Patents

Literature

69results about How to "Increase settlement rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

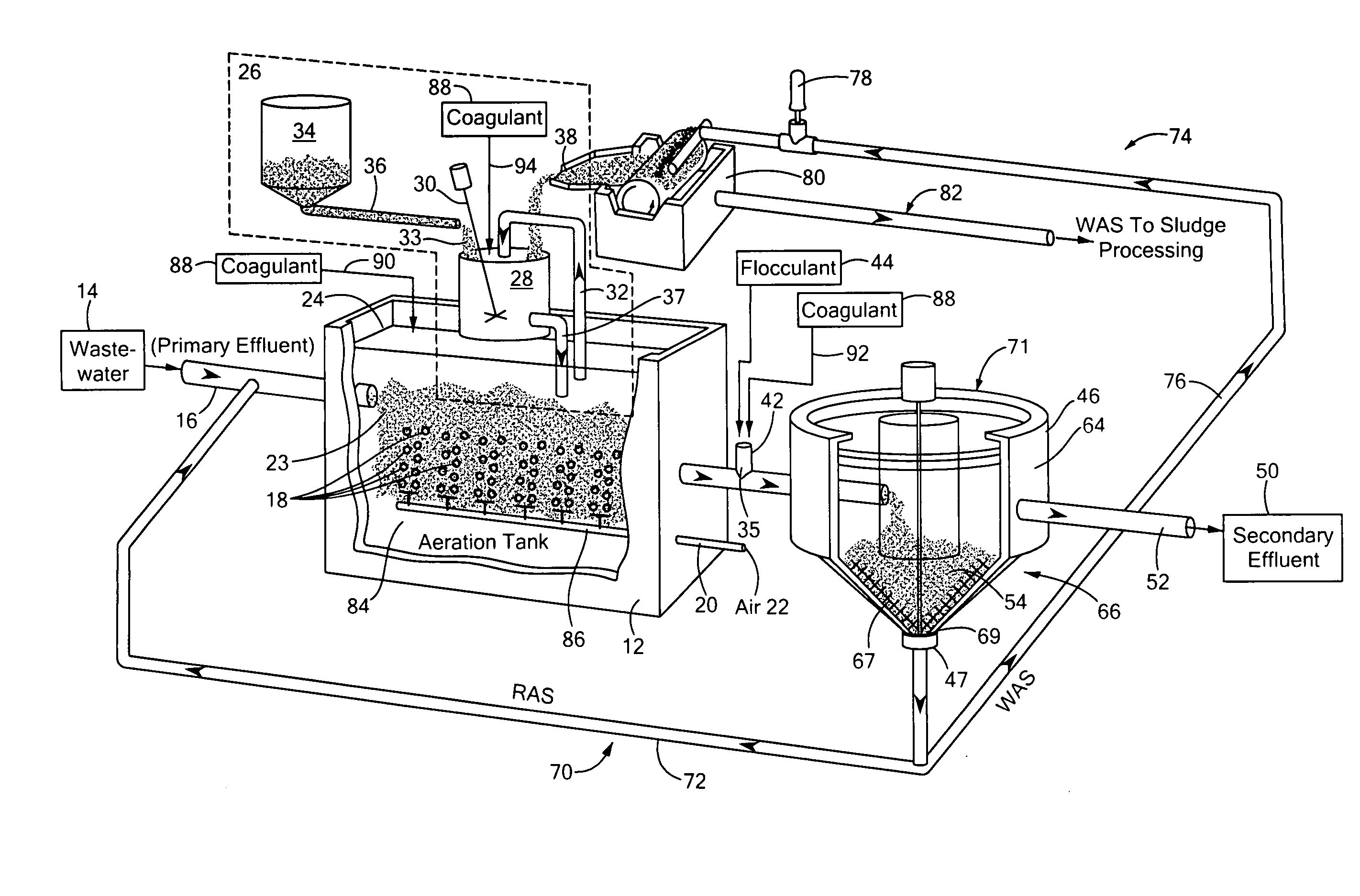

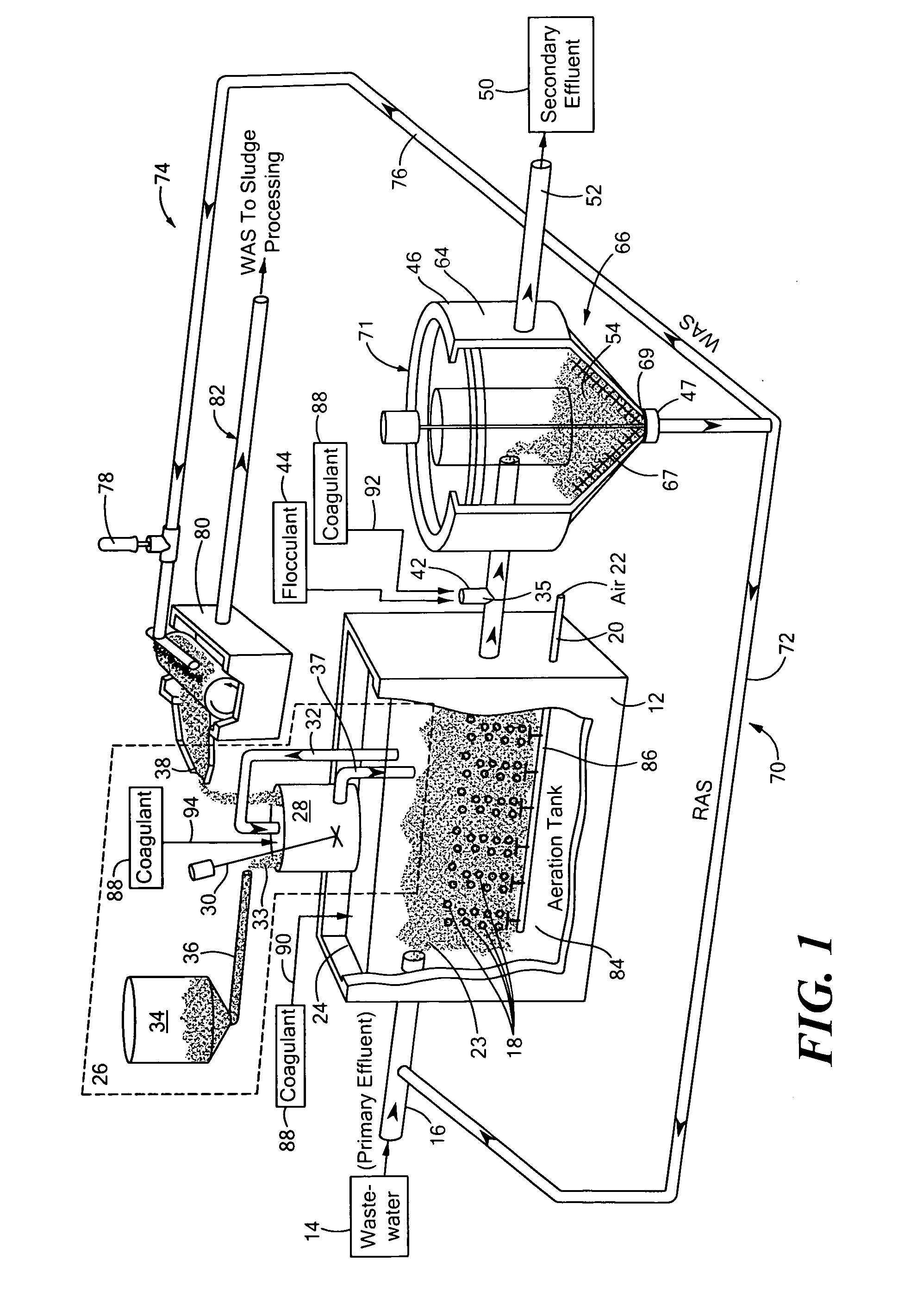

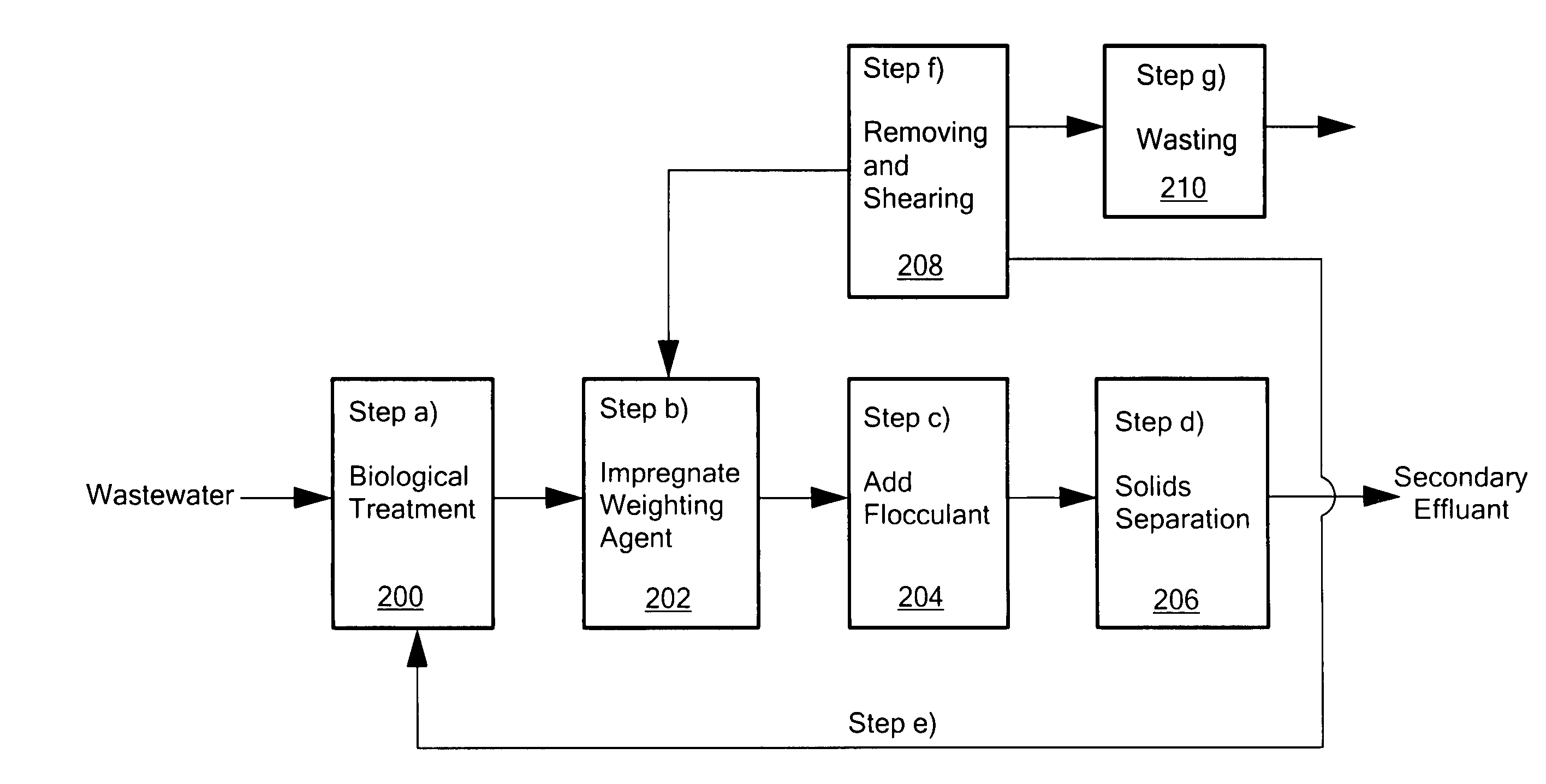

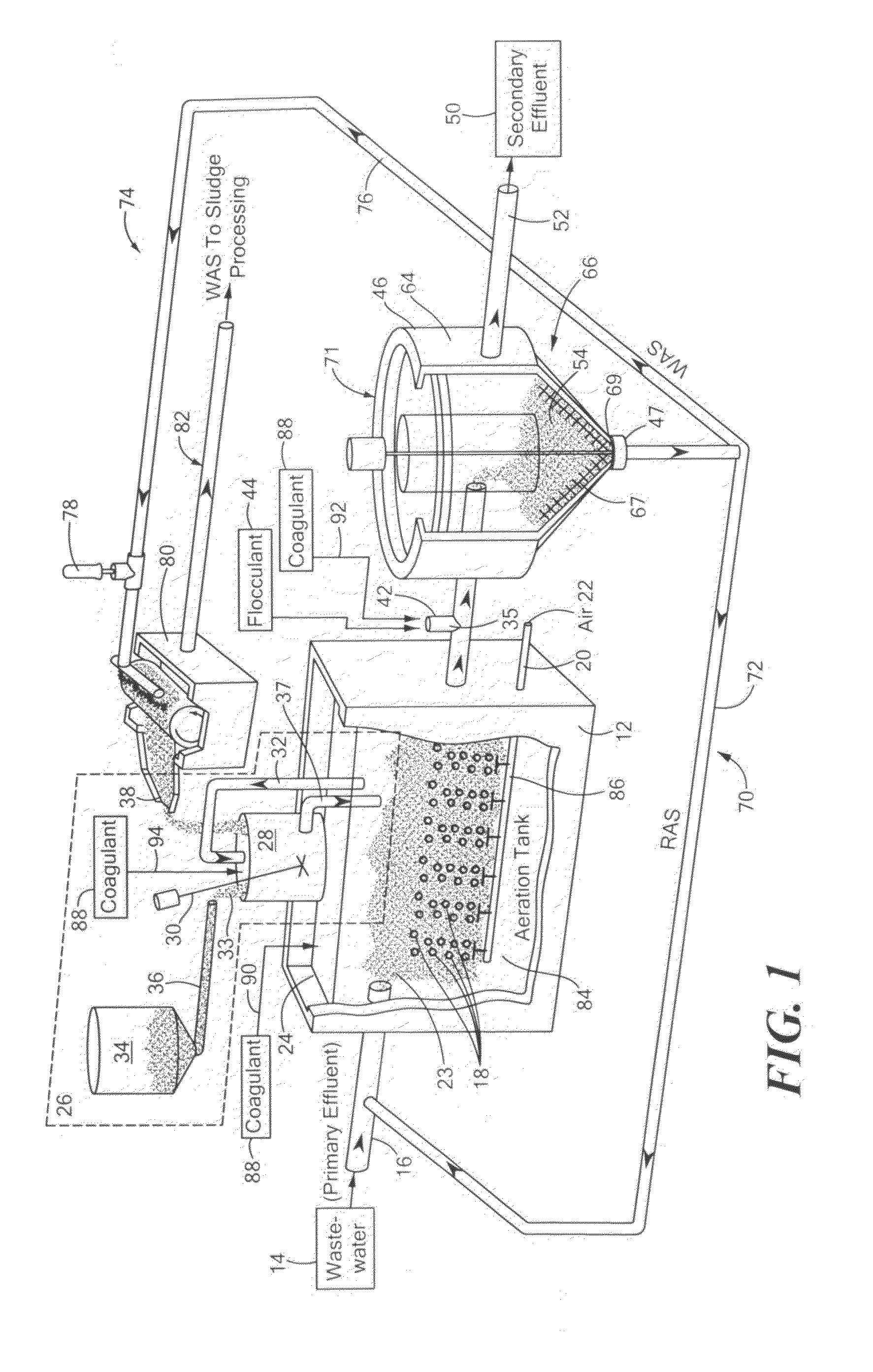

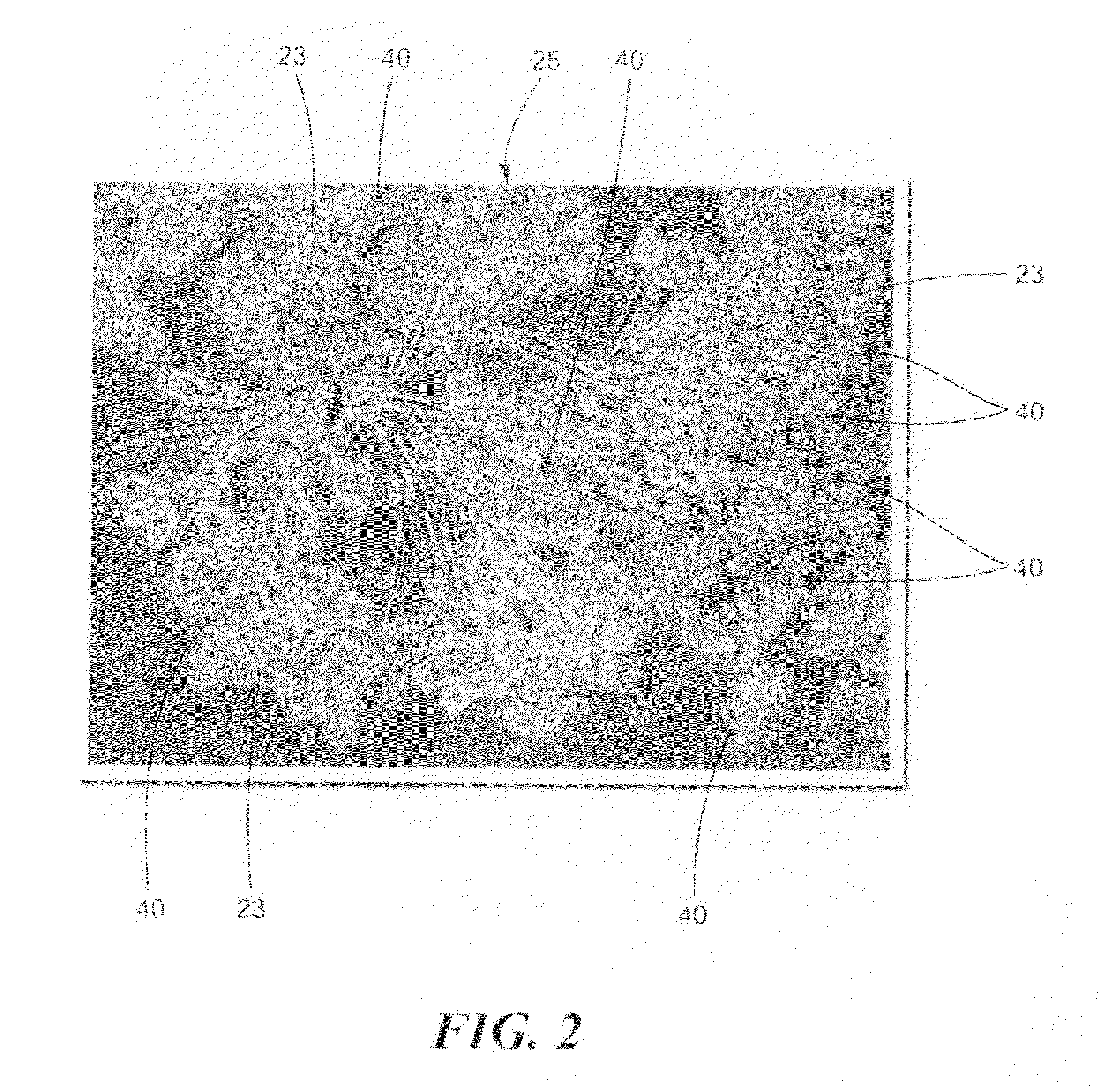

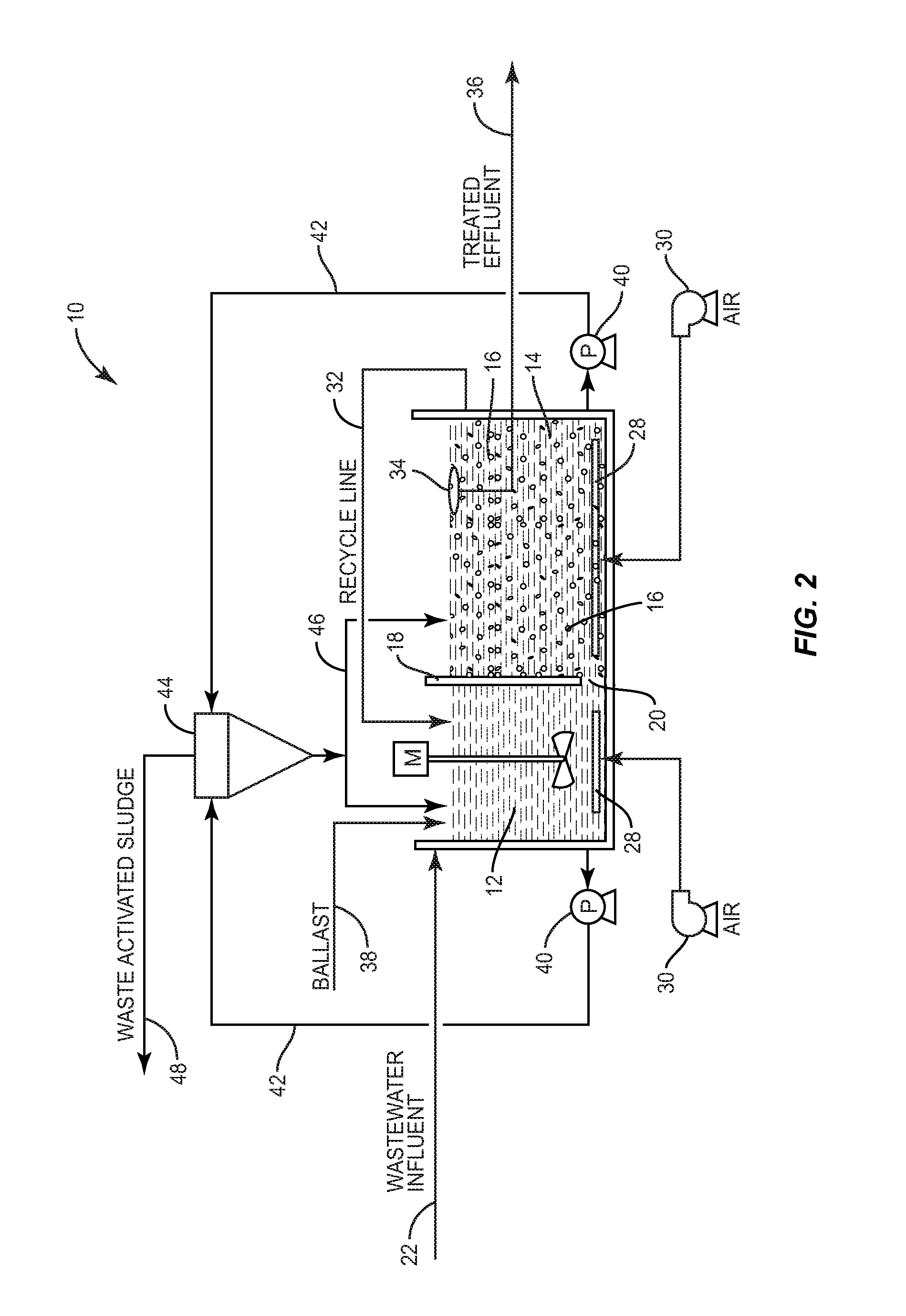

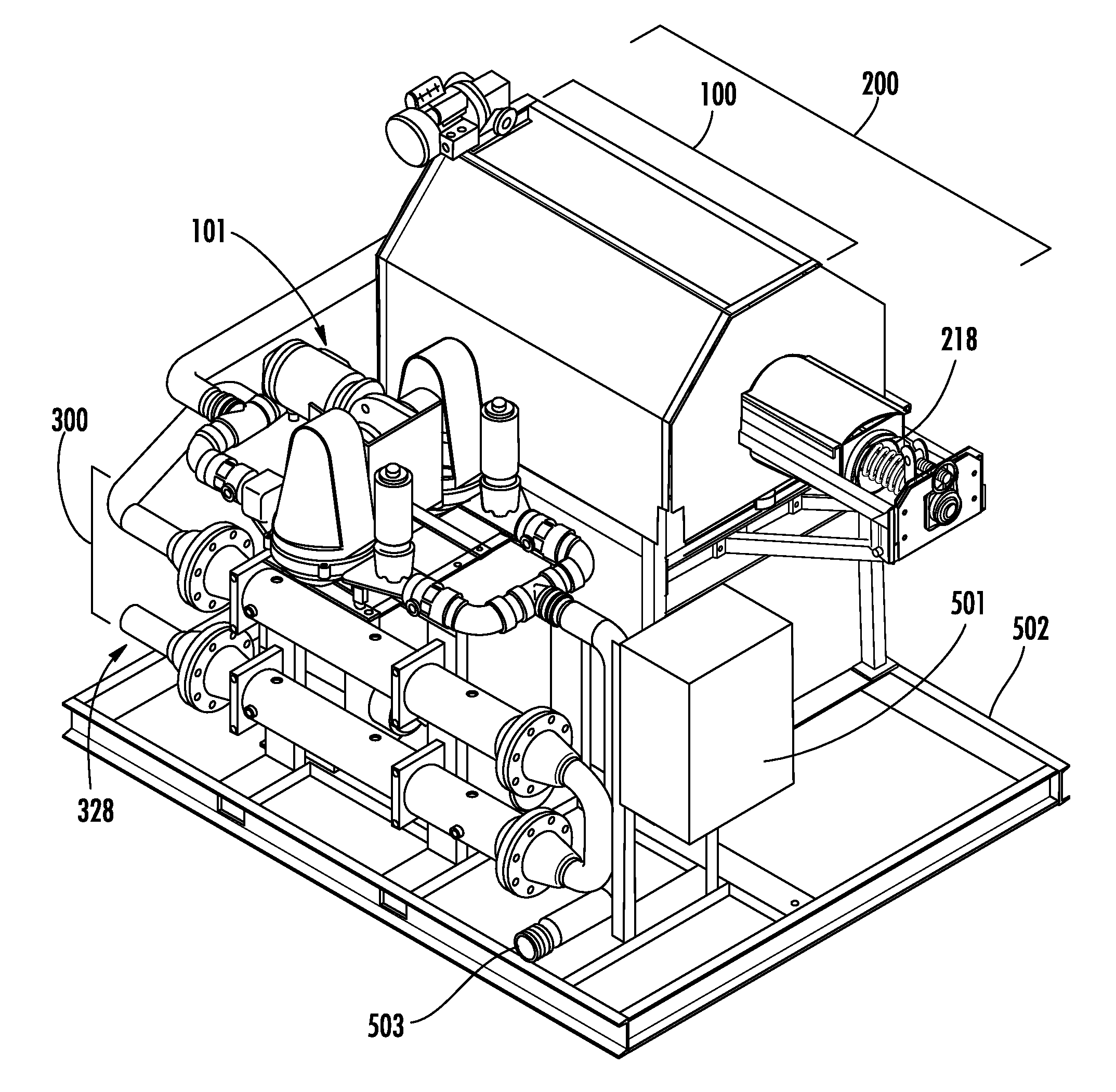

System and method for enhancing an activated sludge process

ActiveUS20080203015A1Enhance settlingGood thickeningTreatment using aerobic processesOther chemical processesMixed liquor suspended solidsInjection port

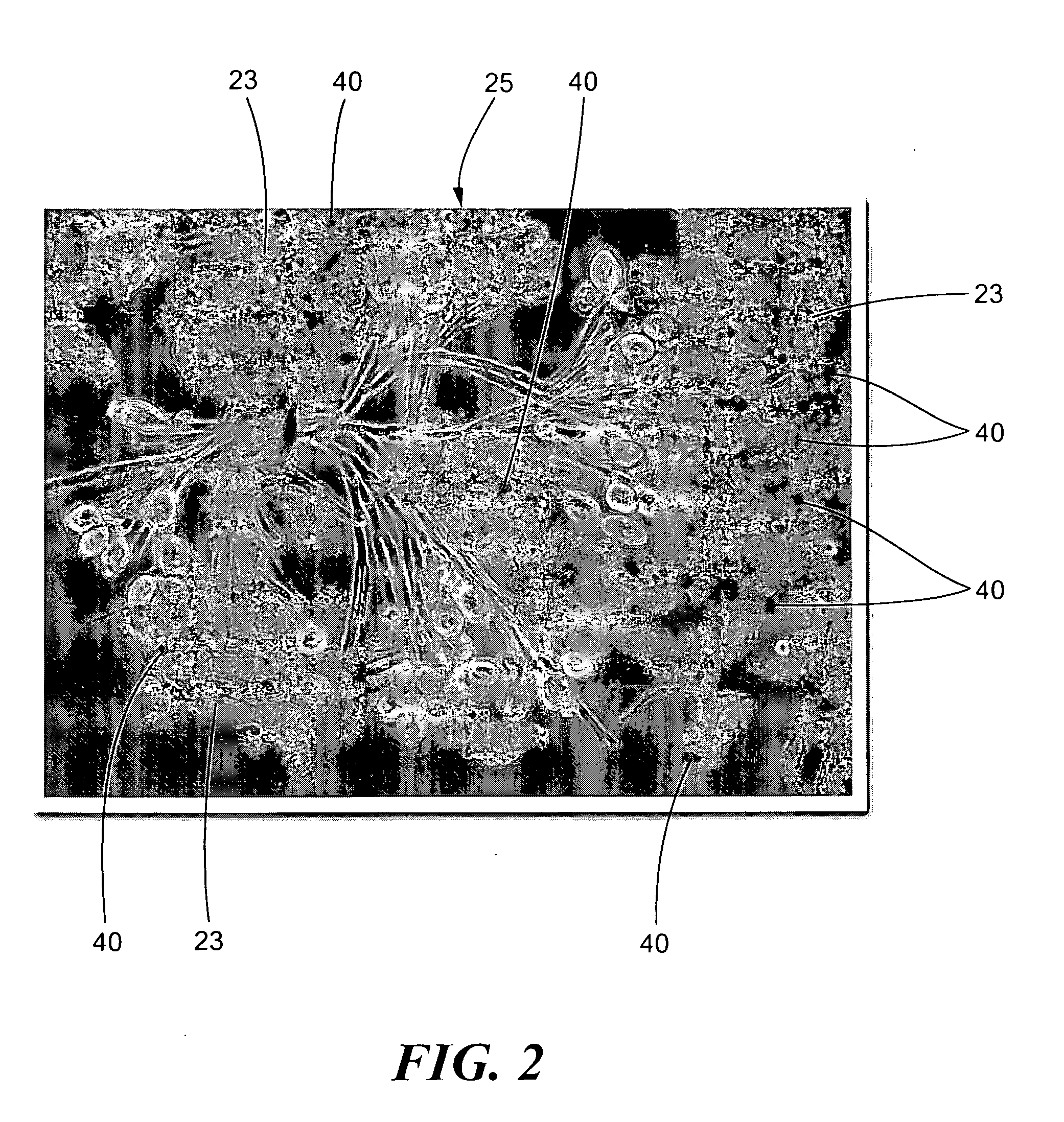

A system for enhancing an activated sludge process that includes at least one aeration tank subsystem for receiving a flow a wastewater and for introducing dissolved oxygen to a population of microorganisms to promote growth of biological flocs in a mixed liquor defined by a concentration of mixed liquor suspended solids. A weighting agent impregnation subsystem includes an impregnation tank for mixing the mixed liquor, virgin weighting agent, and recycled weighting agent to impregnate the weighting agent into biological flocs suspended in the mixed liquor to form weighted biological flocs. A flocculant injection port located downstream from at least one aeration tank for introducing a flocculant to the mixed liquor for enhancing settling and thickening of the weighted biological flocs and for providing agglomeration of non-impregnated biological flocs and / or partially impregnated biological flocs with weighted biological flocs. At least one clarifier separates and collects the weighted biological flocs from the mixed liquor to provide a secondary effluent and a settled sludge. A return activated sludge subsystem recycles the majority of the settled sludge to the at least one aeration tank. A weighting agent recovery subsystem removes and shears the remaining settled sludge and recovers the weighting agent therefrom and reintroduces the weighting agent to the at least one aeration tank. A wasting subsystem wastes the remaining sludge of the weight agent recovery subsystem to control the population of the microorganisms in the mixed liquor.

