System and method for advanced treatment and reuse of dyeing wastewater

A technology for advanced treatment of printing and dyeing wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of low pulverized coal adsorption efficiency, long hydraulic retention time, and electrode short circuit and other problems, to achieve the effect of long working life, short residence time and low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

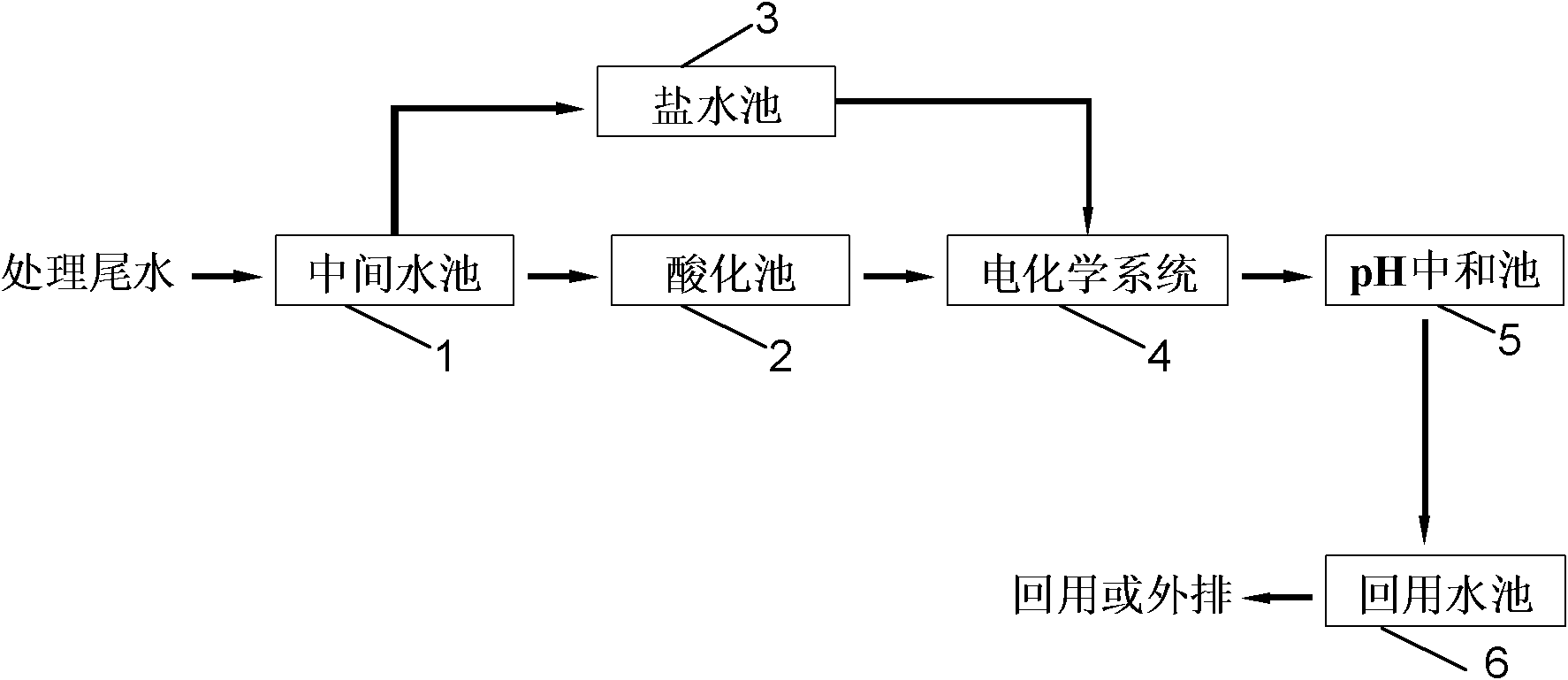

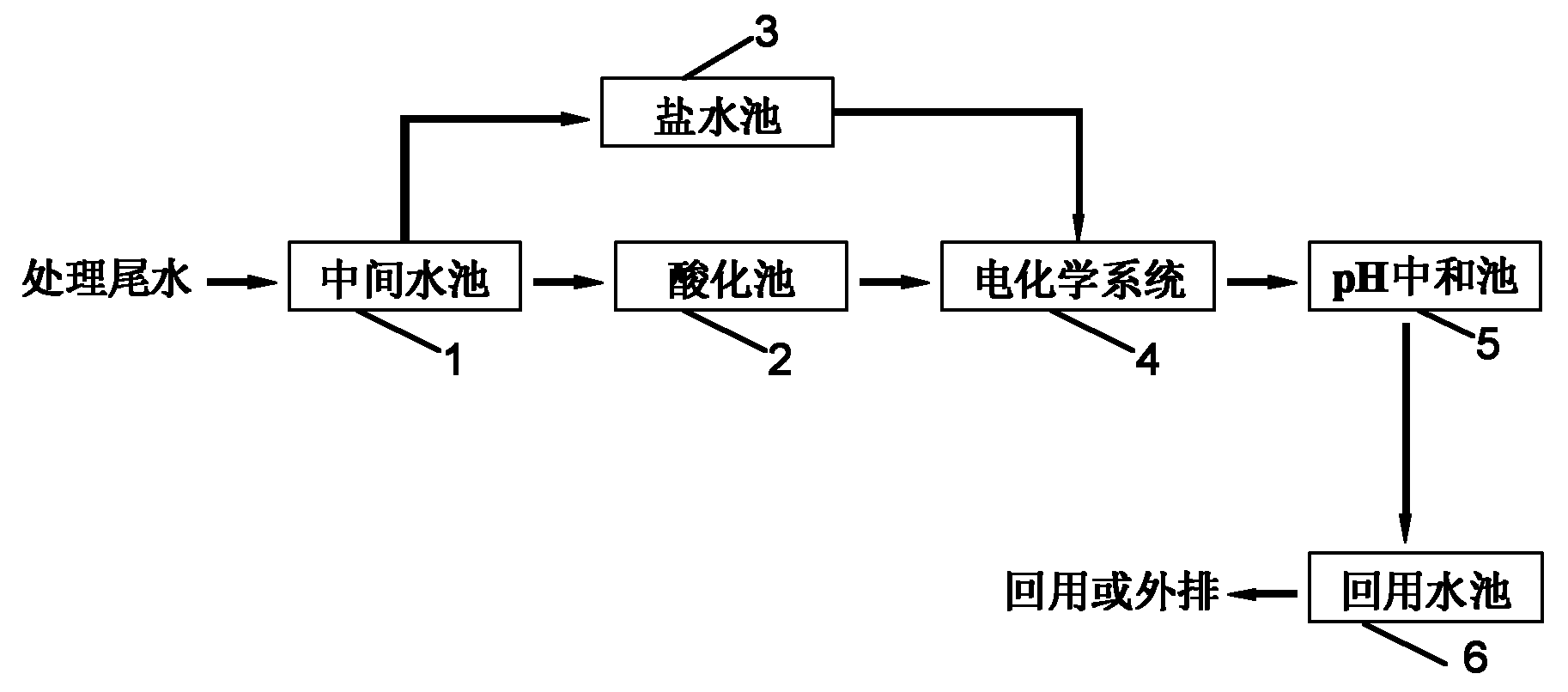

[0032] Such as figure 1 As shown, on the basis of the traditional anaerobic-aerobic-coagulation process structure, the printing and dyeing wastewater advanced treatment and reuse system of the present invention is added: the system includes an intermediate water tank 1, an acidification tank 2, a salt water tank 3, and an electrochemical system 4 , PH neutralization pool 5 and reuse pool 6; the intermediate pool 4, acidification pool 5, electrochemical system 4, pH neutralization pool 5 and reuse pool 6 are connected in sequence via PPR pipes; the input of the salt pool 3 The end is connected to the intermediate pool, and the output end is connected to the electrochemical system; the electrochemical system 4 is composed of a potentiostat, an electrode group and an electrolytic cell. The electrode group is arranged in parallel and alternately with the anode group and the cathode group, and the cathode group is a mesh metal Titanium, the anode group is a mesh titanium-based Pt co...

Embodiment 2

