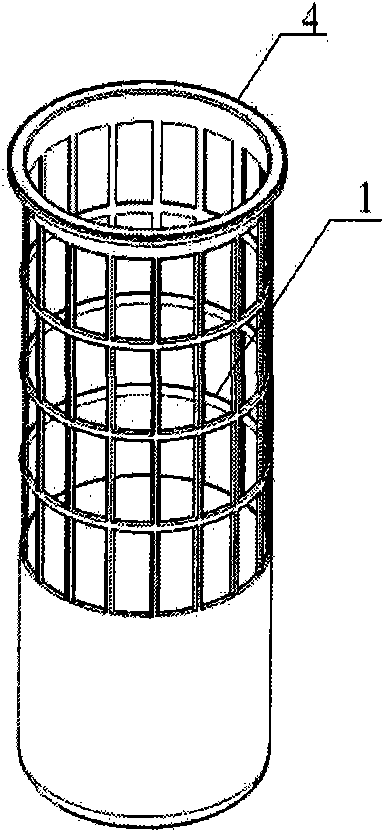

Combined ecological floating bed for water planting plants and flowers

InactiveCN101874469AReduce CODReduce BODAgriculture gas emission reductionCultivating equipmentsFlower gardenNitrogen

The invention relates to a combined ecological floating bed for water planting plants and flowers, which is characterized by comprising one or more ecological floating bed units which are combined, interconnected and fixed to form the combined ecological floating bed for the water planting plants and flowers with various patterns; the ecological floating bed unit comprises a planting basket, a floating bed framework and a foam piece, wherein the planting basket is placed in a planting basket placing port of the floating bed framework; the foam piece is sleeved in a cavity of the floating bed framework; and a plurality of ecological floating bed units are connected to form a large-area water planing plant-flower garden or a fixed green ecological floating island. The ecological floating bed has the advantages of unique structure, convenient manufacture and low cost, can effectively reduce the content of phosphorus and nitrogen-like eutrophic salts polluting the water and COD and BOD, promote the water quality from VI class to III class and beautify the environment, and can be widely applied to the water surfaces of extensive polluted rivers and lakes.

