Patents

Literature

75 results about "Physical Treatment Methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are a number of treatment methods that physical therapists use to help patients. Some of these methods include: Teaching and practice of functional developmental, motor, and mobility skills. Therapeutic exercise for strengthening, endurance, and joint mobility. Balance and coordination activities.

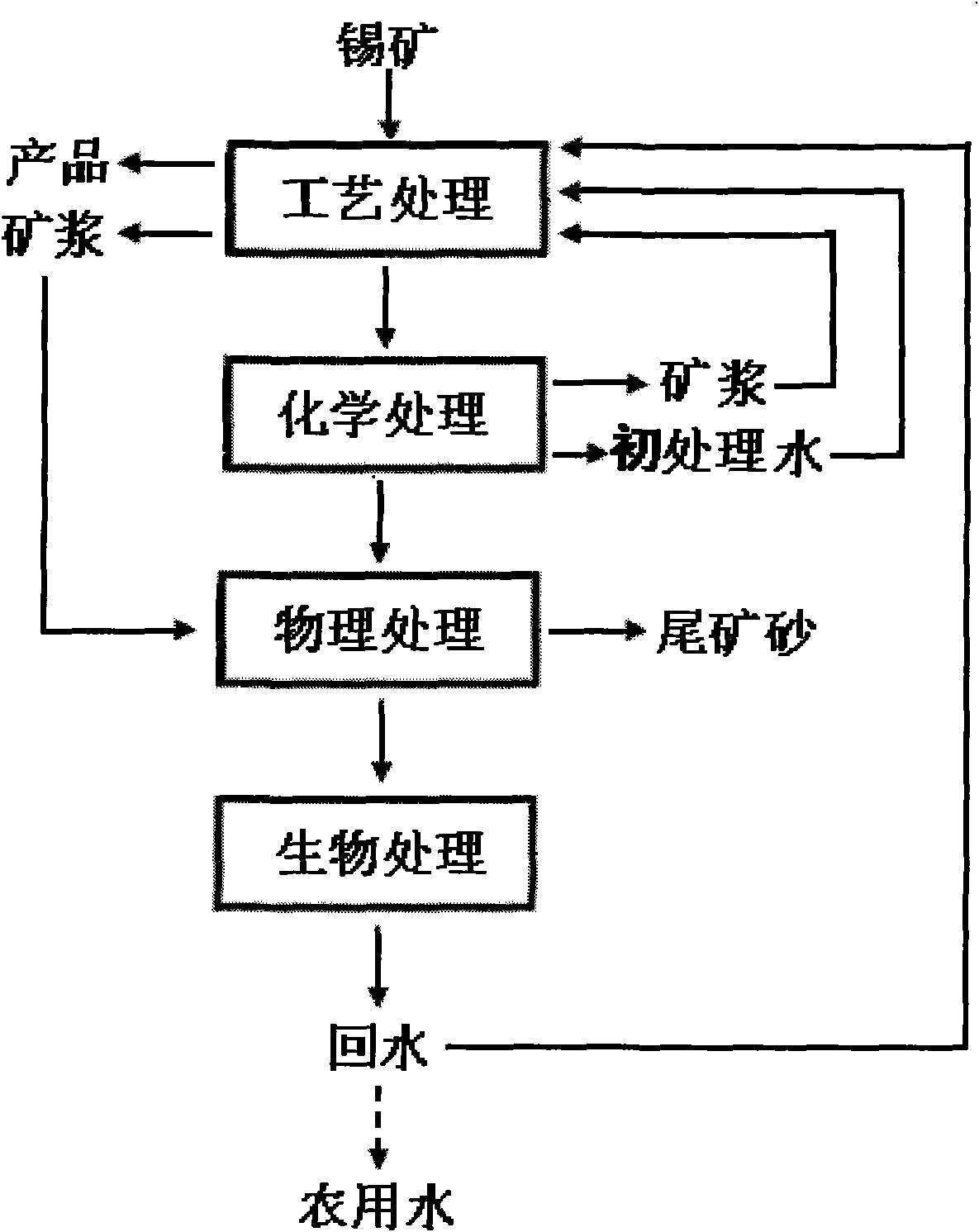

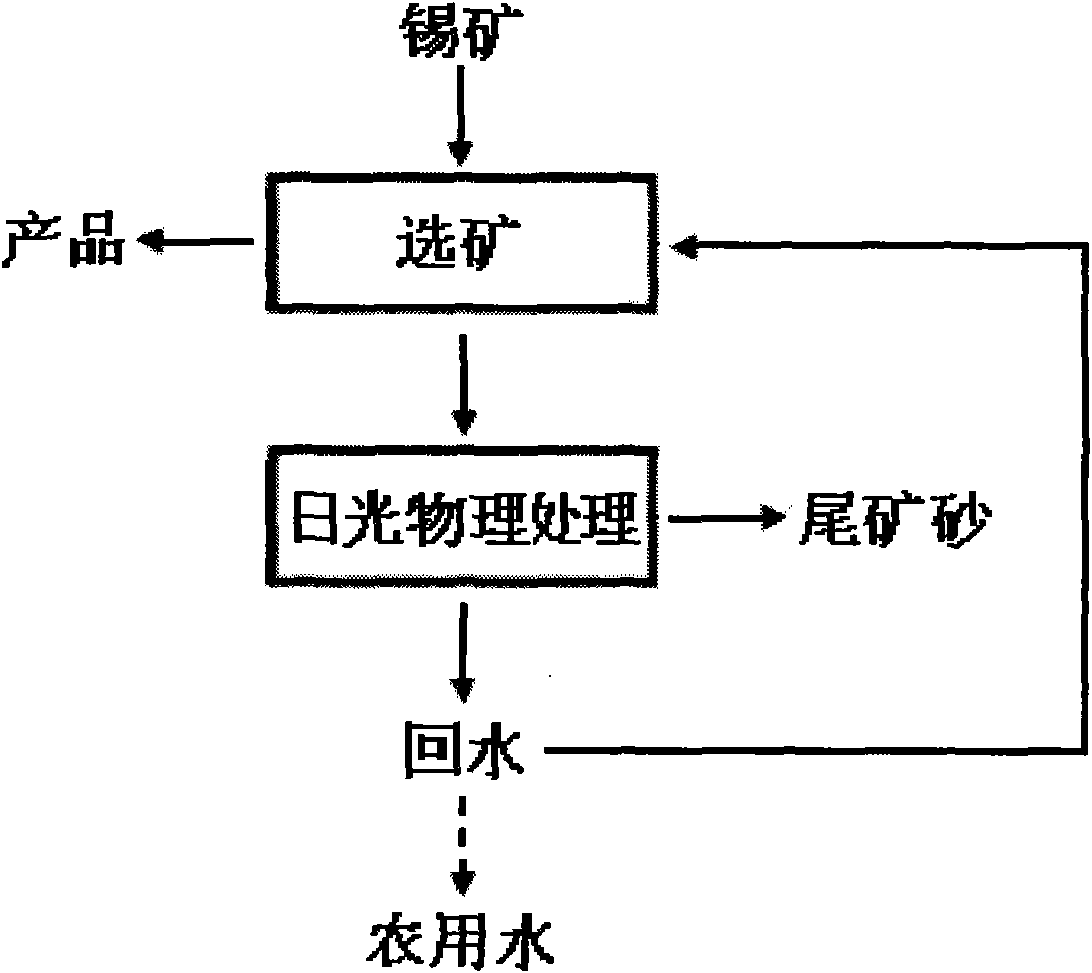

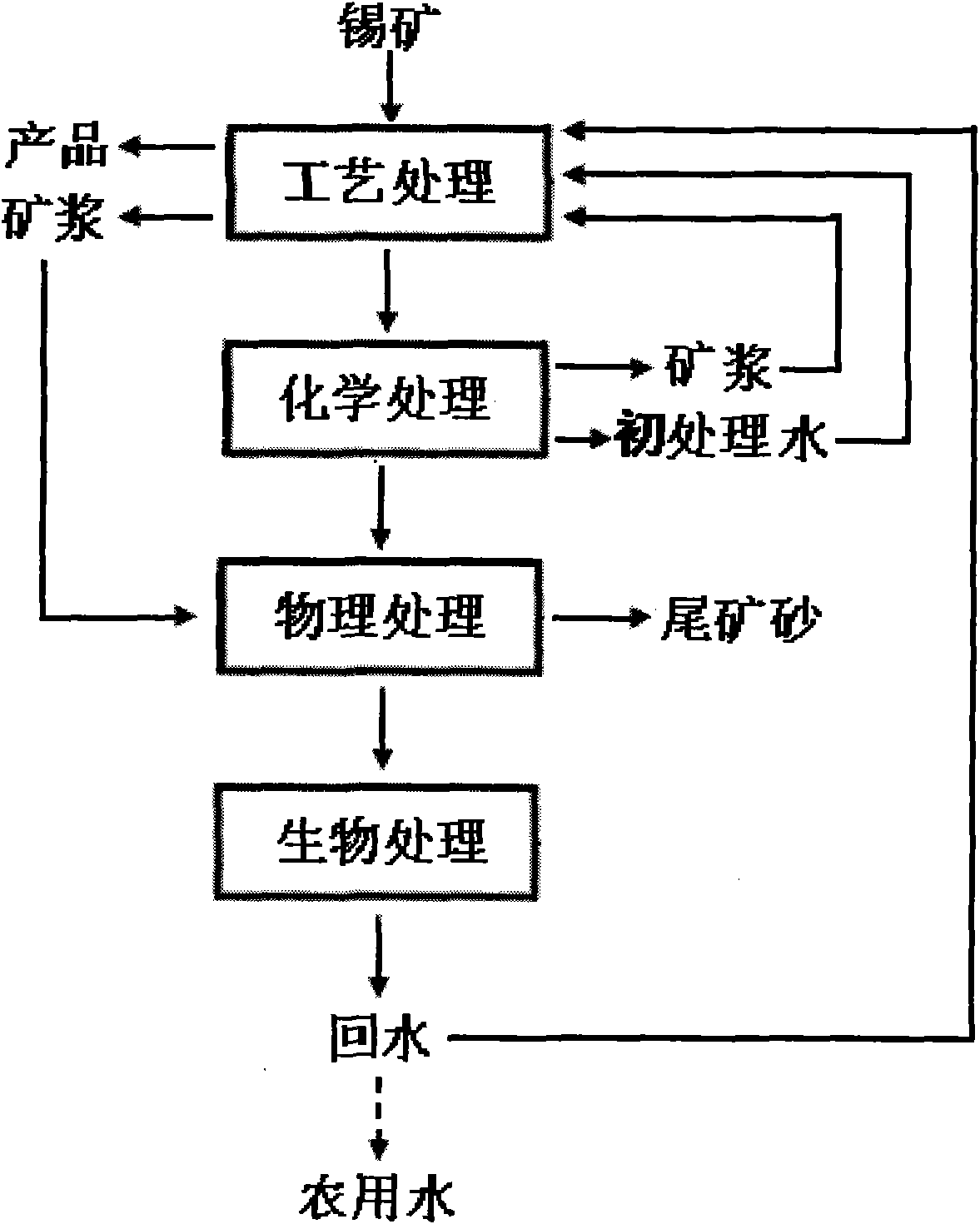

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

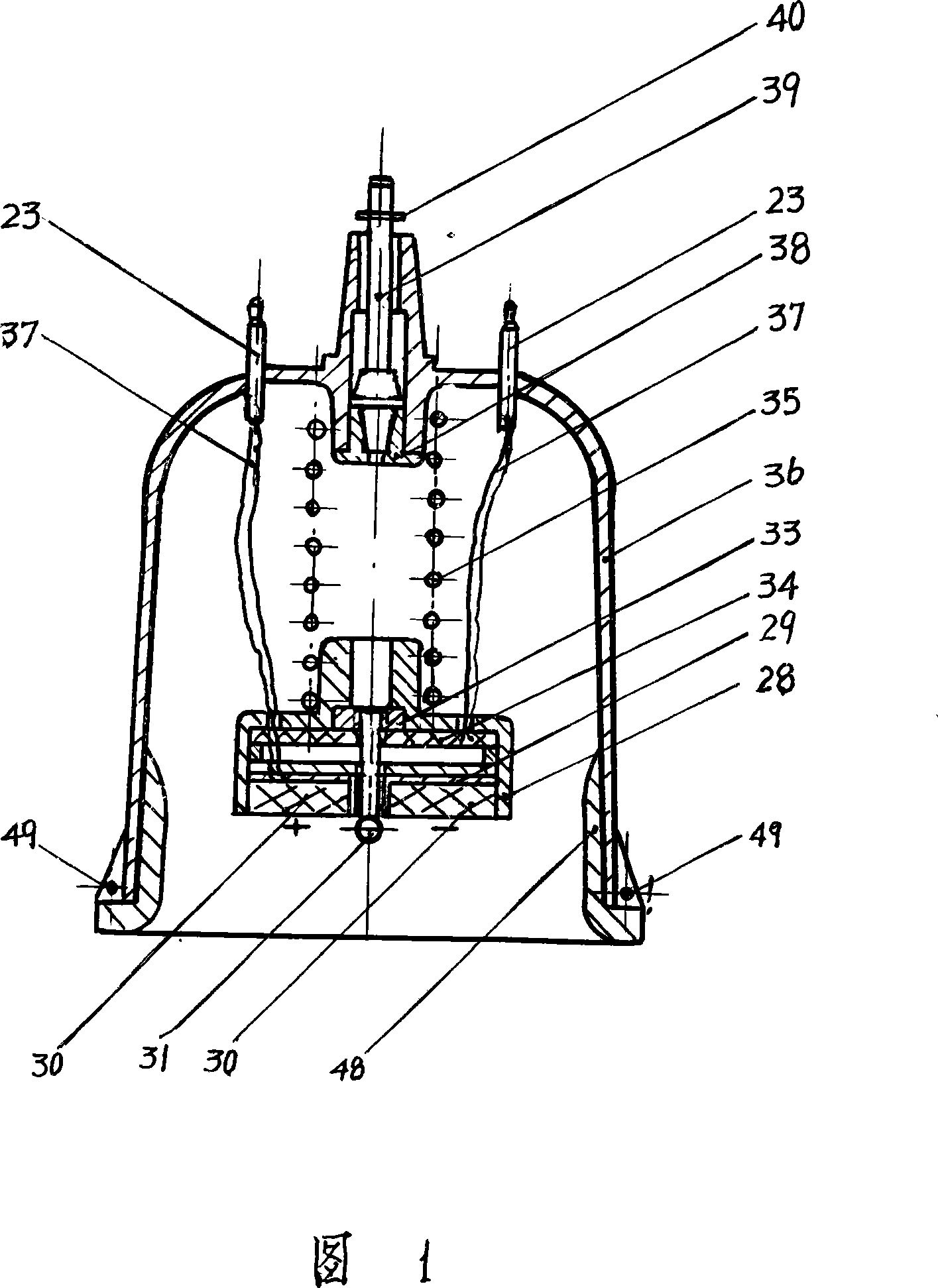

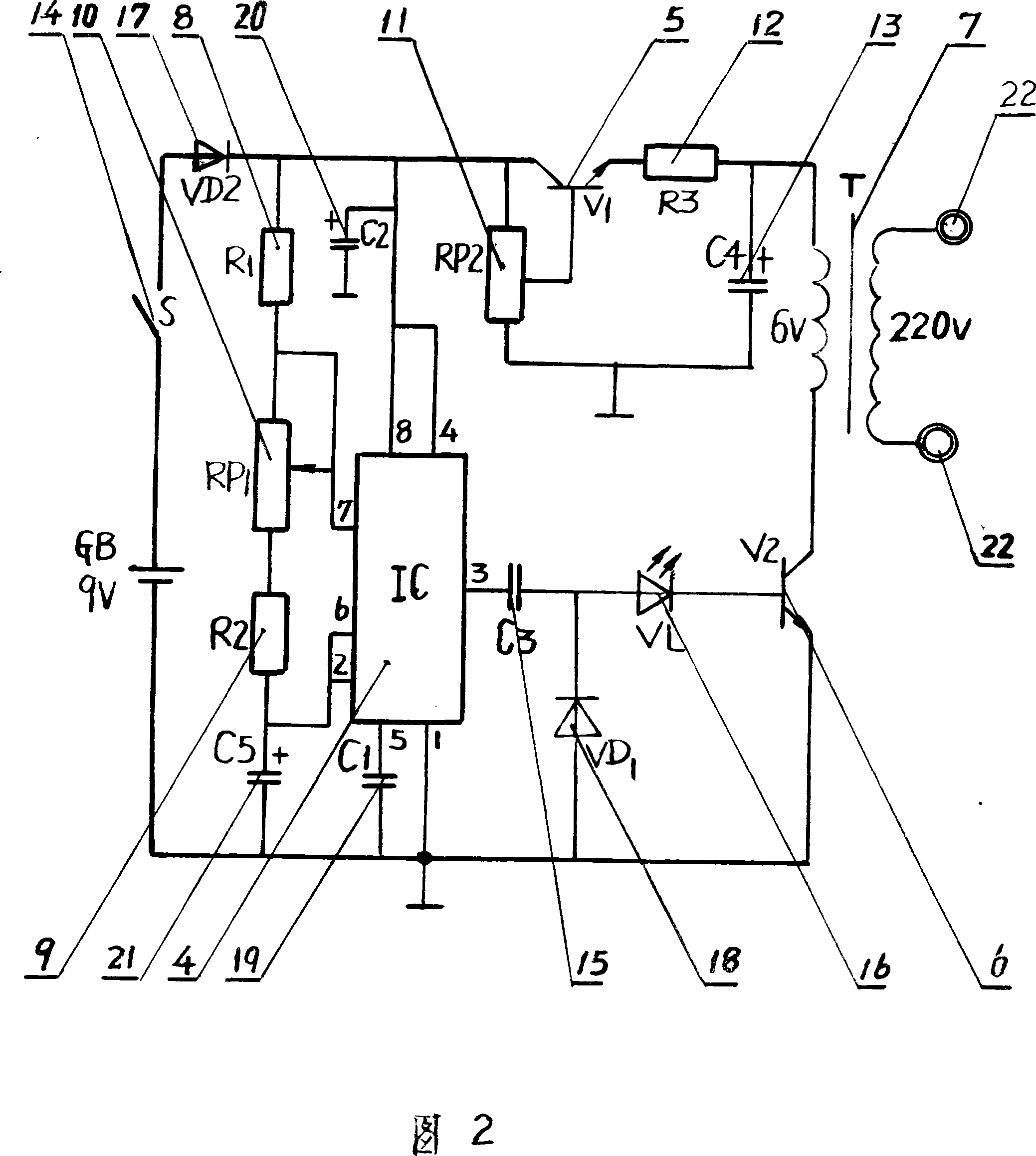

Composite energy electron impulse medicaments leading-in cupping instrument

InactiveCN101234229AStimulate physiological potentialStrong magnetic forceElectrotherapyMedical devicesHuman bodyPhysical Therapy Modality

The invention provides a cupping device of compound energy electronic pulse drug introduction which is suitable for health care and physical therapy fitness of human body. By adopting the latest modern nanometer silver material technology, conventional natural jades, the high-tech rare earth permanent magnetic material technology, the modern low-frequency electronic pulse technology and combining the conventional Chinese physical treatment method of cupping physical treatment, the cupping device designs a compound novel cupping physical treatment device with the superposition of a plurality of energies, thus improving and extending the functions and application scales of electronic pulse instrument. The cupping device has the advantages of improving the human blood circulation, increasing the microcirculation, promoting the metabolism function, relaxing human muscles and stimulating the points to provide a novel compound energy physical treatment health care cupping electronic pulse device.

Owner:林子淇

Physical treatment method for directly adsorbing lake eutrophic water body by using natural zeolite powder

PendingCN102070218AGood removal effectLow costEnergy based wastewater treatmentWater/sewage treatment by sorptionBenzeneNitrogen

The invention relates to a physical treatment method for directly adsorbing a lake eutrophic water body by using natural zeolite powder. The powder of 40 to 300 meshes or even less than 40 meshes is directly put into the lake eutrophic water body; the natural zeolite powder has capacity of adsorbing pollution elements and high exchange capacity, and directly adsorbs nitrogen, phosphorus, benzene, arsenic and other metal elements in the eutrophic water body; the effect of removing pollutants is better, the exchange capacity is highest and the capacity utilization rate is also highest when the particle size of the natural zeolite powder is smaller; and the powder of different particle sizes is adopted according to different types of lakes, and the characteristic that the effect is more obvious when specific surface area is larger is exerted. A practical method which saves time, labor and treatment cost, and is worthy of being selected by domestic pollution treatment enterprises, easy to implement and quick in response is provided for domestic lake eutrophication physical treatment.

