Patents

Literature

50results about How to "Reduce pollution index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

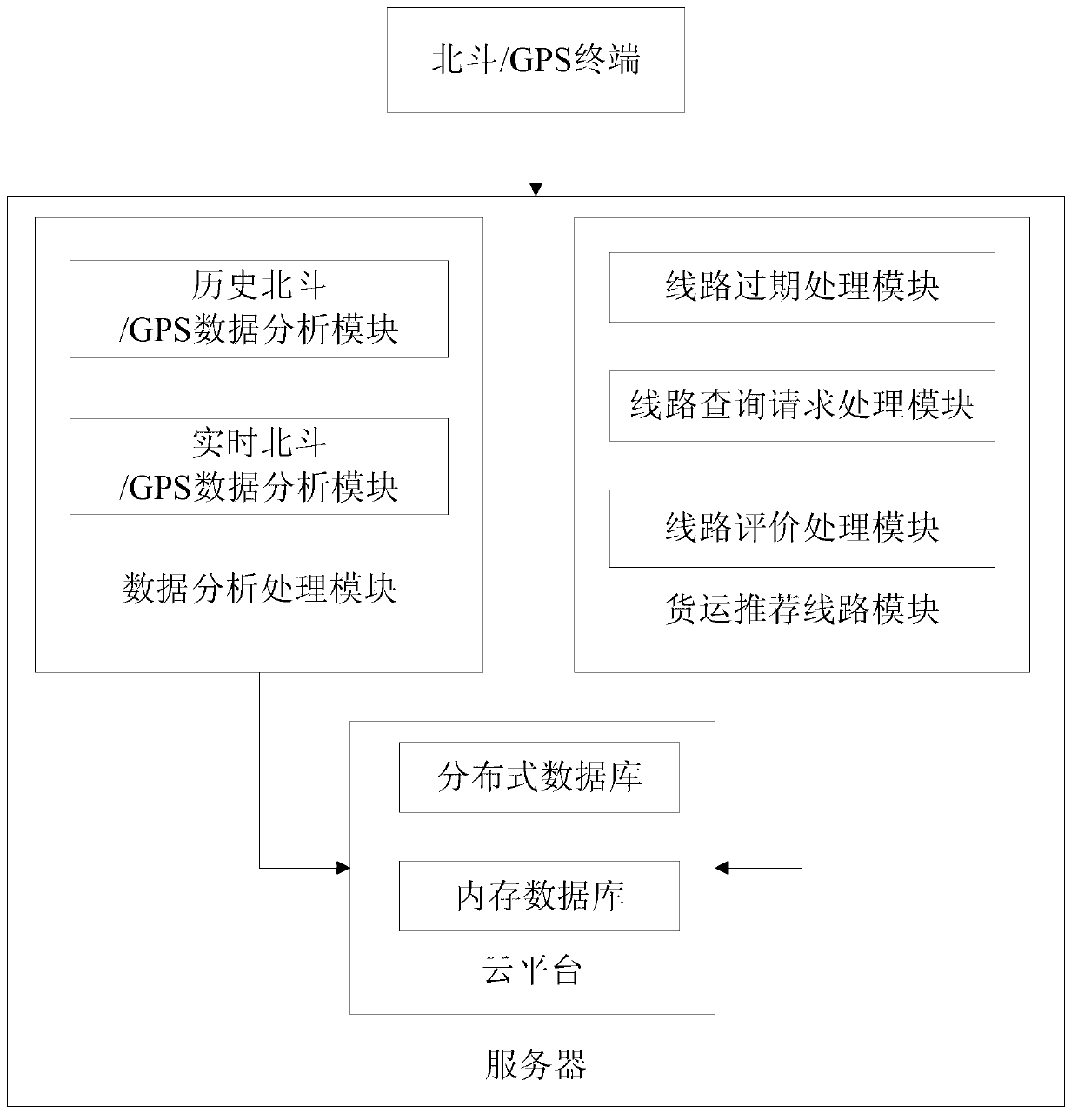

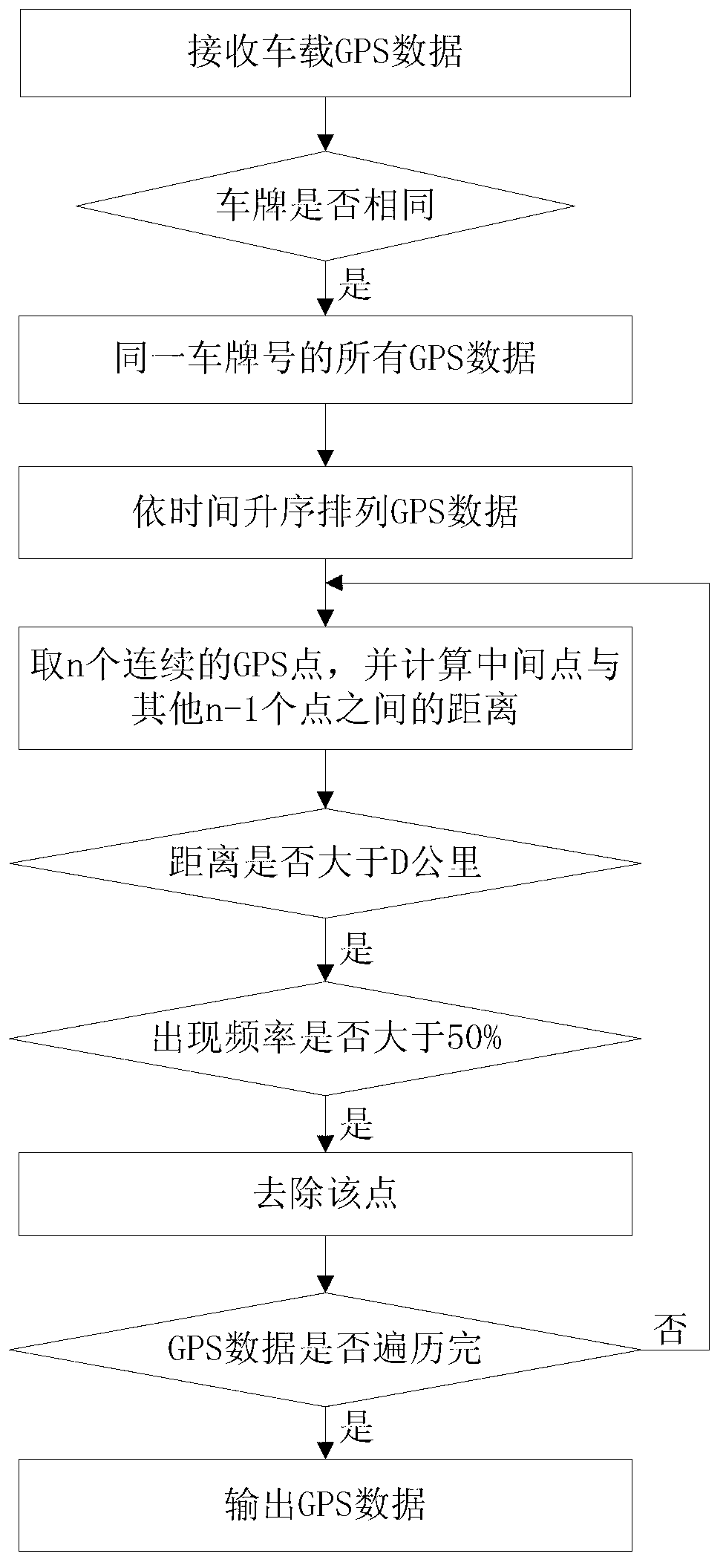

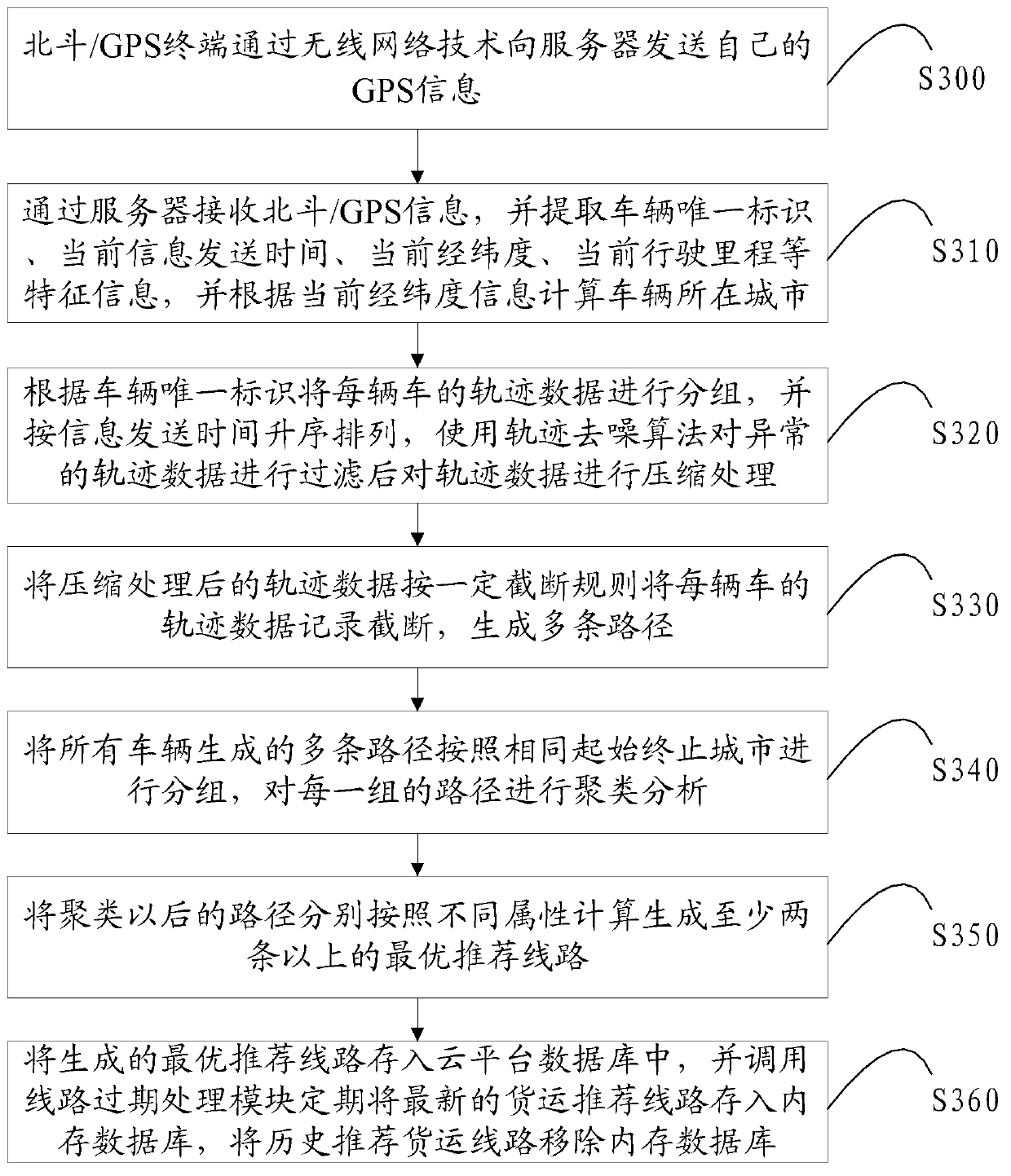

Line recommendation system and method based on Beidou satellite/GPS (global positioning system) data

ActiveCN103278833AIncrease profitEasy to scheduleSatellite radio beaconingLogistics managementComputer science

The invention relates to a line recommendation system and method based on Beidou satellite / GPS (global positioning system) data. The line recommendation system based on Beidou satellite / GPS (global positioning system) data comprises a Beidou / GPS terminal and a server, wherein the Beidou / GPS terminal is used for positioning and sending the Beidou / GPS information of a vehicle; the server is used for receiving the Beidou / GPS information of the vehicle; according to the unique identification of the vehicle, the track data of each vehicle is grouped; according to a truncation rule, the track data record of each vehicle is truncated to generate a plurality of paths; and after the paths are subjected to clustering analysis, a recommendation line is output according to different attributes. When the invention is implemented, the problem of insufficient instantaneity of the freight recommendation line can be solved, a proper freight line can be conveniently selected for a driver according to the practical situation, and the logistics industry efficiency and the use ratio of a freight vehicle can be improved.

