Patents

Literature

37results about How to "Reduce the cost of dosing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for treating desulfurization wastewater in zero-discharge manner on basis of electrodialysis

InactiveCN106241972AReduce membrane fouling indexGuarantee long-term stable operationWater treatment parameter controlGeneral water supply conservationChemistryTreatment phases

Owner:SHENGFA ENVIRONMENT PROTECTION TECH XIAMEN CO LTD +1

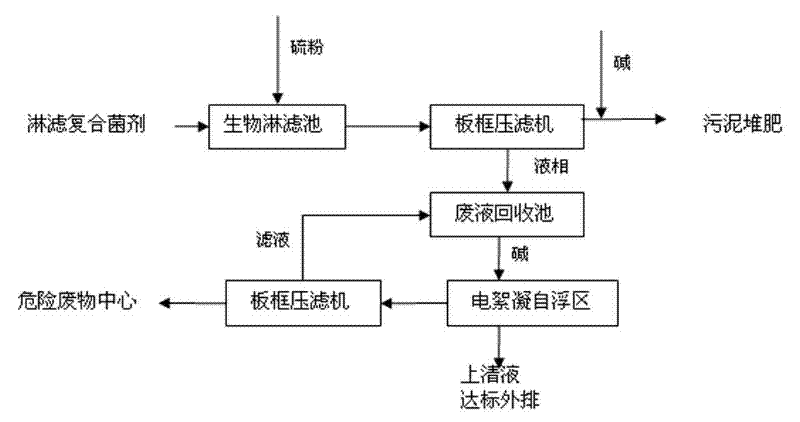

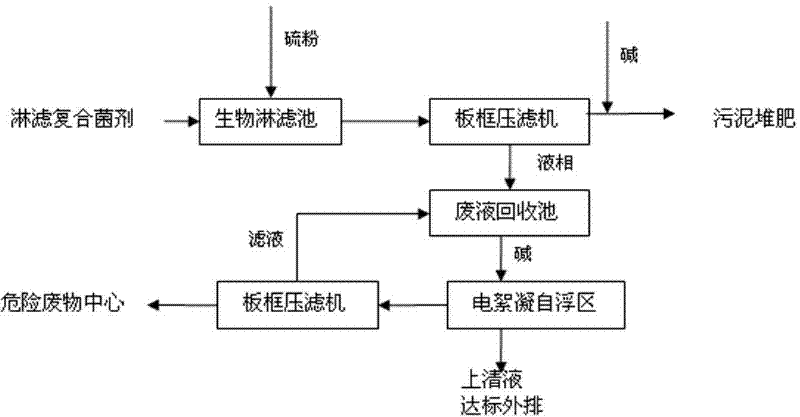

Process for removing heavy metal from sludge of sewage treatment plants

InactiveCN101913745AIncrease growth activityReduce dehydration costsClimate change adaptationWater contaminantsFlocculationSludge compost

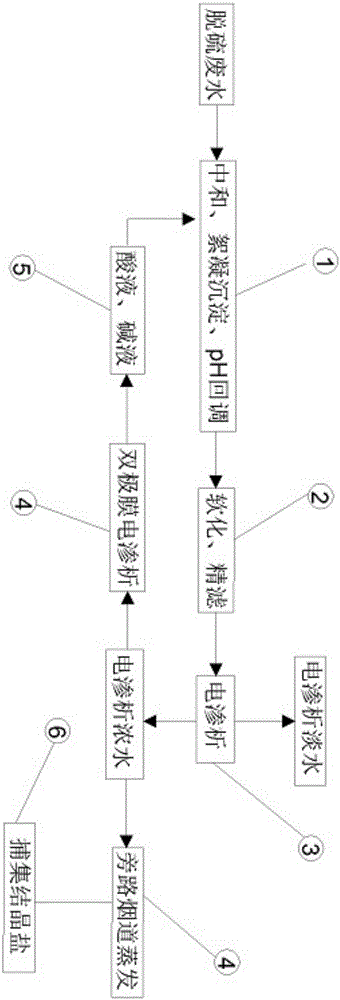

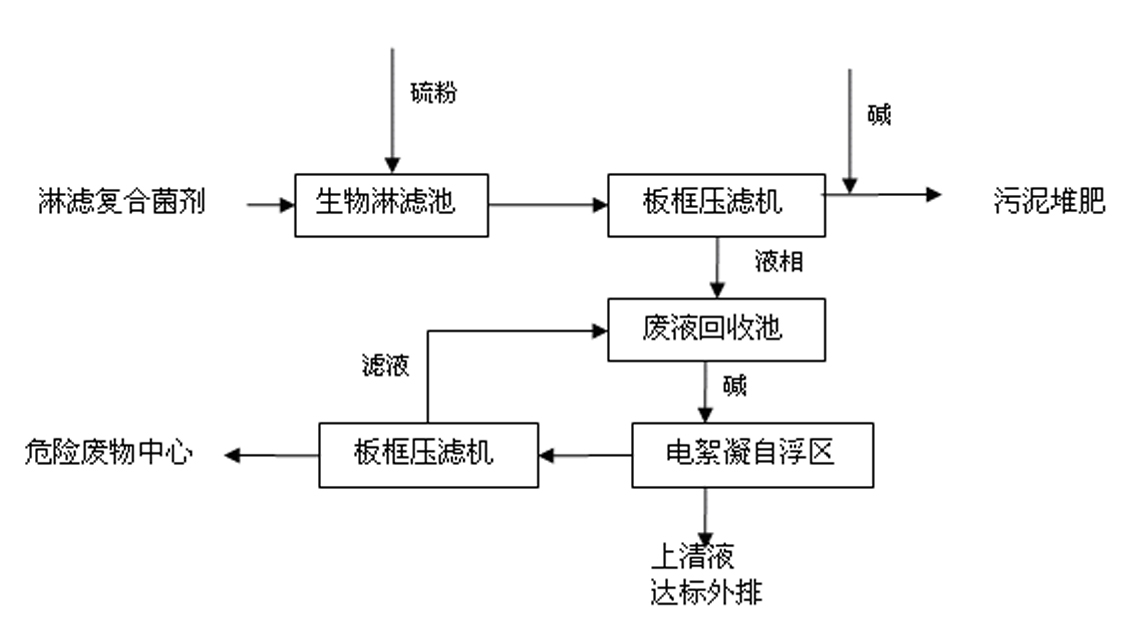

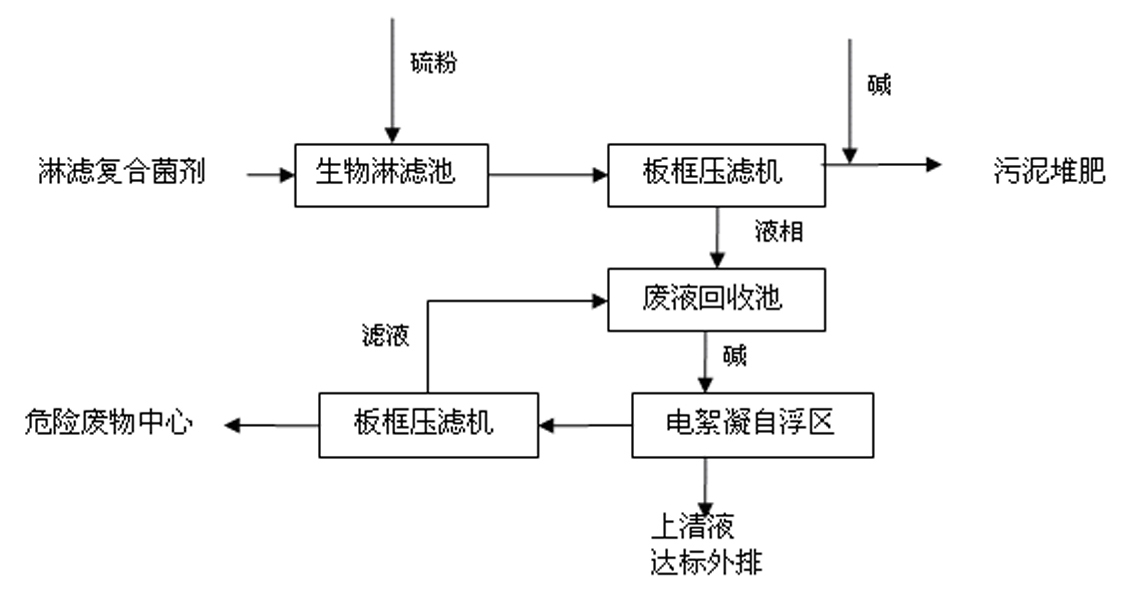

The invention discloses a process for removing heavy metals from sludge of sewage treatment plants. The process comprises the following steps of: adding 0.5 to 30g of elemental sulfur in each litre of sludge in a bioleaching tank, respectively inoculating 1 to 5 percent of thiobacilli and 1 to 3 percent of acidophilus moulds in the bioleaching tank, carrying out aerated bioleaching on the obtained sludge for 2 to 6 days until the pH value of the obtained sludge in the bioleaching tank is less than 2, and pumping the sludge subjected to bioleaching treatment in a plate-and-frame filter press by using a pump to carry out filter press separation so as to obtain sludge from which heavy metal is removed and sewage containing the heavy metal; adding alkali into the sludge from which heavy metal is removed to neutralize the sludge and then transporting the sludge to a sludge composting plant for composting; adding alkali into the sewage containing the heavy metal until the pH value of the sewage is about 7, then putting the sewage into an electrolytic flocculation floatation device to carry out electrolytic flocculation and self-floatation treatments on the sewage, and after the obtained liquid supernatant reaches the standard, draining the liquid supernatant; and pumping the flocculated scum of the pollutant in water into the plate-and-frame filter press for separation to obtain corresponding filter liquor and sludge, wherein the filter liquor is drained to a waste liquor recovery tank, and the sludge is transported to a hazardous waste disposal center for treatment. The process of the invention has the advantages of shortening the lixiviation period, improving the lixiviation efficiency and the variety of lixiviated heavy metal, ensuring the stability of removing heavy metal, and saving equipment investment.

Owner:湖南德施普生物科技有限公司

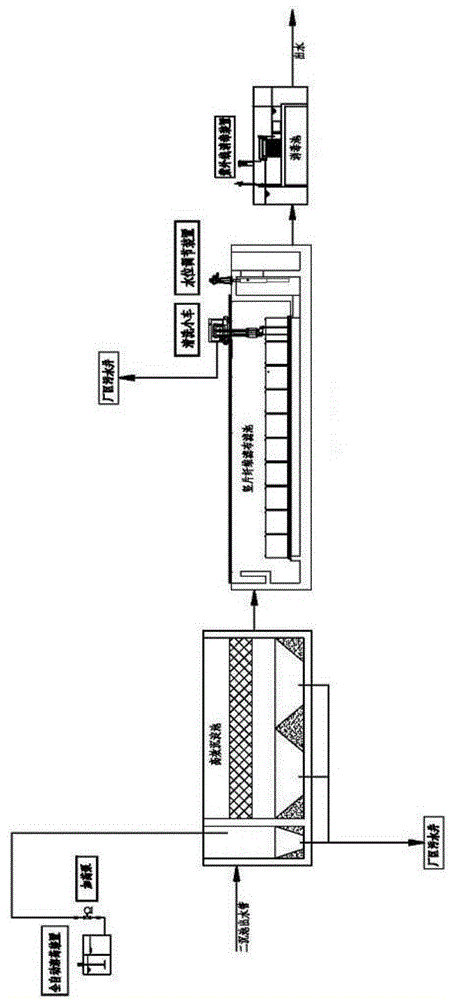

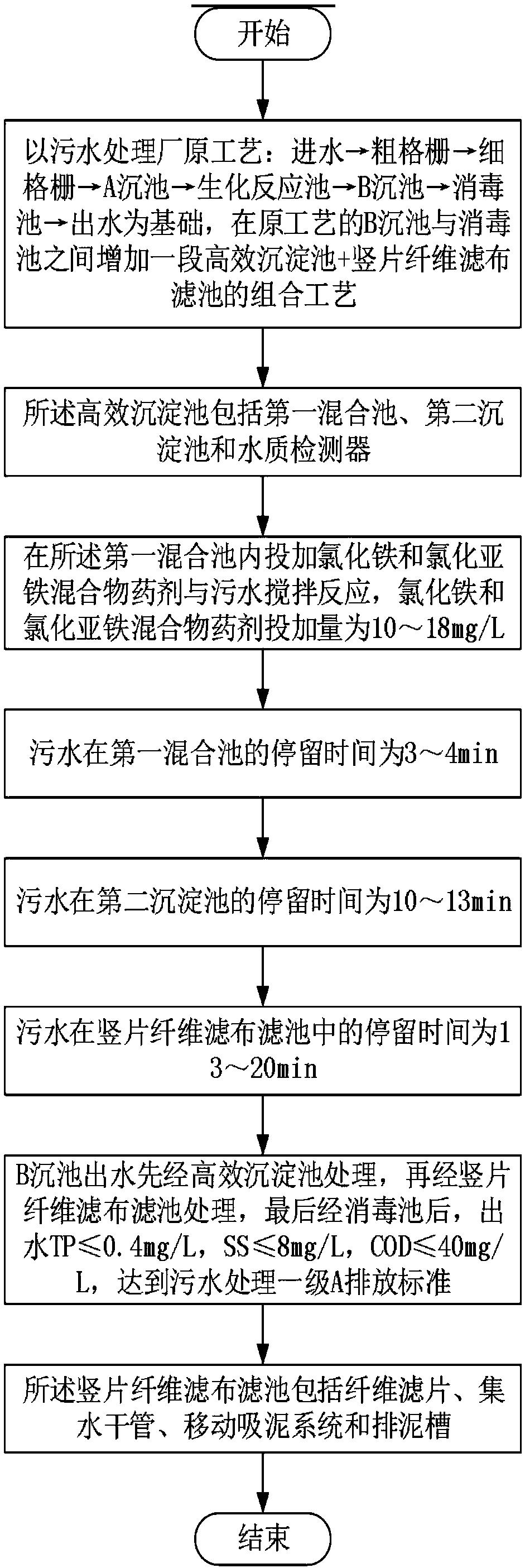

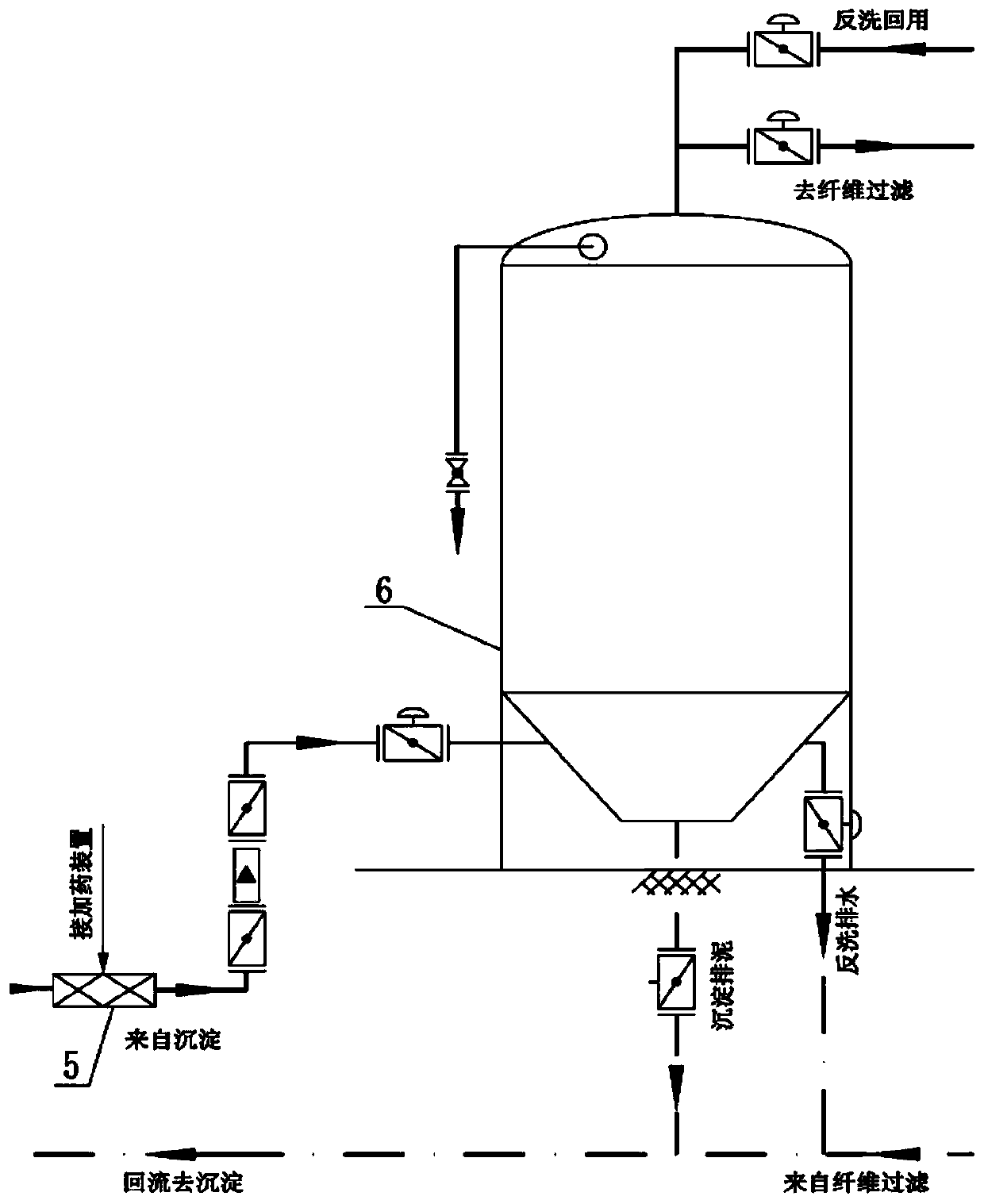

Advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction

ActiveCN103848542ASolve the problem that phosphorus cannot be removed by using aloneReduce pool capacityMultistage water/sewage treatmentPolyacrylamideSewage

