Patents

Literature

2434results about How to "Simple organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

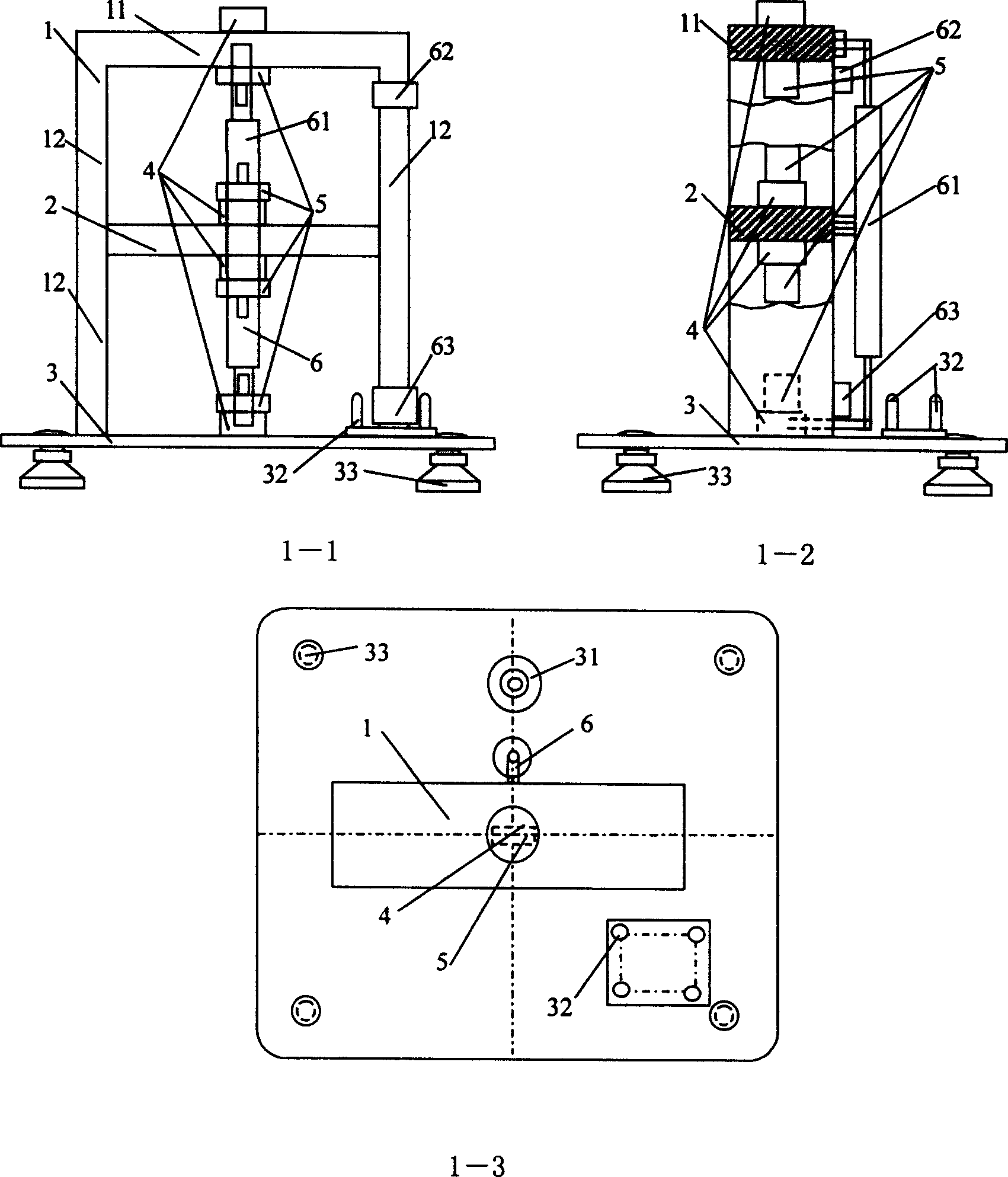

Combined measuring method and device for stretching, compressing, bursting and prick-cut

InactiveCN1587964AEasy to holdQuick gripMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesYarnFiber

The invention relates to a combining ability and displacement measuring method and device of textile materials containing fiber, yarn, cloth, film and composite material, by which combining ability-displacement curve and stress-strain carve and measurement of associative characteristic value are obtained. The measuring device is consisted of multi-functional clamper suitable for textile materials, frame top beam, middle beam and under beam where sensor and multi-functional clamper can be installed, driving element controlled by middle beam, force and displacement signal collection card And computer with modules of program control and data processing. The invention includes the following properties that force sensor can be fitted on anywhere of the under beam, which can measure force value of moving terminal, and its structure is simple, operation is convenient and multi-functional clamper can be replaced fast and conveniently.

Owner:DONGHUA UNIV

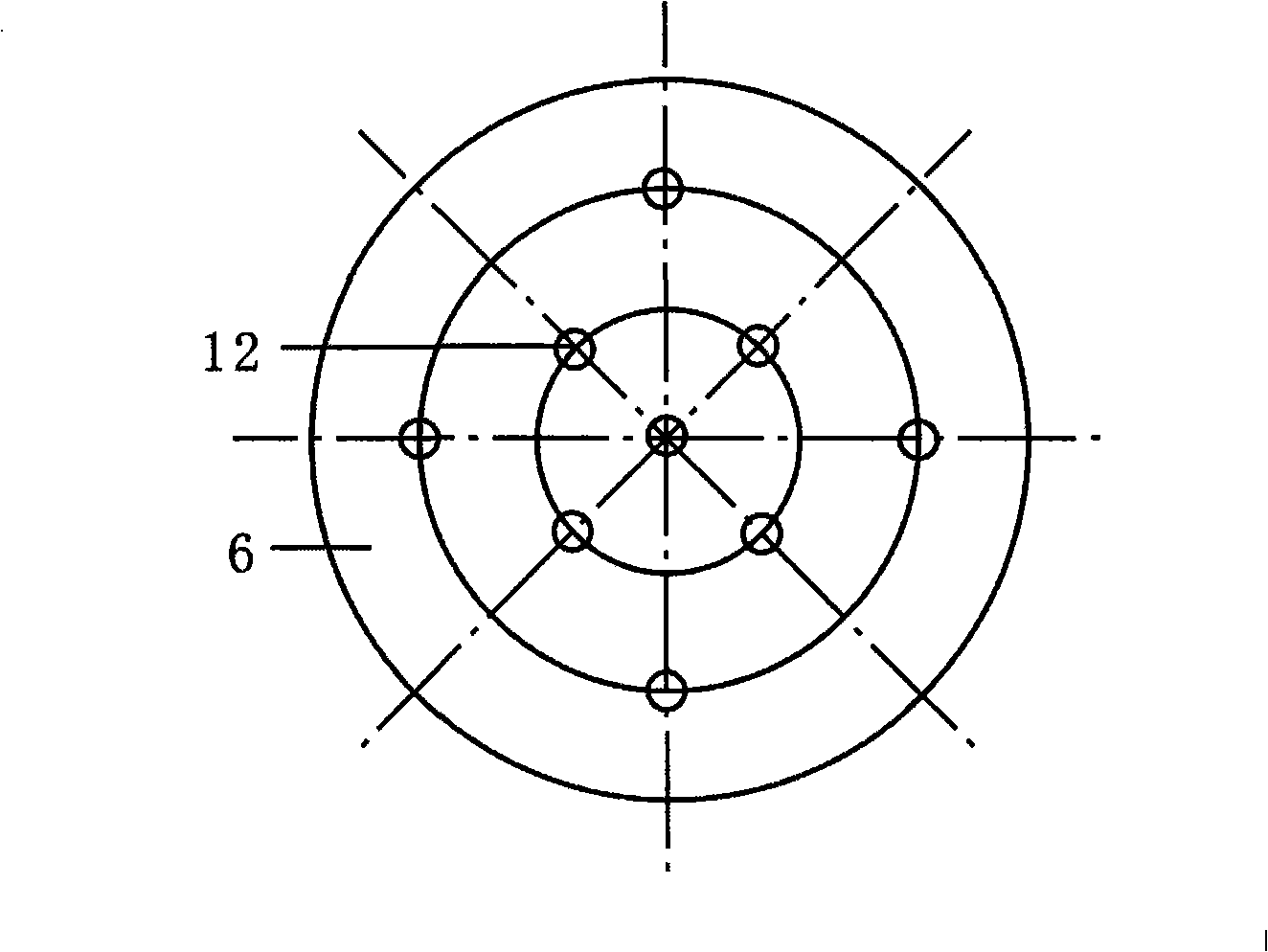

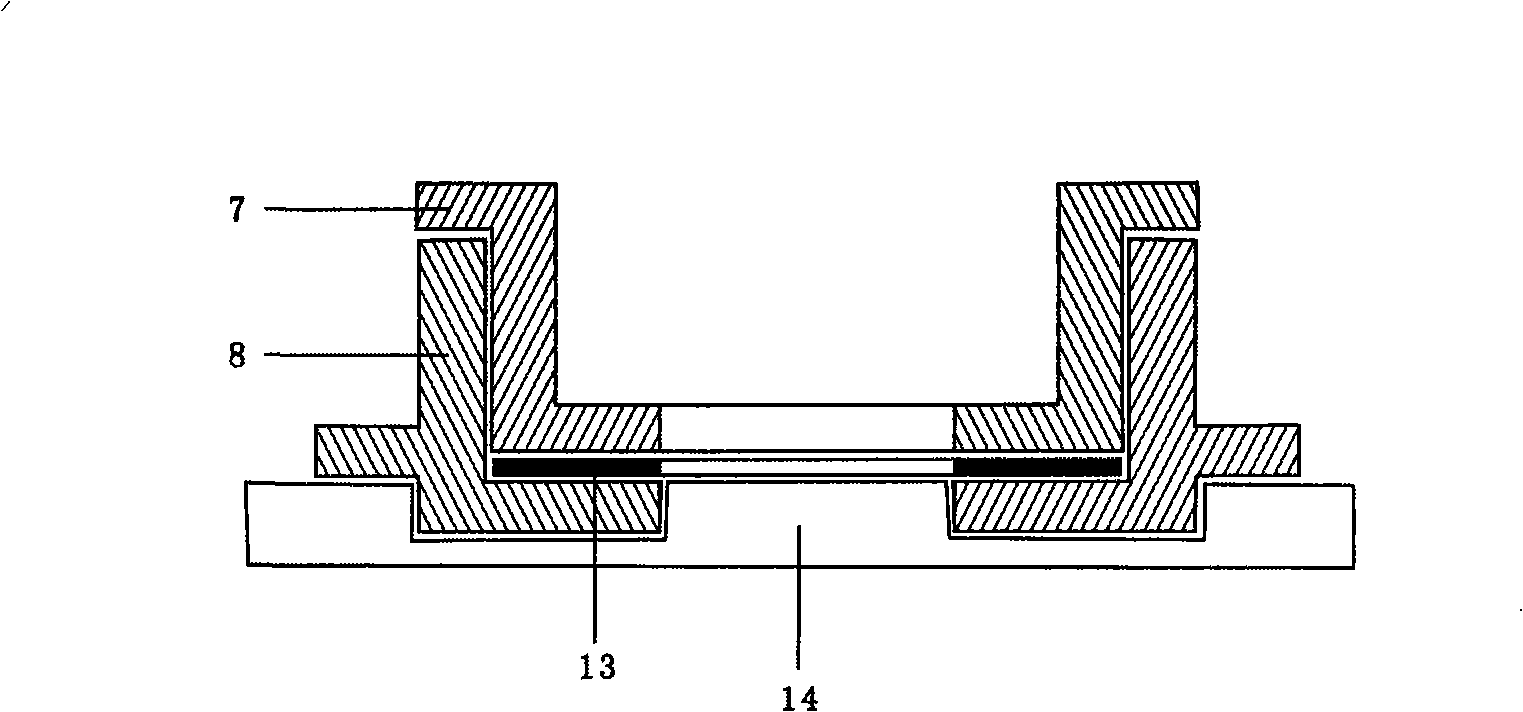

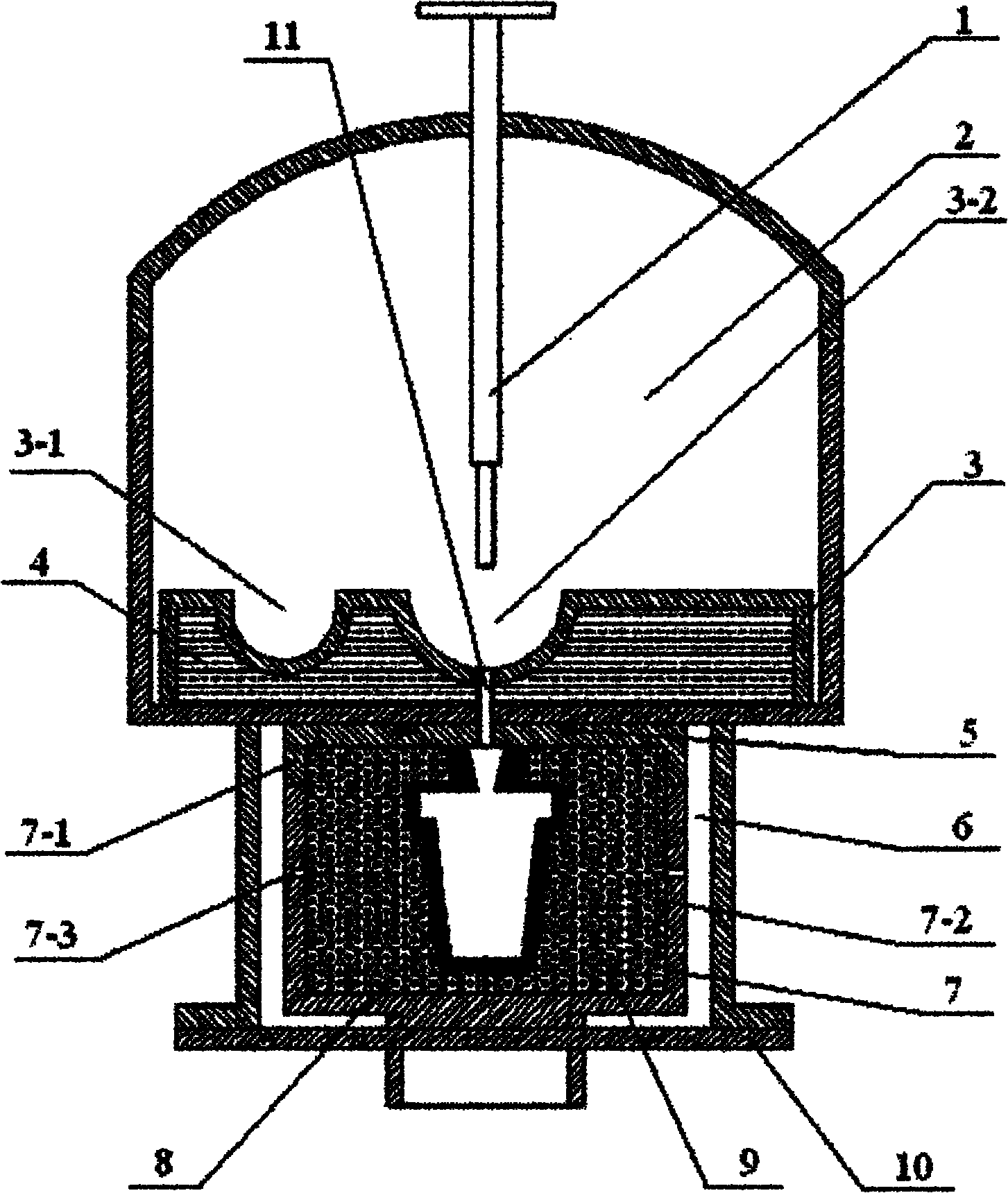

Fabric three-dimensional pressure simulation test system

ActiveCN101354296AEasy to retractSimple organizationForce measurementTextile testingUltrasound attenuationEngineering

The invention relates to a fabric three-dimensional pressure analog test system which is used for testing the dynamic contact pressure and the pressure attenuation characteristics of fabrics. The measuring principles of the invention refers to measuring dynamic clothing pressure during a process of fabric three-dimensional deformation by a pressing ball embedded with nine highly precise pressure sensors to press against the fabrics; the pressing ball is transmitted by a driving device, which can press against the fabrics for more than several thousand times so as to measure pressure fatigue. A pressure-displacement curve, a pressure-time curve and a pressure attenuation curve of each sensing point are respectively obtained by the processing of a computer. The analog test system of the invention has simple structure and convenient operation and is a testing instrument that can effectively and objectively evaluate fabric pressure performance.

Owner:DONGHUA UNIV +1

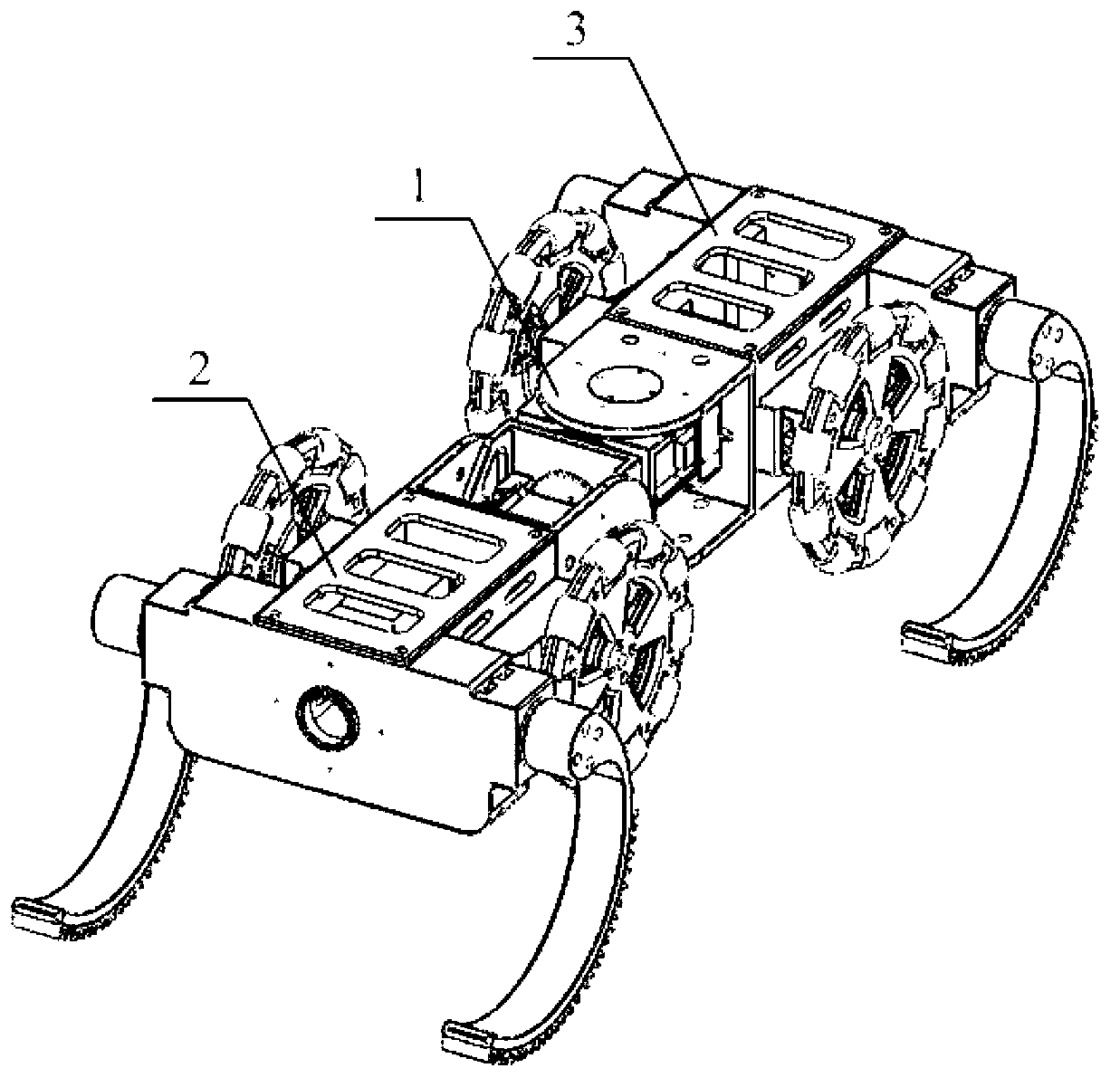

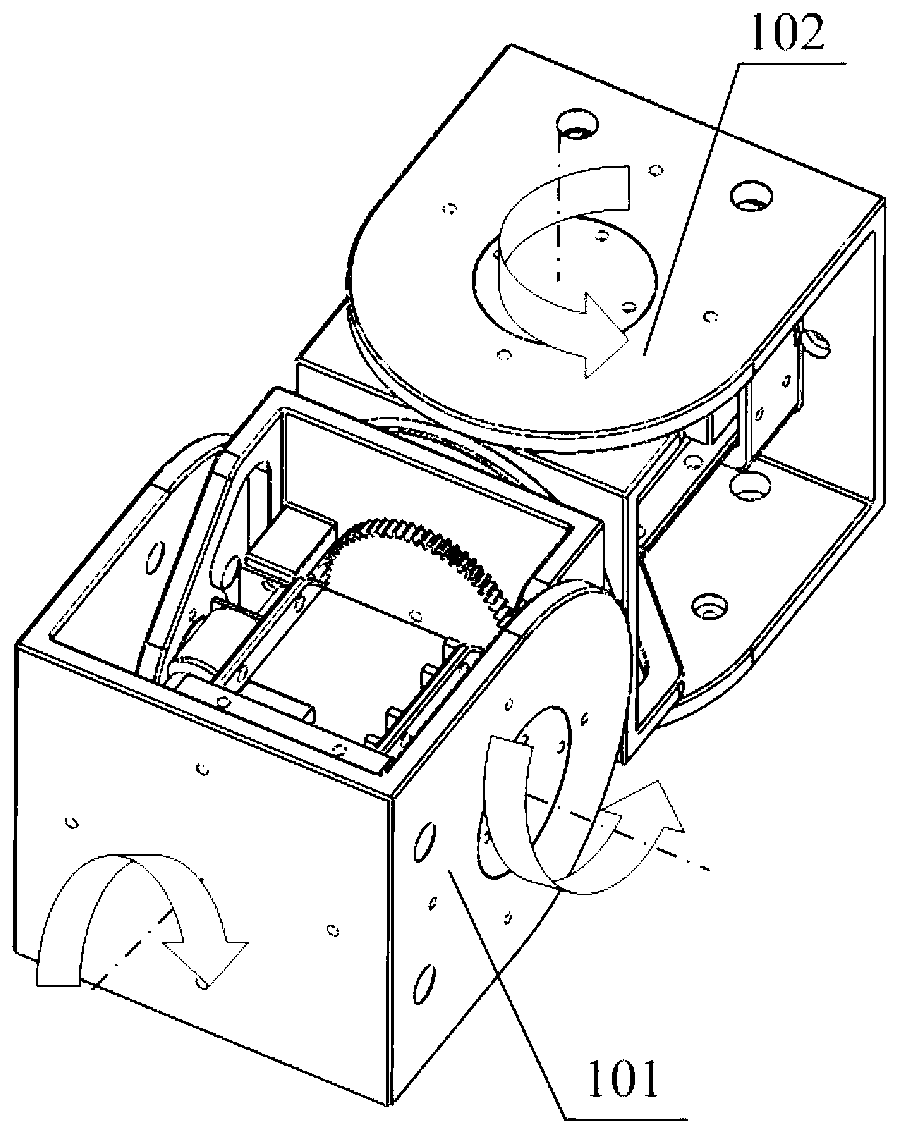

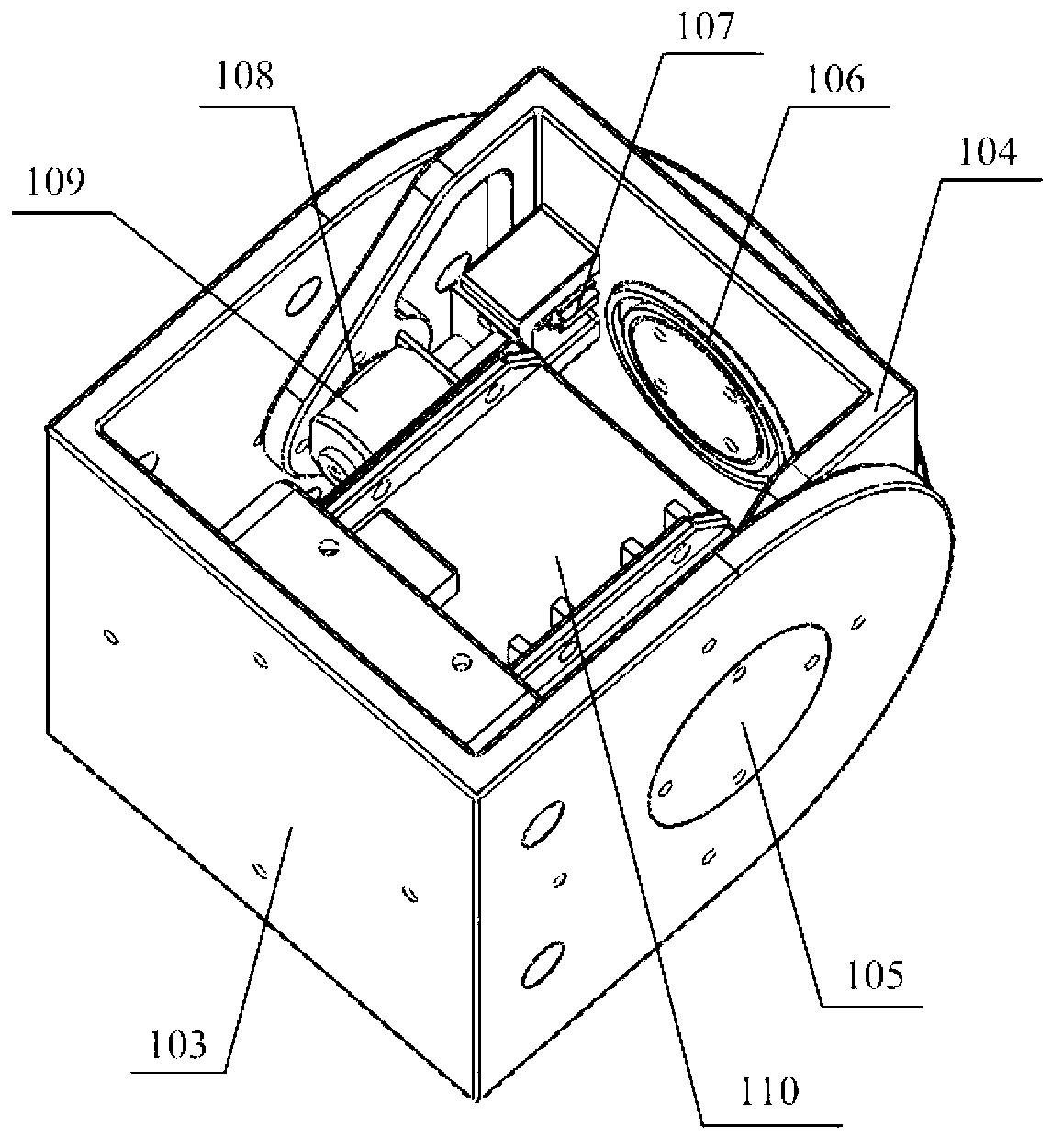

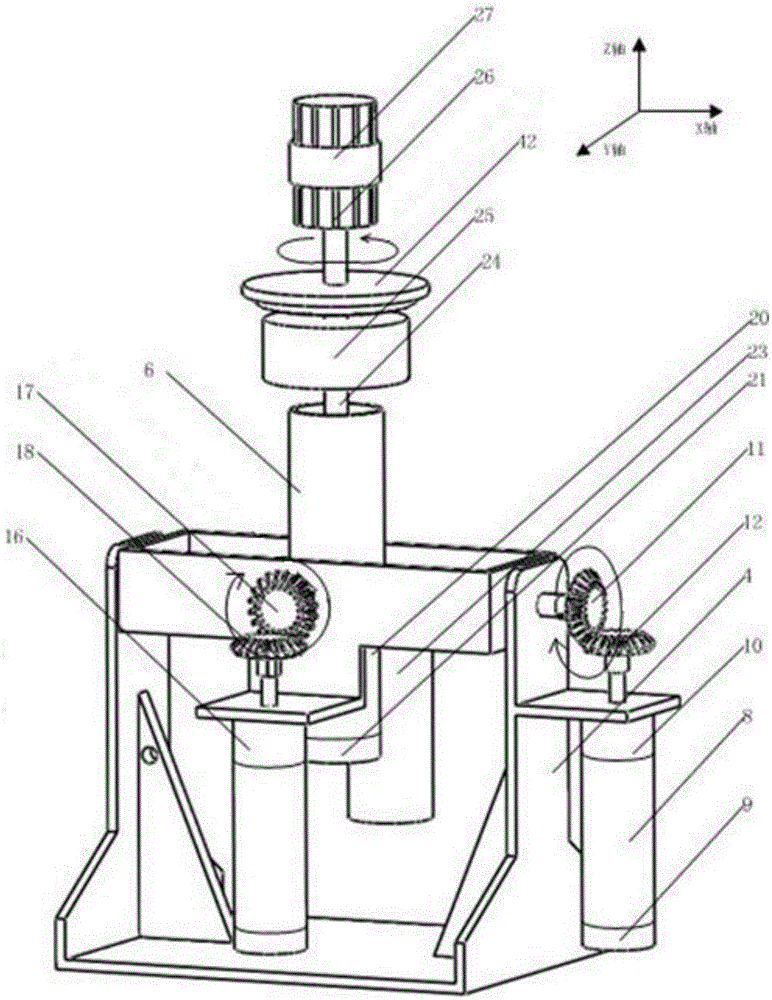

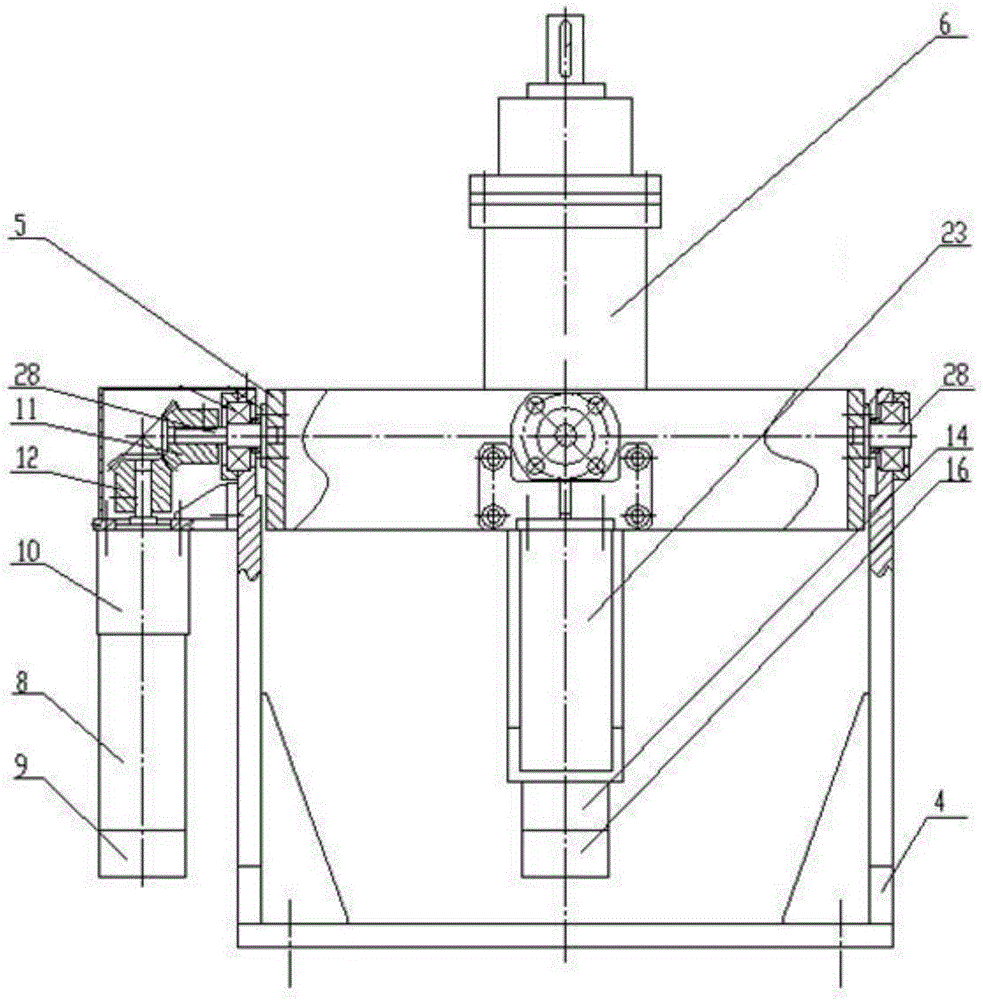

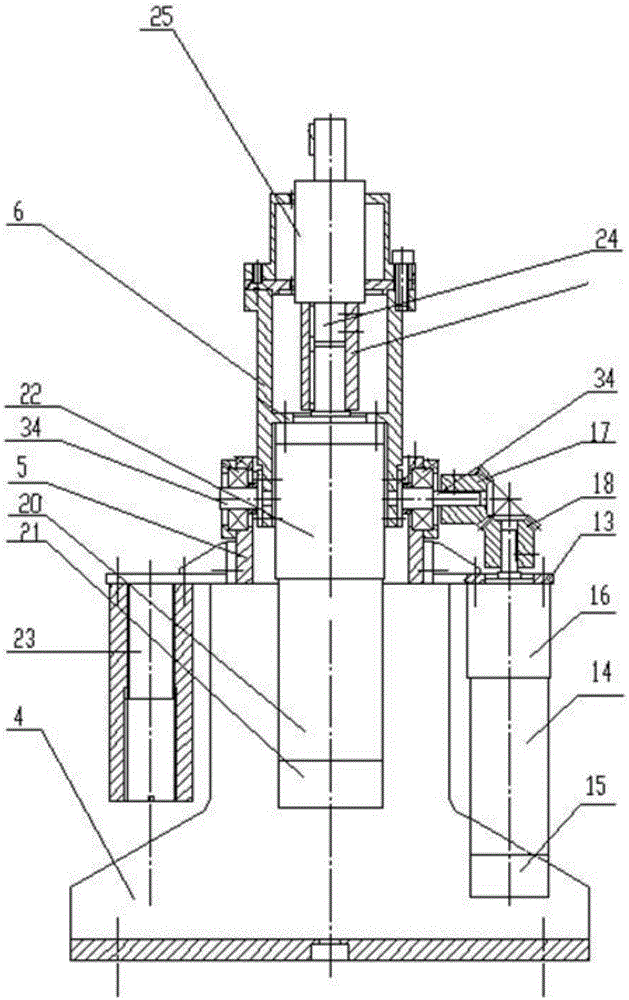

Wheel leg type mobile robot with flexible trunk

InactiveCN103241303AAvoid overall overturningFlexibleProgramme-controlled manipulatorVehiclesLeg typeGear wheel