Owner:深圳市北斗智能科技有限公司

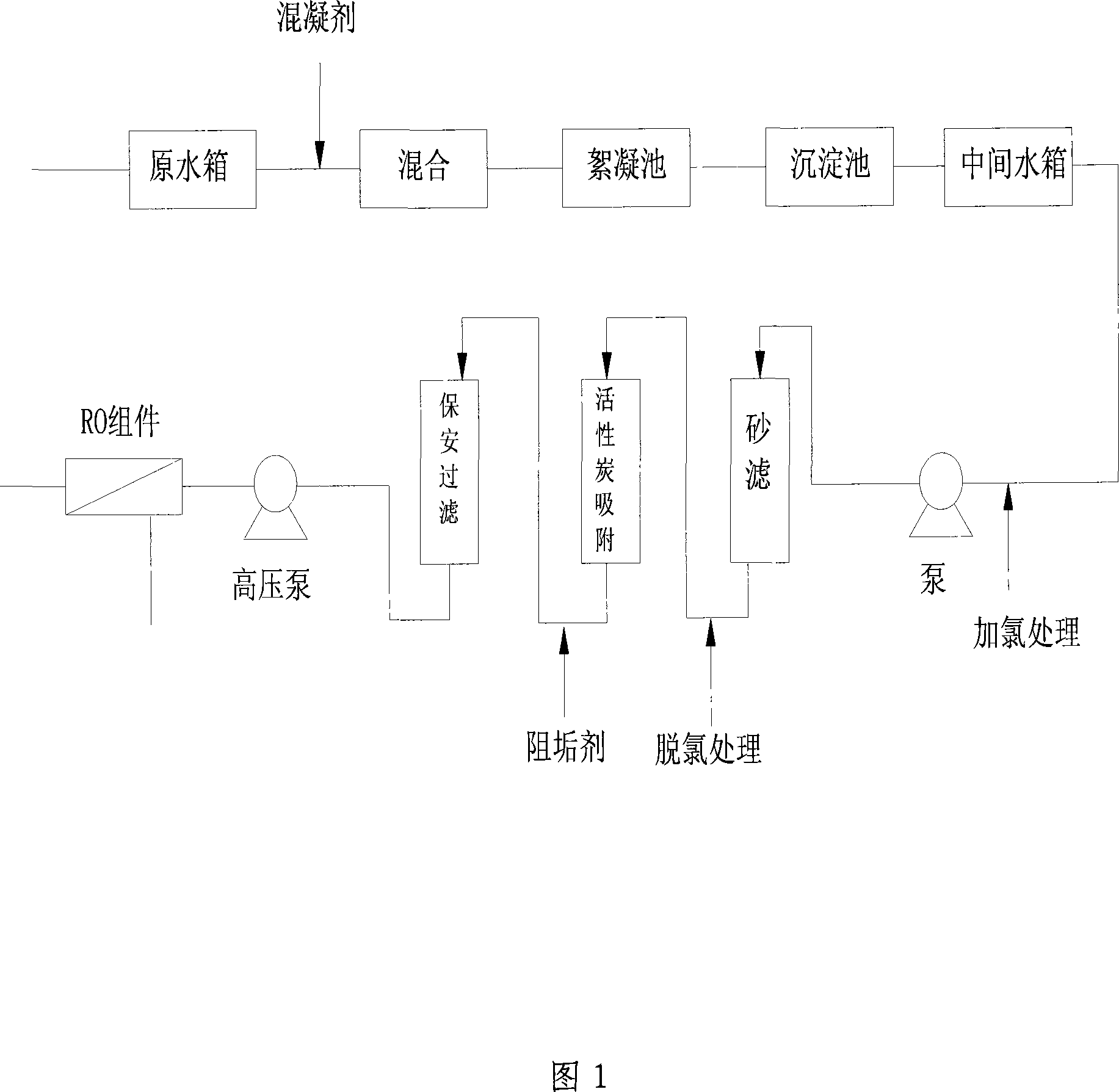

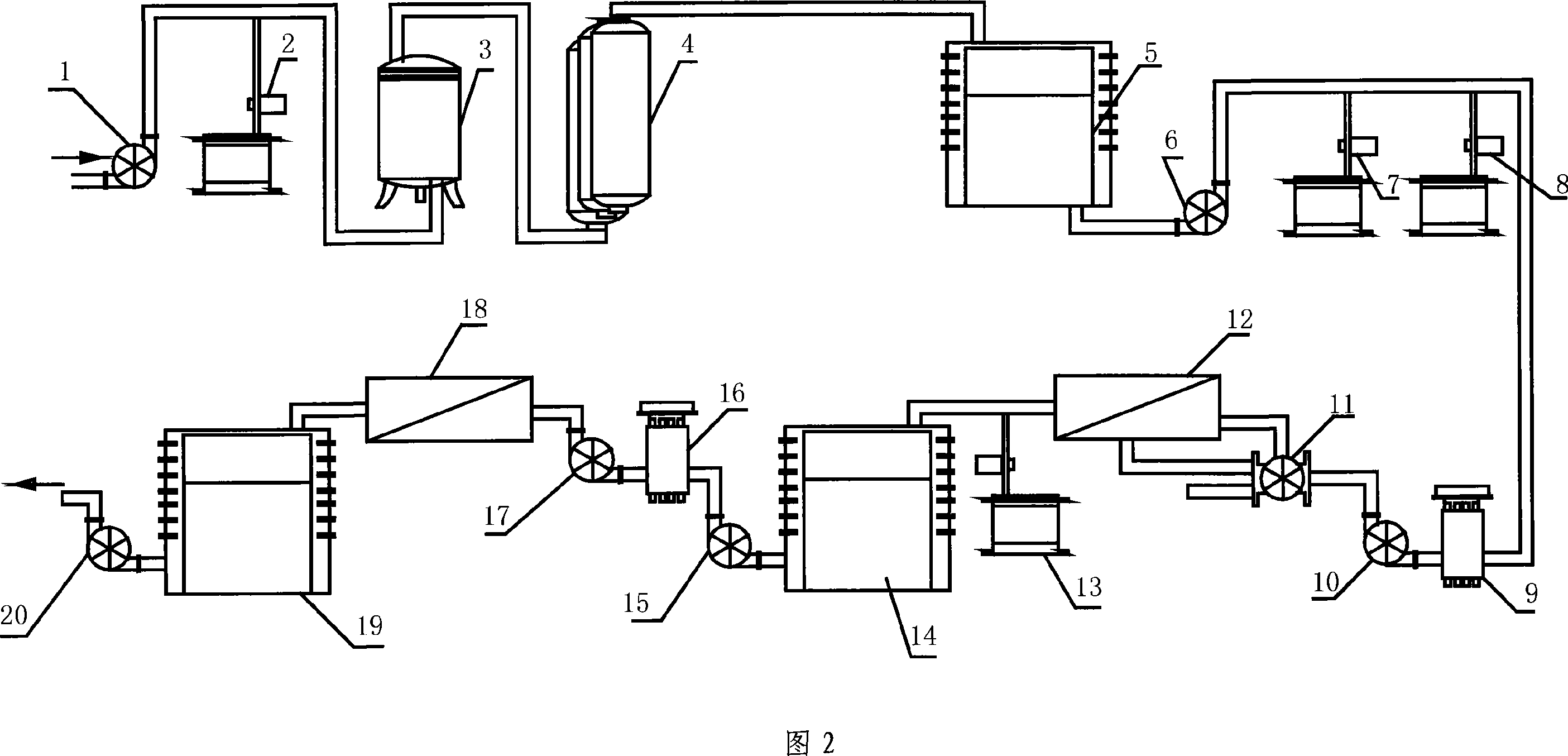

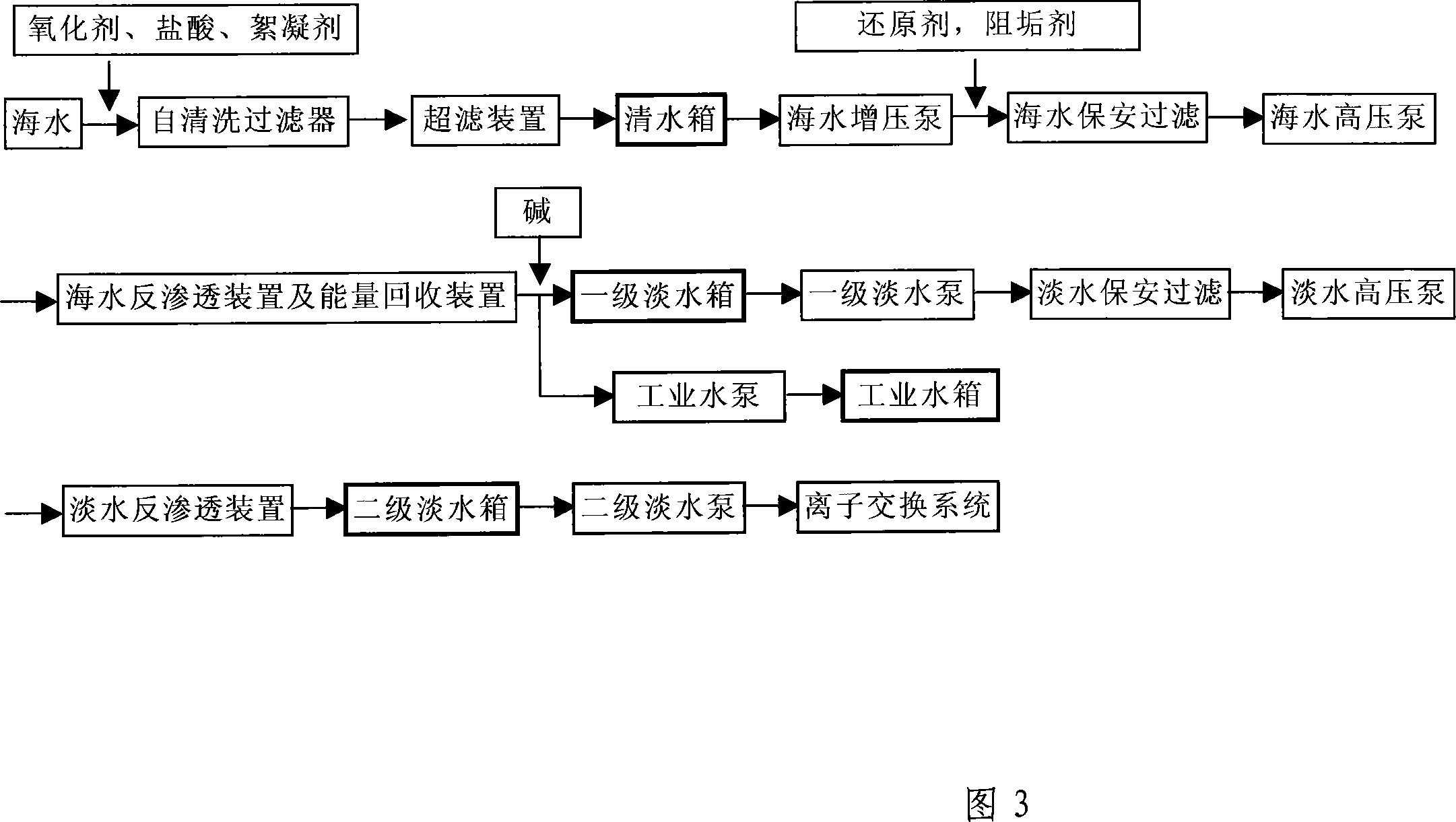

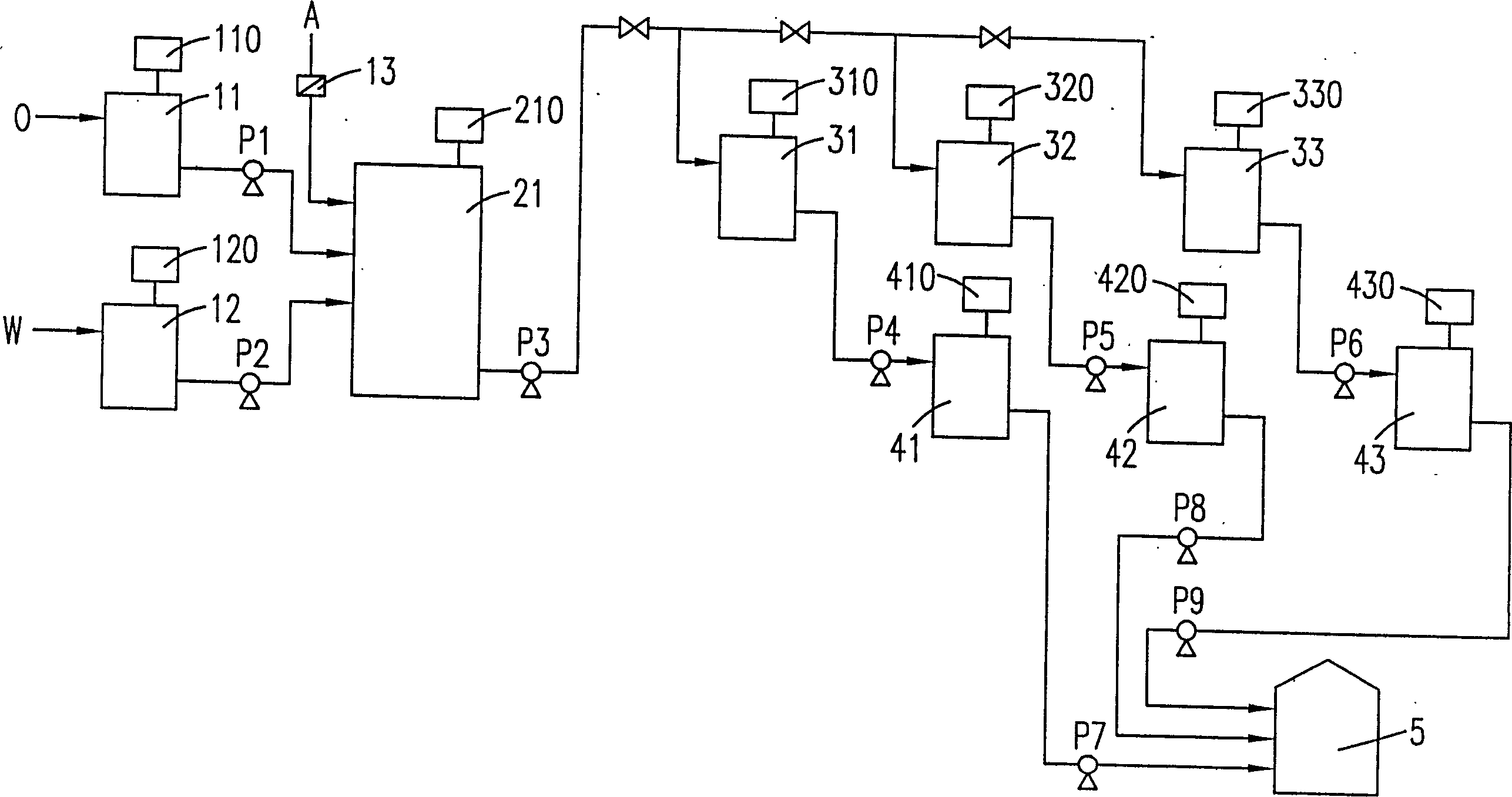

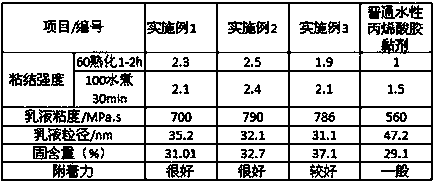

Membrane integration process for desalinizing sea water

InactiveCN101058470AImprove protectionAvoid harmGeneral water supply conservationSeawater treatmentWater desalinationSeawater reverse osmosis

The invention discloses a seawater desalinating technique through film integrated method, which comprises the following steps: passing the seawater through self-rinsing filter; predisposing the rinsed seaward into hyperfilter device; boosting the seawater through the boost pump; removing possible micro-particle in the inlet water of counter-osmosis system of the seawater through seawater safety filter; elevating the inlet pressure of the counter-osmosis system of the seawater; desalinating through counter-osmosis system of the seawater; removing micro-particle in the inlet water of counter-osmosis system of the fresh water through fresh water safety filter; elevating the inlet pressure of the counter-osmosis system of the fresh water; desalinating through counter-osmosis system of the fresh water. The invention reduces the adding quantity of the chemicals and rinsing times of reverse osmosis membrane effectively, which improves automatic degree with stable property and small equipment occupying area.

Owner:CHINA RAILWAY FIRST GRP CO LTD

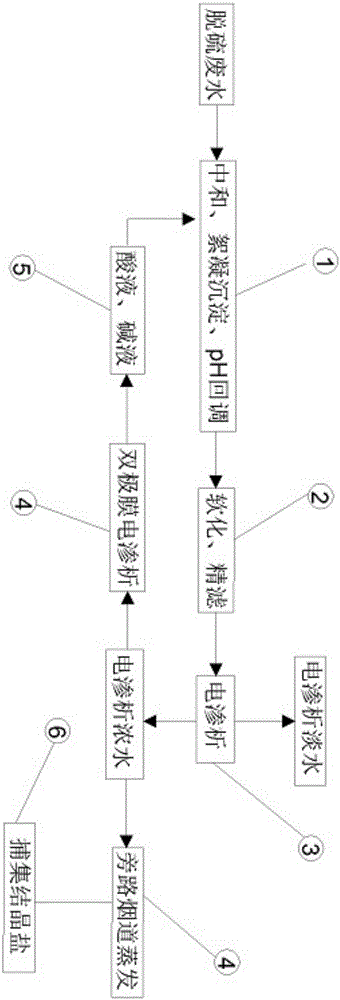

Method and system for treating desulfurization wastewater in zero-discharge manner on basis of electrodialysis

InactiveCN106241972AReduce membrane fouling indexGuarantee long-term stable operationWater treatment parameter controlGeneral water supply conservationChemistryTreatment phases

Owner:SHENGFA ENVIRONMENT PROTECTION TECH XIAMEN CO LTD +1

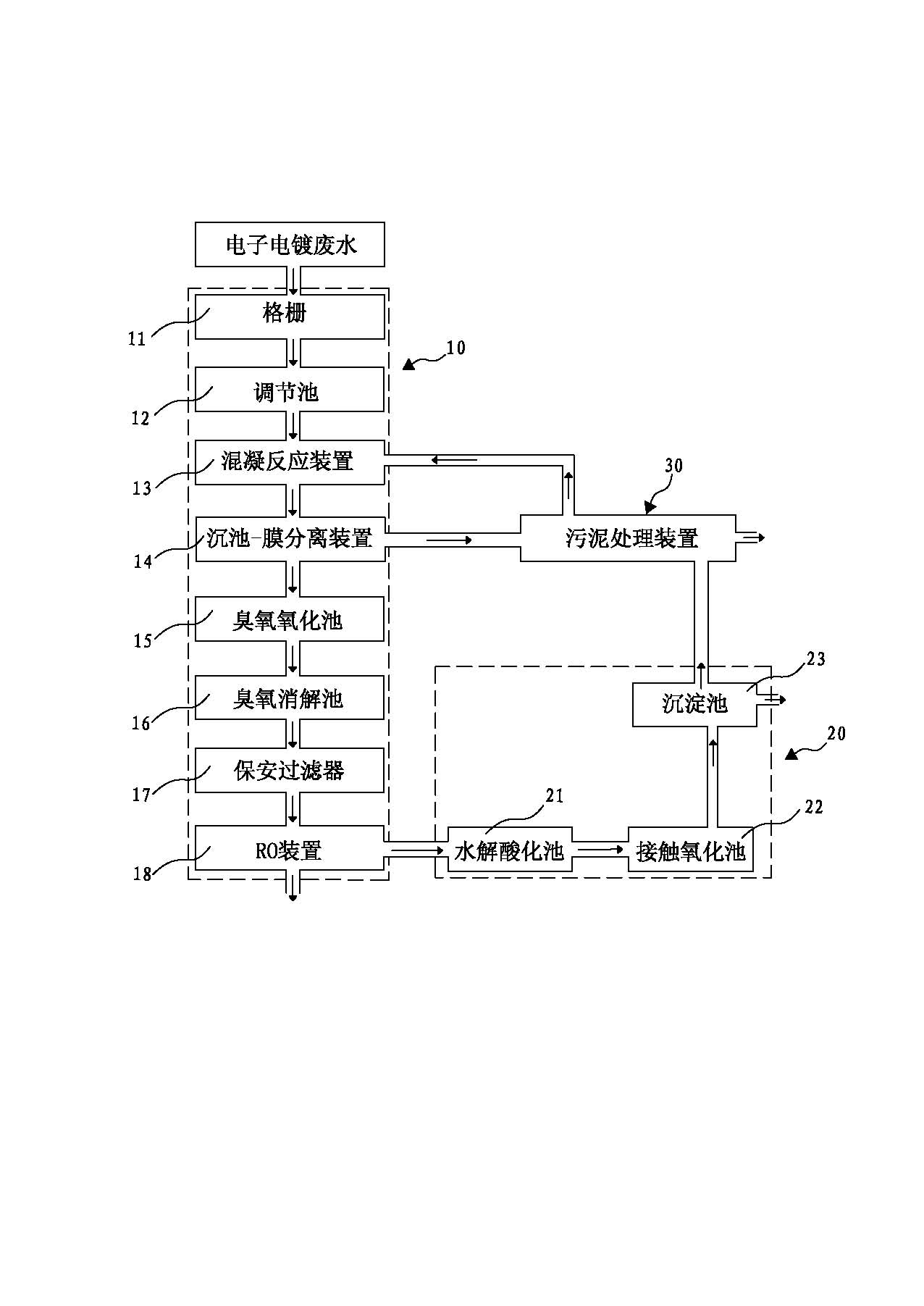

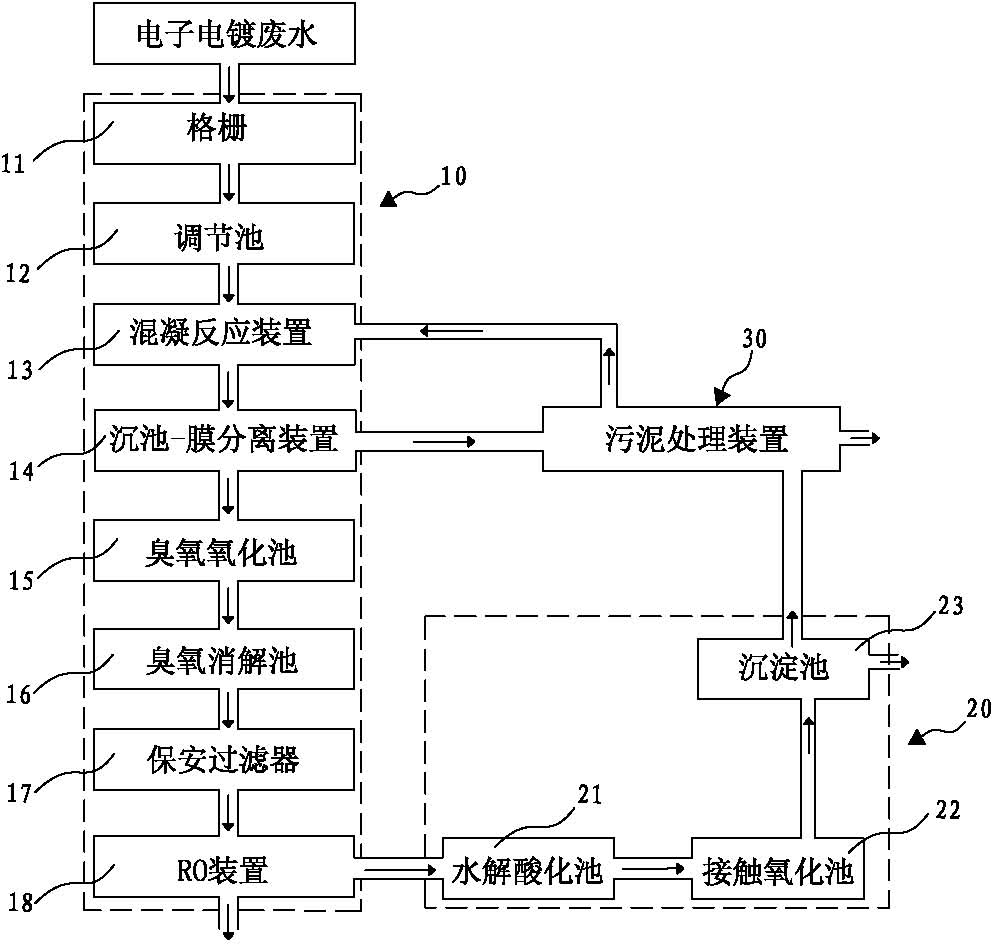

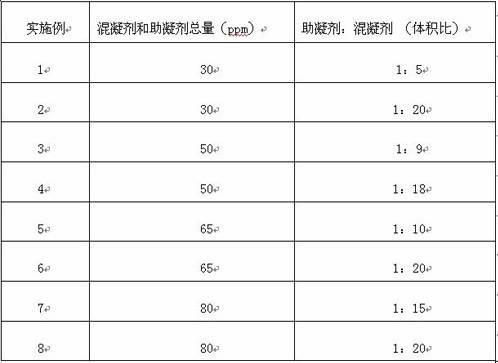

System and method for treatment and recovery of electronic electroplating wastewater

ActiveCN102674626ALong storage timeShort activation timeWaste water treatment from metallurgical processMultistage water/sewage treatmentCondensed waterEngineering

The invention discloses a system and a method for treatment and recovery of electronic electroplating wastewater. The system comprises a wastewater recovery and treatment unit and an RO (reverse osmosis) concentrate treatment unit. A grille, an adjusting tank, a coagulation reaction device, a settlement and membrane separation device, an ozone oxidation tank, an ozone digestion tank, a cartridge filter and an RO device are connected to the wastewater recovery and treatment unit sequentially. A hydrolytic acidification tank, a contact oxidation tank and a settling tank are connected to the RO concentrate treatment unit. The electronic electroplating wastewater is treated through the grille, the adjusting tank, the coagulation reaction device, the settlement and membrane separation device, the ozone oxidation tank, the ozone digestion device, the cartridge filter and the RO device. RO fresh water is then reused on an electronic electroplating line. RO condensed water is effectively treated through the hydrolytic acidification tank and the contact oxidation tank and stably meets the primary specification GB8978-1996 of integrated wastewater discharge standard, and discharge requirements DB4426-2001 of discharge limits of water pollutants of Guangdong.

