Patents

Literature

65results about How to "Adjustable movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

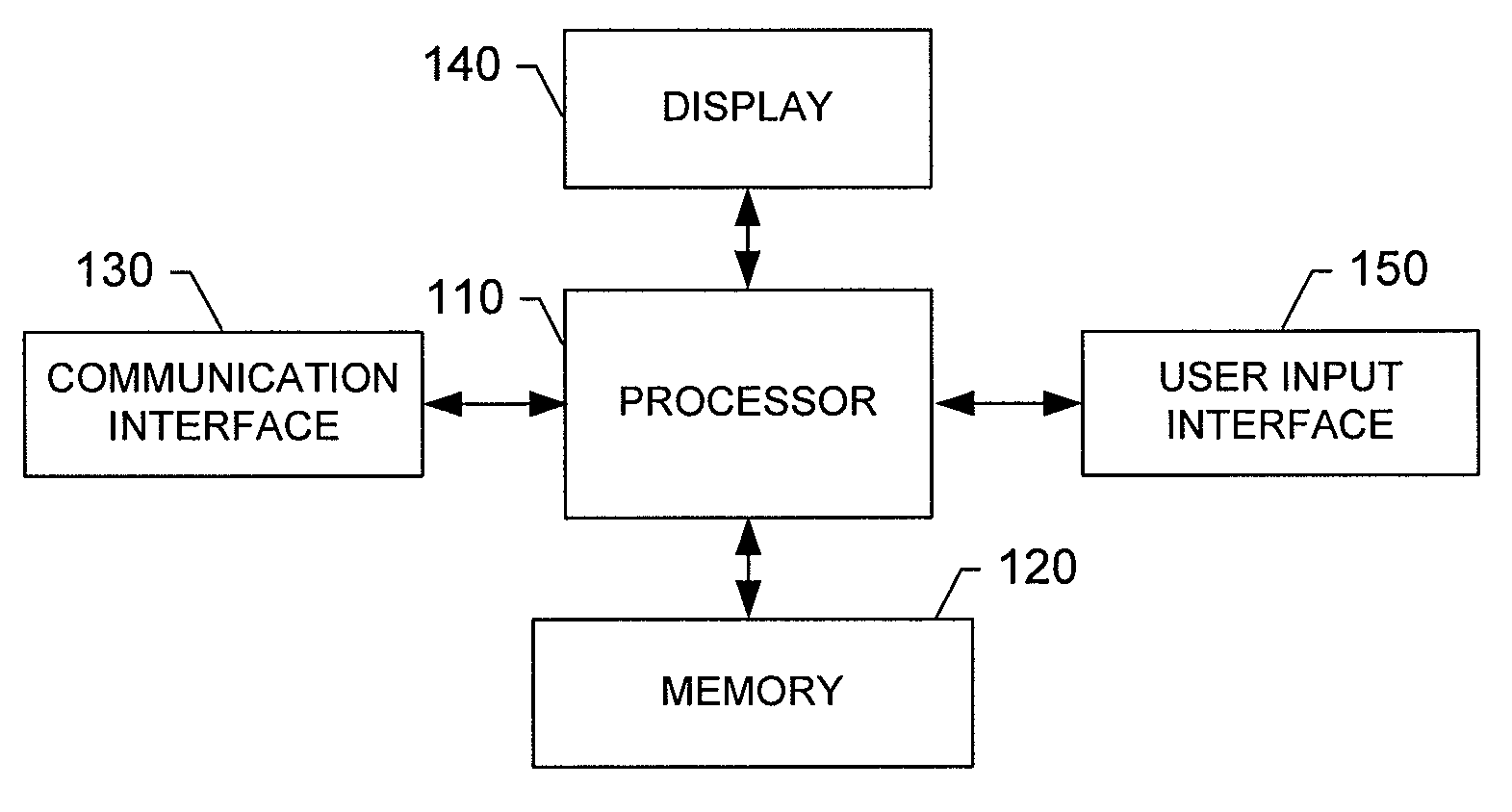

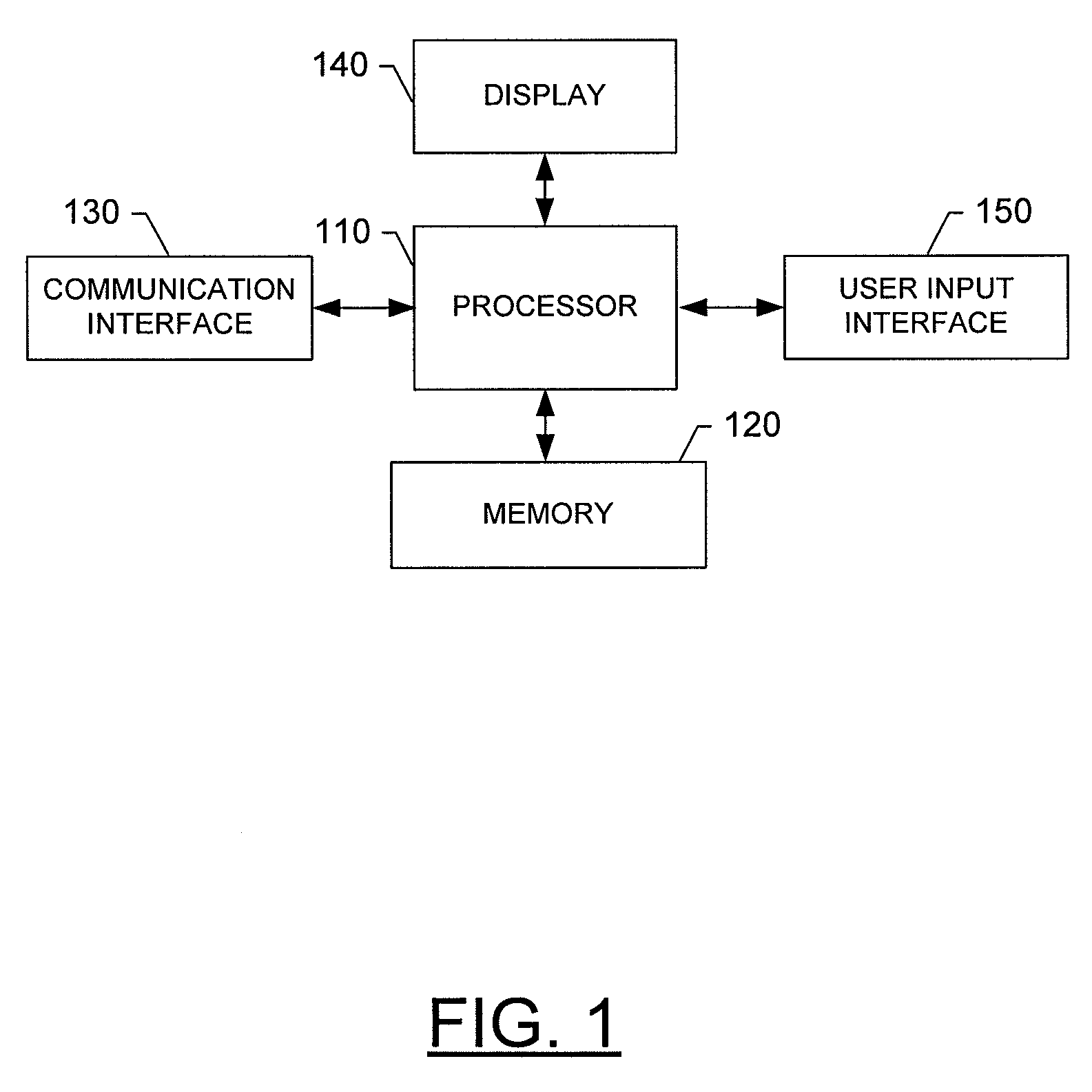

Apparatus, method and computer program product for using variable numbers of tactile inputs

InactiveUS20090160778A1Adjustable movement speedUnauthorised/fraudulent call preventionInput/output processes for data processingTouchpadTouchscreen

An apparatus, method and computer program product are provided for using varying numbers of tactile inputs to manipulate different features of an electronic device. In particular, varying numbers of tactile inputs resulting from a user touching the electronic device touchscreen or touchpad may be used in order to adjust the speed of movement of an image displayed on the electronic device. Varying numbers of tactile inputs may likewise be used to adjust in various manners an adjustable feature represented by an icon displayed on the electronic device display screen. Finally, varying numbers of tactile inputs may further be used in order to unlock an electronic device in a secure, yet simple, manner.

Owner:NOKIA CORP

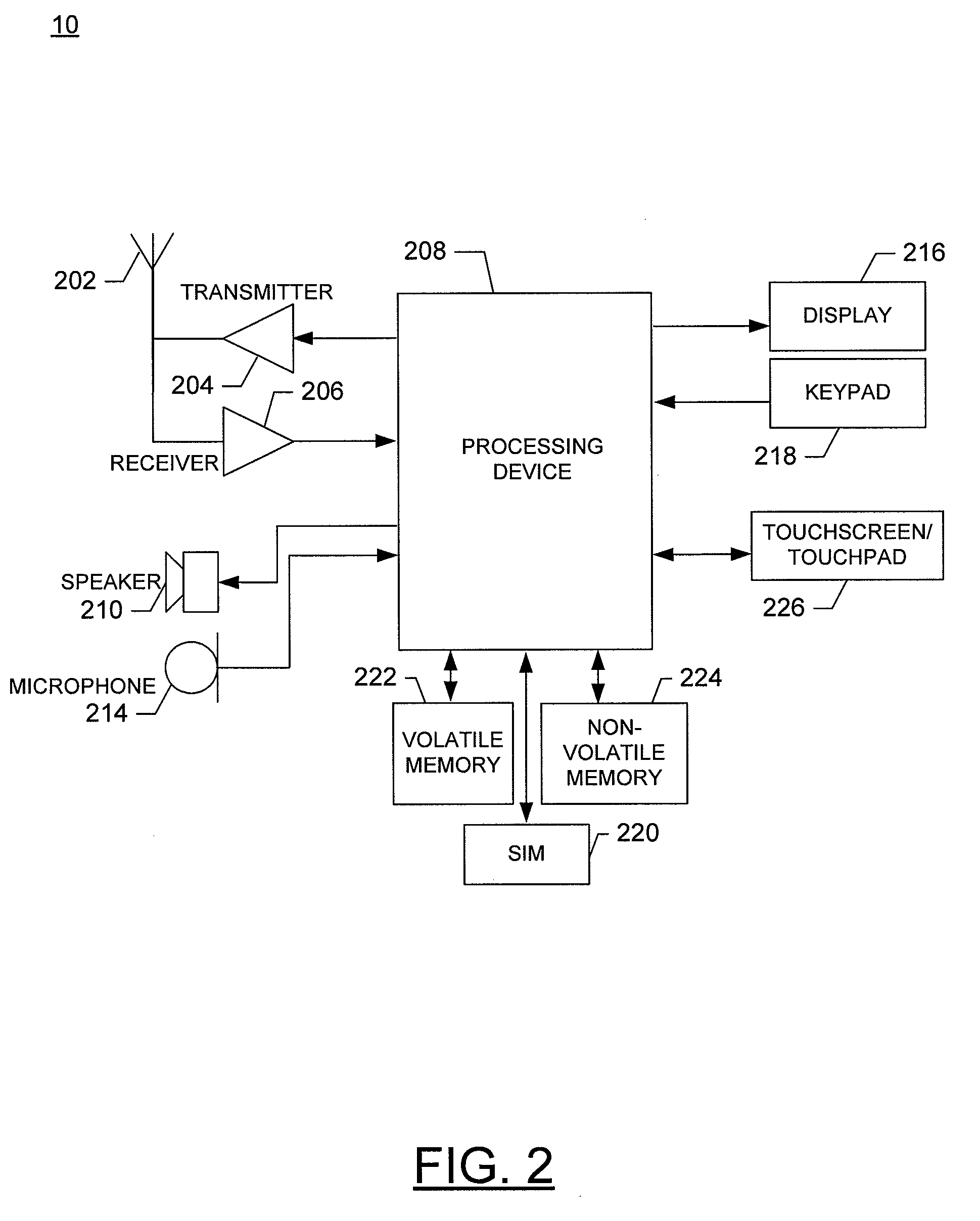

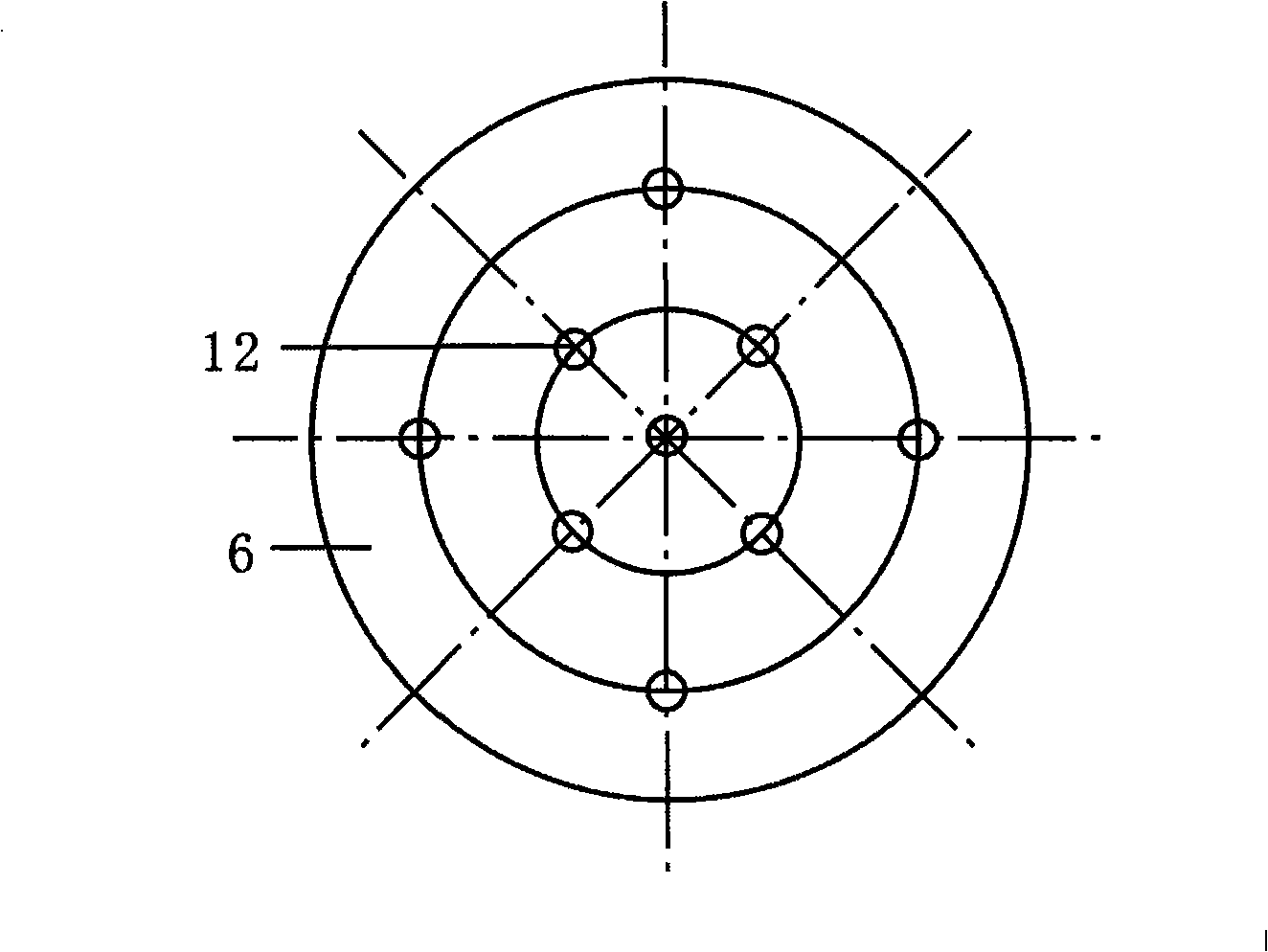

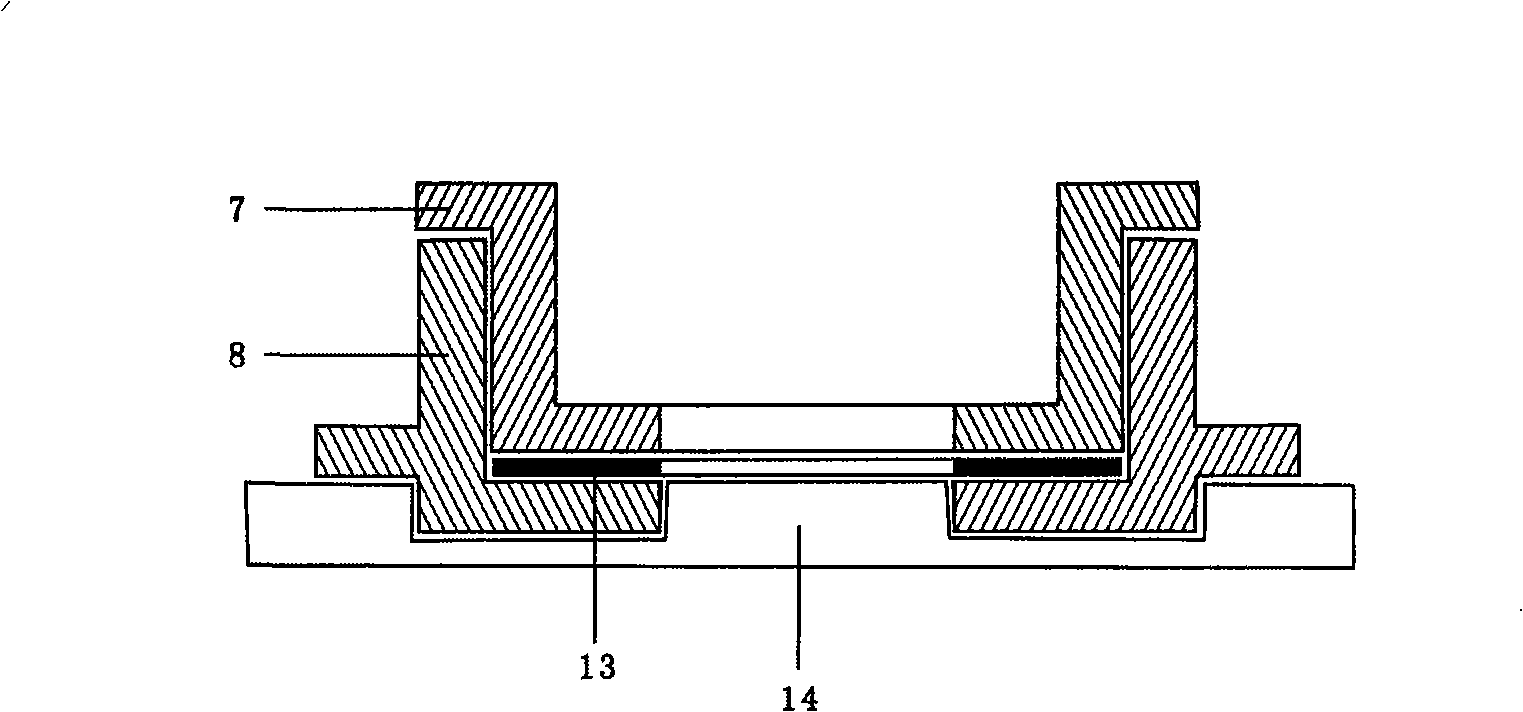

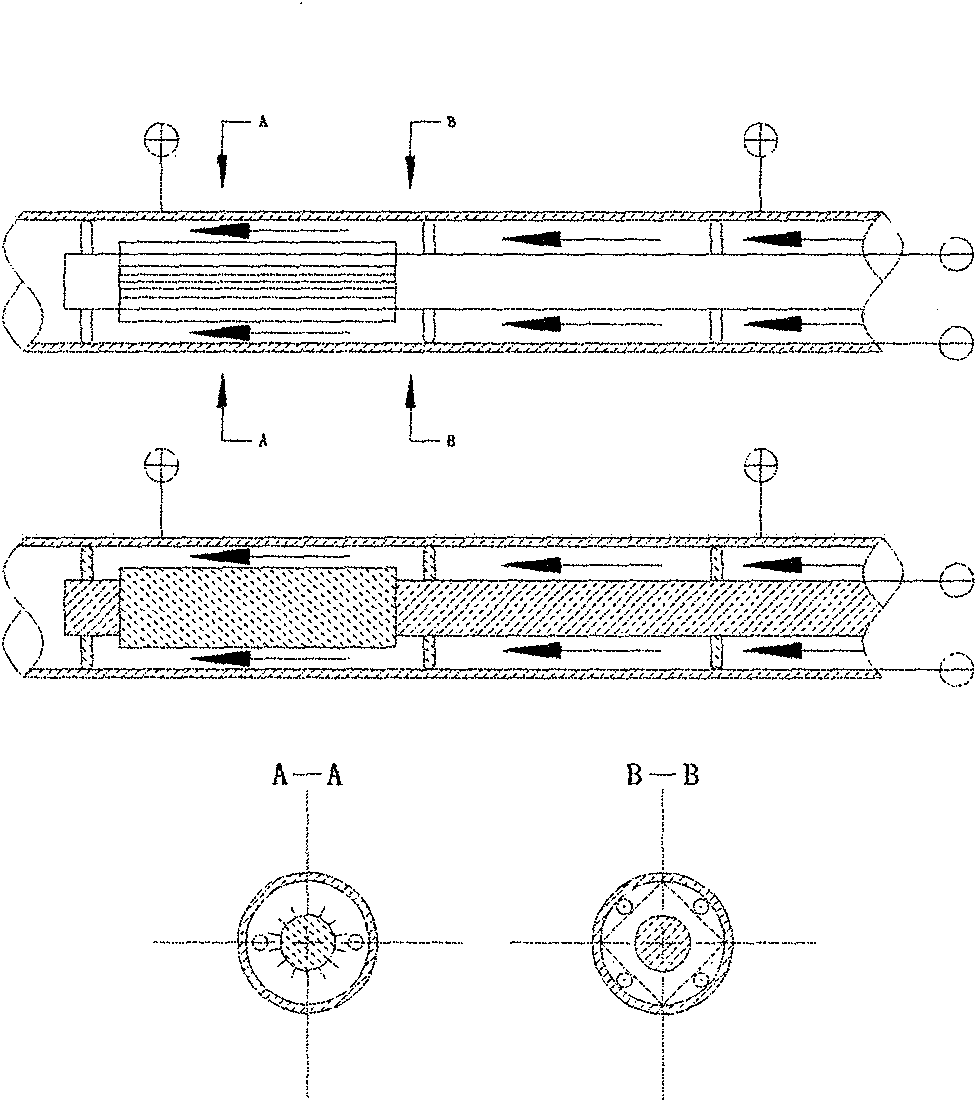

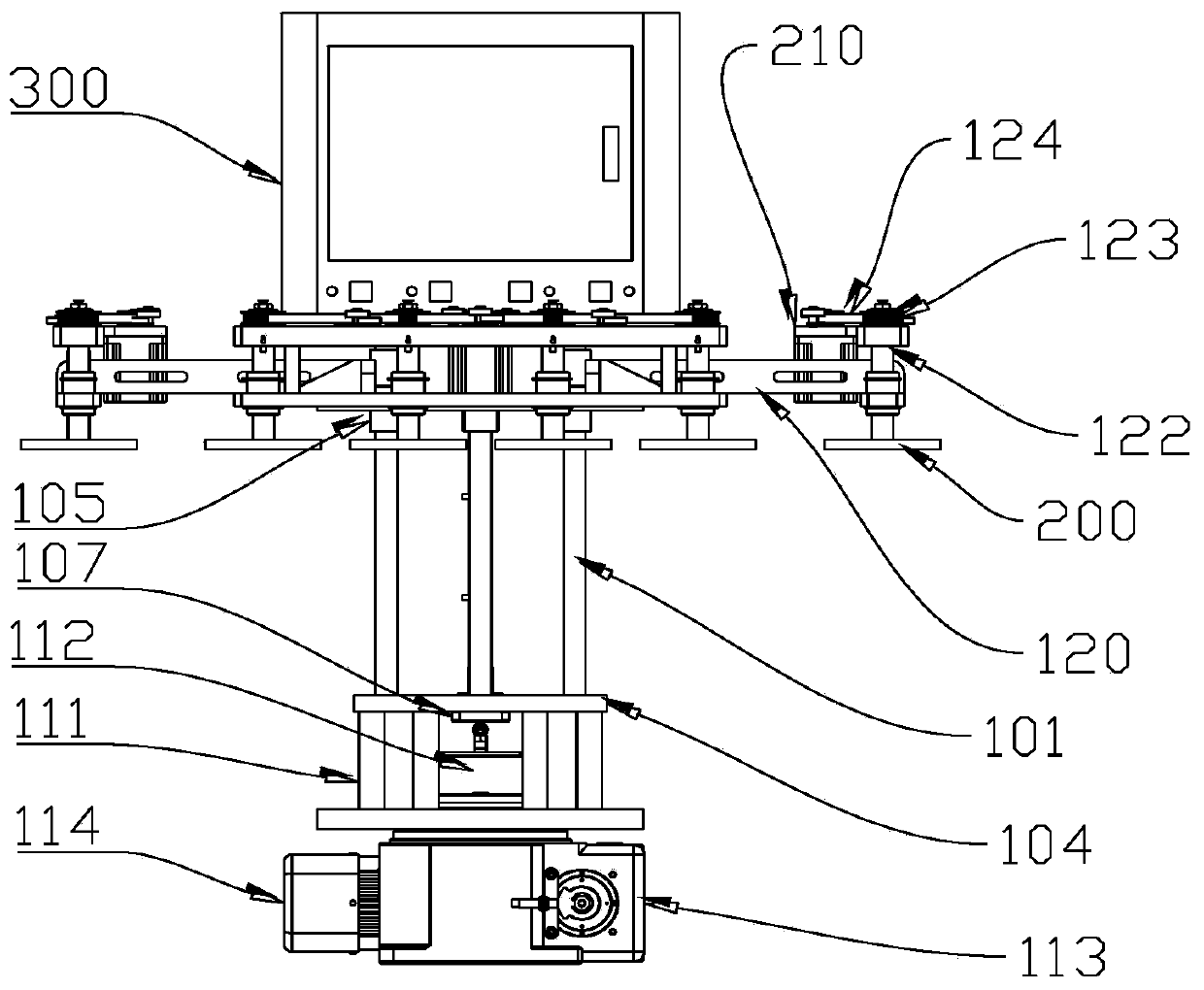

Fabric three-dimensional pressure simulation test system

ActiveCN101354296AEasy to retractSimple organizationForce measurementTextile testingUltrasound attenuationEngineering

The invention relates to a fabric three-dimensional pressure analog test system which is used for testing the dynamic contact pressure and the pressure attenuation characteristics of fabrics. The measuring principles of the invention refers to measuring dynamic clothing pressure during a process of fabric three-dimensional deformation by a pressing ball embedded with nine highly precise pressure sensors to press against the fabrics; the pressing ball is transmitted by a driving device, which can press against the fabrics for more than several thousand times so as to measure pressure fatigue. A pressure-displacement curve, a pressure-time curve and a pressure attenuation curve of each sensing point are respectively obtained by the processing of a computer. The analog test system of the invention has simple structure and convenient operation and is a testing instrument that can effectively and objectively evaluate fabric pressure performance.

Owner:DONGHUA UNIV +1

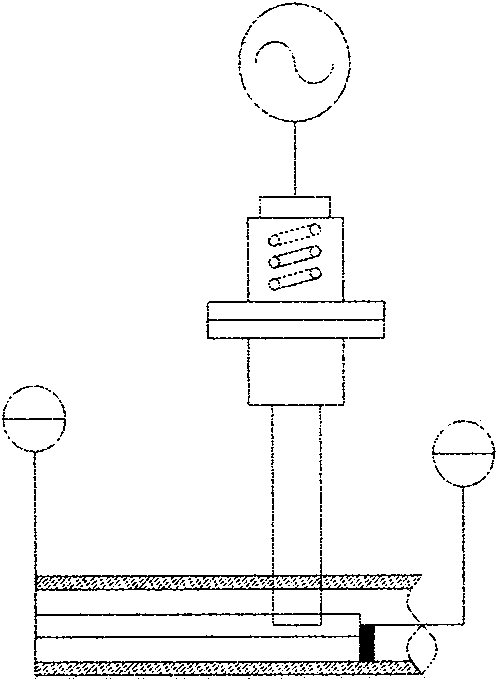

Method for core-crossing hanging large-scale motor hydraulic ram lifting

ActiveCN101277049AWork around space constraintsHigh lifting control precisionLifting devicesManufacturing dynamo-electric machinesElectric machineHydraulic ram

The present invention relates to a method for installing the large-scale electric motor, and especially to a method for coaxially hanging the large-scale electric motor. The method comprises the following procedures: a procedure 1, surveying on site to ensure the installing position of the rail of the hydraulic jacking device, and measuring the service performance of the hydraulic jacking device; a procedure 2, hoisting and unloading the stator of the electric motor, hoisting the stator with the hydraulic jacking device, and orienting the orientation of the load side of the stator; a procedure 3, hoisting and unloading the rotor of the electric motor and installing an extended shaft, hoisting the rotor with the hydraulic jacking device, and installing the extended shaft on the coupler of the rotor with a travelling crane; a procedure 3, core pulling, regulating the central height of the rotor, moving the hoisting device on which the rotor is hanged to pull the rotor on the stator; and a procedure 4, installing the electric motor to the right position. The method of invention overcomes the conditional restriction that the hoisting capacity of the travelling crane between the vehicles is not enough and the clearance height of the clearance height is not enough. The method of the invention overcomes the restriction of the space at the circumference of the base of the electric motor, smoothes the hoisting operation and saves the working procedure of adjusting at the installing position of the electric motor.

