Patents

Literature

1200results about How to "Simple process equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

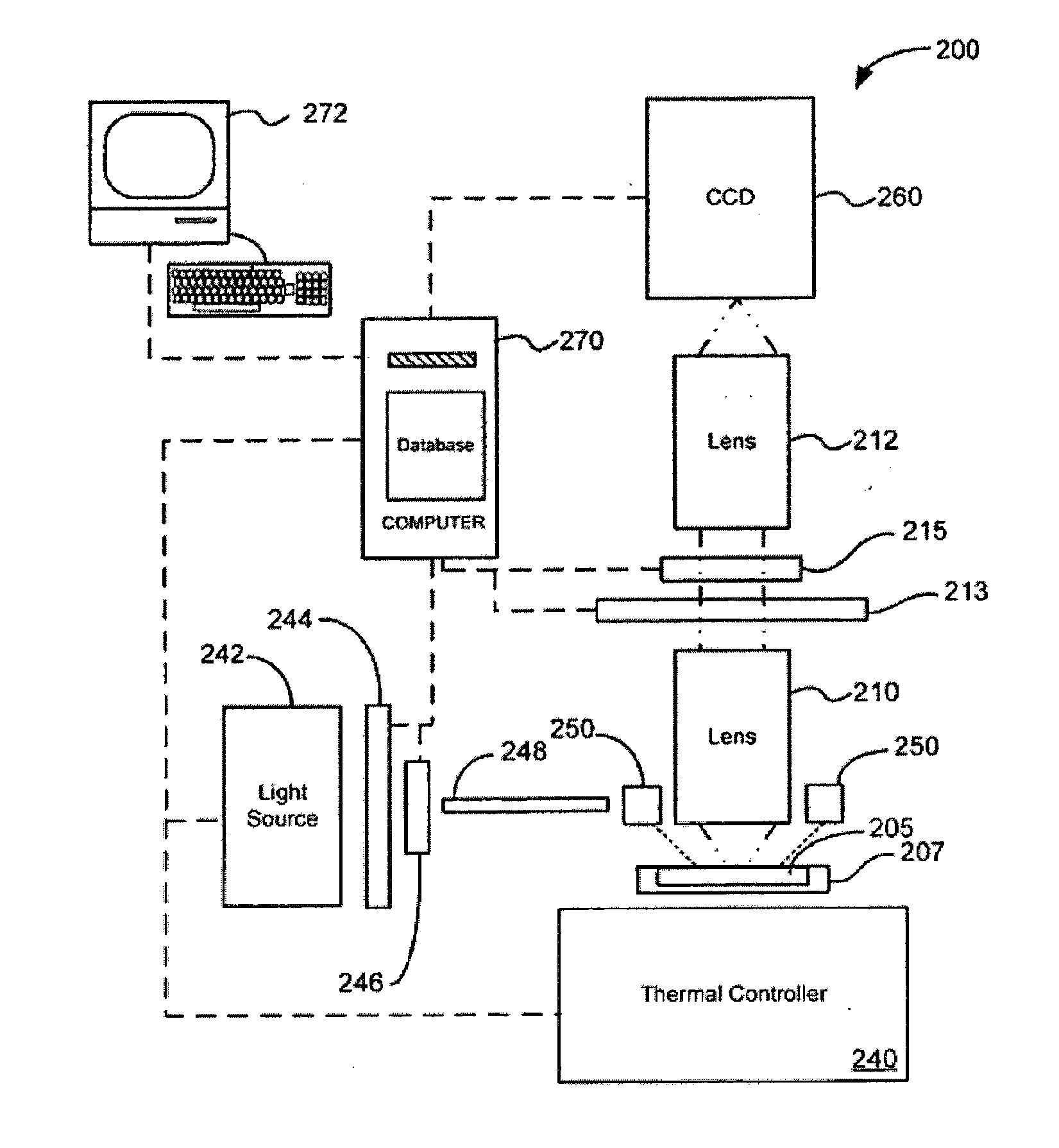

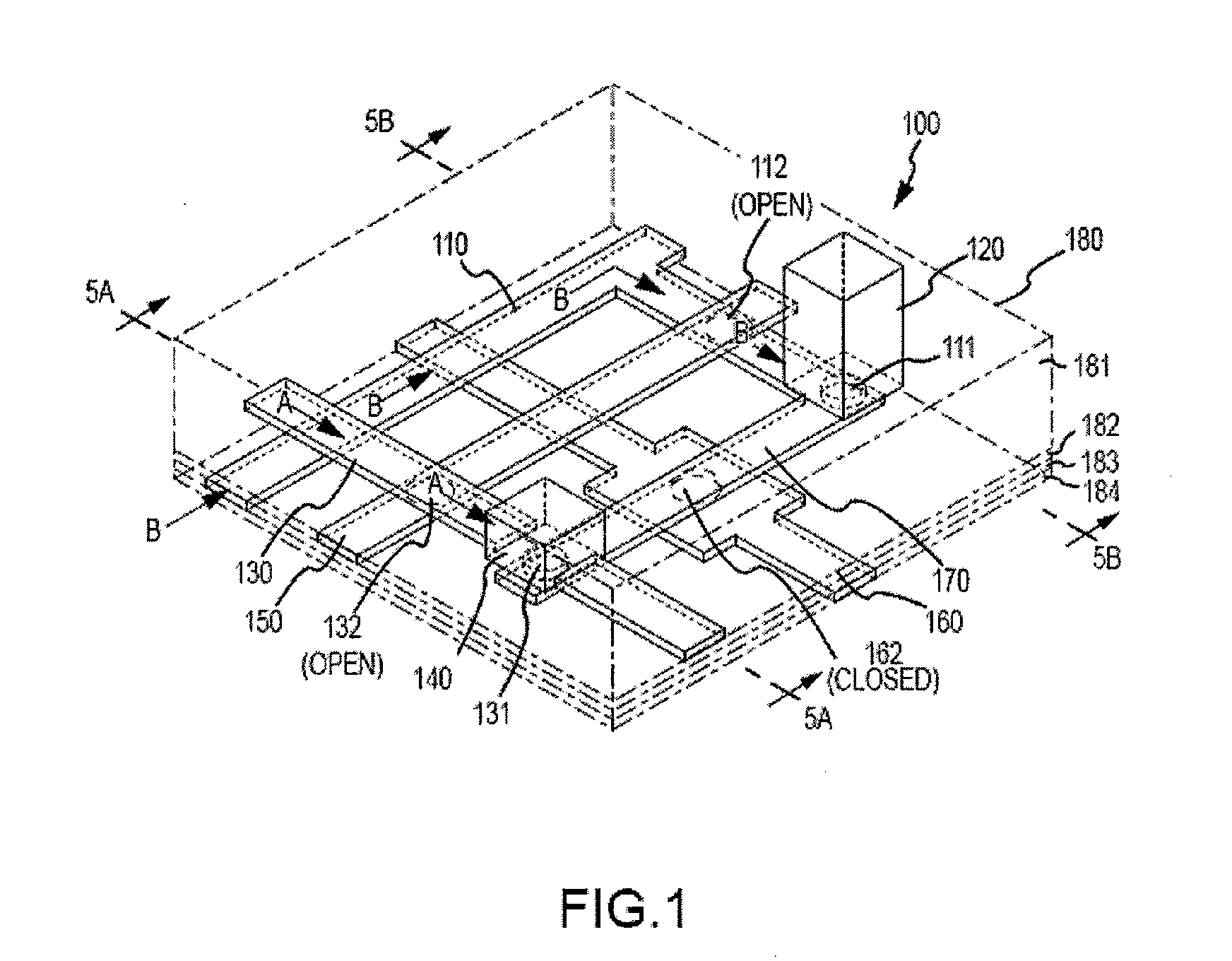

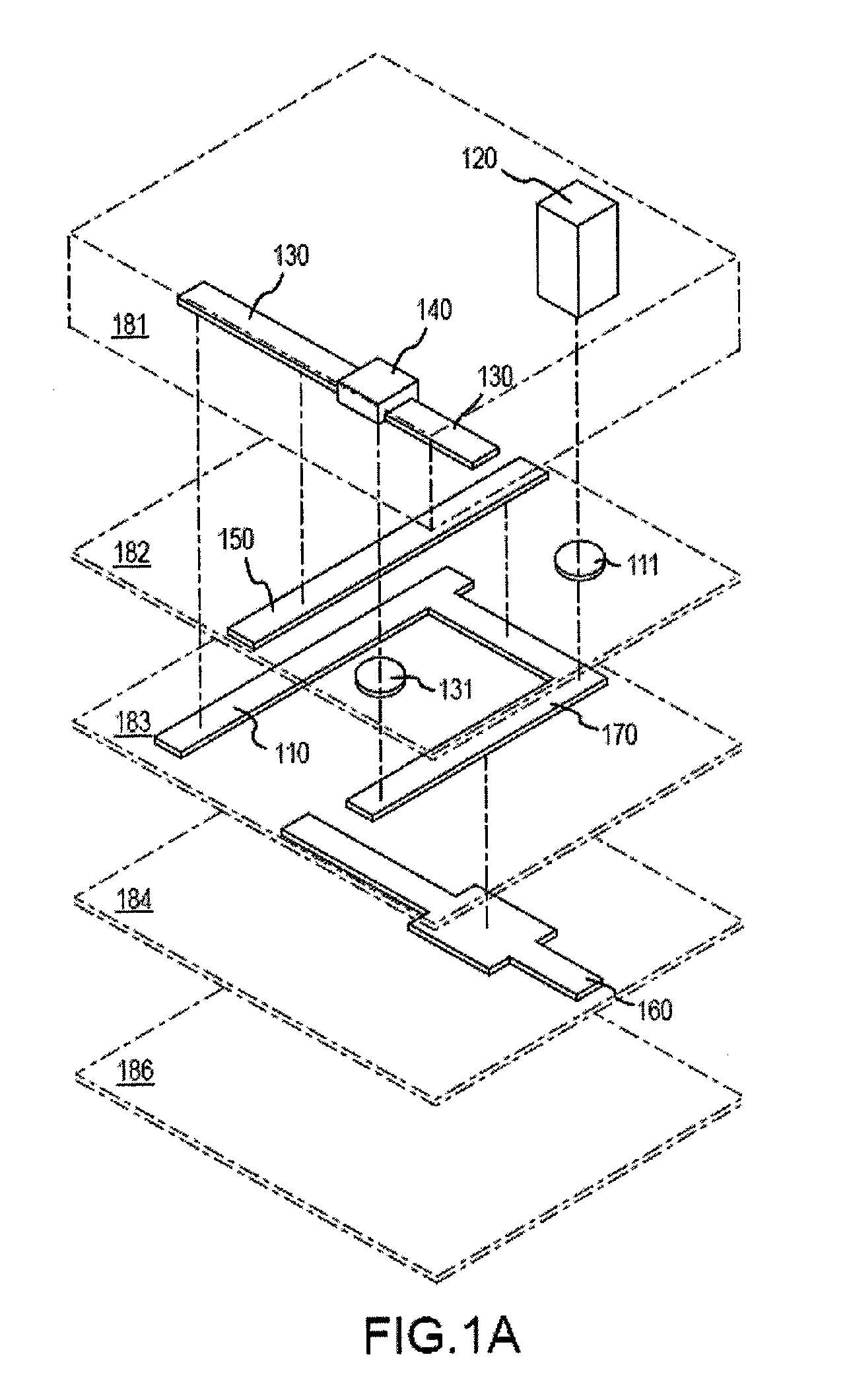

Microfluidic devices and methods

ActiveUS20100230613A1Shorten mixing timeManufacturing yield rate is increasedOptical radiation measurementHeating or cooling apparatusTemperature controlFluorescent imaging

Embodiments of the present invention provide improved microfluidic devices and related apparatus, systems, and methods. Methods are provided for reducing mixing times during use of microfluidic devices. Microfluidic devices and related methods of manufacturing are provided with increased manufacturing yield rates. Improved apparatus and related systems are provided for supplying controlled pressure to microfluidic devices. Methods and related microfluidic devices are provided for reducing dehydration of microfluidic devices during use. Microfluidic devices and related methods are provided with improved sample to reagent mixture ratio control. Microfluidic devices and systems are provided with improved resistance to compression fixture pressure induced failures. Methods and systems for conducting temperature controlled reactions using microfluidic devices are provided that reduce condensation levels within the microfluidic device. Methods and systems are provided for improved fluorescent imaging of microfluidic devices.