Owner:DONGGUAN KEDA ENVIRONMENTAL PROTECTION ENG

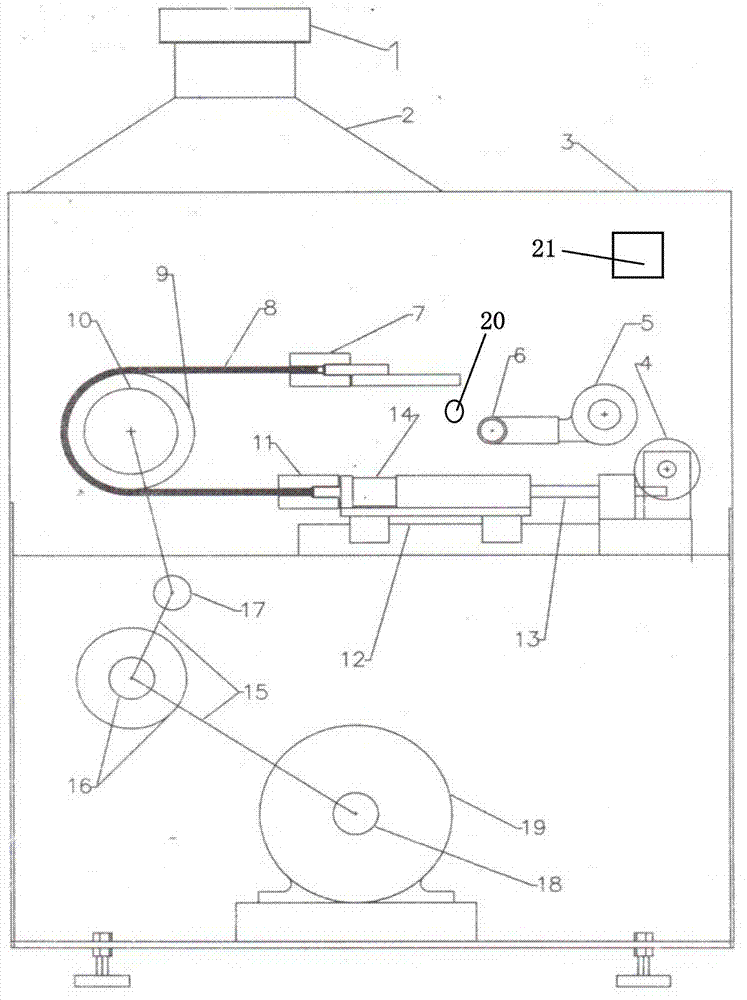

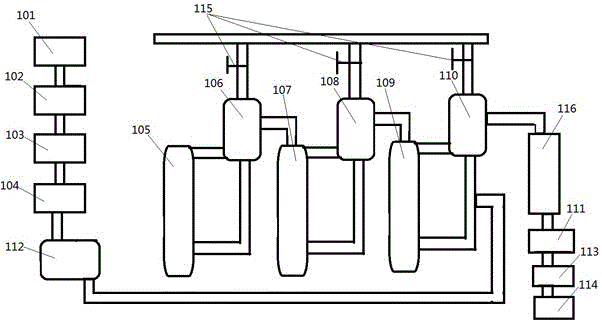

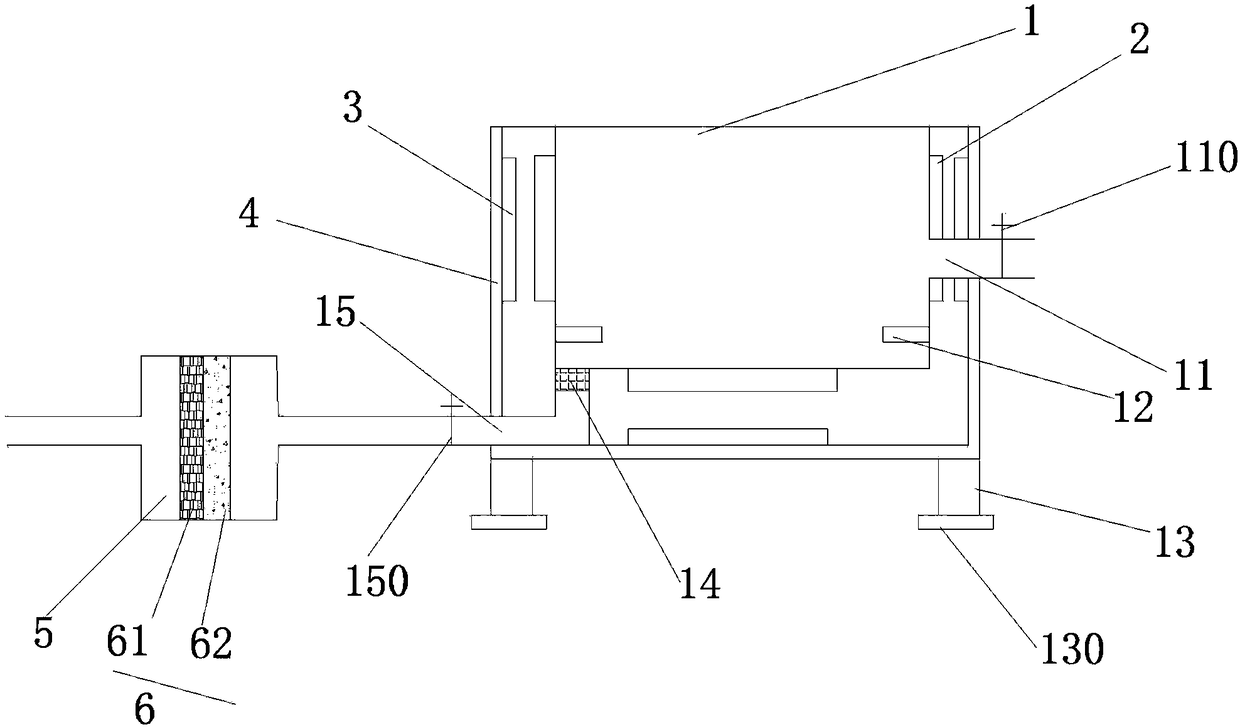

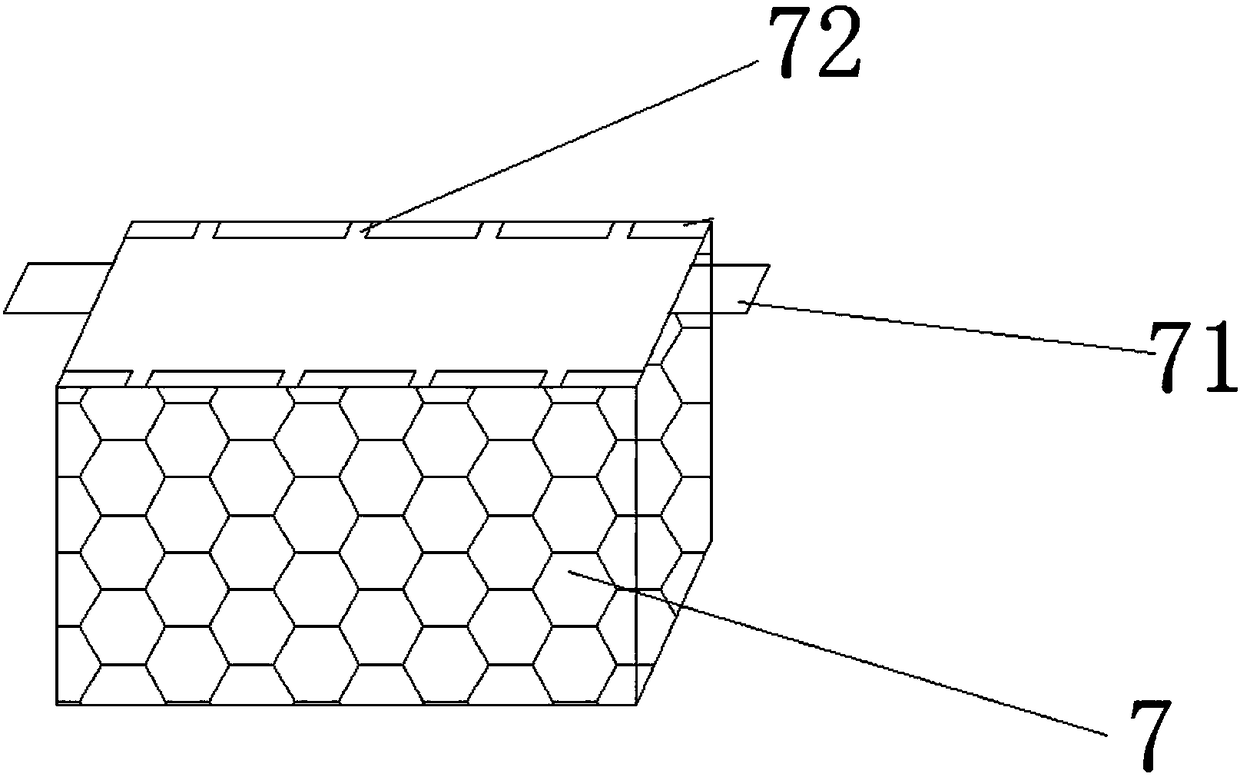

Intelligent roller friction testing machine of conveyor belt

InactiveCN102788734AConstant tension with automatic increaseReduce pollution indexUsing mechanical meansInvestigating abrasion/wear resistanceAuto regulationBall screw

The invention relates to an intelligent roller friction testing machine of a conveyor belt. The intelligent roller friction testing machine comprises a drive system and a tension system, wherein the drive system is used for driving a roller to rotate, and the tension system is used for regulating the tension of a sample to be detected in real time. The intelligent roller friction testing machine is characterized in that the tension system comprises a tension sensor which is arranged on a linear guide rail and is capable of automatically detecting the tension, and the tension sensor is connected with a direct current motor by a ball screw. The intelligent roller friction testing machine provided by the invention is suitable for roller friction tests of a fabric core flameproof conveyor belt and other flameproof conveyor belts. The testing machine comprises an intelligent testing device which can be used for automatically adjusting a constant tensioning force, automatically increasing the constant tensioning force according to a standard after operating during a certain time, automatically detecting a broken belt, automatically detecting open fire, automatically detecting temperature, printing an operation test curve and reporting data; and moreover, a fully enclosed smoke collecting and discharging device is adopted, so that an environment pollution index is reduced.

Owner:青岛双凌科技设备有限公司

Pharmaceutical wastewater treating system and method

InactiveCN105000734AImprove processing efficiencyReduce pollution indexMultistage water/sewage treatmentWater/sewage treatment by neutralisationVapor–liquid separatorWater treatment system

The invention provides a pharmaceutical wastewater treating system, and relates to the field of environmental protection. The pharmaceutical wastewater treating system comprises a mixing tank, a settling tank, a multi-stage electrolytic tank, a multi-stage Fenton phase tank, a first heater, a first evaporator, a second heater, a second evaporator, a third heater, a third evaporator, a gas-liquid separator and an intermediate tank. The mixing tank is communicated with the settling tank, the multi-stage electrolytic tank is connected with the multi-stage Fenton phase tank, the multi-stage Fenton phase tank is connected with the first heater, the first evaporator is communicated with the second heater, the second evaporator is communicated with the third heater, the third evaporator is connected with the gas-liquid separator, the intermediate tank is connected with the multi-stage Fenton phase tank, and the intermediate tank is connected with a third circulation pipe through a vacuum pipe. The pharmaceutical wastewater treating system is high in waste treatment efficiency, the pollution index of treated waste water is greatly reduced, and the content of organics and the content of hazardous substance are obviously reduced. The invention further provides a treating method.

Owner:四川珍福堂商贸有限公司

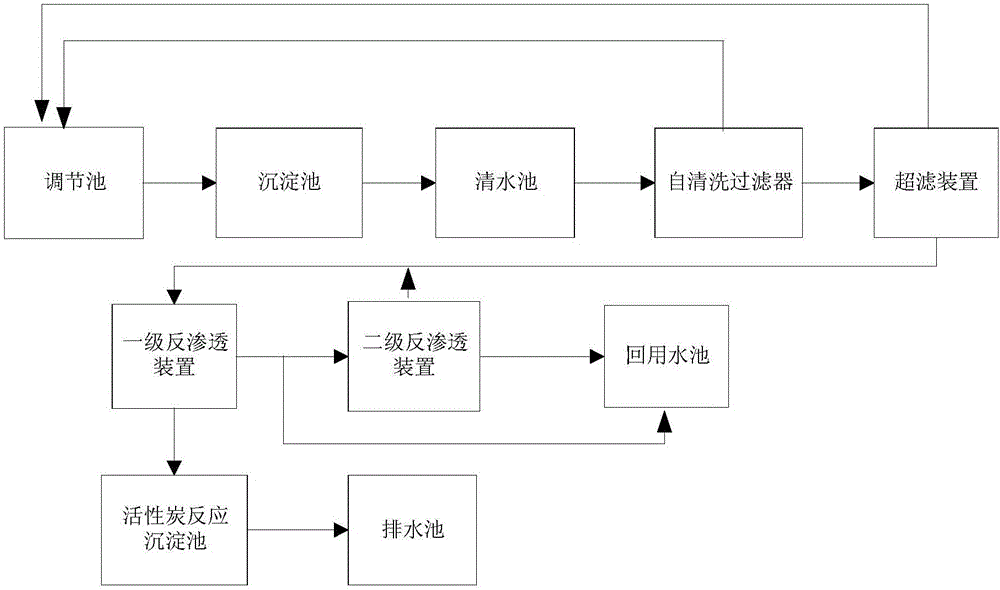

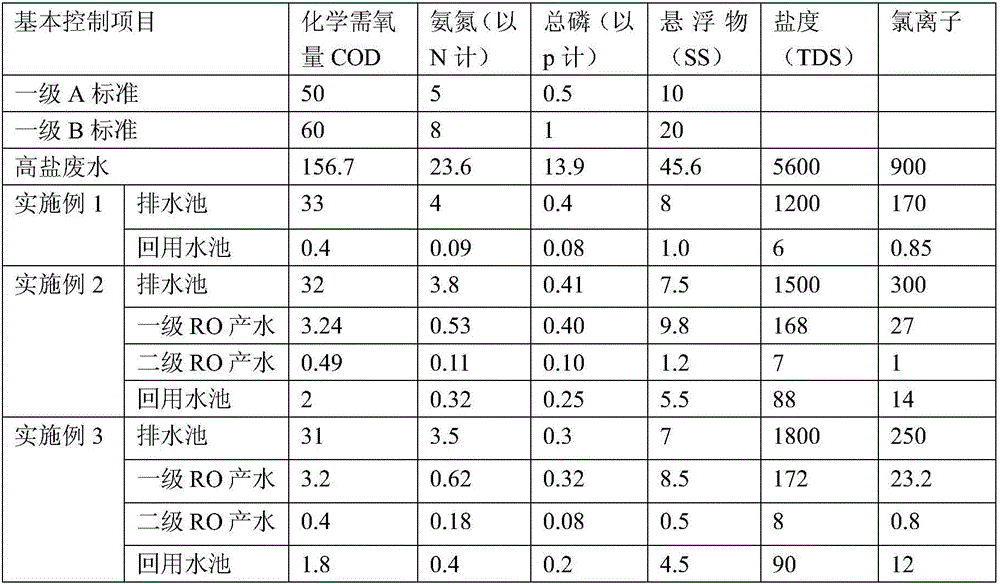

High-salt wastewater treatment reuse system and method

PendingCN106745981AReduce hardnessReduce loadTreatment involving filtrationMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention discloses a high-salt wastewater treatment reuse system and method. The system comprises a regulating tank, a precipitation tank, a clean water tank, a self-cleaning filter, an ultrafiltration device, a primary reverse osmosis unit and a secondary reverse osmosis unit, wherein the regulating tank is used for balancing the water quality and avoiding the precipitate; the precipitation tank is connected with the regulating tank, and used for precipitating water from the regulating tank; the clean water tank is connected with the precipitation tank, and used for regulating the pH value of upper clean water in the precipitation tank; the self-cleaning filter is connected with the clean water tank, and used for filtering the water from the clean water tank; the ultrafiltration device is connected with the self-cleaning filter, and used for carrying out ultrafiltration on the produced water from the self-cleaning filter; the primary reverse osmosis unit is connected with the ultrafiltration device, and used for carrying out primary reverse osmosis treatment on the produced water from the ultrafiltration device; and the secondary reverse osmosis unit is connected with the primary reverse osmosis unit, and used for carrying out secondary reverse osmosis treatment on the produced water of the primary reverse osmosis unit, thereby obtaining the reused produced water. The system can effectively lower the carbonate hardness and remove partial organic matters and colloids. The system has the advantages of high desalting rate and high recovery rate.

