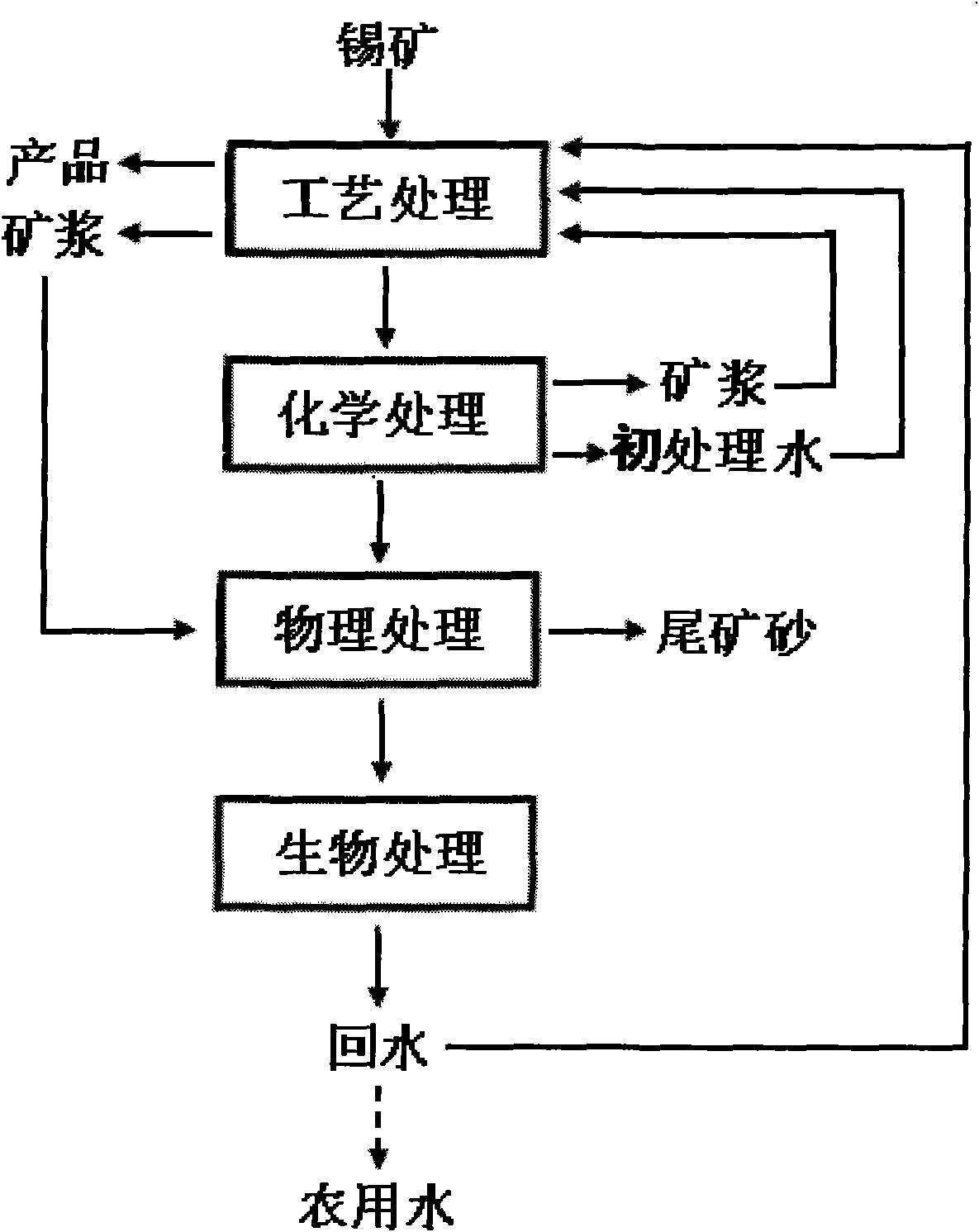

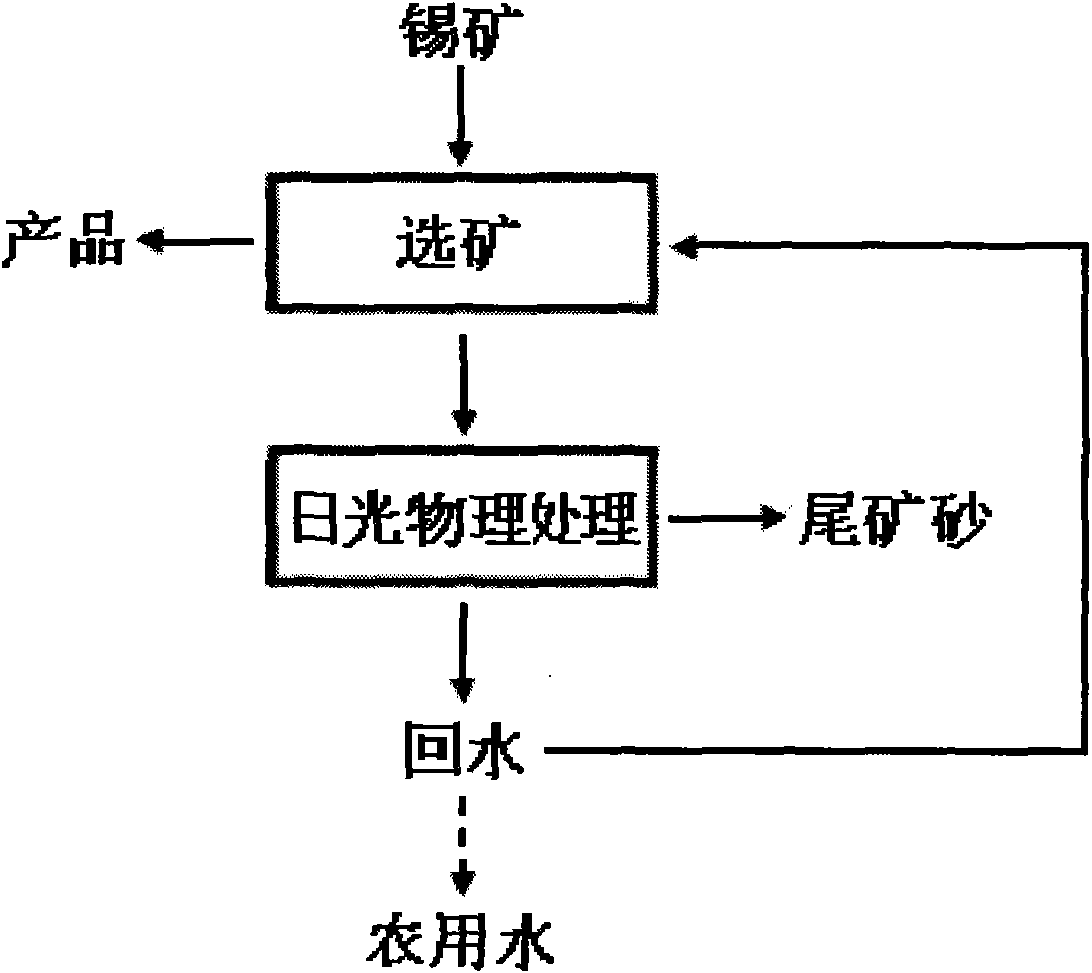

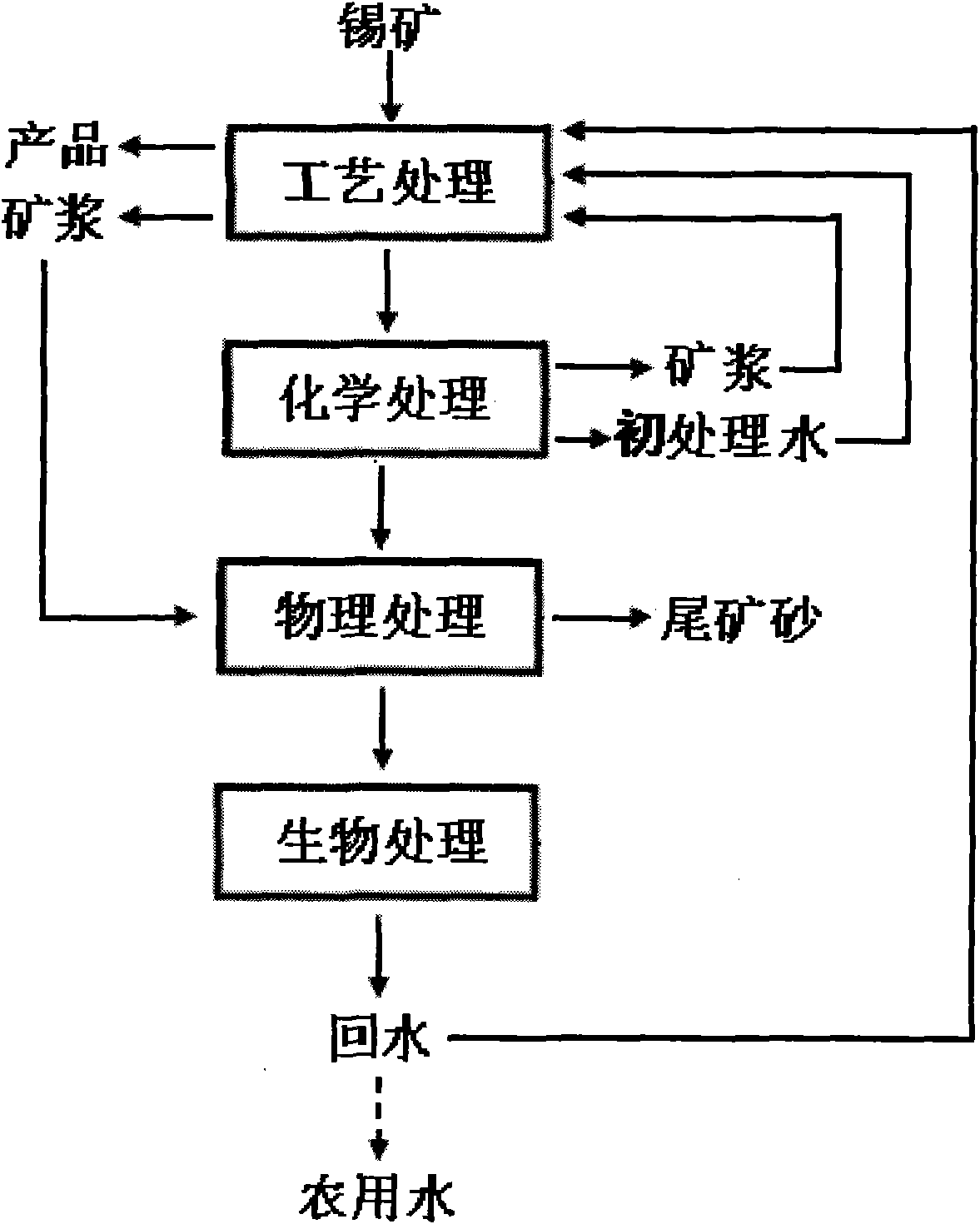

Four-step method for processing and recycling tin ore floatation wastewater

A mineral processing wastewater treatment cycle technology, applied in the direction of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the waste of water resources, low utilization rate of return water, and ineffective treatment of mineral processing wastewater Very ideal and other issues, to achieve the effect of increasing the sedimentation rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In tin ore beneficiation, the combined beneficiation technology of flotation-magnetic separation-gravity separation is adopted. First, gravity separation and high-efficiency discarding technology are used for beneficiation. The production rate is 30%, and the tailings with a particle size of 3-4mm and a tin content of less than 0.1% have achieved the purpose of high-efficiency discarding, increased the content of tin metal entering the main process, and reduced the amount of water and chemicals used in the main process; Then apply selective grinding technology, adopt different grinding media and different