Owner:EVOQUA WATER TECH LLC

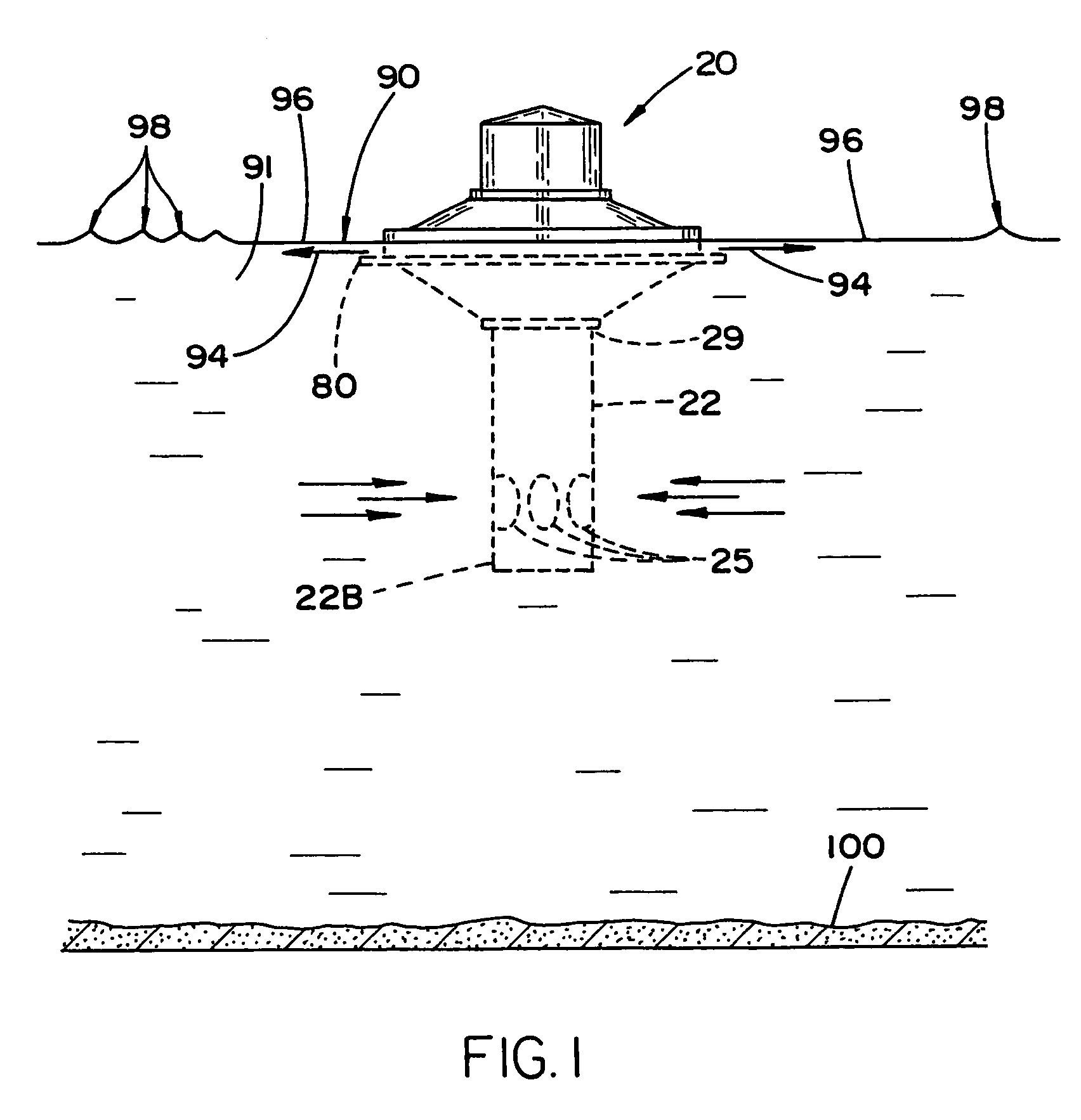

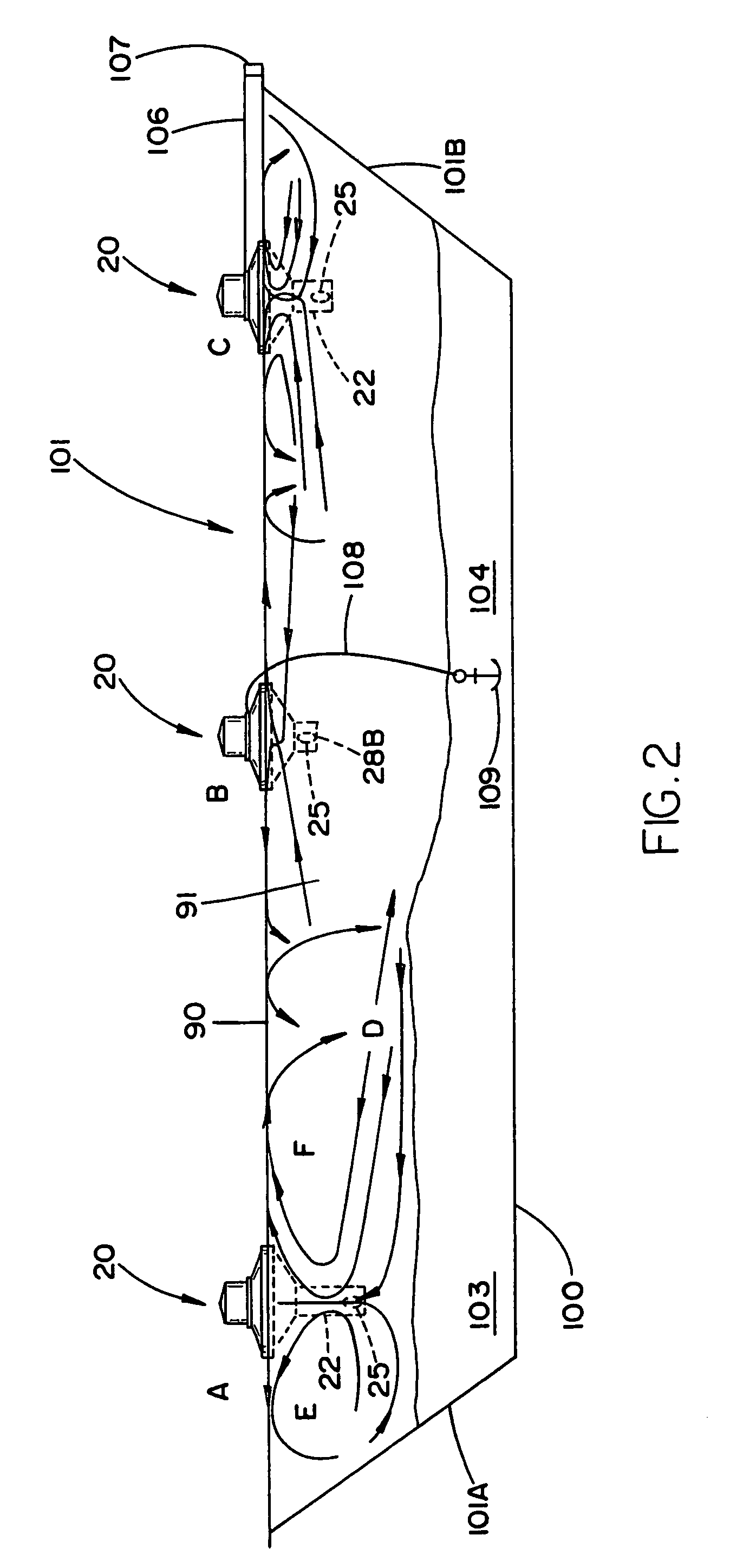

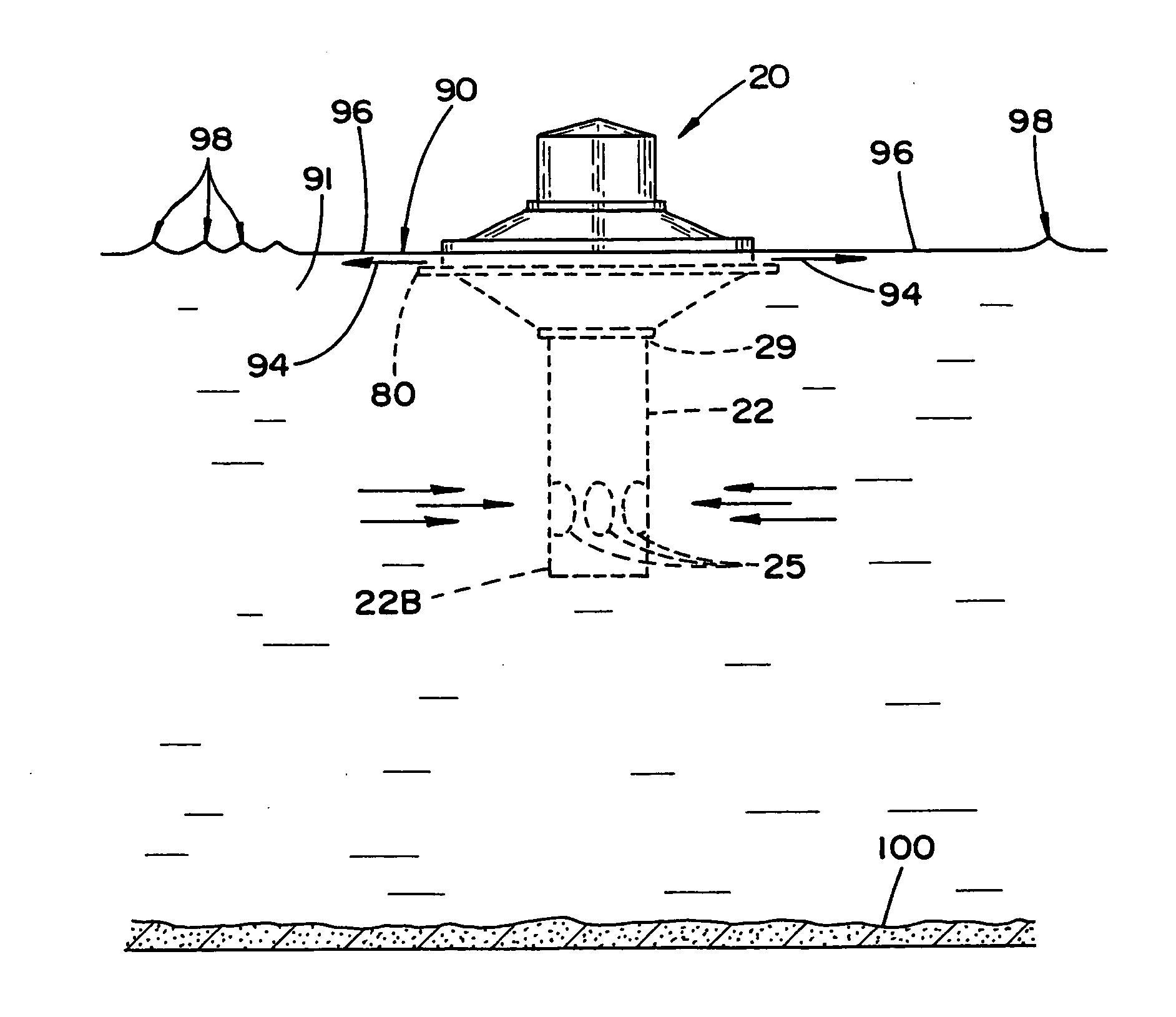

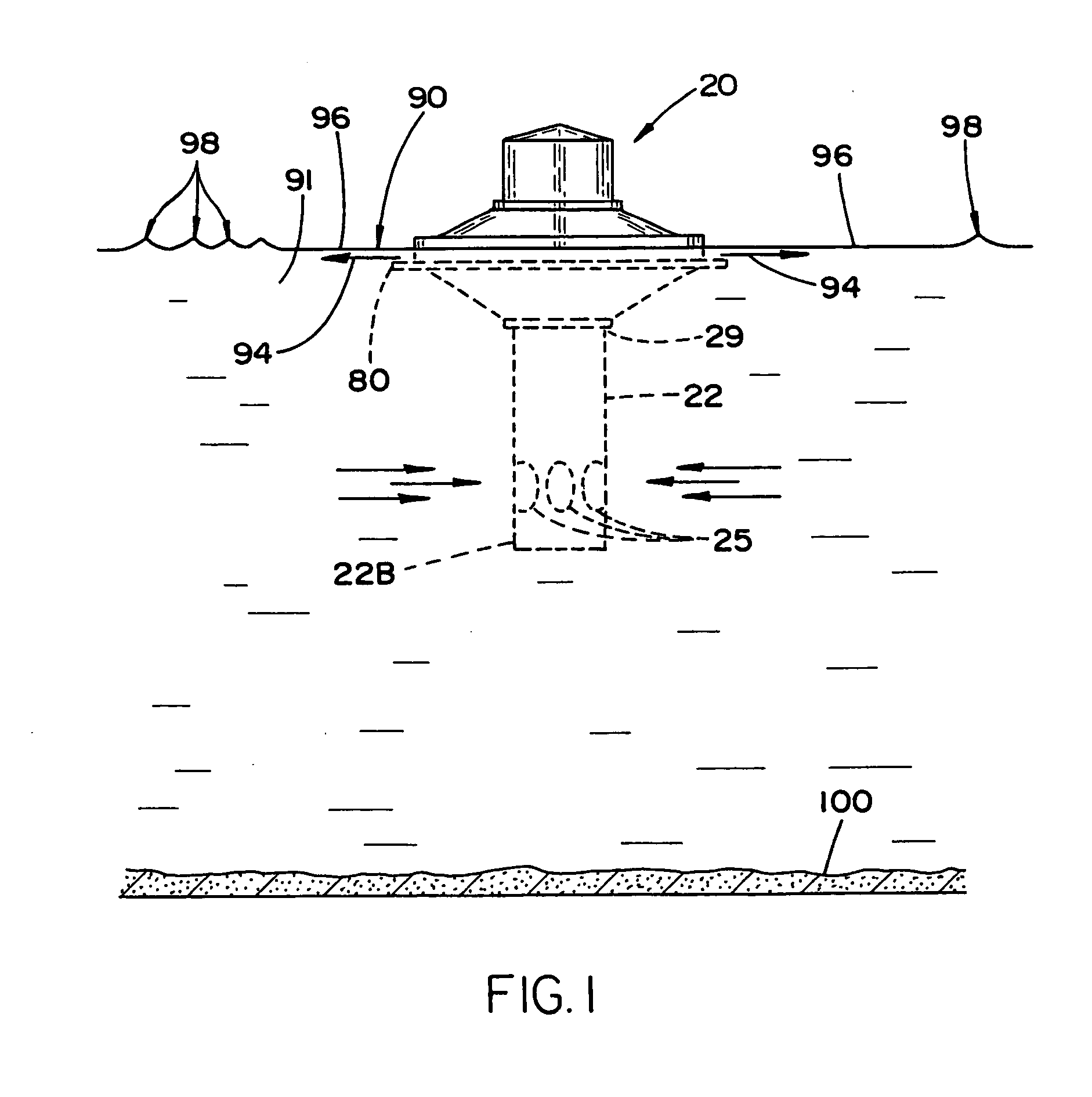

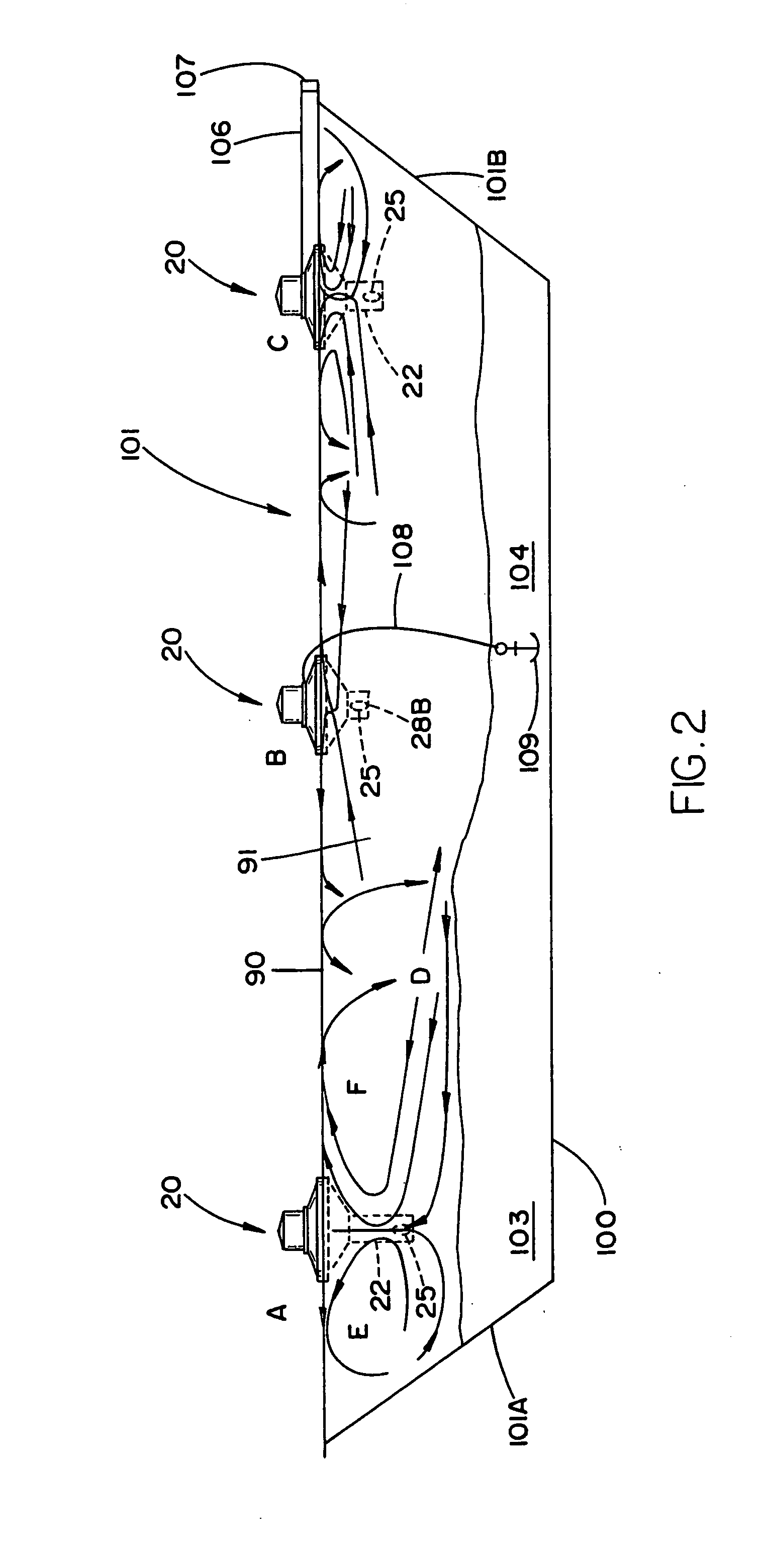

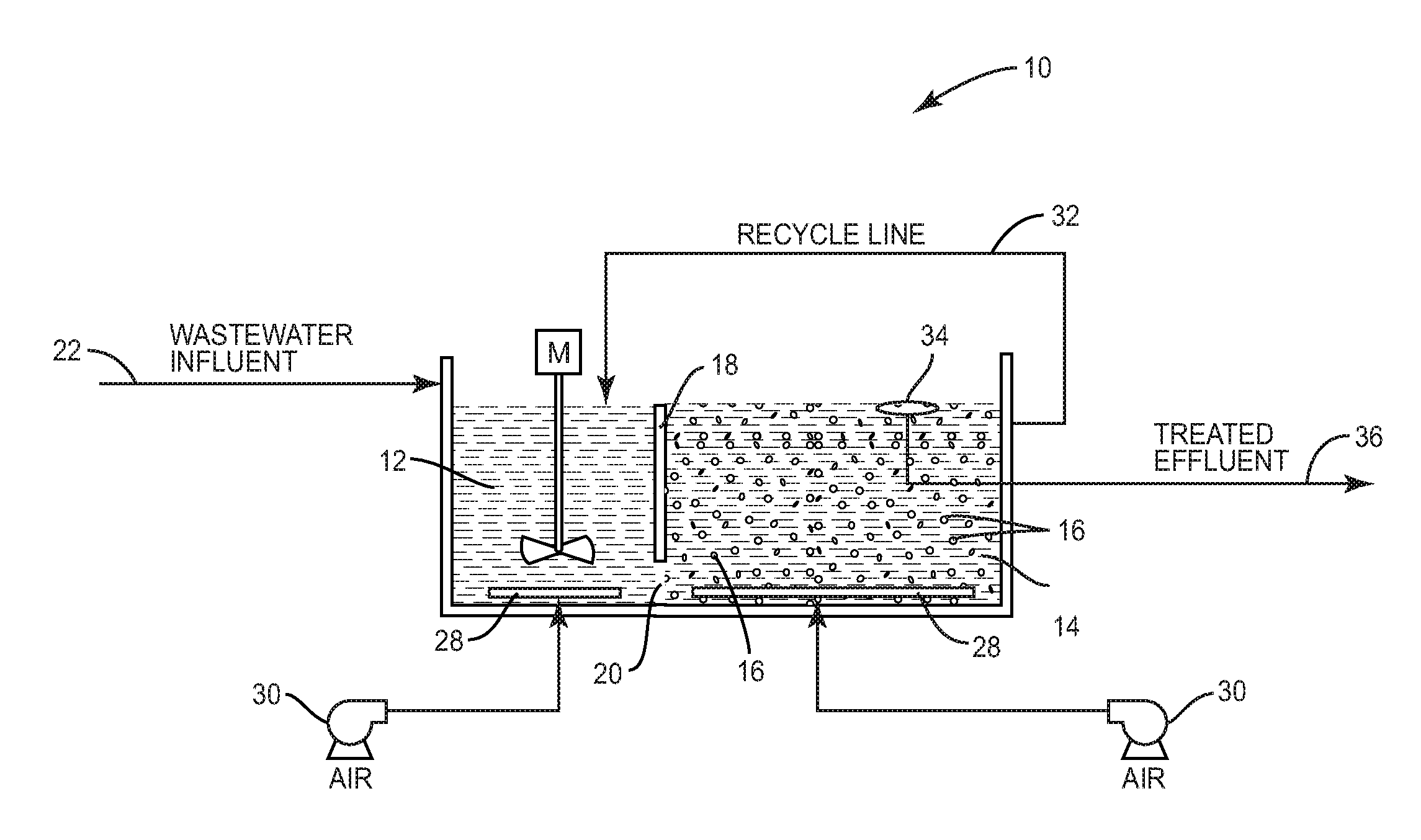

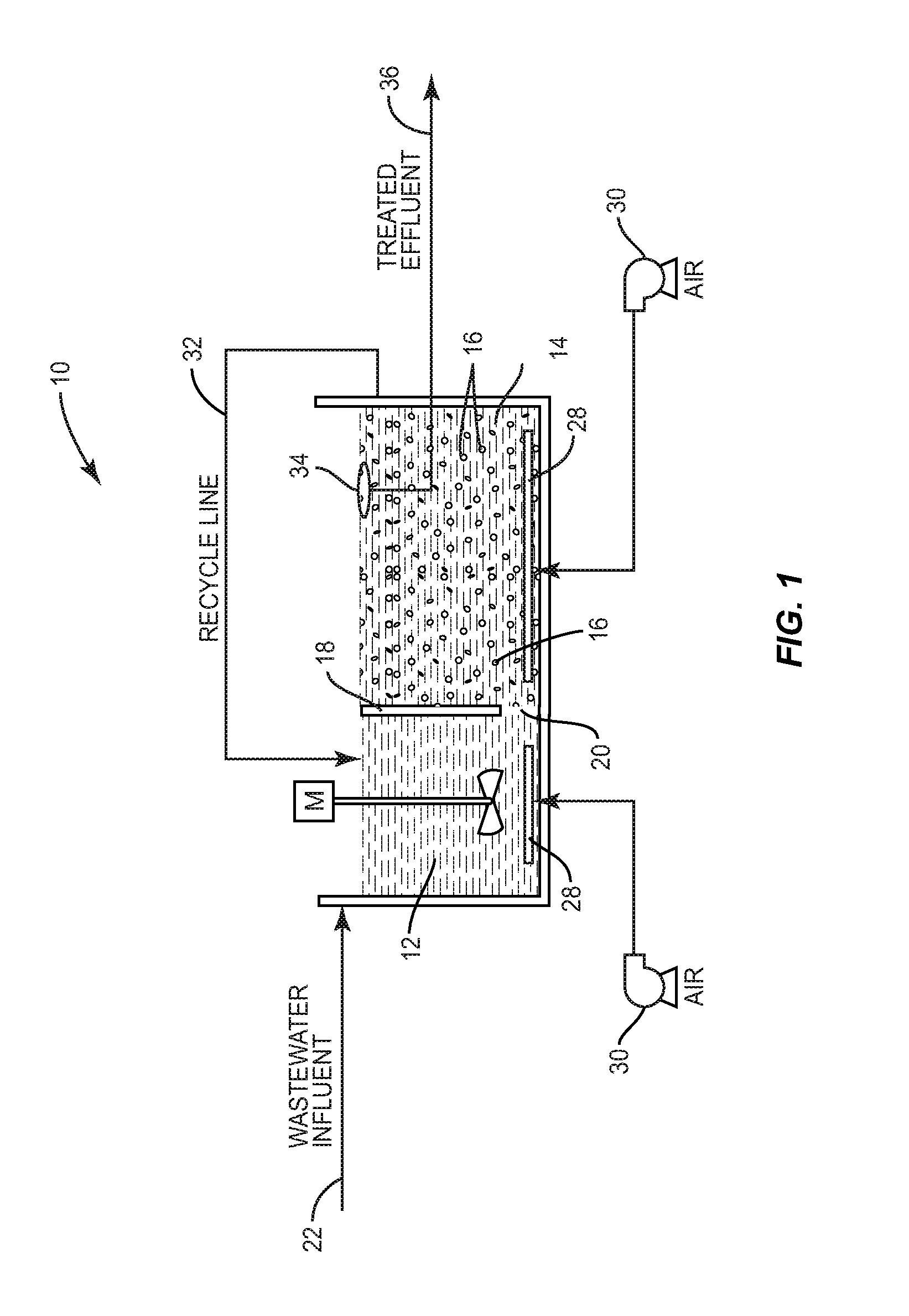

Process and apparatus for increasing biological activity in waste treatment in bodies of water

ActiveUS7329351B2Improve biological activityIncrease oxygenTreatment using aerobic processesLighting and heating apparatusImpellerMotor drive

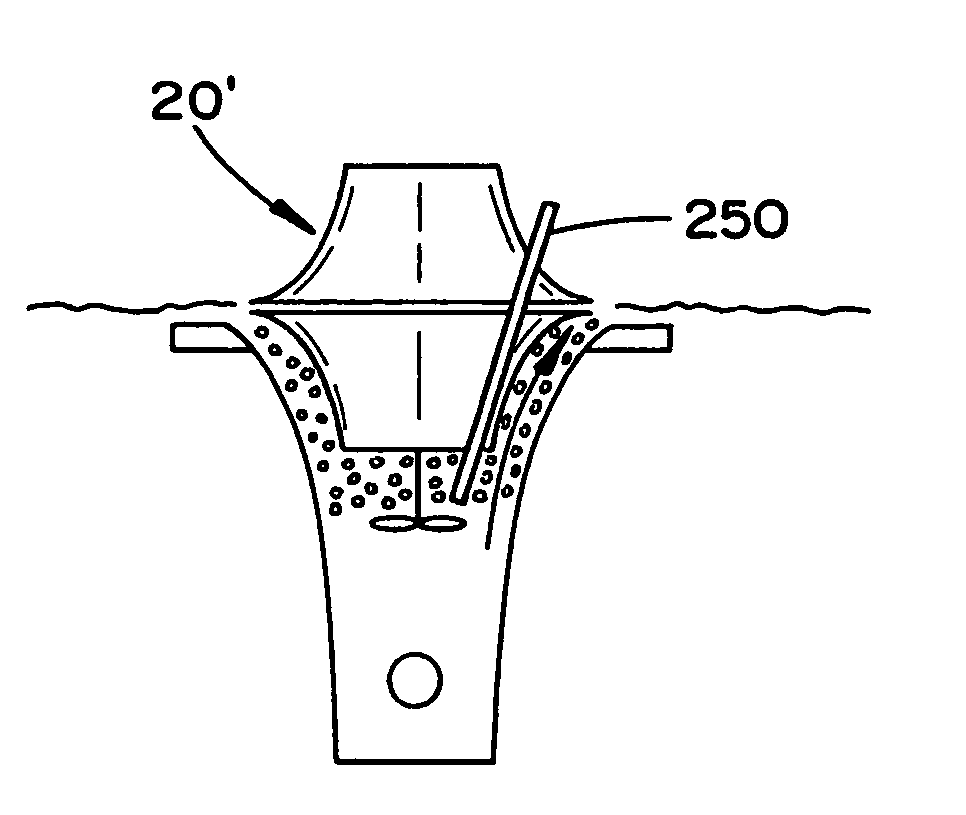

A process and apparatus for increasing biological activity in waste treatment ponds and lagoons. In this process a floating fluid circulator having an annular space between nested frusto-conical surfaces is operated in a pond or lagoon. An aerator within the scope of the floating fluid circulator is provided. That aerator includes an upper float chassis having a frusto-conical configuration, a sectional diverter arranged in a lower portion of the upper float chassis, the sectional aerator having a lower diverter portion and motor driven means mounted on the upper float chassis connected to a rotatable impeller.