Owner:张媛洁

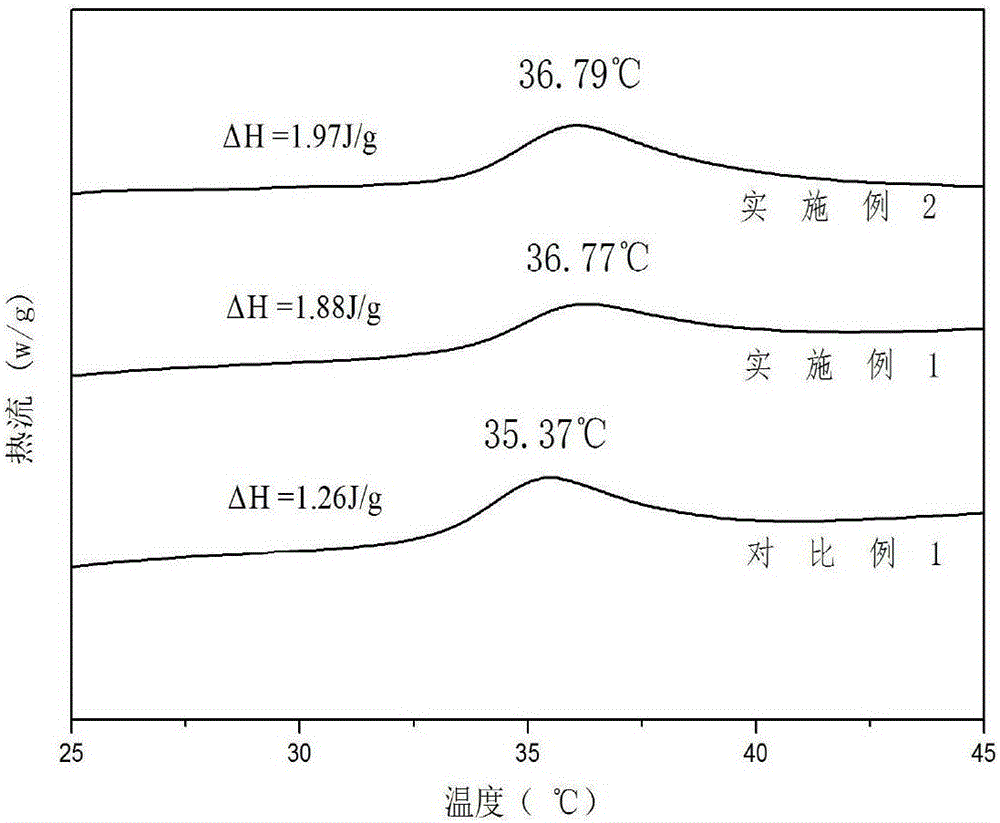

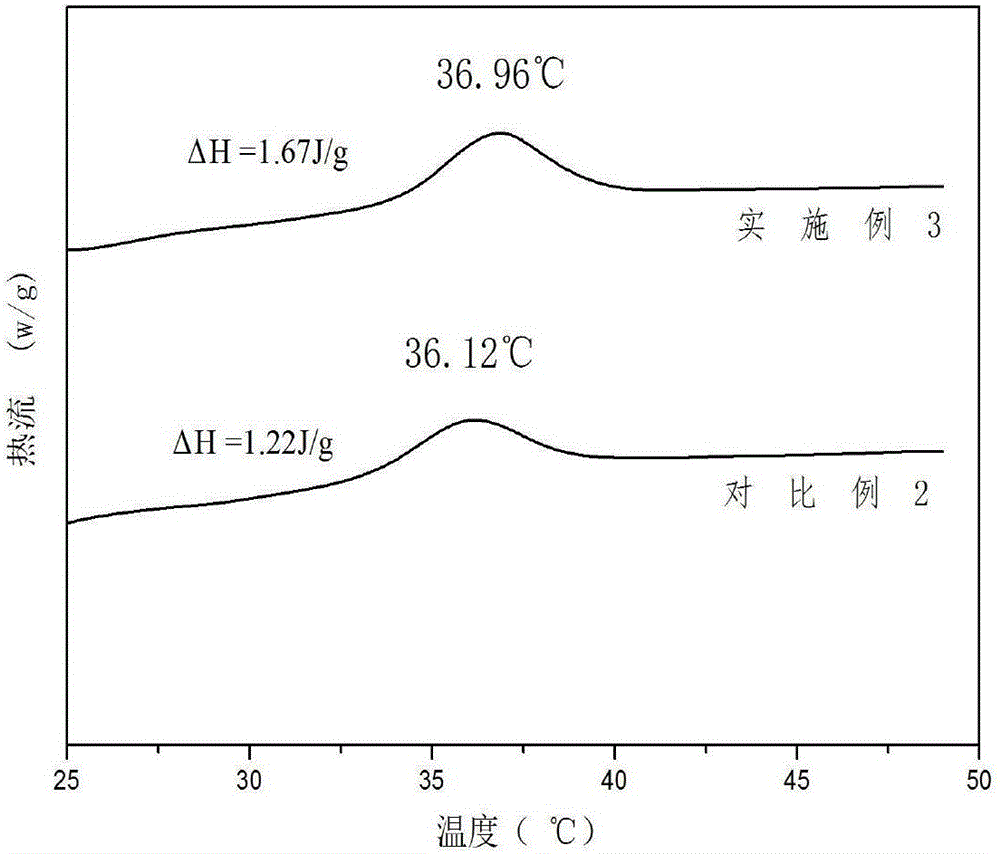

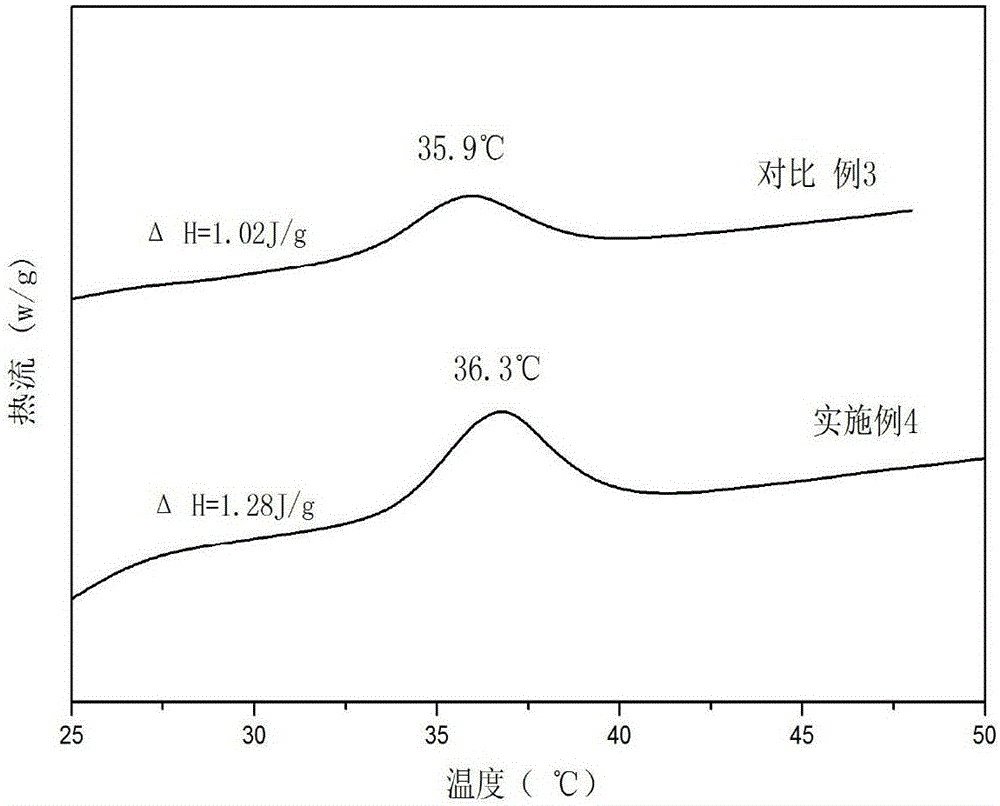

Method for preparing slowly digestible starch by pressure and heat collaborative double-enzyme treatment

InactiveCN103194508AReduce digestionIncrease nutritionFermentationDigestible starchGlycoside formation

The invention discloses a method for preparing slowly digestible starch by pressure and heat collaborative double-enzyme treatment. The method comprises the steps of putting 5-45% of starch milk into a high-pressure sterilization pan to carry out pressure heat reaction, adjusting pH to 4.0-7.5, adding beta-amylase of which the dosage is 50-450U / g of starch at 45-75 DEG C to keep for 1-8hrs; carrying out high-temperature enzyme deactivation; adjusting pH to 4.0-7.5, adding glucose glycosides enzyme at 40-75 DEG C, wherein the dosage is 100-500U / g of starch; keeping for 6-48hrs; carrying out high-temperature enzyme deactivation; naturally cooling, drying by an air dry oven, crushing and screening to obtain the product. By adopting the method, the starch is taken as the material; the content of the slowly digestible starch is greatly improved by a biotechnology in cooperation with a physical treatment method; the technology of preparing the slowly digestible starch is simplified; the yield is effectively improved; and the energy consumption is reduced. The slowly digestible starch produced by the method has the characteristics of retarding digestion, strengthening nutrition and the like.

Owner:SOUTH CHINA UNIV OF TECH

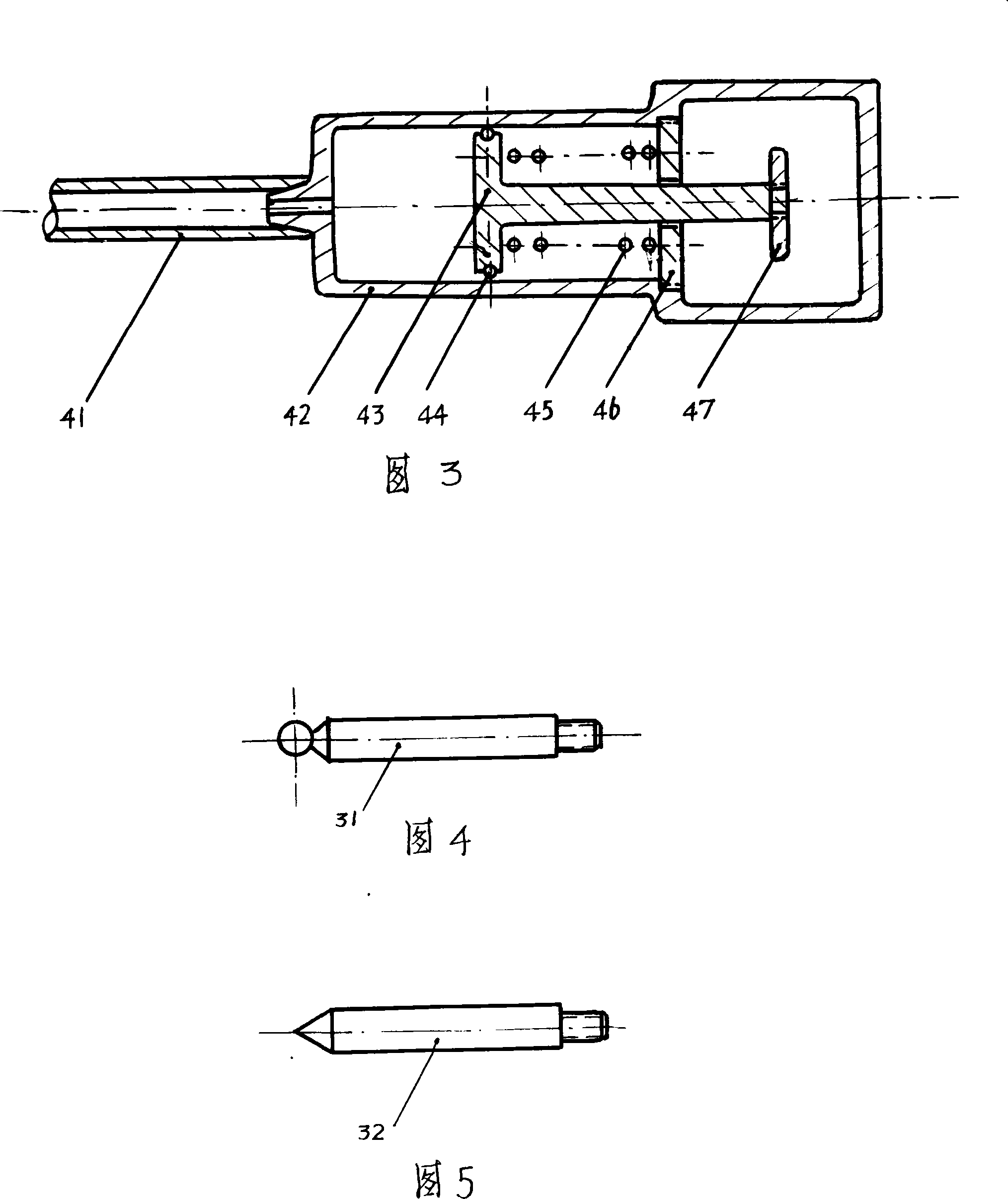

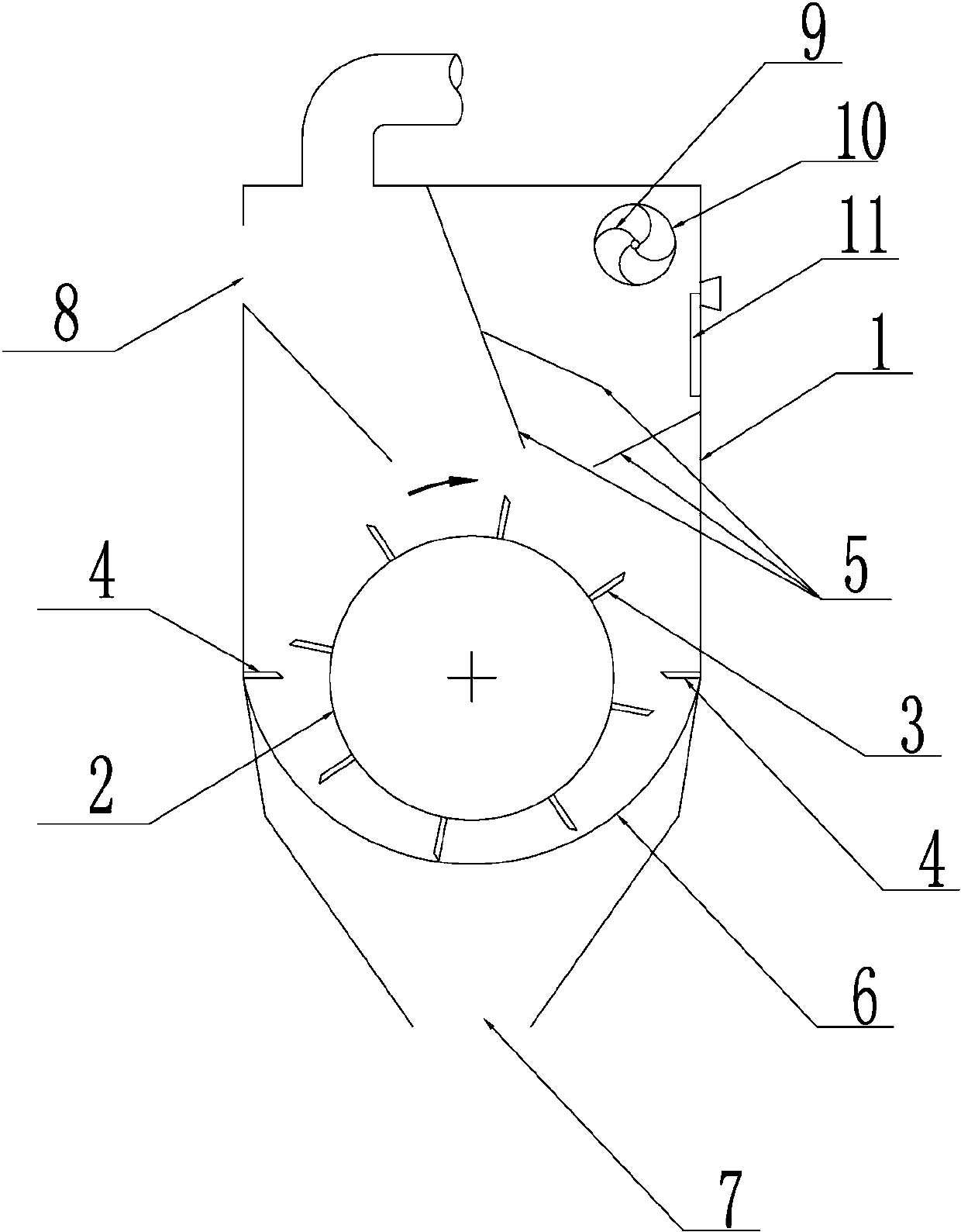

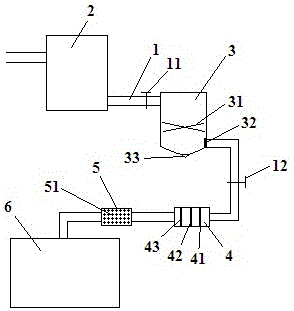

Hydrodynamic cavitation based organic-water pollution degradation system

InactiveCN106186179ANo secondary pollutionShorten the timeWater treatment parameter controlWater treatment compoundsTreatment effectCavitation

The invention relates to a hydrodynamic cavitation based organic-water pollution degradation system which comprises a sewage pool, a pore-plate cavitation device, a vortex cavitation device and a water purification pool. The sewage pool is connected with a first water pump through a second water pipe, the first water pump is connected with the pore-plate cavitation device through a third water pipe, the pore-plate cavitation device is connected with the vortex cavitation device through a fifth water pipe, and the vortex cavitation device is connected with the water purification pool through a water pipe. By the arrangement that hydrodynamic cavitation is directly utilized without adding chemical reagents during the process, and secondary pollution is avoided; compared with a traditional physical treatment method, the hydrodynamic cavitation based organic-water pollution degradation system is simple in equipment structure, low in cost, obvious in treatment effect and high in effect.

Owner:JIANGSU UNIV

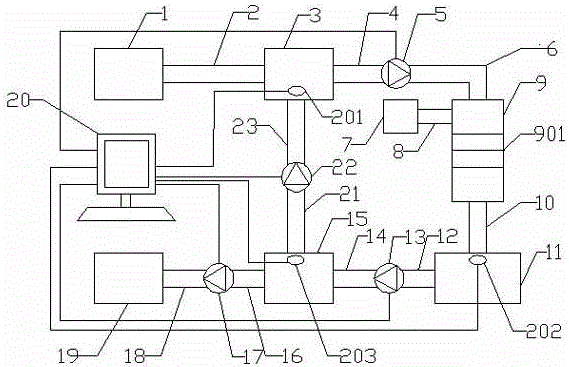

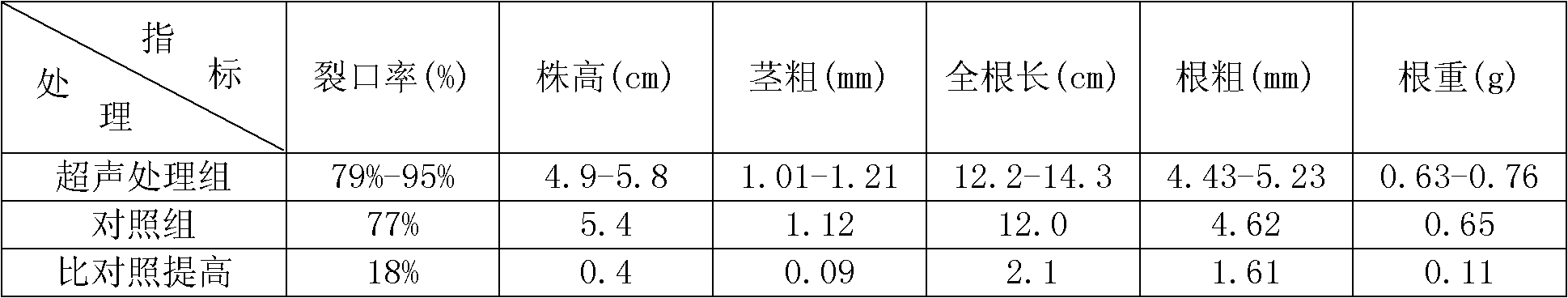

Physical treatment method for ginseng seeds

ActiveCN102487626APromote riftPromote germinationSeed and root treatmentPlant cellBiomedical engineering

The invention relates to a plant seed treatment method, namely a physical treatment method for ginseng seeds. The method comprises the following steps of: (1) stratification pretreatment: soaking the picked ginseng seeds into normal-temperature clean water for 24 hours, filling the ginseng seeds into a bag, putting the bag into an ultrasonic container with set parameters, performing ultrasonic treatment under the condition that the ultrasonic frequency is 30 to 100kHz, the ultrasonic treatment temperature is 15 to 60 DEG C, the ultrasonic treatment power is 200 to 700W and the ultrasonic treatment time is 10 to 40 minutes, standing for 1 to 5 days after the treatment and performing conventional stratification treatment; and (2) sowing pretreatment: performing treatment according to the ultrasonic method in the (1) before sowing, and sowing. By the method, wall breakage or deformation of plant cell tissues can be promoted, so that cracking and germination of the seeds are promoted, the cracking rate and the germination rate are effectively improved, and physiological after-ripening, growth, development and matter accumulation of ginseng are facilitated.

