Patents

Literature

102results about How to "Biochemical improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

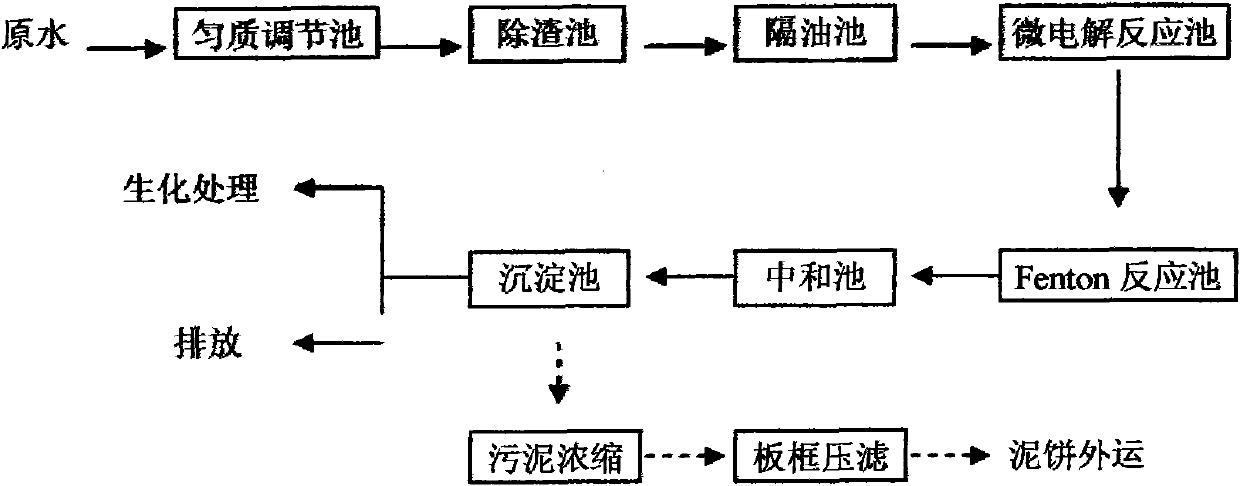

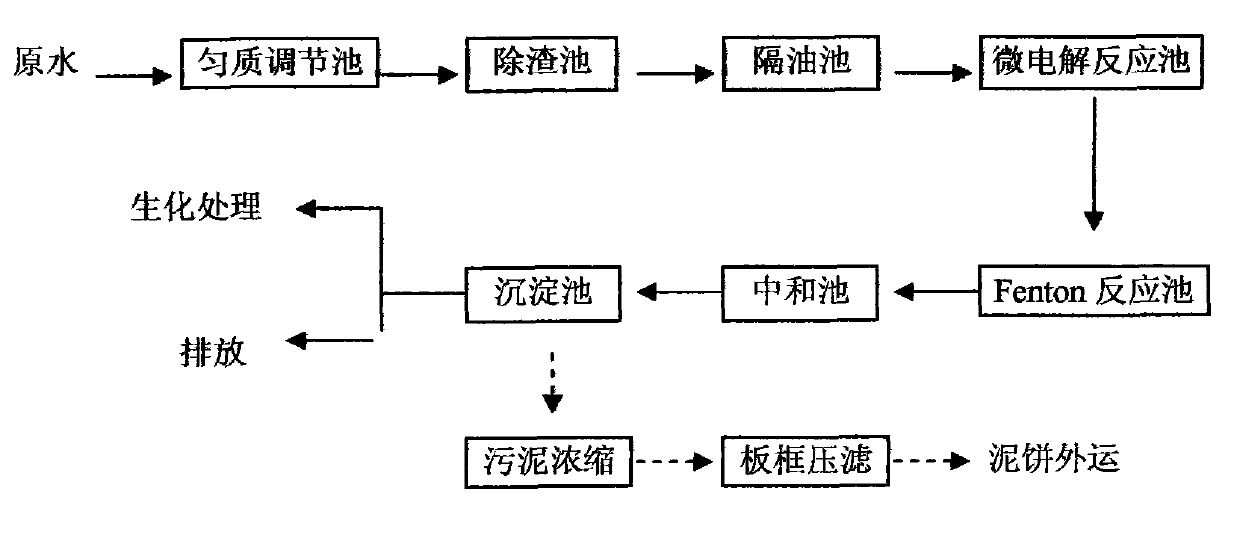

Pretreatment process of organic silicon wastewater

InactiveCN102001775AReduce loadReduce effluent CODMultistage water/sewage treatmentChemistryStrong acids

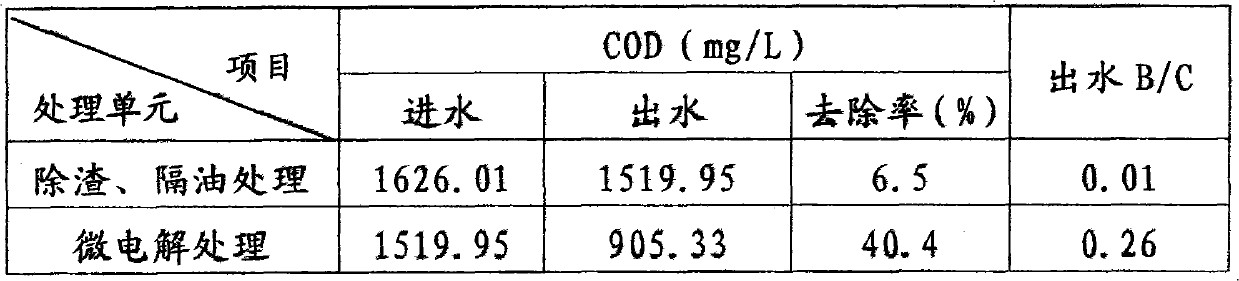

The invention discloses a pretreatment process of organic silicon wastewater, comprising the steps of homogeneous treatment, slag removal, oil removal, iron-carbon micro-electrolysis process, Fenton process, neutralization deposition and overflow and discharge of supernate. Aiming at the strong acid characteristic of the organic silicon wastewater, the iron-carbon micro-electrolysis can be directly carried out after the homogeneous impurity removal; partial COD (Chemical Oxygen Demand) can be degraded while the biochemical quality of the wastewater is improved and the pH value is improved; then hydrogen peroxide is directly added to form a Fenton system; a strong oxidant is formed to damage the structure of organic matters and chromophonic groups in the wastewater and effectively oxidize so as to remove the organic matters which are difficult to degrade and cannot be removed by the traditional wastewater treatment technology, and thereby the aims of further reducing the COD and improving the biodegradability of the wastewater can be improved. The organic silicon wastewater can reach the national third-grade discharge standard after being subjected to neutralization and the precipitation and reach the national first-grade discharge standard after being subjected to biochemical treatment. The pretreatment process has the advantages of low cost and stable treatment effect and is simple for operation.

Owner:蓝星环境工程有限公司

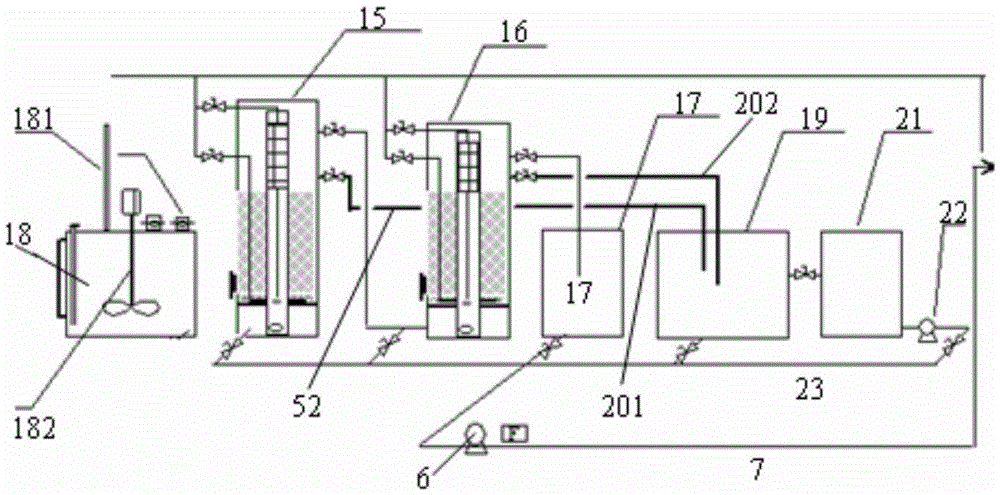

Low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device

InactiveCN105481177AIncrease reaction rateImprove biodegradabilityWater treatment compoundsHeterogenous catalyst chemical elementsActivated sludgeCellulose

The invention discloses a low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device, comprising a catalytic oxidation pond, an oxidation stabilization pond and a rear biochemical BAF pond, wherein the catalytic oxidation pond is filled with ozone-catalytic particles in a static bed form, and a comprehensive dilution tank is provided with a charging hole and a stirrer; the ozone-catalytic particles are prepared from 88.7-91.3 parts of activated aluminium oxide particles, 1.2-1.5 parts of copper oxide, 4-7 parts of polyethylene glycol, 1.5-2 parts of polyvinyl alcohol, 0.8-1 part of titanium dioxide, 0.3-0.5 part of hydroxyl propyl cellulose and 0.2-0.4 part of manganese dioxide; the lower part and the upper part of an aerobic tank in the rear biochemical BAF pond are respectively provided with a lower sieve plate and an upper sieve plate, the lower sieve plate, the upper sieve plate and the side wall of the aerobic tank form an aerobic cavity, and a plurality of aerobic activated sludge particles and a plurality of second masson pines as a filler are arranged in the aerobic cavity. The low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device oxidizes a macromolecular organic matter hard to degrade into a micromolecular organic matter easy to biochemically treat, and the biochemical property of effluent is further improved.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

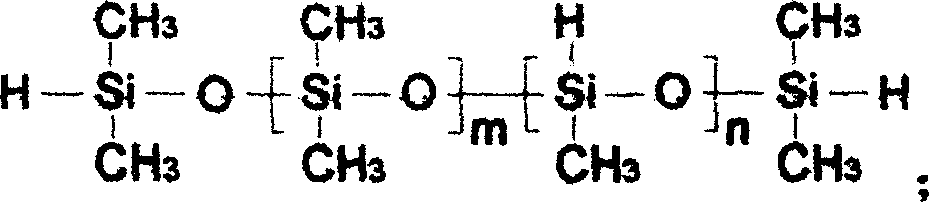

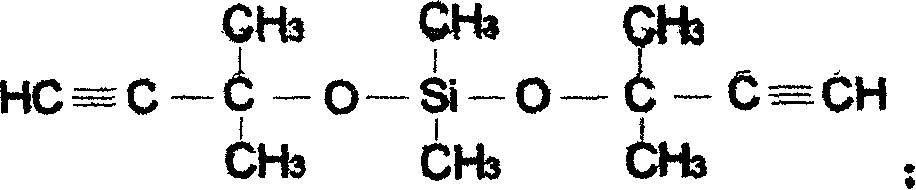

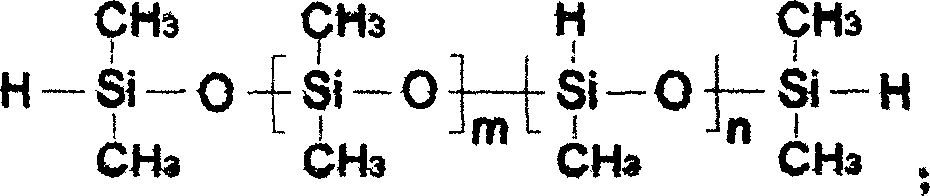

Bicomponent platinum catalyst vulcanizer and its preparation method

The present invention relates to a double-component platinum catalyst curing agent. It includes agent A and agent B which can be uniformly mixed when they are used, in which the agent A is mixture of vinyl raw rubber, gas phase white carbon black and platinum complex, and the agent B is mixture of vinyl raw rubber, gas phase white carbon black, silicon oil whose end contains hydrogen and inhibitor. When the agent A and agent B are mixed, their mass ratio is agent A: agent B = (0.8-1.0)(1.0-1.5). Said invention also provides the preparation method of said double-component platinum catalyst curing agent.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

Pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw

InactiveCN106701836APromote degradationLarge specific surface areaBiofuelsSolid fuelsPretreatment methodBiofuel

The invention discloses a pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw, and relates to the field of comprehensive utilization of all components of plant straw, wherein the pretreatment method comprises the steps: plant straw after being cut into sections is successively subjected to washing treatment for two times before and after steam explosion, steam explosion treatment, extrusion treatment, crushing treatment, pre-enzymolysis treatment, cracking treatment, and enzymolysis treatment, and finally a pre-product for preparing the biomass fuels is obtained; a straw washing liquid obtained after washing treatment and an extrusion liquid obtained after extrusion treatment are used for producing marsh gas, and a liquid, gas and solid biomass fuels can be obtained after the pre-product is treated. The method realizes separation and high-valued complete utilization of the all components of the plant straw, namely hemicellulose, cellulose, lignin and a small amount of components, can achieve no pollutant emission, and has the advantages of easy industrialization operation, good economic benefits, and remarkable comprehensive social benefits.

Owner:北京利晟新能生物科技中心(有限合伙)

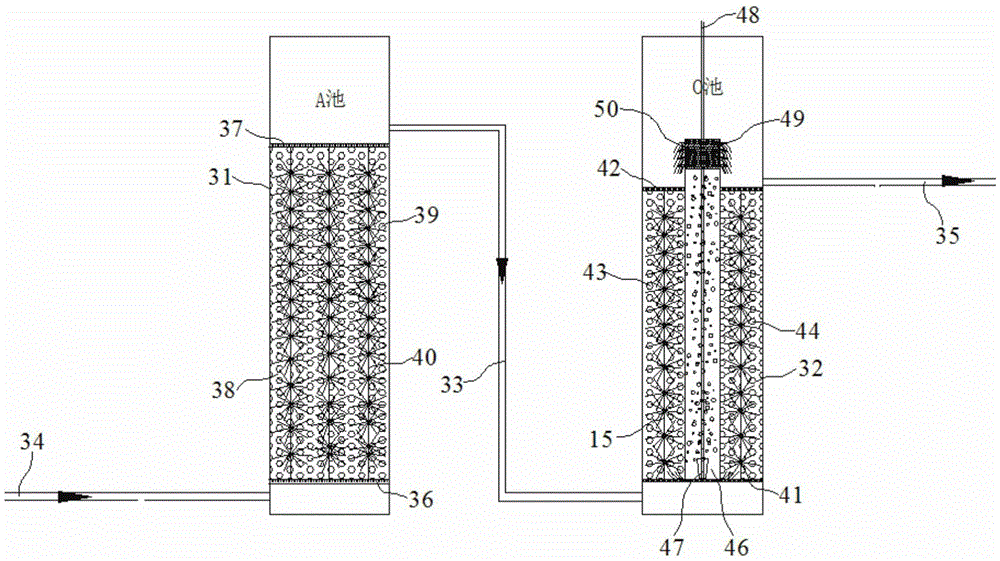

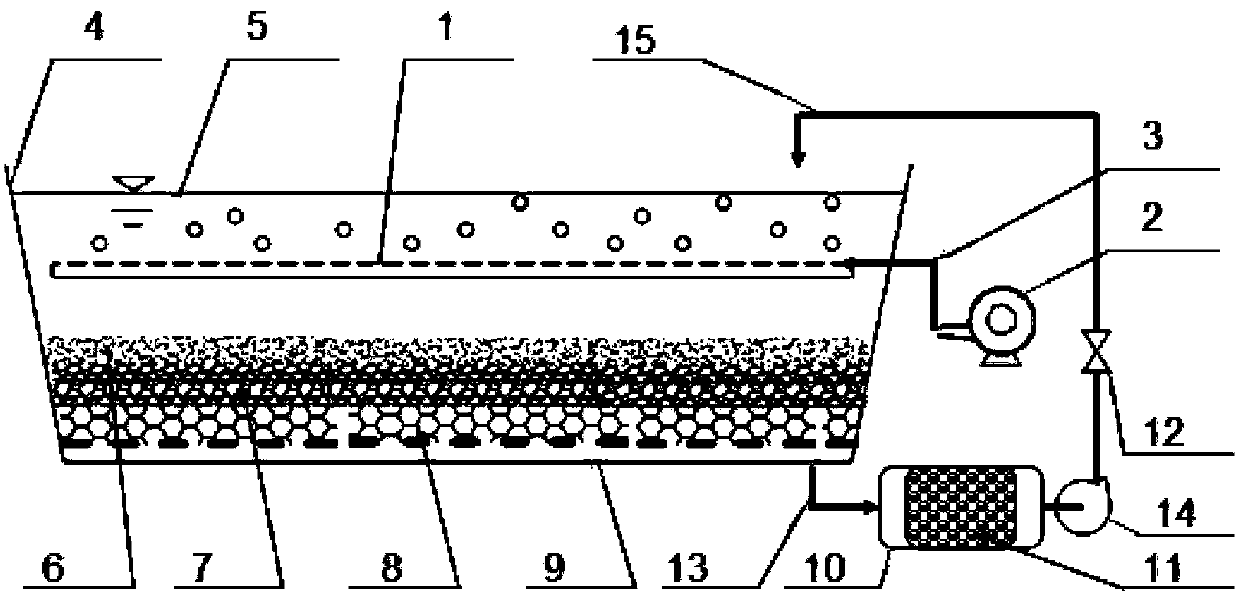

In-situ water repair method for clean aquaculture

InactiveCN103420544AEfficient purificationBiochemical improvementMultistage water/sewage treatmentAeration systemSludge

The invention relates to an in-situ water repair method for clean aquaculture. Polluted aquaculture water is pushed by liquid level difference, and organic pollutants are removed by ecological infiltration in forms of interception, absorption and degradation which are in coordination. When water discharged from the pool-bottom water collecting tank enters a solidified bioreactor, solidified microaerobic microorganism in a carrier is activated to provide a rich microaerobic microbial community source for the ecological infiltration system. The water containing the microbial community is pumped back to the water system of the aquaculture pool, the microorganism reproduces massively under the action of a shallow aerating system, the microorganism uses the pollutants of the required nutrients, and accordingly aquaculture water can be purified effectively, and clean aquaculture is achieved. The ecological infiltration pool-bottom system is built by directly using the bottom space of the aquaculture pool, the processing system does not occupy floor space, sludge is not generated, cost is saved, the solidified microorganism carrier in long in service life, in-situ aquaculture water purification and up-to-standard pollutant discharge are achieved, and evident comprehensive benefits are achieved.

