Patents

Literature

54 results about "Froth treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

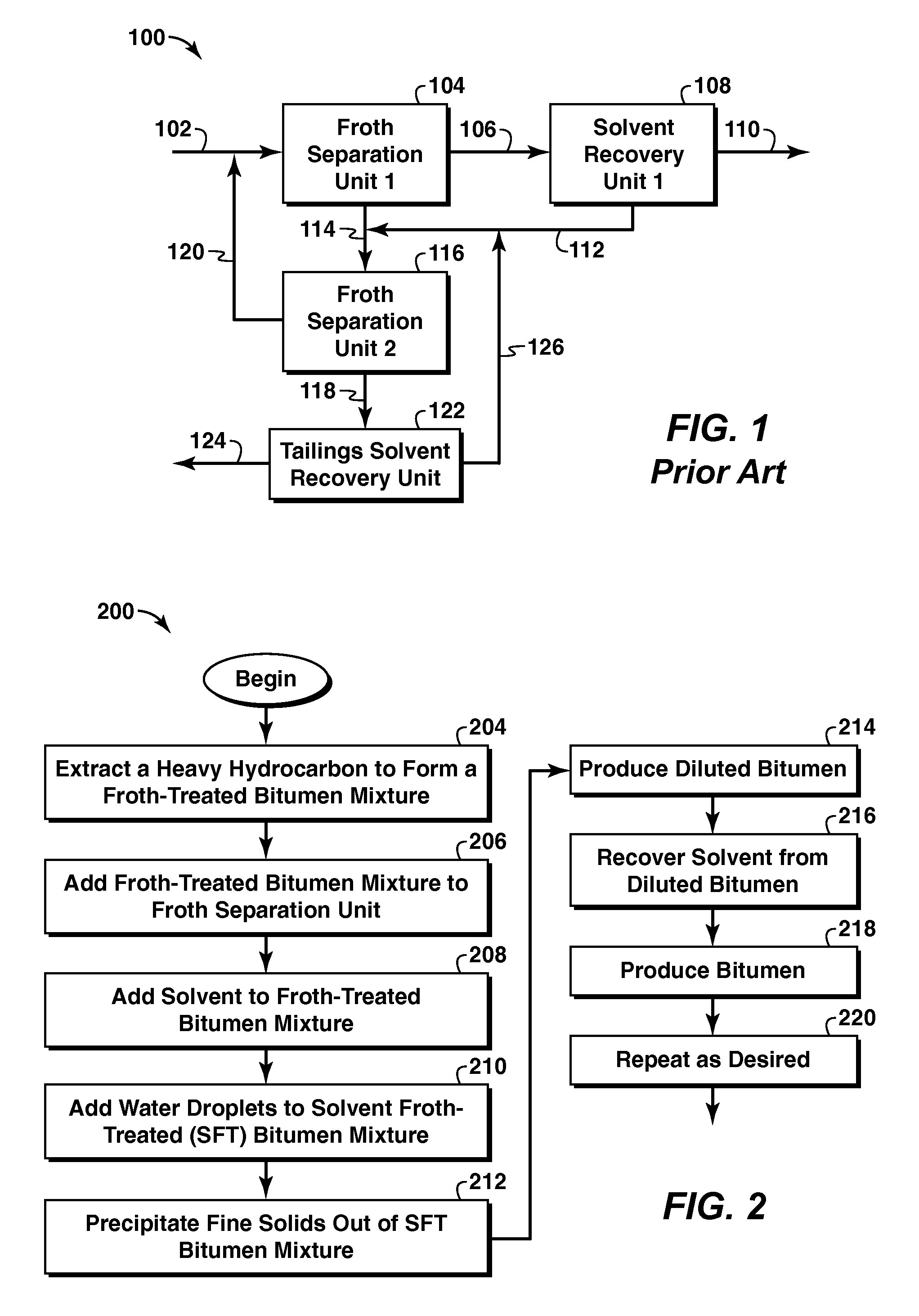

Froth treatment is an oil refining technique which converts bitumen recovered from oil sands into diluted bitumen, a marketable product, which can be shipped through an oil pipeline to an oil refinery or oil terminal. The process removes heavier hydrocarbon compounds producing dilbit which can flow through a pipeline. The product can then be sold or upgraded further.

Upgrading Bitumen In A Paraffinic Froth Treatment Process

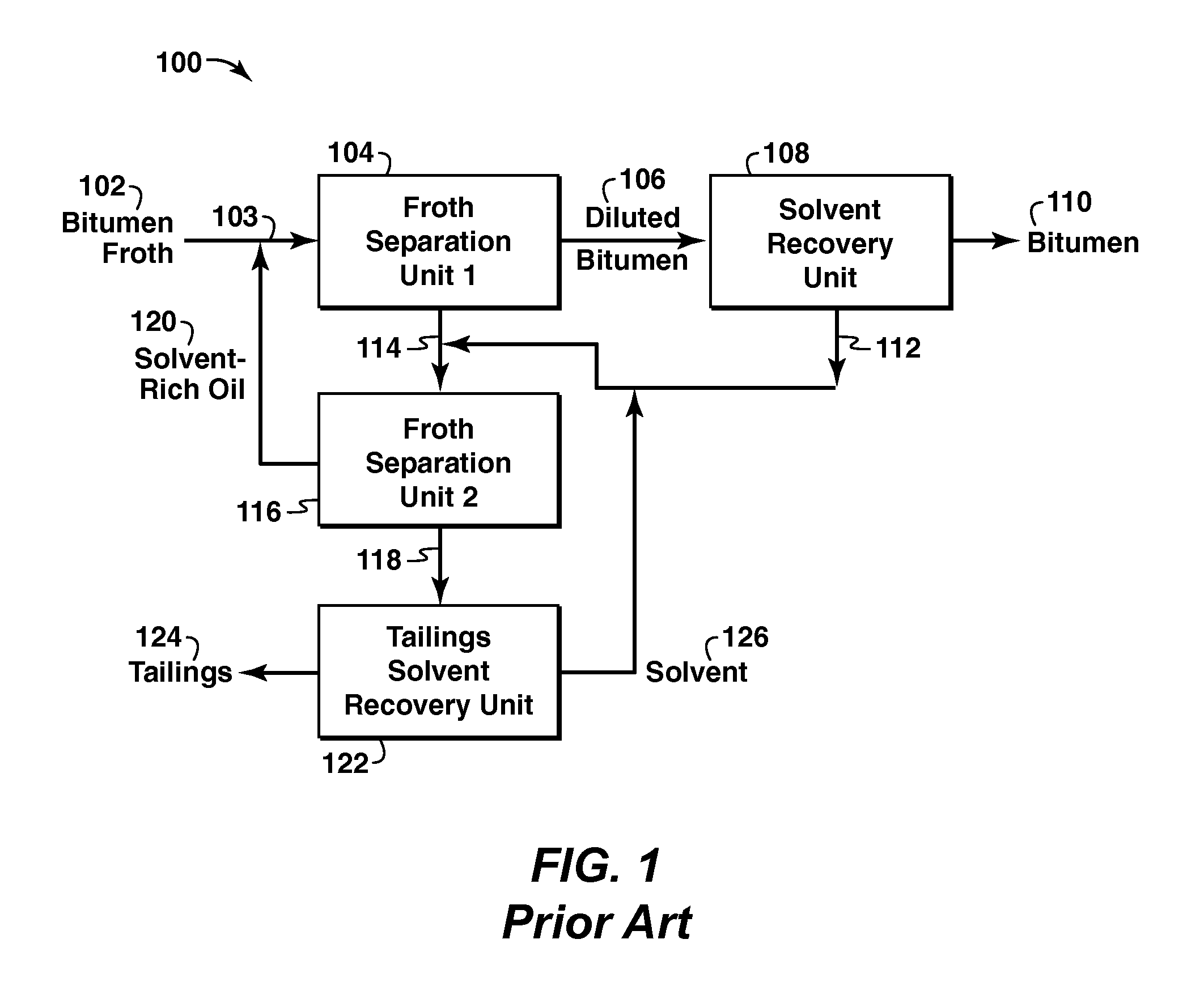

ActiveUS20090200209A1Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

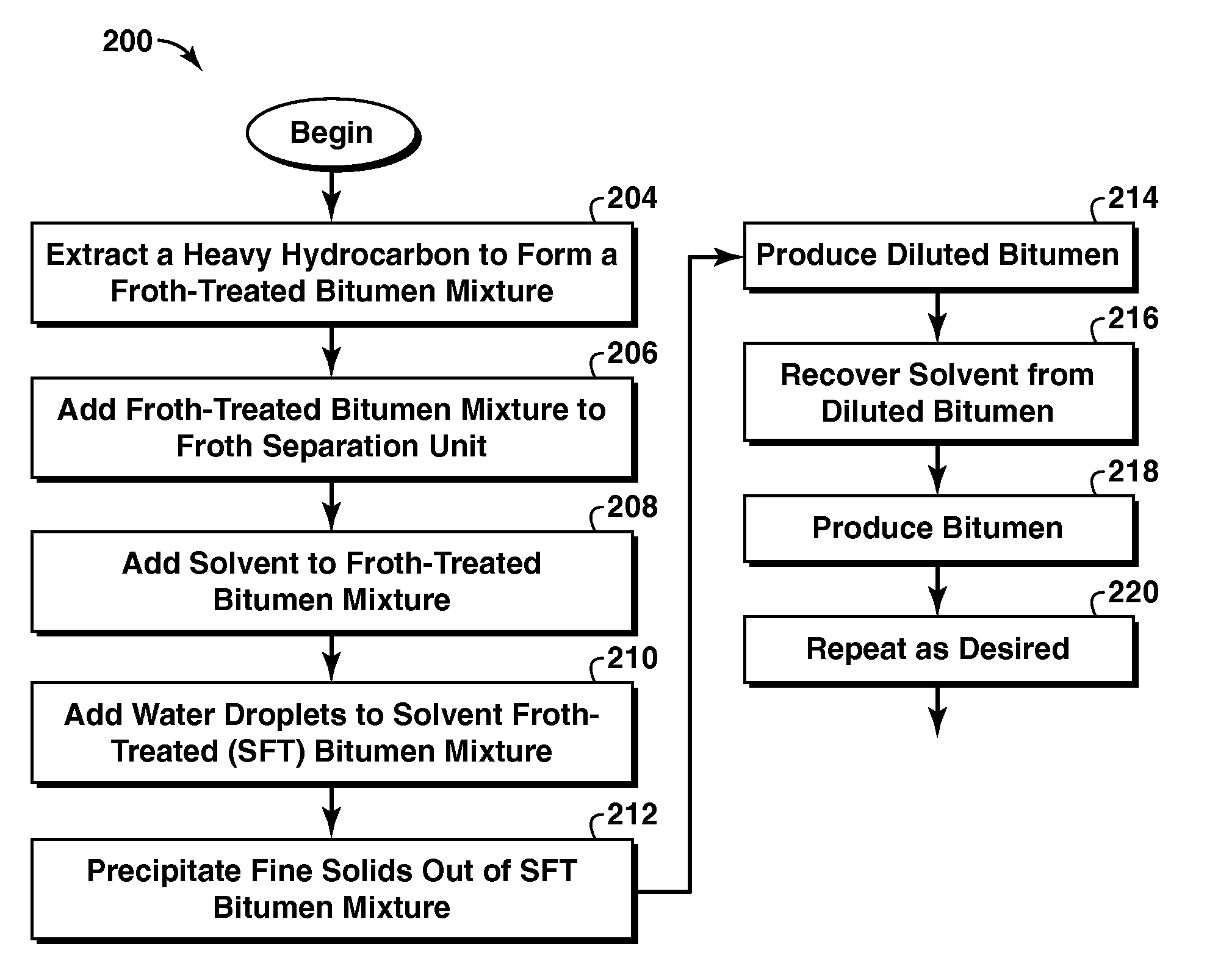

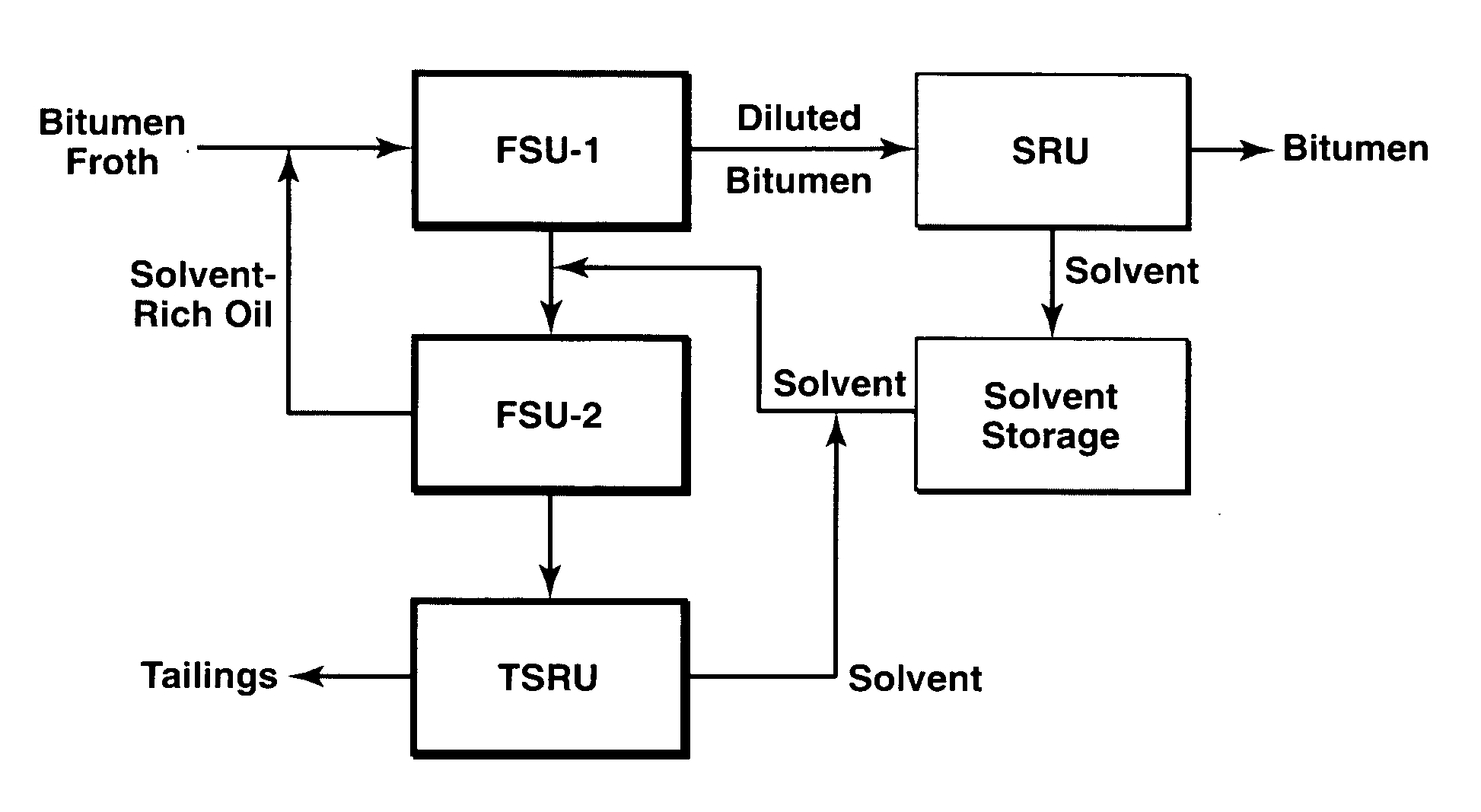

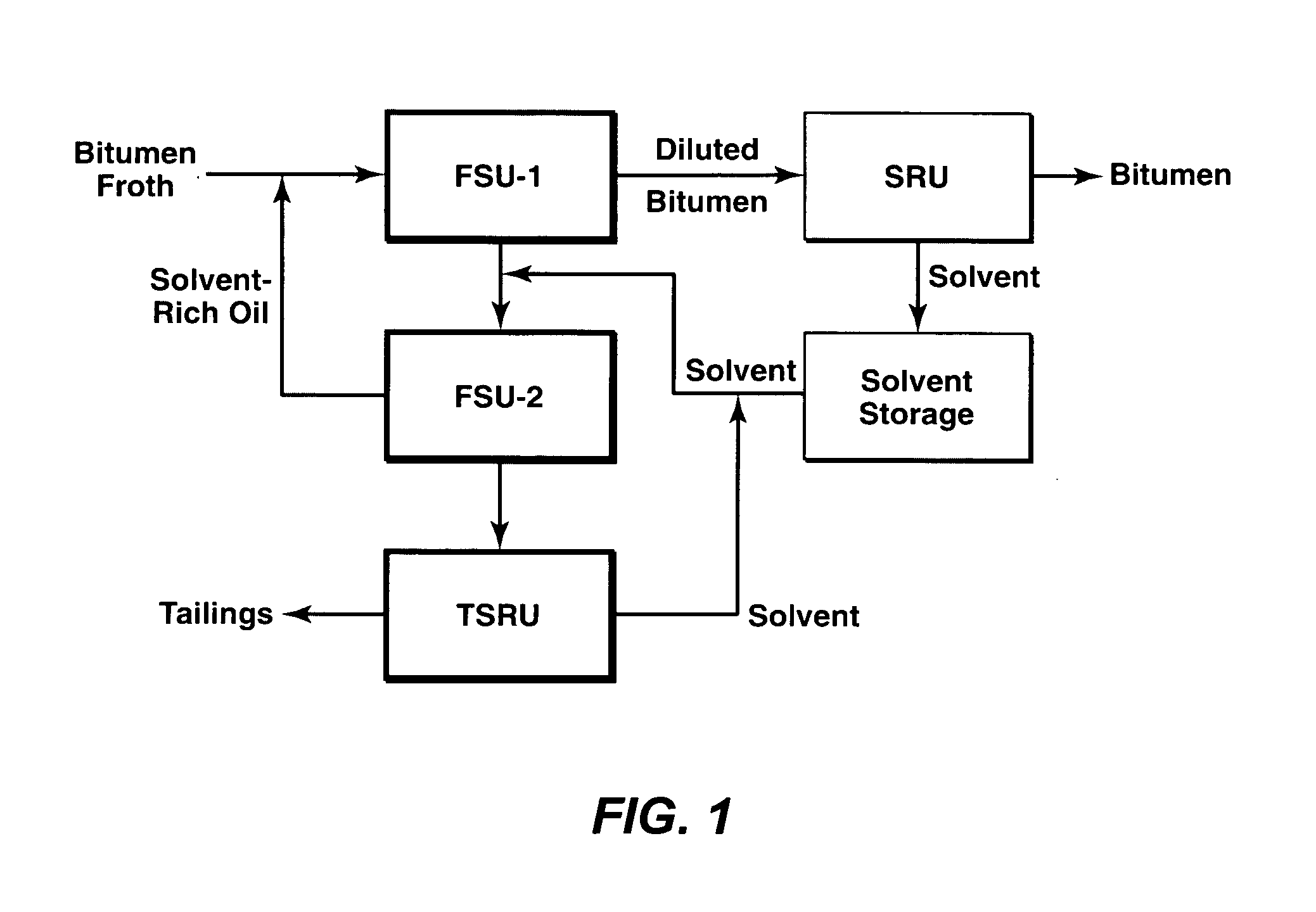

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

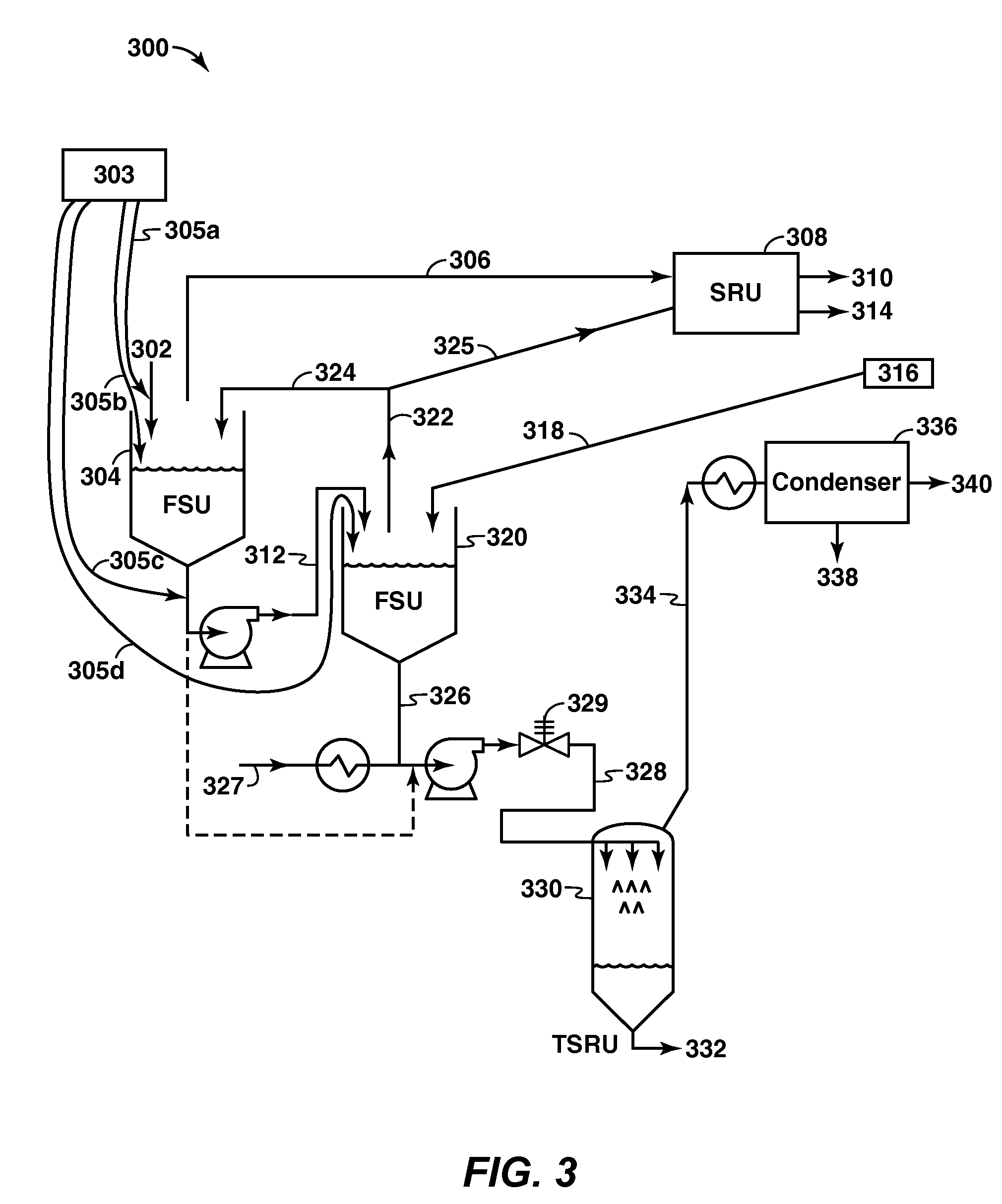

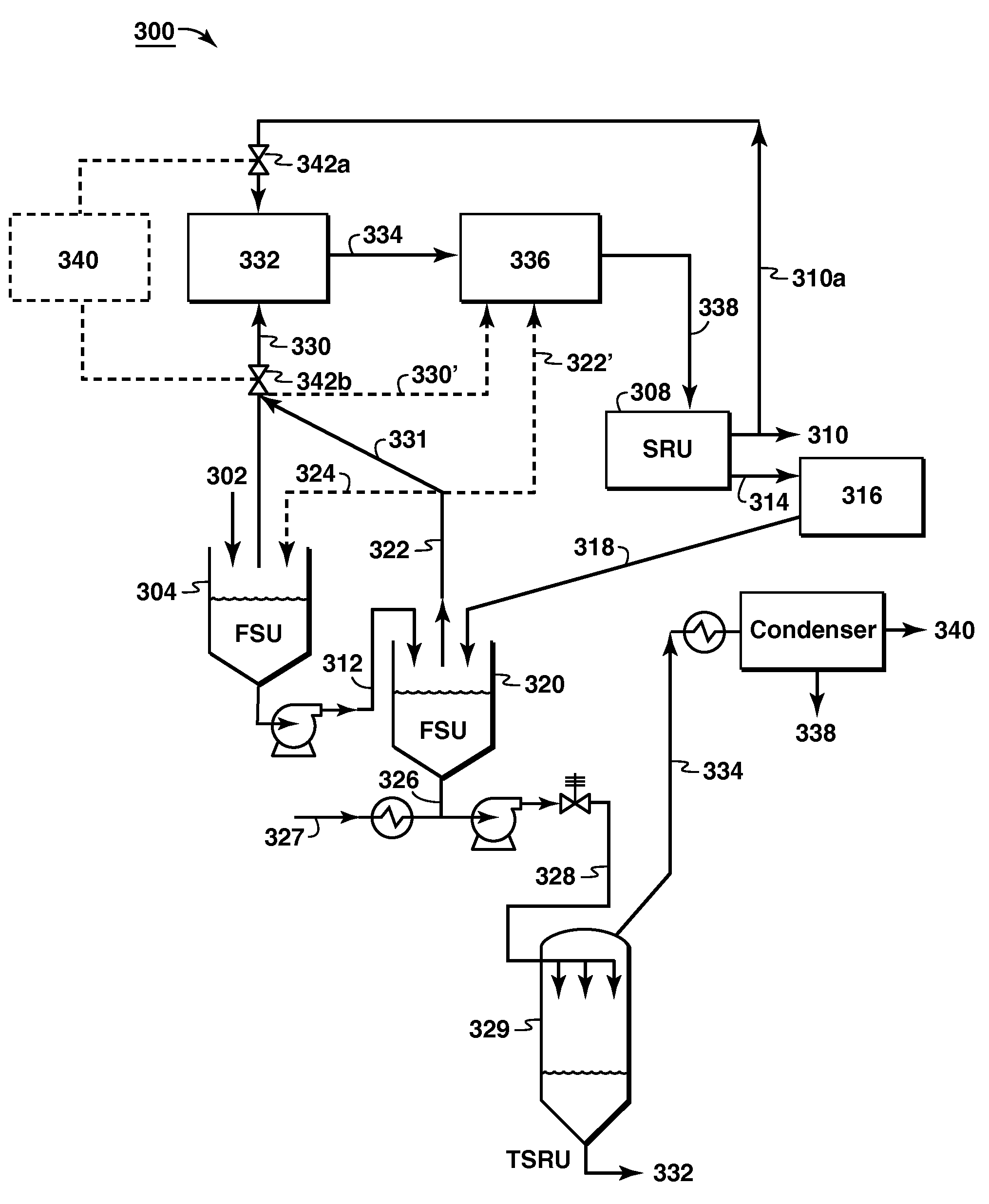

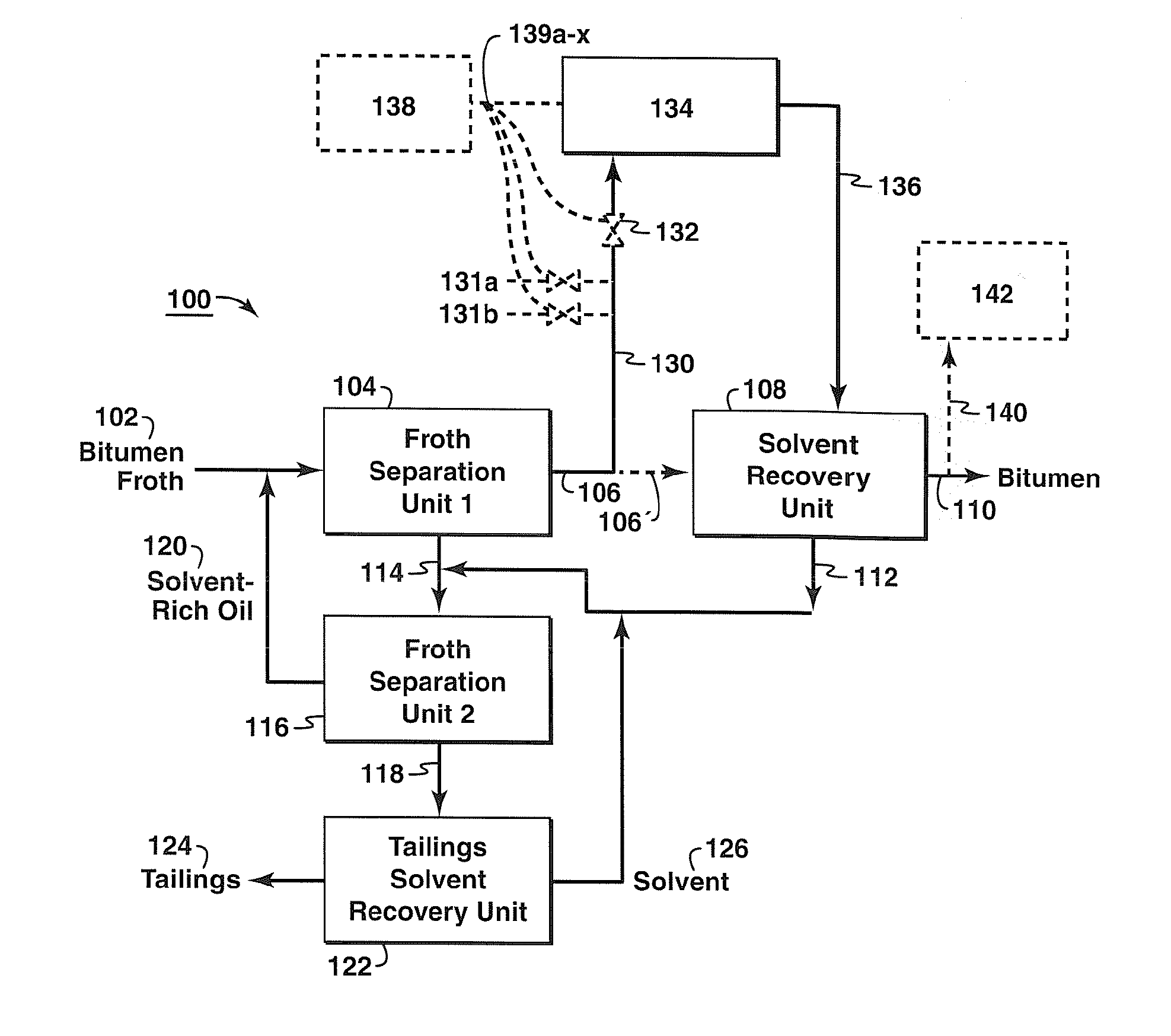

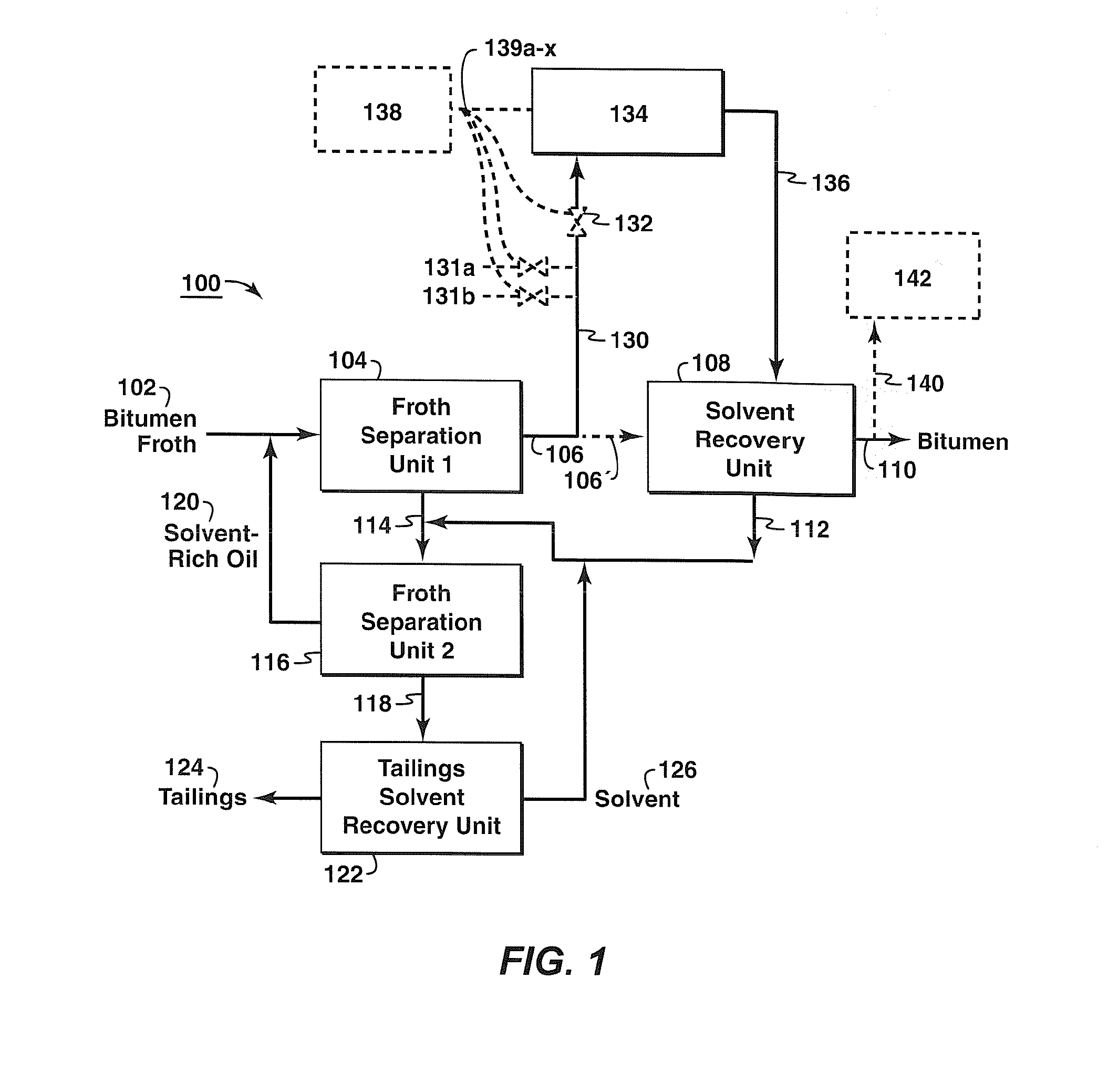

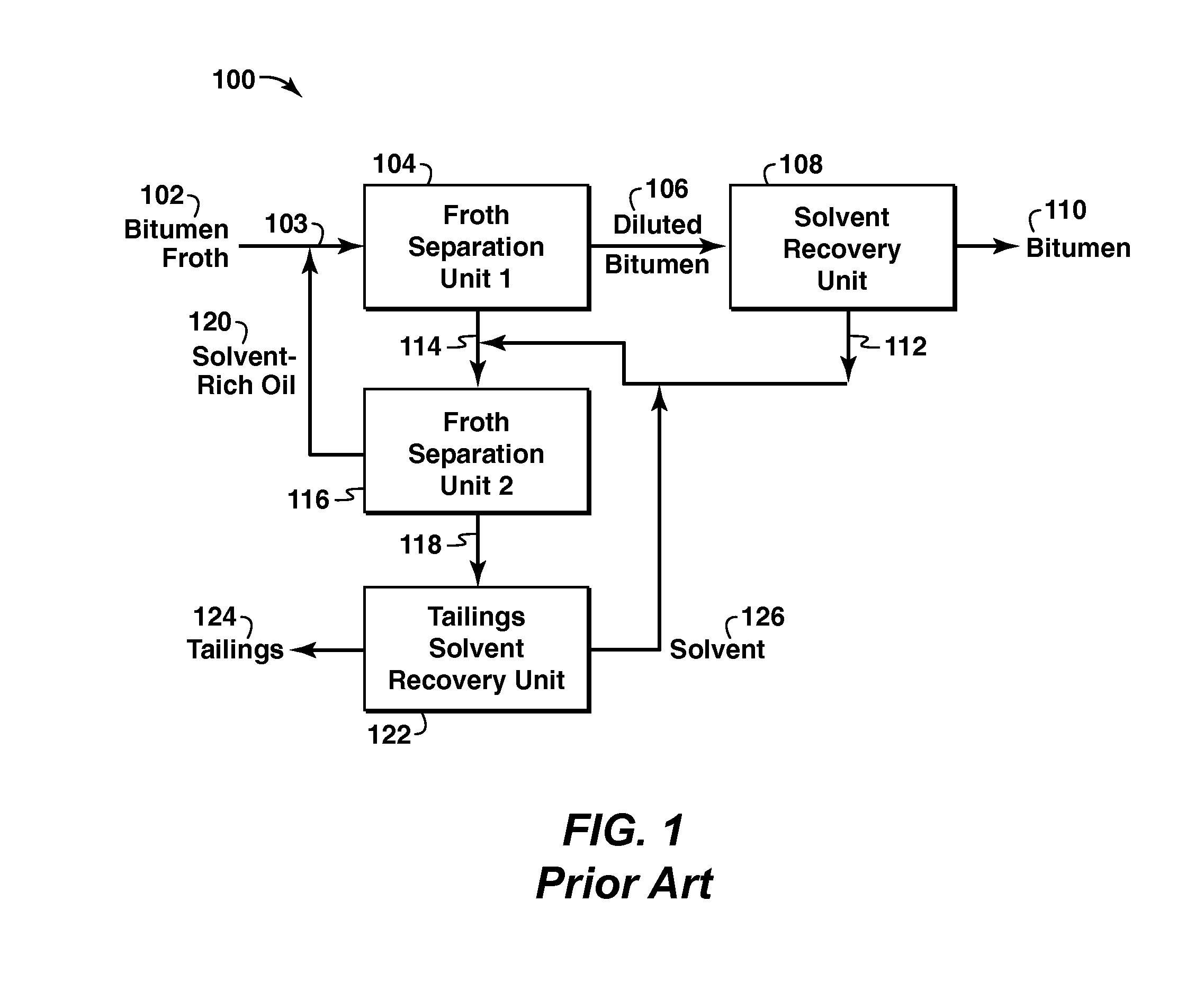

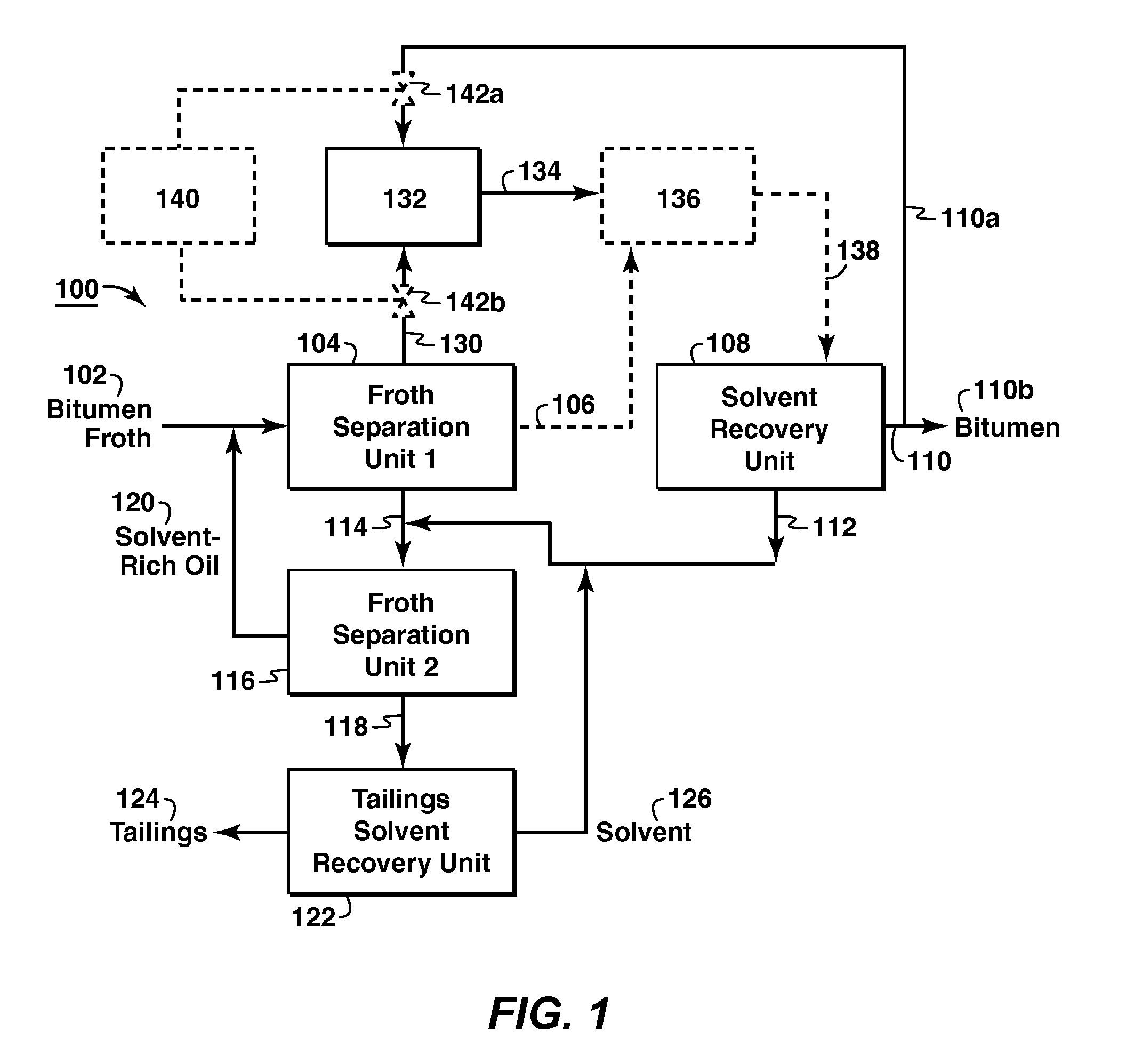

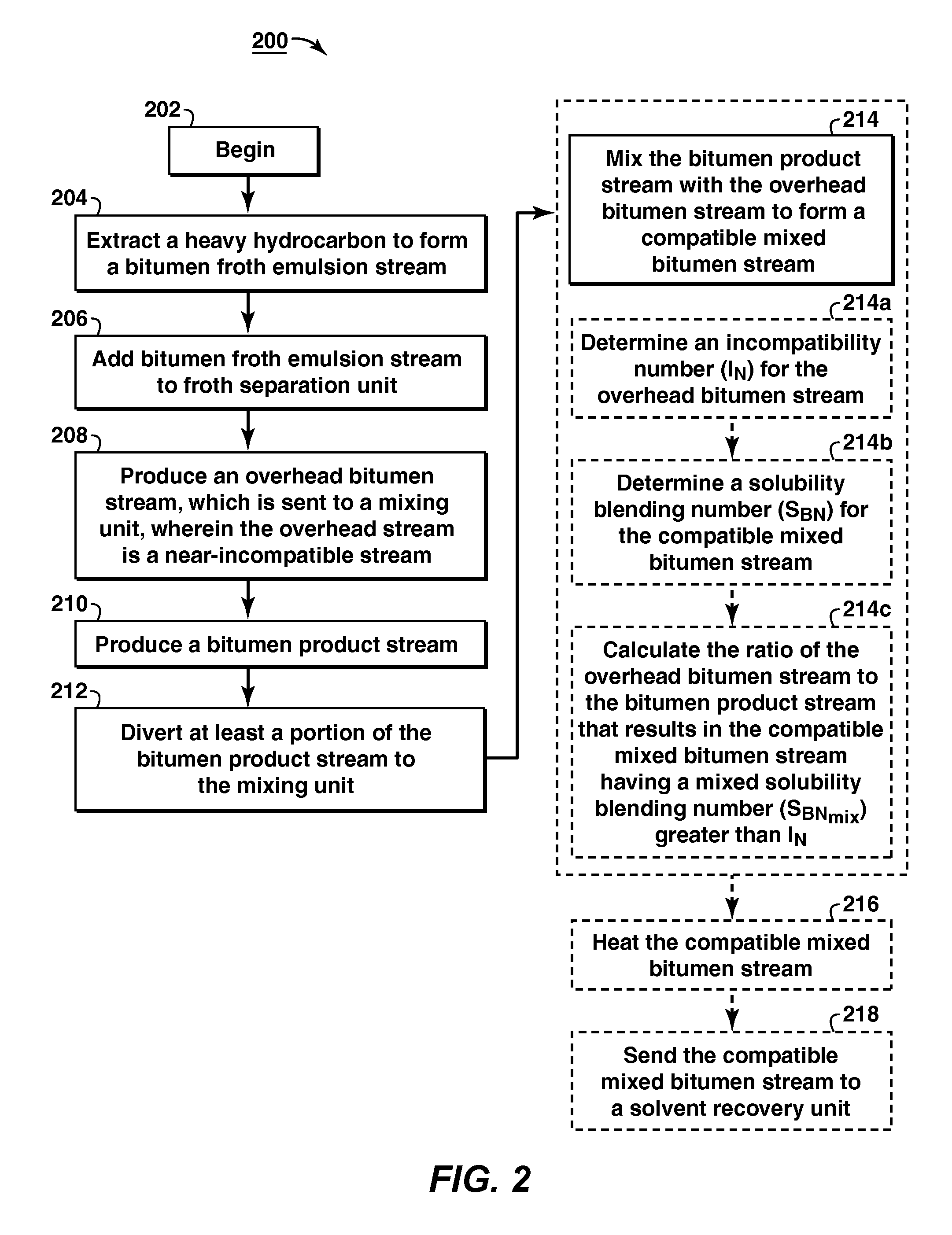

Fouling Reduction In A Paraffinic Froth Treatment Process By Solubility Control

ActiveUS20090321324A1Increase solubility parameterSolubility parameter is greatWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxSolubility

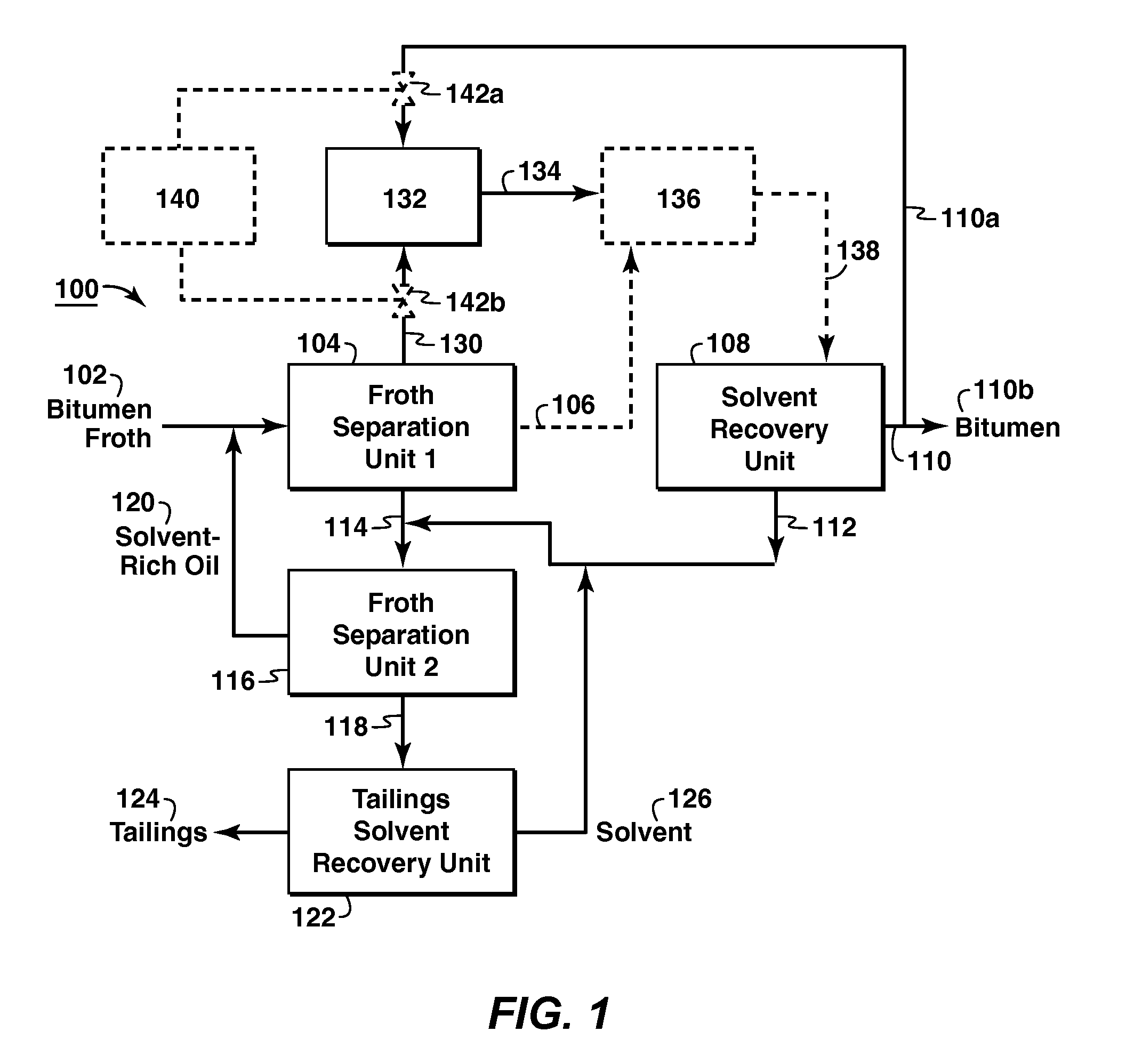

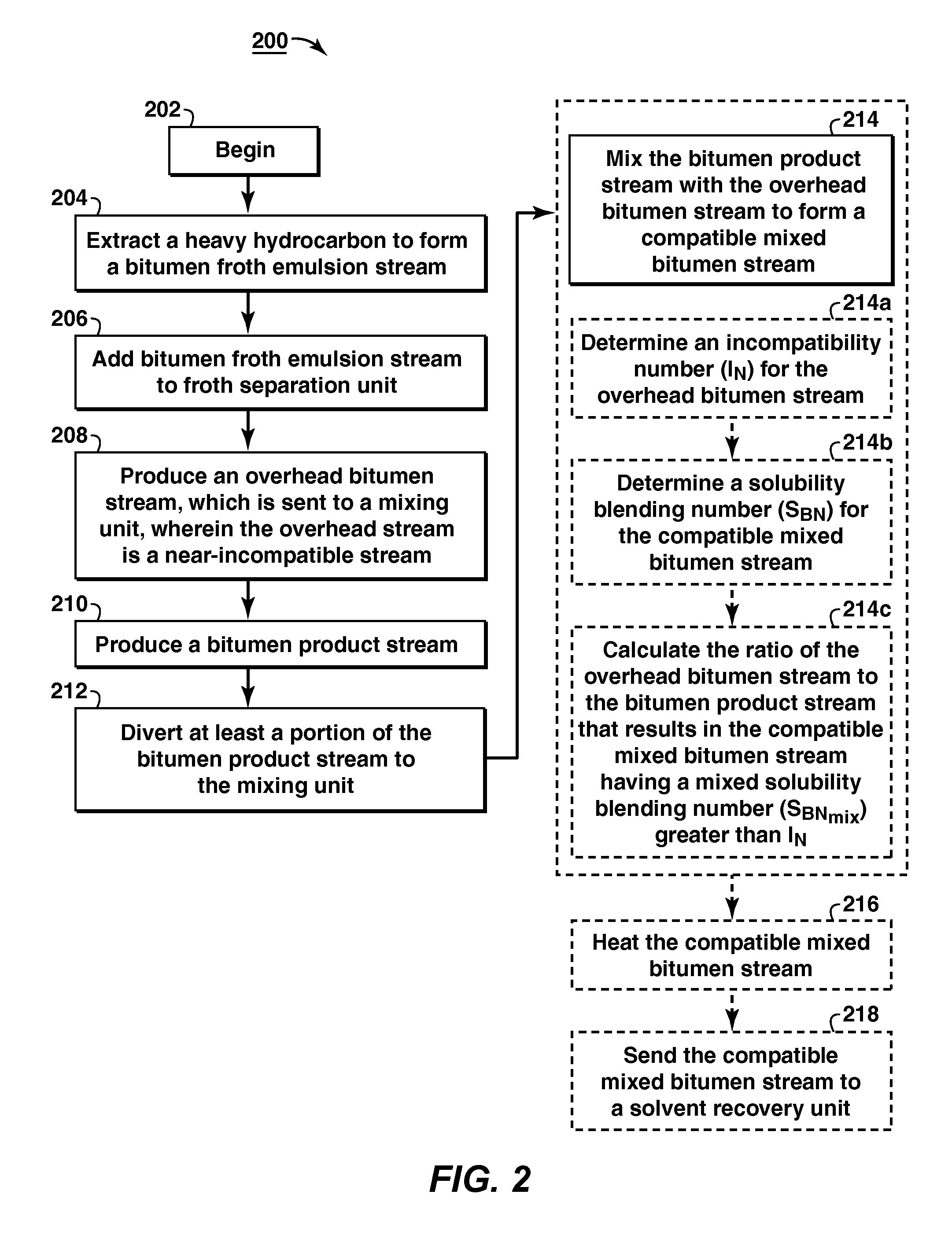

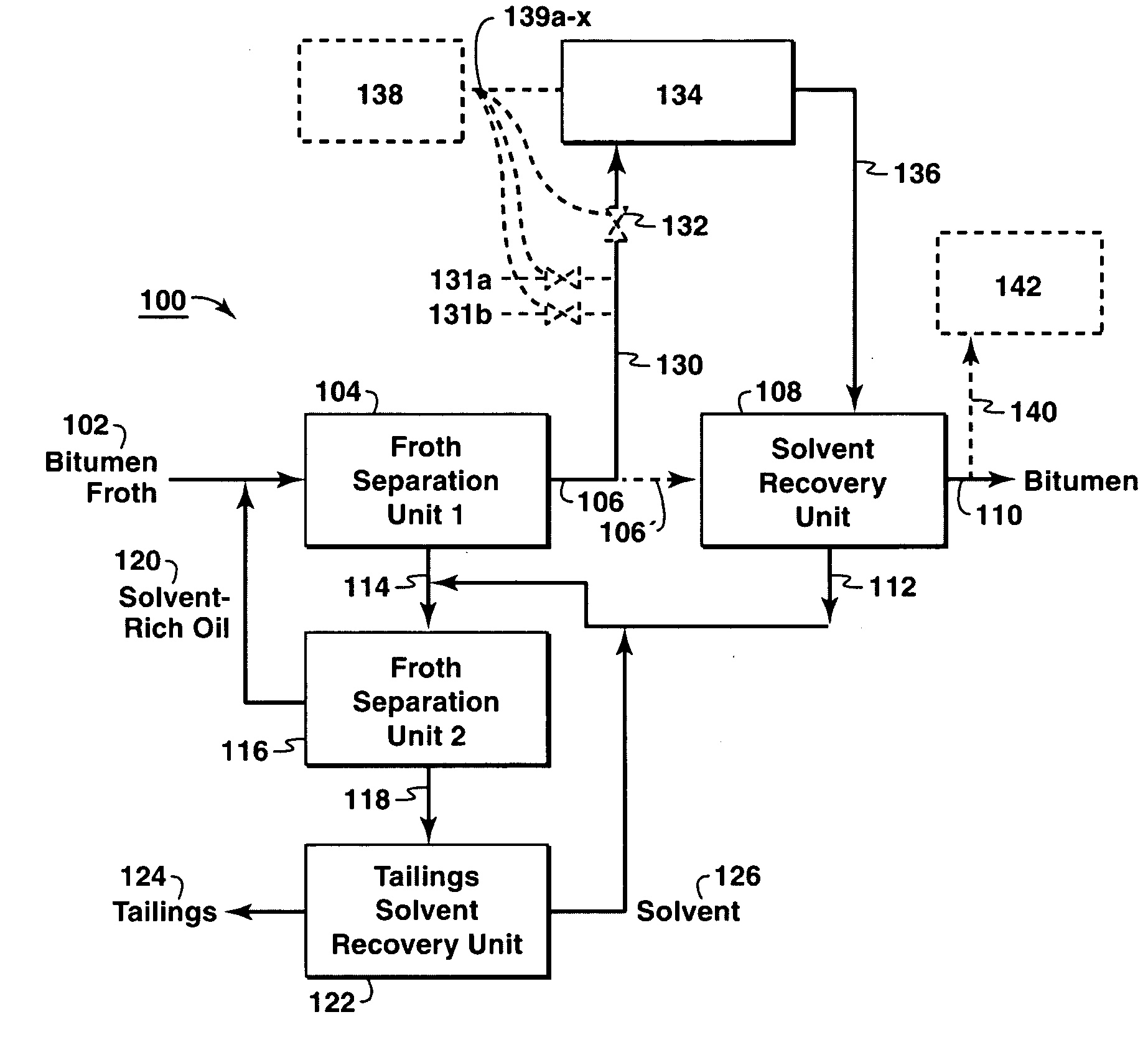

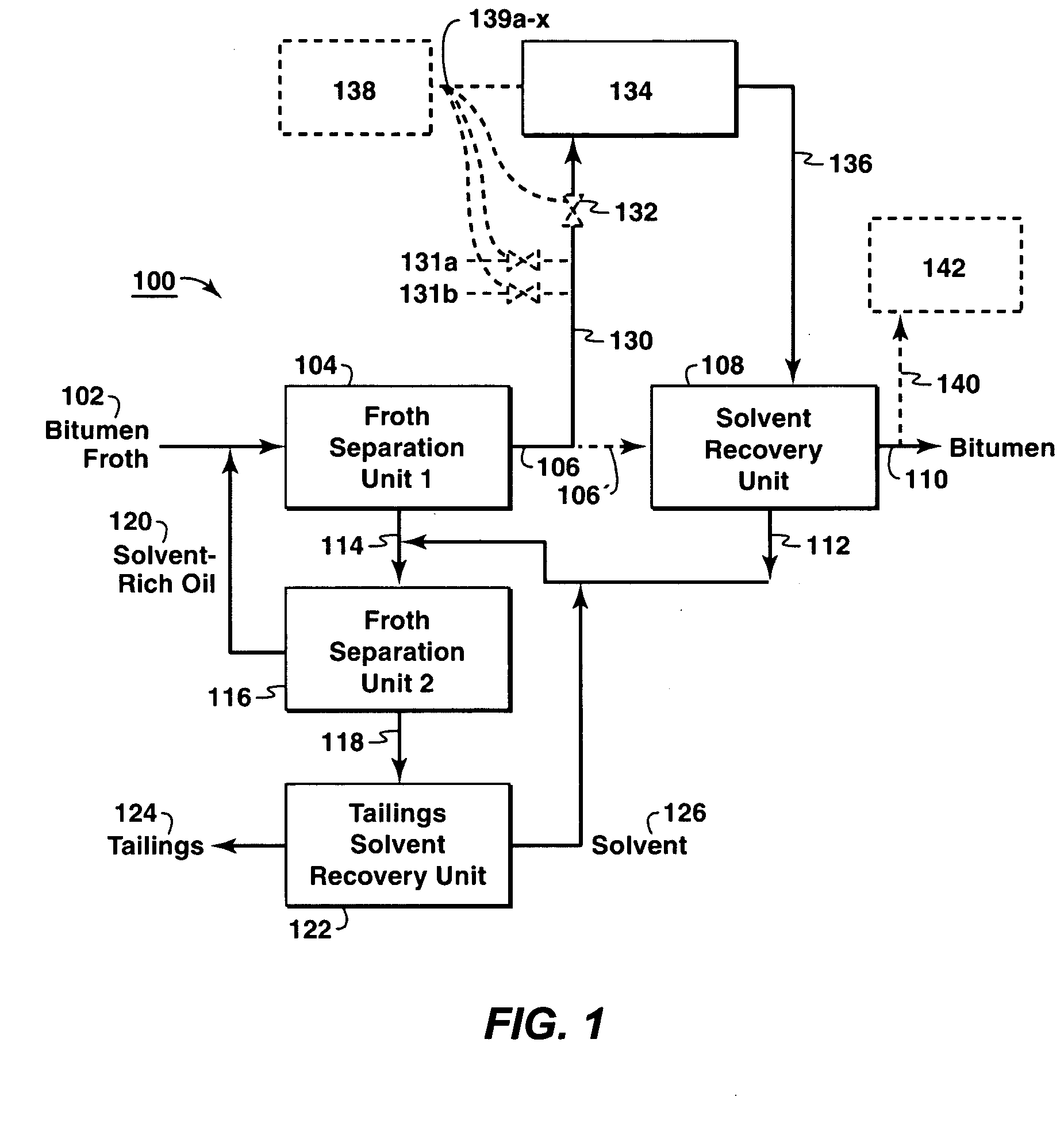

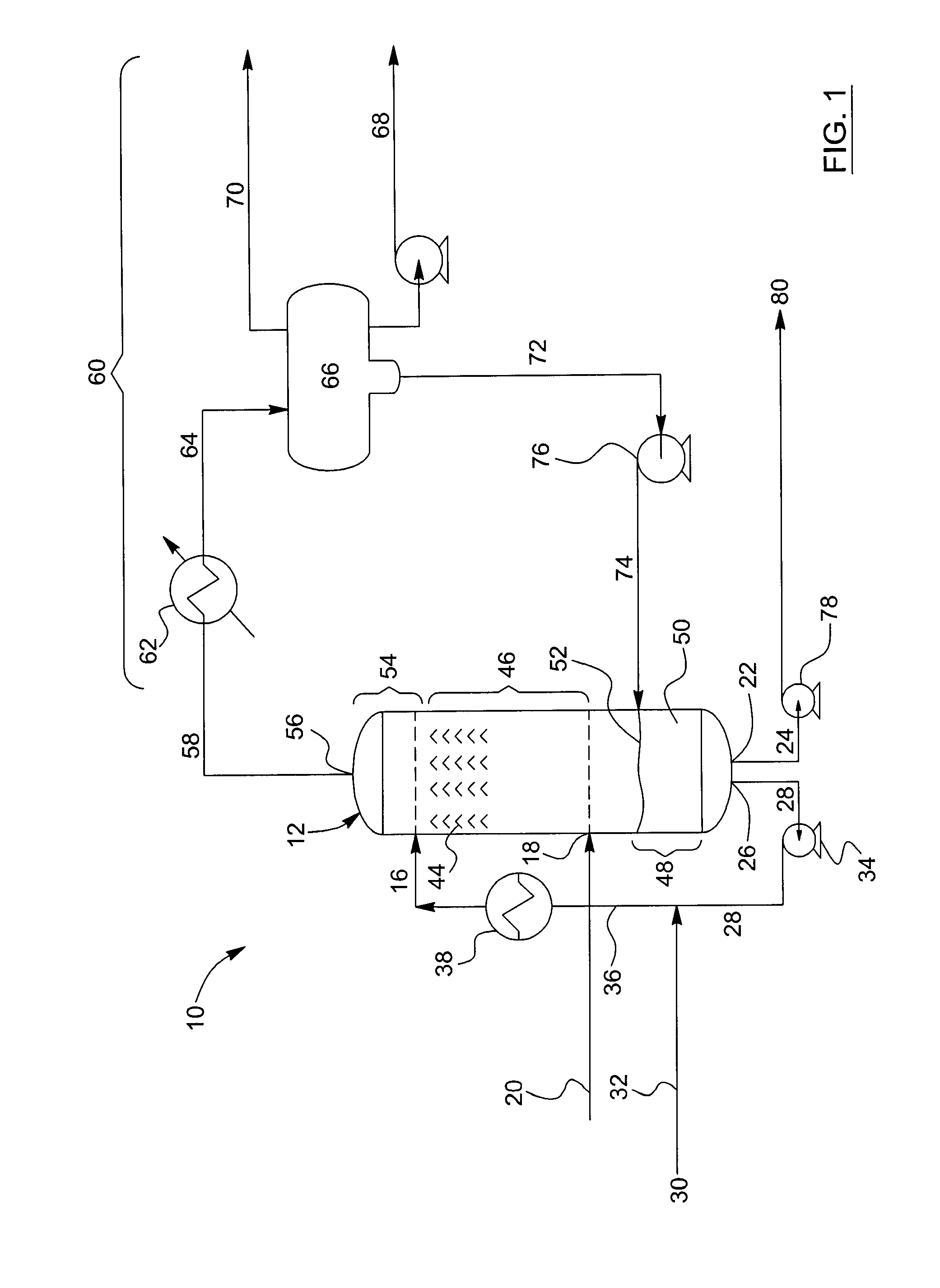

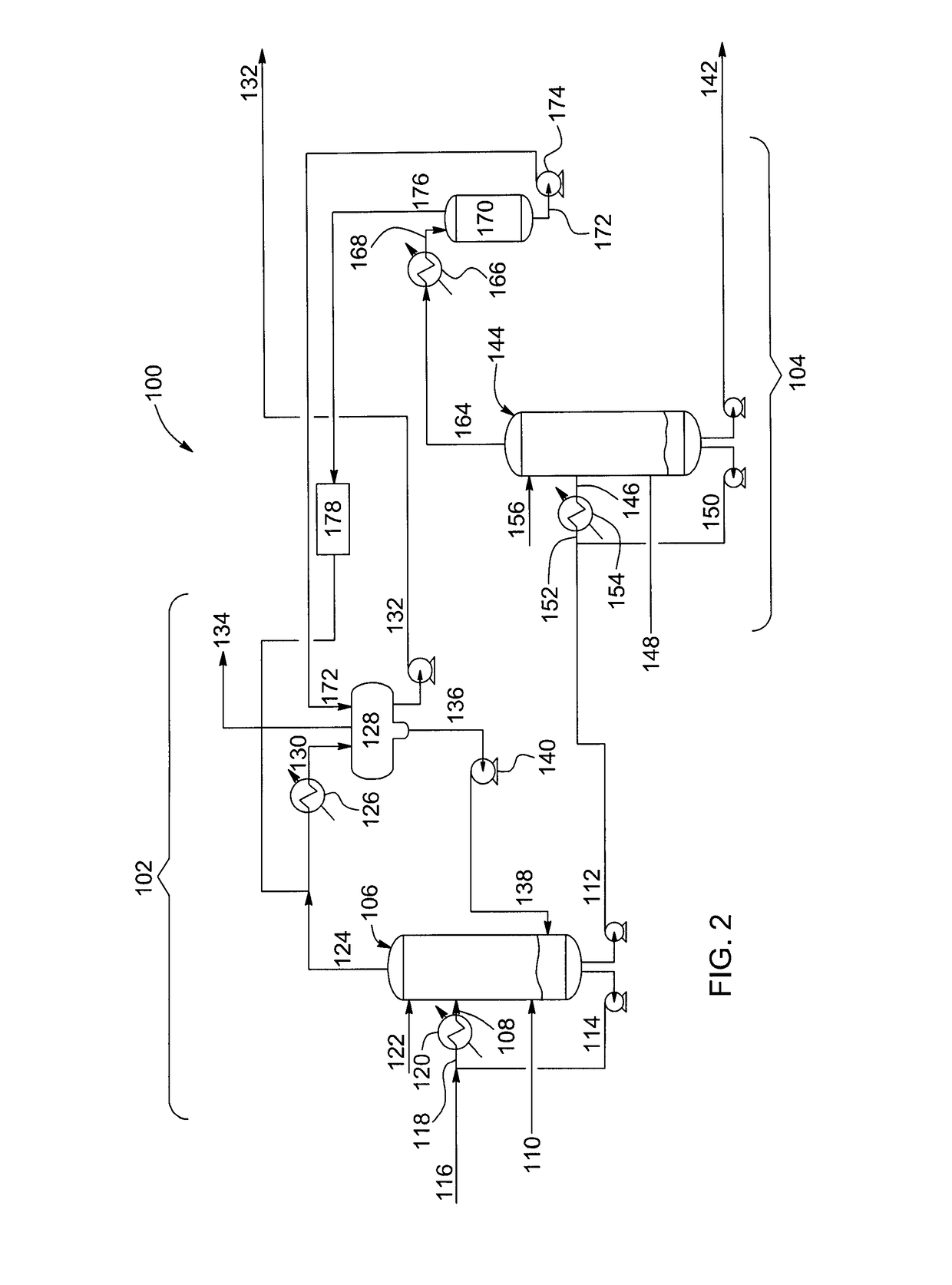

The disclosure relates to improved bitumen recovery processes and systems. In particular, the disclosure teaches processes and systems for recovering heavy crude oil while avoiding fouling of equipment by recycling at least a portion of a product bitumen from a solvent recovery unit for mixing with an overhead bitumen stream that may be a diluted bitumen stream containing solvent and bitumen. The overhead bitumen stream is a near-incompatible stream and the stream of mixed overhead bitumen stream and the treated bitumen stream is a compatible stream that will not foul equipment upon heating.

Owner:EXXONMOBIL UPSTREAM RES CO

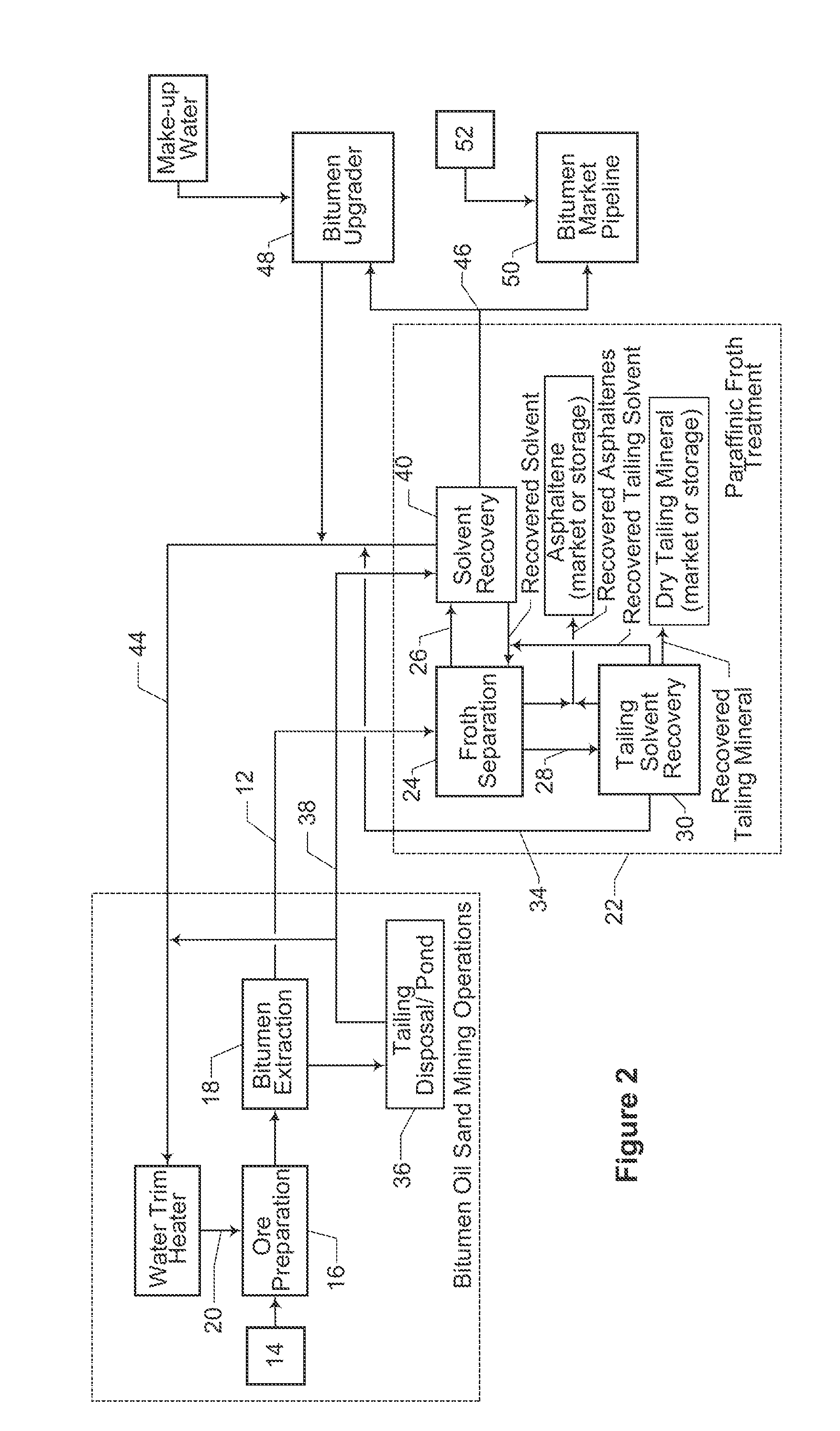

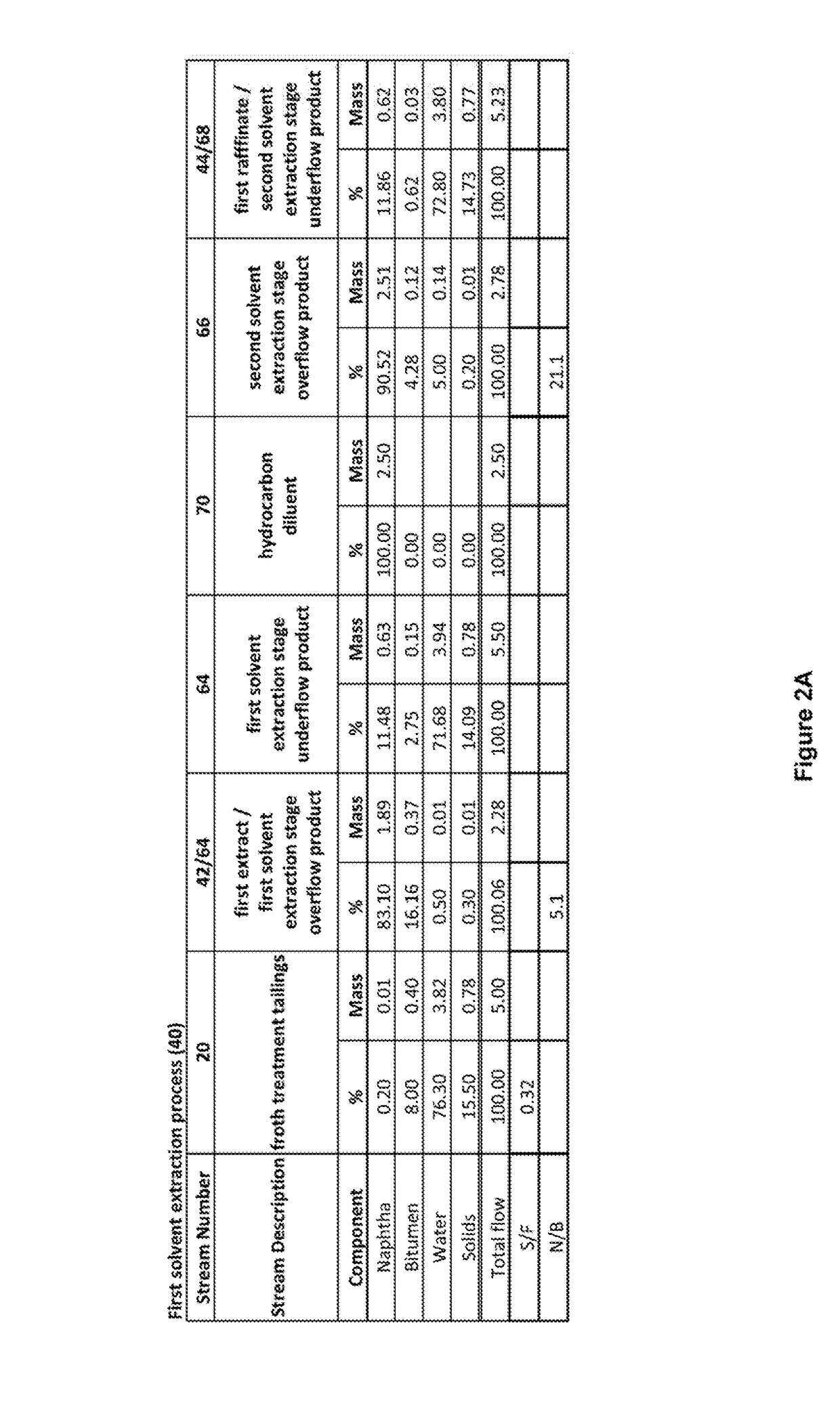

Process and system for recovery of asphaltene by-product in paraffinic froth treatment operations

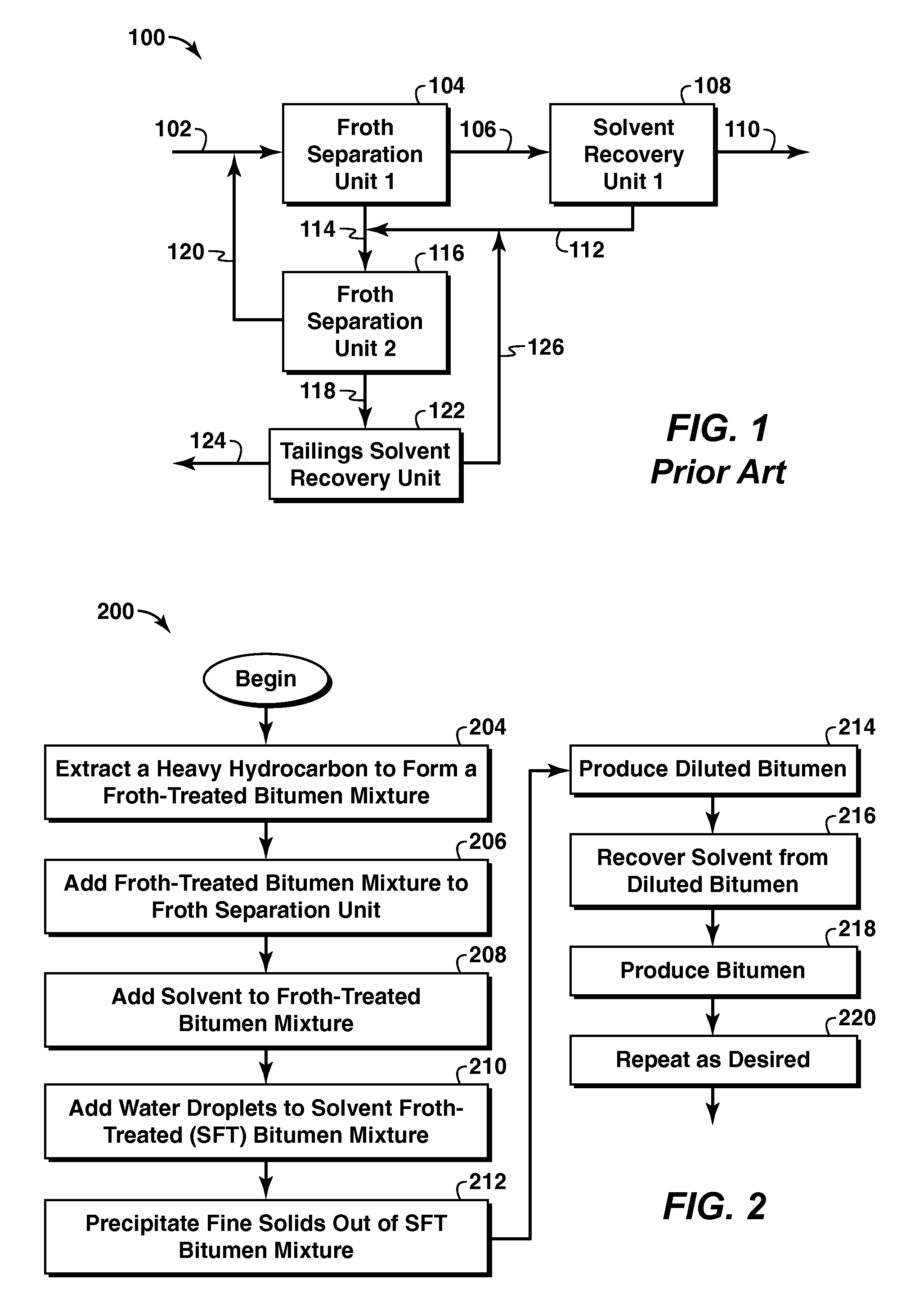

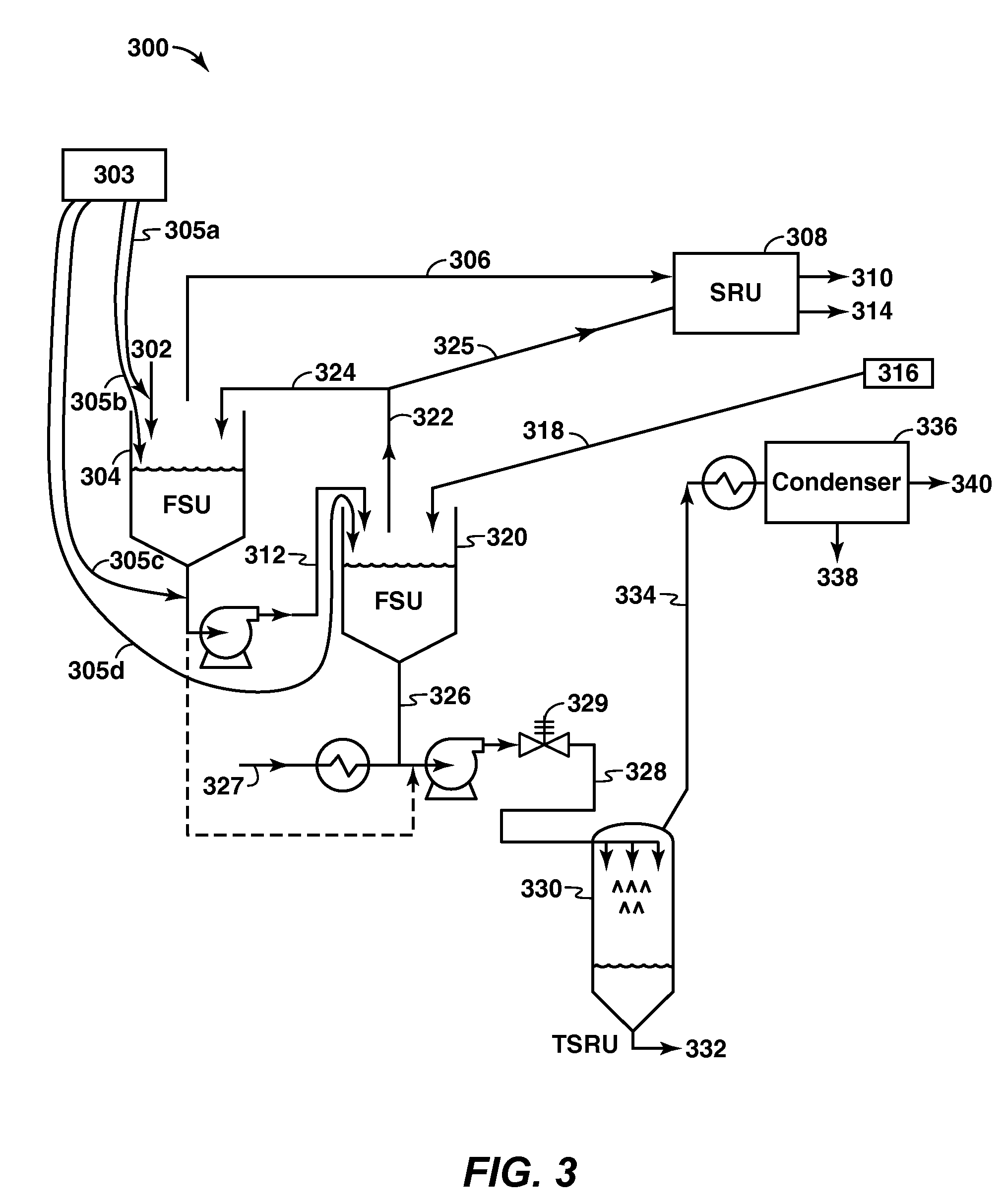

ActiveUS20100096297A1Improved quality and cleanlinessIncrease heightWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial refining stagesParaffin waxThree stage

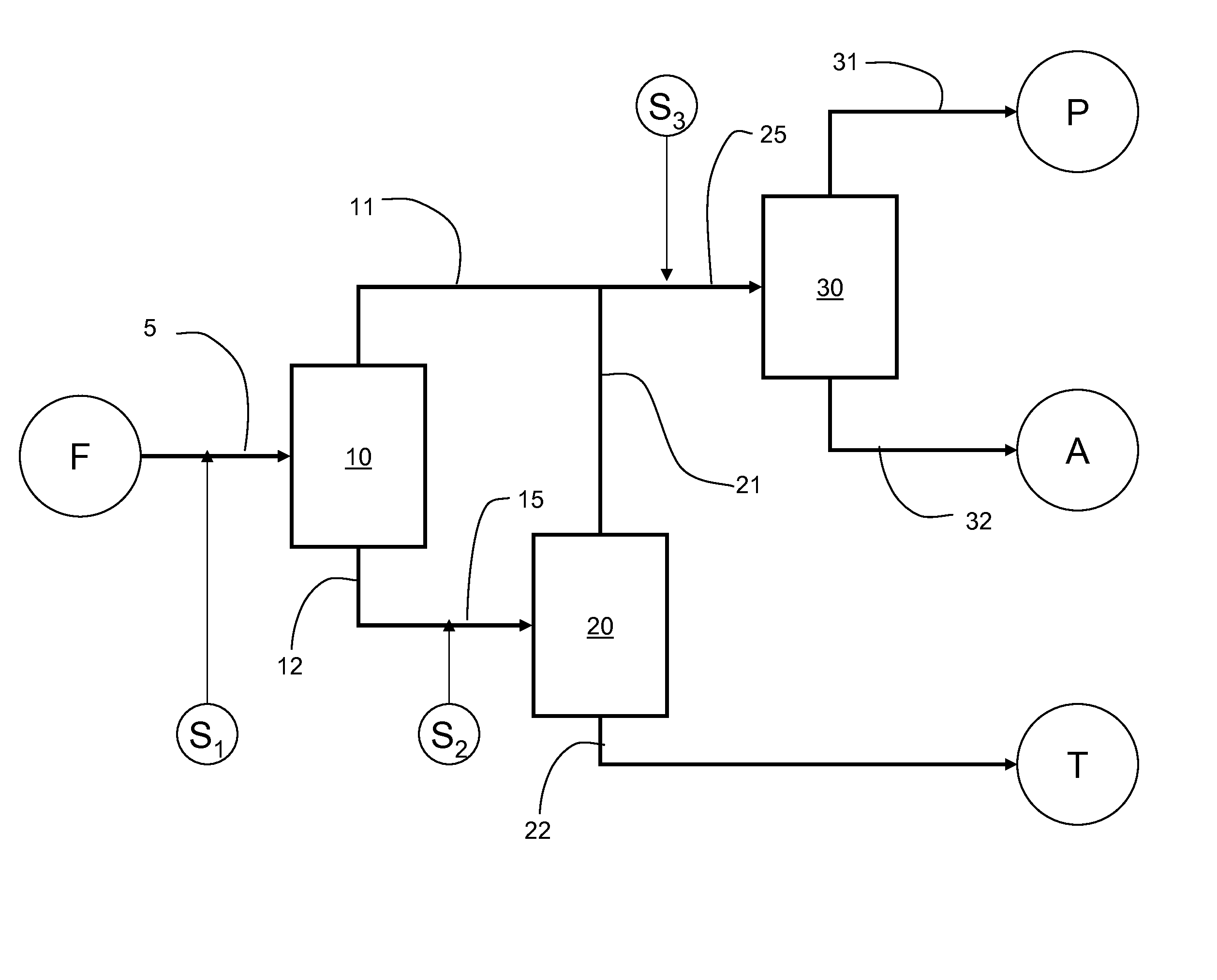

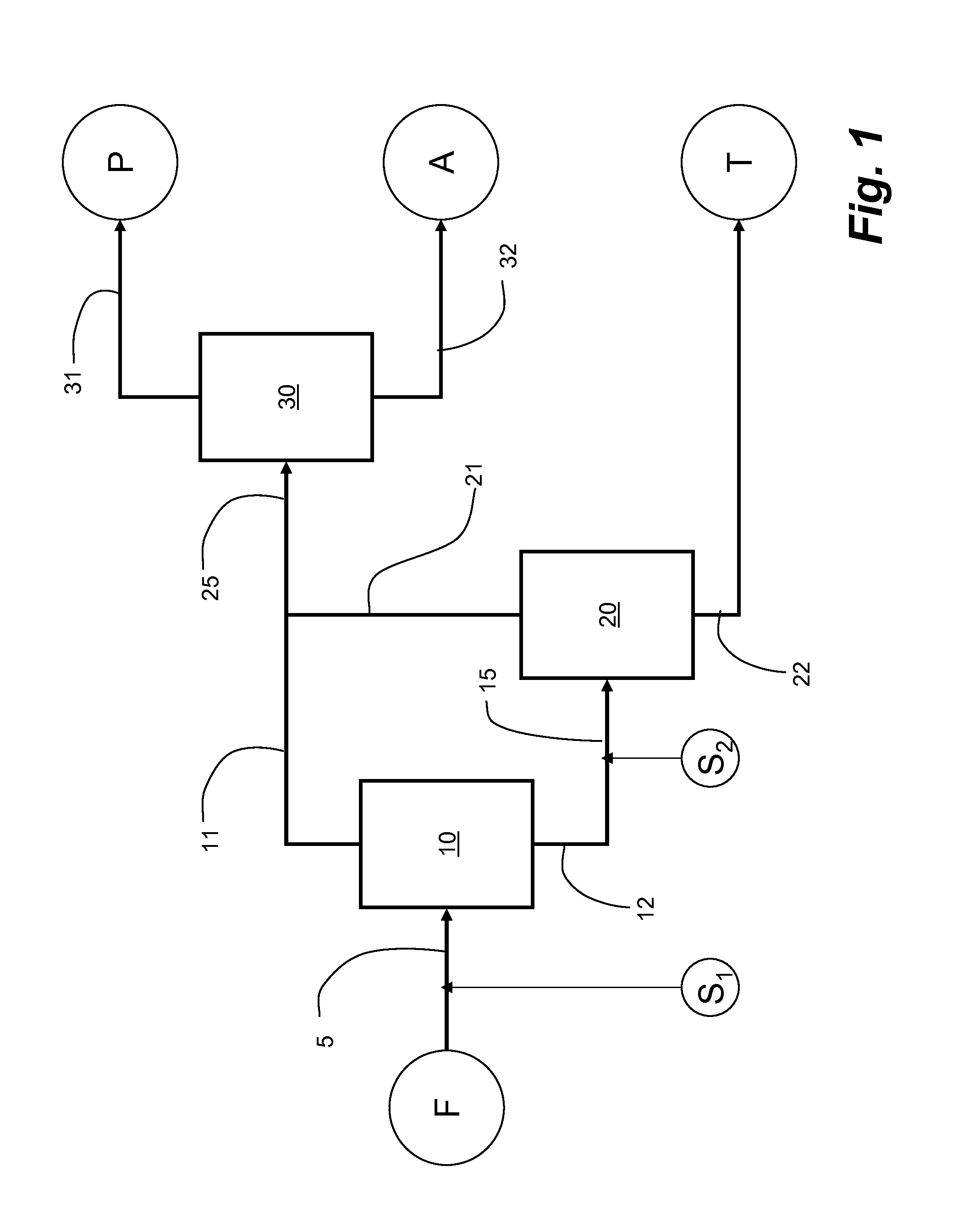

A process for treating bitumen froth with paraffinic solvent is provided which uses three stages of separation. Froth and a first solvent are directed to a first stage at a solvent / bitumen ratio for precipitating few or substantially no asphaltenes. A first stage underflow is directed to a second stage and a first stage overflow is directed to a third stage. A second stage underflow is directed to waste tailings and the second stage overflow joins the first stage overflow. A third stage underflow is recovered as an asphaltene by-product and a third stage overflow is recovered as a diluted bitumen product. At least a second solvent is added to one or both of the second or third stages for controlling a fraction of asphaltenes in the third stage underflow. Asphaltene loss to waste tailings is minimized and asphaltenes are now recovered as asphaltene by-product.