Owner:CHINA MCC20 GRP CORP

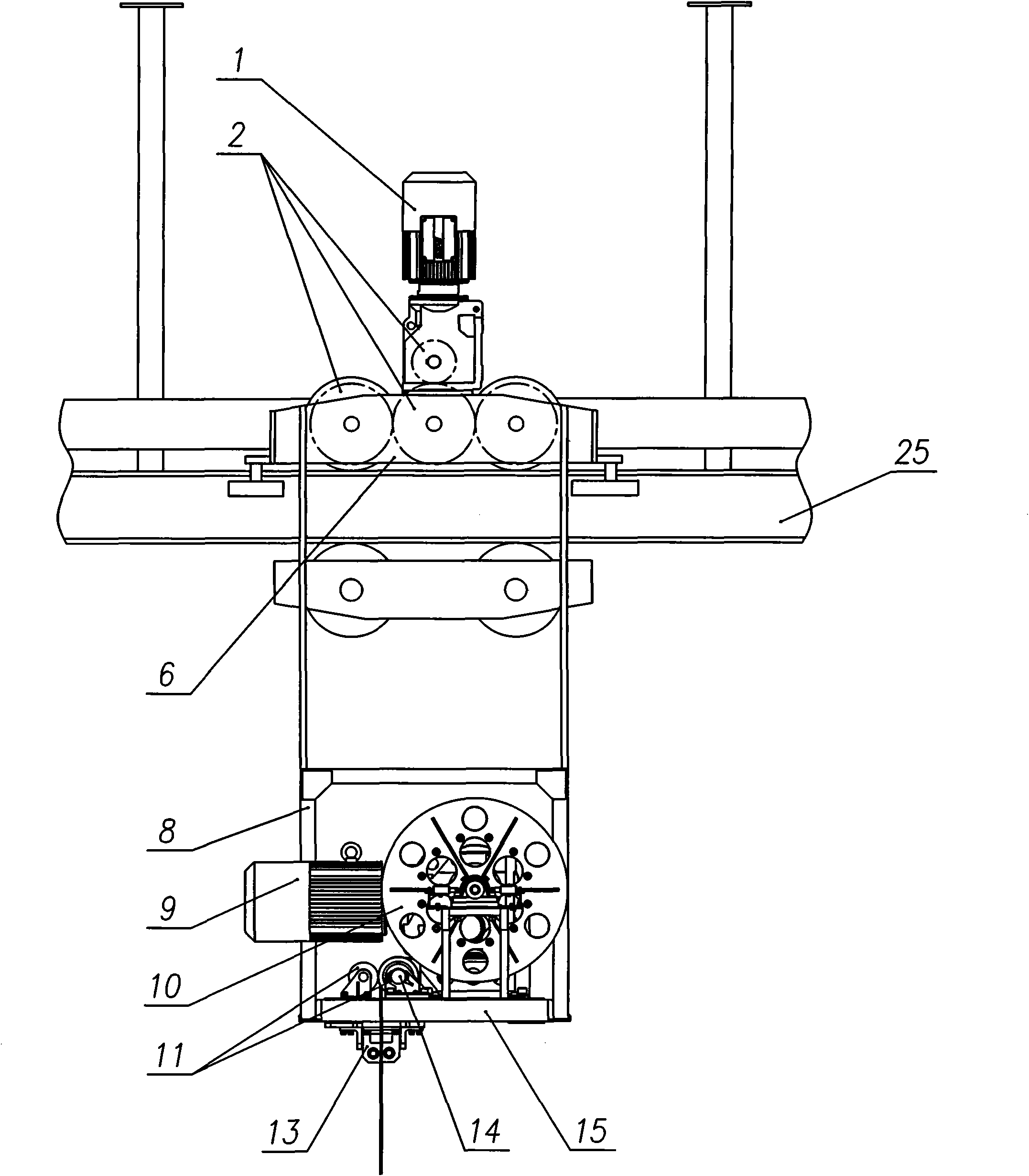

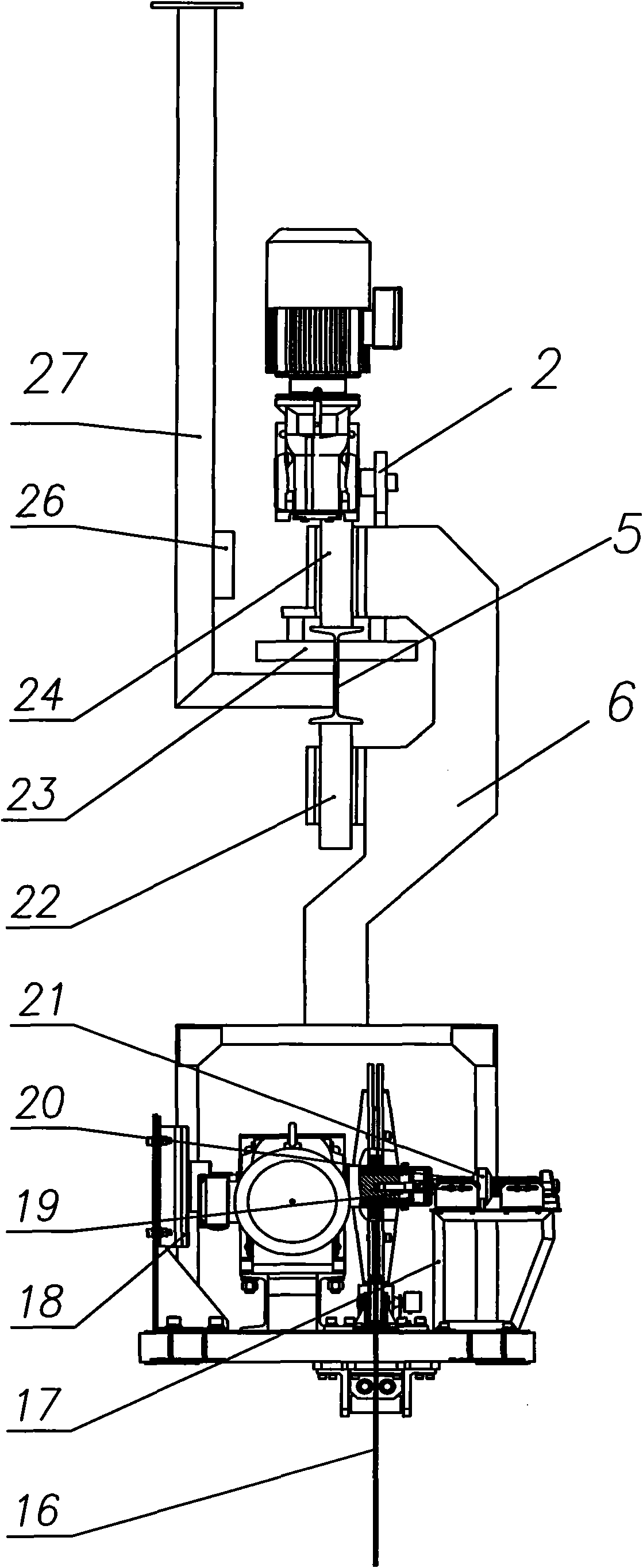

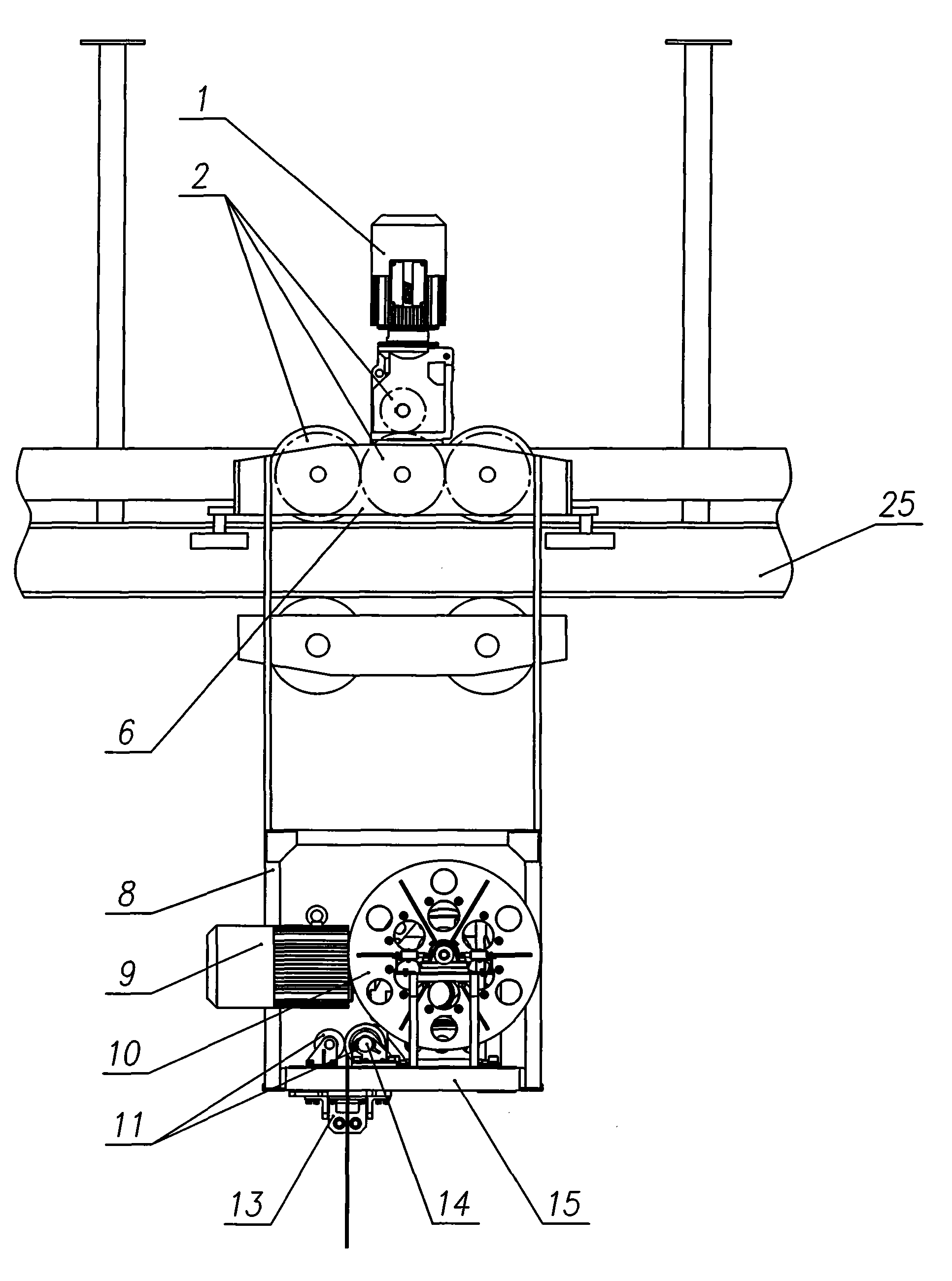

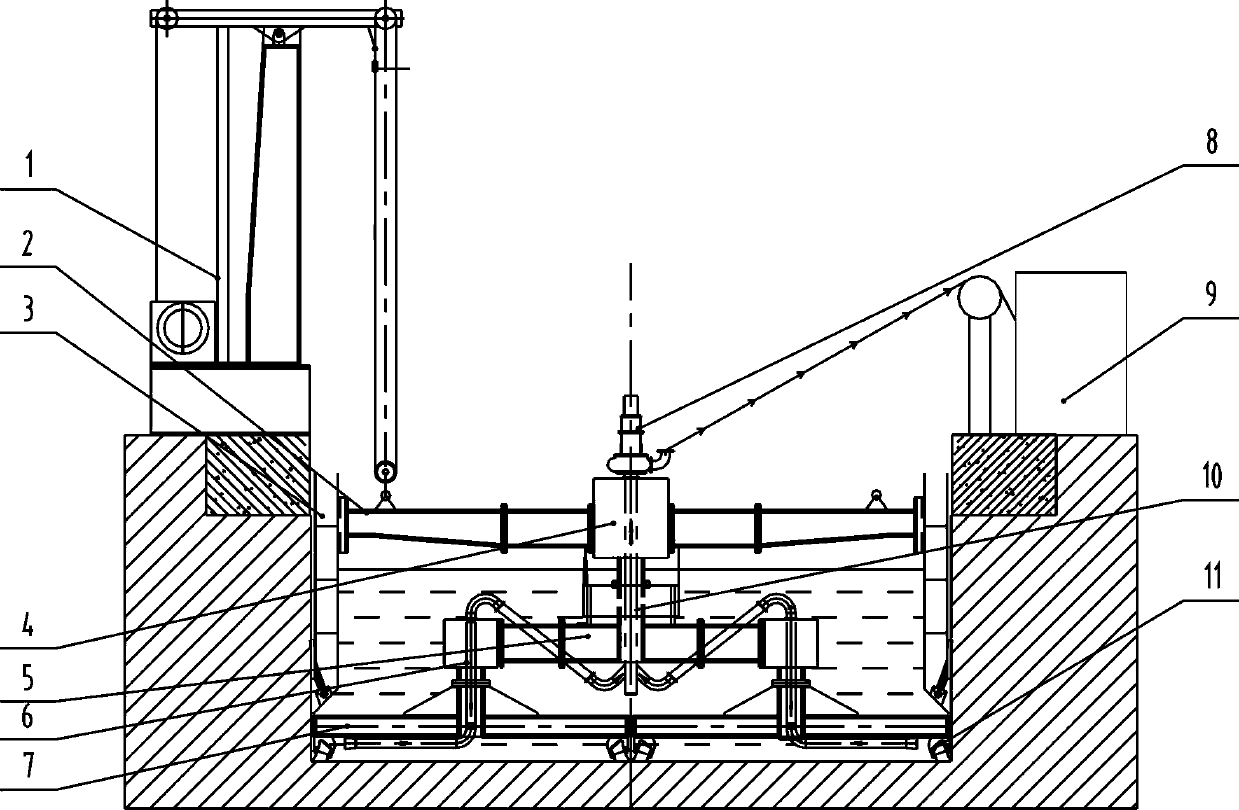

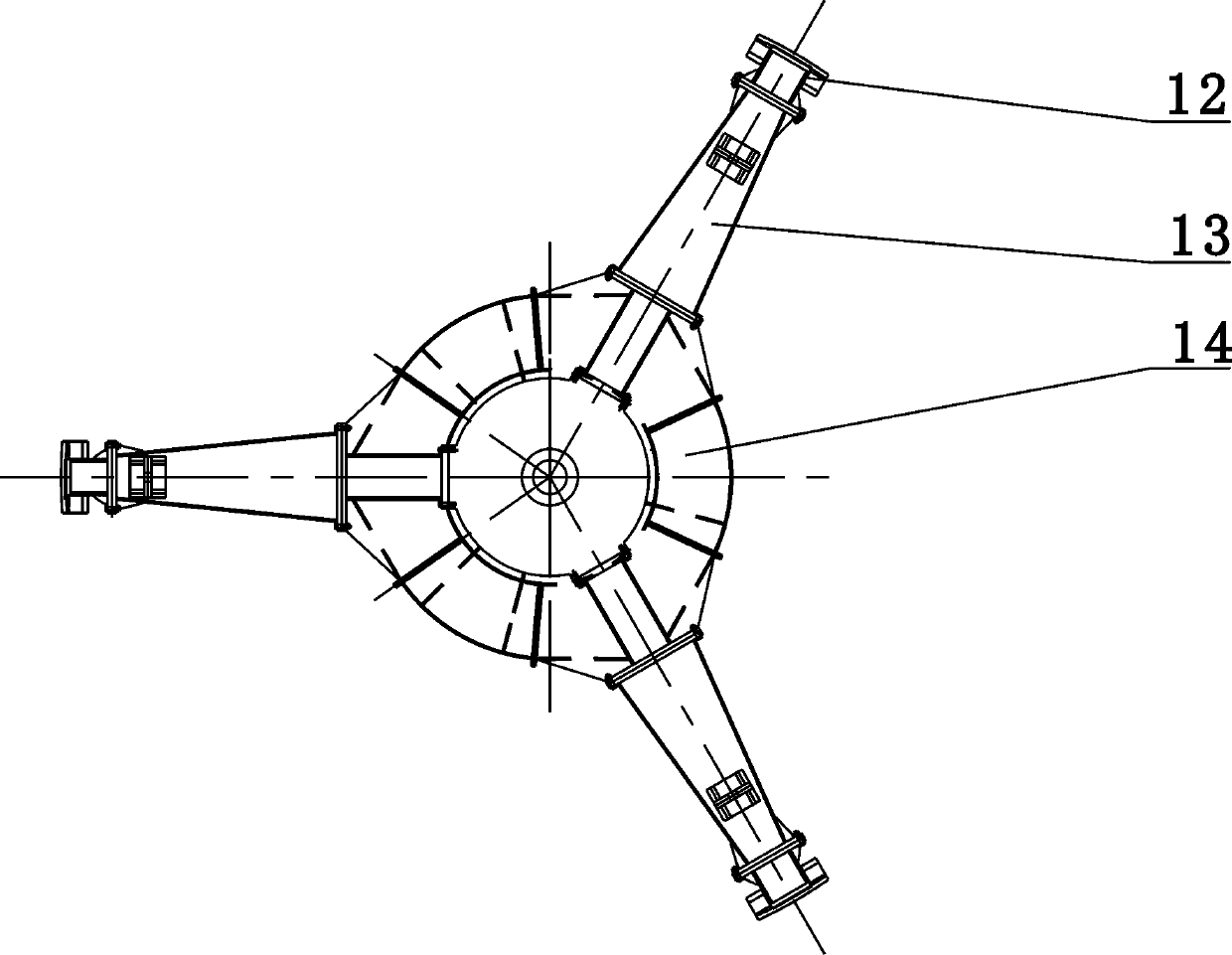

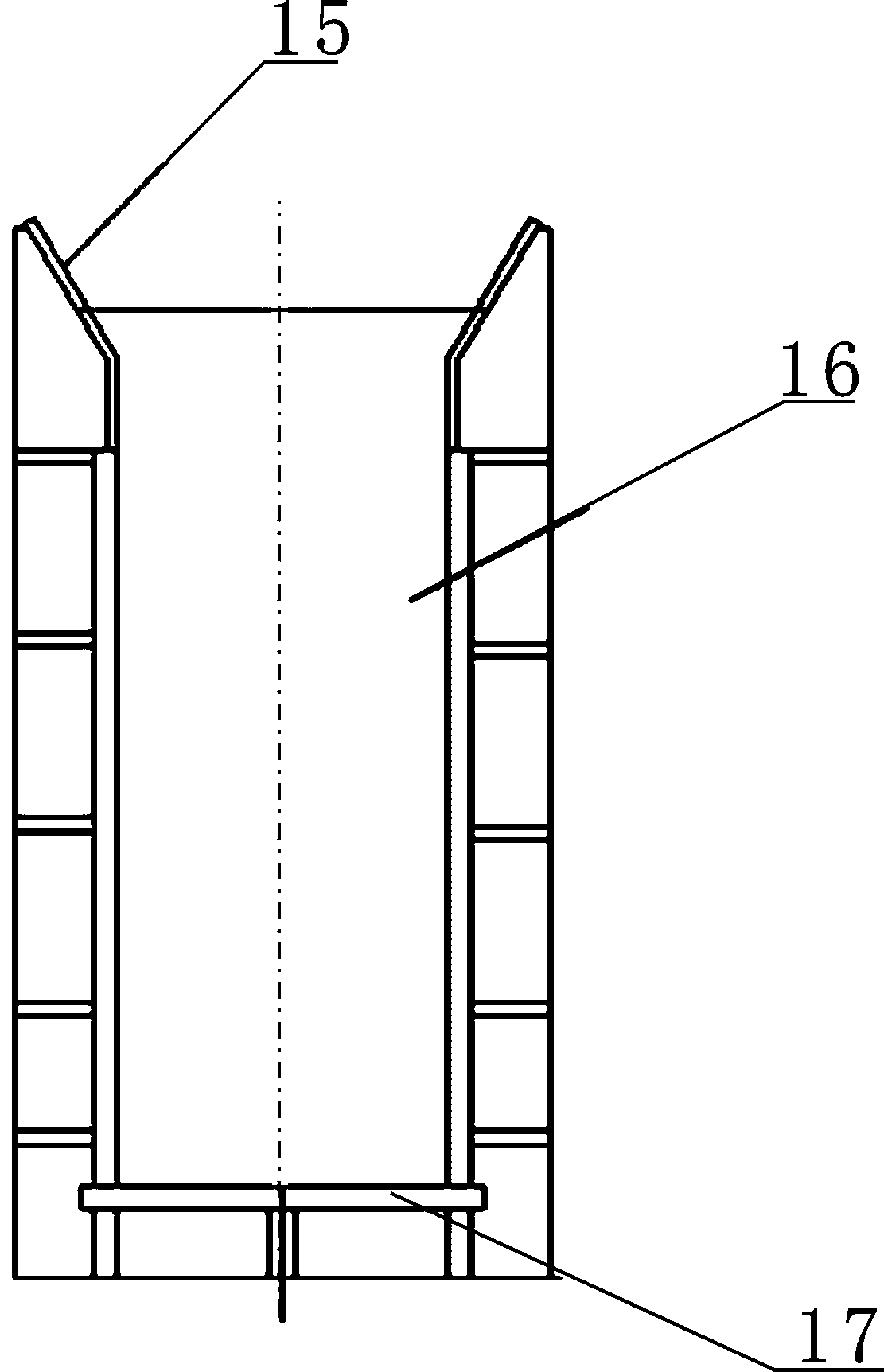

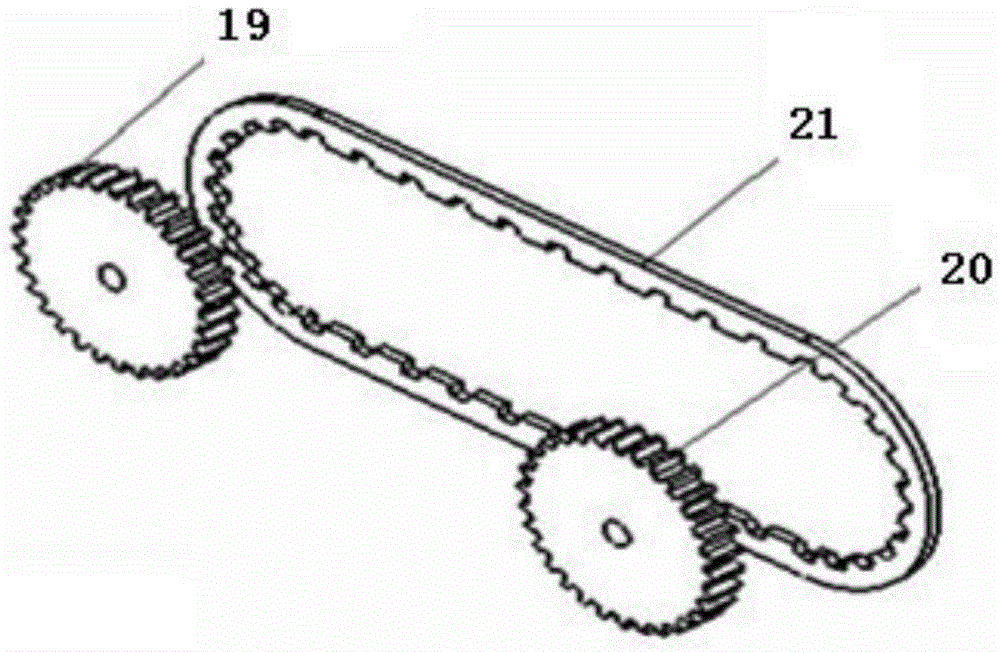

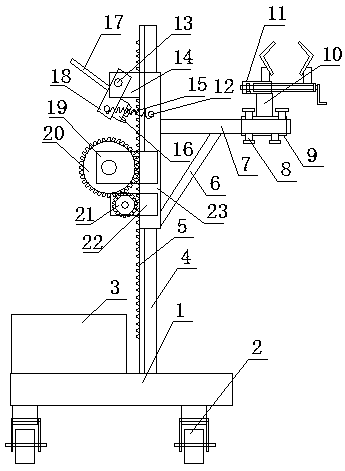

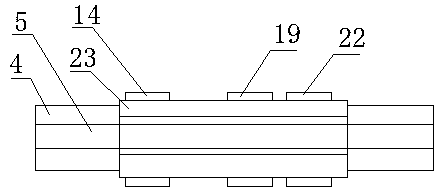

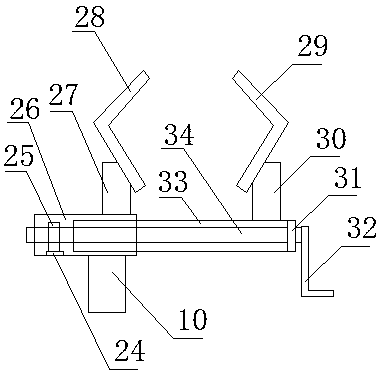

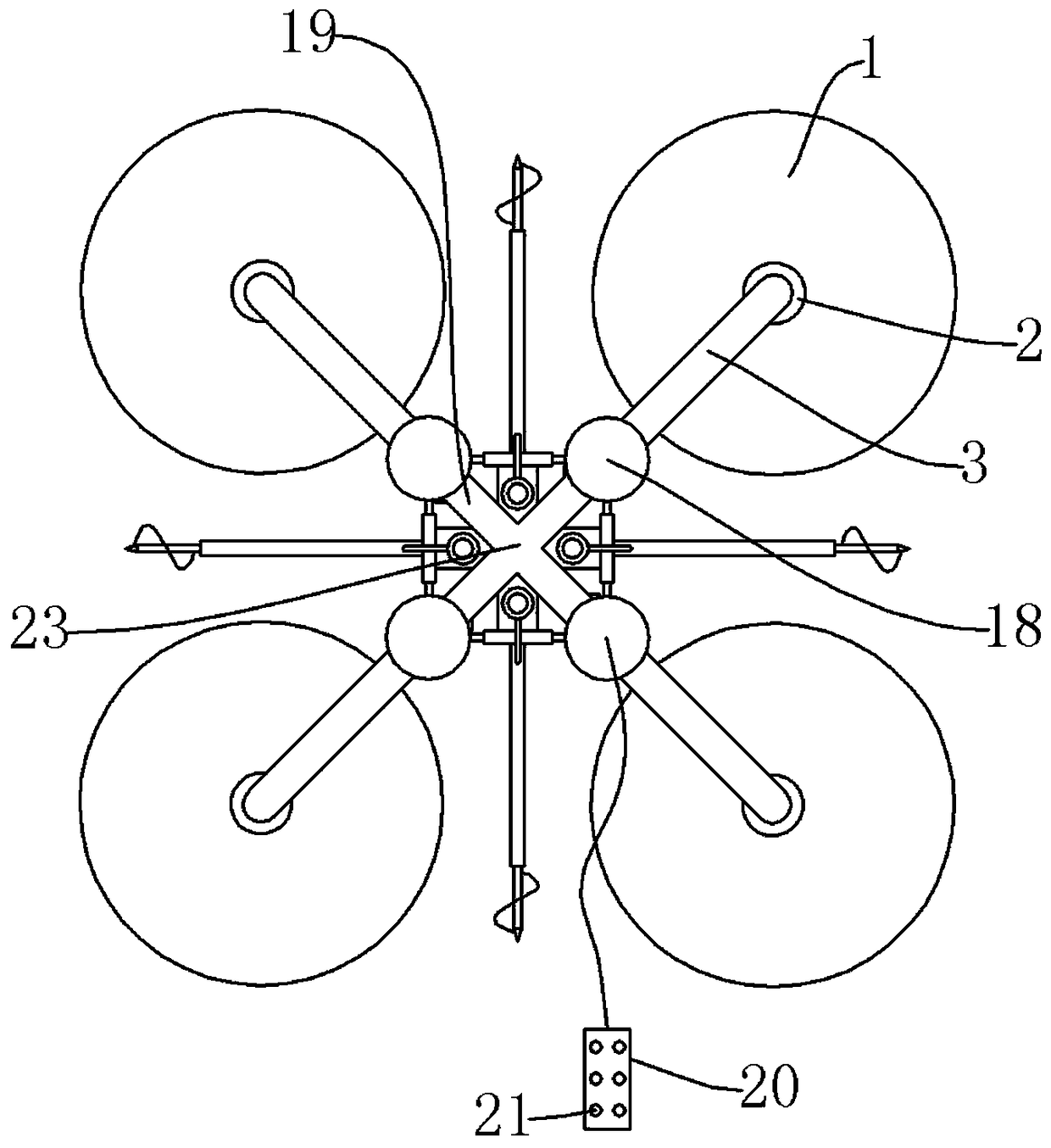

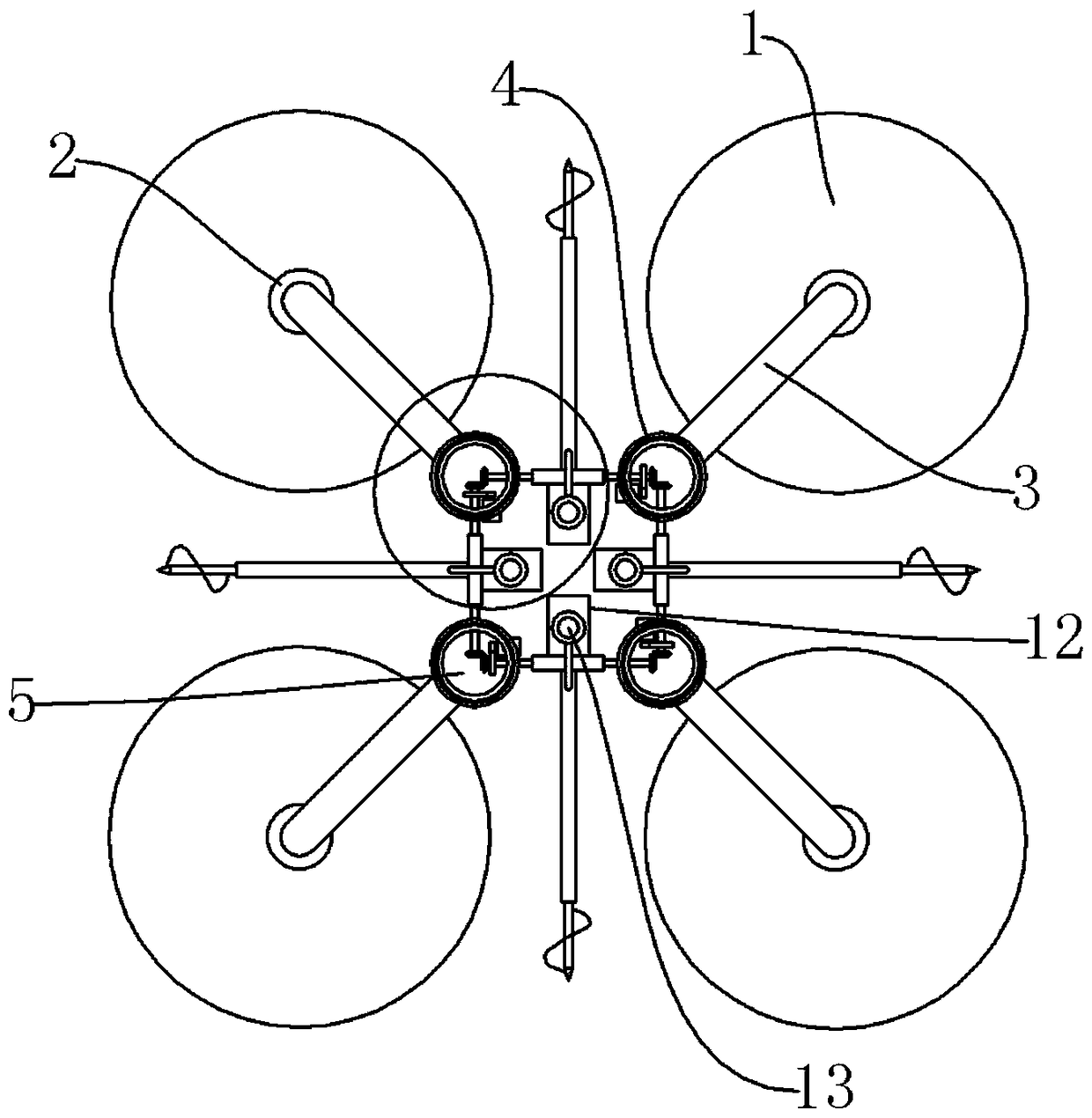

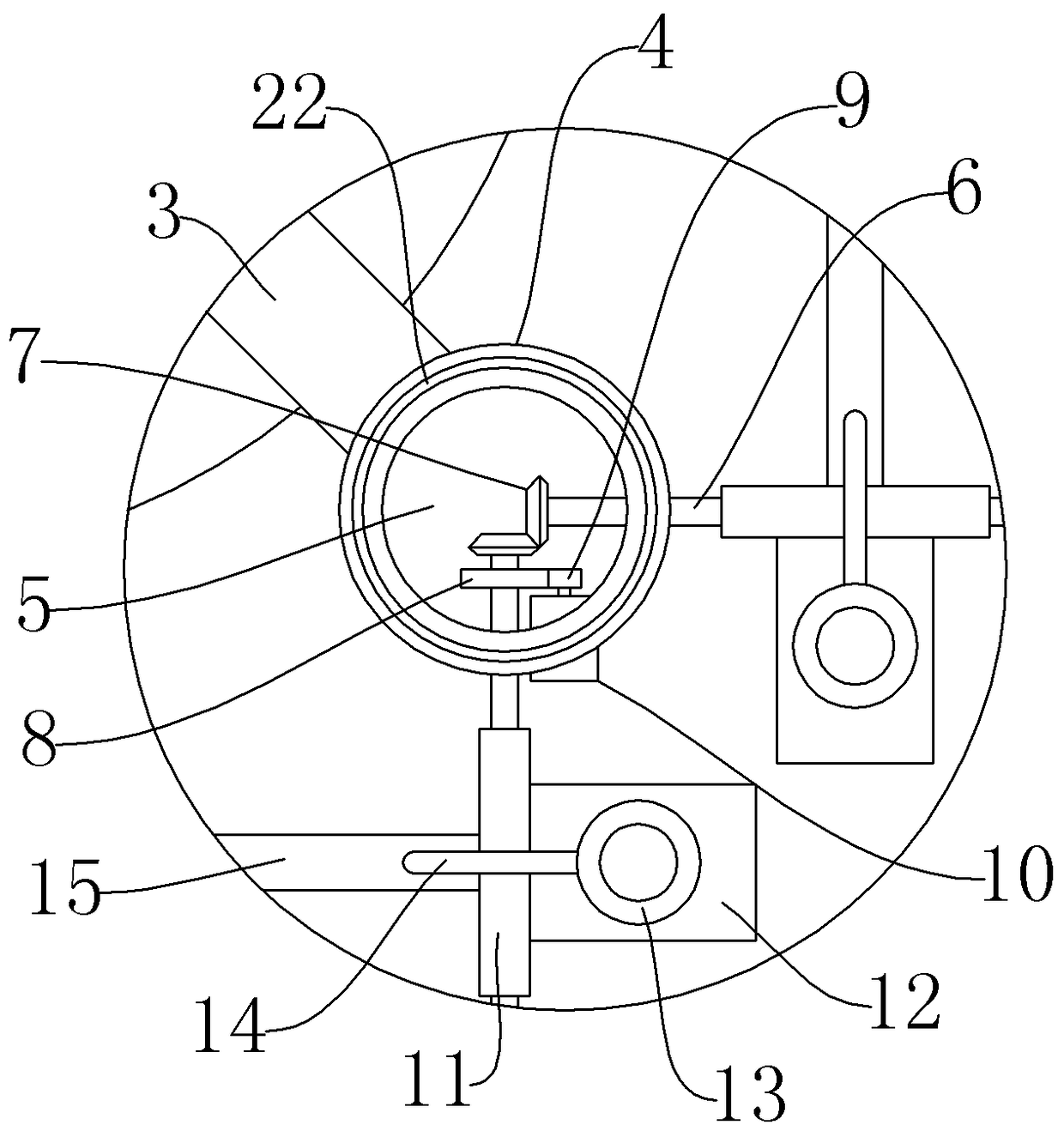

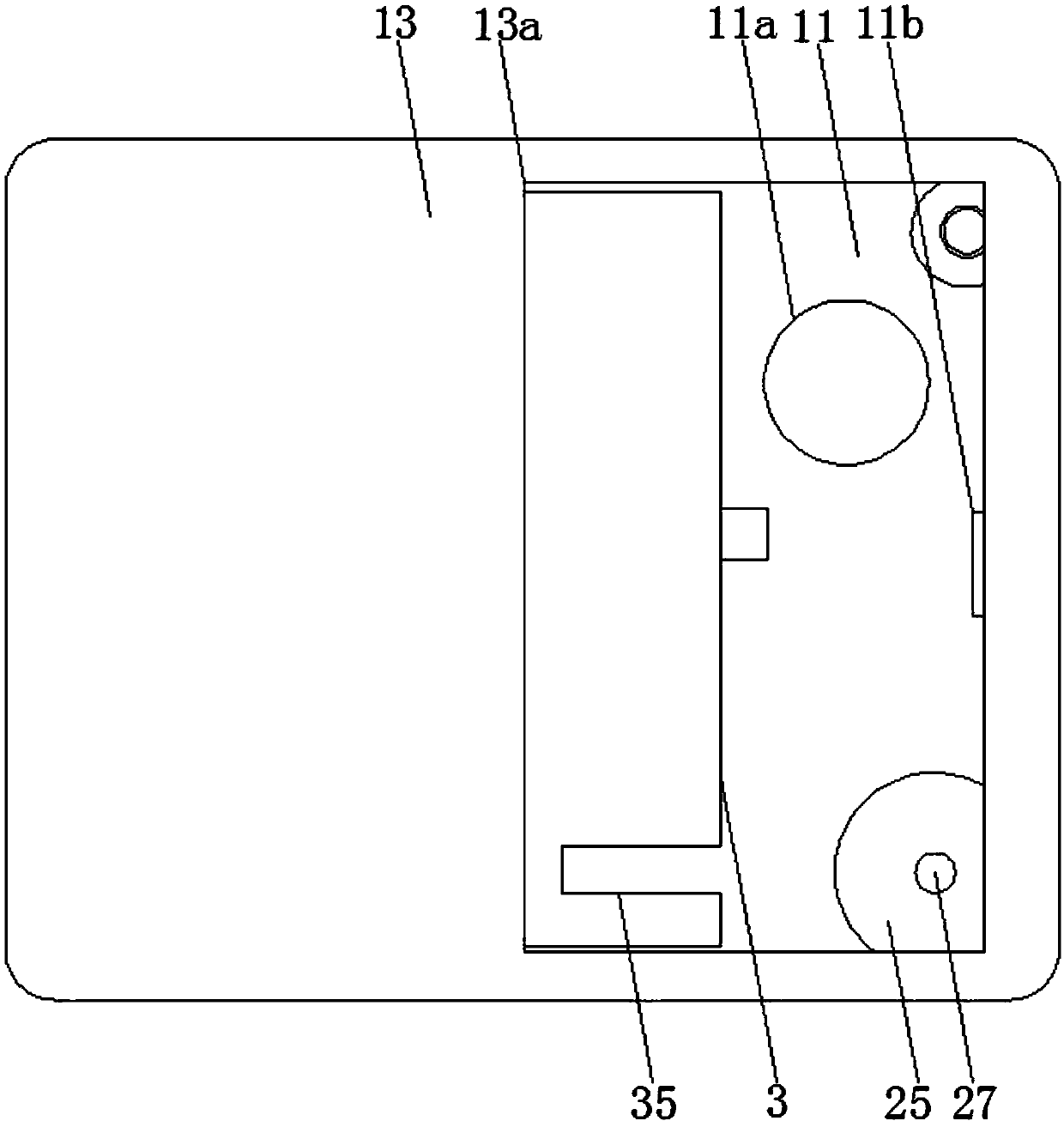

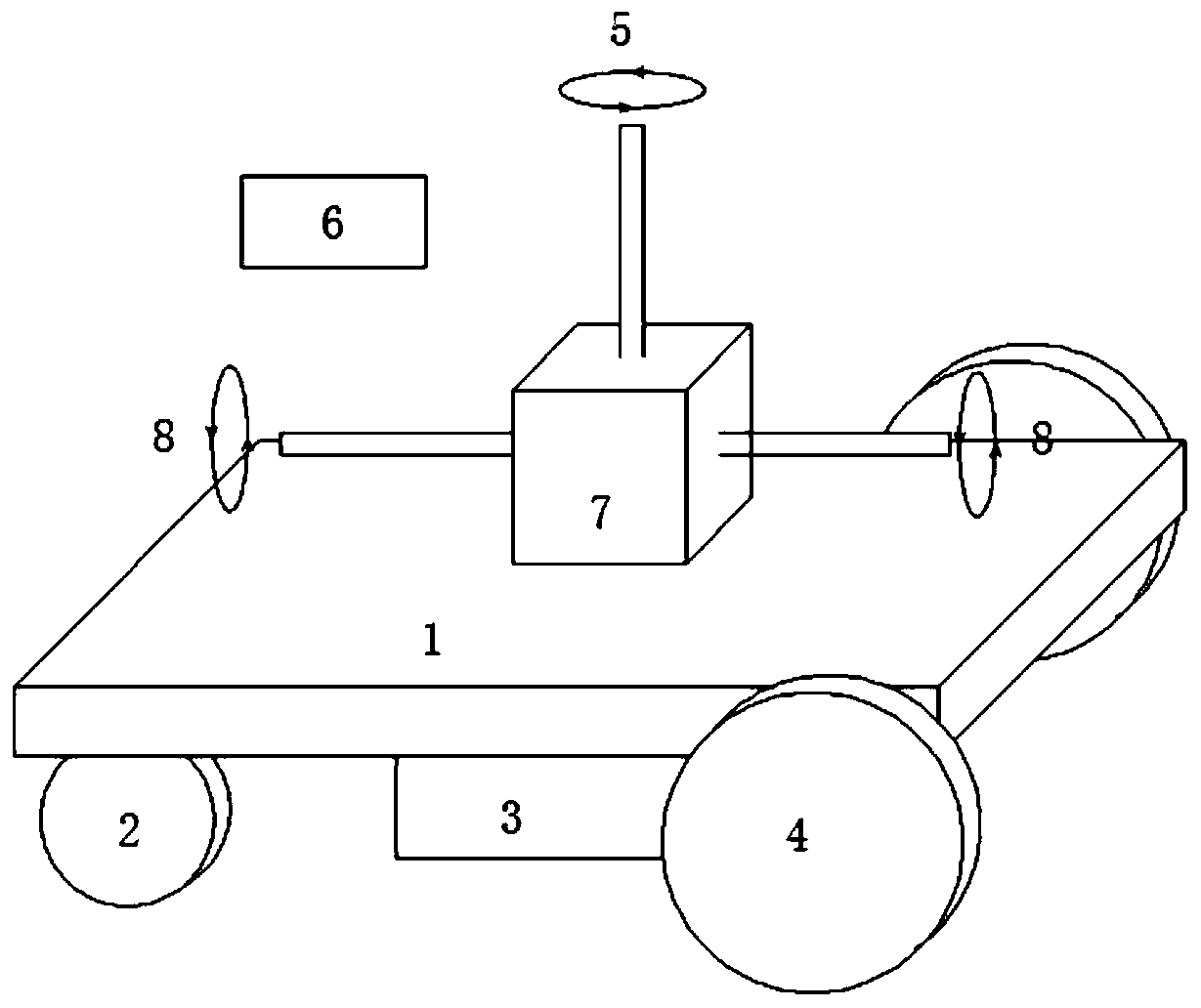

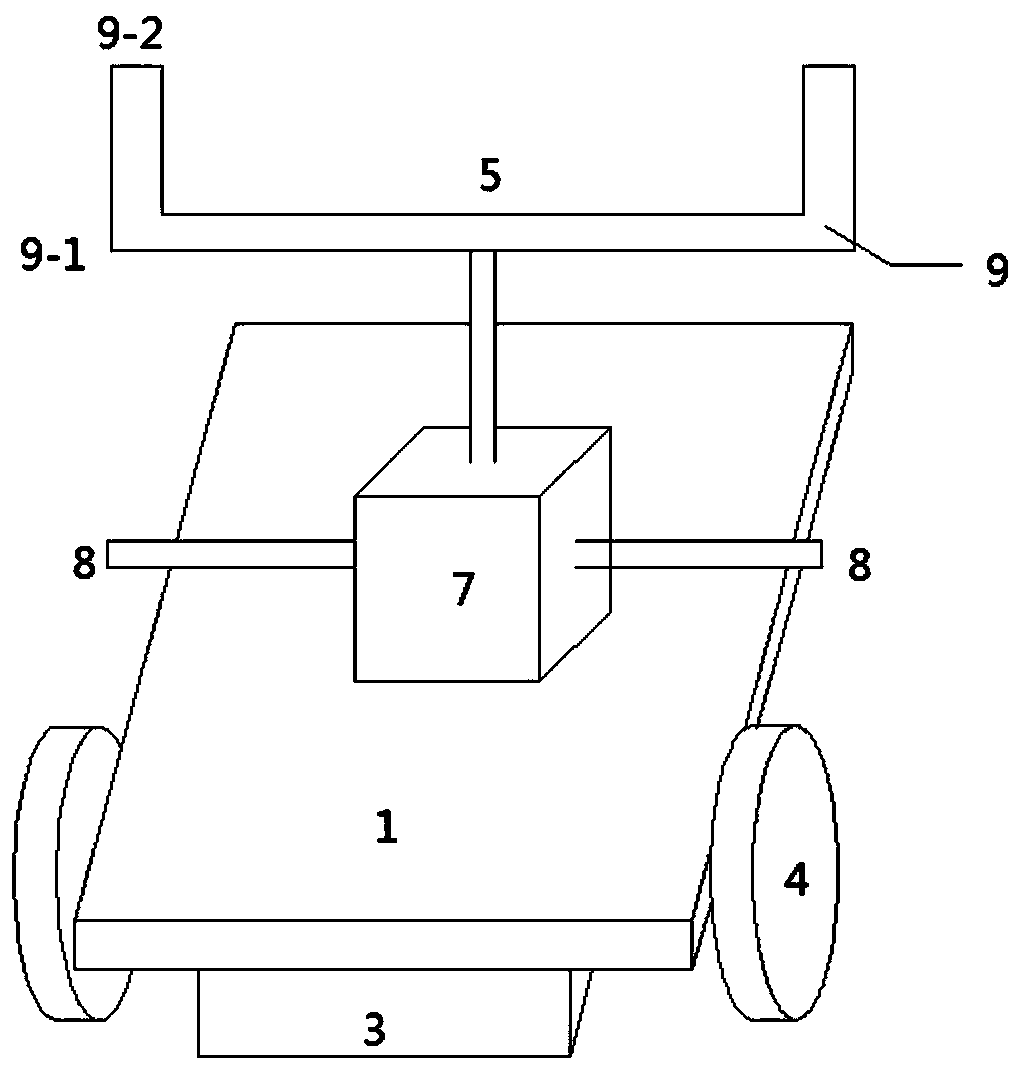

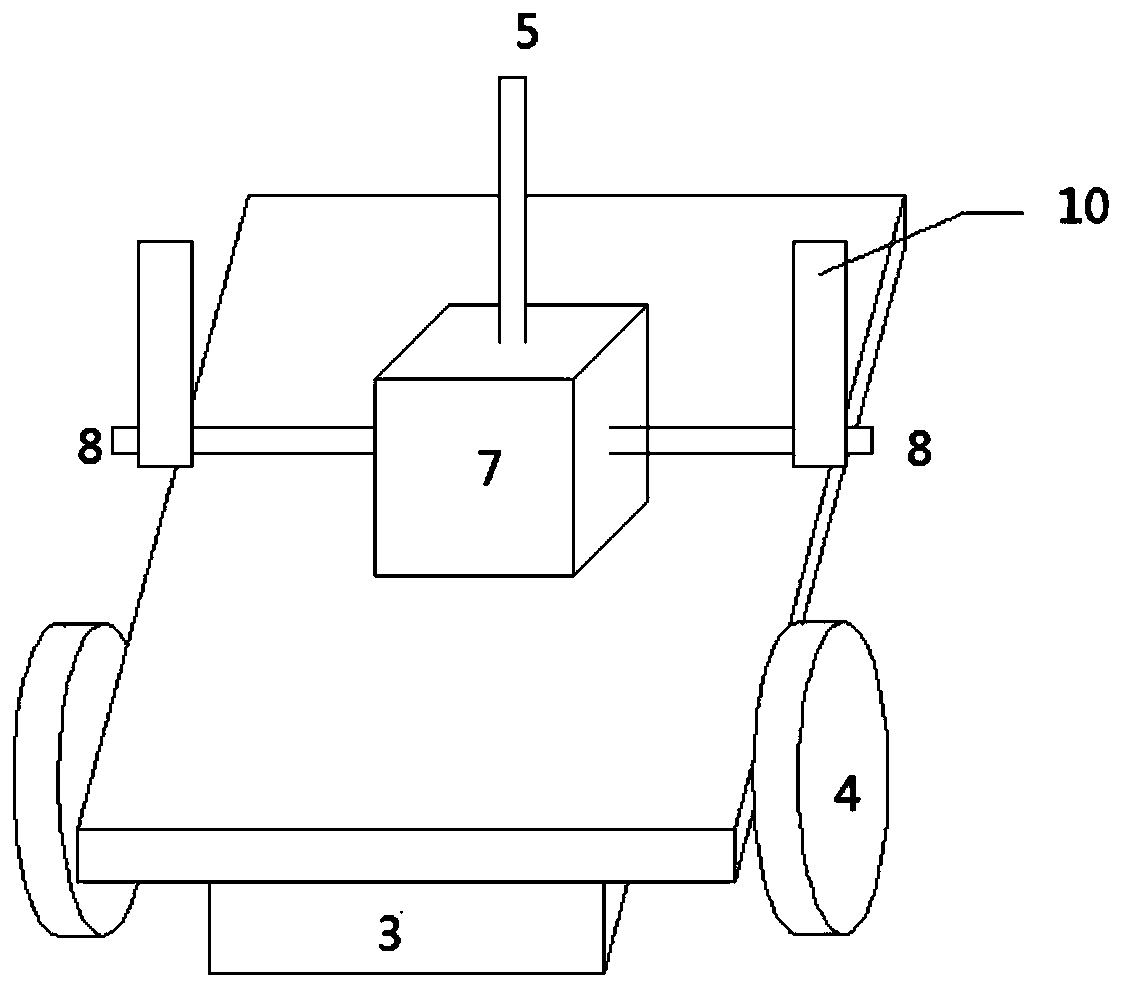

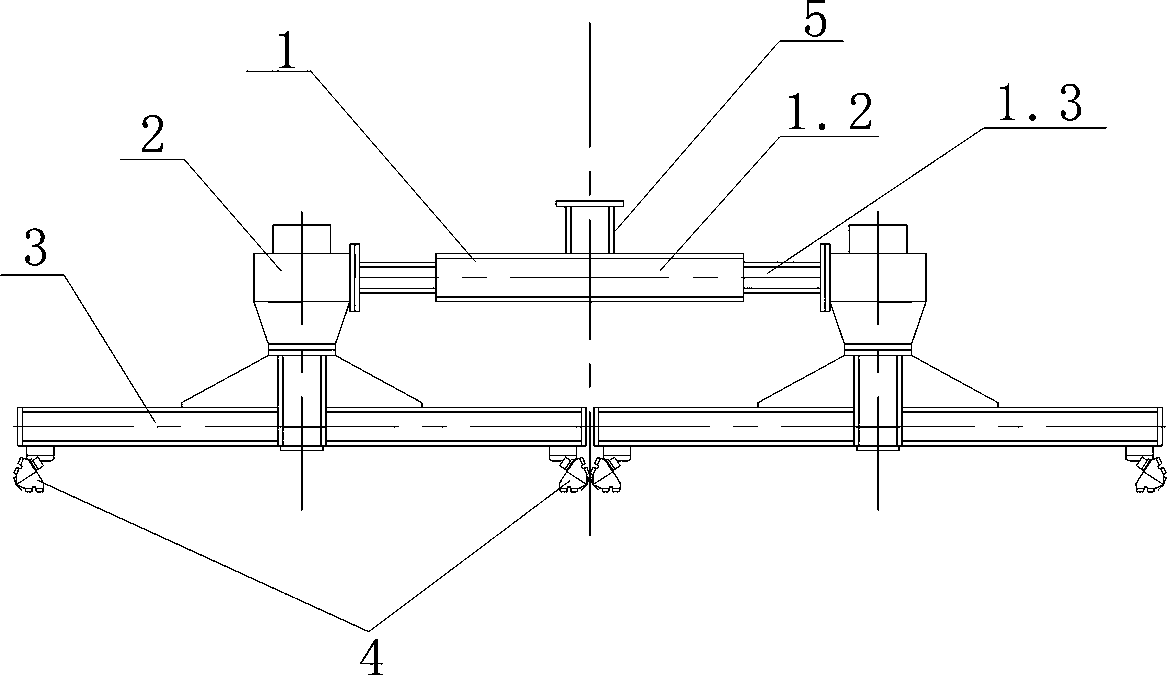

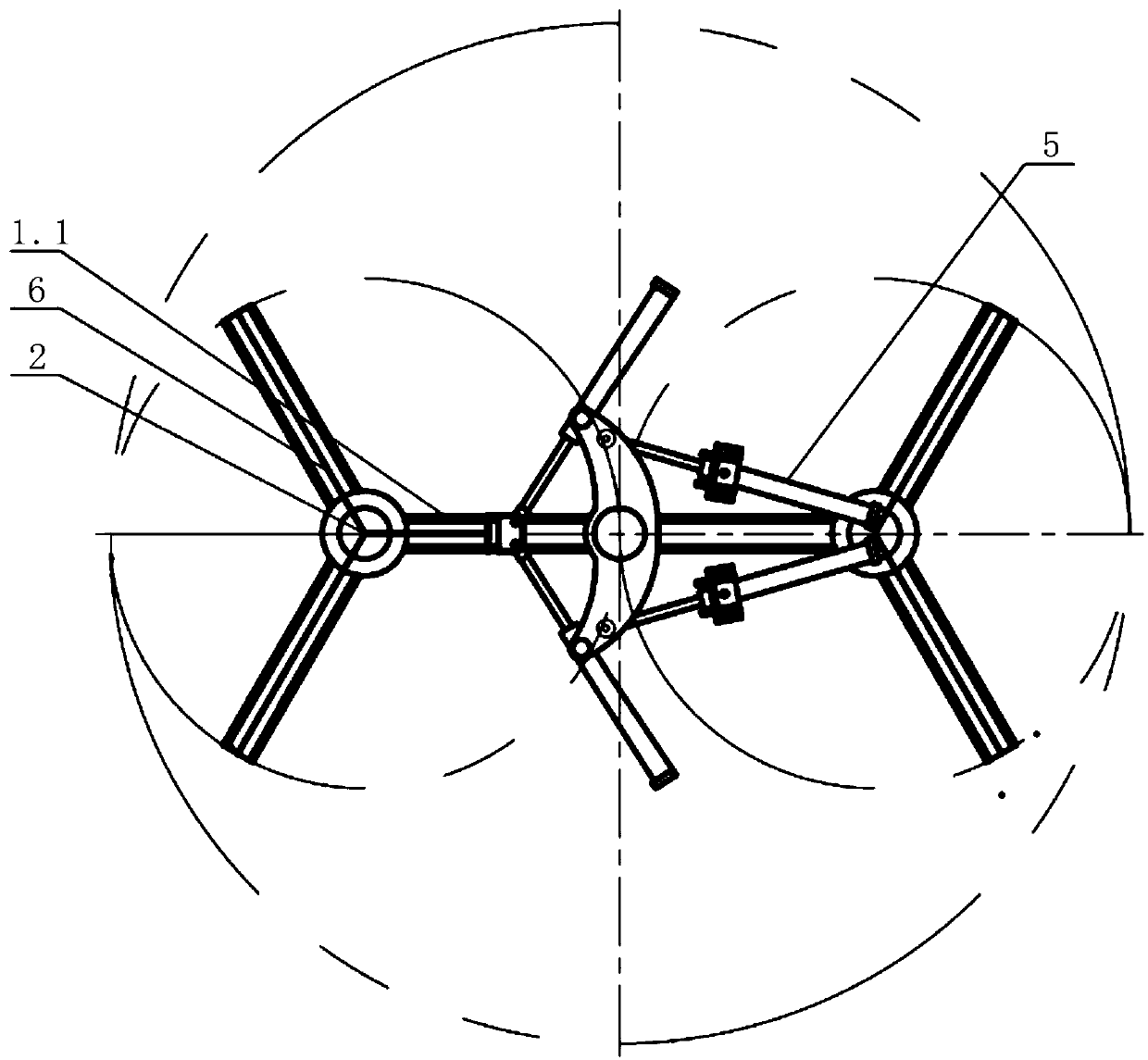

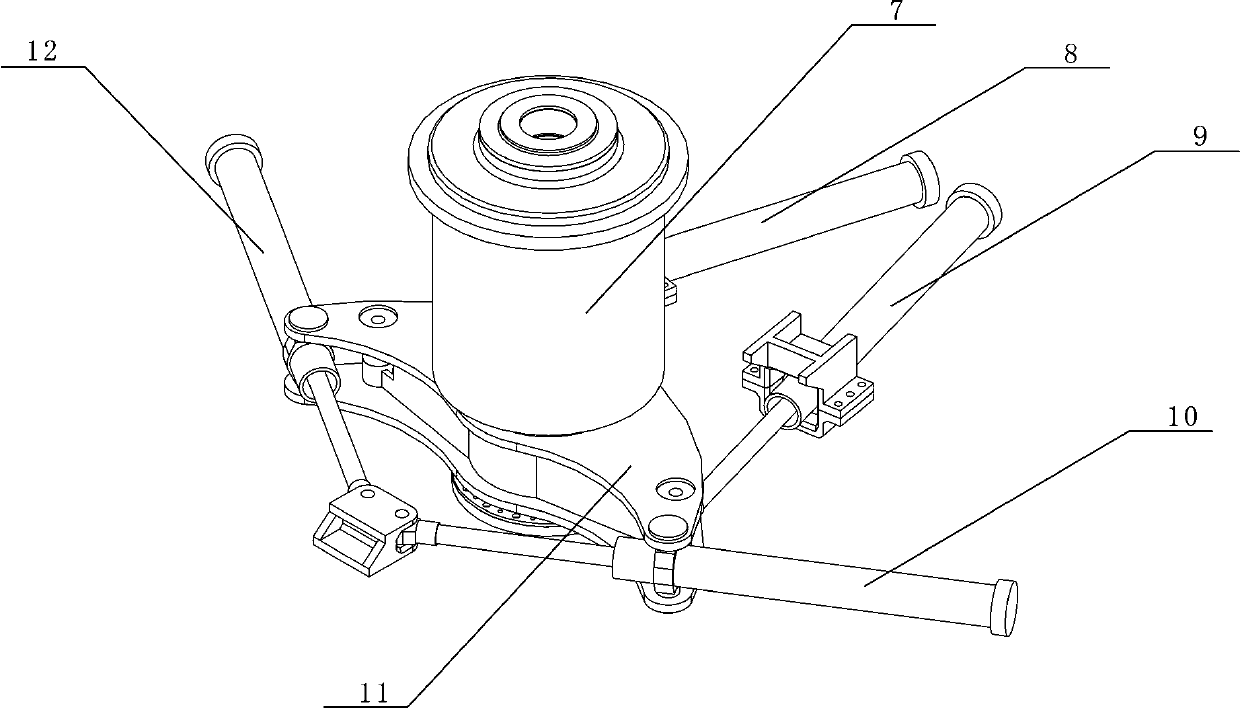

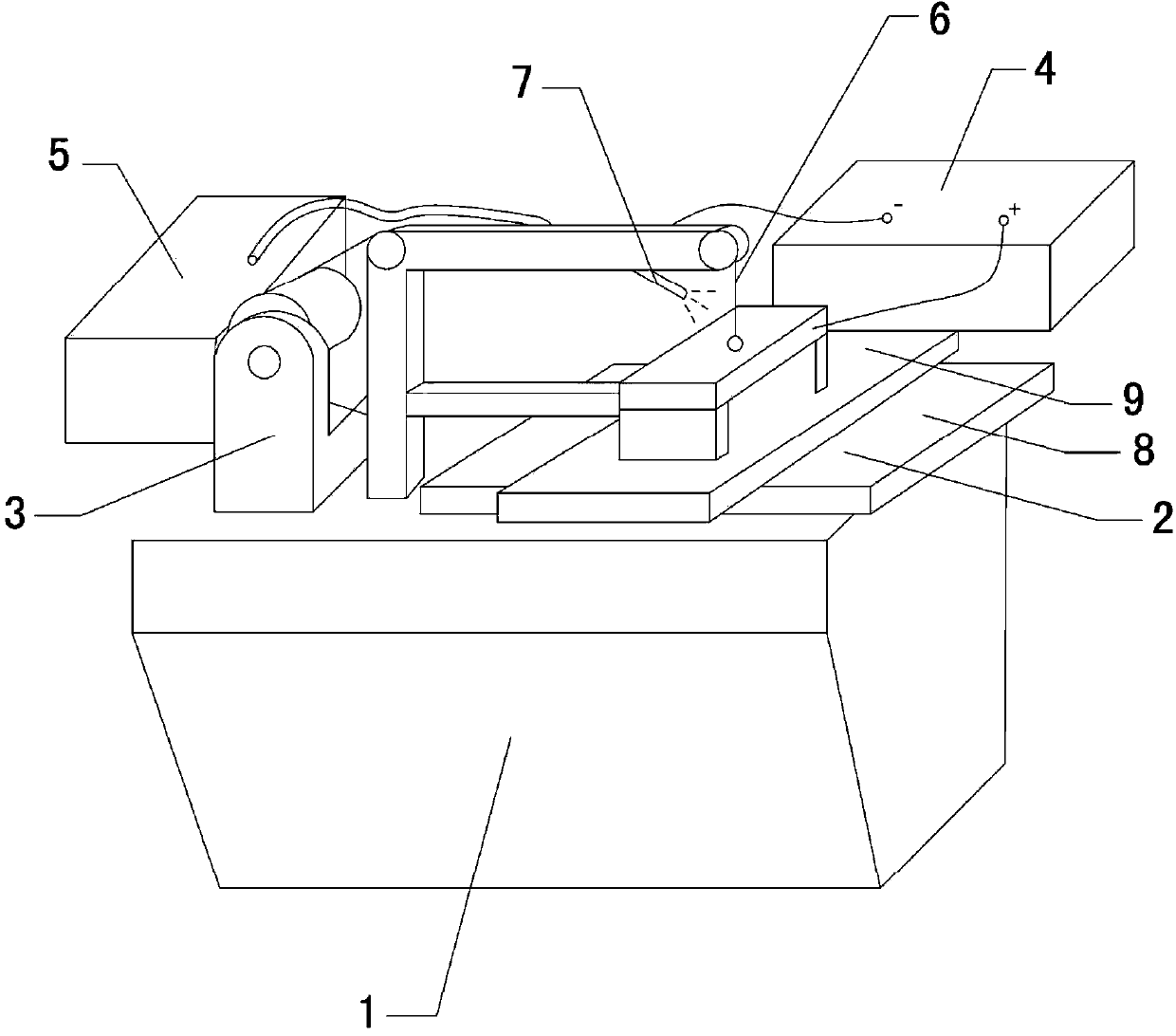

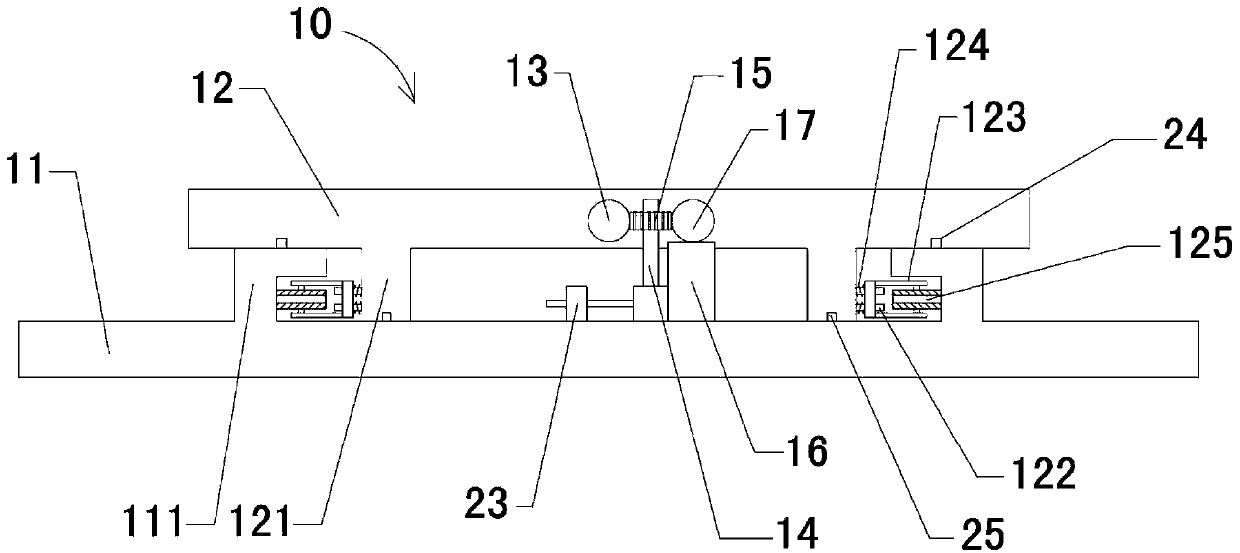

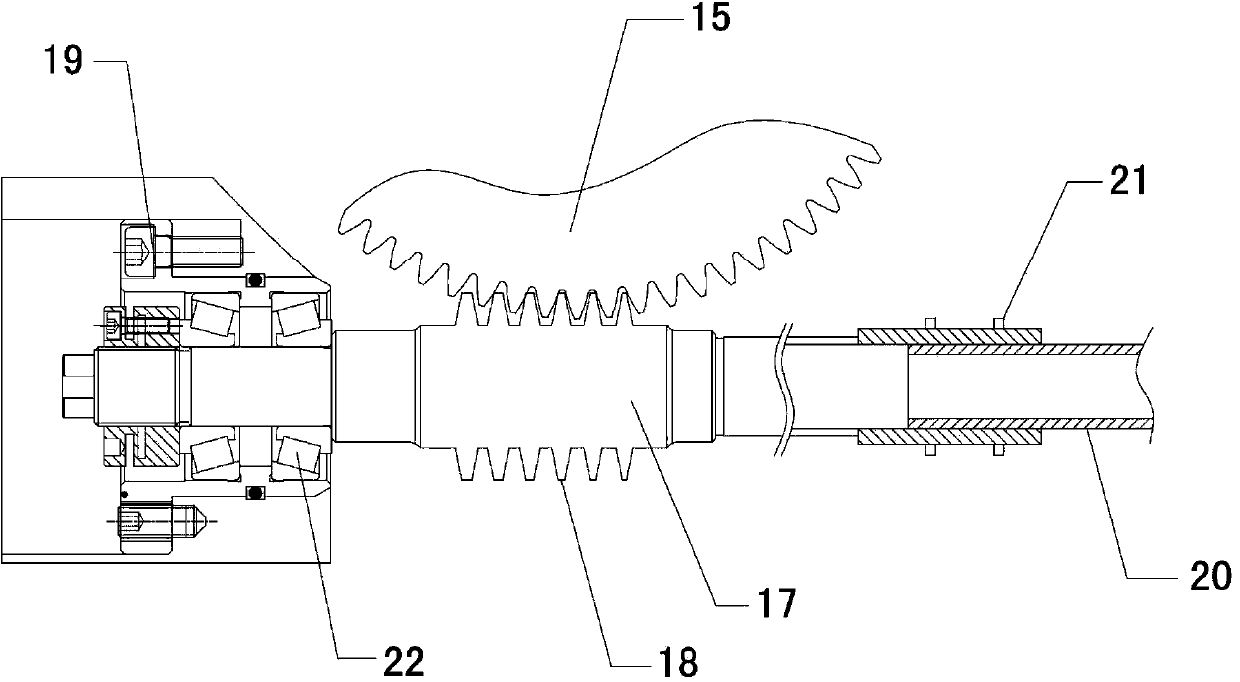

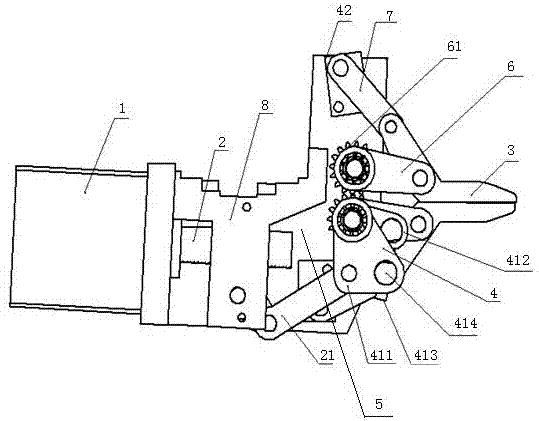

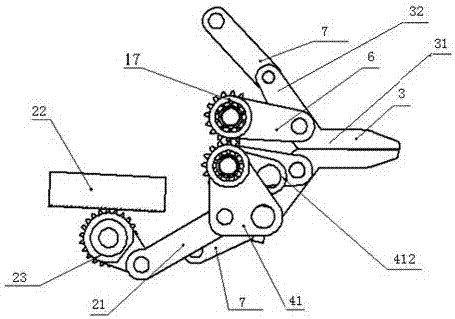

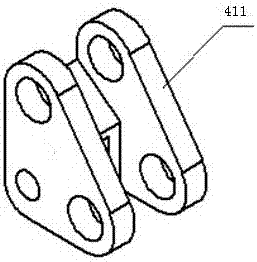

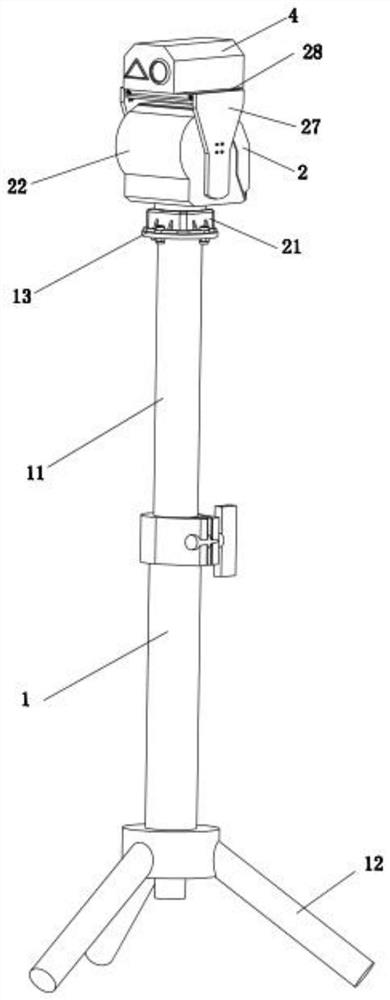

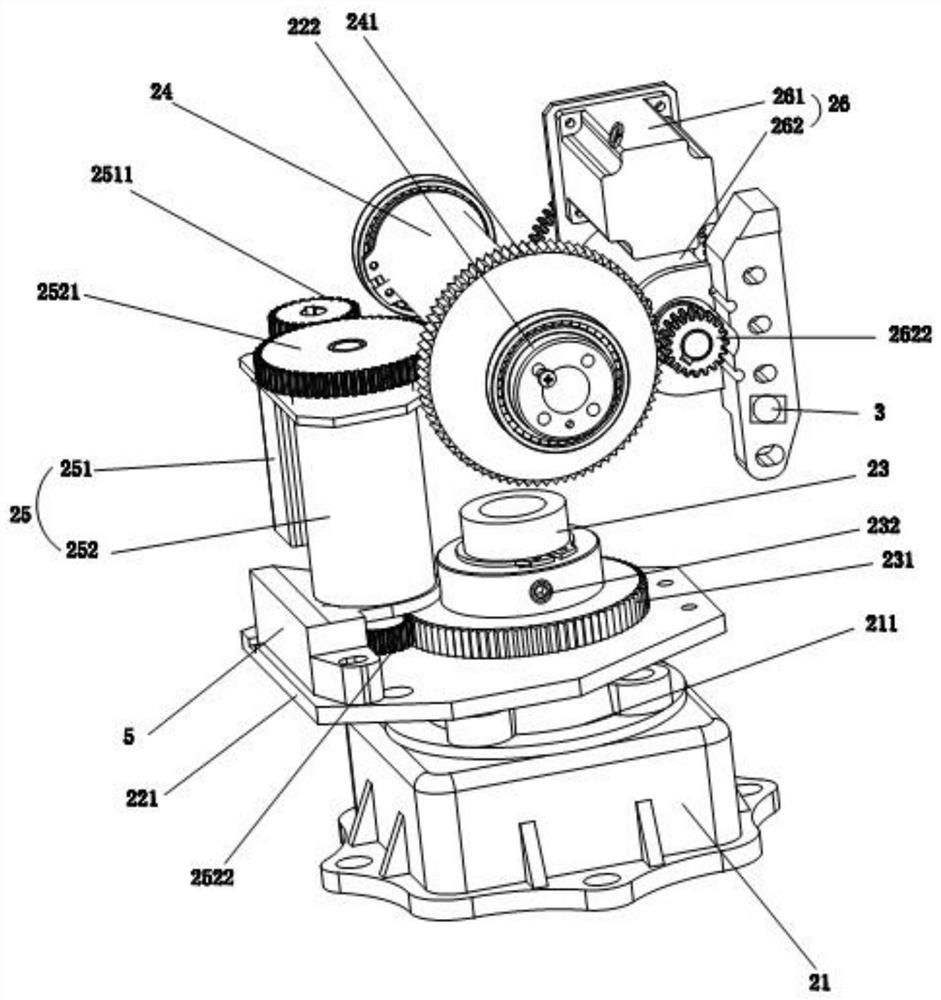

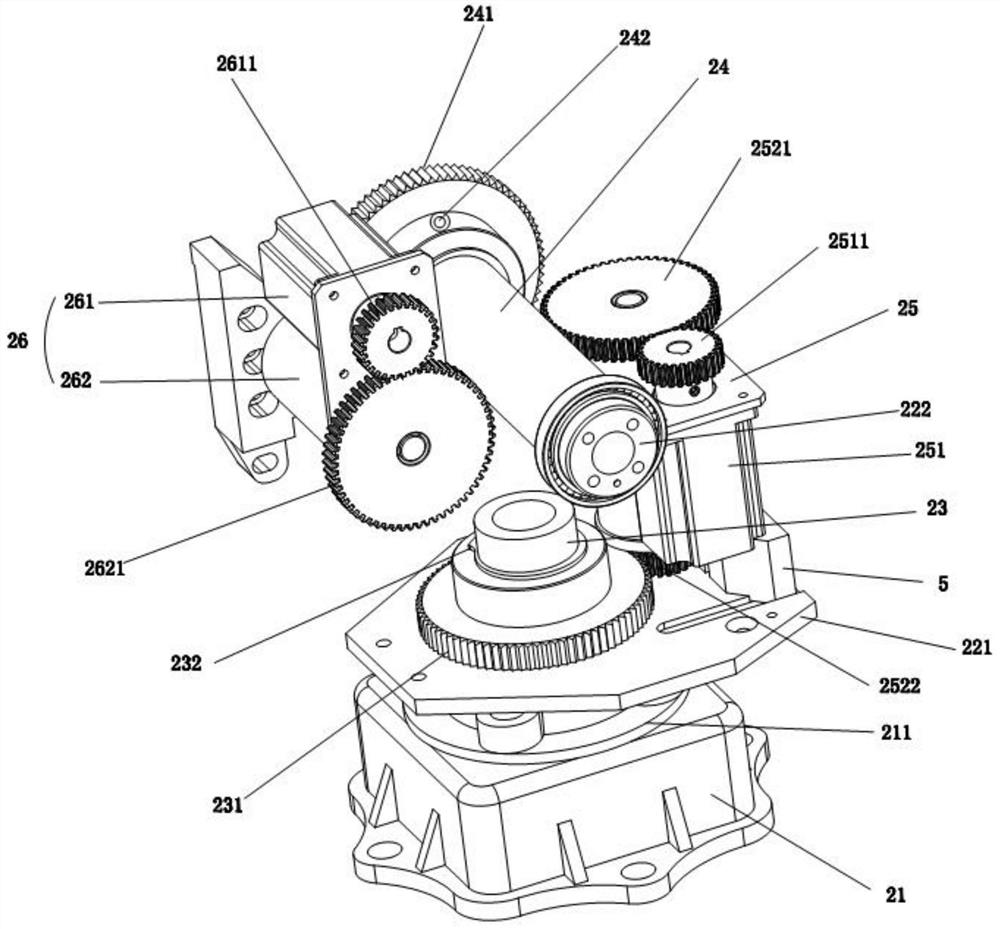

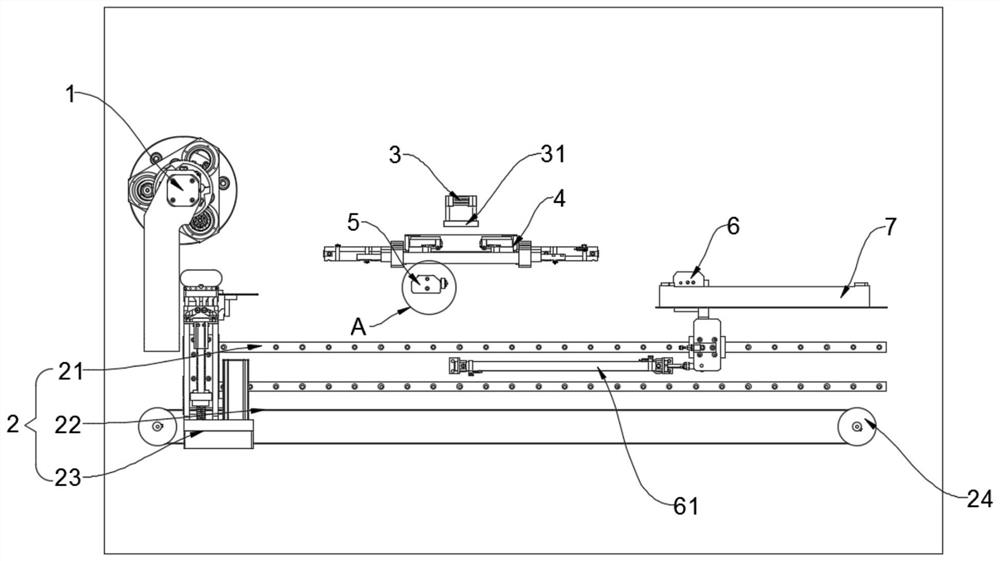

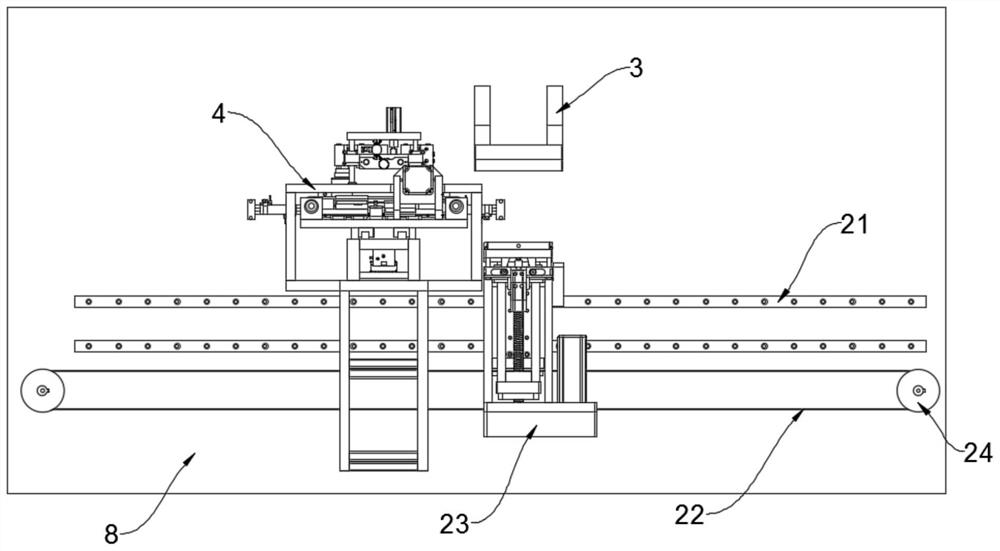

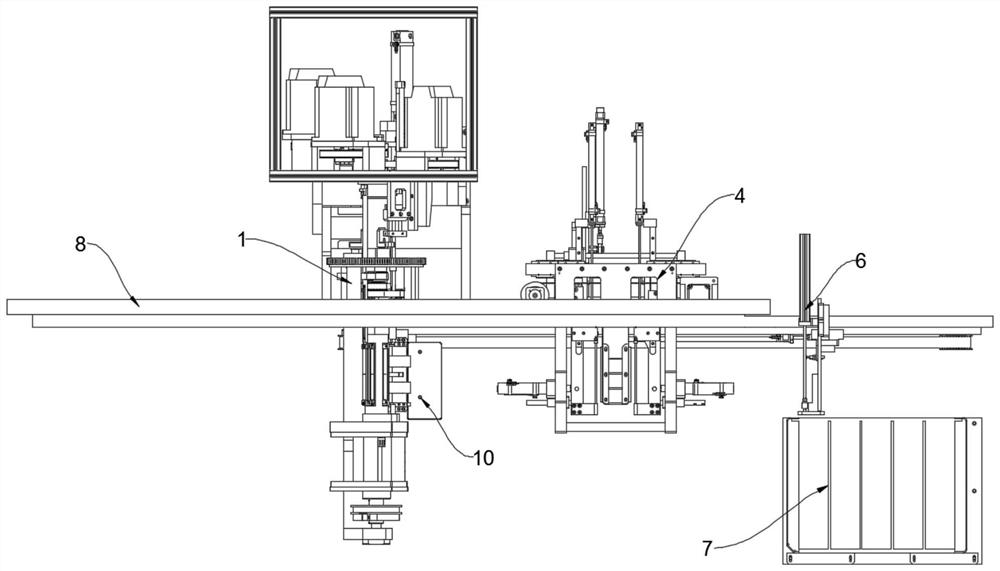

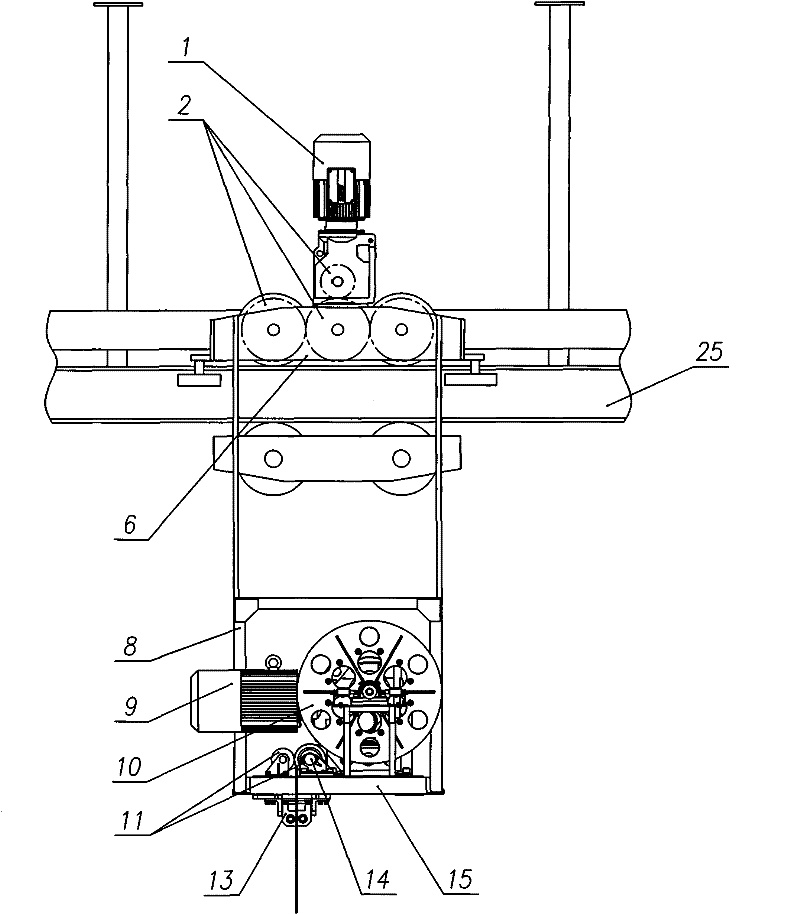

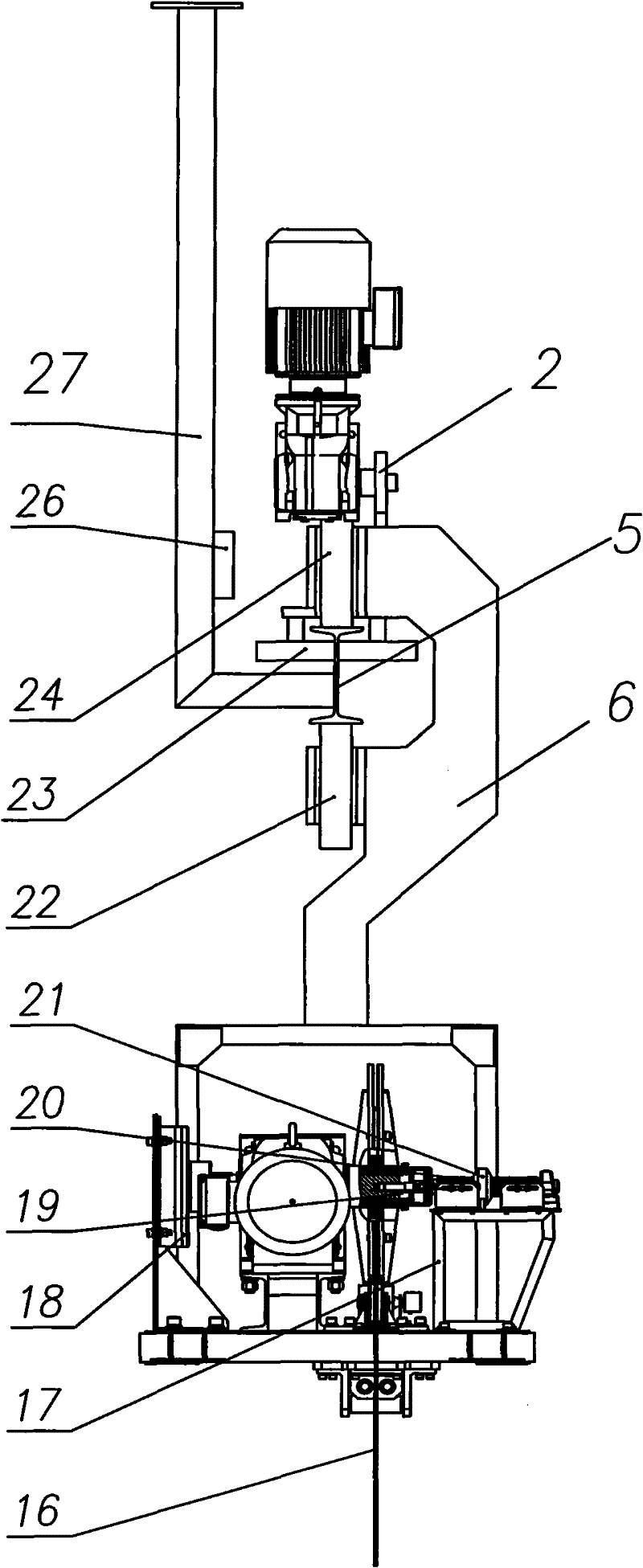

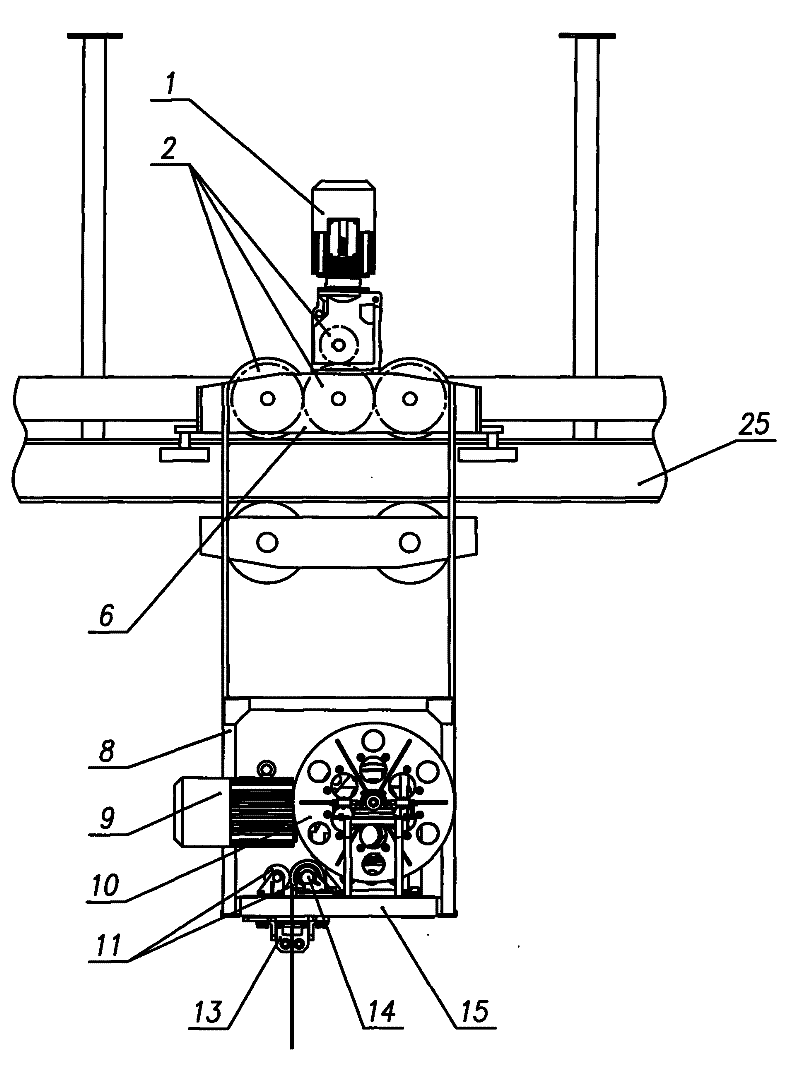

Movement mechanism