Owner:GUANGXI UNIV

Biodegradable biopolymers, method for their preparation and functional materials constituted by these biopolymers

InactiveUS20080124473A1Strong resistancePromote degradationPowder deliveryPeptide/protein ingredientsCellulosePolyvinyl alcohol

A biodegradable biopolymer material consists of silk fibroin from domesticated silkworm; silk fibroin from wild silkworm; a composite material comprising silk fibroin from domesticated silkworm and silk fibroin from wild silkworm; or a composite material comprising either silk fibroin from domesticated silkworm or silk fibroin from wild silkworm and at least one secondary substance selected from the group consisting of cellulose, chitin, chitosan, chitosan derivatives, keratin from wool and polyvinyl alcohol. The material may be prepared by, for instance, casting an aqueous solution of domesticated silkworm silk fibroin on the surface of a substrate and then cast drying the applied solution. The biodegradable biopolymer material is effectively used as, for instance, a metal ion-adsorbing material, a sustained release substrate for a useful substance such as a medicine, a biological cell-growth substrate and a biodegradable water-absorbing material.

Owner:NAT INST OF AGROBIOLOGICAL SCI

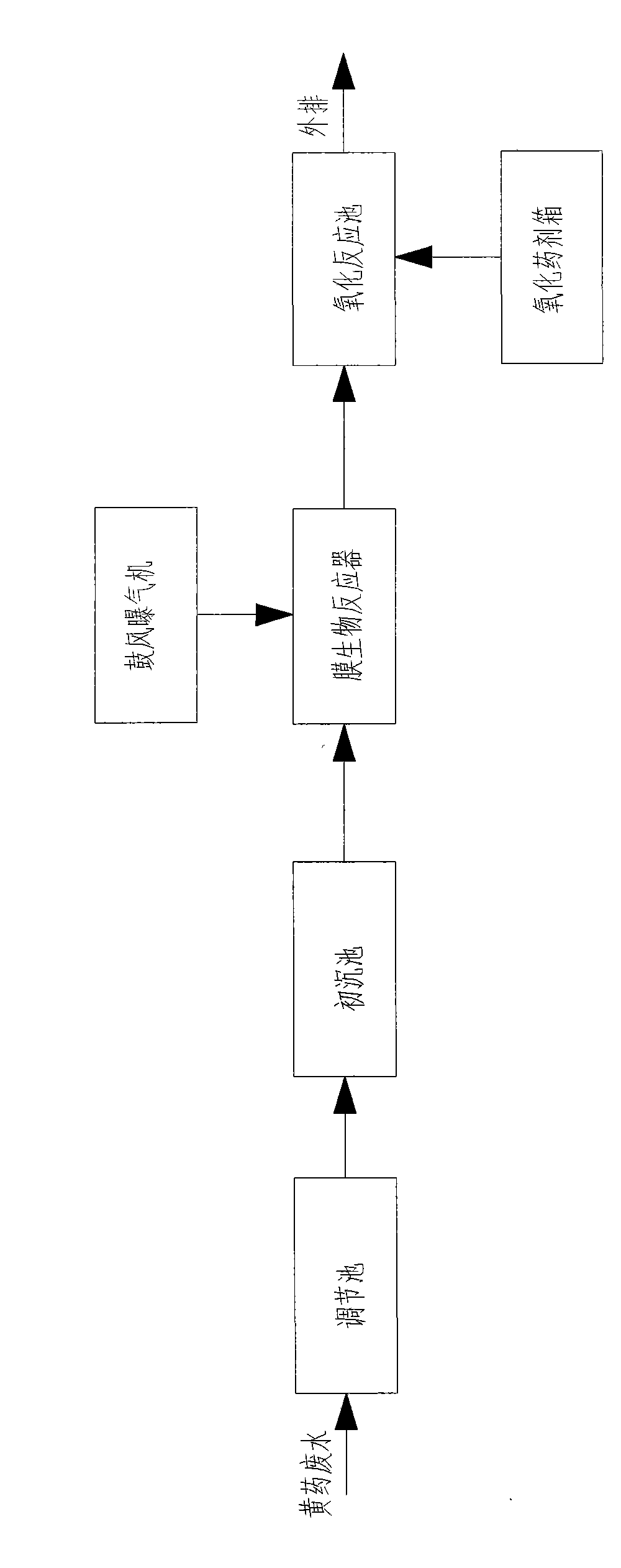

Method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation

InactiveCN101591121AFully degradedAvoid the danger of cloggingWater contaminantsWater/sewage treatment bu osmosis/dialysisOxygenOxidative treatment

The invention relates to a method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation, which belongs to the technical field of sewage treatment. The method comprises two sections of treatment processes, namely the film biodegradation and the hydrogen peroxide oxidation. The method comprises the following steps: controlling the volume loading of a film bioreactor to between 3.0 and 5.0 kgCOD / (m.d), controlling the hydraulic power residence time in the reactor to between 18 and 36 hours and the sludge residence time to between 75 and 150 days, controlling the dissolved oxygen concentration to between 2.5 and 4.0 milligrams per liter, controlling the temperature in the reactor to between 20 and 35 DEG C and the active sludge concentration to between 10,000 and 15,000 milligrams per liter, and controlling the sludge loading to between 0.11 and 0.17 kgCOD / (kgMLSS.d); and adjusting the pH value of the sewage in a reaction tank to between 3 and 5, adding 5 to 10 mg / L H2O2 to perform oxidation treatment for 30 to 60 minutes, and after the oxidation treatment, discharging the purified water. Through the treatment by the method, the removal rate of the COD and the xanthate reaches more than 90 percent and more than 99 percent respectively.

Owner:NORTHEASTERN UNIV

Comprehensive wastewater reuse treatment method for waste incineration power plant

ActiveCN104445747ABiochemical goodGood water qualityWaste based fuelTreatment with anaerobic digestion processesHeavy metalsFlue gas

The invention discloses a comprehensive wastewater reuse treatment method for a waste incineration power plant. The method comprises the steps of production sewage pre-treatment, flue gas wastewater pre-treatment, domestic sewage pre-treatment, landfill leachate pre-treatment, reverse osmosis deep treatment and dehydration treatment. According to the method, landfill leachate and domestic sewage are mixed and subjected to facultative and aerobic treatment, so that COD and NH3-N in the landfill leachate can be effectively reduced, the proportion of pollutants in sewage can be balanced, the mixed liquid has good biodegradability, and the effluent quality is good; the pretreated production wastewater, the biodegraded landfill leachate and domestic sewage are subjected to combined deep treatment, and only one set of treatment device is needed, so that the investment cost is reduced; and sewage combined treatment is adopted, so that the content of COD and heavy metal ions in the sewage which enters a reverse osmosis system can be effectively reduced, the problem of reverse osmosis membrane blockage can be effectively relieved, the frequency of chemical cleaning can be reduced, and the service life of the reverse osmosis membrane can be prolonged.

Owner:CHINA FIRST HEAVY IND

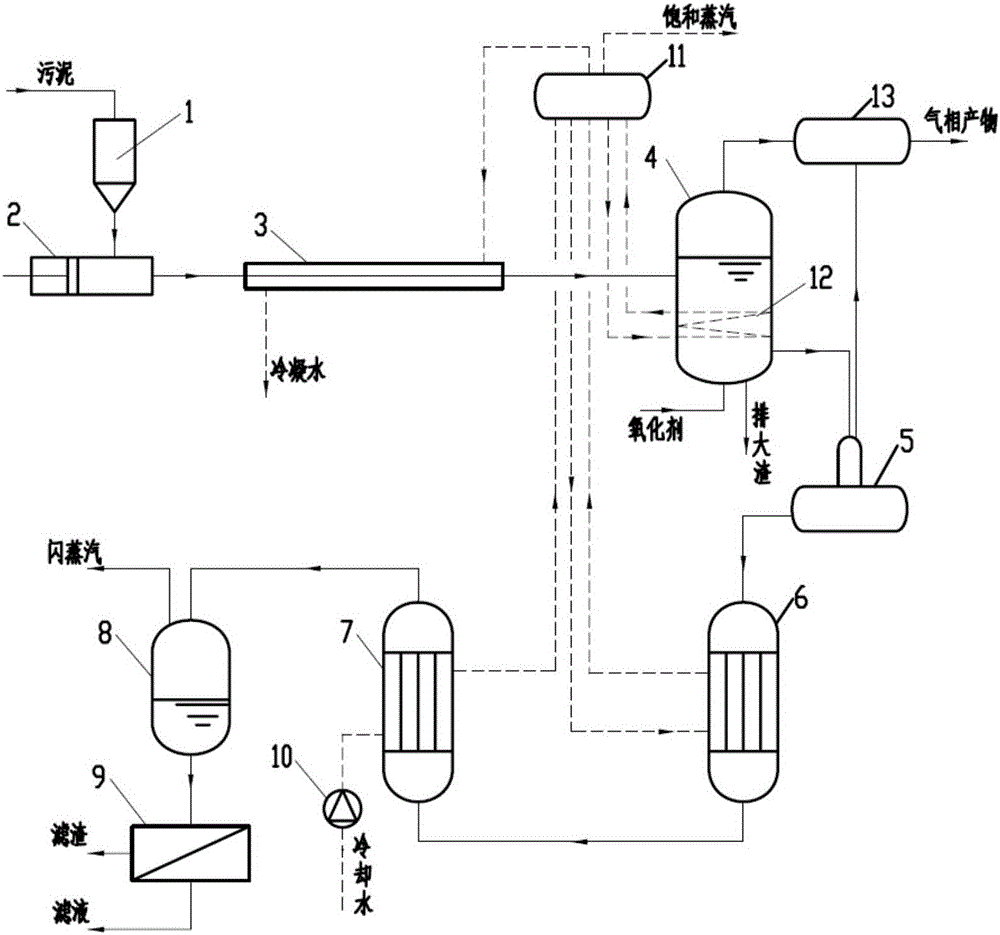

Method and continuous system for treating wet organic waste

PendingCN105967490AImprove mobilitySolve pipeline blockageSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningChemistryCorrosion

The invention discloses a method and a continuous system for treating wet organic waste, and belongs to the field of environmental protection / sewage treatment / sludge treatment. The method includes steps of conveying and preheating raw materials; carrying out hydrothermal oxidation reaction; removing oxygen from oxidation reaction products; recycling reaction heat; carrying out flash dehydration; carrying out mechanical dehydration; treating filter liquid; treating tail gas. The continuous system comprises a wet organic waste raw material pump, a sleeve heater, a hydrothermal oxidation reactor, an oxygen remover, waste heat recycling heat exchangers, a byproduct steam plant, a flash plant, a dehydration plant and a tail gas treatment plant. The method and the continuous system have the advantages that the continuous system is simple, the wet organic waste can be directly treated without being dried, the reaction is easy to maintain under self-heating conditions without external heat, a large quantity of heat of the high-temperature materials can be recycled, the method and the continuous system are high in energy utilization rate, and a large quantity of economic byproducts (steam) can be generated; problems that existing raw material preheating heat exchangers are vulnerable to blocking and existing waste heat recycling heat exchangers are vulnerable to corrosion can be solved by the aid of the method and the continuous system.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Carbon source supplement used by sewage plant at low temperature and preparation method

InactiveCN109761374AImprove biological activityBiochemical improvementWater contaminantsBiological water/sewage treatmentSodium acetateGlycerol

The invention belongs to the technical field of water treatment, and specifically relates to a carbon source supplement used by a sewage plant at a low temperature. The carbon source supplement is prepared from the following components in percentage by weight: (1) 10 to 30 percent of sodium acetate, (2) 1 to 5 percent of molasses, (3) 5 to 15 percent of methanol, (4) 1 to 5 percent of glycerol, (5) 1 to 10 percent of acetic acid, (6) 1 to 10 percent of sodium carbonate, (7) 1 to 15 percent of glucose, (8) 1 to 5 percent of starch and (9) the balance of water. The carbon source supplement disclosed by the invention can be widely applicable to the sewage plant to supplement a carbon source, and a remarkable biochemical effect can also be obtained even under the situation that the water temperature in winter is lower.

Owner:URUMQI KEFAZHAN FINE CHEM

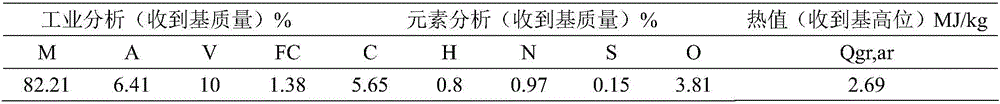

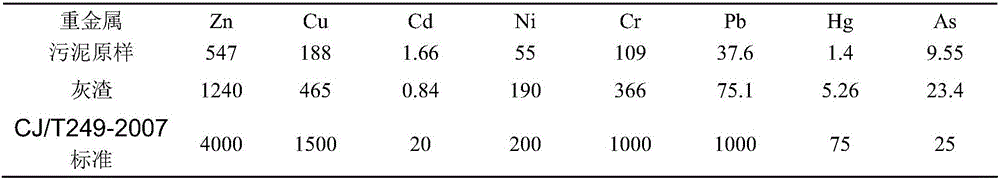

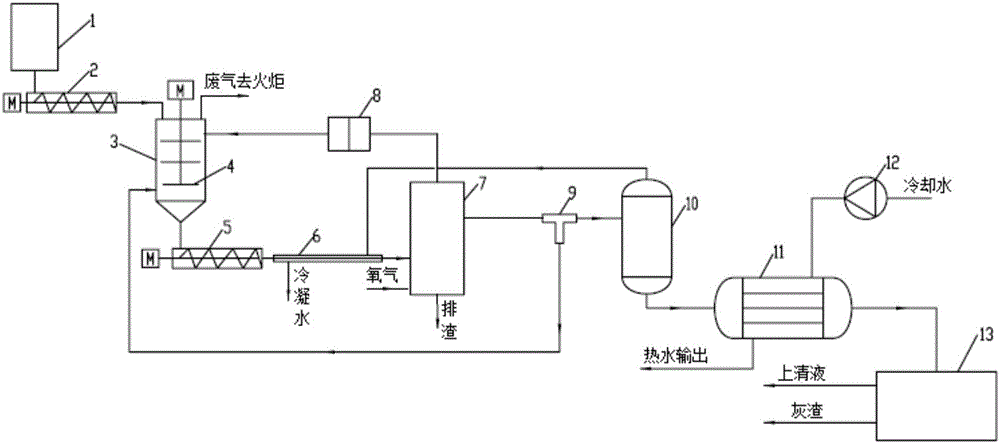

Sludge hydrothermal oxidization reaction system and method with function of product reflux pretreatment

ActiveCN106630526AFully warmed upLow viscositySludge treatment by thermal conditioningSludge treatment by oxidationLiquid productSludge

