Testing device capable of observing cohesive sediment flocculation and settling under different velocity gradients

A test device and velocity gradient technology, applied in the measurement device, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of small sedimentation cylinder height, floc separation, no vibration grid, etc., to avoid mutual interference, measurement The effect of improving accuracy and preventing image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

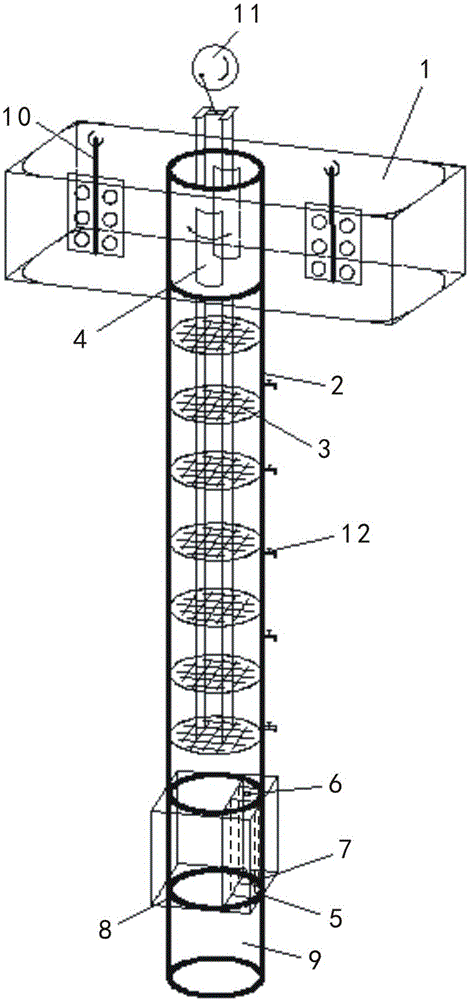

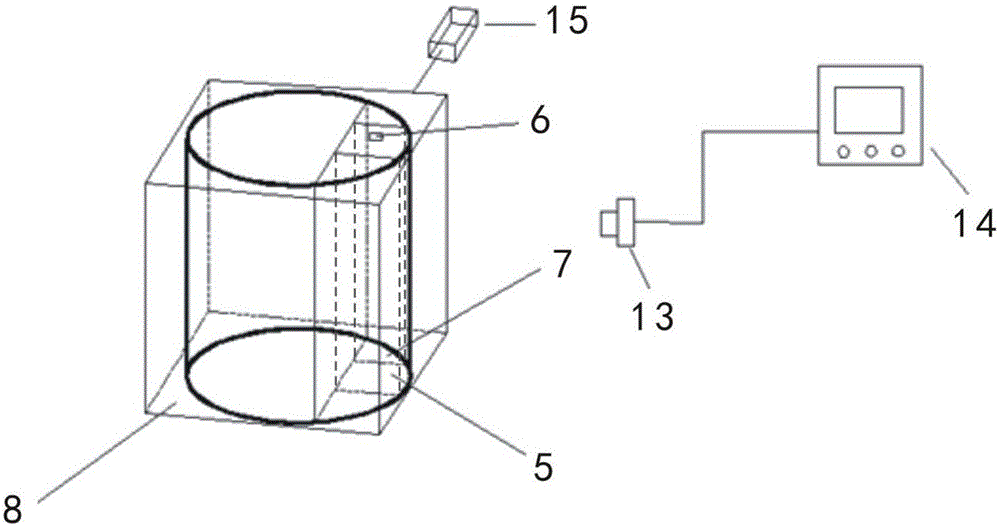

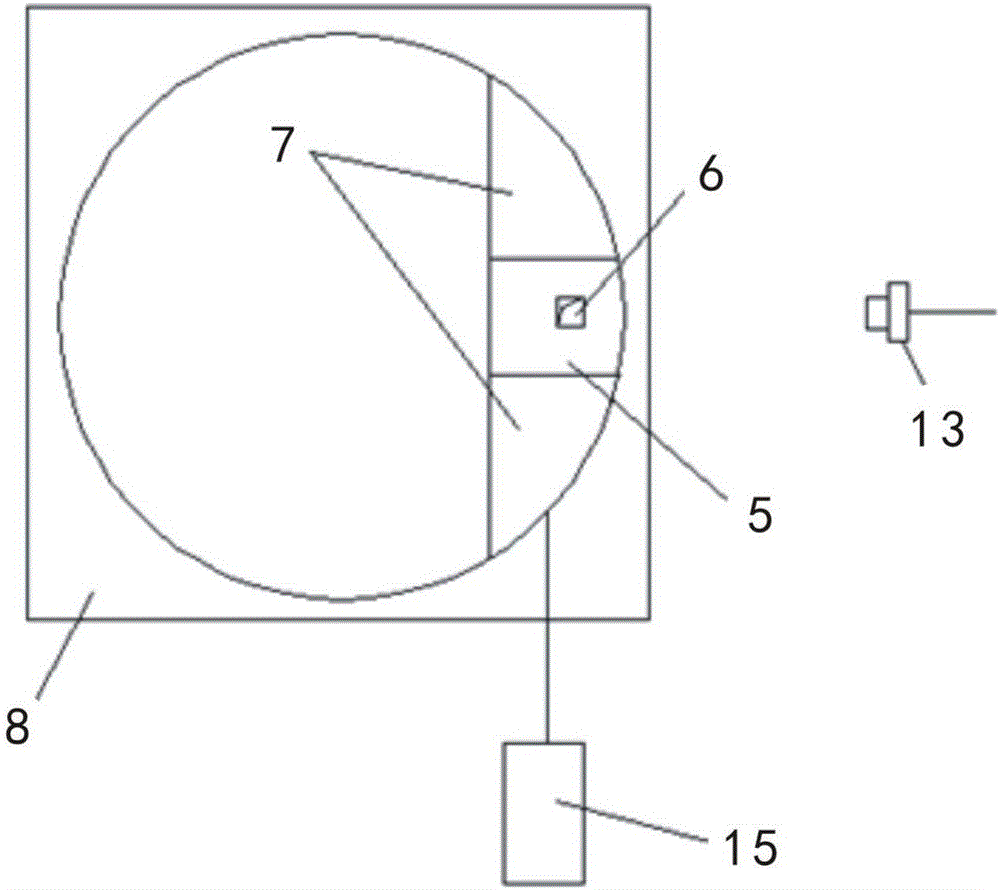

[0019] like figure 1 , figure 2 and image 3 As shown, the test device of the present invention that can observe the flocculation and sedimentation of viscous sand under different velocity gradients includes a water collection tank 1, a motor 11, an agitator 10, a hollow settling column 2, a grid 3, a floc separation chamber 5, a clear water Box 8, clear water chamber 7, sediment collection chamber 9, laser emitter 15, camera 13 and image acquisition host 14, agitator 10 is arranged in the described water collecting tank 1, vertically and the cylindrical hollow of upper and lower ends all open The upper part of the settling column 2 is communicated with the water collecting tank 1, the upper part of the hollow settling column 2 is placed in the collecting tank 1, and the upper pipe wall of the hollow settling column 2 is provided with an inlet and outlet 4 which can be o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com