Active seaweed fertilizer and production method thereof

A production method and technology of seaweed fertilizer, applied in fertilization equipment, fertilizer mixture, application, etc., can solve problems such as difficult plant absorption and utilization, affecting the use effect of seaweed fertilizer, destroying the activity of nutrients in seaweed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: produce active seaweed fertilizer of the present invention

[0072] The implementation steps of this embodiment are as follows:

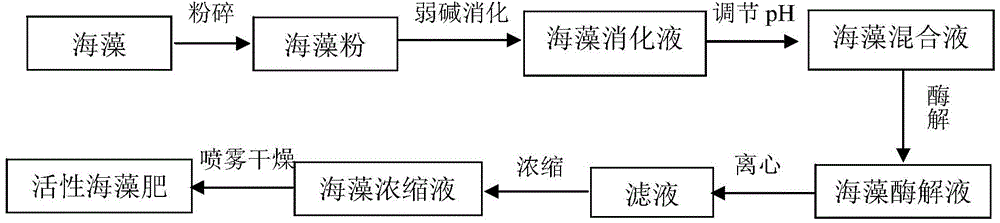

[0073] The specific production process is attached figure 1 .

[0074] A. to digest

[0075] According to the mass ratio of seaweed and weak base being 6:1, the pulverized dry Sargassum raw material is mixed evenly with an aqueous sodium carbonate solution with a concentration of 0.0034g / ml, and then digested at a temperature of 58°C and stirred for 1.8h to obtain a A kind of seaweed digestive juice;

[0076] B. Enzyme hydrolysis

[0077] Adjust the pH of the digestive solution obtained in step A to 6.8 with an aqueous solution of citric acid at a concentration of 0.2g / ml, then add 0.04% compound enzyme based on the mass of the digestive solution, mix well, and then proceed at a temperature of 30°C with stirring Enzymolysis for 18 hours to obtain an enzymolysis solution;

[0078] Described compound enzyme consists of 25 pa...

Embodiment 2

[0082] Embodiment 2: produce active seaweed fertilizer of the present invention

[0083] The implementation steps of this embodiment are as follows:

[0084] A. to digest

[0085] According to the mass ratio of seaweed and weak base of 5:1, the pulverized dry kelp raw material is mixed evenly with potassium bicarbonate aqueous solution with a concentration of 0.001g / ml, and then digested at a temperature of 50°C and stirred for 1.0h to obtain a A kind of seaweed digestive juice;

[0086] B. Enzyme hydrolysis

[0087] Adjust the pH of the digestive solution obtained in step A to 7.0 with an aqueous solution of citric acid at a concentration of 0.4g / ml, then add 0.10% compound enzyme based on the mass of the digestive solution, mix well, and then proceed at a temperature of 35°C with stirring Enzymolysis for 16 hours to obtain an enzymolysis solution;

[0088] Described compound enzyme consists of 18 parts by weight of cellulase sold by Sukehan (Weifang) Bioengineering Co., ...

Embodiment 3

[0092] Embodiment 3: produce active seaweed fertilizer of the present invention

[0093] The implementation steps of this embodiment are as follows:

[0094] A. to digest

[0095] According to the mass ratio of seaweed and weak base of 8:1, the crushed dry Ascophyllum nodosum raw material is mixed evenly with potassium carbonate aqueous solution with a concentration of 0.004g / ml, and then digested at a temperature of 60°C and stirred for 1.2h to obtain a seaweed digestive juice;

[0096] B. Enzyme hydrolysis

[0097] Adjust the pH of the digestive solution obtained in step A to 6.8 with an aqueous solution of citric acid at a concentration of 0.6g / ml, then add 0.01% compound enzyme based on the mass of the digestive solution, mix well, and then proceed at a temperature of 40°C with stirring Enzymolysis for 15 hours to obtain an enzymolysis solution;

[0098] Described compound enzyme consists of 35 parts by weight of cellulase sold by Sukehan (Weifang) Bioengineering Co., Lt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com