Patents

Literature

1524results about How to "Mild operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

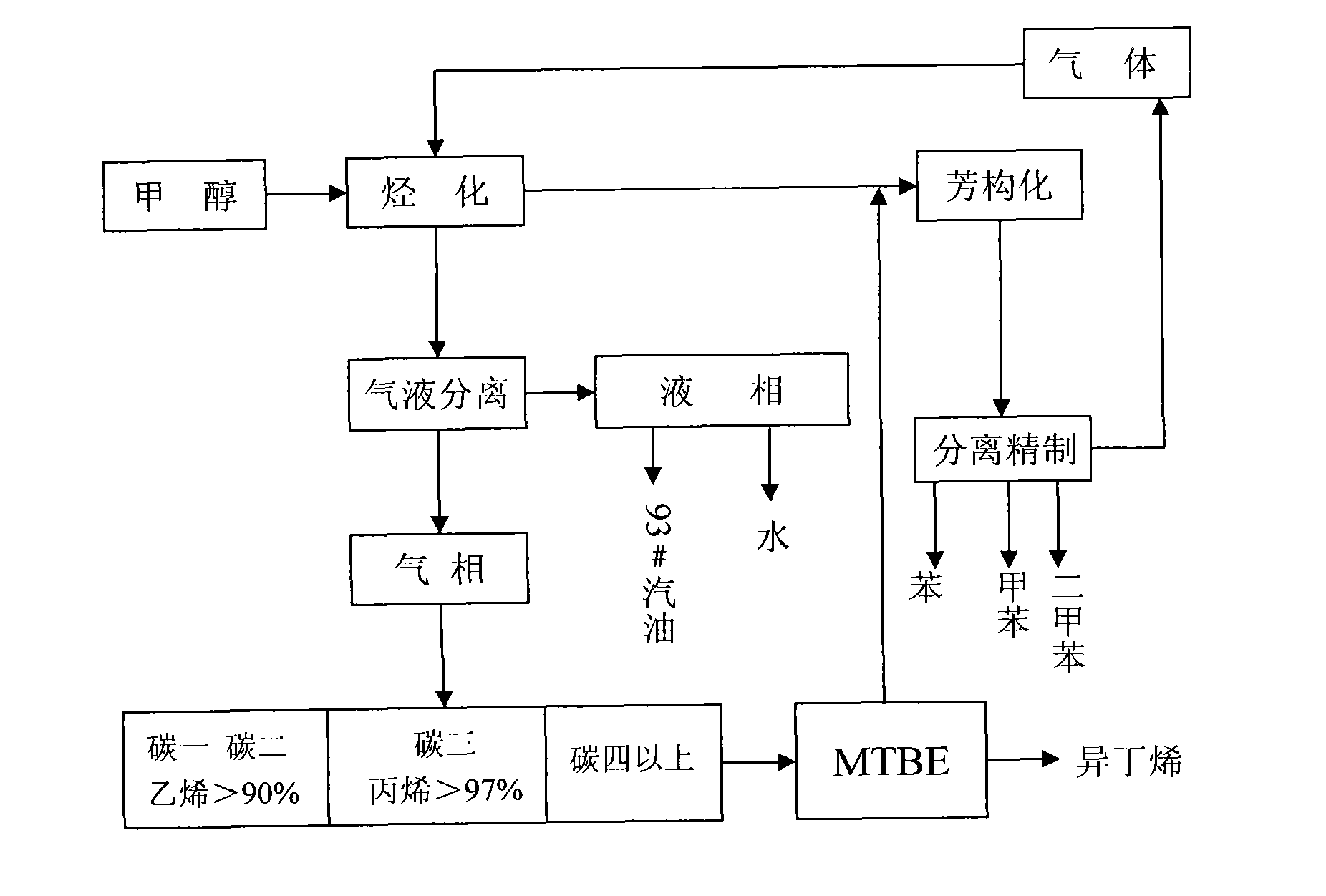

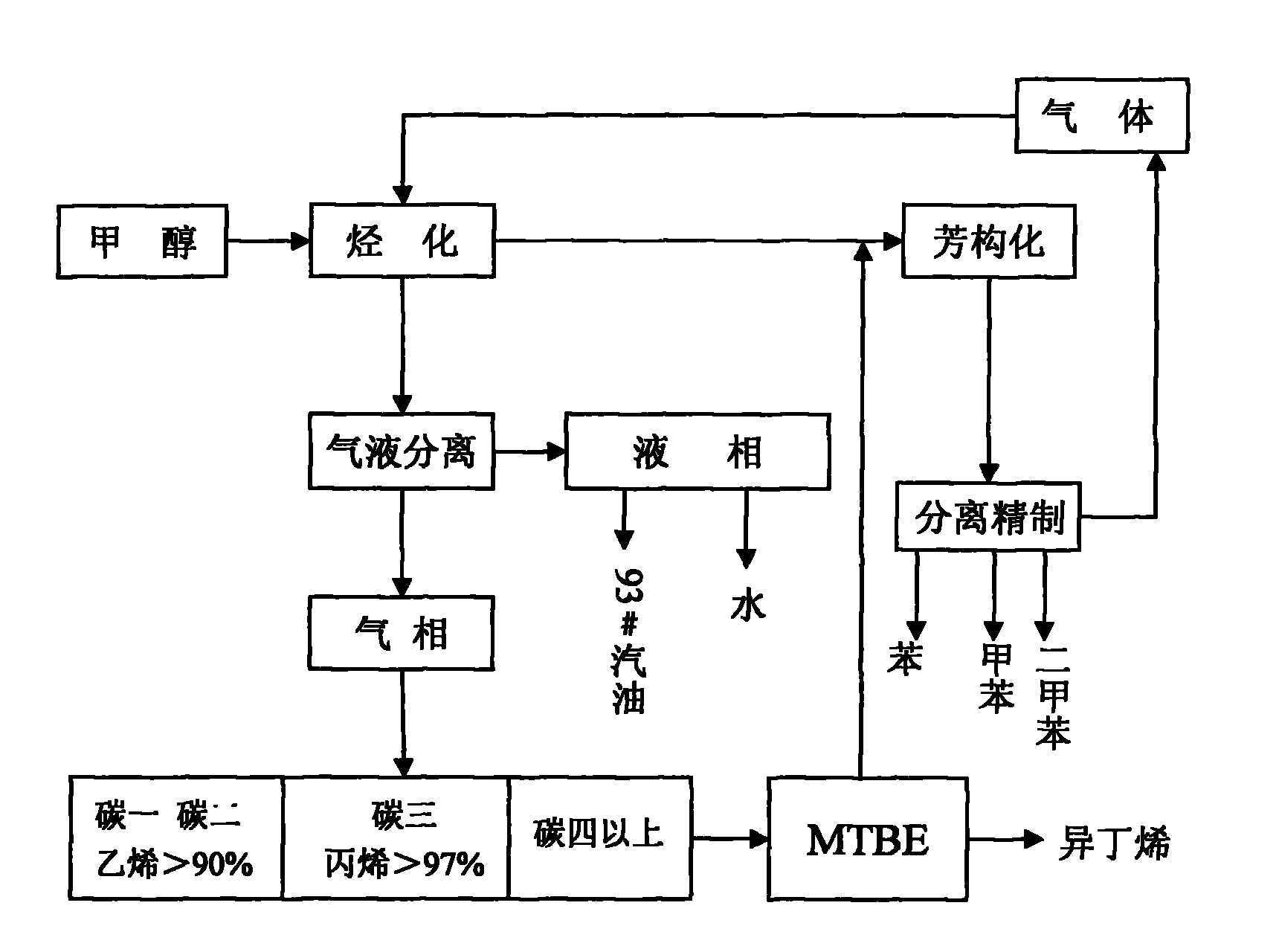

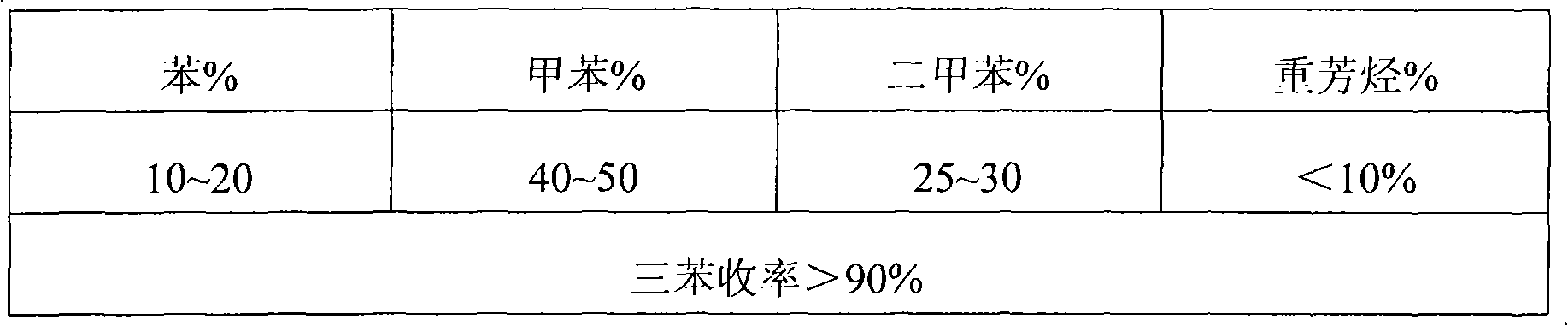

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

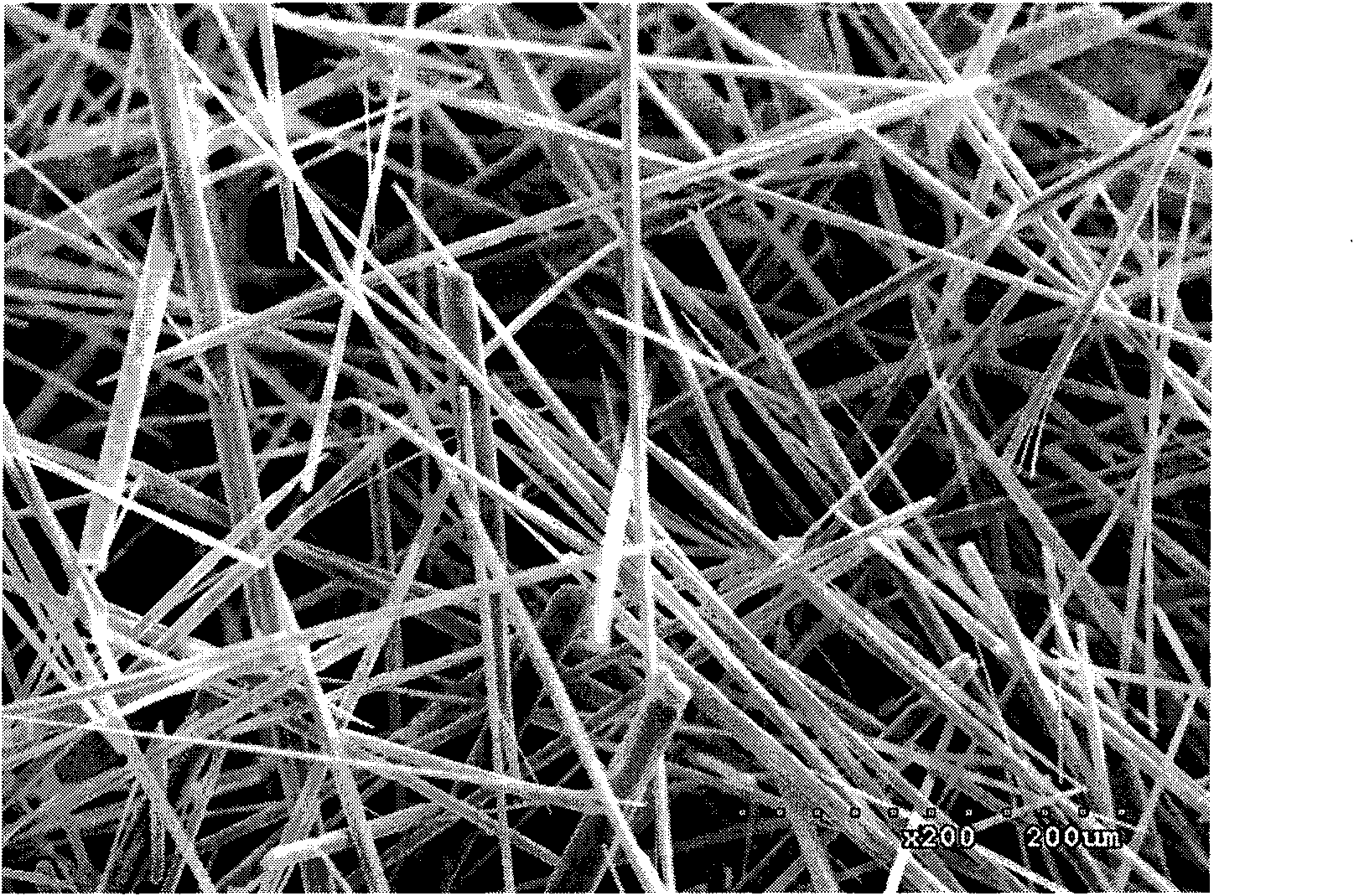

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

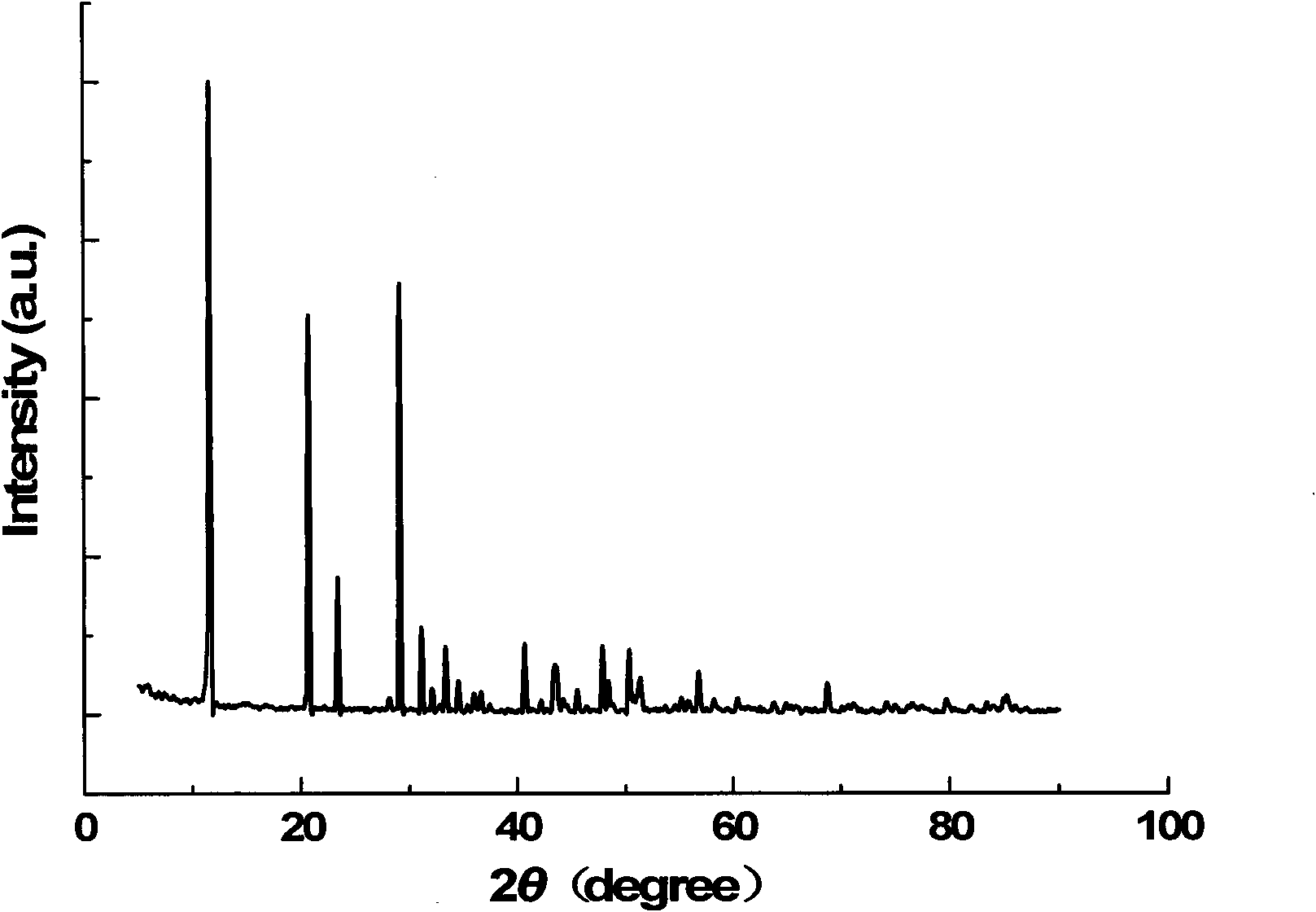

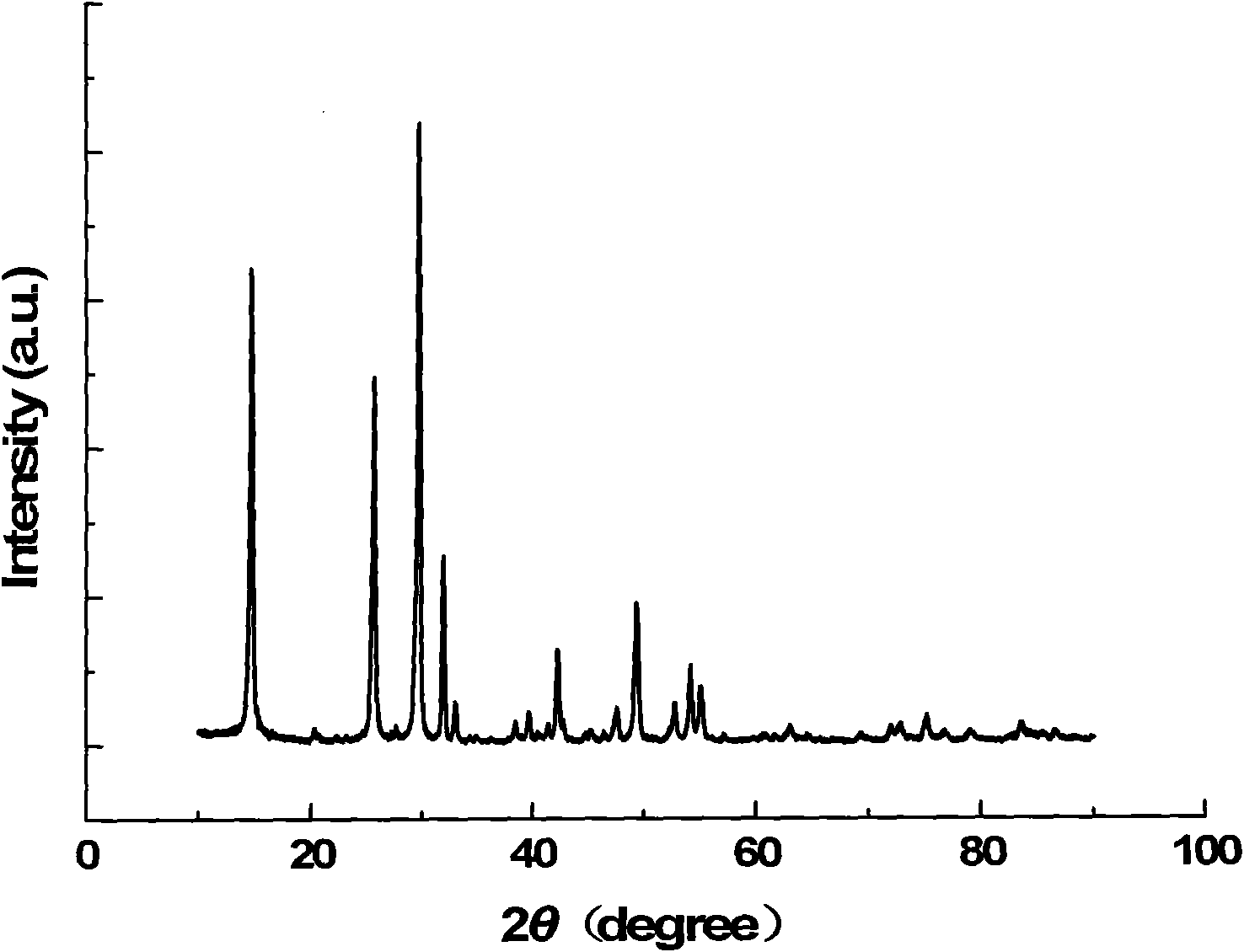

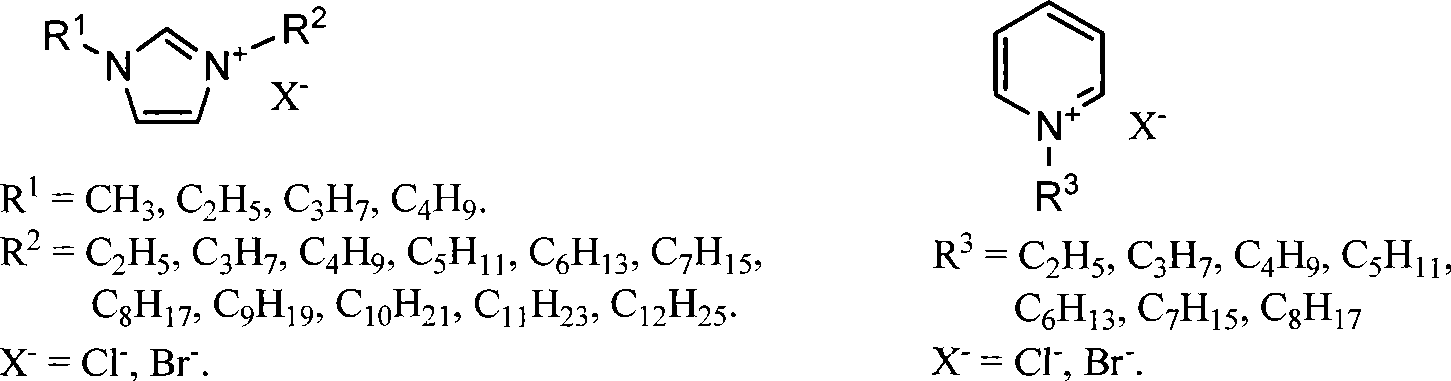

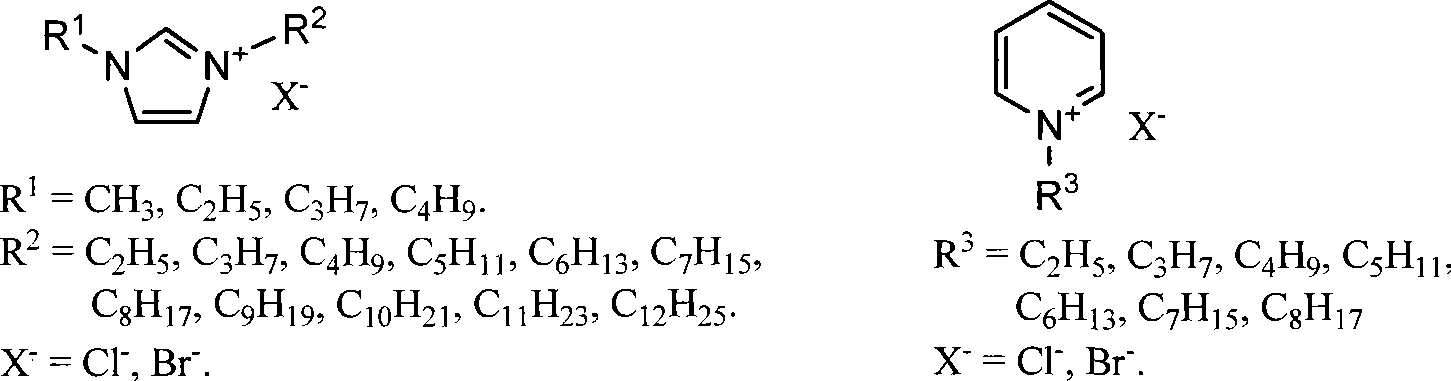

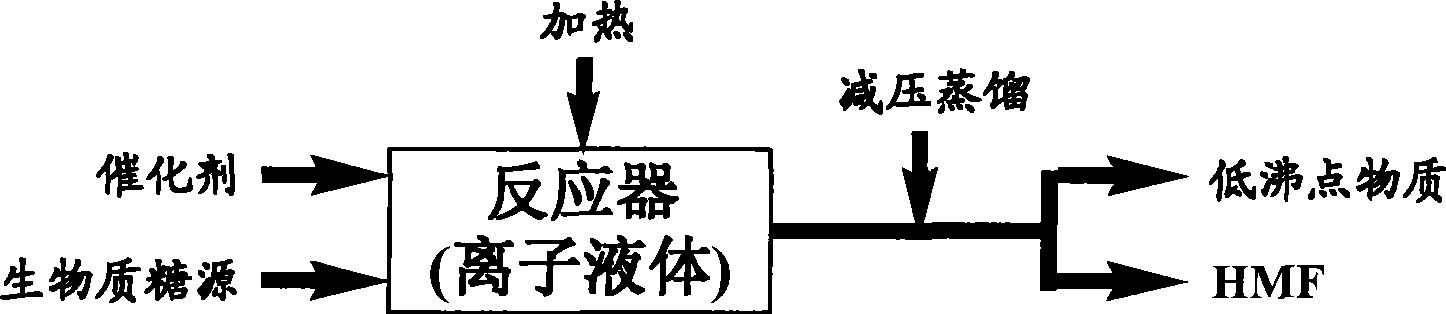

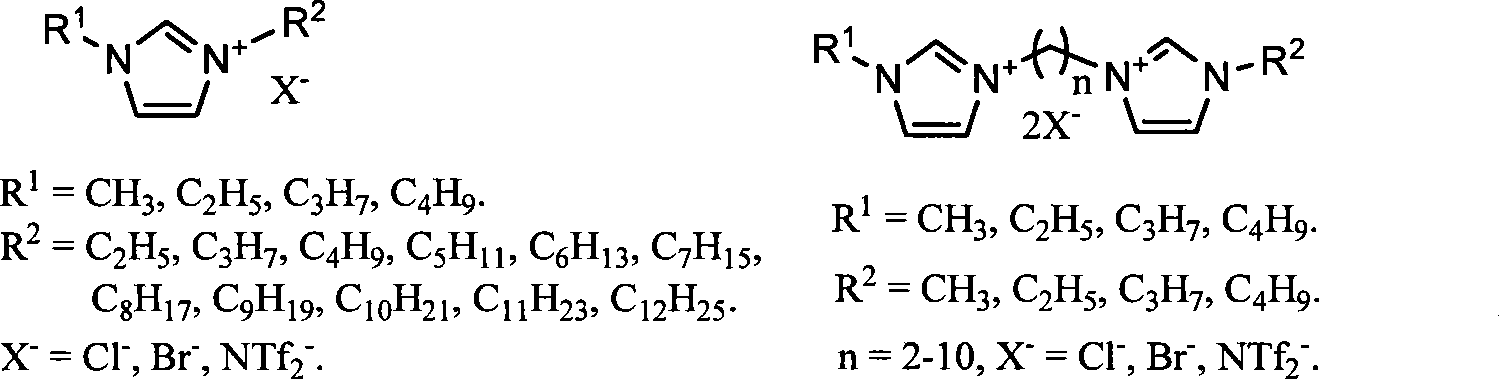

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101386611ALow costCorrosion resistance requirements are not highOrganic chemistryAlternative fuelsSolvent

The invention relates to a method for transforming biomass sugar source into 5-hydroxymethyl-furfural, in particular to a method for preparing the 5-hydroxymethyl-furfural. The method comprises the following steps: using ionic liquid as a solvent, hexose or hexose source biomass as raw material substrates, and 0.5 to 50 percent (relative to the mass of the biomass sugar source) of acidic ionic liquid, inorganic acid or organic acid as a catalyst, and performing the reaction of materials for 1.5 minutes to 23 hours at normal pressure and at a temperature of between 80 DEG C and 100 DEG C to efficiently generate HMF. The method has the advantages of high HMF selectivity, less acid consumption, moderate operating conditions, fast reaction, reusable ionic liquid, simple process, environment protection and the like, and opens up a new approach for preparing commodity chemicals and replacing fuels starting from renewable biological resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101456850ALow costCorrosion resistance requirements are not highOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlternative fuelsSolvent

The invention relates to a method for preparing 5-hydroxymethylfurfural (HMF) by transforming a biomass saccharine source. The method comprises the following concrete steps: using an ionic liquid as a solvent, hexose or hexose source biomass as a raw material substrate, and acid as a catalyst, heating the mixture to react for 5 minutes to 20 hours at normal pressure, and then depressurizing and distilling the mixture under the condition that an operation temperature is not higher than 180 DEG C to