Patents

Literature

65 results about "Volume loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

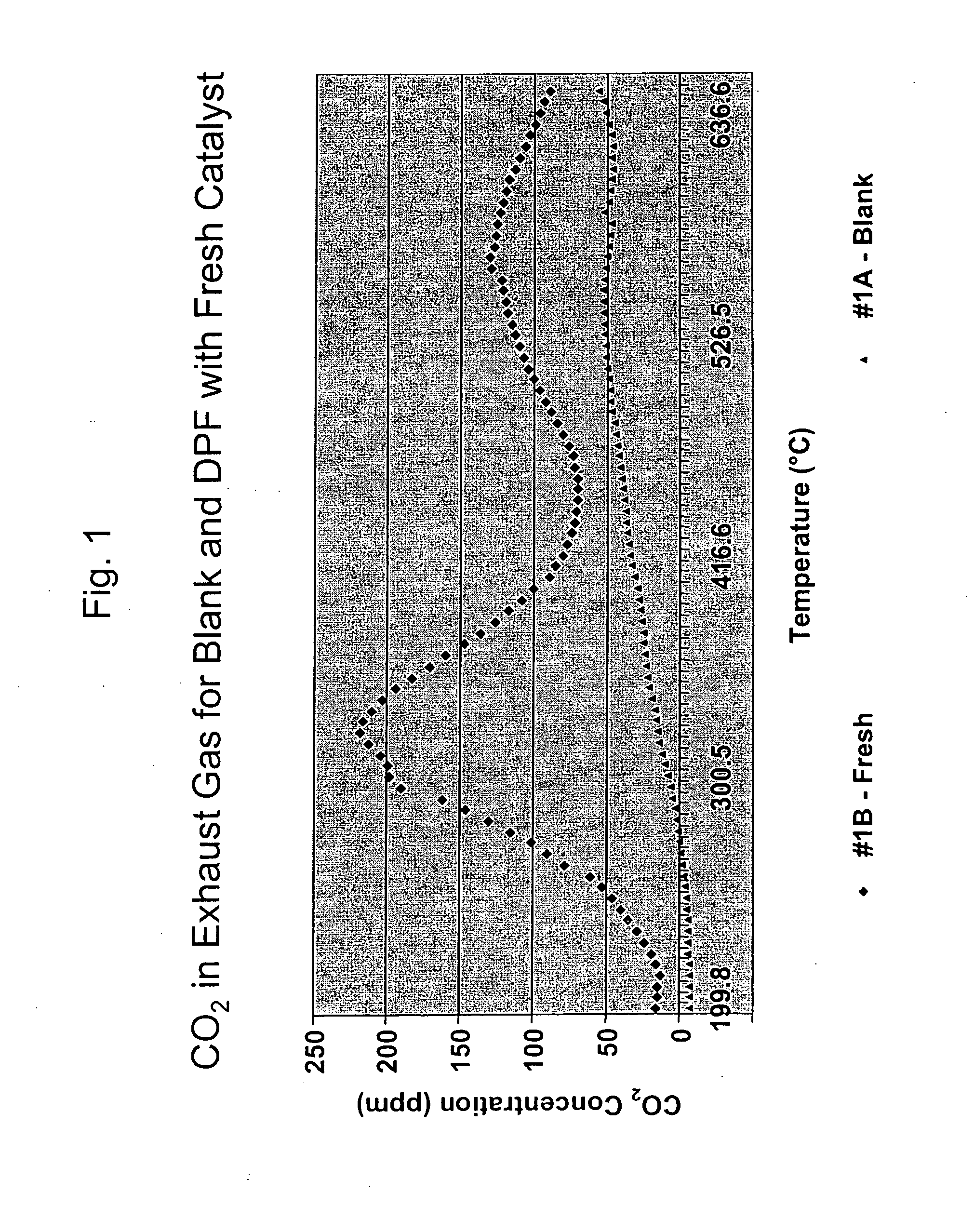

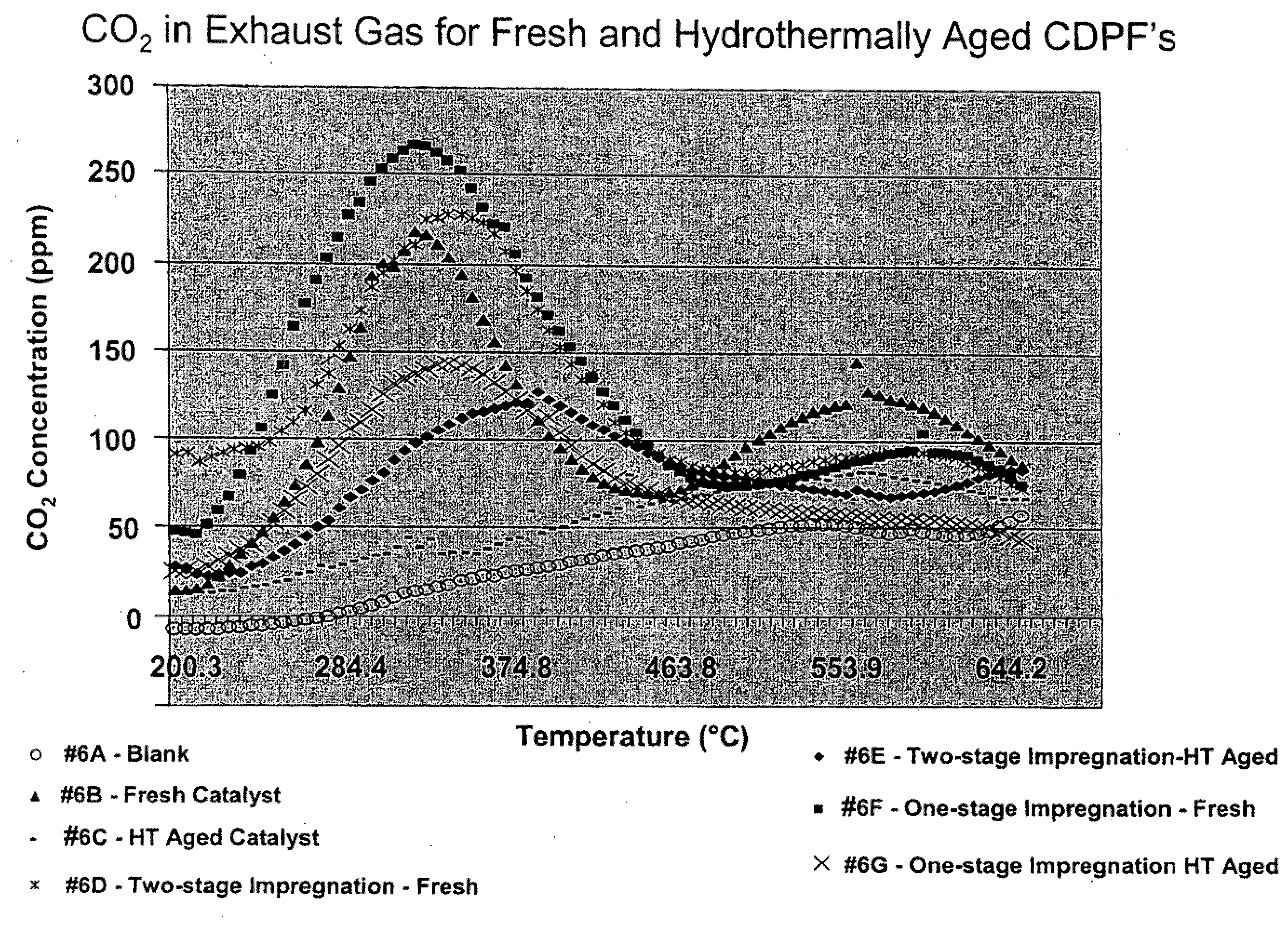

Platinum group metal-free catalysts for reducing the ignition temperature of particulates on a diesel particulate filter

