Patents

Literature

122 results about "Settling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Settling Rates. The rate at which solids settle depends on the force causing the settling, the dimensions of the solid, and the fluid viscosity in which the solid is settling.

Oil based concentrated slurries and methods for making and using same

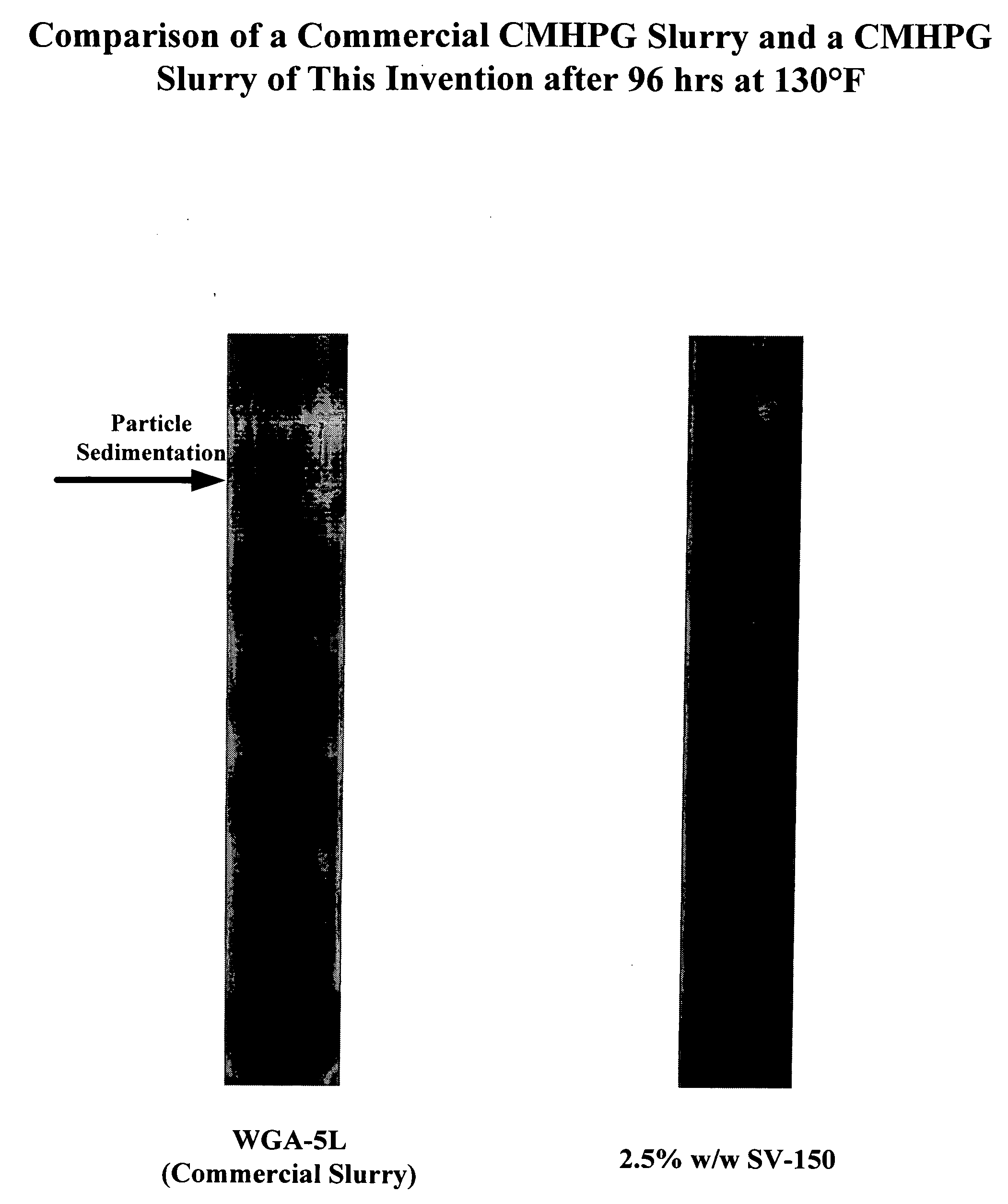

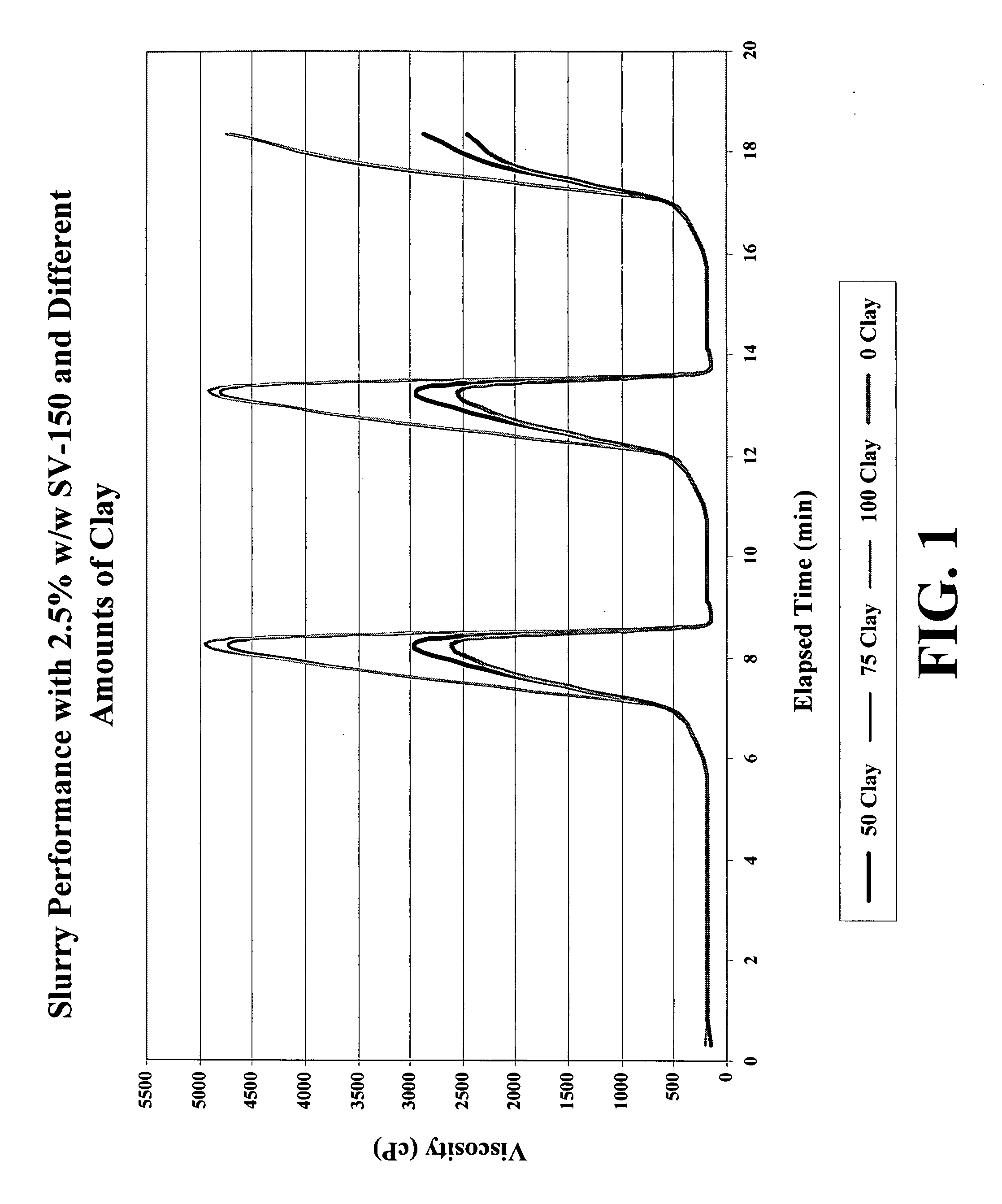

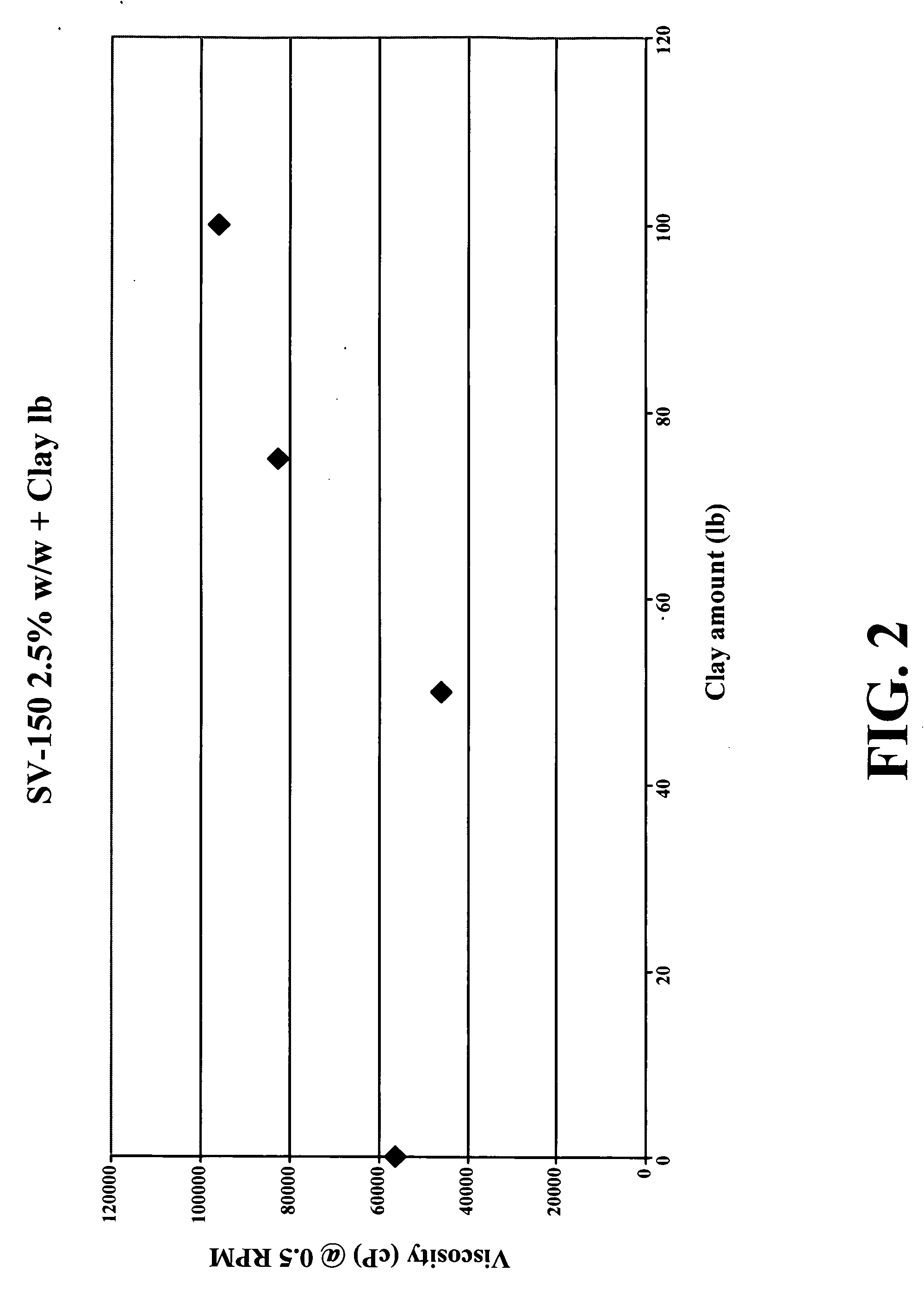

InactiveUS20080318812A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

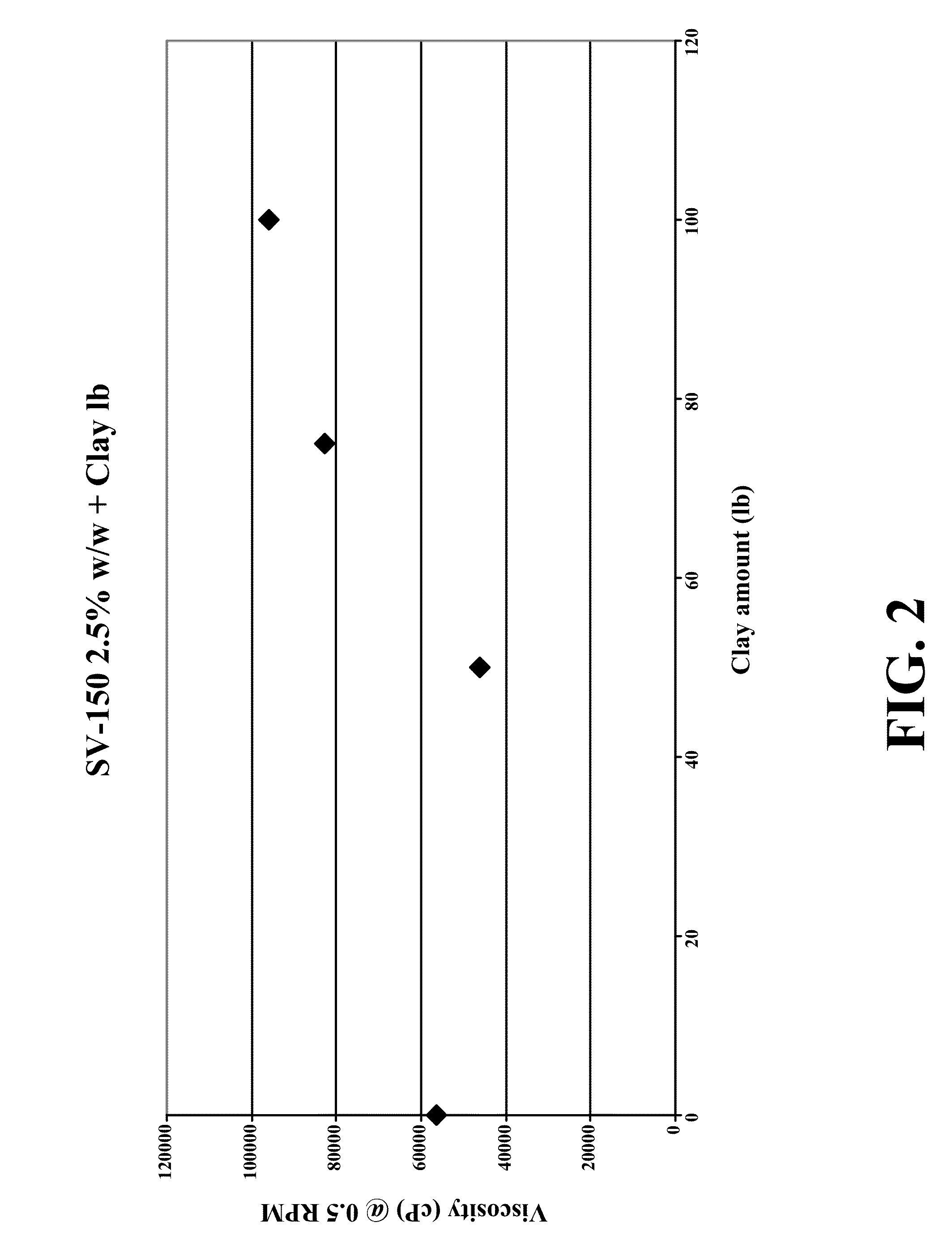

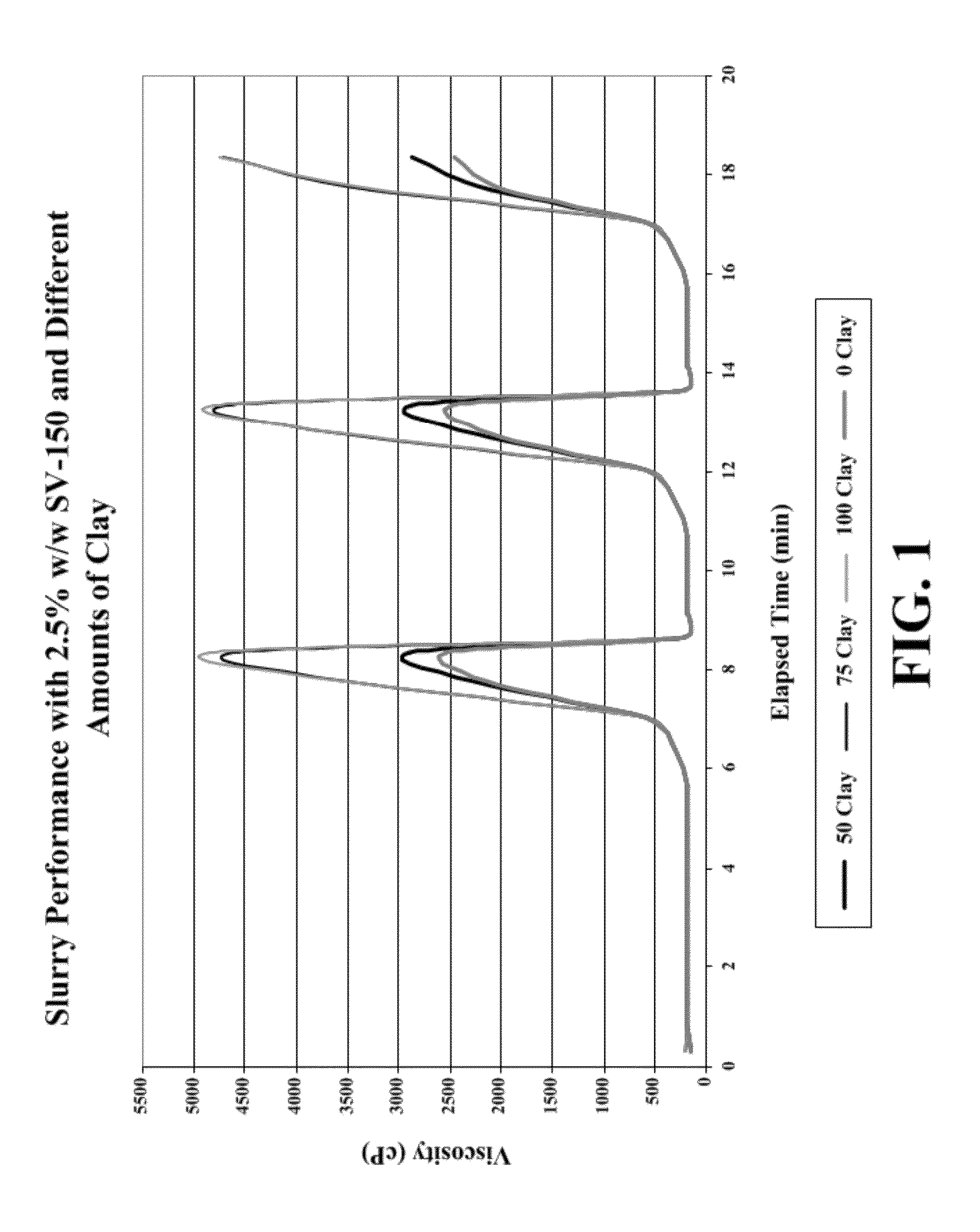

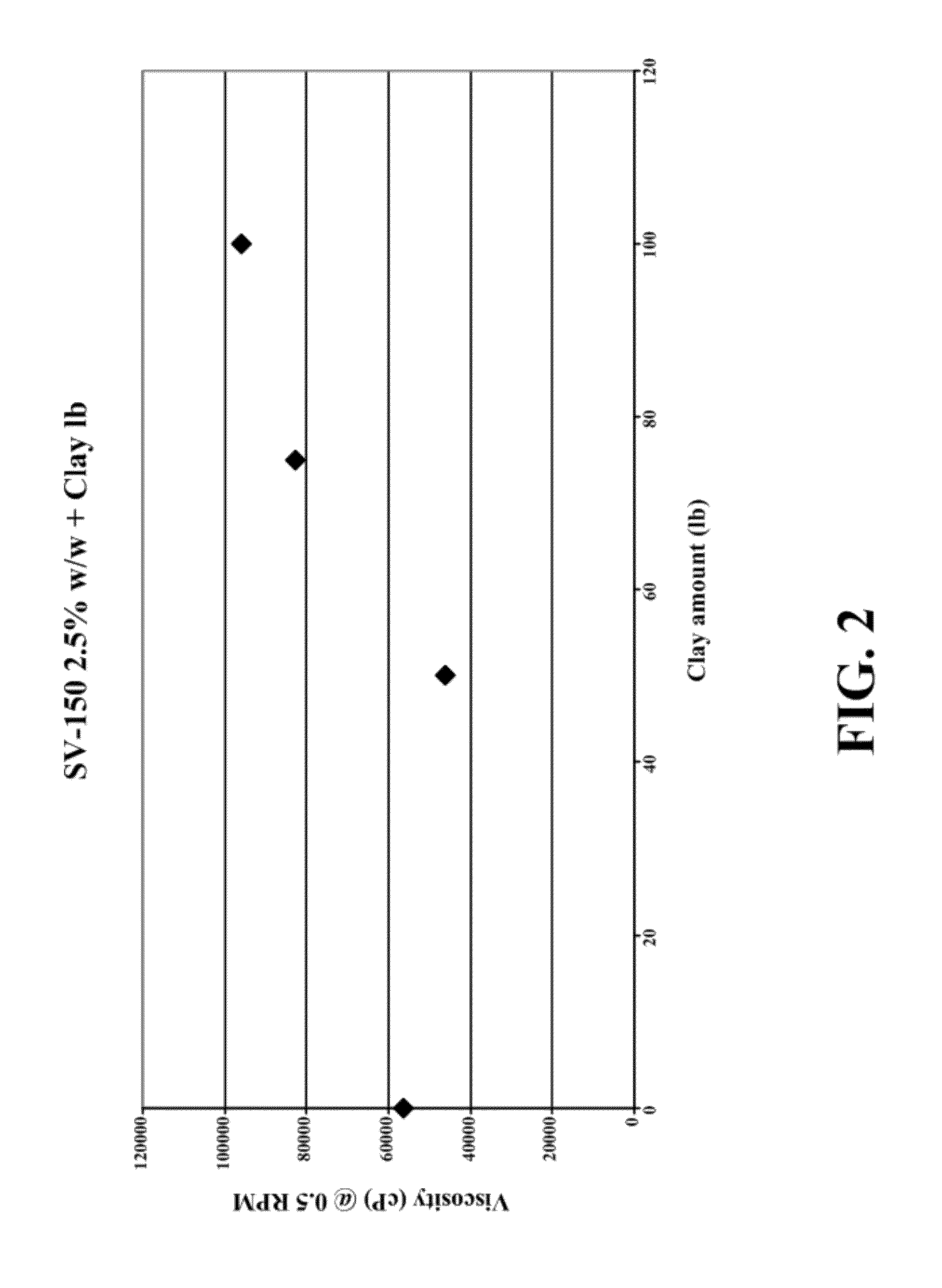

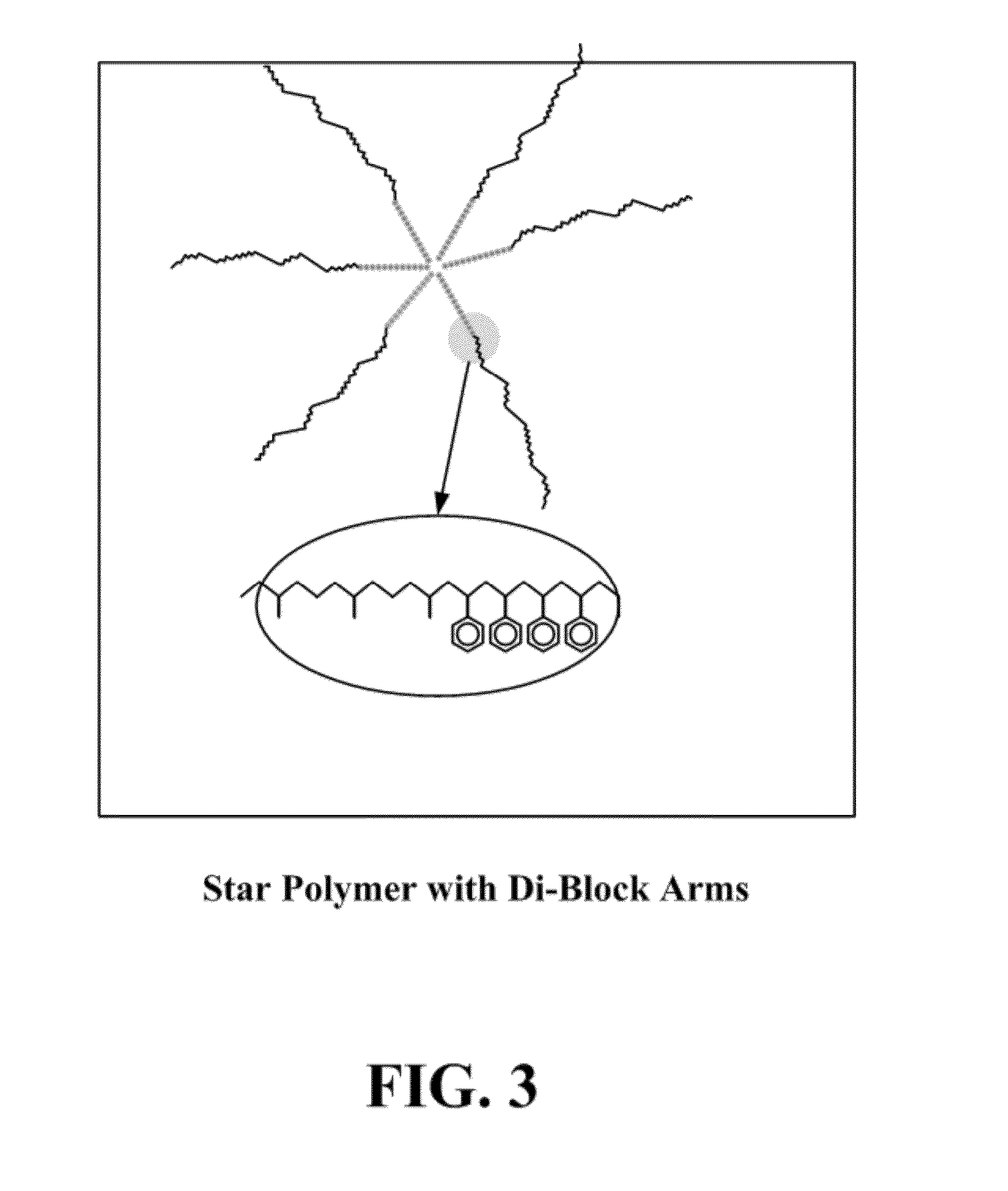

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

Low concentrations of gas bubbles to hinder proppant settling

InactiveUS20100252262A1Low densityReduce sedimentation rateFluid removalFlushingFracturing fluidBuoyancy