Owner:ABSOLUTE AERATION

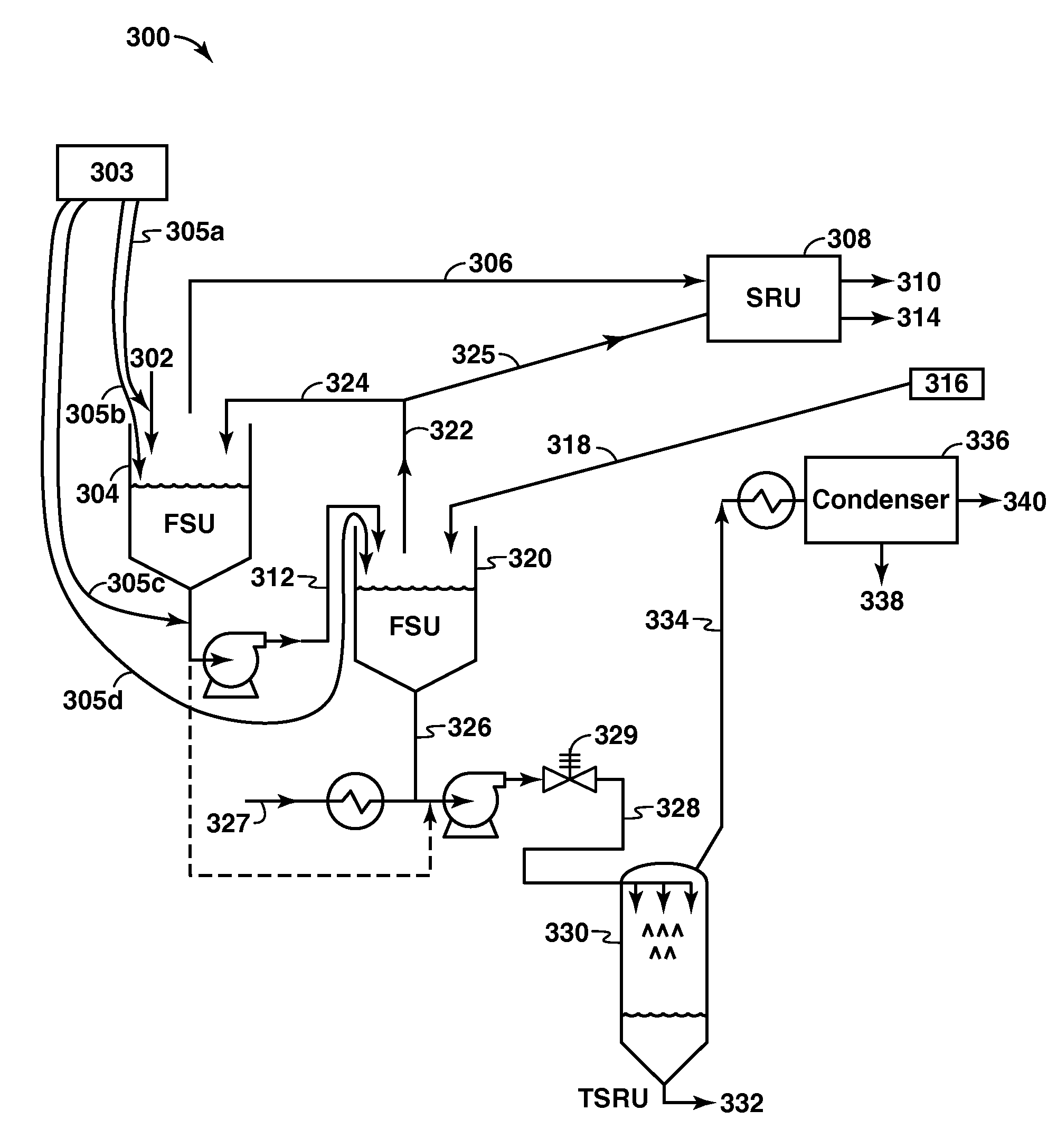

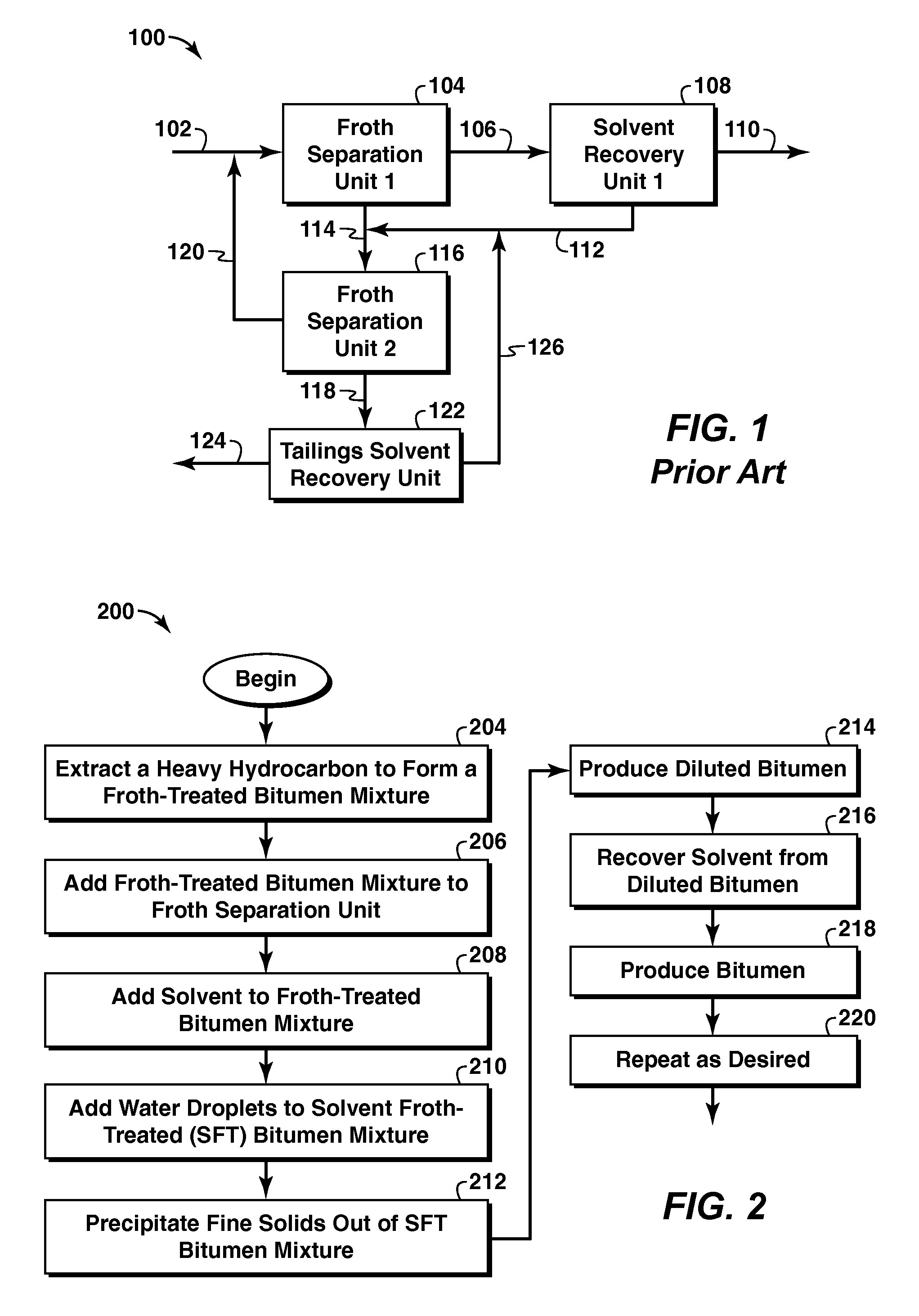

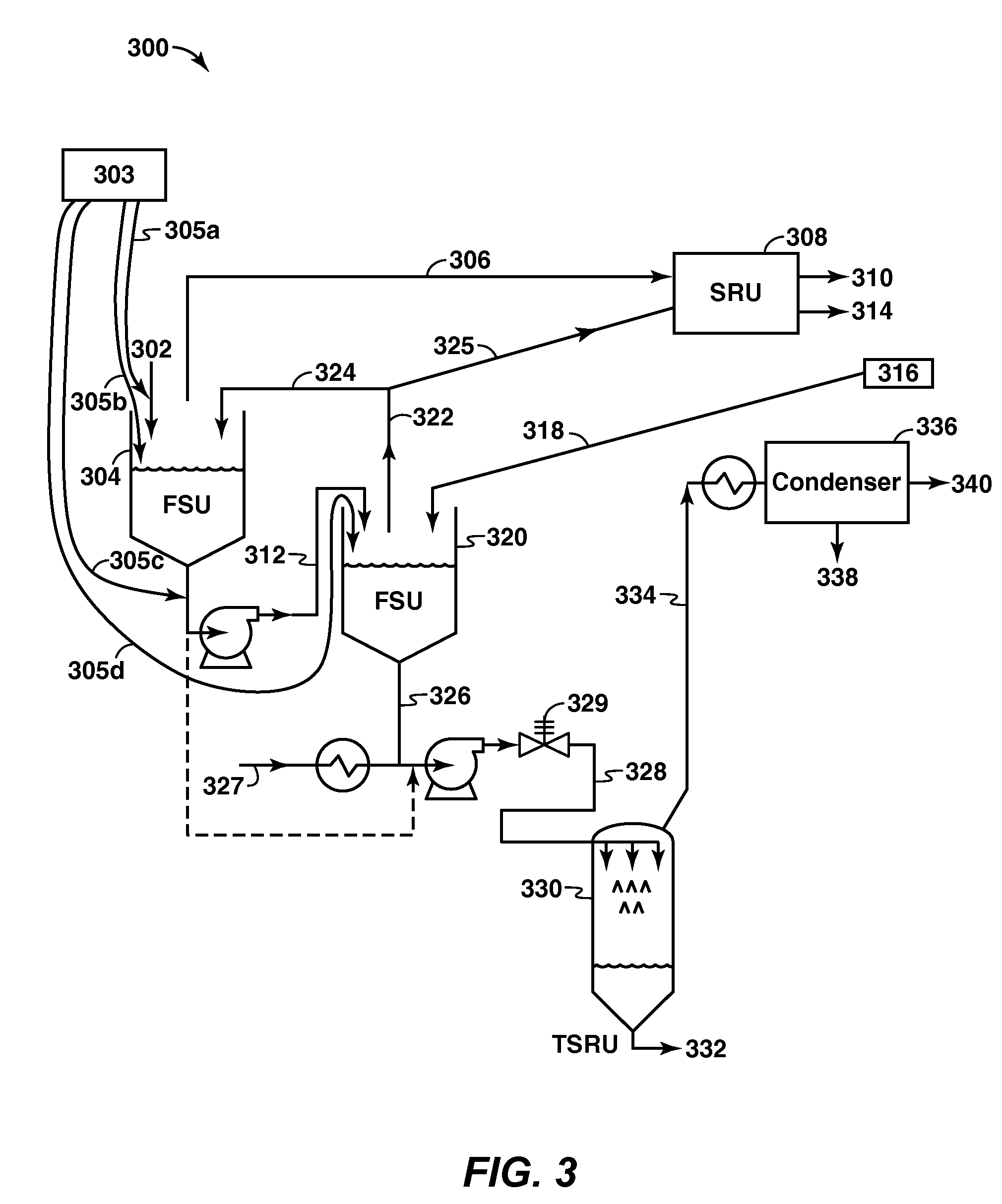

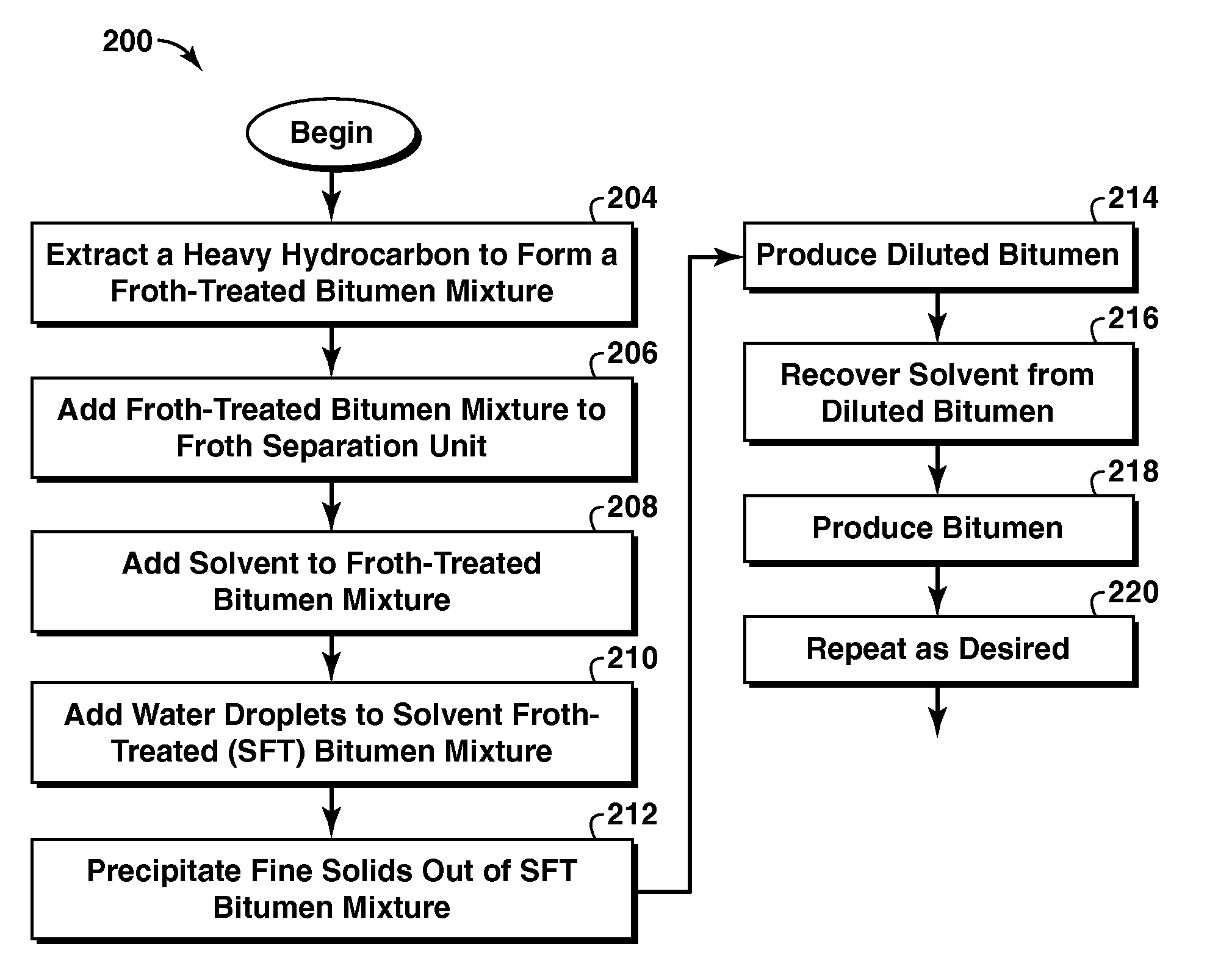

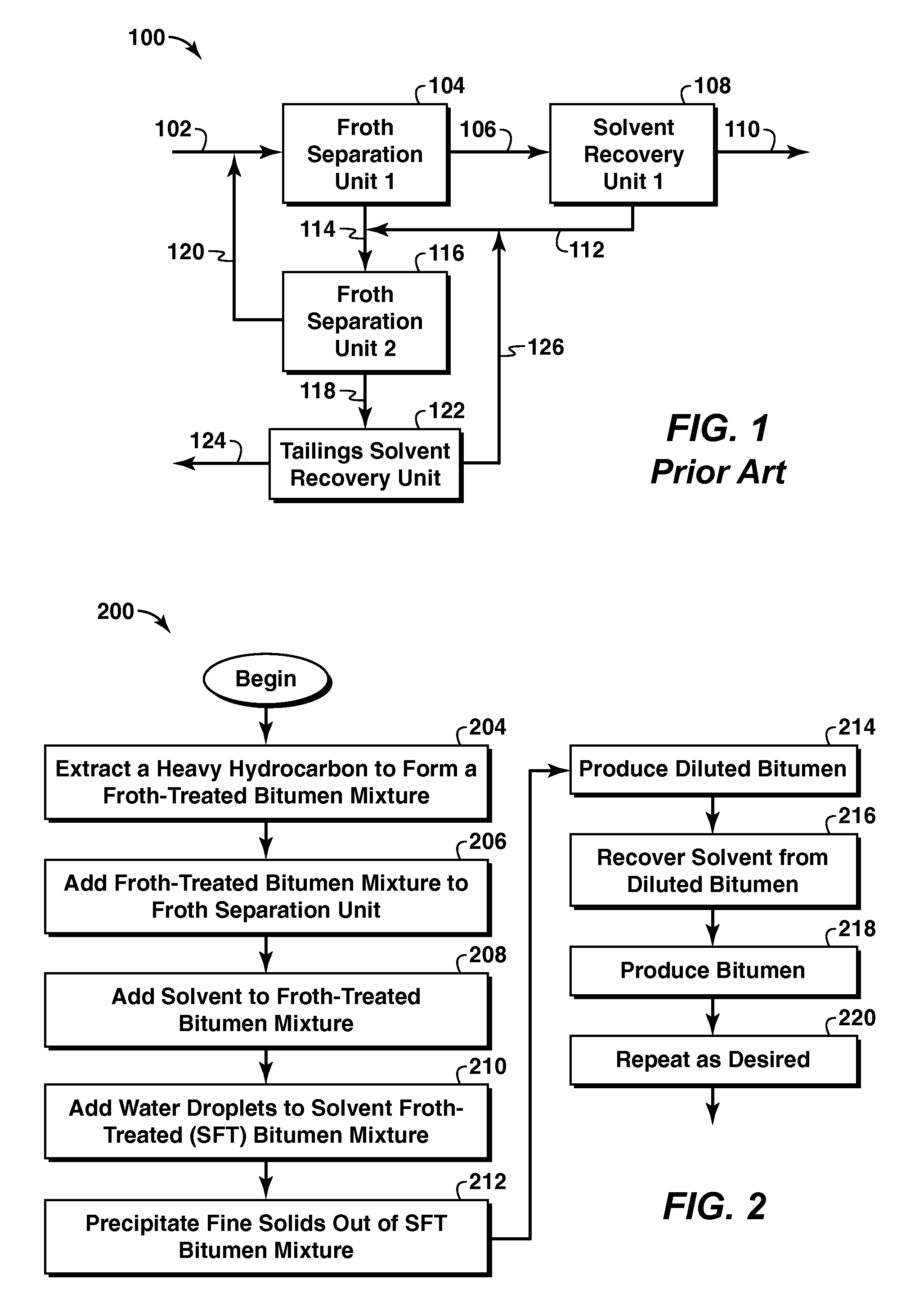

Upgrading Bitumen In A Paraffinic Froth Treatment Process

ActiveUS20090200209A1Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

Process and apparatus for increasing biological activity in waste treatment in bodies of water

ActiveUS20070039878A1Improve biological activityIncrease oxygenTransportation and packagingWater aerationImpellerMotor drive

A process and apparatus for increasing biological activity in waste treatment ponds and lagoons. In this process a floating fluid circulator having an annular space between nested frusto-conical surfaces is operated in a pond or lagoon. An aerator within the scope of the floating fluid circulator is provided. That aerator includes an upper float chassis having a frusto-conical configuration, a sectional diverter arranged in a lower portion of the upper float chassis, the sectional aerator having a lower diverter portion and motor driven means mounted on the upper float chassis connected to a rotatable impeller.

Owner:ABSOLUTE AERATION

System and method for enhancing an activated sludge process

ActiveUS7695623B2Increase settlement rateSpeed up the processTreatment using aerobic processesMixing methodsMixed liquor suspended solidsInjection port

A system for enhancing an activated sludge process that includes at least one aeration tank subsystem for receiving a flow a wastewater and for introducing dissolved oxygen to a population of microorganisms to promote growth of biological flocs in a mixed liquor defined by a concentration of mixed liquor suspended solids. A weighting agent impregnation subsystem includes an impregnation tank for mixing the mixed liquor, virgin weighting agent, and recycled weighting agent to impregnate the weighting agent into biological flocs suspended in the mixed liquor to form weighted biological flocs. A flocculant injection port located downstream from at least one aeration tank for introducing a flocculant to the mixed liquor for enhancing settling and thickening of the weighted biological flocs and for providing agglomeration of non-impregnated biological flocs and / or partially impregnated biological flocs with weighted biological flocs. At least one clarifier separates and collects the weighted biological flocs from the mixed liquor to provide a secondary effluent and a settled sludge. A return activated sludge subsystem recycles the majority of the settled sludge to the at least one aeration tank. A weighting agent recovery subsystem removes and shears the remaining settled sludge and recovers the weighting agent therefrom and reintroduces the weighting agent to the at least one aeration tank. A wasting subsystem wastes the remaining sludge of the weight agent recovery subsystem to control the population of the microorganisms in the mixed liquor.

Owner:EVOQUA WATER TECH LLC

Method for removing metals from acid mine drainage

InactiveUS20040094484A1Increase settling velocityHigh densityWaste water treatment from quariesSolid waste disposalFerrous saltsSludge

A method for removing metal contaminants from acidic mine wastewater using lignin derivatives, such as lignosulfonates and kraft lignin, an alkali coagulant, such as a lime compound, and an alkaline composition for increasing the pH. The lignin derivatives are dispersed in the wastewater and the coagulant is added, increasing the pH to about 4.5-8.5 and causing the formation of a floc. The alkaline composition is then added to bring the pH to about 9 to 10, causing the further formation of a floc. Optionally, air oxidation is carried out, reducing the pH to about 8.1-8.6. Optionally, a ferric or ferrous salt may also be added. The flocs comprise metal-lignin colloids, metal hydroxides and metal salts. The flocs coagulate to form a sludge. Optionally, fly ash or diatomaceous earth may be added to increase the density and stability of the sludge. The sludge that is formed contains the metals and is separated from the treated water by filtration.

Owner:NORAM ENG & CONSTRS

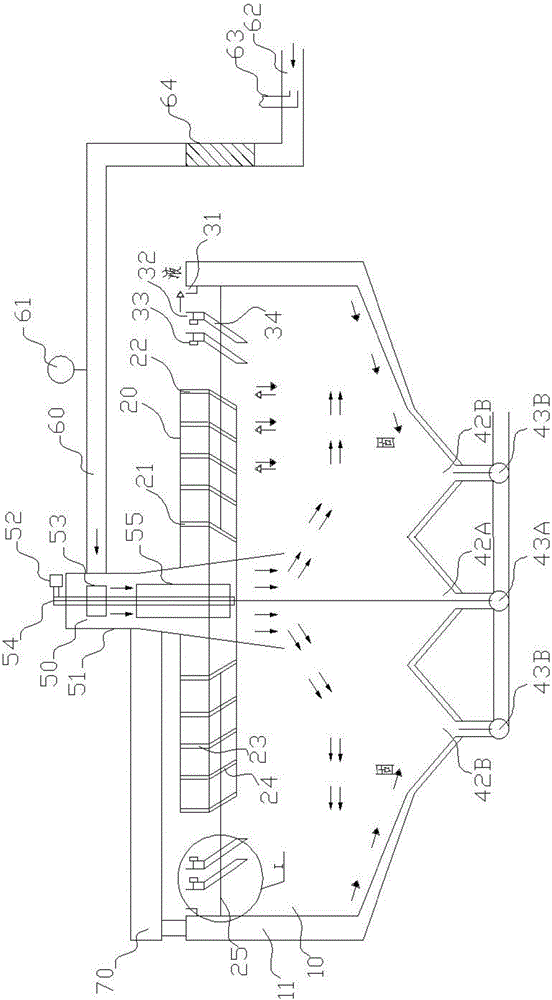

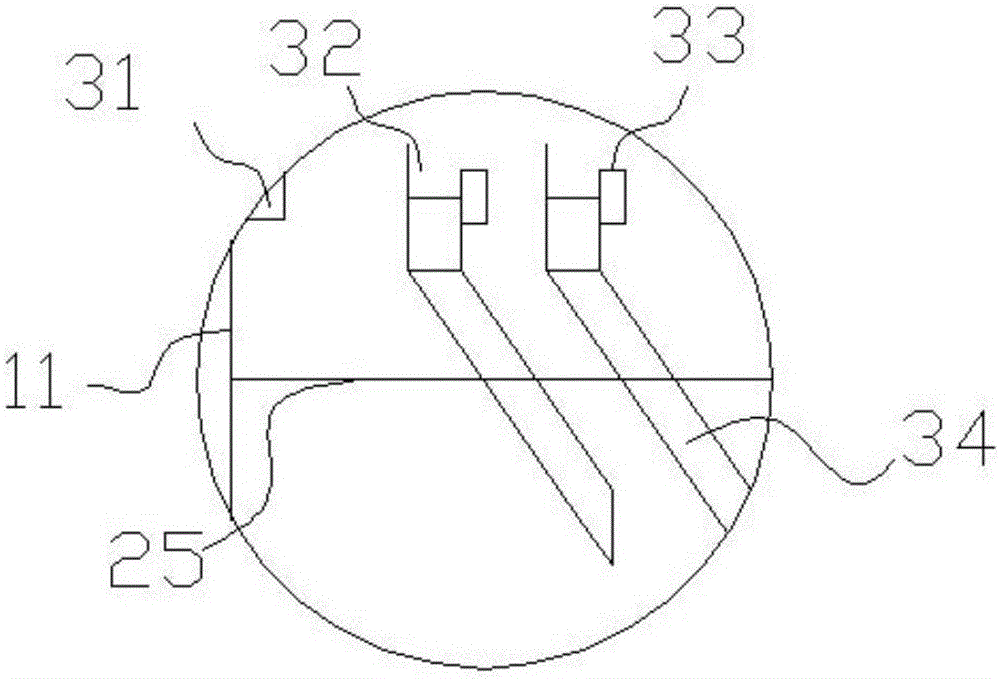

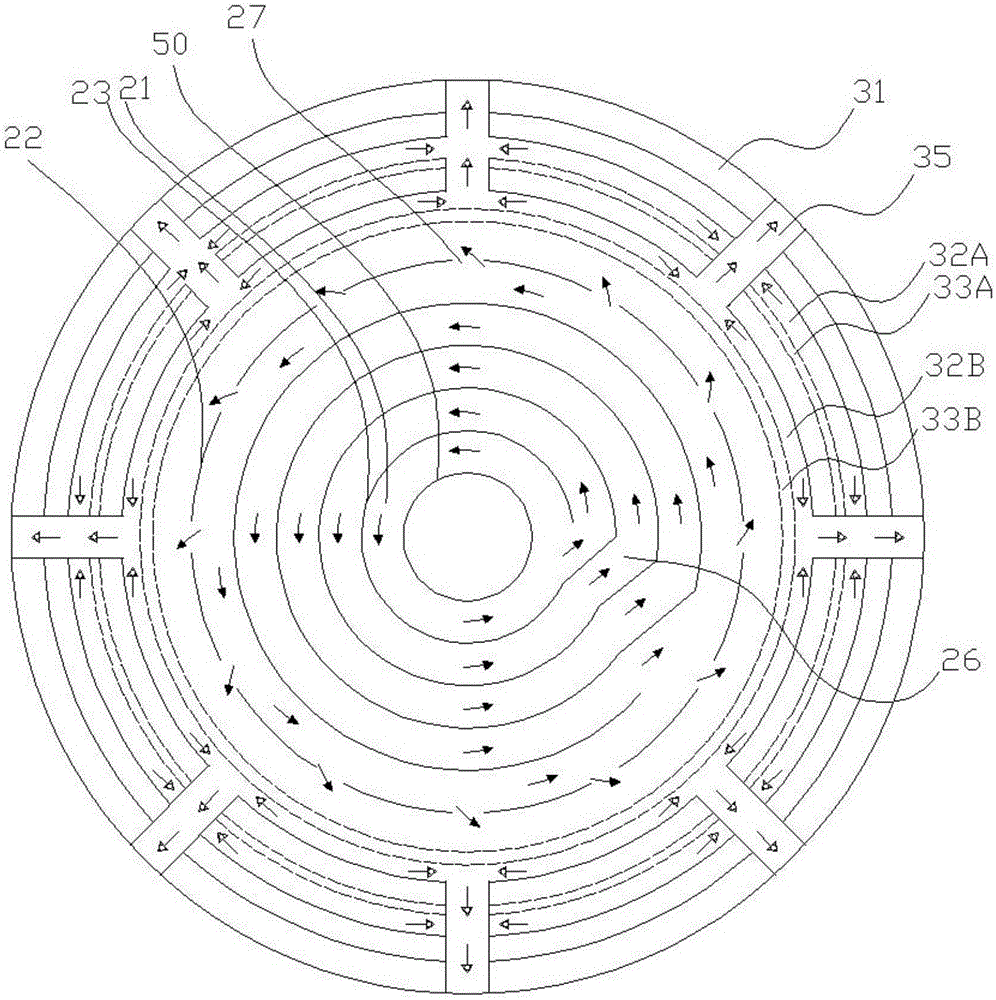

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

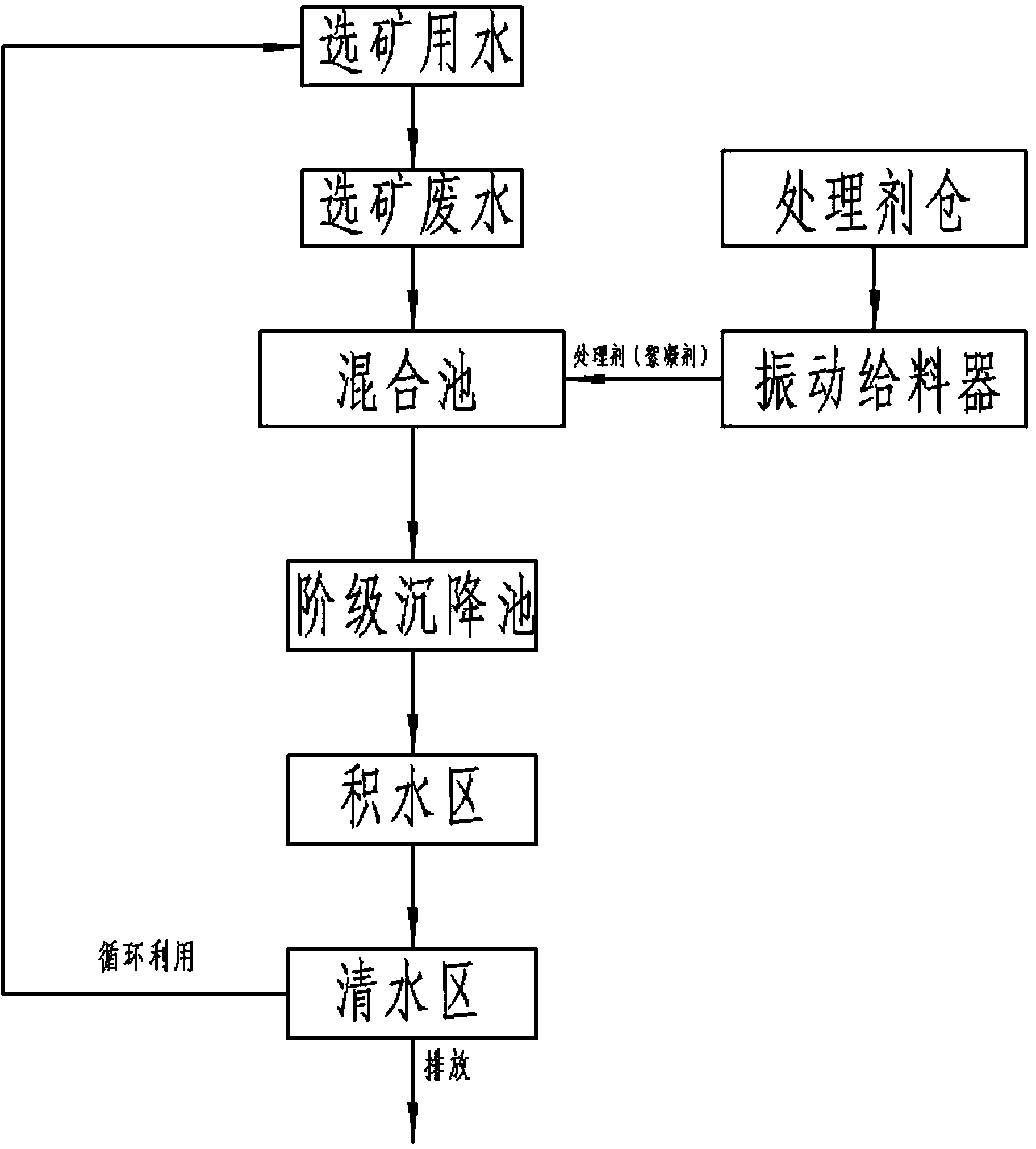

Polymetallic ore beneficiation wastewater recycling method

InactiveCN103708591AReduce productionIncrease the amount of purificationWater/sewage treatment by flocculation/precipitationSlagWater circulation

The invention provides a polymetallic ore beneficiation wastewater recycling method. The polymetallic ore beneficiation wastewater recycling method is characterized by comprising two steps of physical treatment and biological treatment. According to the polymetallic ore beneficiation wastewater recycling method, the existing beneficiation wastewater output equipment and tailings ponds of aluminium and zinc beneficiation industries are used, wastewater treating agents such as calcium hydroxide, saponification slag and calcium carbide are added to wastewater in a mixing tank so as to ensure that suspended matters in the wastewater settle, the wastewater is purified so as to meet the technical requirements that obtained clear water is continuously used for beneficiation, the content of suspended matters in the treated water is less than 100mg / L, the pH value of the treated water is 8, and the cyclic utilization of the beneficiation wastewater is realized. The polymetallic ore beneficiation wastewater recycling method has the characteristics of low investment, low running cost, energy conservation, emission reduction and cyclic economy and is suitable for the cyclic utilization of the polymetallic ore beneficiation wastewater.