Owner:常州华钛化学有限公司 +1

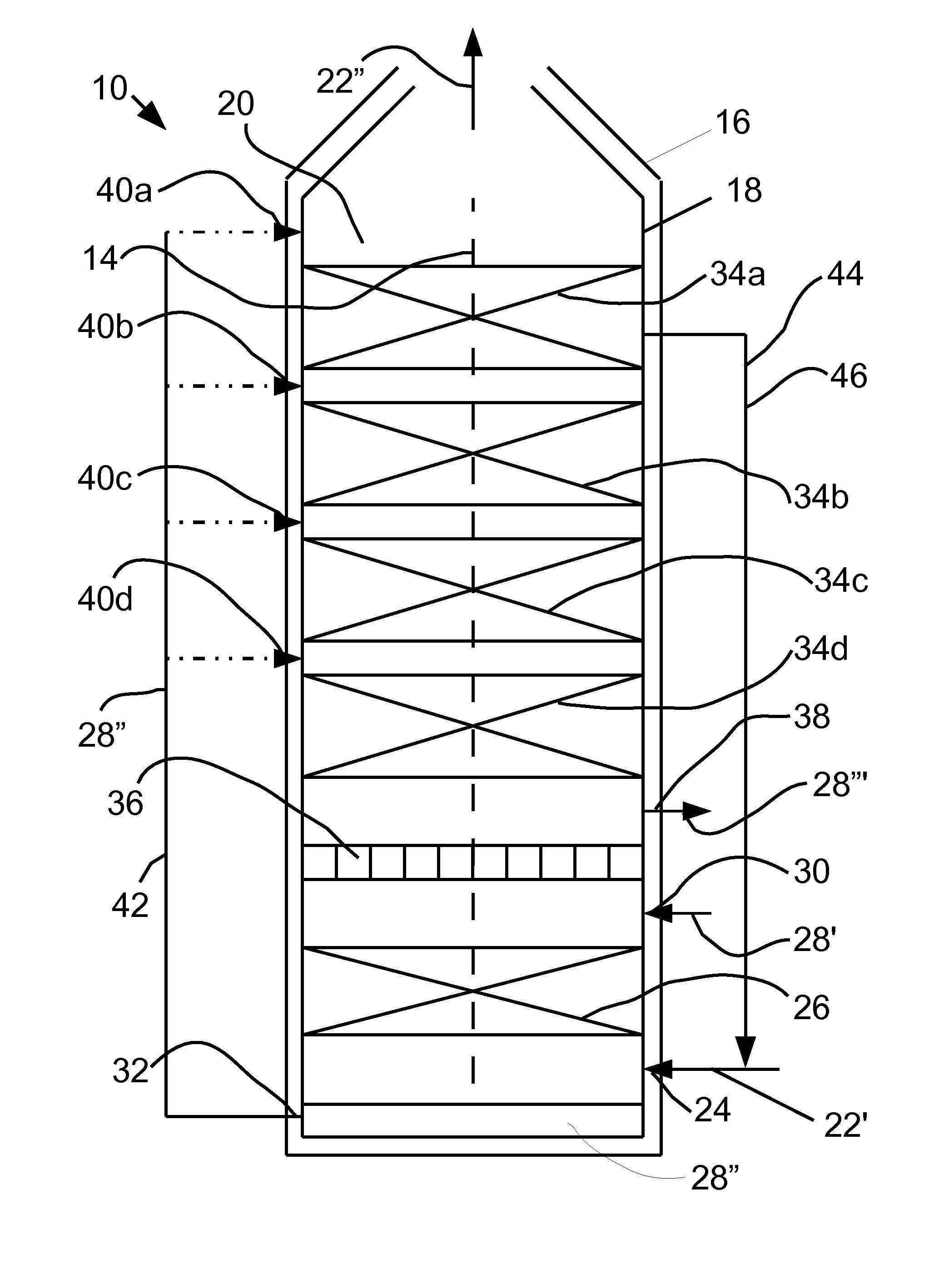

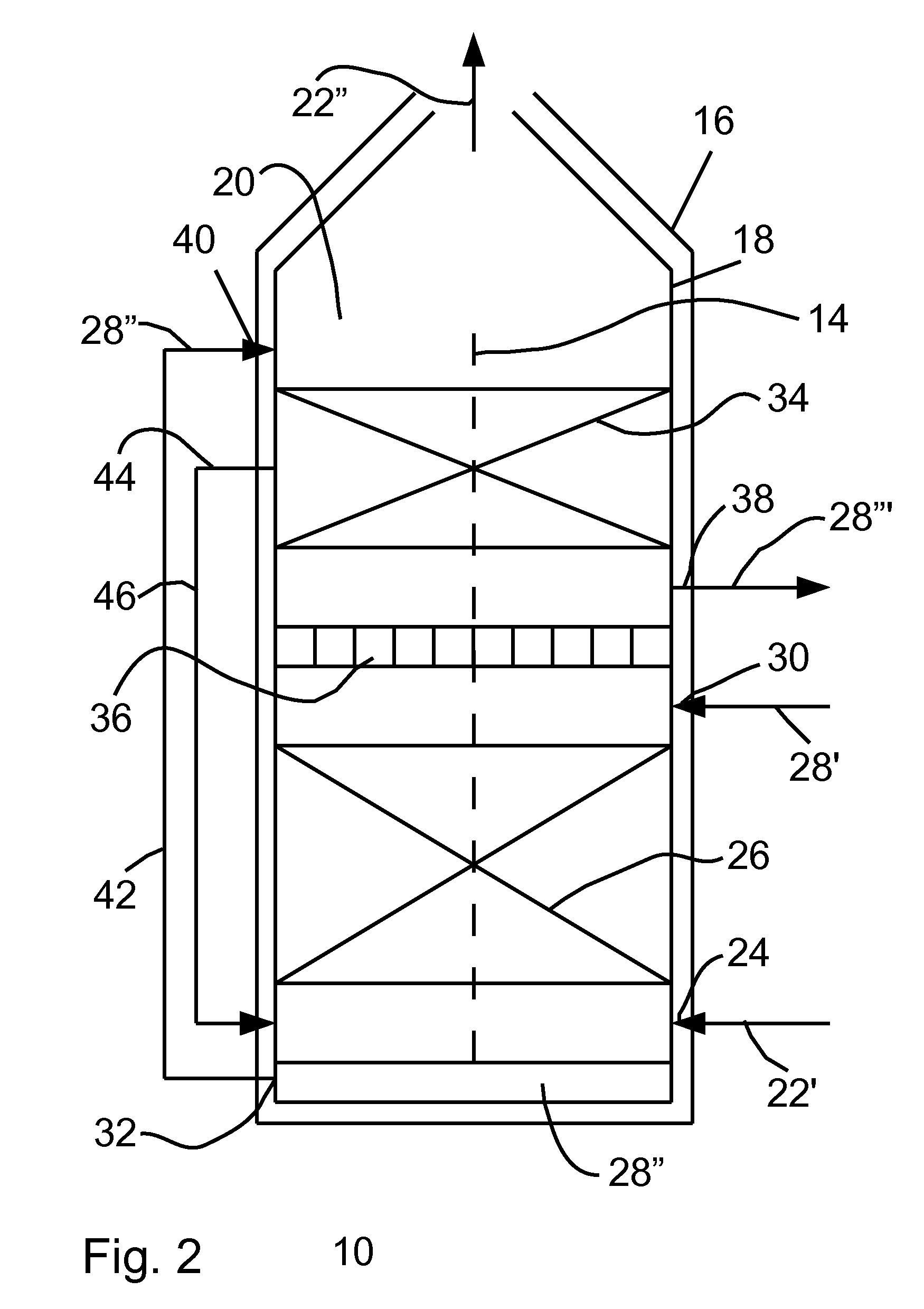

Shipboard Vessel Having a Vertically Aligned Scrubber and Process Component

InactiveUS20100224070A1Storage requirementReduce CODGas treatmentLiquid degasificationWastewaterSeawater

The vessel apparatus processes exhaust gases and effluent seawater on a ship. Structurally, the vessel apparatus includes a vertically oriented vessel. Further, a scrubber is positioned within the vessel to remove pollutants from the exhaust gases with seawater. Also, an effluent seawater processing component is positioned in the vessel above the scrubber. Between the processing component and the scrubber is a liquid barrier that prevents effluent seawater from entering the top of the scrubber while allowing exhaust gases to pass from the scrubber to the top of the vessel. For operation of the apparatus, effluent seawater resulting from the scrubbing process is recirculated from below the scrubber to a location in the vessel above the processing component. As a result, the effluent seawater may be processed above the scrubber.

Owner:PATTERSON RONALD G +1

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

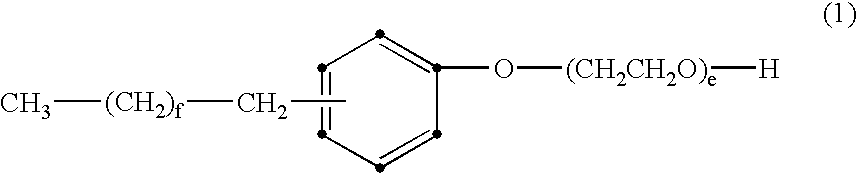

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

ActiveCN103045288AReduce CODMild operating conditionsOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid. The comprehensive treatment method comprises the steps of: 1, acidizing high-sulphur high-COD caustic sludge waste liquid by using an N2 / SO2 mixed gas, when the pH value of the waste liquid reaches 2-6, stopping acidizing; 2, sending tail gas discharged in the acidizing process in the step 1 to a sulphur production device for preparing sulphur; 3, settling the waste liquid generated in acidizing treatment in the step 1and recovering an oil phase; 4, further reducing the COD of the waste liquid by adopting an extraction method when the COD of the waste liquid after the oil phase is separated in the step 3 is always high; and 5, regenerating the waste liquid extracted in the step 4 by using lime. The comprehensive treatment method is low in investment, is mild in operation conditions, is capable of recycling the caustic sludge waste liquid, avoiding the impact of the high-concentration wastewater on a wastewater treatment field, is also capable of recovering sulfide and crude carbolic acid from the caustic sludge waste liquid, and has a certain economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