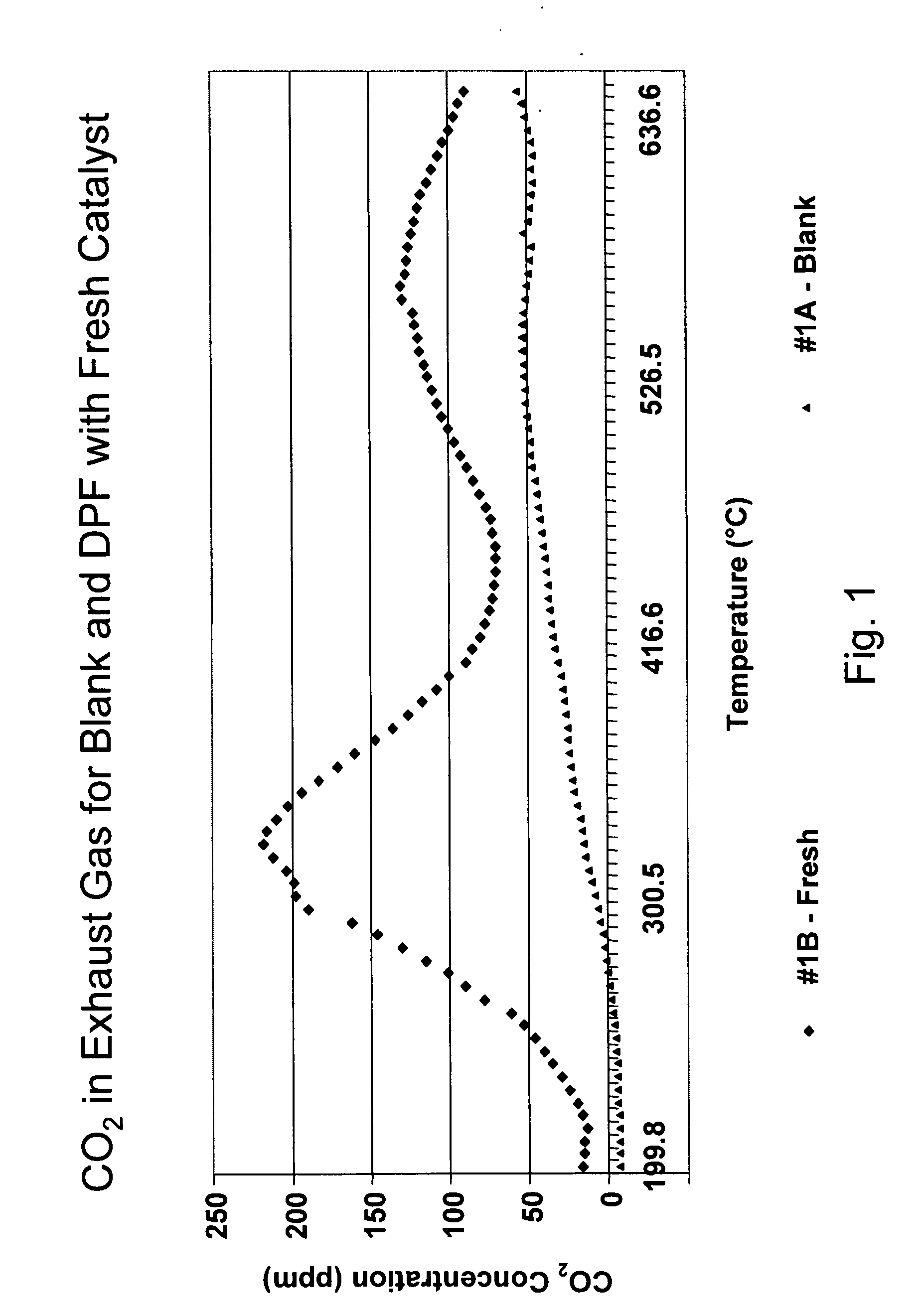

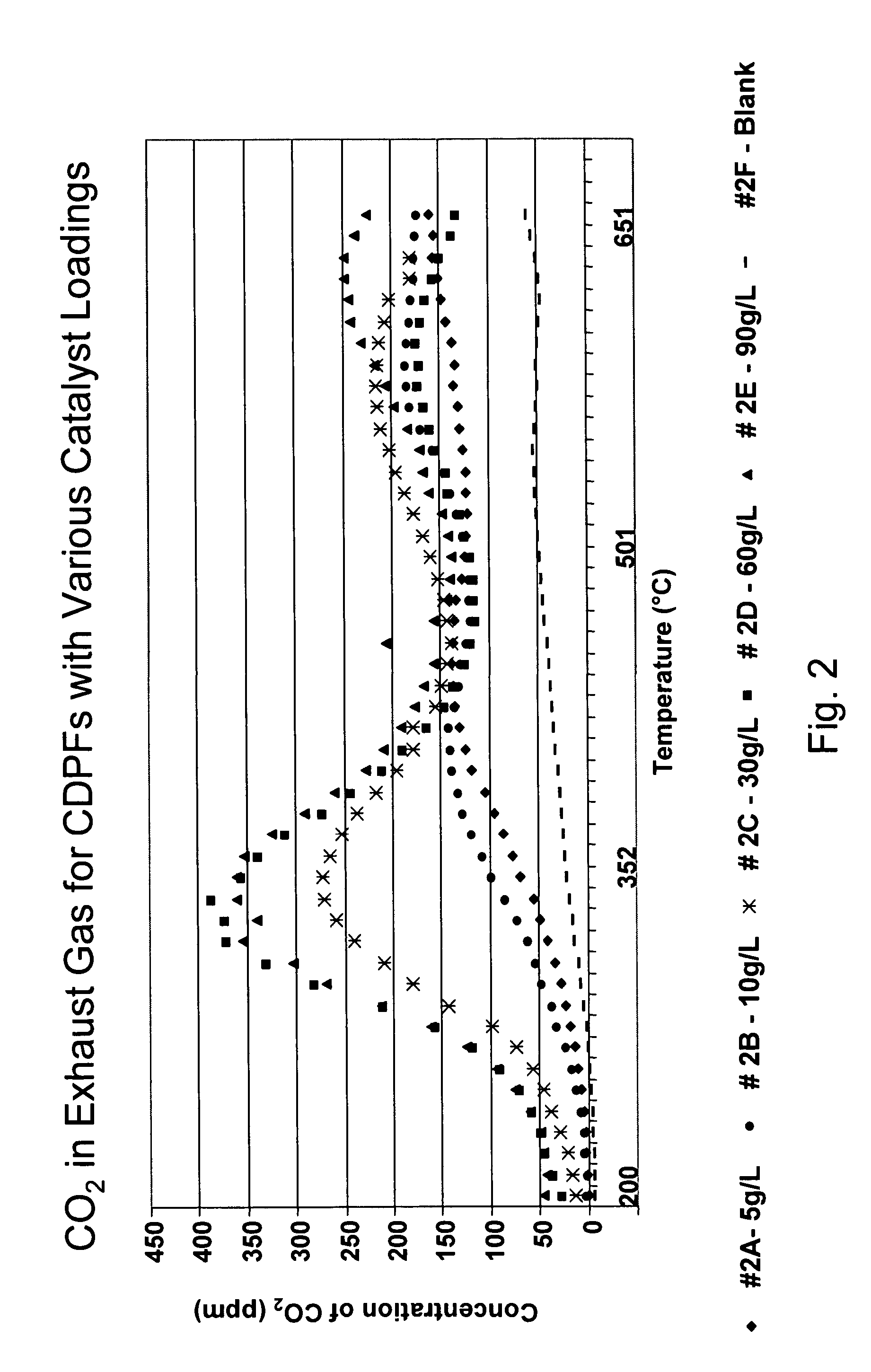

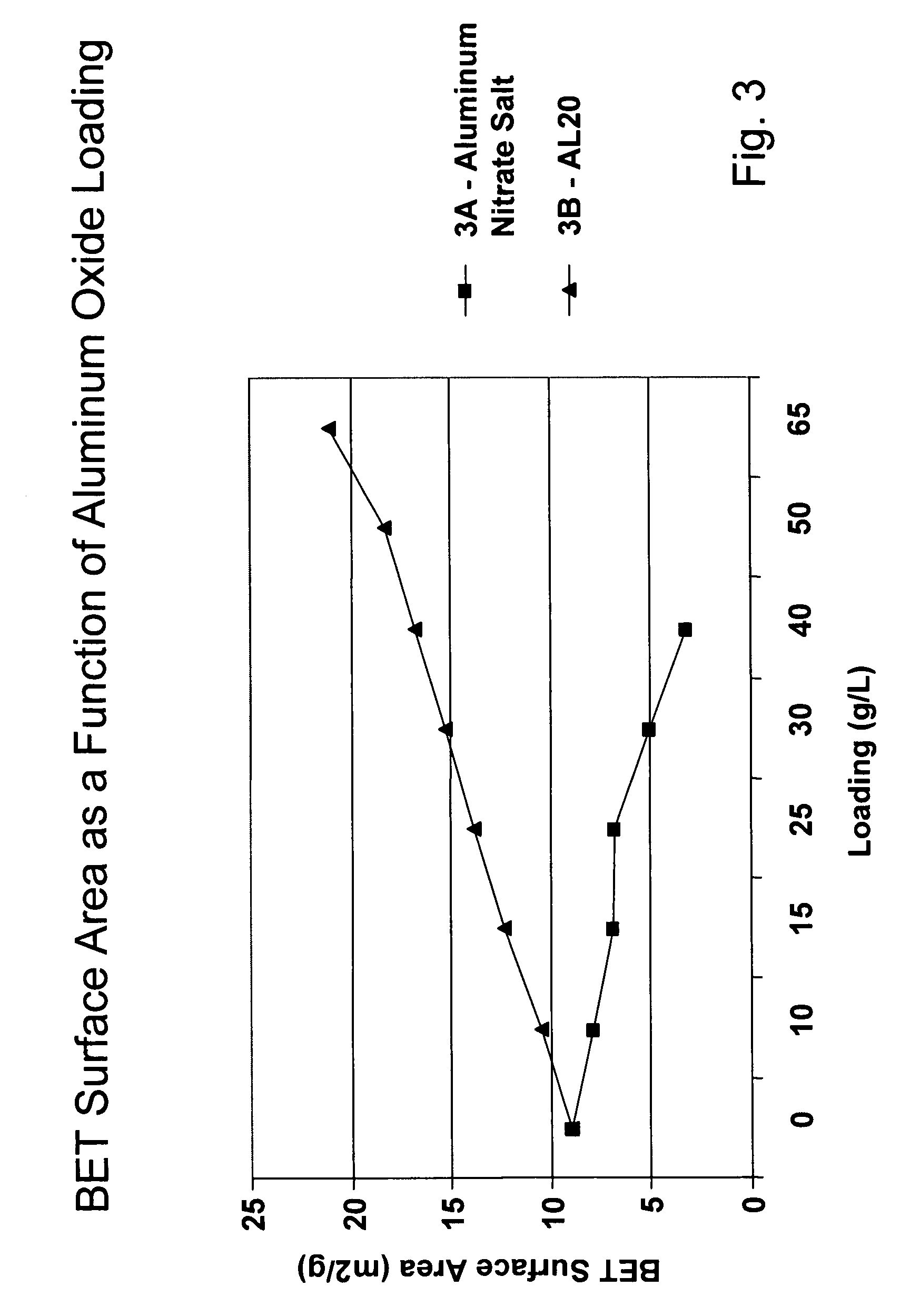

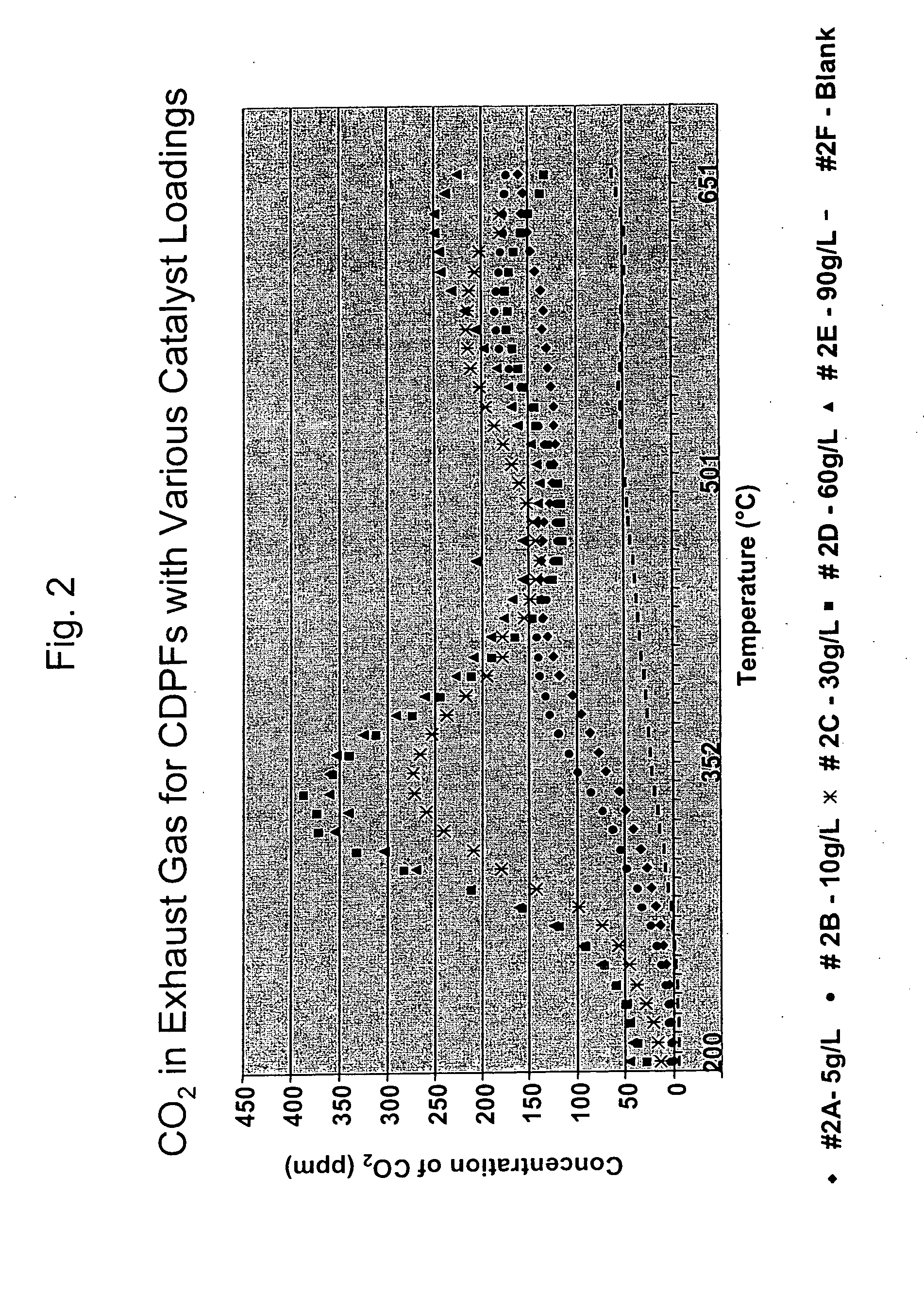

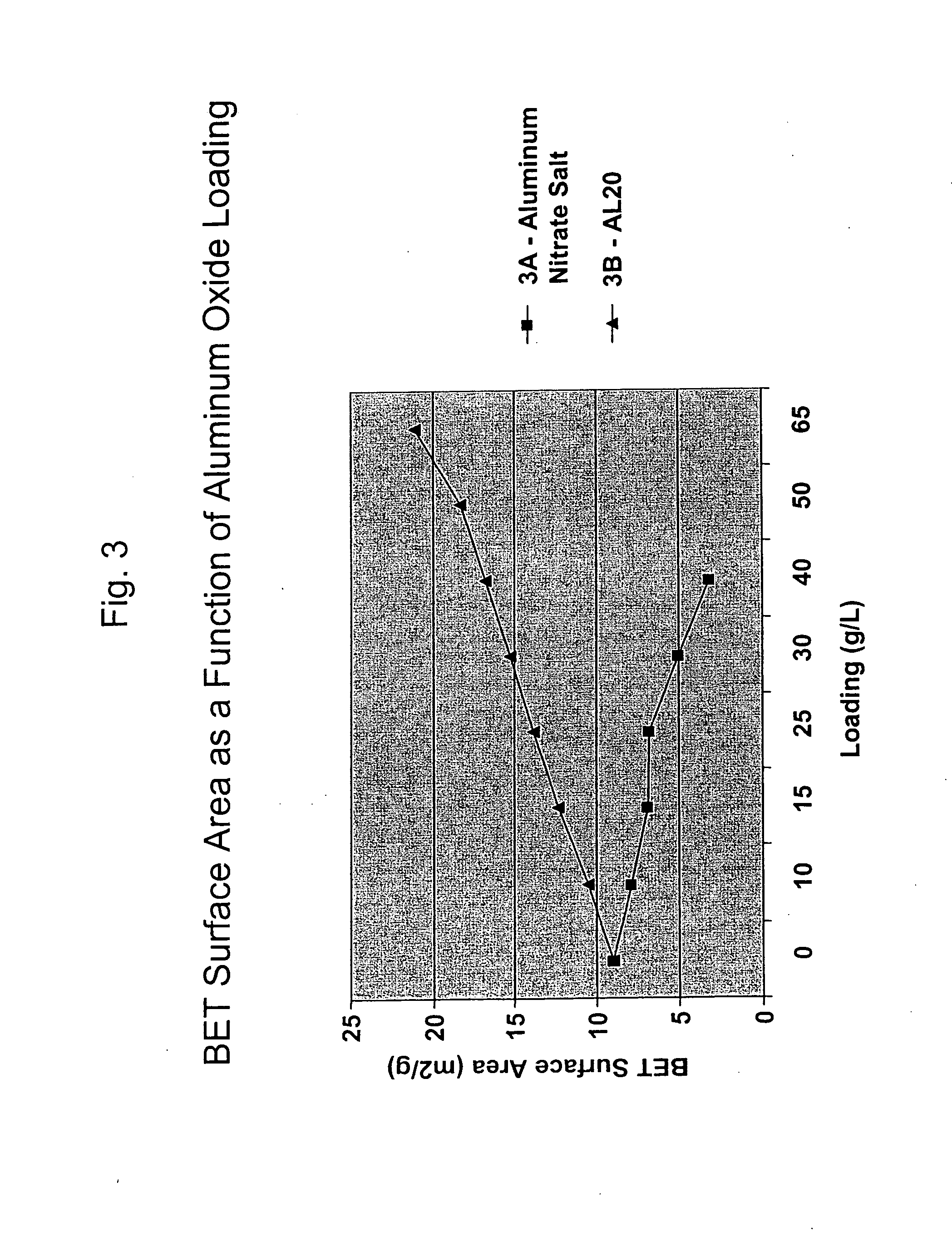

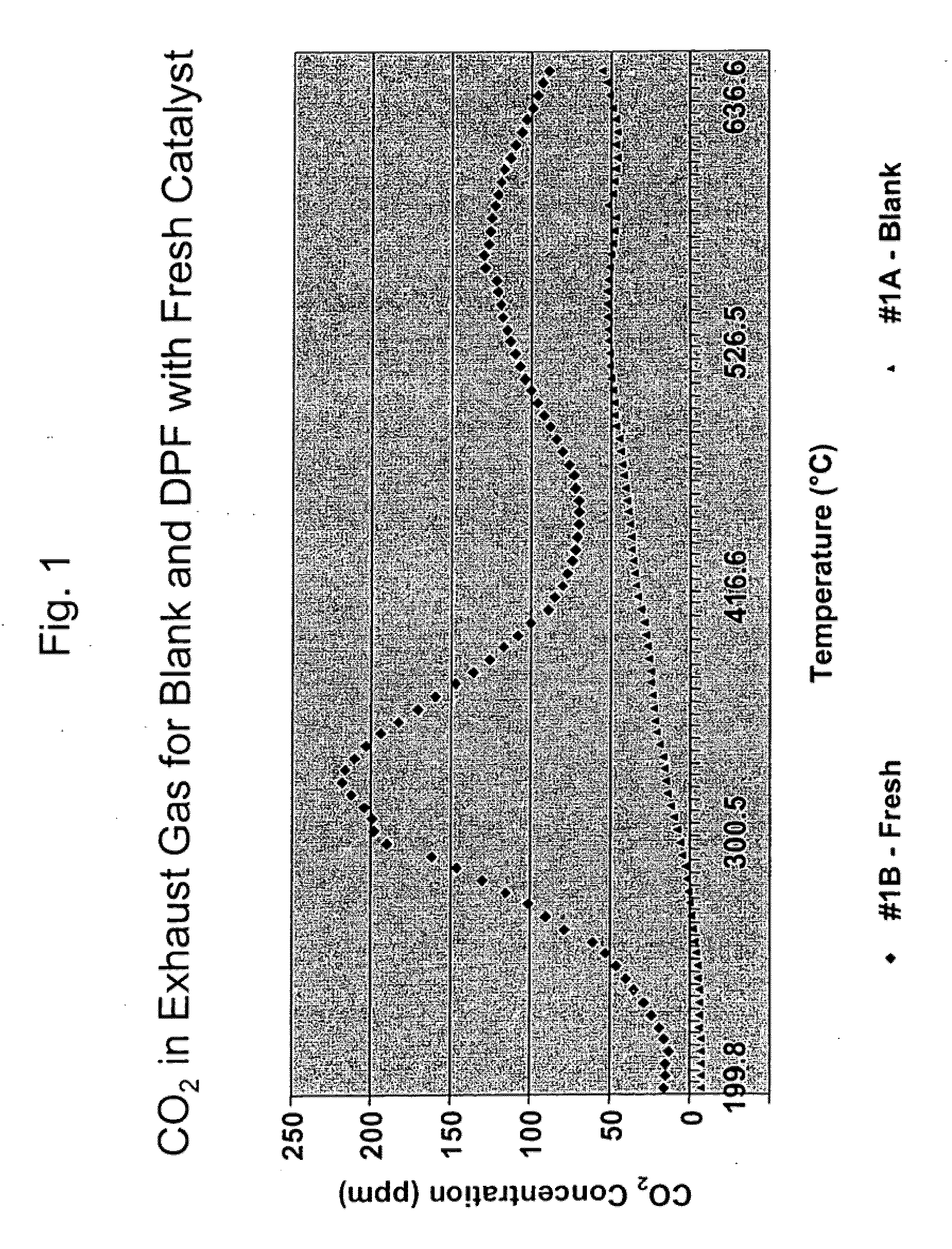

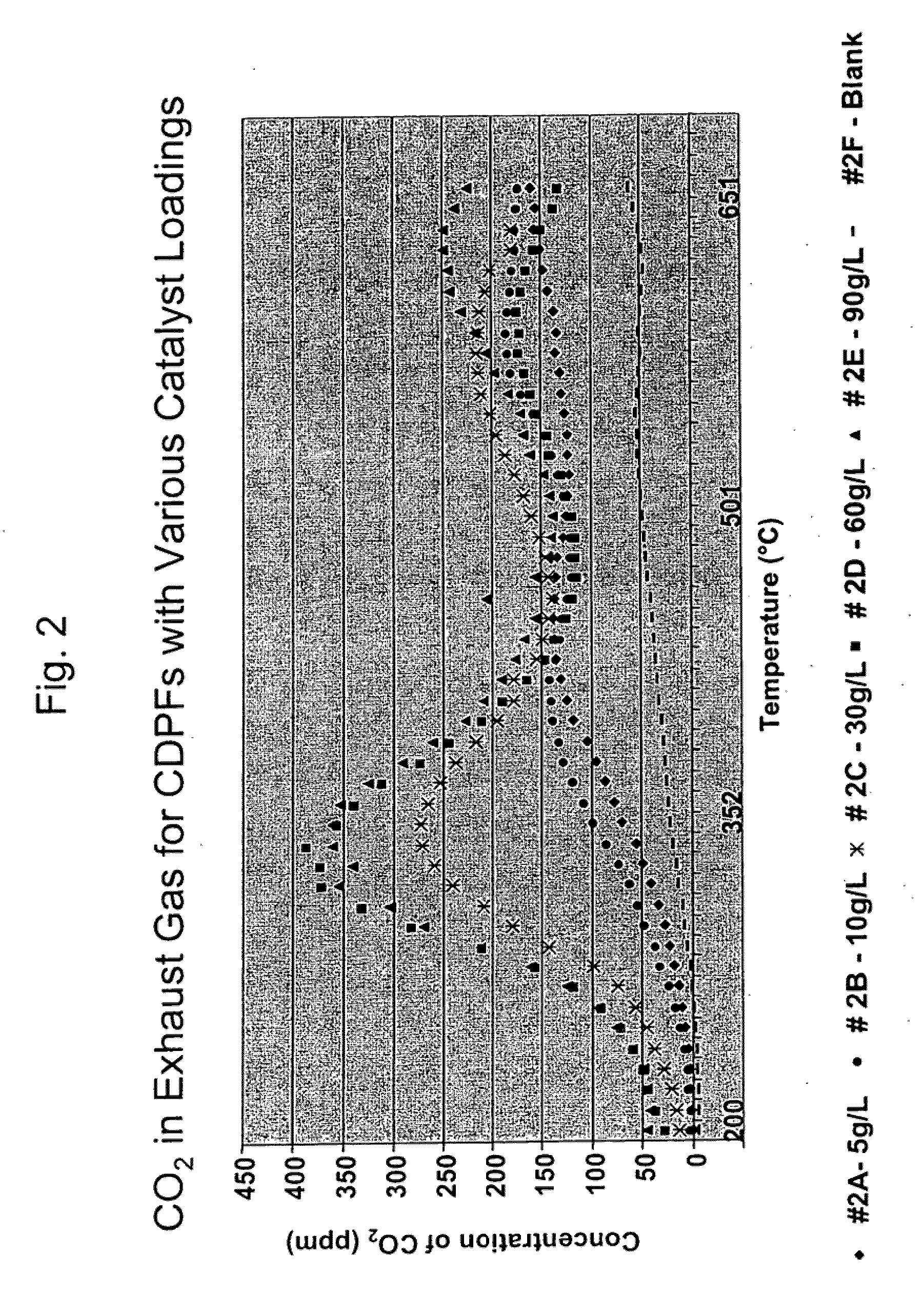

A catalyzed diesel particulate filter (CDPF) and a method for filtering particulates from diesel engine exhaust are provided, where the catalyzed diesel particulate filter includes a substrate and a catalyst composition, where the catalyst composition contains at least one first component, at least one second component, and at least one third component, where the first component is at least one first component selected from the group consisting of cerium and a lanthanide and mixtures thereof, the at least one second component is selected from the group consisting of cobalt, copper, manganese and mixtures thereof; and the third component comprises strontium, where the first component, the second component, and the third component are in an oxide form after calcination. The catalyst on the catalyzed diesel particulate filter lowers the temperature at which particulates are removed from the CDPF by oxidizing the particulates on the filter. The catalyzed diesel particulate filter may also include a washcoat. Washcoats prepared from colloidal aluminum oxide may have higher surface areas and pore volumes loadings than washcoats containing aluminum oxide prepared from aluminum nitrate.

Owner:CATALYTIC SOLUTIONS INC

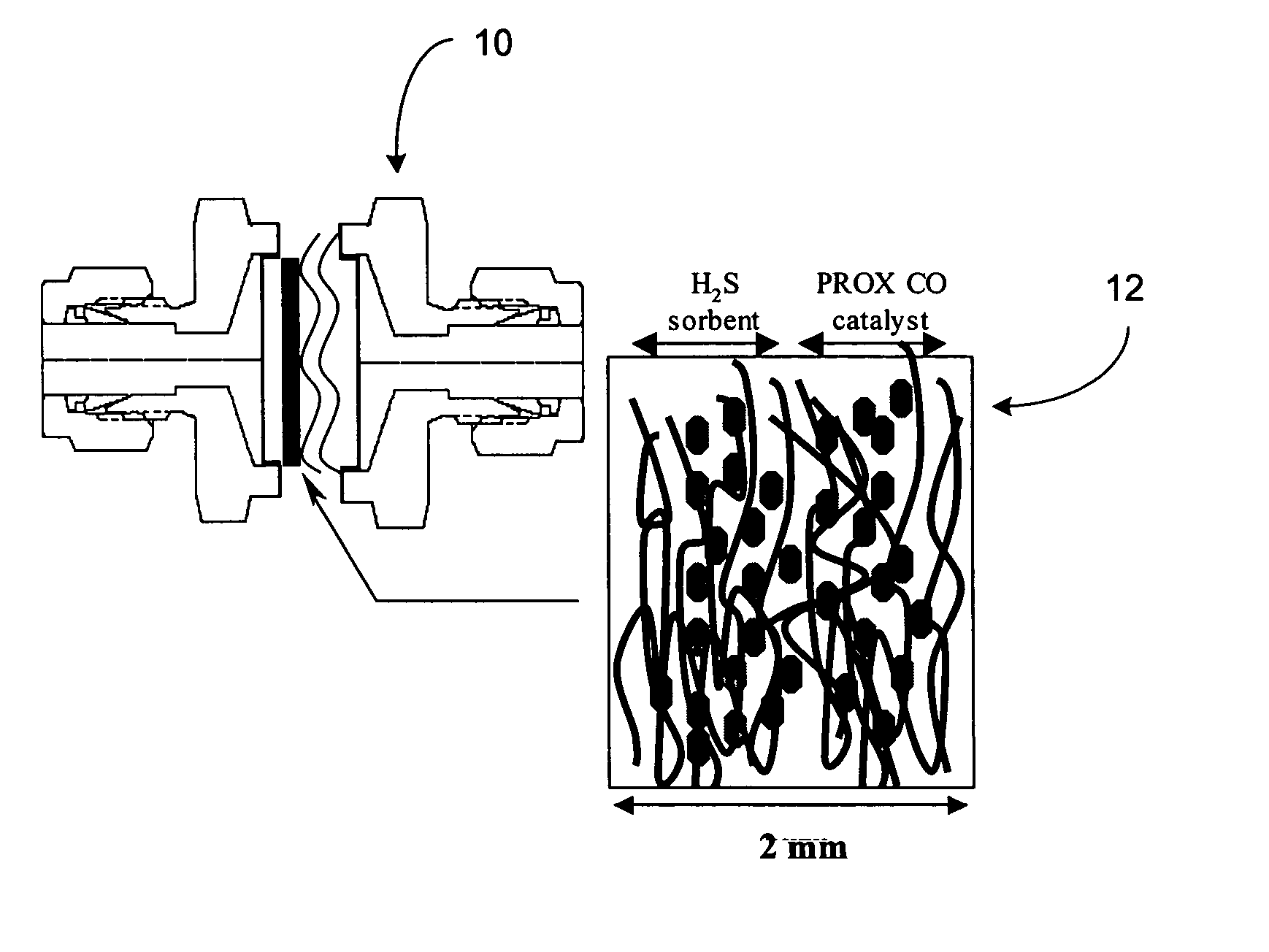

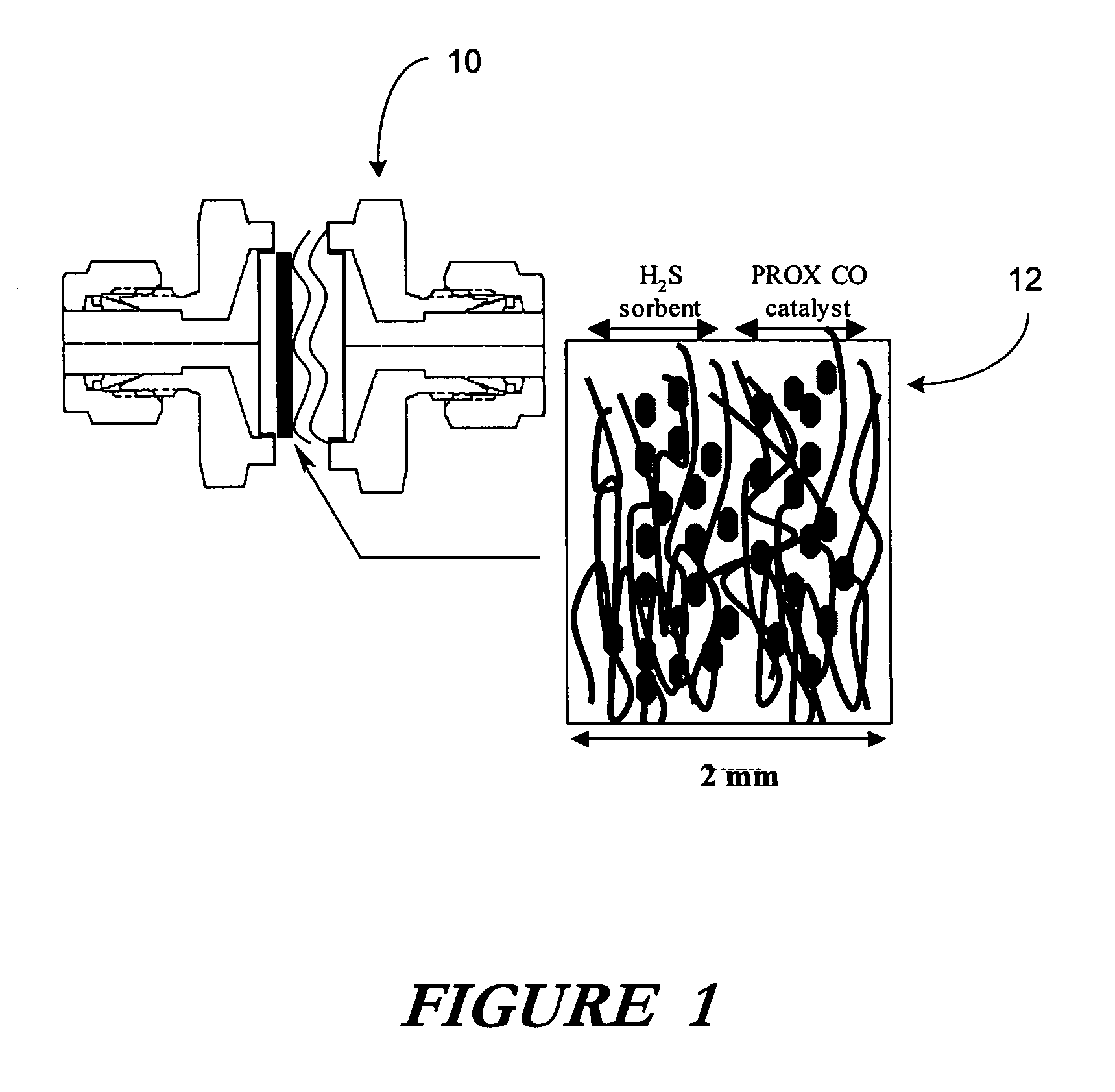

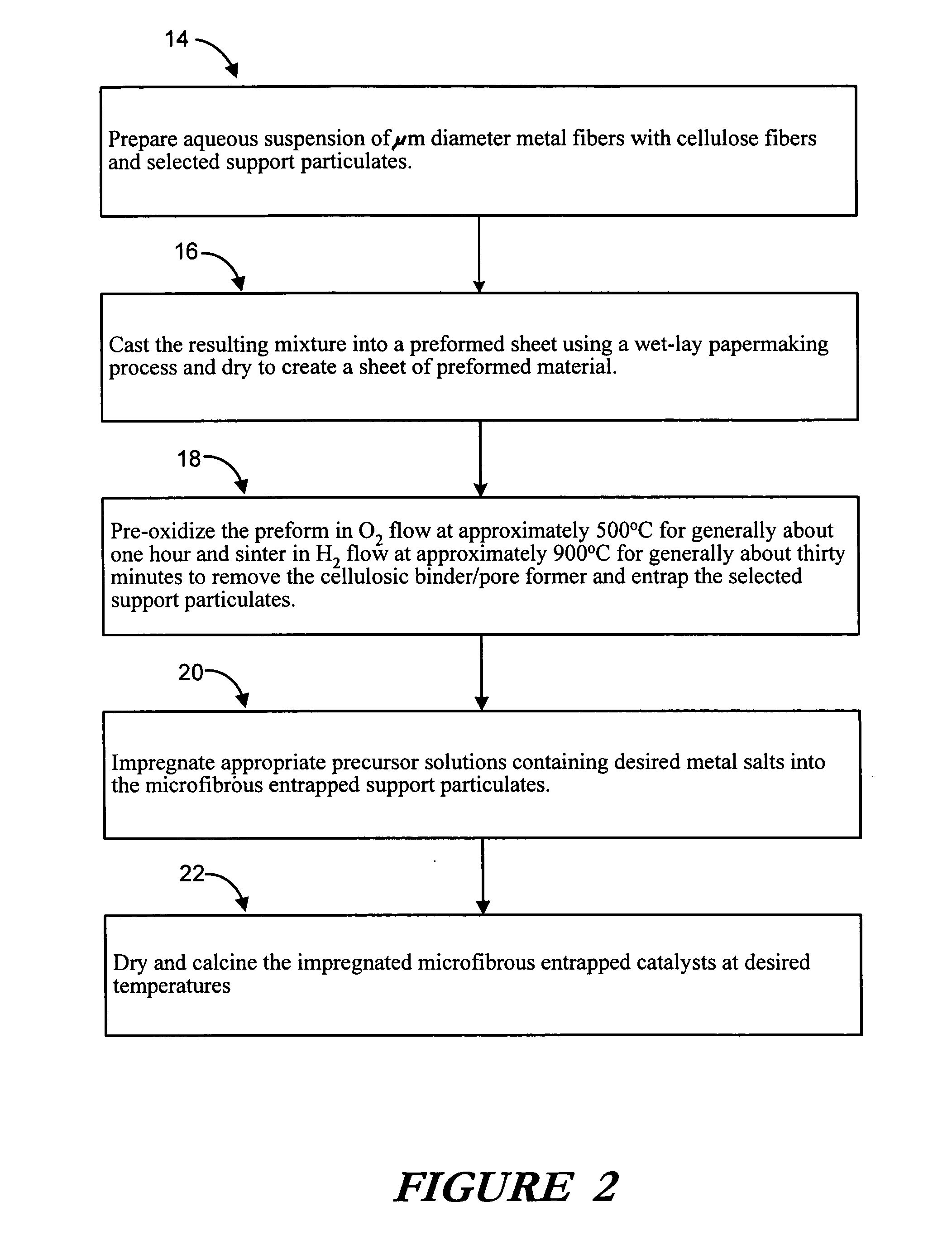

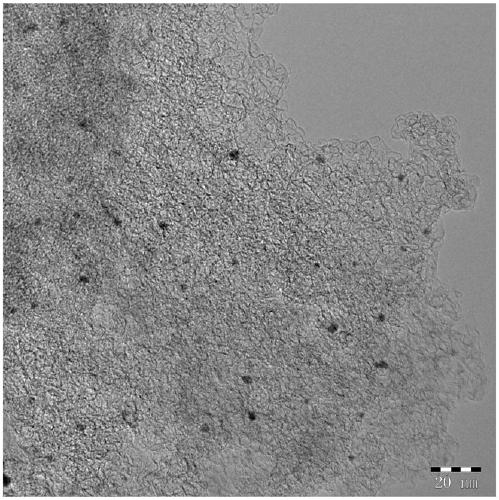

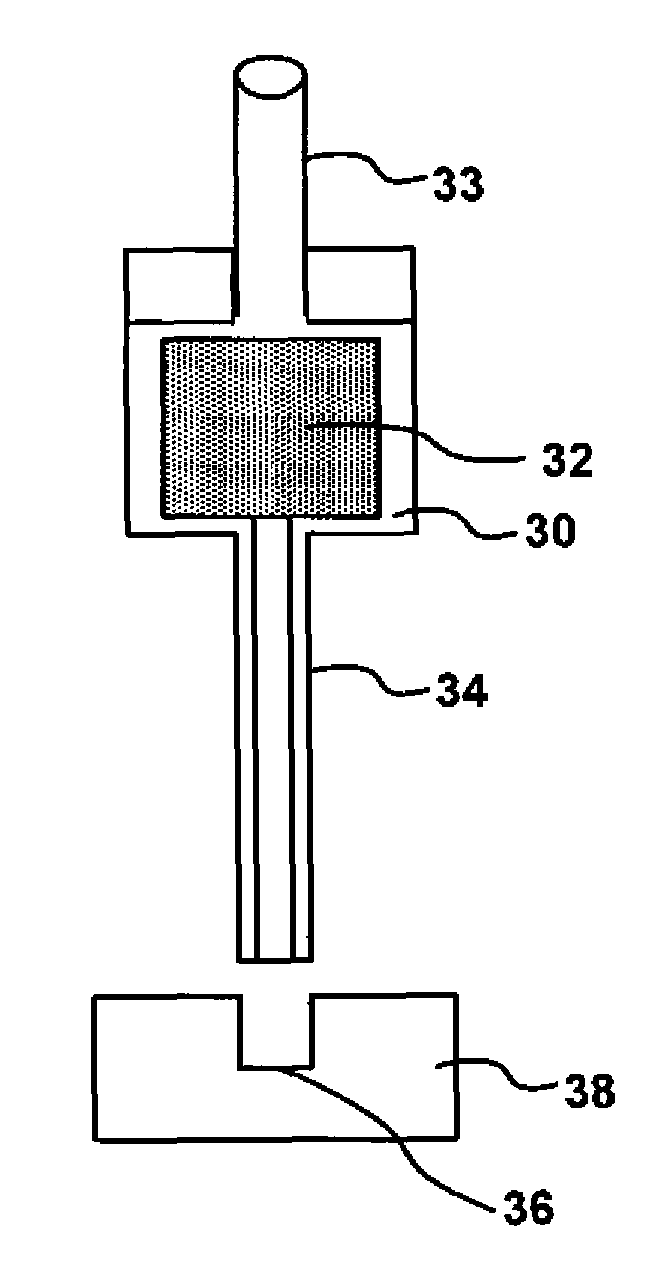

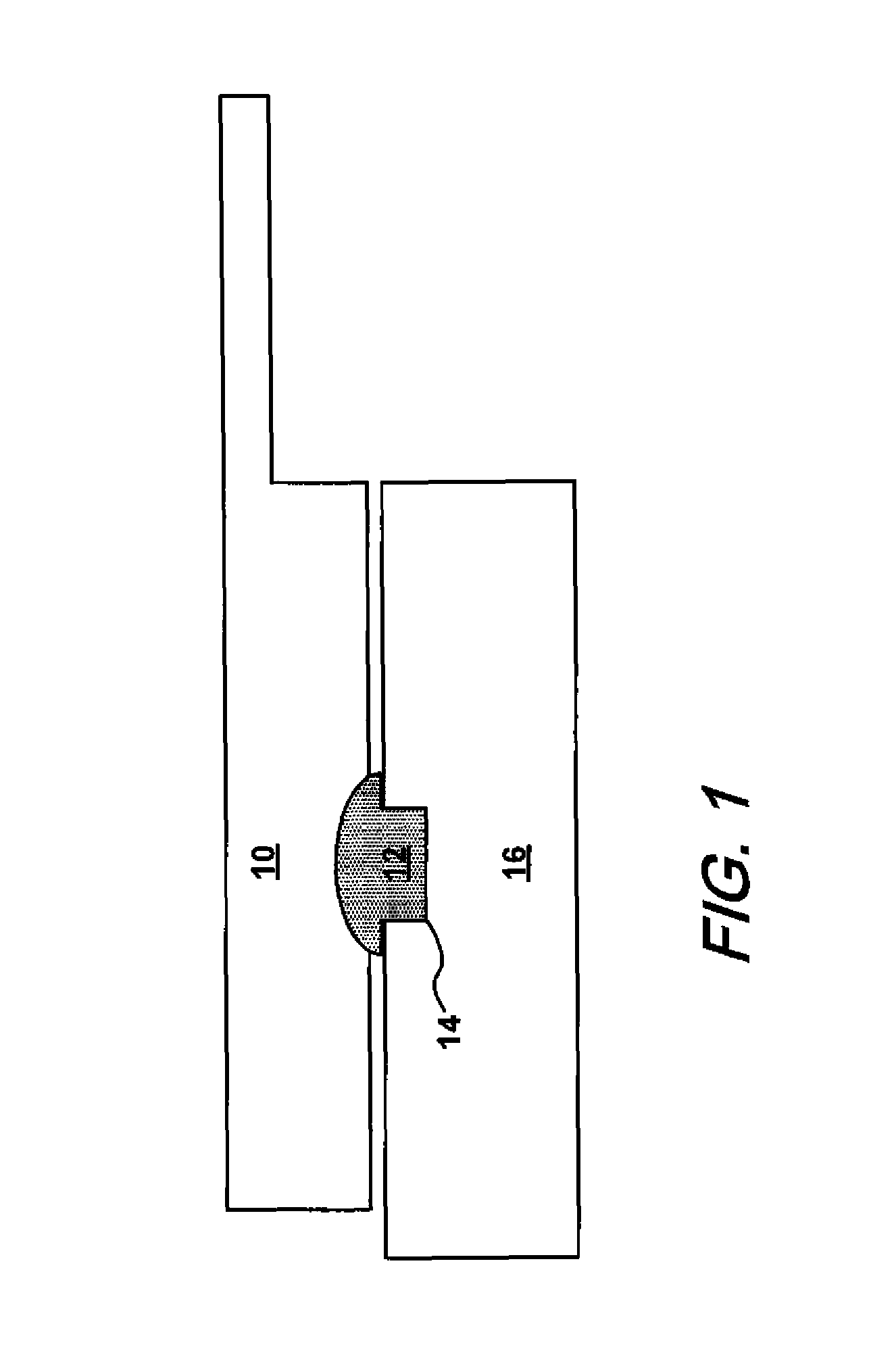

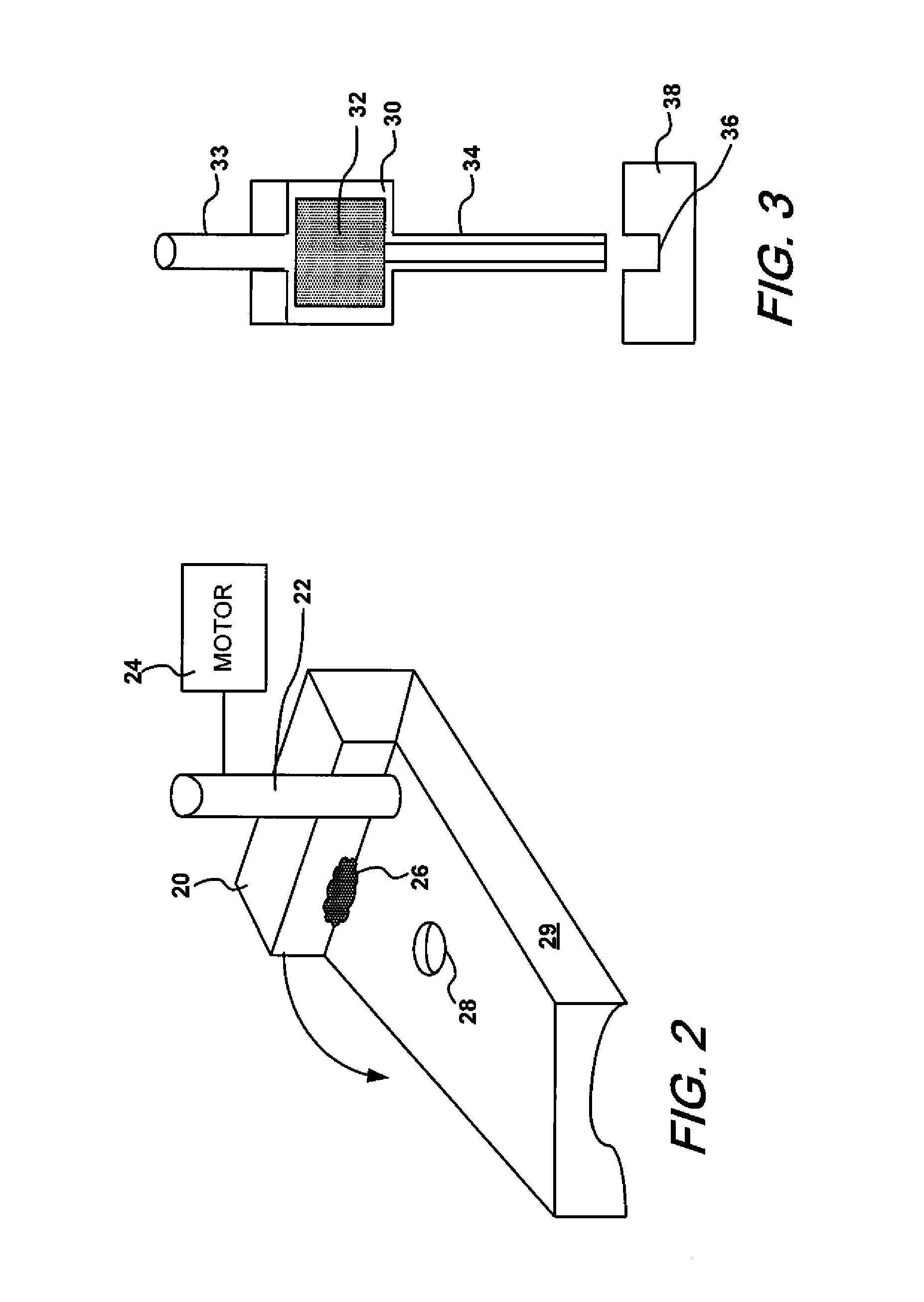

Microfibrous entrapment of small reactive particulates and fibers for high contacting efficiency removal of contaminants from gaseous or liquid streams

ActiveUS20050169820A1High contacting efficiency removalHigh contact efficiencyHydrogen separation by selective and reversible uptakeCombination devicesParticulatesFiber

A microfibrous matrix with embedded supporting particulates / fibers and chemically reactive materials is provided as a filtration system for the removal of contaminants and other harmful agents from liquid and gaseous streams. Such filter may be used for example to protect the intolerant anodes and cathodes of fuel cells from damaging H2S while simultaneously aiding the selective conversion of CO to CO2 in fuel streams predominated by hydrogen. In general, the reactive materials utilized as well as the supporting matrix of fibers may be broadly selected to remove specific contaminants at specific reaction conditions inherent to the application. Such materials may include chemically reactive materials as high surface area carbons, zeolites, silicas, aluminas, inorganic metal oxides, polymer resins, ZnO, ZnO / Carbon, Pt / γ-Al2O3, PtCo / γ-Al2O3, ZnO / SiO2 and various other catalysts, sorbents or reactants. In an alternative embodiment, entrapped sorbents and other reactants may be used to provide a highly efficient gas and / or liquid separation and purification methodology for gas masks, building filtration systems, and / or as polishing media located downstream of traditional packed bed filtration systems so as to achieve the high volume loading / capacity of the packed bed along with the overall contacting efficiency of the outlet polishing layer.

