Patents

Literature

951results about How to "Good corrosion inhibition effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

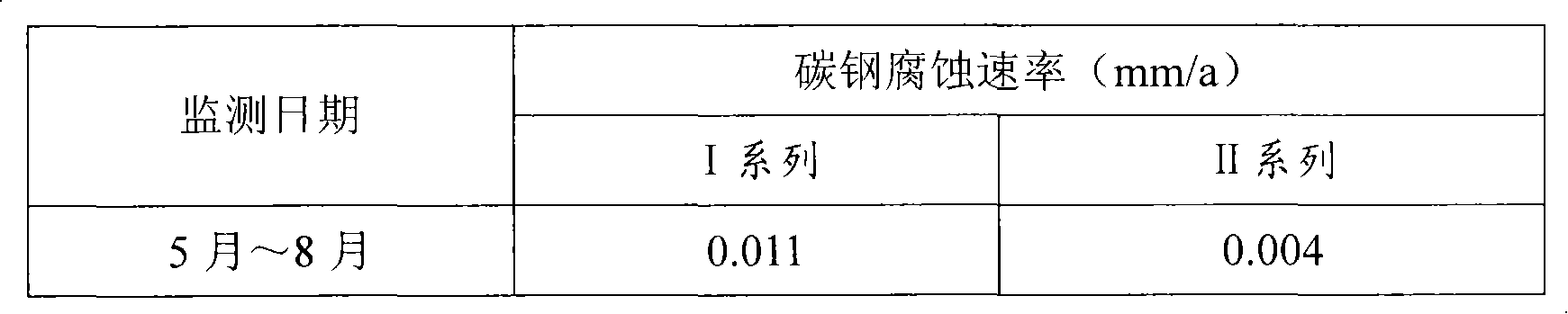

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

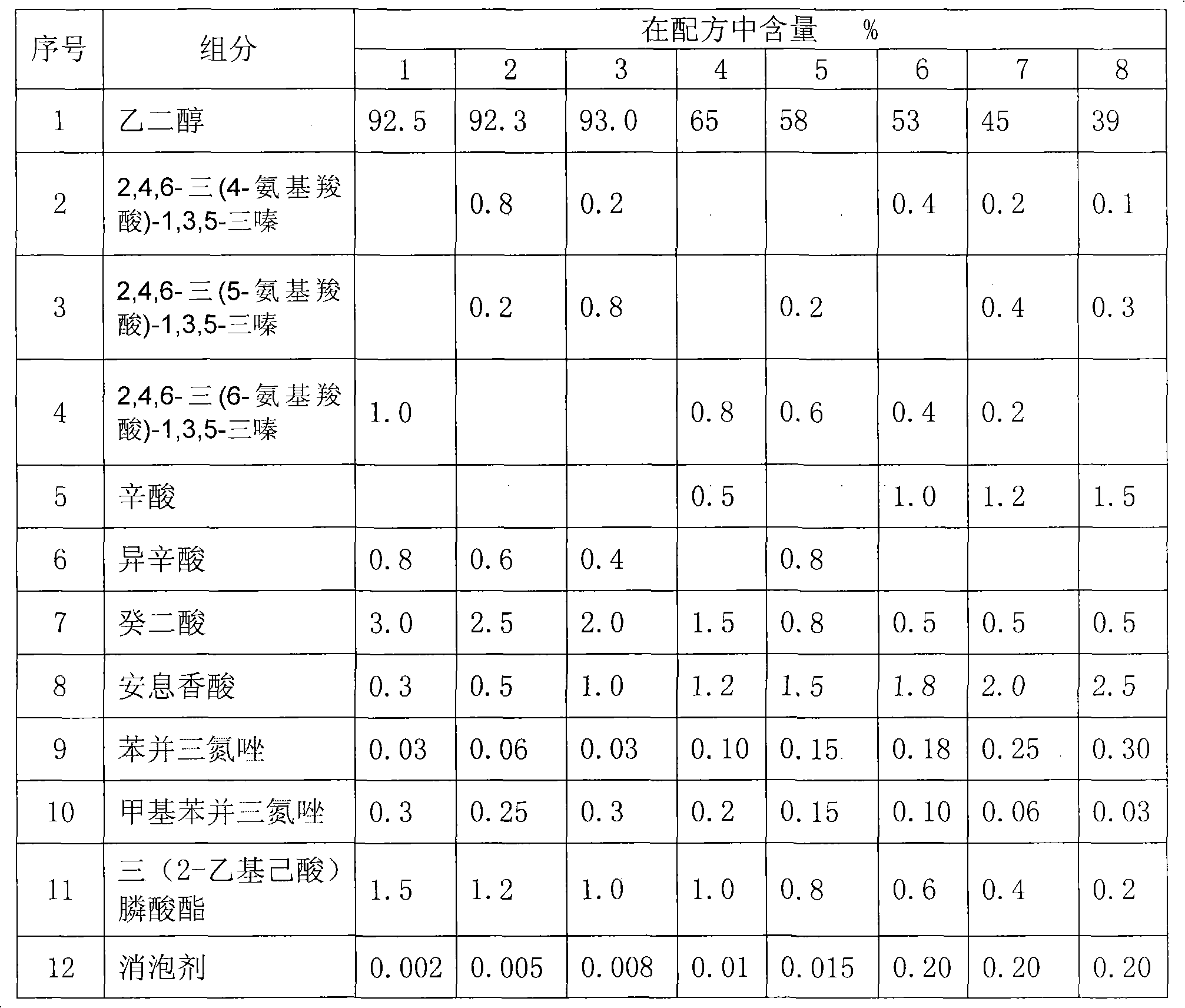

Engine coolant

ActiveCN101768428AAvoid corrosionGood corrosion inhibitionHeat-exchange elementsIonAutomotive engineering

The invention provides an all-organic type engine coolant which comprises glycol, fat carboxylic acid, tricarboxylic acid, benzoic acid, tri (2-ethylhexoic acid) phosphonate, imidazoles compound, defoamer and deionized water. The engine coolant of the invention contains no inorganic salts, such as amines, borate, nitrate, nitrite, silicate, and the like, so the engine coolant is environment-friendly, can prevent all the contacted metal and nonmetal materials in the engine cooling system from being corroded, has an obvious engine coolant effect on various metals, particularly solves the problem that the cast aluminum using a traditional organic acid engine coolant becomes black generally, can be stabled in a relative low density and bigger PH value range, and has the advantages of long-time storage and use.

Owner:北京蓝星清洗有限公司

Water-base cleaning agent composition capable of quickly removing carbon deposit and heavy oil

InactiveCN101445939AEasy to cleanSolve problems that cannot be dissolved and are difficult to removeWater basedFuel oil

This invention claims a water-base cleaning agent composition capable of quickly removing carbon deposit and heavy oil, which can greatly improving performances of removing each heavy oil stain, cleaning dirt, resisting hard water and corrosion inhibition, especially the strongest performance of removing the carbon deposit at the metallic surface, solving the problems the current technology cannot remove each carbon deposit attached to the metal surface and the impurity cannot dissolve. This invention is realized by using following technical scheme: mixing 1% to 5% of synergistic agent, 0% to 10% of sodium hydroxide, 15% to 18% of activating agent, 0 to 5% of energizer, 4% to 8% of inhibiter, 0.5 to 1.5% of stabilizing agent, 0 to 5% of additive with water to prepare the water-base cleaning agent composition. This invention is suitable for cleaning components in the processing processes of each metal, alloy and non-metal in the machine manufacture and maintenance process, and cleaning the carbon deposit and the heavy oil stain. This invention is a non-ODS environmentally friendly water-base cleaning agent.

Owner:PLA NO 5719 FACTORY

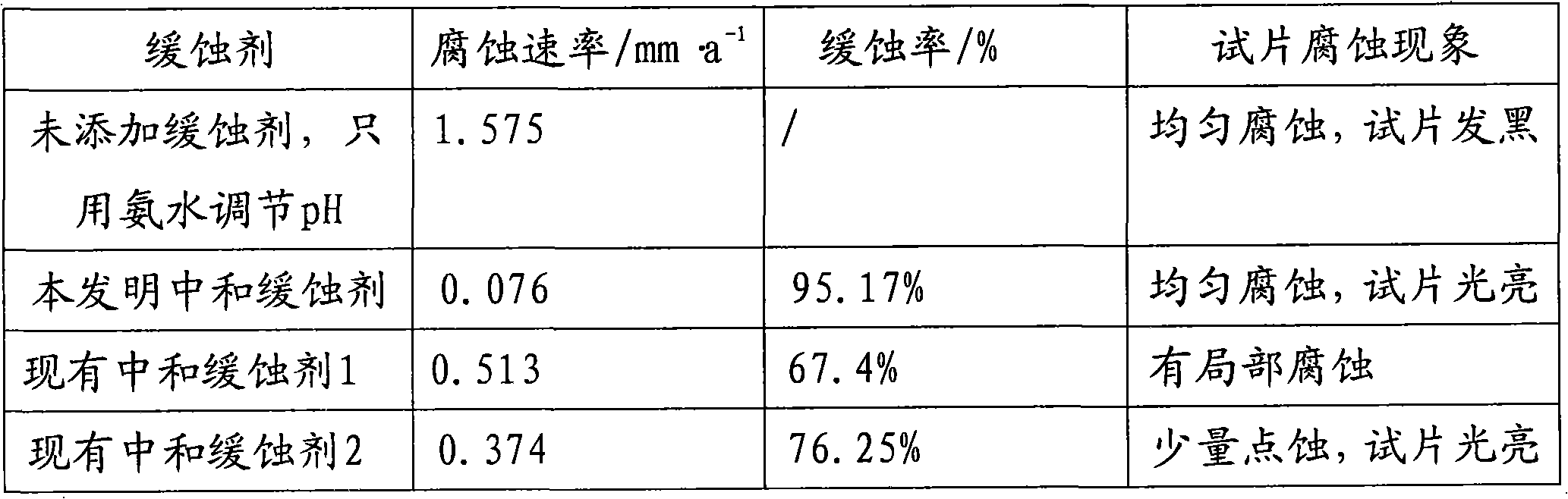

Neutral corrosion inhibitor

The invention belongs to the field of chemical additives and discloses a neutral corrosion inhibitor. The neutral corrosion inhibitor comprises the following components of: by weight, 1-5% of a dispersant, 15-40% of neutralizing organic amine, 4-10% of a water-soluble imidazoline compound, 1-5% of an alkynol compound, 4-15% of a nitrogen-containing adsorption type corrosion inhibitor, and 20-55% of a solvent. The neutral corrosion inhibitor provided by the invention has an effect of neutralizing acidic matters, and also has the efficacy of forming film on metal surface. By the adoption of the neutral corrosion inhibitor, the fouling and secondary corrosion problems caused by dew spot corrosion and ammonium salt deposition can be solved.