The invention discloses a sludge hydrothermal oxidization reaction system and method with a function of product reflux pretreatment, and belongs to the field of municipal sludge treatment. A gaseous product generated through hydrothermal oxidation is led out from the top of a reactor, residual oxygen and produced carbon dioxide after the reaction are removed, and then the gaseous product is introduced into a sludge pretreatment tank and directly contacted with sludge for preheating the sludge; a divided flow part of a liquid product flows back to the sludge pretreatment tank; steam and hot water preheat sludge under the stirring action, and the problem that heat recovered by the system is not enough to preheat the sludge to reach the feeding temperature is solved; the residual liquid product is treated with a vacuum flashing method, flash steam is recovered and sent to a pretreatment sludge feeding pipe for tracing heat, and meanwhile, a liquid phase after flash deoxidization enters a downstream heat-exchange device for waste heat recovery. With the adoption of measures, high-temperature material heat of the system can be recovered to preheat sludge, corrosion of dissolved oxygen to a heat exchanger can be relieved, system investment is reduced, and energy utilization rate and economic efficiency of the system are increased.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

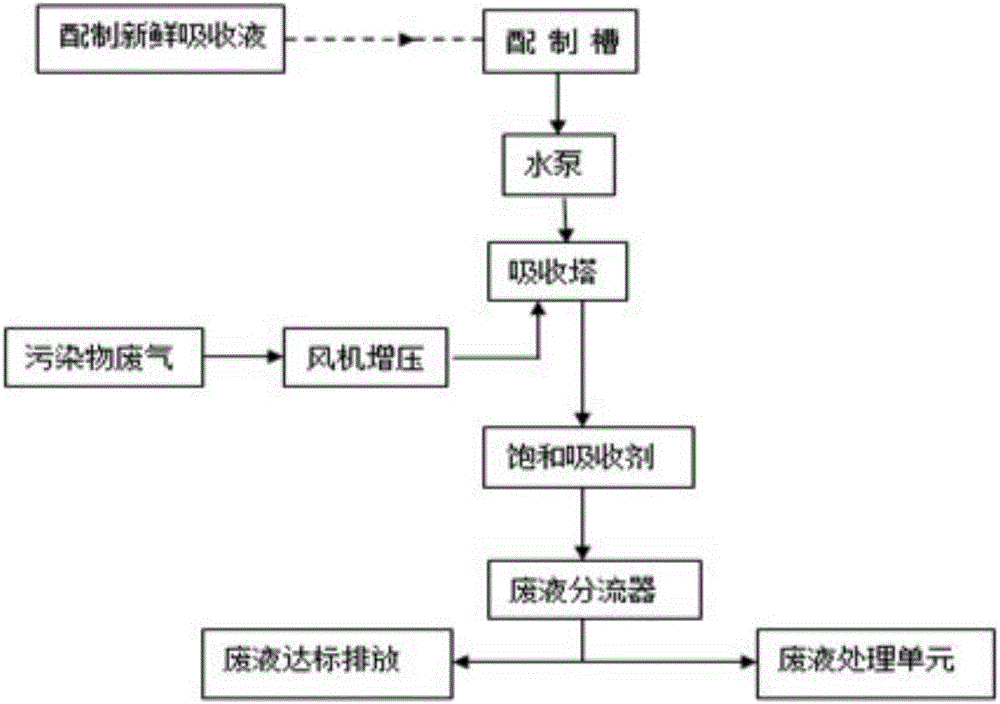

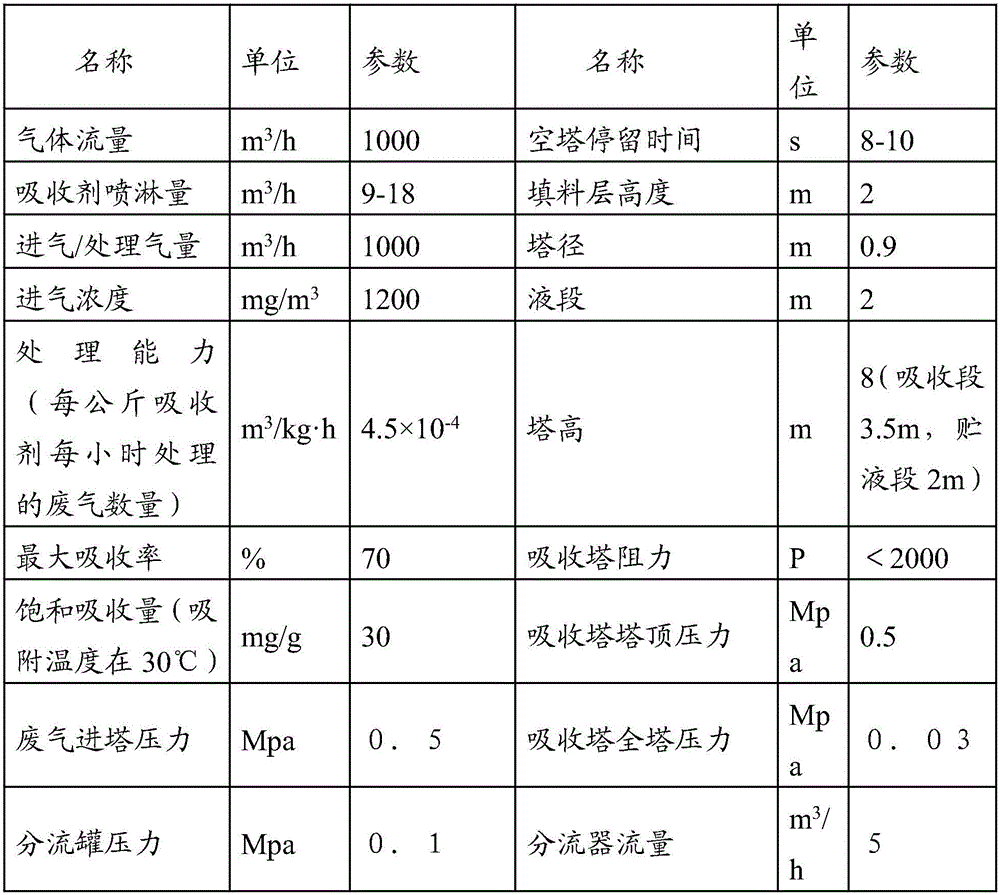

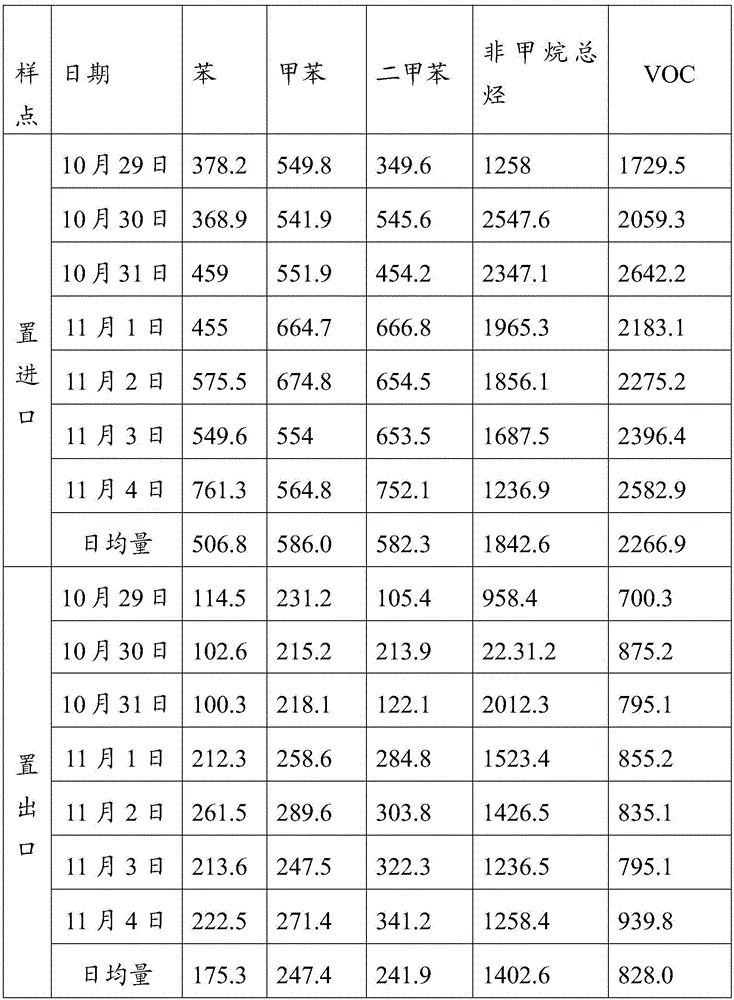

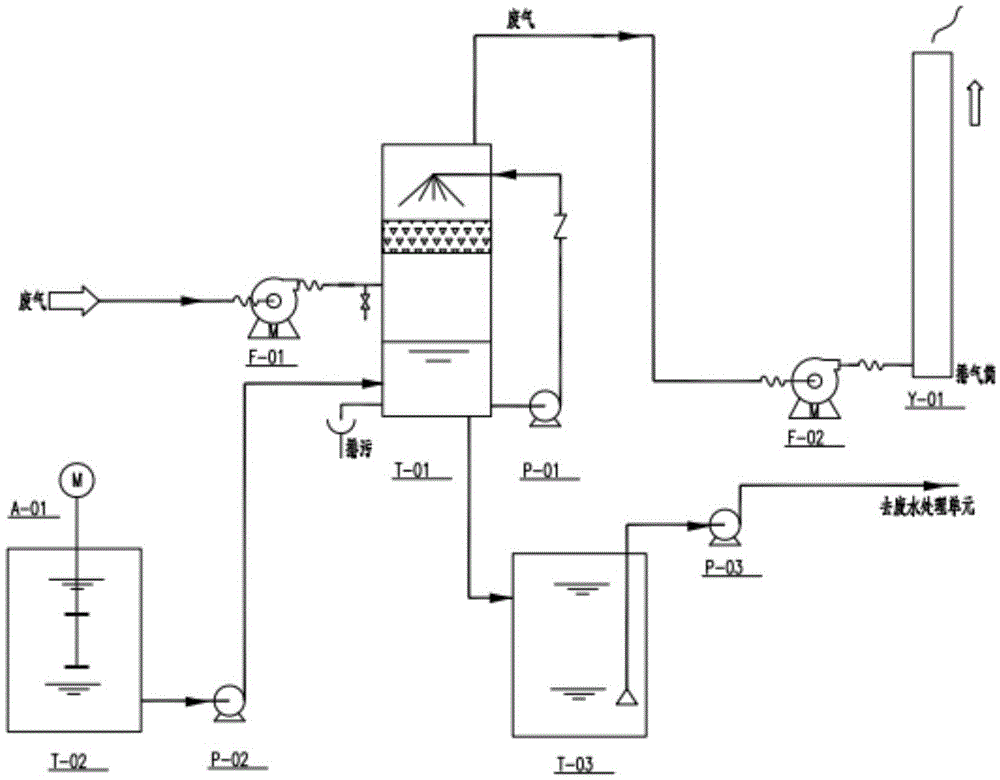

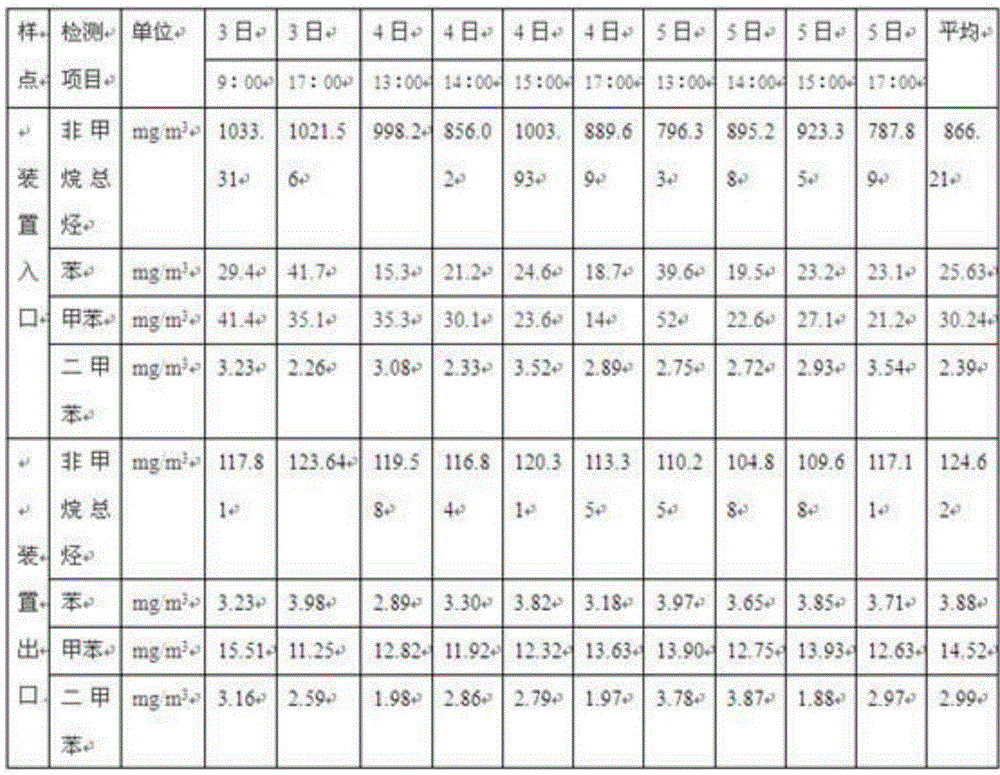

Absorbent for removing VOC waste gas and preparation method thereof

InactiveCN105727693AGood processing effectBiochemical improvementGas treatmentDispersed particle separationChemistryGlycerol

The invention discloses an absorbent for removing VOC waste gas and a preparation method thereof. The absorbent is prepared from, by mass, span 80 1.8%, Tween 80 7.2%, n-butyl alcohol 3%, glycerol 1%, biodiesel 20%, water 60.6%, hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine 1.4%, 1% mass concentration of sophorolipid 1% and 3.9% mass concentration of rhamnolipid 4%. A preparation method comprises the steps that the span 80 and the Tween 80 are mixed and stirred evenly, the n-butyl alcohol, the glycerol, the biodiesel, the water, the rhamnolipid, the sophorolipid and the hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine are sequentially added during stirring, and even stirring is performed to complete the preparation of the absorbent. The absorbent uses an organic solvent as a raw material, the rhamnolipid and the sophorolipid having stronger benzene series adsorption capacity are added, the absorption effect is enhanced, the biochemical properties of discharged waste gas absorption liquid are good, the absorbent can be directly used in an existing sewage treatment system for treatment, and a good treatment effect is obtained.

Owner:BEIJING VICTEX ENVIRONMENTAL PROTECTION TECH DEV

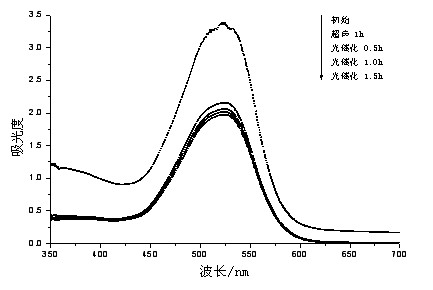

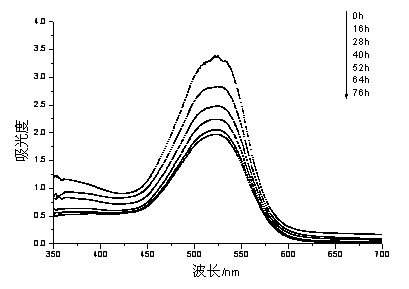

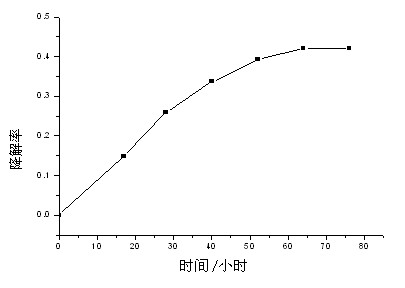

Water treatment method of microbial fuel cell

InactiveCN102603041AReduce processing costsLow selectivityWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsMixed fuelEnvironmental chemistry

The invention discloses a water treatment method of a microbial fuel cell. After waste water difficult to degrade is catalyzed by TiO2 with visible-light activity under visible light or sunlight, the waste water difficult to degrade and waste water easy for biochemistry are mixed to together serve as a carbon source of a microbial fuel cell, so that the degradation rate of the waste water difficult to degrade is enhanced; meanwhile, the invention provides a method for enhancing the bioavailability and the efficiency of the microbial fuel cell by combining a mixed fuel technology of photocatalytic treatment; the power density and the water treatment efficiency of the microbial fuel cell can be enhanced; and moreover, the utilization range of organic waste water can be widened.