Owner:青岛锦龙弘业环保有限公司

Method for co-producing ethanol, cellulose and compound fertilizer by using crop straw as raw material

InactiveCN101696428AIncrease profitSolve the disadvantages that only a single product can be extractedBiofuelsFermentationCelluloseFiltration

The invention discloses a method for co-producing ethanol, cellulose and compound fertilizer by using crop straws as a raw material, which comprises: adding coarsely ground crop straws and acidic aqueous solution of which the pH value is 2 to 4 in mass part ratio of 1:2-3 into a cooking kettle and heating the mixture to 60 to 90 DEG C to cook the mixture for 4 to 8 hours; squeezing reactants to obtain solution, neutralizing the solution, regulating the concentration of the solution to 15 to 25 percent, producing ethanol by the conventional fermentation process, washing the straw residues obtained after squeezing by clean water, using the liquid obtained after the washing in the feeding of next batch of raw material, washing and squeezing the resulting material again, and mixing the obtained straw residue with aqueous solution containing a lignin leaching agent in a mass part ratio of 1:6-8, heating the mixture to 60 to 90 DEG C for cooking the mixture for 4 to 8 hours, filtering the mixture to obtain a coarse product of cellulose, washing and bleaching the coarse product of cellulose, filtering the coarse product of cellulose under compression for dewatering and drying the coarse product of cellulose to obtain a finished product of cellulose, wherein the bleaching liquid is used in the reaction of the next batch of raw material; and concentrating residual liquid obtained after the extraction of ethanol and the filtration of the coarse product of cellulose, drying the concentrate by spray for granulation, and making the compound fertilizer. As the method can extract ethanol and coproduce the cellulose and the compound fertilizer, so the drawbacks of single product production, waster source waste and heavy environmental pollution in the prior art are avoided.

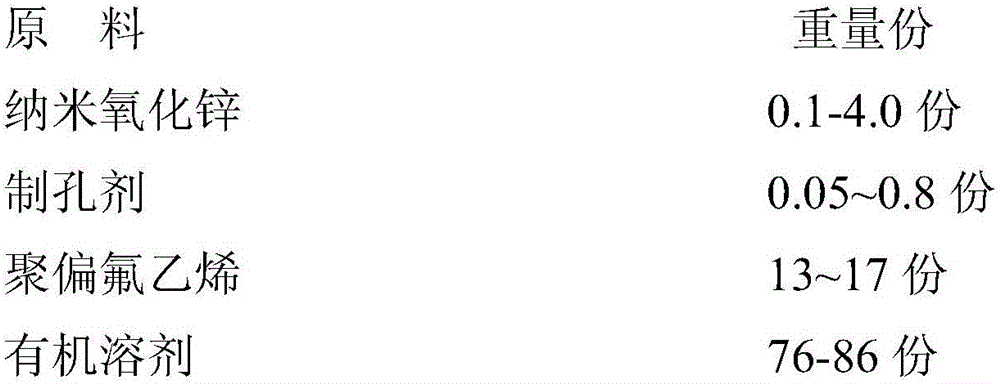

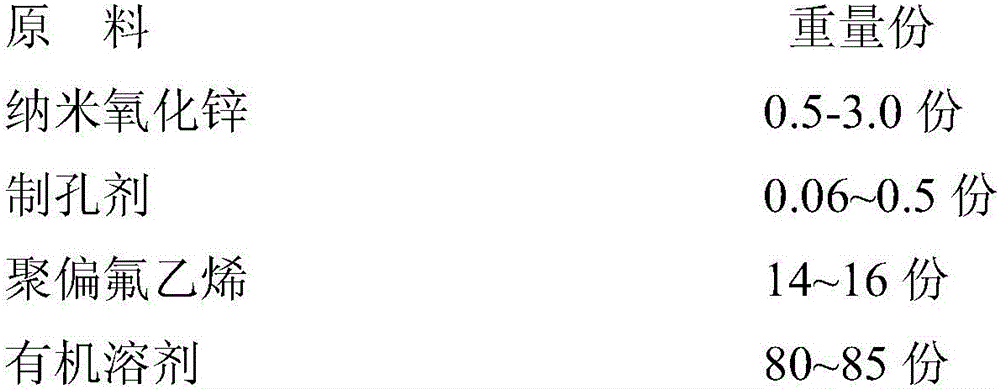

Polyvinylidene fluoride (PVDF) antibacterial film doped with nano-zinc oxide and preparation method

InactiveCN106110902AWide variety of sourcesSimple processSemi-permeable membranesMembranesNano zinc oxidePolyvinylidene fluoride

The invention discloses a PVDF antibacterial film doped with nano-zinc oxide and a preparation method. The film is prepared by certain parts, by weight, of nano-zinc oxide, pore-foaming agent, organic solvent and PVDF, the steps are that (1) the weighed pore-foaming agent and nano-zinc oxide are added to the organic solvent for ultrasonic dispersion; (2) the weighed PVDF is added to the organic solvent, and the mixture is heated, stirred, stood and defoamed to obtain a casting film liquid; (3) after the casting film liquid is scrapped into a film, the film is placed into a solidification liquid and soaked until the film falls, and the PVDF antibacterial film doped with the nano-zinc oxide is obtained. The formula is reasonable, the use is convenient, the antibacterial rate of the PVDF antibacterial film doped with the nano-zinc oxide can be improved by more than 60%, the film contamination index is reduced by 80%, and the microbial contamination resistance of the film is remarkably enhanced. The water flux is improved by more than 100%, and the hydrophilia is improved remarkably.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Emulsion synthetic fuel oil and manufacturing method thereof

InactiveCN1504545ABurn fullyReduce pollution indexRefining by water treatmentLiquid carbonaceous fuelsFuel oilSurface-active agents

The invention provides an emulsified synthetic fuel and method of manufacture, wherein the emulsified synthetic fuel is in water-in-oil shape, its composition is, 550-800 parts by weight of fuel oil, 200-450 parts by weight of water, and 2-20 parts by weight of addition agent, the addition agent comprises non-ionic surface active agent with a HLB value of 2.5-8, a stabilizer and an anti-oxidizing agent. The invention also discloses the process for preparing the emulsified synthetic fuel.

Owner:蔡坤穆

Method for extracting cellulose, lignose and compound fertilizer from cotton-seed hull

InactiveCN101476252AIncrease profitSolve the disadvantages that only a single product can be extractedLignin derivativesPaper material treatmentFiberCellulose

The invention provides a method for extracting cellulose, lignin and composite fertilizer from cottonseed shell, which comprises the following steps: adding lignin dissolving agent and water into a container according to the proportion of 1-5:1000; adding 10-20 liquid amount of cottonseed shells; heating to 70-90 degrees centigrade and keeping for 6-10 hours; separating out crude fibers, rinsing, refining and drying to obtain the finished fiber product; sending the rinsed solution into the socking container for reuse; acidifying the solution in the first boiling pool, and press filtering to precipitate solid that is lignin; adjusting the pH value of the solution after lignin extraction to neutral, concentrating, drying, granulating to obtain composite fertilizer. Besides the cellulose, the invention can co-produce lignin and composite fertilizer, changes improves the abuses of single product, water resource waste and serious environment pollution existing in the current technologies in our country.

Owner:JIAHE BIOTECH

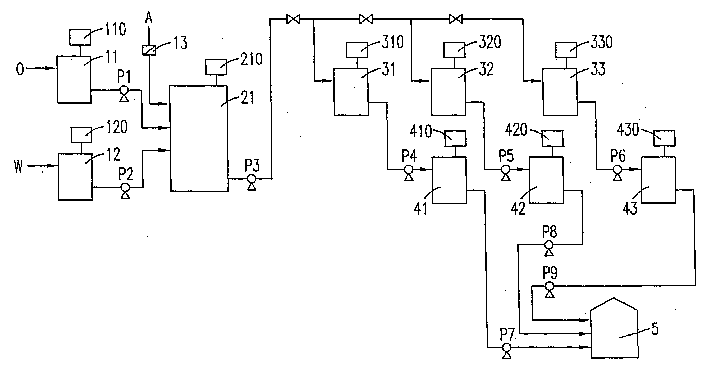

Aqueous acrylic acid adhesive and preparation method thereof

InactiveCN108084927AReduce pollution indexHigh water resistance and temperature resistanceAcid polymer adhesivesChemical industryAdhesive

The invention belongs to the field of a chemical industry, and especially relates to an aqueous acrylic acid adhesive and a preparation method thereof. The aqueous acrylic acid adhesive comprises thefollowing components in parts by weight: 15-20 parts of acrylic acid, 10-15 parts of methyl acrylate, 10-15 parts of ethyl acrylate, 10-15 parts of acrylic acid-2-ethylhexyl acrylate, 10-15 parts of methyl methacrylate, 10-15 parts of butyl acrylate, 5-10 parts of dimethylolpropionic acid, 5-10 parts of an emulsifier, 5-8 parts of triethylamine, 3-5 parts of a silane coupling agent, 3-5 parts of ablocking agent, 3-5 parts of an adhesion agent, 3-5 parts of aqueous silicone oil, and 300-500 parts of deionized water. The technology is simple and easy to control, and a polymerization system is stable; the obtained adhesive has the advantages of good mechanical stability, storage stability, and compatibility with a general auxiliary agent, and is suitable for industrial production.

Owner:辽宁东夫材料科技有限公司

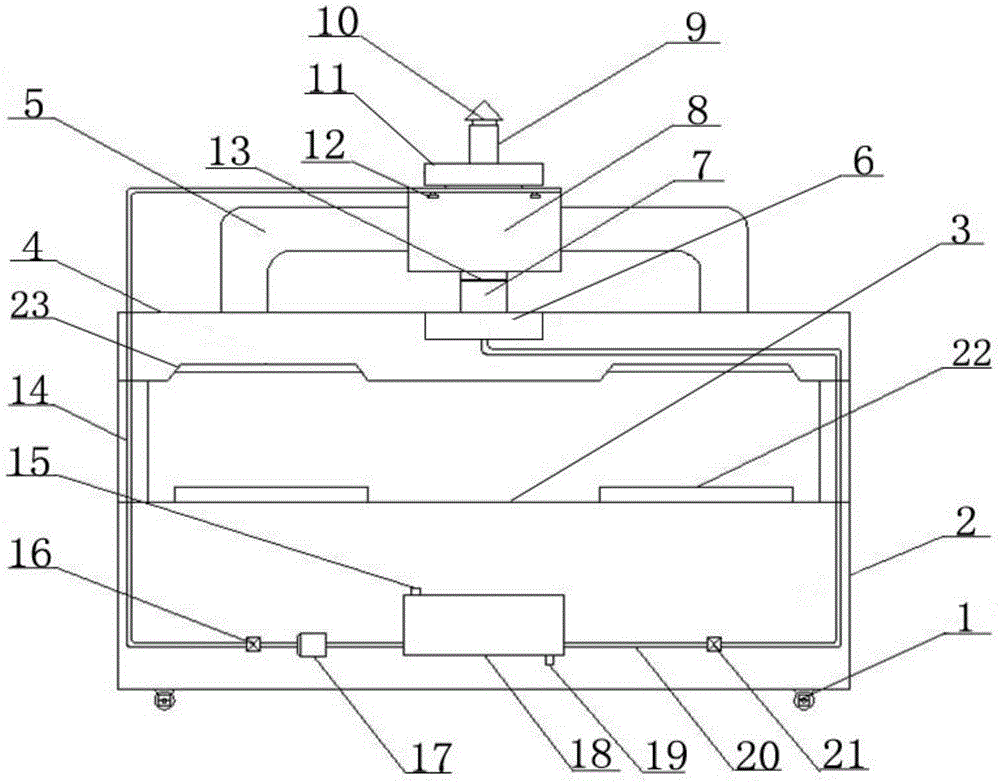

Medical ultrasonic cleaning machine

InactiveCN108580413AReduce pollution indexDoes not affect normal workCleaning using liquidsUltrasonographyMegasonic cleaning

The invention discloses a medical ultrasonic cleaning machine. The medical ultrasonic cleaning machine comprises an ultrasonic cleaning box. An inner cavity is formed in the ultrasonic cleaning box. Acoustic panels are fixedly arranged on the outer sidewalls of the inner cavity. A semiconductor condensation plate is arranged on the surface of a noise reduction plate. Heating wires are arranged onthe inner sidewalls of the inner cavity. The bottom of the ultrasonic cleaning box is provided with water outlet holes. The right sidewall of the ultrasonic cleaning box is provided with a water inlethole. Fixed rods perpendicular to the sidewalls are arranged on the sidewalls of the ultrasonic cleaning box. The fixed rods are used for supporting a cleaning basket. The two sides of the cleaning basket are provided with a plurality of clamping grooves. A hollowed-out net plate is clamped to the clamping grooves. The top of the ultrasonic cleaning box is provided with a box cover. A hollow cavity is arranged on the inner side of the box cover. The hollow cavity is filled with noise reduction plate. In the ultrasonic process, if a temperature sensor senses that the water temperature in the ultrasonic cleaning box is higher than the set temperature, the semiconductor condensation plate is turned on to reduce the water temperature, and the purpose of controlling the water temperature to beconstant is achieved.

Owner:SUZHOU BAILI MEDICAL PROD

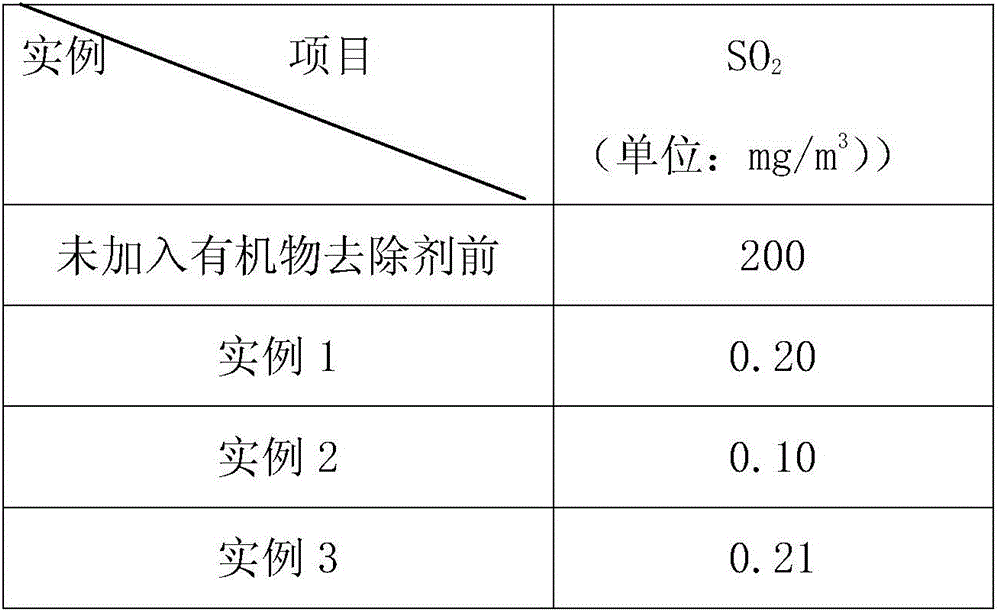

Novel sulfur dioxide adsorbent

InactiveCN106310868AGood removal effectReduce pollution indexGas treatmentOther chemical processesSodium bicarbonateActivated carbon

The invention discloses novel sulfur dioxide adsorbent, prepared from, by weight, 10-20 parts of activated carbon, 8-10 parts of sodium carbonate, 8-10 parts of sodium bicarbonate and 5-10 parts of zeolite powder, 5-10 parts of ferric chloride, 8-10 parts of sodium percarbonate, 8-10 parts of citric acid, 3-5 parts of sodium hypochlorite, and 20-30 parts of water. Compared with existing technology, the invention has the following beneficial effects: 1, the invention cannot only have stronger effect of removing sulfur dioxide, but also greatly decrease air pollution index; 2, the preparing technology is relatively simple and cost is low.