obtain the HMF after the reaction is ended; and after the distilled remainder is cooled, directly adding the remainder into the biomass saccharine source, and repeating the processes of reaction and separation to obtain the HMF, so as to realize recycling of an ionic liquid catalyst system and semi-continuous preparation of the HMF. By using the method, once through yield of the HMF reaches as high as 94 percent. The method has the advantages of high selectivity, low acid consumption, mild condition, quick reaction, reusability of the ionic liquid, low cost, simple process, environmental protection, semi-continuous production and the like, and provides new technology for industrialized production of the HMF by transforming the biomass saccharine source, so as to develop a new path for preparing common chemicals in a large scale by using biomass resources and replacing fuels.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

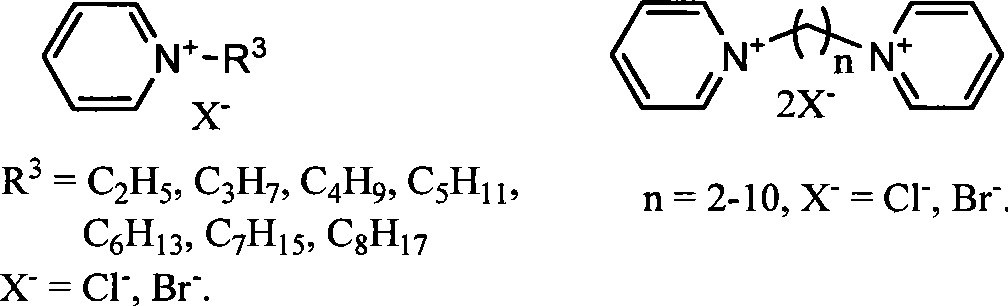

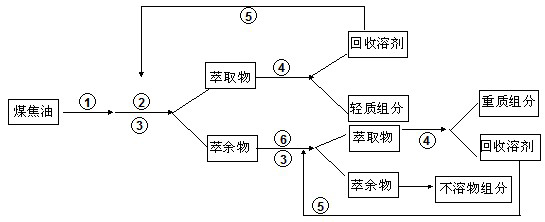

Extracting and separating method of high-temperature coal tar

InactiveCN102492451AHigh purityEfficient separationTar working-up by solvent extractionTime rangeDistillation

An extracting and separating method of high-temperature coal tar belongs to a coal tar separation method. The extracting and separating method includes the step of adding No.1 or No.2 solvent into the coal tar at the ordinary pressure for secondary extraction and separation. Extraction processes are carried out under the pretreatment condition of sufficiently mixing and heating, heating temperature is lower than 150 DEG C, raw materials of the coal tar are respectively mixed with the No.1 or No.2 solvent according to the volume proportion of 1:2 to 4, extraction time ranges from 1 to four hours, extracts and raffinate are obtained after the No.1 solvent and the coal tar are filtered and separated when the system is balanced, and the No.1 solvent is recovered by distillation and recycled. The extracting and separating method has the advantages that energy saving effect of equipment is evident, process is simple and convenient, operation conditions are moderate, manufacturing cost and investment of the equipment are low and benefits are evident. Adding quantity of the solvent and extraction operation parameters are changed, separation depth and process capacity of the coal tar can be flexibly mastered and selectively controlled.