Owner:STANDARD BIOTOOLS INC

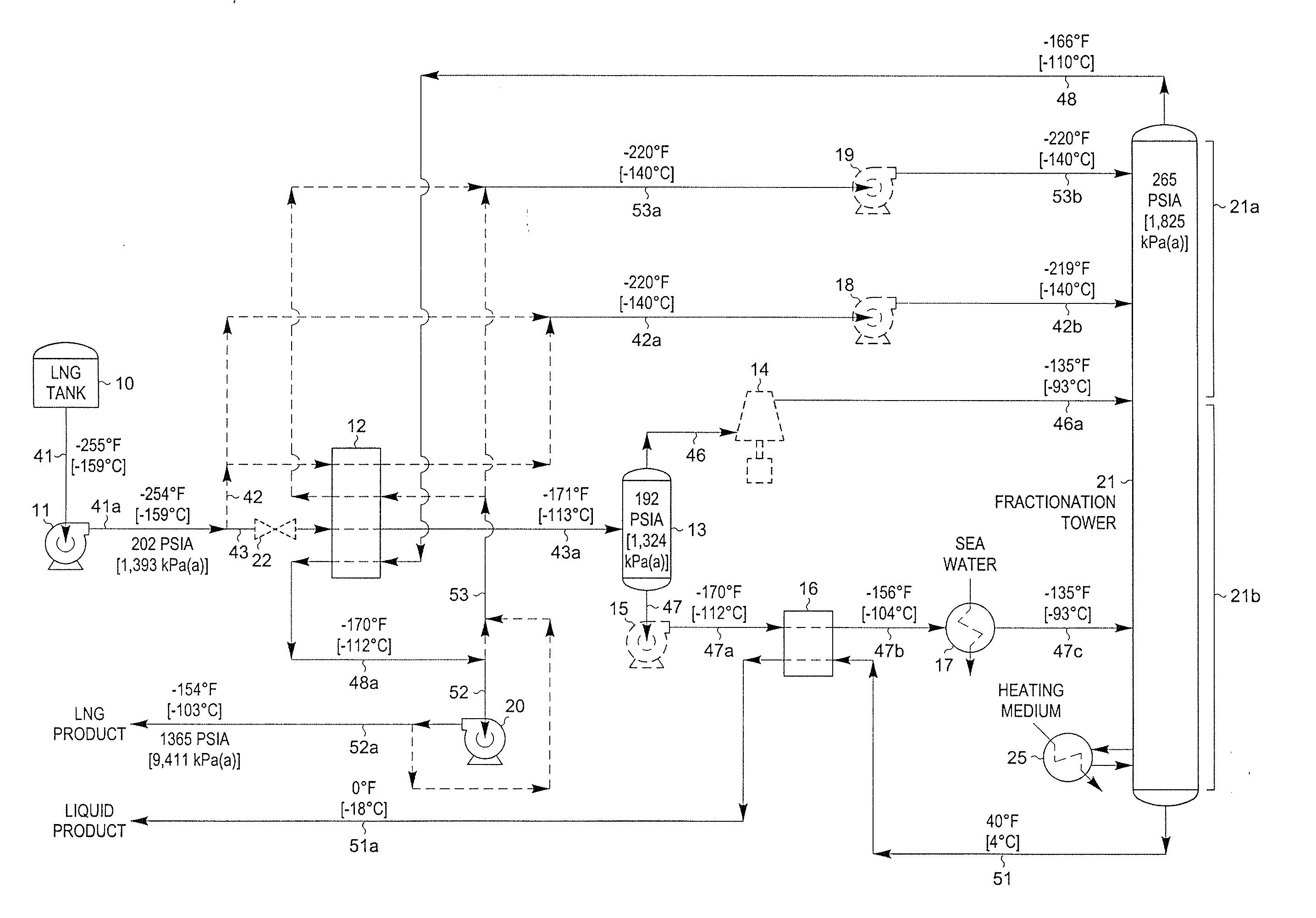

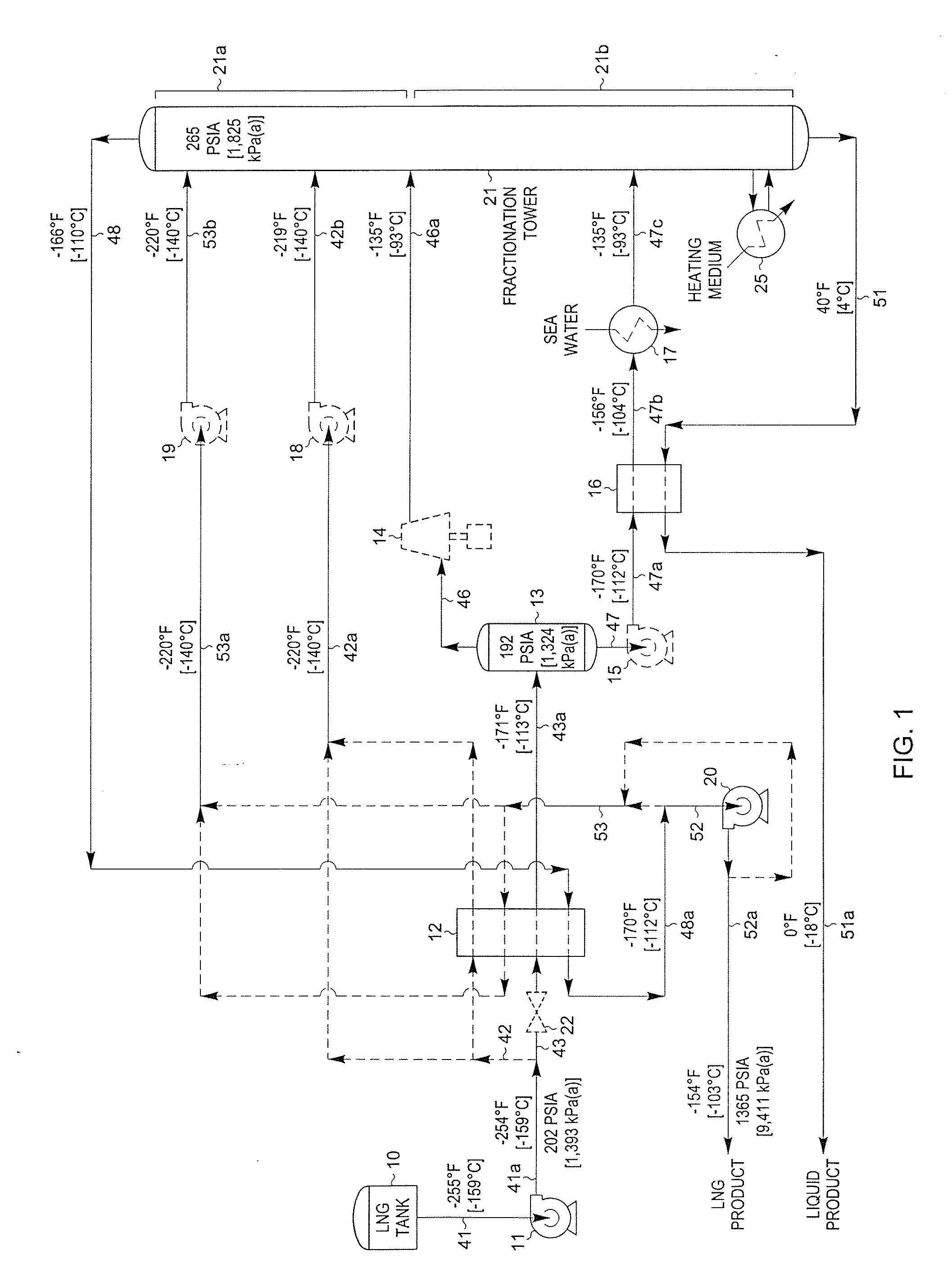

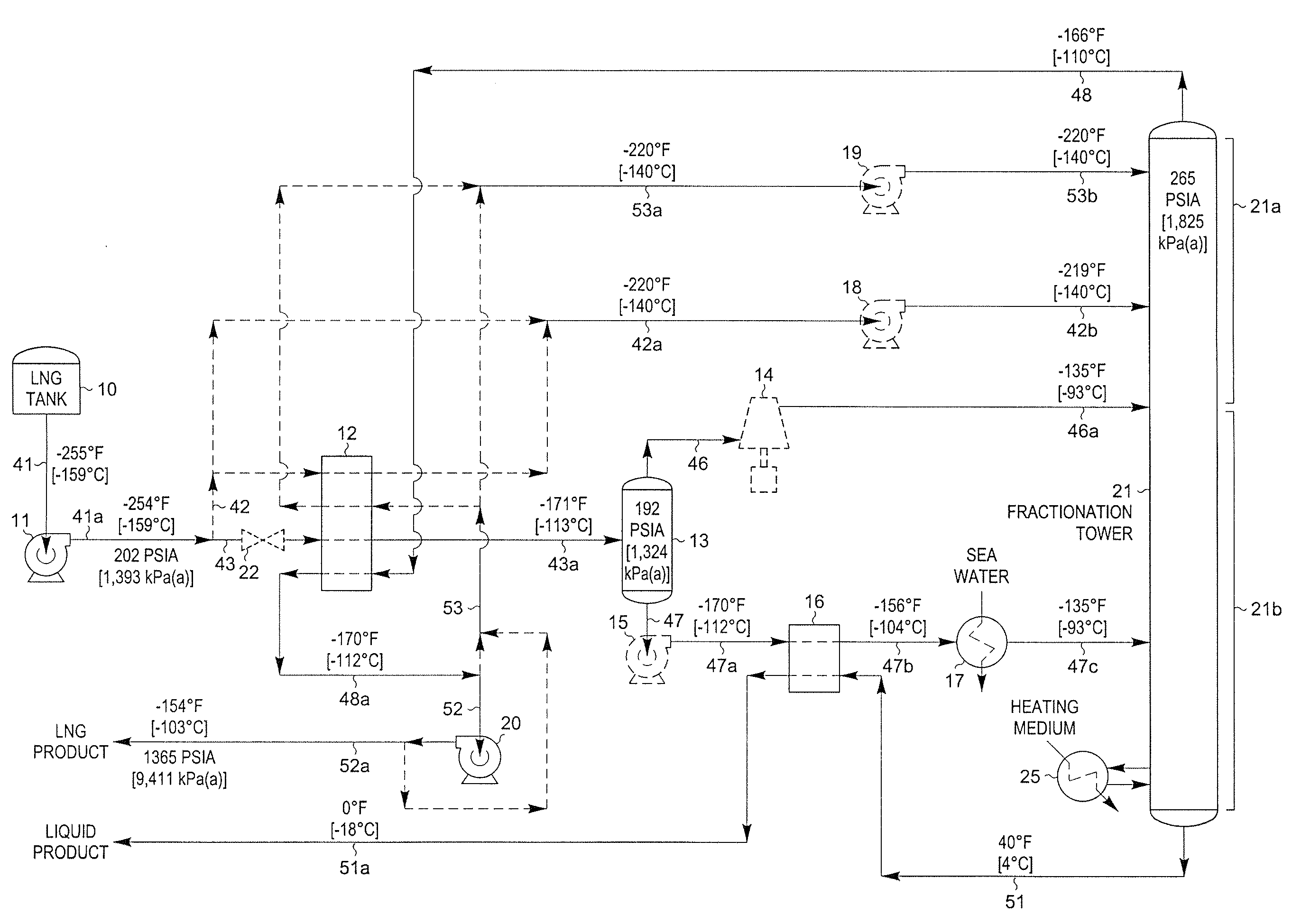

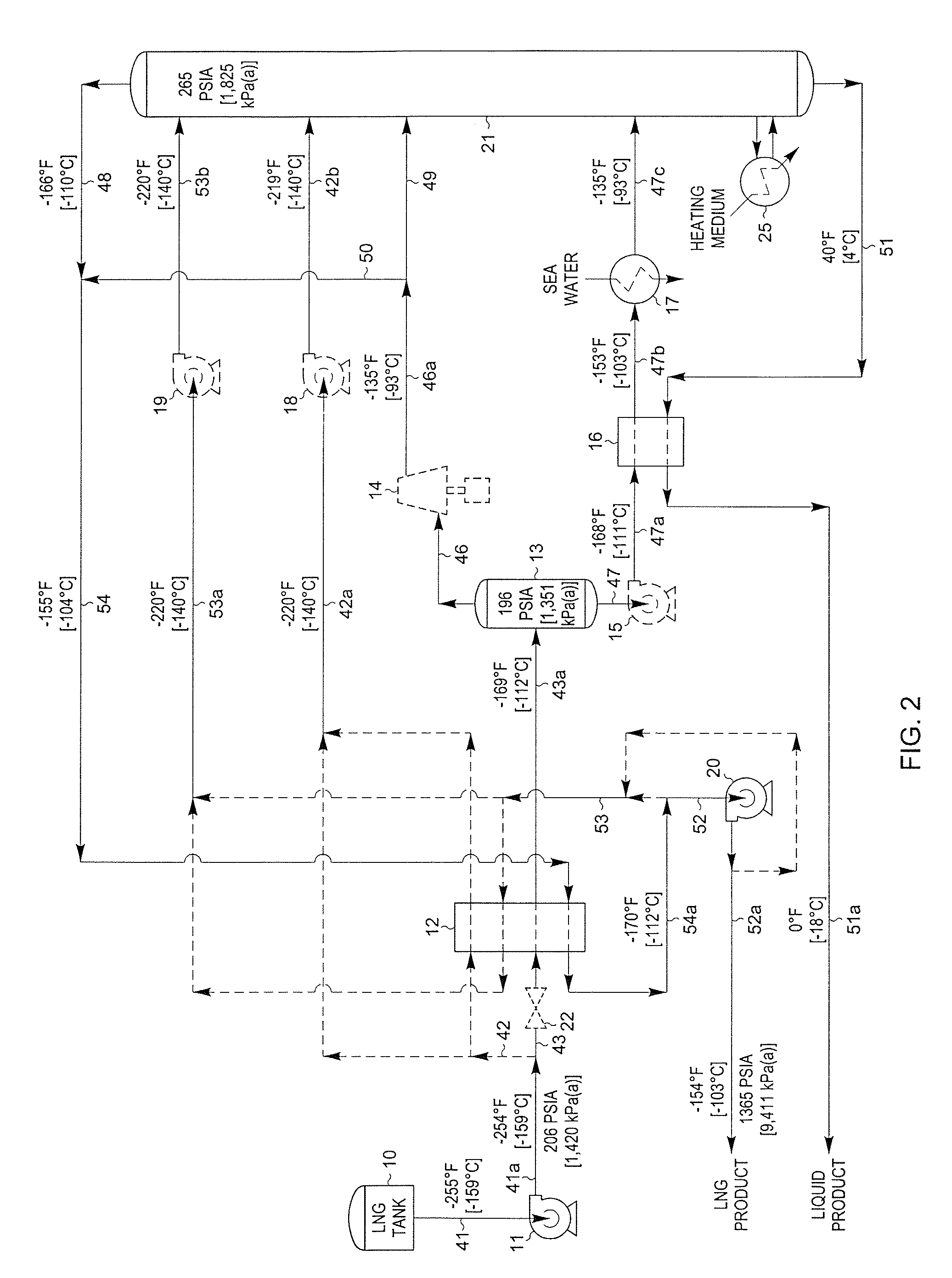

Liquefied Natural Gas Processing

ActiveUS20080000265A1Simple process equipmentReduce investmentSolidificationLiquefactionChemistryLiquefied natural gas

A process and apparatus for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at an upper mid-column feed point. The second portion is directed in heat exchange relation with a warmer distillation stream rising from the fractionation stages of the column, whereby this portion of the LNG feed stream is partially vaporized and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG product stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The partially vaporized portion of the LNG feed stream is separated into vapor and liquid streams which are thereafter supplied to the column at lower mid-column feed positions. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:UOP LLC

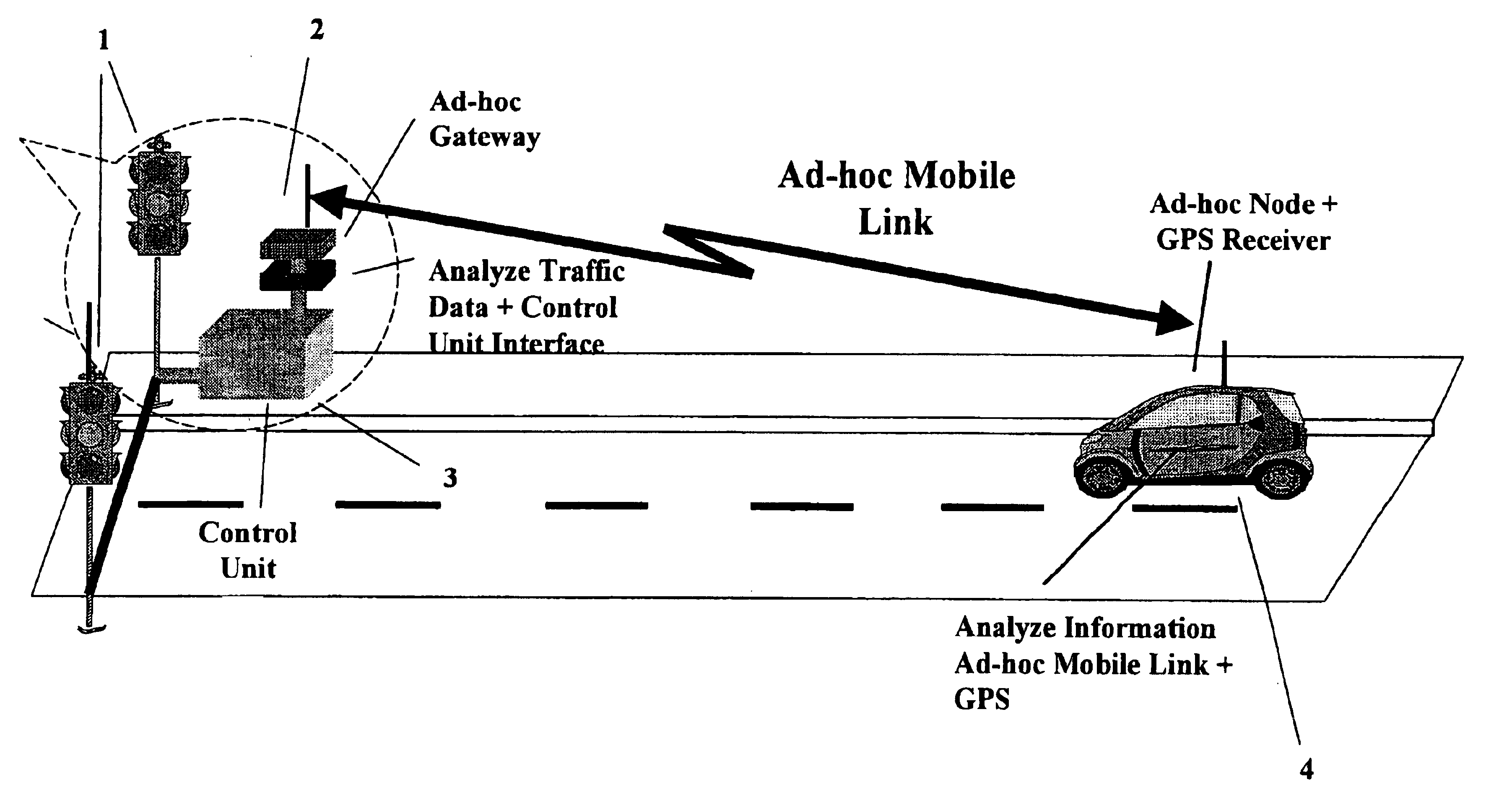

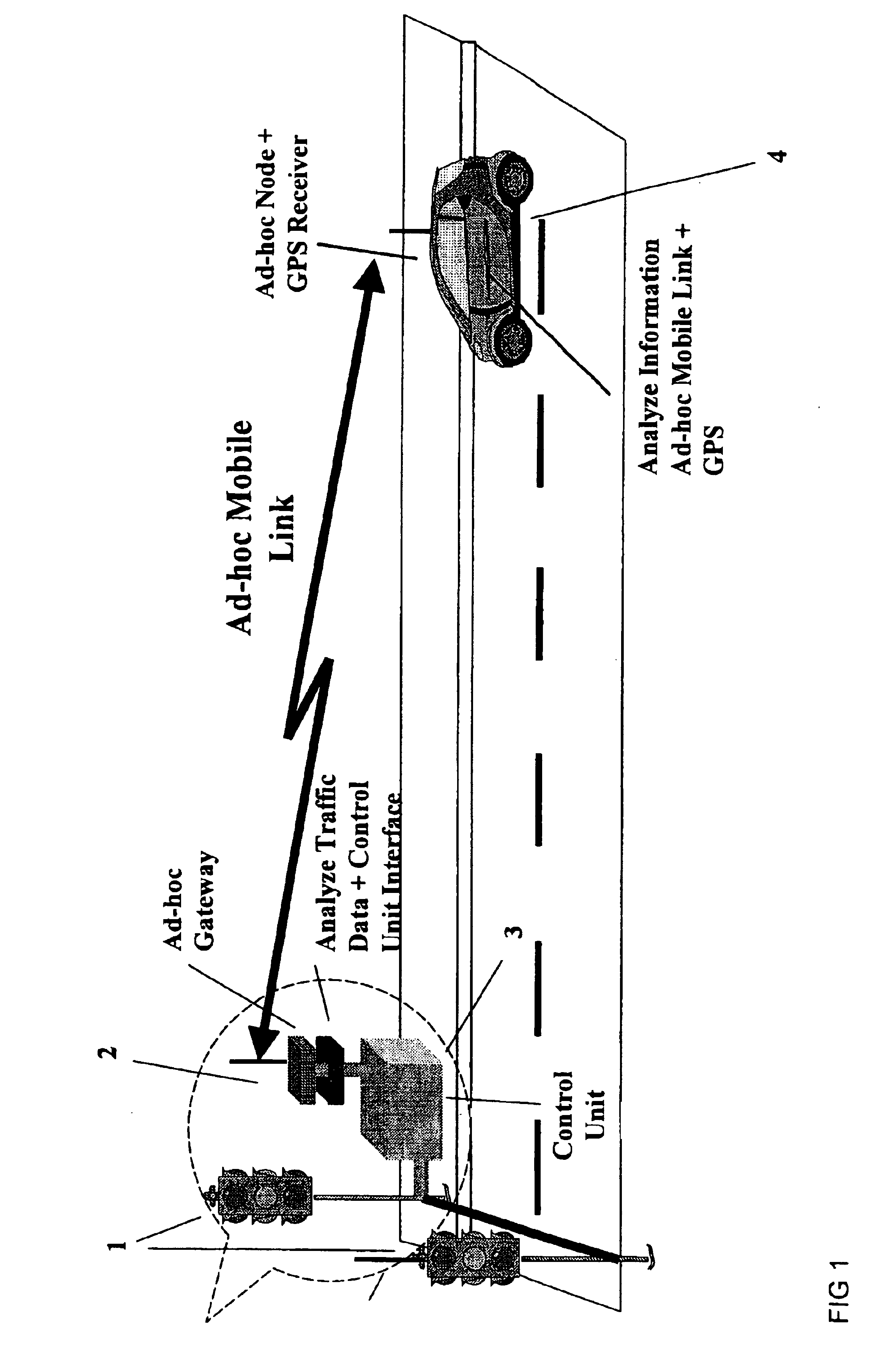

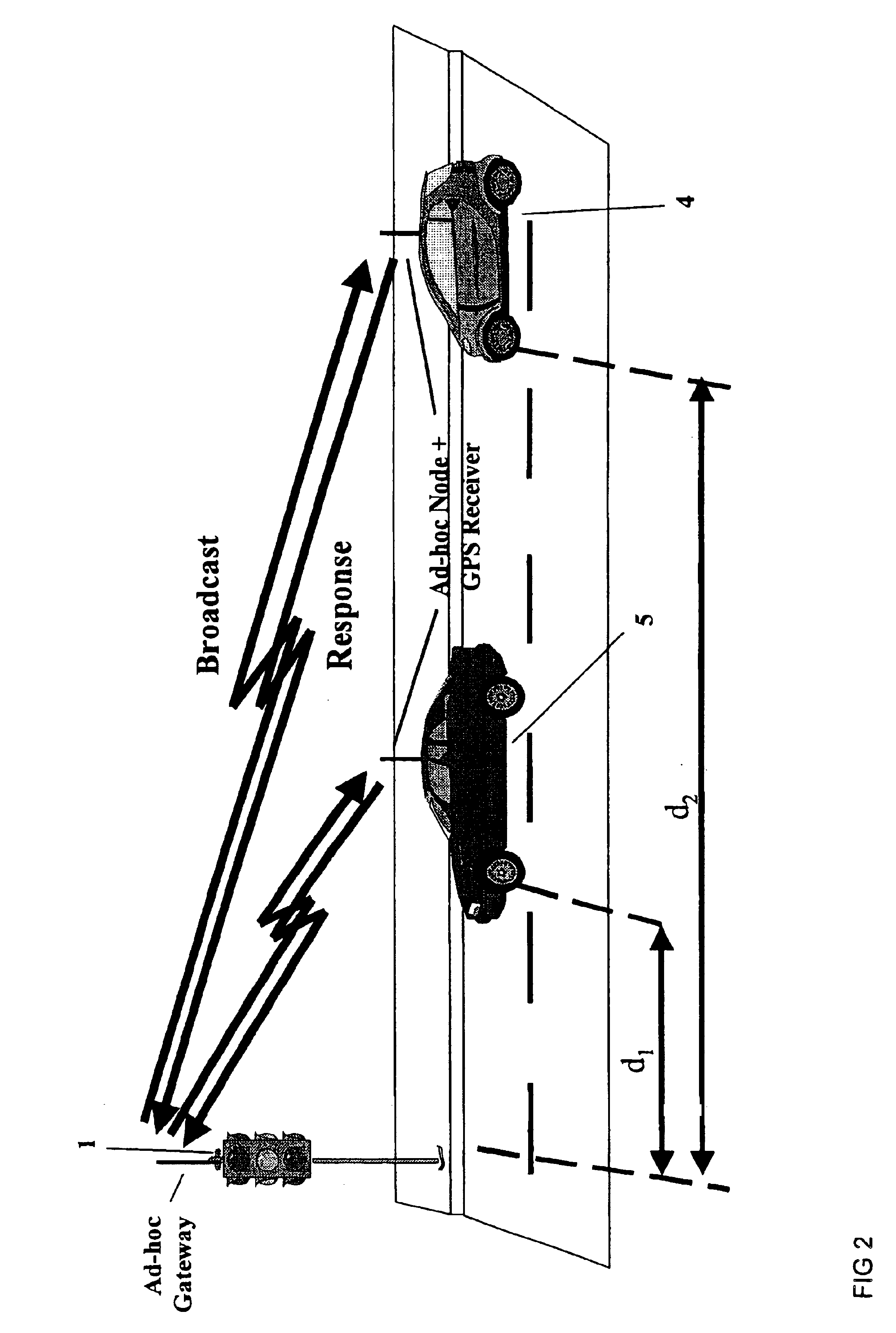

Method and arrangement for controlling a system of multiple traffic signals

InactiveUS6985090B2Simple process equipmentReduce sensitivityControlling traffic signalsAnalogue computers for vehiclesWireless transmissionTraffic signal

A method and arrangement for controlling a system of multiple traffic signals for regulating the traffic of vehicles is described. Traffic data is transmitted by wireless transmission to traffic data processing units assigned individually to a locally limited group of traffic signals, and each traffic data processing unit performs an analysis of the local traffic situation for the environment of the locally limited group of traffic signals up to, at the maximum, the neighboring locally limited groups of traffic signals.

