Preparation method for suspension

A suspension and solution technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of different effects, speed up the precipitation process, and difficulty in large-scale production, and achieve good practicability and simplify the preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The embodiment of the present invention relates to a suspension preparation method. In terms of the overall design idea, the preparation method mainly includes the following steps:

[0056] Step a: selecting the particles to be dispersed as the dispersed phase;

[0057] Step b: Select continuous phase A and continuous phase B of the liquid medium dispersant, wherein the wettability of continuous phase A and particles is greater than that of continuous phase B and particles, and the continuous phase A and continuous phase B are mutually soluble , and the density between them is similar;

[0058] Step c: mixing the continuous phase A and the continuous phase B until the two are miscible to obtain a compound liquid;

[0059] Step d: Disperse the particles in the compounding liquid to obtain a suspension.

[0060] Among them, the preparation method of this embodiment will be specifically described by using the suspension as the electrorheological fluid, but in addition to...

Embodiment 1

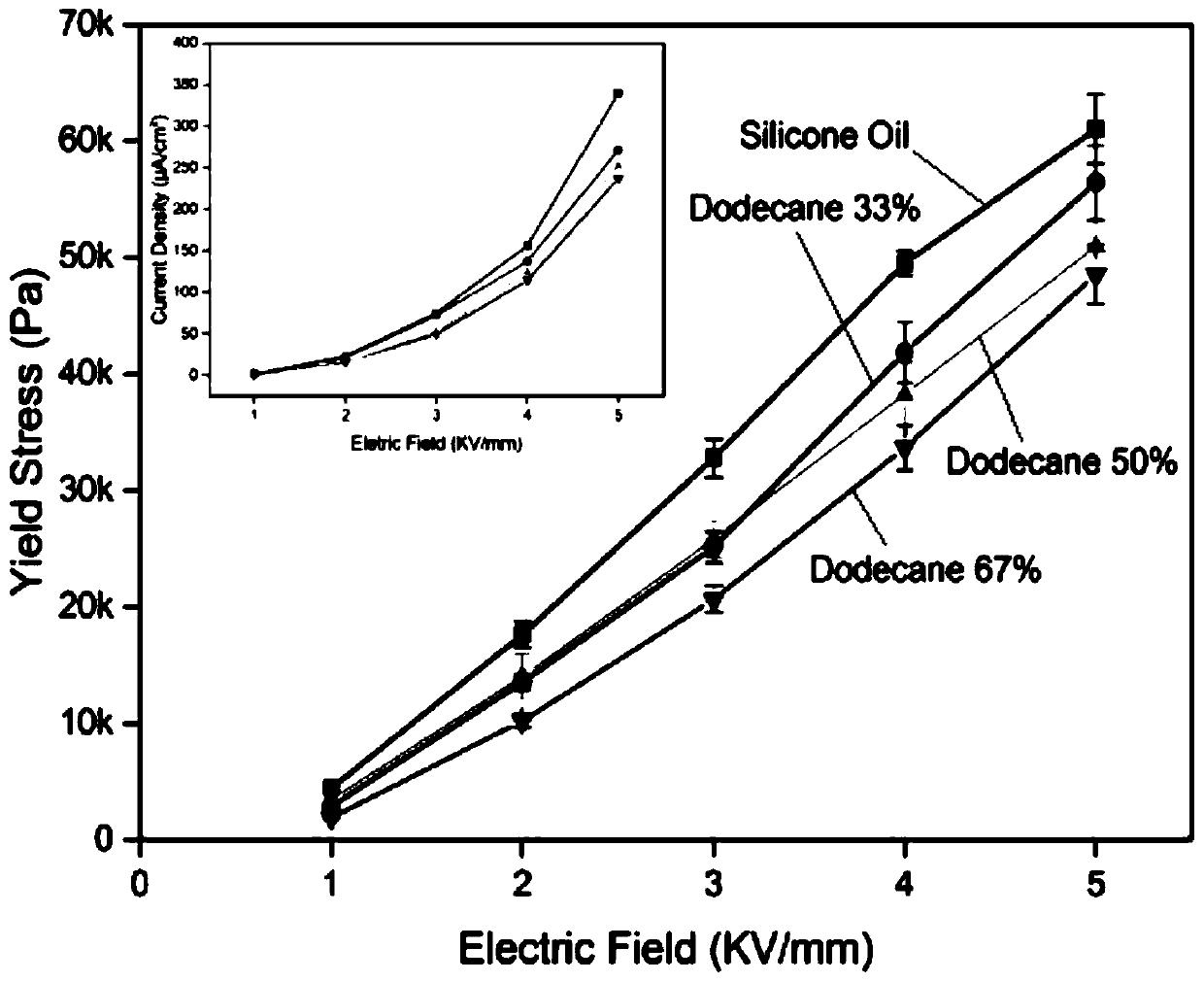

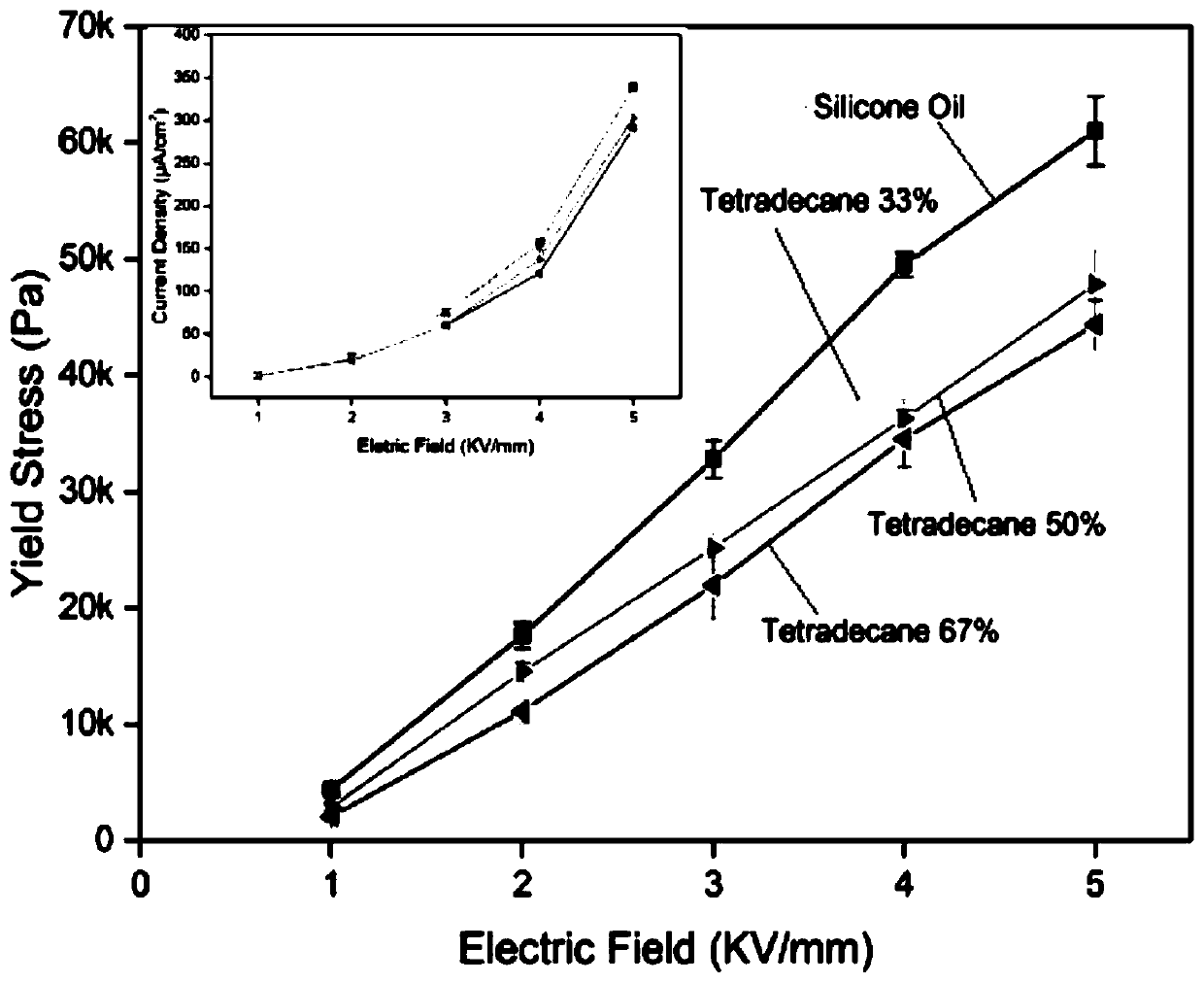

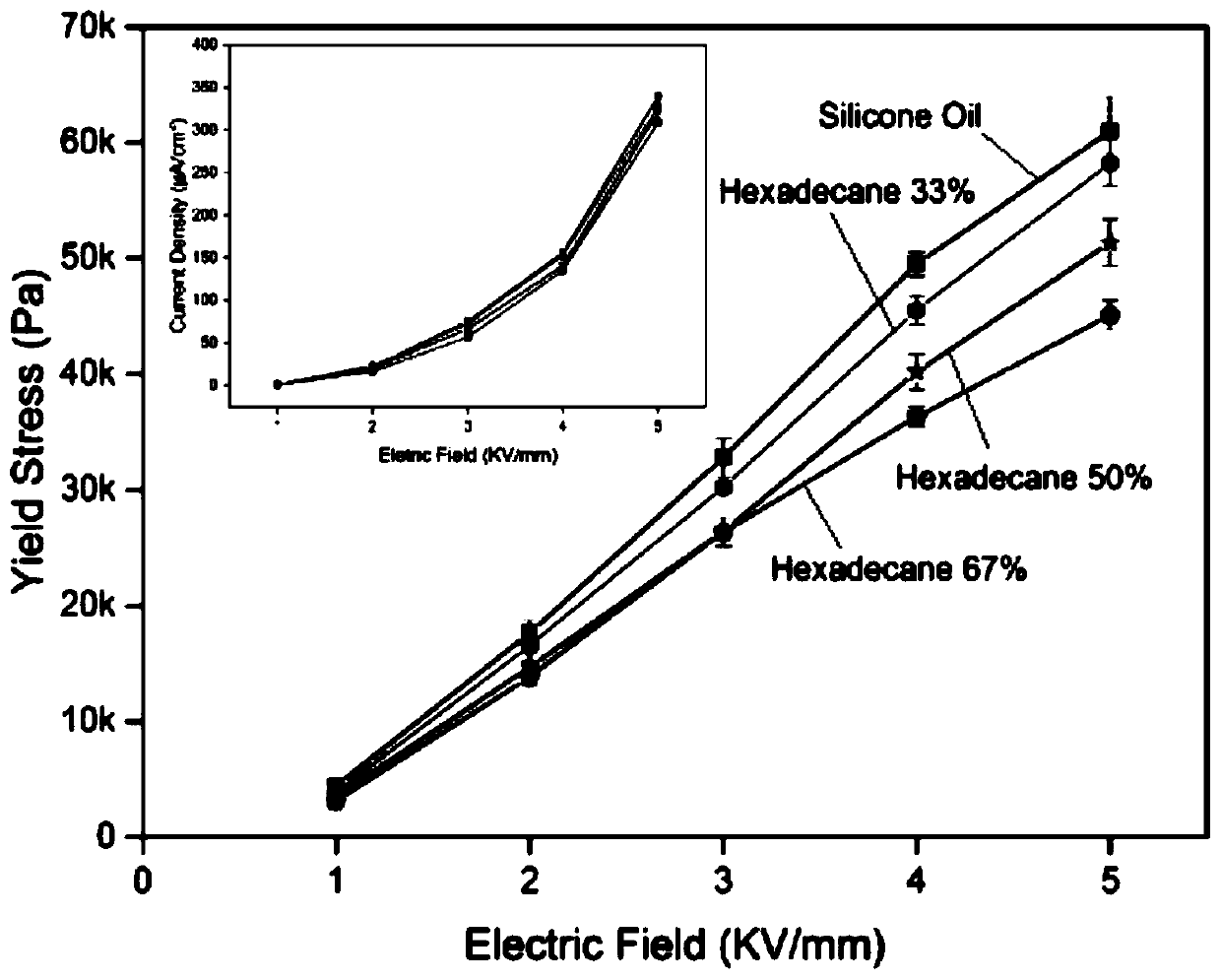

[0082] This example is for the preparation of (silicone oil+alkane)-based giant electrorheological fluid.

[0083] The dispersion media used in this embodiment are: 10cSt silicone oil (Silicone oil), dodecane (Dodecane), tetradecane (Tetradecane), hexadecane (Hexadecane), wherein the silicone oil is specifically dimethyl silicone oil. Table 1 is The contact angles between GER particles and the above four liquids measured by K100 mechanical surface tensiometer can be seen from Table 1 that the wetting of silicone oil to GER particles is better than that of alkanes, so it is selected as continuous phase A, and alkanes as continuous phase B .

[0084] Table 1. Relative contact angles of the continuous phase and GER particles

[0085] gamma d

gamma d

gamma Polarity contact angle Powder 8.1 68.8 76.9 Polar Silicone oil 18.5 0.7 19.2 Waek polarity 3.6° Dodecane 25.4 0 25.4 Non-polar 82.6° Tetradecane 26.5 0 26....

Embodiment 2

[0094] This example is to prepare (silicone oil+alkane derivative)-based giant electrorheological fluid.

[0095] In the preparation of giant electrorheological fluids, the liquid alkane derivatives that can be used include chlorododecane, phenyldodecane, 1-phenylheptane, 1-phenyloctane, 1-phenylnonane, 1 -Phenyl-n-decane, 1-phenylundecane, etc. As an example, the specific dispersion medium used in this embodiment is: 10 cSt silicone oil and dodecylbenzene, and the specific silicone oil is still dimethyl silicone oil.

[0096] Figure 16 It is the (ΔP)2-t relationship diagram measured by the JF99A powder contact angle measuring instrument based on the Washburn method, and the relative contact angles of GER particles with silicone oil and dodecylbenzene are shown in Table 2. It can be seen from Table 2 that the wetting of the silicone oil to the particles is better, so it is selected as the continuous phase A, and dodecylbenzene is used as the continuous phase B. The (silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com