Owner:陈永桥

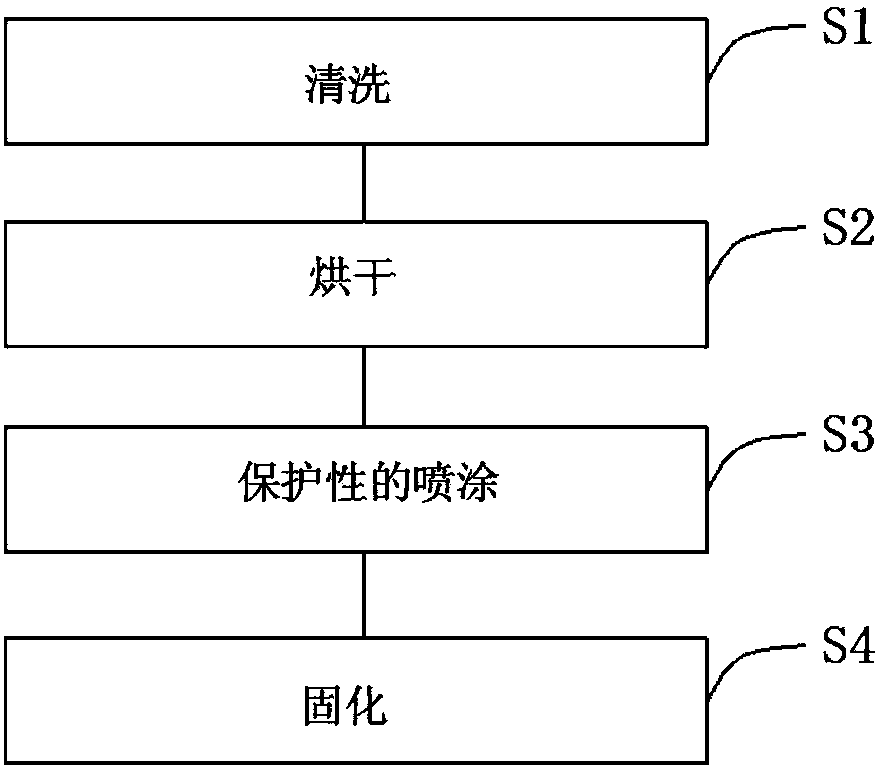

Process for uniform spraying of metal framework

InactiveCN104043574AUniform thicknessReduce pollution indexPretreated surfacesCoatingsMetal frameworkWorking environment

The invention provides a process for uniform spraying of a metal framework. The process includes the following steps that firstly, the surface of the metal framework is cleaned; secondly, the surface of the metal framework is dried; thirdly, at room temperature, protective spraying is conducted through a vacuum spraying machine; fourthly, curing is conducted, wherein baking temperature ranges from 100 DEG C to 160 DEG C, and time ranges from 5 min to 30 min. By the adoption of the process, the thicknesses of sprayed films are uniform, no compressed air exits in paint, no mixture of the paint and the air exists, and the pollution index of the spraying working environment is small.

Owner:WUZHOU HENGSHENG ELECTRONICS

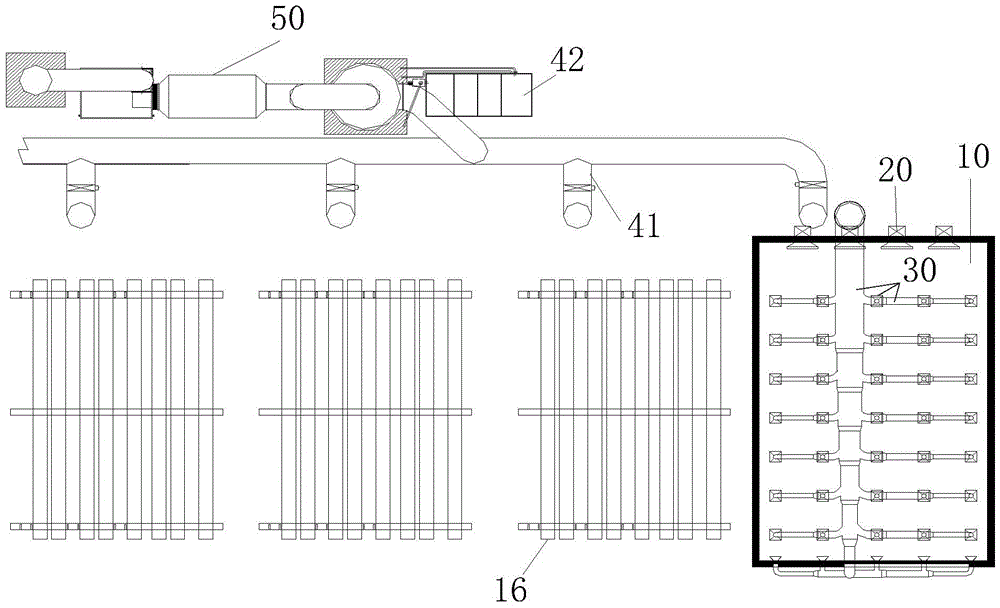

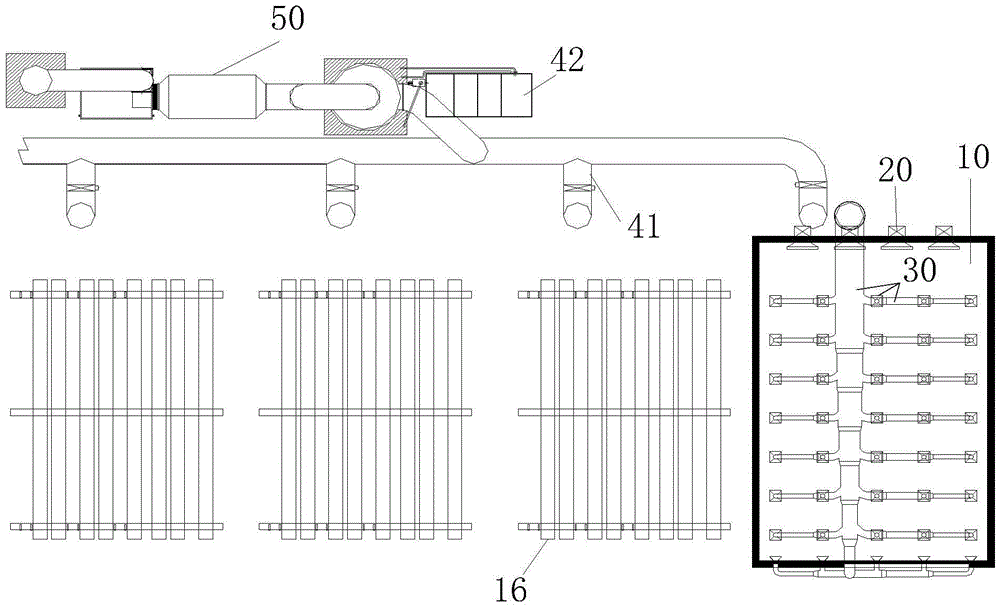

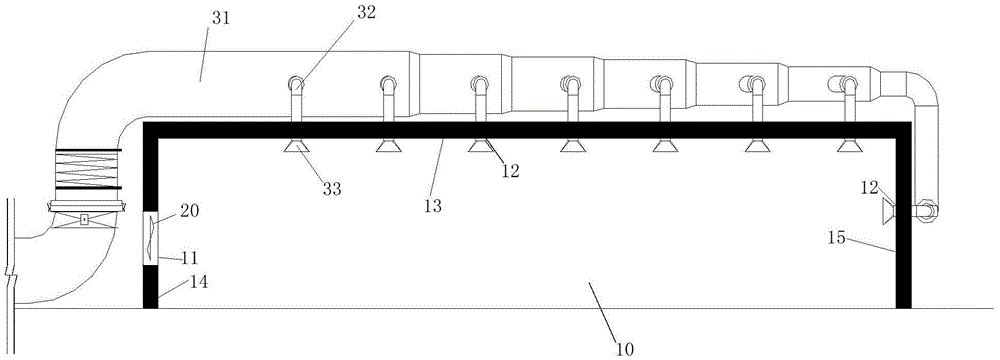

Steel structure spraying system with purifying function

ActiveCN105562272AReduce pollutionEmission reductionLiquid surface applicatorsUsing liquid separation agentSpray towerAtmospheric pressure

An embodiment of the invention provides a steel structure spraying system with a purifying function. The steel structure spraying system with the purifying function comprises a spraying region, an air supply unit, an exhaust unit, a spraying workstation, a spraying reaction region and a photolysis reaction region, wherein the spraying region comprises a spraying cabin; the spraying cabin comprises a cabin body; a plurality of air inlets and a plurality of air outlets are formed in the cabin body; an air supply opening of the air supply unit supplies air into the spraying cabin through the air inlets; an air sucking opening of the exhaust unit discharges the air from the inside of the spraying cabin through the air outlets; the spraying workstation is arranged in the spraying cabin; the height of the spraying workstation is suitable so as to facilitate spraying operation; the air supply unit and the exhaust unit guarantee that the inside of the spraying cabin has required working air pressure; the spraying reaction region comprises a spraying tower; a spraying air inlet is formed in the lower part of the spraying tower; a spraying air outlet is formed in the top of the spraying tower; the spraying air inlet communicates with an exhaust air outlet of the exhaust unit of the spraying region; the photolysis reaction region comprises a reaction body; a photolysis air inlet is formed in one end of the reaction body; a photolysis air outlet is formed in the other end of the reaction body; and the photolysis air inlet communicates with a spraying air outlet of the spraying tower.

Owner:DUOWEI UNION GRP +2

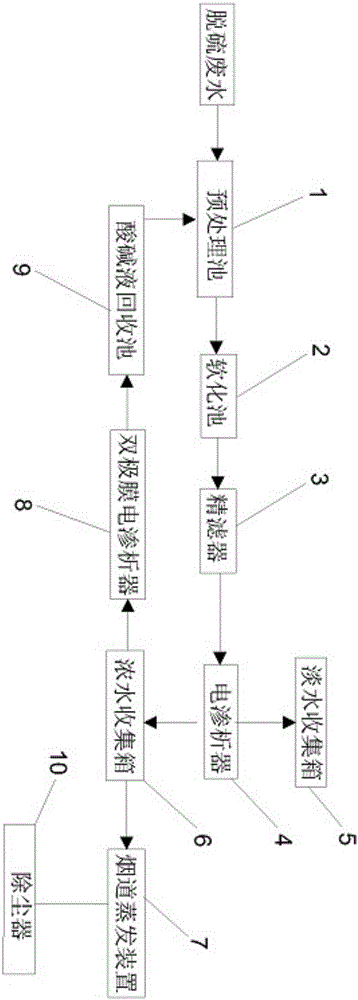

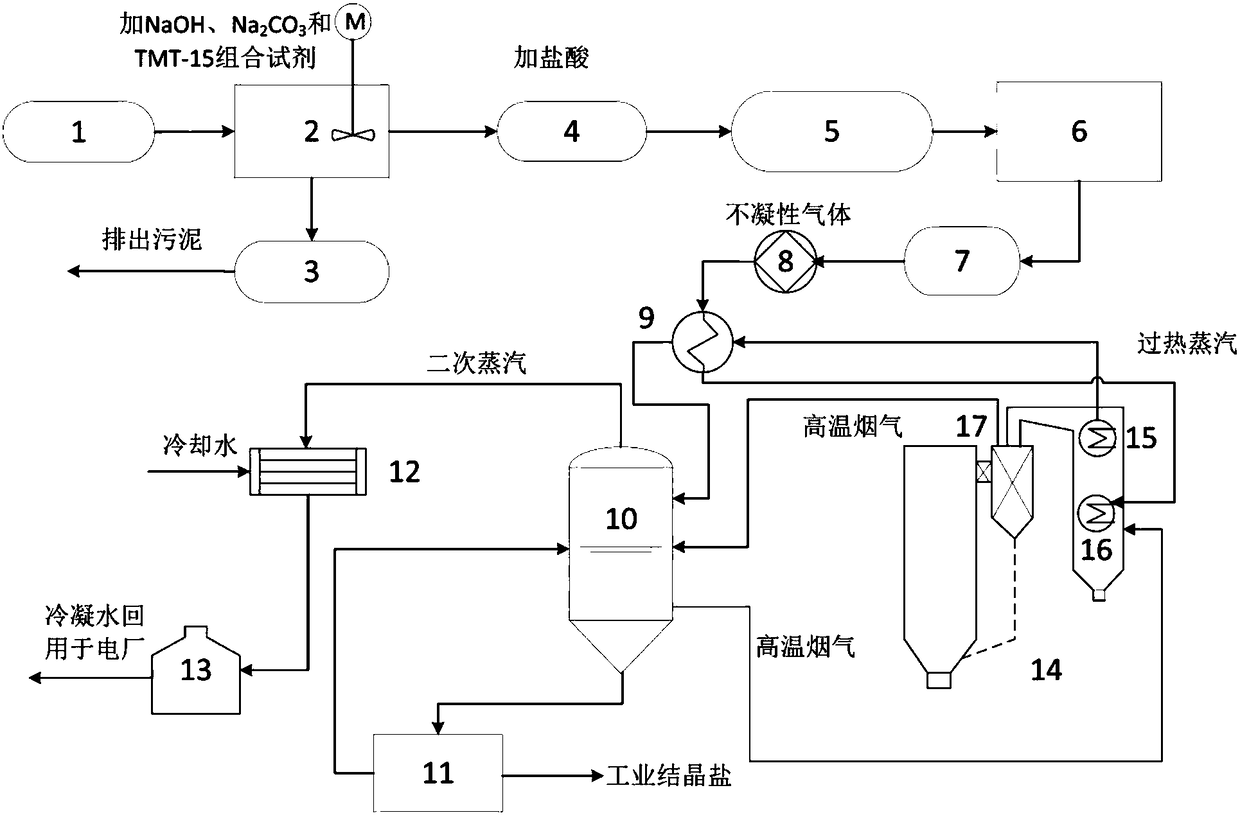

Zero emission treatment system and zero emission treatment method for desulfurization waste water from ultra-supercritical circulating fluid bed (CFB) boiler

PendingCN108558110AEfficient use ofIncrease heat transfer temperature differenceSludge treatmentWater contaminantsFiltrationHigh energy

The invention discloses a zero emission treatment system and a zero emission treatment method for desulfurization waste water from an ultra-supercritical circulating fluid bed (CFB) boiler. The zero emission treatment system comprises a chemical pretreatment system, a membrane filtration system, an electrodialysis system, a desulfurization waste water preheating system, a desulfurization waste water evaporator, a solid-liquid separation device and a vapor condensation device. High-temperature flue gas at an exit position of a cyclone separator of the ultra-supercritical CFB boiler is used as aheat source to evaporate and crystallize the desulfurization waste water, superheated steam at an inlet header of a rear platen superheater of the super-supercritical CFB boiler is used as a heat source for the preheated desulfurization waste water, and the membrane filtration system provided with a microfiltration device and the electrodialysis system used for concentration reduction are additionally arranged, so that the defects of high energy consumption and high equipment investment cost of the existing multi-effect evaporation technology are overcome, the desulfurization efficiency can be improved, equipment scaling is effectively avoided, system handling load is reduced, economic benefit is significantly improved, the energy is saved, and the operating cost is reduced.

Owner:XI AN JIAOTONG UNIV

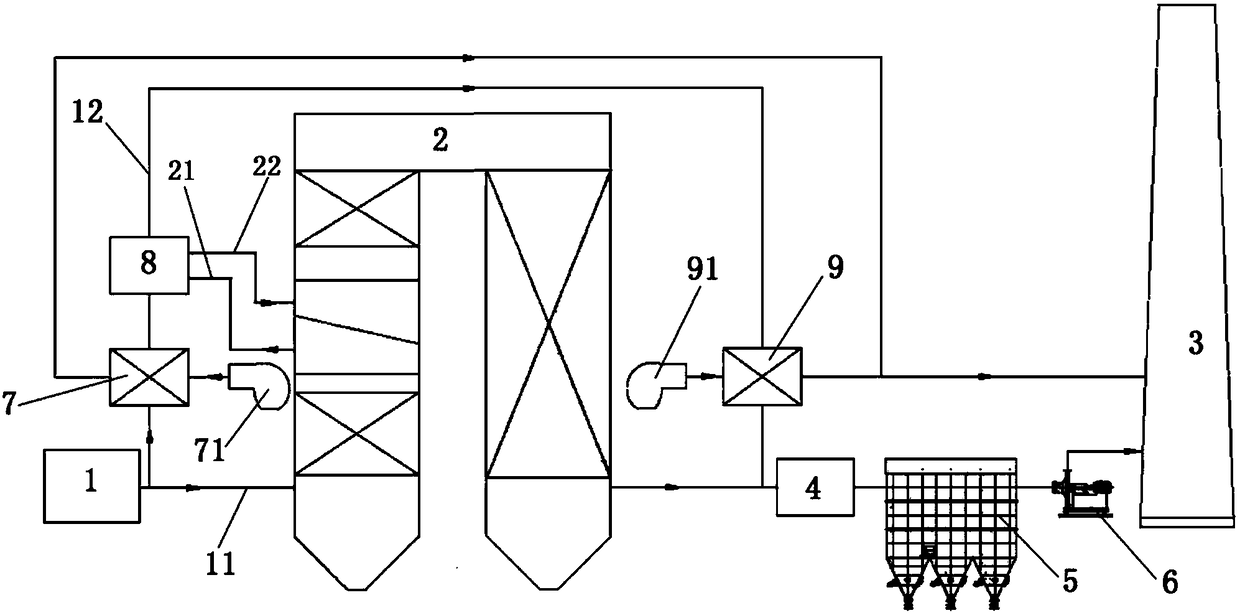

Glass kiln flue gas bypass desulfurization and denitrification system

InactiveCN108426458AEasy to clean and maintainLow costIncreasing energy efficiencyWaste heat treatmentFlue gasEmission standard

The invention relates to a glass kiln flue gas bypass desulfurization and denitrification system. The system comprises a glass kiln, a waste heat boiler and a chimney, wherein the waste heat boiler, adesulfurization tower, a dust remover and an induced draft fan are connected between a main flue of the glass kiln and the chimney, a bypass flue is arranged on the main flue in a communicating mode,a first flue gas cooler, a denitrification reactor and a second flue gas cooler are sequentially connected to the bypass flue, a flue which is cooled by the second flue gas cooler is connected to a flue gas inlet of the desulfurization tower, a first air blower and a second air blower are connected to the heat exchange air inlet ends of the first flue gas cooler and the second flue gas cooler correspondingly, and the heat exchange air outlet ends of the first flue gas cooler and the second flue gas cooler are connected to the chimney through pipelines in a communicating mode. The system has the advantages that during temporary maintenance of the glass kiln, the pollution index discharged flue gas is effectively reduced to meet the emission standard, in addition, the manufacturing cost islow, the temperature of flue gas can be effectively decreased to about 340 DEG C to enter the denitrification reactor, and further, the second flue gas cooler can enable the temperature of the flue gas subjected to denitrification to be decreased to 220 DEG C.