Owner:CHINA UNIV OF MINING & TECH

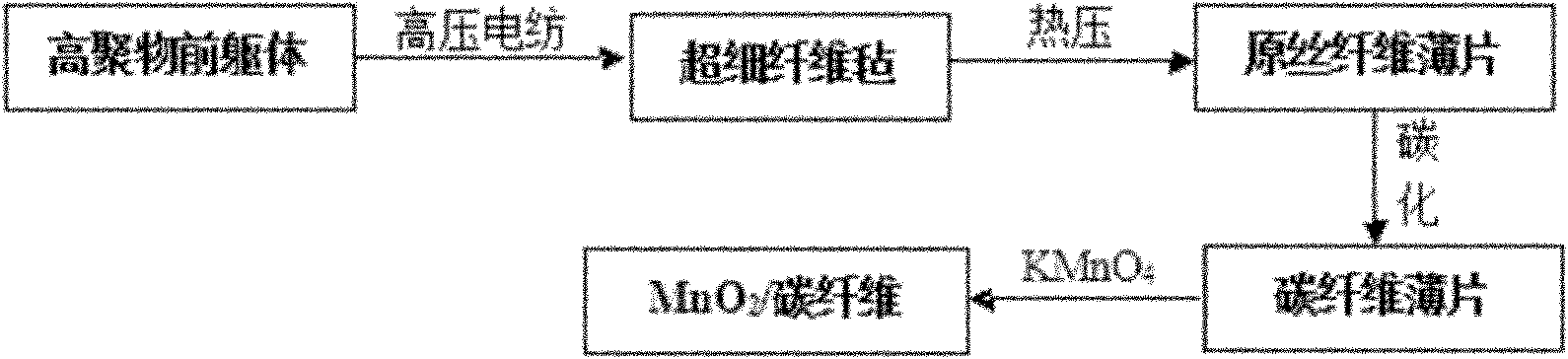

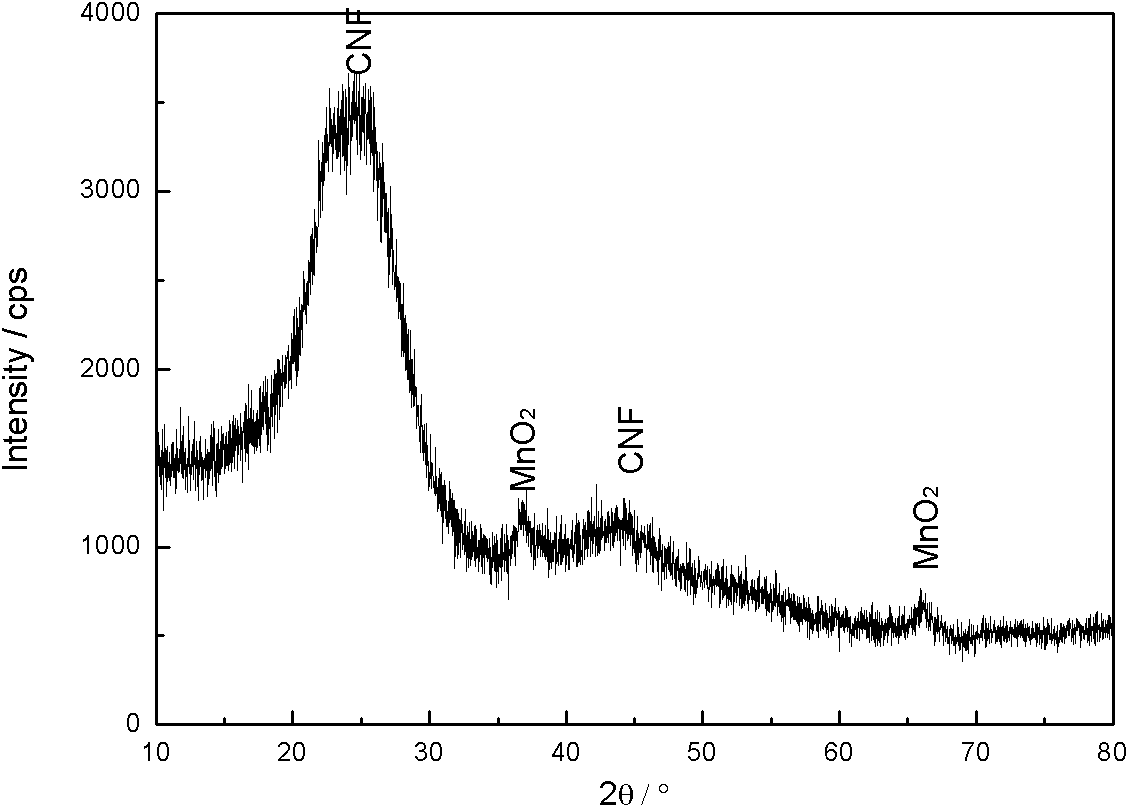

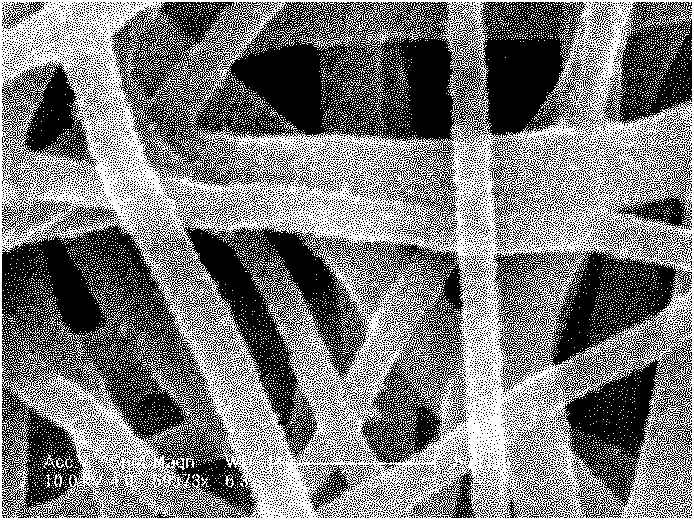

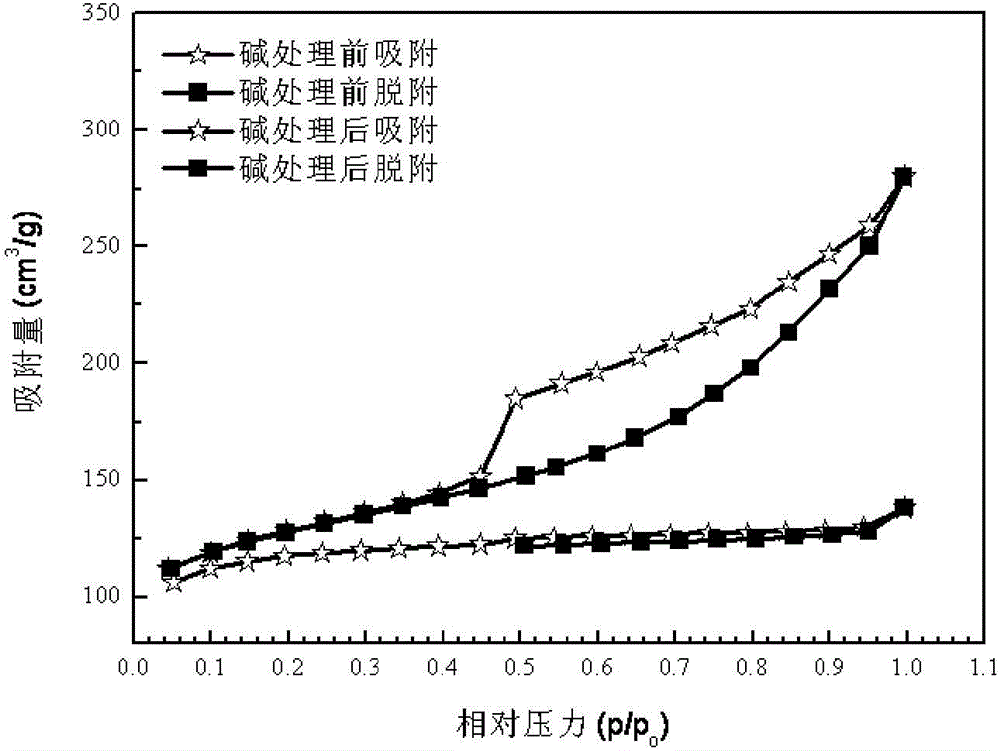

Self-supporting super capacitor electrode material and preparation method thereof

ActiveCN102087921AHigh yieldImprove mechanical stabilityElectrolytic capacitorsFiberCarbon nanofiber

The invention discloses a self-supporting super capacitor electrode material and a preparation method thereof, belonging to the field of super capacitor electrode materials. The method is characterized by preparing a nano-micro fiber felt from polymer solution through high-voltage electrospinning, carrying out hot pressing and carbonizing to obtain a carbon nano fiber felt, soaking the carbon nano fiber felt in potassium permanganate solution at a certain temperature for a period of time, then washing the sheet with deionized water and ethanol several times to remove impurities, and drying at 60-110 DEG C for 8-24 hours, thus obtaining the manganese dioxide and carbon nano fiber composite electrode material. The manganese dioxide and carbon nano fiber composite electrode material prepared by the method dispenses with extra current collectors, conductive additives and binders, can be directly used, and has the characteristics of high electrode mechanical stability, self current collection, high active substance loading, excellent electrochemical performance and the like.

Owner:TSINGHUA UNIV

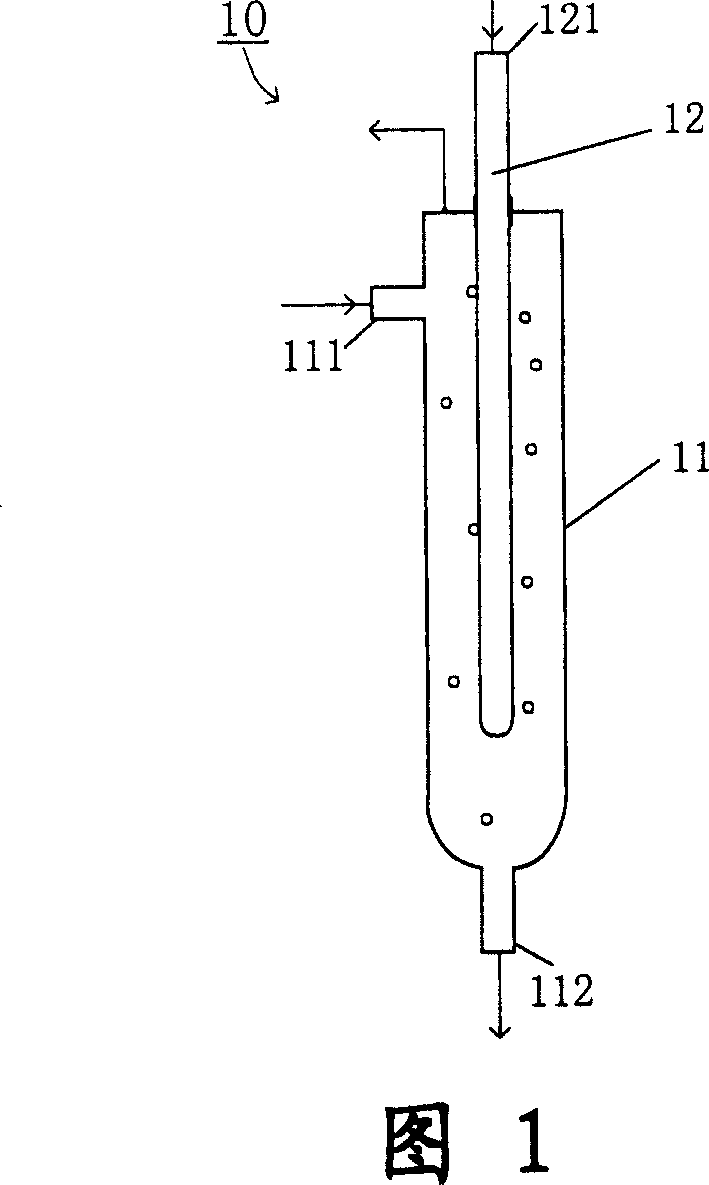

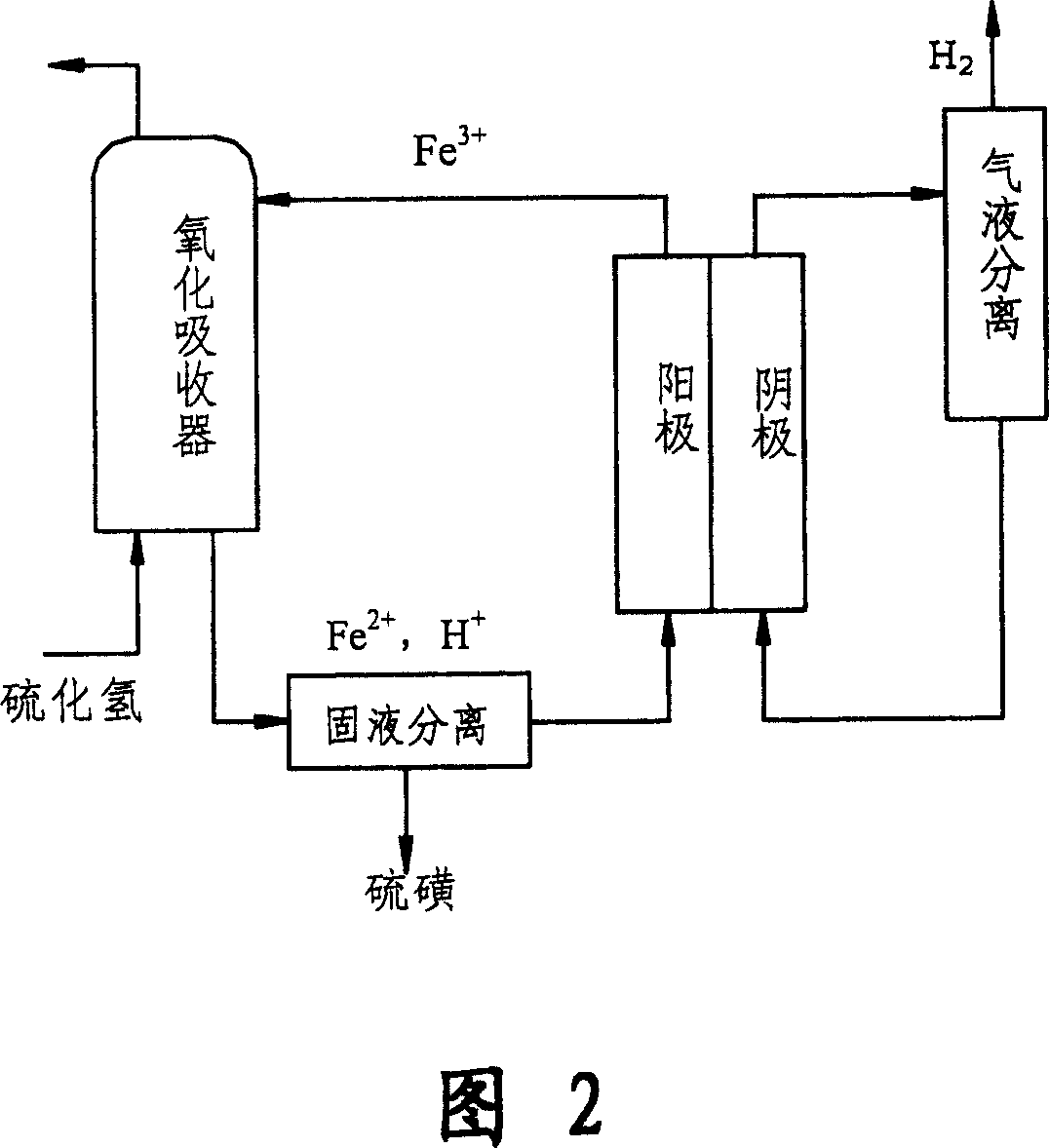

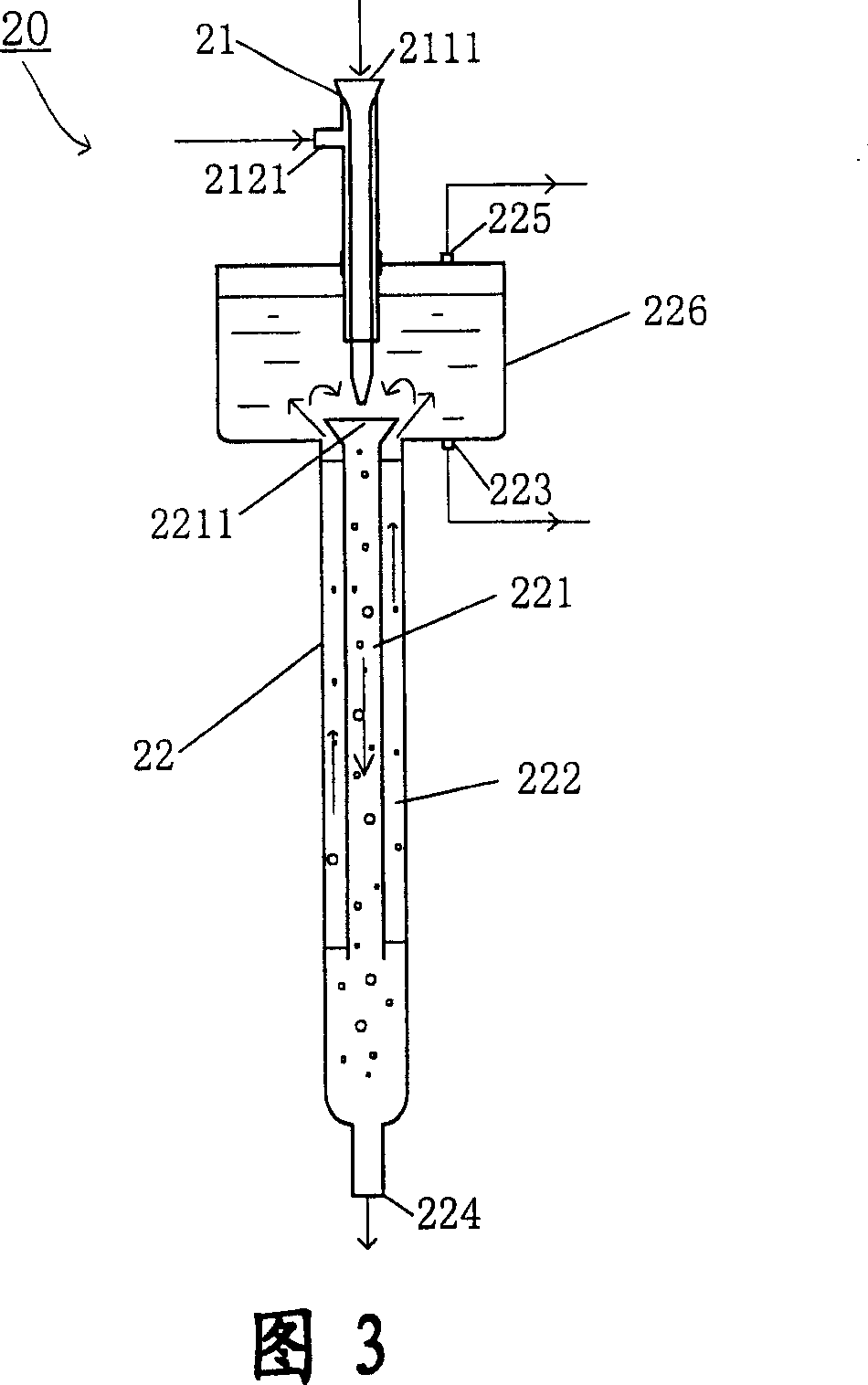

Method for recovering sulfur and making hydrogen from hydrogen sulfide

InactiveCN101028920AIncrease contact timeAvoid cloggingElectrolysis componentsSulfur preparation/purificationCyclic processHydrogen

A process for recovering sulfur and preparing H2 from the hydrogen sulfide at same time is characterized by that an internal circulation absorption type reactor and an electrolyzing reactor with dual electrode plates are simultaneously used for the oxidizing absorption reaction and electrolytic regeneration reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for catalytic preparation of 5-hydroxymethyl furfural from carbohydrates

InactiveCN102101851ALow costGood choiceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNiobiumSolid acid

The invention relates to a niobium-containing compound catalyst for efficiently converting carbohydrates into 5-hydroxymethyl furfural, which has high activity and selectivity for preparing hydroxymethyl furfural (HMF) by dehydrolyzing saccharides and is an ideal catalyst for preparing HMF. When the reaction is performed under moderate conditions, the target product HMF can have a high yield. The catalyst is environment-friendly, is easy to separate and recycle, can be reused, is convenient and practical to operate, and can not corrode the equipment, thereby being an ideal solid acid catalyst for preparing HMF, and having significant industrial application meanings.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