A wheel leg type mobile robot with a flexible trunk is composed of the robot trunk, a front wheel leg device and a rear wheel leg device. The robot trunk is formed by connecting two isomorphic joint modules. Each joint module is composed an outer U-shaped frame, an inner U-shaped frame, an overturning steering gear, rotating shafts, a steering gear output disc, a direct-current motor, a direct-current motor output gear, a rotating gear, a bearing and a rotating disc. The overturning steering gear is fixed in the outer U-shaped frame and drives the inner U-shaped frame to be overturned up and down, and the direct-current motor output gear is meshed with the rotating gear to drive the rotating disc. The front wheel leg device comprises a steering gear box, steering gears, steering gear output discs, universal wheels and legs. The rear wheel leg device and the front wheel leg device are basically identical and only different in leg orientations, four steering gears and the steering gear box are fixedly connected through screws, and the universal wheels and the legs are respectively fixedly connected with steering gear rotating shafts. The wheel leg type mobile robot with the flexible trunk is simple in structure, can continuously move when overturned, and has high environment adapting capability.

Owner:SOUTHEAST UNIV

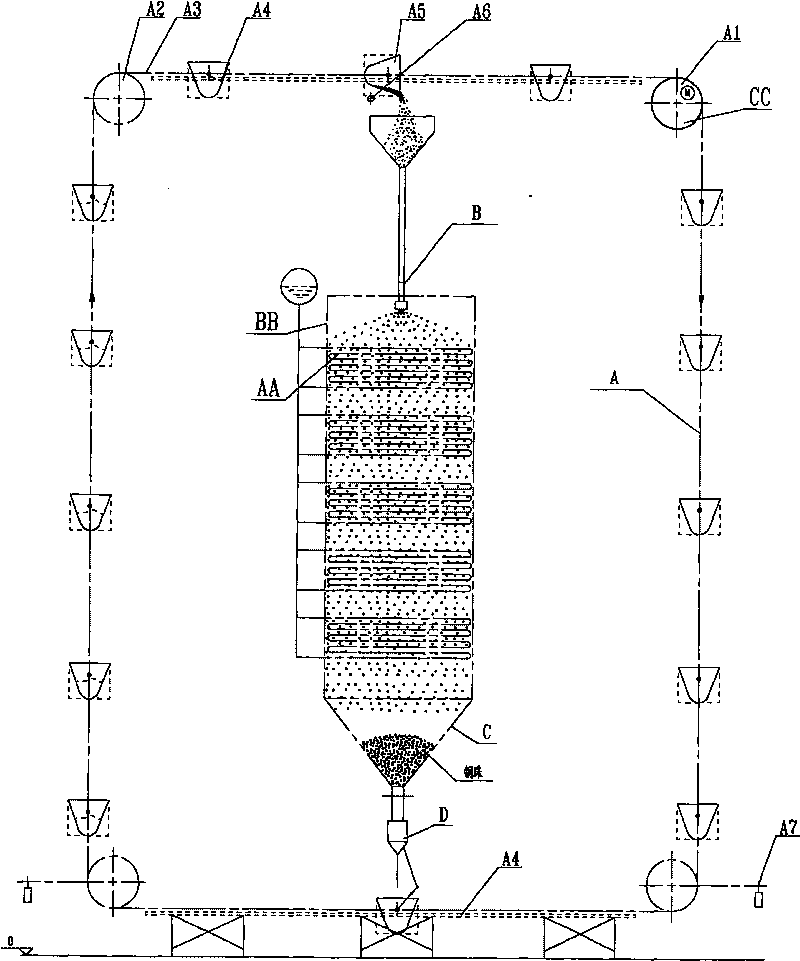

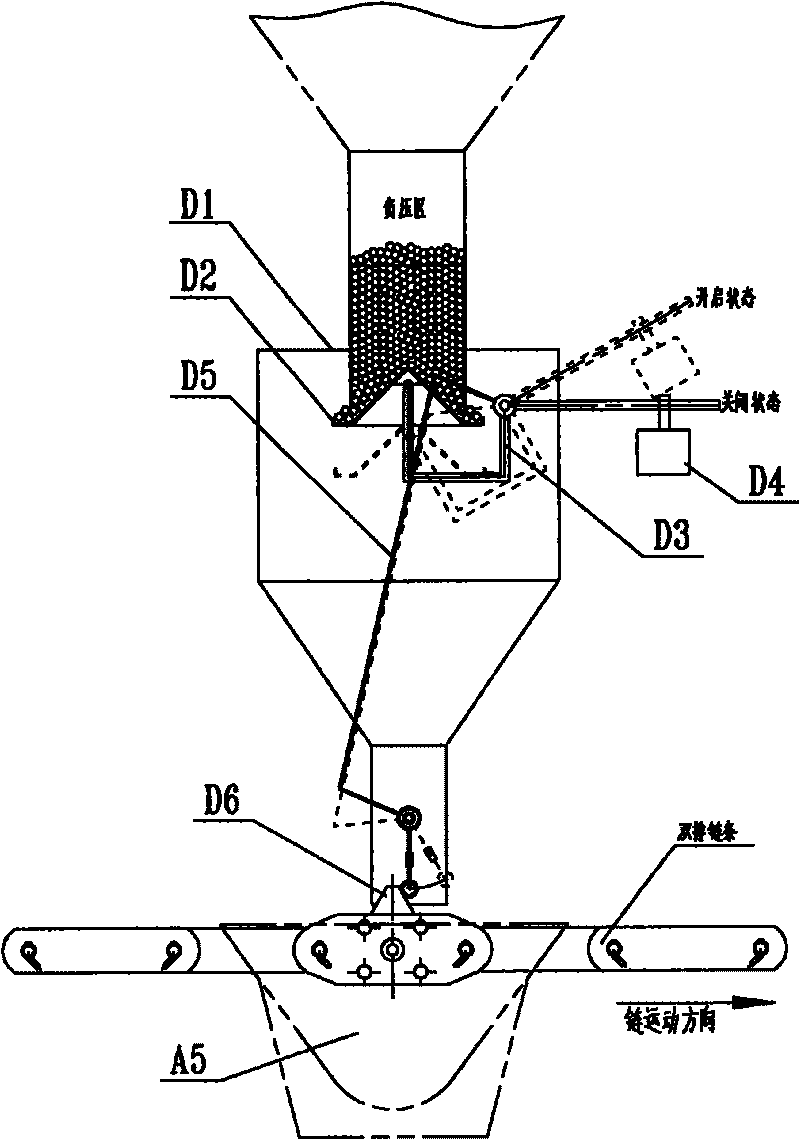

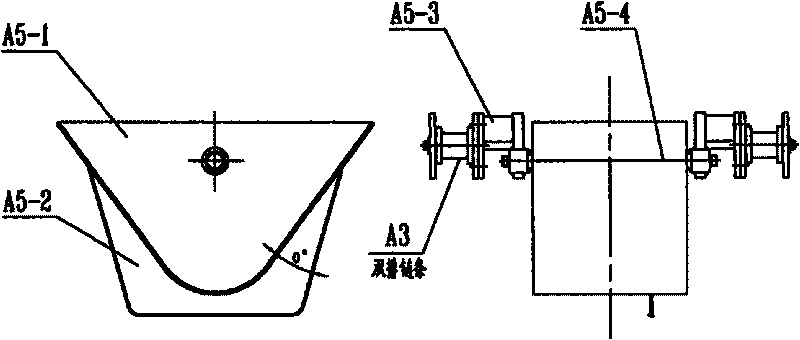

Residual heat boiler of steel ball dedusting type ore heat furnace

ActiveCN101701775AEfficient removalGuaranteed uptimeIncreasing energy efficiencySolid removalBottom ashDrive wheel

The invention relates to a residual heat boiler of a steel ball dedusting type ore heat furnace. The residual heat boiler at least comprises a boiler heated surface, a seal boiler flue gas passage, a furnace top and a furnace bottom ash hopper, wherein the boiler heated surface comprises coil pipe groups; and the seal boiler flue gas passage is formed at the periphery of the boiler heated surface. The residual heat boiler is characterized in that the furnace top is provided with a steel ball spreading device, a steel ball separating and collecting device is arranged under the furnace bottom ash hopper; a circulating type steel ball mechanical transporting device is arranged between the steel ball spreading device and the steel ball separating and collecting device; the circulating type steel ball mechanical transporting device comprises at least one drive wheel, at least three driven wheels, a double-row chain, a horizontal guide rail, a steel ball transporting hopper and a mechanical discharge blocking wheel; the at least one drive wheel and the at least three driven wheels are fixed on a boiler frame, and the steel ball transporting hopper is hung on the double-row chain surrounded between the drive wheels and the driven wheels; and the furnace top is provided with the mechanical discharge blocking wheel capable of turning over the steel ball transporting hopper. The invention has simple mechanism, recycled steel ball, mechanical automation running, low investment and running cost and favorable dedusting effect, and the like, can effectively remove and collect accumulated ash and sticking dust on the residual heat boiler heated surface of the ore heat furnace and greatly develops the energy-conservation and emission-reduction technology of the ore heat furnace smelting industry.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

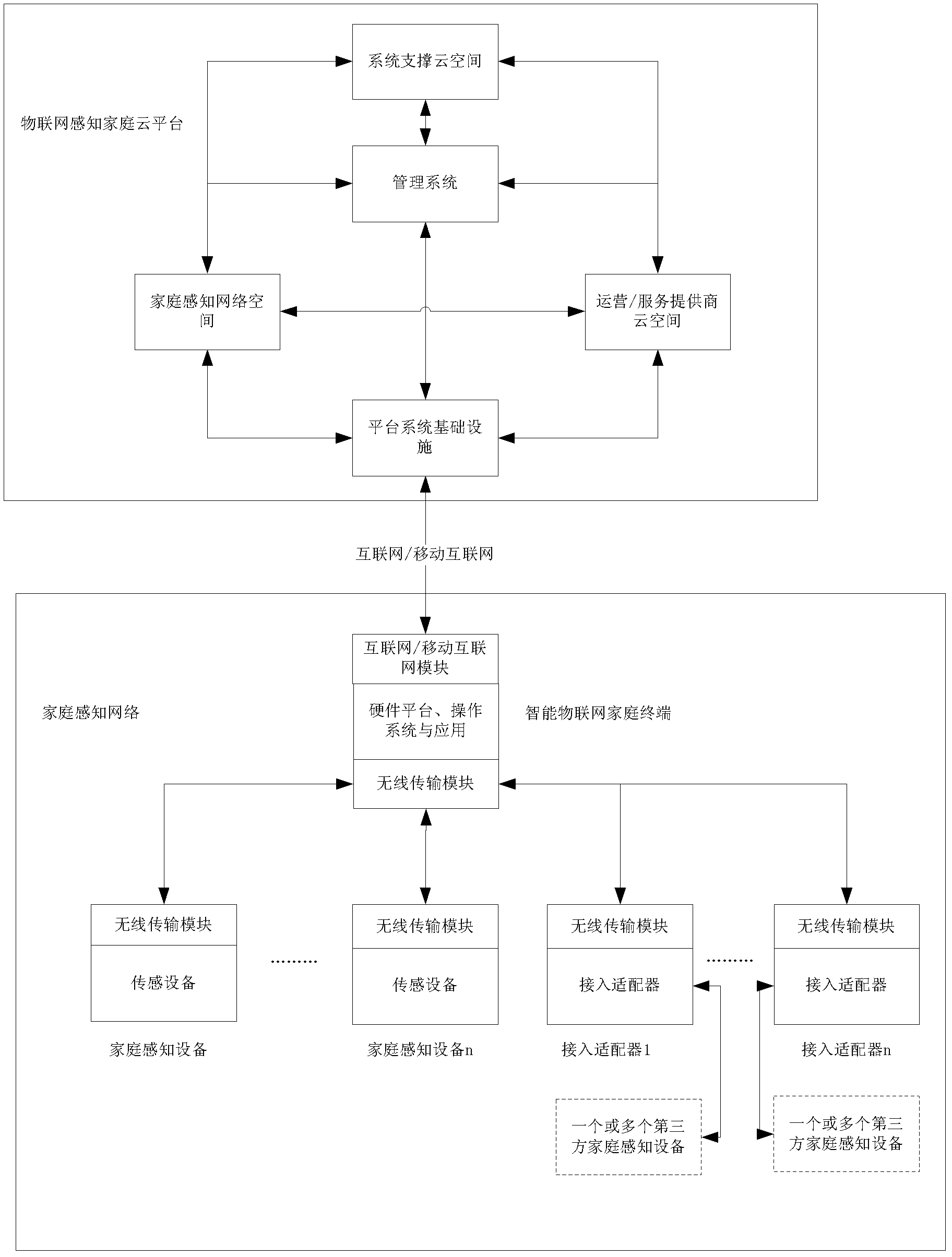

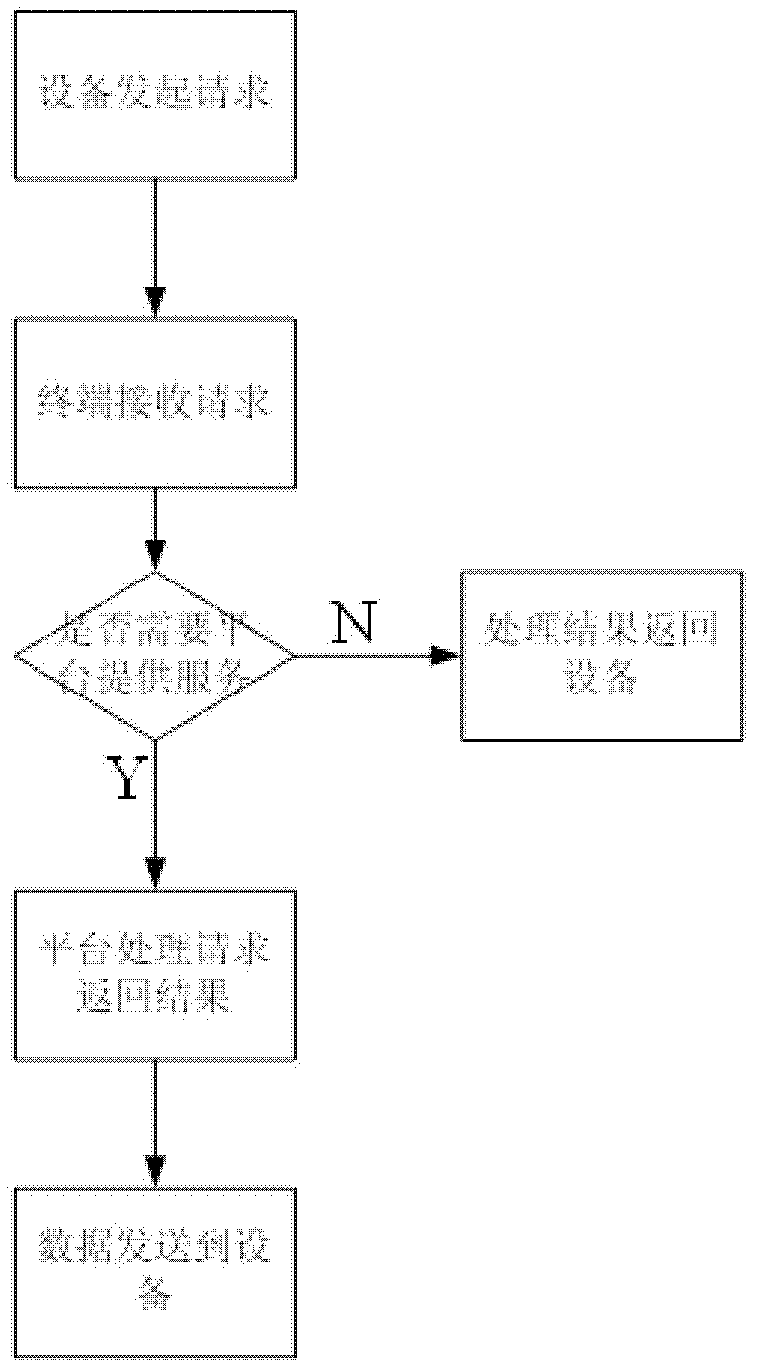

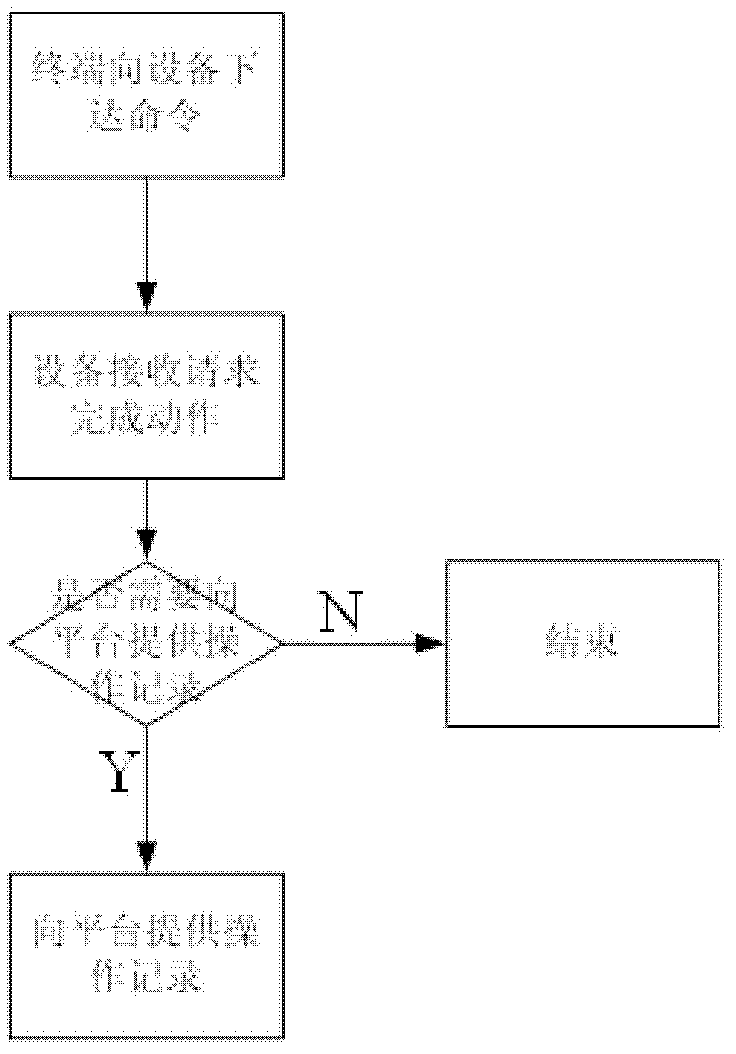

IOT sensing family cloud platform system

InactiveCN102624925AEasy to installEasy to install and deployData switching by path configurationWireless transmissionDistributed services

The invention discloses an IOT (Internet of things) sensing family cloud platform system which comprises an IOT sensing family cloud platform and a family sensing network which are connected by a network. The family sensing network comprises various family sensing equipment, a plurality of access adapters and a family IOT intelligent terminal which are networked by a wireless transmission module with an intelligent self-networking function; the family IOT intelligent terminal is used for connecting the IOT sensing family cloud platform with the family sensing network as a gateway; and the IOT sensing family cloud platform comprises a platform system infrastructure, an operation management system, a family sensing network cloud space, an operator / service provider cloud space and a system supporting cloud space. The system integrates the family sensing network with the IOT sensing family cloud platform by utilizing a software / hardware integrated assembly technology to form an integrated distributed service system structure and a sensing family system which can be interconnected, is easy to expand, has diversified services and can provide the high-quality services is constructed.

Owner:江苏运赢物联网产业发展有限公司

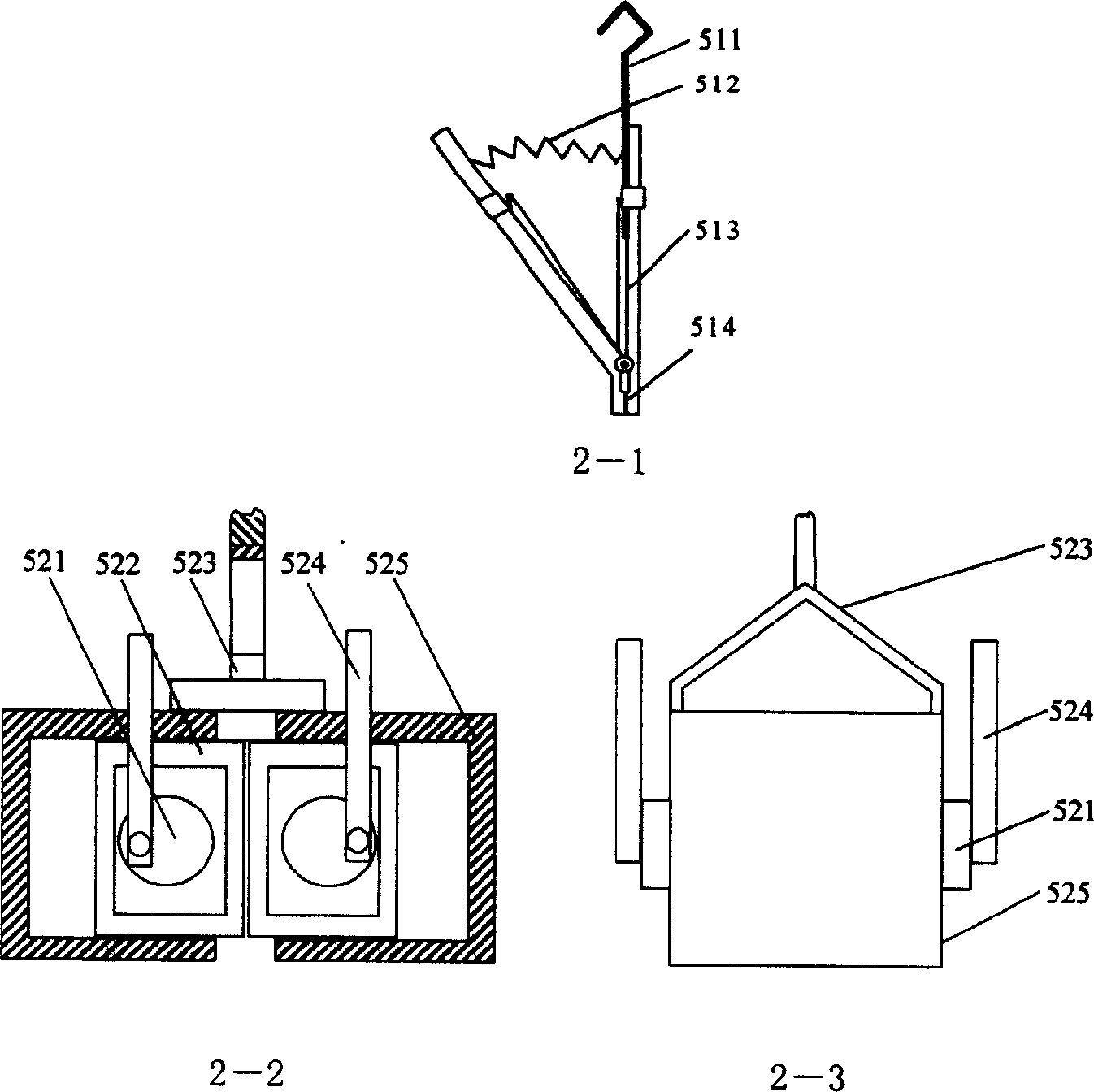

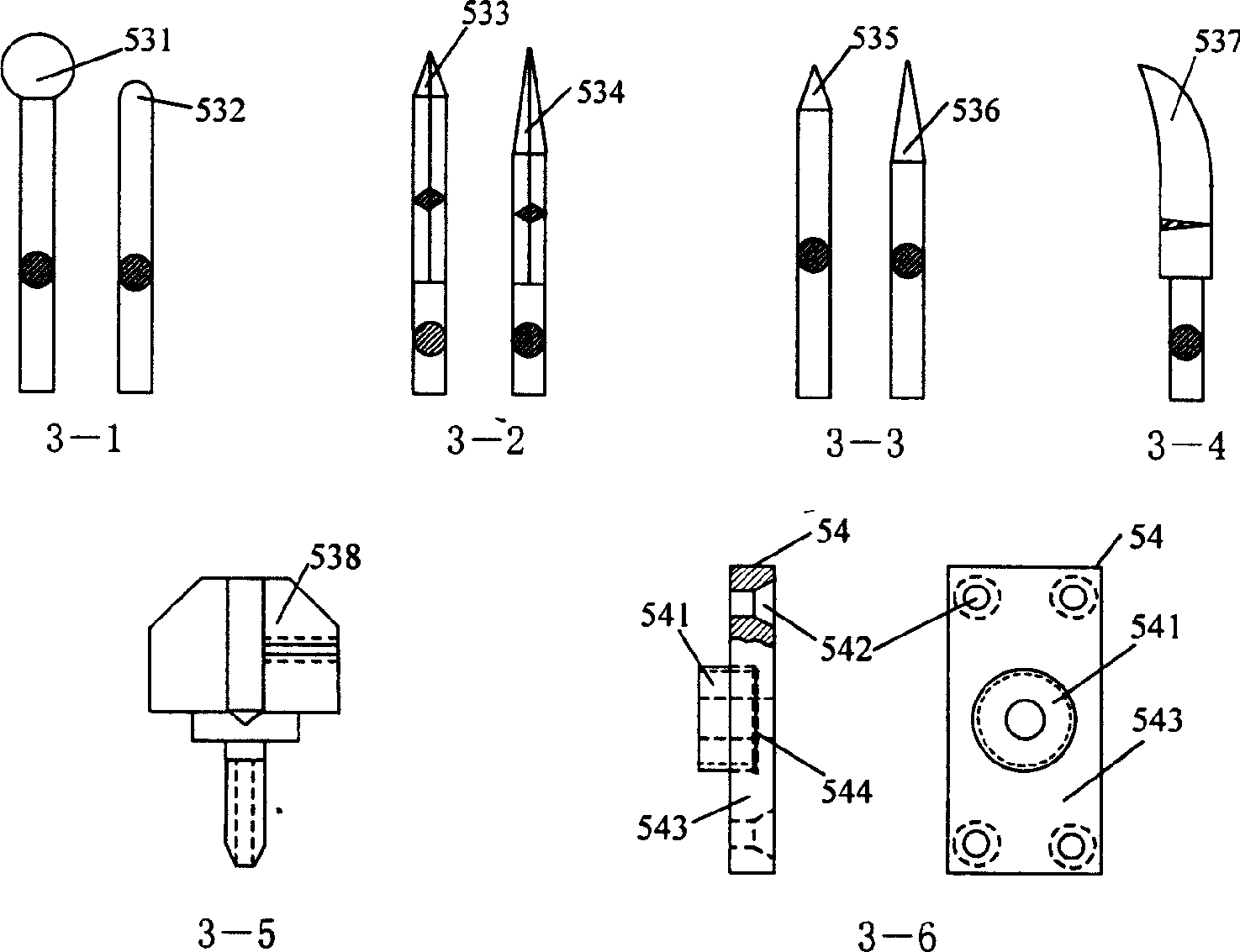

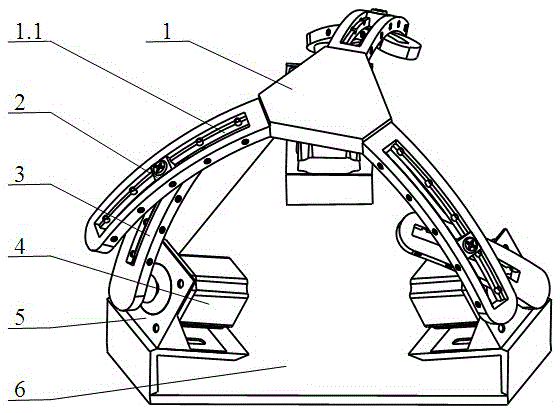

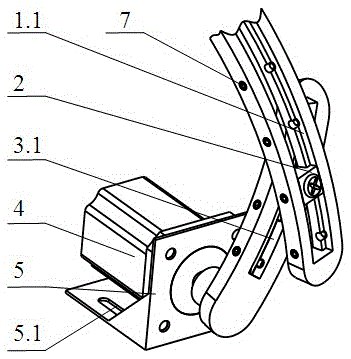

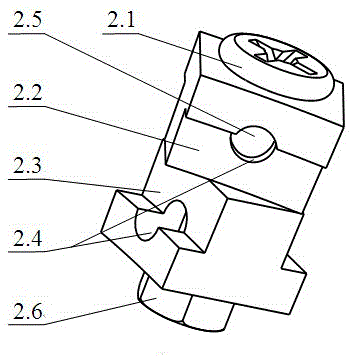

Multi-freedom micro-mechanical arm for minimally invasive operation

ActiveCN101011292ASimple organizationImprove reliabilitySuture equipmentsInternal osteosythesisClutchManipulator

