Novel bactericidal corrosion inhibitor

A corrosion inhibitor, a new type of technology, applied in the direction of corrosion/scaling inhibition of treatment equipment, petroleum industry, water/sludge/sewage treatment, etc., it can solve the problems of increasing cost investment, lack of bactericidal effect, etc., and achieve low cost of dosing , good corrosion inhibition and sterilization effect, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

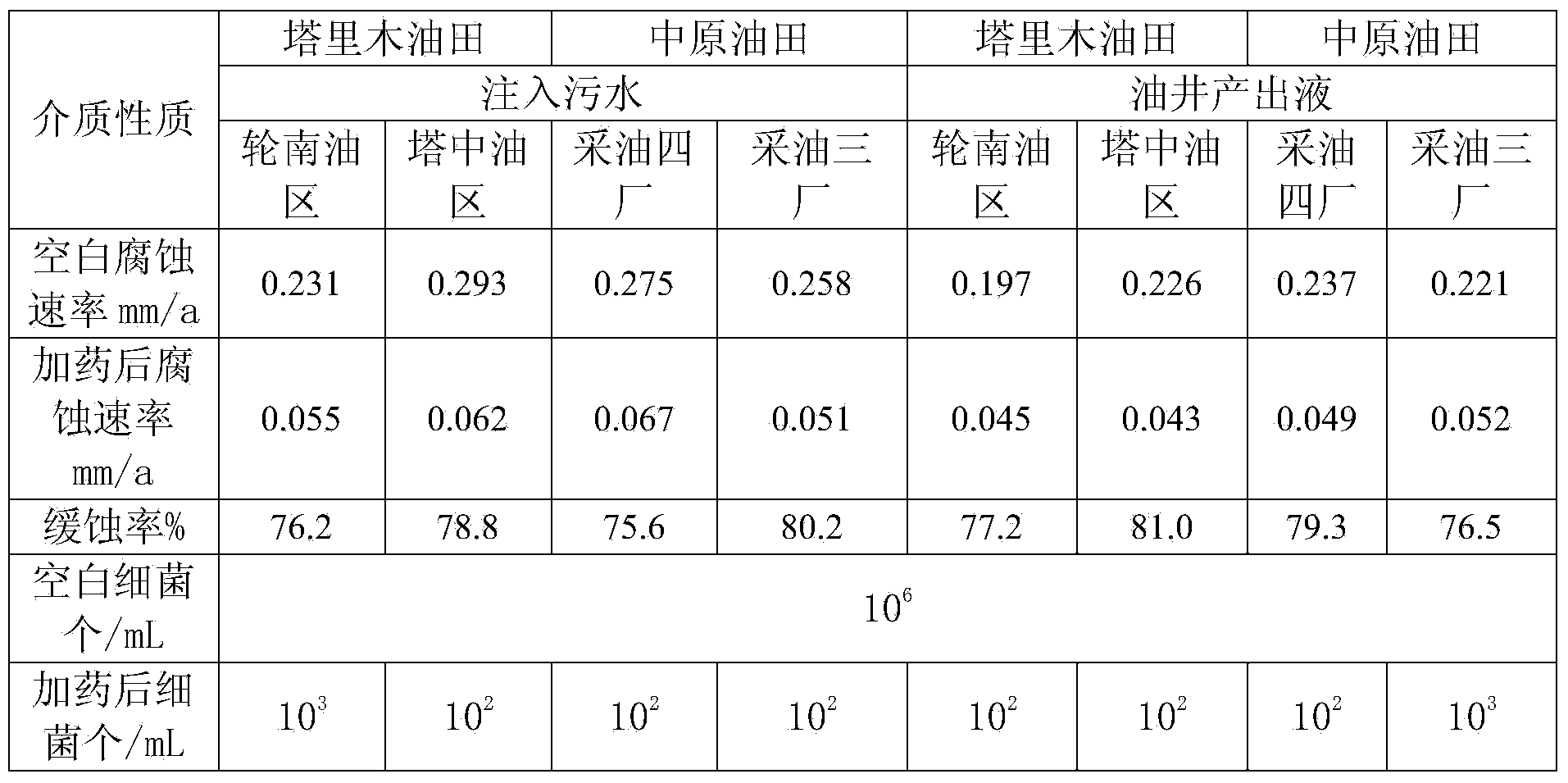

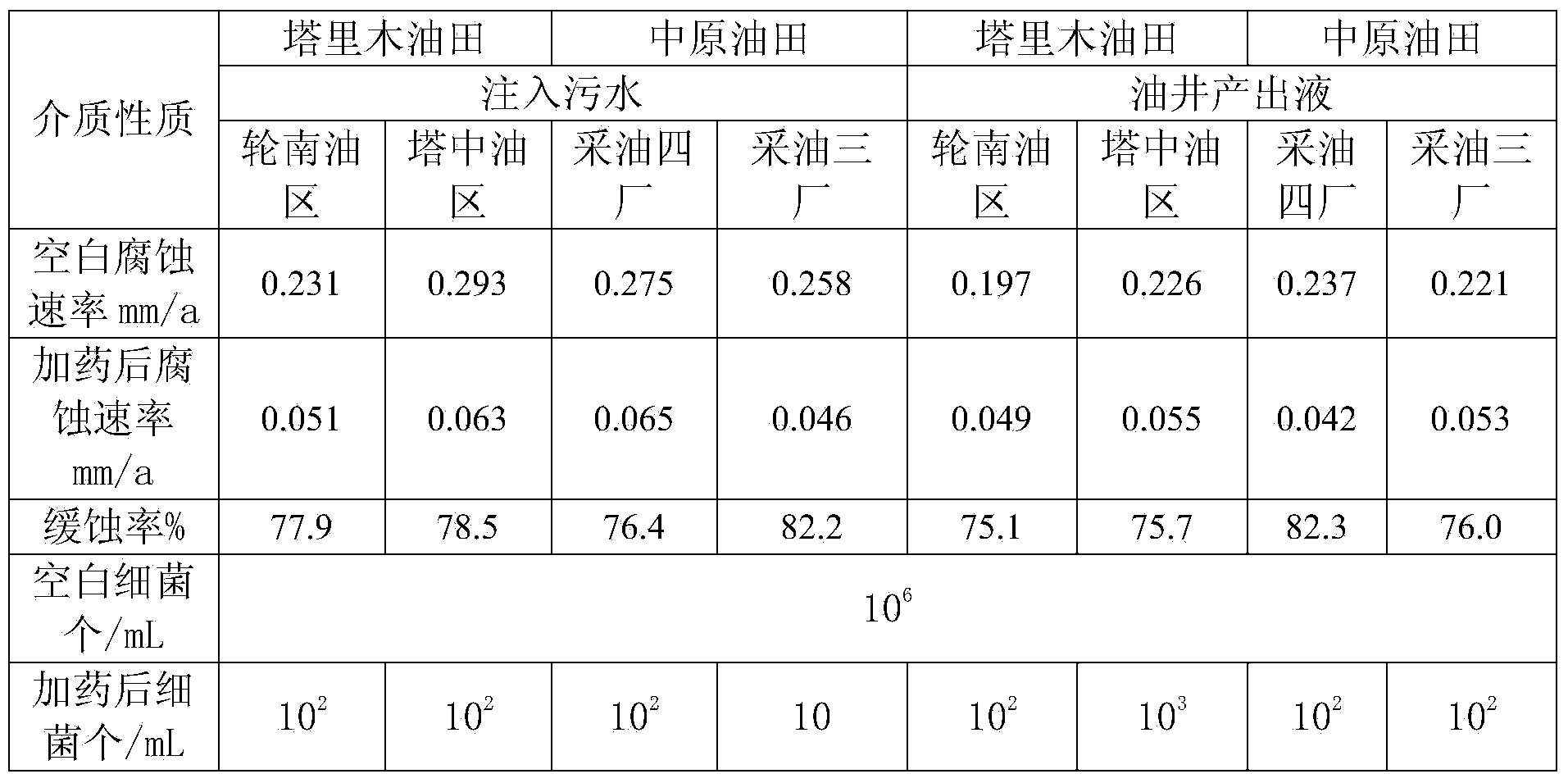

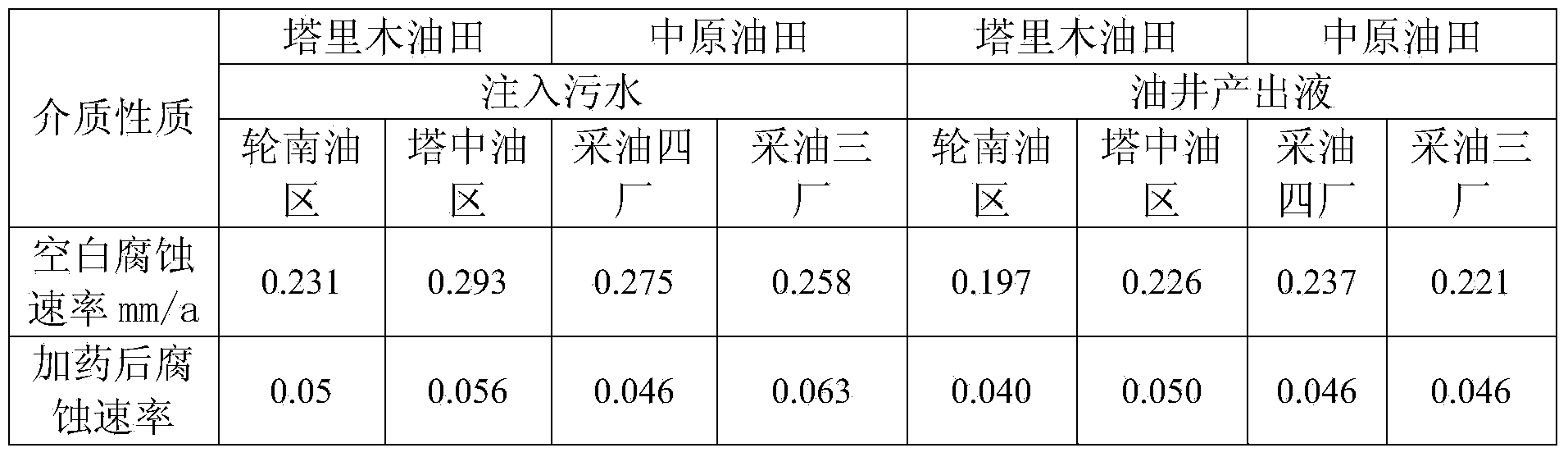

Examples

Embodiment 1

[0027] Formula composition: based on 100% of composition mass, quinoline and alkyl tertiary ammonium diquaternary ammonium salt 15%, alkyl tertiary ammonium diquaternary ammonium salt 10%, organic urea compound 5%, organic amine compound 4% , 10% of alkyl quaternary ammonium salt, 3% of glutaraldehyde, 3% of acetylene alcohol, 5% of higher fatty amide derivatives, 4% of alkylphenol polyoxyethylene polyoxypropylene ether, and the rest is water.