Owner:CLEARWATER INT LLC

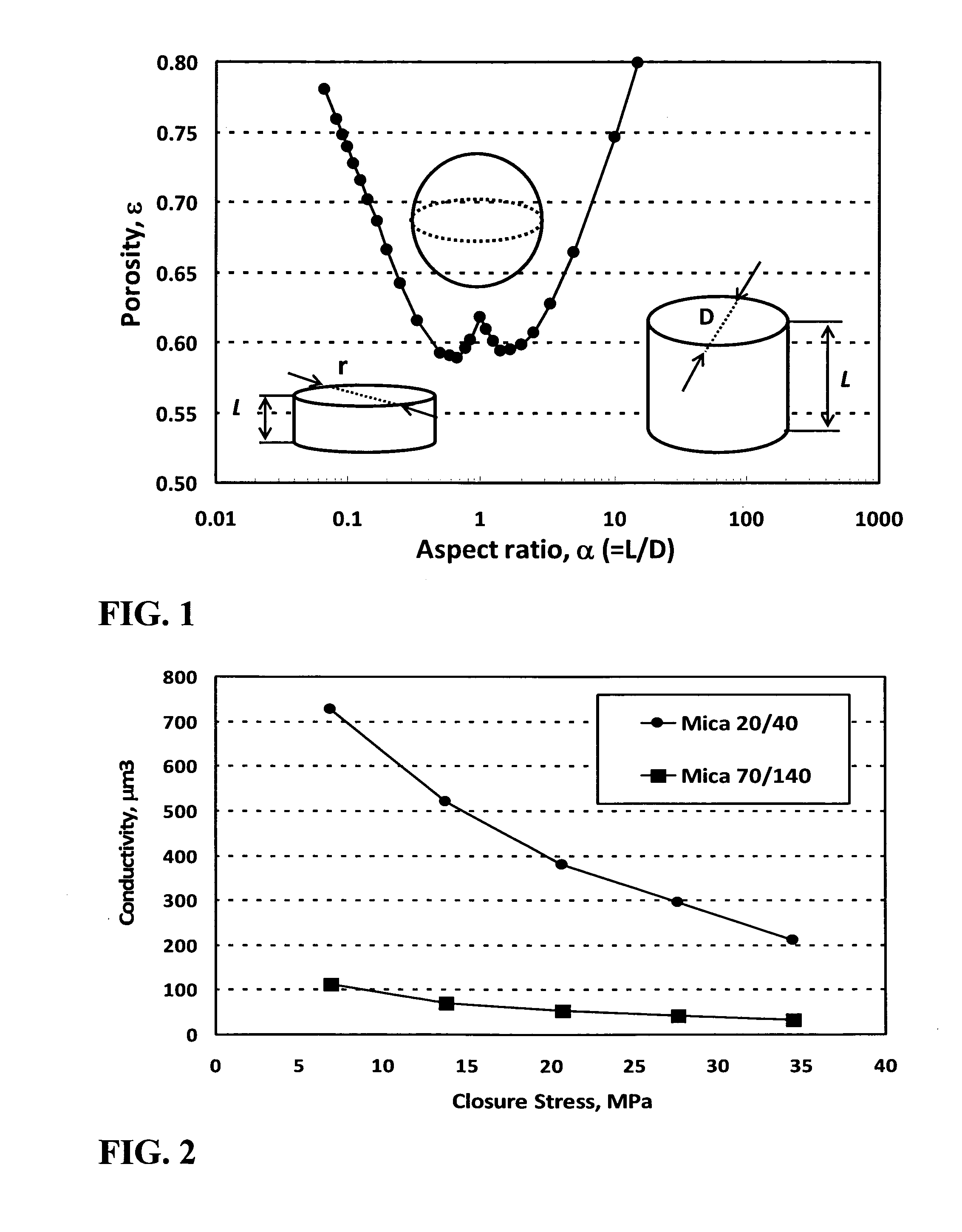

Hydraulic Fracturing Proppants

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

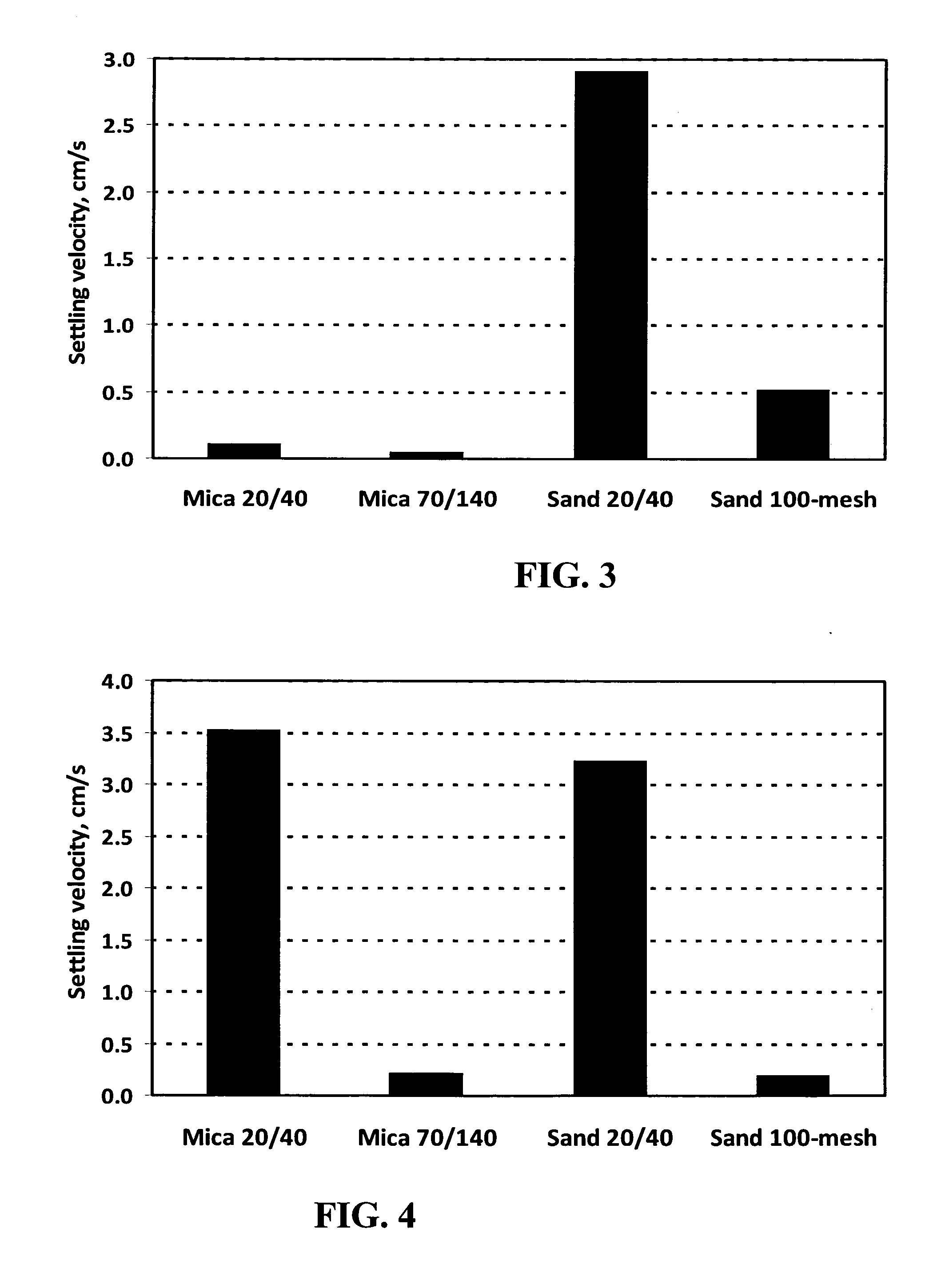

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

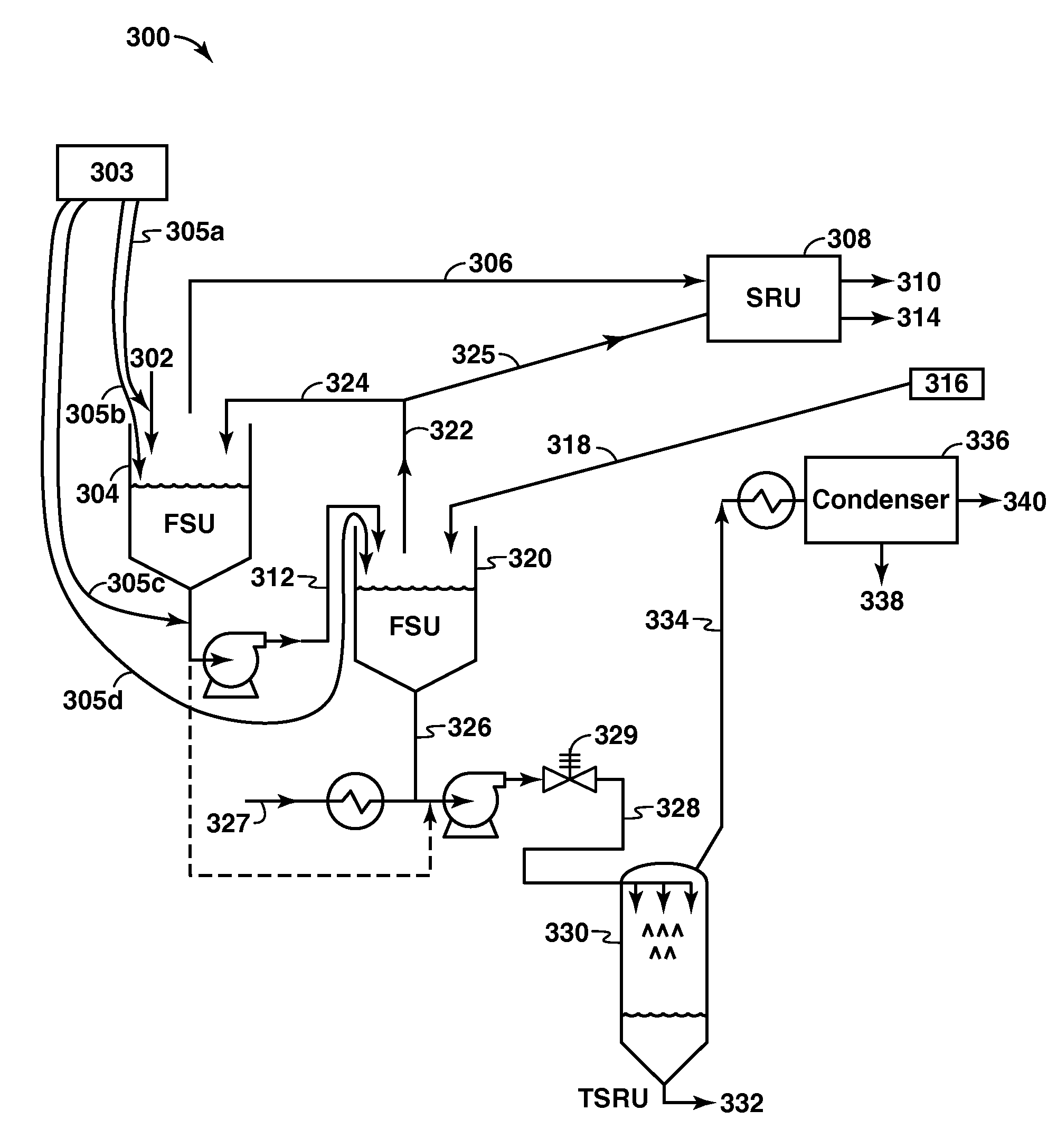

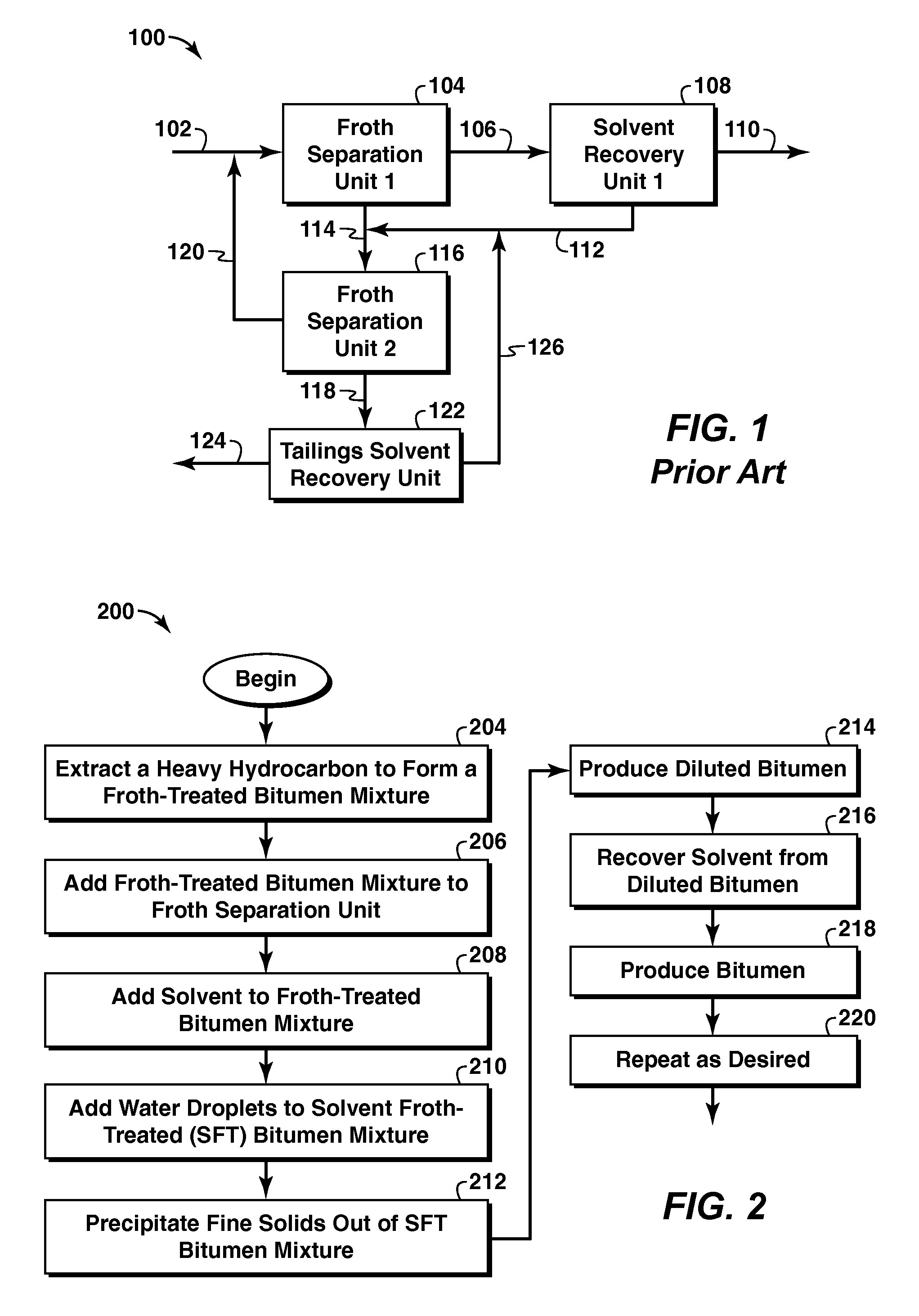

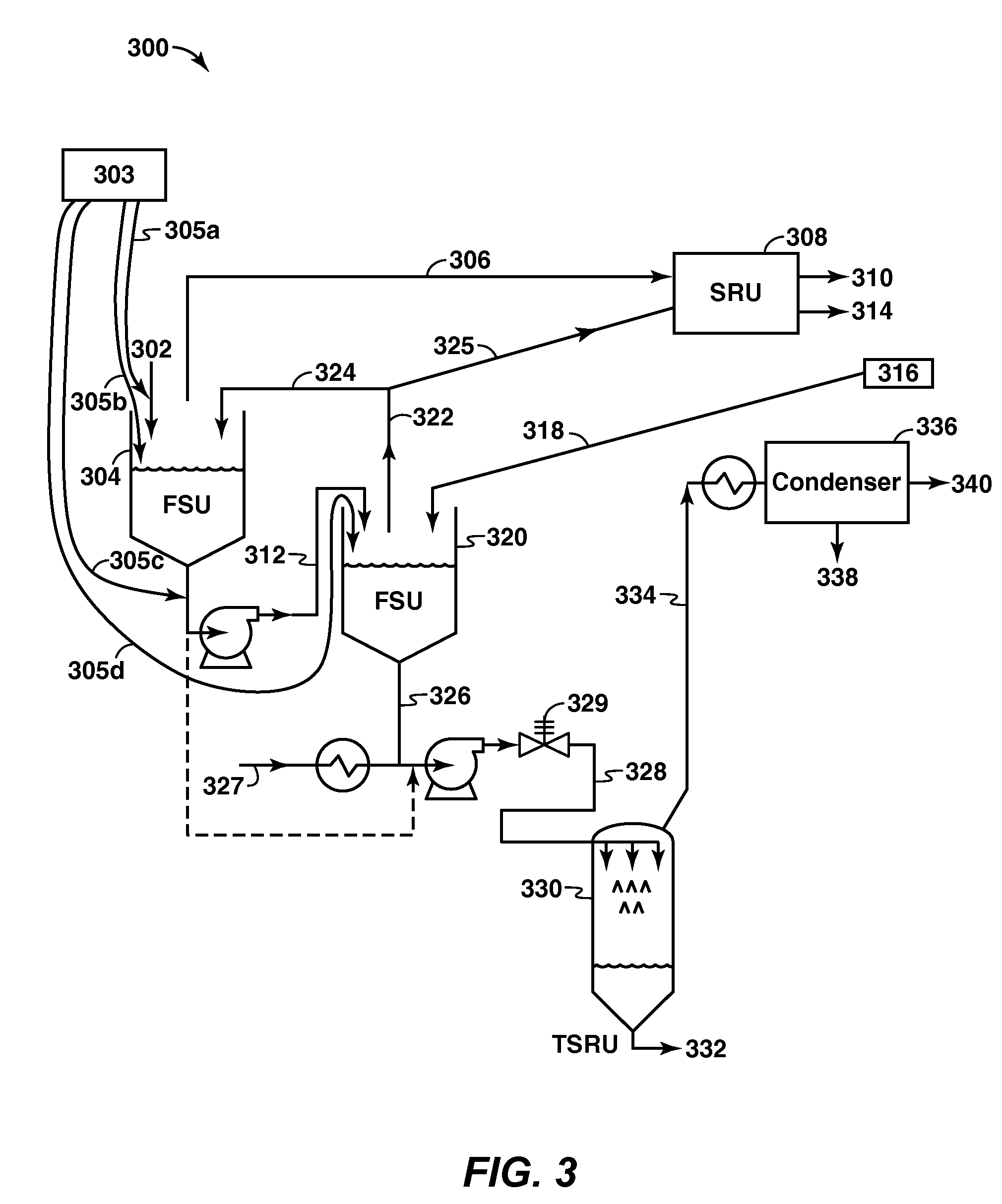

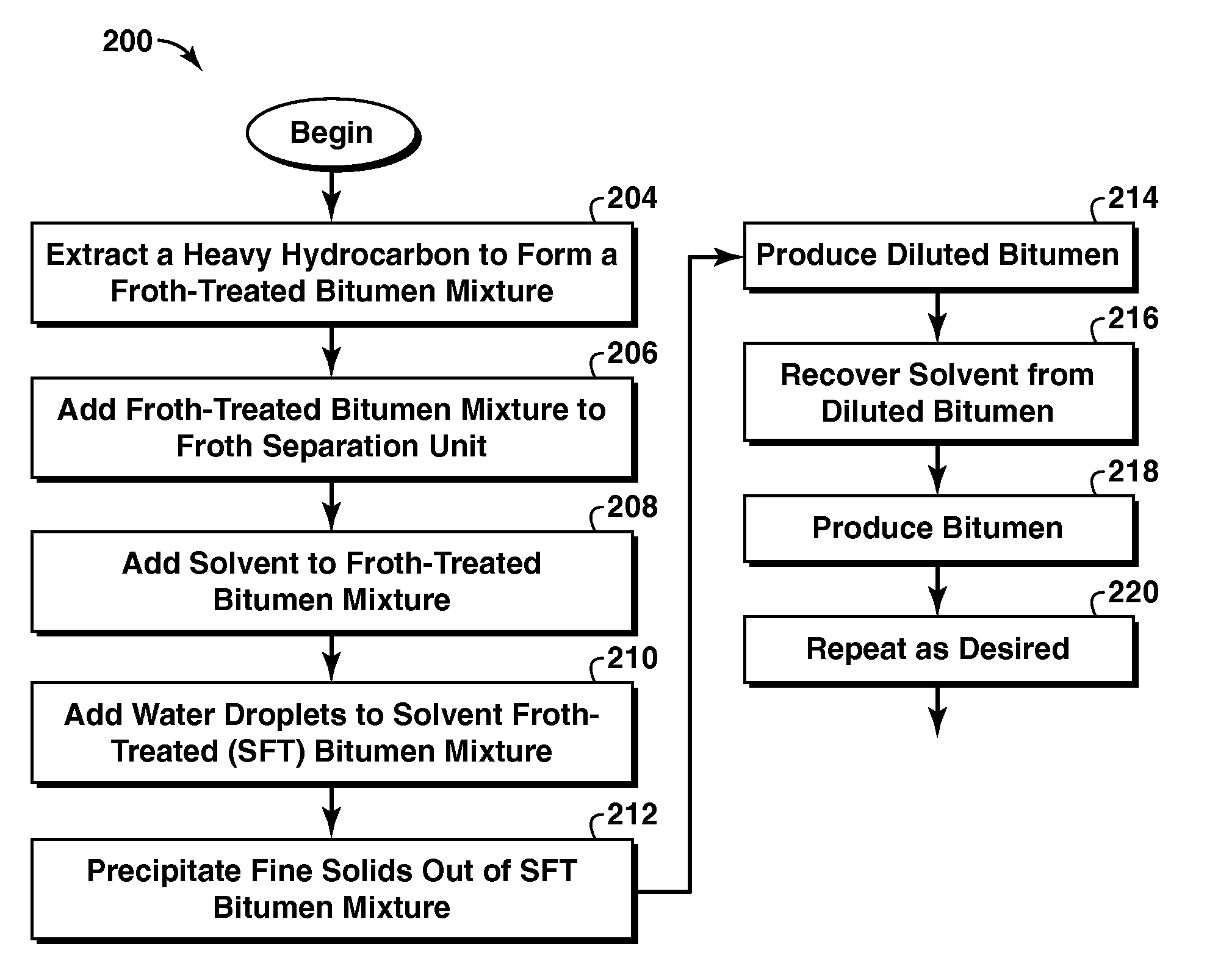

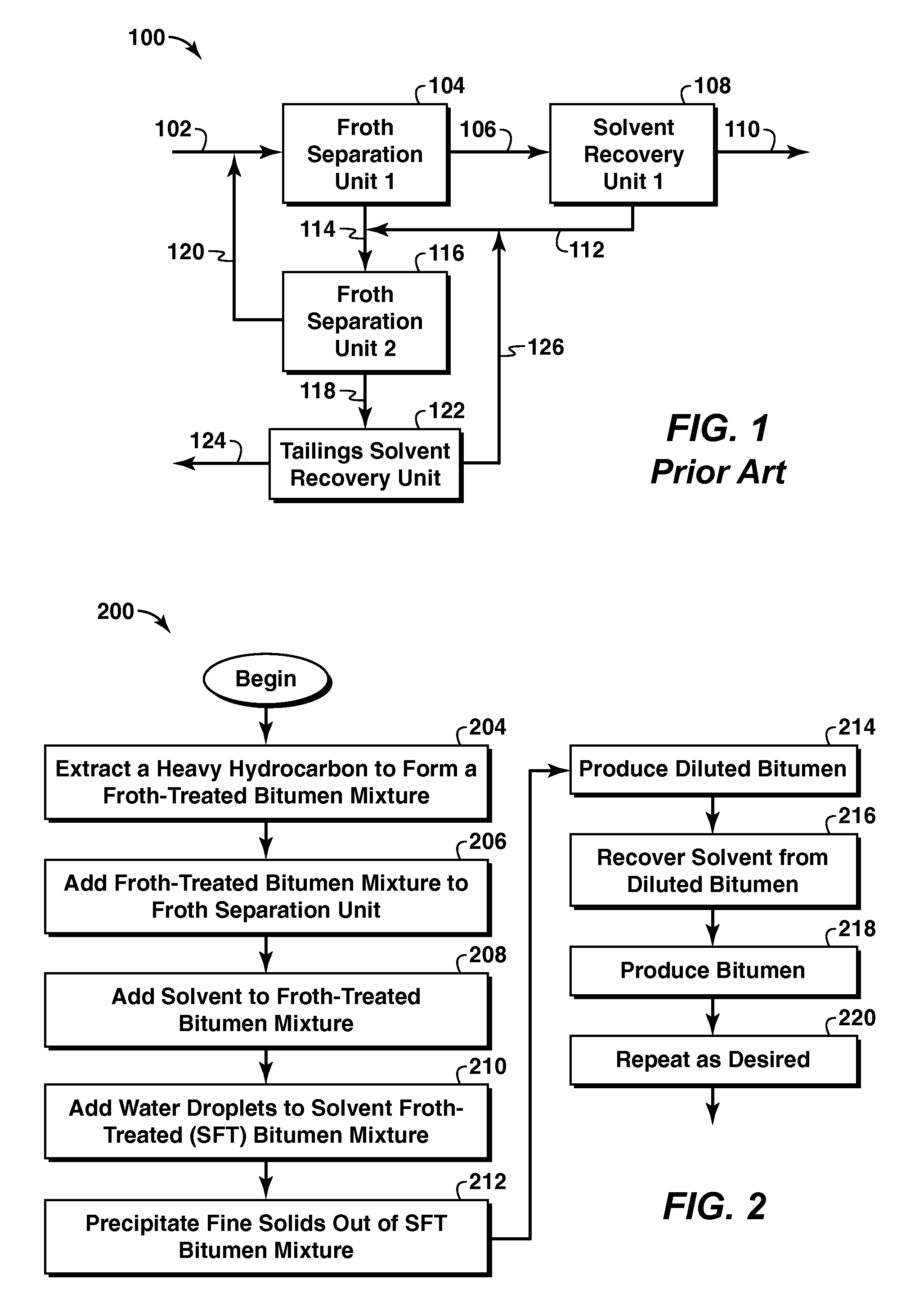

Upgrading Bitumen In A Paraffinic Froth Treatment Process

ActiveUS20090200209A1Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

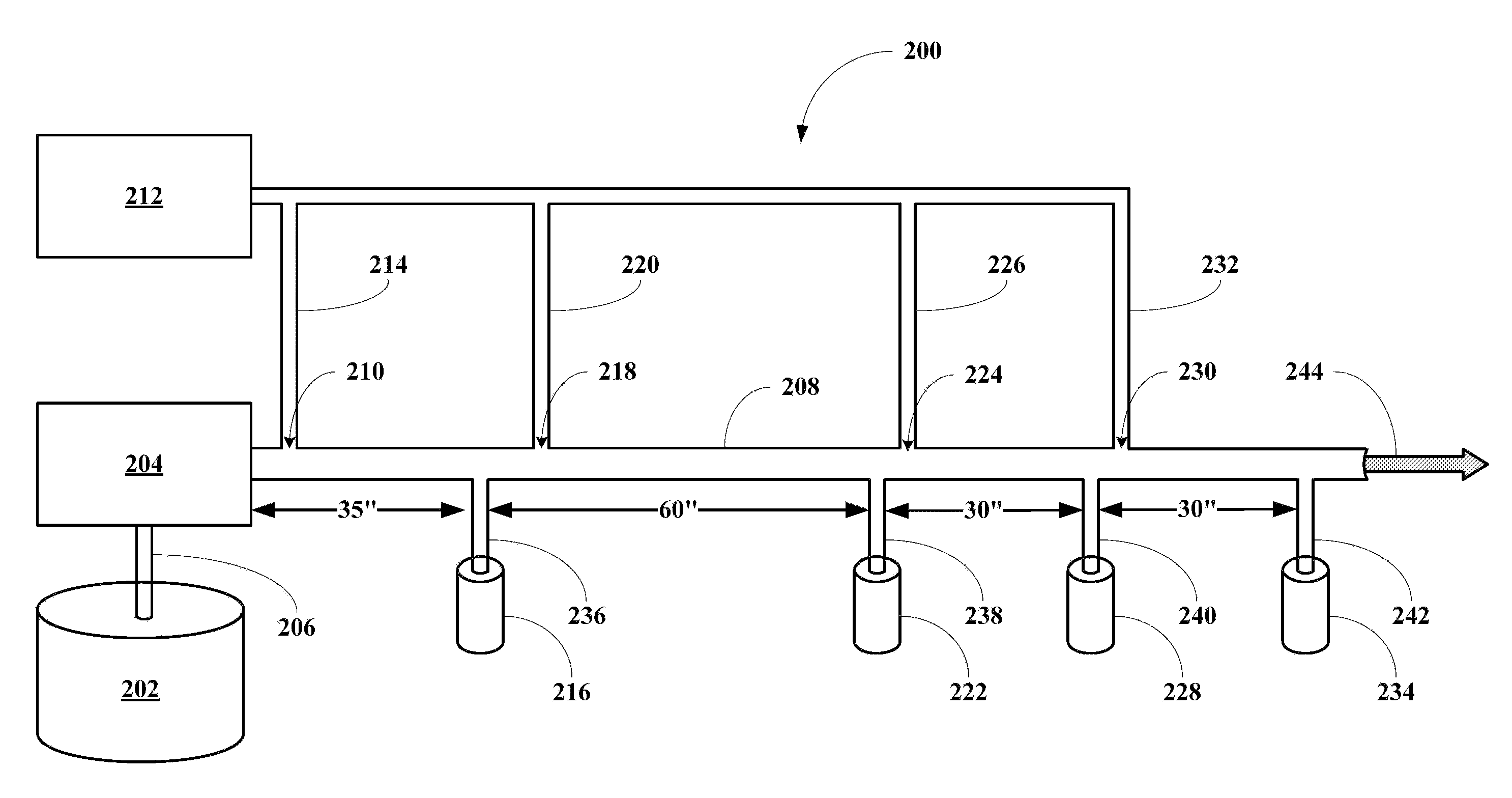

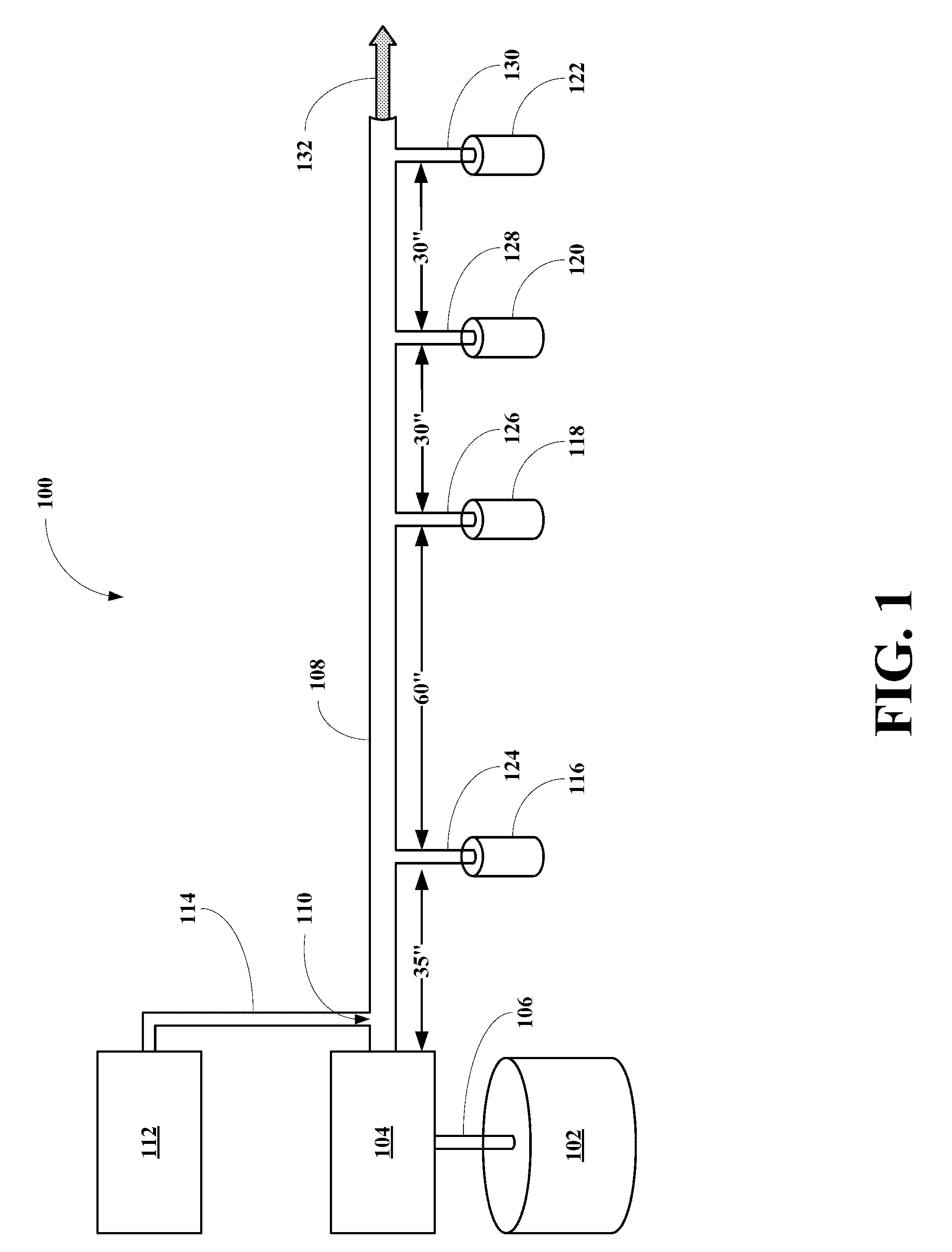

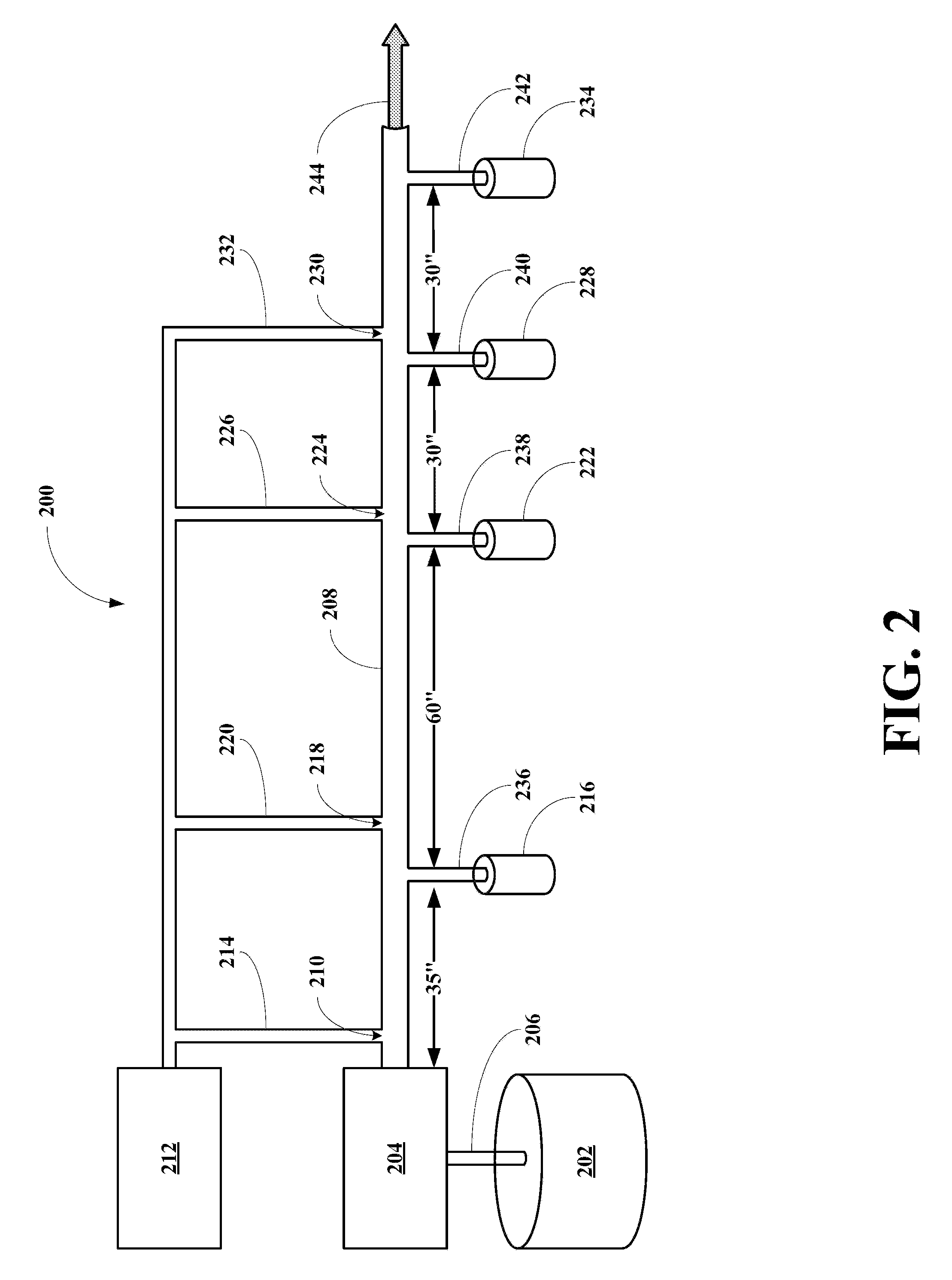

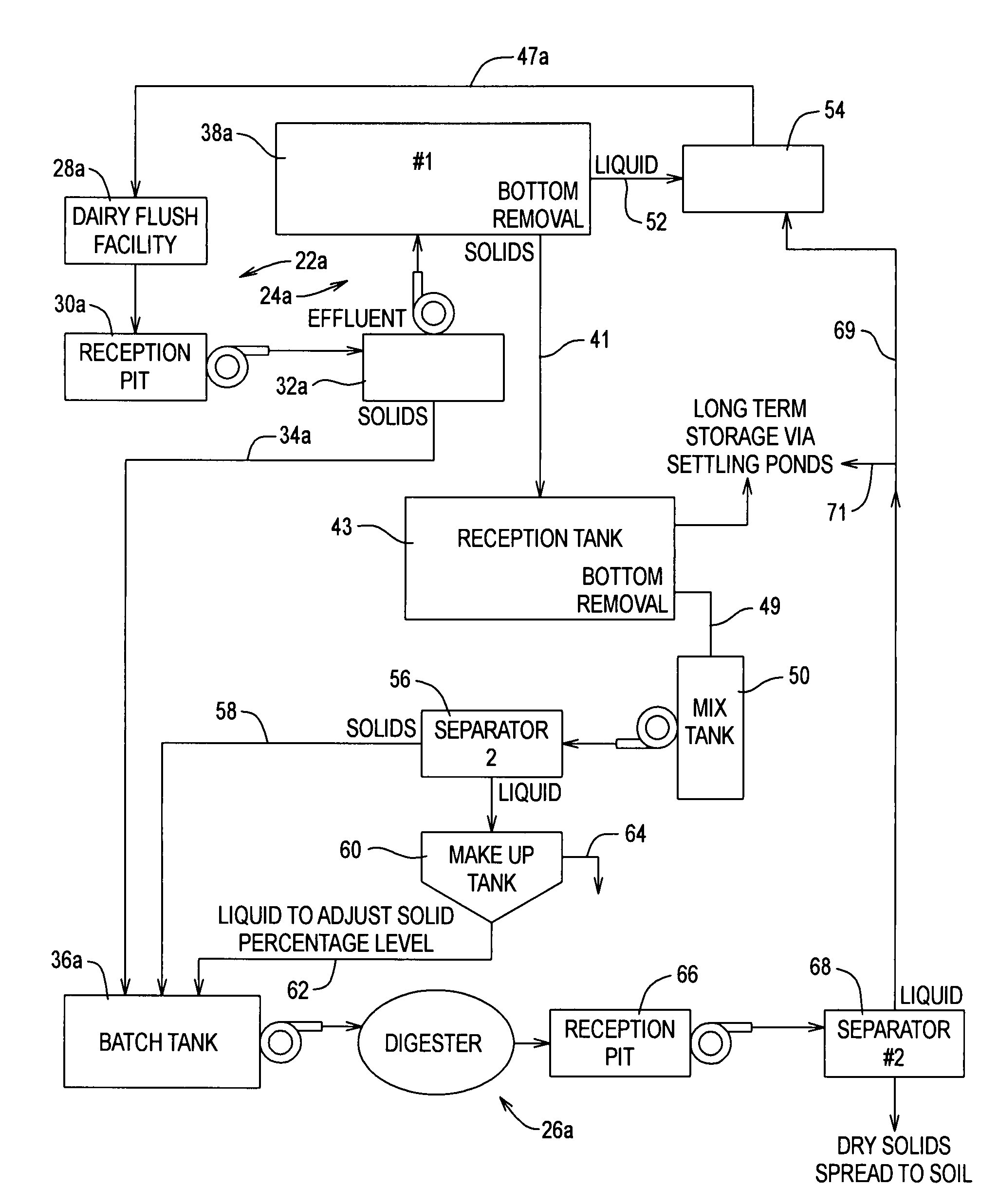

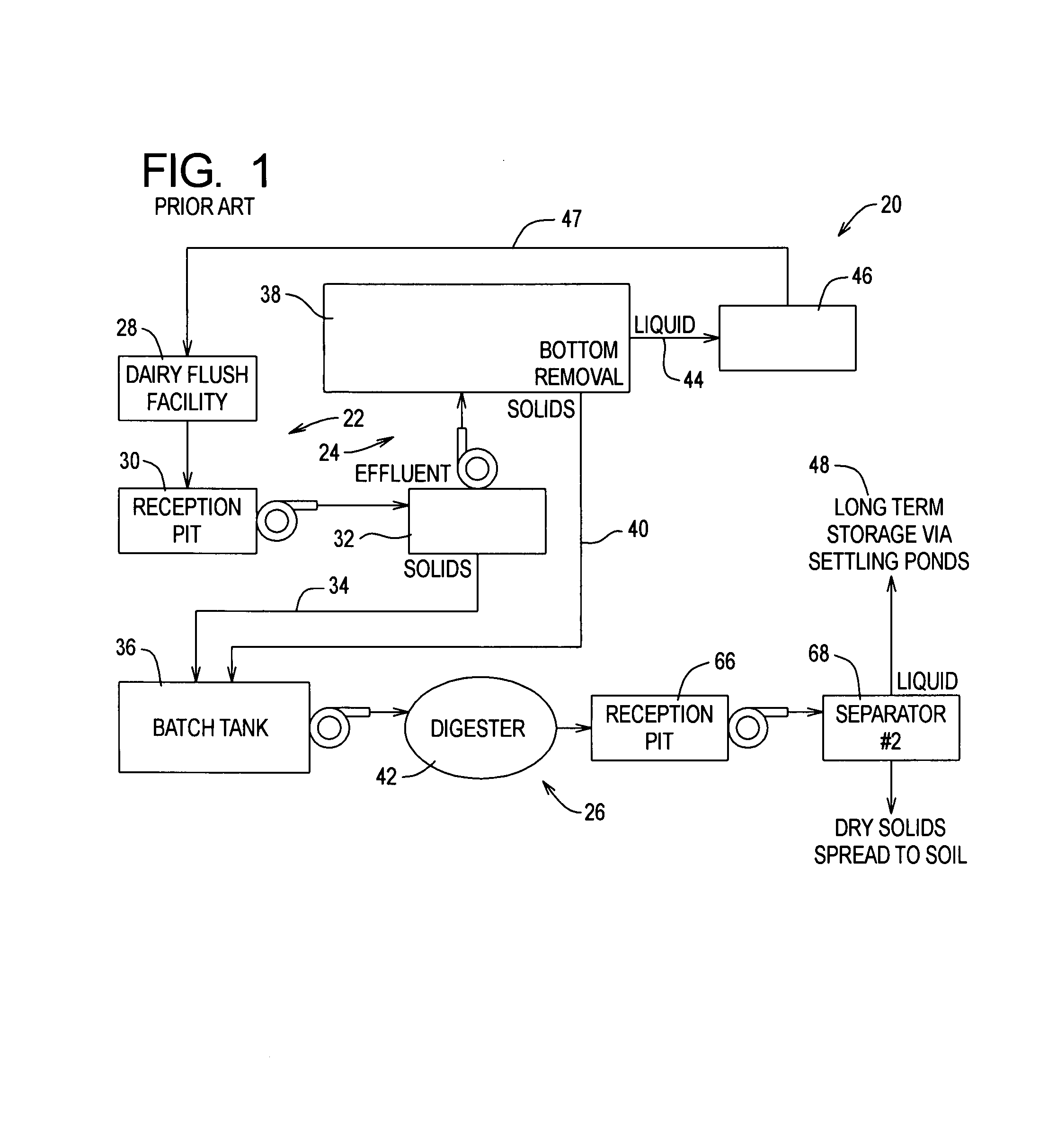

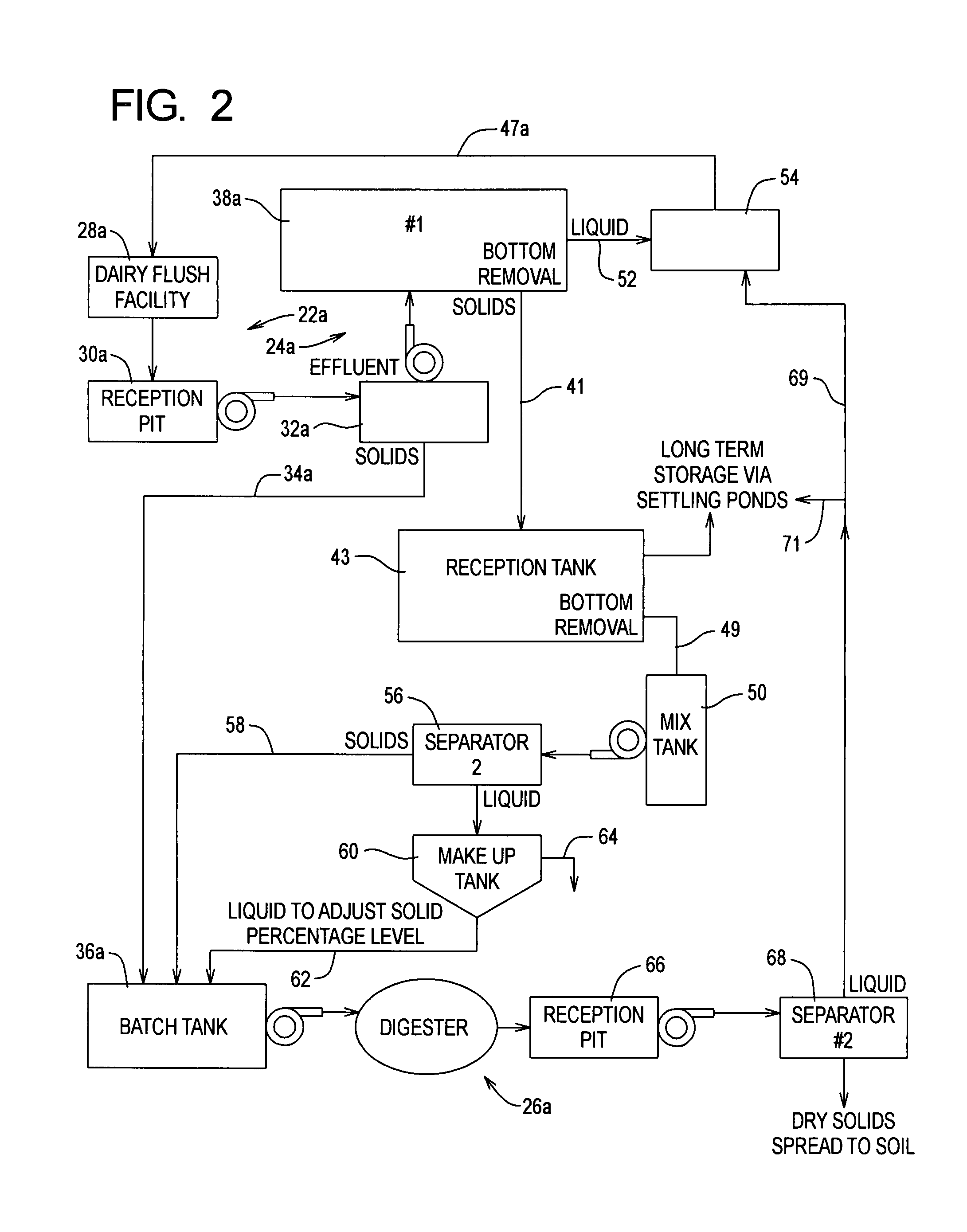

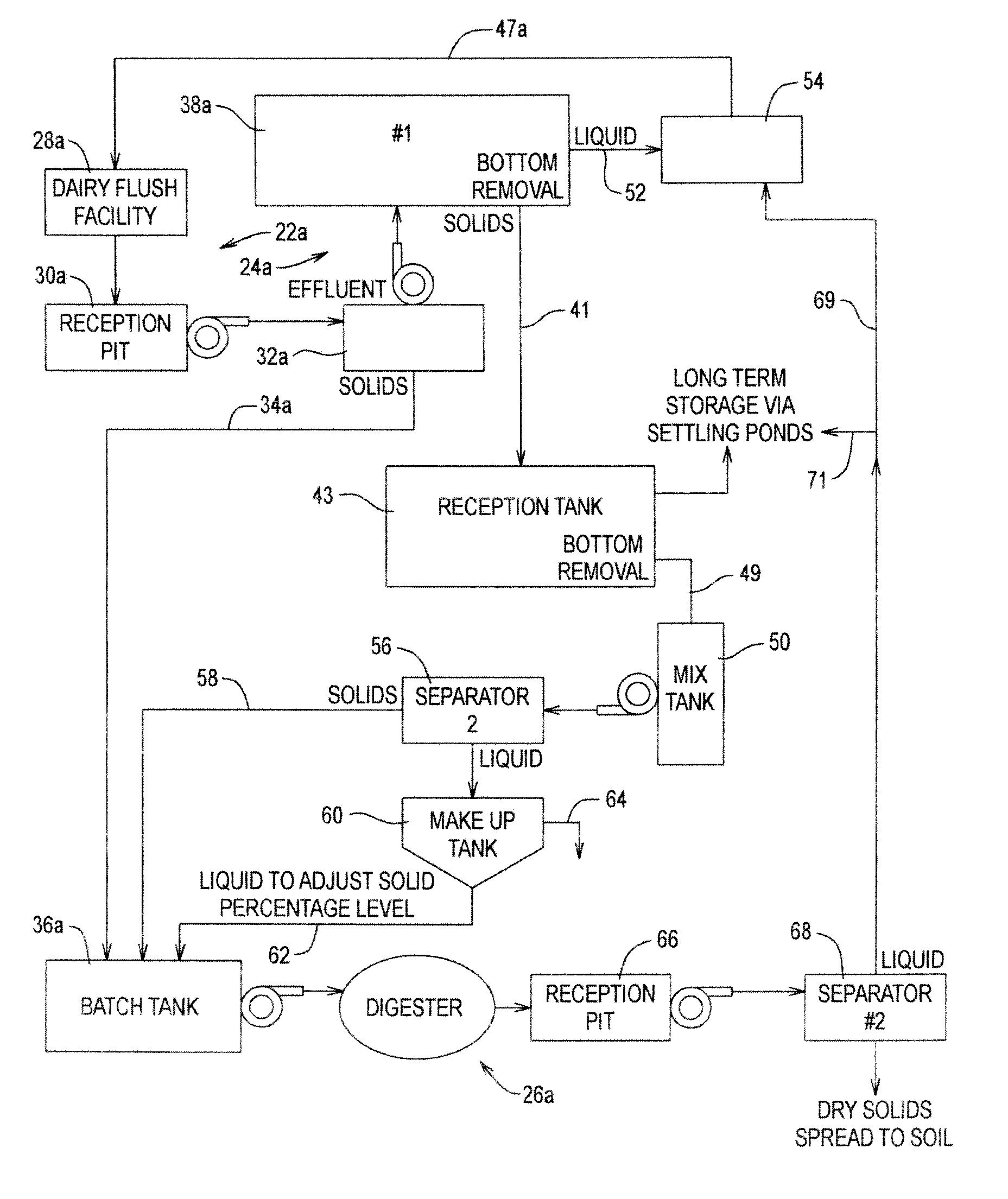

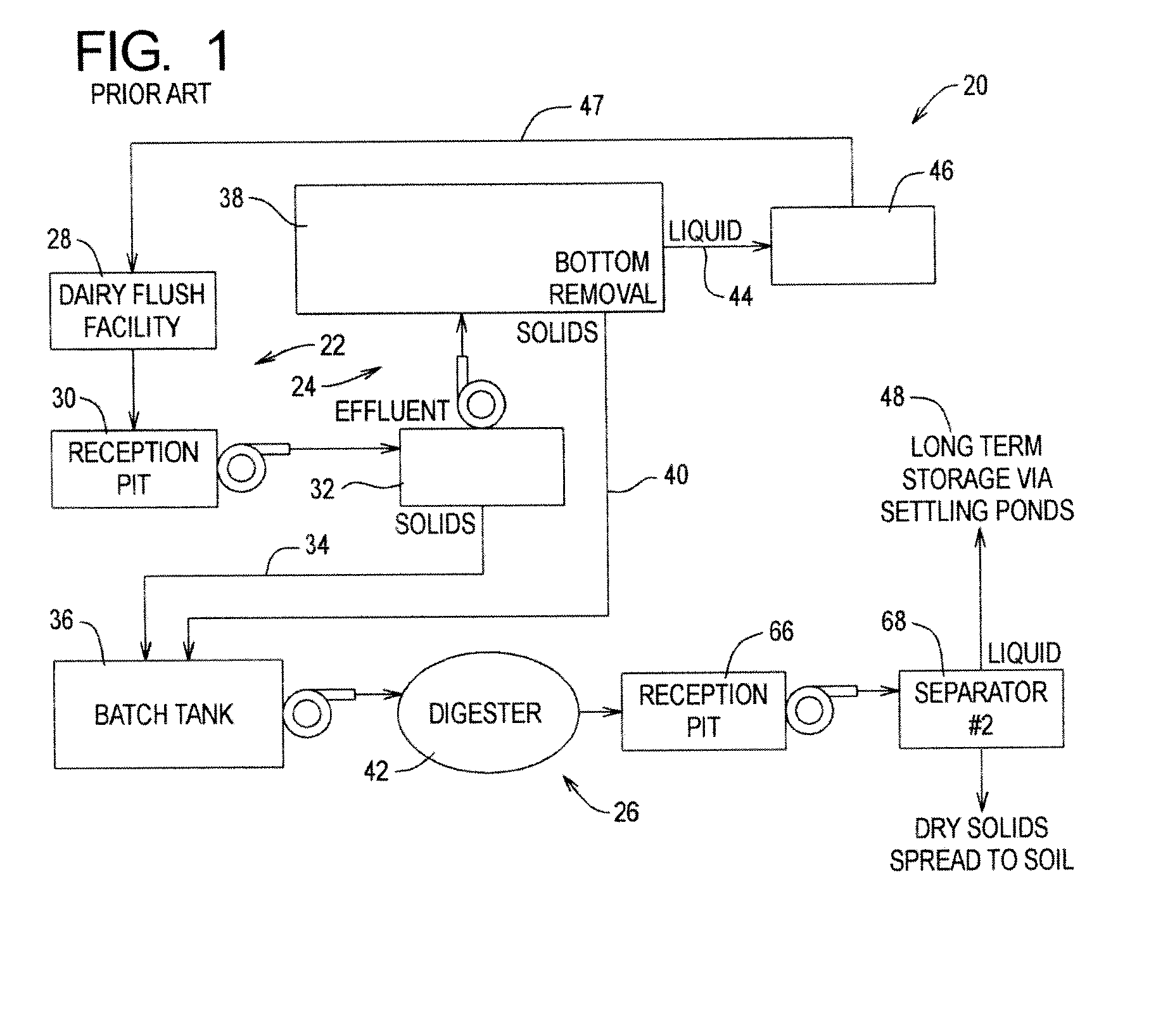

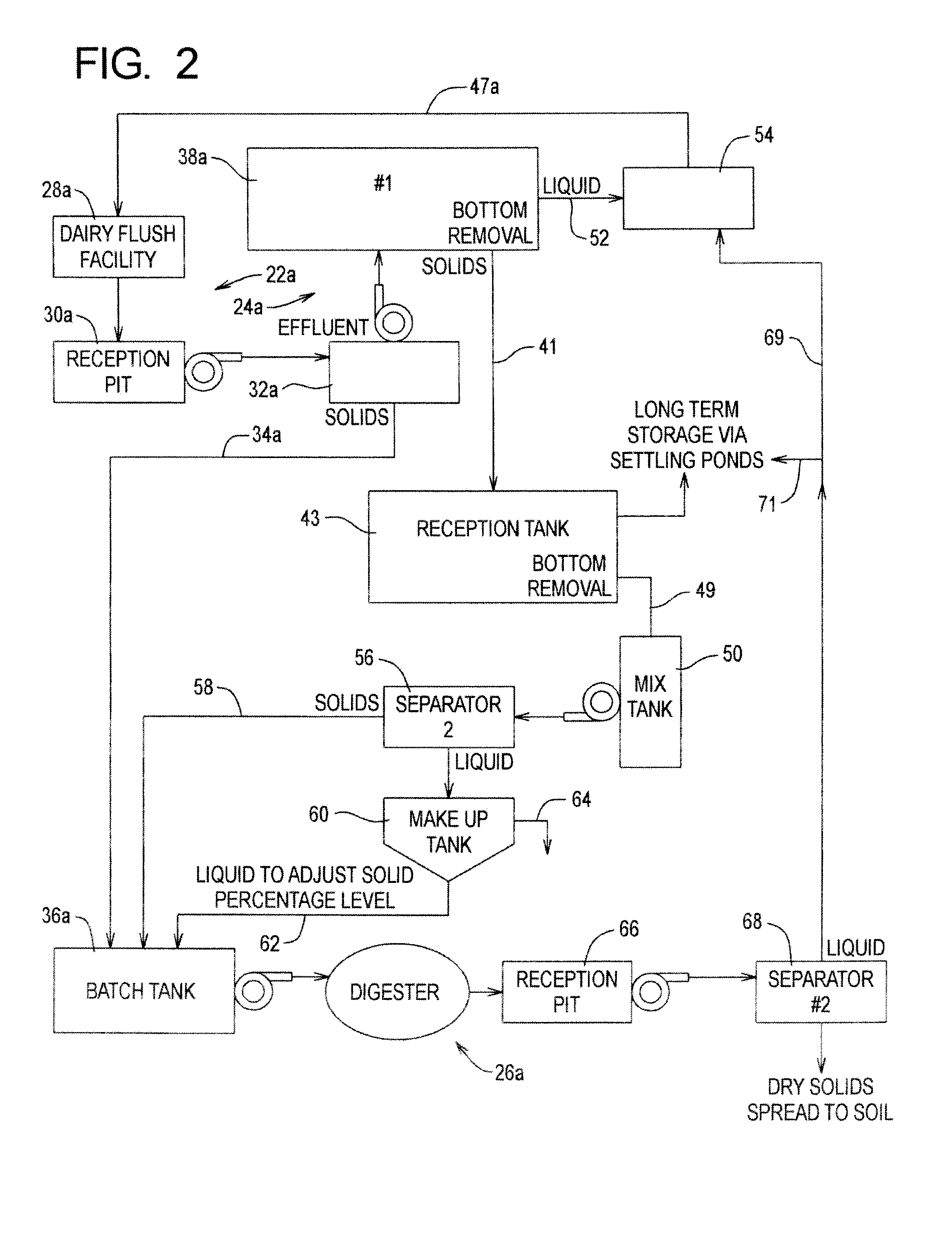

Manure separation for digester method and apparatus

ActiveUS7306731B1Liquid separation auxillary apparatusBio-organic fraction processingWaste managementSettling rate

A method and apparatus for removing settleable solids and unsettleable solids from a partially closed flush system in a diary milking operation whereby a first processing tank bottom removes settleable solids contained therein where the net current flow vertically in the process tank is less than the settling rate of the settleable solids contained therein. The process tank batch feeds a plurality of thickening tanks that are each allowed to settle for a period of time before transferring fluid is to a second separator. The method and apparatus is particularly conductive for feeding a digester.

Owner:DARITECH

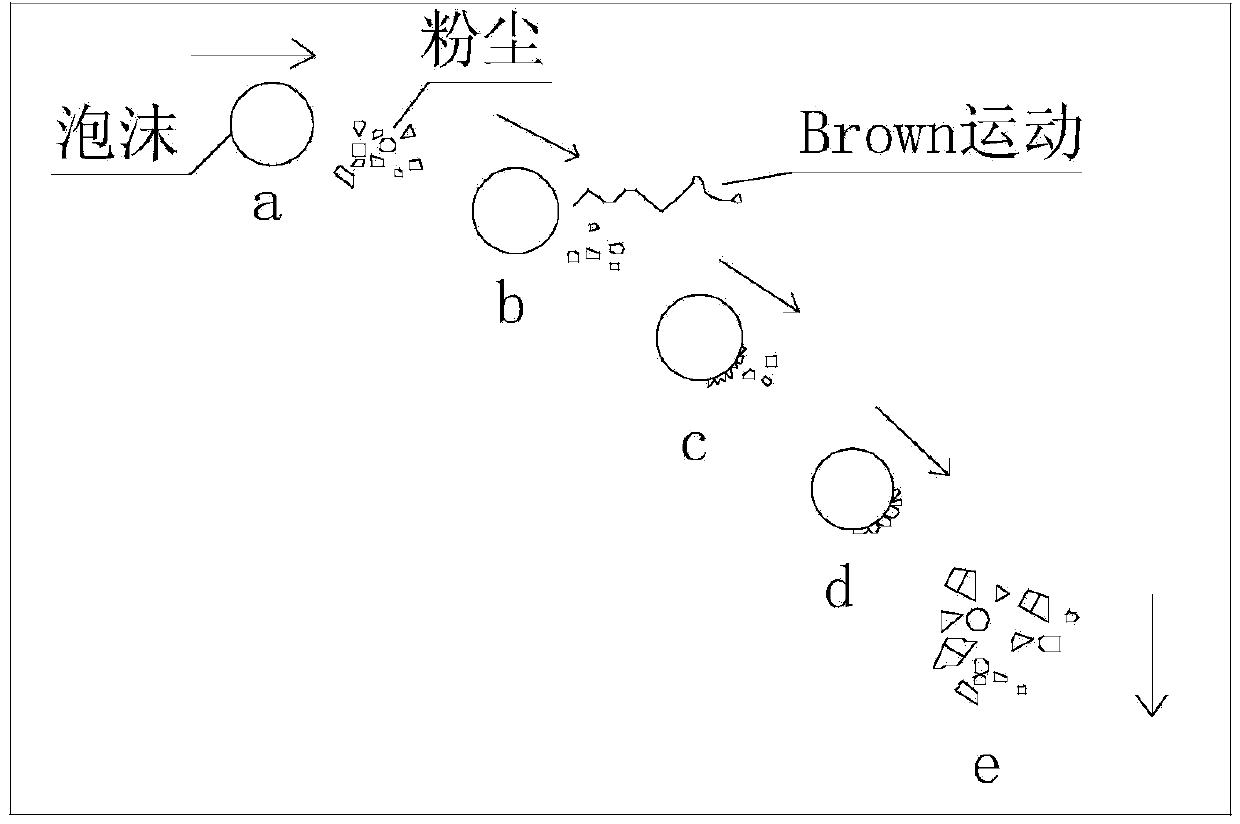

Novel foam dedusting agent for coal mine

ActiveCN103806930AImprove wetting abilityImprove dust collection efficiencyDust removalFire preventionFoaming agentSurface layer