Owner:CANADIAN NATURAL RESOURCES

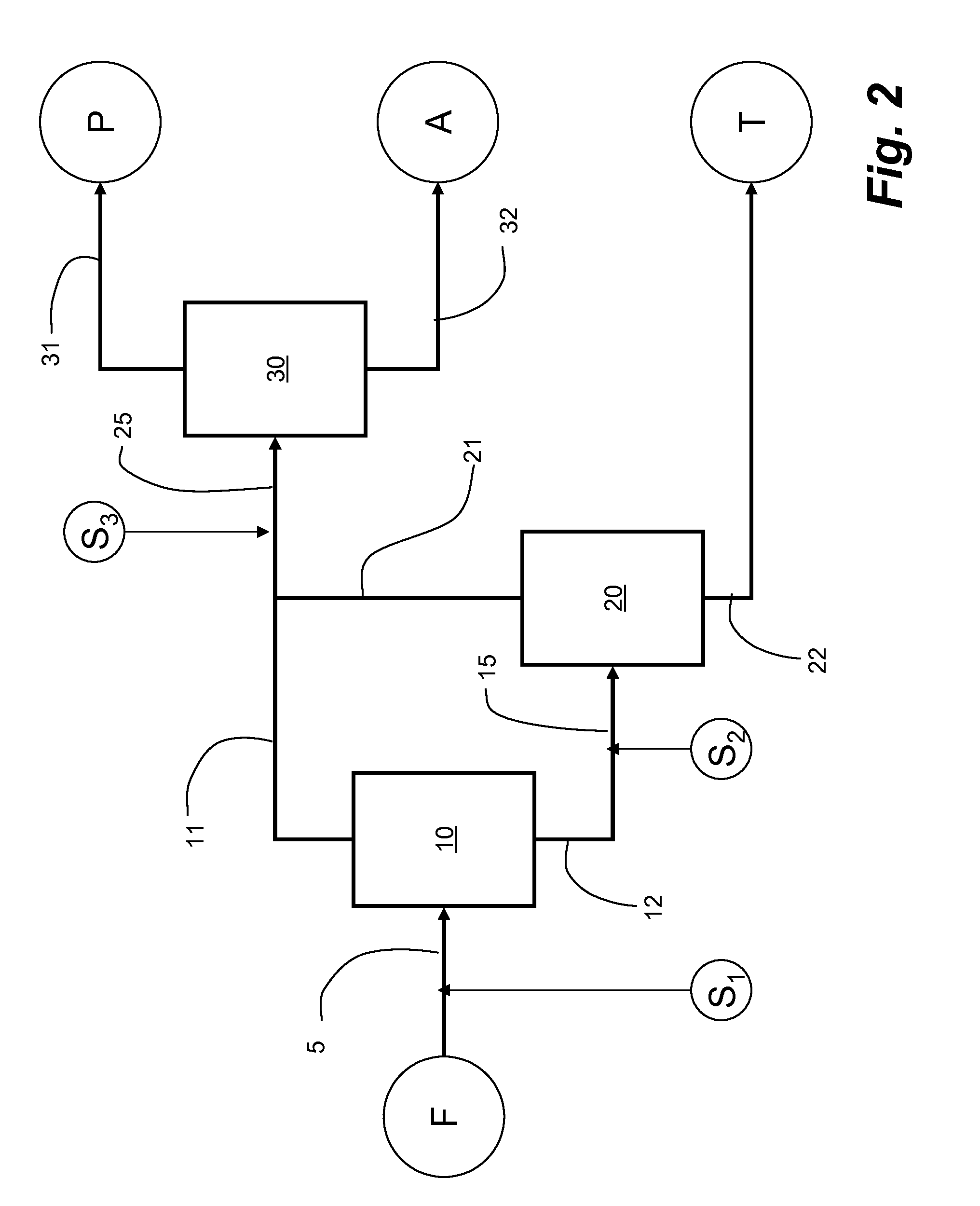

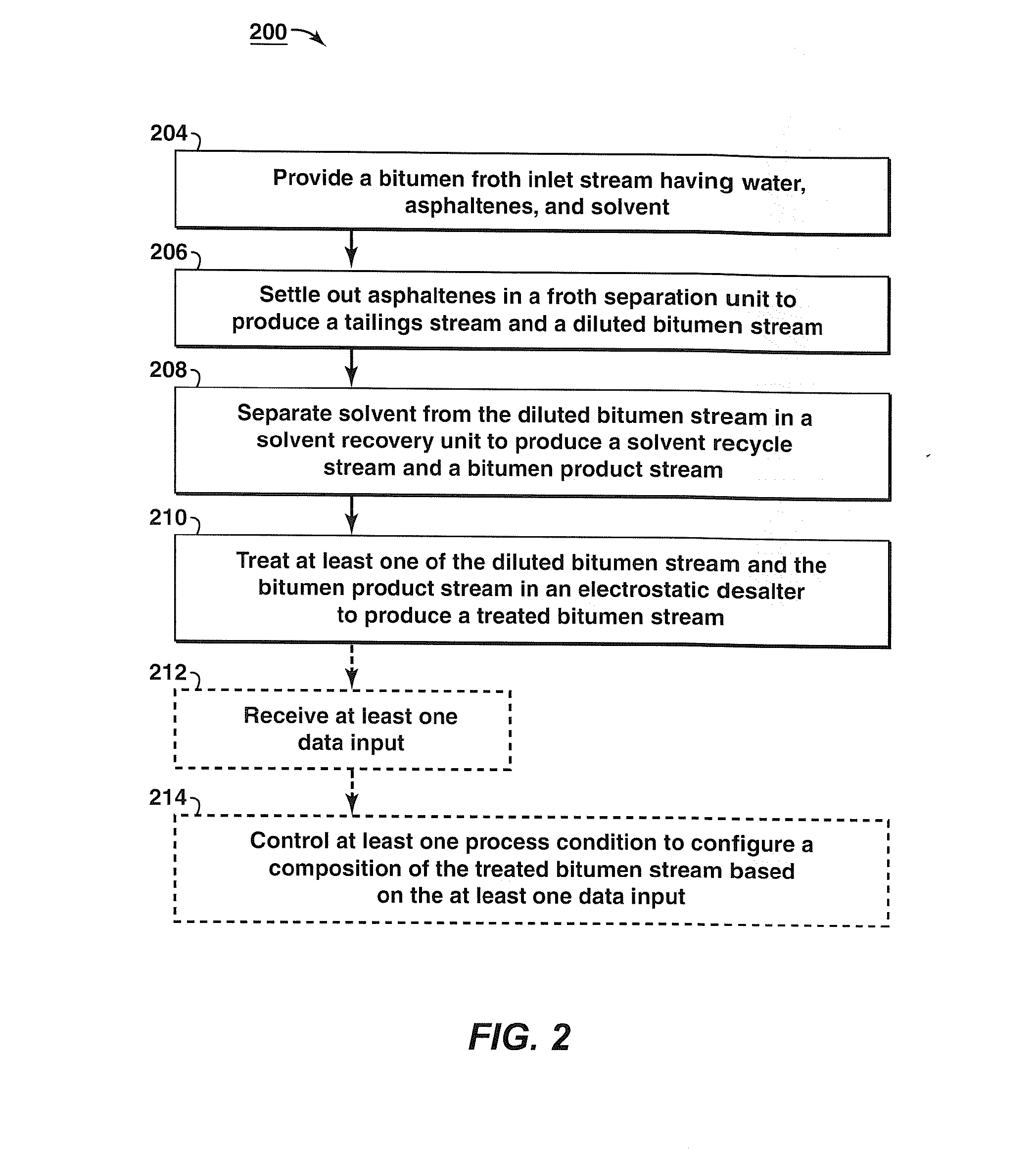

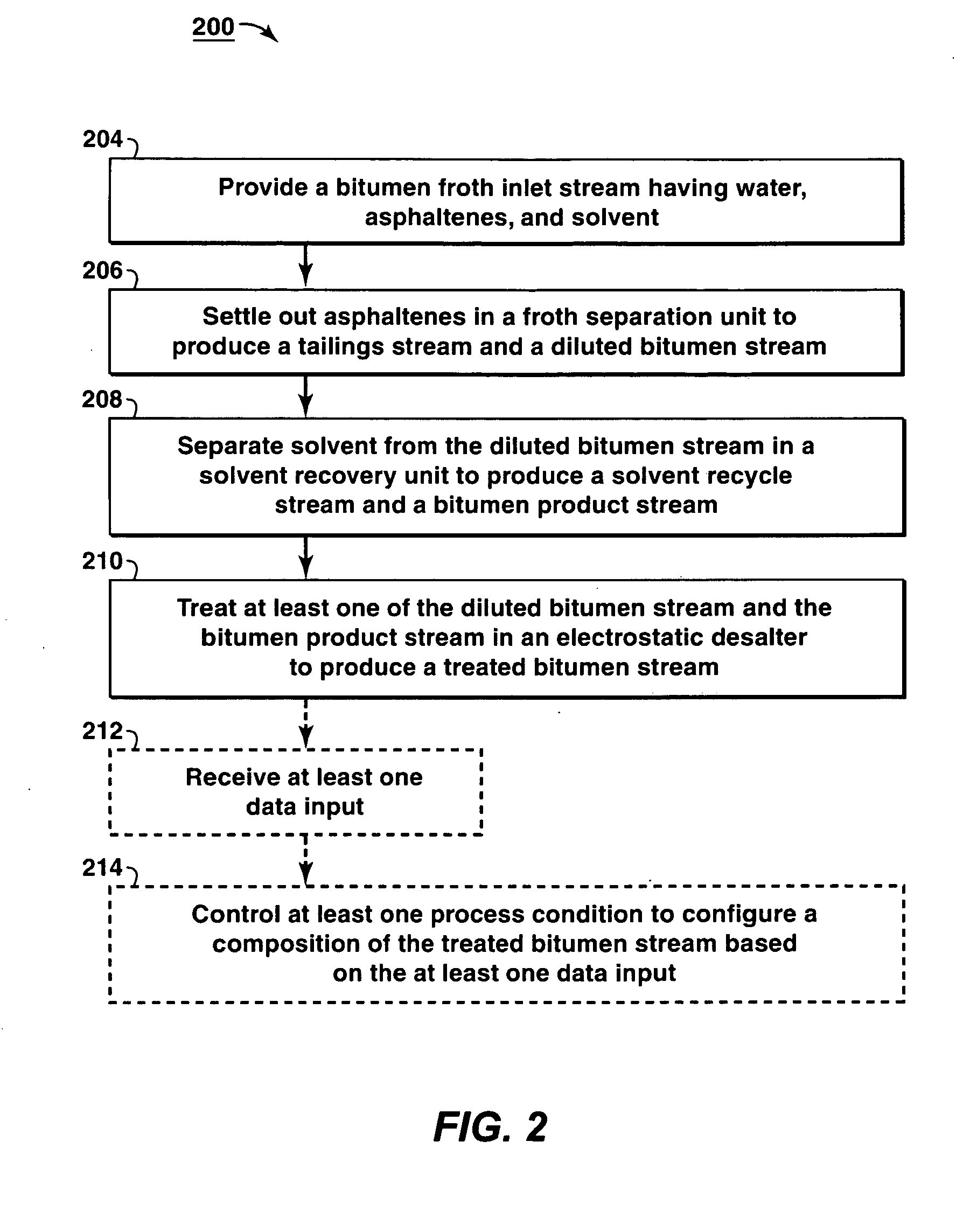

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

InactiveUS20120217187A1Working-up pitch/asphalt/bitumen by selective extractionDewatering/demulsification with electric/magnetic meansFuel oilDesalter

Owner:SHARMA ARUN K +1

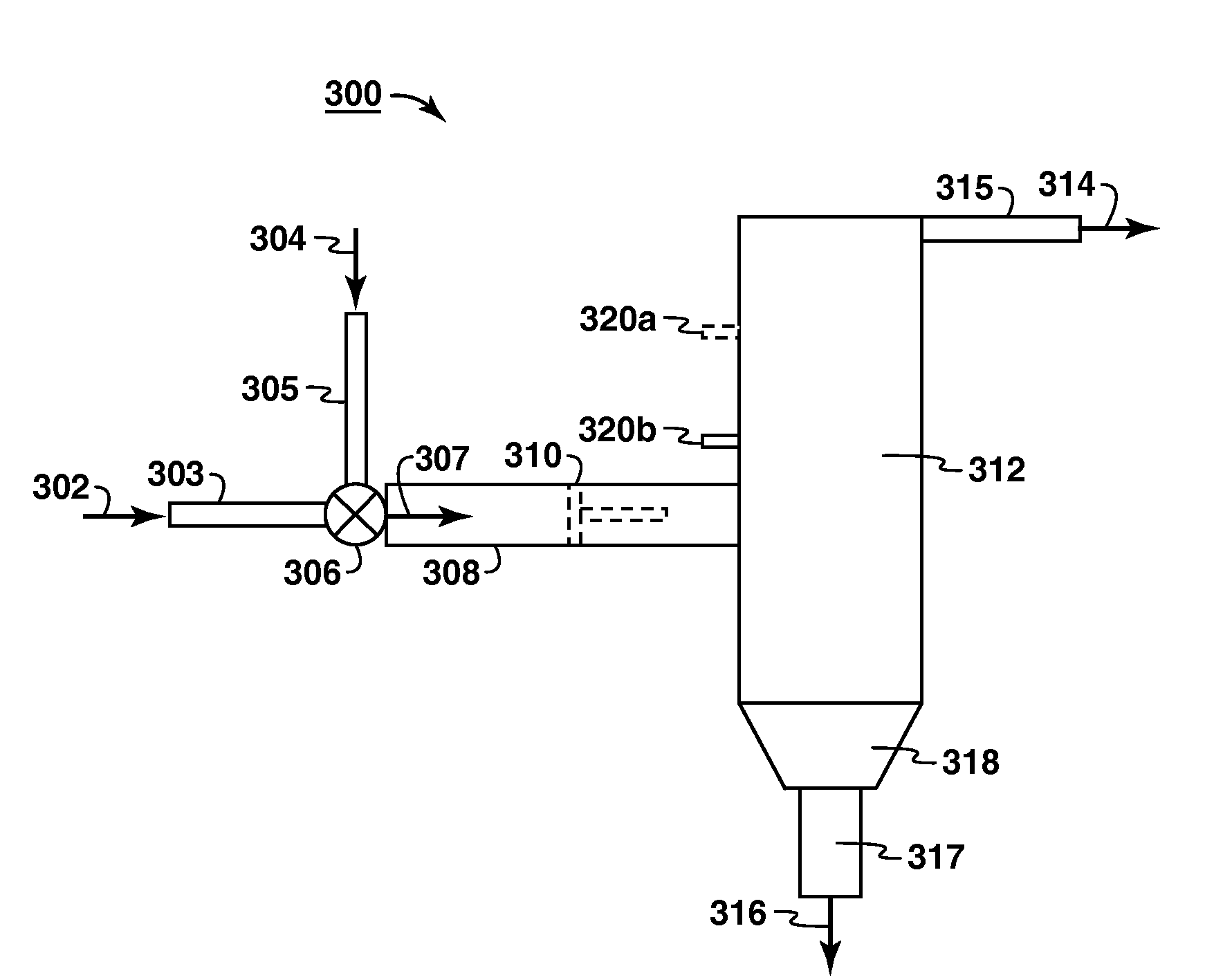

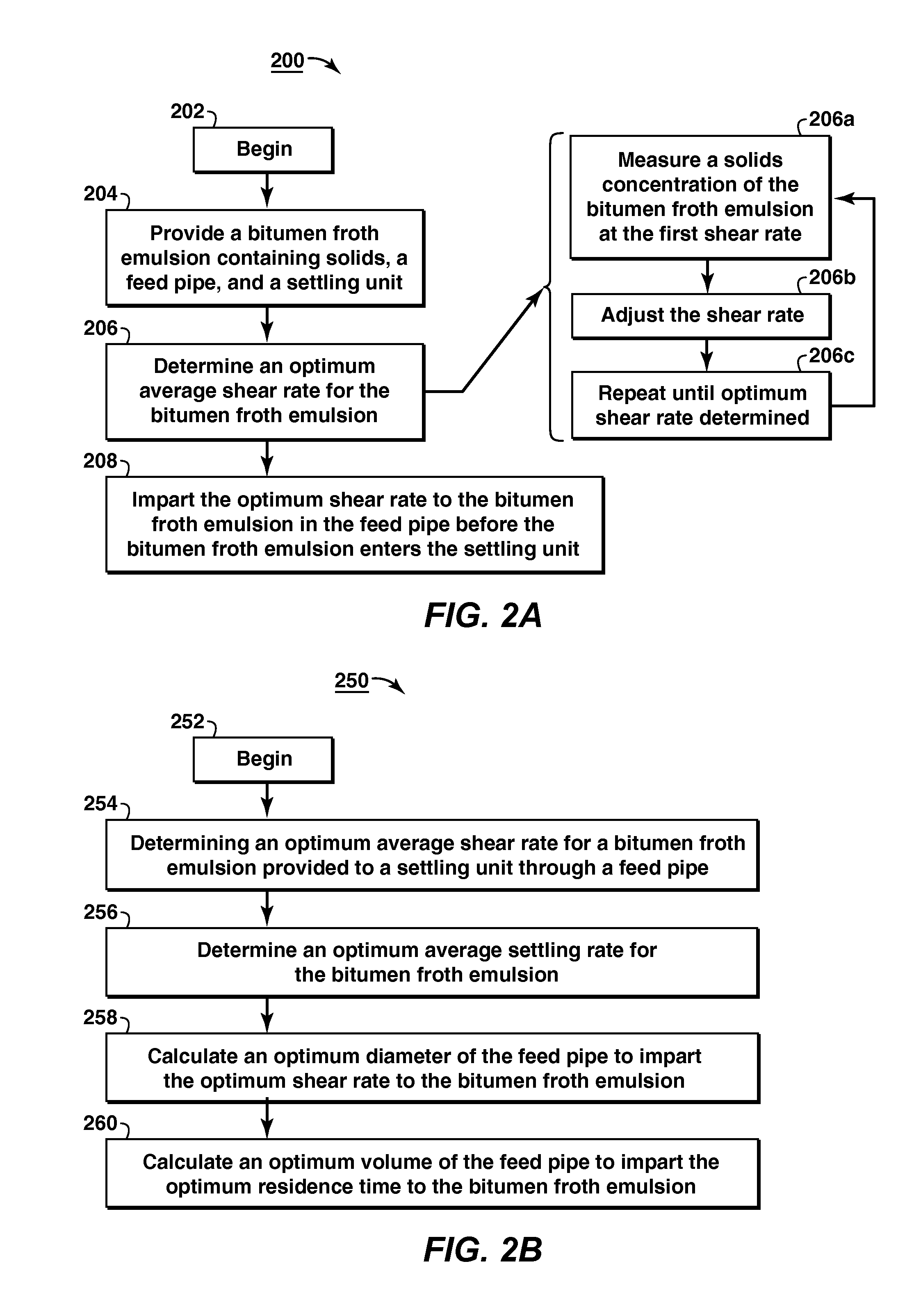

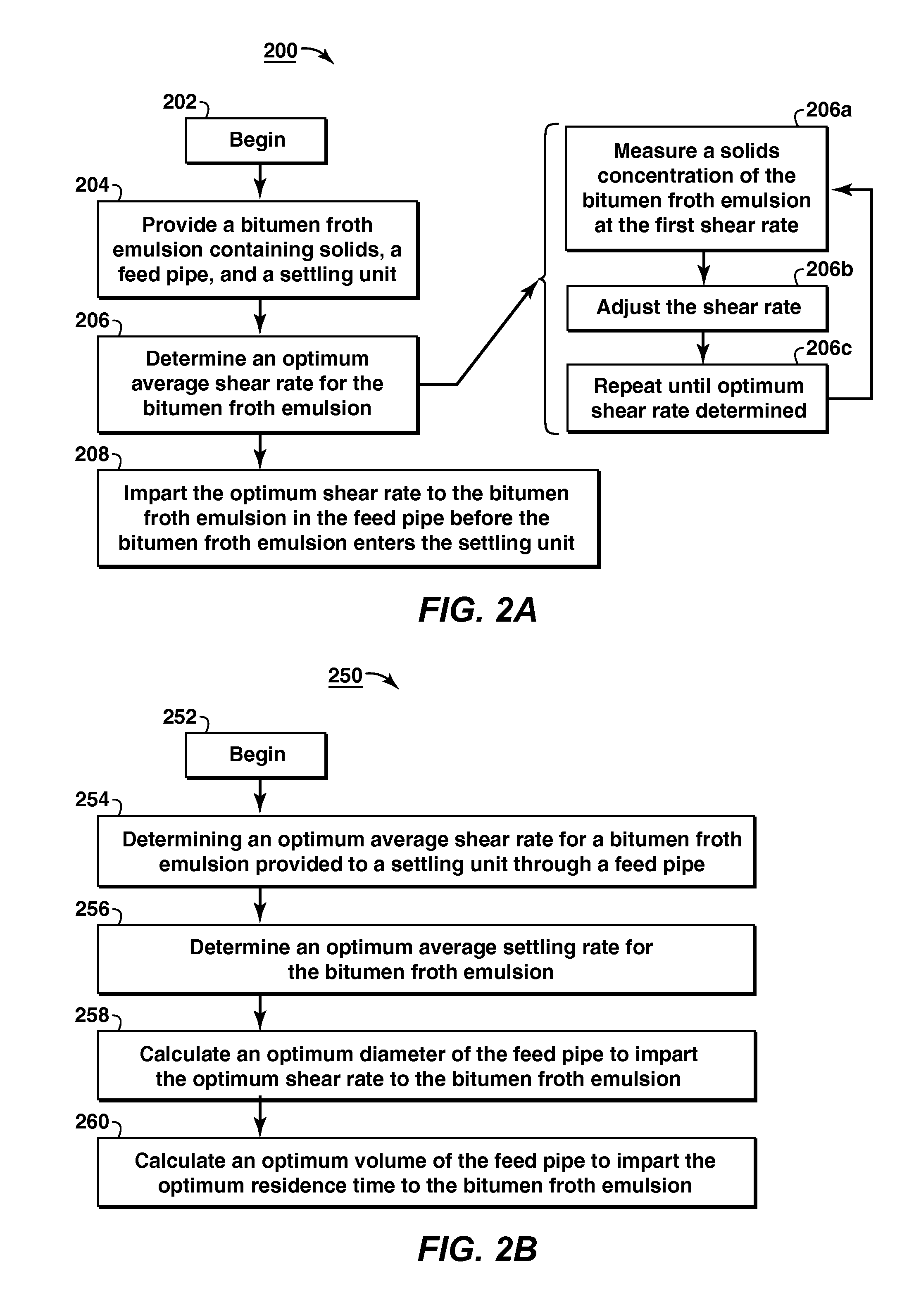

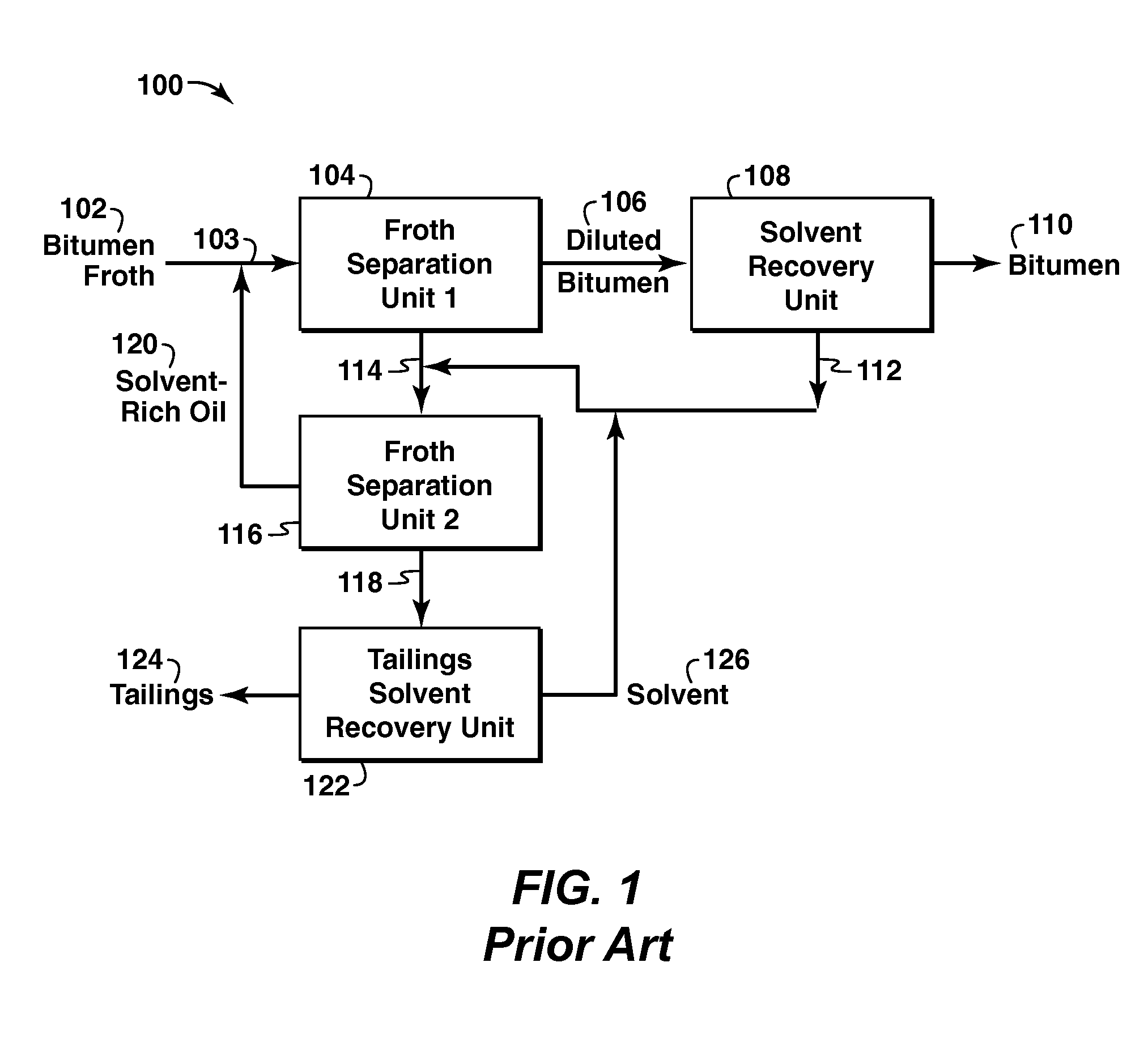

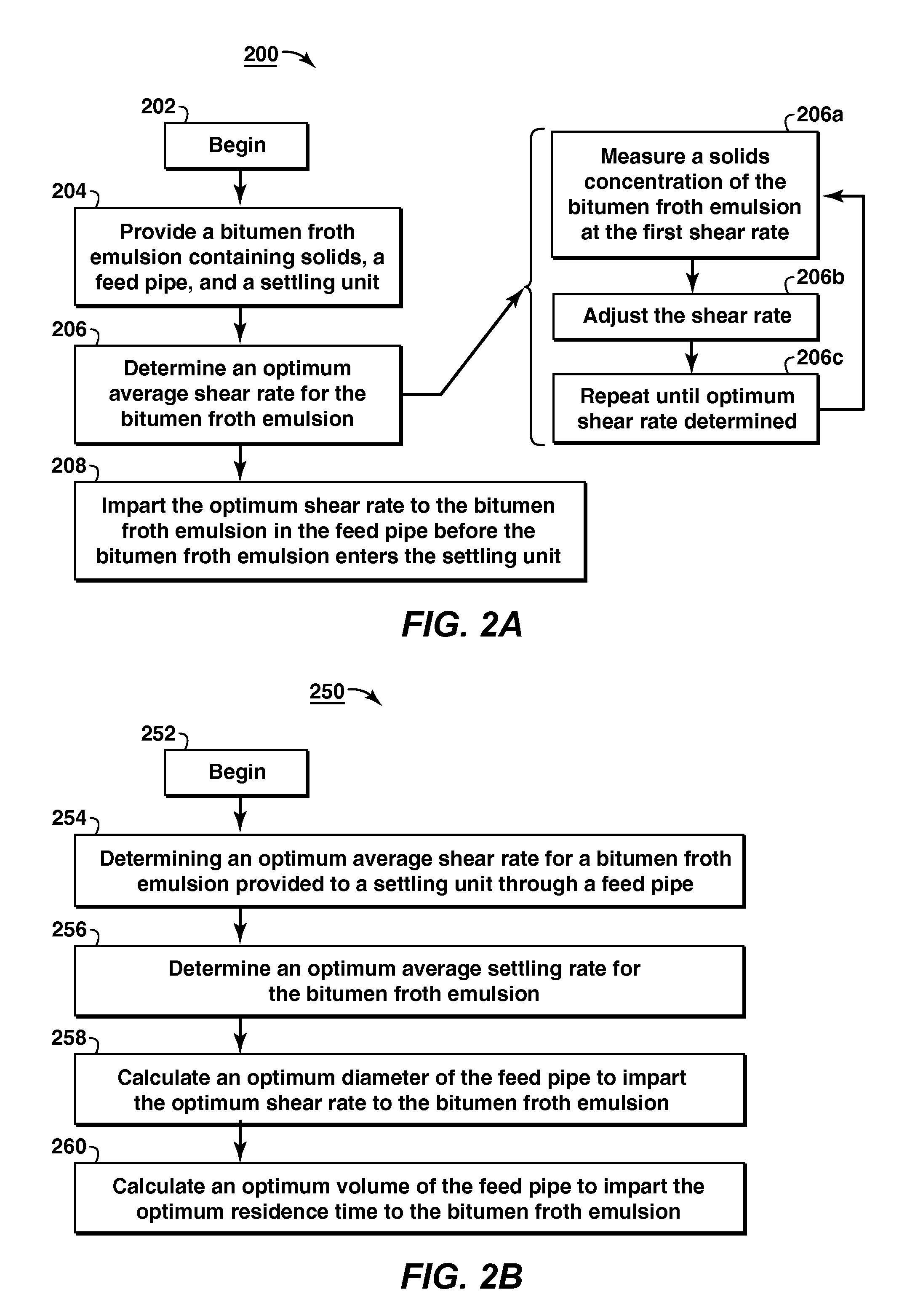

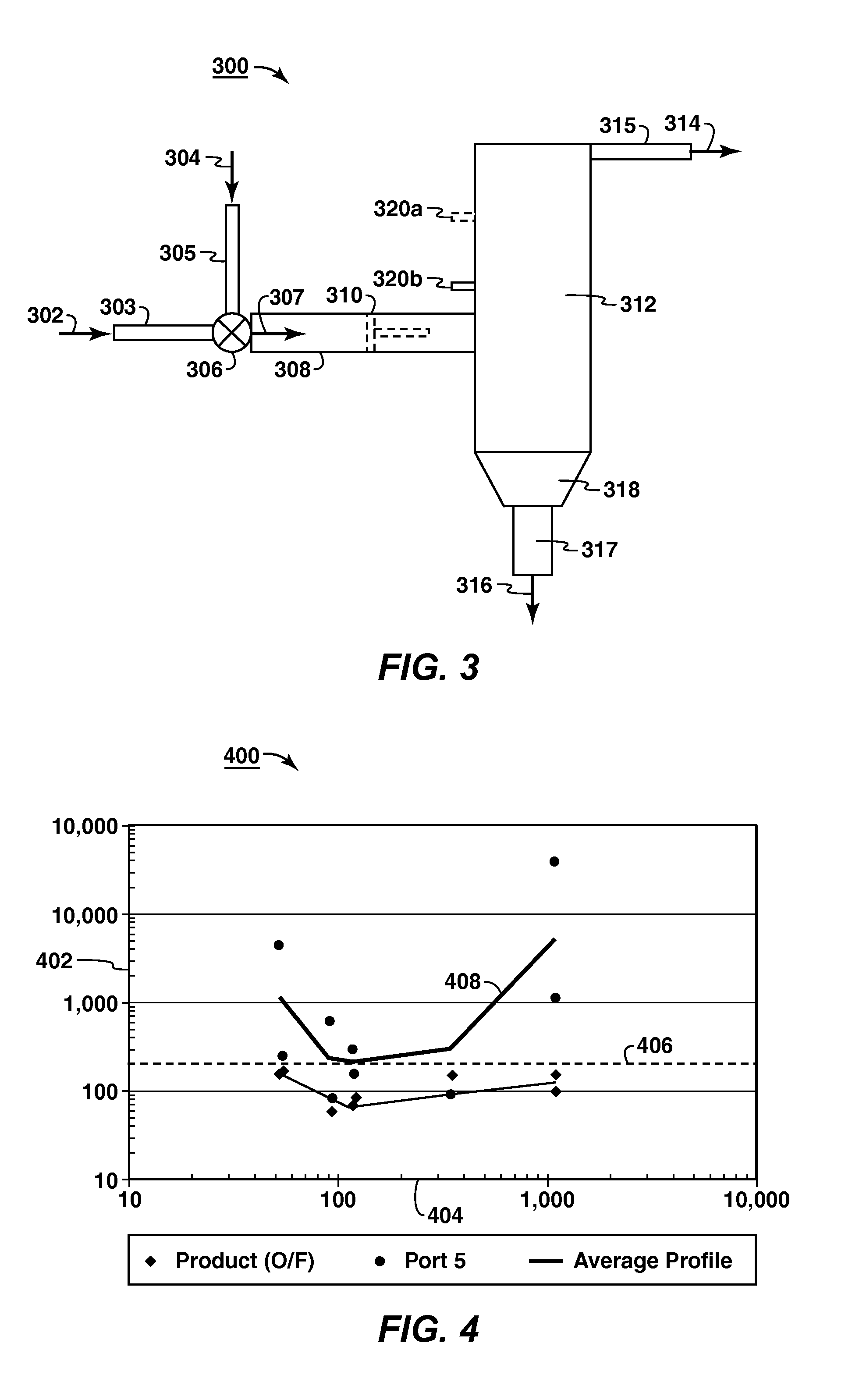

Optimizing feed mixer performance in a paraffinic froth treatment process

ActiveUS20090321322A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxShear rate

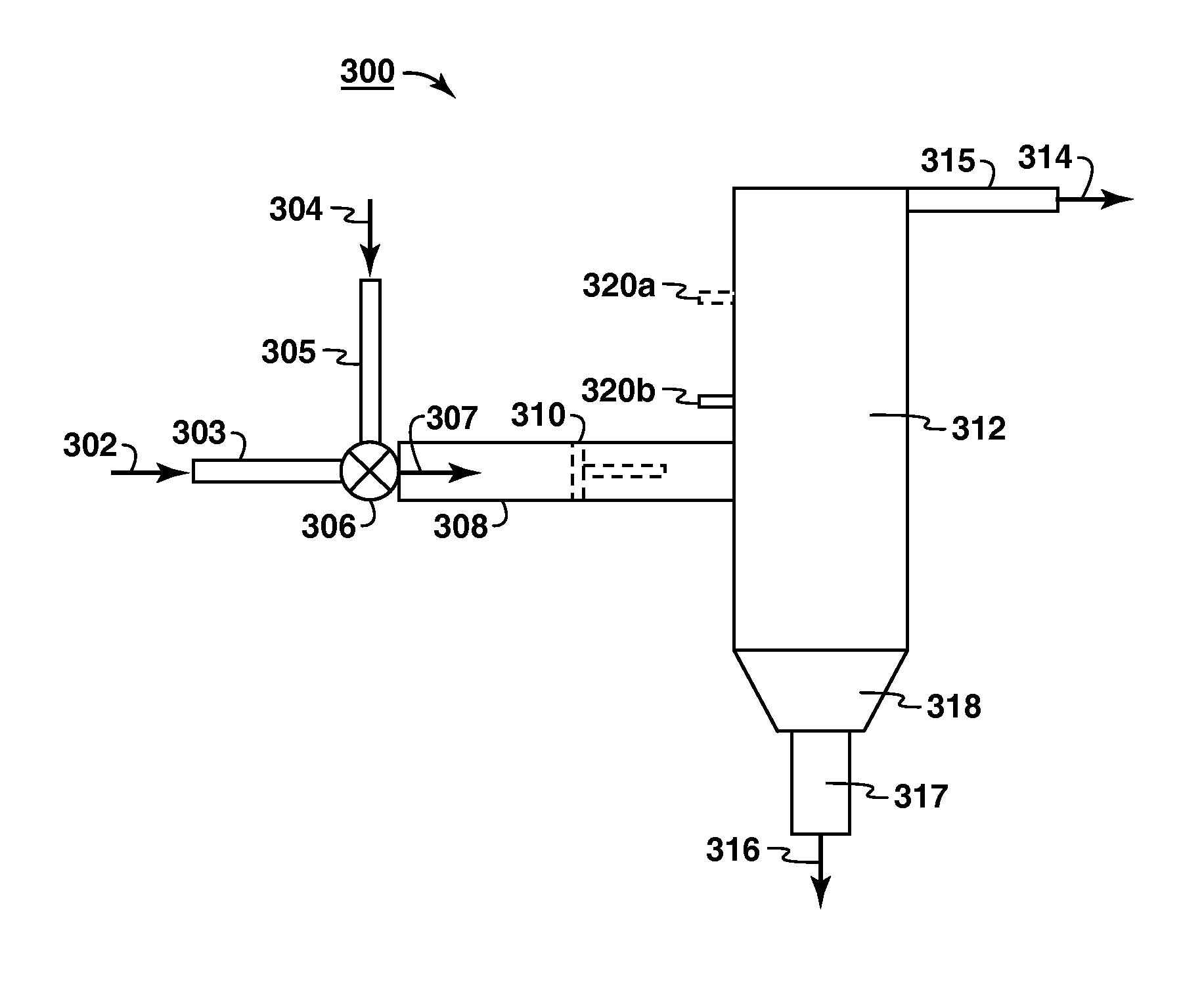

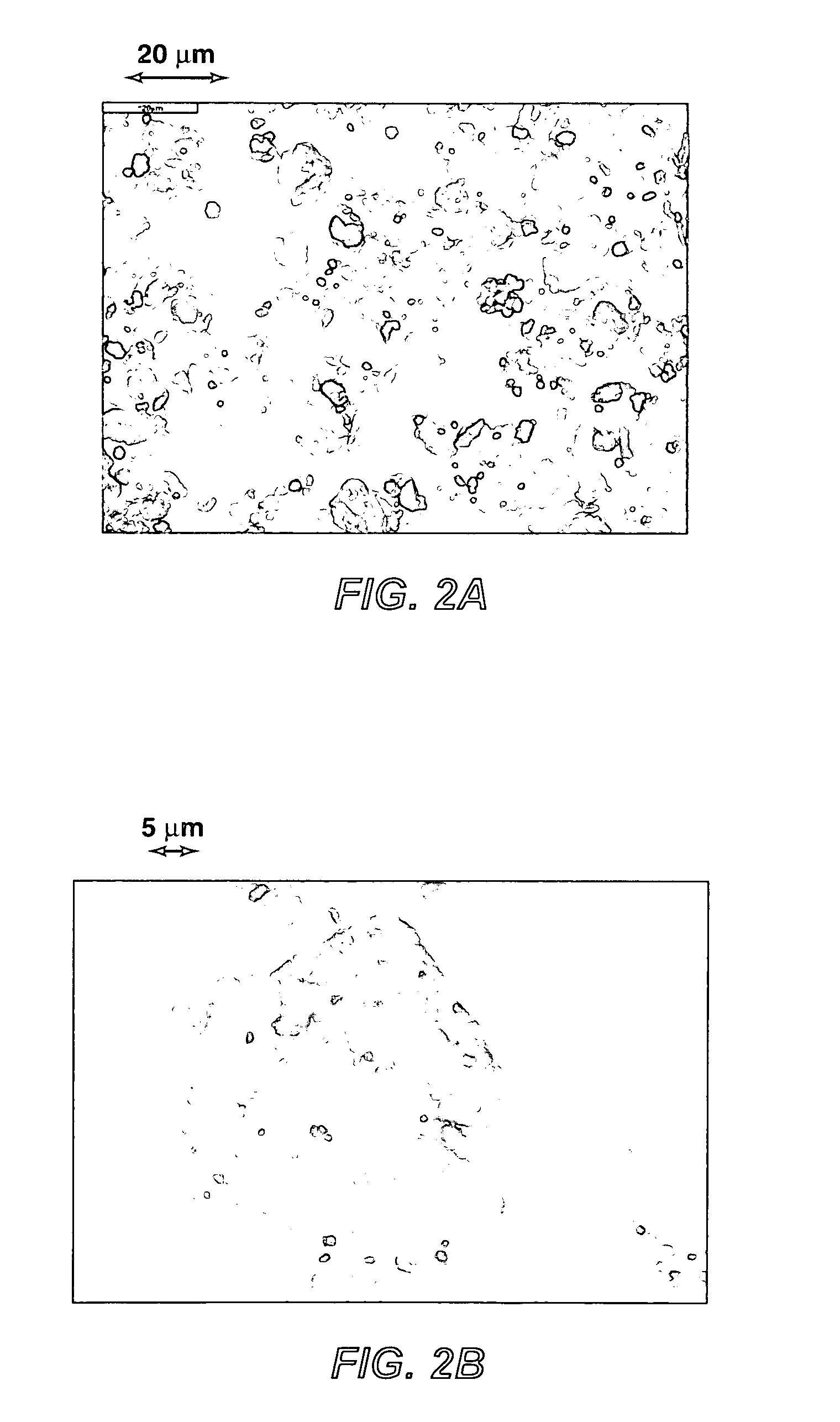

The invention relates to improved bitumen recovery processes and systems. One process provides for operation of a bitumen froth treatment plant at optimum shear rates in the feed pipe carrying the bitumen froth to the froth settling unit. Another process provides for optimizing the design of a bitumen froth treatment plant by optimizing the diameter of the feed pipe to impart an optimum shear rate to the bitumen froth mixture and further optimizing the volume of the feed pipe to impart an optimum residence time for the bitumen froth stream in the feed pipe. An optimal plant design is also disclosed, the plant including optimal diameter and volume of the feed pipe.

