Method for processing sewerage by A/O biological contact oxidation process

A technology of biological contact and oxidation, which is applied in the field of environmental engineering, can solve the problems of sludge swelling, poor water quality adaptability, unstable effluent water quality, etc., and achieves convenient membrane removal, good sewage treatment effect, and beneficial metabolism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

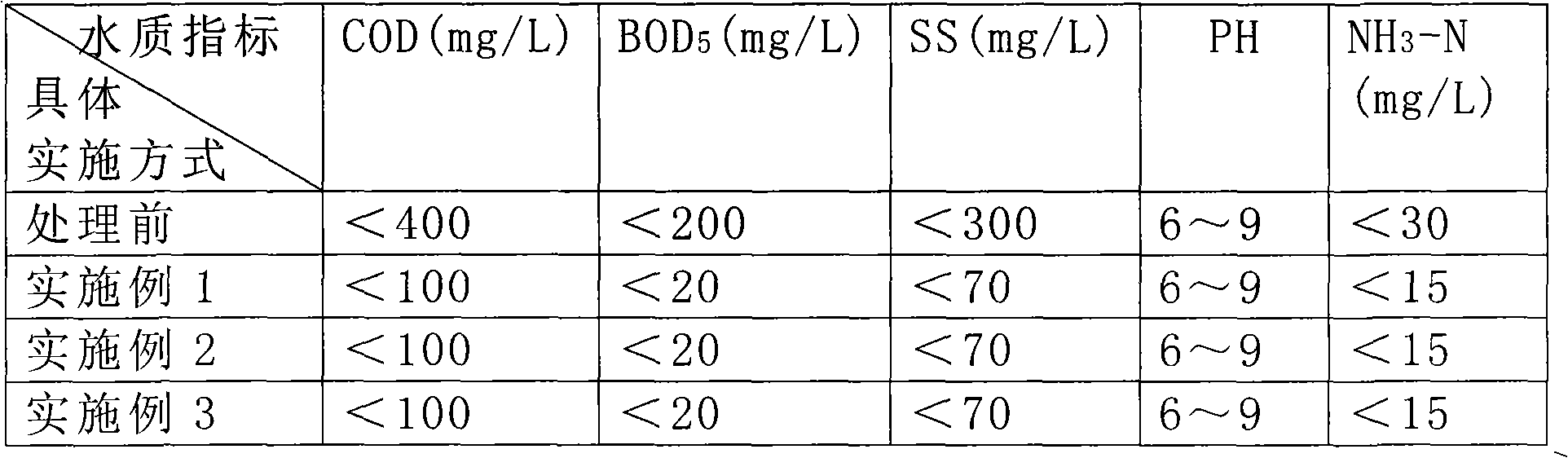

[0027] The water quality of the sewage to be treated is shown in Table 1. After the above-mentioned sewage flows into the domestic sewage sump with the specification of 2.0m×2.0m×1.0m after pretreatment for 8 hours, it is passed through the sewage lifting pump (model: SF-10- 1: Power: 0.55KW) into the hydrolysis tank;