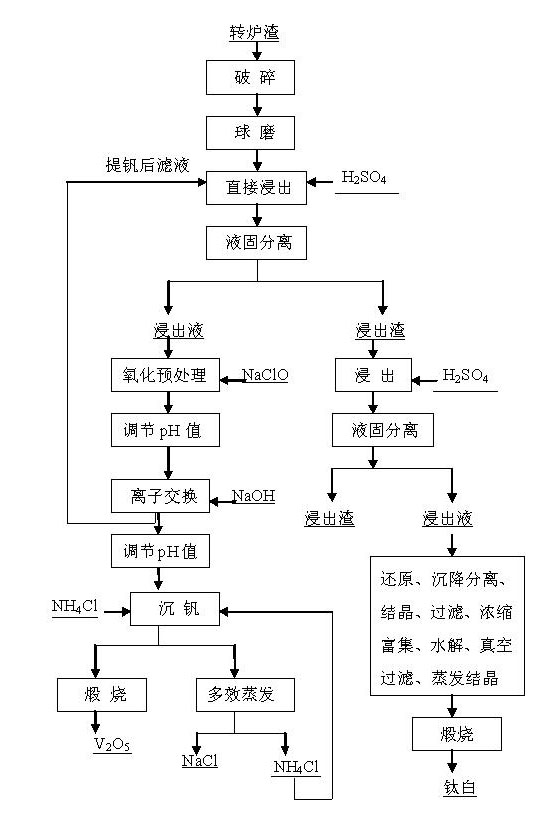

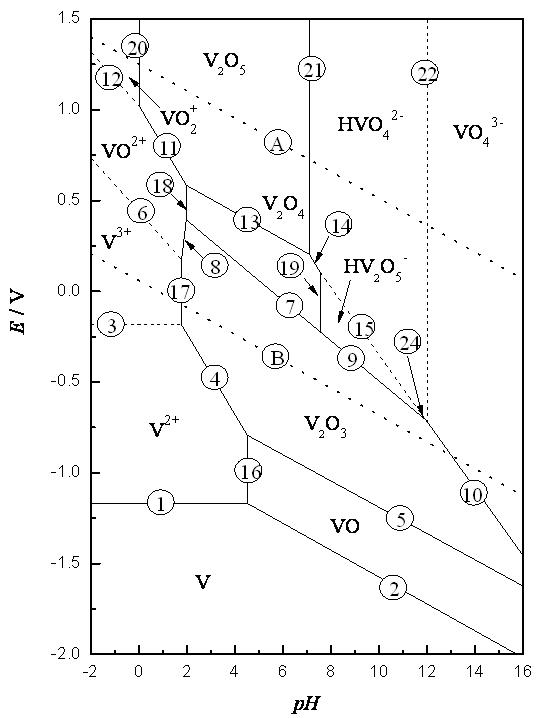

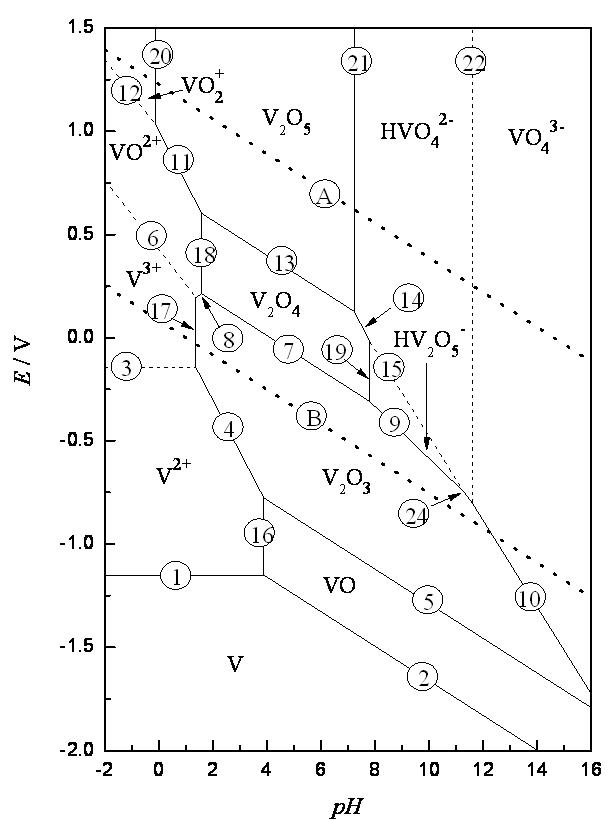

Method for wet-process vanadium extraction by using vanadium- and titanium-containing converter slag

ActiveCN101967563AShort processReduce energy consumptionProcess efficiency improvementIon exchangeAmmonium metavanadate

The invention discloses a method for wet-process vanadium extraction by using vanadium- and titanium-containing converter slag, which comprises: performing acid leaching directly by using 5 to 30 mass percent sulfuric acid; adding NaClO into the leachate to perform oxidization treatment, performing ion exchange purification and separation by using alkalescent anion exchange resin which is transformed by sulfuric acid, and desorbing by using NaOH; adding ammonium chloride into stripping liquid to precipitate vanadium, filtering and calcining ammonium metavanadate filter cake to obtain powdered vanadium pentoxide; and processing titanium-enriched leaching residue to obtain titanium dioxide. In the invention, the direct leaching of converter vanadium-titanium slag is realized, process flow in shortened, the pollution caused by adding oxidant is avoided, and due to the use of the low-concentration sulfuric acid, the material consumption and the requirements on the corrosion resistance of equipment are reduced at the same time. The method realizes the comprehensive recovery and utilization of all valuable elements, belongs to a novel all wet-process smelting technique, and avoids waste discharge in a whole process.

Owner:NORTHEASTERN UNIV

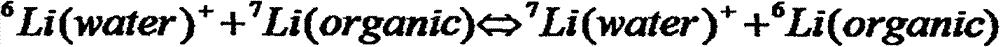

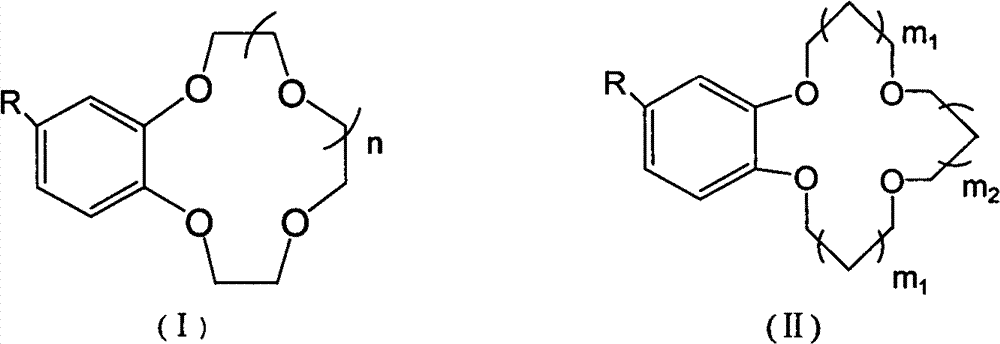

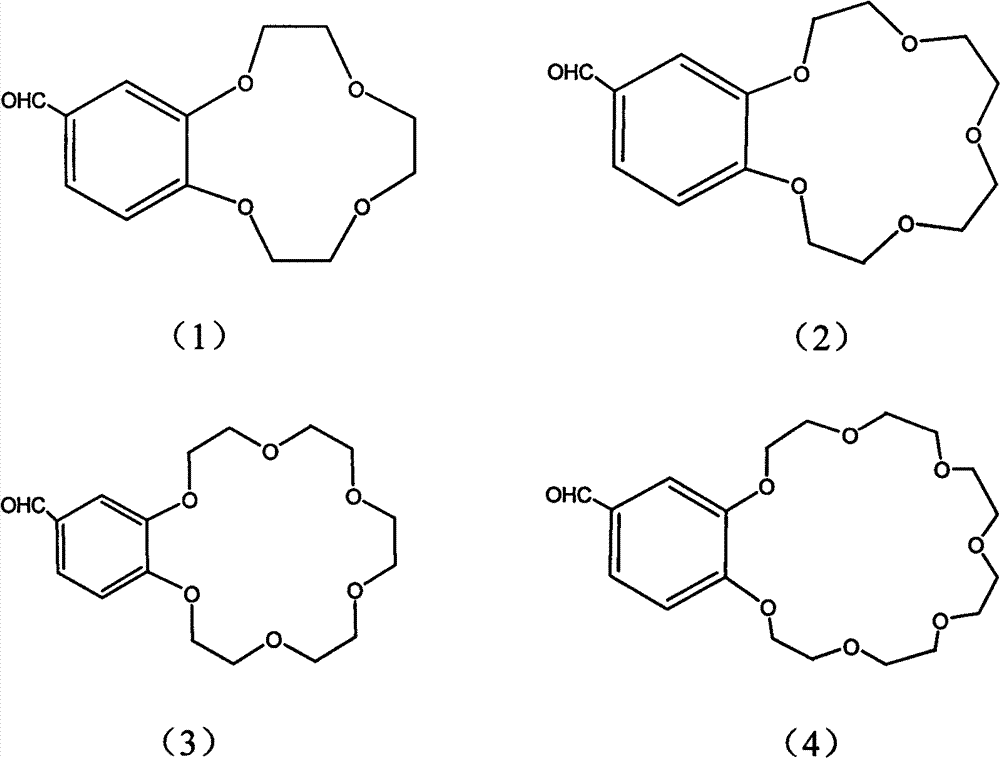

Benzocrown ether graft polymer with lithium isotopic separation effect and preparation method thereof

ActiveCN102786616AIncrease loading capacityExcellent separation factorOther chemical processesIsotope separationBackbone chainSolvent

The invention provides a benzocrown ether graft polymer with a lithium isotopic separation effect and a preparation method thereof. As for the polymer, hydroxyl-contained polyvinyl alcohol or polyethylene-vinyl alcohol is adopted to serve as a main chain; benzocrown ether is adopted to serve as a side hung group; and the main chain and the side hung group are connected together through chemical bonds so as to form the benzocrown ether graft polymer. The preparation method comprises the following steps: dissolving the active hydroxyl-contained polyvinyl alcohol or the polyethylene-vinyl alcohol and the benzocrown ether with an active carboxyl functional group or an aldehyde group in a solvent; performing esterification or aldolization under the action of a catalyst at a certain temperature; completing the chemical grafting of the benzocrown ether with the polyvinyl alcohol or the polyethylene-vinyl alcohol; and finally adding a precipitating agent so as to obtain the graft polymer through precipitation. The graft polymer provided by the invention, which contains the benzocrown ether group, has a good lithium isotopic separation effect. Moreover, through adjusting the size of the crown ether ring, the graft polymer can be used for recognition and separation of heavy metal ions, and has an extensive application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

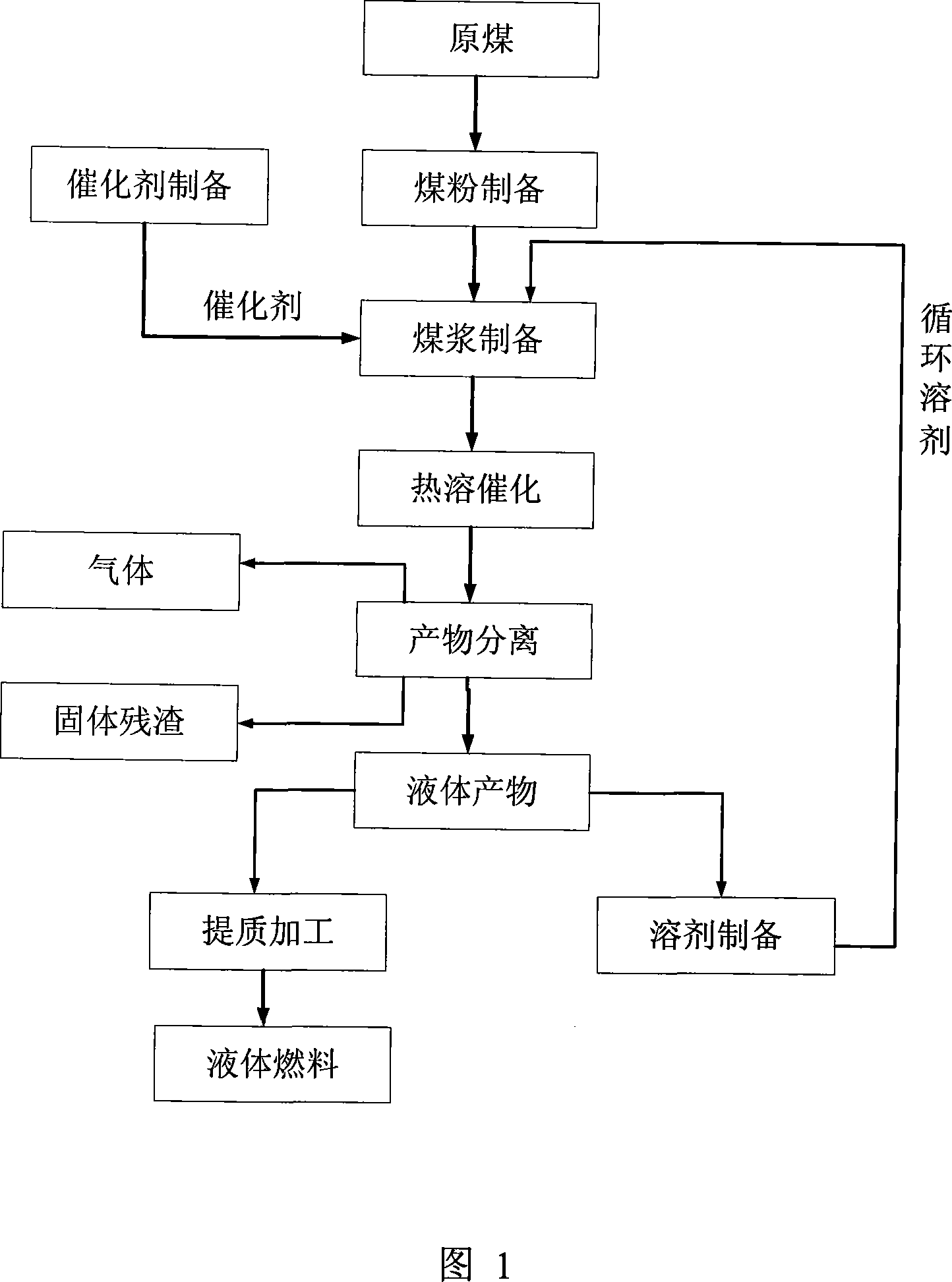

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

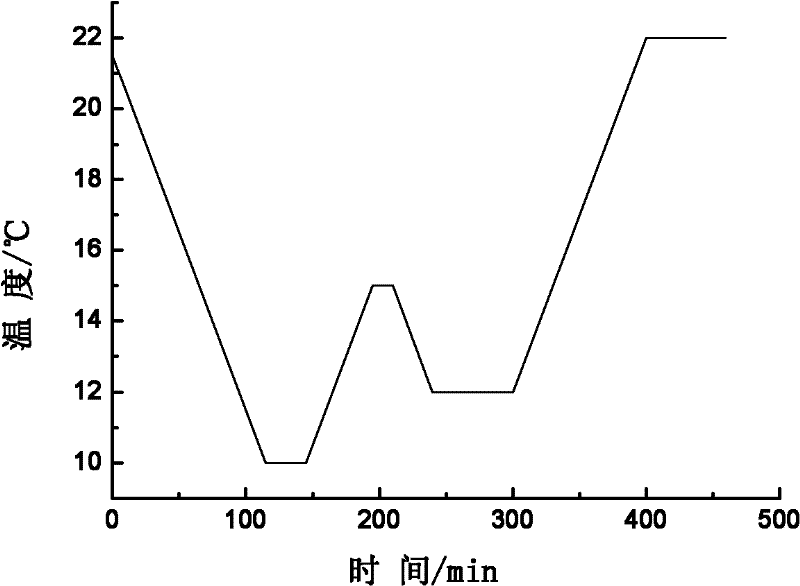

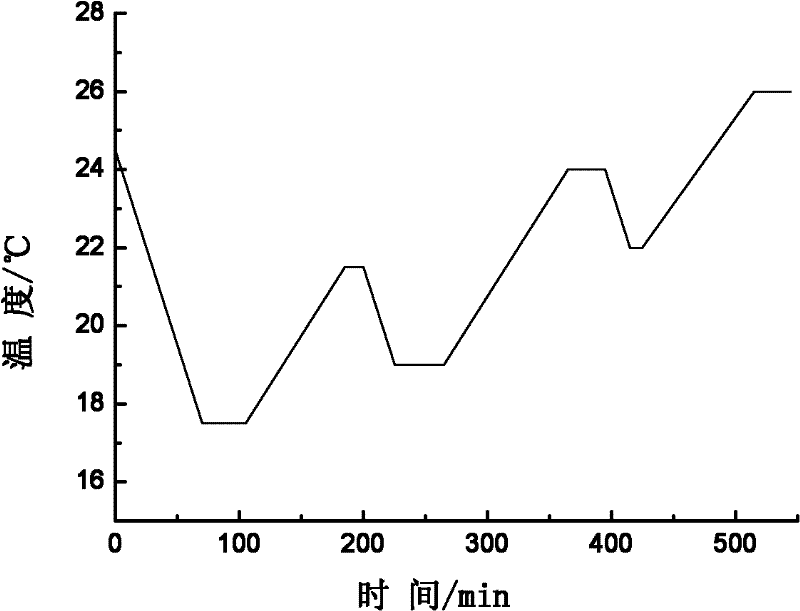

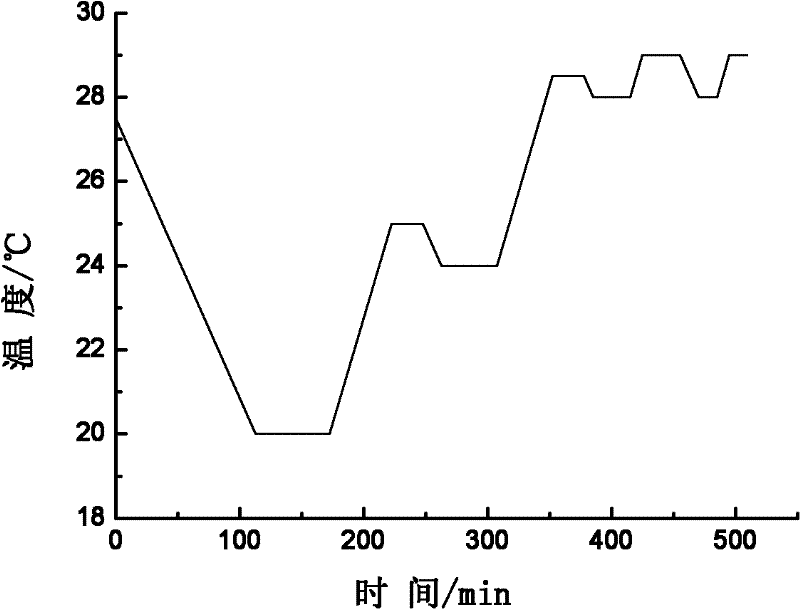

Static multistage melting crystallization method for preparing electronic grade phosphoric acid

InactiveCN102198937AEasy to operateReduce energy consumptionPhosphorus compoundsLiquid productPhosphoric acid

The invention provides a static multistage melting crystallization method for preparing electronic grade phosphoric acid. The method comprises the following steps of: adding phosphoric acid liquid serving as a raw material into a crystallization tower at one time, and introducing a cooling / heating medium to a crystallization tower jacket to control the temperature of the phosphoric acid liquid; adding crystal seeds into the crystallization tower at constant temperature when the phosphoric acid liquid is cooled to the temperature of between 15 and 28 DEG C; and performing static melting crystallization operations of two to four stages by the following steps of: cooling and crystallizing the materials, discharging partial mother solution at constant temperature, heating and melting to the constant temperature, continuously performing the operation of next stage at the temperature, and gradually discharging the mother solution for N times in equal mass to gradually improve the purity of the phosphoric acid crystal. Finally, the left crystal in the tower is the product, and the crystal is melted by heating and collected. The method is simple in operation, low in energy consumption and mild in operating conditions; the product has high purity; an 88 to 90 percent electronic grade phosphoric acid liquid product is directly obtained; and the product purity index accords with multiple standards of domestic and foreign users.