Owner:EXXONMOBIL UPSTREAM RES CO

Method and system for reclaiming waste hydrocarbon from tailings using solvent sequencing

InactiveUS8454821B2Working-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionParaffin waxEmulsion

Owner:EXXONMOBIL UPSTREAM RES CO

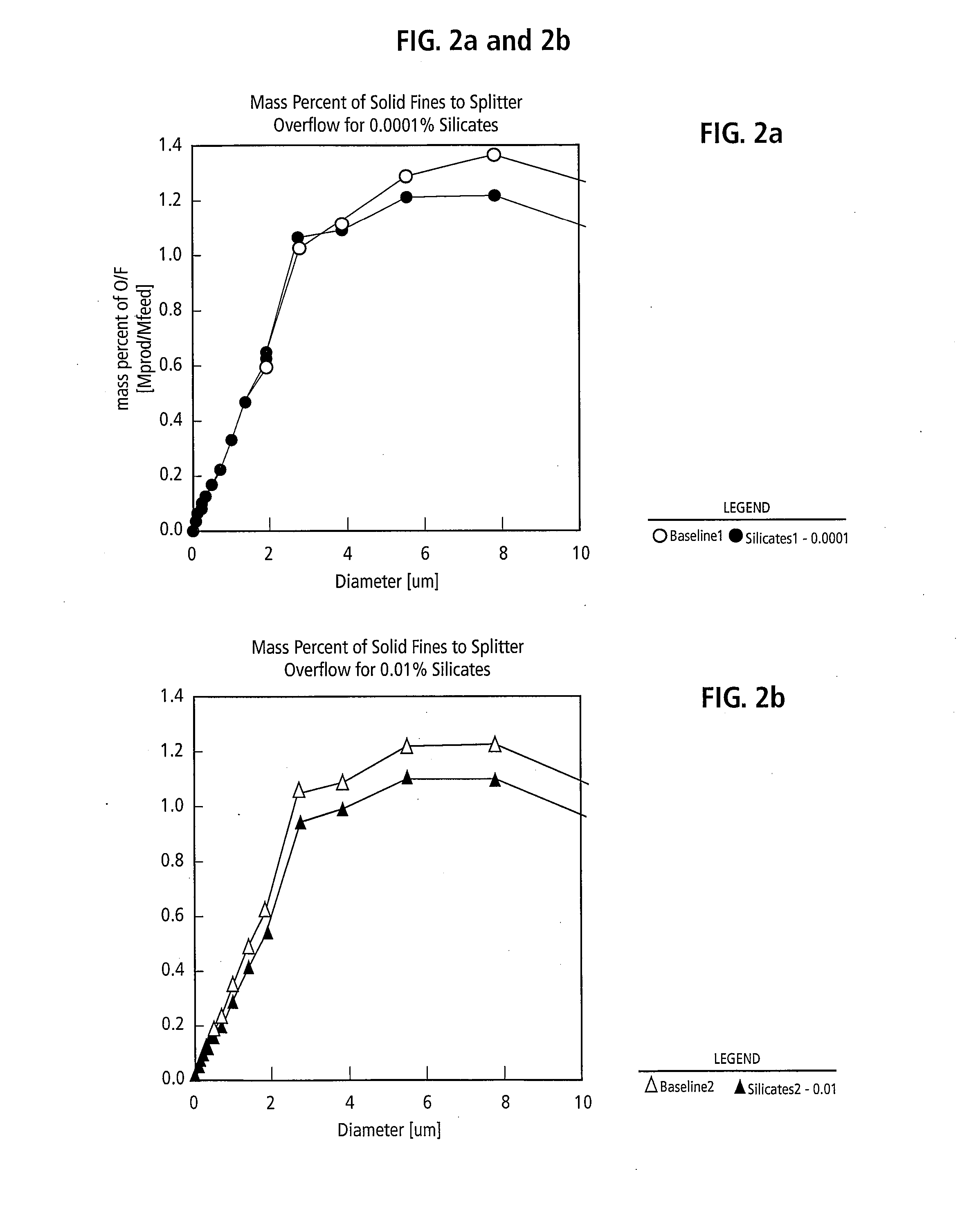

Silicates addition in bitumen froth treatment

A method for processing a bitumen froth comprising bitumen, water and solids including fine solids for reducing the solids concentration in diluted bitumen is provided comprising diluting the bitumen froth with a hydrocarbon diluent to form a dilfroth; adding a sufficient amount of a silicate to the dilfroth to cause a substantial amount of fine solids to associate with the water instead of the diluted bitumen; and allowing the diluted bitumen to separate from the water containing the substantial amount of fine solids to produce a dilbit having less than 3 percent by weight solids.

Owner:RICE UNIV +1

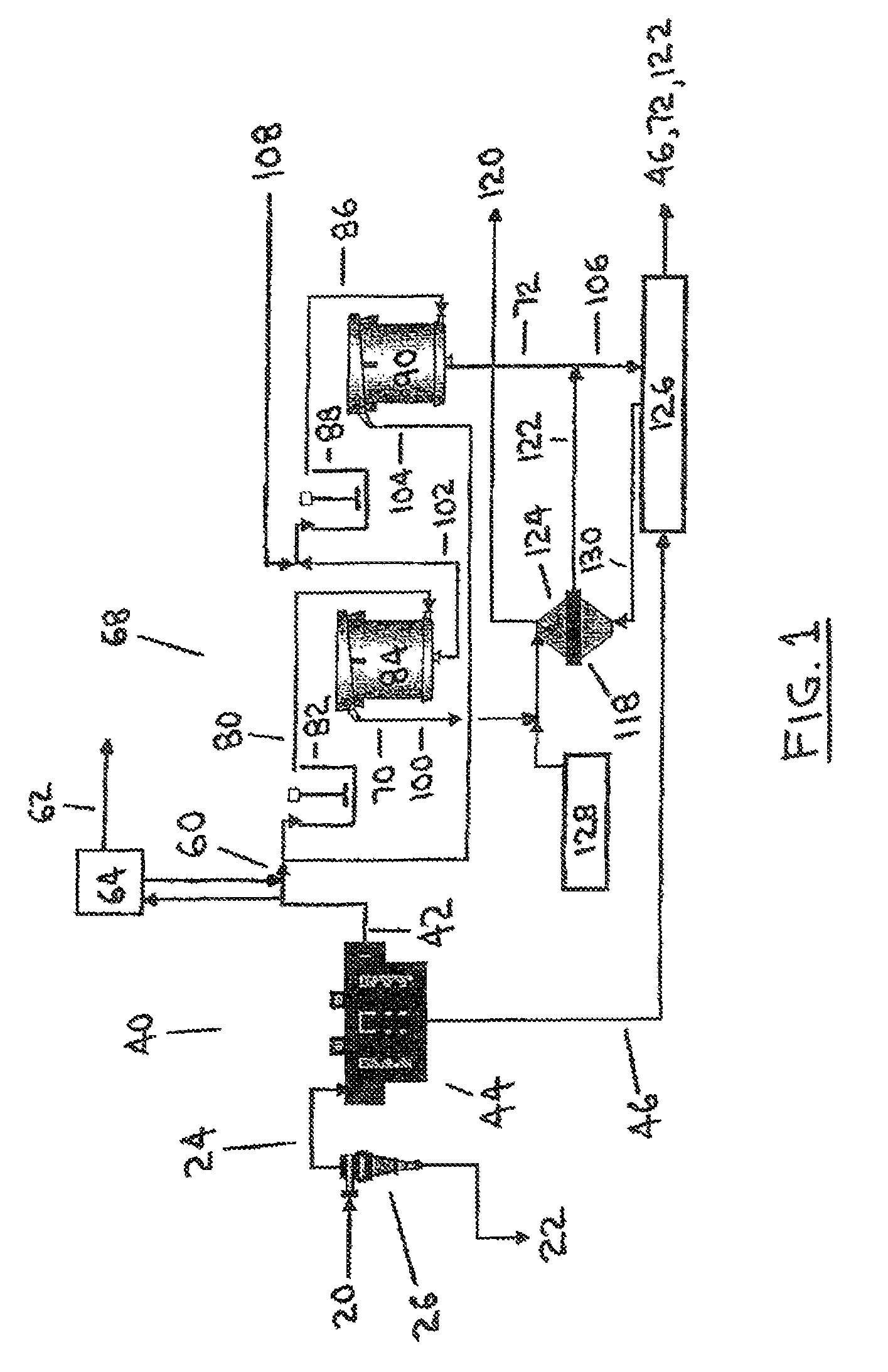

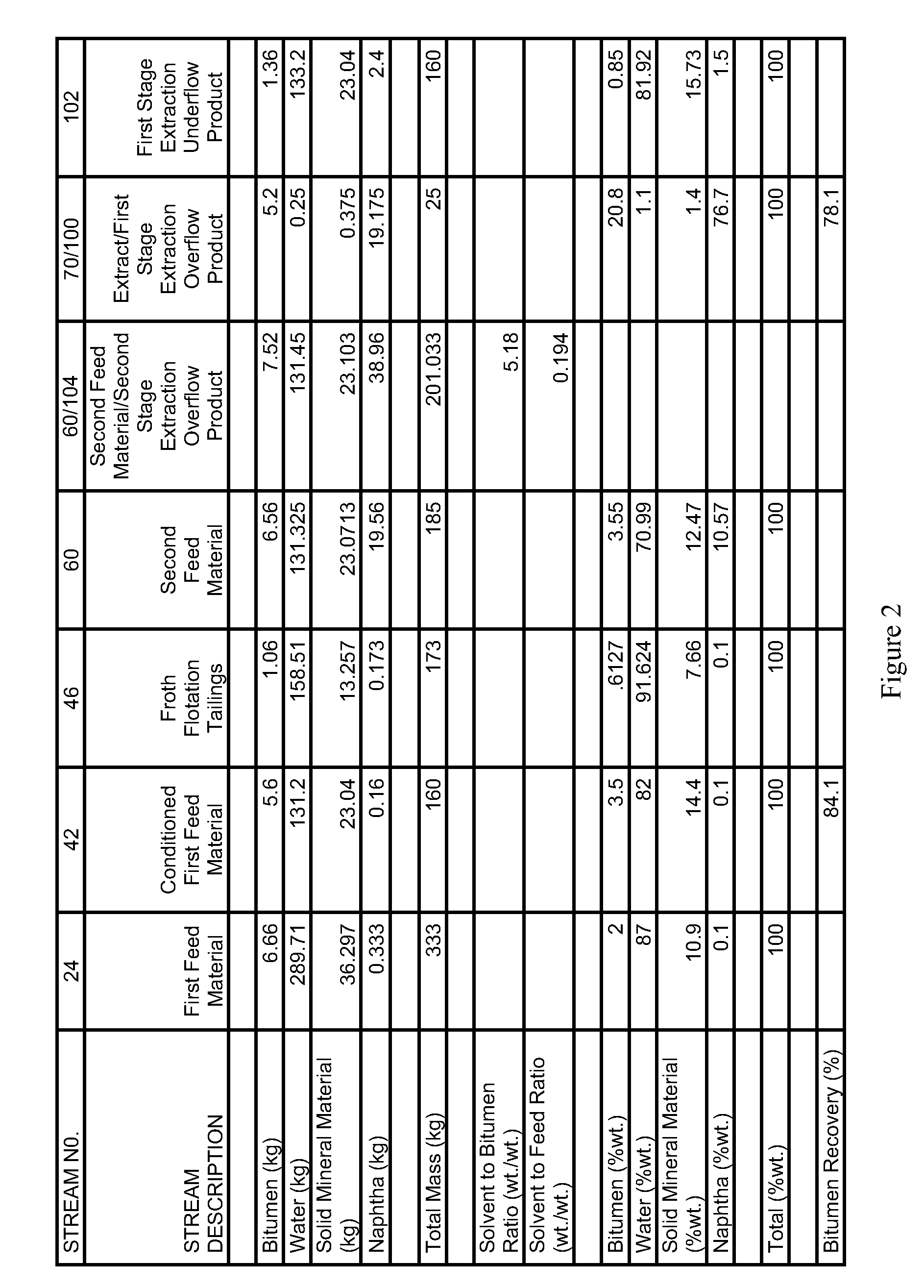

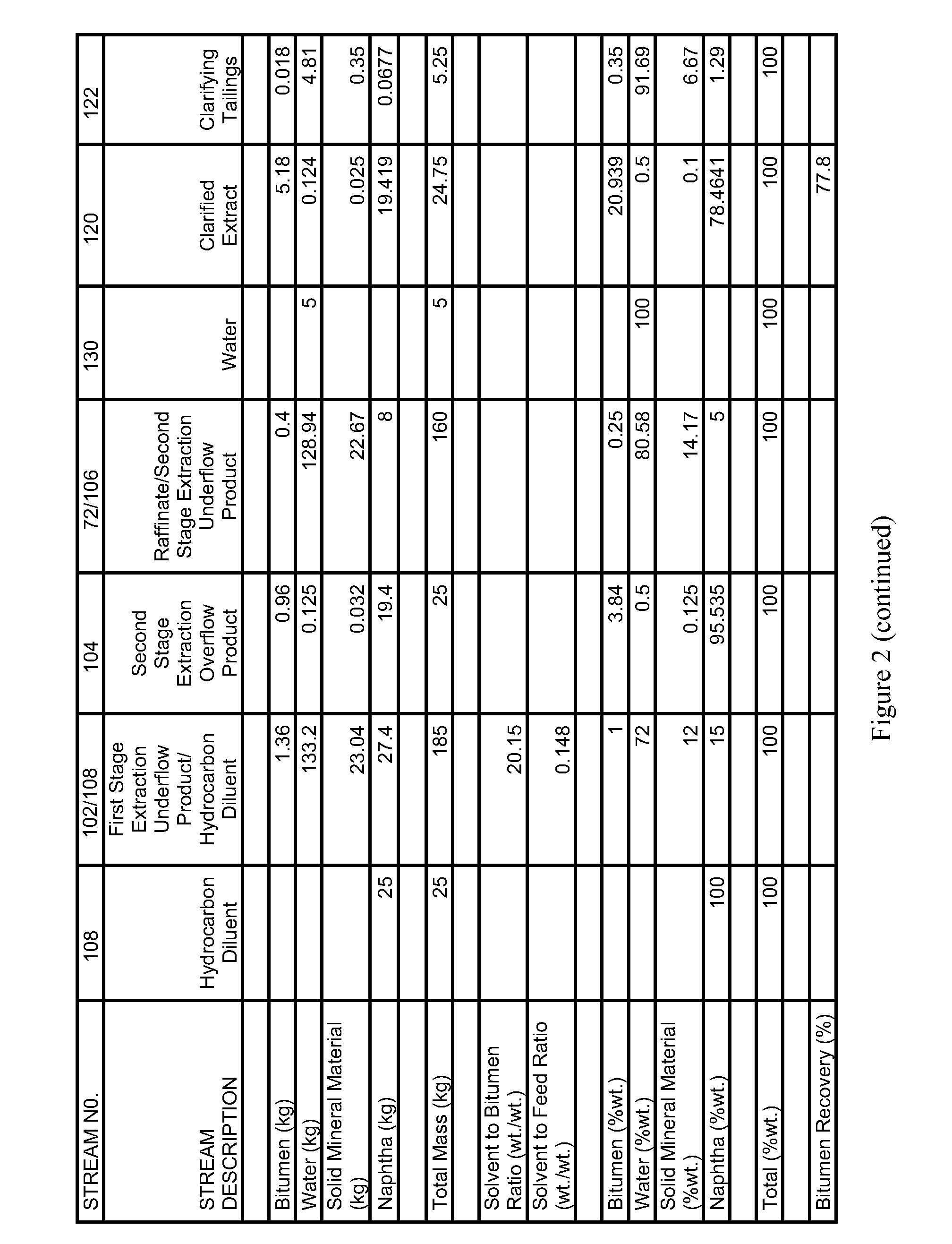

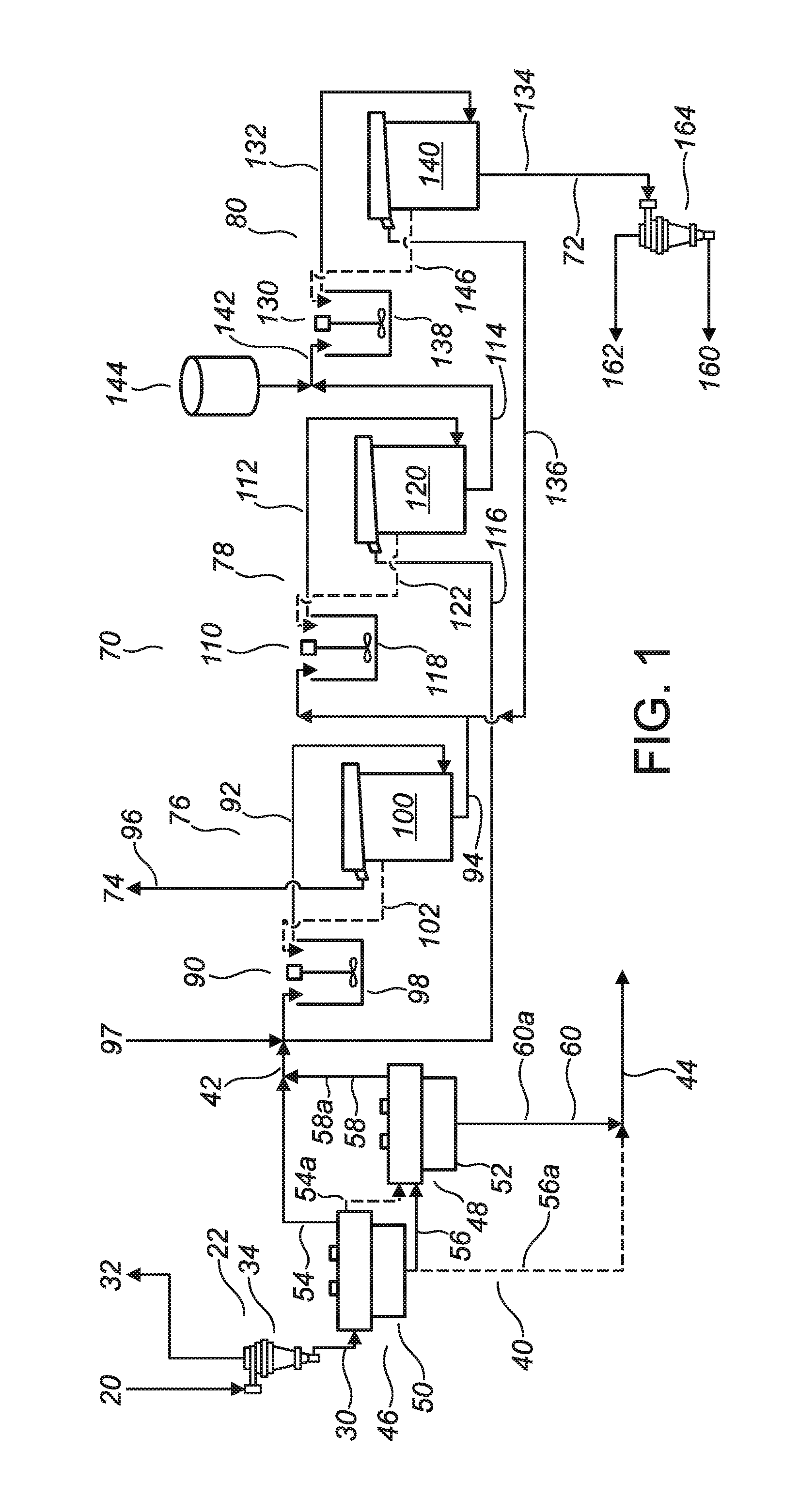

Recovery of bitumen from froth treatment tailings

ActiveUS8382976B2Easy to separateReduce precipitationLiquid hydrocarbon mixture productionFlotationFroth treatmentSolvent extraction

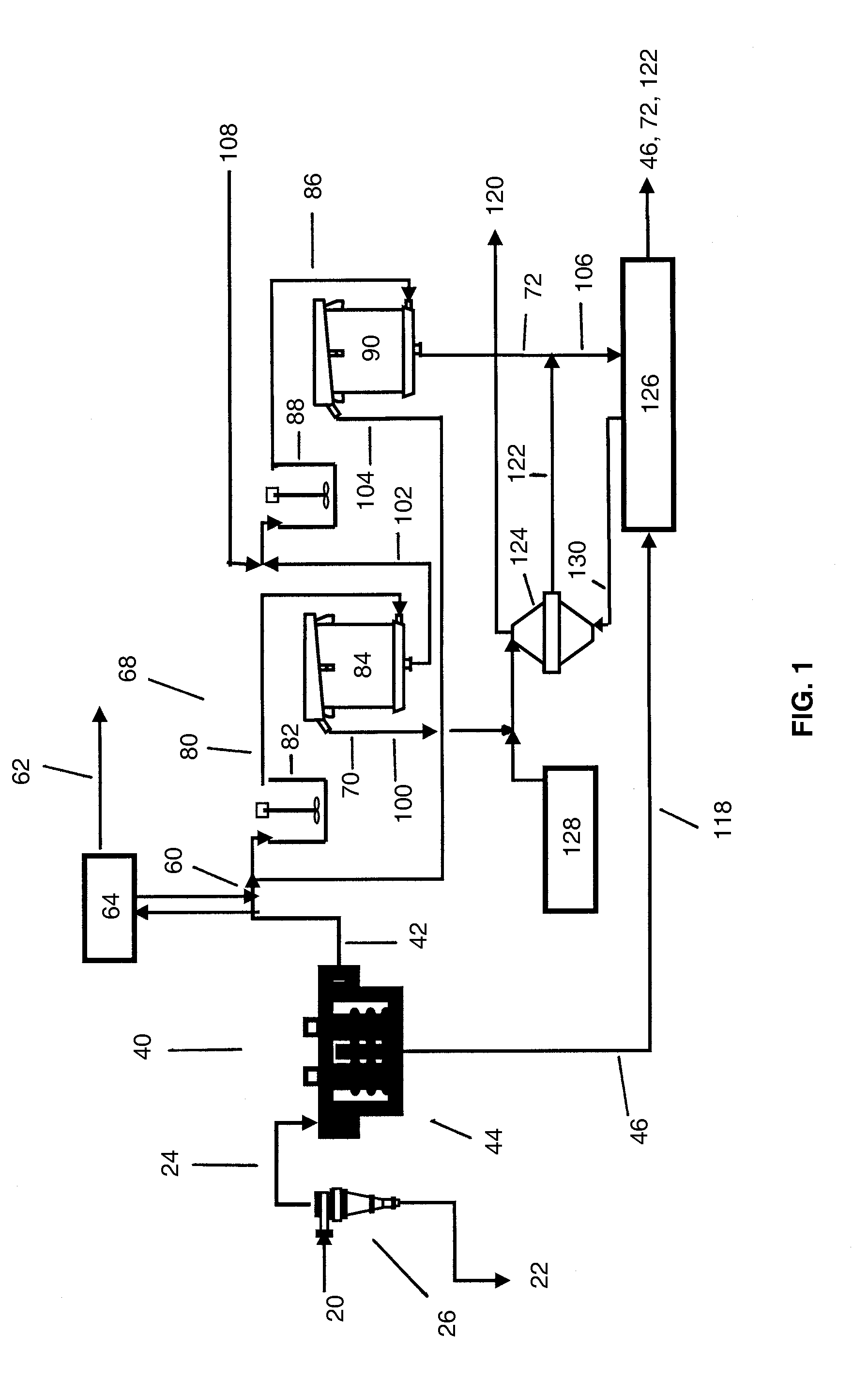

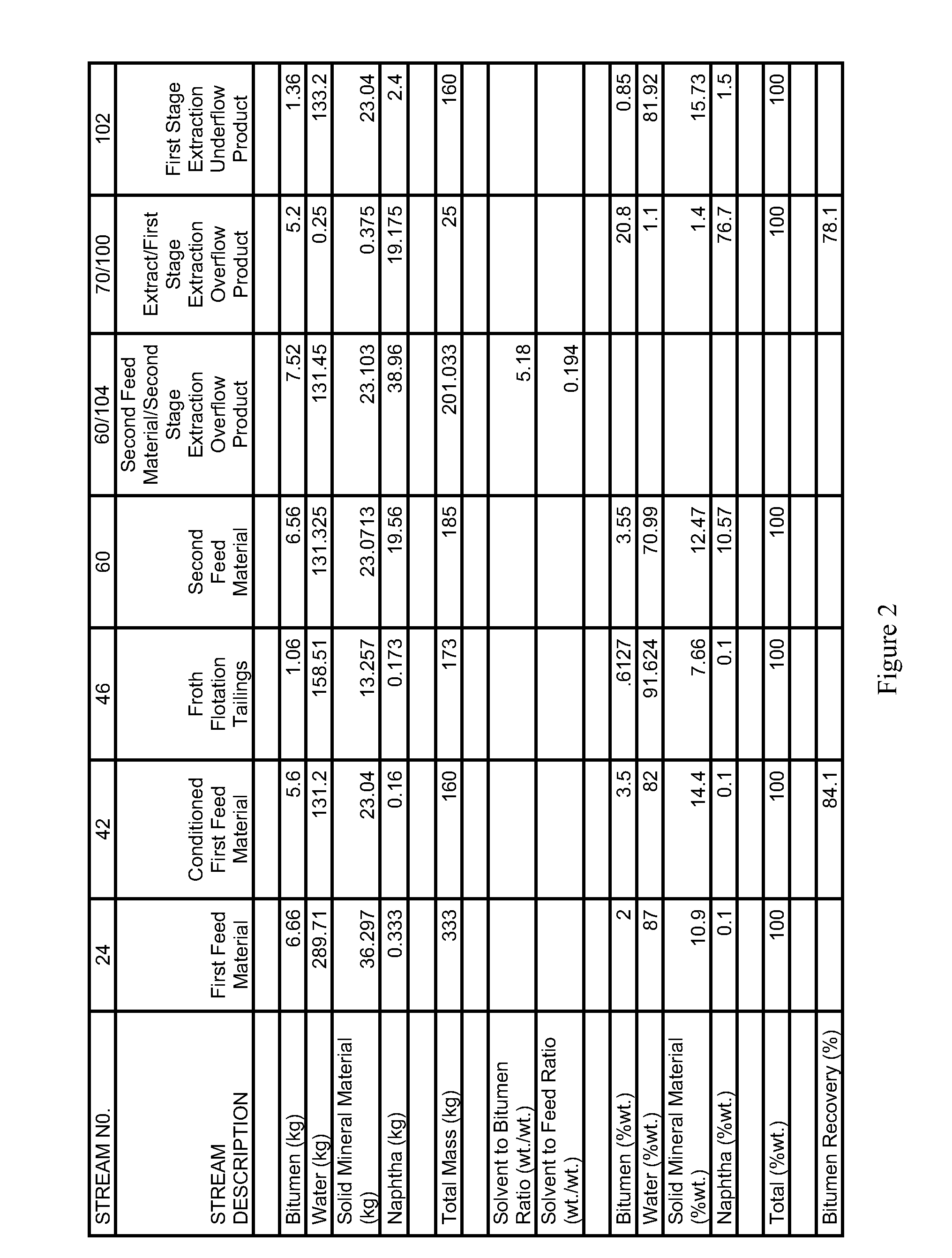

A method for recovering a tailings bitumen from a froth treatment tailings, including providing a first feed material which is derived from the froth treatment tailings, conditioning the first feed material in order to produce a conditioned first feed material, providing a second feed material which is derived from the conditioned first feed material, and subjecting the second feed material to solvent extraction in order to produce an extract containing an amount of the tailings bitumen. The method may further include dewatering the conditioned first feed material in order to produce the second feed material and may further include clarifying the extract to produce a clarified extract containing an amount of the tailings bitumen.

Owner:TITANIUM CORP

A system and method for treatment of oil sand tailings or oil sand ore pulp

InactiveCN102676199AEasy disposalSolid waste disposalLiquid hydrocarbon mixture productionFroth treatmentMaterials science

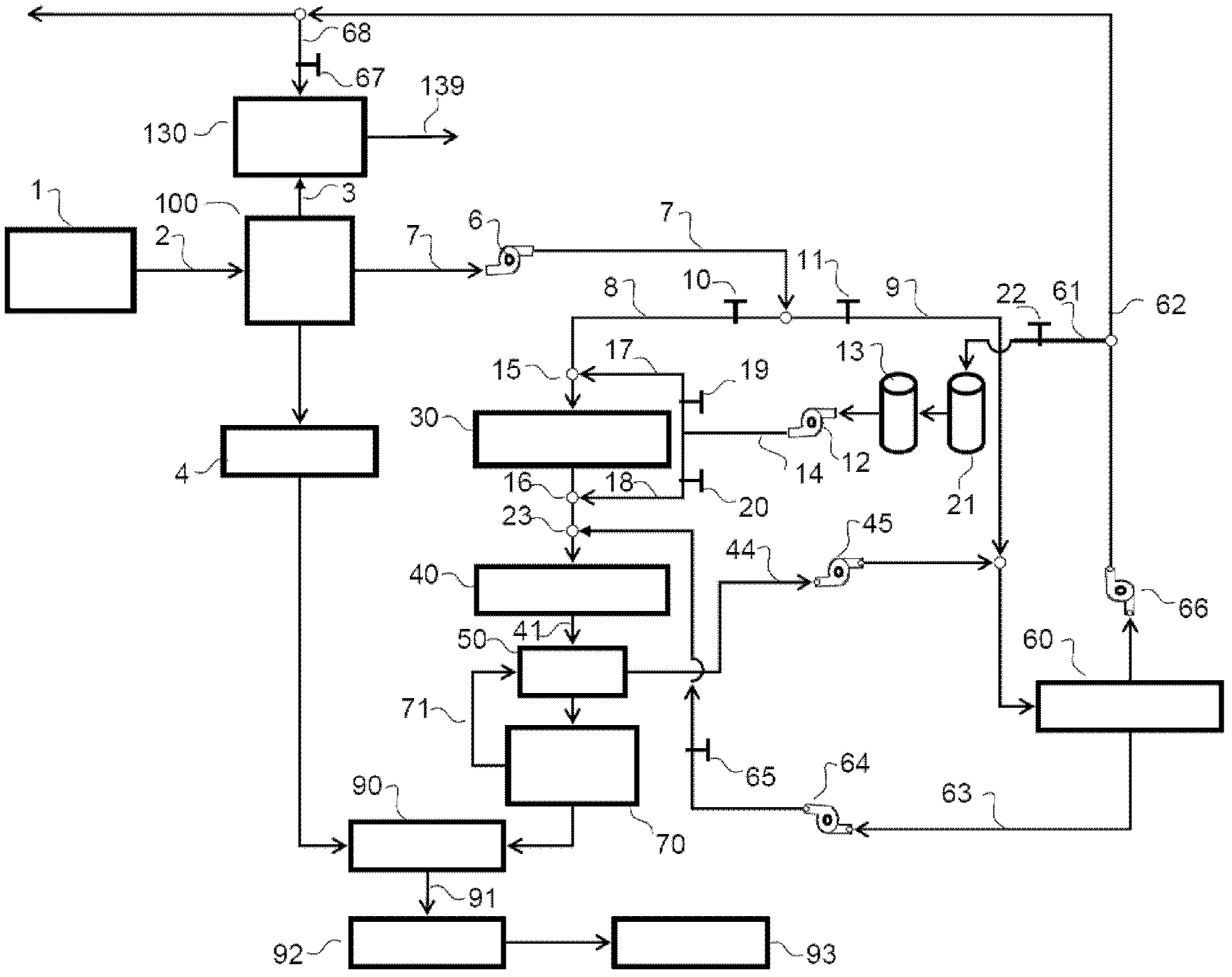

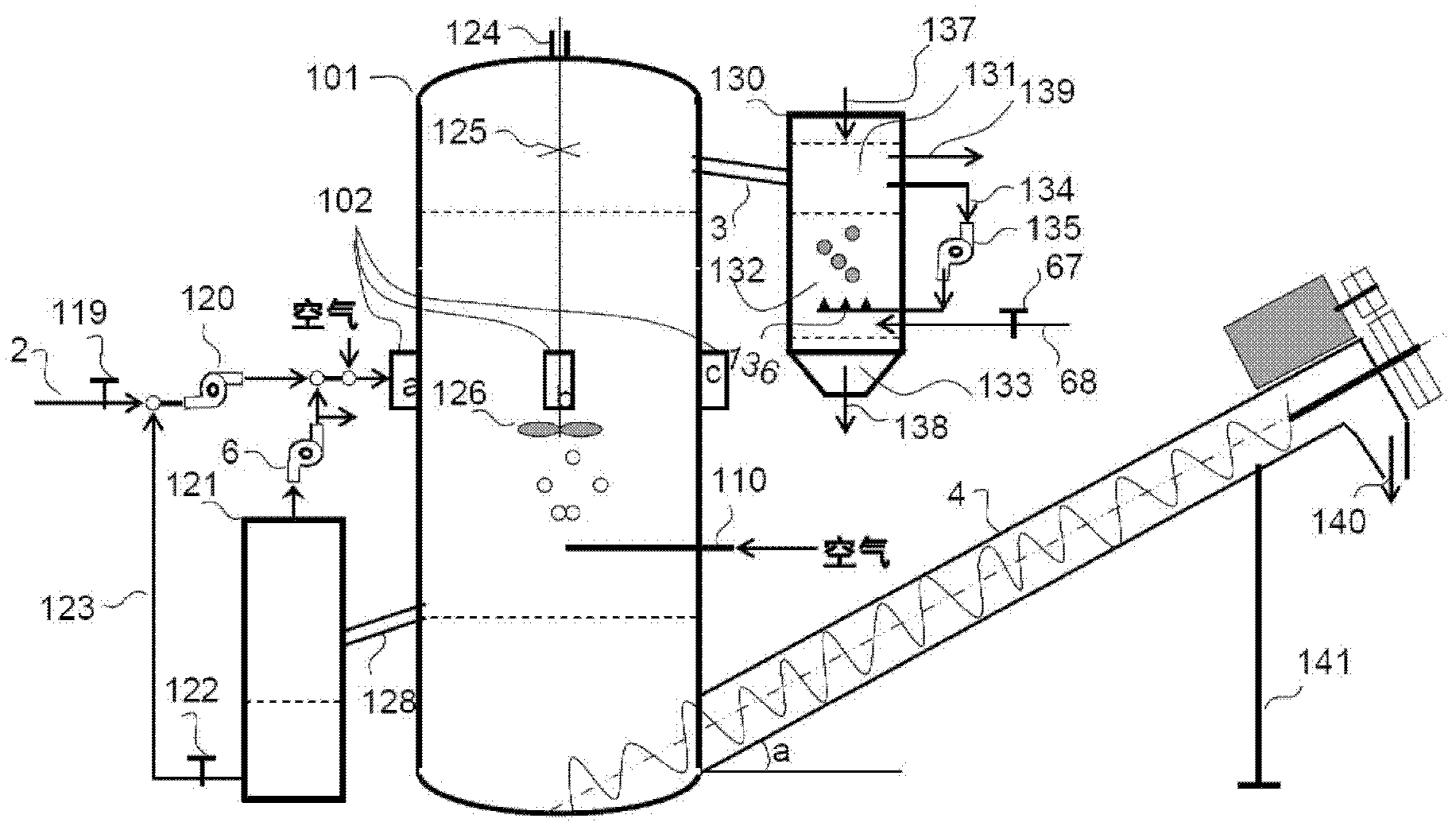

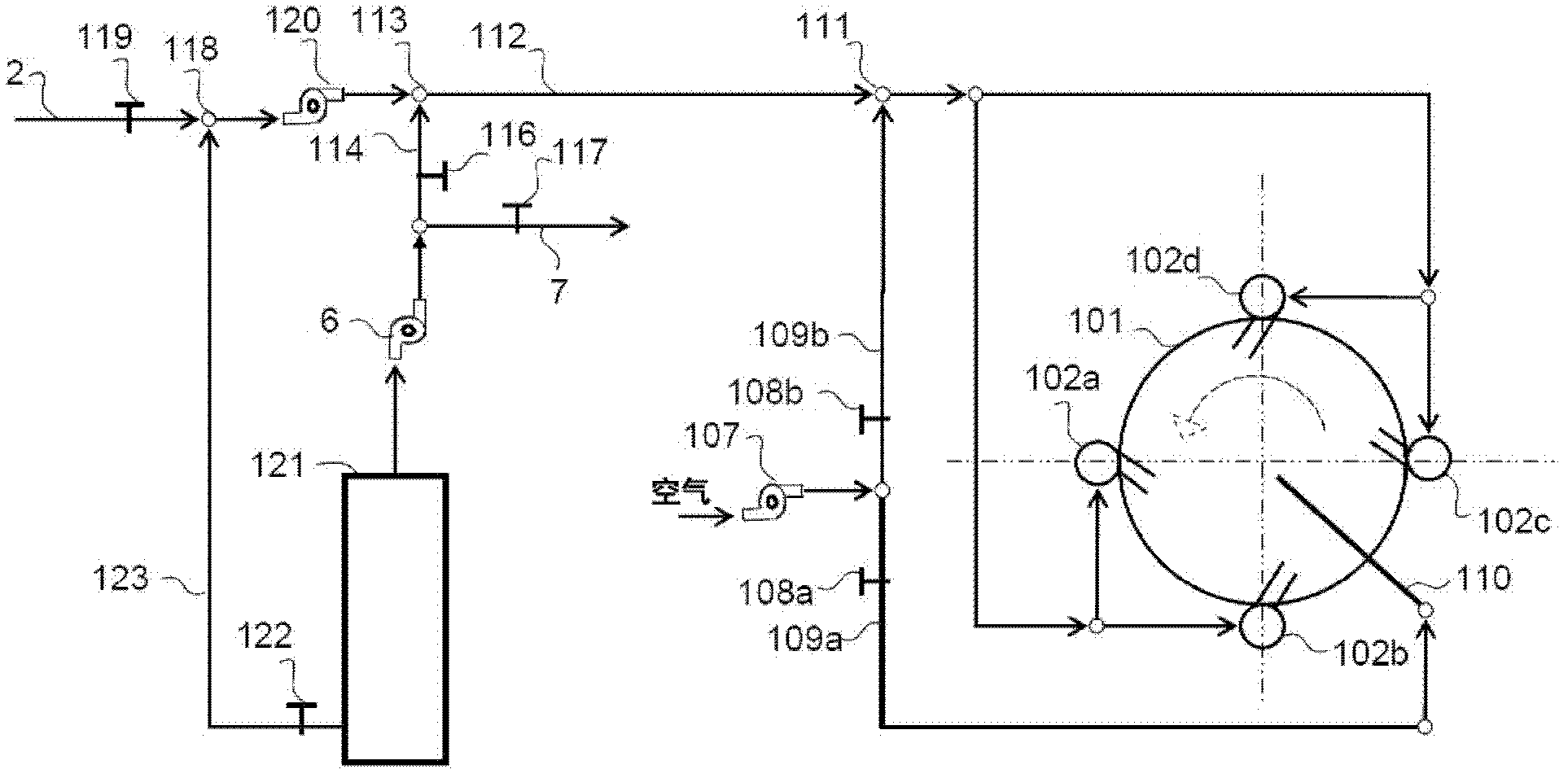

The present invention provides a system and method for treatment of oil sand tailings or oil sand ore pulp, wherein the system comprises a bitumen recovery apparatus to separate oil sand tailings or oil sand ore pulp into bitumen froth, coarse sand, and fine tailings; a tailings thickening apparatus to thick the fine tailings to form fine earth mud; a tailings solidification step to solidify the fine earth mud and the coarse sand; and a bitumen froth treatment apparatus (130) to extract the bitumen from the bitumen froth; and a method for treating oil sand tailings or oil sand ore pulp is also provided. Via the above technical scheme, residual bitumen can be recovered from oil sand tailings or oil sand ore pulp, and oil sand tailings are consolidated, so that treatment can be easily performed in an economic and environmental way.