Owner:SIEMENS AG

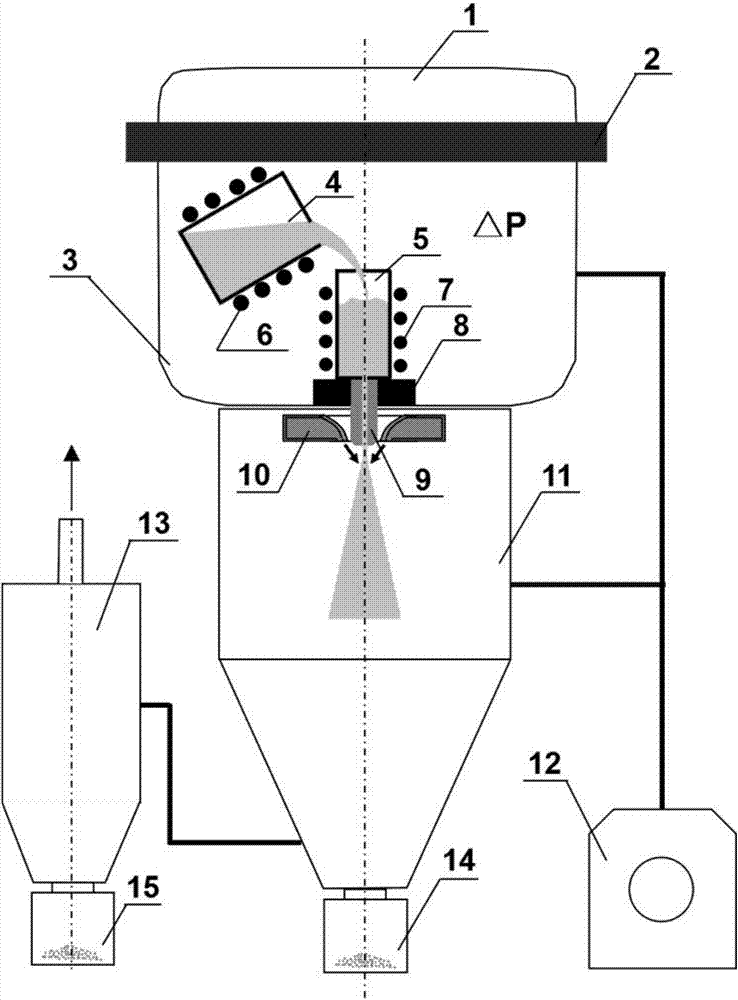

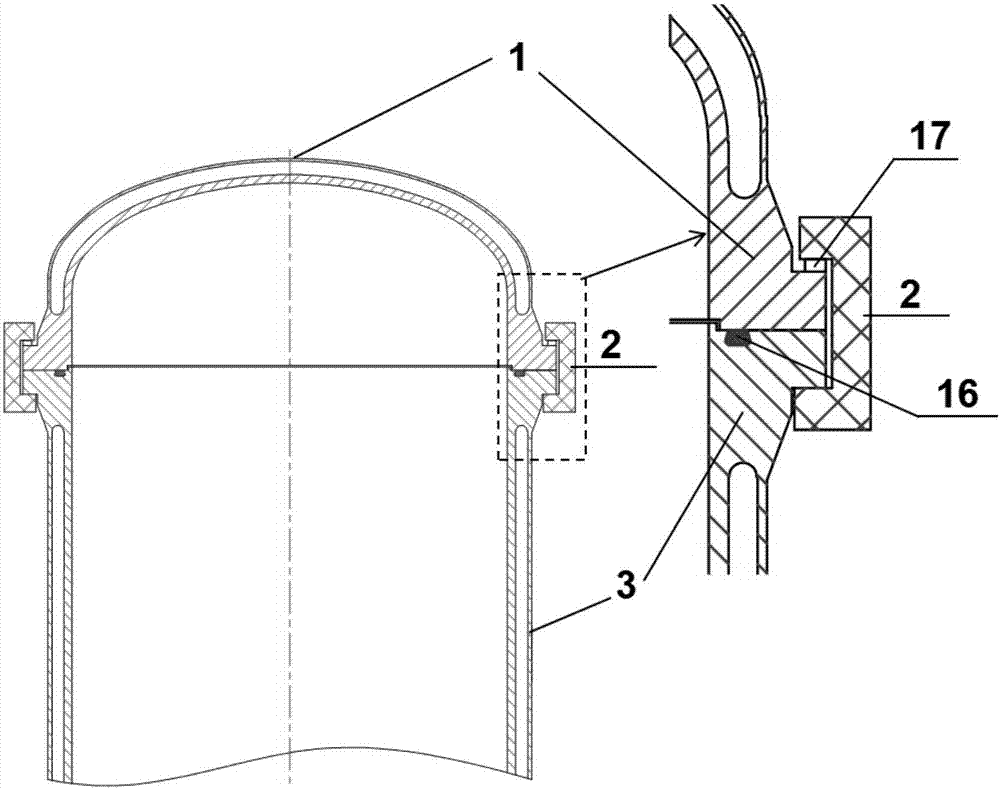

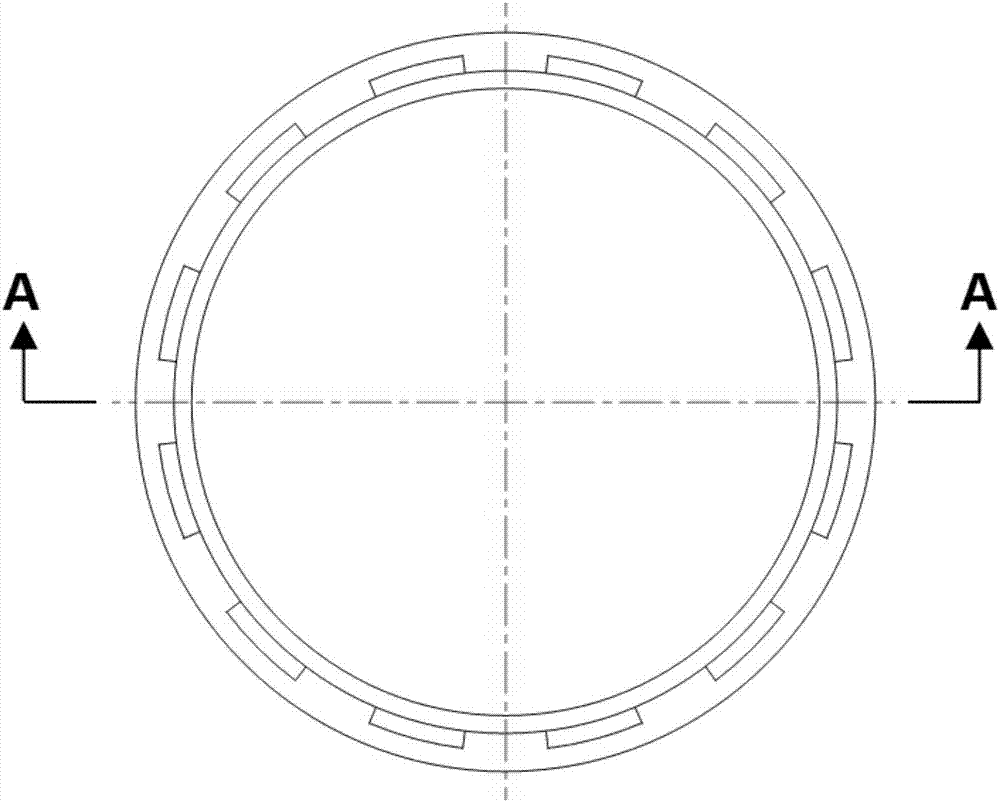

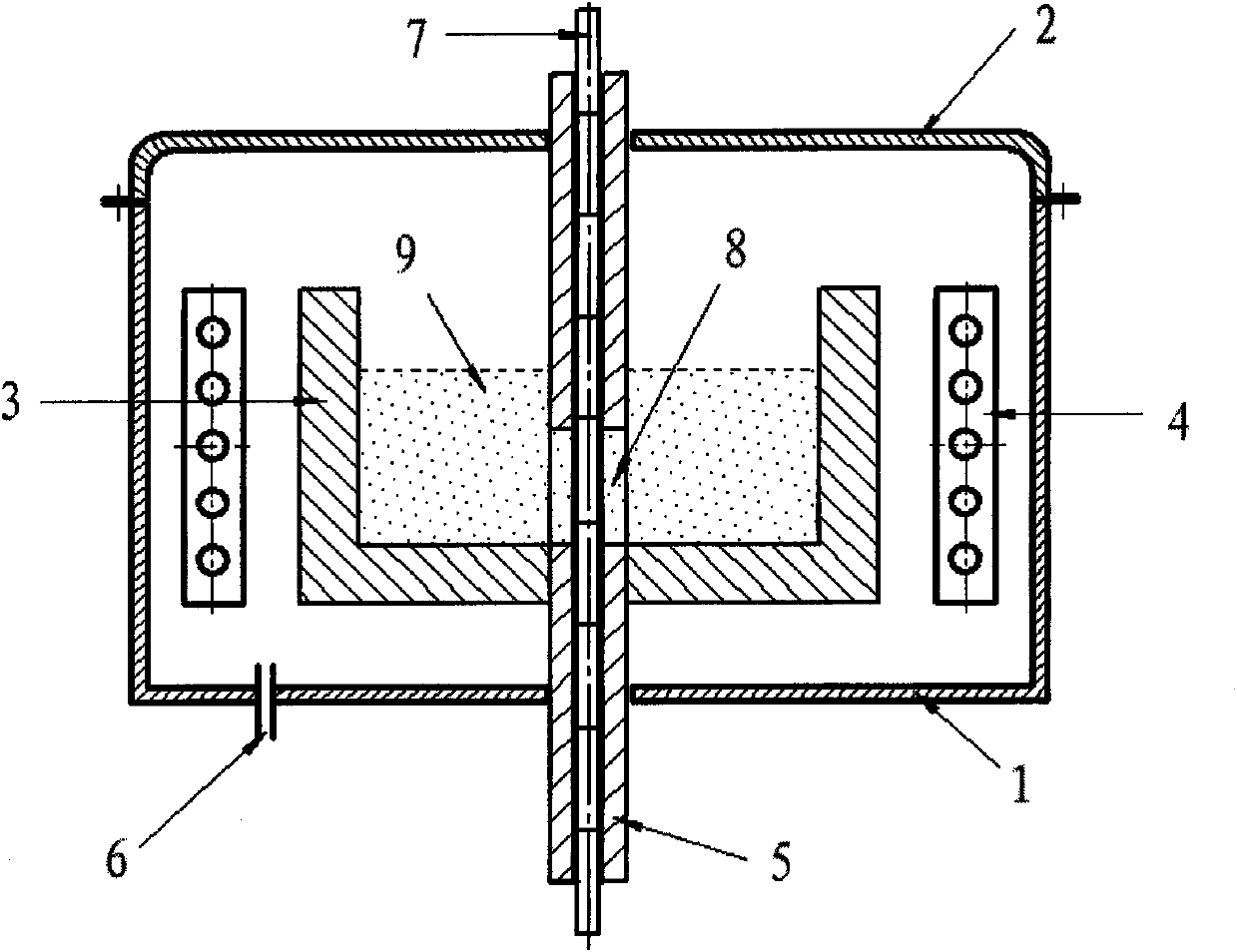

Gas atomization preparing method for micro spherical metal powder and equipment thereof

ActiveCN107262730AIncrease characteristic surface energyHigh yield of fine powderTransportation and packagingMetal-working apparatusPositive pressureProduct gas

The invention belongs to the technical field of preparing a metal powder material and provides a gas atomization preparing method for micro spherical metal powder and equipment thereof. The preparing method comprises the technological process of smelting a material, driving molten metal jet flow through positive pressure, atomizing gas, carrying out cooling, collecting powder, detecting performance, and carrying out screening, packaging and the like, by reducing the outlet hole diameter of a flow guide nozzle, inert gas is reversely filled into a smelting chamber to certain positive pressure, the smelting chamber in the gas atomizing equipment is designed into a pressure container, a locking sealing device is adopted in the connecting portion of a furnace cover and a furnace body, the smelting chamber and an atomizing tank are designed into cavities which are isolated mutually and communicate only through the flow guide nozzle, and the fine powder yield of the metal powder is effectively increased. Compared with the existing gas atomizing metal powder preparing technology, the fine powder yield of the metal powder prepared by the utilization of the method is high, size distribution is narrow, the sphericity degree is good, the oxygen content is small, atomized gas consumption is low, and the technology equipment is simple, high in continuity and suitable for industrialized production and can be widely applied.

Owner:有研金属复材技术有限公司

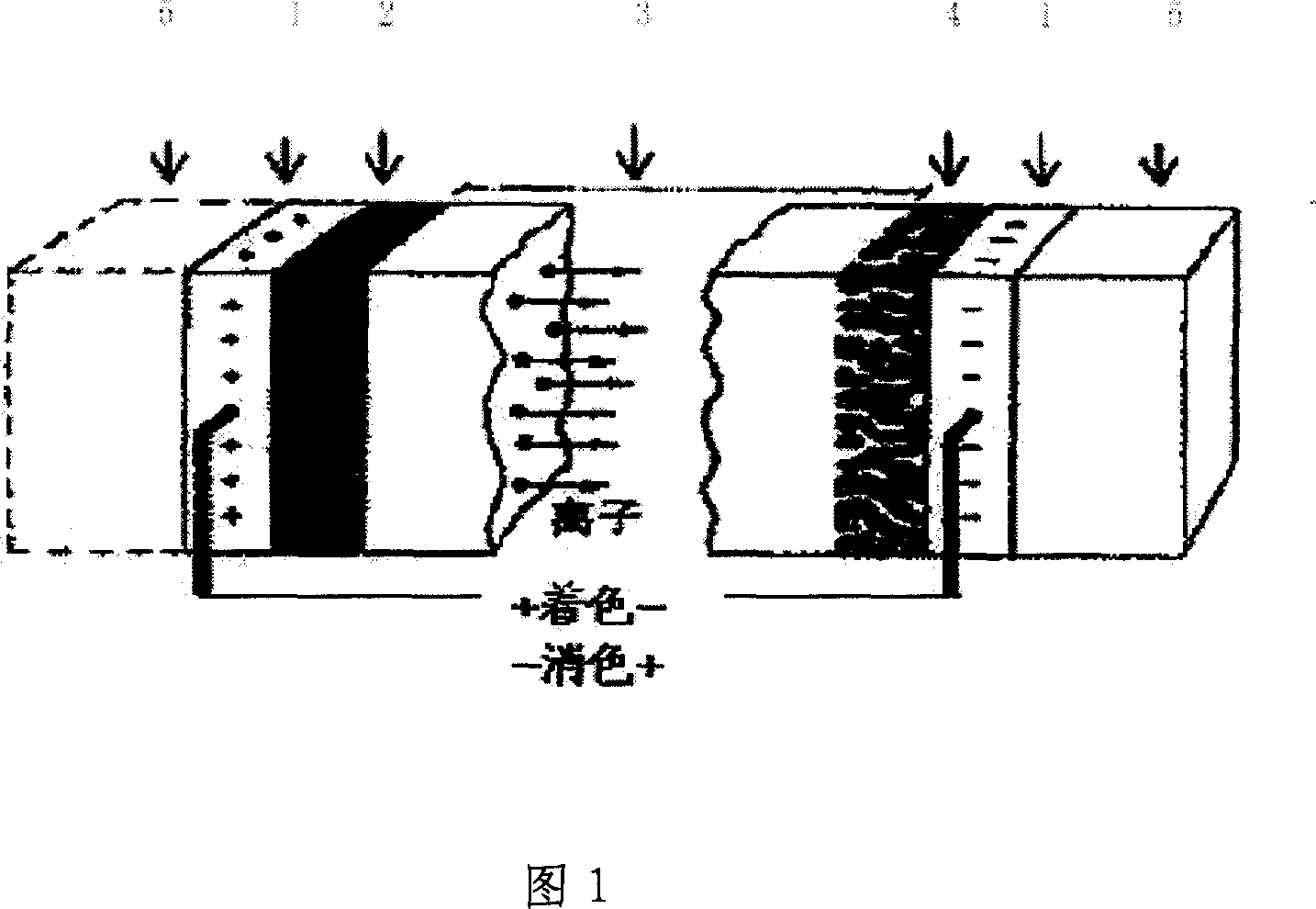

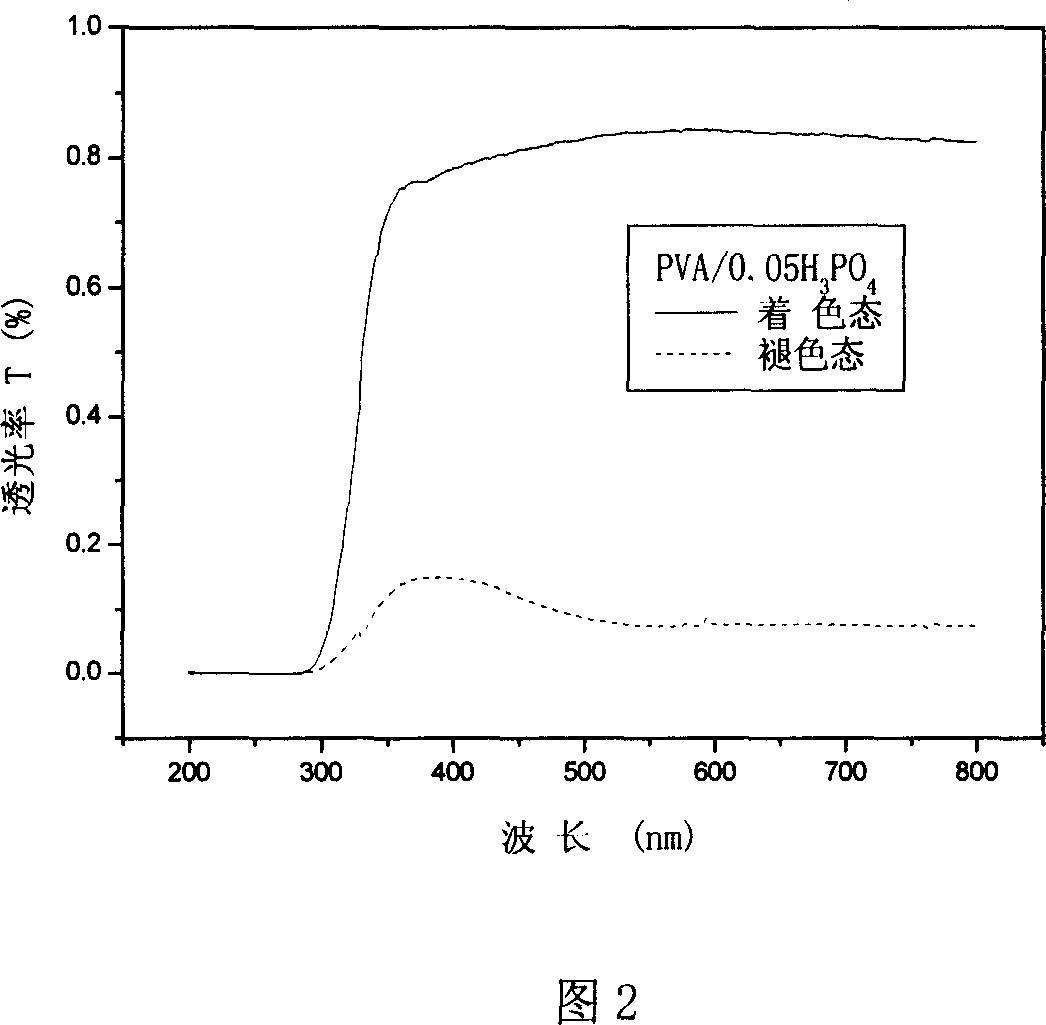

Method for preparing full solid electrochromic device with sol-gel

The related manufacture method for full-solid photochromic device comprises: with sol-gel method, preparing the transparent conductive layer, the photochromic layer, the ion conductive layer and the ion storage layer in turns; then assembling together. Compared with prior art, this invention is low cost and easy controlled, and fit to large-scale industrial production.

Owner:TONGJI UNIV

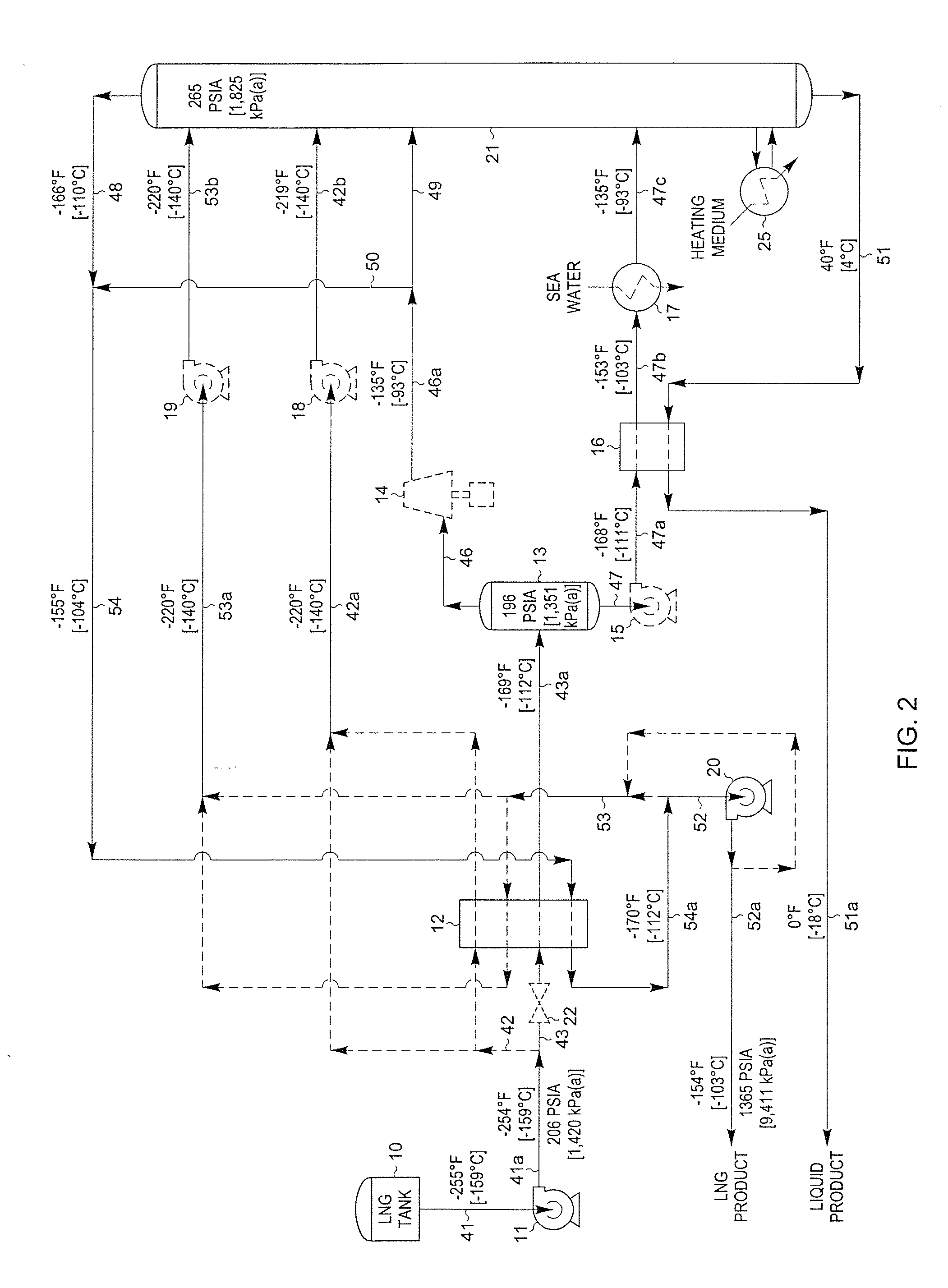

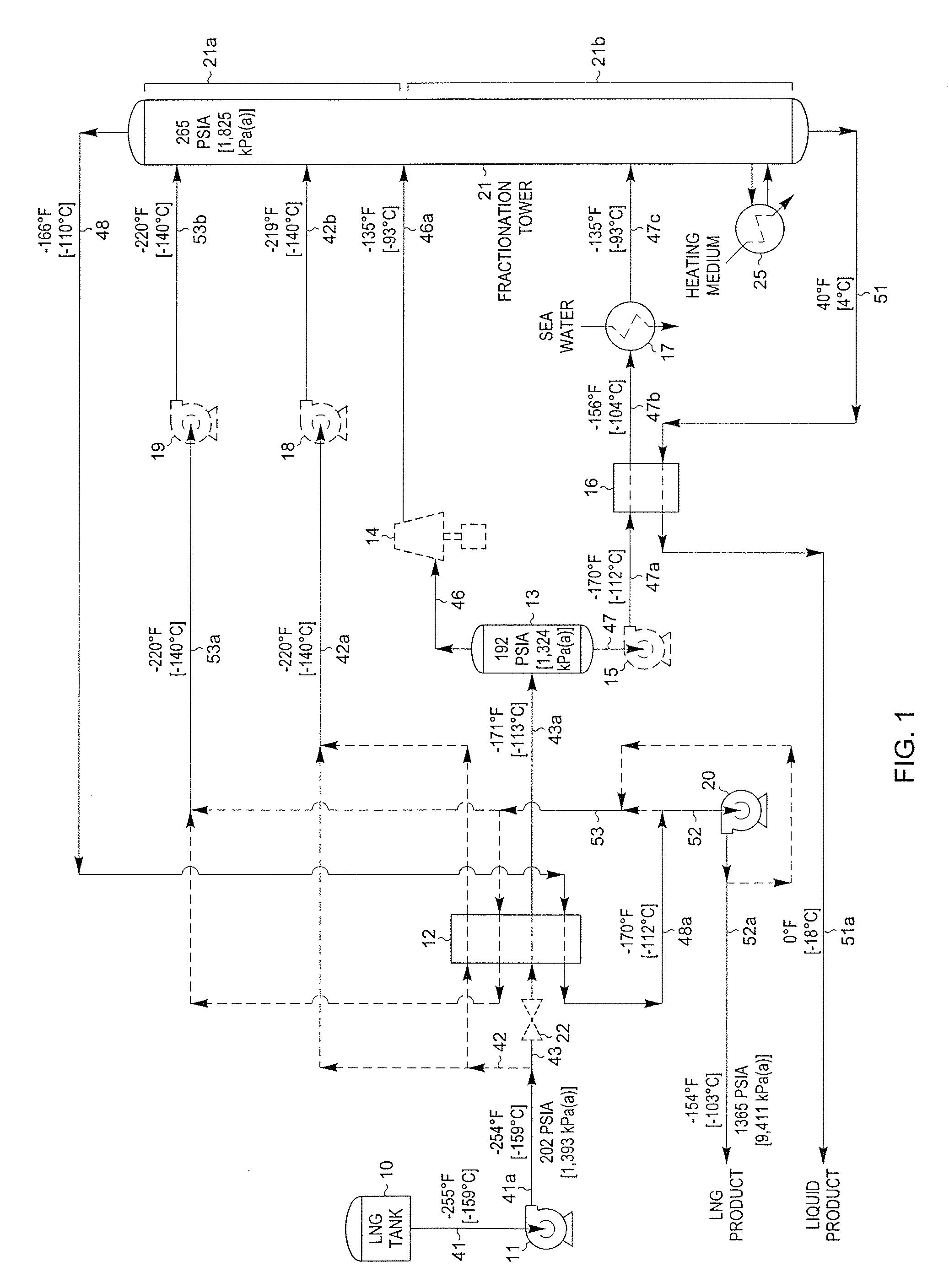

Liquefied natural gas processing

ActiveUS7631516B2Simple process equipmentReduce investmentSolidificationLiquefactionLiquid productReflux

A process and apparatus for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at an upper mid-column feed point. The second portion is directed in heat exchange relation with a warmer distillation stream rising from the fractionation stages of the column, whereby this portion of the LNG feed stream is partially vaporized and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG product stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The partially vaporized portion of the LNG feed stream is separated into vapor and liquid streams which are thereafter supplied to the column at lower mid-column feed positions. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:UOP LLC

