Emulsion synthetic fuel oil and manufacturing method thereof

A chemical synthesis and fuel oil technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as inability to ignite, emulsified fuel oil is difficult to ignite, and limit industrial utilization, and achieve the effect of reducing pollution index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

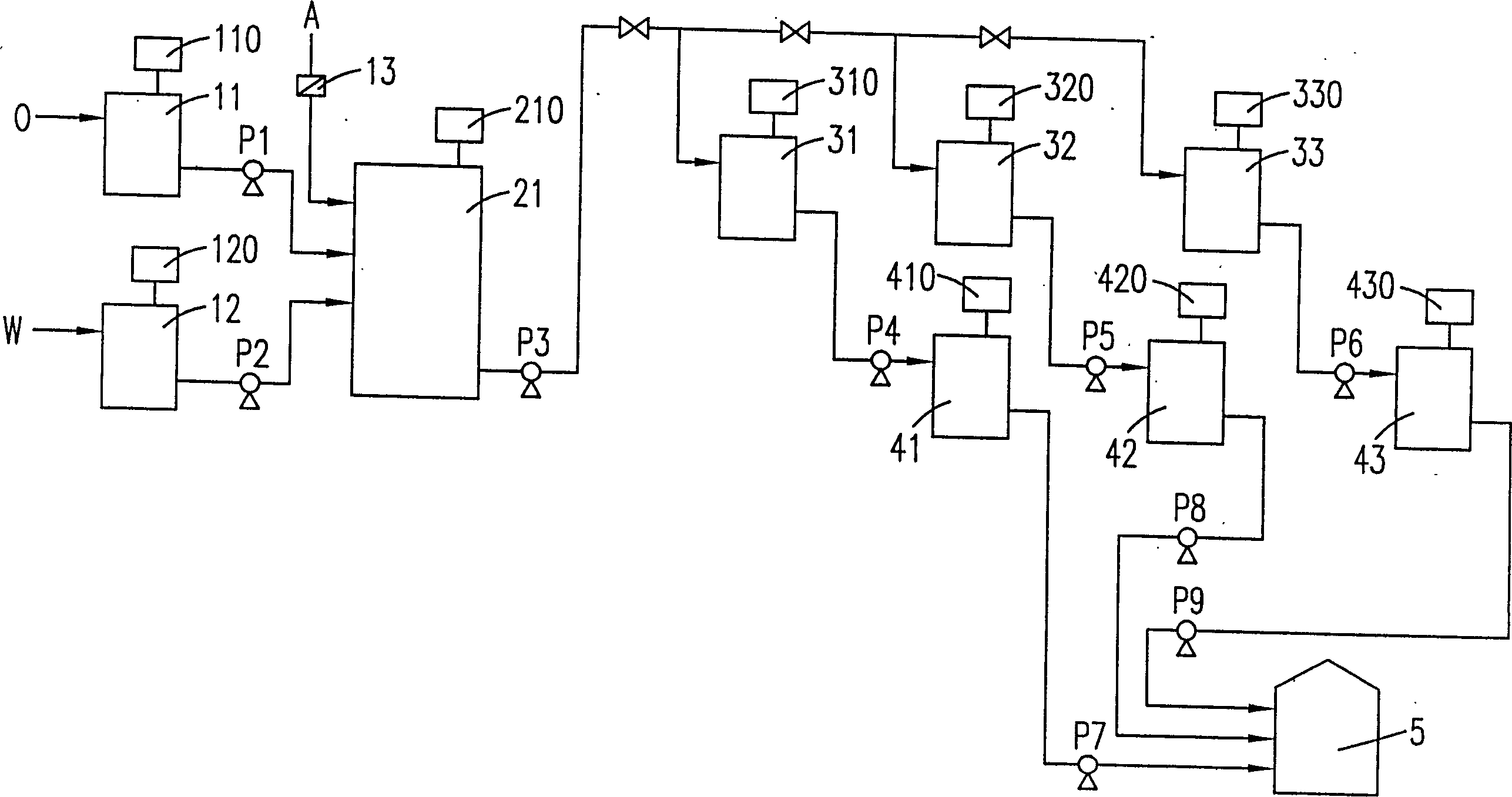

[0032] figure 1 It is a flow chart of producing emulsified synthetic fuel oil in the specific embodiment of the present invention, and the figure relates to fuel oil 0, water W, additive A, heating tank 11, heating tank 12, oil pump P1, water pump P2, oil pumps P3-P9, automatic heating Note equipment 13, preliminary reactor 210, reactors 31, 32 and 33, stirring devices 310, 320 and 330, reactors 41, 42 and 43, stirring devices 410, 420 and 430, and storage tank 5. The device used is designed to produce 1 ton of emulsified synthetic fuel oil in batches, and the production time of each batch is 15-30 minutes. The production process is as follows:

[0033] Send 600 kg of heavy oil O and 400 kg of water W preheated to 40-60°C into the heating tank 11 and the heating tank 12 respectively, and heat the heating tank 11 and the heating tank 12 to 75°C within 10-20 minutes. ~90°C. Wherein the heating tank 11 and the heating tank 12 are heated by steam at a pressure of 5 to 8 atmosphe...

Embodiment 2 to 10

[0040] Except the consumption of heavy oil, water and additive, all the other manufacturing processes are identical with embodiment 1.

[0041] The consumption of heavy oil, water and additive among the embodiment 2 to 10 is as shown in table 1:

[0042] Example

Heavy oil (kg)

water (kg)

Additive (kg)

2

550

450

20

3

550

450

8

4

600

400

12

5

600

400

8

6

600

400

2

7

700

300

6

8

700

300

12

9

800

200

6

10

800

200

14

[0043] The emulsified fuel oil prepared in each of the above Examples 1-10 was measured with a Parr1266 Calorimeter microcomputer calorimeter to measure its calorific value, and the results are shown in Table 2.

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com