ActiveCN102114355AAdjustable movement speedRich aerial performancesStage arrangementsArtist equipmentsEngineering

Owner:华强方特(深圳)智能技术有限公司

Sinking rotary shaft boring machine

The invention provides a sinking rotary shaft boring machine, and relates to the technical field of shaft boring machine engineering machinery. The machine comprises a boring mechanism, a power lifting mechanism arranged on the ground for lifting the boring mechanism, a slurry separation mechanism for discharging and processing used for lifting, discharging and treating mud slurry mud generated after the boring mechanism breaks earth in a shaft and an operation control system for controlling the operation of each of the above mechanisms, the boring mechanism includes a boring frame, a drill arm, a main drive device for driving the rotation of the drill arm, a drilling tool and auxiliary drive devices for driving the drilling tool to rotate, and the lower portion of the main drive device isconnected with the middle of the drill arm; at least two auxiliary drive devices are mounted on the drill arm, and the lower portions of each auxiliary drive device is connected with the drill tool;the machine has reasonable design and small space occupation, full-section excavation is achieved by the rotation of the drill arm and the drilling tool, the rotation speed and direction of the drillarm and the drilling tool can be adjusted, and the machine is suitable for different geological conditions.

Owner:CHINA CONSTR UNDERGROUND SPACE +1

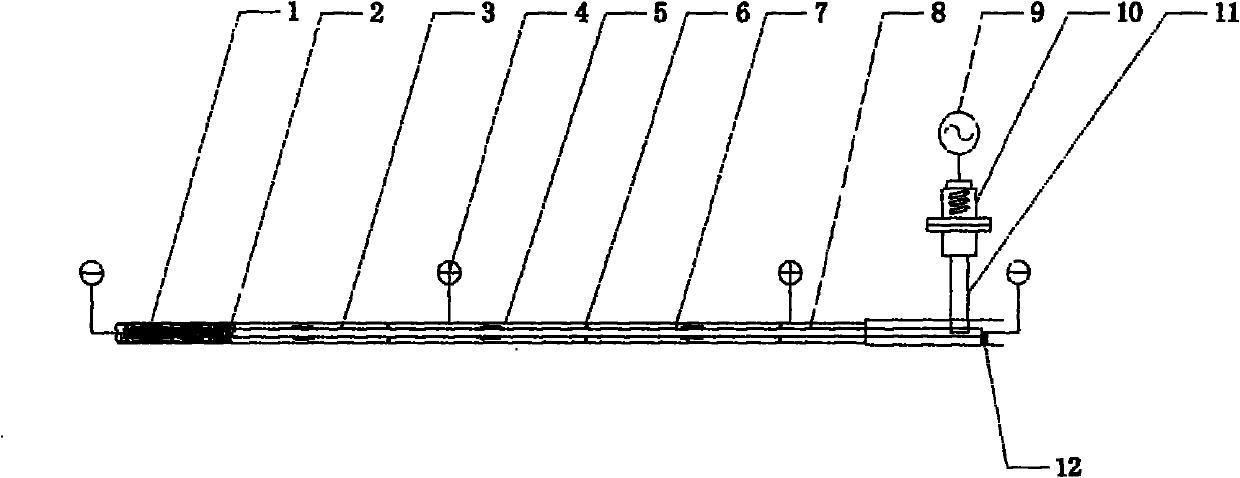

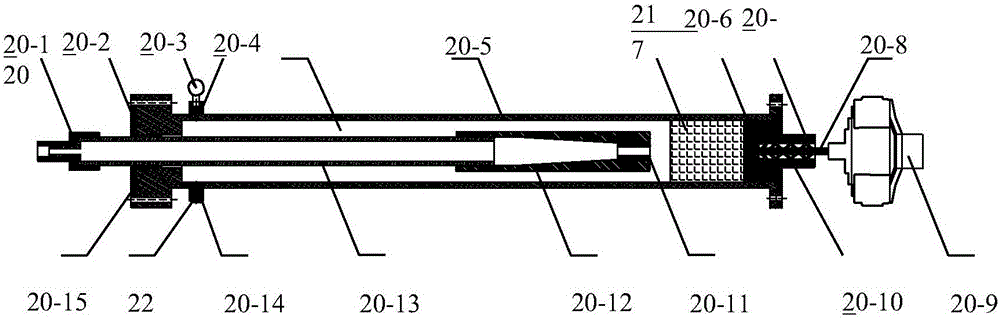

Movable electrode (cathode) for stainless steel inner tube electropolishing

InactiveCN102703963AAdjust movement speedAdjustable movement speedElectrolysis componentsCopper electrodeSheet structure

The invention relates to a movable electrode (cathode) for stainless steel inner tube electropolishing processing; the electrode is movable, and the moving speed can be adjusted continuously according to the processing quality and requirements; materials with good conductivity performance are selected, and have a length of about 100 mm-200 mm; an insulation ring is mounted between the electrode and a stainless steel tube inner wall; the movable electrode is fixed at a center position of a shaft of the stainless steel tube so as to allow the distance between the cathode and an anode (the stainless steel tube) to be the same; and thus the processed electropolishing quality is consistent; the copper electrode is not cylinderical, but has a sheet structure, which increases the conductive area of the cathode and improves the electropolishing quality. Adequate intervals are left between the movable electrode (cathode) and the stainless steel tube inner wall to be processed, and thus the flow of electropolishing liquid is not interfered; on one hand, the discharge of gas generated during electropolishing is quite facilitated; on the other hand, wastes generated during electropolishing is taken away timely. Both length and size ranges of stainless steel tubes to be processed are enlarged greatly, and the quality is ensured.

