Patents

Literature

126results about How to "Prolong settling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

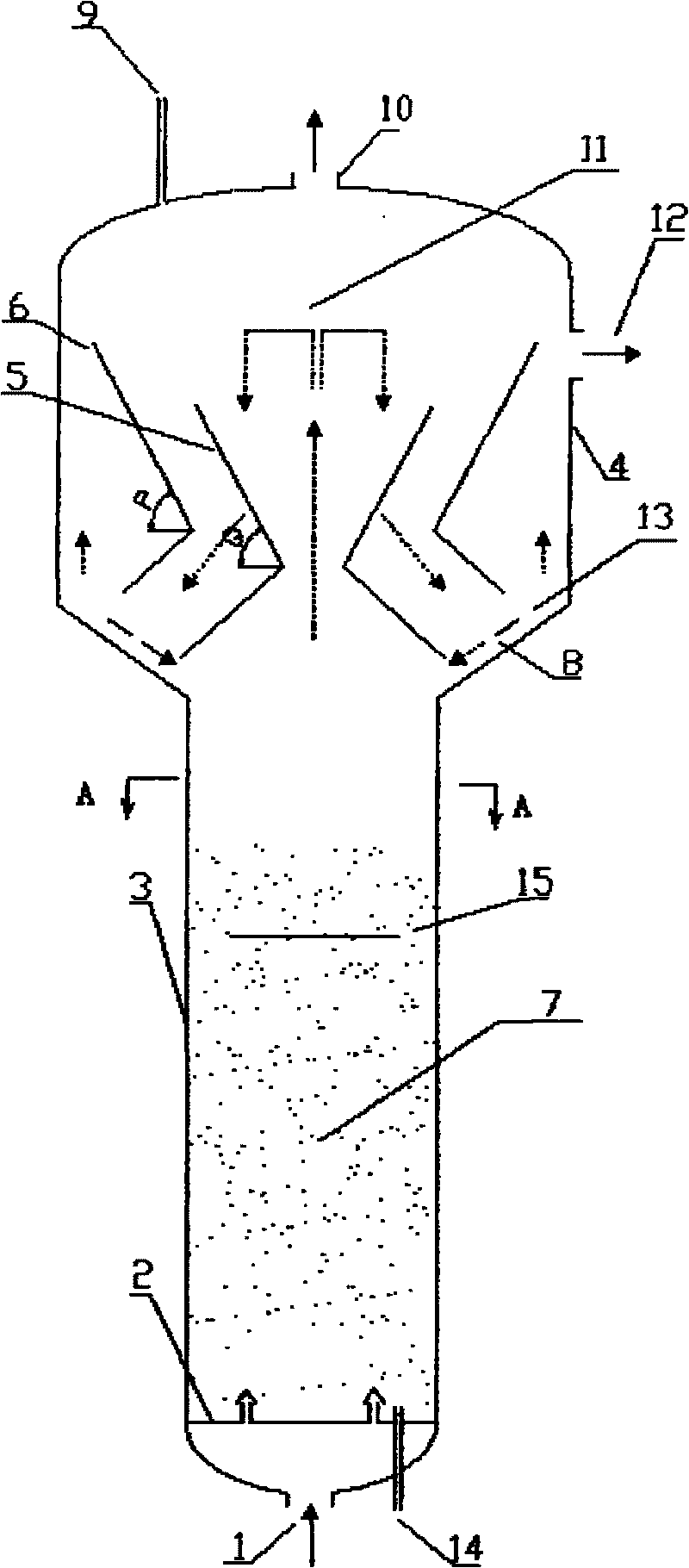

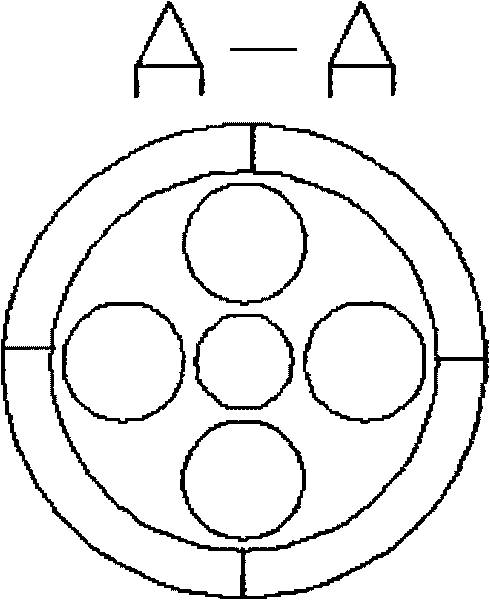

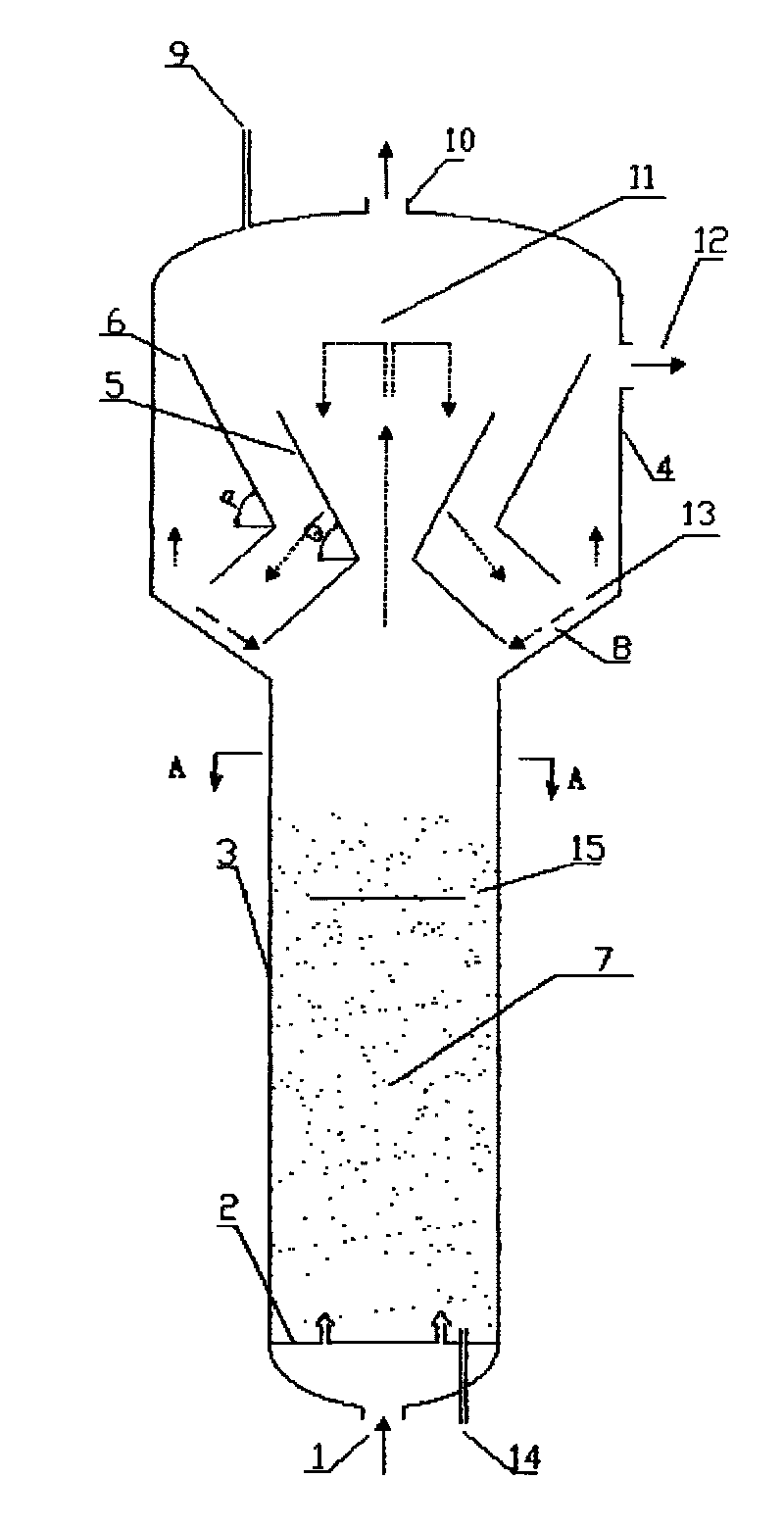

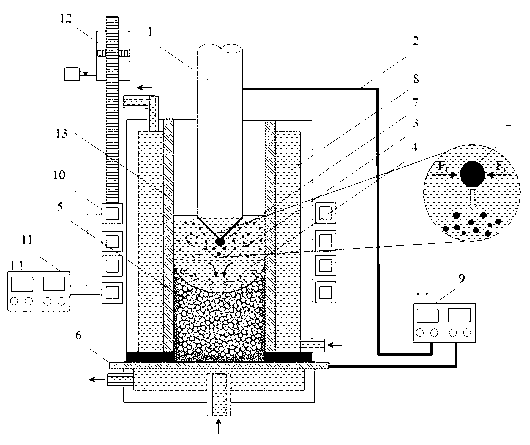

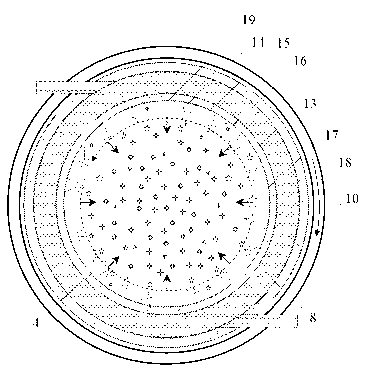

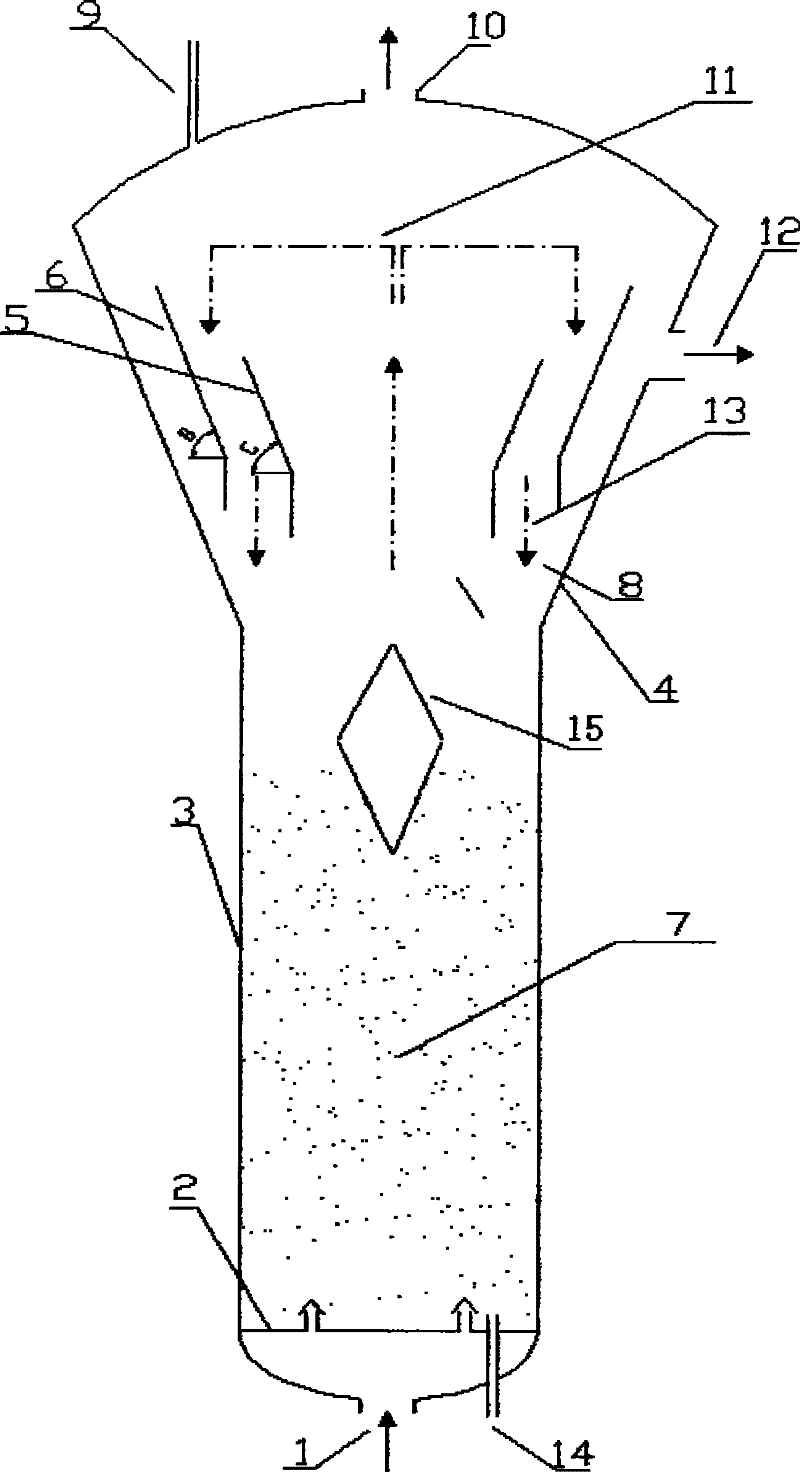

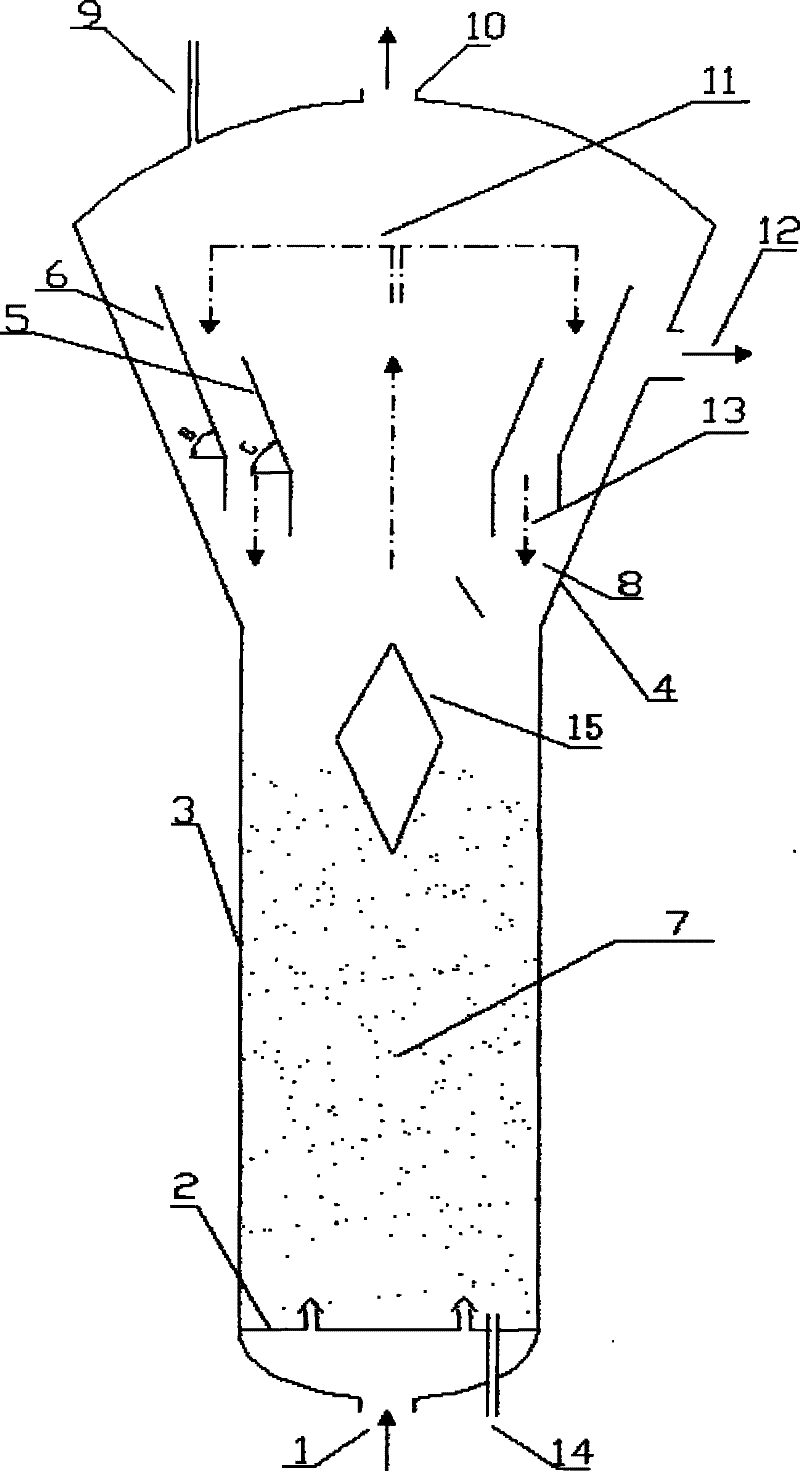

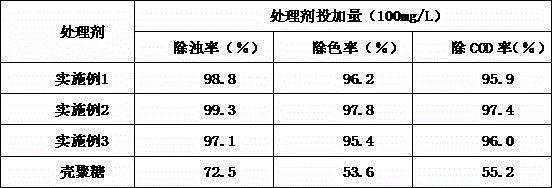

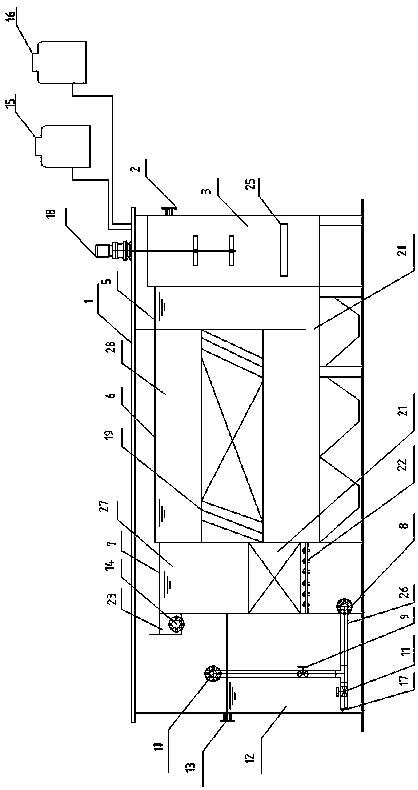

Fluidized bed reactor

ActiveCN101721960AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

The invention discloses a fluidized bed reactor which comprises a reactor shell and a three-phase separator, the three-phase separator is arranged at the upper part inside the reactor shell and is of a sleeve structure comprising an inner sleeve and an outer sleeve, the upper ends and lower ends of the inner sleeve and the outer sleeve are both of opening structures, the inner sleeve and the outer sleeve are respectively composed of an upper section and a lower section, the upper sections of the inner sleeve and the outer sleeve are in reverse frustum structures, and the lower sections of the inner sleeve and the outer sleeve are in frustum structures. By designing a novel three-phase separating structure, the invention can further improve separating effect, reduce catalyst carrying-out amount, and enhance the operation elasticity of the three-phase separator. The reactor is mainly applicable to chemical reactions between liquid and gas substances of different types and solid particles under contact condition, and has the advantages of large catalyst inventory, high reactor use ratio, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ternary compound potassium ion battery plus plate material

ActiveCN1956242AAvoid local overconcentrationIncrease contactElectrode manufacturing processesLithium compoundsLithium compoundSolvent

A method for preparing positive electrode material of ternary composite Li ion cell includes mixing soluble compound of Ni and Mn as well as Co to be transition metal soluble, filling certain amount of ammonia water in reactor then adding transition metal solution into reactor by ejecting gun and pumping mixed liquid of ammonia and sodium hydroxide into reactor by precipitation then wet-mixing it with Li compound, sintering mixture of presoma and Li compound with high temperature under oxygen atmosphere then grinding sintered material to obtain positive electrode material.