Owner:AUBURN UNIV

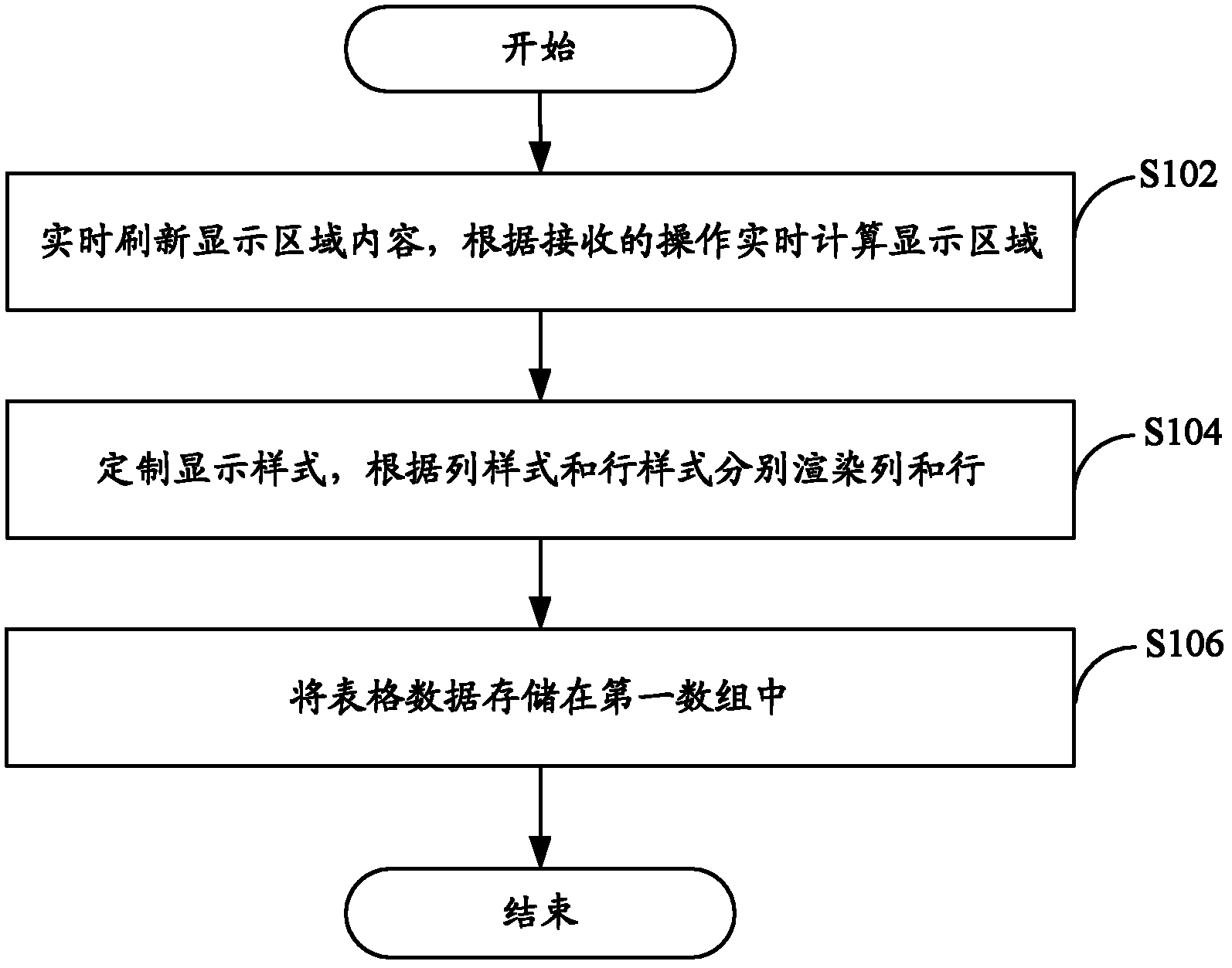

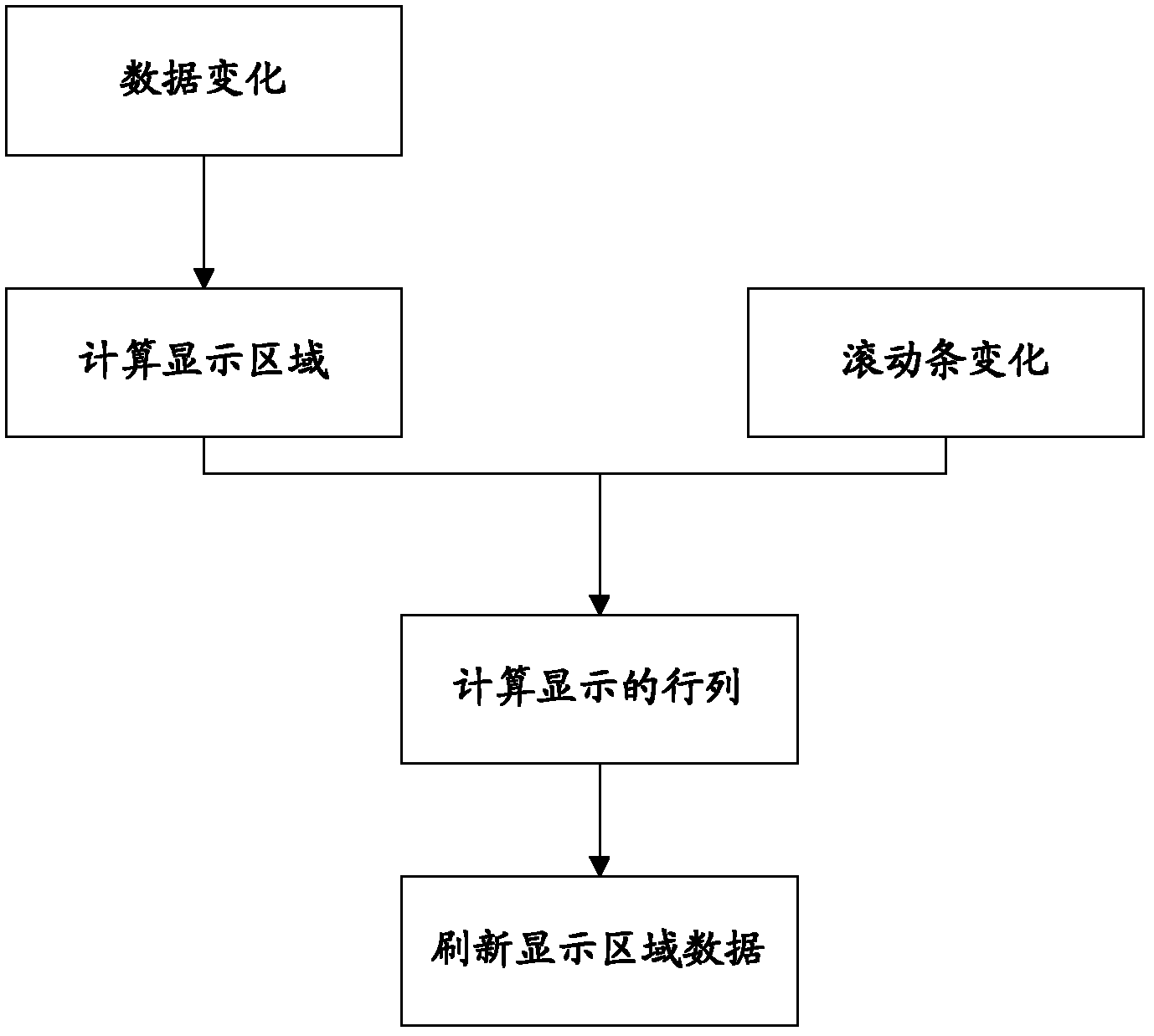

Page tabular display method

InactiveCN103164401AAvoid deadlockTable display data is convenientSpecial data processing applicationsData displayArray data structure

The invention discloses a page tabular display method. The page tabular display method comprises refreshing content of a display area in real time, and calculating the display area in real time according to received operation; customizing a display style, and respectively carrying out render on a column and a line according to a column type and a line type; and storing table data on a first array. According to the page tabular display method, tabular data display is enabled to be convenient and rapid, a page deadlock problem caused by large data volume loading is solved, and the defects that digital ohmmeter (DOM) elements are overmuch, and loading and search is slow when table data volume is large are overcome.

Owner:航天信息软件技术有限公司

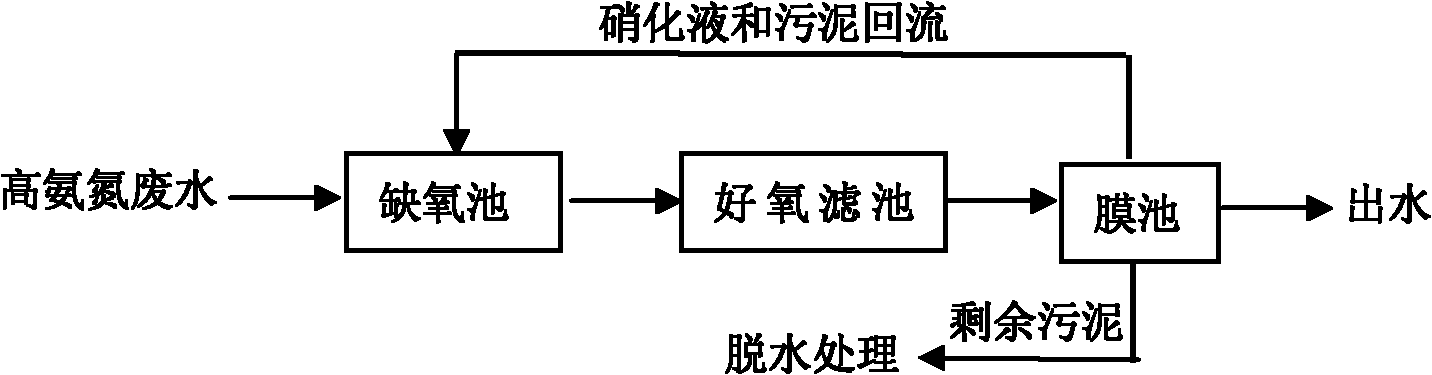

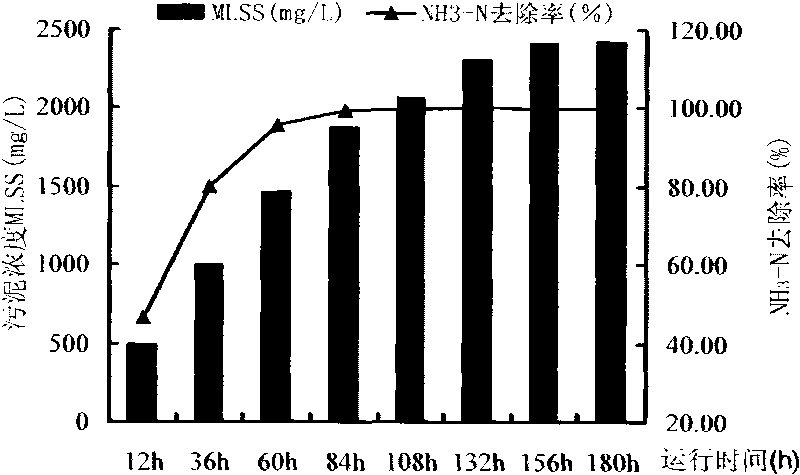

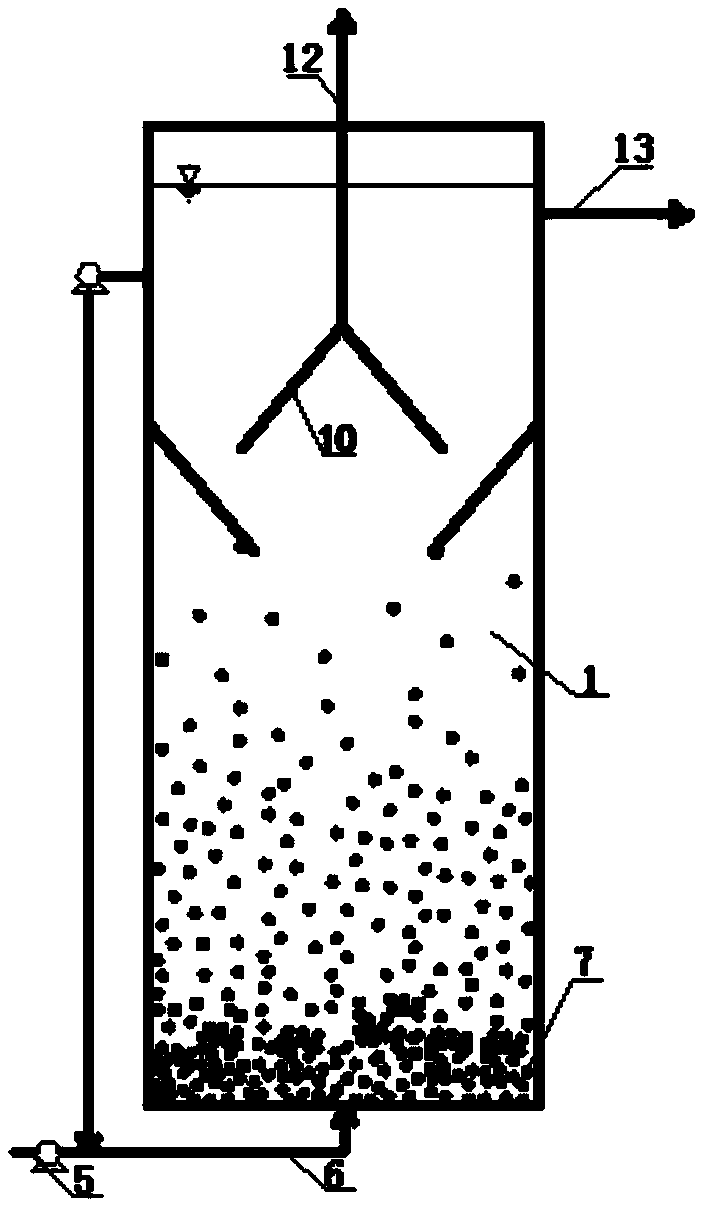

Bioaugmentation treatment technology of high ammonia nitrogen wastewater

InactiveCN101973678AIncrease the number ofSmall footprintMultistage water/sewage treatmentHigh concentrationSludge

The invention relates to a bioaugmentation treatment technology of the high ammonia nitrogen wastewater. The treatment technology is characterized in that under the condition that dissolved oxygen exists in the high ammonia nitrogen wastewater, an aerobic pool, an aerobic filter and a membrane pool are established, wherein by utilizing the metabolism of the aerobic microorganism, high concentration of organic substances are degraded, the organic substances with high molecular weight and energy are converted to substances with low molecular weight and energy; the aerobic pool adopts internal circulation and large-scale external circulation hydraulic agitation; and the aerobic filter is filled with novel fixed enzyme-floating filler and immobilized microorganism and microporous aeration and jet aeration are combined for aeration, thus the flow pattern of the nitrification filter is improved. Compared with the prior art, the system of the invention has high sludge concentration and the corresponding volume loading is also high, thus the floor space is small and the capital cost is low; the conversion rate and utilization rate of atmospheric oxygen is high, the effect of mass transfer is good, the anti-shock loading capability of the system is high, the effluent quality is stable; the operating cost is low; the density is increased relatively, the solid-liquid separating effect is good and the yield of excess sludge is low.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

Platinum group metal-free catalysts for reducing the ignition temperature of particulates on a diesel particulate filter

A catalyzed diesel particulate filter (CDPF) and a method for filtering particulates from diesel engine exhaust are provided, where the catalyzed diesel particulate filter includes a substrate and a catalyst composition, where the catalyst composition contains at least one first component, at least one second component, and at least one third component, where the first component is at least one first component selected from the group consisting of cerium and a lanthanide and mixtures thereof, the at least one second component is selected from the group consisting of cobalt, copper, manganese and mixtures thereof; and the third component comprises strontium, where the first component, the second component, and the third component are in an oxide form after calcination. The catalyst on the catalyzed diesel particulate filter lowers the temperature at which particulates are removed from the CDPF by oxidizing the particulates on the filter. The catalyzed diesel particulate filter may also include a washcoat. Washcoats prepared from colloidal aluminum oxide may have higher surface areas and pore volumes loadings than washcoats containing aluminum oxide prepared from aluminum nitrate.

Owner:ALIVE KESHAVARAJA +2

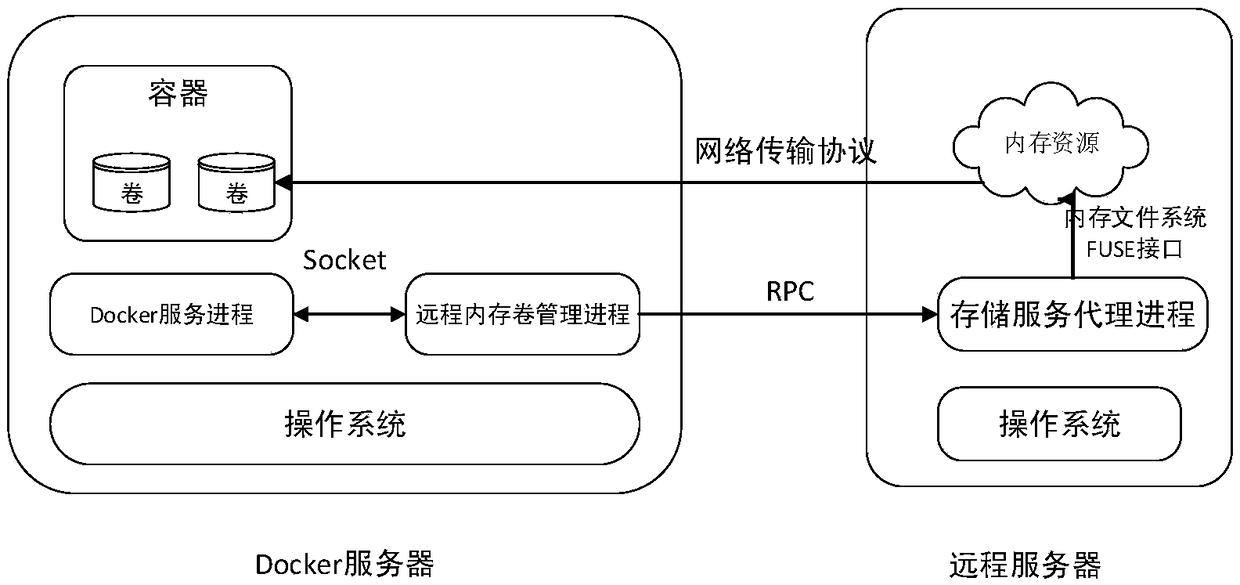

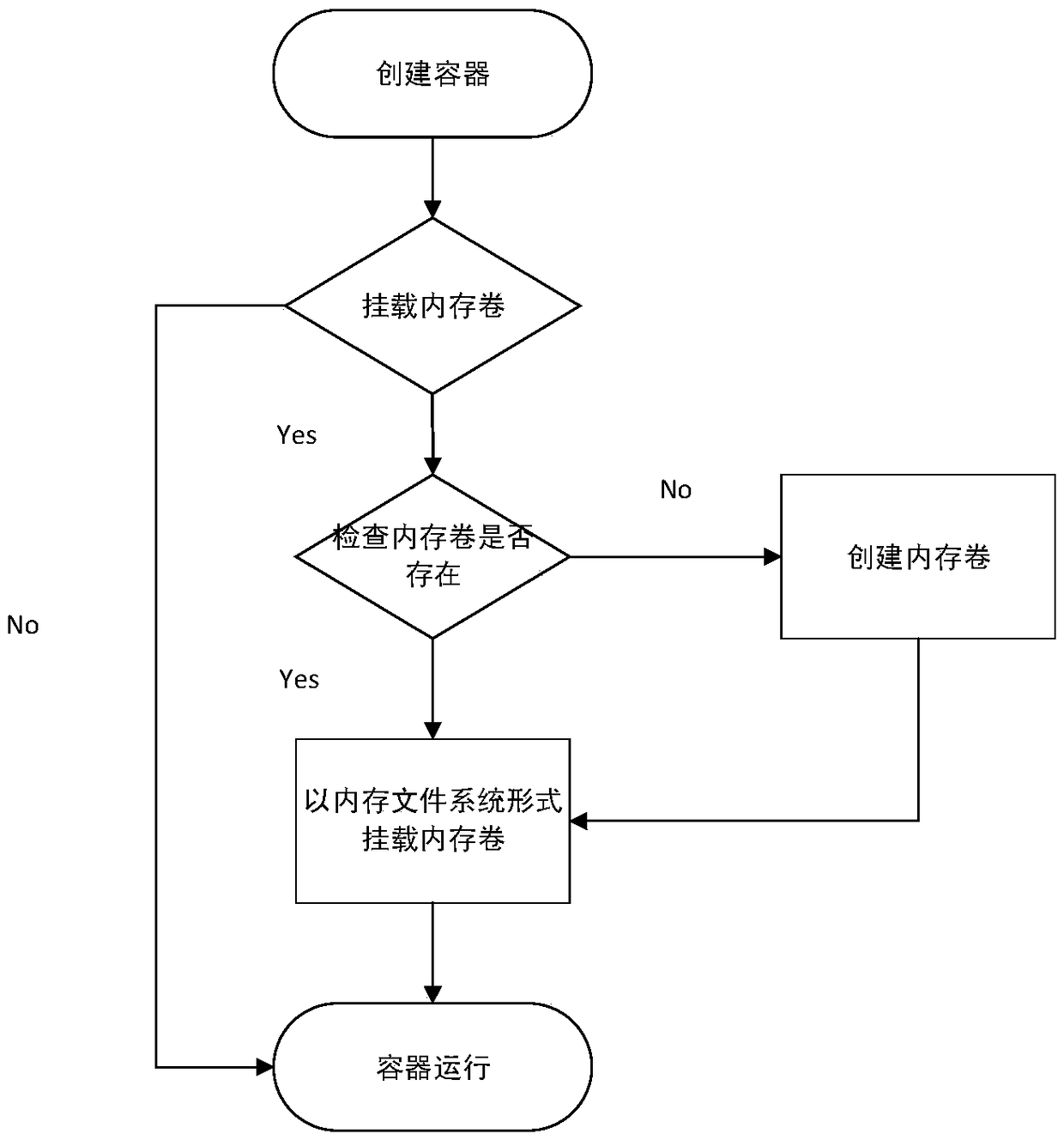

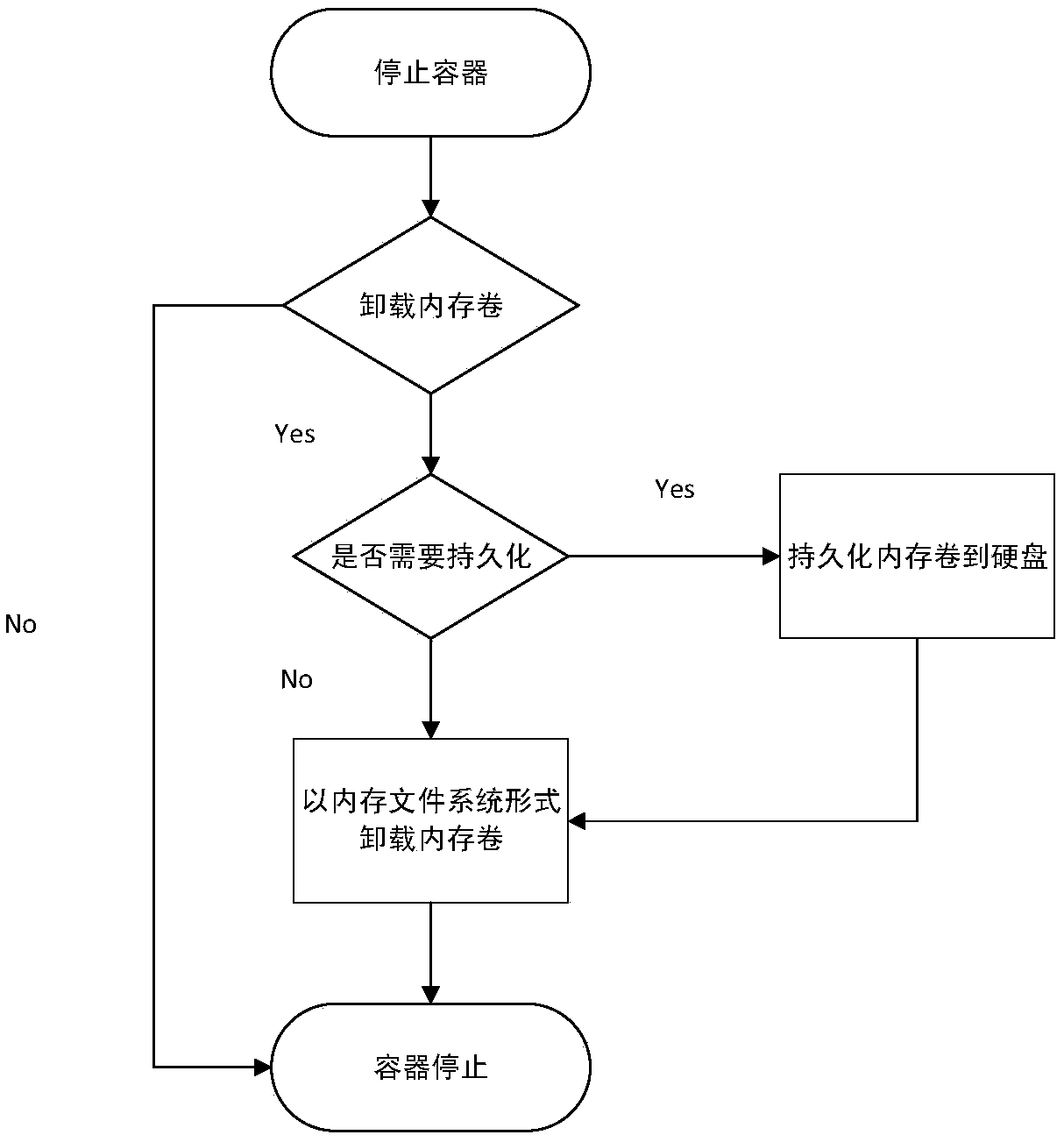

Remote memory volume management method and system of Docker container

The invention discloses a remote memory volume management method and a remote memory volume management system of a Docker container. The method comprises building, loading, unloading and destroying operations of a remote memory volume. The operation of building the remote memory volume comprises the steps of when a remote memory volume management process receives a remote memory volume building request, acquiring an IP address of a storage node from a storage server cluster, and recording a mapping relation between a remote memory volume name and the IP address of the storage node; the operation of loading the remote memory volume comprises the step of when the remote memory volume loading request is received, connecting to the storage node, wherein the agent process of the storage node loads the remote memory volume to a local node; the operation of unloading the remote memory volume comprises the step of when a remote memory volume unloading request is received, informing the agent process to unload the remote memory volume; and the operation of destroying the remote memory volume comprises the step of when a remote memory volume destroying request is received, informing the agent process to release remote memory volume resources. According to the method provided by the invention, the IO performance of the application in the Docker container on the local node is improved.