Owner:SHANGHAI MINOW SMOOTH IND TRADE

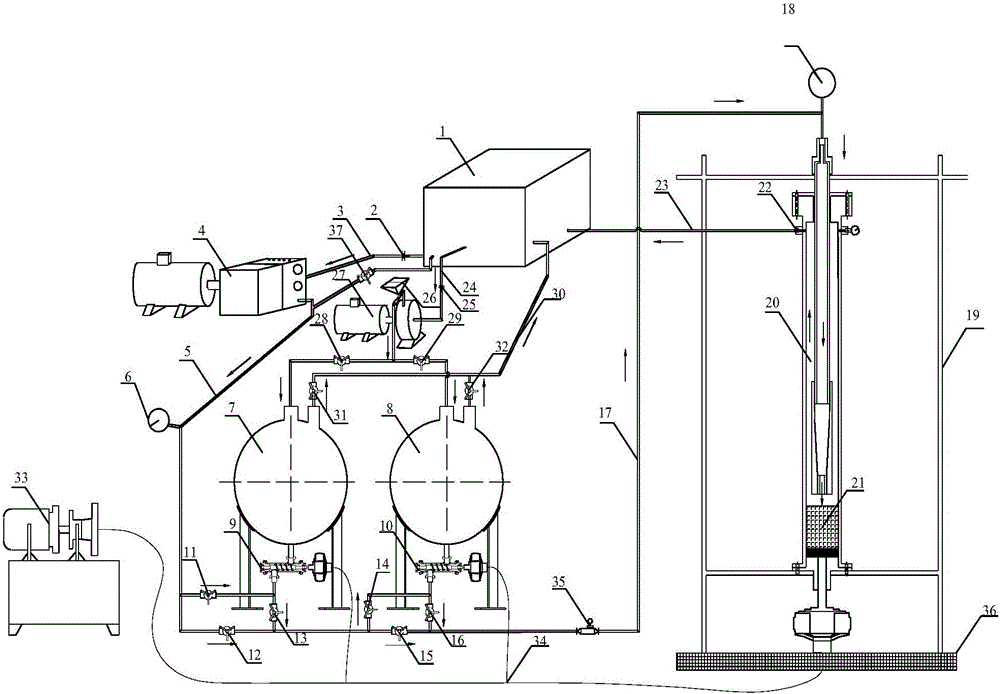

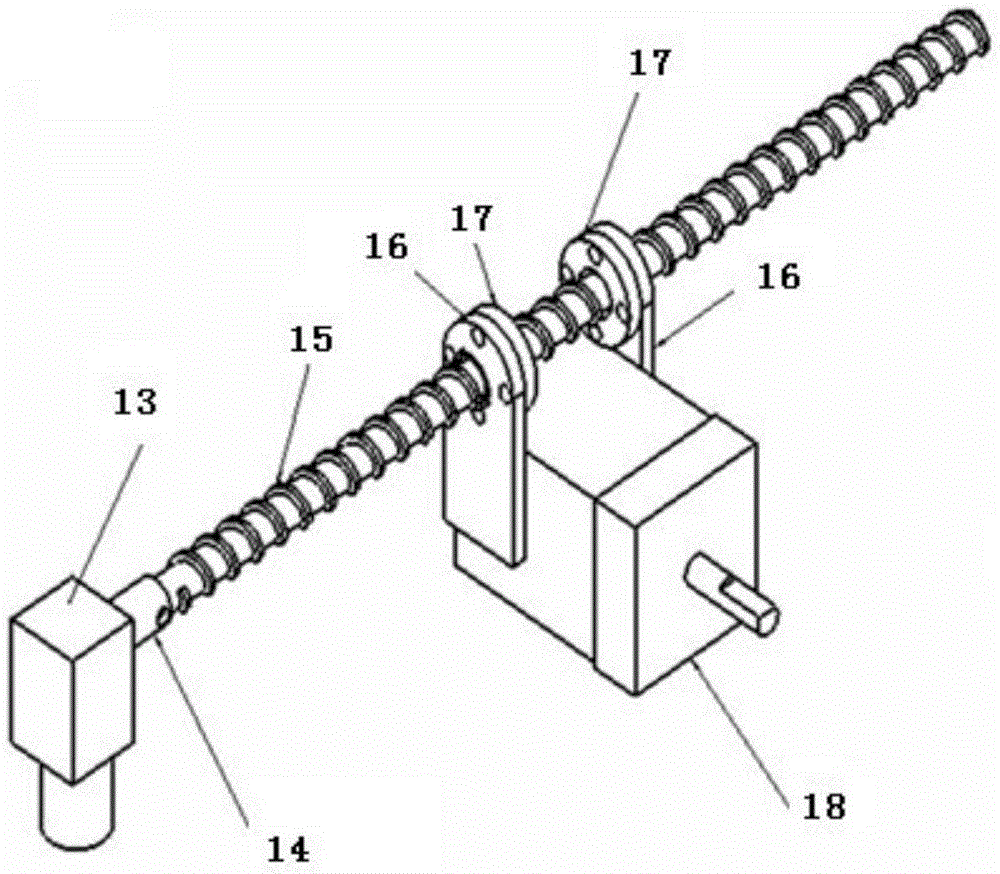

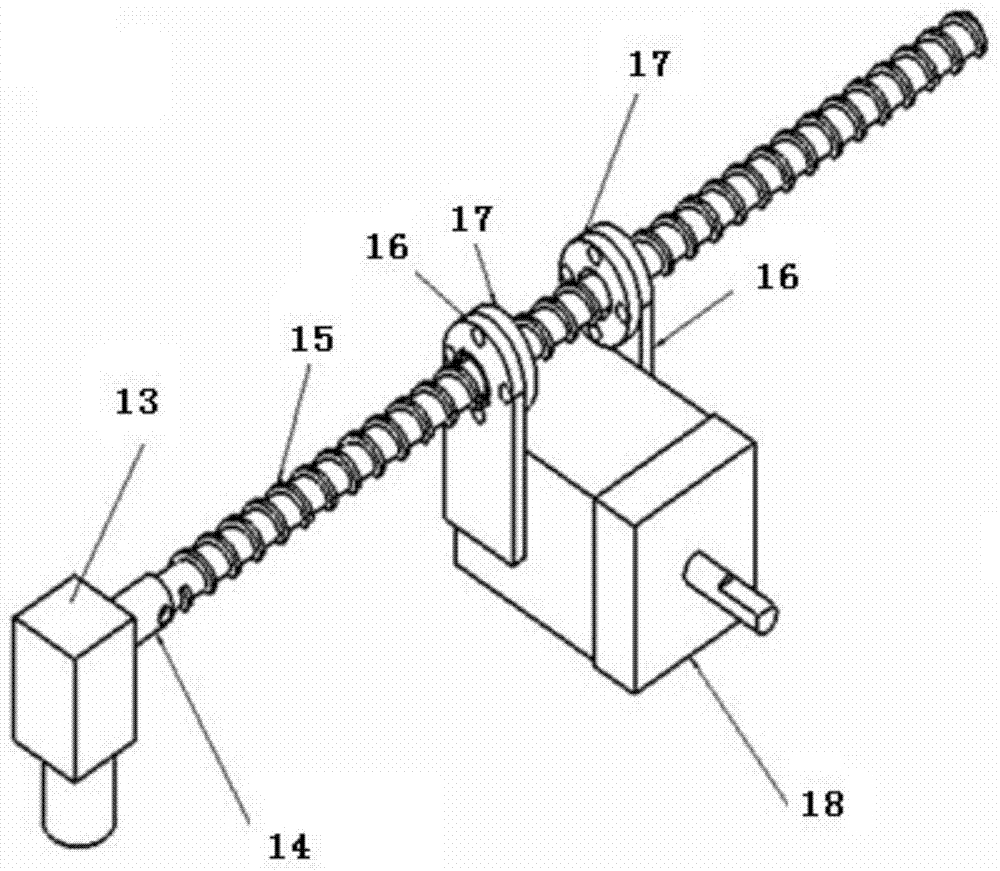

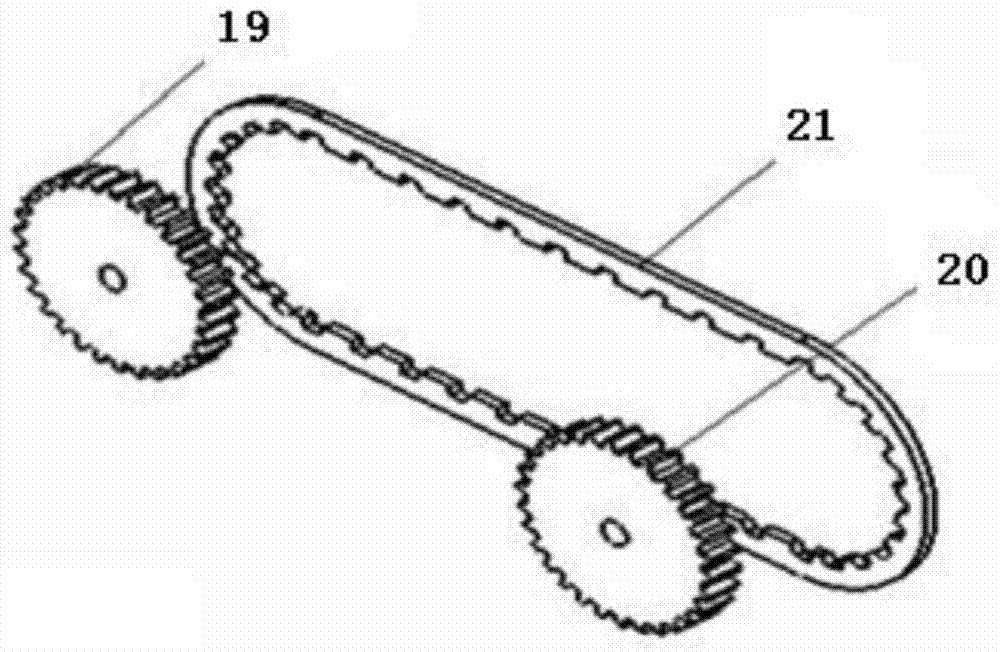

Comprehensive experimental facility for breaking rocks with steel particle jet impact

ActiveCN105715211AUniform and stable additionGuaranteed Particle ConcentrationDrill bitsStructural/machines measurementWater storage tankHigh pressure water

The invention belongs to the field of oil drilling, and in particular relates to a comprehensive experimental facility for breaking rocks with steel particle jet impact. The comprehensive experimental facility comprises a water storage tank, a high-pressure pump, a high-pressure pipeline, a pressure gauge, high-pressure sphere tanks, an auger conveying device, a high-pressure valve, a test stand, a high-pressure experimental wellbore, rocks, a mortar pump, an injection type funnel, a hydraulic power unit, a hydraulic pipeline, a mass flow meter and a high-pressure diverting valve etc., wherein the auger conveying device can control the particle concentration of high-pressure water flow, the mass flow meter can be used for measuring and judging whether injection of steel particles is completed or not, the confining pressure of steel particle jet rock breaking can be regulated by a pressure regulating nozzle, and the two high-pressure sphere tanks work alternatively so that steel particles can be injected uninterruptedly into the high-pressure pipeline. The particles are delivered along with liquid, and the system drive is achieved by a hydraulic motor. The comprehensive experimental facility can be used for carrying out experimental analysis of the effect law of various parameters such as hydraulic power, lithological characters and jet on rock breaking efficiency, which provides theoretical guidance and equipment support for popularization and application of the technology of particle impact drilling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

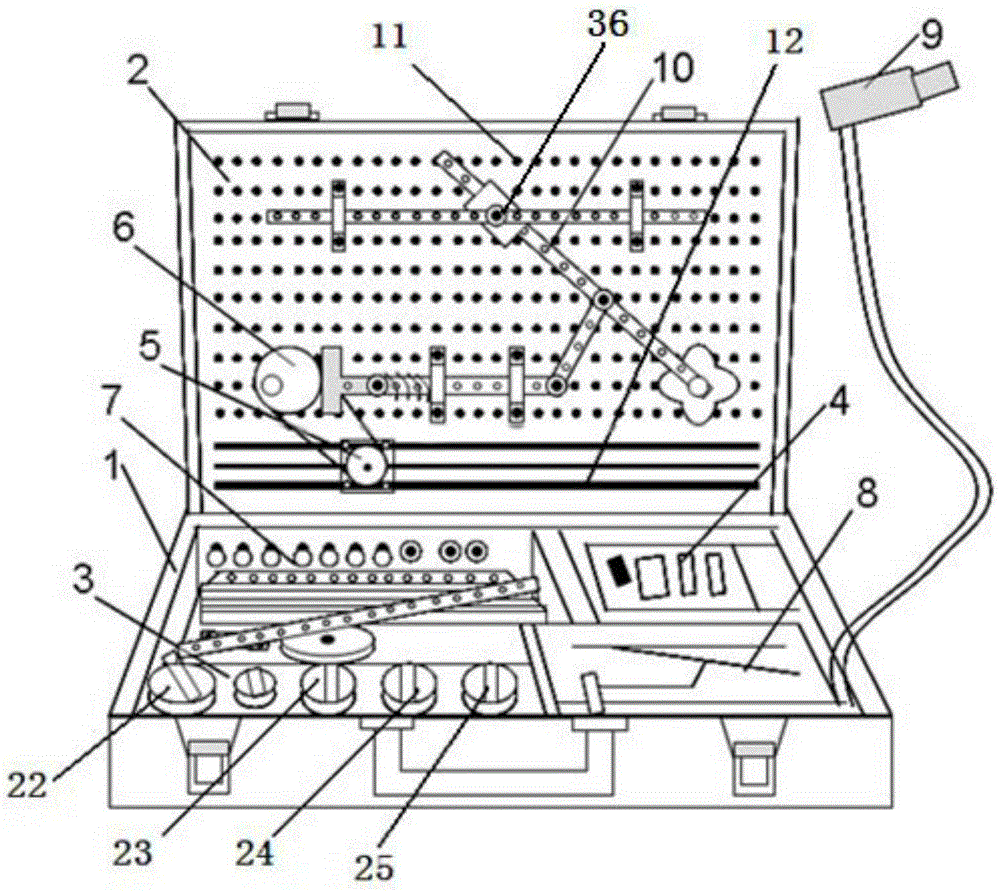

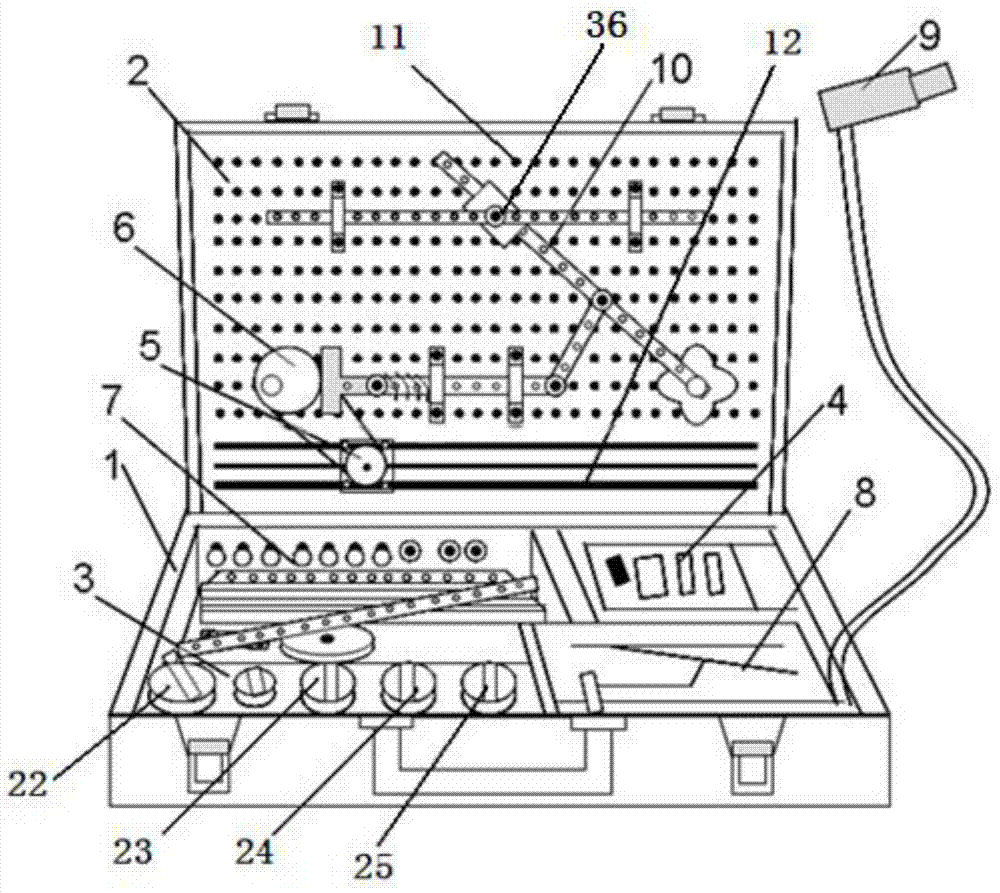

Portable assembled theoretical mechanics teaching aid

InactiveCN105390051AAdjustable movement speedReduce weightEducational modelsEngineeringMechanical engineering

The invention discloses a portable assembled theoretical mechanics teaching aid comprising a light flip right-angle hexahedral portable box body. A background motherboard is installed inside a box cover of the box body. The bottom of the box body is divided through PPT plastic filling into a console, an automatic drive device, a teaching aid general parts storage room and a puzzle introduction block placement room. The upper part of the background motherboard is uniformly provided with small circular holes into which pins can be inserted. The lower part of the background motherboard is provided with a horizontal slide on which a walking drive device is installed, and the walking drive device is connected with a transmission device and is connected through a circuit with the console. The portable assembled theoretical mechanics teaching aid has a simple and novel structure and complete functions, is made of good material, and is light. The whole device is installed inside a suitcase and can be easily carried by teachers to the class. Students can assemble the mechanism and control the motion of the mechanism, so that students are inspired to think deeply and further understand the mechanics theory.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

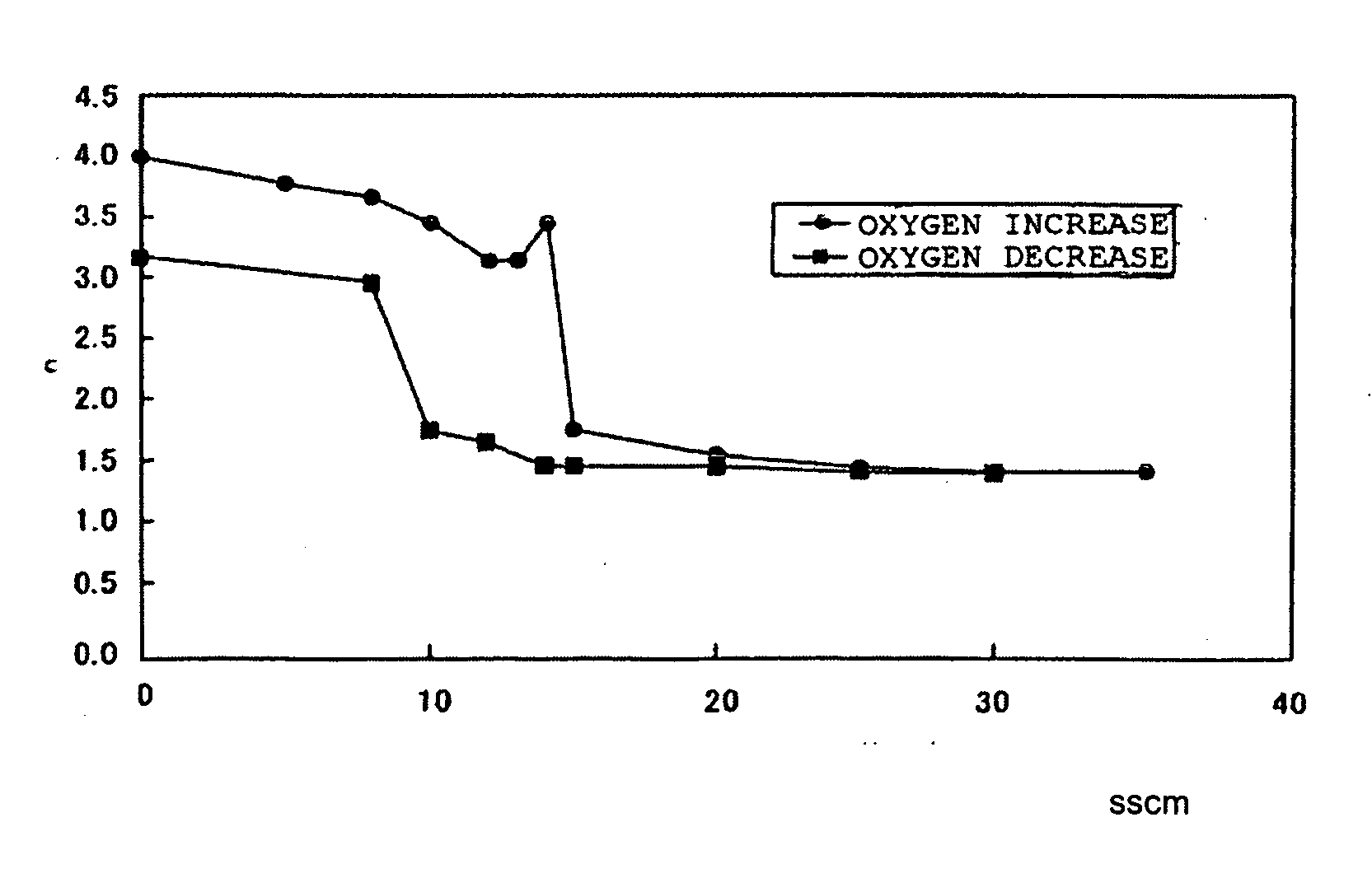

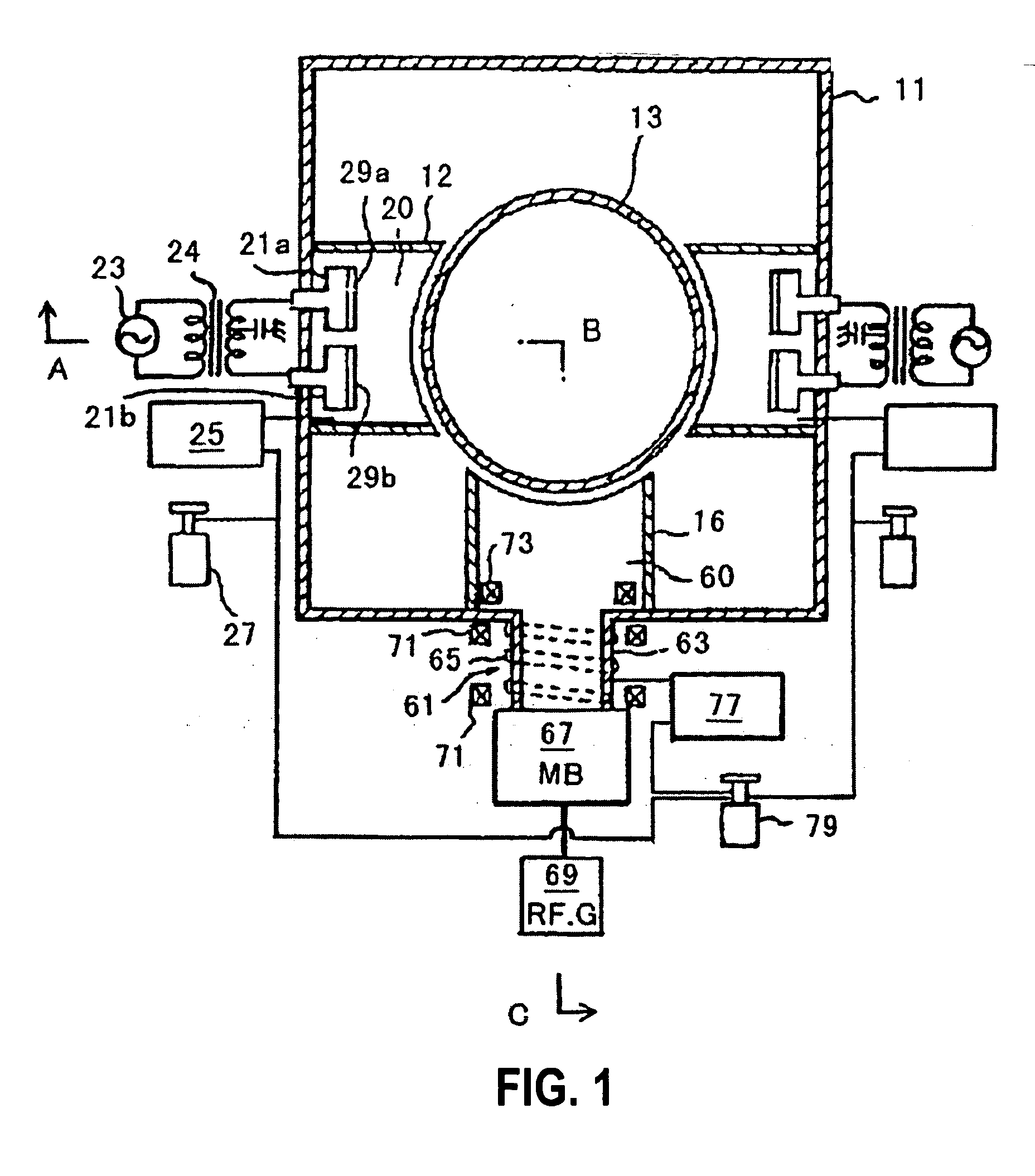

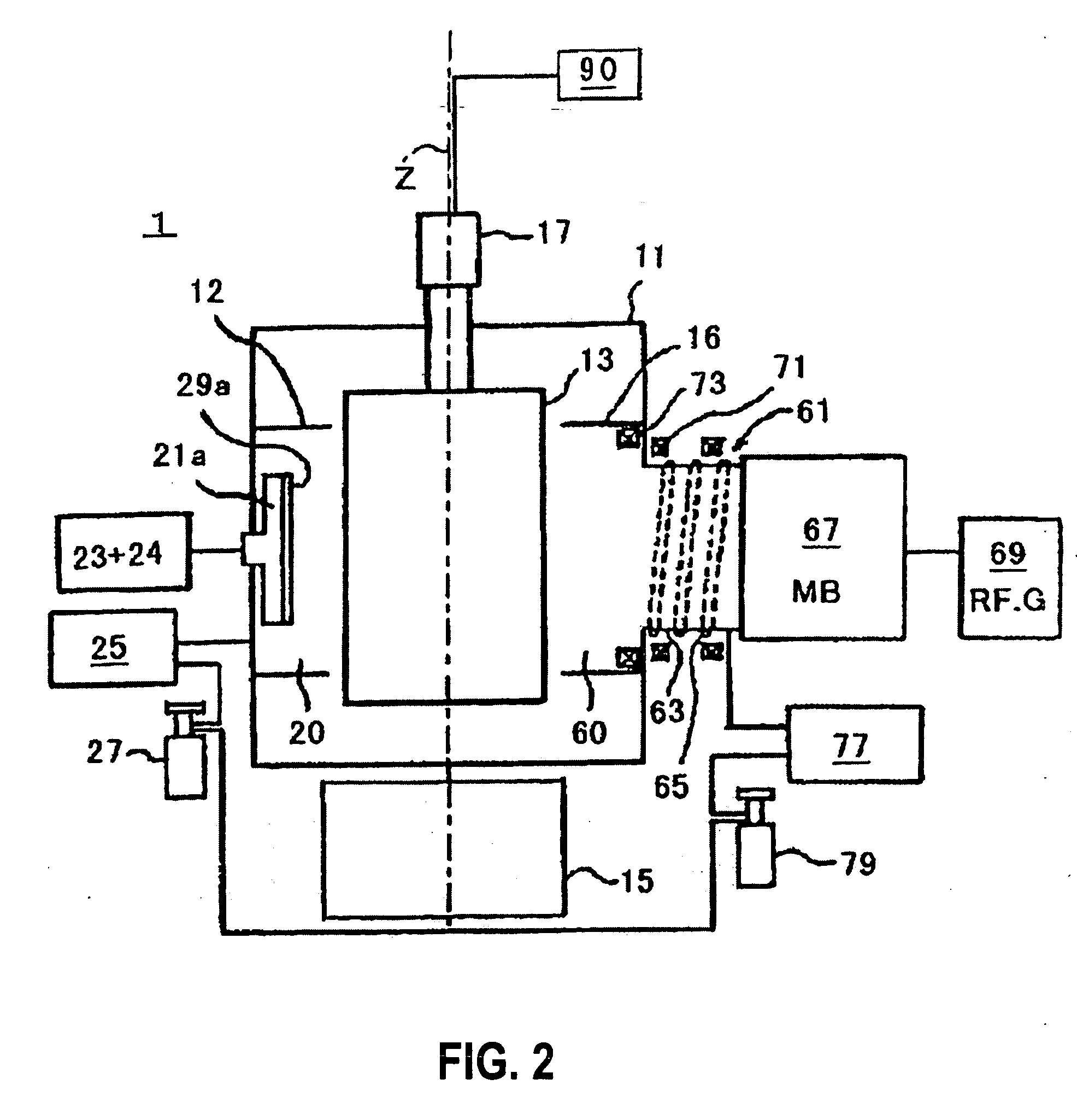

Thin film forming method and forming device therefor

InactiveUS20060189046A1Good reproducibilityLimit on characteristicSolid-state devicesVacuum evaporation coatingOptoelectronicsHysteresis phenomenon

A method of forming a thin film of the present invention comprises: an optical characteristic adjusting step of repeatedly conveying a substrate holder between a zone to perform an intermediate thin film forming step and a zone to perform a film composition converting step while controlling a conveying speed of the substrate holder for holding a substrate, and adjusting a film composition of a finally formed thin film to form the thin film having an optical characteristic value of a region where a hysteresis phenomenon occurs.

Owner:SHINCRON KK

Adjustable type fixed clamping and conveying system and method for aluminum profile machining

The invention relates to an adjustable type fixed clamping and conveying system for aluminum profile machining. The adjustable type fixed clamping and conveying system for aluminum profile machining comprises a movable platform plate; the right side position of the middle of the movable platform plate is fixedly connected with a supporting square column; a conveying rack is welded to the middle position of the left side of the supporting square column; a movable frame is clamped in and installed on the other side, away from the conveying rack, of the supporting square column; clamping column supporting plates, large gear supporting plates and small gear supporting plates are correspondingly welded to the two outer side walls of the movable frame from top to bottom; a clamping column plateis arranged between the clamping column supporting plates; the upper portion of the clamping column plate is supported and installed through a clamping column fixing stud; a pushing rod is fixedly connected to the upper side face of the clamping column plate; and a clamping column rack is arranged on the lower side face of the clamping column plate. The system can effectively achieve clamping on aluminum profile, the clamping height can be conveniently adjusted, the moving speed is controlled through a large gear and a small gear, the speed is adjustable, fixing is facilitated so that it is avoided that the aluminum profile slides, conveying and moving of the whole system are also convenient, and the using effect of the adjustable type fixed clamping and conveying system for aluminum profile machining is improved.