The invention discloses an advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction. The advanced wastewater treatment technology is a combined technology of an efficient settling basin and a riser fiber filter cloth filter tank added between a secondary sedimentation tank and a disinfecting tank of the original process of a sewage treatment plant; an efficient sedimentation tank is composed of two modules of a quick mixing region and an efficient sedimentation region; a FeCl3 chemical is fed to the quick mixing region so as to be agitated to react with sewage; the adding amount of the FeCl3 chemical is 5-8mg / L; the standing time of the quick mixing region is 1.5-2 minutes; the standing time of the efficient sedimentation region is 15-20 minutes; the standing time of the riser fiber filter cloth filter tank is 8-12 minutes; effluent of the secondary sedimentation tank is firstly processed by the efficient sedimentation tank, and then processed by the riser fiber filter cloth filter tank, finally achieves the first level A of discharge standard for sewage treatment after passing through the disinfecting tank. By adopting the advanced wastewater treatment technology, the problems that the efficient sedimentation tank process is independently used, so that effluent SS is unstable, and the filter cloth filter tank is independently used and thus phosphorus cannot be removed are effectively solved, a flocculating agent does not need to be excessively fed again, the dosing cost is greatly reduced, and fouling on an online monitoring instrument probe caused by feeding polyacrylamide (PAM) is avoided.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

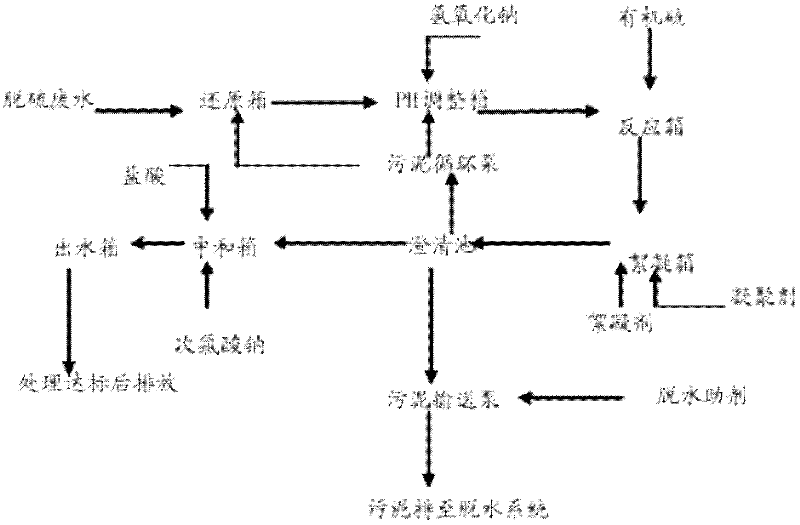

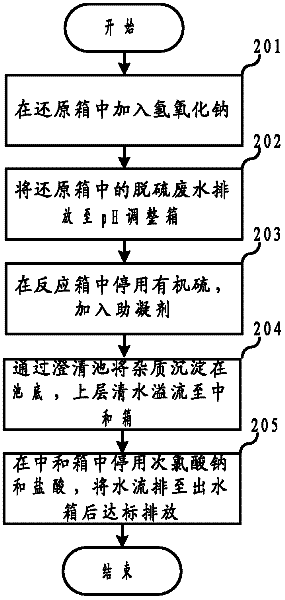

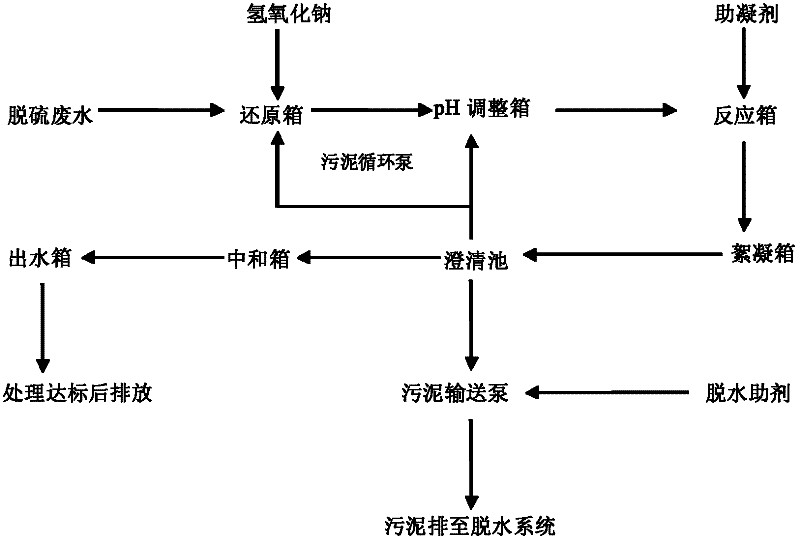

Desulfurization wastewater treatment method

InactiveCN102259997AAffect effluent qualityReduce typesMultistage water/sewage treatmentWater/sewage treatment by neutralisationSuspended particlesWater quality

The invention relates to sewage treatment, and discloses a desulfurization wastewater treatment method. In the present invention, the organic sulfur in the reaction box and the coagulant in the flocculation box are disabled. The coagulation aid is directly added to the desulfurization wastewater adjusted by the pH value. At the same time, the dosing port and dosing position are adjusted. The dispersed suspended particles in the desulfurization wastewater are condensed into larger flocs. After passing through the clarification and concentration tank, impurities such as heavy metals in the wastewater are deposited at the bottom of the tank, and the upper layer of clear water overflows to the neutralization tank. Further, stop using sodium hypochlorite and hydrochloric acid in the neutralization box, move the dosing point of sodium hydroxide from the pH adjustment box to the reduction box, and move the dosing point of the coagulant from the flocculation box to the reaction box to Reduce the types of chemicals that need to be added in the treatment of desulfurization wastewater, reduce the complexity of dosing, avoid affecting the effluent quality of desulfurization wastewater due to excessive dosing, and also reduce the cost of dosing.

Owner:上海申欣环保实业有限公司

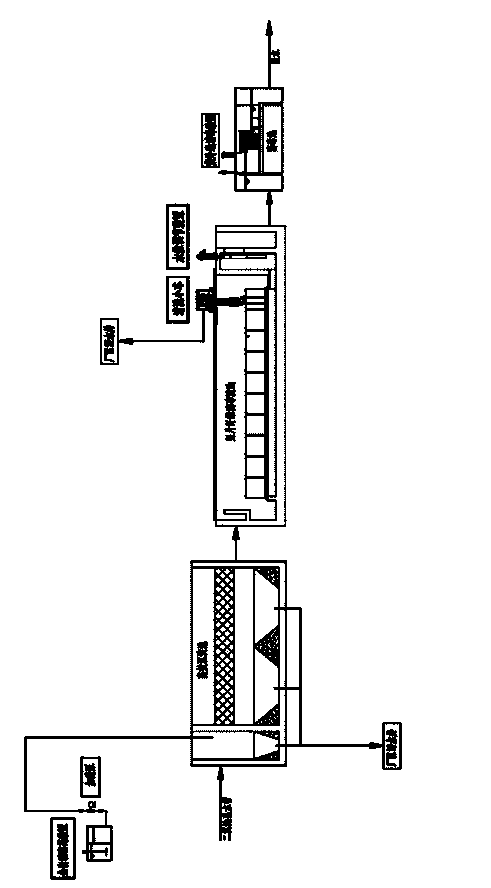

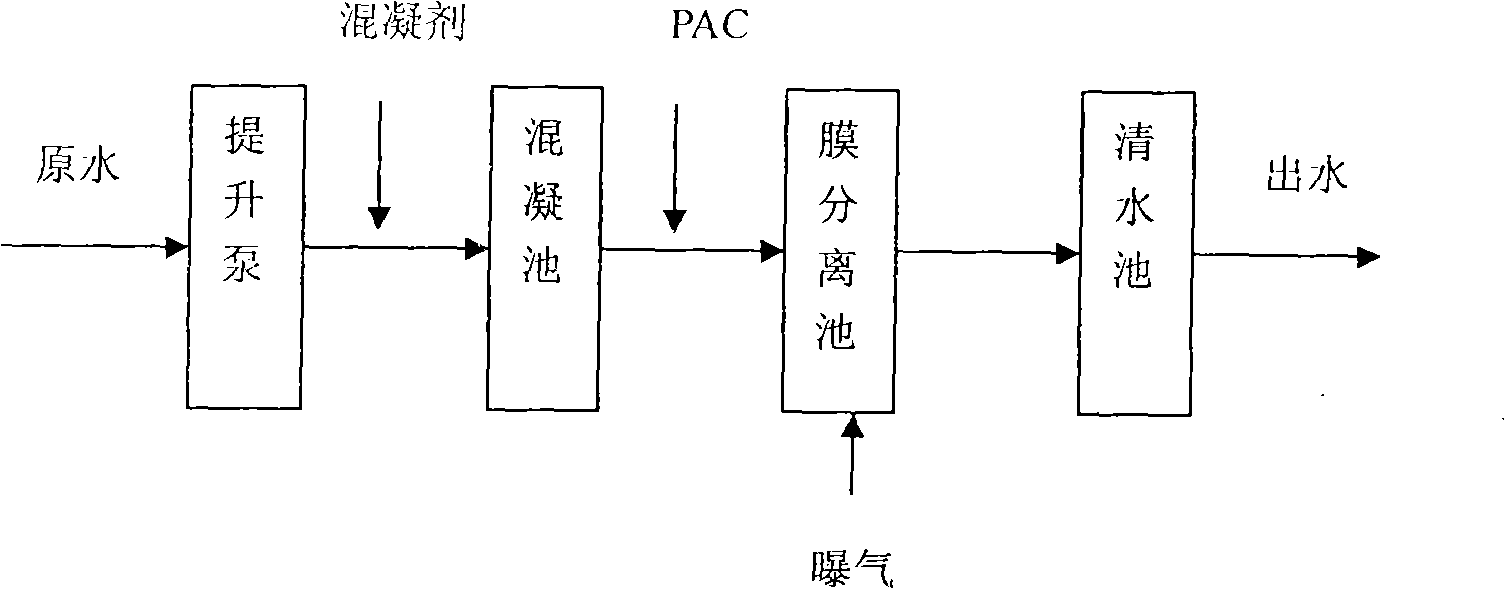

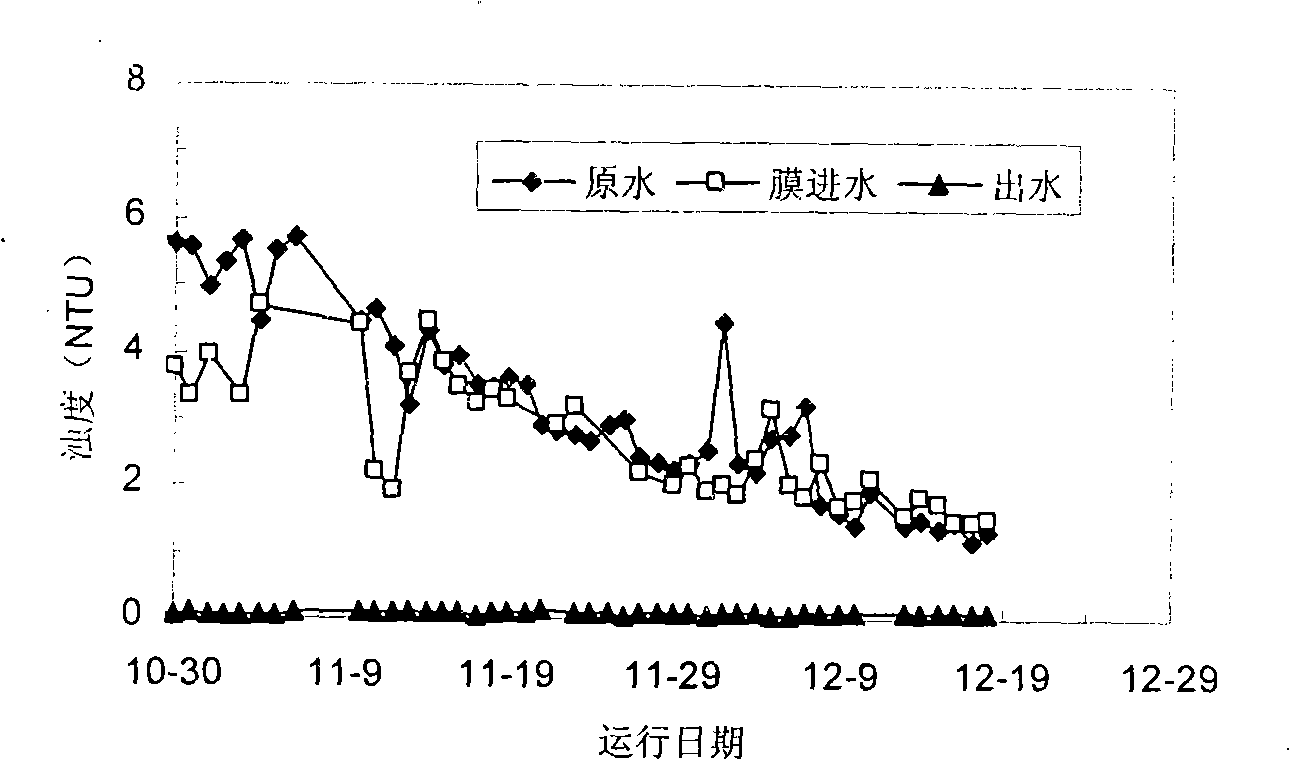

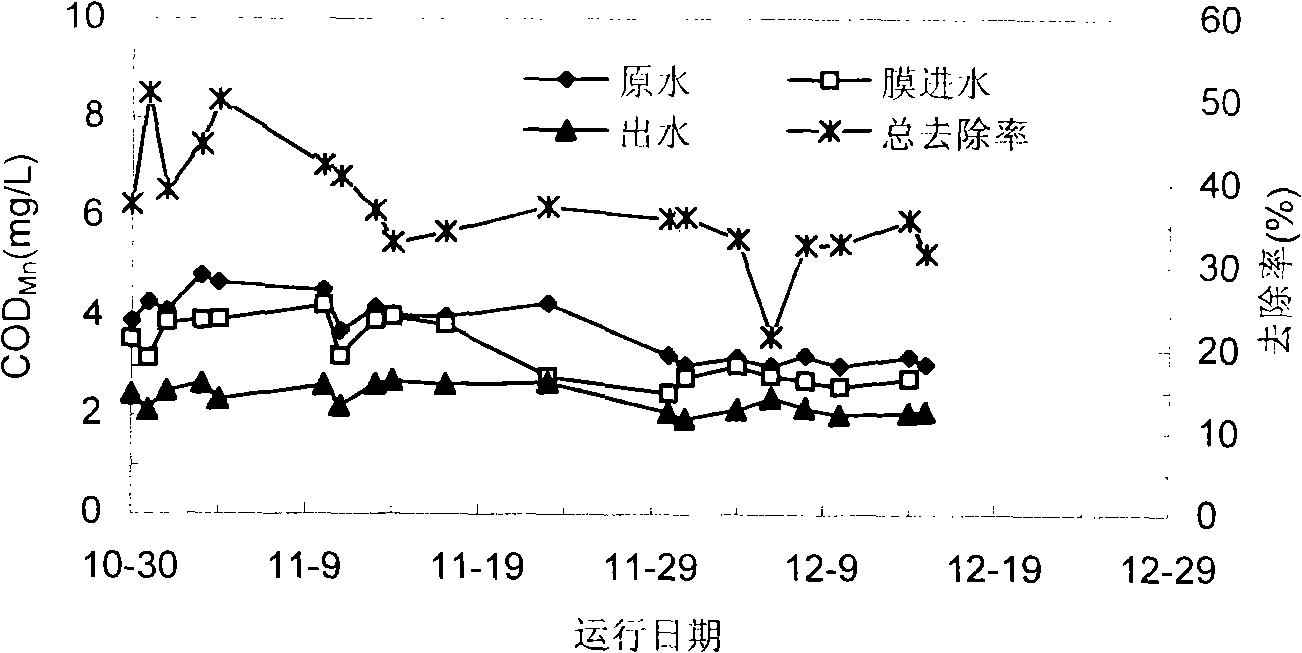

Technological process and apparatus for drinking water treatment by film method

InactiveCN101279805AEfficient removalImprove water qualityWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention provides a film method drinking water treatment equipment and a treatment method thereof. According to the treatment equipment of the invention, the film method drinking water treatment equipment comprises: a pretreatment unit, a coagulation tank and a film separation tank; a wide grille and a Y-shaped pipeline filter, etc. are arranged in the pretreatment unit for pre-treating the raw water and avoiding the blockage to a water pump and an inlet water meter by impurities in the raw water; the coagulation tank is a mechanical coagulation tank for coagulating the raw water; and the film separation tank adopts a curtain type membrane module structure to filter the raw water. The raw water is put with a coagulant after going through the pretreatment unit and then enters the coagulation tank, and the water treated by coagulation is treated by components of the curtain type membrane module. The drinking water treatment equipment adopts the combination of coagulation and membrane filtration to treat the micro-polluted surface water, and can fully prevent bacteria and effectively remove various suspended particles, bacteria, algae, COD and organic matters in water, thereby ensuring the excellent water quality with nearly zero water suspended substance.

