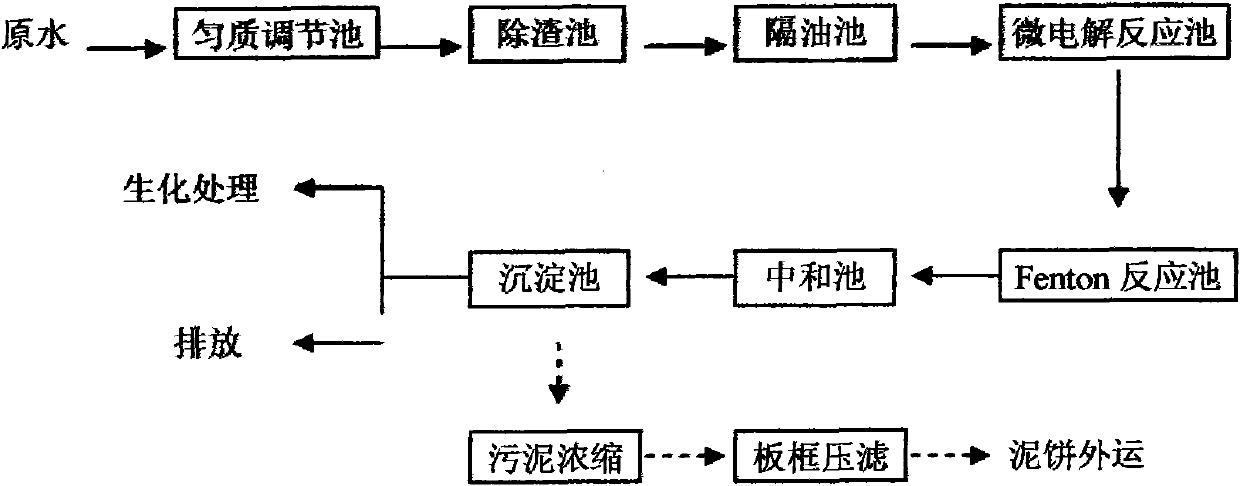

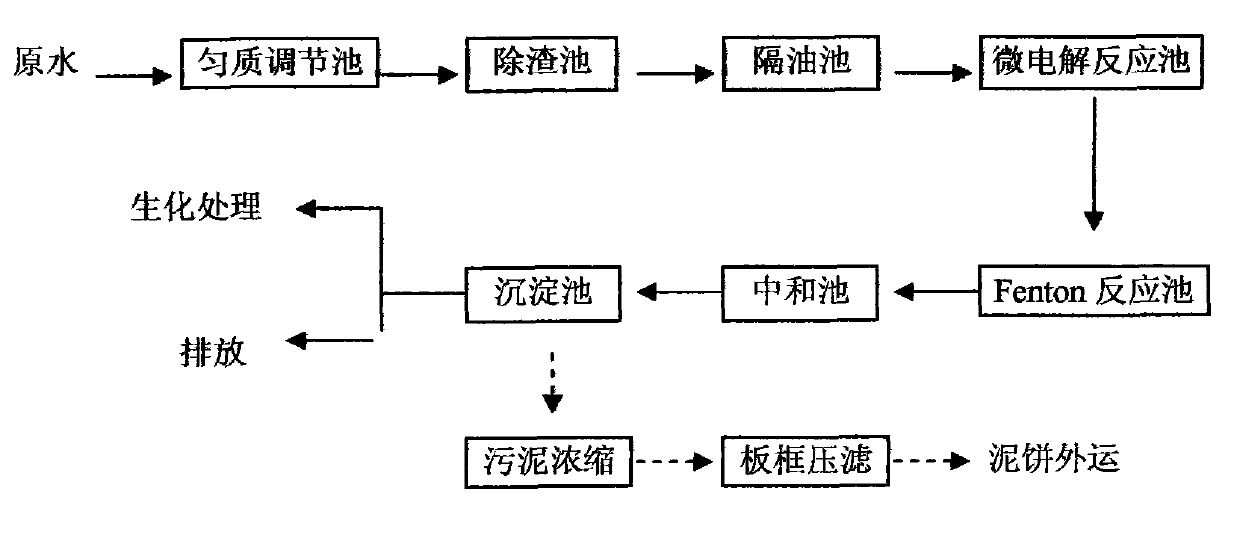

Pretreatment process of organic silicon wastewater

An organosilicon and pretreatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the iron-carbon micro-electrolysis treatment process cannot achieve the treatment effect and the treatment cost remains to be Reduction, limited redox capacity and other problems, to achieve the effect of improving biodegradability, reducing load, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

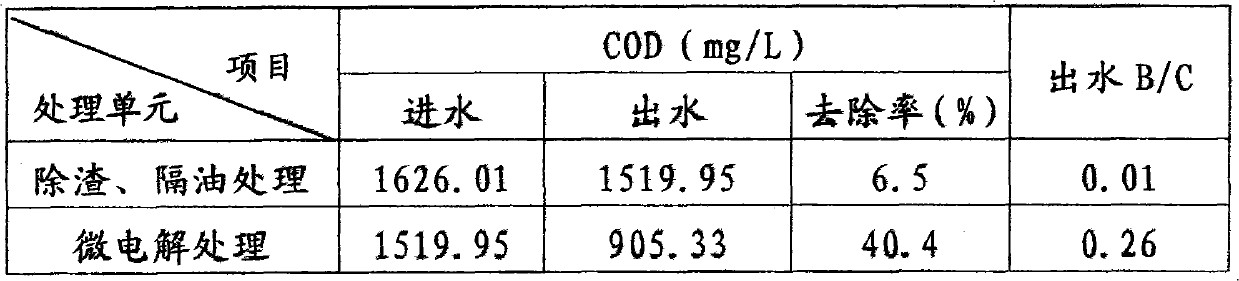

[0033] The organic silicon waste water of an organic silicon factory is used as the water to be treated, and the process of the present invention is used for treatment. The specific process steps are as follows:

[0034] 1) Homogenization: The organosilicon wastewater is homogeneously treated in the regulating tank, the COD is 1626.01mg / L, the pH value is 1.1, and the chloride ion (Cl-) concentration is 14981mg / L;

[0035] 2) Slag removal and oil separation treatment: The homogenized organic silicon wastewater is subjected to slag removal and oil removal treatment to remove most of the scum and oil slicks visible to the naked eye;

[0036] 3) Micro-electrolysis: The effluent from slag removal and oil separation treatment is treated by iron-carbon micro-electrolysis process. The iron-carbon micro-electrolysis process adopts filler-type iron-carbon micro-electrolysis process. combined micro-electrolysis filler): water (volume ratio)=1: 3, reacted for 1.5 hours under aeration co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com