Patents

Literature

104 results about "Emulsified fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsified Fuels are emulsions composed of water and a combustible liquid, either oil or a fuel. Emulsions are a particular example of a dispersion comprising a continuous and a dispersed phase. Most commonly used emulsion fuel is water-in-diesel emulsion. In the case of emulsions both phases are the immiscible liquids, oil and water. Emulsion fuels can be either a microemulsion or an ordinary emulsion (sometimes referred to as macroemulsion, to differentiate them from microemulsions). The essential differences between the two are stability (microemulsions are thermodynamically stable systems, whereas macroemulsions are kinetically stabilized) and particle size distribution (microemulsions are formed spontaneously and have dimensions of 10 to 200 nm, whereas macroemulsions are formed by a shearing process and have dimensions of 100 nm to over 1 micrometer). Microemulsions are isotropic whereas macroemulsions are prone to settling (or creaming) and changes in particle size over time. Both use surfactants (also called emulsifiers) and can be either water-in-oil (invert emulsions), or oil-in-water (regular emulsions) or bicontinuous (also called multiple or complex emulsions).

Emulsified fuels and engine oil synergy

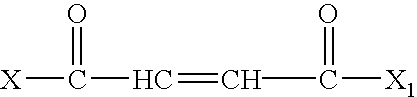

InactiveUS20050039381A1Emission reductionLimited wear protectionLiquid carbonaceous fuelsAdditivesParticulatesNitrogen oxides

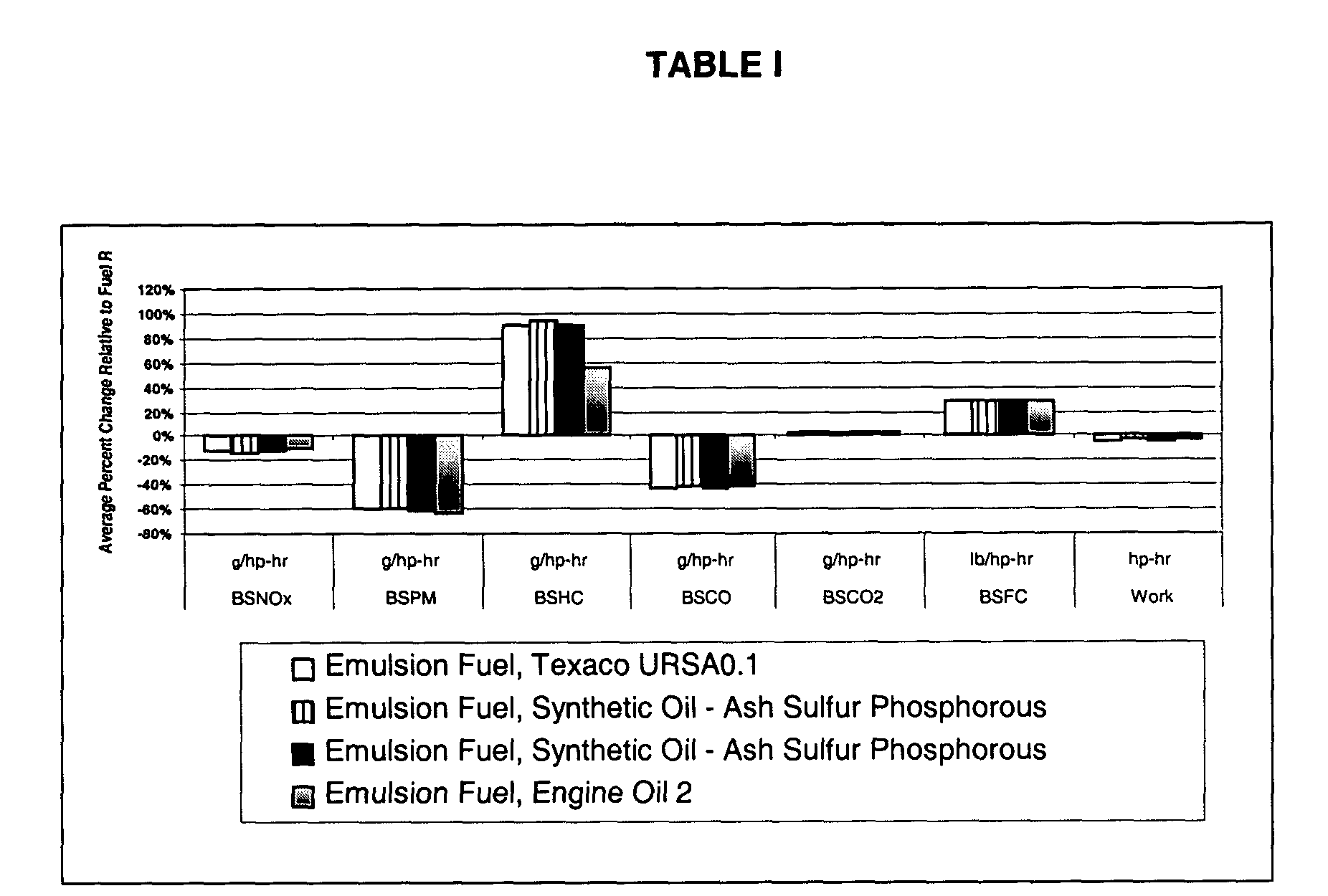

The invention relates to the use of an emulsified fuel in combination with an engine oil that shows a synergistic effect in reducing emissions such as particulate matter, hydrocarbons and / or nitrogen oxides (NO, NO2, N2O, collectively NOx) and / or reducing wear from an engine.

Owner:THE LUBRIZOL CORP

Emulsified fuels and engine oil synergy

InactiveUS7413583B2Emission reductionReduces soluble organic fraction fractionNon-fuel substance addition to fuelEngine operationsParticulatesNitrogen oxide

Owner:THE LUBRIZOL CORP

Method of Controlling a Combustor for a Gas Turbine

A method of controlling a combustor of a gas turbine is disclosed. The method includes operatively disposing a combustor can in a combustor of a gas turbine. The combustor can comprising a plurality of combustor fuel nozzles, each having a fuel injector and configured to selectively provide a liquid fuel, a liquid fluid or liquid fuel and liquid fluid to a fuel injector nozzle that is configured to provide, respectively, a plurality of liquid fuel jets, a plurality of liquid fluid jets or a combination thereof, that are in turn configured to provide an atomized liquid fuel stream, an atomized liquid fluid stream, or an atomized and emulsified liquid fuel-liquid fluid stream, respectively. The method also includes selectively providing an amount of fuel, fluid or a combination thereof to the fuel injector nozzle to produce an atomized fuel stream, atomized fluid stream, or an atomized and emulsified fuel-fluid stream, respectively.