Owner:GUANGXI KESHENGDA MACHINERY MFG

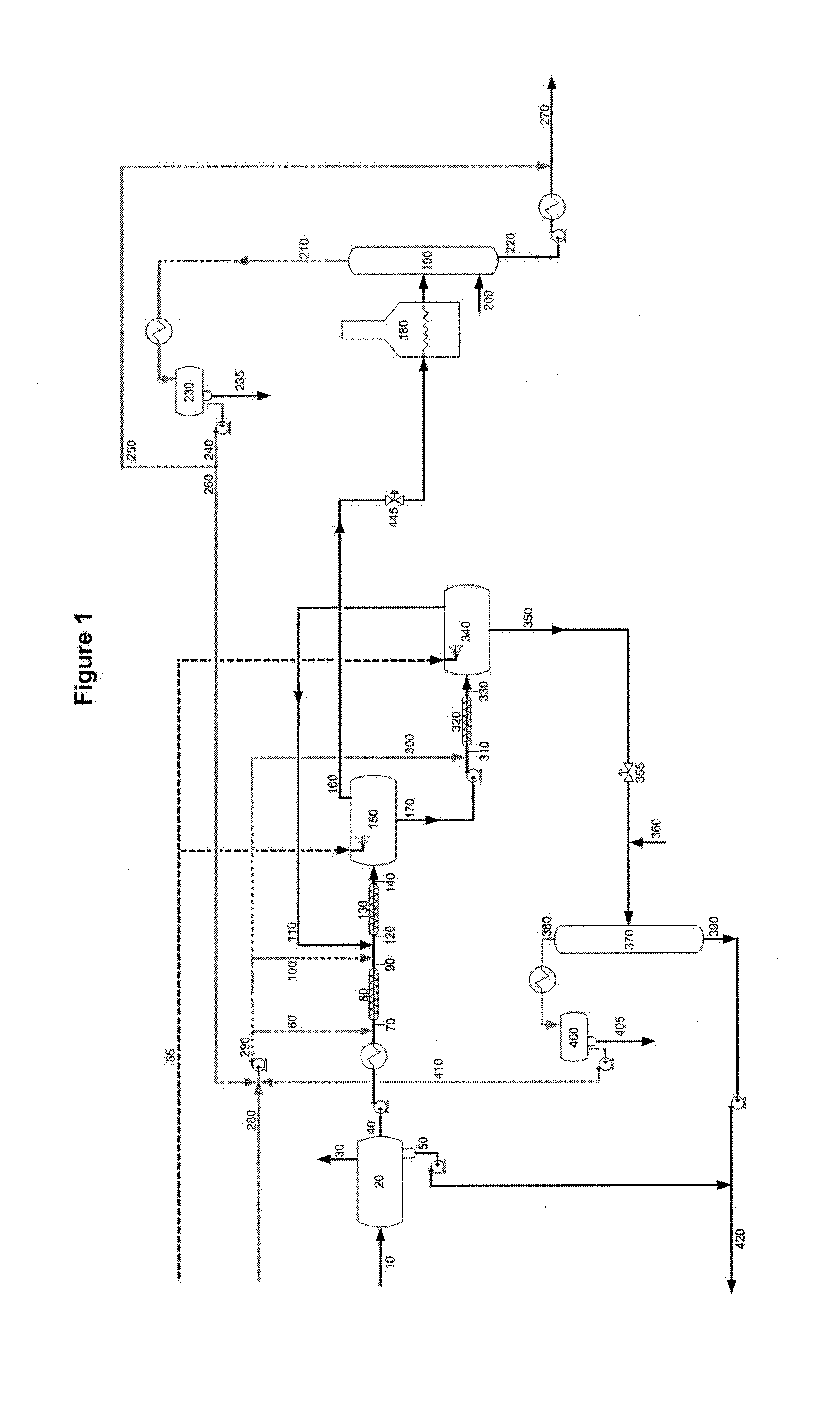

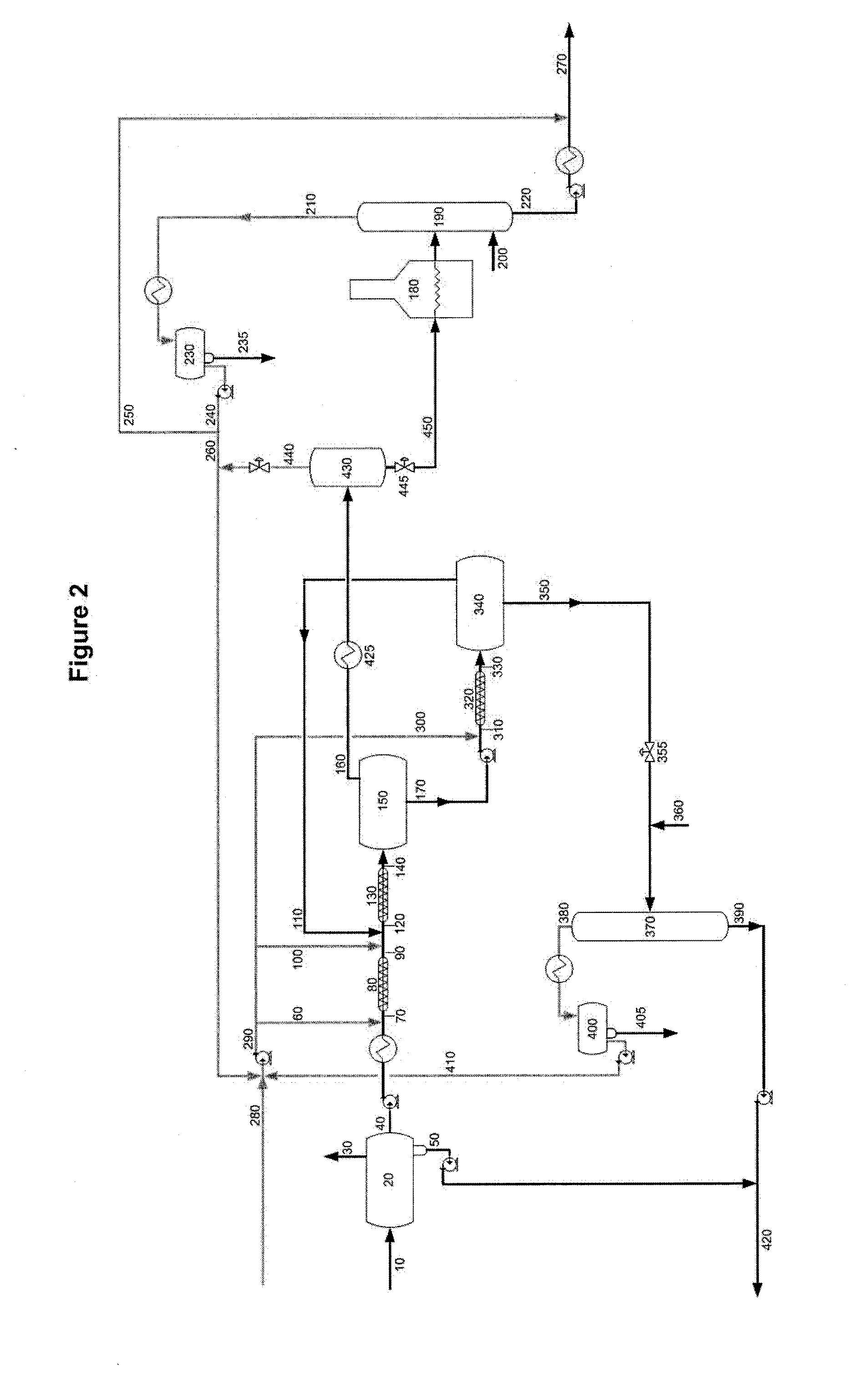

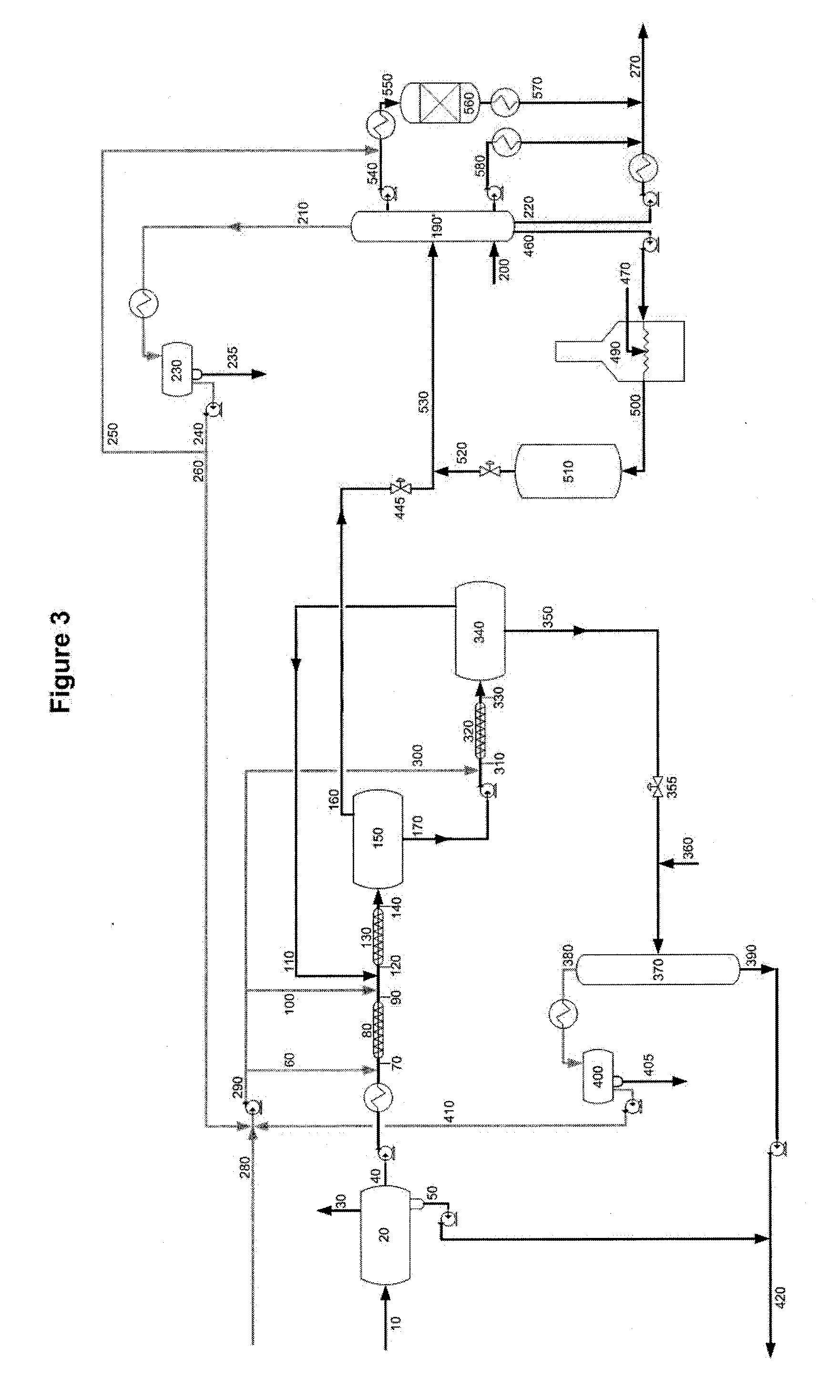

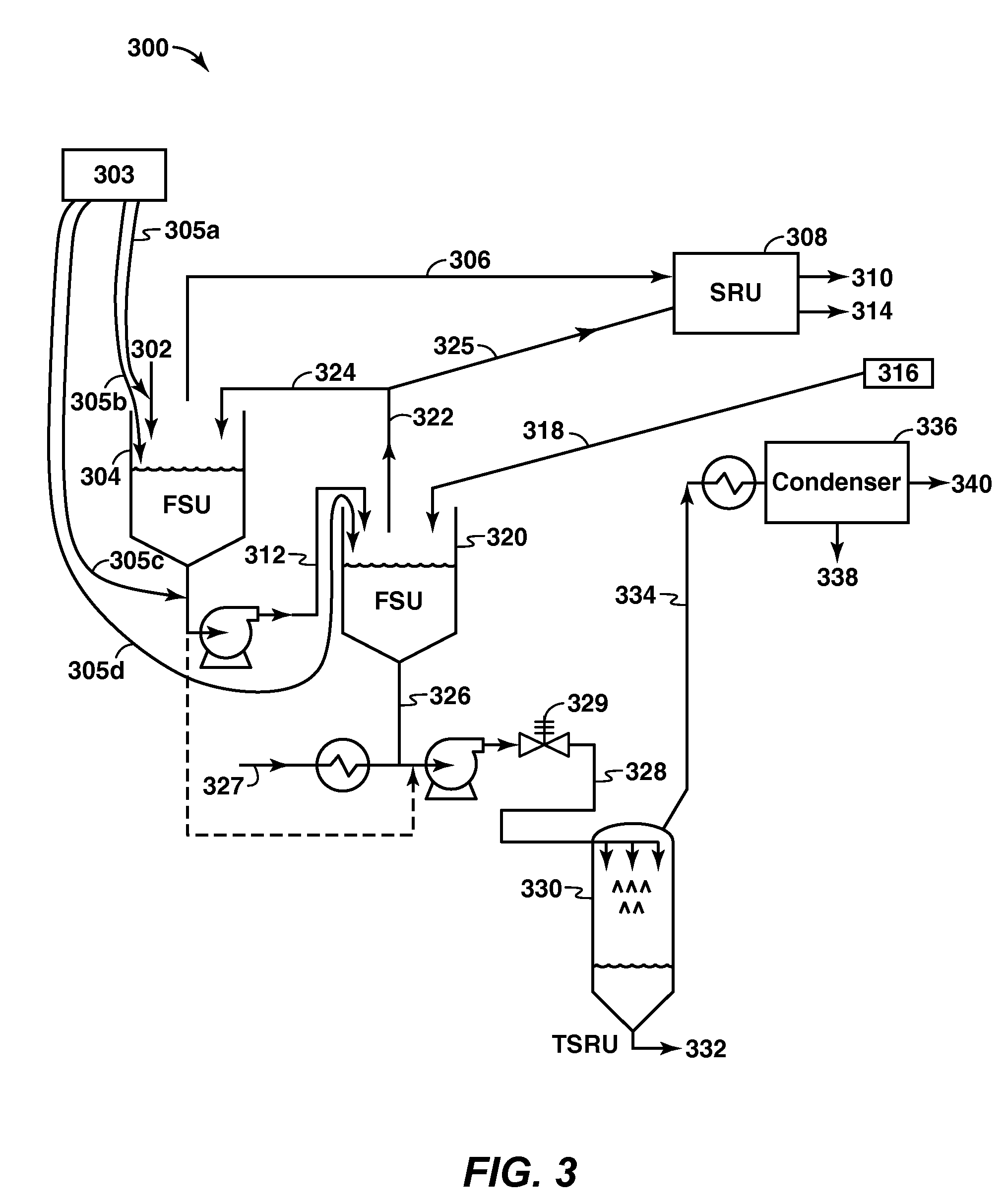

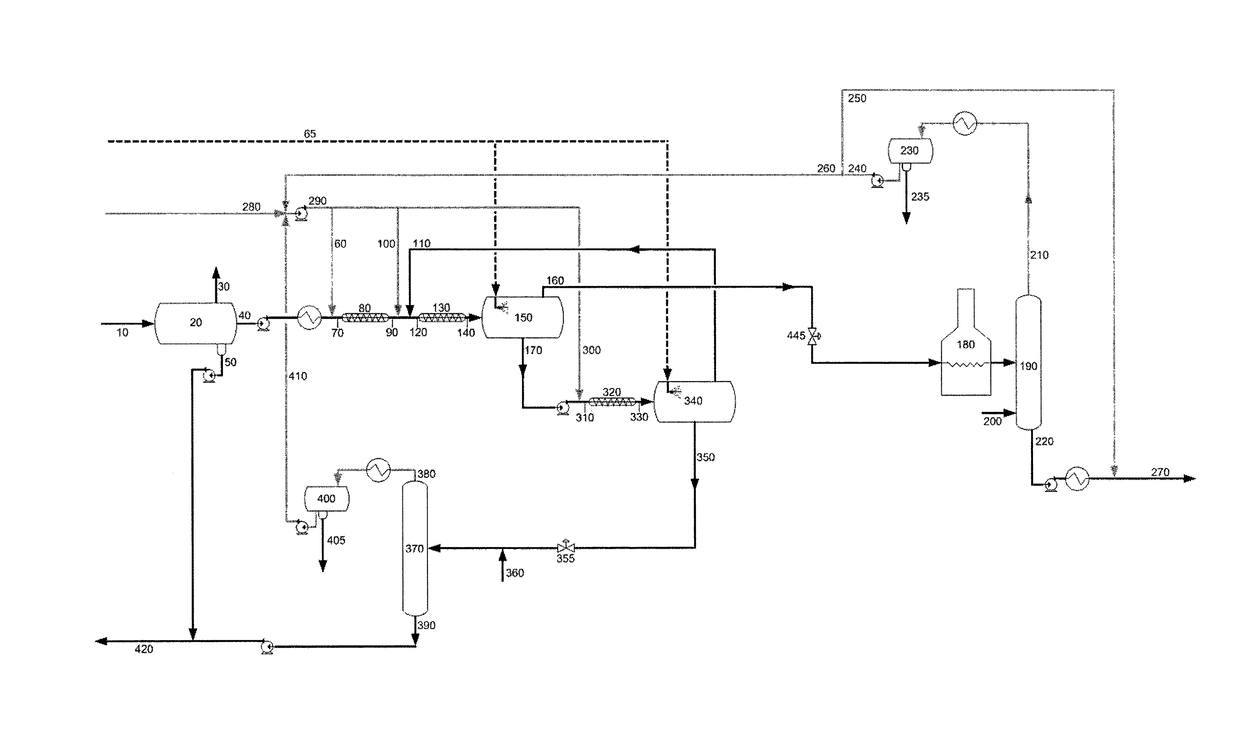

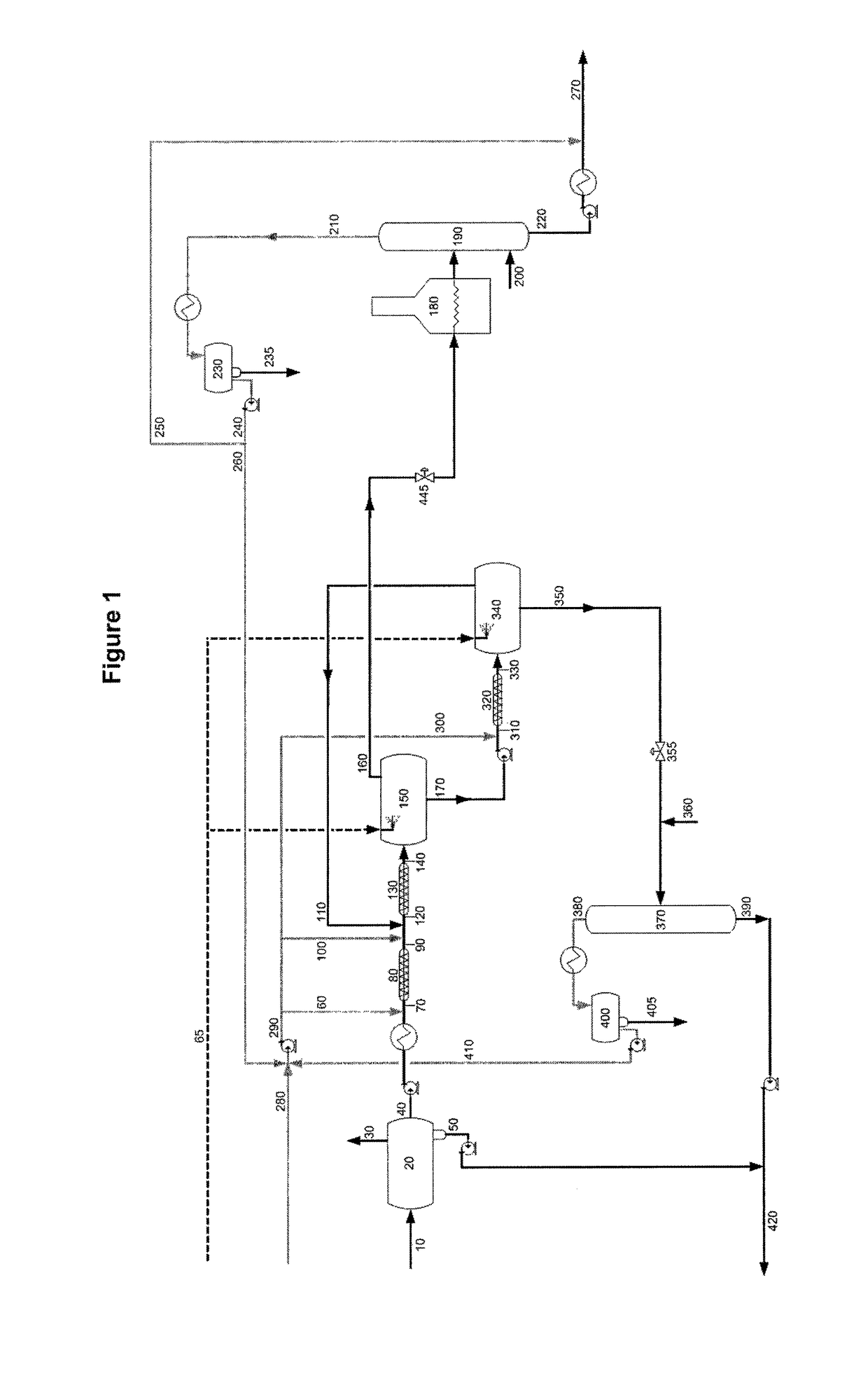

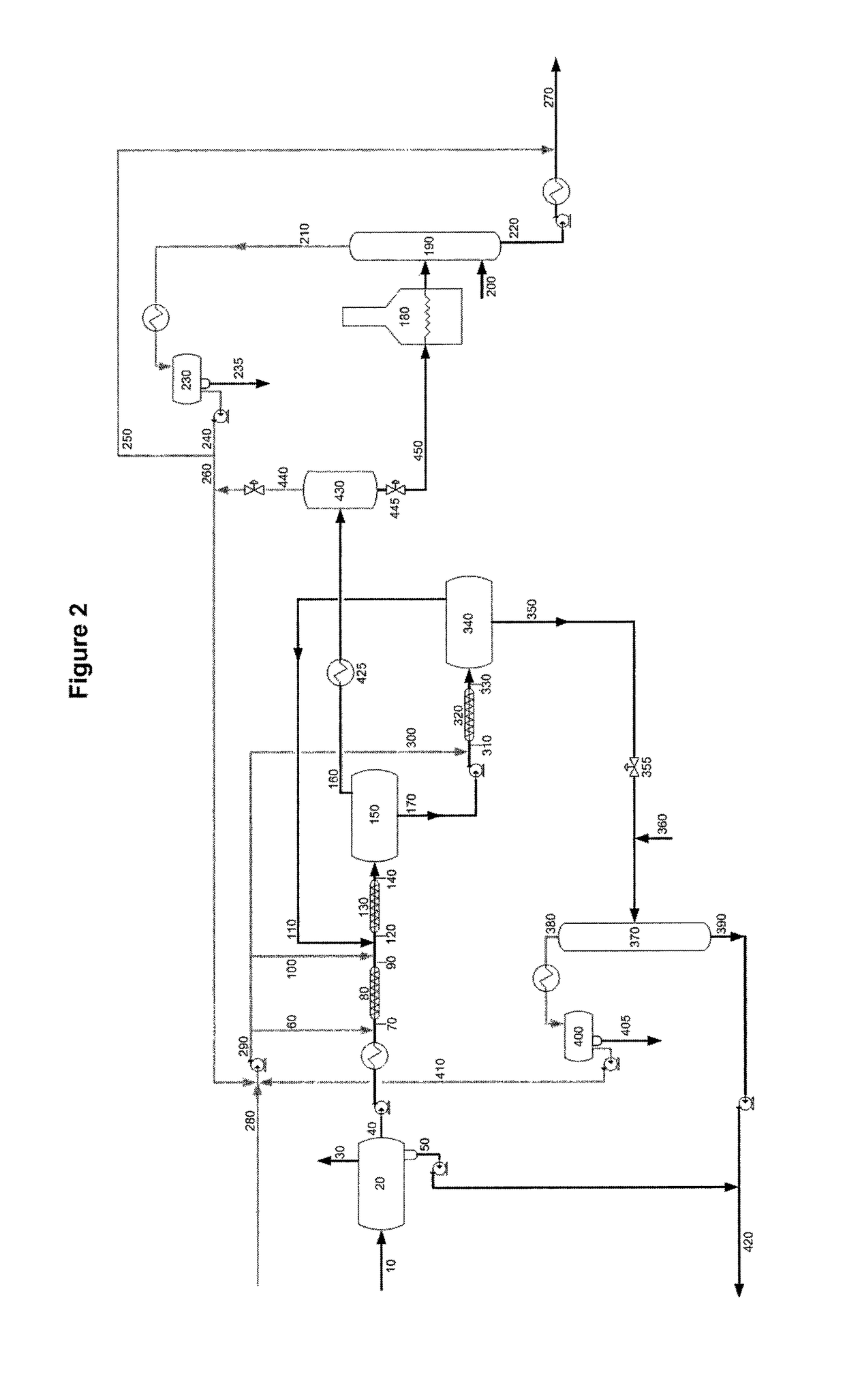

Integrated central processing facility (CPF) in oil field upgrading (OFU)

ActiveUS20140138287A1Conducive to agglomerationIncreased floc sizeThermal non-catalytic crackingTreatment with plural serial stages onlyAlkaneDiluent

A process for upgrading oil including optionally pre-treating a heavy oil including at least one dissolved gas, asphaltenes, water, and mineral solids; reducing at least one dissolved gas content from said heavy oil, optionally further reducing water content from said heavy oil; adding a paraffinic solvent to said heavy oil, at a predetermined paraffinic solvent:heavy oil ratio, facilitating separation of asphaltenes, water, and mineral solids from the heavy oil resulting in a de-asphalted or partially de-asphalted oil (“DAO”)-paraffinic solvent stream, comprising a low asphaltenes content DAO-paraffinic solvent stream and an asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the paraffinic solvent and water from the asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the DAO-paraffinic solvent stream into a paraffinic solvent rich stream and a DAO stream; and optionally adding diluent to the DAO stream resulting in transportable oil.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

Method and system for treating wastewater in an integrated fixed film activated sludge sequencing batch reactor

InactiveUS20150321937A1Increase capacityEasy to settleWater treatment compoundsWater/sewage treatmentActivated sludgeSequencing batch reactor

An integrated fixed film activated sludge sequencing batch reactor is provided where both suspended biomass and biomass supported on biofilm carriers are utilized to biologically treat wastewater received by the sequencing batch reactor. The sequencing batch reactor includes two hydraulically connected tanks with suspended biomass being contained in at least one tank and biomass supported on biofilm carriers in the other tank.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