Owner:WUHAN RUNERHUA TECH

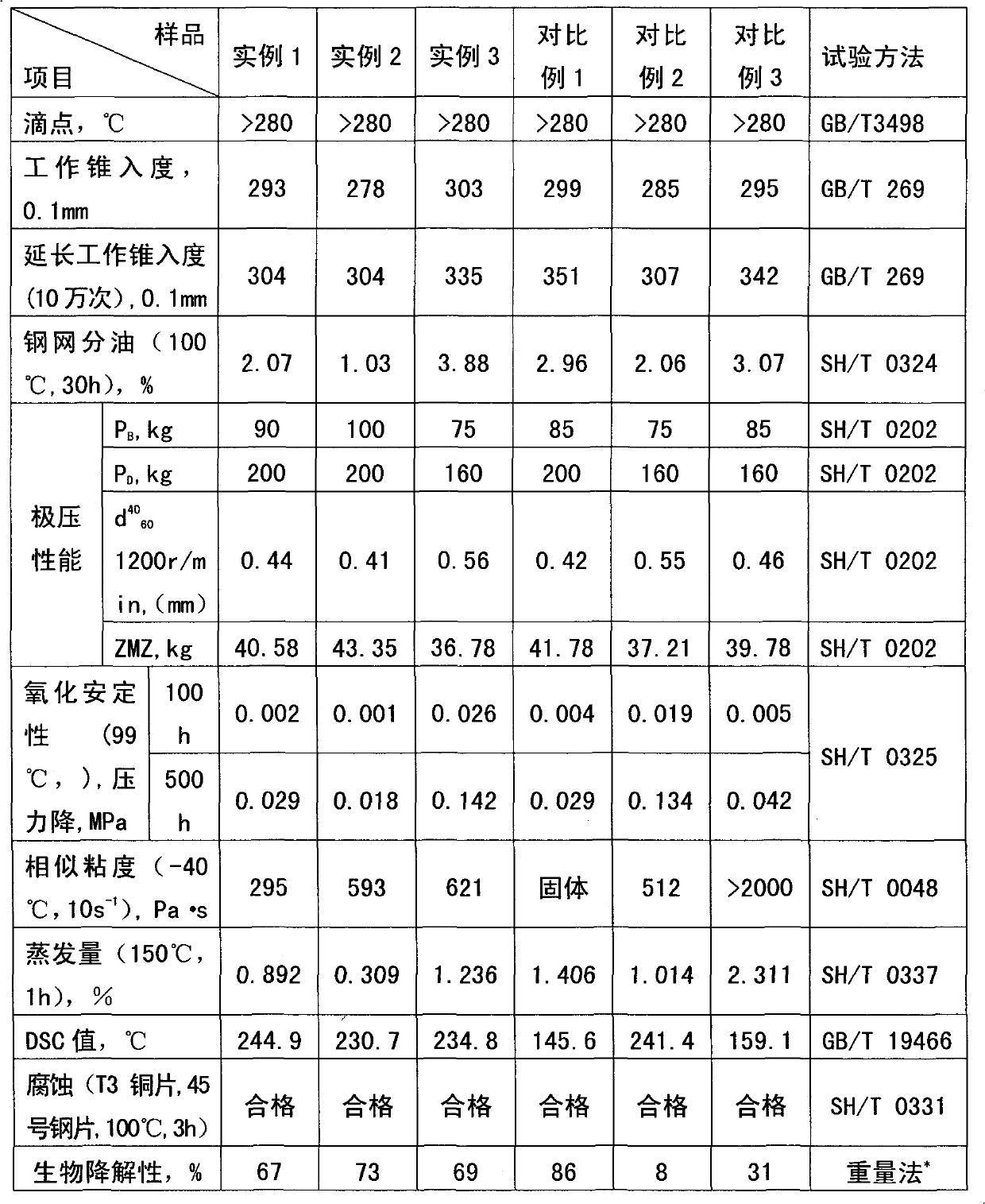

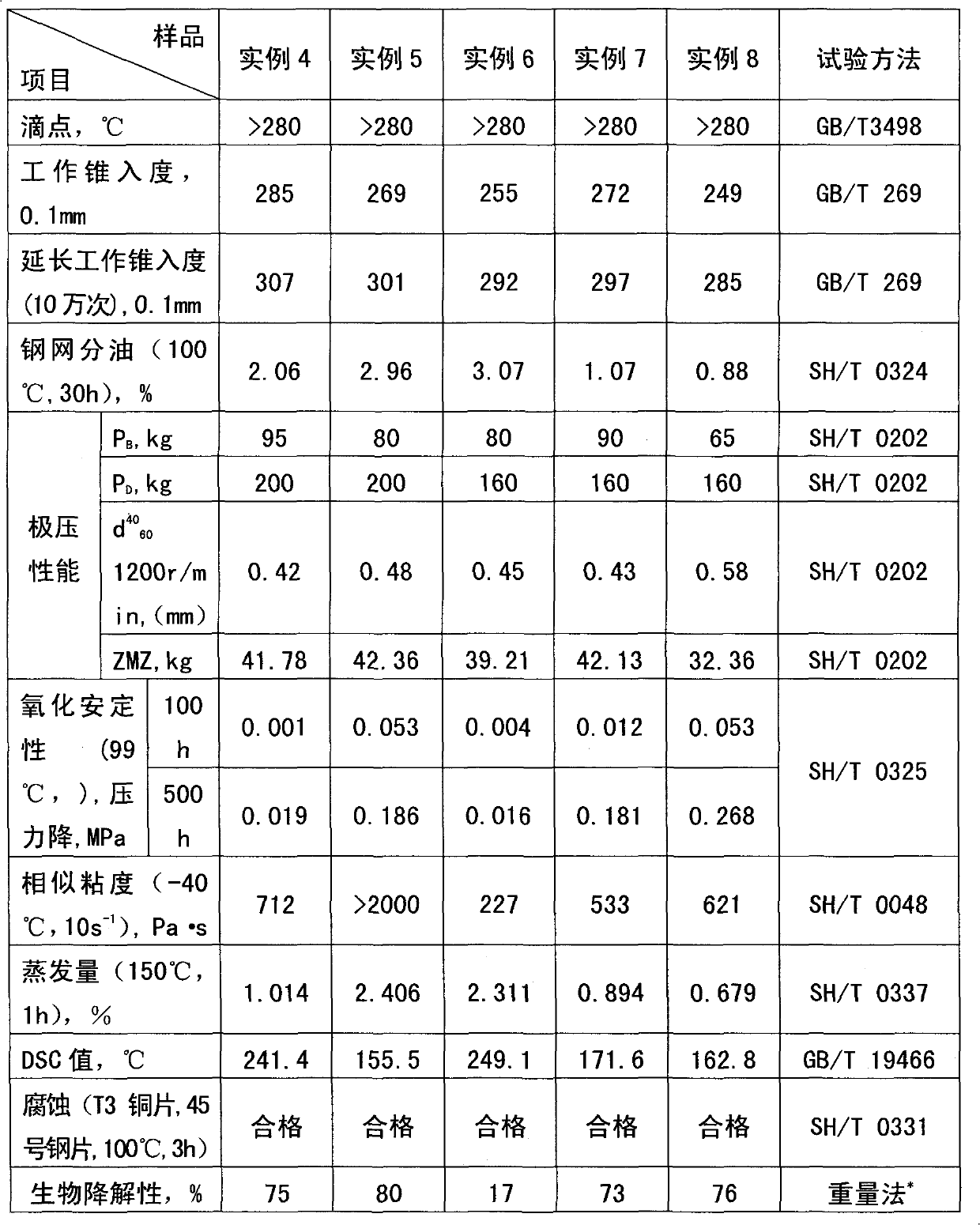

Environmental protection type lubricating grease composition and method for preparing same

ActiveCN102199471AWide high and low temperature adaptabilityGood biodegradabilityLubricant compositionChemistryAntioxidant

The invention provides an environmental protection type lubricating grease composition. The composition comprises basic grease and an additive, wherein the basic grease comprises the following ingredients in percentage by weight: 60 to 95 percent of basic oil and 5 to 40 percent of composite lithium soap thickener; and the additive comprises the following ingredients based on the 100 weight percent of the basic oil: 0.05 to 2 percent of antioxidant, 0.5 to 10 percent of extreme pressure anti-wear agent and 0.1 to 2 percent of anti-rusting agent. The environmental protection type lubricating grease composition has high high-low temperature adaptability, high biodegradability, excellent an anti-oxidation, shear resistance and extreme pressure wear resistance and high anti-rusting property and corrosion inhibition, and is suitable to be used as the lubricating grease for bearings of electromotors of rail locomotives.