Owner:GENERAL ELECTRIC CO

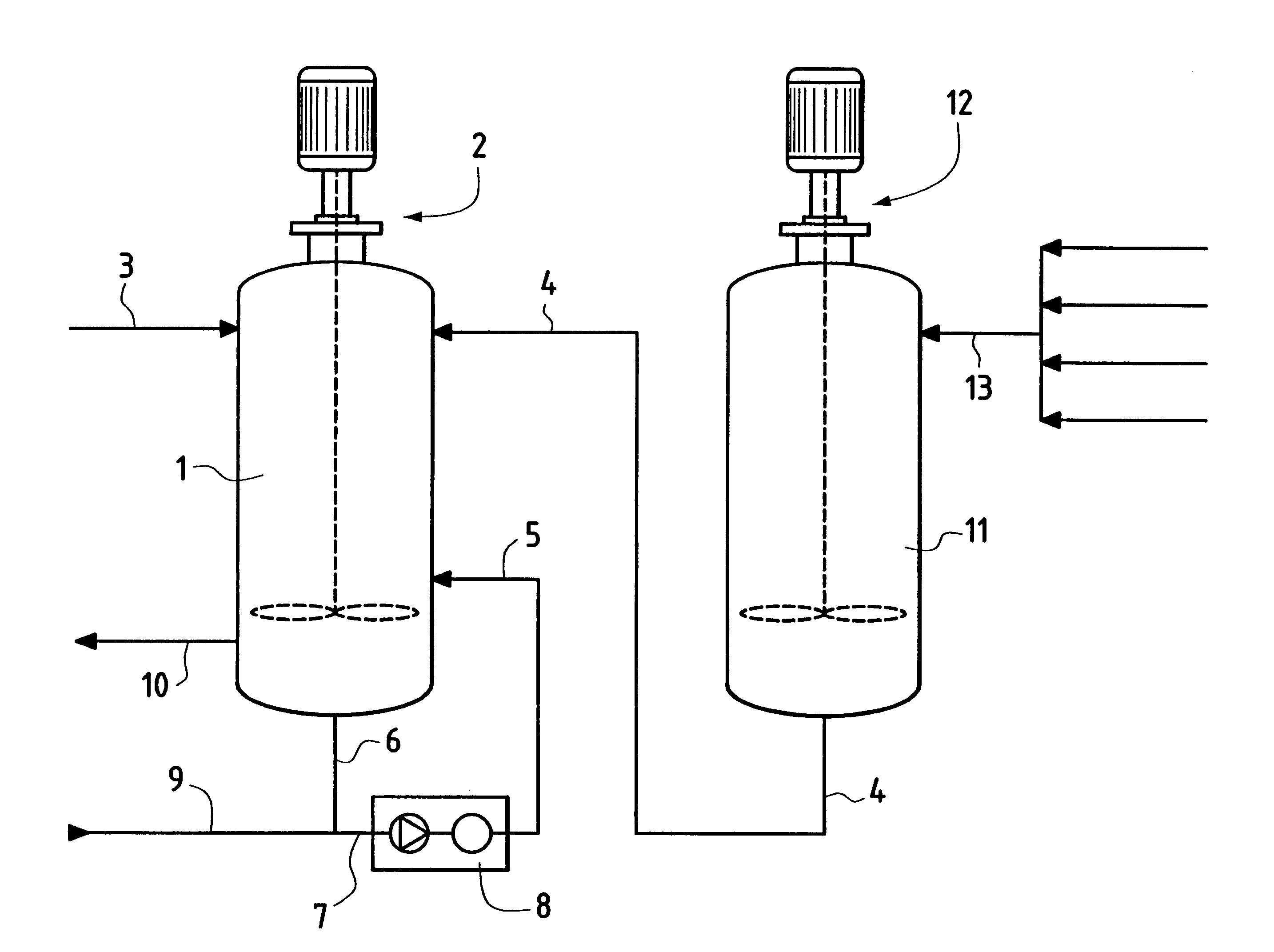

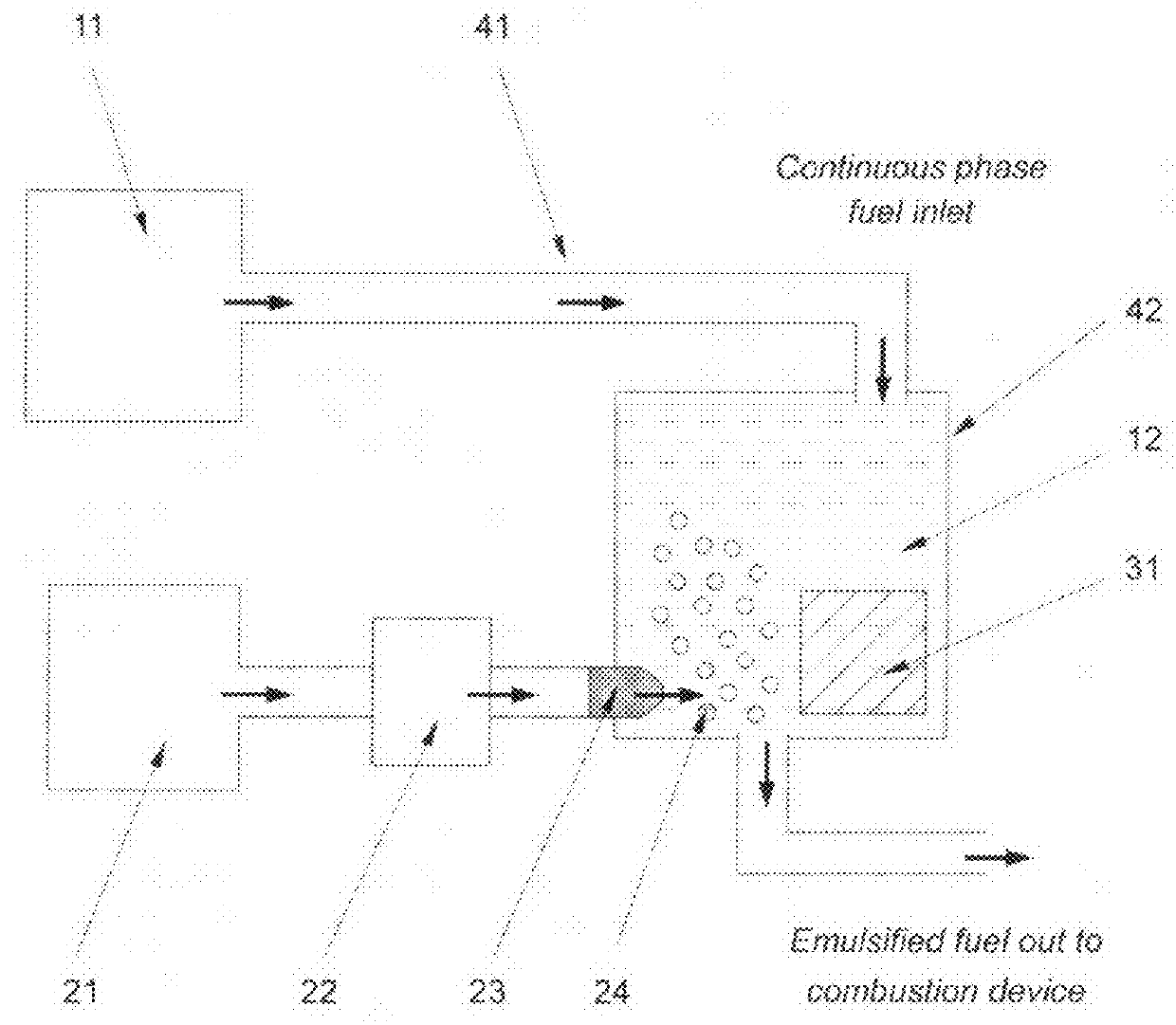

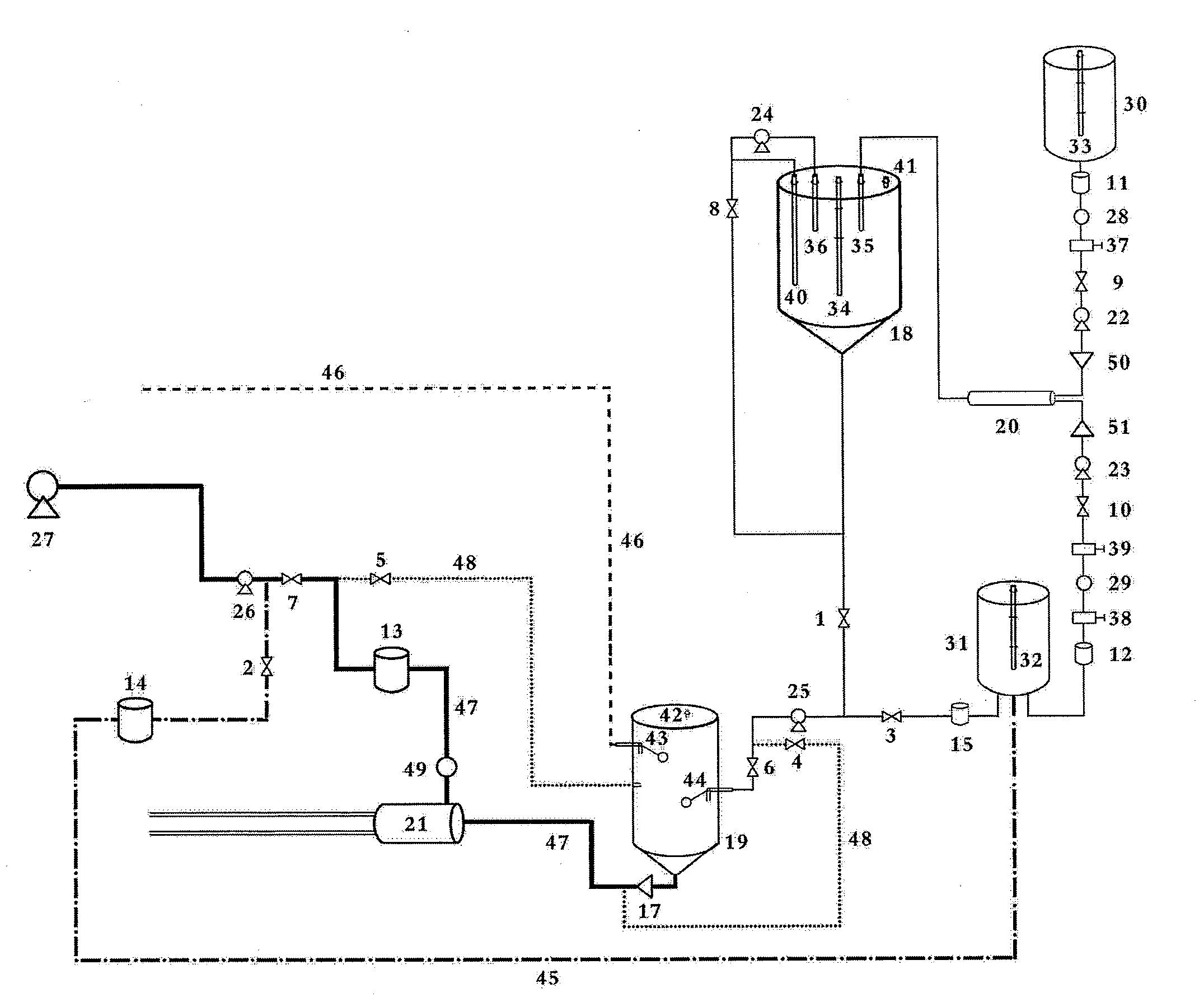

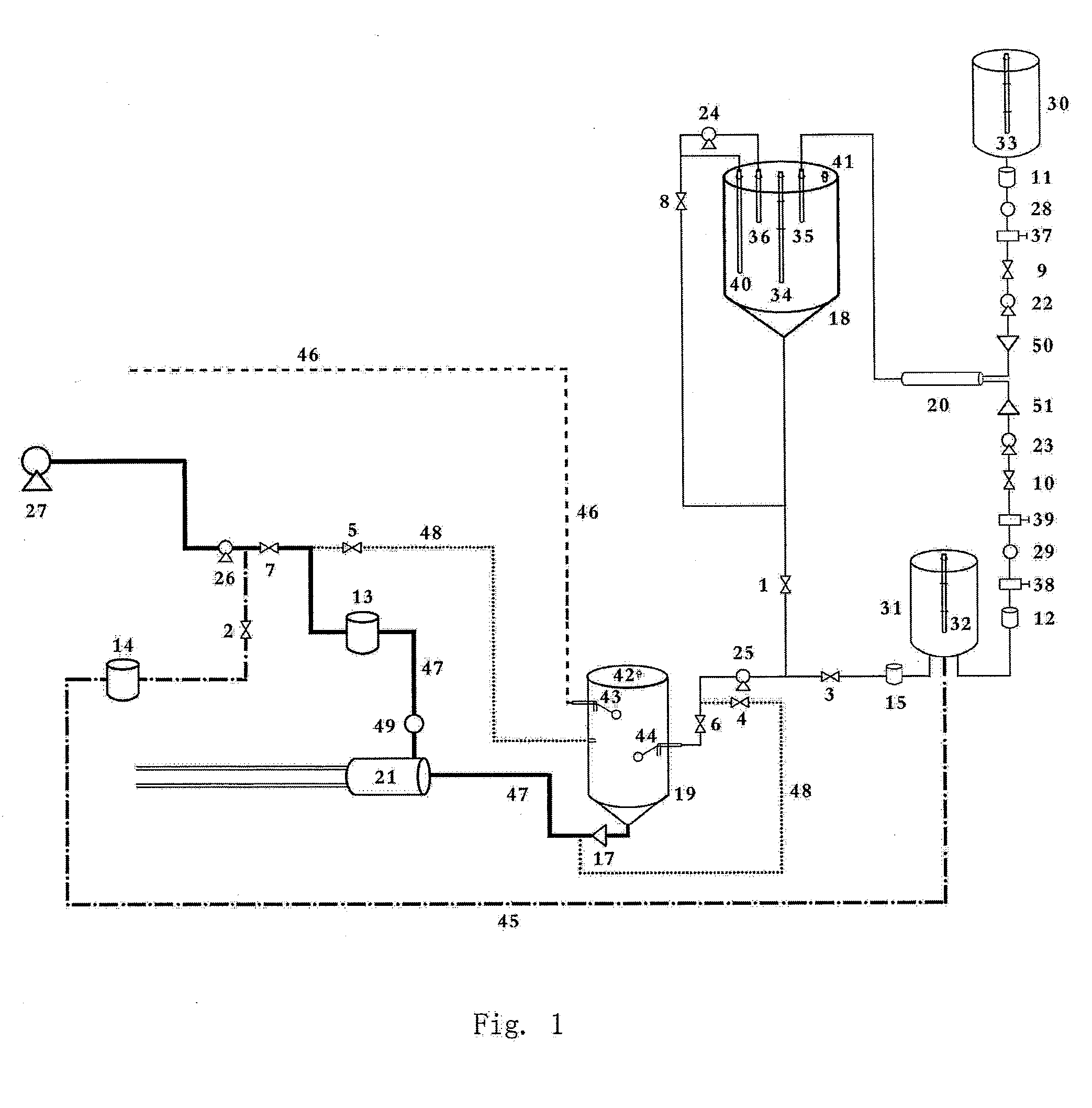

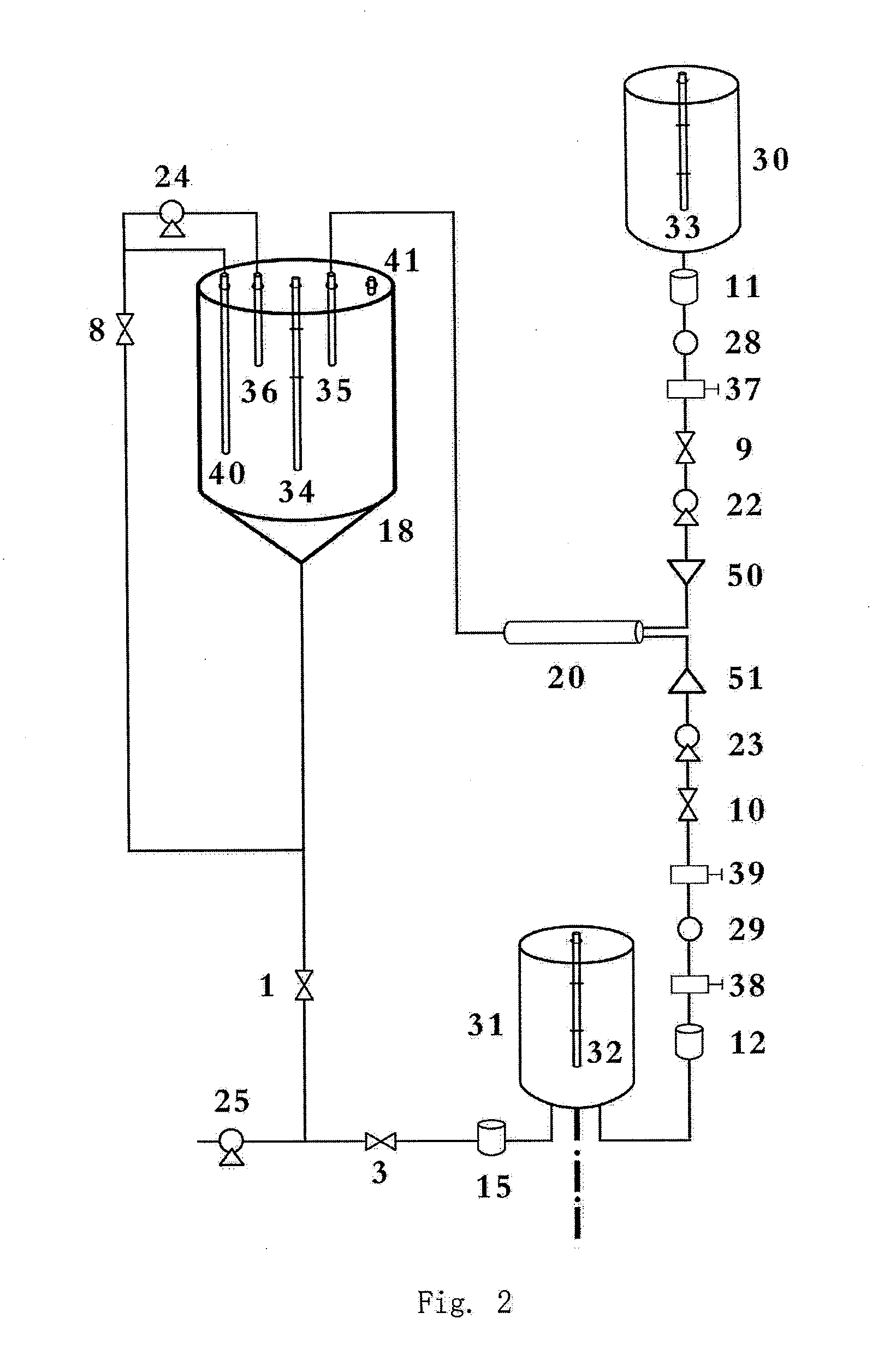

Method for preparing an emulsified fuel and implementing device

InactiveUS6589301B1Avoid water pollutionReduce exhaust emissionsFlow mixersTransportation and packagingEngineeringEmulsified fuel

A process and apparatus for industrial-scale preparation of an emulsified fuel including a water phase in a continuous organic phase which contains less than 20% by volume of water, and at least one additive necessary for forming the emulsified fuel. The fuel is formed by mixing and homogenizing the organic phase and the additives, forming a volume V, inside an homogenization tank with internal circulation rate Qc, such that Qc / V>=100 h-1, circulating the homogenized fluid in a branch loop emerging from the tank at a rate Qcirc, and through at least one emulsifying system located on said loop, at a rate such that 0 h<V / Qcirc<=2 h, feeding the aqueous phase into the branch loop upstream of the emulsifying system, and maintaining the homogenization in the tank and the circulation of the liquid in the branch loop until the emulsion acquires a desired characteristic of storage stability.

Owner:ELF FRANCE

Method of forming and combusting water-in-fuel oil emulsion

InactiveUS6066186AImprove thermal efficiencyReduce expensesOther chemical processesMixing methodsPollutant emissionsWater in oil emulsion

A method of forming particles of capsularized emulsion fuel with high combustion efficiency and low pollutant emission. The method includes the steps of preparing an emulsion fuel oil and disperse phase of water generally uniformly distributed and suspended in the dispersion medium of oil, and spraying the emulsion fuel oil into minute particles so that substantially each of the particles has a core encapsulated by fuel oil. The emulsion fuel oil includes an emulsifying additive solution essentially consisting of NaOH, CaCl2 and water in a weight ratio ranging from about 10:10:100 to about 50:50:100 and a mixture of water and oil. The mixture of water and oil has an exemplified weight ratio ranging from about 5:95 to about 30:70. In the emulsion fuel oil, an example of a weight ratio of the mixture of oil and water and the emulsifying additive solution ranges from about 1:0.003 to about 1:0.002.

Owner:GOS

Method for preparing micro-emulsified procetane

InactiveCN102250656AImprove physical and chemical propertiesEasy to useLiquid carbonaceous fuelsAlkylphenolPolyethylene glycol

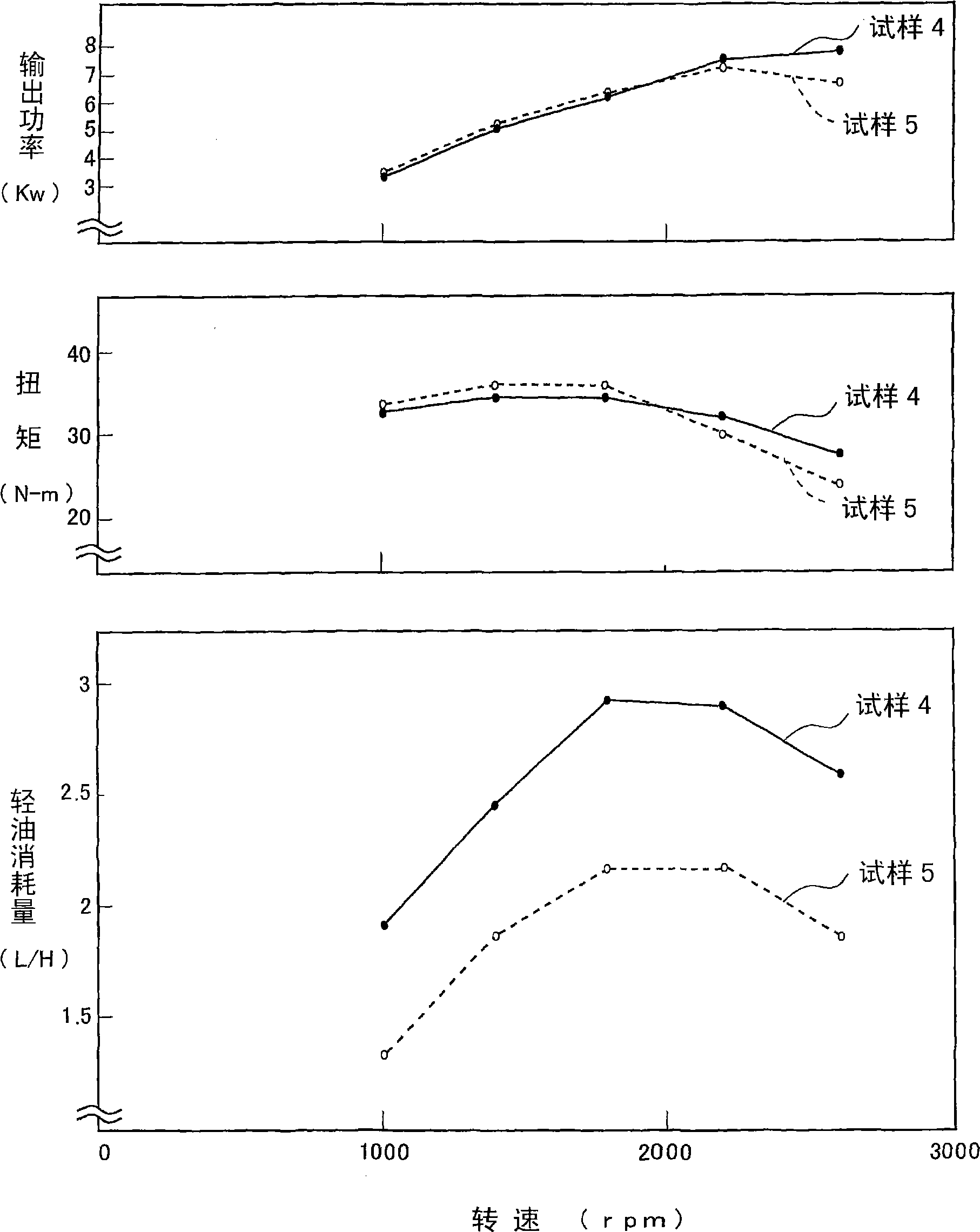

The invention provides a method for preparing a micro-emulsified procetane. The method comprises the following steps of: selecting the following components in percentage by weight: 60% of oleic acid, 10% of naphthenic acid, 6% of ethanolamine, 2% of triethanolamine, 7% of cyclohexylamine, 3% of n-butyl alcohol, 3% of isopropanol, 2% of Span-80, 0.5% of Span-20, 0.5% of polyethylene glycol, 2% of alkylphenol polyoxyethylene ether OP4, 0.5% of alkylphenol polyoxyethylene ether OP10 and 3.5% of conditioning agent; agitating the mixture at room temperature and normal pressure for 40-60 minutes toprepare the micro-emulsified procetane. By using the method provided by the invention, the physicochemical performance and use effects of the emulsified fuel gas are improved and energy is saved by more than 30%; the exhaust gas purification rate is more than 30-60%, the cost is reduced by more than 15-20% and the dynamic performance and the oil consumption of the micro-emulsified procetane have little difference from those of pure diesel oil.

Owner:QUANZHOU XINRAN ENVIRONMENTAL PROTECTION ENERGY

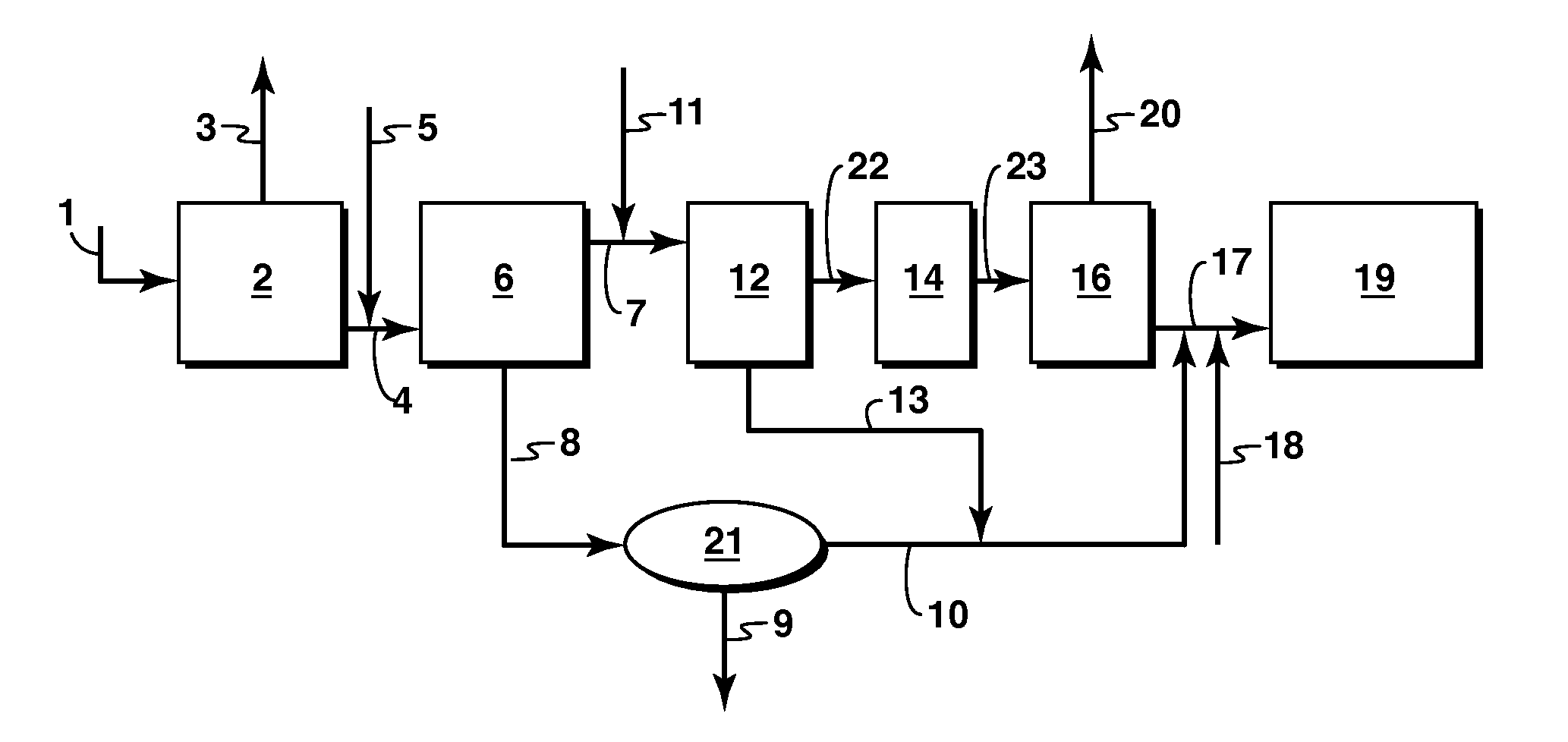

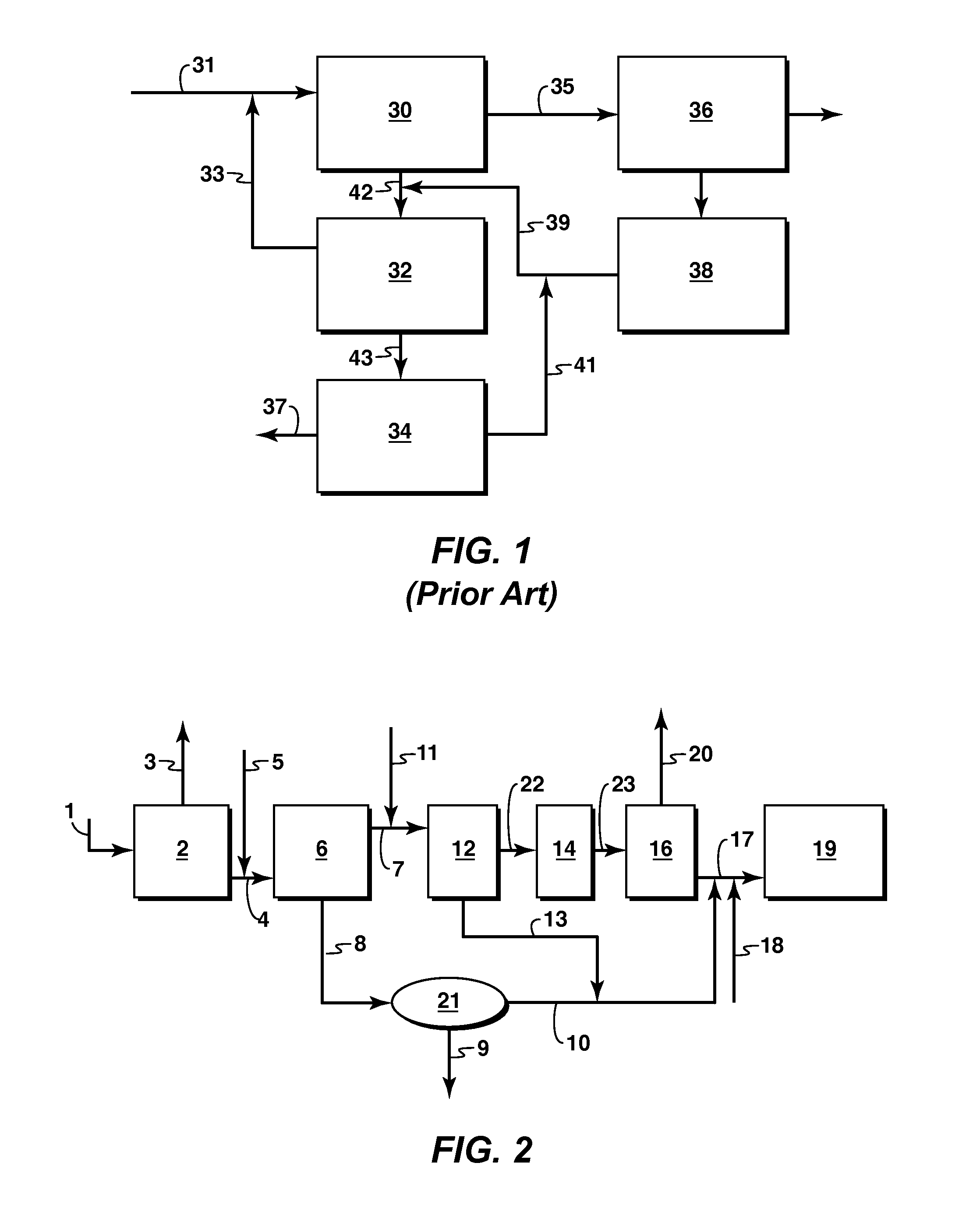

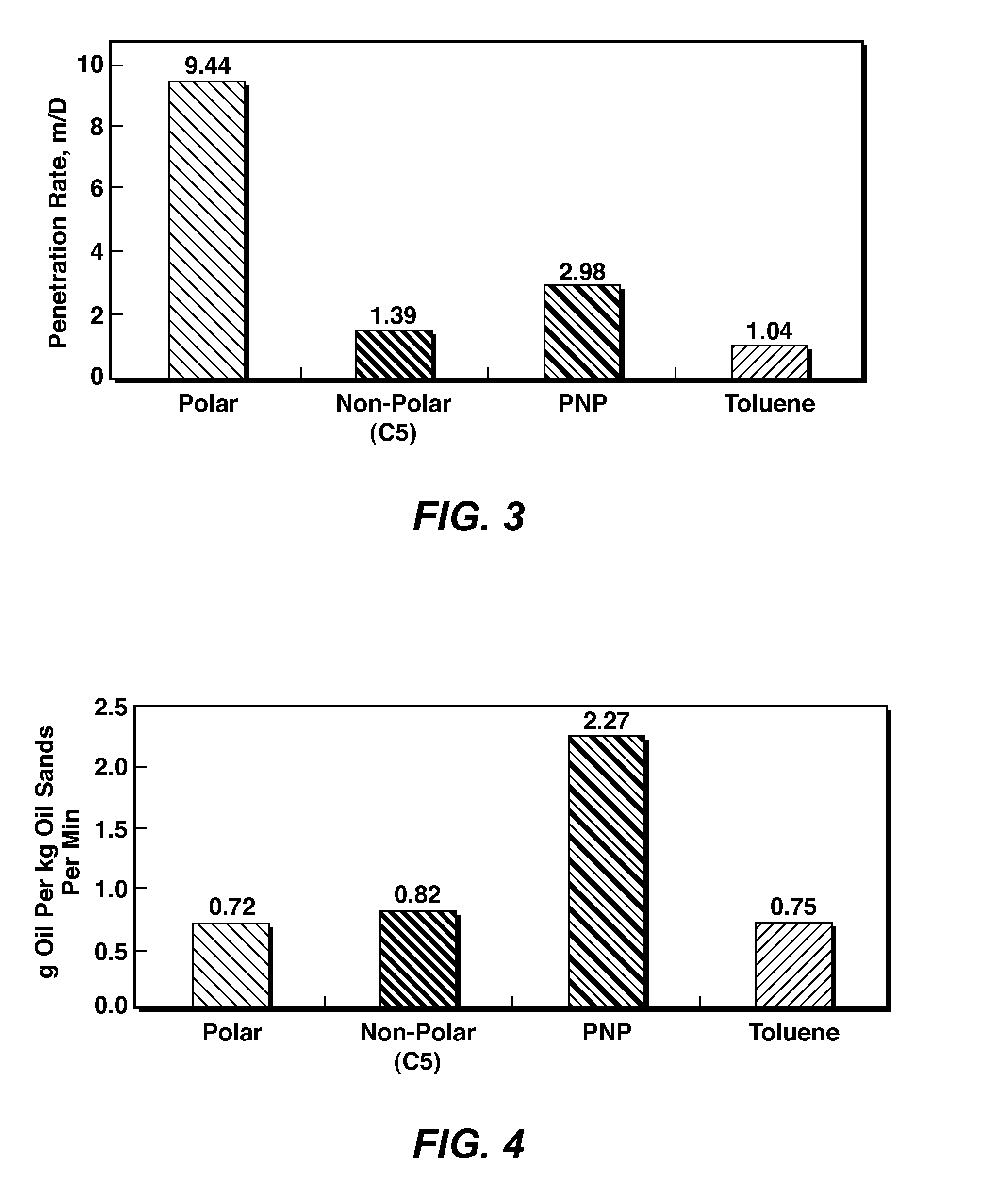

Method And System For Reclaiming Waste Hydrocarbon From Tailings Using Solvent Sequencing

InactiveUS20110210044A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxFroth flotation

A method and system for extracting hydrocarbon products from waste tailings of a froth flotation unit and a paraffinic froth treatment process are provided. Bitumen and asphaltenes from the waste tailings are extracted using a serial addition of an aromatic solvent, followed by a polar-non-polar solvent. The method and system divert valuable hydrocarbons from tailings ponds. The hydrocarbon product can be used as a coating material or an emulsion fuel, for example.