Owner:JILIN JIAN YISHENG PHARMACEUTICAL CO LTD

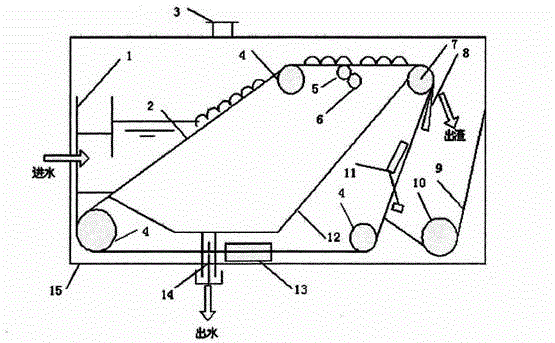

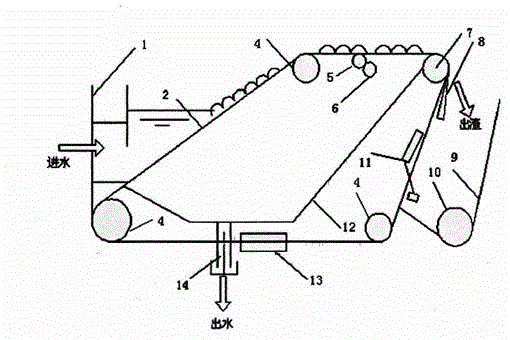

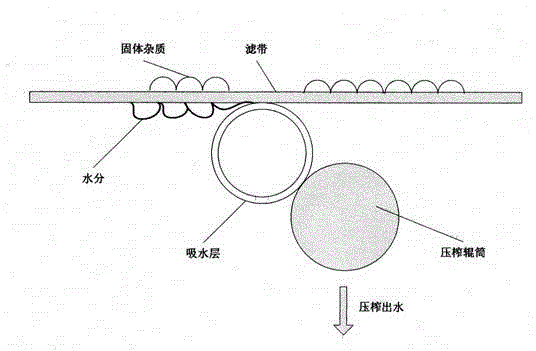

Polluted and waste water front-end physical treatment method

InactiveCN102974167AImprove interception effectImprove water resistanceMoving filtering element filtersWater useSlag

The invention relates to a polluted and waste water front-end physical processing method for removing solid impurities from water. The method uses a filtering and cleaning device, which comprises a filter strip, a water absorption roller, a pressing roller, a scraper, an air knife and an ultrasonic cleaning apparatus. The method comprises the following steps: first, separating solid impurities from water using the interception function of the filter strip; and then stripping water and suspension impurities intercepted on the surface and in clearances of the filter strip off the filter strip through absorption by the water absorption roller, squeezing by the pressing roller, scratching by the surface of the scraper, high speed air curtain blowing generated by the air knife, and ultrasonic cleaning by the ultrasonic cleaning device, thus realizing the clean filter strip, and at the same time effectively controlling water in the discharged slag, facilitating subsequent processing after discharging the slag, and maintaining good environmental sanitation condition.

Owner:上海雨泽环保科技有限公司

Method for aerating separating and purifying weak acidic harmful gas dissolved in waste water

InactiveCN101157487AIncreased content of dissolved substancesReduce pollutionDispersed particle separationWater/sewage treatment by degassingActivated carbonWastewater

The invention provides an aerating method for separating and purifying weak acidic harmful gases dissolved in waste water. The method comprises aerating and purging weak acidic harmful gases such as hydrogen sulfide, etc. in circulating water or the waste water with air or other gases; gases stripped out via aeration are introduced into an activated carbon adsorption tower or a wet adsorption purification tower and emitted to the atmosphere after purification. The method belongs to a physical treatment method and the stripping separation rate can exceed 90 percent. Not only hydrogen sulfide can be effectively removed, but also the circulating water can be reused, so the invention does not have the problem that the quality of the circulating water can be deteriorated due to the increase of accumulative concentration of acids, alkali and salts produced in the treatment by drug administration method.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

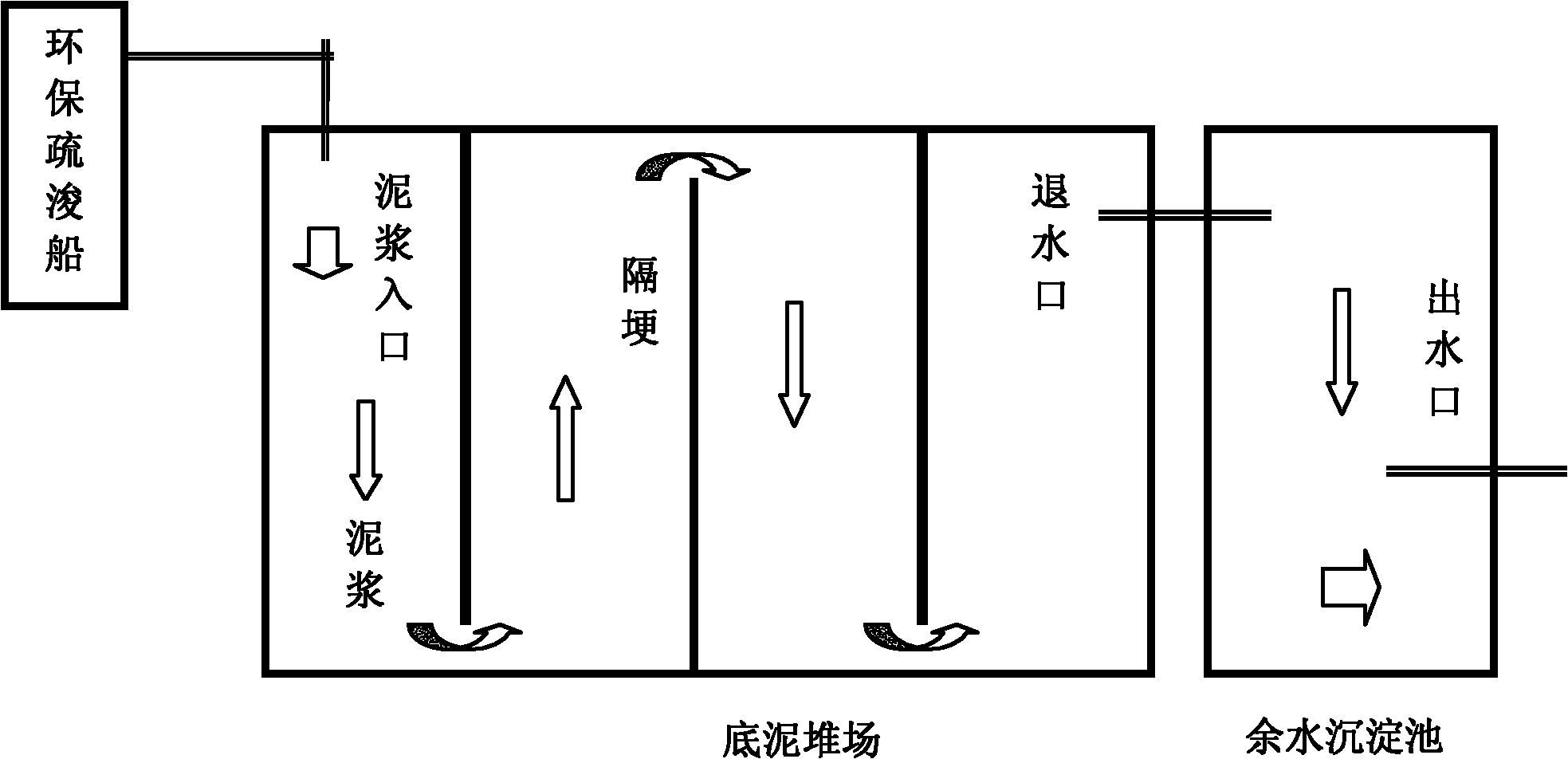

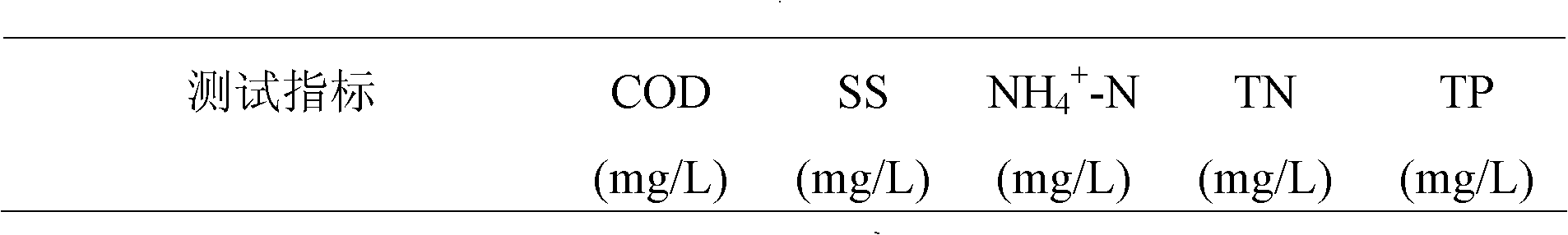

Technique for treating remaining water of desilted sediment in Lake Tai

InactiveCN102107936AEfficient removalGood removal effectSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationChemical treatmentChemical oxygen demand

The invention discloses a technique for treating remaining water of desilted sediment in Lake Tai, which comprises steps as follows: mud, which is desilted from Lake Tai, is discharged into a mud discharge yard through a mud discharge inlet of the mud discharge yard; the mud flows in the mud discharge yard and settles in a sediment heaping yard of the mud discharge yard; the remaining water of the mud flows to a water recession port of the mud discharge yard; a compound flocculant is added to remaining water at the water recession port; and the remaining water is discharged into a remaining water settling tank to carry out settling treatment. By organically combining a physical treatment method and a chemical treatment method, the technique disclosed by the invention can effectively remove COD (chemical oxygen demand), NH4<+>-N, TP (total phosphorus), SS (suspended sediment) and the like in water; and the reasonable site selection and design of the mud discharge yard are beneficial to the natural settling of the SS in water so as to reduce the consumption of the flocculant, the compound flocculant can thoroughly purify the remaining water, and the mutual cooperation exerts the optimal advantages of every treatment method, thereby achieving the goal of high-efficiency treatment of remaining water.

Owner:NANJING UNIV

Method for treating food processing organic wastewater containing high-concentration fat and suspended matter

InactiveCN102531283ALow costReduce pollutionMultistage water/sewage treatmentHigh concentrationWastewater

The invention relates to a method for treating food processing organic wastewater containing high-concentration fat and suspended matters. The method is characterized in that the food processing organic wastewater containing the high-concentration fat and suspended matters flow into a static placing tank through a workshop drainage ditch, a plurality of metal grid filter screens are arranged in the drainage ditch, and grids are 4-mesh to 10-mesh and are not equal to intercept large suspended matters; an upper fat interception plate and a lower fat interception plate are arranged in the static placing tank, the wastewater is statically placed in the static placing tank for 1-2d, the fat which is suspended on the surface is intercepted by the upper fat interception plate, sediments settled at the bottom are intercepted by the lower fat interception plate and the second-grade discharge standard in the national discharge standard GB8978-1996 is satisfied. The method has the technical effects that the wastewater can be continuously treated, the cost is low by adopting a physical treatment method, the method can be easily popularized and used and the pollution is minimized.

Owner:NANCHANG UNIV

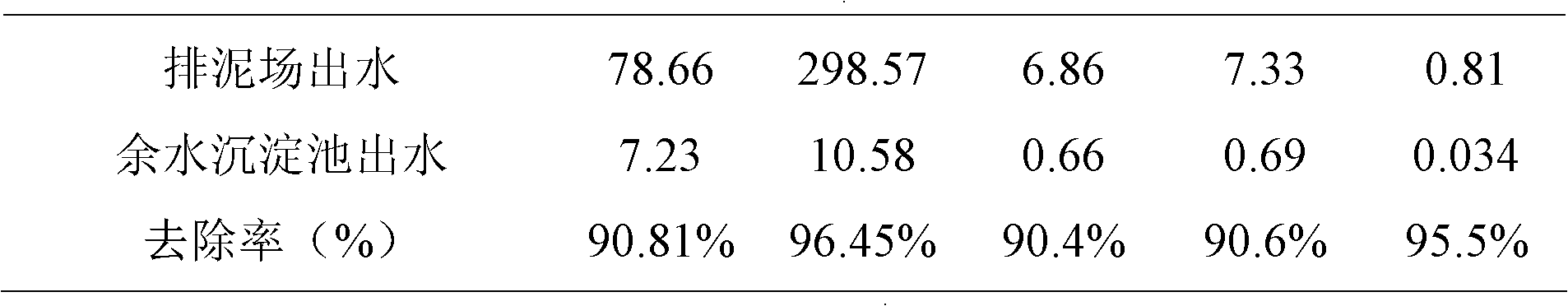

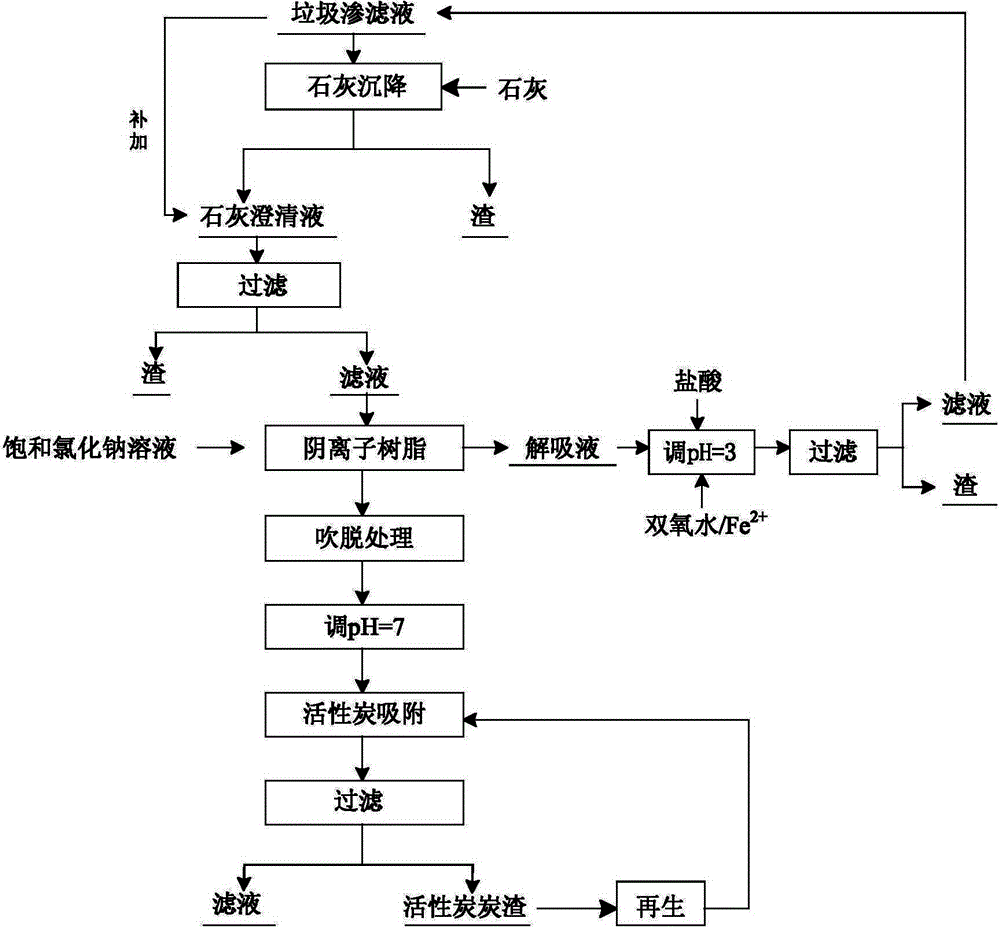

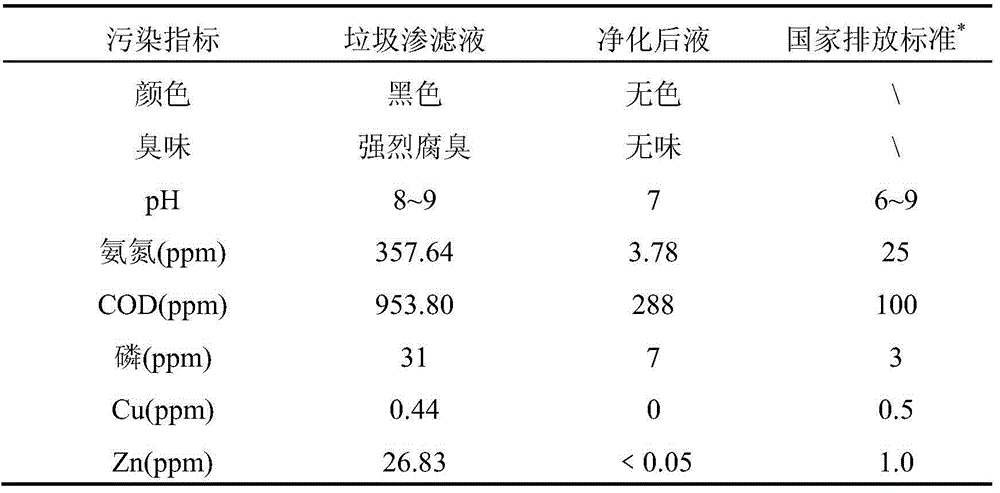

Processing method of landfill leachate

ActiveCN103601313ASimple processEasy to operateWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentChemical treatmentFiltration

The invention discloses a processing method of landfill leachate. The processing method comprises following steps: the landfill leachate is mixed with lime for sedimentation processing so as to obtain a sedimentation liquid containing solid slag; the sedimentation liquid containing solid slag is subjected to first filtration processing so as to obtain the solid slag and a first filtrate; the first filtrate is subjected to first absorption processing using anion exchange resin so as to obtain a first after absorption liquid and adsorption saturated anion exchange resin; the first after absorption liquid is subjected to air stripping so as to obtain an after air stripping liquid; the after air stripping liquid is subjected to second absorption processing using active carbon so as to obtain a second after absorption liquid; and the second after absorption liquid is subjected to second filtration processing so as to obtain an after purified liquid and active carbon slag. According to the processing method, the landfill leachate is processed via combination of chemical treatment methods and physical treatment methods, cost is low, effect is obvious, decoloration and deodorization can be realized effectively, heavy metal ions and ammonia nitrogen are removed effectively, and COD index is reduced greatly.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