Owner:CHINA PETROLEUM & CHEM CORP +1

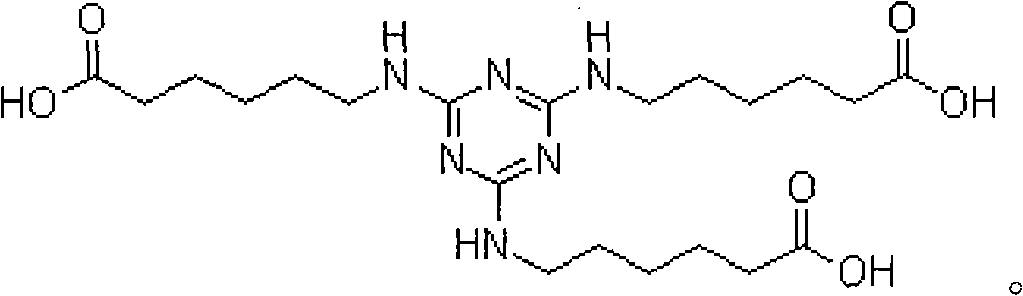

Low phosphine compound slow corrosion antisludging agent

InactiveCN1781858AImprove corrosion inhibition effectReduce dosageScale removal and water softeningCarbon steelChemistry

Owner:NANJING UNIV OF SCI & TECH

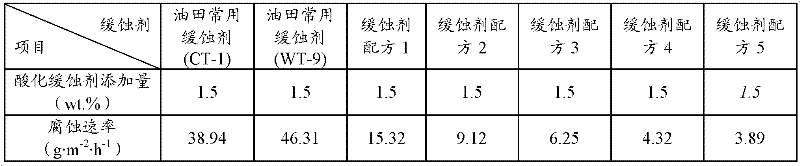

Environmental-protection type multifunctional efficient acid washing mist inhibition corrosion inhibitor

The invention belongs to the technical field of metal surface cleaning treatment, and more particularly relates to an environmental-protection type multifunctional efficient acid washing acid inhibition corrosion inhibitor, which is formed by mainly compounding 2-6 parts of a surfactant, 8-15 parts of a corrosion inhibitor, 0.5-1 part of a penetrating agent, 2-4 parts of an acid washing accelerating agent, 74-87.5 parts of water, and other components, wherein the product achieves the optimal mist inhibition corrosion inhibition effect in the acid washing through the synergy effect of various components. The corrosion inhibitor of the present invention has the following beneficial effects that: (1) the rust removing is fast, the rust removing speed is significantly increased with the additions of the penetrating agent and the accelerating agent, and the rust can be completely removed within 5-30 min when the addition amount is 2%; (2) the mist inhibition property is good, and the good mist inhibition effects are provided for hydrofluoric acid, nitric acid, and the like; and (3) the corrosion inhibition is good .

Owner:浏阳市三鹰新材料有限责任公司

High-COD special non-phosphorus corrosion and scale inhibitor and preparation method thereof

ActiveCN104261575AGood anti-scaling effectGood corrosion inhibition effectSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsTungstateWater quality

The invention provides a high-COD (Carbon Oxide Demand) special non-phosphorus corrosion and scale inhibitor and preparation method thereof. The corrosion and scale inhibitor mainly comprises cyclodextrin or cyclodextrin derivatives, a soluble metal salt, a copolymer containing a sulfonic acid group, a homopolymer containing carboxylic acid, an acrylic acid / ethyl acrylate / 2-acrylamide-2-methallylsulphonate copolymer, tetrahydroglyoxaline matters, sodium gluconate, and quaternary ammonium salt. The non-phosphorus corrosion and scale inhibitor is suitable for an open circulated cooling water system, and suitable for surface water high in COD and free of treatment, and the non-phosphorus corrosion and scale inhibitor is added into the circulated cooling water system by an automatic reagent feeding device. The non-phosphorus corrosion and scale inhibitor is environmentally-friendly, avoids using phosphorous compounds or non-renewable molybdate or tungstate, has the characteristic of being free from phosphorus and nitrogen, meets the requirement of environmental protection, reduces the environmental burden, has a sterilizing ingredient at the same time, and effectively reduces the problems of bacterial corrosion and algae growth in a circulated water system.

Owner:SHANDONG TIANQING TECH DEV

Corrosion inhibitor and preparation method thereof

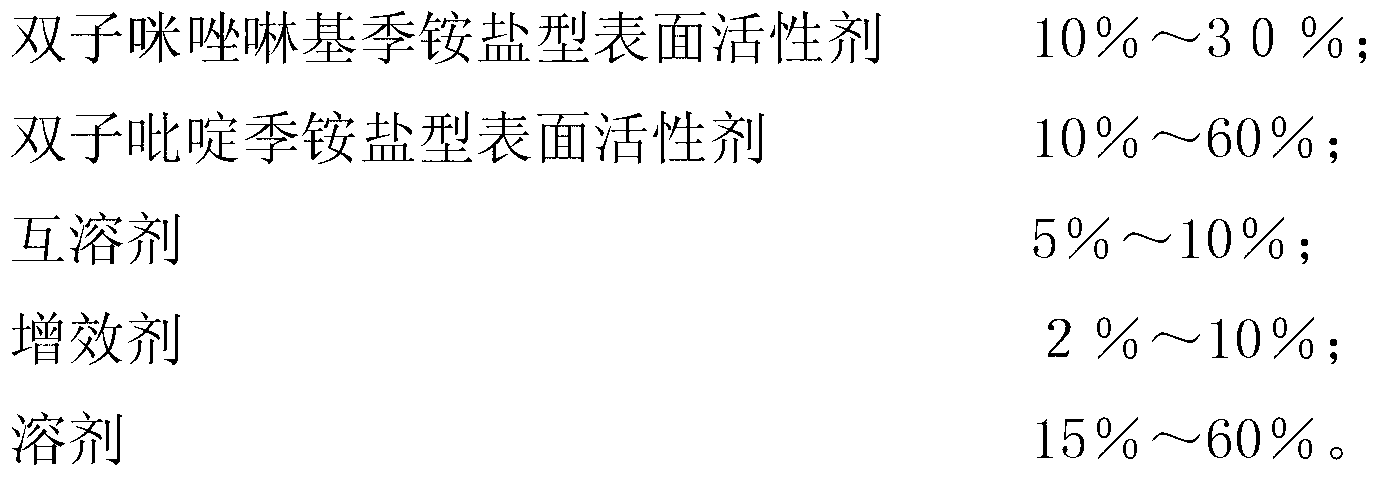

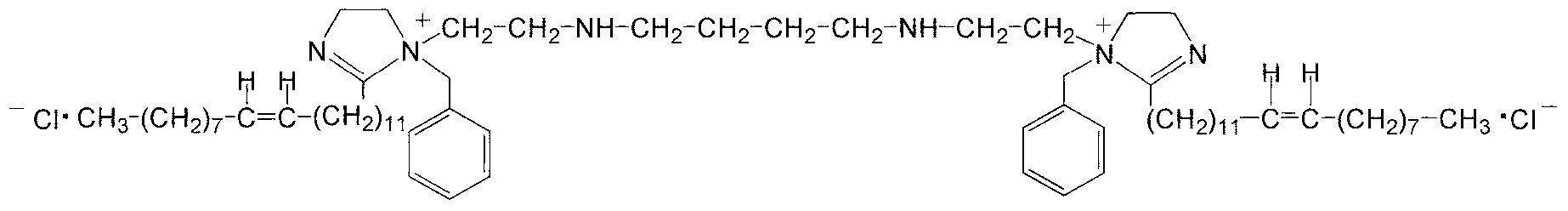

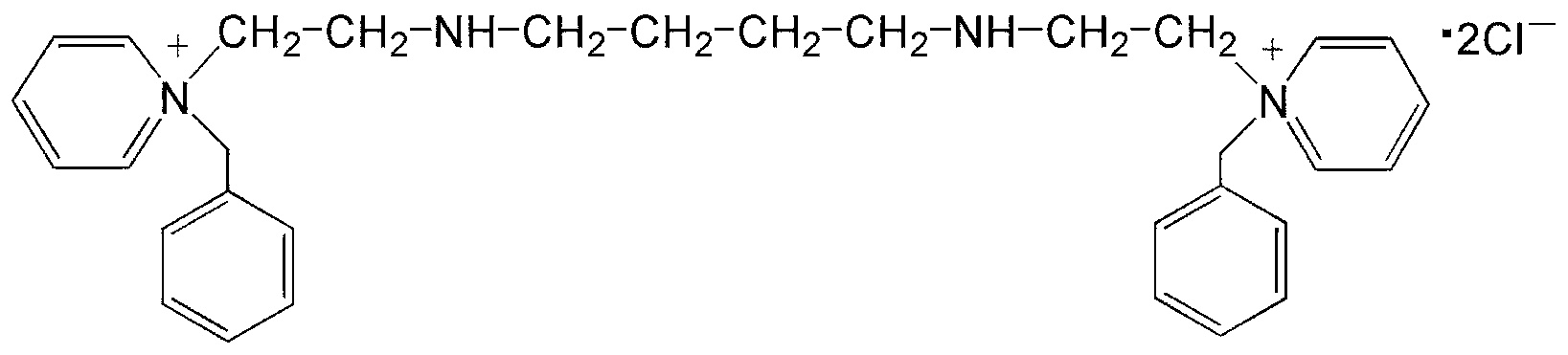

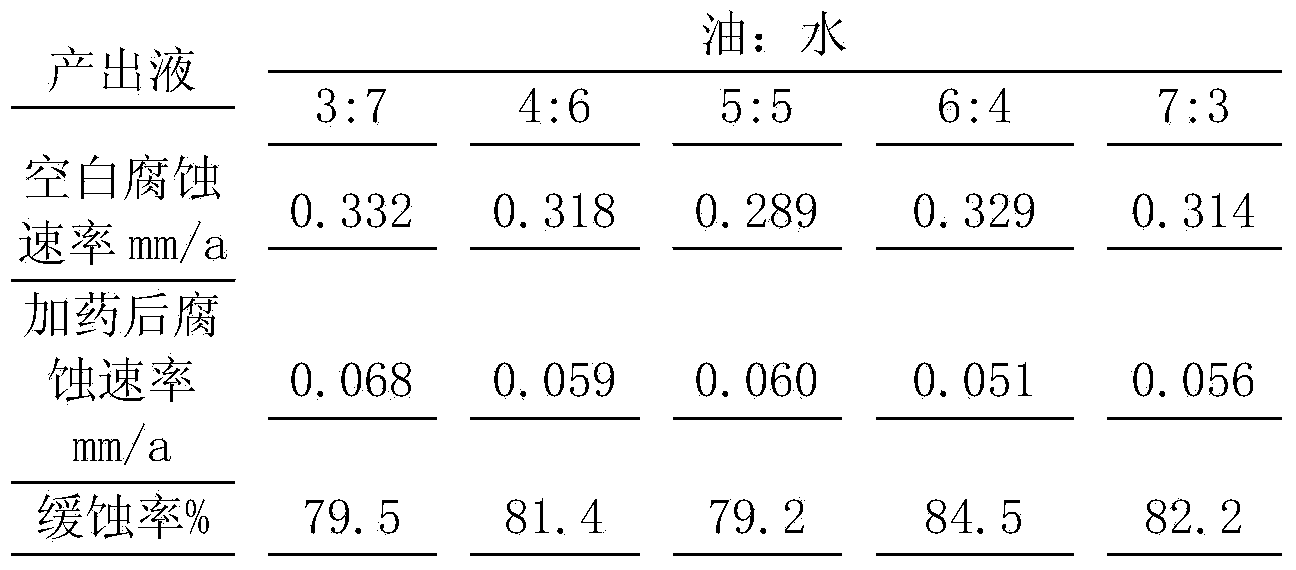

ActiveCN103289671AGood dispersionImprove thermal stabilityDrilling compositionBorehole/well accessoriesSolventPyridine