Owner:BYD CO LTD

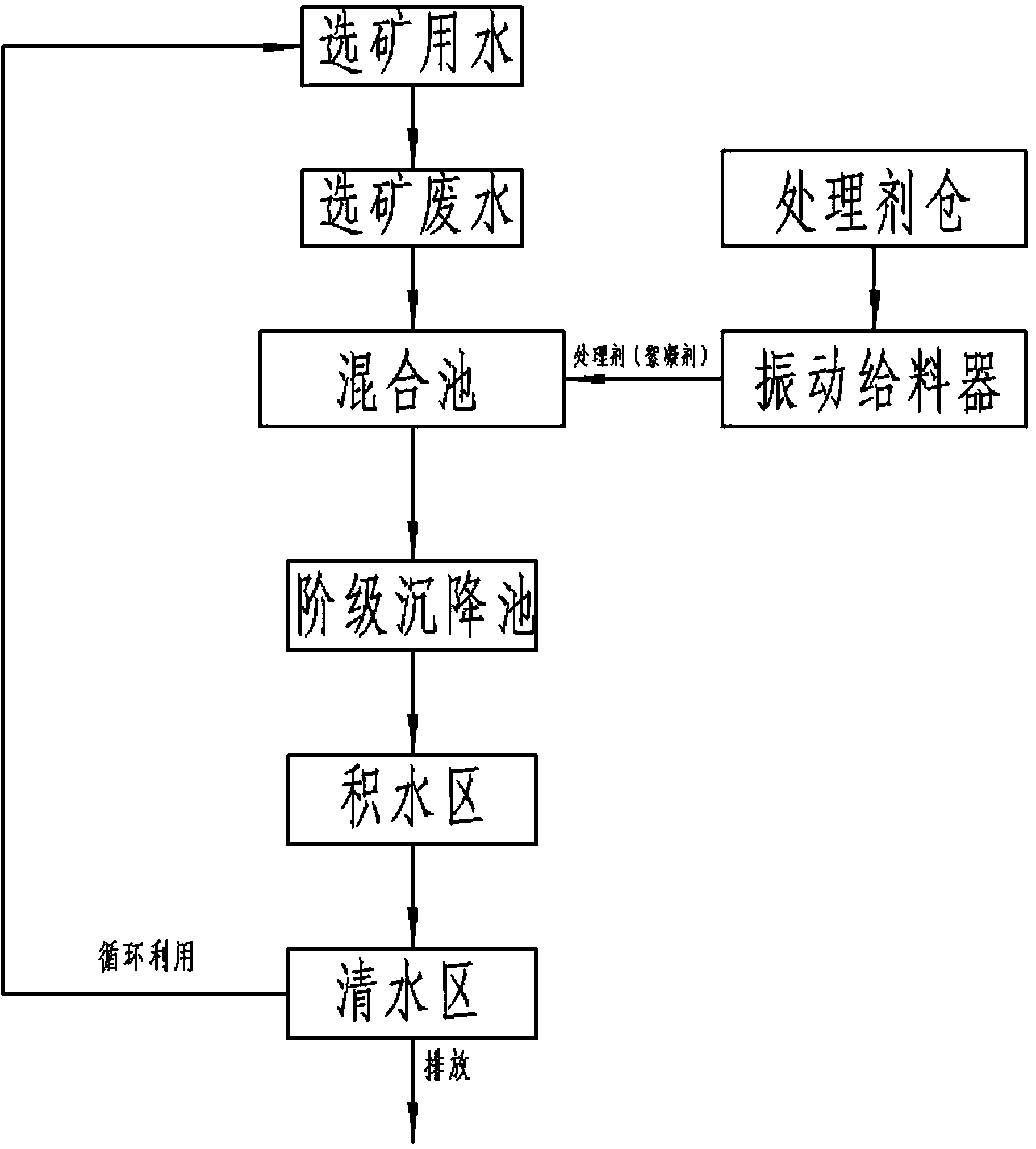

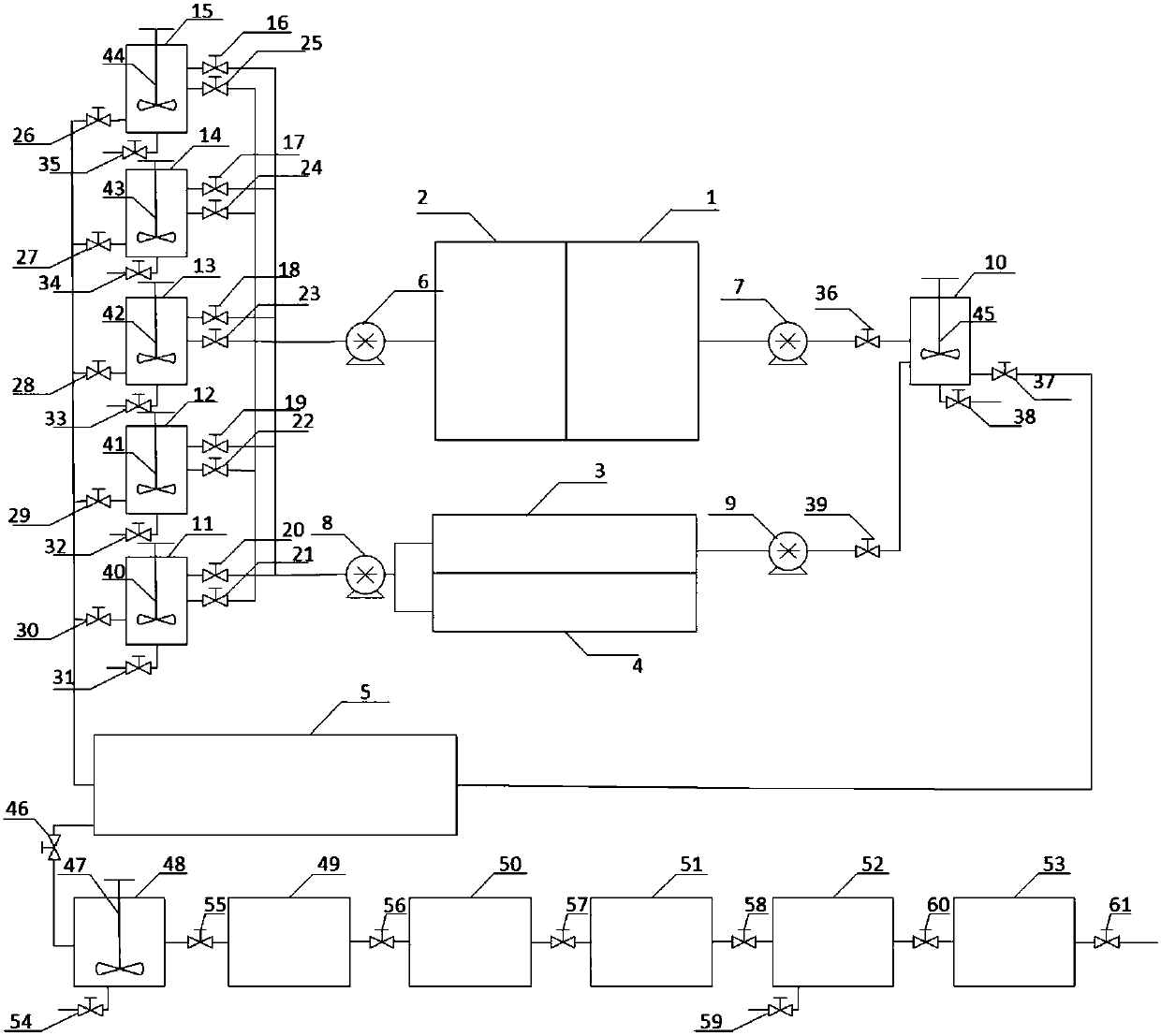

Polymetallic ore beneficiation wastewater recycling method

InactiveCN103708591AReduce productionIncrease the amount of purificationWater/sewage treatment by flocculation/precipitationSlagWater circulation

The invention provides a polymetallic ore beneficiation wastewater recycling method. The polymetallic ore beneficiation wastewater recycling method is characterized by comprising two steps of physical treatment and biological treatment. According to the polymetallic ore beneficiation wastewater recycling method, the existing beneficiation wastewater output equipment and tailings ponds of aluminium and zinc beneficiation industries are used, wastewater treating agents such as calcium hydroxide, saponification slag and calcium carbide are added to wastewater in a mixing tank so as to ensure that suspended matters in the wastewater settle, the wastewater is purified so as to meet the technical requirements that obtained clear water is continuously used for beneficiation, the content of suspended matters in the treated water is less than 100mg / L, the pH value of the treated water is 8, and the cyclic utilization of the beneficiation wastewater is realized. The polymetallic ore beneficiation wastewater recycling method has the characteristics of low investment, low running cost, energy conservation, emission reduction and cyclic economy and is suitable for the cyclic utilization of the polymetallic ore beneficiation wastewater.

Owner:GUANGXI KESHENGDA MACHINERY MFG

Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

The invention discloses a method for controlling electroslag melting casting by an added transient magnetic field. The method includes adding a transient magnetic field to a melting end of an electroslag remelting mother electrode, a liquid slag tank and a metal melting tank so that the transient magnetic field acts on large metal molten drops which are generated by initial melting at the tail end of the electrode and are converging to become big; under joint action of alternating lorentz force and pressure waves generated by the transient magnetic field, dispersing the metal molten drops in a burst manner into small metal molten drop groups, and randomly dispersing the small metal molten drop groups into the liquid slag tank to sufficiently contact with liquid slag after passing the liquid slag tank; after washing, enabling included foreign substances and impurities in the small metal molten drops to enter the liquid slag quickly, slowly settling and converging the foreign substances and impurities into the metal melting tank below the liquid slag tank, and finally crystallizing and solidifying to form solidified cast ingots. The invention further provides an electroslag melting casting device. By adding the transient magnetic field during electroslag melting casting and fining the molten drops by the aid of unique electromagnetic effect of the transient magnetic field, the purposes of improving refining efficiency, fining crystalline grains and reducing segregation of cast ingots are achieved, and industrial application value is realized.

Owner:SHANGHAI UNIV

Epoxy micaceous iron ash primer

The invention relates to the technical field of oil paints, in particular to an epoxy micaceous iron ash primer. The epoxy micaceous iron ash primer comprises the following components in parts by weight: 20-30 parts of epoxy resin, 20-25 parts of acrylic resin, 10-15 parts of mica iron oxide, 2-5 parts of curing agent, 2-4 parts of acrylic acid, 0.2-0.8 part of dispersing agent, 0.2-0.5 part of wetting agent, 20-25 parts of diluent and 0.08-0.12 part of anti-settling agent. The technical scheme provided by the invention has the following beneficial effects: organic modified bentonite is added in the epoxy micaceous iron ash primer so that the leveling property of a coating is good without sagging, and the settling time of the pigments is prolonged; furthermore, the epoxy micaceous iron ash primer provided by the invention hardly falls off, can be quickly dried, has strong impact force resistance, excellent adhesive force, flexibility, water resistance and excellent anti-rust performance, is environment-friendly, and has no harm to a human body in construction.

Owner:DANYANG YONGSHENG PAINT

Slow-setting cement grout

Disclosed is slow-setting cement grout. The ratio of basic cement grout includes that the water-cement ratio is 1-1.25:1, 1.5-2wt% of a suspending agent and a retarder are adulterated in the basic cement grout, the retarder is a mixture mixed by one, two or more of six retarders including sodium pyrophosphate, sodium tripolyphosphate, tartaric acid, potassium sodium tartrate, citric acid or zinc chloride according to arbitrary mixing ratio, wherein the mixing amount of the sodium pyrophosphate is 0.1%-0.5%, the mixing amount of the sodium tripolyphosphate is 0.1%-0.6%, the mixing amount of the tartaric acid is 0.2-0.4%, the mixing amount of the potassium sodium tartrate is 0.4%-0.5%, the mixing amount of the citric acid is 0.05%-0.35%, and the mixing amount of the zinc chloride is 0.2%-0.3%, and the suspending agent is sodium bentonite. The slow-setting cement grout has the advantages that stability of the cement grout is enhanced, settling time of cement particles is prolonged, and the concretion ratio of the grout is increased.

Owner:CHINA COAL NO 5 CONSTR

External refining method for smelting ferrovanadium

The invention belongs to the field of metallurgy, and specifically relates to an external refining method for smelting a ferrovanadium alloy. The invention aims at providing an external refining method for smelting ferrovanadium, with regard to problems of a high vanadium content, high power consumption, serious electric furnace body erosion and the like in slag in a last smelting period of an existing ferrovanadium smelting method adopting a multi-period method. The method comprises two-period electric furnace smelting, a primarily-molten alloy after deslagging is cast in an ingot mould filled with a refining material and subjected to a mixing reaction after the smelting is completed, and external refining is carried out. The method is capable of greatly reducing a single-furnace power-on time, reducing furnace lining erosion of an electric smelting furnace, and prolonging an alloy deposition time, thus increase for an alloy yield is benefited, and remarkable social and economic benefits are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

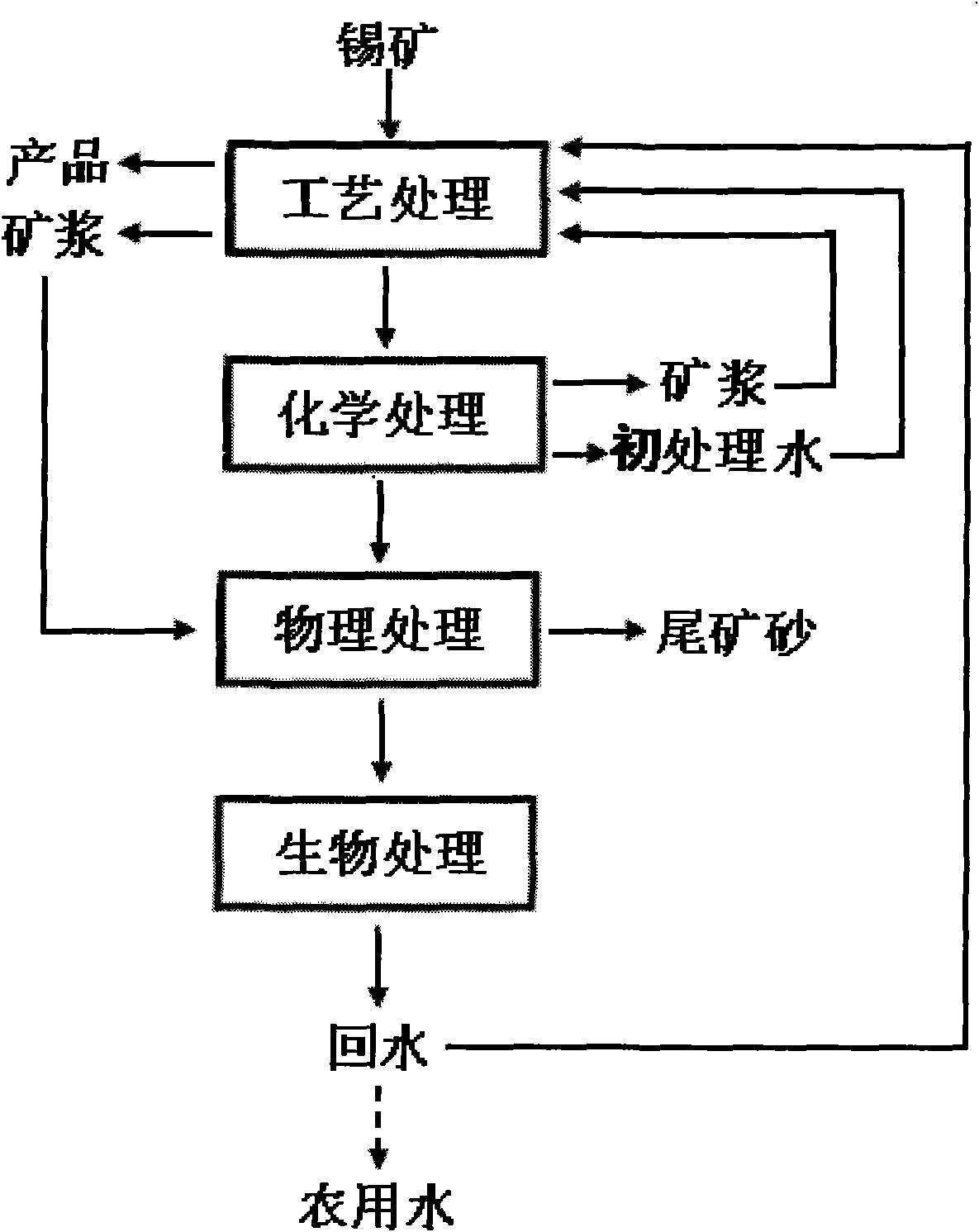

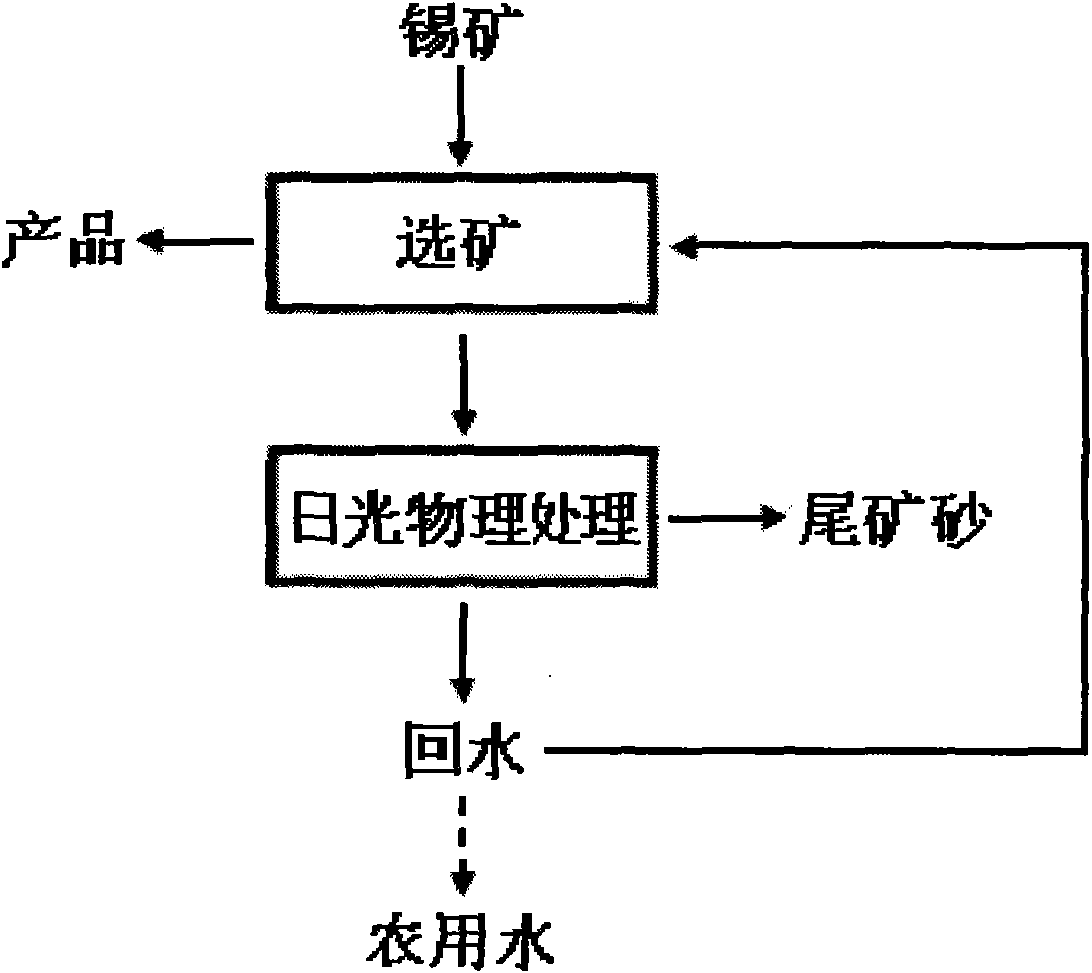

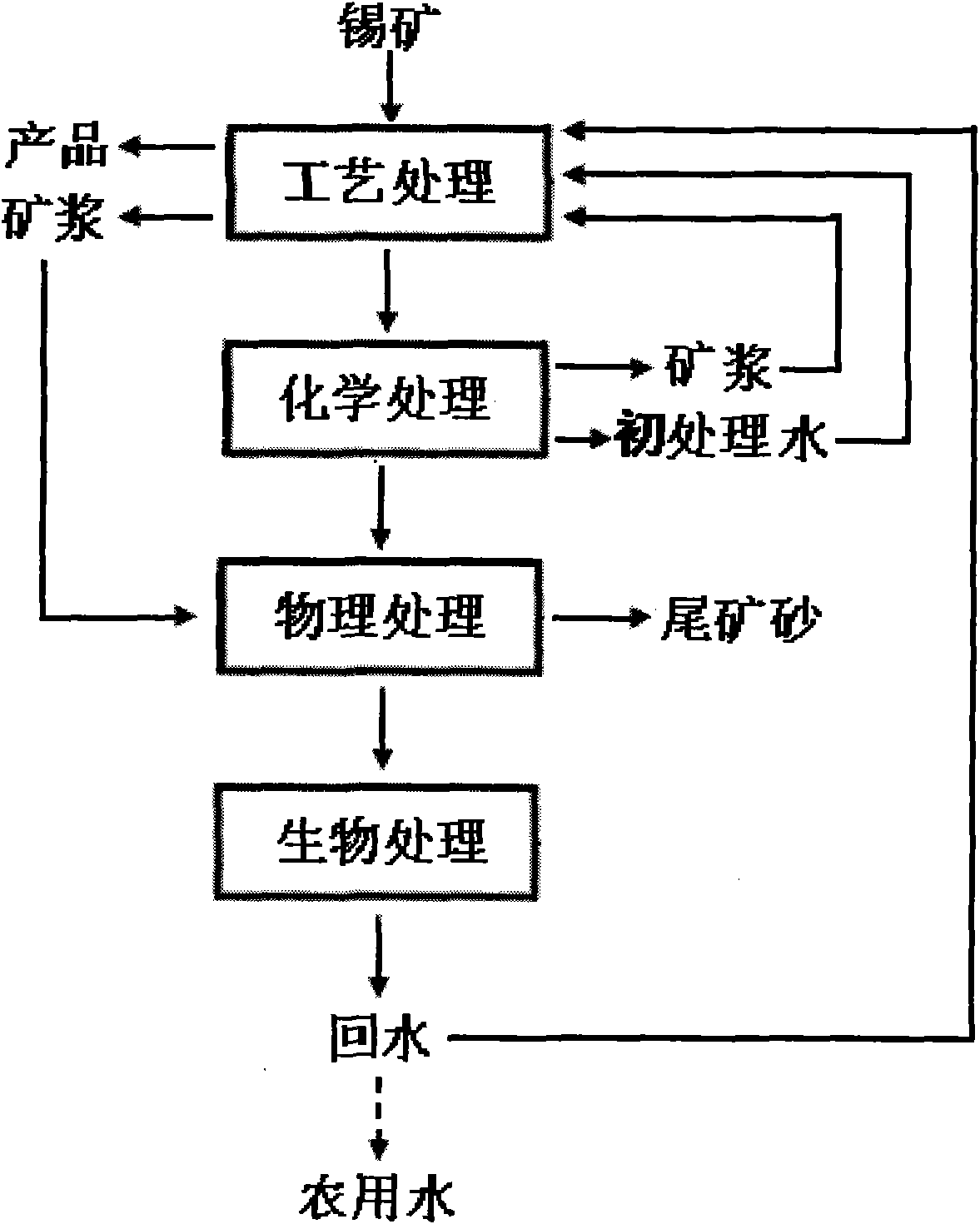

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

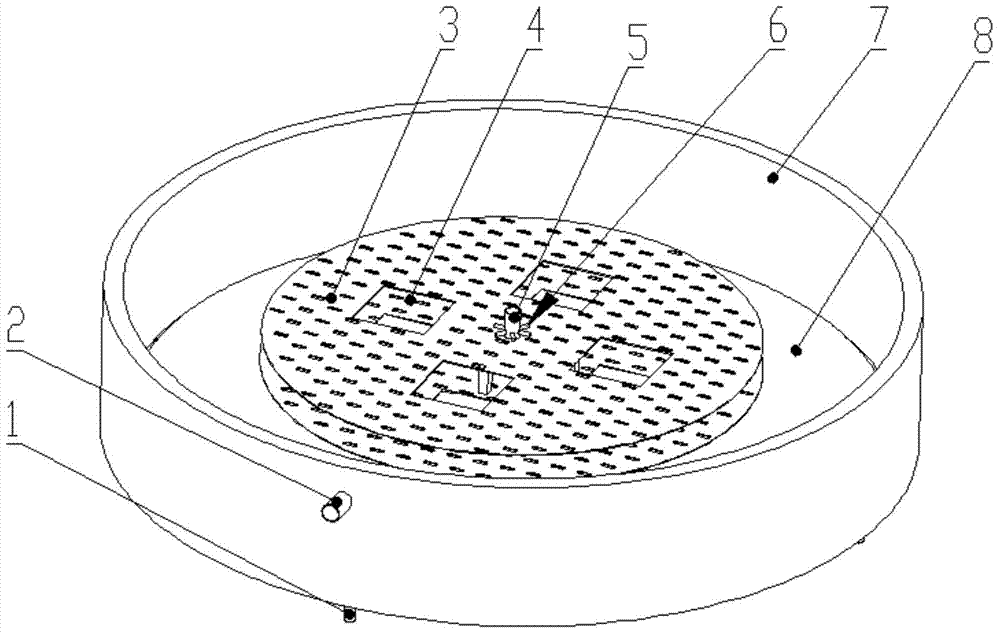

Layered high-density demersal breeding fish pond

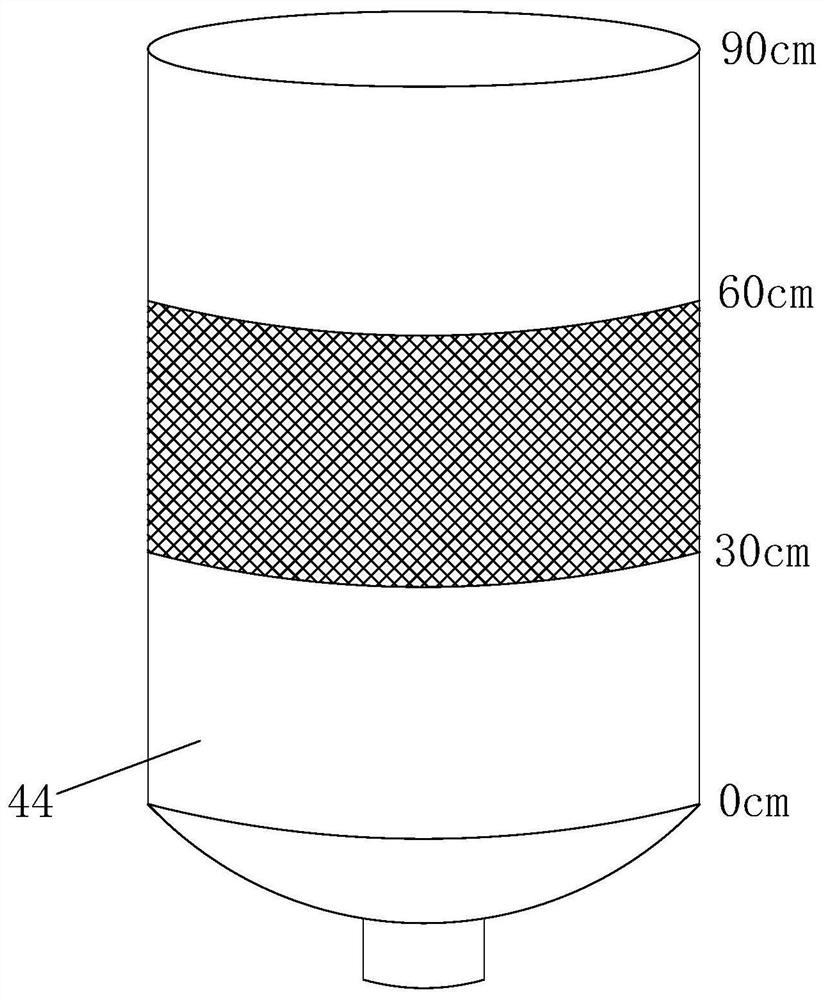

InactiveCN104756933AImprove comfortIncrease oxygen concentrationPisciculture and aquariaHigh densityMaximum diameter