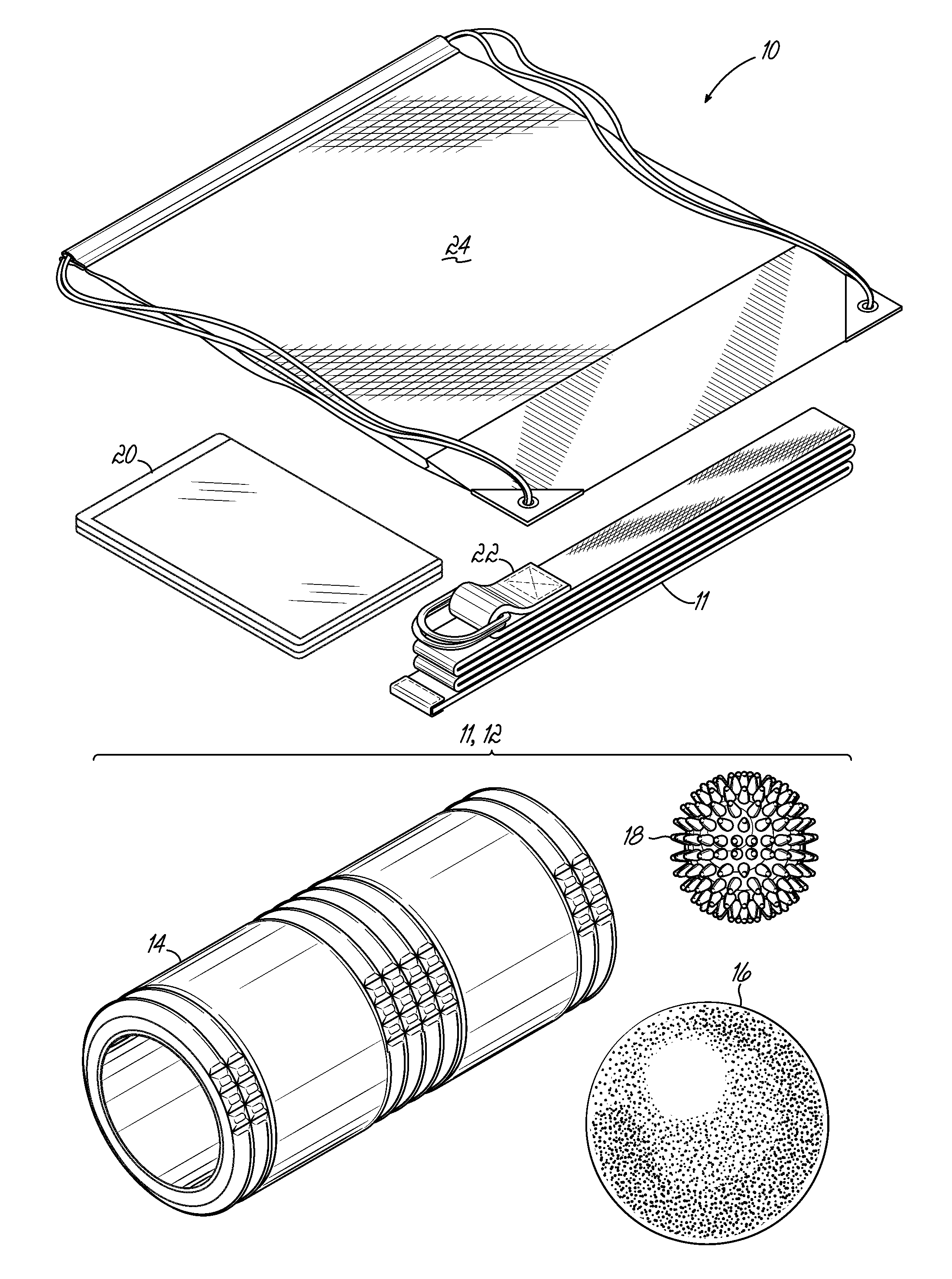

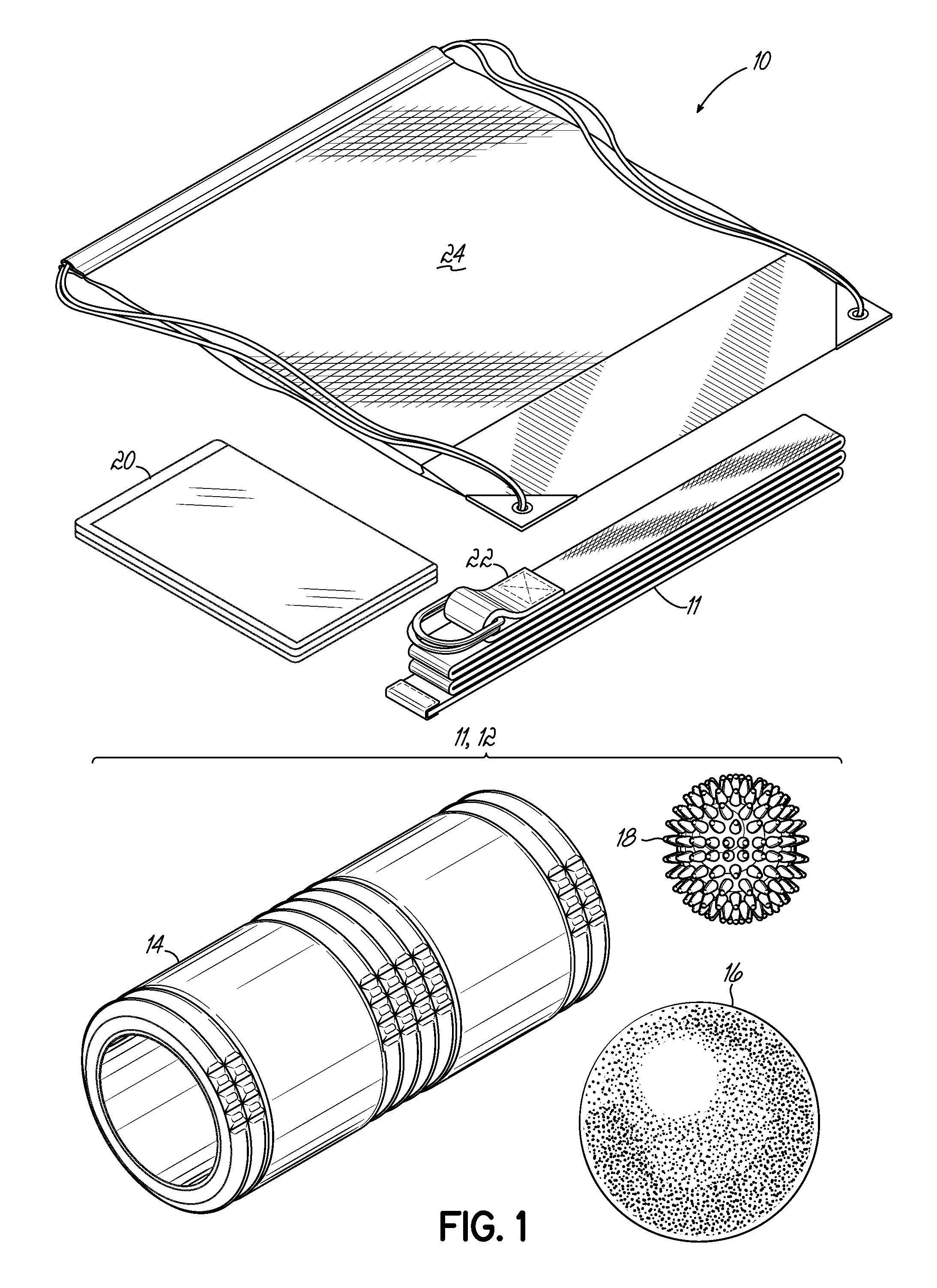

Method for relieving pain and a kit therefor

InactiveUS20140272850A1Cosmonautic condition simulationsSport apparatusComputer sciencePain alleviation

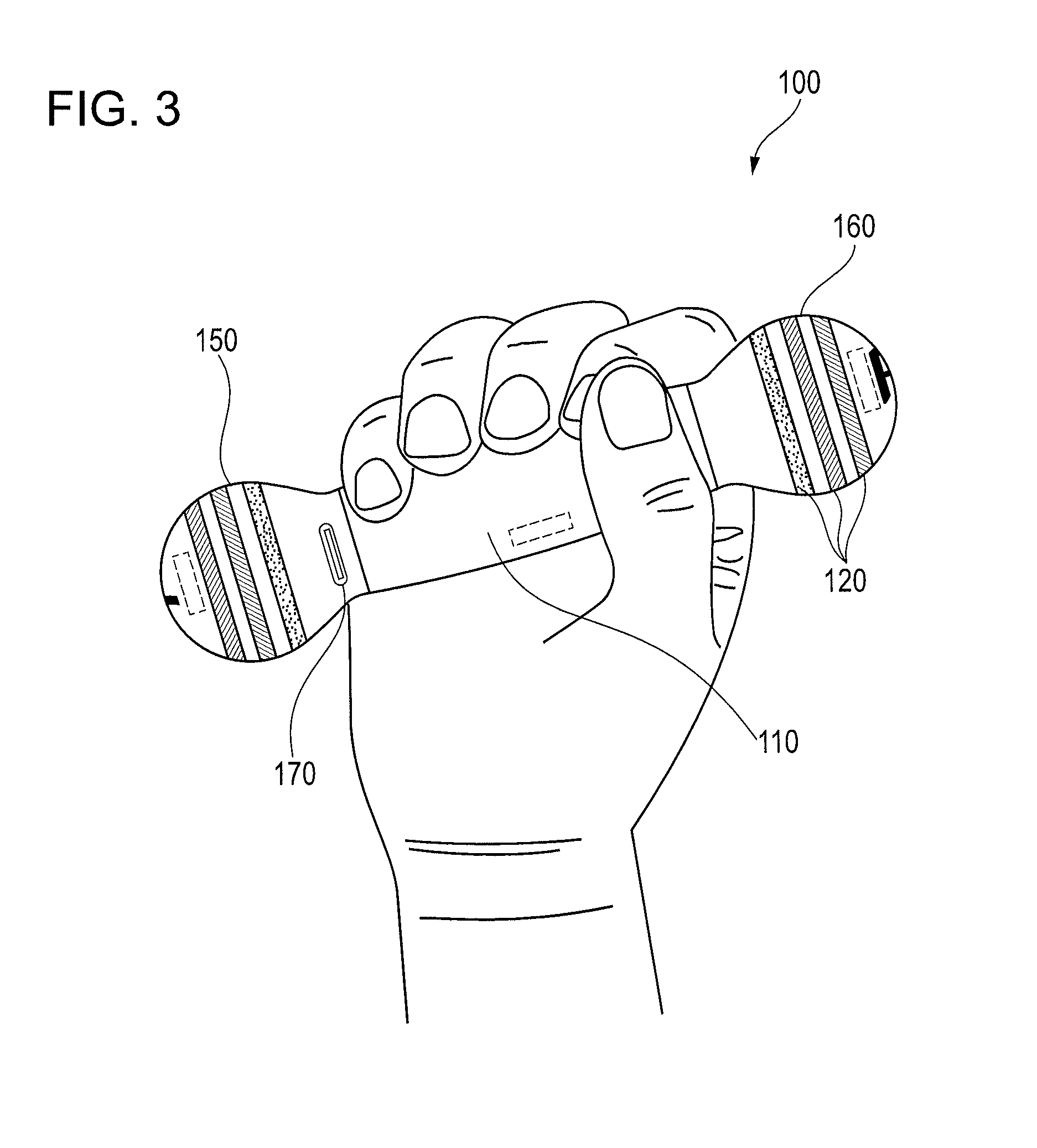

A kit for use in physical therapy by a person includes a tension release device and a set of instructions associated with the kit. The set of instructions is in the form of written instructions and / or audio / visual instructions. The set of instructions includes an instruction to place pressure on a muscle of a person with the device, an instruction to stretch the muscle, and an instruction to strengthen at least one core muscle. The instruction to place pressure may be provided before the instruction to stretch, and the instruction to stretch may be provided before the instruction to strengthen. The kit may include other tension release devices. A method of physical therapy for use by a person includes providing a tension release device to apply pressure to a muscle of the person and providing a set of instructions to perform.

Owner:VITALITY LLC +1

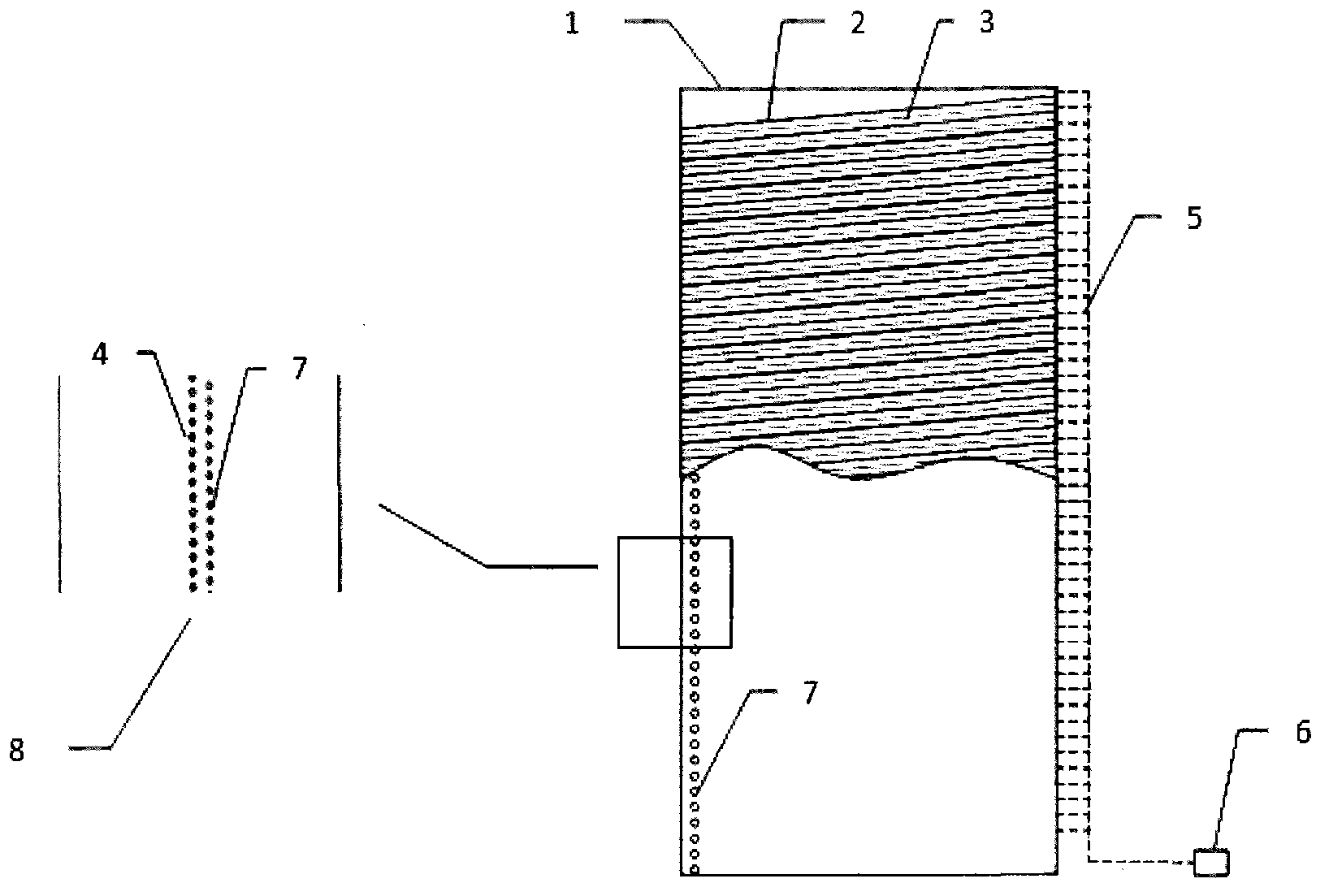

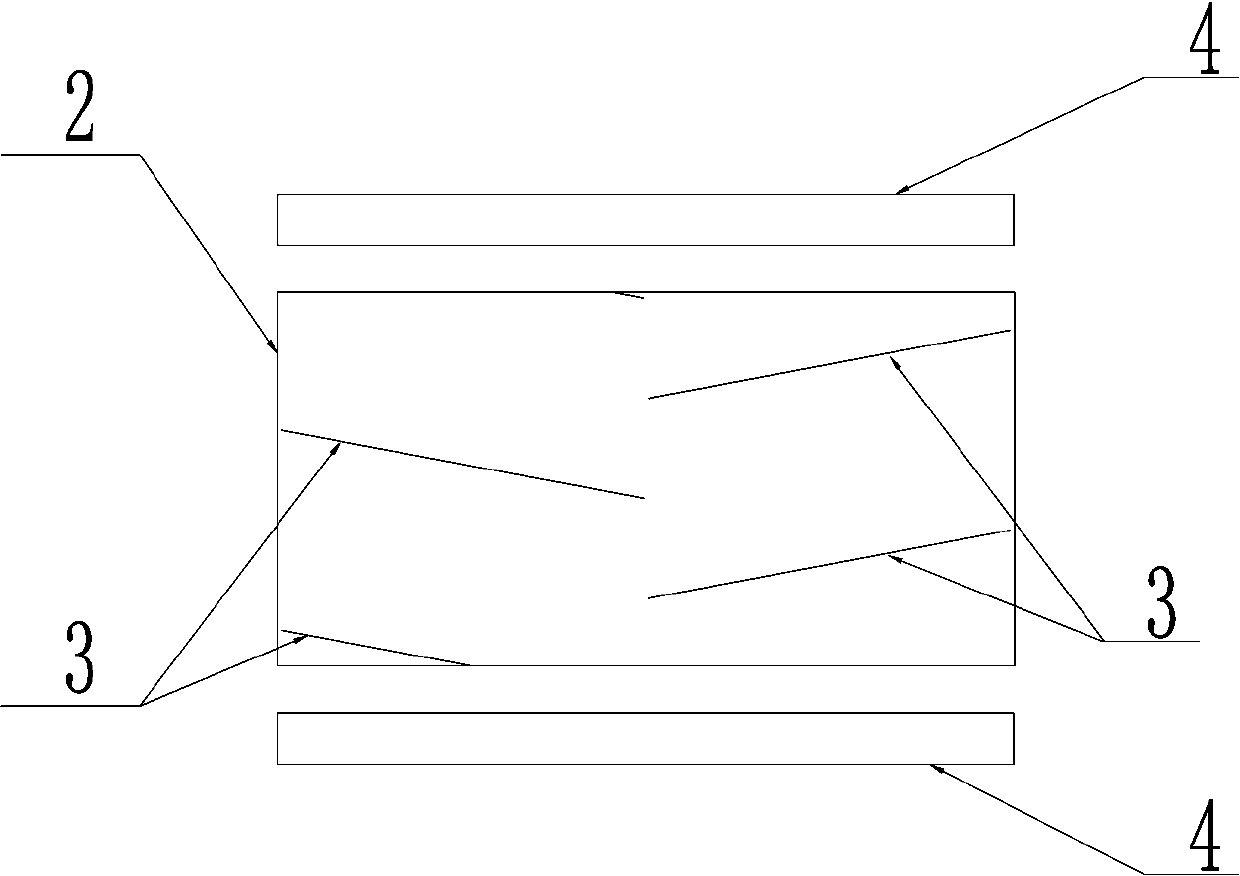

Membrane module for recovering lightweight microscale oil stain in water area

InactiveCN104209004AQuick washEasy to cleanSemi-permeable membranesWater cleaningPetroleum PollutionOil water

The invention relates to a membrane module (1) for recovering lightweight microscale oil stain in a water area, which is characterized by comprising an oil-water separating membrane (2), a spacing membrane (3), a water inlet pipeline (4), an oil outlet pipeline (5), an oil storage tank (6) and a water outlet pipeline (7). A main functional part is capable of separating oil and water by the oil-water separating membrane (2) which can change a hydrophilic and hydrophobic structure by following the temperature change, membrane obstruction status can be improved by adjusting temperature, membrane cleaning process is simple, and membrane usage life is long. According to the invention, a laying design of the membrane is in a tilting mode, characteristic of oil part on water surface and an overflow principle are used to realize the oil-water separation. The membrane module can be used in water surface large scale ship oil-overflowing accidents, overflowed oil is recovered, and then residual lightweight microscale oil stain is treated by a physical treatment method and a routine machinery recovery device, key monitoring water area polluted by slight petroleum for long time can be treated, and effect of no secondary pollution and deep treatment for the water body petroleum pollution can be reached.

Owner:BEIHANG UNIV

Method for separating pectin from fructus momordicae production waste residue

The invention relates to a method for separating pectin from fructus momordicae production waste residue. The method comprises: (1) hot water extraction: adding hot water to fructus momordicae production waste residue, carrying out stirring extraction, and filtering to obtain an extraction liquid; (2) micro-filtration: making the extraction liquid obtained in the step (1) pass through a ceramic membrane, and collecting a ceramic membrane permeation liquid; (3) nano-filtration: making the ceramic membrane permeation liquid obtained in the step (2) pass through a nano-filtration membrane, and collecting a nano-filtration membrane trapping liquid; (4) decolorizing: adding active carbon to the nano-filtration membrane trapping liquid obtained in the step (3), heating, carrying out thermal insulation stirring, and filtering to obtain a decolorizing liquid; and (5) concentration drying: carrying out pressure reducing concentration on the decolorizing liquid obtained in the step (4), and carrying out microwave drying to obtain the fructus momordicae pectin. According to the present invention, the fructus momordicae pectin obtained according to the method is light yellow powder, has the total galacturonic acid of more than or equal to 70%, and has excellent pectin quality and excellent pectin content; and the method uses the completely physical treatment method so as to provide advantages of safety, green properyy, and environmental protection.