Owner:EXXONMOBIL UPSTREAM RES CO

High-performance low-cost environment-friendly porous granular ammonium nitrate-fuel oil explosive and preparation method thereof

InactiveCN103382143AImprove mixing uniformityGood explosive performanceExplosivesExplosive AgentsProcess engineering

The invention discloses a high-performance low-cost environment-friendly porous granular ammonium nitrate-fuel oil explosive and a preparation method thereof. The high-performance low-cost environment-friendly porous granular ammonium nitrate-fuel oil explosive comprises, by mass: 90 to 97% of porous granular ammonium nitrate, and 3 to 10% of a micro-emulsified fuel oil or emulsified fuel oil. The micro-emulsified fuel oil or the emulsified fuel oil is composed of a fuel oil, an emulsifier and a solvent; the high-performance low-cost environment-friendly porous granular ammonium nitrate-fuel oil explosive is prepared by mixing the micro-emulsified fuel oil or the emulsified fuel oil with porous granular ammonium nitrate. The porous granular ammonium nitrate-fuel oil explosive possesses excellent explosive performance and environmental protection performance, and is low in production cost.

Owner:NEW RESOURCES SHANGHAI ENVIRONMENTAL PROTECTIONTECH CO LTD

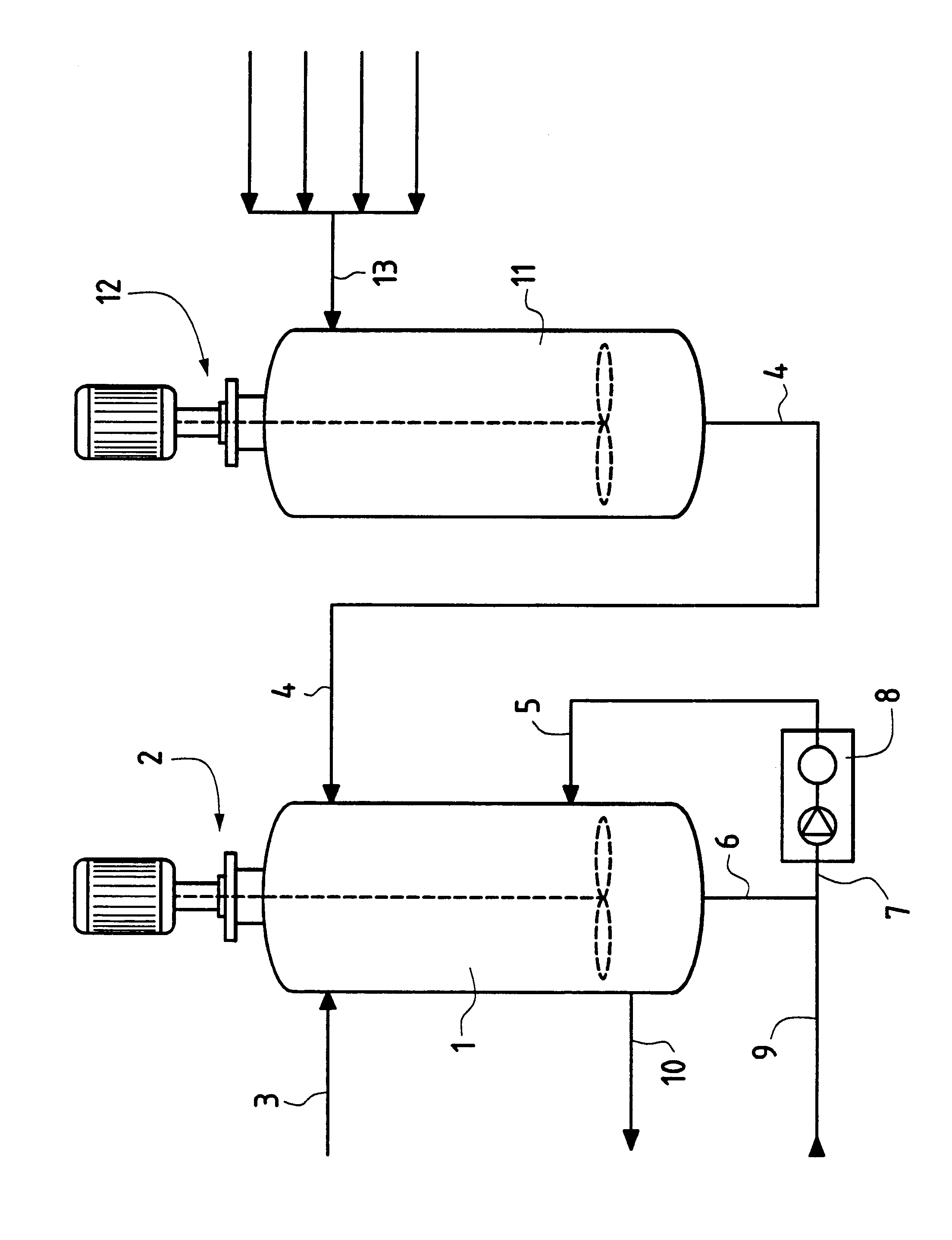

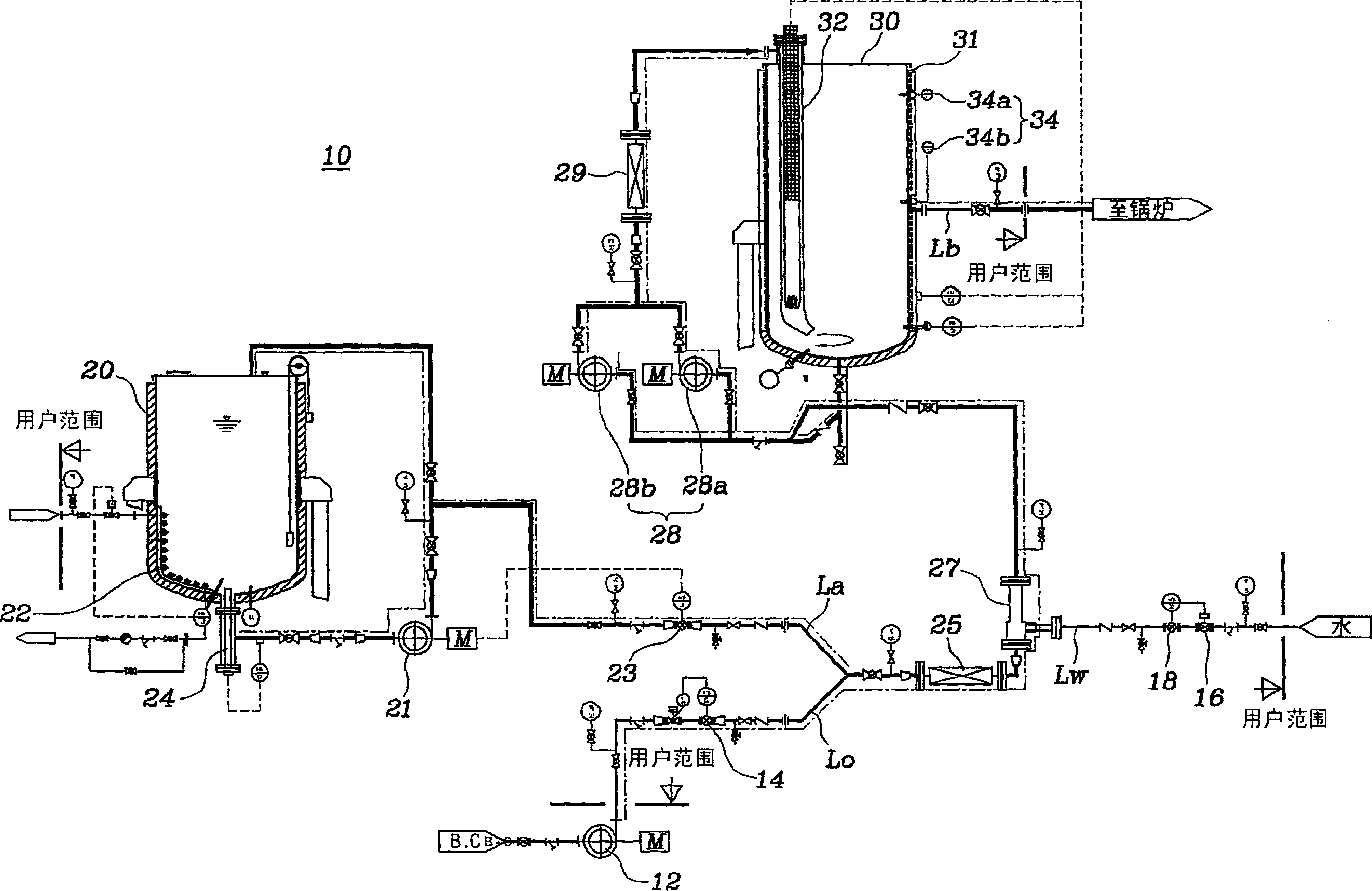

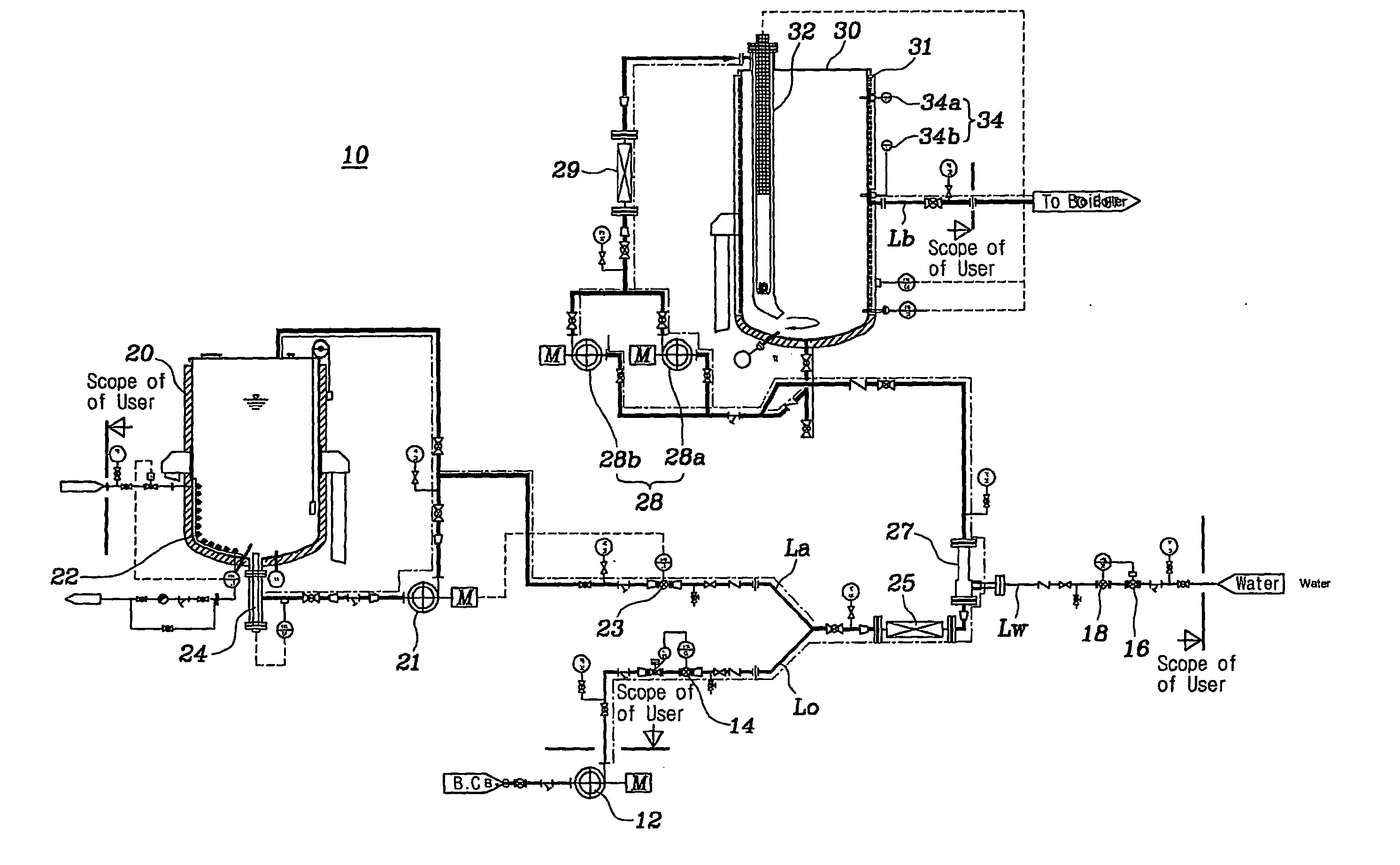

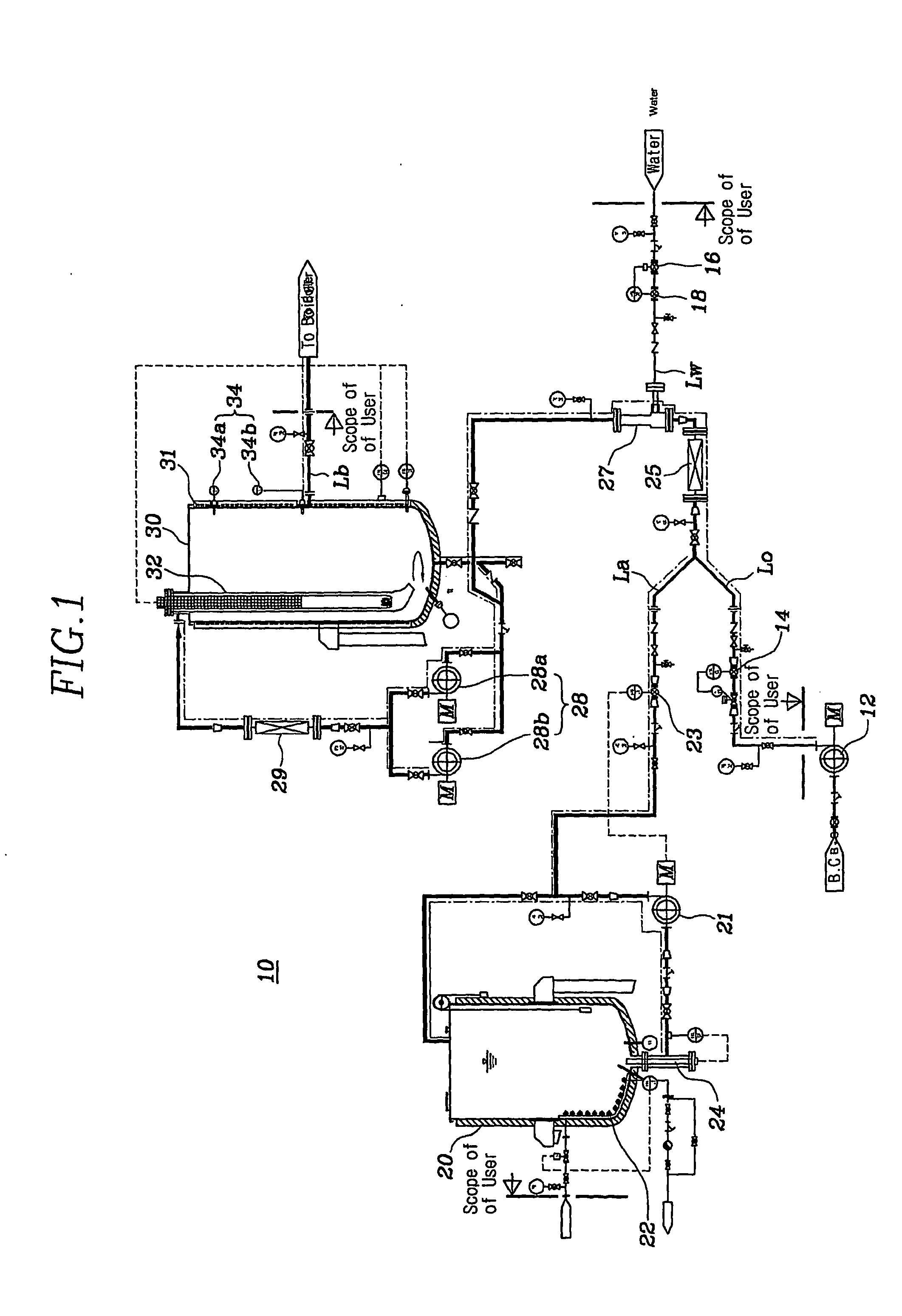

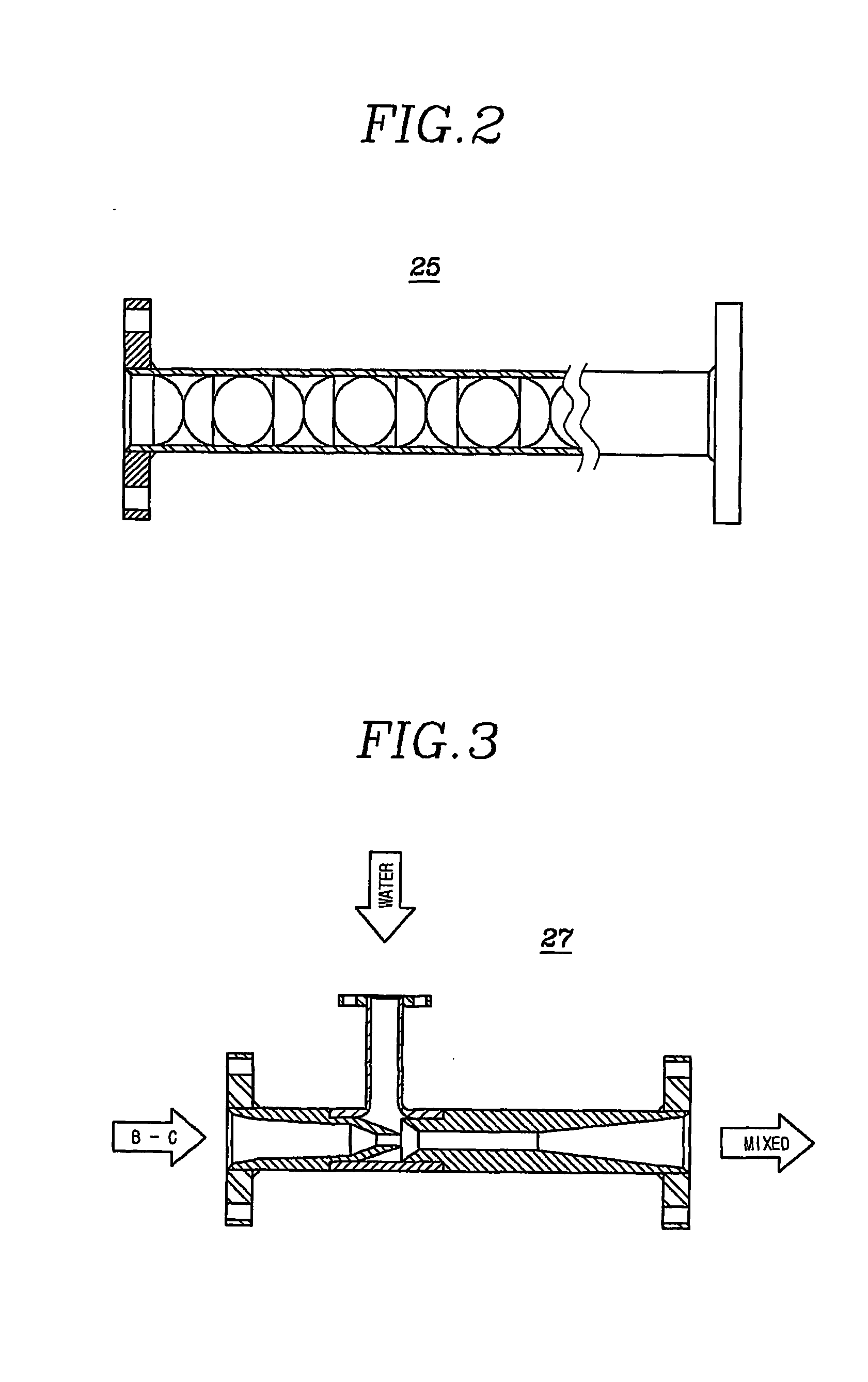

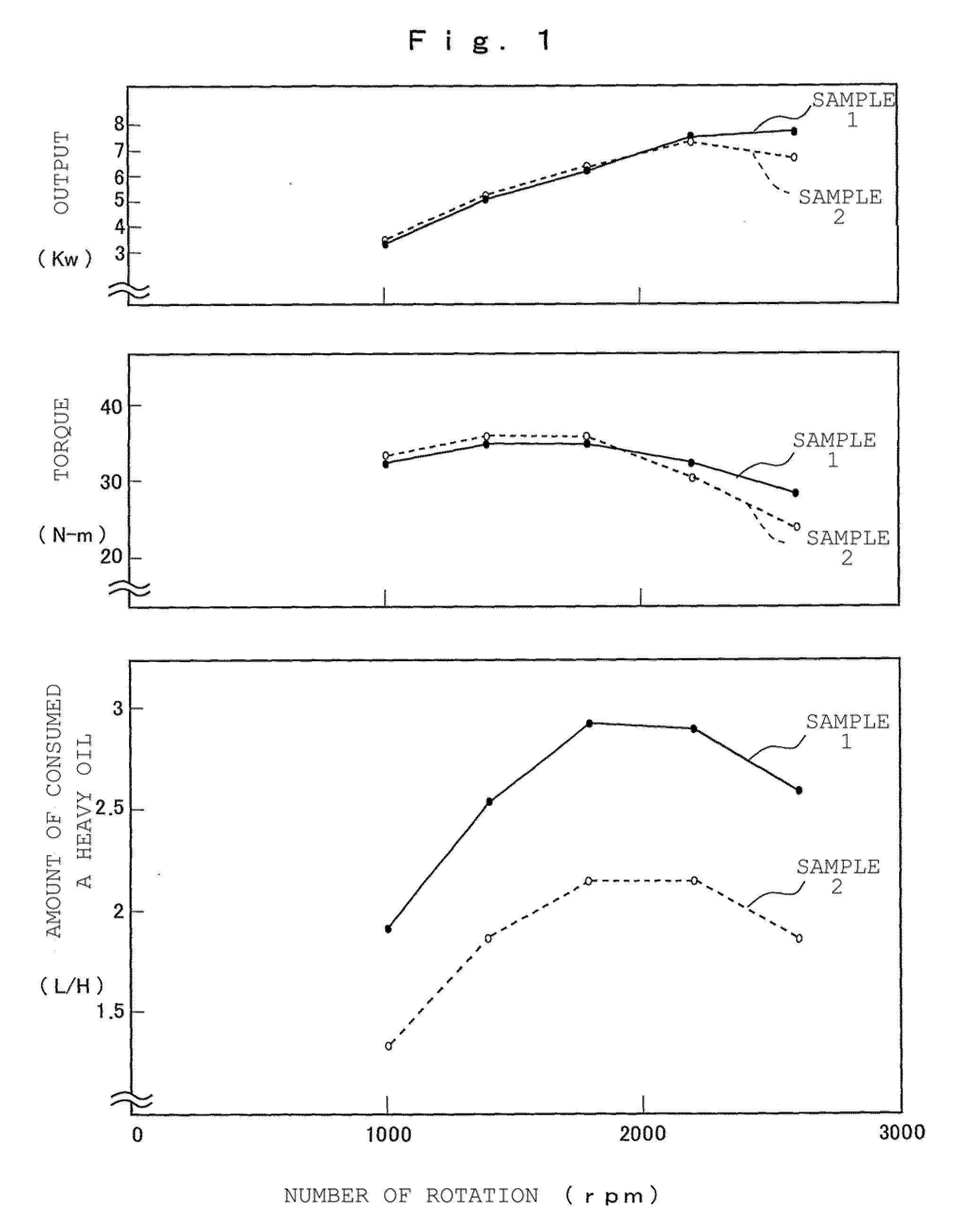

Apparatus for producing water-in-oil emulsified fuel and supplying the same

InactiveCN1694946AReduce operating costsLow costFlow mixersTransportation and packagingProcess engineeringEmulsified fuel