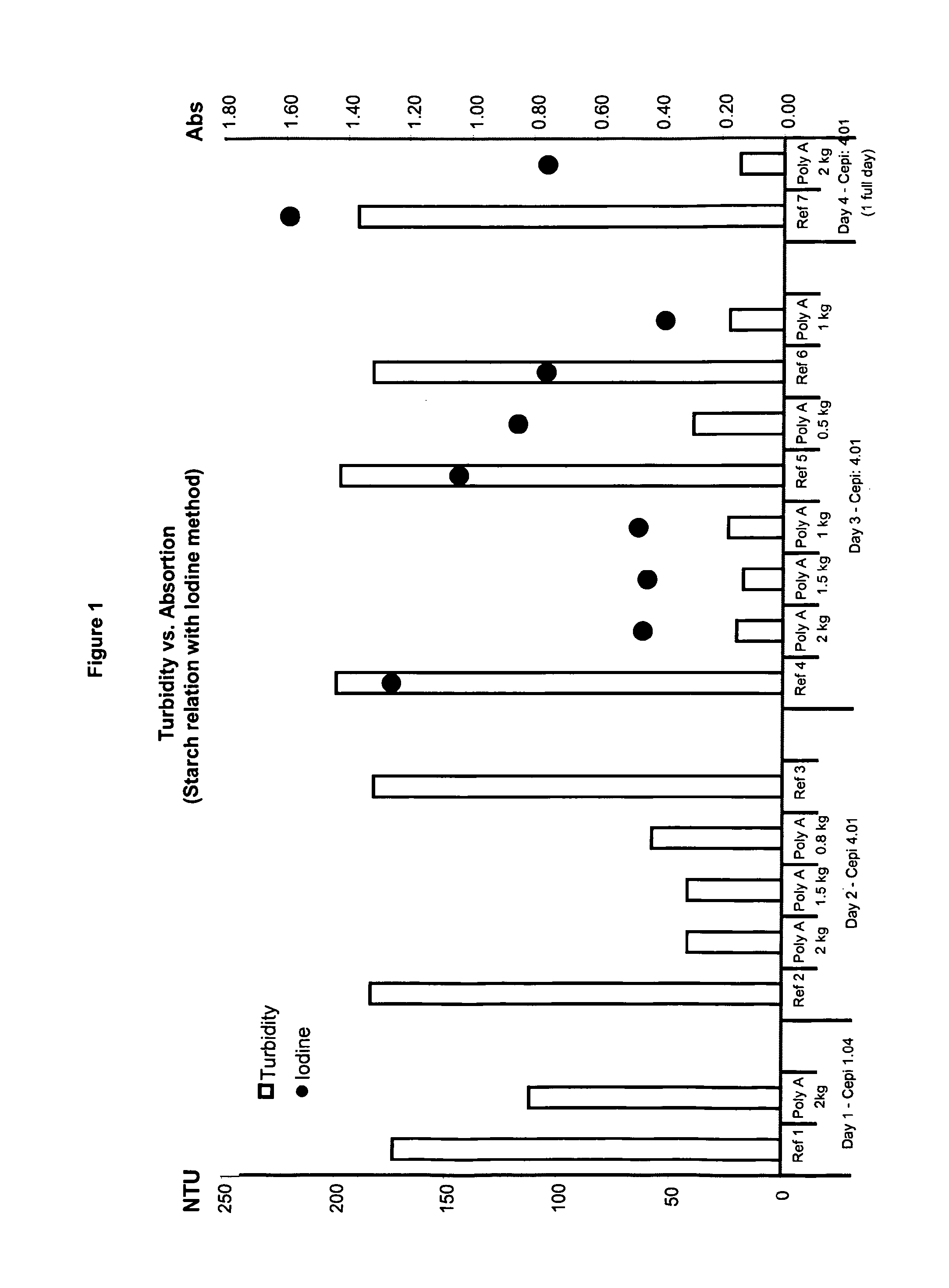

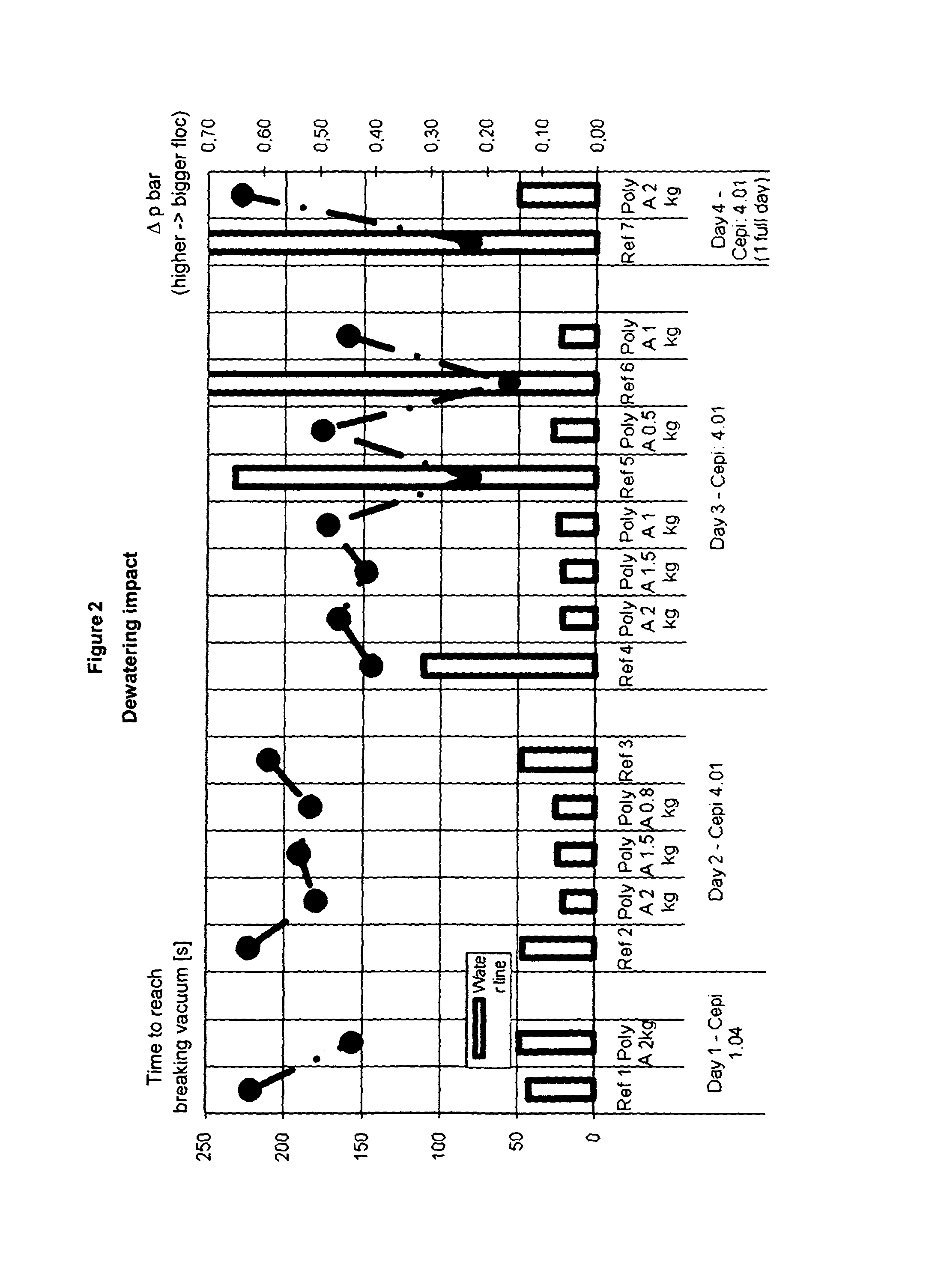

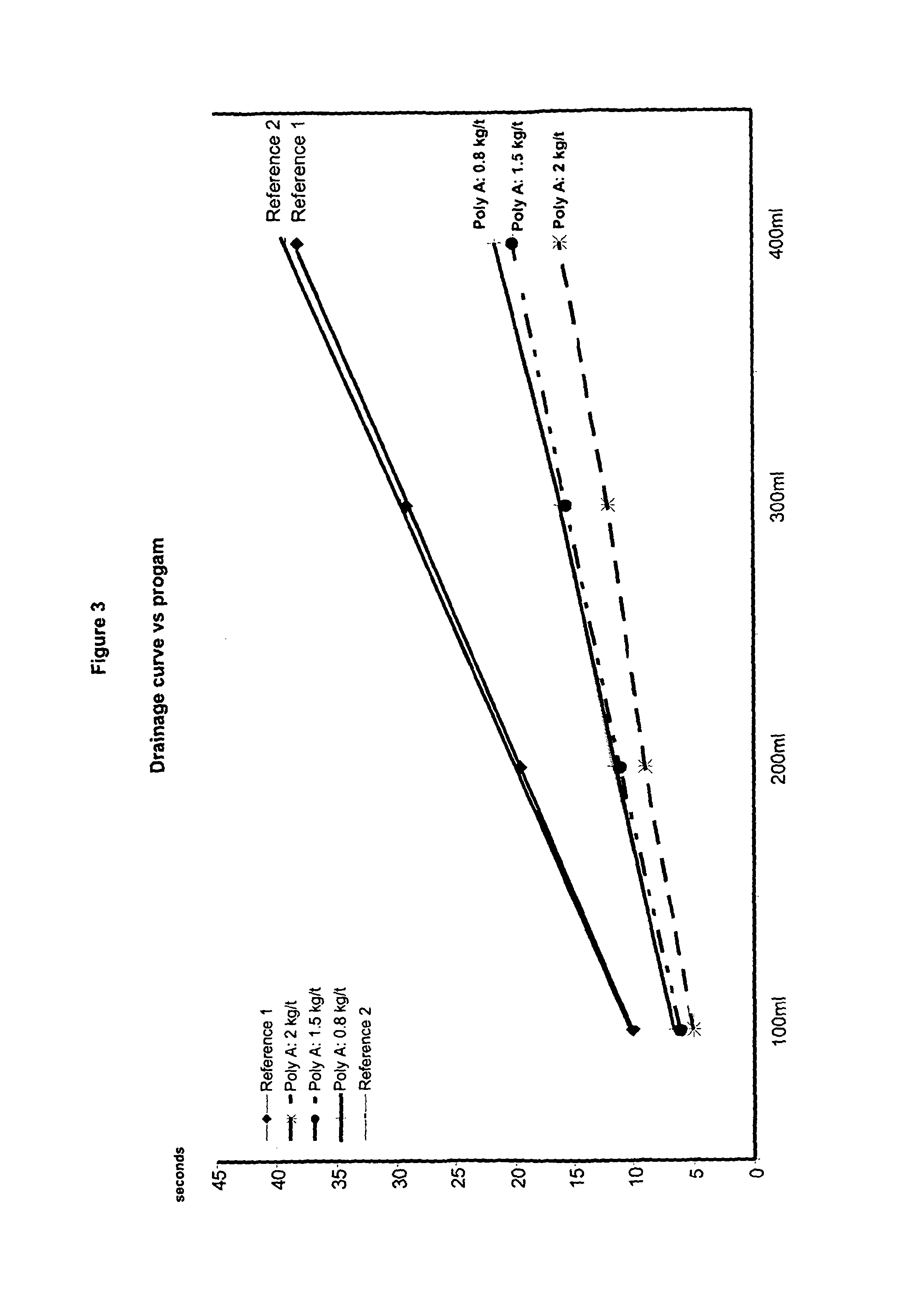

Method for increasing the advantages of starch in pulped cellulosic material in the production of paper and paperboard

ActiveUS8758562B2Avoid degradationPrevent degradationNatural cellulose pulp/paperSpecial paperCellulosePaperboard

The invention relates to a method for increasing the benefit from starch in pulped, preferably repulped cellulosic material at paper or paperboard manufacturing comprising the steps of (a) pulping a cellulosic material containing a starch; (b) treating the cellulosic material containing the starch with one or more biocides, preferably in the thick stock area; and (h) adding an ionic polymer and preferably, an auxiliary ionic polymer to the cellulosic material; wherein the ionic polymer and the optionally added auxiliary ionic polymer preferably have a different average molecular weight and preferably a different ionicity, wherein the ionicity is the molar content of ionic monomer units relative to the total amount of monomer units.