Owner:SOUTHEAST UNIV

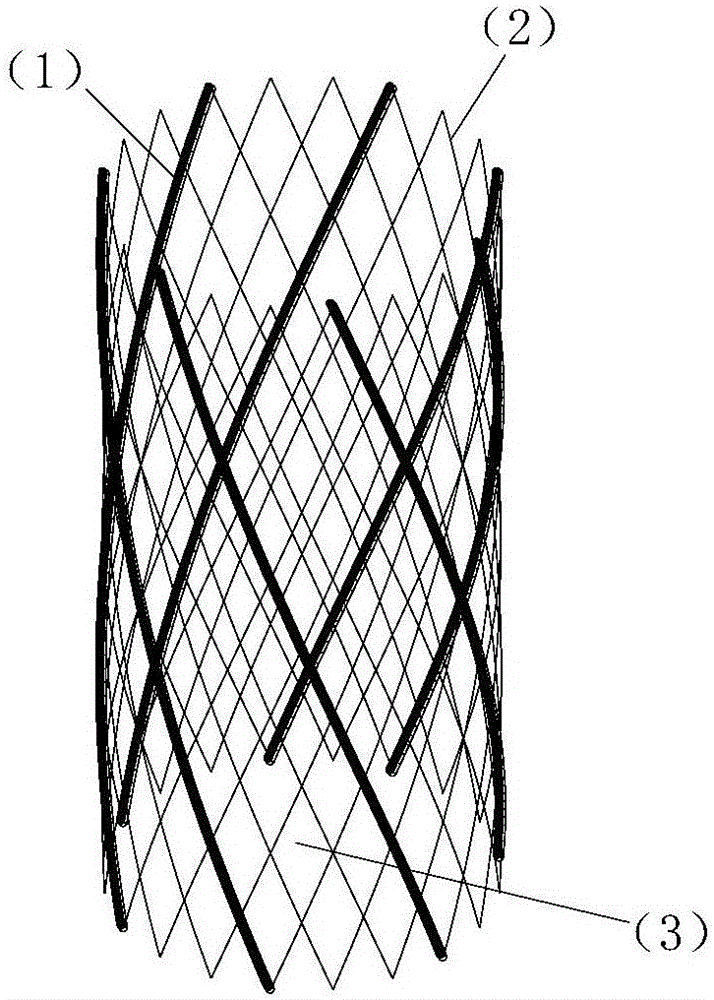

Micropore biofilm carrier filler based on mesh structure

ActiveCN105906035AIncrease load capacityImprove stabilityBiological treatment apparatusSustainable biological treatmentBiofilmPolymer science

The invention discloses a micropore biofilm carrier filler based on a mesh structure and belongs to the field of sewage and wastewater treatment. A polyethylene or polypropylene high-molecular polymer serves as the main carrier material, auxiliary materials polyvinyl alcohol and limestone powder are added, the adding amount of polyvinyl alcohol is 10% of the total weight of the main material and the auxiliary materials, limestone powder is 150-200-mesh powder, and the adding amount of limestone powder is 15-20% of the total weight of the main material and the auxiliary materials. The whole structure is a web cylinder, an elevated fin is arranged every other several netting wires outside the web cylinder in the direction of the netting wires, the elevated fins are integrated with the web cylinder, and the elevated fin and the web cylinder are made of the same material. A biofilm carrier is provided with two-grade gaps, the first-grade microbubble gaps are formed through foaming, and the second-grade fine gaps are formed through acid dissolution of small limestone granules. The filler has high bacteria adhesiveness property, high biological film load performance and excellent biological film stability after biofilm formation, and therefore excellent biochemical performance is realized.

Owner:BEIJING UNIV OF TECH

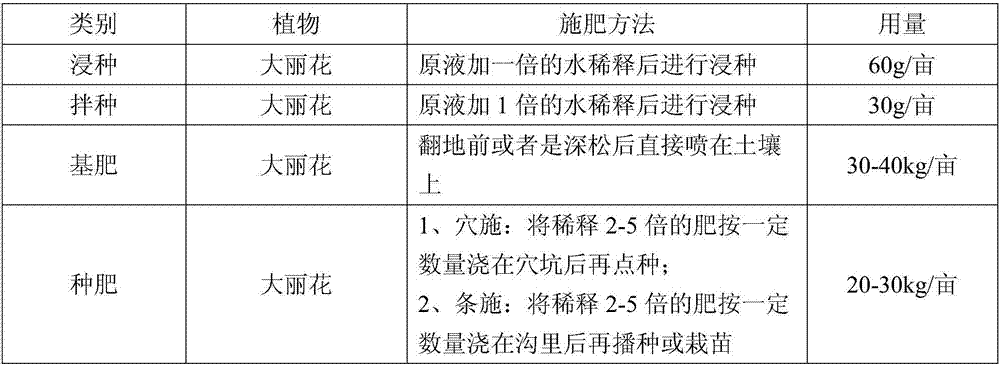

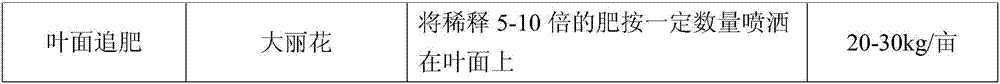

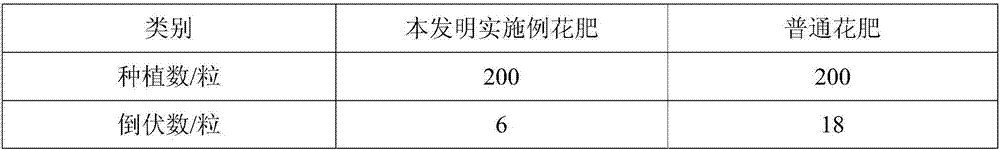

Liquid fertilizer special for Dahlia pinnata and manufacture method thereof

InactiveCN106966790AEasy to viewReduce usageAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMaifan StoneHydroxycitric acid

The invention belongs to the technical field of fertilizers and discloses a liquid fertilizer special for Dahlia pinnata, made from, by weight, 15-50 parts of monopotassium phosphate, 10-30 parts of potassium sulfate, 5-30 parts of calcium nitrate, 1-10 parts of citric acid, 5-45 parts of Maifan stone extract, 3-10 parts of a growth regulator, 3-10 parts of plant extract, 10-24 parts of a wetting agent, and 1000-3500 parts of water. The invention also discloses a manufacture method of the liquid fertilizer special for Dahlia pinnata, comprising the sequential steps of mixing well raw materials, and adding citric acid to adjust pH of the solution to 5.5-7. The liquid fertilizer according to the invention is prepared specially in accordance with the growth features of Dahlia pinnata, the liquid fertilizer has complete nutrition, the fertilizer utilization rate of Dahlia pinnata is increased effectively, and absorption by Dahlia pinnata, promotion of adult-plant blossoming, sterilization and disinfecting, lodging resistance and healthy growth are facilitated.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Advanced treatment method and device of coking wastewater

PendingCN107698112AHigh recovery rateSolve processing problemsWater treatment compoundsSpecific water treatment objectivesEcological environmentUltrafiltration

The invention discloses an advanced treatment method and device of coking wastewater and relates to the technical field of coking wastewater treatment. The advanced treatment method of coking wastewater comprises steps as follows: (1) treating the coking wastewater with a biochemical method; (2) adding a gangue-based inorganic polymer coagulant and performing efficient coagulation and filtration;(3) performing adsorption with reproducible filler, and enabling a desorption solution to flow back to a biochemical device for biochemical treatment after microelectrolysis and Fenton treatment; (4)sequentially performing ultrafiltration, nanofiltration and reverse osmosis treatment and treating reverse-osmosis high-concentration brine water through membrane distillation and crystalizing coupling. A series of environmental protection problems caused by drainage of the coking wastewater are solved, and the method and the device have very remarkable social and environmental benefits, also haveprofound significance in survival and sustainable development of the coking industry, improvement of the ecological environment and water resource saving and are suitable for large-scale popularization in the coking industry.

Owner:山西焦化股份有限公司

Treatment method of acrylic acid wastewater

InactiveCN109354310AReduce the amount of waterAchieve removalWater contaminantsMultistage water/sewage treatmentSludgeOxygen

The invention discloses a treatment method of acrylic acid wastewater, and belongs to the field of wastewater treatment method, according to the method, the acrylic acid wastewater is introduced to acoagulation reaction tank, so that most of the suspended impurities in the wastewater can be removed, and the sludge and water in the effluent after the coagulation reaction are separated by flowing through a sedimentation tank. The supernatant is introduced into a biochemical system, and the organic pollutants are degraded through one-stage continuous aerobic / ABR anaerobic / two-stage continuous aerobic / BAF aerobic, and the whole organic nitrogen of the wastewater is subjected to ammoniated, nitrated and denitrified reactions. The sediment sludge is subjected to external transportation treatment, the supernatant is discharged after reaching the standard. The biochemical combination process simultaneously ammoniates, nitrates and denitrifies the whole organic nitrogen of the wastewater, andtreats ammonia and nitrogen and whole nitrogen as important pollution indexes for treatment, and the operation cost is low. After the effluent is treated through biochemical treatment, the COD, ammonia nitrogen and whoel nitrogen are completely discharged according to the standard. Good environmental effect is provided.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

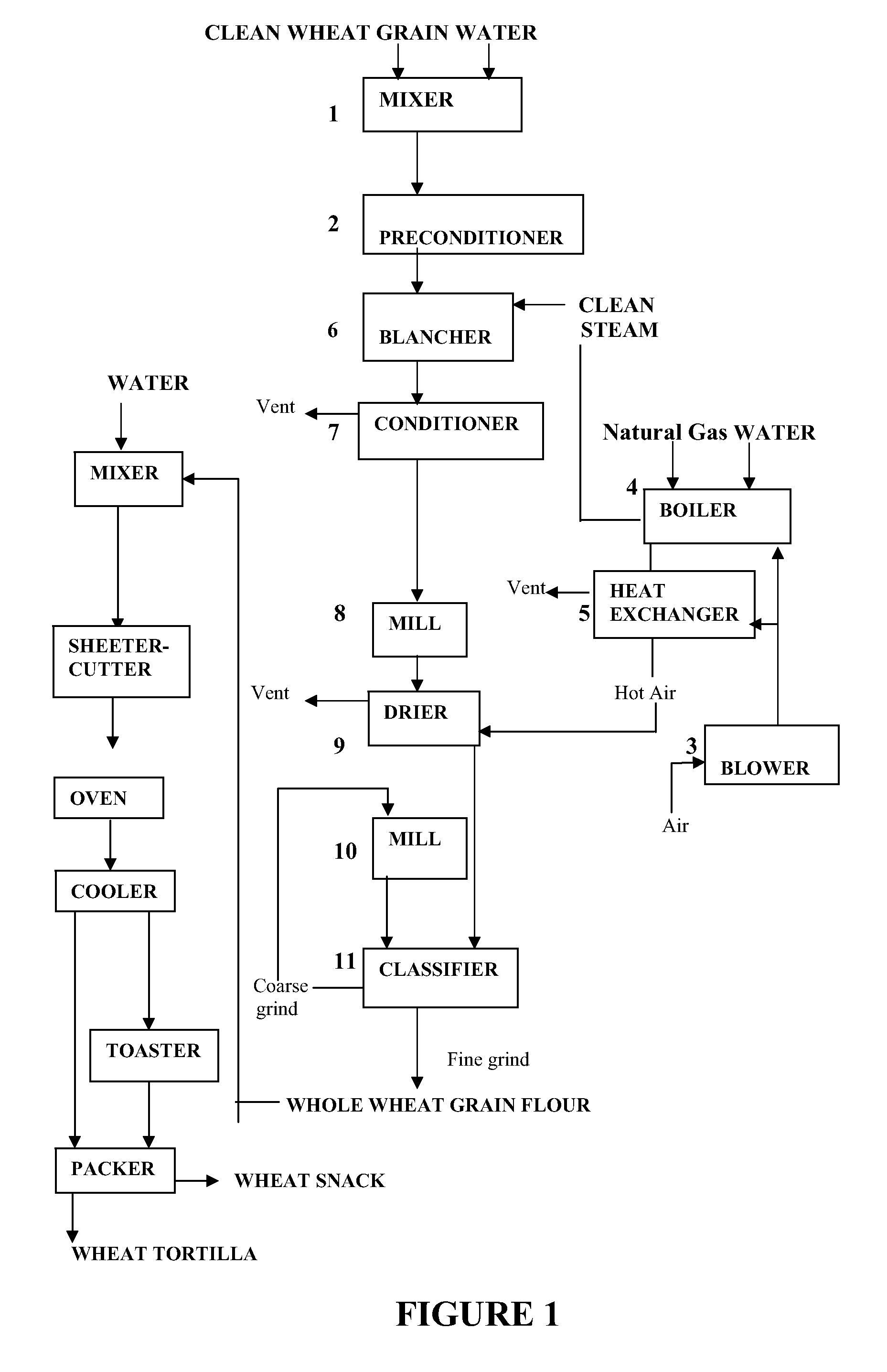

Water and energy saving process for making whole grain and whole gluten-free grain flour