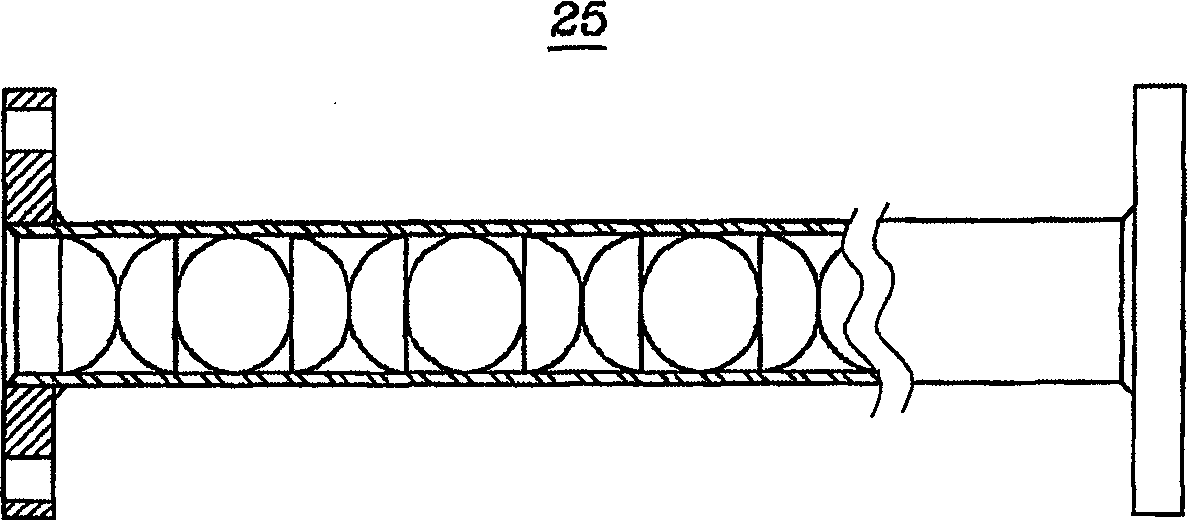

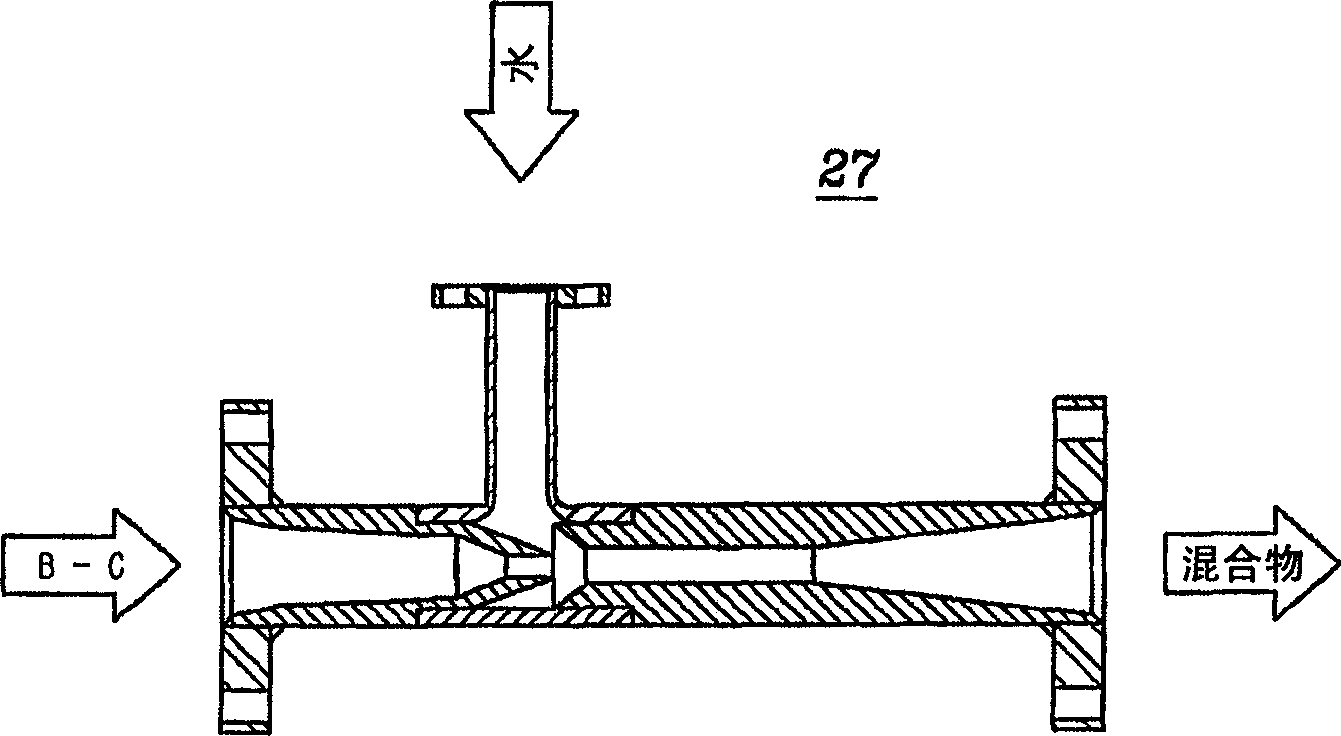

The present invention relates to an apparatus for producing and supplying water-in-oil emulsified fuel that supplies to a boiler water-in-oil emulsified fuel, which is emulsified by mixing an emulsifier and water in crude oil such as bunker C oil or bunker A oil. The apparatus for producing and supplying water-in-oil emulsified fuel includes an additive storage tank for storing an emulsifier; an emulsion tank for storing water-in-oil emulsified; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion. The second mixing section is realized through a circulation system that includes an emulsion tank, a mixer pump, and a double mixer. Following the supply of a predetermined amount of the raw materials, emulsified fuel mixed in the circulation system is continuously circulated even if raw material supply is stopped such that emulsified fuel that is always in a uniform state is supplied while maintaining a predetermined ratio, a predetermined moisture particle state, and a predetermined temperature.

Owner:朴吉远

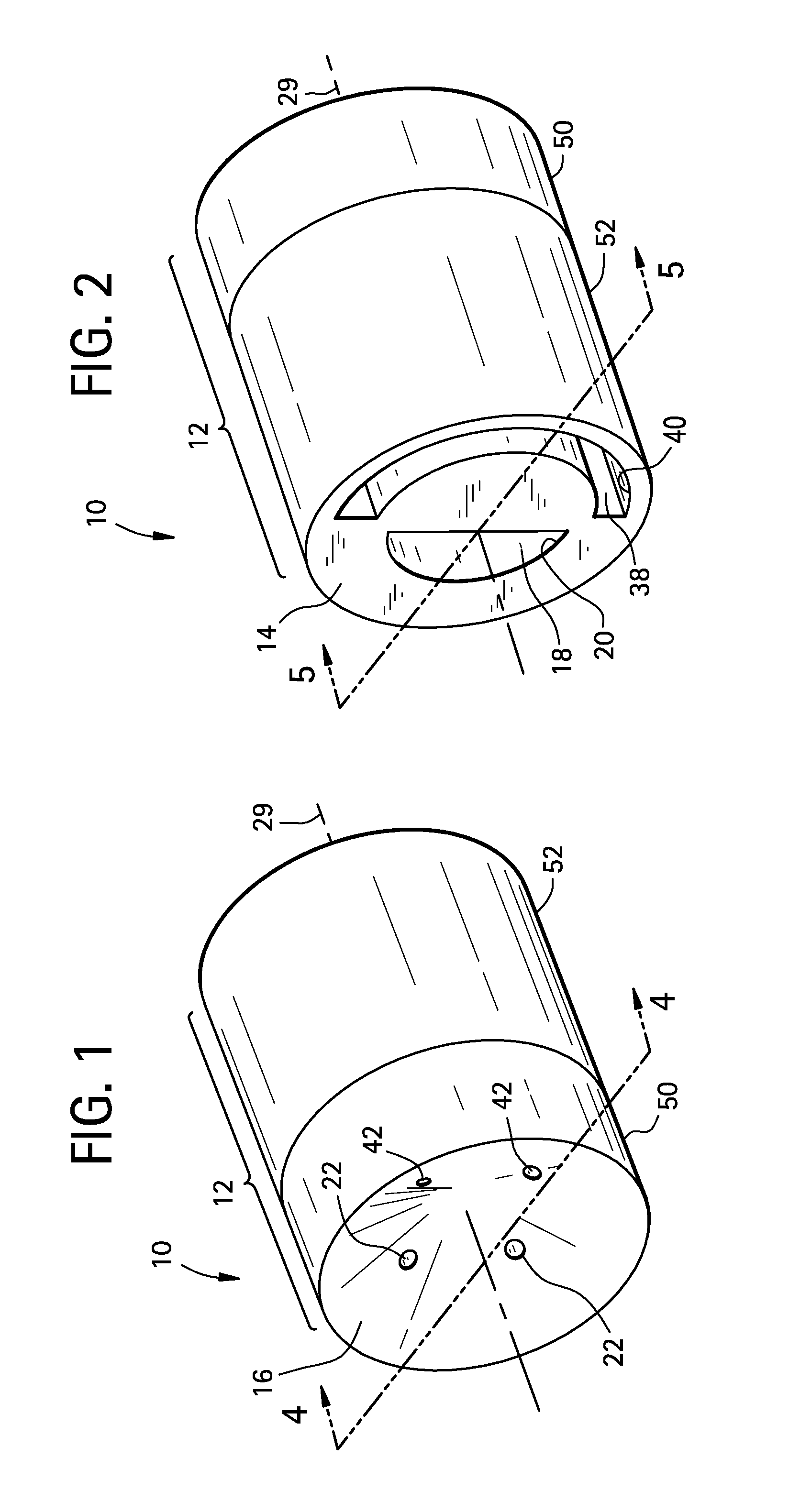

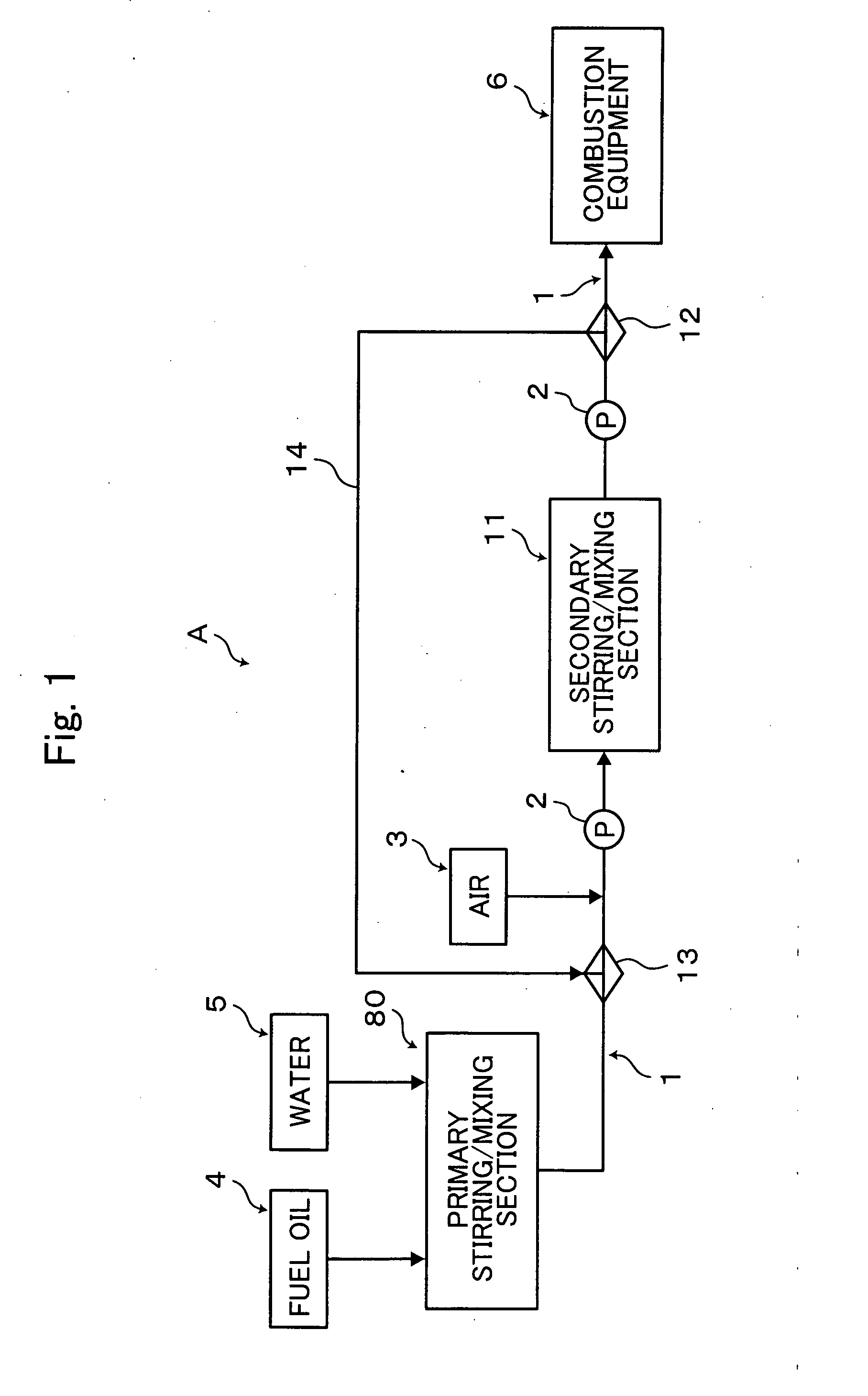

Emulsion fuel and process and equipment for the production of the same

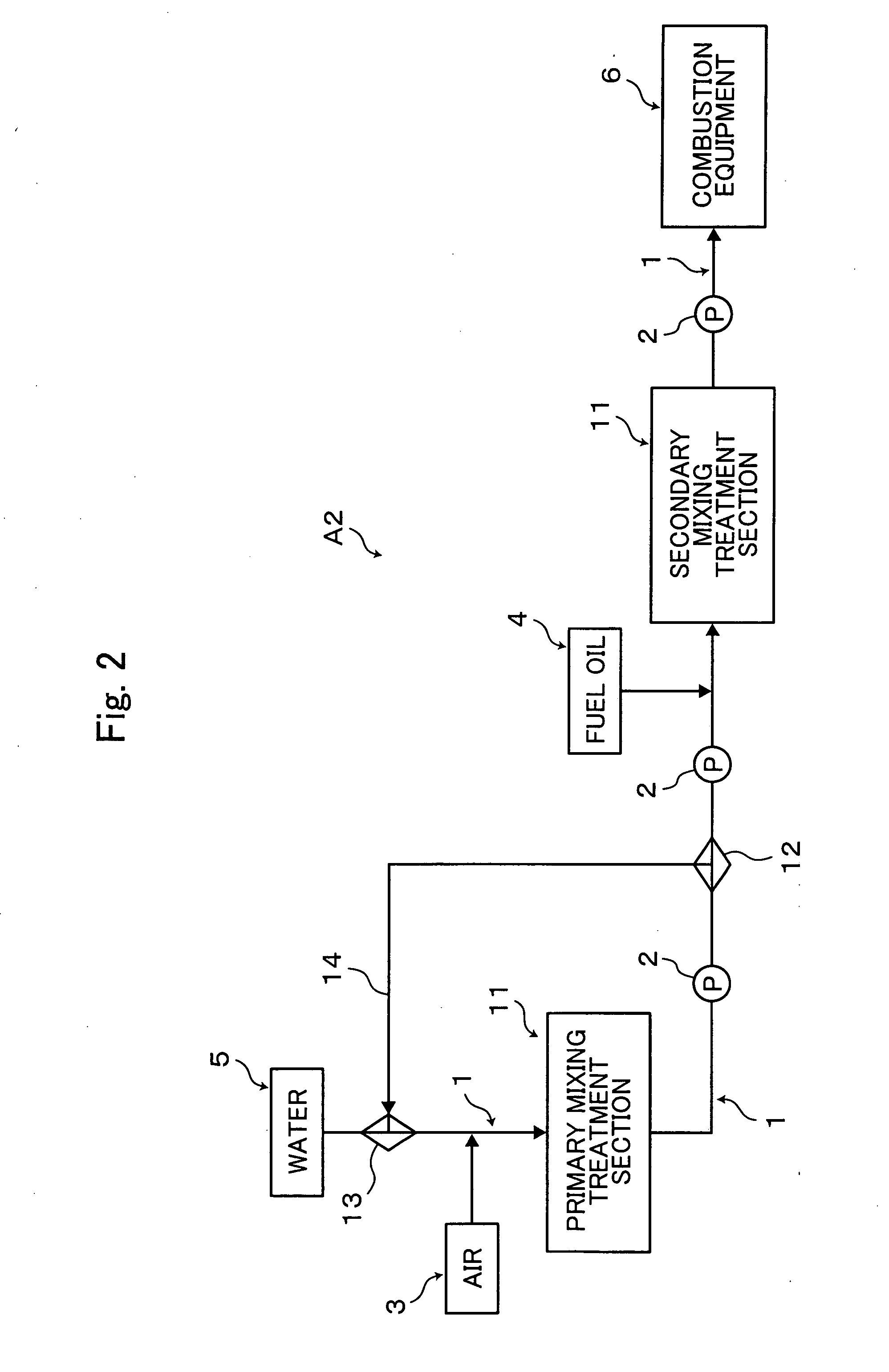

InactiveUS20100236134A1Improve surface activityPrevent coalescenceLiquid fuel feeder/distributionNon-fuel substance addition to fuelEngineeringFuel oil

An emulsion fuel is provided which is usable as a fuel for combusting an internal combustion engine under an appropriate combustion condition. A slight amount of air is added to, and is mixed with, a liquid mixture between a fuel oil as a continuous phase and water as a dispersed phase. In this manner, since air bubbles reduced in buoyancy is hydrophobic, the air bubbles do not adhere the surfaces of water droplets, and are dispersed in the fuel oil, increasing a gas-liquid interfacial area (combustion surface area) and exerting surface activity (similar to the function of a surfactant) due to electrostatic polarization. This makes it possible to prevent the coalescence of fine water droplets and stabilize the water droplets in the emulsion fuel. As a result, in the emulsion fuel, dispersion of water droplet diameters is homogenized, and even if the emulsion fuel is combusted by means of combustion equipment, for example, good combustion efficiency can be ensured, and further, a disadvantage that soot or black smoke is generated can be eliminated.