Owner:杭州伯勒智能工程有限公司

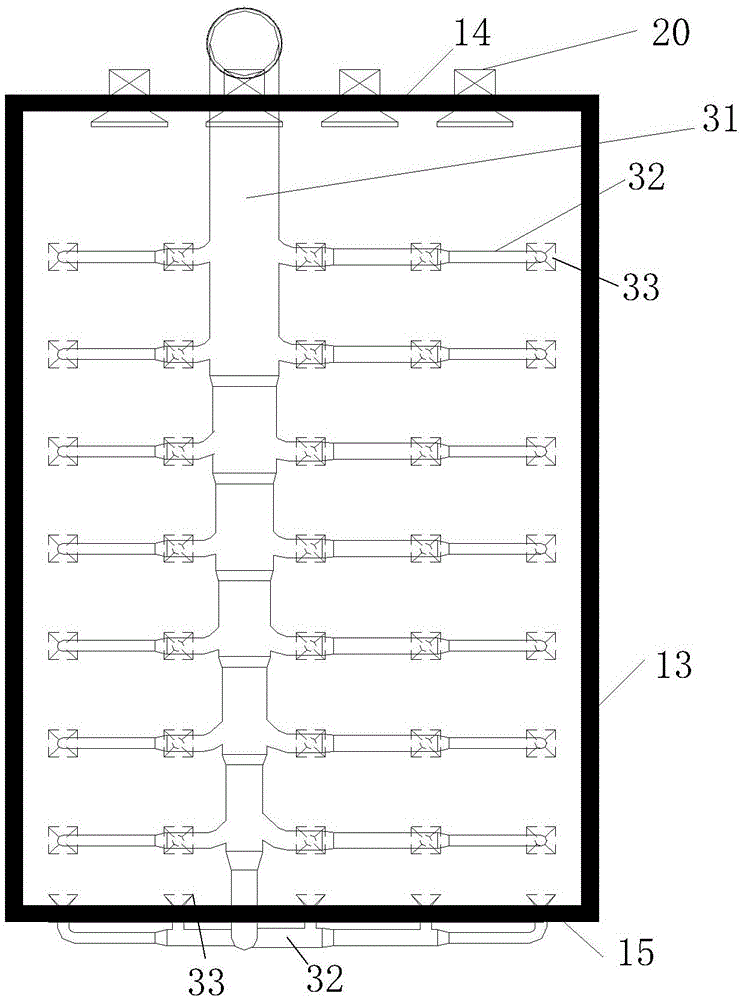

Sewage treatment system adopting photocatalytic degradation membrane separation

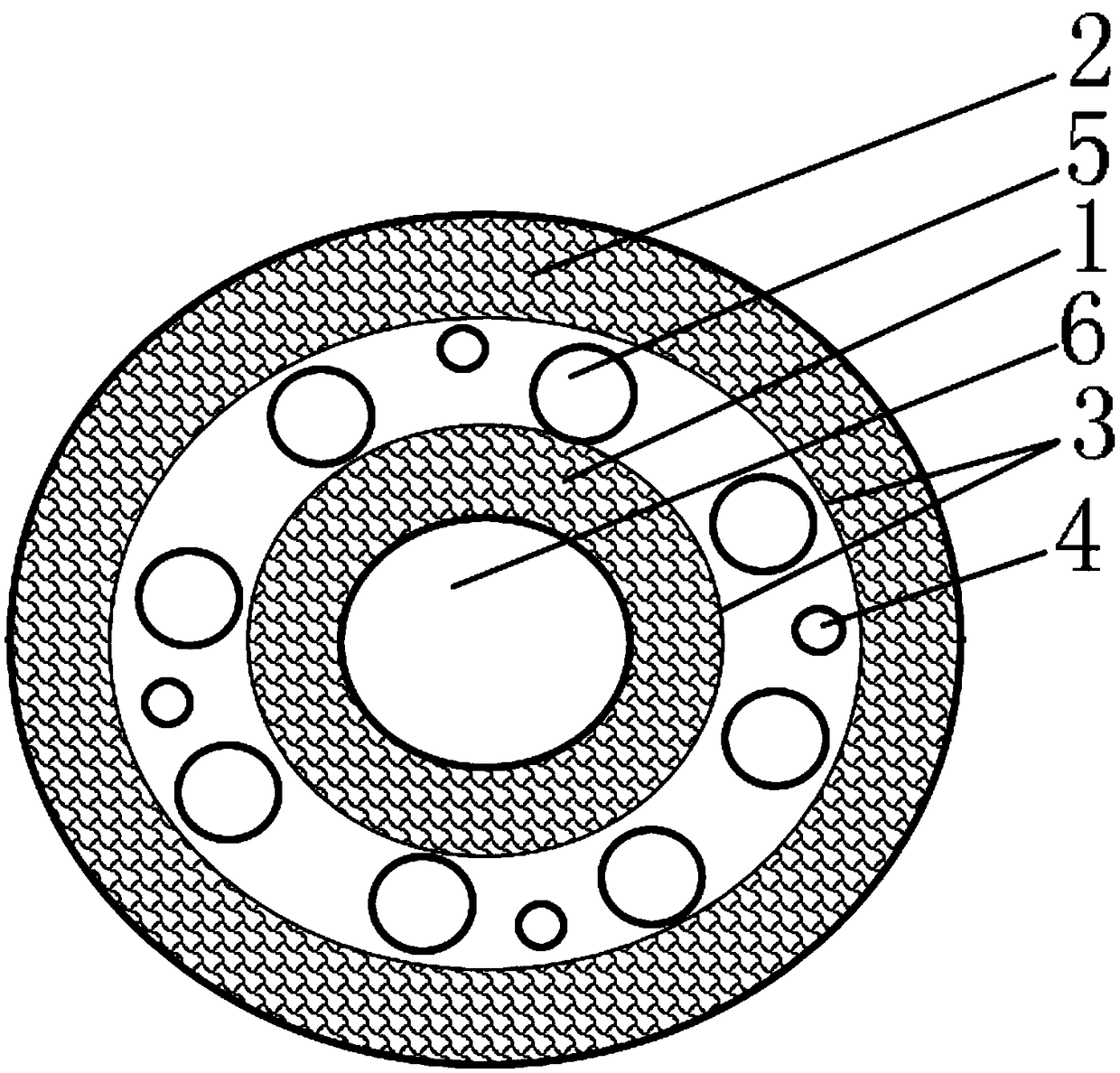

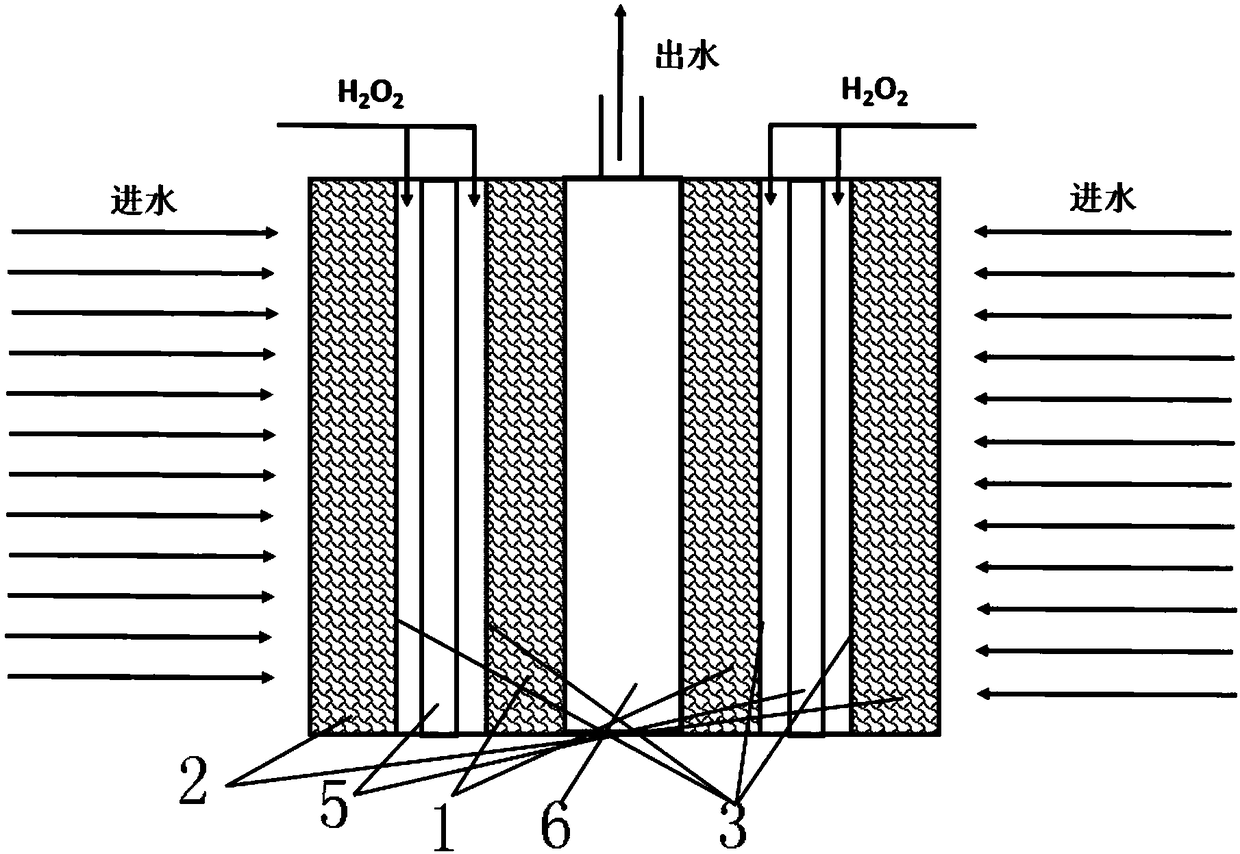

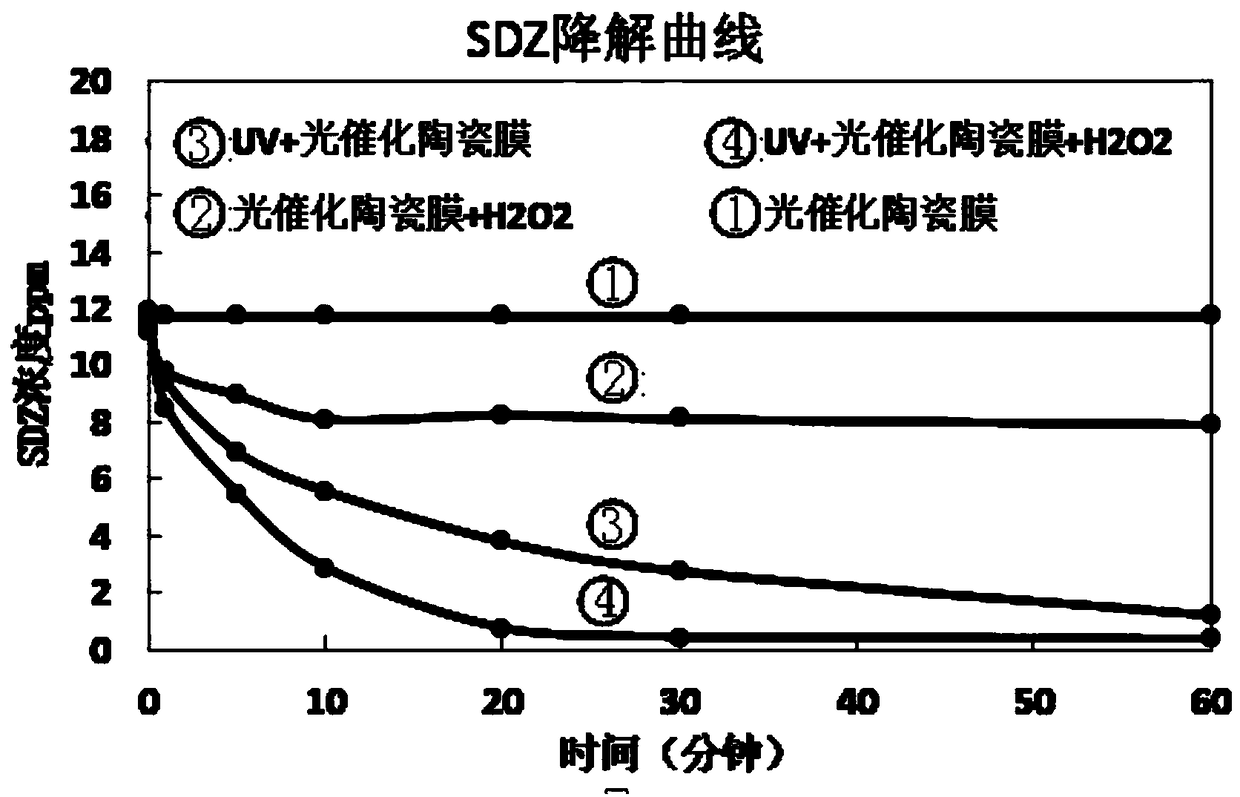

InactiveCN108502969AImprove pollutionExtended service lifeWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationNano catalyst

The invention discloses a sewage treatment system adopting photocatalytic degradation membrane separation and relates to the technical field of membrane separation sewage treatment. The sewage treatment system comprises a double-layered pipe type ceramic membrane, wherein an ultraviolet lamp tube is arranged between inner and outer membranes of the double-layered pipe type ceramic membrane; nano-photocatalysts are arranged on the outer surface of the inner membrane and the inner surface of the outer membrane; the double-layered pipe type ceramic membrane adopts a filtering manner from outsideto inside and treated water is output from an inner cavity of the inner membrane of the double-layered pipe type ceramic membrane; hydrogen peroxide is input into an inner cavity between the inner andouter membranes; under the irradiation of ultraviolet light, the hydrogen peroxide has photo-Fenton reaction under the action of a catalyst to stimulate a lot of hydroxyl free radicals, so that pollutants are degraded. According to the sewage treatment system disclosed by the invention, high-concentration organic wastewater is selectively degraded; the degradation efficiency is high and the degradation is complete; nano-grade catalysts in a reaction liquid system can be recycled, and constant and catalytic properties of the catalysts in a reactor are kept; the system is continuously, effectively and stably operated and the anti-pollution performance and service life of the membrane are improved.

Owner:BEIJING JIAOTONG UNIV

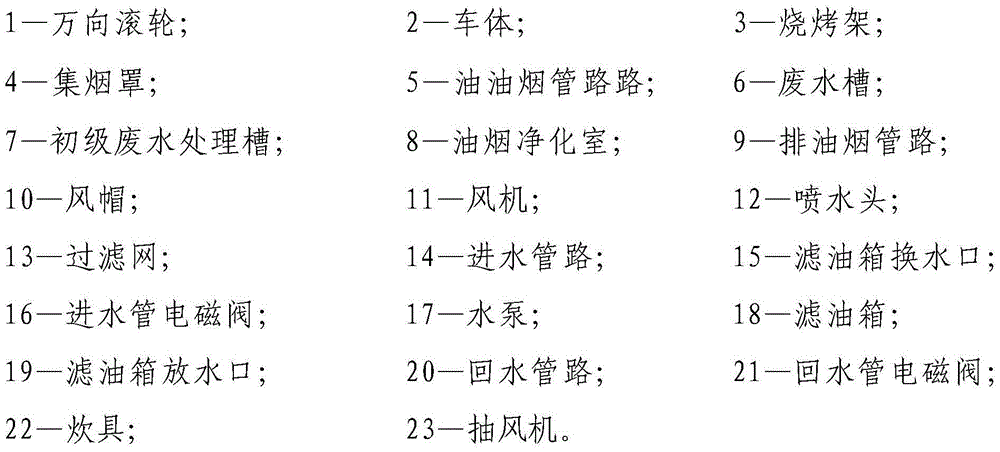

Water spray lampblack purification barbecue trolley

InactiveCN104654406ASimple structureNovel and reasonable designCombination devicesDomestic stoves or rangesFuel tankSmoke hood

The invention discloses a water spray oil fume purification barbecue trolley. The water spray oil fume purification barbecue trolley comprises a trolley body, and universal rollers which are installed on four corners of the bottom of the trolley body, wherein a barbecue frame is horizontally arranged in the middle of the trolley body, the barbecue frame is provided with a cooker, the top end of the trolley body is provided with a smoke collection cover, an exhaust fan is arranged in the smoke collection cover, the smoke collection cover is connected with an oil fume purification chamber by virtue of an oil fume pipeline, the top end of the oil fume purification chamber is provided with a fan, the top end of the fan is provided with an oil fume discharge pipeline, the bottom end of the oil fume purification chamber is provided with a primary waste water treatment trough, the bottom end of the primary waste water treatment trough is communicated with a waste water trough, the waste water trough is connected with an oil filter box by virtue of a water return pipeline, the oil filter box is connected to one end of a water inlet pipeline, the other end of the water inlet pipeline is provided with a water spray head, and the water spray head is installed on the top end of the oil fume purification chamber. The water spray oil fume purification barbecue trolley is simple and reasonable in structure, the environmental pollution caused by barbecue can be alleviated, the sanitation of food can be guaranteed, the cost is low, the practicability is high, and the water spray oil fume purification barbecue trolley can be popularized to use.