grinding strength grinding processes according to different grades and particle sizes of tin ore, reduce over-grinding of tin ore, and make more than 70% of the metal by gravity separation The method is recovered, which reduces the flotation load and reagent consumption, and the recovery rate of cassiterite is increased to more than 65%; then the selective grinding tech...

Embodiment 2

[0034] In tin ore beneficiation, the combined beneficiation technology of flotation-magnetic separation-gravity separation is adopted. First, gravity separation and high-efficiency discarding technology are used for beneficiation. The yield rate is 30%, and the tailings with a particle size of 2-3mm and a tin content of less than 0.1% have achieved the purpose of high-efficiency discarding, increased the content of tin metal entering the main process, and reduced the water consumption and chemical dosage of the main process; Then apply selective grinding technology, adopt different grinding media and different grinding strength grinding processes according to different grades and particle sizes of tin ore, reduce over-grinding of tin ore, and make more than 70% of the metal by gravity separation The method is recovered, which reduces the flotation load and reagent consumption, and the recovery rate of cassiterite is increased to more than 65%; then the selective grinding techno...

Embodiment 3

[0036] In tin ore beneficiation, the combined beneficiation technology of flotation-magnetic separation-gravity separation is adopted. First, gravity separation and high-efficiency discarding technology are used for beneficiation. The production rate is 30%, and the tailings with a particle size of 1-3mm and a tin content of less than 0.1% have achieved the purpose of high-efficiency discarding, increased the content of tin metal entering the main process, and reduced the amount of water and chemicals used in the main process; Then apply selective grinding technology, adopt different grinding media and different grinding strength grinding processes according to different grades and particle sizes of tin ore, reduce over-grinding of tin ore, and make more than 70% of the metal by gravity separation The method is recovered, which reduces the flotation load and reagent consumption, and the recovery rate of cassiterite is increased to more than 65%; then, the selective grinding tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com