The invention discloses a corrosion inhibitor and a preparation method thereof. The corrosion inhibitor is composed of the following components in percentage by mass: 10-30% of a bis-imidazoline quaternary-ammonium-salt surfactant, 10-60% of a bis-pyridine quaternary-ammonium-salt surfactant, 5-10% of a mutual solvent, 2-5% of a synergist, and 15-60% of a solvent. The corrosion inhibitor disclosed by the invention is good in corrosion inhibition effect, and capable of being used at a high temperature.

Owner:安东地质工程技术研究院(北京)有限公司

Brownized treatment liquid for increasing adhesion of internal copper surface of circuit board and polymer material

InactiveCN1564650AGood corrosion inhibition effectImprove efficiencyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentIonWater soluble

The multibond liquid consists of sulfur acid, hydrogen peroxide, halide ion, water-soluble poymer, inhibitor, triazole sulfone methanes, 1-substiteunt Benzotriazole, 4-substiteunt Benzotriazole or 5-monomethyl-substituent Benzotriazole.

Owner:GUANGDONG TONESET SCI & TECH +1

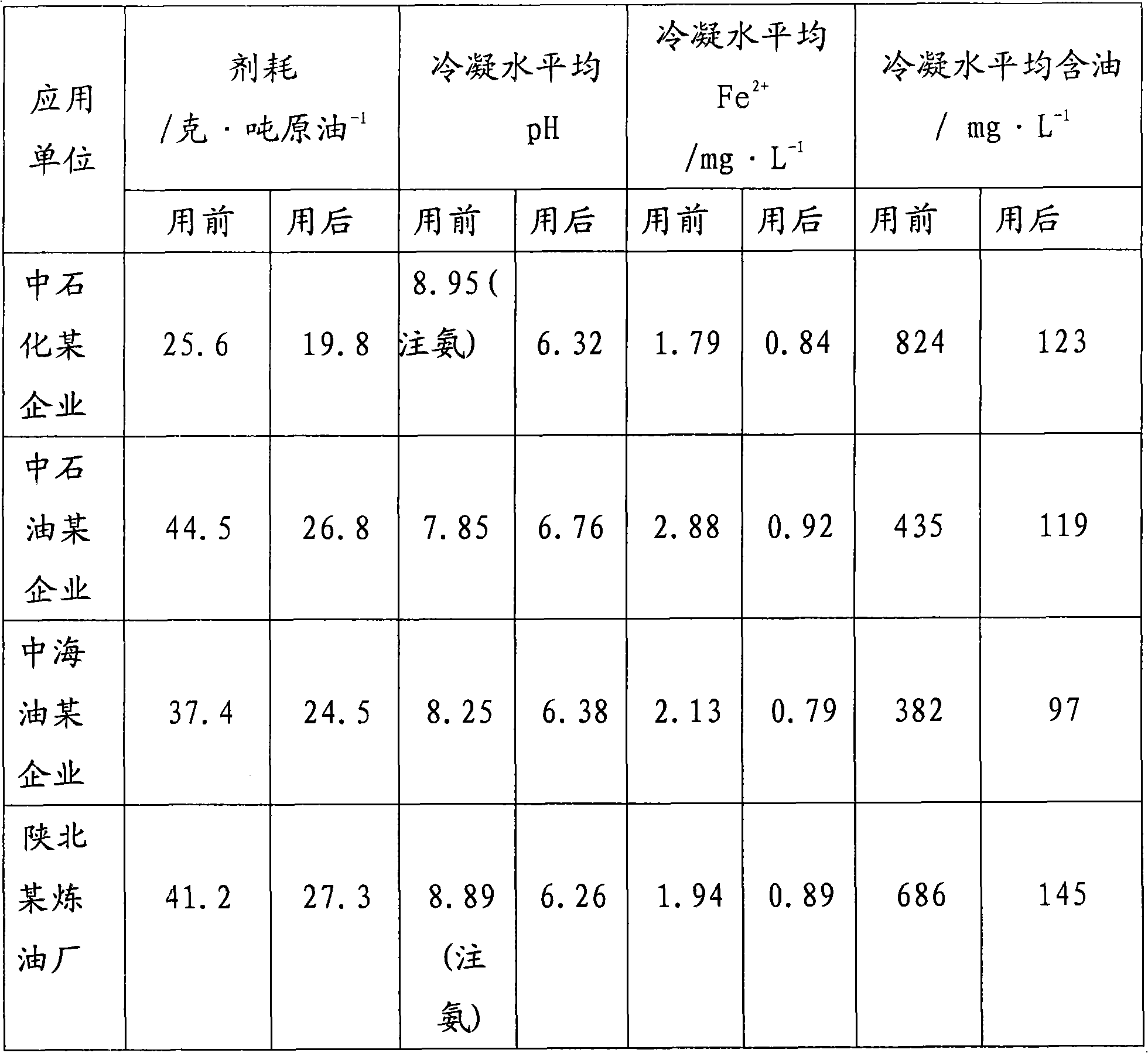

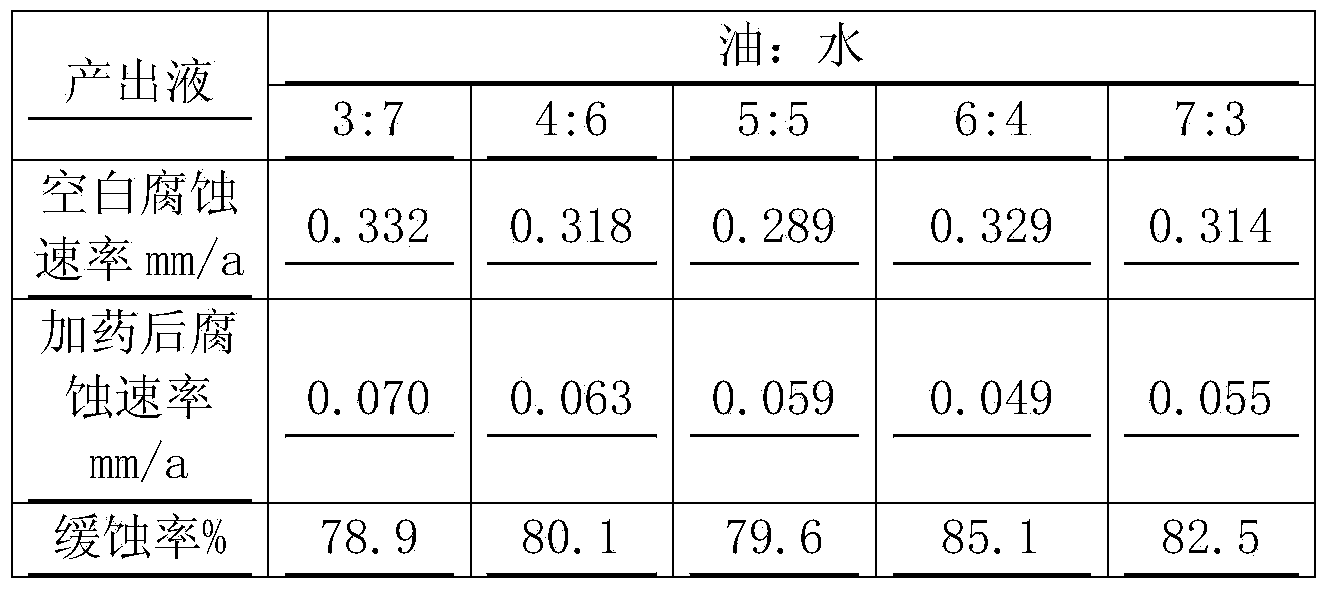

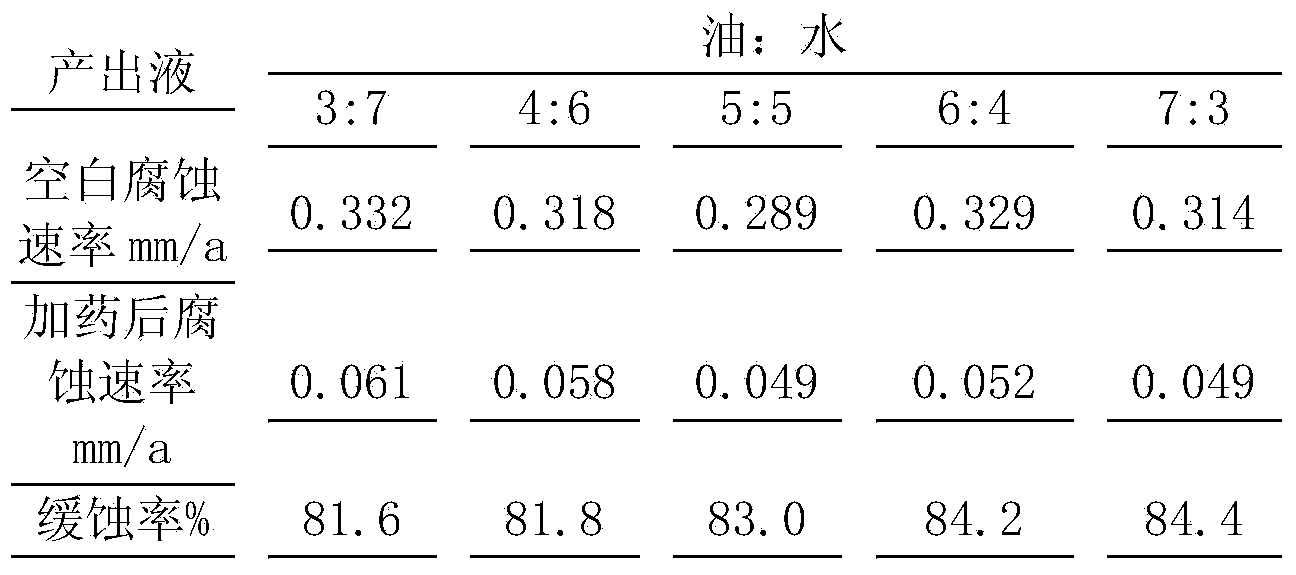

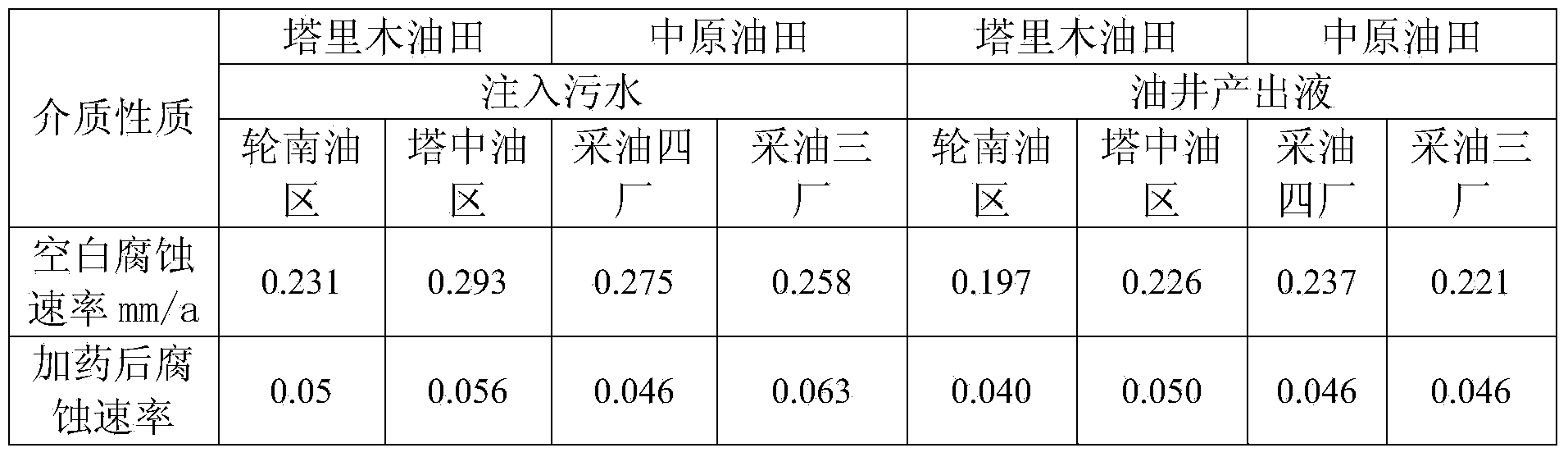

Oil-water medium corrosion inhibitor for corrosion control on oilfield-production oil gas water collection and transmission system

ActiveCN104073810AWide adaptabilityGood compatibilityBorehole/well accessoriesAlkylphenolFatty alcohol

The invention relates to an oil-water medium corrosion inhibitor for corrosion control on an oilfield-production oil gas water collection and transmission system, which comprises 1-25% of bis quaternary ammonium salts of imidazoline and alkyl-tert ammonium, 0.5-10% of sulfhydryl alkyl acid, 1-15% of organic urea compound, 1-10% of thiocyanide, 1-15% of alkyl quaternary ammonium salts, 0-10% of fatty alcohol polyethenoxy ether, 0-10% of alkylphenol polyoxyethylene and the balance of water. The corrosion inhibitor can control the corrosion of the oilfield-production oil gas water collection and transmission system with different oil-water ratio media; and when the charging amount reaches 100 mg / L, the corrosion inhibition rate can reach 75% above, and the corrosion rate can be controlled at 0.076mm / a below, thereby solving the problems of small property change application range of oil well production solution media, low corrosion inhibition rate and influence of emulsification on demulsification in the corrosion inhibitor on the market.

Owner:XIAN HUANUO ENVIRONMENTAL PROTECTION CO LTD

Acid corrosion inhibitor

The present invention belongs to the field of chemical technology, and discloses one kind of acid corrosion retardant. The acid corrosion retardant contains urotropine, thiourea, benzotriazole, mercaptobezothiazole, sodium silicate and water. The acid corrosion retardant of the present invention is developed based on that some acids and some metals have high corrosion retarding rate.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and preparation method thereof

ActiveCN104891684AGood synergyNo distractionScale removal and water softeningWater treatmentCorrosion

The invention relates to a phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and a preparation method thereof, belonging to the technical field of water treatment. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water is prepared from the following raw materials in percentage by weight: 5-20% of sodium molybdate, 5-20% of urotropine, 10-30% of polyepoxysuccinic acid, 1-5% of azole derivative, 5-20% of hydroxypropyl methacrylate, 5-15% of acrylic acid-acrylate-sulfonate terpolymer, 5-15% of sodium humate, 0.1-1% of fluorescent tracer, 0.5-2% of caustic soda flakes and the balance of deionized water. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water can not interfere with other water treatment agents, is free of phosphorus, zinc and other components harmful to the environment, and can effectively solve the problems of corrosion and scales in the bitter-based high-salt-content high-pH system. The invention also relates to a simple and convenient preparation method.