Owner:ZHEJIANG UNIV

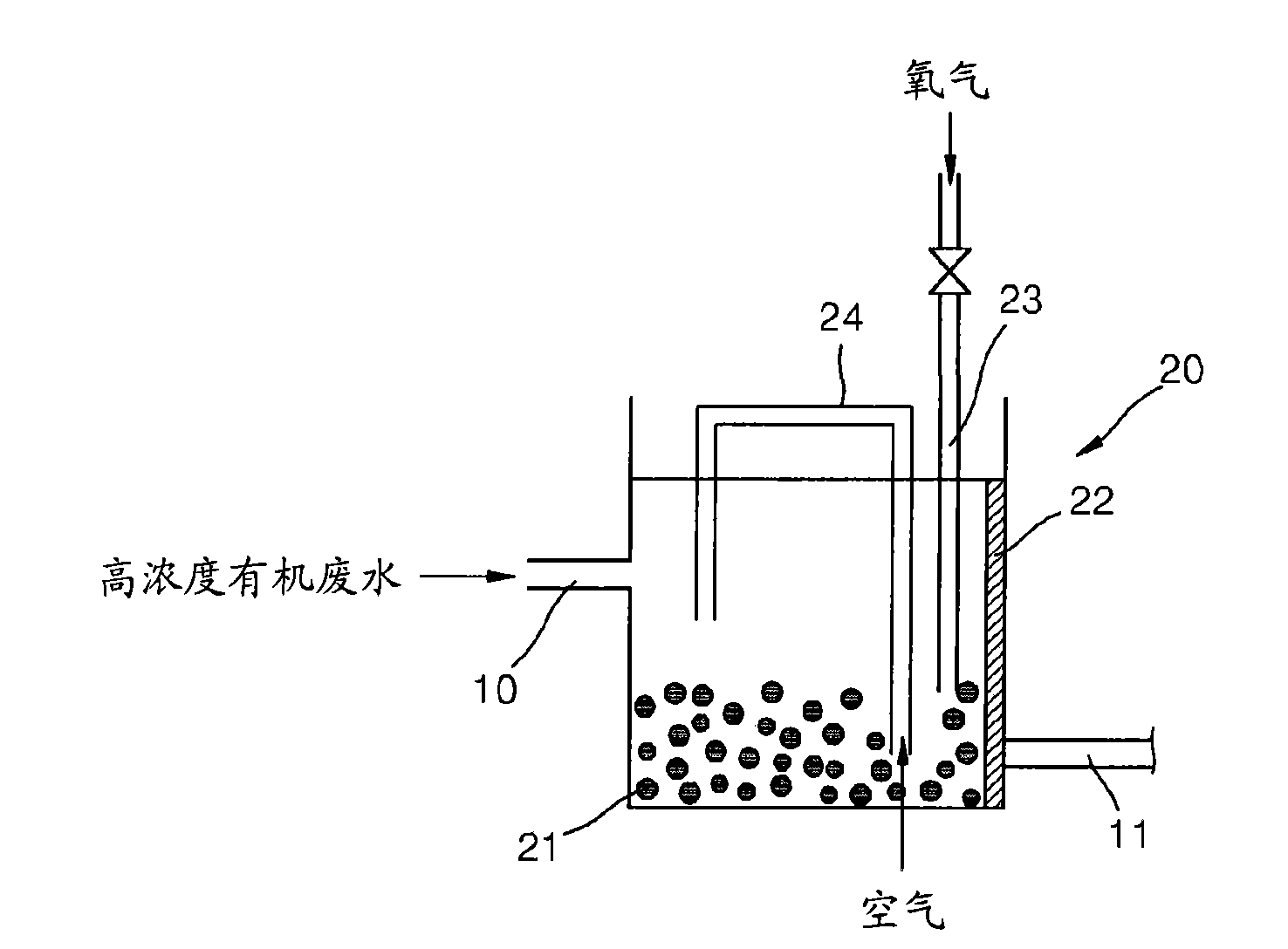

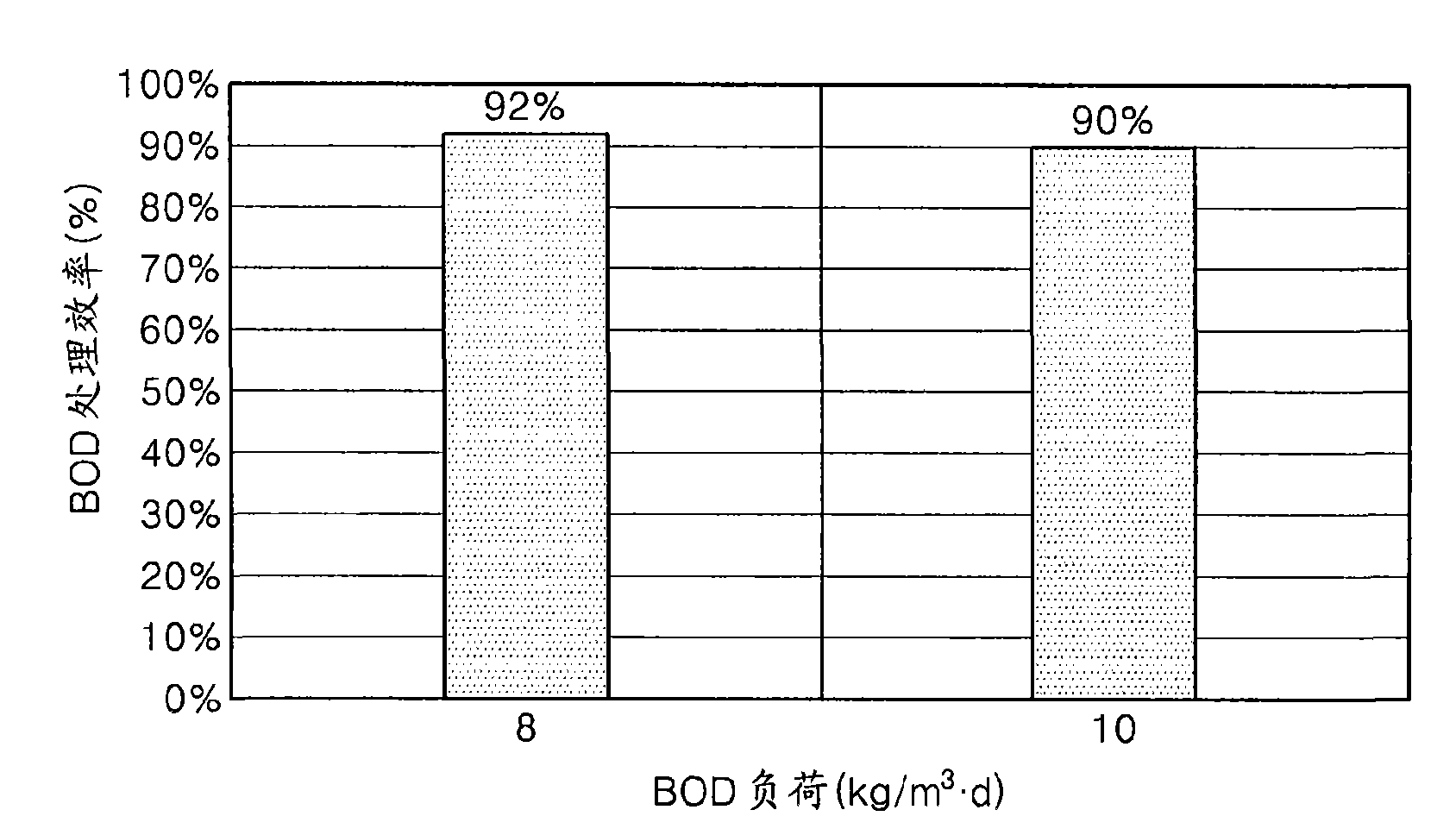

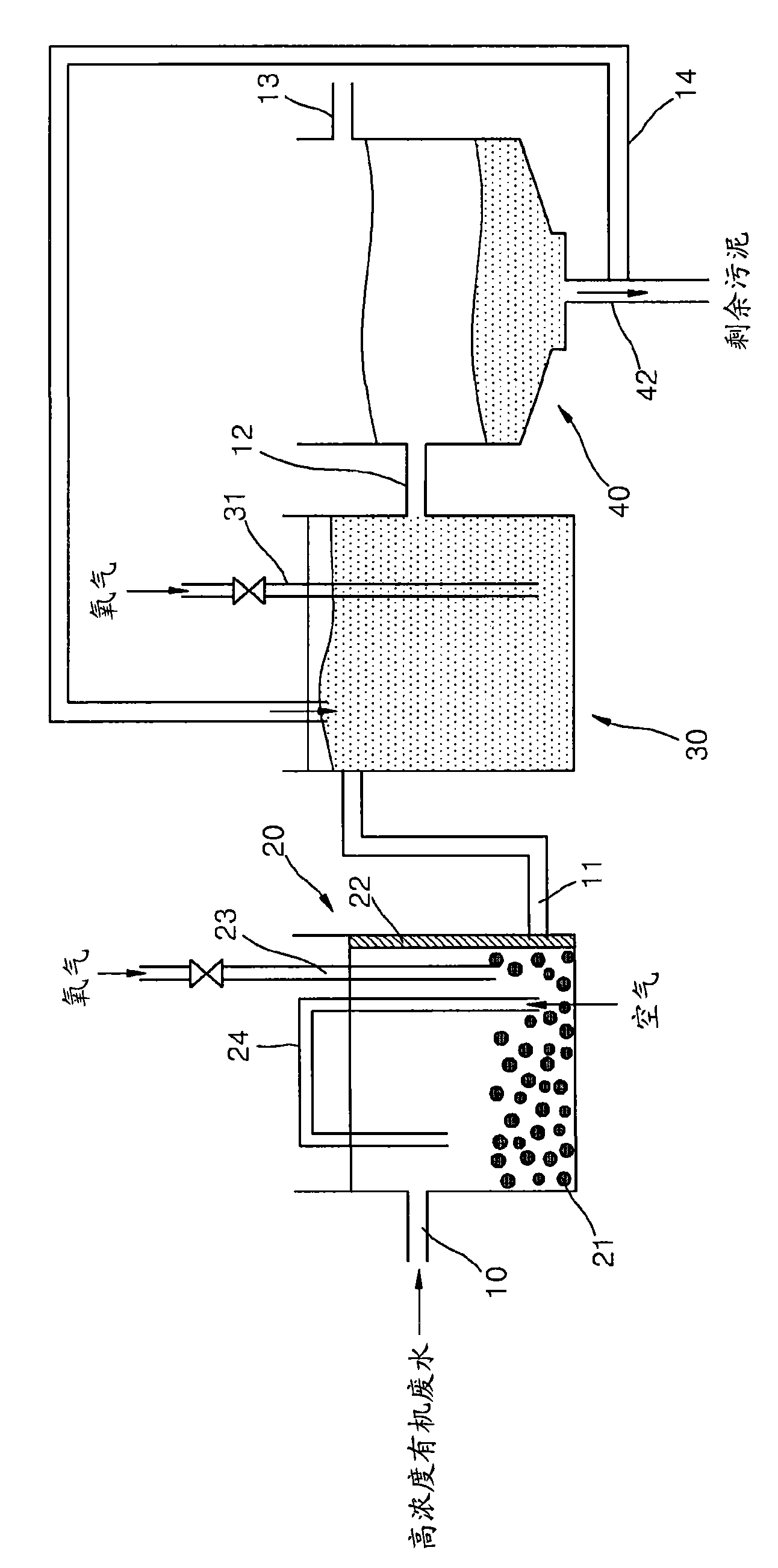

Apparatus for treating high concentration organic waste water and method of treating high concentration organic waste water using the same

ActiveCN101553436AEasy to replaceLow costSustainable biological treatmentBiological water/sewage treatmentWater useHigh concentration

An apparatus for treating high concentration organic waste water and a method of treating the organic waste water using the same are provided. The apparatus for treating high concentration organic waste water includes a carrier reactor that receives organic waste water to be treated and oxidation decomposes organic materials included in organic waste water using aerobic microorganisms adhered to carriers, wherein the carriers are foamed polymer particles on which a mixture of at least one adhesive resin and finely ground active carbon with a mixing ratio of 60:40 to 50:50 by weight is coated.The apparatus for treating high concentration organic waste water does not require sludge recycle, can be readily manufactured using an existing apparatus for treating high concentration organic wastewater, and thus, manufacturing costs can be reduced, and can operate at high organic material loading and a high BOD volume loading.

Owner:SAMSUNG ENGINEERING CO LTD

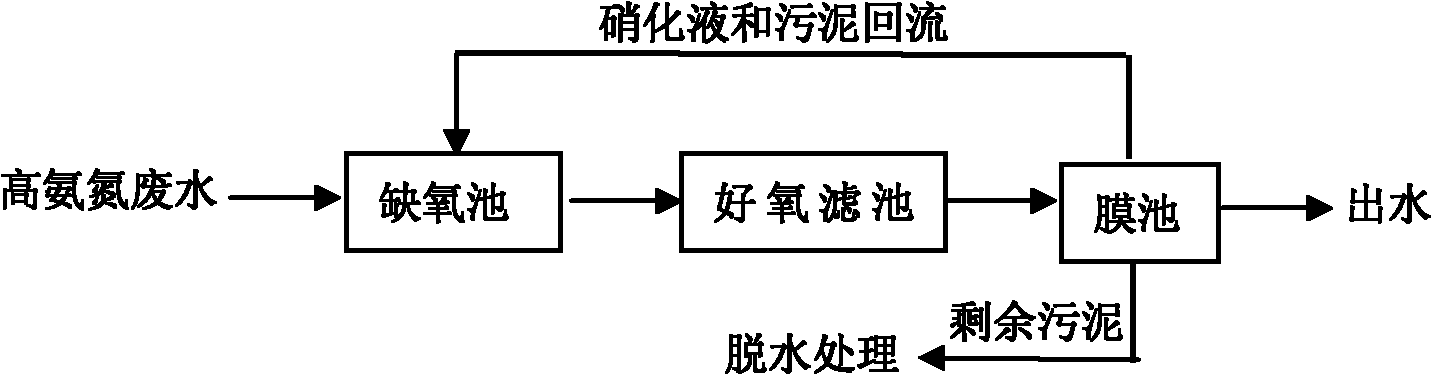

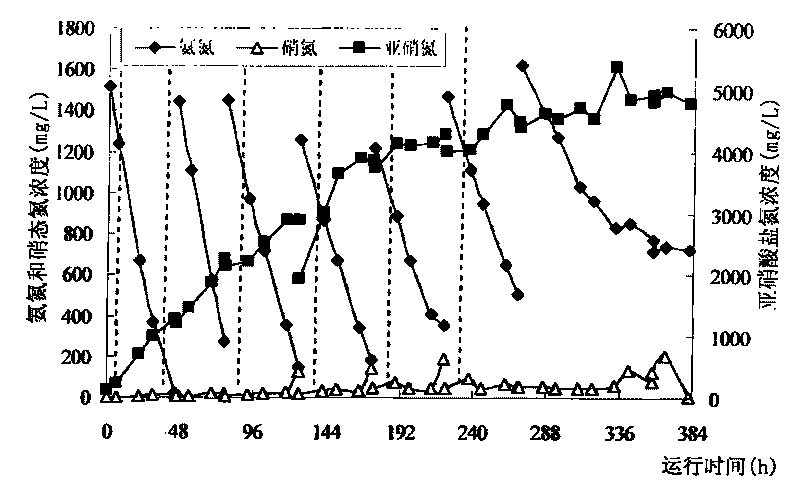

Ammonia-contained waste water high-efficiency biochemical processing method

ActiveCN101723512AReduce productionImprove impact performanceTreatment with aerobic and anaerobic processesActivated sludgeNitration

The invention relates to an ammonia-contained waste water high-efficiency biochemical processing method which comprises the following steps of: firstly putting an inoculant into a bioreactor for extensive culture, wherein the inoculant is a microbial flora of Nitrosomonas sp., Denitrobacter sp., Rhodanobacter sp. and the like, and high ammonia nitrogen and high pH value are used as the conditions of the extensive culture; throwing the microbial flora after the extensive culture or a mixture of the microbial flora and aerobic activated sludge of a sewage plant into a nitration reaction pond to process high-ammonia nitrogen low-COD waste water. The processing method has nonstrict requirements for a temperature range and dissolved oxygen concentration. The method not only has the advantages of energy consumption reduction, carbon source saving, sludge production capacity decrease and the like, but also has the characteristics of high volume loading of ammonia nitrogen removal, good processing effect, strong impact resistant capability, stable system operation and the like and is a processing method with stronger synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mangneto modified ceramsite filler, preparation method thereof and application of modified filler in wastewater processing

InactiveCN102351306ALarge specific surface areaGood chemical stabilitySustainable biological treatmentBiological water/sewage treatmentRetention timeProcessing cost

The invention which discloses a mangneto modified ceramsite filler, a preparation method thereof and an application of the modified filler in wastewater processing belongs to the wastewater processing field. The modified filler is a magnetic filler which treats ceramsite as a base material and contains mixed magnetic powder, a biological affinity substance and a dispersant. The preparation methodof the modified filler comprises the following steps: 1, respectively immersing ceramsite in an acid liquor and an alkali liquor; 2, adding modification materials, and processing; and 3, mixing, and molding calcining. A method for improving the biological processing of the wastewater with the modified filler is characterized in that: the mangneto modified ceramsite filler is filled in an aerobic reactor according to a packing ratio of 35-50%, the wastewater is introduced, the retention time is 4-6, the volume loading is controlled at 0.5-2kgCOD / (m<3>.d), and the gas-water ratio in the aeration process is 5-15:1. Characteristics of the mangneto modified ceramsite filler are fully utilized in the invention to allow the wastewater processing efficiency to be improved, the wastewater processing cost to be saved, the service life of advanced processing equipment to be prolonged and large scale industrialization application to be easy.

Owner:NANJING UNIV

Platinum group metal-free catalysts for reducing the ignition temperature of particulates on a diesel particulate filter

A catalyzed diesel particulate filter (CDPF) and a method for filtering particulates from diesel engine exhaust are provided, where the catalyzed diesel particulate filter includes a substrate and a catalyst composition, where the catalyst composition contains at least one first component, at least one second component, and at least one third component, where the first component is at least one first component selected from the group consisting of cerium and a lanthanide and mixtures thereof, the at least one second component is selected from the group consisting of cobalt, copper, manganese and mixtures thereof; and the third component comprises strontium, where the first component, the second component, and the third component are in an oxide form after calcination. The catalyst on the catalyzed diesel particulate filter lowers the temperature at which particulates are removed from the CDPF by oxidizing the particulates on the filter. The catalyzed diesel particulate filter may also include a washcoat. Washcoats prepared from colloidal aluminum oxide may have higher surface areas and pore volumes loadings than washcoats containing aluminum oxide prepared from aluminum nitrate.

Owner:ALIVE KESHAVARAJA +3

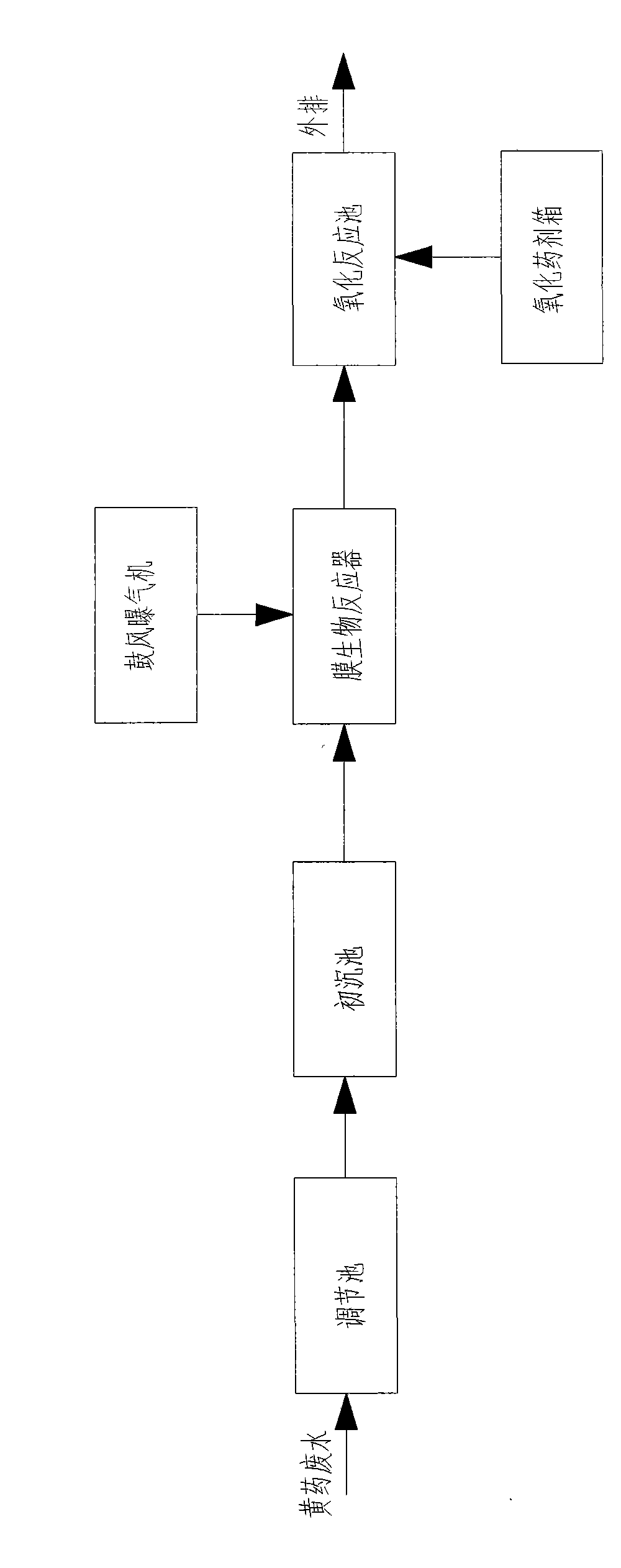

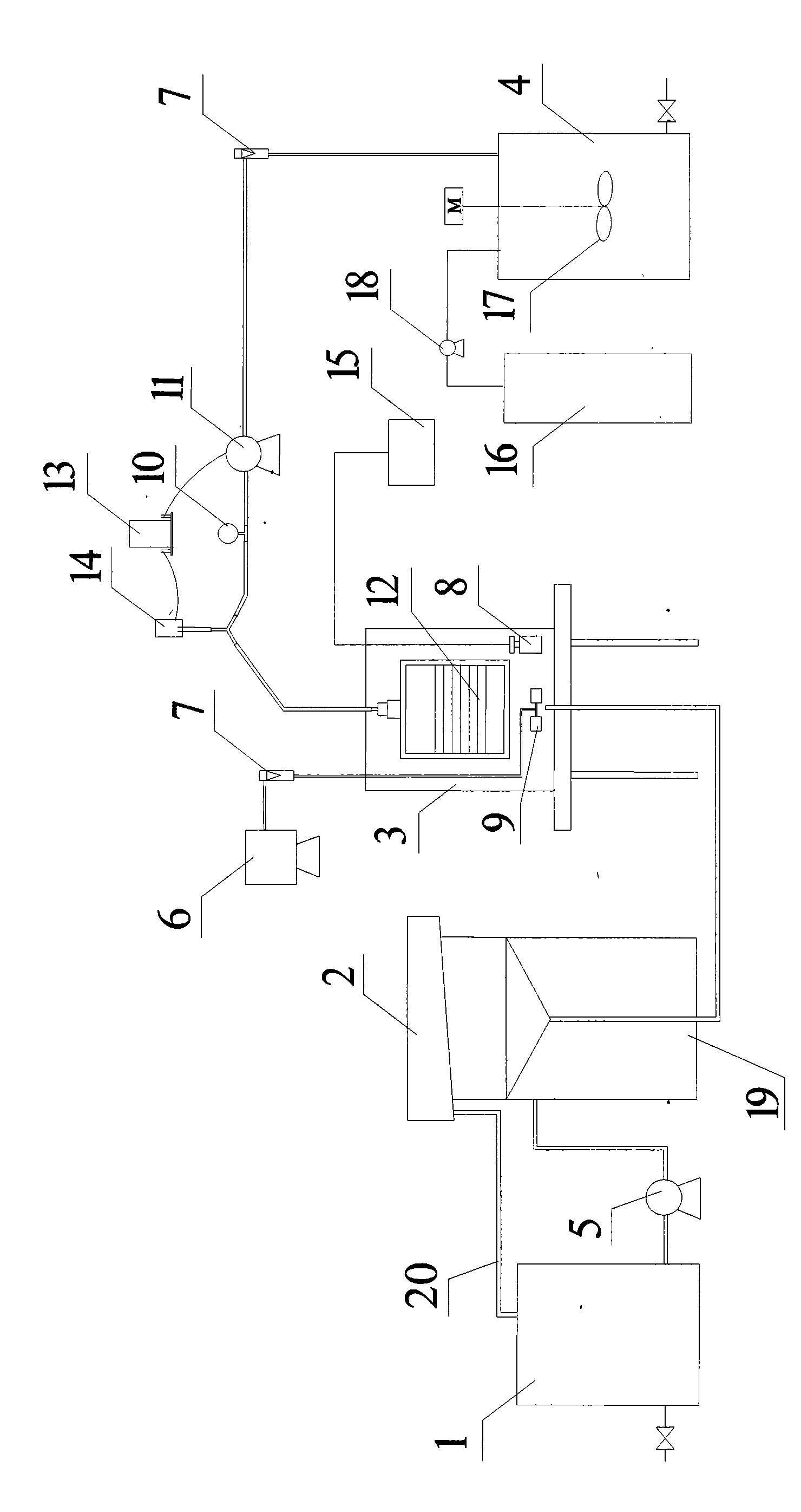

Method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation

InactiveCN101591121AFully degradedAvoid the danger of cloggingWater contaminantsWater/sewage treatment bu osmosis/dialysisOxygenOxidative treatment

The invention relates to a method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation, which belongs to the technical field of sewage treatment. The method comprises two sections of treatment processes, namely the film biodegradation and the hydrogen peroxide oxidation. The method comprises the following steps: controlling the volume loading of a film bioreactor to between 3.0 and 5.0 kgCOD / (m.d), controlling the hydraulic power residence time in the reactor to between 18 and 36 hours and the sludge residence time to between 75 and 150 days, controlling the dissolved oxygen concentration to between 2.5 and 4.0 milligrams per liter, controlling the temperature in the reactor to between 20 and 35 DEG C and the active sludge concentration to between 10,000 and 15,000 milligrams per liter, and controlling the sludge loading to between 0.11 and 0.17 kgCOD / (kgMLSS.d); and adjusting the pH value of the sewage in a reaction tank to between 3 and 5, adding 5 to 10 mg / L H2O2 to perform oxidation treatment for 30 to 60 minutes, and after the oxidation treatment, discharging the purified water. Through the treatment by the method, the removal rate of the COD and the xanthate reaches more than 90 percent and more than 99 percent respectively.