The invention relates to a layered high-density demersal breeding fish pond. The layered high-density demersal breeding fish pond is that at least one inhabiting layer structure is arranged in the center of the bottom surface of the fish pond; the inhabiting layer structures are overlapped, each comprising an inclination support for supporting a horizontal circular porous separating plate; the aperture of the porous separating plate is more than the maximum diameter of particle feed; the porous separating plate is provided with at least one fish passing hole through which fish can cross the upper layer and the lower layer to move; a water feeding pipe is vertically arranged in the center of the fish pond and horizontally communicated with horizontal water distributing pipes; each inhabiting structure is corresponding to at least four water distributing pipes; the bottom structure of the fish pond is high in middle, low in four sides, and about 3 to 5 degrees in gradient; a circle of downwards-concave sewage collecting tanks is formed in the bottom part of the wall of the fish pond; a plurality of sewage draining pipes are arranged below the sewage collecting tanks; a water returning pipe is arranged on the sidewall of the fish pond; a circulating water pump is arranged between the water returning pipe and the water feeding pipe to provide water circulating power. According to the layered high-density demersal breeding fish pond, water is treated by physical filtering, biological filtering, oxygen increase, sterilizing and other purifying links and then is recycled, so that breeding with circulating water can be achieved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

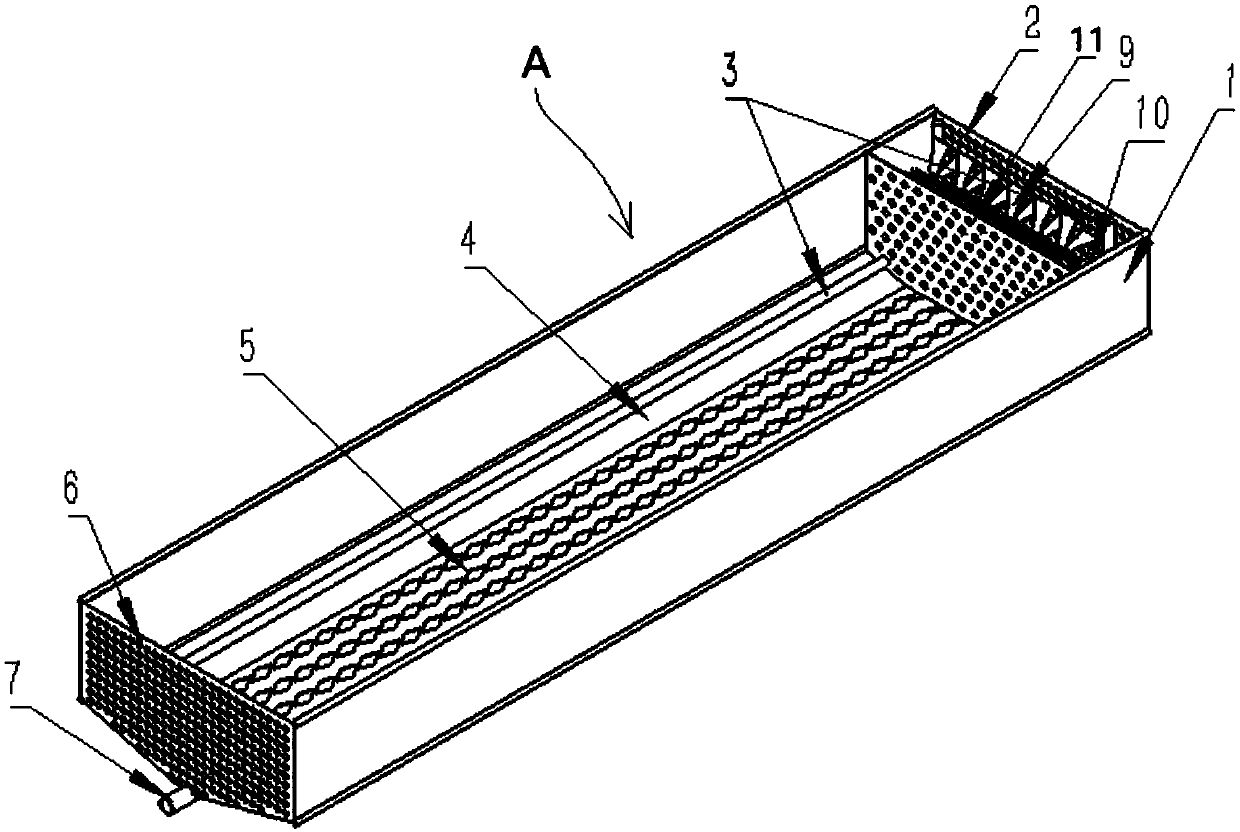

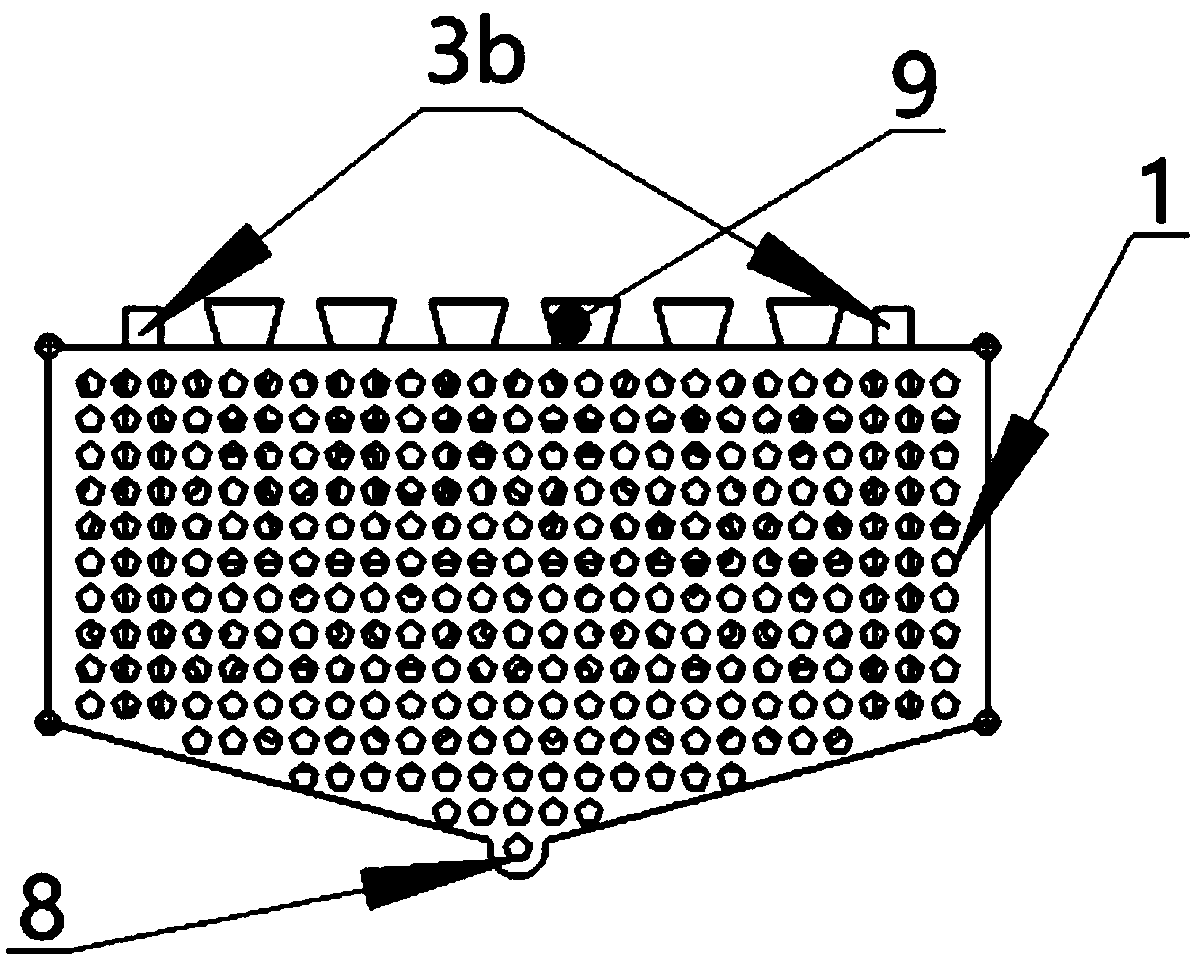

Layered demersal breeding net cage

InactiveCN109526829AImprove the microenvironment of lifeIncrease breeding densityClimate change adaptationPisciculture and aquariaThree-dimensional spaceEngineering

The invention relates to a layered demersal breeding net cage which comprises a cage body. The cage body comprises a water inlet net sheet, a middle net sheet, a water outlet net sheet, two net cage side walls and a net cage bottom surface. The net cage bottom surface comprises two inclined surfaces. An isolating grid or a cage sheet is arranged above the net cage bottom surface. The space on theisolating grid or the cage sheet is a fish living area. A dirt collecting area is formed between the isolating grid or the cage sheet and the net cage bottom surface. At least one horizontal microporous aerating pipe is mounted on the side wall of each net cage in the water inlet-outlet direction. A drainage pipe is fixedly connected to the outer side of the water outlet net sheet. At least one dirt collecting groove in connection and communication with the drainage pipe is formed at the connection of the two inclined surfaces. The layered demersal breeding net cage integrates various functions such as flow plugging, inner circular river diversion, oxygenation, drainage and the like in the net cage design. By isolating the living area from the dirt collecting area, the three-dimensional space of the water body of the net cage is utilized fully, so that the living micro-environment of fishes is improved and the breeding density is improved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

