Method of diaphragm separation electrolyzing integrated treatment of wate, water containing heavy metal copper

A membrane separation and heavy metal technology, applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of high separation efficiency of membrane separation method, inability to dispose of concentrated liquid, low energy consumption, etc., to avoid environmental problems. Pollution and waste of resources, avoid secondary pollution, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

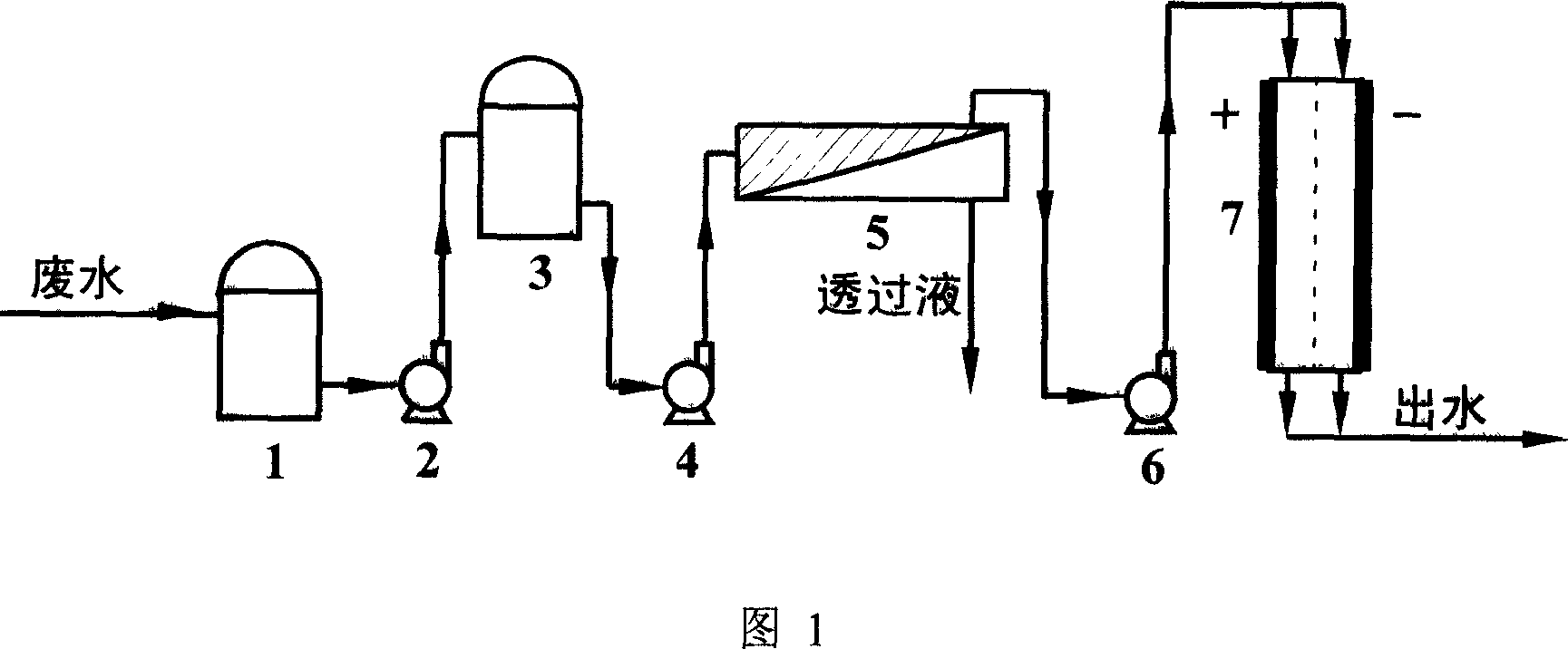

Embodiment 1

[0018] Add 2 L of waste water with a Cu concentration of 16.24 mg / L into the settling tank 1, settle by gravity for 24 hours at 20° C., and take the supernatant, which is fed into the micron filter 3 (pore size 5 μm) through the booster pump 2 . The filtered filtrate is injected into the membrane separator 5 through the high-pressure pump 4, and the membrane in the membrane separator is GE company DL polyvinyl alcohol and polypiperazine amide hybrid composite nanofiltration membrane, and the membrane molecular weight cut-off is 150~300 Dalton (Dalton ), membrane flux 28L / m 2 h, the filtrate flow rate is 1L / min, at 20°C and 0.6MPa, after membrane separation for 15 hours, the measured Cu concentration in the concentrate is 137.83mg / L, and the Cu concentration in the permeate is 6mg / L, Cu concentration The multiple is 8.49 times, the interception rate of Cu by the nanofiltration membrane is greater than 90%, and the permeate after membrane separation is reused in the production p...

Embodiment 2

[0020] The method of this embodiment is the same as that of Example 1, and the effect of treating wastewater with different nanofiltration membranes is specifically investigated.

[0021] Add 2 L of waste water containing Cu concentration of 16.24 mg / L into the settling tank 1, and settle by gravity for 24 hours at 20° C. to take the supernatant, which enters the micron filter 3 (pore size 5 μm) through the booster pump 2 . The filtered filtrate is injected into the membrane separator 5 through the high-pressure pump 4, and the membrane in the membrane separator is a composite nanofiltration membrane of GE company DK polyvinyl alcohol and polypiperazine amide, and the molecular weight cut-off of the membrane is 150~300 Dalton (Dalton ), membrane flux 18L / m 2 h, the filtrate flow rate is 1L / min, at 20°C and 0.6MPa, after membrane separation for 15 hours, the Cu concentration in the concentrate is measured to be 119.46mg / L, and the Cu concentration in the permeate is 3mg / L. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com