Owner:SOLENIS TECH CAYMAN

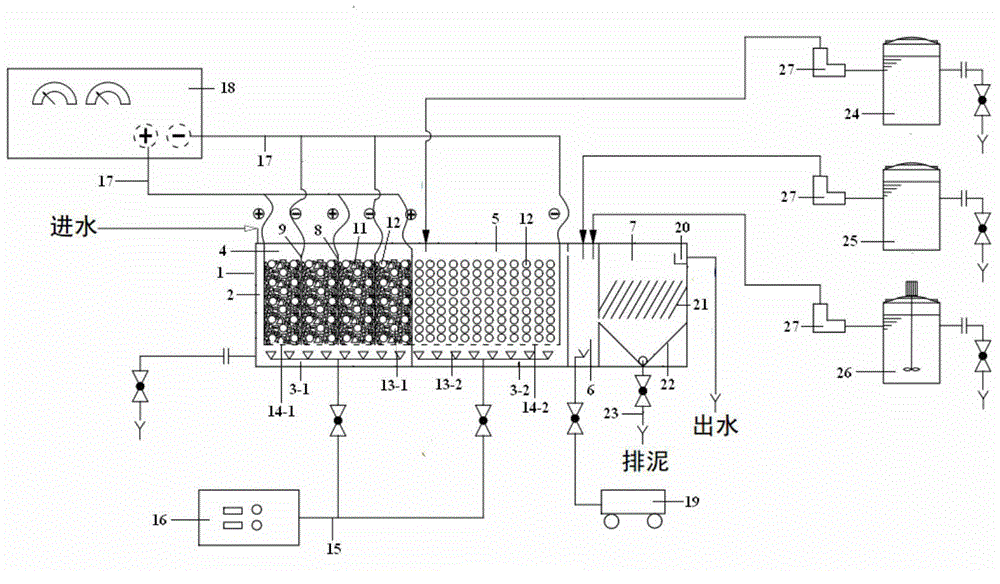

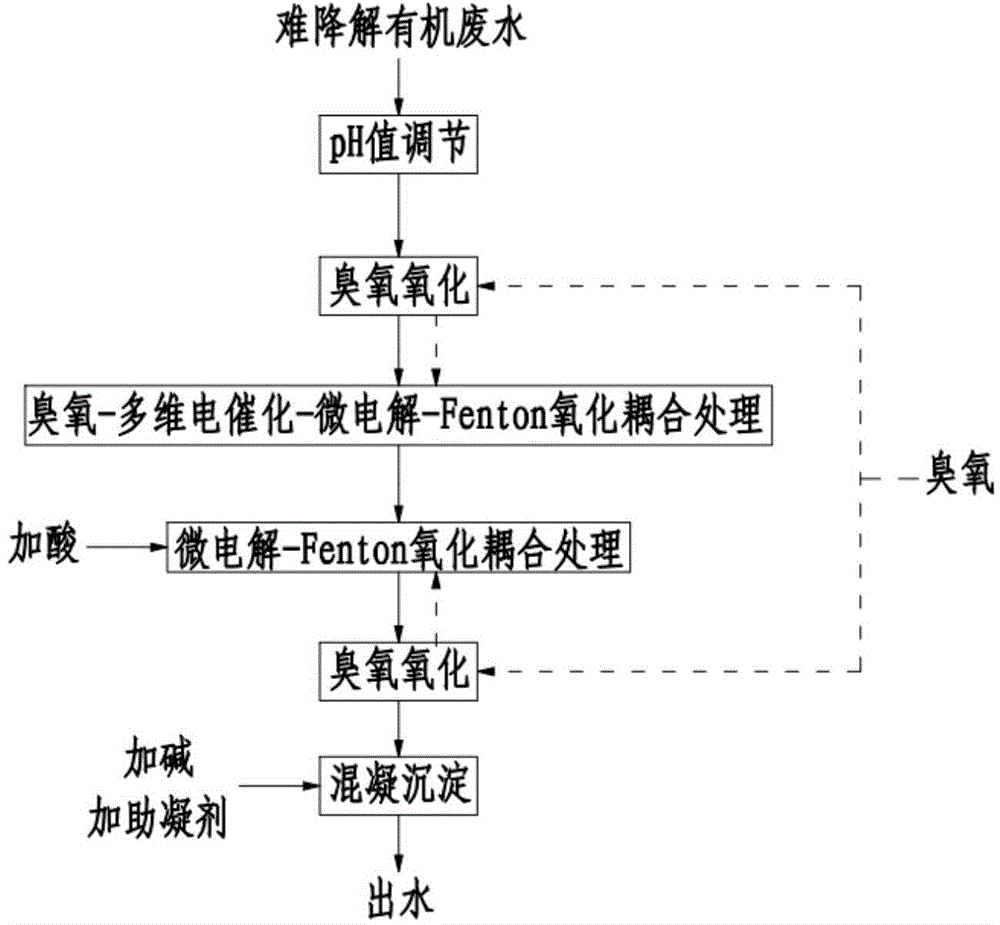

Advanced oxidative coupling device and process for treating organic wastewater difficult to degrade

ActiveCN104787941AImprove removal efficiencyLow running costWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisMulti dimensional

The invention discloses an advanced oxidative coupling device and process for treating organic wastewater difficult to degrade. A main device body comprises an ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area, an ozone oxidation-microelectrolysis / Fenton area, a coagulation area and an inclined plate sedimentation area, wherein the ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area comprises a multi-dimensional electrolysis / microelectrolysis area at the upper part and an ozone oxidation area at the lower part; the ozone oxidation-microelectrolysis / Fenton area comprises a microelectrolysis / Fenton area at the upper part and an ozone oxidation area at the lower part. The device combines four levels of advanced oxidation systems, and electrocatalytic oxidation, ozone oxidation, Fenton oxidation and a microelectrolysis reaction are mutually coupled in function, so that an organic matter difficult to degrade is subjected to multi-level oxidation to realize complete oxidative cracking; when the device is used for treating the organic wastewater difficult to degrade, the yield and the production rate of *OH are increased, the liquid phase transfer process is accelerated, the overall current efficiency of the device is increased, operation expenses are saved, flexible regulation and control of a process unit are realized, and the device can be used for treating various kinds of organic wastewater difficult to degrade.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