Owner:顾国兴

Recovery of bitumen from froth treatment tailings

ActiveUS20100258478A1Easy to separateReduce precipitationLiquid hydrocarbon mixture productionFlotationFroth treatmentSolvent extraction

A method for recovering a tailings bitumen from a froth treatment tailings, including providing a first feed material which is derived from the froth treatment tailings, conditioning the first feed material in order to produce a conditioned first feed material, providing a second feed material which is derived from the conditioned first feed material, and subjecting the second feed material to solvent extraction in order to produce an extract containing an amount of the tailings bitumen. The method may further include dewatering the conditioned first feed material in order to produce the second feed material and may further include clarifying the extract to produce a clarified extract containing an amount of the tailings bitumen.

Owner:TITANIUM CORP

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

ActiveUS20090321323A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionFoam separationDesalter

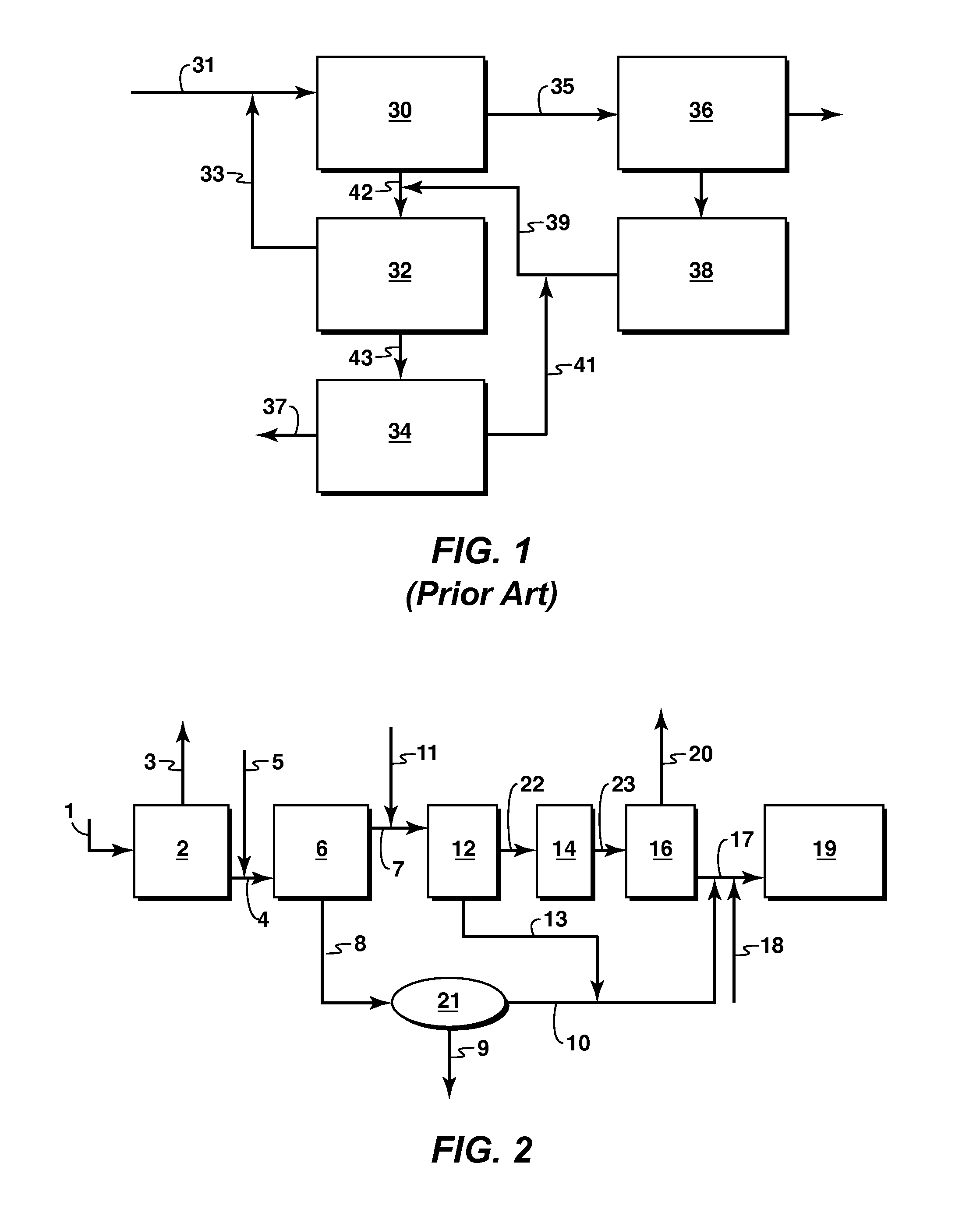

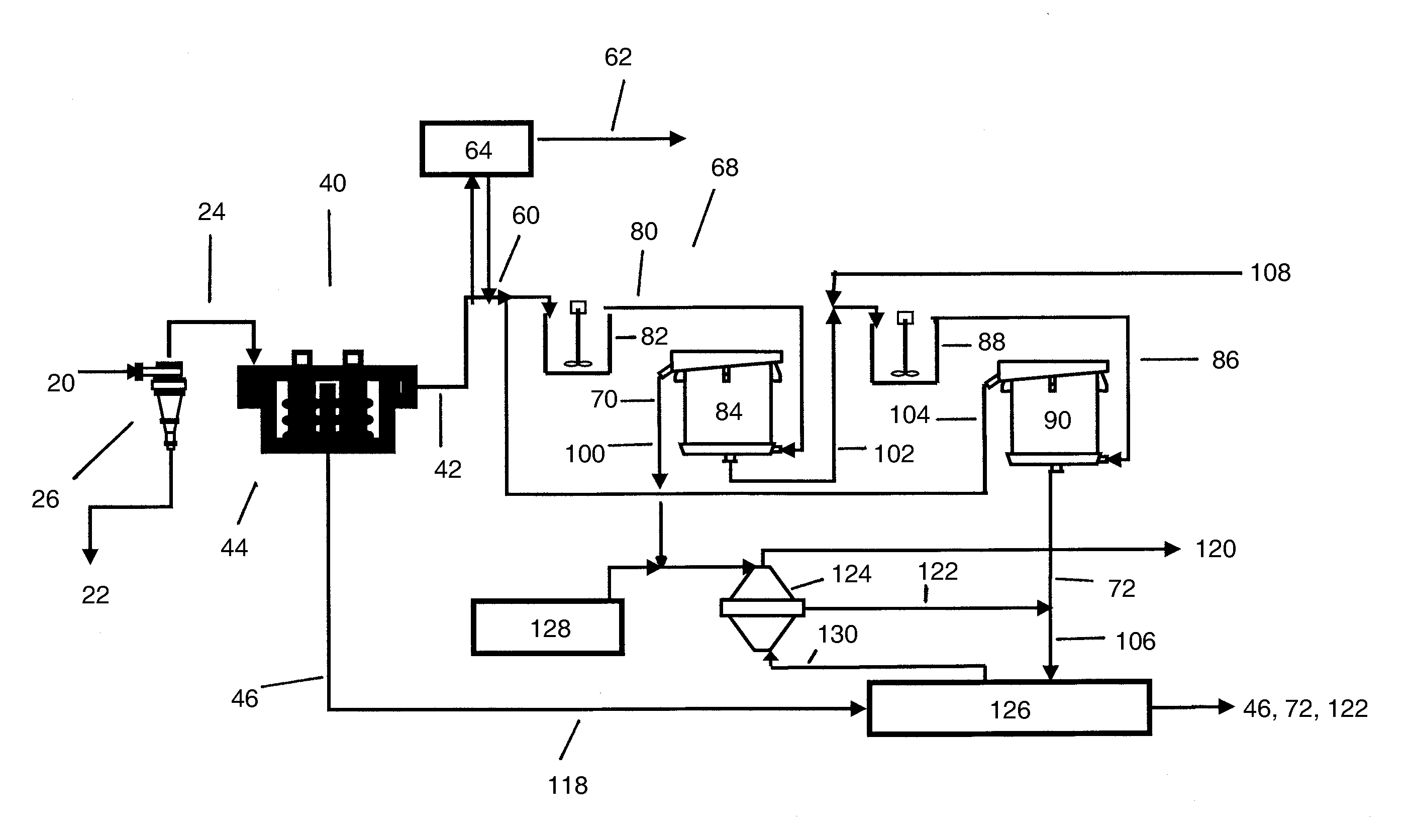

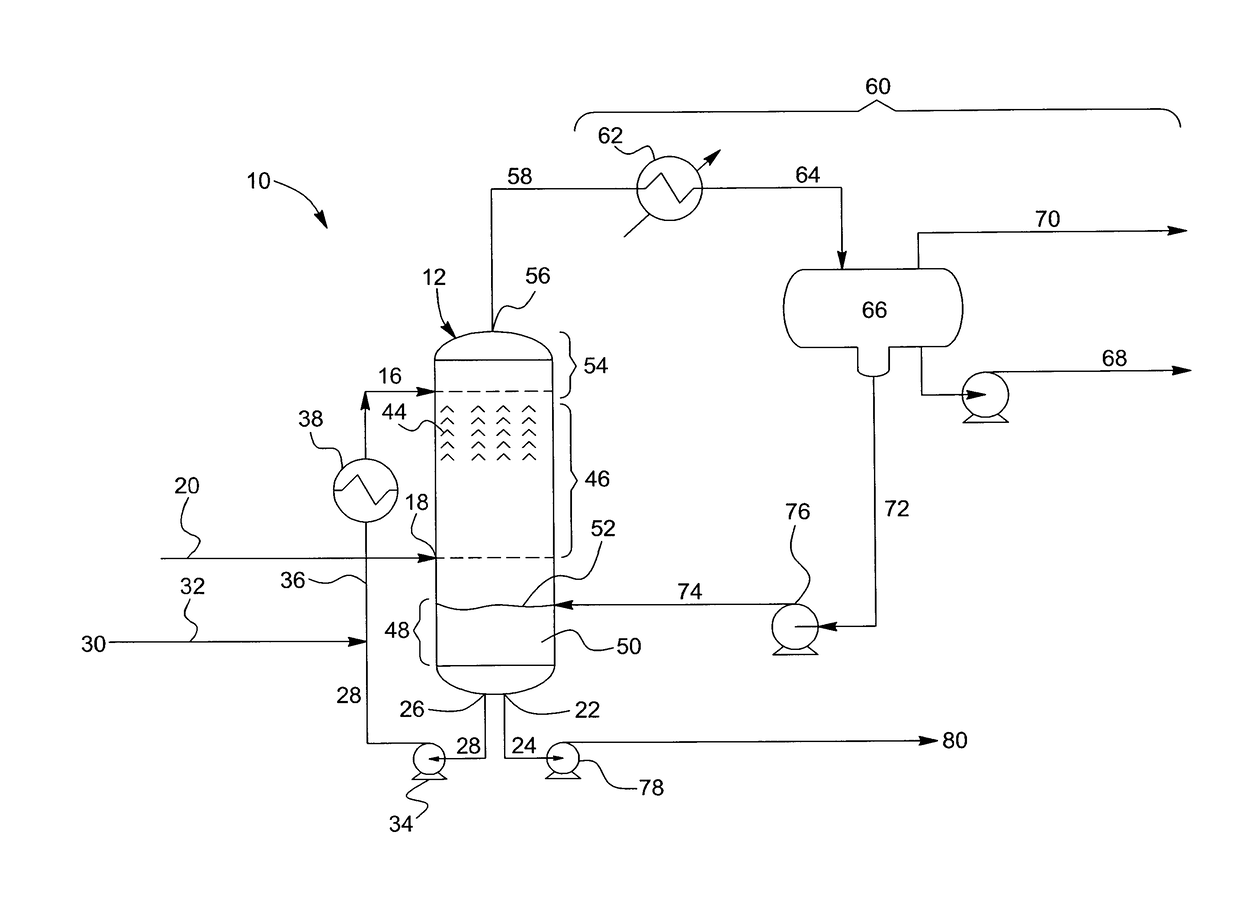

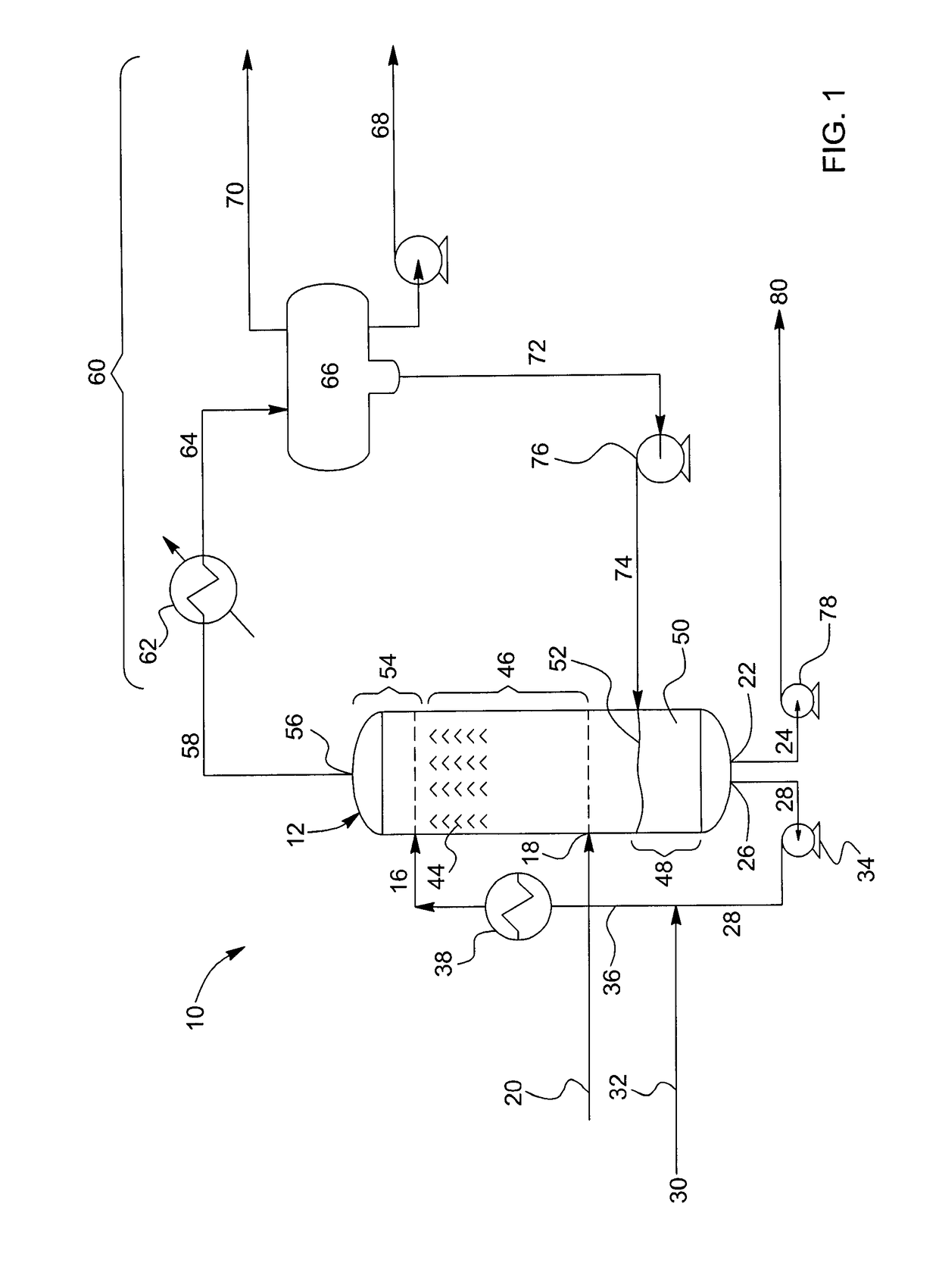

The invention relates to improved bitumen recovery processes and systems. The process may include providing a bitumen froth feed stream, separating the stream in a froth separation unit to produce a diluted bitumen stream, treating the diluted bitumen stream in an electrostatic desalter to produce a treated bitumen stream, and separating the treated bitumen stream into a solvent recycle stream and a bitumen product stream. The system may include a combined AC / DC desalter with a control unit for optimizing the treatment process to produce a product bitumen stream using less solvent and smaller separators than conventional bitumen froth treatment plants and processes.

Owner:EXXONMOBIL UPSTREAM RES CO

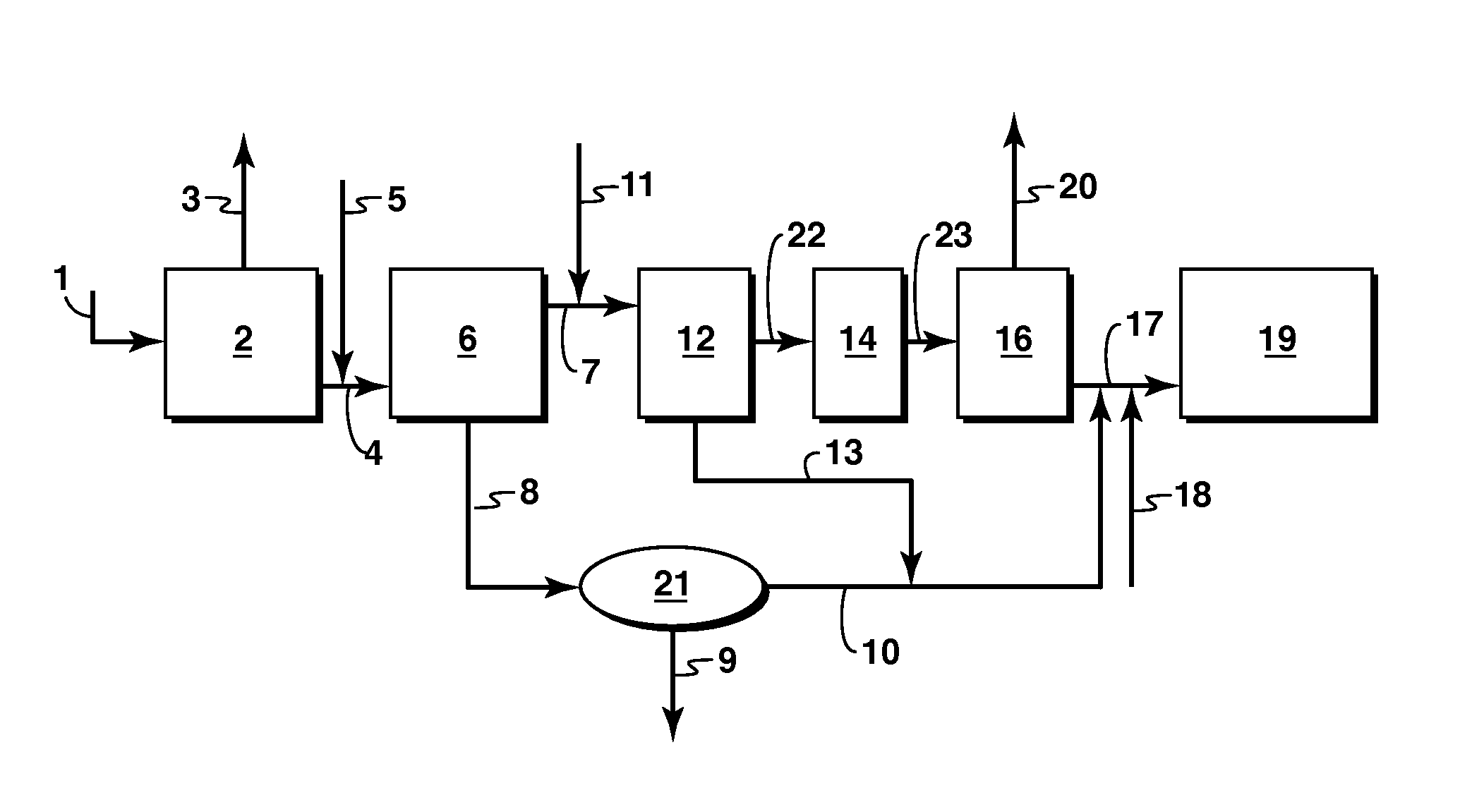

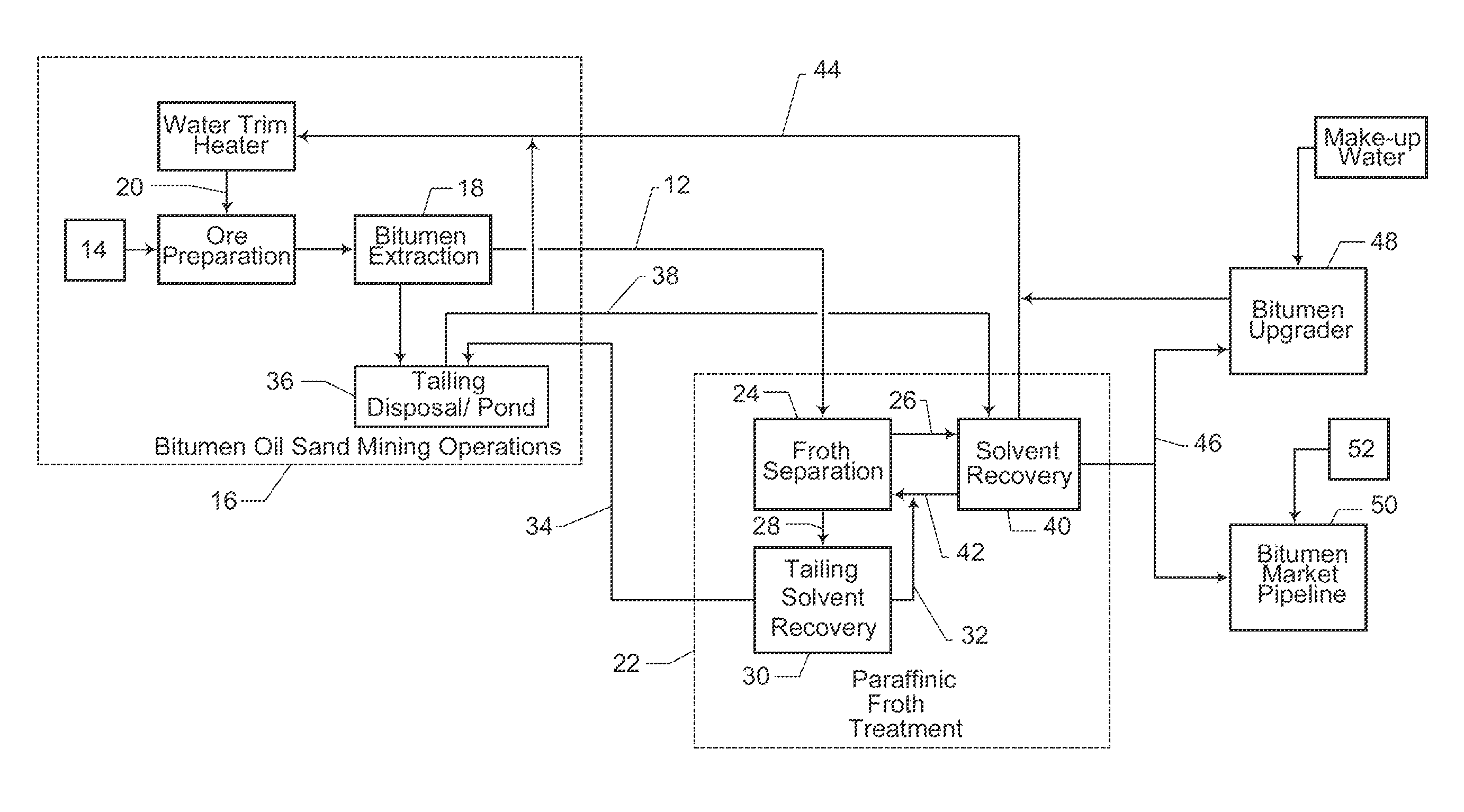

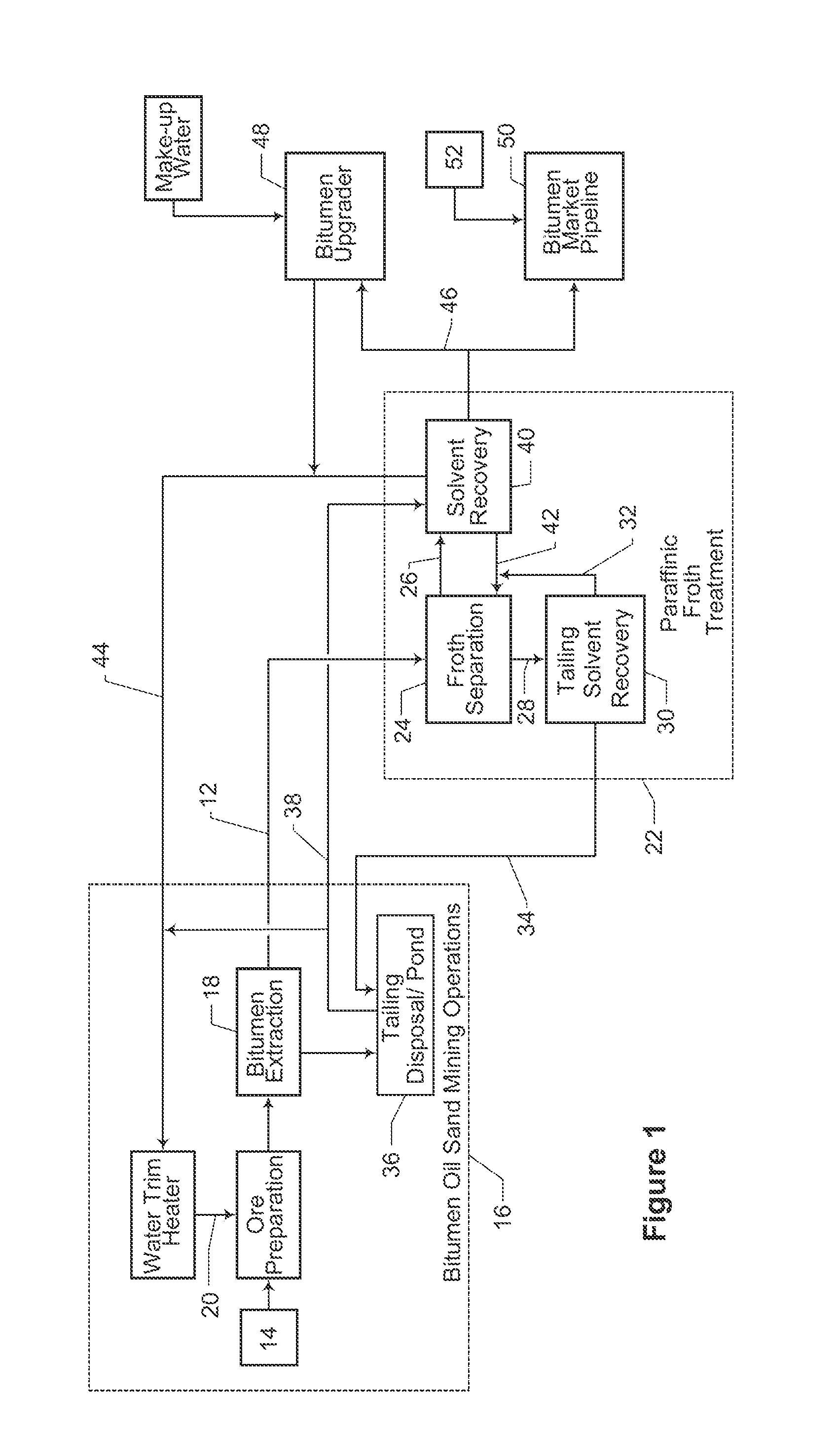

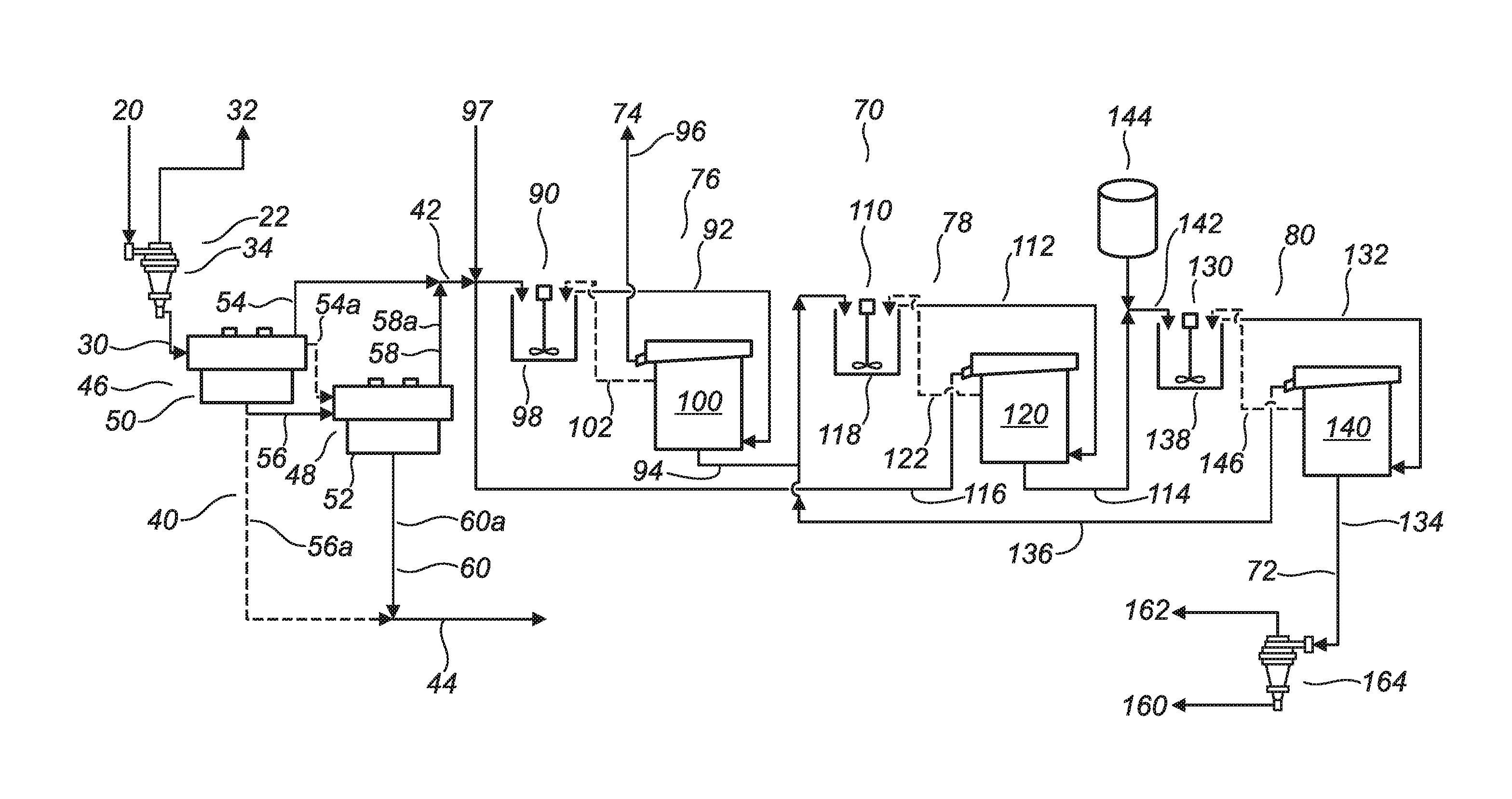

Process For Integration of Paraffinic Froth Treatment Hub and A Bitumen Ore Mining and Extraction Facility

ActiveUS20130313886A1Minimize transportation heat lossSoil-shifting machines/dredgersLiquid hydrocarbon mixture productionParaffin waxEnvironmental engineering

A process for regionalization of mining bitumen-containing oil sands ore for extraction and conversion to produce dry bitumen comprises operating multiple separate oil sands ore mining and extraction facilities or in situ thermal recovery facilities, to produce separate bitumen froth streams; operating a regional paraffinic froth treatment (PFT) hub for receiving a portion of each of the separate bitumen froth streams and treating the bitumen froth streams to produce the dry bitumen; optionally providing a portion of the dry bitumen stream to the bitumen upgrading facility and another portion of the dry bitumen stream to a bitumen market pipeline or remote upgrading facility; and optionally comprising regionalization of water distribution where by-product waters are recovered from the PFT hub and the upgrading facilities and distributed to the mining and extraction facilities for use as extraction processing water to produce the bitumen froth streams.

Owner:TRUENORTH ENERGY CORP

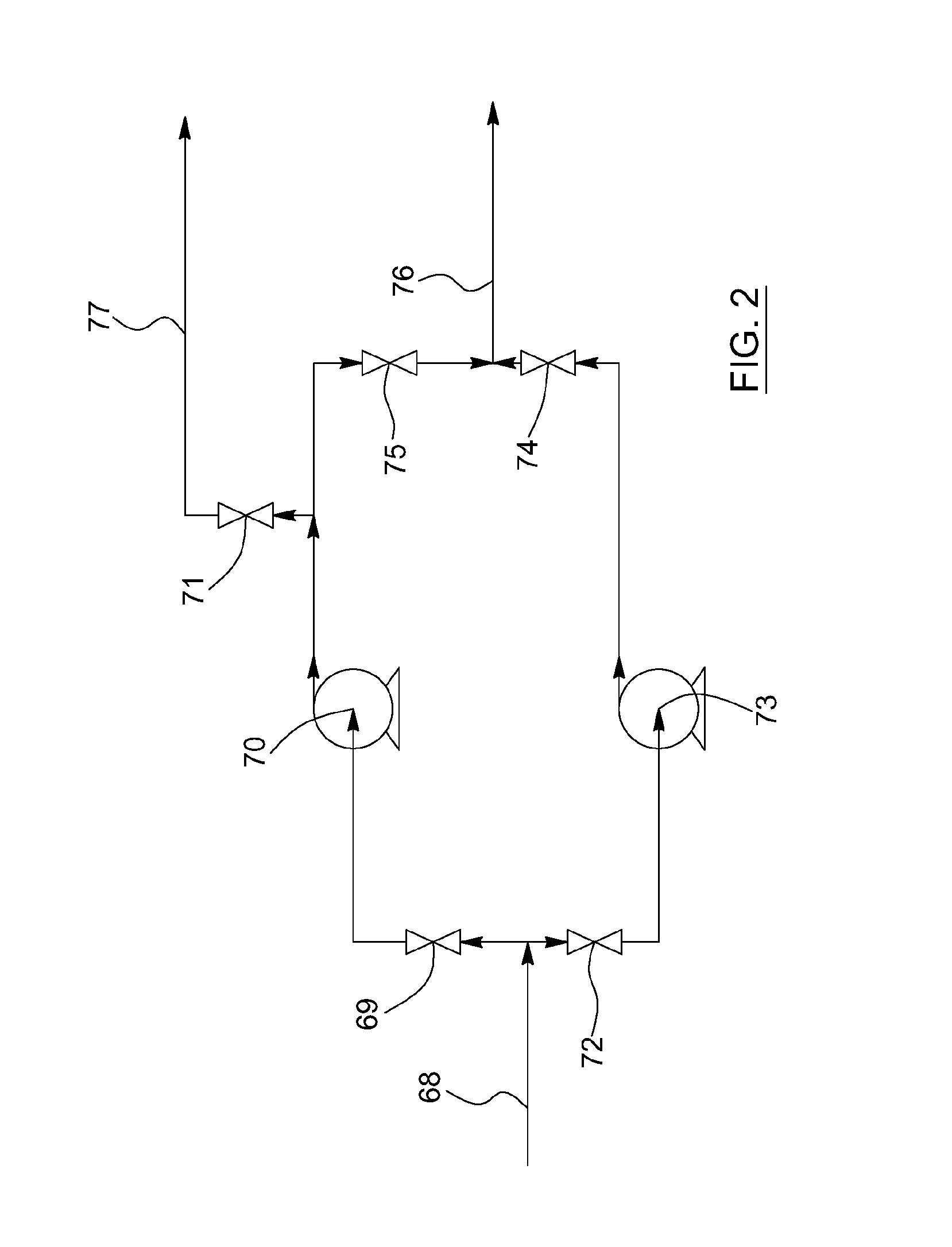

Process and unit for solvent recovery from solvent diluted tailings derived from bitumen froth treatment

ActiveUS20130345485A1Sufficient pressurePromote recoveryEvaporationLiquid hydrocarbon mixture productionSolventFroth treatment

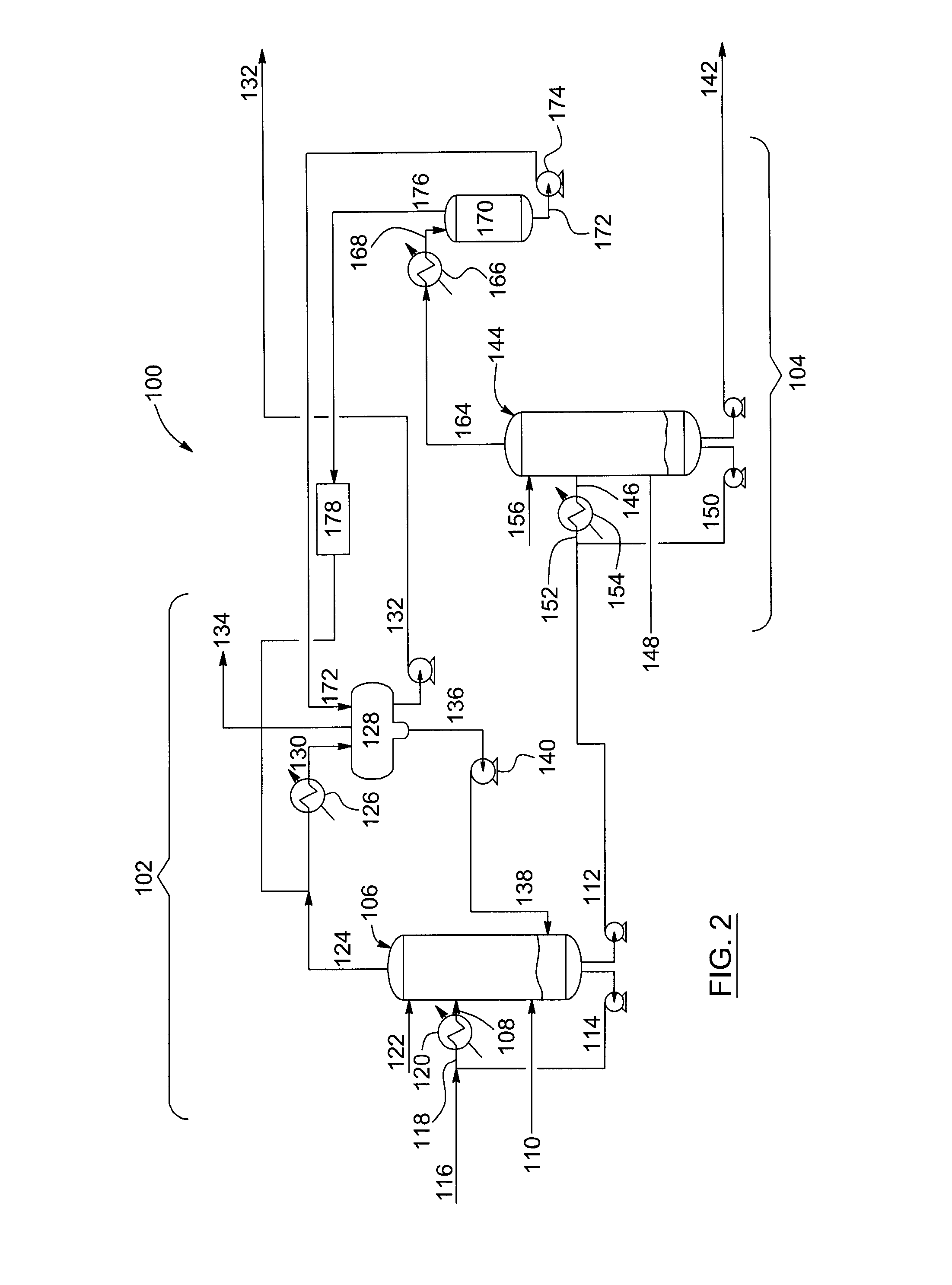

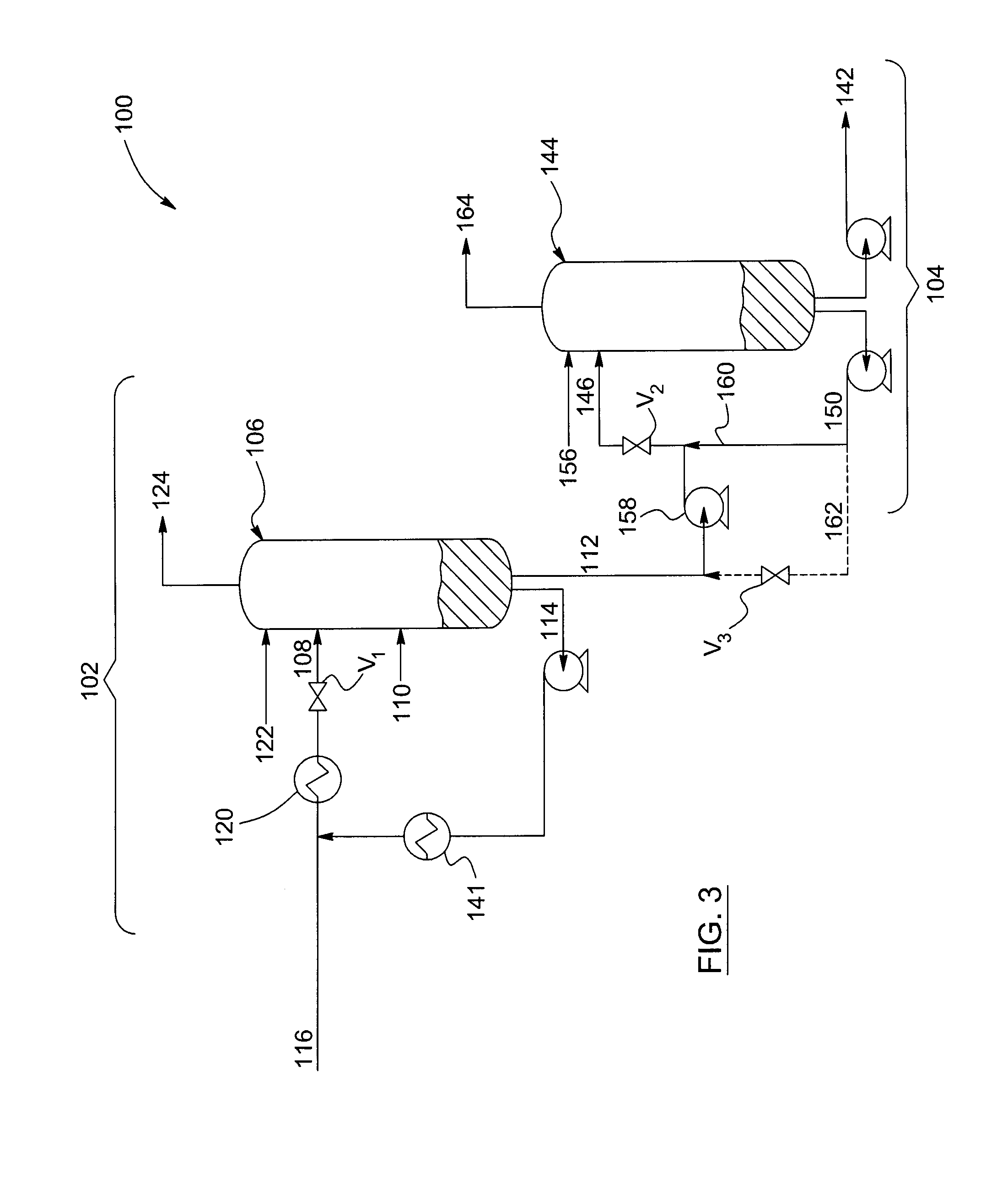

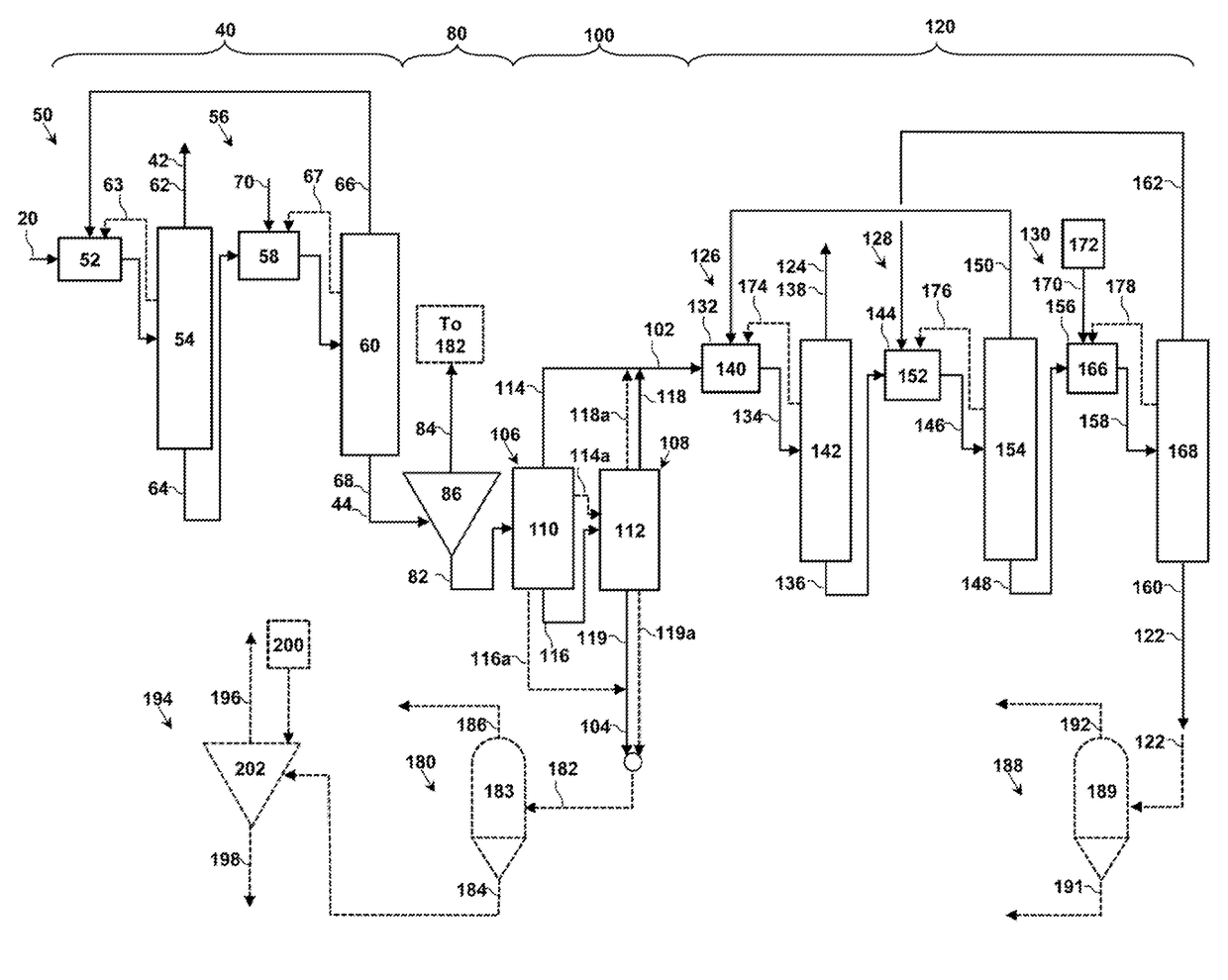

A TSRU for recovering solvent from solvent diluted tailings includes a separation apparatus receiving the tailings and producing solvent and solvent recovered tailings. The separation apparatus includes a vessel, a tailings outlet, a solvent outlet, a tailings inlet for supplying a variable flow of the tailings to the vessel and a tailings recycle line connected to the tailings inlet for recycling part of the solvent recovered tailings into the variable flow of the diluted tailings to produce a flow rate controlled feed for introduction into the vessel. A tailings solvent recovery process includes separating the diluted tailings into recovered solvent and solvent recovered tailings, discharging the solvent recovered tailings, and recycling a portion of the solvent recovered tailings back into the variable flow of the diluted tailings. A method of controlling feed flow rate to a tailings solvent recovery vessel is also provided.