The invention relates to a multi-freedom micro mechanical hand used in micro-hurt surgery. The invention comprises a base, an upper drawing device with terminal tool transmitter, a lower drawing device, a self-rotation device and an executor of terminal tool, and a transmitter box. The servo motor of base via the coupler is connected with the lower clutch disc fixed on the motor frame via rolling bearing; the transmitter box is arranged on the upper face of motor frame; the upper and lower drawing devices and the self-rotation device are in the transmitter box, while the upper ends are fixed on the top face of transmitter box and lower ends are through the bottom of box to connect the lower clutch disc, and the front ends via their own upper drawing sheath, lower drawing sheath and self-rotation muffle are connected from up to down; the lower end of self-rotation muffle is connected with the executor of terminal tool. The invention has bend freedom, therefore, the terminal tool can be switched freely, with simple structure, high bearing ability and reliable transmission of terminal tool.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

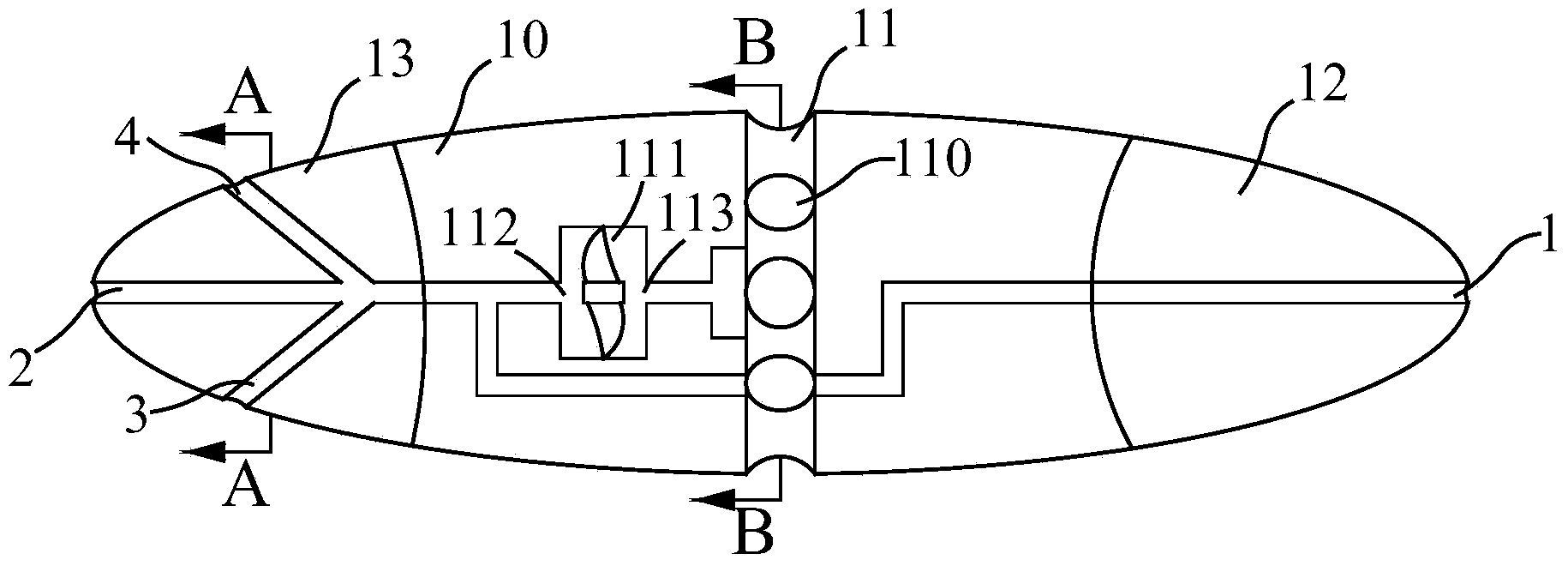

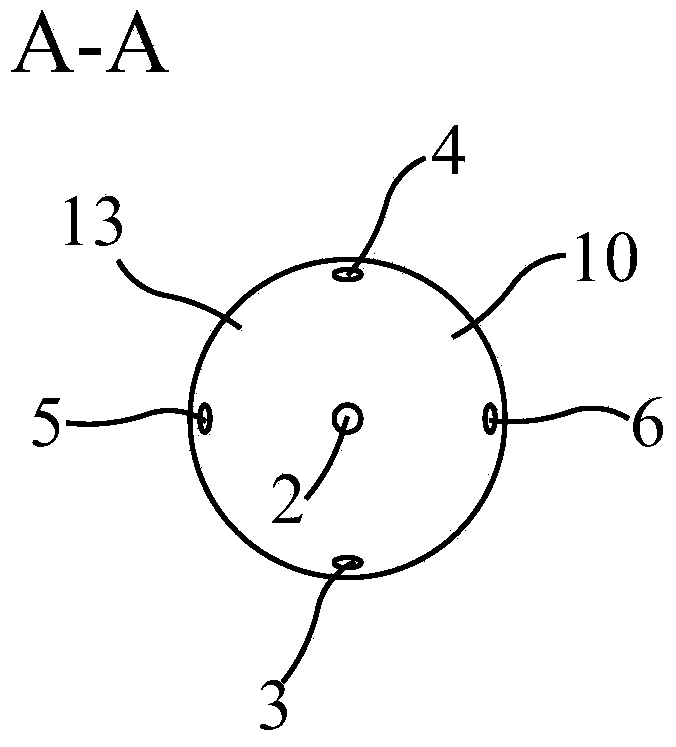

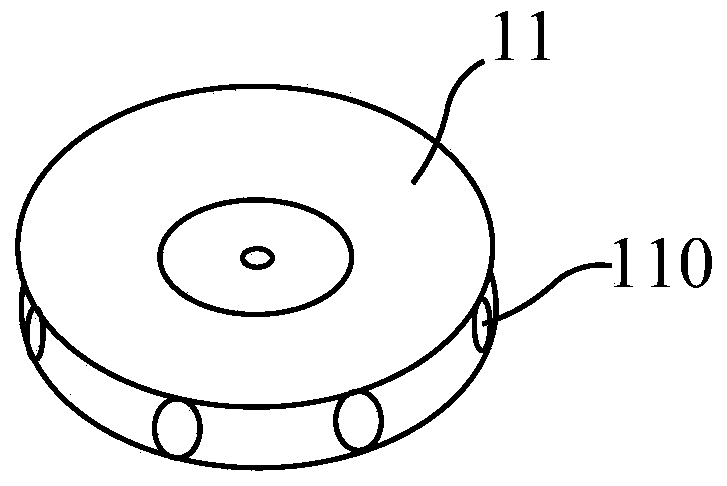

Underwater vehicle with water jet propulsion technology adopted

InactiveCN103523192AIncrease flexibilitySatisfy the control conditionPropulsive elementsUnderwater vesselsControl systemMarine engineering

The invention discloses an underwater vehicle with the water jet propulsion technology adopted. The underwater vehicle comprises an underwater propulsion device (10) and a control system. The underwater propulsion device (10) comprises a tail portion (13), a water inlet disk (11) and a head portion (12) which are sequentially arranged from left to right. A jet which is used for providing propulsion power is respectively formed in the tail portion (13) and the head portion (12). The water inlet disk (11) is provided with a water inlet used for sucking water and a high-pressure pump used for converting sucked-in water into high-pressure water flow, and the high-pressure pump is respectively connected with the jets through pipelines. Propulsion power on the jets is provided by the high-pressure water flow obtained from the conversion by the high-pressure pump. The caliber of the water inlet (110) of the water inlet disk is larger than the caliber of the jets. Electromagnetic valves are arranged on the pipelines between the jets and a water outlet (115) of the high-pressure pump. Both the high-pressure pump and a water control device are connected with the control system mutually.

Owner:ZHEJIANG UNIV +1

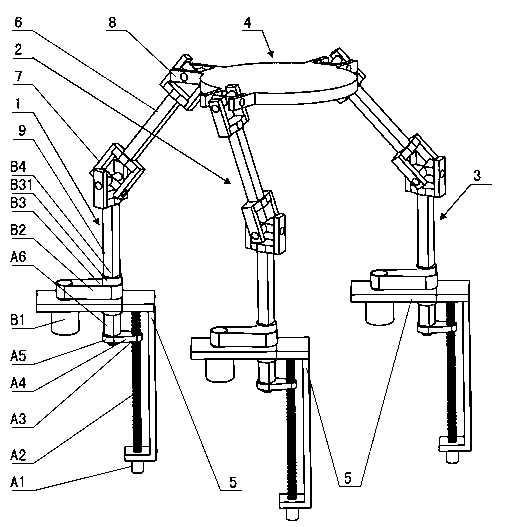

Six degree-of-freedom three-limb parallel robot mechanism

ActiveCN102699904ASimple organizationLight in massProgramme-controlled manipulatorSix degrees of freedomEngineering

The invention discloses a six degree-of-freedom three-limb parallel robot mechanism which comprises a base, a moving platform and three kinetic limbs. The three kinetic limbs have same structures and are connected between the base and the moving platform. The six degree-of-freedom three-limb parallel robot mechanism is characterized in that each of the kinetic limbs comprises a screw pair, a driving turning pair, a nut turning pair, a moving pair, an upper hook joint and a lower hook joint, wherein the driving turning pair and the nut turning pair are coaxially arranged, the screw pair is fixed on the base and connected with a first motor in a driving mode, and the first motor is fixed on the base; turning axes of the two turning pairs are parallel to an axis of the screw pair, the driving turning pair is installed on the base, and the nut turning pair is installed on a nut; the moving pair is composed of a sliding rod and a hollow turning shaft of the driving turning pair, the sliding rod penetrates through the hollow turning shaft in a nest mode, the moving direction of the sliding rod is parallel to an axis of the diving turning pair, the driving turning pair is driven by a second motor by means of a transmission mechanism, and the second motor is fixed on the base; and the lower hook joint is installed at the tail end of a moving auxiliary sliding rod piece, and the upper hook joint is connected with the moving platform.

Owner:唐山海容智能机器人科技有限公司

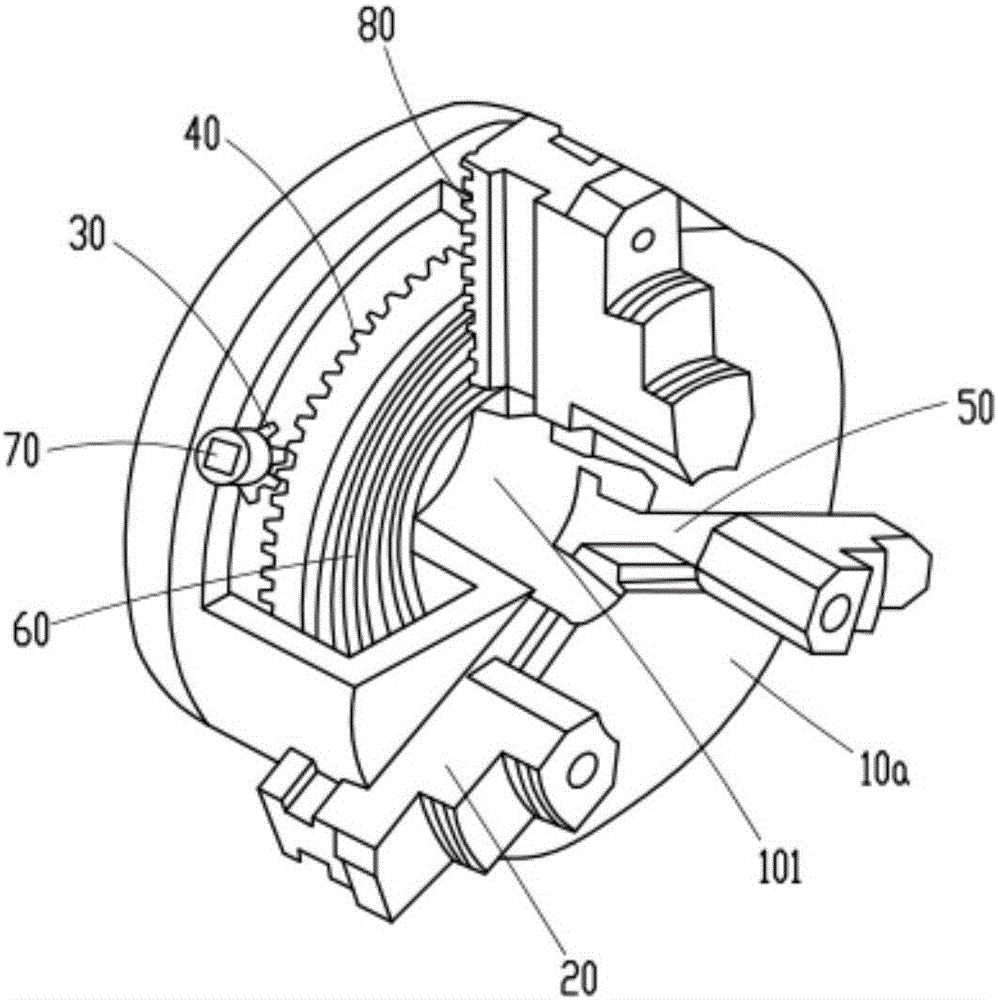

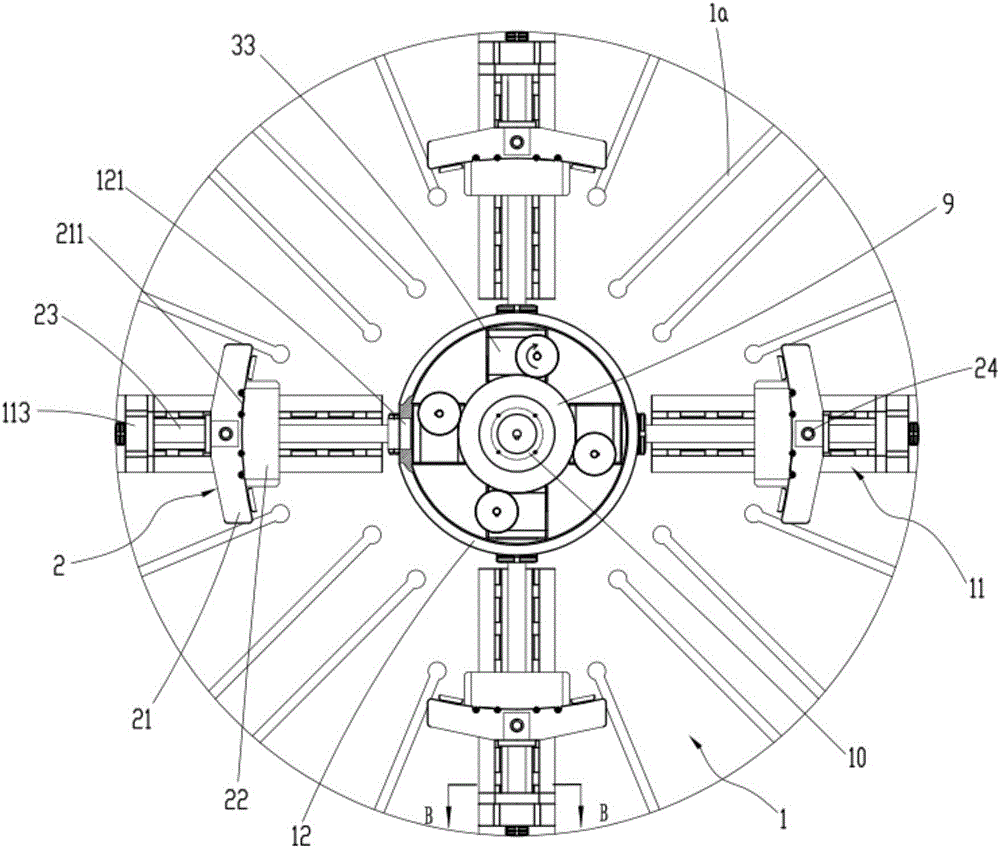

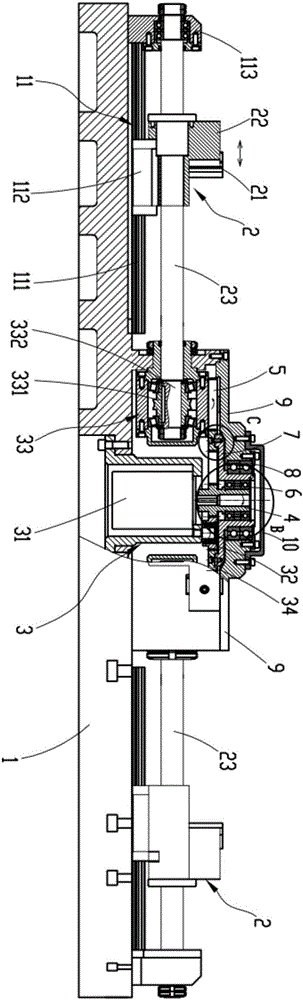

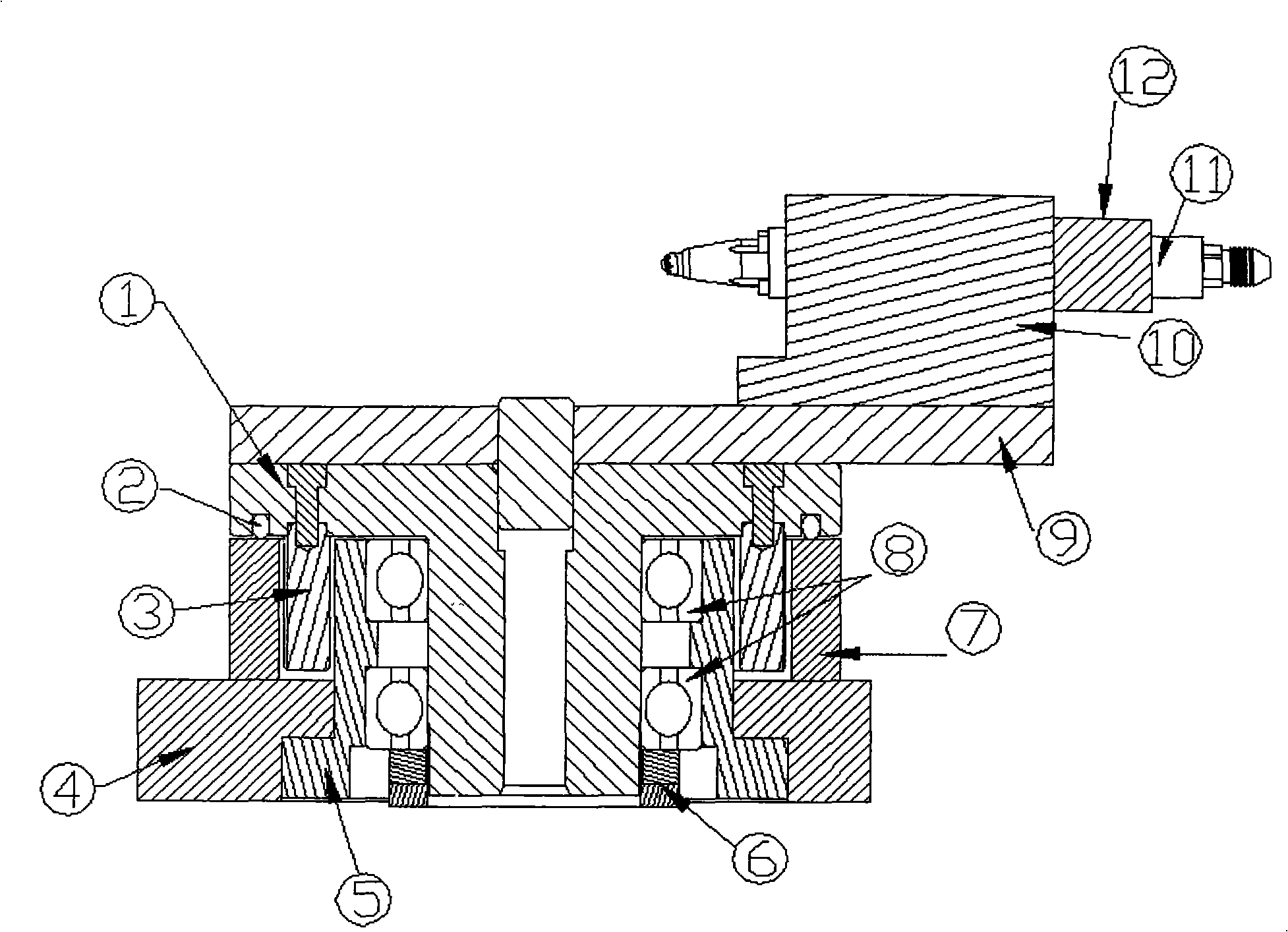

Precise self-centering chuck suitable for super-large workpieces

The invention relates to a precise self-centering chuck suitable for super-large workpieces. The precise self-centering chuck suitable for the super-large workpieces comprises a chuck body and a plurality of jack catch mechanisms arranged on the chuck body in a sliding mode. A jack catch driving mechanism is further arranged on the chuck body and comprises a numerical control moment motor, a plurality of transition gears, a plurality of double-enveloping speed reducers and a first gear. The inner circular surface and the outer circular surface of the first gear are provided with inner teeth and outer teeth correspondingly. The numerical control moment motor is provided with motor teeth. The multiple transition gears are all engaged with the motor teeth and the inner teeth of the first gear. The outer teeth of the first gear are engaged with second gears of the multiple double-enveloping speed reducers. The double-enveloping speed reducers drive the jack catch mechanisms to reciprocate to clamp or release the annular workpieces to be machined. The numerical control moment motor is used for sequentially driving the multiple transition gears and the double-enveloping speed reducers to rotate in a matched mode, so that the multiple jack catch mechanisms move inwards or outwards synchronously. The super-large annular workpieces are subjected to automatic centering clamping or releasing, and the clamping positioning accuracy is high.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

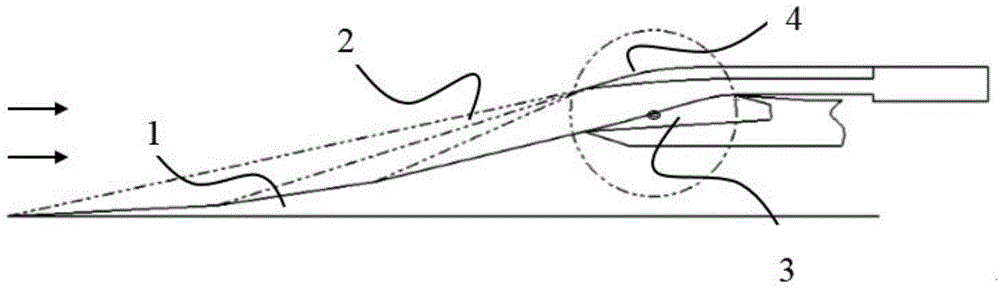

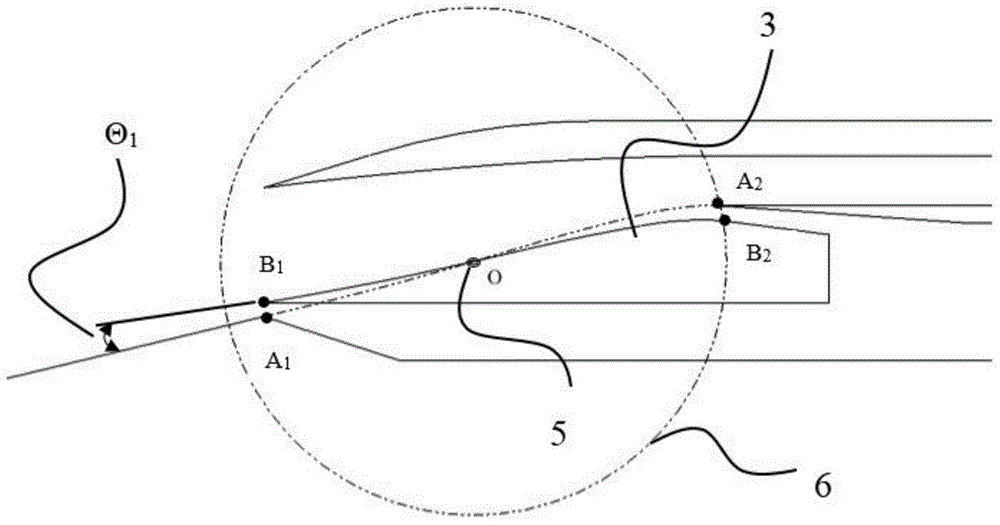

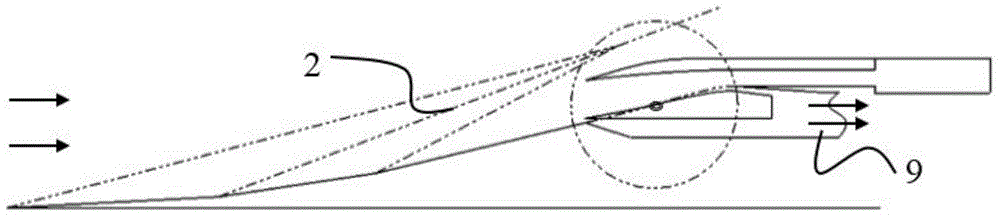

Binary hypersonic-velocity variable-geometry air inlet way with rectangular inlet, design method thereof and working method thereof

ActiveCN104863715AReduce the starting Mach numberImprove starting performanceGas turbine plantsJet propulsion plantsFlight vehicleTrailing edge

The invention discloses a binary hypersonic-velocity variable-geometry air inlet way with a rectangular inlet, a design method thereof and a working method thereof, and is applied to an air breathing type hypersonic flight vehicle propelling system. A part adjustable top plate capable of partially rotating is designed and mounted based on a traditional hypersonic-velocity air inlet way structure with a rectangular section; the position of the part adjustable top plate is adjusted according to flying conditions of a flight vehicle; the part adjustable top plate rotates by a small angle to form front and back two flow leakage windows; a front edge is designed near the section of the inlet; and a back edge is designed in the connected place of the part adjustable top plate and a throat way. A boundary layer developed from a part precursor or a large separation package formed by not starting is discharged by using simple rotation; and the starting capacity of the air inlet way is improved through the flow leakage of the throat way. The starting performance of the air inlet way can be prominently improved by only two times of rotating adjustments of the air inlet way in the starting acceleration process. The small-angle rotation variable-geometry process is easier to realize; the restarting control timeliness is better; the flowing control to the air inlet way is more comprehensive; and the pneumatic performance of the air inlet way is comprehensively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