The invention discloses a novel foam dedusting agent for a coal mine. The novel foam dedusting agent comprises, by weight, 0.5%-0.7% of foaming agent, 0.04%-0.06% of foam stabilizer, 0.4%-0.5% of wetting agent and 98.74%-99.06% of water. Modified alkyl glycoside, carboxymethylcellulose, alkylphenol ethoxylates and the water are sufficiently mixed; then, the mixed liquor is poured into a mine foam dedusting foam maker to form foams; the foams are conveyed to a dust source to cover the dust source, so that dust produced by the dust source is caught and settles, and finally good underground work environments are guaranteed. A hydrophobic grouping (lipophilic group) of wetting agent molecules adsorbed on the surface layer of the water makes contact with the coal dust first and is composed of organic carbon chains, the molecular characteristics of the hydrophobic grouping are similar to the molecular characteristics of the surface of the coal dust, the hydrophobic grouping can adsorb the coal dust more easily than water molecules, and therefore the dust catching efficiency of the foams is improved, the dust settling rate exceeds 95%, and dust settling efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Oil based concentrated slurries and methods for making and using same

InactiveUS8728989B2Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

Oil based concentrated slurries and methods for making and using same

ActiveUS20140315763A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

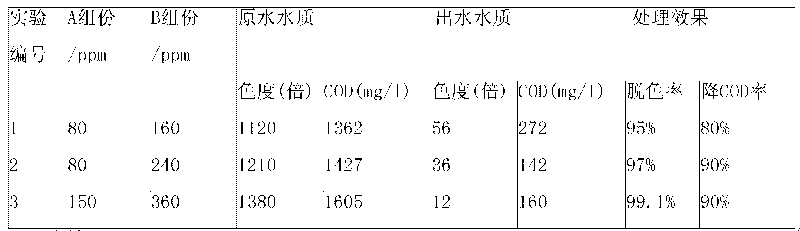

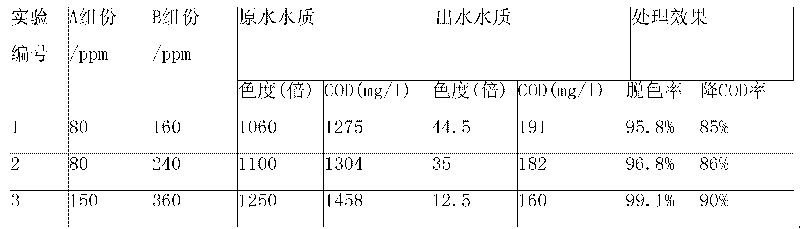

Preparation method of flocculent decolouring agent of printing and dying wastewater

InactiveCN101759264ASettling fastGood flocculation effectWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationChemical oxygen demandProcessing cost

The invention discloses a preparation method of a flocculent decolouring agent of printing and dying wastewater. The method comprises the following steps: adding formaldehyde of 15-30 parts by weight to a reaction kettle, and then adding dicyandiamide of 20-40 parts by weight and ammonium chloride of 10-25 parts by weight thereto, heating the mixture for 1-2 hours at 50 DEG C to 