Owner:TRUENORTH ENERGY CORP

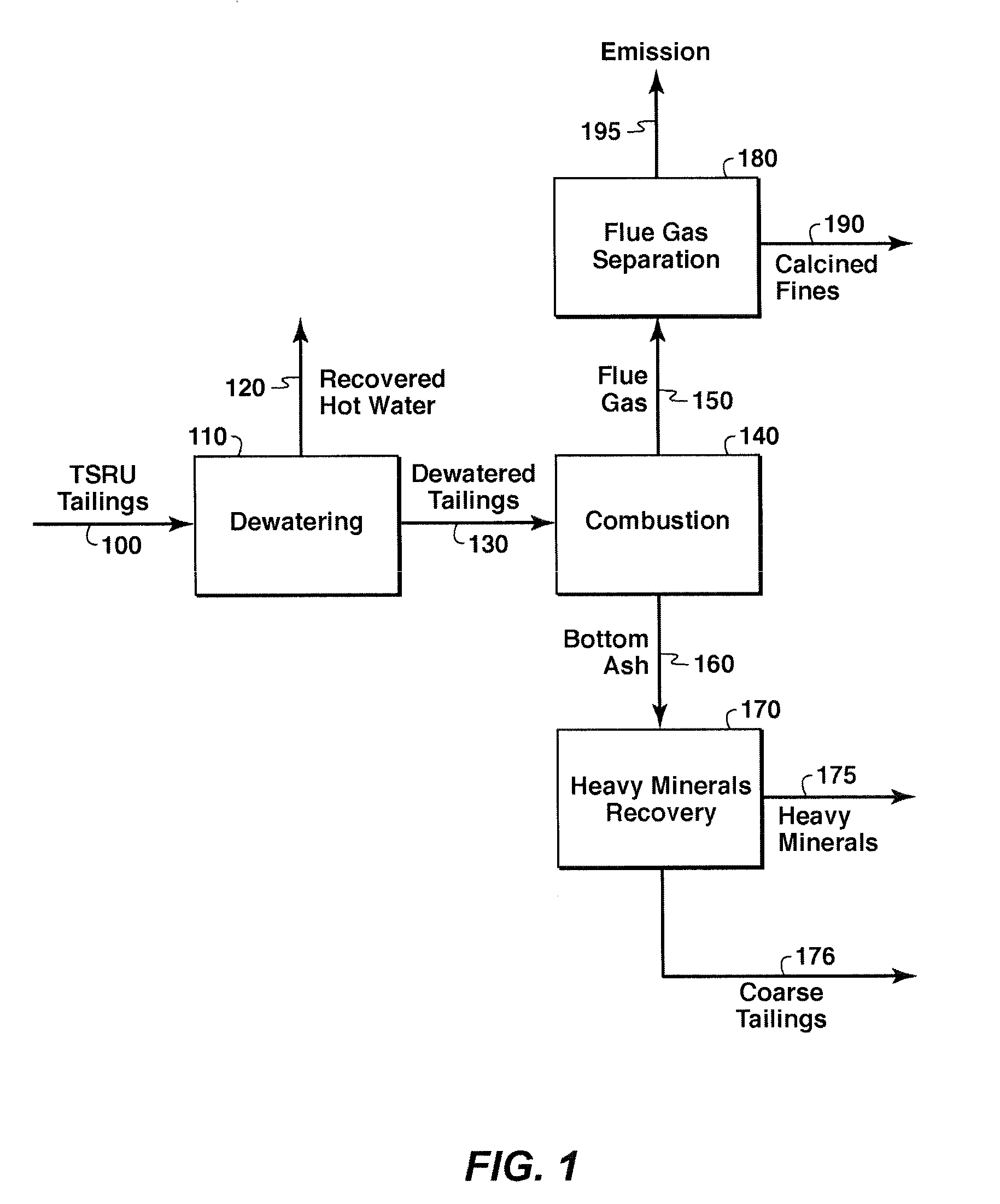

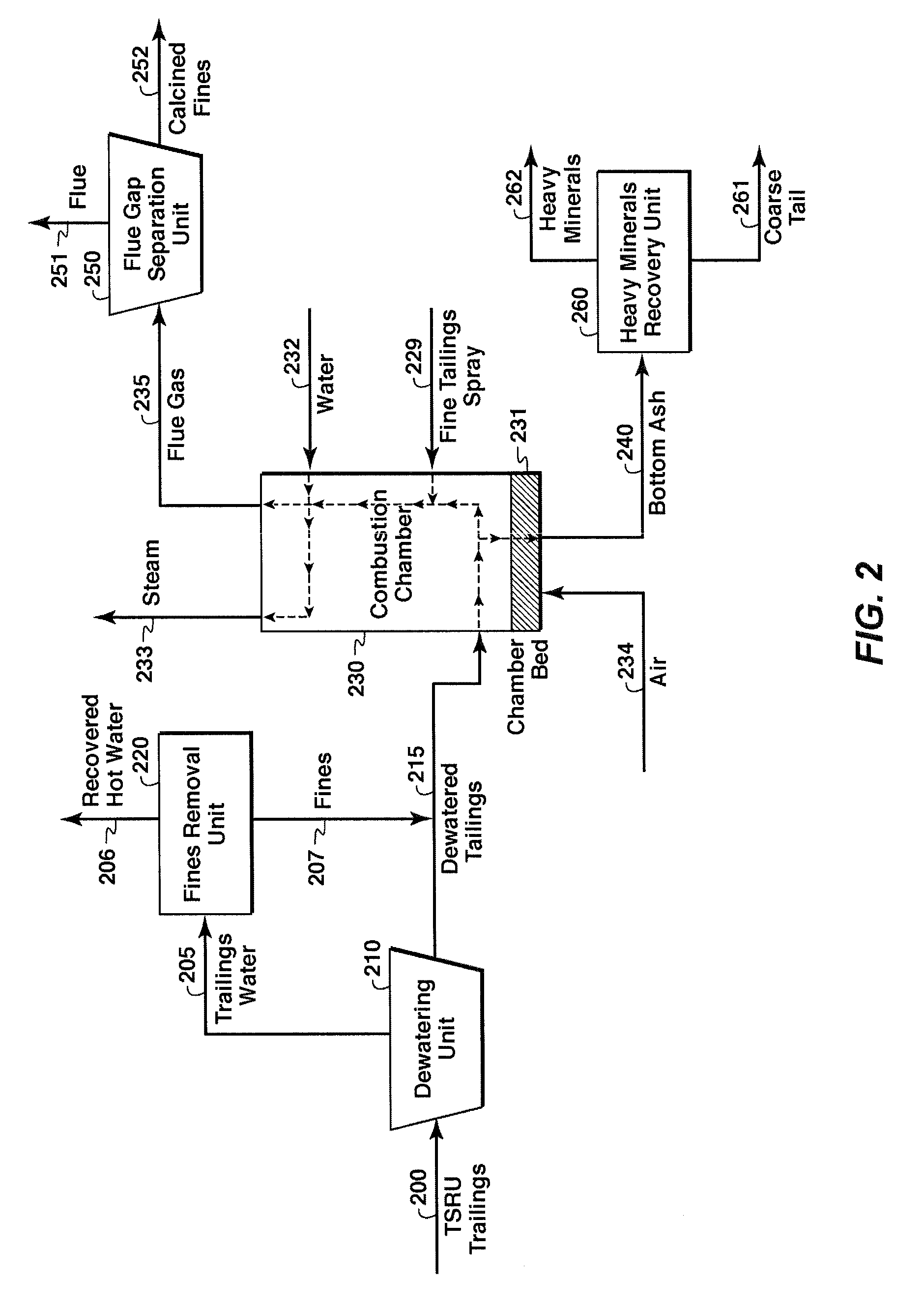

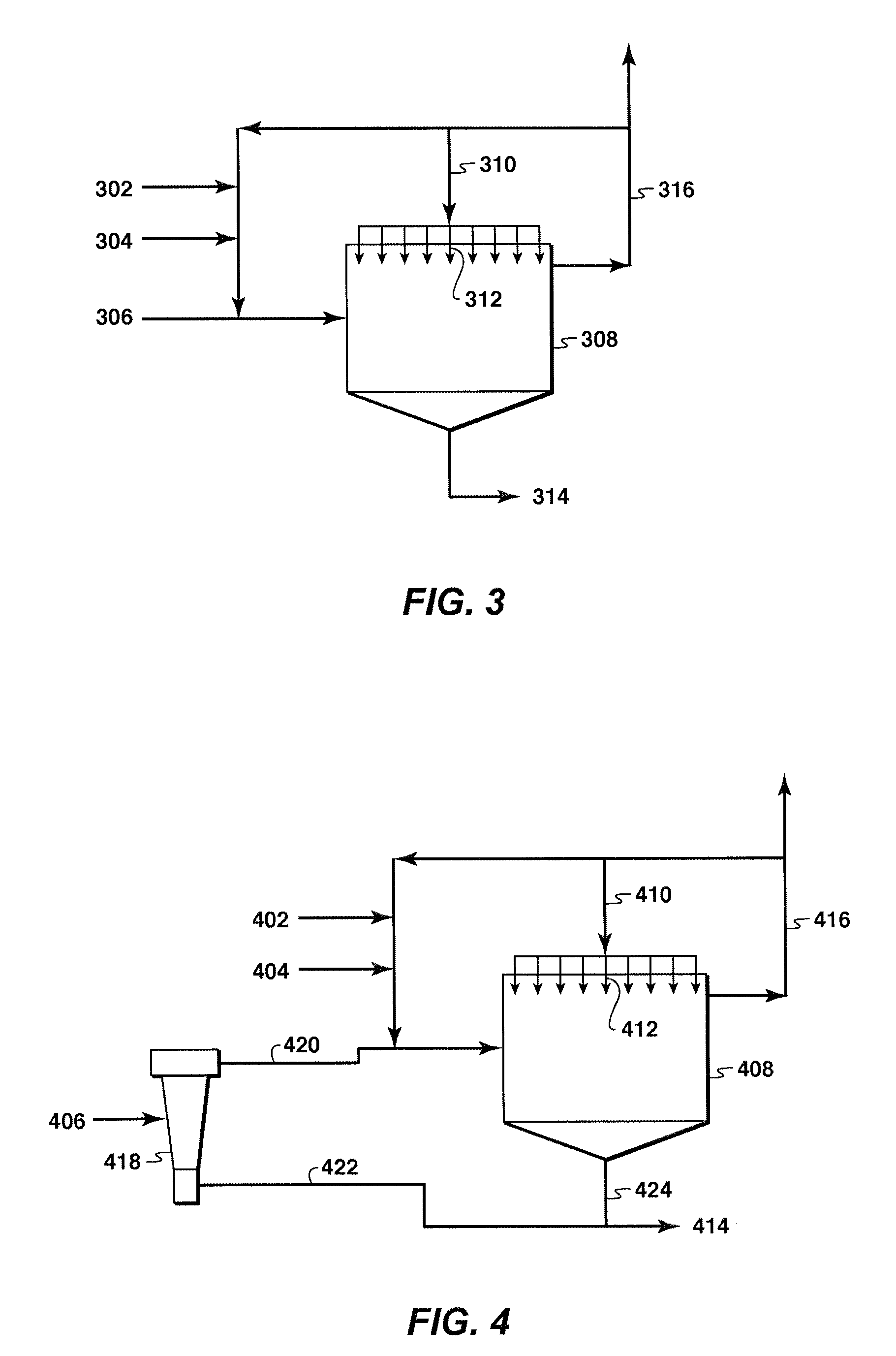

System and method for treating tailings from bitumen extraction

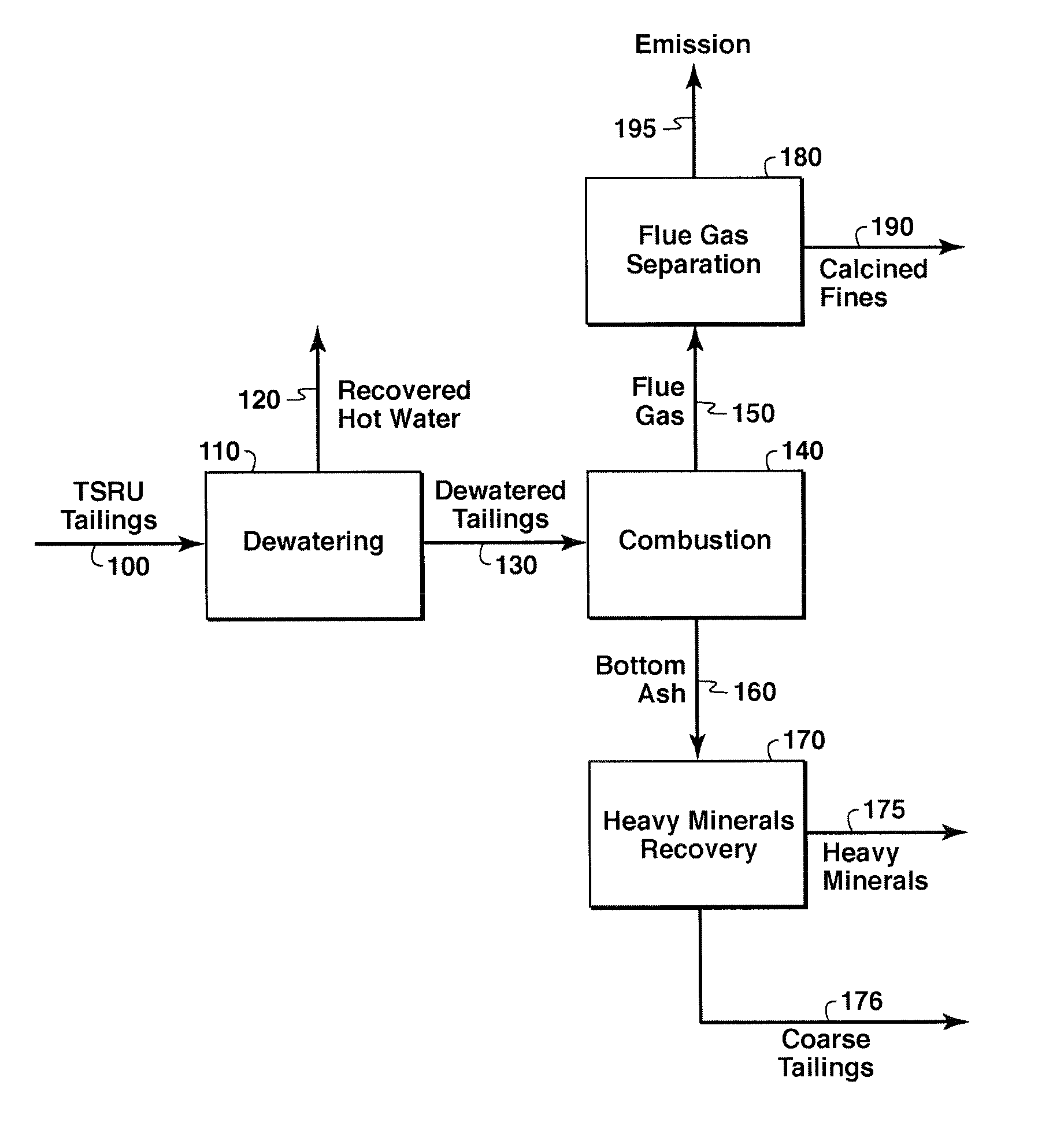

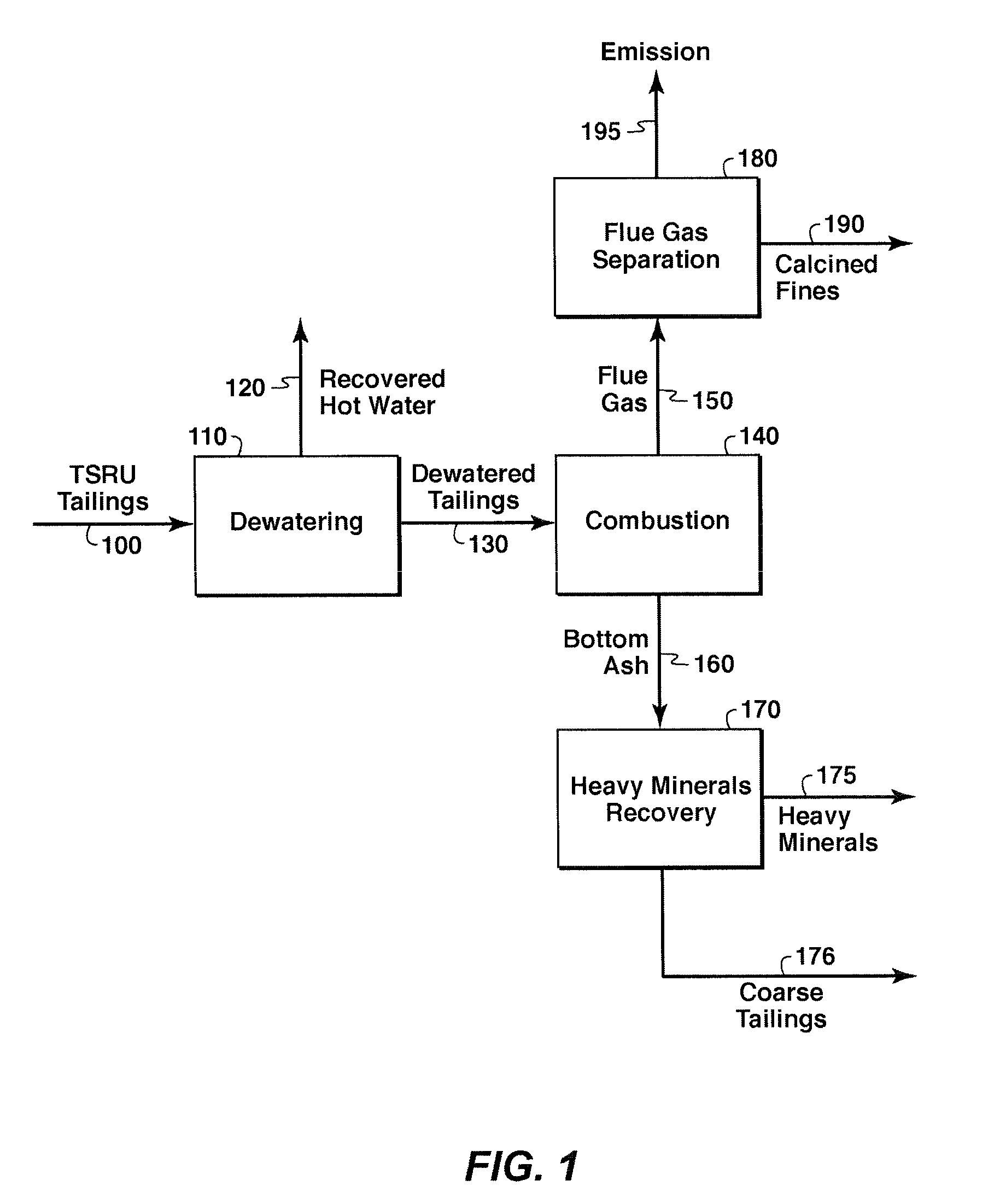

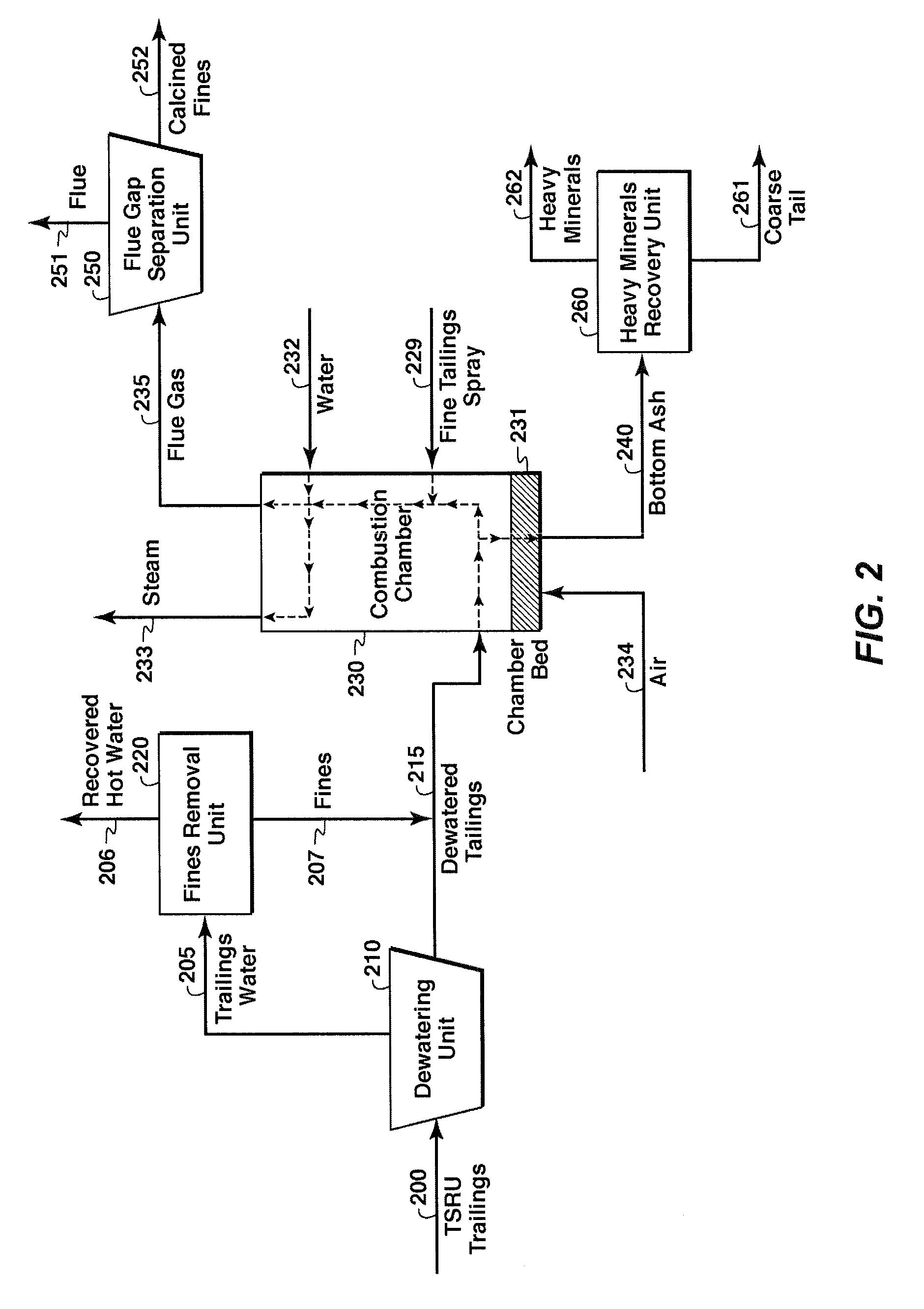

ActiveUS8252107B2Lower energy requirementsMinimal useAluminium compoundsSolid waste managementBottom ashFlue gas

A system and method for treating tailings from a bitumen froth treatment process such as TSRU tailings. The tailings are dewatered and then combusted to convert kaolin in the tailings into metakaolin. Calcined fines and heavy minerals may be recovered from the combustion products, namely from the flue gas and bottom ash.

Owner:EXXONMOBIL UPSTREAM RES CO

Fouling reduction in a paraffinic froth treatment process by solubility control

ActiveUS8354020B2Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxSolubility

The disclosure relates to improved bitumen recovery processes and systems. In particular, the disclosure teaches processes and systems for recovering heavy crude oil while avoiding fouling of equipment by recycling at least a portion of a product bitumen from a solvent recovery unit for mixing with an overhead bitumen stream that may be a diluted bitumen stream containing solvent and bitumen. The overhead bitumen stream is a near-incompatible stream and the stream of mixed overhead bitumen stream and the treated bitumen stream is a compatible stream that will not foul equipment upon heating.

Owner:EXXONMOBIL UPSTREAM RES CO

Upgrading bitumen in a paraffinic froth treatment process

ActiveUS8357291B2Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

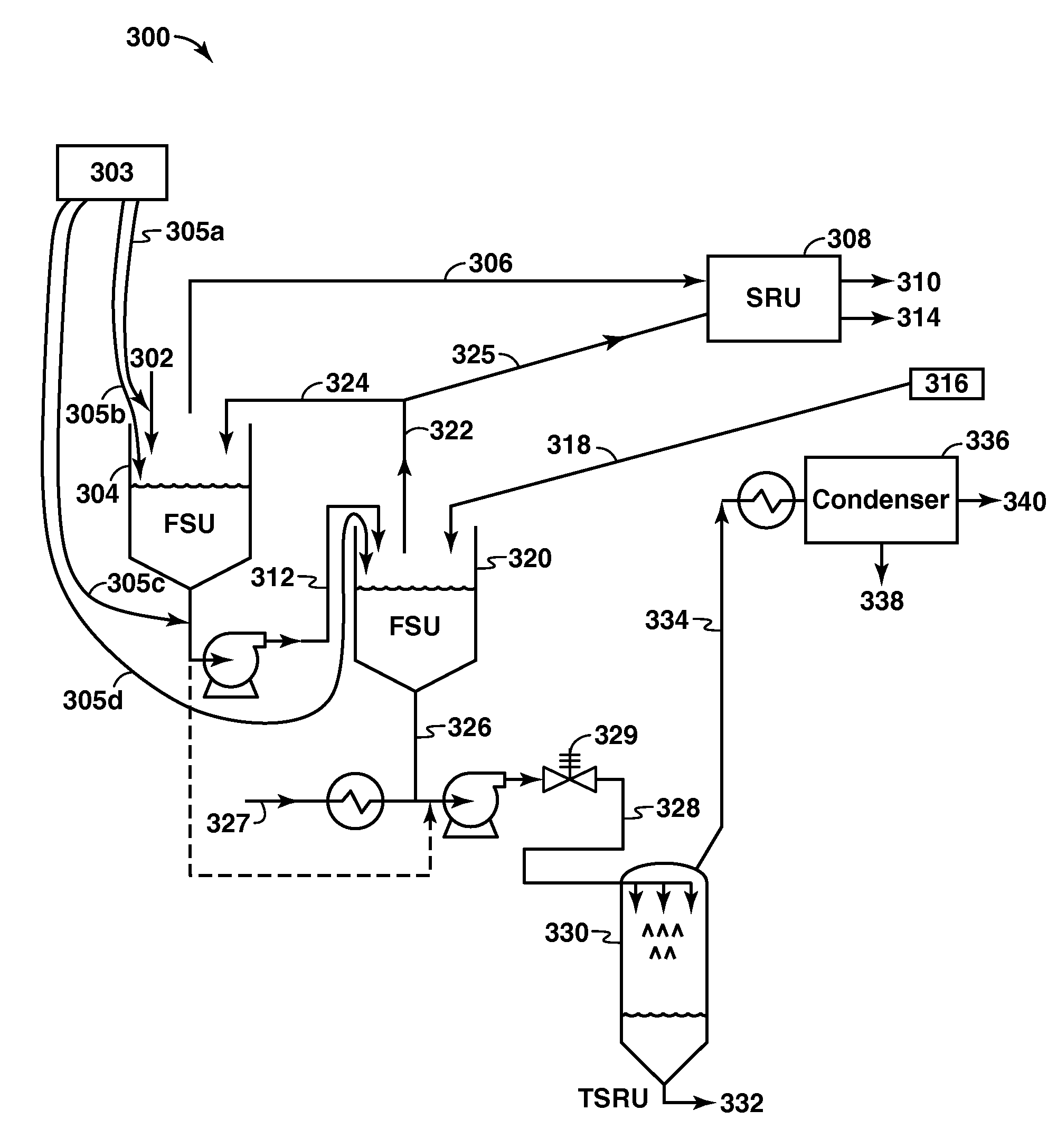

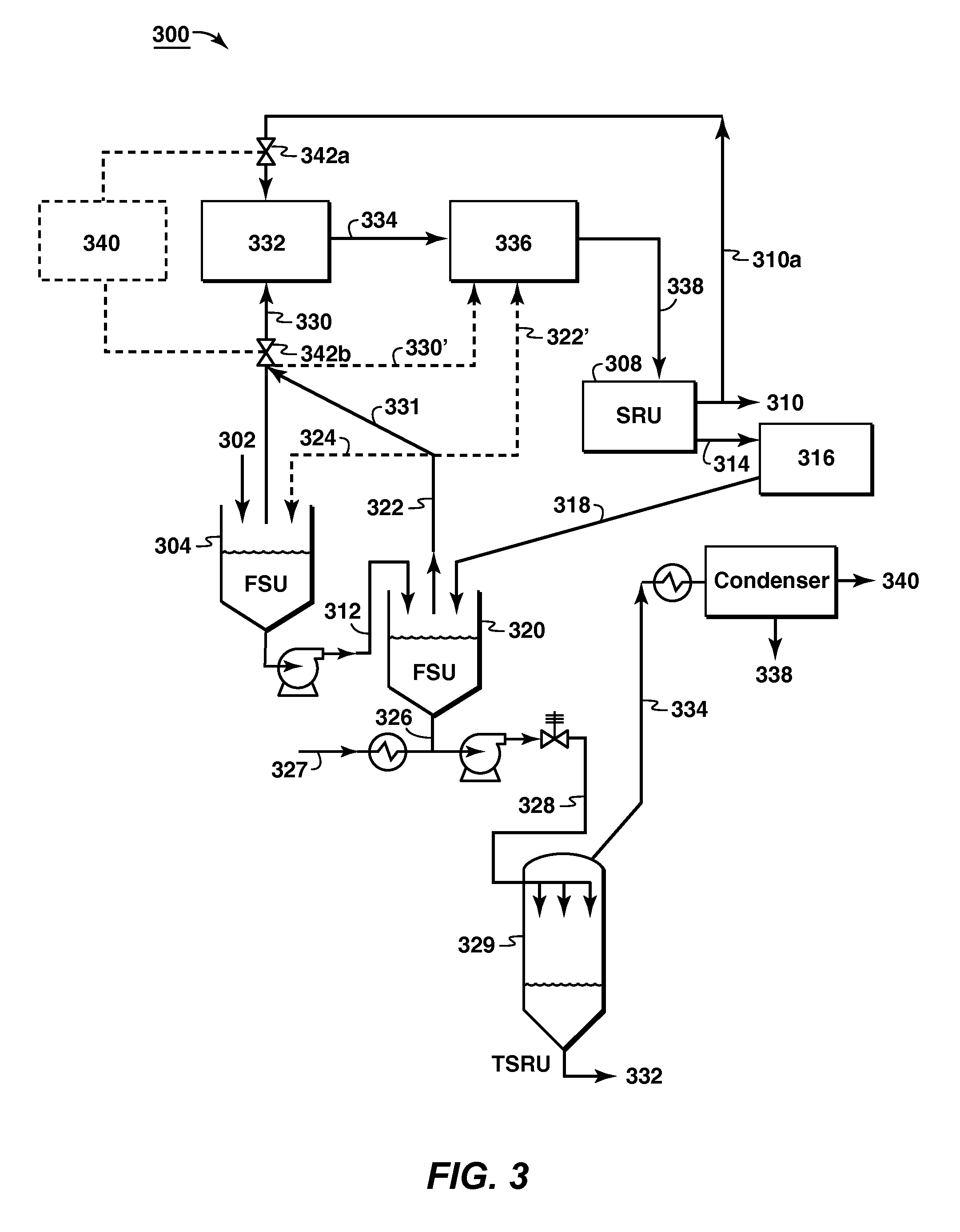

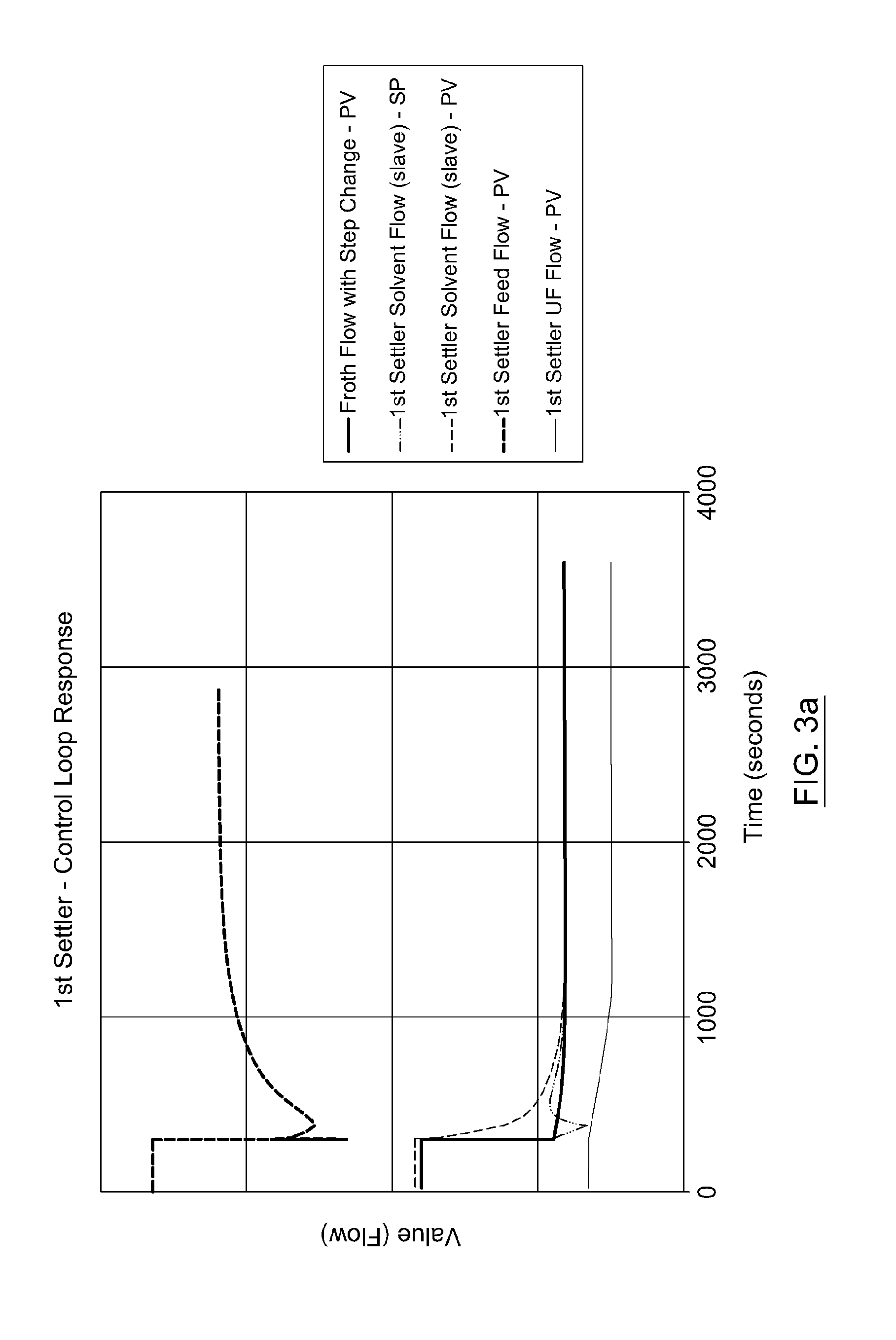

Enhanced Turndown Process for a Bitumen Froth Treatment Operation

ActiveUS20140048450A1Good dissolution stabilityReduce rateLiquid hydrocarbon mixture productionHydrocarbon oils treatmentThermodynamicsFroth treatment

A process for operating a bitumen froth treatment operation in turndown mode includes adding solvent to bitumen froth to produce diluted bitumen froth and separating it into diluted bitumen and solvent diluted tailings and in response to a reduction in bitumen froth flow recirculating part of the diluted bitumen into the bitumen froth and returning part of the solvent diluted tailings into the step of separating. A method for turndown of separation vessel for PFT includes sustaining the feed flow to vessel; maintaining solvent-to-bitumen ratio in the diluted bitumen froth; and retaining water, minerals and asphaltenes in a lower section of the vessel while sustaining an outlet flow. The use of diluted bitumen derived from PFT as a viscosity modifying agent of the bitumen froth and an associated process are also provided.