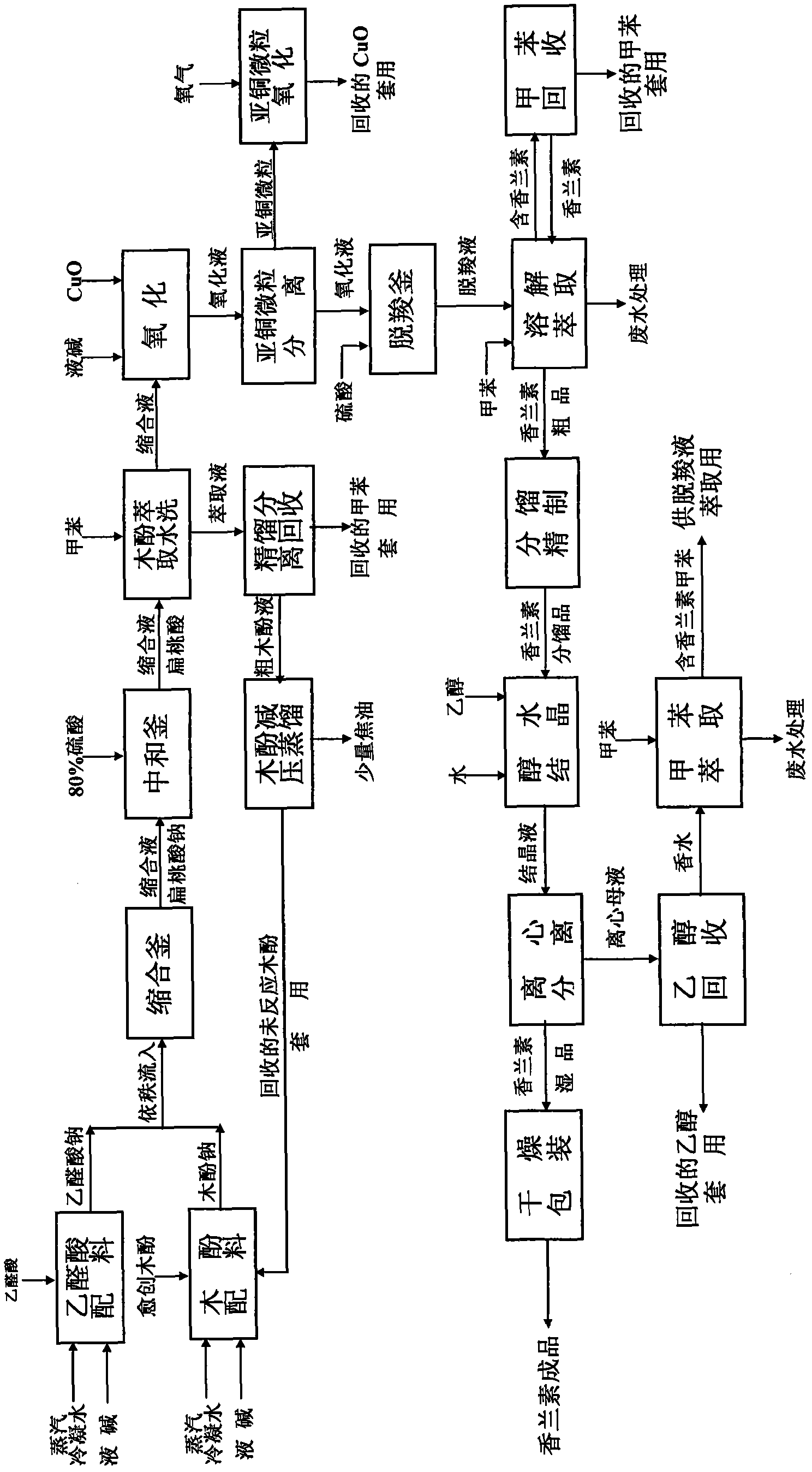

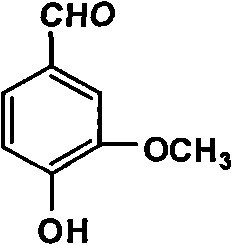

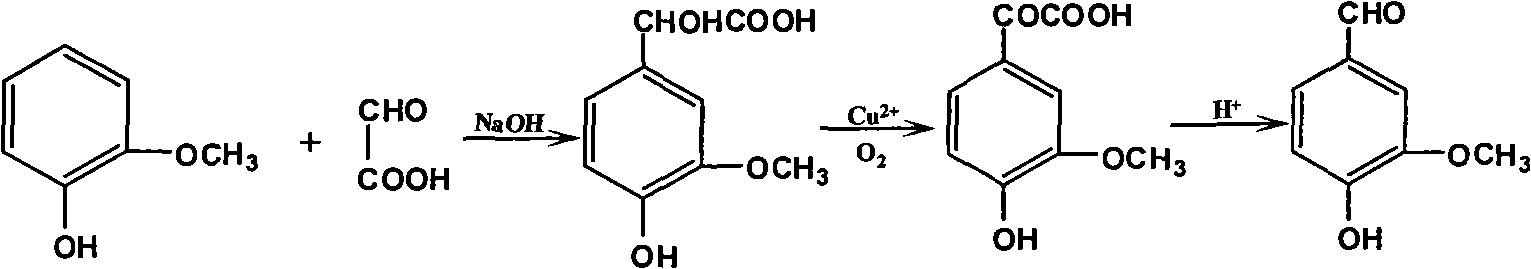

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

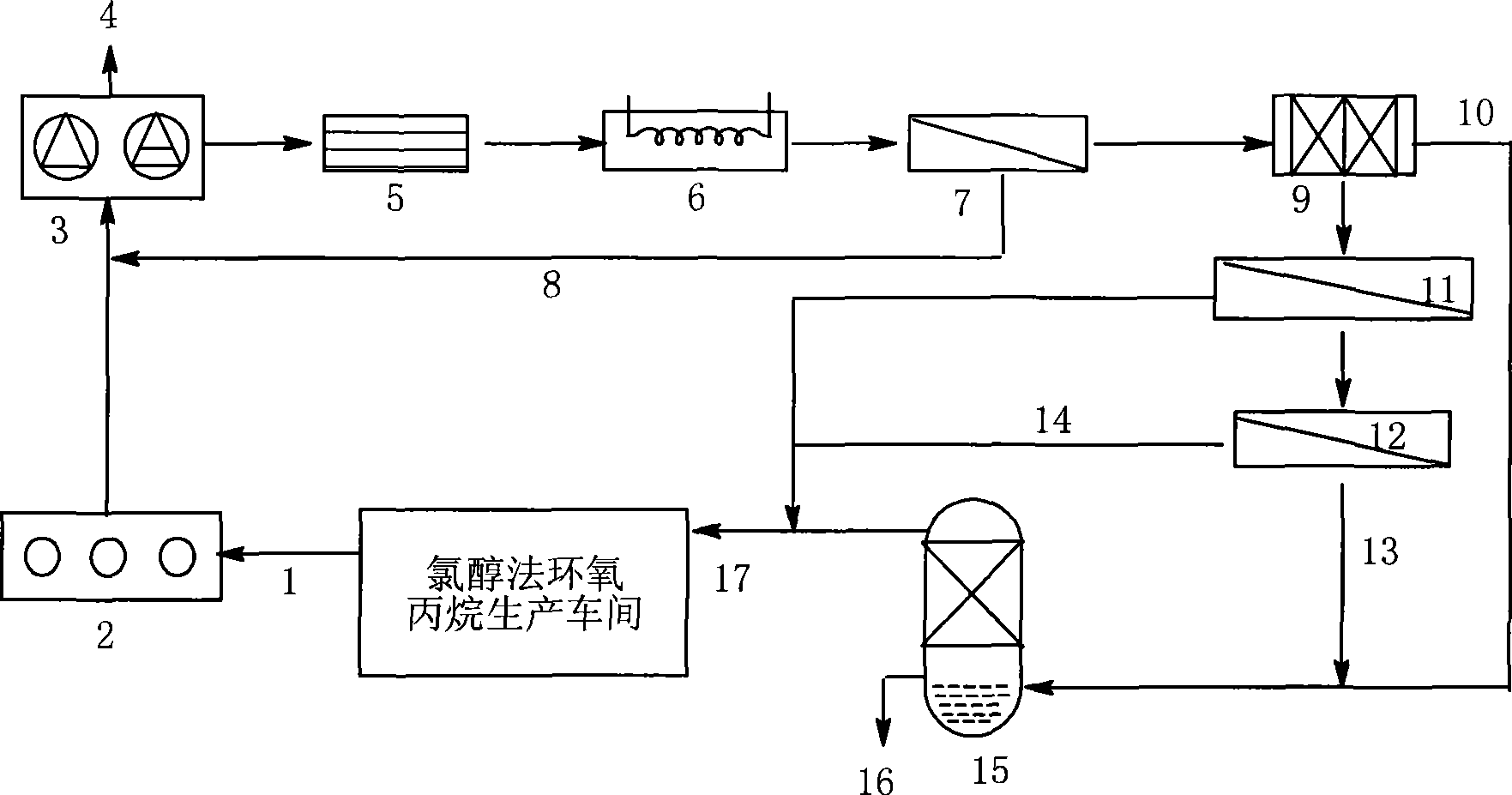

Process for treating saponification wastewater by chlorohydrination

ActiveCN101481190ASmooth cycle processingTroubleshoot placement issuesCalcium/strontium/barium chloridesDispersed particle separationChemical treatmentSocial benefits

The invention discloses a chemical processing method, and in particular discloses a method for recovering and reusing saponified waste water generated by a chlorohydrination method. The invention uses the novel film method and the salt and water recovering and reusing method to process the saponified waste water generated by a chlorohydrination method, and the technical designs, such as gas flotation, crystallizing prevention, ceramic film filtration, heat exchange, electrodialysis concentration, vaporizing recovery and the like are applied in the method. The invention has the advantages that the zero discharge of the waste water is basically realized, the salt and the water can be recovered, the small land area is occupied, the running expense is low, and the economic and social benefits are high. The invention can be widely used in the factories using the chlorohydrination method for producing propylene oxide.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Monocrystalline silicon wafer alcohol-free texturing process and texturing additive

ActiveCN104576831AReduce CODReduce the cost of cashmereAfter-treatment detailsFinal product manufactureAlcohol freePotassium hydroxide

The invention relates to a monocrystalline silicon wafer alcohol-free texturing process and a texturing additive. Firstly, a silicon wafer is placed in preprocessing liquid so as to be preprocessed for 60 s to 300 s, and the silicon wafer is then placed in texturing liquid for texturing. The monocrystalline silicon texturing process includes the steps that deionized water is heated to 70 DEG C to 90 DEG C, sodium hydroxide or potassium hydroxide is added, and monocrystalline silicon texturing corrosive liquid is acquired. When the texturing additive is adopted for texturing, isopropanol or ethyl alcohol is not needed, tiny, even and dense pyramid texturing faces can be acquired, texturing cost is reduced, and environmental pollution is avoided. The preprocessing process is added before the texturing step, the silicon wafer acquired after texturing can be cleaner, rework caused by white spot fingerprints and the like can be reduced, and certain practical value is achieved.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