60 DEG C, warming up to 70 DEG C to 80 DEG C to continuously react for 2-4h; cooling to 50 DEG C to 60 DEG C, adding urea of 0-5 parts by weight to the mixture to react for 2-4 hours to obtain a component A; mixing industrial waste alumina mud with hydrochloric acid, heating the mixture to 70 DEG C to 80 DEG C to react for 2-4 hours, and curing for 12-24 hours after cooling to obtain a component B. When in use, according to the specific ingredients of the printing and dying wastewater, the component A and the component B are mixed in a ratio of 2-3:1 and then added to the printing and dying wastewater. After the product is added to the wastewater, the effect on flocculation is good, the settling rate of dirt is rapid, the decolouring ratio is up to 95-99%, the COD (Chemical Oxygen Demand) is reduced by 80-90%, 90% of processed wastewater can be reused, and the processing cost is decreased evidently.

Owner:江门市冠达化工科技有限公司

Processes for Treatment of Wastewater, Separation, Deodorisation and Re-Use of Biosolids

InactiveUS20080209968A1Reduction tendencyAvoid developmentBiocideBio-organic fraction processingRed mudCompost

The present invention relates to a process for treating wastewater containing suspended solids comprising adding to the wastewater a treating substance in an amount sufficient to enhance at least one of (a) the settling rate of the solids, (b) the bulk density of the solids and (c) the filterability of the solids, said treating substance being selected from the group consisting of (i) bauxite refinery residue known as red mud, and (ii) red mud that has been at least partially reacted with calcium and / or magnesium ions so as to have a reaction pH, when mixed with five times its weight of water, of less than 10.5. In addition, the invention relates to processes for reducing the concentration of dissolved phosphorus-containing species in wastewater, for decreasing the odour of a material having an odour due to the presence of one or more sulphur-containing substances and for decreasing the propensity to develop odours and a composting process.