Owner:TIANJIN UNIV

Preparation method of high-molecular-weight aliphatic polyester

The invention discloses a preparation method of high-molecular-weight aliphatic polyester, comprising the following steps of: using monomer aliphatic diacid diester and aliphatic diol as reaction materials; reacting the reaction materials and a catalyst in a nitrogen atmosphere for 1-5 hours under the condition of normal pressure and temperature of 160-200 DEG C; and reacting for 1-6 hours under the conditions of absolute pressure of 30-300Pa and temperature of 190-240 DEG C to obtain the high-molecular-weight aliphatic polyester as an objective product of the invention. The obtained high-molecular-weight aliphatic polyester has weight average molecular weight Mw value of 50-250k and a molecular weight distribution Mw / Mn value of 1.9-2.2. Compared with the prior art, the invention has theadvantages of few by-products, high product yield, mild operation condition, low device cost and stable product quality and is suitable for industrial production.

Owner:SHANGHAI HUAYI GRP CO

Base oildeemulsifier in high performance

ActiveCN101050380ASimple processMild operating conditionsHydrocarbon oil dewatering/demulsificationDemulsifierProton

This invention discloses a method for synthesizing a high-efficiency crude oil demulsifier from cornstarch and conventional polyether demulsifier by graft copolymerization. The method comprises: (1) adding solvent and cornstarch into a reaction kettle with a stirrer, slowly adding proton acid (20-80 wt.% of cornstarch), and stirring for 1-4 h; (2) adding polyether demulsifier and solvent, and refluxing under heating for 2-8 h; (3) adding NaOH solution for neutralization, ending NaOH addition when the pH value is 6.5-8.0, and reacting for 1-3 h until the solution is transparent. The demulsifier has such advantages as simple process, mild operation conditions, wide applications, and good demulsification effect.

Owner:DAQING HUAYING CHEM IND

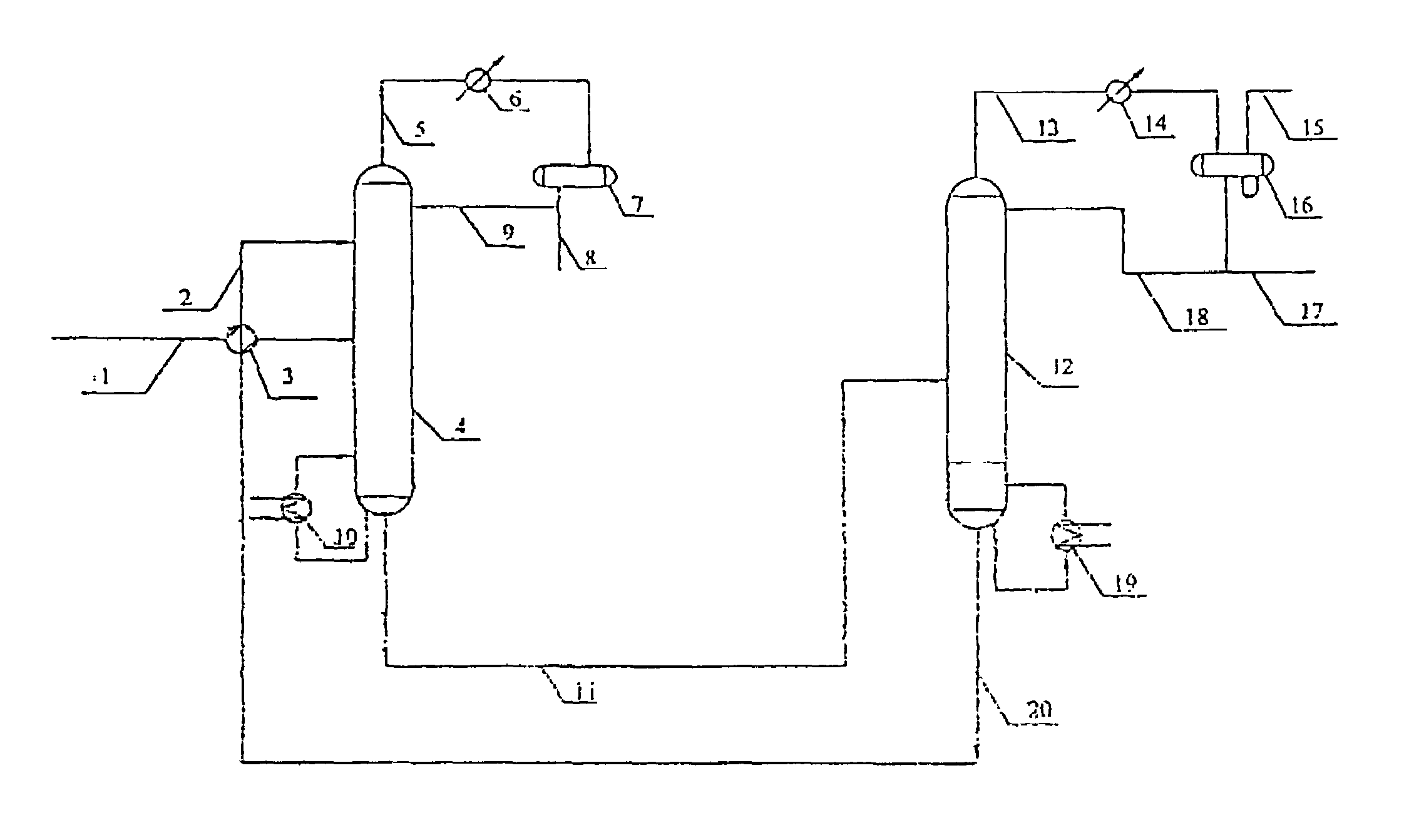

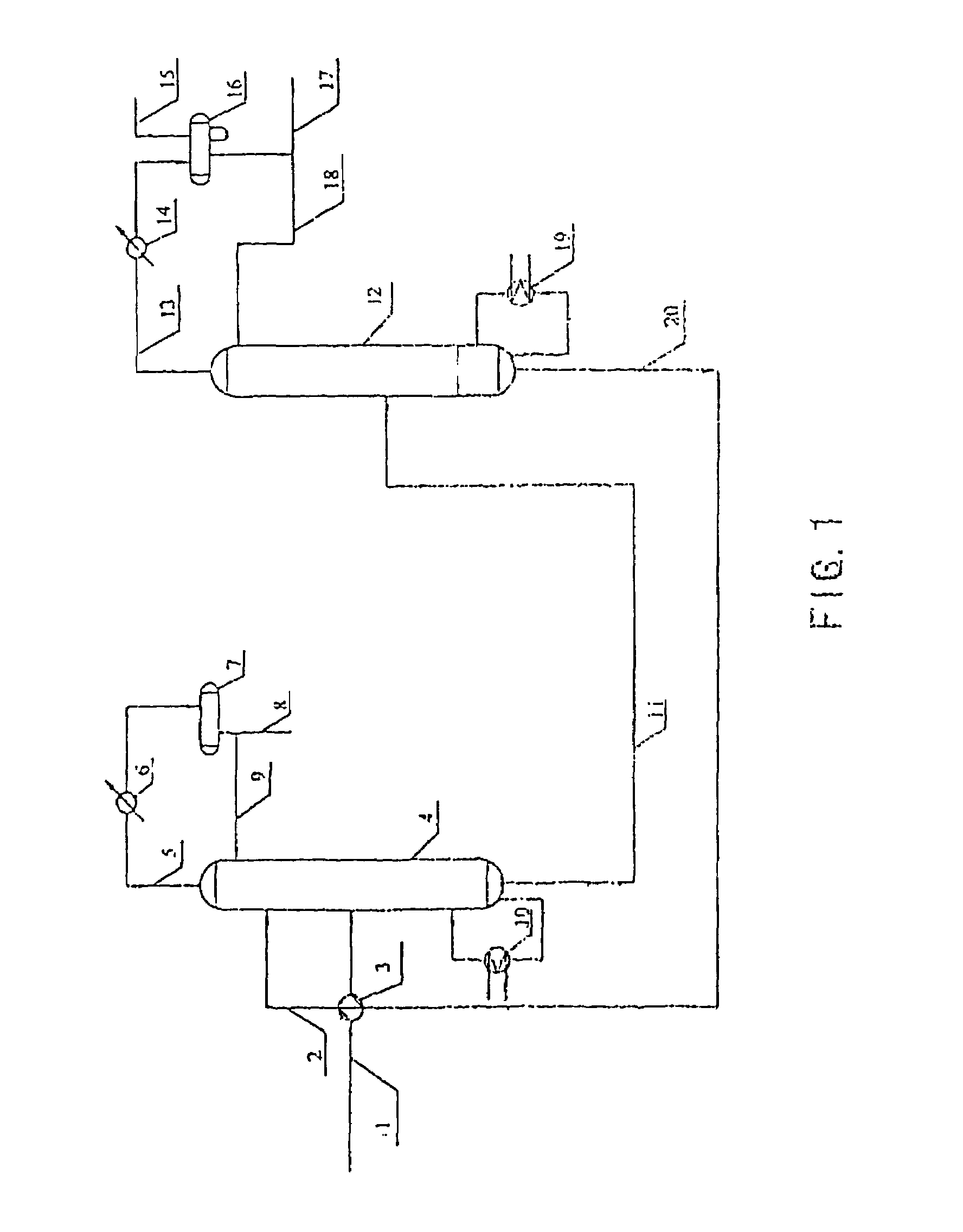

Process for separating aromatics by extractive distillation and a composite solvent used therein

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

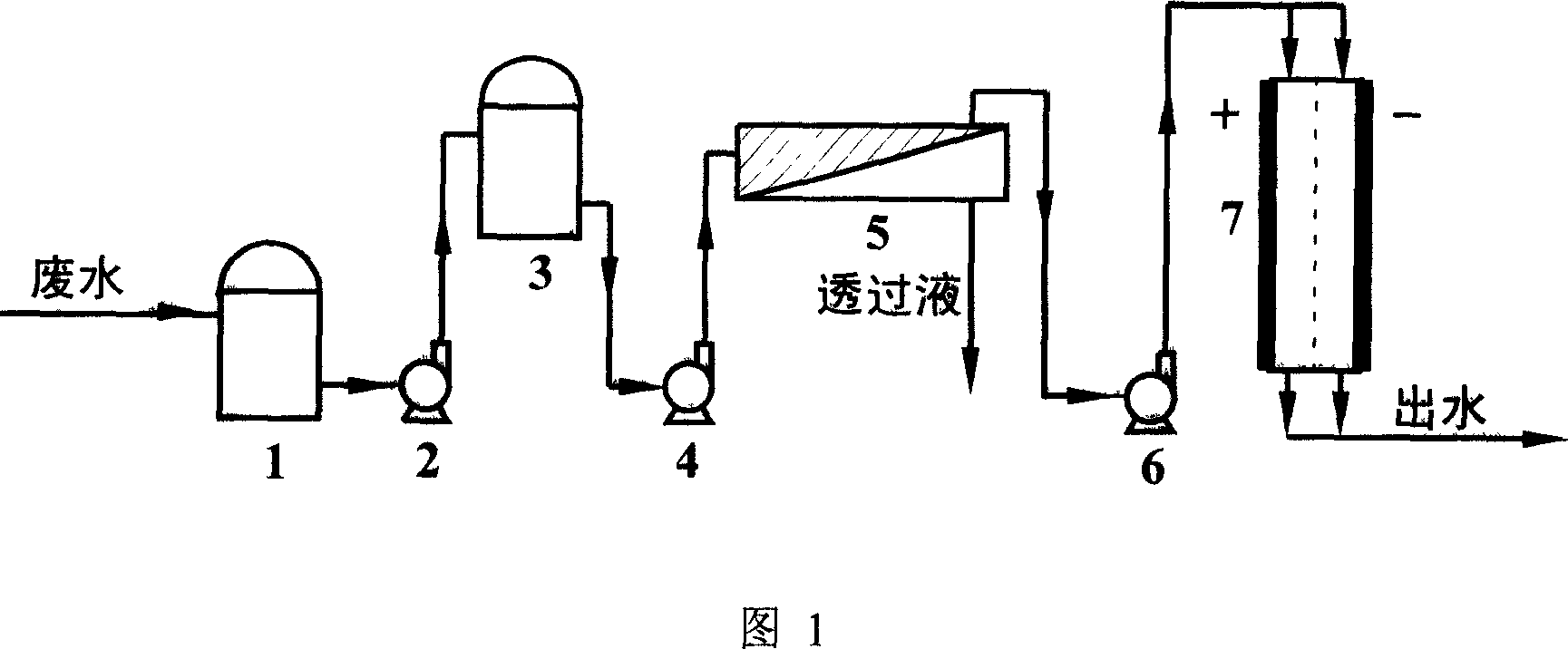

Method of diaphragm separation electrolyzing integrated treatment of wate, water containing heavy metal copper

InactiveCN101024533AAvoid wastingSimple process equipmentPhotography auxillary processesWater contaminantsElectrolysisEconomic benefits

The invention discloses a method used membrane separating-electrolyzing integration to process heavy metal copper containing waste water. It includes the following step: gravity setting, micron filtering, and membrane separating. The concentrated solution is poured into the electrolytic reactor after pH value regulating to deposit heavy metal copper on its negative pole board by energizing to reduce. The residual liquid can be reused in the production technology. The invention can reclaim the metal copper from the heavy metal copper containing waste water, realize water resource reuse. In addition, it has simple device, convenient operation, high recovery ratio, comprehensive utilization ratio, good economic benefit.

Owner:TIANJIN UNIV

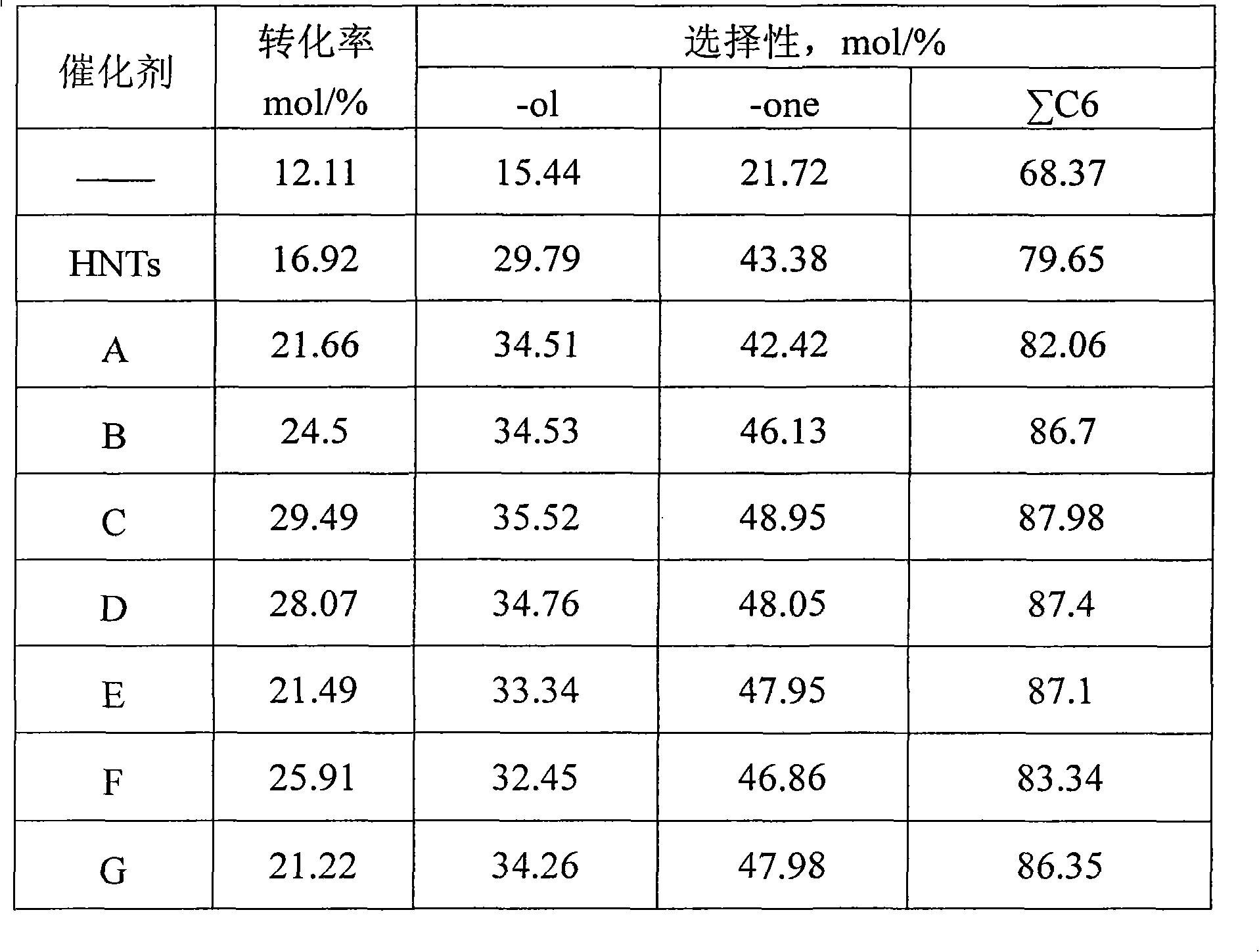

Preparation method and application of load type nano-gold catalyst

InactiveCN101829567AImprove loading efficiencyEasy to operatePreparation by oxidation reactionsCarbonyl compound preparation by oxidationHalloysiteGold particles

The invention discloses a preparation method and an application of a load type nano-gold catalyst. The preparation method comprises the following steps of: (1) adding 2.0g of halloysite nanotube carrier, 2.05 to 6.15mL of chlorogold acid solution with a concentration of 10g / L and 40 to 120mL of deionized water to a 250mL flask with three necks; (2) putting the flask into an oil bath with the temperature of 60 DEG C; adjusting the pH of the solution to 8 to 12 by using 4.0M ammonia water; then carrying out stirring reflux at 95 DEG C-105 DEG C for 1 hour; filtering; rinsing for 5 minutes by using 10 to 20mL of 4.0M ammonia water; washing twice with 15 to 20mL of hot water; drying for 1 to 2 hours at 100 DEG C; and finally roasting for 3 to 4 hours in air at 300 DEG C to obtain the load type nano-gold catalyst. The invention has the advantages of simple and convenient preparation method, uniformly dispersed gold particles and high loading efficiency. The catalyst provided by the invention can be used for cyclohexene oxidation of cyclonene and cyclohexenol, with the advantages of mild reaction condition, good activity and selectivity and less catalyst utilization quantity.