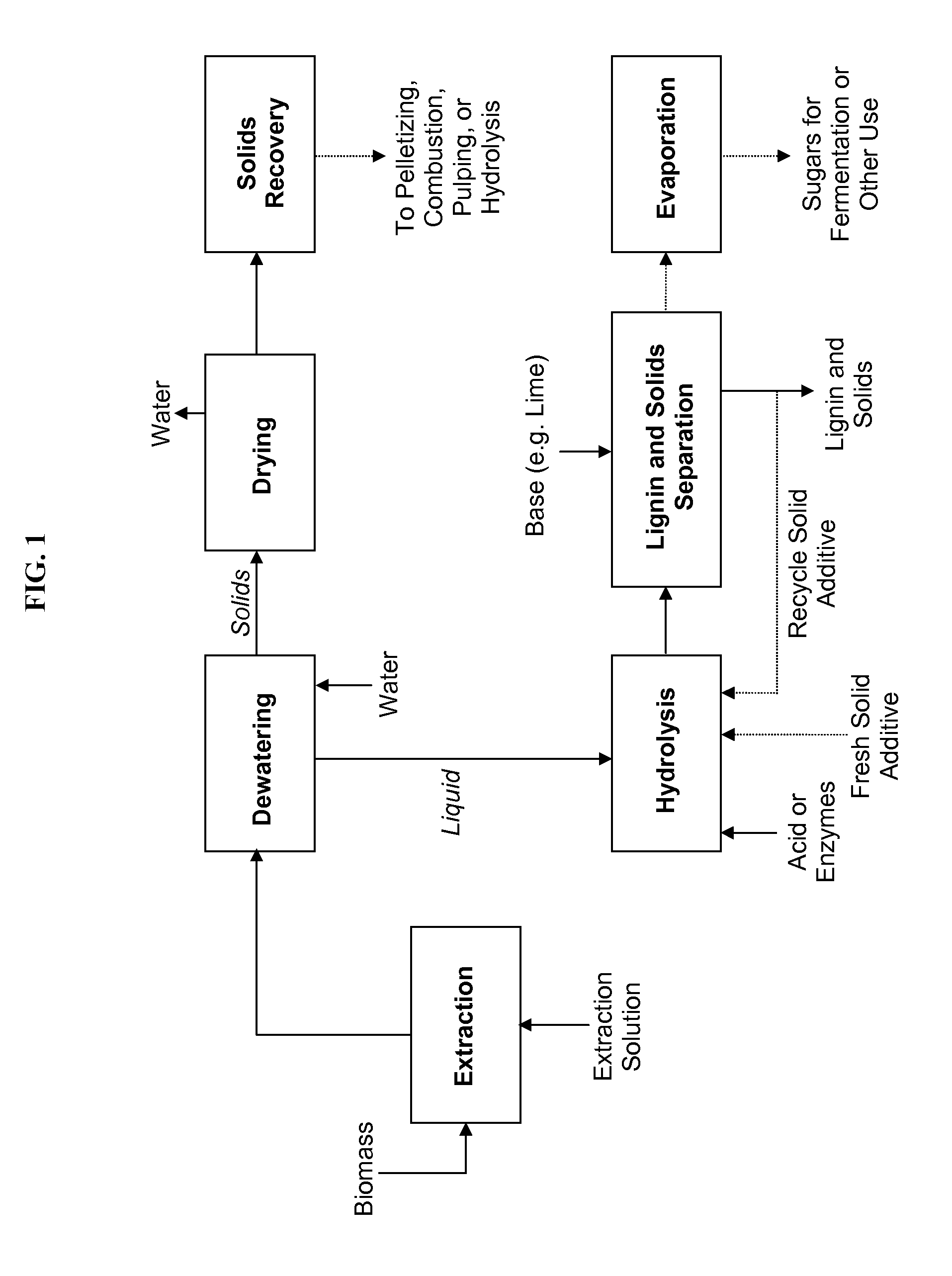

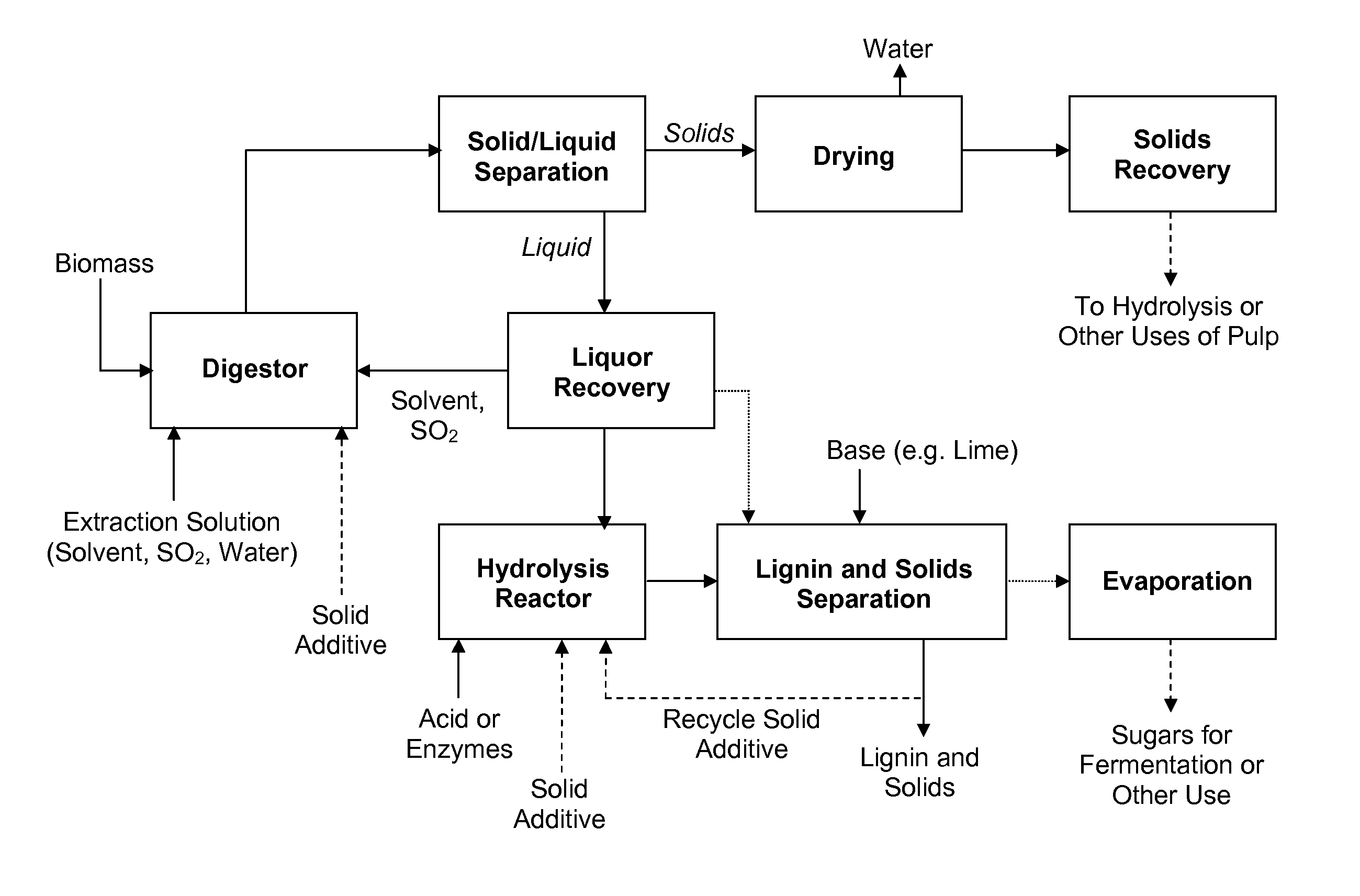

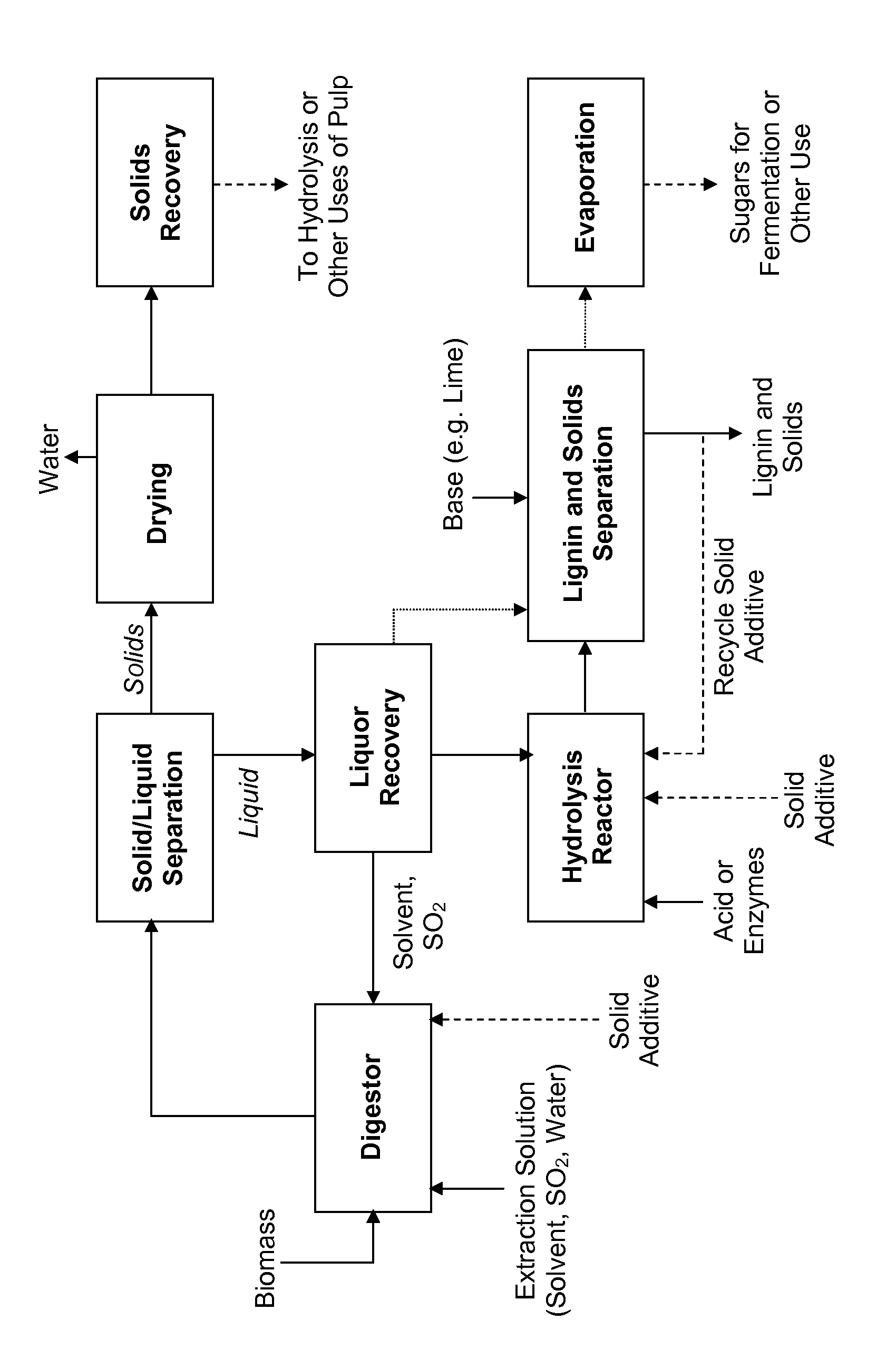

Processes and apparatus for lignin separation in biorefineries

The present invention generally provides methods of improving lignin separation during lignocellulosic biorefining, comprising the steps of (i) catalyzing fractionation or hydrolysis with an acid to release sugars into an acidified solution containing lignin, (ii) neutralizing the acidified solution with a base to form a salt in a neutralized solution; (iii) in a separation unit, separating the salt and the lignin, each in free or combined form, from the neutralized solution; and then (iv) recycling a portion of the salt and optionally a portion of the lignin to step (i) to combine, physically or chemically, with the lignin, to improve lignin separation in the separation unit. In certain embodiments, the acid is a sulfur-containing acid and the base is lime, forming gypsum which is then recycled, in part, to the hydrolysis reactor.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Upgrading bitumen in a paraffinic froth treatment process