Owner:HUNAN HUACHENG BIOTECH

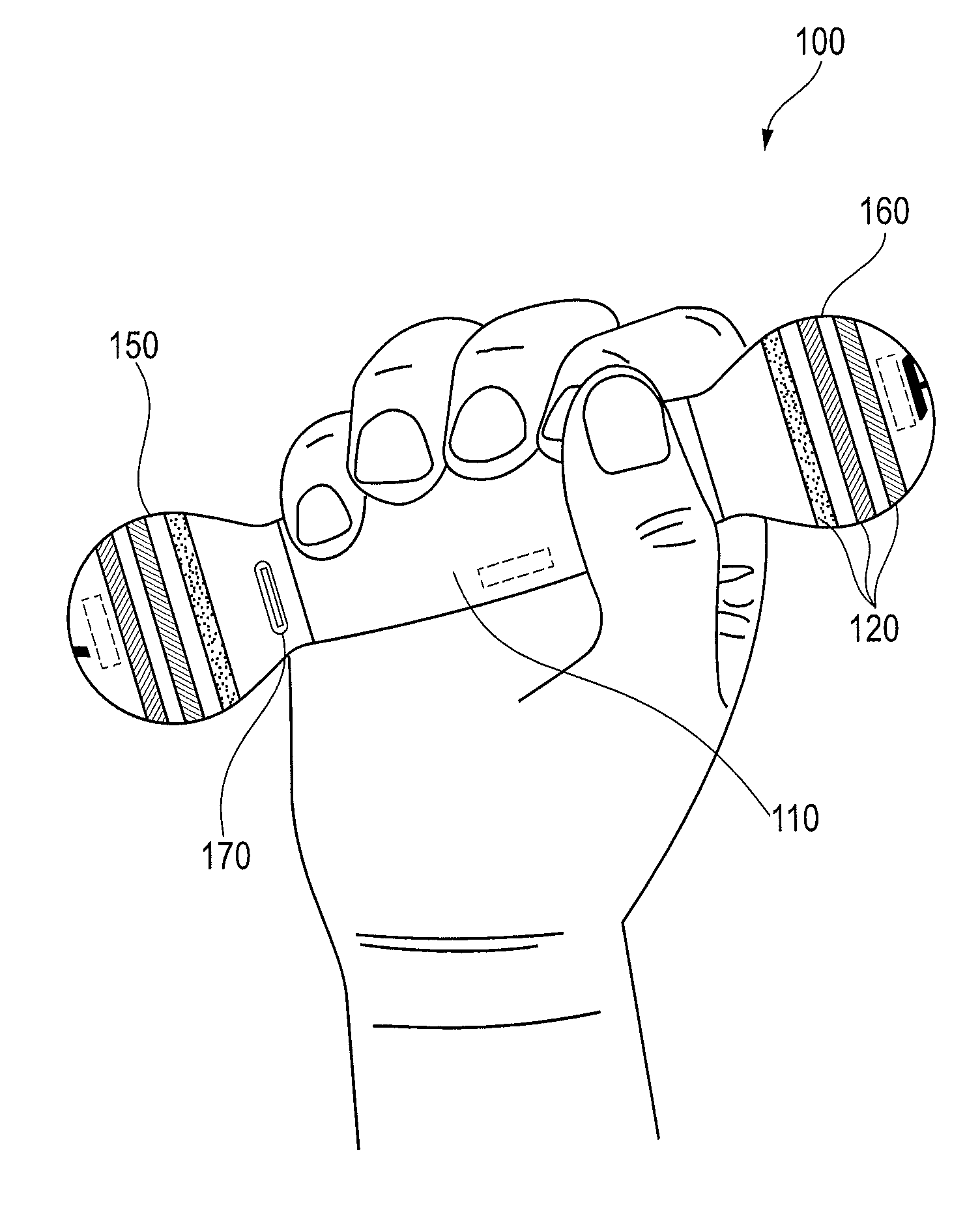

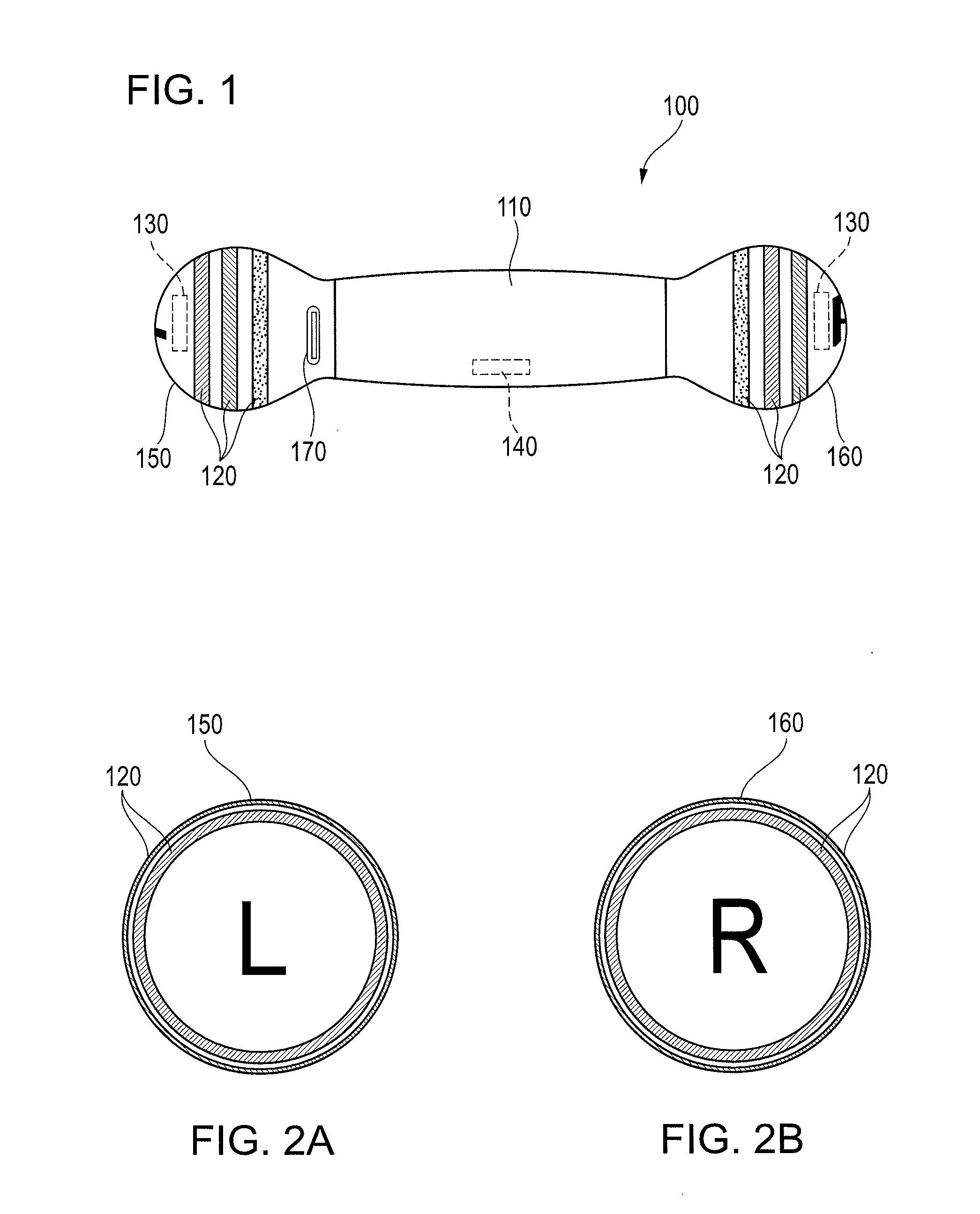

Digital instrument for use in physical therapy and method for administering physical therapy using same

InactiveUS20130138021A1Easy to controlChiropractic devicesEye exercisersGrip forceCanine physical therapy

The present invention relates to a digital instrument for use in physical therapy, including a gripping force measurement bar which measures the gripping force of a hand when the bar is grasped, a sensor portion which measures the rotation of a wrist when the wrist is turned while the gripping force measuring bar is grasped, a display device which visually displays the degree of the gripping force or the extent to which the wrist is rotated, and a memory portion which stores the degree of the gripping force of a measured value relating to the rotation of the wrist. The invention also relates to a physical therapy method using the instrument. According to the present invention, the degree of motion is assessed on a real-time basis, the degree of motion is easily controlled, and an exercise activity is rendered more interesting since the degree of the gripping force or the extent to which the wrist is rotated is measured and visually displayed.

Owner:MIKESELL DANIEL +1

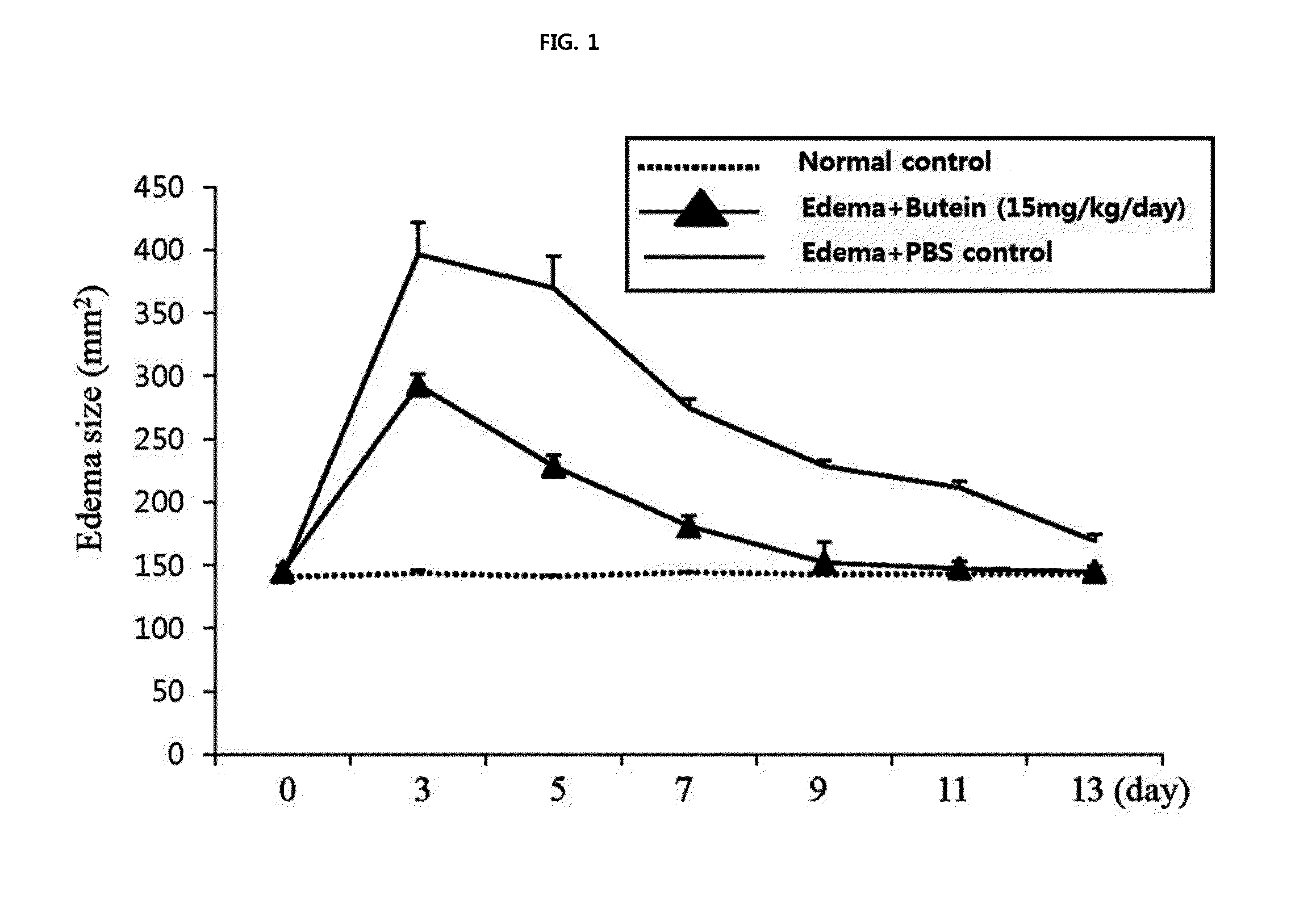

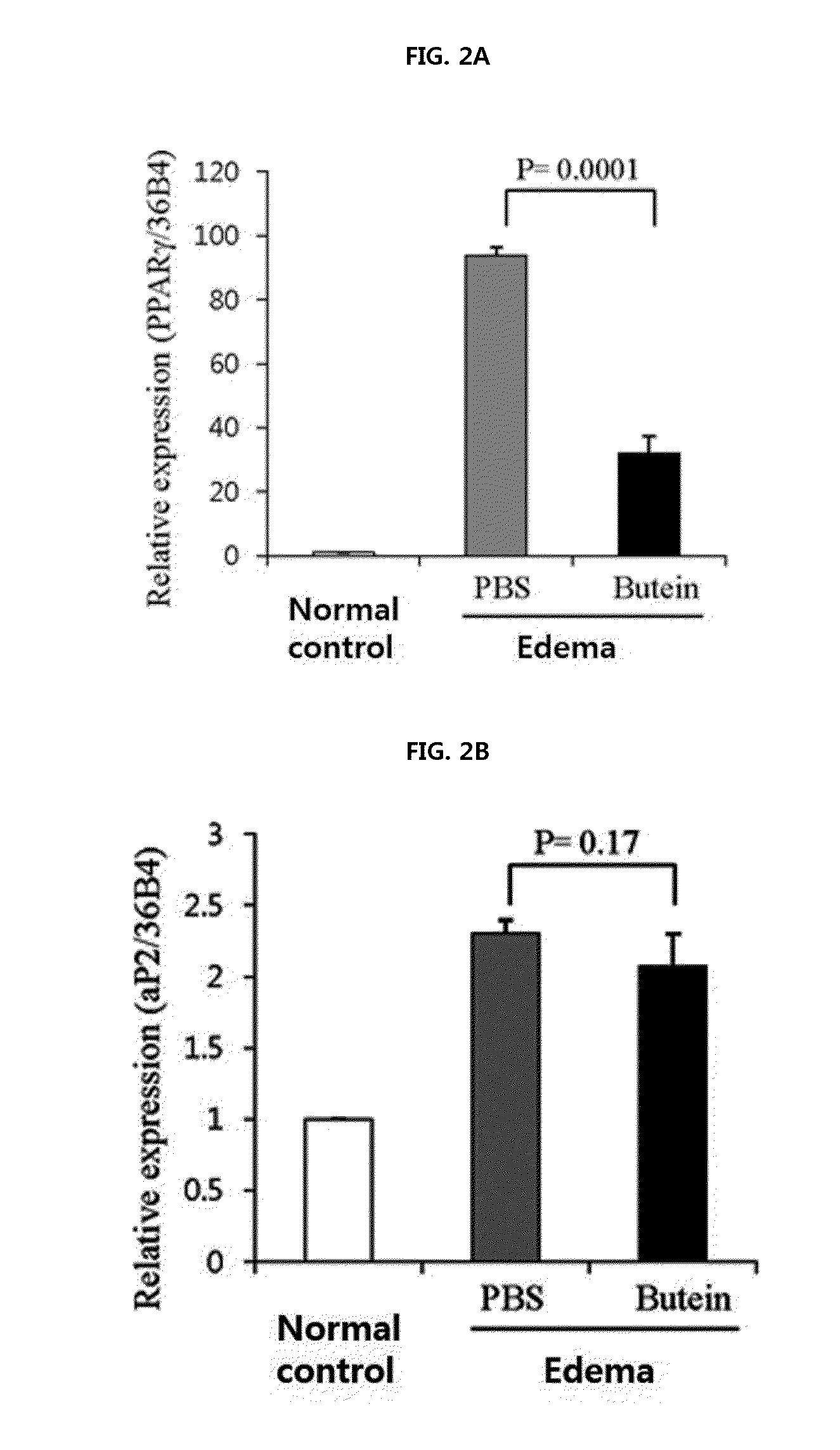

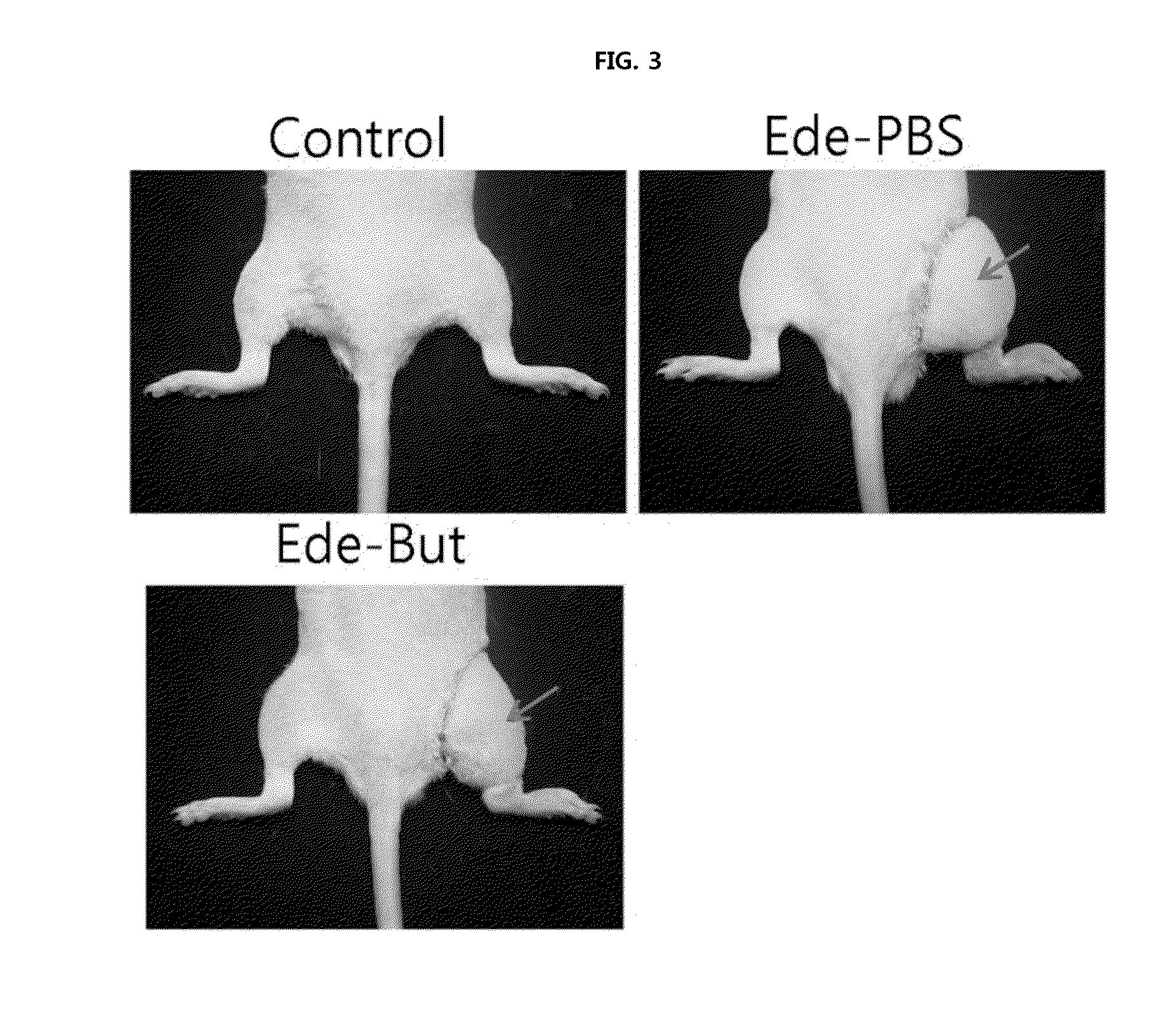

Composition for preventing or treating edema containing flavonoid compound

Provided is a method of treating edema using a flavonoid compound or a pharmaceutically acceptable salt thereof, and by the method, acquired edema triggered due to cancer treatments can be cured. A composition containing the flavonoid compound is a chemical approach to a conventional physical treatment method, and when the composition is administered to an edema-induced mouse, a considerable reduction in size of edema is observed.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