Owner:INLEN CHEM TECH +1

Corrosion and scale inhibitor for high-chlorine and high-calcium water-quality

InactiveCN101028957AIncrease the allowable concentrationControl formationScale removal and water softeningManganeseWater quality

A corrosion-retardant scaling inhibitor for the high-Cl and -Ca water contains proportionally phosphonylic acid, polyphosphonic acid, organic phosphonate, Zn sale, Mn salt, polyacrylic acid, antimildew agent and purified water.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Chemical stainless steel polishing solution

The invention discloses a chemical stainless steel polishing solution which comprises the following components in content: 80mL / L to 120mL / L of 68% nitric acid, 50mL / L to 150mL / L of 40% hydrofluoric acid, 50mL / L to 120mL / L of 30% hydrogen peroxide, 50mL / L to 80mL / L of 85% phosphoric acid, 50mL / L to 80mL / L of 98% concentrated sulfuric acid, 10mL / L to 30mL / L of 95% ethanol, 5g / L to 15g / L of urea, 20g / L to 40g / L of a brightening agent, 0.5g / L to 2g / L of a fog inhibitor and 2g / L to 6g / L of a corrosion inhibitor. The chemical polishing solution is stable in polishing speed; a processed stainless steel workpiece is flat in surface, bright, free of dust, also stable in performance, capable of being stored for a long time and low in production cost; during polishing, irritant acidic gas is small in volatility.

Owner:HUBEI UNIV OF EDUCATION

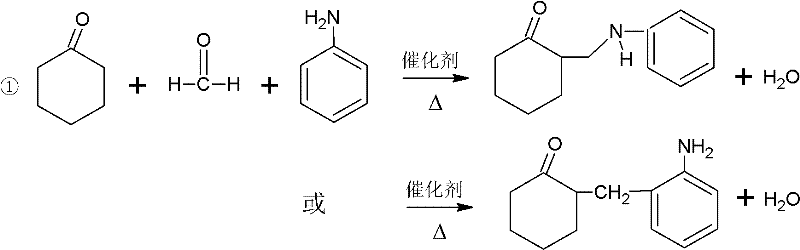

High-temperature acidic corrosion inhibitor and preparation method thereof

InactiveCN102226081AImprove high temperature resistanceGood corrosion inhibitionDrilling compositionAlkylphenolKetone

The invention relates to a high-temperature acidic corrosion inhibitor, which is characterized in that the high-temperature acidic corrosion inhibitor comprises the following components in parts by weight: 100 parts of solution containing 40-50 wt% ketone-aldehyde-amine condensate, 3-15 parts of propiolic alcohol, and at least one component selected from potassium iodide, formamide, antimonous oxide and antimonous chloride (wherein potassium iodide is 3-12 parts, formamide is 8-15 parts, antimonous oxide is 3-12 parts, antimonous chloride is 3-12 parts), wherein the solution containing 40-50 wt% ketone-aldehyde-amine condensate is prepared by mixing a ketone-aldehyde-amine and an alcohol solvent of alkylphenol polyoxyethylene based on a ratio of 1: (10-15). The invention also relates to a method for preparing the high-temperature acidic corrosion inhibitor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Anti-oxidation metal surface treatment agent

InactiveCN104862680AHigh tensile strengthImprove thermal stabilityMetallic material coating processesPolyvinyl alcoholHeat stability

The invention discloses an anti-oxidation metal surface treatment agent. The anti-oxidation metal surface treatment agent consists of the following raw materials in parts by weight: 13-20 parts of polyvinyl alcohol, 0.4-1 part of tea saponin, 0.8-1 part of sodium citrate, 0.2-0.3 part of lauryl mercaptan, 0.1-0.3 part of 2-thiol group benzimidazole, 0.1-0.2 part of antioxidant BHT, 0.4-1 part of calcium lignosulphonate, 2-3 parts of amino tri(methylene phosphonic acid), 6-8 parts of sericin, 0.08-0.1 part of boric acid, 10-20 parts of methyl benzotriazole, and 180-200 parts of de-ionized water. The water soluble high-molecular polyvinyl alcohol is mixed with the sericin and is modified by the boric acid to improve the tensile strength and the heat stability of a blended membrane; corrosion inhibition alkali liquid using the methyl benzotriazole as a main material is added, so that the film attached on the metal surface is more uniform and stable to protect a metal material from being corroded by harmful media in atmosphere and water so as to achieve a better corrosion inhibition effect; and the added 2-thiol group benzimidazole and antioxidant BHT can improve the oxidation resistance of the metal surface treatment agent.

