Surface polishing and grinding process and equipment used for long rod part with specially-shaped section

A special-shaped section, long rod technology, used in metal processing equipment, grinding/polishing equipment, grinders, etc., can solve the problems of difficult to guarantee the surface quality of parts, inconsistent surface polishing quality of parts, harsh workshop environment, etc., to reduce labor costs. use, achieve centering positioning, and improve the effect of polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to better understand the patent of the present invention, the patent of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

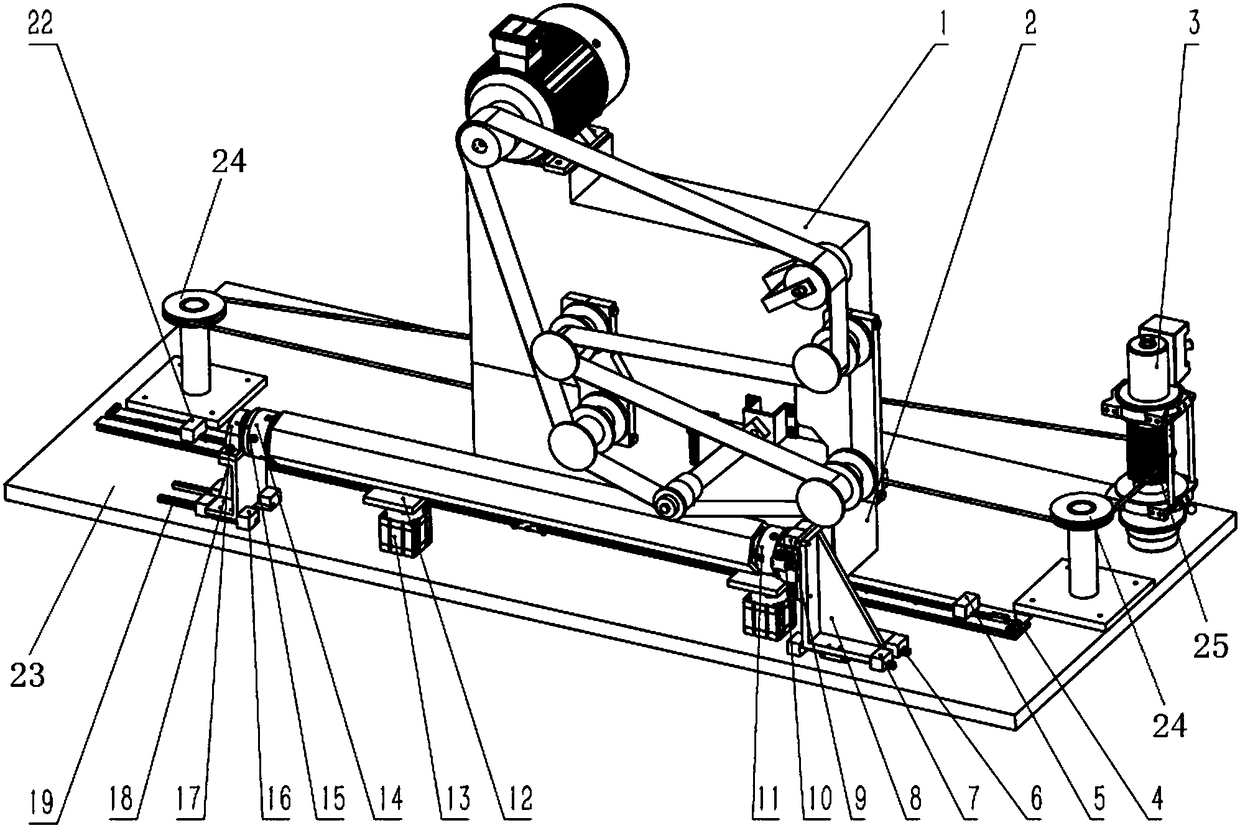

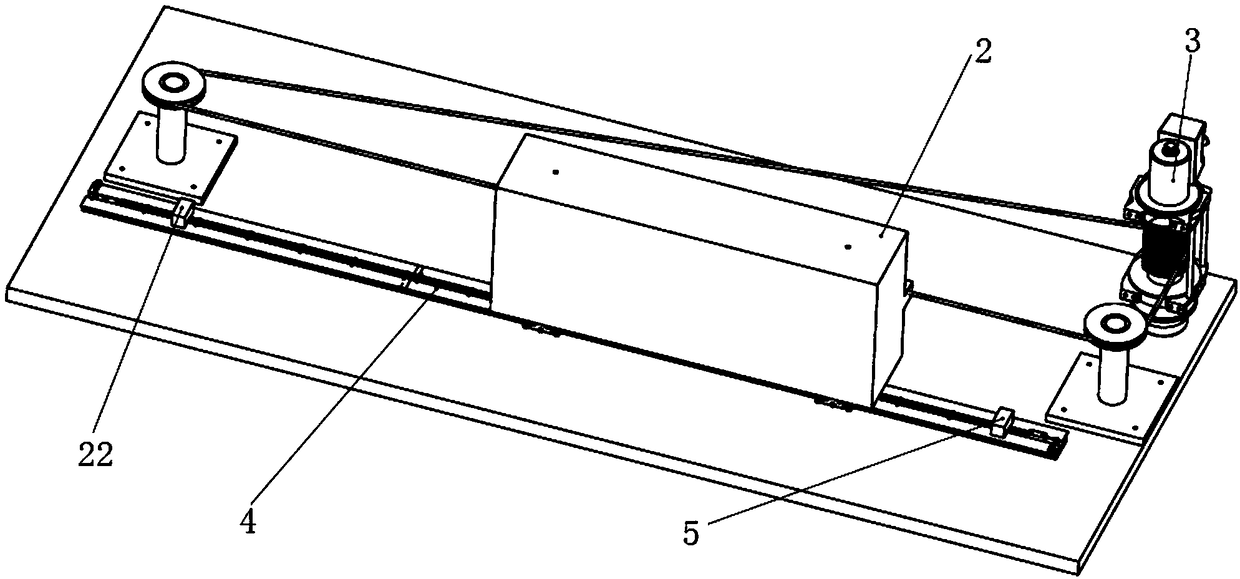

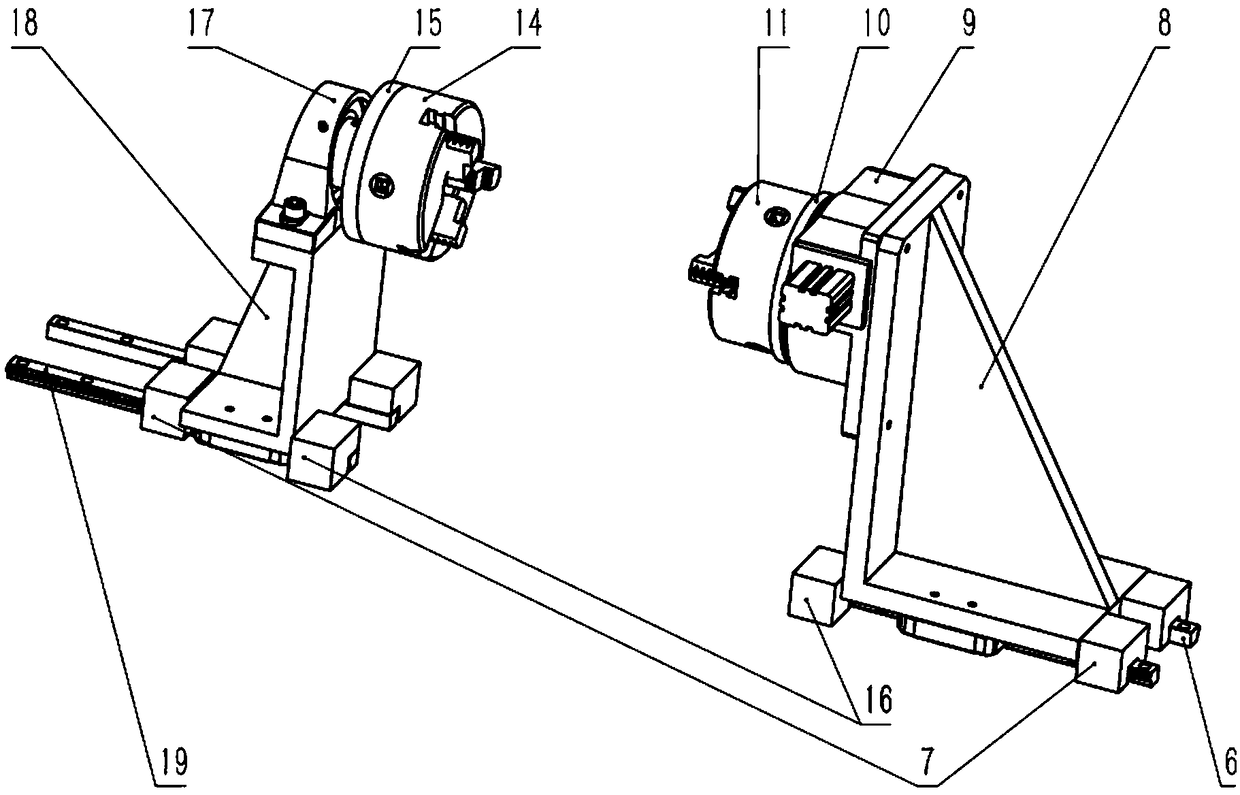

[0038] Such as figure 1 The overall schematic diagram of the equipment shown includes a belt machine 1, a slide seat 2, a linear motion drive device 3, a slide rail 4, a guide rail A 6, a guide rail B 19, a travel switch A 5, a travel switch B 22, two sets of guide rail brakes 7, Mounting seat A 8, mounting seat B 18, indexing plate 9, chuck connecting flange A 10, chuck connecting flange B 15, chuck A 11, chuck B 14, two sets of blocks 16, bearing 17. The belt machine 1 is installed on the sliding seat 2, and the sliding seat 2 can move linearly along the slide rail 4 under the drive of the linear motion driving device 3. During this stroke, the contact wheel of the belt machine 1 and the parts to be thrown Grinding surface or edge contacts, finishes the polishing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com