[0039] Such as figure 1 As shown, on the basis of the traditional anaerobic-aerobic-coagulation process structure, the printing and dyeing wastewater advanced treatment and recycling system of the present invention is added: the system includes an intermediate water tank 1, an acidification tank 2, a salt water tank 3, and an electrochemical system 4 , PH neutralization pool 5 and reuse pool 6; the intermediate pool 4, acidification pool 5, electrochemical system 4, pH neutralization pool 5 and reuse pool 6 are connected in sequence via PVC pipes; the input of the salt pool 3 The end is connected to the intermediate pool, and the output end is connected to the electrochemical system; the electrochemical system 4 is composed of a potentiostat, an electrode group and an electrolytic cell. The electrode group is arranged in parallel and alternately with the anode group and the cathode group, and the cathode group is a mesh SUS304 Stainless steel, the anode group is a mesh titanium...

Embodiment 3

[0046] Such as figure 1 As shown, on the basis of the traditional anaerobic-aerobic-coagulation process structure, the printing and dyeing wastewater advanced treatment and reuse system of the present invention is added: the system includes an intermediate water tank 1, an acidification tank 2, a salt water tank 3, and an electrochemical system 4 , PH neutralization pool 5 and reuse pool 6; the intermediate pool 4, acidification pool 5, electrochemical system 4, pH neutralization pool 5 and reuse pool 6 are connected in sequence via PPR pipes; the input of the salt pool 3 The end is connected to the intermediate pool, and the output end is connected to the electrochemical system; the electrochemical system 4 is composed of a potentiostat, an electrode group and an electrolytic cell. The electrode group is arranged in parallel and staggered between the anode group and the cathode group, and the cathode group is a plate-shaped metal Copper, the anode group is a plate-shaped titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com