Owner:ANHUI HAODING METAL PROD LIMITED

Corrosion inhibitor

InactiveCN103695927ACreate pollutionGood corrosion inhibition effectHeat-exchange elementsPhosphateAlloy

The invention discloses a corrosion inhibitor, belonging to the field of a corrosion remover for a cooling system of an automobile. The corrosion inhibitor comprises the following substances by weight percent: 1-8% of villiaumite, 0.5-1.5% of molybdate, 0.0008-0.001% of a water stabilizer, 0.15-0.25% of borate, 0.25-0.35% of silicate, 0.3-2.5% of carboxylate, 3-5% of aromatic azole and the balance being deionized water. By adopting the embodiment of the invention, a certain ratio of villiaumite, molybdate, the water stabilizer, borate, silicate, carboxylate, aromatic azole and deionized water are compounded, so that excellent corrosion inhibition and antiscaling function can be generated on a plurality of metals or alloys (such as aluminum, copper, steel, cast iron, soldering tin, magnesium and alloys thereof) by using the efficient synergic effects of the raw materials, and the corrosion effect adaptability is strong. Furthermore, by adopting the corrosion inhibitor provided by the embodiment of the invention, use of nitrite, chromate, phosphate or amine salt is avoided, and environment pollution is avoided.

Owner:CHERY AUTOMOBILE CO LTD

Multi-component corrosion and scale inhibitor

ActiveCN104609579AReduce phosphorus contentReduce dosageScale removal and water softeningOrganic solventMolybdate

The invention relates to a corrosion and scale inhibitor, which comprises a component A and a component B, wherein the component A comprises an organic phosphine compound, a multipolymer dispersant and deionized water; the component B comprises polyphosphate, inorganic zinc salt and molybdate, wherein the mass ratio of the component A to component B is 2:1-1:2. The corrosion and scale inhibitor also comprises a component C, wherein the component C comprises an azole compound, a hydroxide, an organic solvent and deionized water. Compared with a traditional single liquid corrosion and scale inhibitor, the corrosion and scale inhibitor of the invention has strong composite formula adaptability, ratio and dilution times can be timely adjusted according to client on-site water quality; for the terminal clients, storage space is saved, transport cost is reduced, and usage cost of its agent is reduced simultaneously.

Owner:OCHEMATE MATERIAL TECH CO LTD

Imidazolyl lysine salt ionic liquid steel corrosion inhibitor and application thereof

The invention discloses an application of ionic liquid which serves as a steel corrosion inhibitor. The imidazolyl lysine salt ionic liquid serves as a corrosion inhibitor, only the corrosion inhibitor is required to be added into a solution contacted with steel, and the corrosion inhibitor is easy to operate and good in corrosion inhibition effect. The corrosion inhibitor is environment-friendly, high in solubility and biodegradability and good in corrosion inhibition effect, and solves the problems that the conventional corrosion inhibitor has large toxic and side effects, low biodegradation, poor environment friendliness and the like.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Low-corrosion and high-efficiency chlorine salt deicing agent and preparation method thereof

ActiveCN104293298ALow costWide variety of sourcesOther chemical processesChemical adsorptionTemperature and pressure

The invention discloses a low-corrosion and high-efficiency chlorine salt deicing agent, which is prepared from the following raw materials in percentage by mass: 85%-98% of sodium chloride, 1%-10% of a corrosion inhibitor and 1%-5% of an adjuvant, wherein the corrosion inhibitor is prepared from sodium silicate, disodium hydrogen phosphate, sodium tartrate and sodium citrate; and the adjuvant is prepared from sodium humate, urea and heteroauxin. Silicate in the corrosion inhibitor disclosed by the invention can form a protective film on the metal surface to avoid corrosion to metal caused by chlorine salt and synergistic effect of disodium hydrogen phosphate and sodium silicate; the corrosion inhibition effect is enhanced; a chemical adsorption layer is formed by coordinated complexation of polar radical of sodium citrate and sodium tartrate donor and a metal surface; a dual-electric layer structure is formed on the metal surface; a drainage layer is formed by nonpolar radical directional arrangement; chemical corrosion of metal is prevented; and the damages to soil and plants can be reduced by urea, sodium humate and heteroauxin. The preparation method disclosed by the invention is simple, mild in condition, available in raw materials, and easy to put into industrial application, and can be carried out under normal temperature and pressure.

Owner:黄山九星环保科技股份有限公司

Corrosion inhibitor and its application

ActiveCN102560501ANo pollution in the processGood corrosion inhibition effectRare-earth elementSteelmaking

The invention discloses a corrosion inhibitor, which comprises borate, alkali metal salt and / or alkali, rare earth element salt and polycarboxylate. The polycarboxylate is C6 or C7 organic carboxylate. The invention also discloses an application of the corrosion inhibitor in a closed circulating cooling water system for steelmaking as a metal corrosion inhibitor. The inventive corrosion inhibitor has good corrosion inhibition effect on common metal material, can be applied to metal corrosion inhibition of closed circulating cooling water systems, and is friendly to environment and human body.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

Novel bactericidal corrosion inhibitor

InactiveCN104003528AWide adaptabilityGood corrosion inhibition and sterilization effectScale removal and water softeningTreatment apparatus corrosion/fouling inhibitionQuinolineAlkylphenol

The invention discloses a novel bactericidal corrosion inhibitor. The corrosion inhibitor comprises the following components in percentage by mass: measured by the mass of the composition as 100%, 1-30% of biquaternary ammonium salt of quinoline and alkyl tertiary ammonium, 1-30% of biquaternary ammonium salt of alkyl tertiary ammonium, 1-15% of organic urea compound, 1-10% of organic amine compound, 1-20% of alkyl quaternary ammonium salt, 1-10% of glutaraldehyde, 1-10% of alkynyl alcohol, 1-10% of higher fatty acid amides derivative, 1-10% of alkylphenol polyoxyethylene polyoxypropylene ether and the balance of water; the corrosion inhibitor disclosed by the invention can control the corrosion of media with different oil-water ratios in the oil well output liquid of an oil-gas-water gathering and transportation system in the oilfield production, when the corrosion inhibitor addition reaches 100mg / L, the inhibition rate can reach above 75%, the corrosion rate can be controlled at below 0.076mm / a, the sterilization rate reaches above 99%, and the problems that the adaptation range of a commercially available corrosion inhibitor to the change in the properties of the media of the oil well output liquid is small, the inhibition rate is low, the emulsion affects demulsification and the commercially available corrosion inhibitor can not control the bacterial reproduction of the medium are solved.

Owner:XI'AN PETROLEUM UNIVERSITY

Water-based metal detergent and preparation method thereof

The invention discloses a water-based metal detergent which is composed of the following components in percentage by mass: 1-5% of anionic surfactant, 1-10% of nonionic surfactant I, 1-10% of nonionic surfactant II, 1-10% of nonionic surfactant III, 2-5% of corrosion inhibitor, 1.5-2.2% of assistant, 20-30.3% of organic alkali, 0.3-0.83% of defoaming agent and the balance of water. The higher-turbidity low-foam surfactants are introduced to effectively enhance the cleaning effect of the detergent. The oxidation-type corrosion inhibitor and adsorption-type corrosion inhibitor are compounded to enhance the corrosion inhibition effect. The organic phosphine is used instead of inorganic phosphorus, and thus, the detergent is safe and environment-friendly, thereby implementing zero addition of nitrites, silicates, ozonosphere-consuming substances and the like. The detergent has the advantages of favorable cleaning and corrosion inhibition effects, low foam, easy rinsing, stable performance and simple preparation technique, and has important practical application meanings.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Water-soluble chitosan phosphate, and preparation application and thereof

The invention relates to a seawater corrosion inhibitor for carbon steel, particularly a water-soluble chitosan phosphate, and preparation and application thereof. The structural formula of the water-soluble chitosan phosphate is disclosed in the specification, wherein n is approximately equal to 685. The water-soluble chitosan phosphate can be used as a corrosion inhibitor for carbon steel. The product provided by the invention can prevent general corrosion and partial corrosion of medium-carbon steel in the seawater contact process. The compound can not be used as a metal corrosion inhibitor yet. The corrosion inhibitor provided by the invention has the advantages of simple production process, low manufacturing cost, low consumption and low toxicity, can effectively inhibit corrosion attack of the seawater onto the carbon steel, and has wide application prospects.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

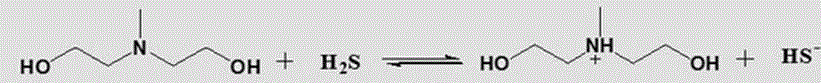

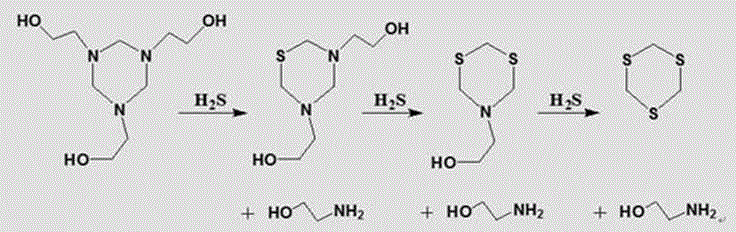

Desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide

ActiveCN105112087AGet rid of usabilityGet rid of performance constraintsWater/sewage treatment by degassingRefining with aqueous alkaline solutionsSodium acetateNuclear chemistry

The invention discloses a desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide. The desulfurizer comprises, by mass, 25 to 40% of hydroxyethyl-hexahydro-s-triazine, 5 to 10% of micro-molecular alcohol, 1 to 2% of an osmotic agent sodium sulfosuccinate, 1 to 2% of acetic acid, 0.1 to 0.2% of sodium acetate and 0.02 to 0.04% of an antifoaming agent, with the balance being water, wherein the micro-molecular alcohol is methanol, or ethanol or a mixture of methanol and ethanol, and the antifoaming agent is a water-soluble polyether or silicone oil antifoaming agent. The desulfurizer provided by the invention has a simple formula, is intermiscible with water in any ratio and can effectively reduce hydrogen sulfide in crude oil or sewage; the desulfurizer rapidly reacts with hydrogen sulfide and a reaction product is soluble in water and does not block a pipeline; moreover, an s-triazine main agent has good scale-inhibition, anti-scale and sterilization properties; and the hydrogen sulfide removing agent in the invention overcomes the problems that an alcamine desulfurizer has rapidly reduced desulphurization efficiency at high temperature and hydrogen sulfide removed through reaction may be reversibly released again, and has a temperature application range of 0 to 120 DEG C.