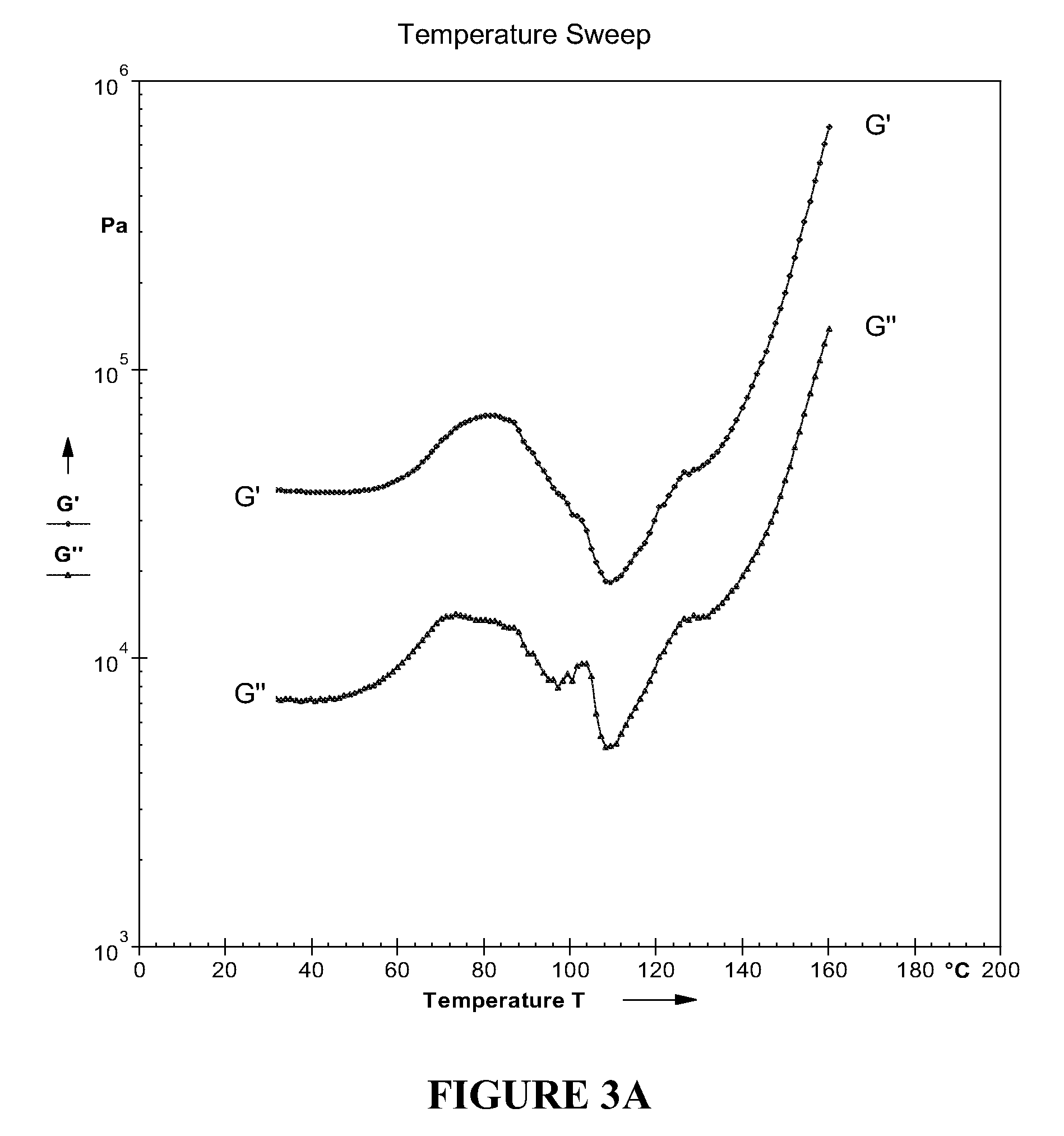

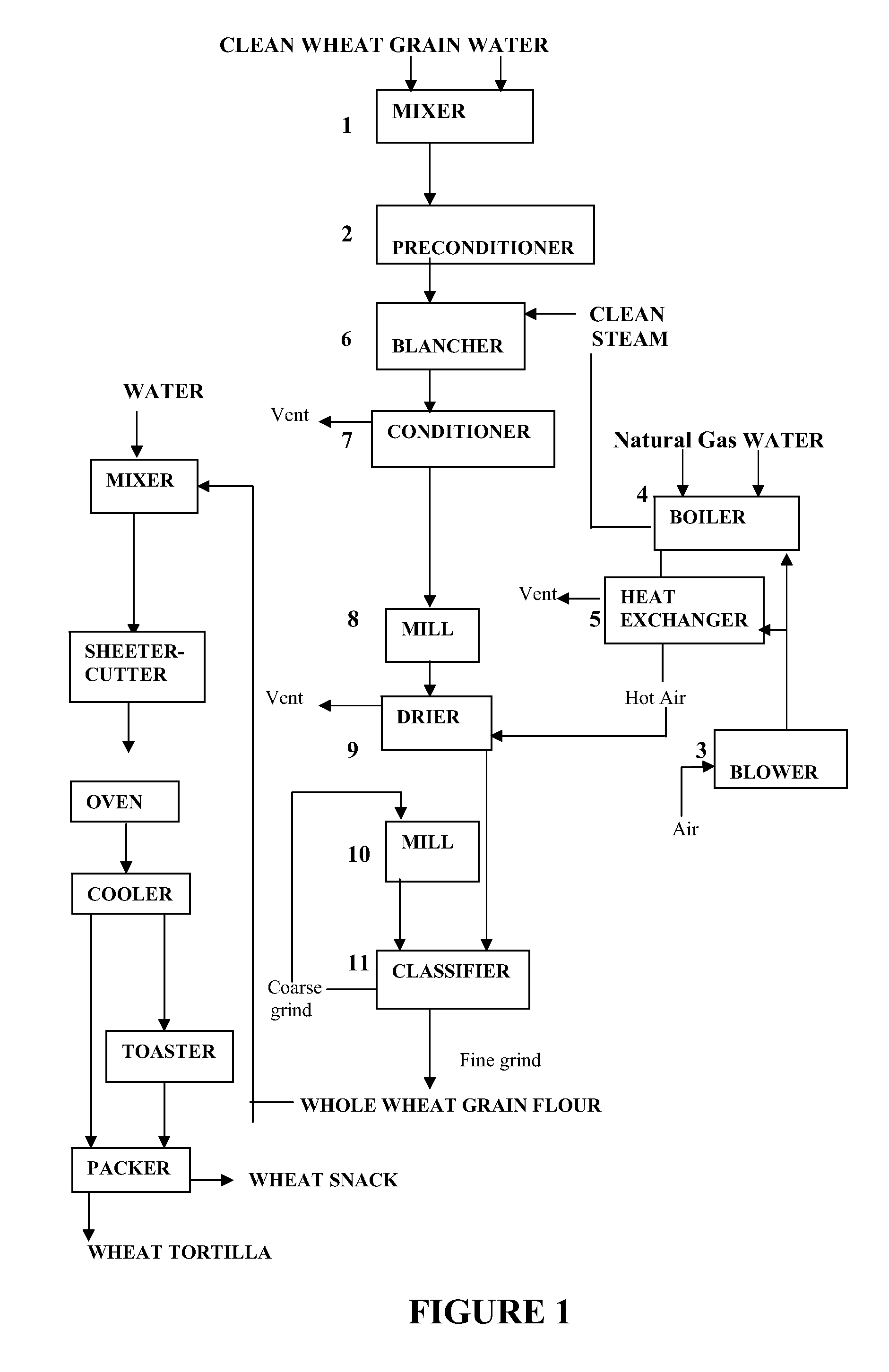

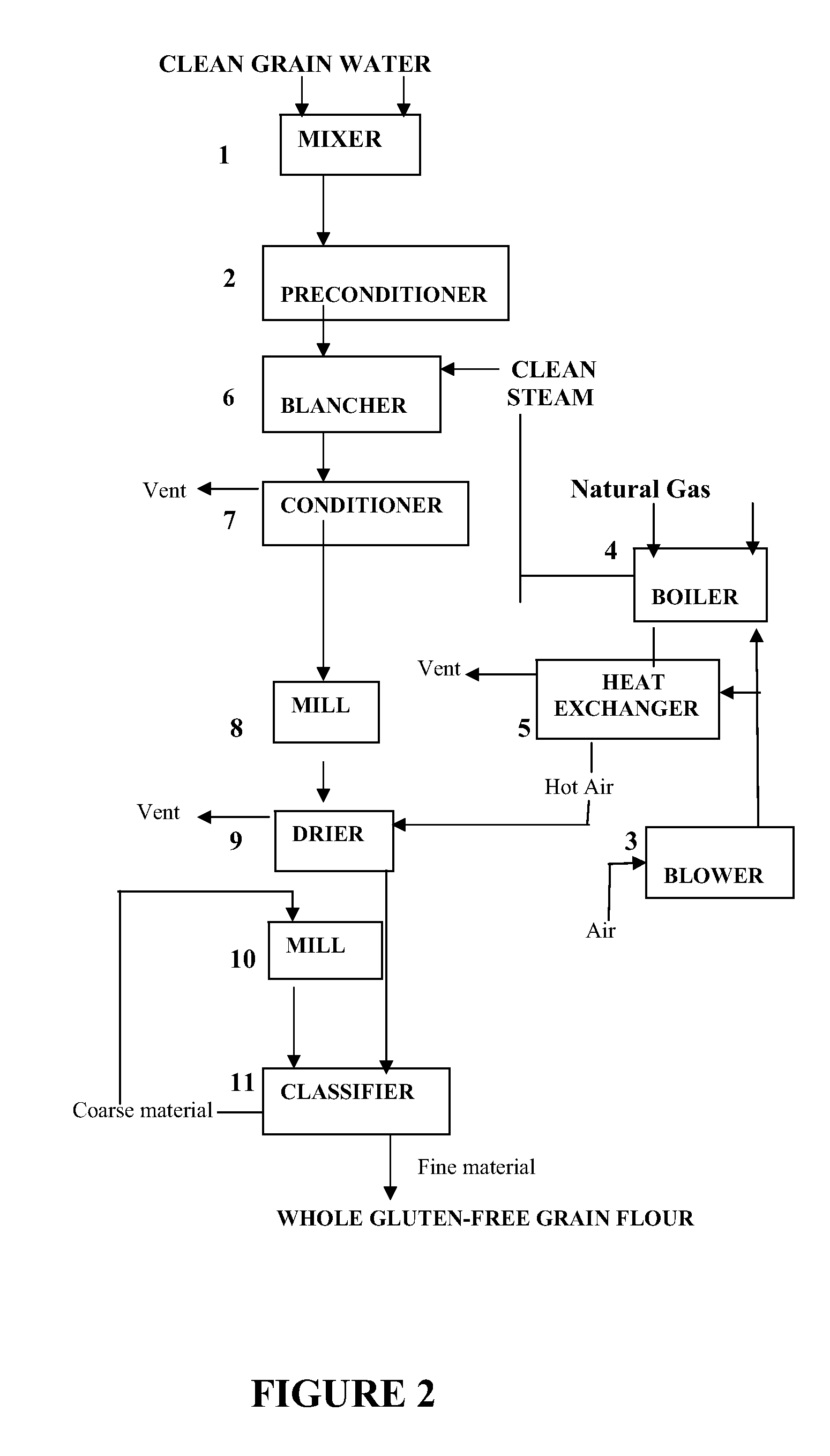

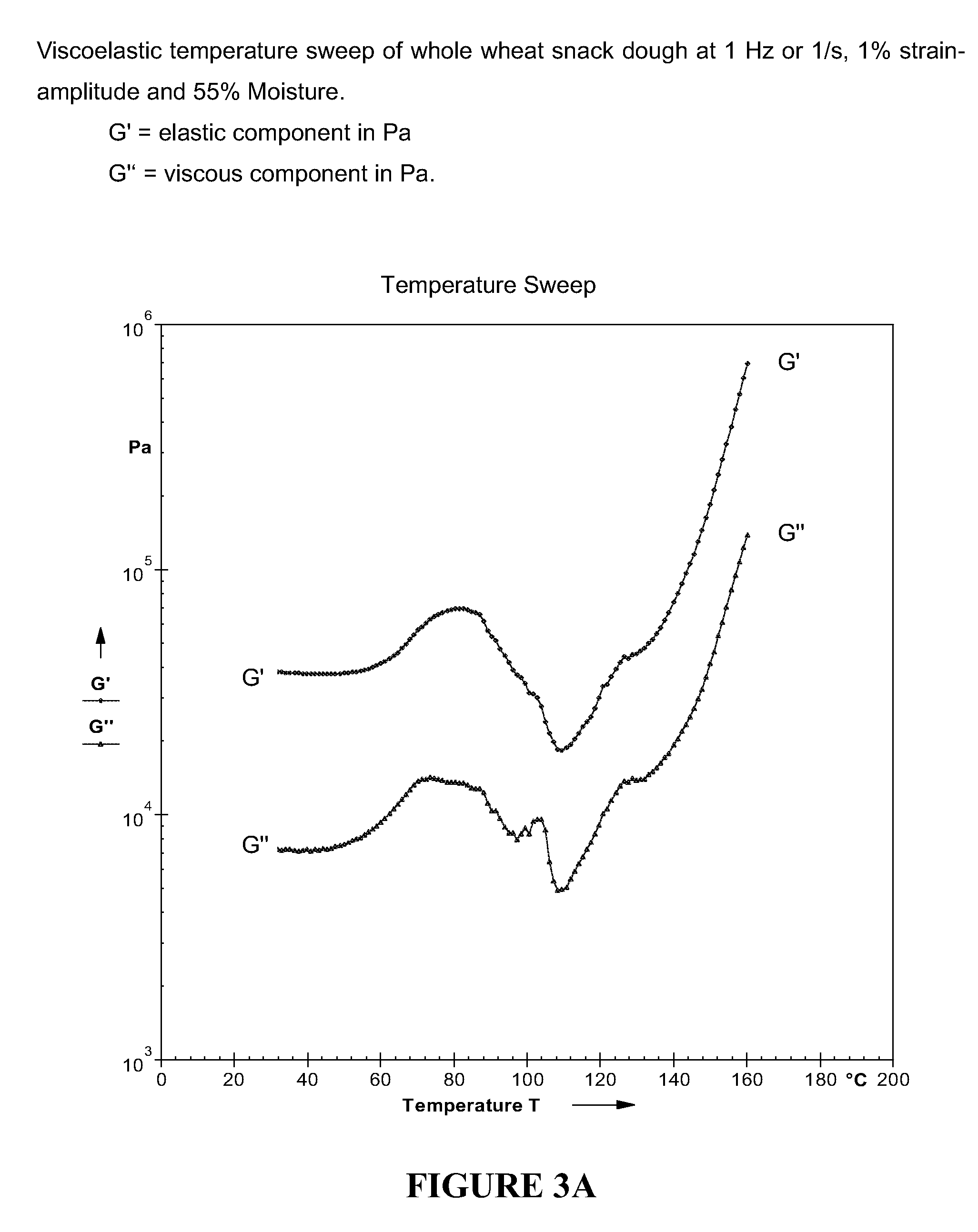

ActiveUS20160175845A1Biochemical improvementHigh viscoelasticityClimate change adaptationSaving energy measuresWater savingViscosity

A water saving and energy saving process the continuous production of whole grain flour and whole gluten-free flour is provided. The process includes preconditioning whole-grain or seed with water and uses an energy efficient blanching treatment with saturated steam. The process also provides flour having a bimodal size mixture of material having improved viscosity. The whole grain and whole gluten-free flour can be used to prepare grain products and baked foods.

Owner:GRUMA S A B DE CV

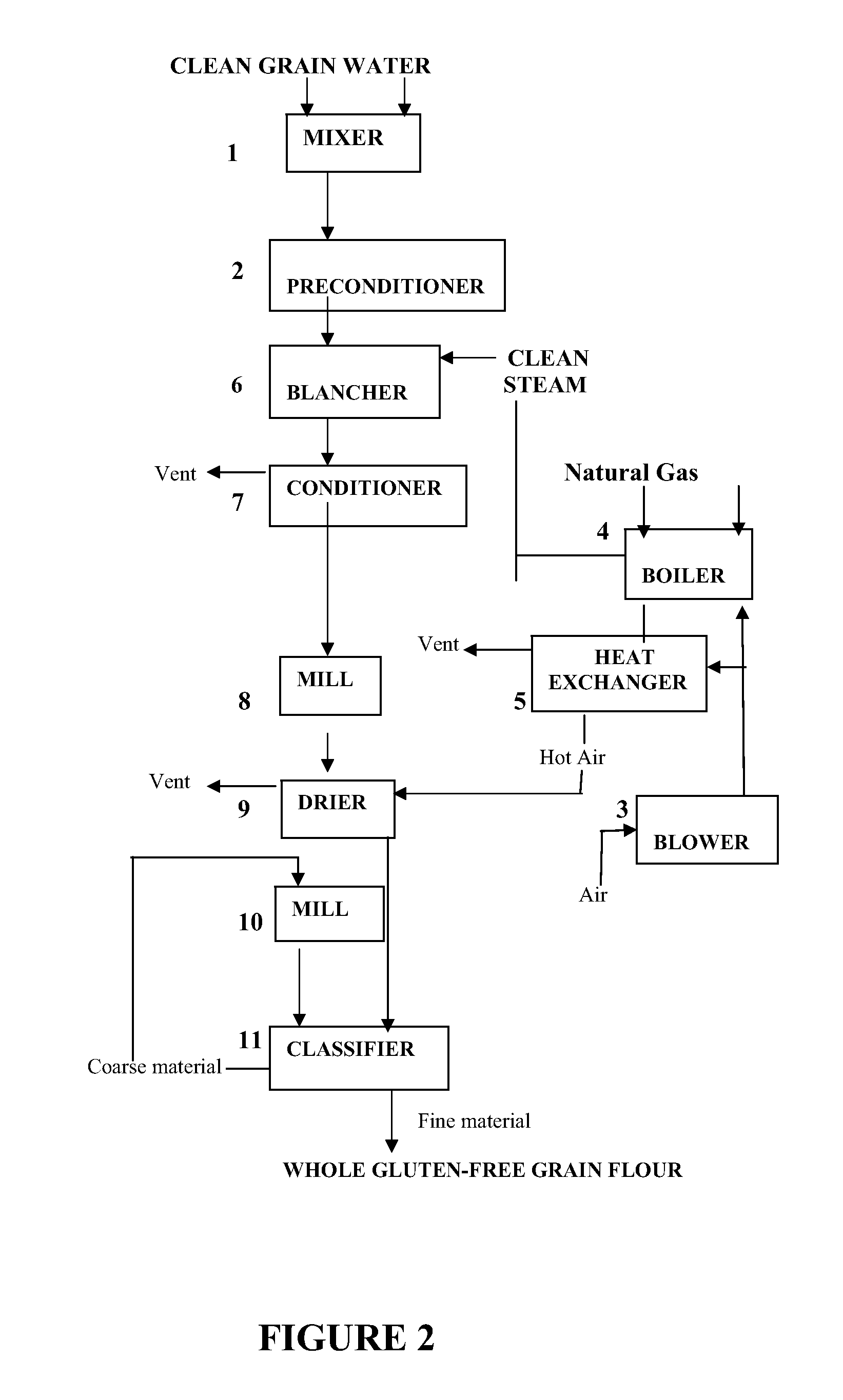

Water and energy saving process for making whole grain and whole gluten-free grain flour

ActiveUS20160175844A1Biochemical improvementHigh viscoelasticityClimate change adaptationSaving energy measuresWater savingViscosity

A water saving and energy saving process the continuous production of whole grain flour and whole gluten-free flour is provided. The process includes preconditioning whole-grain or seed with water and uses an energy efficient blanching treatment with saturated steam. The process also provides flour having a bimodal size mixture of material having improved viscosity. The whole grain and whole gluten-free flour can be used to prepare grain products and baked foods.