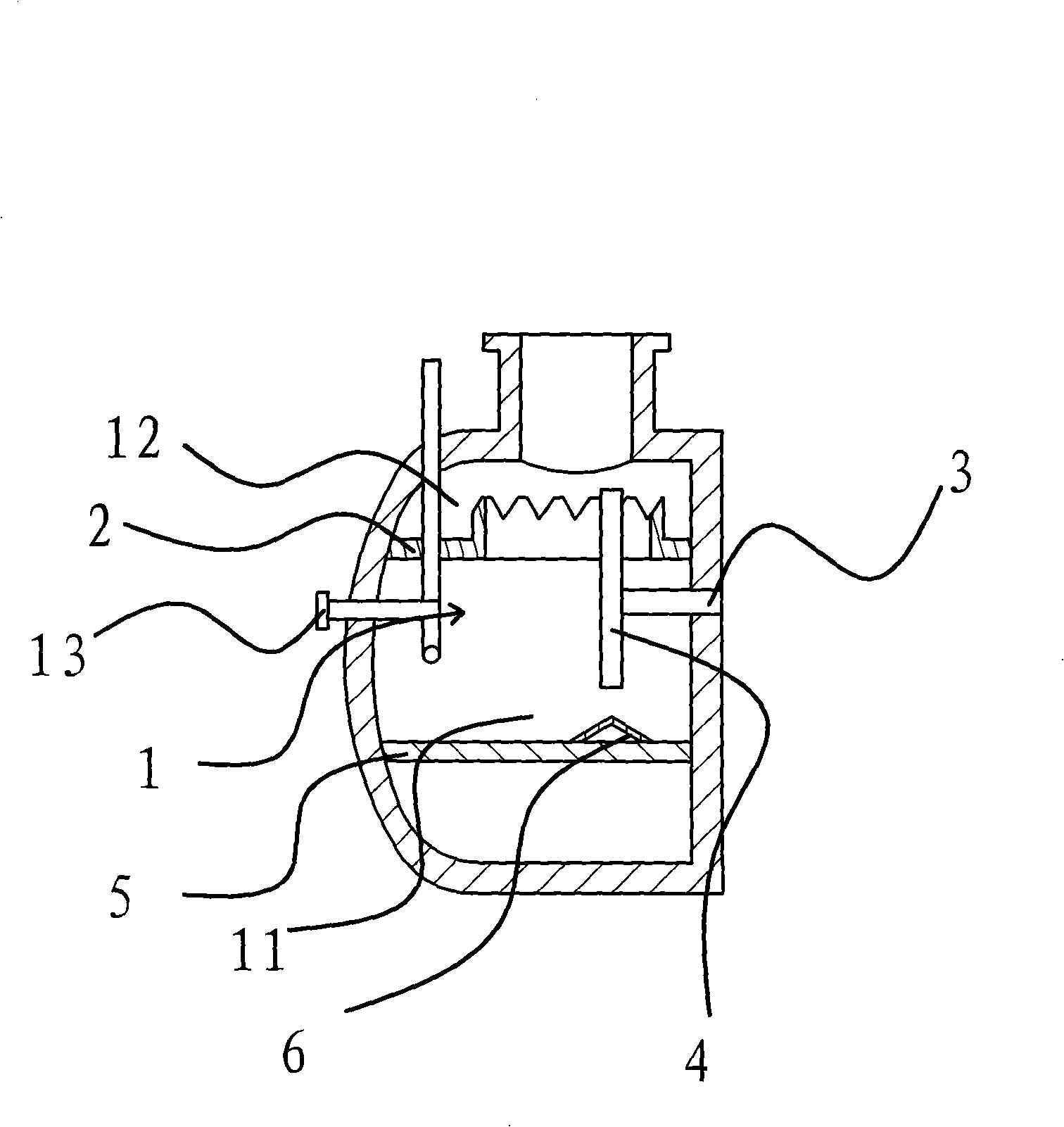

[0028]The hydrolysis tank is filled with polyethylene plastic semi-soft floating ball filler, and the anaerobic sludge is cultivated intermittently. The specific process is to pour the anaerobic sludge that has been statically cultivated for about 2 weeks into the hydrolysis tank. About 1 / 10 of the total volume of the hydrolysis tank, fill the hydrolysis tank with artificial water distribution, and then aerate once with a Roots fan (power 0.75kw, inlet flow rate 1.09m3 / min, speed 1140r / min, boost pressure 19.6KPa) Oxygen sludge is evenly distributed in the hydrolysis tank, and after standing for a period of time, a dense and dense biofilm is formed on the inner...

Embodiment 2

[0032] The pretreatment time of domestic sewage in the sump is 10 hours. The hydrolysis tank is filled with moso bamboo fiber semi-soft floating ball packing. Anaerobic bacteria or anoxic bacteria are cultivated with the activated sludge in the sewage itself. The biomass of anoxic bacteria is 80g / m 3 , anaerobic bacteria or anoxic bacteria hydrolyze the sewage in the hydrolysis tank for 4 hours, and the aerobic tank is filled with moso bamboo fiber semi-soft floating ball fillers that account for 3 / 4 of the volume of the entire aerobic tank. Bacteria are cultivated by the activated sludge in the sewage itself, and the biomass of aerobic bacteria is 70g / m 3 , the aerobic bacteria aerated the sewage in the aerobic tank for 10 hours, and the other technological processes were the same as those in Example 1, so no further details were given. The water quality indicators of the test are shown in Table 1, and the water that passes the test can be directly discharged into the enviro...