Owner:NORTHEASTERN UNIV

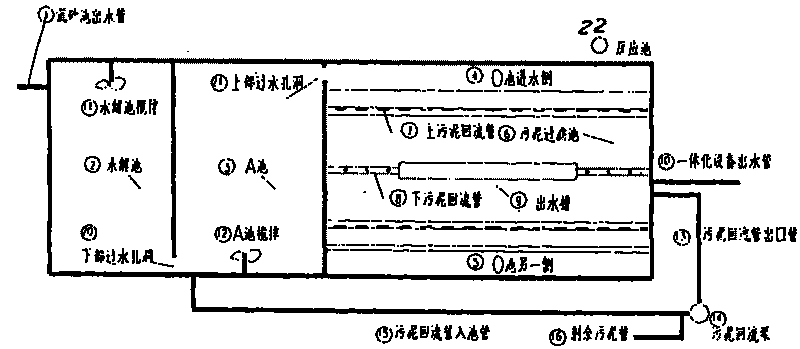

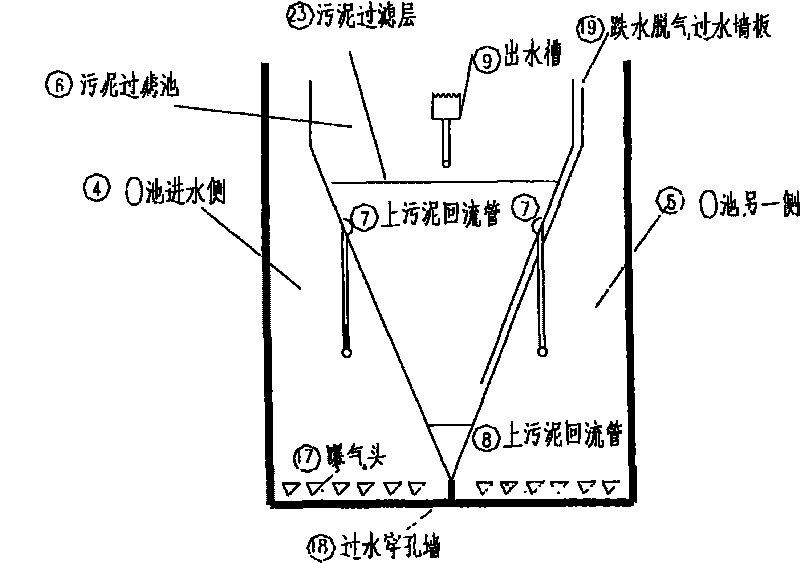

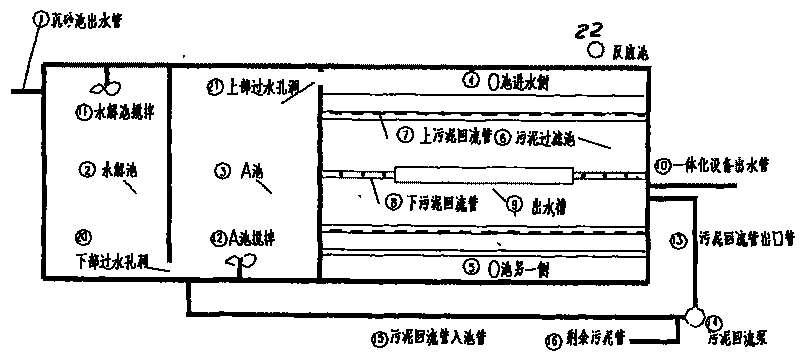

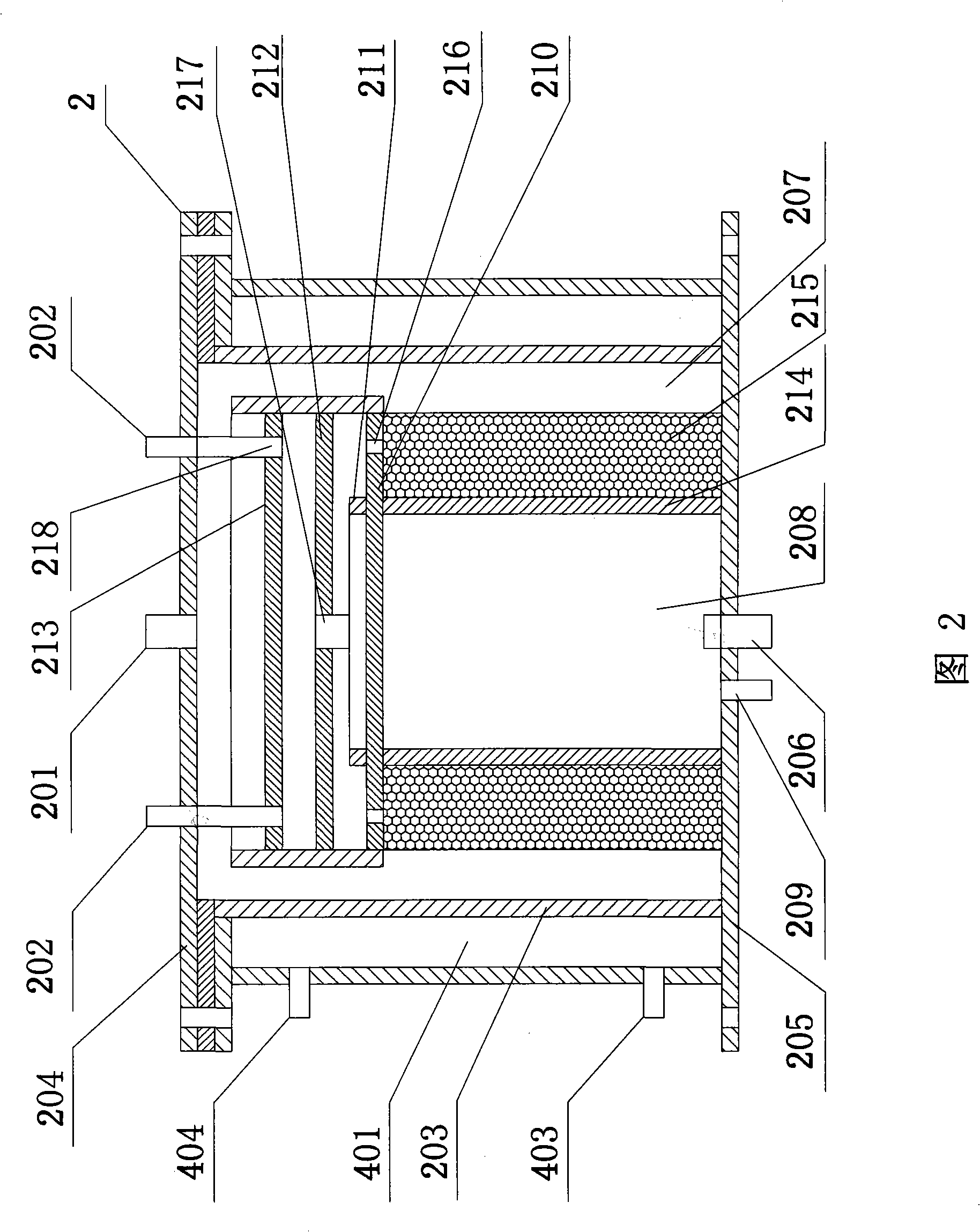

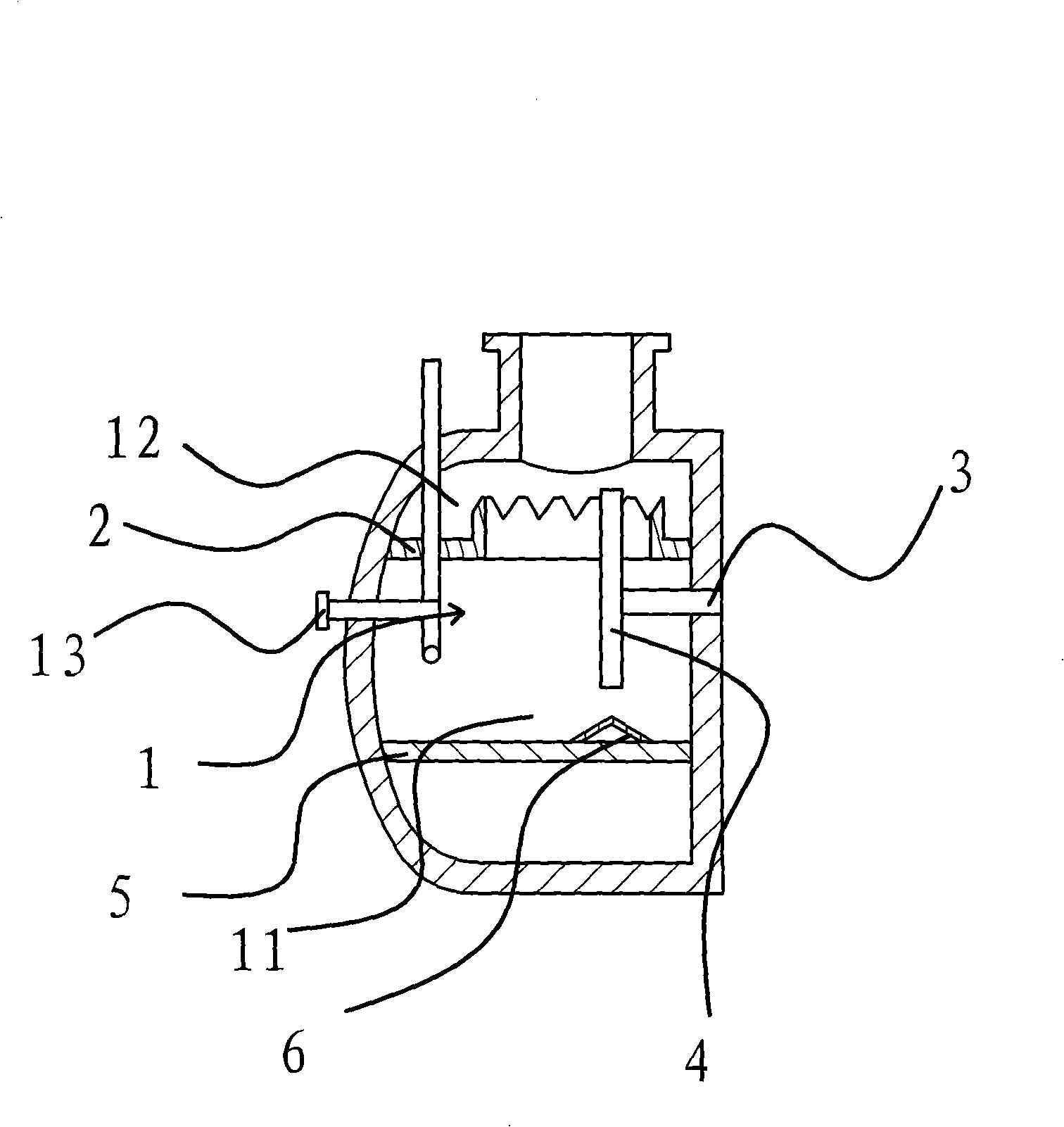

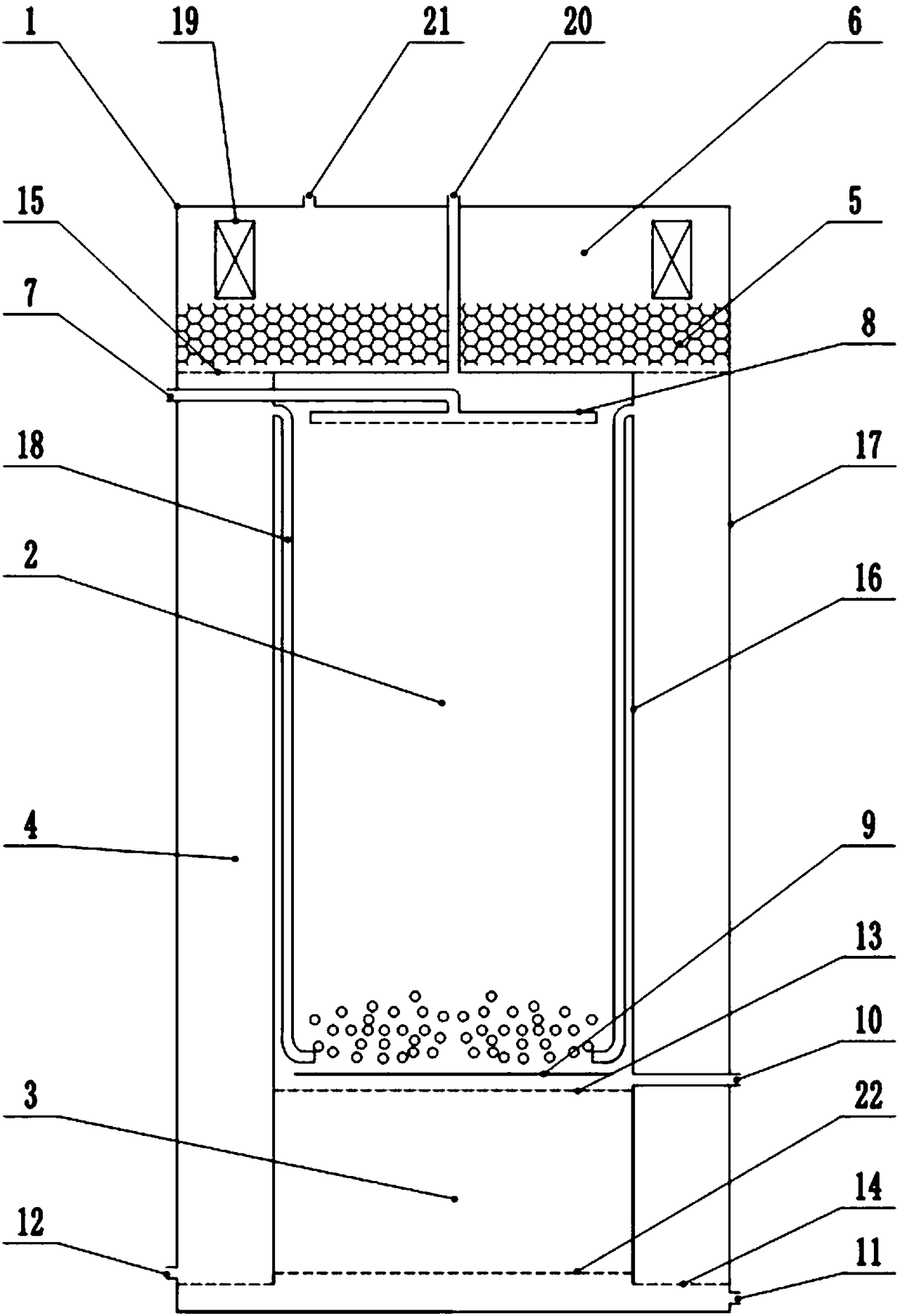

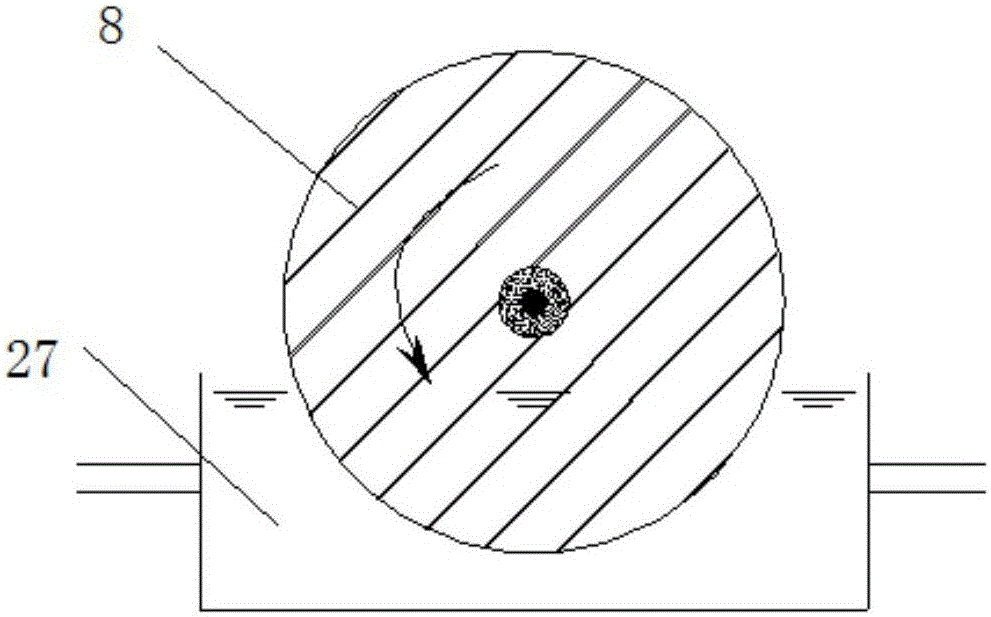

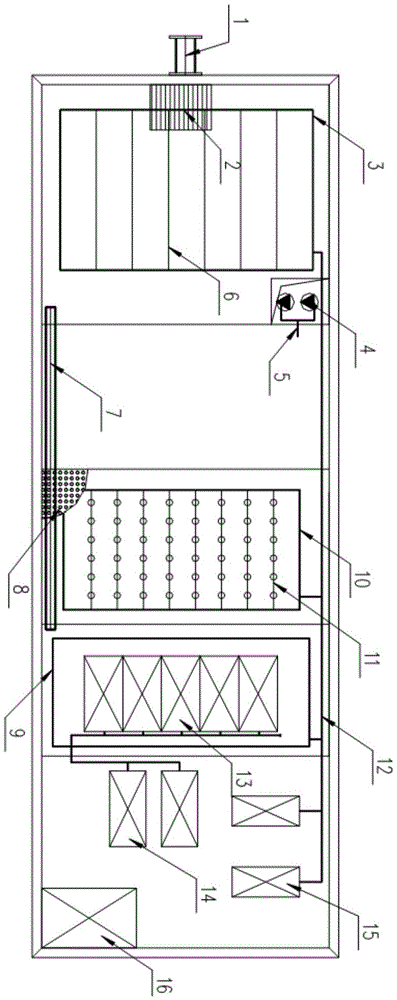

Improved integrated A/O sewage treatment equipment

ActiveCN101708918AStrong resistance to shock loadsIncrease sludge concentrationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeBiochemical engineering

The invention relates to improved integrated A / O sewage treatment equipment which is suitable for treating urban area and scattered point source domestic sewage which has middle and small-size amount and large concentration change range, can separate the sludge from the urban area and scattered point source domestic sewage efficiently, can ensure that a biochemical reaction tank keeps high sludge concentration and can reduce the volume of the biochemical reaction tank. The improved integrated A / O sewage treatment equipment consists of a hydrolytic tank, an A tank, a biochemical reaction tank and a sludge return pump. The hydrolytic tank is connected with the A tank; the A tank is connected with the biochemical reaction tank and the sludge return pump; the A tank comprises an upper water-pass hole, an A tank stirrer and a sludge return and tank enter pipe; the biochemical reaction tank comprises a sludge filter tank and an O tank; and the sludge return pump is arranged outside the biochemical reaction tank. The improved integrated A / O sewage treatment equipment has high sludge concentration and volume loading, can ensure that the reactor maintains the sludge concentration of 4000-4500mg / L, can reduce the design volume of the reactor by 20-30% and can save the capital construction cost. The invention can realize the modular production and is convenient to manage and run due to the integrated design.