Owner:TRUENORTH ENERGY CORP

Method for processing froth treatment tailings

ActiveUS20110233115A1Promote recoveryIncrease volumeDewatering/demulsification with mechanical meansLiquid hydrocarbon mixture productionFroth treatmentMaterials science

Owner:TITANIUM CORP

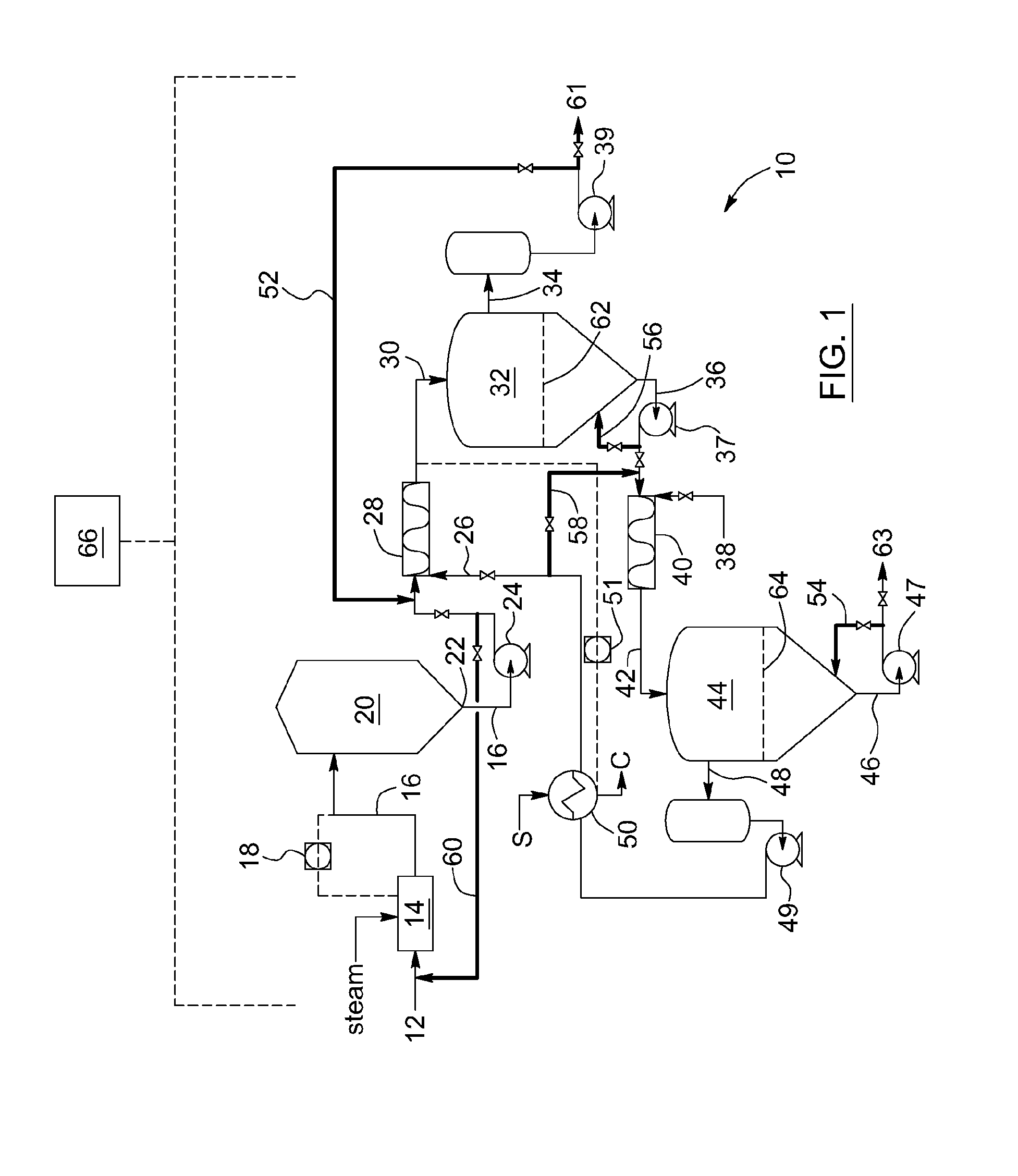

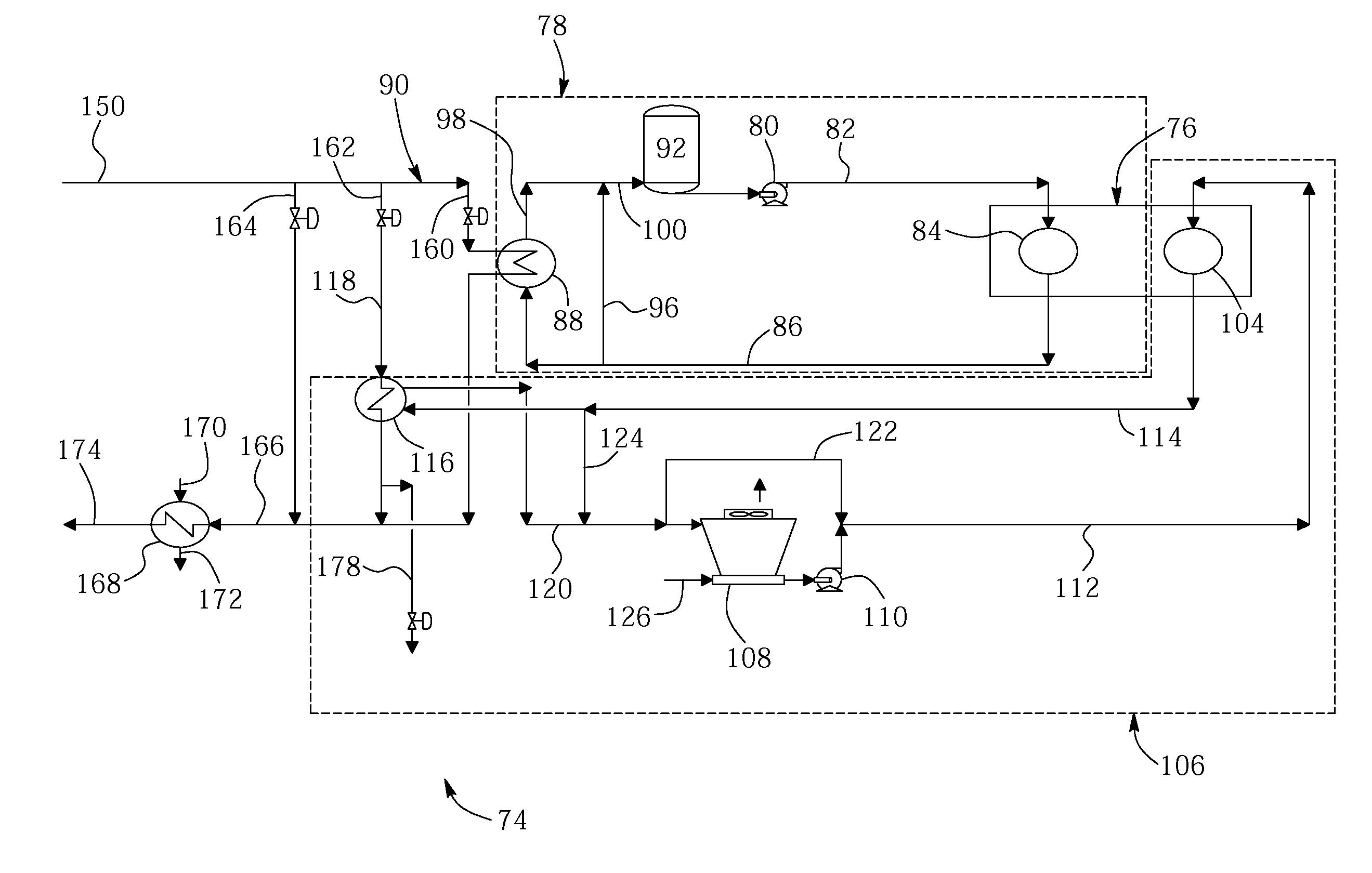

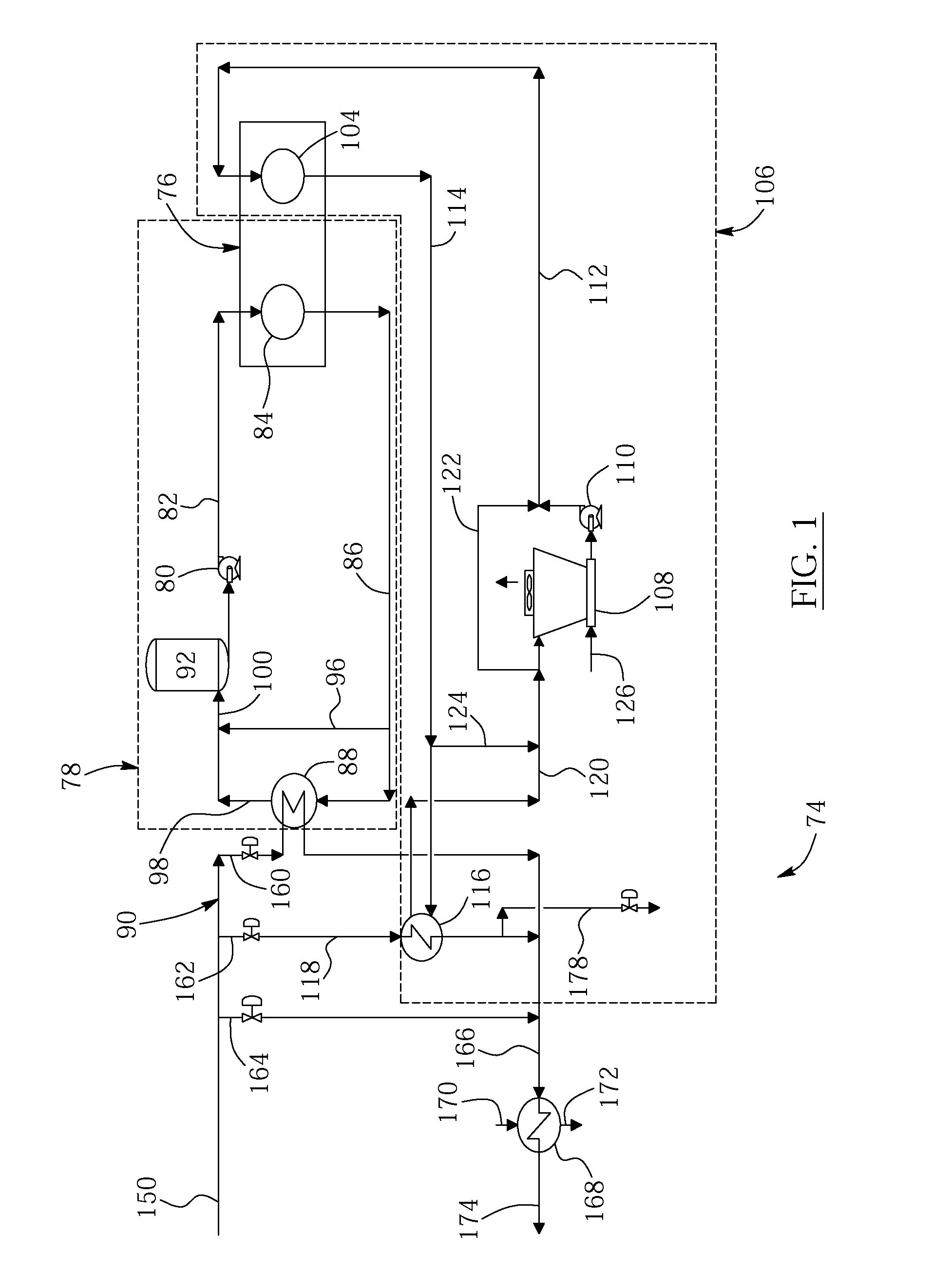

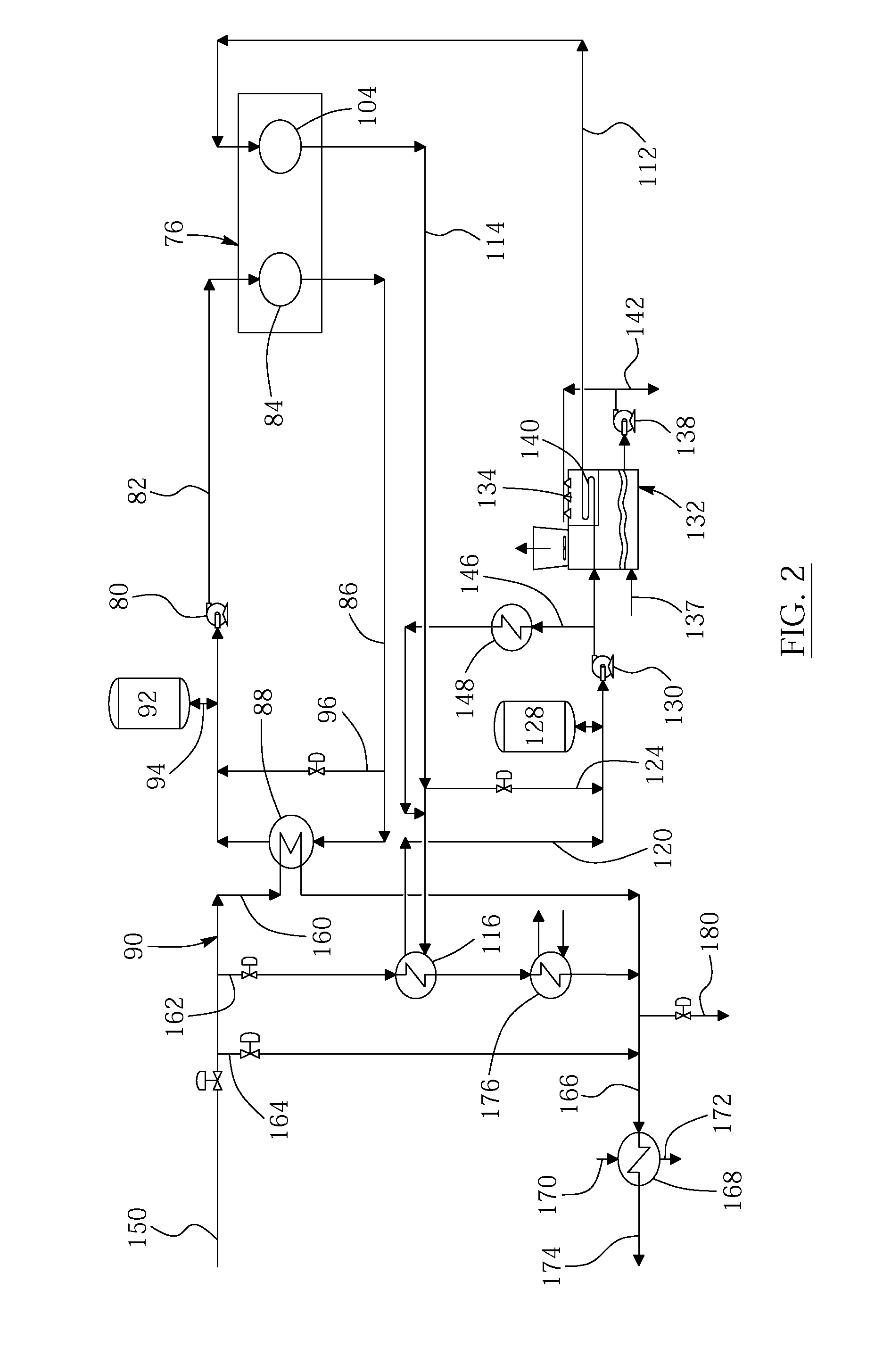

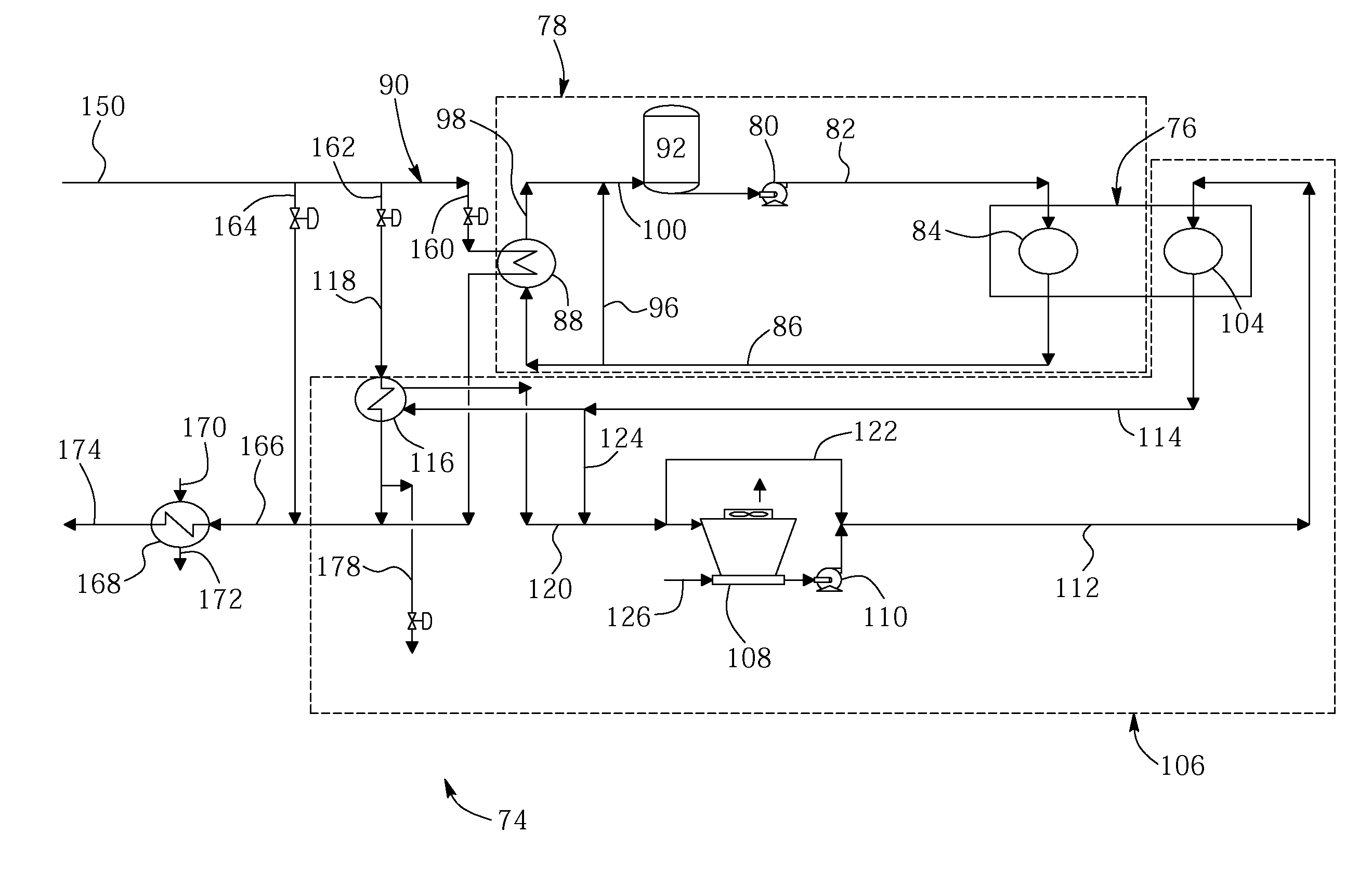

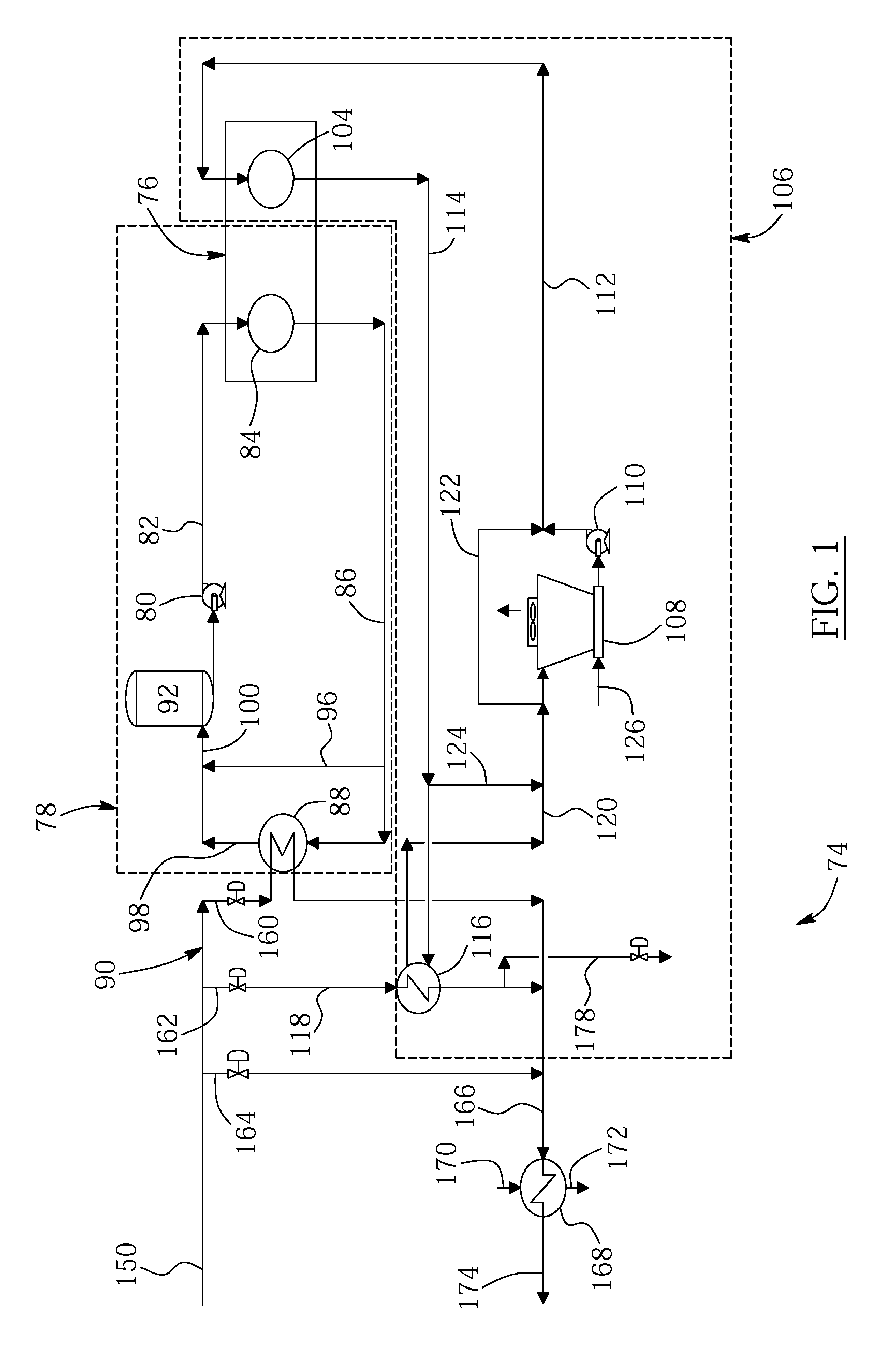

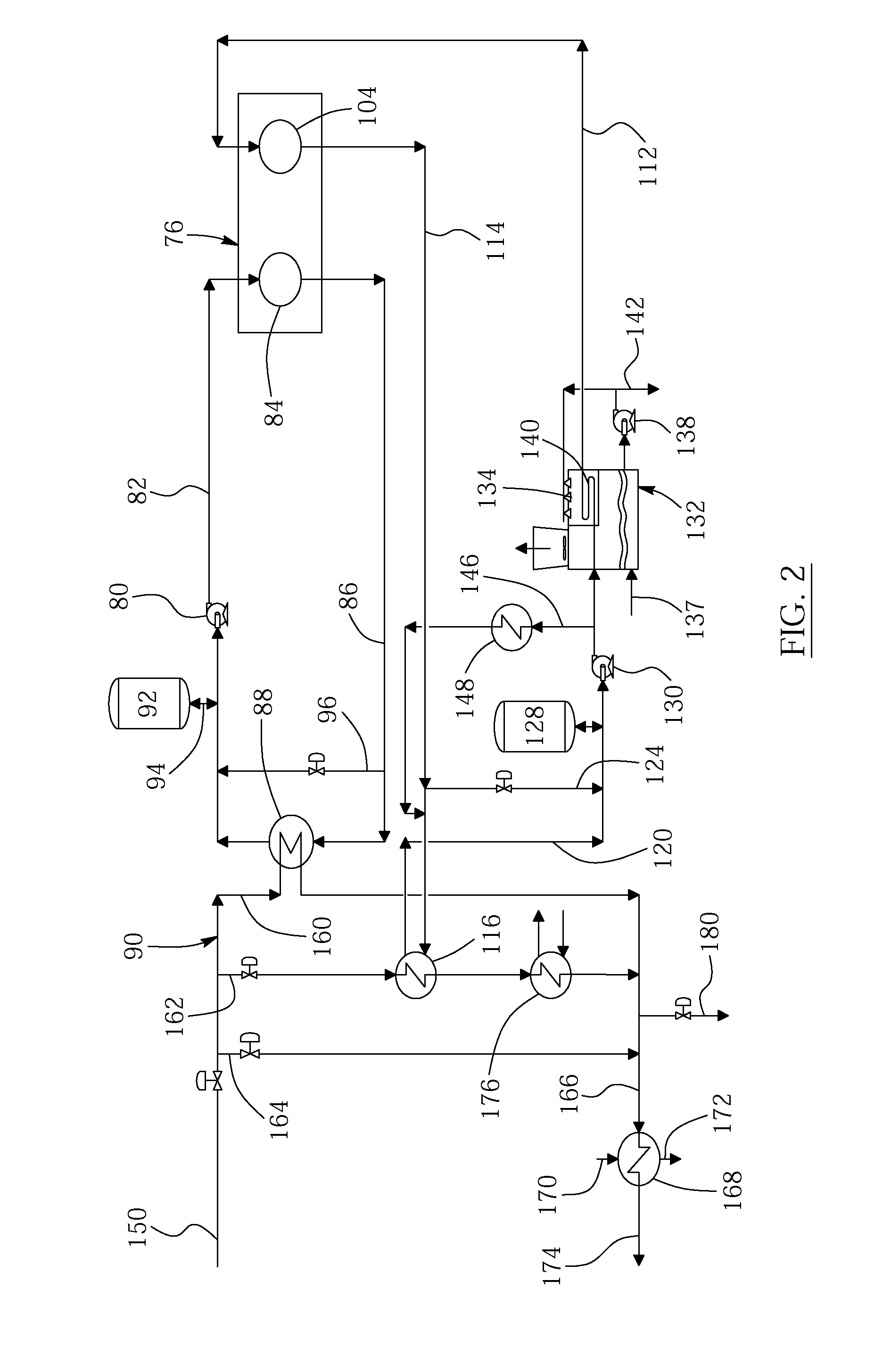

Heat Recovery for Bitumen Froth Treatment Plant Integration with Sealed Closed-Loop Cooling Circuit

ActiveUS20140291209A1Reduce dirtRecuperative heat exchangersLiquid hydrocarbon mixture productionClosed loopProcess engineering

A system and process for recovering heat from a bitumen froth treatment plant use a sealed closed-loop heat transfer circuit. The system has a heat removal exchanger associated with the plant and receiving hot froth treatment process stream; heat recovery exchanger; the circuit; and an oil sands process fluid line. The circuit includes piping circulating heat exchange media having uncontaminated and low fouling properties. The piping includes a supply line to the heat removal exchanger and a return line for providing heated media to the recovery exchanger. The circuit has a pump for pressurizing the heat exchange media; a pressure regulator for regulating pressure of the media. The pump and the pressure maintain the media under pressure in liquid phase. The oil sands process fluid is heated producing a cooled media for reuse in the heat removal exchanger. High and low temperature heat removal exchangers can be used.

Owner:TRUENORTH ENERGY CORP

System and Method For Treating Tailings From Bitumen Extraction

ActiveUS20110036272A1Lower energy requirementsMinimal useAluminium compoundsSolid waste managementBottom ashFlue gas

A system and method for treating tailings from a bitumen froth treatment process such as TSRU tailings. The tailings are dewatered and then combusted to convert kaolin in the tailings into metakaolin. Calcined fines and heavy minerals may be recovered from the combustion products, namely from the flue gas and bottom ash.

Owner:EXXONMOBIL UPSTREAM RES CO

Process and unit for solvent recovery from solvent diluted tailings derived from bitumen froth treatment

ActiveUS9676684B2Sufficient pressurePromote recoveryEvaporationLiquid hydrocarbon mixture productionSolventFroth treatment

A TSRU for recovering solvent from solvent diluted tailings includes a separation apparatus receiving the tailings and producing solvent and solvent recovered tailings. The separation apparatus includes a vessel, a tailings outlet, a solvent outlet, a tailings inlet for supplying a variable flow of the tailings to the vessel and a tailings recycle line connected to the tailings inlet for recycling part of the solvent recovered tailings into the variable flow of the diluted tailings to produce a flow rate controlled feed for introduction into the vessel. A tailings solvent recovery process includes separating the diluted tailings into recovered solvent and solvent recovered tailings, discharging the solvent recovered tailings, and recycling a portion of the solvent recovered tailings back into the variable flow of the diluted tailings. A method of controlling feed flow rate to a tailings solvent recovery vessel is also provided.

Owner:TRUENORTH ENERGY CORP

Optimizing Feed Mixer Performance In A Paraffinic Froth Treatment Process

InactiveUS20120279824A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionShear rateProcess engineering

The invention relates to improved bitumen recovery processes and systems. One process provides for operation of a bitumen froth treatment plant at optimum shear rates in the feed pipe carrying the bitumen froth to the froth settling unit. Another process provides for optimizing the design of a bitumen froth treatment plant by optimizing the diameter of the feed pipe to impart an optimum shear rate to the bitumen froth mixture and further optimizing the volume of the feed pipe to impart an optimum residence time for the bitumen froth stream in the feed pipe. An optimal plant design is also disclosed, the plant including optimal diameter and volume of the feed pipe.

Owner:EXXONMOBIL UPSTREAM RES CO

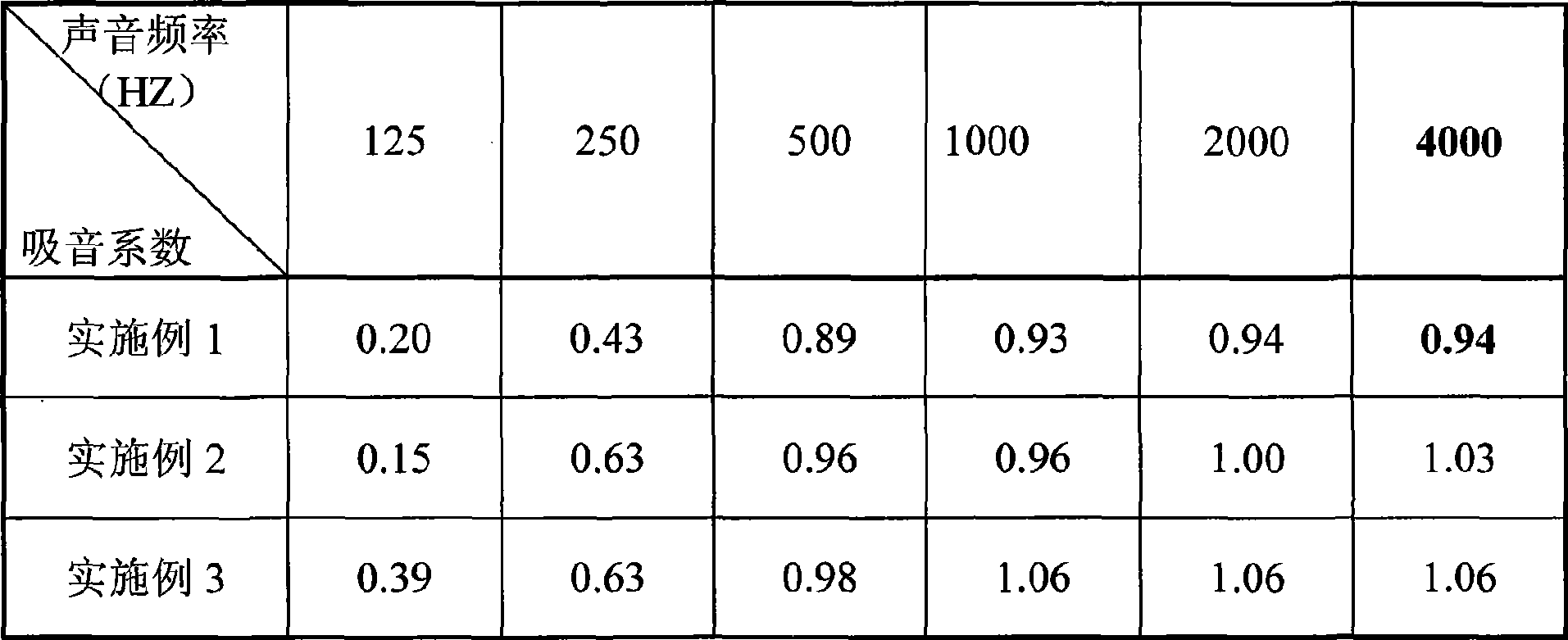

Heavy soundproof material, producing method thereof and baffles using the same

InactiveCN101423359AProtect environmentHigh densitySolid waste managementNoise reduction constructionAcoustic boardFroth treatment

The invention provides a heavy acoustic material with lead-zinc tailings, which contains lead-zinc tailings coarse grains the grain size of which is between 4 and 6 millimeters, lead-zinc tailing medium grains the grain size of which is between 2 and 3 millimeters, lead-zinc tailing fine grains the grain size of which is smaller than 1 millimeter, hard asphalt, and soft asphalt. The invention also provides a method for producing the heavy acoustic material with the lead-zinc tailings and an acoustic board using the acoustic material. The materials of the invention belong to heavy materials, and the densities of formed acoustic barriers are more than 200 kilograms per square meter to have good effect on sound insulation. At the same time, the asphalt is viscoelastic materials and has good damping performance, and the heavy acoustic materials prepared from the lead-zinc tailings which are used as main aggregates have good acoustic performance, are moisture-proof and cheap, and are convenient for construction. If the heavy acoustic material is measured in terms of the internal damping of an asphalt layer, the loss factor (percent) thereof can reach between 20 and 40 percent. At the same time, a porous sound-absorbing material synthesized from the lead-zinc tailings obtained through frothing treatment can be more widely used in sound insulation for various buildings.

Owner:北京开云科技有限公司

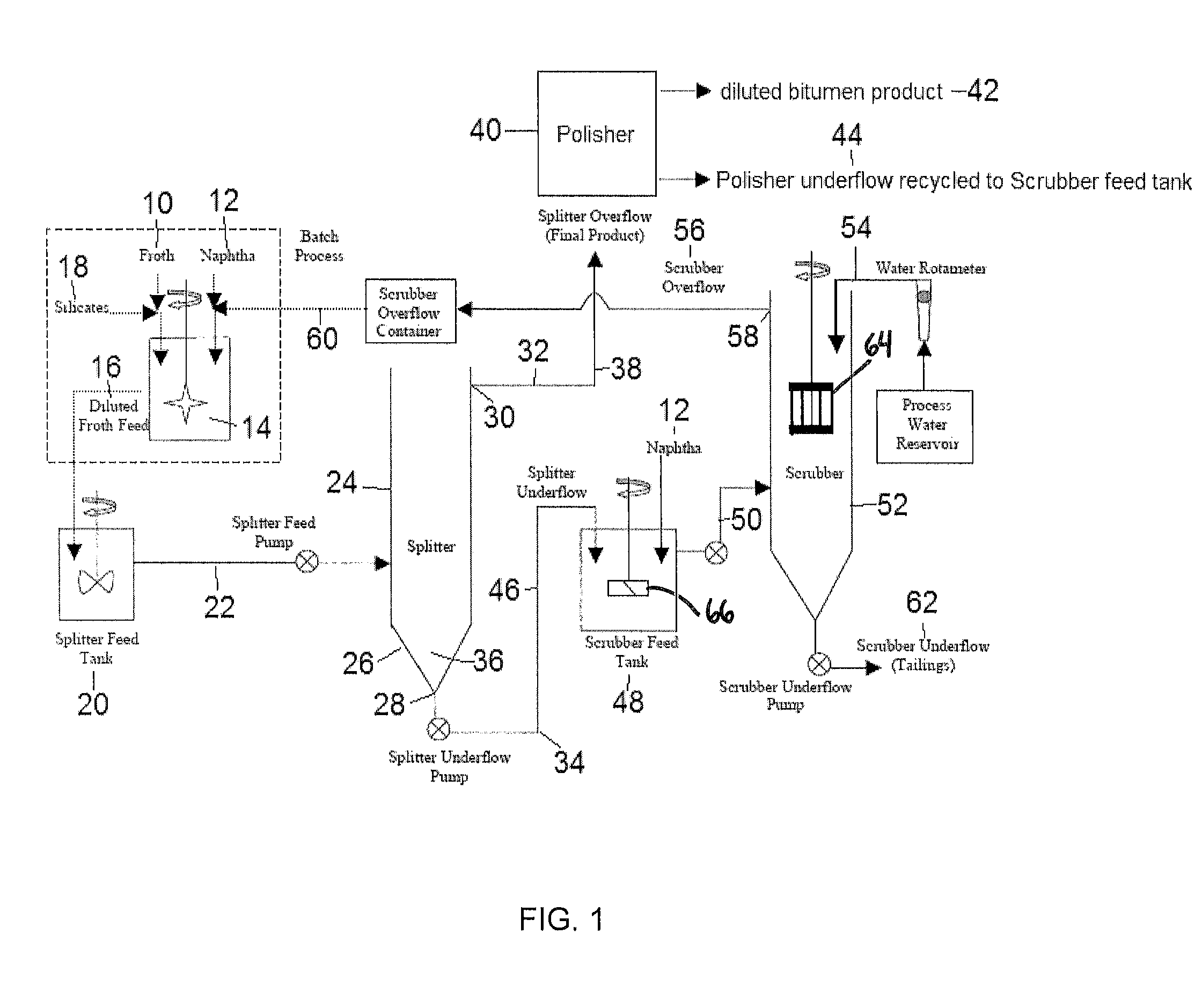

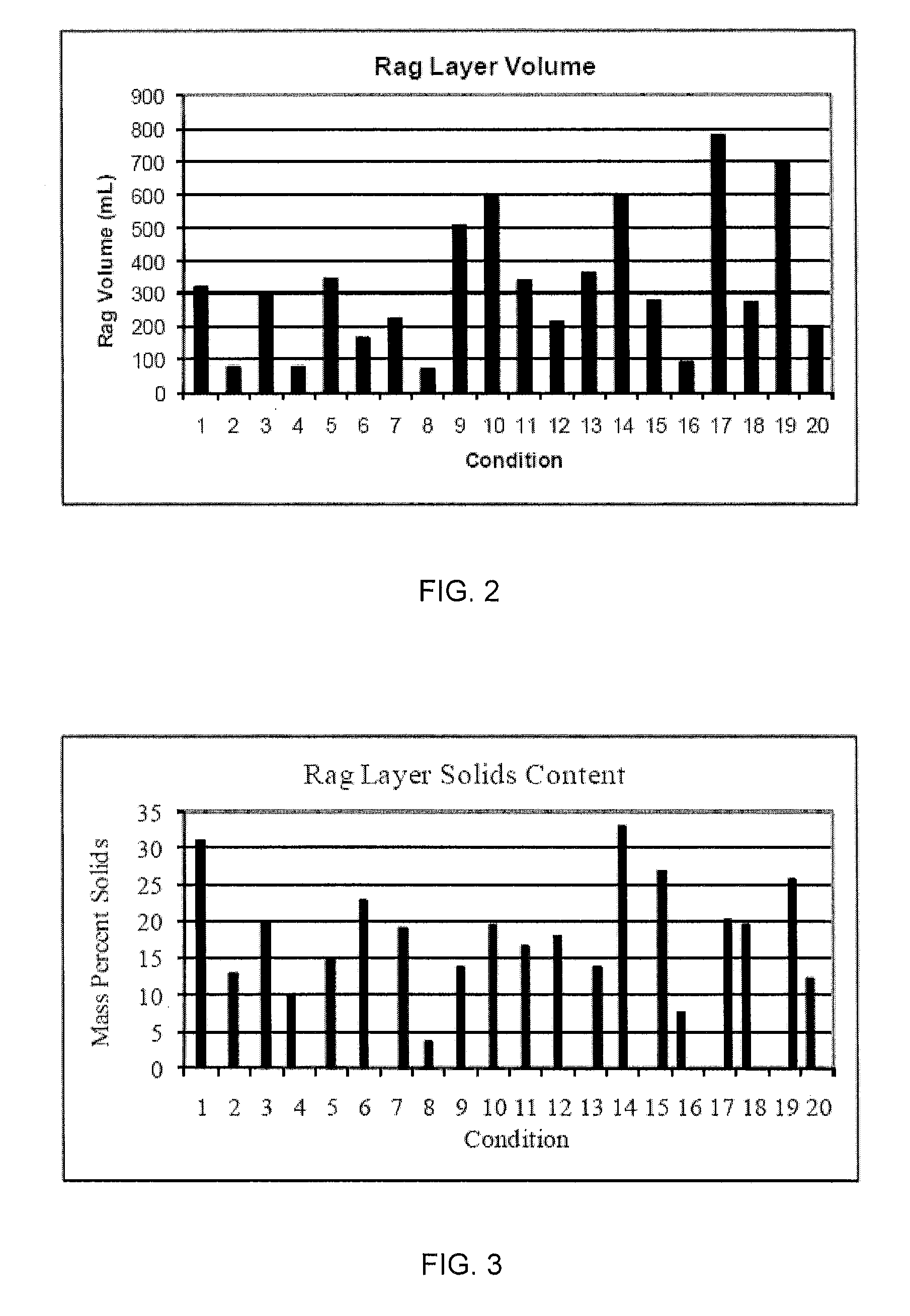

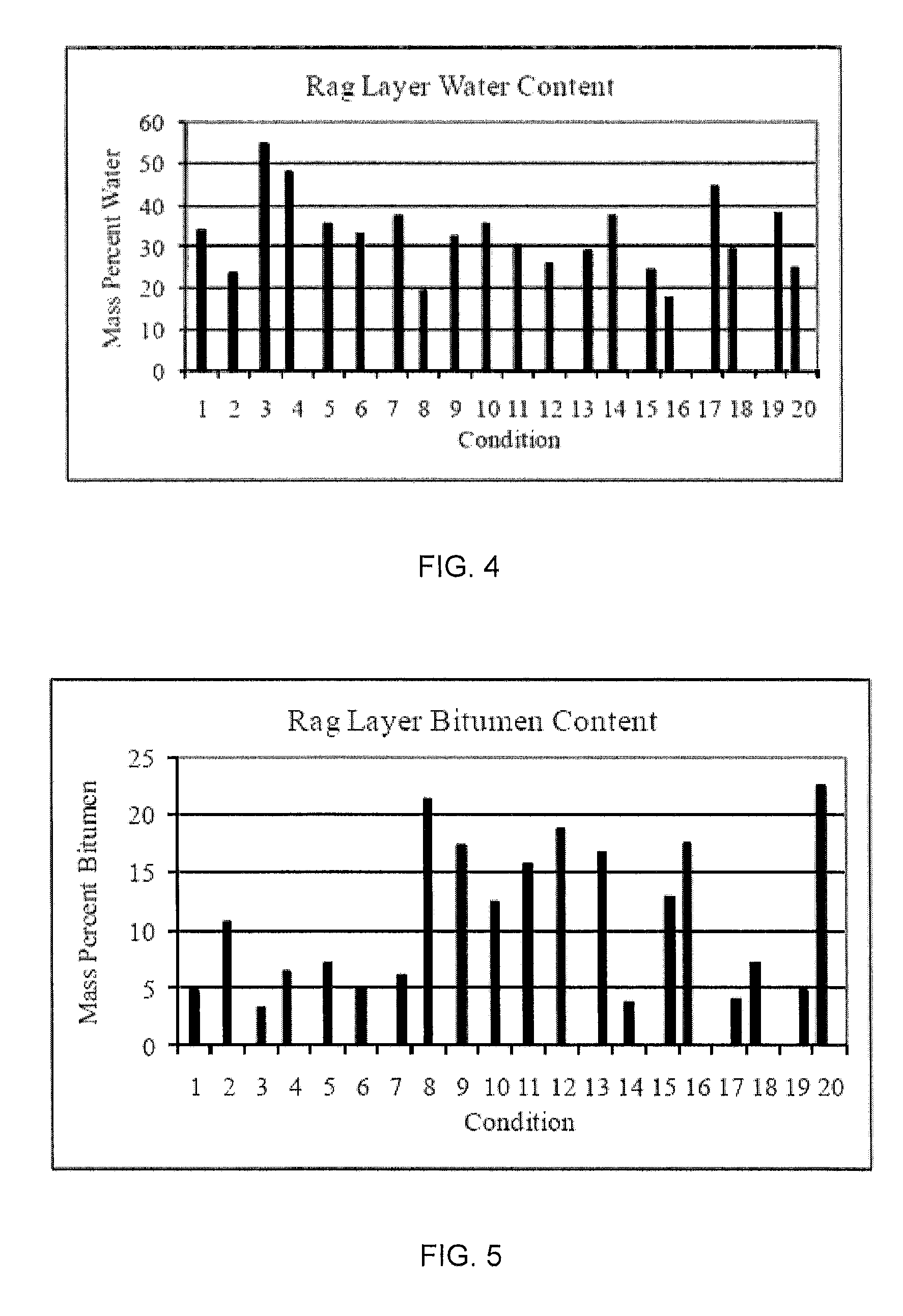

Method for reducing rag layer volume in stationary froth treatment

InactiveUS20150008161A1Lower the volumeEfficient reductionLiquid hydrocarbon mixture productionNaphthaDiluent

