Method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation

A hydrogen peroxide and combined treatment technology, applied in the field of environmental protection, can solve problems such as reduced operating costs, and achieve the effects of stable effluent quality, easy automatic control, and high pollutant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

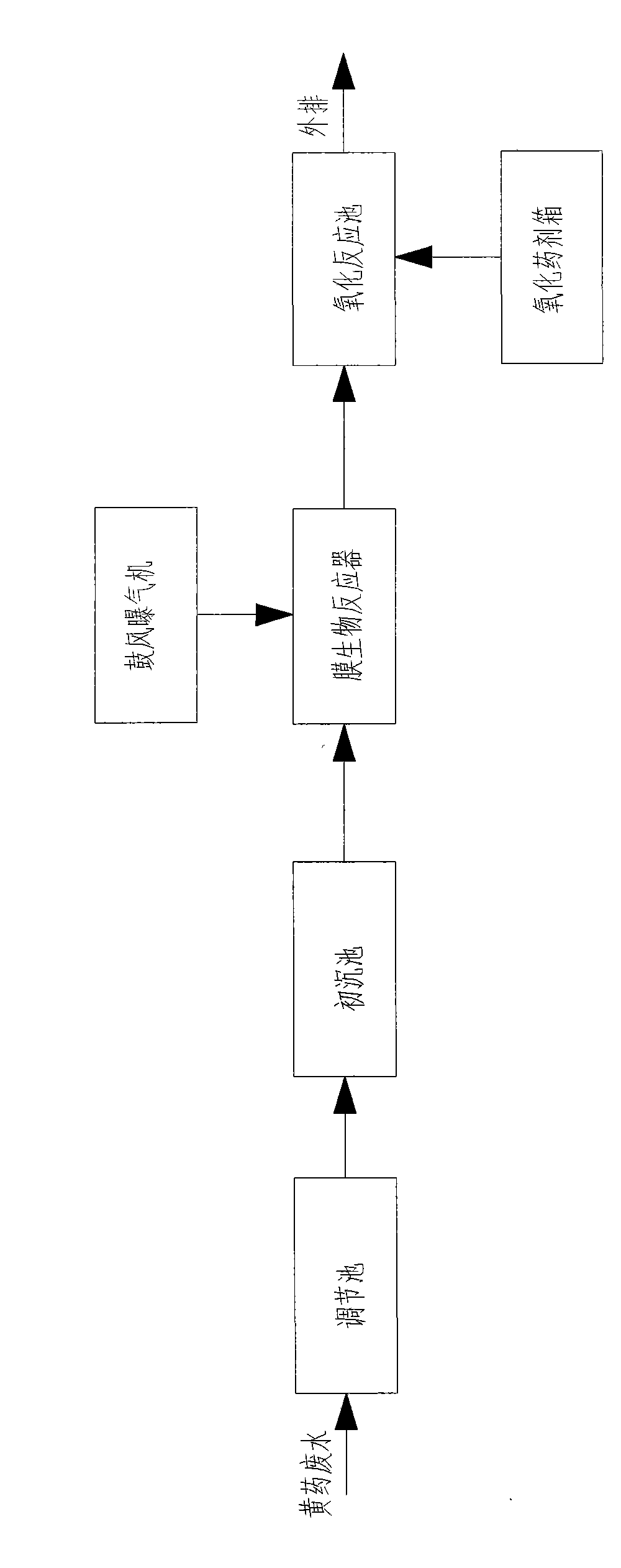

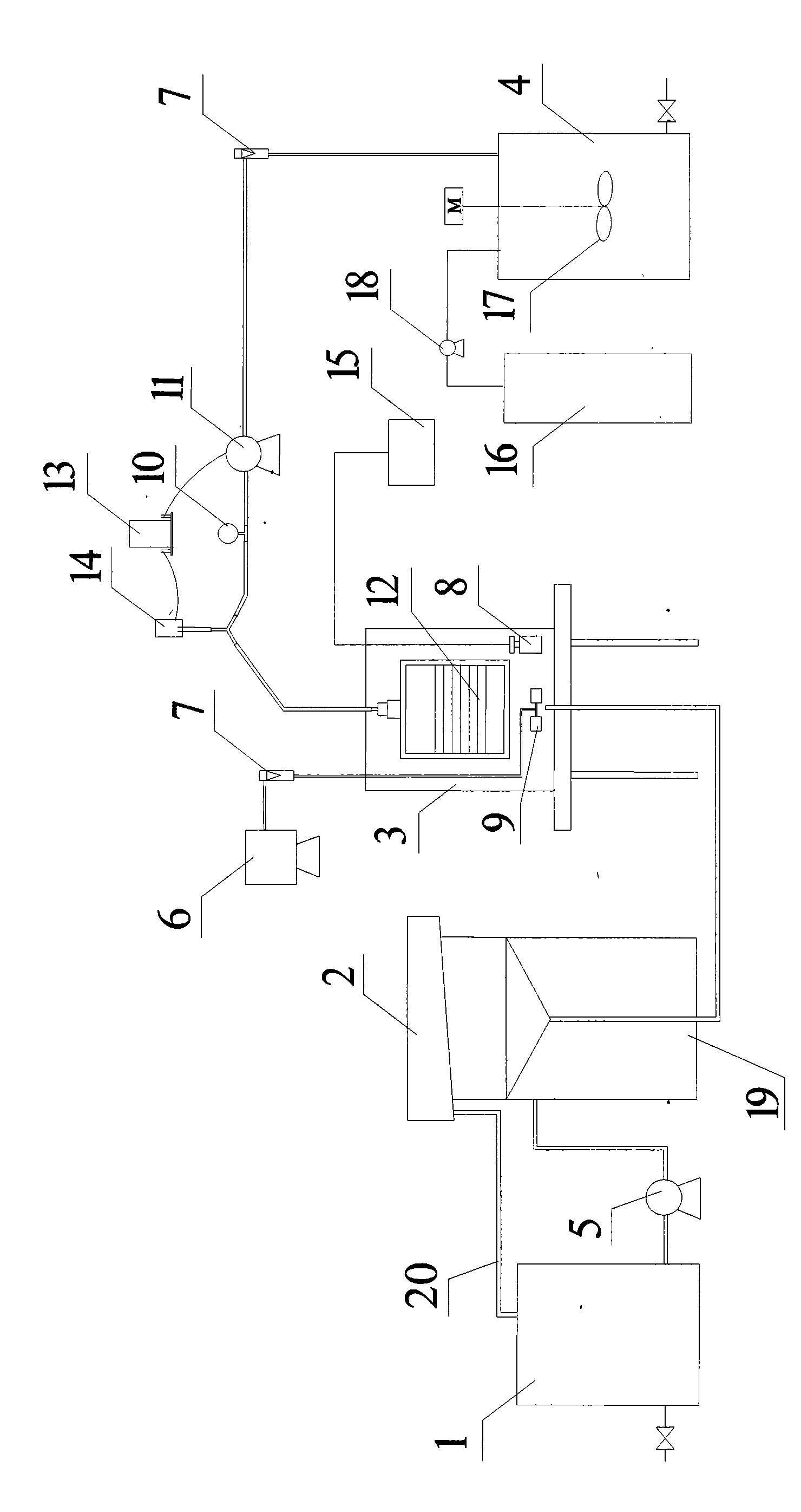

[0043] The method of the present invention includes two-stage treatment processes, namely, membrane biodegradation treatment and hydrogen peroxide oxidation treatment, and the steps are as follows.

[0044] 1. Membrane biodegradation;

[0045] The xanthate wastewater to be treated is introduced into the adjustment tank, and transported into the primary sedimentation tank by a sewage pump, and the sewage enters the membrane bioreactor from the primary sedimentation tank.

[0046] The start and stop of the extraction pump is controlled by the time relay. The operation parameters of the extraction pump are: run for 10 minutes and stop for 2 minutes. When the extraction pump stops, the time relay controls the solenoid valve to start working, and the solenoid valve changes from the closed state to the open state. , the outlet pipe of the membrane bioreactor is connected to the atmosphere, and the negative pressure generated during the pumping process of the extraction pump is quick...

Embodiment 2

[0054] 1. Membrane biodegradation;

[0055] The xanthate wastewater to be treated is introduced into the adjustment tank, and transported into the primary sedimentation tank by a sewage pump, and the sewage enters the membrane bioreactor from the primary sedimentation tank.

