Method for brewing yellow wine rich in soluble dietary fiber

A dietary fiber and rice wine brewing technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of unsuitable application in the food industry, low yield of soluble or insoluble dietary fiber, etc., to enrich soluble dietary fiber, broaden utilization channels, and reduce energy consumption. Consumption and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

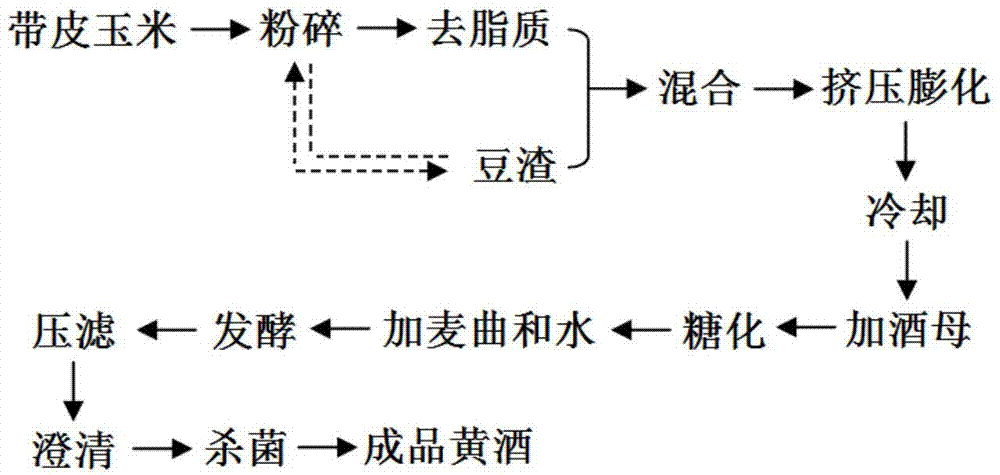

Method used

Image

Examples

Embodiment 1

[0032] (1) Pretreatment of corn with skin and bean dregs: fresh corn with skin, dried at low temperature (30°C), crushed, passed through a 100-mesh sieve, removed fat, and set aside; fresh bean dregs, dried at low temperature (30°C), crushed , passed through a 100-mesh sieve, mixed with corn flour in a ratio of 1:10, added water to adjust the humidity to 18%, and set aside;

[0033] (2) Extrusion and expansion: the mixed material after humidity adjustment is not added with enzyme preparation, and the material is extruded and expanded by a twin-screw extruder. The first section of the twin-screw extruder, the second section of the sleeve The temperature of the cylinder, the third sleeve and the fourth sleeve is 40°C, 60°C, 75°C and 150°C respectively, the temperature is automatically controlled and adjusted, the screw speed is 50rpm, and the extrudate is cooled and crushed for use;

[0034] (3) Multi-enzyme system fermentation: the extrudate treated in step (2) is added to dist...

Embodiment 2

[0039] (1) Pretreatment of corn with skin and bean dregs: fresh corn with skin, dried at low temperature (45°C), crushed, passed through a 100-mesh sieve, without removing fat, and set aside; fresh bean dregs, dried at low temperature (45°C), passed through Pulverize, pass through a 100-mesh sieve, mix with corn flour in a ratio of 1:20, add water to adjust the humidity to 58%, and set aside;

[0040] (2) Extrusion and expansion: the mixed material after humidity adjustment is not added with enzyme preparation, and the material is extruded and expanded by a twin-screw extruder. The first joint sleeve and the second joint sleeve of the twin-screw extruder The temperature of the cylinder, the third sleeve and the fourth sleeve is 40°C, 60°C, 70°C and 140°C respectively, the temperature is automatically controlled and adjusted, the screw speed is 300rpm, and the extrudate is cooled and then crushed for use;

[0041](3) Multi-enzyme system fermentation: after the extrudate treated...

Embodiment 3

[0046] (1) Pretreatment of corn with skin and bean dregs: fresh corn with skin, dried and crushed, passed through a 10-mesh sieve, de-lipidized, and set aside; Mix at a ratio of 1:10, add water to adjust the humidity to 35%, and set aside;

[0047] (2) Extrusion and expansion: the mixed material after humidity adjustment is added with enzyme preparation, and the material is extruded and expanded by a twin-screw extruder. The first section of the twin-screw extruder, the second section of the sleeve , The temperature of the third sleeve and the fourth sleeve is 35°C, 45°C, 65°C and 100°C respectively, the temperature is automatically controlled and adjusted, the screw speed is 100rpm, and the extruded product is cooled for later use;

[0048] (3) Multi-enzyme system fermentation: the extrudate treated in step (2) is added to distiller's yeast and then saccharified and fermented; after the saccharified mash has reached a certain level (fermented for 4 days), wheat koji, water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com