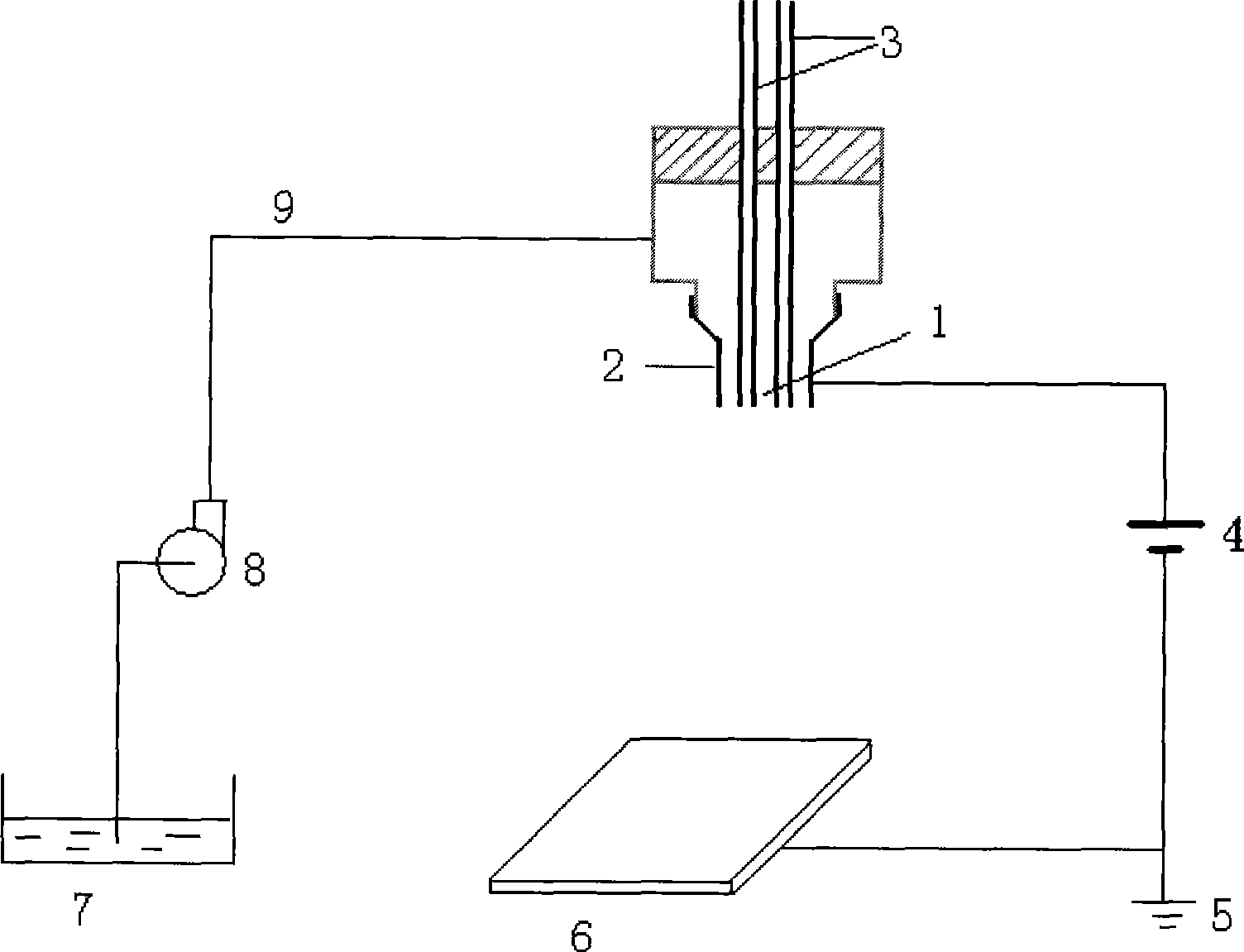

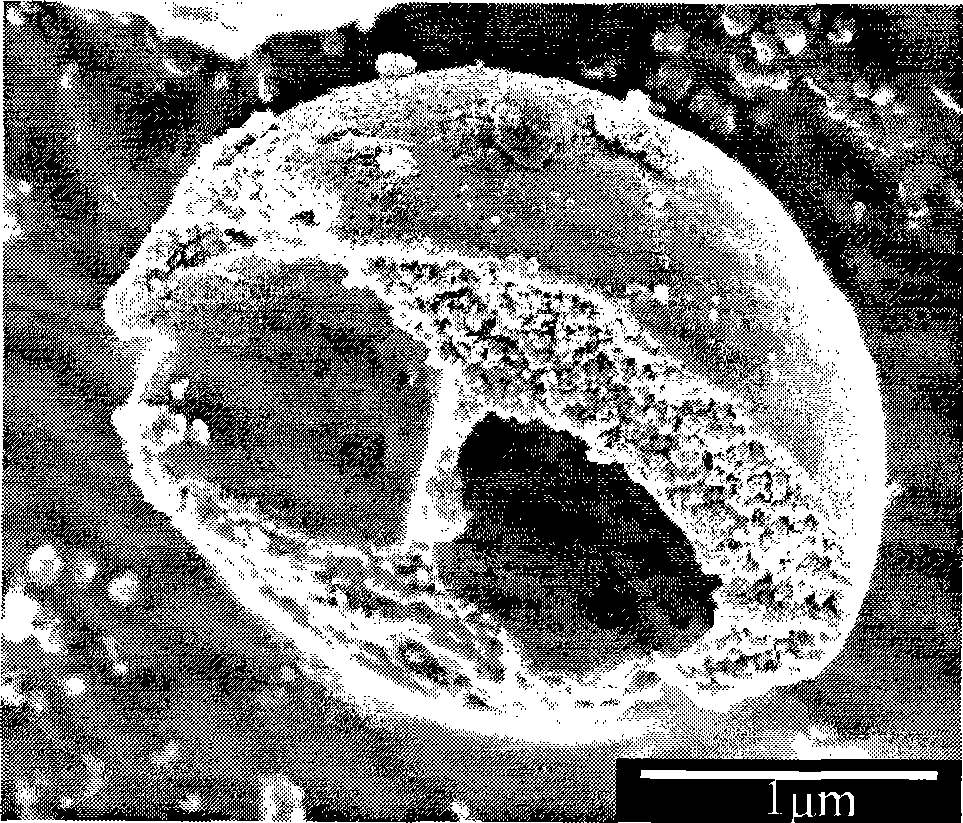

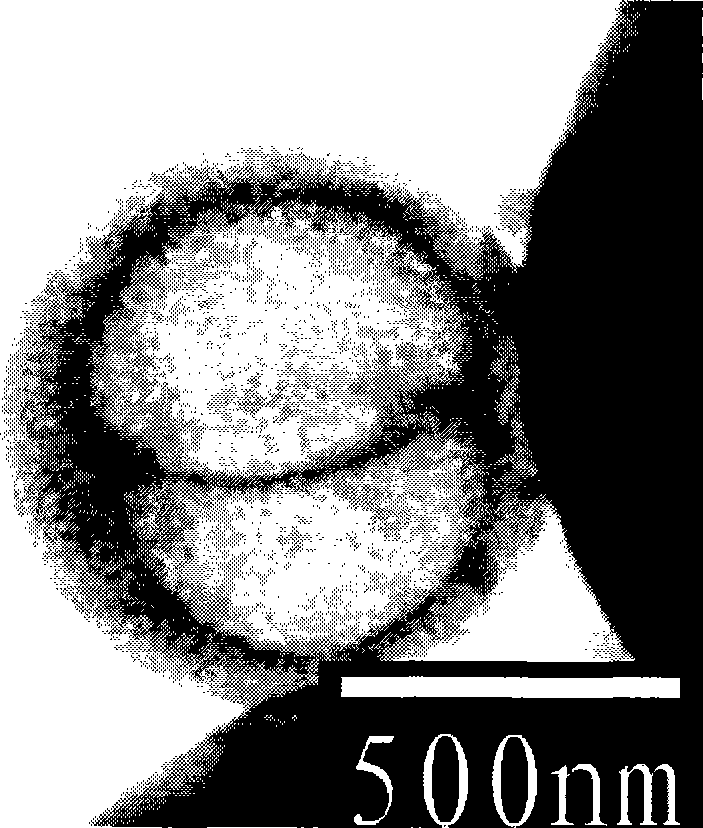

Multi-cavity composite micro/nano capsule and preparation method and device thereof

InactiveCN101391199AKind of precise controlPrecisely control the numberMicroballoon preparationMicrocapsule preparationMaterials preparationEngineering

The invention belongs to the field of micron-nanometer material preparation and application, more particular relates to a multi-cavity composite micron / nanometer capsule and a multi-cavity micron / nanometer ball as well as the preparation method and device thereof. The multi-cavity composite micron / nanometer capsule is of a ball structure with micron and nanometer size, a plurality of cavities are arranged inside the ball, and the number of the cavities can be controlled; the cavities are separated and mutually independent by inner walls made of shell material; the cavities can respectively load different nuclear materials or same nuclear material, and the variety, the number and the distribution in the ball can be accurately controlled; the nuclear materials are mutually independent, do not contact mutually and do not contact with the outside environment directly; the shell material which forms the multi-cavity composite micron / nanometer capsule is different from the nuclear material; and the nuclear materials are selectively removed to obtain the micron / nanometer structure with multiple cavities. The preparation method is a multiple-fluid composite electric injection method, and the device has the characteristic that a multiple-fluid composite spray head is adopted. The multi-cavity micron / nanometer capsule provided by the invention is applied to coatings for environment sensitive materials and reactive materials, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Porous refractory material and preparation method thereof

InactiveCN105481464ALow costSimple process equipmentSolid waste disposalCeramicwarePorosityThermal insulation

The invention relates to a porous refractory material and a preparation method, and relates to the technical field of refractor materials. The preparation method is characterized in that fly ash and a natural mineral material magnesite are adopted as main raw materials; and the porous refractory material is prepared through the processes such as blending and mixing, molding, drying, sintering and the like. Among the raw materials, the addition amount of fly ash is 10.0-90.0wt%, the addition amount of magnesite is 5.0-85.0wt%, the addition amount of a pore-forming agent is 5-15.0wt%, and the addition amount of a binding agent is 1-8wt%. A main phase of the porous refractory material prepared through high-temperature sintering is forsterite. The material has the characteristics of high porosity, low volume density, high strength, good thermal insulation effect, low cost and the like. According to the invention, a novel technical approach is provided for high-efficiency value-added exploitation of solid wastes such as fly ash and magnesite.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing nanosilver/nano silicon dioxide-containing antibacterial biological dressing

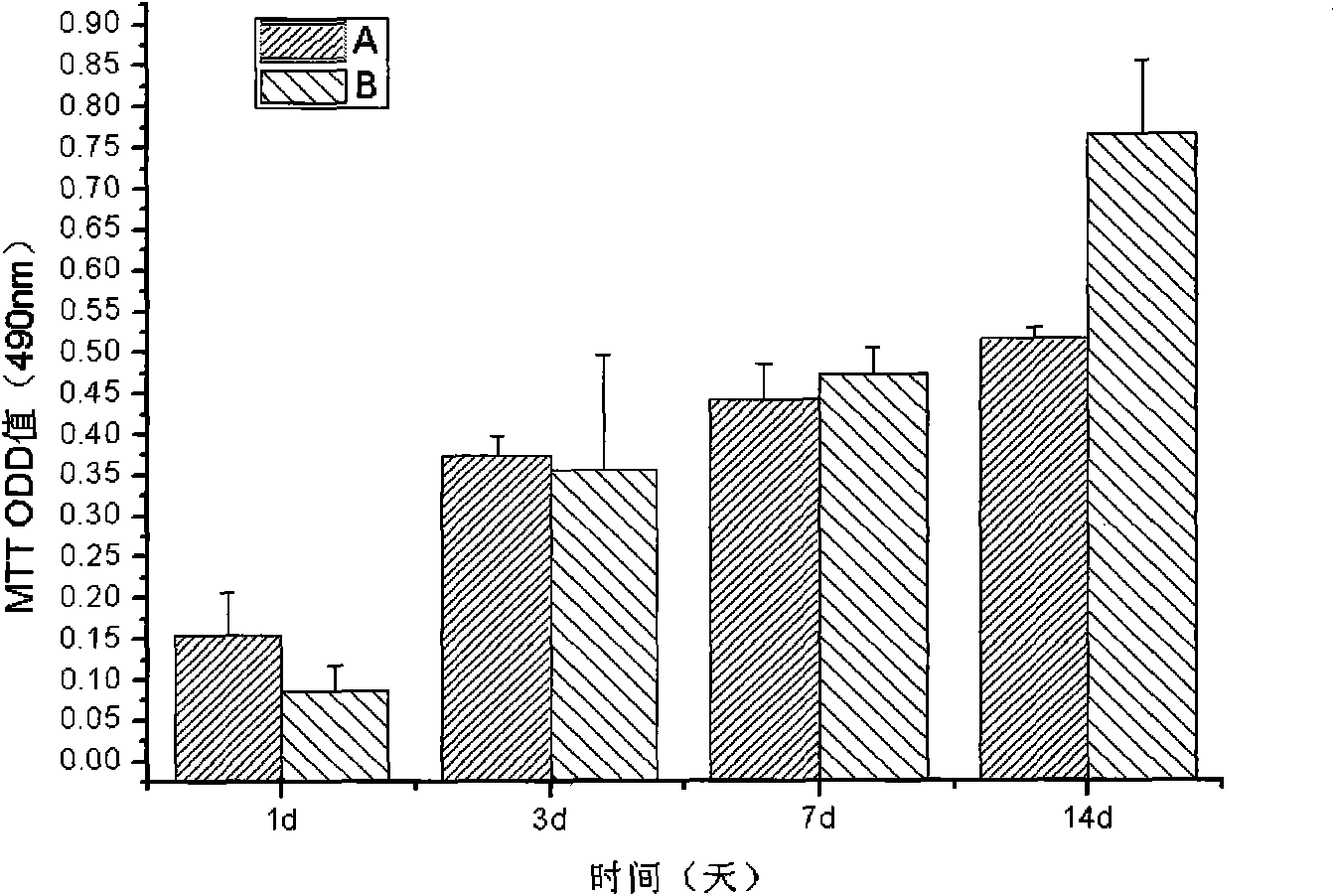

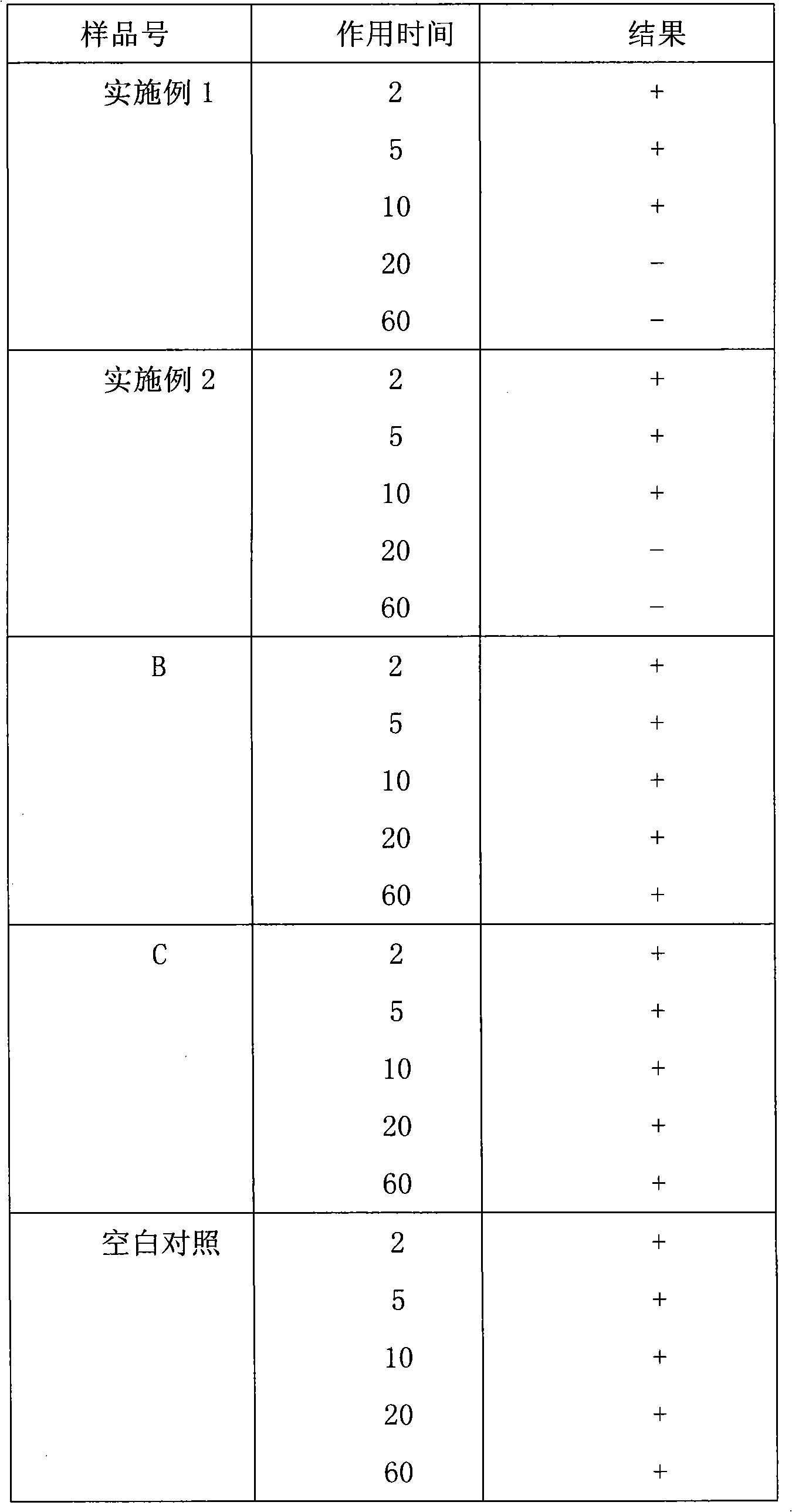

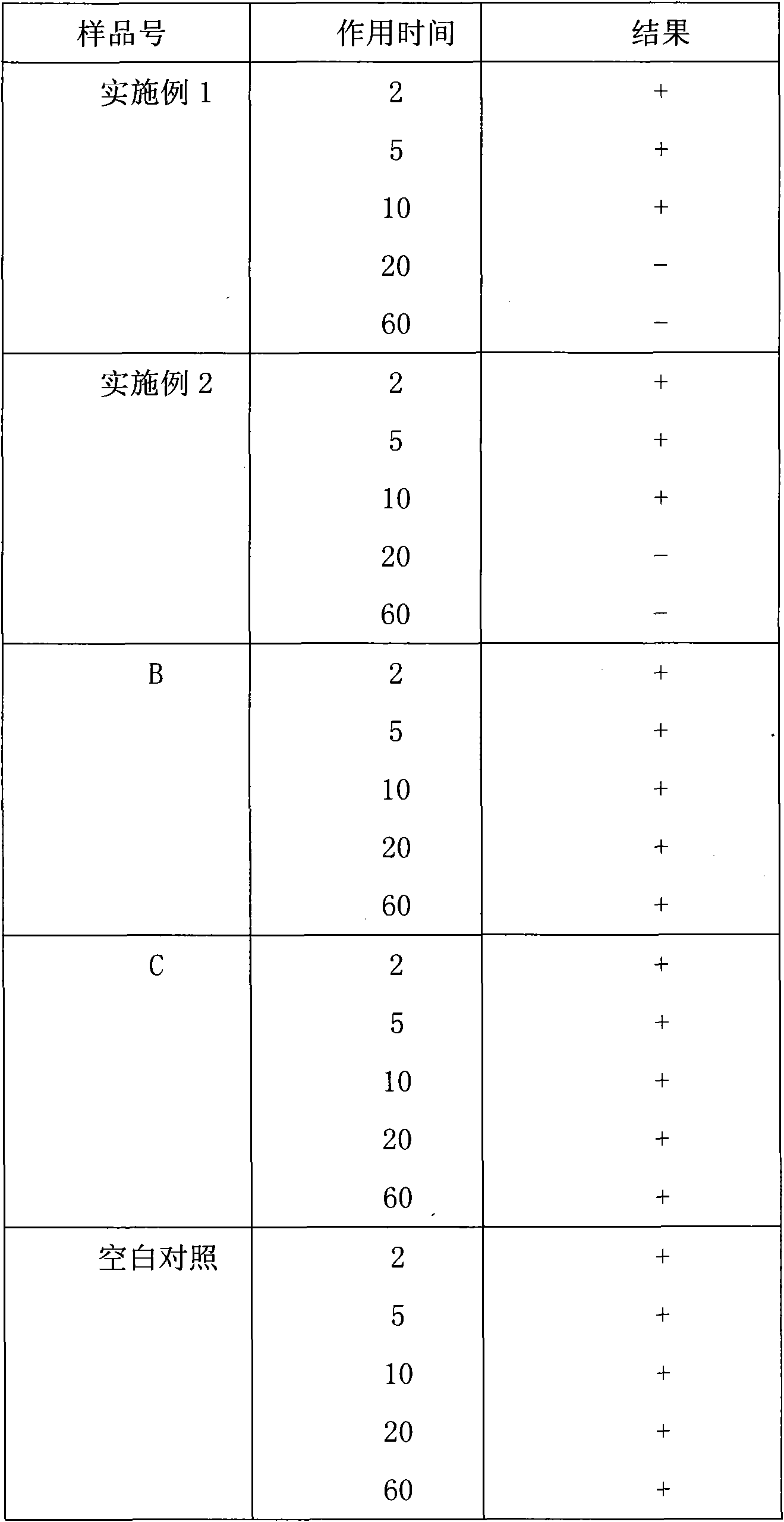

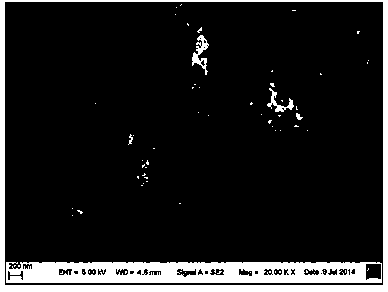

InactiveCN101912634AGood biocompatibilityGood hemostasis and antibacterialAbsorbent padsBandagesFiberBiological dressing

The invention discloses a method for preparing a nanosilver / nano silicon dioxide-containing antibacterial biological dressing, and relates to the field of antibacterial biological dressings. The nanosilver / nano silicon dioxide-containing antibacterial biological dressing is prepared by adding mixed solution of chitosan and polyvinyl alcohol and silver-carried silicon dioxide powder during the acetalation of the polyvinyl alcohol. The nanosilver / nano silicon dioxide-containing antibacterial biological dressing of the invention can accelerate the wound healing, slowly release the silver nanoparticles and continuously act on reproductive bacteria, has the characteristic of durable and high-efficiency sterilization and does not produce medicament resistance; and through the researches on the toxicity of the material to mouse fibroblast cells, the product does not produce obvious toxicity to the cells but promotes the growth of the cells.