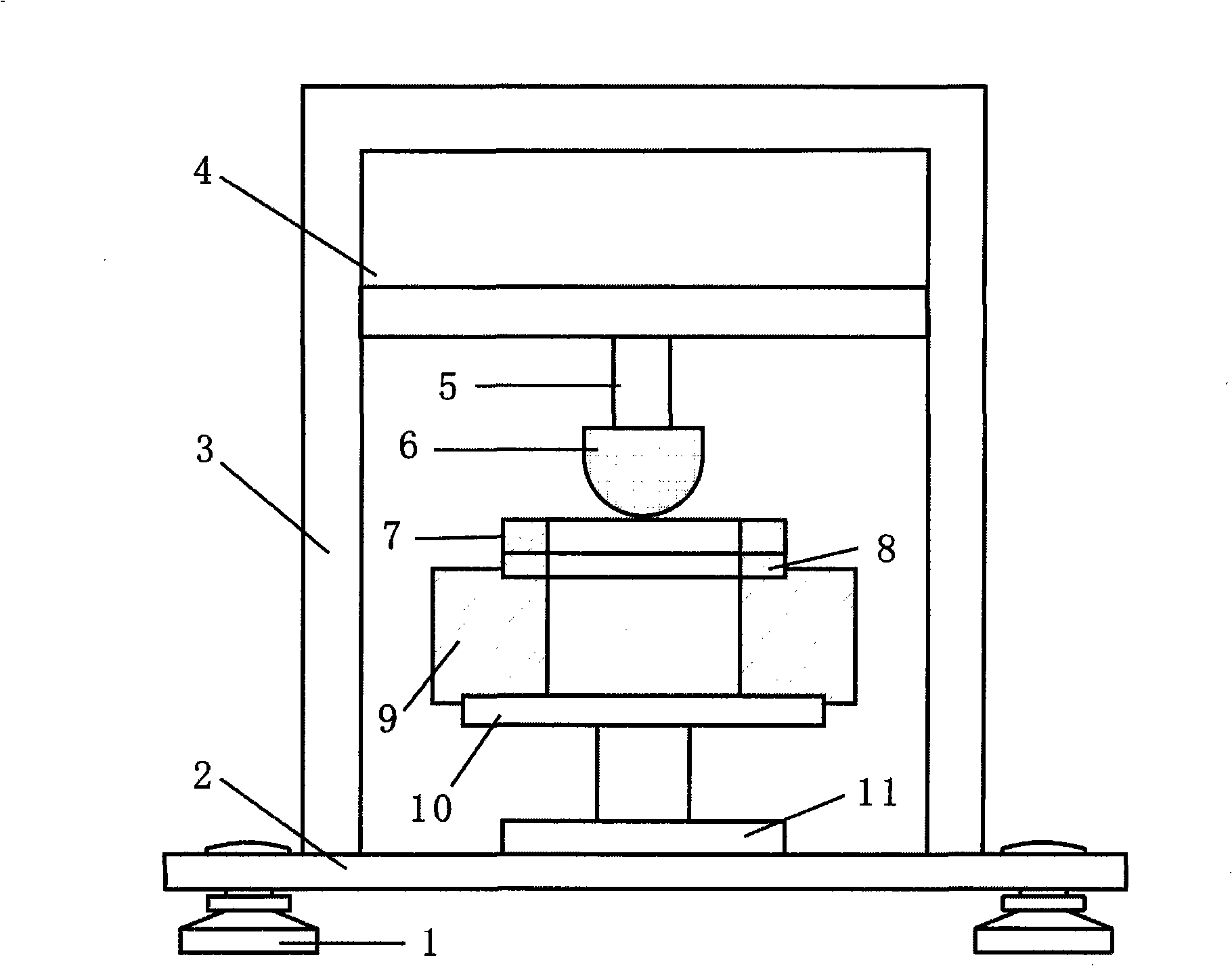

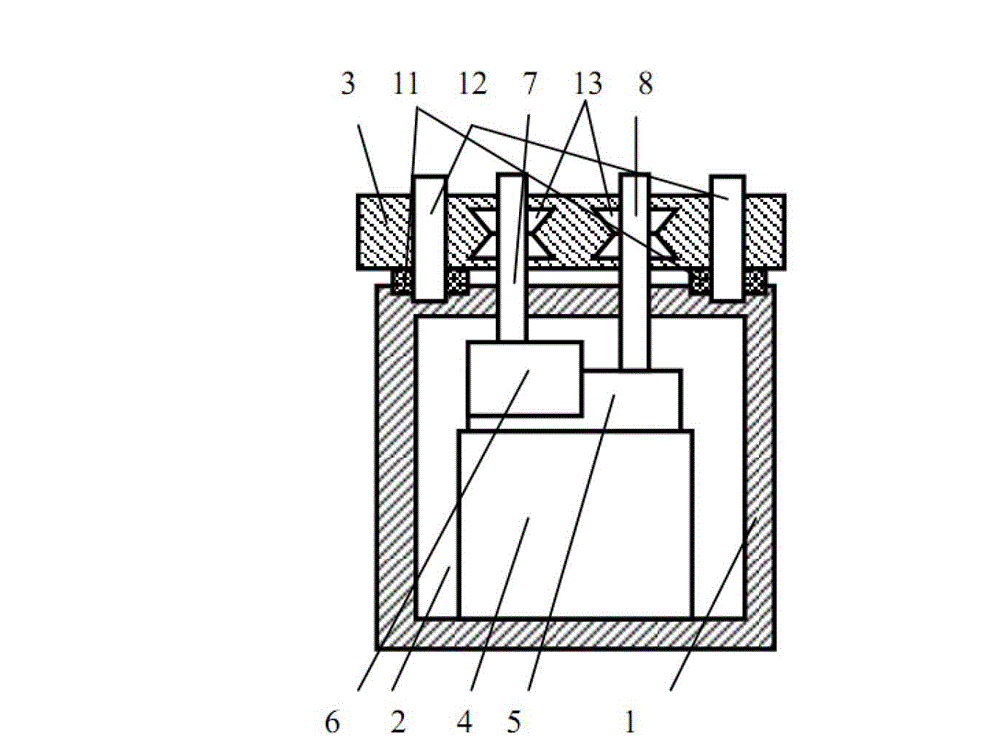

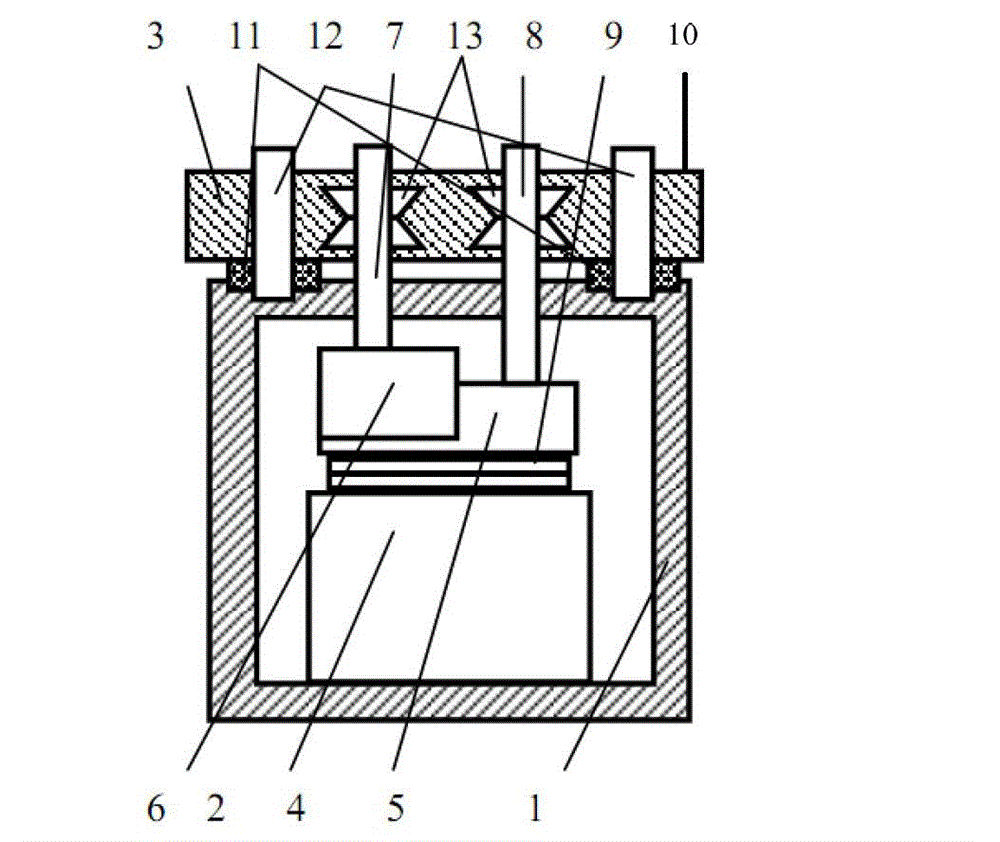

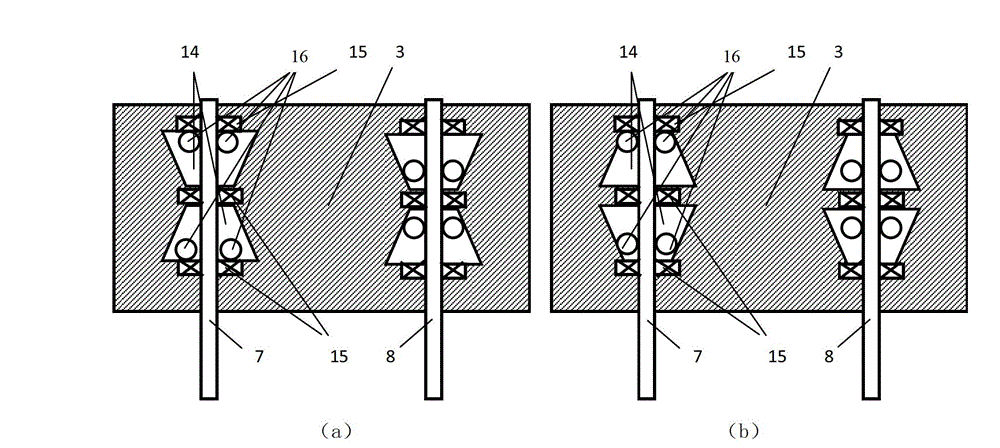

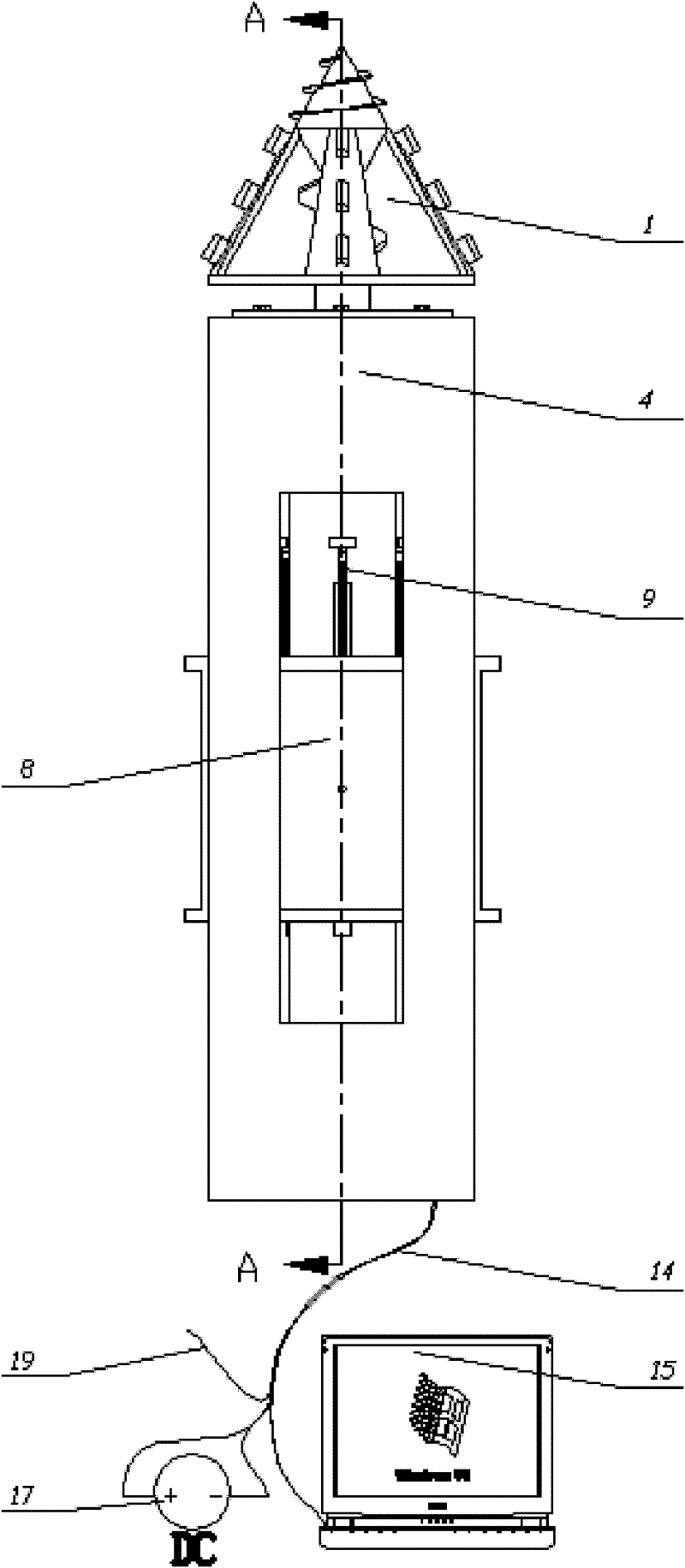

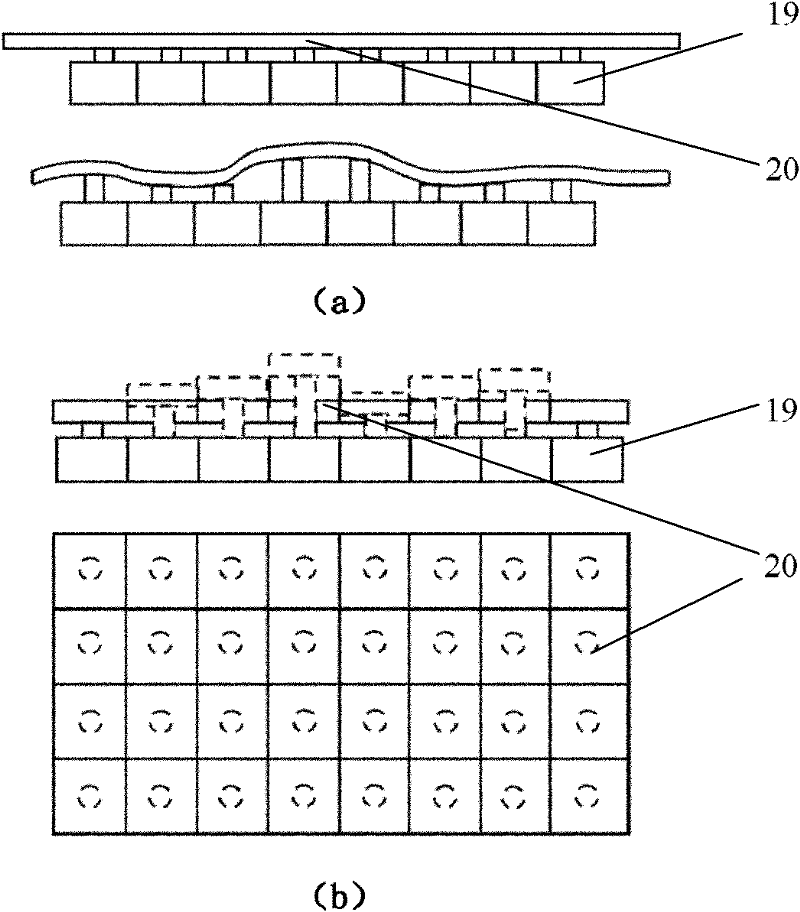

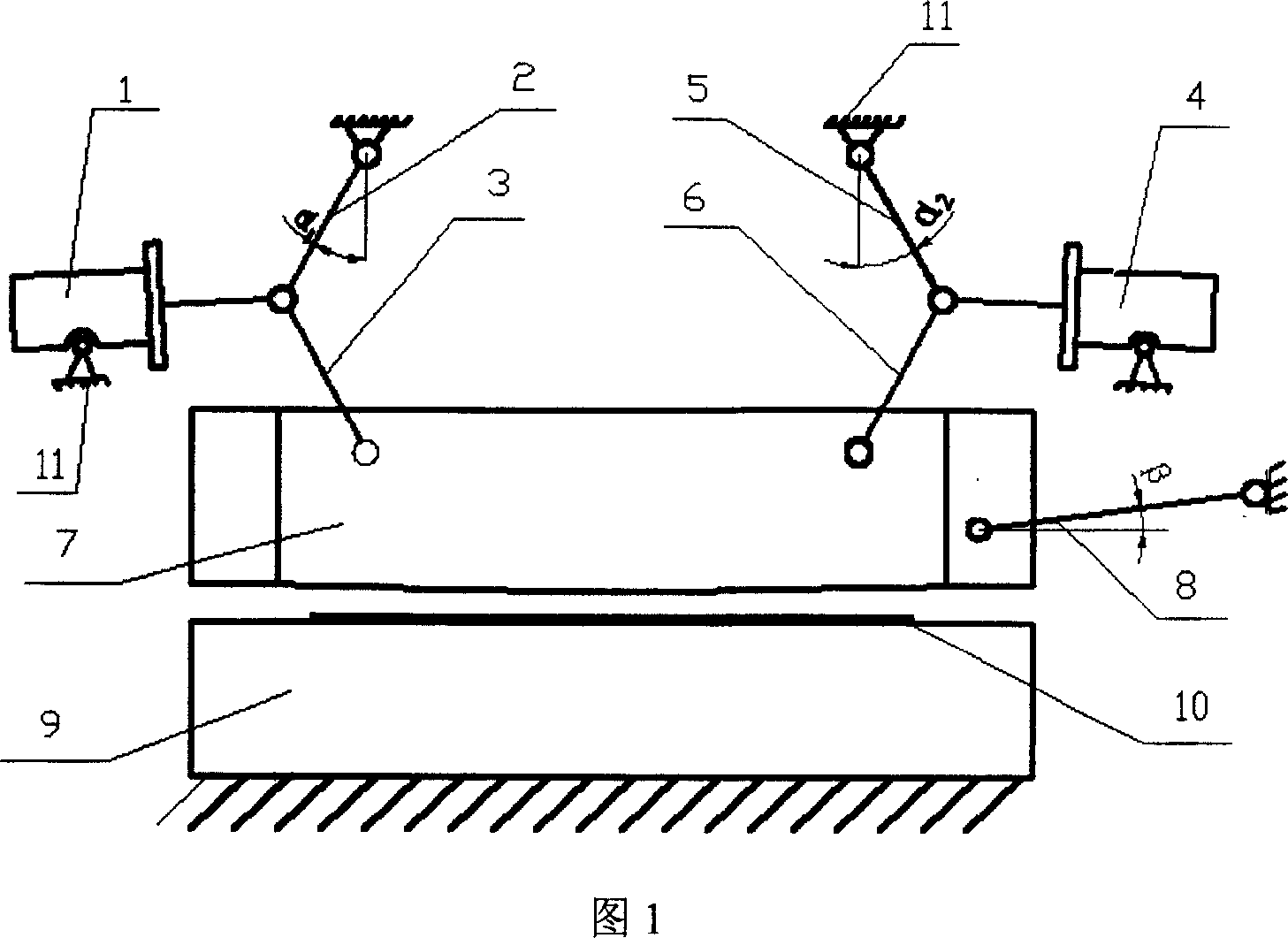

Vibrating platform with precise driving mechanism

ActiveCN102721520AAchieving large-amplitude drivingEasy to drive with large amplitudeVibration testingEngineeringHeavy load

A vibrating platform with a precise driving mechanism in the technical field of precise driving comprises a support frame, at least one driving mechanism arranged in the support frame and a vibrating platform body connected with the driving mechanism. The driving mechanism comprises a driver, a driver outputting rod, a drive displacement amplifying mechanism, an amplifying displacement output end rod and a direct displacement output end rod, wherein the driver, the driver outputting rod and the drive displacement amplifying mechanism are sequentially arranged from bottom to top, and the amplifying displacement output end rod and the direct displacement output end rod are respectively arranged on the drive displacement amplifying mechanism and the driver outputting rod. The vibrating platform with the precise driving mechanism produces direct displacement driving vibration based on flexible deformation of an intelligent material, is simple in structure, high in reliability and drive efficiency, accurate and controllable in amplitude and capable of achieving wide amplitude particularly from nanometer to a plurality of millimeters and achieving a wideband from a quasi-static state to high frequency, and has heavy-load vibrating capability.

Owner:SHANGHAI JIAO TONG UNIV

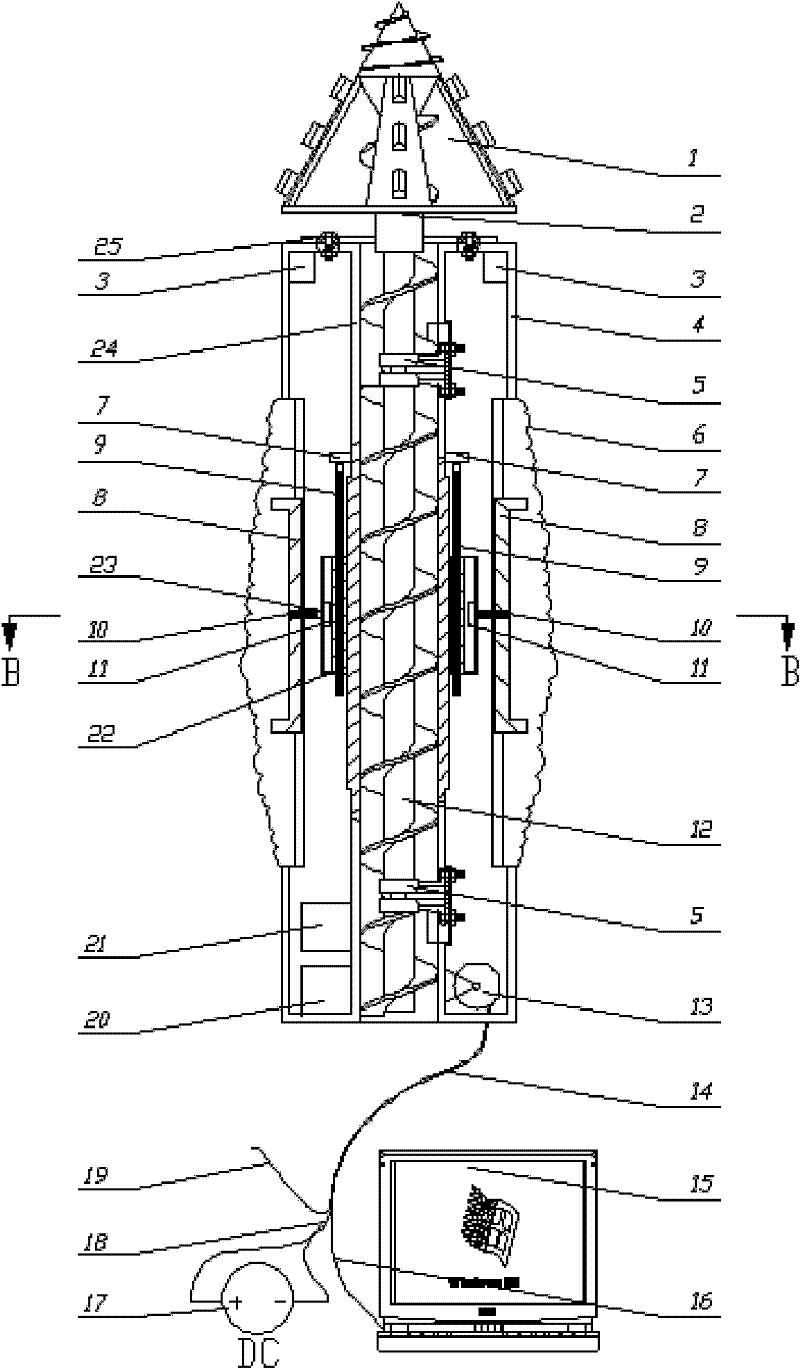

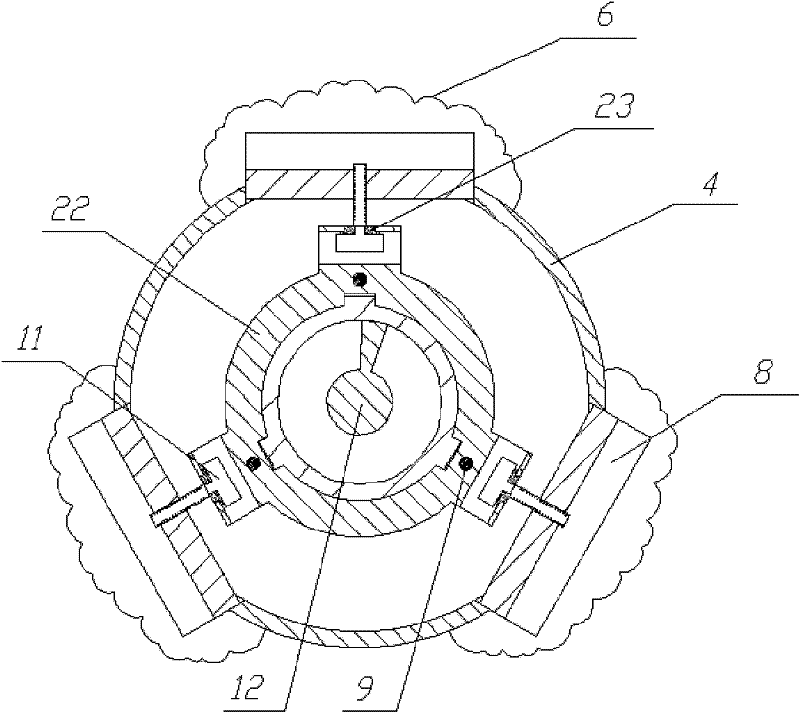

Self-propelled drilling robot

InactiveCN102518395AImprove drilling efficiencyWell drilledDrilling rodsBorehole drivesGyroscopeControl system

The invention discloses a self-propelled drilling robot which comprises a drilling system, a power system and a control system, wherein the drilling system is used for realizing cutting and conveying of soil; the power system is used for providing the motion capability; the control system is used for controlling the drilling system and the power system; the power system is connected with the drilling system through a transmission; and the control system is in communication connection with the power system and the drilling system. Under the drive of a motor, the robot can realize moving forwards and steering by being pushed by supporting feet. Moreover, the robot is provided with a detection device, a gyroscope and a control circuit board. The application of a combined cable to transmission of a power source and information is beneficial for implementing remote real-time monitoring on the robot by personnel above the ground. The robot has simple mechanism and compact structure, is provided with a drill bit and a dumping device, is beneficial for moving in a self-propelled mode, can successfully drill into the ground, can freely move and steer in the soil, and is suitable for exploration of underground mineral resources, geological exploration, earthquake and mining disaster rescue and the like.