Owner:GRUMA S A B DE CV

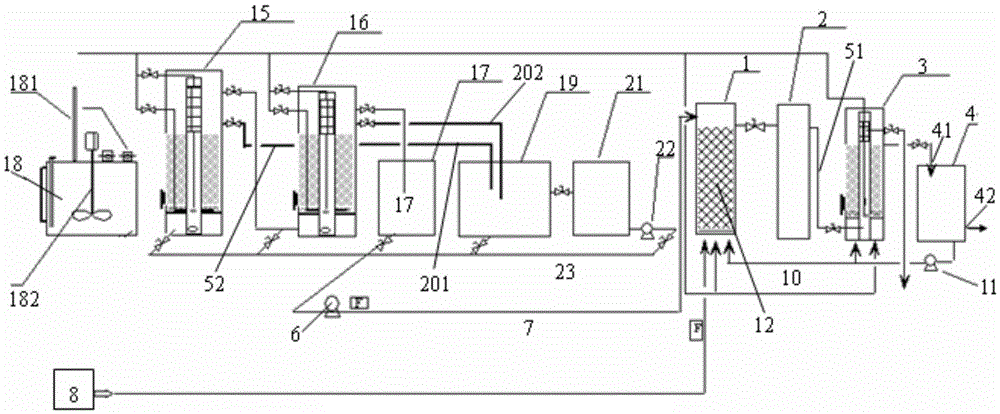

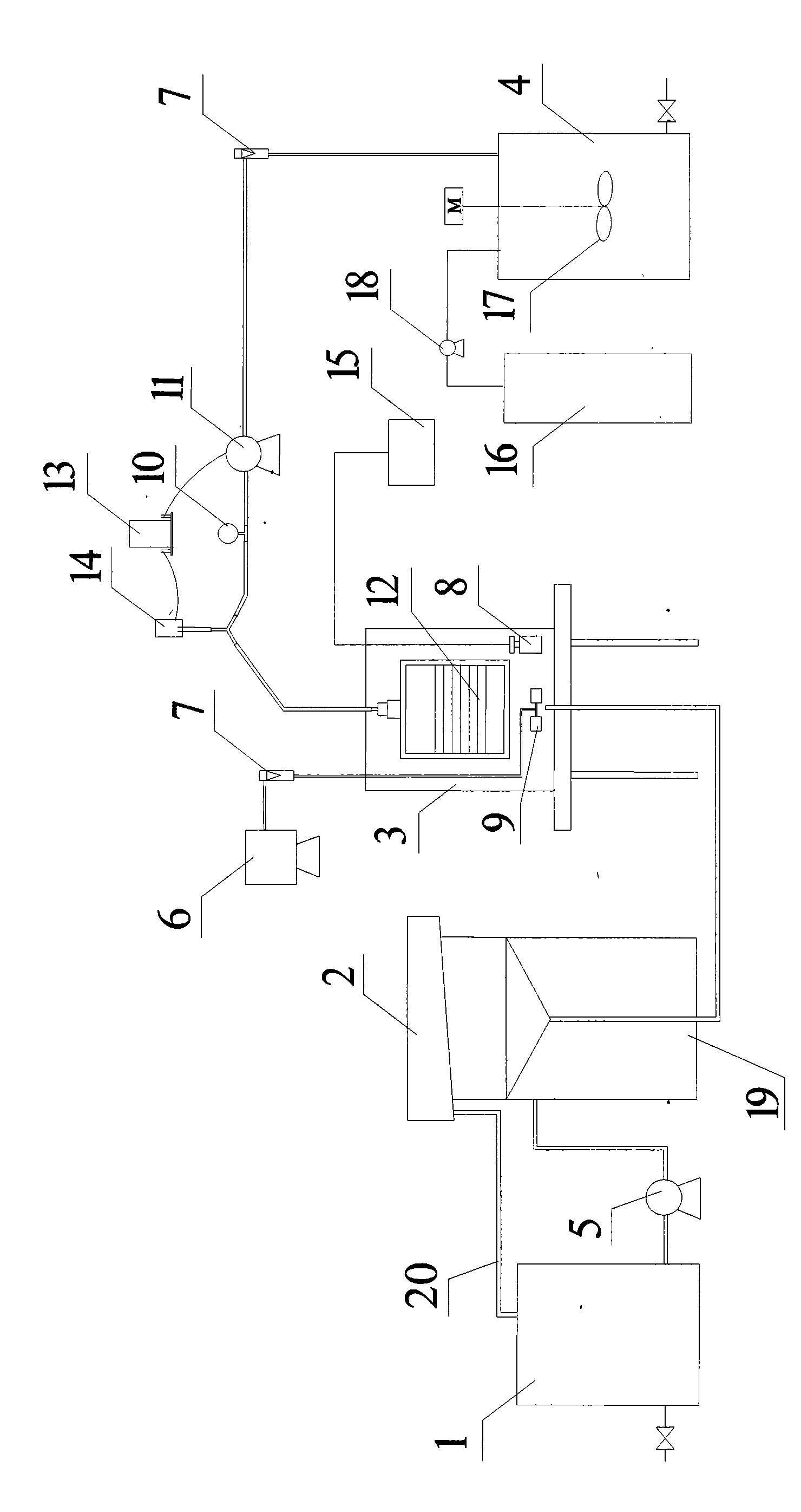

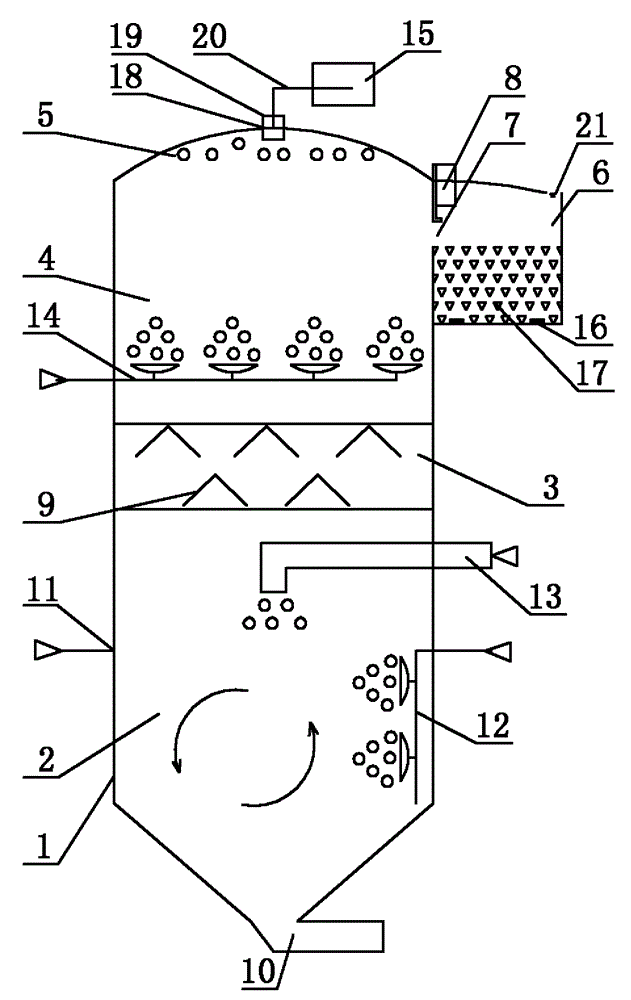

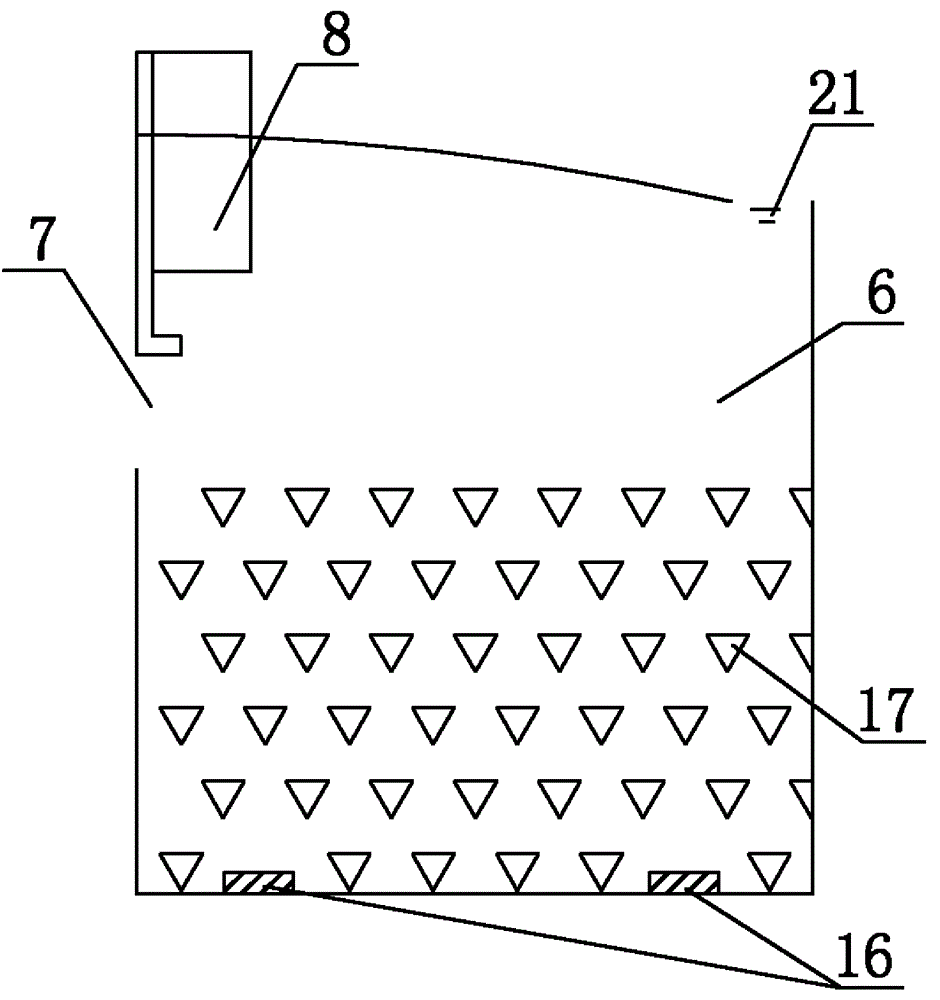

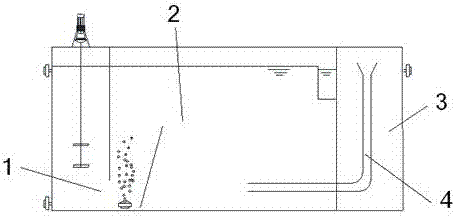

Integral pretreatment device for leachate in waste incineration power plant

ActiveCN104150648ABiochemical improvementOrganic load reductionMultistage water/sewage treatmentElectrolysisPower station

The invention provides an integral pretreatment device for leachate in a waste incineration power plant. The device is arranged before rear-end biochemical treatment, has the characteristics of capability of efficiently degrading organic macromolecules, adjusting the carbon-nitrogen ratio and improving the biodegradability of the leachate, and is low in land cost due to small occupied area. The device comprises a shell and is characterized in that the shell is vertically arranged; an aeration dosing silt removal region, a mud-water separation region, an ammonia nitrogen blowoff region and a waste gas collection region are arranged in the shell in sequence from bottom to top; a mixed reaction cavity is formed in the top of one side of the shell; a water-passing hole is formed in the side wall, in the ammonia nitrogen blowoff region, at the upper part of the shell; the water-passing hole is communicated with the mixed reaction cavity in the outer side; an electrolysis and micro-electrolysis mixed reactor is arranged in the mixed reaction cavity; a doser is also arranged in the mixed reaction cavity; a three-phase separator is arranged in the mud-water separation region.

Owner:WUXI HUAGUANG BOILER

Biological absorbent for treating hydrocarbon organic waste gas and preparation method thereof

InactiveCN105617856AAvoid secondary pollutionGuaranteed uptimeGas treatmentDispersed particle separationSolubilityBiodiesel

The invention discloses a biological absorbent for treating hydrocarbon organic waste gas and a preparation method thereof. The biological absorbent is prepared from the following ingredients in percentage by weight: 2-6% of 25g / l rhamnolipid fermentation broth, 0.3-0.5% of sodium oleate, 2% of biodiesel, 91-95% of functional bacterium solution with bacterium concentration of 1010-1011 bacteria / ml, and 0.5% of nutritive salt. The biological absorbent has the beneficial effects that a surface active agent system and biodiesel form emulsion, so that the organic waste gas with poor water solubility is dissolved into a biodiesel phase and then degraded by microorganisms in the emulsion, so that up-to-stand emission of hydrocarbonaceous organic waste gas with poor water solubility is achieved.

Owner:BEIJING VICTEX ENVIRONMENTAL PROTECTION TECH DEV

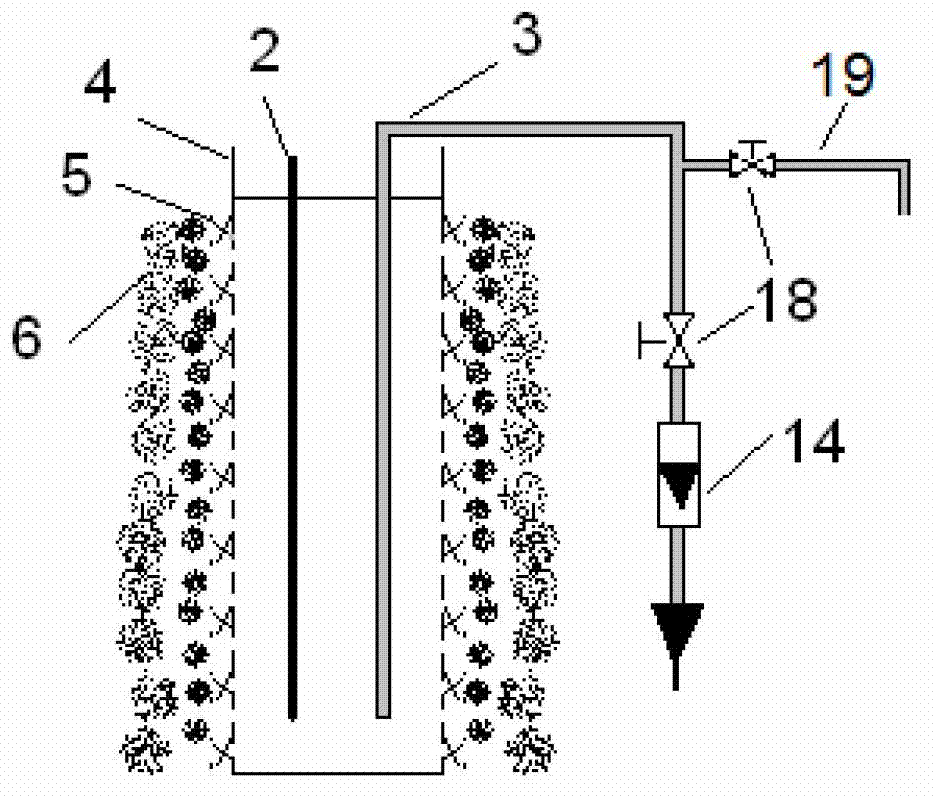

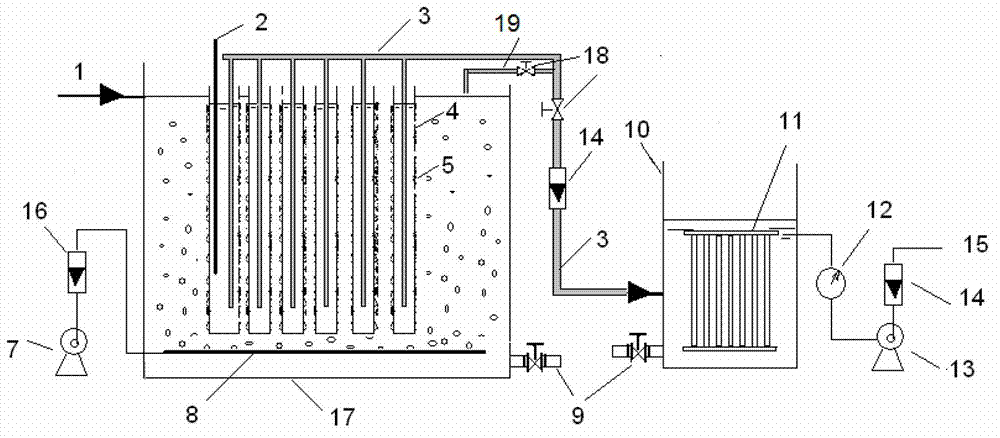

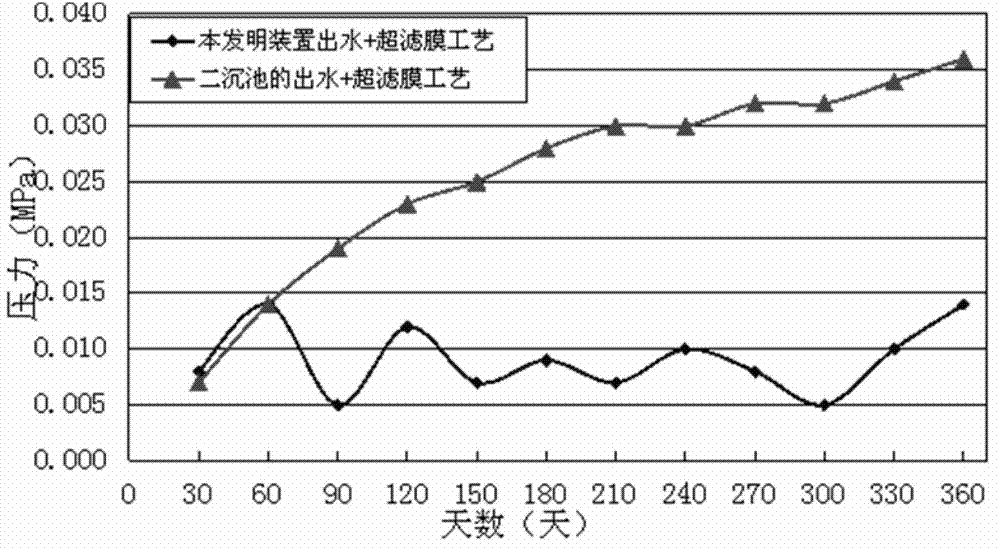

Floccule self-filtering device and using method thereof

InactiveCN102949874AReduce aeration costsHigh power consumptionSustainable biological treatmentStationary filtering element filtersSiphonSludge

The invention discloses a floccule self-filtering device which comprises a plurality of self-filtering units connected in parallel. Each self-filtering unit comprises a supporting structure; the outer surface of each supporting structure is coated with a porous filtering material layer; a floccule layer is arranged outside each porous filtering material layer; a water pipe is arranged in each supporting structure and is connected to an external siphon water outlet pipe; and the floccule layers are formed by floccule interception sludge of the porous filtering material layers. Effluent generated by the self-filtering device disclosed by the invention enters a subsequent fine pore film filtering system by a siphonic manner, so that the high-efficiency operation of the subsequent system is ensured. The cheap and simple self-filtering device carries out pretreatment of sludge and water separation, so that the effluent has an excellent water quality and the total operation cost of the integral process is reduced. Particularly, the self-filtering device disclosed by the invention is combined with an immersion-type ultrafiltration system, replaces a conventional MBR (Membrane Biological Reactor) and is used for deeply treating sewage and wastewater; the treatment cost of per ton of water only occupies 20 to 30 percent of that of a conventional MBR process; and the water quality of the effluent is superior to that of effluent generated by the conventional MBR.