Owner:TIANJIN POLYTECHNIC UNIV +1

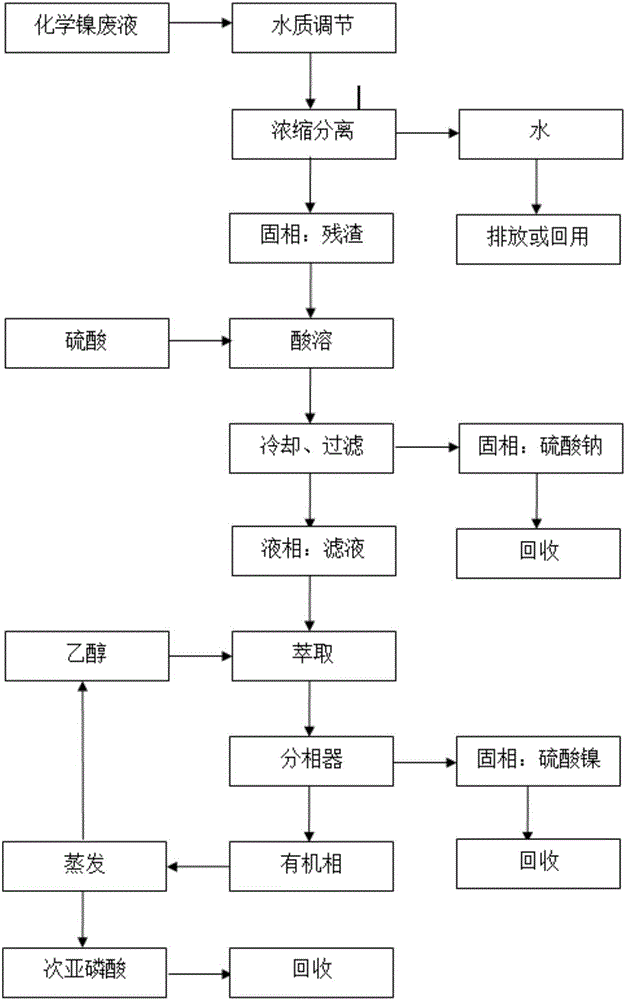

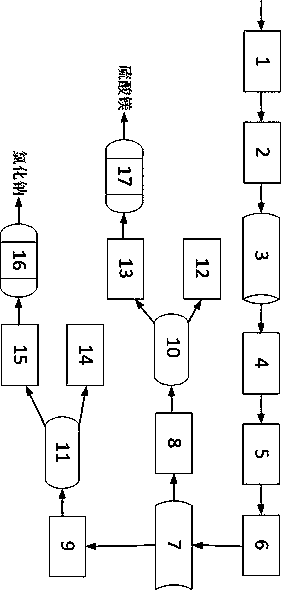

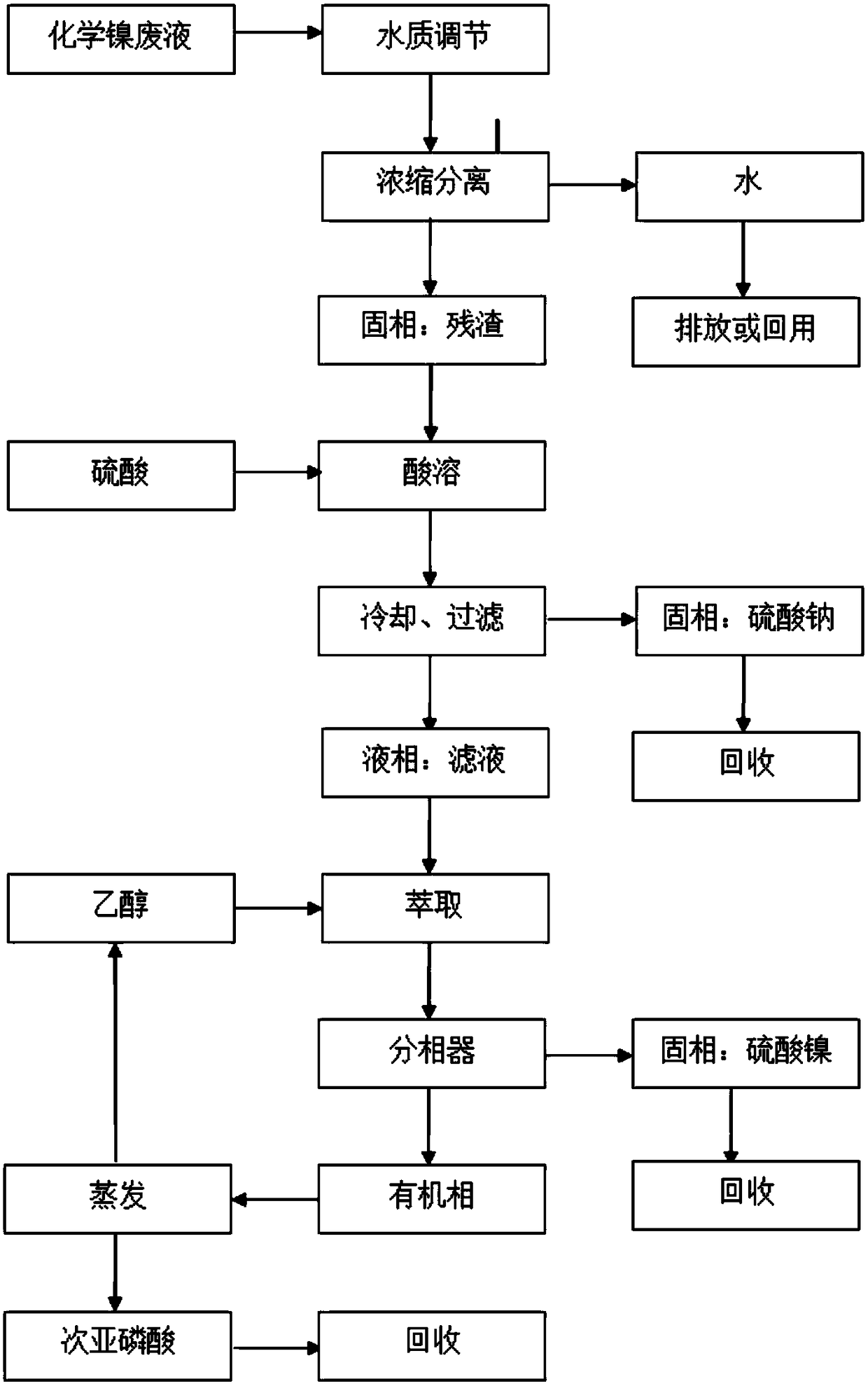

Resource utilization zero-emission recycling process method of chemical waste nickel liquid

ActiveCN106045123AThe process steps are simpleImprove operational safetyWater contaminantsWaste water treatment from metallurgical processZero emissionResource utilization

The invention discloses a resource utilization zero-emission recycling process method of a chemical waste nickel liquid. The resource utilization zero-emission recycling process method is characterized by comprising the following steps: I, concentrating and separating the chemical waste nickel liquid, namely, adjusting the pH value of the chemical waste nickel liquid to be 3-5, performing low-temperature negative pressure evaporation concentration, and rising the temperature to 95-110 DEG C, wherein the negative pressure condition is minus 0.09 - minus 0.1MPa and the boiling temperature is not greater than 70 DEG C; II, separating sodium sulfate by an acid solution, namely, performing slow soaking dissolution on chemical nickel residues by a sulfuric acid solution in stirring so as to obtain a sulfuric acid leaching agent; after sufficient cooling, and performing filtration to obtain filtrate and sodium sulfate crystal; III, extracting and separating nickel sulfate, namely, adding ethanol into the filtrate, leaving to stand to layer, and performing solid-separation separation so as to obtain nickel sulfate solid for resource recycling and reuse; IV, recycling ethanol. By adopting the resource utilization zero-emission recycling process method disclosed by the invention, the chemical solid nickel waste can be completely recycled, the requirements of environment-friendliness of waste liquid recycling and zero emission are met indeed, and the required social environment capacity is greatly reduced.

Owner:苏州市东方环境工程有限公司

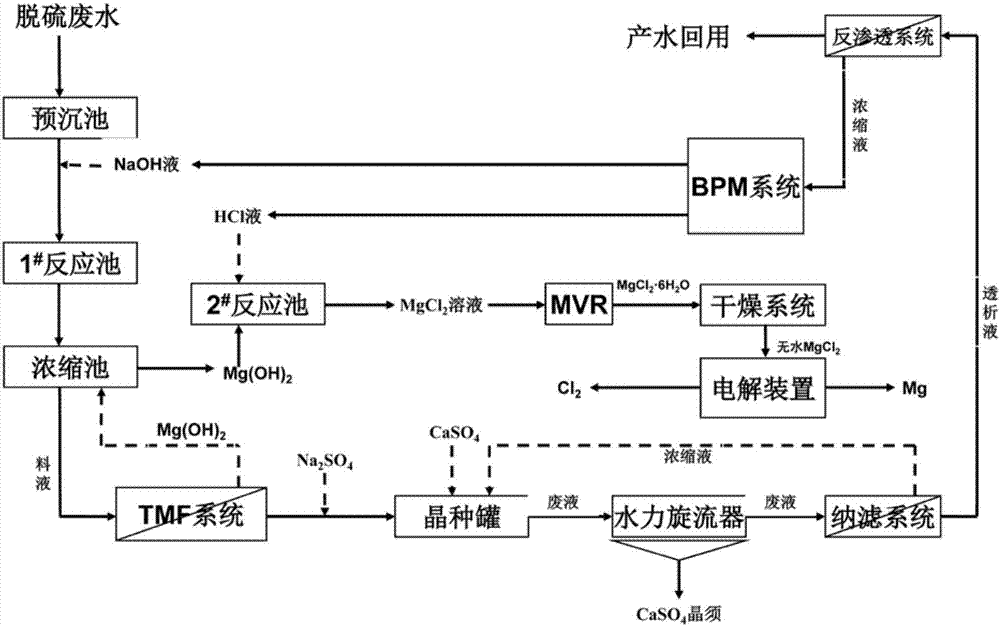

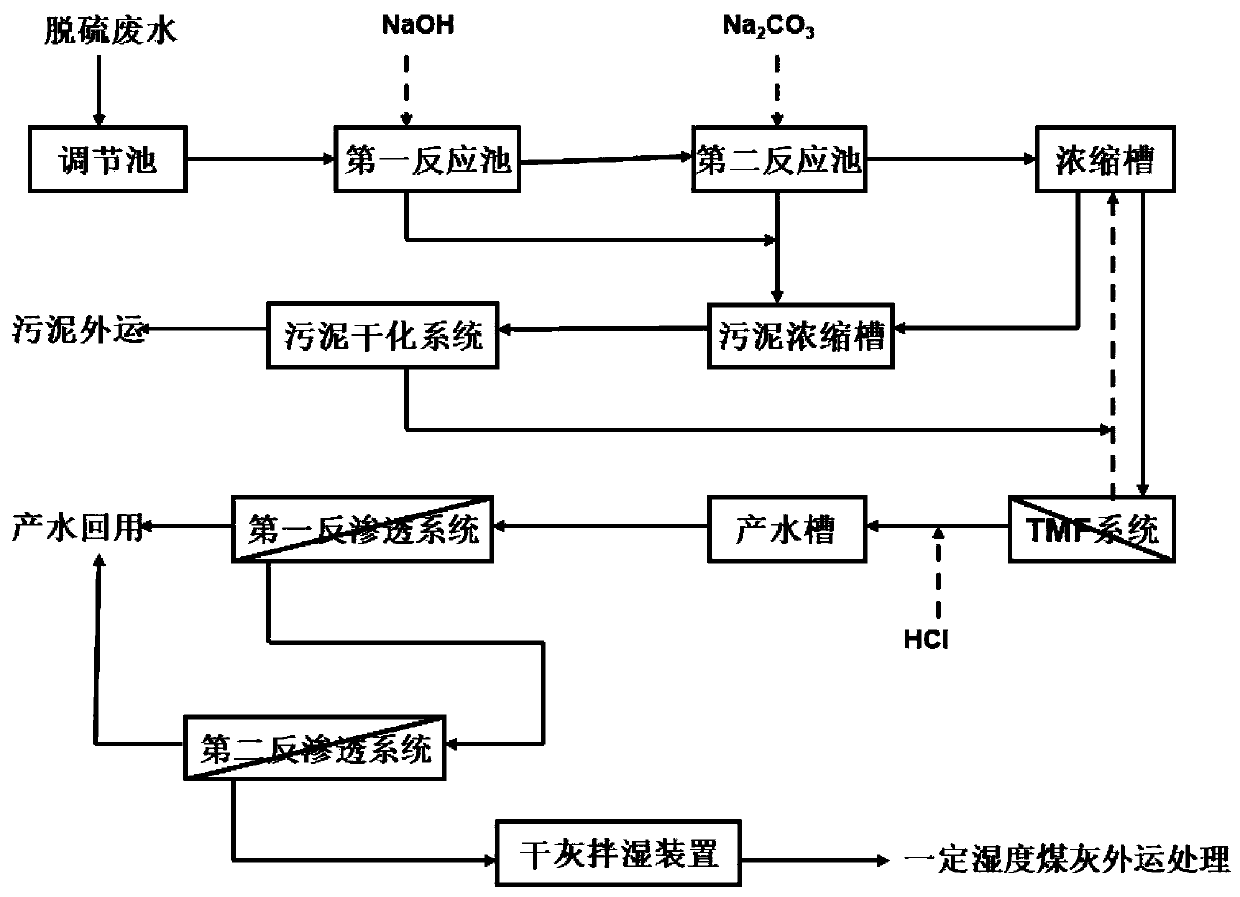

Recycling treatment process for thermal power plant desulfurization wastewater

InactiveCN107311350AReduce productionImprove stabilityCellsCalcium/strontium/barium sulfatesElectrolysisPower station

The invention discloses a recycling treatment process for thermal power plant desulfurization wastewater. The process includes: 1) subjecting desulfurization wastewater to triple box treatment, and then letting the treated wastewater enter a pre-sedimentation tank; 2) adding NaOH and letting it overflow into a 1# reaction tank to undergo reaction; 3) letting the effluent water of the 1# reaction tank enter a concentration tank, transporting the feed liquid in the concentration tank into a TMF system for filtering, returning the formed Mg(OH)2 to the concentration tank, and discharging Mg(OH)2 into a 2# reaction tank; 4) letting the TMF system produced water enter a seed crystal tank, outputting the waste liquid to a hydrocyclone, and making the clear liquid obtained by the hydrocyclone enter a nanofiltration system; 5) returning the concentrated liquid obtained by the nanofiltration system to the seed crystal tank, making the dialysate enter a reverse osmosis system, and conducting electric treatment on the obtained concentrated liquid; and 6) subjecting the MgCl2 feed liquid formed in the 2# reaction tank to evaporative crystallization to form MgCl2 crystals, and then conducting re-drying to obtain anhydrous MgCl2, and carrying out electrolytic treatment on the anhydrous MgCl2 to obtain elemental Mg and Cl2. The "chemical reaction+TMF system+seed crystal tank+hydrocyclone+nanofiltration system+reverse osmosis system+bipolar membrane" process involved in the invention can reuse 90% or more of water, and can utilize Mg, CaSO4 and NaCl in wastewater.

Owner:上拓环境科技(长兴)有限公司

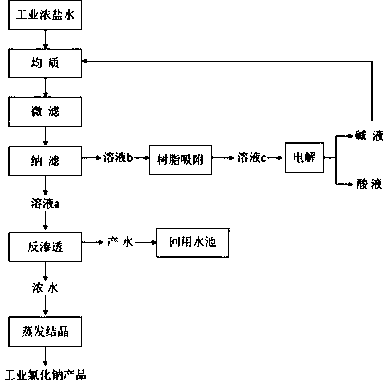

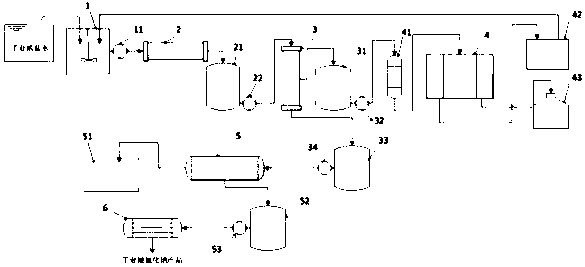

Industrial brine resource utilization method and system

InactiveCN109081488AHigh degree of resource utilizationNo hazardous waste dischargeWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentProcess systemsElectrolysis

The invention discloses an industrial brine resource utilization method and system. The industrial brine resource utilization method comprises mixing and homogenizing industrial brine and alkali liquor, regulating the pH to 11-12, removing precipitates from the mixed solution through a microfiltration system, regulating back the pH of microfiltration discharged solution, utilizing a nanofiltrationsystem to obtain a solution a mainly containing monovalent salt and a solution b mainly containing divalent salt, performing concentration and evaporative crystallization on the solution a through areverse osmosis system to obtain industrial sodium chloride, and performing resin exchange on the solution b to further remove calcium and magnesium ions for electrolysis to obtain alkali liquor and sulfuric acid solution, wherein the alkali liquor is returned for pH regulation of the industrial brine. According to the industrial brine resource utilization method, the monovalent salt solution obtained from nanofiltration salt separation is processed through reverse osmosis concentration and evaporative crystallization to produce the industrial sodium chloride, the divalent salt solution is electrolyzed, the alkali liquor produced through electrolysis returns to the softening pretreatment section of the industrial brine, so that the chemical adding cost of the pretreatment process can be greatly reduced; meanwhile, the entire process system of the industrial brine resource utilization method is skillful in design free from discharge of salt impurities; by recycling the alkali liquor produced during electrolysis, the chemical adding cost of the system can be reduced, and the degree of resource utilization of the industrial brine can be greatly improved.