Owner:SOUTH CHINA UNIV OF TECH

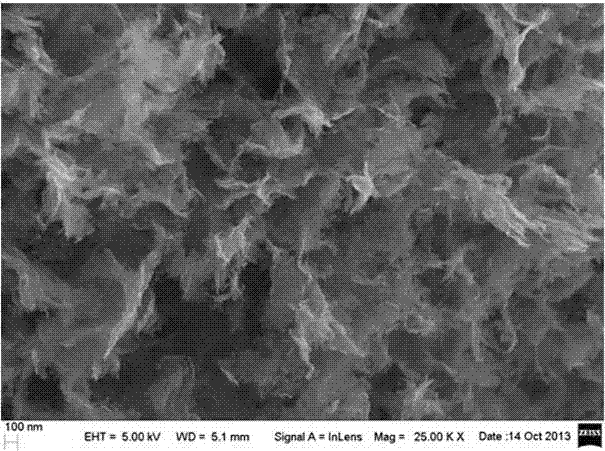

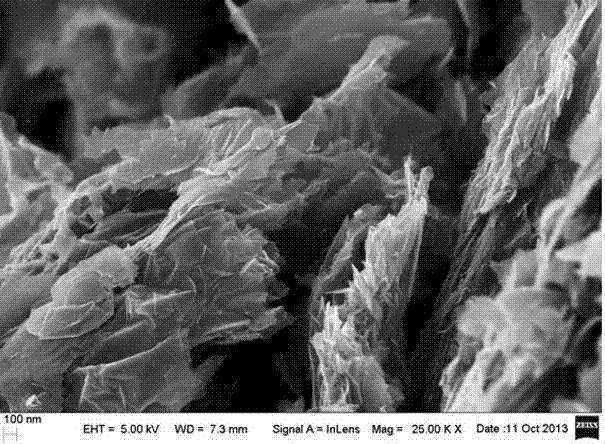

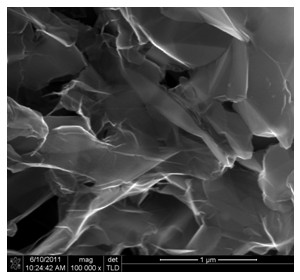

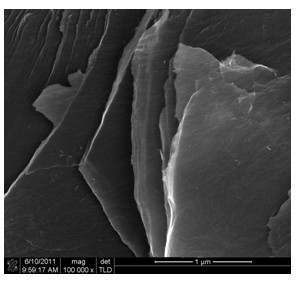

Preparation method of low-cost porous graphene

Owner:FUZHOU UNIV

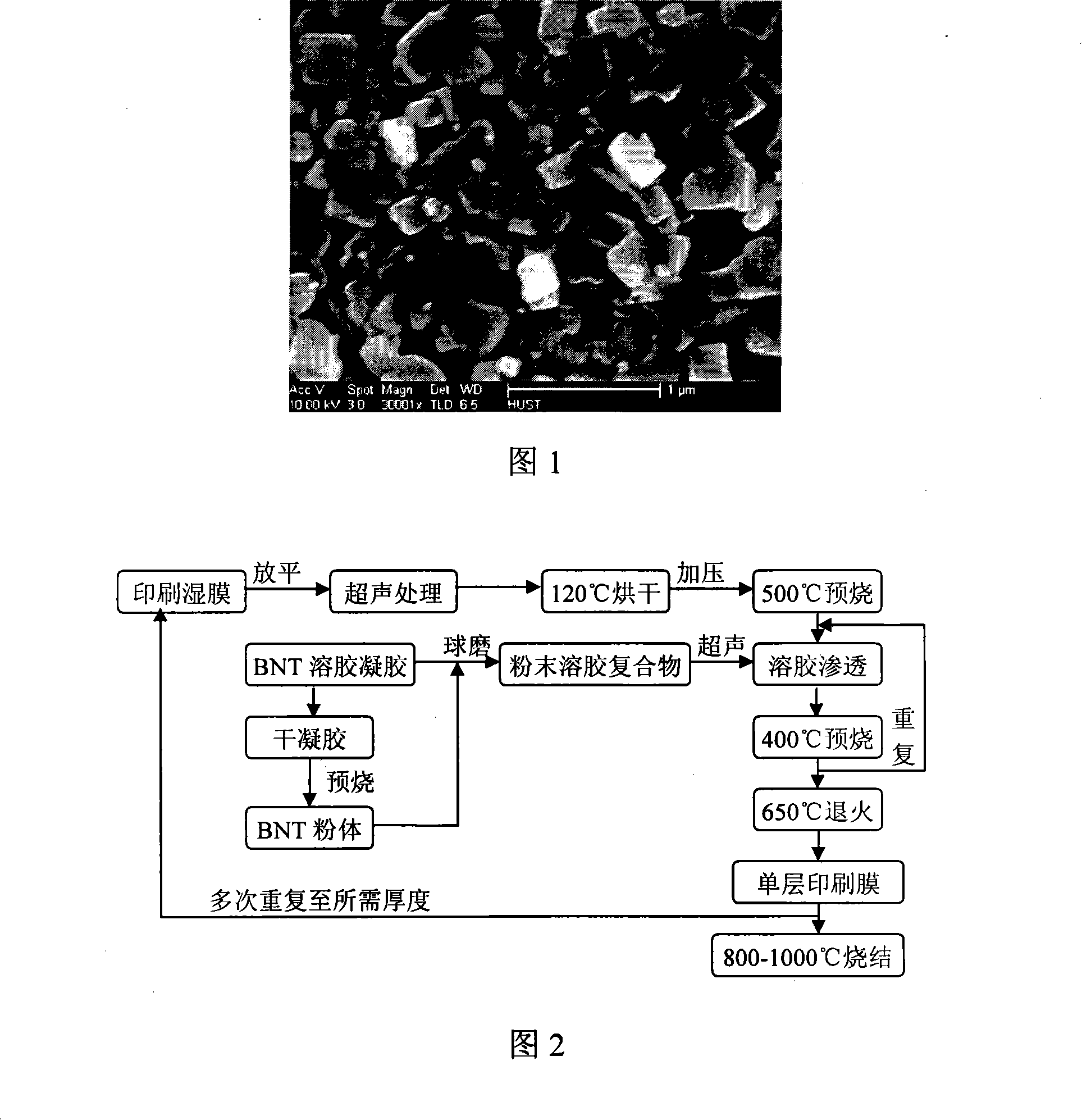

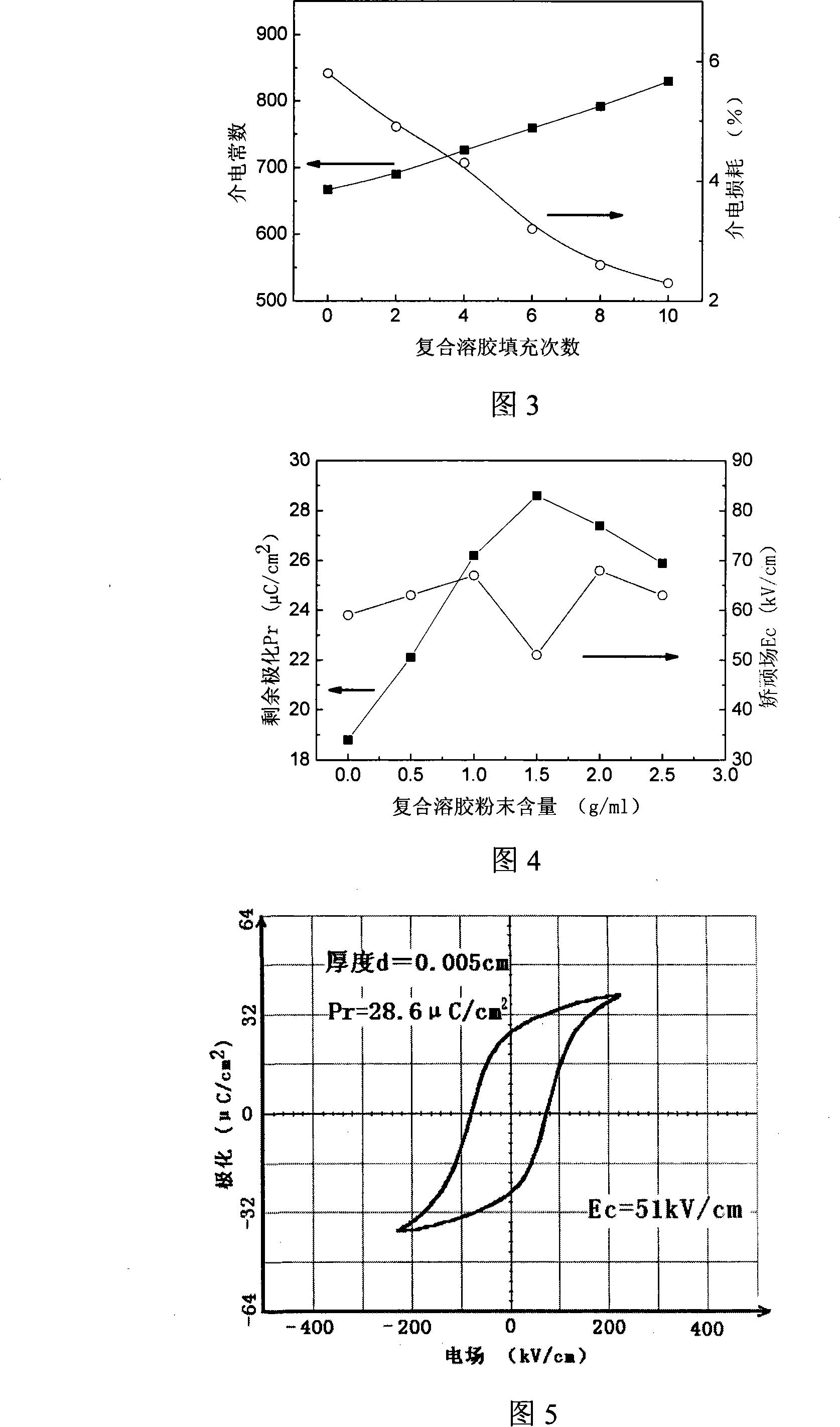

Method for preparing bismuth sodium titanate base leadless piezoelectricity thick film

The invention discloses a process for preparing natrium bismuthate titanate based lead-free piezoelectric thick films, the steps are that (1) ceramic powder materials, constitutional formula of which is (Na0.5Bi0.5)(1-x)BaxTiO30 C04B 35 / 64 C04B 35 / 468 C04B 35 / 475 C04B 35 / 462 2 11 3 2008 / 1 / 9 101215172 2008 / 7 / 9 000000000 Huazhong University of Science & Technology Wuhan 430074 Jiang Shenglin Zhang Haibo Zeng Yike Zhong Nanhai Liu Yaoping caobao jing 42201 The Patent Agency of Huazhong University of Science and Engineering No.151 Louyu Road, Wuchang, the City of Wuhan, Hubei Province 430074

Owner:HUAZHONG UNIV OF SCI & TECH

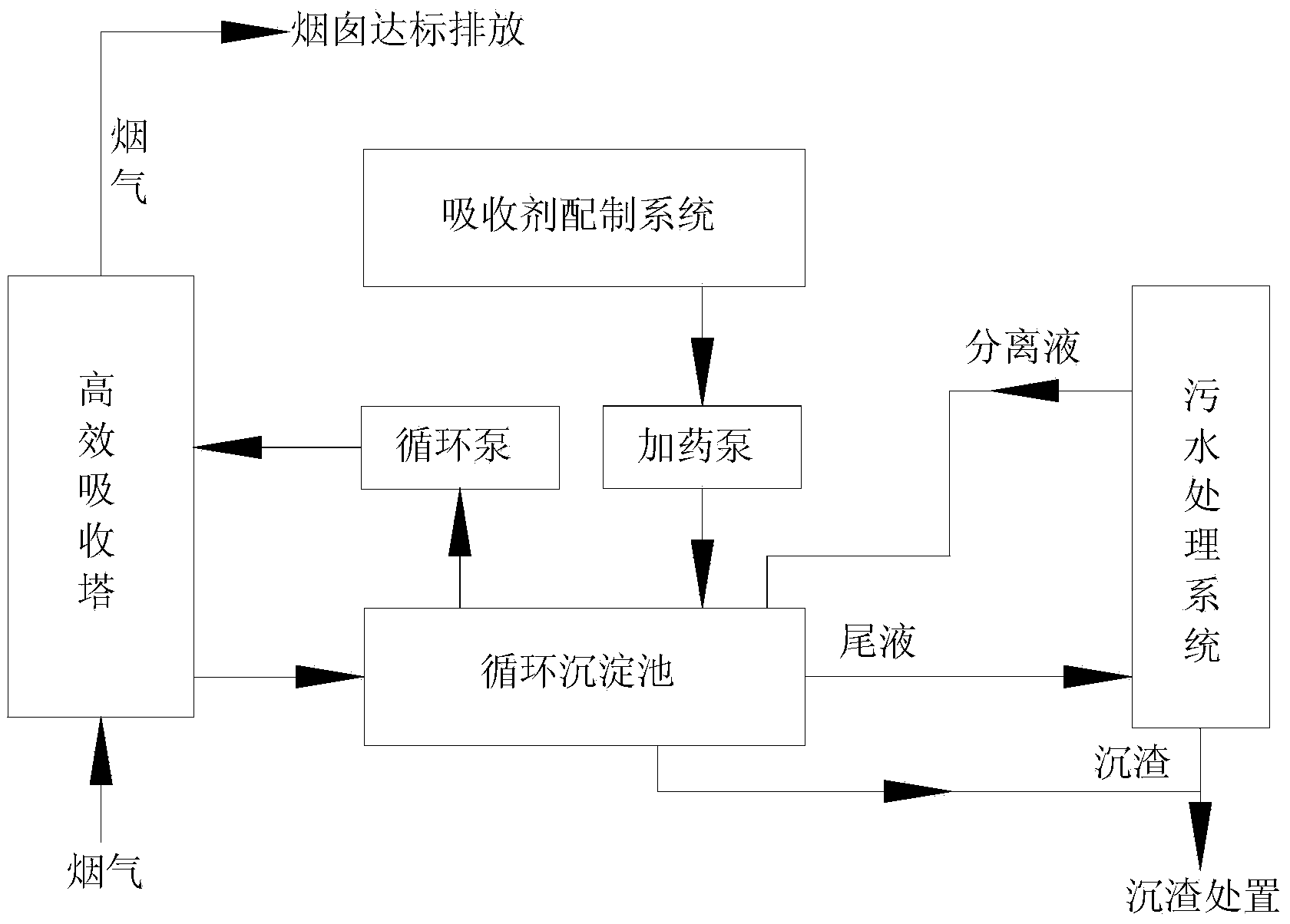

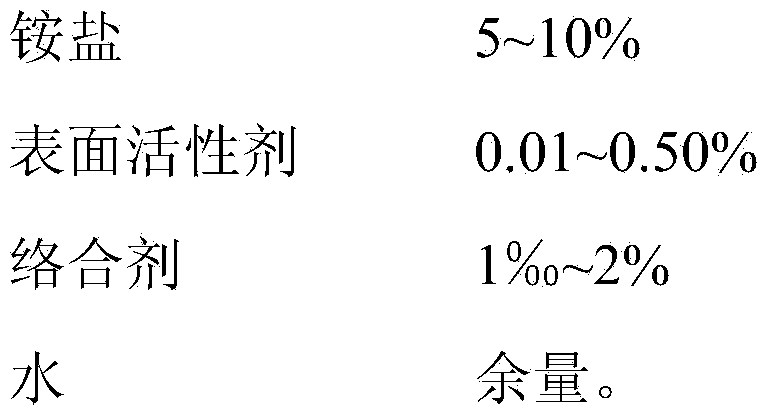

Absorbent capable of simultaneously performing desulfurization, denitrification and VOCs (Volatile Organic Compounds) removal on flue gas as well as preparation and application of absorbent

ActiveCN103721550AImprove removal efficiencySimple process equipmentUsing liquid separation agentAir quality improvementProcess equipmentFlue gas

The invention discloses an absorbent capable of simultaneously performing desulfurization, denitrification and VOCs (Volatile Organic Compounds) removal on flue gas as well as a preparation and an application of the absorbent. The absorbent is prepared from the following components by mass percentage: 5% to 10% of ammonium salt, 0.01% to 0.50% of a surfactant, 0.1% to 2% of a complexing agent and the balance being water. The absorbent can be used for efficiently and simultaneously purifying multiple contaminants such as dust, SO2, NOX and the VOCs in the flue gas by using one set of equipment. The absorbent has the advantages that contaminant removal efficiency is high, process equipment is simple, small in occupation area and low in investment and running cost, system is easy to control and manage, and the like. The raw materials of the absorbent are easily available and low in cost. The absorbent is simple and safe to transport, store, prepare and use and low in production cost.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

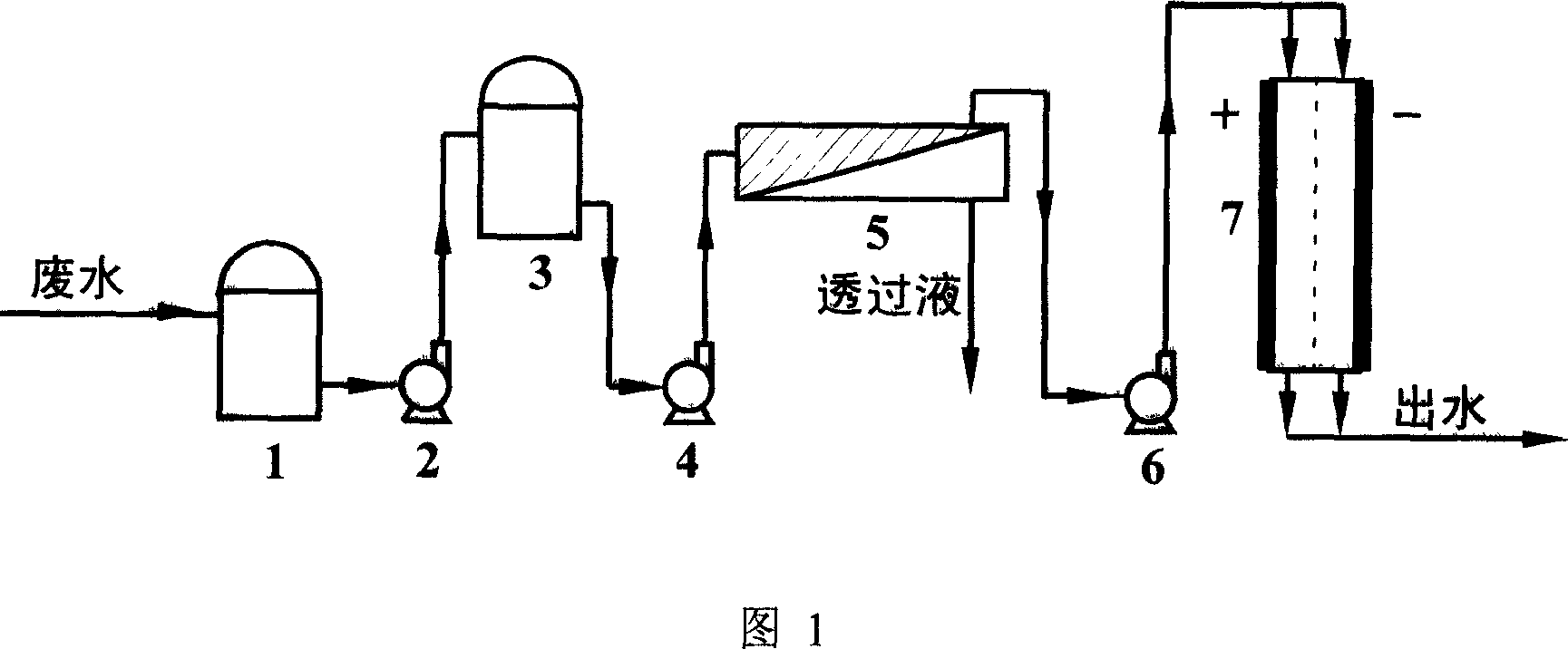

Method of diaphragm separation electrolyzing integrated treatment of wate, water containing heavy metal copper

InactiveCN101024533AAvoid wastingSimple process equipmentPhotography auxillary processesWater contaminantsElectrolysisEconomic benefits

The invention discloses a method used membrane separating-electrolyzing integration to process heavy metal copper containing waste water. It includes the following step: gravity setting, micron filtering, and membrane separating. The concentrated solution is poured into the electrolytic reactor after pH value regulating to deposit heavy metal copper on its negative pole board by energizing to reduce. The residual liquid can be reused in the production technology. The invention can reclaim the metal copper from the heavy metal copper containing waste water, realize water resource reuse. In addition, it has simple device, convenient operation, high recovery ratio, comprehensive utilization ratio, good economic benefit.

Owner:TIANJIN UNIV

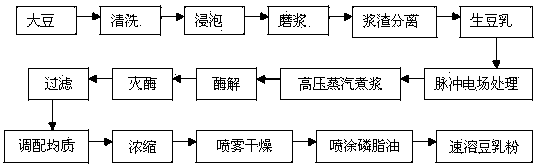

Method capable of improving instant dissolving performance of soybean milk powder

ActiveCN103583700AGood instant solubilityNo beany smellMilk substitutesFood scienceProcess equipmentSoybean product

The invention relates to a method capable of improving the instant dissolving performance of soybean milk powder and belongs to the technical field of soybean product processing. The method comprises the following steps: (1) adding weak alkali water into soaked soybeans according to a certain proportion for pulping and after pulping, carrying out pulp and residue separation to obtain raw soybean milk; (2) after pulsed electric field processing is performed on the raw soybean milk, adding a proper amount of emulsifier, then carrying out high-pressure steam pulp boiling to obtain cooked soybean milk, adding a proper amount of citric acid into the cooked soybean milk, then adding protease for enzymolysis, carrying out enzyme deactivation and filtering after enzymolysis, adding a certain amount of a reducing agent into the filtered soybean milk to carry out blending and uniform mixing, carrying out vacuum concentration after the blended soybean milk is homogenized, and after concentration, carrying out spray-drying and spraying of soybean phospholipid oil to obtain the instant soybean milk powder. The method has the advantages that the requires process equipment is simple, and is safe to operate; according to the method, the pulsed electric field technology and the enzymolysis technology are utilized; by the synergistic effect of the added reducing agent and emulsifier, the instant dissolving performance of the prepared soybean milk powder is improved; meanwhile, the prepared soybean milk powder has no beany flavor and bitter taste.