Owner:ZHEJIANG UNIV

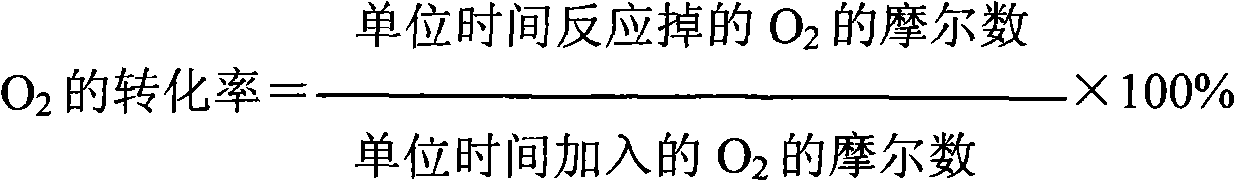

Reaction system and preparation method for nitrous alkyl ester

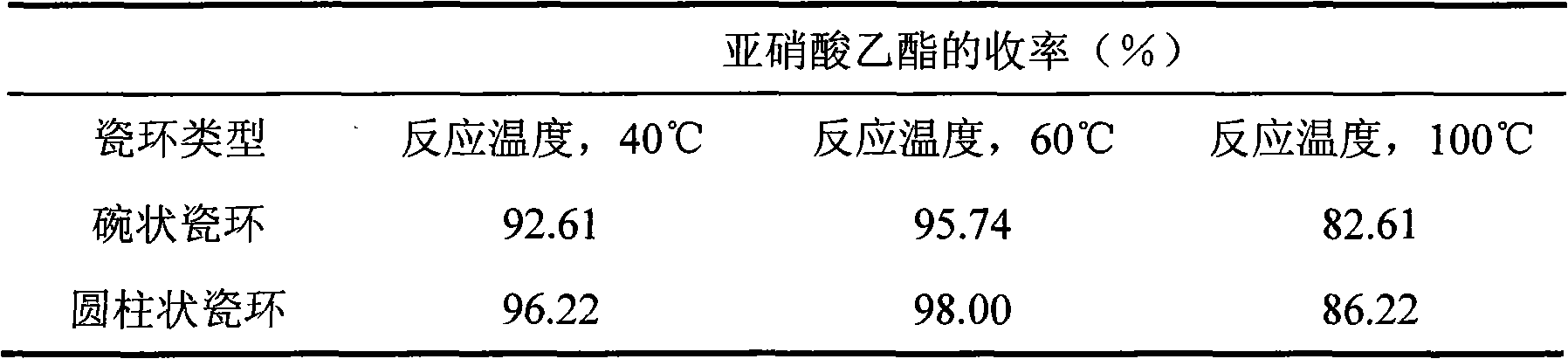

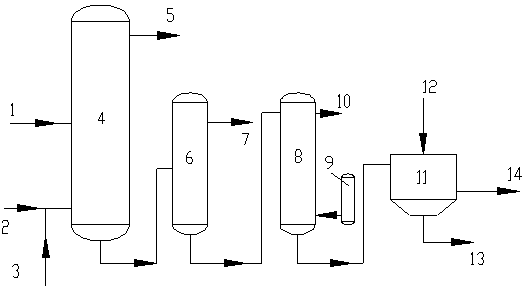

InactiveCN101314569AHigh yieldImprove efficiencyLiquid-gas reaction processesNitrous acid preparation ester preparationRetention timeGas phase

The invention relates to a reaction system for alkyl nitrite and a preparation method for the alkyl nitrite. The preparation method comprises the following steps that: a trickle-bed reactor is adopted and porcelain ring filler is filled into the trickle-bed reactor; liquid added into the reactor forms liquid membranes on the filler; alkyl alcohol is taken as a liquid-phase raw material and nitric monoxide, oxygen and nitrogen are taken as gas-phase raw materials; and gas and liquid phases are reacted in the trickle-bed reactor by means of co-current flow or countercurrent flow under the condition of nitrogen protection so as to generate the alkyl nitrite. The mol ratio of the alkyl alcohol to NO is between 2 to 1 and 7 to 1, and the mol ratio of the NO to O2 is between 4 to 1 and 8 to 1; the reaction temperature is between 40 and 100 DEG C, and the reaction pressure is between 0.1 and 1.0 MPa; and the retention time of continuous feeding of liquid-phase alkyl alcohol in the trickle-bed reactor is between 10 and 500 minutes, and the retention time of continuous feeding of gas phase in the trickle-bed reactor is between 0.02 and 1 minute. The reaction system and the preparation method have the advantages that: the operating condition is mild; the reaction time is short; the conversion rate of the raw materials, and the selectivity and the yield of products are high; and the whole reaction system is convenient for realizing continuous production, etc.

Owner:TIANJIN UNIV

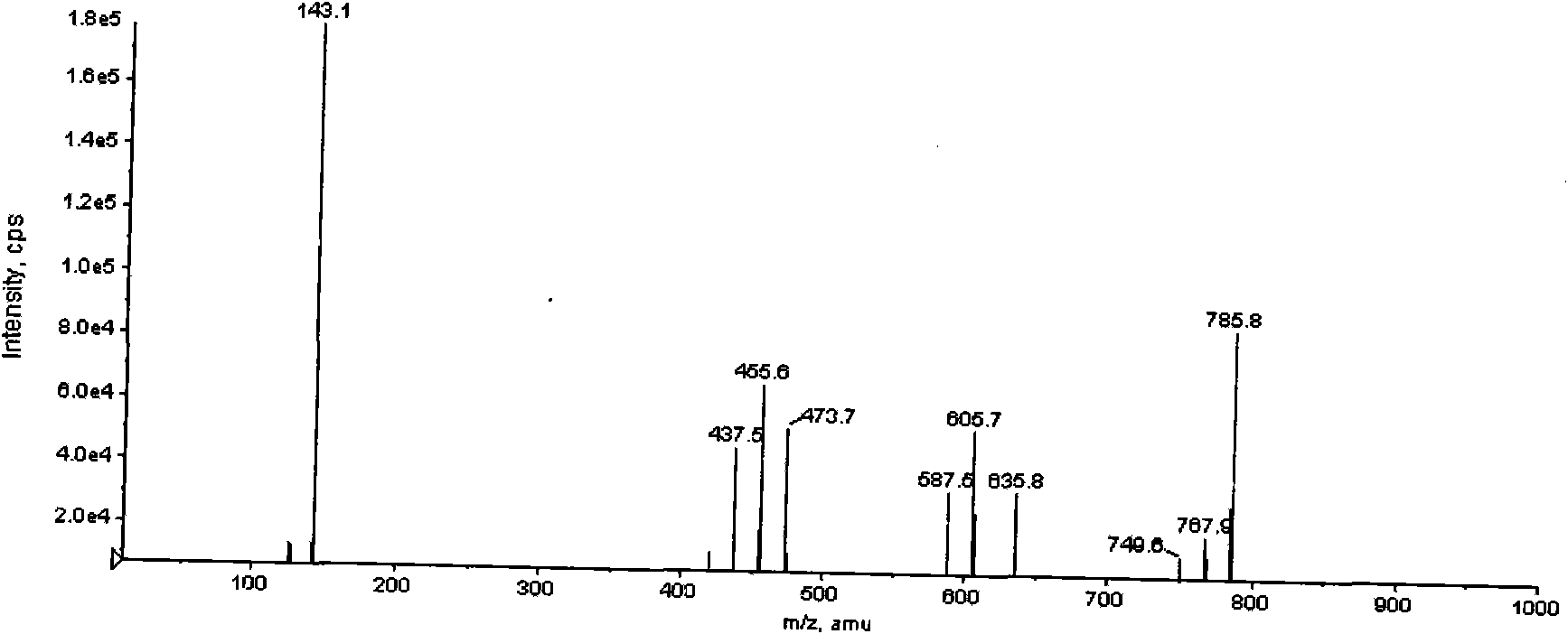

Separating and extracting method of Bacillus subtilis lipopeptide antibiotic substance

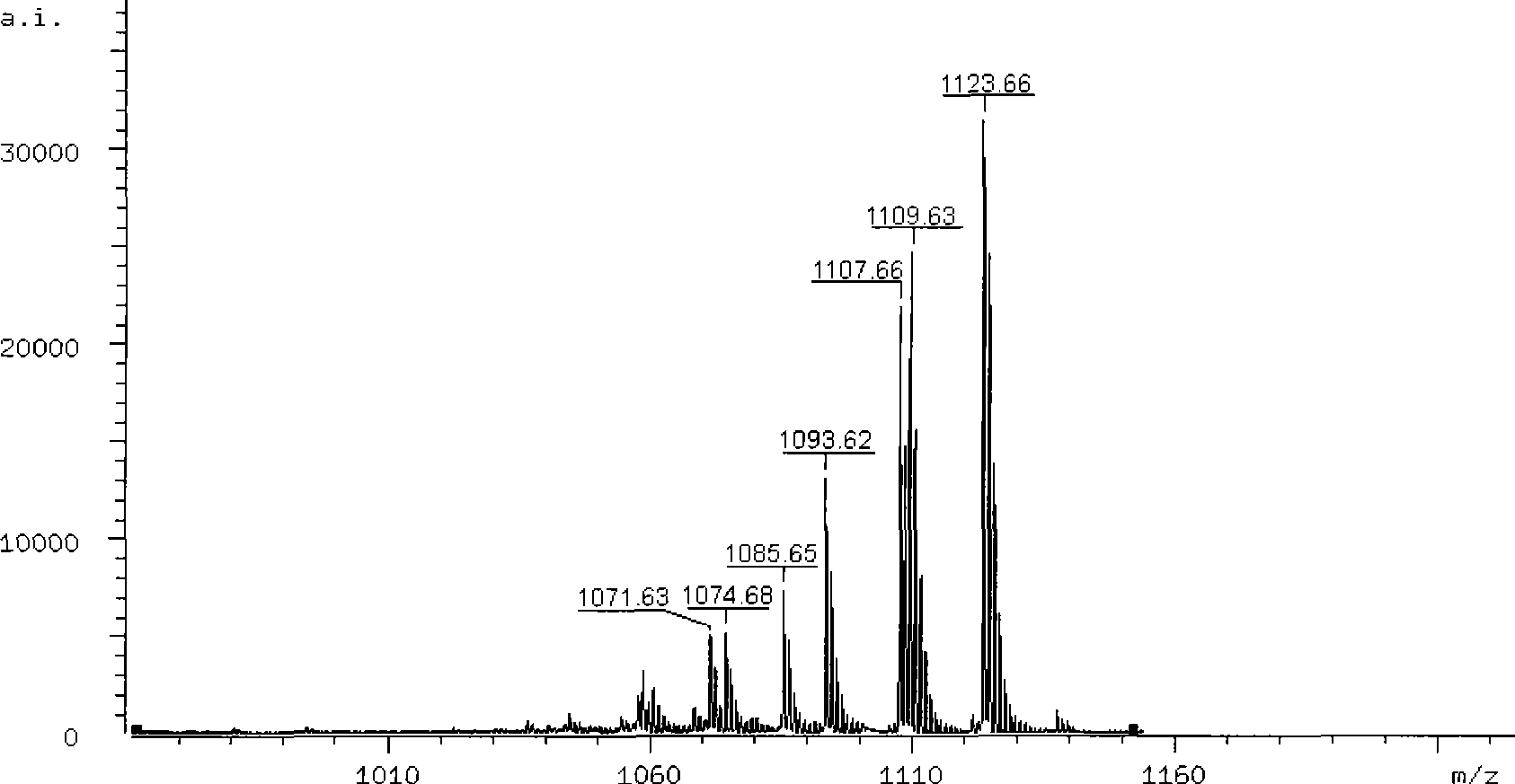

InactiveCN101372502ASimple preparation processMild operating conditionsMicroorganism based processesPeptide preparation methodsMass spectrum analysisChemistry

The invention relates to the field of biotechnology, in particular to a method for separating and extracting bacillus subtilis lipopeptid antibacterial material. The method more particularly comprises the steps Sephadex G-25 column chromatography is carried out on crude extract of fermentation liquor of the bacillus subtilis, active peak is collected by chromatography, and the Sephadex G-25 column chromatography is carried out on the active peak which is collected by Sephadex G-25 column; the active peak is collected, and the obtained substance is seven lipopeptid antibacterial materials after being detected by mass spectrum. Furthermore, the extracted lipopeptid antibacterial material has good inhibition effect on multiple pathogenic fungis, and has the advantages of stable temperature and pH value, prolease hydrolysis resistance, etc.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

ActiveCN103045288AReduce CODMild operating conditionsOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid. The comprehensive treatment method comprises the steps of: 1, acidizing high-sulphur high-COD caustic sludge waste liquid by using an N2 / SO2 mixed gas, when the pH value of the waste liquid reaches 2-6, stopping acidizing; 2, sending tail gas discharged in the acidizing process in the step 1 to a sulphur production device for preparing sulphur; 3, settling the waste liquid generated in acidizing treatment in the step 1and recovering an oil phase; 4, further reducing the COD of the waste liquid by adopting an extraction method when the COD of the waste liquid after the oil phase is separated in the step 3 is always high; and 5, regenerating the waste liquid extracted in the step 4 by using lime. The comprehensive treatment method is low in investment, is mild in operation conditions, is capable of recycling the caustic sludge waste liquid, avoiding the impact of the high-concentration wastewater on a wastewater treatment field, is also capable of recovering sulfide and crude carbolic acid from the caustic sludge waste liquid, and has a certain economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