ActiveUS8357291B2Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

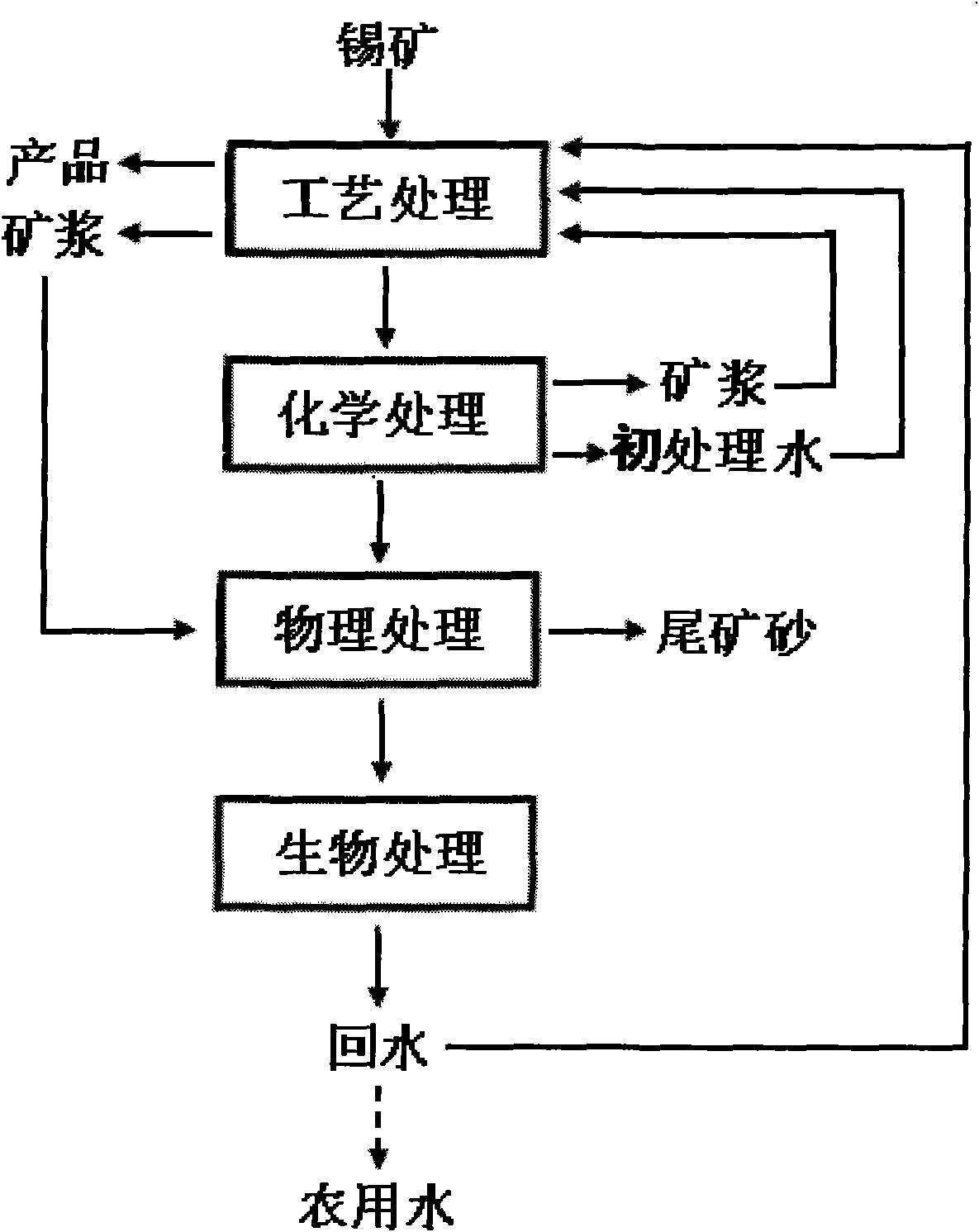

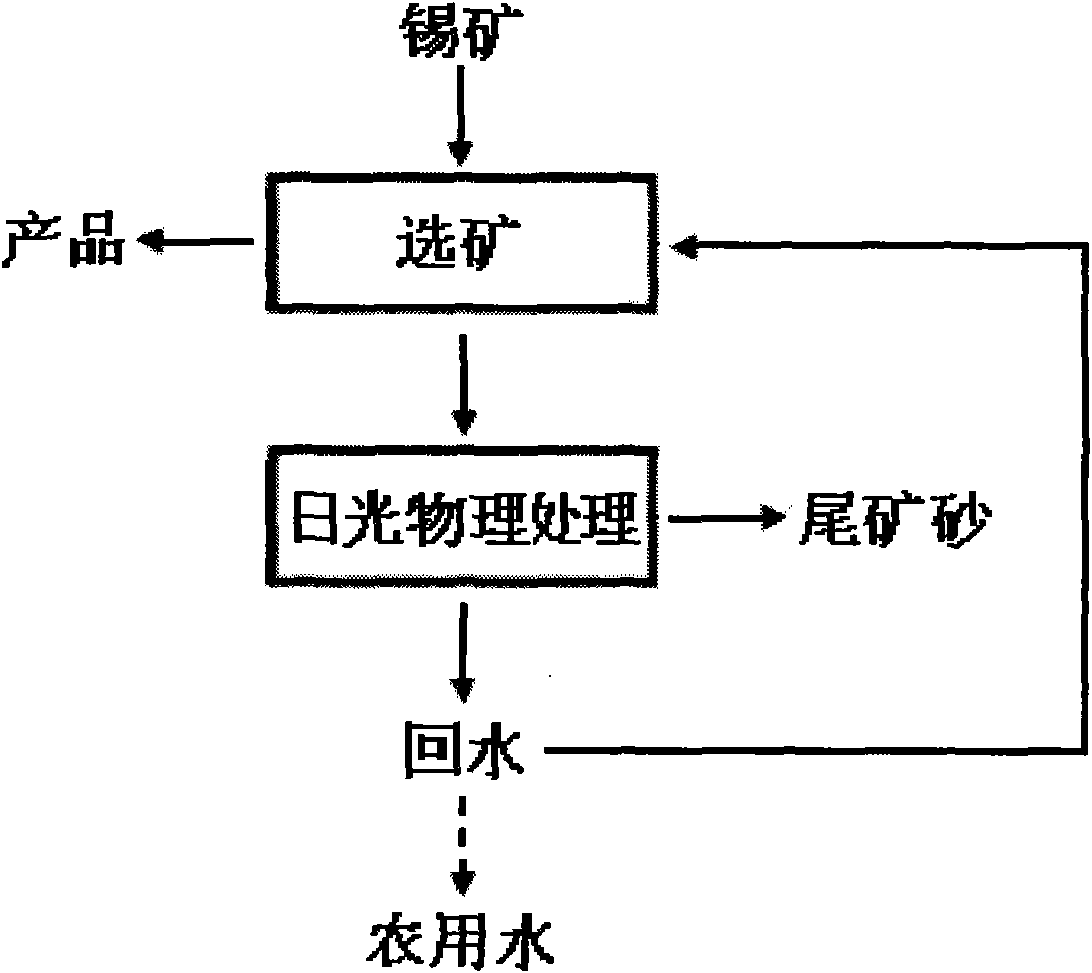

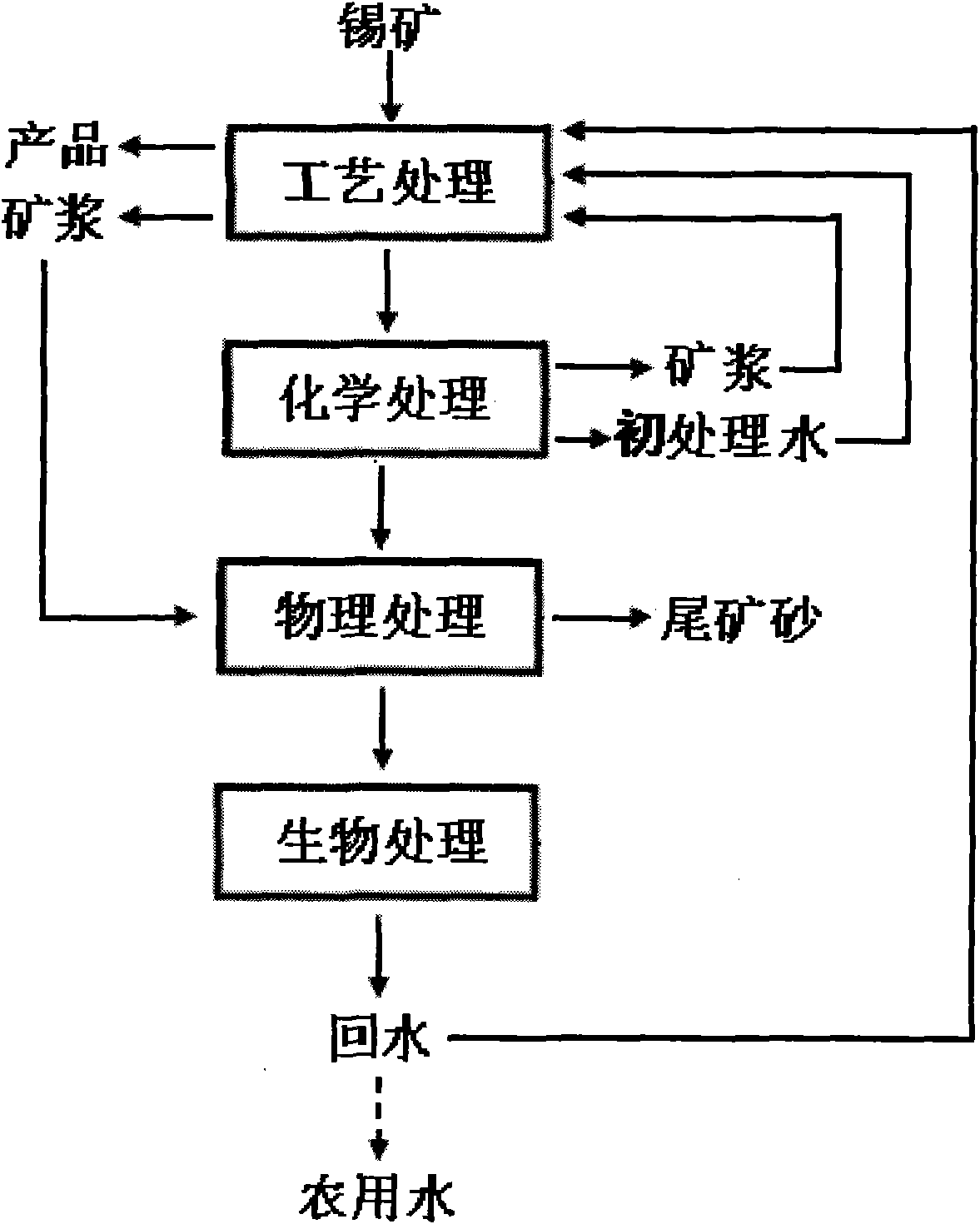

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

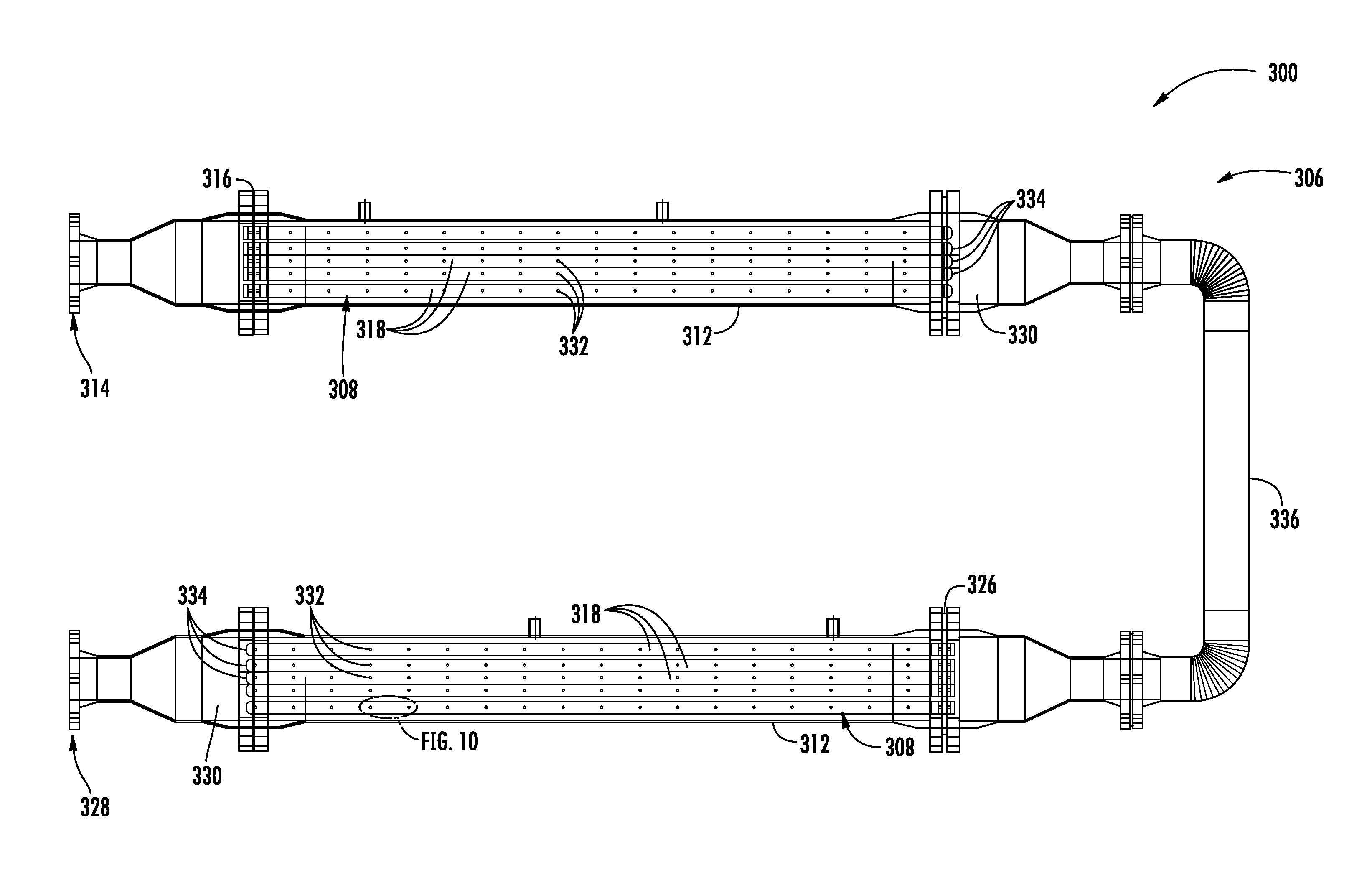

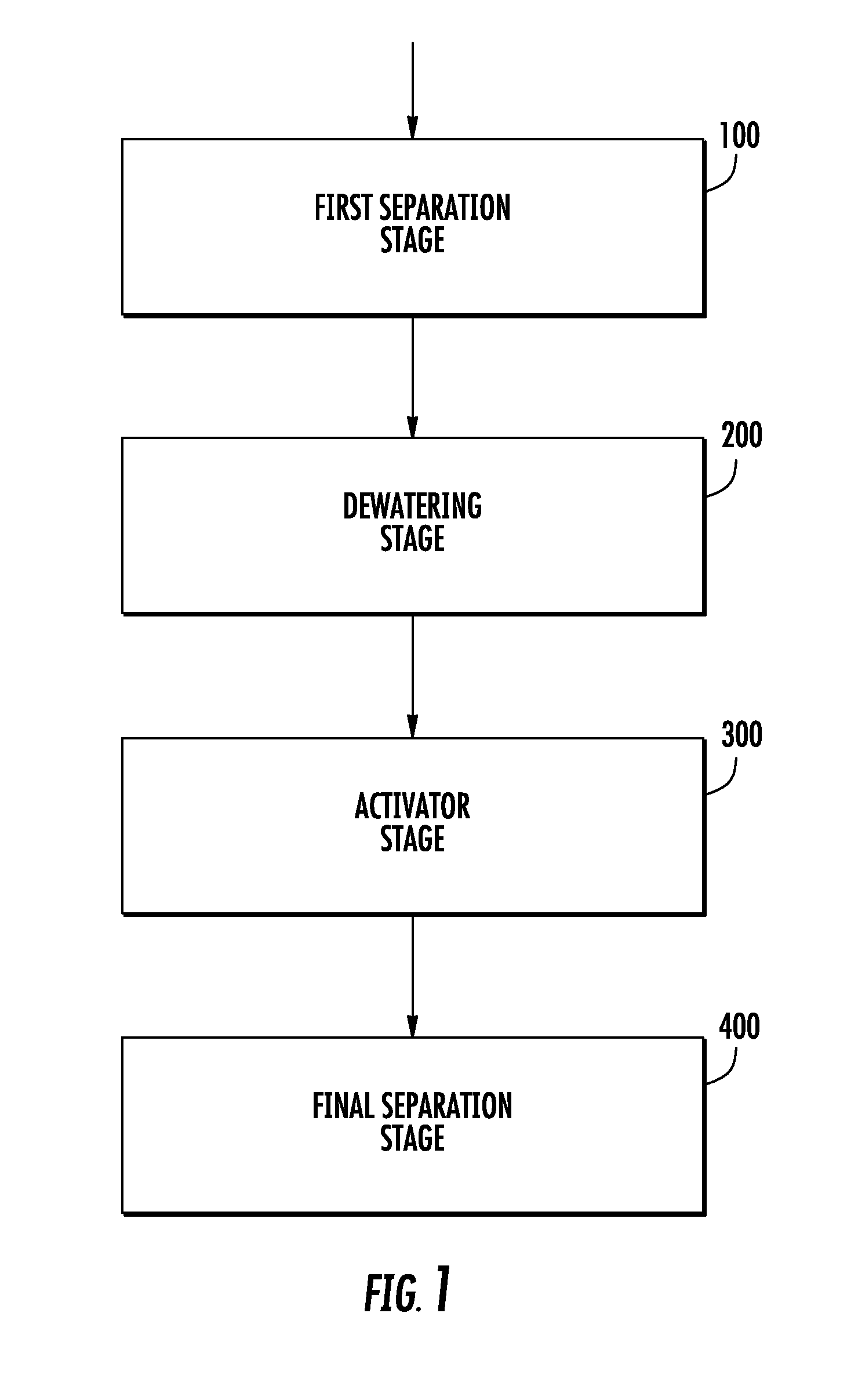

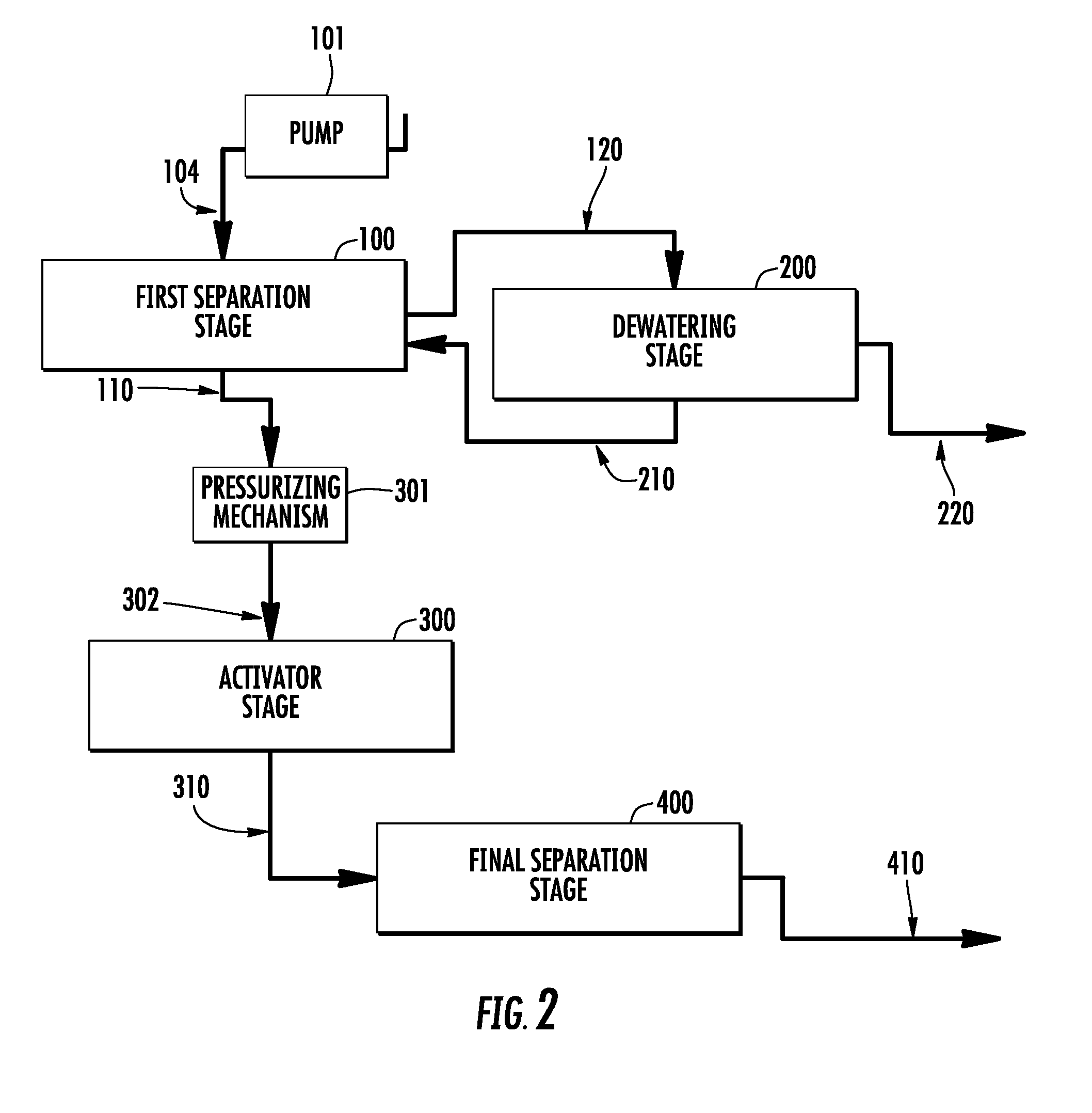

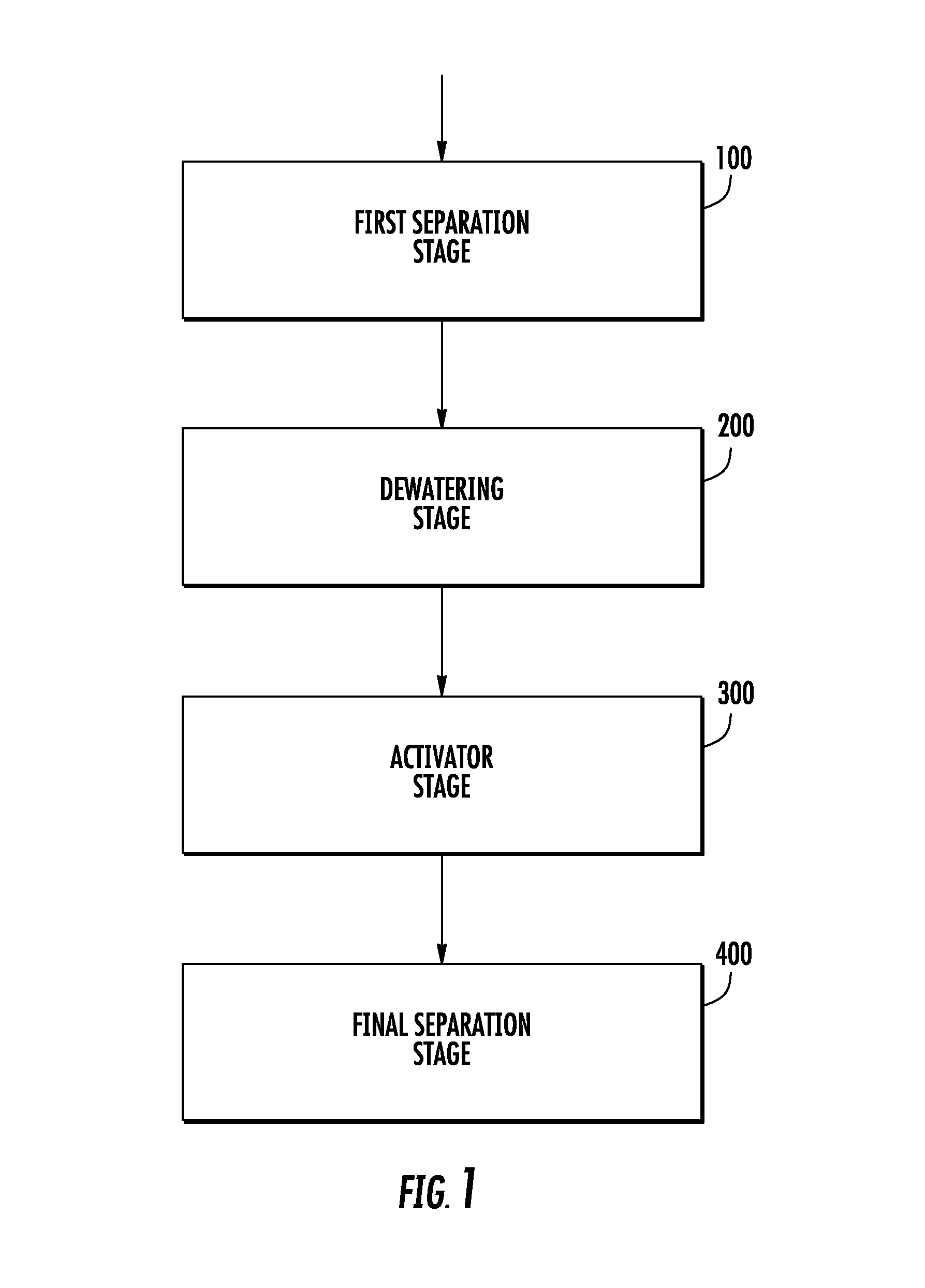

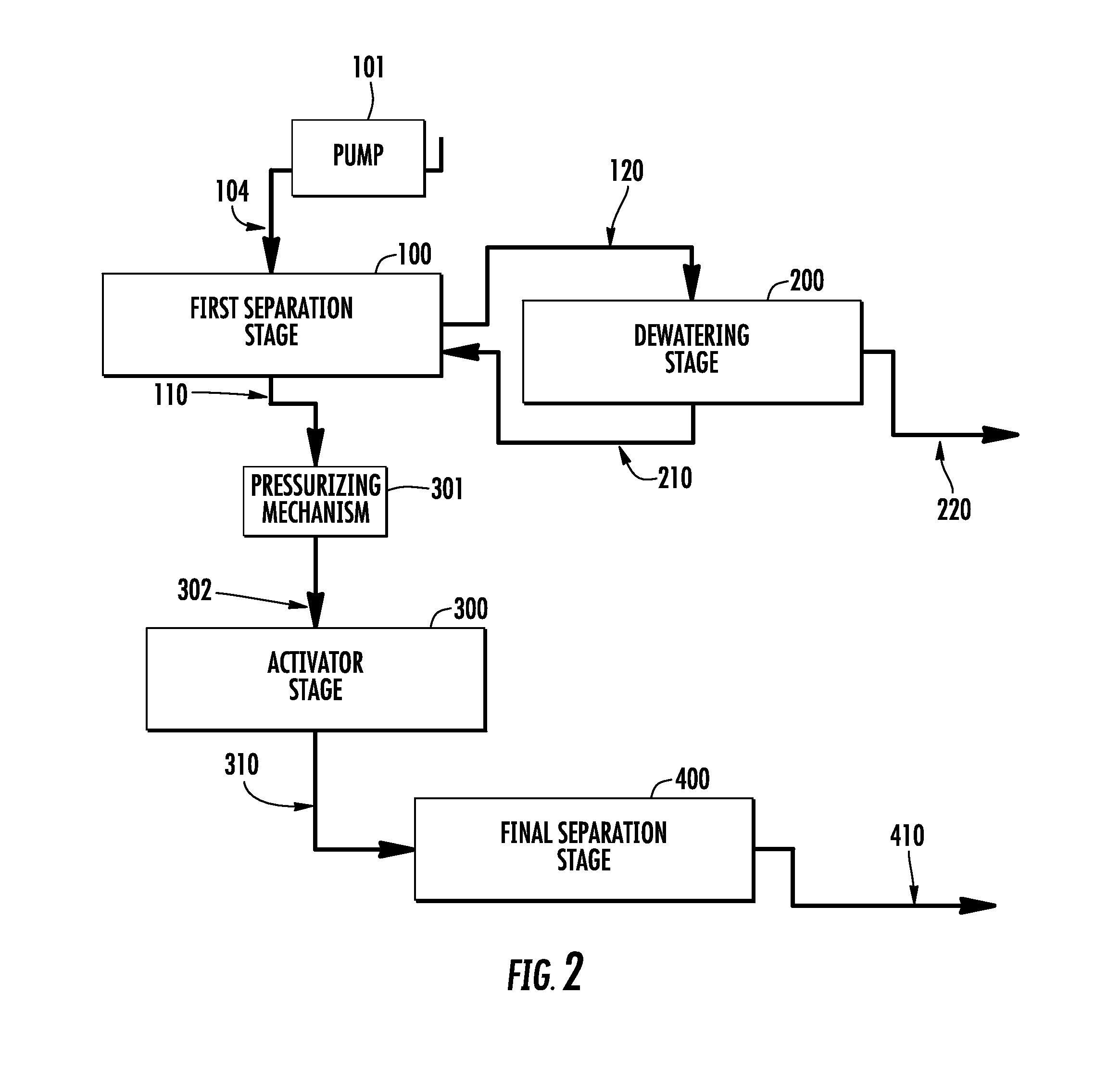

Waste separation and processing system

ActiveUS20120152861A1Increase settlement rateElectrostatic separatorsExcrement fertilisersPollutantChemistry

A multi-stage method of reducing solids and contaminants from liquid waste and other suitable streams without the use of chemical flocculants or polymers is disclosed.

Owner:MIDWESTERN IP

Medical hemostatic sponge and preparation method

The invention discloses a medical hemostatic sponge and a preparation method. The sponge is a milk-white loose and porous sponge material composed of bletilla mannan extracted from the dry tubers of orchid bletilla, wherein the essential of the preparation method is that mannan in bletilla is extracted out by water extraction and alcohol precipitation processes at first, and then is prepared into the loose and porous sponge material by a vacuum freeze-drying technology. The sponge is wide in material source, low in cost, non-immunogenicity, high in adhesion speed for wound surface, high in adhesion firmness, remarkable in physical hemostatic effect, soft in performance, capable of being used without pre-treatment, extremely high in cost performance, and capable of replacing the existing gelatine hemostatic sponge.

Owner:刘明远

Integrated central processing facility (CPF) in oil field upgrading (OFU)

ActiveUS9650578B2Increase settlement rateDecreases size and costThermal non-catalytic crackingTreatment with plural serial stages onlyAlkaneDiluent

A process for upgrading oil including optionally pre-treating a heavy oil including at least one dissolved gas, asphaltenes, water, and mineral solids; reducing at least one dissolved gas content from said heavy oil, optionally further reducing water content from said heavy oil; adding a paraffinic solvent to said heavy oil, at a predetermined paraffinic solvent:heavy oil ratio, facilitating separation of asphaltenes, water, and mineral solids from the heavy oil resulting in a de-asphalted or partially de-asphalted oil (“DAO”)-paraffinic solvent stream, comprising a low asphaltenes content DAO-paraffinic solvent stream and an asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the paraffinic solvent and water from the asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the DAO-paraffinic solvent stream into a paraffinic solvent rich stream and a DAO stream; and optionally adding diluent to the DAO stream resulting in transportable oil.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

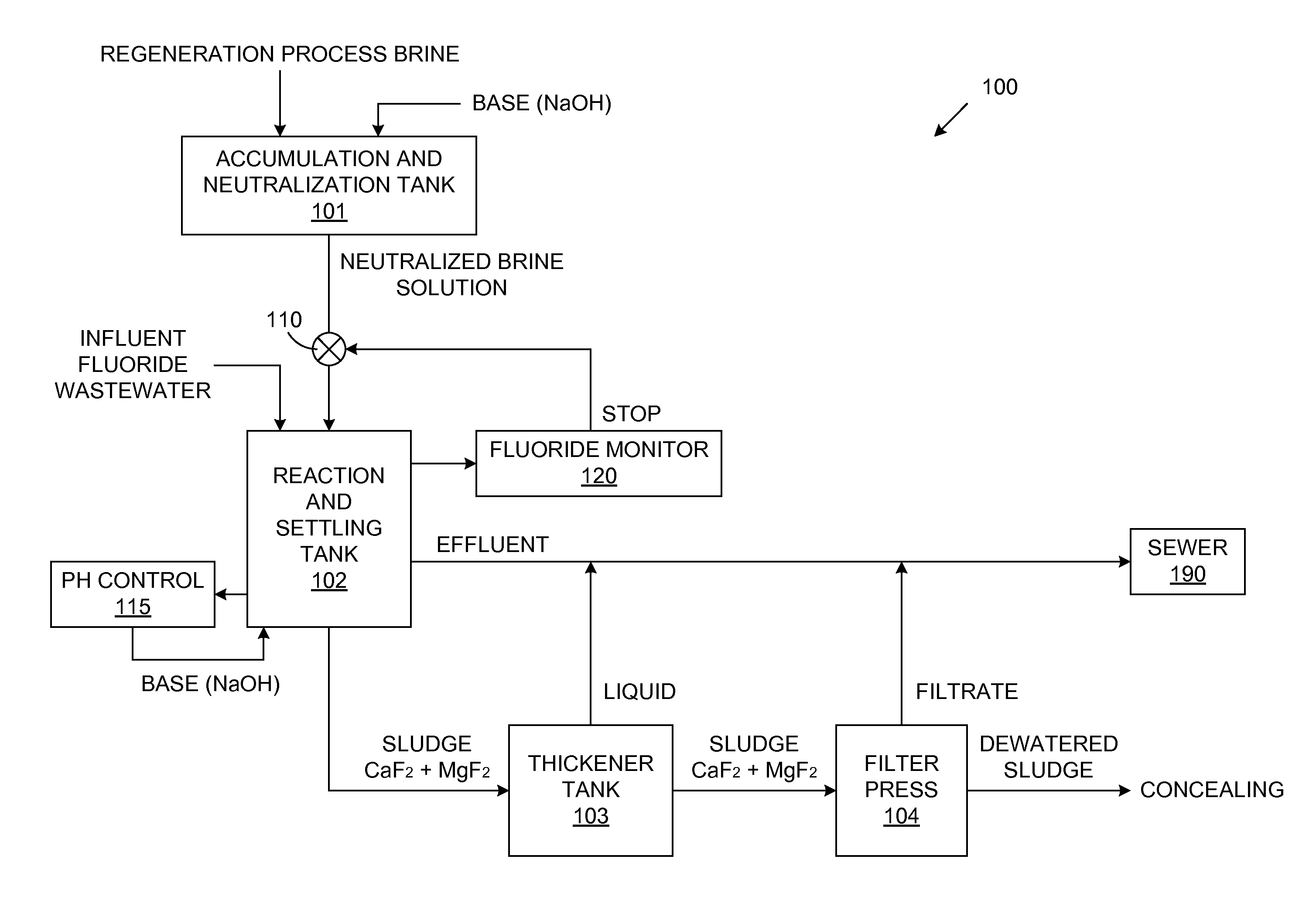

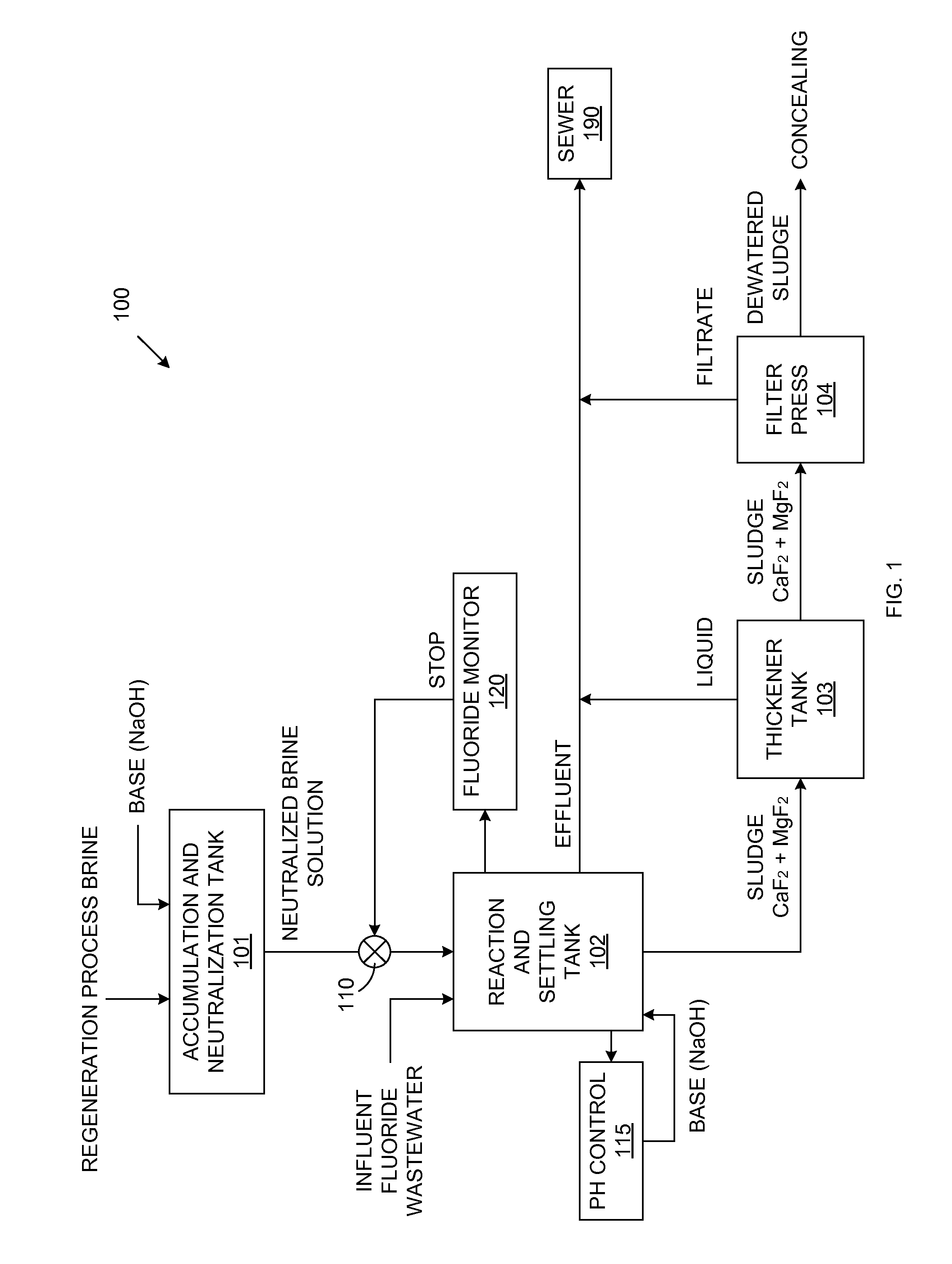

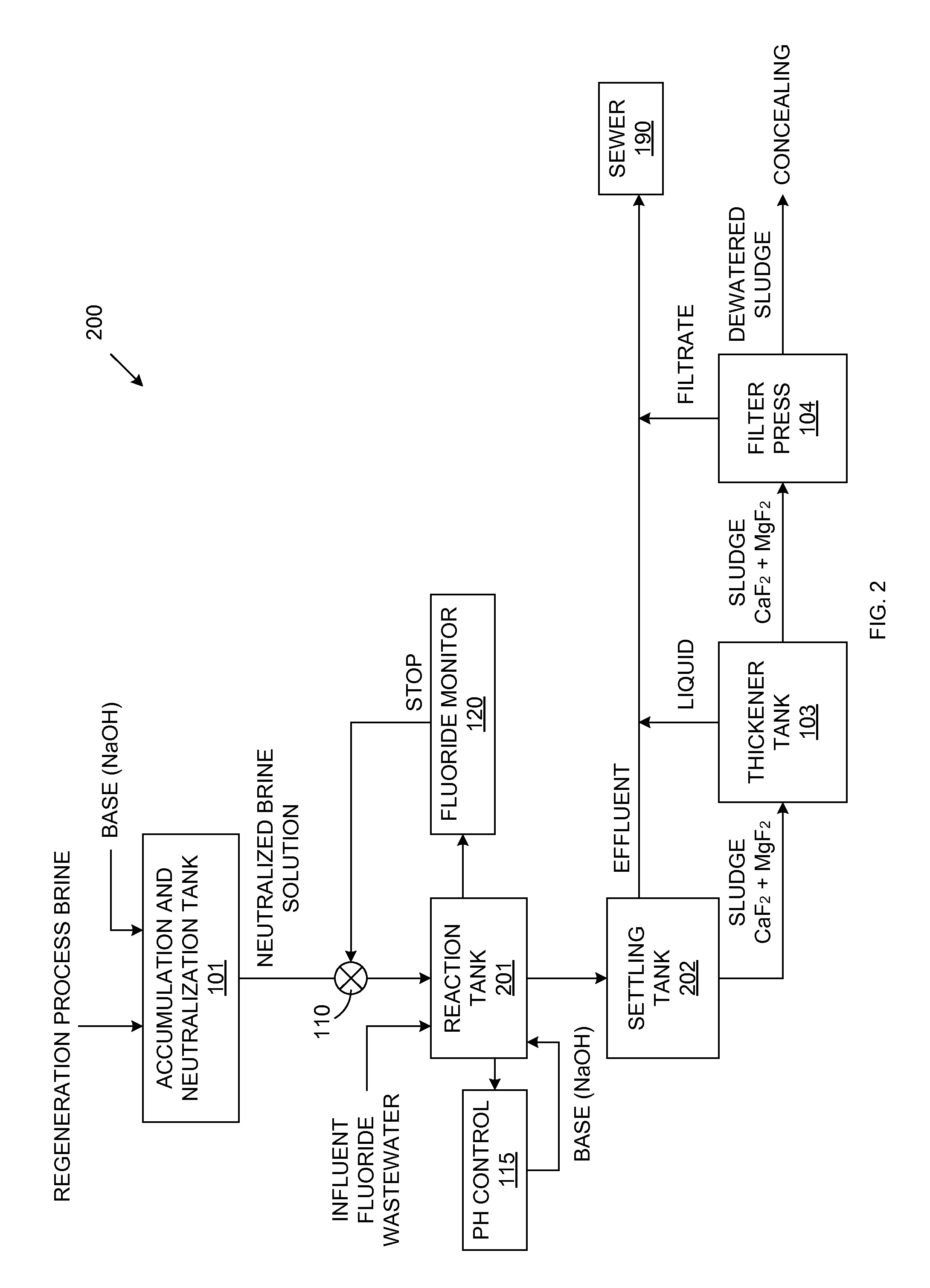

Cost-Efficient Treatment Of Fluoride Waste

ActiveUS20130161264A1Readily availableIncrease settlement rateSludge treatmentIon-exchanger regenerationIon exchangeIon

A method and system for processing fluoride-containing wastewater includes treating the wastewater with brine (waste) created by the regeneration process implemented by in ion exchanging water softener. The brine, which is typically disposed of, contains both calcium and magnesium salts, in varying concentrations and ratios. The regeneration process brine is added to the fluoride-containing wastewater within a reaction tank, and the fluoride ion concentration is monitored. When the fluoride ion concentration falls below a predetermined level (e.g., 15 ppm), the flow of regeneration process brine is stopped. A pH controller monitors the pH within the reaction tank, and adds a basic agent to ensure that the pH remains above a predetermined level (e.g., pH>9). The pH control results in a clear effluent, and a sludge having a high settling rate and a high dewater ability.

Owner:TOWER SEMICONDUCTOR

Method for preparing medical antisepsis and anti-inflammation sponge

The invention discloses a method for preparing medical antisepsis and anti-inflammation sponge. The preparing method comprises the following steps that components are weighed according to the weight part proportion, the weighed components are arranged into a stirrer to be stirred, the stirring rotating speed is 50-100 rpm, and the stirring time is 30 min; the obtained mixed solution is poured into a film forming device, the film forming device is arranged in a vacuum freezing drying machine for freeze drying for 15 h to 35 h, and then the medical antisepsis and anti-inflammation sponge is obtained. The raw materials of the preparing technology are wide in source and low in cost. The prepared medical sponge is free of immunogenicity, the bonding speed to the wound surface is high, bonding firmness is high, the physical hemostatic effect is obvious, the performance of the medical sponge is flexible, the medical sponge can be used without preprocessing, and the cost performance is extremely high.

Owner:SUZHOU BEC BIOLOGICAL TECH

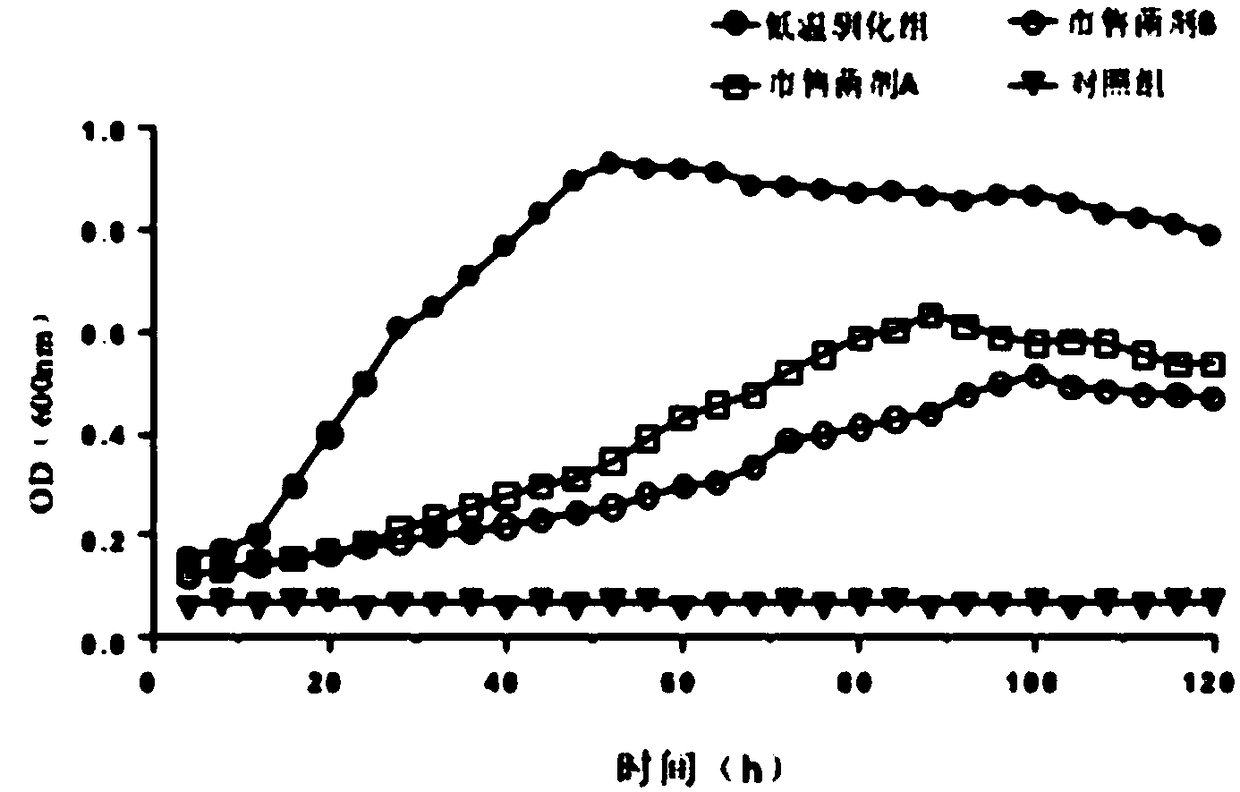

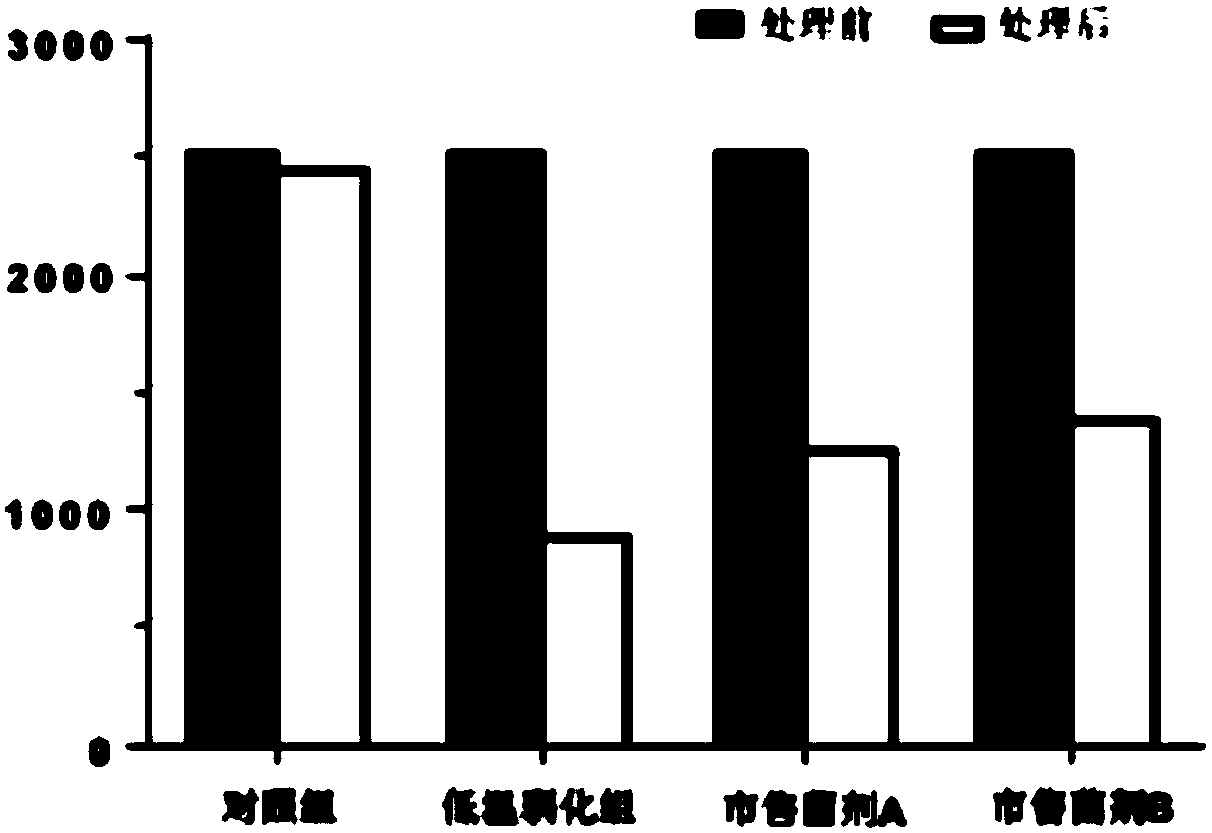

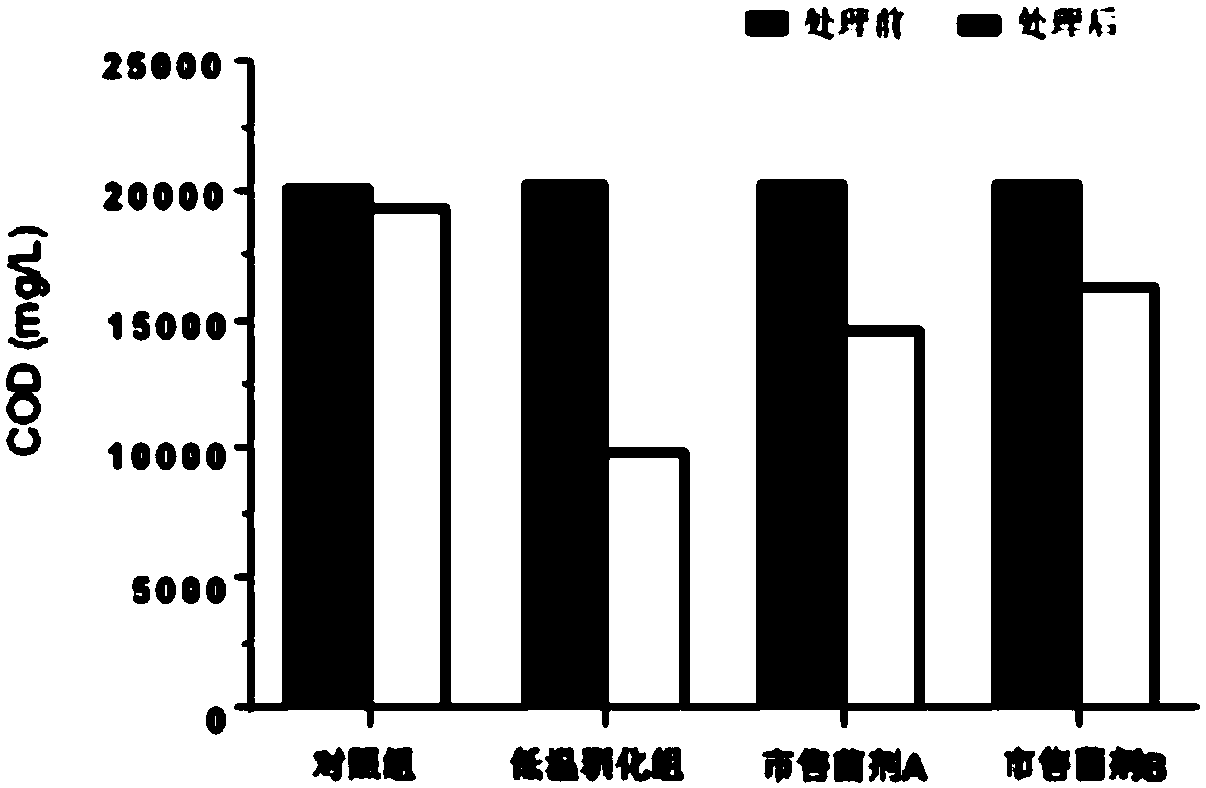

Method for preparing low temperature-resistant garbage treatment composite microbial agent

The invention belongs to the technical field of microbes, and particularly relates to a method for preparing a low temperature-resistant garbage treatment composite microbial agent. The method comprises the following steps: strain collection, strain separation, strain enrichment, strain acclimation, primary strain screening, low temperature acclimation, and preparation of the composite microbial agent. The composite microbial agent prepared by the method of the invention is better than commercial common microbial agents in microbial agent growth, the removal rate of ammonia nitrogen and COD inlandfill leachate and the enzyme production activity of the cellulose at a low temperature of 10 DEG C; and outdoor simulated reactor test results show that the temperature of the center of the garbage rises fast, the concentrations of ammonia nitrogen and COD in the landfill leachate are low, and the sedimentation rate of the garbage after a reaction is high. The composite microbial agent is suitable for solid garbage treatment in northwest regions, and has a good application prospect.

Owner:SOUTHWEST BRANCH OF NORTHWEST RES INST CO LTD OF C R E C

Preparation method of waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating

InactiveCN110698951AReduce reunionImprove reflectivityAnti-corrosive paintsEpoxy resin coatingsZinc phosphateFirming agent

The invention discloses a preparation method of a waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating. The preparation method comprises the following steps: adding water, a substrate wetting agent, a defoaming agent, an anti-flash-rust agent and a coalescing agent into a paint mixing tank and carrying out dispersing; adding waterborne bisphenol A epoxy resinand performing dispersing; adding a pH regulator to regulate a pH value and carrying out dispersing; adding anionic emulsified asphalt and carrying out dispersing; adding an inorganic bentonite thickener to regulate viscosity; and carrying out dispersing to obtain a component A of the coating; adding water, a defoaming agent, a dispersing agent and an anti-settling agent into another paint mixingtank and carrying out dispersing; adding dry-process modified sericite powder and zinc phosphate, and carrying out sanding and dispersing; adding a waterborne modified amine curing agent and carryingout dispersing to obtain a component B; and mixing inorganically coated rutile titanium dioxide, precipitated phase silicon dioxide, hollow microspheres, a dispersing agent, a waterborne epoxy curingagent and a waterborne epoxy emulsion, carrying out grinding and dispersing, and mixing the formed mixture with the component A of the coating, the component B and chemically surface-modified shell powder to obtain the waterborne coating.