Owner:永和食品(中国)股份有限公司

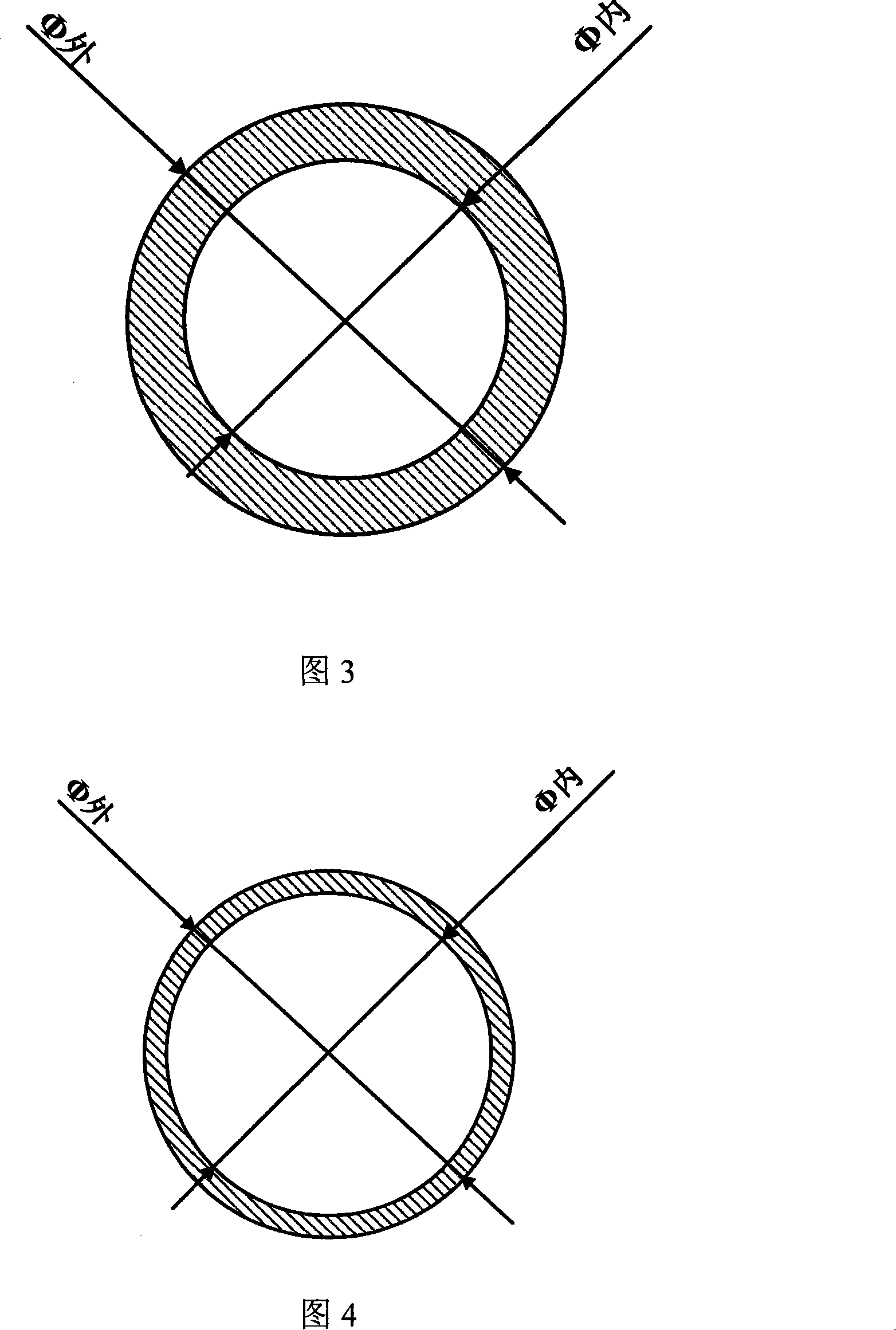

Process technique of high-strength titanium alloy pipes

InactiveCN101176882AImprove yieldImprove performanceRoll mill control devicesFurnace typesAcid washingIngot

The invention relates to a processing technology of high-strength titanium alloy tubes, belonging to the material processing technical field. The processing technology follows the steps below: first, making the vacuum secondary smelting TB2 alloy ingot into 380mm diameter through cogging-forging and hot-rolling, getting a TB2 rolling rod; second, processing the TB2 rolling rod to obtain 52 mm to 54 mm smooth rod in Diameter by bar drawing machine, heating up to 950 to 1000 degree C, keeping the temperature for 30 to 50 minute, rotary piercing on the two-roller rotary piercing machines, obtaining a tube blank of outside diameter from 55mm to 58mm, insid diameter from 39mm to 42 mm; third, make the rotary piercing tube blank process heating up to 770 to 800 degree C, keeping the temperature for 30minute to 50minute, air-cooled annealing and sandblasting, removal of the oxidation scale of the internal and external surface at the process of acid washing, obtaining a cold rolling tube blank; fourth, processing the cold-rolled tube blank with 6 pass cold rolling of the LD60 cold-rolling tube mill, the intermediate annealing temperature is from 760 to 790 degree C, obtaining a finished tube.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

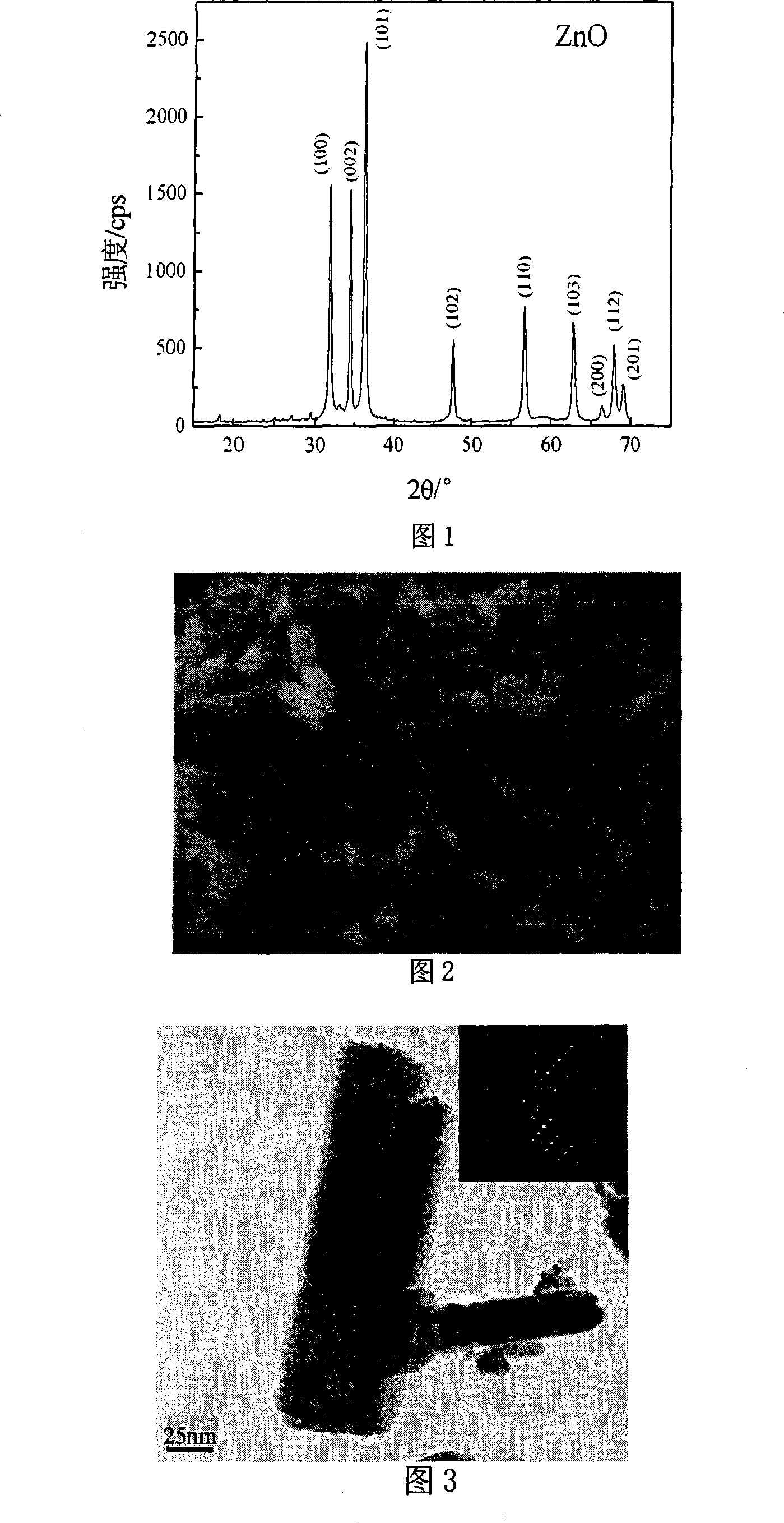

Method for preparing ZnO nano rod

InactiveCN101182028ASimple process equipmentEasy to operateNanostructure manufactureZinc oxides/hydroxidesProcess equipmentFiltration

A preparation method of ZnO nanorods, at first adding analytically pure zinc nitrate hexahydrate into distilled water to make a zinc nitrate transparent solution; adding sodium hydroxide or urea to the zinc nitrate transparent solution to form a precursor solution; pouring the precursor solution Put it into the hydrothermal reaction kettle, then seal the hydrothermal reaction kettle, put it into the temperature-pressure dual-control microwave hydrothermal reaction instrument; after the reaction is completed, cool it down to room temperature naturally; open the hydrothermal reaction kettle, the product is collected by filtration, and then separately Washing several times with deionized water, absolute ethanol or isopropanol, and drying to obtain the final ZnO nanorods. The invention adopts the microwave hydrothermal method without post-processing, and the process equipment is simple, and the obtained nanorods have a narrow diameter distribution of about 20nm-50nm, and the ZnO nanorods with a length ranging from tens of nanometers to hundreds of nanometers have a short reaction period and can be repeated. Sex is well prepared. The method not only greatly reduces the preparation cost, but also has simple operation, short reaction cycle and good repeatability.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing white carbon black from secondary carbon component

The twice carbon separating process for preparing silica white includes introducing CO2 gas to sodium silicate solution to lower the pH value to 9-10.5, solid-liquid separating, further introducing CO2 gas to the solution to lower the pH value to 7-8, solid-liquid separating, washing and stoving to obtain coarse silica while product, soaking or boiling in strong acid solution, washing and stoving to obtain silica while product. The present invention may have the sodium silicate solution obtained through soaking high silicon slag from producing aluminum sulfate, aluminum chloride, ferrous metal and non-ferrous metal and with high impurity content as the material, and the silica while product has high purity, fine granularity and high whiteness.

Owner:PINGSHUO INDAL

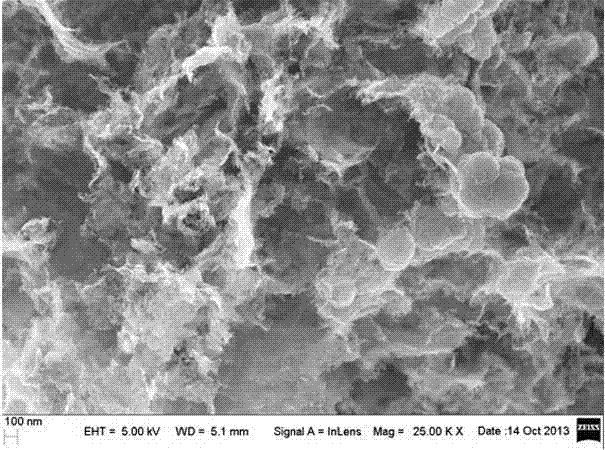

Preparation method of graphene oxide and polyvinyl alcohol hybrid aerogel

InactiveCN105521770AUniform cellsStrong water absorptionOther chemical processesWater contaminantsCross-linkPolyvinyl alcohol

The invention belongs to the technical field of preparation of aerogel having a water treatment function, in particular relates to a preparation method of graphene oxide and polyvinyl alcohol hybrid aerogel. The preparation method comprises the following five processing steps: preparing a graphene oxide dispersing solution; preparing a graphene oxide / chitosan mixed solution; preparing a self-foaming solution; preparing a gel solution; preparing graphene oxide / chitosan and polyvinyl alcohol hybrid aerogel. The preparation method is characterized in that the graphene oxide and polyvinyl alcohol hybrid aerogel is prepared by fully mixing the graphene oxide dispersing solution with distilled water, glacial acetic acid and chitosan powder and then adding polyvinyl alcohol, a filling agent, a cross-linking agent, a foaming agent and a catalyst in the mixture. The graphene oxide and polyvinyl alcohol hybrid aerogel prepared by the invention is strong in water absorbing capacity, high in hydrophily and quick in adsorption rate and can be reused after regeneration and can be used for industrial wastewater treatment. The preparation method of the graphene oxide and polyvinyl alcohol hybrid aerogel, disclosed by the invention, has the advantages that the principle is simple, the operation is easy, processing equipment is simple, the cost of raw materials is low, and the preparation method is beneficial for industrialization.

Owner:QINGDAO UNIV

Chemical vapor deposition process of preparing Sic nanotube

The preparation process of SiC nanotube includes the following steps: 1. cleaning and drying graphite sheet as substrate; 2. soaking the substrate in catalyst solution including catalyst comprising organic compound of Fe, Co, Ni and other metals and co-catalyst comprising organic compound of S; 3. chemically vapor depositing gas source compound comprising organic compound capable of being gasified and containing Si-C bond in the carrier gas comprising N2, H2, NH3 or their mixture and with the molar ratio to the gas source compound of 4.5-7.0 at the temperature of 800-1100 deg.c for 0.8-1.5 hr; and 4. purifying treatment. The present invention has the advantages of: low preparation temperature, easily controlled reaction process, simple technological apparatus, low cost, high yield, high product purity, homogeneous product size distribution and easy use in large scale production.

Owner:NAT UNIV OF DEFENSE TECH

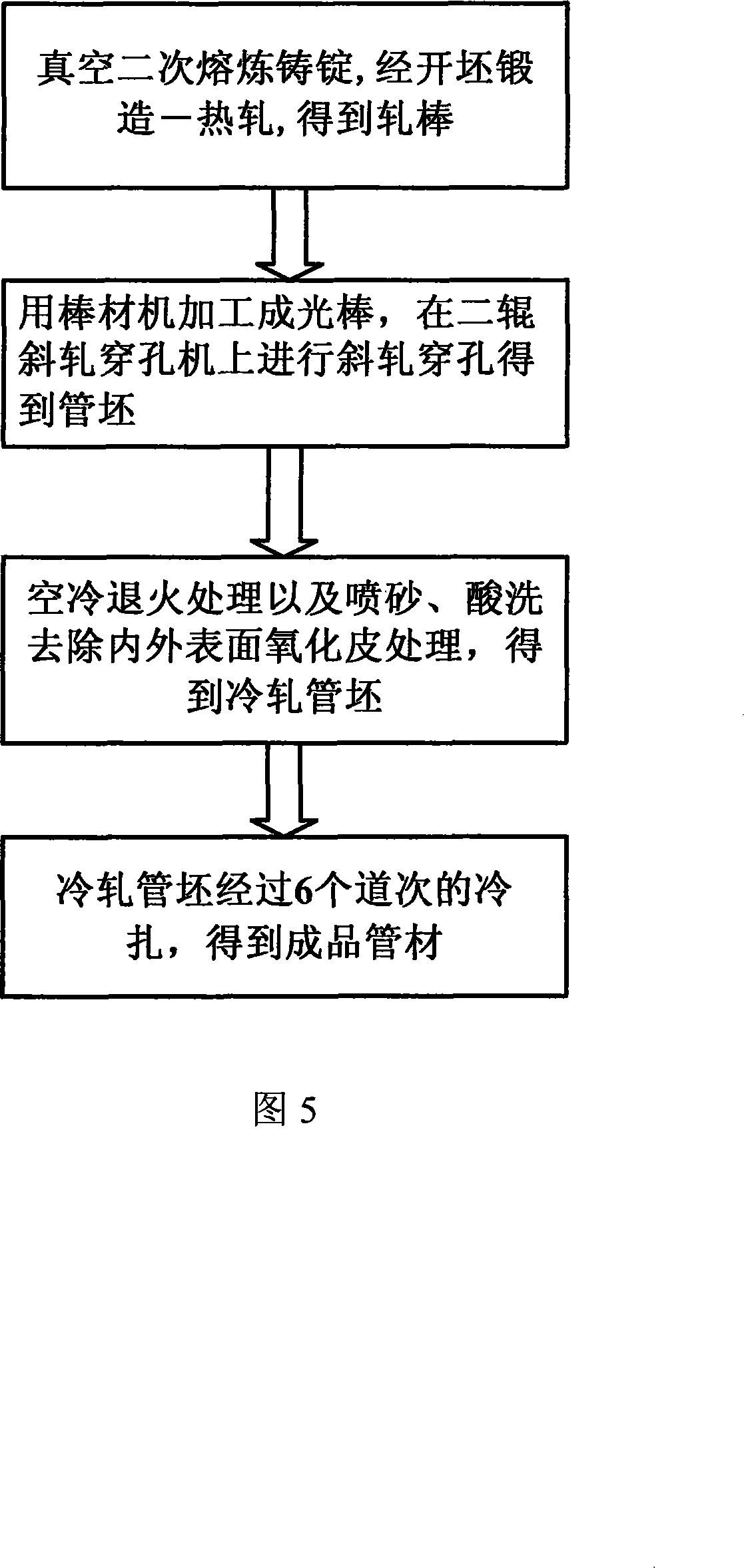

Processing method of high-strength titanium alloy thin-walled tube stock

The invention relates to a processing method of high-strength titanium alloy thin-walled tube stock, belonging to the field of material processing. The processing method comprises the following steps: 1) ingot casting titanium alloy at the temperature of 1100-1200 DEG C, cogging and forging, heating obtained bar stock to the temperature of 900-950 DEG C, conducting heat preservation for 30-50 minutes, and one-time hot-rolling on a rapid forging press to obtain titanium alloy forged bars; 2) finishing and drilling the titanium alloy forged bars to obtain tube blank; 3) preheating a central spindle to be spinned before hot spinning, with the preheating temperature not lower than the temperature of 350 DEG C; and conducting heat preservation on the tube blank at the temperature of 700-750 DEG C for 30-40 minutes, and multichannel hot spinning process; and 4) finishing the interior and exterior of the obtained hot spinned tube blank, and cold spinning and forming on a cold spinning machine to obtain finished products of the tube blank. The processing method adopts rapid forging blank making and spinning process for processing the titanium alloy thin-walled tube stock with higher requirements for room temperature strength and deformation resistance, has simple processing equipment and easy molding, and can effectively improve the quality and yield of alloy tube blank.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparing method for transparent conductive oxide film

ActiveCN102646759ASimple process equipmentGood film uniformitySemiconductor devicesElectrically conductiveChemistry

The invention relates to the semiconductor photoelectric material field, and provides a preparing method for transparent conductive oxide film. The method includes the following steps: step one, obtaining a sol solution of zinc salt or indium salt and doped metal salt, wherein, viscosity of the sol ranges from 15m Pa.s to 20 m Pa.s, concentration of zinc or indium in the zinc salt or the indium salt ranges from 0.1 mol / L to 1 mol / L, the mole ratio of zinc and the doped metal salt is between 0.001 and 0.03, and the mole ratio of indium and the doped metal salt is between 0.05 and 0.15; step two, immersing media into the sol solution and allowing the mixture to stand for 1s to 30s, pulling the media out of the sol solution at a speed of 1 cm / min to 300 cm / min, maintaining the media for 0.5 min to 30 min at a temperature in a range of 80 DEG C to 300 DEG C, and cooling the media; step three, repeating step two till the thickness of the film on the media achieves the required thickness, and obtaining the transparent conductive oxide film. The transparent conductive oxide film prepared through the method has the advantages of being high in rate of finished products, capable of preparing film with large areas, high in material using ratio, and suitable for mass production.