Owner:TONGJI UNIV

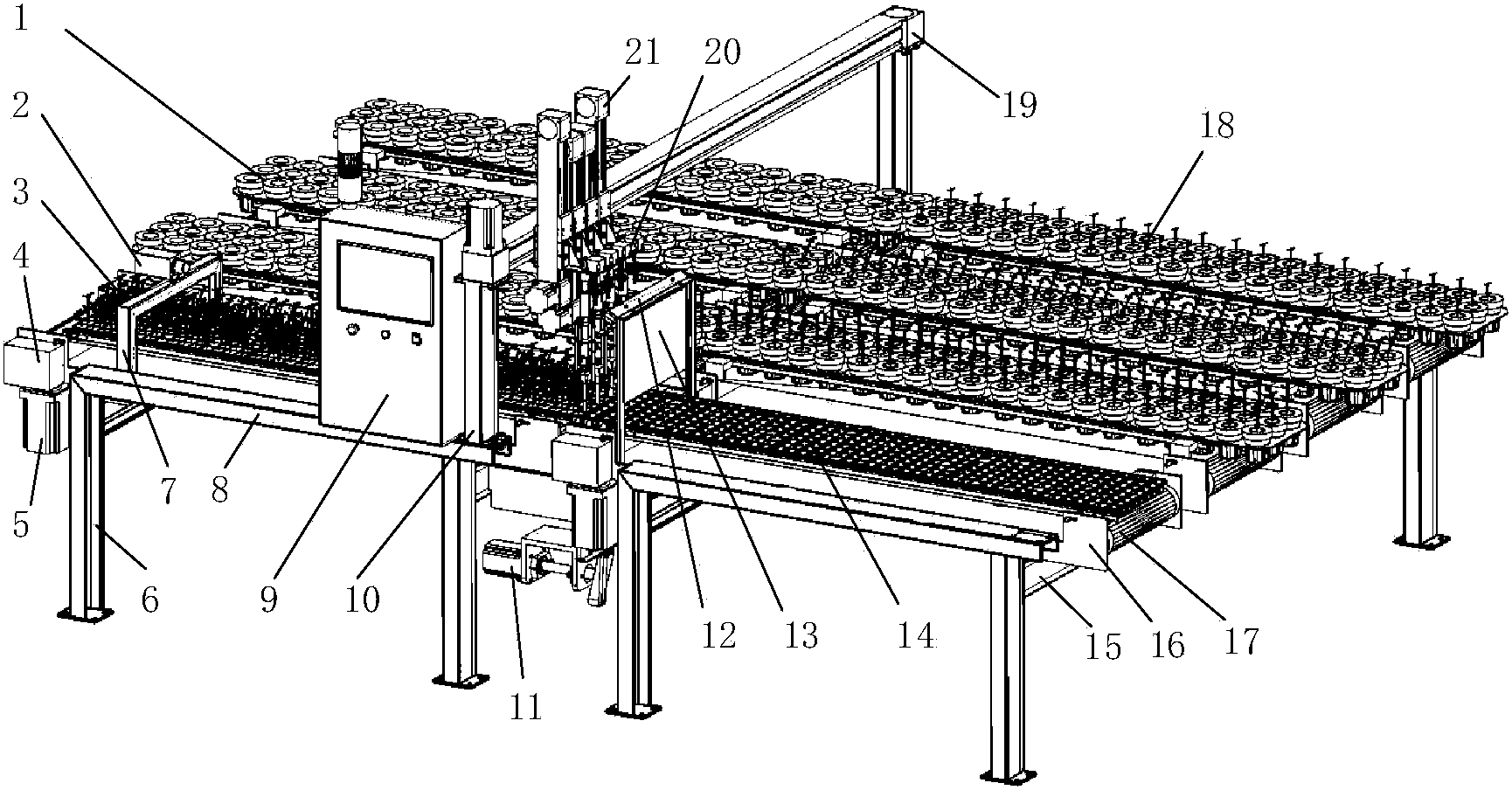

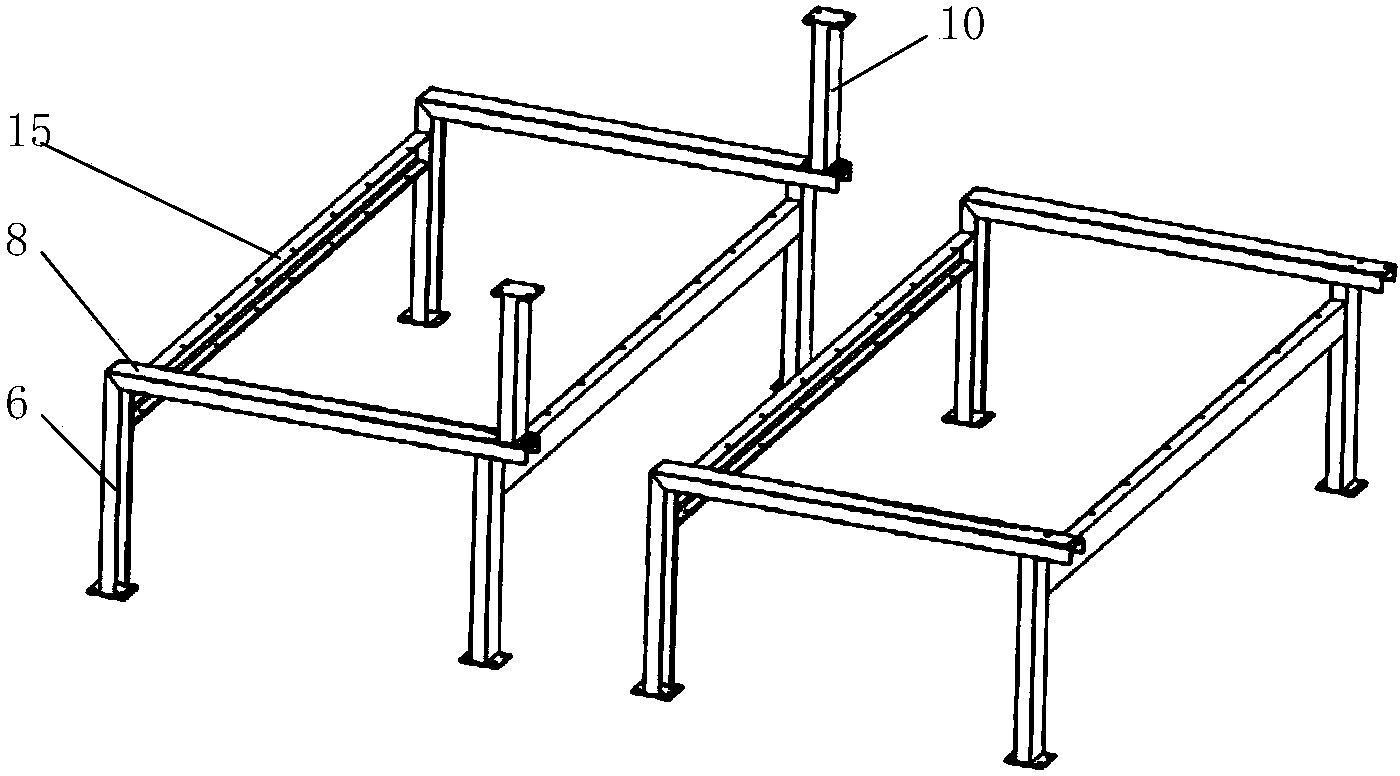

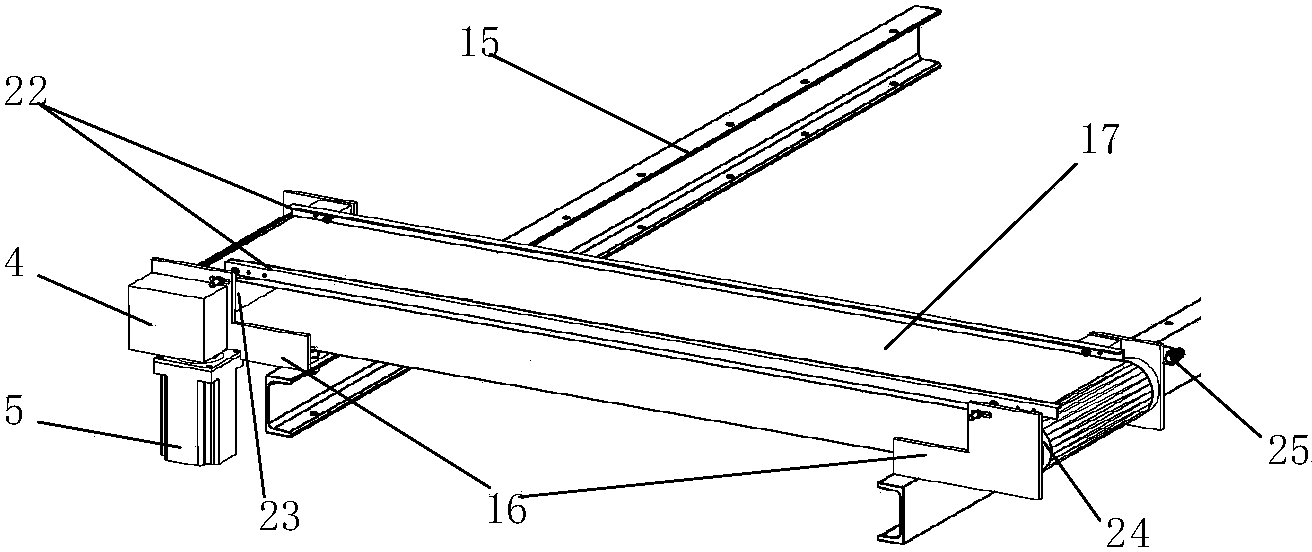

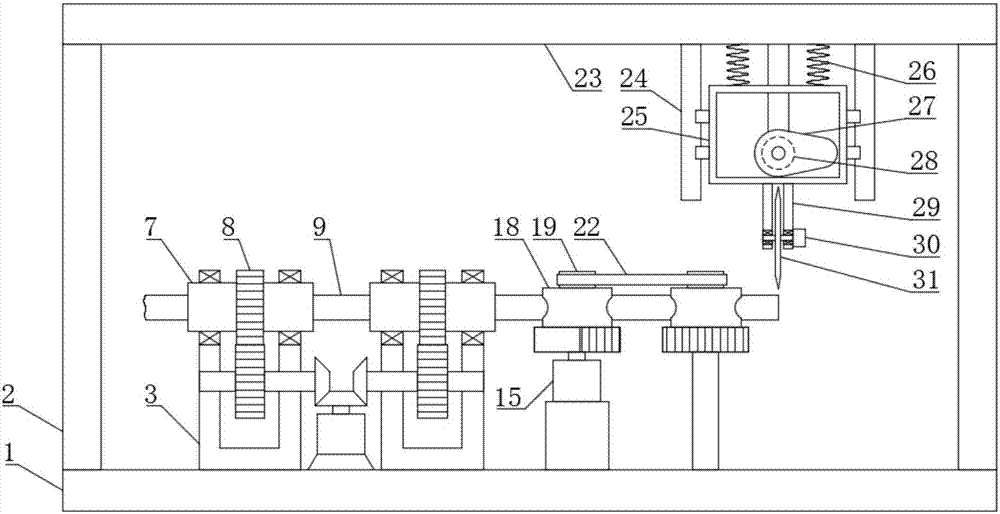

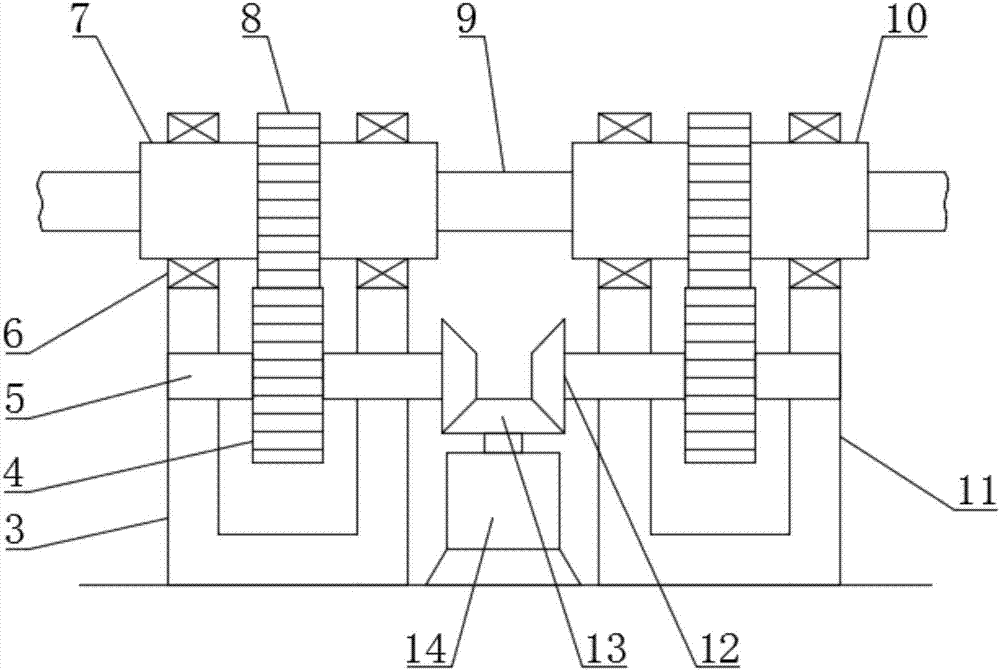

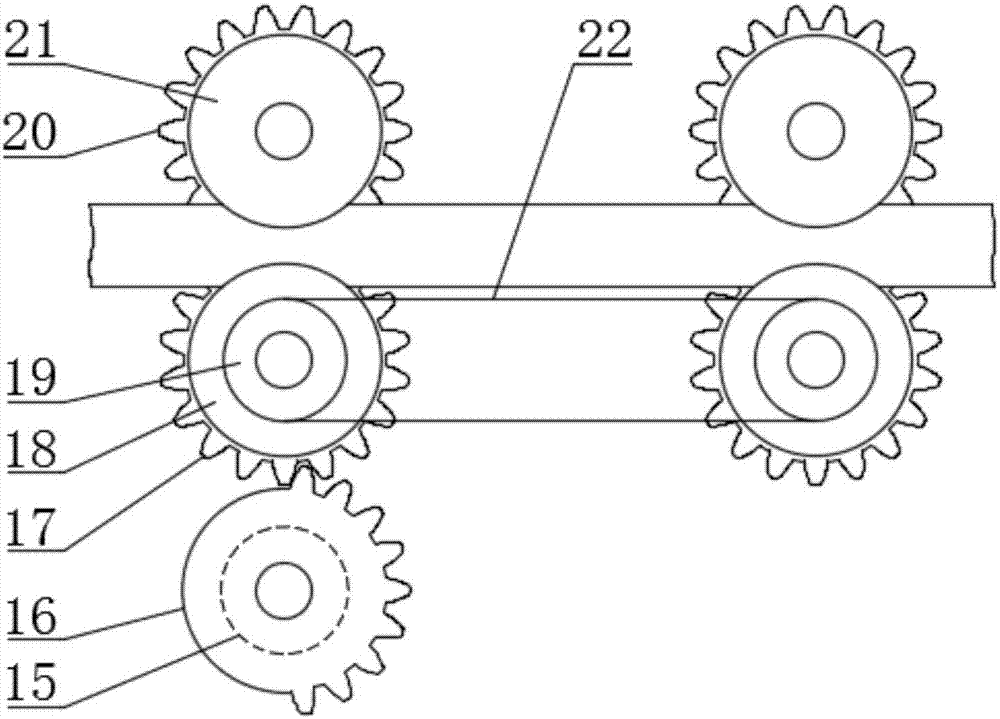

Intelligent seed and seedling sorting and transplanting machine

The invention belongs to the technical field of intelligent equipment for modern agriculture, and relates to a seed and seedling sorting and transplanting device which comprises a base bracket, wherein the base bracket comprises base bracket upright posts (6), base bracket connecting beams (8) and base bracket beams (15). The seed and seedling sorting and transplanting device is characterized by also comprising a flat belt conveying device, a seed and seedling jacking rotating device, a seed and seedling pot moving device, an end effector and an image information acquisition device. A modular design is adopted for each part of the intelligent seed and seedling sorting and transplanting device, a transmission structure is compact, mechanism simplicity is ensured, the flat belt conveying device and the seed and seedling jacking rotating device are stable and reliable, a motor is adopted as a power device, and the number of other auxiliary equipment is reduced; a single camera, a background board, a light source and seed and seedling rotation are matched to acquire images, and a plurality of transplanting fitness parameters of seeds and seedlings can be simultaneously acquired, so that the cost is lowered, and the processing speed of system data is improved.

Owner:CHINA AGRI UNIV

Steel pipe rust removing and cutting integrated machine for building

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

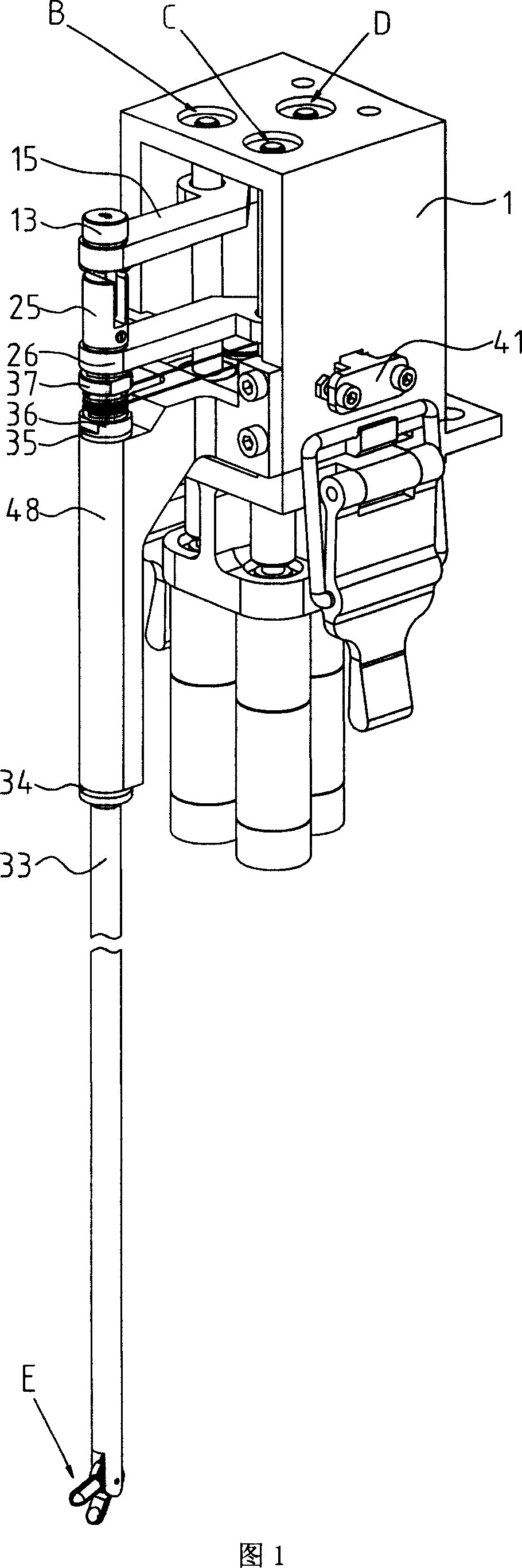

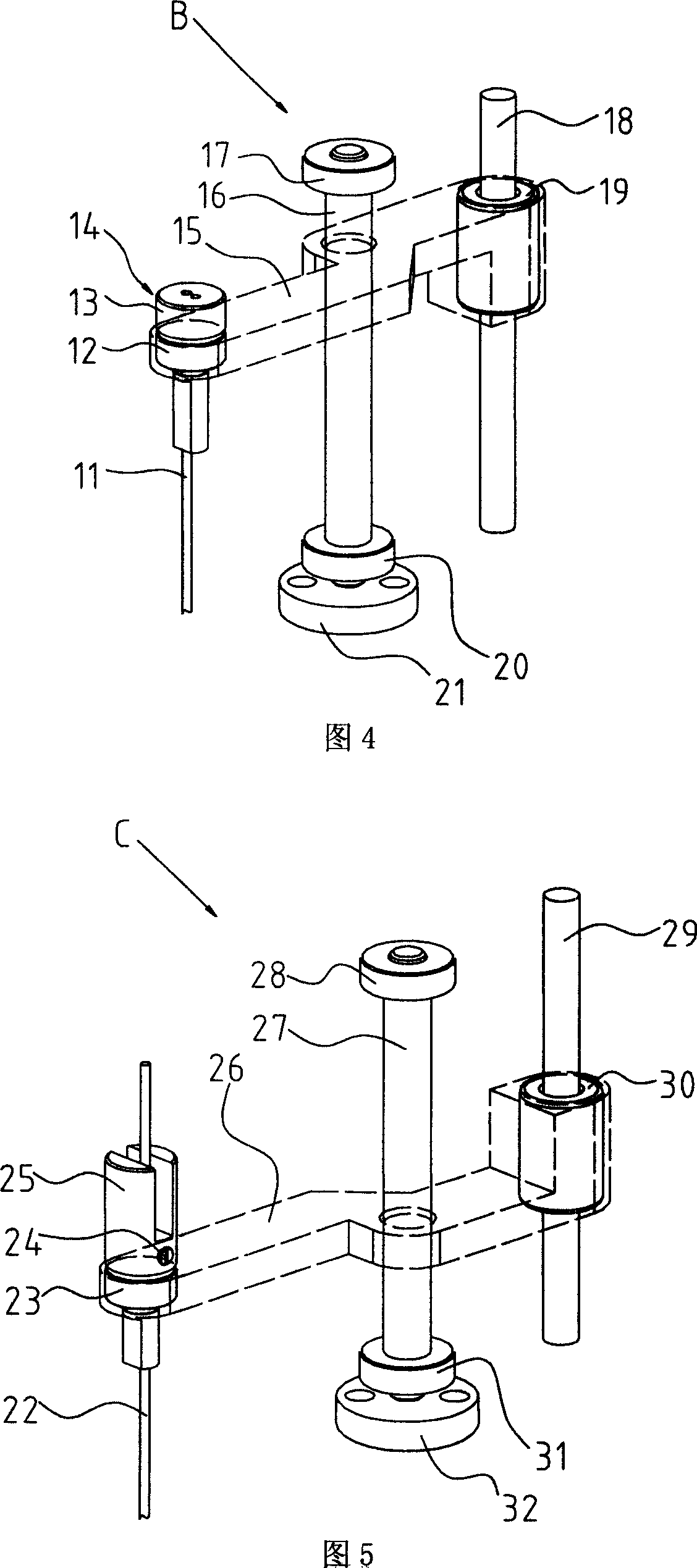

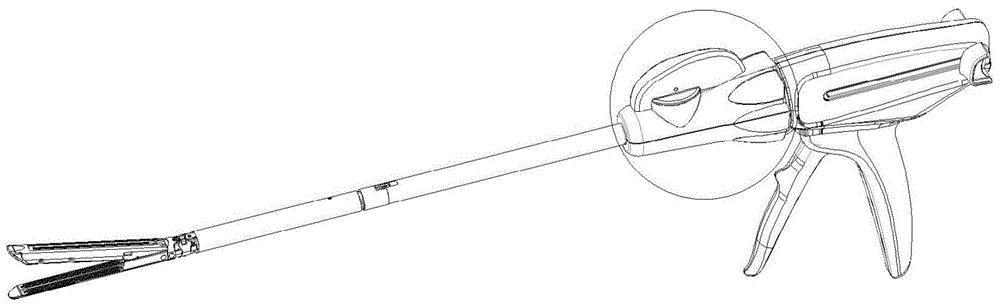

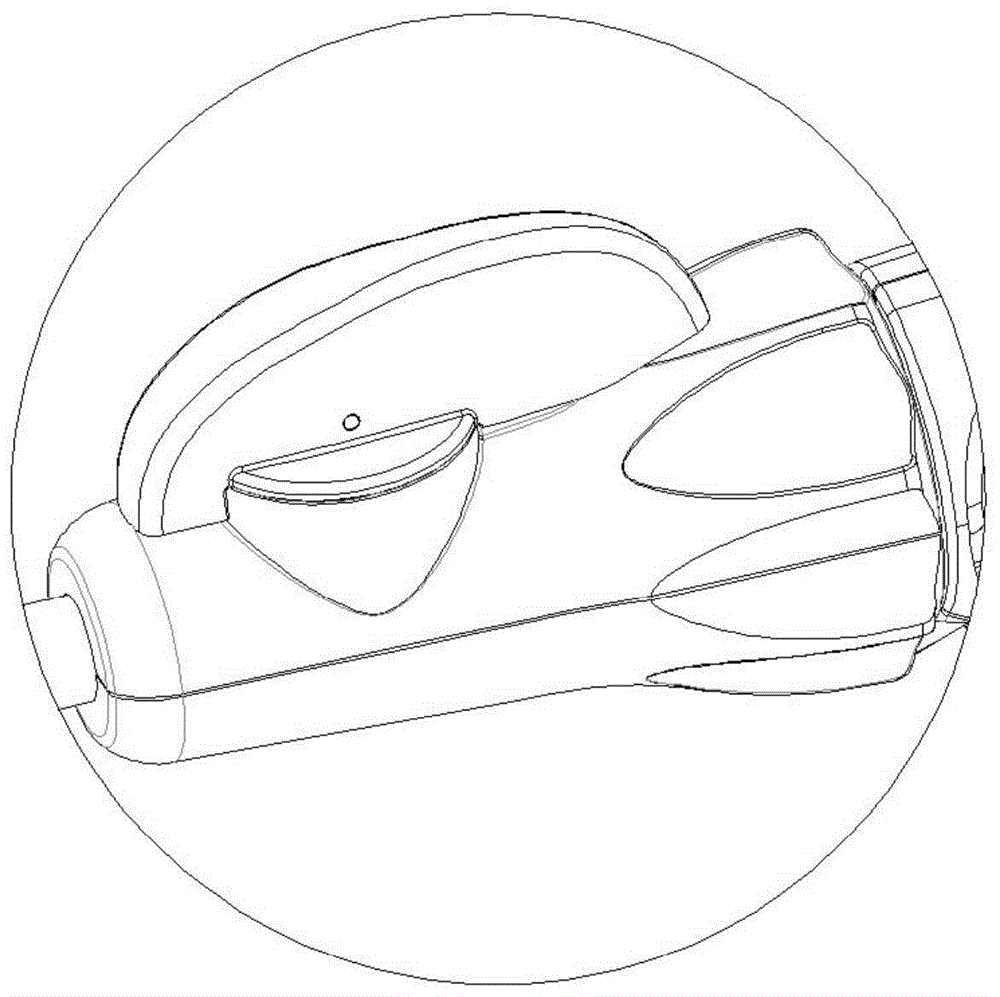

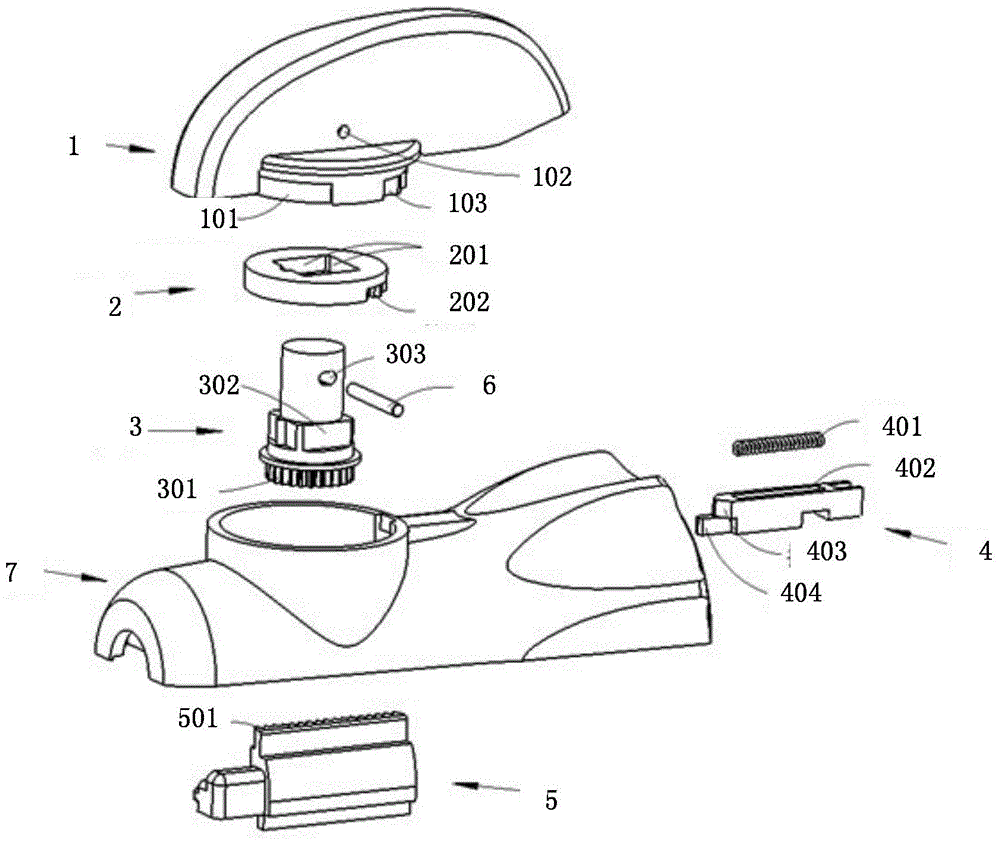

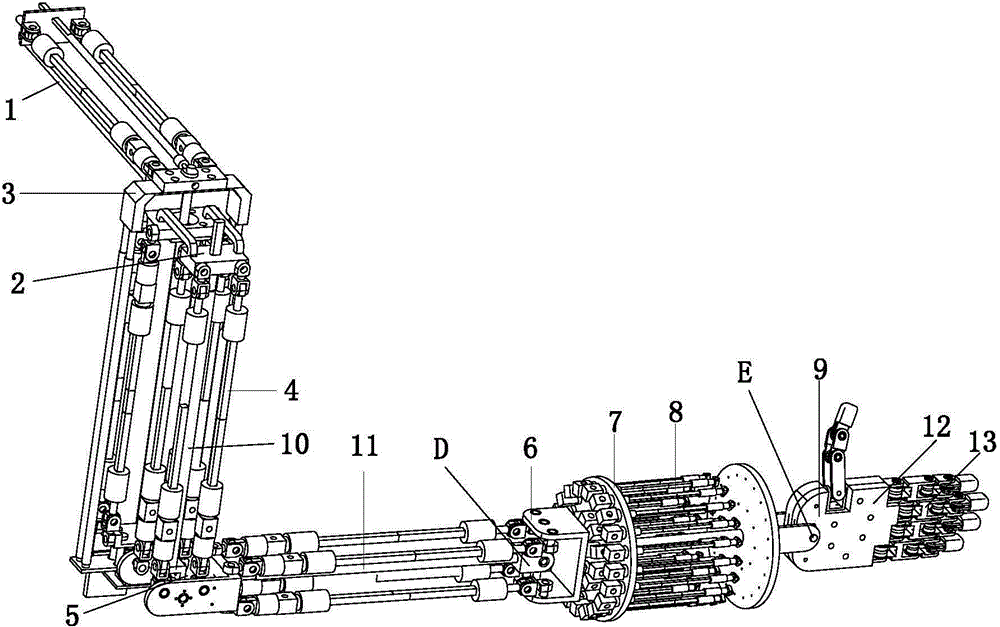

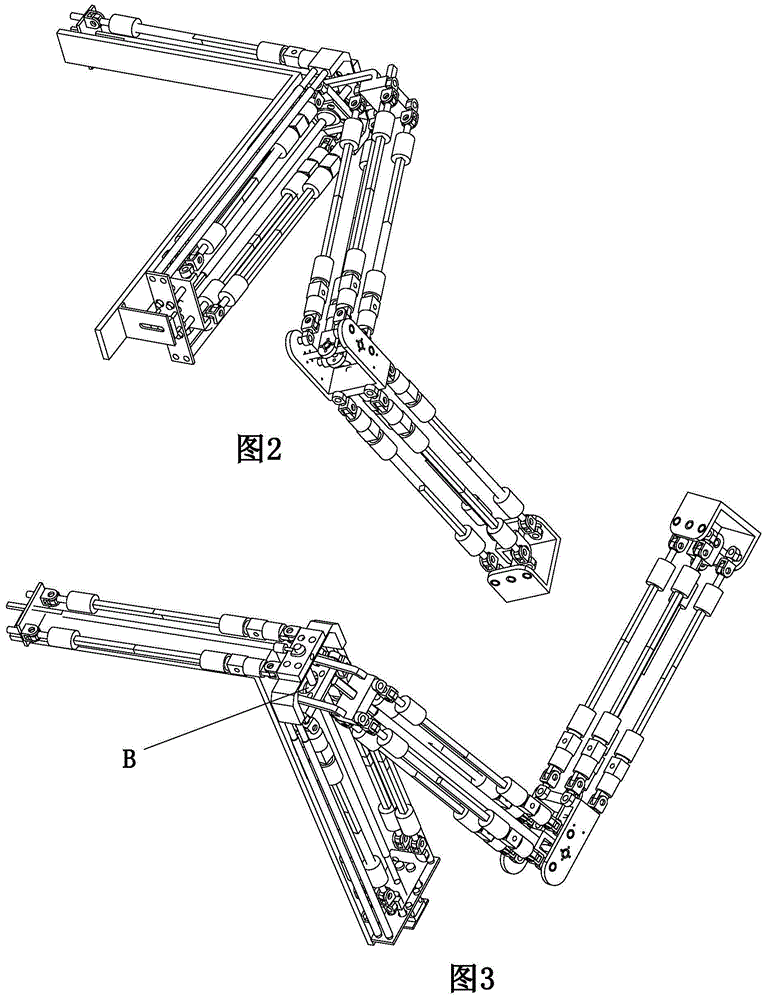

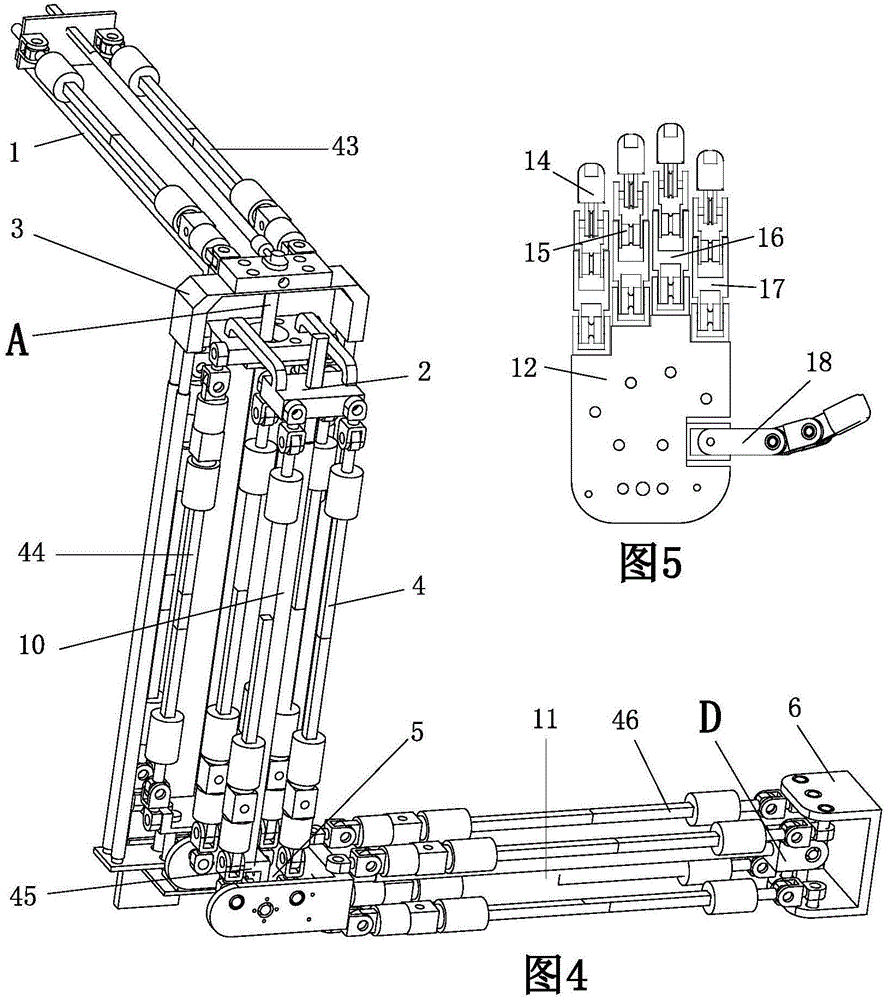

Surgical instrument and bending control mechanism thereof

ActiveCN104546048ASimple organizationEasy to manufactureSurgical staplesSurgical forcepsLocking mechanismAngular degrees

The invention provides a surgical instrument and a bending control mechanism thereof. The bending control mechanism of the surgical instrument comprises a steering power input mechanism A, a steering power transmission mechanism B, a locking mechanism C and a linear power output mechanism D. Furthermore, the steering power input mechanism A and the steering power transmission mechanism B which are coaxially arranged have a rotatable angle range in the circumferential direction, and the steering power input mechanism A sequentially passes through relative angles which are respectively an angle I, an angle range II and an angle III during the process of being rotated from an angle at one end of the rotatable angle range to another angle at the other end relatively to the steering power transmission mechanism B, wherein the angle I or the angle III corresponds to a swerve, and the angle range II corresponds to a locking state. The surgical instrument and the bending control mechanism thereof can solve swerving and fixing problems of medical apparatus and instruments in a human body in surgery, and reduce risk in the surgery.