Owner:LONG JIANG ENVIRONMENT PROTECTION GROUP SHARE +1

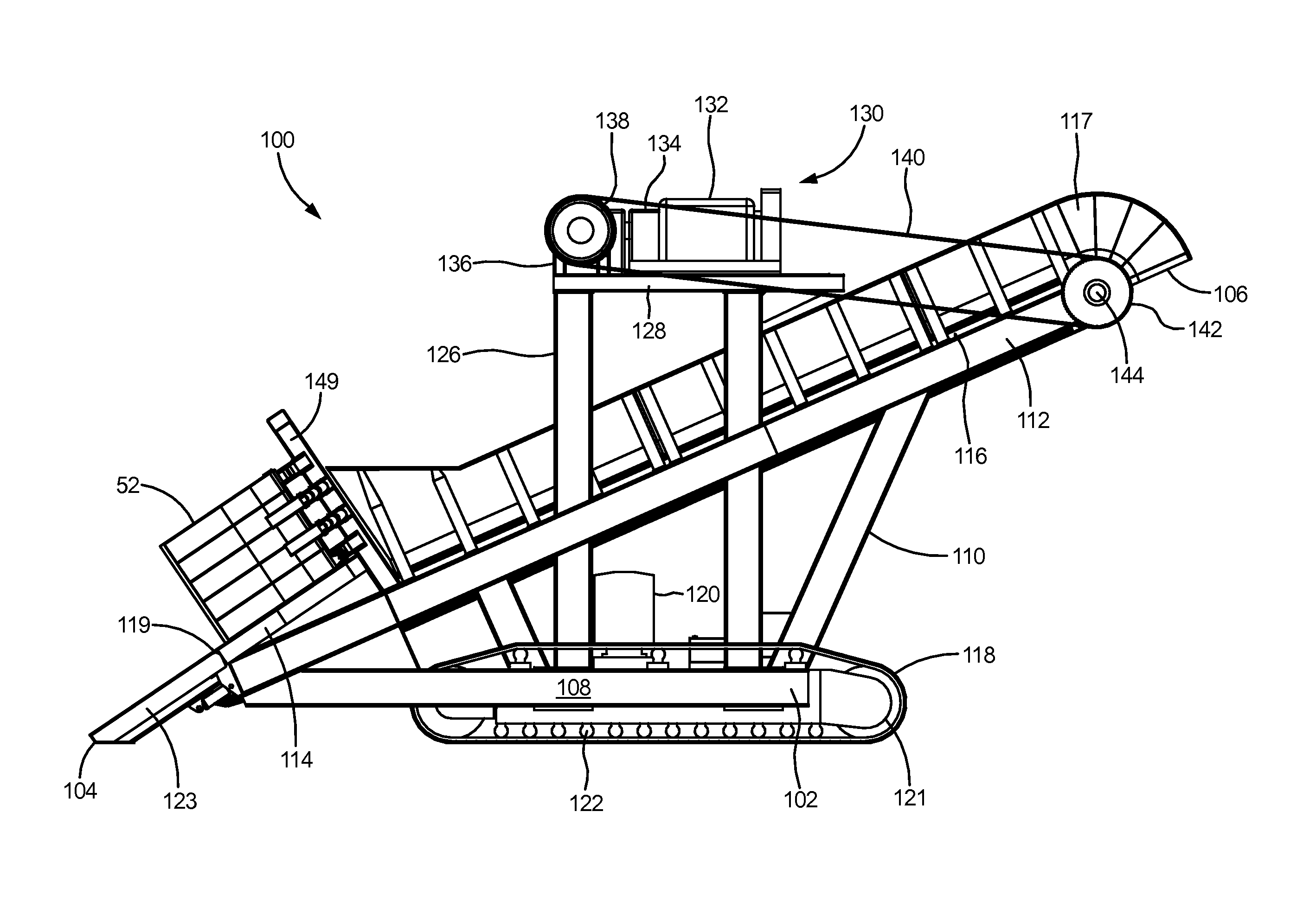

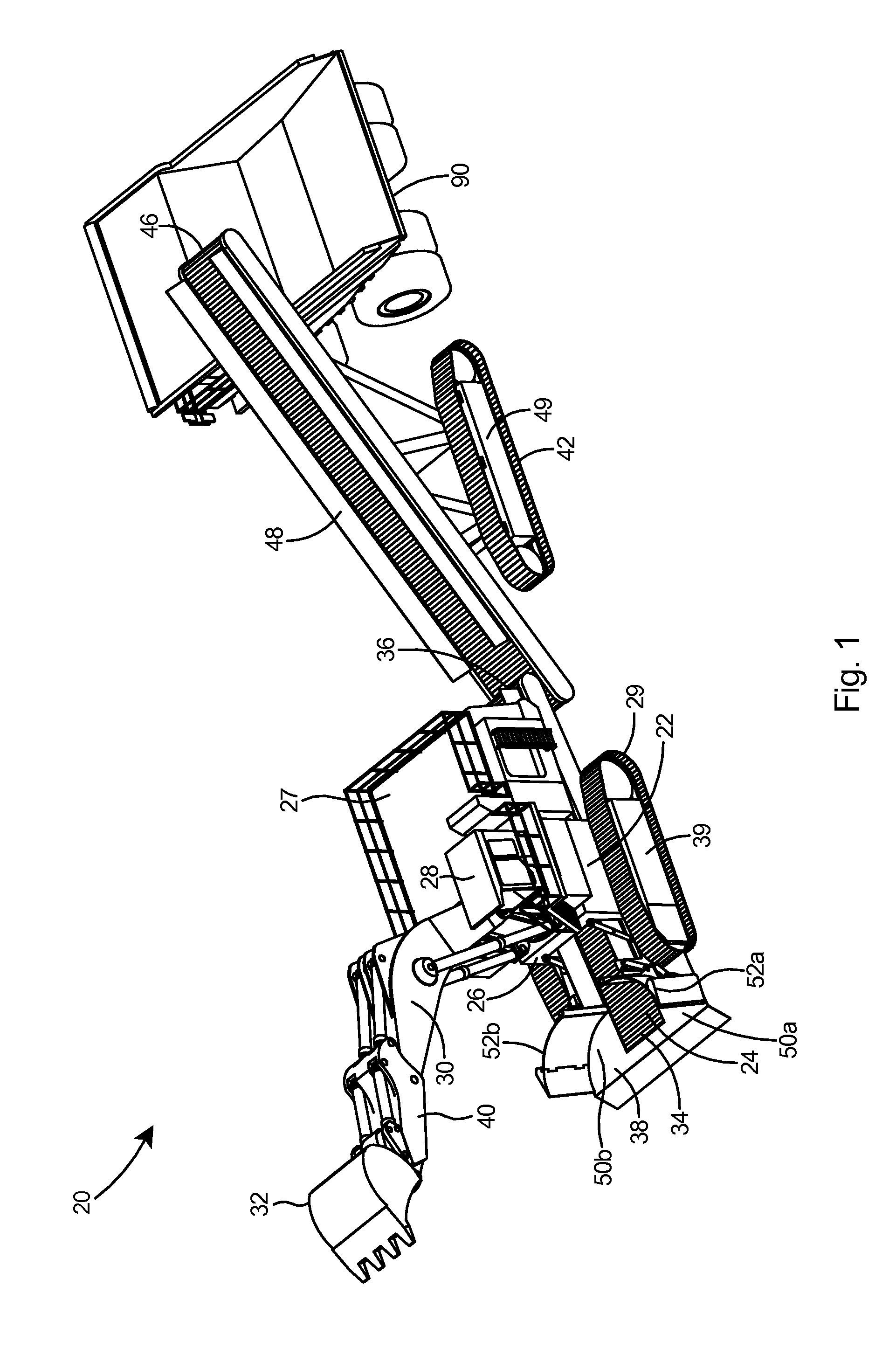

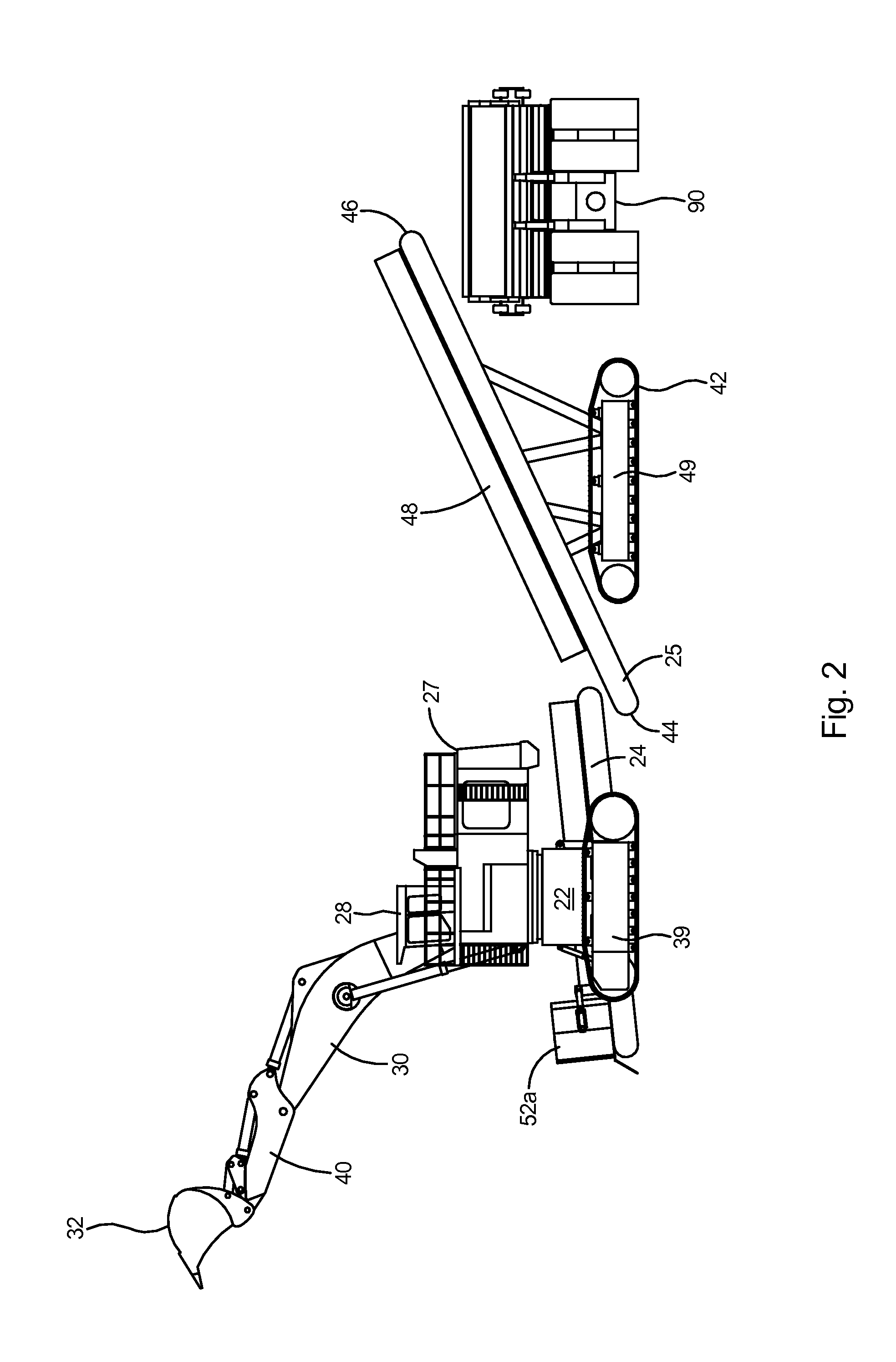

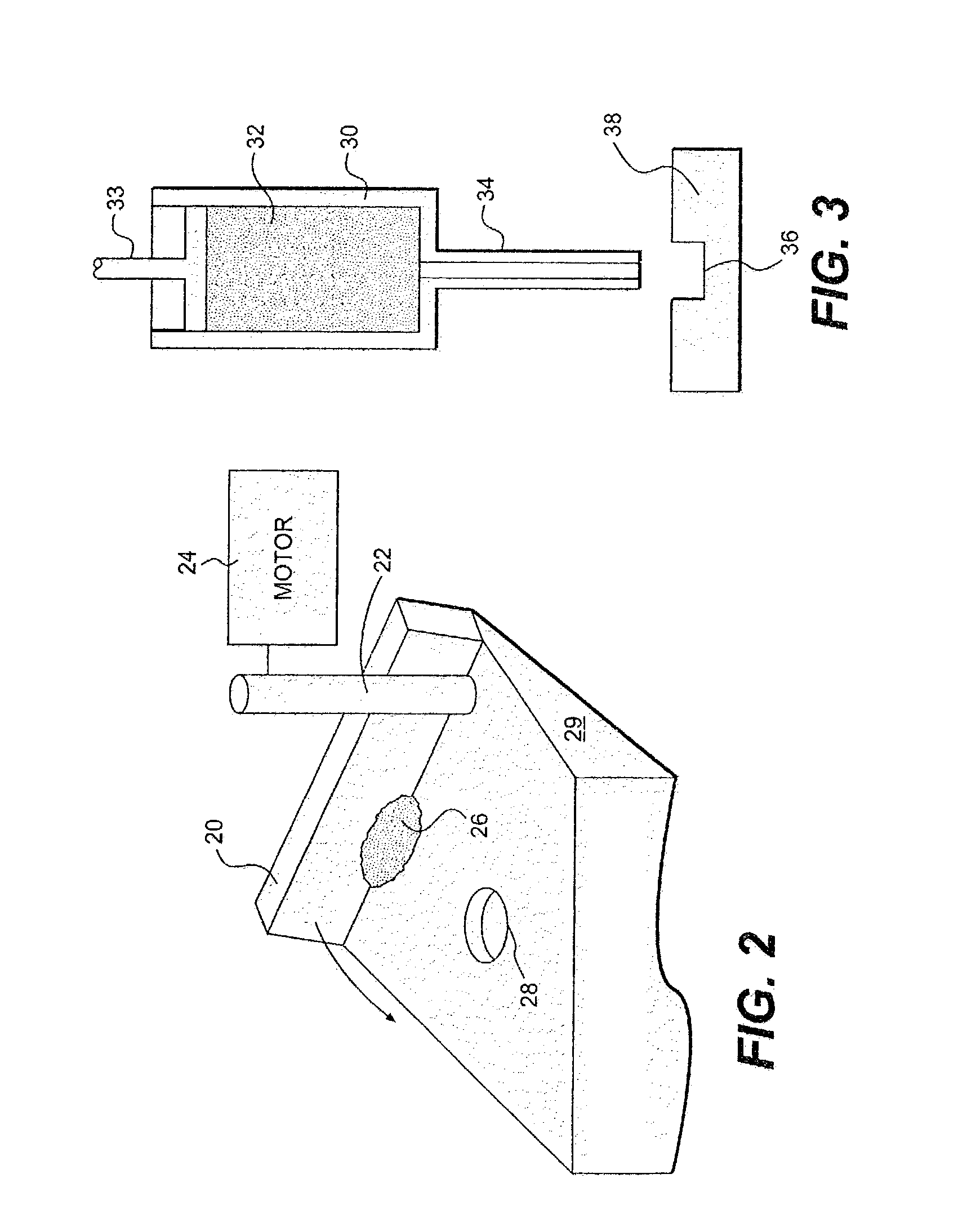

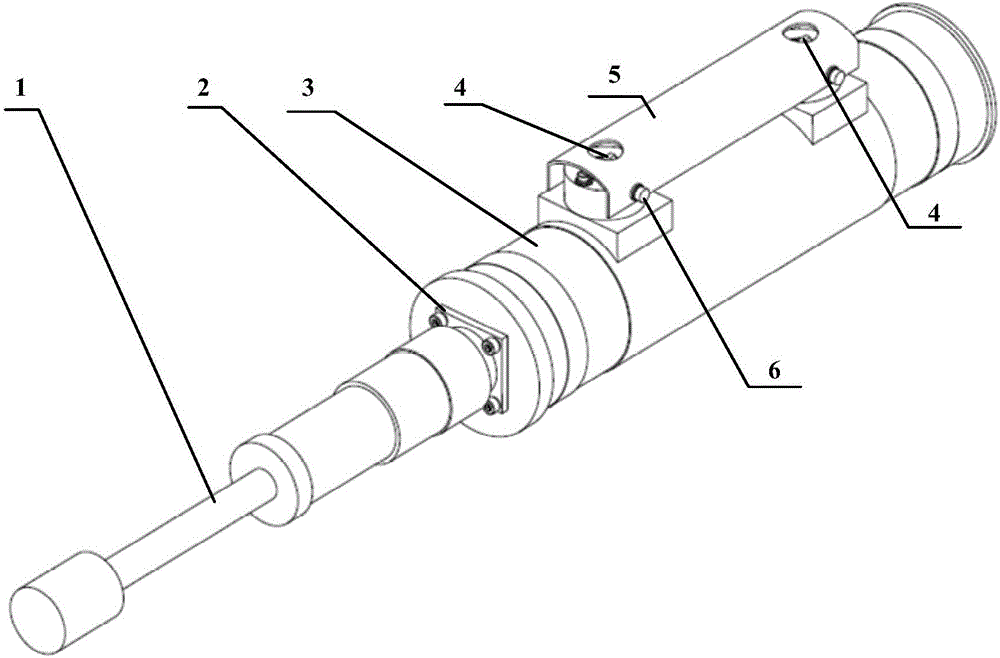

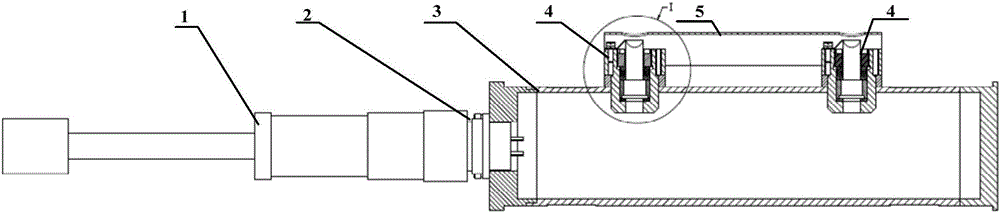

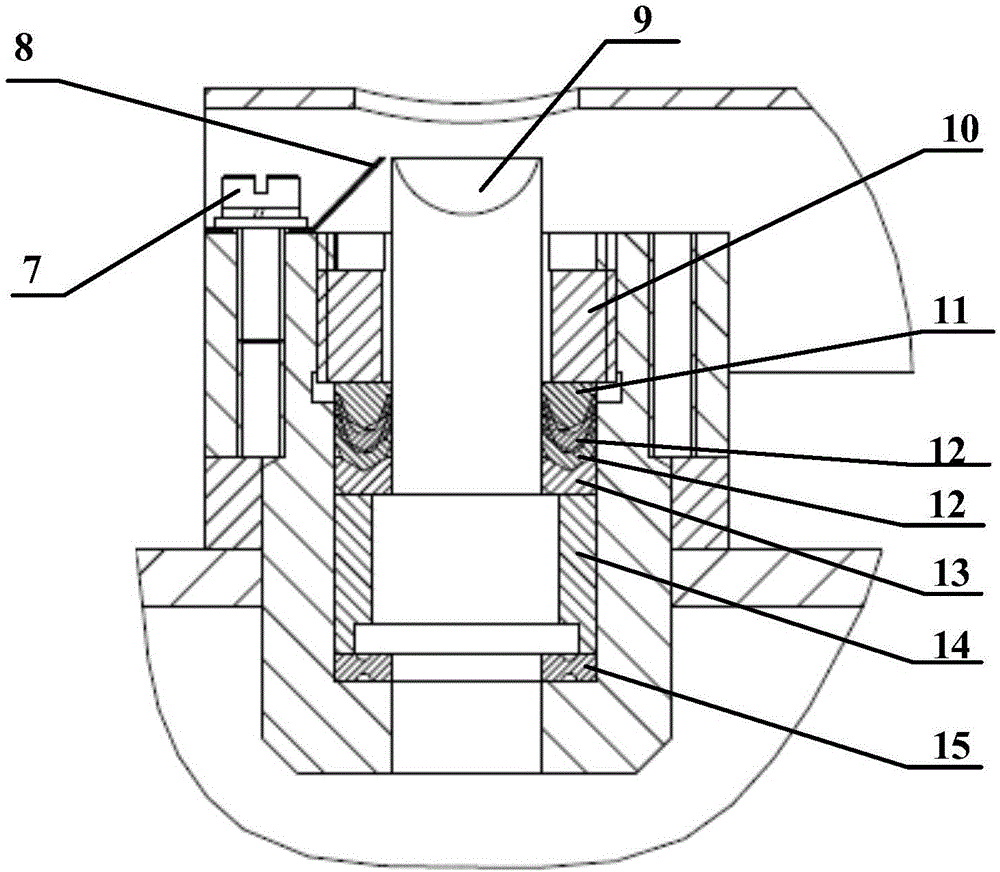

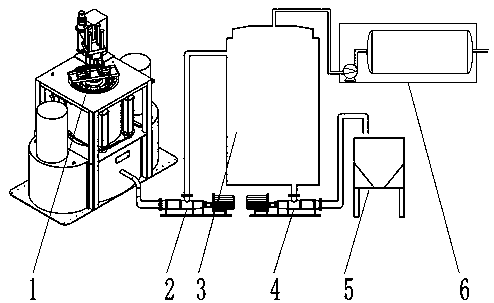

High volume loading and stacking apparatus and method

ActiveUS20150175363A1Eliminate needEliminate the problemConveyorsMechanical machines/dredgersSprocketMechanical drive

A loading apparatus and method including a stacker conveyor having paired crawler tracks, an inclined conveyor, and an intake end and a discharge end. A wide apron is positioned at the intake end of the conveyor. The apron includes a left-hand side and right-hand side load receiving area that are arranged on opposing sides of the feeder conveyor. Two double hinged feeder blades are positioned at a rear edge of the apron. The feeder blades are arranged to operate asynchronously. Each feeder blade includes a main blade and a wing blade. A straight mechanical drive unit including an engine and two planetary gearboxes that generate the torque required to drive the conveyor. The drive unit includes a torque converter and two planetary gearboxes with planetary sprockets. A chain extends between each planetary sprocket and a corresponding head shaft sprocket on a main head shaft which drives the conveyor.

Owner:LOWERY STERLING WAYNE

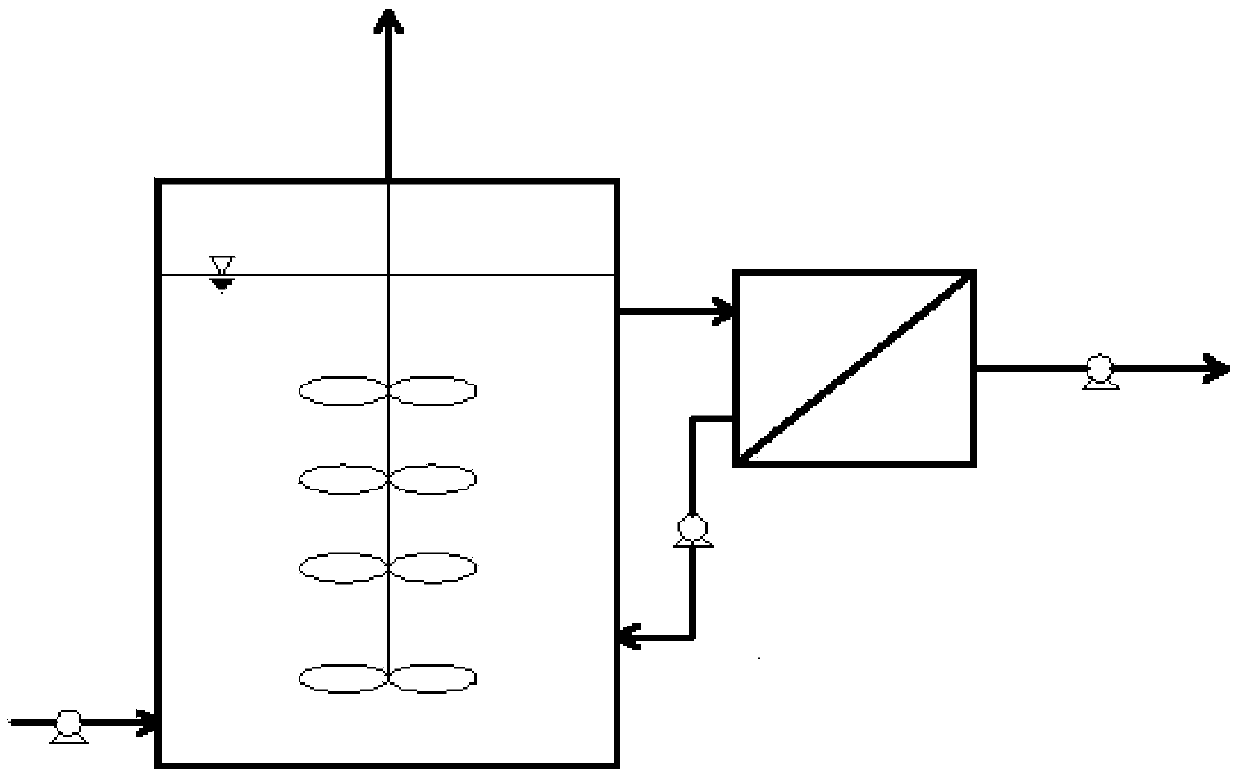

Anaerobic-micro-aerobic membrane bioreactor and operation method thereof

ActiveCN105366806AReduce pollutionReduce pollution loadWaste based fuelTreatment with anaerobic digestion processesFiltration membraneCollection system

The present invention relates to an anaerobic-micro-aerobic membrane bioreactor and an operation method thereof, and belongs to the technical field of waste anaerobic biological treatment. The bioreactor combines an Upflow Anaerobic Sludge Bed body portion with a two stage membrane module, wherein the body portion comprises a granular sludge anaerobic reaction zone, a three-phase separator, a settling zone and a biogas collection system; and the two stage membrane module are an ultrafiltration membrane module and a nano filtration membrane module, respectively, and an aeration system is arranged at the bottom of the ultrafiltration membrane module. Concentrated water trapped by the ultrafiltration membrane module and the nano filtration membrane module flows back to the bottom of the settling zone, and in the micro-aerobic environment, hardly degradable organic matters are further degraded. The volume loading rate of the reactor in treating hardly degradable organic waste water of pharmacy and coal chemistry can reach about 15 kg COD / (m<3>.d). The anaerobic-micro-aerobic membrane bioreactor and the operation method of the present invention solve the problems that in the prior art when the efficient anaerobic reactors represented by UASB treat hardly degradable waste water, the hydraulic retention time is long, the effect is not ideal, the conventional anaerobic membrane bioreactors have significant membrane contamination, and the hardly degradable organics removal effect is poor.

Owner:TSINGHUA UNIV +1

Pipe gas phase biological filtering device

InactiveCN101264422ASolve highResolves low volume loadsDispersed particle separationAir quality improvementLiquid wasteGas phase

The invention relates to a tubular gaseous biological filtering device, comprising a waste gas feeding device, a biofilter and a nutrient solution feeding device, wherein, the biofilter comprises a cylindrical casing, a top cover plate, a bottom plate and a tubular filling device arranged in the inner cavity of the cylindrical casing, an air inlet and a nutrient solution inlet are arranged on the top cover plate, a waste liquid discharge outlet and an exhaust outlet are arranged on the bottom plate, a ring shape gas passage is formed between the tubular filling device and the internal wall of the cylindrical casing, the central hollow cavity of the tubular filling device can form a tube gas chamber, one end of the tube gas chamber is communicated with the air inlet and the other end is communicated with the outside world through the exhaust outlet, the circular filler layer of the tubular filling device is communicated with the inlet of nutrient solution, the waste gas feeding device and the nutrient solution feeding device are separately connected with the air inlet of the biofilter and the inlet of the nutrient solution. The tubular gaseous biological filtering device has the advantages of simple and compact structure, tubular porous filling structure and inward or outward airflow mode for filling with small filling thickness, large volume loading and high handling capacity.

Owner:HUNAN UNIV

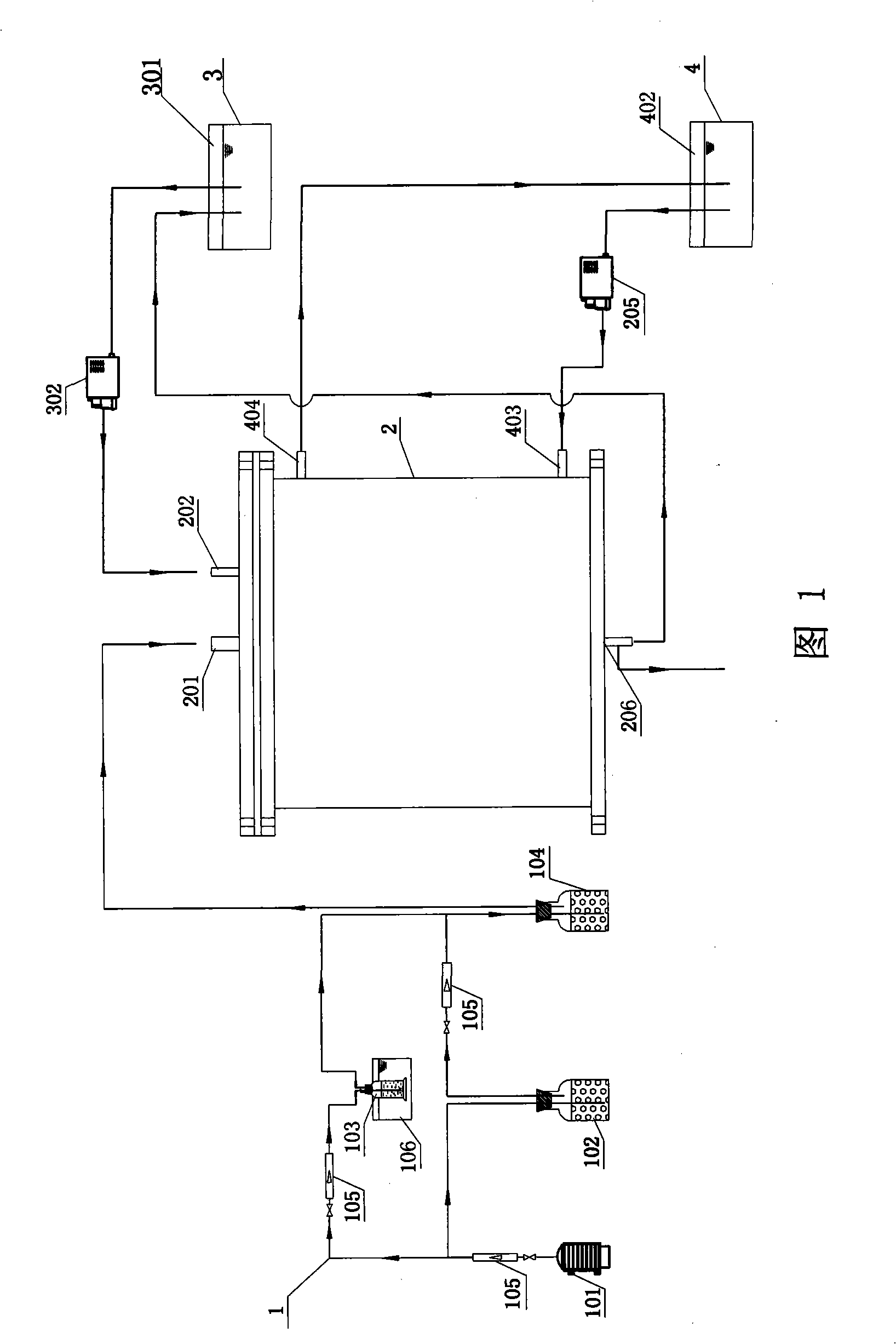

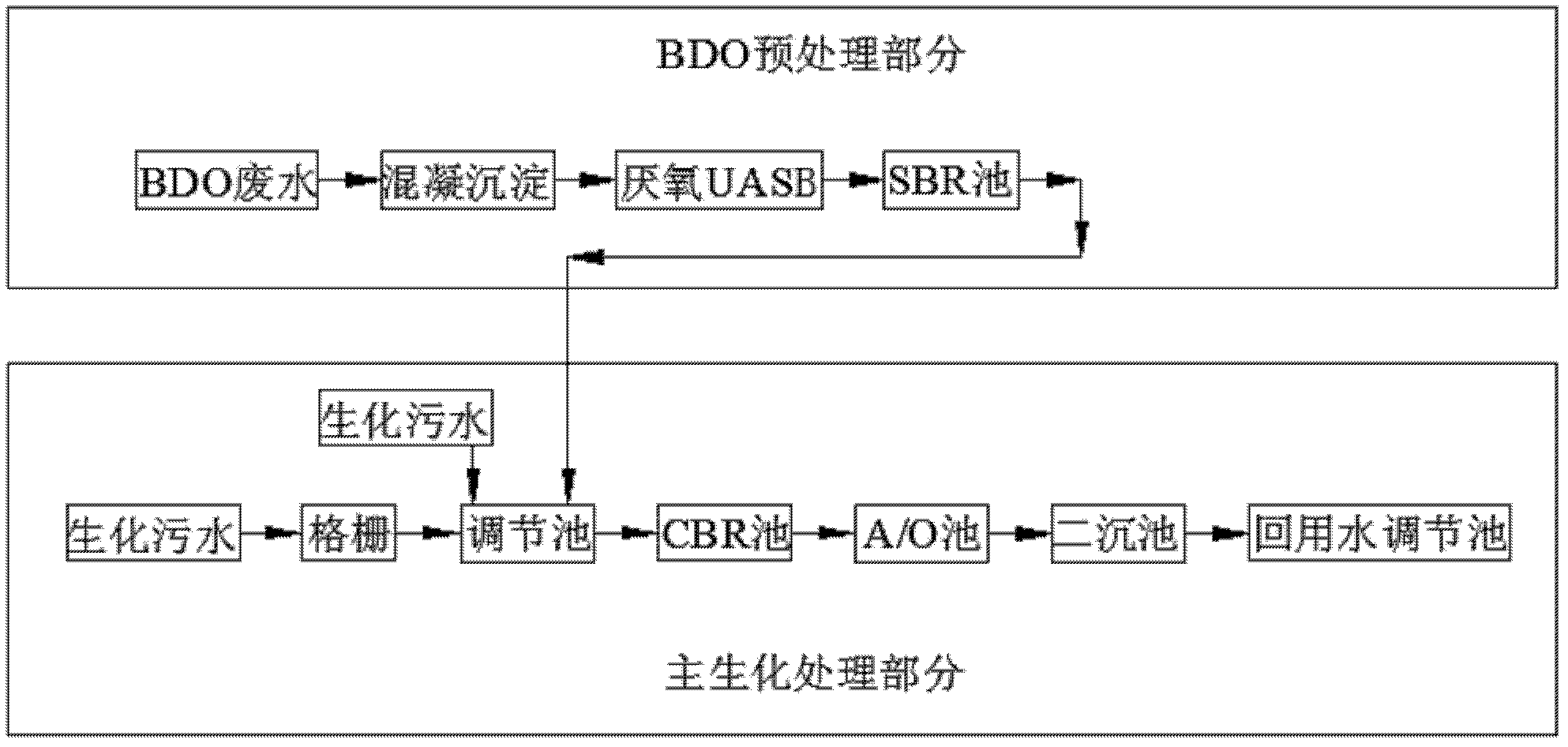

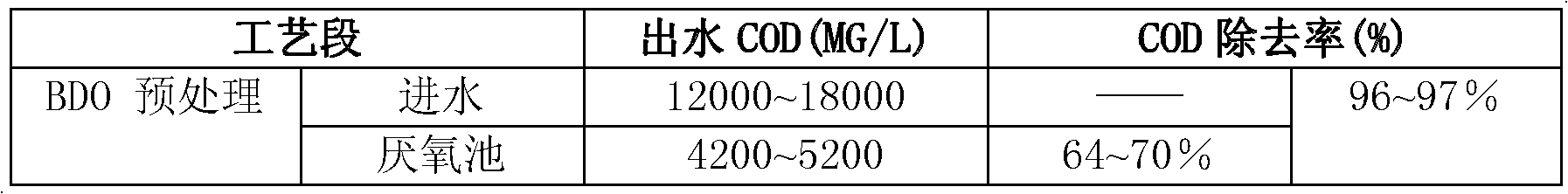

Method for biochemical treatment and standard discharge of sewage of coal chemical industry

ActiveCN102674627AStrong impact resistanceImprove impact resistanceMultistage water/sewage treatmentHigh concentrationActivated sludge

The invention provides a method for biochemical treatment and standard discharge of sewage of coal chemical industry. The method comprises the steps of BDO (1,4-butanediol) pretreatment and main biochemical treatment, wherein the BDO pretreatment is performed sequentially through a coagulative precipitation tank, an anaerobic tank and a SBR (sequencing batch reactor) tank; the main biochemical treatment is performed sequentially through an aerobic carrier fluidized bed reactor, a pre-denitrification tank, an aerobic activated sludge tank and a secondary sedimentation tank; and a mixed liquor which flows out of the aerobic activated sludge tank partially or entirely flows back into the pre-denitrification tank. The whole process is high in volume loading and impact resistance, and operates safely and stably. The whole biochemical system has high impact resistance; and the treatment effect is slightly affected by the change of the temperature. The whole system has a compact structure and is small in floor area. After high-concentration BDO sewage is pretreated, chemical oxygen demand (COD) of an effluent can be stably maintained to be less than 500mg / L, so that the main biochemical treatment can be easily performed; and after the sewage of the coal chemical industry is subjected to main biochemical treatment, the COD of an effluent can be stably maintained to be less than 50mg / L, so that the national first-class discharge standard is met, and the investment and operation cost is saved.