Owner:萧县金虹新型防水建材有限公司

Processes and apparatus for lignin separation in biorefineries

ActiveUS9322072B2High densityIncrease settlement rateWaste based fuelLignin derivativesOligomerFractionation

The present invention generally provides methods of improving lignin separation during biomass fractionation with an acid to release sugars and a solvent for lignin (such as ethanol). In some embodiments, a digestor is employed to fractionating a feedstock in the presence of a solvent for lignin, sulfur dioxide, and water, to produce a liquor containing hemicellulose, cellulose-rich solids, and lignin. A solid additive is added to the digestor, wherein the solid additive combines with at least a portion of the lignin. Then a mixture of lignin and the solid additive is separated from the liquor, prior to hemicellulose recovery. Optionally, a solid additive may also be introduced to a hydrolysis reactor for converting hemicellulose oligomers to monomers, to improve separation of acid-catalyzed lignin. In some embodiments, the solid additive is gypsum or a gypsum / lignin mixture.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

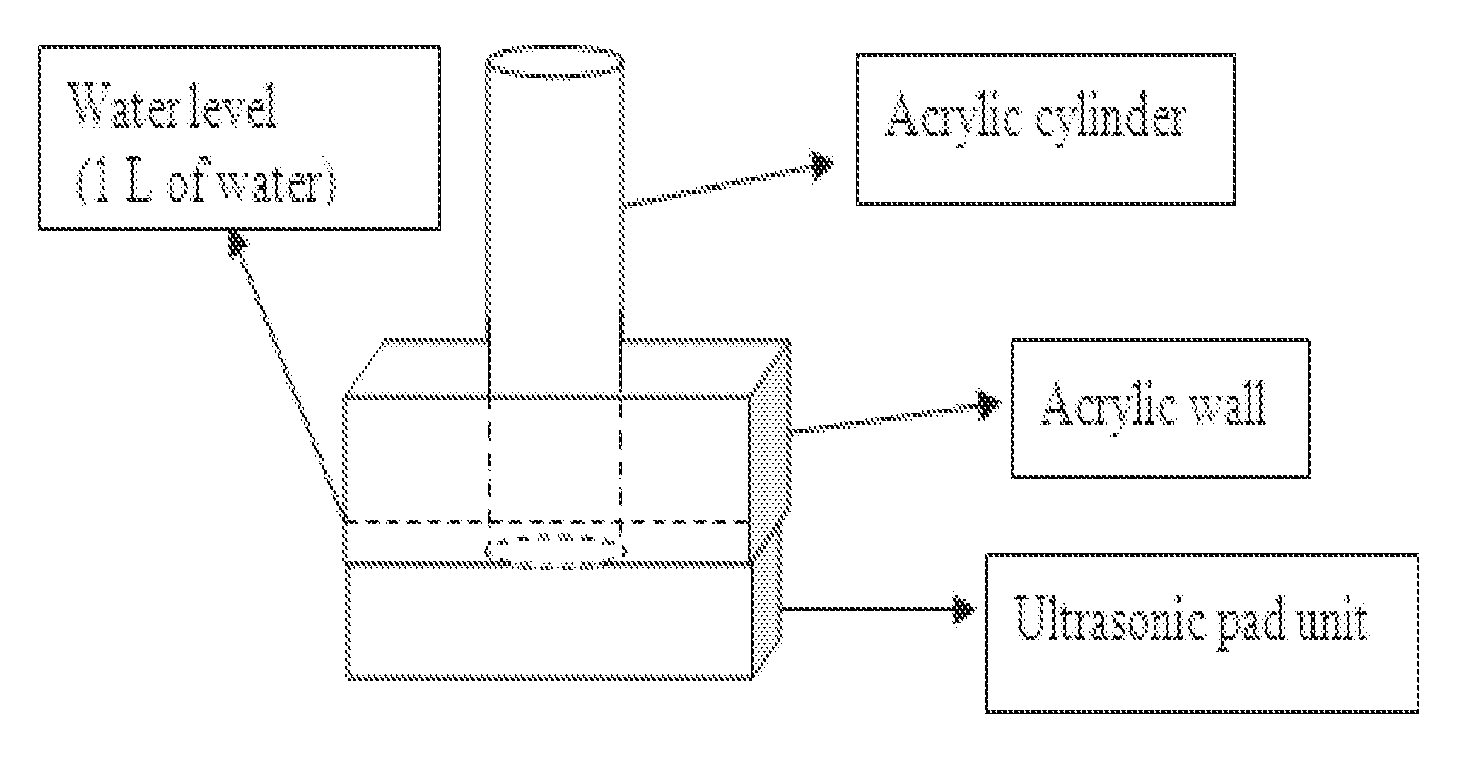

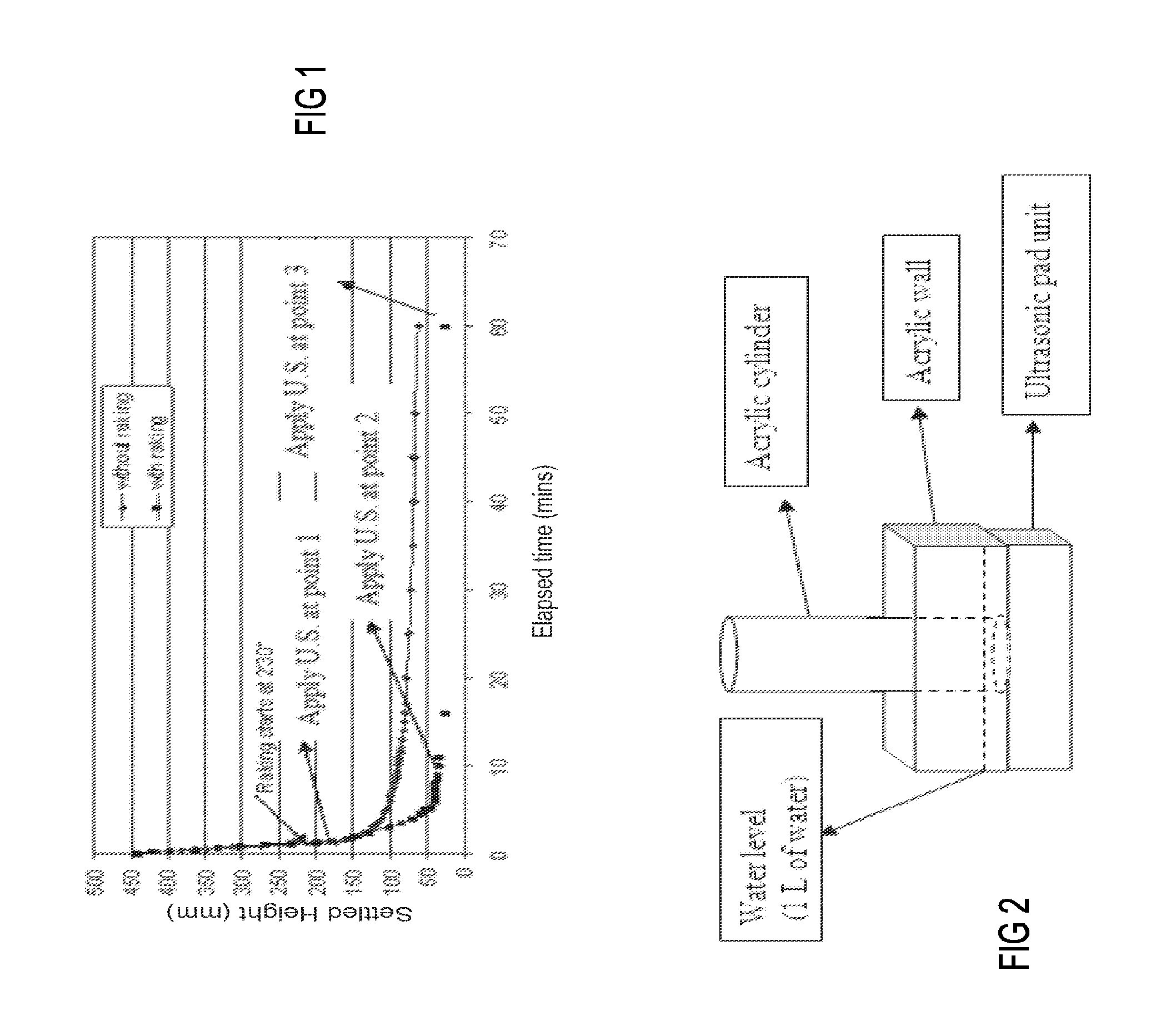

Gravity sedimentation process and apparatus

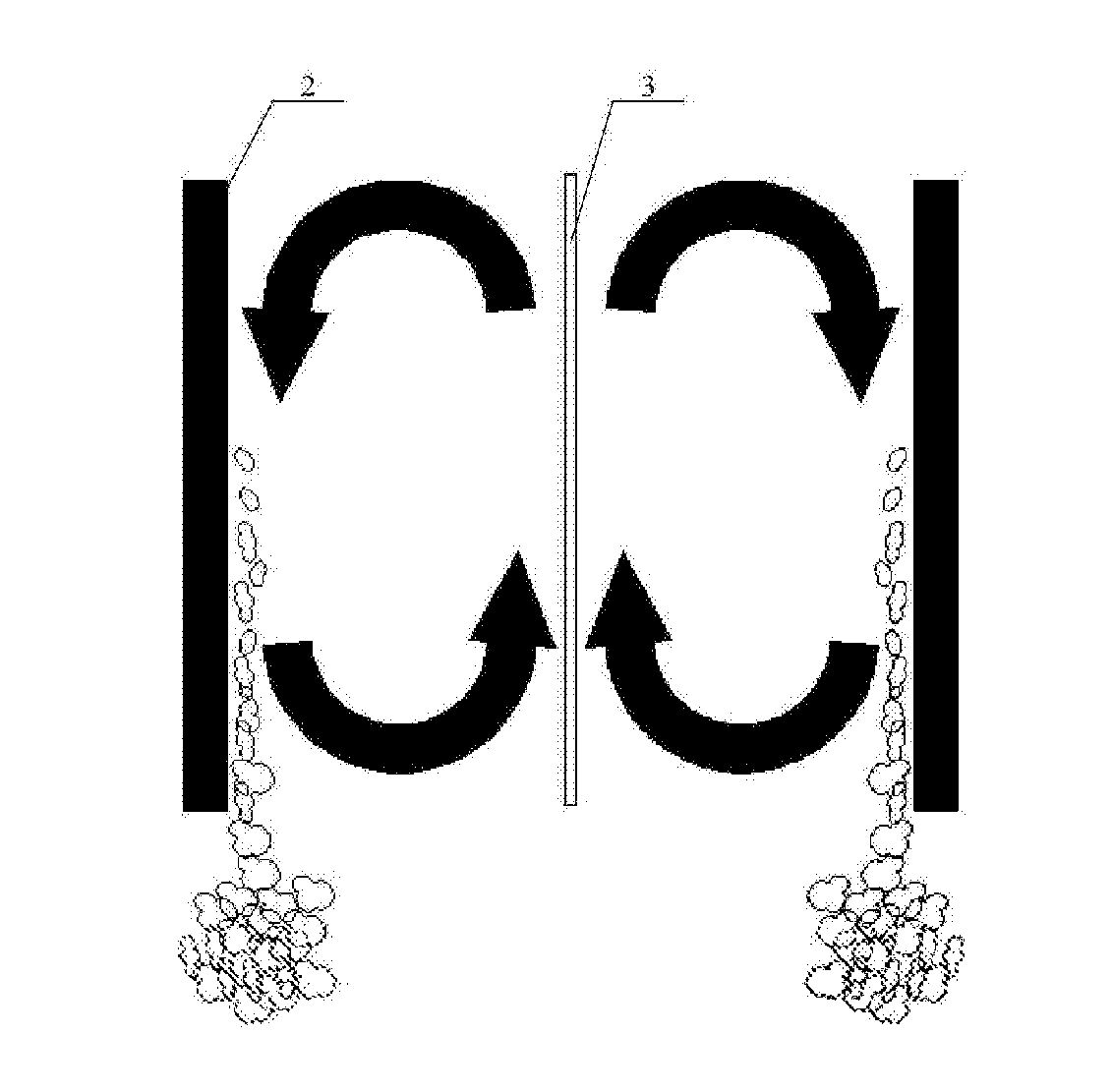

InactiveUS20130206703A1Increase settle rateImprove solid densityWater/sewage treatment with mechanical oscillationsDifferential sedimentationProcess engineeringEngineering

A gravity sedimentation process for the treatment of a slurry in a thickener to separate a solid from a liquid, the thickener having, at steady-state, a hindered settling zone and a compression zone, the process including the application of an effective amount of ultrasonic energy to the slurry in a transition zone within the hindered settling zone.

Owner:CRC CARE +2

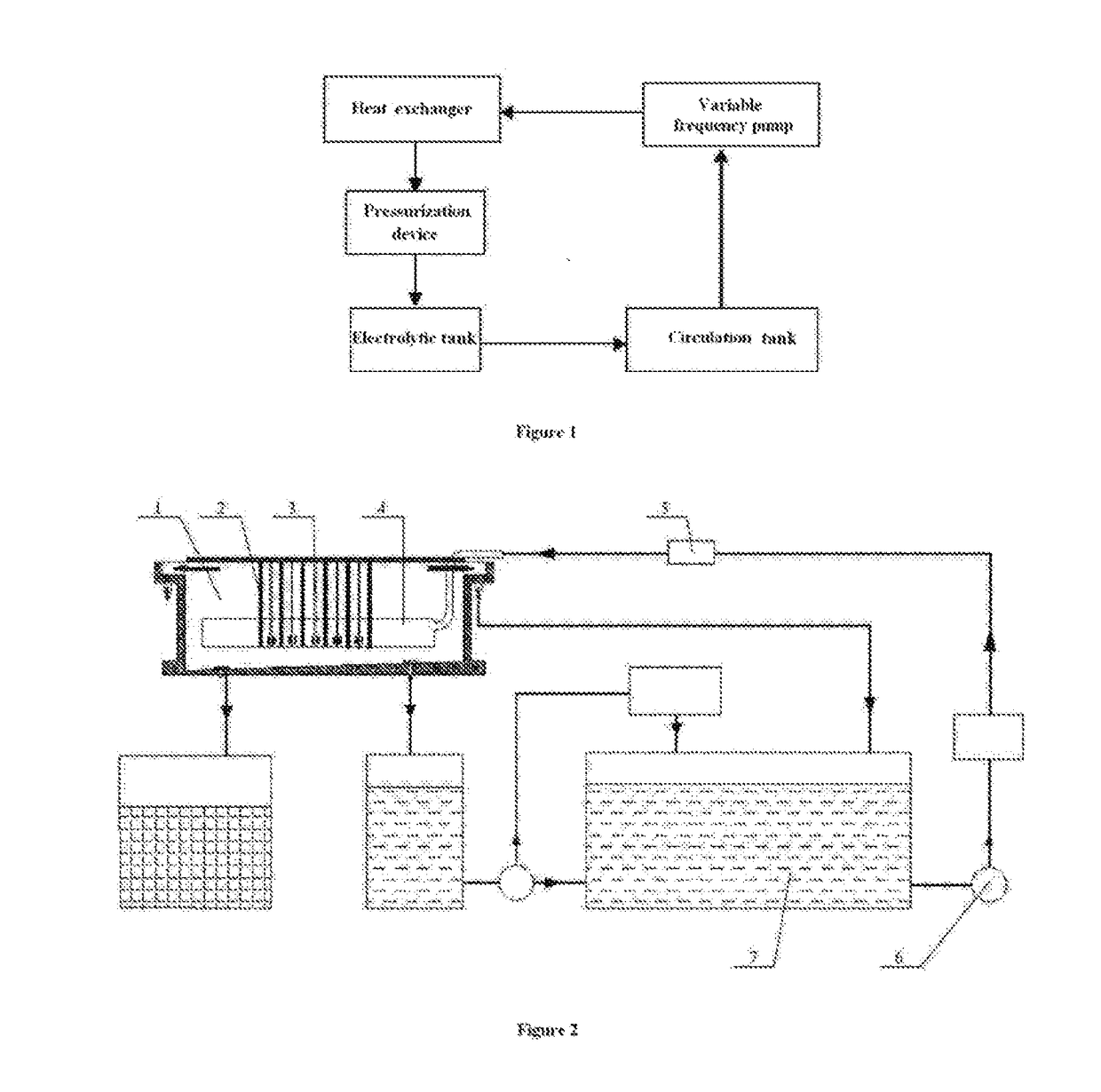

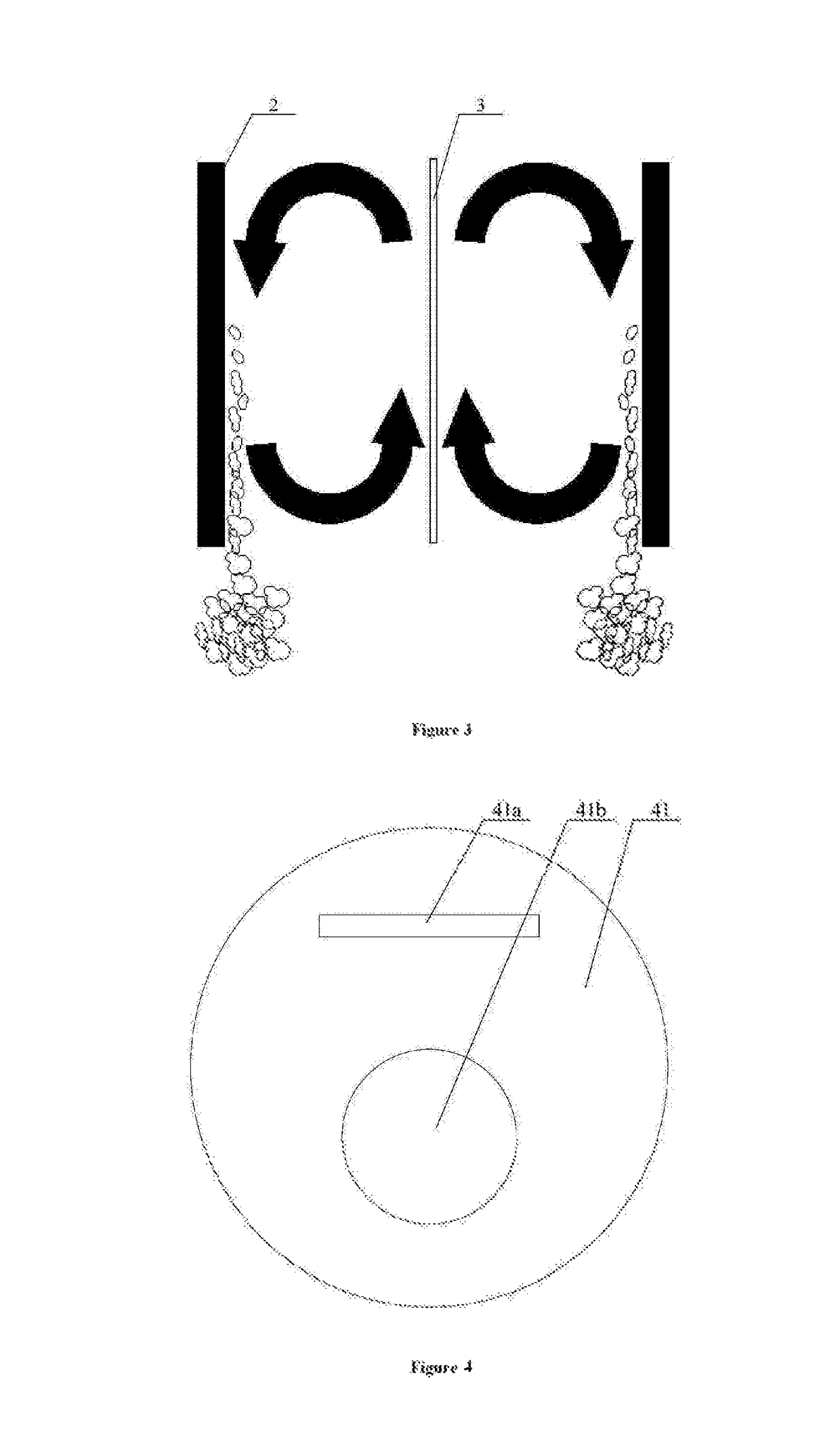

Parallel Jet Electrolytic Process and Device

ActiveUS20170081771A1Eliminate concentration polarizationAvoid anode passivation phenomenonElectrolysis componentsPhotography auxillary processesEngineeringElectrolyte

The invention discloses a parallel jet electrolytic process, wherein an electrolyte after being pressurized is jetted in parallel from a position at the bottom and near a surface of a cathode at a rate of 0.5-2.5 m / s into a gap between the cathode and an anode. During the production process, the pressurized electrolyte is jetted in parallel along the surface of the cathode, and the electrolyte flows from bottom to top at the cathode side and moves from top to bottom at the anode side simultaneously, which thus achieves a side cutting function on the cathode and the anode; and the side cutting flow of the electrolyte from top to bottom at the anode is able to greatly increase the settling rate of the anode slime and avoid its adhesion to the anode to form an anode slime layer. The invention also provides a parallel jet electrolytic device.

Owner:YANGGU XIANGGUANG COPPER

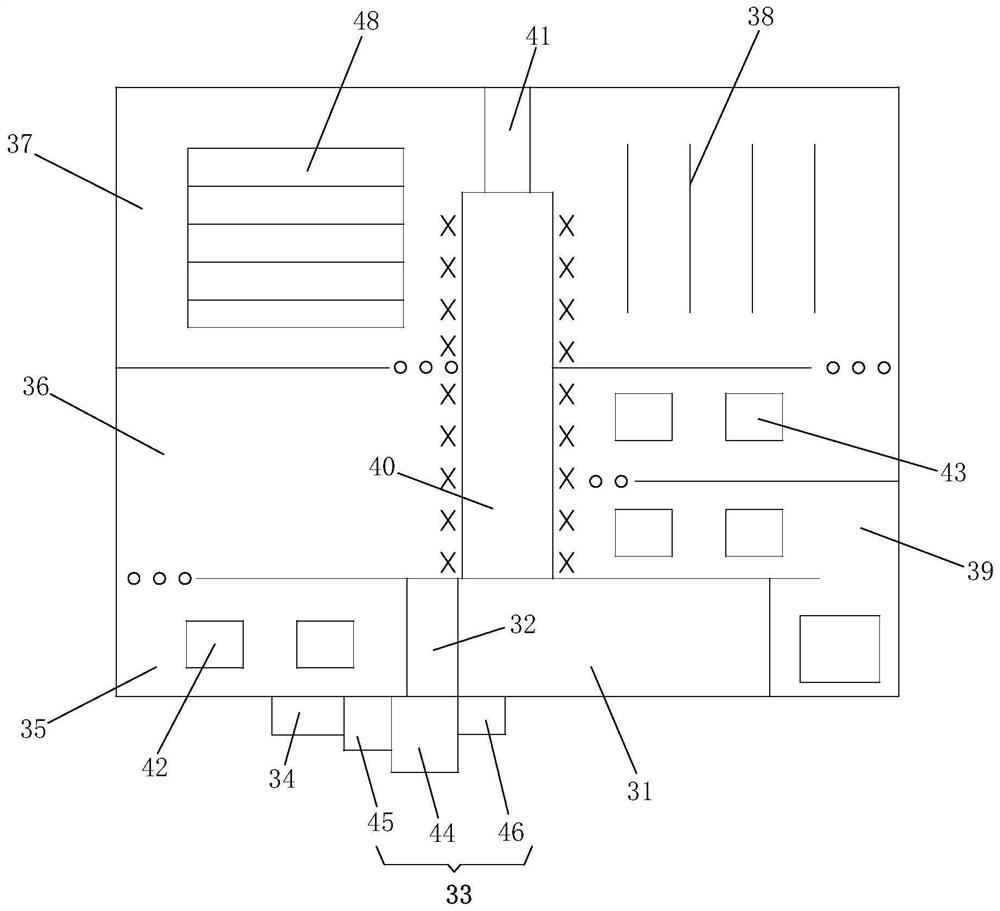

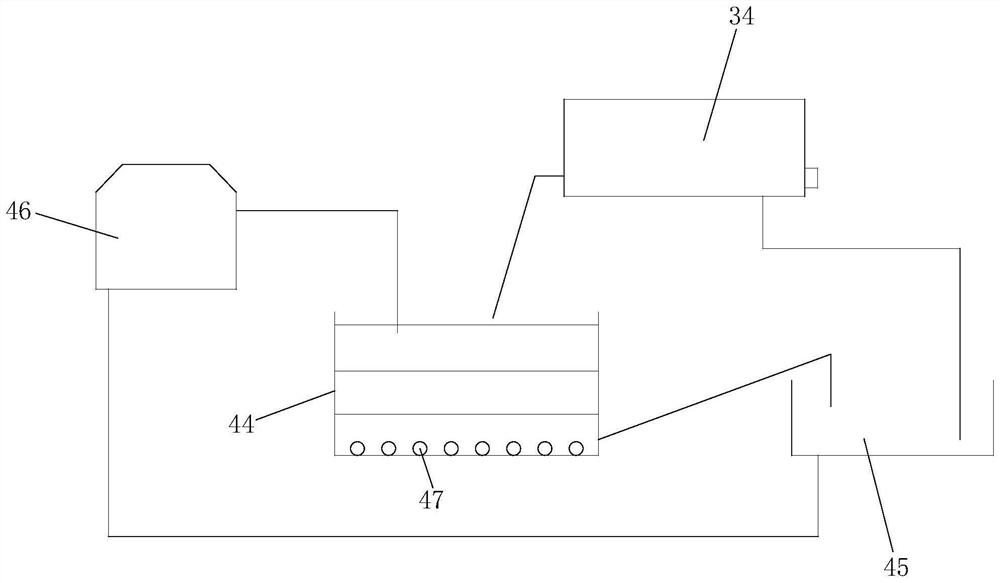

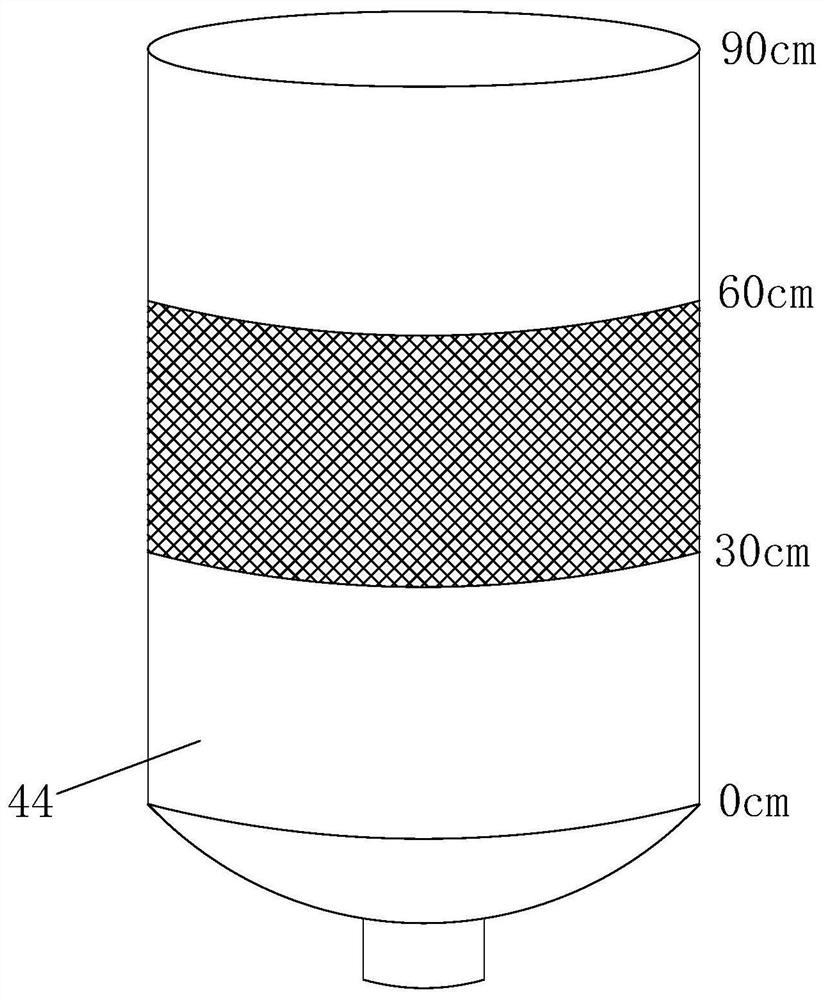

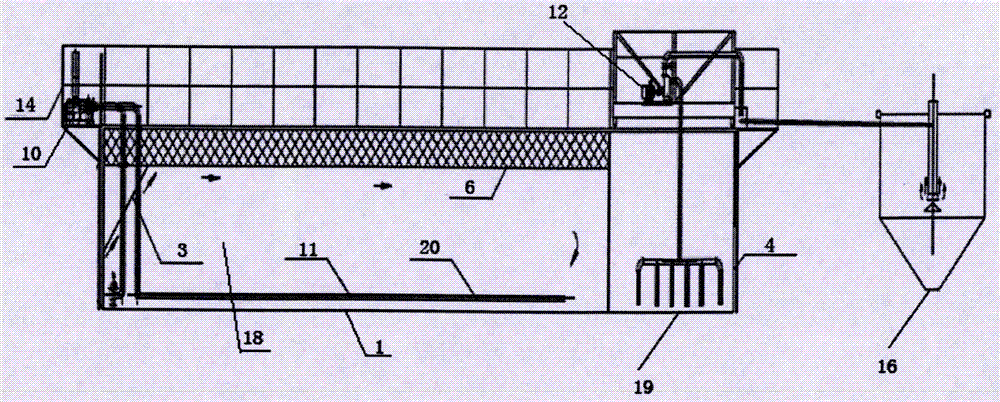

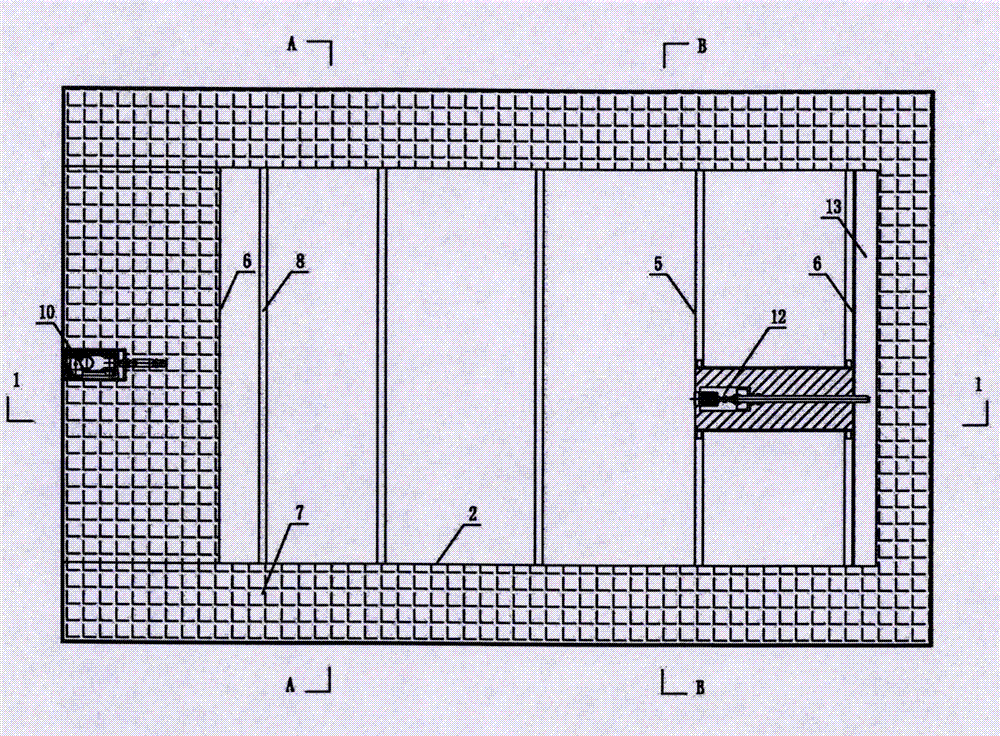

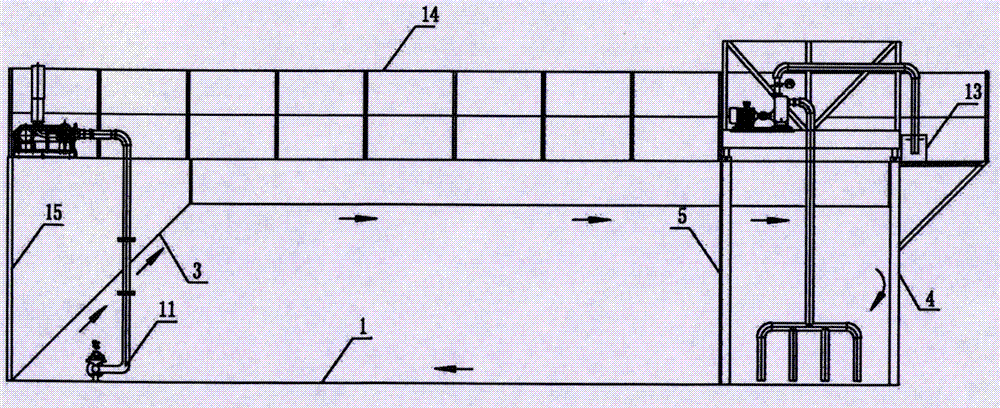

Pond engineering circulating water zero-discharge culture system

ActiveCN112335596AEasy to handleShort solution timeWater contaminantsWaste water treatment from animal husbandryWaste collectionSewage

The invention discloses a pond engineering circulating water zero-discharge culture system. The culture system comprises a culture area, a sewage collection area, a waste collection area, a solid-liquid separation device, a purification area I, a filter feeding area, a sedimentation area, a biochemical area and a purification area II. The sewage collection area is used for collecting sewage generated in the culture area, and the waste collection area is used for collecting sewage in the sewage collection area and conducting layering; the solid-liquid separation device is used for carrying outsolid-liquid separation on the bottom-layer sewage, and the purification area I is provided with an aquatic plant floating bed I; filter feeding organisms are cultured in the filter feeding area, andthe sedimentation area is used for settling the sewage; the biochemical area is used for receiving supernatant liquor and supernatant liquid and performing aeration treatment on mixed liquid; and thepurification area II is used for purifying and treating the mixed liquid treated by the biochemical area and conveying a purified water body to the culture area. According to the sewage collection area, a flow field in circulating water and a space of an outer pond are reasonably utilized, culture tail water treatment and production are organically combined together, 60%-90% of water body area canbe used for tail water treatment, and large-density culture can be realized.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

Waste separation and processing system

ActiveUS8980086B2Increase settlement rateElectrostatic separatorsExcrement fertilisersLiquid wastePolymer

A multi-stage method of reducing solids and contaminants from liquid waste and other suitable streams without the use of chemical flocculants or polymers is disclosed.