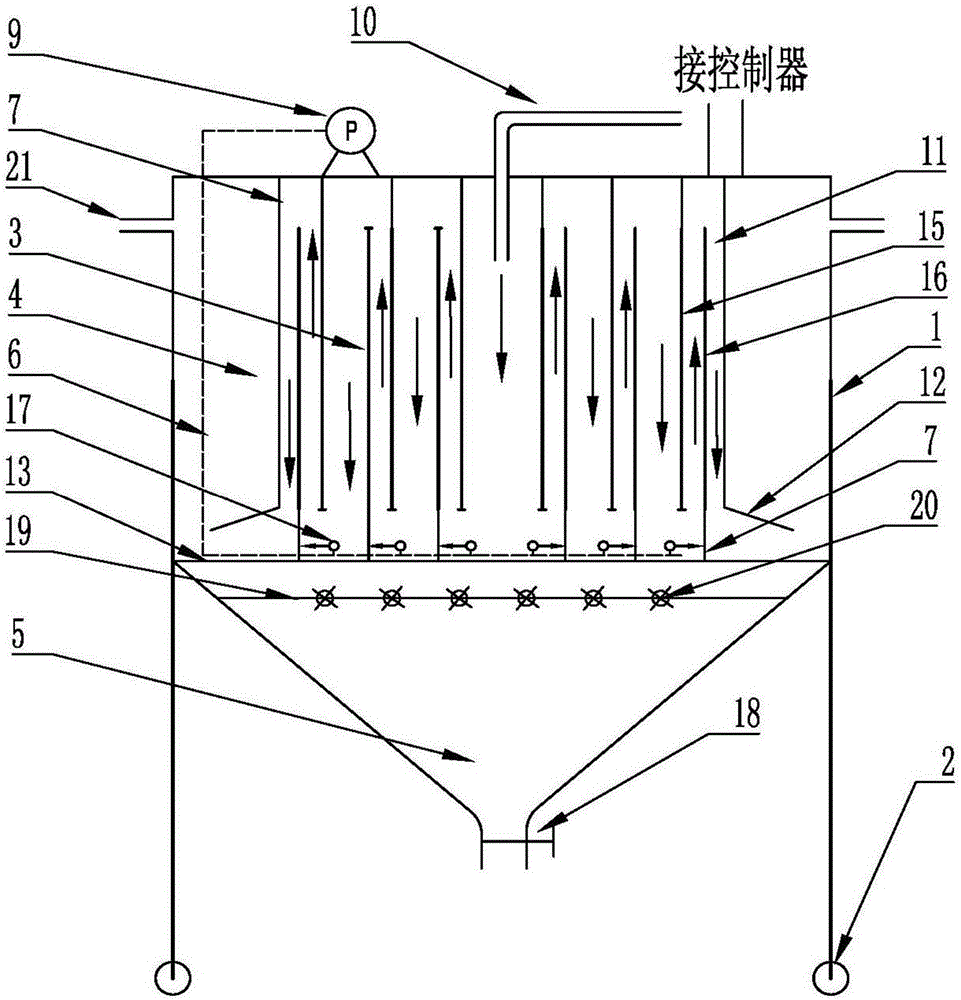

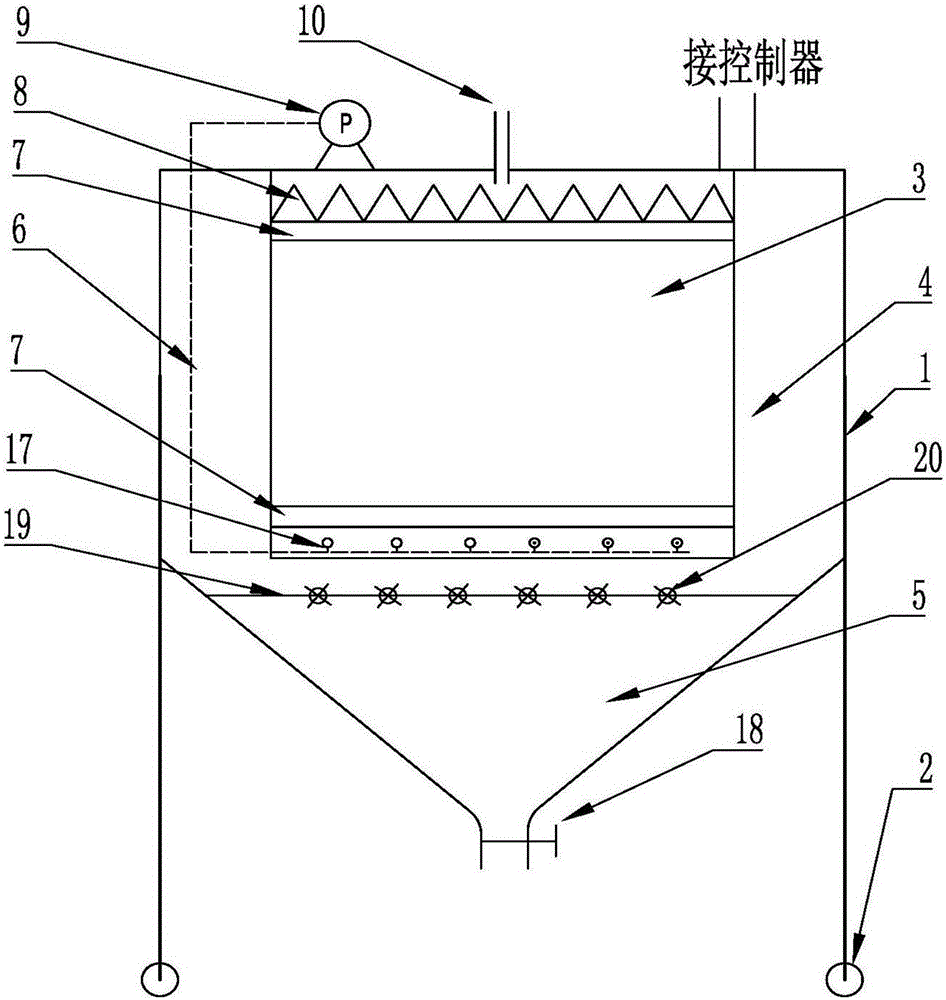

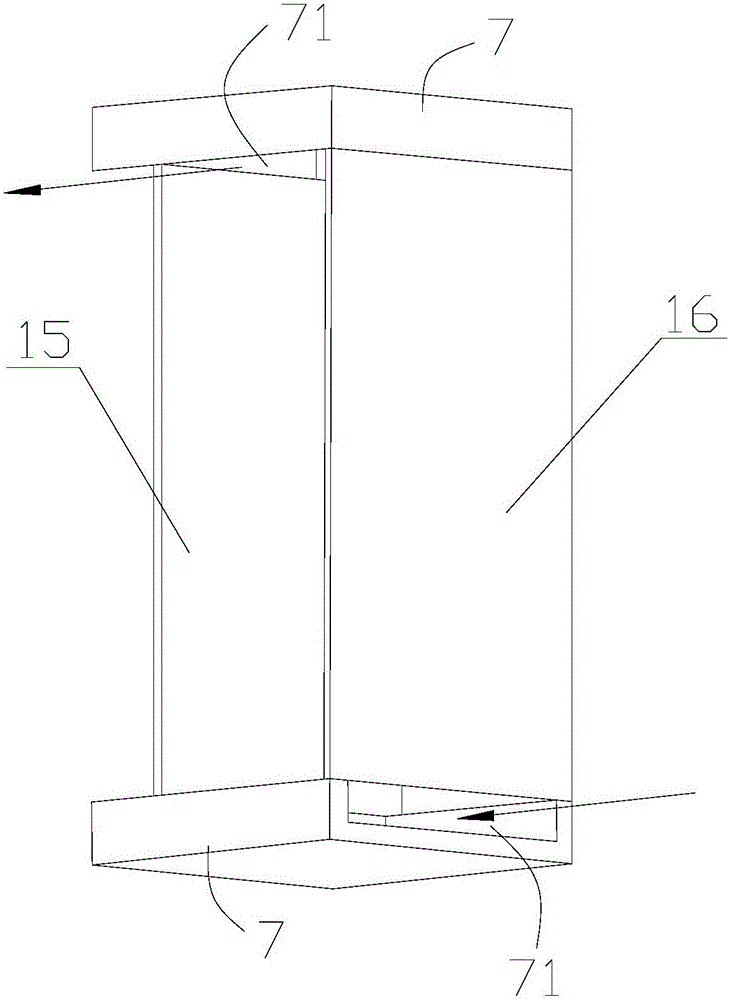

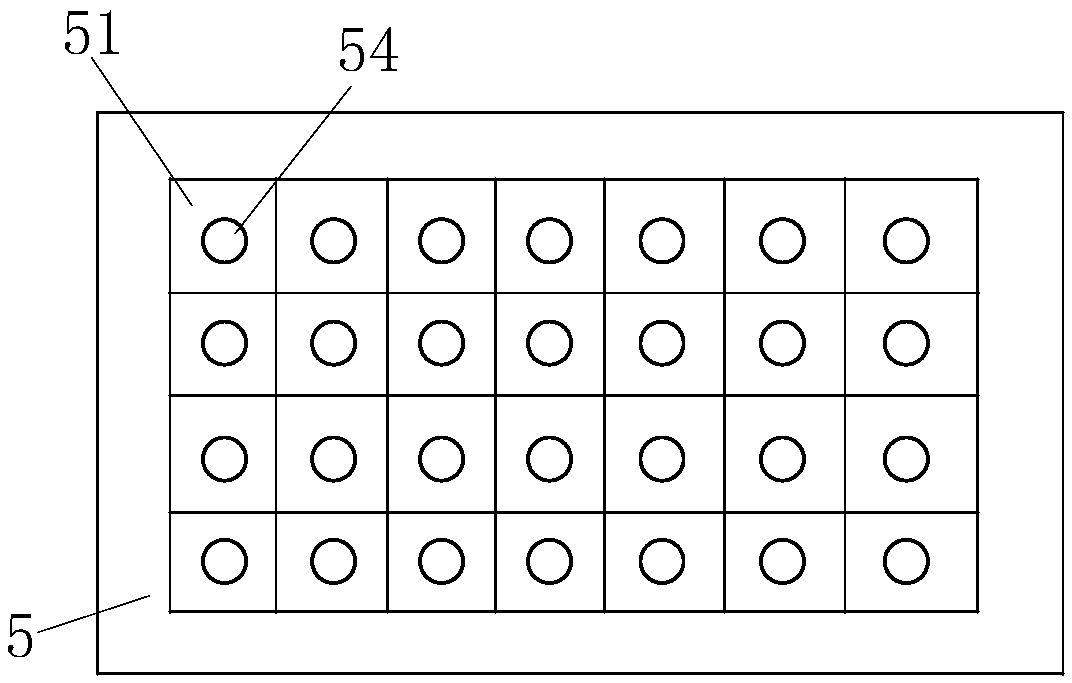

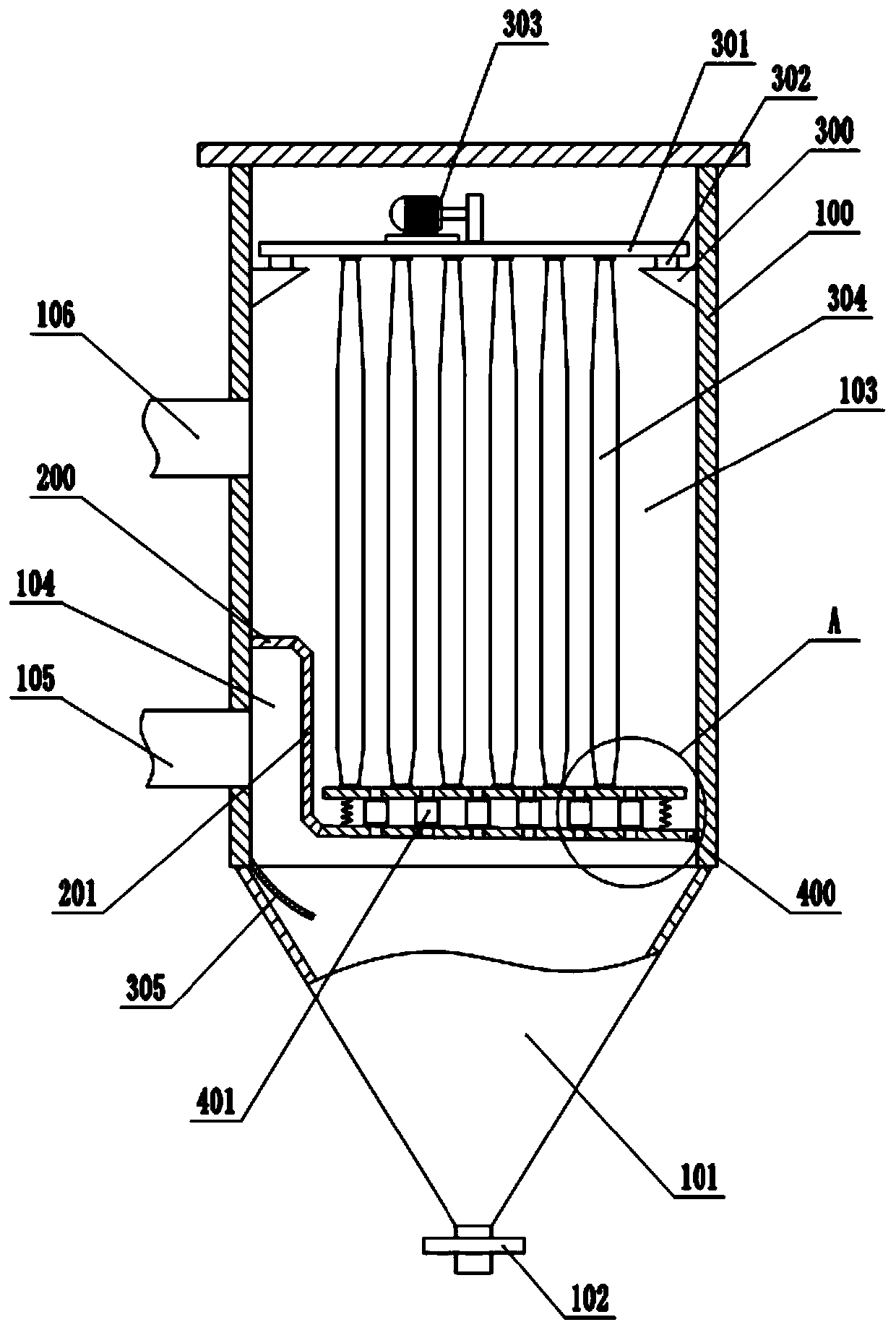

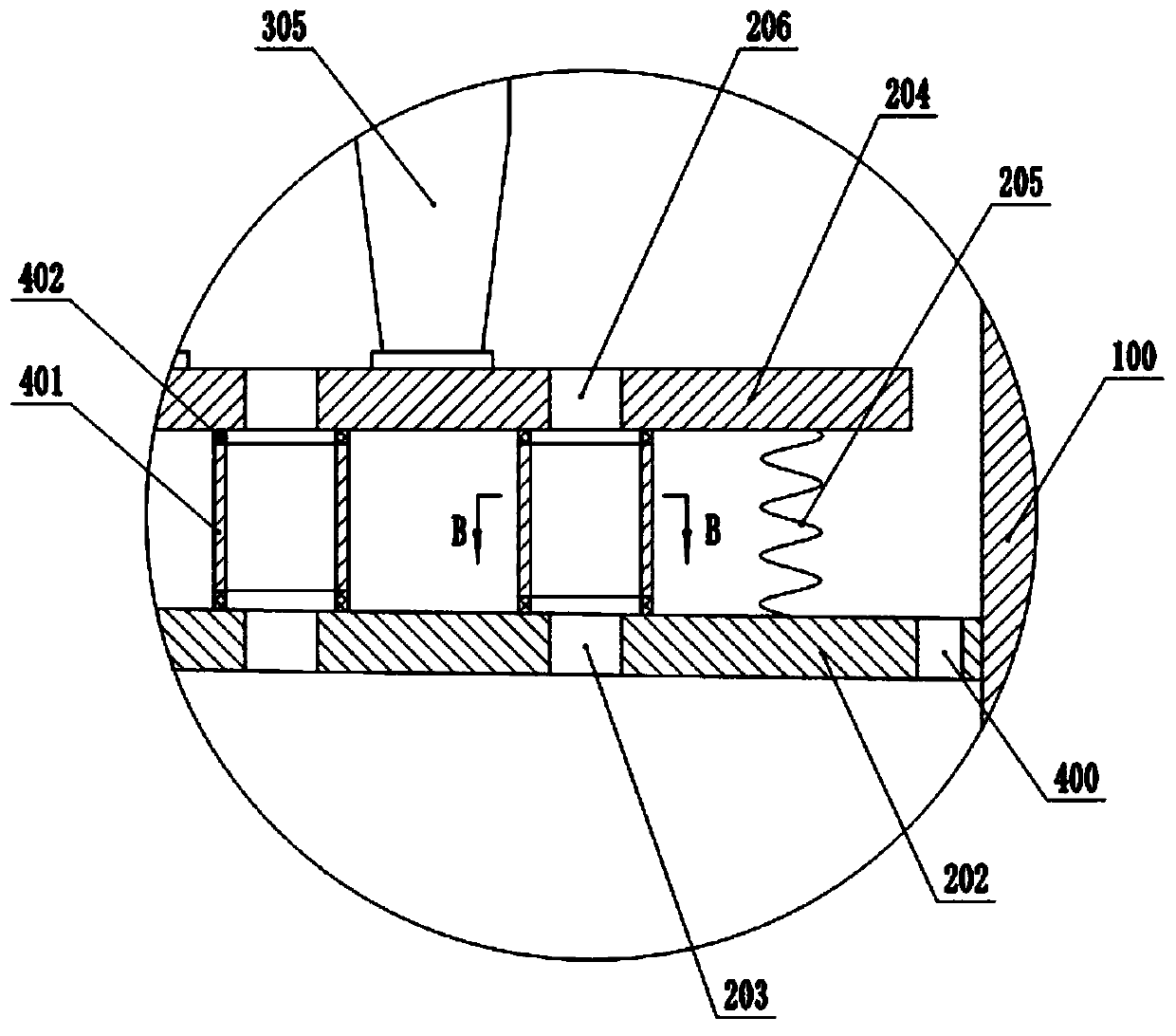

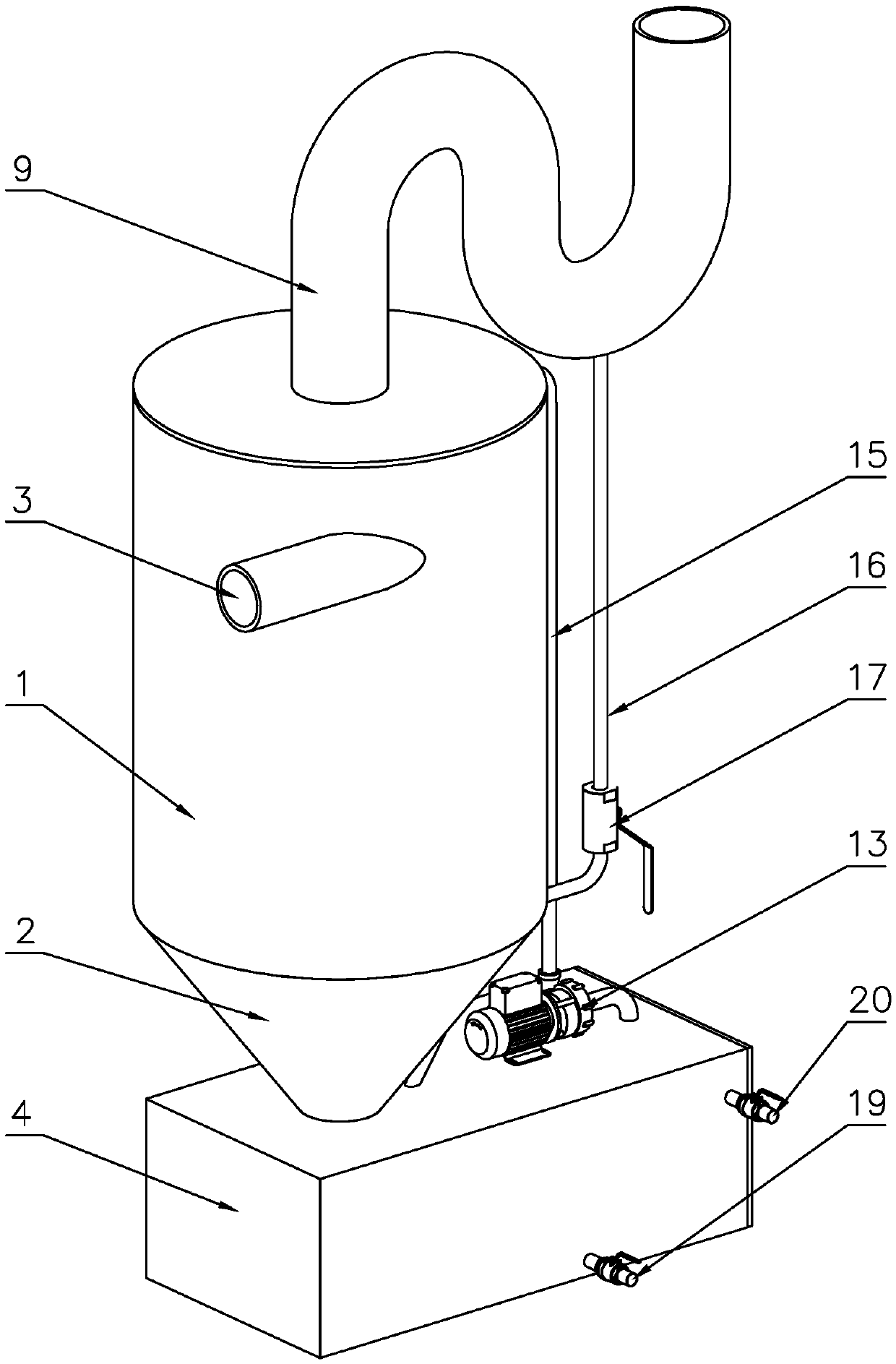

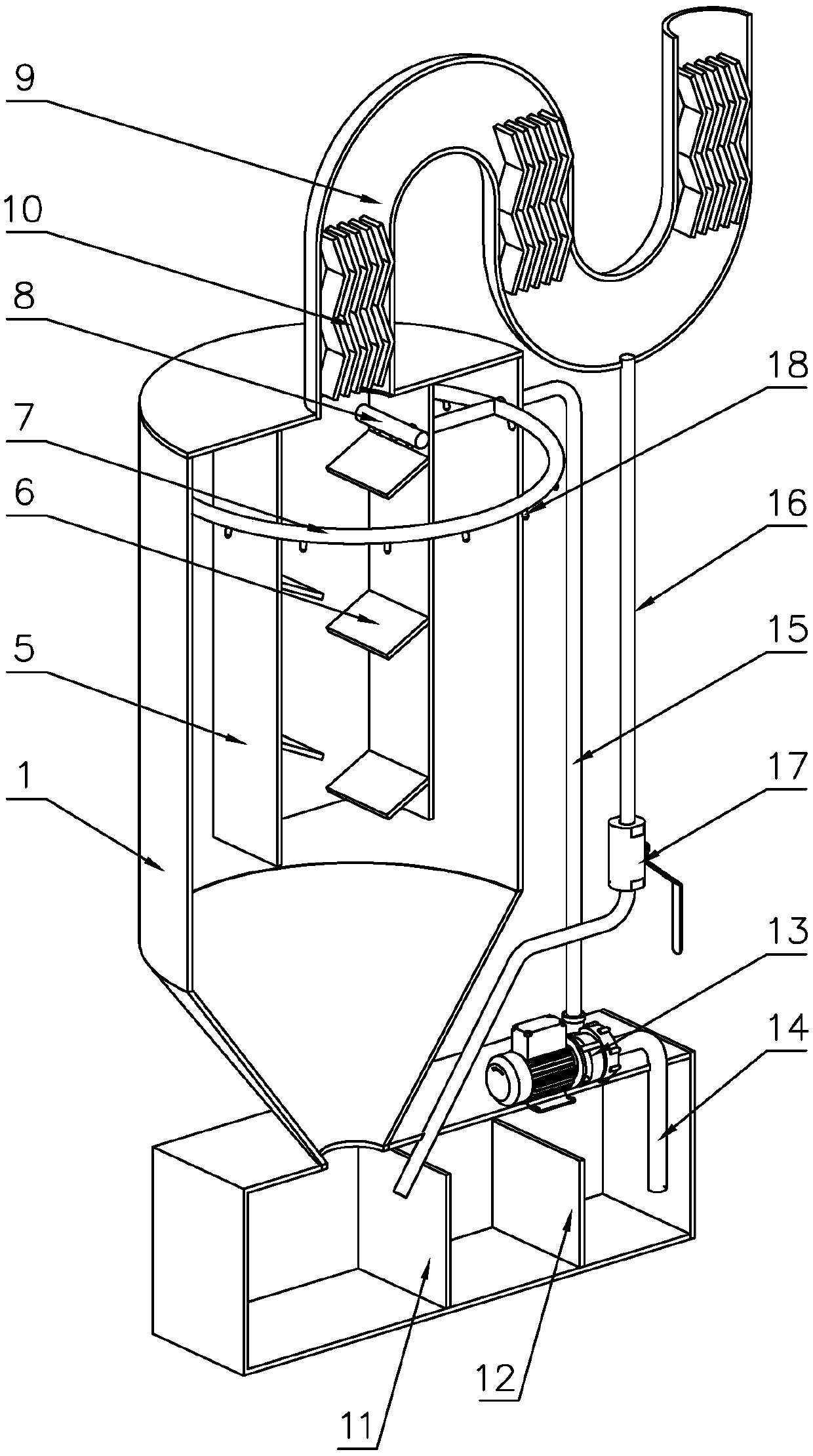

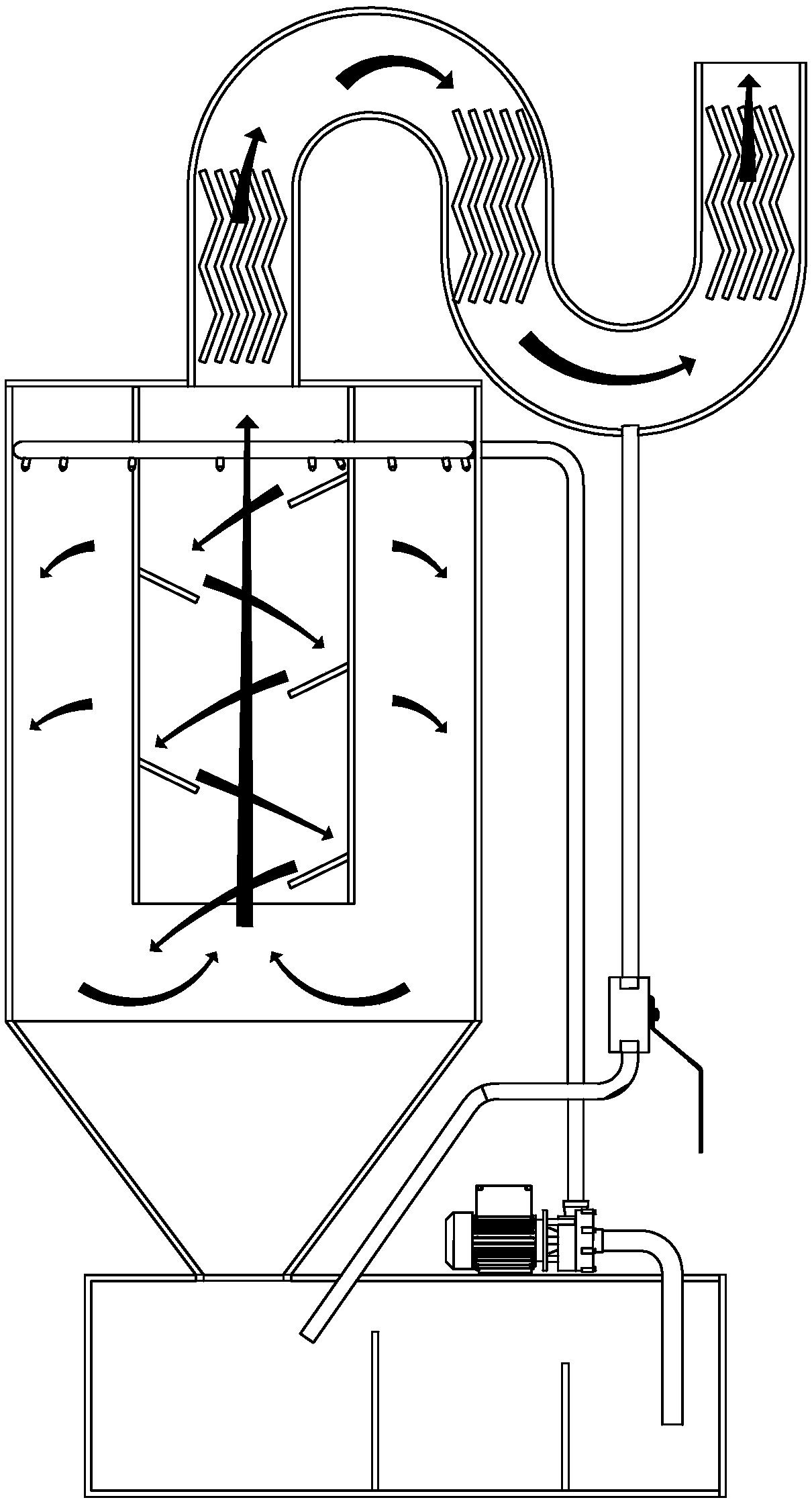

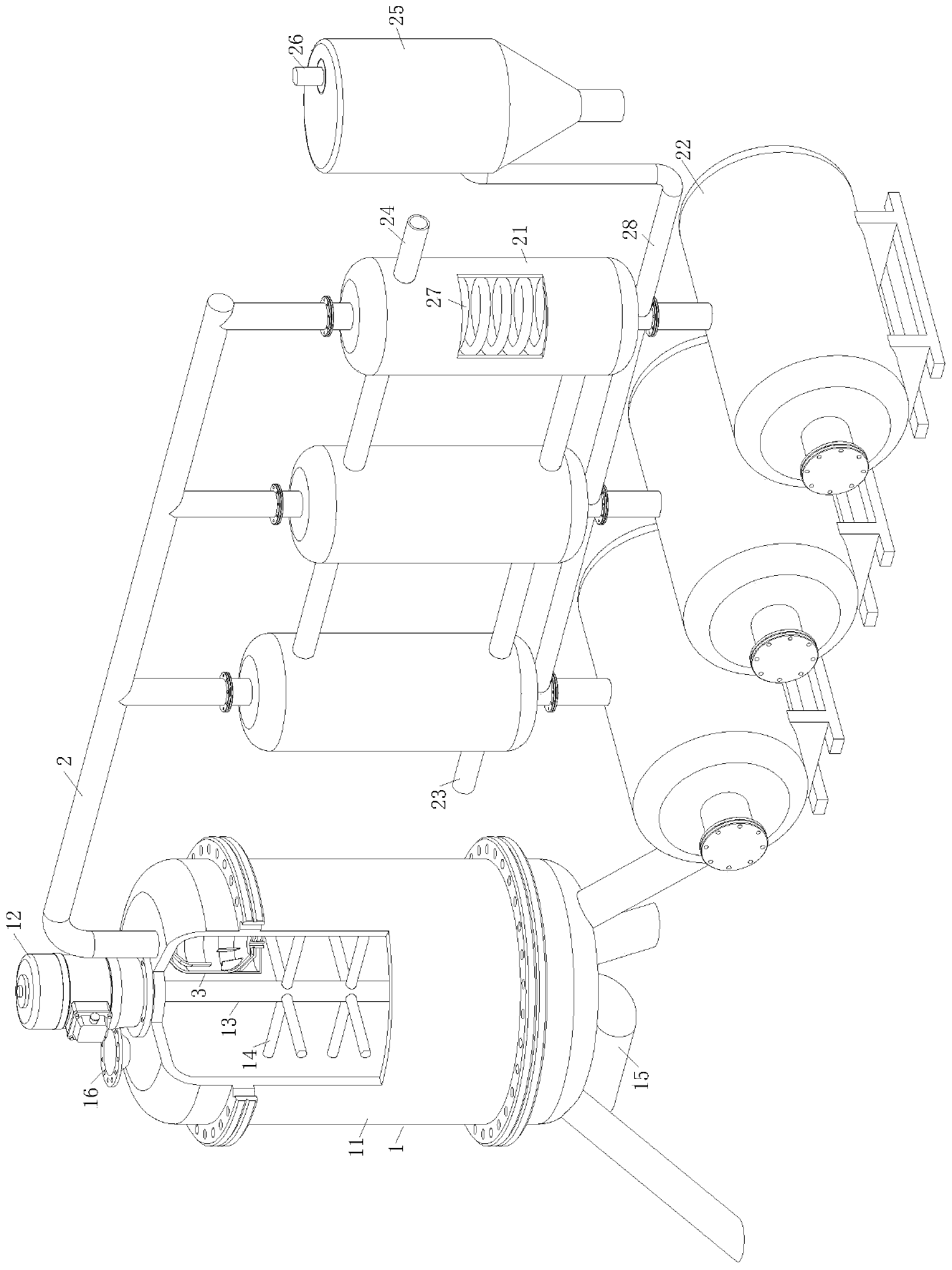

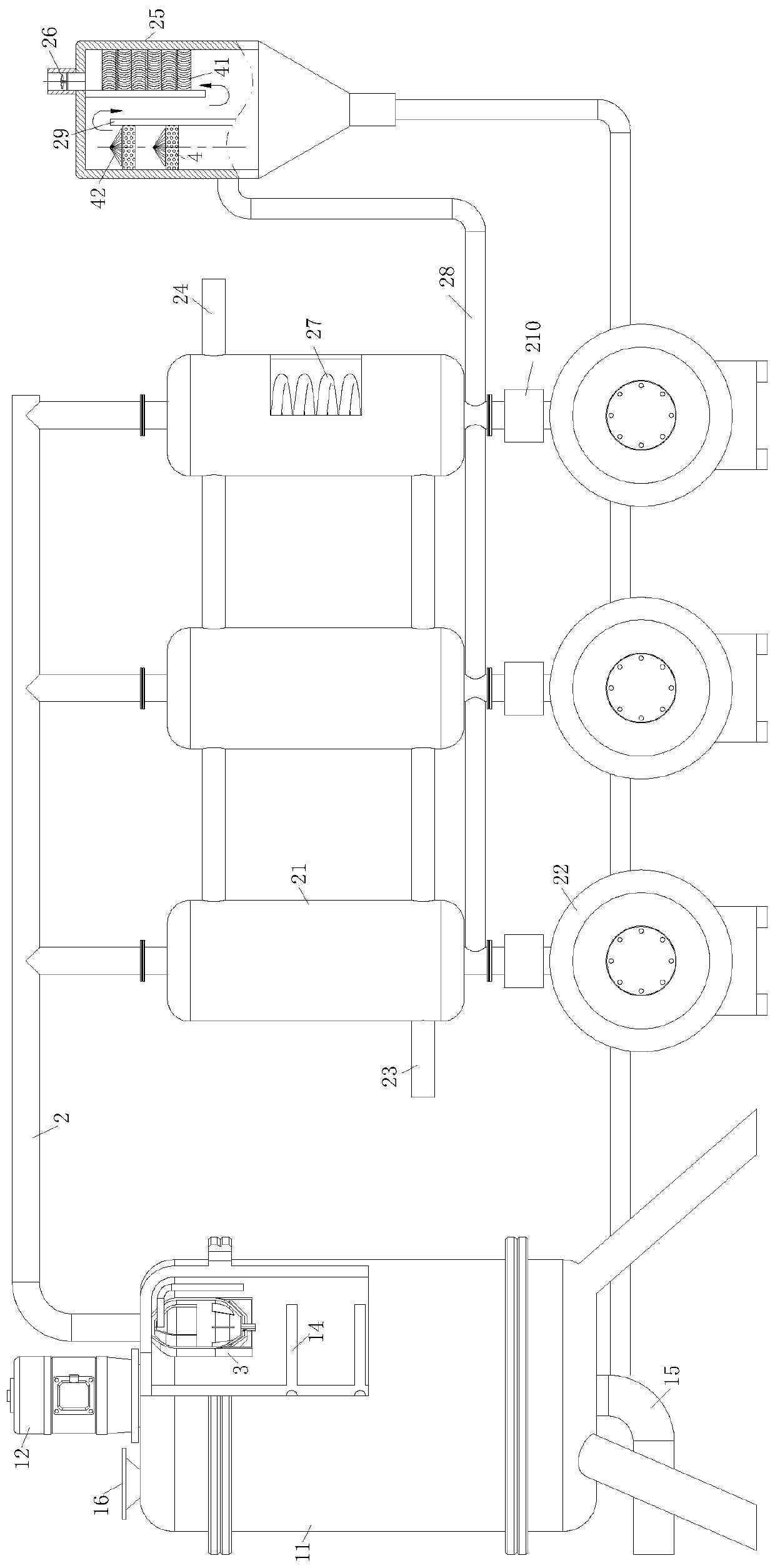

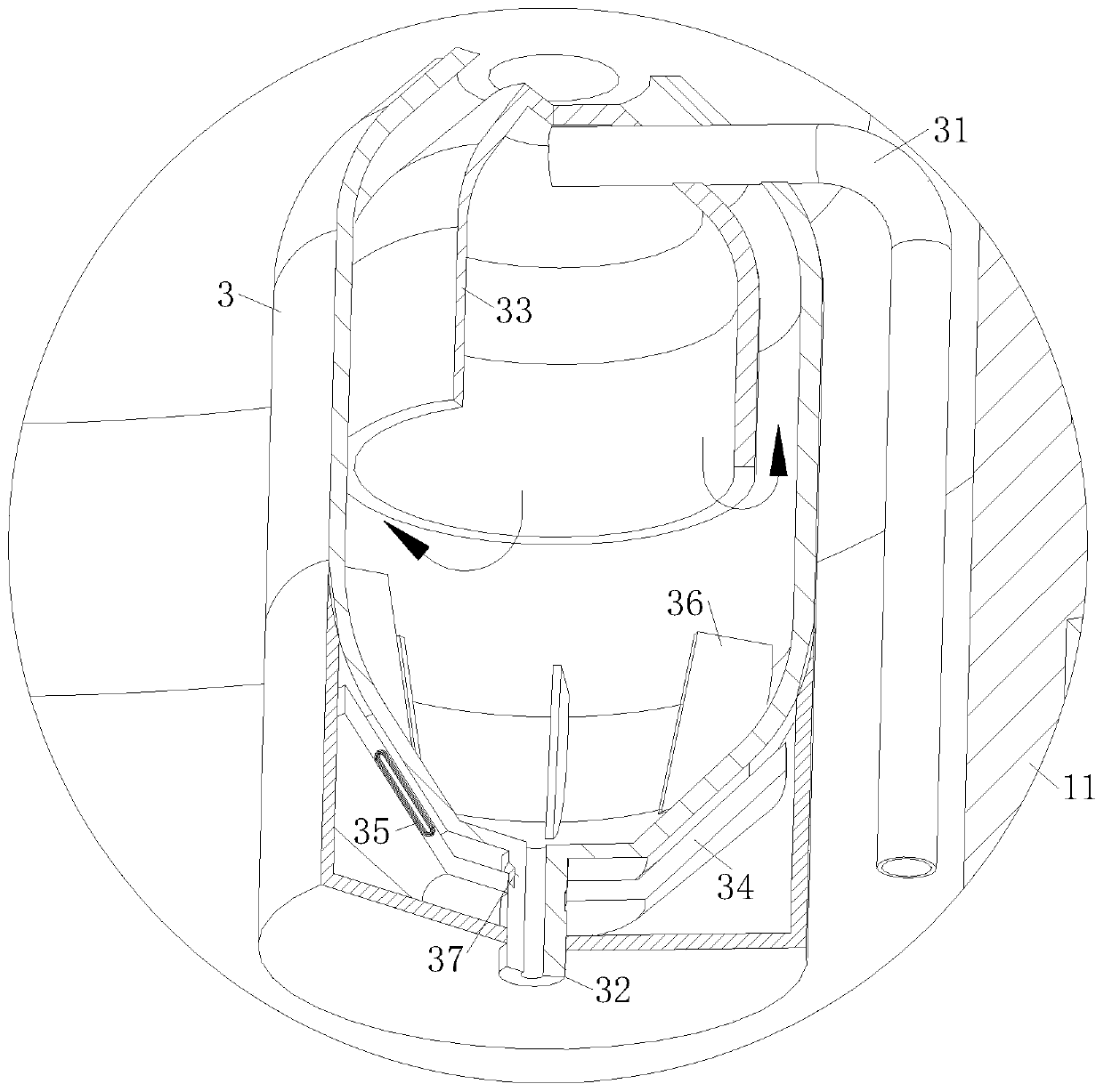

High-concentration suspended substance electric-flocculation/floc separation precipitation integrated treatment device