Owner:SINOPEC CHANGCHENG ENERGY CHEM NINGXIA CO LTD +1

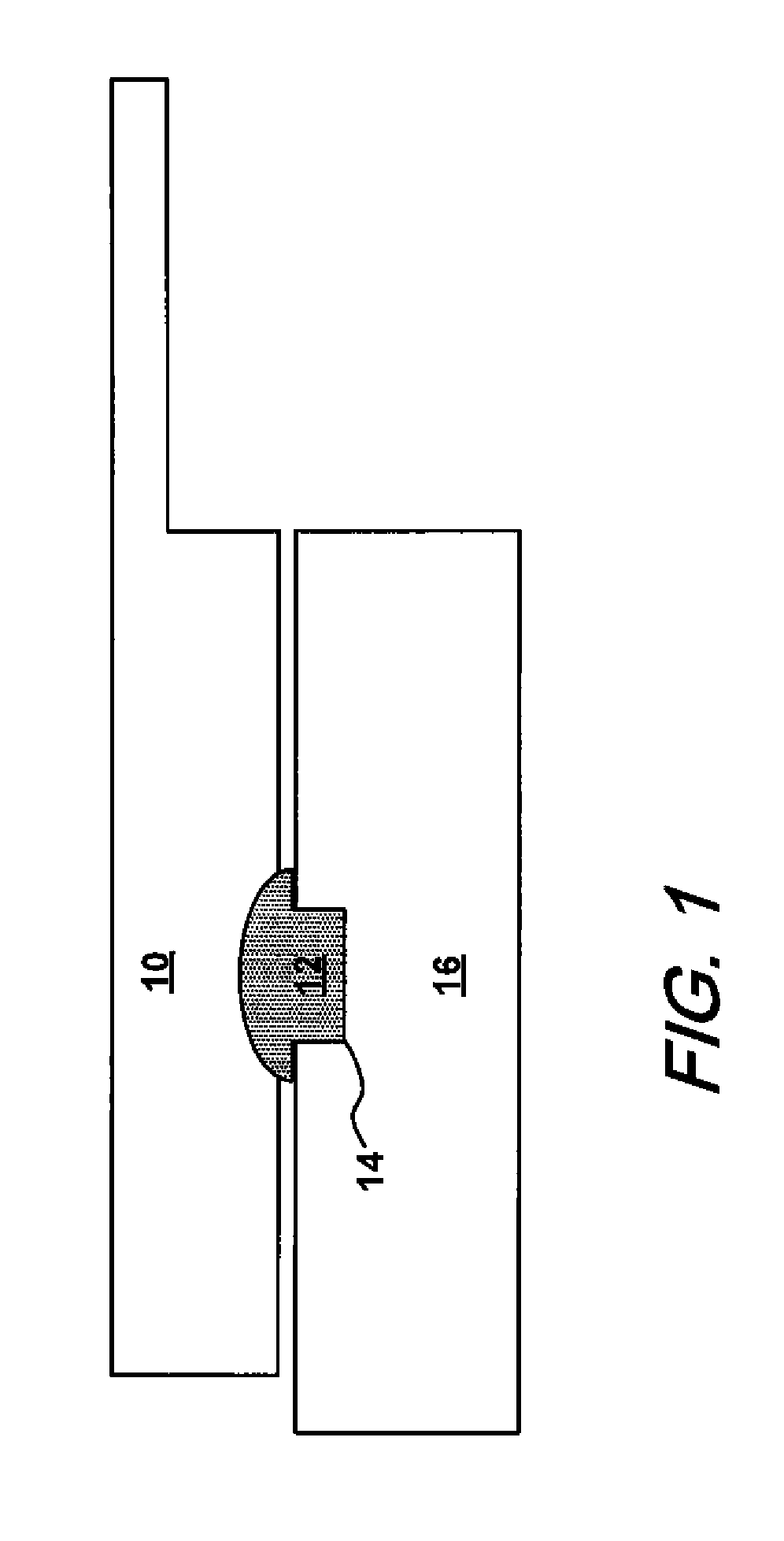

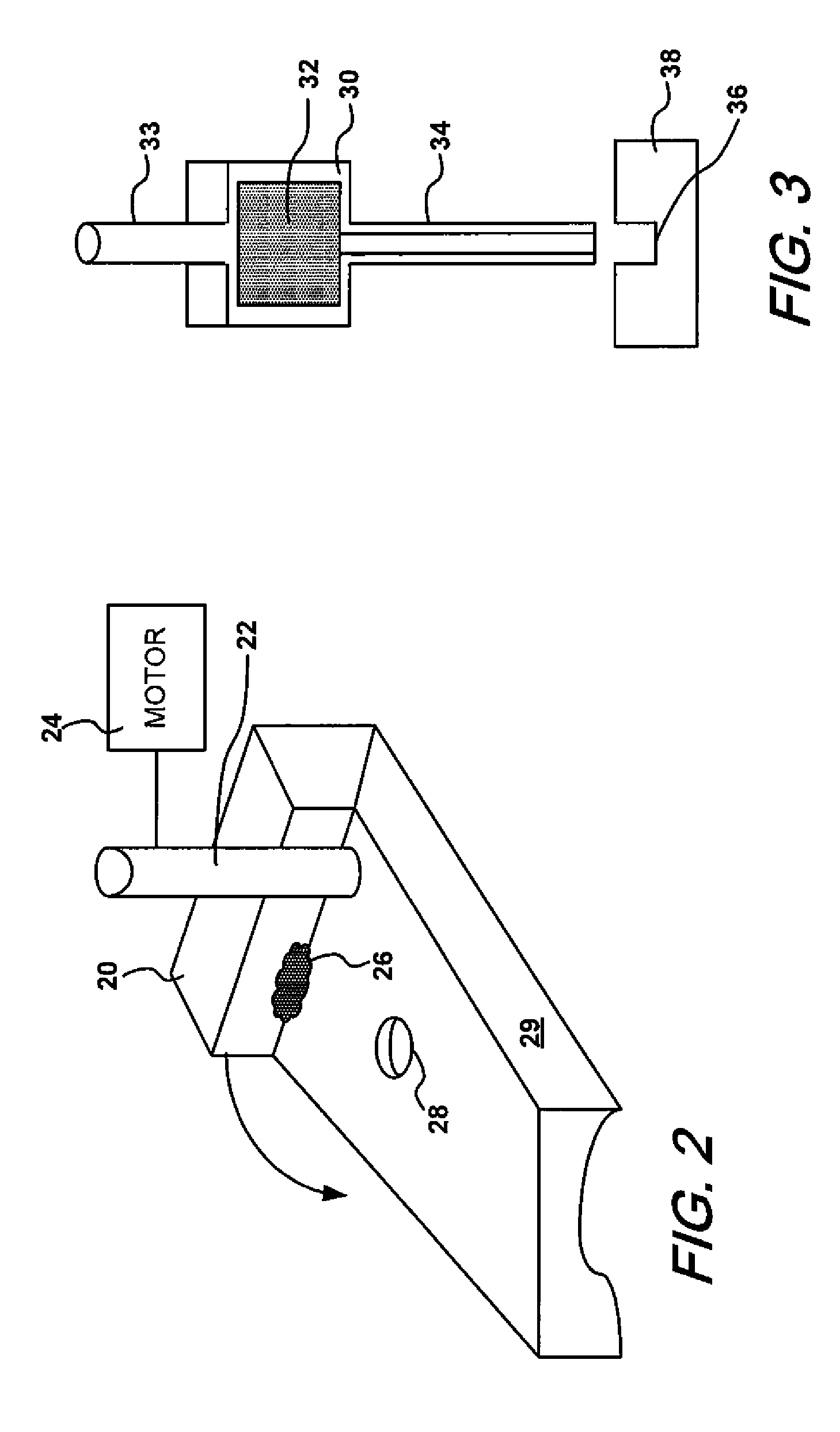

Methods for making and using high explosive fills for very small volume applications

InactiveUS7052562B1Change viscosityIncrease physical strengthAmmunitionBlastingEvaporationEngineering

High explosives suitable for filling very small volume loading holes in micro-electric initiators for micro-electro-mechanical mechanisms, used as safe and arm devices, are prepared from slurries of crystalline energetic materials and applied using various methods. These methods include swipe loading, pressure loading and syringe loading. A volatile mobile phase may be added to the slurry so as to partially dissolve the energetic material so that, upon evaporation of the mobile phase, the energetic material precipitates and adheres to the loading hole.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

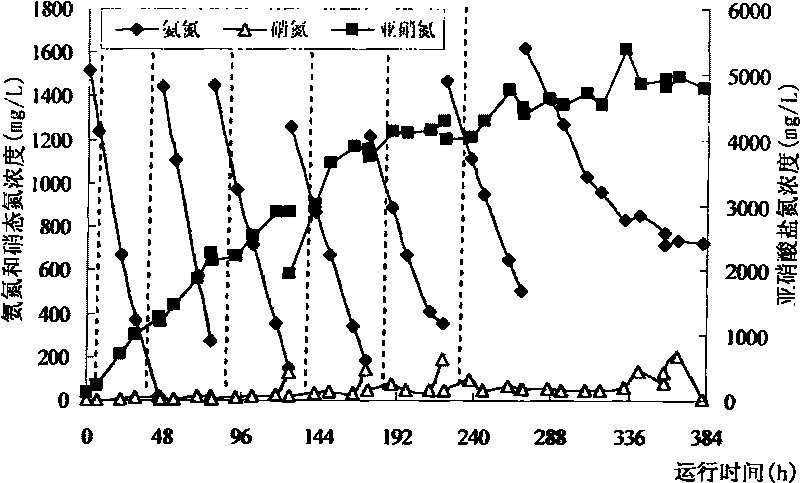

Culture method of aerobic denitrification particle sludge

InactiveCN101928067AHigh volume loadImprove removal efficiencyTreatment with aerobic and anaerobic processesActivated sludgeNitrite

The invention relates to the technical field of a culture method of particle sludge in a biological treatment technology of waste water, in particular to a culture method of aerobic denitrification particle sludge. The method comprises the following steps: putting inoculated activated sludge into an upflow-type aerobic sludge bed reactor; pumping in waste water containing nitrite and nitrate and organic matters from the bottom of the reactor; ensuring that the waste water flows out of the upper part of the reactor after passing through the reactor; and meanwhile, adopting air aeration, obtaining favourable aerobic denitrification particle sludge after the materials are cultured for 35-120 days. The aerobic denitrification particle sludge obtained by the method has good performance, and the volume loading, the removal efficiency and the operation stability of the reactor can be improved.

Owner:DONGGUAN UNIV OF TECH

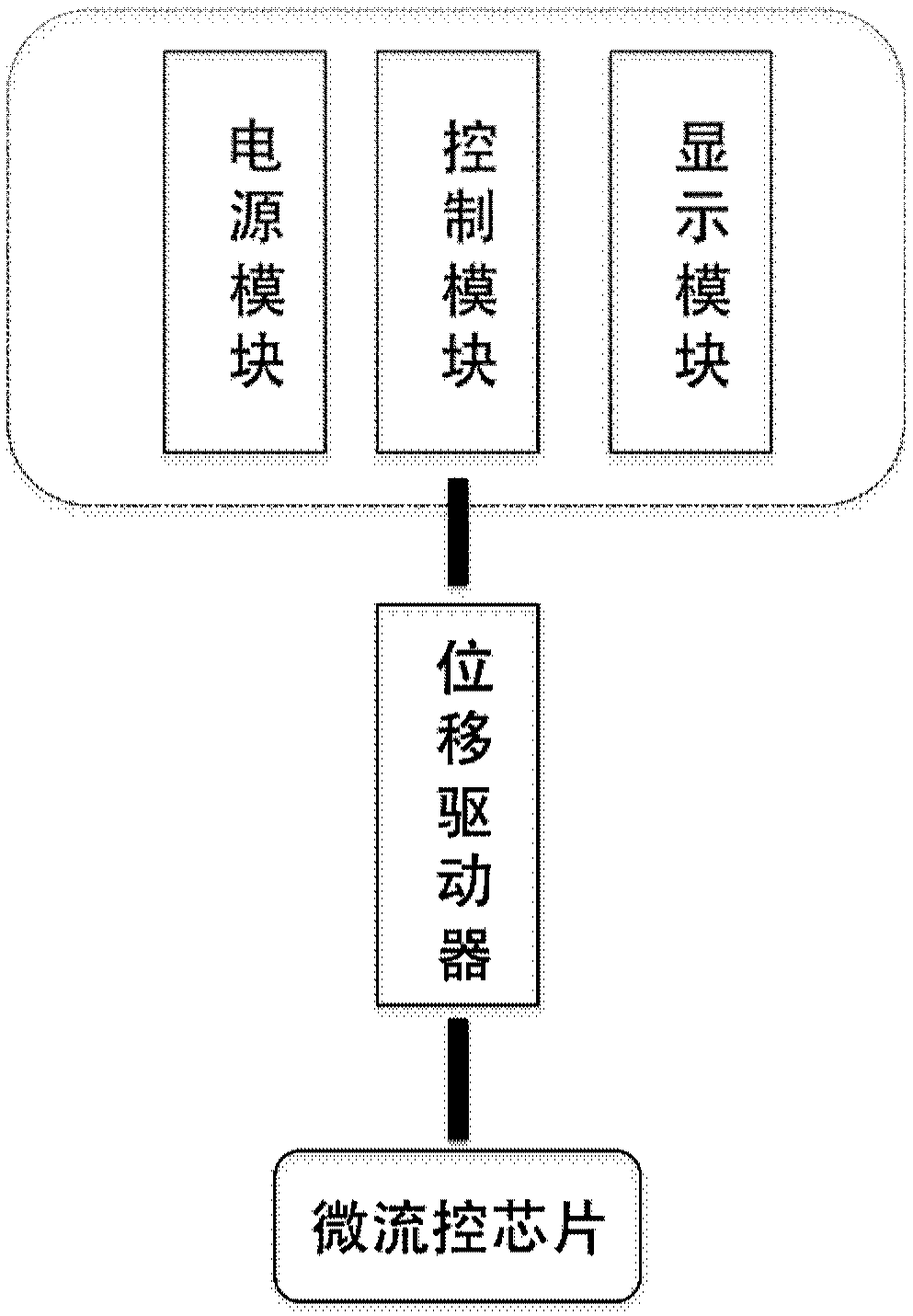

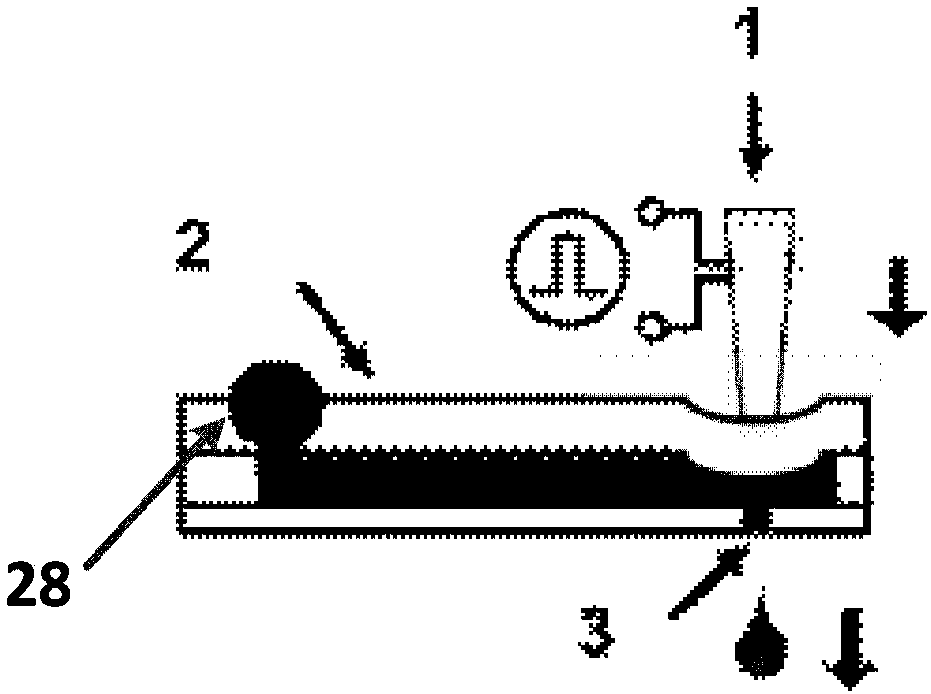

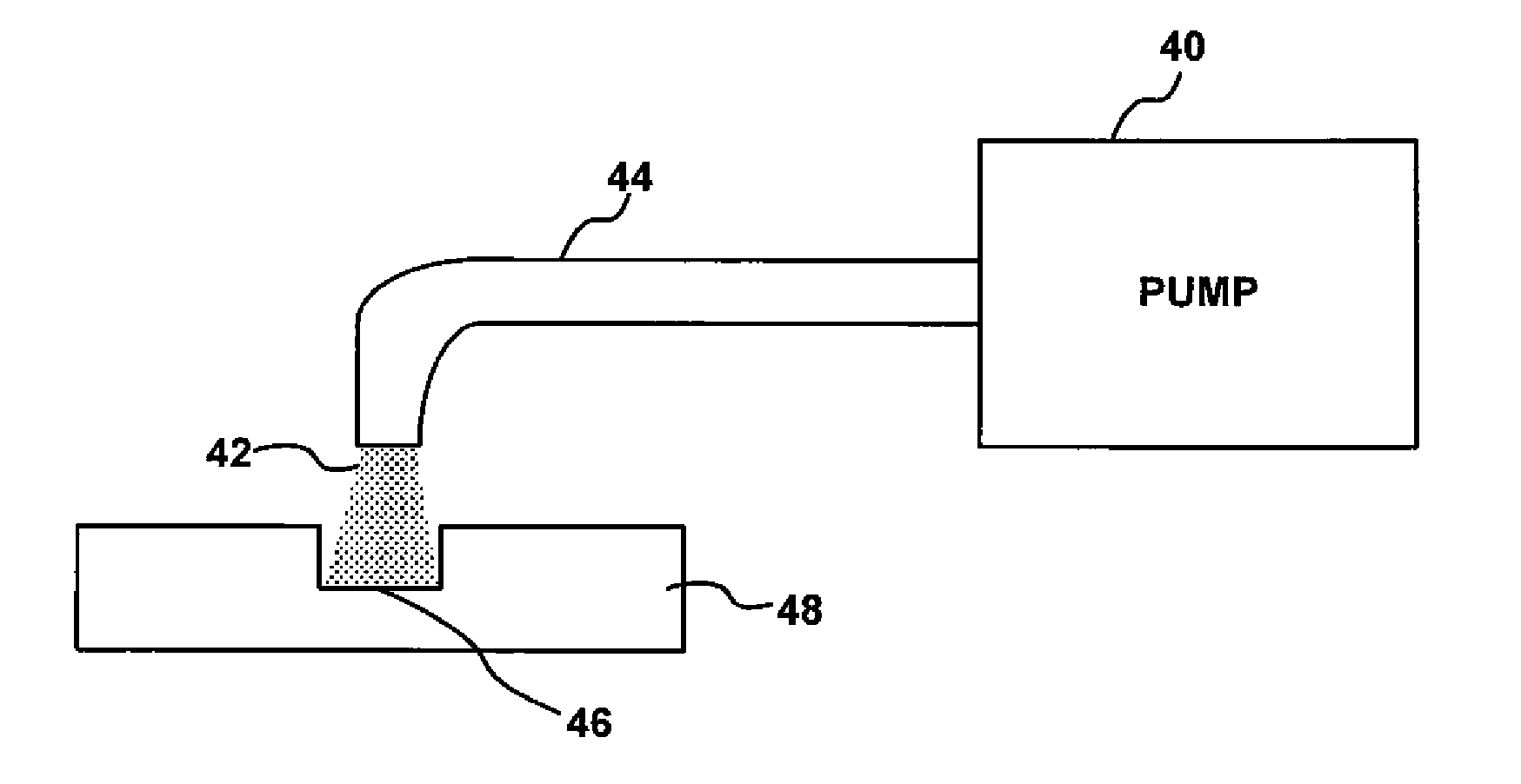

Electric microfluidic droplet dispenser

ActiveCN107824229AEasy to useAvoid cleaningBurettes/pipettesFluid controllersMicrofluidic chipVolume loading

The present invention provides an electric microfluidic droplet dispenser. The dispenser prints liquid in a microfluidic chip into droplets with uniform volume based on a principle of microfluidic impact printing, and controls the loading volume by utilizing the number of times of printing, in other words, the number of droplets. A liquid is pre-injected into a replaceable microfluidic chip, and an electronic control system is used to set and control the number of printing droplets. With adoption of the electric microfluidic droplet dispenser of the invention, the volume of an individual droplet is smaller, typically is 0.1 nanoliter to 10 nanoliters, and a single droplet volume CV value is less than 3.4%. When sub-microliter volume loading is performed by multiple printing, the average effect further reduces the random error. The microfluidic chip is made of polymer materials, and thus is low in cost and replaceable. The microfluidic chip is isolated from an actuator, therefore cleaning is not needed and no cross-contamination exists. The remaining volume of a liquid is less than 1 microliter, therefore waste is less. A single-chip microcomputer is used to control the number of printing droplets, therefore automatic printing and liquid distribution are achieved; and the electric microfluidic droplet dispenser can extract a liquid as well as dispense a liquid, and thus is diversified in functions.

Owner:UNIV OF SCI & TECH OF CHINA

Methods for making and using high explosive fills for MEMS devices

Secondary crystalline high explosives are disclosed which are suitable for filling very small volume loading holes in micro-electric initiators for micro-electro-mechanical mechanisms (MEMS), used as safe and arm (S&A) devices. The explosives are prepared by adding the such a high explosive to an aqueous first volatile mobile phase, adding such a high explosive to a non-aqueous second volatile mobile phase, mixing the first and second volatile mobile phases and then loading the combined phases into the MEMS device and allowing the aqueous and non-aqueous solvents to evaporate depositing the high explosive. Enhanced adhesion between the deposited high explosive and enhanced rheological properties can be obtained by adding a polymeric binder to both mobile phases.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Pt-Fe/C catalyst as well as preparation method and application thereof

PendingCN109225258ASimple preparation stepsEvenly dispersedOrganic compound preparationAmino compound preparationReaction temperatureSolvent

The invention discloses a Pt-Fe / C catalyst as well as a preparation method and application thereof. The catalyst is composed of an active component and a carrier, wherein the active component is platinum, iron and oxide of iron; the carrier is active carbon; Pt accounts for 0.5-3% of the total mass of the catalyst, and a Fe / Pt mass ratio is (0.5 to 4) : 1. The preparation method of the catalyst comprises the following preparation steps: preparing a platinum-iron active component impregnation solution, performing equal-volume loading, performing in-situ reduction, washing and drying. The catalyst is used for preparing chloroaniline by chloronitrobenzene hydrogenation though a no-solvent method; dechloridation can be effectively restrained in case of not adding a dehalogenation inhibitor, and the advantages of good reaction activity and high selectivity are achieved. Under the conditions of no solvent and auxiliaries, the dosage of the catalyst is 0.8% of the mass of chloronitrobenzene,the reaction temperature is 90 DEG C, hydrogenation pressure is 1.0 MPa, reaction can be completed with two hours, and dechlorination amount is less than 0.1%.