Owner:MG GROW UP CORP +1

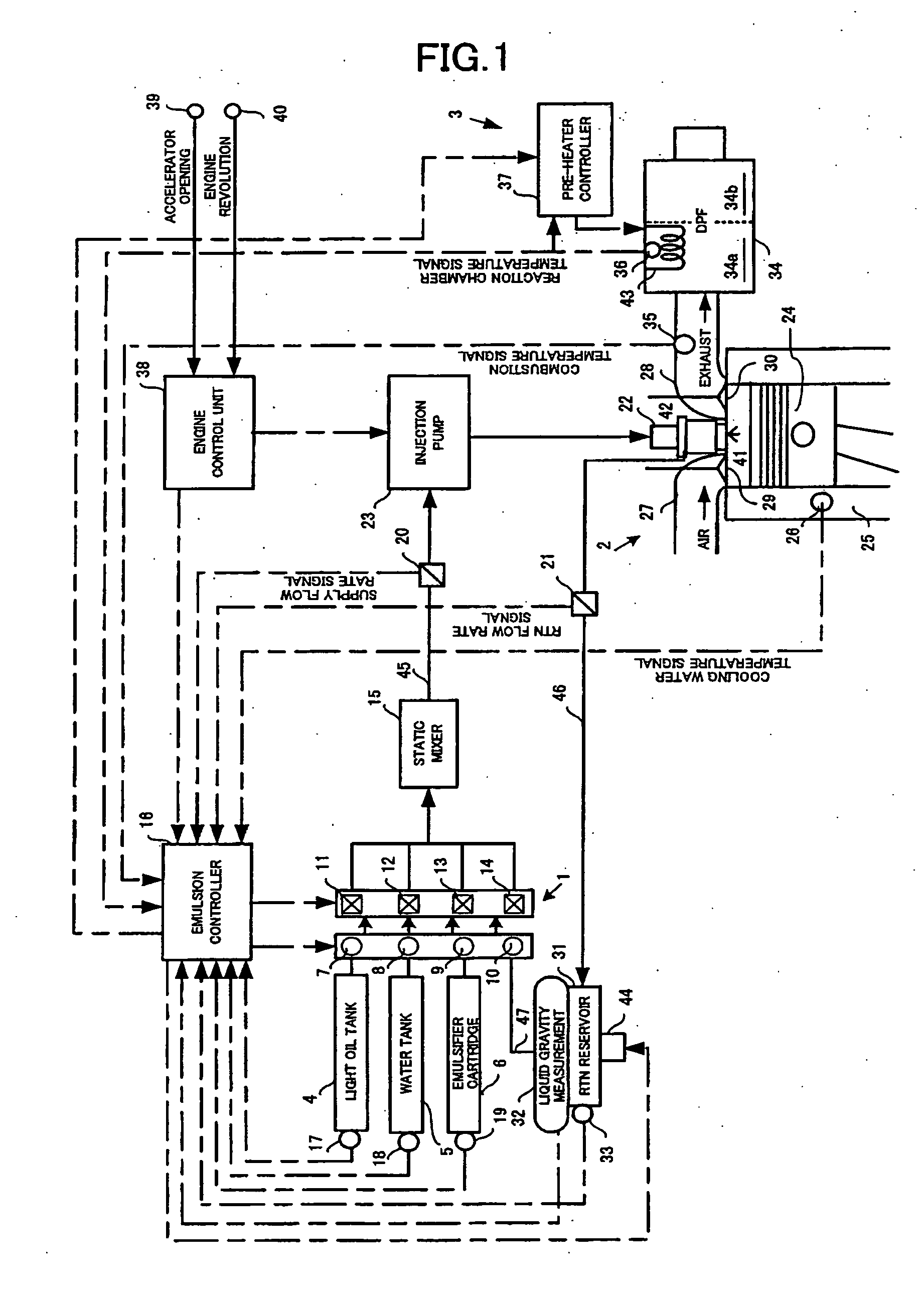

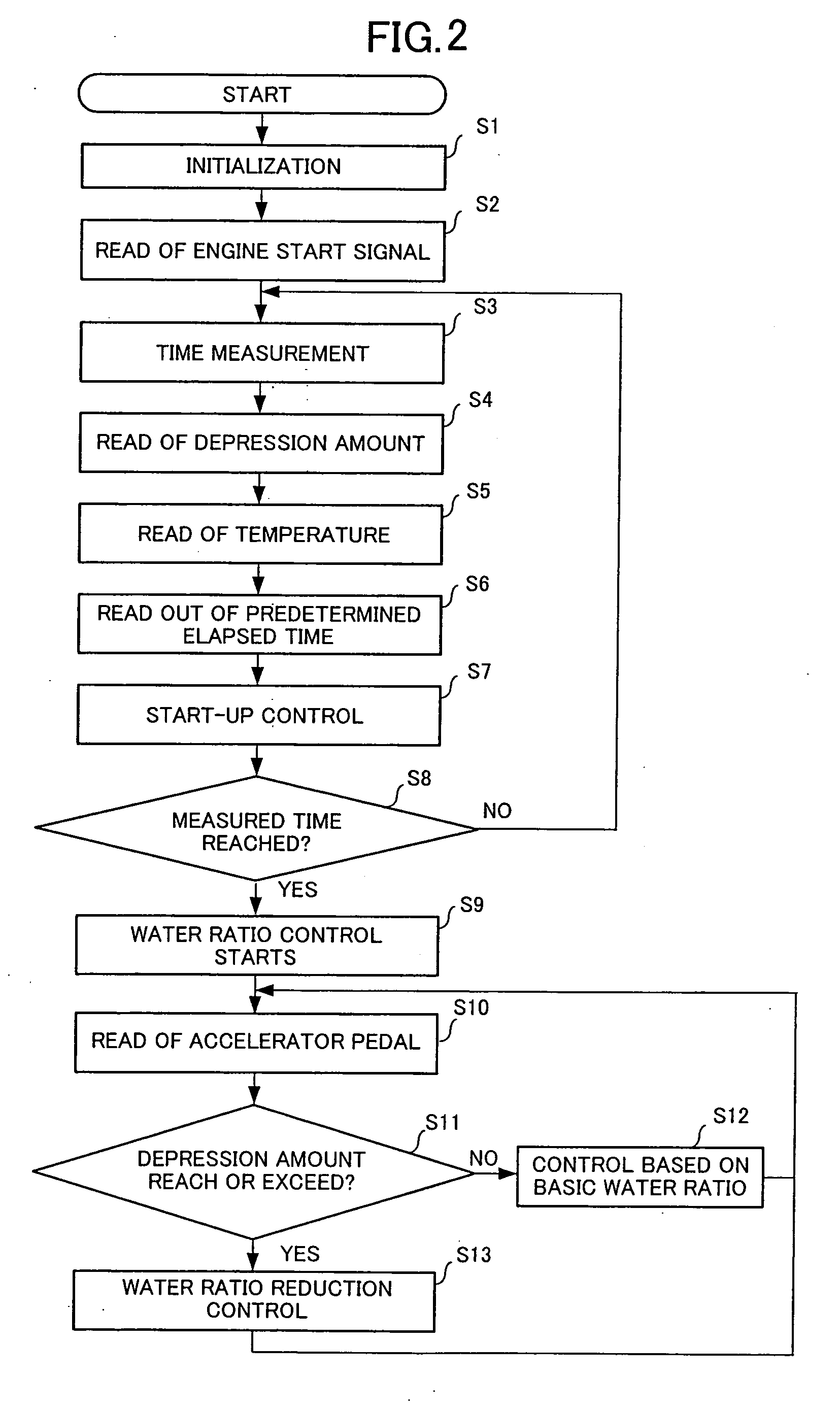

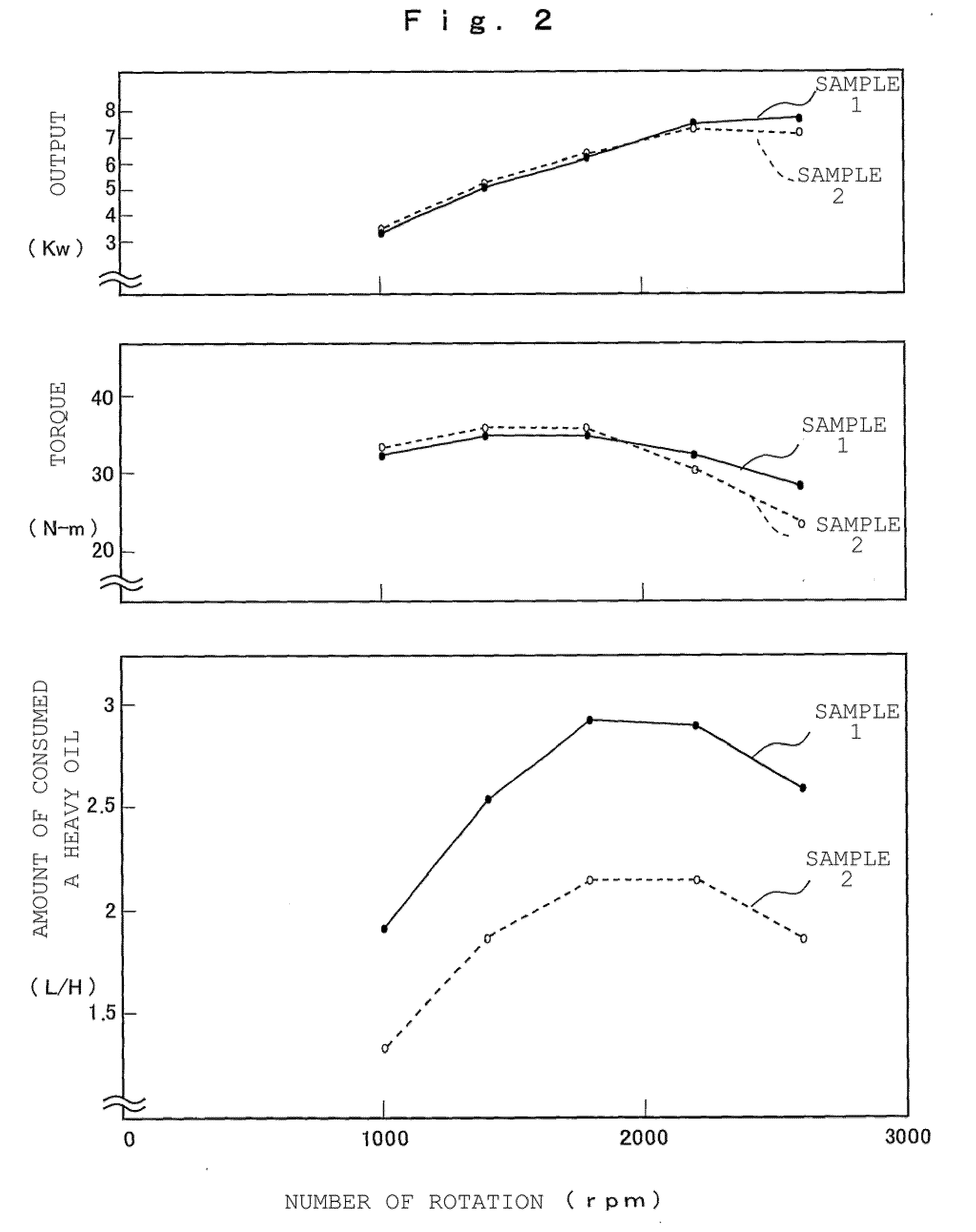

Diesel engine exhaust purifier

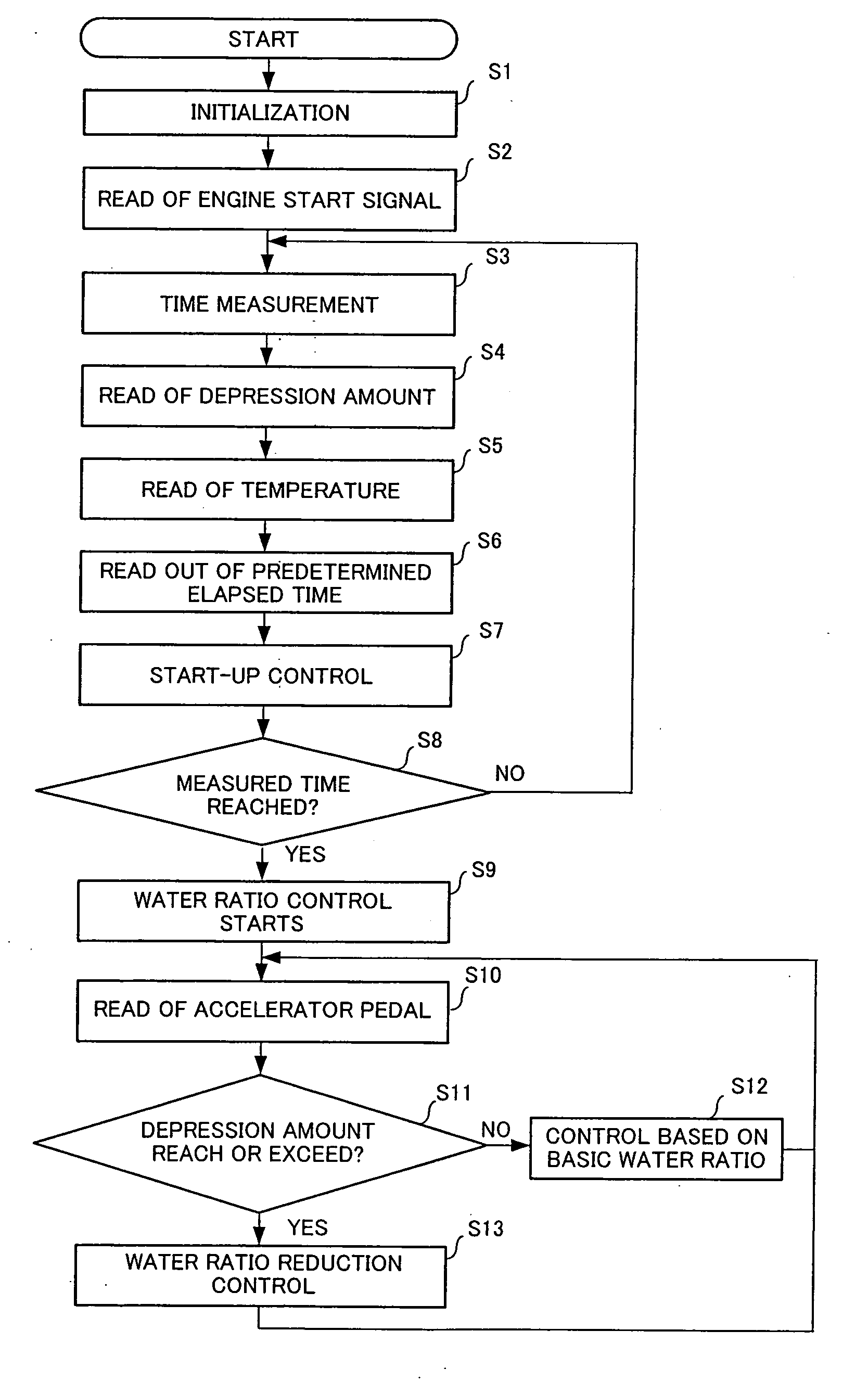

InactiveUS20100263623A1Reduce the production of nitrogen oxidesReduce the temperatureElectrical controlInternal combustion piston enginesCombustion chamberSteep slope

An exhaust emission control apparatus for diesel engines is offered which is capable of achieving better power performance and exhaust emission purification efficiency in an optimally reconciled manner, and from which torque deficiency during hill climbing on a steep slope is eliminated. Emulsified fuel including light oil, water and emulsifier supplied respectively from a light oil tank 4, a water tank 5 and an emulsifier cartridge 6, of which the water ratio is adjusted by flow variable control valves 11-13, is supplied to a combustion chamber 4. The water ratio is normally set to a basic water ratio corresponding to the signal of an accelerator opening sensor 39 (Step S32). However, when a difference between target acceleration and actual acceleration of a vehicle corresponding to the accelerator pedal opening exceeds a predetermined value (Step S36), the basic water ratio is corrected so as to reduce the water ratio (Step S37).

Owner:LENZ ENVIRONMENTAL RESOURCES

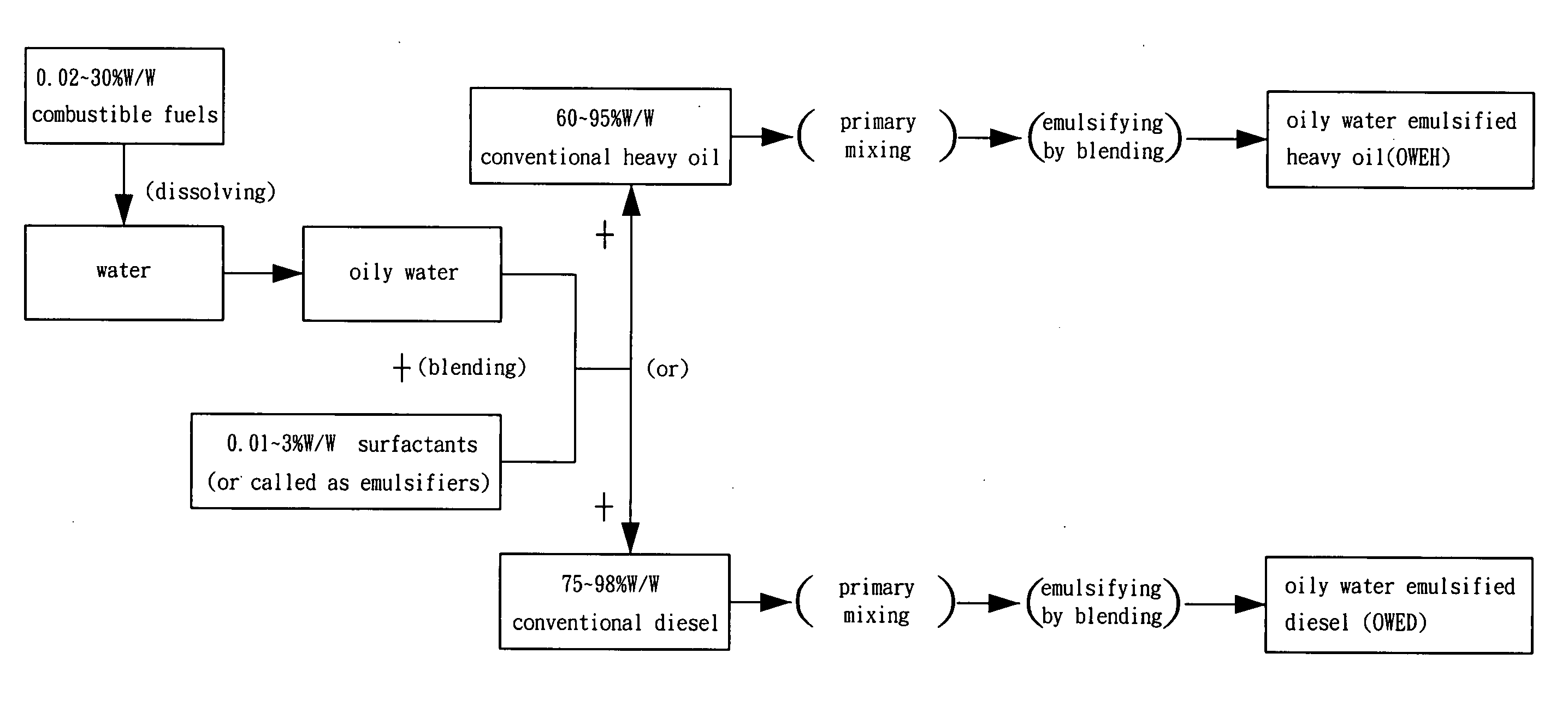

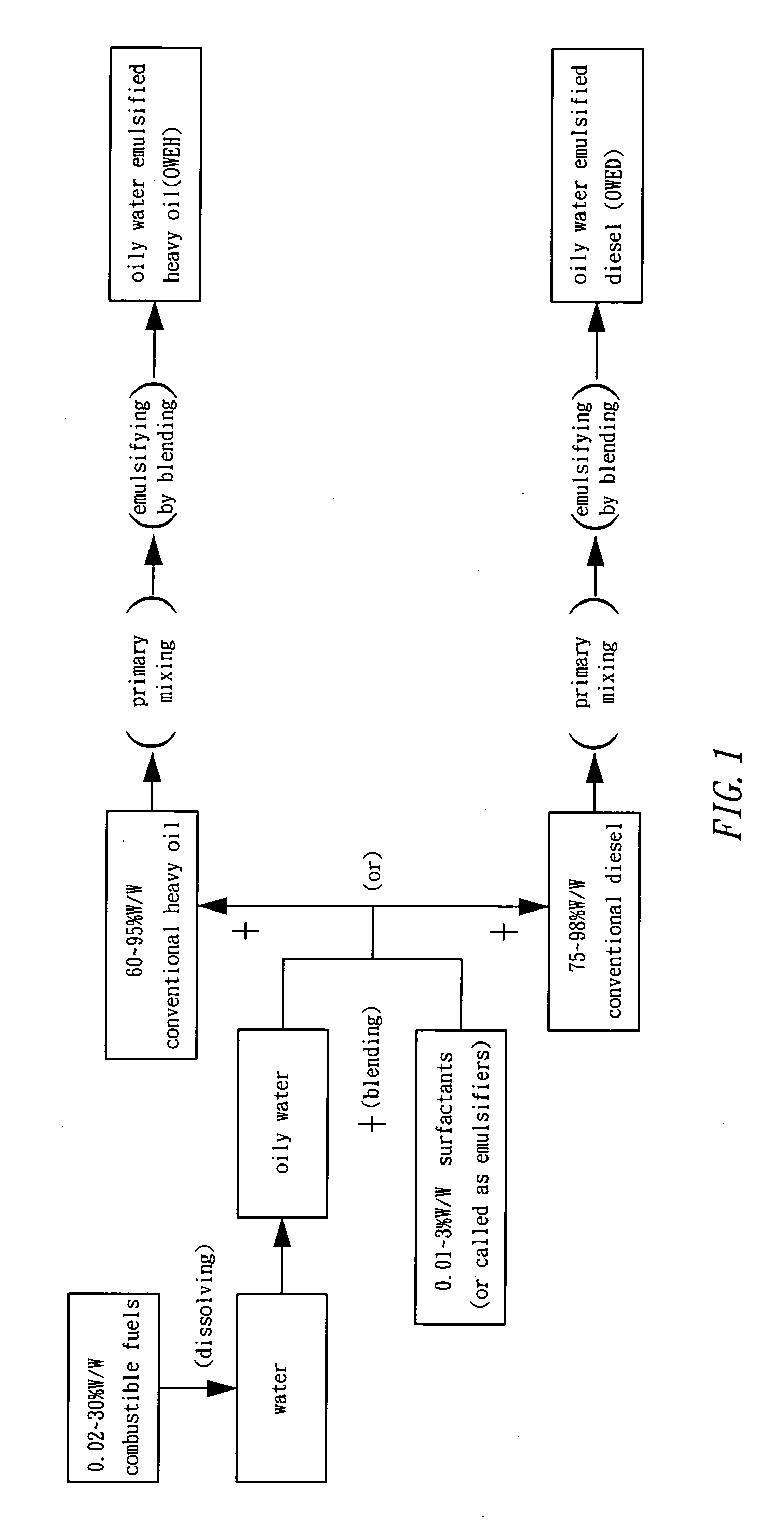

Process for manufacturing emulsified fuels by using oily water

The invention relates to a process for manufacturing emulsified fuels by using “oily water” that is proceeded by following steps: (1) preparing the “oily water” that has 0.02—30% (w / w) of combustible fuels dissolved in water and is blended with surfactants (or called as emulsifiers) by 0.01˜3% (w / w); (2) primarily mixing the emulsified “oily water with surfactants”, that was finished by step (1), with 60˜95% (w / w) of heavy fuel oil (abbreviation as heavy oil) or with 75˜98% (w / w) of diesel, respectively; and (3) keeping the mixtures that were finished by step (2), respectively, and mixed up further by using homogenizer to become an “oily water emulsified heavy oil” (OWEH) or an “oily water emulsified diesel” (OWED).