ActiveCN105692814ACompact structureImprove space utilizationWater/sewage treatmentWaste water treatment from vehicle washingHigh concentrationFlocculation

The invention provides a high-concentration suspended substance electric-flocculation / floc separation precipitation integrated treatment device which comprises a flocculation purifier and a controller connected with the flocculation purifier, wherein the flocculation purifier is a cone-cylinder container of which the upper part is a cylinder and the lower part is a cone; a flocculation reaction region positioned in the cylinder region, a floc separation region and a floc precipitation region positioned in the cone region are arranged in the flocculation purifier; a water body guide tank and a plurality of electric-flocculation electrode sheet sets connected in series are arranged in the flocculation reaction region; the water body guide tank guides the water body to sequentially flow through the electrode sheet sets to perform multiplex flocculation; the upper part of the flocculation reaction region is provided with an air compressor and a water inlet pipe; and the controller is used for controlling the flow rate of the influent water and the working parameters of the electrolysis electrodes. The device has the advantages of compact structure, continuous process and high space utilization ratio, prolongs the contact time between high-concentration suspended substances and active substances generated by the electrolytic anode, and ensures the high-concentration suspended substance treatment effect.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

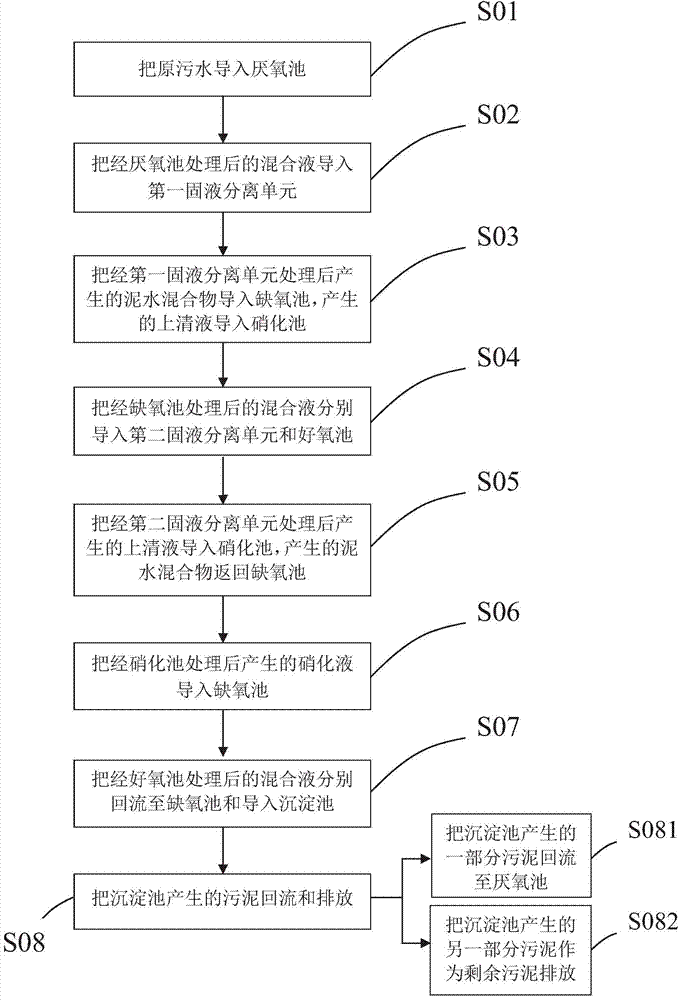

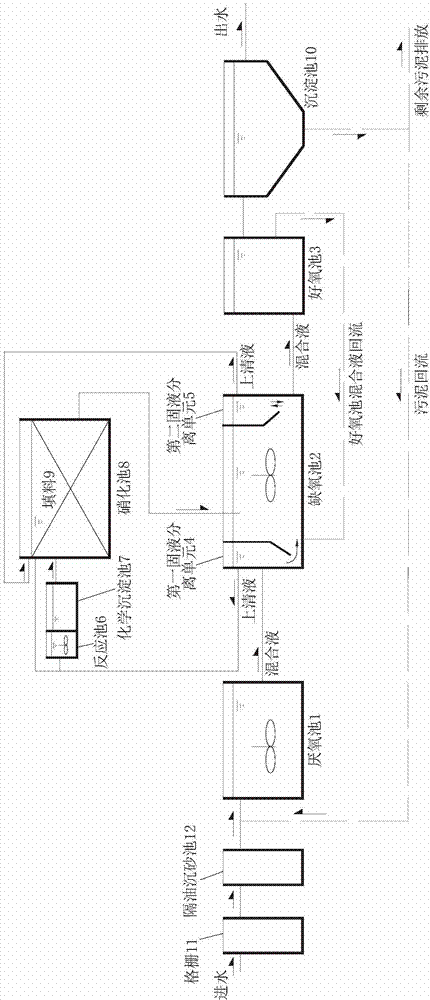

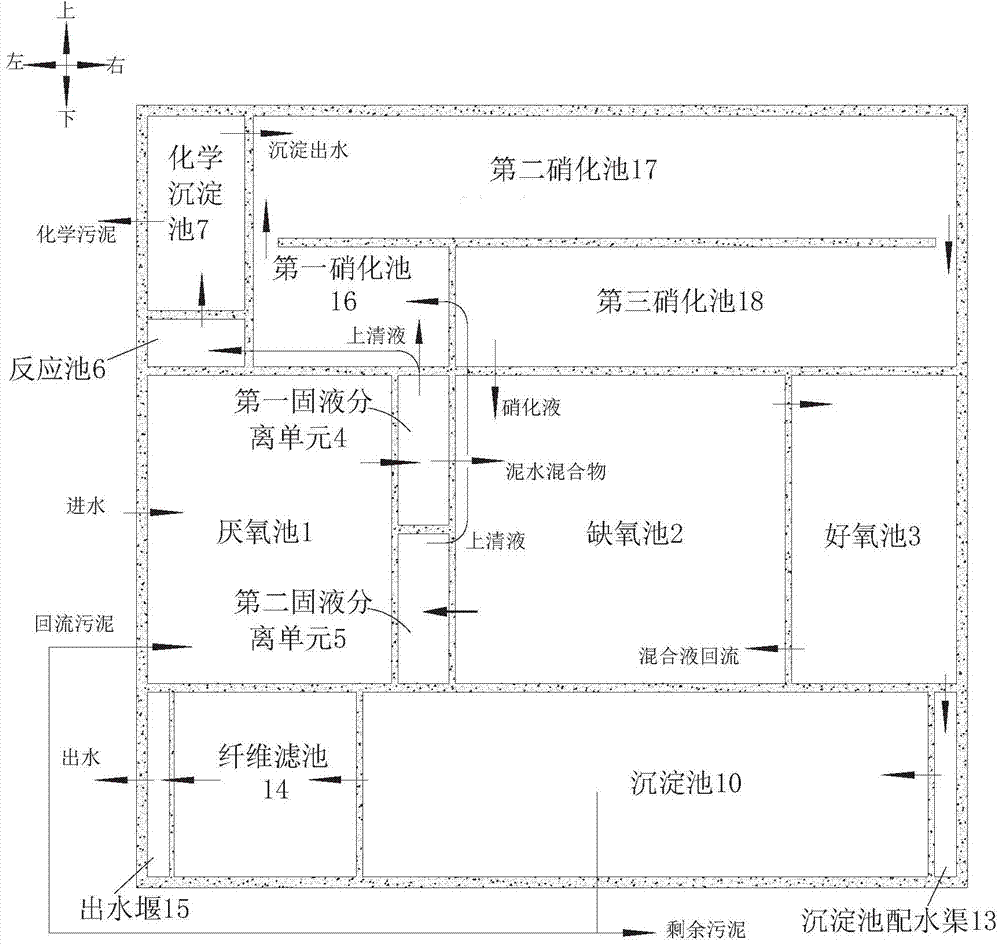

Method and device for advanced sewage nitrogen and phosphorus removal

ActiveCN103482829AOvercoming the Sludge Age (SRT) ParadoxSolve problemsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentNitrogen removalAfter treatment

The invention discloses a method and device for advanced sewage nitrogen and phosphorus removal. The method comprises the steps of (I) guiding raw sewage into an anaerobic tank; (II) guiding the mixed liquid after treatment in the anaerobic tank into a first solid-liquid separation unit, guiding the supernate into a nitrifying tank, and guiding the produced mud-water mixture into an anoxic tank; (III) guiding the mixture after treatment in the anoxic tank into a second solid-liquid separation unit and an aerobic tank respectively; (IV) guiding the supernate produced after treatment by the second solid-liquid separation unit into the nitrifying tank, and returning the mud-water mixture into the anoxic tank; (V) guiding the nitrified liquid after treatment in the nitrifying tank into the anoxic tank; (VI) enabling the mixed liquid after treatment in the aerobic tank to flow back to the anoxic tank, and guiding into a sedimentation tank; (VII) performing backflow and discharge on the sludge produced by the sedimentation tank. By adopting the method and device disclosed by the invention, the competition conflict for a carbon source between phosphorus removal and nitrogen removal of the sewage treatment system is solved, advanced sewage phosphorus and nitrogen removal can be realized, and the standing time of the solid-liquid separation unit is short. The method and the device are suitable for building a new sewage plant, and the transformation of an existing sewage plant is easily realized by separating tanks of the A2 / O technology.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

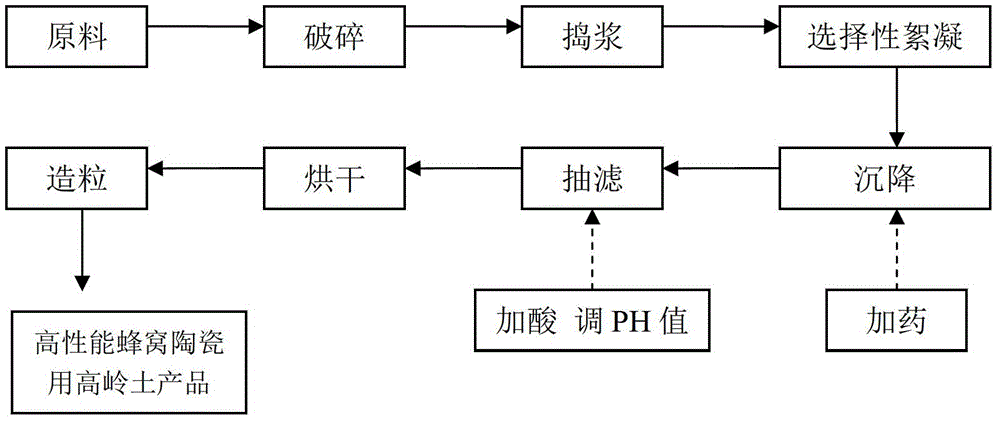

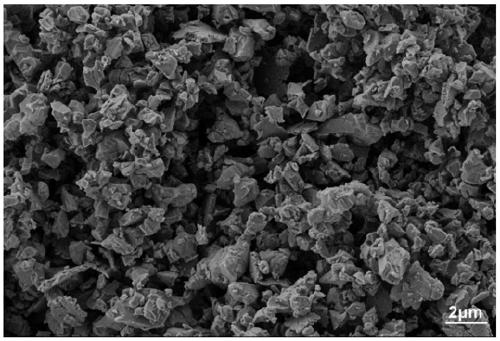

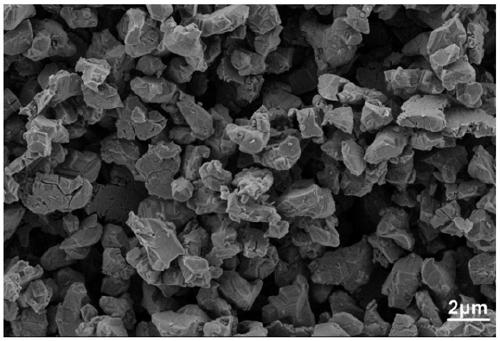

Preparation method of kaolin for high-performance honeycomb ceramic

The invention relates to a preparation method of kaolin for high-performance honeycomb ceramic, which is characterized by sequentially comprising the following steps: crushing; pulping; selectively flocculating; settling, controlling the mass concentration of the ore pulp at 12-18%, adding water glass of which the mass concentration is 7-13% and sodium hexametaphosphate, measuring the temperature and liquid level of the ore pulp in a settling basin, calculating the settling time according to a simplified empirical formula t=Tn*h / d2 based on the Stokes law (wherein d in the simplified formula represents the granule size of granules and is valued at 3), and standing at the settling time, wherein after standing, the granule size of granules of the underlayer ore pulp is more than 3 micrometers, and the granule size of granules of the supernatant ore pulp is less than 3 micrometers; and performing vacuum filtration, drying, and granulating to ensure that the mass percent of Fe2O3 contained in the kaolin product is less than or equal to 0.20%, the sum of the mass percents of contained K2O and Na2O is less than or equal to 0.4%, the content of granules of which the granularity is less than 2 micrometers is more than or equal to 91% and the bulk density is 0.30-0.36g / cm<3>. Thus, the invention satisfies application in high-performance honeycomb ceramic industry.

Owner:中国高岭土有限公司

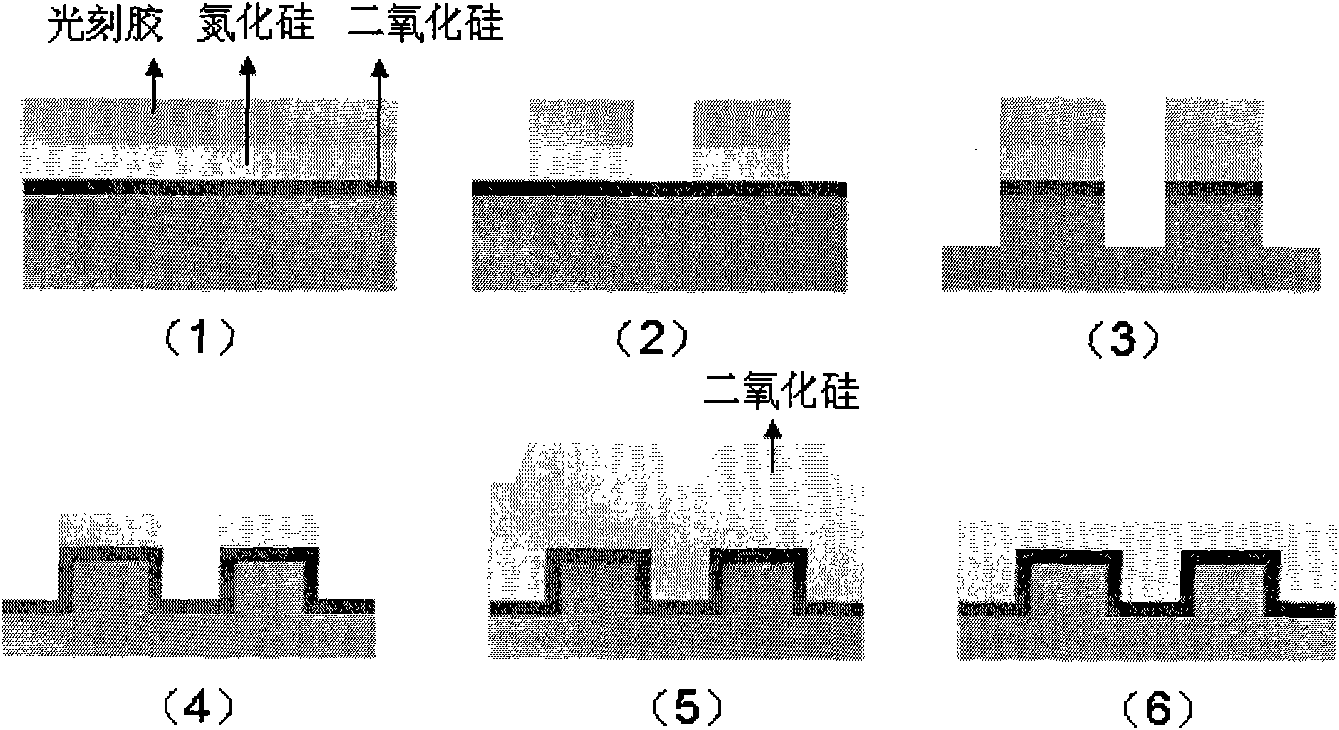

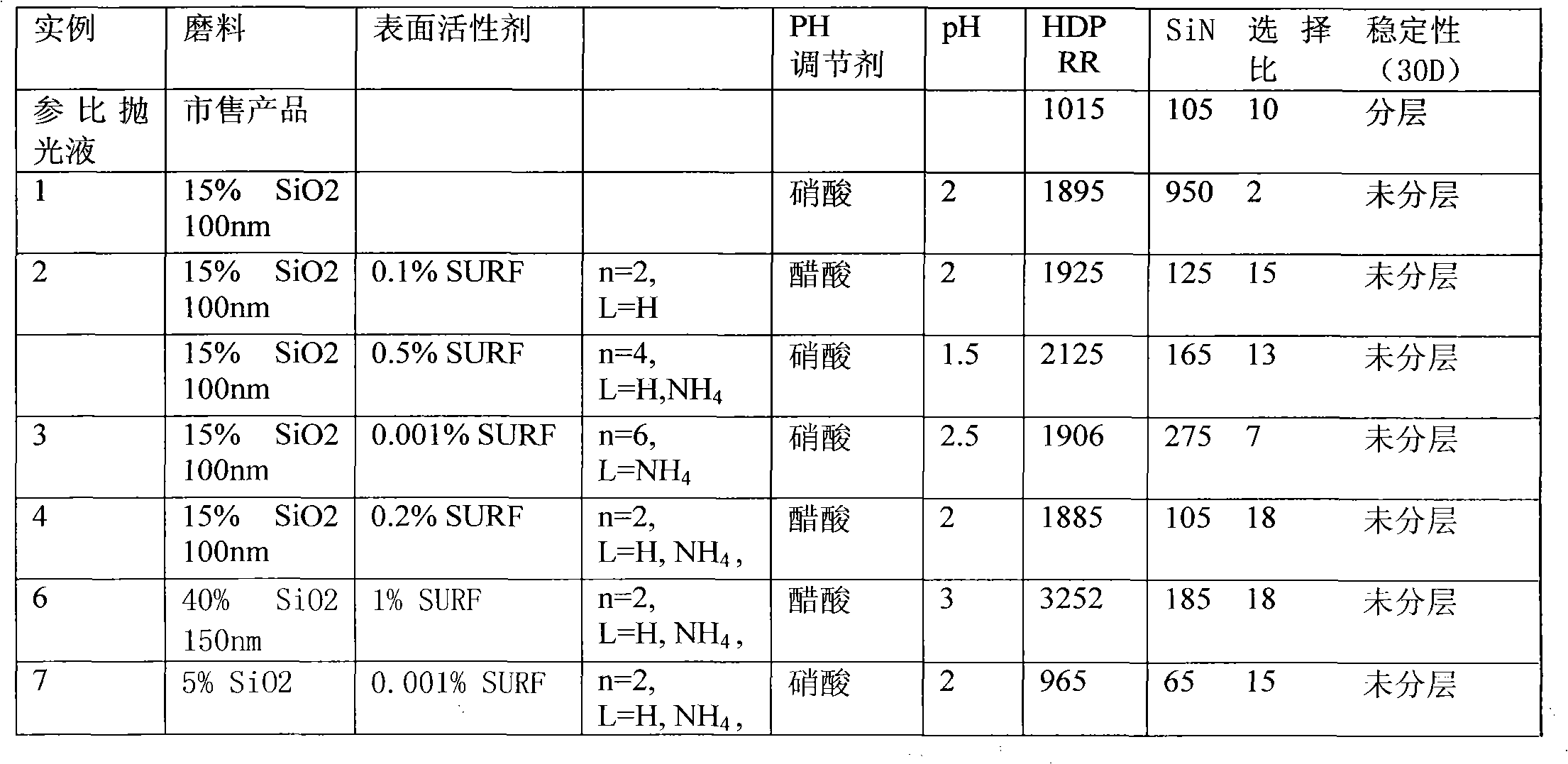

Chemically mechanical polishing solution

InactiveCN102464945AHigh HDP removal rateProlong settling timePolishing compositions with abrasivesWater solubleHigh silica

The invention discloses a chemically mechanical polishing solution used for shallow-trench isolation. The polishing solution at least contains one silicon-based abrasive material, one water-soluble anionic surfactant and one pH regulator, and has higher silica removal rate and lower silicon nitride removal rate, a polished surface is smooth and clean, and the chemically mechanical polishing solution has good stability and is suitable for the chemical-mechanical planarization for the shallow-trench isolation.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Nickel-containing industrial wastewater treatment device and process

InactiveCN107759006AProlong settling timeEasy to handleTreatment using aerobic processesWater contaminantsConstructed wetlandElectroless nickel

The invention discloses a device and a process for treating nickel-containing industrial wastewater. The device comprises a set of combined reactors, chemical nickel wastewater and electronickelling wastewater are respectively treated with a chemical precipitation method, the precipitation time is prolonged, and the natural precipitation and water discharge is realized. Ammonia nitrogen is treatedby an ammonia nitrogen blowing and lifting device, and finally, the COD (chemical oxygen demand) is efficiently treated in a classified manner with an anaerobic-aerobiotic-artificial wetland system combination method. The actual nickel-containing industrial wastewater is inflow water, nickel is removed and recovered in the form of a chemical precipitate by controlling the material addition amountand the reaction time, meanwhile, the COD and the ammonia nitrogen are efficiently removed with a physical-biological combination method, and finally, effluent reaches the national discharge standard. On the basis that the wastewater is effectively treated, the recovery of the nickel is improved, and the device and the process have the advantages of simple process method, low operating cost and the like.