Owner:BEIJING ORIGIN WATER FILM TECH

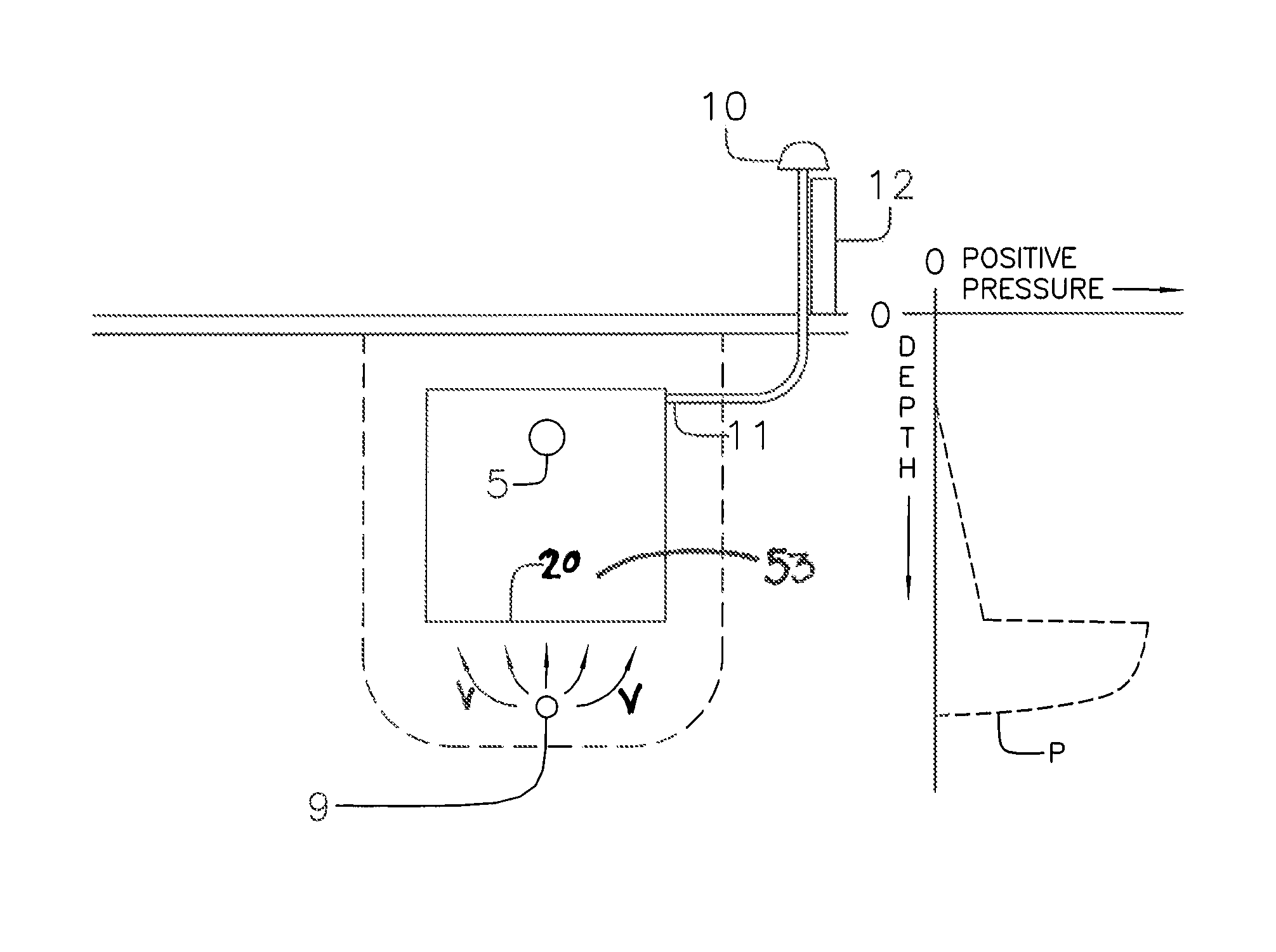

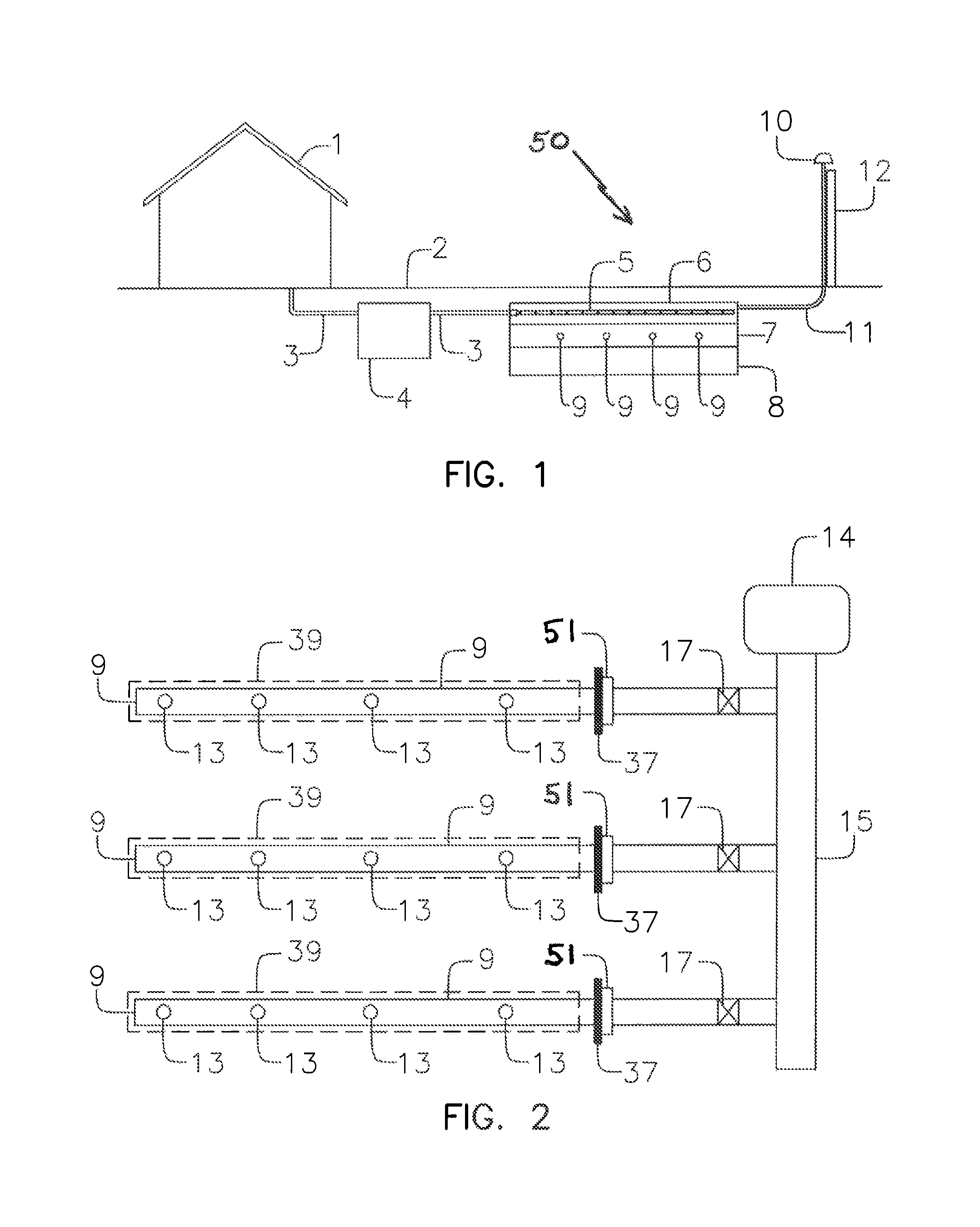

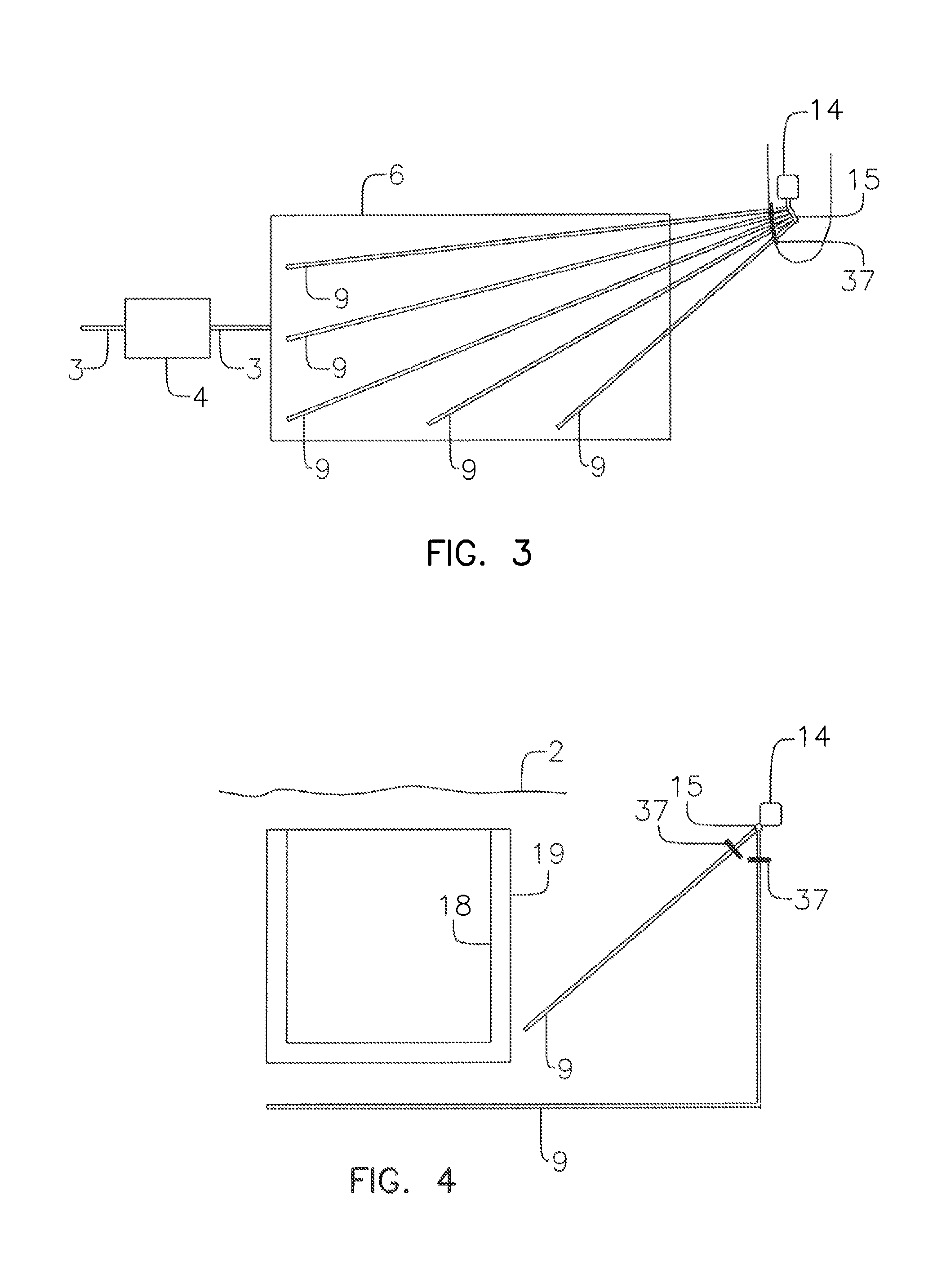

Method for enhanced aerobic activity and bio-mat control for onsite wastewater disposal systems

ActiveUS8974670B1Increase aerobic activityImprove breathabilityWater treatment parameter controlTreatment using aerobic processesSystems designSludge

The present invention provides an aeration lateral system designed to be site specific for new septic disposal areas or retro fitting to existing septic disposal areas to break up the biological clogging sludge mat at the interface of the wastewater and imported sand or native soil fill under or adjacent to disposal areas of a typical septic system. The lateral system provides uniform or other site specific distribution of fluids about the bio-mat of a wastewater disposal area, with lateral spacing and hole spacing varying based on the type of disposal area being utilized. The lateral system can also be utilized to provide continuous low volume air supply system to a wastewater disposal area or peat filter module. The air lateral installation includes methods to minimize airflow disturbance of the soil and methods to prevent air leakage.