Owner:徐东

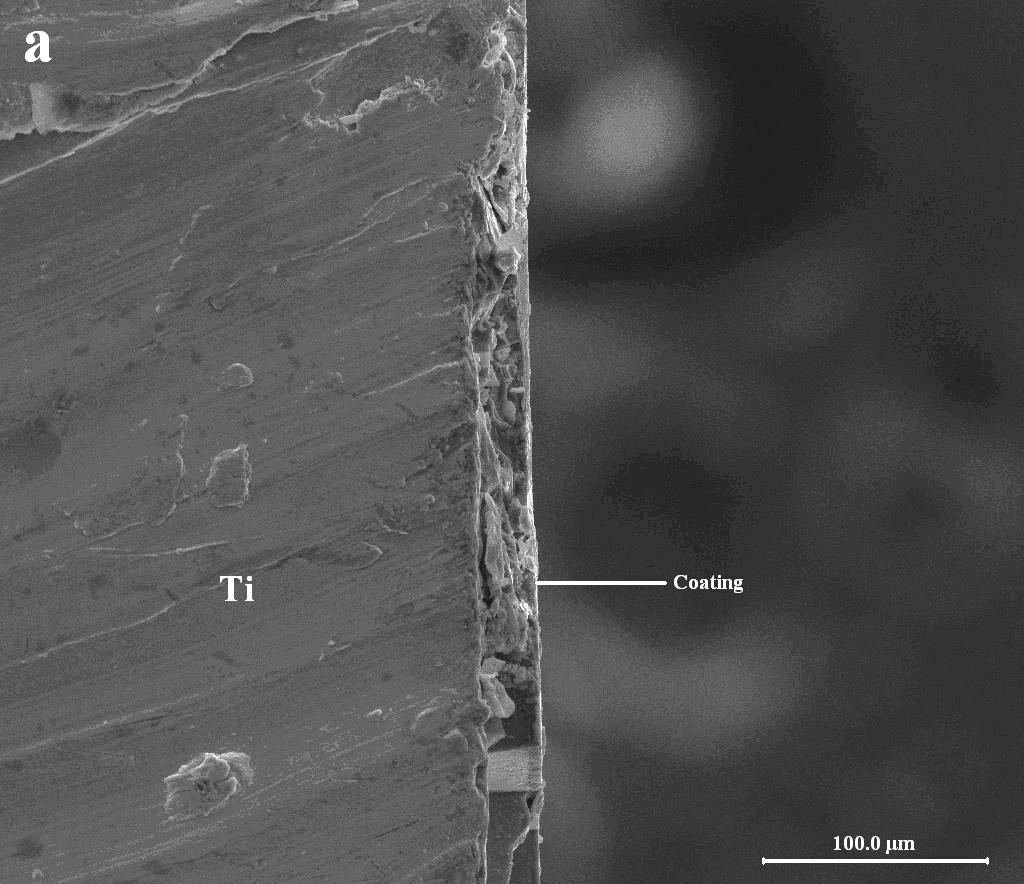

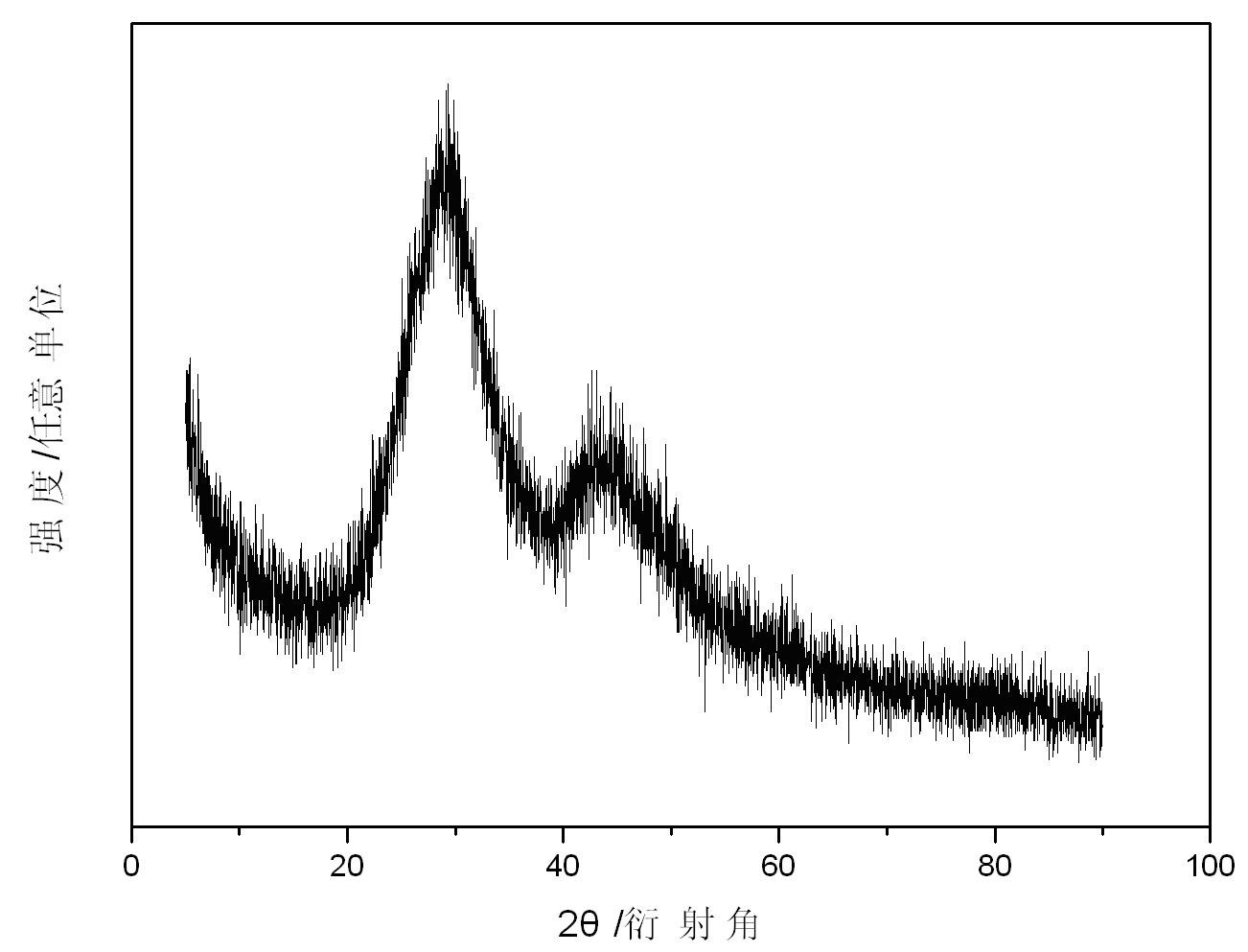

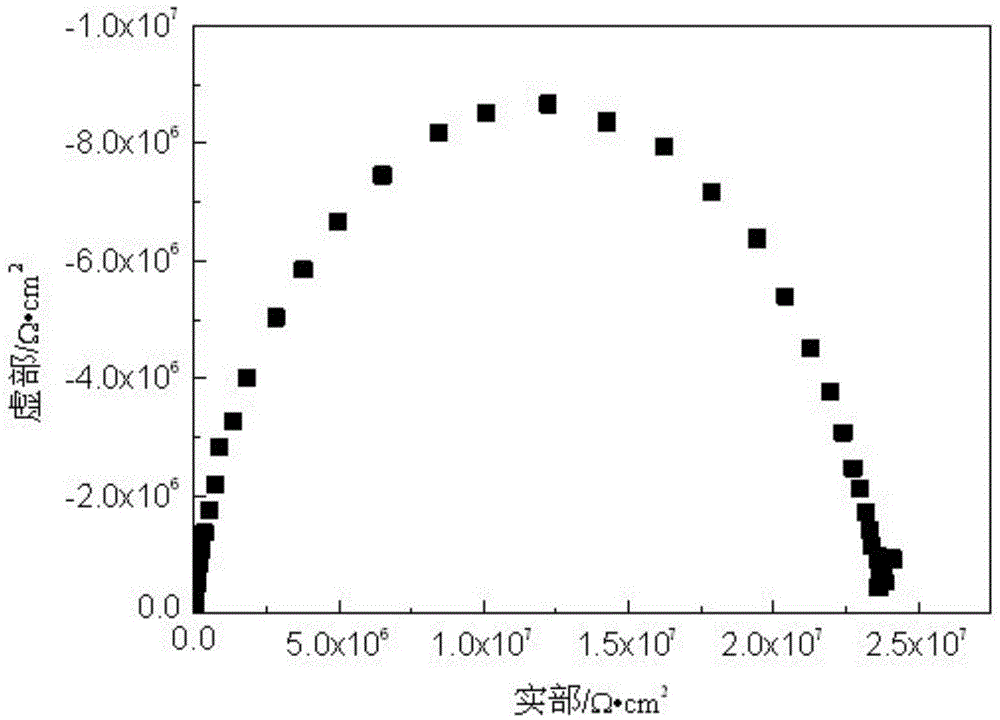

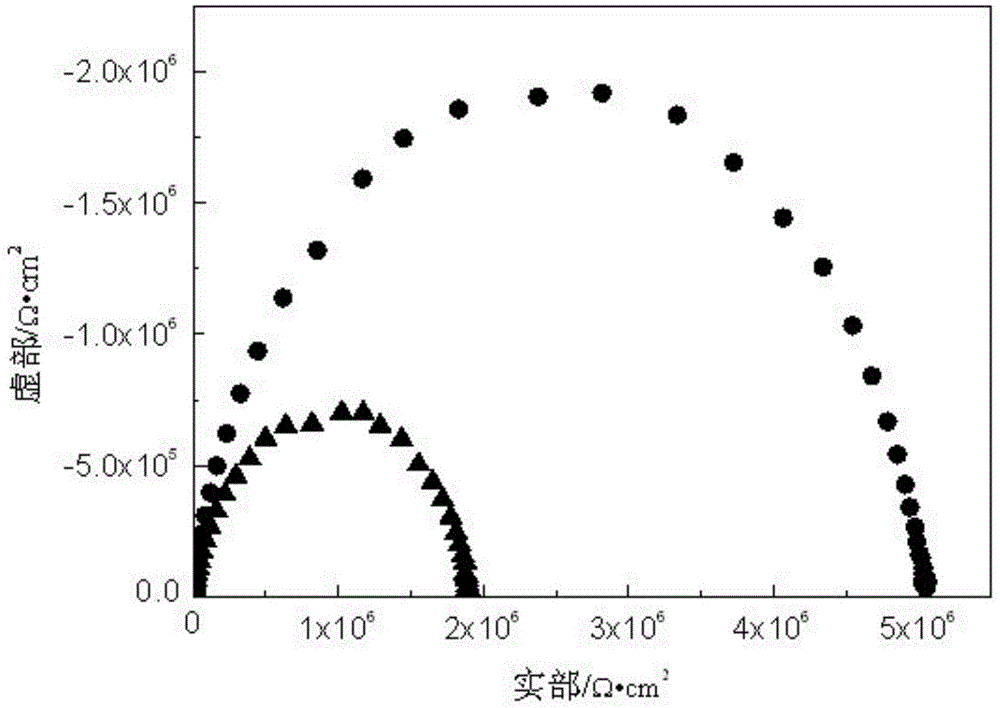

Preparation method and application of antibacterial glass coating of antibacterial bone fracture plate

The invention relates to a preparation method and application of an antibacterial glass coating of an antibacterial bone fracture plate. The method comprises the following steps: preparing sterile ion-containing borate bioactive glass, crushing the glass, and screening into glass powder with a certain size; adding a liquid-phase solvent, adhesive and stabilizer to the glass powder to prepare uniform glass slurry; coating the glass slurry to the surface of a titanium or titanium alloy bone fracture plate by utilizing a mechanical immersion method or a low temperature spraying method, drying with infrared ray or heat, and curing the slurry to the surface of the bone fracture plate; and volatilizing the solvent and the additives by virtue of high temperature sintering treatment, re-melting the residual glass powder to form molten glass, and adhering to the surface of the bone fracture plate to form the antibacterial glass coating capable of resisting bacteria and promoting tissue growth. The preparation method has the advantages of simple production process, easiness in operation, low cost and scale production; and the antibacterial glass coating has the functions of effective antibacterial performance and bioactivity in promotion of bone cell growth.

Owner:TONGJI UNIV +1

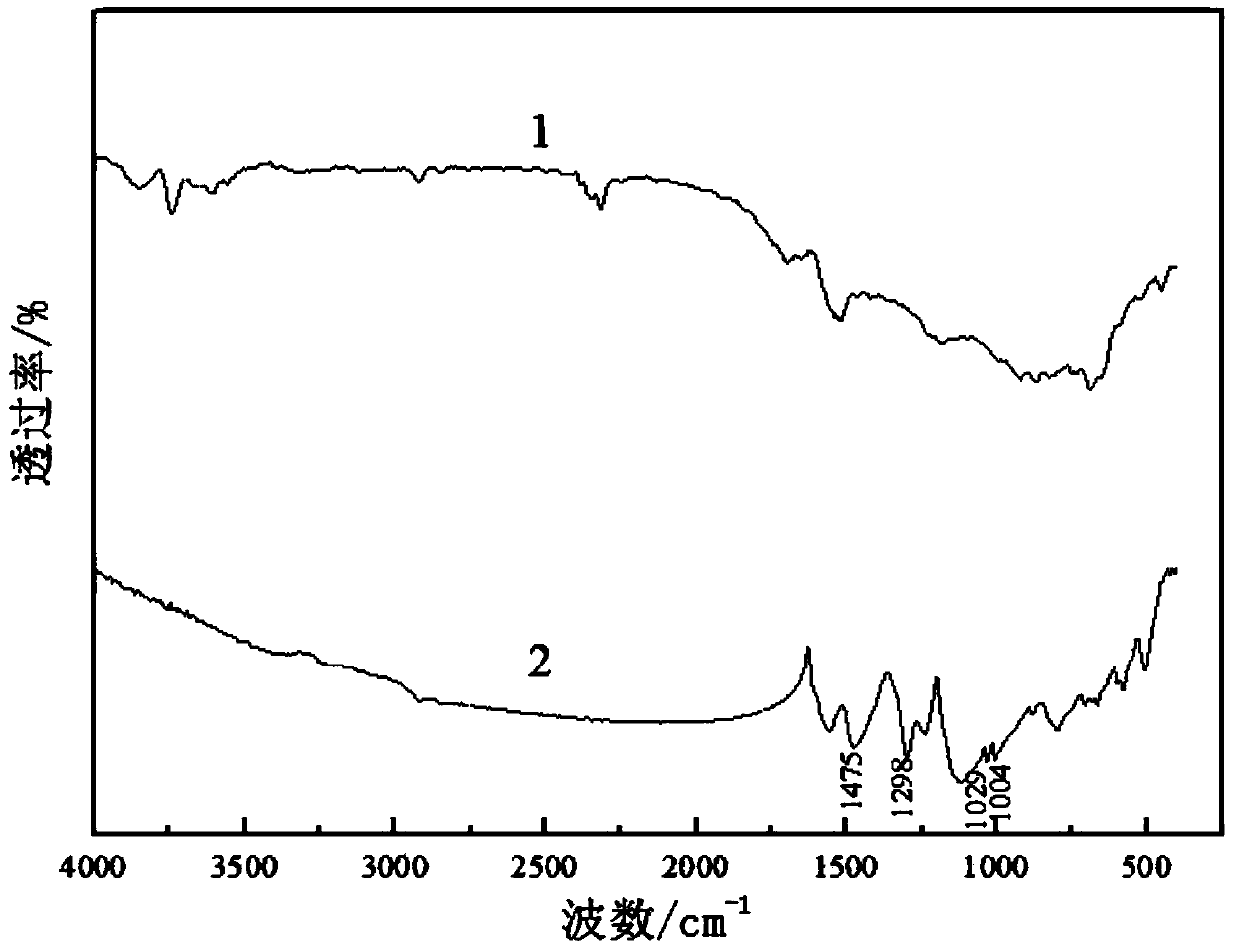

Doped-state polyaniline epoxy paint and preparation method thereof

InactiveCN103980798AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyProcess equipment

The invention discloses doped-state polyaniline epoxy paint and a preparation method thereof. The preparation method includes following steps: preparing doped-state polyaniline in a manner of chemical polymerization with ammonium persulfate being an oxidizing agent and phosphoric acid being a doping agent, preparing intrinsic-state polyaniline through a dedoping process, carrying out a secondary doping reaction between the intrinsic-state polyaniline and dodecylbenzene sulfonic acid to prepare secondarily-doped-state polyaniline, mixing the secondarily-doped-state polyaniline with epoxy resin to prepare the polyaniline epoxy paint having a good anti-corrosion performance. In the technical scheme of the invention, a coating prepared from the secondarily-doped-state polyaniline not only has a high electrical conductivity but also has a high anti-corrosion performance. The preparation method is simple in required processing equipment, is relatively low in cost and is easy to achieve industrialization.

Owner:TIANJIN UNIV

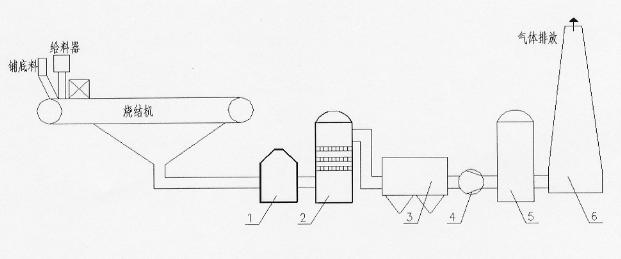

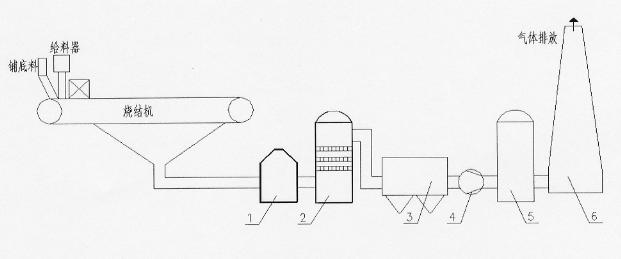

Denitration system and method for sintering flue gas without ammonia reducing agent

InactiveCN102188904ASimple processSimple process equipmentLighting and heating apparatusDispersed particle separationChemical equationProcess engineering

The invention relates to a denitration system and method for sintering flue gas without using ammonia as a reducing agent. The system comprises a sintering machine, and a heater, a denitration reactor, a deduster, a blower fan, a desulfurization tower and a chimney sequentially connected with the sintering machine. The denitration reactor is arranged before the deduster; that is, the deduster is arranged between the heater and the denitration reactor. A catalyst layer is provided in the denitration reactor. The method comprises the following steps that: sintering flue gas is heated by the heater to an appropriate temperature before the deduster and is sent to the denitration reactor; NOx is removed by a catalytic reduction in the denitration reactor under the influence of a catalyst, wherein the chemical equation for the removing of NOx is 2NO +2CO =N2 + 2CO2; the reacted sintering flue gas is emitted into the atmosphere after dedusting and desulphurization. According to the invention, the ammonia reducing agent needs not to be added, the catalyst is widely available and cheap, and investment and operation cost needed is low; the reducing agent used in the invention is CO reduction ingredients in the sintering flue gas instead of ammonia, thereby avoiding many problems resulting from the utilization of an ammonia reducing agent.