Owner:NAUVEAU TECH INVESTMENTS

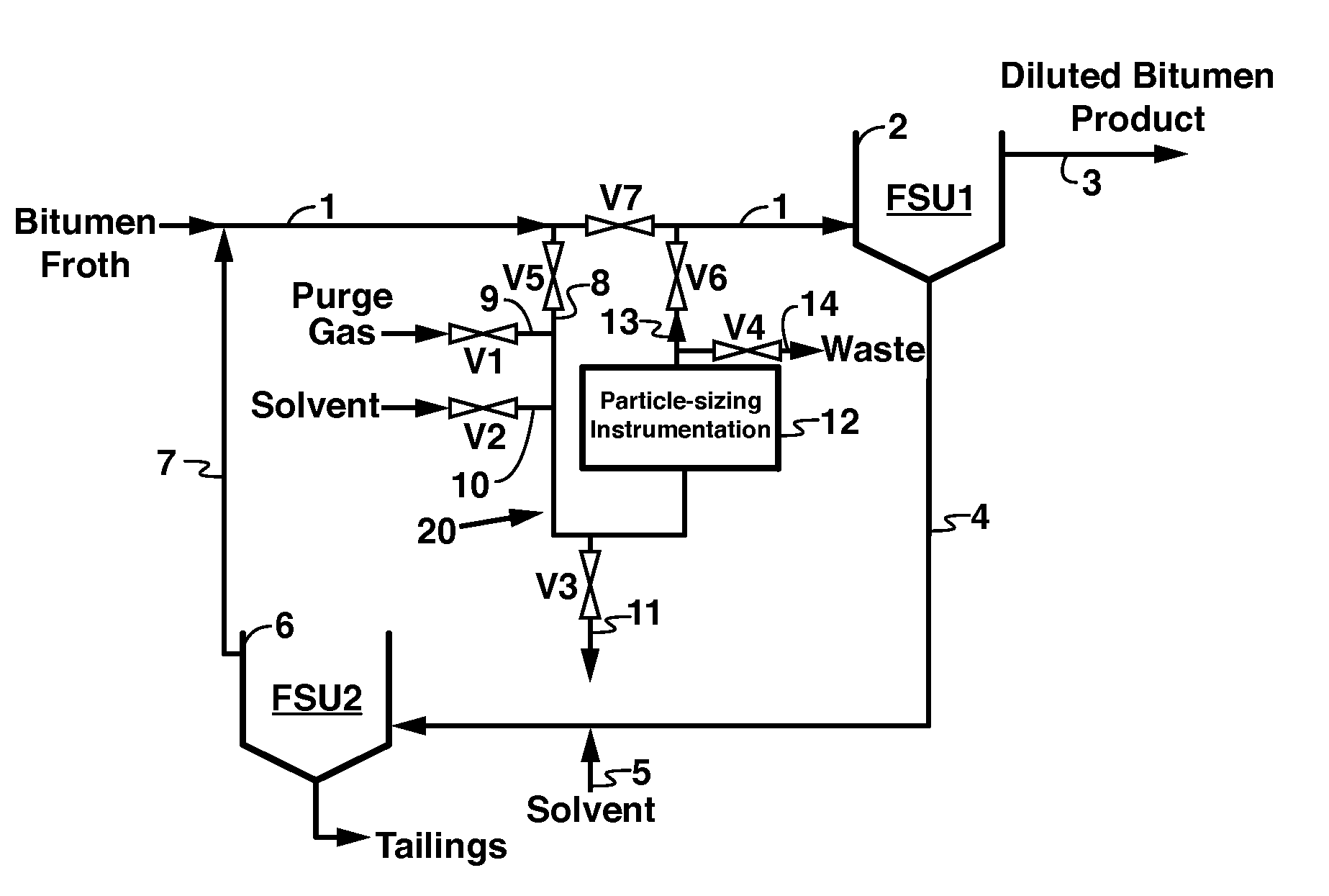

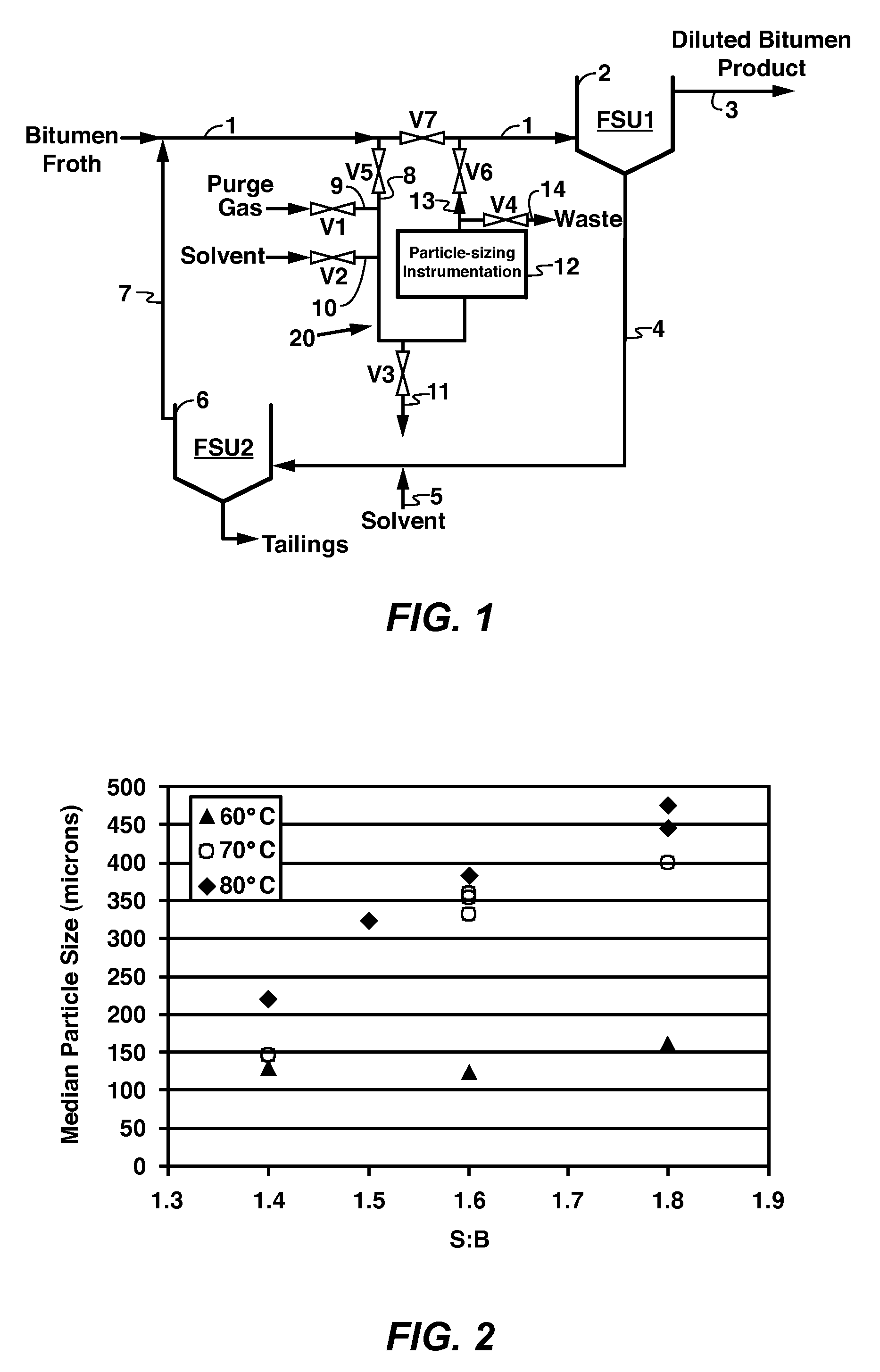

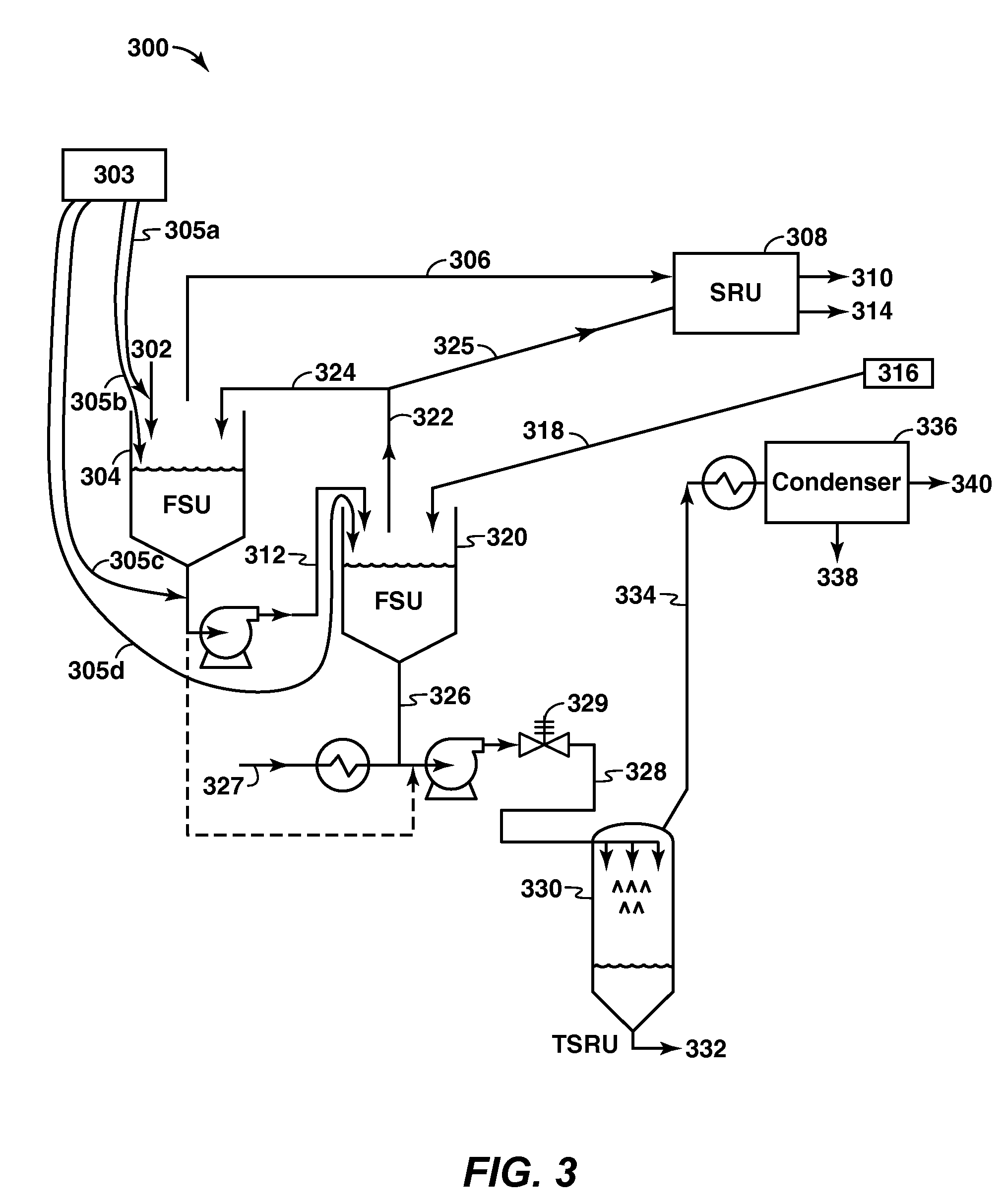

Method Of Removing Solids From Bitumen Froth

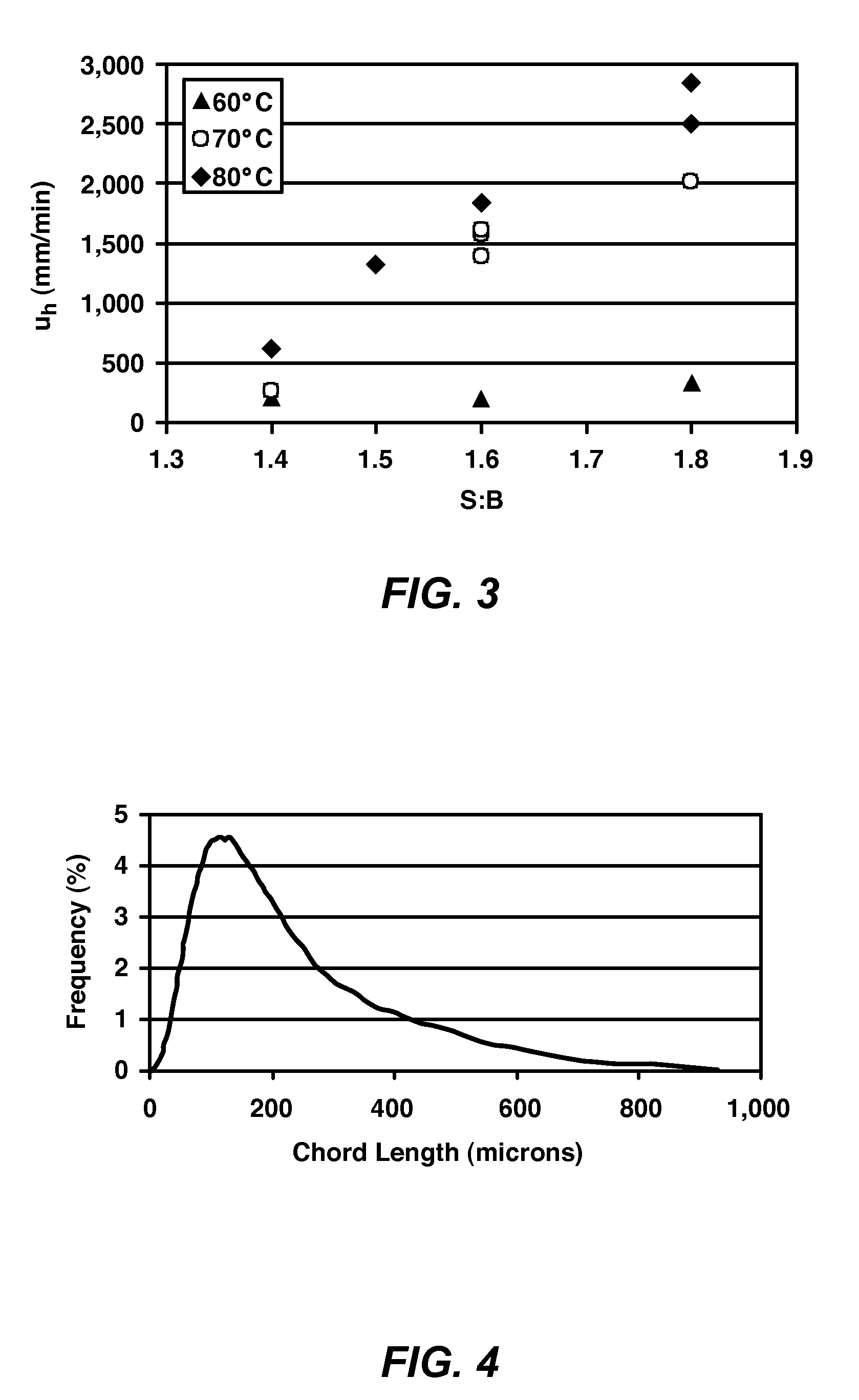

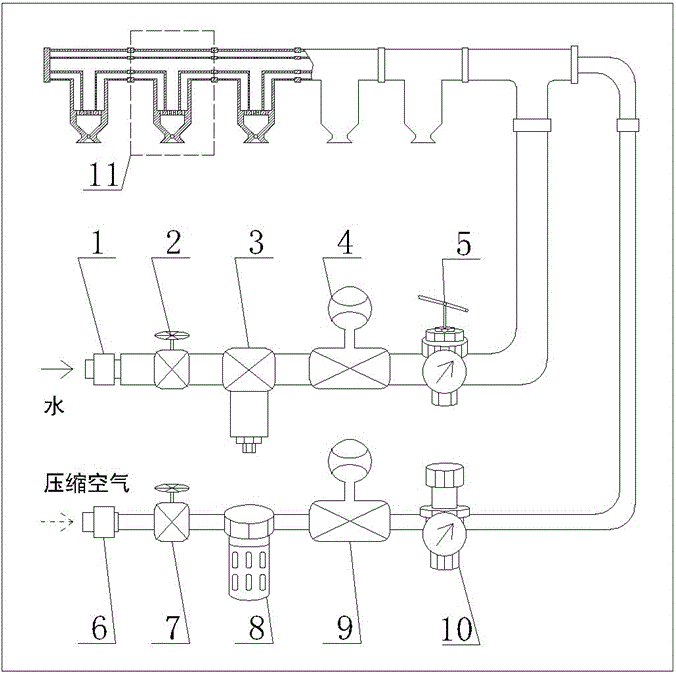

A paraffinic solvent, gravity-based process is disclosed for removing solids content from bitumen froth streams comprising the steps of placing particle-sizing instrumentation in a bitumen froth inlet stream to a gravity settling vessel subsequent to the addition of paraffinic solvent. The addition of solvent forming aggregates. A representative particle size distribution of entrained aggregates is measured with the particle-sizing instrumentation. The settling rate of the aggregates from the particle size distribution is determined mathematically. Operating data is collected while repeating one or more times the foregoing process steps and while changing one or more process conditions of the gravity-based process. A set of operating conditions are then established based upon particle size and settling rate from the generated data. The paraffinic solvent, gravity-based process is operated by adjusting process conditions to optimize the settling rate of the aggregates based upon the established set of operating conditions.

Owner:HOMMEMA SCOTT E

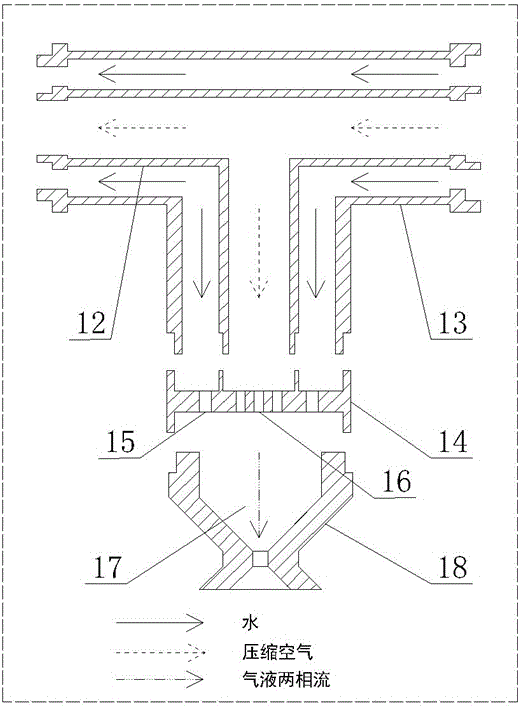

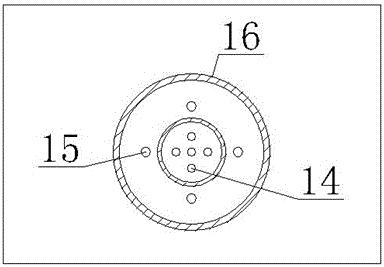

Mining bubble atomization water mist dust settling device

InactiveCN105863720AQuick installationQuick disassemblyDust removalFire preventionWater sourceRespirable dust

The invention discloses a mining bubble atomization water mist dust settling device. On the basis of traditional water mist dust settling of a mine, the mine atomizing dust settling device which is good in atomizing effect, high in dust settling rate, low in water consumption and air consumption, not prone to nozzle blockage, convenient to install, capable of saving energy and environmentally friendly is designed according to the bubble atomization principle. The mining bubble atomization water mist dust settling device is mainly characterized in that by means of an existing underground dustproof pipeline and a compressed air pipeline, a water source and an air source do not need to be pressurized, and no strict requirement for the size relationship of water pressure and air pressure exits; on the basis of not conducting any changing or adding auxiliary devices, water mist good in atomizing effect is produced, dust settling effect is greatly improved, and remarkable effect can be achieved for preventing and treating respirable dust; meanwhile, plenty of water sources is saved, and underground working conditions are effectively improved; when dust settling is conducted in places such as coal faces and driving faces with large gas gushing amount, part of air carried in the water mist can have an effect on diluting gas and preventing local gas from exceeding the limit to a certain extent.