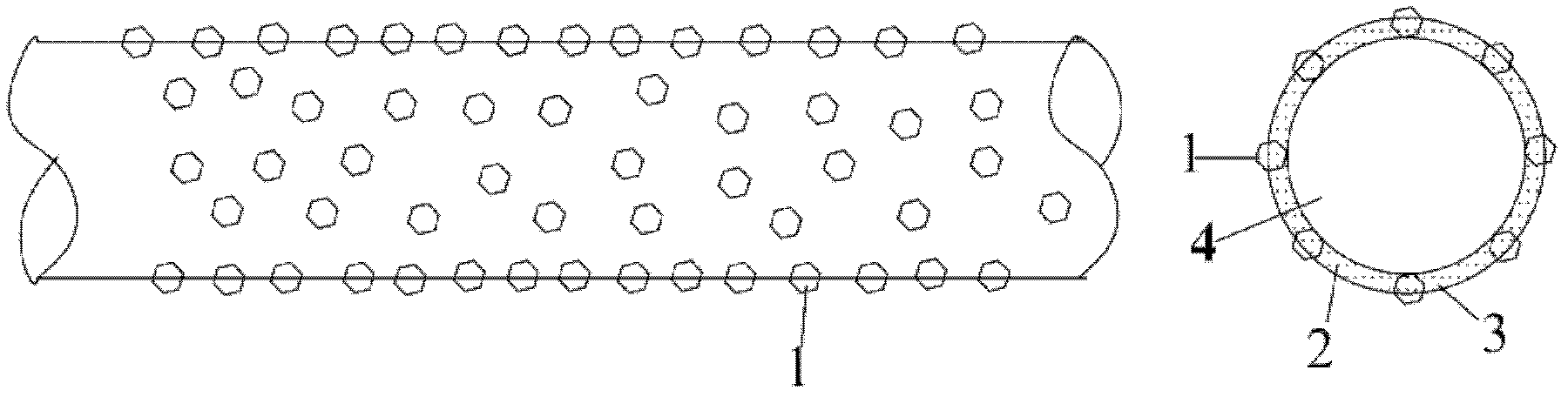

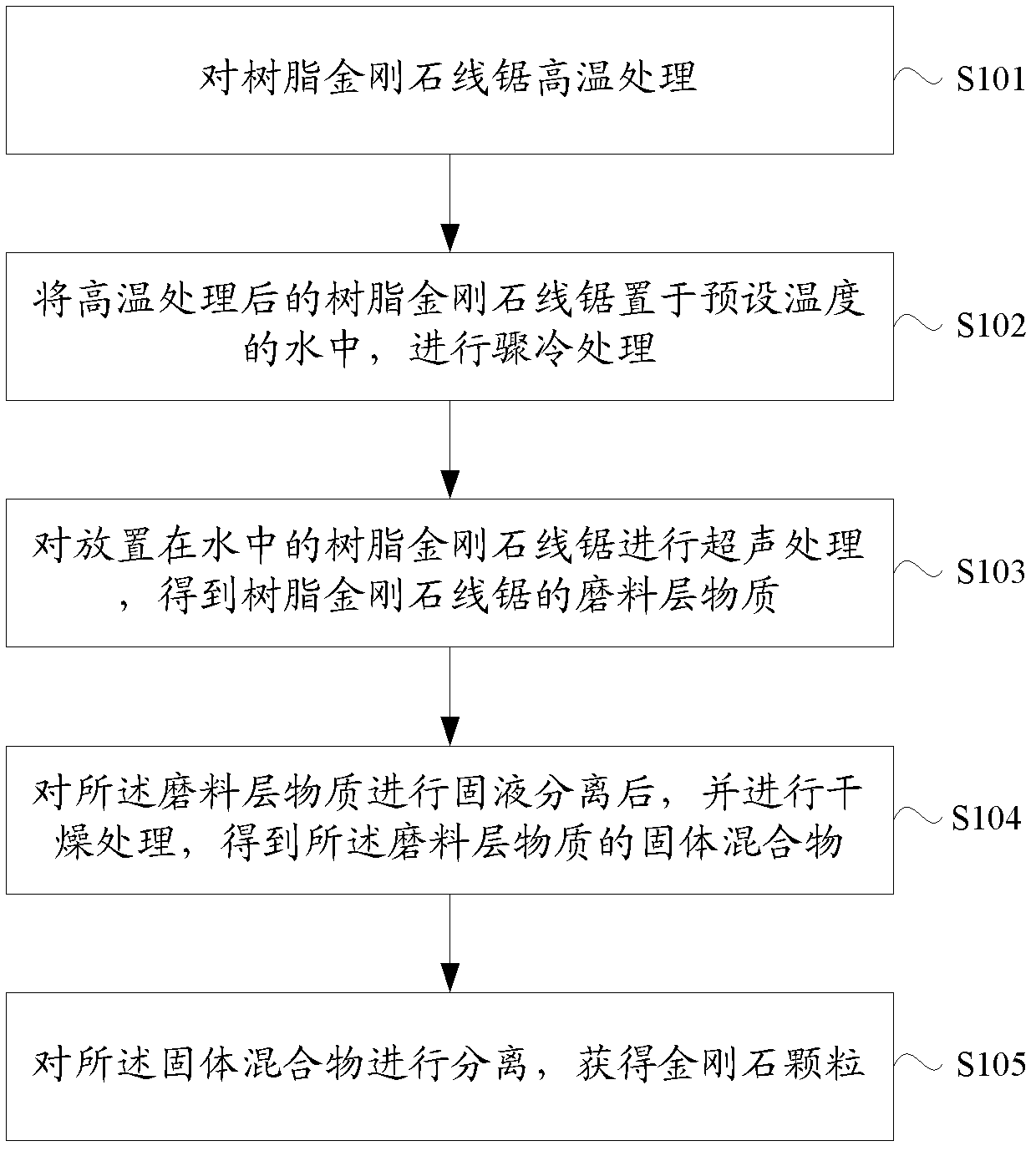

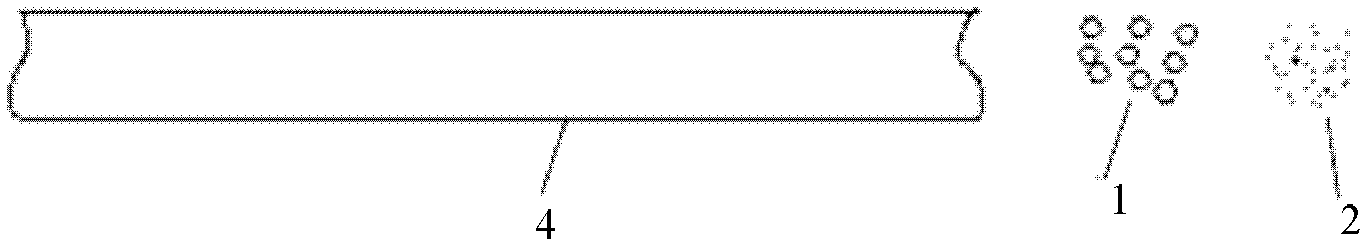

Diamond recovery method for resin diamond scroll saw

The invention discloses a diamond recovery method for a resin diamond scroll saw. The method includes subjecting the resin diamond scroll saw to a high-temperature processing; placing the processed resin diamond scroll saw into water with a preset temperature and performing quenching; subjecting the resin diamond scroll saw placed in the water to an ultrasonic processing to obtain abrasive layer materials of the resin diamond scroll saw; subjecting the abrasive layer materials to solid-liquid separation and drying processing to obtain a solid mixture of the abrasive layer materials; and separating the solid mixture to obtain diamond particles. In the scheme, physical treatment methods such as high temperature, quenching and ultrasonic mode are used for recovering the diamond particles, and the recovery of the diamond particles is achieved in an environment-friendly mode.

Owner:南通江涌投资开发有限公司

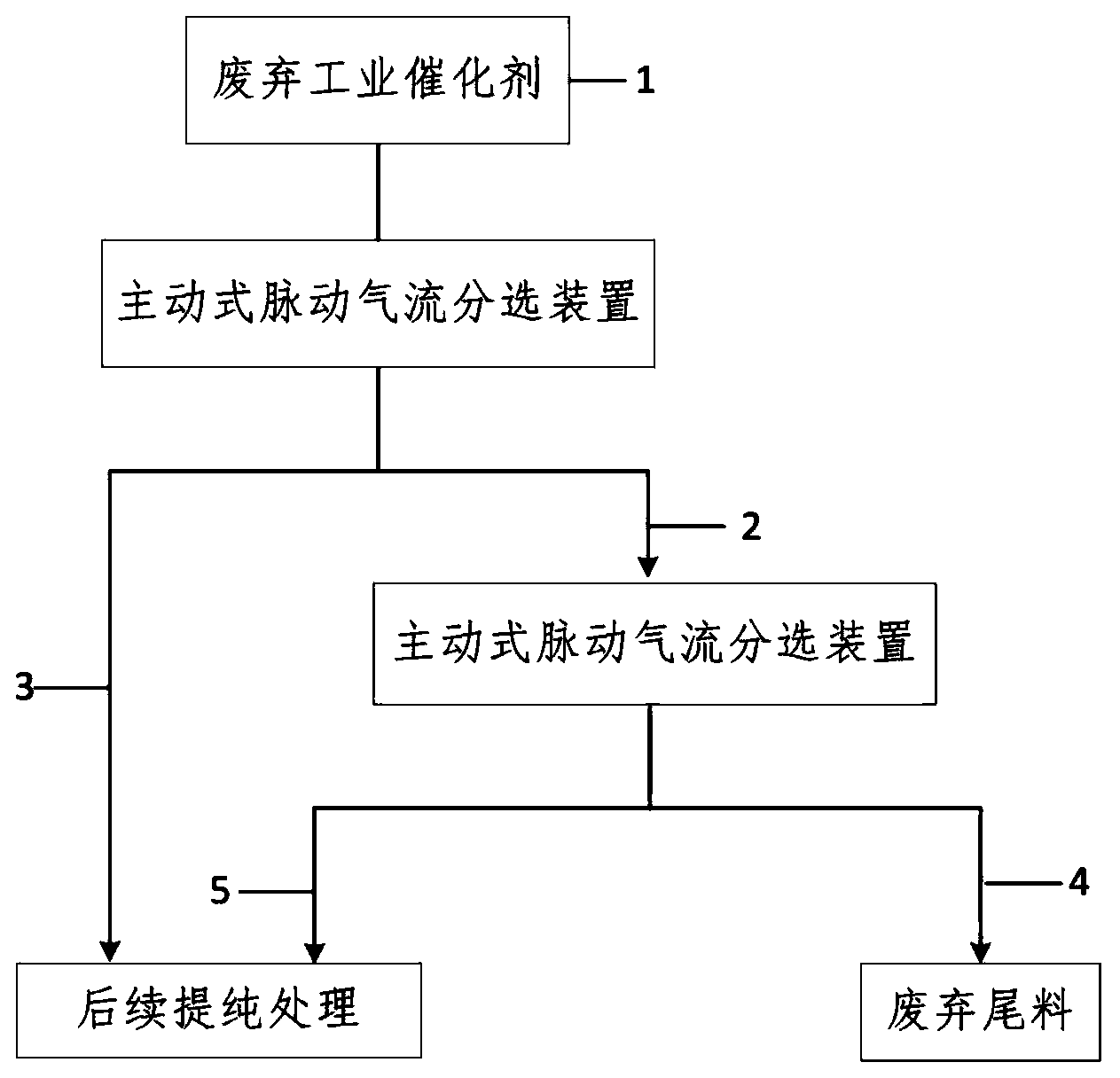

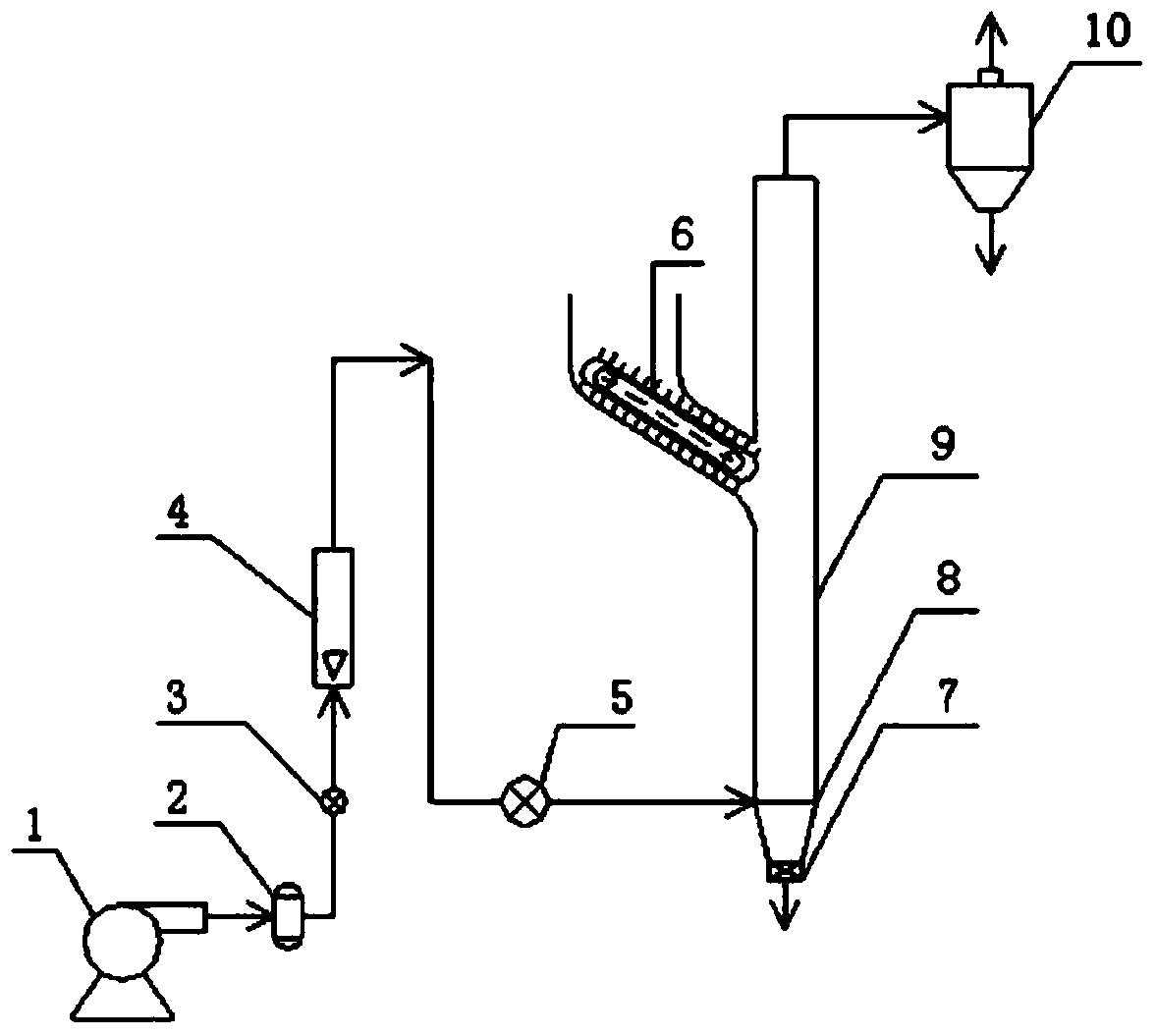

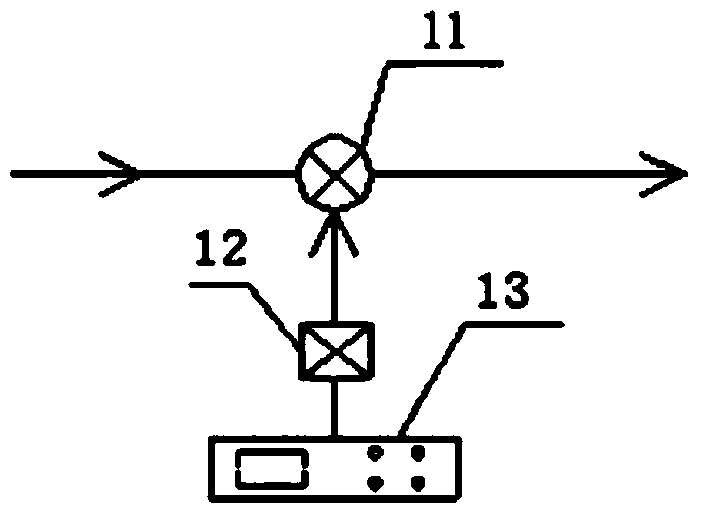

Dry method recovery process of re-integrated waste industrial catalyst and device thereof

ActiveCN103773960AAdaptableEfficient separationGas current separationProcess efficiency improvementRecovery methodMagnetic bead

The invention relates to a dry method recovery process of a re-integrated waste industrial catalyst and a device thereof, belonging to the recovery methods and devices of waste industrial catalysts. In the whole process adopting a physical treatment method, the re-integrated waste industrial catalyst is roughened at one time and scavenged or refined at one time or many times through an active pulse airflow sorting device to finally efficiently separate noble metal-enriched cavernous bodies and sintered magnetic beads to realize dry method recovery of the re-integrated waste industrial catalyst so as to provide advantages to subsequently purifying the enriched noble metals, thereby avoiding the defect that cavernous bodies are easy for argillization by a wet process to produce sewage to lead to secondary pollution. The active pulse airflow sorting device can obtain the sorting efficiency which is higher than that of conventional airflow sorting, and can efficiently separate the re-integrated waste industrial catalyst in a dried sorting environment, so that the device has the advantages of high sorting efficiency, small energy consumption, simplicity and agility in flow and the like.

Owner:CHINA UNIV OF MINING & TECH

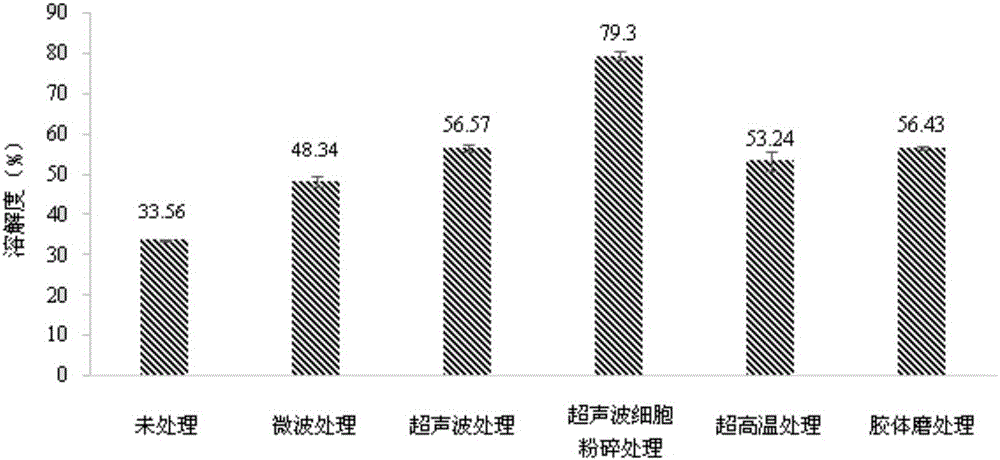

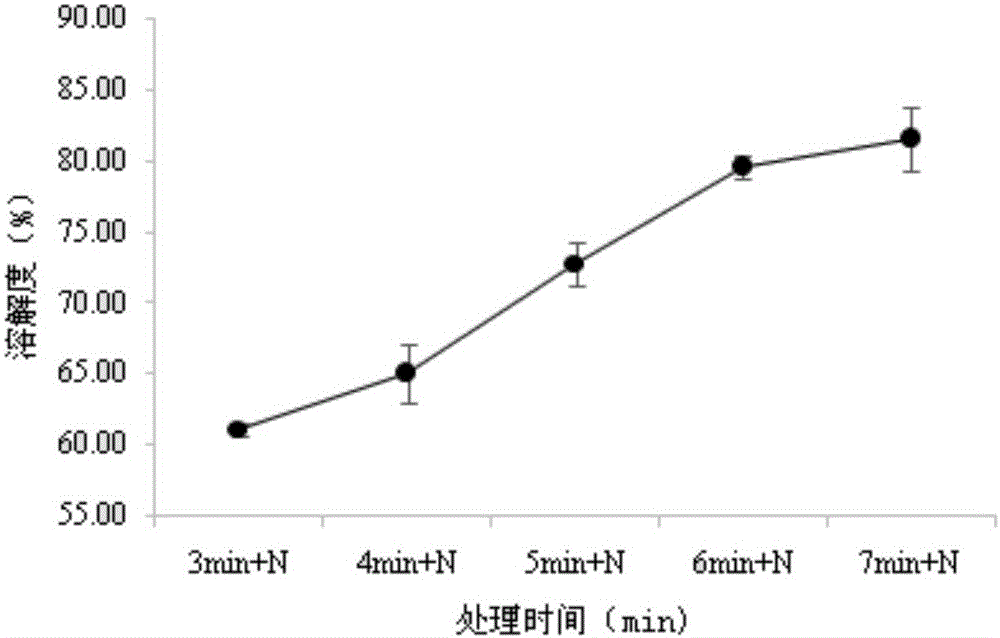

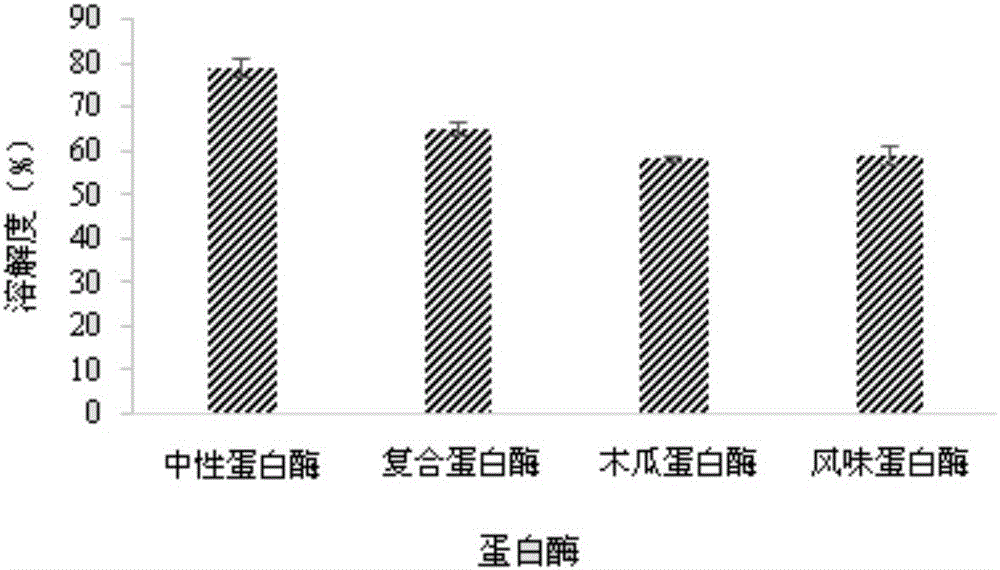

Method for increasing solubility of rice protein

The invention relates to extraction of rice protein, and particularly discloses a method for increasing the solubility of the rice protein. The method comprises the following steps of conducting ultrasonic cell crushing on the rice protein, and conducting enzymolysis by utilizing neutral protease to increase the solubility of the rice protein. Physical treatment methods and types of protease are screened by a great number of objective experiments and multi-factor optimization is performed based on the screening, and the technical scheme capable of remarkably increasing the solubility of the rice protein is finally determined. The method is simple in operation, mild in condition, short in treatment period and quick in solubility improvement. After the rice protein is treated by applying the method, the solubility of the rice protein can be increased from 0.62 percent to 79.30 percent.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