Owner:新疆天普石油天然气工程技术有限公司

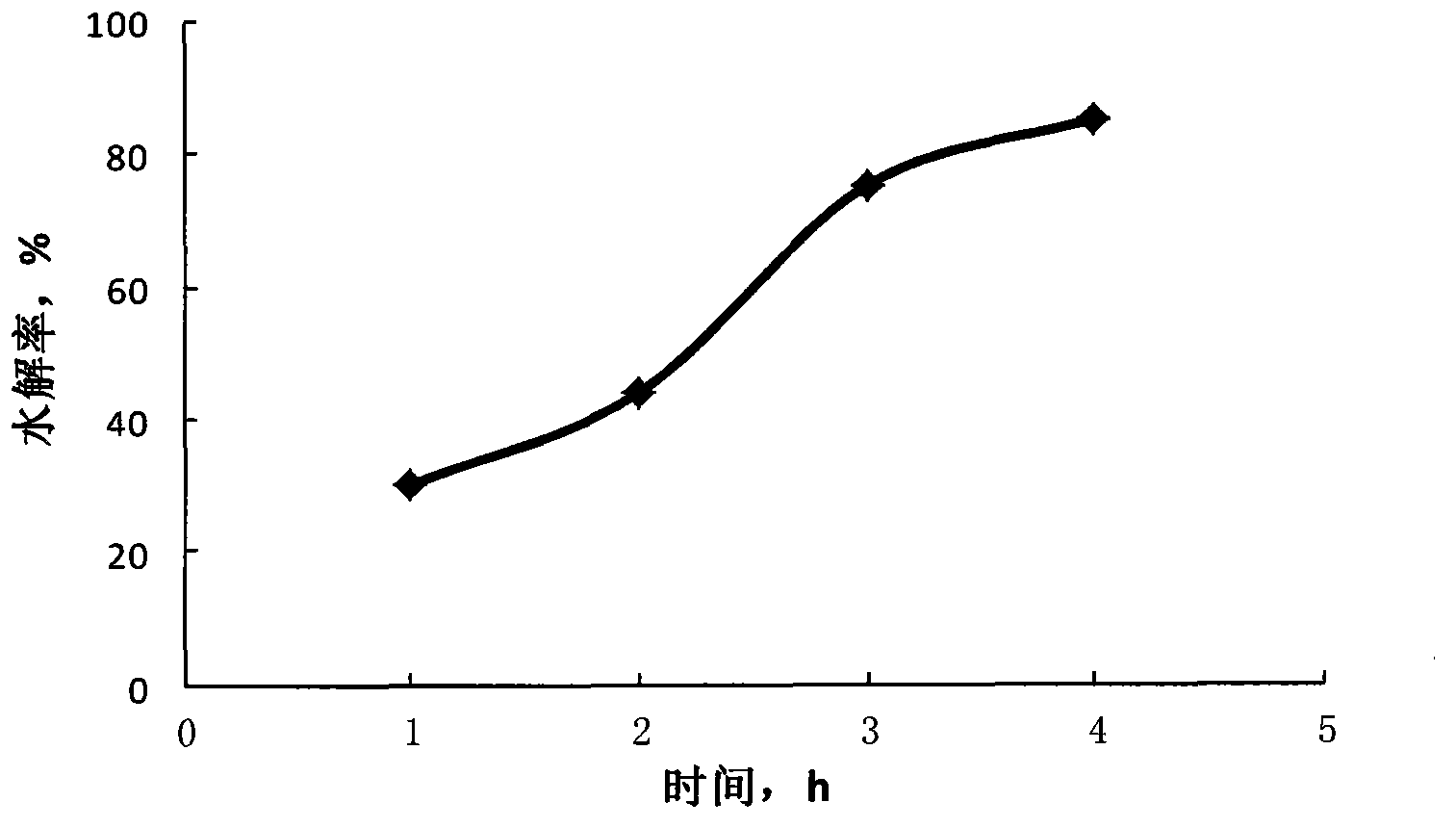

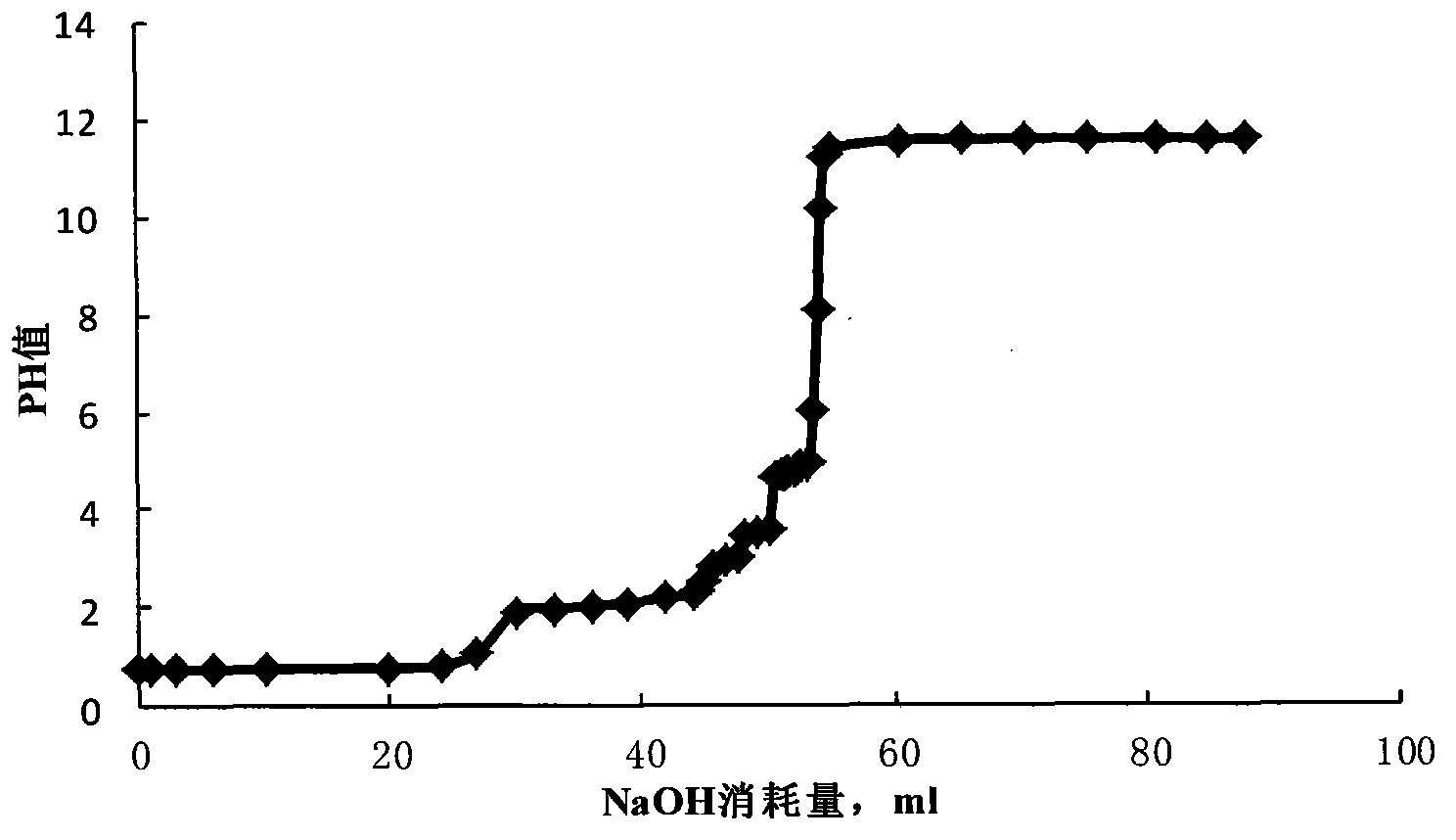

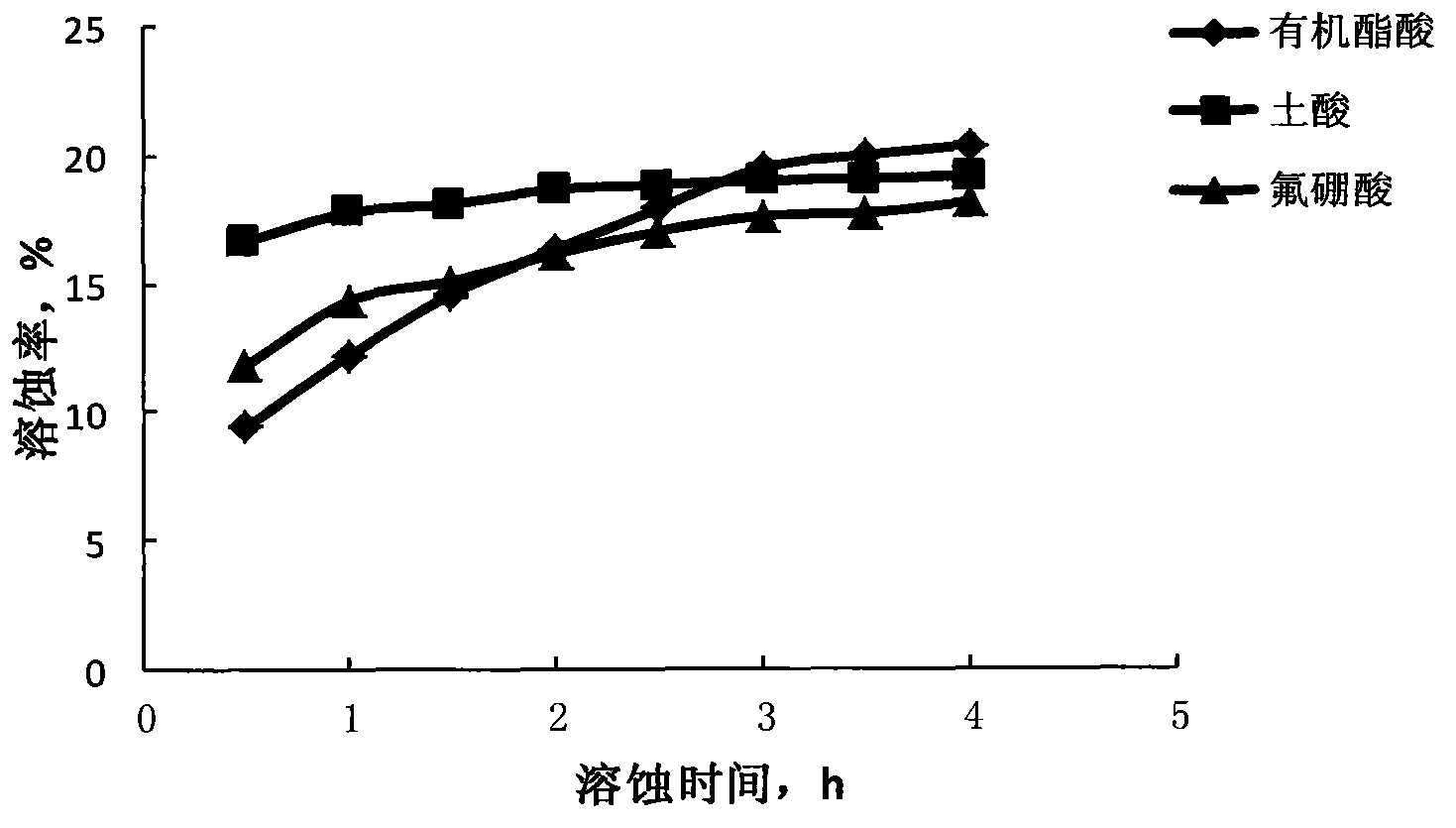

Retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification

The present invention discloses a retardance and low damage acid solution system for high temperature condensate oil gas reservoir acidification. The acid solution system is suitable for acidification modification of high temperature deep well, particularly condensate gas reservoir, and comprises the following components, by weight, 0.5-3 parts of hydrofluoric acid or 6-12 parts of fluoroboric acid, 8-10 parts of an organic ester, 0.01-0.05 part of a catalyst, 0.1-1 part of a corrosion inhibitor, 0.1-1 part of an iron ion stabilizer, 0.1-1 part of a clay stabilizer, 1-2 parts of a cleanup additive, and 80-100 parts of water. According to the present invention, effects of retardance and corrosion inhibition of the acid solution system can be well achieved at a high temperature, and water blocking can be released and acid solution backflow can be easily achieved with the finally produced methanol and the carbon dioxide.

Owner:SOUTHWEST PETROLEUM UNIV

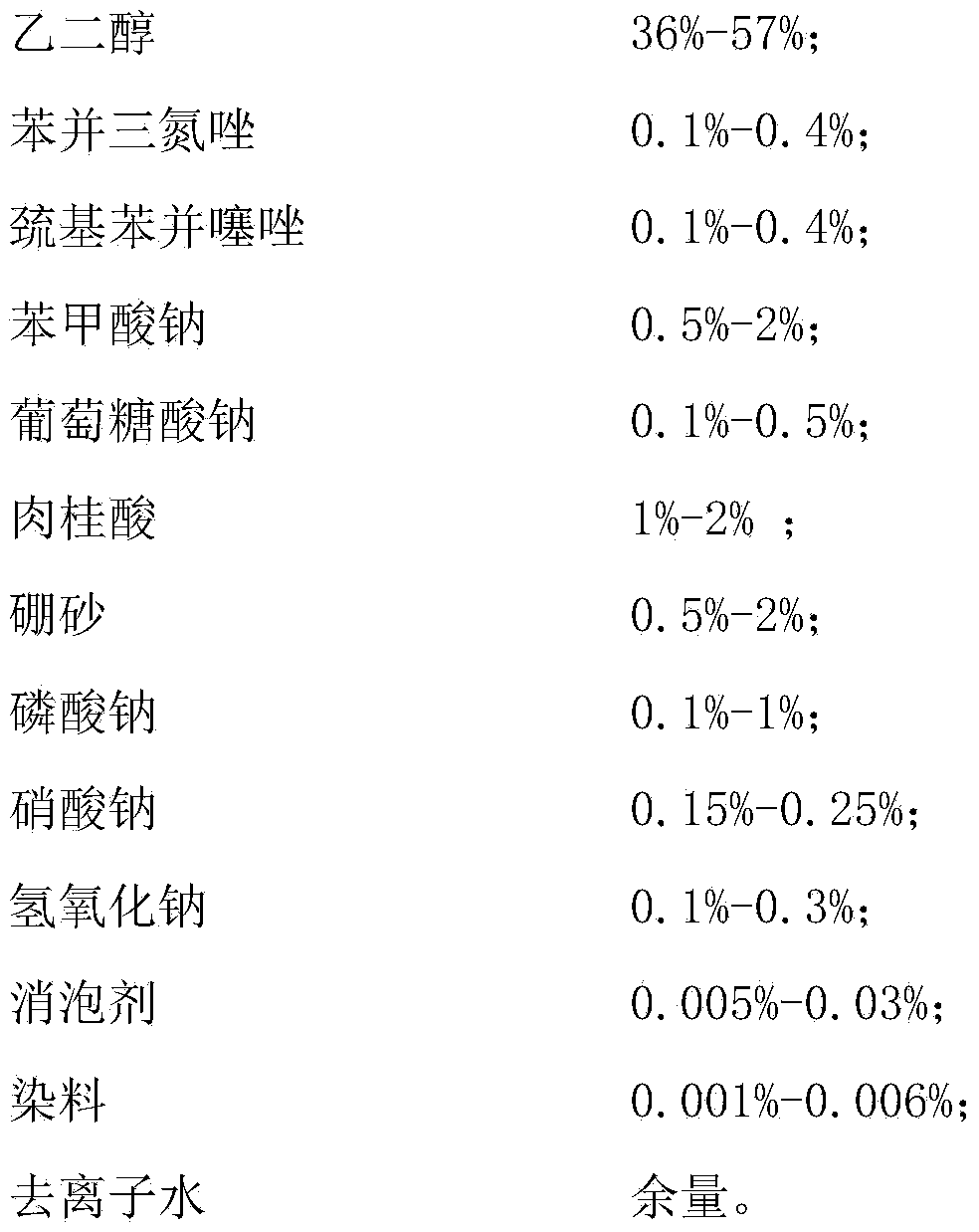