Owner:LEE WEN JHY

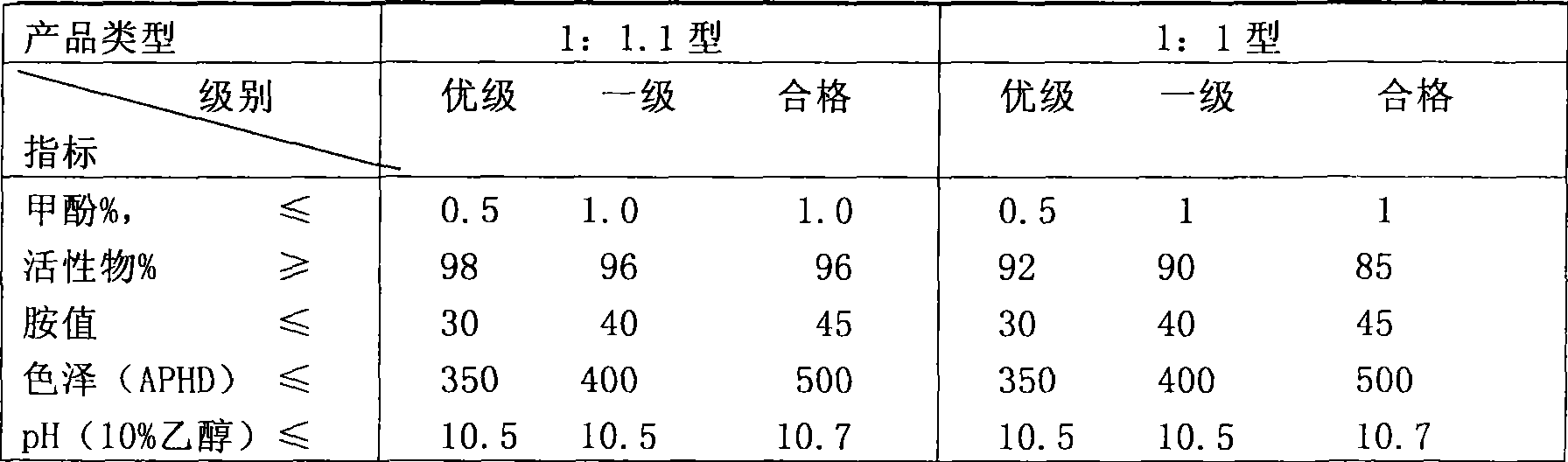

Emulsion for fuel oil and its emulsified fuel oil

InactiveCN1328112AReduce concentrationLower emission rateRefining by water treatmentFuel oilEngineering

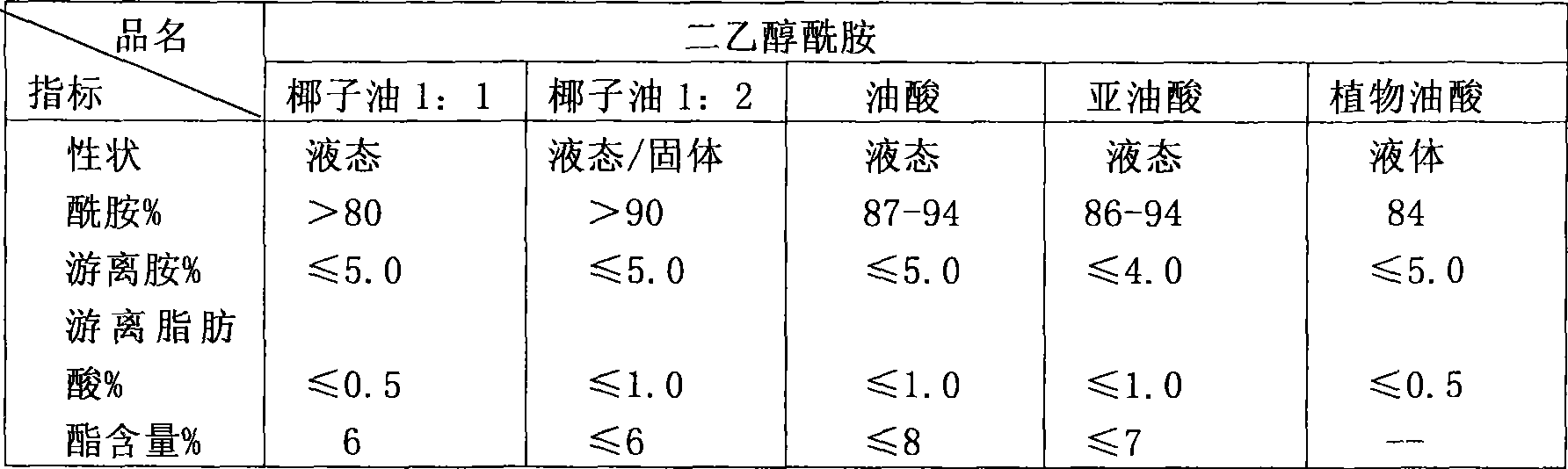

Am emusifying liquid for fuel oil is prepared from 6 surfactants including rosin solution, alkanolamide, lipoacyl diethanolamine, fatty alcohol polyoxyethylene ether, etc. and water. It can be used along with water to obtain emulsified diesel oil or emulsified heavy oil. Its advantages are high stability of emulsified fuel oil within 3 months, saving oil by 15-25%, no black smoke in tail gas, andreducing smoke by 64%, co by 62%, SO2 by 58% and No by 51%.

Owner:陈平

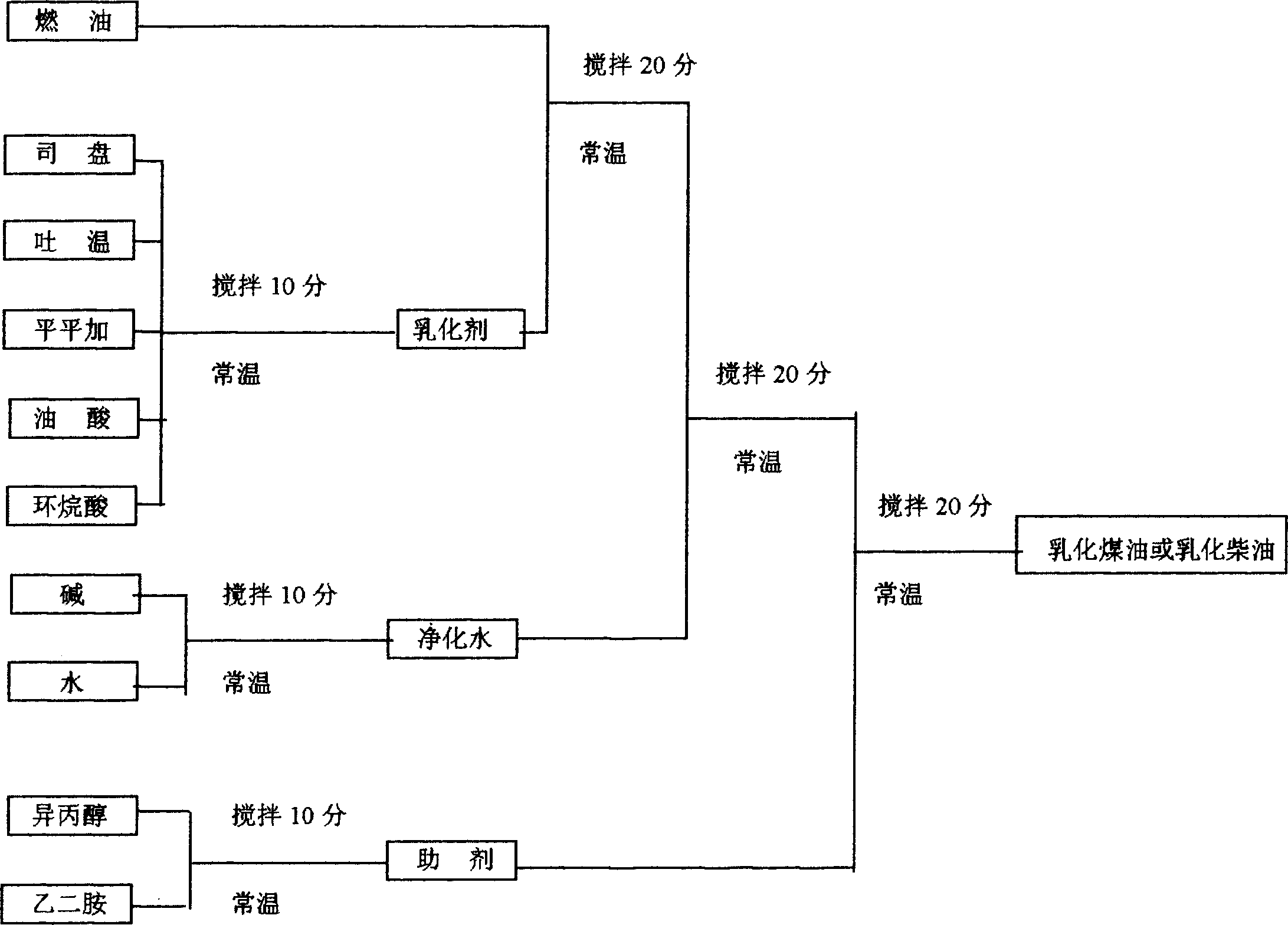

Micro emulsion fuel production process and formula

InactiveCN1422934ALow content of harmful ingredientsReduce odorRefining by water treatmentEngineeringEmulsified fuel

The invention is a producing technique of micro-emulsified fuel and the formula. Its character: according to the weight percentage, emulsifying agent 6-9%, fuel 70-80%, purified water 15-20% and assistant 0.4-0.7%, mix them and fully stir to make the micro-emulsifier fuel. It adopts the micro-emulsifier techinque. It can alone be used and also mixed with similar fuel for use.

Owner:徐涛

Apparatus for producing water-in-oil emulsifield fuel and supplying the same

InactiveUS20060143978A1Reduce fuel consumptionGood emulsified stateFlow mixersTransportation and packagingProcess engineeringEmulsified fuel

The present invention relates to an apparatus for producing and supplying water-in-oil emulsified fuel that supplies to a boiler water-in-oil emulsified fuel, which is emulsified by mixing an emulsifier and water in crude oil such as bunker C oil or bunker A oil. The apparatus for producing and supplying water-in-oil emulsified fuel includes an additive storage tank for storing an emulsifier; an emulsion tank for storing water-in-oil emulsified; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion. The second mixing section is realized through a circulation system that includes an emulsion tank, a mixer pump, and a double mixer. Following the supply of a predetermined amount of the raw materials, emulsified fuel mixed in the circulation system is continuously circulated even if raw material supply is stopped such that emulsified fuel that is always in a uniform state is supplied while maintaining a predetermined ratio, a predetermined moisture particle state, and a predetermined temperature.

Owner:PARK GIL WON

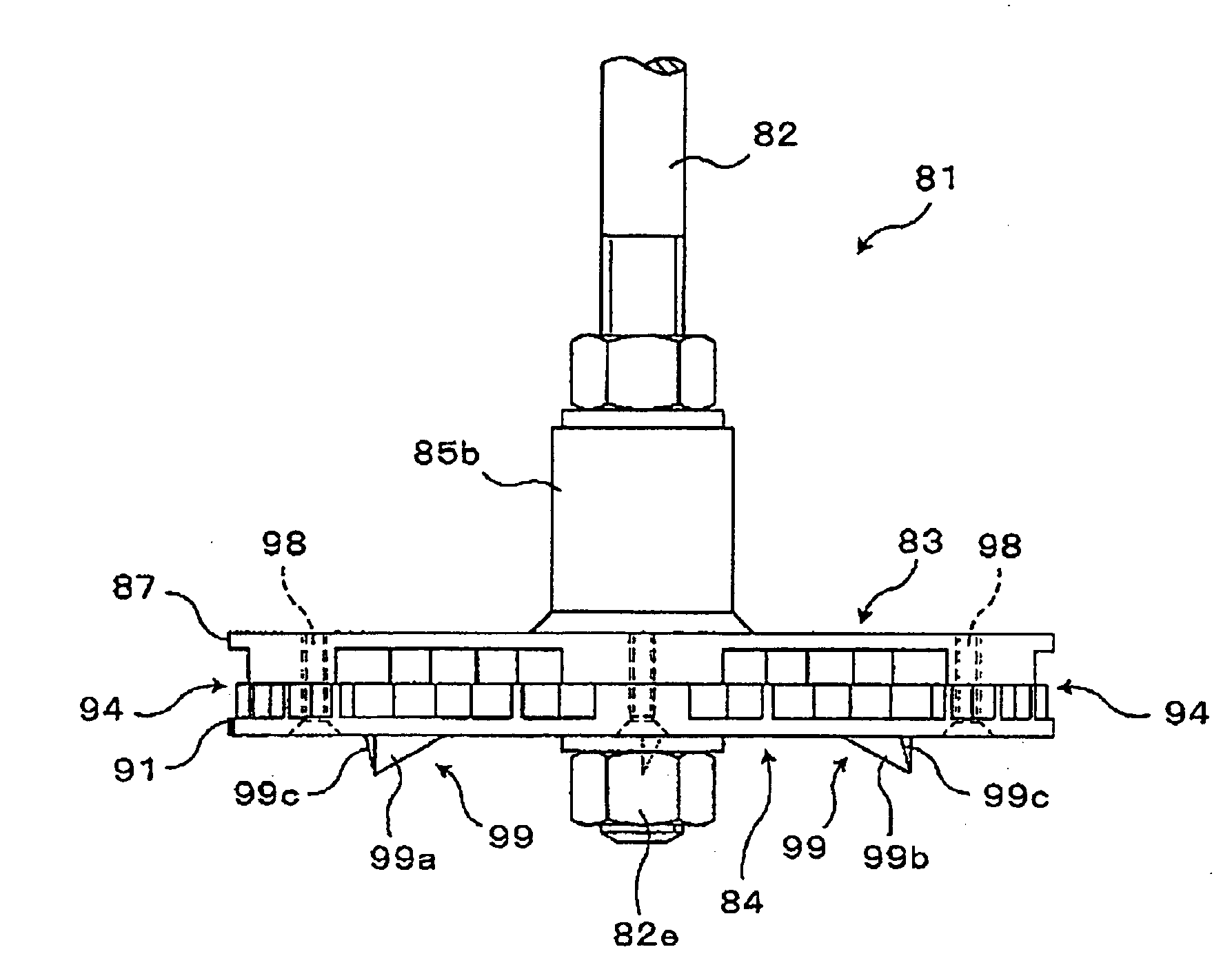

Method for production of emulsion fuel and apparatus for production of the fuel

InactiveUS20100186288A1Improve efficiencyWell mixedLiquid fuel feeder/distributionTransportation and packagingHigh energyEngineering

Disclosed is an emulsion-type water-mixed fuel which is free from separating between an oil and a water, thereby being excellent in stability, has a high combustion efficiency, and an extremely high energy-saving effect. An emulsion fuel, in which an average diameter of the water or the combustible oil is 1,000 nm or less (more preferably, average diameter is 200 to 700 nm), is formed by finely-dividing and mixing the water and the combustible oil by a finely-dividing and mixing means, while adding 10.0 to 150.0 parts by volume of the water with respect to 100 parts by volume of the combustible oil (more preferably, 25.0 to 120.0 parts by volume of the water with respect to 100 parts by volume of the combustible oil). Further, the water to be used preferably has a reduction potential of −100 my or lower, more preferably −300 my or lower.

Owner:NANOMIZER INC

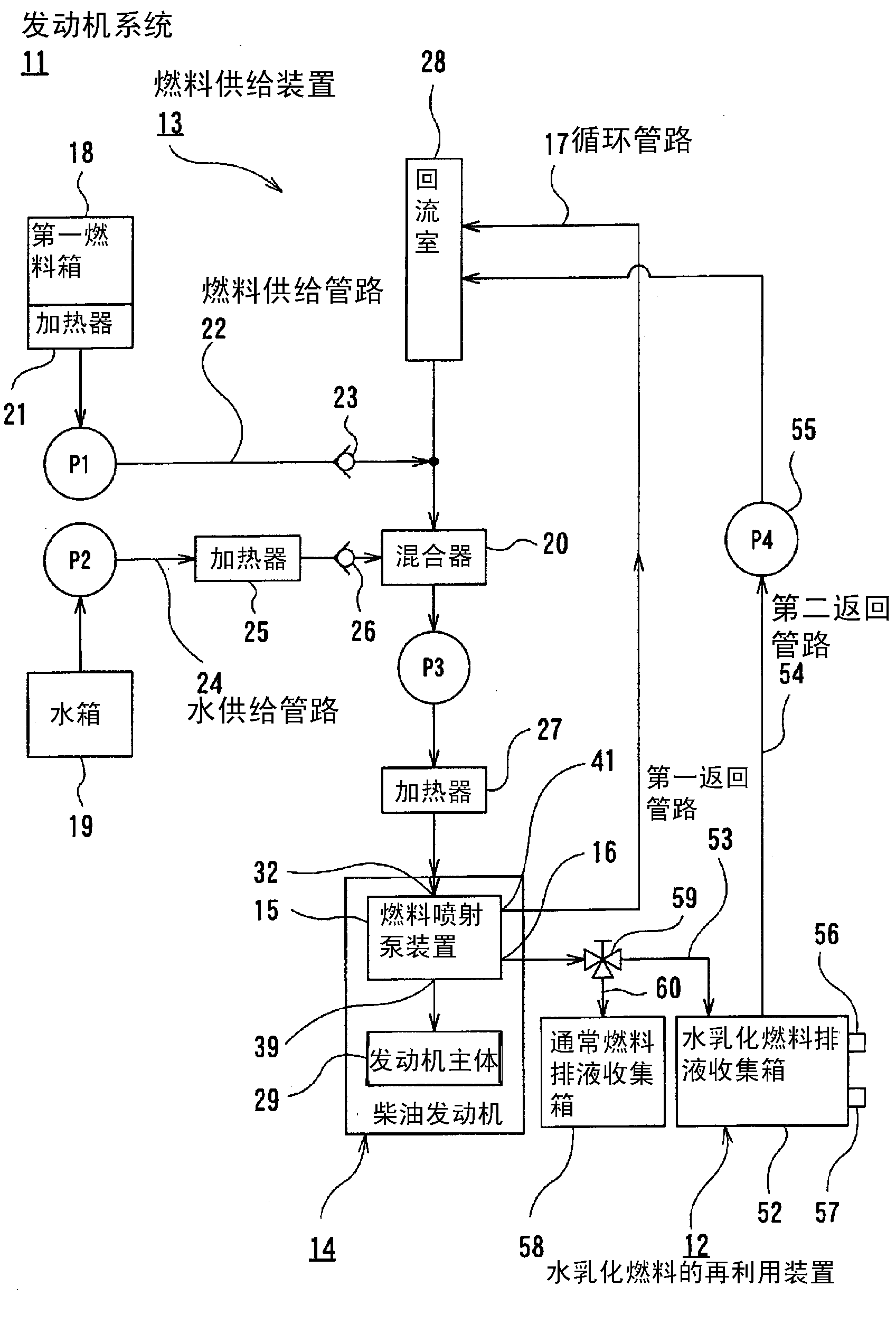

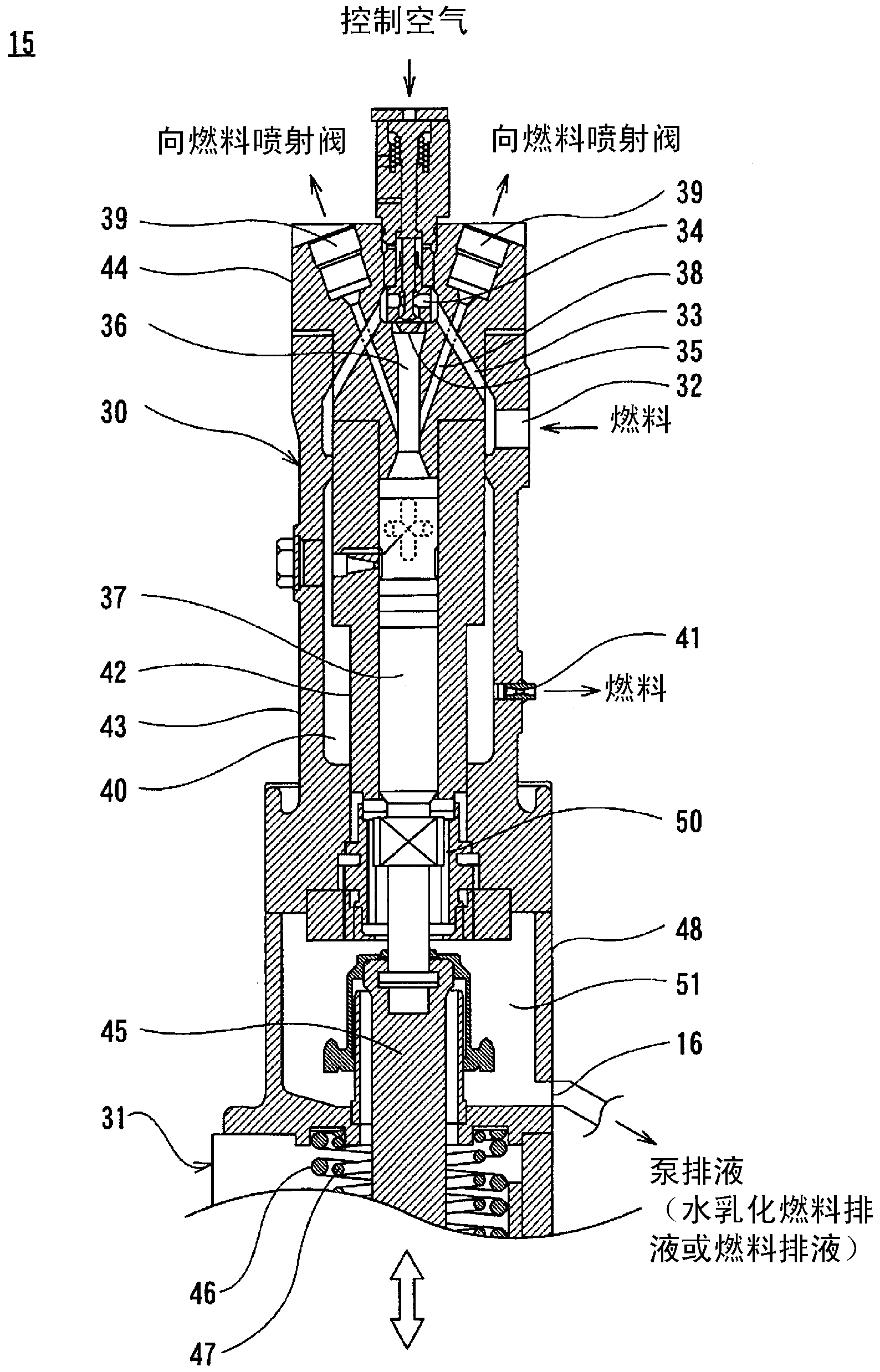

Engine system with reuse device for water emulsion fuel drain

InactiveCN102762845AEfficient use ofInternal combustion piston enginesNon-fuel substance addition to fuelEmulsified fuelFuel injection