Owner:XIAN LIANKONG ELECTRICAL

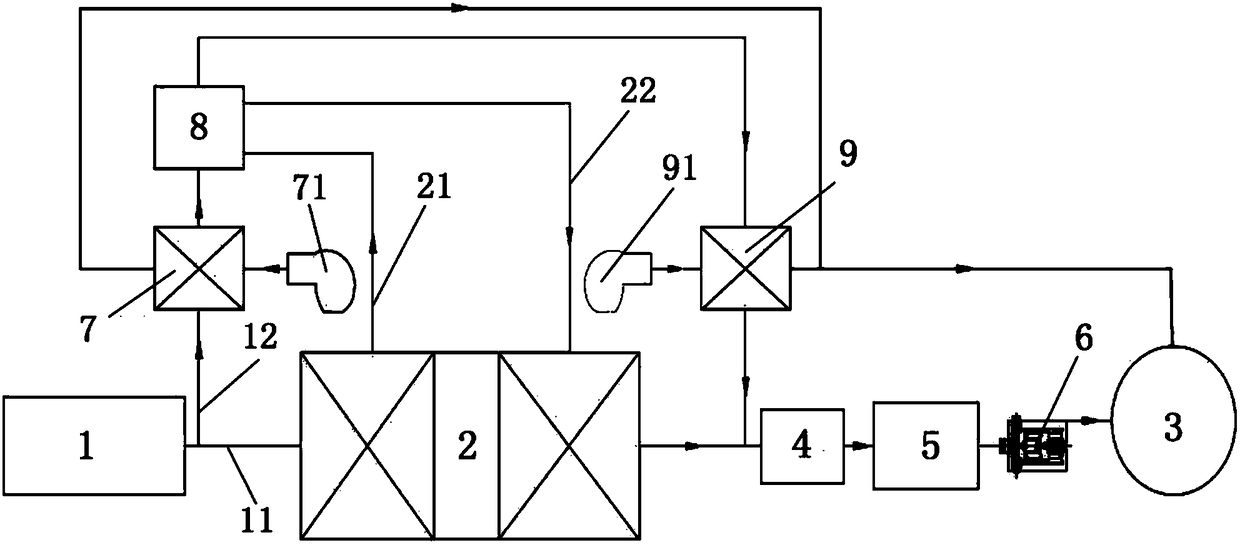

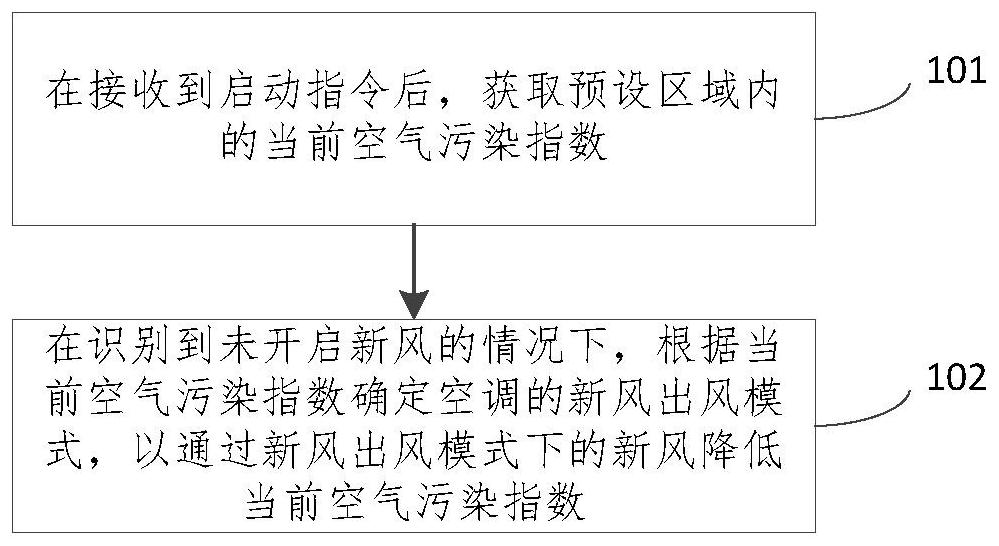

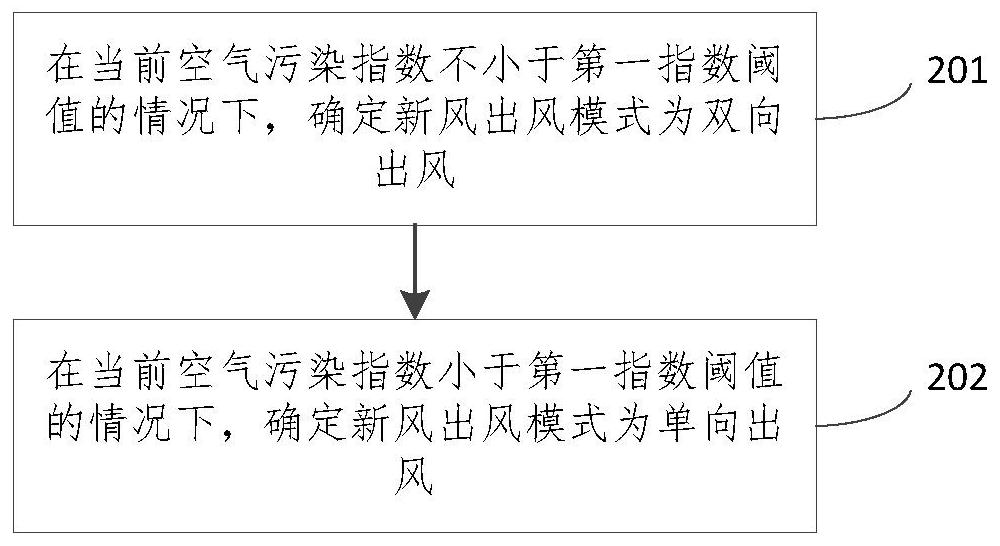

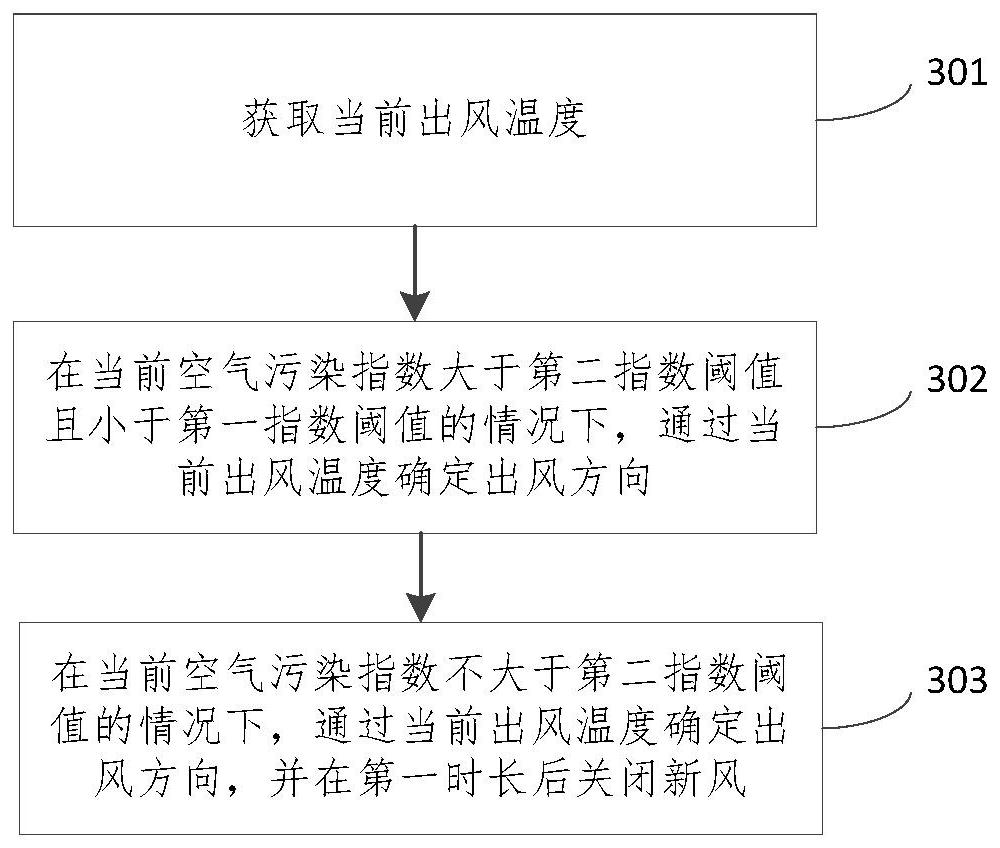

Fresh air discharging method and apparatus for air conditioner, electronic device, and computer readable medium

ActiveCN112229042AReduce pollution indexMechanical apparatusLighting and heating apparatusAir contaminationAir change

The application provides a fresh air discharging method and apparatus for an air conditioner, an electronic device, and a computer readable medium, and belongs to the technical field of air conditioners. The method comprises the following steps of obtaining a current air pollution index in a preset area after a starting instruction is received, wherein the preset area is an area where the air conditioner is adopted to perform fresh air ventilation; and under the condition that the fact that fresh air is not supplied is recognized, determining a fresh air discharging mode of the air conditioneraccording to the current air pollution index, so as to reduce the current air pollution index by the fresh air in the fresh air discharging mode. According to the method, by obtaining the current airpollution index, the fresh air discharging mode is determined according to the obtained current air pollution index; and the obtained current air pollution index is reduced at a maximum rate.

Owner:GREE ELECTRIC APPLIANCES INC

Method for extracting crust element, fats and albumen powder from shrimp and crab

InactiveCN101181080BAvoid destructionSolve the disadvantages that only a single product can be extractedFood scienceWAS PROTEINShrimp

The invention discloses a method for extracting chitin chitosan, fat and protein powder from shrimp and crab. Shrimp and crab are added with water to be heated and cooked and then be added with mixed enzyme fermentation after cooling; shrimp and crab shells filtered from the fermentation broth is added with acid solution to be soaked, alkali is added to neutralize the solution and then chitin product is obtained after filtering, clearing and drying; fat is obtained after the filtered liquid is centrifuged; the rest liquid is protein liquid and protein powder obtained after concentrating, spraying and drying. The method adopts the combined-enzyme method during the lysis and decomposition of the shrimp and crab and avoids the damage to the protein biological potency of the traditional technique of acidolysis decomposition and three high purity products, namely, chitin, fat and protein powder can be separated and extracted in sequence after the primary fermentation, thus solving the shortage that only one product is extracted in the traditional technique; the comprehensive utilization of the raw material is greatly improved and the production process does not pollute the environment.

Owner:QINGDAO BETTER BIO TECH

Method for extracting chondroitin, collagen and high-calcium powder from animal cartilage

InactiveCN101913583BReduce pollution indexReduce acid and alkali consumptionInorganic phosphorous active ingredientsMetabolism disorderInternal temperatureCollagen VI

The invention discloses a method for extracting chondroitin, collagen and high-calcium powder from animal cartilages, comprising the following steps of: a, chopping the cleaned animal cartilages into pieces, adding water for mixing, placing into a reaction still, and heating to denature protein; b, introducing cold water into a jacket of the reaction still for cooling, adding collagenase and papain till the internal temperature of the reaction still is 30-60 DEG C, keeping the temperature of 30-70 DEG C and the PH value of 7-8, and hydrolyzing under stirring; c, roughly filtering a hydrolyzedsolution to obtain cartilage residues containing calcium phosphate; d, finely filtering roughly-filtered liquid by a filter press to obtain clear fine filtrate, and adding ethanol to the fine filter liquor to precipitate chondroitin crystals; and e, after the chondroitin crystals are precipitated, obtaining a mixed solution of the collagen and the ethanol. The invention overcomes the defects of serious pollution and only single product production in the traditional process, enhances the output value rate by more than 30 percent and reduces the comprehensive pollution index of chondroitin production by more than 95 percent.

Owner:QINGDAO BETTER BIO TECH

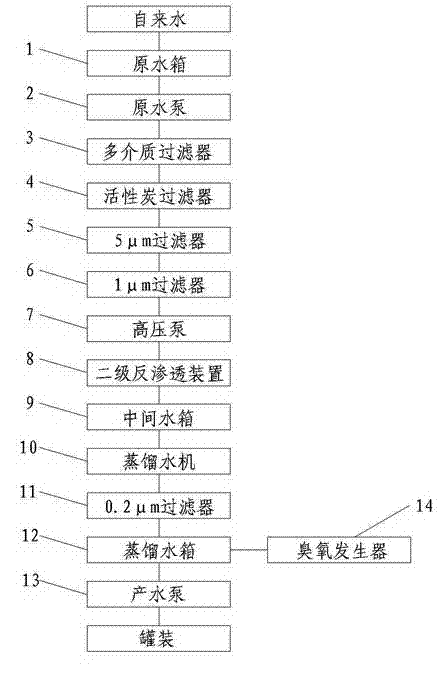

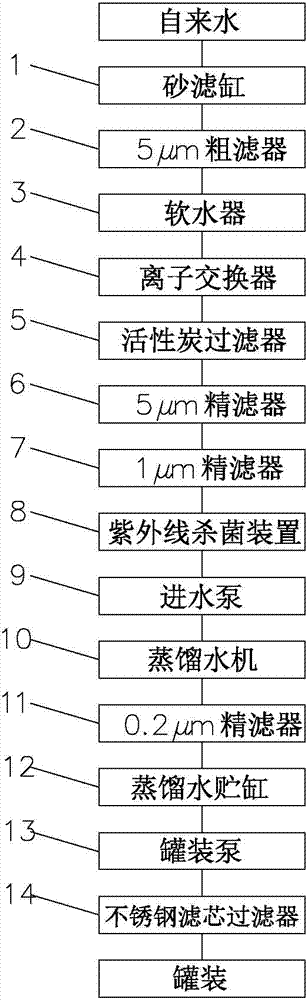

Production apparatus for preparing distilled water by applying reverse osmosis desalination technology

InactiveCN103708663AReduce the residual chlorine valueAvoid damageGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisActivated carbon filtrationWater production

The invention relates to the technical field of distilled water preparation, and concretely relates to a production apparatus for preparing distilled water by applying a reverse osmosis desalination technology. The apparatus comprises a raw water tank, an activated carbon filter, a high pressure pump, a distilled water machine and a distilled water tank, and also comprises a 5mum filter, a 1mum filter, a secondary reverse osmosis device and a 0.2mum filter, and the raw water tank, the activated carbon filter, the 5mum filter, the 1mum filter, the high pressure pump, the secondary reverse osmosis device, the distilled water machine and the distilled water tank are sequentially connected. The apparatus can effectively remove pollutants in water and can guarantee the water output of the distilled water machine.

Owner:东莞日之泉蒸馏水有限公司

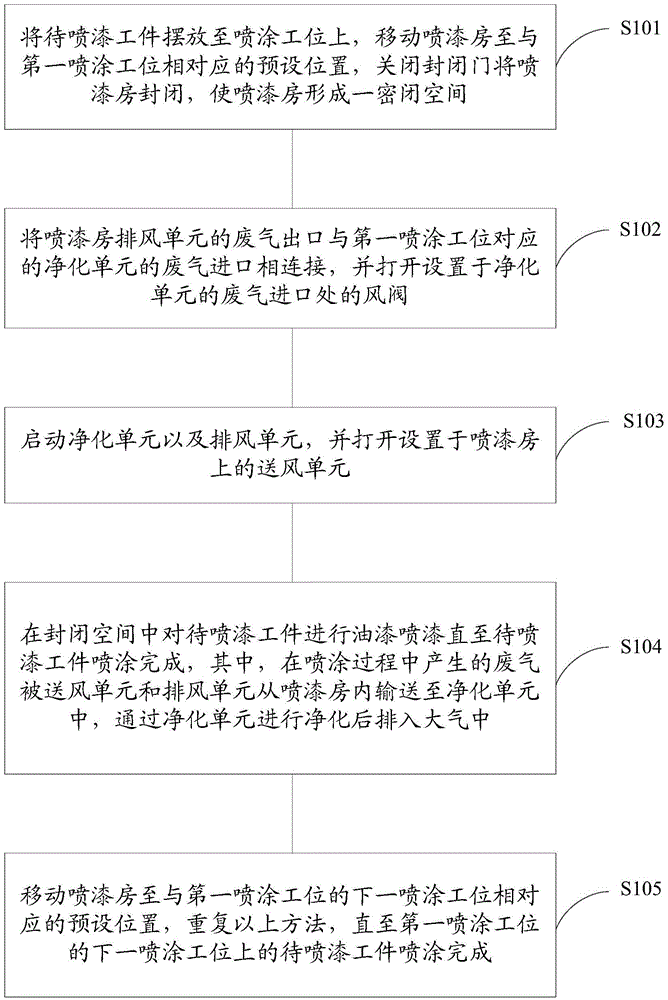

Steel structure spraying method with purification function

ActiveCN105537042AConvenient for centralized processingReduce emissionsLiquid surface applicatorsCoatingsExhaust fumesSpray method

The embodiment of the invention provides a steel structure spraying method with a purification function. The steel structure spraying method with the purification function comprises the steps that workpieces to be sprayed are placed onto spraying stations, a spraying chamber is moved to a preset position corresponding to the first spraying station, and the spraying chamber is sealed by closing a sealing door, so that an airtight space is formed in the spraying chamber; a waste gas outlet of an exhaust unit of the spraying chamber is connected with a waste gas inlet of a purification unit corresponding to the first spraying station, and an air valve is opened; the purification unit and the exhaust unit are started, and an air supply unit is opened; the workpiece to be sprayed is sprayed with paint in the airtight space till spraying of the workpiece to be sprayed is completed, and waste gas generated in the spraying process is delivered into the purification unit from the spraying chamber through the air supply unit and the exhaust unit and exhausted into the atmosphere after being purified through the purification unit; and the spraying chamber is moved to a preset position corresponding to the spraying station next to the first spraying station, and the steps are executed repeatedly till spraying of the workpiece to be sprayed on the spraying station next to the first spraying station is completed.