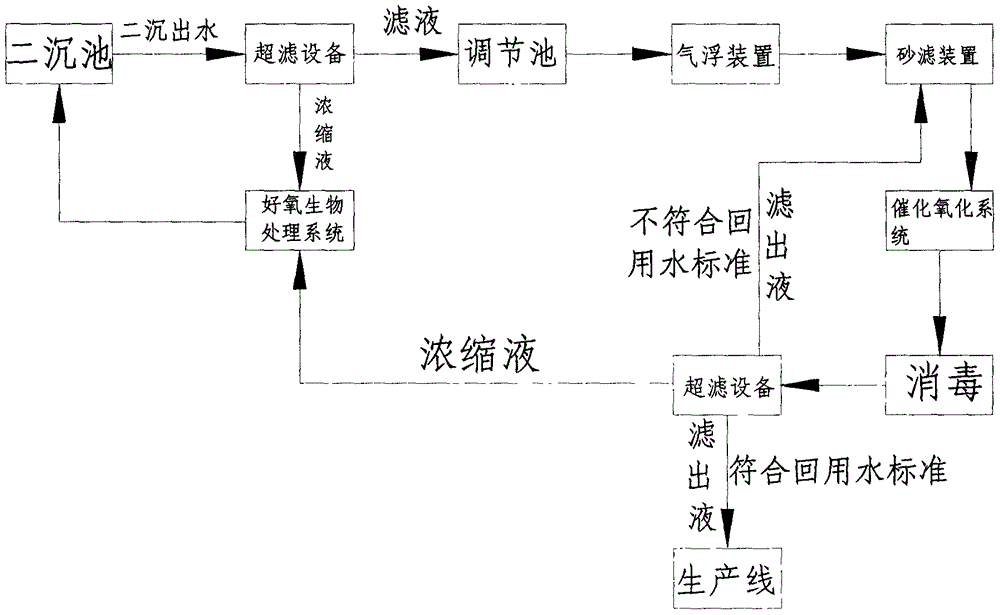

Process for advanced treatment of antibiotic waste water

ActiveCN105923931AAchieve reuseAchieve recyclingWater treatment parameter controlTreatment using aerobic processesChemical treatmentParticulates

The invention relates to a process for advanced treatment of antibiotic waste water. The process is used for further treating the waste water obtained after secondary sedimentation tank treatment during the treatment of the antibiotic waste water, and comprises the following steps: firstly, performing ultrafiltration treatment on the waste water, which is obtained after the secondary sedimentation tank treatment, in an ultrafiltration apparatus so as to filter out macromolecular particulate matters in the waste water, thereby obtaining a concentrated solution and a filtrate; and then, performing degradation treatment on the concentrated solution in an aerobic biological treatment system, delivering the concentrated solution after the degradation treatment in the aerobic biological treatment system into a secondary sedimentation tank, and treating the filtrate by a series of treatment steps of regulation, air flotation, sand filtration, catalytic oxidation, sterilization and detection to obtain recycled water which accords with a recycled water standard. The process provided by the invention combines a chemical treatment method, a physical treatment method and a membrane treatment method together, and has the advantages of short process route, good treatment effect, small produced sludge amount, low system energy consumption, low equipment operating cost, simple operation and small labor intensity.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD

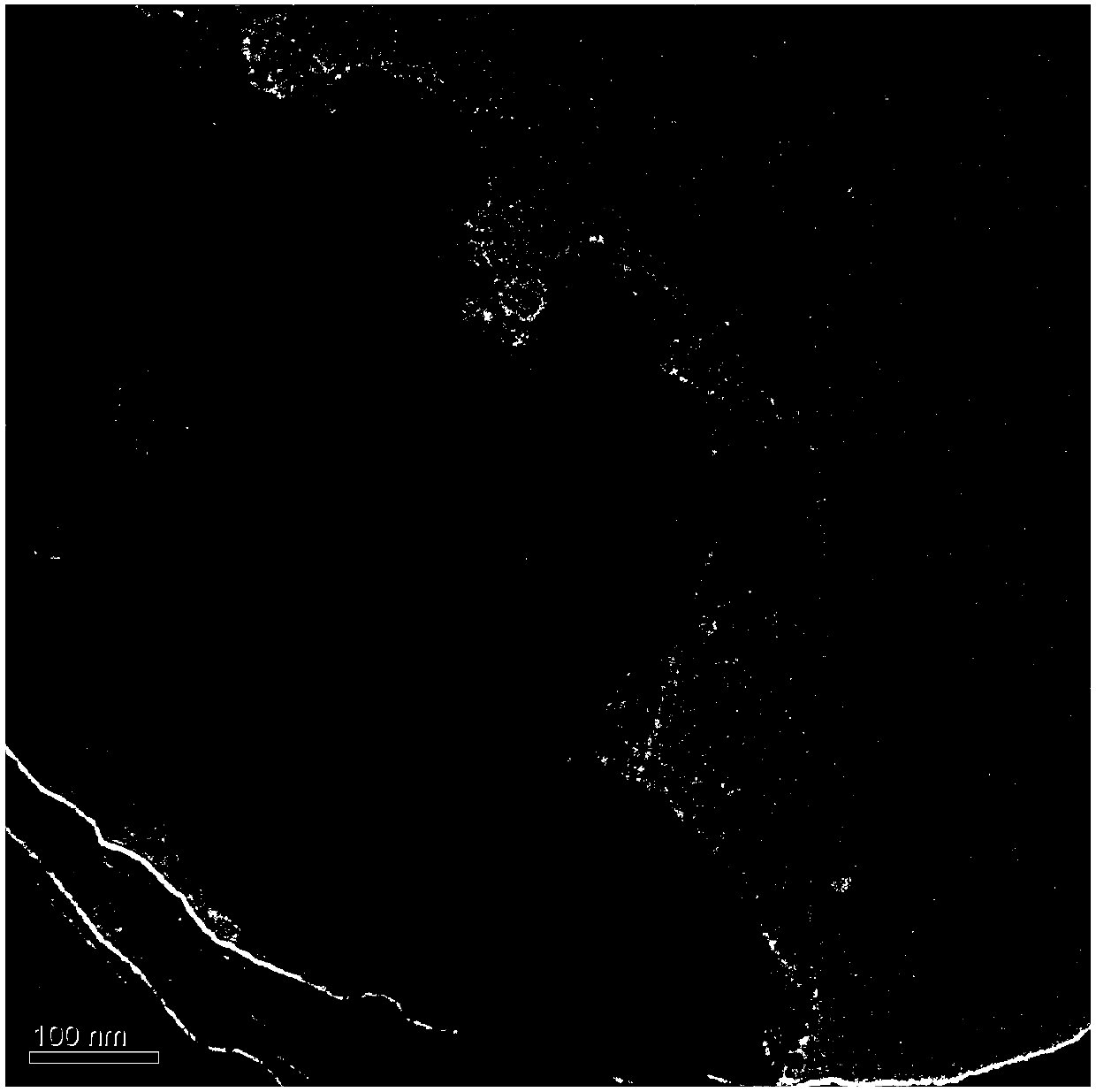

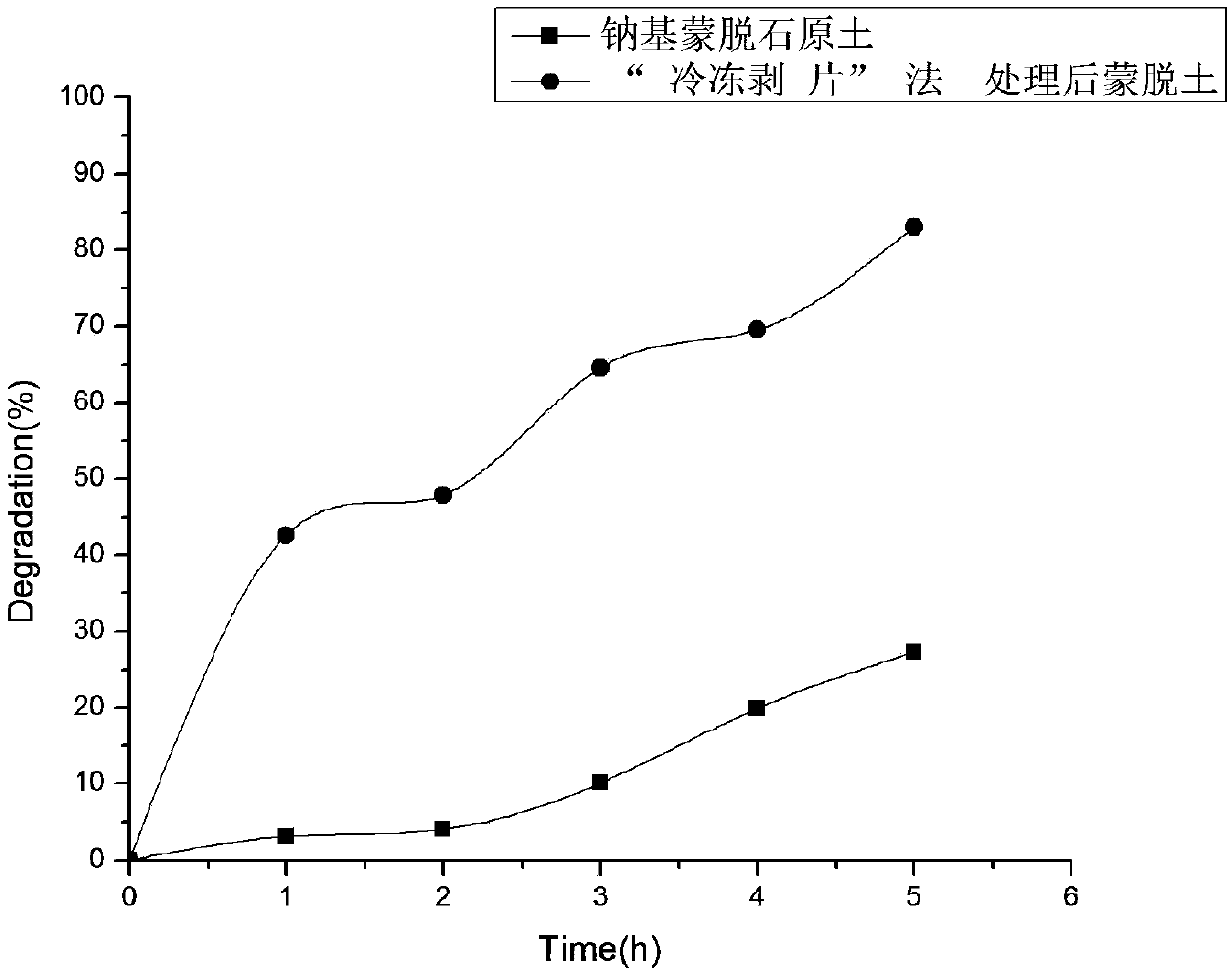

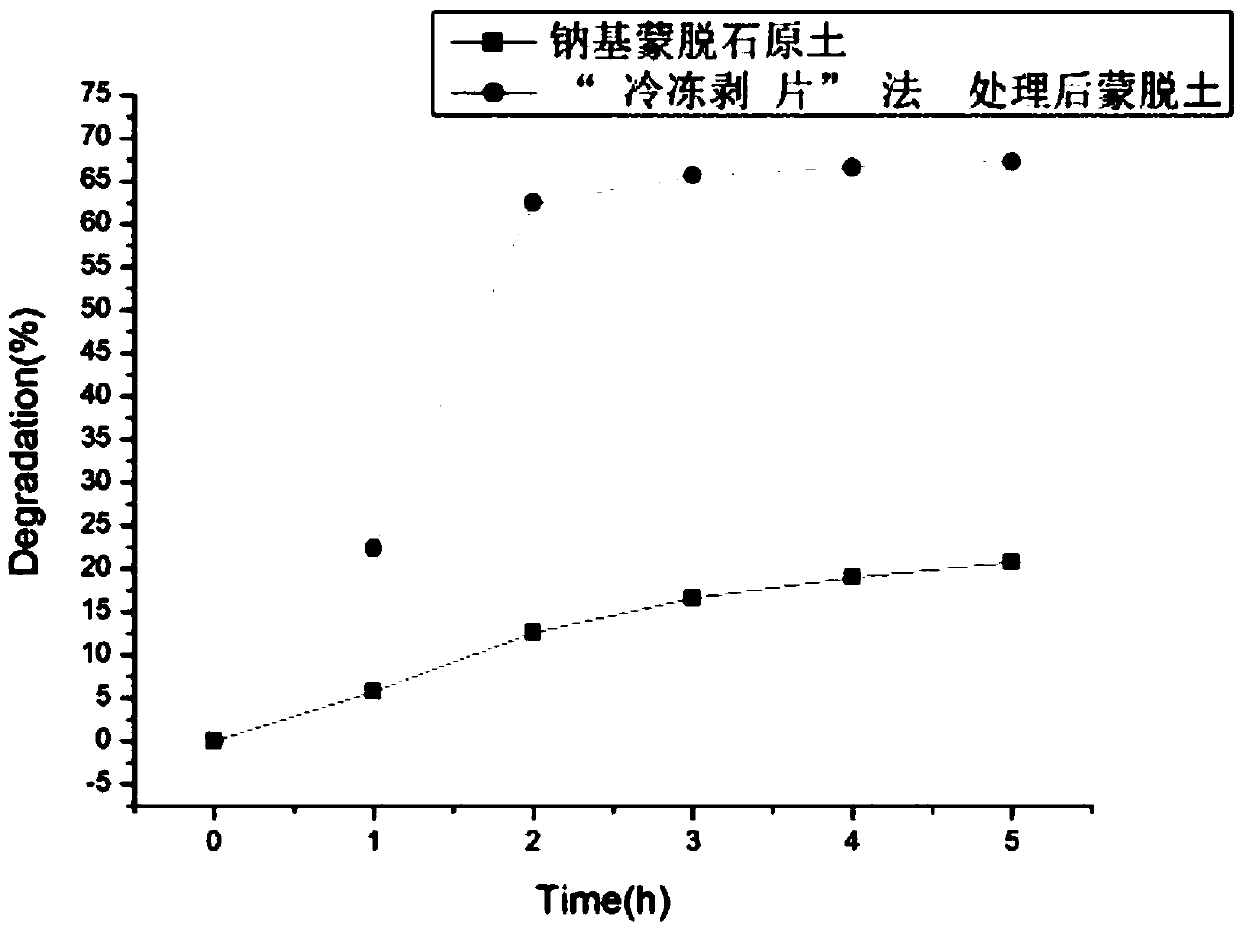

Preparation method of layered silicate mineral material based efficient adsorbent

InactiveCN107583601ALarge specific surface areaAvoid secondary pollutionOther chemical processesWater/sewage treatment by sorptionVacuum pumpingSorbent

The invention discloses a preparation method of a layered silicate mineral material based efficient adsorbent. The preparation method comprises steps as follows: layered silicate mineral is soaked inwater and is filtered after absorbing water sufficiently, and low-temperature drying is performed; freezing treatment is performed, and the temperature is reduced to zero DEG C or lower; an obtained material is put in a vacuum suction filter and subjected to vacuum pumping treatment; finally, the material is subjected to high-temperature drying treatment, and the layered silicate mineral materialbased efficient adsorbent is obtained. A freeze stripping method is a physical modification process performed under the condition that original interlayer spacing of the adsorbent is not changed, andother chemical modifiers are not needed; secondary pollution caused by the modification process is effectively avoided. A layered silicate mineral material is treated with the freeze stripping methodas a physical treatment method, so that the specific surface area of mineral can be increased, and the adsorption capacity of the mineral is greatly improved. Particularly, no chemical reagents are adopted for modification, and secondary pollution to the to-be-adsorbed material is avoided.

Owner:WUHAN UNIV OF TECH

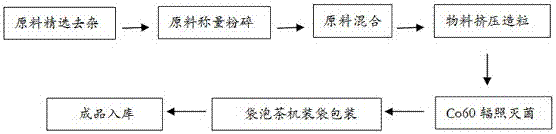

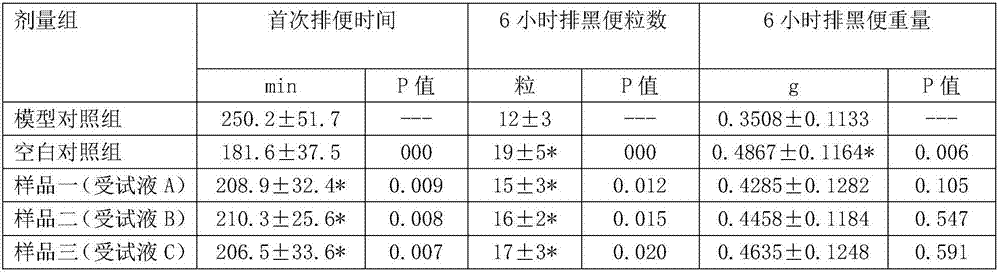

Pure herbal tea bag health care food for moistening intestines to relieve constipation and preparation method thereof

InactiveCN107361173ACompatibility is reasonableAll-around mild flavorPre-extraction tea treatmentMedicinal herbsSenna Leaves

The invention discloses pure herbal tea bag health care food for moistening intestines to relieve constipation and a preparation method thereof and relates to the technical field of health care food. The health care food is prepared from the following Chinese herbal medicines by weight: 20-40 parts of senna leaves, 5-15 parts of green tea, 5-15 parts of black tea, 10-30 parts of cassia seeds, 5-15 parts of poria cocos, 5-15 parts of Chinese yam, 5-15 parts of coastal glehnia roots and 5-10 parts of honey. The preparation method is described as follows: grinding the 8 herbal ingredients directly; mixing the ground ingredients uniformly in a certain proportion; granulating the mixed medicines through ring-die extrusion; and performing sub-packaging on the granulated ingredients through a teabag packaging machine based on the specification of 2.0g-5.0g / bag. Physical treatment methods are adopted for all the steps of the process without adding any auxiliary process materials; and the pollution of waste gas, waste water and waste residues are not produced. The process is simple, convenient, highly efficient, energy-saving and environmentally friendly.

Owner:BEIJING AOTE SHUER HEALTH PROD DEV

Processing method of candied ziziphus mauritiana with unique tastes

ActiveCN106070966AAvoid damageComprehensive cleaningConfectionerySweetmeatsTreatment effectAdditive ingredient

The present invention discloses a processing method of candied ziziphus mauritiana with unique tastes. The processing method comprises the following steps: 1) screening; 2) comprehensive cleaning; 3) line scribing on surfaces; 4) secondary cleaning; 5) draining; 6) ingredient blending in a pot; 7) ziziphus mauritiana slurry preparing; 8) cooking; 9) water evaporation and sugar absorbing; 10) ziziphus mauritiana slurry draining; 11) short time and high temperature drying; 12) shaping; 13) long time and moderate temperature drying; 14) natural cooling; and 15) vacuum packaging. The method conducts a detailed description of the early period treatment processes of the ziziphus mauritiana, and a physical treatment method is used to improve the treatment effects, also improves the treatment efficiency, and improves the line scribing effects. The processed and shaped candied ziziphus mauritiana is unique in mouthfeel and high in transparency.