[0028] The synthesis process of the diquaternary ammonium salt of quinoline and alkyl tertiary ammonium is: add dodecyl tertiary amine in the reaction kettle, then dropwise add equimolar p-dichlorobenzyl, slowly heat up after the dropwise addition to 120°C, the stirring reaction time is 4 hours, and then equimolar quinoline is added dropwise, and the temperature is slowly raised to 160°C after the dropwise addition, and the stirring reaction time is 12 hours.

[0029] The synthesis process of the double quaternary ammonium salt of alky...

Embodiment 2

[0039] Formula composition: based on 100% of composition mass, quinoline and alkyl tertiary ammonium diquaternary ammonium salt 12%, alkyl tertiary ammonium diquaternary ammonium salt 15%, organic urea compound 6%, organic amine compound 3% , 12% of alkyl quaternary ammonium salt, 3% of glutaraldehyde, 2% of acetylene alcohol, 4% of higher fatty amide derivatives, 3% of alkylphenol polyoxyethylene polyoxypropylene ether, and the rest is water.

[0040] The synthetic process method of the double quaternary ammonium salt of quinoline and alkyl tertiary ammonium is: add dodecyl tertiary amine in the reaction kettle, then dropwise add equimolar p-dichlorobenzyl, slowly warm up to 120 °C, the stirring reaction time is 4 hours, and then equimolar quinoline is added dropwise, and the temperature is slowly raised to 160 °C after the dropwise addition, and the stirring reaction time is 12 hours.

[0041] The synthesis process of the double quaternary ammonium salt of the alkyl tertiary...

Embodiment 3

[0051] Formula composition: based on 100% of composition mass, quinoline and alkyl tertiary ammonium diquaternary ammonium salt 10%, alkyl tertiary ammonium diquaternary ammonium salt 15%, organic urea compound 8%, organic amine compound 5% , 15% of alkyl quaternary ammonium salt, 4% of glutaraldehyde, 3% of acetylene alcohol, 5% of higher fatty amide derivatives, 5% of alkylphenol polyoxyethylene polyoxypropylene ether, and the rest is water.

[0052] The synthesis process of the diquaternary ammonium salt of quinoline and alkyl tertiary ammonium is: add dodecyl tertiary amine in the reaction kettle, then dropwise add equimolar p-dichlorobenzyl, slowly heat up after the dropwise addition to 120°C, the stirring reaction time is 4 hours, and then equimolar quinoline is added dropwise, and the temperature is slowly raised to 160°C after the dropwise addition, and the stirring reaction time is 12 hours.

[0053] The synthesis process of the double quaternary ammonium salt of alky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com