Owner:SHANGHAI YISI MEDICAL TECH CO LTD +1

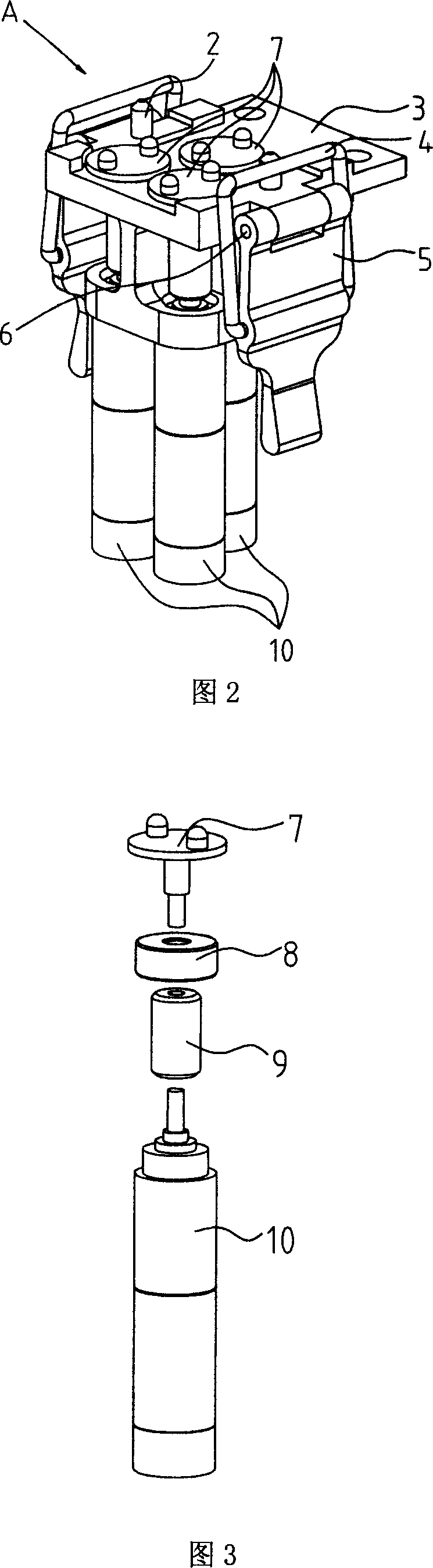

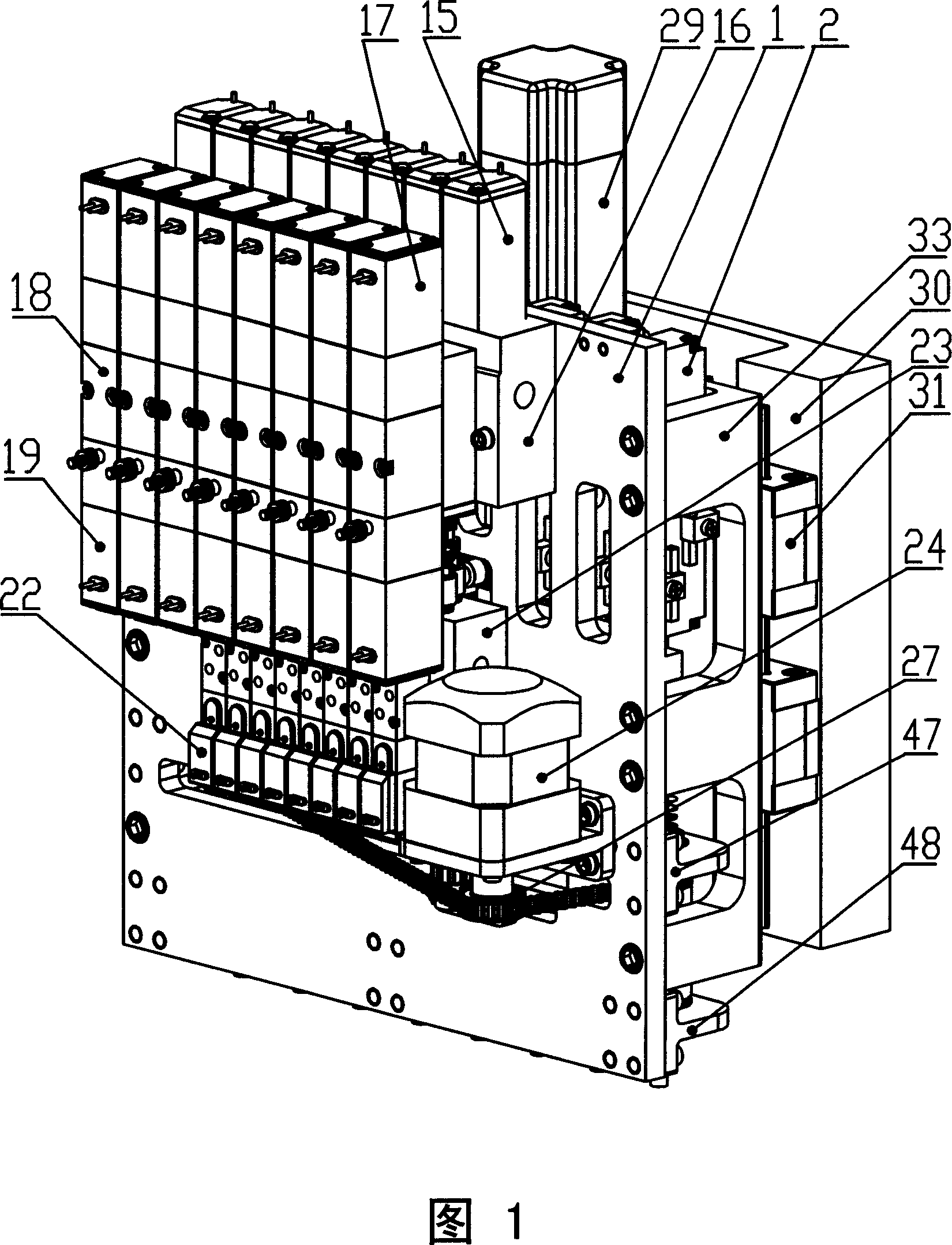

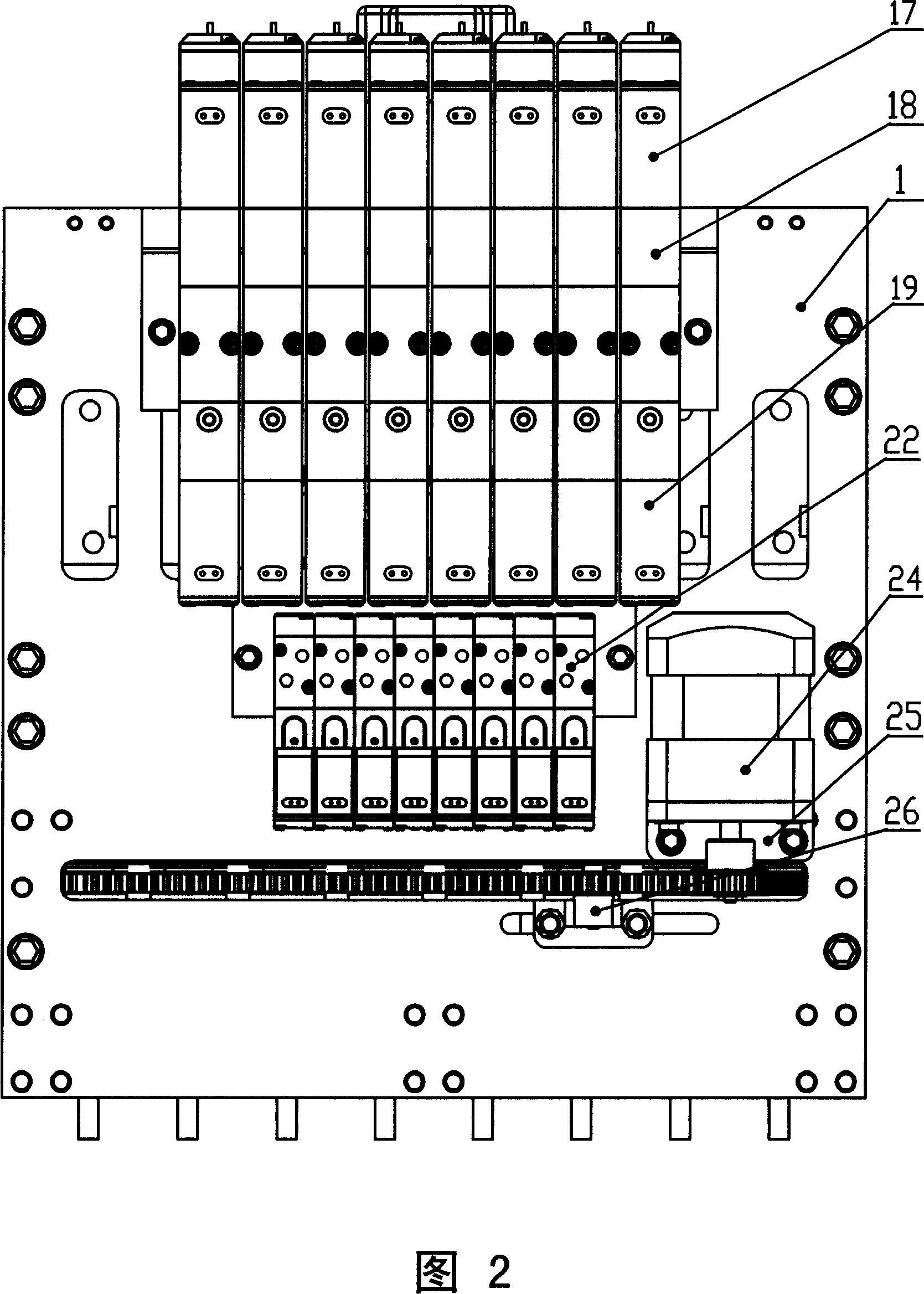

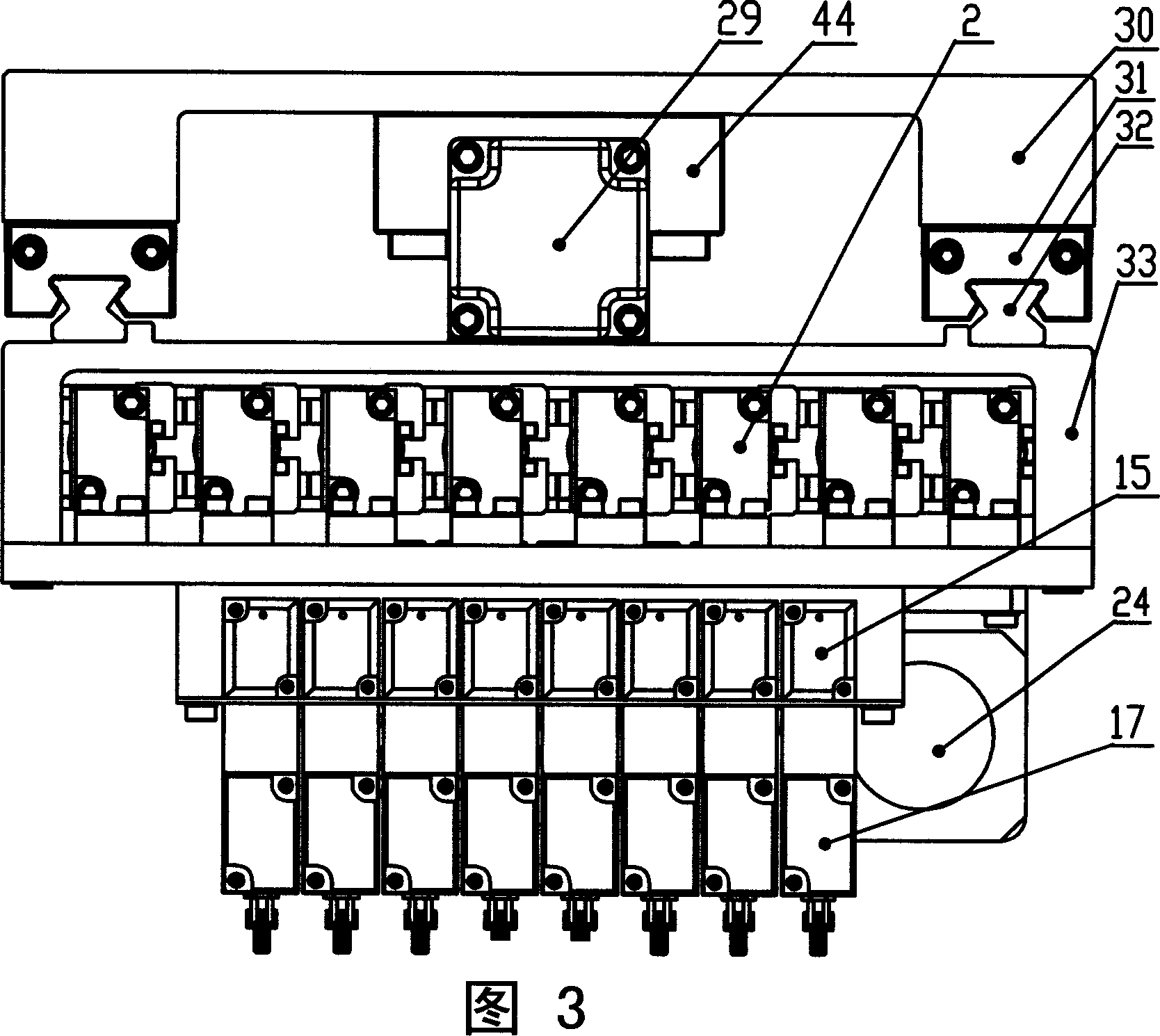

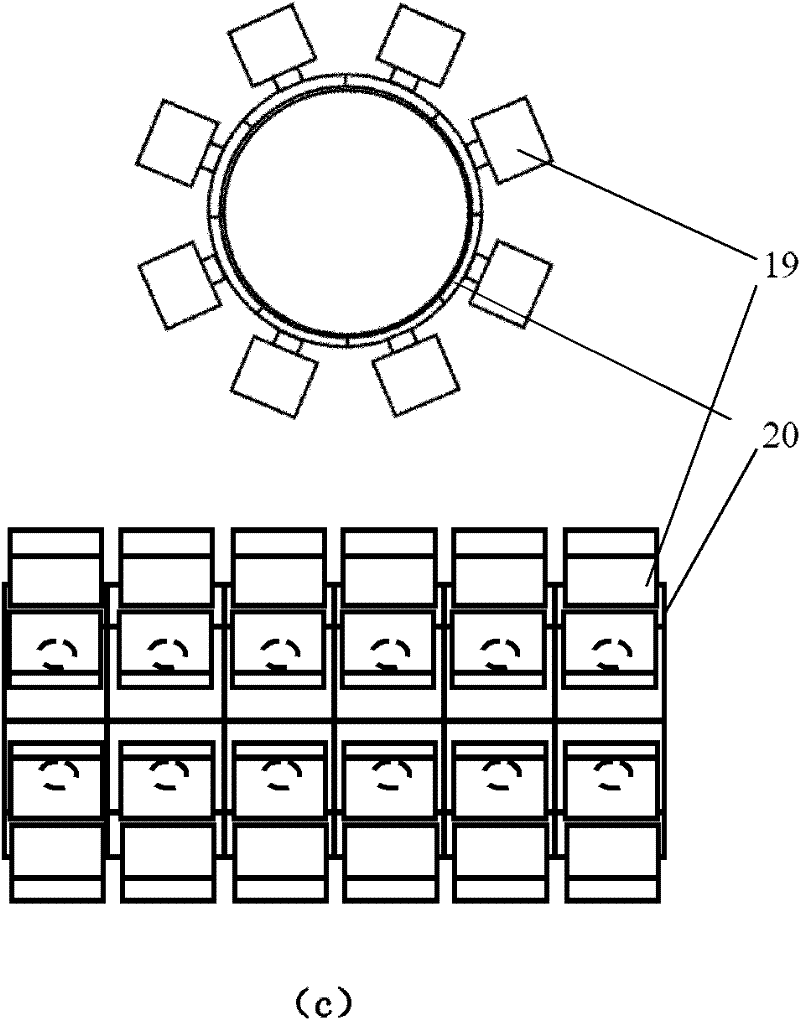

High speed full-automatic paster machine array type mounting head

InactiveCN101098618AReduce the center axis distanceConvenient sourcePrinted circuit assemblingElectrical componentsControl signalControl system

The invention provides a high-speed full-automatic paste machine array paste head, which uses a main frame as core, while other systems and modules are assembly on the main frame. A cylinder module, a cylinder control module, and a Z-axis motion system form the Z-axis motion of the paste head. When in use, the cylinders of the cylinder module execute paste missions in turn, while only one cylinder works at one time. A ball spline module and a theta control system process the bias correction of chop. When moves at theta angle, all splines of the ball spline module work together, while the bias parameter of each spline is realized by a control-software. A vacuum system generates the control signals for the blow and adsorption of a vacuum resource and a chip, while the vacuum resource via a vacuum inlet of a micro cylinder in the cylinder module, a hollow piston rod, and a hollow spline shaft of the ball spline module, transmits vacuum to the end of the paste head to absorb and paste the chip.

Owner:BEIHANG UNIV

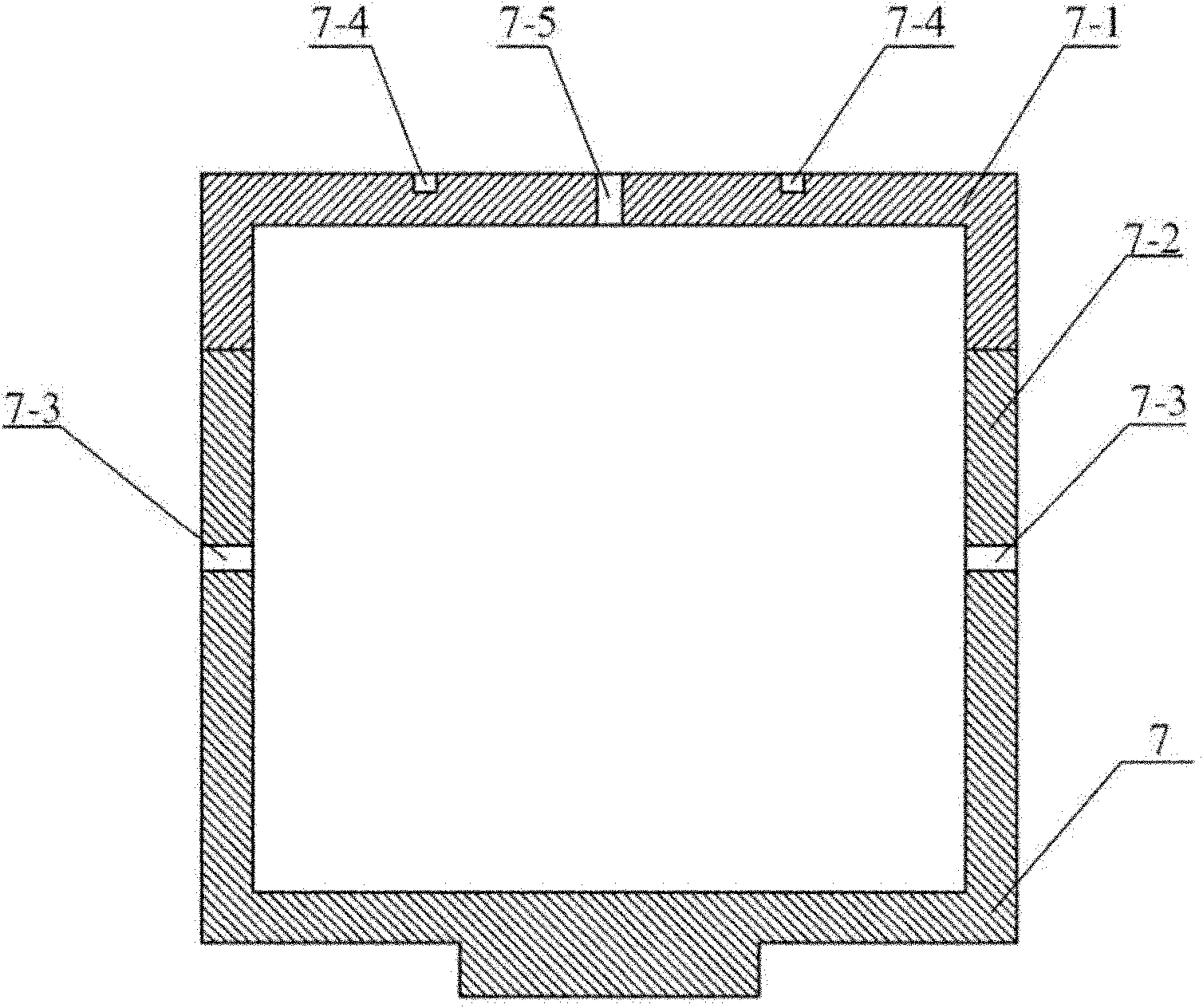

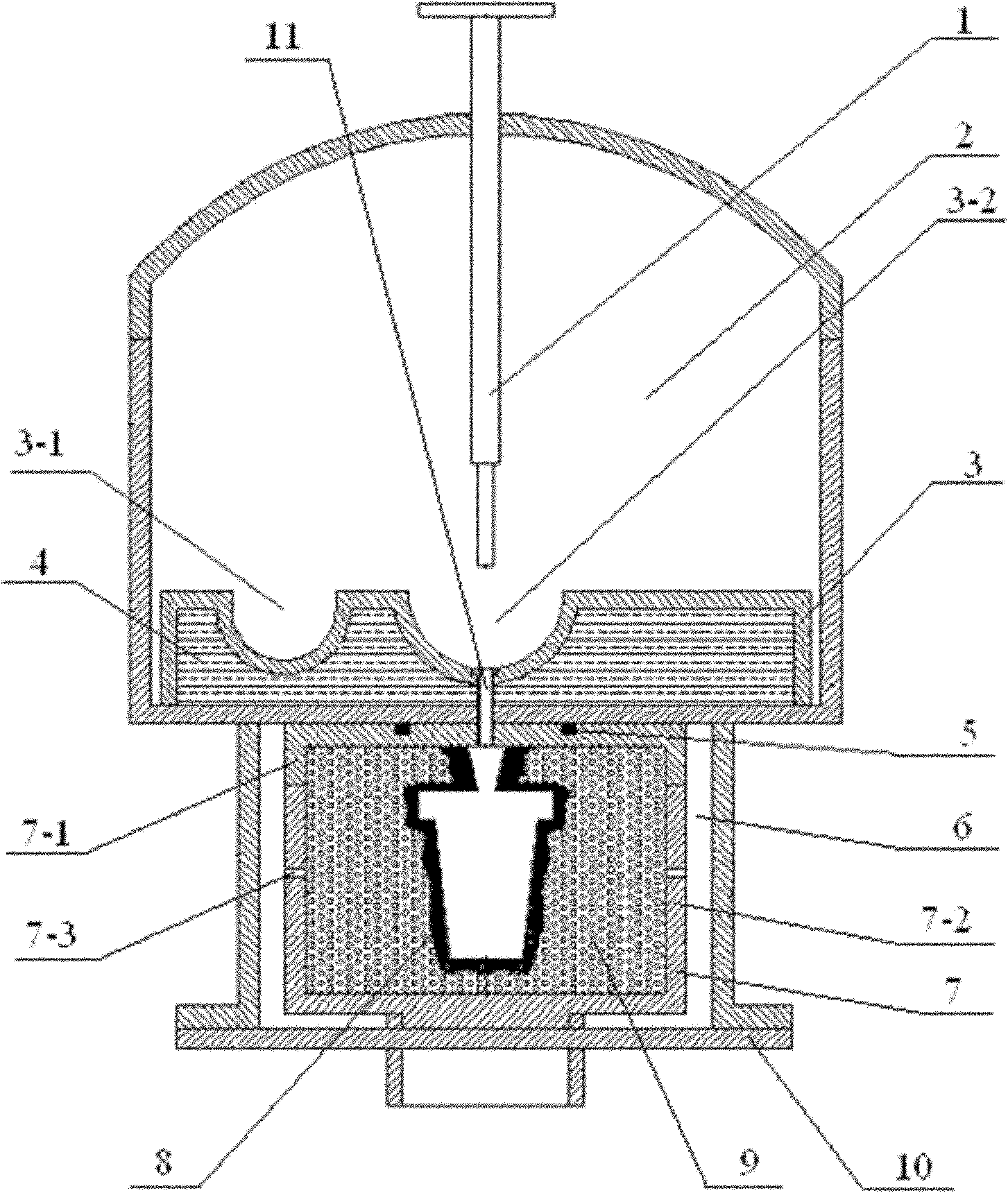

Cast forming method of small titanium alloy or titanium-aluminum alloy complicated casting

InactiveCN102019401AImprove filling abilityImprove efficiencyFoundry mouldsFoundry coresMold fillingIngot

The invention relates to a cast forming method of a small titanium alloy or titanium-aluminum alloy complicated casting, belonging to the casting method of the titanium alloy or titanium-aluminum alloy casting and solving the technical problems that the gravity casting of the traditional titanium alloy member is difficult in smooth mold filling, the centrifugal casting method has complicated process, the material utilization rate is low and the metal bottom-drain type vacuum suction casting method cannot be used for casting and forming thin-walled parts with complicated shapes. The method comprises the steps of: 1. preparing a ventilating shell; 2. preparing a bottom drain type vacuum suction casting container; 3. fixing the shell in the container, fixing the container in a suction casting chamber of a smelting furnace; 4. carrying out electric arc melting on the titanium alloy or titanium-aluminum alloy raw materials to obtain a button ingot; 5. turning the button ingot to a suction casting crucible for smelting to obtain overheating melt; and 6. suction-casting and mold-filling, and cooling to finally obtain the casting. The yield by the method is not less than 90 percent; and the method is a simple near net shape forming method, can be used for preparing a titanium and titanium-aluminum alloy blade, a worm wheel, artware and other small complicated castings.

Owner:HARBIN INST OF TECH

Intelligent force feedback handle and control method thereof

The invention discloses an intelligent force feedback handle and a control method thereof. The handle comprises an X-axis rotation part, a Y-axis rotation part, and a Z-axis rotation part. The X-axis rotation part comprises an inner frame and an X-axis driving device for driving the inner frame to rotate about the X axis. The Y-axis rotation part comprises a center cylinder and a Y-axis driving device for driving the center cylinder to rotate about the Y axis. The Z-axis rotation part comprises a handle operation lever and a Z-axis driving device for driving the handle operation lever to rotate about the Z axis. The center cylinder is rotationally arranged in a hollow frame body of the inner frame, and the rotation direction of the center cylinder and the rotation direction of the inner frame are perpendicular to each other. The handle operation lever is rotationally arranged inside the center cylinder around the axis, and the handle operation lever and the center cylinder are coaxial. The size of the handle is optimized, and the method achieves an intelligent damping control effect and an automatic reset effect.

Owner:SOUTHEAST UNIV

Reconfigurable spherical parallel robot

InactiveCN105538296ARealize mutual conversionImplement resizingProgramme-controlled manipulatorWorking environmentRobot

The invention belongs to the technical field of spherical parallel robots, and particularly relates to a reconfigurable spherical parallel robot which aims at switching between multiple configurations without being detached. The reconfigurable spherical parallel robot comprises a movable platform, driving branch chains and a fixed platform, wherein the movable platform and the fixed platform are connected through the three driving branch chains of the same structure. A slide rail I of the movable platform and a slide rail II of an arc-shaped rod piece are connected through a combined slide block. The combined slide block can slide on the slide rail I of the movable platform and the slide rail II of the arc-shaped rod piece. The fixed platform is fixedly connected with a motor support. The reconfigurable spherical parallel robot is higher in flexibility, better in softness and higher in adaptability to the working environment.