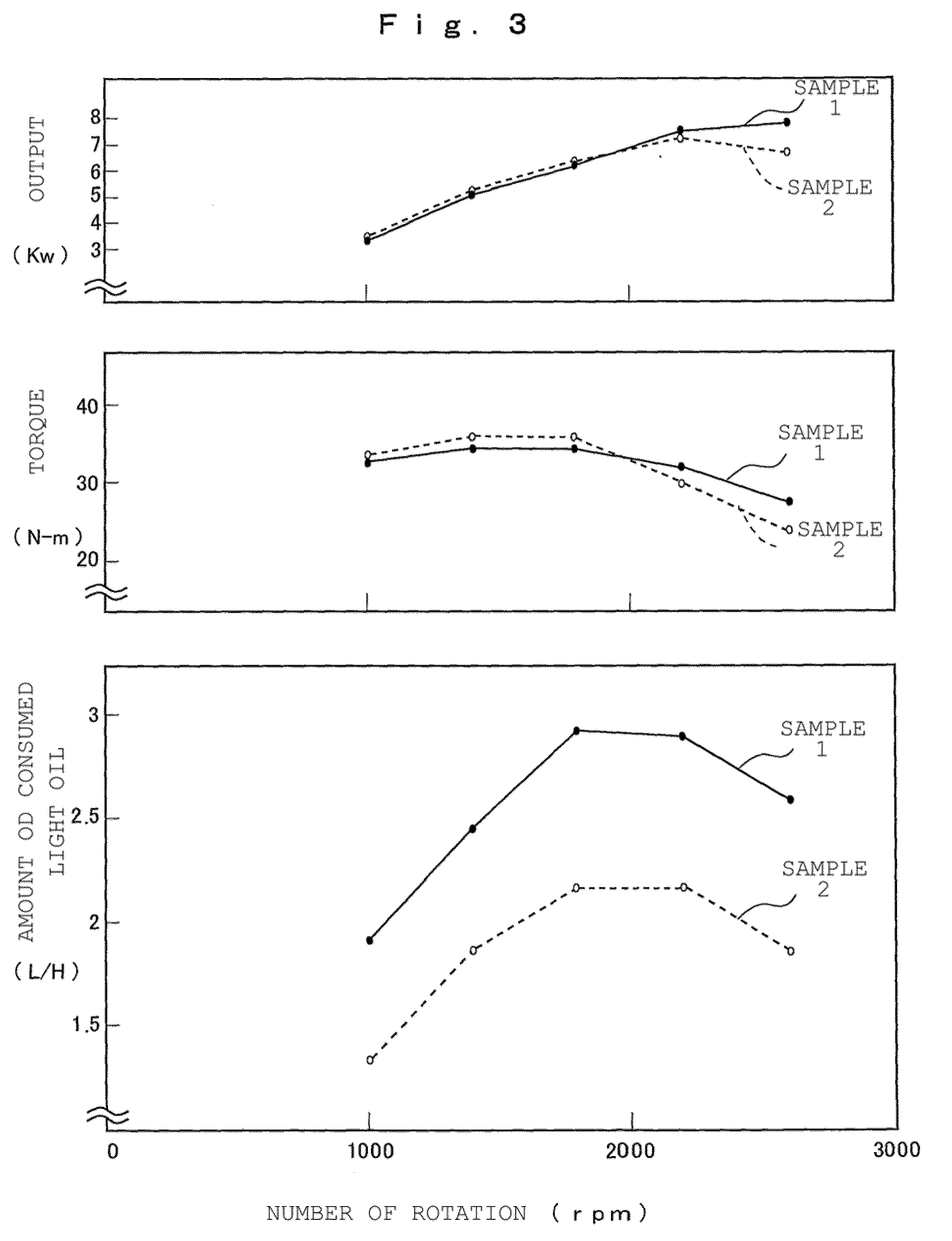

Disclosed is an engine system wherein used water emulsion fuel discharged from a drain port of a fuel injection pump device is returned to a circulation line after being stored for a relatively short period of time, and is reused as water emulsion fuel. An engine system (11) is provided with a circulation line (17) through which water emulsion fuel circulates; a fuel injection pump device (15) having a fuel inlet (32) to which water emulsion fuel is supplied from the circulation line (17), and a fuel outlet (41) through which the water emulsion fuel is returned to the circulation line (17); and an engine main body (29) to which the water emulsion fuel is supplied by the fuel injection pump device (15). The engine system is further provided with a used water emulsion fuel storage tank (52) for storing used water emulsion fuel discharged from a drain port (16) of the fuel injection pump device (15), and a second return line (54) and a drain charging pump (55) for returning the used water emulsion fuel stored in the drain storage tank (52) to the circulation line (17).

Owner:KAWASAKI HEAVY IND LTD

Emulsifying agent for fuel-oil and its preparing method

InactiveCN101024778AImprove stabilityImprove fuel economyRefining by water treatmentFuel oilCarbon chain

The invention relates to an emulsifier used for fuel oil. It includes the following steps: adding hydrophilic unsaturation carbon chains material into deionized water; adding surface activating agent into light oil; adding the material in the first step into the material made from the second step; adding initiator into the material made from the third step, and sending into reactor, after reacting, adding initiator to continue reacting and cooling. The invention has the advantages of simple technology, high safety, and is easy to populized.

Owner:汕头市大千高新科技研究中心有限公司

Microemulsified fuel oil and preparation thereof

InactiveCN101412922AClear appearanceTransparent appearanceRefining by water treatmentSide effectInternational standard

The invention relates to micro-emulsification fuel oil and a method for preparing the micro-emulsification fuel oil by using garbage oil. The method comprises the following steps: using waste oil or oil foot as a main raw material, synthesizing a high-quality composite emulsifying agent by the raw material through three steps of aminolysis reaction, and thinning the raw material to 0.1 to 2 mu m by a high shear homogenizer to prepare the micro-emulsification fuel oil of A type, B type and C type respectively. The micro-emulsification fuel oil comprises the components in weight percentage: 76 to 84 percent of diesel oil, 8 to 12 percent of the composite emulsifying agent, and 8 to 12 percent of water. Except water content, other indexes of product quality of the micro-emulsification fuel oil accord with the diesel oil of international standard. The fuel oil has favorable ignition performance and no side effect for an engine, and can be stored for more than half a year. The method is suitable for oil for power of equipment such as various vehicles, ships, boilers, and the like, has cut-down function for tail gas discharge and effect reaching 30 to 50 percent, and has the characteristics of high heating value and low discharge. The micro-emulsification fuel oil is used for reducing fuel cost greatly at the same time of saving energy; and the developed micro-emulsification technique can meet the requirement of large-scale industrialized production.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

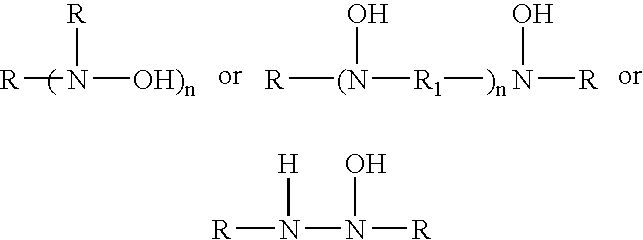

Nano emulsified fuel addtiive and its perparing method

InactiveCN1587357ALower emission valueReduce concentrationLiquid carbonaceous fuelsPolyethylene glycolAlkylphenol

The present invention discloses nanometer emulsified fuel additive and its preparation process, and belongs to the field of liquid fuel additive technology. The fuel additive is prepared with the components including triethyl tetramine, diethyl ethanolamine, AE03 or AE04, alkylphenol ethoxylate, polyethylene glycol lauryl ether, ethylene glycol monomethyl ether, sorbitan oleate, fatty acid ester, isopropyl nitrate, cobalt naphthenate, acetone and ferrocene. It has an oil saving rate of 7-12 % and obvious pollution reducing effect.

Owner:谢学秀

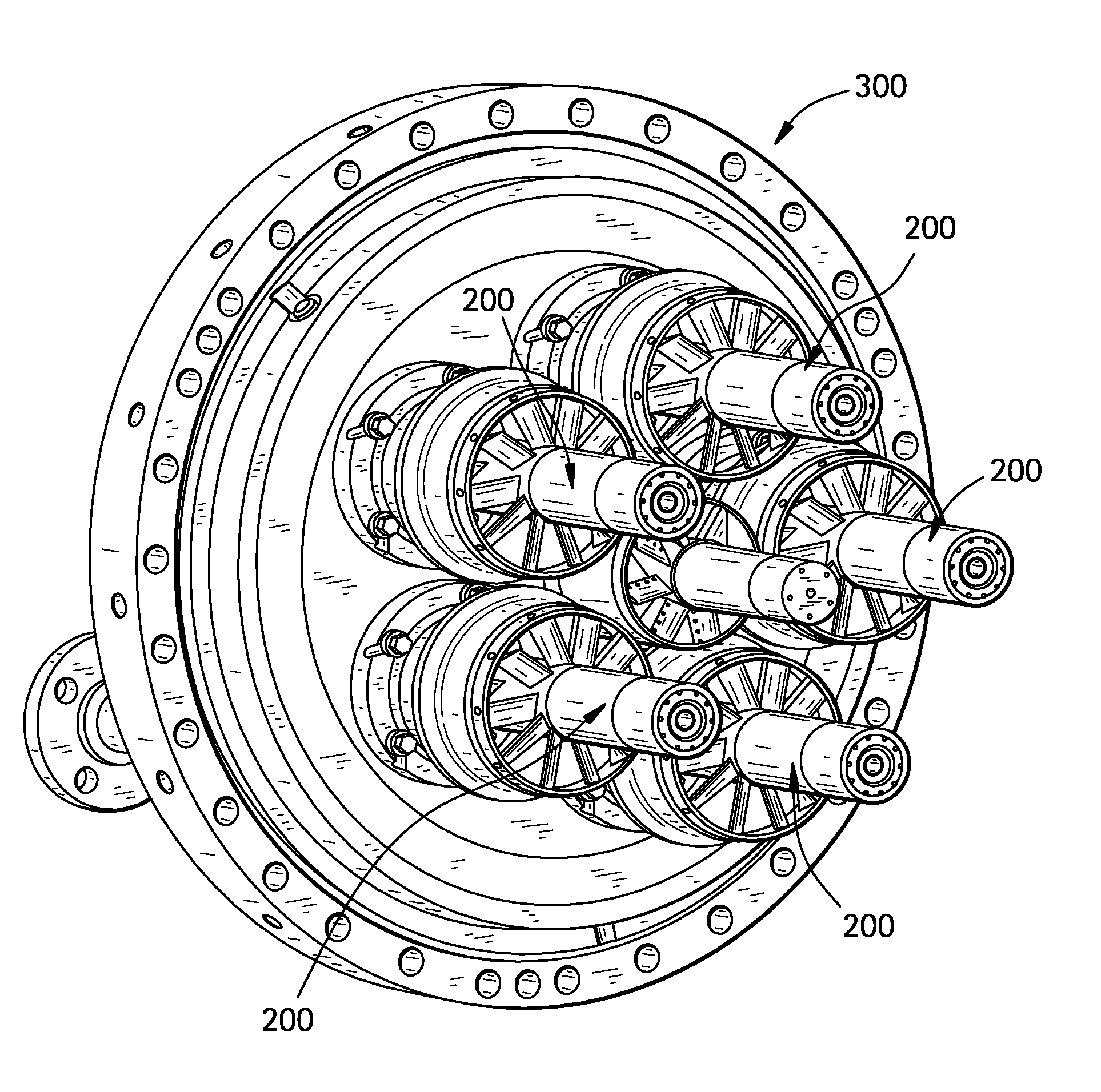

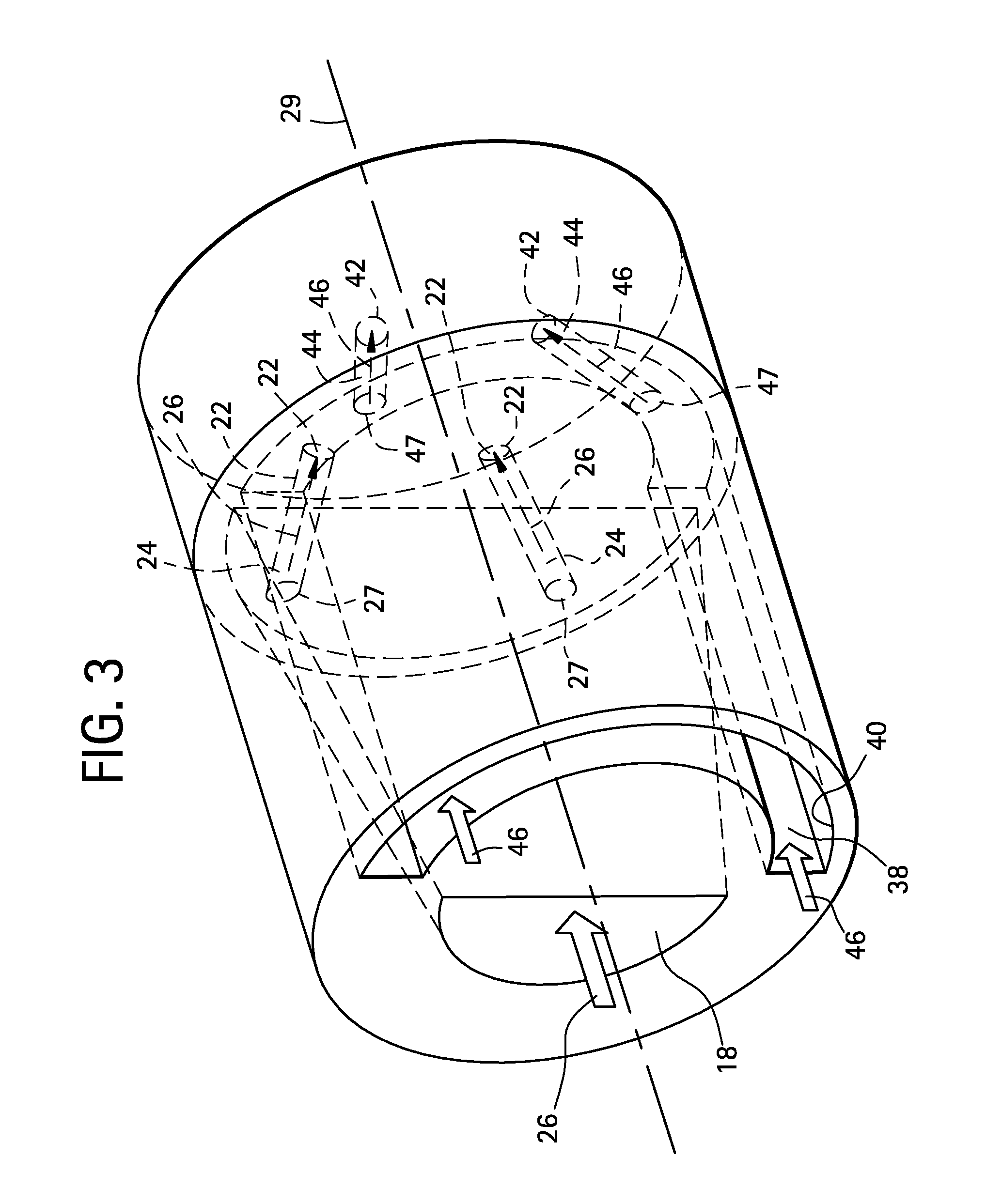

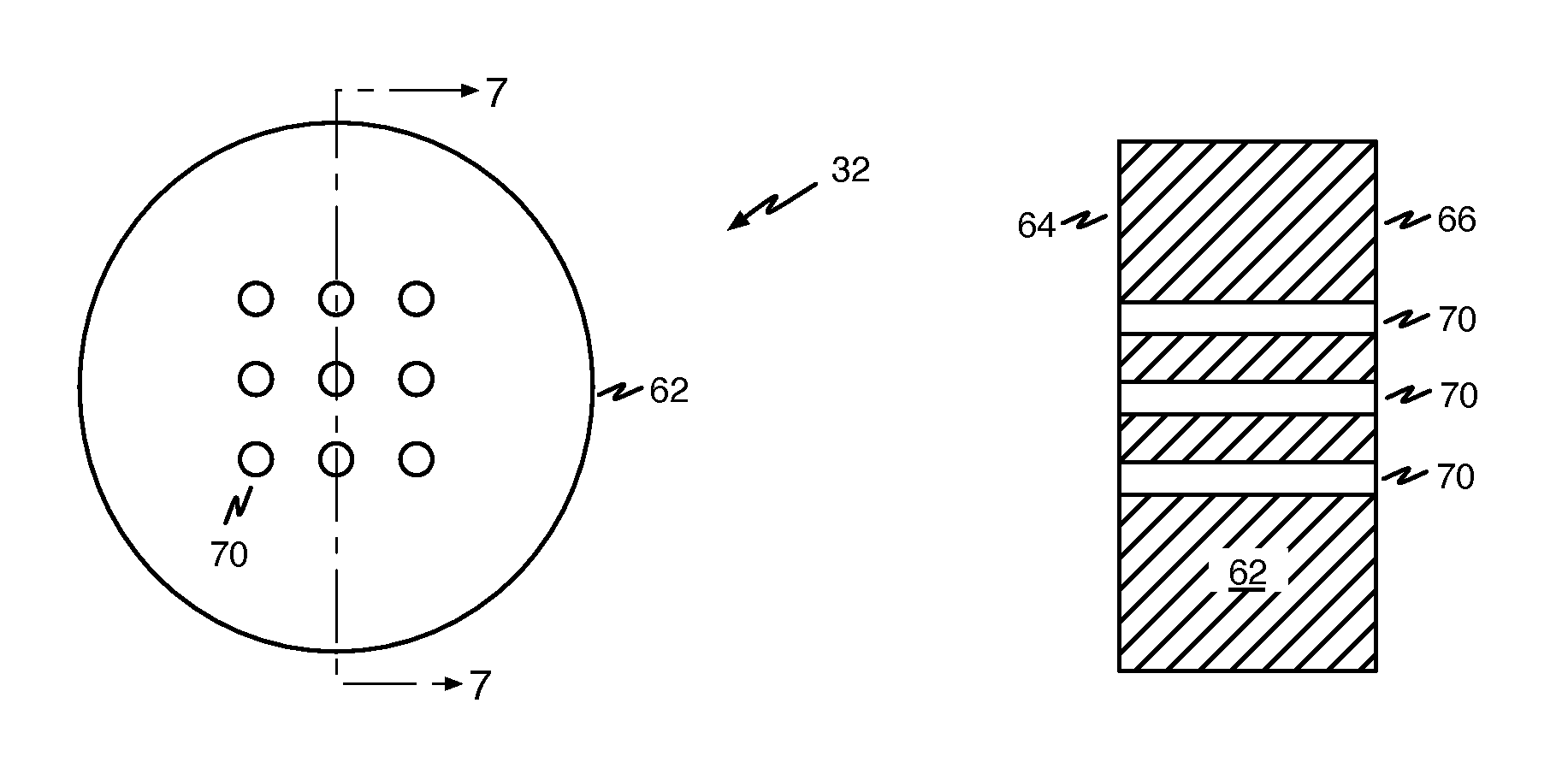

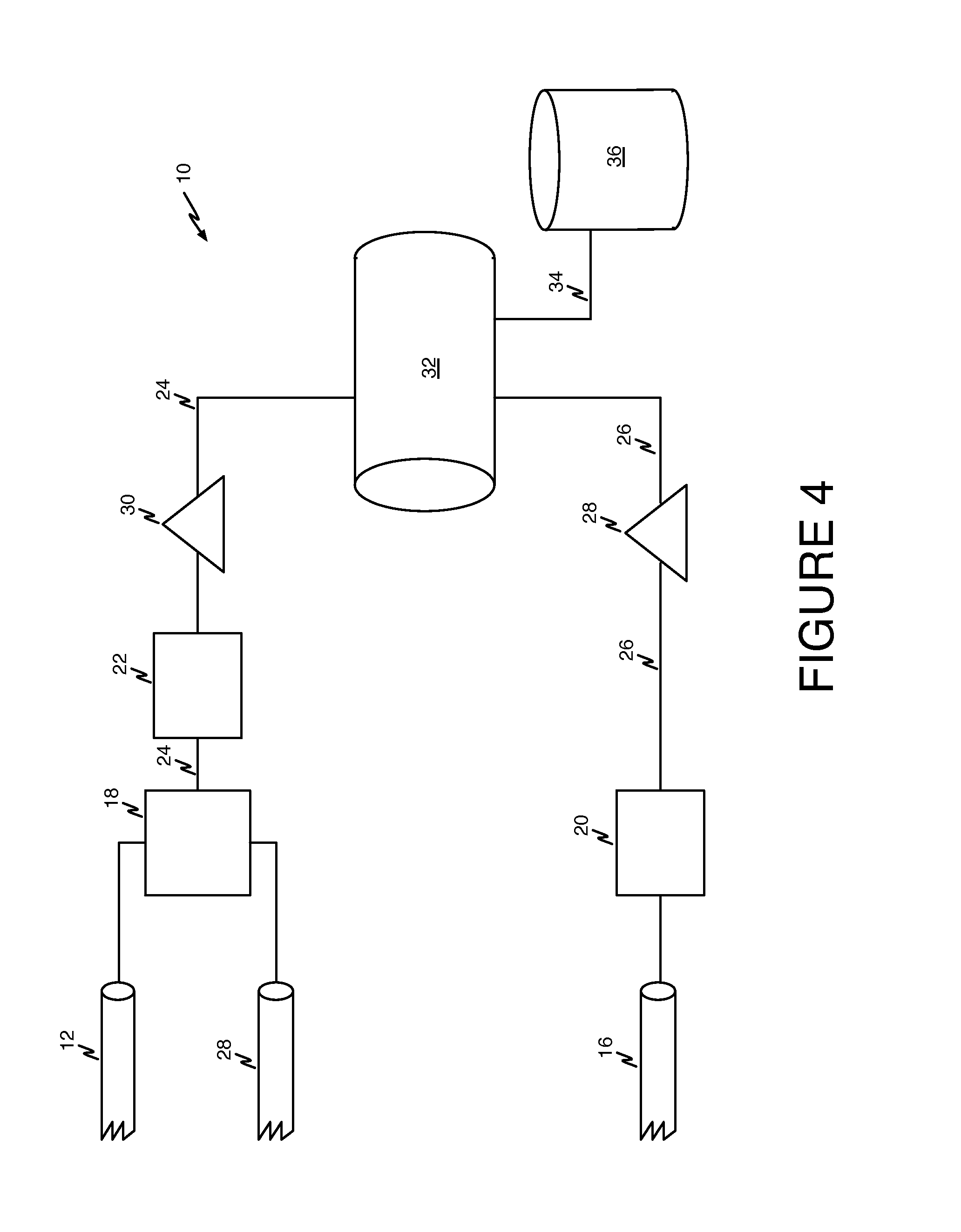

Mixing apparatus and method for manufacturing an emulsified fuel

ActiveUS8192073B1InexpensiveEnsure uniformity of dispersionFlow mixersTransportation and packagingProcess engineeringEmulsified fuel