Owner:张细望

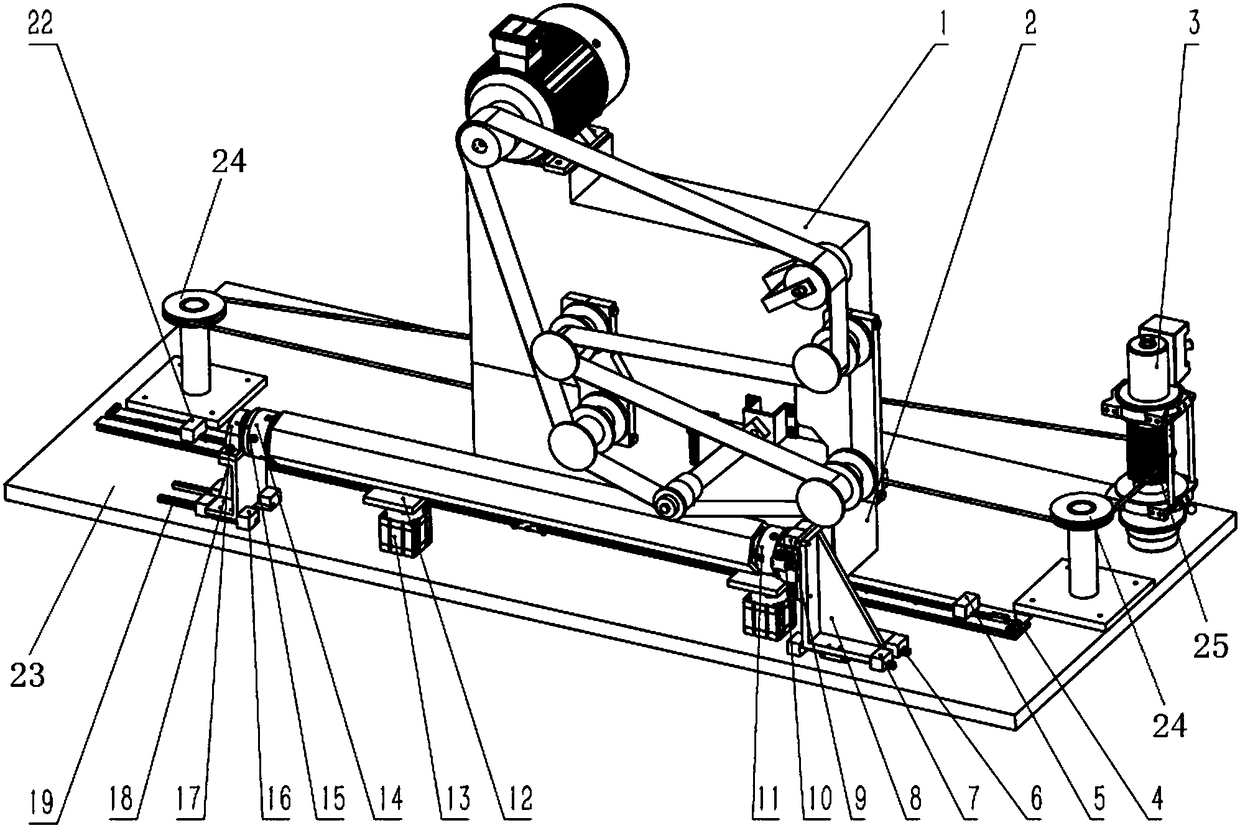

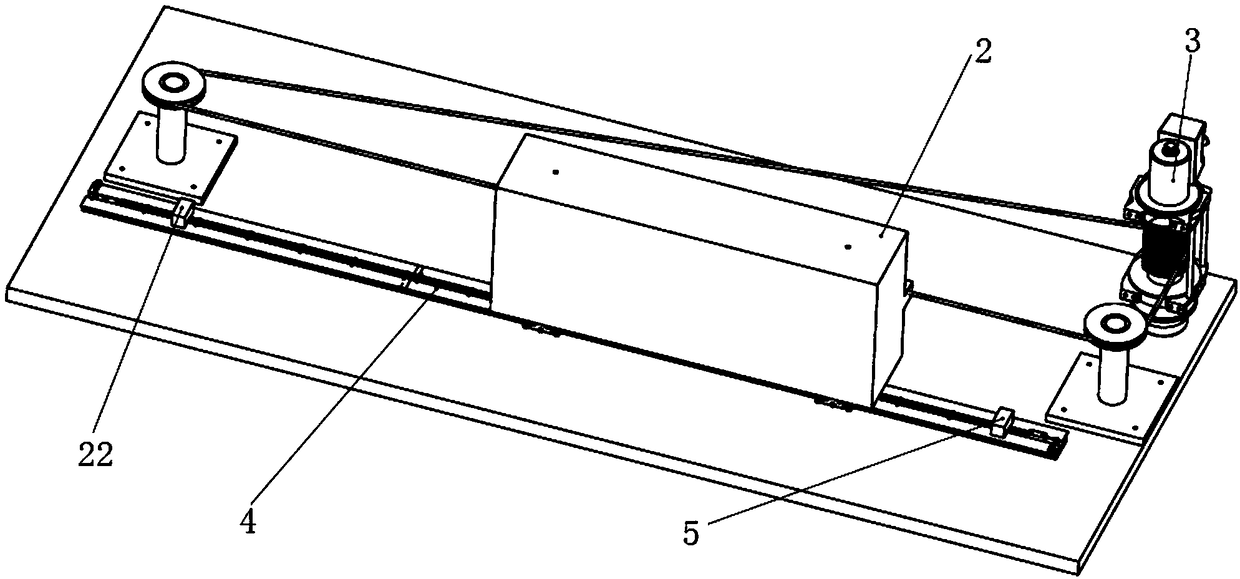

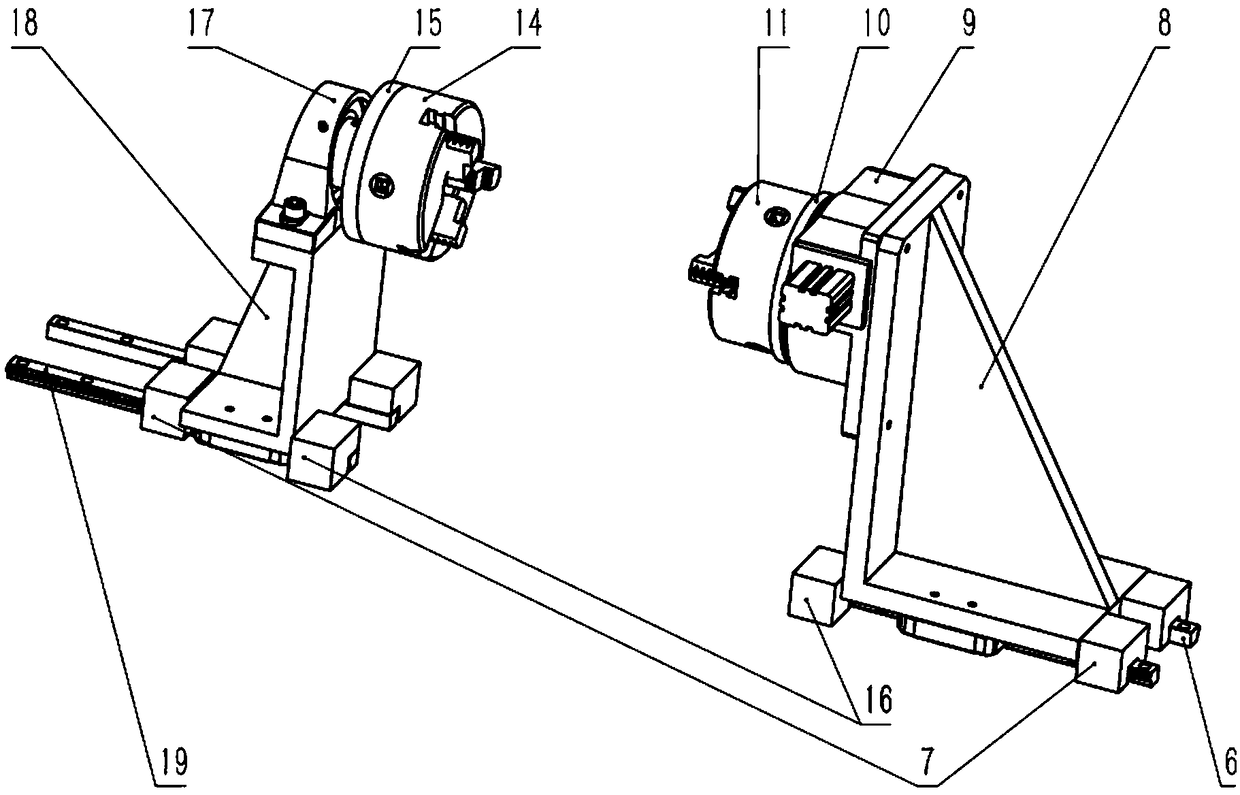

Surface polishing and grinding process and equipment used for long rod part with specially-shaped section

ActiveCN108500792AImprove polishing qualityGuaranteed cutting forceBelt grinding machinesGrinding work supportsLinear motionGrinding process

The invention discloses a surface polishing and grinding process and equipment used for a long rod part with a specially-shaped section. The equipment comprises a belt grinder, a travelling mechanismand a clamping mechanism with a turnover function, wherein the travelling mechanism comprises a slide rail and a slide base mounted on the slide rail; the slide base is driven by a linear motion drivedevice to move back and forth along the slide rail; the belt grinder is fixedly mounted on the slide base; a belt grinder contact wheel presses an abrasive belt to a to-be-polished and to-be-grindedsurface or edge of a workpiece for polishing and grinding the to-be-polished and to-be-grinded surface or edge of the workpiece; a supporting mechanism is arranged between a drive rotary mechanism anda driven rotary mechanism; the workpiece is firstly placed onto the clamping mechanism, and the travelling mechanism drives the belt grinder to move back and forth for polishing and grinding the workpiece; after one surface is polished and grinded, turnover can be performed through a turnover mechanism; and after polishing and grinding are completed, the clamping mechanism is loosened and the supporting mechanism is withdrawn, so that the workpiece can be taken out. The surface polishing and grinding equipment is consistent in polishing and grinding effect of each part of the workpiece, is good in polishing and grinding quality of the workpiece, is stable in performance, and can be suitable for various long rod parts with specially-shaped sections.

Owner:WUHAN UNIV OF TECH

Driving structure for sinking-method rotation-type vertical shaft tunnelling machine

PendingCN109538213AAdjustable movement speedVariable movement speedBorehole drivesShaft sinkingEngineeringMechanical engineering

The invention discloses a driving structure for a sinking-method rotation-type vertical shaft tunnelling machine and relates to a driving structure. The driving structure comprises a tunnelling rack,a drilling arm and a driving mechanism, the driving mechanism comprises a main driving device and multiple sub driving devices, the main driving device and the sub driving devices are of the same structure, and the tunnelling rack is connected to the exterior of the main driving device; the drilling arm is connected to the lower portion of the main driving device, the sub driving devices are arranged on the drilling arm at intervals, the main driving device comprises a first outer box, a main driving motor and a first gear box, the main driving motor and the first gear box are installed in thefirst outer box, and the first outer box is fixedly installed in the middle of the tunnelling rack; an output shaft of the main driving motor is connected with a drive gear of the first gear box, andthe lower portion of a driven gear of the first gear box extends out of the first outer box and is connected with the middle of the drilling arm; two or more sub driving devices are installed on thedrilling arm. According to the driving structure, through rotation of the drilling arm and a drilling tool body, all-cross-section tunnelling and all-cross-section cutting are achieved, the rotation speed and rotation direction of the drilling arm and the drilling tool body can be adjusted, and the driving structure is suitable for different geological conditions.

Owner:CHINA CONSTR UNDERGROUND SPACE +1

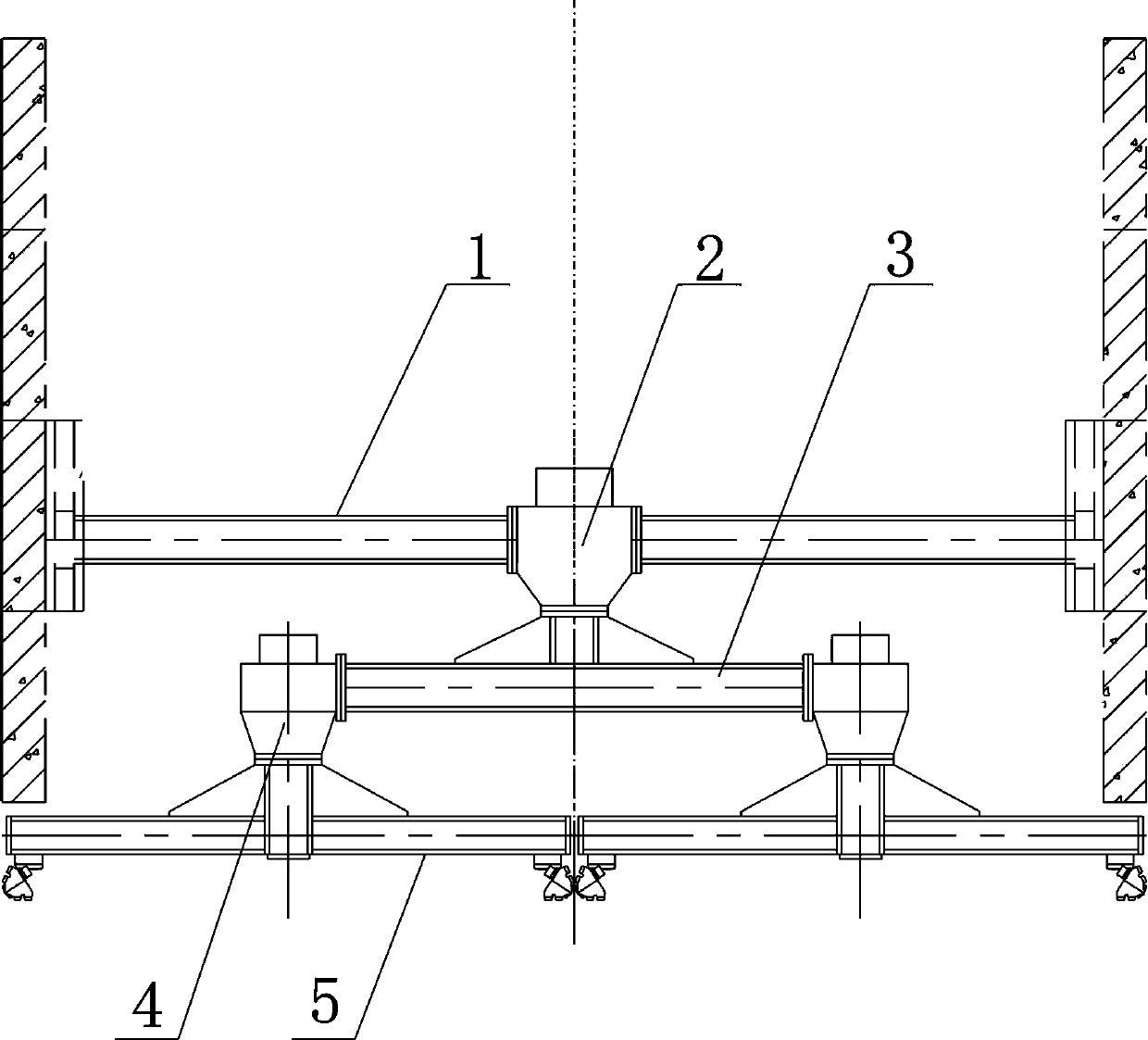

Mobile catenary for electrified railway coaling station

ActiveCN105172618AThe division of force is reasonableIncrease stiffnessTrolley linesElectricityBusbar

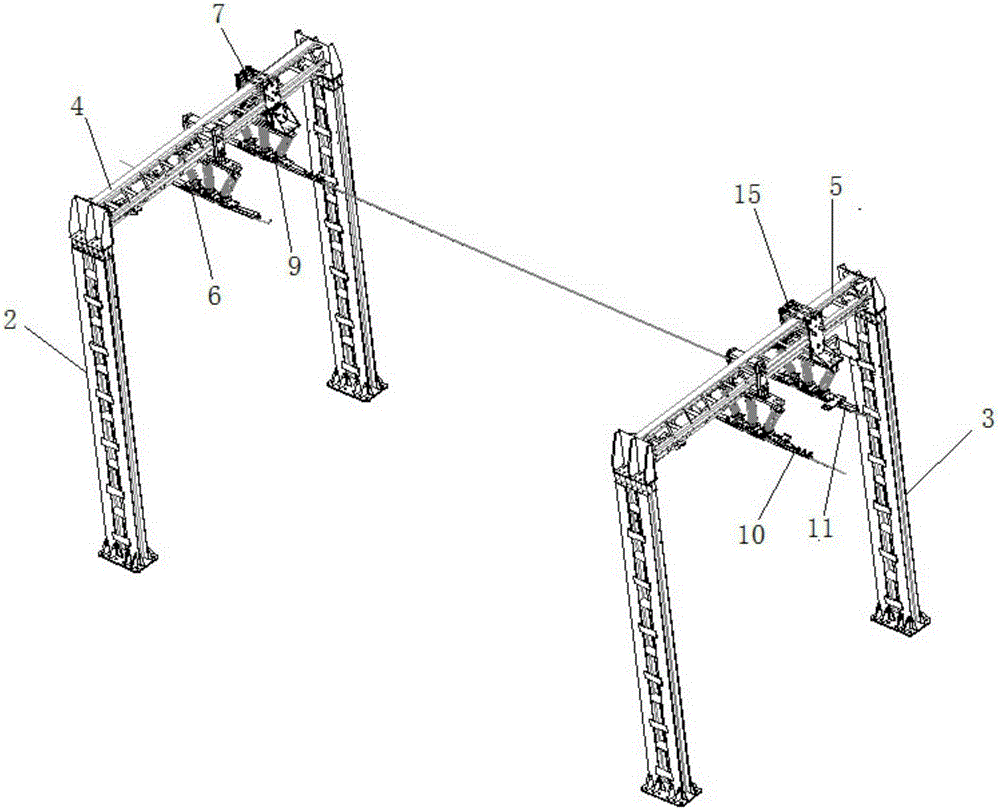

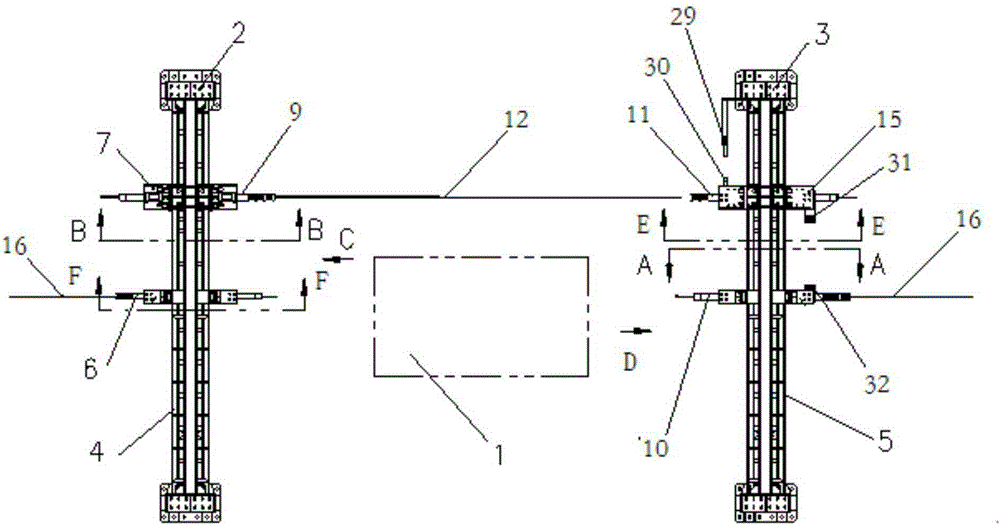

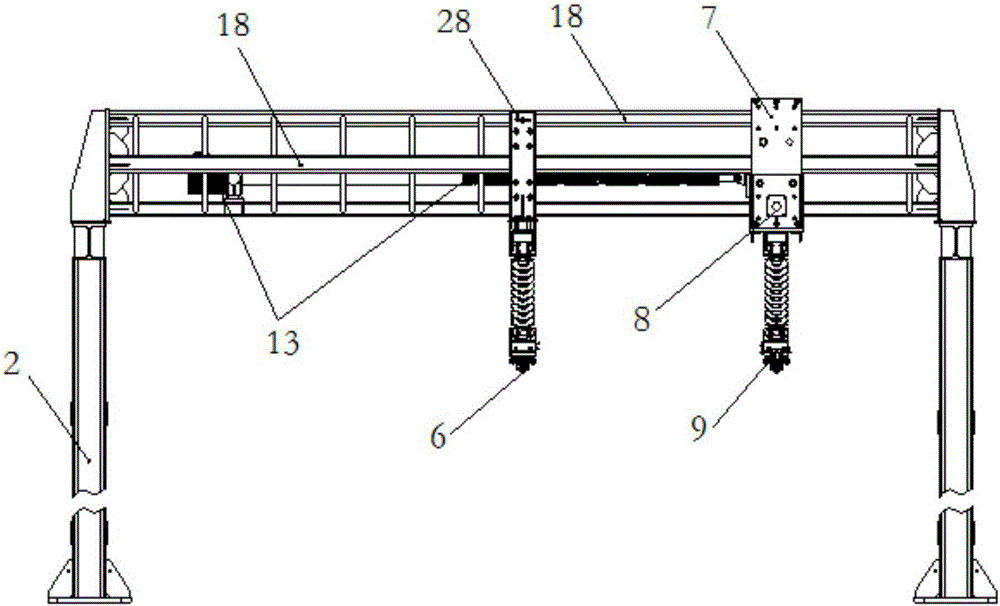

The invention discloses a mobile catenary for an electrified railway coaling station. A left portal frame and a right portal frame stretch across lines on the two sides of a hopper bin; a left fixed busbar and a right fixed busbar are rigidly suspended below the middles of a left cross beam and a right cross beam; a left moving trolley is mounted on the left cross beam; a tension compensation trolley is mounted on the left moving trolley; a left mobile busbar is rigidly suspended below the tension compensation trolley; a right moving trolley is mounted on the right cross beam; a right mobile busbar is rigidly suspended below the right moving trolley; a mobile contact line is connected between the left mobile busbar and the right mobile busbar; a left electric push rod and a right electric push rod mounted at the front parts of the left cross beam and the right cross beam are respectively connected with the left moving trolley and the right moving trolley so as to drive the mobile contact line to move forwards and backwards in the direction parallel to the lines; the tension compensation trolley moves to provide tension for the mobile contact line or release the tension of the mobile contact line; and the left fixed busbar and the right fixed busbar are respectively connected with flexible contact lines on the outer sides of the left fixed busbar and the right fixed busbar. During coaling, the mobile contact line is moved away, and the mobile contact line is moved to a position above the railway so as to provide electricity for an electric locomotive when a train enters and leaves a coaling zone.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