Owner:国能朗新明环保科技有限公司

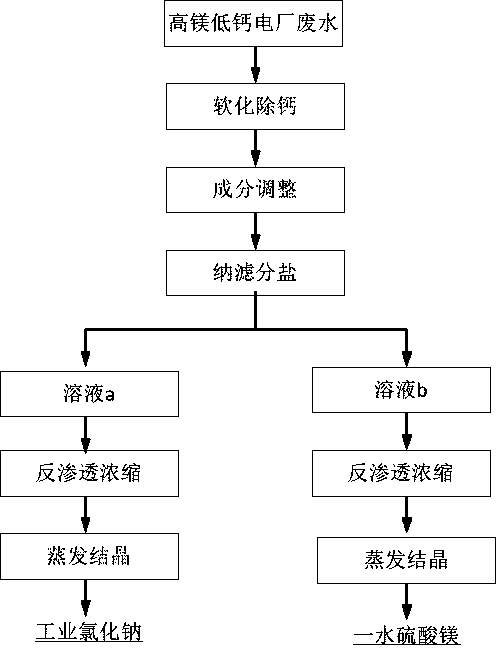

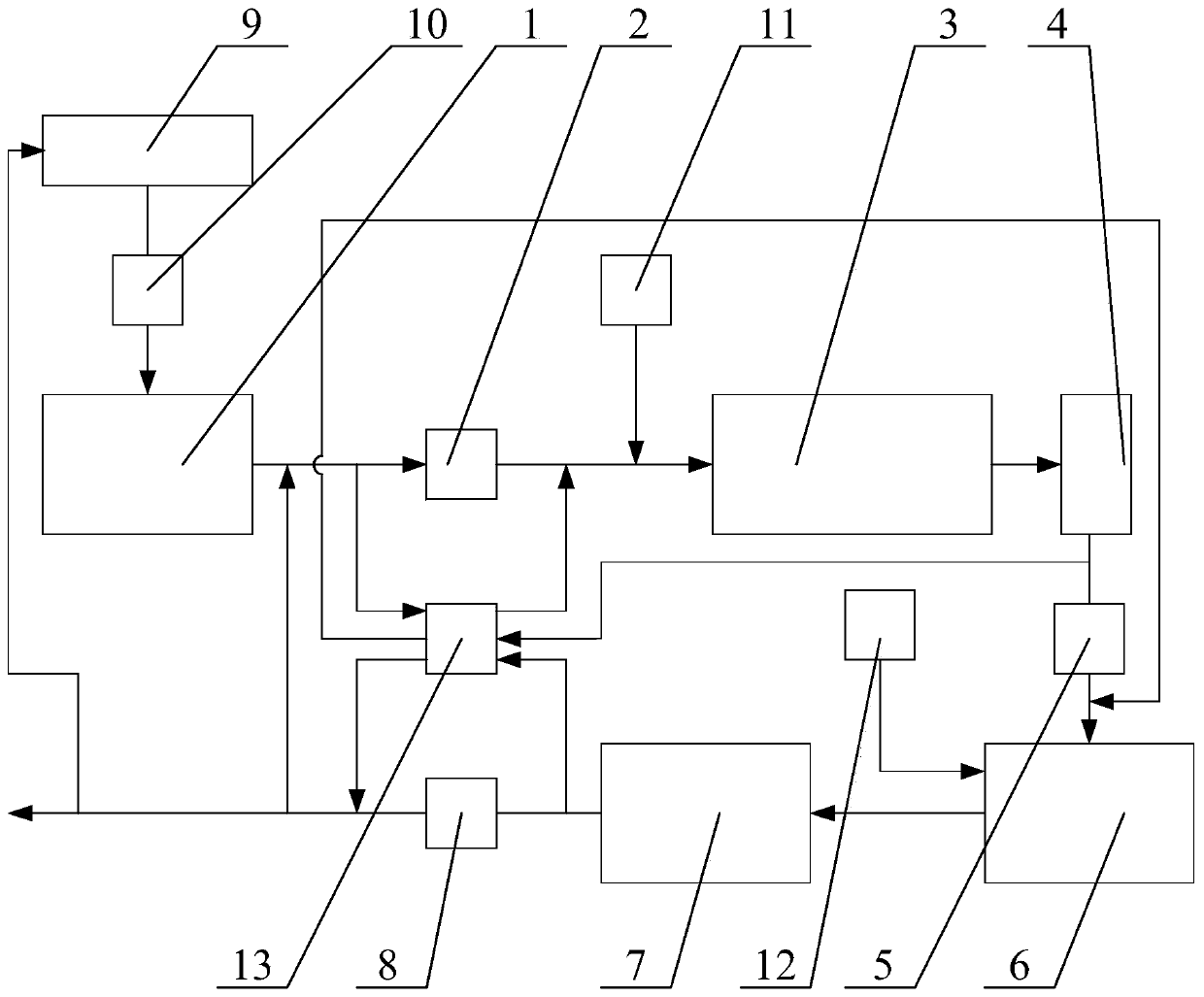

Method and device for recycling high-magnesium wastewater from power plants

PendingCN109516627AEfficient separationReduce the cost of dosingTreatment involving filtrationWater softeningPre treatmentHigh magnesium

The invention discloses a method and a device for recycling high-magnesium wastewater from power plants and belongs to the technical field of water treatment. The method for recycling high-magnesium wastewater from power plants comprises the following steps: softening and removing calcium; adjusting compositions; nano-filtering and separating salt; concentrating and crystallizing. The device for recycling high-magnesium wastewater from power plants comprises a softening pretreatment system, a composition adjusting system, a nano-filtering and salt-separating system, a reverse osmosis concentration system and an evaporative crystallization system which are connected with each other in turn along a flowing direction of wastewater. According to the method for recycling high-magnesium wastewater from power plants disclosed by the invention, calcium ions in water can be effectively removed, magnesium ions can be fully utilized and dosing cost of pretreatment can be greatly lowered. Sodium chloride products and magnesium sulfate products acquired by utilizing the method and device provided by the invention are high in purity and high in recovery rate.

Owner:国能朗新明环保科技有限公司

Advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction

ActiveCN103848542BSolve the problem that phosphorus cannot be removed by using aloneReduce pool capacityMultistage water/sewage treatmentFiberWastewater

The invention discloses an advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction. The advanced wastewater treatment technology is a combined technology of an efficient settling basin and a riser fiber filter cloth filter tank added between a secondary sedimentation tank and a disinfecting tank of the original process of a sewage treatment plant; an efficient sedimentation tank is composed of two modules of a quick mixing region and an efficient sedimentation region; a FeCl3 chemical is fed to the quick mixing region so as to be agitated to react with sewage; the adding amount of the FeCl3 chemical is 5-8mg / L; the standing time of the quick mixing region is 1.5-2 minutes; the standing time of the efficient sedimentation region is 15-20 minutes; the standing time of the riser fiber filter cloth filter tank is 8-12 minutes; effluent of the secondary sedimentation tank is firstly processed by the efficient sedimentation tank, and then processed by the riser fiber filter cloth filter tank, finally achieves the first level A of discharge standard for sewage treatment after passing through the disinfecting tank. By adopting the advanced wastewater treatment technology, the problems that the efficient sedimentation tank process is independently used, so that effluent SS is unstable, and the filter cloth filter tank is independently used and thus phosphorus cannot be removed are effectively solved, a flocculating agent does not need to be excessively fed again, the dosing cost is greatly reduced, and fouling on an online monitoring instrument probe caused by feeding polyacrylamide (PAM) is avoided.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

System for recycling sludge subjected to chemical drying

InactiveCN102923925AReduce the amount of secondary dosageImprove drying effectSludge treatment by de-watering/drying/thickeningSludge cakeTherapeutic effect

The invention utilizes a recycling technology performing drying treatment of raw sludge by using sludge subjected to chemical drying treatment. By recycling treated sludge, the raw sludge can be evenly and well mixed with a composite reagent in the treatment process, and good effect is played on moisture removal. The treatment process comprises the steps of 1 using chemical drying to treat the sludge and fully mixing the sludge and the composite reagent; 2 performing air-curing and smashing; enabling the moisture content to be reduced to be 30-40% after the sludge subjected to chemical drying is dried naturally, using a sludge smashing device to smash sludge cakes into 0.5-1mm of powder-like particles, and smashing the sludge particles to be approximate to power after further drying; and 3 performing circulating input, mixing power obtained through the drying and smashing and an early-added reagent in the composite reagent, further adding other reagents in the composite reagent and then performing the circular process. The system for recycling the sludge subjected to chemical drying takes the sludge treatment cost and treatment effect as main factors and reduces secondary environment pollution.

Owner:SHENYANG JIANZHU UNIVERSITY

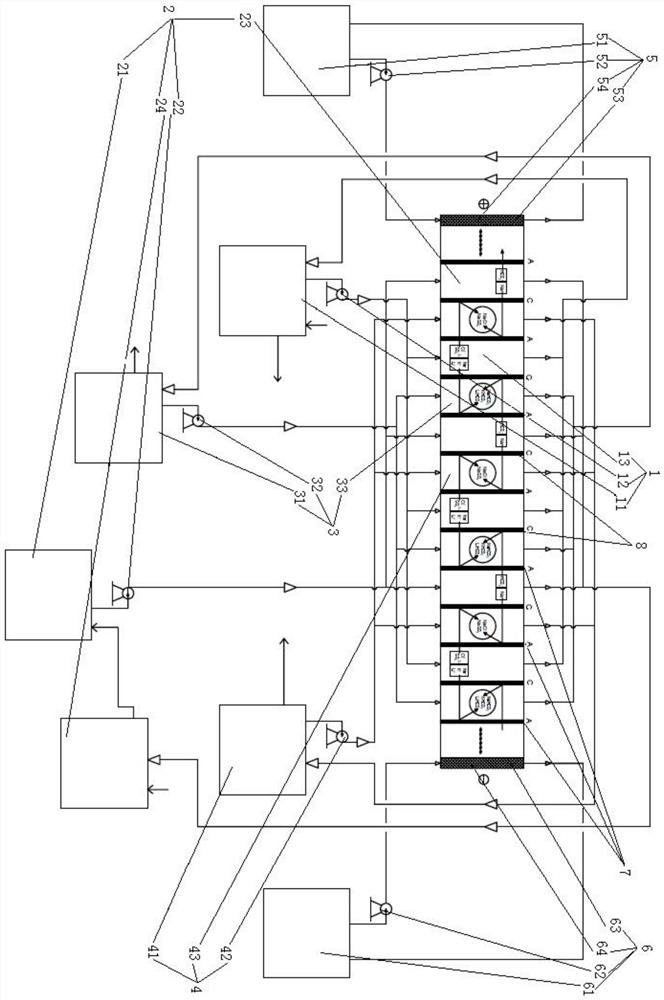

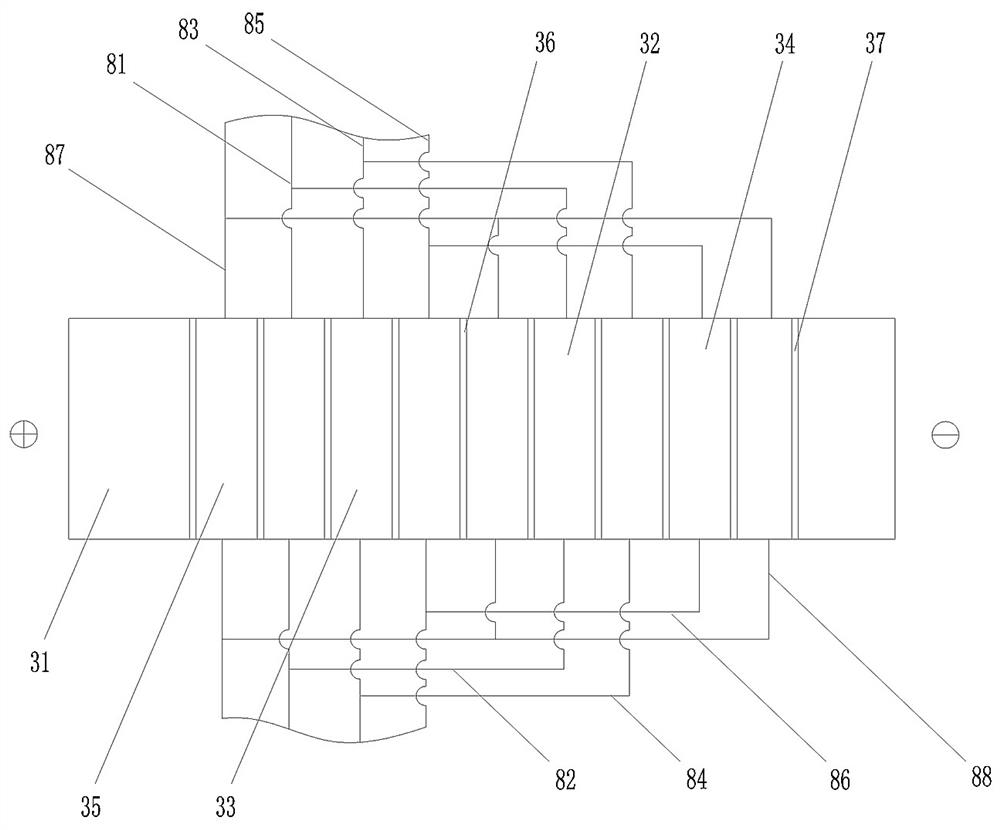

A four-channel electrodialysis device for extracting lithium from salt lakes and a method for extracting lithium from salt lakes

ActiveCN110917882BShort processSmall footprintMembranesGeneral water supply conservationSalt lakeEnvironmental engineering

The invention discloses a four-channel electrodialysis device for extracting lithium from a salt lake and a method for extracting lithium from a salt lake in the related technical field of lithium salt production. The four-channel electrodialysis device comprises a first electrodialysis circulating device, a second electrodialysis circulating device, a third electrodialysis circulating device, a fourth electrodialysis circulating device, an anolyte circulating device and a catholyte circulating device, and four electrodialysis channels are formed. The method for extracting lithium from a saltlake comprises the steps of pretreatment, four-channel electrodialysis and evaporation precipitation. A four-channel electrodialysis module of a special structure is adopted, and the occupied area isreduced. The two steps of agent adding and lithium bicarbonate concentration are integrated, and the whole technological process of salt lake lithium extraction is shortened. The dosing cost is saved.The problem of sulfate scaling on the concentrated solution side of the electrodialysis unit is avoided. The process of preparing lithium carbonate by evaporation precipitation is simple to operate.

Owner:杭州匠容道环境科技有限公司

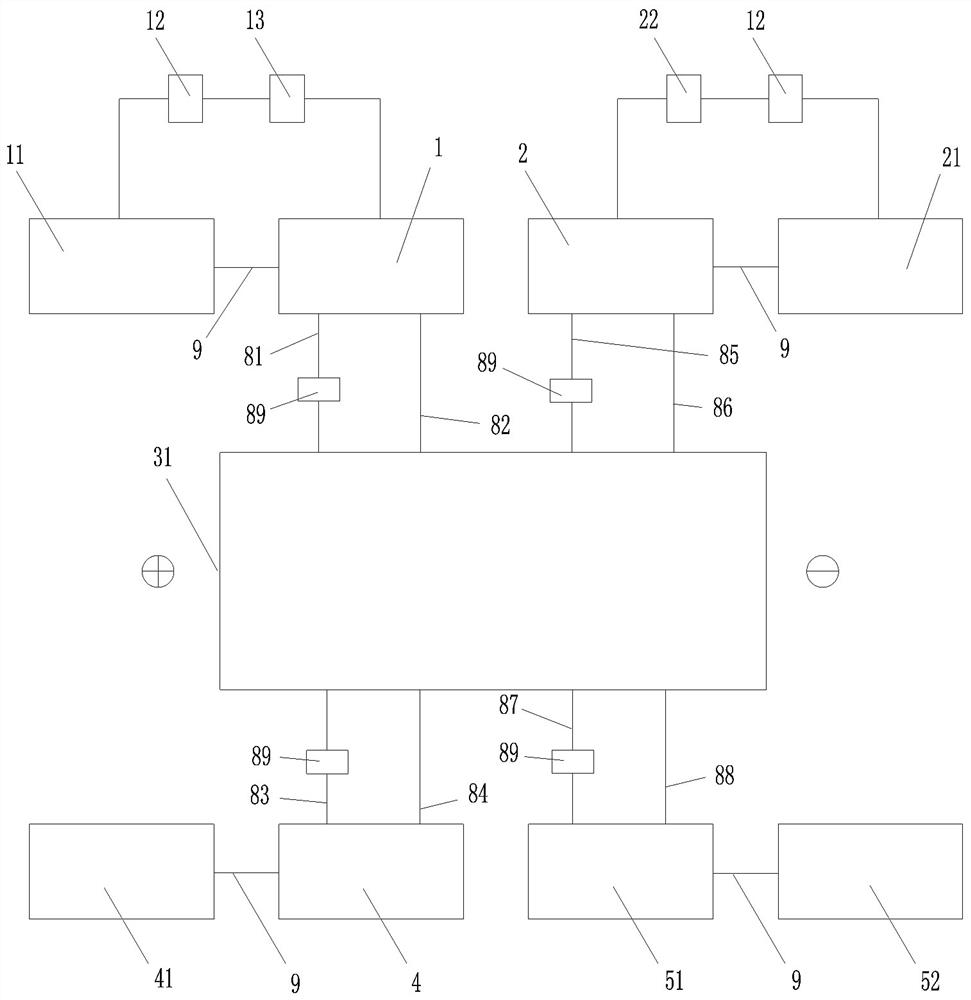

Method and device for preparing ammonium sulfate and sodium bicarbonate from sodium sulfate and ammonium bicarbonate

ActiveCN112850747AGood for salt makingReduce energy consumptionCarbonate preparationAmmonia compoundsSodium bicarbonateSulfate radicals

The invention relates to a method and a device for preparing ammonium sulfate and sodium bicarbonate from sodium sulfate and ammonium bicarbonate. The method comprises the following steps of pretreating a sodium sulfate stock solution and an ammonium bicarbonate stock solution, so that sodium sulfate and ammonium bicarbonate pass through an electrodialysis unit arranged in an electric field, recombining sodium ions and sulfate ions in the sodium sulfate stock solution and ammonium ions and bicarbonate ions in the ammonium bicarbonate stock solution to form an ammonium sulfate solution and a sodium bicarbonate solution, and leading out the ammonium sulfate solution and the sodium bicarbonate solution to an evaporative crystallization unit to obtain ammonium sulfate crystals and sodium bicarbonate crystals. By arranging the electrodialysis module, ions of the sodium sulfate stock solution and the ammonium bicarbonate stock solution are re-paired to form the concentrated solution, and the concentrated solution is evaporated and crystallized to prepare the high-purity sodium bicarbonate crystal and ammonium sulfate crystal, so that the whole technological process is free of additional chemicals, the chemical adding cost is saved, the technological process is short, the required equipment is small in occupied area, and the utilization rate of the raw material medicament is higher.