Owner:ZHONGBEI UNIV

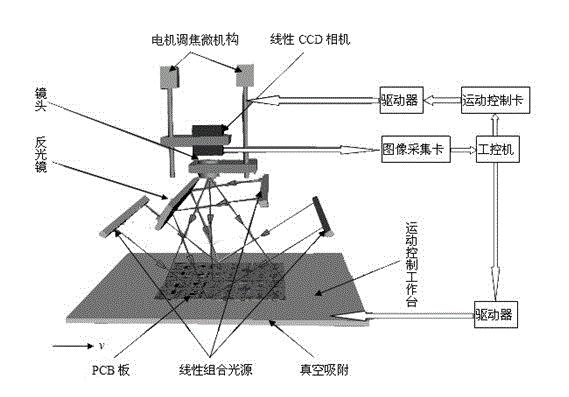

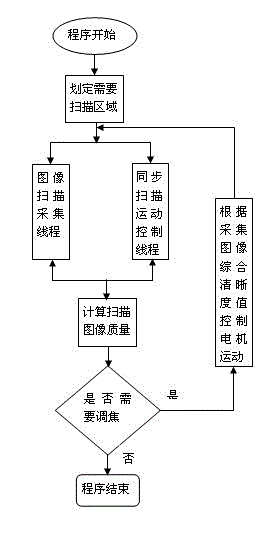

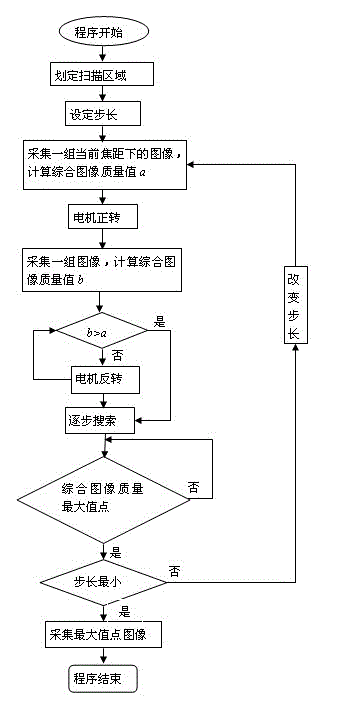

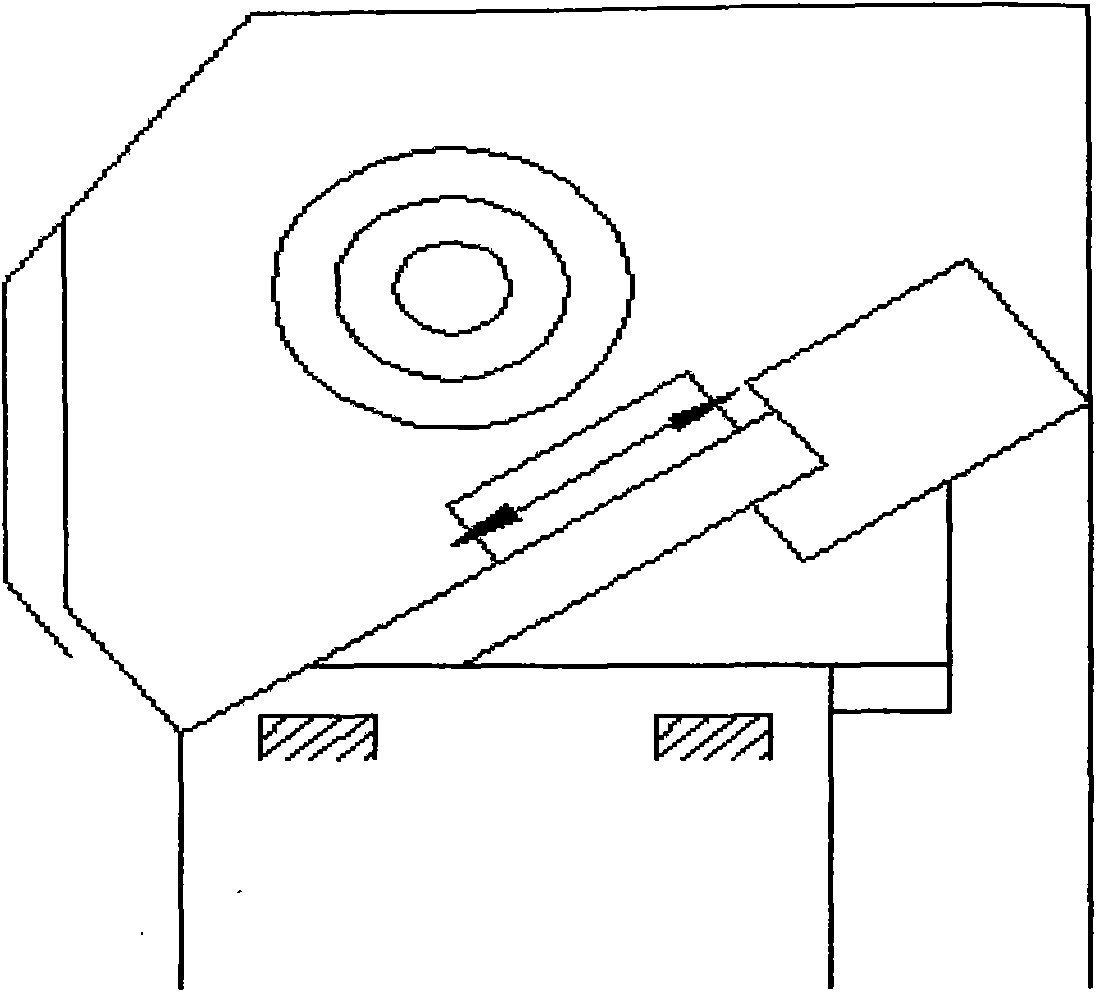

System and method of linear array CCD camera multi-point automatic focusing

InactiveCN102724401ASolve failureResolve accuracyTelevision system detailsColor television detailsComputer graphics (images)Imaging quality

The invention provides a system and a method of linear array CCD camera multi-point automatic focusing, wherein the method comprises dividing a PCB board into a plurality of areas, selecting an area needed to be scanned; opening a linear array CCD camera, collecting images containing contour information of the PCB board, determining image quality four-neighborhood definition weight coefficients of each area according to complexity levels of the contour information of different areas, and judging the optimal collecting image quality according to a comprehensive definition of the image. The technical solution provided by the invention is simple, practical, and convenient to implement, and has a strong versatility. The technical problem of malfunction or inaccurate focusing of a range-measurement system can be satisfactorily solved, and the mechanism is simple and highly accurate.

Owner:SHENZHEN UNIV

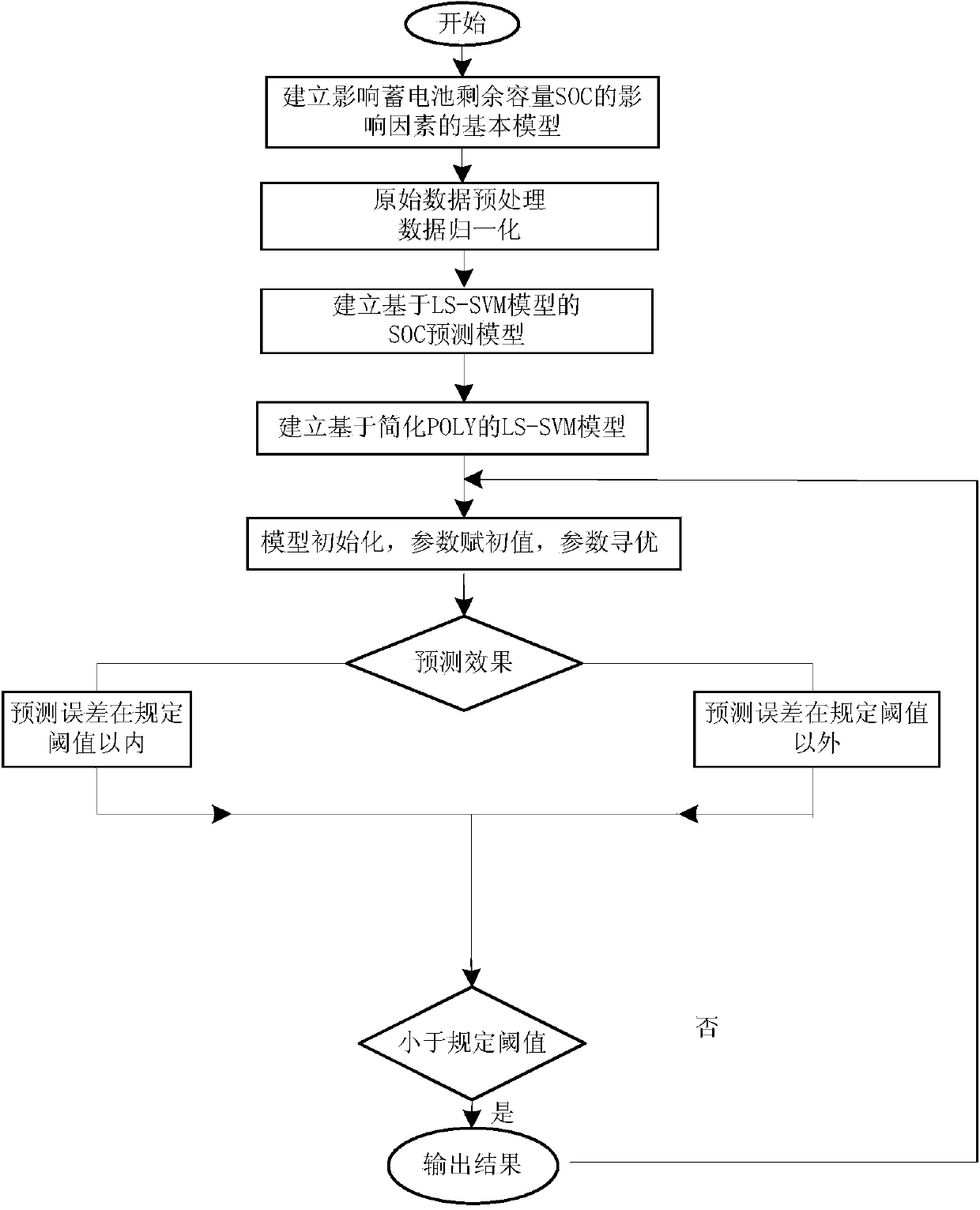

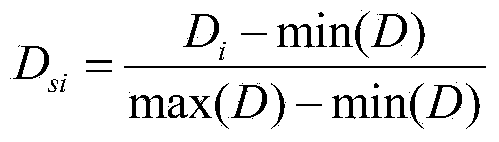

Residual battery capacity detection method based on simplified least square support vector machine

InactiveCN104182630ASimple structureSimple organizationSpecial data processing applicationsTest sampleAlgorithm

The invention discloses a residual battery capacity detection method based on a simplified least square support vector machine. The method includes establishing a basic model of influence factors influencing the residual battery capacity; pre-processing original data; normalizing the pre-processed data entirely; selecting kernel function to establish a least square support vector machine mathematical model; inputting the normalized data into the least square support vector machine mathematical model, adopting part of data to serve as training samples, adopting the rest as test samples, and outputting and acquiring the data sequence predicating result, namely the estimated residual battery capacity; setting parameters of the kernel function; adopting a manner of crossed validation to perform parameter optimization on the parameter of the model; comparing the acquired residual battery capacity with the actual residual battery capacity, and figuring out the error between the estimated value and the actual value; judging whether the estimated error is smaller than the threshold or not; if the estimated error is smaller than the threshold, outputting the predicating result; if not, performing parameter optimization once again. The method has the advantages of low hardware cost and high detection accuracy.

Owner:STATE GRID CORP OF CHINA +1

Self-adaption MDOF (Multi-Degree Of Freedom) humanoid manipulator based on pneumatic artificial muscle

InactiveCN104589310AReduce volumeMeet performance needsProgramme-controlled manipulatorJointsControl systemMulti degree of freedom

The invention relates to a self-adaption MDOF (Multi-Degree Of Freedom) humanoid manipulator based on pneumatic artificial muscle and aims at providing a manipulator which has certain functions of human hands and also has the characteristics of practicability, smoothness, safety, small size, lightness, easiness in control and simple mechanism. According to the technical scheme, the self-adaption MDOF humanoid manipulator based on the pneumatic artificial muscle comprises an air course control system, a manipulator mechanism and an artificial muscle system, wherein the manipulator mechanism comprises a mechanical big arm, a mechanical forearm, a hand and five fingers; the artificial muscle system comprises a plurality of third pneumatic artificial muscles, a plurality of fourth pneumatic artificial muscles, a plurality of first pneumatic artificial muscles, a plurality of fifth pneumatic artificial muscles and a plurality of second pneumatic artificial muscles; the mechanism big arm is driven by the third pneumatic artificial muscles and the fourth pneumatic artificial muscles; the mechanism forearm is driven by the first pneumatic artificial muscles; a wrist joint is driven by the fifth pneumatic artificial muscles; the five fingers are driven by the second pneumatic artificial muscles.

Owner:ZHEJIANG SCI-TECH UNIV

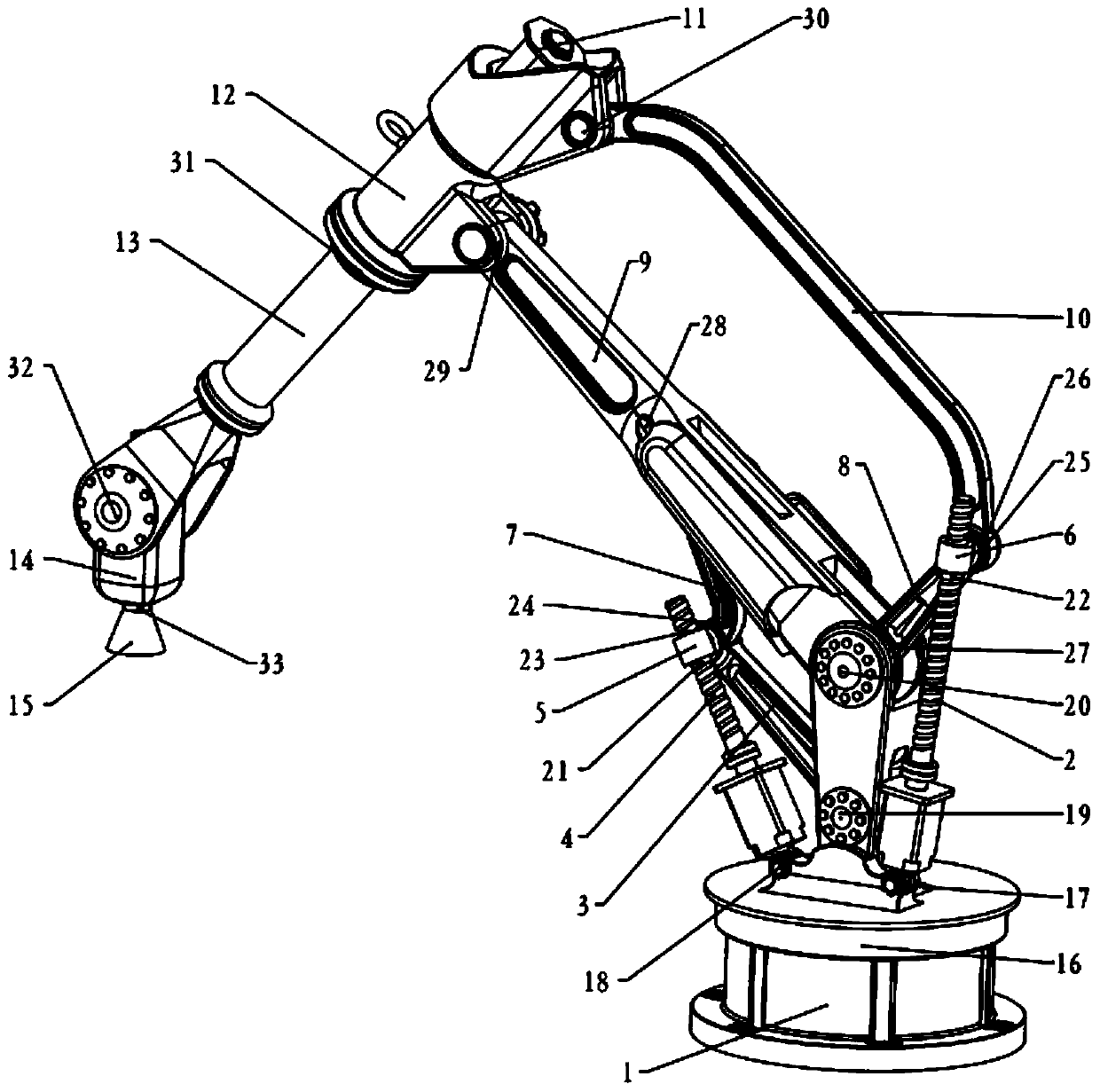

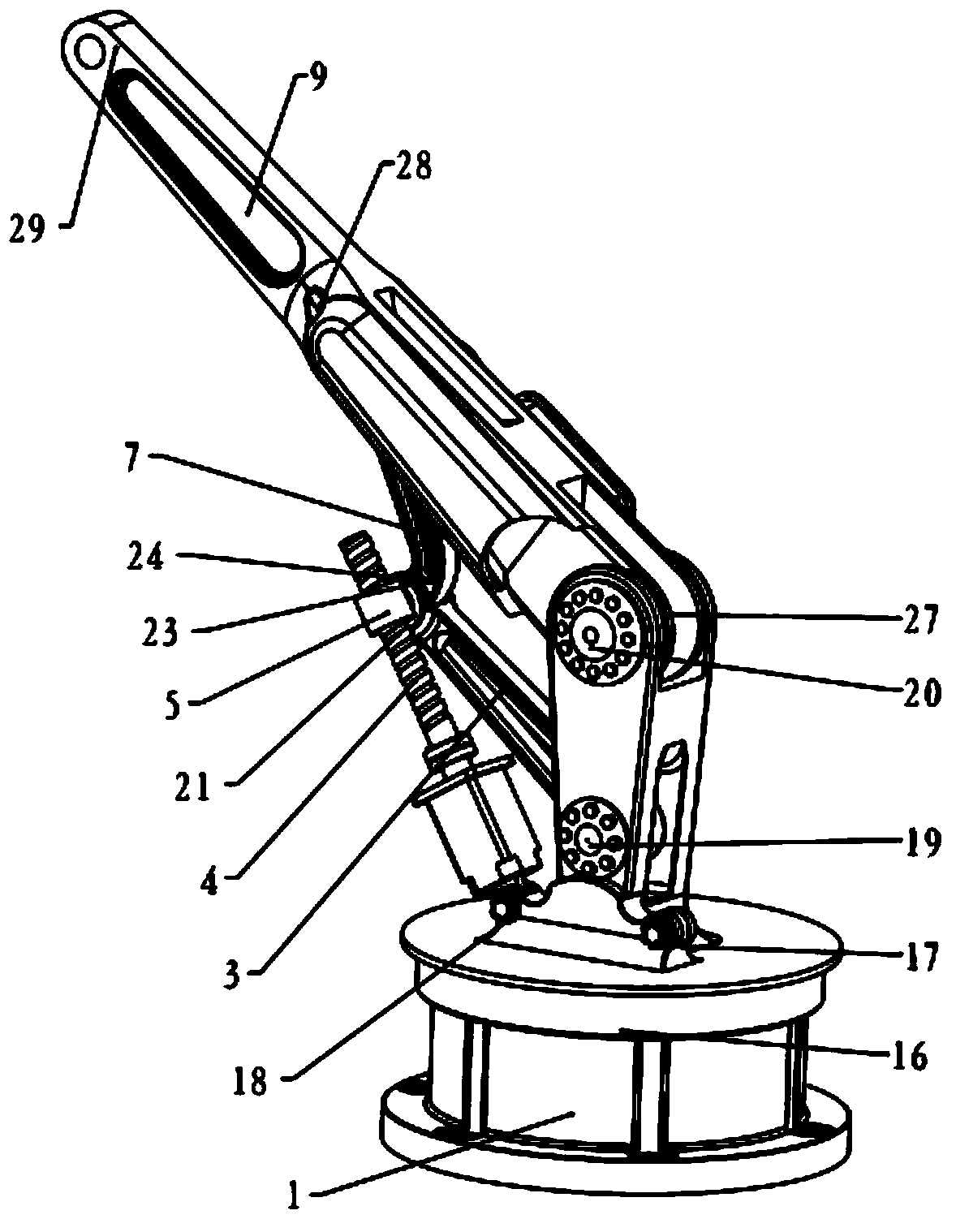

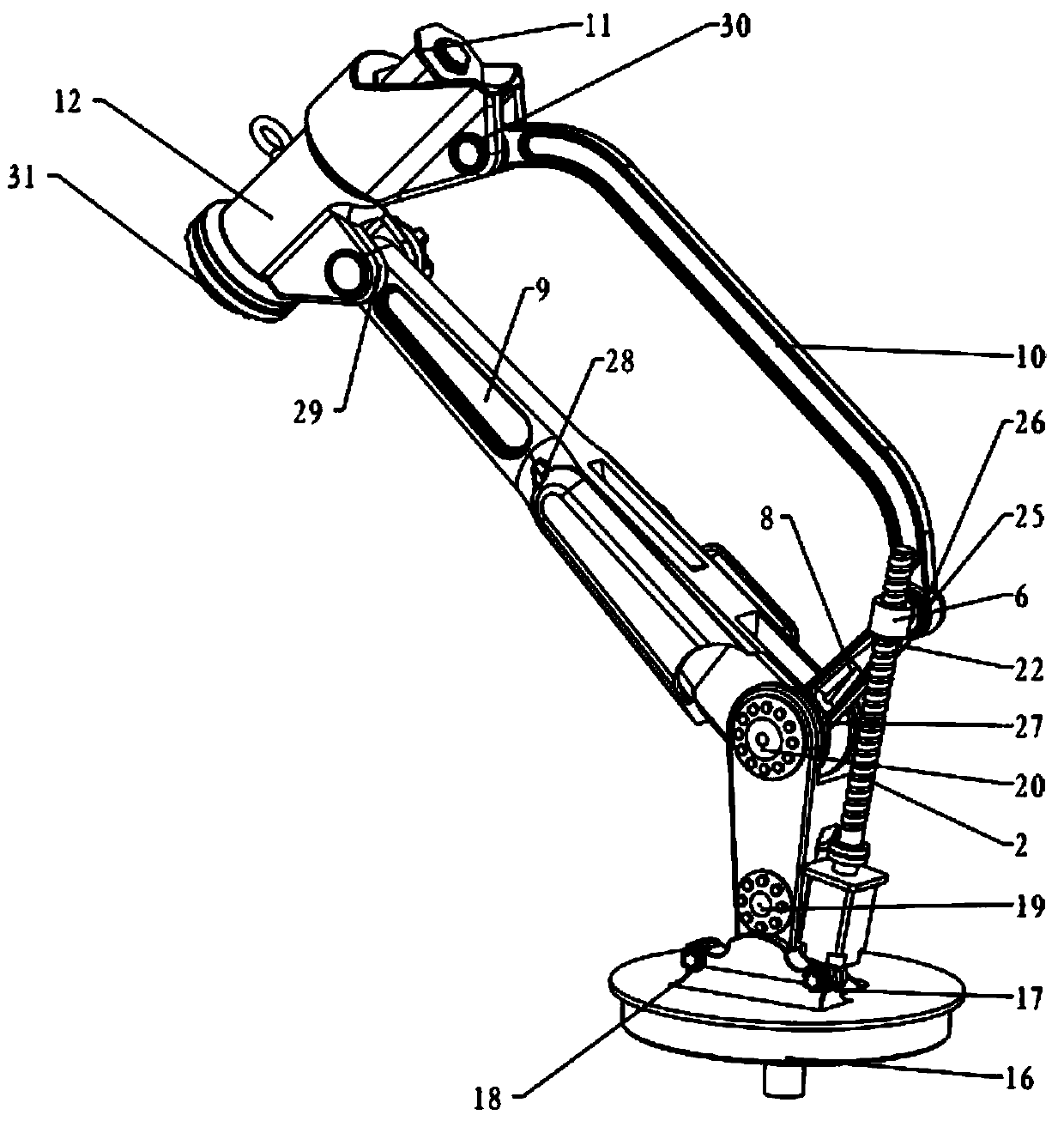

Six-freedom-degree industrial robot with ball screw pair transmission

InactiveCN103737577ARealize two-dimensional translationRealize three-degree-of-freedom attitude adjustmentProgramme-controlled manipulatorBall screw driveDrive motor

The invention relates to a six-freedom-degree industrial robot with ball screw pair transmission. Waist whole circle rotating is achieved through a waist swing mechanism, a shoulder swing mechanism and an elbow swing mechanism form a two-freedom-degree parallel mechanism to achieve two-dimensional horizontal moving, and ball screws are driven by motors arranged on a swing platform respectively. Three mutual-orthometric rotating shafts connected through a front arm rotating mechanism, a wrist swing mechanism and a tool clamping base swing mechanism are driven independently by three motors respectively, and three-freedom-degree gesture adjusting of an executing tail end tool is achieved. The advantage of the large working space of a serial mechanism is kept, ball screw transmission is used, the rigidness of the mechanism is guaranteed, the positions of the driving motors are lowered, good dynamic characteristics are obtained, bearing capacity is large, high-speed or superspeed operation can be easily achieved, and the six-freedom-degree industrial robot has the advantages that side gaps do not exist, rigidness is high, micro-motion feeding can be conveniently achieved, accumulated errors are small, motion accuracy is high, positive and athwart kinematics solving is convenient, and control is convenient.

Owner:GUANGXI UNIV

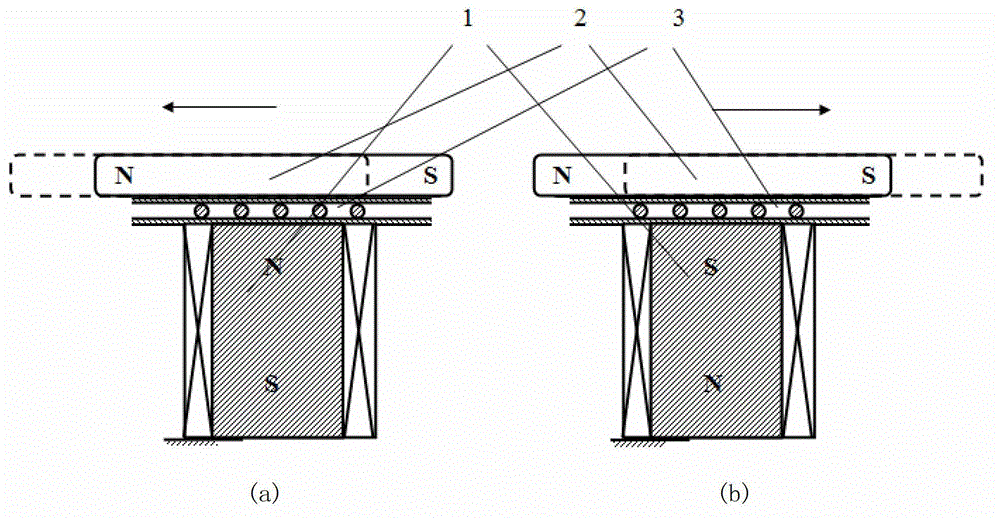

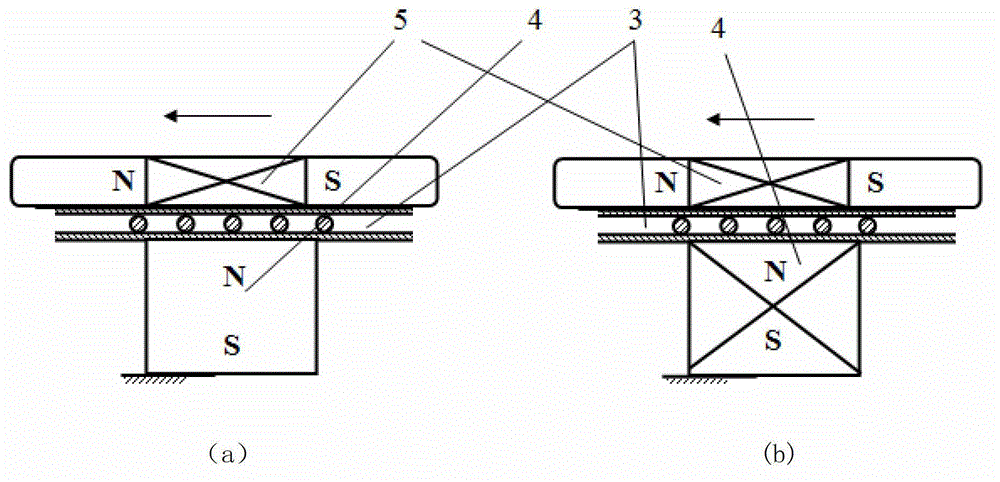

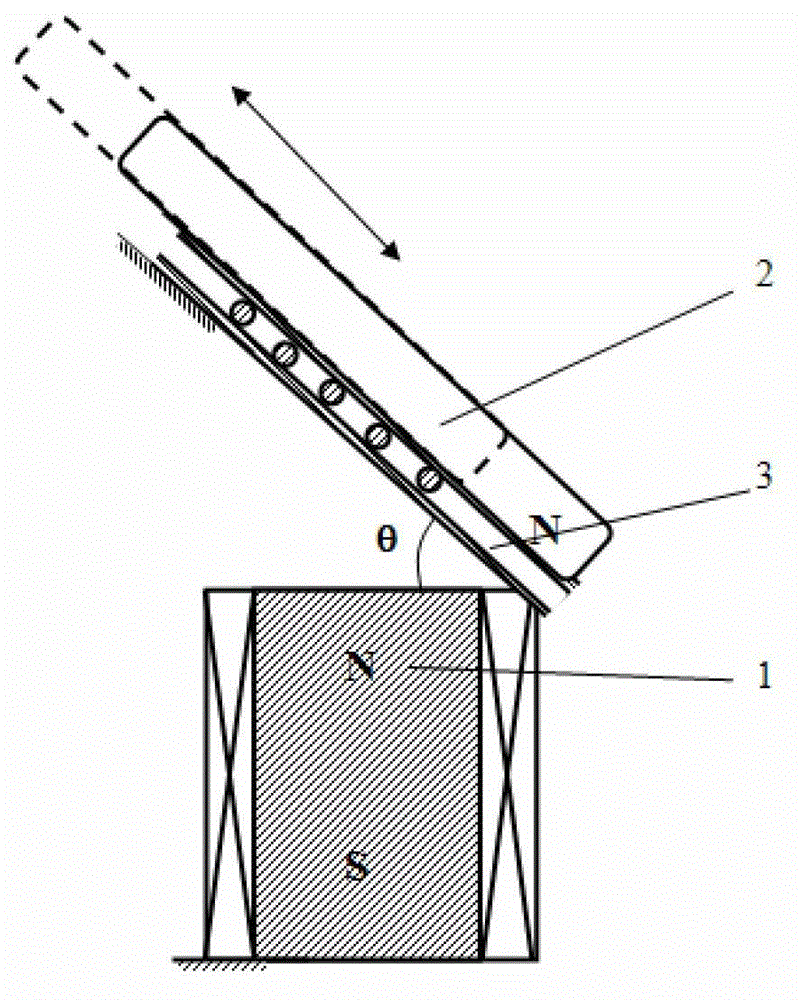

Shift driving device and combination thereof based on interaction of permanent magnet and electromagnet

ActiveCN102946164ASimple organizationImprove rigidityMechanical energy handlingMagnetic polesEngineering

The invention discloses a shift driving device and a combination thereof based on the interaction of a permanent magnet and an electromagnet. The device comprises a driving component, a motion initiating component and a guide component, wherein the driving component and the motion initiating component interacts with each other, the guide component is arranged between the driving component and the motion initiating component for restricting the shift direction of the motion initiating component, a fixed electromagnet or a fixed permanent magnet is used as the driving component, and a mobile permanent magnet or a mobile electromagnet is used as the motion initiating component. The device has the advantages of direct motion driving, simple mechanism, great rigidity, accurate driving shift, simplicity and convenience in control, rapid driving response and high efficiency. Linear reciprocating translational motion or rotating motion is directly generated based on the displacement of magnetic poles. Large stroke and micro stroke are easily realized. Motion force, shift distance and shift accuracy can be controlled through the accurate application of a magnetic field or the intensity of current. The magnetic field is directly used for driving, and a larger driving magnetic field is produced under the combined action of an electromagnetic field and a permanent magnetic field, so that the mechanism has larger driving force.