Owner:TAIYUAN UNIV OF TECH

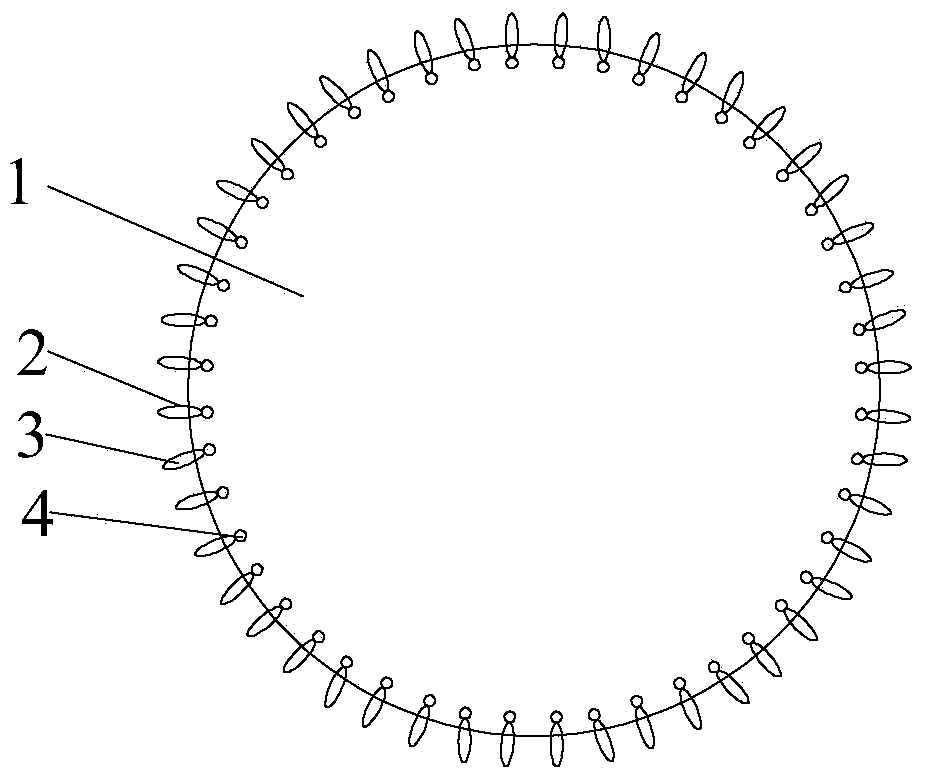

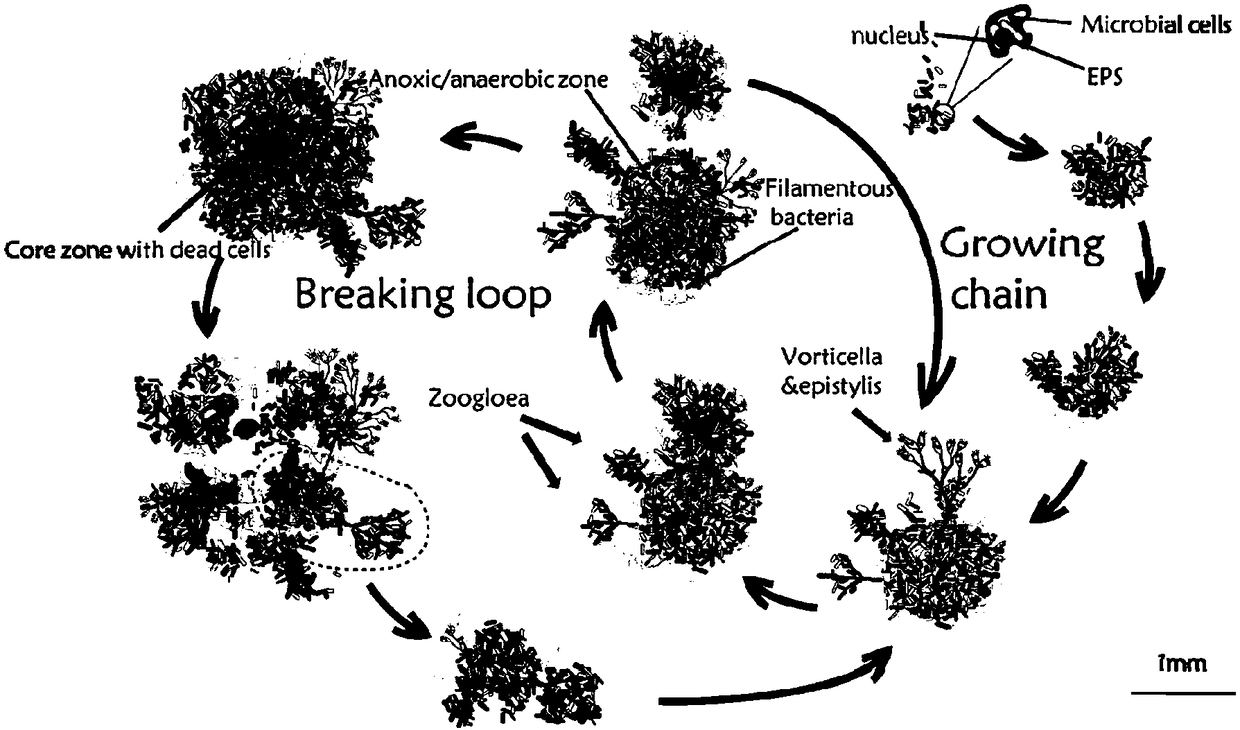

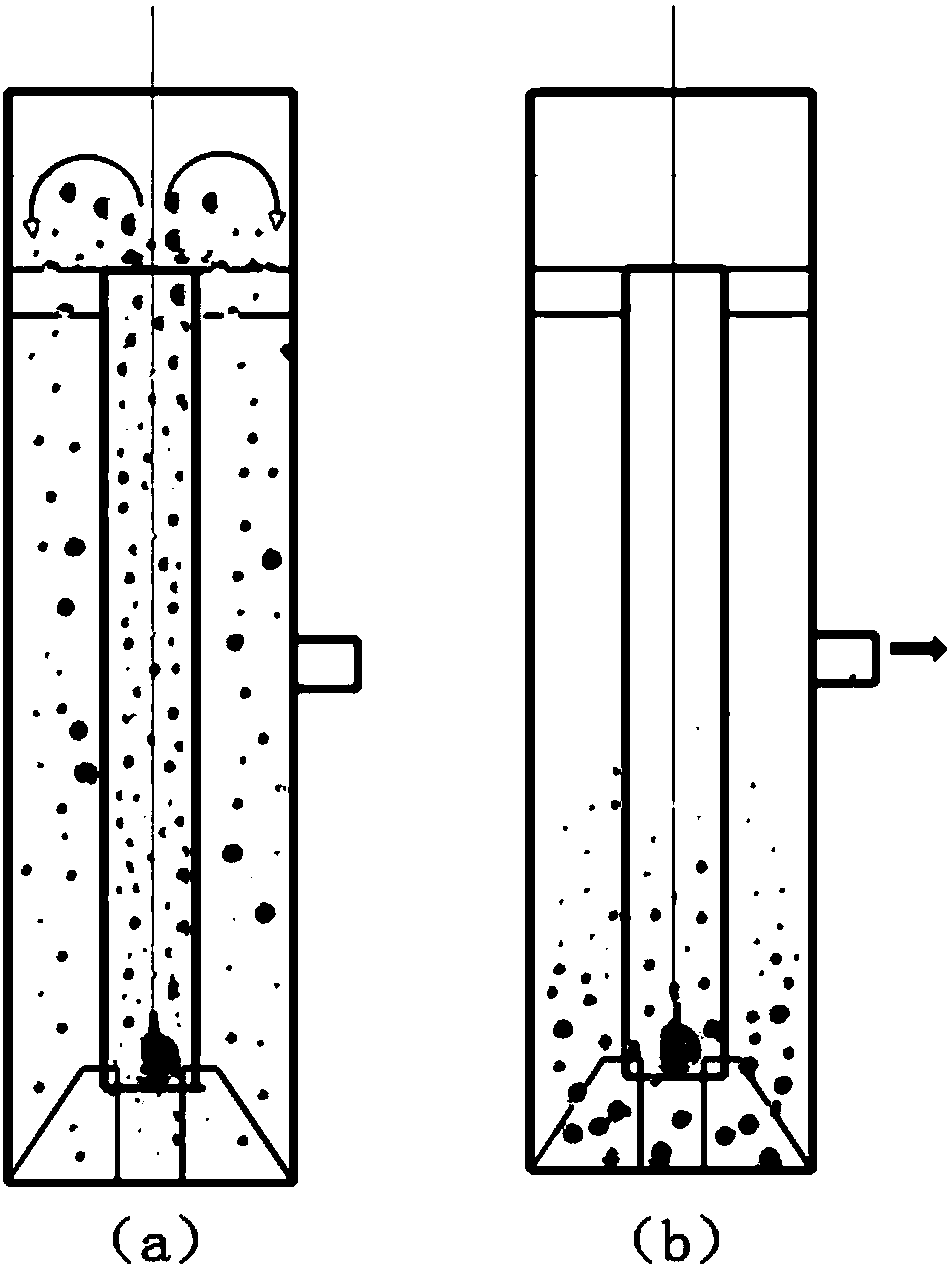

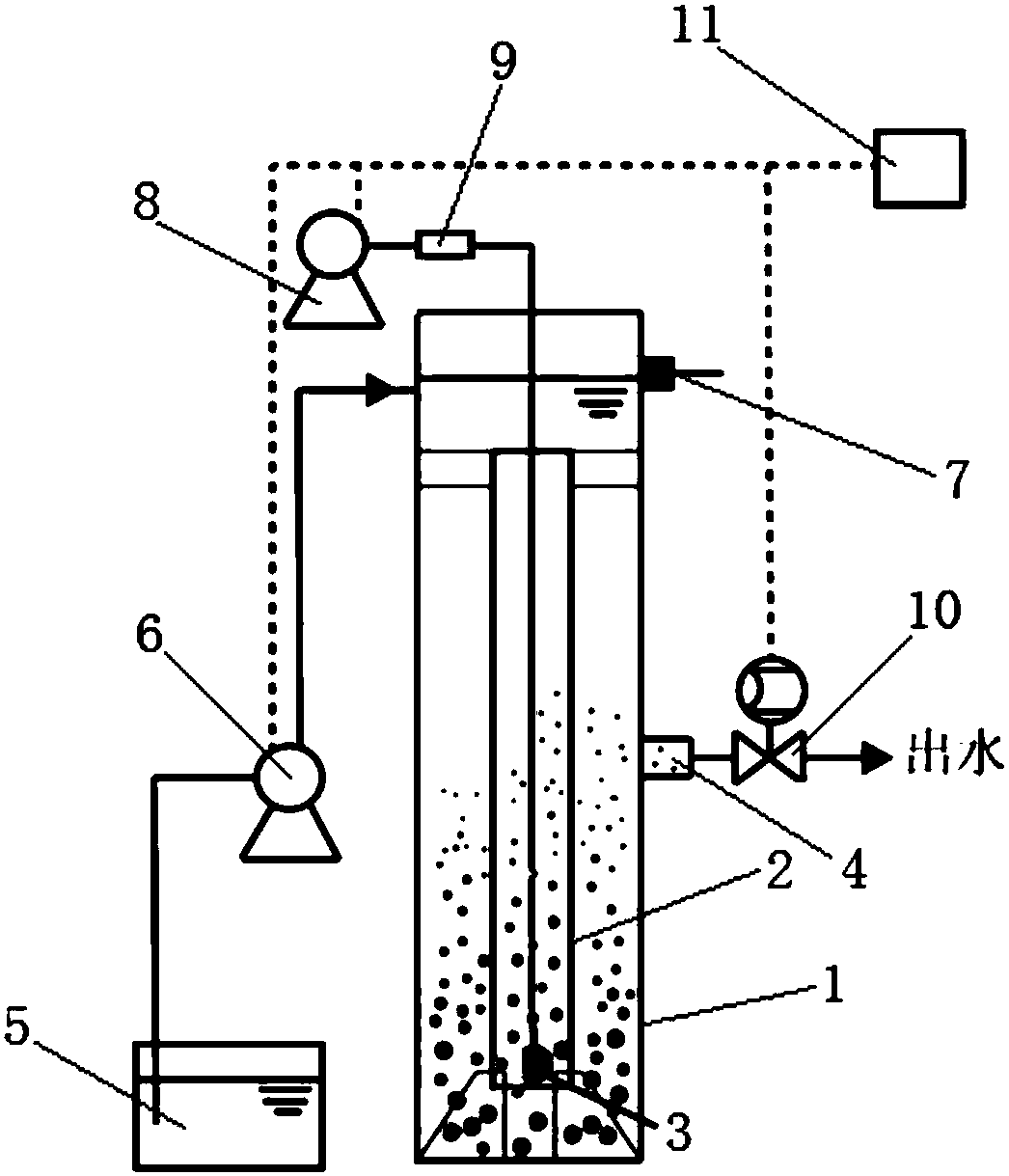

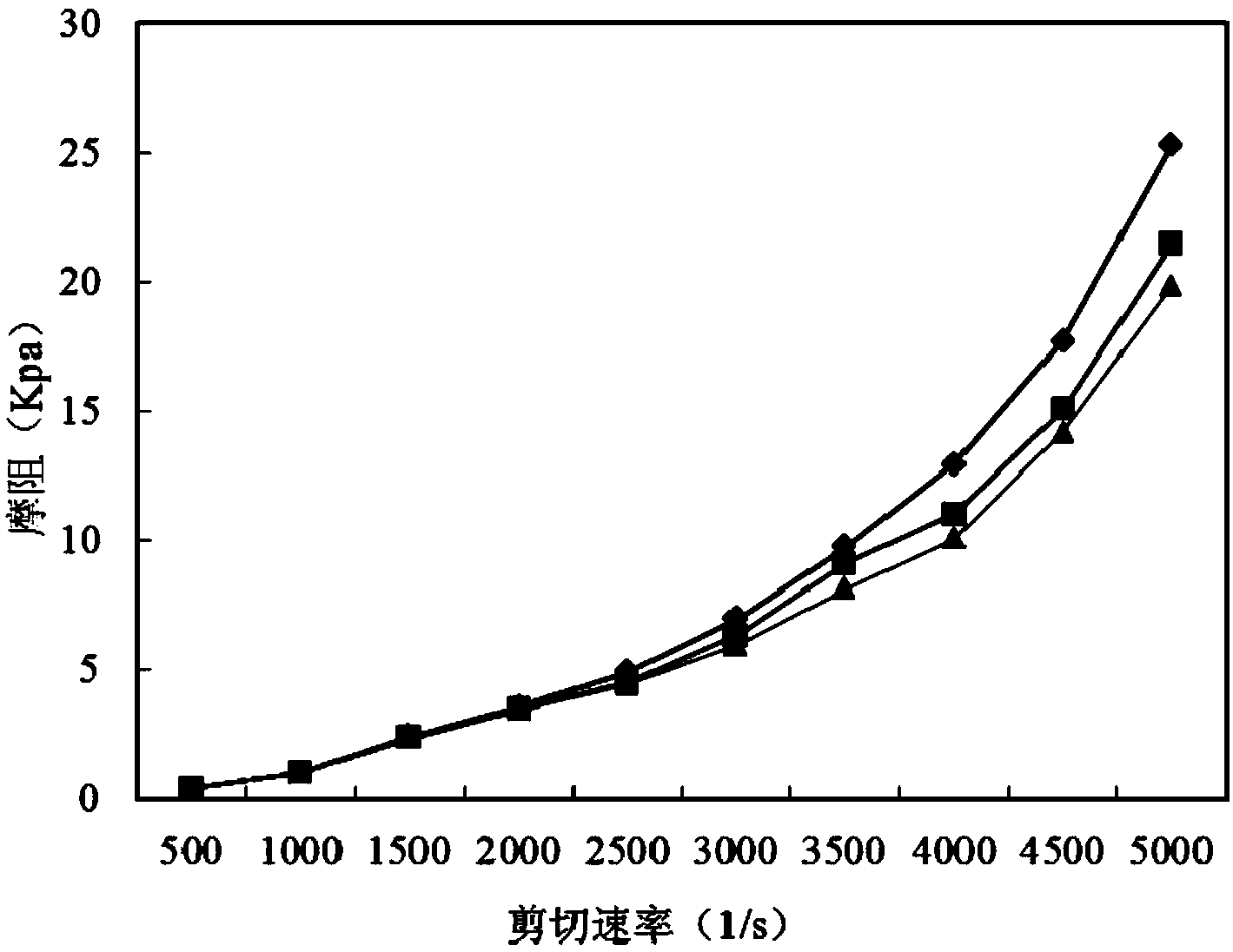

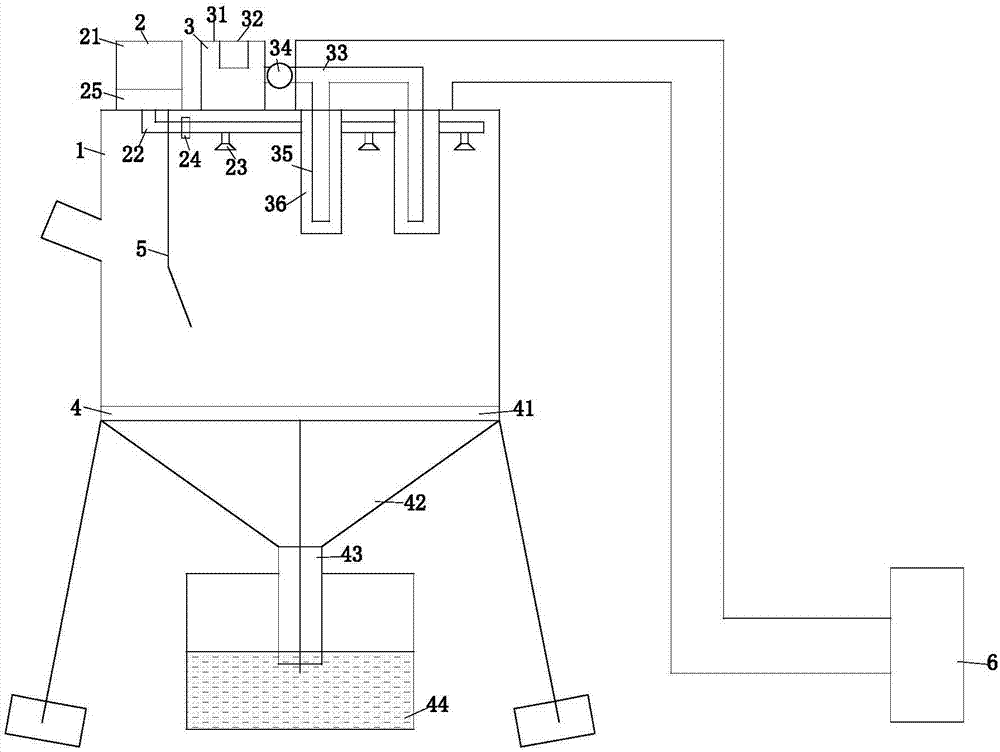

Method and device for culturing AGS (aerobic granular sludge)

InactiveCN108191049AImprove biological activityGood removal effectWater treatment compoundsBiological treatment apparatusActivated sludgeAirlift reactor

The invention belongs to the field of wastewater treatment and particularly discloses a method and a device for culturing AGS (aerobic granular sludge). The culture method comprises steps of manual simulation wastewater preparation, inoculation, sludge culture and the like and specifically comprises the steps as follows: traditional activated sludge is taken as inoculated sludge, an SBAR (sequencing batch airlift reactor) is inoculated with the activated sludge after aeration, circulating culture is sequentially performed in a water inlet-aeration-sedimentation-drainage-anaerobic manner, anaerobic granular sludge is added after the sludge is acclimatized and stabilized, crystal nucleuses for inducing growth of aerobes is provided, and the AGS is prepared after a certain period of culture.Compared with AGS obtained through culture of common activated sludge, the AGS has greater advantages in the aspects of granule specific gravity, settling rate and microbial activity.

Owner:SHANGHAI HEYUAN ENVIRONMENTAL PROTECTION GRP +1

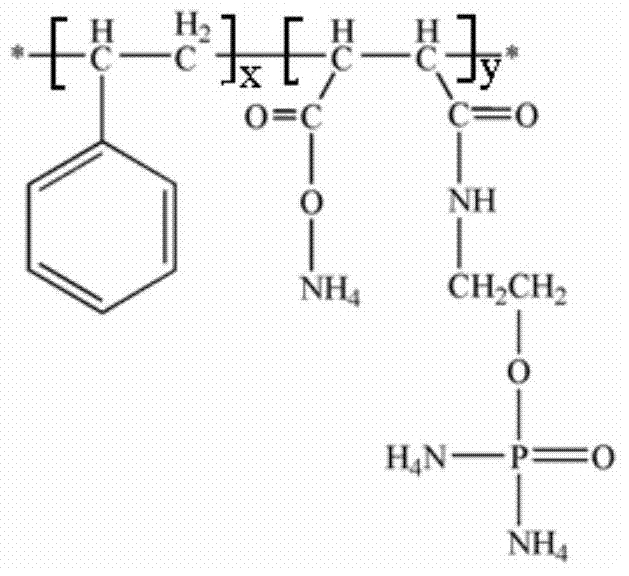

Nano composite fiber clean fracturing fluid and preparation method thereof

InactiveCN103555312AImprove sand carrying capacityReduce sedimentation rateDrilling compositionLoss rateFiber

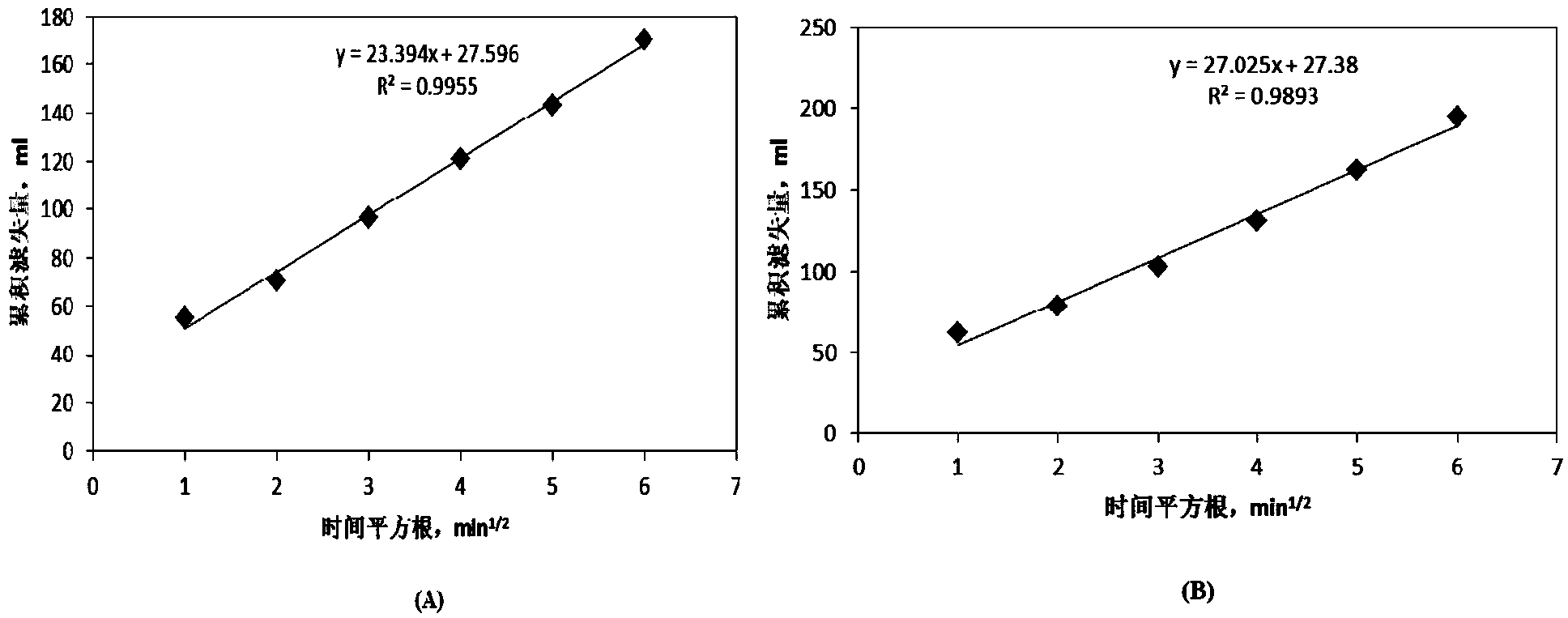

The invention provides a nano composite fiber clean fracturing fluid which comprises the following components in percentage by weight: 0.01wt%-0.2 wt% of nano fiber complex, 0.8wt%-1.5wt% of fiber dispersant, 3wt%-5wt% of anti-swelling agent, 0.3wt%-0.6wt% of conditioner, 0.1wt%-0.3wt% of anti-scale agent and the balance of water, wherein the nano fiber complex is polymer / inorganic ion nano composite fiber, polymer / carbon nano tube composite fiber or polymer / layered filler composite fiber. Since the nano composite fiber is uniformly dispersed in the fracturing fluid, a fiber network can be formed, the sand carrying property of the fracturing fluid is improved, the settling mode is changed, and the settling rate of a propping agent is reduced. Moreover, the nano composite fiber also can effectively prevent backflow of the propping agent and effectively reduce the filter loss rate, and the damage rate on a coal seam is only 3-10%.