Owner:浙江志澄环境资源科技有限公司

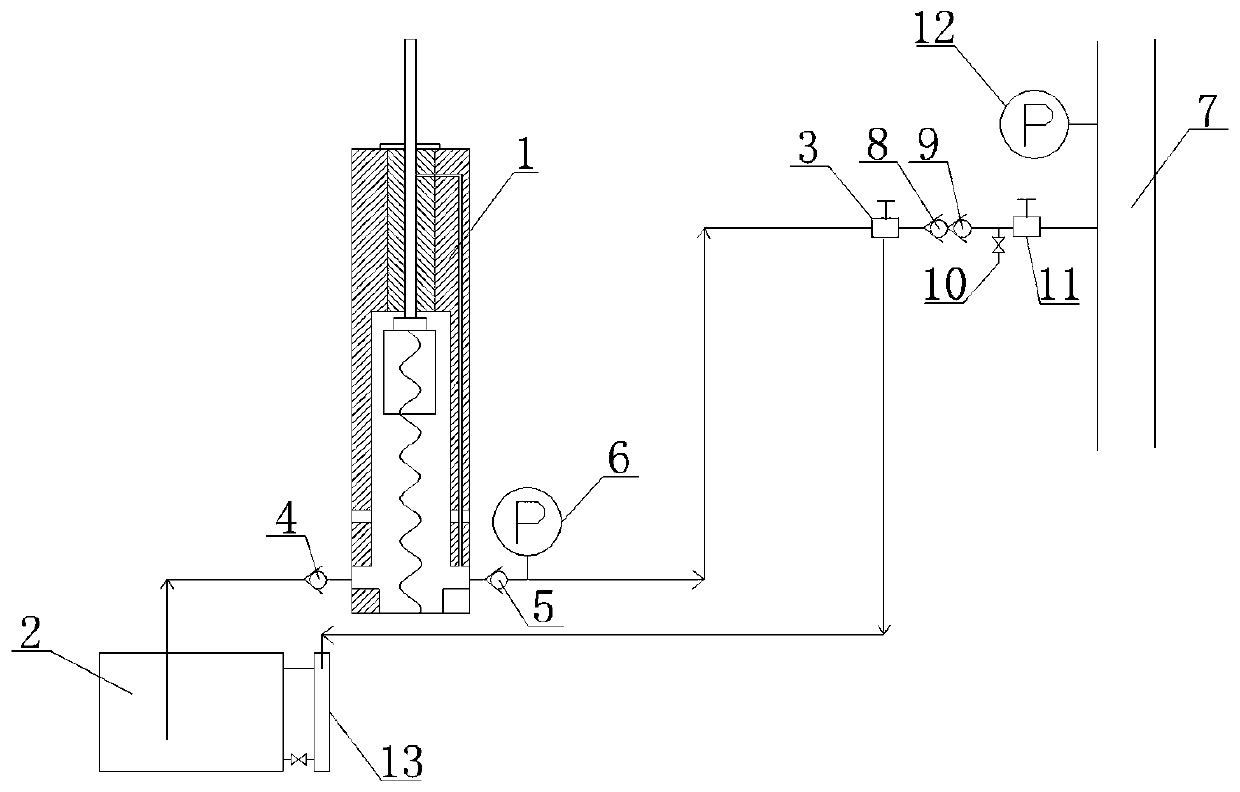

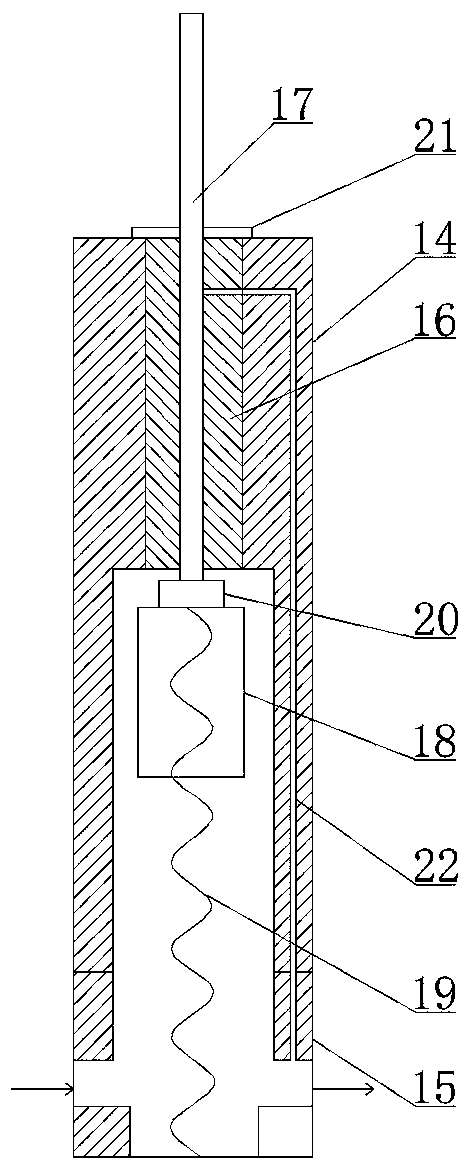

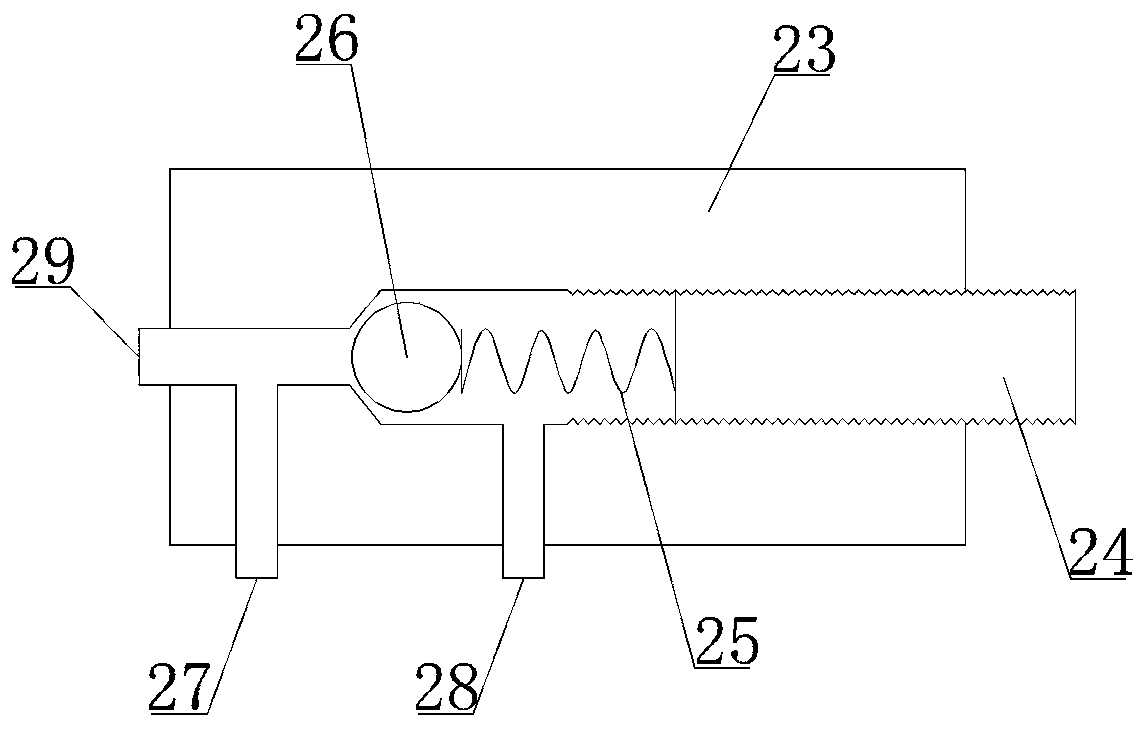

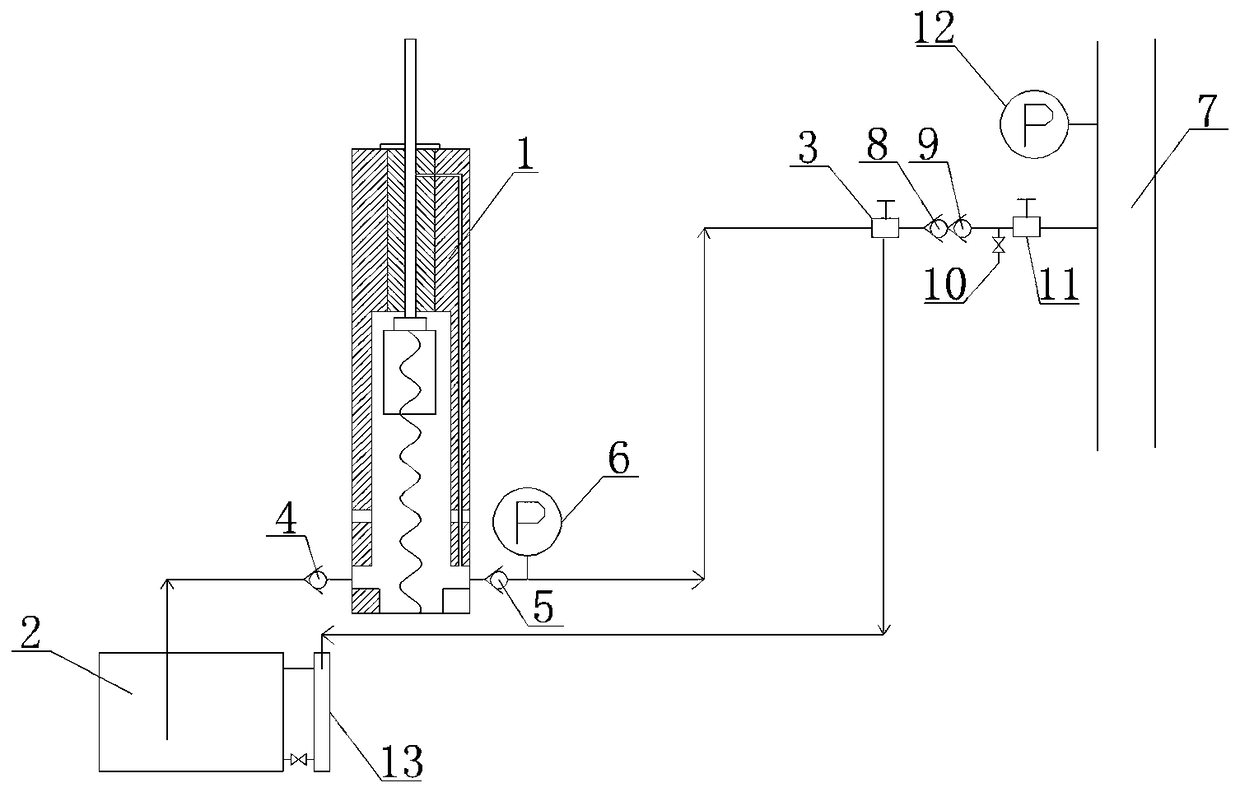

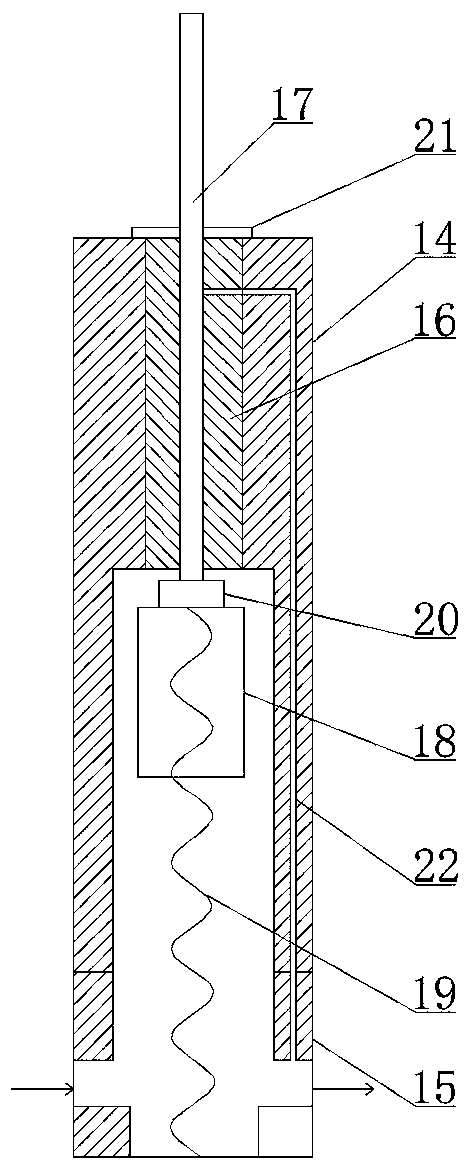

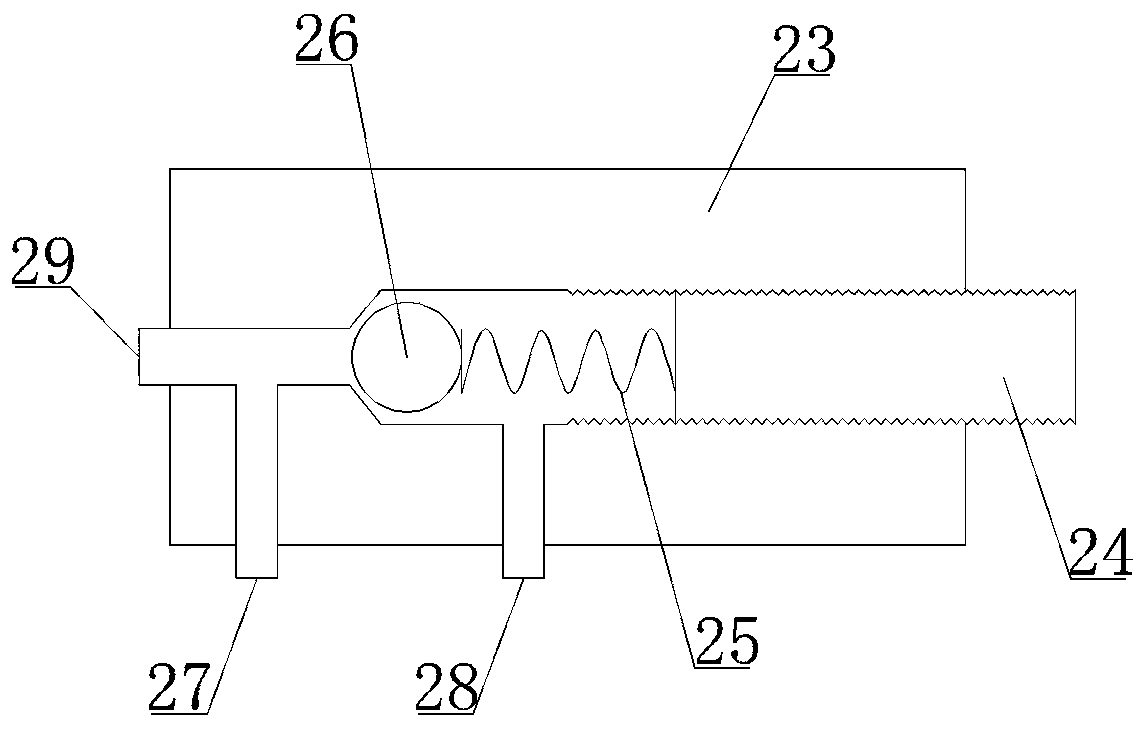

Polished rod kinetic energy chemical feeding device

ActiveCN107829716ADoes not affect other operationsEasy maintenanceFluid removalLine tubingCompound (substance)

The invention provides an optical rod kinetic energy chemical feeding device. An inlet pipeline of a chemical feeding pump is connected with a chemical feeding barrel, the inlet of the chemical feeding pump is provided with a one-way valve A, an outlet pipeline of the chemical feeding pump is connected to a pressure regulating valve, a one-way valve B is arranged at an outlet of the chemical feeding pump, the back side of the one-way valve B is provided with a pressure gauge A, an outlet pipeline of the pressure adjusting valve is connected to a well pipeline, the pressure gauge B is arrangedon the well pipeline, a one-way valve C, a one-way valve D, a discharging valve and a switching valve are sequentially arranged at the back side of an outlet of the pressure adjusting valve, and a reflux inlet pipeline of the pressure adjusting valve is connected to the top of a liquid lever meter. The optical rod kinetic energy chemical feeding device has the advantages that the kinetic energy ofan oil pumping machine is fully utilized to serve as motive power of the chemical feeding pump, addition of extra power equipment is not required, the device is easy to maintain, the organic cooperation between the device and a wellhead does not influence other operation of the wellhead, and the effect of reducing the chemical feeding cost can be achieved; the chemical feeding amount can be adjusted, and accurate medicine addition can be achieved without stopping operation of the well; the device is small in size, easy to install, less in maintenance demand and attractive in appearance.