Owner:HUNAN UNIV

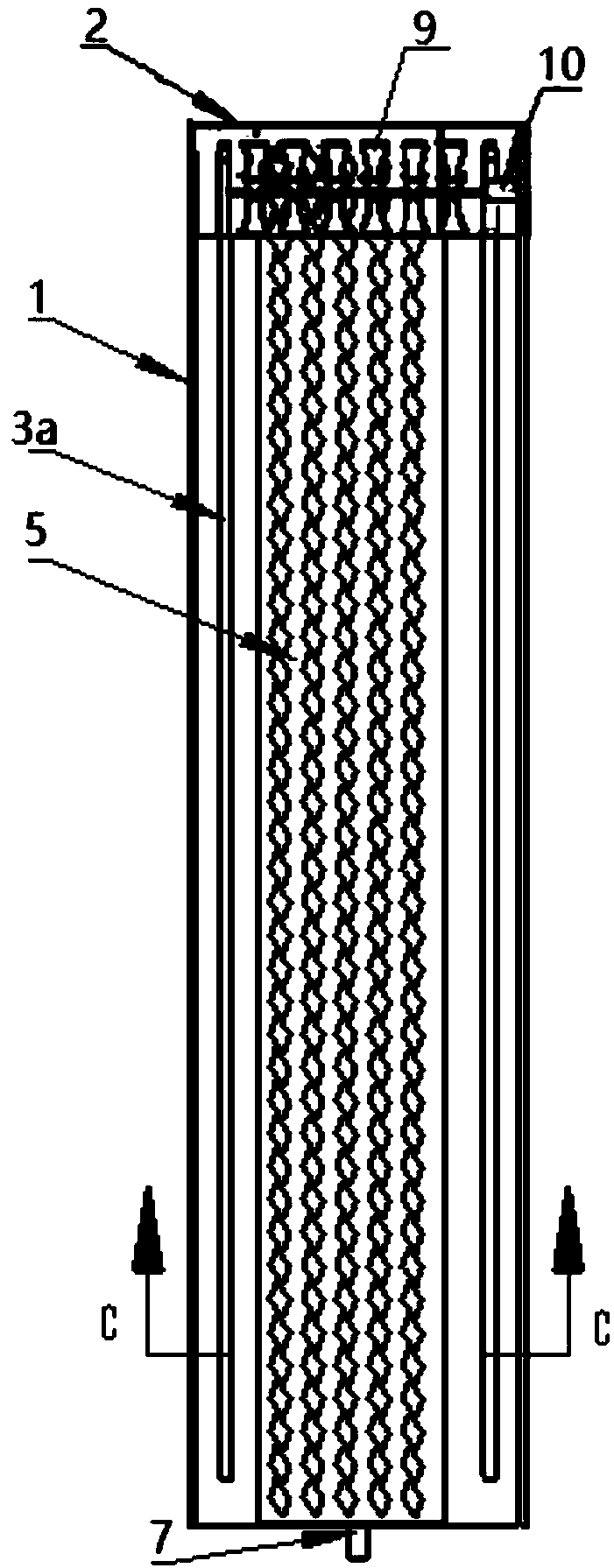

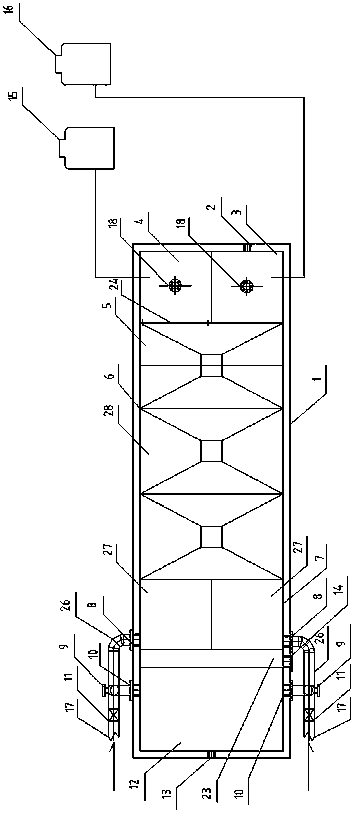

Fluidized bed reactor

ActiveCN101721961BGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

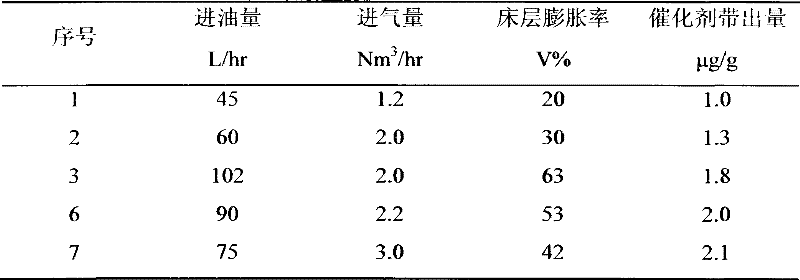

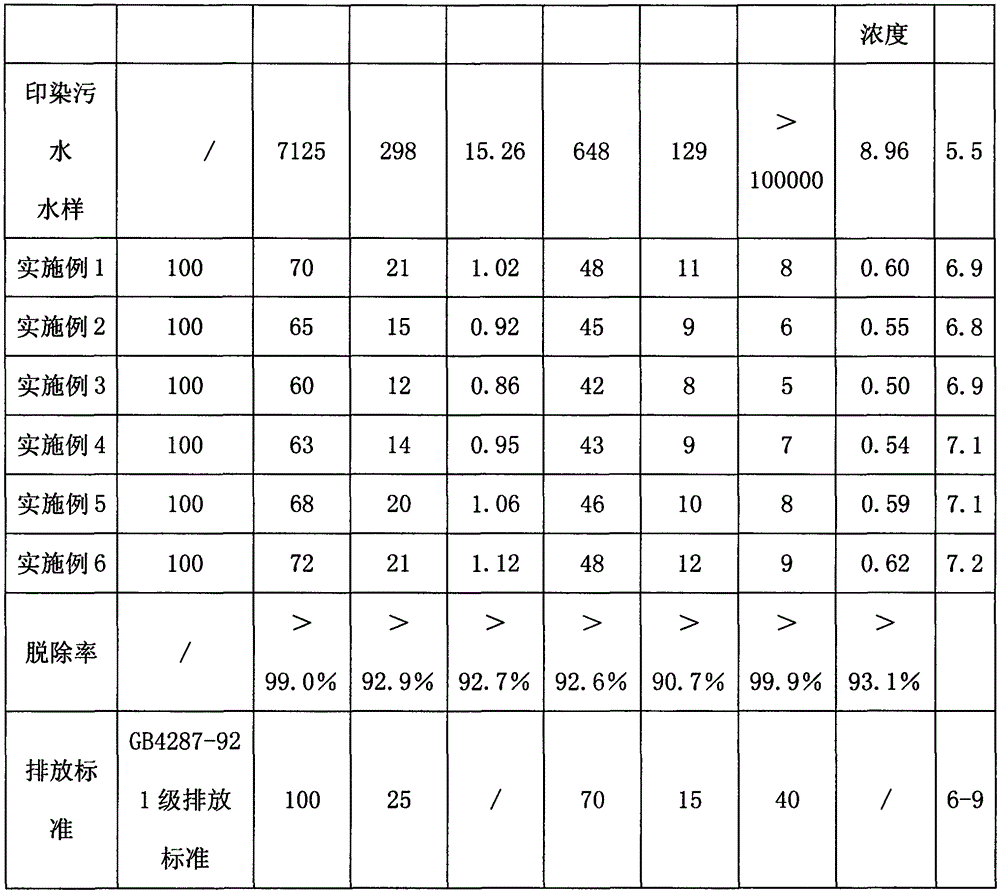

Dyeing wastewater treating agent and preparing method thereof

InactiveCN105084481AStrong adsorption capacityProlong settling timeWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationActivated carbonUrea

The invention discloses a dyeing wastewater treating agent and a preparing method thereof. The dyeing wastewater treating agent is prepared from aluminum hydroxide gel, sodium metaaluminate, lime, grain starch, sodium silicate, sodium lignin sulfonate, activated carbon, a powder auxiliary, urea and water. The aluminum hydroxide gel, the sodium metaaluminate, the sodium silicate, the sodium lignin sulfonate, the activated carbon and the powder auxiliary are sequentially added to a reaction kettle, the lime is added into water to prepare lime water, the lime water is slowly added into the reaction kettle while being stirred, heating is conducted at a constant temperature, and stirring is even; then, cooling is conducted, and the grain starch and the urea are added to be evenly stirred at the constant temperature. According to the dyeing wastewater treating agent and the preparing method thereof, organic pollutants and heavy metal in wastewater can be effectively removed, the settling time of aggregates can be shortened, the cost of wastewater treatment is reduced, and the efficiency of wastewater treating is improved.

Owner:宁波保税区维迪克环保科技有限公司

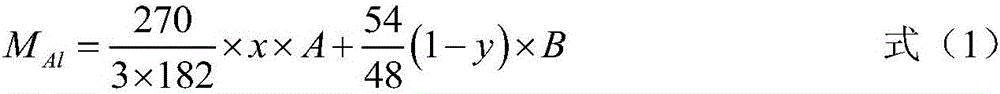

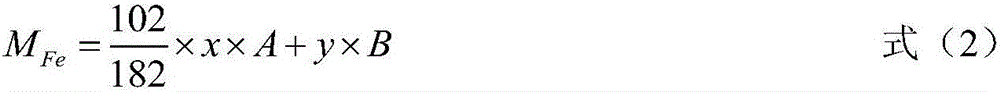

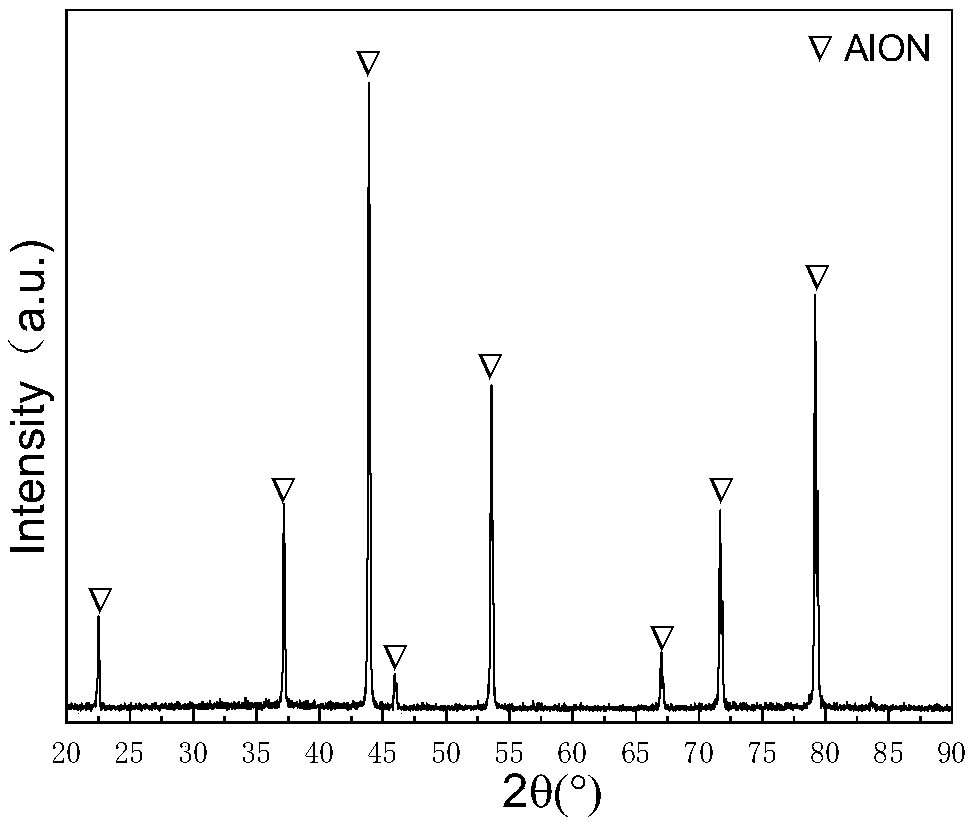

Fractionation method for AlON transparent ceramic powder

The invention relates to a fractionation method for an AlON transparent ceramic powder, and relates to the technical field of preparation of transparent ceramic powders. The fractionation method for the AlON transparent ceramic powder comprises the following steps: mixing the AlON transparent ceramic powder, a dispersing agent PVP (Poly Vinyl Pyrrolidone) and a solvent absolute ethyl alcohol to obtain an AlON suspension; after carrying out repeated centrifugal separation on the suspension, carrying out washing by utilizing the absolute ethyl alcohol; and carrying out drying. By adopting the fractionation method for the AlON transparent ceramic powder, which is disclosed by the invention, the powder does not need to be preprocessed; the solvent is the absolute ethyl alcohol and is toxic-free and harmless; the PVP is adopted as the dispersing agent; and by controlling a rotating speed and centrifugation time of a centrifugal machine, effective separation on different sizes of particles in the AlON powder can be implemented. Moreover, in the separation process, introduction of harmful impurities is avoided; the suspension is stable in performance and long in settling time; the fractionation method is convenient to operate; and after separation, the PVP can be effectively removed by ethanol washing.

Owner:DALIAN MARITIME UNIVERSITY

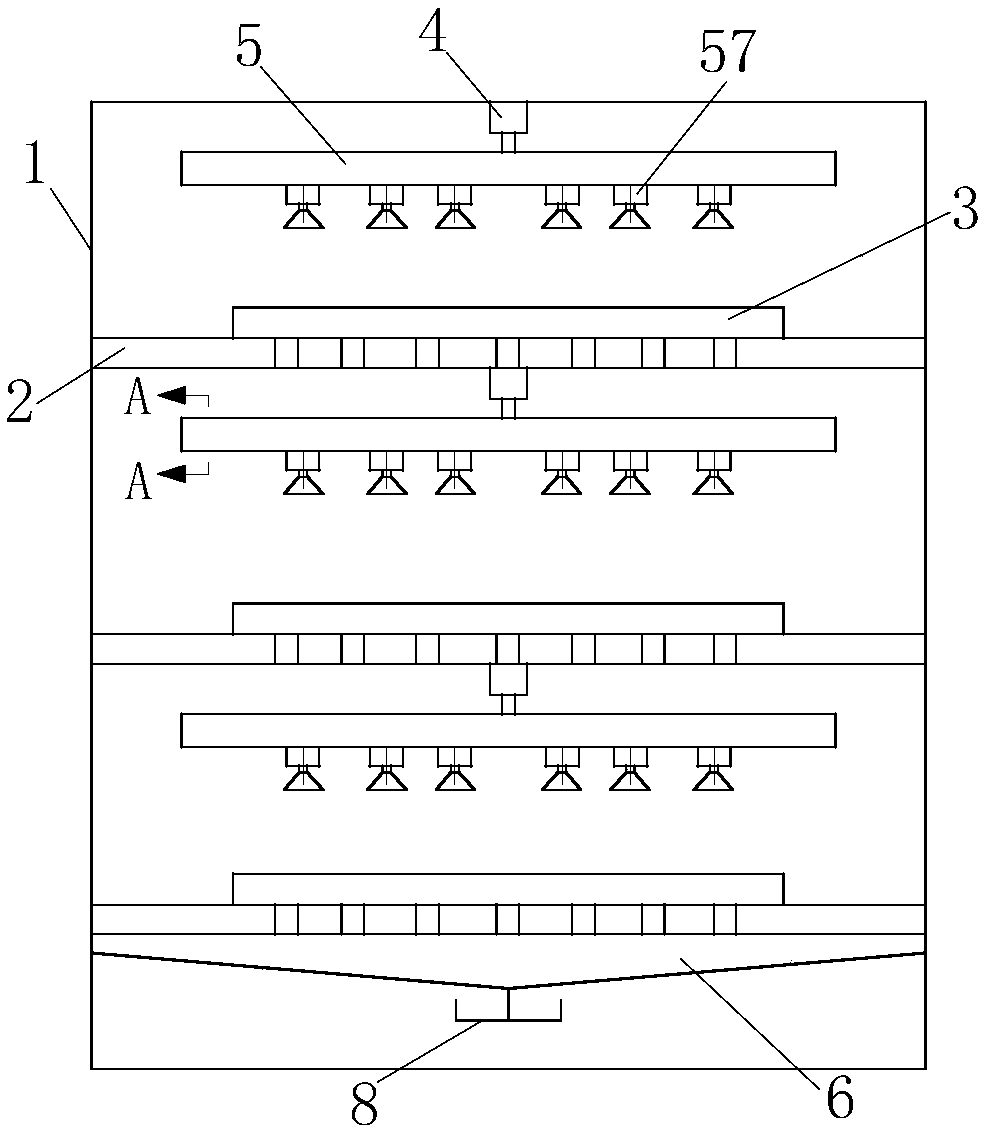

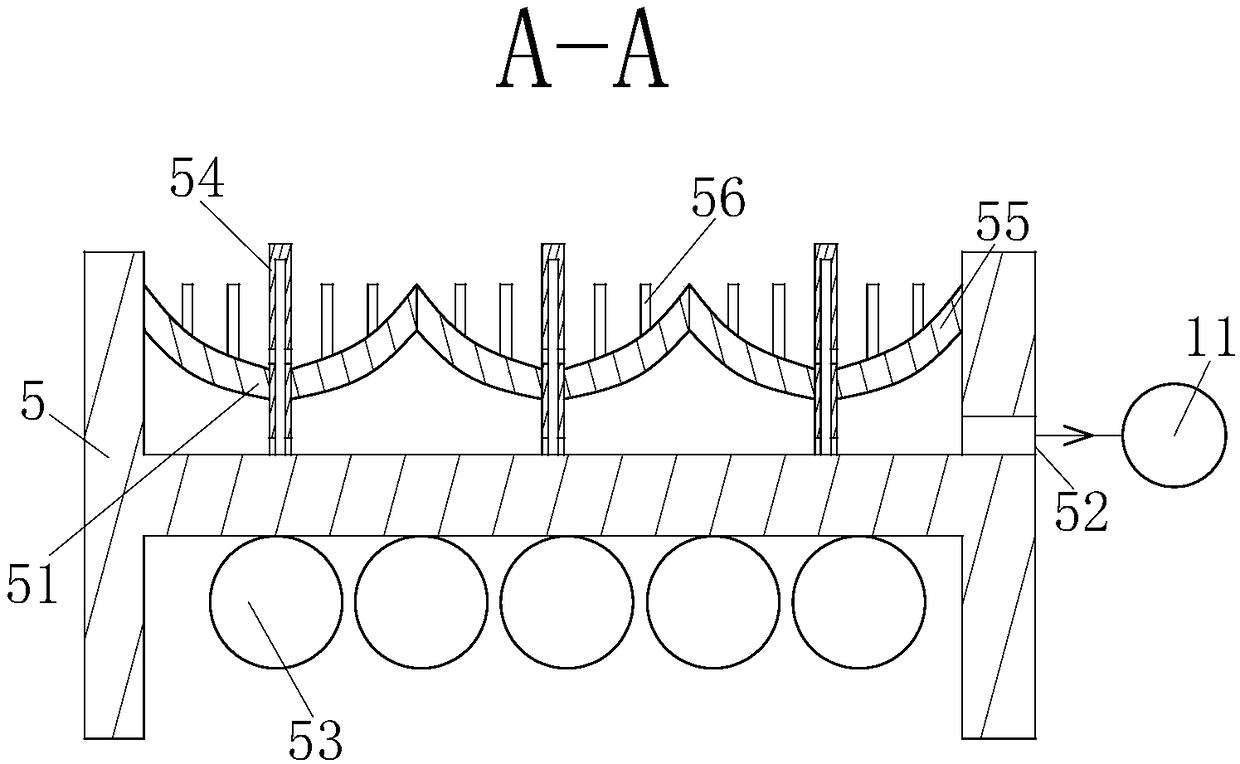

Intelligent cultivation system of plant factory

ActiveCN108887038AImprove practicalityAvoid wastingClimate change adaptationPressurised distribution of liquid fertiliserBreathingFixed frame

The invention belongs to the technical field of plant culture, in particular to a plant factory intelligent culture system, comprising a cultivation box, a fixing frame, a culture basin, an air cylinder and a lamp frame. The fixing frame is fixed in the cultivation box, and a through hole is arranged at the bottom of the fixing box, and the through hole is used for ventilation; The culture basin is arranged on a fixed frame, and a through hole 2 is arranged at the bottom of the culture basin, the culture basin is used for cultivating plants, and the through hole 2 is used for breathing; A plurality of cylinders are arranged at the top of the box body and the bottom of the fixing frame respectively; The lamp frame is arranged in the cultivation box through an air cylinder and a piston rod;The invention is suitable for cultivating large quantities of plants, and the cultivated plants have high quality.

Owner:花垣县十八洞泡桐中药材种植有限公司

Equipment for removing lead in wastewater of lead storage battery

ActiveCN104003553AMake sure the effluent contains leadEfficient removalMultistage water/sewage treatmentWater dischargeWastewater

The invention discloses equipment for removing lead in wastewater of a lead storage battery. The equipment is characterized by comprising a first-stage reaction zone, a second-stage reaction zone, a settling zone, a filtering zone and an effluent zone, wherein a water inlet is formed in the upper end of the side wall of the first-stage reaction zone; the first-stage reaction zone is connected with the second-stage reaction zone by virtue of a first-stage reaction zone water outlet in the lower end of the first-stage reaction zone; the second-stage reaction zone is connected with the settling zone by virtue of a second-stage reaction zone water outlet; the settling zone is connected with the filtering zone and is used for distributing water in an overflowing water discharge mode; the filtering zone is connected with two sides of the effluent zone by virtue of filtering zone water outlet tubes at bottoms on two sides of the filtering zone; the first-stage reaction zone is further connected with a lead removing agent adding device; the second-stage reaction zone is connected with a coagulation aid agent adding device. The equipment is simple to operate, high in treatment efficiency and small in occupied area, an efficient lead removing technique, a settlement technique and a filtration technique are integrated, and the problems that lead-containing wastewater of the conventional lead storage battery industry cannot stably meet the standard after being treated and a great amount of hazardous wastes are generated are solved.

Owner:NANJING GW ENVIRONMENT ENG

Low-production-cost polydopamine compound oil paint flocculant

InactiveCN106587375AReduce common ingredientsStable common ingredientsWater treatment compoundsSpecific water treatment objectivesFlocculationMicrosphere

The invention discloses a low-production-cost polydopamine compound oil paint flocculant which is prepared by the following steps: (1) separation and purification of strains; (2) screening of the strains; (3) fermentation cultivation of the strains; and (4) preparation of compound magnetic microspheres. The flocculant has the beneficial effects that the flocculation speed is high, the settling time is long, the feeding quantity is small, common components in oil paint can be stably coagulated, the wastewater treatment cost can be lowered, and the application prospects are wide.