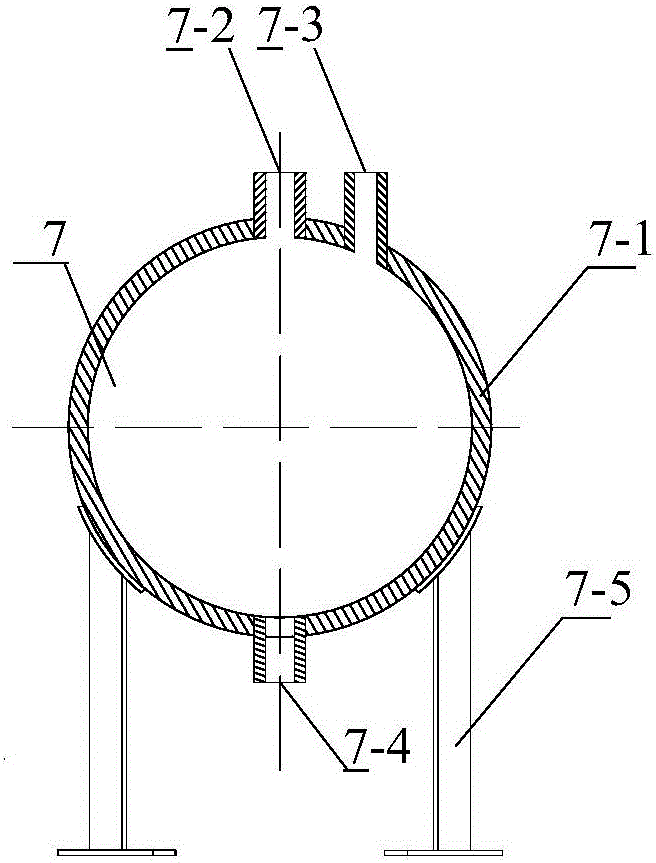

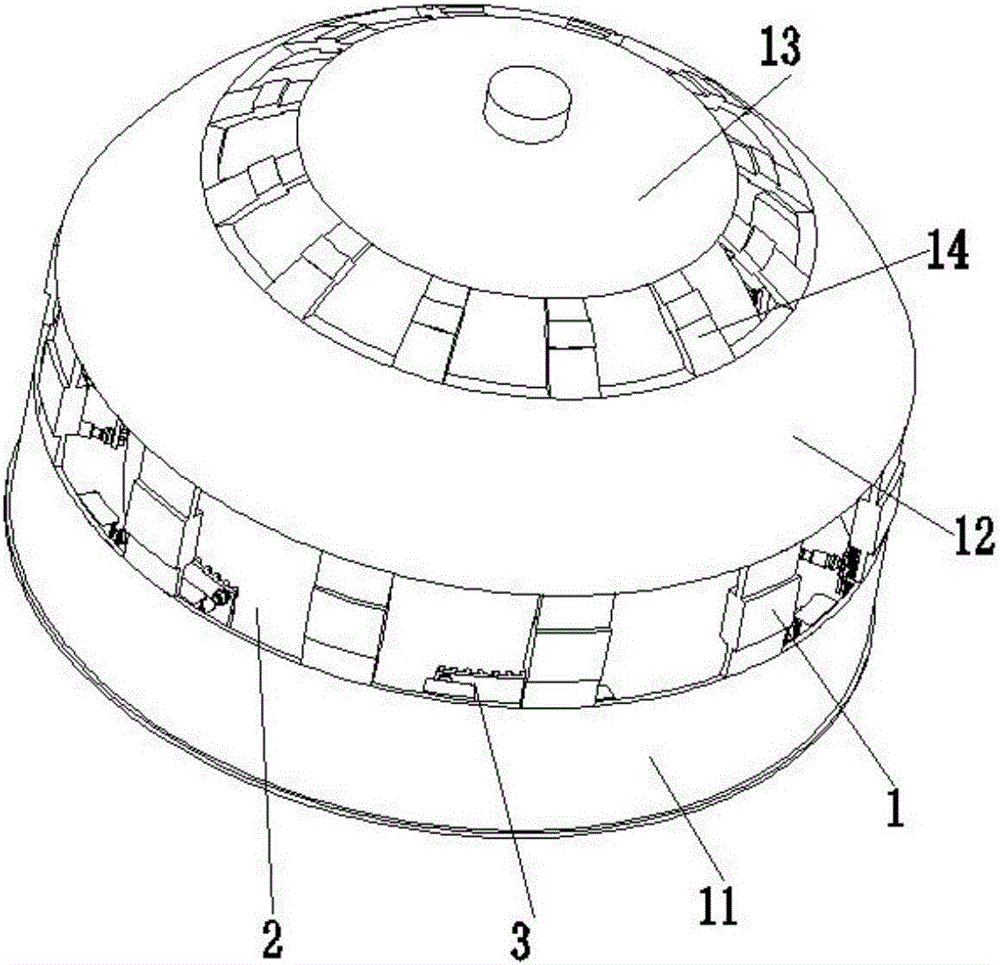

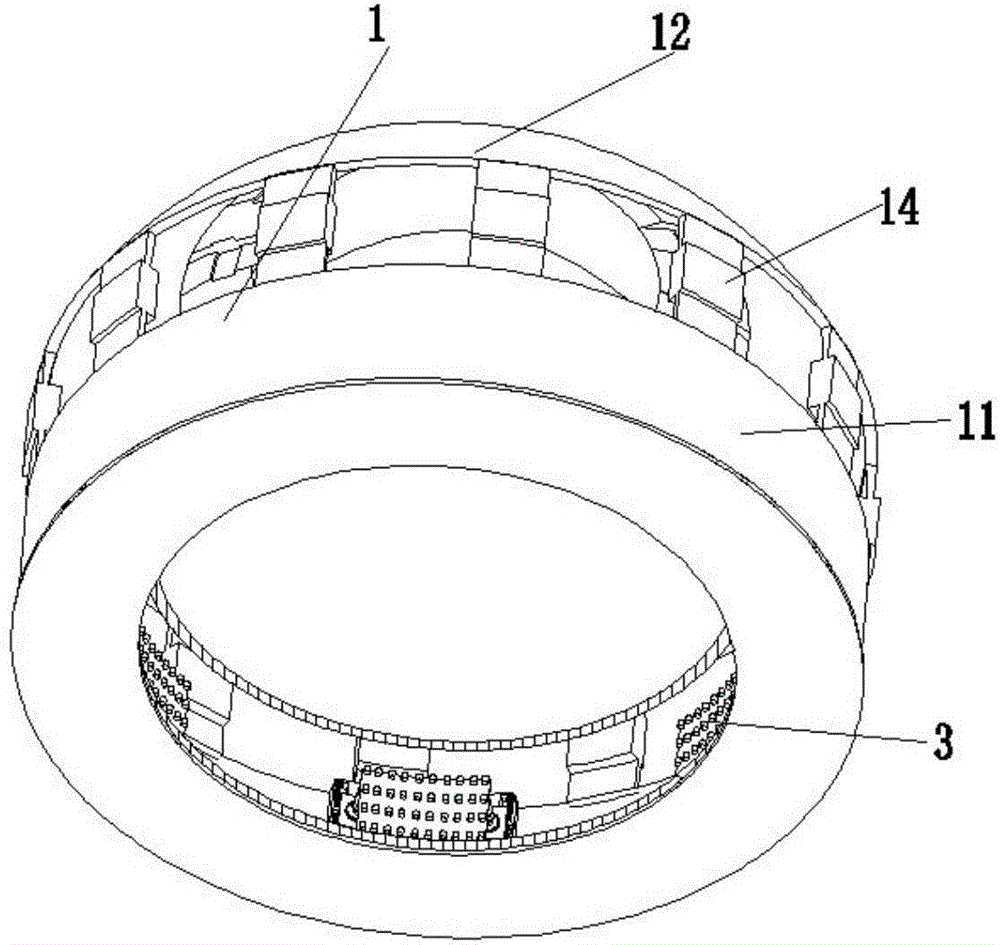

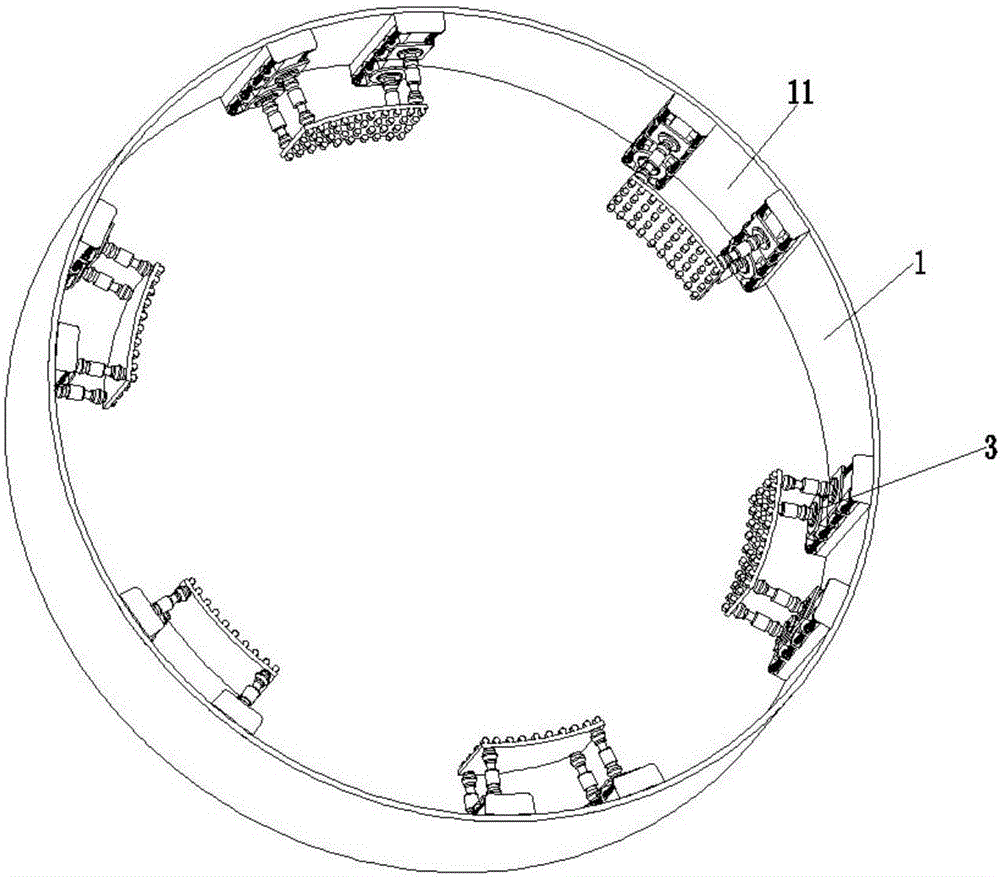

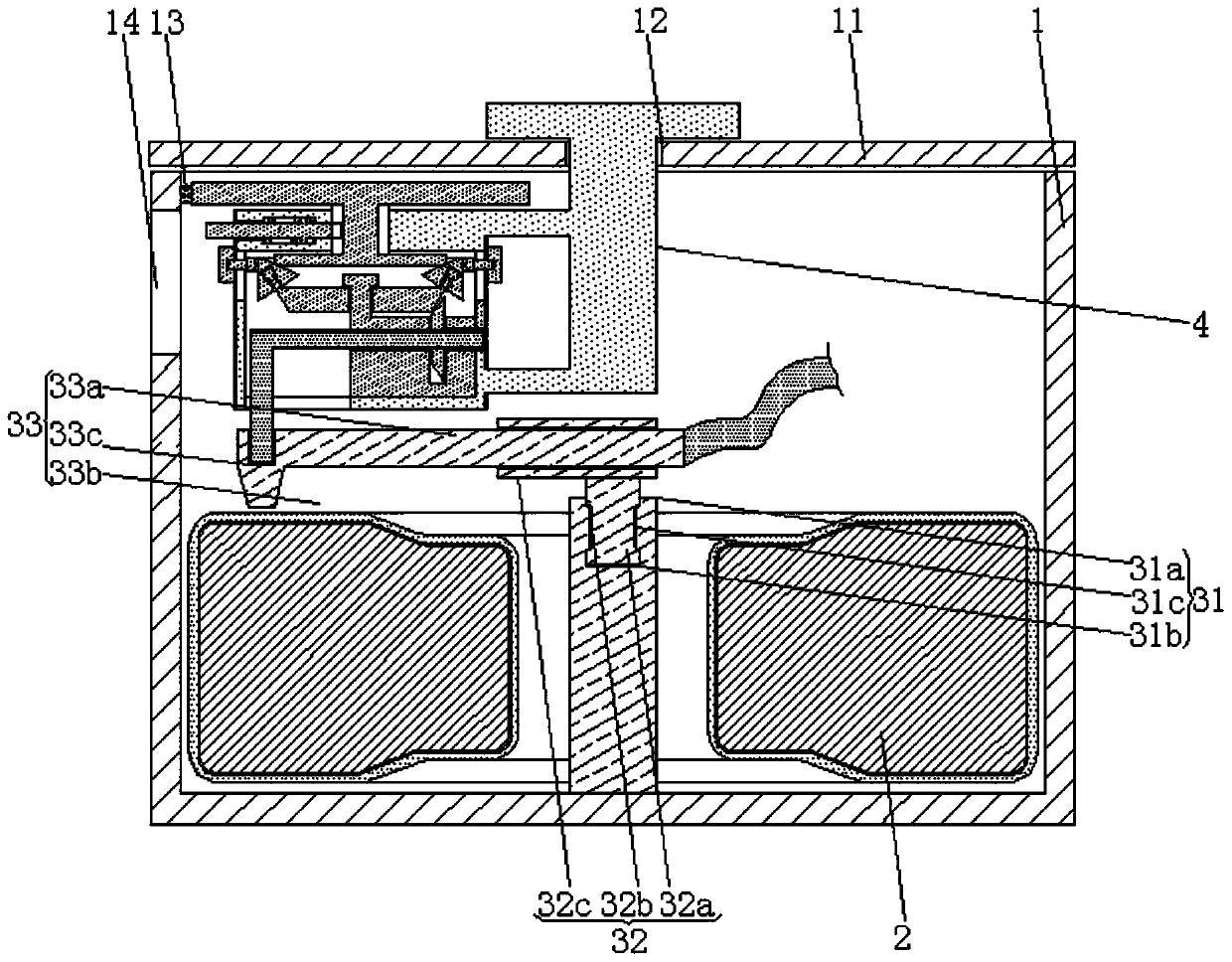

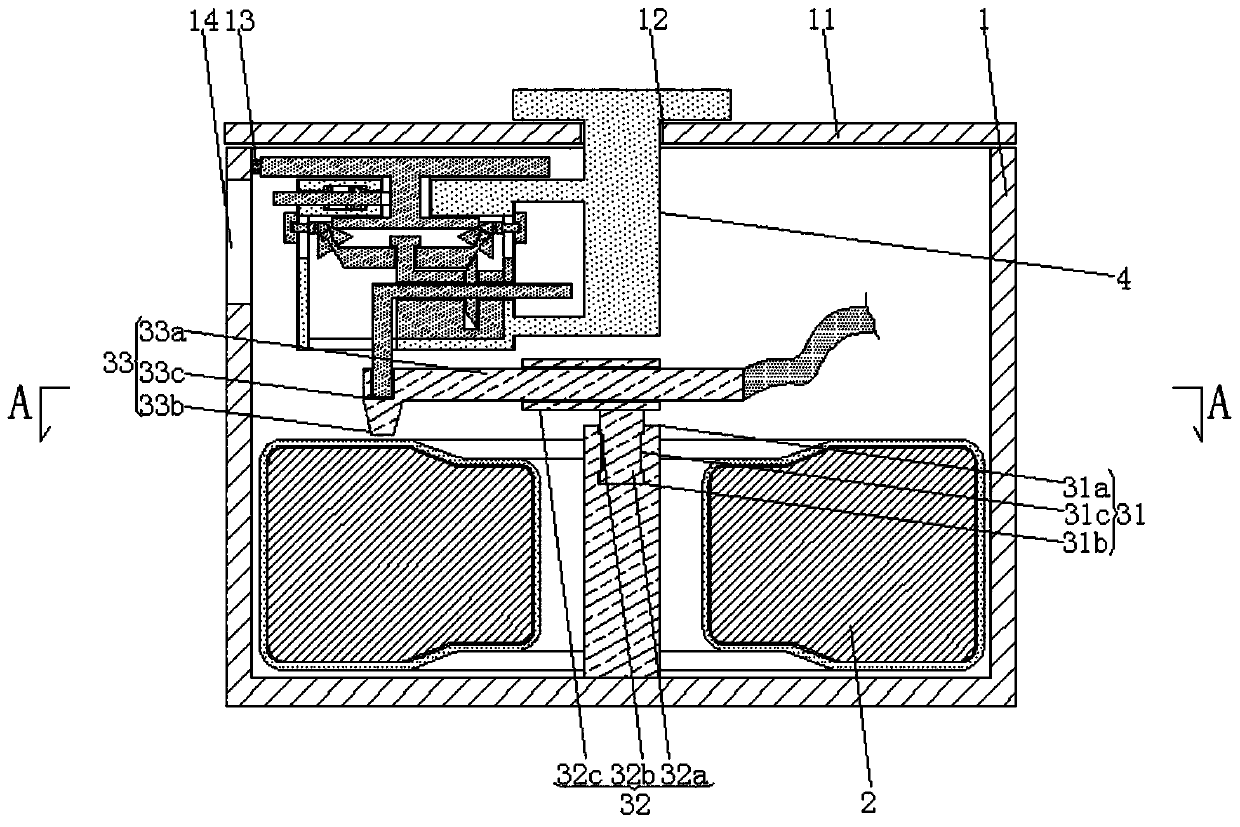

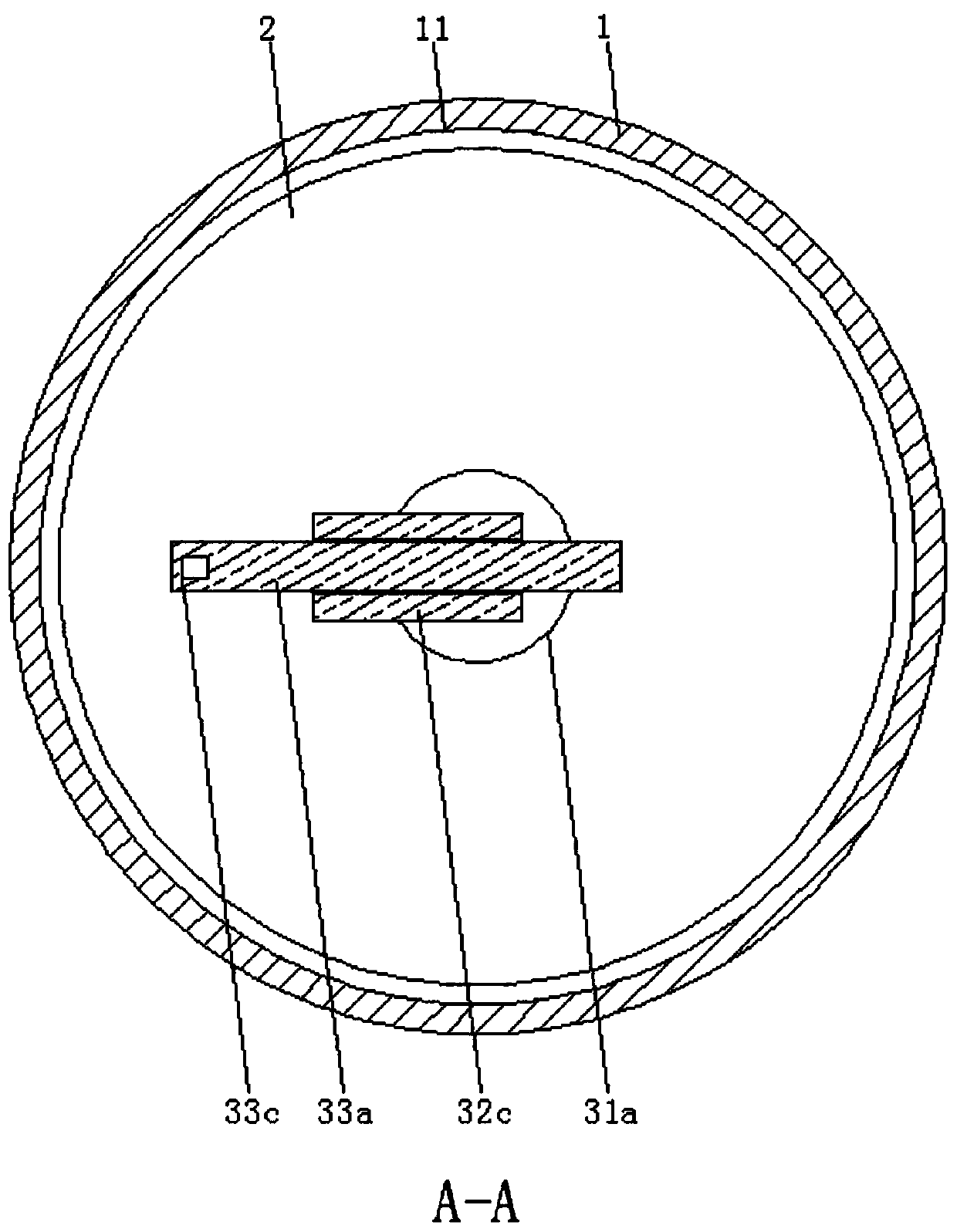

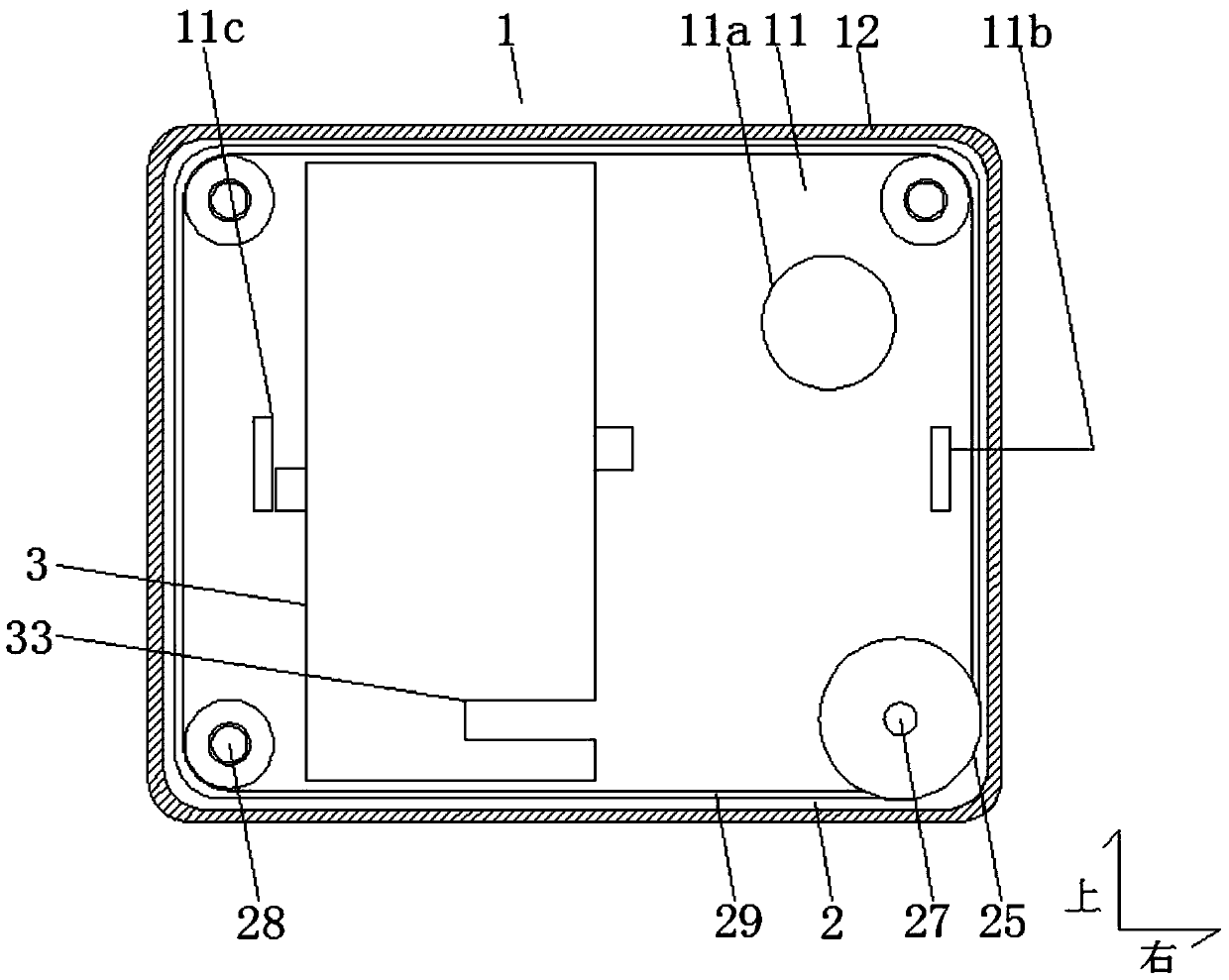

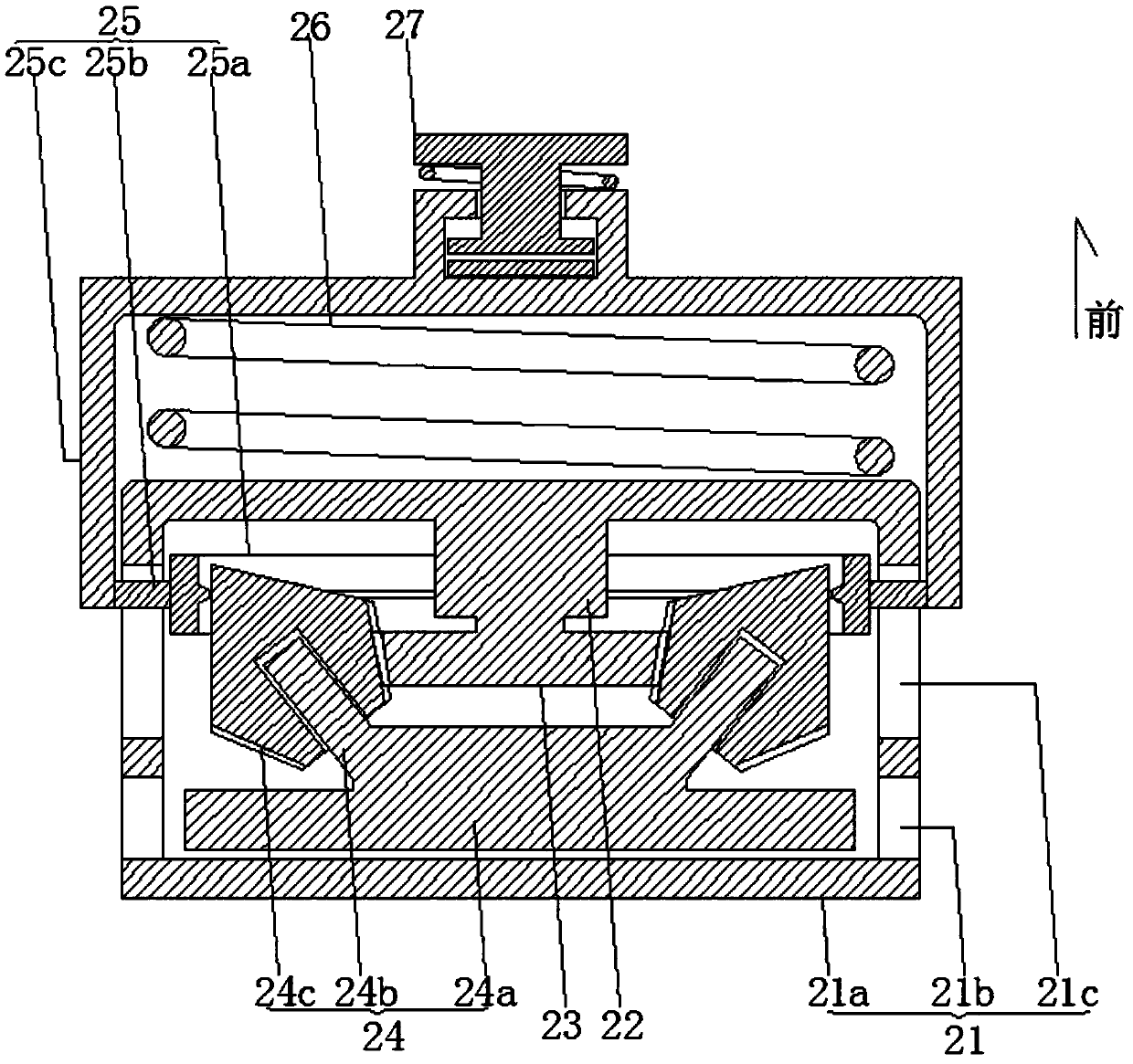

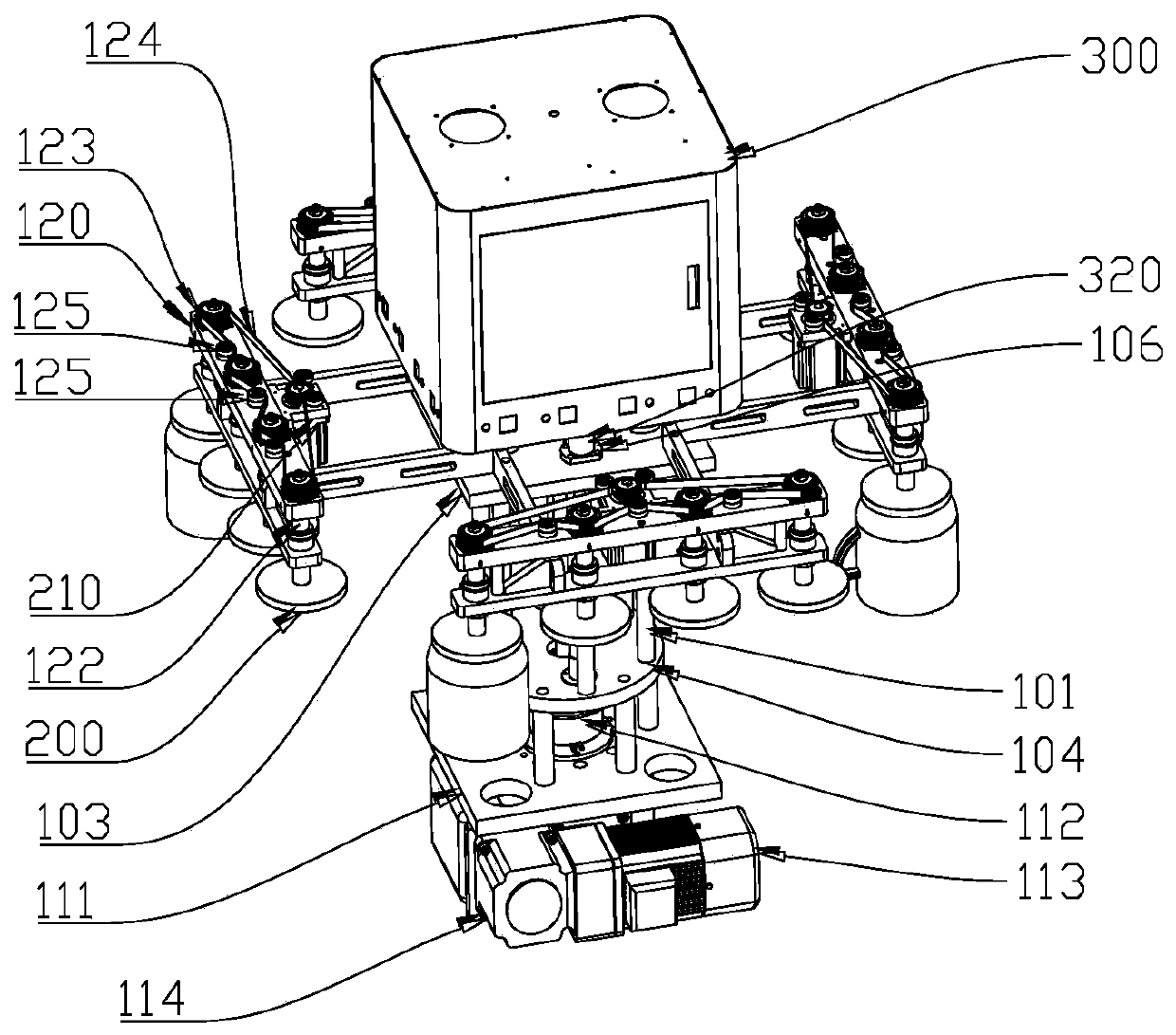

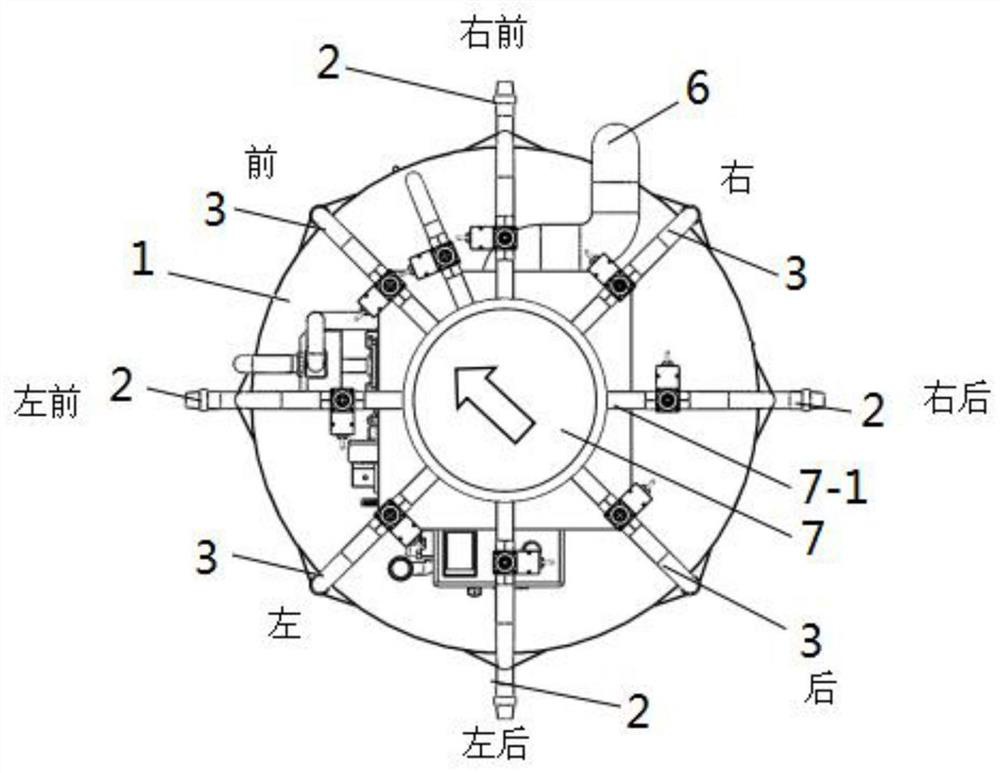

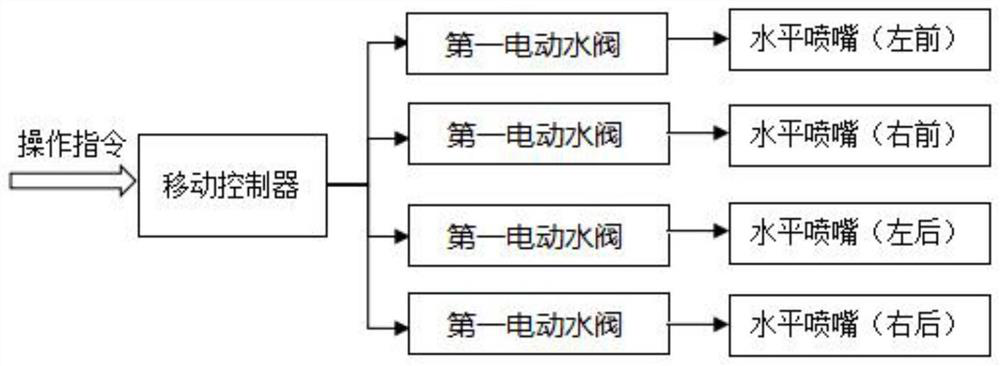

Special massage head hood for head massage health-care robot

InactiveCN105769533AComprehensive contactCompact structureVibration massagePhysical medicine and rehabilitationMassage

The invention relates to a special massage head hood for a head massage health-care robot. The special massage head hood comprises an outer shell, an inner shell and massage execution devices, wherein the outer shell and the inner shell are of semi-spherical shell structures, the inner shell is positioned in the outer shell, an annular accommodating cavity is formed between the inner shell and the outer shell, the massage execution devices are uniformly mounted in the annular accommodating cavity formed between the inner shell and the outer shell in sequence, one end of each massage execution device is connected with the outer shell, and the other end of each massage execution device contacts the inner shell. The special massage head hood can realize the movements towards four degree-of-freedom directions, namely, one translation movement and three rotation movements, the movement effects are good, a plurality of movement degrees of freedom are available, the contact with the head is comprehensive, the movement and rotation speeds are adjustable, the special massage head hood can be used by people of all ages, the applicability is wide, and thus the massage effects of the special massage head hood are improved.

Owner:朱晓霞

Adjustable transformer

InactiveCN110098038AAvoid damageAvoid reciprocating frictionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerConductor Coil

The invention relates to an adjustable transformer, which comprises a housing and an annular core and further comprises a carbon brush and an adjusting device. According to the adjustable transformerof the invention, the adjusting device drives the carbon brush to rotate in the circumferential direction and adjusts the position of the brush head in the radial direction; the reciprocating frictionbetween the brush head and a winding of the annular core on the same circular trajectory is avoided so as to prevent the damage of the winding of the annular core; the moving direction of a sliding brush rod can also be switched so as to enable the brush head to have two moving modes such as expansion and relaxation in the radial direction, and the brush head is enabled to be continuously used; the moving speed of the brush head is very slow, so that it is unnecessary to manually change the moving direction of the sliding brush rod for many times; and the moving speed of the sliding brush rodcan also be adjusted.

Owner:吕娜

Portable Assembled Theoretical Mechanics Teaching Aids

InactiveCN105390051BAdjustable movement speedReduce weightEducational modelsMechanical engineeringMotherboard

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

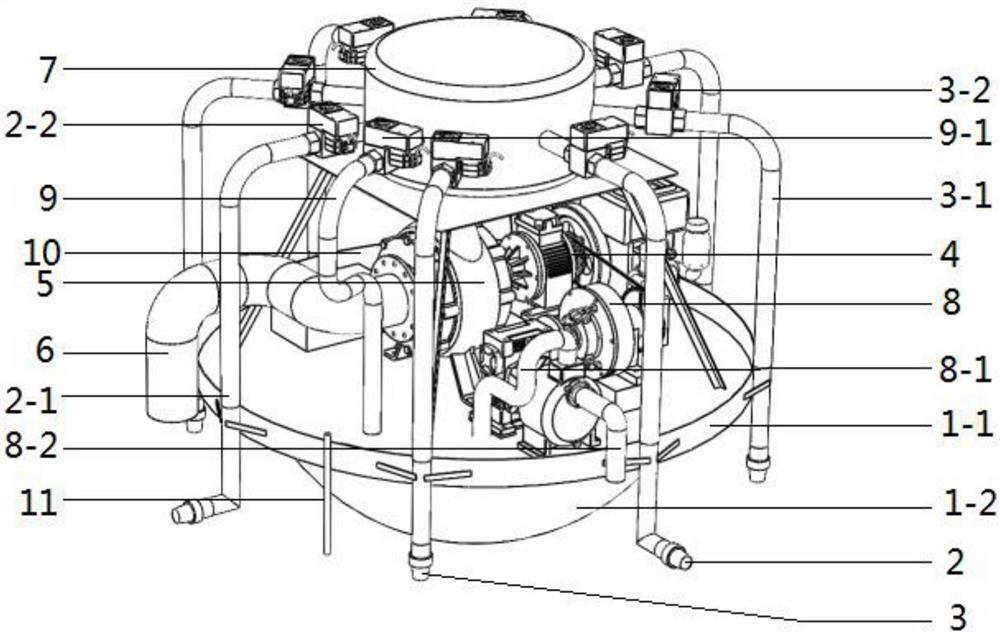

Float-type aeration stirring machine for sewage treatment

InactiveCN108408817AAdjustable movement speedSuitable for useWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationPropellerAir pump

The invention discloses a float-type aeration stirring machine for sewage treatment. The float-type aeration stirring machine for the sewage treatment comprises multiple installing plates distributedin central symmetry. The inner side face of each installing plate is fixedly provided with a stirring motor, and the outer side face of each installing plate is fixedly provided with a stirring cylinder. The stirring cylinder is internally provided with a stirring shaft of which one end is fixedly connected with an output shaft of the stirring motor in a rolling mode. The outer side face of the stirring cylinder is provided with an air inlet communicated with the interior of the stirring cylinder. The outer surface of the stirring motor is fixedly provided with an air pump. The air pump is communicated with the air inlet through an air pipe. The beneficial effect is that the float-type aeration stirring machine for the sewage treatment can be freely moved without installing a water flow propeller, and the moving speed is adjustable, the aeration area is large, the aeration speed is rapid, the efficiency is high, and the float-type aeration stirring machine is particularly suitable foran aeration tank in larger area.