Owner:JRL INNOVATIONS

Biodegradable biopolymers, method for their preparation and functional materials constituted by these biopolymers

InactiveUS20080131520A1Strong resistancePromote degradationPowder deliveryAnthropod material medical ingredientsCellulosePolyvinyl alcohol

Owner:NAT INST OF AGROBIOLOGICAL SCI

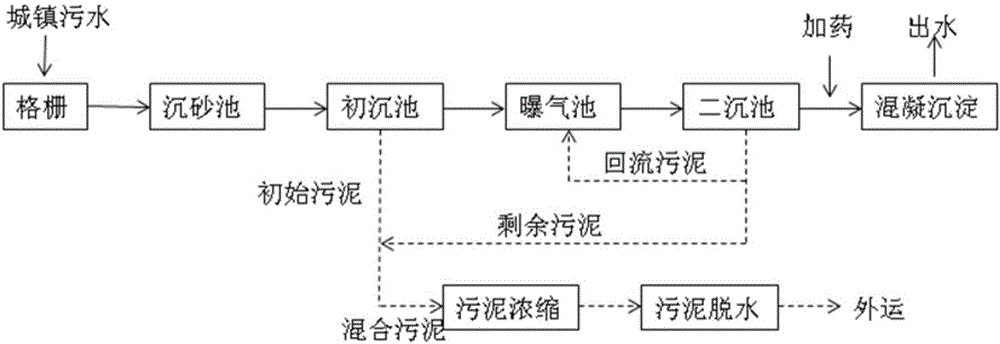

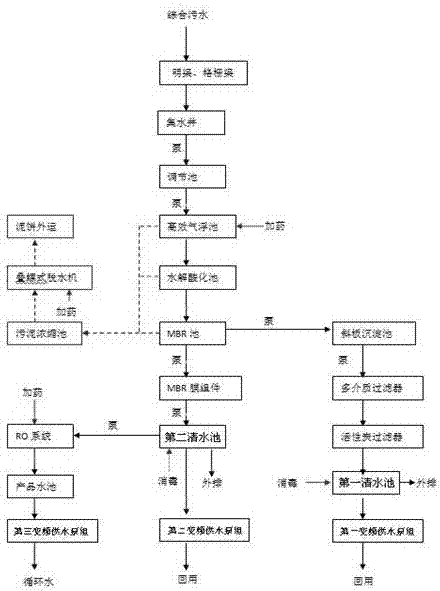

Comprehensive treatment method for sewage of cigarette factory

InactiveCN107512830ABiochemical improvementActive and stableWater treatment parameter controlSludge treatment by de-watering/drying/thickeningActivated sludgeReclaimed water

The invention discloses a comprehensive treatment method for sewage of a cigarette factory. According to the comprehensive treatment method, sewage is introduced into a grating channel through an open channel to be filtered, then the filtered sewage is introduced into a water collection well; sewage in the water collection well is pumped into an adjustment tank; the sewage in the adjustment tank is pumped into an efficient air floatation tank to be subjected to solid-liquid separation, and water subjected to solid-liquid separation enters an effluent stabilizing region; after being subjected to air floatation, the effluent flows into a hydrolysis acidification tank and enters an MBR tank; after reacting in the MBR tank, liquid is subjected to mud-water separation by virtue of an MBR membrane assembly, isolated activated sludge flows back to the MBR tank, and filtered liquid enters a second clean water tank; disinfected liquid is pumped into an RO system, effluent of the RO system enters a product water tank and is supplemented to a circular cooling water system through a third frequency-variable water supply pump; and sludge discharged from the efficient air floatation tank, the hydrolysis acidification tank and the MBR tank enters the same sludge concentration tank and is dehydrated through an overlapped screw type dehydration machine. The comprehensive treatment method has a good biochemical effect, the effluent can be directly reused, reclaimed water treatment processes can be selected according to water seasons and time frames, and the operation is positive and stable.

Owner:江苏国盛华清环保科技有限公司

Method for treating sewage generated in ammonia synthesis process using coal as raw material

InactiveCN102351383ALow priceImprove solubilityMultistage water/sewage treatmentSodium acetateChemical oxygen demand

The invention provides a method for treating sewage generated in the ammonia synthesis process using coal as a raw material. The method comprises the following steps of: settling sewage sediments, introducing the sediments into a first-stage anaerobic tank, a first-stage oxic tank, a second anaerobic tank and a second-stage oxic tank sequentially, and performing two-stage anaerobic / oxic (A / O) biochemical treatment to reduce ammonia nitrogen content and chemical oxygen demand in the sewage, wherein the sewage is subjected to denitrification in the first-stage anaerobic tank and the second-stage anaerobic tank, and is subjected to nitrosation in the first-stage oxic tank and the second-stage oxic tank. The method is characterized by comprising the following step of: putting glucose and sodium acetate in the weight ratio of 1:(3-15) into the second-stage anaerobic tank, wherein 0.4 to 0.5 kilogram of glucose and sodium acetate are put into each ton of sewage according to the total addition amount. The glucose and the sodium acetate are mixed and matched according to a proportion, so that the method has a good treatment effect on the sewage and is lower in cost. Simultaneously, after the glucose and the sodium acetate are added according to the proportion, compared with a method in which white sugar and the glucose are purely added, the method has the advantages that: the total addition amount of a carbon source can be reduced.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

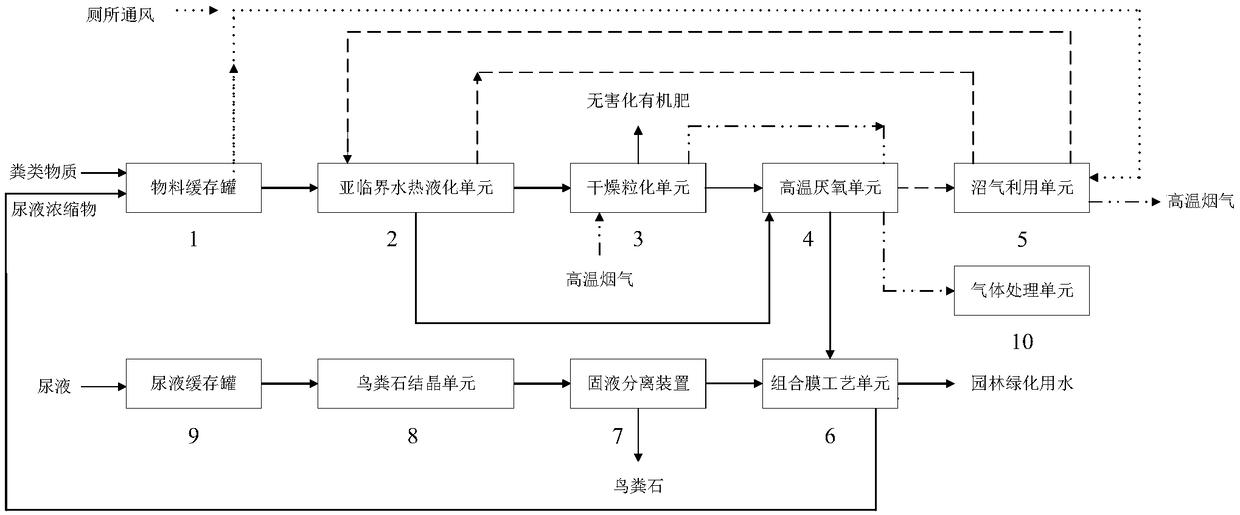

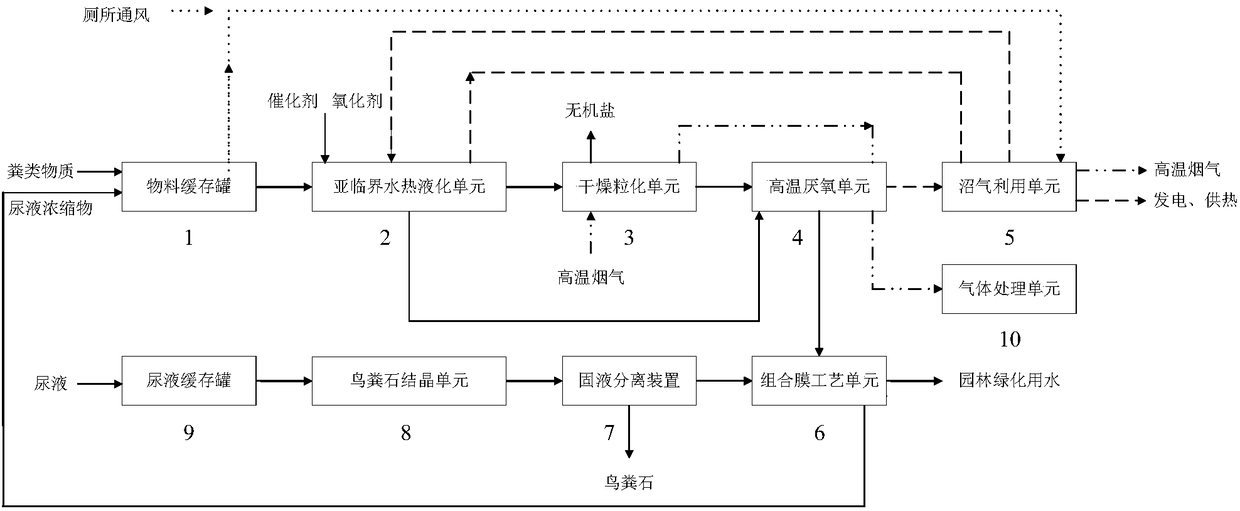

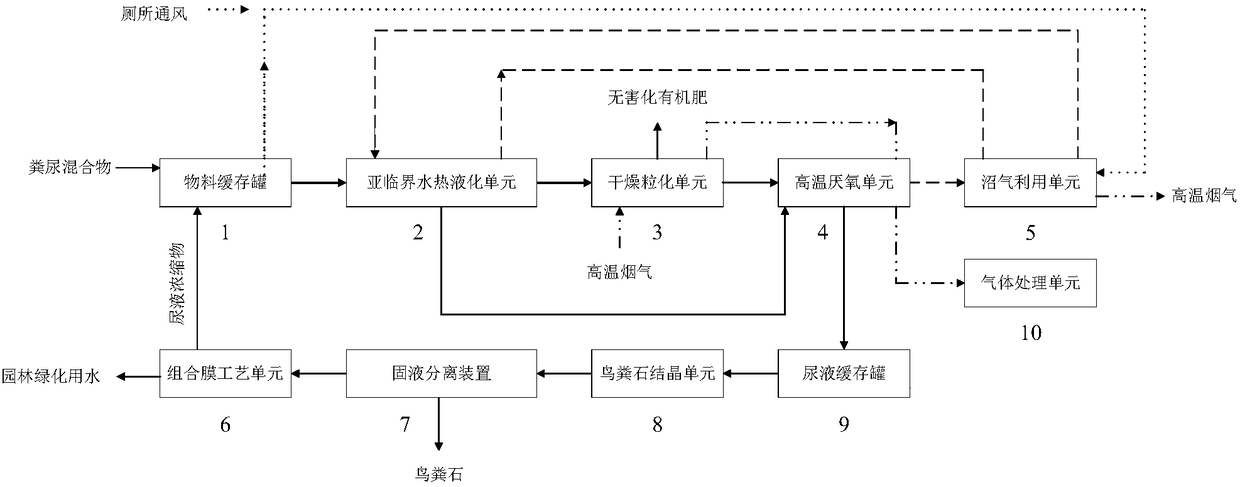

Multi-technique coupling bio-toilet feces treatment system with subcritical hydrothermal liquidation as key point and method

PendingCN108585407AGuaranteed uptimeImproved separation propertiesSludge treatment by pyrolysisTreatment with anaerobic digestion processesFecesLandscaping

The invention discloses a multi-technique coupling bio-toilet feces treatment system with subcritical hydrothermal liquidation as a key point and a method and belongs to the technical field of chemical engineering and environment protection. The system comprises a material buffer tank, a subcritical hydrothermal liquidation unit, a drying pelletizing unit, a high-temperature anaerobic unit, a biogas utilization unit, a combined membrane process unit, a solid-liquid separation device, a struvite crystallization unit, a urea buffer tank and a gas treatment unit. By adopting the system, a subcritical hydrothermal liquidation technique is adopted as a key point, and with the combination of a high-temperature anaerobic process and biogas recycling, heat balance can be achieved; on the basis ofseparation properties of the combined membrane process unit, biosecurity of produced water for landscaping can be ensured. Feces substances are harmlessly treated and stabilized into an organic fertilizer, nitrogen and phosphorus in urea are recycled in a mode of struvite, water in excrement and urea is harmlessly treated and recycled as landscaping water, and smell is subjected to high-temperature combustion treatment, so that harmless treatment on gases, liquids and solids is achieved, and good economic benefits and economic benefits can be achieved.

Owner:XI AN JIAOTONG UNIV +1

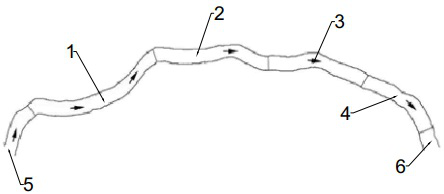

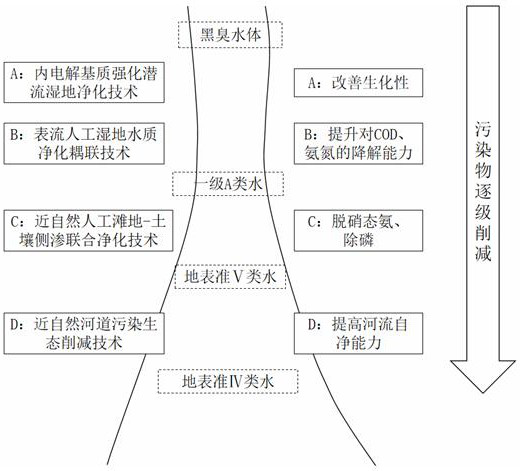

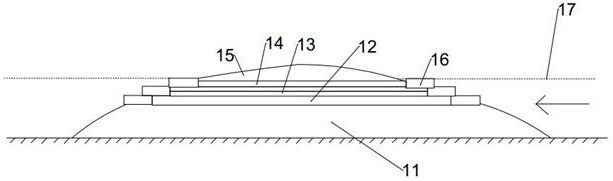

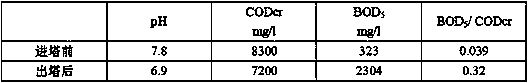

Cascade treatment and purification system and method for black and odorous rivers

ActiveCN113402033ASolve the problem of poor biodegradabilityImprove self-cleaning abilityTreatment by combined electrochemical biological processesWater contaminantsConstructed wetlandIndustrial waste water

The invention discloses a cascade treatment and purification system and method for a black and odorous river. The cascade treatment and purification system comprises a subsurface flow wetland purification river reach, a surface flow wetland purification river reach, a near-natural beach land purification river reach and a near-natural pollution reduction river reach which are sequentially arranged on a main river channel from a sewage estuary to a downstream river, an in-situ purification island and a subsurface wetland are arranged on the subsurface flow wetland purification river reach, and an internal electrolysis matrix is arranged in the in-situ purification island; a side groove connected with the main river channel is formed in the surface flow wetland purification river reach, and a surface flow constructed wetland is arranged in the side groove; a side seepage ditch with the head end and the tail end connected with the main river channel is arranged on the near-natural beach land purification river reach, and side seepage walls are arranged on the two sides of the side seepage ditch respectively; and a river center island is arranged on the near-natural pollution reduction river reach, and indigenous stain-resistant plants are planted on the river center island and the main river channel. The system and method are suitable for treatment and purification of heavy-pollution black and odorous rivers lack of natural runoff, and main incoming water of the heavy-pollution black and odorous rivers is treated town sewage and industrial wastewater.

Owner:NANJING UNIV ECOLOGICAL RES INST OF CHANGSHU

Methylamine wastewater pretreatment catalyst as well as preparation method thereof and application thereof in methylamine wastewater treatment

ActiveCN104289224AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationPtru catalystCatalytic decomposition

The invention discloses a method for preparing a methylamine wastewater pretreatment catalyst. The method comprises the following steps: roasting crushed magnetite with the specific surface area of 200-300 m<2> / g for 3-5 hours under 600-800 DEG C, cooling to 20-28 DEG C, then adding the magnetite in a 30-40wt% nanometer TiO2 impregnating solution and standing for 12-24 hours, subsequently drying under 105-120 DEG C until the mass ratio of the magnetite to nanometer TiO2 is (3-4) to 1, and finally roasting for 6-8 hours under 1000-1200 DEG C to obtain the methylamine wastewater pretreatment catalyst. The catalyst prepared according to the method has the relatively high catalytic activity and stability, and can effectively catalyze and decompose hydrogen peroxide to produce hydroxyl radicals, and thus organic pollutants in waste water can be degraded, the structure of organic pollutants in methylamine wastewater can be changed, and the biochemical ability of the catalyst can be effectively improved; meanwhile, the catalyst produced according to the method has the magnetism, is easily recovered, repeatedly utilized and environmentally-friendly, and can be produced and applied in large scale.

Owner:HENAN HONGKANG ENVIRONMENTAL PROTECTION TECH

Liquid microbial saline-alkaline land improvement fertilizer and preparation method thereof

InactiveCN109694266ARapid cultivationImprove decomposition rateBio-organic fraction processingBioloigcal waste fertilisersPulp and paper industryFermentation broth

The invention provides a liquid microbial saline-alkaline land improvement fertilizer and a preparation method thereof. The preparation method comprises the following steps: 1) collecting salt crust from a target plant to be improved, and preparing brine from the collected salt crust; 2) uniformly mixing crop straws, kelp powder and peanut oil cakes, spraying the brine to the obtained mixture, adding a fermentation culture product of mixed florae, performing primary fermentation, extracting the obtained primary fermentation solution, and filtering the primary fermentation solution to obtain aprimary fermentation filtrate; 3) drying a primary fermentation solid substance obtained after the filter-out of the fermentation solution, carrying out soaking fermentation in a biogas slurry, extracting the obtained secondary fermentation solution, and filtering the secondary fermentation solution to obtain a secondary fermentation filtrate; 4) mixing the secondary fermentation filtrate and theprimary fermentation filtrate with dry Enteromorpha powder, sunflower disk powder, straw vinegar and starch processing wastewater, adding an EM strain to the obtained mixture, and performing sealing fermentation; and 5) filtering the obtained fermentation solution, collecting the obtained filtrate, and adding indole-3-butyric acid potassium salt and forchlorfenuron to the filtrate to obtain the liquid microbial saline-alkaline land improvement fertilizer.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com