Owner:SHENGLI XINDA IND GRP

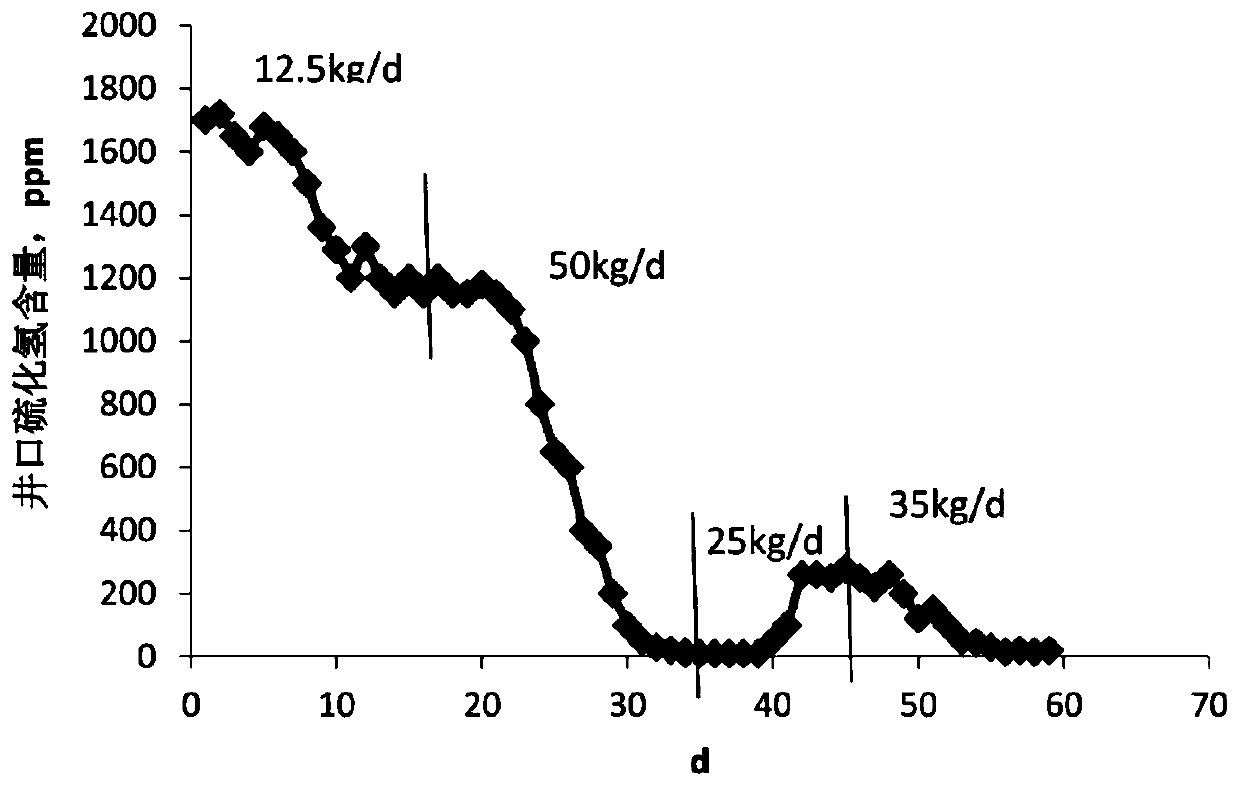

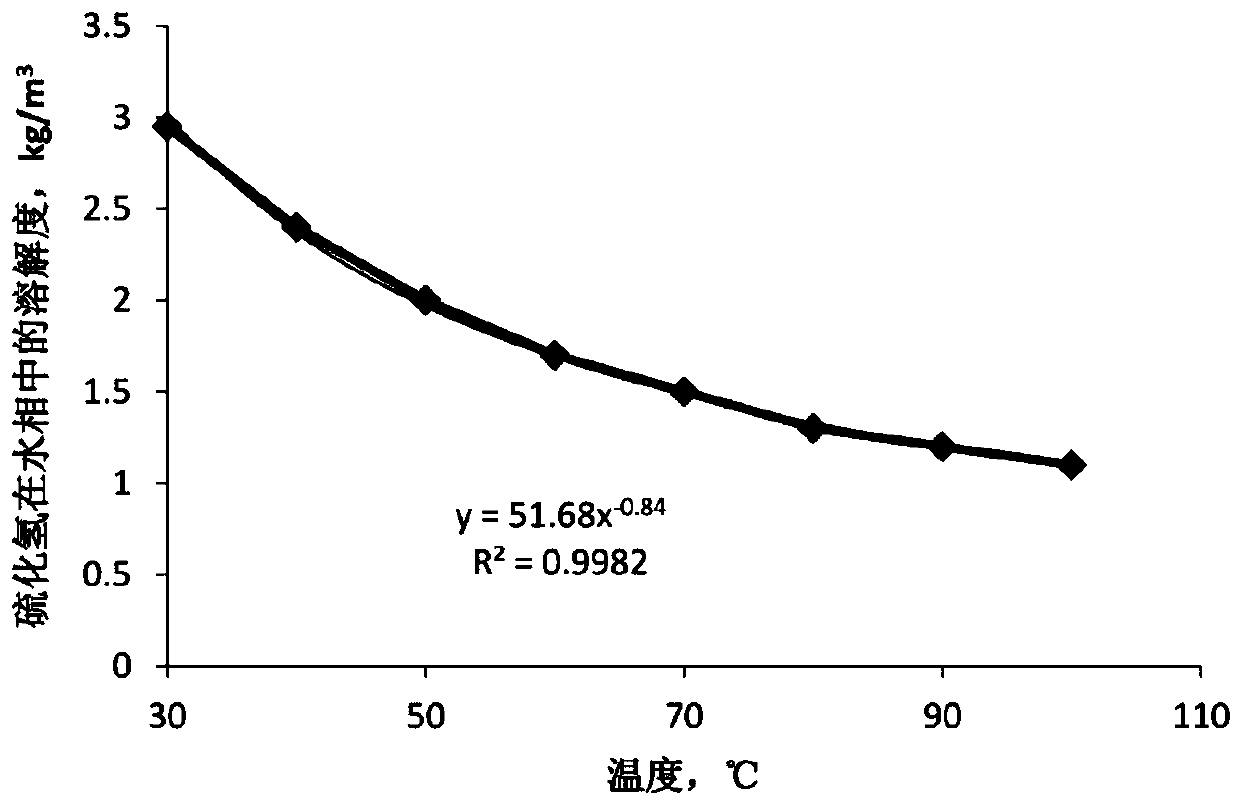

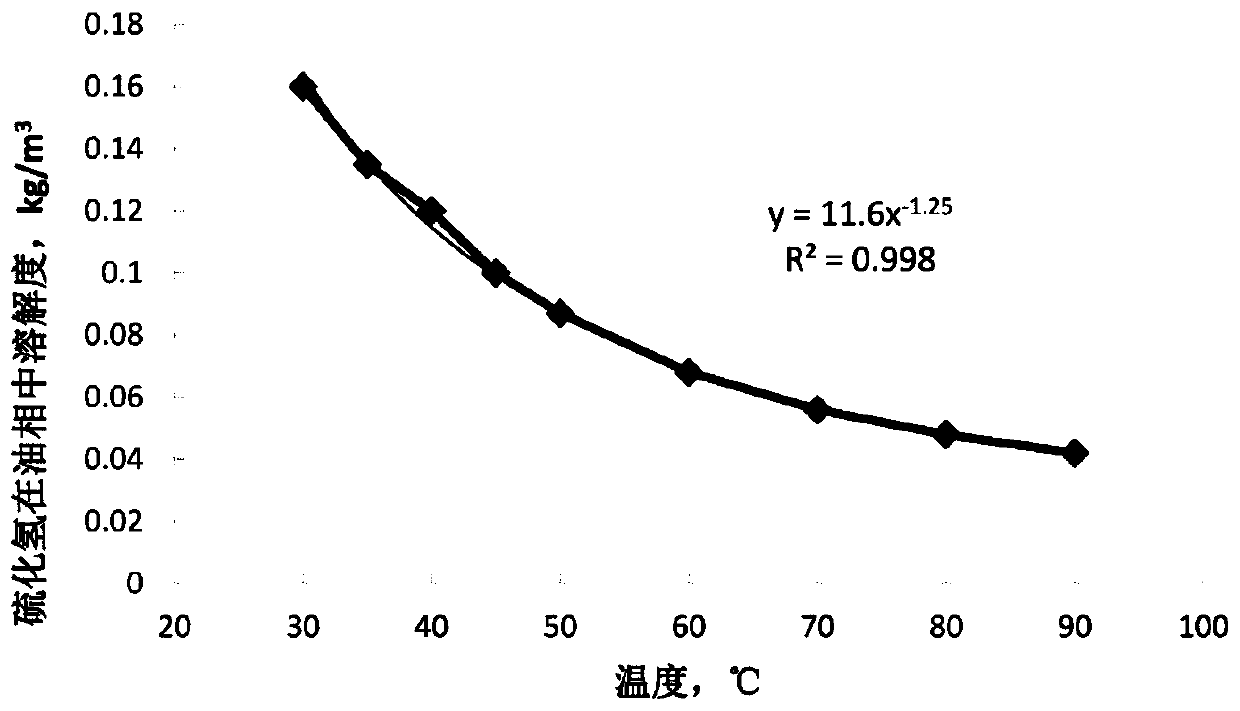

Method for determining total output of hydrogen sulfide in oil well

InactiveCN110596318AAccurately reflectShorten the compliance cycleMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsGas phaseOil phase

The invention belongs to the technical field of safety production and environmental protection, and particularly relates to a method for determining total output of hydrogen sulfide in an oil well, and the method specifically comprises the following steps of determining the content of gas phase hydrogen sulfide in the test oil well; determining the content of aqueous phase hydrogen sulfide in thetest oil well; determining the content of hydrogen sulfide in the oil phase; determining the output of the gas phase hydrogen sulfide; determining the output of the aqueous phase hydrogen sulfide; determining the output of the oil phase hydrogen sulfide; and determining the total output of hydrogen sulfide in the test oil well. The method provided by the invention, by not only considering gas phase hydrogen sulfide, but also considering aqueous phase and oil phase hydrogen sulfide, more accurately reflects the actual situation of the total amount of hydrogen sulfide in the oil well to providea reliable basis for the source treatment of hydrogen sulfide of the oil well, shortens the treatment cycle of hydrogen sulfide compliance by more than 60% and increases the compliance rate of hydrogen sulfide dosing treatment in the oil well to reduce hidden safety hazards, and effectively reduces the amount of dosing to save the cost of dosing by 30%.

Owner:CHINA PETROLEUM & CHEM CORP +1

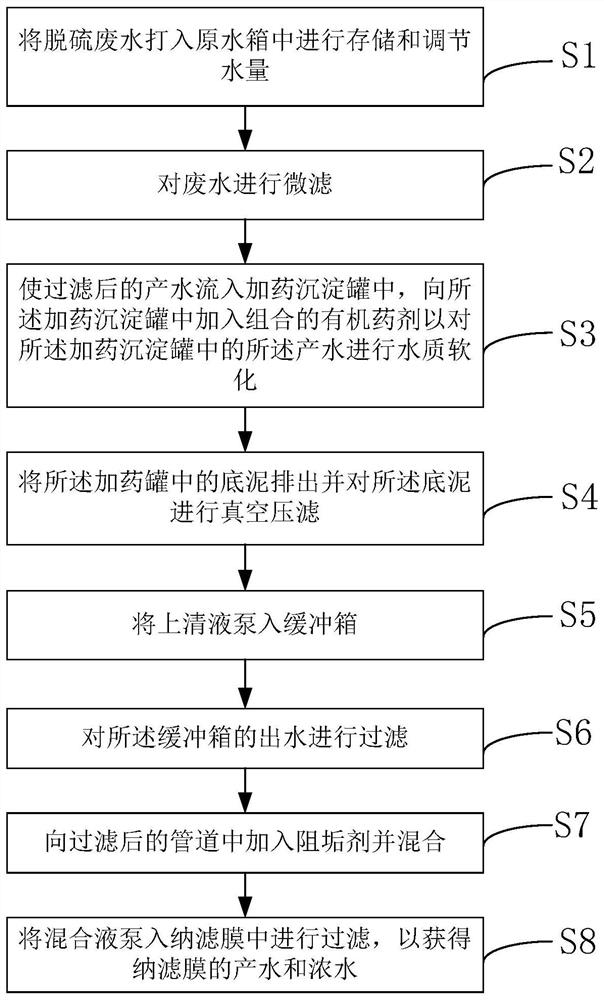

Desulfurization wastewater softening and membrane concentration method

PendingCN113003762ANo foulingReduce retentionWater contaminantsScale removal and water softeningSulfate radicalsWastewater

The invention relates to a desulfurization wastewater softening and membrane concentration method. The method comprises the following steps: pumping desulfurization wastewater into a raw water tank for storage and water quantity adjustment; carrying out microfiltration on the wastewater; enabling the filtered produced water to flow into a dosing settling tank, and adding a combined organic medicament into the dosing settling tank so as to soften the water quality of the produced water in the dosing settling tank; discharging the bottom mud in the dosing tank, and carrying out vacuum filter pressing on the bottom mud; pumping the supernate into a buffer tank; filtering water discharged from the buffer tank; adding a scale inhibitor into the filtered pipeline and mixing; and pumping the mixed solution into a nanofiltration membrane for filtering to obtain produced water and concentrated water of the nanofiltration membrane. The desulfurization wastewater softening and membrane concentration method disclosed by the invention has the advantages that calcium ions are complexed and precipitated, the removal rate of magnesium ions is relatively low, the magnesium ions and chloride ions and sulfate ions in the wastewater are not precipitated under an acidic condition, and the membrane is not polluted and blocked, so that a large amount of dosing cost can be reduced.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Process for removing heavy metal from sludge of sewage treatment plants

InactiveCN101913745BIncrease growth activityReduce dehydration costsClimate change adaptationWater contaminantsFlocculationSulfur

Owner:湖南德施普生物科技有限公司

Sewage treatment method suitable for upgrading and reconstruction of sewage plant

The invention relates to a sewage treatment method suitable for upgrading and reconstruction of a sewage plant. The method comprises an original process of the sewage treatment plant and an efficientsedimentation tank and vertical fiber filter cloth filter combined process added between a sedimentation tank B and a disinfection tank of the original process, wherein the original process is based on water inlet, coarse screen, fine screen, sedimentation tank A, biochemical reaction tank, sedimentation tank B, disinfection tank and water outlet; an efficient sedimentation tank comprises a firstmixing tank, a second sedimentation tank and a water detector; 10-18 mg / L of an iron chloride and ferrous chloride mixture reagent is added to the first mixing tank to react with sewage with stirring;the sewage stays in the first mixing tank for 3-4 min. With the adoption of the sewage treatment method suitable for upgrading and reconstruction of the sewage plant, two problems of phosphorus removal and suspended solid removal in the original process can be solved simultaneously, and the dosage cost can be reduced.

Owner:SUZHOU UNIV OF SCI & TECH

Coking wastewater treatment process

PendingCN113912221AQuick responseThe amount of pollutants adsorbed by the reaction is smallFatty/oily/floating substances removal devicesWater contaminantsCyanide compoundCoking wastewater

The invention belongs to the technical field of wastewater treatment, and discloses a coking wastewater treatment process. According to the primary adsorption treatment reaction, a reaction agent is added to serve as an oxidizing agent, organic pollutants in the wastewater are oxidized to generate an intermediate product rich in carboxyl, and the intermediate product rich in carboxyl is efficiently adsorbed and removed by means of nascent oxyhydroxide generated in the oxidation reaction process. The reaction time is not less than 30 minutes, treatment is performed by adopting stirring or aeration, and precipitation can be performed after standard values of CODcr less than or equal to 80 mg / L, ammonia nitrogen less than or equal to 10 mg / L and cyanide less than or equal to 0.2 mg / L are detected. The medicament is combined with stirring or aeration, so that the adsorption time of various pollutants is prolonged, and the adsorption capacity is improved. An adsorption reaction agent is added for reaction, a large number of groups are generated, the specific surface area of the groups is increased, various organic pollutant monomers are adsorbed to the maximum extent, and therefore the removal efficiency is maximized.

Owner:詹长贵

Oil well polished rod kinetic energy dosing device

The invention provides an optical rod kinetic energy chemical feeding device. An inlet pipeline of a chemical feeding pump is connected with a chemical feeding barrel, the inlet of the chemical feeding pump is provided with a one-way valve A, an outlet pipeline of the chemical feeding pump is connected to a pressure regulating valve, a one-way valve B is arranged at an outlet of the chemical feeding pump, the back side of the one-way valve B is provided with a pressure gauge A, an outlet pipeline of the pressure adjusting valve is connected to a well pipeline, the pressure gauge B is arrangedon the well pipeline, a one-way valve C, a one-way valve D, a discharging valve and a switching valve are sequentially arranged at the back side of an outlet of the pressure adjusting valve, and a reflux inlet pipeline of the pressure adjusting valve is connected to the top of a liquid lever meter. The optical rod kinetic energy chemical feeding device has the advantages that the kinetic energy ofan oil pumping machine is fully utilized to serve as motive power of the chemical feeding pump, addition of extra power equipment is not required, the device is easy to maintain, the organic cooperation between the device and a wellhead does not influence other operation of the wellhead, and the effect of reducing the chemical feeding cost can be achieved; the chemical feeding amount can be adjusted, and accurate medicine addition can be achieved without stopping operation of the well; the device is small in size, easy to install, less in maintenance demand and attractive in appearance.