Owner:CHINA UNITED COALBED METHANE +1

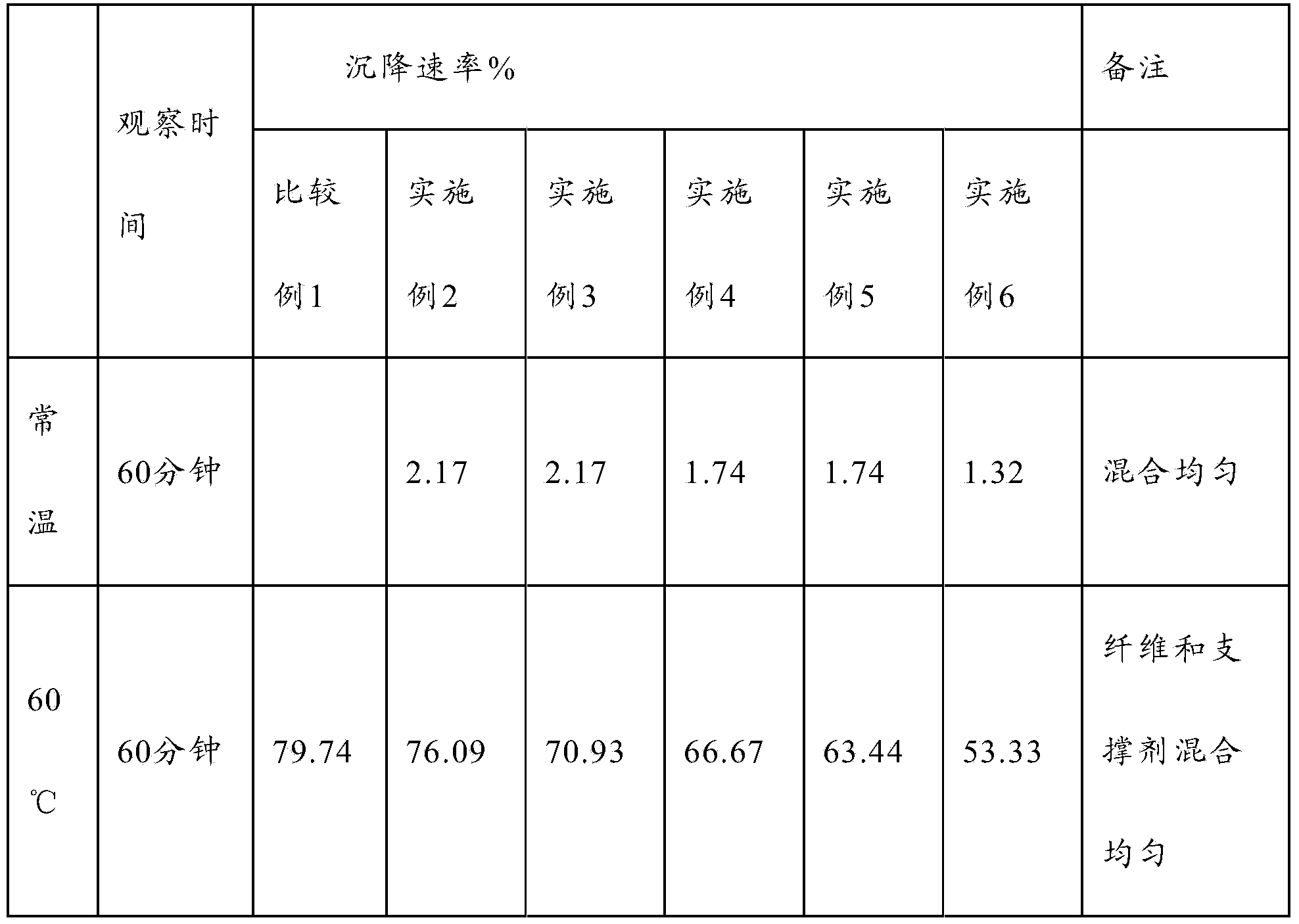

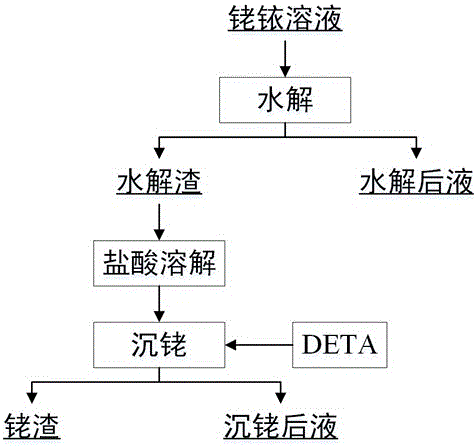

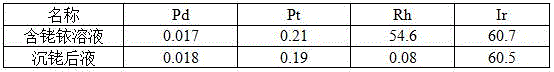

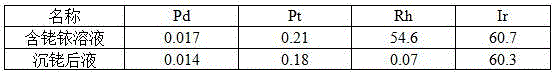

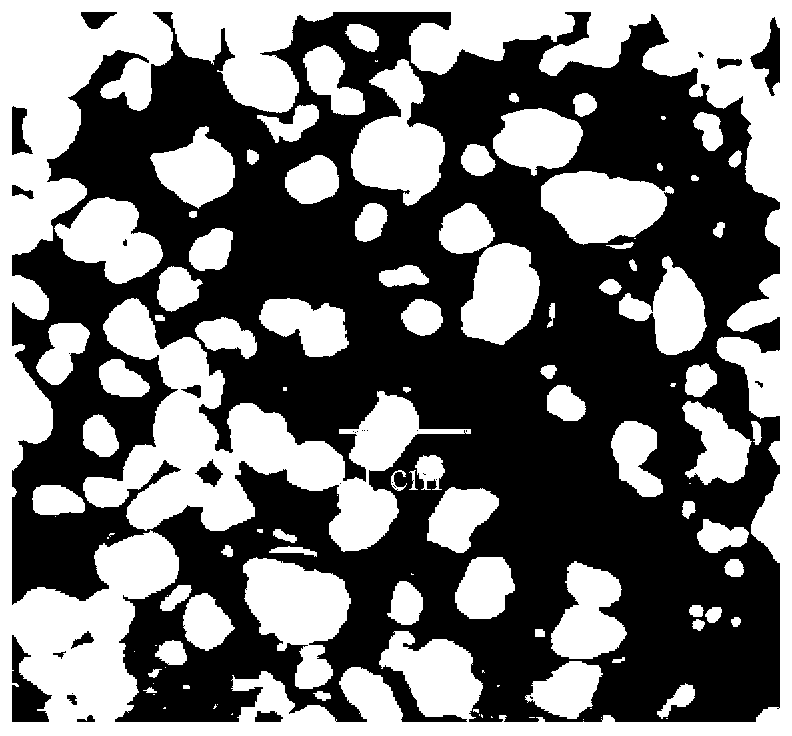

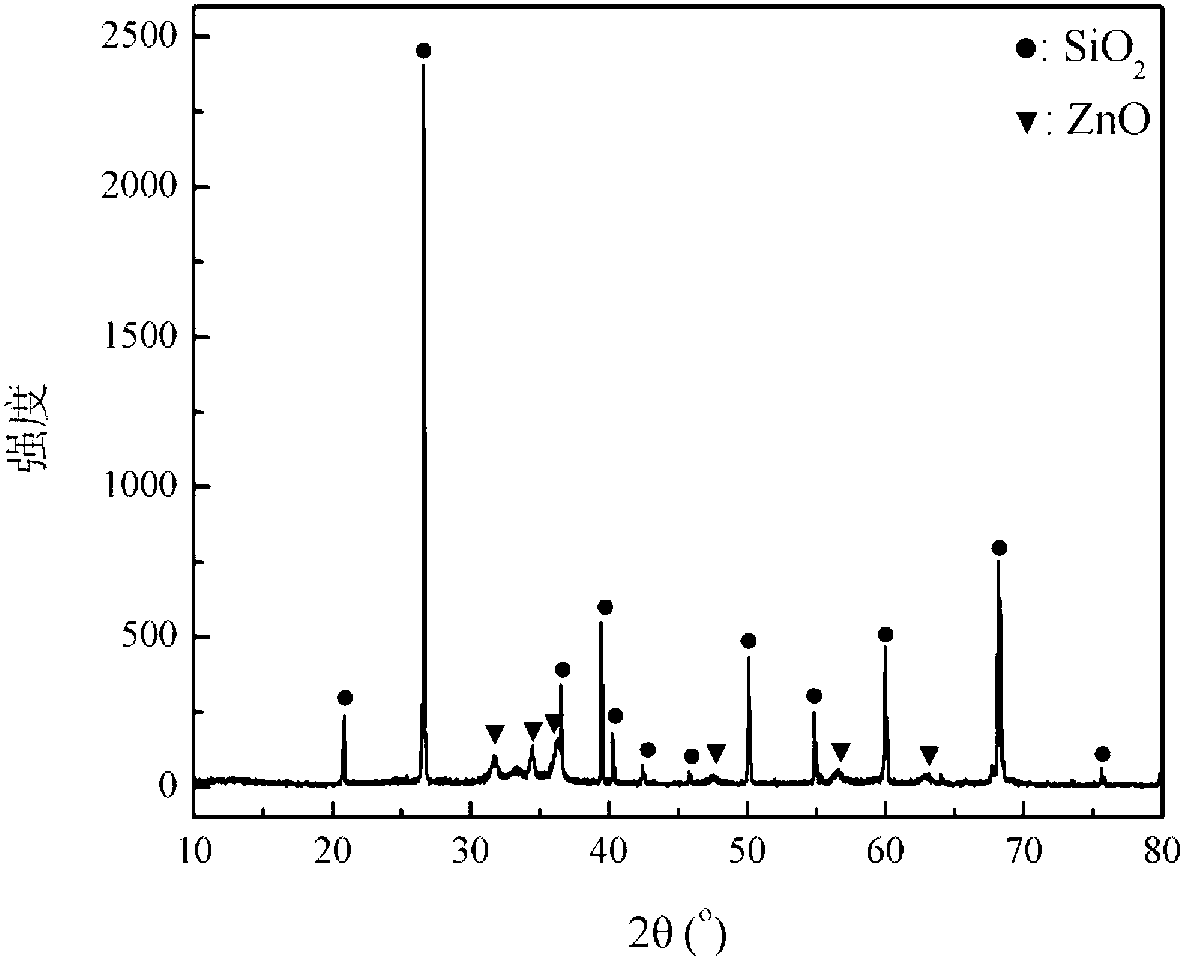

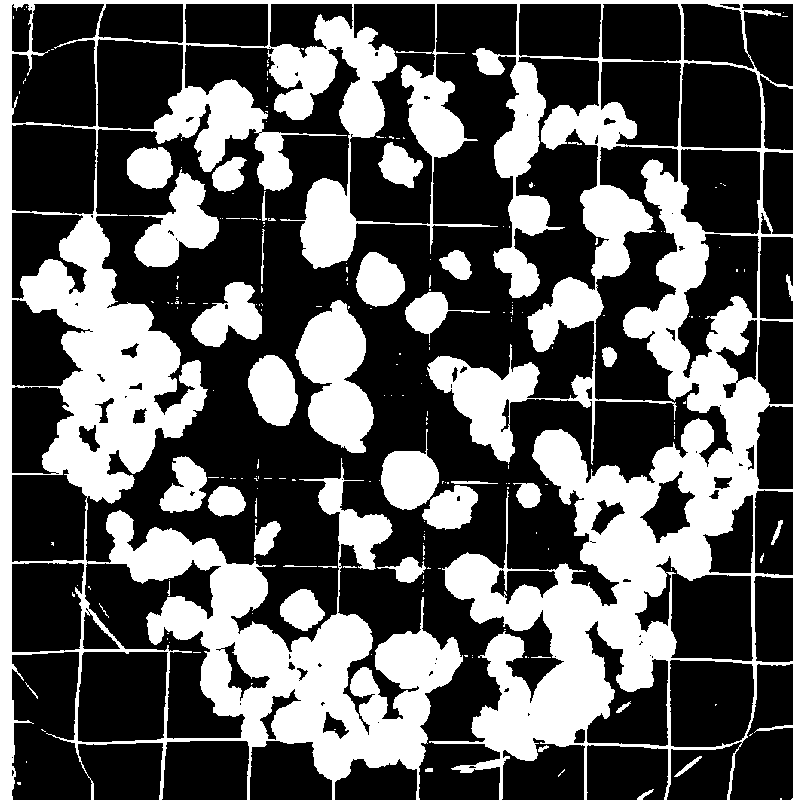

Novel process for separating rhodium and iridium

ActiveCN106282562AImprove separation efficiencyShorten the production cycleProcess efficiency improvementIridiumSlag

The invention discloses a novel process for separating rhodium and iridium. The novel process includes the steps that (1) a strong oxidant is added into a solution containing rhodium and iridium to control the potential, and precious metal ions in the solution are converted into the high valence state; (2) the pH value of feed liquid is controlled through adding of liquid caustic soda, chlorine is introduced till the pH value is lowered to 8-9, and rhodium and iridium are transferred into slag after the procedure is repeated three times; and (3) the rhodium and iridium slag is dissolved through added hydrochloric acid, the acidity is controlled, the potential of the feed liquid is controlled to 900-950 mV by adding the strong oxidant, the temperature is controlled, and rhodium is settled by adding a reagent DETA. The novel process has the beneficial effects that 1, the rhodium and iridium separating efficiency is improved, and the rhodium settling rate is 99% or over; and 2, compared with a TBP rhodium and iridium separating process, the production cycle is shortened by 60% through the novel process.

Owner:JINCHUAN GROUP LIMITED

Method for forming non-biological granular sludge in heavy metal waste water treatment process

ActiveCN103288191AStable structureAccelerated settlementWater contaminantsWater/sewage treatment by flocculation/precipitationSludgeWater quality

The invention discloses a method for forming non-biological granular sludge in a heavy metal waste water treatment process, belonging to the environmental engineering field. Chemical sludge obtained in a heavy-metal-containing waste water treatment process is flocculent suspended state sludge mostly, stability, settleability and dehydration property are poorer, and effluent quality and technology operating efficiency are seriously influenced. Inspired by an induction kernel hypothesis and an extracellular polymeric substance hypothesis for forming the biological granular sludge, an improved parallel flow charging control crystallization process is applied in the invention, a heavy metal precipitation reaction mechanism is changed, and seed crystals and a flocculating agent are added, so that the non-biological heavy metal granular sludge is obtained. The method for forming the non-biological granular sludge has the advantages that an operation cycle is short, a flow path is simple, operation is easy, stability of the heavy metal chemical sludge can be effectively improved, moisture content of settled sludge is reduced by 7-8% compared with common flocculent sludge, and settling rate is increased by 4-5 times.

Owner:CENT SOUTH UNIV

Upgrading bitumen in a paraffinic froth treatment process

ActiveUS8357291B2Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

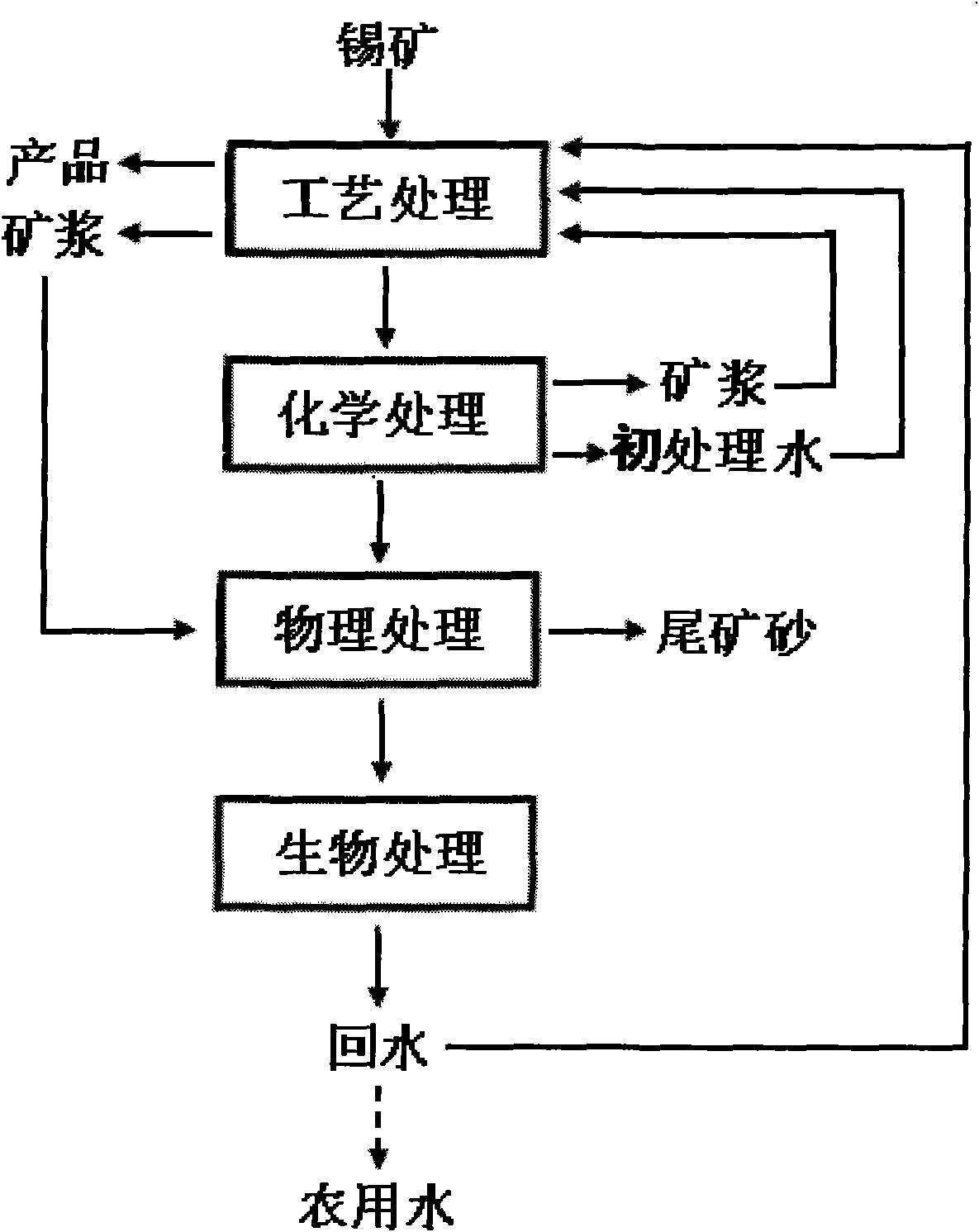

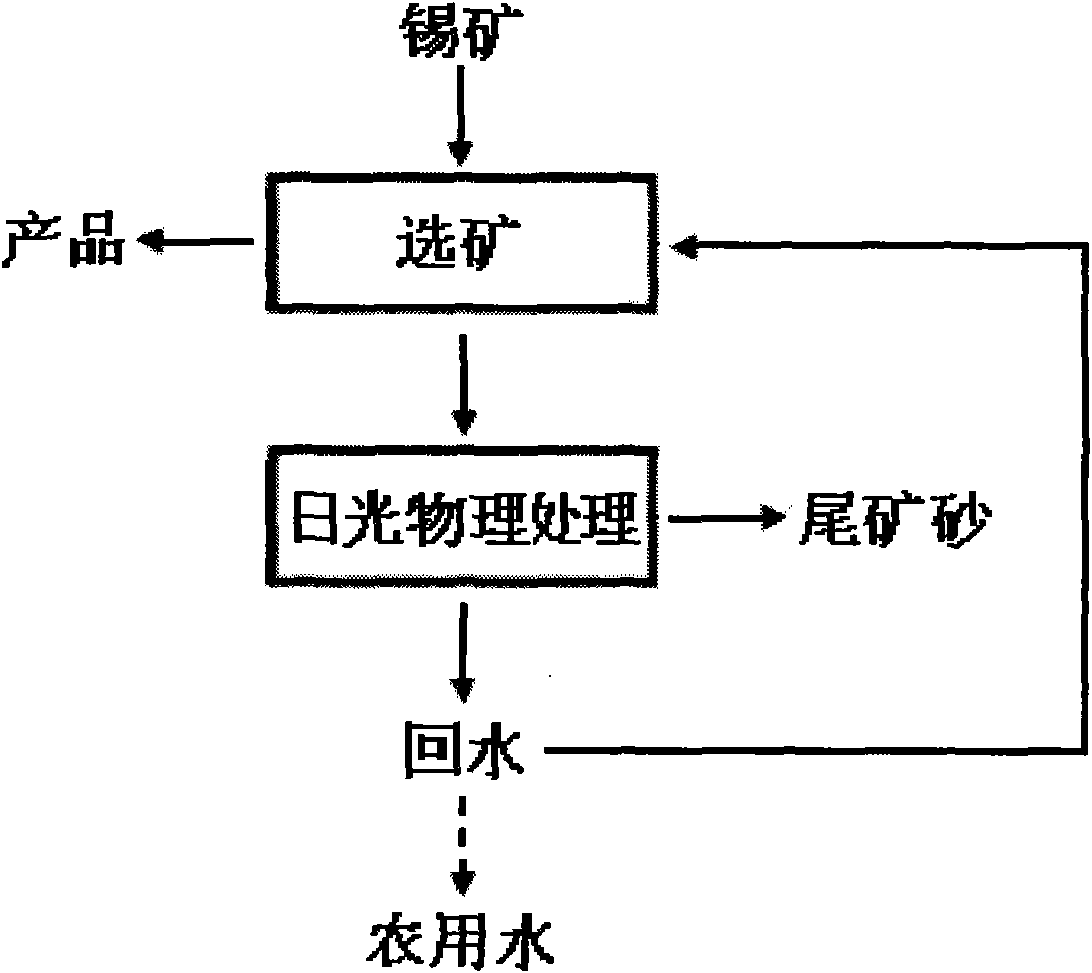

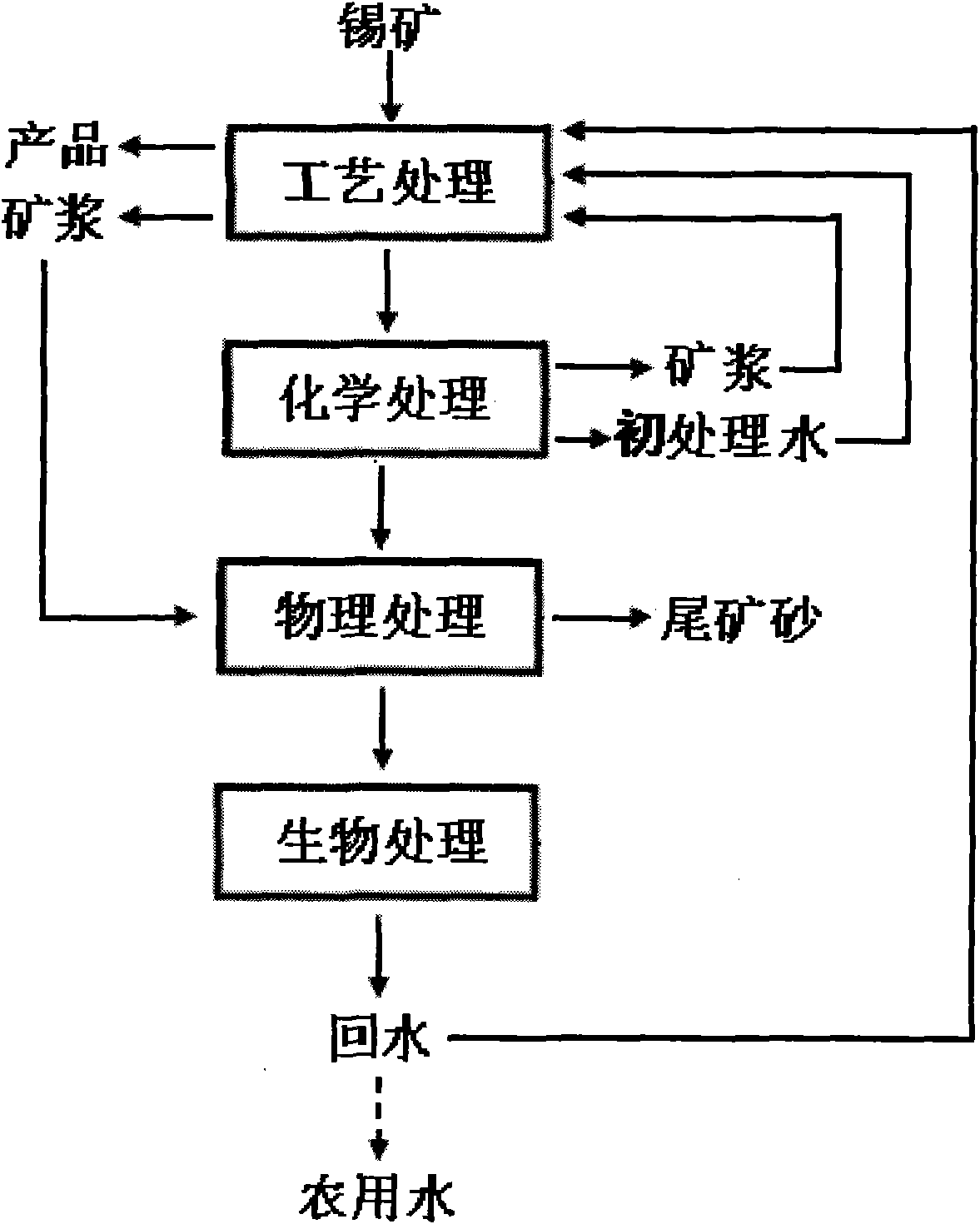

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

Process for preparing lithium carbonate by virtue of spodumene sulfuric acid method

InactiveCN108793205AIncrease sedimentation rateIncrease productionLithium carbonates/bicarbonatesPregnant leach solutionLithium sulphate

The invention discloses a process for preparing lithium carbonate by virtue of a spodumene sulfuric acid method, relating to steps for preparing a lithium sulfate leaching solution and causticizing the lithium sulfate leaching solution in the process for producing lithium carbonate by virtue of the spodumene sulfuric acid method. The process comprises the steps of carrying out crushing, ball milling, roasting, sulfuric acid roasting and leaching, and neutralizing acid liquid to a pH value of 6.5 in the leaching solution by virtue of CaCO3 so as to enable the leaching environment of lithium sulfate to be faintly acid, so that magnesium and calcium ions are effectively removed, the drag-out quantity of lithium is relatively low, the recovery rate of lithium is relatively high, the settling rate of lithium carbonate is increased to a great extent, the yield of lithium carbonate prepared by virtue of the spodumene sulfuric acid method is further increased, and resources are saved.

Owner:萍乡市拓源实业有限公司

Method of recovering crystalline material and compositions therefrom

ActiveUS20070149836A1Molecular sieve catalystsCatalyst activation/preparationMolecular sieveCrystalline materials

A method for recovering molecular sieve crystals from a synthesis mixture that comprises adding at least one flocculant having a certain molecular weight and a certain charge density that contribute to the acceleration of the settling rate of the molecular sieve crystals and compositions made from the method.

Owner:EXXONMOBIL CHEM PAT INC

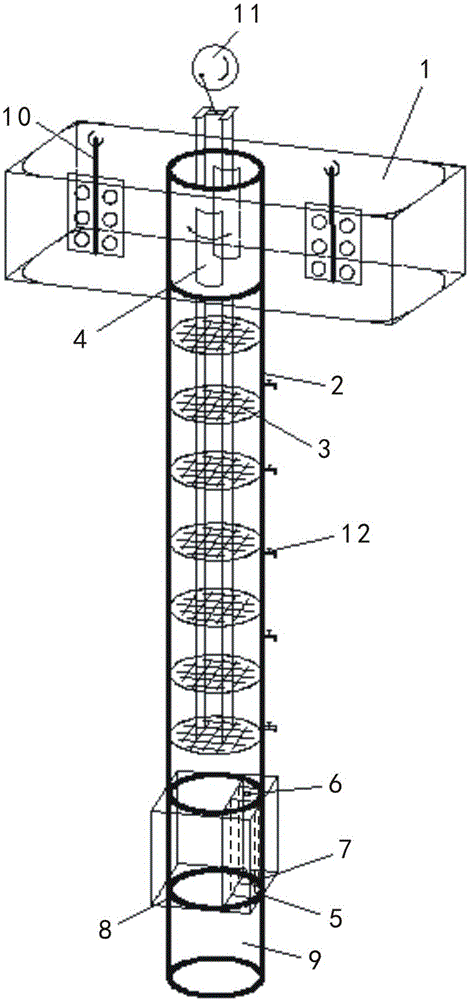

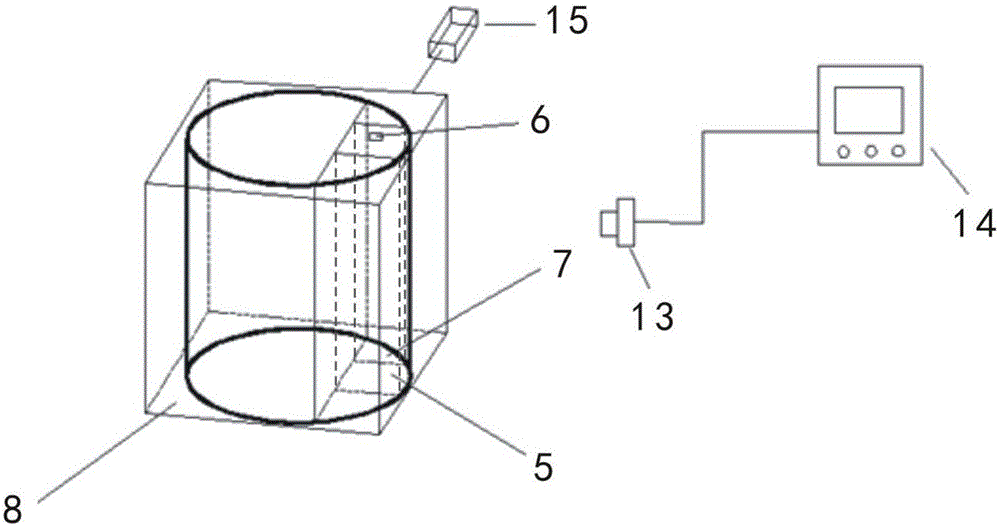

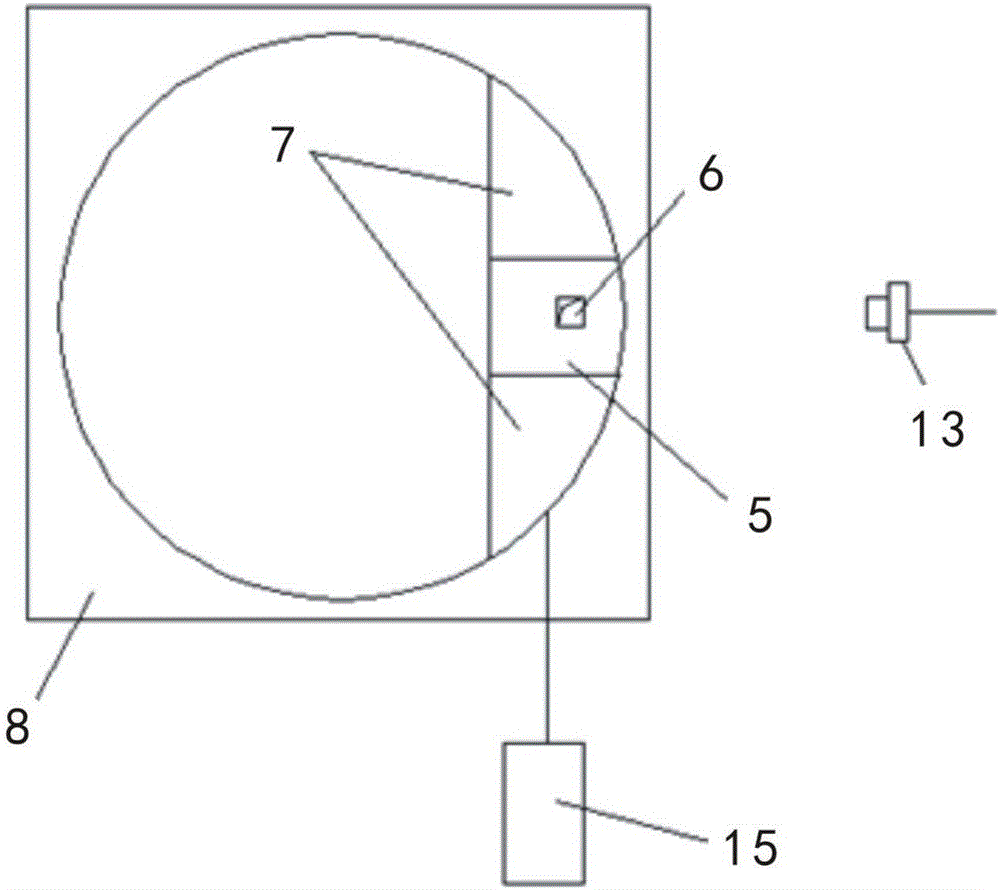

Testing device capable of observing cohesive sediment flocculation and settling under different velocity gradients

ActiveCN106769717ARealize timing and quantitative dischargeAvoid deformationParticle size analysisEngineeringSettling column

The invention discloses a testing device capable of observing cohesive sediment flocculation and settling under different velocity gradients. The upper part of a vertical hollow settling column in the upper and lower ends of which openings are formed is communicated with a water collection tank; the upper end of a floc separation chamber is connected with the lower end of the hollow settling column; a floc collection opening used for collecting one part of floc in the hollow settling column into the floc separation chamber is formed in the upper end of the floc separation chamber; a sediment collection chamber is formed below the floc separation chamber and is used for collecting other floc which is not introduced into the floc separation chamber; and an image acquisition device is mounted beside the floc separation chamber. Due to the design of the hollow settling column, the sediment floc is in a settling state; due to the designed floc separation chamber, one part of detected floc is separated from the other floc, and the condition that too much floc is mutually interfered is avoided, so that the measurement accuracy is obviously improved and due to the image acquisition device, the floc image is acquired so as to analyze the particle size and settling rate of the floc formed after cohesive sediment flocculation and settling.