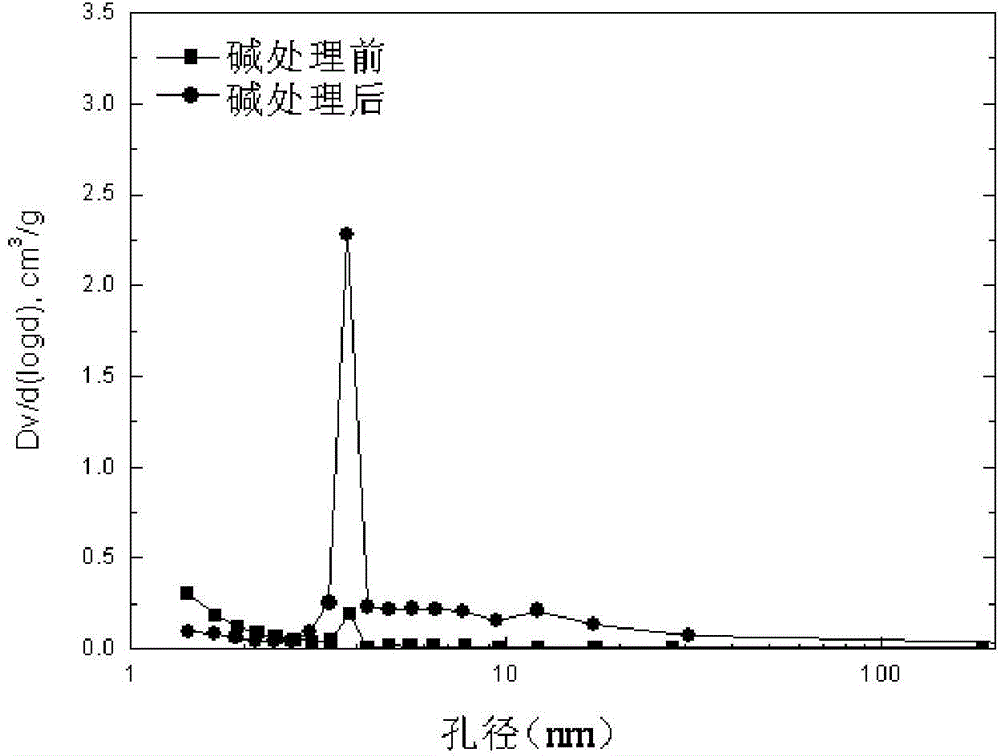

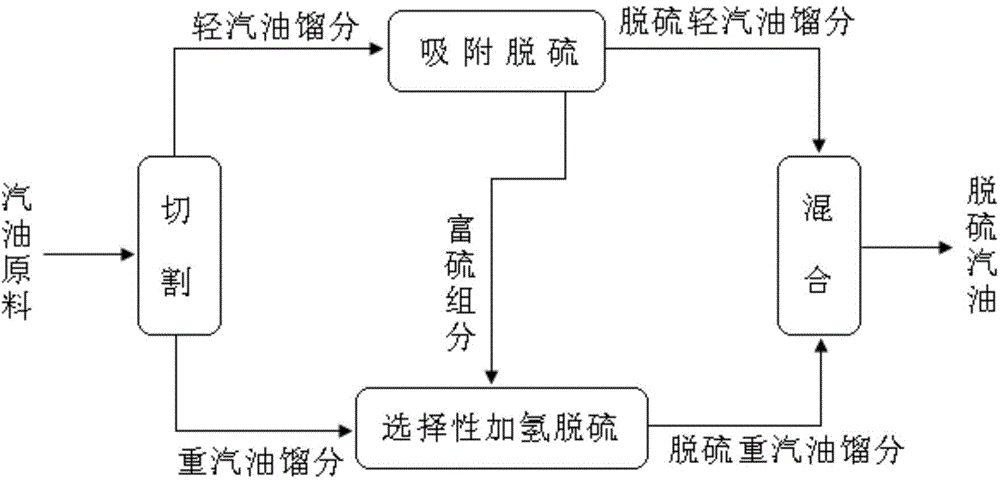

Gasoline desulfurization method

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

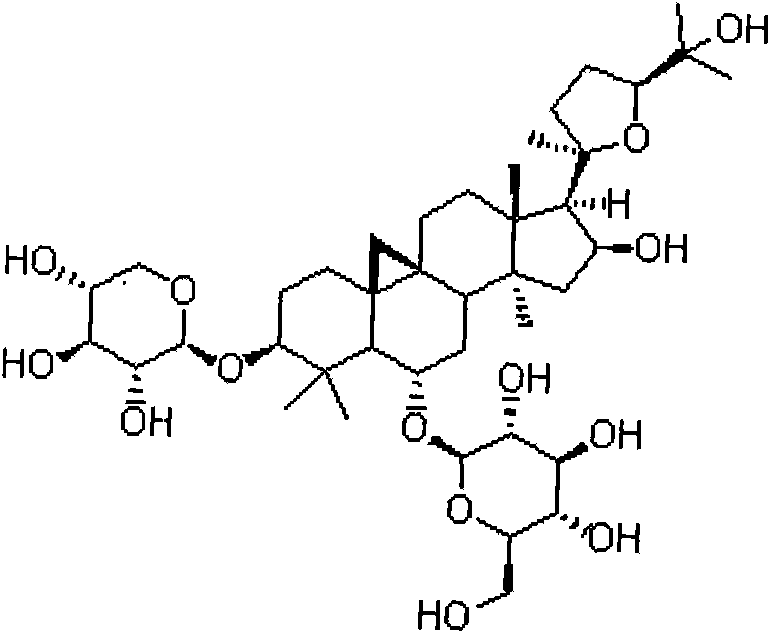

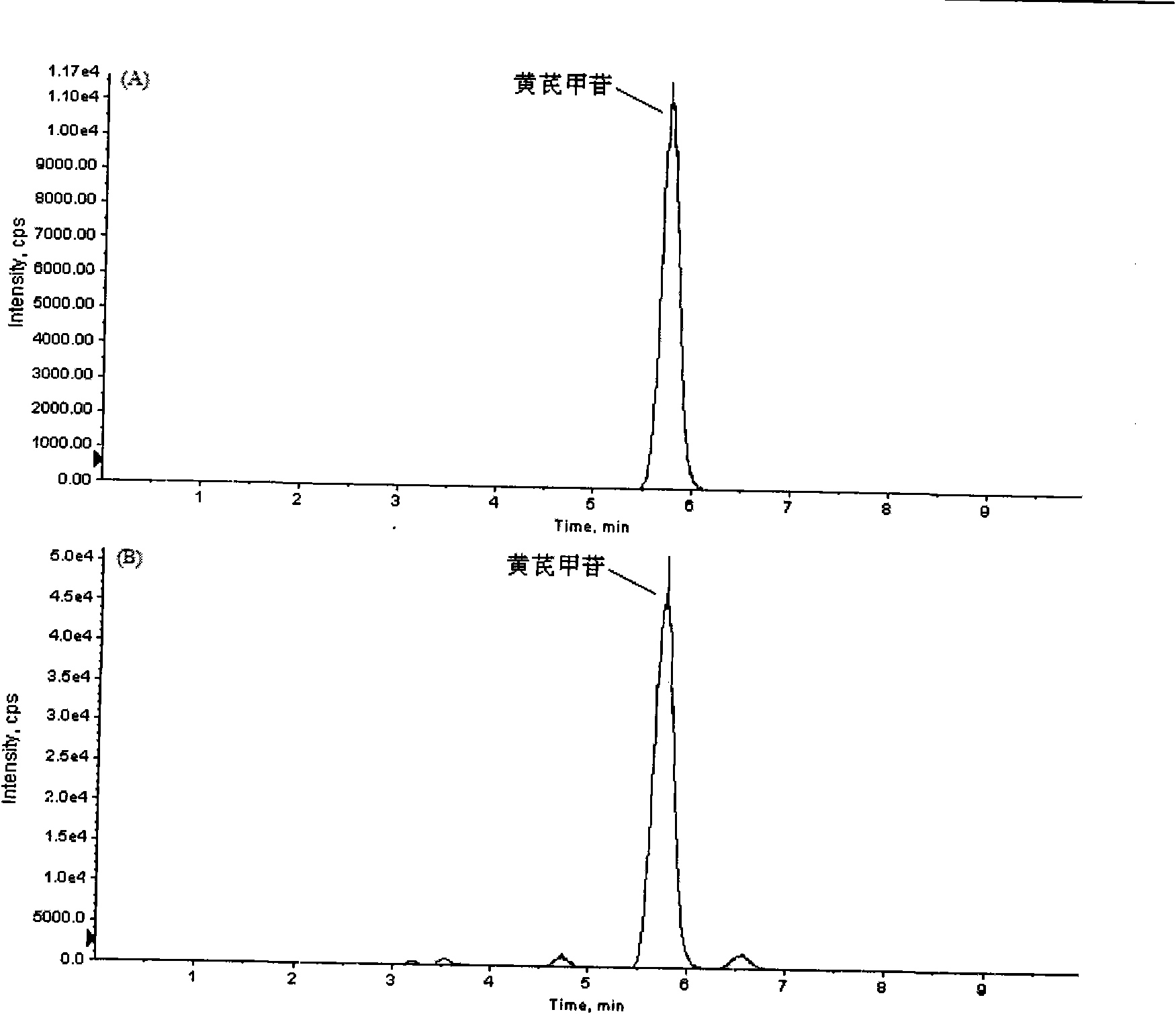

Method for extracting, separating and purifying Astragaloside IV from Astragalus mongholicus

The invention relates to a method for extracting, separating and purifying a functionality active component Astragaloside IV from a common used traditional Chinese medicine Astragalus mongholicus, and aims to provide a simple, safe, economic and effective method for extracting, separating and purifying the Astragaloside IV from the Astragalus mongholicus with high purity. The adopted technical scheme is as follows: taking traditional Chinese medicine Astragalus mongholicus as a raw material; and adopting a series of original and efficient technologies for extracting, separation and purifying such as homogenate extraction-mixing enzyme induction biotransformation technology, negative pressure cavitation suspension extraction technology, saponin derivant hydrolysis converting technology, liquid-liquid extraction technology, macroporous absorption resin enrichment technology, normal phase silica gel medium pressure column chromatography technology and devitrification at a low temperature, recrystallization technology and the like to obtain the Astragaloside IV with high purity and yield, wherein the yield thereof can be more than 0.08% and the purity can be more than 95%. The raw material used in the invention is the common used traditional Chinese medicine Astragalus mongholicus, and has abundant resources; the production process of the Astragaloside IV is simple and practicable; the target compound has high yield and purity; and the method is suitable for the industry production and application, has high additional value and excellent market application prospective.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Nanofiltration treatment method of desulfurization waste water

ActiveCN105236659AAchieve recyclingNovel processing methodMagnesium sulfatesMultistage water/sewage treatmentInorganic saltsWastewater

The invention provides a nanofiltration treatment method of desulfurization waste water. The method comprises the following steps that 1, pH of the desulfurization waste water is adjusted to range from 8.5 to 9.5, and TMT-15 and sodium carbonate are added to remove calcium ions and heavy metal elements; 2, the desulfurization waste water treated in the first step is filtered, and nanofiltration treatment is conducted on the filtered desulfurization waste water to obtain separation liquor and concentrated liquor; 3, crystallization treatment is conducted on the separation liquor to obtain NaCl solid salt, the concentrated liquor is treated according to the second step, nanofiltration treatment is repeatedly conducted on the concentrated liquor to make the recovery rate of NaCl in the desulfurization waste water treated in the first step reach above 80%, and MgSO4 solid salt is obtained through crystallization treatment. According to the nanofiltration treatment method of the desulfurization waste water, the treatment method is simple, the cost is low, operation is easy, the operation conditions are mild, the operation method is flexible, and recycling of various inorganic salt in the desulfurization waste water is achieved.

Owner:BEIJING WOTEER WATER TECH

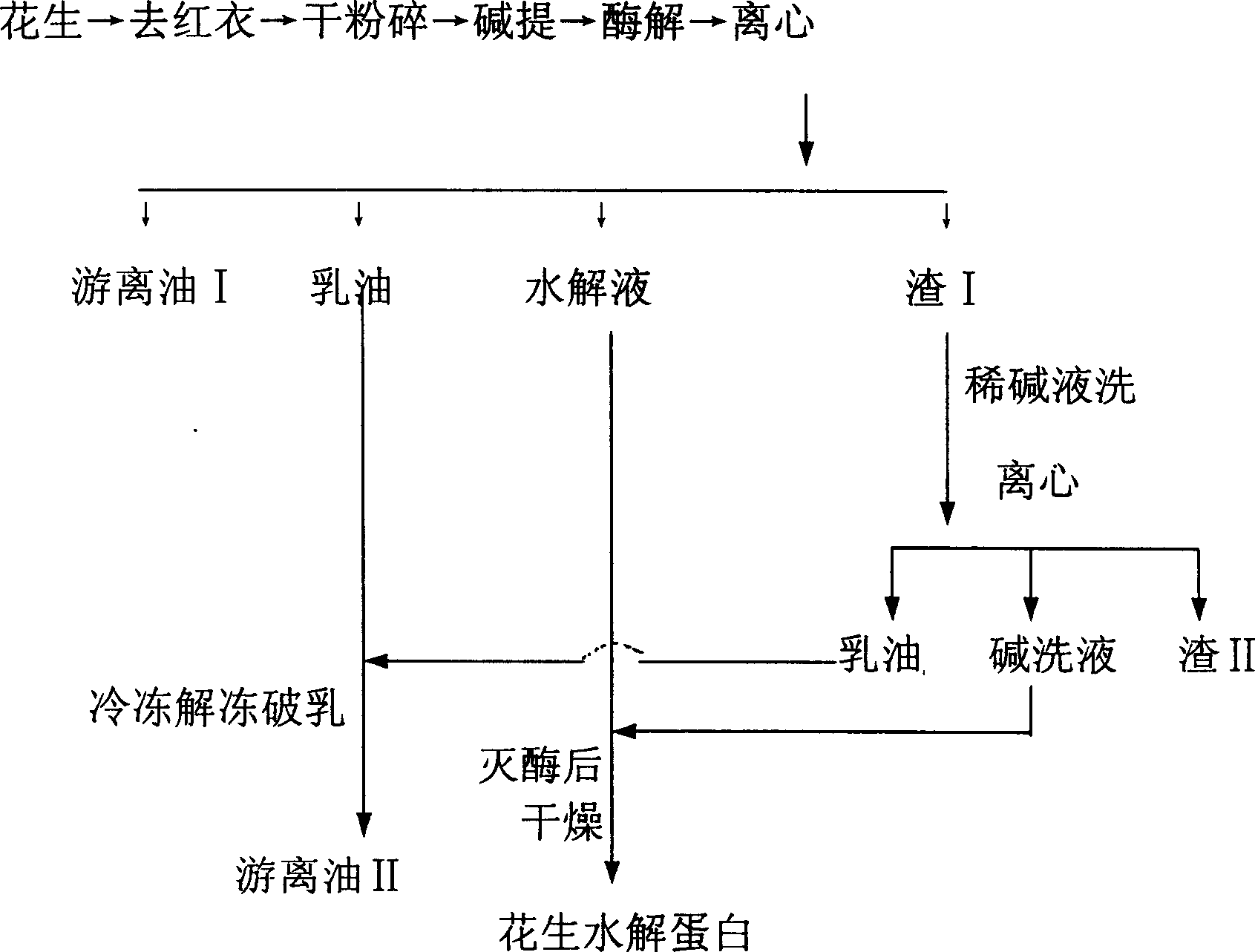

Technology of extracting oil and hydrolyzed protein from peanut using hydroenzyme method

InactiveCN1555714AQuality improvementOperational securityProtein composition from vegetable seedsEdible oils/fatsNutritive valuesAlkaline proteinase

A process for extracting oil and hydrolytic protein from peanut by water-enzyme method includes such steps as extracting emulsified oil by use of alkaline proteinase, and demulsifying it by freezing and thawing to obtain free oil while recovering hydrolytic protein powder in the form of micropeptide. Its advantages are high oil output and high nutritive value.

Owner:JIANGNAN UNIV

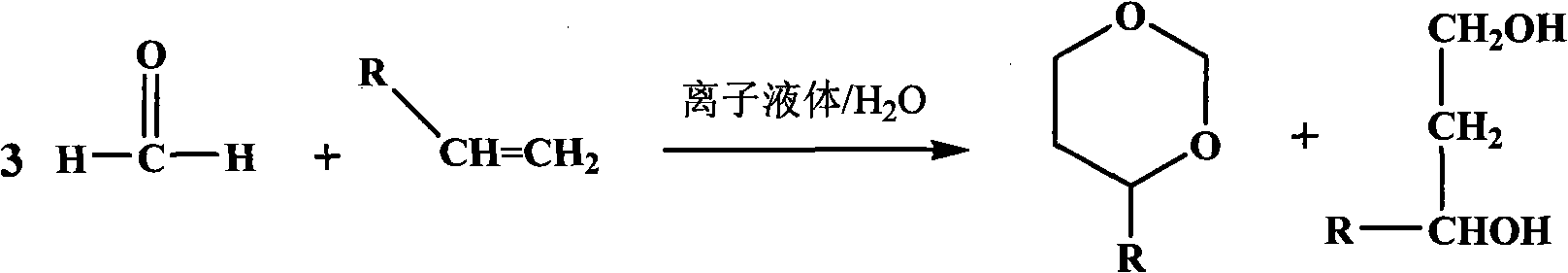

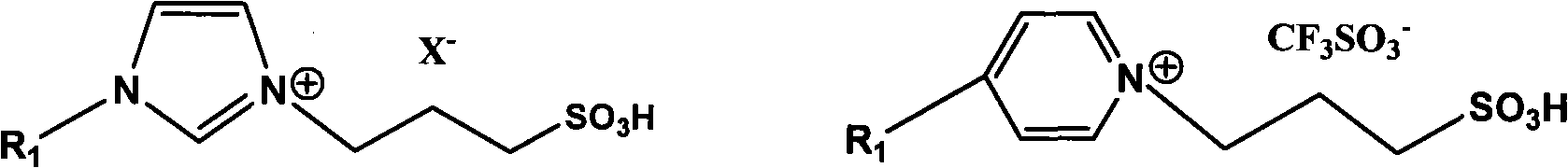

Method for catalytic synthesis of 1,3-dibasic alcohol or cyclic acetal of 1,3-dibasic alcohol by using ionic liquid

InactiveCN101665409AReduce dosageHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholDiol

The invention discloses a method for synthesizing 1,3-dibasic alcohol or cyclic acetal of 1,3-dibasic alcohol(1,3-dioxane derivative)by using a functional acid ionic liquid serving as a catalyst to catalyze the condensation reaction of formaldehyde and alkene. In the method, the aqueous solution of formaldehyde and the alkene are used as reactants to the 1,3-dibasic alcohol or cyclic acetal of 1,3-dibasic alcohol(1,3-dioxane derivative) under a mild reaction condition in the presence of the functional acid ionic liquid serving as the catalyst. The method has the advantages of readily availablereaction materials, low-corrosivity high-catalytic activity reusable catalyst, high product selectivity, simple reaction process, easy operation and strong controllability.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