Embodiment 3

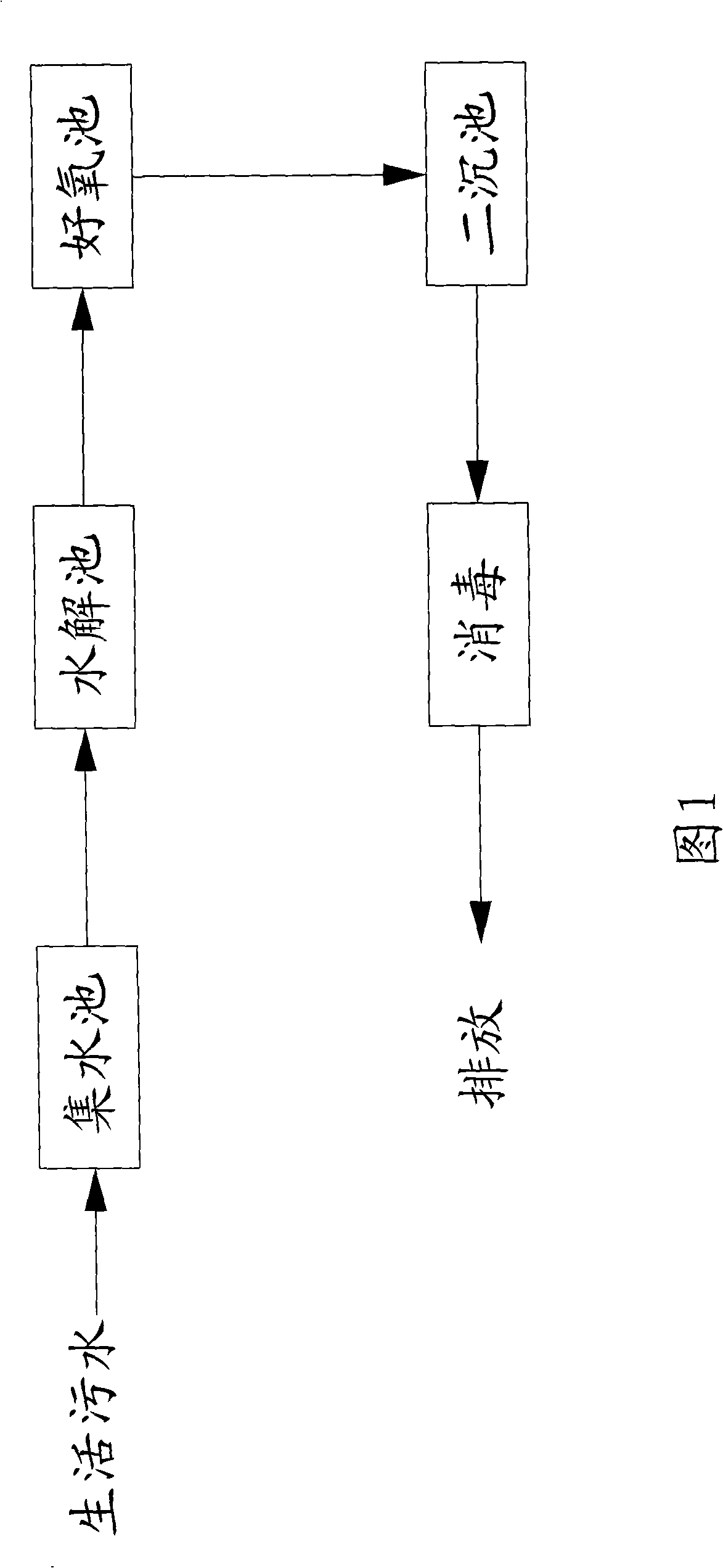

[0034] The pretreatment time of domestic sewage in the sump is 15 hours. The hydrolysis tank is filled with polypropylene plastic semi-soft floating ball packing. The biomass of bacteria is 100g / m 3 , anaerobic bacteria or anoxic bacteria hydrolyze the sewage in the hydrolysis tank for 3 hours, and the aerobic tank is filled with moso bamboo fiber semi-soft floating ball fillers that account for 2 / 3 of the volume of the entire aerobic tank. Bacteria are cultivated by the activated sludge in the sewage itself, and the biomass of aerobic bacteria is 50g / m 3 , the aerobic bacteria aerated the sewage in the aerobic tank for 12 hours, and the other technological processes were the same as those in Example 1, so no further details were given. The water quality indicators of the test are shown in Table 1, and the water that passes the test can be directly discharged into the environment. The entire process flow chart is shown in Figure 1.

[0035] Table 1: Comparison of waste water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com