Owner:SHENGLI XINDA IND GRP

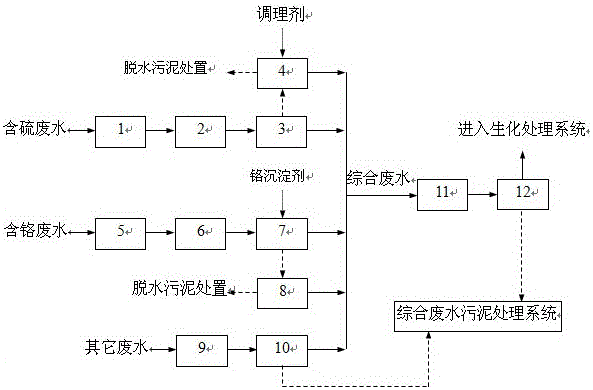

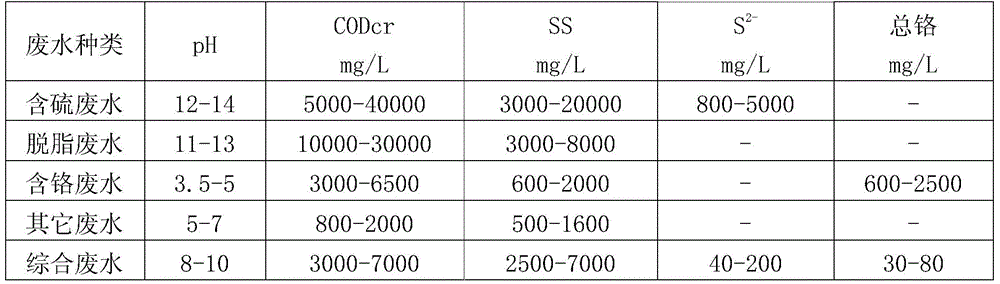

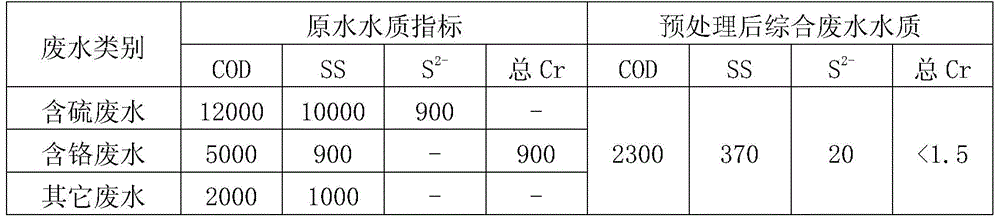

A kind of pretreatment method of tannery wastewater

ActiveCN104803549BReduce SS contentReduce the difficulty of dehydrationWaste water treatment from animal processingMultistage water/sewage treatmentPretreatment methodHazardous substance

A tannery wastewater pretreatment method comprises the following steps: (1), precipitating sulfur-containing wastewater, discharging supernatant after precipitation and dewatering sludge after precipitation; (2), carrying out chromium removal treatment on chromium-containing wastewater through an alkali precipitation method and discharging supernatant after precipitation; (3), carrying out precipitation treatment on other wastewater, discharging supernatant after precipitation and mixing sludge with comprehensive wastewater sludge generated in the step (4); (4), enabling effluents discharged in the step (1), (2) and (3) to enter an adjusting tank to be mixed into comprehensive wastewater, lifting the mixed wastewater to a coagulating precipitation tank after adjusting, and carrying out biochemical treatment on supernatant after precipitation. According to the invention, the SS pollution load in the pre-treated comprehensive wastewater is reduced by 95% or above, the COD pollution load in the pre-treated comprehensive wastewater is reduced by 70% or above, the total nitrogen load in the pre-treated comprehensive wastewater is reduced by 30% or above, the content of toxic and harmful substances such as sulfide and total chromium is effectively controlled, and the requirement for stable operation of subsequent biological treatment is met. The treatment effect is stable and the stable operation of a biological system is facilitated.

Owner:山东省环科院环境工程有限公司

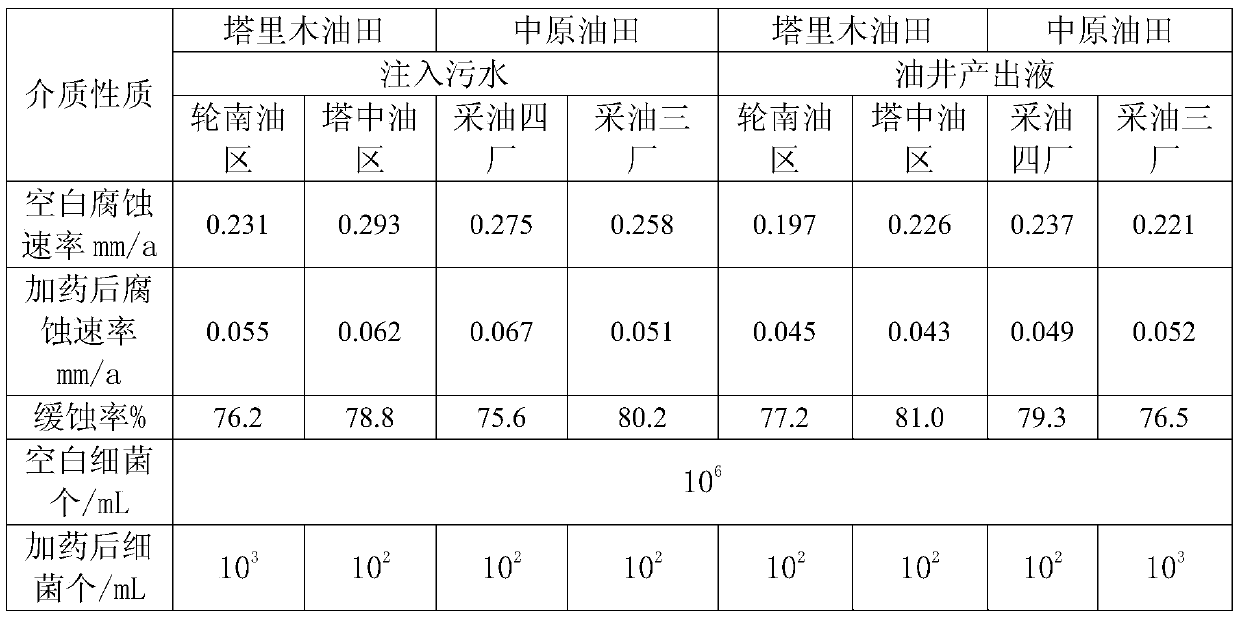

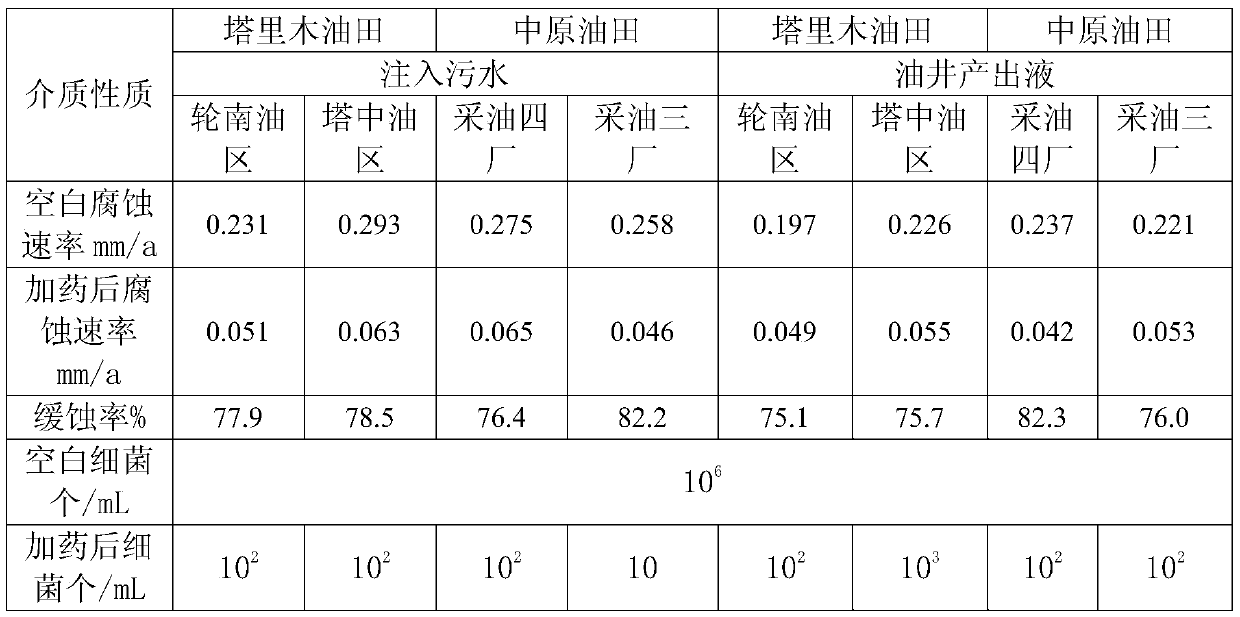

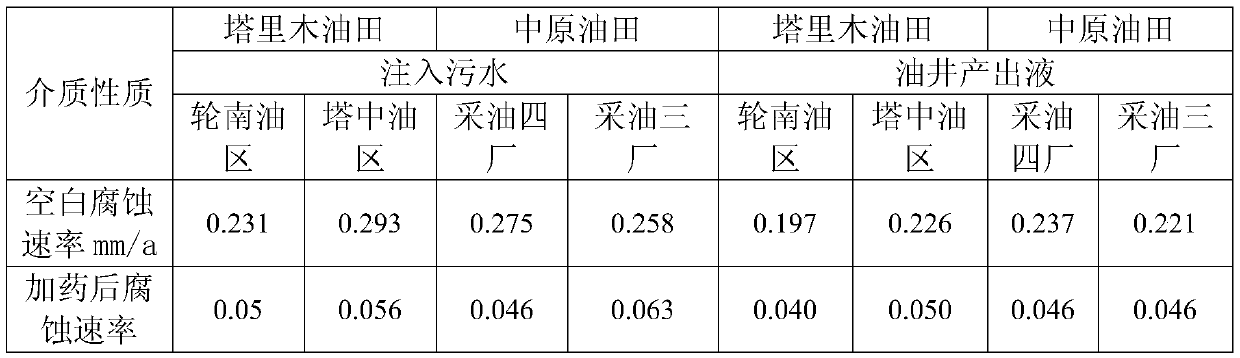

A New Bactericidal Corrosion Inhibitor

InactiveCN104003528BWide adaptabilityGood corrosion inhibition and sterilization effectScale removal and water softeningTreatment apparatus corrosion/fouling inhibitionQuinolineAlkylphenol

The invention discloses a novel bactericidal corrosion inhibitor. The corrosion inhibitor comprises the following components in percentage by mass: measured by the mass of the composition as 100%, 1-30% of biquaternary ammonium salt of quinoline and alkyl tertiary ammonium, 1-30% of biquaternary ammonium salt of alkyl tertiary ammonium, 1-15% of organic urea compound, 1-10% of organic amine compound, 1-20% of alkyl quaternary ammonium salt, 1-10% of glutaraldehyde, 1-10% of alkynyl alcohol, 1-10% of higher fatty acid amides derivative, 1-10% of alkylphenol polyoxyethylene polyoxypropylene ether and the balance of water; the corrosion inhibitor disclosed by the invention can control the corrosion of media with different oil-water ratios in the oil well output liquid of an oil-gas-water gathering and transportation system in the oilfield production, when the corrosion inhibitor addition reaches 100mg / L, the inhibition rate can reach above 75%, the corrosion rate can be controlled at below 0.076mm / a, the sterilization rate reaches above 99%, and the problems that the adaptation range of a commercially available corrosion inhibitor to the change in the properties of the media of the oil well output liquid is small, the inhibition rate is low, the emulsion affects demulsification and the commercially available corrosion inhibitor can not control the bacterial reproduction of the medium are solved.

Owner:XI'AN PETROLEUM UNIVERSITY

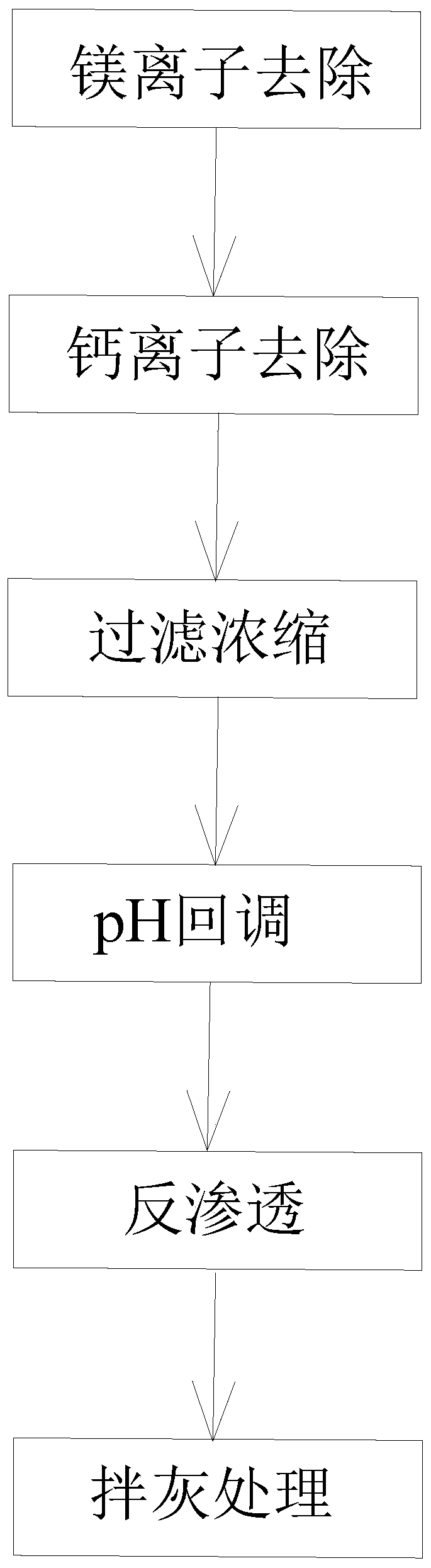

Wastewater treatment method

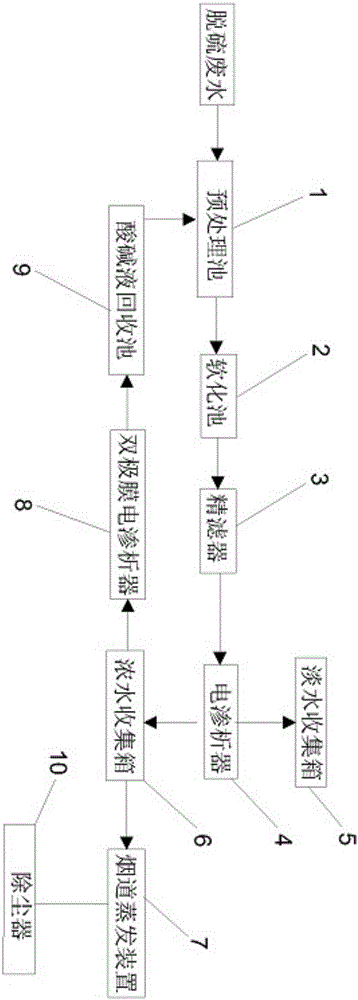

InactiveCN110818126AReduce the cost of dosingReduce productionWater contaminantsTreatment involving filtrationFiltrationReverse osmosis

The invention discloses a wastewater treatment method. Wastewater is recycled and used after steps of magnesium ion removal, calcium ion removal, filtration concentration, pH correction, reverse osmosis and ash mixing treatment. The wastewater treatment method has low cost of softening chemicals, no evaporation crystallization is needed, and the wastewater has a high water resource utilization rate.