Owner:CHONGQING RES ACAD OF ECO ENVIRONMENTAL SCI

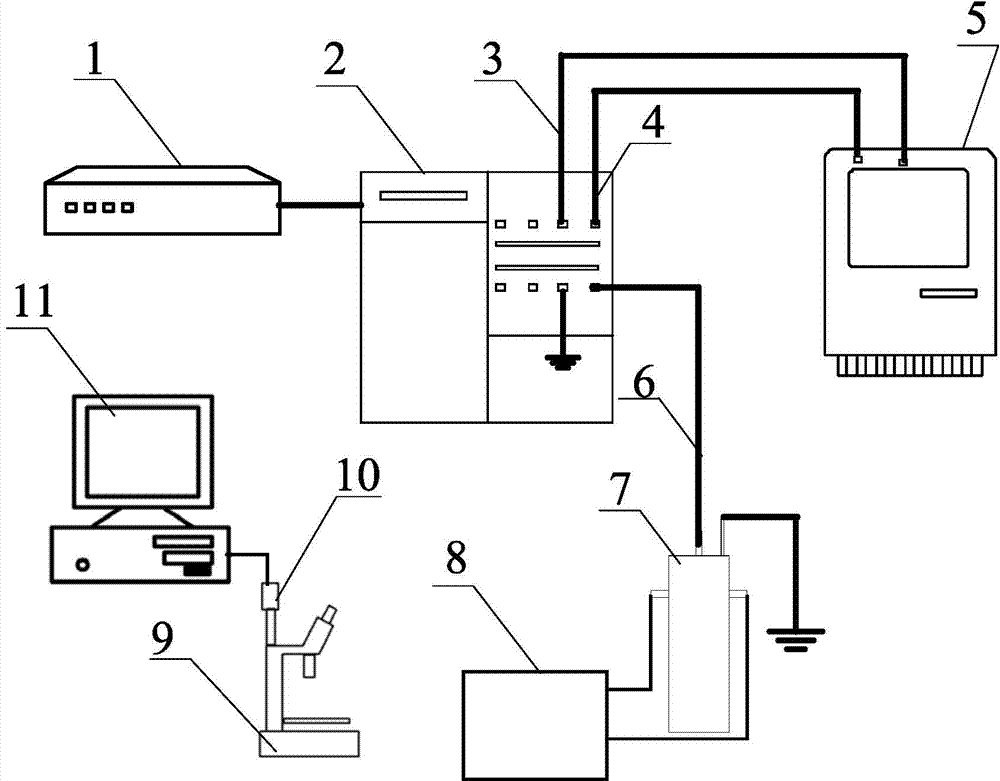

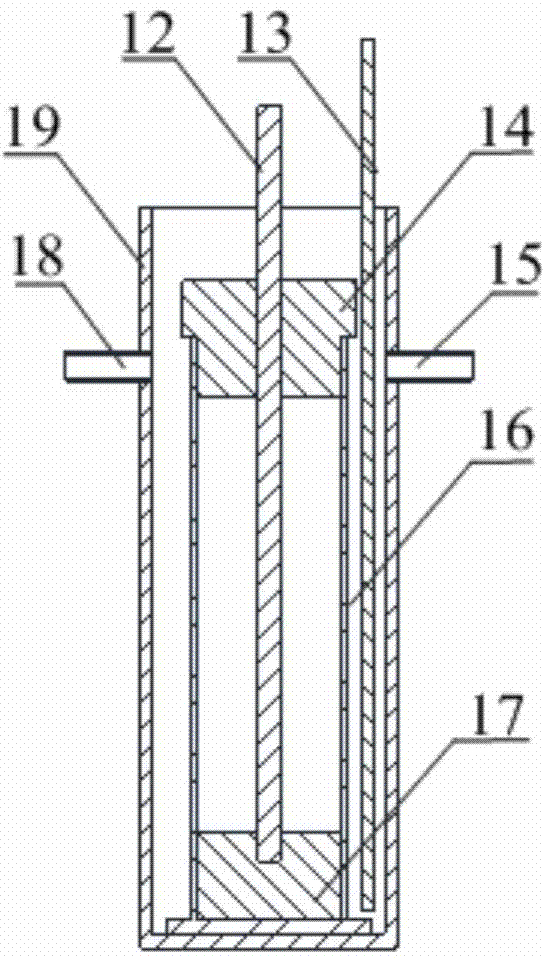

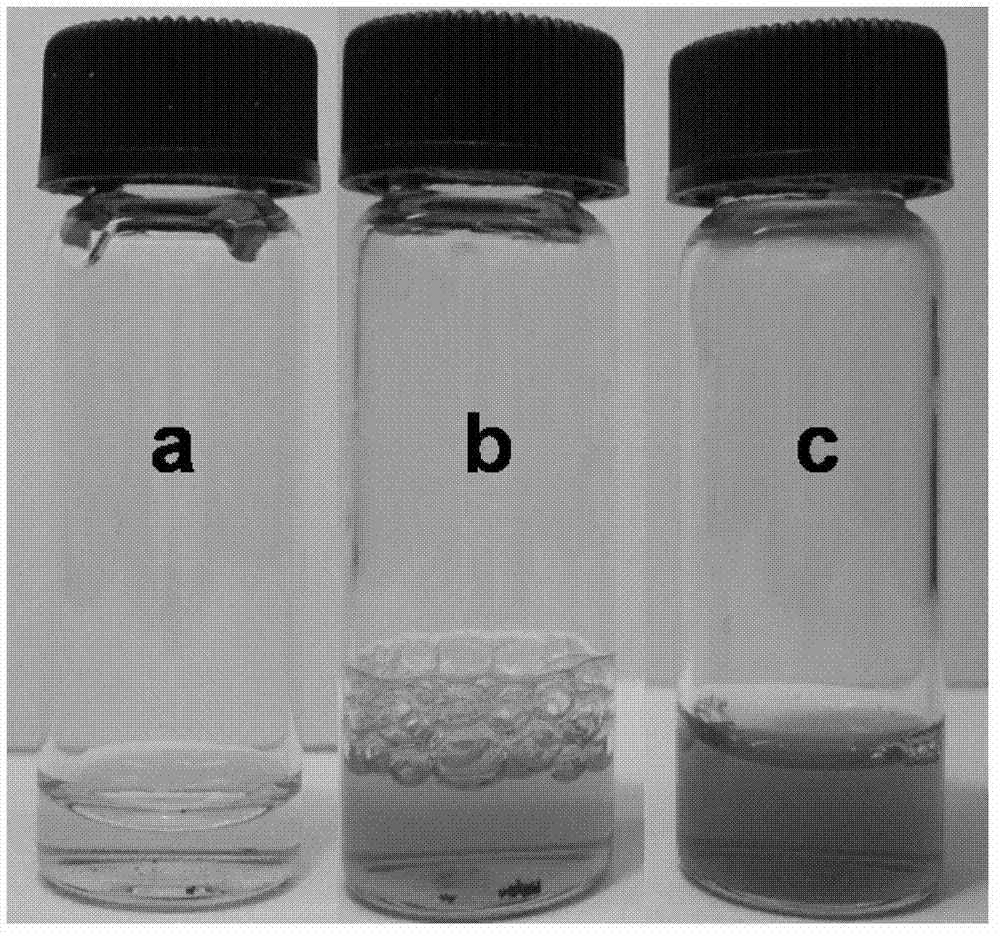

Rapid evaluation system and rapid evaluation method for electrostatic coalescence

ActiveCN104515692AQuick evaluationGuaranteed uptimeDewatering/demulsification with electric/magnetic meansStructural/machines measurementMeasurement deviceEngineering

Disclosed are a rapid evaluation system and a rapid evaluation method for electrostatic coalescence. By the rapid evaluation system and the rapid evaluation method, coalescence effect of coaxially cylindrical electrostatic coalescers can be evaluated, and electric field parameters can be optimized. The rapid evaluation system comprises a power supply device, a small electrostatic coalescer and a measuring device. The power supply device refers to a waveform generator and a high-voltage current amplifier and is capable of applying high voltage to the small electrostatic coalescer to enable water drops in a water-in-oil emulsion to coalesce. An oscilloscope connected to the high-voltage current amplifier is capable of displaying voltages and currents between two electrodes in real time and collecting and storing the voltages and the currents for energy consumption ratio analysis. Changes before and after water drop grain diameter electrification are analyzed by combing microscopic photographing with an image processing technique, and water settling rate and separation effect can be analyzed by a gravity settling method, so that the optimal electric field parameters are determined. The rapid evaluation system and the rapid evaluation method have the advantages of convenience in use and rapidness in testing, the basis can be provided for design of the electrostatic coalescers and equipment selection, equipment design is more reasonable, and high efficiency in use is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Industrial dust remover

InactiveCN107158868AImprove filtering effectDust removal speed is fastCombination devicesInlet channelSprayer

The invention relates to the field of environment-friendly appliances, particularly an industrial dust remover. The industrial dust remover comprises a shell, a water sprayer, a dust remover, a collecting device, a baffle plate, a blower and a controller, wherein the shell is provided with a gas inlet channel and a gas outlet channel; the gas outlet channel is connected with the blower; and the blower is used for drawing out the purified gas. The industrial dust remover is characterized in that traveling wheels are arranged under the shell; the water sprayer is installed on the top of the shell, and used for settling dust obtained by the collecting device and cleaning the collecting device; the dust remover is installed in the upper position inside the shell, and used for removing dust in the gas; the collecting device is used for collecting and storing the dust generated in the dust removal process; the baffle plate is installed inside the shell in the position adjacent to the gas inlet channel; and the bottom of the baffle plate is arranged obliquely. The industrial dust remover is used for reducing the dust discharge amount in industrial production, can enhance the dust settling rate and clean the collecting device, and has better filtering effects.

Owner:贵州南剑环保节能科技有限公司

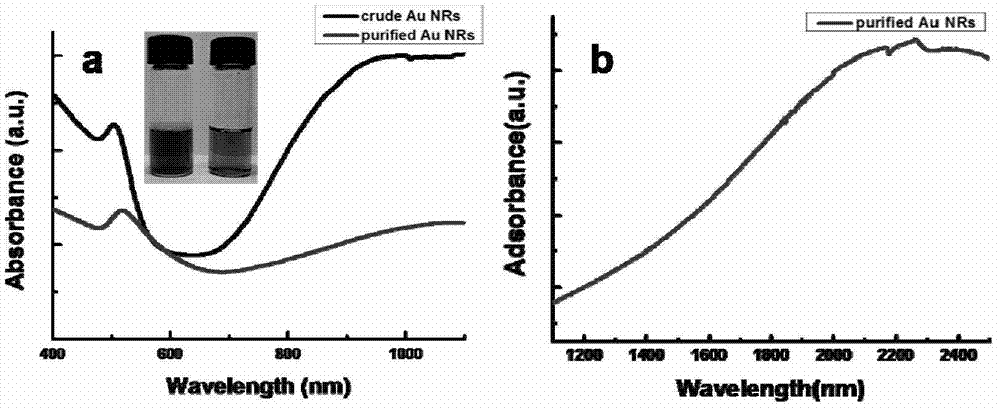

Method for dispersing, purifying and/or assembling nano gold rods

ActiveCN102728831ARealize human controlMild reaction conditionsCoatingsSpecial surfacesRoom temperatureRepeatability

The invention discloses a method for dispersing, purifying and / or assembling nano gold rods. According to the method, 'dendritic' surfactant C18N3 with acid and alkali response is used as a protective agent, and a good dispersion system of the nano gold rods can be obtained under low surfactant concentration. At normal temperature, the system is regulated to alkali through standard NaOH, so that the settling rates of the nano gold rods and other nano particles in the system are different and the nano gold rods are purified; and the pH of the purified nano gold rod system is regulated through HCl, so that a large-area assembly of the nano gold rods can be obtained. The method is mild in reaction conditions, can be operated at the normal temperature, is easy to operate, short in reaction period, beneficial to reducing time and cost, cheap and readily available in raw materials required by the reaction, high in repeatability and high in purification yield, and reduces the production cost. The reaction is simple and feasible, factors which are difficult to control are eliminated, and artificial control of product yield and assembly area can be well realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

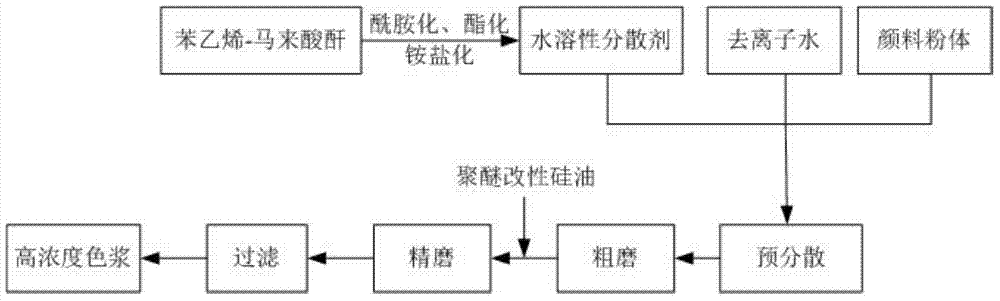

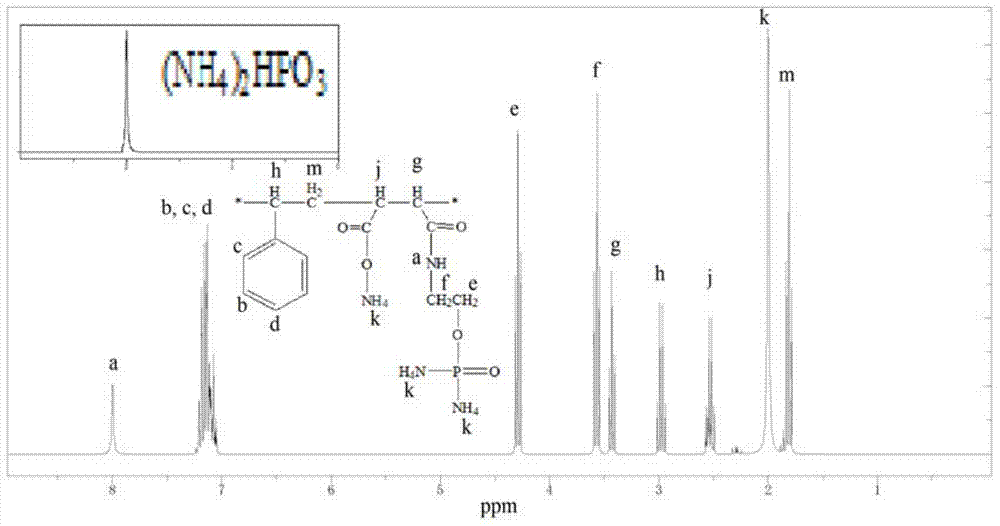

High-concentration neutral ink color paste and preparation method thereof

ActiveCN104845453AAchieve wrappingIncrease steric hindranceInksPigment pastesHigh concentrationHigh-speed grinding

The invention discloses high-concentration neutral ink color paste and a preparation method thereof. The solid content of the high-concentration neutral ink color paste is not lower than 40 weight percent, ; the particle size D90 of color paste particles is not greater than 250nm, ; the high-speed settling rate of the color paste is not greater than 50 micrometers / min, and the color paste has lower viscosity of 70 to 200mPs. The invention also provides a preparation method of the high-concentration neutral ink color paste. The preparation method comprises the following steps of firstly, generally performing amidation, esterfication, ammonia salt treatment and modification on conventional styrene-maleic anhydride to obtain a water soluble dispersant; secondly, adding the water soluble dispersant and pigment according to a certain proportion for stirring and dispersing; thirdly, performing high-speed grinding and coarse grinding, lengthening a long-chain polyether modified silicone surfactant by coarse grinding; fourthly, performing fine grinding and impurity filtering treatment to obtain the high-concentration neutral ink color paste. The high-concentration neutral ink color paste prepared by the invention has high concentration, lower viscosity and better stability, has excellent matching property for preparing neutral ink at a later stage, and has a broad application prospect in the application of blending the neutral ink.

Owner:LOTUS STATIONERY

Manure separation for digester method and apparatus

ActiveUS20090090679A1Liquid separation auxillary apparatusBio-organic fraction processingMilk productsWaste management

A method and apparatus for removing settleable solids and unsettleable solids from a partially closed flush system in a dairy milking operation whereby a first processing tank bottom removes settleable solids contained therein where the net current flow vertically in the process tank is less than the settling rate of the settleable solids contained therein. The process tank batch feeds a plurality of thickening tanks that are each allowed to settle for a period of time before transferring fluid is to a second separator. The method and apparatus uses the solids for feeding a digester.

Owner:DARITECH

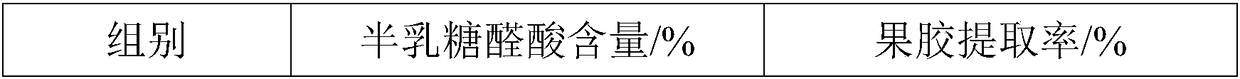

Process of extracting high-purity pectin from apple pomace

The invention discloses a process of extracting high-purity pectin from apple pomace, and relates to the technical field of pectin extraction. The process comprises the following steps: (1) rinsing for impurity removal; (2) powdering; (3) acid extraction; (4) decoloration; (5) concentration; (6) pectin settlement; (7) purification; (8) drying and powdering. According to the process, soluble sugarand part of pigments are removed from the apple pomace through rinsing operation; the apple pomace is granulated through the powdering operation to promote rapid leaching of the pectin during subsequent acid extraction; the pigments in a pectin extracting solution are effectively removed through the decoloration operation; by use of a pectin settling agent, the pectin settling rate and the pectinpurity are improved, so that the content of galacturonic acid in the prepared finished pectin is up to 85 percent or above, and the pectin extraction rate is up to 90 percent or above.

Owner:DANGSHAN HAISHENG PECTIN

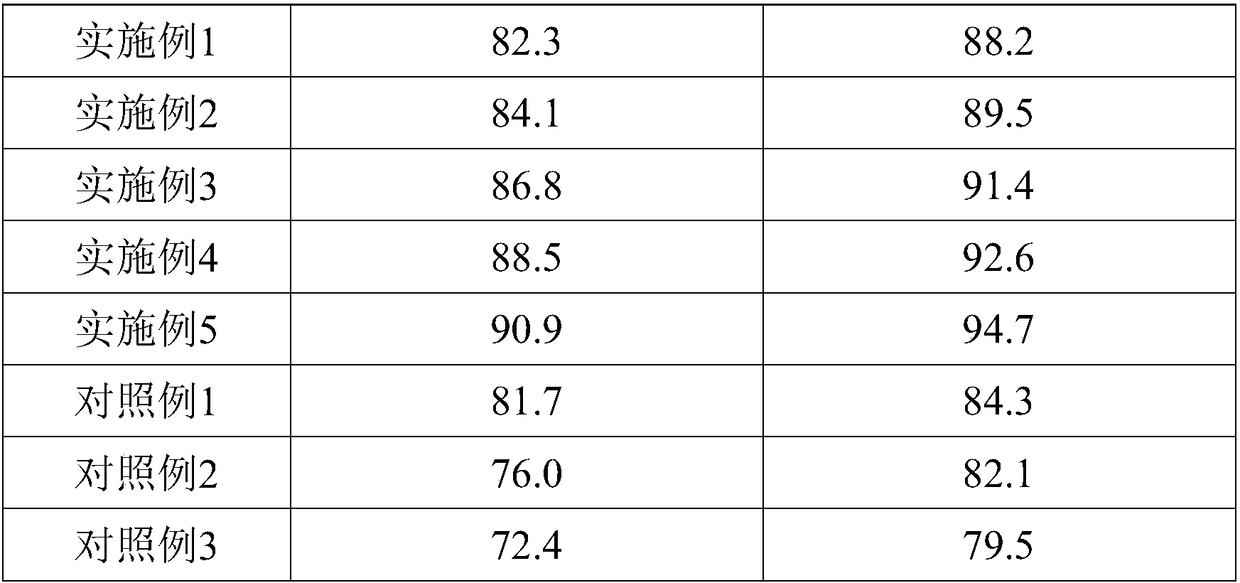

Method for reducing gold extraction residual liquid

The invention discloses a method for reducing gold extraction residual liquid, and relates to a process for separating platinum palladium and other metals from the gold extraction residual liquid by using sodium hydrogen sulfite and settling zinc magnesium powder to separate rhodium iridium and base metals; after the acidity of the gold extraction residual liquid is adjusted, the sodium hydrogen sulfite is reduced; the zinc magnetism powder is settled through once reducing liquid; and rhodium refining and iridium refining are respectively performed for produced rhodium iridium slag after the separation of rhodium and iridium to generate rhodium powder and iridium powder accordant with the national standards. The method is simple in process flow, convenient for operation and reasonable in procedure joint. The method can enable the copper content in the subsequently produce once reducing liquid to largely reduce; the platinum and palladium settling rates are both higher than 99%; the once reducing liquid is prepared to secondary reducing liquid by the replacement of zinc magnesium powder; the settling rates of noble metals in the secondary reducing process are higher than 99.95%; the rhodium iridium slag weight generated by secondary reduction is reduced by above 65% compared with a traditional process; the method can shorten the process flow of rhodium and iridium refining; and the product pass percent is largely increased.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com