Owner:CHENZHOU GAOXIN PLATINUM +1

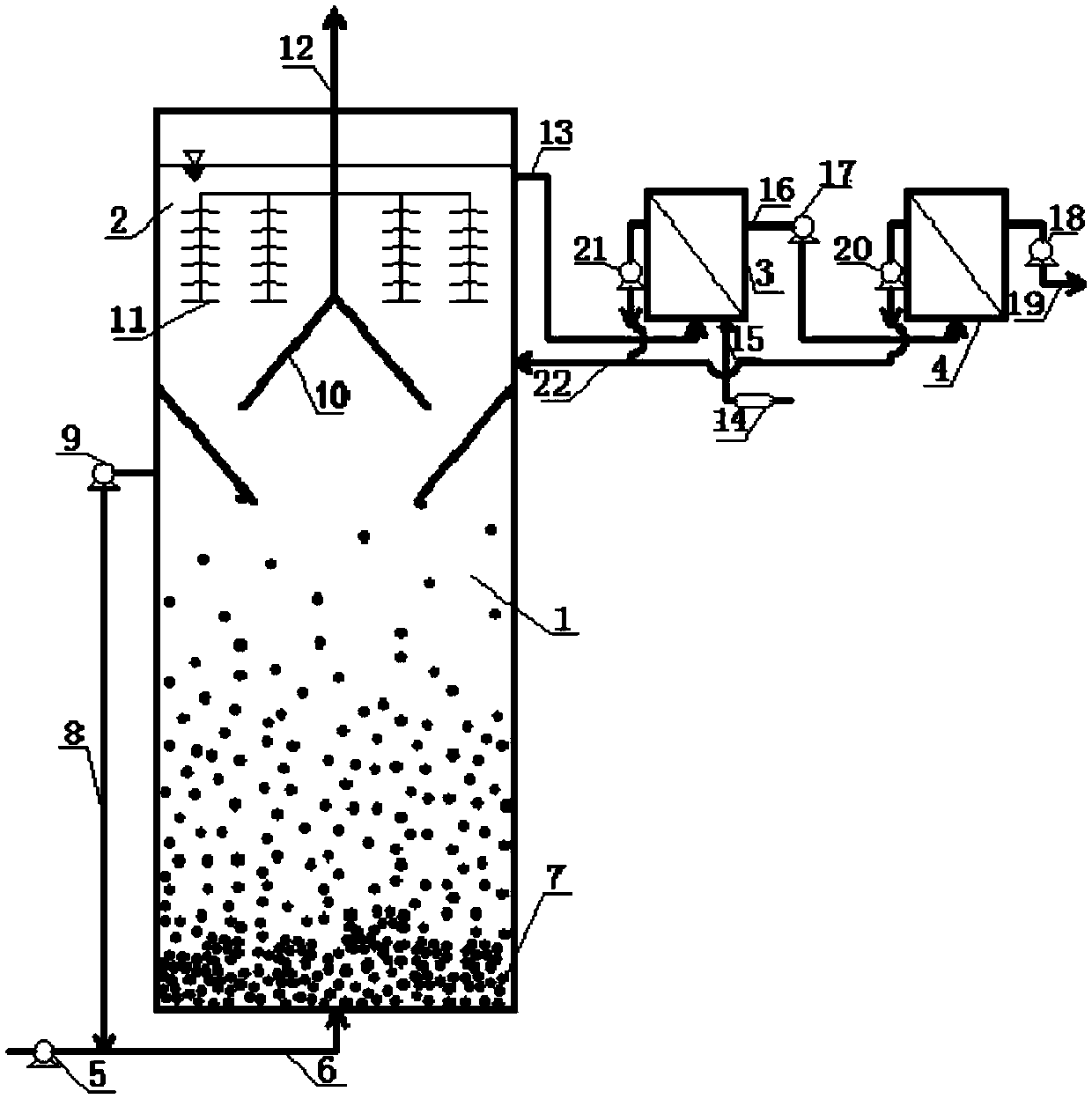

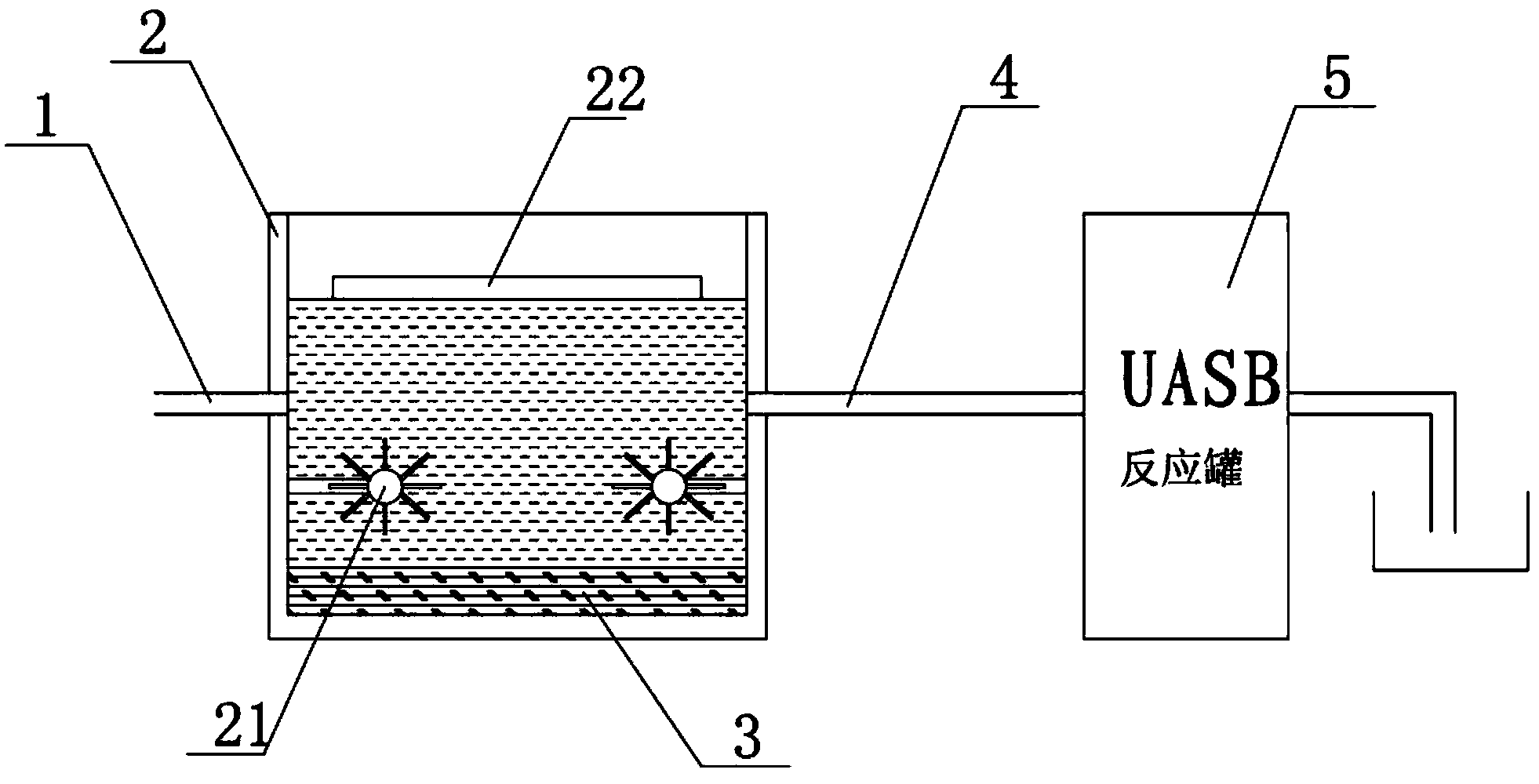

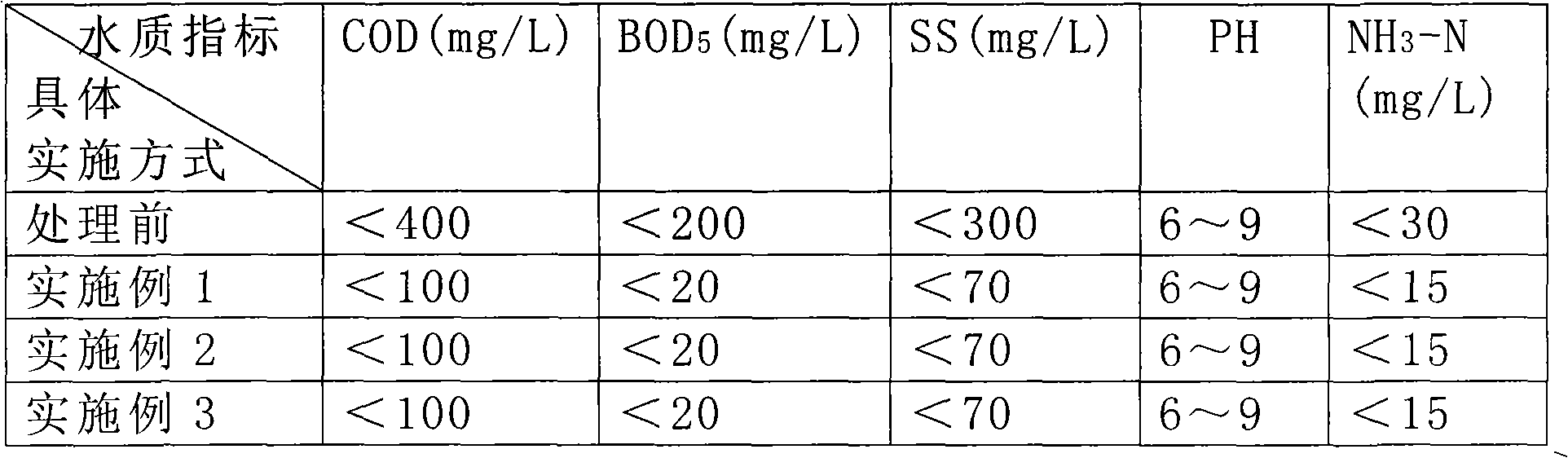

Pre-acidification anaerobic UASB treatment device and method for sewage

InactiveCN103351058AImprove biodegradabilityHigh removal rateWaste based fuelTreatment with anaerobic digestion processesWater pipeVolume loading

The invention relates to a pre-acidification anaerobic UASB (up-flow anaerobic sludge blanket) treatment device and method for sewage. The device comprises a regulation pool and a UASB reaction tank. A water inlet pipe is connected to the left side of the regulation pool, the bottom of which is provided with a layer of concentrated sludge. Sewage is injected into the regulation pool over the concentrated sludge through the water inlet pipe. Stirrers are symmetrically installed on two side walls in the regulation pool. The right side of the regulation pool is communicated with the UASB reaction tank through an overflow pipe. After pre-acidification treatment of the sewage in the regulation pool by acidification bacteria in the sludge, the sewage then enters the UASB reaction tank. The structure of the device is simple, and the operation process is simple. Transformation is carried out on the existing regulation pool, in which acidification bacteria are domesticated to improve the biodegradability of wastewater. The discharged water is led into the UASB reaction tank to improve the volume loading of UASB, and the anaerobic COD (chemical oxygen demand) removal rate can be effectively improved by 5%-10%.

Owner:ZHEJIANG YISHENG PETROCHEM

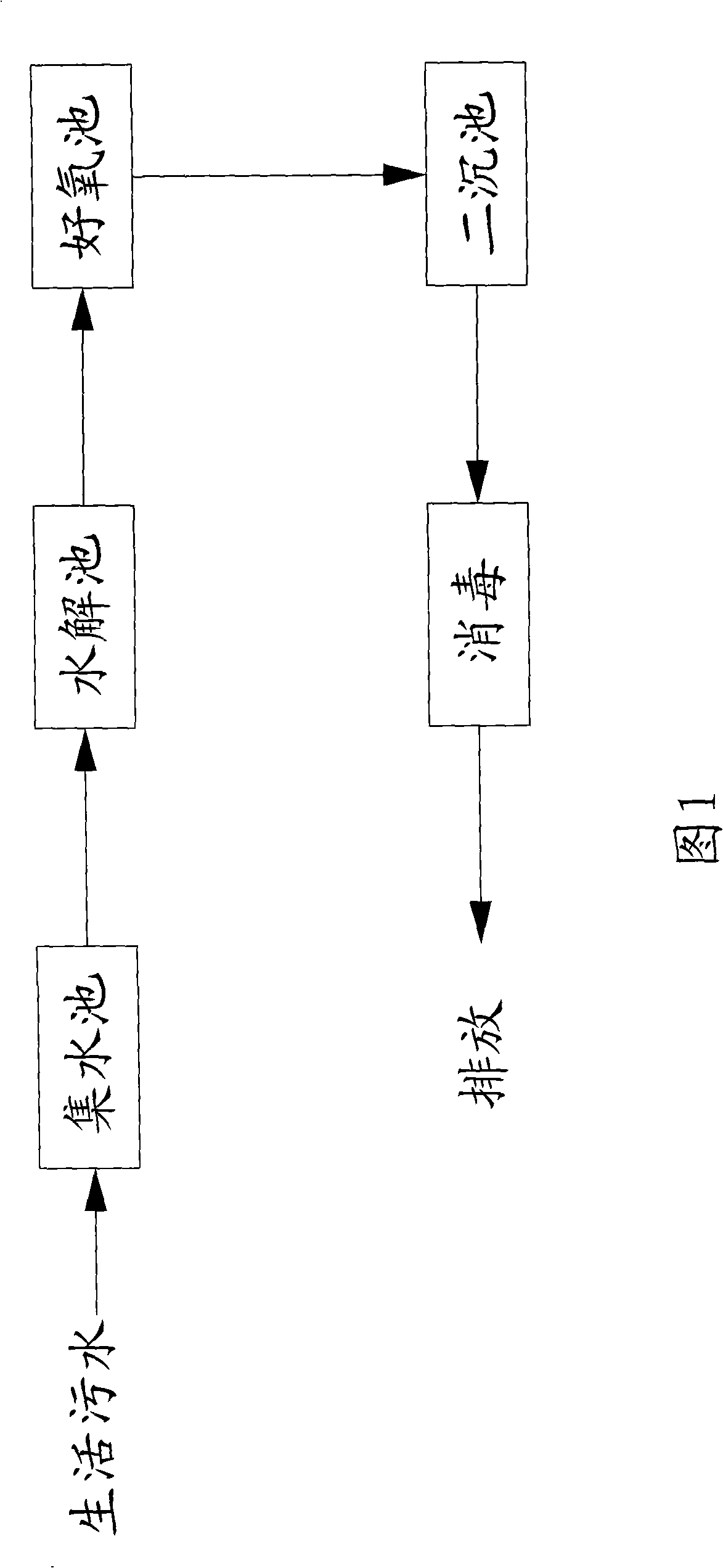

Method for processing sewerage by A/O biological contact oxidation process

InactiveCN101327990AEasy to handleDecompose in timeTreatment with aerobic and anaerobic processesSludgeWater quality

The invention provides a sewage treatment method using A / O biological contact oxidation process belonging to environmental engineering technology field, which solves the problems that in the prior art the adaptability of water quality is not strong, the impact resistance perfermance is weak, the effluent water quality is unstable and sludge bulks or the like. The sewage treatment method using A / O biological contact oxidation process comprises the following steps: A. pretreatment; B. hydrolytic treatment; C. aeration treatment; D. deposition and disinfection, and has advantages of high volume loading, rapid rate of biodegradation and low cost.

Owner:台州盛世环境工程有限公司

Autotrophic nitrogen removal membrane bioreactor

InactiveCN108373203AHigh volume loadImprove processing efficiencyWater contaminantsTreatment involving filtrationAutomatic controlOxygen

The invention provides an autotrophic nitrogen removal membrane bioreactor. The main body of the membrane bioreactor is of a cylinder structure, is divided into a partial nitrosification region, a transition region, an anaerobic ammonium oxidation region, a filter material filtering region, a membrane treatment region according to functions, and comprises an inner cylinder, an outer cylinder, a water inlet pipe, a water distribution disc, an aeration disc, a disc sieve plate, an annulus sieve plate, a filler bearing pore plate, a filter material bearing annulus plate, a membrane component, anaeration residual gas outward discharge pipe, a gas outward discharge pipe, a self-backflow pipe, an aerobic dredge pipe, a transition region dredge pipe and an anaerobic dredge pipe. The membrane bioreactor has good denitrification efficacy, effluent can be directly recycled, and the reactor is efficient and steady in performance and has the following advantages: (1) volume loading is high, treatment efficiency is high, and effluent can be directly recycled after disinfection; (2) adverse effect to anaerobic ammonium oxidation microorganisms in the aeration process is avoided; (3) autonomousblending of a biological functional zone is realized; (4) investment and operation cost is saved; (5) operation and management are convenient, and automatic control is easy to realize.

Owner:山东格瑞博环保科技有限公司

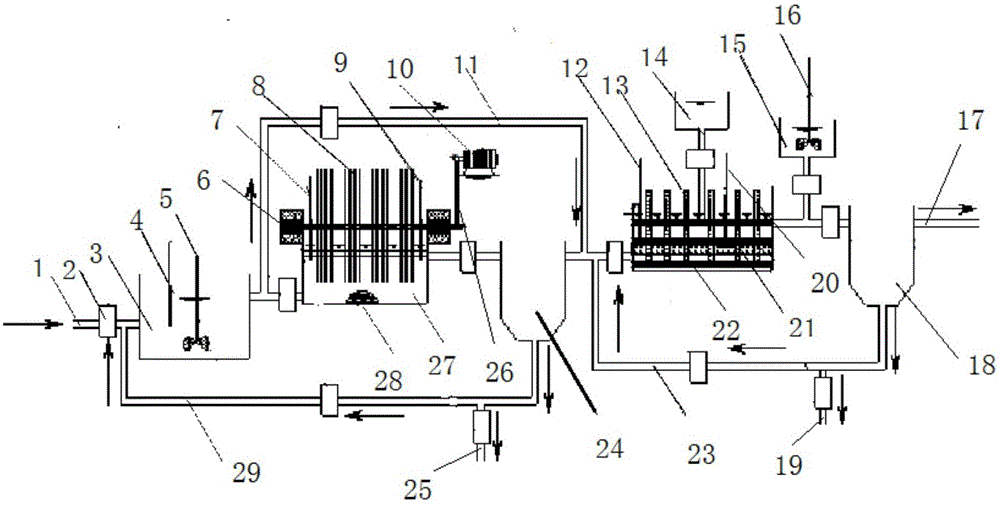

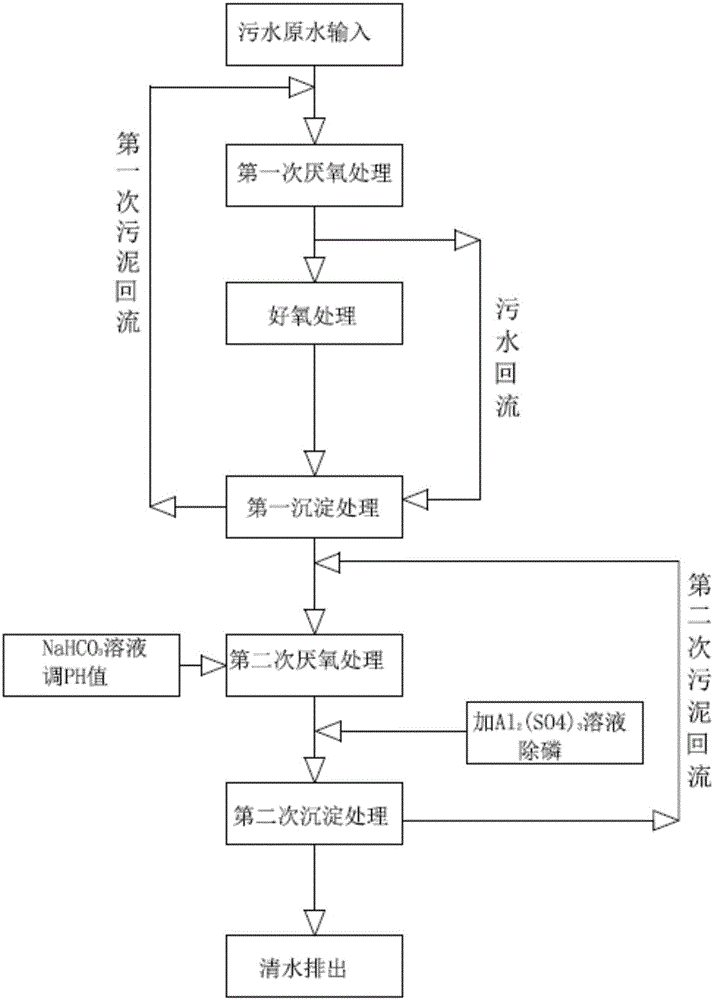

Town sewage treatment system and method

InactiveCN105060632ALow mud productionRemoves high volume loadsMultistage water/sewage treatmentAeration rateSludge

The invention relates to the technical field of town sewage and concretely relates to a town sewage treatment system and method. The town sewage treatment system comprises a first anaerobic pond, an aerobic tank, a first sedimentation basin, a second anaerobic pond and a second sedimentation basin, and the above units are orderly connected. A biological rotating disc and an aerator are arranged in the aerobic tank. A 3D elastomeric material, a temperature controller and a heating belt are arranged in the second anaerobic pond. A NaHCO3 solution storage tank is arranged in the second anaerobic pond. An Al2(SO4)3 solution storage tank is arranged between the second anaerobic pond and the second sedimentation basin. The town sewage treatment system is provided with a first sludge return branch, a second sludge return branch and a sewage shunting branch. The first sludge return branch and the second sludge return branch are respectively provided with sludge outlets. The town sewage treatment system can reduce an aeration rate and energy consumption, does not discharge carbon dioxide greenhouse gas, can reduce a mud yield of anaerobic ammonium oxidation bacteria, realizes high TN removal volume loading and reduces a land occupation area.

Owner:北京泰昌科睿环保科技有限公司

Two-point-type liquid level sensor for measuring rocket storage tank volume loading liquid level

InactiveCN106768183AImprove machinabilityWork reliablyMachines/enginesLevel indicatorsRocketVolume load

The invention provides a two-point-type liquid level sensor for measuring the rocket storage tank volume loading liquid level. A liquid level probe assembly senses changes of the loading liquid level by means of characteristics of photoelectric signals in a water medium, and the liquid level probe assembly is connected to and installed on a sensor body through a fastener; a protective cover is connected to the sensor body through a screw for protecting the liquid level probe assembly; a cable assembly and a waterproof sealing socket are connected to achieve the signal output function of the sensor. The working medium is water, the sensor is mainly used for measuring the important liquid level point of loaded volume, obtained after production, of a rocket storage tank, liquid level signals are provided for a volume measuring system, and the characteristics of the photoelectric signals in the water medium can be used, so that the signals of the loading liquid level point are obtained, and the sensor for measuring the rocket storage tank volume loading liquid point has the advantages of being good in machinability, reliable in working, high in measuring precision, convenient to use and the like.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

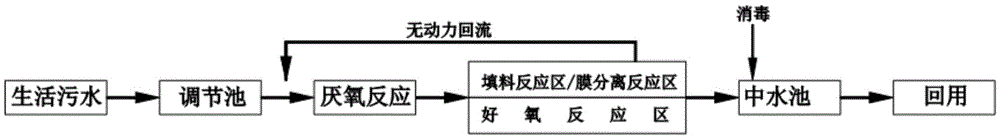

Unpowered backflow integrated reclaimed water reuse device

ActiveCN105541029AHigh volume loadSmall footprintTreatment with anaerobic digestion processesMultistage water/sewage treatmentAeration systemSeparation technology

The invention discloses an unpowered backflow integrated reclaimed water reuse device which is composed of an adjusting tank, an anaerobic reaction area, an aerobic reaction area and an equipment installing area. A grid basket, a stirring device, an adjusting tank aeration main pipe, a liquid level meter and a lift pump are arranged in the adjusting tank. Filler, a hydraulic power baffle plate and a backflow pipeline are arranged in the anaerobic reaction area. The aerobic reaction area is divided into a filler reaction area and a membrane separation reaction area. MBBR filler is arranged in the filler reaction area. An MBR membrane reactor is arranged in the membrane reaction area. An air lift sludge device and a double-aeration system are arranged in the aerobic reaction area. The equipment installing area is provided with an MBR suction pump, an aeration fan and a cleaning and disinfecting device. The filler with the large specific surface area and the membrane separation technology are combined, the device has a high volume loading rate, is low in energy consumption, easy to operate, high in self-control performance, capable of efficiently removing BOD5, COD, NH3-N and SS and suitable for occasions such as hospitals, wine shops and urban resident areas short of land, and the occupied area of equipment is small.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

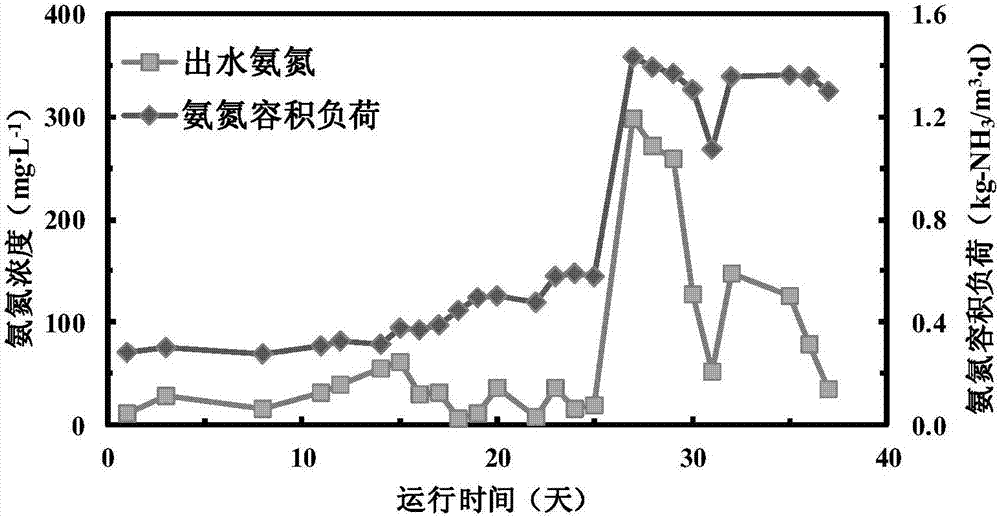

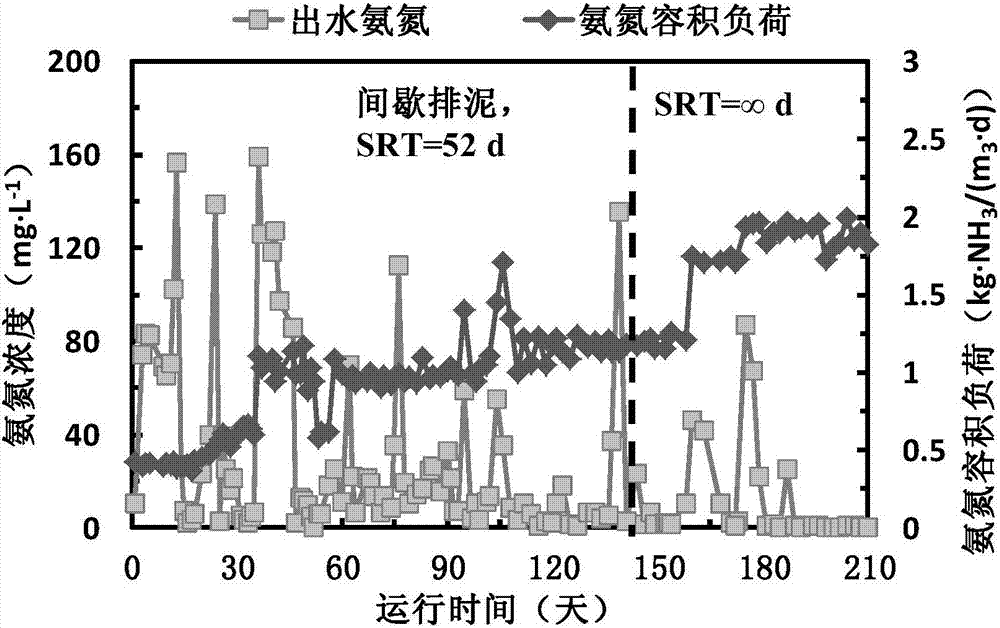

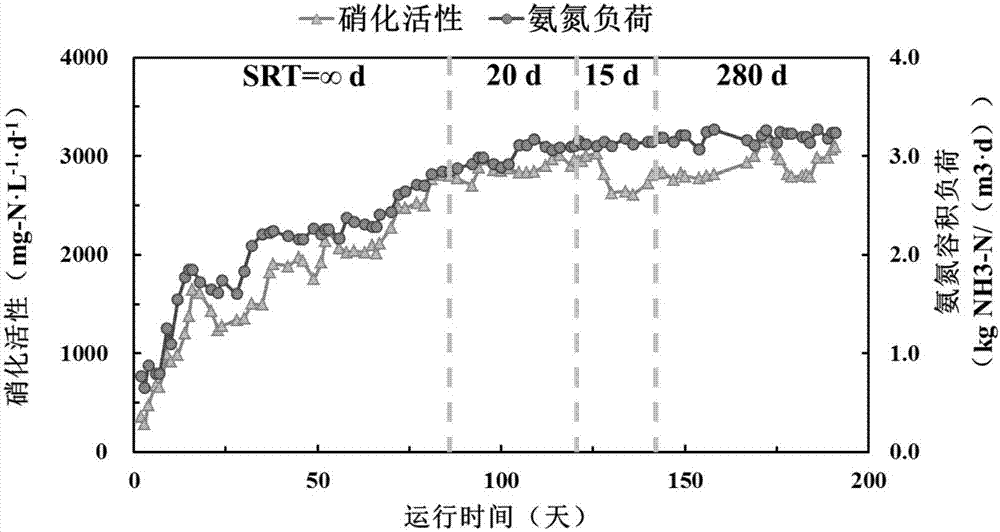

Preparation method for high-adaptability nitrifying bacterial agent

ActiveCN106947711AEasy to makeIncrease the number ofWater treatment parameter controlBacteriaAlkalinityNitrifying bacteria

The invention discloses a preparation method for a high-adaptability nitrifying bacterial agent. The preparation method comprises the steps of: 1) inoculating active sludge on a membrane biological reactor, and continuously feeding a culture solution, composed of sewage, inorganic ammonia nitrogen, a phosphate buffer solution and an alkalinity regulator, into the membrane biological reactor; (2) firstly, setting SRT as non-sludge discharge status, and controlling the ammonia nitrogen volume loading of the membrane biological reactor to be lower than 1.5 kg-N / (m<3>*d), and then stepwise increasing the ammonia nitrogen loading until a maximum value; and 3) finally determining minimum value of the SRT and under the minimum value of the SRT, continuously discharging the nitrifying bacterial agent. The preparation method can produce nitrifying bacteria, which are homologous with the bacteria from a sewage treatment plant, within a short time. The nitrifying bacteria have high degradation activity on ammonia nitrogen, have good adaptability and are low in addition frequency.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

Recycling system for steam explosion of blue-green algae

PendingCN110330362AAvoid layeringAvoid phenomena such as scumBio-organic fraction processingOrganic fertiliser apparatusHydrolysisFermentation

The invention relates to a recycling system for steam explosion to break wall and detoxification of blue-green algae and belongs to the field of solid waste recycling. The recycling system mainly comprises four process stages: steam explosion liquefaction, liquid fermentation, biogas pressure storage and liquid fertilizer package. By using the instant catapult steam explosion (ICSE) process, the macromolecular structure of blue-green algae cells are instantly degraded only with saturated steam, the biological activity of the blue-green algae is killed and a production approach of algal toxin is blocked off; the produced algal toxin is sheared and degraded by molecules, and the morphology of the blue-green algae is changed from solid state into liquid state; then the blue-green algae subjected to steam explosion undergo acid-catalysed hydrolysis and liquid anaerobic fermentation in a liquid fermentation reactor; the volume loading is as high as 5 to 10 kgCOD / day.m<3>. Through a series of biodegradation processes, the blue-green algae are finally transformed into biogas and liquid organic fertilizer. In the integral treatment flow of the blue-green algae, no synthetic substances areadded or no polluted emission is produced.

Owner:清正生态科技(苏州)有限公司

High explosive fills for very small volume applications

InactiveUS7976654B1Change viscosityIncrease physical strengthLoomsAmmunitionOrganic fluidEvaporation

High explosives suitable for filling very small volume loading holes in micro-electric initiators for micro-electro-mechanical mechanisms, used as safe and arm devices, are prepared from slurries of crystalline energetic materials including organic liquid and applied using various methods. These methods include swipe loading, pressure loading and syringe loading. The organic liquid serves as a volatile mobile phase in the slurry so as to partially dissolve the energetic material so that, upon evaporation of the mobile phase, the energetic material precipitates and adheres to the loading hole.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com