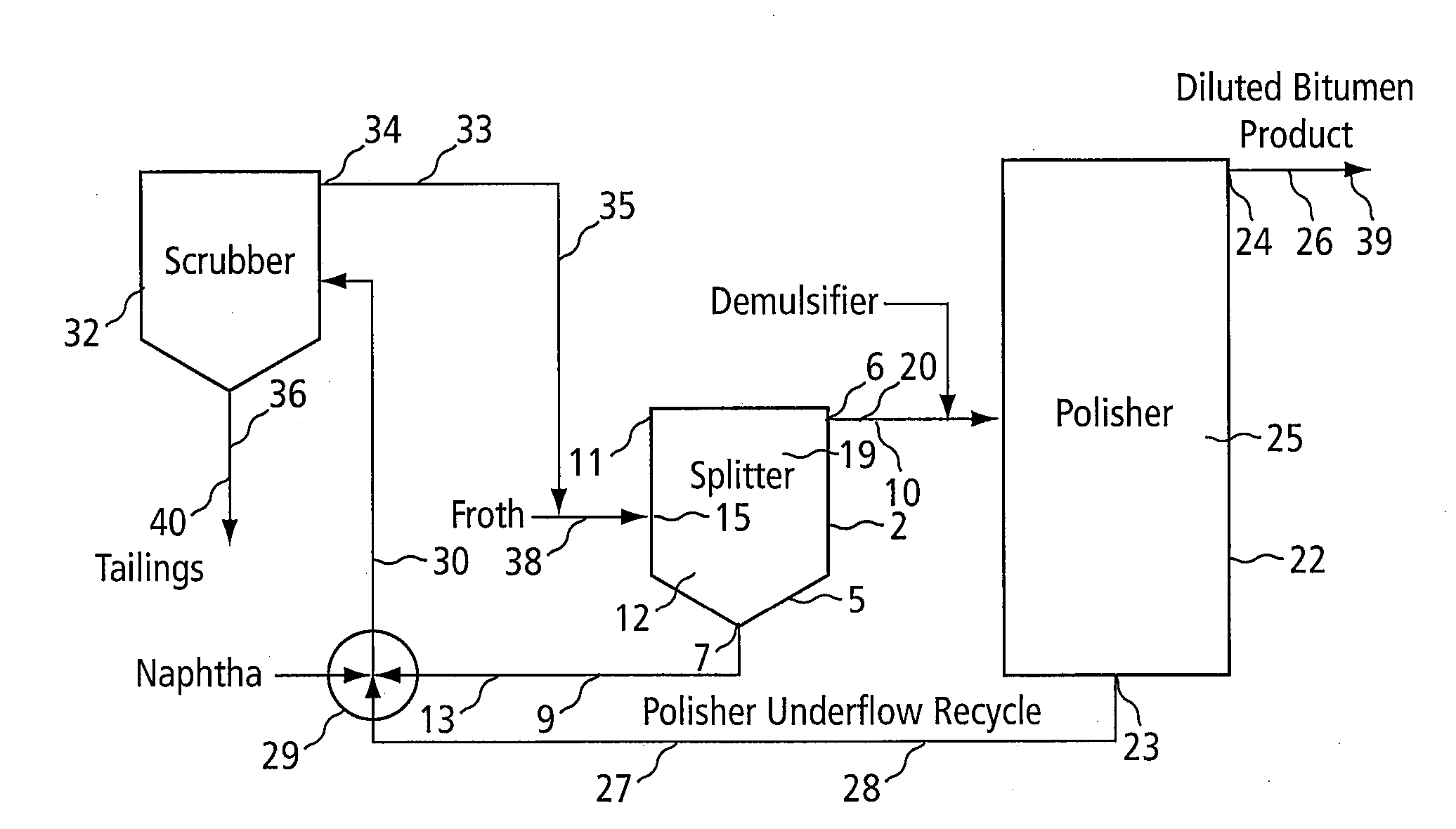

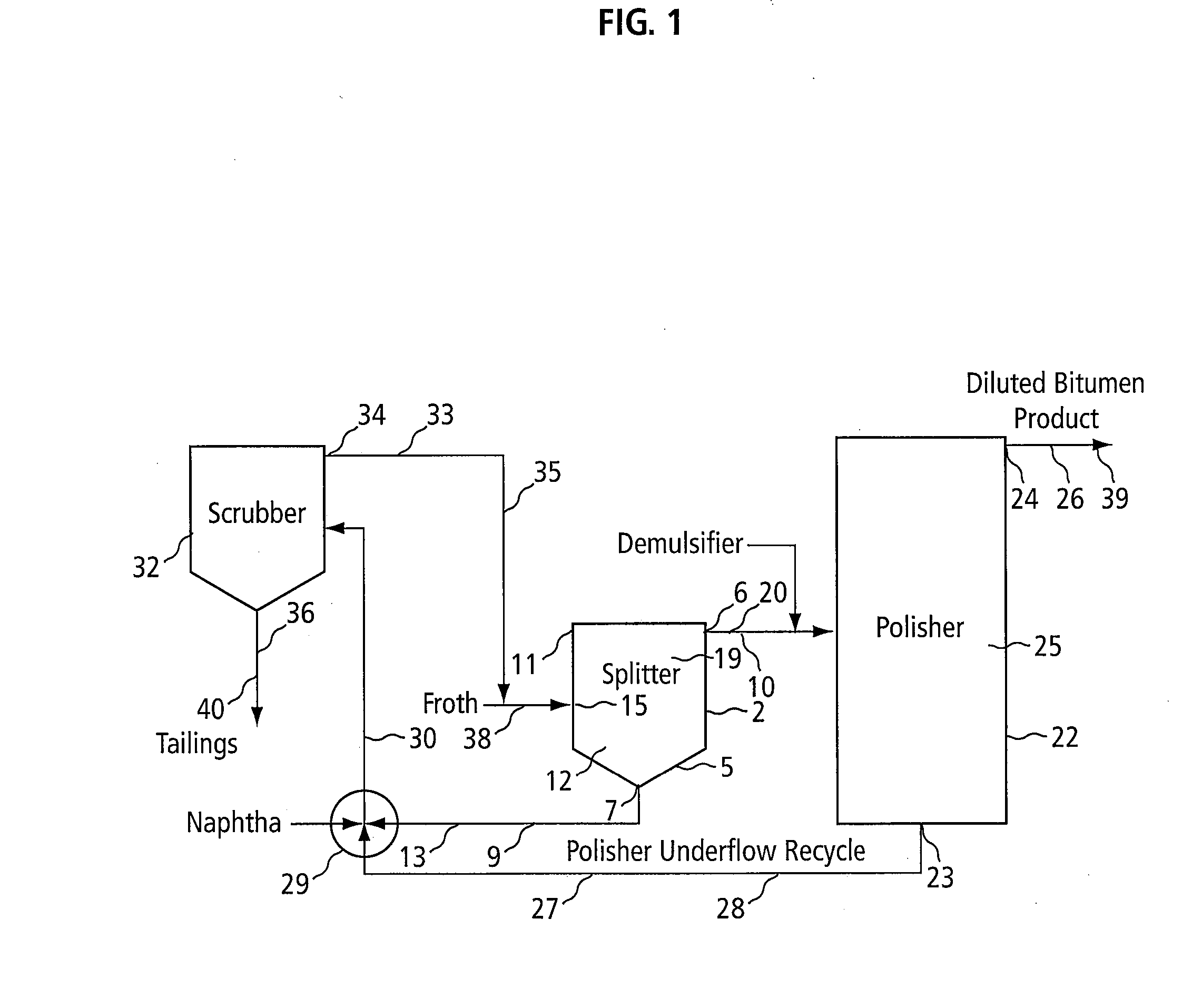

A method for reducing rag layer volume in a stationary bitumen froth treatment process is provided, comprising subjecting dilfroth having a naphtha diluent to bitumen ratio of about 0.7 to gravity settling in a splitter vessel to produce an overflow stream of raw dilbit and an underflow stream of splitter tails; mixing the splitter tails with a naphtha diluent to give a mixture having a naphtha diluent to bitumen ratio of less than about 6:1 in a scrubber feed tank; and subjecting the mixture to gravity settling and agitation in a scrubber vessel to produce an overhead stream of scrubber hydrocarbons and an underflow stream of scrubber tails.

Owner:SYNCRUDE CANADA LTD

Optimizing feed mixer performance in a paraffinic froth treatment process

ActiveUS8252170B2Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxShear rate

The invention relates to improved bitumen recovery processes and systems. One process provides for operation of a bitumen froth treatment plant at optimum shear rates in the feed pipe carrying the bitumen froth to the froth settling unit. Another process provides for optimizing the design of a bitumen froth treatment plant by optimizing the diameter of the feed pipe to impart an optimum shear rate to the bitumen froth mixture and further optimizing the volume of the feed pipe to impart an optimum residence time for the bitumen froth stream in the feed pipe. An optimal plant design is also disclosed, the plant including optimal diameter and volume of the feed pipe.

Owner:EXXONMOBIL UPSTREAM RES CO

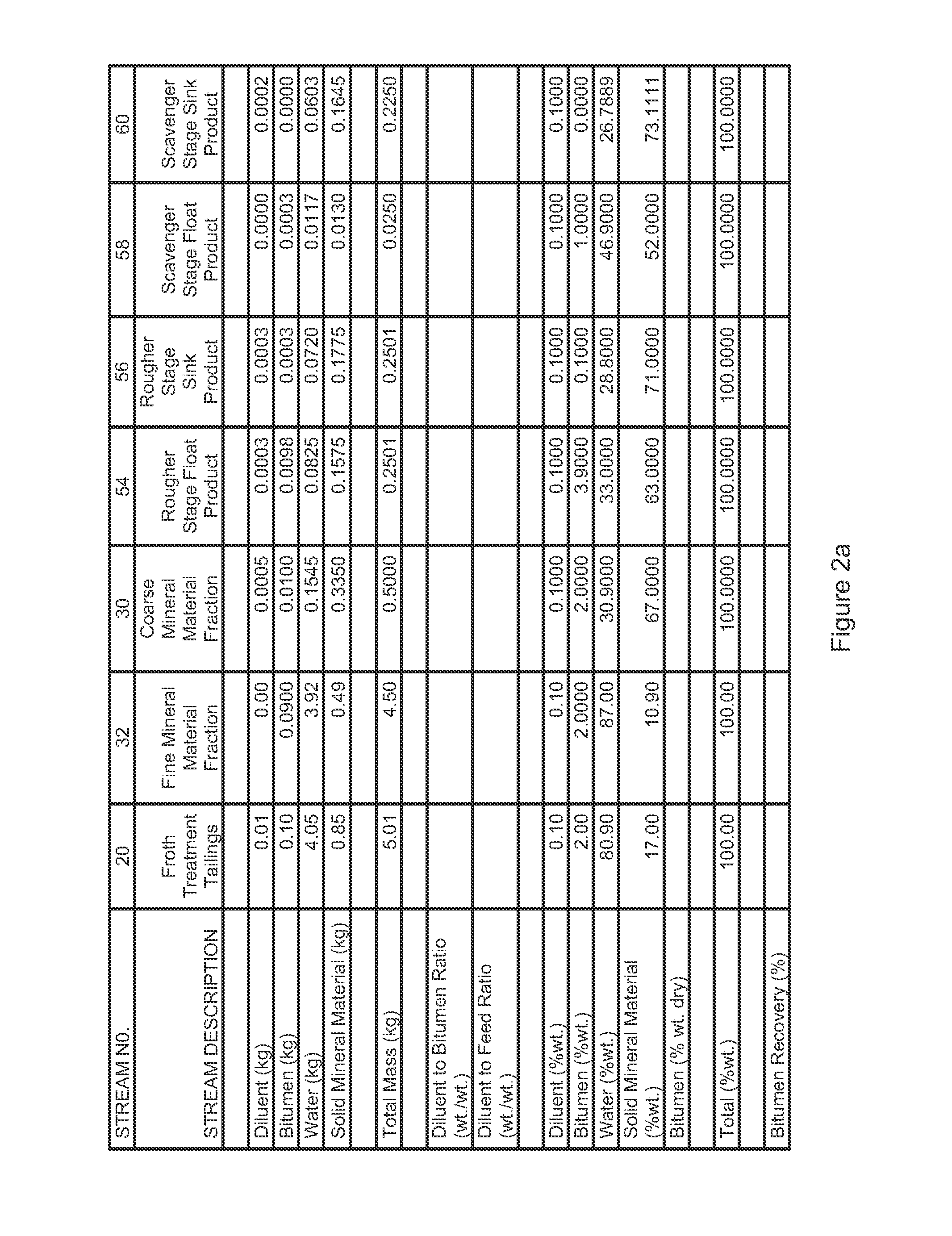

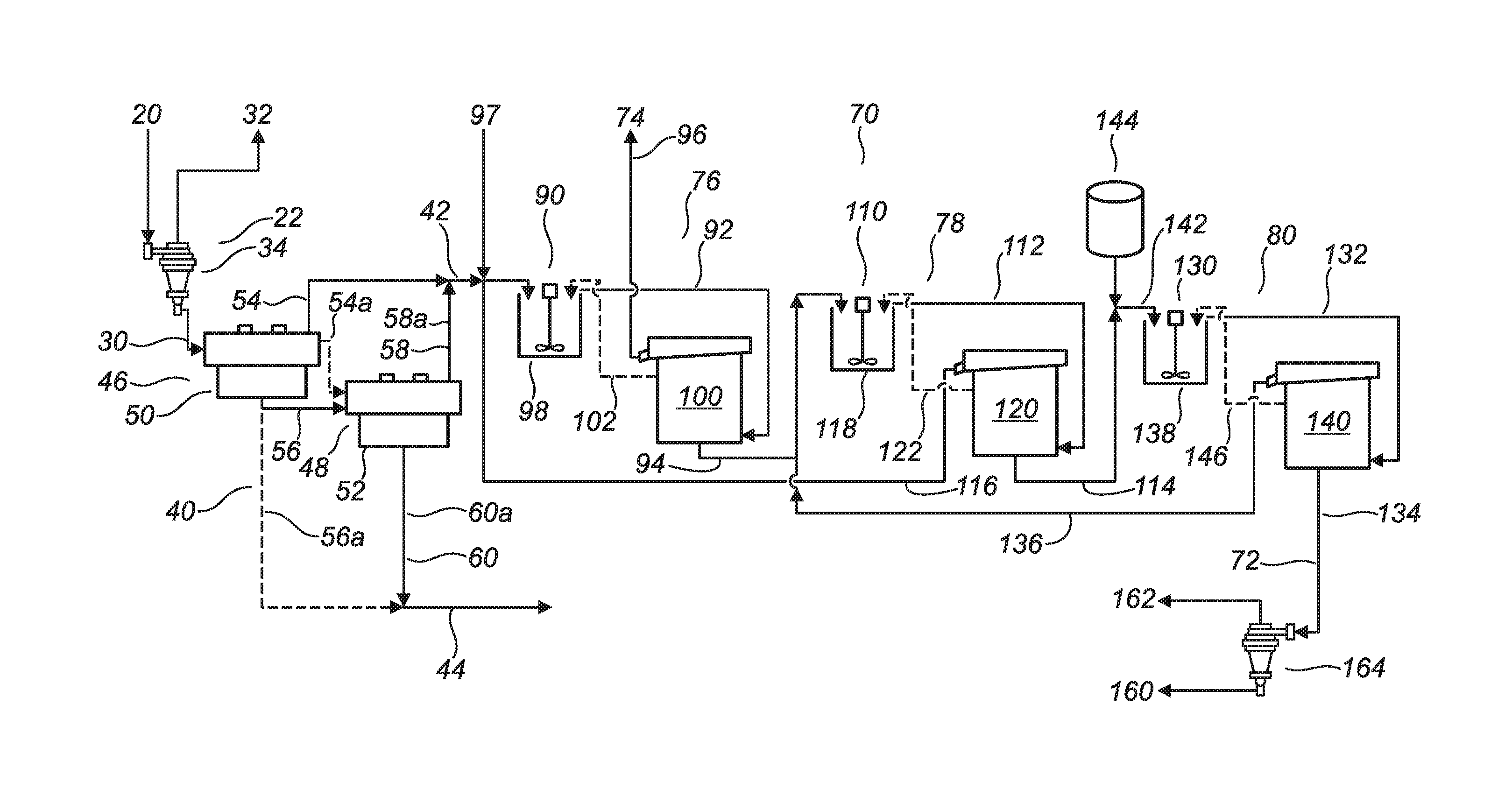

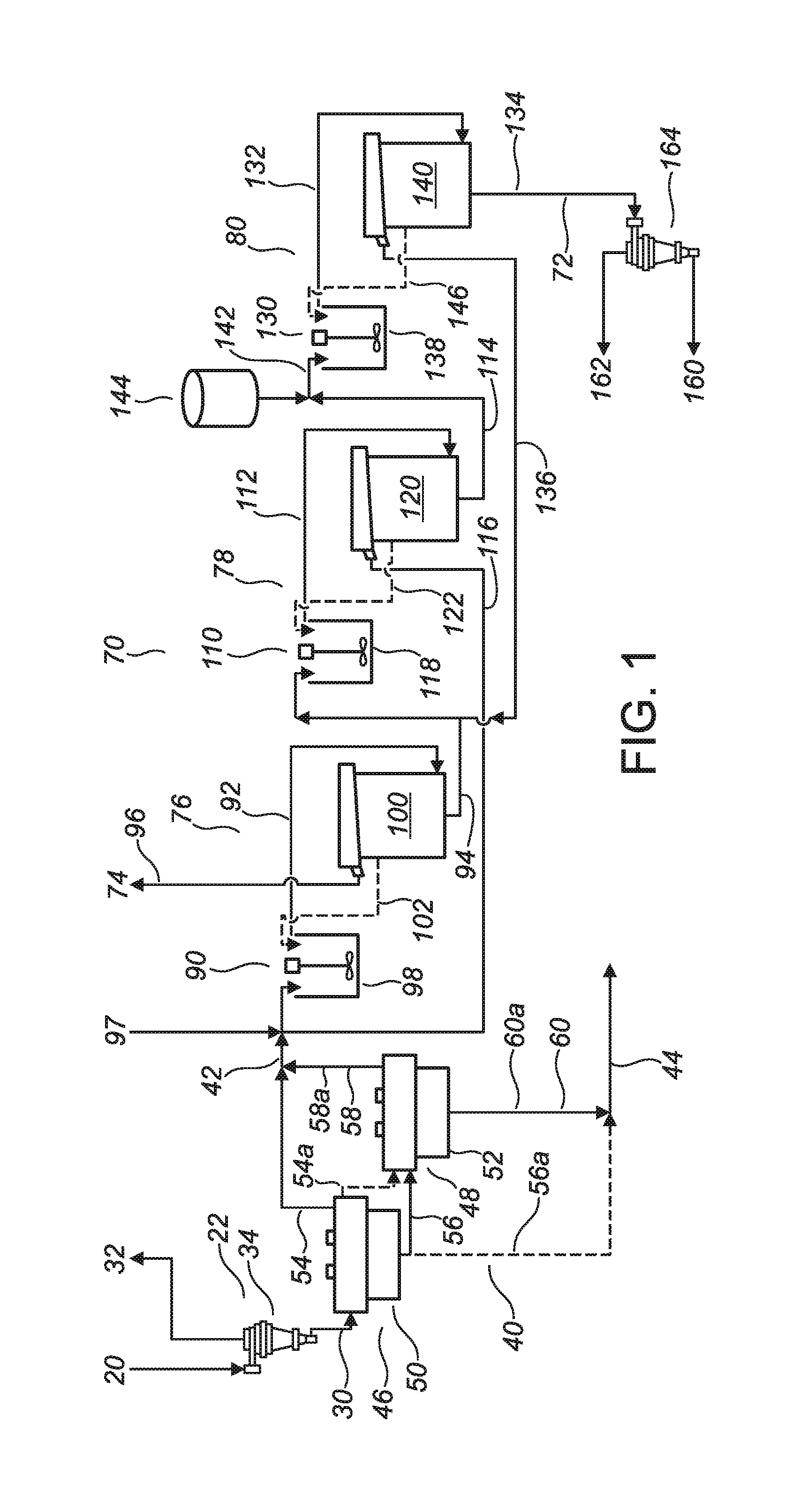

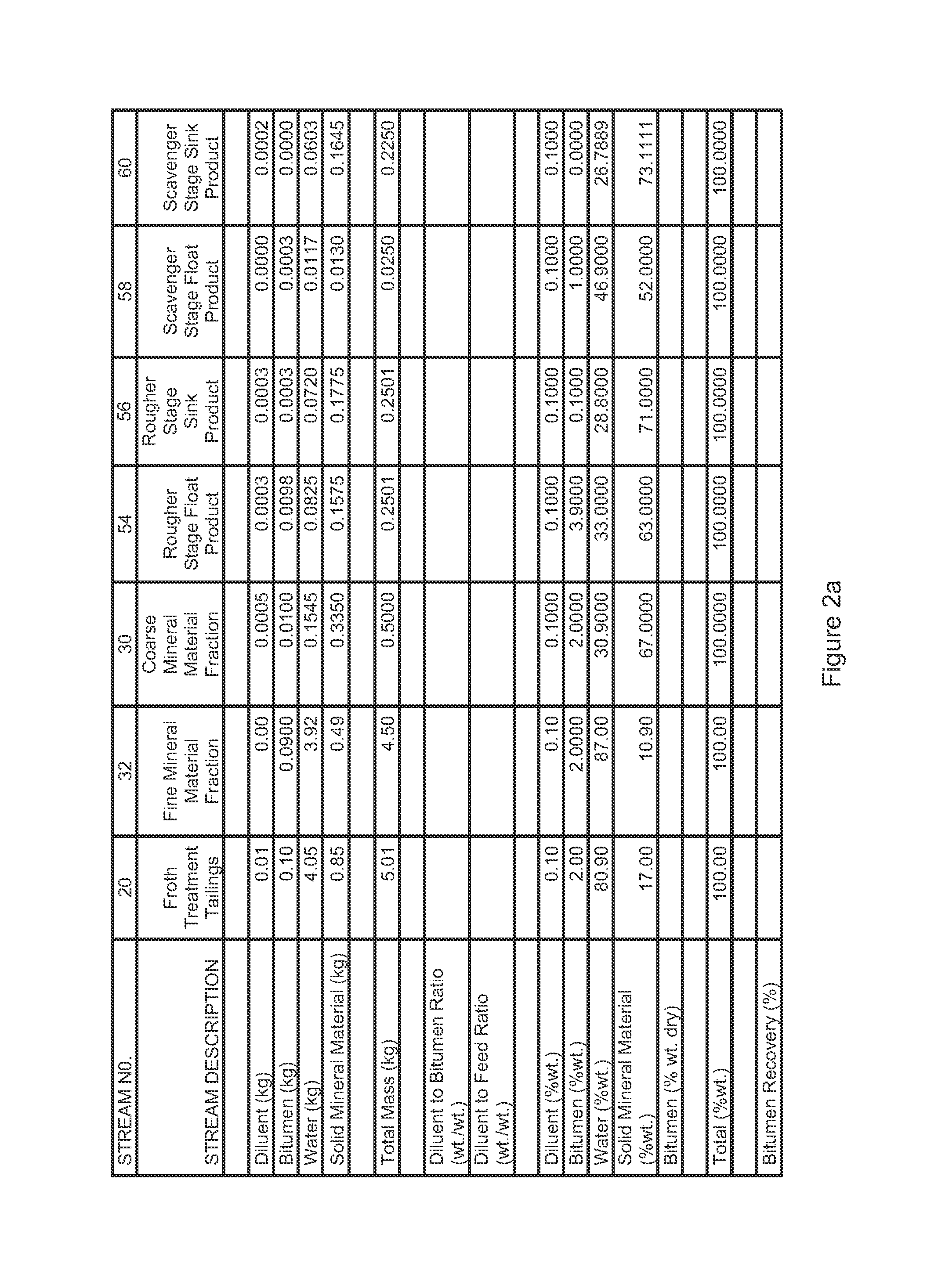

Method for processing froth treatment tailings

ActiveUS8852429B2Easy to separatePromote recoveryDewatering/demulsification with mechanical meansRefining with acid-containing liquidsFroth treatmentMaterials science

A method for processing froth treatment tailings, including separating the froth treatment tailings in order to produce a coarse mineral material fraction and a fine mineral material fraction therefrom, subjecting the coarse mineral material fraction to froth flotation in order to produce a heavy mineral concentrate and a coarse mineral material tailings therefrom, and subjecting the heavy mineral concentrate to solvent extraction in order to produce a debitumenized heavy mineral concentrate and a bitumen extract therefrom.

Owner:TITANIUM CORP

Method For Cleaning Fouled Vessels In The Parraffinic Froth Treatment Process

A method of cleaning fouled vessels in the paraffinic froth treatment process (PFT). The foulant comprises asphaltenes. Foulant is at least partially removed from a surface of a vessel or conduit used in a PFT process by spraying a liquid against the foulant on the surface to physically remove at least a portion of the foulant from the surface. The liquid may be a PFT-compatible liquid, water, or a combination thereof. The method may be effected in the substantial absence of a foulant-dissolving agent.

Owner:EXXONMOBIL UPSTREAM RES CO

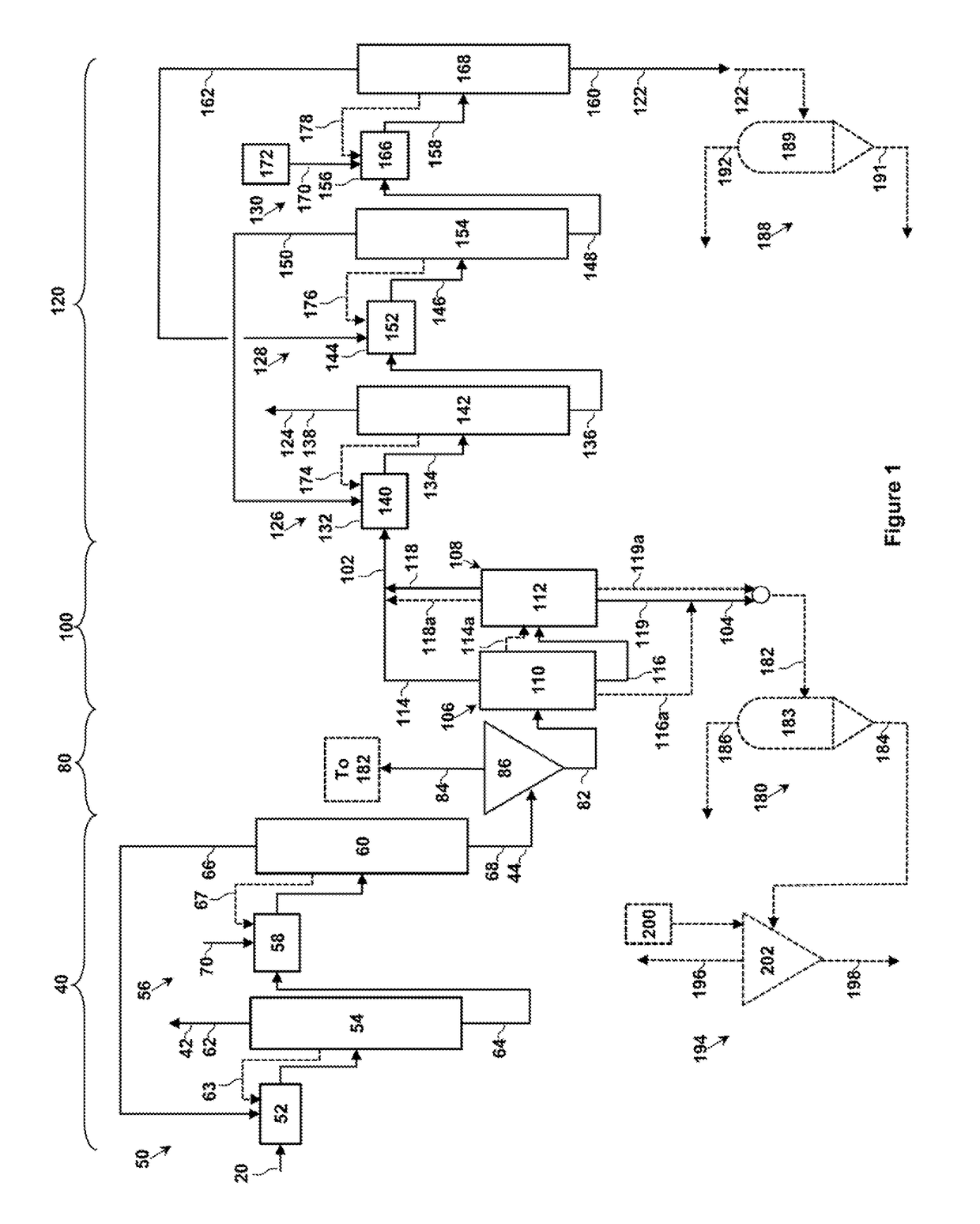

Process for recovering bitumen from froth treatment tailings

ActiveUS20170335200A1Easy to processEasy to separateLiquid hydrocarbon mixture productionNitrogenRaffinate

A method for processing a froth treatment tailings separated from a bitumen froth produced in a process for recovering bitumen from oil sand ore, includes subjecting the froth treatment tailings to a first solvent extraction process to produce a first extract including bitumen, and a first raffinate, subjecting the first raffinate to a separation process to produce a fine mineral material fraction including fine solid mineral material having a particle size less than 44 microns and a coarse mineral material fraction including a coarse mineral material having a particle size equal to or greater than 44 microns, subjecting the coarse mineral material fraction to a froth flotation process to produce a heavy mineral concentrate and a coarse mineral material tailings, and subjecting the heavy mineral concentrate to a second solvent extraction process to produce a second extract including bitumen and a second raffinate including a debitumenized heavy mineral concentrate.

Owner:TITANIUM CORP

Heat recovery for bitumen froth treatment plant integration with sealed closed-loop cooling circuit

ActiveUS9207019B2Reduce dirtRecuperative heat exchangersLiquid hydrocarbon mixture productionClosed loopProcess engineering

A system and process for recovering heat from a bitumen froth treatment plant use a sealed closed-loop heat transfer circuit. The system has a heat removal exchanger associated with the plant and receiving hot froth treatment process stream; heat recovery exchanger; the circuit; and an oil sands process fluid line. The circuit includes piping circulating heat exchange media having uncontaminated and low fouling properties. The piping includes a supply line to the heat removal exchanger and a return line for providing heated media to the recovery exchanger. The circuit has a pump for pressurizing the heat exchange media; a pressure regulator for regulating pressure of the media. The pump and the pressure maintain the media under pressure in liquid phase. The oil sands process fluid is heated producing a cooled media for reuse in the heat removal exchanger. High and low temperature heat removal exchangers can be used.

Owner:TRUENORTH ENERGY CORP

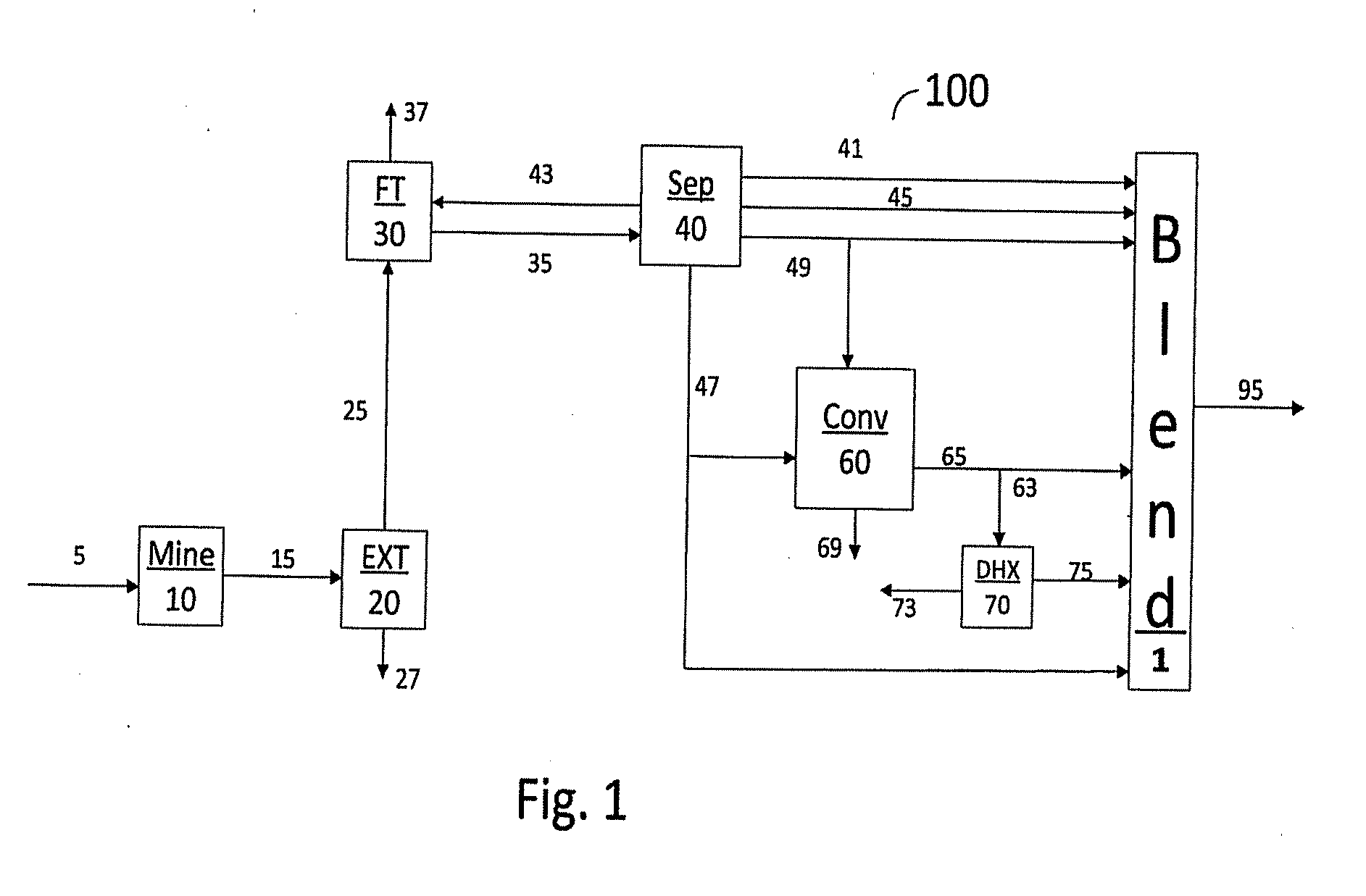

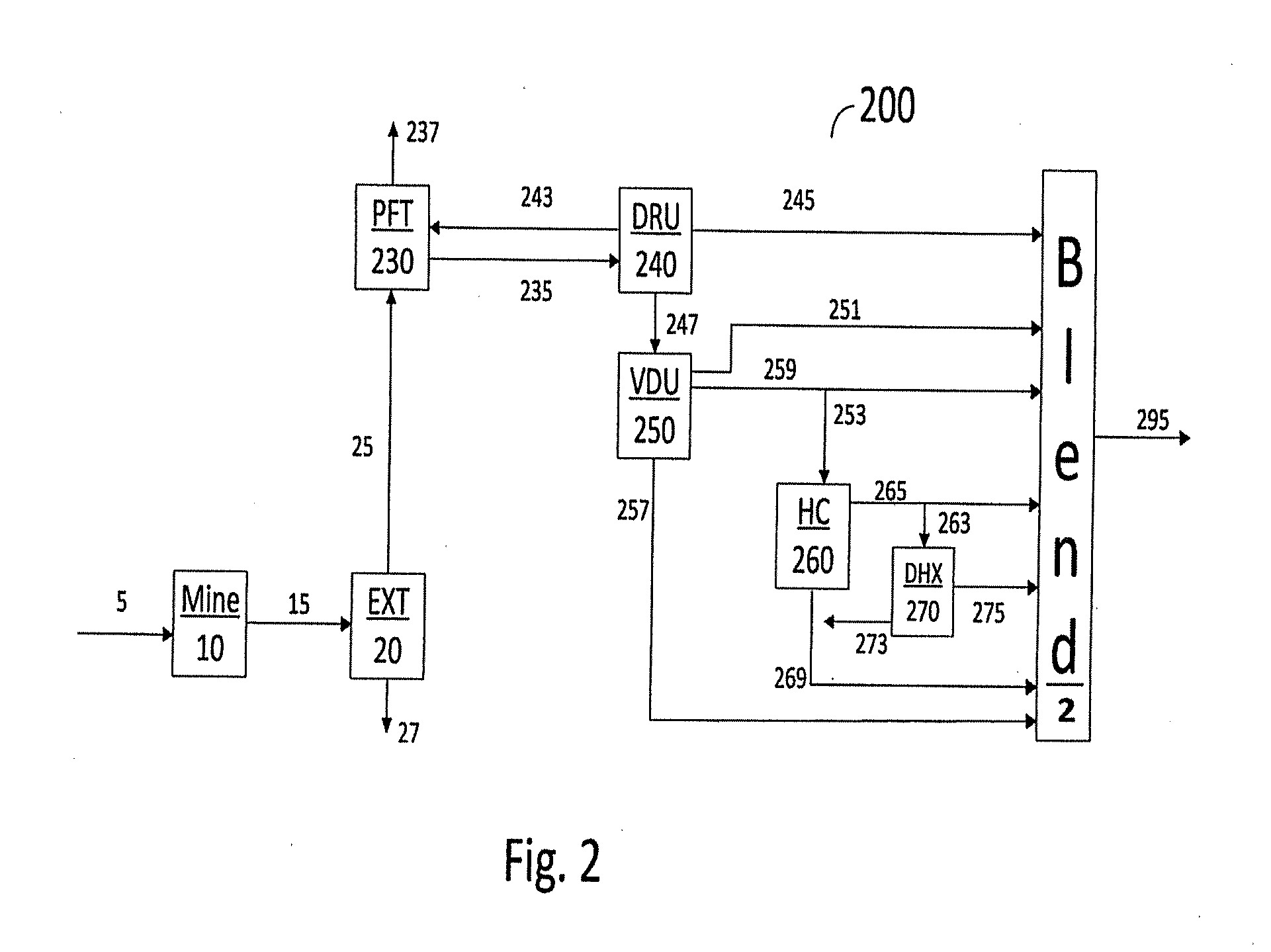

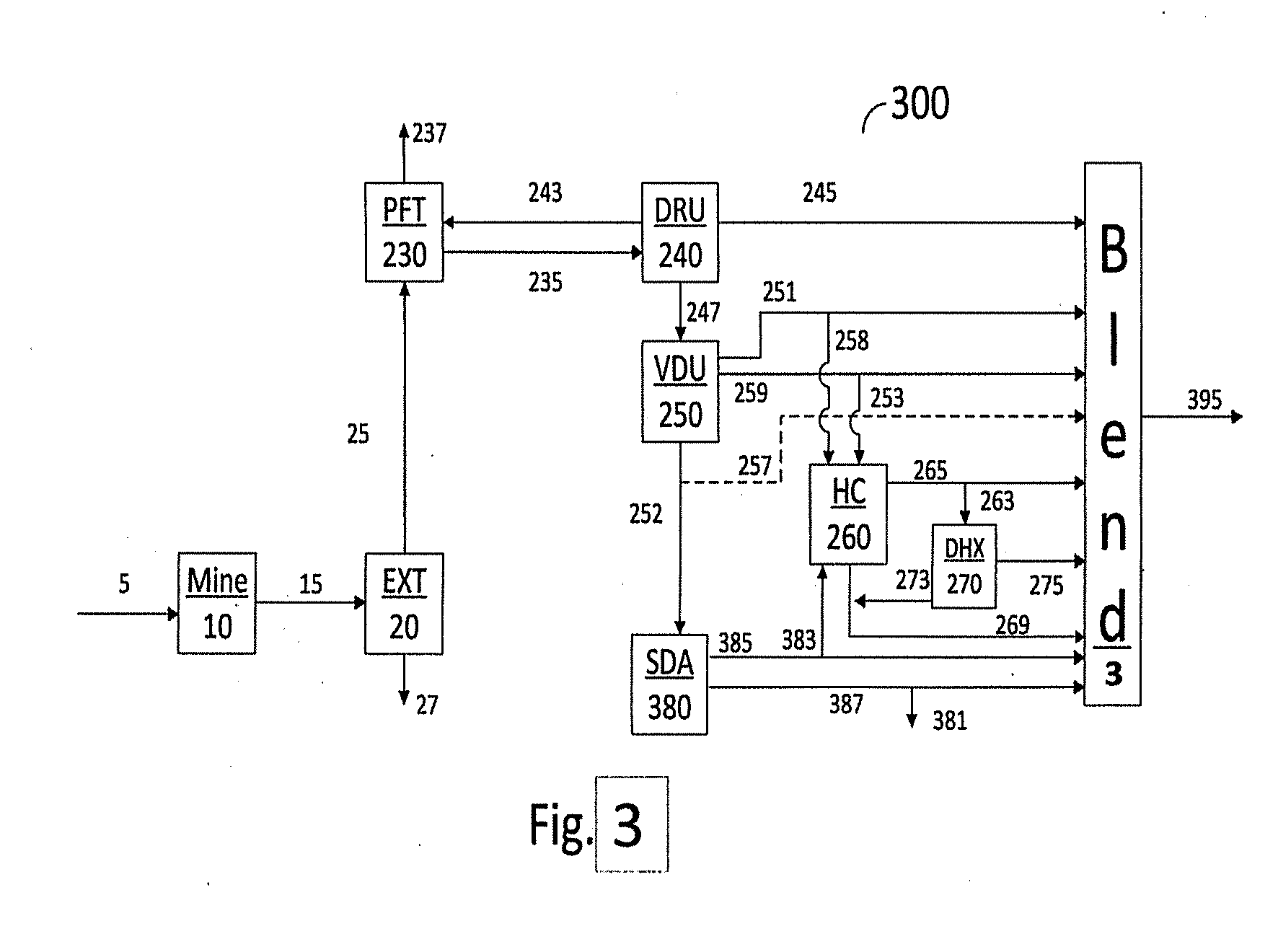

Process for treating mined oil sands deposits

InactiveUS20140311952A1Contributes to economic efficiencyInhibit productionUnderground miningTreatment with plural serial stages onlyPipeline transportDiluent

Disclosed is a method for improving a heavy hydrocarbon, such as mined bitumen, to a lighter more fluid product and, more specifically, to a hydrocarbon product that is refinery-ready and that meets pipeline transport criteria without requiring the addition of diluent. The invention is suitable for enhancing recovery from mined Canadian bitumen, but has general application for processing any heavy hydrocarbon, converting the heavy hydrocarbon to a product that is more suitable for pipeline transport. The invention is directed to a process for converting a heavy hydrocarbon stream into a pipelineable product, said process comprising: (a) using a froth treatment process to separate bitumen present in the heavy hydrocarbon stream from water creating a solvent / bitumen stream and a water-rich stream; (b) extracting the solvent / bitumen stream to generate multiple product streams comprising: i) a bitumen bottoms stream; ii) a virgin heavy vacuum gas oil stream; iii) a light virgin vacuum gasoil stream; and iv) a light virgin atmospheric gas oil stream; (c) converting, in a conversion unit, a portion of the heavy vacuum gas oil stream and / or bitumen bottoms obtained from step (b) to produce a stream of lighter hydrocarbons; and (d) blending a portion or all of the virgin heavy vacuum gas oil stream, the light virgin vacuum gasoil stream, the light virgin atmospheric gas oil stream from step (b) and the stream of lighter hydrocarbons produced in step (c) to create a pipelineable product.

Owner:CANADIAN NATURAL RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com