[0056] The start and stop of the extraction pump is controlled by the time relay. The operation parameters of the extraction pump are: run for 15 minutes and stop for 5 minutes. When the extraction pump stops, the time relay controls the solenoid valve to start working, and the solenoid valve changes from the closed state to the open state. , the outlet pipe of the membrane bioreactor is connected to the atmosphere, and the negative pressure generated during the pumping process of the extraction pump is quickly eliminated, so as to achieve the effect of slowing down the membrane pollution.

[0057] The volumetric load of the control membrane bioreactor is kept at 5.0kgCOD / (m 3 d), the hydraulic retention...

Embodiment 3

[0064] 1. Membrane biodegradation;

[0065] The xanthate wastewater to be treated is introduced into the adjustment tank, and transported into the primary sedimentation tank by a sewage pump, and the sewage enters the membrane bioreactor from the primary sedimentation tank.

[0066] The start and stop of the extraction pump is controlled by the time relay. The operation parameters of the extraction pump are: run for 12 minutes and stop for 3 minutes. When the extraction pump stops, the time relay controls the solenoid valve to start working, and the solenoid valve changes from the closed state to the open state. , the outlet pipe of the membrane bioreactor is connected to the atmosphere, and the negative pressure generated during the pumping process of the extraction pump is quickly eliminated, so as to achieve the effect of slowing down the membrane pollution.

[0067] The volumetric load of the control membrane bioreactor is kept at 3.8kgCOD / (m 3 d), the hydraulic retention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com