Owner:MIDWESTERN IP

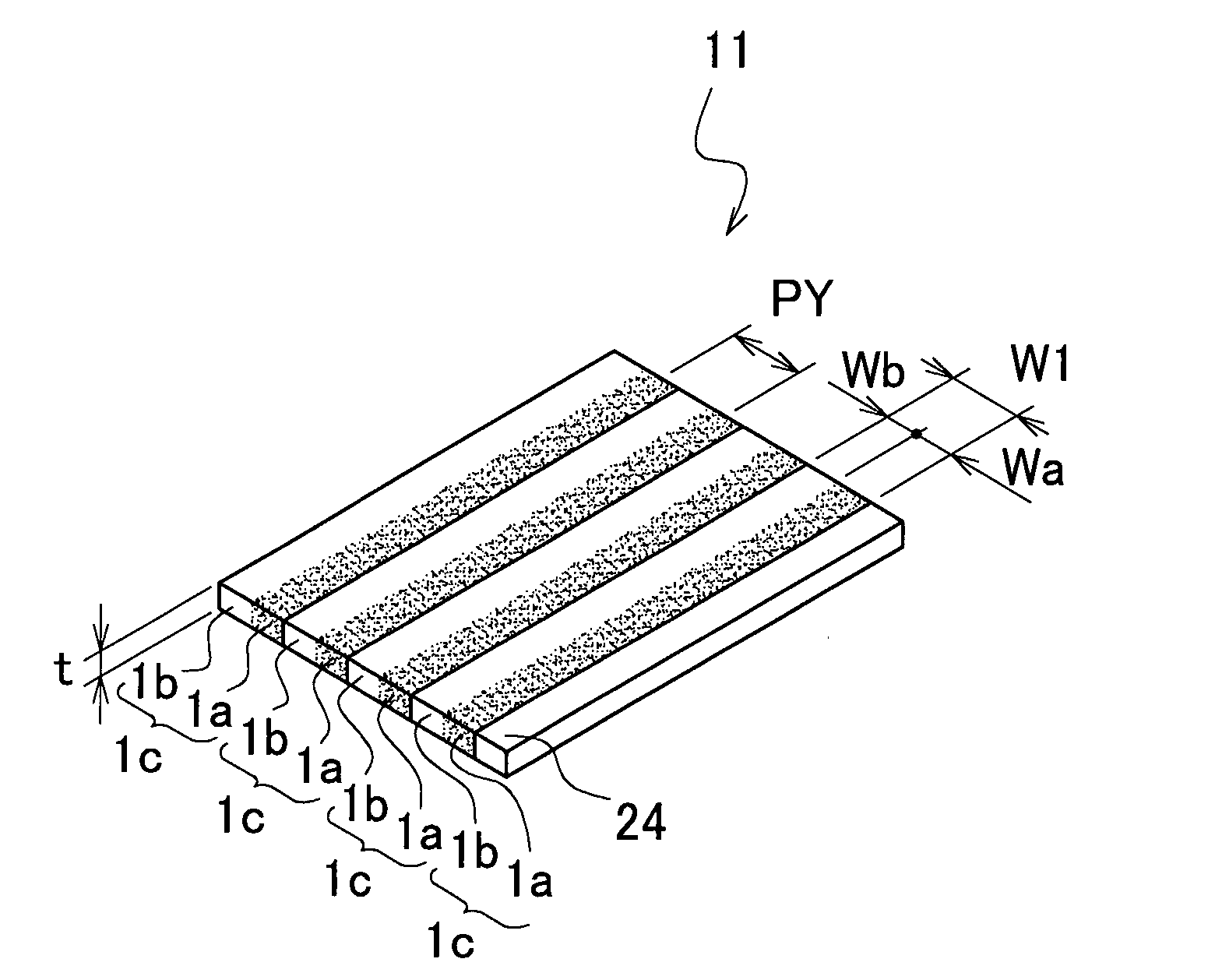

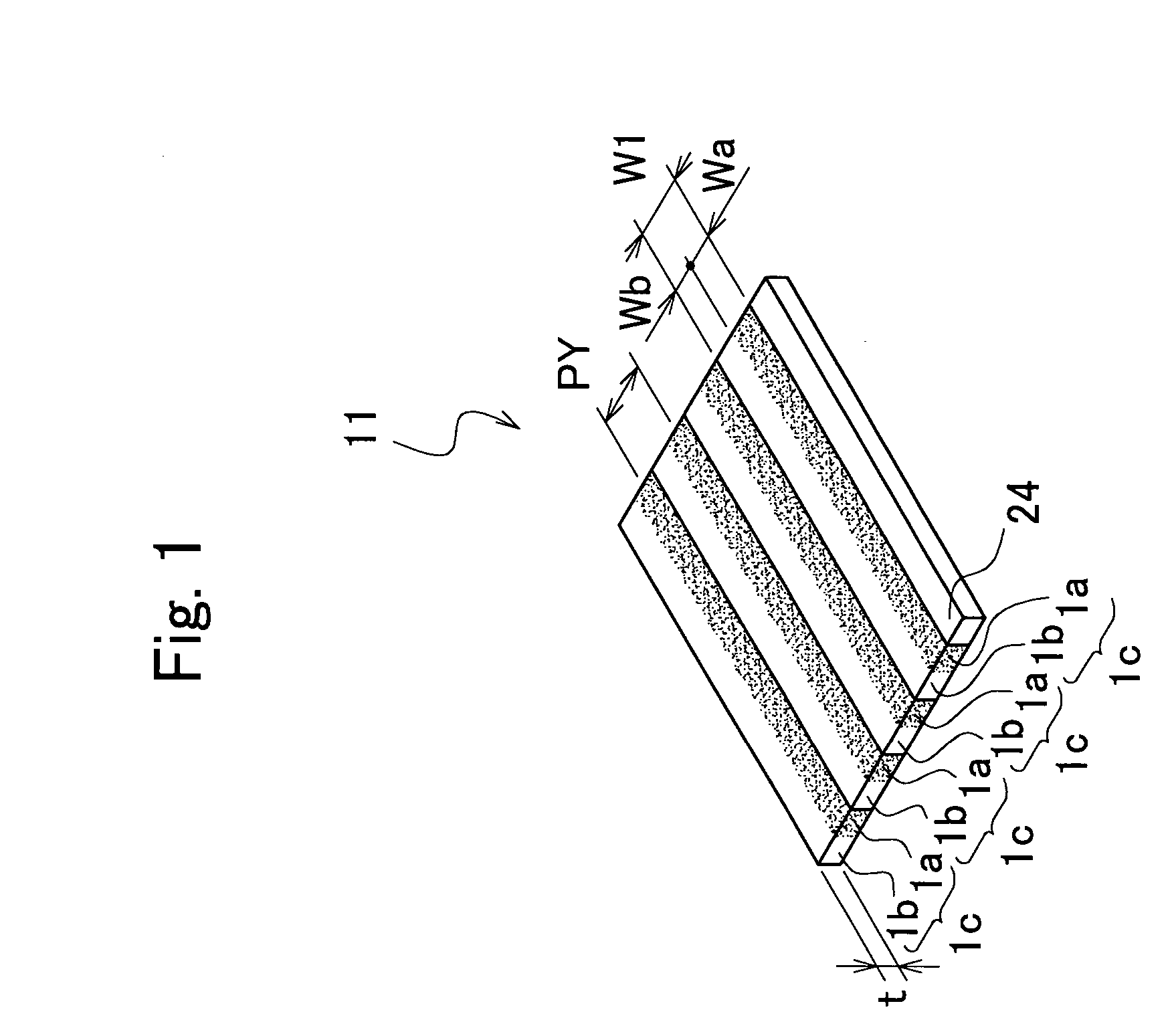

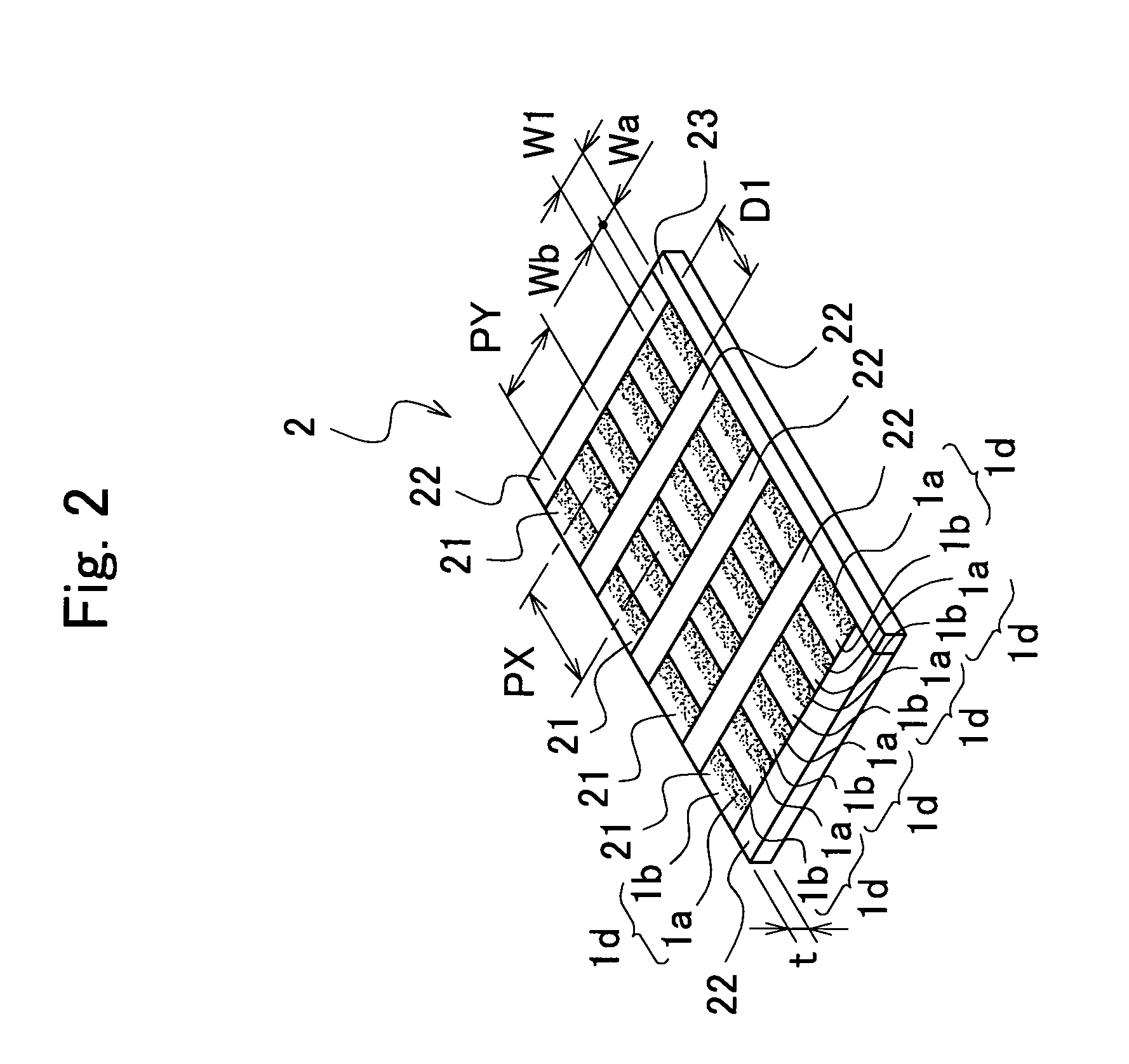

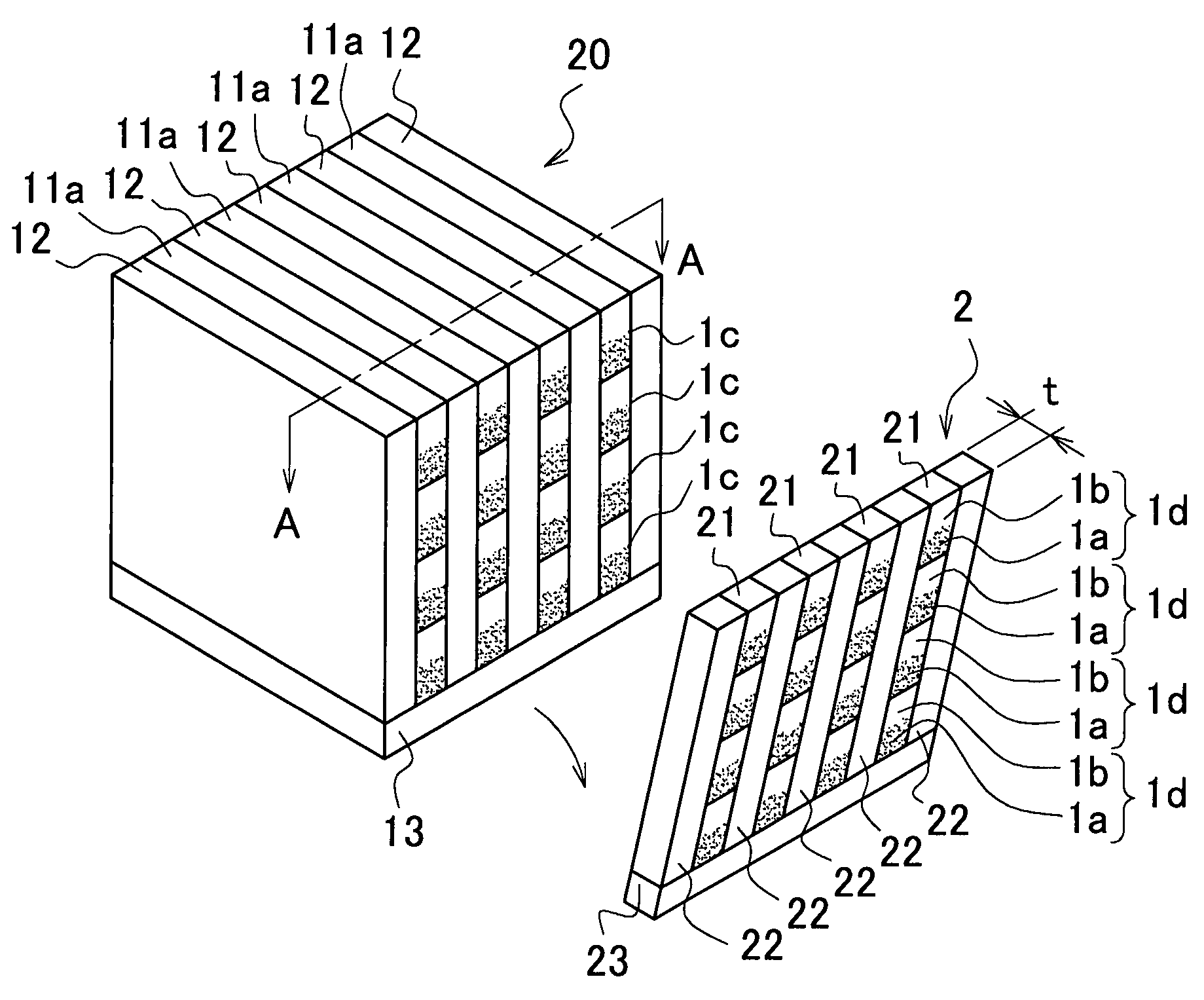

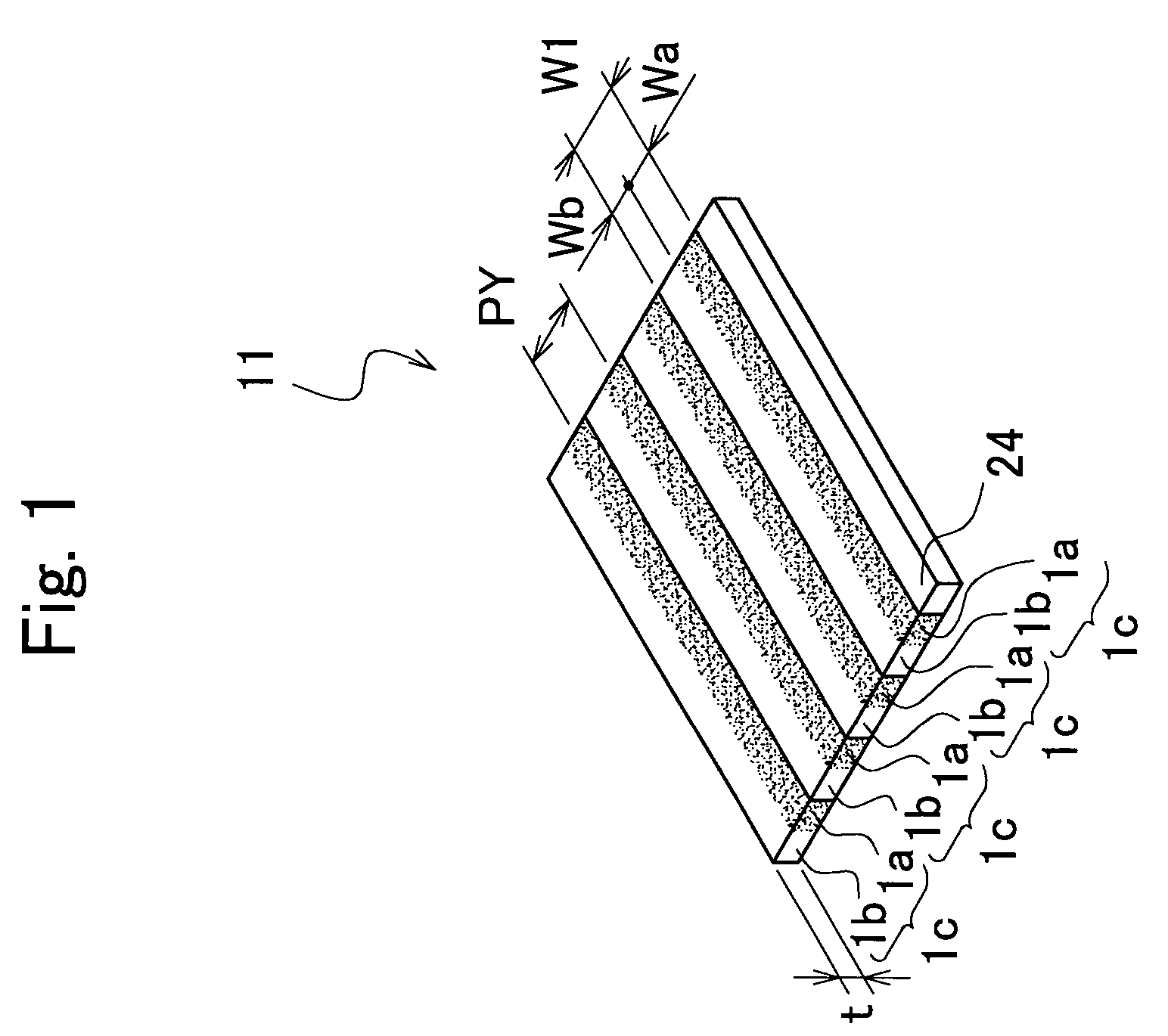

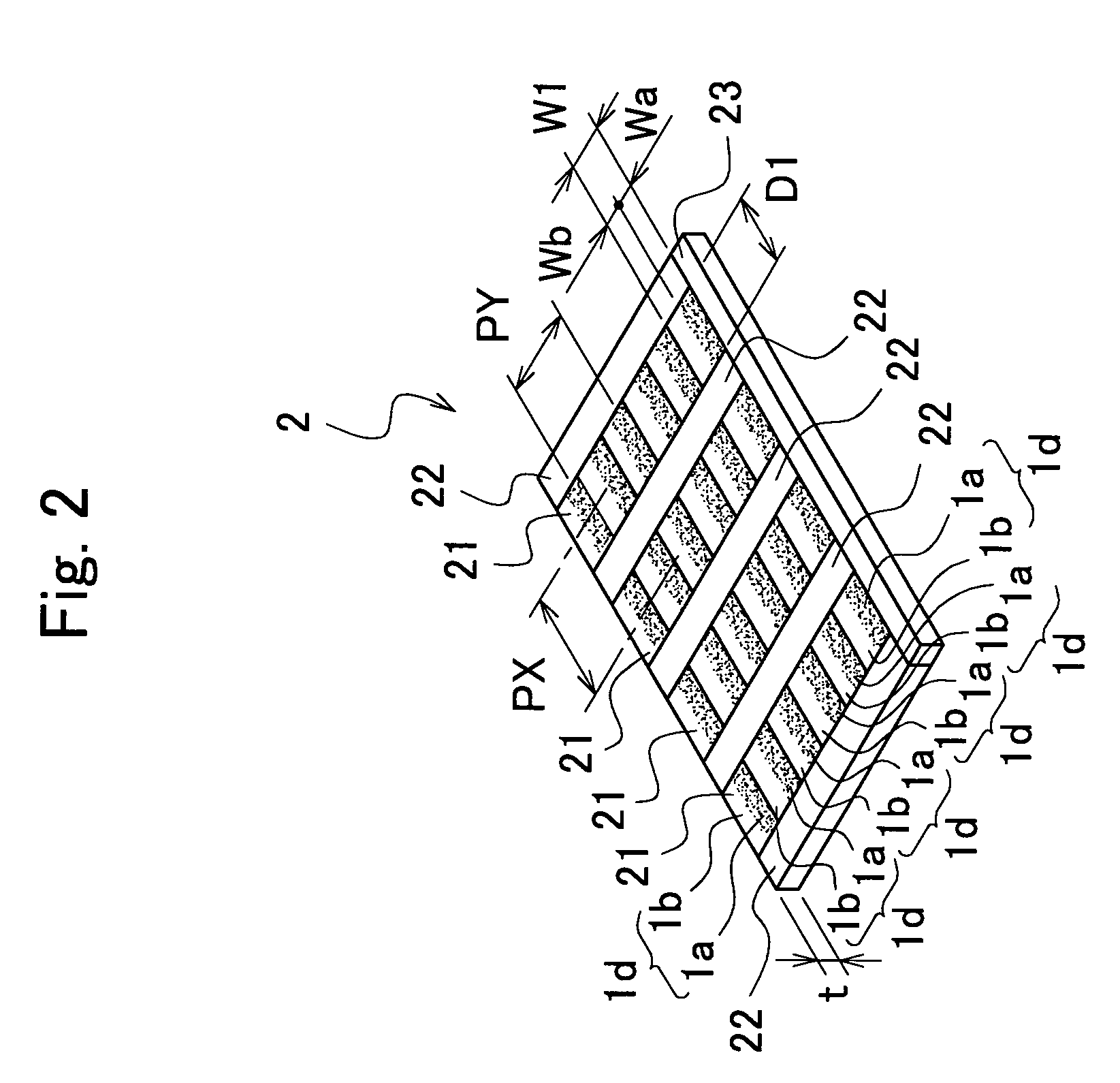

Anisotropic conductive sheet and manufacture thereof

InactiveUS20050194697A1Improve productivityUniform densityPrinted circuit assemblingNon-insulated conductorsElastomerOptoelectronics

An anisotropic conductive sheet manufactured through improved manufacturing steps and a method of manufacturing the same. Conductive portions are unevenly arranged in a nonconductive elastomer having fluidity and serving as a matrix, the conductive portions highly densely containing the conductive particles having a specific gravity greater than that of the matrix component, the conductive particles are unevenly dispersed to form substantially nonconductive portions, and the conductive portions and the nonconductive portions are integrally cured to mold anisotropic conductive pieces. The anisotropic conductive pieces are so laminated that the conductive portions and the nonconductive portions are alternately arranged thereby to obtain a first laminate, and the first laminate is cut maintaining a predetermined thickness to obtain a zebra-like sheet. A second laminate obtained by alternately laminating the zebra-like sheets and the elastomer sheets is cut maintaining a predetermined thickness to obtain an isotropic conductive sheet in which the conductive portions are arranged like a matrix.

Owner:JST MFG CO LTD

Aquaculture net cage

InactiveCN107047417AEffective isolationReduce churnClimate change adaptationPisciculture and aquariaAquatic productEngineering

The invention discloses an aquaculture net cage which comprises a rectangular cage body; the cage body is provided with a bottom plate, two long side lateral plates and two short side lateral plates; each of the long side lateral plates is of a steel plate structure; each of the short side lateral plates is of a steel wire mesh structure or a steel wire mesh is arranged at the upper part of one side in the short side lateral plate, a steel plate is arranged at the lower part, and the steel wire mesh structure is formed on the other side; the short side lateral plate on the left side is inclined, and the short side lateral plate on the right side is vertical; both the long side lateral plates and the short side lateral plates are provided with reinforcing bars; a corridor is arranged at the top of the rectangular cage body; an aeration fan is arranged on the corridor; an aeration pipeline is connected to the aeration fan and extends to the bottom of the cage body. The aquaculture net cage disclosed by the invention has the benefits that the fish farming yield per mu rises, so that the fish yield with a floor area of 1 / 5 is equivalent to mu yield obtained by traditional farming; the plate type structure of each of the long side lateral plates can be effectively isolated from an external water body, so that dissolved oxygen and baits are controlled in equipment, and the loss of the baits is reduced.

Owner:BEIJING SHUNXIN ZHUOXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Chinese and western combined medicine for treating chronic enterogastritis and ulcer and its prepn

InactiveCN1383894AQuick resultsGood treatment effectPeptide/protein ingredientsDigestive systemTreatment effectSide effect

The composite Chinese and Western medicine for treating chronic enterogastritis is prepared with the materials including immature bitter organe, bletilla tuber, dahurian angelica root and yeast. It has fast and high curative effect and no side effect.

Owner:吴鸿

Anisotropic conductive sheet and manufacture thereof

InactiveUS7304390B2Increase settlement rateUniform densityPrinted circuit assemblingNon-insulated conductorsElastomerOptoelectronics

An anisotropic conductive sheet manufactured through improved manufacturing steps and a method of manufacturing the same. Conductive portions are unevenly arranged in a nonconductive elastomer having fluidity and serving as a matrix, the conductive portions highly densely containing the conductive particles having a specific gravity greater than that of the matrix component, the conductive particles are unevenly dispersed to form substantially nonconductive portions, and the conductive portions and the nonconductive portions are integrally cured to mold anisotropic conductive pieces. The anisotropic conductive pieces are so laminated that the conductive portions and the nonconductive portions are alternately arranged thereby to obtain a first laminate, and the first laminate is cut maintaining a predetermined thickness to obtain a zebra-like sheet. A second laminate obtained by alternately laminating the zebra-like sheets and the elastomer sheets is cut maintaining a predetermined thickness to obtain an isotropic conductive sheet in which the conductive portions are arranged like a matrix.

Owner:JST MFG CO LTD

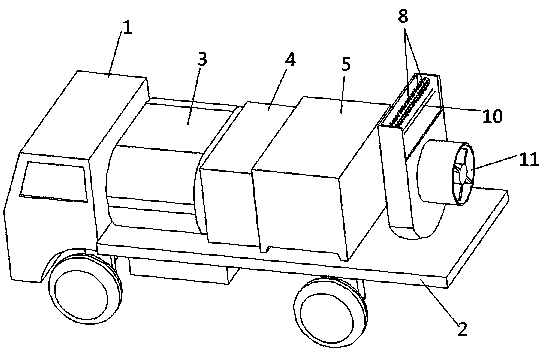

Urban air purification vehicle

PendingCN110481414AImprove adsorption capacityIncrease settlement rateMechanical apparatusLighting and heating apparatusHigh pressure waterUrban area

The invention discloses an urban air purification vehicle. The urban air purification vehicle comprises a traction part and a cargo carrying part, a water tank, a generator, a high-pressure water pumpand a spraying device are arranged on the cargo carrying part, and the spraying device comprises a shell. One side of the shell is connected with a high-pressure fan, an air outlet is formed above the shell, a plurality of fine atomization nozzles are installed at the air outlet and connected with the high-pressure water pump through the pipelines, and a negative ion generator is further arrangedat the air outlet. The device is good in water atomization, high in lift and high in haze settling rate, can effectively filter and purify the particulate matters, can save the water effectively, andavoids the situation that the ground is muddy, so that the traveling is affected.

Owner:河北蓝川科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com