Owner:BAOSTEEL ENG & TECH GRP

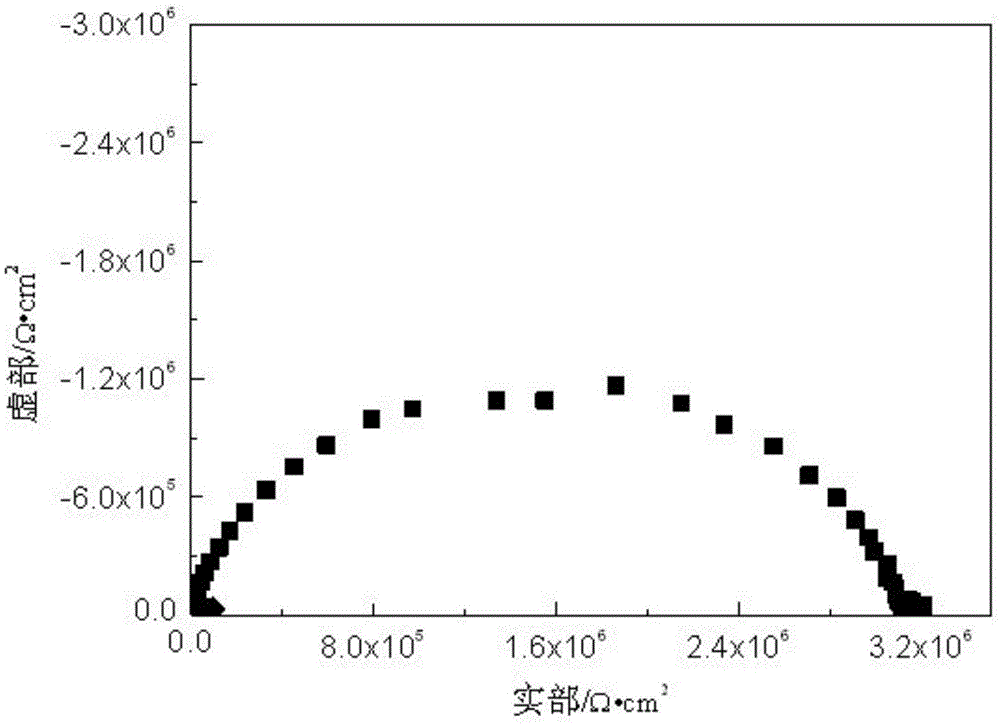

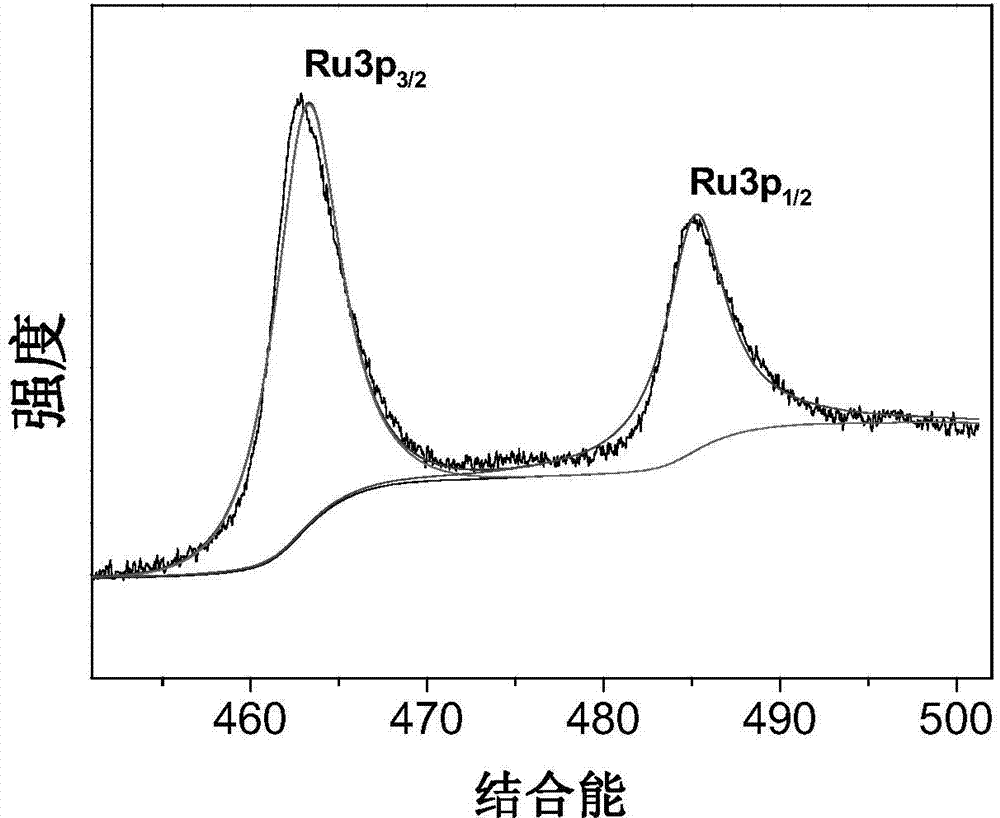

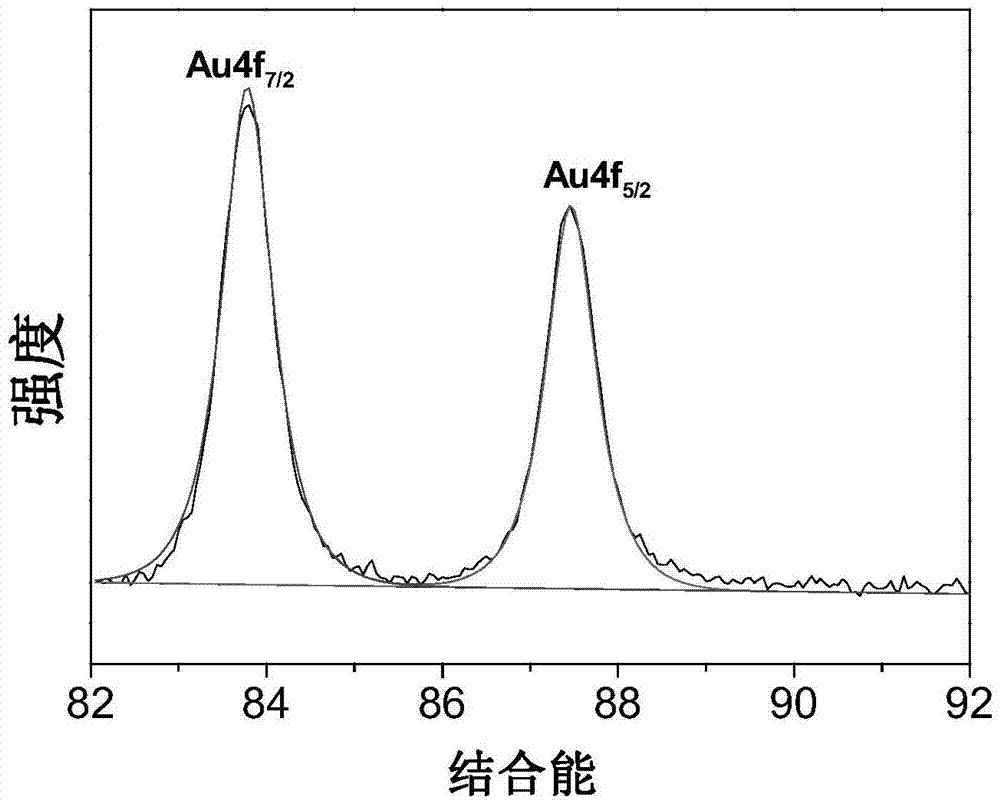

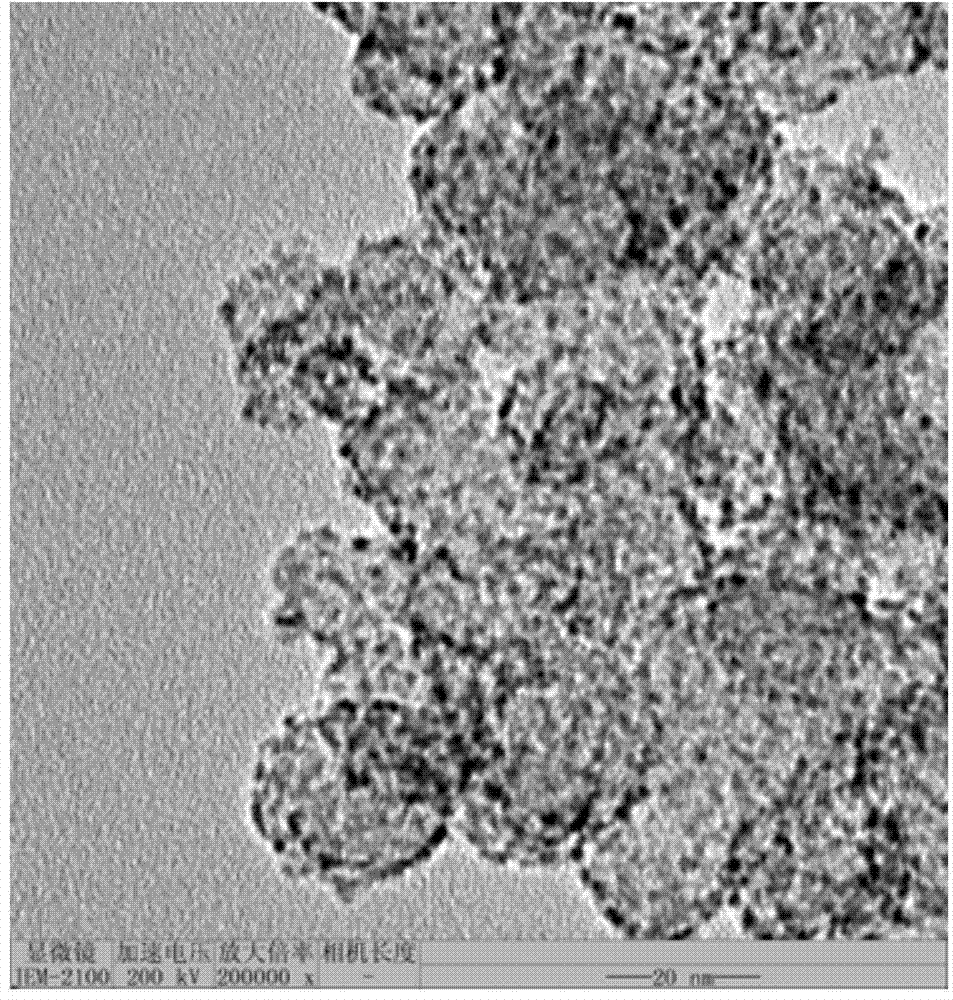

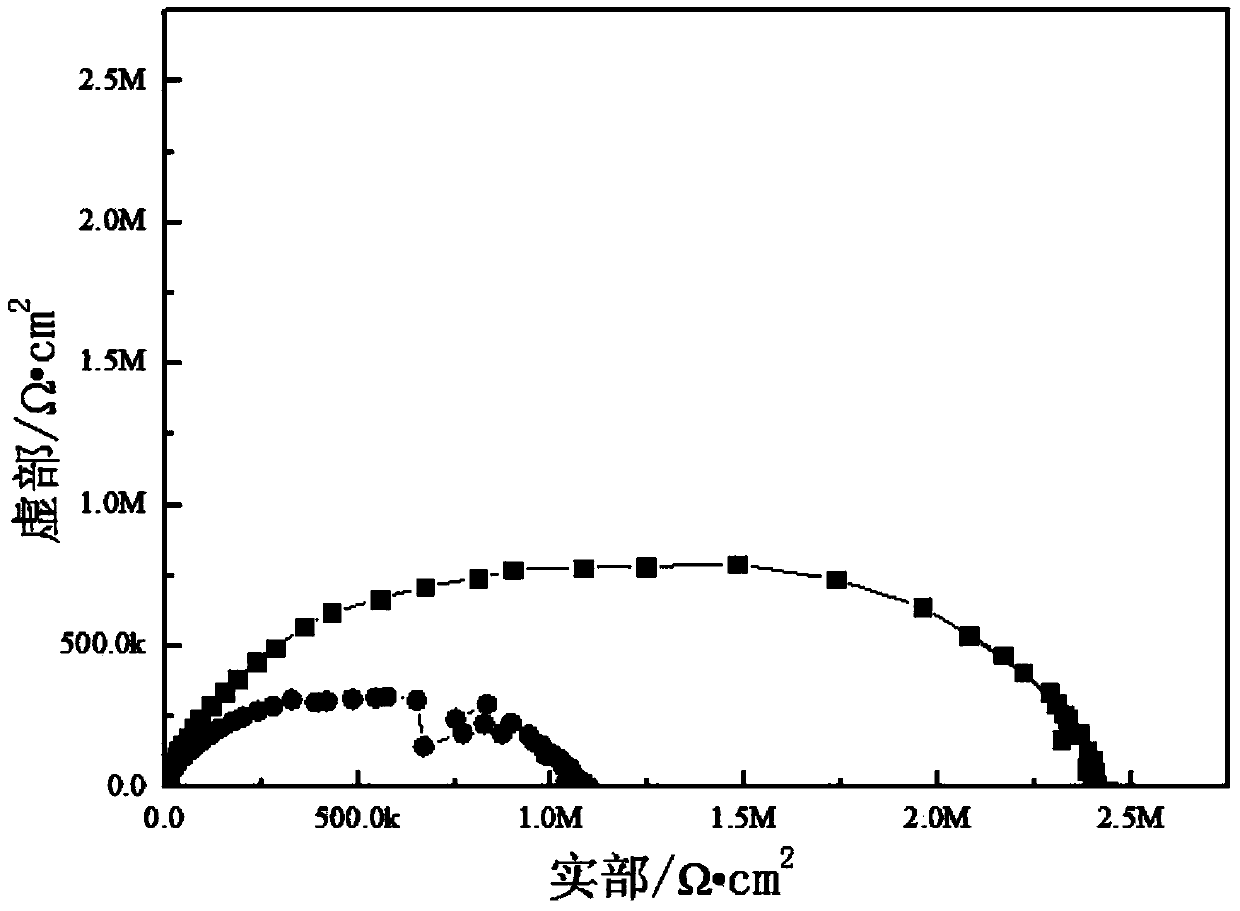

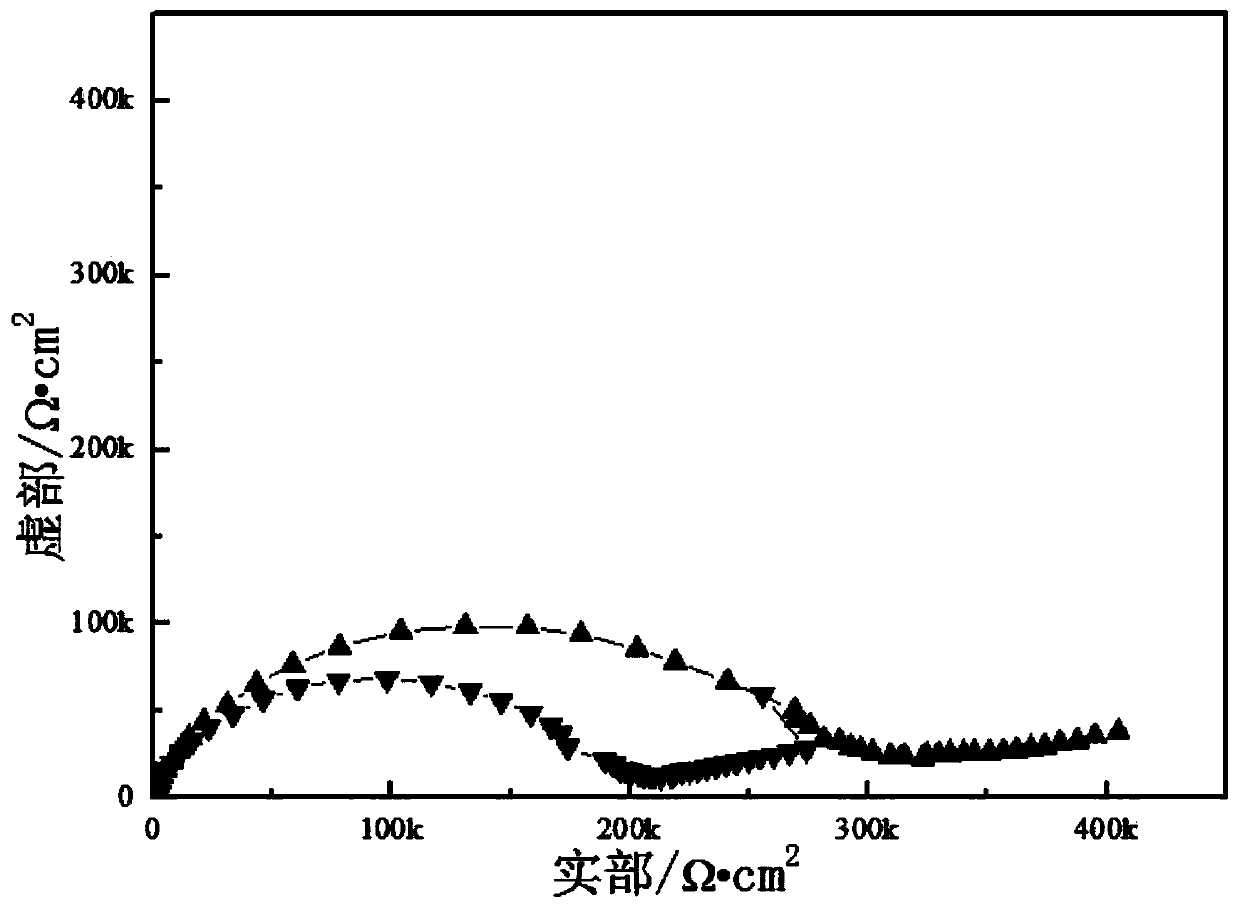

Ruthenium dioxide-based composite nano-material and preparation method thereof

ActiveCN104124071AEvenly dispersedImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesBULK ACTIVE INGREDIENT

The invention discloses ruthenium dioxide-based composite nano-material and a preparation method thereof. The preparation method includes that dispersing carbon matrix in water, adding ruthenium source and oxidized metal source, regulating the pH value of the solution, after stirring to adsorb, performing oil bath reaction, centrifuging, washing, and roasting in an inert atmosphere to obtain the composite nano-material. The preparation method is easy to operate, high in yield, low in cost and environmental friendly, and the prepared ruthenium dioxide / metal nano-particle / carbon composite nano-material is featured with small active ingredient size, large specific surface area and uniform dispersion. The ruthenium dioxide is hydrous ruthenium dioxide which belongs to good reversible charging / discharging active substances, and the metal nano-particle is easy to adsorb protons and transmit electrons to improve the electro-chemical performance of the ruthenium dioxide / metal nano-particle / carbon composite nano-material. The ruthenium dioxide / metal nano-particle / carbon composite nano-material can be used as super-capacitor electrode material and has excellent electro-chemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

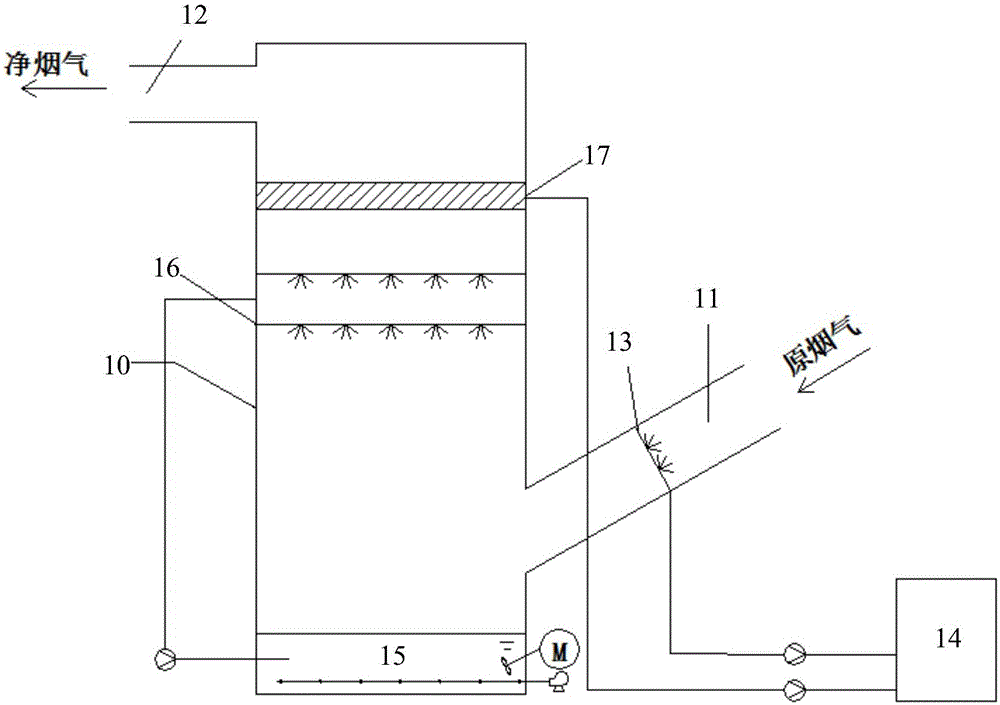

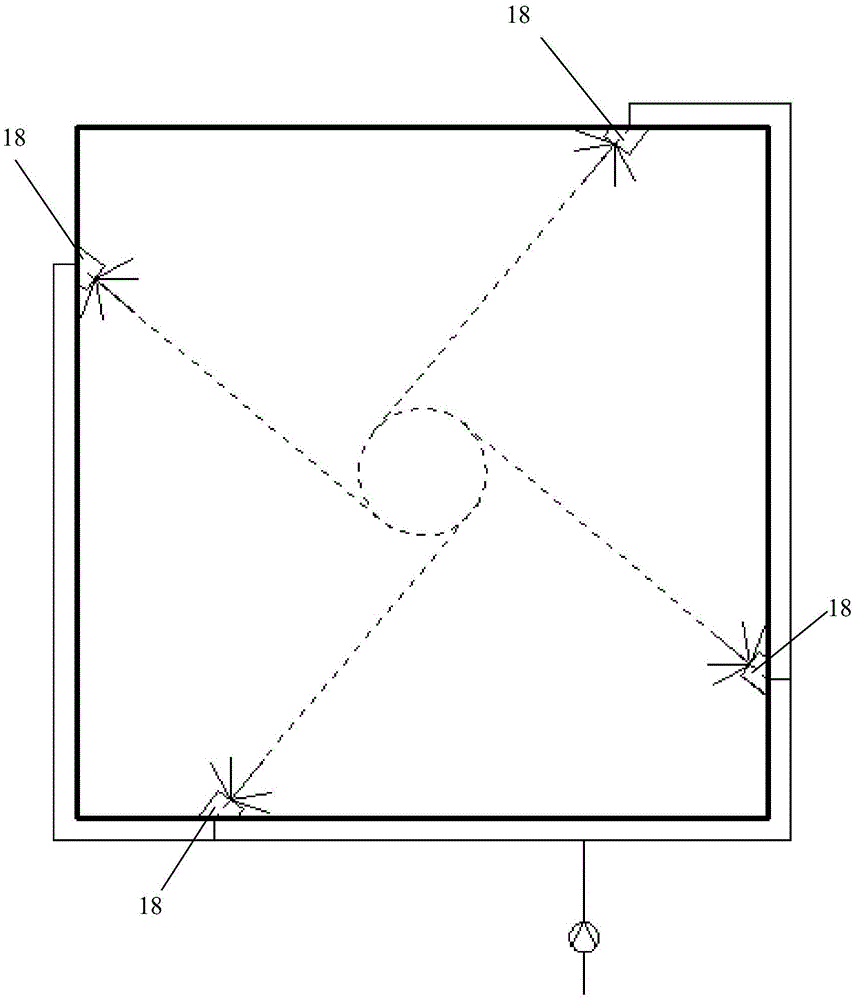

Flue gas composite phase change dust removal and desulfurization technology and device

ActiveCN105107365ASimple process equipmentLess investmentCombination devicesUsing liquid separation agentWater vaporFlue gas

The invention discloses a flue gas composite phase change dust removal and desulfurization device. The device comprises a desulfurizing tower (10). The lower portion of the side wall of the desulfurizing tower (10) is connected with an inlet flue (11). The upper portion of the side wall of the desulfurizing tower (10) is connected with an outlet flue (12). A vortex phase changer (13) is arranged on the inlet flue (11) of the desulfurizing tower (10) and comprises a plurality of sets of atomization nozzles (18). The atomization nozzles (18) are symmetrically arranged on the side wall of the inlet flue (11). Openings of the atomization nozzles (18) face the interior of the inlet flue (11) and are eccentrically arranged relative to the inlet flue (11). Spraying water sprayed by the atomization nozzles (18) in the vortex phase changer (13) can enable flue gas in the inlet flue (11) to generate rotational flow. The invention further discloses a flue gas composite phase change dust removal and desulfurization technology. The composite phase change condensation principle is utilized for enabling supersaturated water vapor to be condensed on the surfaces of fine particles, and the fine particle collection efficiency of the desulfurizing tower is improved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

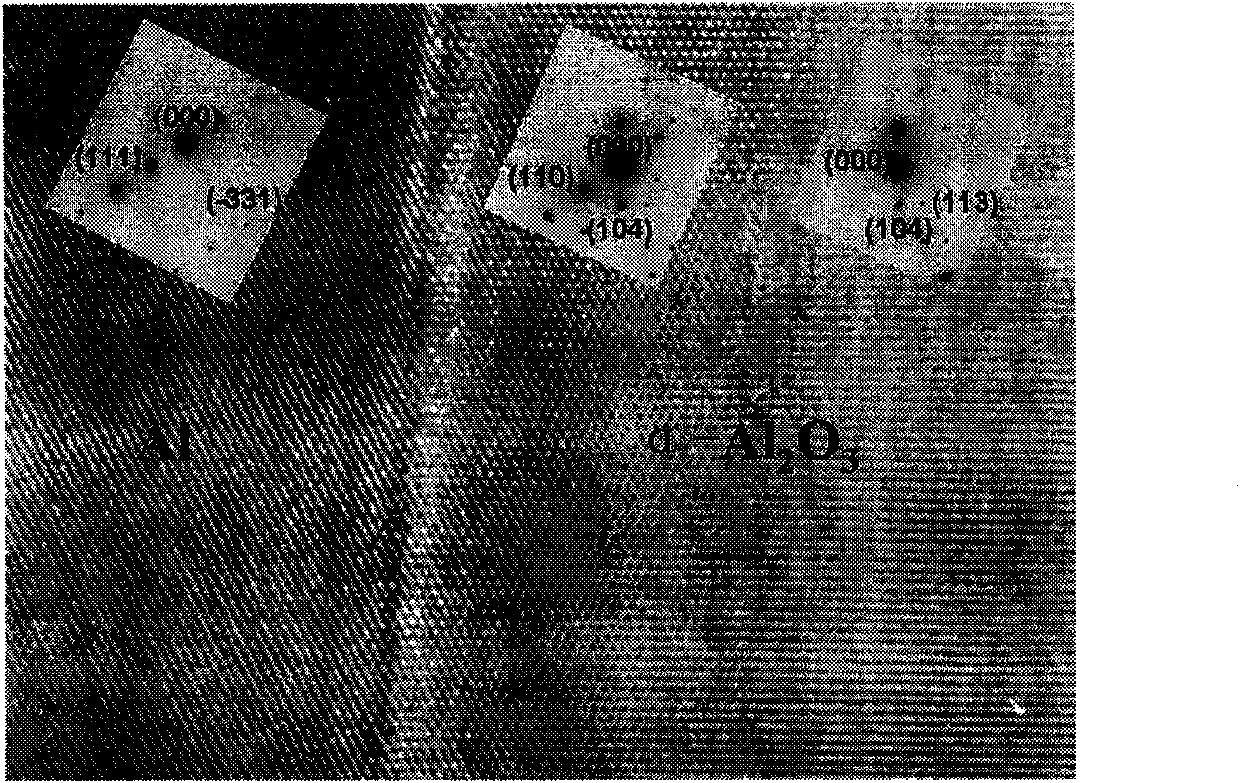

Method for connecting ceramic and metal

The invention discloses a method for connecting ceramic and ceramic, and ceramic and metal. The method comprises the following steps of: 1) forming a compact aluminum or aluminum alloy thin film with thickness of several to tens of microns on a connecting surface of the ceramic to obtain the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film; and 2) connectingthe ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the metal by using the aluminum or aluminum alloy thin film, or connecting the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film by using the aluminum or aluminum alloy thin film. Compared with the prior art, the method has the advantages that: oxide inclusion originated from an aluminum surface oxide film is not formed on the interface between the aluminum film and the ceramic, which is formed by the method, the ceramic is firmly connected with the ceramic or the metal and the ceramic and the metal do not fall off easily, and the separating and peeling strength between the thin film and a ceramic chessboard is greater than or equal to 4.1N / cm. After an aluminum brazing process or an aluminum or aluminum alloy workpiece connection are adopted, defects of the connecting interface of the aluminum or aluminum alloy workpiece and the ceramic are avoided, the 90-degree tear strength of the connection can reach over 12kg / cm, fracture does not occur on the interface, and the ceramic and metal are connected very firmly.

Owner:TSINGHUA UNIV

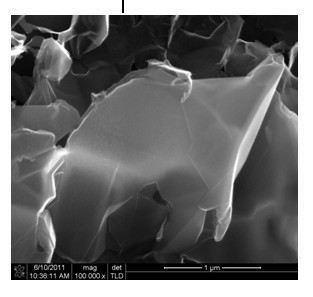

Low-cost carbon graphene sheet and preparation method thereof

The invention discloses a low-cost carbon graphene sheet and a preparation method thereof. The preparation method comprises the following steps of: mixing a carbon material (coal, coke, resin carbon, graphite, bamboo charcoal or active carbon) as a raw material and an additive; then preparing the graphene sheet through processes, namely vacuum carbonization, pickling, ball milling, and the like, at low cost. The graphene sheet prepared through the preparation method disclosed by the invention has the advantages of less structural defect, low preparation cost, easiness for operation, greenness, environmental protection, easiness for industrialization and outstanding economic and social benefits.

Owner:FUZHOU UNIV

Method for numerously preparing asphalt-based graphene material with low cost

The invention discloses a method for numerously preparing a graphene material, which takes asphalt as a raw material and comprises the processes of preparing, pyrolyzing and carrying out carbonization. Compared with the conventional preparation of the graphene material, the method disclosed by the invention has low preparation cost, little equipment investment, simplicity for operating, no pollution, and easiness for realizing industrialization; and in addition, the purity of a product is high, the structure defect of the product is little, and the performance of the product is excellent.

Owner:FUZHOU UNIV

Nano-composite electric conduction anticorrosive paint and preparation method thereof

InactiveCN103627297AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxySolubility

The invention discloses nano-composite electric conduction anticorrosive paint and a preparation method thereof. The preparation method is characterized in that firstly organic acid dodecylbenzene sulfonic acid is used as a doping agent so as to overcome the low solubility of doped polyaniline, a carbon nanotube is used for improving the electric conductivity of composite powder, and then the carbon nanotube is compounded with a precursor of organic acid dodecylbenzene sulfonic acid doped polyaniline and epoxy resin so as to prepare the nano-composite electric conduction anticorrosive paint. According to the technical scheme, the polyaniline / carbon nanotube and the epoxy resin are compounded, so that the excellent characteristics of the polyaniline / carbon nanotube and the epoxy resin are organically combined together. The nano-composite electric conduction anticorrosive paint has relatively high electric conduction performance and very high anticorrosive performance and is relatively low in cost; required processing equipment is simple; the industrialization of the nano-composite electric conduction anticorrosive paint is easy to realize.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com