Owner:TALISMAN CAPITAL TALON FUND

Infrared aided fuel emulsion

Owner:ALDI FAR IR PROD INC

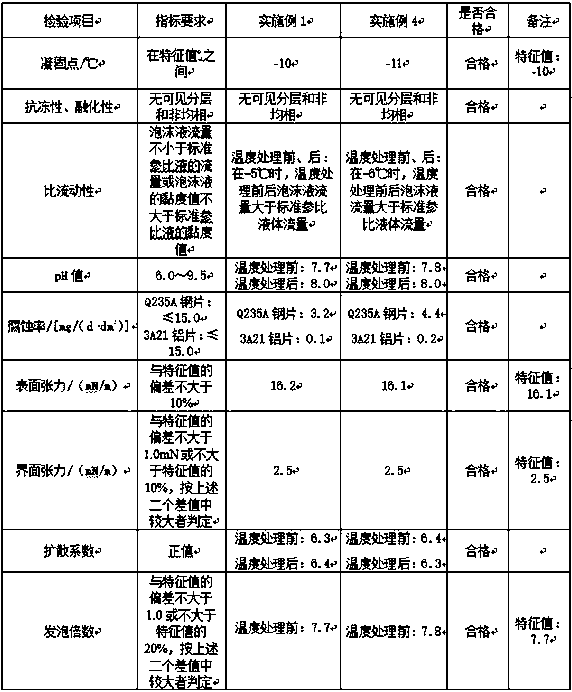

Hydrocarbon flammable liquid flowing fire extinguishing agent

InactiveCN110960824AWide range of fire extinguishing application scenariosEfficient fire fightingFire extinguisherFoaming agentActive agent

The invention discloses a hydrocarbon flammable liquid flowing fire extinguishing agent which is characterized by comprising the following components in percentage by weight: 1.5%-15% of a foaming agent, 2%-10% of a fluorine surfactant, 4%-15% of an emulsifier, 0.2%-5% of a stabilizer, 3%-15% of a cosolvent, 5%-15% of an antifreeze agent, 0.5%-3% of a flame retardant, 0.1%-1% of a preservative andthe balance of water. The hydrocarbon flammable liquid flowing fire extinguishing agent has the advantages that through the triple effects of fuel emulsification, water film forming isolation, foam covering and the like, the synergistic fire extinguishing is realized, and the problems of low fire extinguishing speed, poor cooling effect, poor anti-reburning effect and the like of flammable liquidflowing fire in the prior art are solved.

Owner:应急管理部天津消防研究所

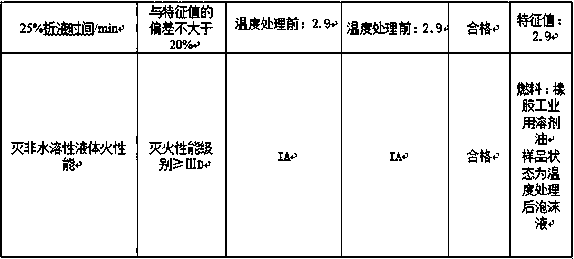

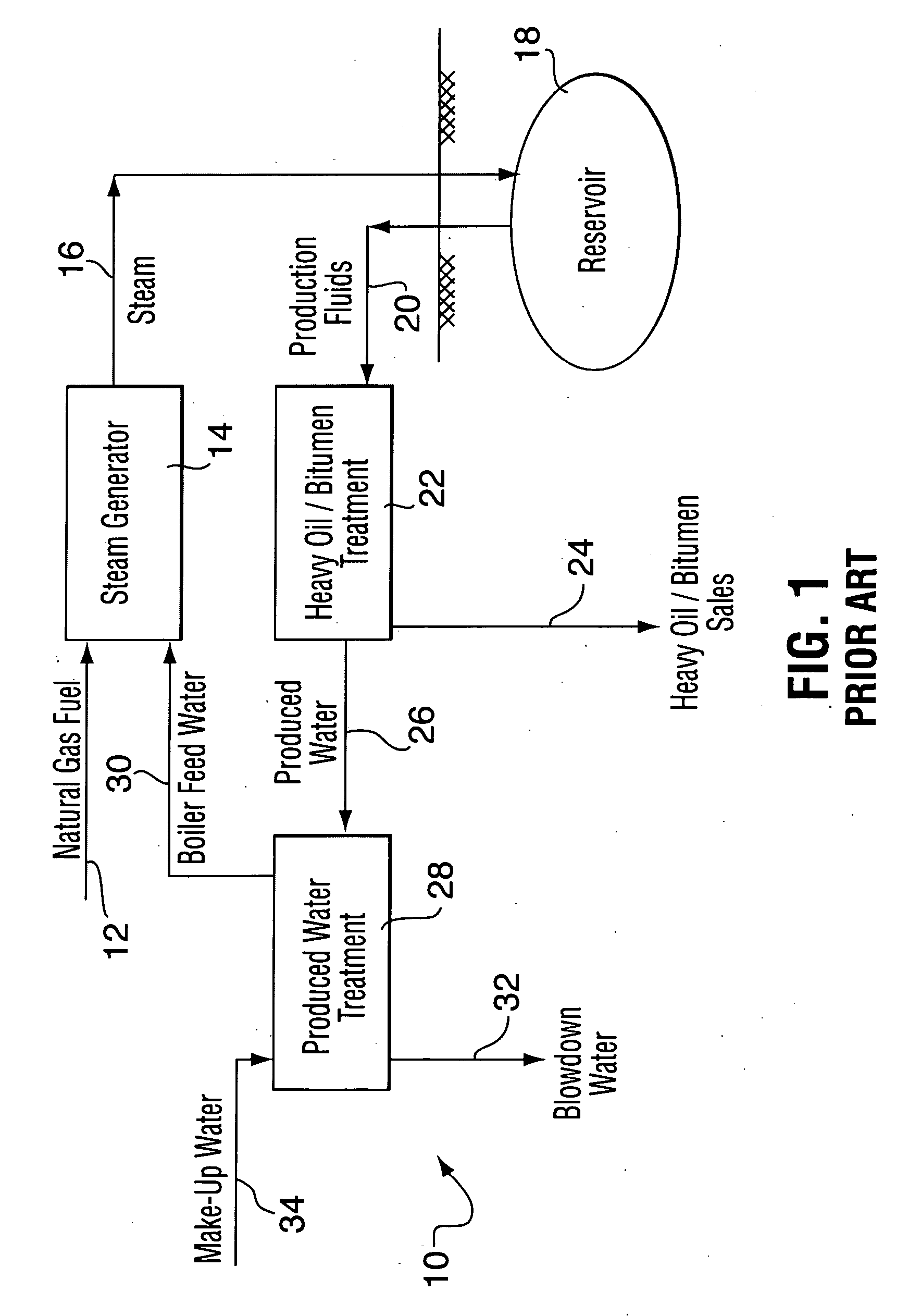

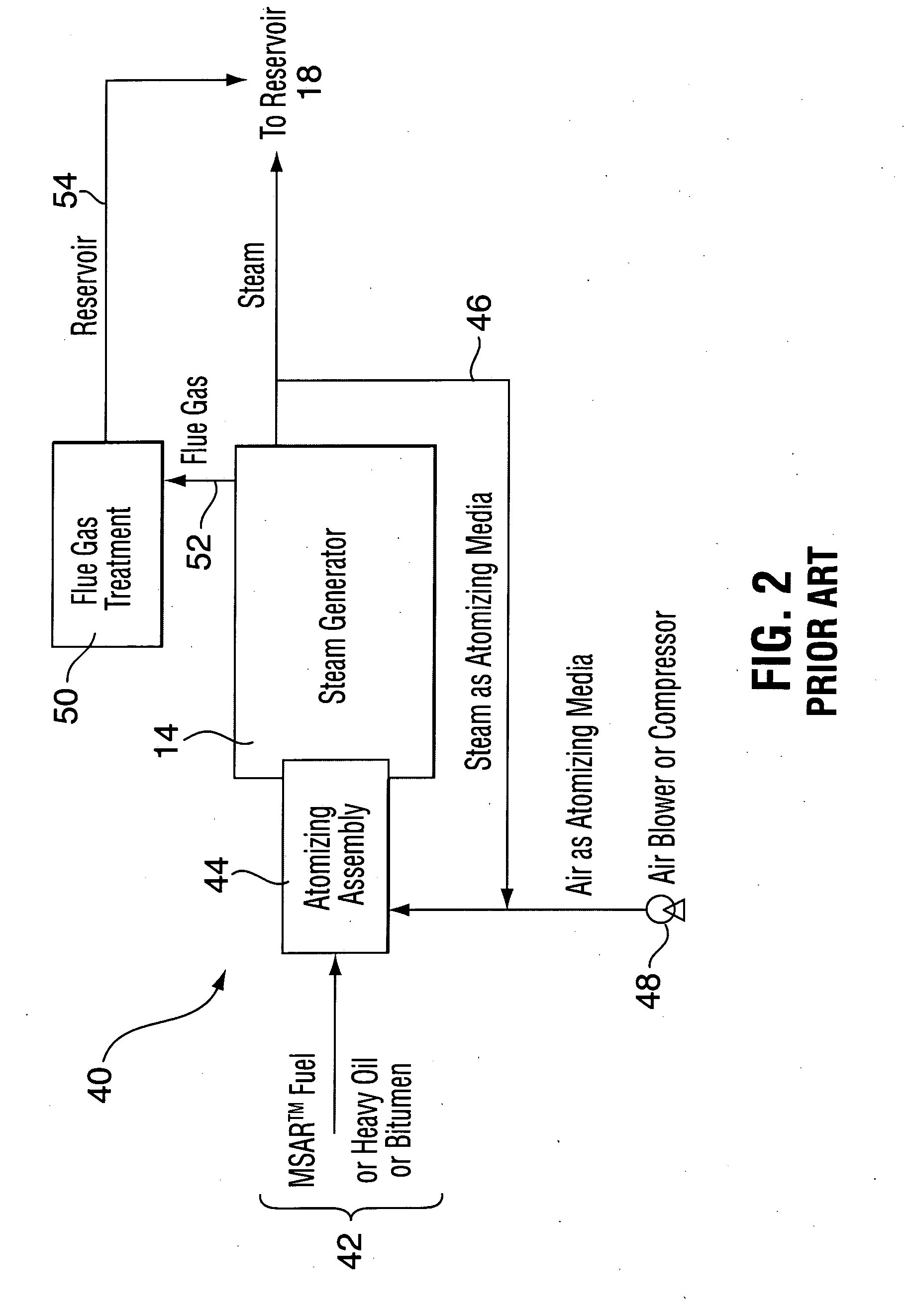

Alternate atomizing medium for burning efficiency of emulsion fuels, heavy oils and bitumens

A method for augmenting the heat enthalpy of an emulsified alternate fuel. An atomizing medium containing produced solution gas is used to atomize the emulsified fuel and add to the heat content of the emulsified fuel enhancing combustion. Alternate embodiments include the use of other gaseous hydrocarbon material as the atomizing medium either utilized alone or mixed with air or steam.

Owner:DIAMOND QC TECH

Emulsion fuel oil additive and manufacturing method thereof

The invention relates to an emulsion fuel oil additive for mixing fuel oil and water to form emulsion fuel oil, wherein the emulsion fuel oil additive comprises, an emulsifier for forming water-in-oil type emulsion fuel oil with the fuel oil and the water, a combustion adjuvant for accelerating the ignition of the emulsified fuel oil, a stabilizing agent for proceeding a chemical reaction at specific temperature to form an interfacial film between the water-oil phase interface of the emulsion fuel oil, an anti-oxidizing agent for preventing the long term storage deterioration of the emulsion fuel oil, and an accelerating agent for accelerating the emulsification between the fuel oil and the water and the formation of interfacial film to the stabilizer.

Owner:蔡坤穆 +1

Method for production of emulsion fuel and apparatus for production of the fuel

InactiveCN101535718ALiquid fuel feeder/distributionTransportation and packagingOil phaseEmulsified fuel

Disclosed is an emulsion-type water-mixed fuel which causes no separation between an oil phase and an aqueous phase and therefore has excellent stability, has a high combustion efficiency, and an extremely high energy-saving effect. Specifically disclosed is an emulsion fuel in which an aqueous phase or an oil phase has an average particle diameter of 1000 nm or less (more preferably 200 to 700 nm), which can be produced by finely dividing and mixing 100 parts by volume of a combustible oil with 10.0 to 150.0 parts by volume (more preferably 25.0 to 120.0 parts by volume) of a water by a finely-dividing / mixing means while adding the water tothe combustible oil. The water preferably has a reduction potential of -100 mv or lower, preferably -300 mv or lower.

Owner:奈欧麦勒日本株式会社

Production process for recycling phenol residual liquid

InactiveCN106986739AOrganic compound preparationDistillation purification/separationDistillationFuel oil

The invention belongs to the field of environmental protection and chemical engineering, and particularly relates to a production process for recycling phenol residual liquid. The production process is implemented by the aid of a raw material storage tank, a delivery pump, a tower bottom kettle, an electric heater, a rectifying tower, a condenser, a vacuum pump, a reflux ratio controller, collecting tanks, a venturi tube mixer, a phenol collecting tank, an extracting and separating tank, a circulating pump, a forced mixer, a static mixer, a pressure pump, an emulsifier storage tank, a fuel oil storage tank, an emulsified fuel oil collecting tank, a cryogenic device and an activated carbon adsorption device. The production process mainly includes process procedures of crude distillation separation, rectification separation, phenol purification, waste gas treatment and residue recycling. The process procedures are in intermittent production modes.

Owner:乐陵力维化学品有限责任公司

Emulsion fuel and method of preparing the same

The emulsion fuel according to the present invention is prepared by emulsifying about 55 to 90 % by weight of a mixture of heavy oil, 45 to 10 % by weight of water, and 0.3 to 0.8 % by weight of a catalyst. The catalyst comprises caustic soda (sodium hydroxide) and calcium dichloride in half and half. The calcium chloride can be partly substituted with calcium sulfate.

Owner:金浩均

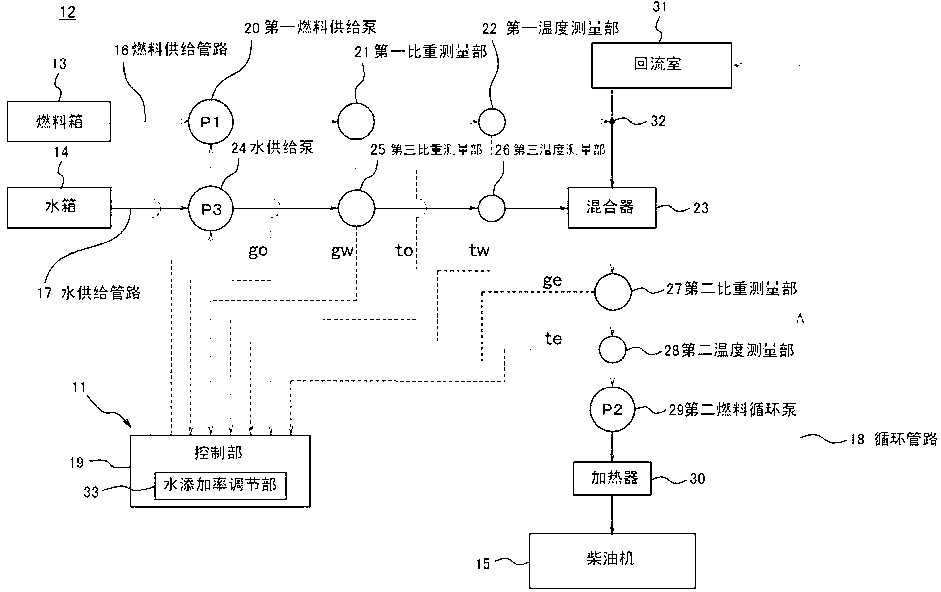

Specific gravity monitoring control device and fuel supply apparatus provided with same

InactiveCN103003634AProper and stable combustion efficiency operationProper and stable operationLiquid fuel feeder/distributionElectrical controlEmulsionFuel oil

Provided is a specific gravity monitoring control device capable of measuring and monitoring the specific gravity of fuel oil actually used when water emulsion fuel is produced by adding water to the fuel oil, and capable of producing the water emulsion fuel with an accurate target additional water weight ratio by adjusting the amount of the water to be added to the fuel oil using the specific gravity of the fuel oil obtained by the measurement. The specific gravity monitoring control device has a configuration in which when fuel oil is emulsified by adding water to the fuel oil, water emulsion fuel with a desired accurate target additional water weight ratio (T) can be produced by measuring the specific gravity of the fuel oil by a first specific gravity measuring unit (21), making a calculation using a first measured specific gravity (go) obtained by the measurement by the first specific gravity measuring unit (21), and adjusting the amount of the water to be added to the fuel oil on the basis of the result of the calculation.

Owner:KAWASAKI HEAVY IND LTD

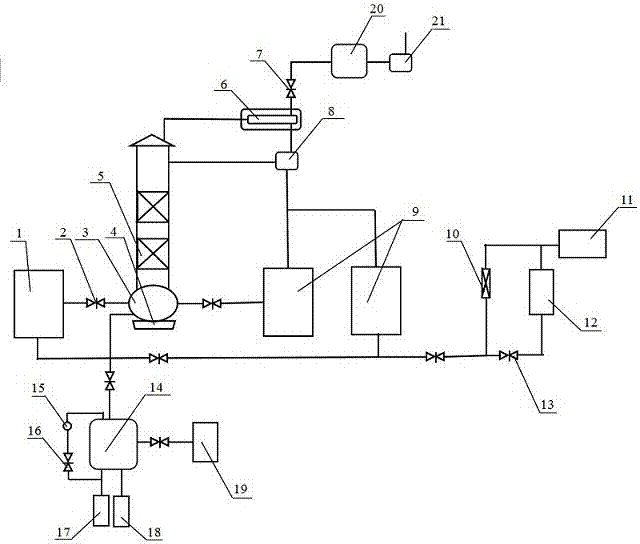

Emulsion fuel enabling system and method

ActiveUS20120240875A1Increase moisture contentLow speed stabilityNon-fuel substance addition to fuelInternal combustion piston enginesOil waterEmulsified fuel

Disclosed are a system and a method for promoting the formation of the emulsified fuel of a diesel engine. The system includes a viscous oil-water tank; an emulsified fuel mixing device for mixing viscous oil-water with diesel fuel to obtain emulsified fuel; a dual-fuel return fuel emulsification-promoting device connecting to a diesel tank, the emulsified fuel mixing device, and the return fuel pipe and the main fuel pipe of the engine respectively; a heat-exchanging device for heating the emulsified fuel from the dual-fuel return fuel emulsification-promoting device by the cooling water of the engine; a first purifying pipe and a second purifying pipe for purifying the main fuel pipe; and a dual-fuel management device for switching between the diesel fuel supply and the emulsified fuel supply according to the temperature of the cooling water, and after the ignition switch of the engine is closed, for controlling the diesel fuel to clean up the emulsified fuel in the engine, in the main fuel pipe and in the devices. By using the system, the water content of the emulsified fuel can be up to 33% and the diesel engine can keep essentially unchanged power, start easily and run steadily.

Owner:SHENZHEN LOKABEN CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com