Owner:SHANGHAI JIAO TONG UNIV

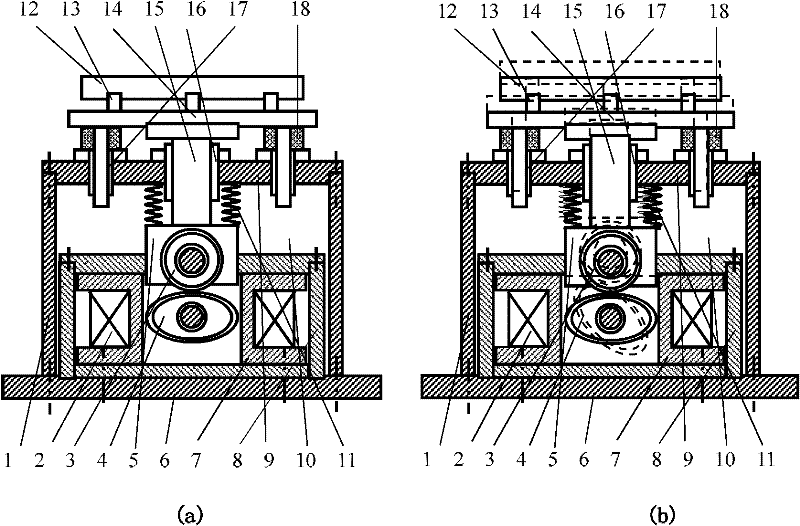

Force-controlled electromagnetic permanent magnetic composite excitation vibration platform

ActiveCN102205308AEnables direct vibration driveImprove driving efficiencyMechanical vibrations separationVibration testingMagnetic energyWide band

The invention discloses a force-controlled electromagnetic permanent magnetic composite excitation vibration platform in the technical field of electromagnetic drivers. The force-controlled electromagnetic permanent magnetic composite excitation vibration platform comprises a shell, electromagnetic coils, magnetic energy bodies and a carrying mechanism, wherein the two magnetic energy bodies are respectively arranged inside the shell in a manner of a horizontal rotating shaft and are in mutual contact, the two electromagnetic coils are respectively arranged inside the shell and positioned at two sides of the magnetic energy bodies, and the carrying mechanism is movably arranged on the top of the shell and is in contact with one magnetic energy body. The force-controlled electromagnetic permanent magnetic composite excitation vibration platform is a wide-band large-load and large-displacement vibration device or equipment which has the advantages of simple structure, high reliability and drive efficiency, no moving coil and lead following dragging hidden dangers, accuracy and controllability of amplitude and capability of realizing frequency of below 5Hz, i.e. from quasi-static to high frequency, and is driven by direct displacement generated by the electrically-excited rigid magnetic energy bodies.

Owner:SHANGHAI JIAO TONG UNIV

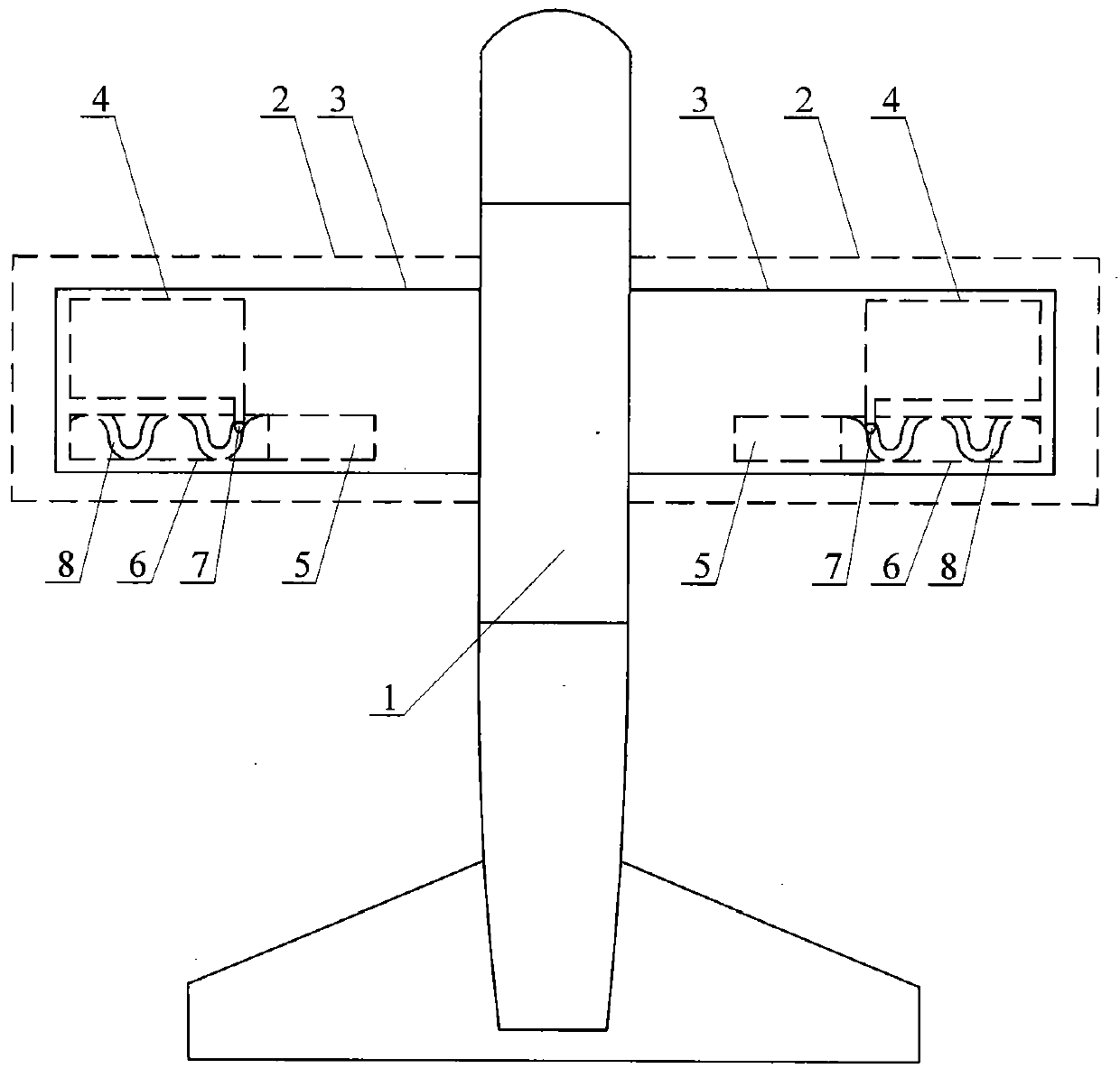

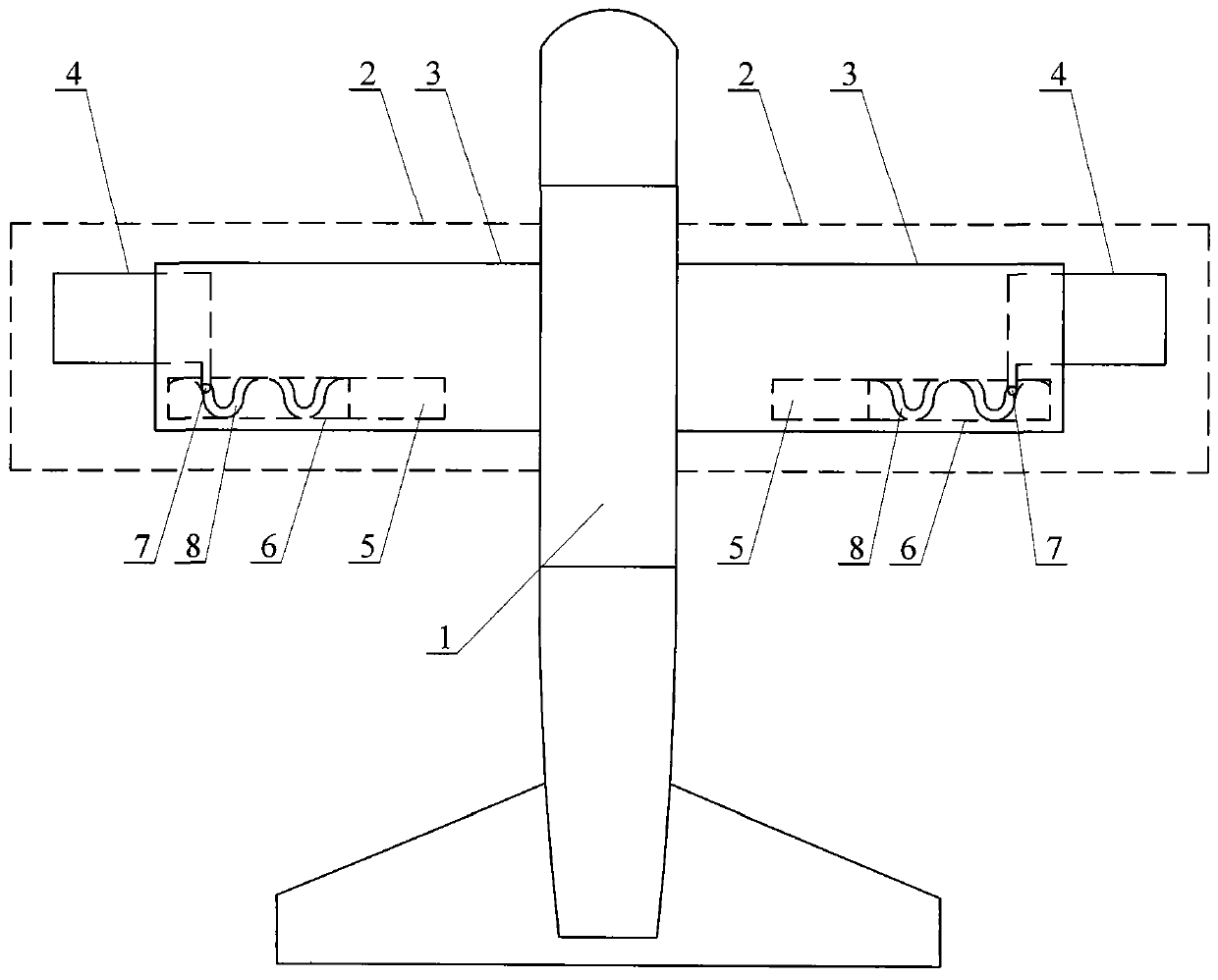

Aircraft with changeable wing shape

An airplane able to change the shape of wing is composed of an airplane body and two wings consisting of fixed wing with one end fixed to airplane body, slide wing installed in the skeleton of said fixed wing and with a roller moving in a spiral slot on a cylindrical body, and the cylindrical body and shape memory alloy bar, which are fixed to each other and installed in the skeleton of said fixed wing. Said shape memory alloy bar is used as the drive source for changing wing shape.

Owner:HARBIN INST OF TECH

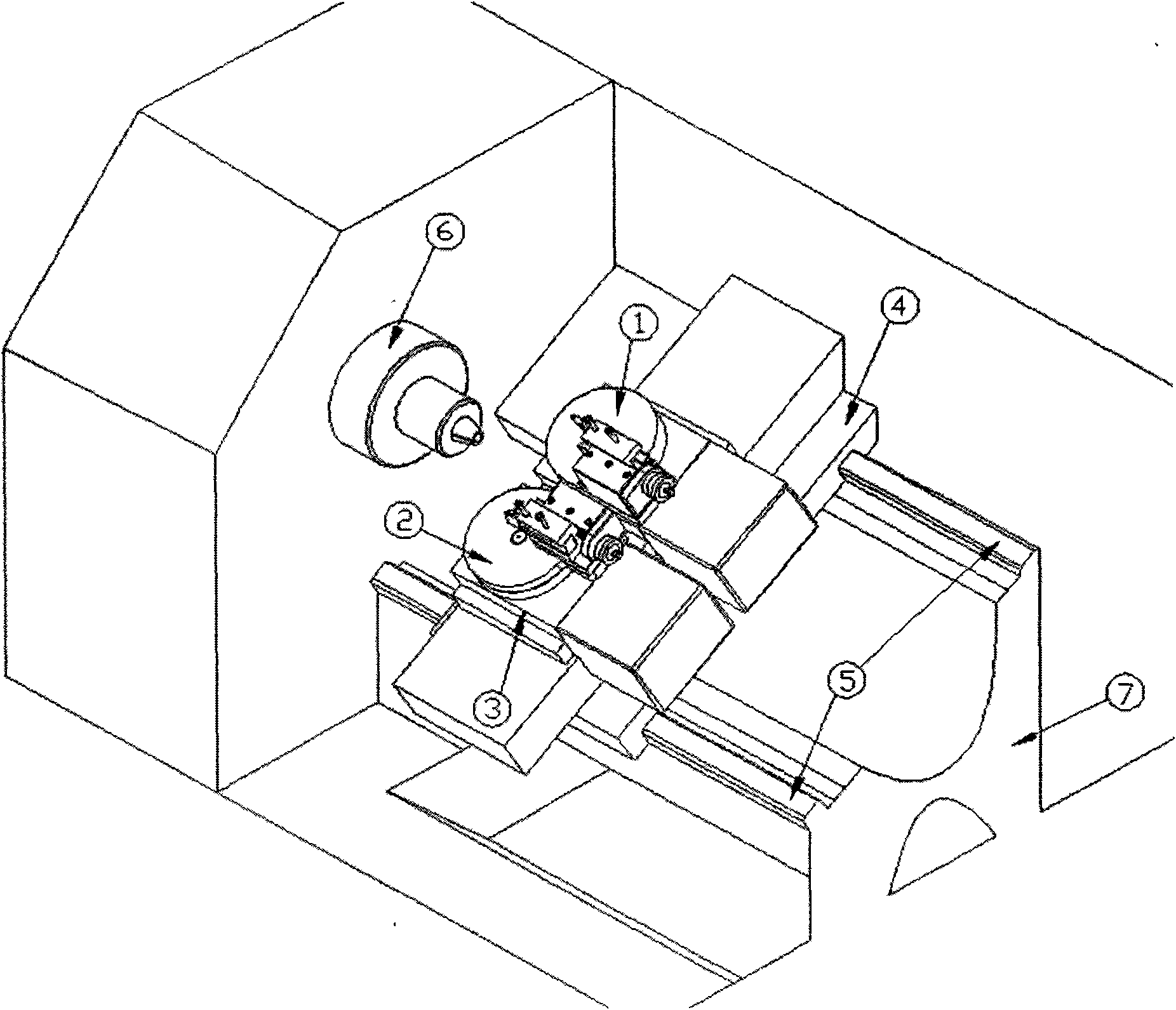

Spherical (spherical surface) mirror surface rolling lathe

ActiveCN101628378ASimple organizationLower center of gravityOther manufacturing equipments/toolsLarge fixed membersQuenchingEngineering

The invention relates to a spherical (spherical surface) mirror surface rolling lathe. A disk revolving tool holder (1) and a disk revolving tool holder (2) which can do circular movement are arranged in the lathe; the disk revolving tool holders are in transmission connection with a servomotor through synchronous belts and synchronous wheels; and a large-diameter thrust bearing (pressure bearing) is used as a tool holder revolving guide rail. The disk revolving tool holder (1) and the disk revolving tool holder (2) are connected with a middle carriage through a disk sealing seat (3), the middle carriage is connected with a large carriage (4) through the guide rail, the large carriage (4) is connected with a guide rail (5), the guide rail (5) is connected with a lathe body (7), and a main shaft (6) is connected with the lathe body (7). One of the tool holders is provided with a special and dismountable cutter system or tool system which is processed by a spherical part surface in a rolling way. The lathe can be used for cutting and processing axisymmetric spherical or externally-forming parabolic parts, and can be used for finely processing the spherical part surface (mirror surface) under the condition that the roughness Ra is smaller than or equal to 0.1 mum. Corresponding devices can be also held on the disk revolving tool holders to develop and upgrade the technologies of drilling, milling, grinding, polishing, quenching and the like, thereby adapting to the processing requirements of spherical (spherical surface) parts in many industries.

Owner:宁波市精恒凯翔机械有限公司

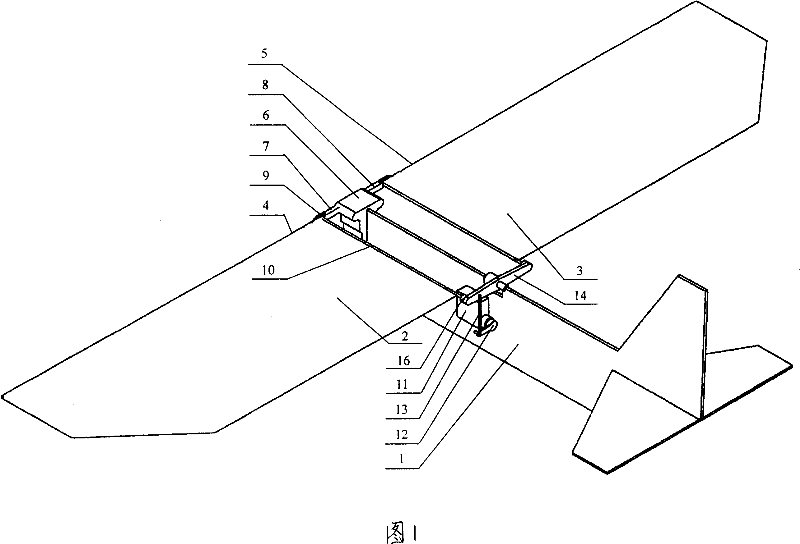

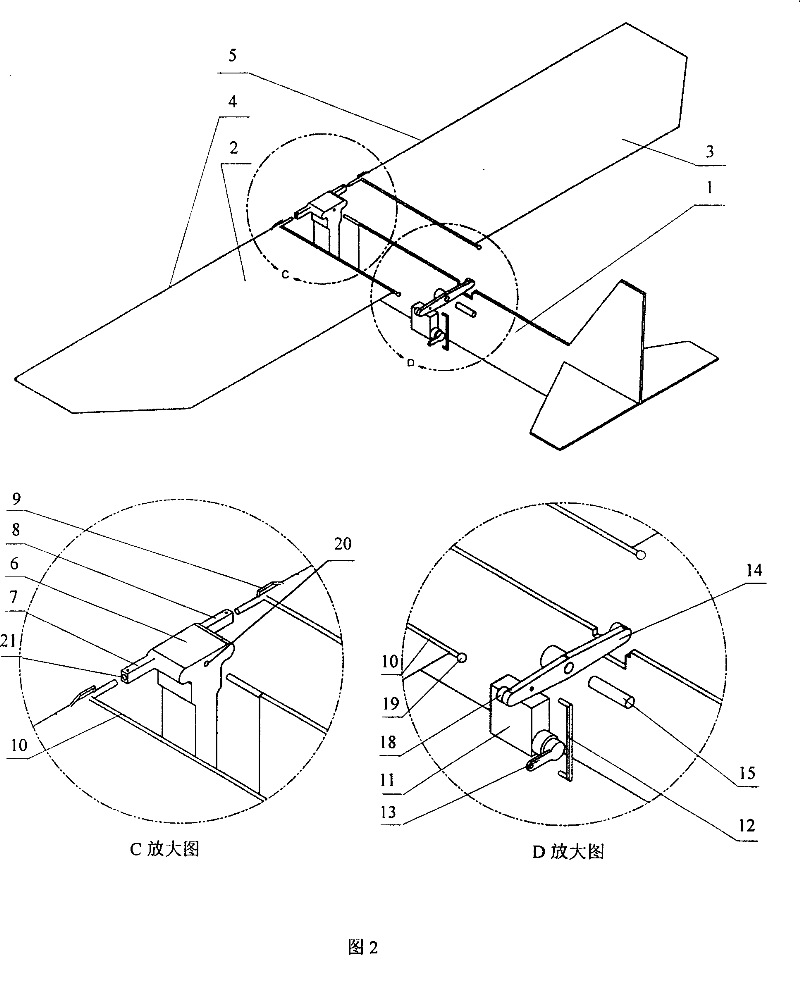

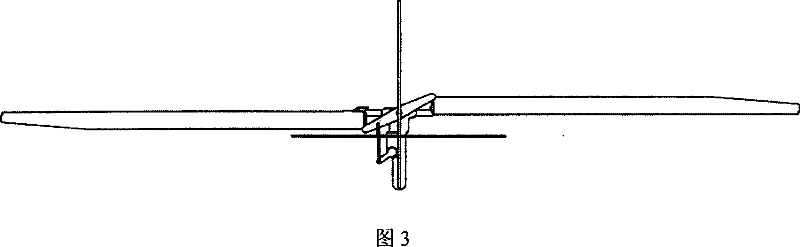

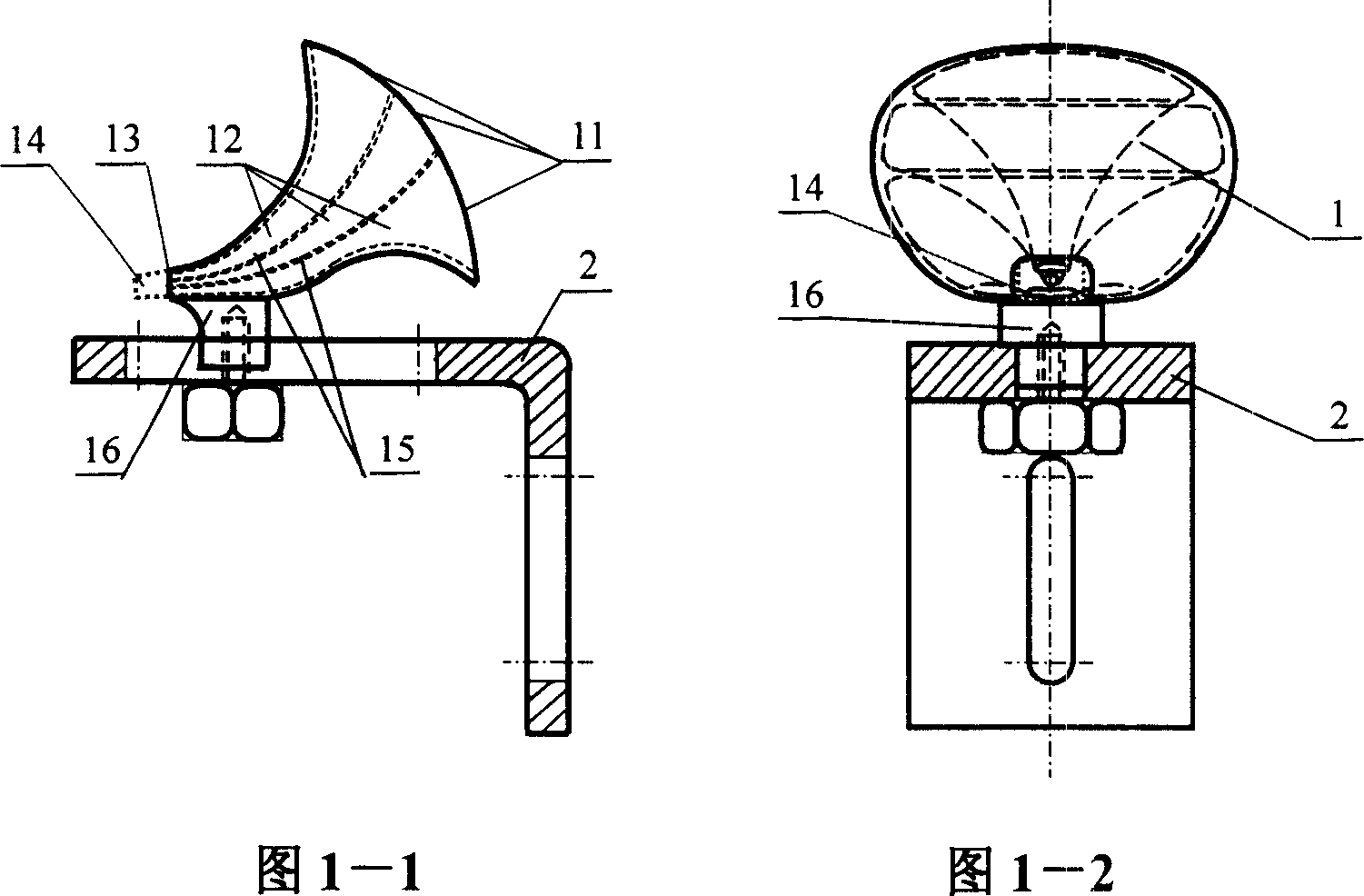

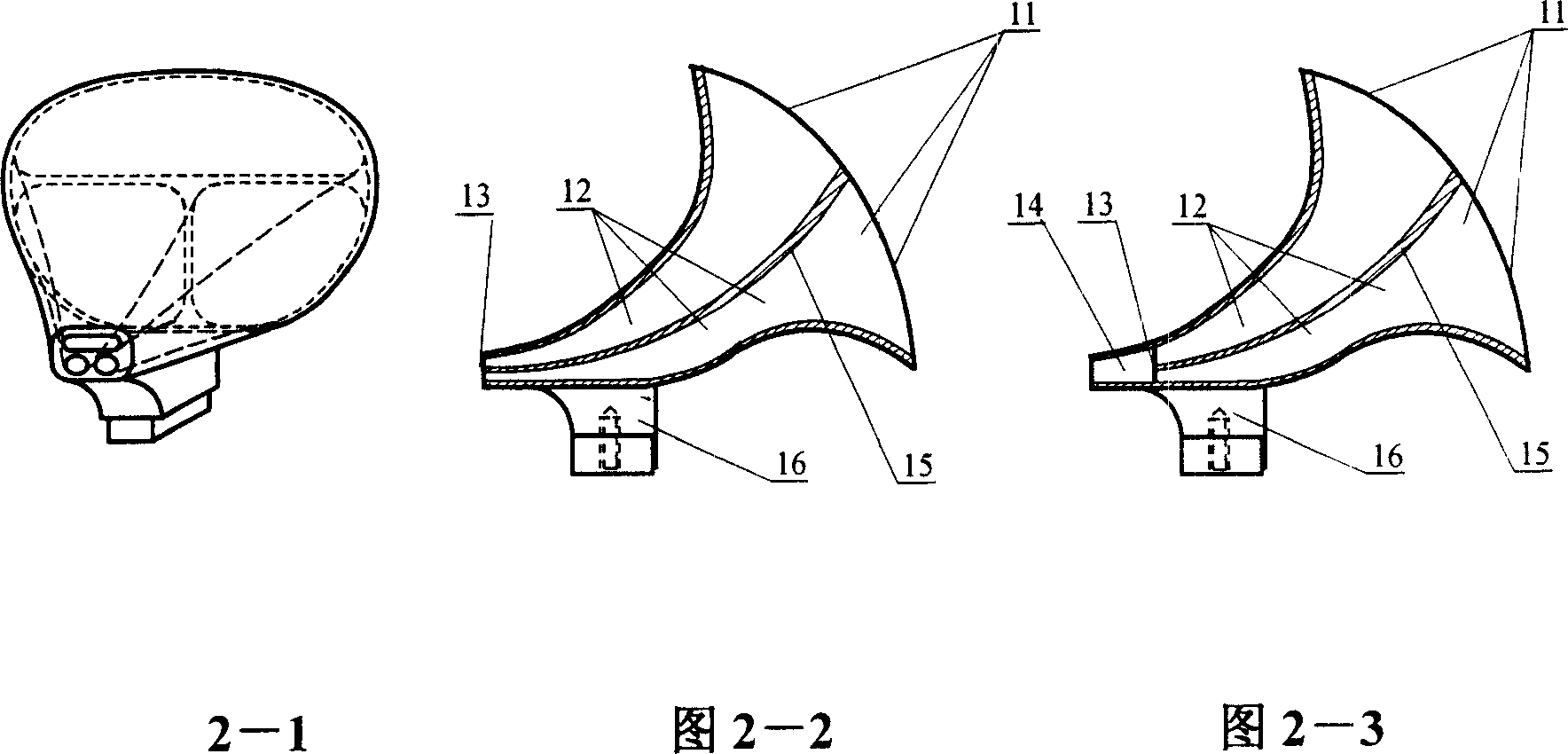

Rolling control mechanism for minitype ornithopter

The invention relates to a roll shifting mechanism for micro flapping wing aircraft. In the invention rockers (7, 8) of flapping mechanism (6) are connected with front main beams (4, 5) of wing actively. One end of rib (10) of wings (2, 3) is fixed with front main beams of wing and the other end is connected with back bracket (14) actively through spherical hinge (16). Rockers (7, 8) of control actuator (11) are connected with the back bracket together by pull rod (13) so that a space swinging rod mechanism is constituted by body (1), rockers (7, 8) of flapping mechanism, wings (2, 3) and back bracket (14). When actuator rocker (12) swings to a certain angle, the pull rod (13) drives the back bracket (14) and the rib (10) move correspondingly. Furthermore, wings (2, 3) are driven to carry pitch motion out so that the wing attack angle at one side increases and the wing attack angle at the other side decreases to form lifting difference and generate roll shifting torque. It is provided with simple mechanism, easy operation and strong reliability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Porous flared feeder, preparation and its use

InactiveCN1587462ASimple organizationLow costContinuous wound-up machinesBiochemical engineeringSingle fiber

The present invention relates to a kind of porous flared feeder for ring spinning and its making process and use. The porous flared feeder of fiber sliver feeder has 2-7 inlet and outlet hole canals, and has several fiber sliver outlet or single fiber sliver outlet with multiple tow converging unit. The feeder is formed through injection molding or injection molding and heat treatment to bend. It may be sued in converging several kinds of tow for composite spinning in various ring spinning machine. The present invention has simple mechanism, low manufacture cost, convenient installation and use and high applicability in composite spinning.

Owner:DONGHUA UNIV

Rolling and cutting metal plate shearing machine

The present invention belongs to the field of metal plate shearing technology, and is especially hydraulic rolling and cutting metal plate shearing machine. The metal plate shearing machine includes hydraulic cylinders, one transmission mechanism and one shearing mechanism; and features two hydraulic cylinders hinged horizontally on the frame, two piston rods, two link rods, two push rod and the upper shearing edge holder hinged successively, and one guide rod hinged between the upper shearing edge holder and the frame. The present invention has the advantages of simplified mechanism, simple and reliable transmission system and greatly raised sheared section quality.

Owner:TAIYUAN HEAVY IND SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com