Owner:TIANCHANG YINHU PAINT

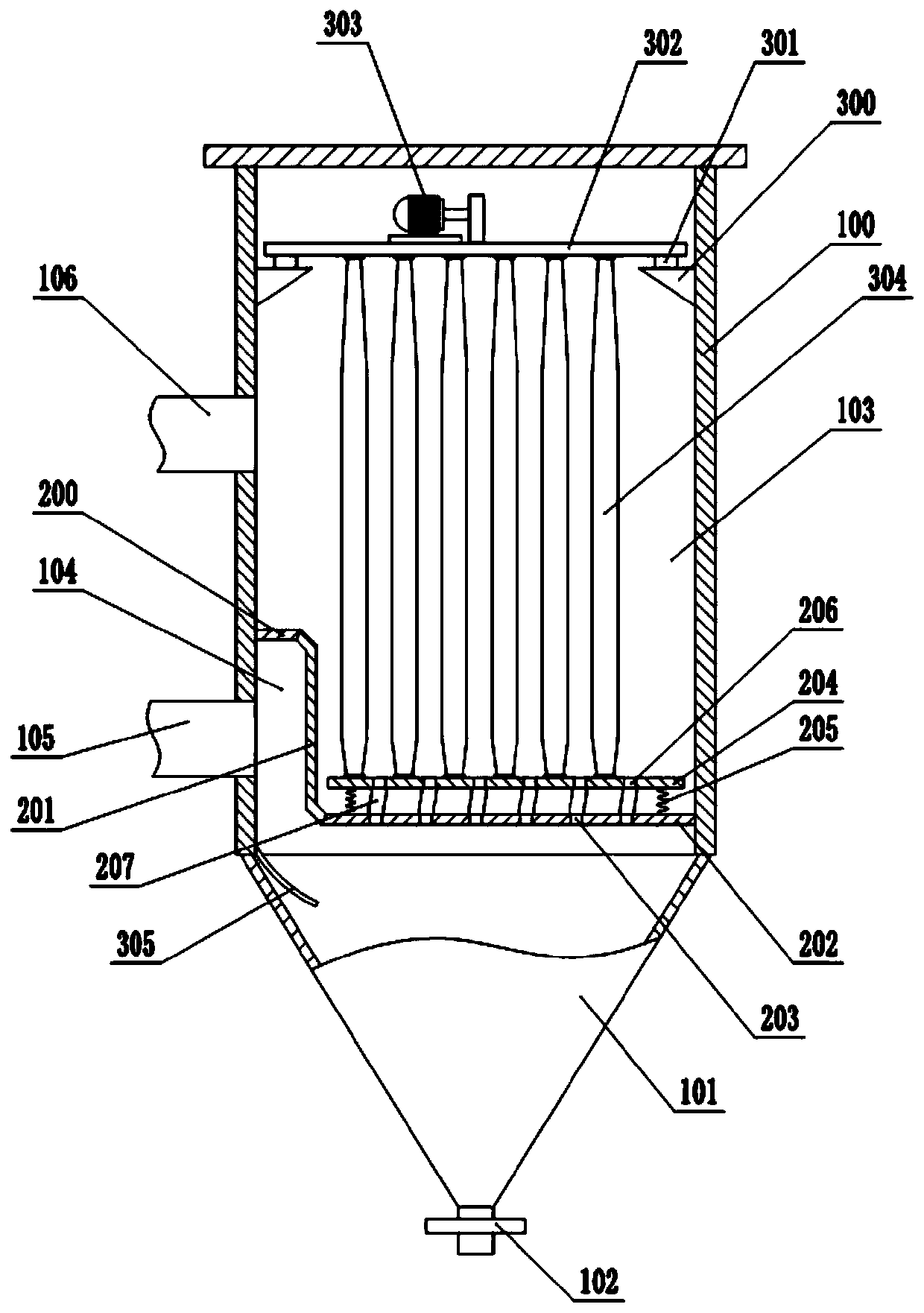

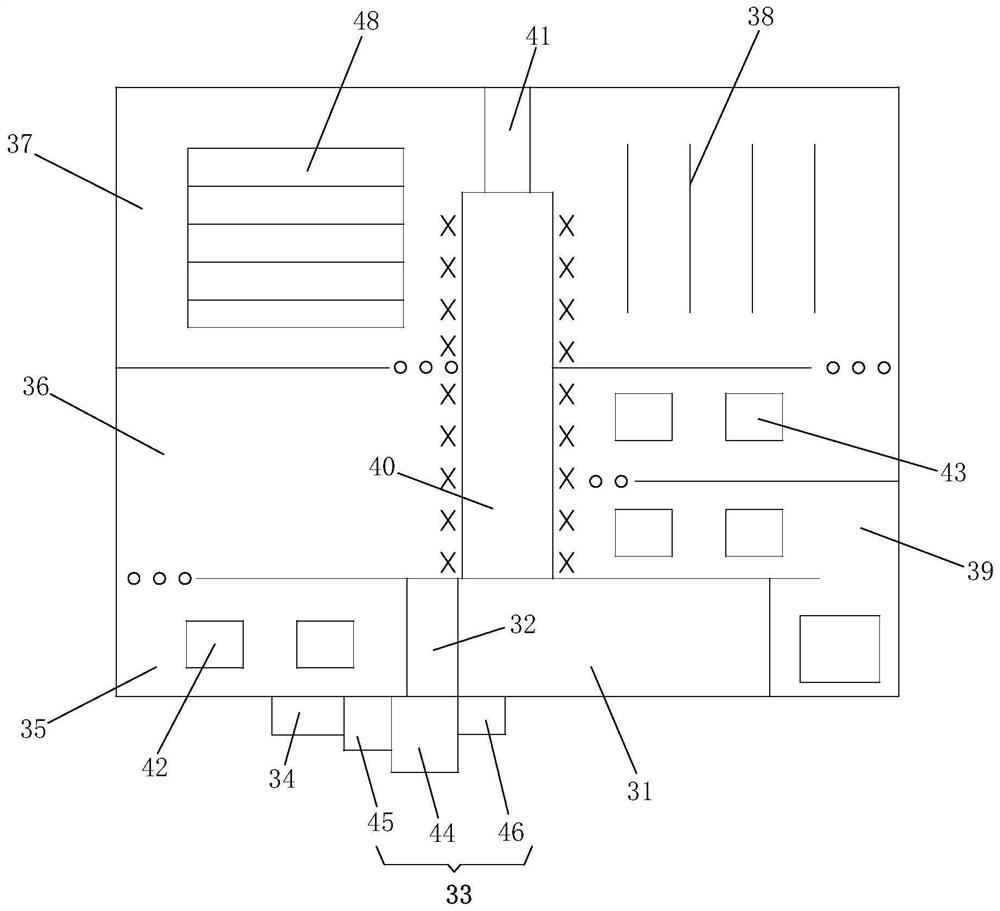

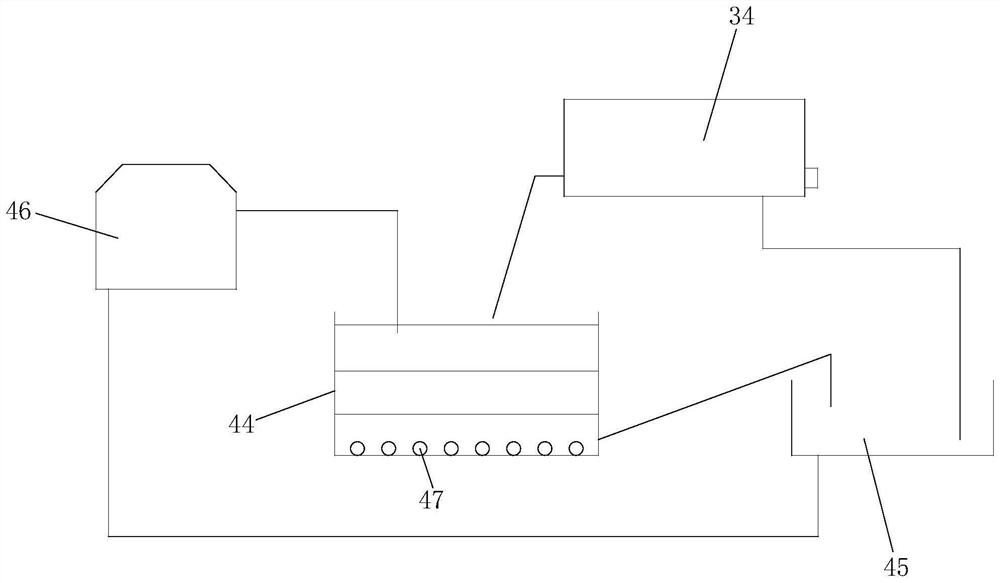

Dust remover for dumping furnace self-baking electrode volatile matter

ActiveCN110339640AExtended service lifeReduce pulling forceCombination devicesDispersed particle filtrationEngineeringElectrode

The invention relates to the technical field of waste-gas treatment equipment, and particularly discloses a dust remover for dumping furnace self-baking electrode volatile matter. The dust remover comprises a box body and an ash hopper; a partition plate is laterally fixed in the box body, the partition plate divides the box body into a purification chamber and a cleaning chamber, and the partition plate is provided with a plurality of through holes I; the box body is provided with a gas inlet communicating with the purification chamber and a gas outlet communicating with the cleaning chamber,a plurality of filter bags located above the partition plate is vertically arranged in the box body, and a vibrating unit vibrating the filter bags is arranged in the box body; and a buffer plate isarranged above the partition plate, the bottoms of the filter bags are fixed on the buffer plate, the baffle plate is connected with the partition plate through elastic parts, the buffer plate is provided with a plurality of through holes II, and each middle pipe communicates with one corresponding through holes I and one corresponding through holes II. The dust remover provided by the invention can solve the problem that connection positions of filter bags and a partition plate are broken because the connection positions are pulled during vibration in the prior art.

Owner:重庆市赛特刚玉有限公司

Pond engineering circulating water zero-discharge culture system

ActiveCN112335596AEasy to handleShort solution timeWater contaminantsWaste water treatment from animal husbandryWaste collectionSewage

The invention discloses a pond engineering circulating water zero-discharge culture system. The culture system comprises a culture area, a sewage collection area, a waste collection area, a solid-liquid separation device, a purification area I, a filter feeding area, a sedimentation area, a biochemical area and a purification area II. The sewage collection area is used for collecting sewage generated in the culture area, and the waste collection area is used for collecting sewage in the sewage collection area and conducting layering; the solid-liquid separation device is used for carrying outsolid-liquid separation on the bottom-layer sewage, and the purification area I is provided with an aquatic plant floating bed I; filter feeding organisms are cultured in the filter feeding area, andthe sedimentation area is used for settling the sewage; the biochemical area is used for receiving supernatant liquor and supernatant liquid and performing aeration treatment on mixed liquid; and thepurification area II is used for purifying and treating the mixed liquid treated by the biochemical area and conveying a purified water body to the culture area. According to the sewage collection area, a flow field in circulating water and a space of an outer pond are reasonably utilized, culture tail water treatment and production are organically combined together, 60%-90% of water body area canbe used for tail water treatment, and large-density culture can be realized.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

Industrial waste gas cyclone desulfurization dust collector

InactiveCN110613998AImprove the effect of gas-liquid separationPrevent outflowCombination devicesGas treatmentCycloneFlue gas

A gas inlet pipe is arranged on one side of the exterior of a dust remover body, a conical hopper is arranged on one side of the lower portion of the dust remover body, and a circulating water tank isarranged on one side of the lower portion of the conical hopper; a circulating water pump is arranged on one side of the upper part of the circulating water tank, and a water outlet pipe of the circulating water pump is connected with an annular pipe which is provided with a plurality of uniformly-arranged spray heads for spraying washing liquid to the inner wall of the dust remover body to forma water film; a ventilating duct is arranged on one side in the dust remover body, a plurality of staggered flow guide plates are arranged on the inner wall of the ventilating duct, a water distribution pipe is arranged on one side of the top flow guide plate and connected with the annular pipe through a pipeline, and a plurality of nozzles are arranged on one side of the lower portion of the water distribution pipe; an air outlet pipe is arranged on one side of the dust remover body. The cyclone dust removal device is used for removing dust from flue gas, and the annular pipes with the nozzles are arranged in the dust remover body, so that a water film is formed on the inner wall of the dust remover body, the desulfurization and dust removal effects of the flue gas are enhanced, and the cyclone dust removal device is suitable for treating high-temperature flue gas.

Owner:邹德学

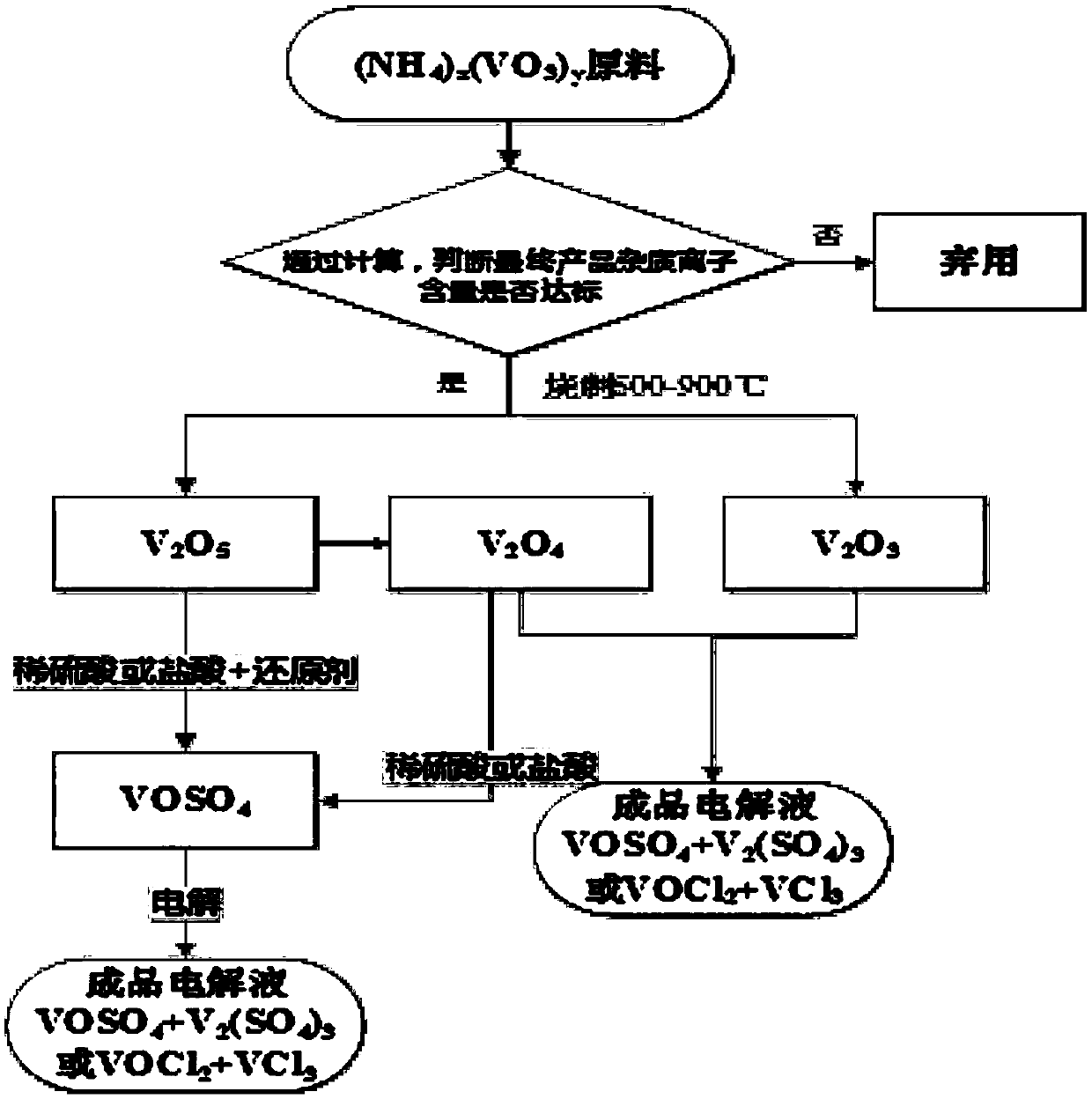

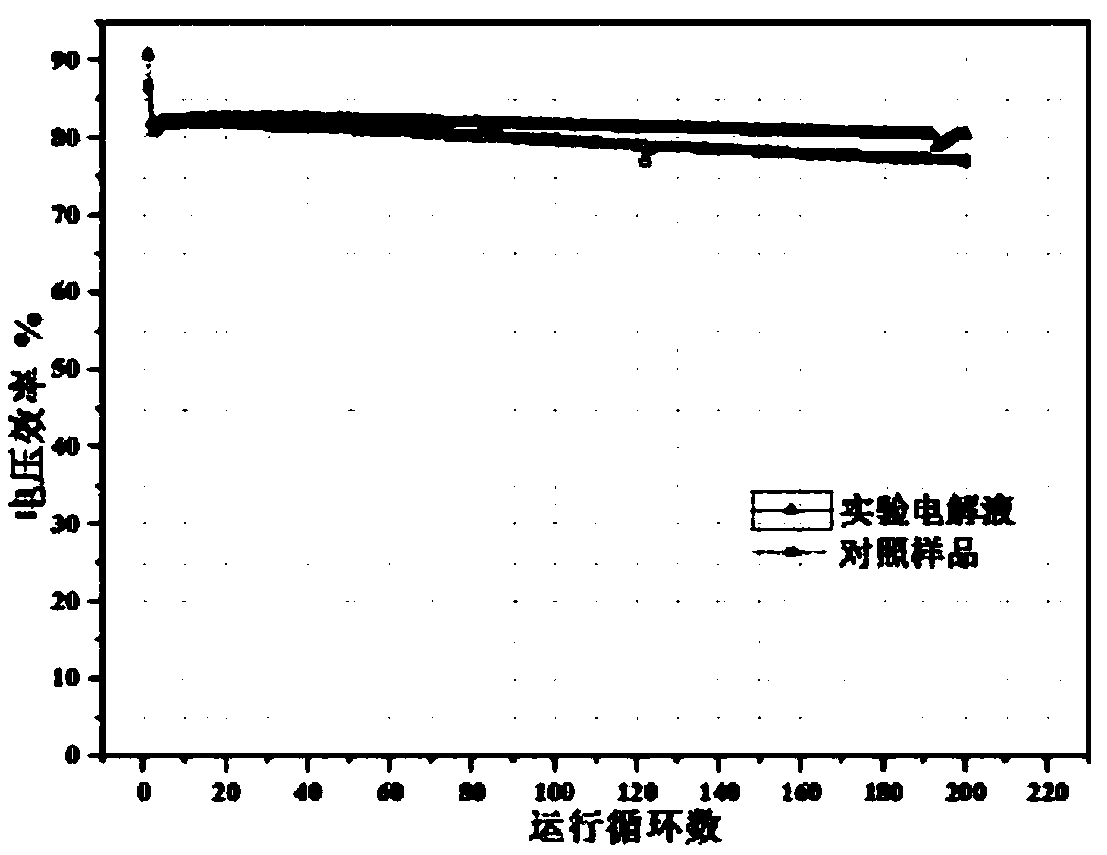

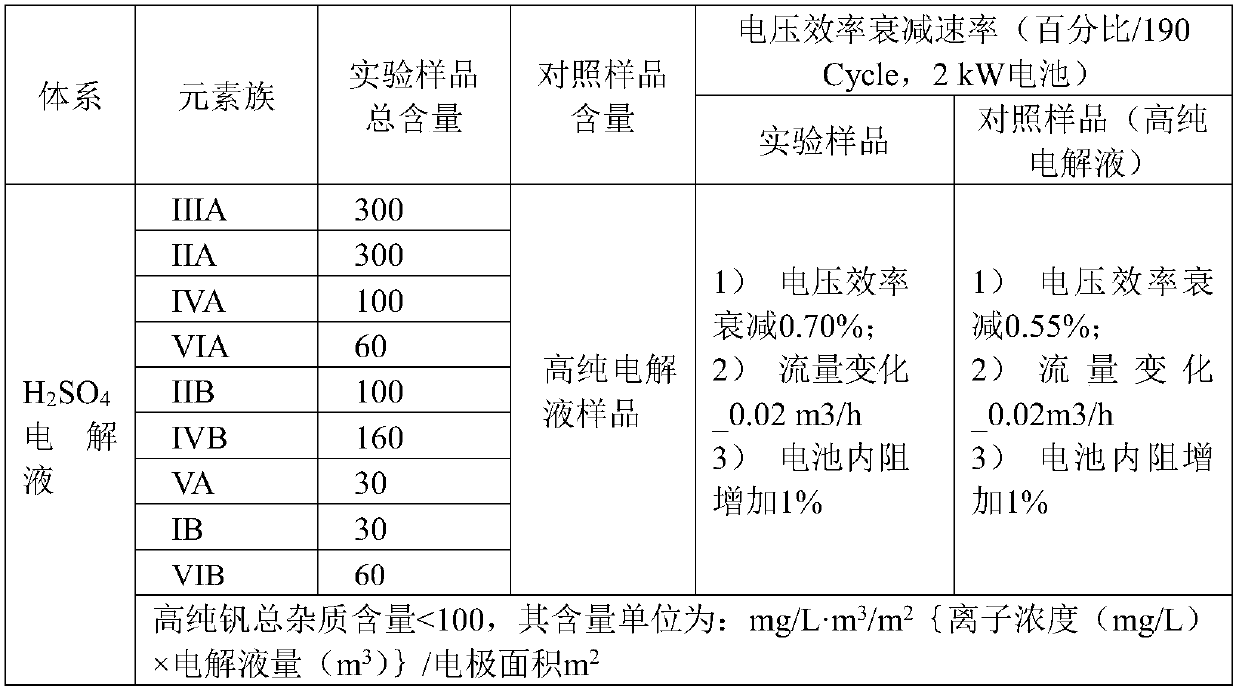

All-vanadium redox flow battery electrolyte formula and process for inhibiting precipitation of easily precipitated element impurities in electrolyte

InactiveCN111200153ALow raw material costReduce manufacturing costRegenerative fuel cellsAcid electrolytesElectrolytic agentEnvironmental engineering

The invention belongs to the field of inhibition of precipitation of easily precipitated elements in an electrolyte, and discloses an all-vanadium redox flow battery electrolyte formula and process for inhibiting precipitation of easily precipitated element impurities in the electrolyte. According to different precipitation characteristics and precipitation conditions of elements prone to precipitation, the highest limit value which can be borne by electrodes in a vanadium electrolyte and a battery is comprehensively considered, the elements prone to precipitation are controlled according to the concentration upper limit when a certain main group (or subgroup) exists at the same time or exists singly, and a concentration interval for long-time safe operation of the system is given. The content of the easily precipitated elements can be effectively controlled, the stability of the electrolyte is improved, the service life of equipment such as a battery resistor is prolonged, and the cost of the electrolyte is effectively reduced.

Owner:DALIAN RONGKE POWER

Industrial dyeing sewage treatment agent and preparation method thereof

InactiveCN105314723ALow costImprove processing efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEmission standardPalygorskite

The invention discloses an industrial dyeing sewage treatment agent and a preparation method thereof. The treatment agent is prepared from following components in mass percent: 25-35% of polyaluminum chloride, 10-12% of lime, 12-18% of grain starch, 9-11% of kaolinite, 4-6% of graphene, 10-12% of palygorskite, 14-16% of kieselguhr, 0.8-1.2% of potassium permanganate and 1.5-2.5% of bleaching powder; the preparation method comprises the following steps: respectively smashing lime, kaolinite, palygorskite and kieselguhr into powder, mixing, and fully and uniformly stirring, adding potassium permanganate, fully mixing, finally, sequentially adding polyaluminum chloride, grain starch, graphene, and bleaching powder, uniformly mixing, smashing, carrying out microwave treatment, bagging and sealing, so as to obtain the industrial dyeing sewage treatment agent. The industrial dyeing sewage treatment agent disclosed by the invention has a high agglomeration effect on organic pollutants and impurities in the dyeing sewage and can effectively remove pollutants in the sewage; the sedimentation time of condensation products is shortened, the sewage treatment efficiency is improved, and the treated sewage can reach the emission standards; the treatment agent is simple and convenient to produce and small in investment, takes effects quickly and is free of secondary pollution.