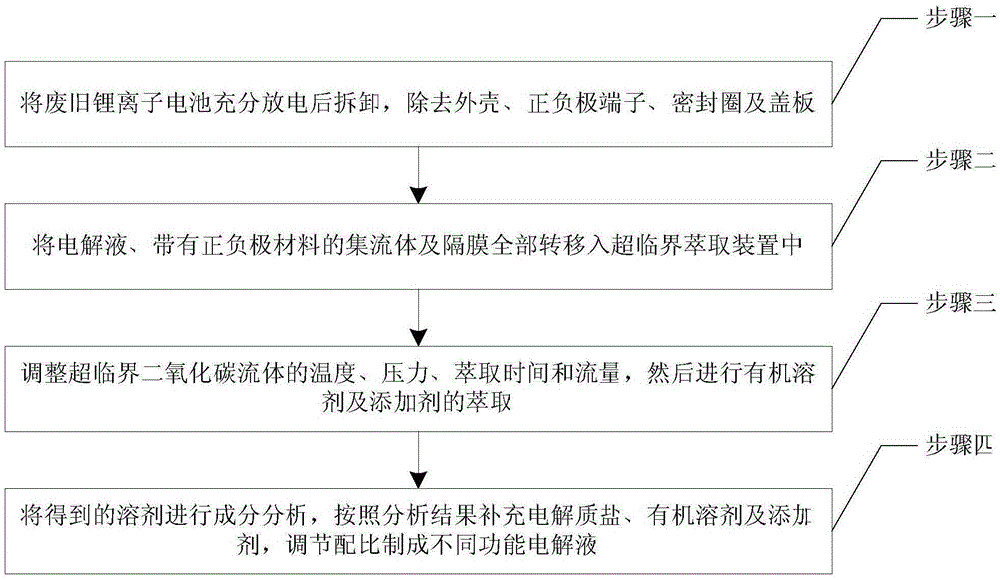

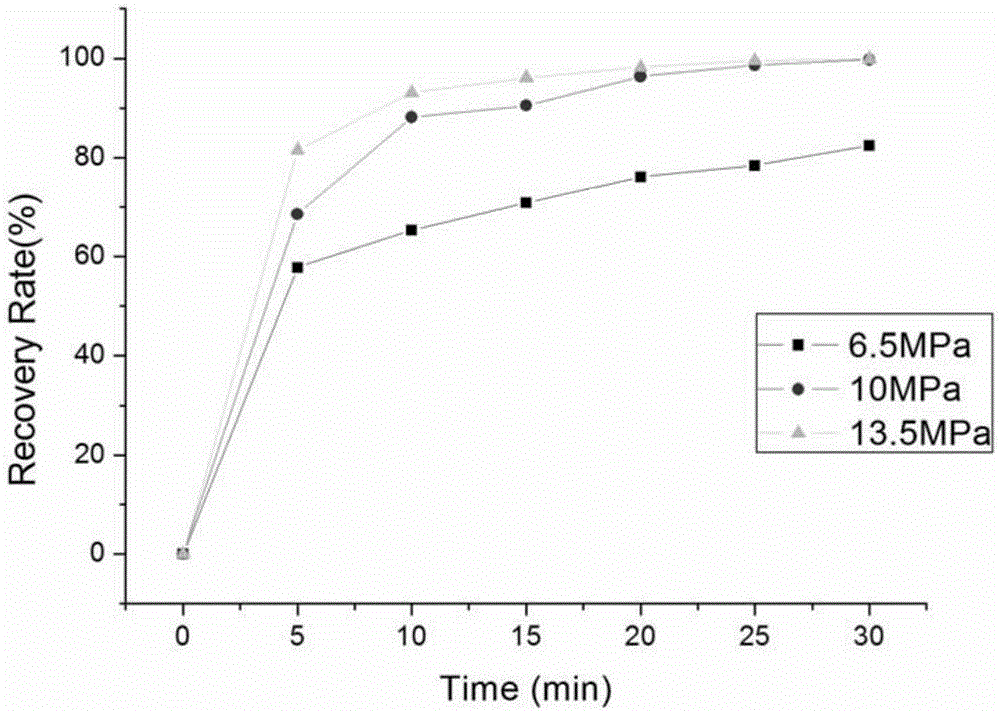

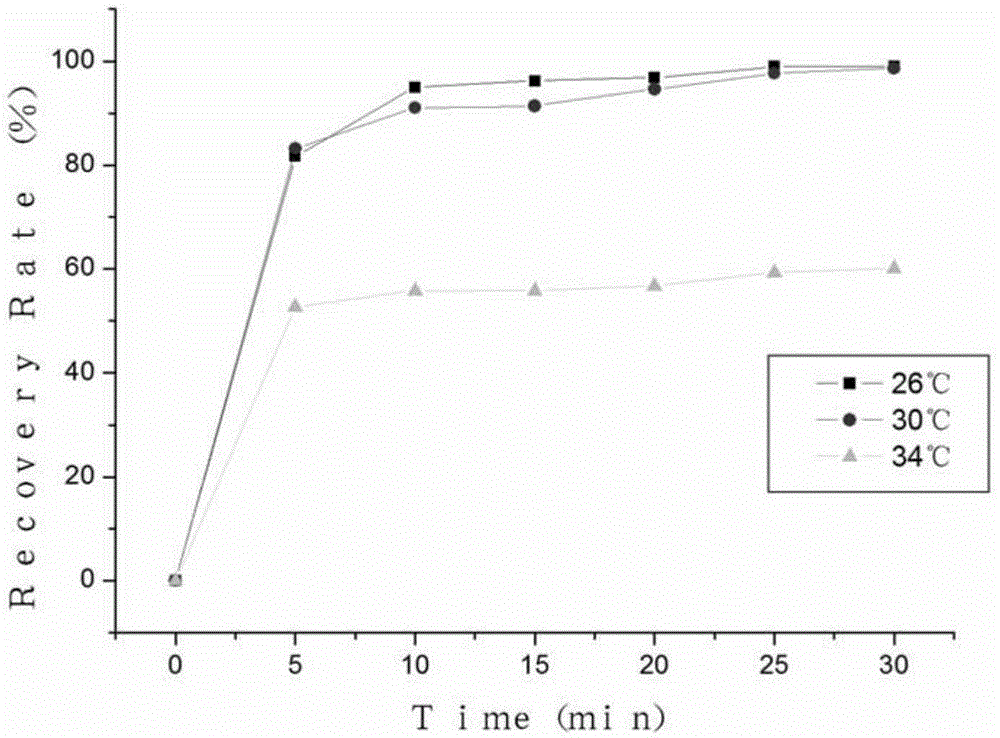

Carbon dioxide subcritical extraction, recycling and reusing method for electrolyte of waste lithium ion battery

ActiveCN105406146AAvoid pollutionAvoid degradationWaste accumulators reclaimingBattery recyclingOrganic solventResource utilization

The invention provides a carbon dioxide subcritical extraction, recycling and reusing method for the electrolyte of a waste lithium ion battery, belonging to the field of recycling and reusing of solid waste. The method comprises the following steps: after complete discharging of the waste lithium ion battery, dismounting the waste lithium ion battery and removing a shell, positive and negative terminals, sealing rings and cover plates; transferring the electrolyte, current collectors with positive and negative electrode materials and a diaphragm into a supercritical extraction apparatus; adjusting the temperature, pressure, extraction time and flow of a supercritical carbon dioxide fluid and extracting an organic solvent and an additive; and subjecting the obtained solvent to component analysis, supplementing electrolyte salt, the organic solvent and the additive according to analysis results and adjusting a ratio to prepare electrolytes with different functions. The method effectively prevents degradation and dissipation of heat-sensitive substances; operation parameters are easy to control; extraction, separation and recovery are integrated together; later complicated treating procedures are omitted; and the utilization rate of resources is higher.

Owner:HARBIN INST OF TECH

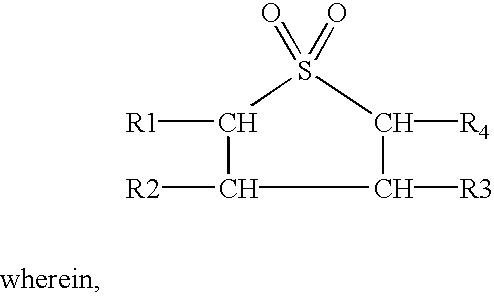

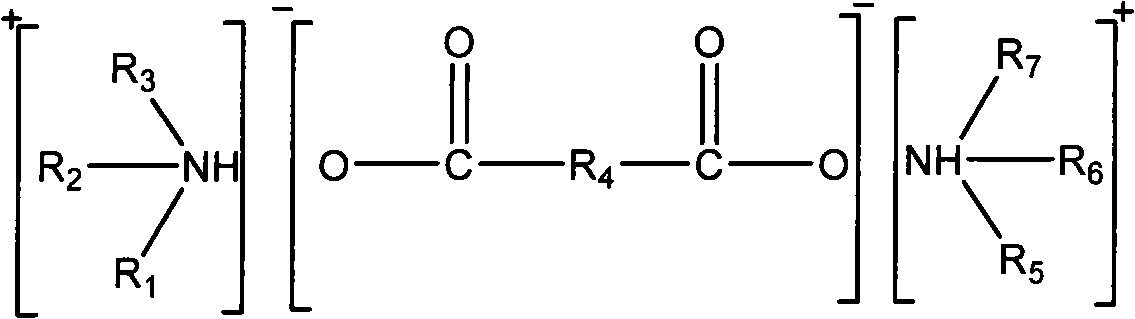

Green high-efficiency recyclable SO2 gas absorbent and preparation thereof

InactiveCN101264414AEasy to operateLower requirementDispersed particle separationAbsorption capacityHydrogen

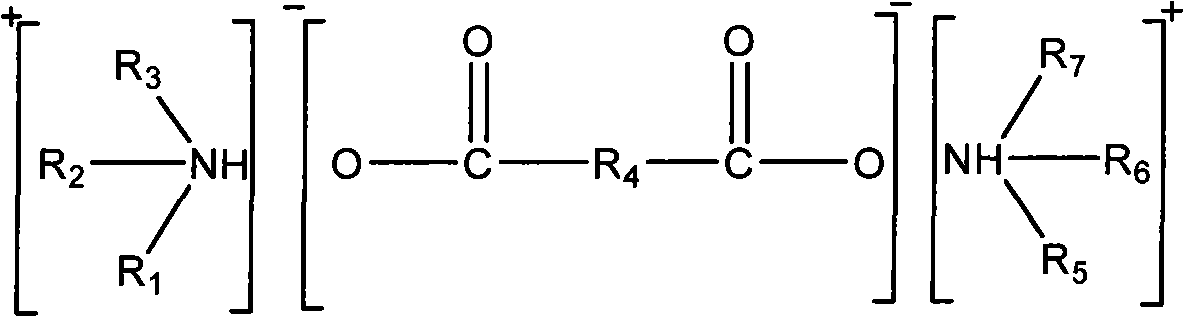

The invention relates to a high-efficient and circulatory SO2 air absorbent and preparation method. The absorbent is an alkaline ionic liquid comprising dicarboxylate of amine shown by the following chemical formulas, wherein, R1, R2, R3, R5, R6, R7 from the alkyl of C1 - C8 or the replace alkyl or hydrogen (H), R4 from CnH2n-2 or the alkyl of CmH2m or the replace hydroxyl; wherein, n=2-8, m=0-8. The preparation method of the absorbent takes amine and dicarboxylate acid as raw materials and comprises a direct action in solvent or without solvent. The ratio of the absorption capacity of SO2 and absorbent molar volume is as high as 2:1; the SO2 can be desorbed for a plurality of times and can be recycled, and achieves rapid absorption and desorption balance; the desorption ratio is more than 90%.

Owner:HEFEI UNIV OF TECH

Novel method for preparing high-purity chlorogenic acid

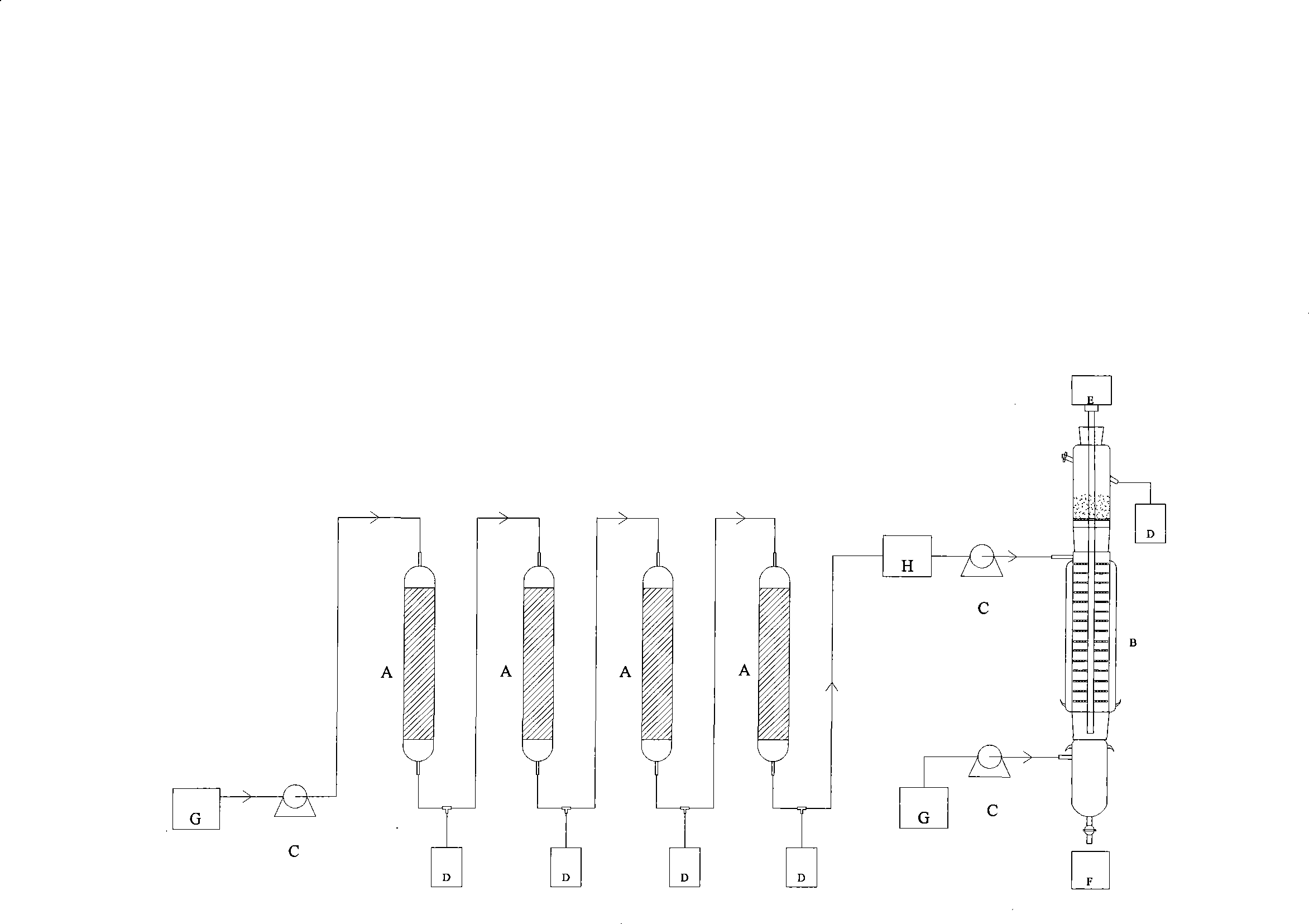

InactiveCN101503356AReduce decompositionHigh purityOrganic compound preparationMetabolism disorderChlorogenic acidOrganic solvent

The invention provides a new method for preparing high purity chlorogenic acid, comprising the steps: after the stock solution of the chlorogenic acid is processed by washing impurity and eluting through at least four levels of macroporous resin series connection adsorption column, and then the eluate is regenerated for continuous countercurrent extraction, so that the high purity chlorogenic acid is obtained. The method is applicable to light concentration stock solution of the chlorogenic acid, and can complete the process of absorbing, washing impurity, eluting, regenerating, countercurrent extracting and recycling the solvent in a semicontinuous way; the handling capacity of samples is large, the operation is simple, the production cost can be lowered, the residual organic solvent is reduced, and the environmental pollution is relieved.

Owner:NANJING UNIV OF TECH

Spray seeding matrix and method for saline land greening by adopting the spray seeding matrix

ActiveCN105347933AEasy to assembleAchieve governanceCalcareous fertilisersSuperphosphatesGreeningSoil surface

The invention provides a spray seeding matrix which is prepared from main materials and assistant materials. The main materials comprises the following materials by mass: 8-12 parts of soils for planting, 6-9 parts of turfy soils, 1.2-1.8 parts of straws, and 1.2-1.8 parts of attapulgite powder; the assistant materials is mainly composed of polyacrylamide and organic fertilizers. The greening method for saline land adopting the spray seeding matrix comprises: uniformly applying a mixture selected from one or more of desulfurized gypsum, calcium superphosphate, cow dung, and humic acid on the soil surface, forming a simple improvement layer, covering a mixture selected from one or more of furnace ash, wheat bran, sawdust, barks and straws on the simple improvement layer to form a saline-alkaline separating layer, and covering the spray seeding matrix on the saline-alkaline separating layer. The method for saline land greening is simply operated, and the plants in the modified saline land grow fine.

Owner:天津港海湾园林绿化有限公司

Recyclable sulfur dioxide gas absorbent and preparation method thereof

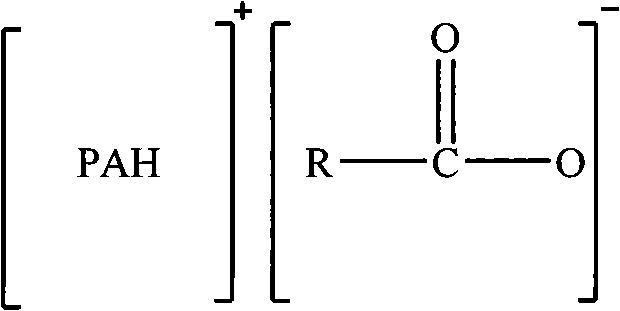

InactiveCN101537300ASynthetic conditions are mildShorten the timeDispersed particle separationDesorptionCarboxylic acid

The invention provides a recyclable sulfur dioxide gas absorbent and a preparation method thereof, wherein the absorbent is an ion liquid with a cation belonging to a multi-nitrogen straight chain amine, which is shown by a chemical formula at the right side, wherein PA is a multi-nitrogen straight chain amine matter and R is H or C1-C2 alkyl. The preparation method of the absorbent is characterized in that t the multi-nitrogen straight chain amine matter and the short chain carboxylate as raw materials and the reaction is carried out in a solvent or carried out directly without a solvent. The absorption amount of the SO2 is increased with the increment of the amount of the functional nitrogen; furthermore, the absorbent can be circularly used repeatedly by desorption, can achieve balanced absorption and desorption quickly, and desorption rate within 1 hour is more than 95% and the absorbent can be used for acidic gasses such as SO2, and the like.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com