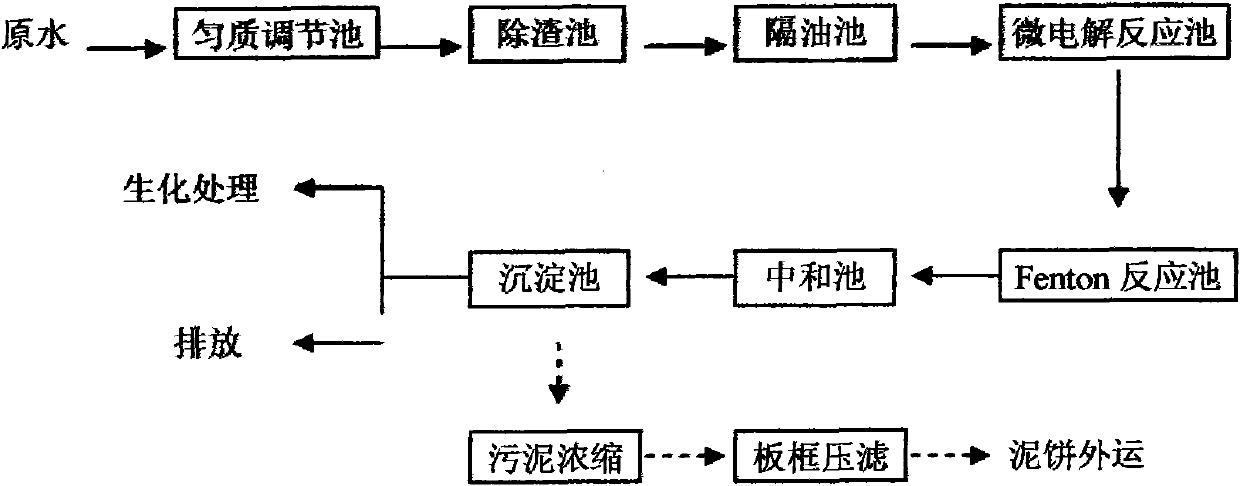

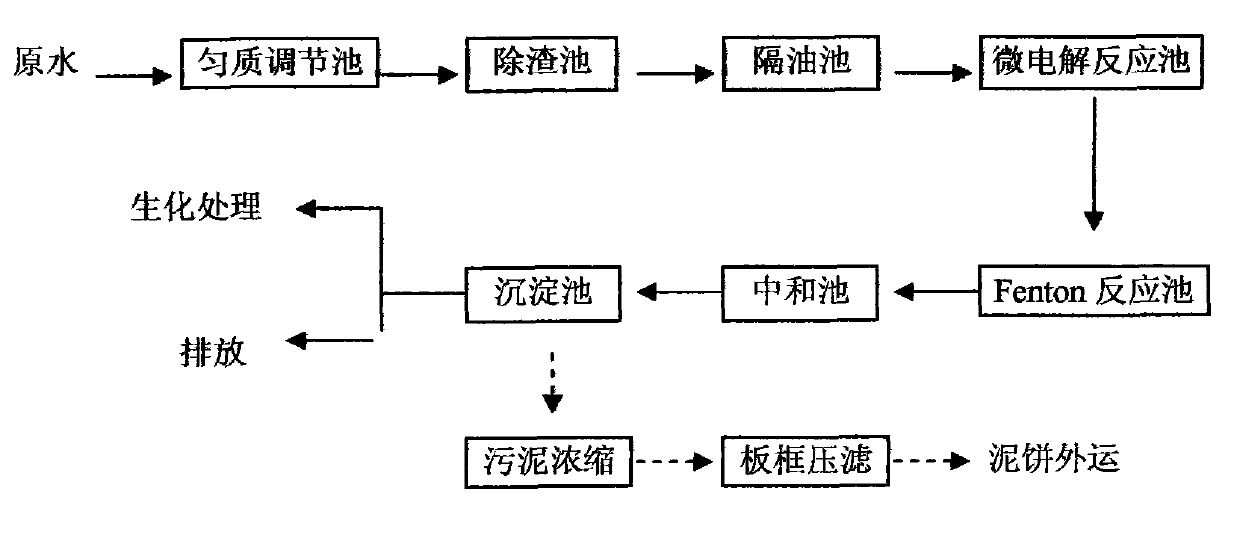

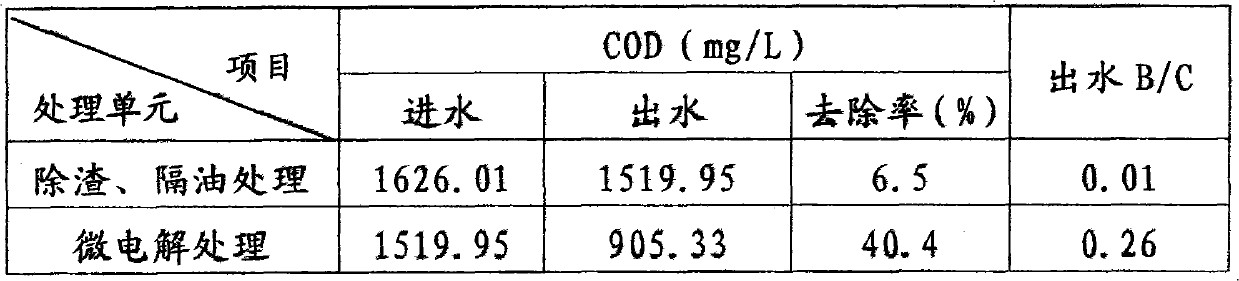

Pretreatment process of organic silicon wastewater

InactiveCN102001775AReduce loadReduce effluent CODMultistage water/sewage treatmentChemistryStrong acids

The invention discloses a pretreatment process of organic silicon wastewater, comprising the steps of homogeneous treatment, slag removal, oil removal, iron-carbon micro-electrolysis process, Fenton process, neutralization deposition and overflow and discharge of supernate. Aiming at the strong acid characteristic of the organic silicon wastewater, the iron-carbon micro-electrolysis can be directly carried out after the homogeneous impurity removal; partial COD (Chemical Oxygen Demand) can be degraded while the biochemical quality of the wastewater is improved and the pH value is improved; then hydrogen peroxide is directly added to form a Fenton system; a strong oxidant is formed to damage the structure of organic matters and chromophonic groups in the wastewater and effectively oxidize so as to remove the organic matters which are difficult to degrade and cannot be removed by the traditional wastewater treatment technology, and thereby the aims of further reducing the COD and improving the biodegradability of the wastewater can be improved. The organic silicon wastewater can reach the national third-grade discharge standard after being subjected to neutralization and the precipitation and reach the national first-grade discharge standard after being subjected to biochemical treatment. The pretreatment process has the advantages of low cost and stable treatment effect and is simple for operation.

Owner:蓝星环境工程有限公司

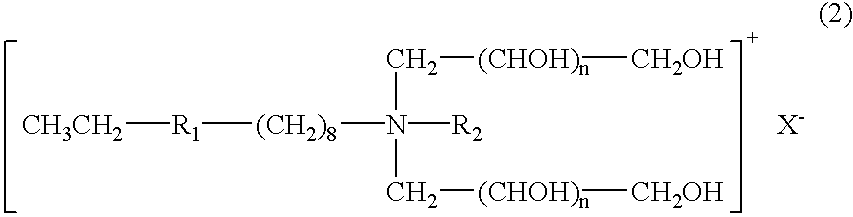

Method of and composition for treating hydrocarbon based materials

InactiveUS6462011B1Promote decompositionReduce CODCationic surface-active compoundsOrganic detergent compounding agentsVegetable oilEmulsion

This application discloses a composition for and a method of using the composition to disperse hydrocarbon based components into a liquid carrier. The composition is comprised of a lower alkyl ester of a fixed oil, such as a modified vegetable oil, in combination with at least one other compound which enhances the ability of the ester to form an aqueous emulsion which can separate and which can alter the wetting character of the ester. The method comprises contacting a material comprised of hydrocarbon based components with an effective amount of composition for a time and a temperature sufficient to disperse the material into a liquid carrier.

Owner:UNITED LAB INT LLC

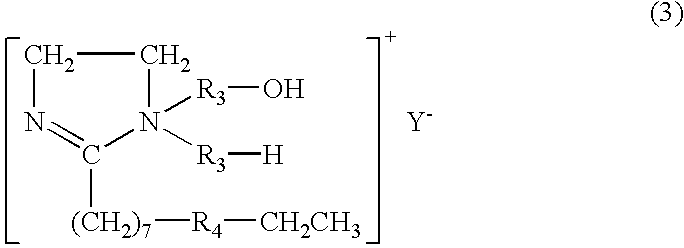

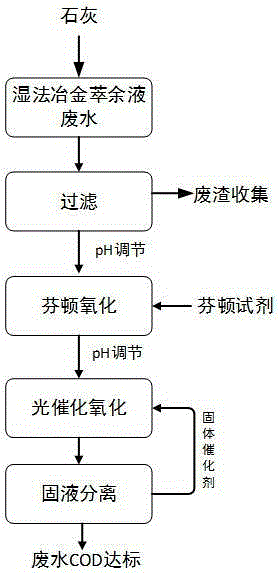

Hydrometallurgy industry raffinate waste water COD removal method

InactiveCN105198139AEfficient Adsorption RemovalReduce CODWaste water treatment from metallurgical processMultistage water/sewage treatmentPhoto catalyticSulfate radicals

The invention discloses a hydrometallurgy industry raffinate waste water COD removal method. According to the method, lime is added into waste water, and is combined with sulfate radical, phosphate radical, carbonate radical, fluorinions, metal ions and the like to generate defecation mud, the defecation mud is taken as an adsorber to remove dispersed oil in the waste water, filter liquor generated after filtering is subjected to pH regulation, then fenton oxidation is performed to degrade macromolecular organic compounds, further pH regulation is performed, then low molecular weight organic matters are deeply degraded by photo-catalytic oxidation, finally solid-liquid separation is performed to obtain a solid catalyst and waste water with the COD content smaller than 100mg / L, and the solid catalyst is returned to photo-catalytic oxidation reaction for cyclic utilization. The method is good in COD removal effect, free of adsorber regeneration and low in operation cost, and has industry application prospect.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com