Owner:范洲卫

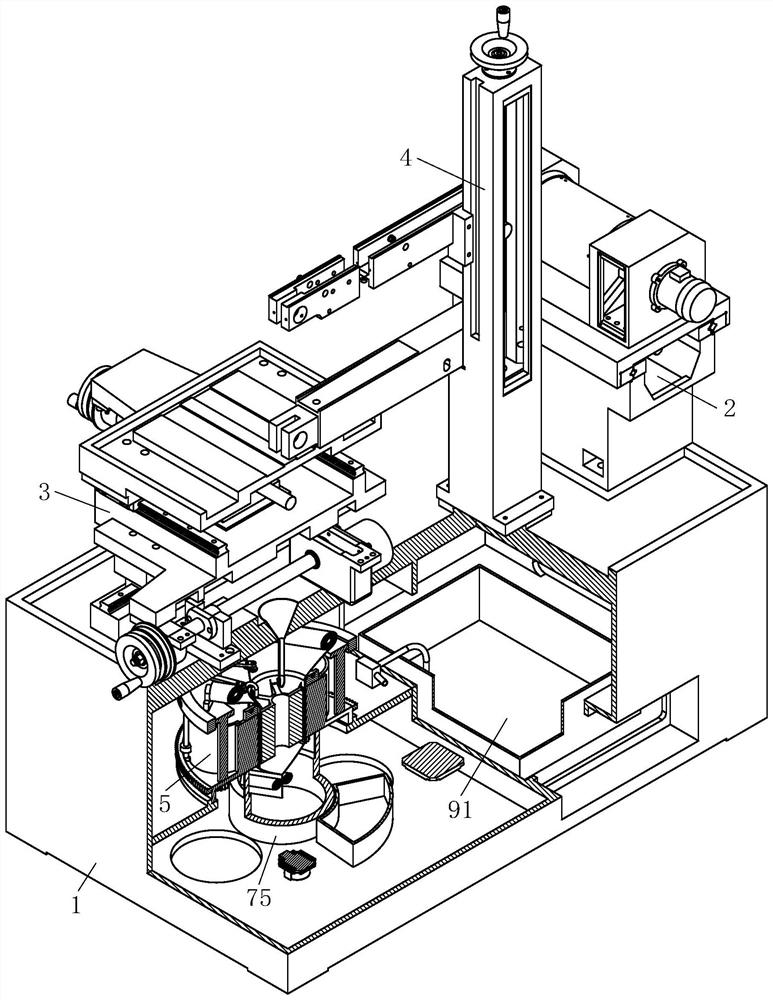

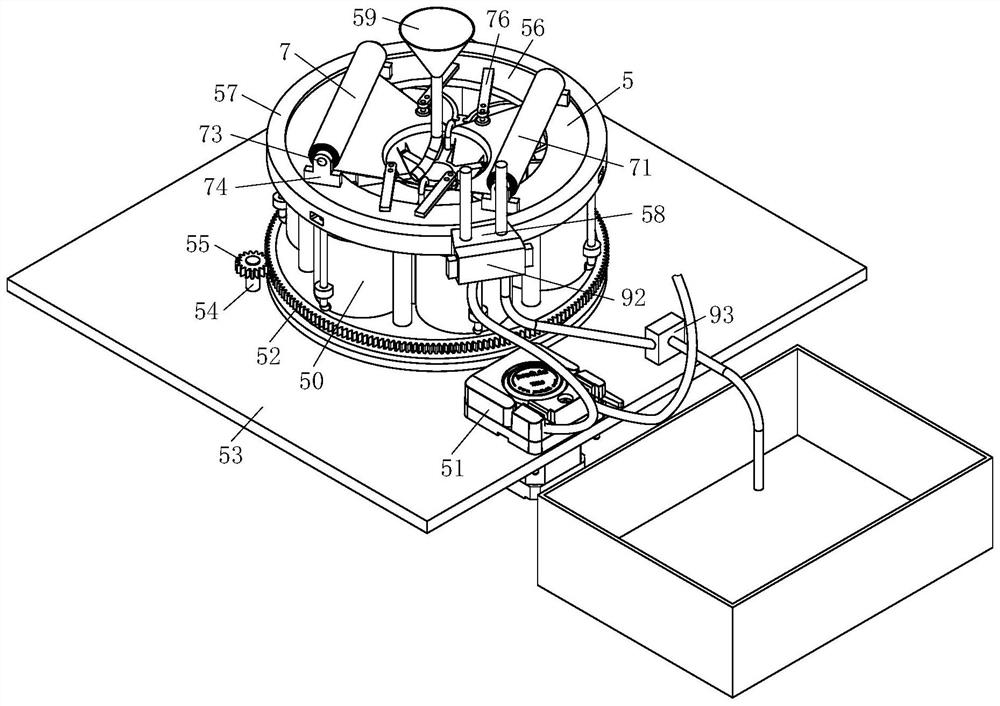

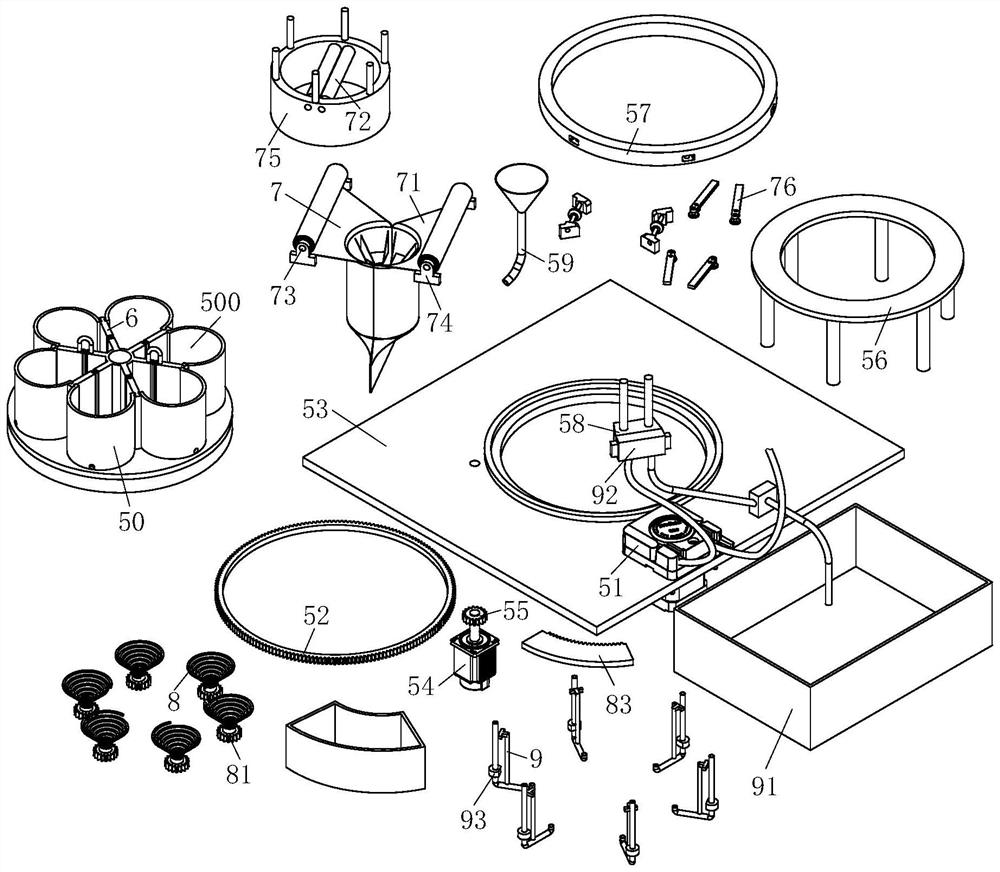

Energy saving and environmentally friendly electric spark oil and residue separating and recycling machine

ActiveCN111570941AProlong settling timeImprove settlement efficiencySedimentation separationMagnetic separationProcess engineeringEnvironmentally friendly

The invention belongs to the technical field of electric spark machining and specifically relates to an energy saving and environmentally friendly electric spark oil and residue separating and recycling machine. The energy saving and environmentally friendly electric spark oil and residue separating and recycling machine comprises a distillation unit; the distillation unit is used for distilling electric spark oil and residues to generate steam; condensing tank communicates with the top of the distillation unit through a gas exhaust pipe; a liquid collection tank communicates with the bottom of the condensing tank; the distillation unit comprises a main furnace; a material discharging pipe is arranged at the bottom of the main furnace; a material inlet is formed in one side of the top of the main furnace; the gas exhaust pipe is positioned on one side, far away from the material inlet, of a speed reduction motor; a speed reduction cylinder communicating with the gas exhaust pipe is arranged in the main furnace; the diameter of the speed reduction cylinder is two times larger than that of the gas exhaust pipe; and the speed reduction cylinder communicates with the interior of the main furnace through an L-shaped gas inlet pipe. According to the energy saving and environmentally friendly electric spark oil and residue separating and recycling machine, through the speed reductioncylinder, the speed of air flow is reduced, the oil residue powder entering into the gas exhaust pipe is reduced, and the purity of distillation oil product is increased.

Owner:浙江来福智能科技有限公司

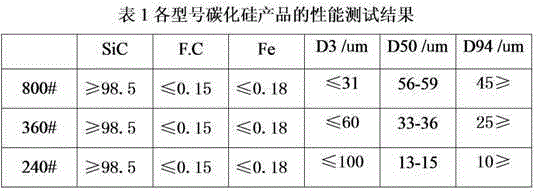

Recycle and reuse method of by-product from production of silicon carbide

The invention discloses a recycle and reuse method of a by-product from production of silicon carbide and aims to solve the technical problem that by-products in production of silicon carbide in the prior art are aggregated, which causes environment pollution and resource waste. The method includes following steps: 1) preparation of slurry; (2) impurity removal; (3) primary classification; (4) secondary classification; and (5) third classification. The recycle and reuse method can effectively classify by-products during a production process of silicon carbide micro powder, can avoid the problems that aggregated by-product cannot be treated well, which causes environment pollution and resource waste. The method achieves recycle of resources, increases utilization rate of resources and improves workshop environment, and achieves great environmental benefit.

Owner:HENAN XINDAXIN SCI & TECH

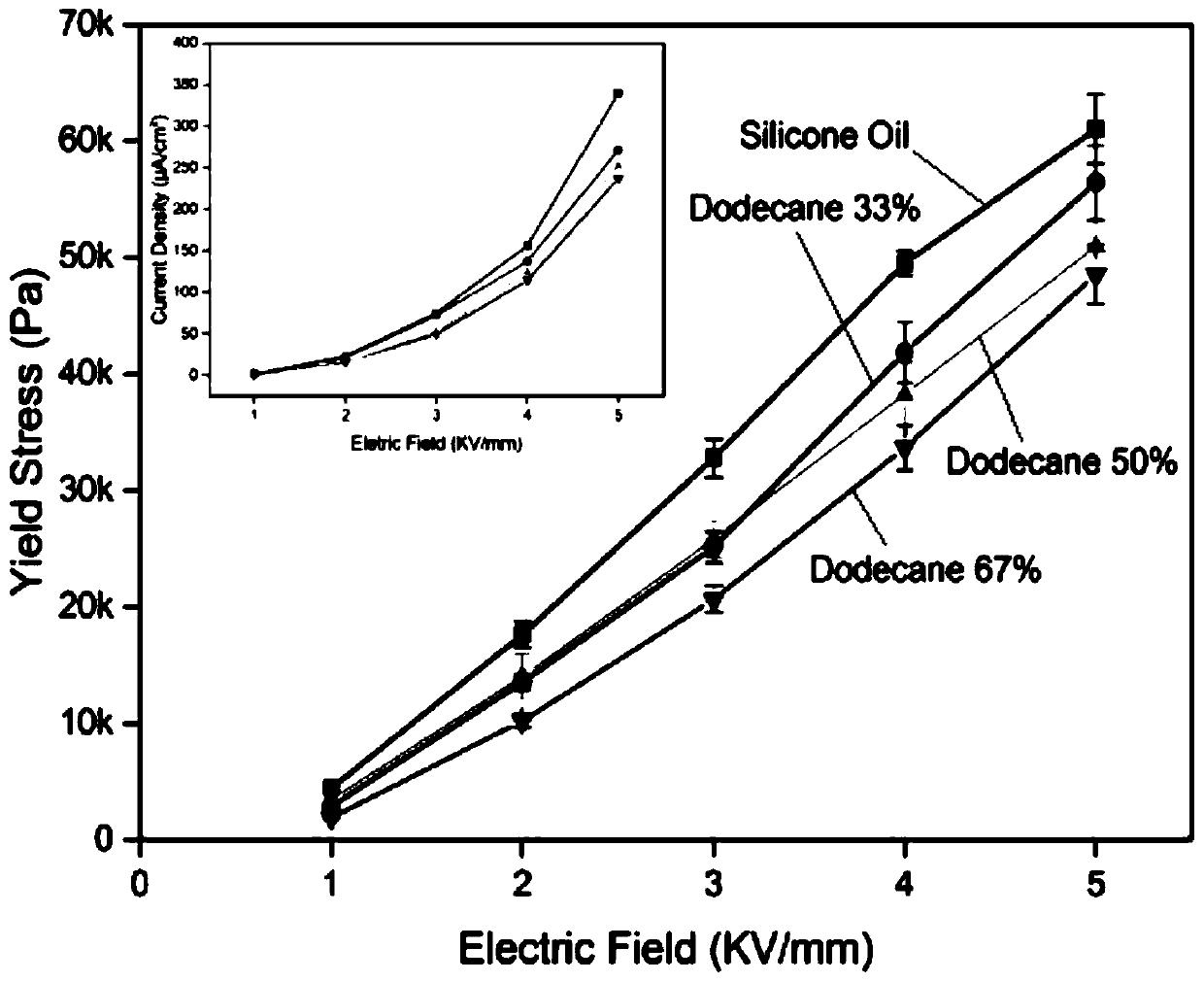

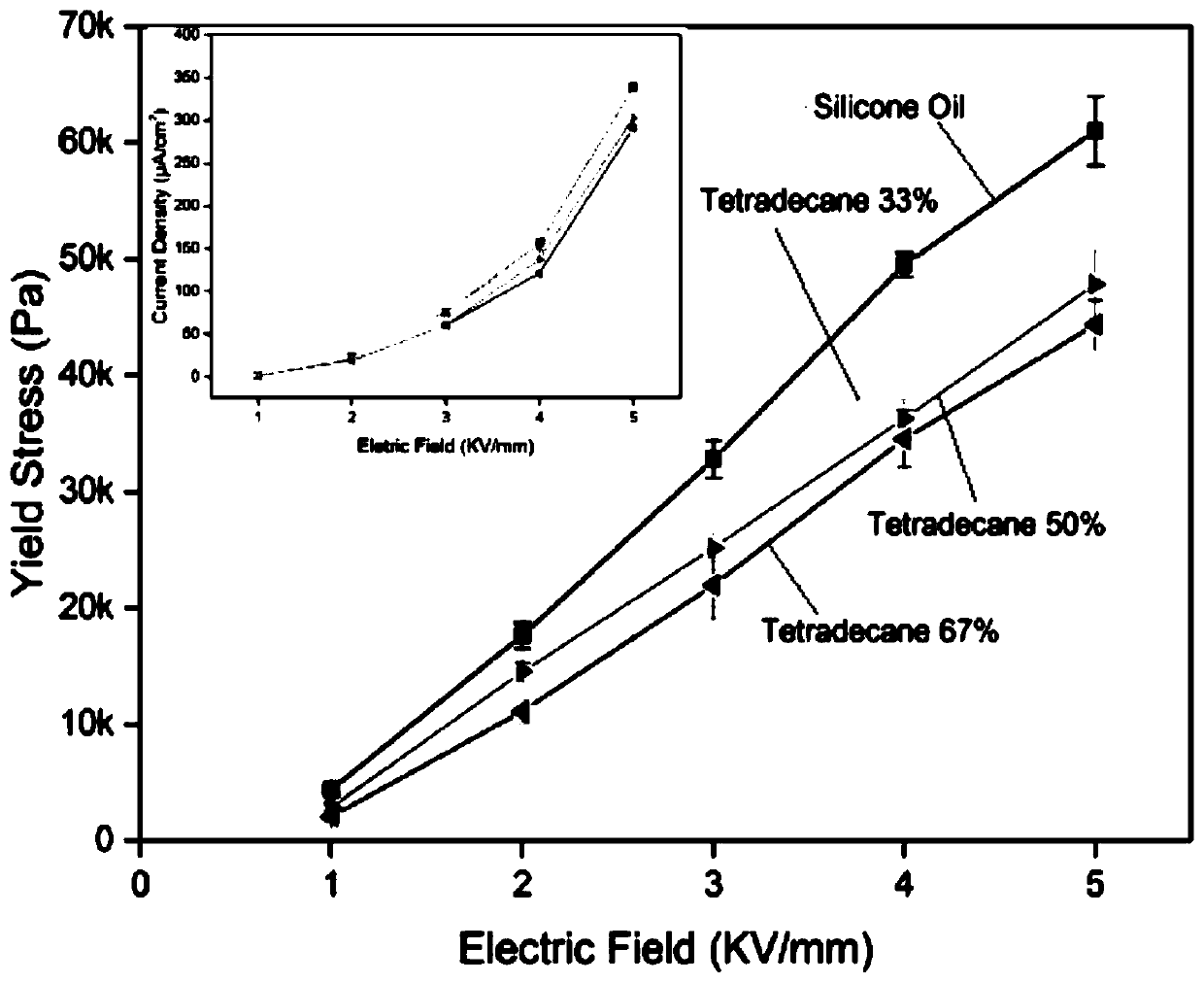

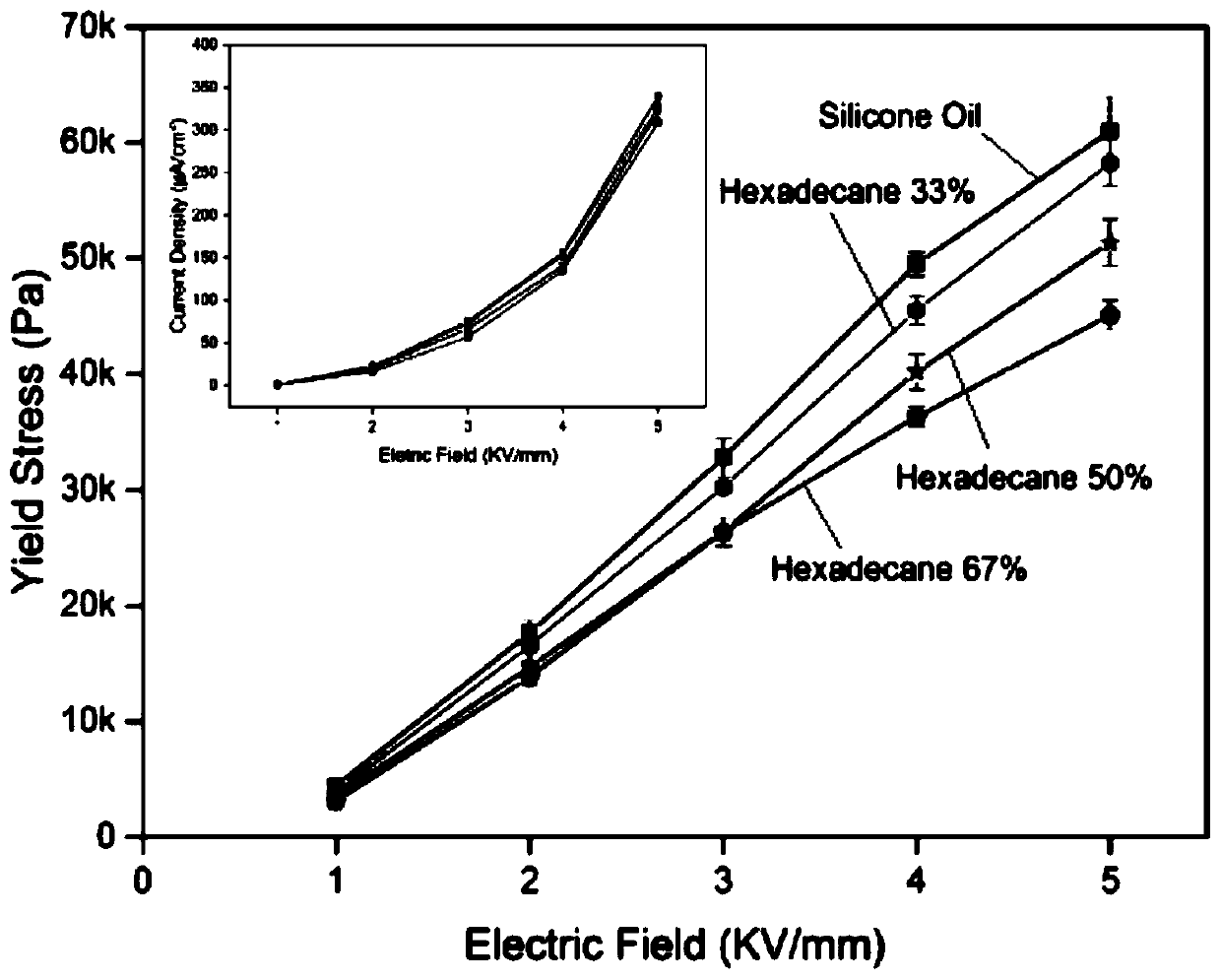

Preparation method for suspension

The invention provides a preparation method for a suspension. The method comprises the following steps: selecting particles to be dispersed as a dispersion phase, and selecting a continuous phase A and a continuous phase B of a liquid medium dispersant, wherein the wettability of the continuous phase A and the particles is greater than the wettability of the continuous phase B and the particles, the continuous phase A and the continuous phase B are mutually soluble, and the density of the continuous phase A is similar to the density of the continuous phase B; and mixing the continuous phase Aand the continuous phase B until the continuous phase A and the continuous phase B are mutually soluble to obtain a compound liquid, and dispersing the particles into the compound liquid to obtain thesuspension. According to the preparation method for the suspension, two liquids with different wettability are compounded to be used as a continuous phase, the liquid phase with poor wettability is added, so that the agglomeration of the particles can be alleviated, the sedimentation and compaction phenomena can be reduced, the sedimentation time of the particles in the suspension can be greatlyprolonged, and the precipitation and compaction of the suspension can be reduced.

Owner:SHANGHAI UNIV

Semiconductor silicon crystal bar slicing processing equipment and silicon powder recovery method thereof

InactiveCN114670346AReduce water permeabilityGuaranteed water permeabilityFine working devicesFiltration circuitsCrystallographyPhysical chemistry

The invention belongs to the technical field of semiconductor processing, and particularly relates to semiconductor silicon crystal bar slicing processing equipment and a silicon powder recycling method thereof.The semiconductor silicon crystal bar slicing processing equipment comprises a lathe bed, a wire conveying mechanism, a workbench, a wire frame and a cooling liquid circulating component; according to the invention, the cooling liquid box is uniformly divided into a plurality of mutually independent cooling liquid chambers along the circumferential direction by the partition pieces, and the cooling liquid containing silicon powder produced by primary slicing and cutting and the cooling liquid pumped by the pump are respectively placed in different cooling liquid chambers; the cooling liquid containing the silicon powder generated by primary slicing and cutting is isolated from the extracted cooling liquid, the situation that the cooling liquid containing the silicon powder disturbs the cooling liquid in the box when flowing into the cooling liquid box is avoided, it is guaranteed that the extracted cooling liquid is precipitated, the content of the silicon powder in the extracted cooling liquid is reduced, and the service life of the cooling liquid is prolonged. The silicon powder in the cooling liquid is prevented from being adhered to the surface of the silicon wafer due to more and more silicon powder, the surface of the silicon wafer is prevented from being polluted, and the surface quality of the cut silicon wafer is further improved.

Owner:侯典宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com