Owner:DUOWEI UNION GRP +2

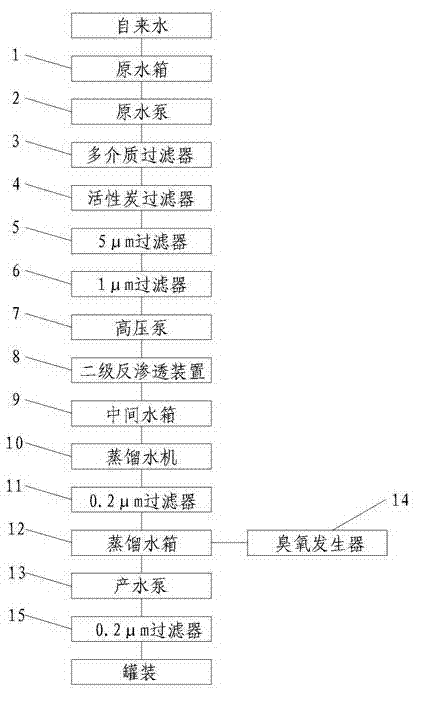

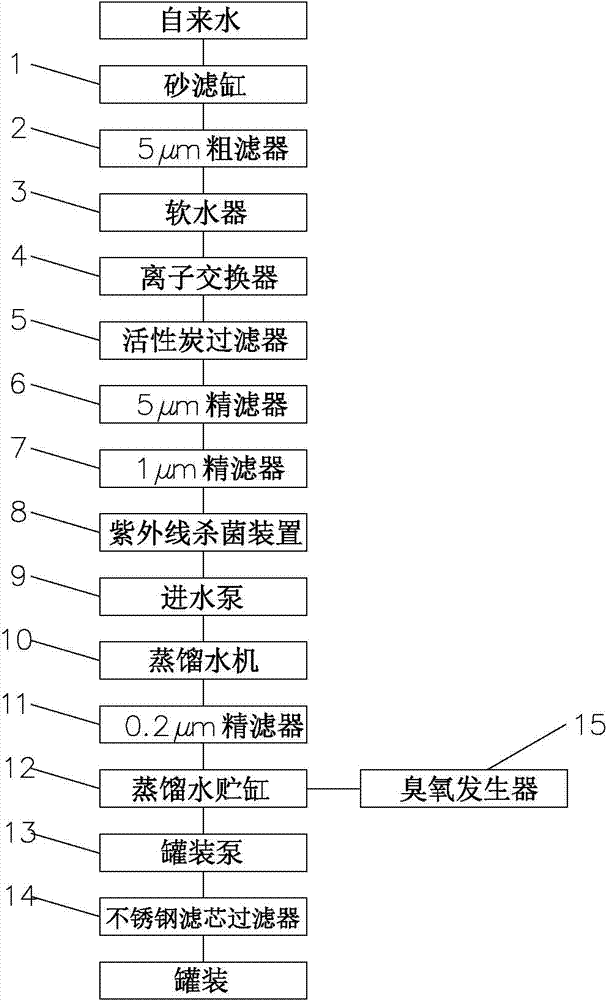

Production device for preparing distilled water by ion exchange technology

InactiveCN103708664AReduce the residual chlorine valuePrevent scalingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater useActivated carbon filtration

The invention relates to a distilled water preparation technology field, concretely a production device for preparing distilled water by an ion exchange technology, comprising: a sand filtration cylinder, an activated carbon filter, an ultraviolet sterilization device, a water inlet pump, a distilled water machine and a distilled water storage cylinder, and further comprising a water softener, an ion exchanger, a 5mum fine filter and a 1mum fine filter, wherein the sand filtration cylinder, the water softener, the ion exchanger, the activated carbon filter, the 5mum fine filter, the 1mum fine filter, the ultraviolet sterilization device, the water inlet pump, the distilled water machine and the distilled water storage cylinder are connected in order; and regenerants are 30% hydrochloric acid and a 30% of regenerant diluted from 99% sheet-shaped solid sodium hydroxide with water. The device provided by the invention can effectively remove pollutants in water and guarantees the water yield of the distilled water machine.

Owner:东莞日之泉蒸馏水有限公司

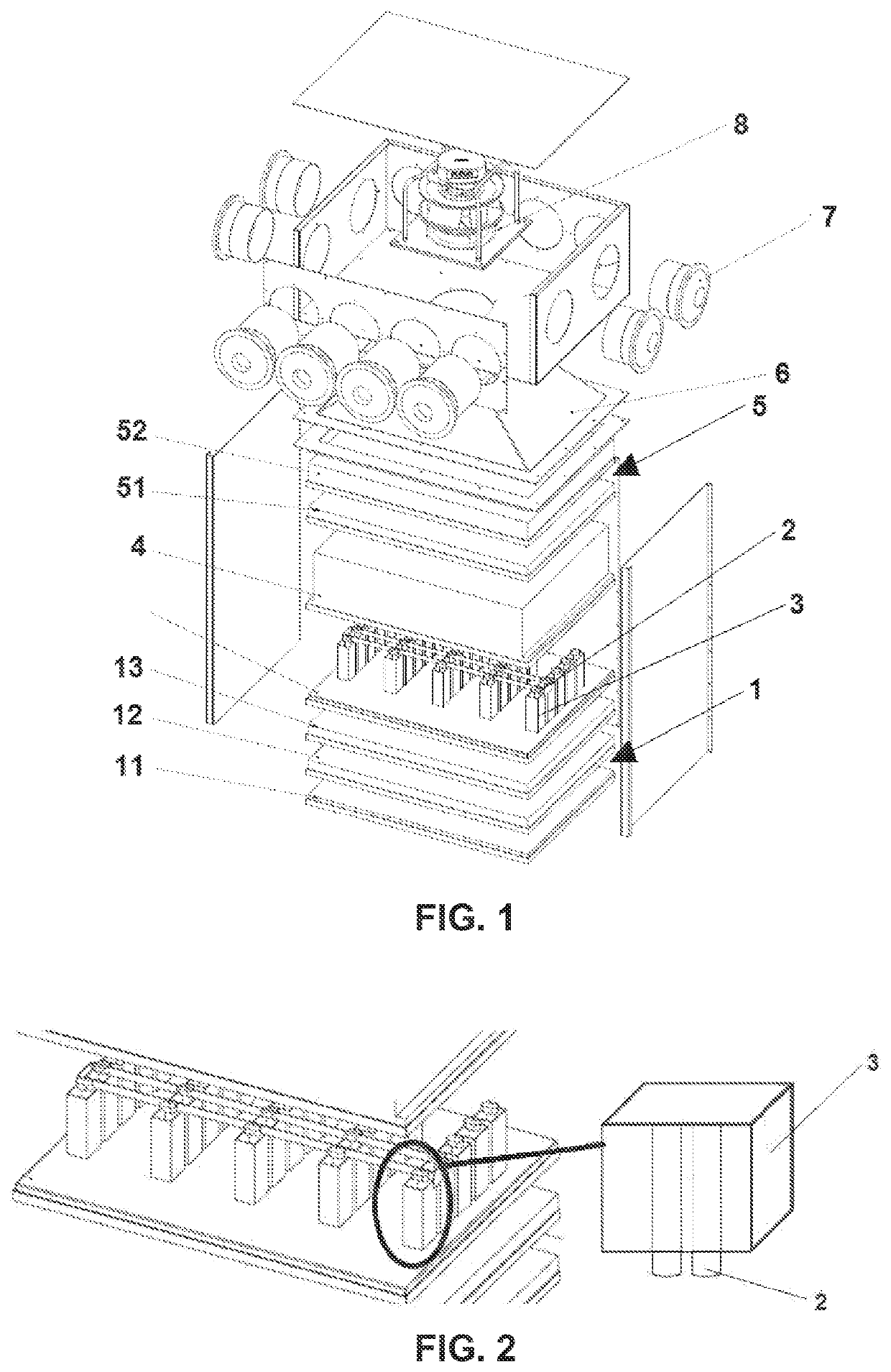

Air Purification Device

PendingUS20220032231A1Increase speedIncrease air velocityDucting arrangementsGas treatmentActivated carbonEnvironmental engineering

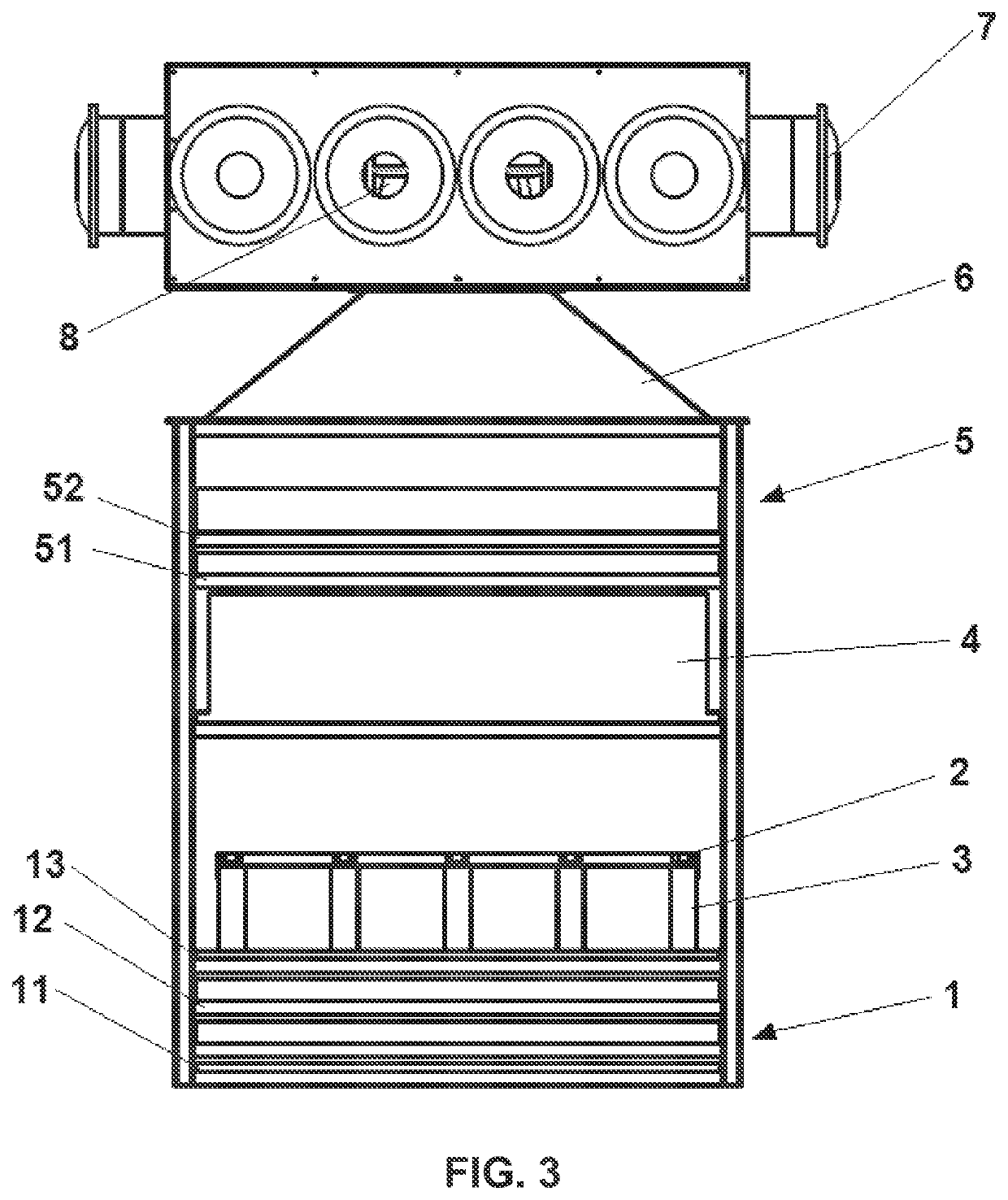

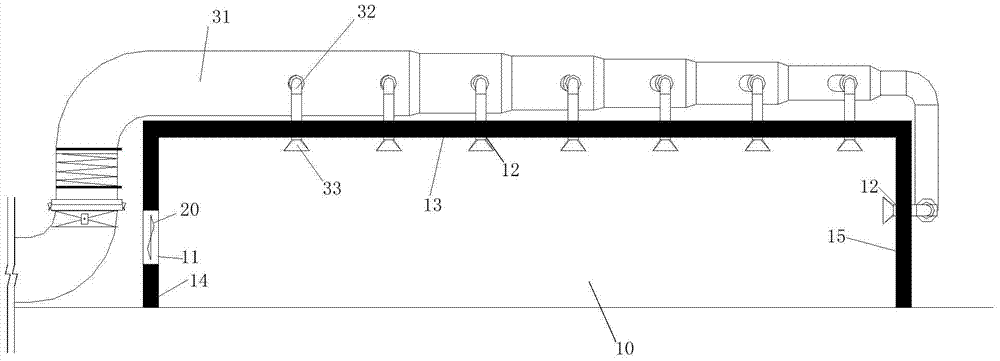

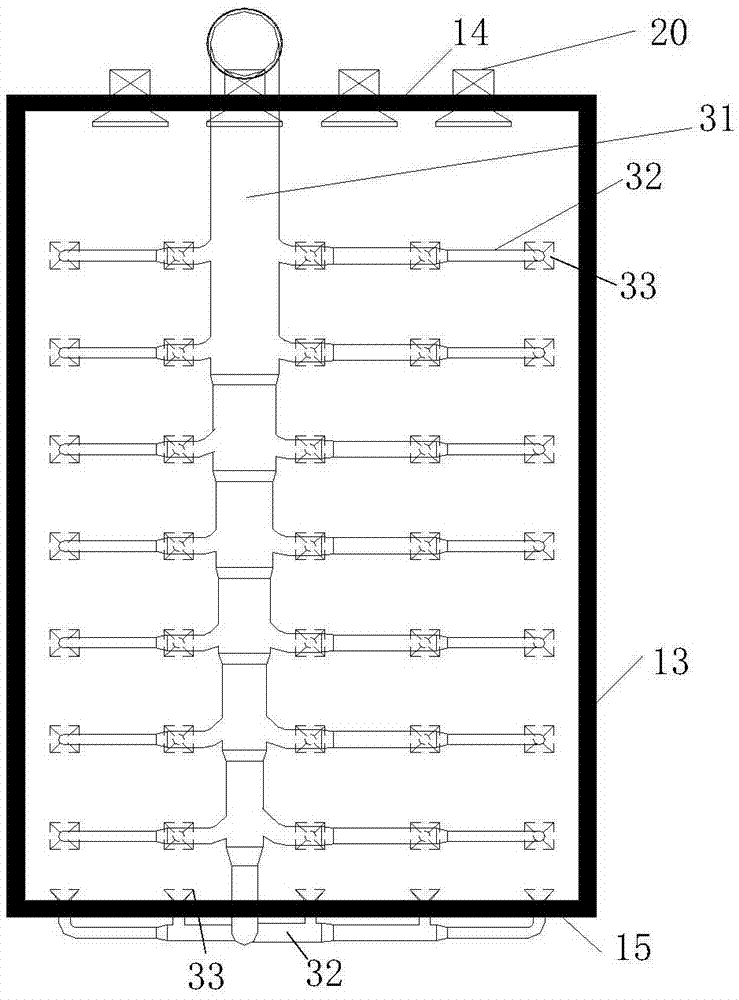

An integrated autonomous air purification device for taking in polluted air, carrying it through the inside of the purification device where it passes through a set of filtering elements (1) that trap the dust particles contained in the air; ultraviolet-light lamps (2) that transform NOX and CO gases in the air into harmless compounds; an activated carbon filter (4) that traps and eliminates the volatile organic compounds and inorganic acidic gases; second filtering elements (5) that carry out a second filtering; and an extraction hood (6) configured to direct the air coming out of the second filtering elements (5) to at least one nozzle (7) that expels the air to the outside of the purification device.

Owner:GINSA ELECTRONICS SL

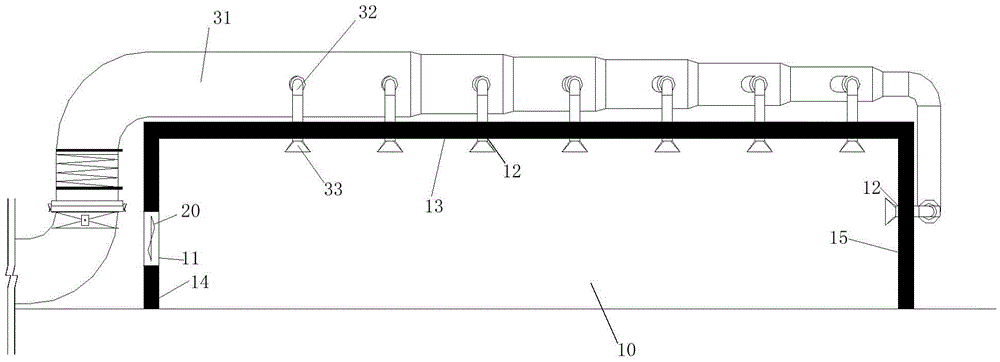

Steel structure spraying system

InactiveCN105436007AReduce pollutionEmission reductionLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention provides a steel structure spraying system. The steel structure spraying system comprises a spraying cabin, an air supply unit, an exhaust unit and a spraying station; the spraying cabin includes a cabin body; multiple air inlets and air outlets are formed in the cabin body; an air supply port of the air supply unit supplies air into the spraying cabin through the air inlets; an air sucking port of the exhaust unit exhausts the air from the spraying cabin through the air outlets; the spraying station is arranged in the spraying cabin, and the height thereof is suitable for a spraying height; and the air supply unit and the exhaust unit guarantee the spraying bin to have needed working air pressure. The steel structure spraying system further comprises a walking unit; the walking unit includes slide rails and slide wheels matched with the slide rails for use; the two slide rails are symmetrically fixed in the boundary of a place to be sprayed; and the multiple slide wheels are fixedly connected with the bottom of a first side plate and the bottom of a second side plate.

Owner:DUOWEI UNION GRP

vitamin b 12 Method for Partially Substituting Production Water for Pleuromutilin Fermentation with Production Wastewater

ActiveCN108913728BReduce manufacturing costAchieving zero emissionsTreatment involving filtrationMicroorganism based processesBiotechnologyUltrafiltration

Owner:HEILONGJIANG LIANSHUN BIOTECHNOLOGY CO LTD

Method for partially replacing water used for fermentation production of tylosin with production wastewater of vitamin B12

The invention relates to a method for partially replacing water used for fermentation production of tylosin with production wastewater of vitamin B12, belonging to a recycling method. According to themethod, production wastewater of vitamin B12 after pretreatment, adsorption treatment, ceramic membrane filtration treatment and ultrafiltration treatment is directly reused in fermentation production of tylosin as water used for production. For the method, the treated production wastewater of vitamin B12 is directly reused in fermentation production of tylosin, thus the zero discharge of the wastewater of vitamin B12 is realized, the environmental pollution index and environmental protection treatment cost are reduced, a reliable basis is provided for the clean industrial production of vitamin B12, meanwhile, the water used for fermentation production of tylosin also can be reduced, thus the production cost of tylosin is reduced, and a guarantee is provided for the sustainable development of tylosin. In the method, the treatment process of the wastewater of vitamin B12 is simple, and the cost is low.

Owner:NINGXIA TAIYICIN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com