Owner:郎溪县侯村蜜枣场

Method for cleaning electrosparking grid mesh

InactiveCN103418584ASimple processShorten the timeCleaning processes and apparatusChemical treatmentChemical physics

The invention discloses a method for cleaning an electrosparking grid mesh. The method includes the steps that the grid mesh is placed into a degreasing solution for degreasing, the grid mesh is treated in a sodium hydroxide solution, the grid mesh is treated under a microscope, a banister brush dipped in absolute ethyl alcohol is used for grooming the surface of the grid mesh until large blots are removed, the grid mesh is placed into a first pickling solution to be treated, the grid mesh is placed into a second pickling solution to be treated, and cleaning, dehydration and drying are conducted in flowing hot water. The method for cleaning the electrosparking grid mesh is simple in technology, the main treatment method of the grid mesh is a physical treatment method, the chemical treatment time and process are reduced, and the original processing size value of the size of the treated grid mesh can be reserved maximally.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Comprehensive chemical and physical treatment method of serpentine

The invention belongs to the technical field of comprehensive utilization of chemistry and chemical engineering of mineral resources and provides a comprehensive chemical and physical treatment method of serpentine for solving the problems of the existing serpentine treatment process of complicated manufacturing process, poor product quality, low utilization rate of effective components and great raw material consumption. The method comprises the following steps: crushing serpentine; by using calcium fluoride as an activating agent and using lauryl sodium sulfate as a catalyst, treating serpentine powder by using concentrated sulfuric acid, and reacting to generate a gas, liquid and a solid precipitate; ammonifying the gas to generate gas phase white carbon black, further separating the liquid, removing impurities, adding ammonia water to precipitate magnesium, precipitating and roasting to decompose to obtain active magnesium oxide, and crystallizing the solution to produce an ammonia sulfate chemical fertilizer. The serpentine is prepared into three main products, namely gas phase white carbon black, active magnesium oxide and the ammonia sulfate fertilizer, two byproducts, namely gypsum and solid phase iron as well as a kind of metal slag, no waste is produced, the serpentine is developed to the uttermost, and final development products are obtained to the uttermost. The raw materials are fully utilized, and the original components are converted into products with high added values.

Owner:于拴全

Method for improving thermal stability of collagen through ultrahigh pressure treatment

InactiveCN105918761AEasy to handleImprove thermal stabilityFood preservationUltra high pressure food processesUltra high pressureFreeze-drying

The invention discloses a method for improving the thermal stability of collagen through ultrahigh pressure treatment. The method comprises the following steps of (1) dissolving natural collagen with an acetic acid aqueous solution so as to obtain a collagen solution; (2) placing the collagen solution in a soft packaging material, and performing vacuumized and sealed packaging; (3) placing the soft packaging material after sealed packaging in an ultrahigh pressure vessel, and performing ultrahigh pressure treatment; and (4) taking out the collagen solution, and performing freeze drying so as to obtain a collagen product of which the thermal stability is improved. According to the method disclosed by the invention, through an ultrahigh pressure physical treatment method, the thermal stability of collagen molecules is effectively improved. Compared with conventional methods of chemical modification, chemical crosslinking and the like, the method disclosed by the invention has the advantages that the basic structural composition of the collagen molecules is not changed, new chemical components are not introduced, the unique bioactivity and the biological safety of the collagen are not changed, and the treatment means are simple and practicable to implement.

Owner:WUHAN POLYTECHNIC UNIVERSITY

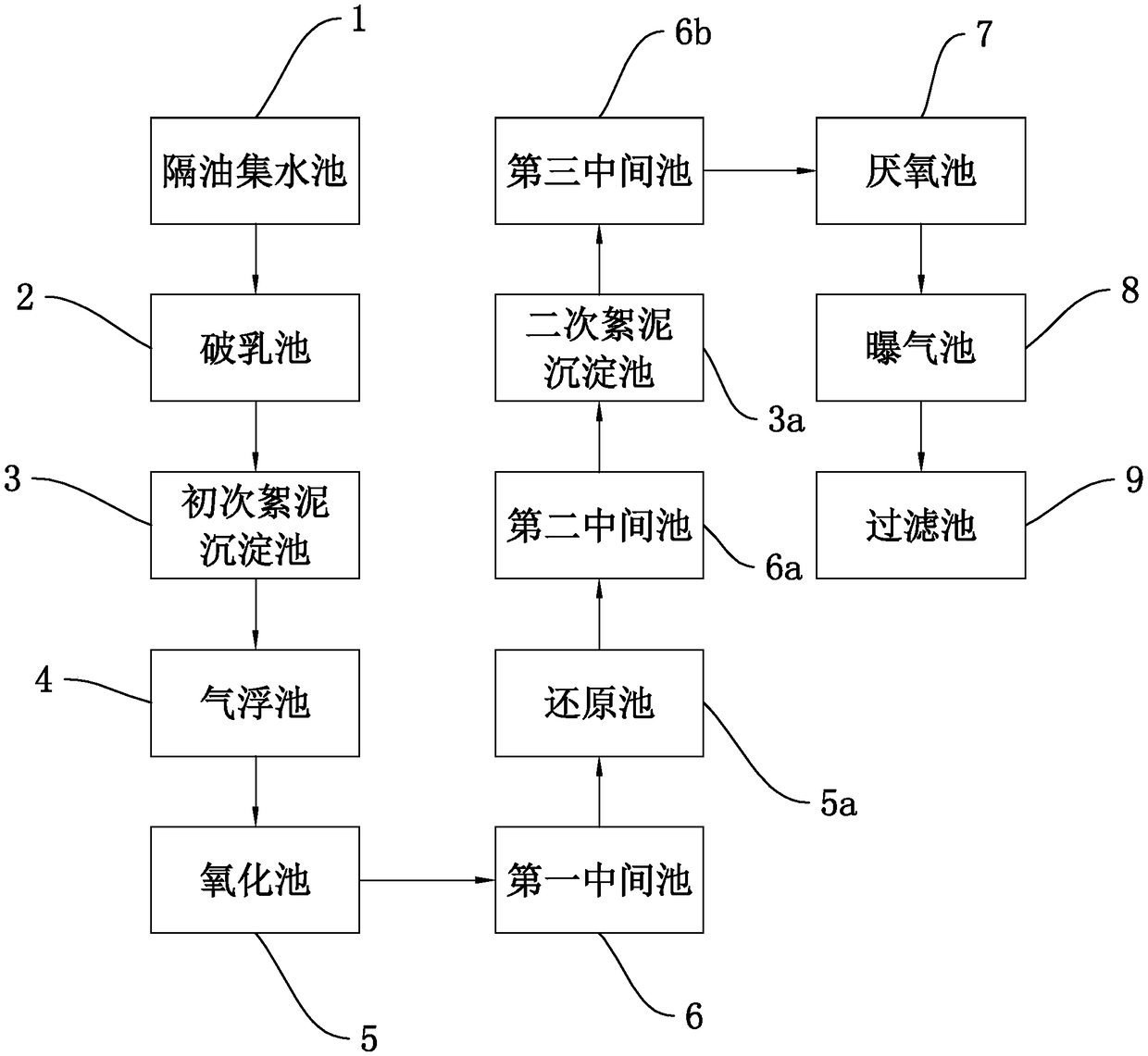

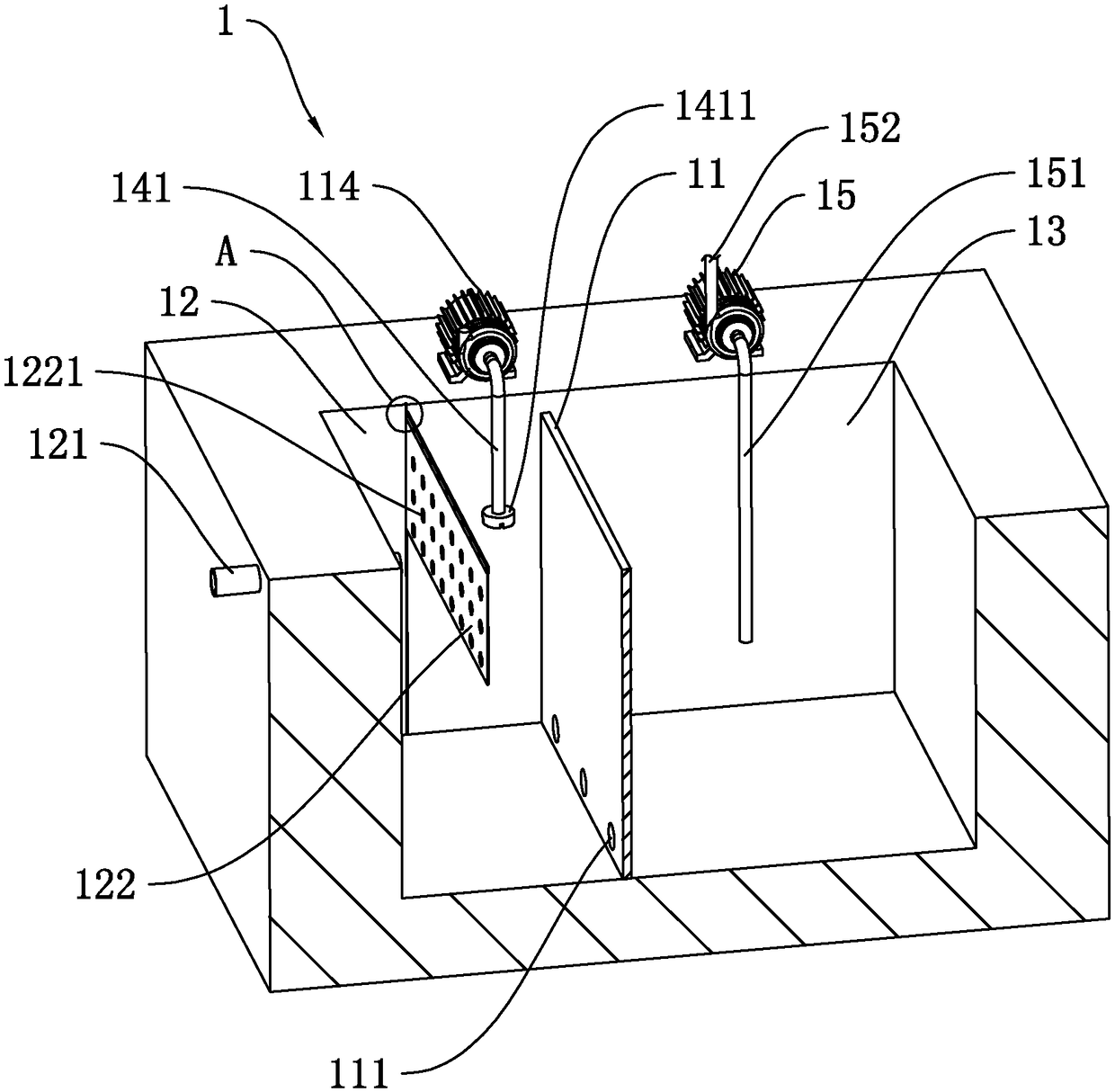

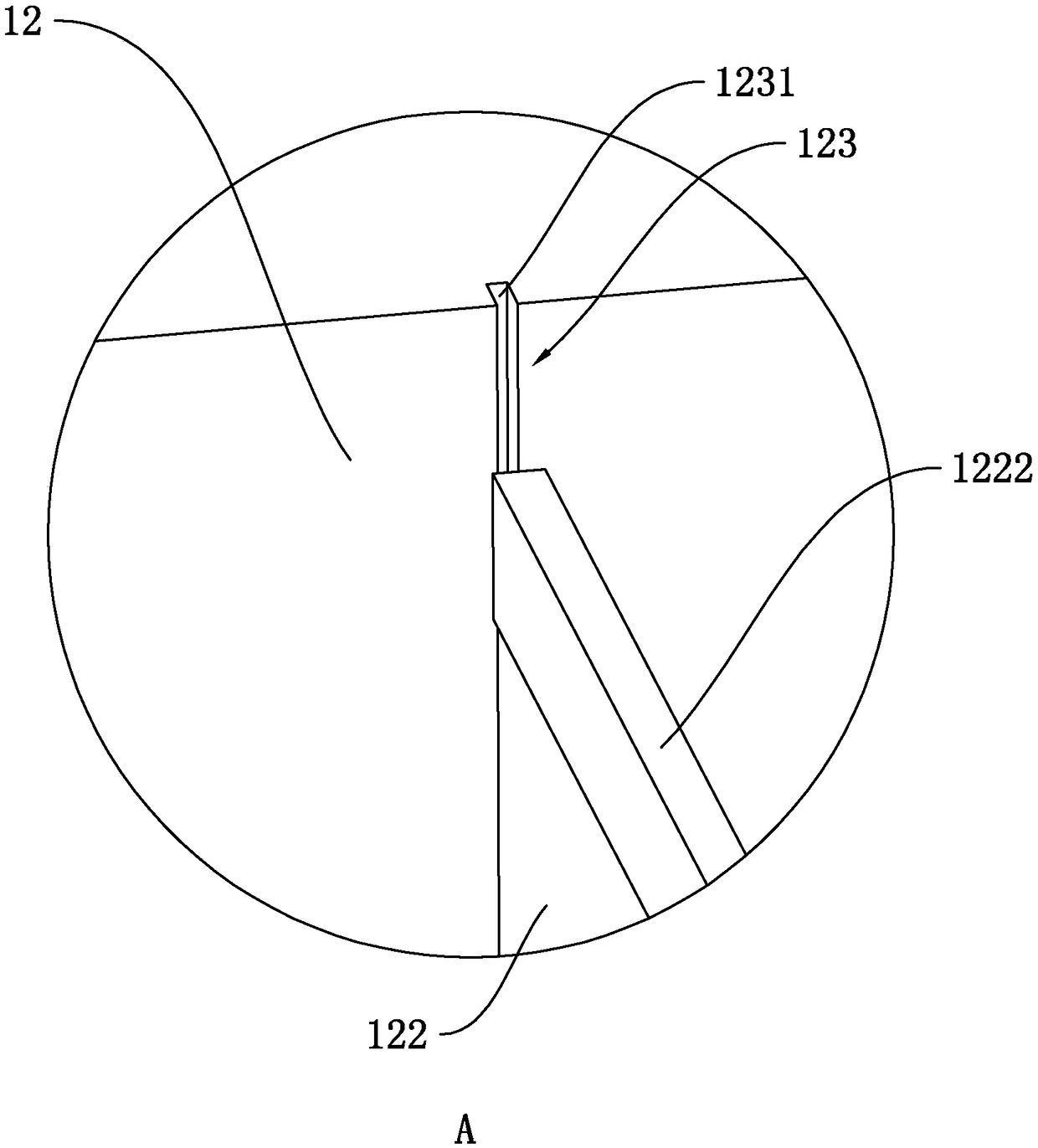

Industrial oily wastewater treatment system

InactiveCN108892320AImprove processing efficiencySmall footprintFatty/oily/floating substances removal devicesTreatment involving filtrationActivated sludgeChemical treatment

The invention relates to industrial wastewater treatment, and discloses an industrial oily wastewater treatment system. According to the technical scheme, the industrial oily wastewater treatment system comprises an oil separation and water collecting pond, a demulsification pond, a primary flocculated mud sedimentation pond, a flotation pond, an oxidation pond, a reduction pond, a secondary flocculated mud sedimentation pond, an anaerobic pond and an aeration pond which are successively connected, a first middle pond is arranged between the oxidation pond and the reduction pond, a second middle pond is arranged between the reduction pond and the secondary flocculated mud sedimentation pond, and a third middle pond is arranged between the secondary flocculated mud sedimentation pond and the anaerobic pond; oil and water are separated preliminarily by the oil separation and water collecting pond; the demulsification pond breaks the emulsion state of the separated wastewater; flocculatesof oil is settled in the primary flocculated mud sedimentation pond; and by chemical reaction in the oxidation pond and the reduction pond, macromolecular organic matters in the wastewater are decomposed; activated sludge is placed in the anaerobic pond and the aeration pond, and low molecular weight organic matters are biochemically degraded; and the industrial oily wastewater is treated by organically combining a physical treatment method, a chemical treatment method and a biological treatment method to achieve an expected emission standard, and thus, the industrial oily wastewater treatment system is effectively and practical.

Owner:浙江海之蓝环保科技有限公司

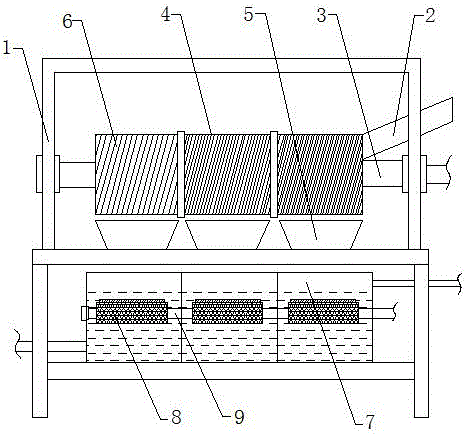

Waste crushing device of aluminum electrolytic capacitor

PendingCN110152826AEasy to recyclePromote fragmentationSolid waste disposalGrain treatmentsPulp and paper industryAluminum electrolytic capacitor

The invention discloses a waste crushing device of an aluminum electrolytic capacitor and separated into metal aluminum, guide needles, electrolytic paper and glue plugs by adopting a physical treatment method. The waste crushing device comprises a box body, and is characterized in that a crushing box is arranged at the upper part of the box body, a feeding opening is formed in the upper part of the crushing box, a discharging opening is formed in the lower part of the crushing box, a net screen is arranged above the discharging opening, a crushing roller driven by the power is arranged in thecrushing box, a moving cutter blade is mounted on the crushing roller, and a fixed cutter blade is mounted on a box body of the crushing box. During working, shearing is conducted on the waste by thefixed cutter blade and the moving cutter blade, so that the waste of the aluminum electrolytic capacitor is separated into the metal aluminum, the guide needles, the electrolytic paper and the glue plugs. The waste crushing device is simple in structure and high in crushing and separating effect, and the metal aluminum, the guide needles, the electrolytic paper and the glue plugs are convenientlyrecycled by adopting the physical treatment method subsequently.

Owner:湖南金福达电子有限公司

Process and special device for treating domestic sewage and waste water of paper mill

InactiveCN101538092AReduce manufacturing costSave energyMultistage water/sewage treatmentWaste water treatment from plant processingLow speedEmission standard

The invention relates to a process and a special device for treating domestic sewage and waste water of a paper mill. At present, the emission of much waste water causes serious pollution to the environment, and the treatment method of the waste water has a biological treatment method, a physical treatment method, and the like. The biological treatment method has long treatment time and low speed; the physical treatment method has high treatment cost and halfway treatment, and can not achieve the emission standard. The invention aims at designing a process and a special device for treating domestic sewage and waste water of paper mill. Waste water treatment agent A comprises the following components according to the weight: 8 portions of furnace dust waste stock and 2 portions of aluminum dust waste stocks; waste water treatment agent B comprises the following components according to the weight: 8 portions of calcium oxide waste stock and 2 portions of aluminum potassium sulfate powder waste stock; and 1 percent of the A component and 99 percent of the domestic sewage are uniformly mixed in a mixing tank according to the weight and then are settled to obtain industrial waste. The invention treats the domestic sewage and the waste water of the paper mill by utilizing the waste water treatment agent, which has high speed and more thorough treatment, can achieve the emission standard, and can be repeatedly utilized, thereby saving water resource.

Owner:武泽成

Printing and dyeing wastewater treatment device

InactiveCN105967375ARealize green environmental protection treatmentAvoid filteringTreatment involving filtrationMultistage water/sewage treatmentChemical treatmentWastewater

The invention provides a printing and dyeing wastewater treatment device, comprising a wastewater tank, an adsorption and clarification tank, a secondary filtering device, a ternary filtering device and a reservoir, which are connected in sequence through a water drainage pipe. Printing and dyeing wastewater is stored in the wastewater tank; the wastewater tank is arranged above the adsorption and clarification tank, the secondary filtering device, the ternary filtering device and the reservoir; after the wastewater in the wastewater tank is purified and filtered through the adsorption and clarification tank, the secondary filtering device and the ternary filtering device under the effect of self weight water pressure, purified water is discharged into the reservoir. The printing and dyeing wastewater treatment device provided by the invention combines a physical treatment method and a chemical treatment method and takes the physical treatment method as a main part; the filtering cost is lower and the filtering effect is better; the utilization of a lot of chemical agents in the prior art and secondary pollution caused by the chemical agents are avoided so that green and environment-friendly treatment of the printing and dyeing wastewater is realized.

Owner:WUXI ANG YIDA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com