Owner:程俊

Automobile fuel tank cap automatically opened and closed

ActiveCN107696852AAvoid problems such as leakageAdjustable movement speedFuel supplyStart stopTransmission belt

The invention relates to an automobile fuel tank cap automatically opened and closed. The automobile fuel tank cap automatically opened and closed comprises a tank cap body, a power device and a driven baffle. The tank cap body is a rectangular hollow shell and comprises a rear bottom board, a peripheral side wall and a front top board. The power device comprises a drive barrel, a drive motor, a sun gear, a planet support, an outer sliding ring, a reset spring, a start-stop switch, turning rolls and a transmission belt. The driven baffle comprises a baffle body, a reversing insertion rod, a left contactor, a right contactor and a pressing side hole. By the adoption of the automobile fuel tank cap automatically opened and closed, the start-stop switch is turned on so that the driven bafflecan be controlled to automatically finish the automatic cap opening action, the cap closing preparation action and the complete cap closing action, fueling operation can be finished through cooperation of inserting and pulling out of a fueling gun, and the problem that gasoline leaks due to the fact that a driver forgets to close a fuel tank cap is solved; and the moving speed of the driven bafflecan be adjusted as well.

Owner:广州市铁研汽车零件有限公司

Self-programmable multi-shaft target shooting robot

InactiveCN110595288AReduce purchase quantityLow costProgramme-controlled manipulatorMovable targetsRemote controlReduction drive

The invention discloses a self-programmable multi-shaft target shooting robot. The self-programmable multi-shaft target shooting robot comprises a chassis, two front wheel brushless hub motors and oneor two rear wheel damping universal wheels; a target seat is arranged above the chassis; three output shafts are arranged on the target seat; a control box is arranged below the chassis and comprisesa battery, a controller, a motor and a speed reducer; the controller controls the rotation of the three output shafts through the motor and the speed reducer; the controller controls the advancing ofthe front wheel brushless hub motors; the robot further comprises a remote control; the remote control comprises a touch screen and can carry out self-programming setting on the rotation angle, speedand time of the three output shafts; and the remote control wirelessly controls the controller. According to the self-programmable multi-shaft target shooting robot, the design of the three output shafts is adopted, and the cost can be reduced by one machine for multiple purposes; the electromechanical integration design is convenient for transportation, use and maintenance; and the mobility control is performed on the position of a product through the remote control, and the rotation angle, speed and time of the three output shafts can be independently programmed and controlled.

Owner:潍坊琢锋智能科技有限公司

Swing-type diameter-variable envelope forming full-section drill tool

PendingCN109882181AAdjustable movement speedAdjustable cutting directionDrill bitsDerricks/mastsHydraulic cylinderDrive shaft

The invention discloses a swing-type diameter-variable envelope forming full-section drill tool, which comprises a swing mechanism, a drill arm, driving devices and a drill tool body. The swing mechanism comprises an outer shell, a first hydraulic cylinder, a second hydraulic cylinder, a third hydraulic cylinder and a fourth hydraulic cylinder, a transmission shaft coaxial with the outer shell ismounted in the outer shell, the upper part and the lower part of the transmission shaft are connected with the inner wall of the outer shell through bearings correspondingly, the lower part of the transmission shaft stretches out of the outer shell, a connecting plate is mounted on the part, outside the outer shell, of the transmission shaft in a sleeving mode, the first hydraulic cylinder and thesecond hydraulic cylinder are rotationally connected to a rack of a shaft tunneling machine in a splayed mode, the ends of piston rods of the first hydraulic cylinder and the second hydraulic cylinder are rotationally connected to the connecting plate, the third hydraulic cylinder and the fourth hydraulic cylinder are rotationally connected to the outer end of the connecting plate in a splayed mode, and the ends of piston rods of the third hydraulic cylinder and the fourth hydraulic cylinder are rotationally connected to the drill arm; and the drill arm is of a telescopic structure, the multiple driving devices are mounted at the end of the drill arm, and each driving device is connected with the drill tool body located below the drill arm. The swing-type diameter-variable envelope forming full-section drill tool can be suitable for different geological conditions, and full-section tunneling is achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Novel CNC wire cutting machine

The invention relates to a novel CNC wire cutting machine which can effectively improve the coordinate accuracy of a horizontal plate and a longitudinal plate. The novel CNC wire cutting machine comprises a machine tool body, a workbench, a wire walking mechanism, a high-frequency pulse power supply, a liquid supply system and an electrode wire. The workbench comprises a horizontal plate, a longitudinal plate and a displacement device. The horizontal plate is arranged on the top face of the machine tool body through the displacement device. The longitudinal plate is arranged on the top of the horizontal plate through the displacement device. The displacement device comprises a bottom plate and a top plate. A thread rod is fixed at the end of the top plate in a parallel mode. A middle rotating shaft is vertically arranged on the bottom plate. A worm wheel is arranged on the middle rotating shaft through a bearing. The worm wheel is meshed with a thread face of the thread rod. A motor box is arranged on the bottom plate. The motor box comprises a speed reducing motor, a worm and a worm adjusting sleeve. One end of the worm is arranged at the output end of the speed reducing motor. Spiral-shaped gear teeth meshed with the worm wheel are arranged on the worm. The thickness of the gear teeth are gradually increased from one end to the other end in the axial direction. The other end of the worm moves relatively in the axial direction in a worm adjusting sleeve.

Owner:TAICANG SHUNCHANG FORGE

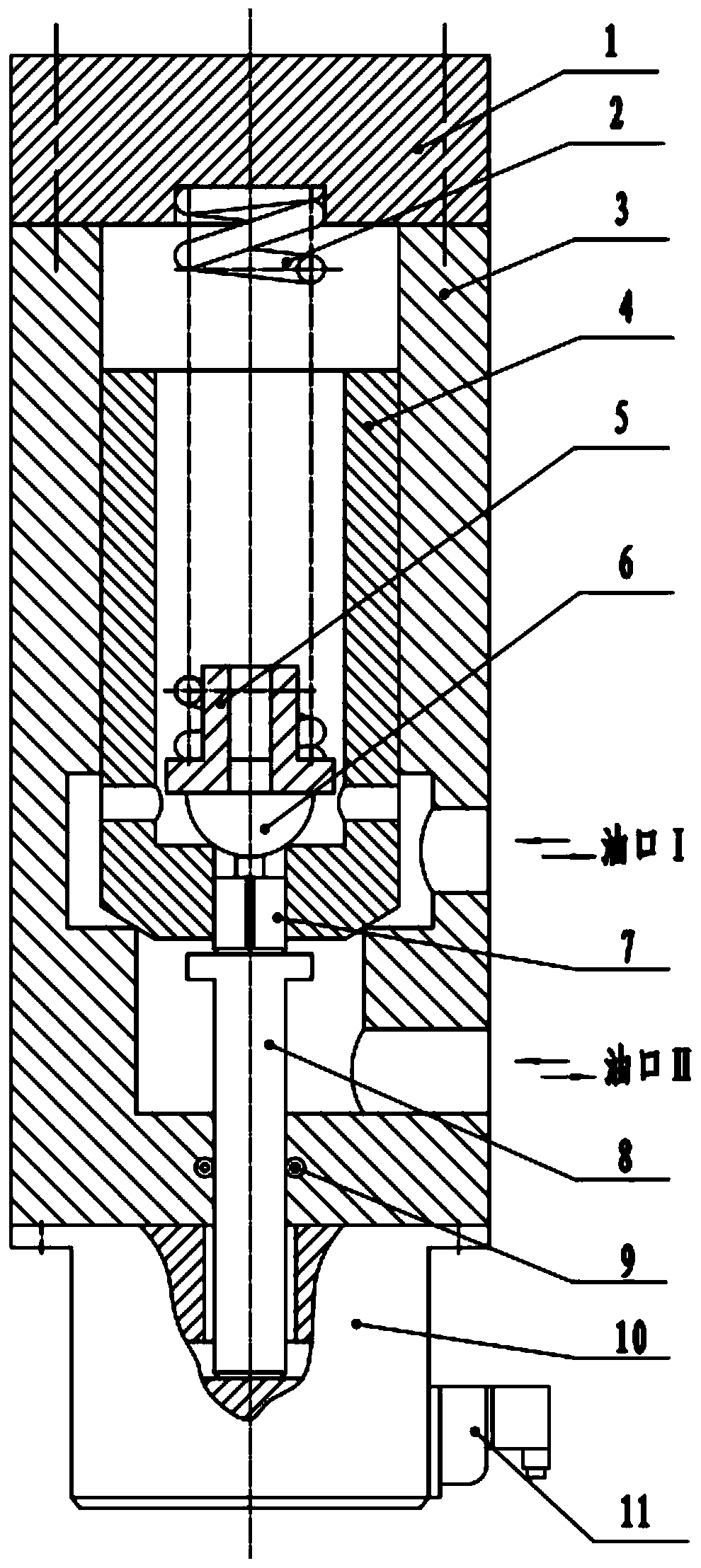

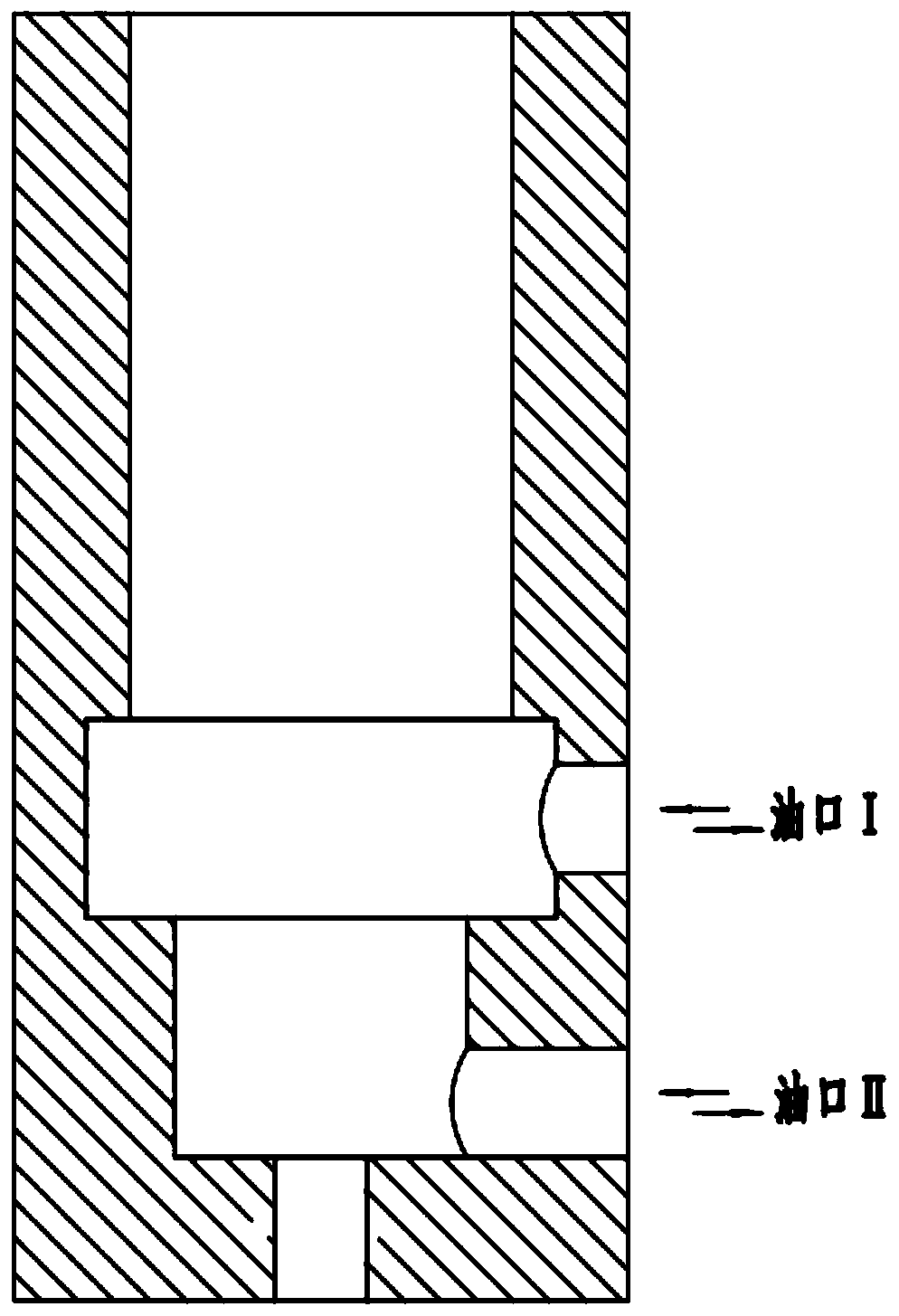

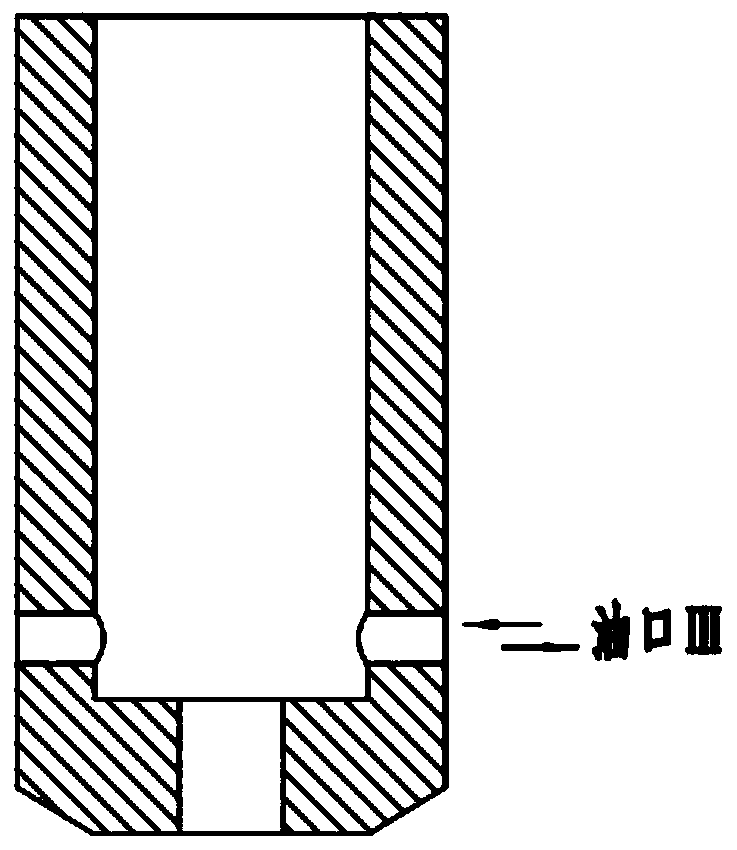

Combined electric-control high-pressure one-way valve

PendingCN109973456AIncrease the level of automationEasy to control from a distanceOperating means/releasing devices for valvesServomotor componentsAutomatic controlEngineering

The invention relates to a combined electric-control high-pressure one-way valve. According to the technical scheme, an electromagnet (10) is fixed at the closed end of a valve body (3), a main valveelement (4) is arranged in the valve body (3), the main valve element (4) is sequentially provided with an unloading valve element (6), a spring seat (5) and a spring (2) from inside to outside, the upper end of an unloading valve element rod (7) is in contact with the lower portion of the unloading valve element (6), the lower end of the unloading valve element rod (7) penetrates out of a valve rod through hole of the main valve element (4) to be in contact with the upper end of a push rod (8), the lower portion of the push rod (8) passes through a push rod through hole of the valve body (3)to be inserted into a circular hole of the electromagnet (10), an annular sealing ring (9) is arranged on the inner wall of the push rod through hole of the valve body (3), the main valve element (4)is a hollow cylinder with one closed end and one open end, the appearance of the closed end is in a circular truncated cone shape, the valve rod through hole is formed in the closed end along the axis, and 2-4 oil ports III are formed closed to the inner end of a hollow cavity of the main valve element (4) in the radial direction. The combined electric-control high-pressure one-way valve has the characteristics that the automatic control level is high, the structure is simple, the influence of the oil return back pressure is avoided, the response speed is high, and an oil way does not need tobe controlled.

Owner:WUHAN UNIV OF SCI & TECH

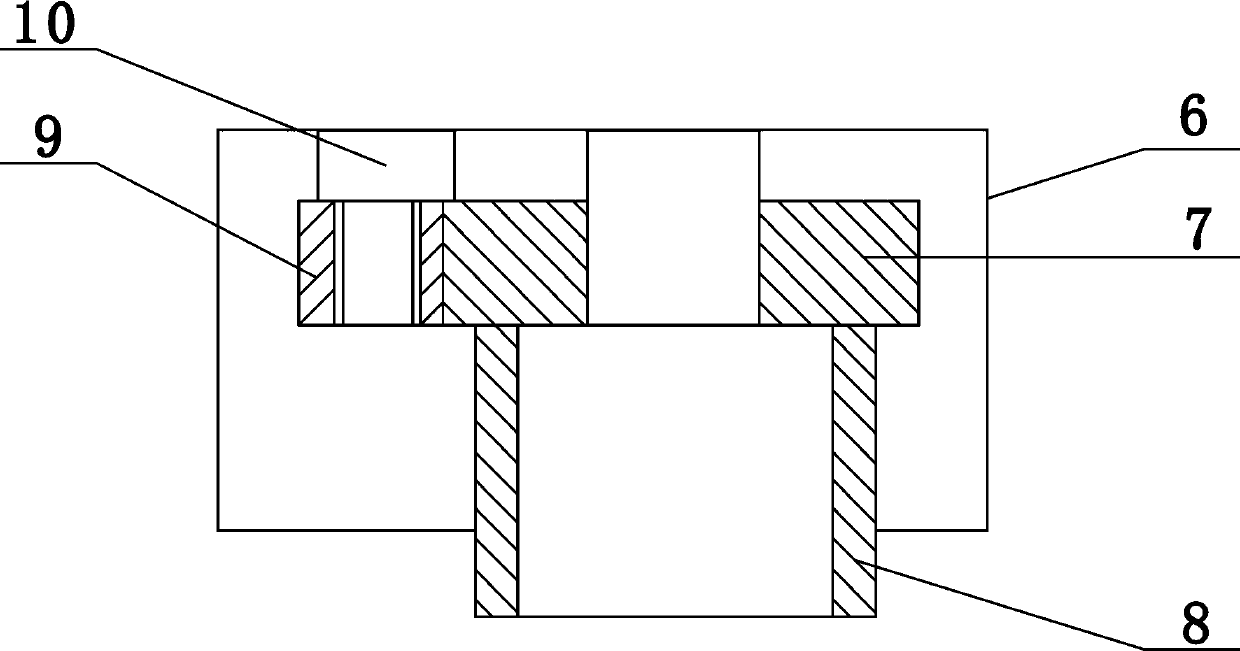

Chuck device

The invention relates to the field of machining machinery, in particular to a chuck device capable of adjusting the clamping strength and controlling the clamping jaw range. The chuck device comprisesa power source, a power transmission structure for power transmission, a clamping jaw structure and a frame, which are connected in sequence; and the clamping jaw structure is rotationally connectedto the frame. The chuck device further comprises an adjusting structure for adjusting the grabbing strength of the clamping jaw structure and finely adjusting the moving range of the clamping jaw structure; the adjusting structure is connected with the clamping jaw structure; and the power transmission structure comprises a connecting rod mechanism for realizing opening and closing motion trajectories of the clamping jaw structure. The chuck device is provided with the adjusting structure; the clamping jaw structure can adjust the clamping strength and finely adjust the moving range of the clamping jaw structure; meanwhile, the connecting rod mechanism is provided for controlling the opening and closing motion trajectories of the clamping jaw structure to realize adjustment of the moving range of the clamping jaw structure and adjustment of the clamping strength; and meanwhile, the clamping is convenient, the moving speed is adjustable, and the clamping effect is excellent.

Owner:GUANGDONG IND TECHN COLLEGE

Laser reverse attack device

The invention discloses a laser reverse attack device which comprises a supporting frame, an XY-axis pan tilt, a controller, an infrared emission gun and a lithium battery, wherein the XY-axis pan tilt is arranged on the supporting frame and used for driving the infrared emission gun to emit infrared laser in all directions, the controller is used for controlling and adjusting the XY-axis pan tiltand the infrared emission gun, and the lithium battery is used for supplying power to the XY-axis pan tilt and the infrared emission gun. The laser reverse attack device has XL two-axis movement capacity, can move horizontally and vertically at the same time, is adjustable in movement speed and angle, and can emit laser signals to an imaginary enemy according to simulation training requirements.

Owner:厦门砺兵智能科技股份有限公司

Brand-new working mode integrating material receiving, chambering, flattening and arranging

PendingCN114121489AAdjustable ascent speedAdjustable descent speedThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention belongs to the technical field of thin film capacitor winding, and particularly relates to a brand new working mode integrating material receiving, chambering, flattening and arranging, which comprises a winding mechanism, a conveying assembly, a flattening mechanism, a chambering mechanism, a first core pushing mechanism and a second core pushing mechanism, the winding mechanism, the conveying assembly, the flattening mechanism and the first core pushing mechanism are all mounted on a substrate, and the conveying assembly is mounted on the substrate. The first core pushing mechanism is fixed on the conveying assembly, the second core pushing mechanism is fixed on the conveying assembly, the reaming mechanism is located above the first core pushing mechanism, the flattening mechanism is located above the reaming mechanism, a finished product arrangement frame is arranged on one side of the conveying assembly, and a rotating shaft of a belt pulley is connected to external power driving equipment. According to the working mode, moving and transferring between the mechanisms can be reduced, the production efficiency is improved, excessive manual debugging can be avoided after production specifications are replaced, automatic adjustment and adaptation can be achieved, and manual labor is reduced.

Owner:CHANGZHOU SAVY MACHINE

Method for core-crossing hanging large-scale motor hydraulic ram lifting

ActiveCN101277049BWork around space constraintsHigh lifting control precisionLifting devicesManufacturing dynamo-electric machinesElectric machineHydraulic ram

Owner:CHINA MCC20 GRP CORP

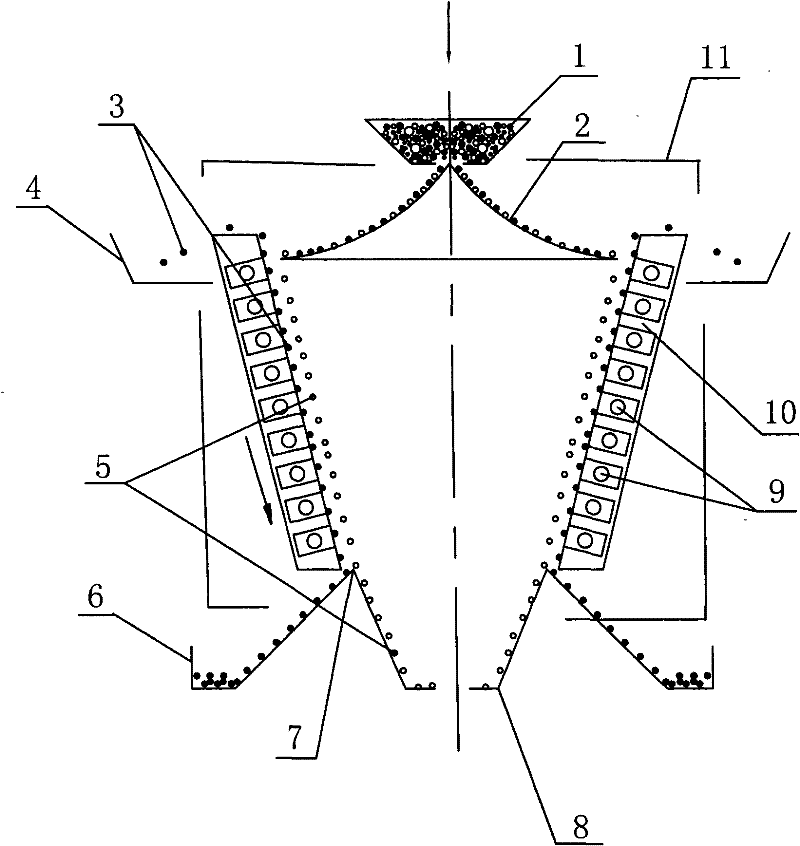

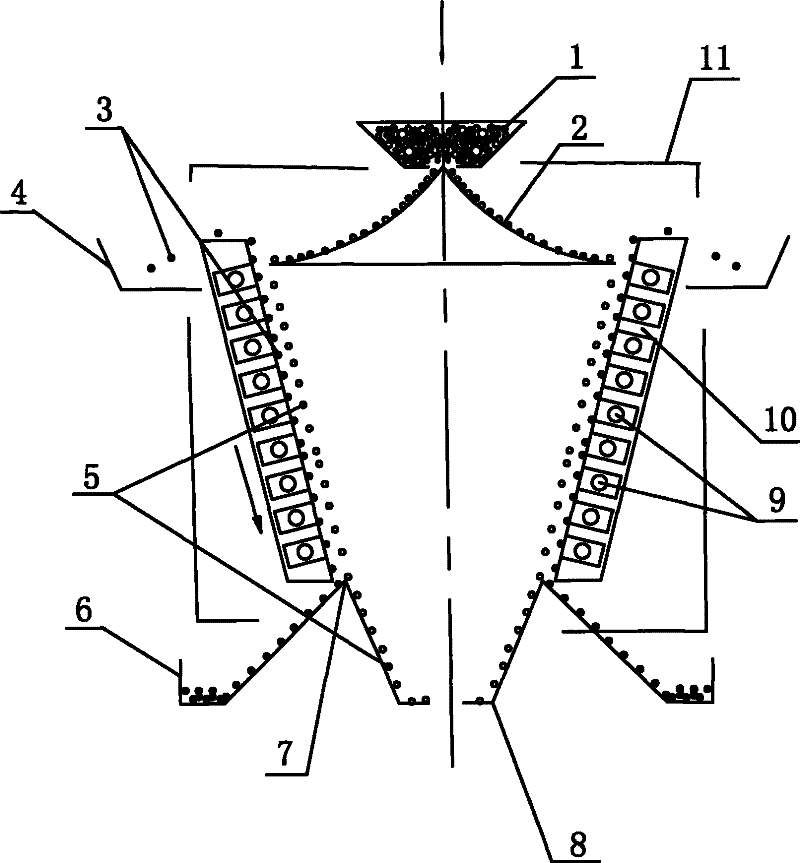

Tapered travelling-wave electromagnetic wave concentrator

InactiveCN101786043BSimple structureEasy maintenanceMagnetic separationFrequency conversionEngineering

The invention discloses a tapered travelling-wave electromagnetic wave concentrator, comprising a machine frame, a feed hopper, a tailing hopper and a concentrated ore hopper; the lower part of the feed hopper is provided with a material dividing cone which is arranged at the upper open end of a tapered linear electric motor, an electromagnetic coil is embedded in the groove of the tapered linearelectric motor, the concentrated ore hopper at the upper part is sleeved at the outlet of the upper end of the tapered linear electric motor, an ore-dividing cone is arranged at the outlet of the lower end of the tapered linear electric motor, the central tapered tailing hopper is arranged at the inner side of the ore-dividing cone, the lower concentrated ore hopper is arranged at the outer side of the ore-dividing cone. The taper travelling-wave electromagnetic wave concentrator has the advantages that the structure is simple, due to the absence of moving parts, the maintenance is very convenient; the concentrator can sort and discharge the magnetic, non-magnetic ore materials continuously; meanwhile, through the electromagnetic regulation or frequency conversion technology, the strengthof the magnetic field and the arc moving velocity of the magnetic field can be adjusted, and the sorting operation for different magnetic minerals and with different sorting speeds can be realized.

Owner:XIANGTAN UNIV

Glaze dipping equipment for ceramic cups

InactiveCN110744690ARealize automatic glaze dippingEasy to achieve adaptive adjustmentCeramic shaping apparatusEngineeringServo

The invention relates to the field of article glazing, and discloses glaze dipping equipment for ceramic cups. The glaze dipping equipment comprises a multi-station support, a station rotary power mechanism, suction heads, suction head power mechanisms and a vertical power mechanism. The multi-station support is arranged on the station rotary power mechanism and can be driven by the station rotarypower mechanism to rotate. Multiple suction head supports are arranged on the multi-station support. The suction head power mechanisms and the multiple suction heads driven by the suction head powermechanisms to rotate are arranged on the suction head supports. The vertical power mechanism is arranged on the multi-station support and can drive the multiple suction head supports to move up and down, and the vertical power mechanism is a servo motor. Automatic glaze dipping is achieved on the cups, the servo motor is used for driving the cups adsorbed by the suction heads to move in the vertical direction, the moving speed can be adjusted, precision is high, displacement height adjusting is simple, adaptive adjusting to different cups can be achieved easily, and efficiency is high.

Owner:湖南三创智能科技有限公司

A paddy field mobile operation platform

ActiveCN110637543BImprove versatilityAvoid destructionPropulsive elementsTransplantingControl systemAgricultural engineering

The invention discloses a paddy field mobile operation platform, which includes a body, a power generating device, a movement control system, a draft control system and an automatic leveling system, and the power generation device, the movement control system, the draft control system and the automatic leveling system are all installed on the body superior. The present invention has a compact overall structure, utilizes water flow pressure to realize platform movement, can make full use of water flow characteristics to reduce power consumption, avoids the use of heavy and complicated traditional walking devices, prevents the entire paddy field mobile operation platform from contacting the ground, and saves mechanical power at the same time It can avoid damage to aquatic crops; the draft control system uses the water filling in the airtight cavity inside the body to adjust the draft depth, so that the platform can meet the operation requirements of waters with different depths, and enhance the versatility and versatility of the platform; the automatic leveling system uses The vertical momentum of the water flow can keep the platform in a horizontal state all the time, which greatly guarantees the safety and quality of the work, and has strong practicability.

Owner:SHANDONG UNIV OF TECH +1

Movement mechanism

ActiveCN102114355BAdjustable movement speedRich aerial performancesStage arrangementsArtist equipmentsEngineeringClassical mechanics

Owner:华强方特(深圳)智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com