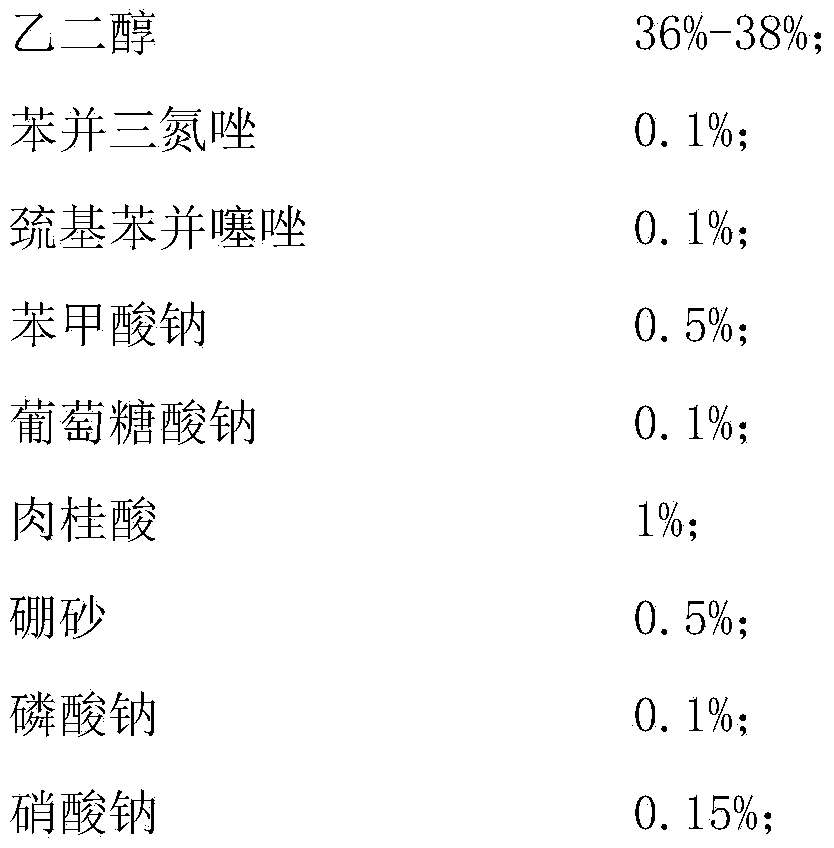

Anti-freezing fluid for solar water heater and preparation method thereof

The invention discloses an anti-freezing fluid for a solar water heater. The anti-freezing fluid is composed of the following components by weight percent: 36-57 percent of glycol, 0.1-0.4 percent of 1H-Benzotriazole, 01.-0.4 percent of mercaptobenzothiazole, 0.5-2 percent of sodium benzoate, 0.1-0.5 percent of sodium gluconate, 1-2 percent of cinnamic acid, 0.5-2 percent of borax, 0.1-1 percent of sodium phosphate, 0.15-0.25 percent of sodium nitrate, 0.1-0.3 percent of sodium hydroxide, 0.005-0.03 percent of an antifoamer, 0.001-0.006 percent of dye and deionized water in balancing amount. The anti-freezing fluid is good in stability, has the PH rangeability smaller than that of a common anti-freezing fluid at high temperature for a long time, does not separate out particles and flocculent precipitates to block a pipeline, and has good rust inhibition effect on metal material for manufacturing the solar heater. Moreover, the invention further provides a preparation method for the anti-freezing fluid, which is simple and easy to operate.

Owner:RICHU DONGFANG SOLAR ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com