Owner:SUNUP ENVIRONMENTAL TECH CO LTD

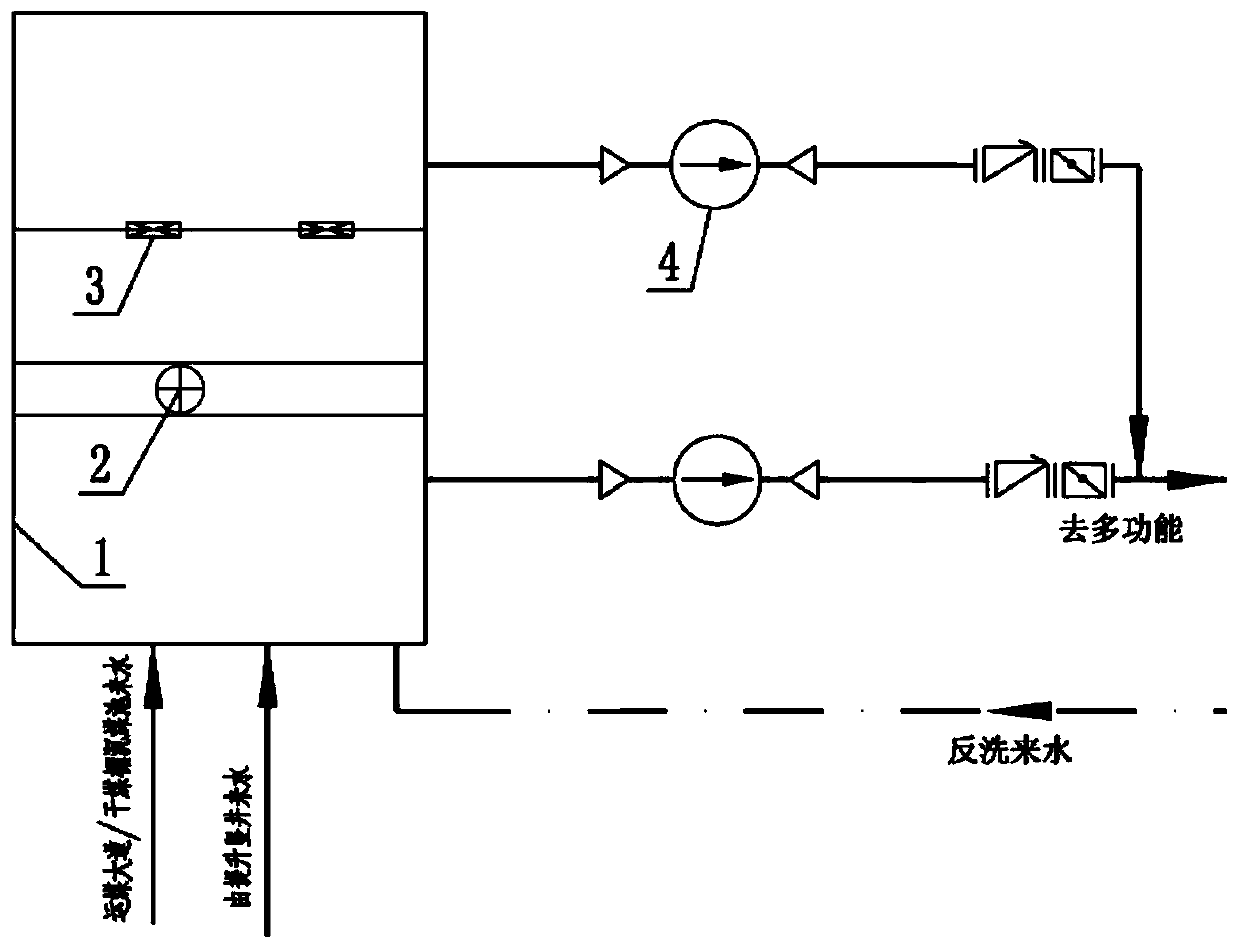

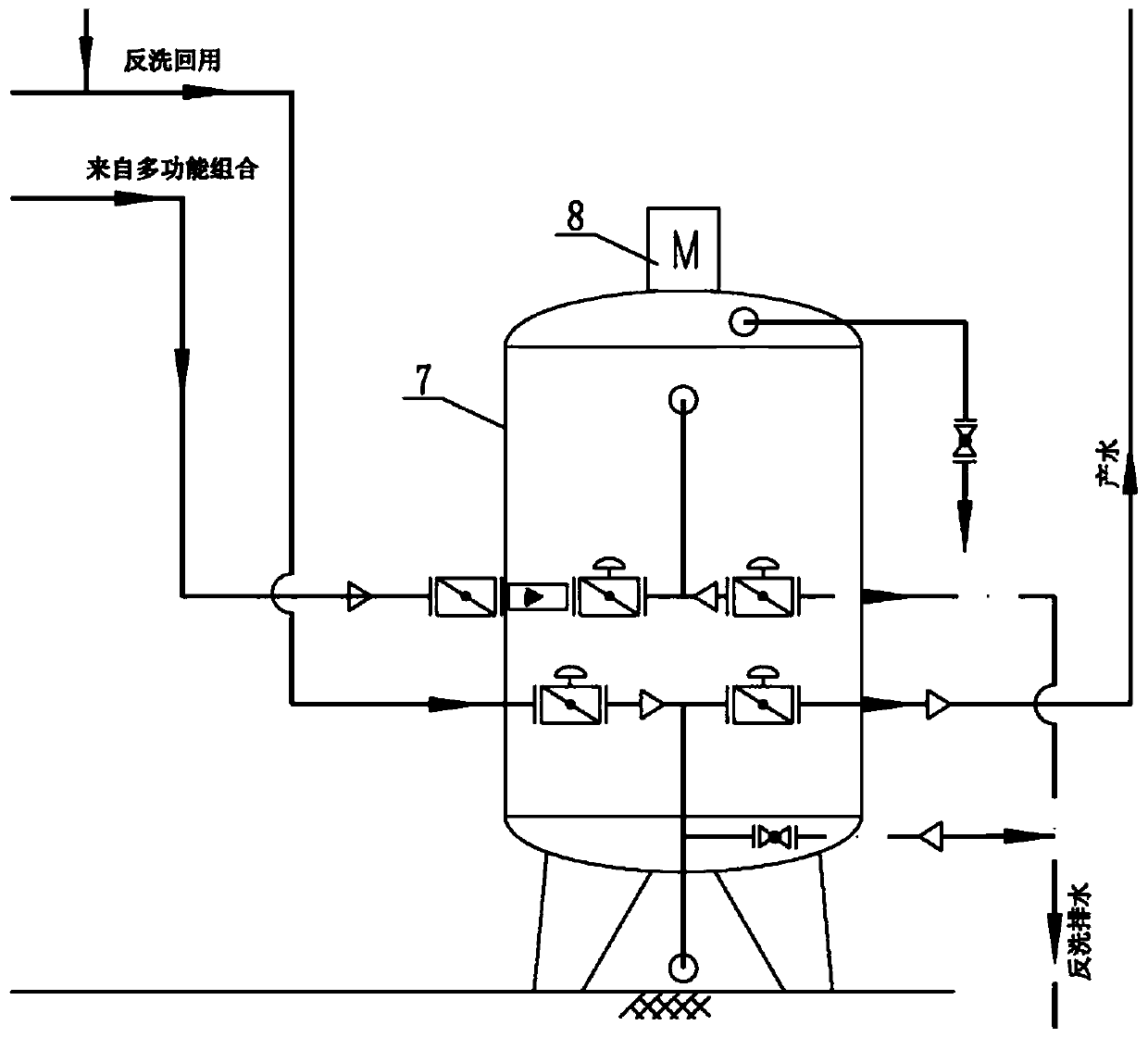

Multifunctional combined coal-containing wastewater treatment method and device

PendingCN111517531AEffective adsorption and retentionHigh dirt holding capacityTreatment involving filtrationMultistage water/sewage treatmentWater useFiber bundle

The invention discloses a multifunctional combined coal-containing wastewater treatment method and a device. The device disclosed by the invention comprises an adsorption coagulating sedimentation system, a multifunctional combined processing system, a fiber bundle filtering system, a reuse water / backwashing system and a combined dosing system. The adsorption coagulating sedimentation system is directly connected with the multifunctional combined processing system; the multifunctional combined processing system comprises a pipeline mixer and a multifunctional combined purifier which are connected through a pipeline, the multifunctional combined treatment system is connected with the combined dosing system through the pipeline mixer, and the multifunctional combined treatment system is sequentially connected with the fiber bundle filtering system and the reuse water / backwashing system through the multifunctional combined purifier; coal-containing wastewater is treated in the device disclosed by the invention. The method and the device have the advantages of low construction investment and good treatment effect, and the effluent can satisfy the national and power industry requirements for treating and recycling the coal-containing wastewater.

Owner:HUNAN PINGAN ENVIRONMENT PROTECTION

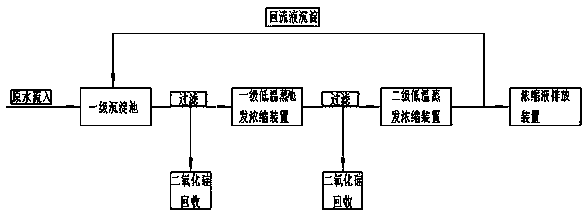

Resourceful treatment method and device for inorganic salts in industrial wastewater

InactiveCN110272159AIncrease concentrationPrevent scalingWater contaminantsMultistage water/sewage treatmentFiltrationEvaporation

The invention provides a resourceful treatment method and device for inorganic salts in industrial wastewater. The resourceful treatment method comprises a primary sedimentation tank, a primary low-temperature evaporation and concentration device, a secondary low-temperature evaporation and concentration device and a concentrated liquid discharging device; the primary sedimentation tank is connected with a raw water inlet and is used to separate out colloidal silicon in raw water, and separated silicon dioxide is recycled after primary filtration; the primary low-temperature evaporation and concentration device is connected with the primary sedimentation tank and is used to concentrate soluble silicon in the raw water to be supersaturated, and then the supersaturated silicon is separated out; the secondary low-temperature evaporation and concentration device is connected with the primary low-temperature evaporation and concentration device and is used to continue concentrating silicon dioxide in the raw liquid to be supersaturated, and the supersaturated silicon dioxide is separated out; and the concentrated liquid discharging device is connected with the secondary low-temperature evaporation and concentration device and is used to discharge the concentrated liquid which is concentrated in place. According to the invention, a low-temperature evaporation crystallization process is adopted, and equipment can be prevented from scaling; a conventional chemical silicon removal process is changed into a whole-process physical silicon removal process, so that reagent adding cost is reduced, and the concentration of recycled silicon dioxide is improved. In addition, the process flow is shortened, the investment amount is small, the recycle degree is large, secondary pollutants are not generated, and the separated silicon dioxide can be completely recycled to a production line.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

A process method for resource recovery of chemical nickel waste liquid with zero discharge

ActiveCN106045123BThe process steps are simpleViolent chemical reactionWater contaminantsWaste water treatment from metallurgical processResource utilizationFiltration

The invention discloses a resource utilization zero-emission recycling process method of a chemical waste nickel liquid. The resource utilization zero-emission recycling process method is characterized by comprising the following steps: I, concentrating and separating the chemical waste nickel liquid, namely, adjusting the pH value of the chemical waste nickel liquid to be 3-5, performing low-temperature negative pressure evaporation concentration, and rising the temperature to 95-110 DEG C, wherein the negative pressure condition is minus 0.09 - minus 0.1MPa and the boiling temperature is not greater than 70 DEG C; II, separating sodium sulfate by an acid solution, namely, performing slow soaking dissolution on chemical nickel residues by a sulfuric acid solution in stirring so as to obtain a sulfuric acid leaching agent; after sufficient cooling, and performing filtration to obtain filtrate and sodium sulfate crystal; III, extracting and separating nickel sulfate, namely, adding ethanol into the filtrate, leaving to stand to layer, and performing solid-separation separation so as to obtain nickel sulfate solid for resource recycling and reuse; IV, recycling ethanol. By adopting the resource utilization zero-emission recycling process method disclosed by the invention, the chemical solid nickel waste can be completely recycled, the requirements of environment-friendliness of waste liquid recycling and zero emission are met indeed, and the required social environment capacity is greatly reduced.

Owner:苏州市东方环境工程有限公司

A sludge separation device

ActiveCN106673397BLow investment costLabor intensiveWater treatment parameter controlSludge treatmentFluid phaseTester device

The invention discloses an oil sludge separating device. The oil sludge separating device comprises an oil sludge pond, a first pump body, a vibrating screen, a first storage tank, a second pump body, a centrifugal machine, a second storage tank and a third pump body which are communicated with one another in sequence. Oil sludge is fed into the vibrating screen from the oil sludge pond through the first pump body for primary separation. A solid-phase object after primary separation is conveyed out, a liquid-phase object after primary separation enters the first storage tank to be deposited, and the deposited liquid-phase object is fed into the centrifugal machine through the second pump body for secondary separation. A solid-phase object after secondary separation is conveyed out, and a liquid-phase object after secondary separation enters the second storage tank. A density tester is arranged in the second storage tank, and a qualified liquid-phase object detected by the density tester is conveyed through the third pump body. The oil sludge separating device provided by the invention can improve the separating efficiency.

Owner:陕西航天德林科技集团有限公司

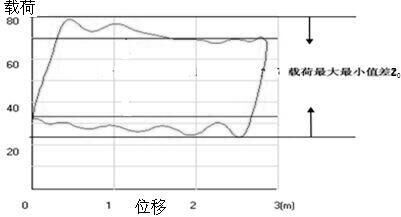

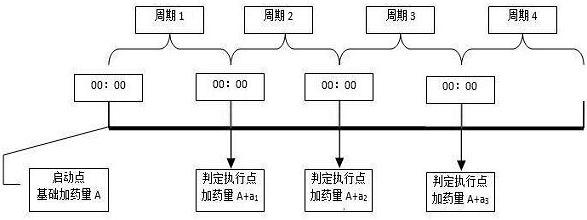

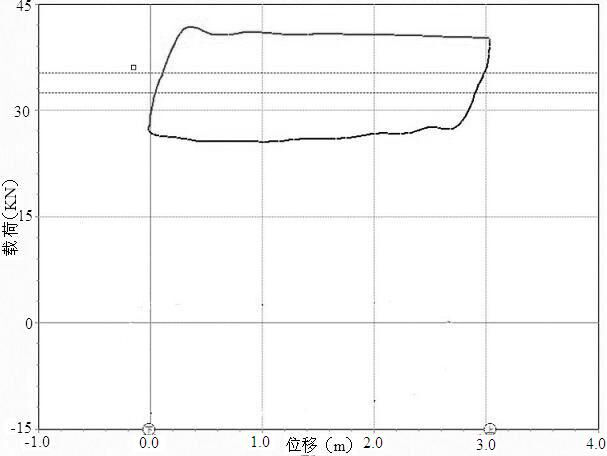

Method for guiding oil well dosing by utilizing oil well indicator diagram data

ActiveCN112483045ARealize intelligent dosing closed-loop controlImprove the level of digital managementConstructionsCleaning apparatusDosing FrequencyProcess engineering

The invention provides a method for guiding oil well dosing by utilizing oil well indicator diagram data. The method is characterized in that an intelligent oil well dosing system is used for conducting periodic dosing in an oil well, the dosing amount in the first period is the basic dosing amount A, then the dosing amount in each period is determined according to the load amplification of an oilwell ground indicator diagram in the previous period, intelligent regulation and control of the oil well dosing system can be achieved through oil well indicator diagram data, the dosing amount of the oil well paraffin remover and inhibitor is automatically set, and intelligent oil well dosing is achieved. According to the method, the labor intensity of worker dosing can be greatly reduced, the use frequency of workers and vehicles can be effectively reduced, the dosing frequency and the dosage can be finely controlled, the wellhead dosing cost can be reduced, and the pump inspection period and the hot washing period of the oil well can be prolonged.

Owner:PETROCHINA CO LTD

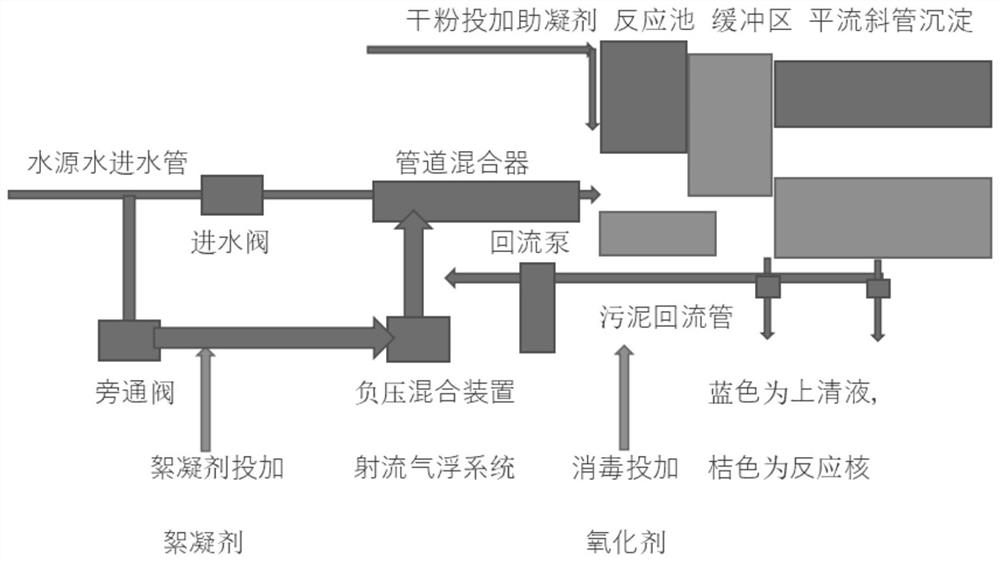

Treatment process of low-temperature and low-turbidity water with iron and manganese exceeding standards

InactiveCN113233636AIncrease dissolved oxygenImprove the coagulation effectWater treatment parameter controlWater contaminantsAutomatic controlWater source

The invention discloses a treatment process of low-temperature and low-turbidity water with over-standard ferro-manganese. The treatment process comprises the following steps: carrying out water-source water floatation treatment, adding a water-source water reaction nucleus, adding quicklime powder at a water inlet of water-source water, adding an oxidizing agent into a water inlet pipeline of the water-source water, and additionally arranging a water-source water automatic control system. The process has the advantages that suspended solids (SS) can be effectively removed; 2, total phosphorus is effectively removed; 3, water source water oxygen ions are effectively increased, and CO2 is reduced; 4, the total nitrogen is effectively removed under the action of increasing oxygen and an oxidizing agent; 5, iron and manganese are effectively removed under the oxidation effect; 6, the turbidity value is effectively reduced and can be controlled to be about 1NTU; 7, the filtering efficiency of the filter tank and the yield are improved; 8, the labor intensity of workers is reduced; 9, the quality of outgoing water can be effectively improved; 10, water resources can be effectively saved; 11, the improvement of the system makes up the production shortages of the existing running waterworks; 12, the investment is saved, the effect is quick, and the existing water treatment process is combined, so that the energy consumption is basically avoided.

Owner:SHENZHEN SINOLEGEND ENVIRONMENTAL PROTECTION SCI & TECH

Landscape water algae pollution treatment method and system

ActiveCN111777141AEliminate the effects of poor sensesReduce turbidityWater/sewage treatment by flocculation/precipitationTreatment control/steeringChlorophyll aEnvironmental engineering

The invention discloses a landscape water algae pollution treatment method and a system. The treatment method comprises the following steps: (1) setting a plurality of detection points in a to-be-treated water area, wherein the distance between every two adjacent detection points is 5-15m, (2) detecting the turbidity and chlorophyll a value of one detection point and judging the algae pollution degree, (3) removing algae at the detection point when the algae pollution degree is more than a preset value, and (4) moving to another detection point and repeating the step (2) until the detection ofall the detection points is completed. The treatment method is suitable for emergency algae removal of closed slow-flow landscape water bodies such as urban rivers and lakes, the algae removal efficiency is high, and secondary outbreak of algae pollution can be avoided.

Owner:天津生态城水务投资建设有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com